Air flow and high frequency combined lignite drying device and process

A combined drying and high-frequency drying technology, applied in the directions of drying gas arrangement, preliminary treatment to promote the drying of solid materials, and combination of dryers, etc. The effect of reducing fuel consumption, reducing losses, and reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

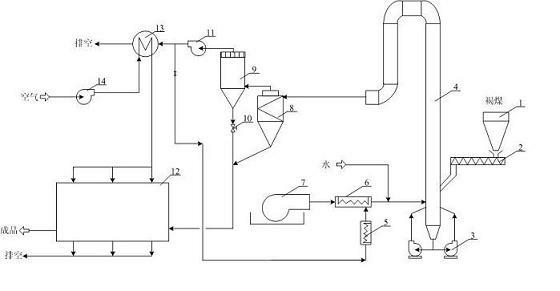

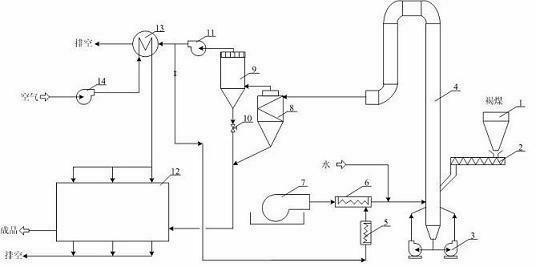

[0029] figure 1 Among them, the airflow and high-frequency combined drying lignite device of the present embodiment is composed of airflow dryer 4, high-frequency dryer 12, external heat exchanger 13, feed bin 1, feeding screw machine 2, fan I11, fan II14 , cyclone dust collector 8, bag dust collector 9, electric heater I5, electric heater II6, oil furnace 7, fan coal mill 3 and discharge valve 10.

[0030] The feeding place of the airflow dryer 4 is connected with the feed screw machine 2, and the feed bin 1 cooperates with the feed screw machine 2 to form a feeding device, and the airflow dryer 4 is also connected with two fan coal mills 3 .

[0031] The smoke inlet of the airflow dryer 4 is connected to the outlet of the electric heater II6, the inlet of the electric heater II6 is connected to the outlet of the fuel burner 7, the electric heater II6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com