Firewood-burning type waste-heat utilization continuous fixation tea strip tidying machine with electric hot air

A technology of finishing machine and electric hot air, applied in air heaters, fluid heaters, tea treatment before extraction, etc., can solve problems such as uneven finishing and insufficient aroma of finished tea, and achieve low fuel consumption and low energy costs , easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

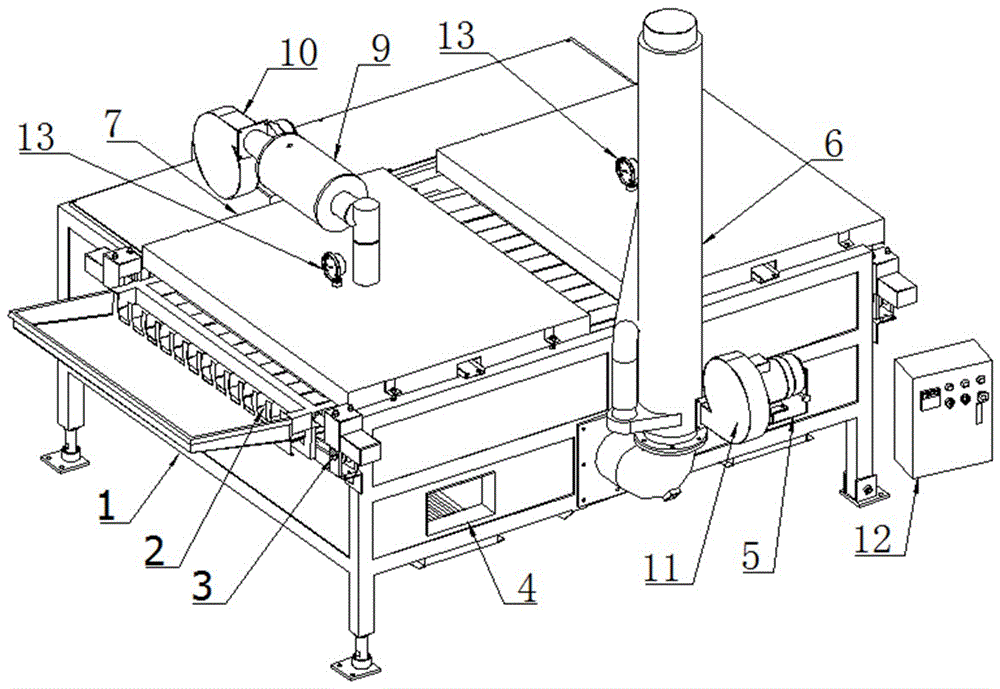

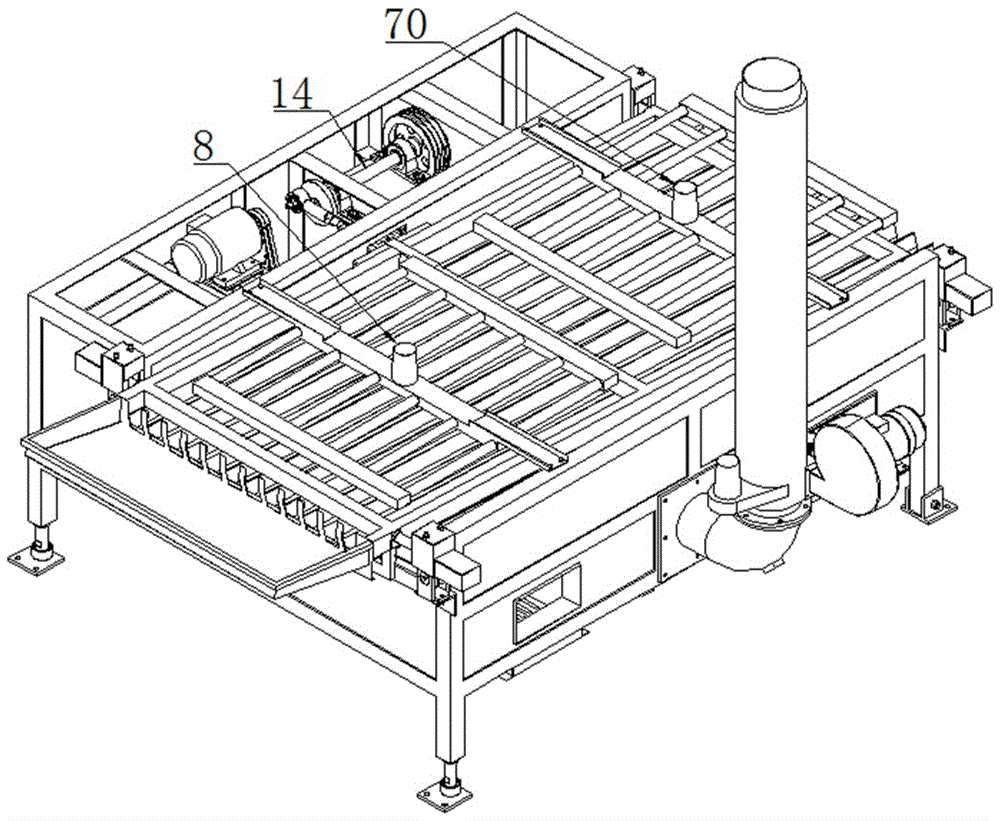

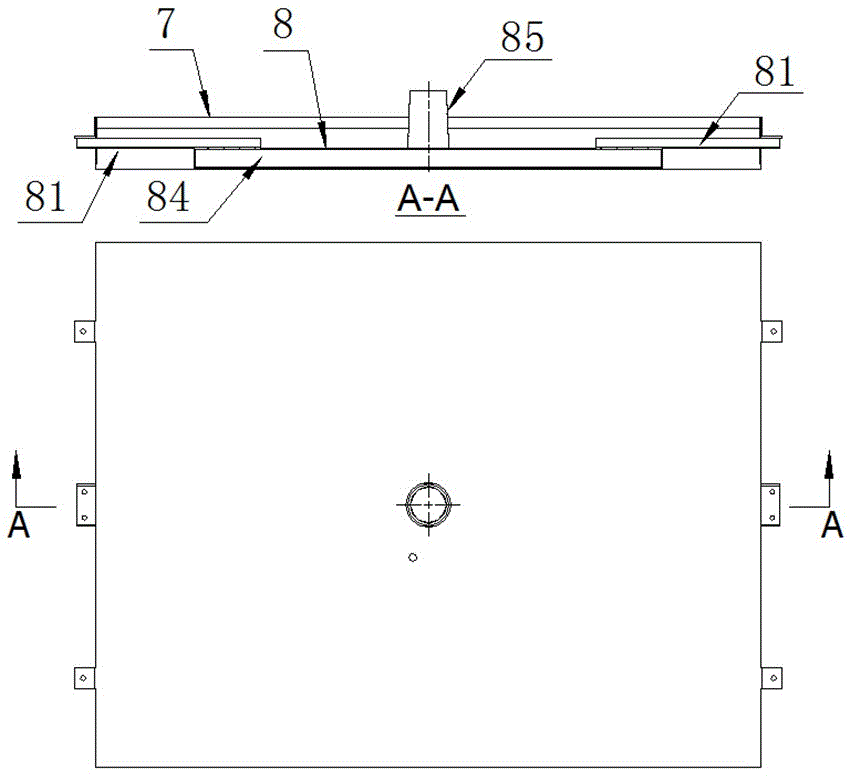

[0028] see Figure 1 to Figure 8 , a wood-fired waste heat utilization continuous finishing machine with electric hot air, including a frame 1, a tank 2, a roller assembly 3, a first hot air cover 7, a first hot air distributor 8, and an electric hot air generator 9 , the first blower fan 10 and the transmission device 14 . The frame 1 is a rectangular parallelepiped frame structure, four corners of the bottom are provided with four supporting legs, the upper plane is an inclined surface along the length direction, and a group of roller assemblies 3 are respectively installed at both ends of the length direction of the inclined surface, each group of roller assemblies 3 There are two rollers, and these two rollers are respectively arranged on both sides of the width direction of the inclined surface; the tank 2 is provided with two sets of slide bars, and each set of slide bars is correspondingly connected to a set of roller assemblies 3; The transmission device 14 is located...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com