Forming method of mixed gas of layered lean-burn spraying-wall face combined-guiding LPG direct injection supercharged engine

A bottom surface and nozzle technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve the problem that the method of forming the mixture has not yet been seen, and achieve the effect of reducing the fuel consumption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

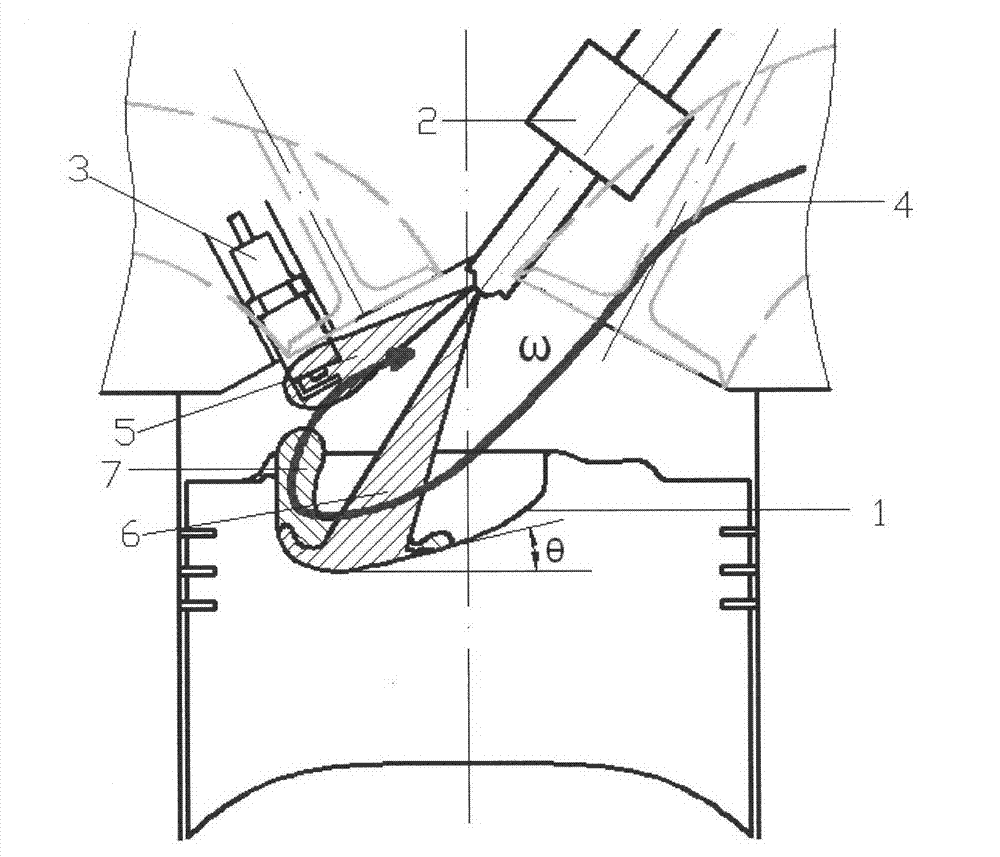

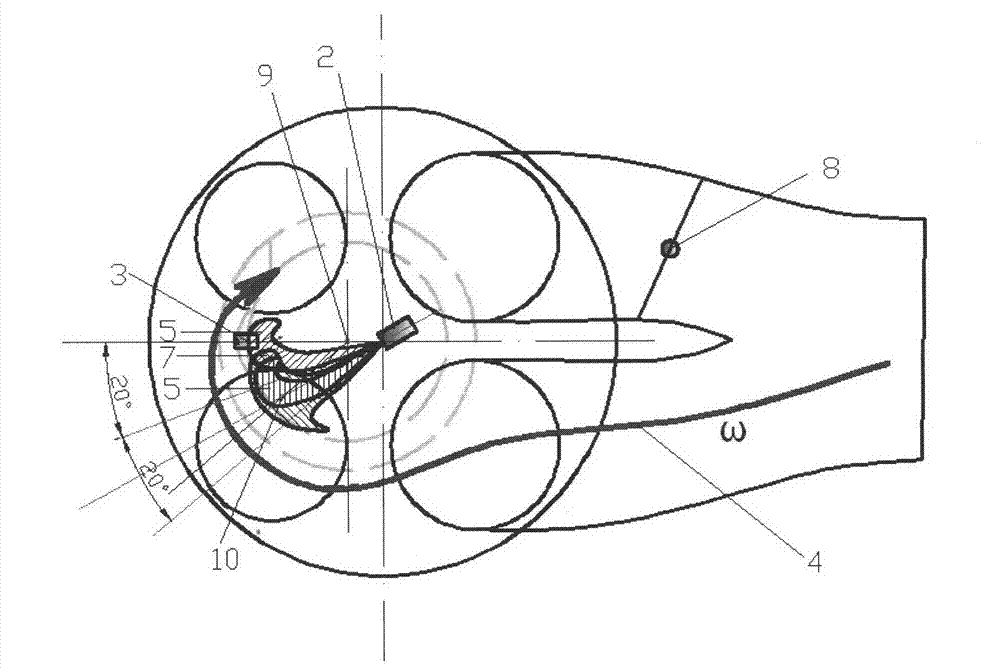

[0015] Embodiment: On the engine of cylinder diameter D=85mm, combustion chamber is made of the dimple 1 that has large inclination angle (θ) bottom surface on the roof top and piston, and compression ratio ε=10.5~11. The spark plug 3 is arranged on the symmetry line of the two exhaust valves and is properly away from the nozzle position, and the three holes (the total area of the nozzle holes A = 0.0643mm 2 ) The nozzle 2 is installed in the center of the combustion chamber, and its axis is inclined to the direction of the spark plug ( figure 1 ). Under the action of the intake vortex 4, the part of the LPG spray 5 sprayed from the 2 holes on the upper part of the nozzle (diameter of the nozzle Φ=0.11mm, and the injection angle rotates 20° and 40° counterclockwise along the horizontal axis) at the later stage of the compression process directly reaches the spark plug near the electrodes. And another part of LPG spray 6 ejected from the 1 hole in the lower part of the nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com