Patents

Literature

88 results about "Symmetry line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Symmetry lines are center lines used as an axis of symmetry for partial views. The line of symmetry is identified by two thick, short parallel lines drawn at right angles to the center line.

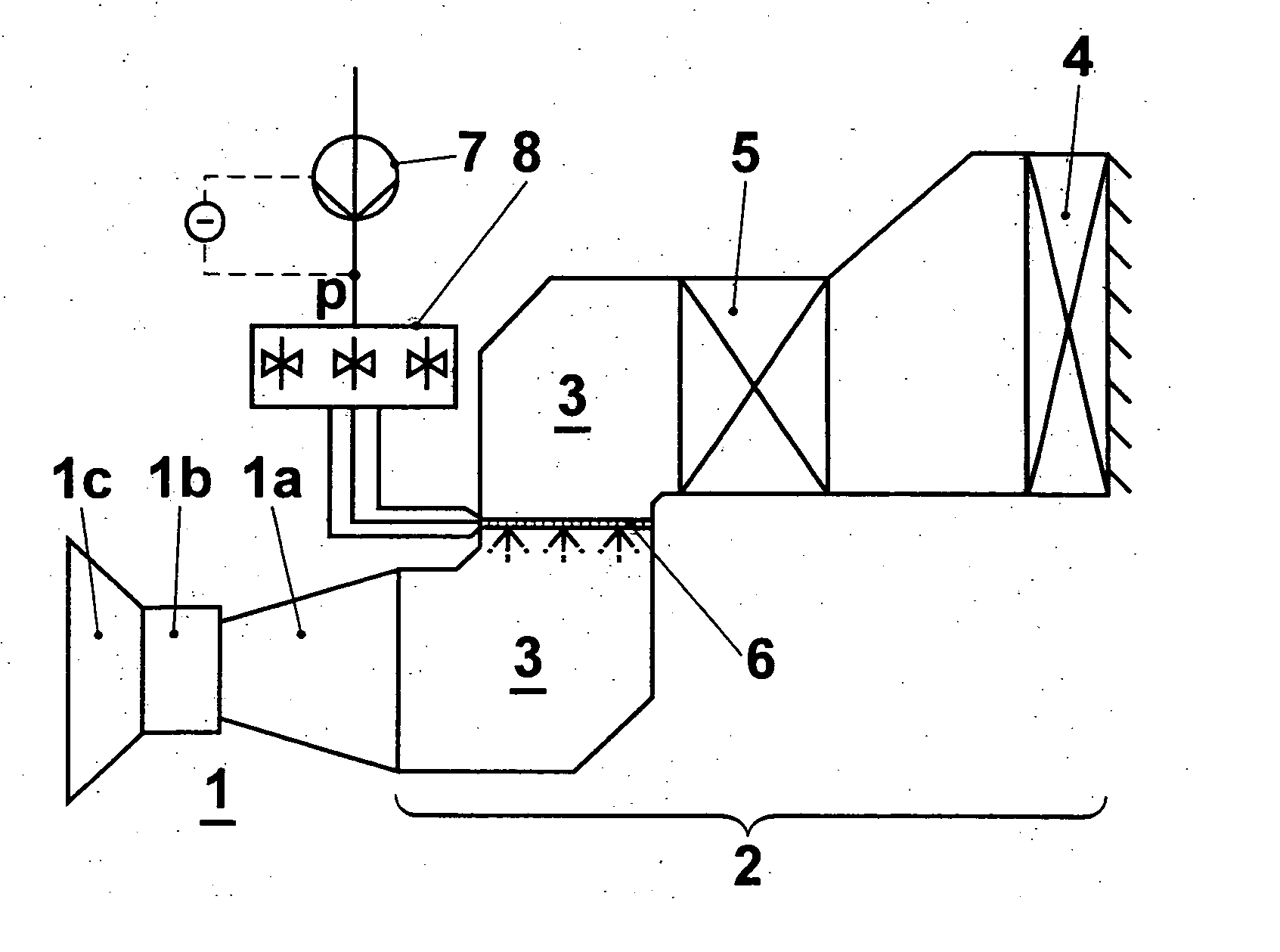

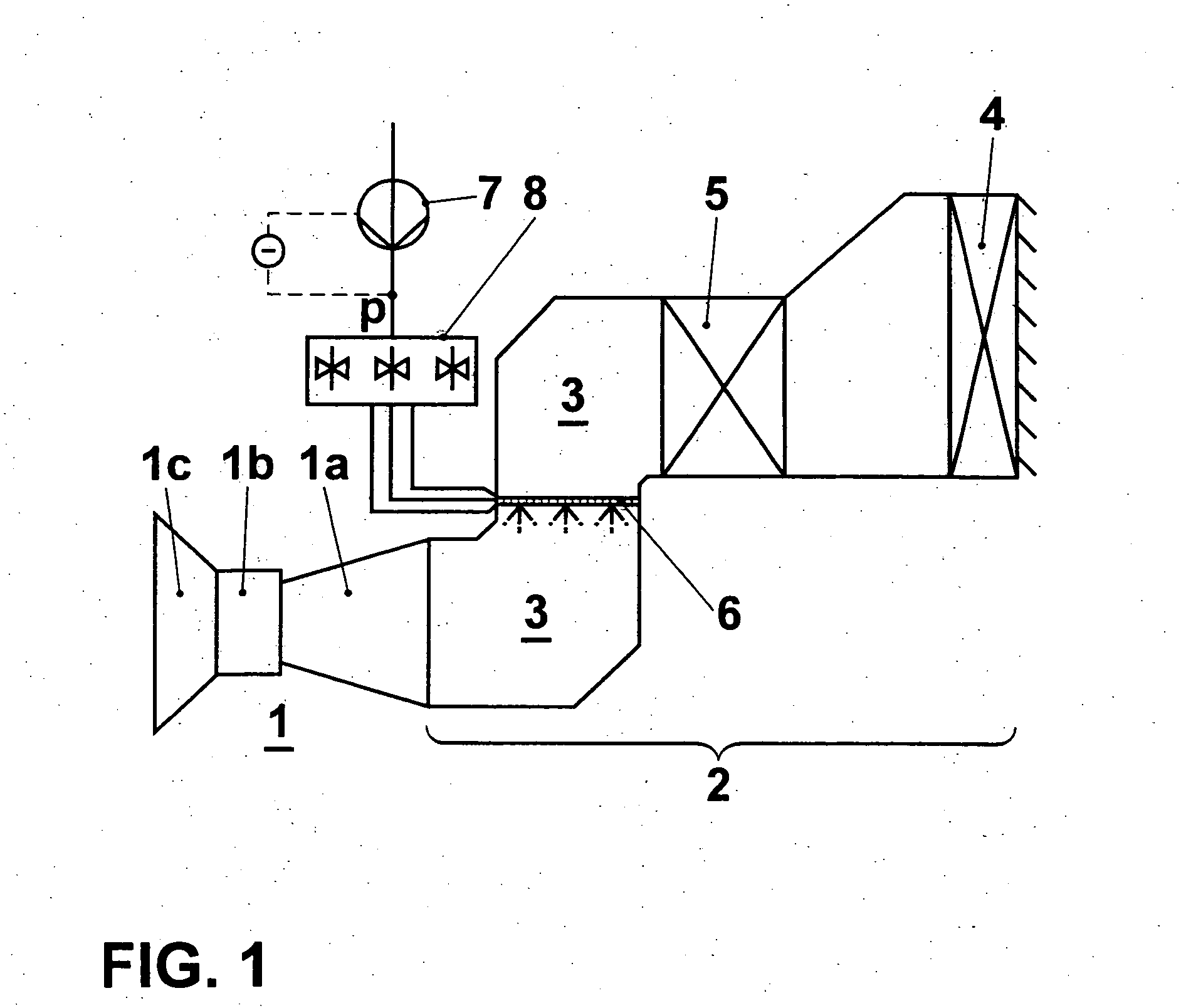

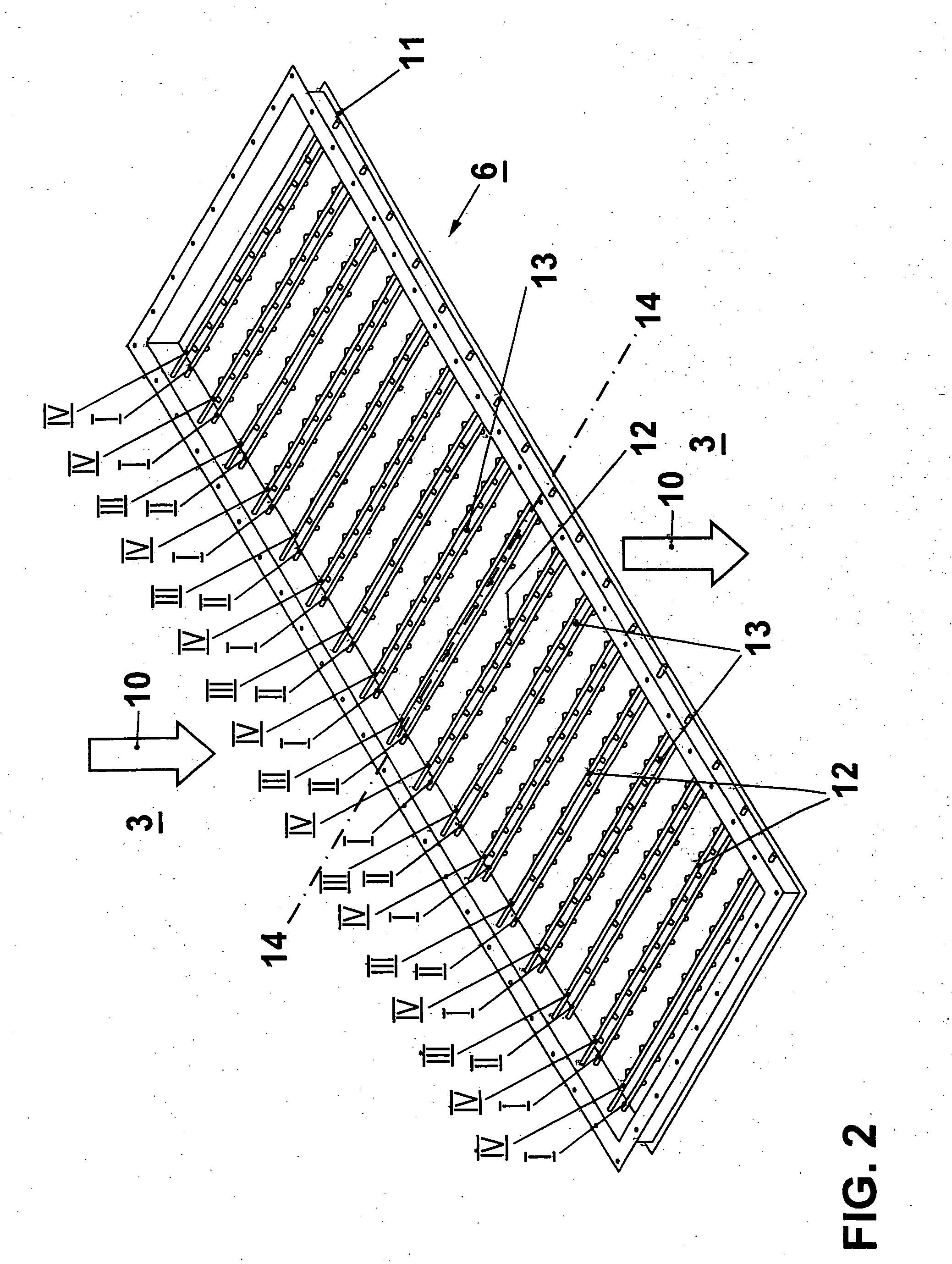

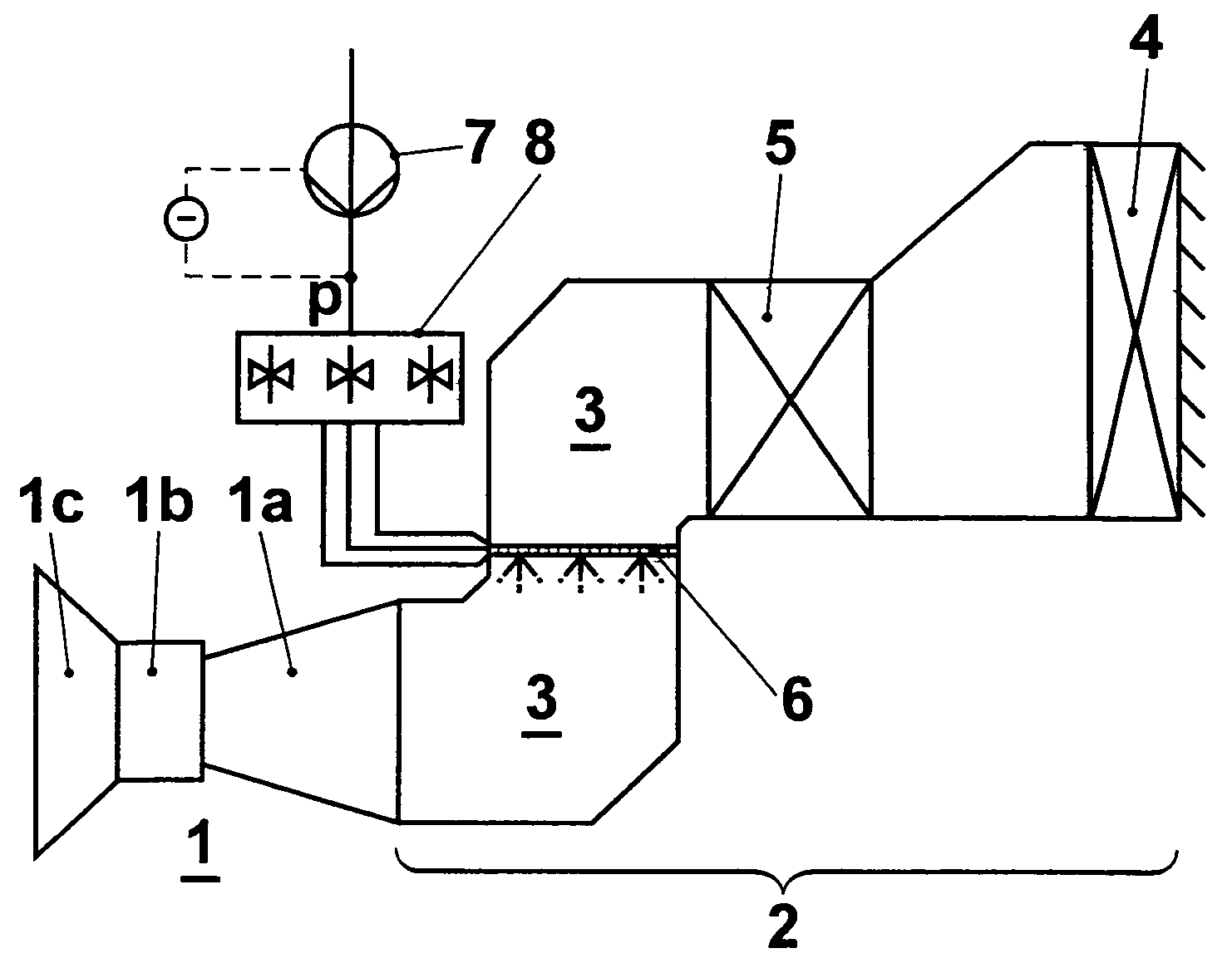

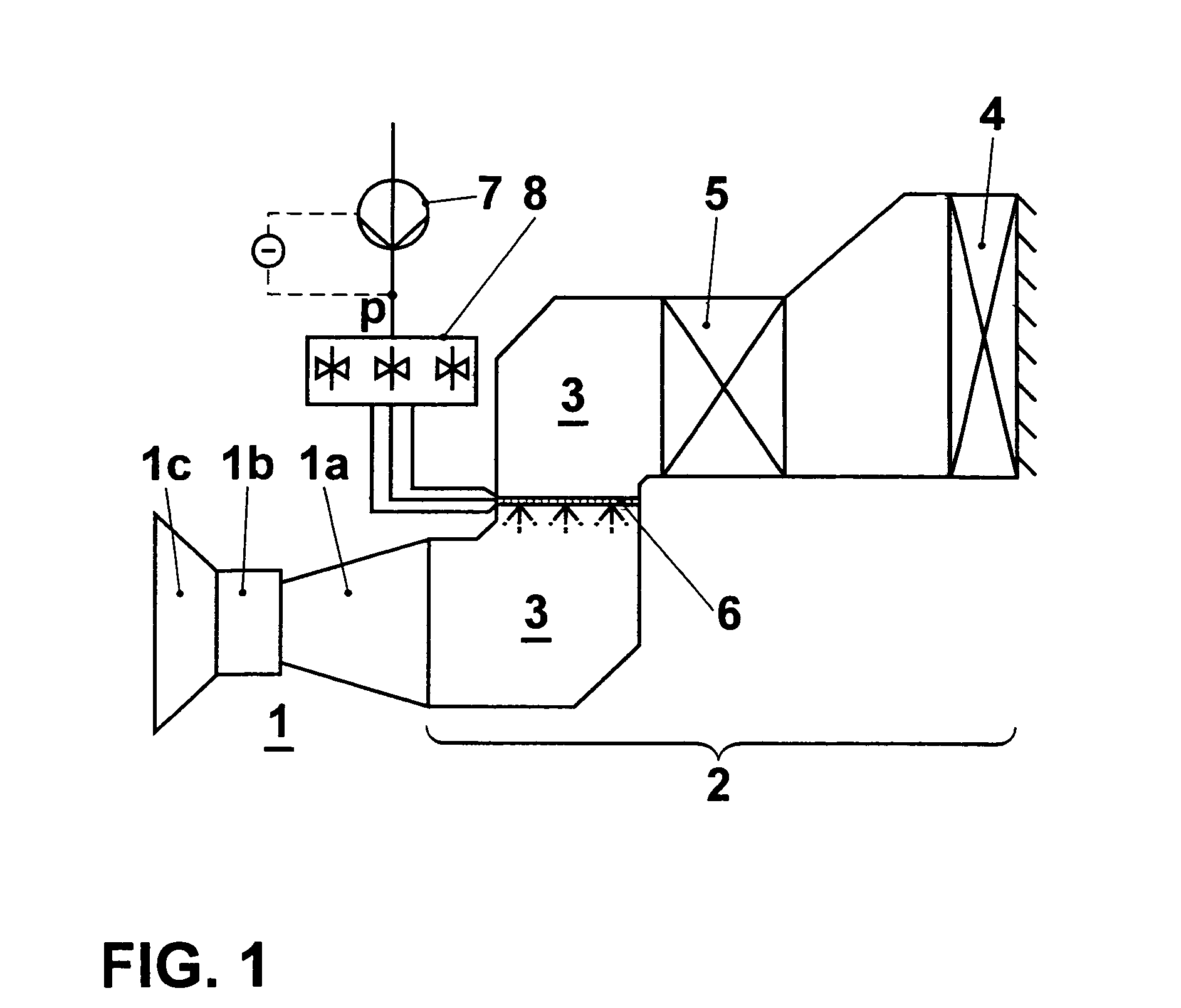

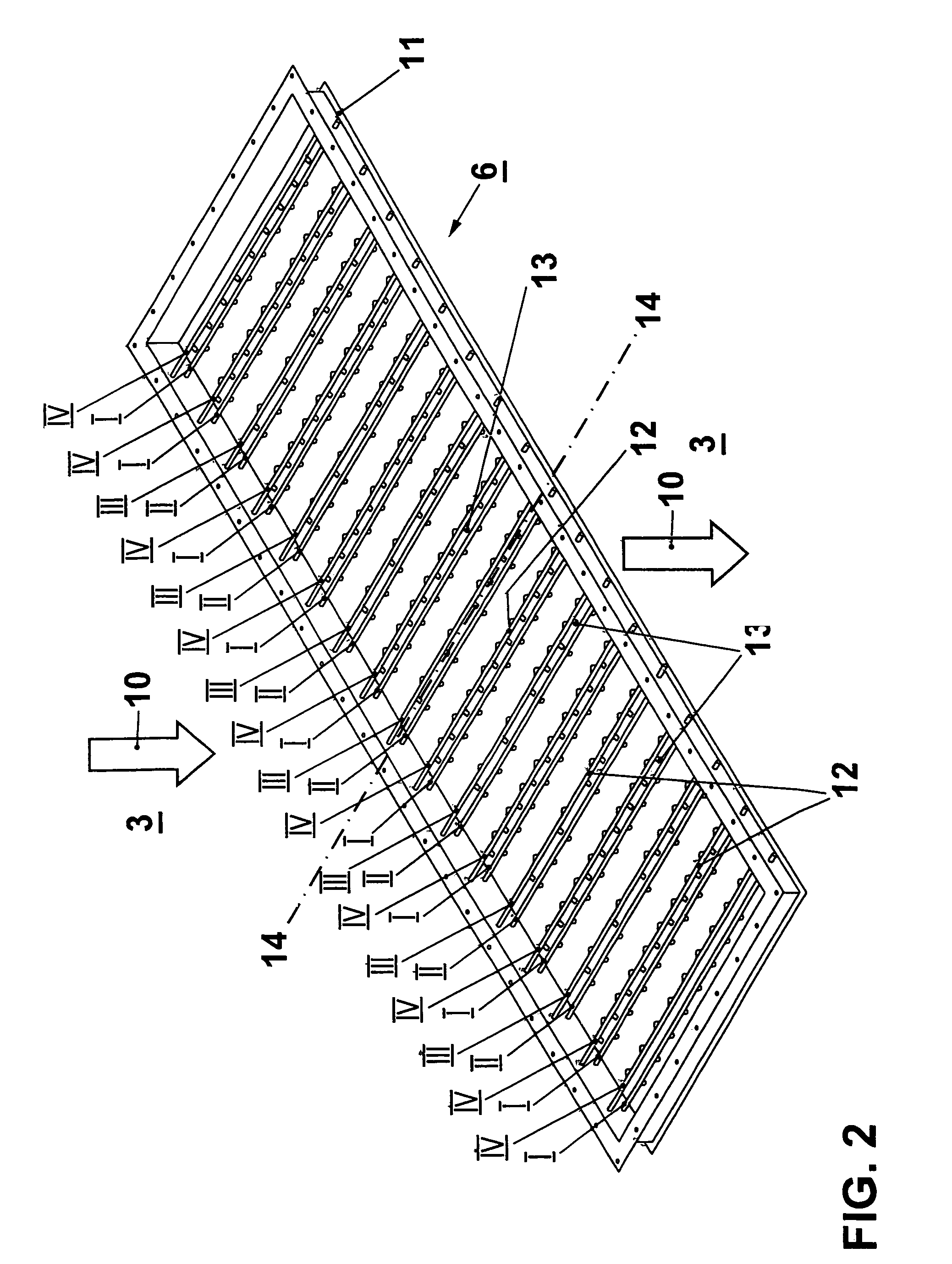

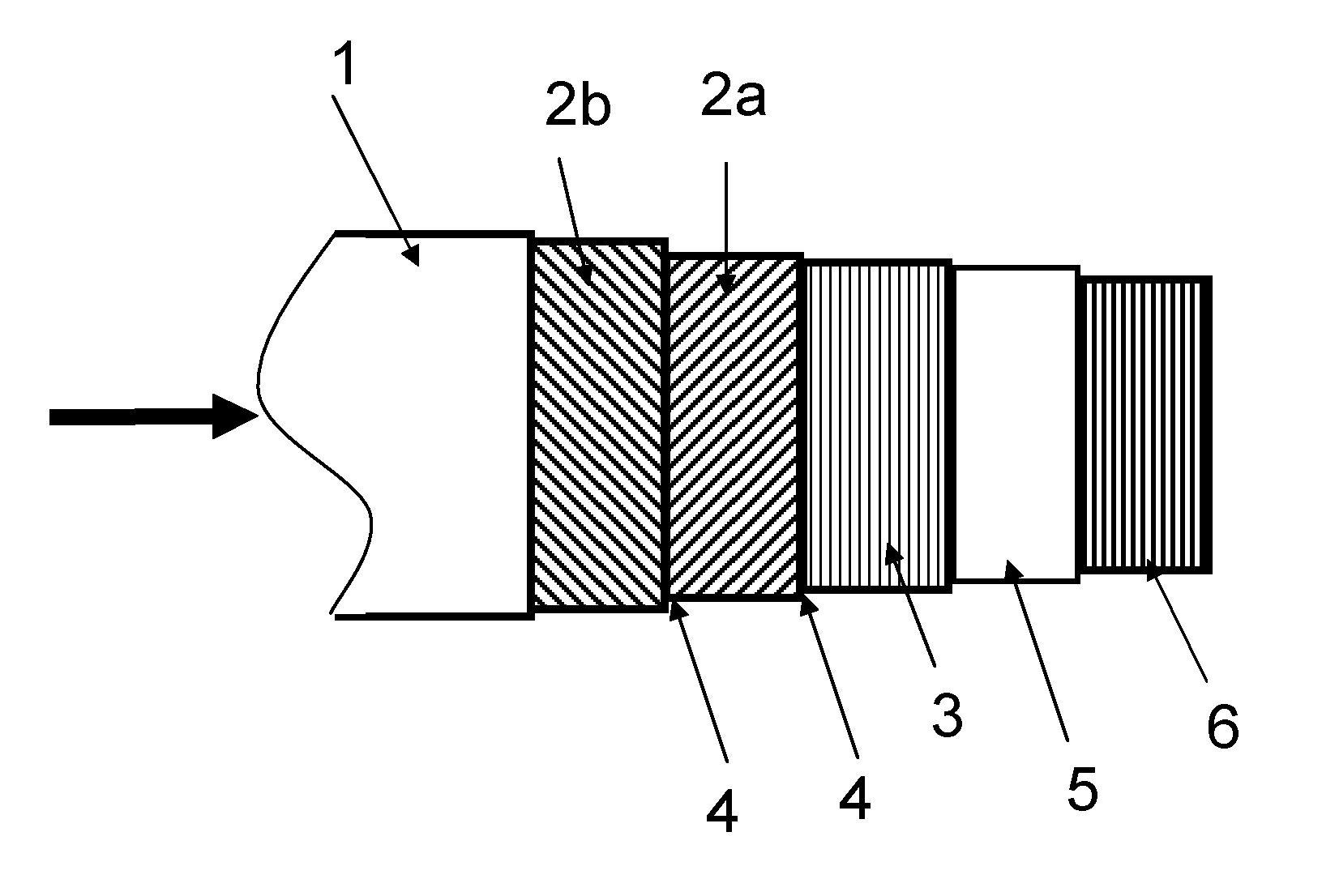

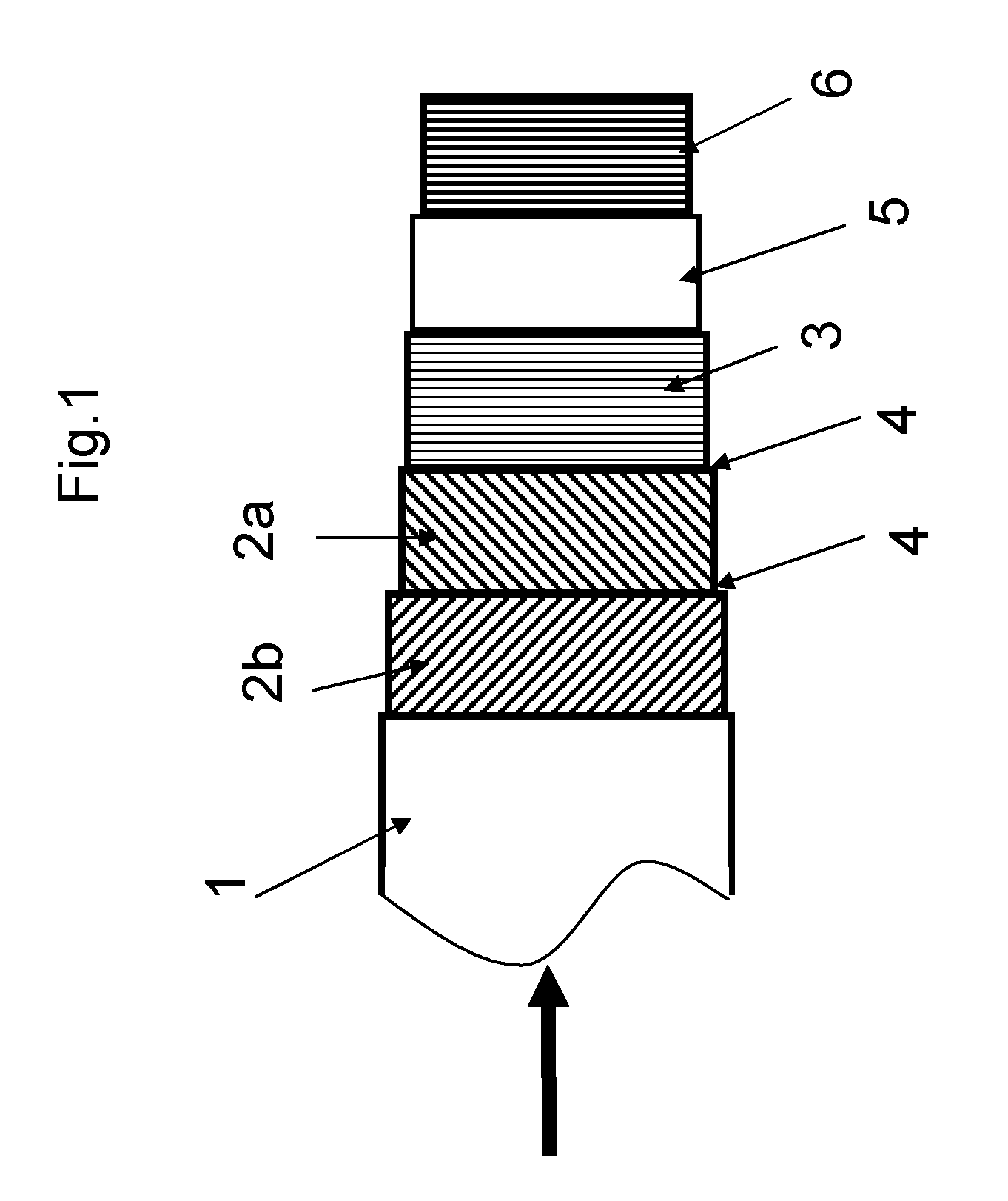

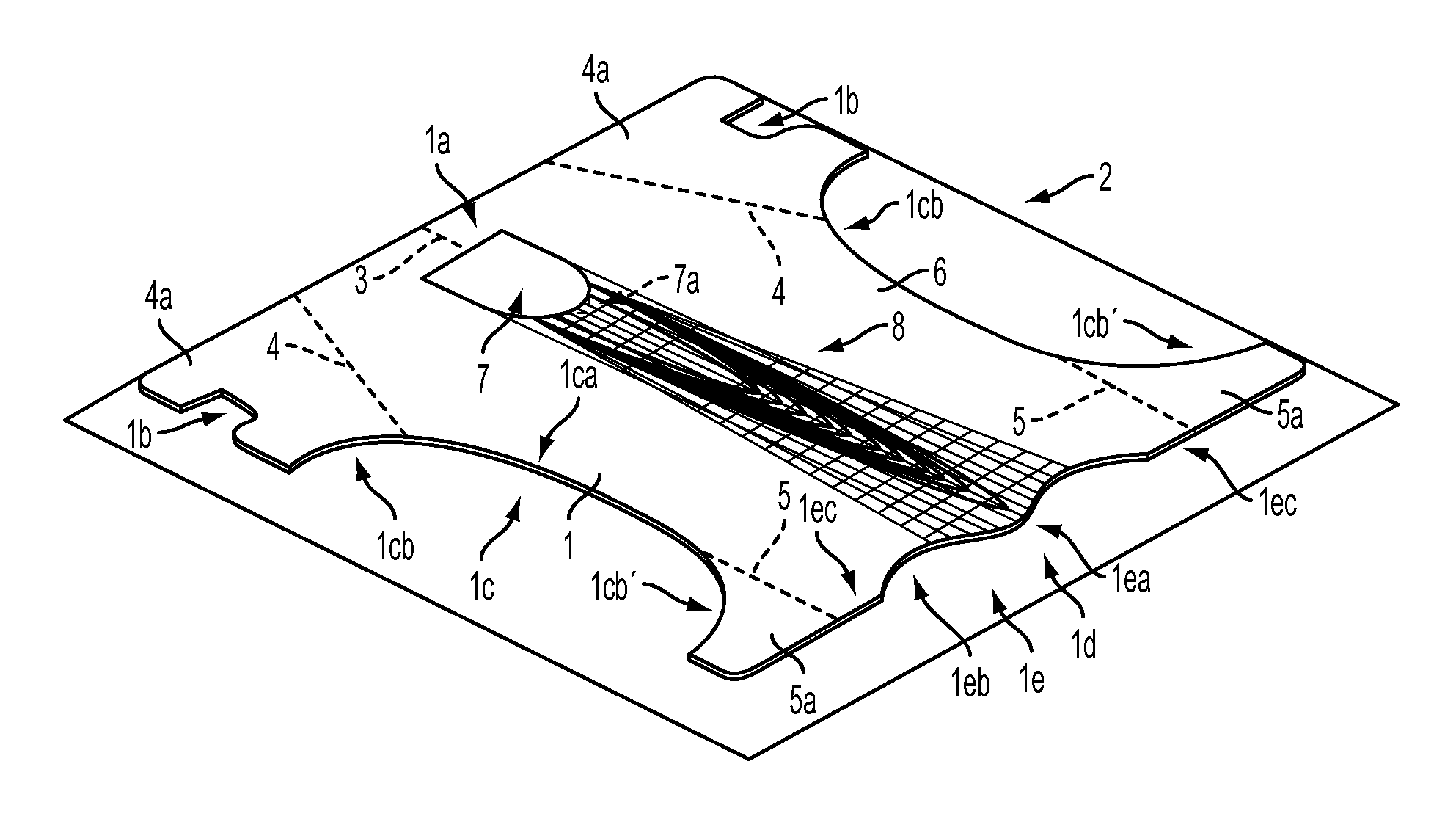

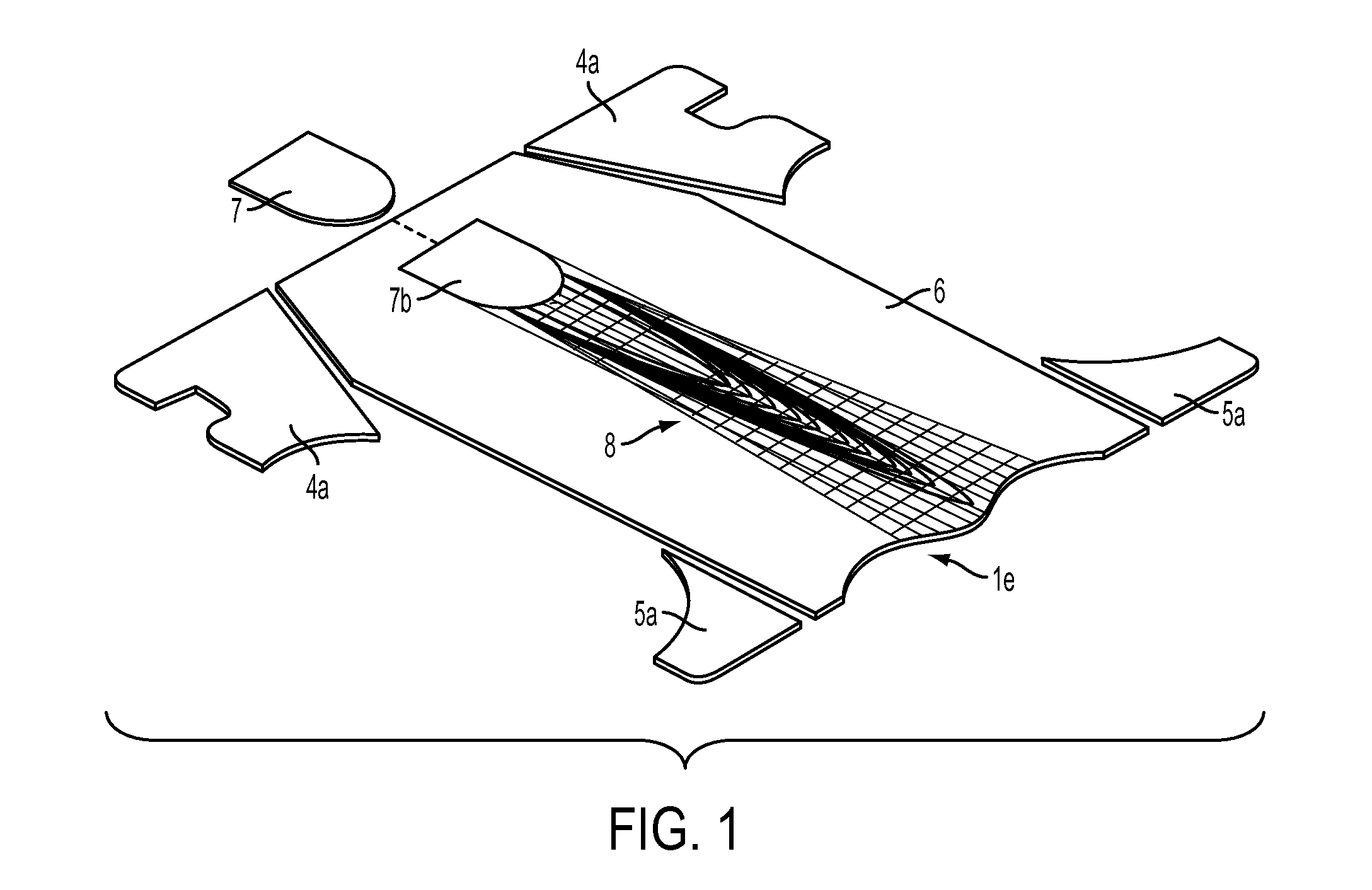

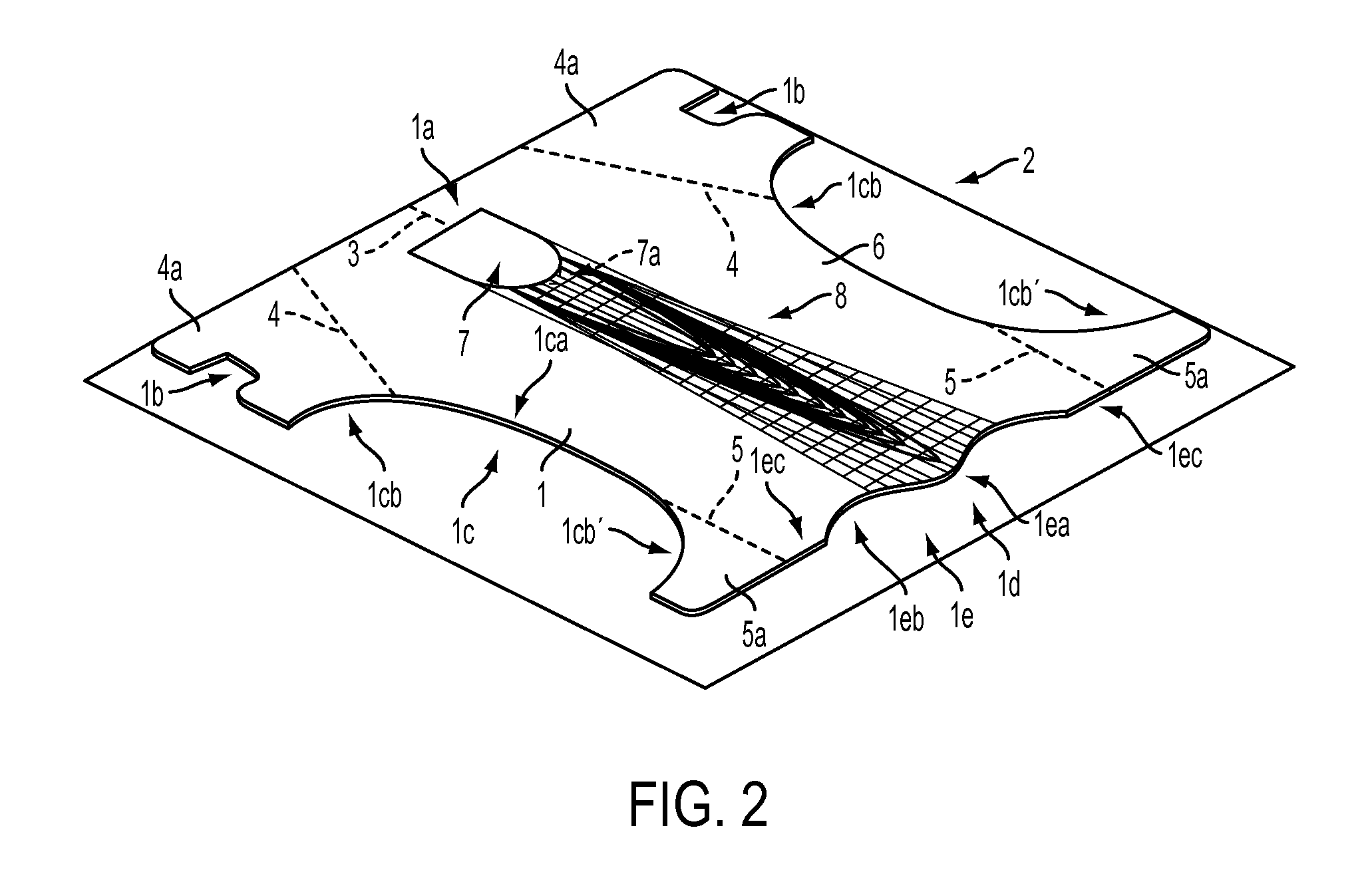

Method of controlling the injection of liquid into an inflow duct of a prime mover or driven machine

InactiveUS20050279101A1Good flexibilityEasy to controlEngine manufactureEngine fuctionsAtomizer nozzleSymmetry line

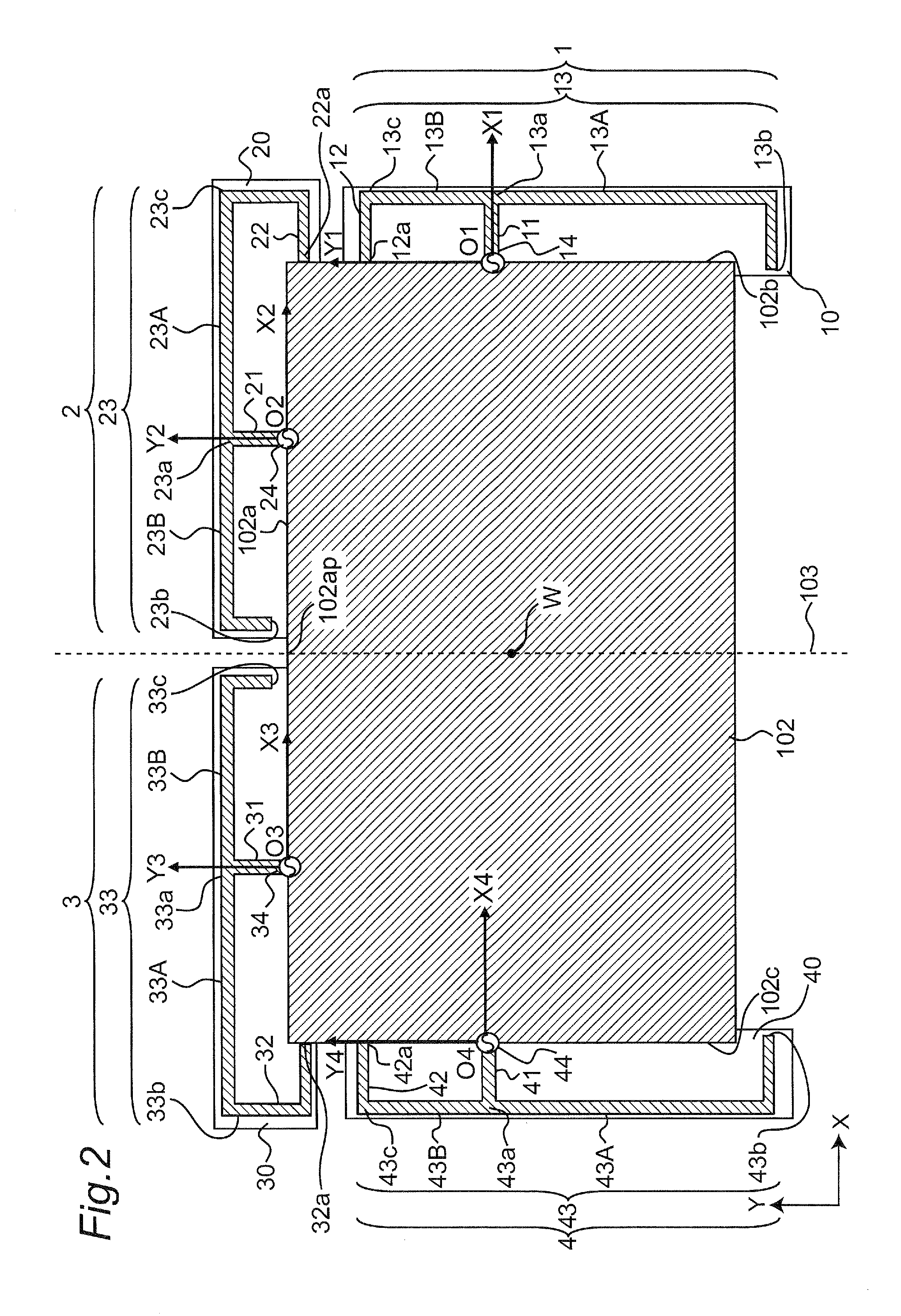

The injection of finely atomized liquid-droplets into the intake air flow of a compressor is used, for example, to improve the output of a gas turbine. If the atomization is effected via pressure atomizer nozzles, it is advantageous, when the injection device is operated with a portion of the design mass flow, to admit liquid to only some of the atomizer nozzles of the injection device. The atomizer nozzles may be arranged on nozzle tubes, liquid being jointly admitted to all the atomizer nozzles arranged on a respective nozzle tube, operated in such a way that the same mass flow is injected on each side of a symmetry line. To this end, nozzle tubes may be combined to form groups, to which liquid is jointly admitted, and the tubes of a group may be arranged in mirror image to one another relative to the symmetry line.

Owner:ANSALDO ENERGIA IP UK LTD

Method of controlling the injection of liquid into an inflow duct of a prime mover or driven machine

InactiveUS7520137B2Good flexibilityEasy to controlEngine manufactureEngine fuctionsSymmetry lineAtomizer nozzle

The injection of finely atomized liquid-droplets into the intake air flow of a compressor is used, for example, to improve the output of a gas turbine. If the atomization is effected via pressure atomizer nozzles, it is advantageous, when the injection device is operated with a portion of the design mass flow, to admit liquid to only some of the atomizer nozzles of the injection device. The atomizer nozzles may be arranged on nozzle tubes, liquid being jointly admitted to all the atomizer nozzles arranged on a respective nozzle tube, operated in such a way that the same mass flow is injected on each side of a symmetry line. To this end, nozzle tubes may be combined to form groups, to which liquid is jointly admitted, and the tubes of a group may be arranged in mirror image to one another relative to the symmetry line.

Owner:ANSALDO ENERGIA IP UK LTD

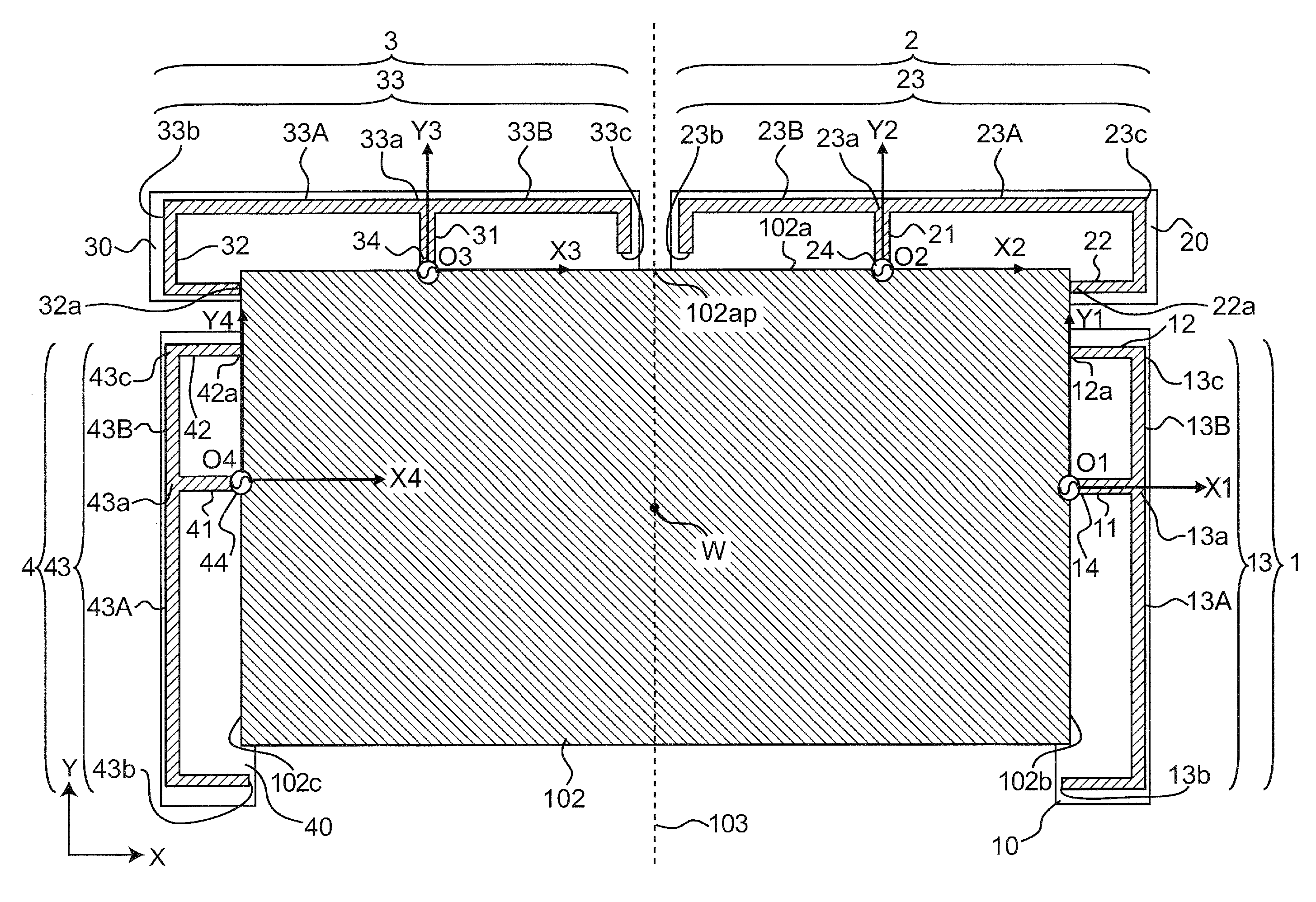

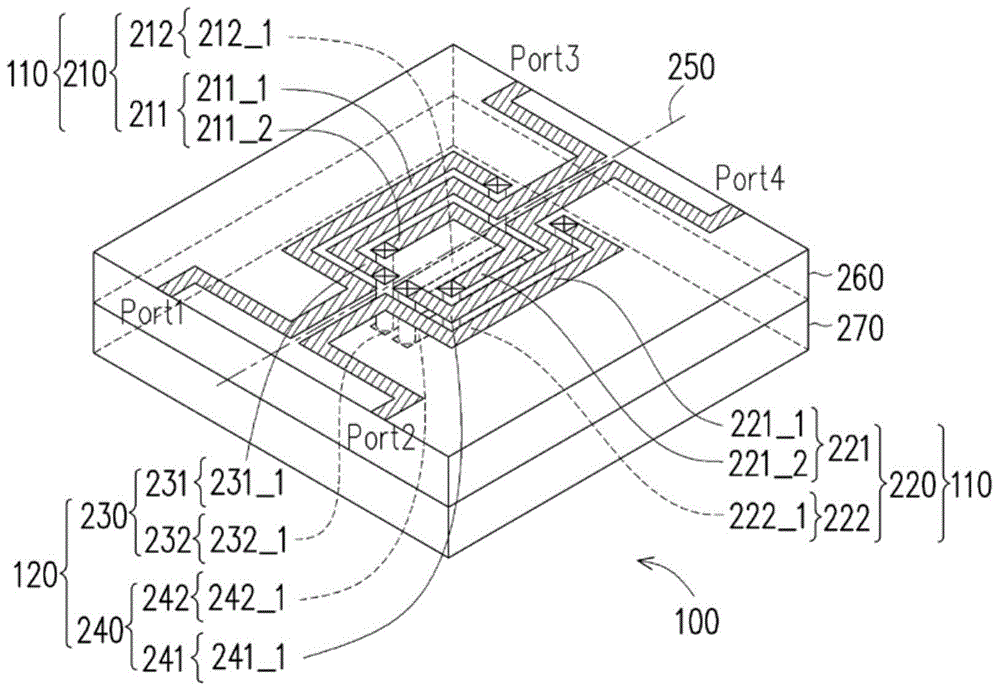

Antenna apparatus including two pairs of antennas provided respectively to be symmetric with respect to symmetric line

ActiveUS20130314297A1High gainPrevent the decrease in the gainSimultaneous aerial operationsElongated active element feedElectrical conductorSymmetry line

An antenna apparatus is configured to include first, second, third and fourth antennas. The first and fourth antennas are provided to be symmetrical with respect to a predetermined symmetry line on the grounding conductor, and the second and third antennas are arranged to be symmetrical with respect to the symmetry line so that the second and third feeding points are separated apart by a predetermined distance. A first antenna element of the first antenna and a fourth antenna element of the fourth antenna are formed to be substantially parallel to a Y-axis direction, and a second antenna element of the second antenna and a third antenna element of the third antenna are formed to be substantially parallel to an X-axis direction.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

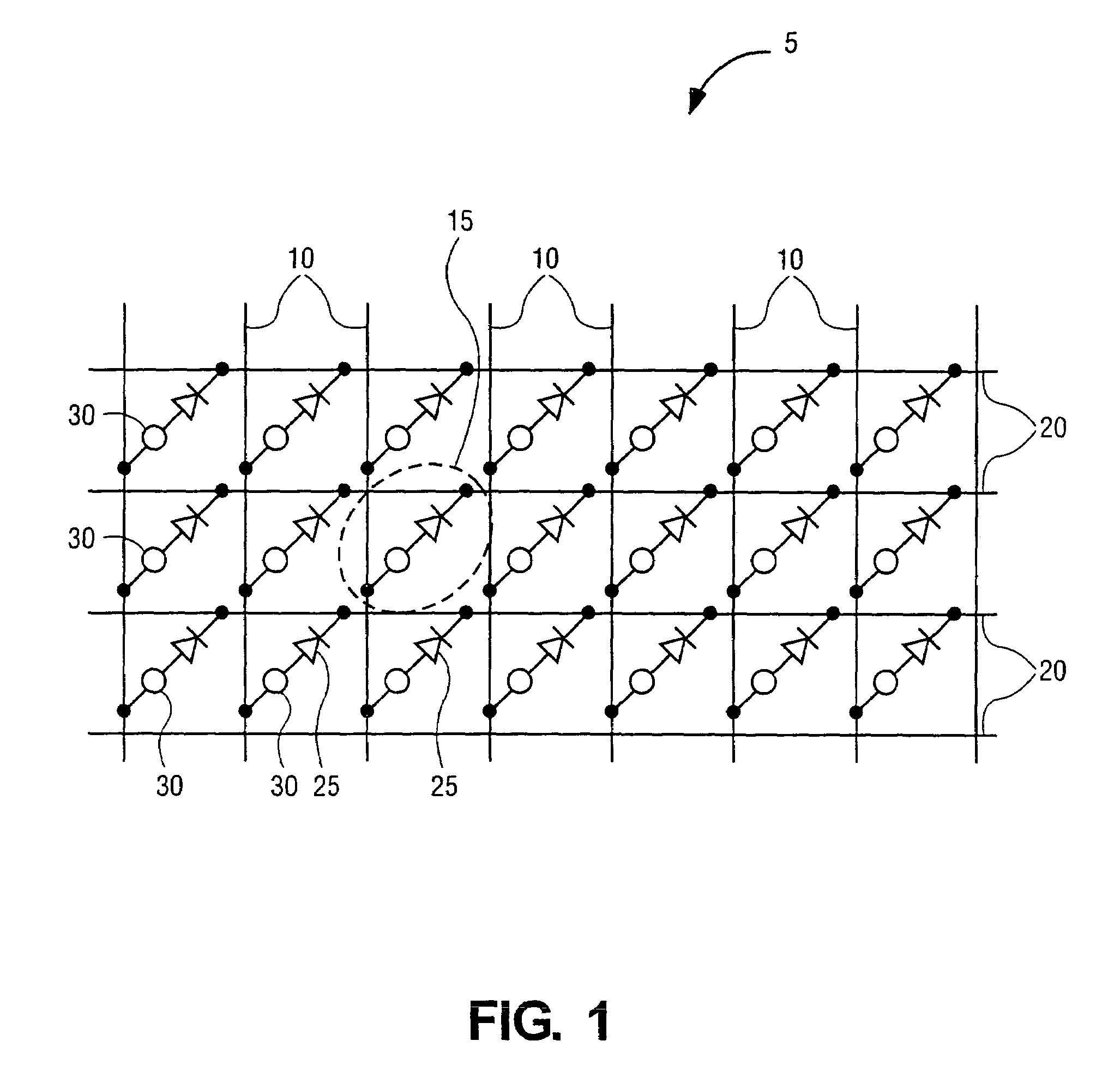

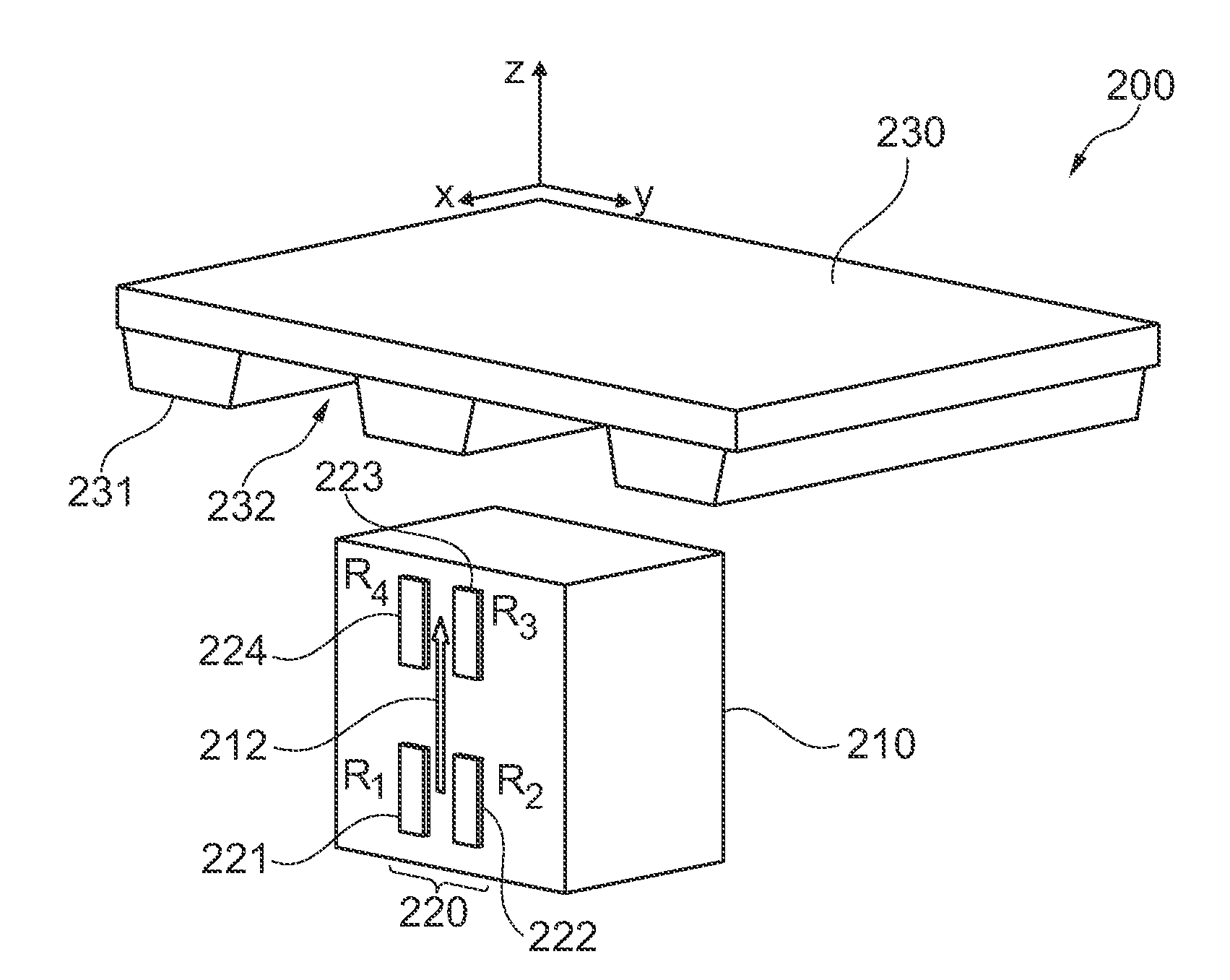

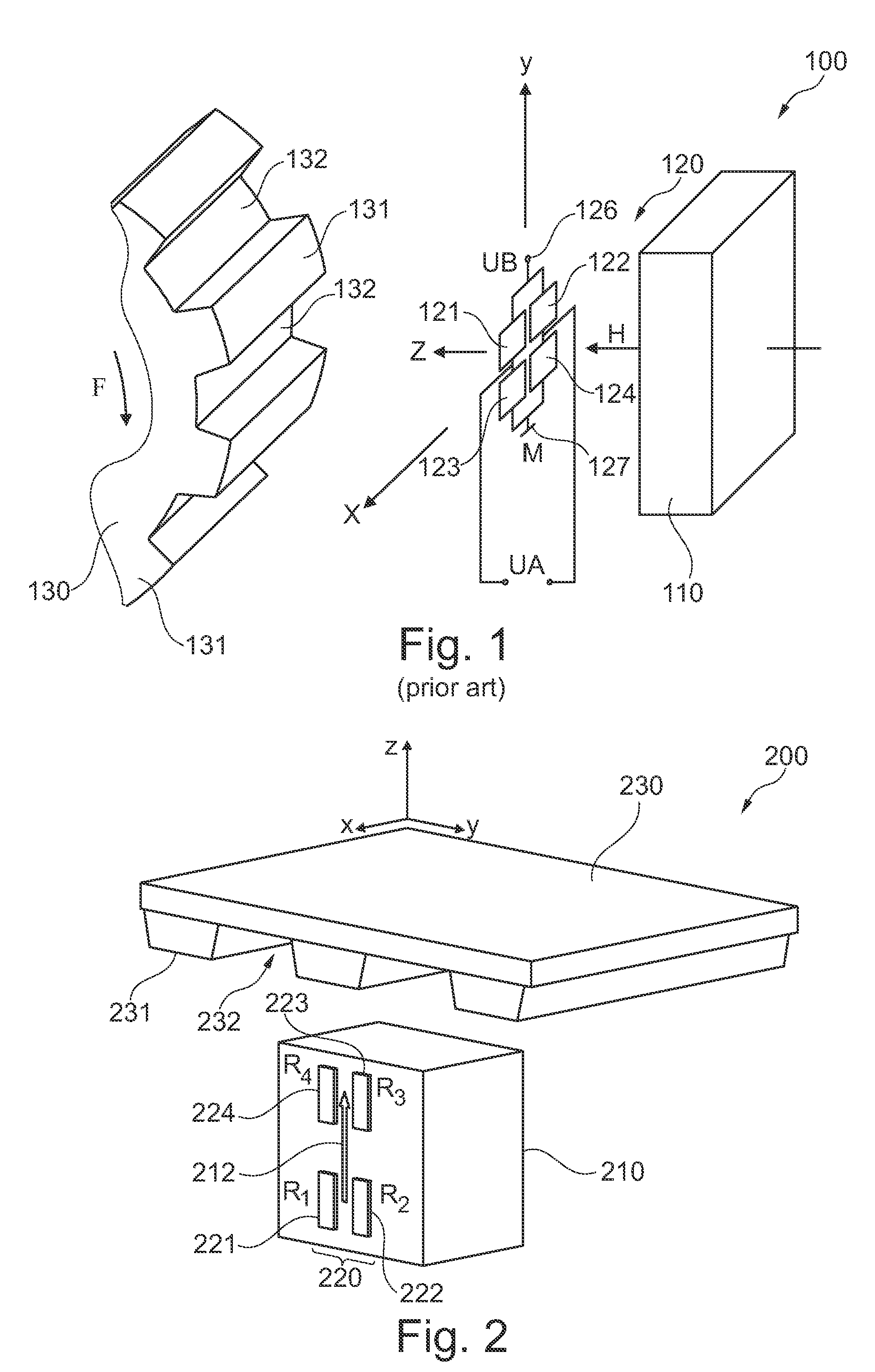

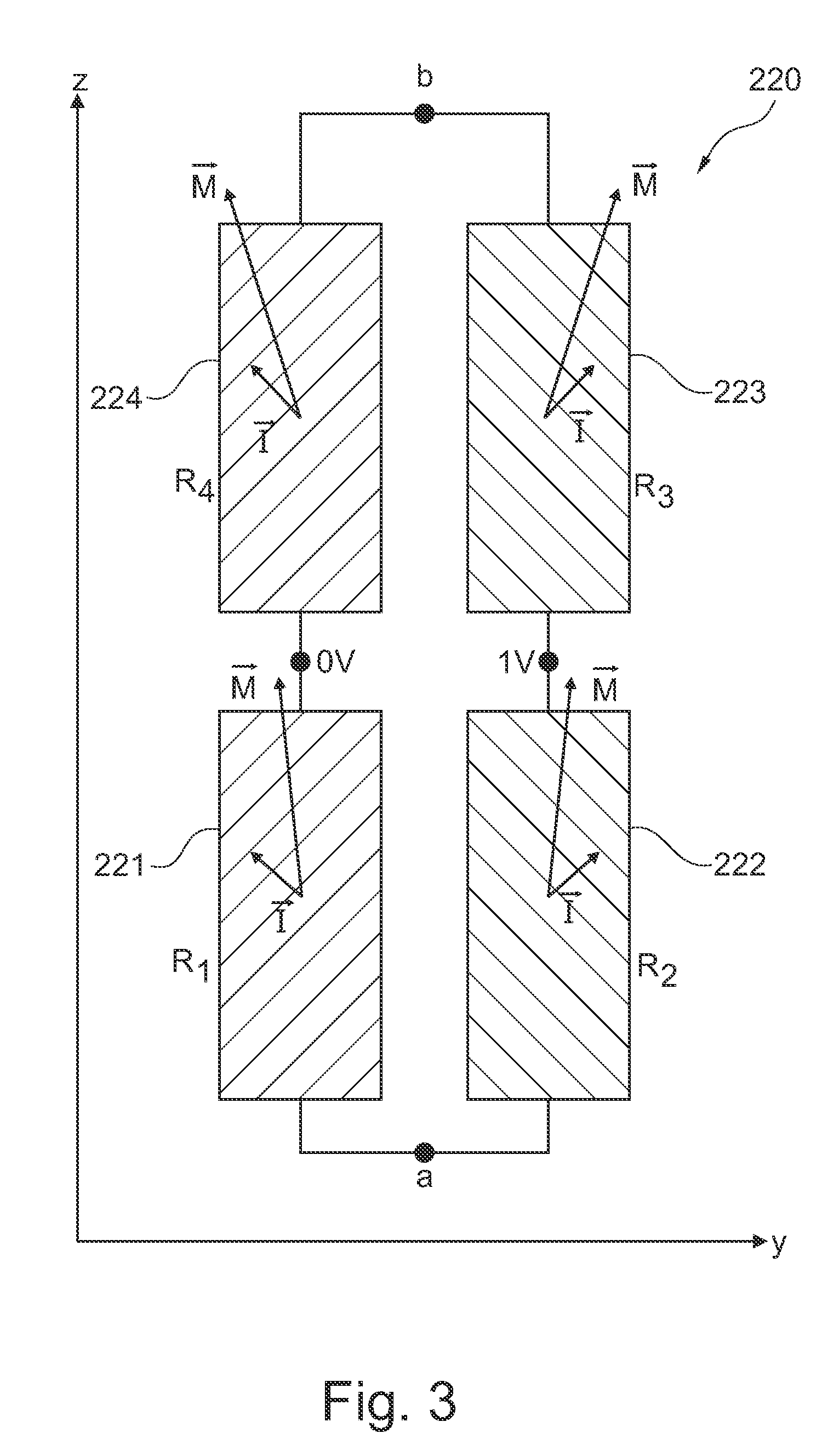

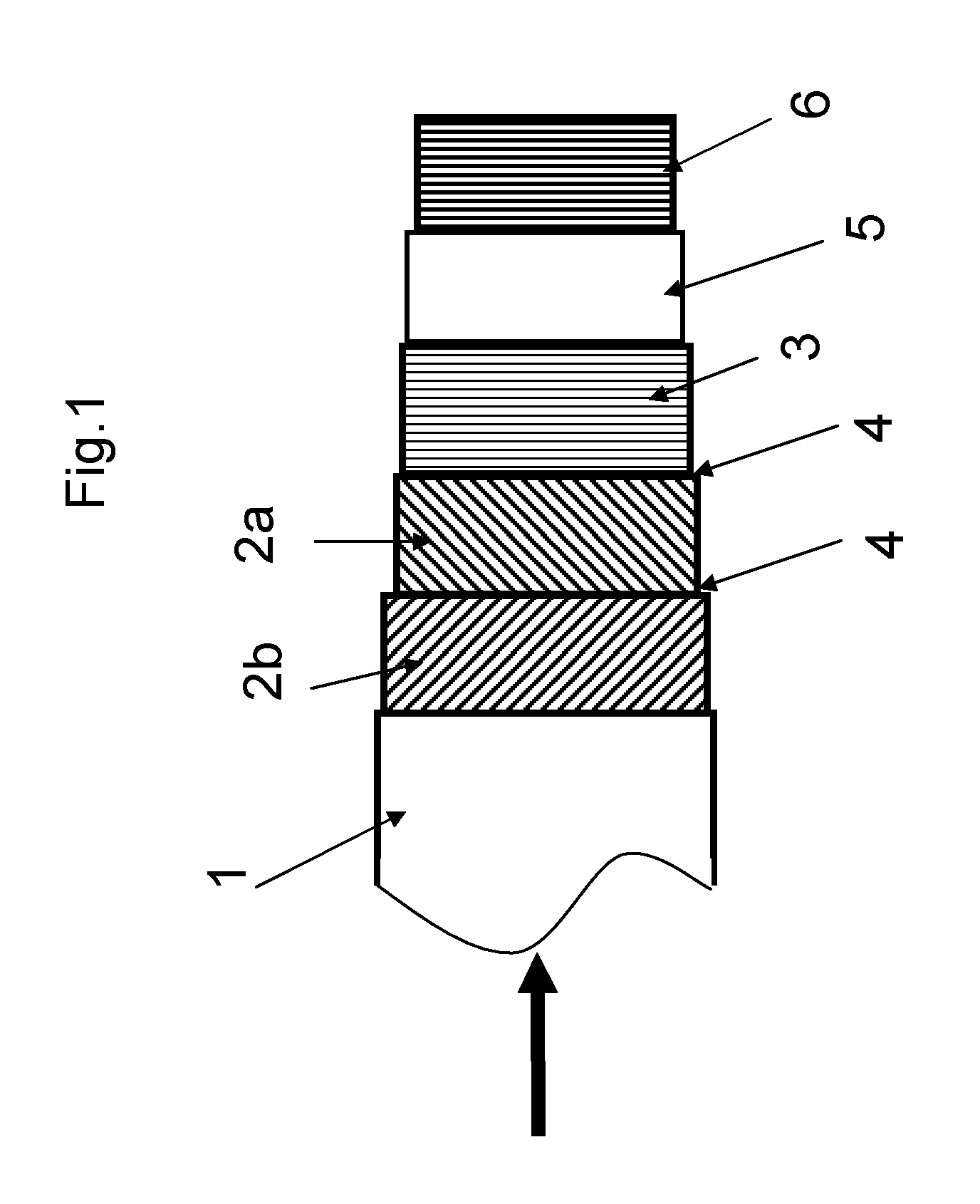

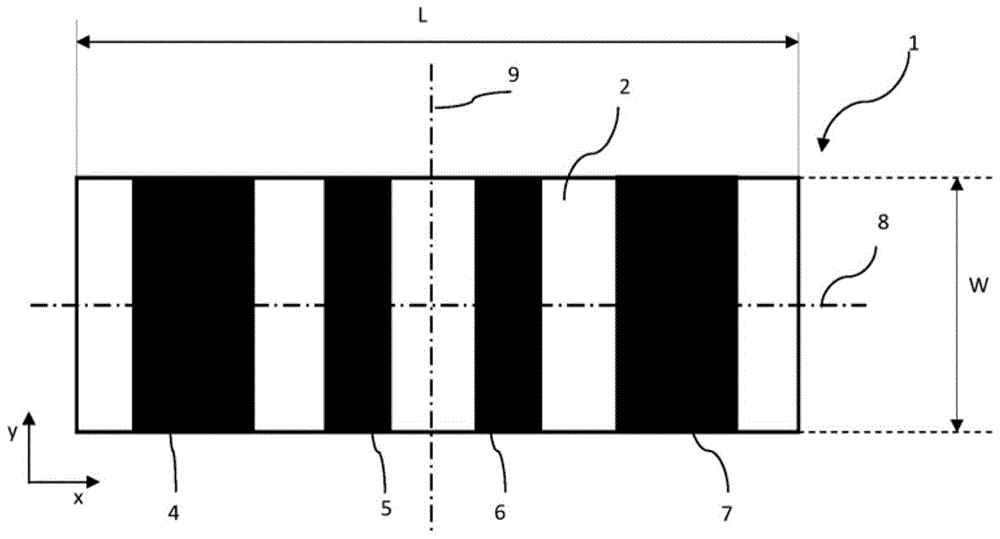

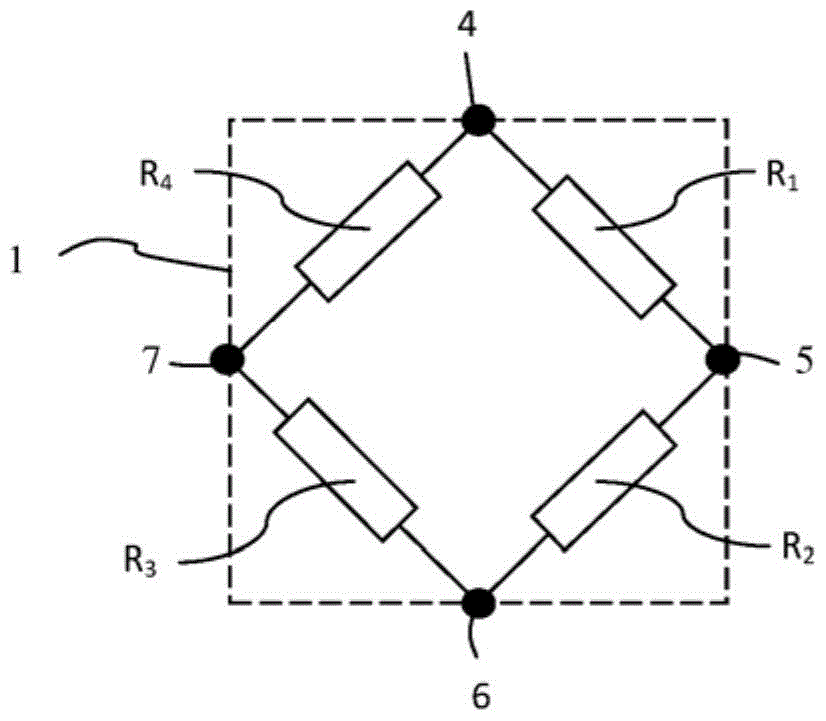

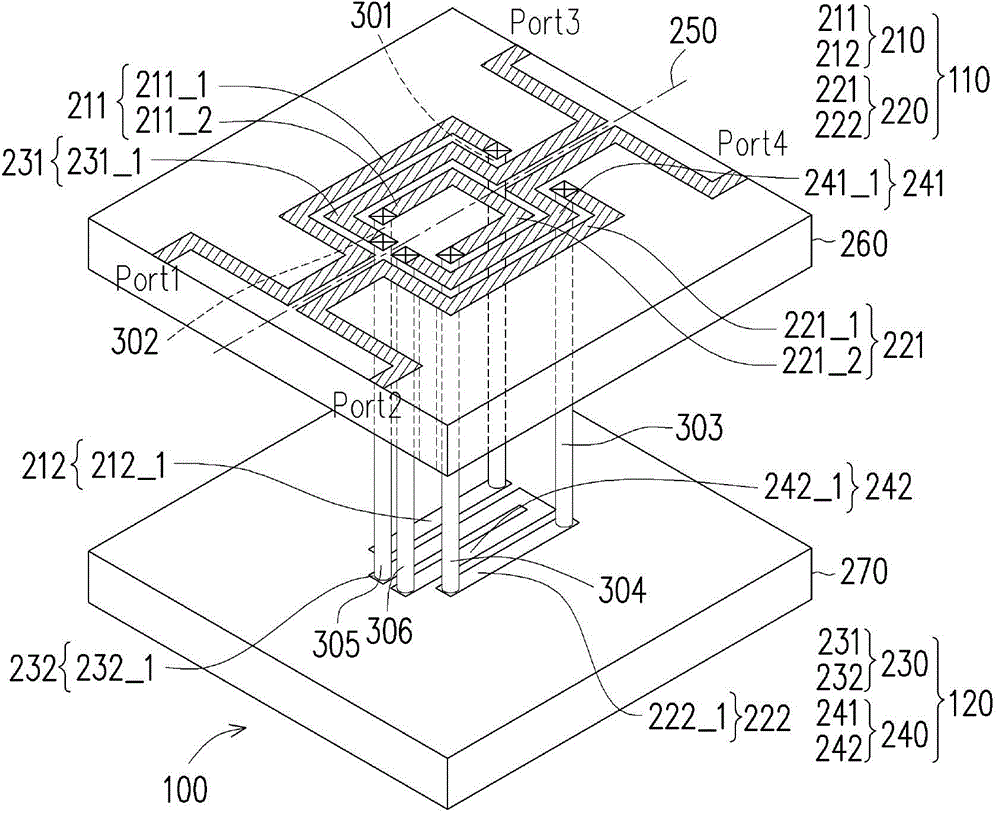

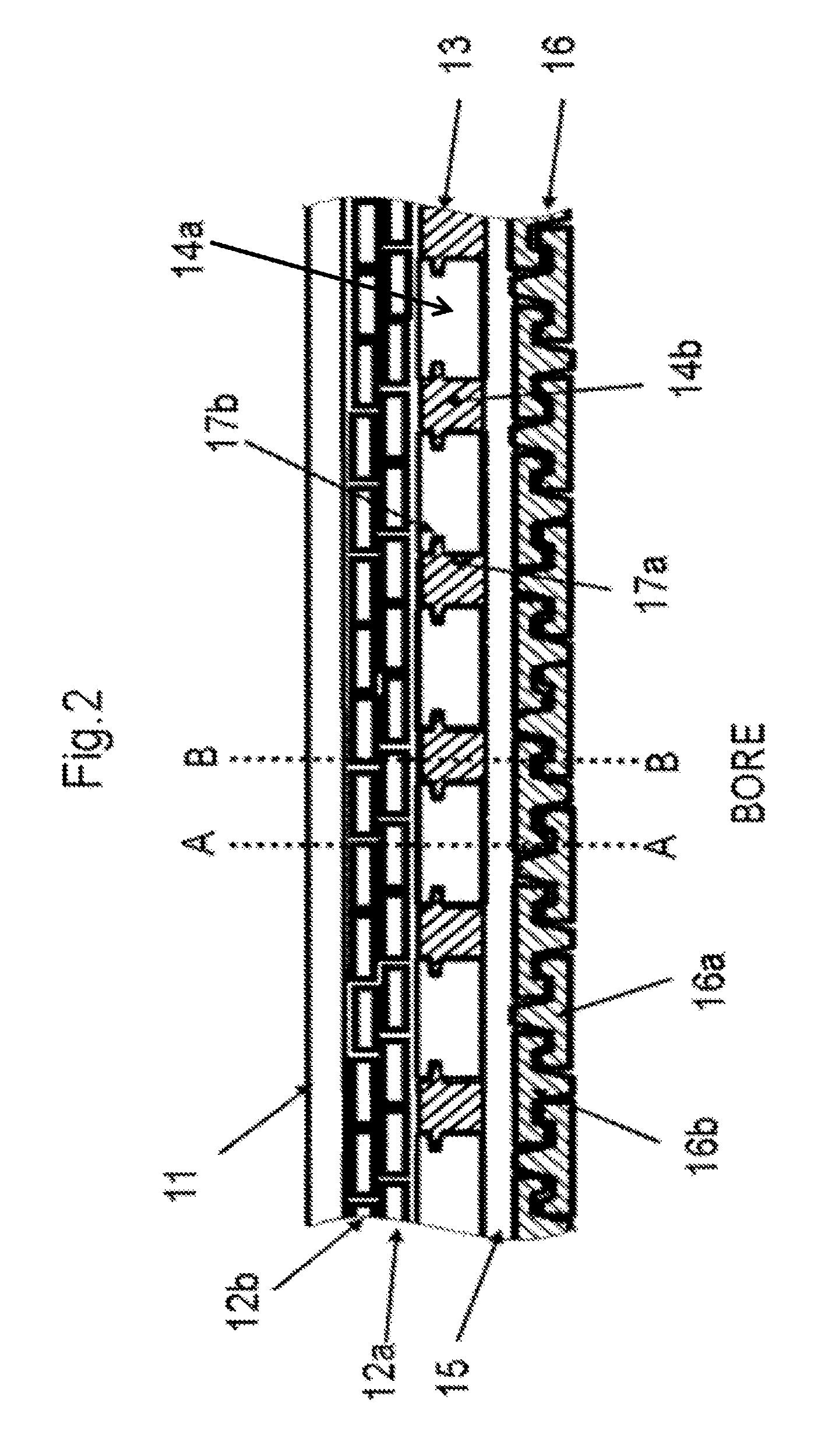

Magnetic field sensor system with a magnetic wheel rotatable around a wheel axis and with magnetic sensor elements being arranged within a plane perpendicular to the wheel axis

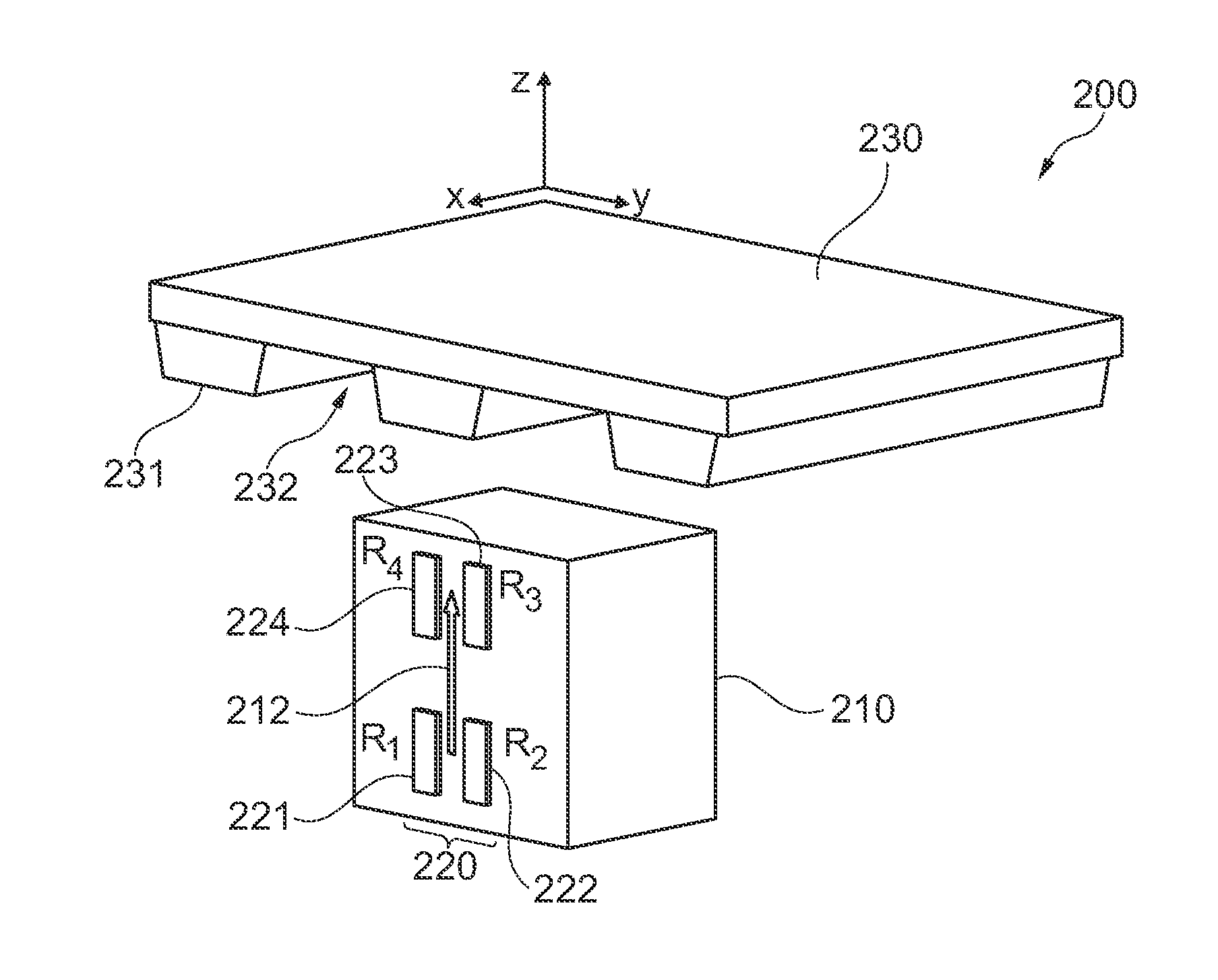

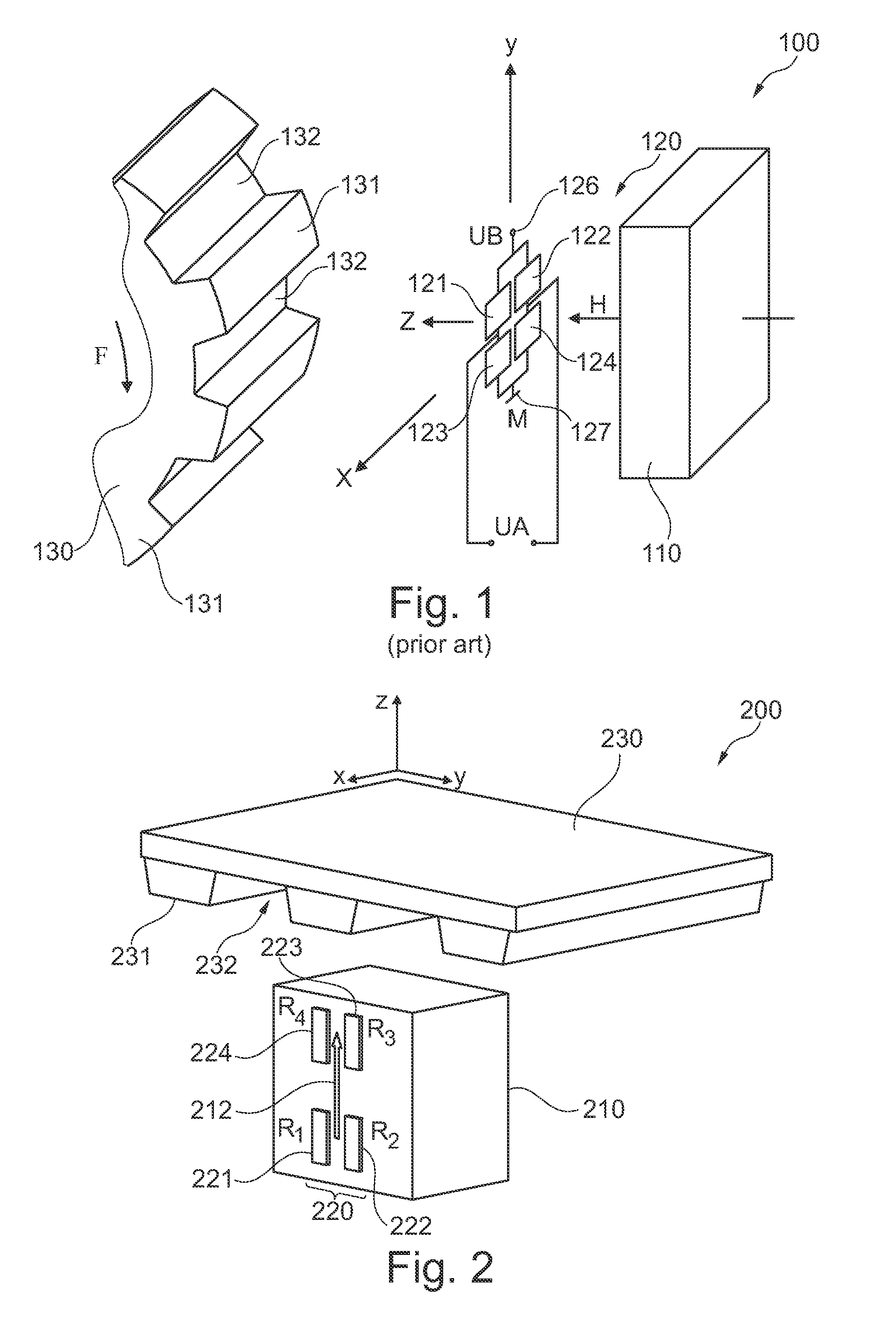

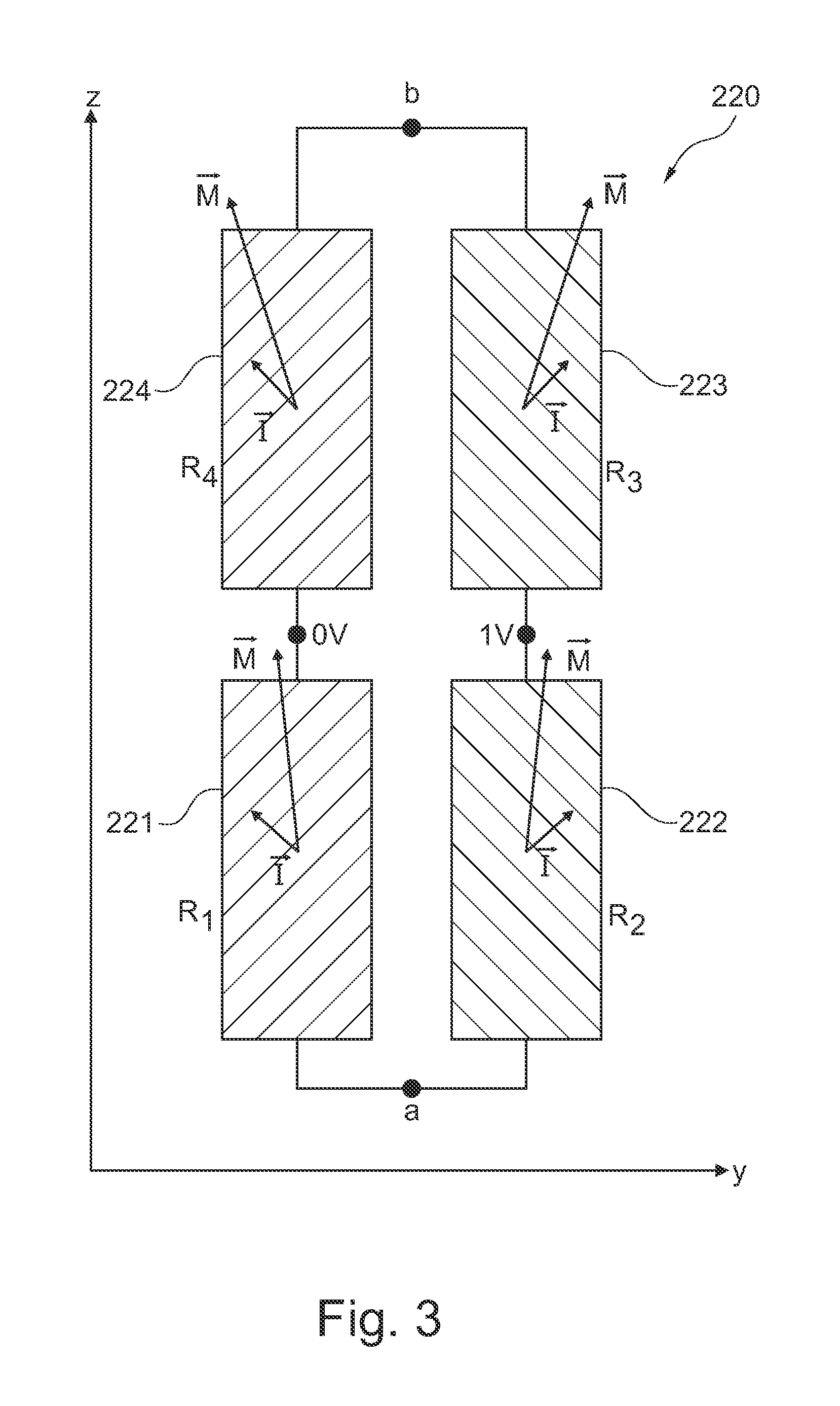

ActiveUS20140232379A1Magnetic-field-controlled resistorsSolid-state devicesSymmetry lineSensor system

It is described a magnetic field differential sensor system for measuring rotational movements of a shaft. The described magnetic field sensor system (200) comprises (a) a biasing magnet (210, 510) configured for generating a biasing magnetic field; (b) a magnetic wheel (230) having a wheel axis and a circumferential surface which comprises a regular structure of teeth (231) and gaps (232) arranged in an alternating manner, wherein (i) the magnetic wheel (230) is attachable to the shaft and (ii) the magnetic wheel (230) can be magnetized by the biasing magnetic field; and (c) a magnetic sensor arrangement (220) comprising four magnetic sensor elements (221, 222, 223, 224) being connected with each other in a Wheatstone bridge configuration. Respectively two of the magnetic sensor elements (221, 222, 223, 224) are assigned to one half bridge of the Wheatstone bridge. Further, the four magnetic sensor elements (221, 222, 223, 224) are arranged within an y-z plane, wherein an x-axis, a y-axis and a z-axis define an orthogonal Cartesian coordinate system in which (i) the x-axis is oriented parallel with the wheel axis of the magnetic wheel (230), (ii) the y-axis is oriented tangential to the circumferential surface of the magnetic wheel (230), and (iii) the z-axis is the symmetry line through the center of the biasing magnet (210, 510) and the center of the magnetic wheel (230). The magnetic sensor elements can be hall sensor elements or magnetoresistive sensor elements (221, 222, 223, 224).

Owner:NXP BV

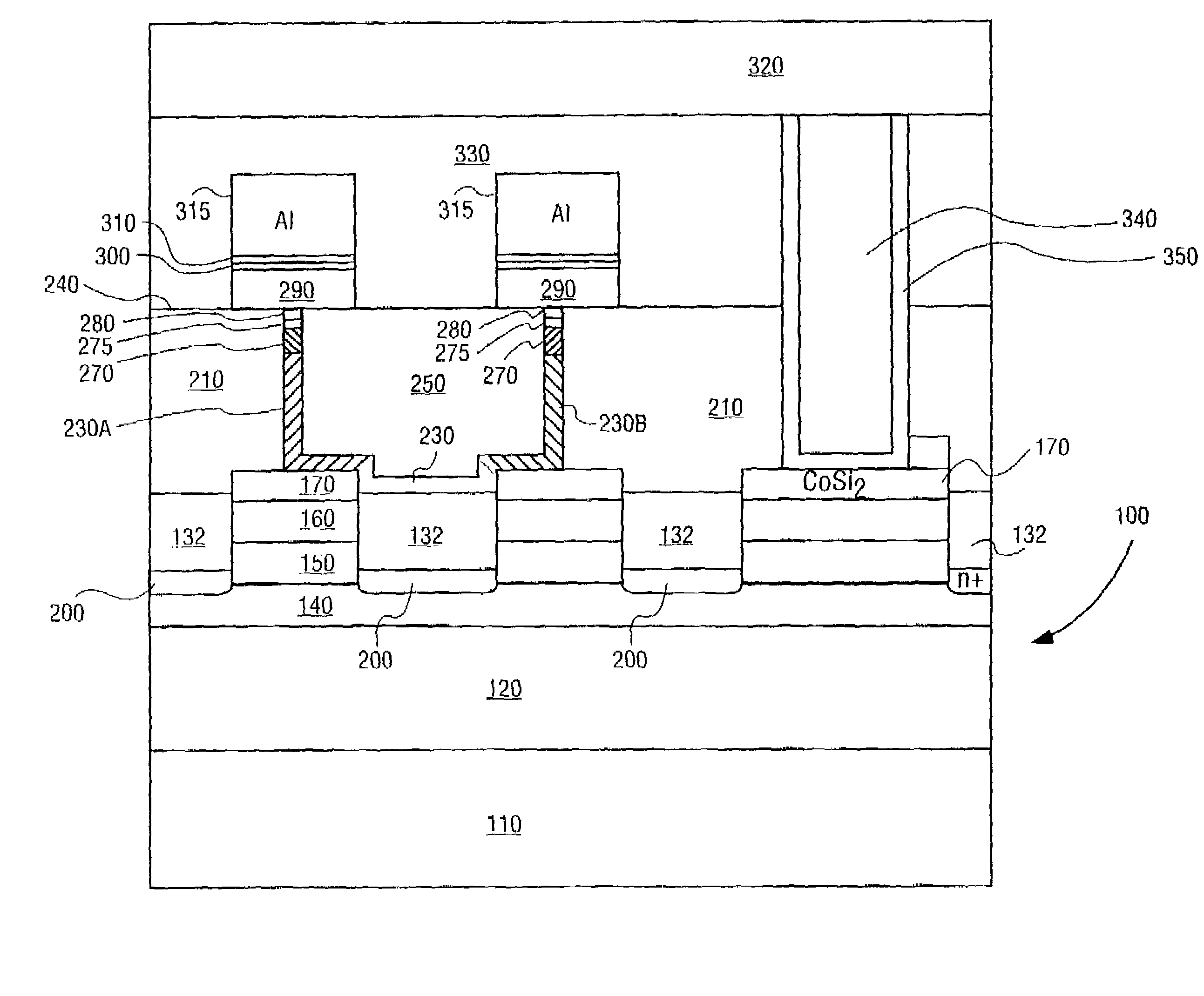

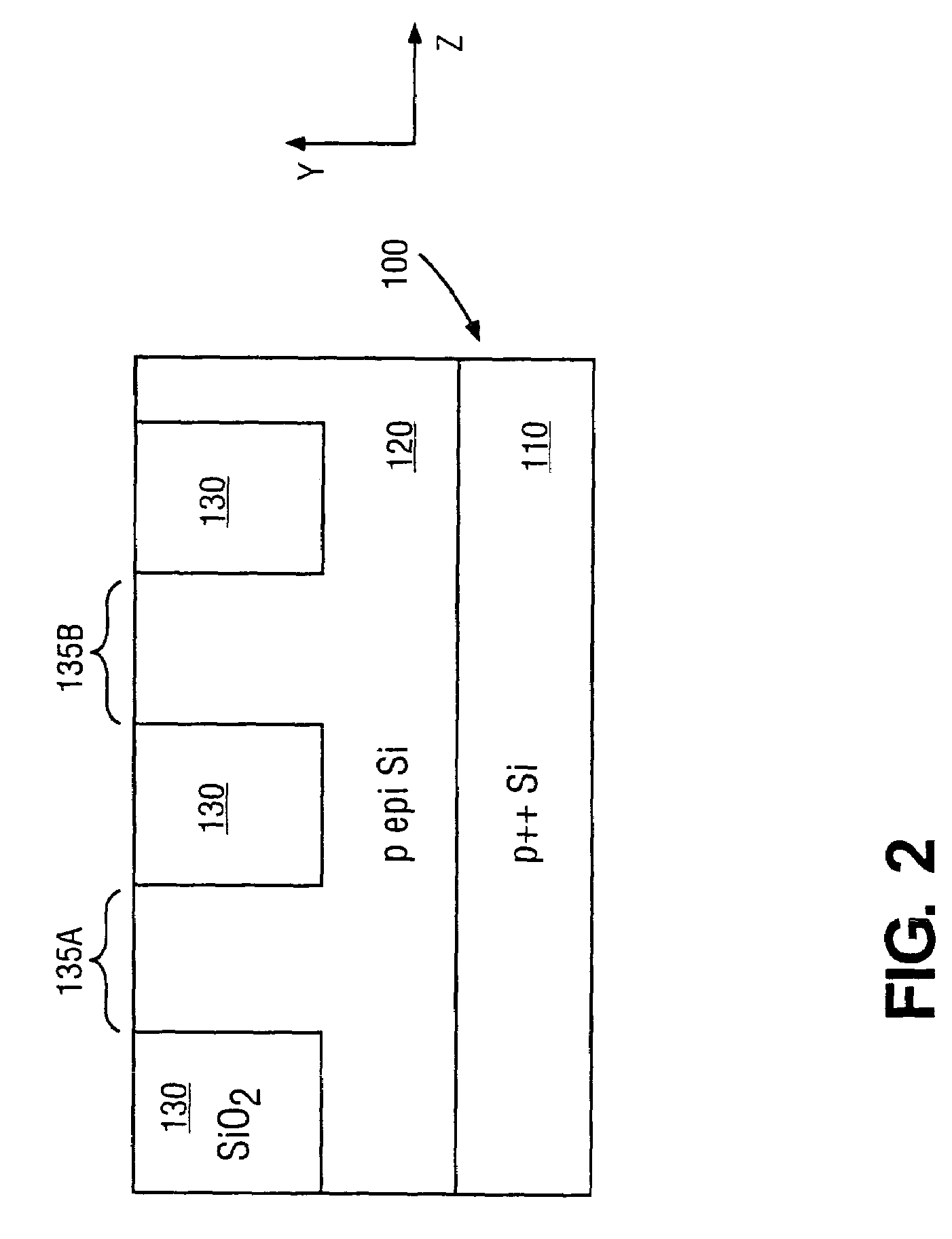

Lower electrode isolation in a double-wide trench and method of making same

InactiveUS6969633B2Solid-state devicesSemiconductor/solid-state device manufacturingPhase-change memorySymmetry line

The invention relates to a phase-change memory device. The device includes a double-wide trench into which a single film is deposited but two isolated lower electrodes are formed therefrom. Additionally a diode stack is formed that communicates to the lower electrode. Additionally, other isolated lower electrodes may be formed along a symmetry line that is orthogonal to the first two isolated lower electrodes. The present invention also relates to a method of making a phase-change memory device. The method includes forming two orthogonal and intersecting isolation structure s around a memory cell structure diode stack.

Owner:OVONYX MEMORY TECH LLC

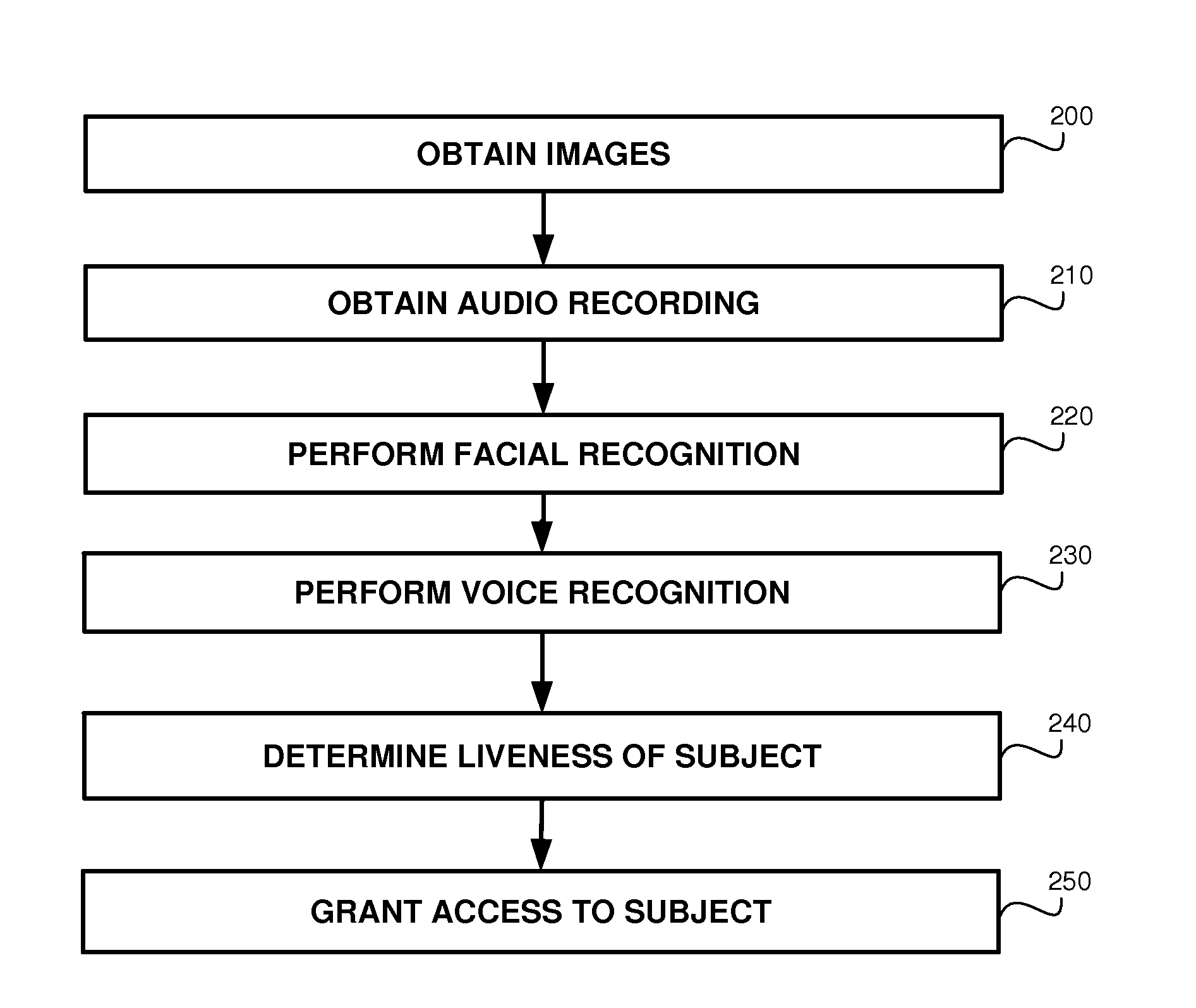

Liveness detector for face verification

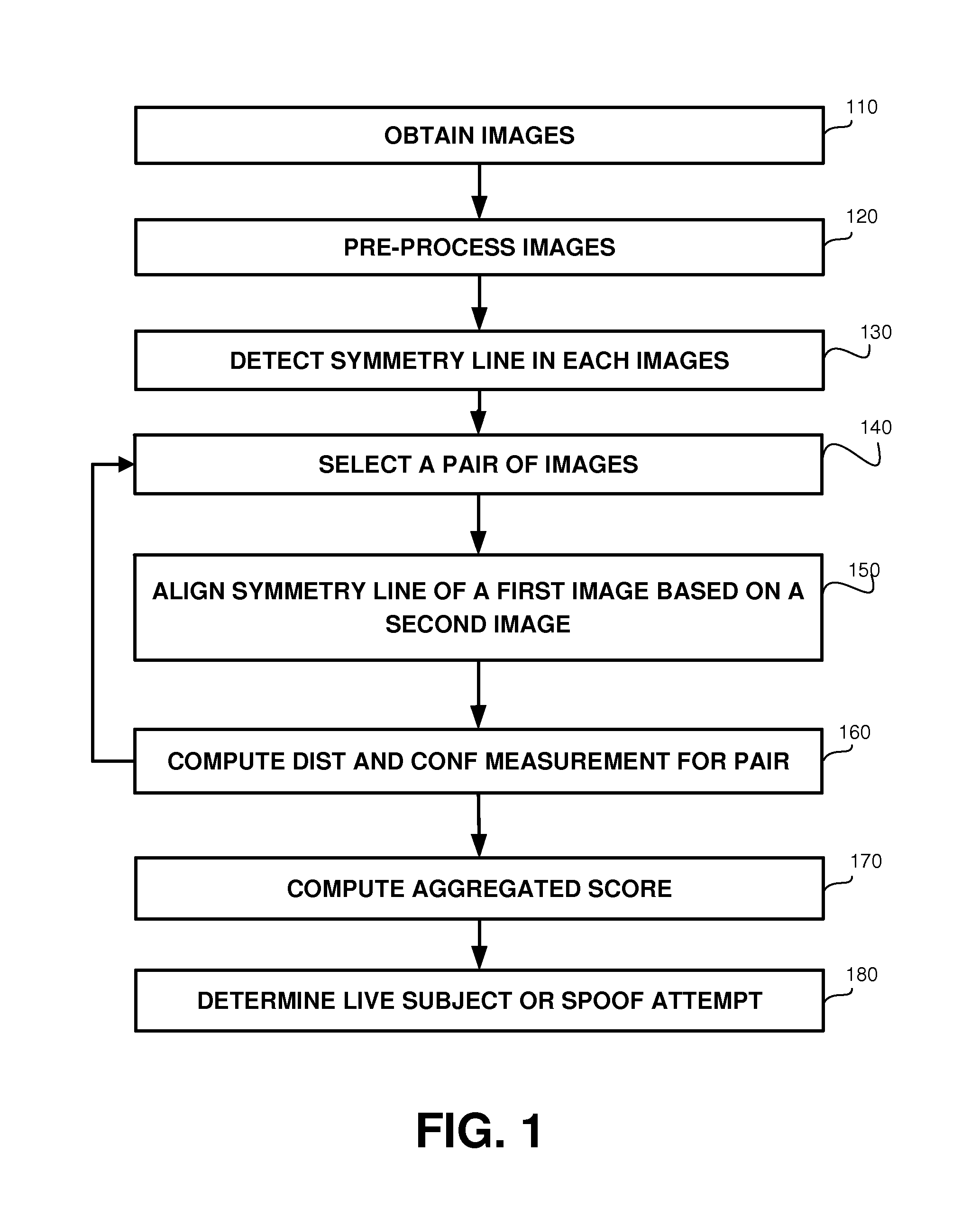

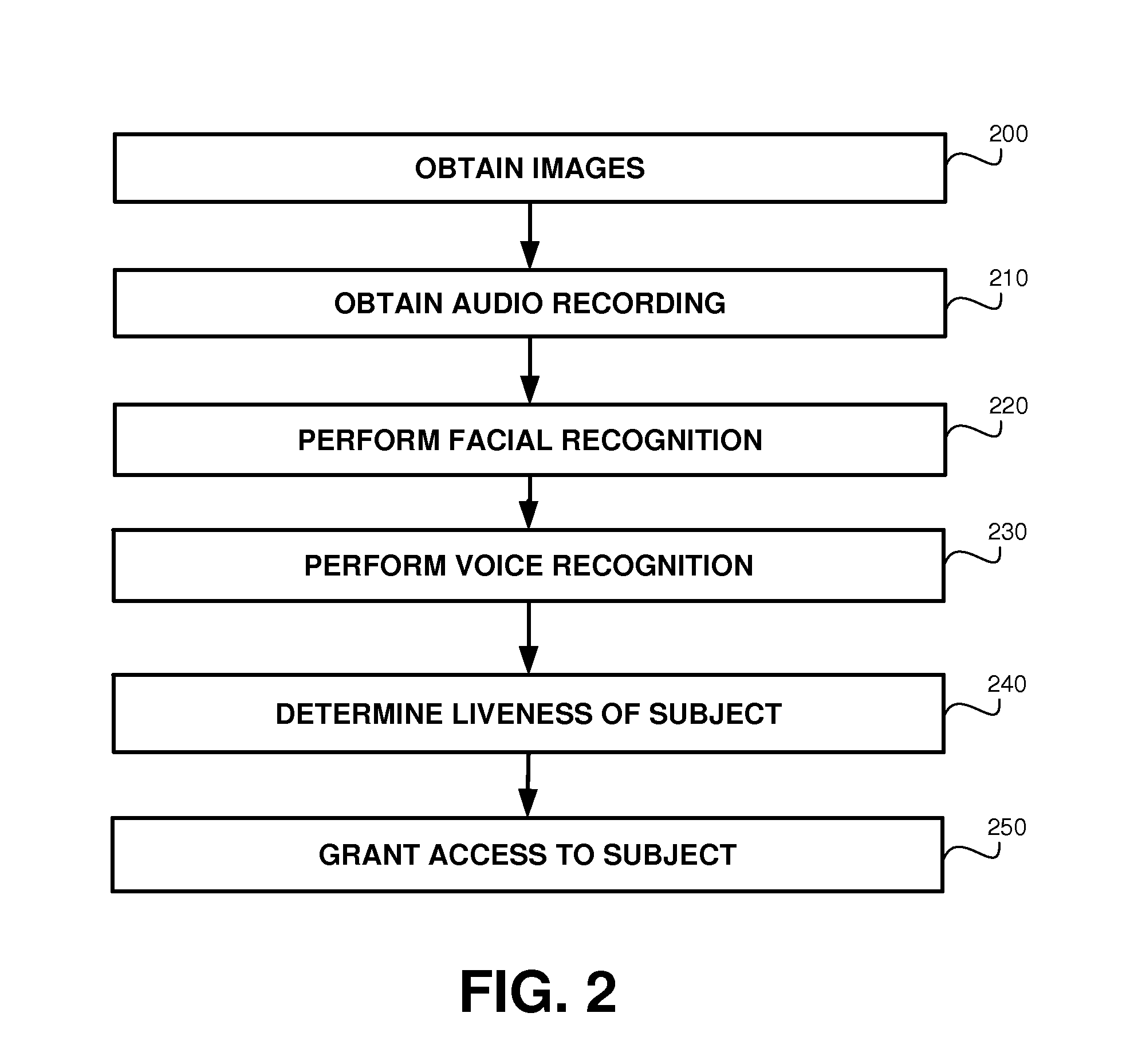

A method, product and system for implementing liveness detector for face verification. A method comprising detecting a symmetry line of the face; and verifying that the subject moved the mouth by computing a score based on values of a pair of images in the symmetry lines, wherein the score is indicative to a difference in the shape of the mouth between the pair of images. Another method comprises: verifying identity of a subject based on facial recognition and voice recognition, said verifying comprise determining there is mouth movement in an image sequence, wherein said determining comprises: in each image of the sequence, detecting a symmetry line of the face; and verifying that the subject moved the mouth, wherein said verifying comprises: computing a score based on comparison of symmetry lines of the face in different images of the set of images; and comparing the score with a threshold.

Owner:IBM CORP

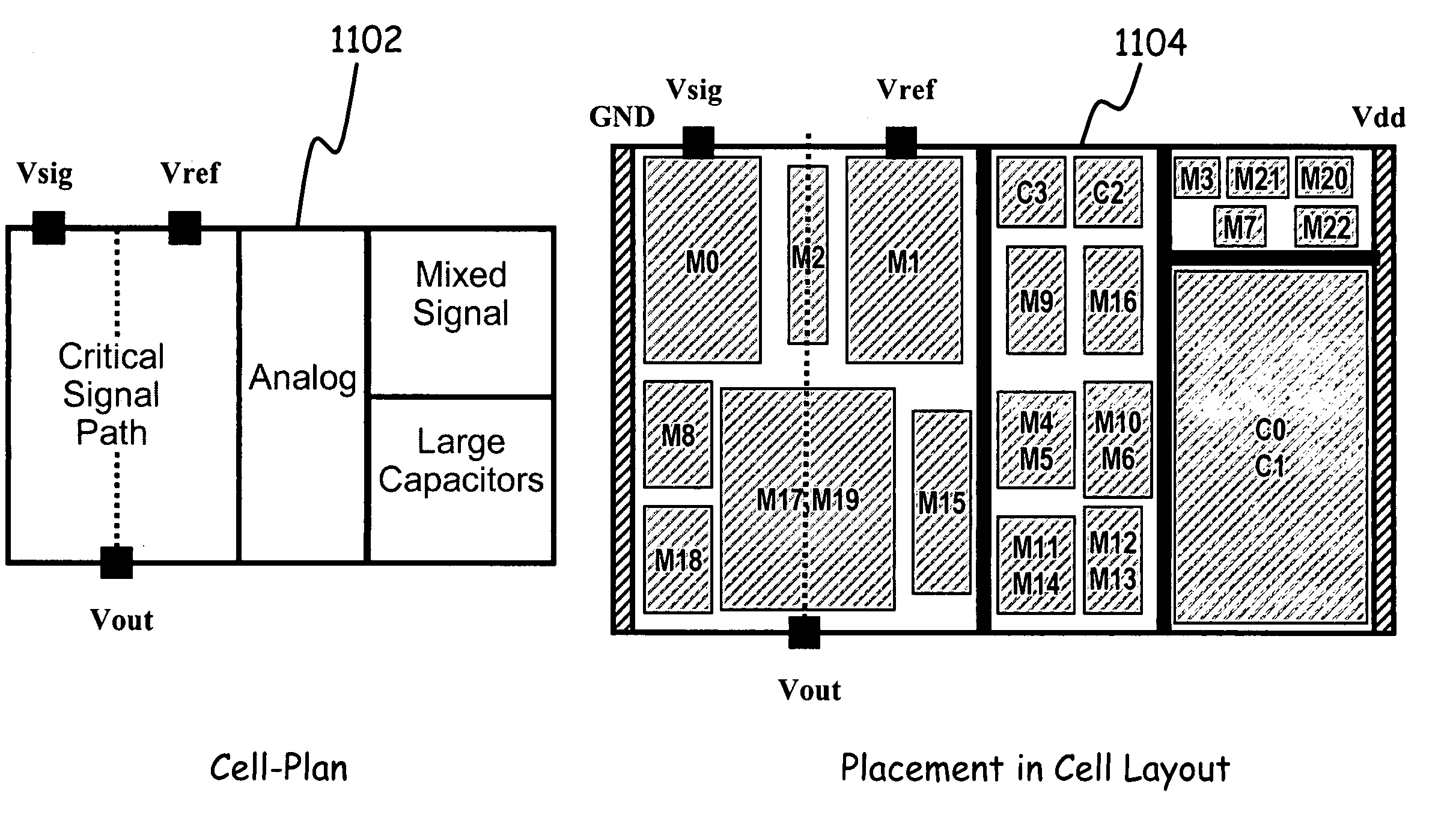

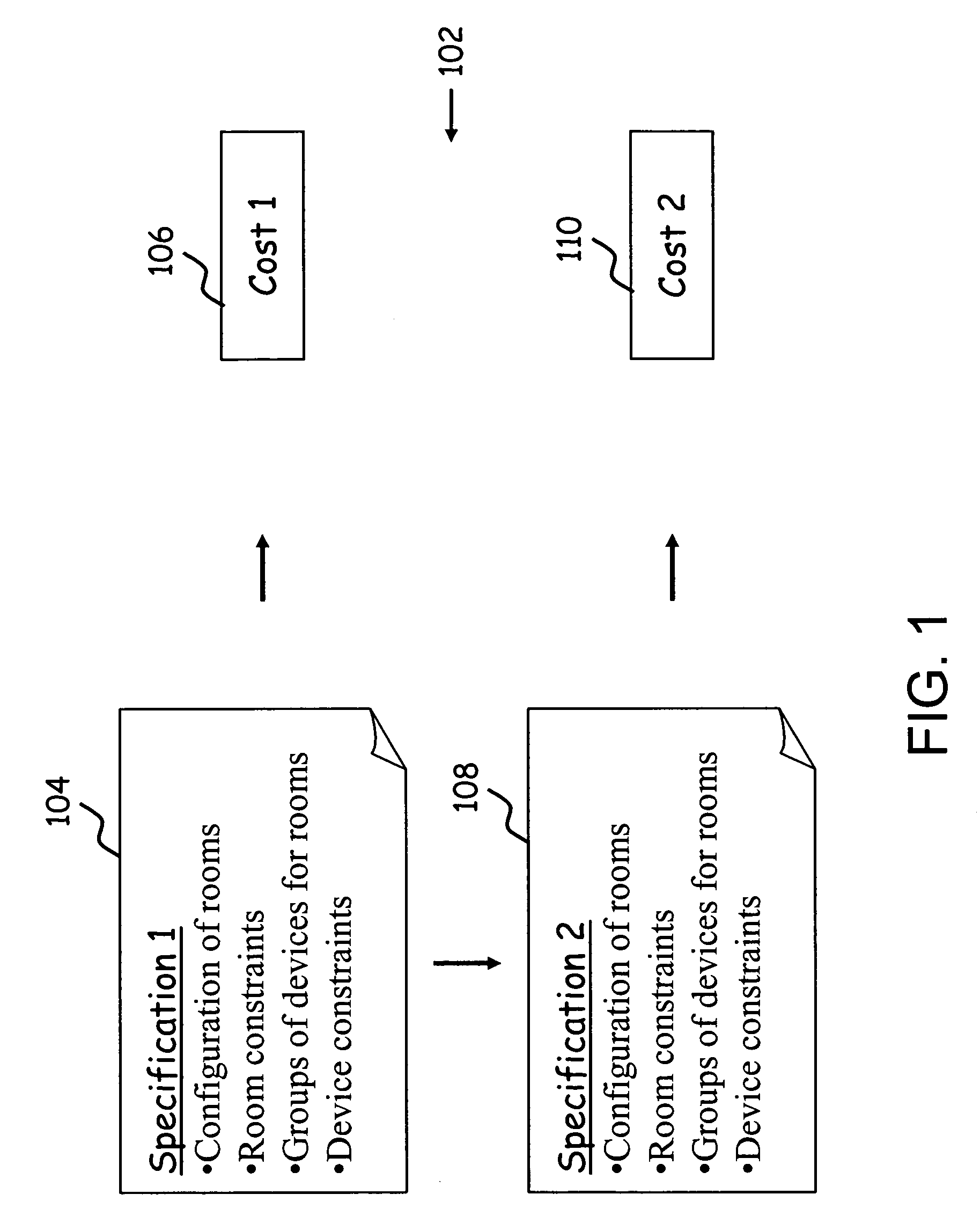

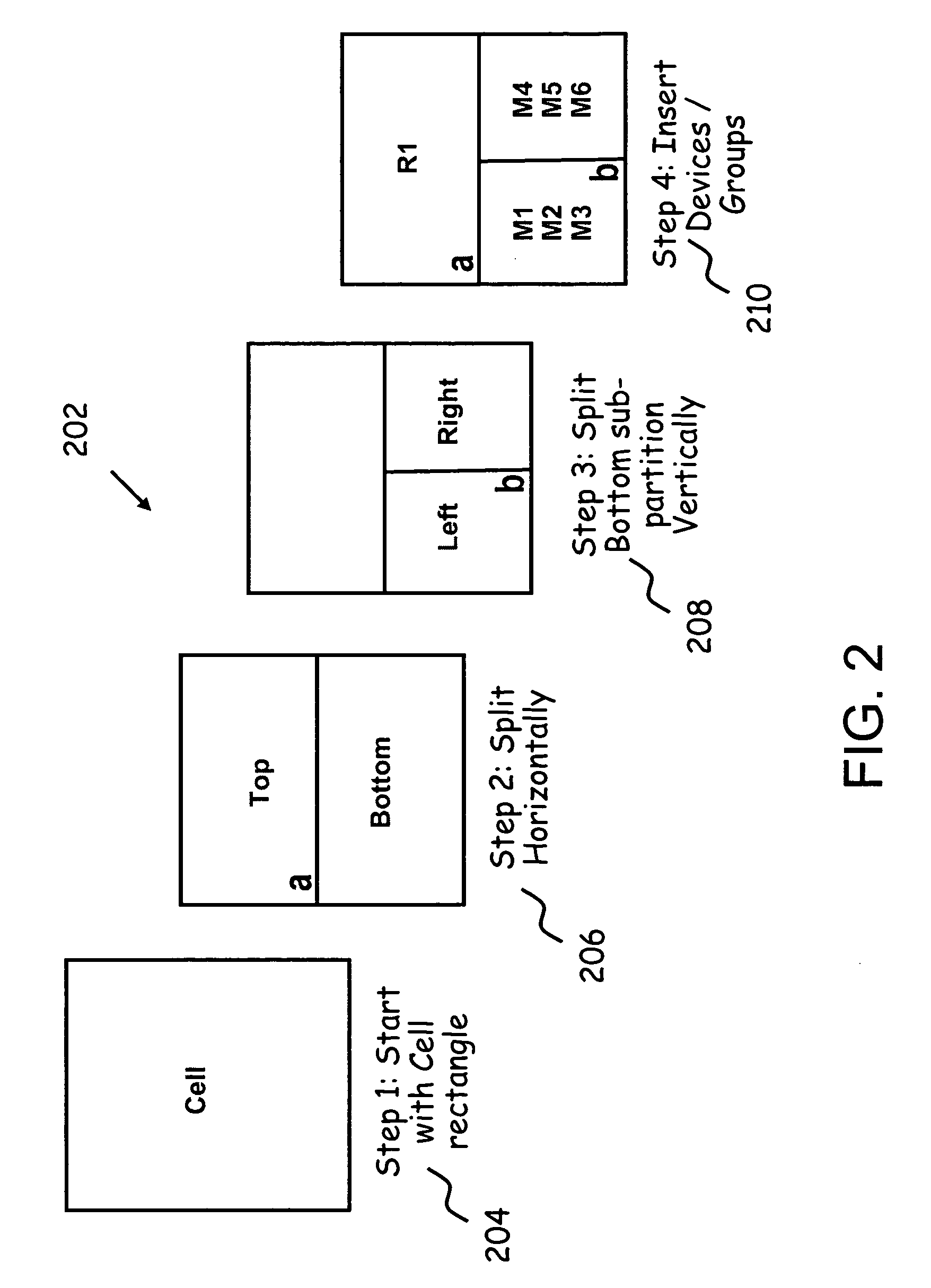

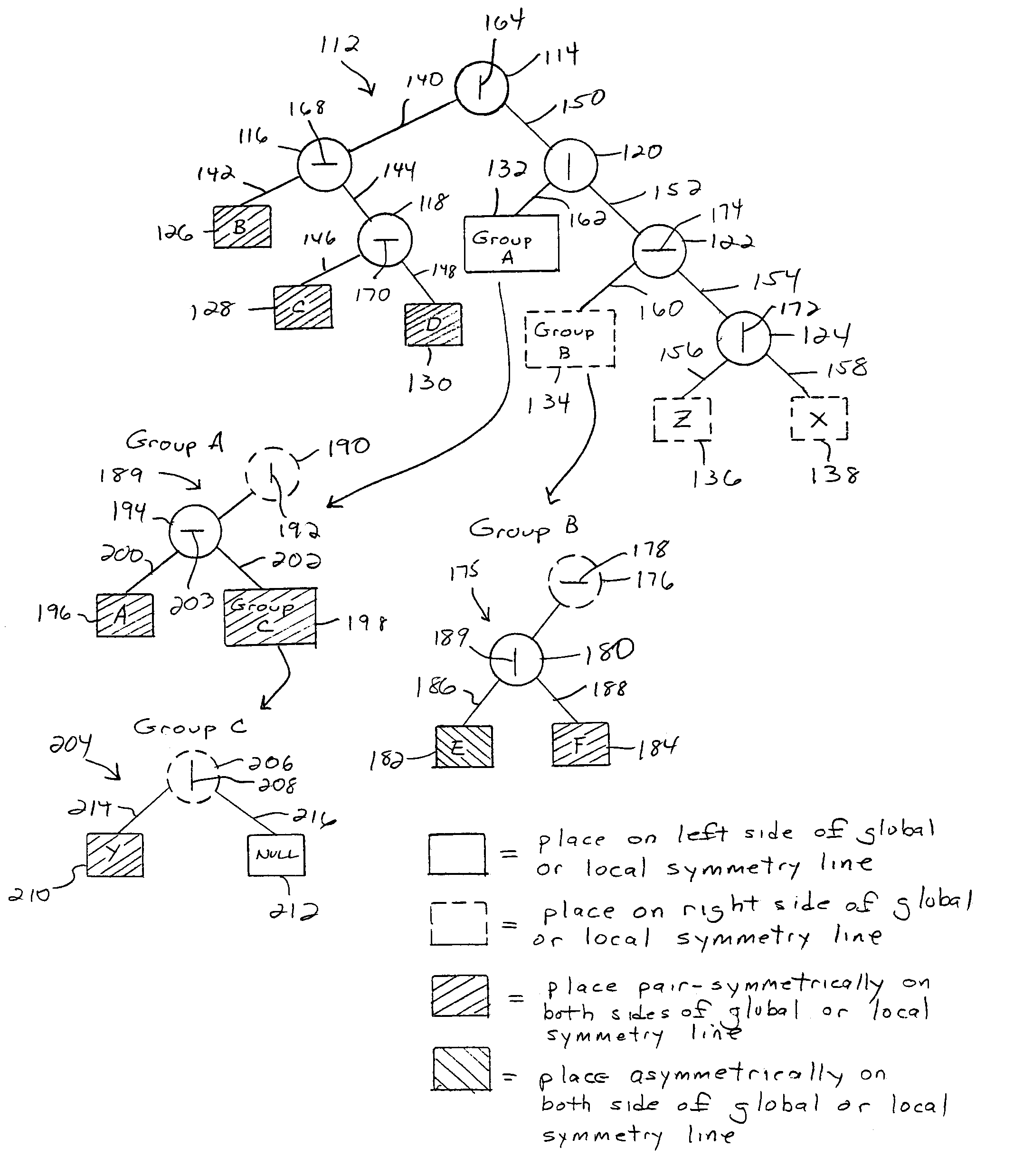

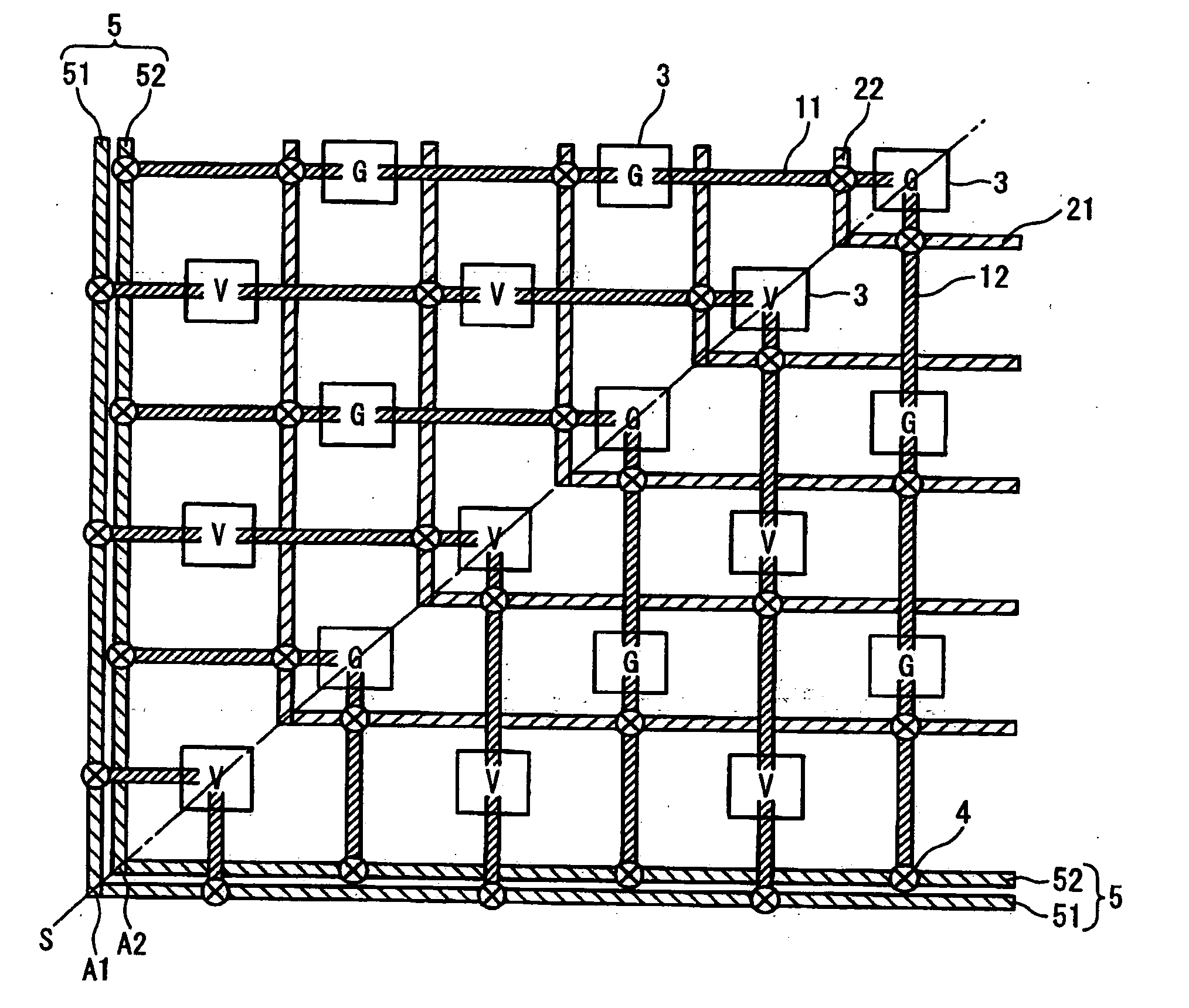

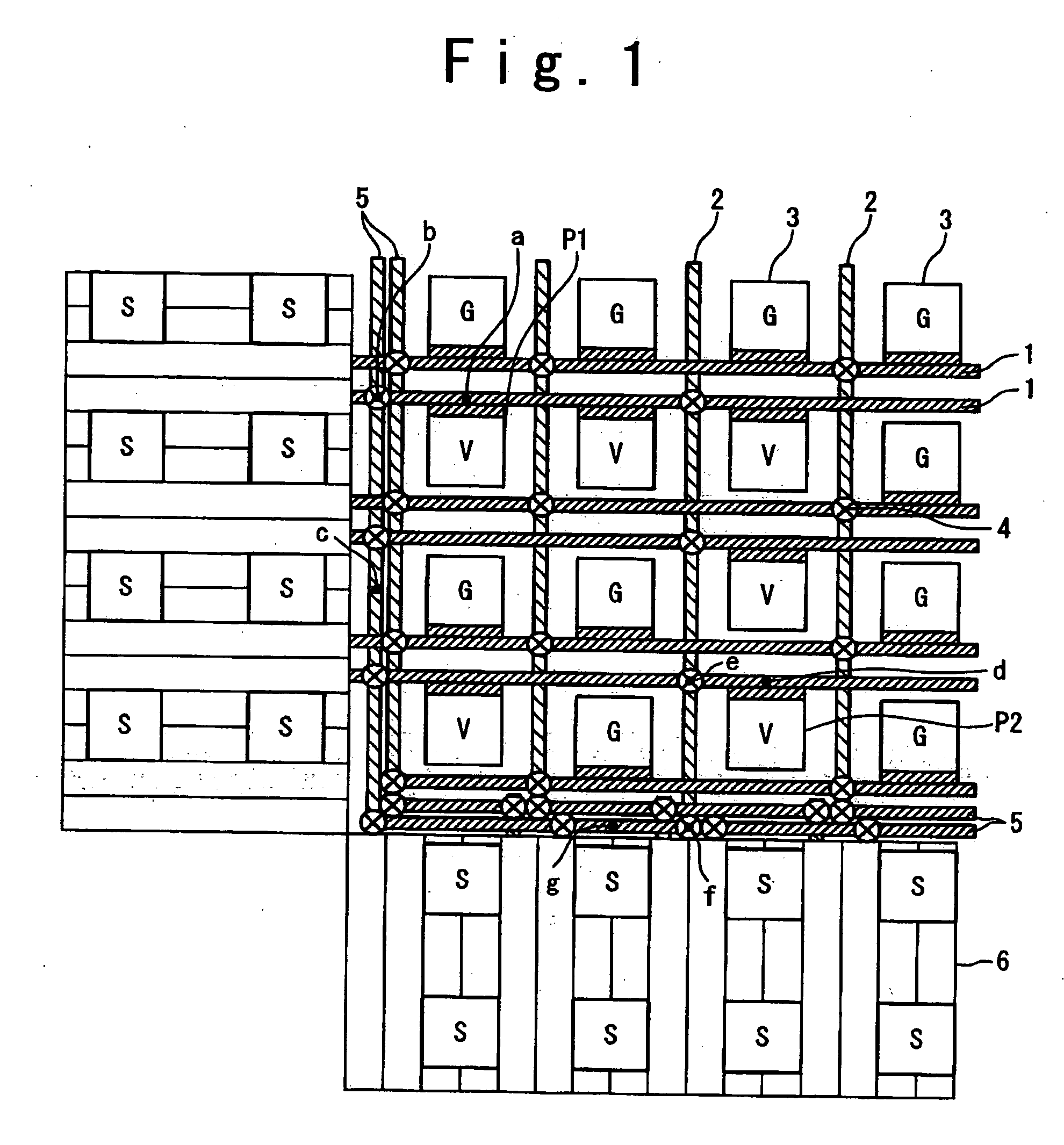

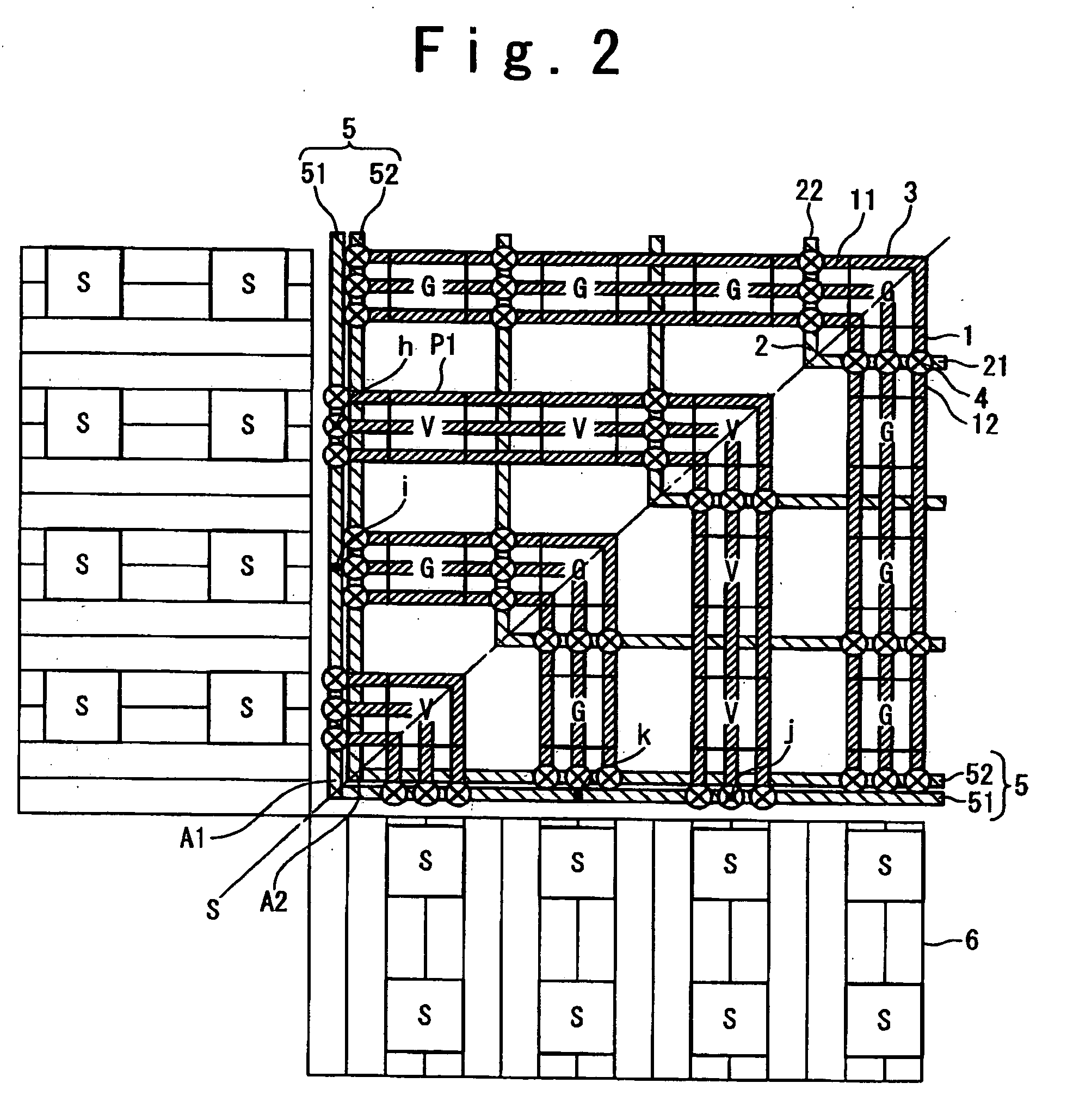

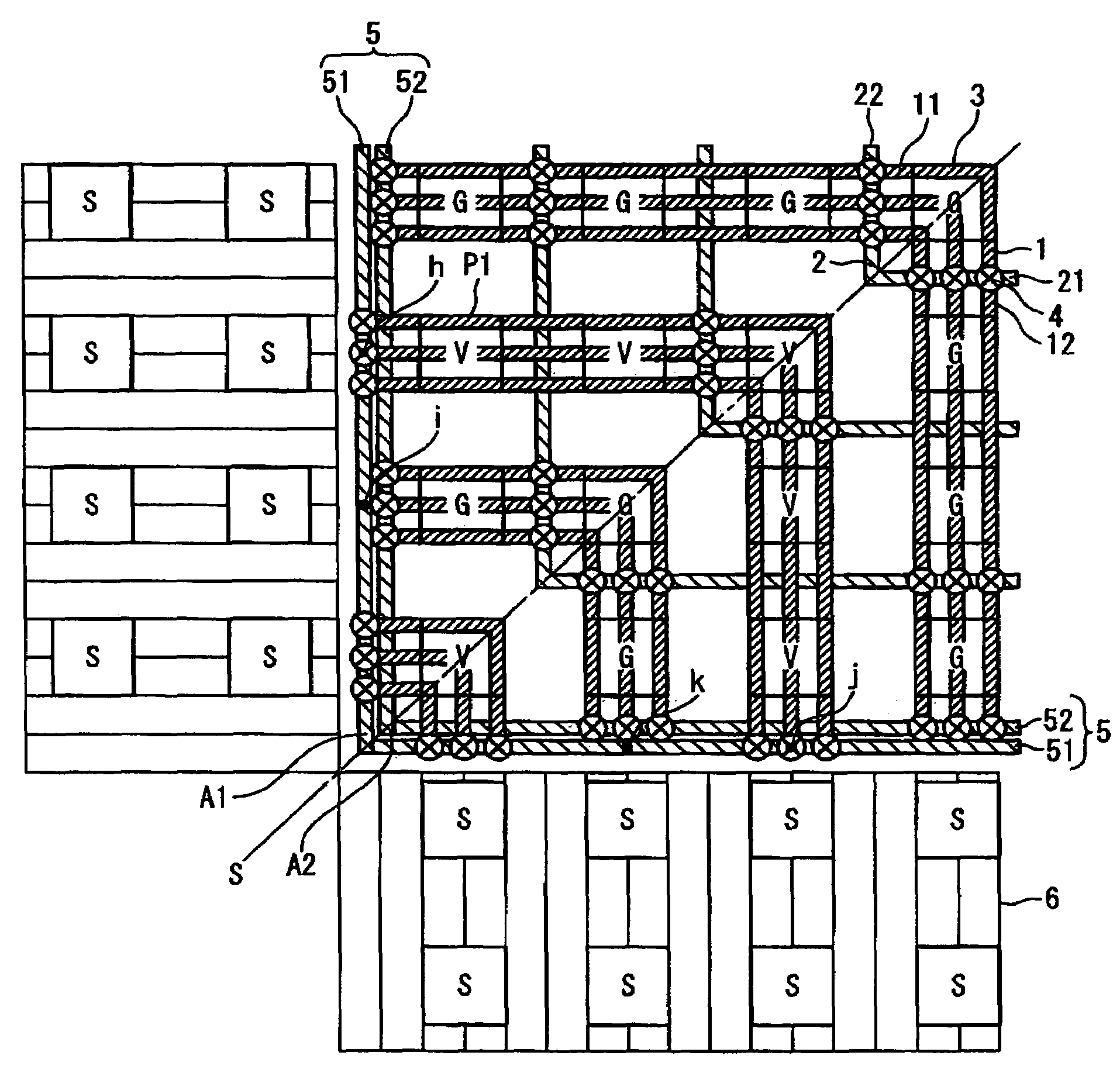

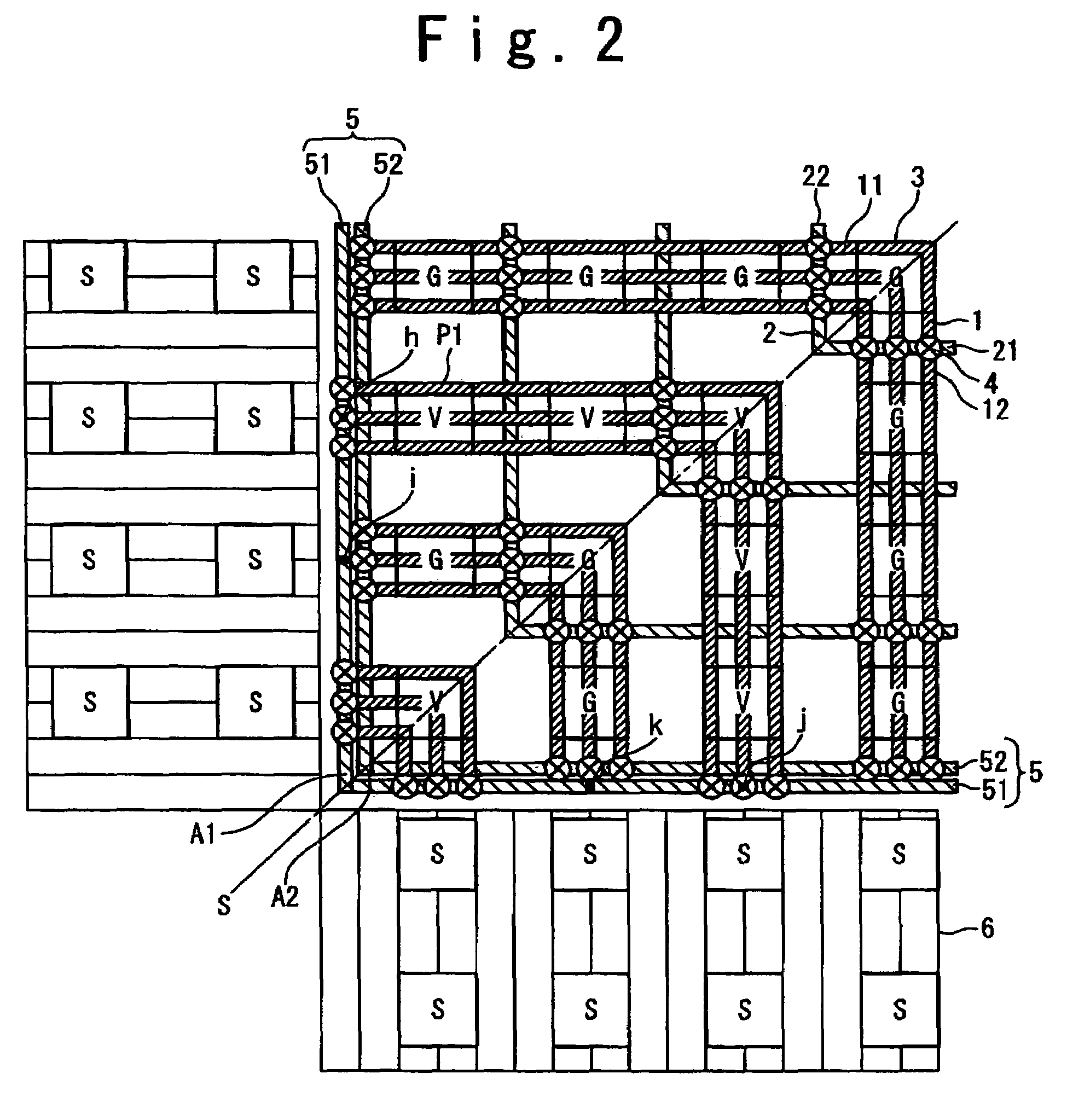

Optimizing circuit layouts by configuring rooms for placing devices

InactiveUS7665054B1Software simulation/interpretation/emulationSpecial data processing applicationsSymmetry lineEngineering

A computer-readable medium stores a specification for a circuit layout. The specification includes: a configuration of rooms for placing devices, one or more room constraints for the configuration of rooms, one or more groups of devices for the rooms, and one or more device constraints for devices in a same room. The configuration of rooms may include a tree-structure for the rooms. The room constraints may include a common symmetry line for a first room and a second room. The device constraints may include a self-symmetry constraint for a first device about a symmetry line in a first room. The device constraints may include a symmetry constraint for a first device and a second device about a symmetry line in a first room. The devices may include analog or RF (radio frequency) devices.

Owner:CADENCE DESIGN SYST INC

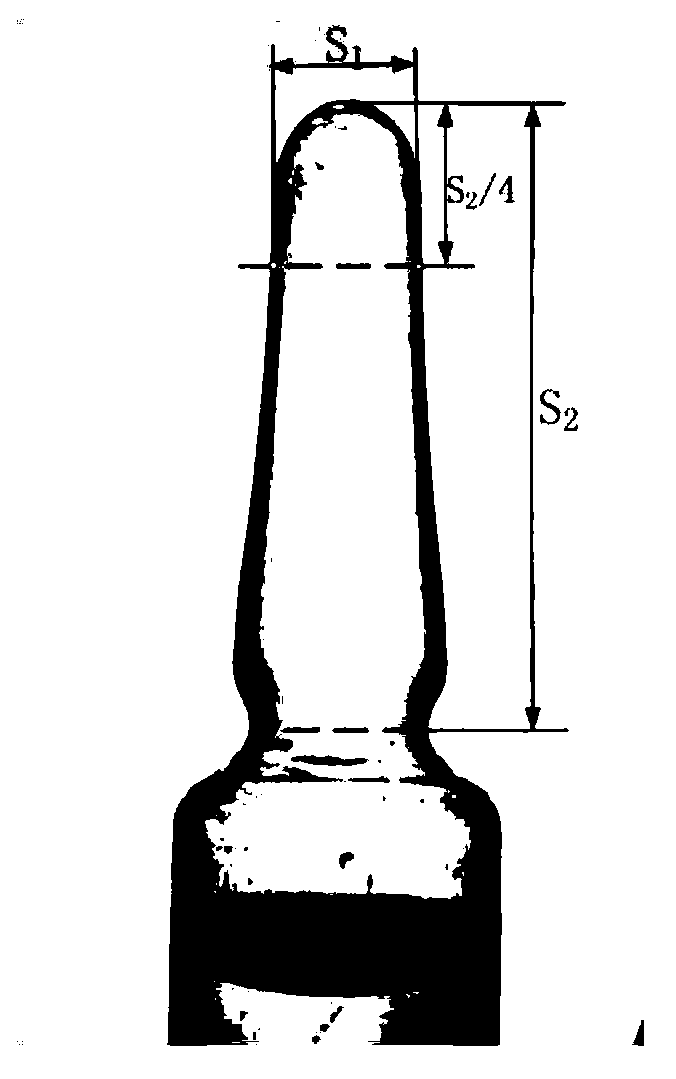

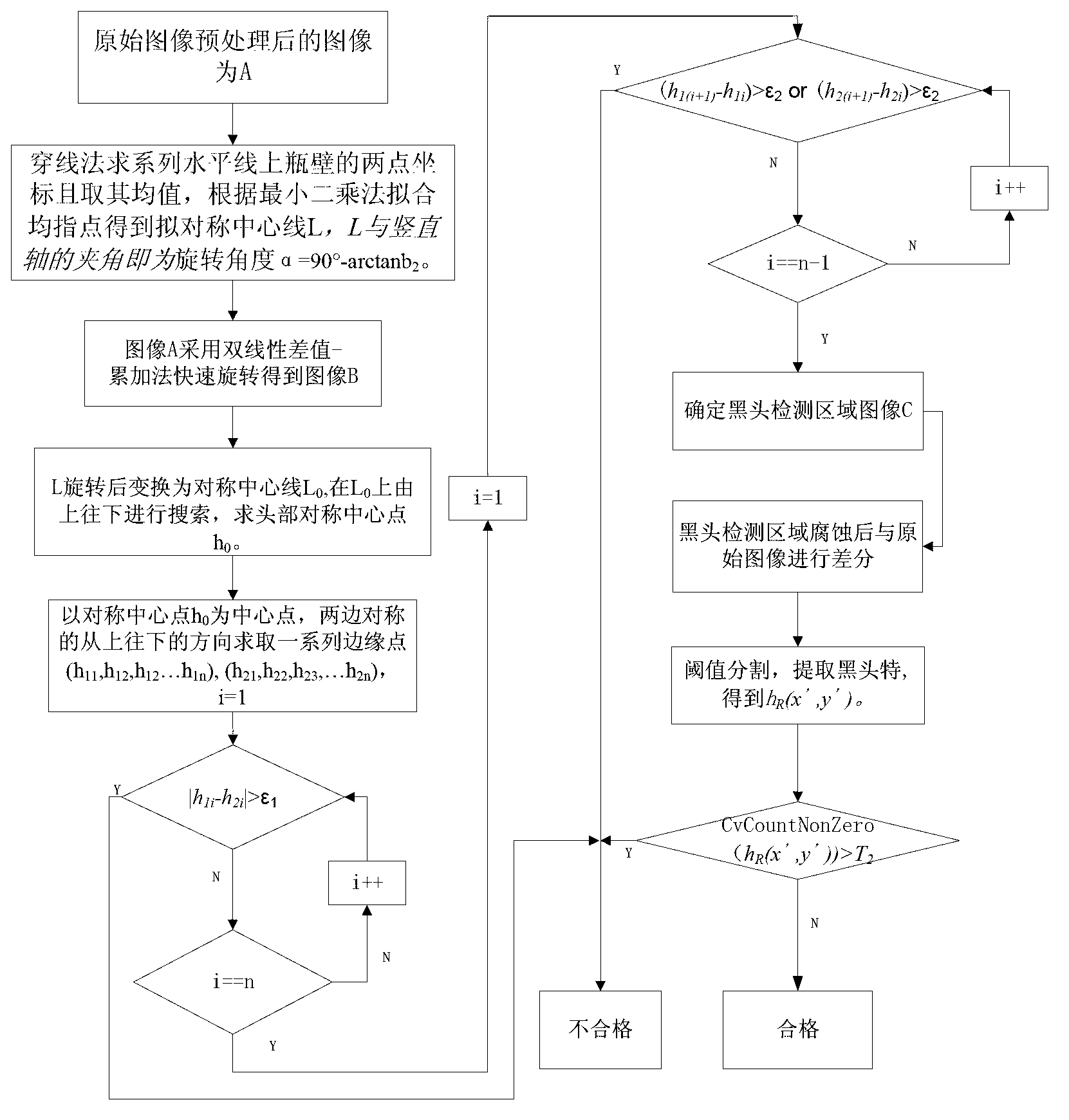

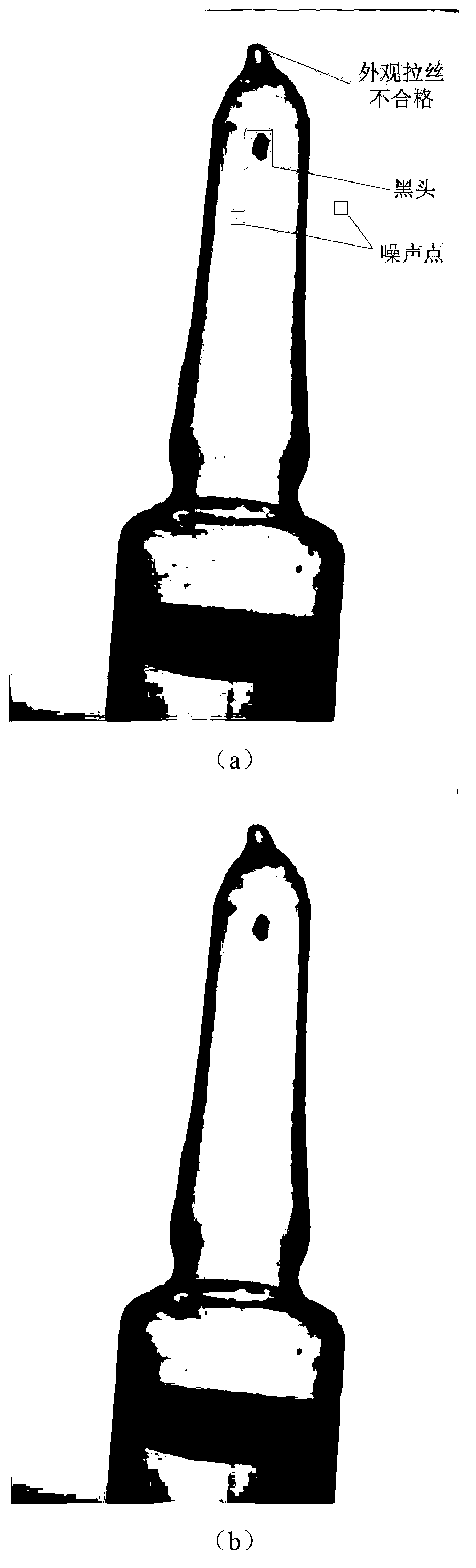

Method for detecting ampoule bottle appearance quality through medical visual inspection robot

ActiveCN103018253AImplement automatic detectionSave resourcesOptically investigating flaws/contaminationSpin imageSymmetry line

The invention discloses a method for detecting ampoule bottle appearance quality through a medical visual inspection robot. The method comprises the steps of (1) acquiring an ampoule bottle image, and preprocessing the image through a median filter; (2) solving an ampoule bottle mimic symmetry line by employing a threading method to obtain a rotating angle alpha; (3) rotating the image by using a bilinear interpolation-summation method; (4) solving a symmetry center line, wherein the intersection of the symmetry center line and the head is a symmetry center point h0; (5) solving a head edge point; (6) enabling the outer curve at the head of the ampoule bottle to have the characteristic of a symmetrical variable trend in a lower parabola shape, and judging whether the ampoule bottle appearance wire-drawing quality is qualified; (7) positioning a black head detection rectangular area; (8) judging whether the black head ampoule bottle appearance is qualified by employing a difference method; and (9) integrating the appearance drawing and black head quality detection result. According to the method, the problems that the manual detection efficiency is low, the consistency is low and the leakage detection rate is high and the like are overcome, and the degree of automation and product quality of the ampoule bottle medicine production are improved.

Owner:HUNAN UNIV

Method for generating constrained component placement for integrated circuits and packages

A method for determining component placement in a circuit includes forming a tree structure that defines the placement of each of a plurality of components associated with the tree structure on a first side, a second side or on both sides of a symmetry line, with at least one component tagged for symmetric placement on both sides of a symmetry line; performing at least one search of the tree structure to determine an initial placement of a subset of the components; and performing another search of the tree structure to determine a final placement of the subset of components whereupon at least a part of each component tagged for symmetric placement is positioned on each side of the symmetry line. The method can be embodied as instructions stored on a computer readable medium which, when executed by a processor, cause the processor to implement the method.

Owner:CADENCE DESIGN SYST INC

Computer-aided discrimination method for Parkinson's disease symptoms based on KINECT bone data

InactiveCN107330249AReduce complexityEnsure normal behaviorDiagnostic signal processingSensorsFrame sequenceComputer-aided

The invention discloses a non-contact detection method for Parkinson's disease. The problem of interference with the normal walking of the detected person that may be caused by the contact type is solved, and the hardware cost and the complexity of the device are reduced. The method includes: collecting bone data through kinect; extracting the central point, and performing low-pass filtering on the point coordinate sequence to obtain a new sequence; extracting "the shortest point of the human body in the walking cycle" to calculate the walking cycle; calculating kinematic parameters and stride parameters. One-way analysis of variance was performed on the six groups of parameter sequences, and the experimental data were selected according to the results and box plots to obtain the normal walking data of the tested subjects. A. From the new data, calculate the displacement sequence of the adjacent frames of the left and right feet, and calculate the correlation coefficient to judge the symmetry; if the symmetry conforms to PD, it is suspected PD; B. For the center point movement acceleration sequence, the observation sequence is calculated through the patient's HMM model parameters. probability to determine whether it is a PD patient. If A and B are satisfied at the same time, PD is diagnosed.

Owner:CHANGZHOU UNIV

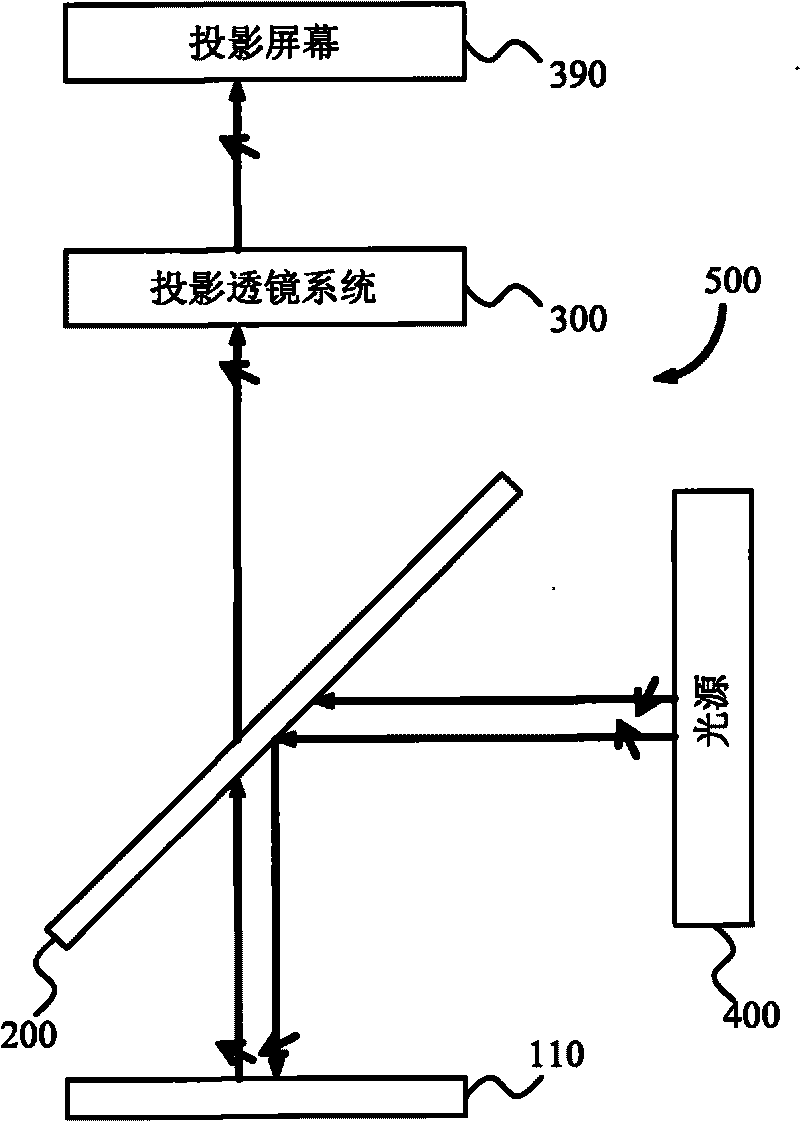

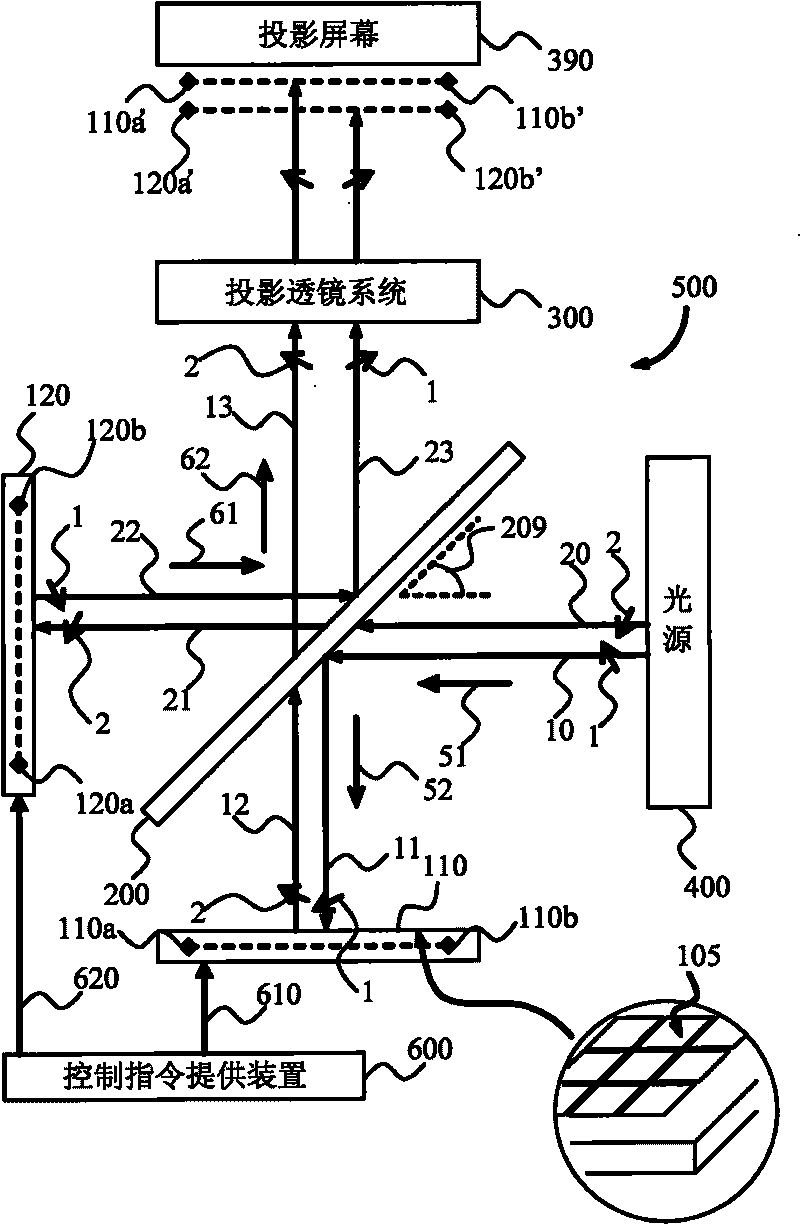

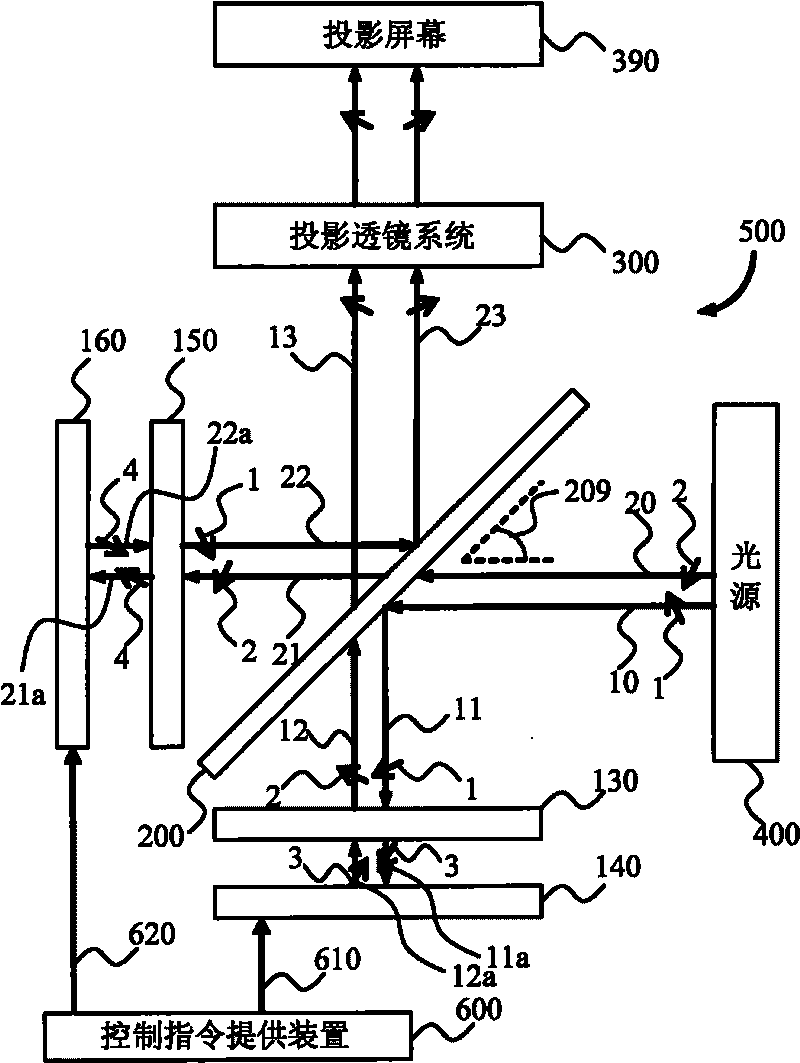

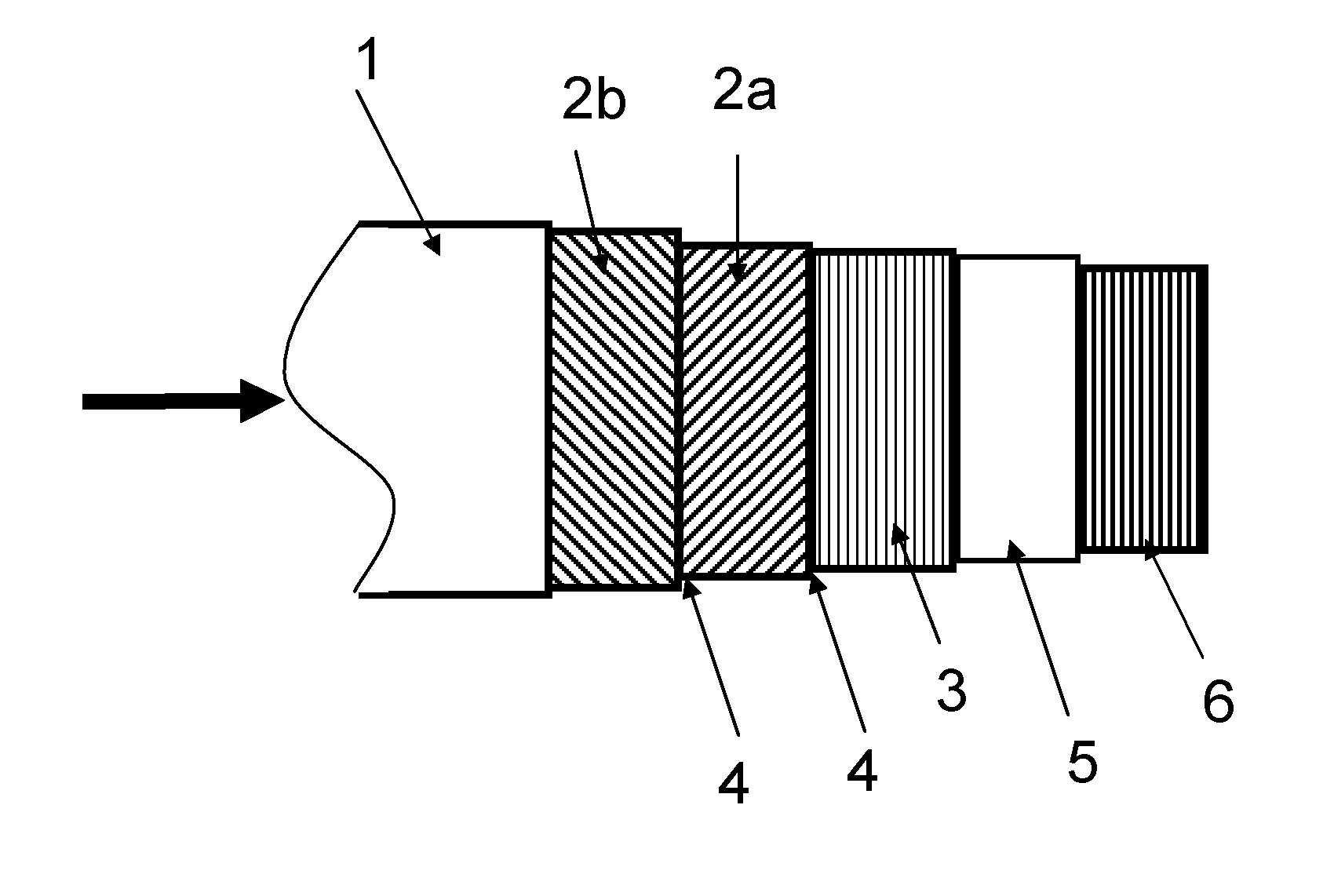

Light projection engine apparatus

InactiveCN101702072AImprove lighting efficiencyProjectorsColor television detailsSymmetry lineOptoelectronics

The inventive embodiment provides a light projection engine apparatus, including: a light source, PBS adopting symmetry lines grid, a first modulation imaging device, a second modulation imaging device, a projection lens system and a control command providing device. The inventive embodiment improves the light efficiency of modulation and image forming by improvements of use ratio of illumination light come form the polarization illumination light of the PBS.

Owner:XIAN ZHONGKE JINGXIANG PHOTOELECTRIC SCI & TECH

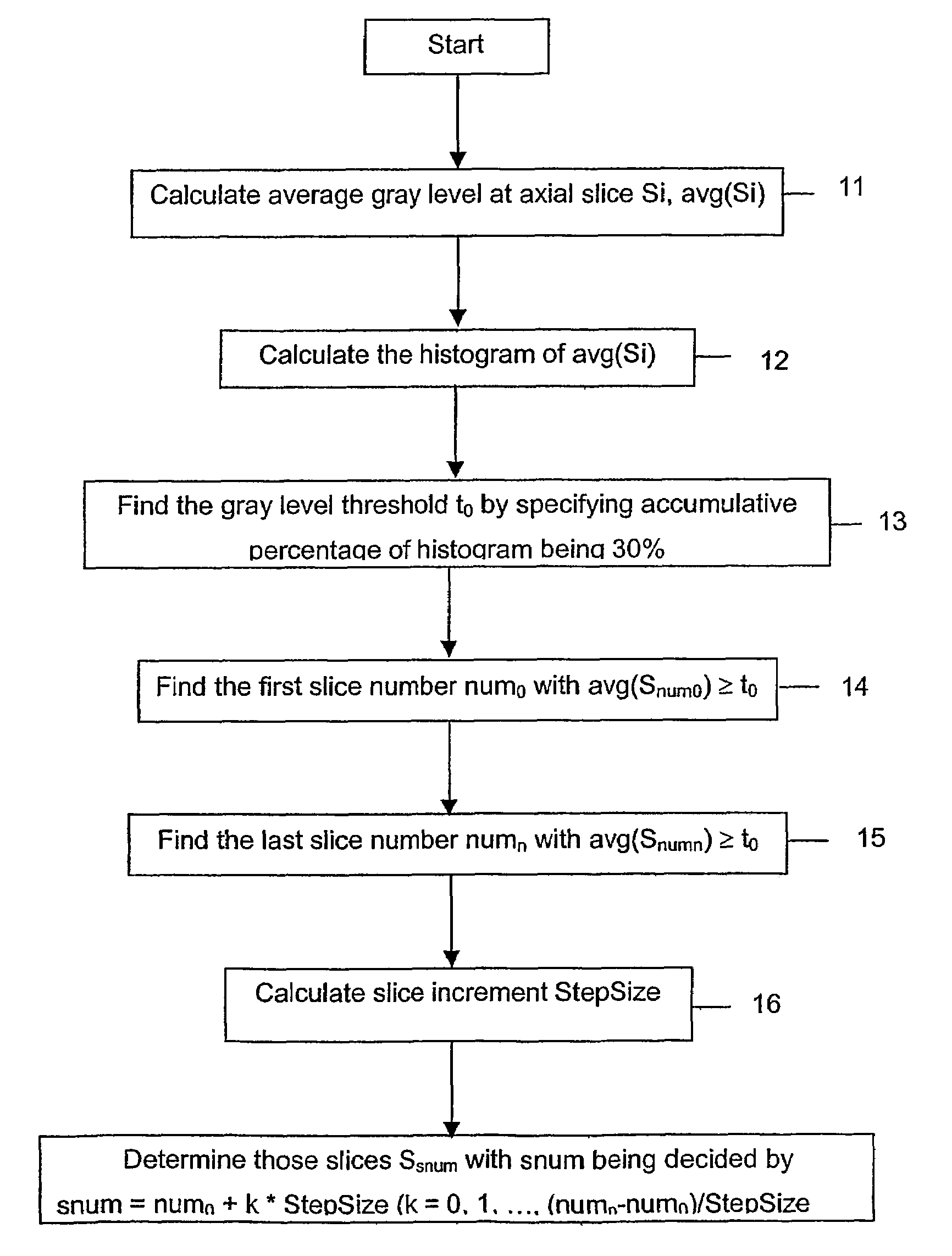

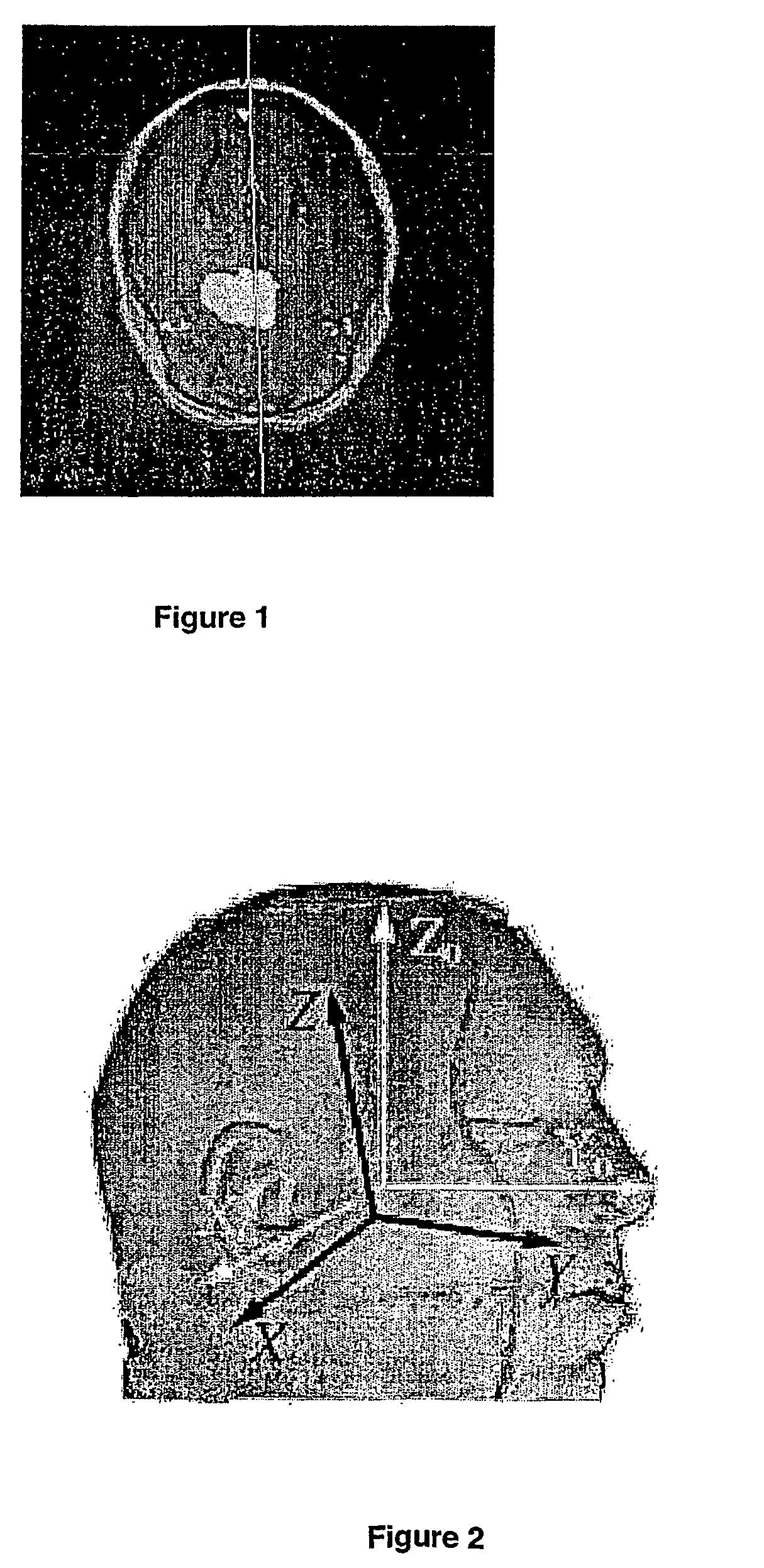

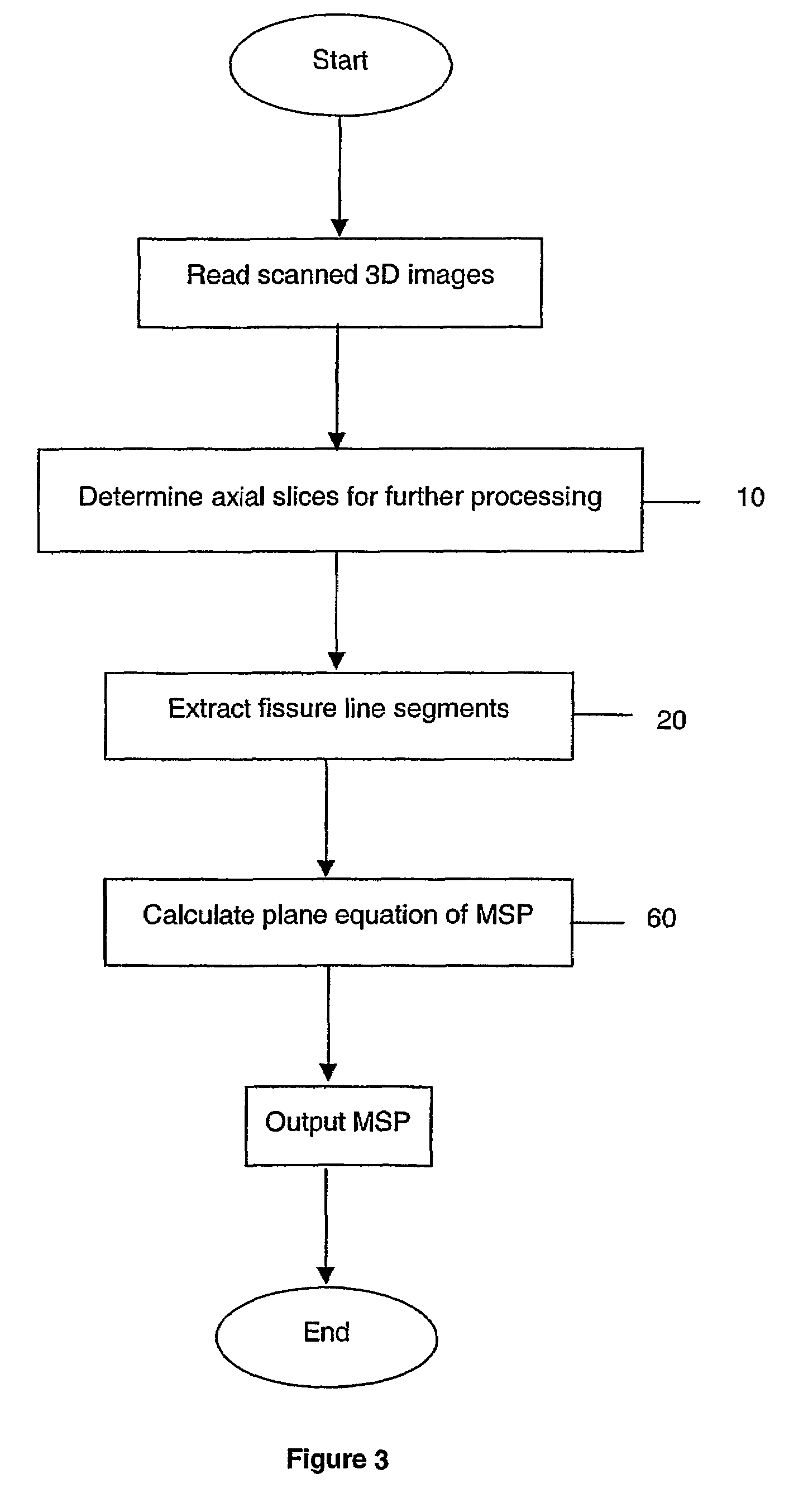

Method and apparatus for determining symmetry in 2d and 3d images

A method of determining symmetry in an image, a method of determining a symmetry plane line segment of a 3D image, a method of determining a symmetry line of a 2D image, and a computer program product. The method includes a) determining at least one searching line segment within a predefined search area of an image portion, the at least one searching line segment including a reference point (x, y) at its center and an angle θ with respect to a predetermined axis of the image portion; b) for each searching line segment, determining a first local characteristic in accordance with a measurement at points adjacent the searching line segment; c) determining the symmetry in the image in accordance with a calculation based on the first local characteristic.

Owner:KENT RIDGE DIGITAL LABS

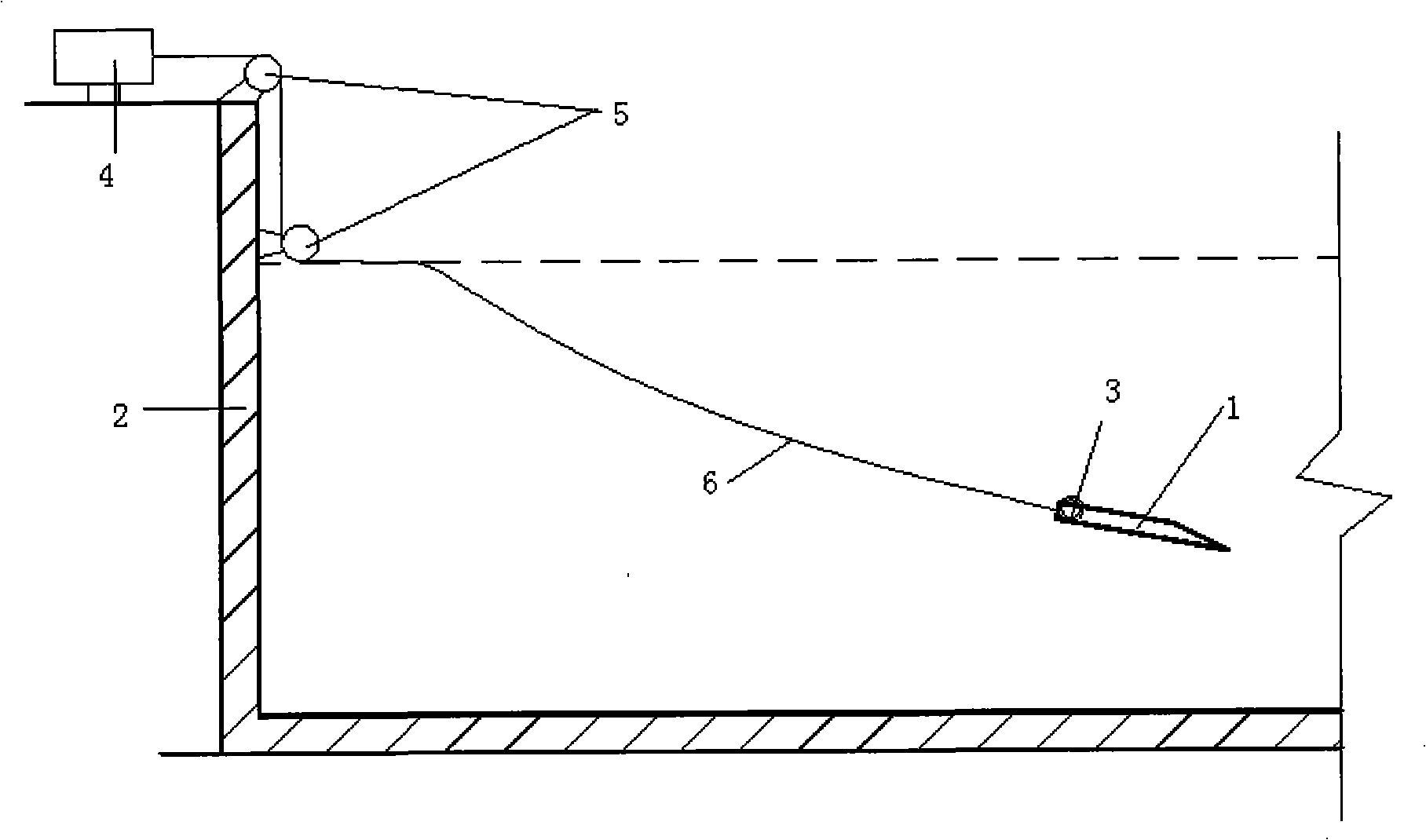

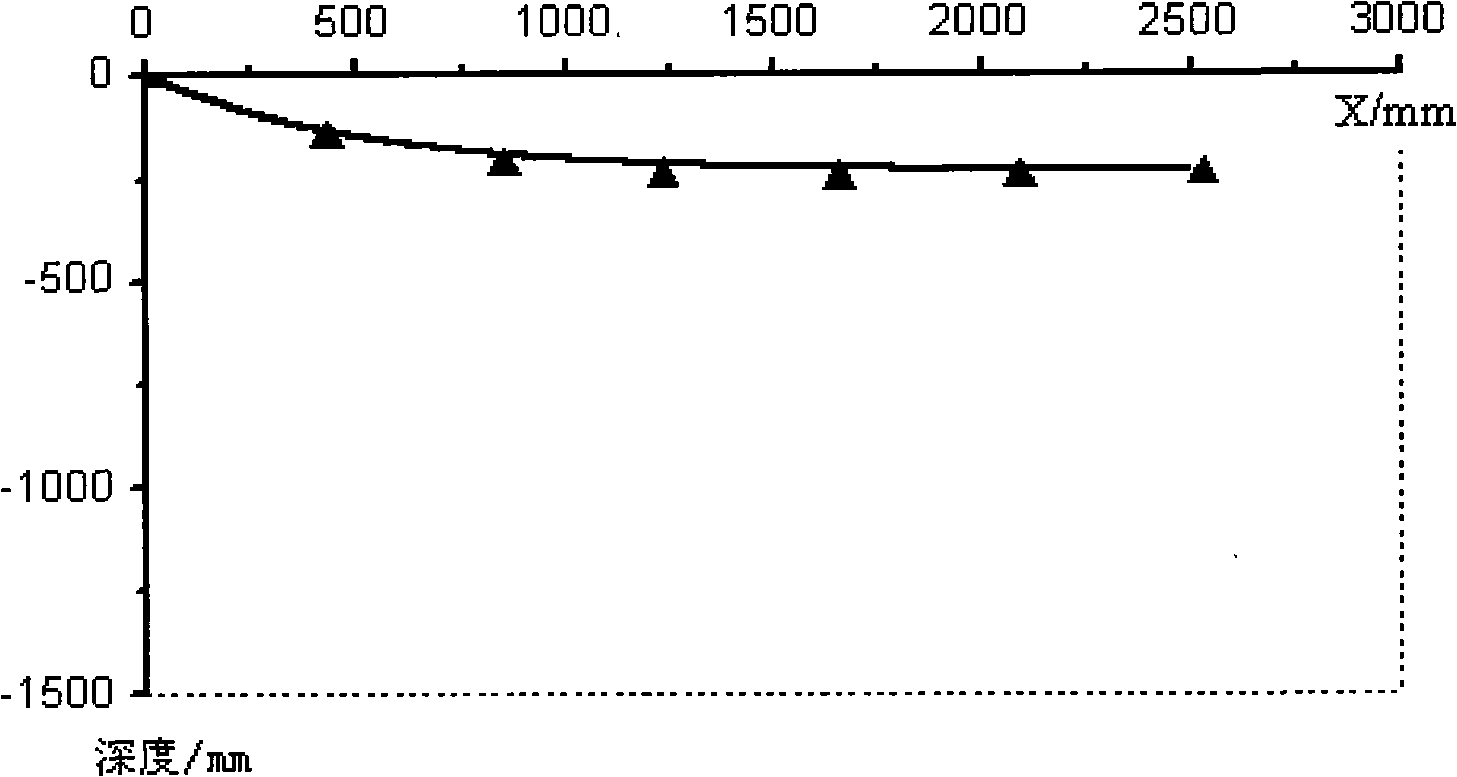

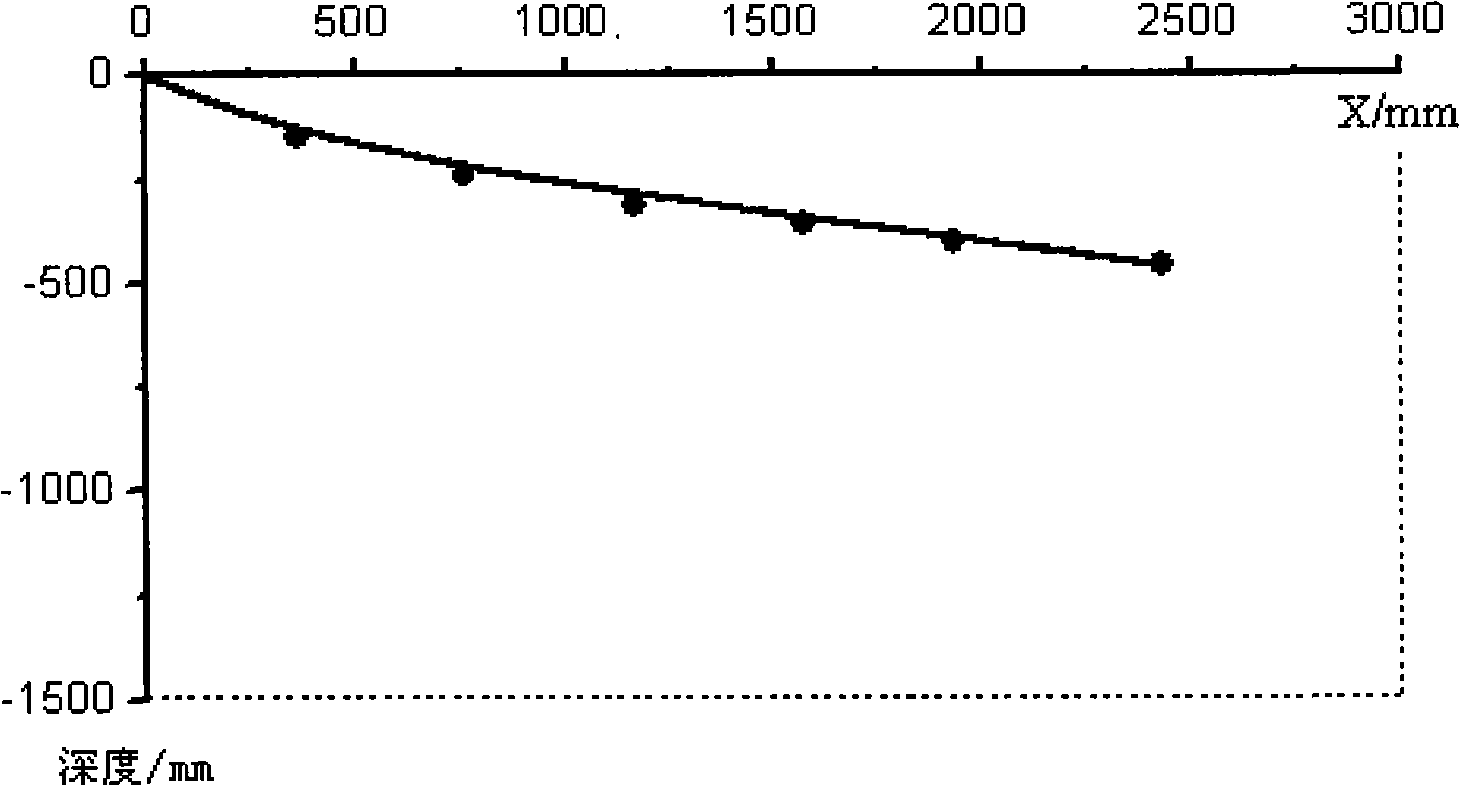

Measuring method of embedded movement locus of towing anchor in soil body and device thereof

The invention belongs to the technical field of ocean engineering and relates to a measuring method of an embedded movement locus of a towing anchor in soil body for an ocean platform anchoring system; the method comprises the following steps: (1) a drawing wire sensor is fixed; (2) a double-shaft tilt angle sensor is embedded in the towing anchor, the axes of the double-shaft tilt angle sensor and the axes of an anchor plate are aligned for ensuring anchor shank connection to be symmetrical by taking the axes of the anchor plate as symmetry line; (3) the drawing wire of the drawing wire sensor is connected to the tail part of the towing anchor by a pulley block; (4) the towing anchor is arranged on a sea bed surface for forming initial embedding angle; (5) horizontal external force is exerted on the towing anchor on the axes of the anchor plate, so as to lead the towing anchor to be embedded in the soil body and collect signals obtained by the drawing wire sensor and the double-shaft tilt angle sensor in a real-time manner; (6) the momentary horizontal and longitudinal coordinates of the towing anchor is computed iteratively for obtaining complete embedded movement locus of the anchor plate in the soil body. The invention provides a measuring device for realizing the method at the same time. The measuring method and the device have the advantages of simple equipment, easy implement and high precision.

Owner:TIANJIN UNIV

Magnetic field sensor system with a magnetic wheel rotatable around a wheel axis and with magnetic sensor elements being arranged within a plane perpendicular to the wheel axis

It is described a magnetic field differential sensor system for measuring rotational movements of a shaft. The described magnetic field sensor system (200) comprises (a) a biasing magnet (210, 510) configured for generating a biasing magnetic field; (b) a magnetic wheel (230) having a wheel axis and a circumferential surface which comprises a regular structure of teeth (231) and gaps (232) arranged in an alternating manner, wherein (i) the magnetic wheel (230) is attachable to the shaft and (ii) the magnetic wheel (230) can be magnetized by the biasing magnetic field; and (c) a magnetic sensor arrangement (220) comprising four magnetic sensor elements (221, 222, 223, 224) being connected with each other in a Wheatstone bridge configuration. Respectively two of the magnetic sensor elements (221, 222, 223, 224) are assigned to one half bridge of the Wheatstone bridge. Further, the four magnetic sensor elements (221, 222, 223, 224) are arranged within an y-z plane, wherein an x-axis, a y-axis and a z-axis define an orthogonal Cartesian coordinate system in which (i) the x-axis is oriented parallel with the wheel axis of the magnetic wheel (230), (ii) the y-axis is oriented tangential to the circumferential surface of the magnetic wheel (230), and (iii) the z-axis is the symmetry line through the center of the biasing magnet (210, 510) and the center of the magnetic wheel (230). The magnetic sensor elements can be hall sensor elements or magnetoresistive sensor elements (221, 222, 223, 224).

Owner:NXP BV

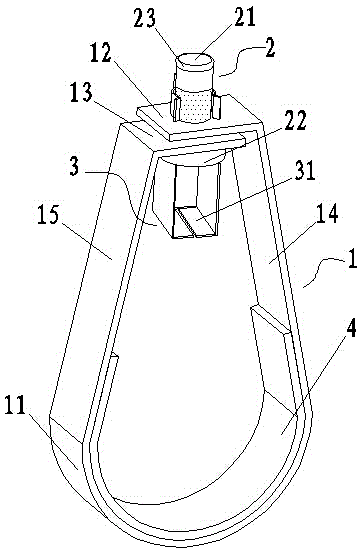

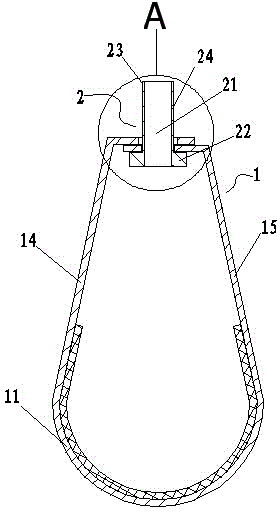

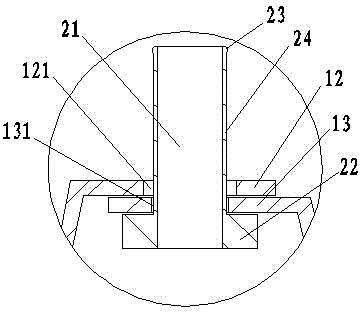

Hanging type pipe clamp

ActiveCN104358932ADon't worry about pairingConnecting piece is separated from clamping piecePipe supportsSymmetry linePipe fitting

The invention discloses a hanging type pipe clamp, which comprises a clamping element and a connecting element, wherein the clamping element is integrally formed through bending an elastic steel bar, the clamping element comprises an arc-shaped accommodating part, a first end part, a second end part, a first transition part and a second transition part, the first end part and the second end part are in vertical laminated arrangement, the first end part is positioned above the second end part, the hanging type pipe clamp also comprises a first connecting hole and a second connecting hole, in a state that the first connecting hole and the second connecting hole share one center line, the center line is the same line as the symmetry line of the arc-shaped accommodating part, the connecting element comprises a sleeve, an annular lug boss and a flange, a penetrated threaded hole is formed inside the connecting element, the flange is formed through reaming after the connecting element passes through the second connecting hole, and the outer diameter of the flange is greater than the hole diameter of the second connecting hole and is smaller than the hole diameter of the first connecting hole. The hanging type pipe clamp has the advantages that the structure is simple, the installation, the storage and the transportation are convenient, in addition, pipe fittings can be effectively protected, and the outer surfaces of the pipe fittings are prevented from being damaged.

Owner:ZHEJIANG BAOLI STEEL ENERGY TECH

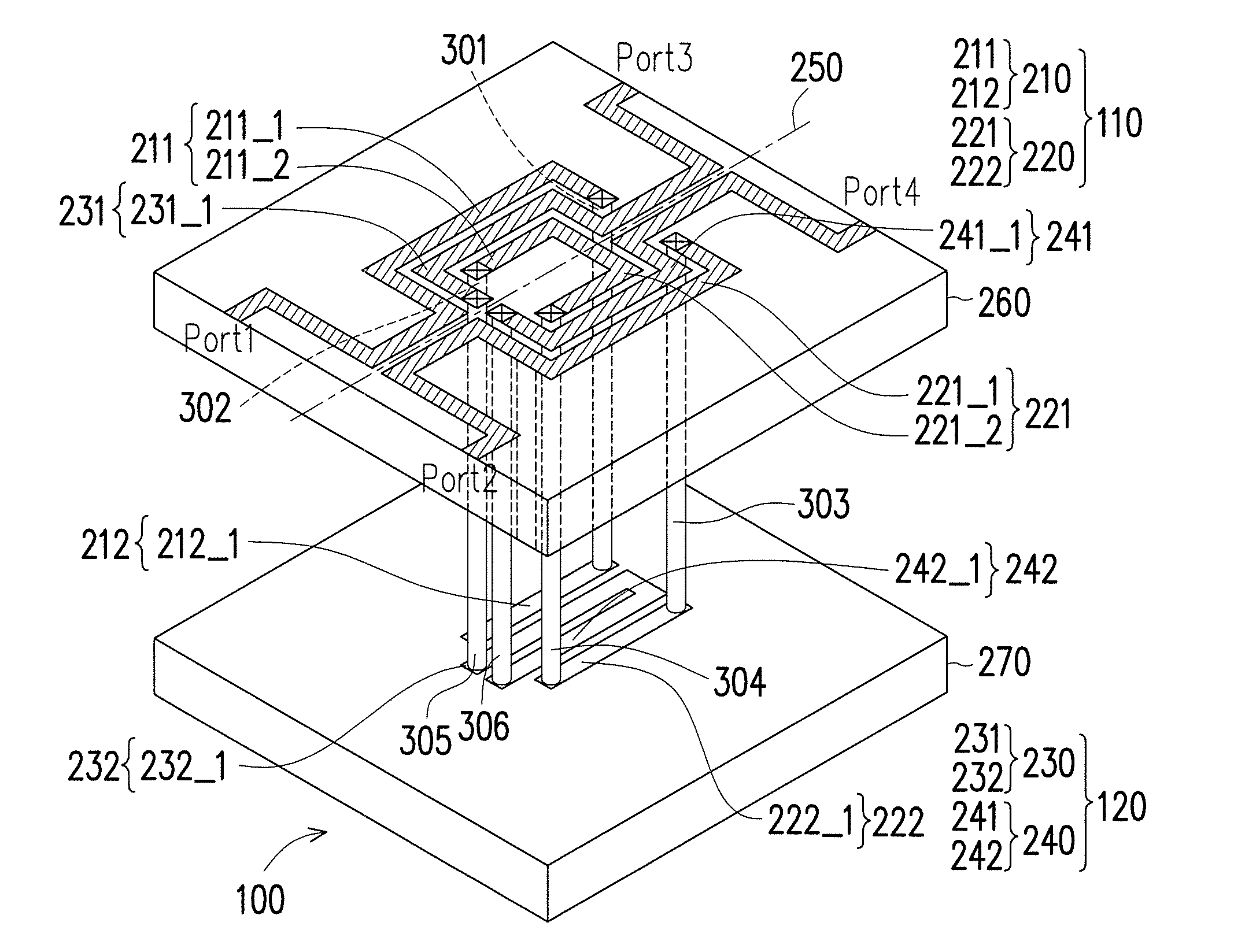

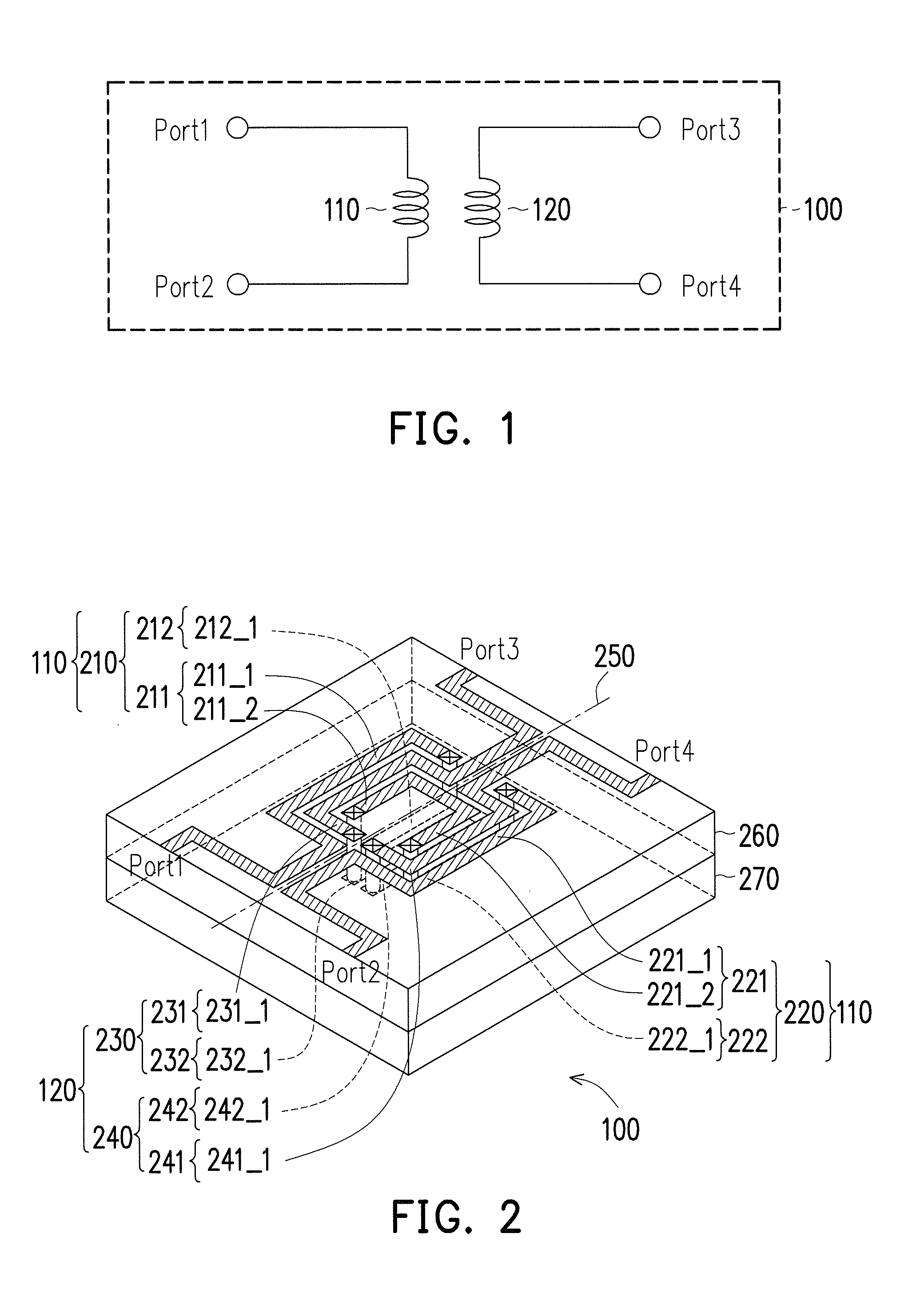

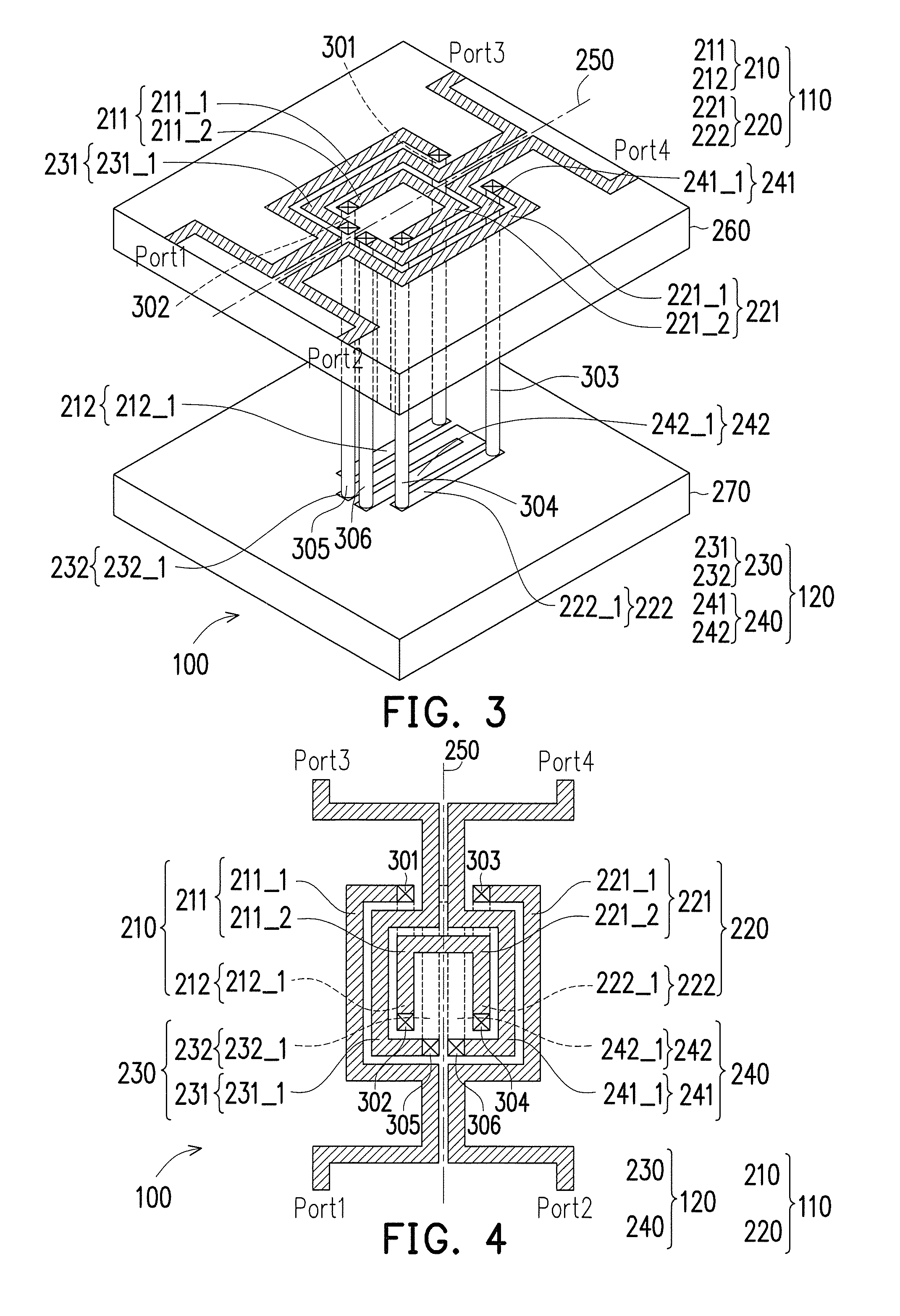

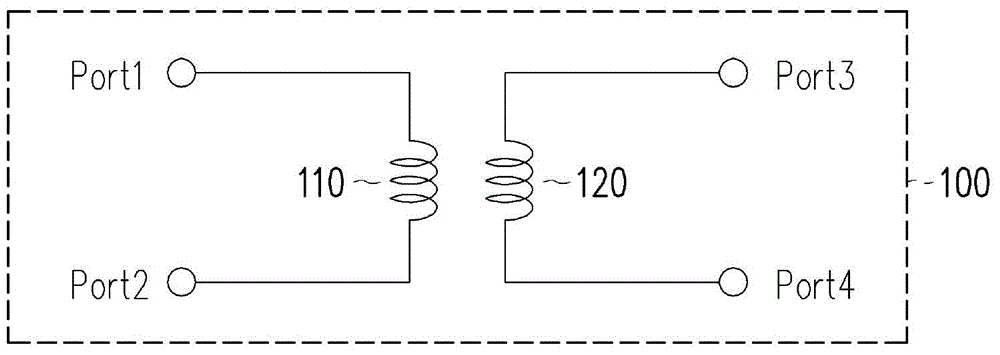

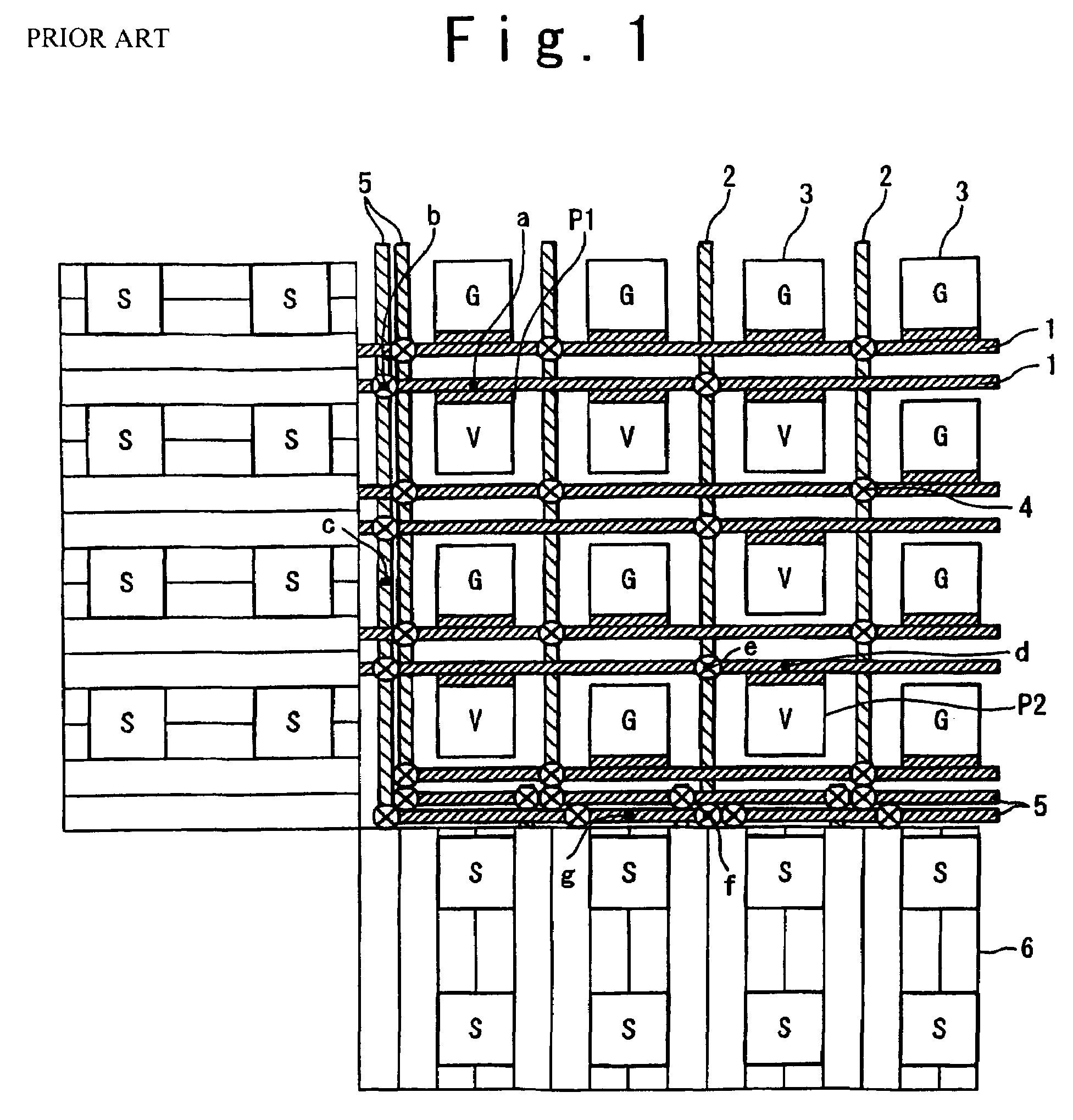

Three-dimension symmetrical vertical transformer

ActiveUS20160012958A1Transformers/inductances coils/windings/connectionsCoilsTransformerSymmetry line

First and second paths of the primary-coil of the transformer are located at different sides of the symmetry-line. First terminals of the first and second paths are first and second ports of the primary-coil. Second terminals of the first and second paths are connected to each other. Two partial paths of the first path are connected to each other by TSV. Two partial paths of the second path are connected to each other by TSV. Third and fourth paths of the secondary-coil of the transformer are located on different sides of the symmetry-line. First terminals of the third and fourth paths are first and second ports of the secondary-coil. Second terminals of the third and fourth paths are connected to each other. Two partial paths of the third path are connected to each other by TSV. Two partial paths of the fourth path are connected to each other by TSV.

Owner:IND TECH RES INST

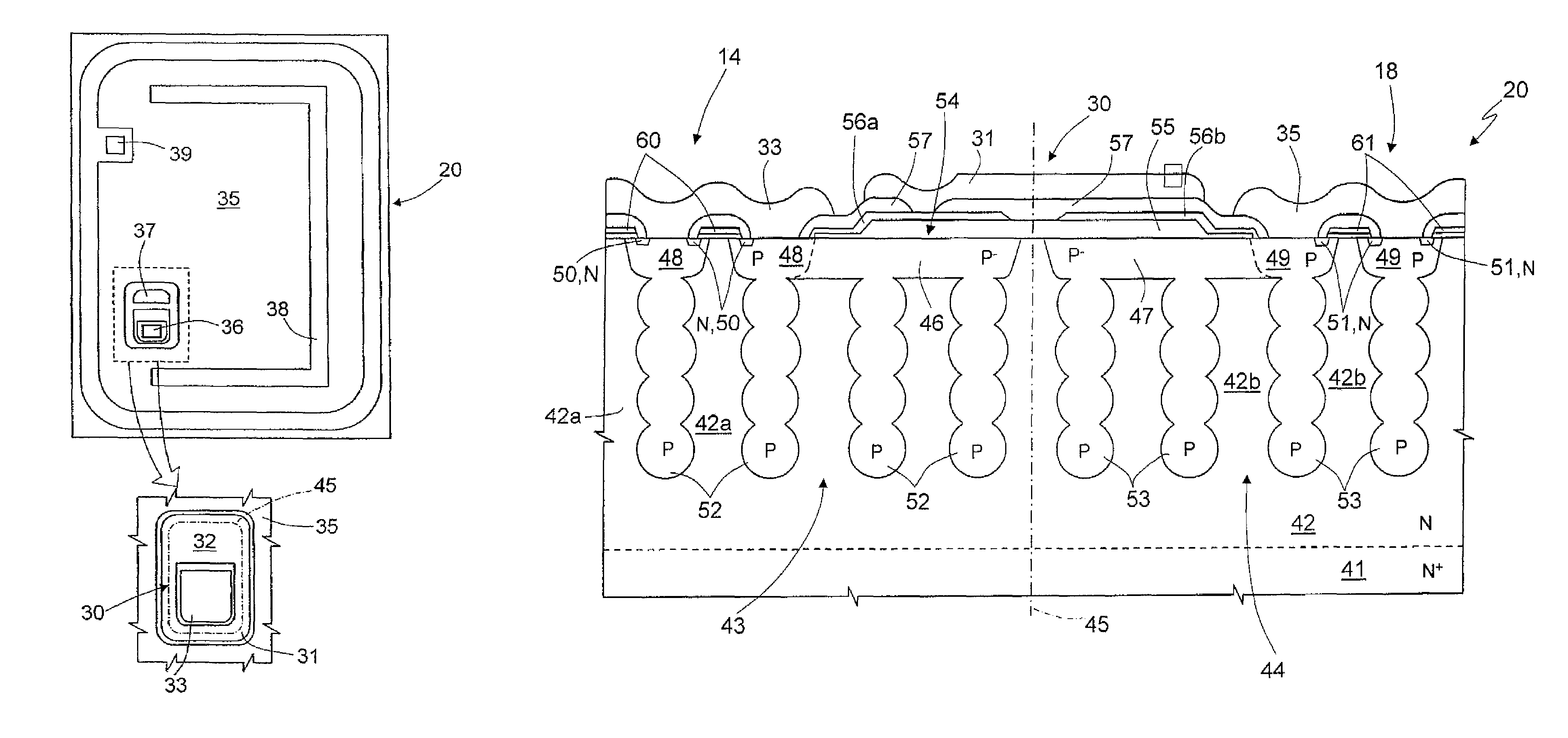

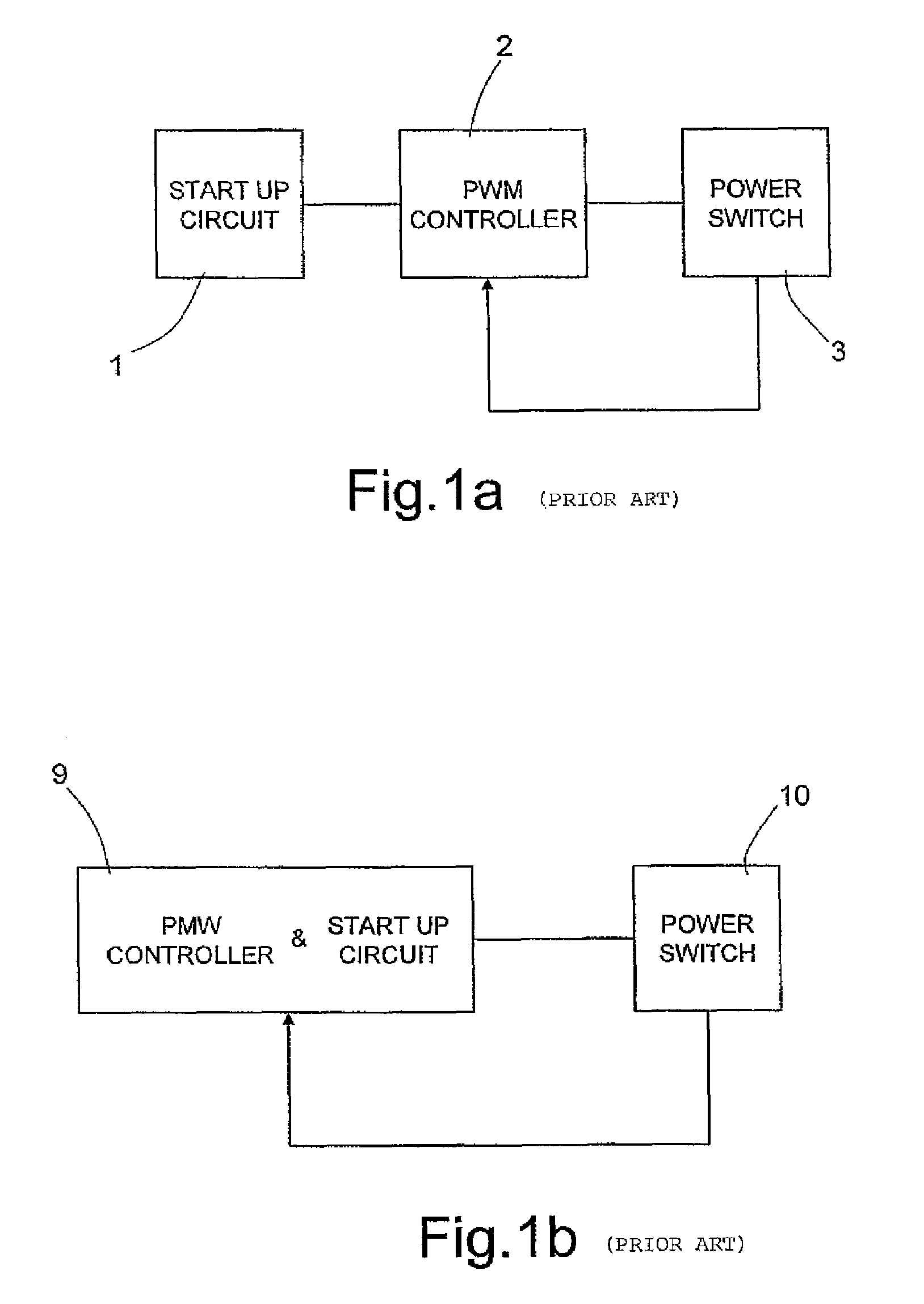

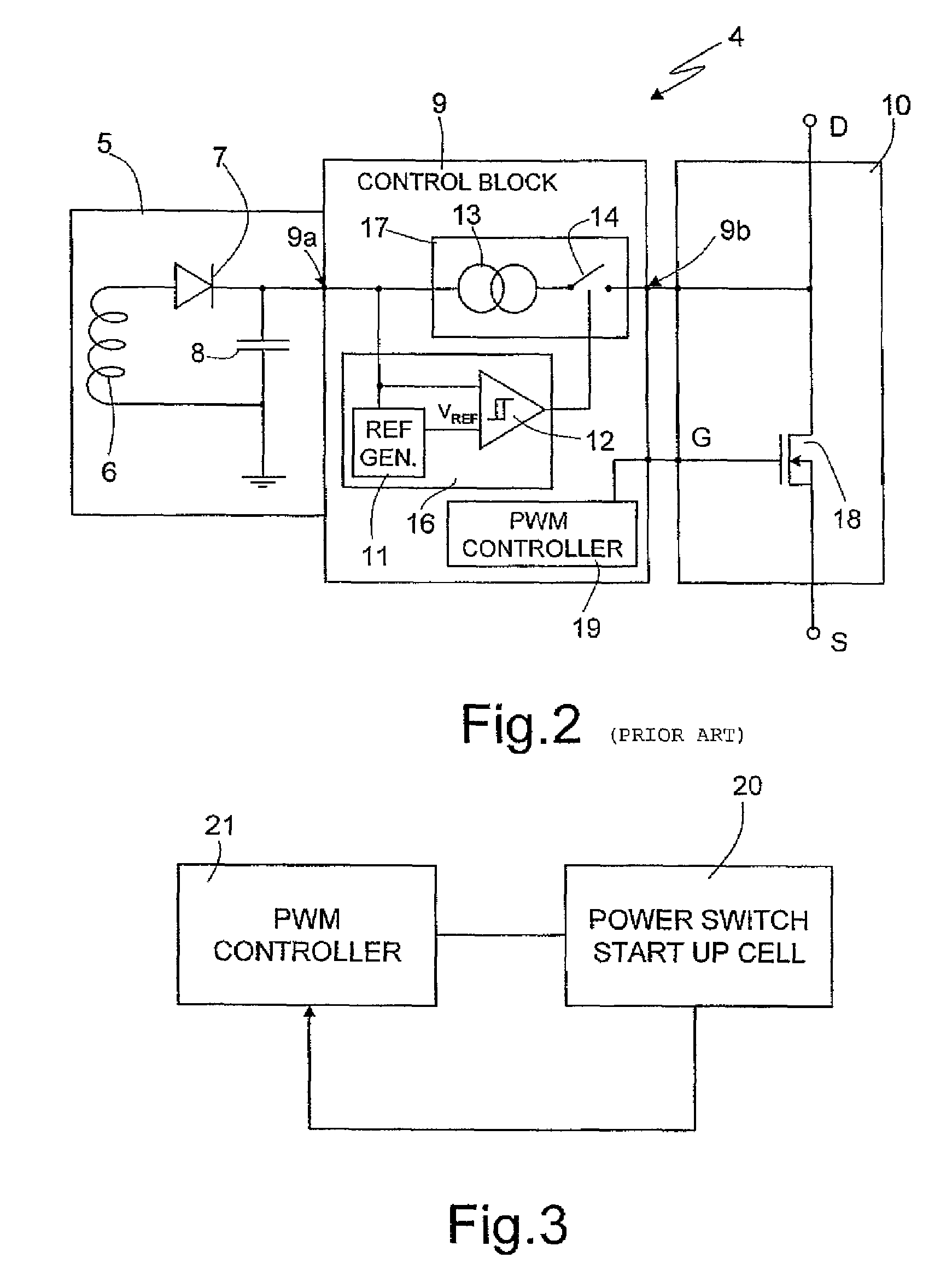

Integrated power device having a start-up structure

An integrated power device includes a semiconductor body of a first conductivity type comprising a first region accommodating a start-up structure, and a second region accommodating a power structure. The two structures are separated from one another by an edge structure and are arranged in a mirror configuration with respect to a symmetry line of the edge structure. Both the start-up structure and the power structure are obtained using MOSFET devices. Both MOSFET devices are multi-drain MOSFET devices, having mesh regions, source regions and gate regions separated from one another. In addition, both MOSFET devices have drain regions delimited by columns that repeat periodically at a fixed distance. Between the two MOSFET devices there is an electrical insulation of at least 25 V.

Owner:STMICROELECTRONICS SRL

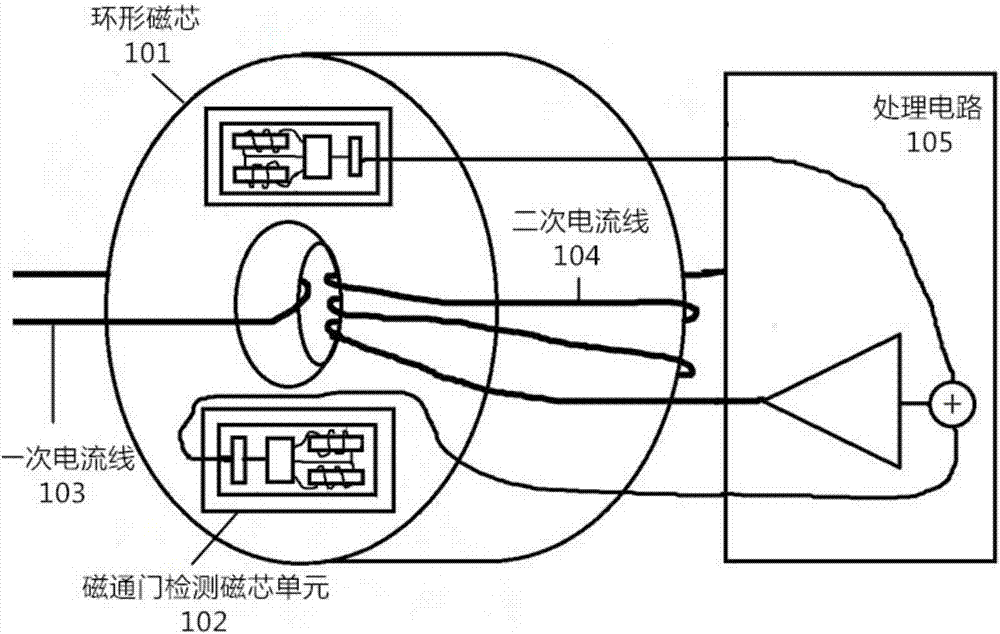

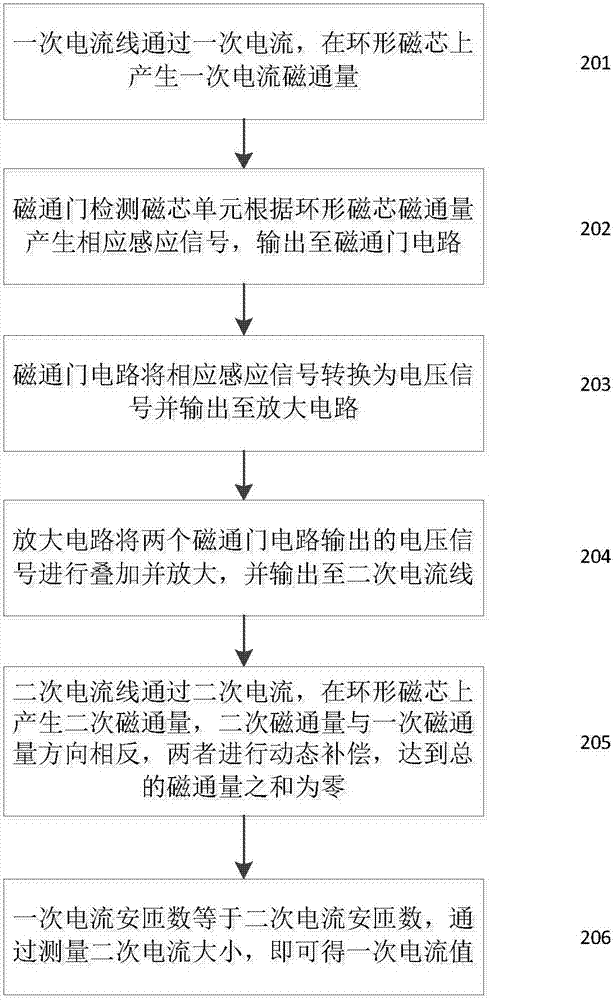

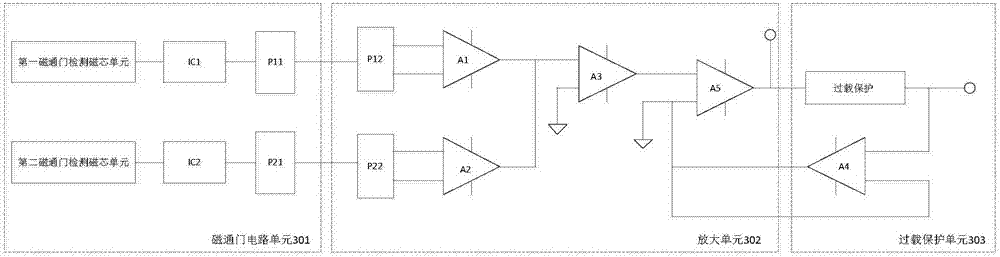

Zero-flux fluxgate current sensor for AC-DC heavy-current measurement

ActiveCN107102187ASolve fever problemImprove anti-interference abilityVoltage/current isolationSymmetry lineDynamic balance

The invention discloses a zero-flux fluxgate current sensor for AC-DC heavy-current measurement. The sensor comprises a primary current line, a secondary current line, an annular magnetic core, a fluxgate measuring magnetic core unit, and a processing circuit. The primary current line passes through the center of the annular magnetic core to be connected with a current line to be measured. The secondary current line is wound around the annular magnetic core. The geometrical symmetry line of the annular magnetic core is provided with two symmetrical grooves. The fluxgate measuring magnetic core unit is fixed in the grooves of the annular magnetic core and is connected with the input end of the processing circuit. The primary current line passes through the center of the annular magnetic core and generates a primary magnetic flux. The fluxgate measuring magnetic core unit generates a voltage signal based on the induced magnetic flux, and the voltage signal outputs secondary current to the secondary current line via the processing circuit. The secondary current line generates a secondary magnetic flux on the annular magnetic core, wherein the secondary magnetic flux forms a dynamic balance with the primary magnetic flux. Based on the measurement result of the secondary current, a primary current value to be measured can be obtained.

Owner:CHINA ELECTRIC POWER RES INST +2

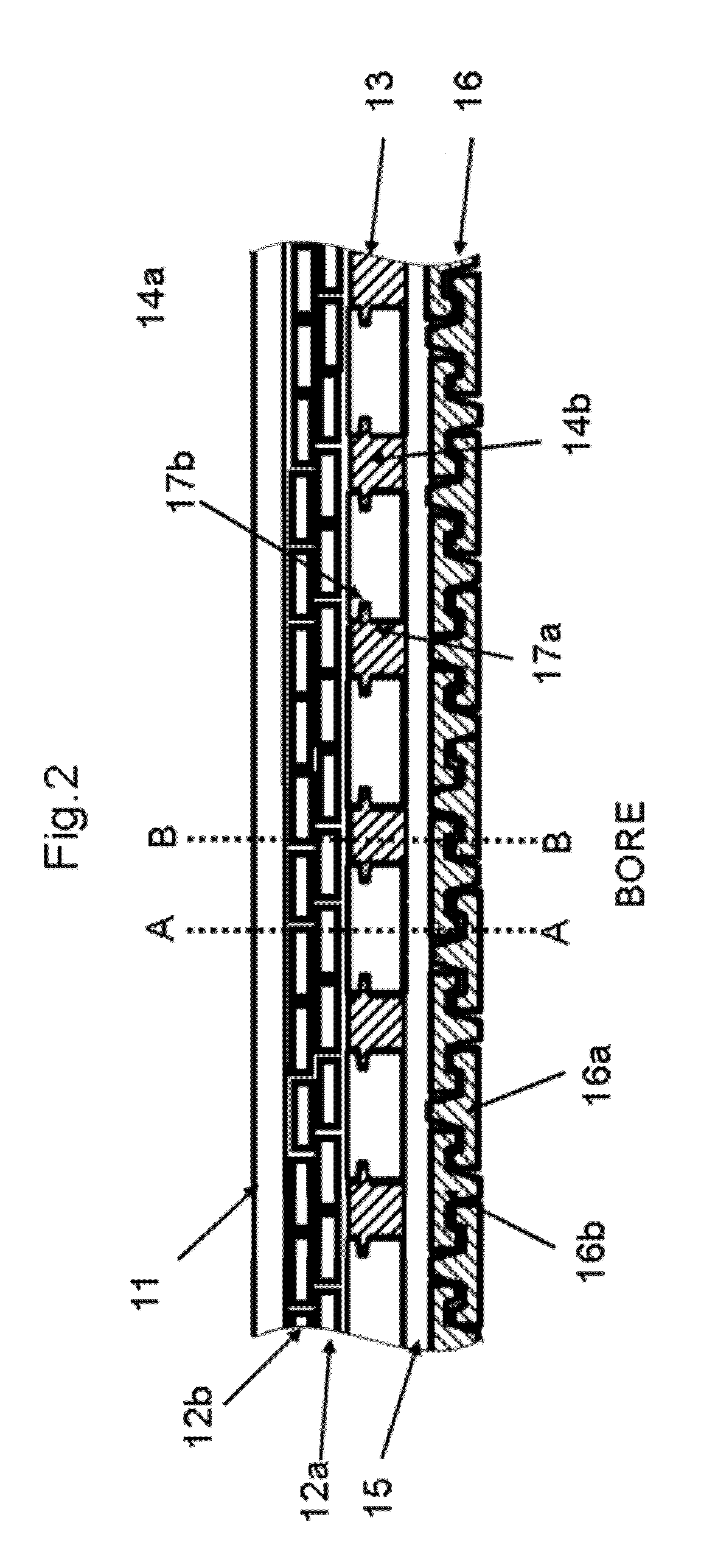

Flexible armored pipe

InactiveUS20140014218A1Easy to produceStrong and durable layerFlexible pipesSymmetry lineEngineering

The invention relates to a flexible armored pipe for transportation of fluids, comprising an inner sealing sheath and at least one displacement reduced armor layer comprising a plurality of elongate elements comprising at least a female type elongate element comprising at least one recess in each opposite side and a male type elongate element comprising at least one protruding tongue in each opposite side and wherein each of the female type and the male type elongate elements are substantially symmetrical in a symmetry line substantially normal to the inner sealing sheath when the pipe is in a non-bended state and where said protruding tongues of said male type elongate element windings are engaged in said recesses of adjacent female type elongate element windings.

Owner:NAT OILWELL VARCO DENMARK

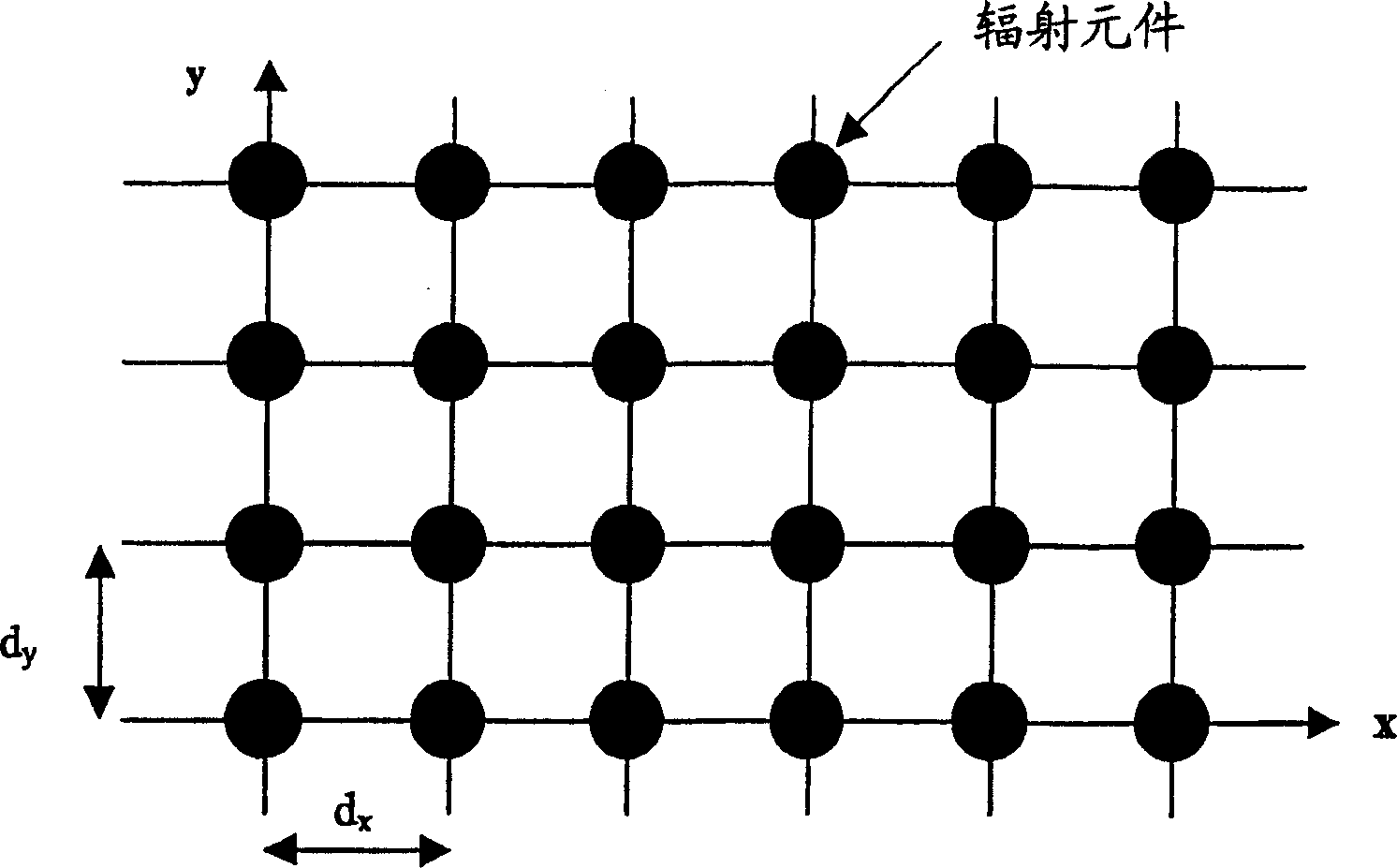

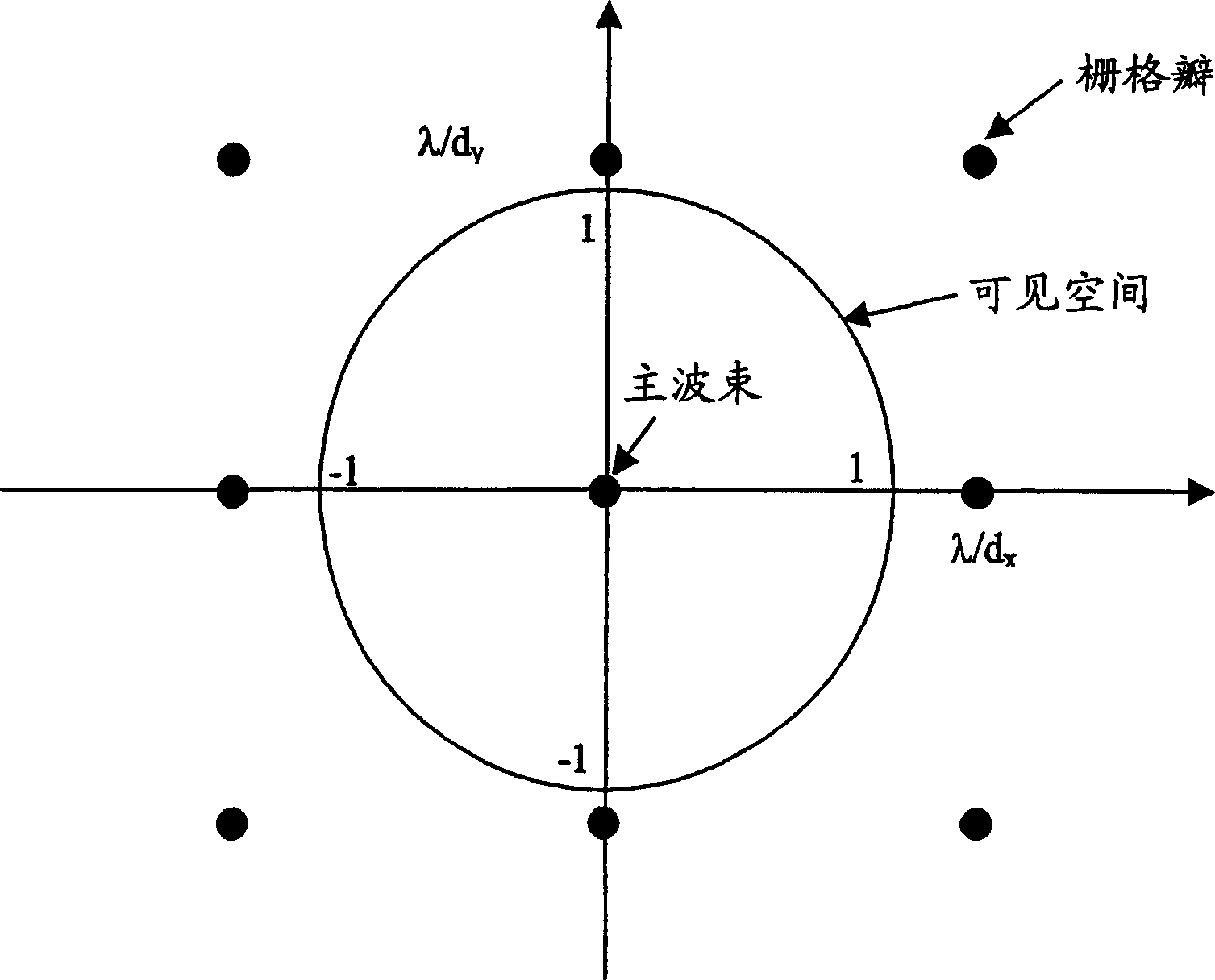

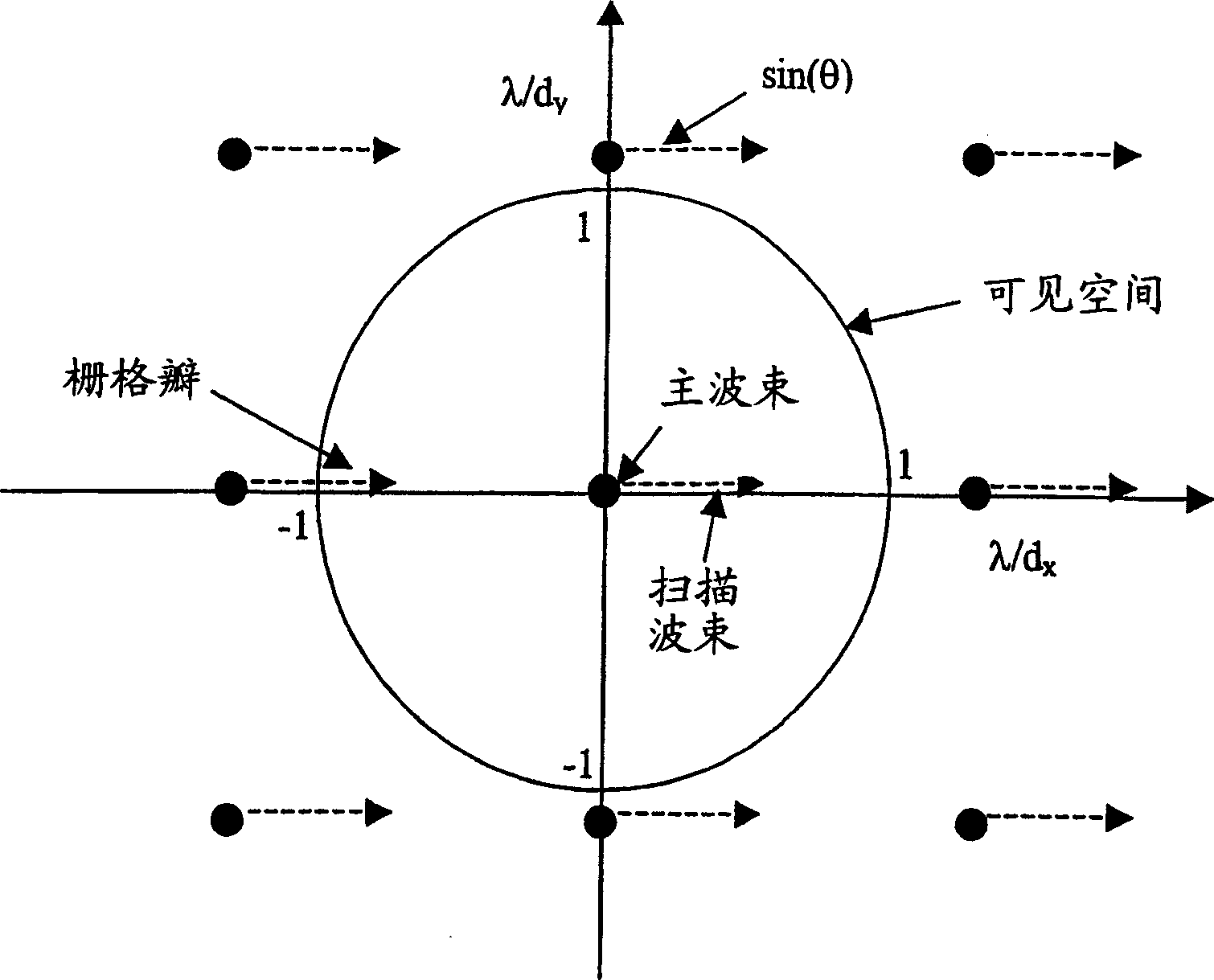

Scanable sparse antenna array

ActiveCN1879258AReduce access to visible spaceLinear waveguide fed arraysAntenna detailsSymmetry lineSide lobe

A sparse array antenna is disclosed. The antenna comprises series-fed antenna array columns tuned to a respective transmit and receive frequency. The transmitting and receiving radiation elements are formed with a given distance between each transmitting radiator element and each receiving radiator element, and the series-fed antenna columns are arranged in parallel, perpendicular to a symmetry line forming a symmetric interleaved transmit / receive array. Furthermore the receiving array columns operate as parasitic elements in a transmit mode and transmitting array columns operate as a parasitic elements in a receive mode, thereby reducing creation of grating lobes. The created sparse array antenna may further be arranged to be scanable to also provide reduced sidelobes entering visual space when scanning the main radiation lobe from an off boresight direction. Typically the series-fed array columns may be formed as extended ridged slotted wave-guides tuned to a respective transmitting or receiving frequency.

Owner:OPTIS CELLULAR TECH LLC

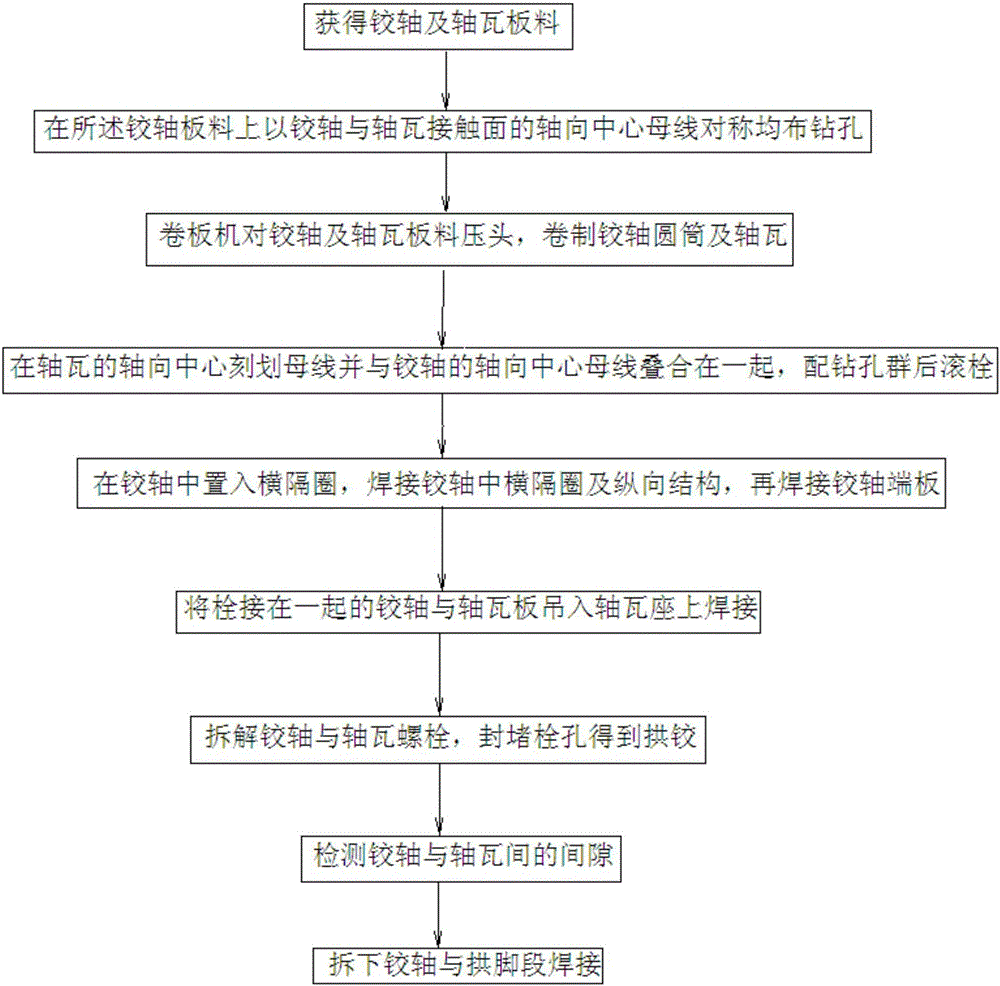

Manufacturing method of arch hinge of steel arch bridge

ActiveCN105127680AIncrease profitLow costBridge structural detailsArch-type bridgeSymmetry lineEngineering

The invention discloses a manufacturing method of an arch hinge of a steel arch bridge and belongs to the technical field of bridge steel structure machining and manufacturing. The manufacturing method of the arch hinge of the steel arch bridge includes the following steps that hinge shaft and bearing bush plate materials are obtained; holes are evenly drilled in the hinge shaft plate material with the axial center generatrix of the contact face of a hinge shaft and a bearing bush being a symmetry line; the ends of the hinge shaft and the bearing bush plate materials are pressed through a veneer reeling machine, and a hinge shaft cylinder and the bearing bush are reeled; a generatrix is formed in the axial center of the bearing bush in an etched manner and coincides with the axial center generatrix of the hinge shaft, and rear rolling bolts of drilled hole groups are arranged; a transverse space ring is placed in the hinge shaft, the transverse space ring in the hinge shaft and a longitudinal structure are welded, and then a hinge shaft end plate is welded; the hinge shaft and a bearing bush plate which are connected together through bolts are hoisted into a bearing bush base to be welded; the hinge shaft and the bearing bush bolts are disassembled, and the arch hinge is obtained after bolt holes are plugged; the gap between the hinge shaft and the bearing bush is detected; and the hinge shaft is disassembled to be welded together with an arch foot section. The manufacturing method of the arch hinge of the steel arch bridge increases material utilizing rate, is not limited by machining of large mechanical cutting equipment, and is low in cost and short in manufacturing period.

Owner:WUCHUAN HEAVY ENG

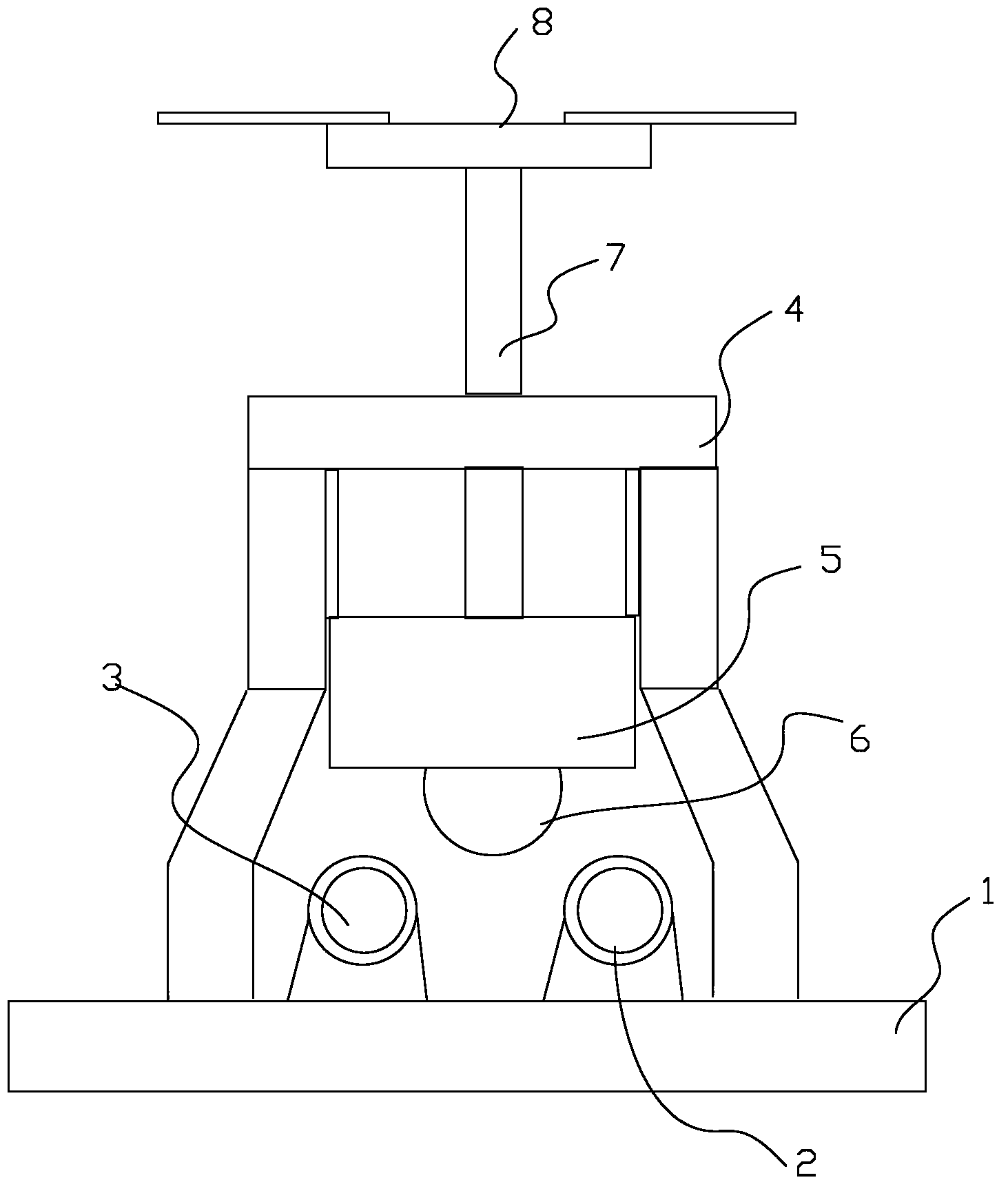

Processing device for arc plates

The invention belongs to the technical field of heating stoves and particularly relates to a processing device for arc plates. The processing device for arc plates comprises an underbed. Two parallel squeeze rollers are symmetrically arranged on the underbed. Two liftable squeeze blocks are symmetrically arranged on two sides of the space above the two squeeze rollers through an upper support. The bottom of each squeeze block is provided with an arc portion. A center line of each squeeze block and a symmetry line of the two squeeze rollers are collinear. The two parallel squeeze rollers are symmetrically arranged on the underbed, the two liftable squeeze blocks are symmetrically arranged on two sides of the space above the two squeeze rollers through the upper support, the bottom of each squeeze block is provided with one arc portion, and the center line of each squeeze block and the symmetry line of the squeeze rollers are collinear; accordingly during processing, a steel plate to be processed is disposed on the two squeeze rollers, the squeeze blocks are then driven to move down, and the steel plate is pressed into an arc shape.

Owner:TIANJIN CAOSHI BOILER

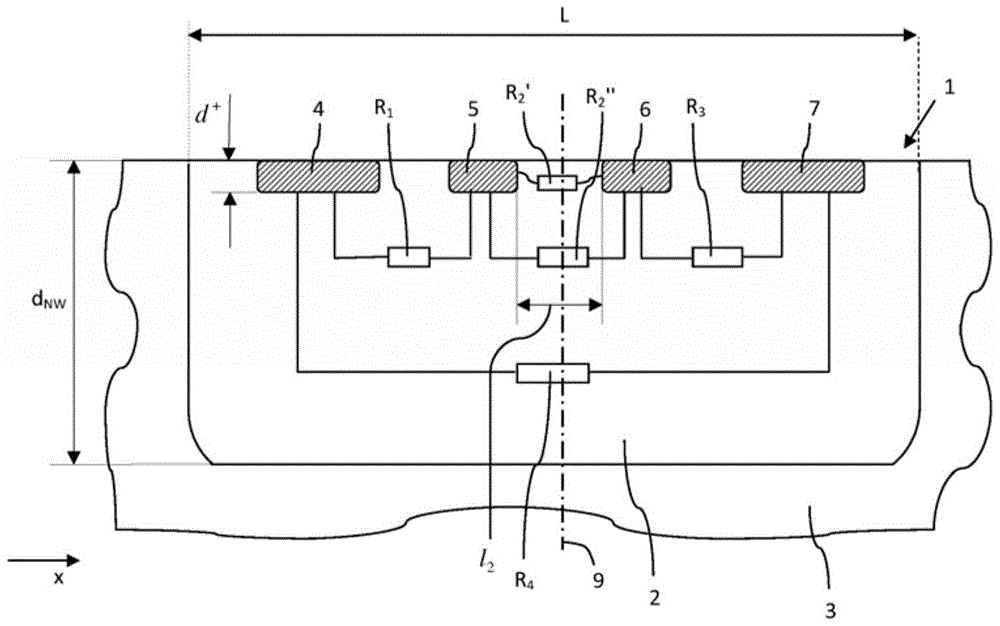

Vertical hall device

ActiveCN105261697AMagnetic measurementsGalvano-magnetic hall-effect devicesSymmetry lineWheatstone bridge

A vertical Hall device (1) has a deep N-well (NW), two inner contacts (5, 6), two outer contacts (4, 7) and, optionally, a central contact (12) disposed at a surface of the deep N-well (NW) and arranged along a straight symmetry line (8). The vertical Hall device (1) is designed according to the invention to have either an effective width of the outer contacts (4, 7) that is bigger than an effective width of the inner contacts (5, 6) and / or a shallow highly doped P + stripe disposed between the inner contacts (5, 6) or between each of the inner contacts (5, 6) and the central contact (12). These measures help to balance the resistances of the Wheatstone bridge which describes the electrical characteristics of the vertical Hall device.

Owner:SENIS

Flip-chip semiconductor device with improved power pad arrangement

InactiveUS20060157868A1Reduces circuit delay differenceSymmetrical distributionSemiconductor/solid-state device detailsSolid-state devicesDevice materialSymmetry line

A semiconductor device is composed of a power supply interconnection extending from a certain starting point in a first direction and also extending from the starting point in a second direction orthogonal to the first direction, a plurality of power pads, and connecting interconnections providing electrical connection between the power supply interconnection and the power pads. The power supply interconnection, the power pads, and the connecting interconnections are arranged in a symmetrical manner with respect to a symmetry line crossing the starting point and extending in a direction at an angle of 45 degree to the first and second directions.

Owner:RENESAS ELECTRONICS CORP

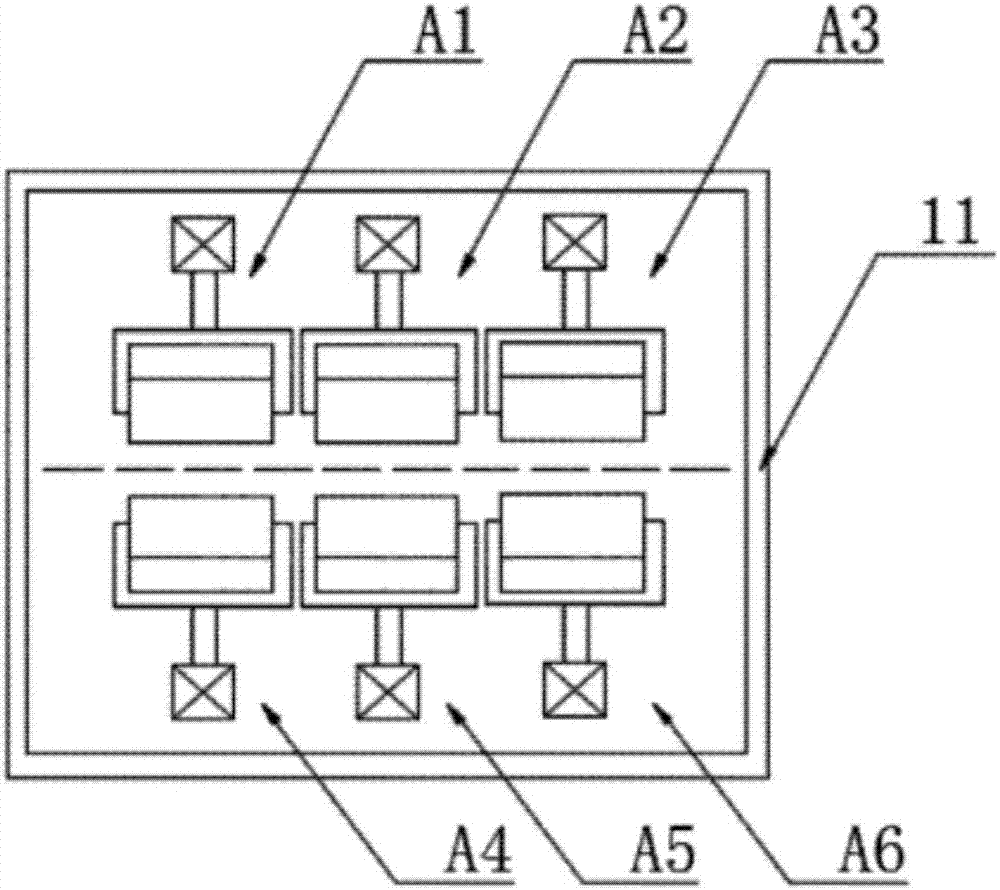

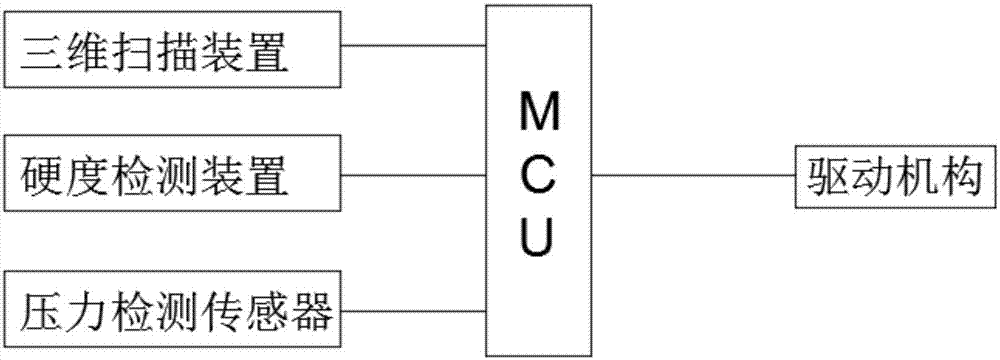

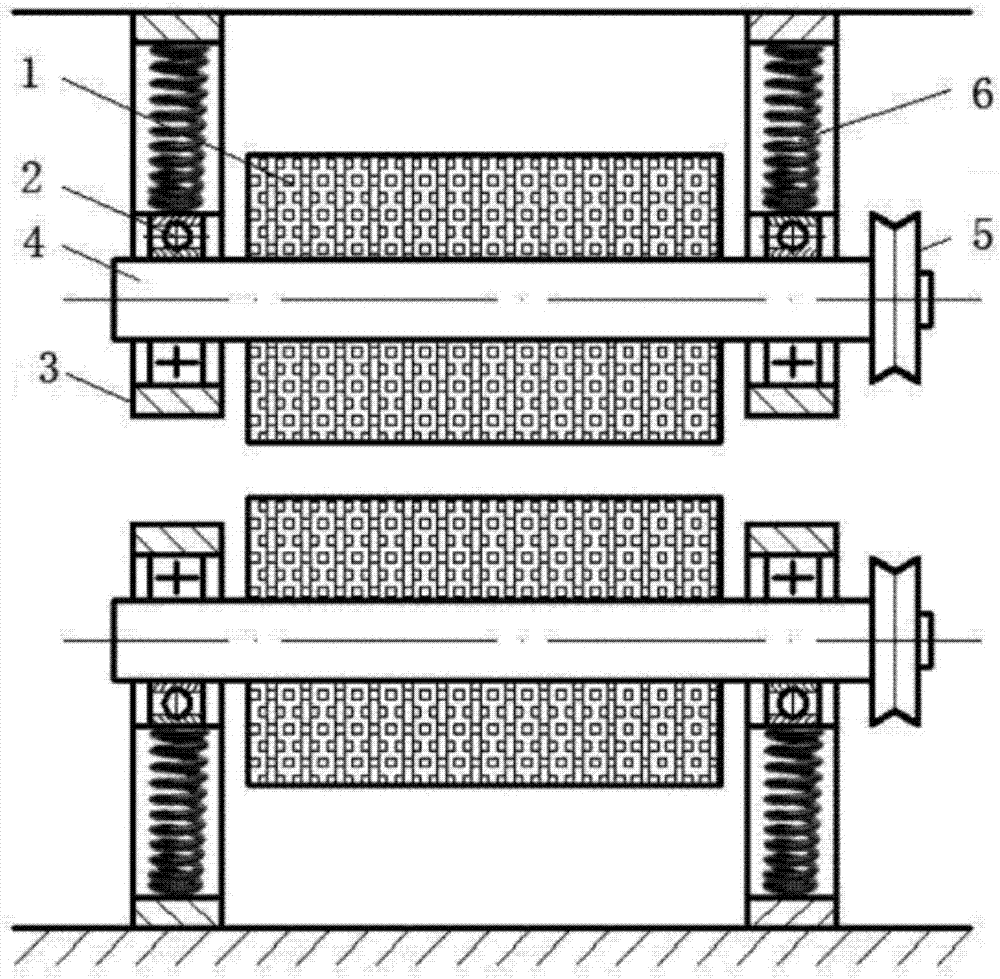

Elastic polishing device and method for special-shaped workpiece

InactiveCN107498446APolished evenlyMove preciselyPolishing machinesAutomatic grinding controlMotor driveSymmetry line

The invention provides an elastic polishing device and method for a special-shaped workpiece and belongs to the technical field of polishing. The elastic polishing device for the special-shaped workpiece comprises a base frame, a master control circuit storing three-dimensional data of the special-shaped workpiece, at least four polishing units and a driving mechanism; the polishing units are symmetrically arranged on the two sides of the base frame and form a symmetry line; and the driving mechanism is controlled by the master control circuit to drive the polishing units to get close to or be far away from the symmetry line so as to adapt to different sizes of different portions of the workpiece. Each polishing unit comprises a support, a mandrel, a polishing wheel and a spring capable of making the polishing wheel elastically move on the support, and further comprises a hardness detecting device used for detecting the workpiece, a motor driving the polishing wheel to rotate and a three-dimensional scanning device; and data generated by the three-dimensional scanning device are transmitted to the master control circuit to make the driving mechanism drive the polishing units to move relative to the symmetry line. The elastic polishing device for the special-shaped workpiece has the beneficial effects that each polishing unit can be flexibly and conveniently controlled, polishing is performed according to different materials, and the polishing effect is good.

Owner:XIAMEN UNIV OF TECH

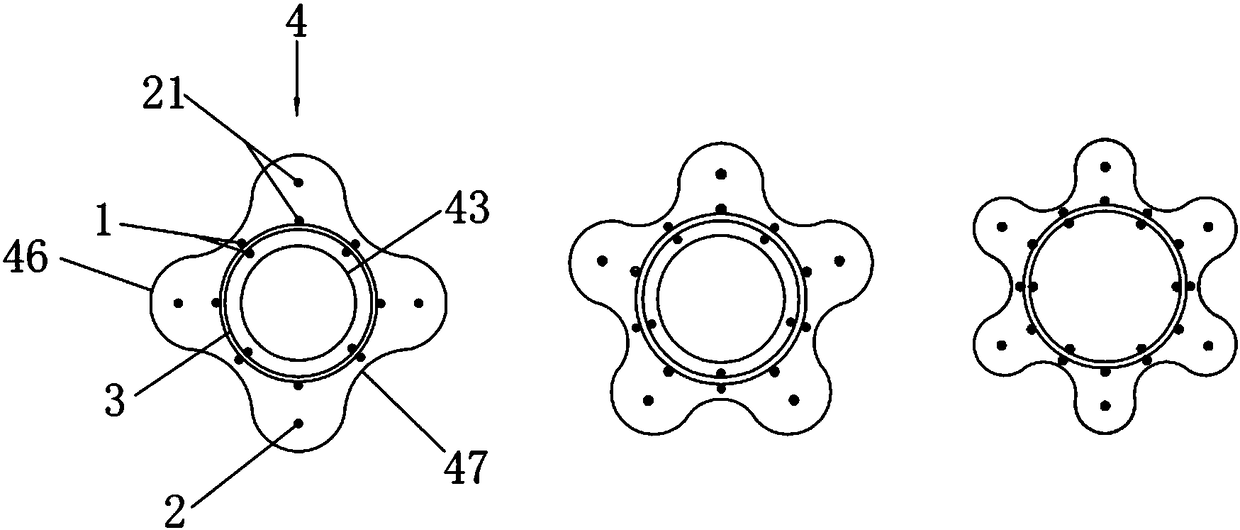

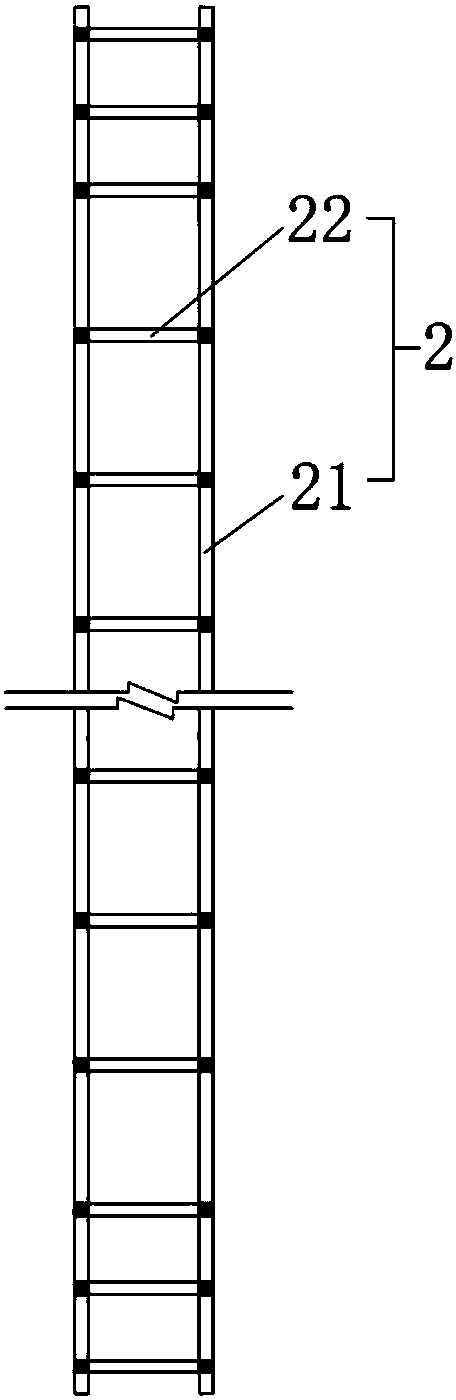

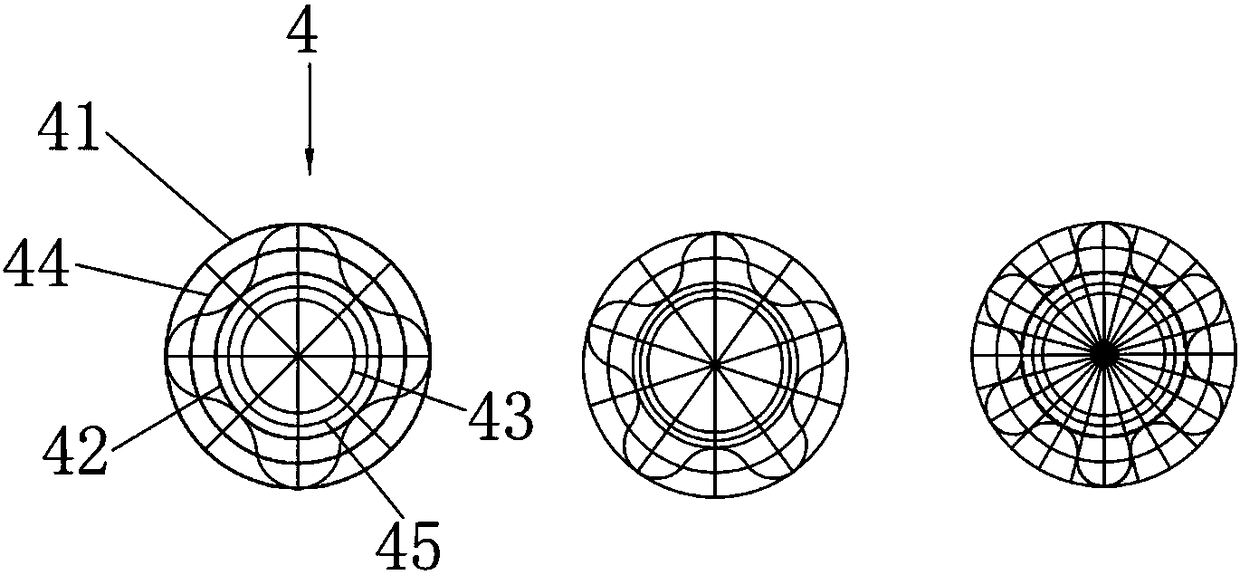

Quincunx concrete pipe pile

PendingCN108221963AImprove stress resistanceImprove tensile propertiesBulkheads/pilesVertical barSymmetry line

The invention provides a quincunx concrete pipe pile. The quincunx concrete pipe pile comprises a pile body and metal plates welded to the upper end and the lower end of the pile body. The pile body comprises a reinforcement cage and concrete filling the reinforcement cage. The cross section of the pile body comprises a hollow inner circle and a quincunx outline. The outline is composed of N convex arcs and N concave arcs at intervals, and the adjacent convex arcs and concave arcs are connected in a streamline mode. The reinforcement cage comprises N pairs of main bars and N reinforcing meshes, and further comprises a plurality of hoops, each pair of main bars are located on the symmetry line of the corresponding concave arcs, each reinforcing mesh is located on the symmetry line of the corresponding convex arcs, the multiple hoops are arranged up and down and are parallel, each hoop is welded and fixed to the N pairs of main bars and the N reinforcing meshes, each reinforcing mesh comprises two vertical bars and a plurality of short bars located between the two vertical bars and used for connecting the two vertical bars, the two vertical bars of each reinforcing mesh are located on the symmetry line of the corresponding convex arcs, are parallel to the main bars, penetrate through the concrete on the pile body in the up and down direction together with the main bars and are welded to a metal plate, and N is a natural number bigger than 3.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Three-dimension symmetrical vertical transformer

ActiveCN105304607AReduce areaSemiconductor/solid-state device detailsSolid-state devicesTransformerSymmetry line

First and second paths of the primary-coil of the transformer are located at different sides of the symmetry-line. First terminals of the first and second paths are first and second ports of the primary-coil. Second terminals of the first and second paths are connected to each other. Two partial paths of the first path are connected to each other by TSV. Two partial paths of the second path are connected to each other by TSV. Third and fourth paths of the secondary-coil of the transformer are located on different sides of the symmetry-line. First terminals of the third and fourth paths are first and second ports of the secondary-coil. Second terminals of the third and fourth paths are connected to each other. Two partial paths of the third path are connected to each other by TSV. Two partial paths of the fourth path are connected to each other by TSV.

Owner:IND TECH RES INST

Flip-chip semiconductor device with improved power pad arrangement

InactiveUS7602058B2Reduce latency varianceSymmetrical distributionSemiconductor/solid-state device detailsSolid-state devicesSymmetry lineElectrical connection

A semiconductor device is composed of a power supply interconnection extending from a certain starting point in a first direction and also extending from the starting point in a second direction orthogonal to the first direction, a plurality of power pads, and connecting interconnections providing electrical connection between the power supply interconnection and the power pads. The power supply interconnection, the power pads, and the connecting interconnections are arranged in a symmetrical manner with respect to a symmetry line crossing the starting point and extending in a direction at an angle of 45 degree to the first and second directions.

Owner:RENESAS ELECTRONICS CORP

Flexible armored pipe

The invention relates to a flexible armored pipe for transportation of fluids, comprising an inner sealing sheath and at least one displacement reduced armor layer comprising a plurality of elongate elements comprising at least a female type elongate element comprising at least one recess in each opposite side and a male type elongate element comprising at least one protruding tongue in each opposite side and wherein each of the female type and the male type elongate elements are substantially symmetrical in a symmetry line substantially normal to the inner sealing sheath when the pipe is in a non-bended state and where said protruding tongues of said male type elongate element windings are engaged in said recesses of adjacent female type elongate element windings.

Owner:NAT OILWELL VARCO DENMARK

Device for making artificial nails

A device for making artificial nails from a synthetic material comprises a semi-rectangular metallic film-coated plastic sheet and a wax-coated sheet. The wax-coated sheet has a first surface, a second surface and adhesive material on one of the surfaces which attaches the wax-coated sheet to the semi-rectangular metal film-coated plastic sheet so that the latter sheet is removable. The semi-rectangular metallic film-coated plastic sheet comprises a dotted symmetry line, a pair of symmetrical internal flaps and a pair of external flaps to fasten the device on a finger of a human hand, a removable cover having a base and an ergonomic design of a human fingernail, which when removed defines a hole shaped as a fingernail, and a central section having a template with a grid for making artificial nails of different sizes ranging from 3 mm to 42 mm.

Owner:LOZA CEBREROS RAFAEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com