Hanging type pipe clamp

A hanging and pipe clamp technology, which is applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of no protective device, damage, and affecting the service life of pipe fittings, etc., and achieve the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The suspension-type pipe clamp of the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

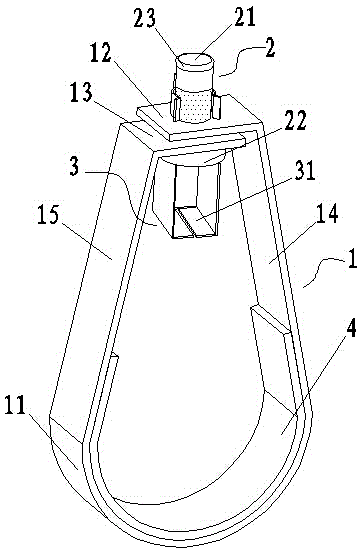

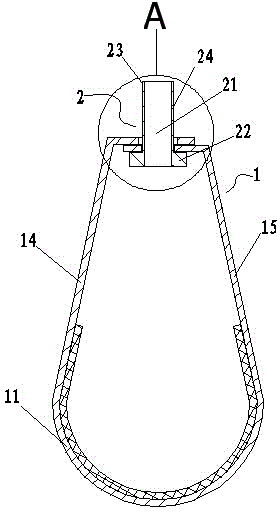

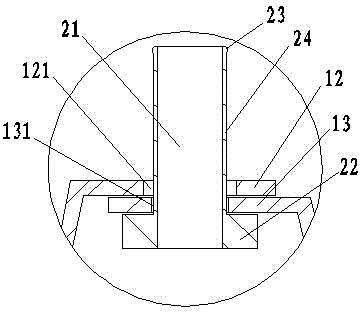

[0022] Such as figure 1 , figure 2 As shown, the hanging pipe clamp of this embodiment includes a clamping part 1 and a connecting part 2. The clamping part 1 is integrally formed by bending an elastic steel bar. The clamping part includes an arc-shaped accommodation part 11 , the first end portion 12 , the second end portion 13 , and the first transition portion 14 and the second transition portion 15 respectively extending from the two ends of the arc-shaped accommodation portion 11 to the first end portion 12 and the second end portion 13 . It should be noted that, the extension directions of the above-mentioned first transition portion 13 and the second transition portion 14 are symmetrical with respect to the line of symmetry of the arc-shaped accommodation portion 11 .

[0023] In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com