Patents

Literature

331results about How to "Easy to screw in" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

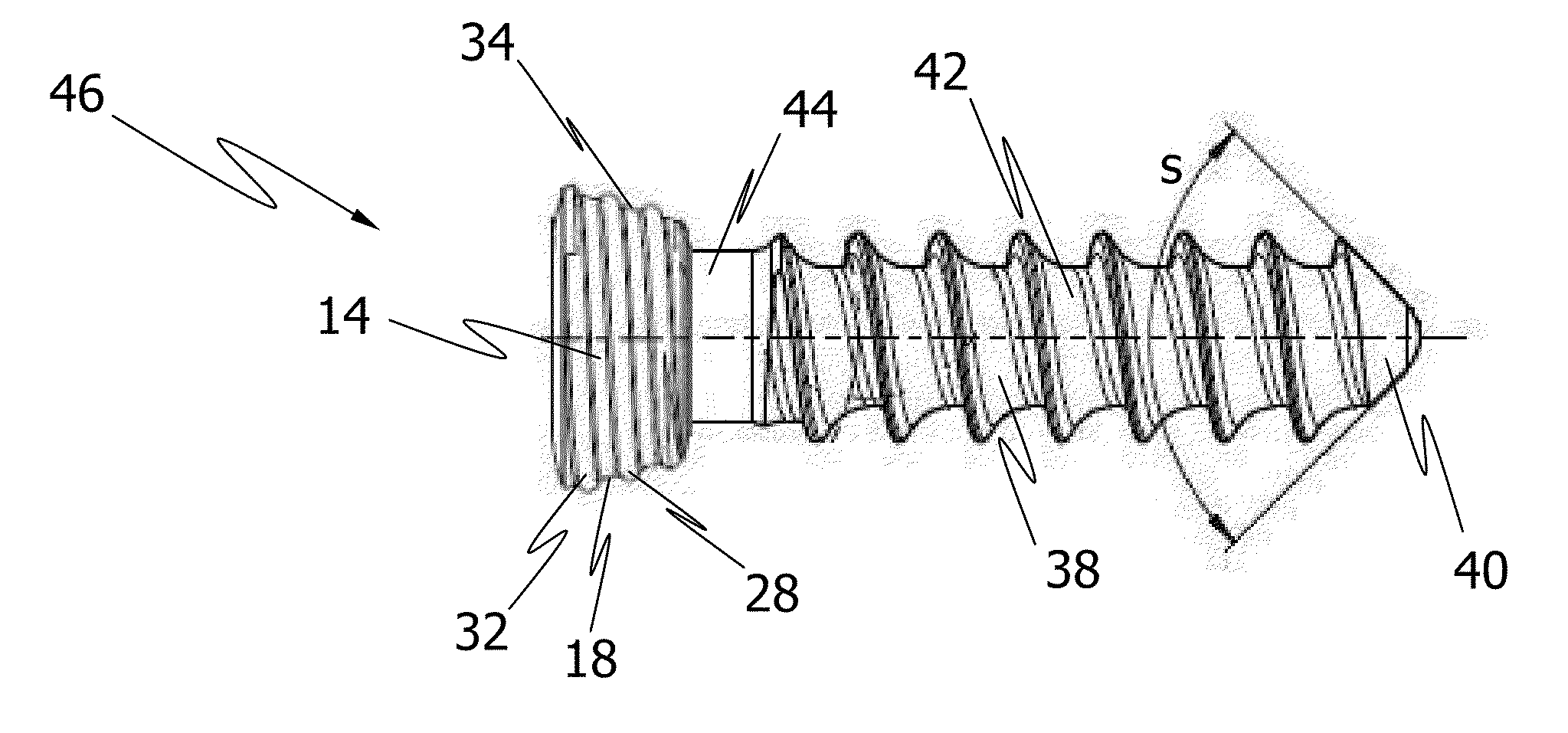

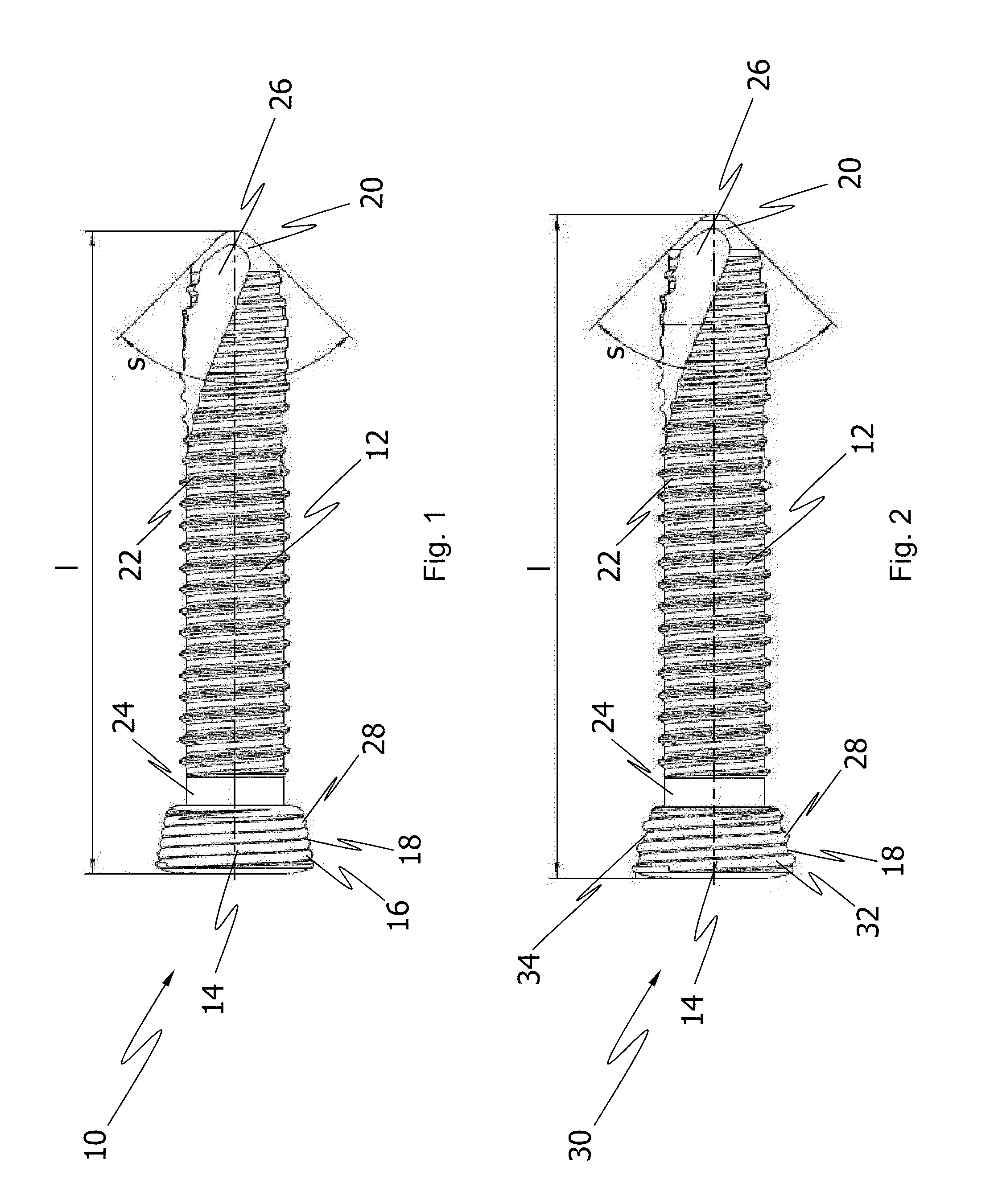

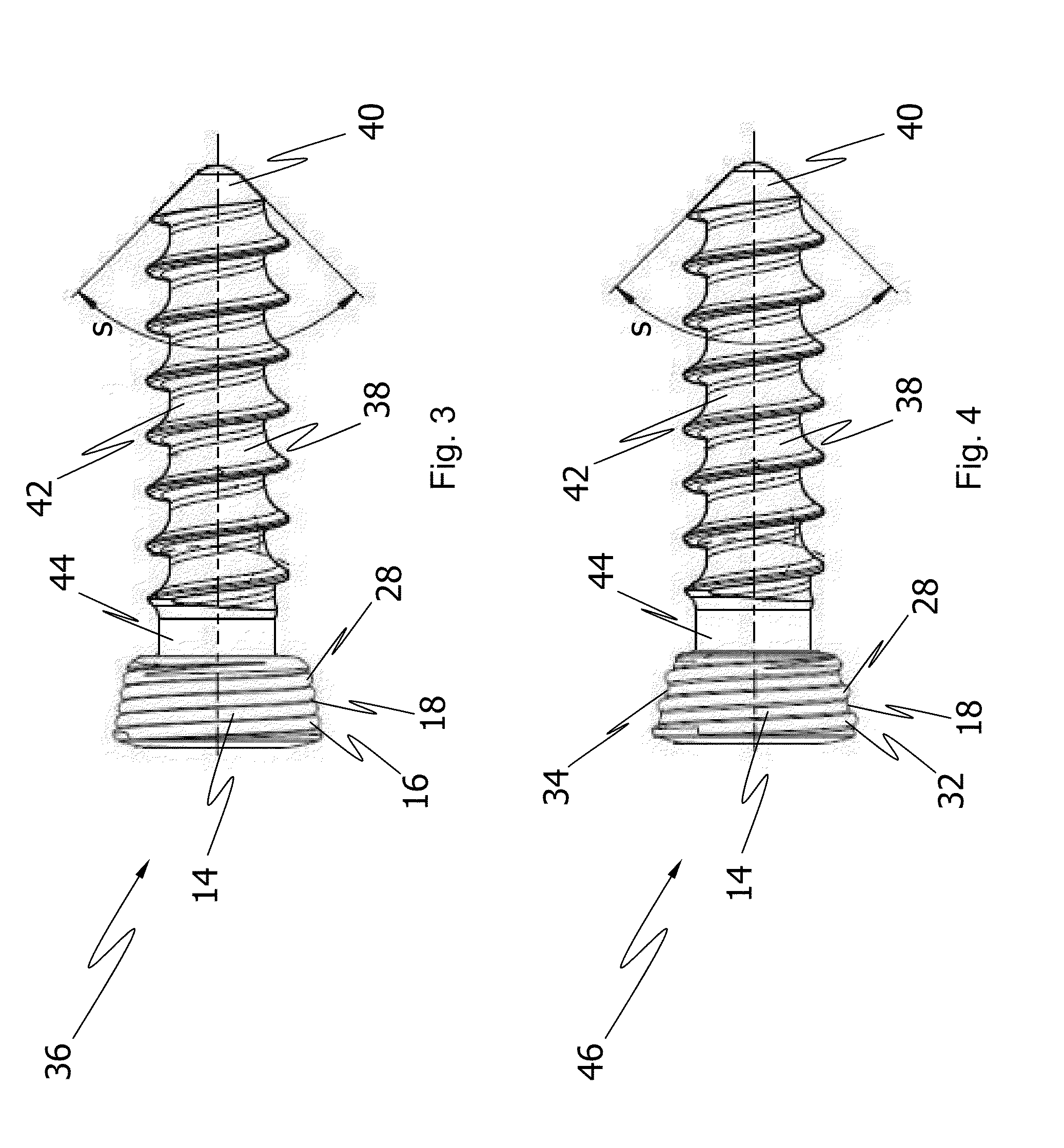

Bone fixation system with curved profile threads

InactiveUS20110218580A1Easy to screw inIncrease engagementSuture equipmentsLigamentsCurve shapePlastic surgery

A bone fastener for use in orthopedic surgery for fixing an implant to bone has a threaded or unthreaded shaft configured to engage bone and a head having a thread on an outer surface to engage the implant. The thread on the head of the fastener has a profile in cross section that includes peaks with a curved shape.

Owner:STRYKER EURO OPERATIONS HLDG LLC

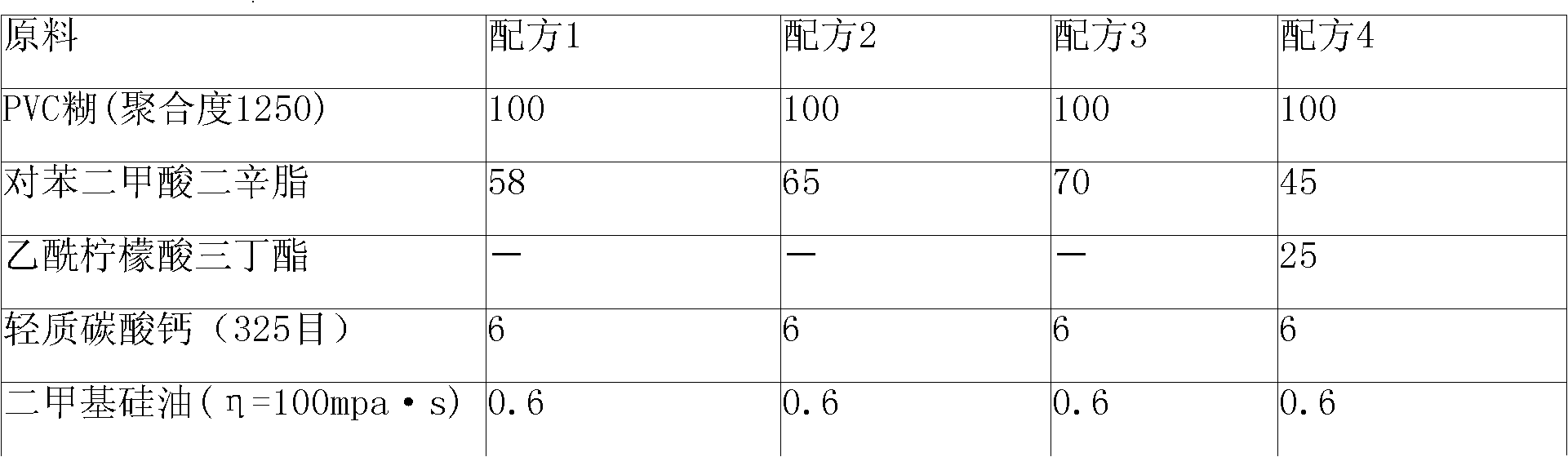

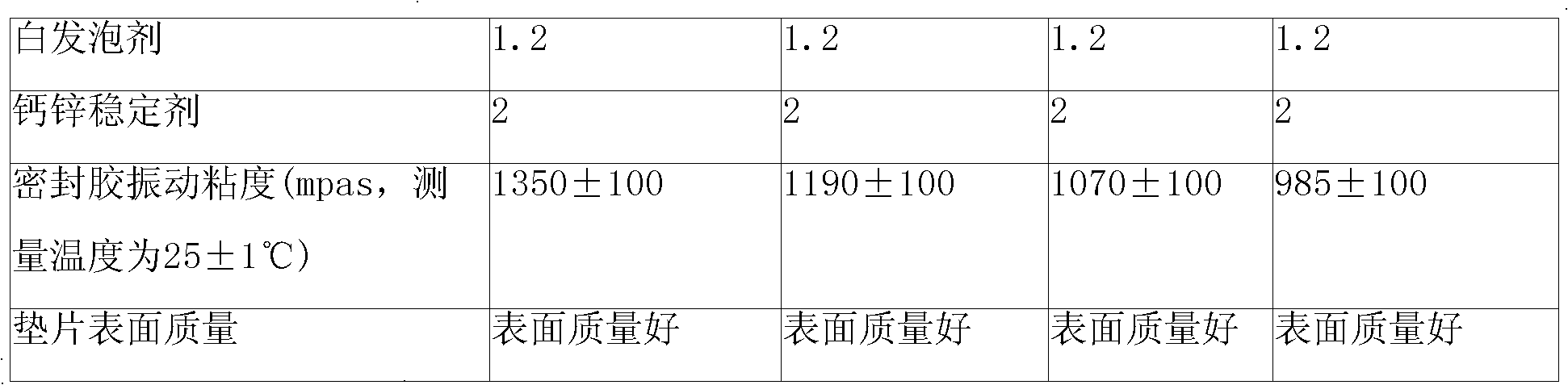

Asepsis environment-protecting polycinyl chloride bottle cap sealant and method for preparing same

InactiveCN101338171ALow priceImprove sealingOther chemical processesAdhesivesPolyvinyl chlorideRapeseed

The invention discloses a nontoxic environment protection polyvinyl chloride sealing gel and a preparation method thereof. The gel is made of pvc paste resin, dioctyl phthalate, acetyl tri-n-butyl citrate, heavy calcium carbonate, calcium-zinc stabilizer, white foaming agent, titanium dioxide, dimethicone and rapeseed oil. Phthalic ester plasticizer is not comprised. The gel meets the requirements of the food safety, and corresponds with the RoHS instruction. The gel is a foot and environmental friendly sealing gel. The using amount of fillings is added. The production cost is lowered. The nontoxic and environmental friendly sealing gel has the advantages of low price, high temperature resistance, good sealing effect and convenient engagement.

Owner:贵州省复合改性聚合物材料工程技术研究中心 +1

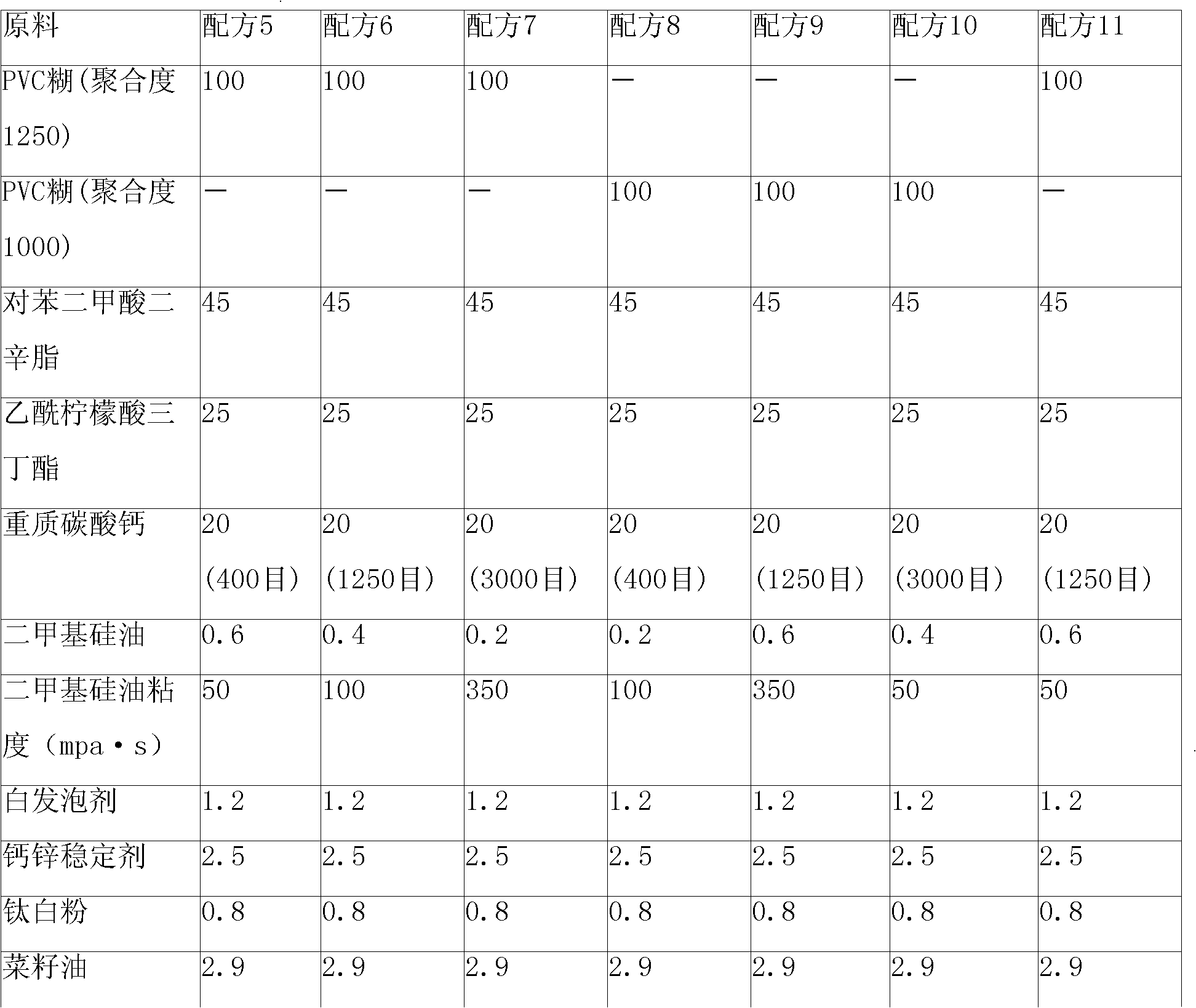

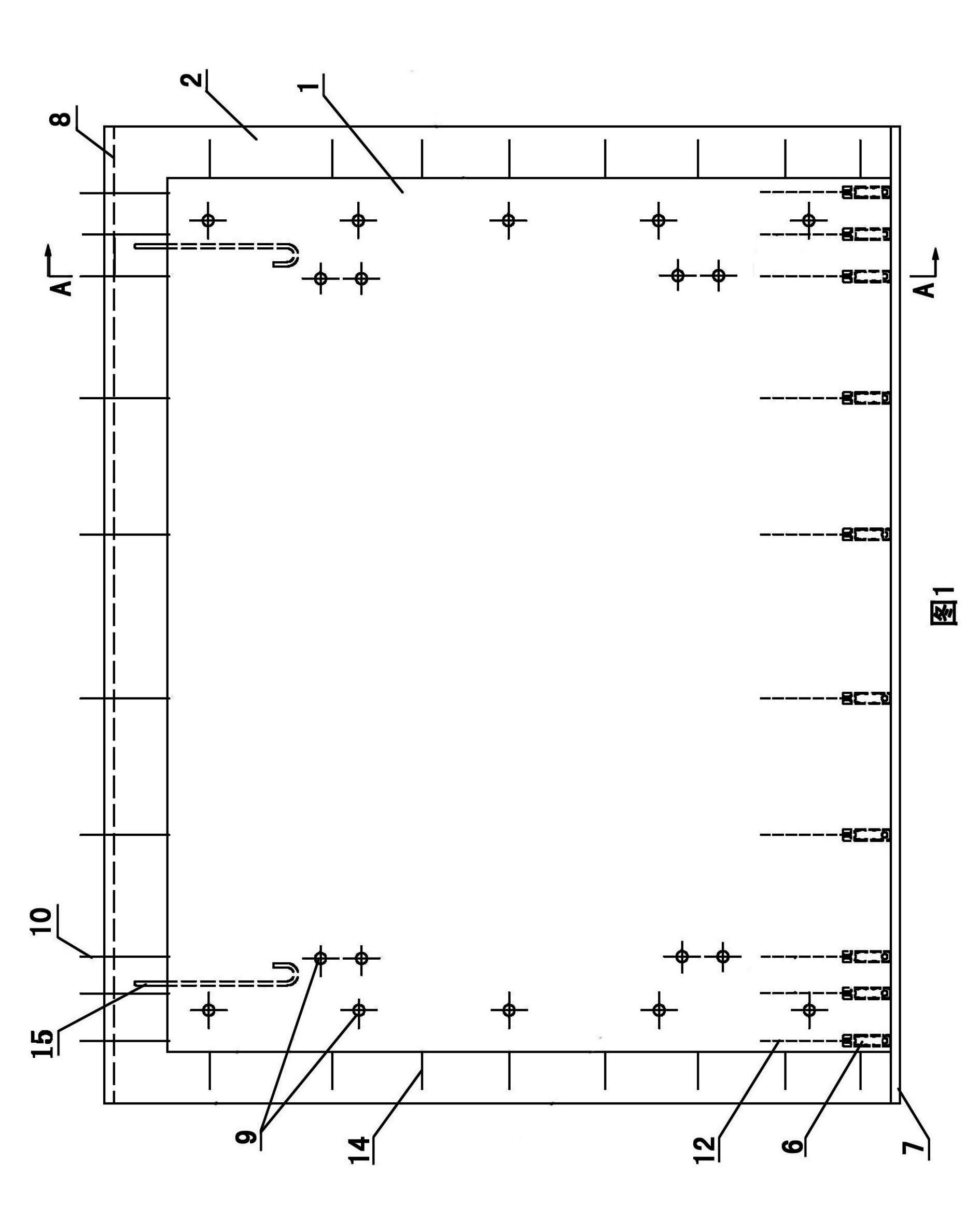

Precast concrete wallboard and preparation method thereof

ActiveCN101831985ALow costGuarantee the construction qualityConstruction materialForms/shuttering/falseworksReinforced concreteArchitectural engineering

The invention relates to a precast concrete wallboard and a preparation method thereof. A wall body has a structural layer and a protection layer from inside to outside, wherein the structural layer is internally provided with a reinforcement cage, and a reinforcement fabric is arranged in the concrete of the protection layer; the protection layer is connected with the structural layer through a transverse connecting reinforcement connected to the reinforcement fabric; the left edge and the right edge of the protection layer protrude out of the structural layer; the lower edge of the protection layer downwards extends out of a protruded port; and the top of the protection layer upwards protrudes out of the structural layer; the upper edge of the protection layer has a dent corresponding to the protruded port of the adjacent precast concrete wallboard on the upper layer; and the two ends of a transverse bar of the reinforcement cage protrudes out of the left side surface and the right side surface of the structural layer of the wall body and form two rows of transverse steel ties bending inwards. The wallboard has the advantages that the construction process is simplified, the construction speed is accelerated, and the construction cost is reduced. Meanwhile, products precast by a factory have uniform specification and quality, and thus, the construction quality of a building structure can be guaranteed sufficiently. The precast concrete wallboard can be widely applied to construction of concrete steel buildings in building industry.

Owner:华筑(辽宁)建筑工程设计有限公司

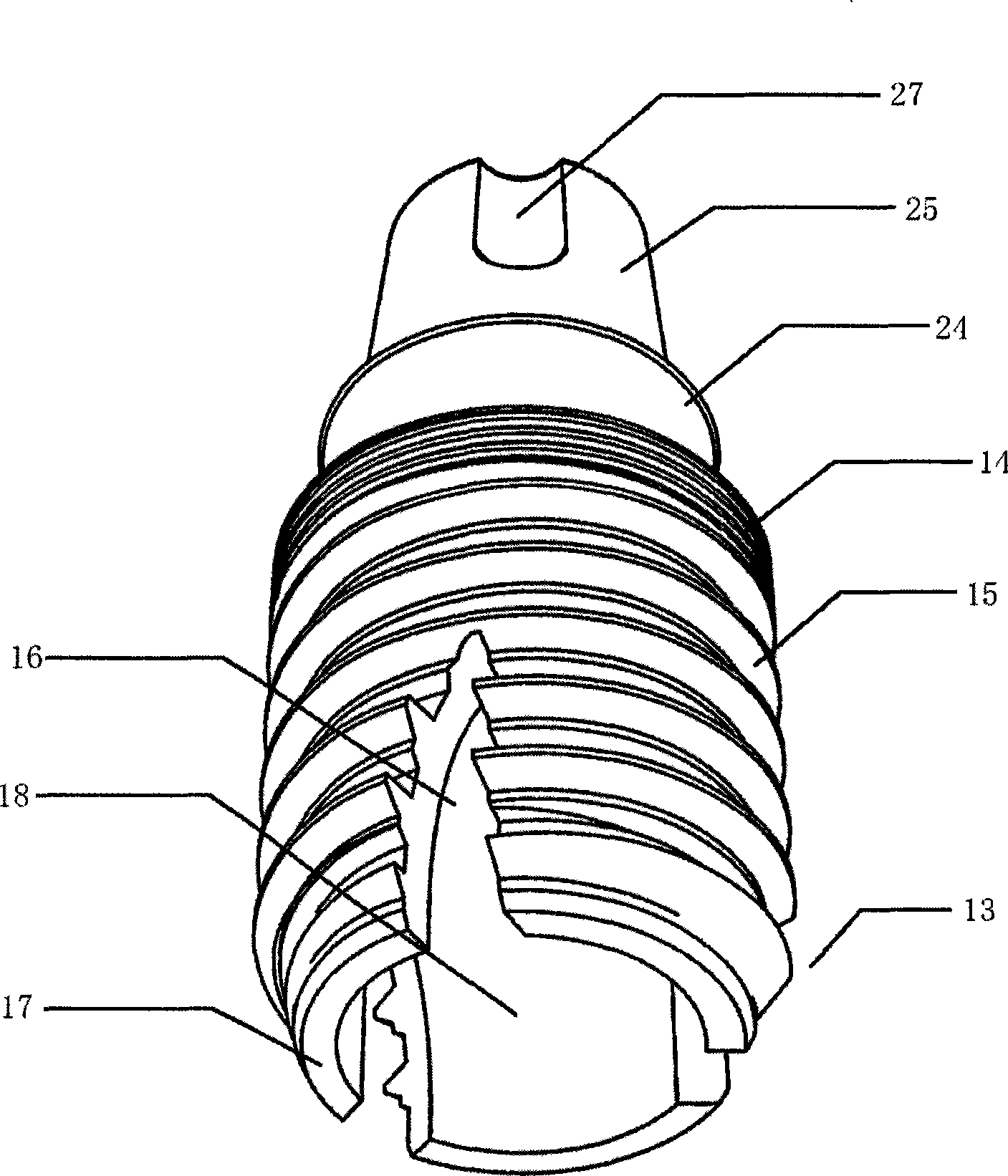

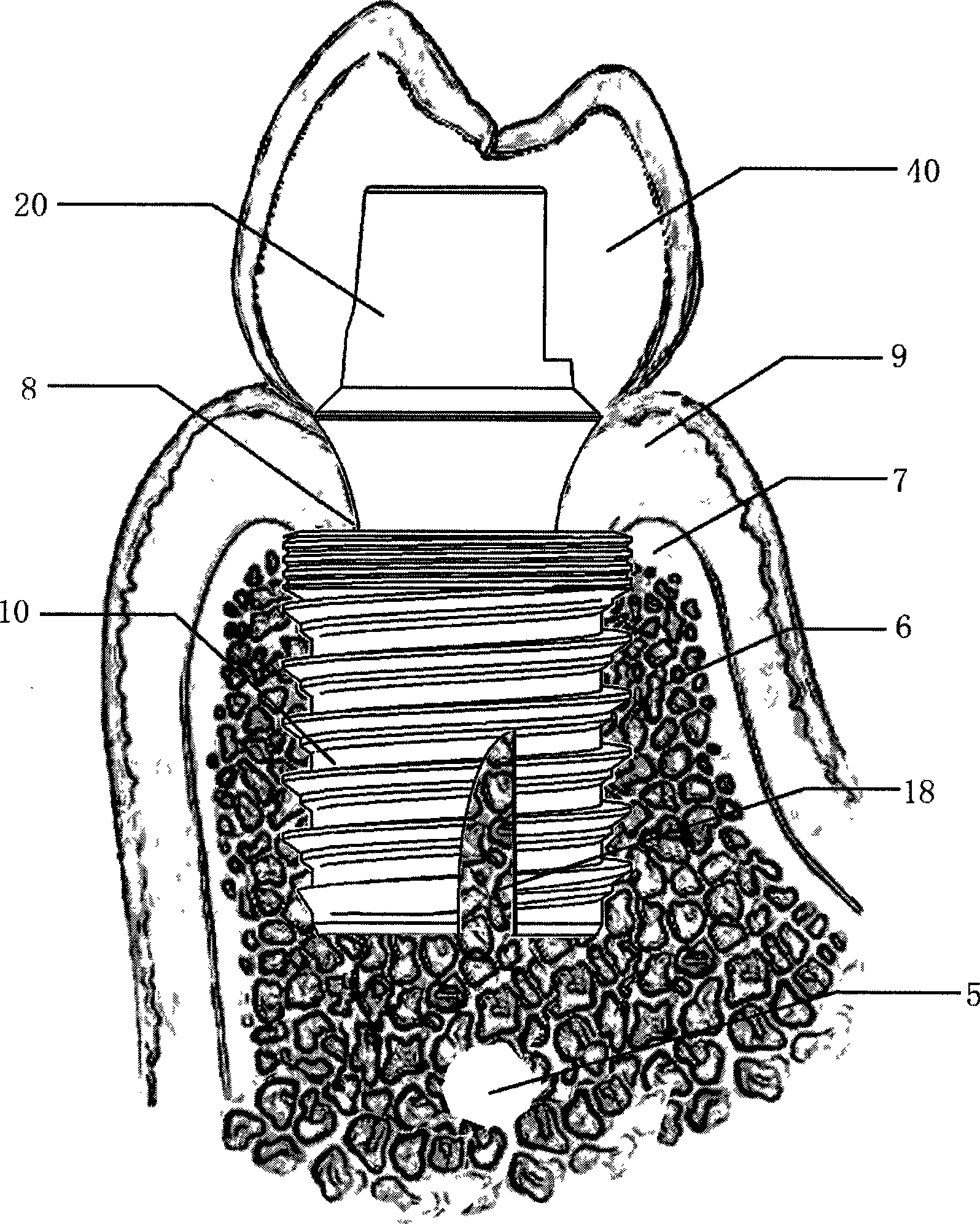

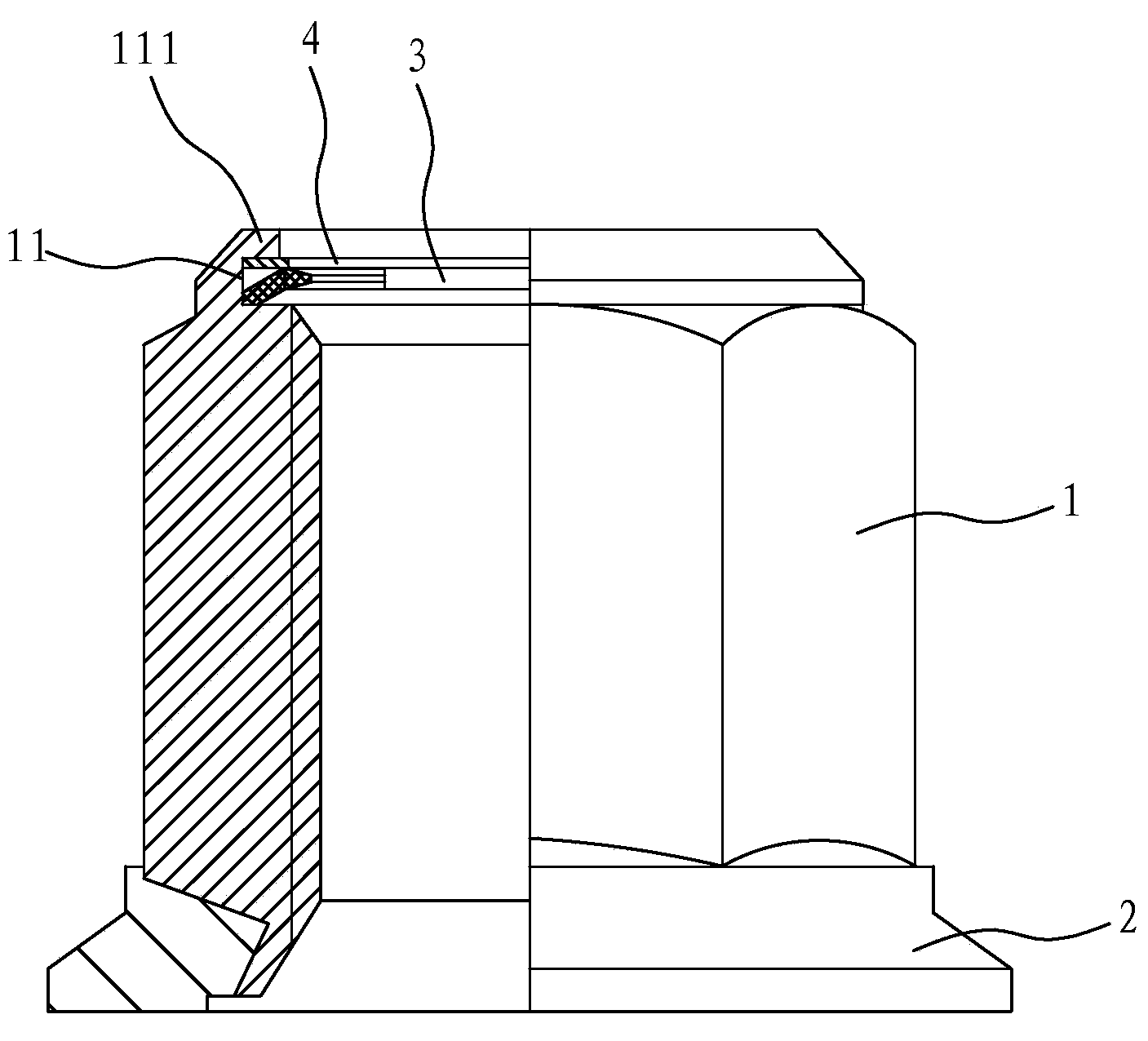

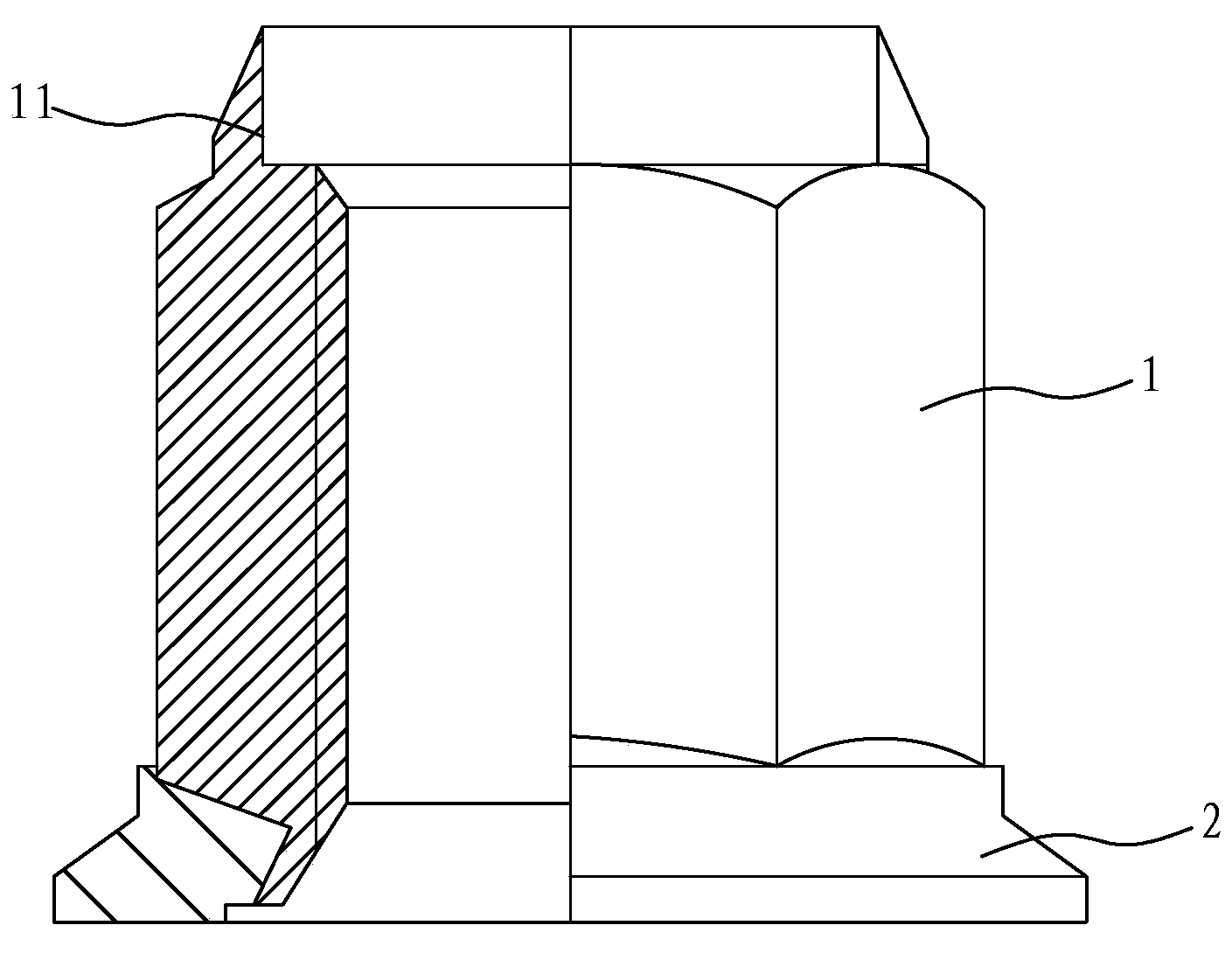

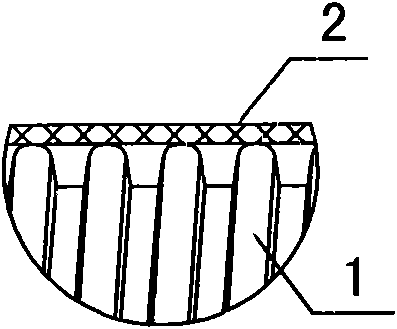

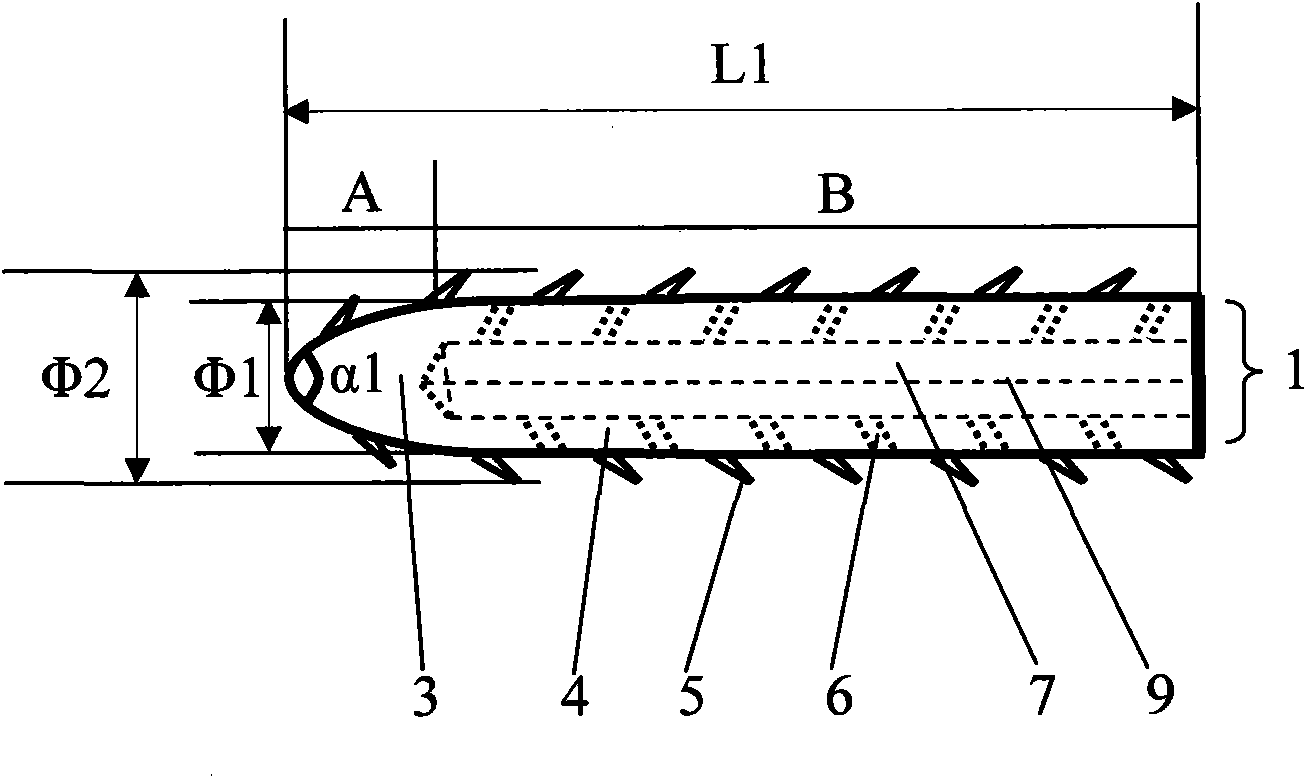

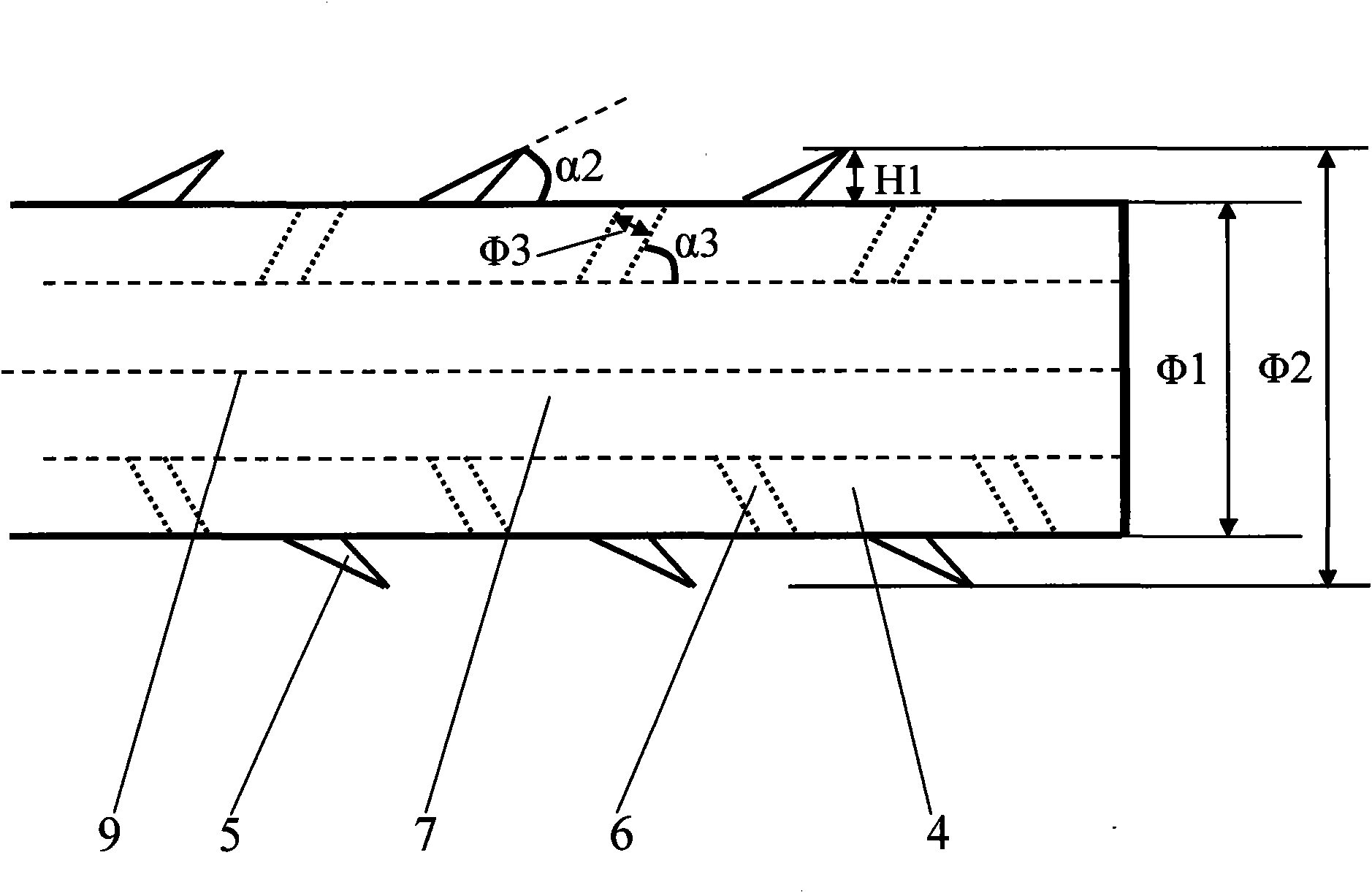

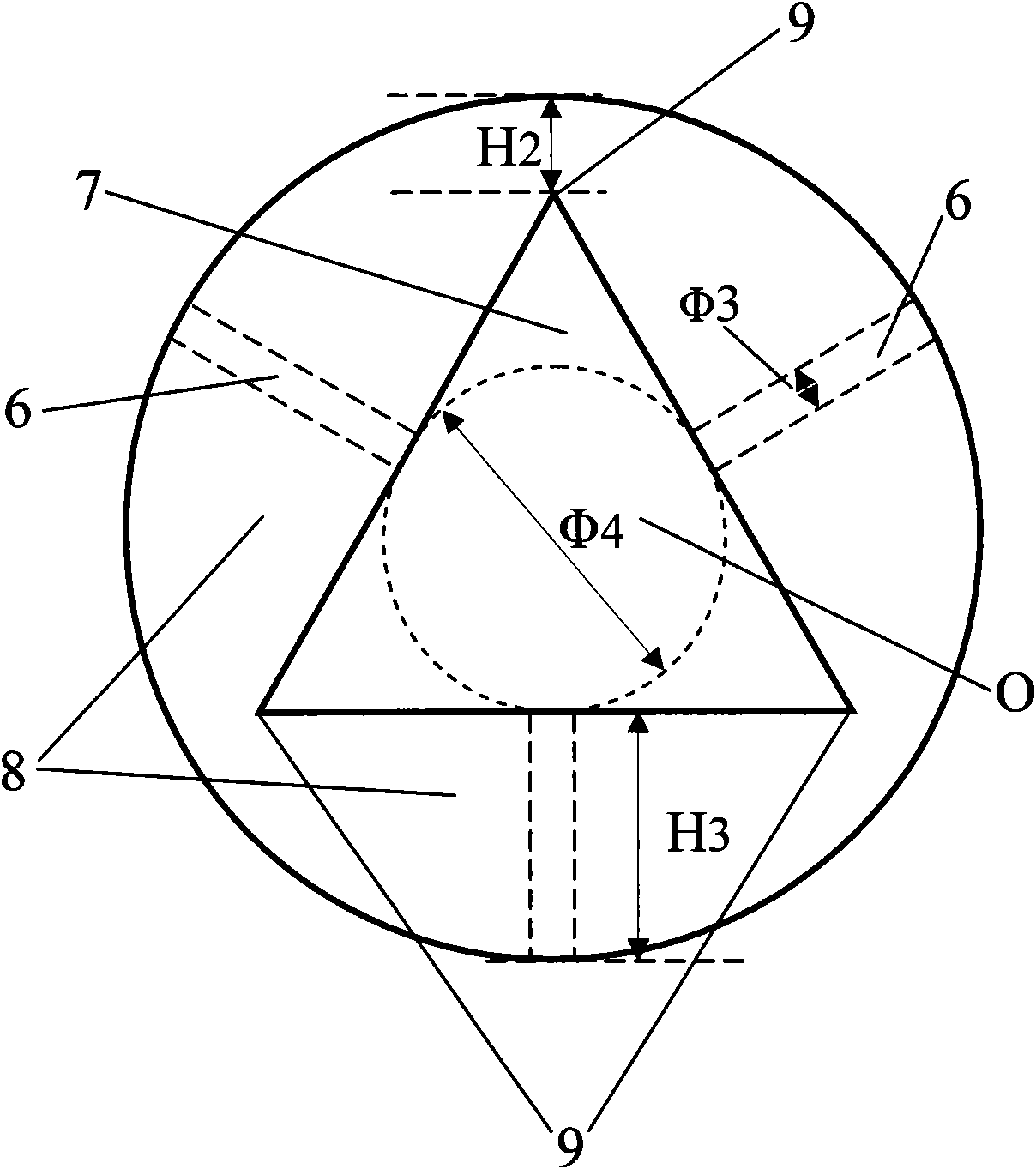

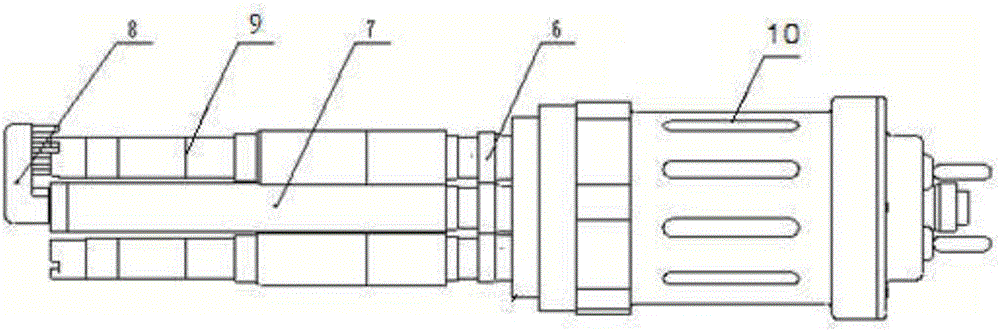

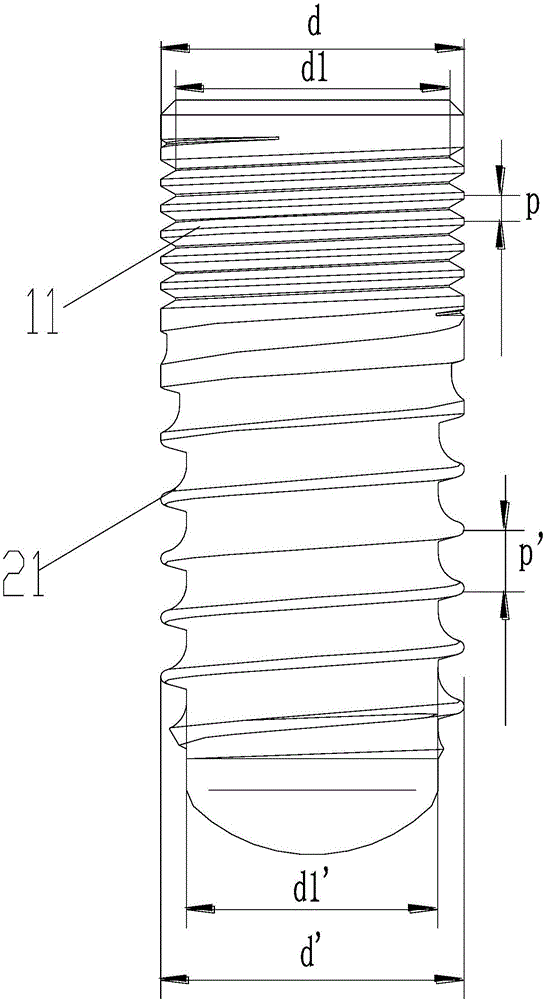

Hollow short grow body of oral cavity tooth grow

The invention relates to a hollow short implant of a dental implant, which comprises an one-stage structure and a two-stage structure, wherein the one-stage implant part is connected with an abutment part into a whole; the two-stage structure comprises an implant, a bridge adapter ring and a central bolt; peripheral cylinder spirochaeta of the implant part is divided into three stages, saw-tooth double thread in the main part of the implant can bear heavier load; the hollow structural design of the implant part keeps live bone column with a base and blood supply so as to enhance the supporting strength of the bone and the implant; a self-tapping socket can make bone tissue of the internal and external of the implant grow through and heal; a platform transfer design allows the epithelial cuff of the gum around the implant more reliable to avoid bone resorption caused by micro moving and micro leakage. The short hollow implant realizes combination of the internal and external bone, increases the combination area and supporting strength for a short or a long term, can be implanted rapidly with high strength, better retention in the early stage, high success rate in a long term, and solves the problem that the upper and lower jaws abrase the dental area in the conventional oral implant technology.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

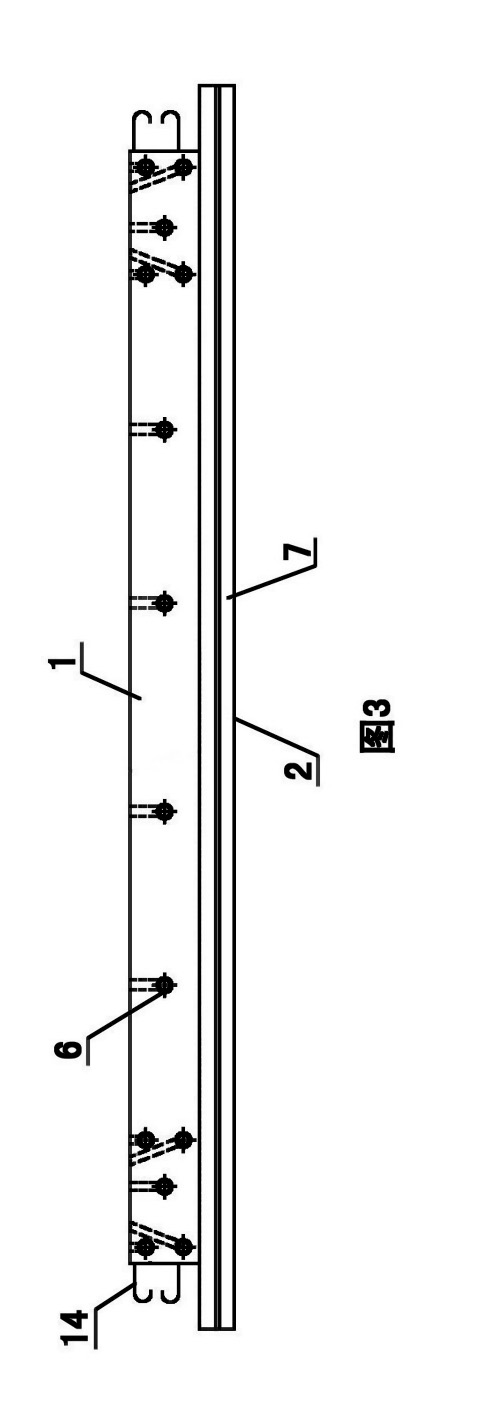

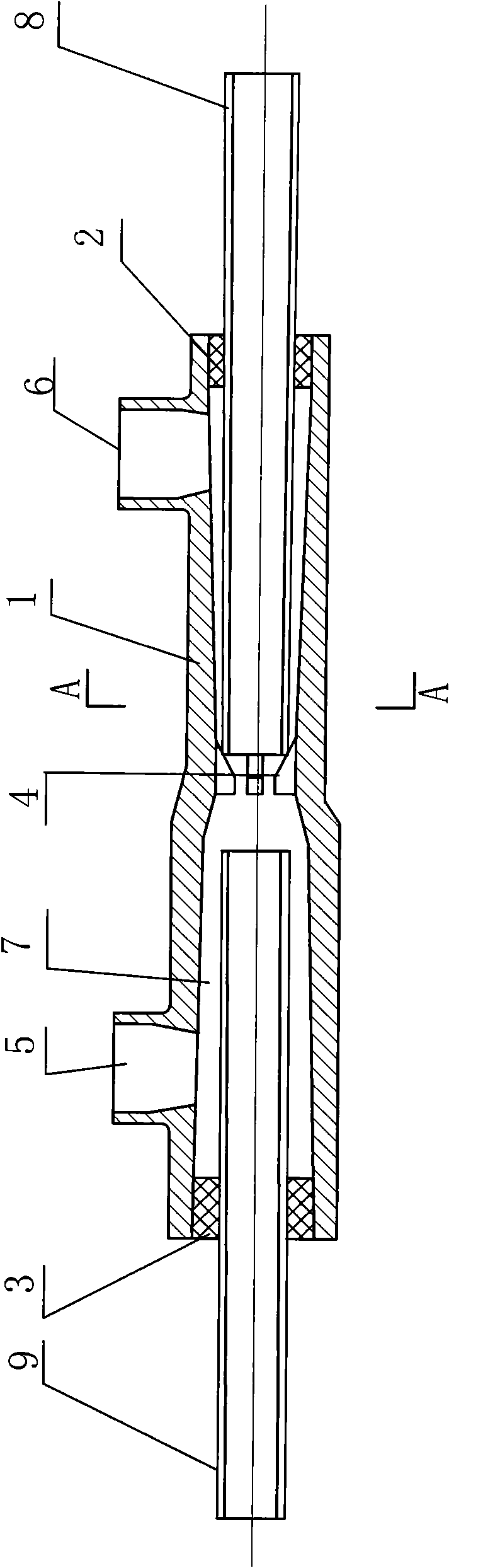

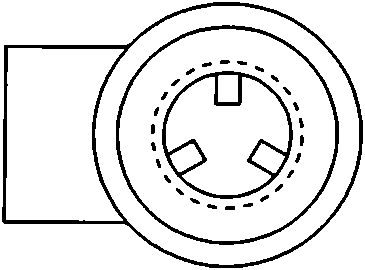

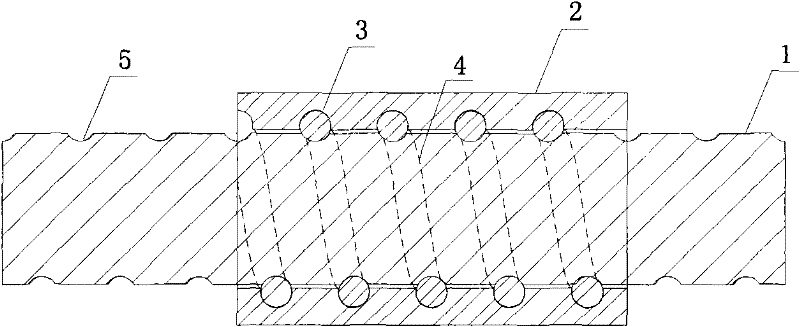

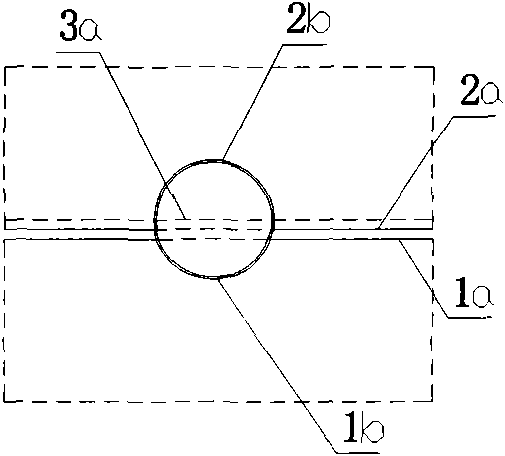

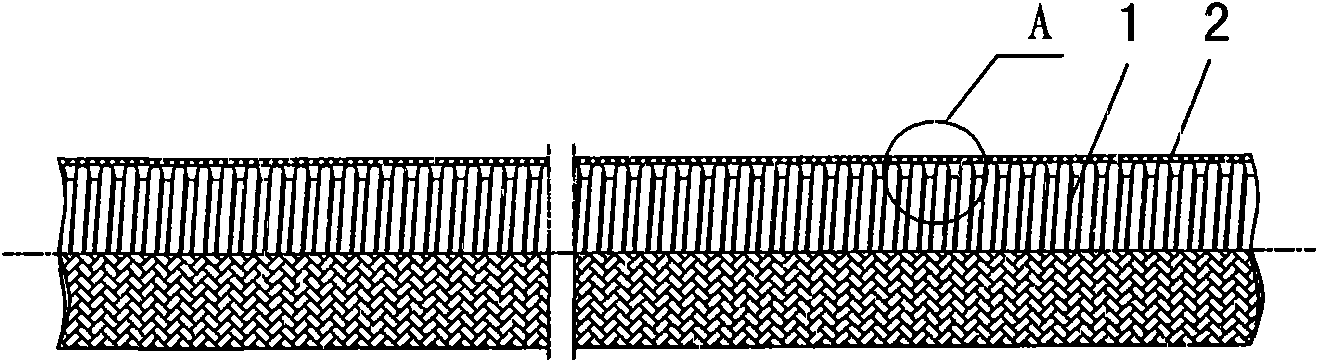

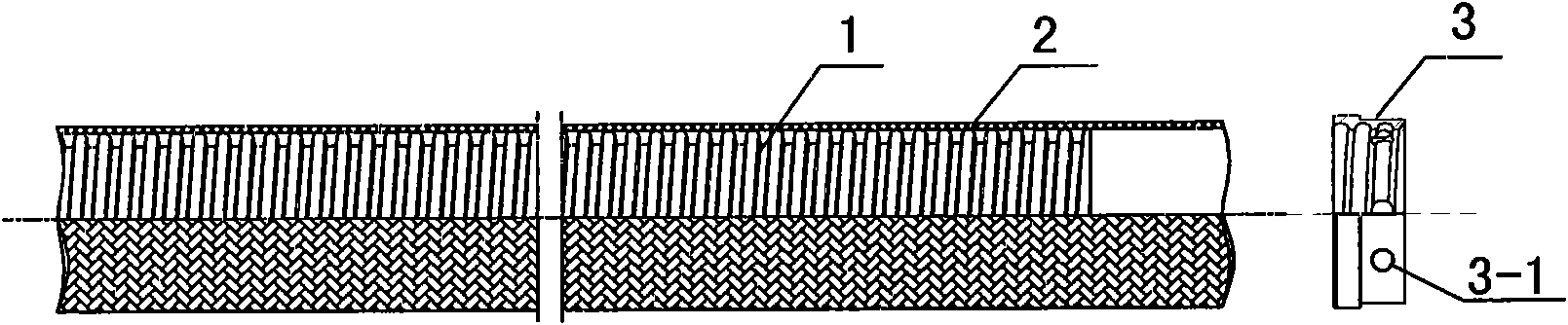

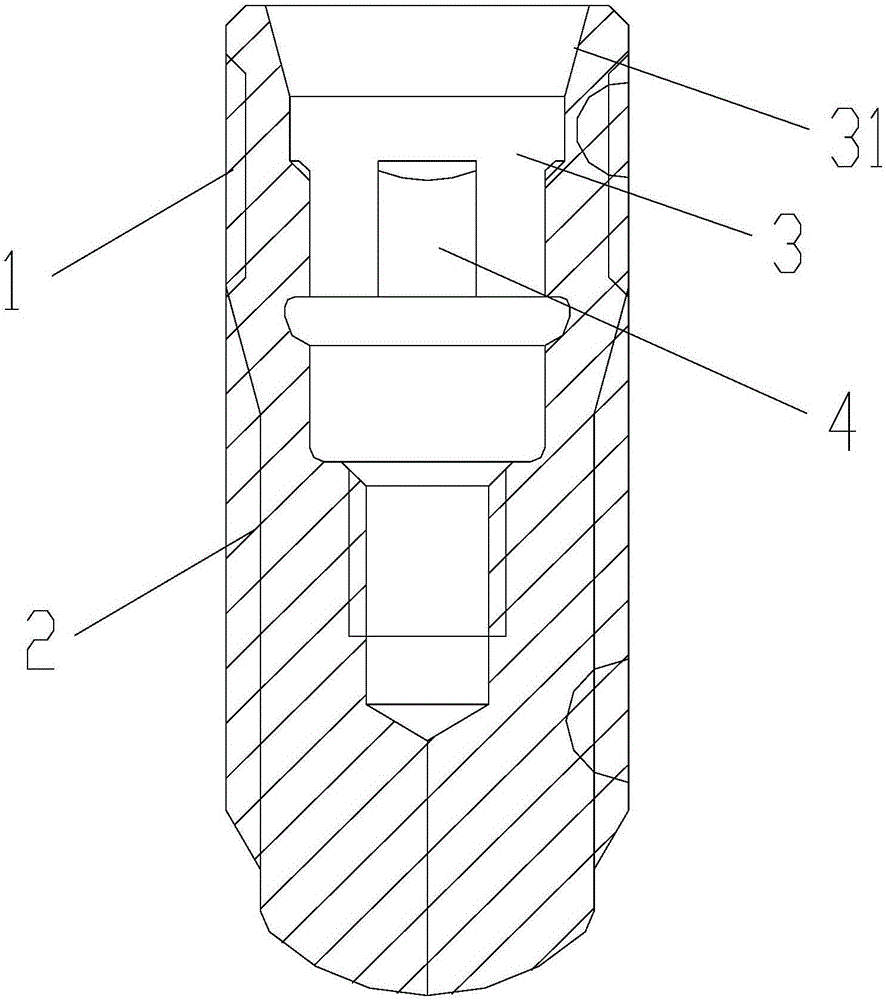

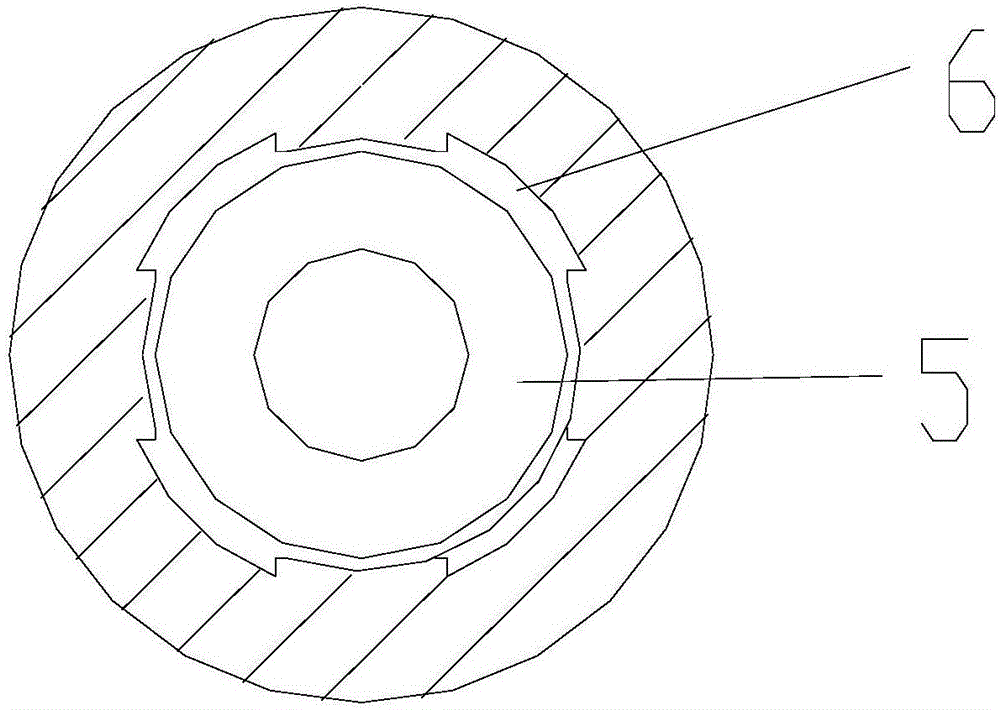

Insertion grouted reinforcing steel bar connecting sleeve and construction method thereof

The invention discloses an insertion grouted reinforcing steel bar connecting sleeve and a construction method thereof. In the conventional cast-in-place concrete structure, the reinforcing steel bars are connected by mechanical connection methods, such as lap joint connection, welded connection, or sleeve extrusion and the like, the construction of the reinforcing steel bar connection is complex, and the connection of the reinforcing steel bars is finished before concrete is deposited, and fabricated construction cannot be performed. The insertion grouted reinforcing steel bar connecting sleeve comprises a sleeve body (1); a through hole (2) is formed in the sleeve body; elastic rubber seal rings (3) are arranged at two ends of the through hole of the sleeve body; one end of the through hole in the sleeve body is large and the other end of the through hole in the sleeve body is small; a group of limited blocks (4) distributed along an inner wall are arranged in the middle in the sleeve body; slopes are formed on the limited blocks toward the insertion direction of the reinforcing steel bars; a grouting hole (5) and a vent hole (6) which are communicated with the interior are formed above the sleeve body; tapered threads are formed at two ends on the inner side of the sleeve body; the small-sized end of the sleeve body is connected with embedded bars (8); and the large-sized end of the sleeve body is connected with rear insertion reinforcing steel bars (9). The insertion grouted reinforcing steel bar connecting sleeve and the construction method thereof are used for fabricated connection of the reinforcing steel bars.

Owner:HEILONGJIANG YUHUI NEW BUILDING MATERIAL

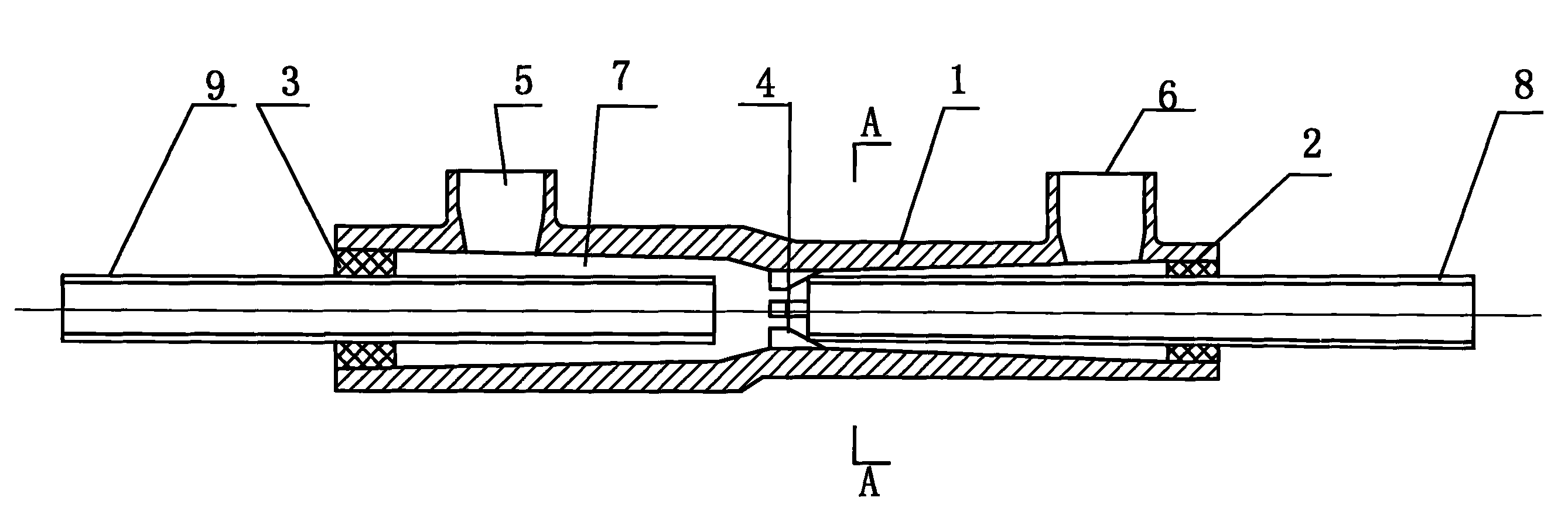

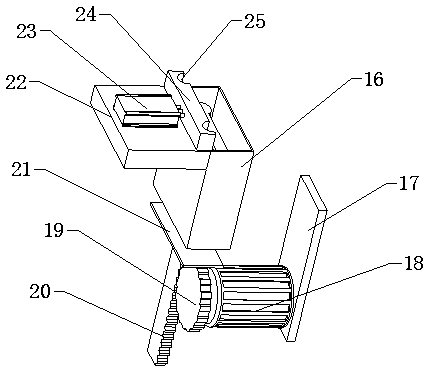

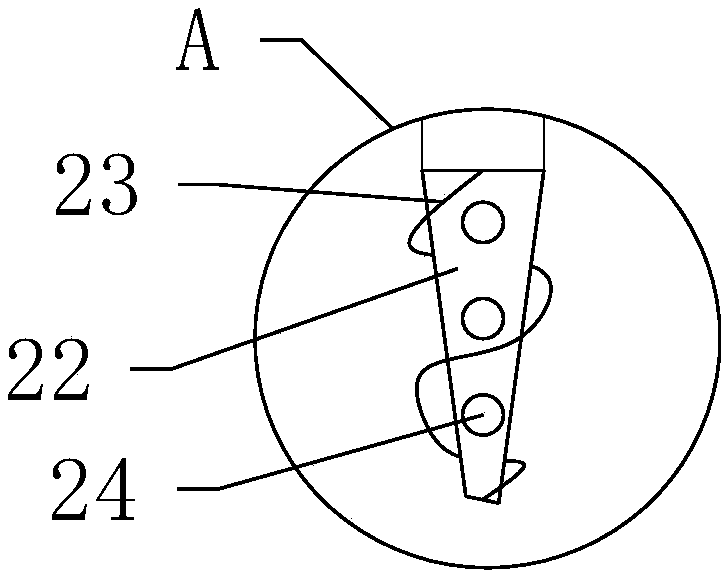

Multifunctional intra-articular fracture guide apparatus

InactiveCN101366657AEasy to disassemble and assembleSimple structureSurgeryArticular fractureEngineering

The invention discloses a multi-function guider for inter-articular fracture, which mainly consists of a main support arm, a guide arm and a fixed rod, wherein both the main support arm and the guide arm are arc-shaped, which can stretch along an arc direction when being sleeved and combined are temporarily fixed via a knob. The front end of the guide arm forms a fixed head pointing to the center of a circle when being bent inwards, the fixed rod can be pulled and arranged on the main support arm radially and flexibly and is fixed via the knob. The front end of the fixed rod forms another fixed head pointing to the center of a circle. The position where the main support arm is sleeved with the guide arm is provided with a plurality of radial through guide holes. The multi-function guider can fix fractured blocks temporarily, defines the direction of a temporarily fixed kirschner wire and the direction of a screw to fix the fractured block without enlarging a notch, and a screw for fixation can be screwed in from a screw guide pin conveniently, thus the multi-function guider is very convenient and practical.

Owner:ARMY MEDICAL UNIV

Joint type portable feet limiter

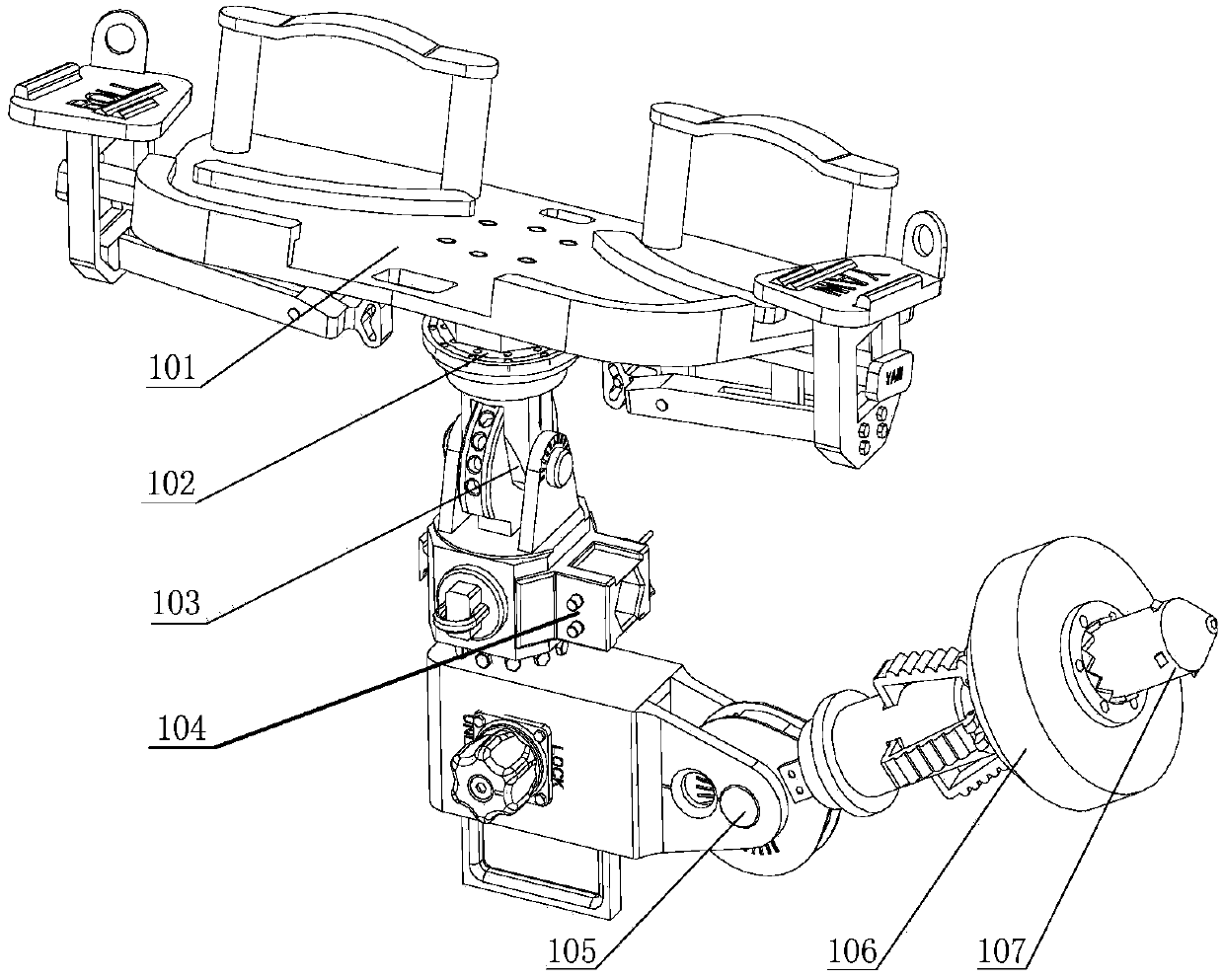

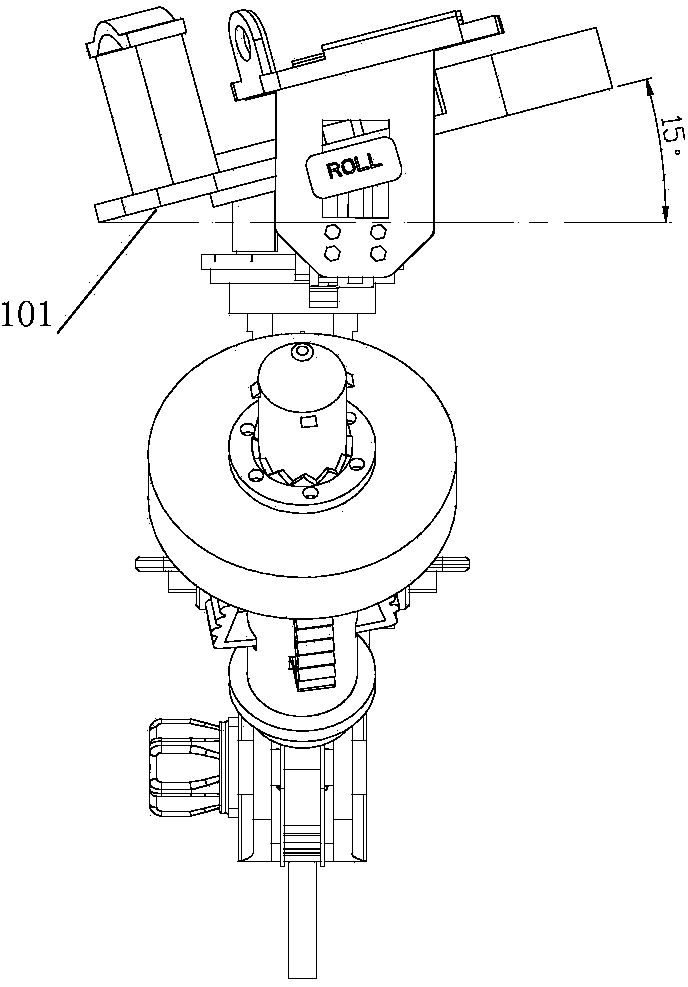

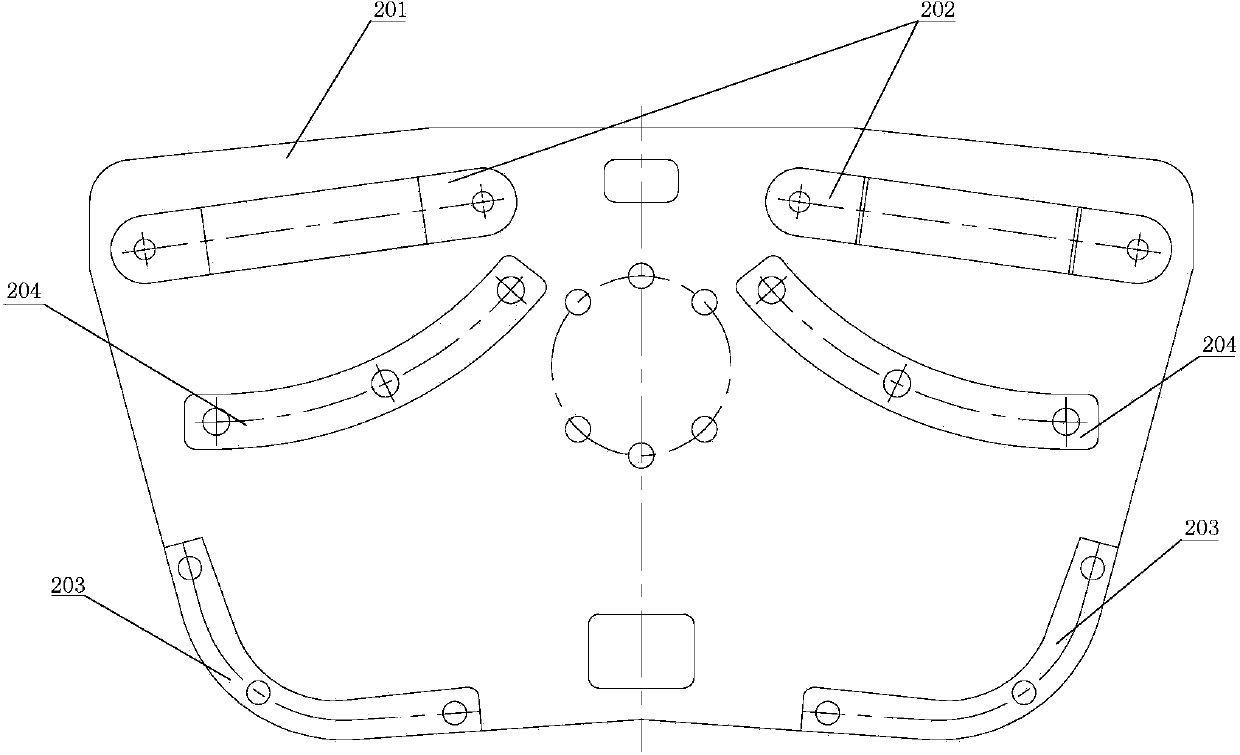

ActiveCN104176278AImprove motion transfer efficiencyReduce operational complexityCosmonautic crew accomodationsEngineeringMechanical engineering

The invention provides a joint type portable feet limiter comprising a limiting pedal, a yaw adjusting joint mechanism, a deflection adjusting joint mechanism and a pitch adjusting joint mechanism. The yaw adjusting joint mechanism comprises a yaw indexing positioning unit. The limiting pedal is mounted on the upper portion of the yaw adjusting joint mechanism. The deflection adjusting joint mechanism is connected to the lower portion of the yaw adjusting joint mechanism. The deflection adjusting joint mechanism comprises a deflection indexing positioning unit. The pitch adjusting joint unit is connected to the lower portion of the deflection adjusting joint mechanism and comprises a pitch indexing positioning unit. A loading limiting mechanism, used for overload protection, and a rapid mounting connector mechanism, used for connecting with other equipment, are mounted on the pitch adjusting joint mechanism. By the use of the feet limiter, a supporting platform is provided for a spaceman to perform real-time pose adjustment in space, operation motions for large-angle pose adjustment are fewer, and physical exhaustion of the spaceman is avoided.

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

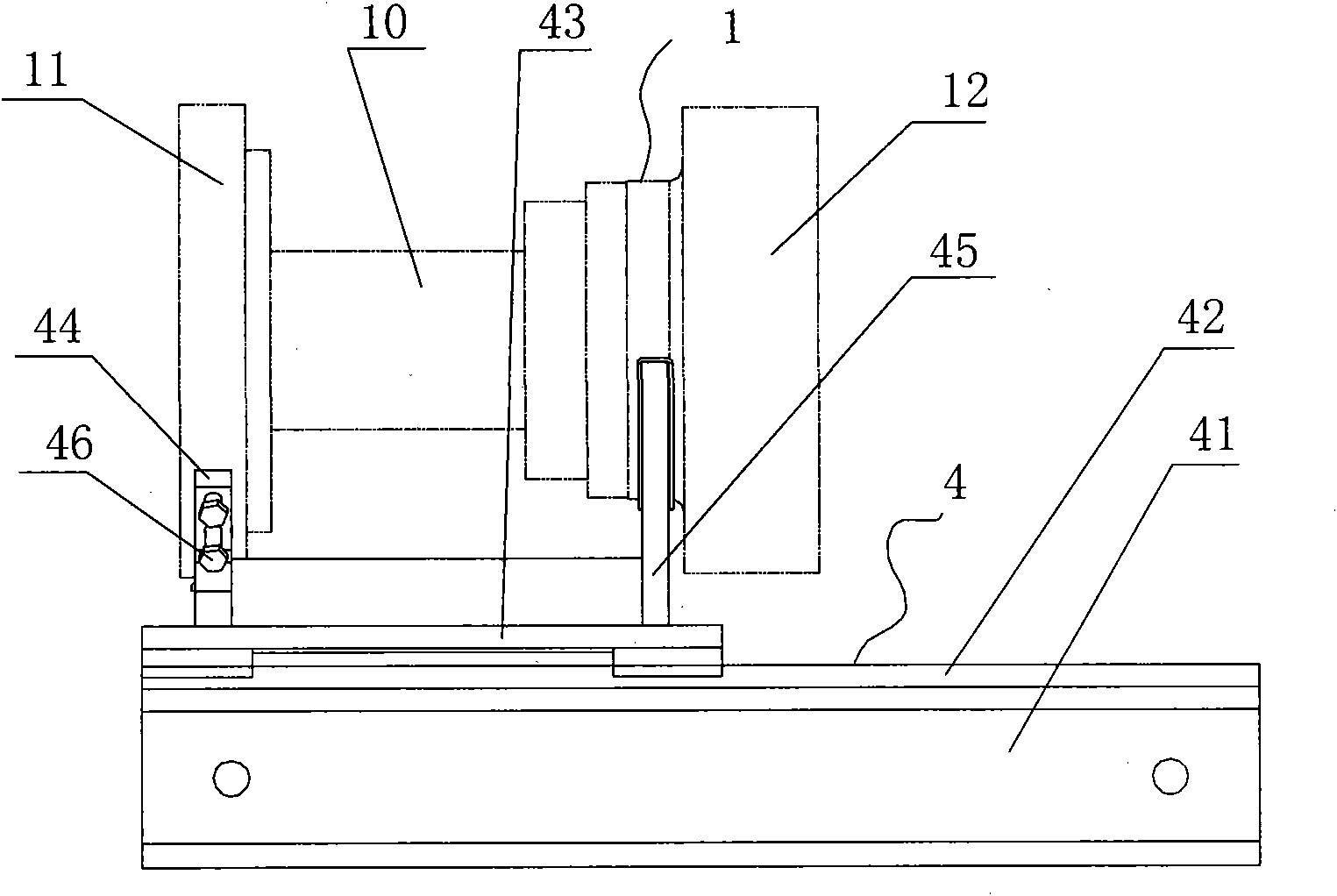

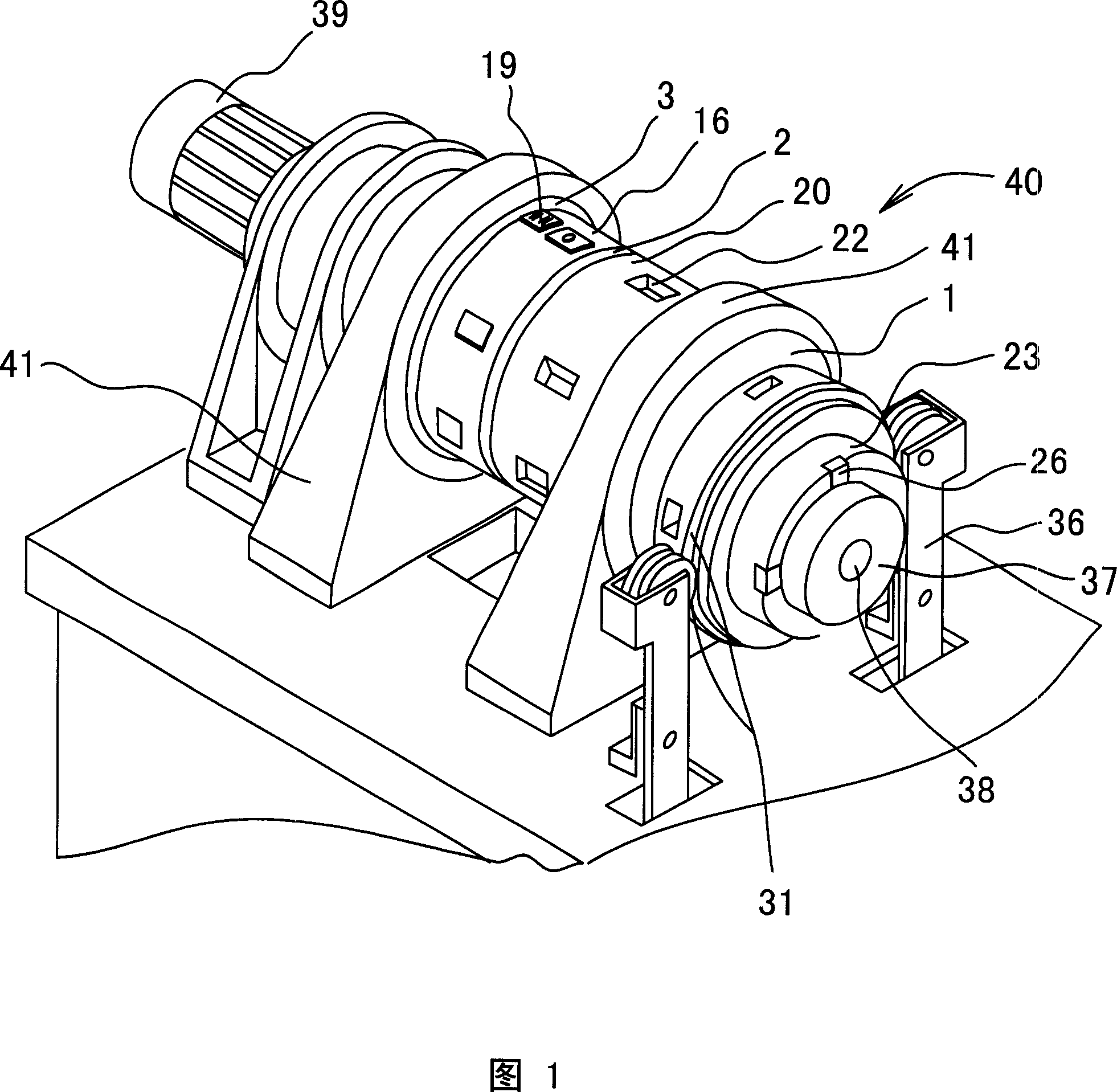

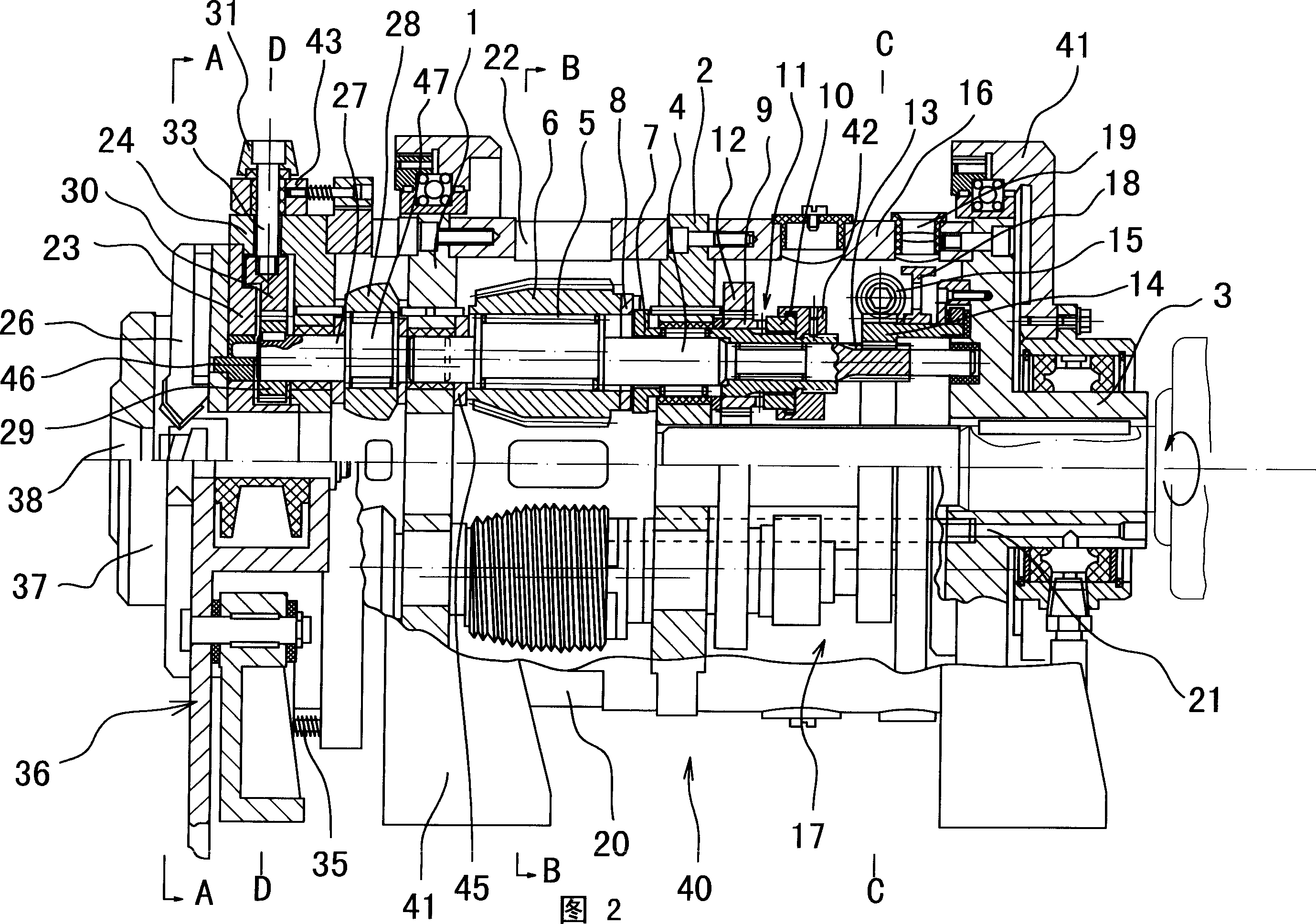

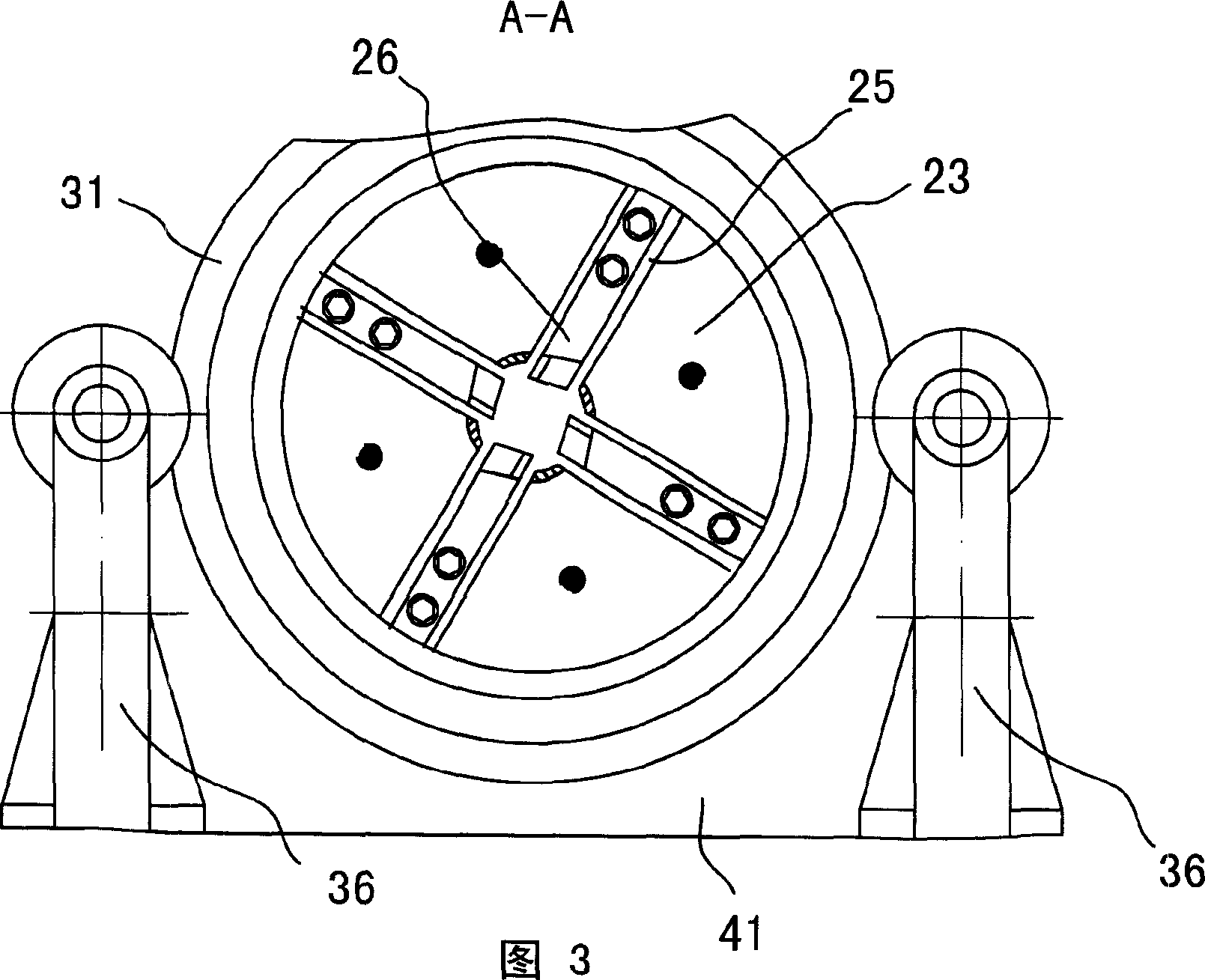

Tool and method for assembling spindle head and center pull rod of gas turbine

ActiveCN101633113ARealize localized assemblySimple structureMetal working apparatusEngineeringScrew thread

The invention discloses a tool for assembling a spindle head and a center pull rod of a gas turbine, wherein the spindle head is provided with a bearing guard, and a clutch and a step-type joint part provided with a threaded bland hole arranged on the head and the tail of the bearing guard respectively, and the head of the center pull rod is provided with a threaded section matched with the threaded blind hole of the joint part of the spindle head. The tool comprises a plurality of roller wheel supporting frames for up-bearing the center pull rod and a spindle head supporting frame, wherein the spindle head supporting frame comprises a bed body, a pair of linear guide rails axially arranged on the bed body, a dragging plate arranged on the bed body and capable of moving forwards and backwards along the linear guide rails, V-shaped lug supports arranged on the dragging plate in tandem and pushing screws at least arranged on two sides of one of the V-shaped lug supports; and the head clutch of the spindle head is supported on the V-shaped lug support at the front end of the dragging plate, while the joint part at the tail of the spindle head is supported on the V-shaped lug support at the rear end of the dragging plate. The invention also discloses a method for assembling the spindle head and the center pull rod of the gas turbine, which is carried out on the assembling tool.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

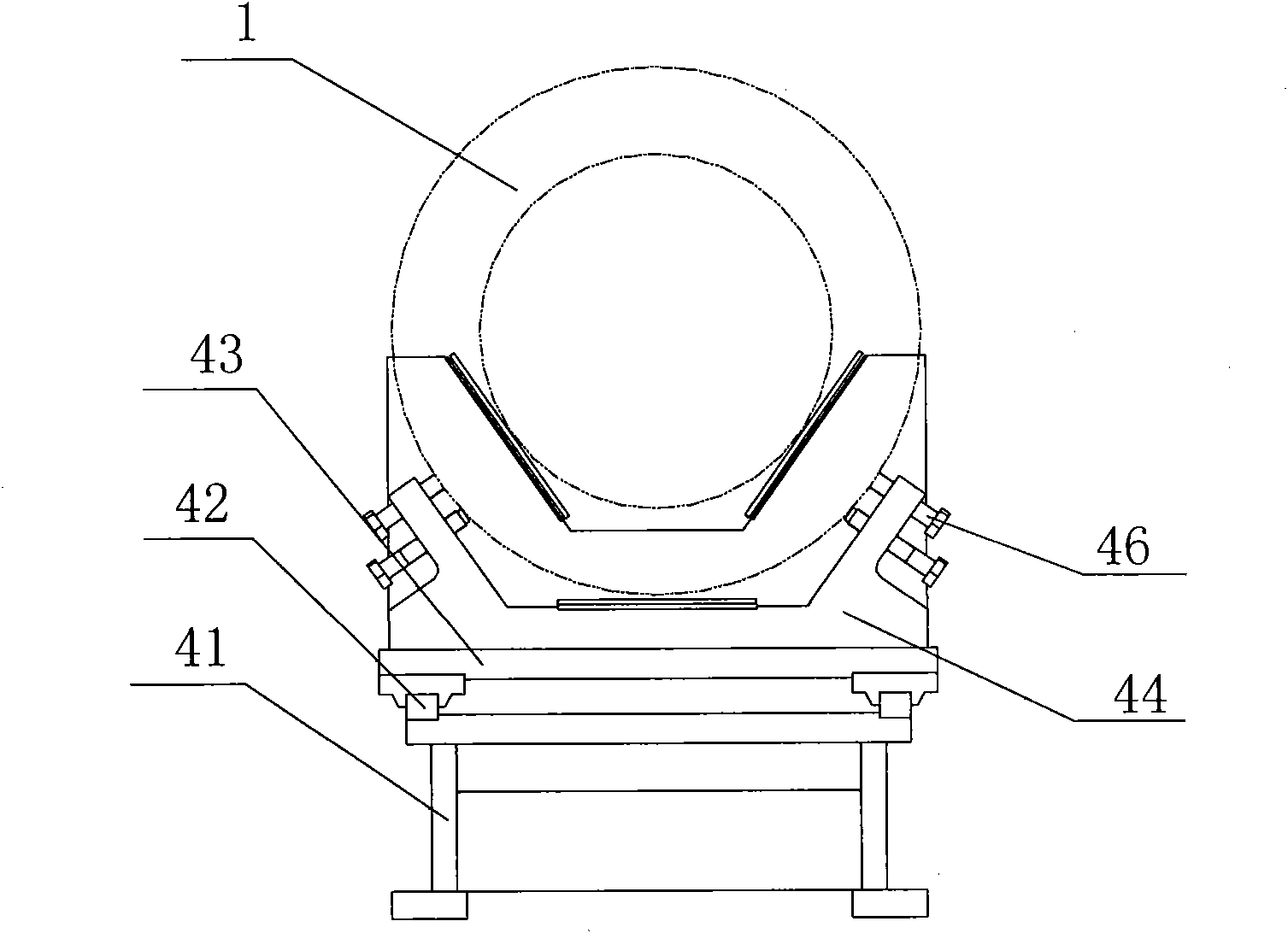

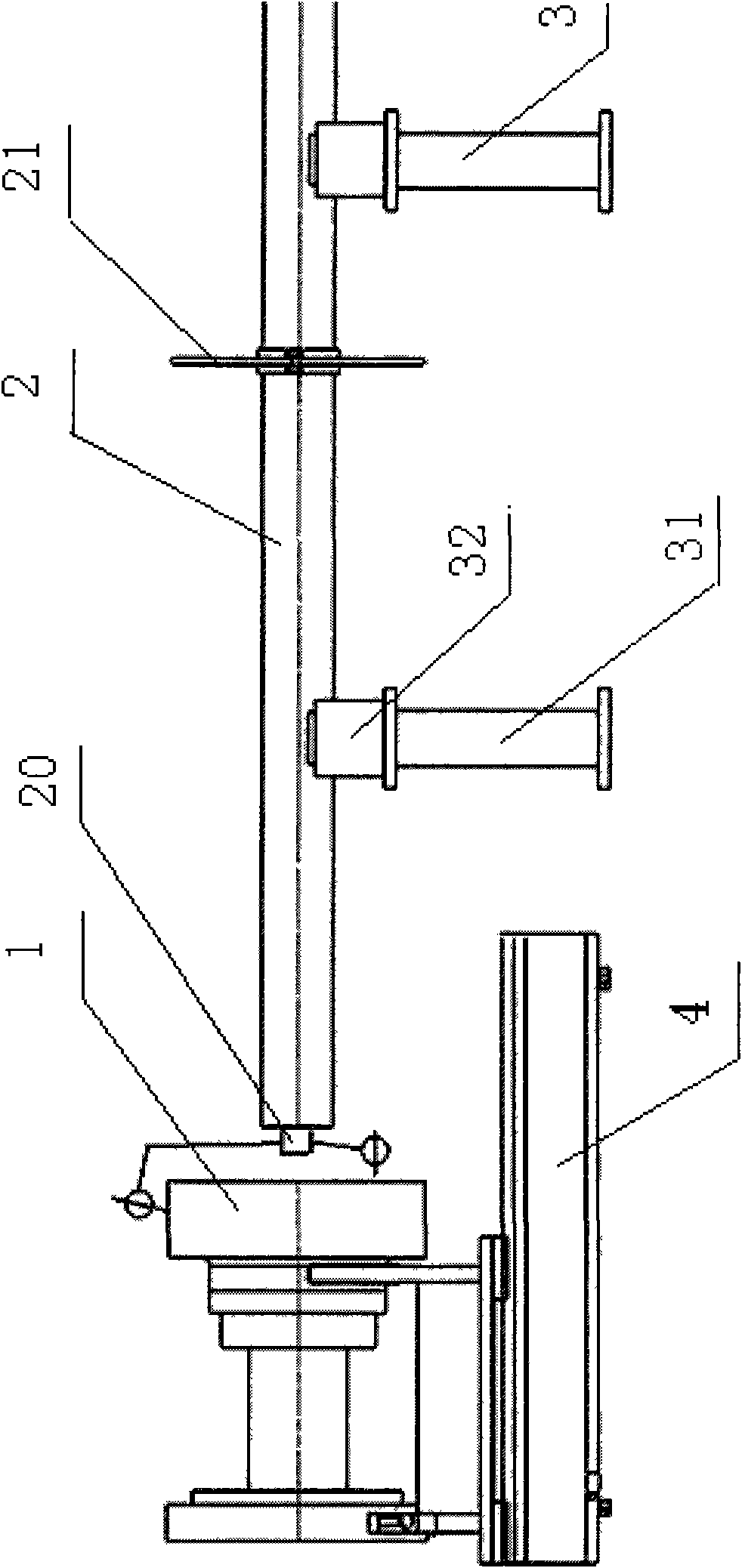

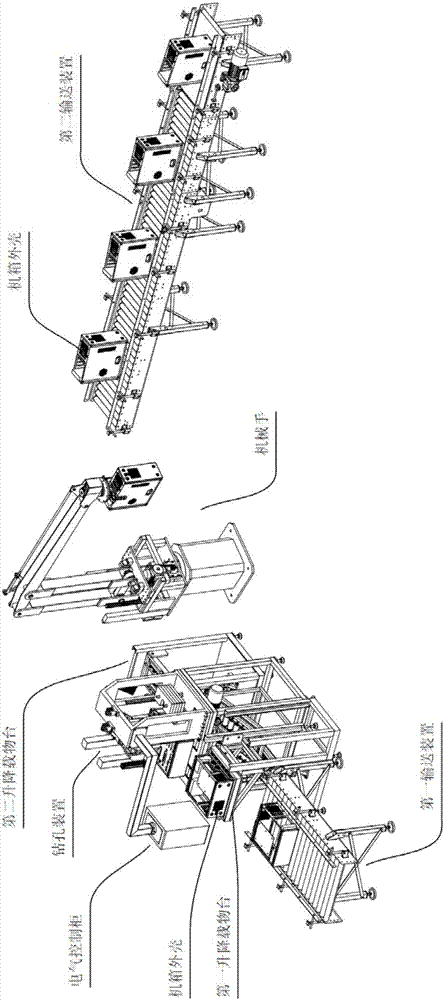

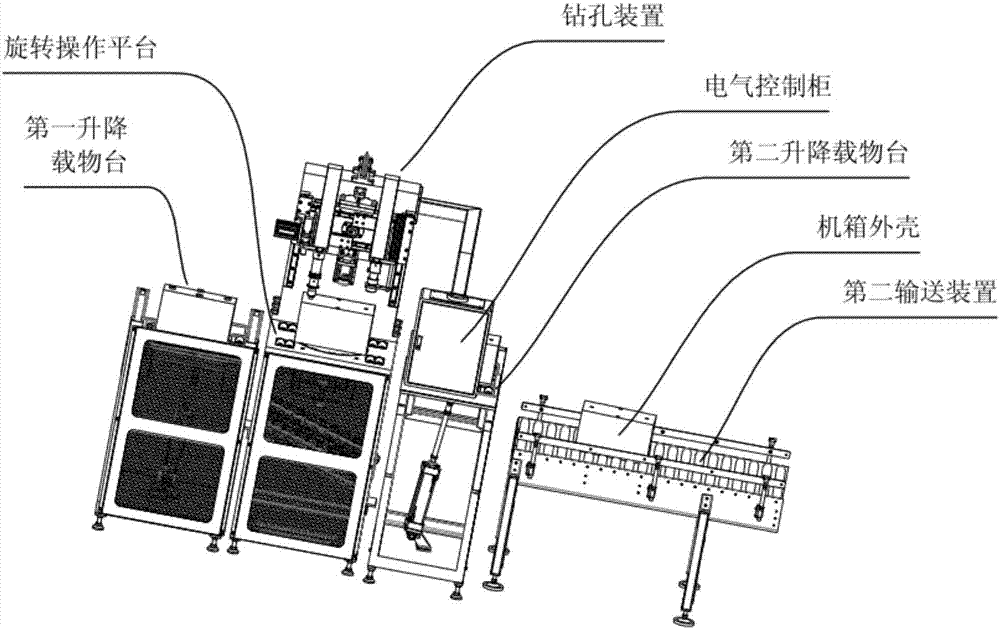

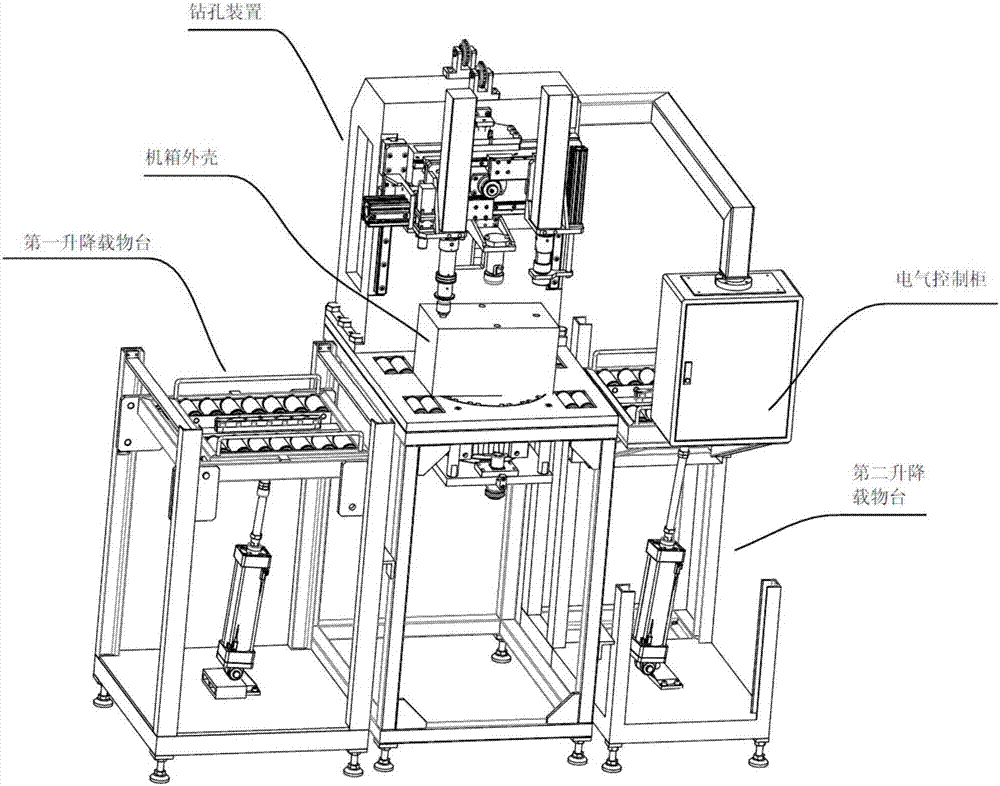

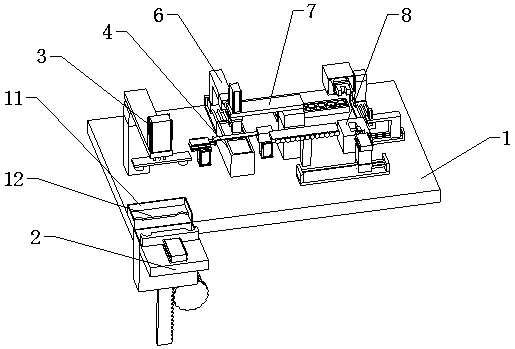

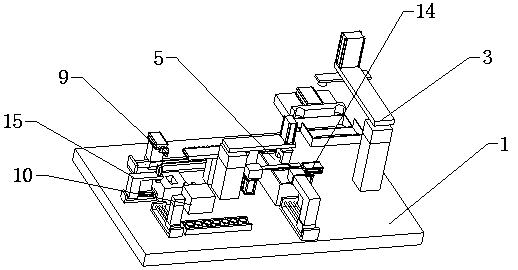

Drilling mechanism for case shells and case assembly system

ActiveCN106881478AEasy to adjustEasy to screw inMetal working apparatusBoring/drilling componentsElectrical controlIndustrial engineering

The invention discloses a drilling mechanism for case shells and a case assembly system. The drilling mechanism comprises a first lifting objective table, a drilling device, a second lifting objective table and an electrical control cabinet, wherein the first lifting objective table is used for lifting to-be-processed case shells to a predetermined height and conveying the to-be-processed case shells to a workbench of the drilling device; the drilling device is used for drilling or punching the to-be-processed case shells which are lifted or conveyed from the first lifting objective table; the second lifting objective table is used for receiving the drilled case shells, and lifting or descending the case shells to predetermined height to enter a conveying station; the electrical control cabinet drives the first lifting objective table and the second lifting objective table to lift or descend, and drives the drilling device to drill. The drilling mechanism can be accurately regulated to a required position for drilling the case shells, and holes drilled in the case shells are in central symmetry, so that a screw turning link and other assembling links in a follow-up station of the case assembling system are convenient.

Owner:HANGZHOU KAIBEI NAITE TECH CO LTD

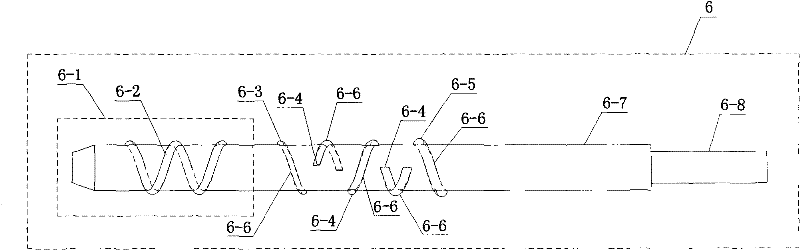

Ball nut with deep groove track and manufacturing method thereof

The invention discloses a ball screw cap with a deep groove track and a manufacturing method thereof. After the ball screw cap is separated from a ball lead screw, balls on the inner circle surface of the ball screw cap is still limited in the deep groove track and are prevented from being scattered, so that the ball screw cap is convenient to be screwed out of and into the ball lead screw. The manufacturing method of the ball screw cap comprises the following steps of: drilling a hole on a blank with the conventional technology to form an inner circle surface; processing the inner circle surface with a turning method or a whirling method to form a spiral groove of which the depth is greater than the ball radius, the opening is a little smaller than the ball diameter, the normal section bottom side is a circular arc and the upper part is rectangular; introducing a spiral cutting tool into the spiral groove for cutting to form a deep groove track; and performing thermal treatment and surface treatment on the deep groove track.

Owner:朱豪东

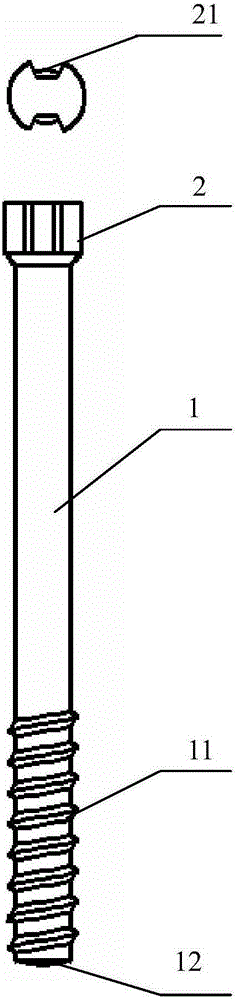

Porous tantalum metal hollow screw and application thereof

ActiveCN105147383APrevent redisplacementReduce deformation and fractureCoatingsFastenersPorous tantalumCannulated screw

The invention discloses a porous tantalum metal hollow screw which comprises a screw rod and a screw cap. The screw rod and the screw cap are integrally formed. A thread is arranged on the outer surface of the front end of the screw rod, and the length ratio of the thread and the screw rod is 1:1.7-2.3. The screw cap is a conical screw cap with a cylindrical screw head, an included angle between the conical surface of the conical screw cap and the central line of the screw rod ranges from 44 degrees to 46 degrees, grooves symmetric about the central line of the screw rod are formed in the outer surfaces of the two sides of the cylindrical screw head, the included angle between the two inclined faces of each groove is 60 degrees, a through hole is formed in the central axis of the screw rod, and a smooth sliding rod is arranged between the thread and the screw cap. By means of the structure of the hollow screw, screwing-in and firm fixation of the hollow screw are facilitated, secondary displacement at a bone fracture part is avoided, the defect that the tail part of the screw is deformed when the screw is screwed in is overcome, force can reach the front end uniformly, and the possibility of deformation and cracking of the screw is reduced.

Owner:赵德伟

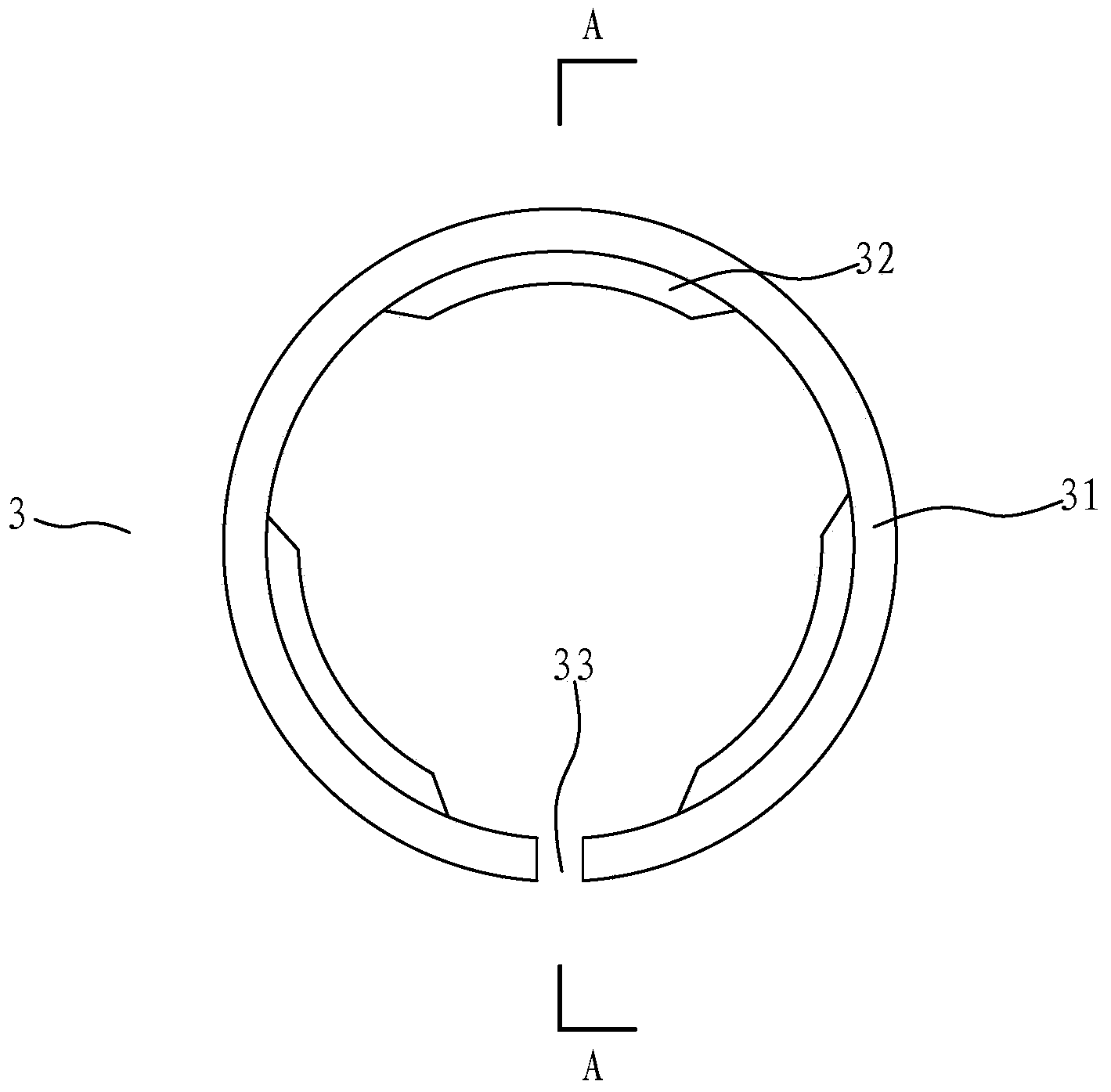

Anti-loose self-locking nut and production method thereof

The invention relates to the field of manufacturing of automobile parts, in particular to an anti-loose self-locking nut simple in structure, capable of effectively preventing the nut from falling off, convenient to mount and dismount and capable of being reused. The anti-loose self-locking nut comprises a nut body and a nut collar rotatably arranged at the lower end of the nut body, a threaded hole is penetratingly arranged in the middle of the nut body, a stepped groove is formed in the upper end of the nut body, a spring steel piece is placed in the stepped groove, a bending portion used for clamping the spring steel piece in the stepped groove is arranged on the upper portion of the stepped groove, the spring steel piece comprises an annular piece and more than two clamping pieces evenly arranged at the upper end of the annular piece and protruding along the radial direction, the annular piece is formed by a tilt surface rotating and scanning around the axis of the threaded hole, the clamping piece protrudes inwardly to extend into the threaded hole of the nut body, and the extending length of the clamping piece is located between the inner diameter and outer diameter of the threaded hole. The invention further comprises a production method of the anti-loose self-locking nut.

Owner:QUANZHOU JINQI MACHINERY PARTS

Corrugated hose with joint jacket and manufacturing method thereof

The invention relates to a corrugated hose with a joint jacket, simultaneously relates to a manufacturing method thereof, and belongs to the technical field of hoses. A hose body consists of a corrugated tube and a woven jacket sleeved outside the corrugated tube; the end head of the hose body is sleeved with a collar which is provided with internal threads matched with corrugation of the corrugated tube, and radial punch holes; the outer end of the hose body and the collar is coated with a joint jacket formed by injection molding; and an inner hole of the joint jacket is percolated and extended with a percolating plastic structure which is combined with the outer wall of the corrugated tube through the punch holes and the gap of a jacket woven structure. The manufacturing method comprises the following main steps: sleeving the woven jacket outside the corrugated tube; screwing the collar to the end head of the hose body; and forming the joint jacket coating at the outer end of the hose body and the collar through the injection molding. The corrugated hose has firm connection, can avoid the damage of the jacket, has good bandability and torsibility, and obviously prolongs the service life.

Owner:JINHUA CHUNGUANG RUBBER & PLASTIC HOSE

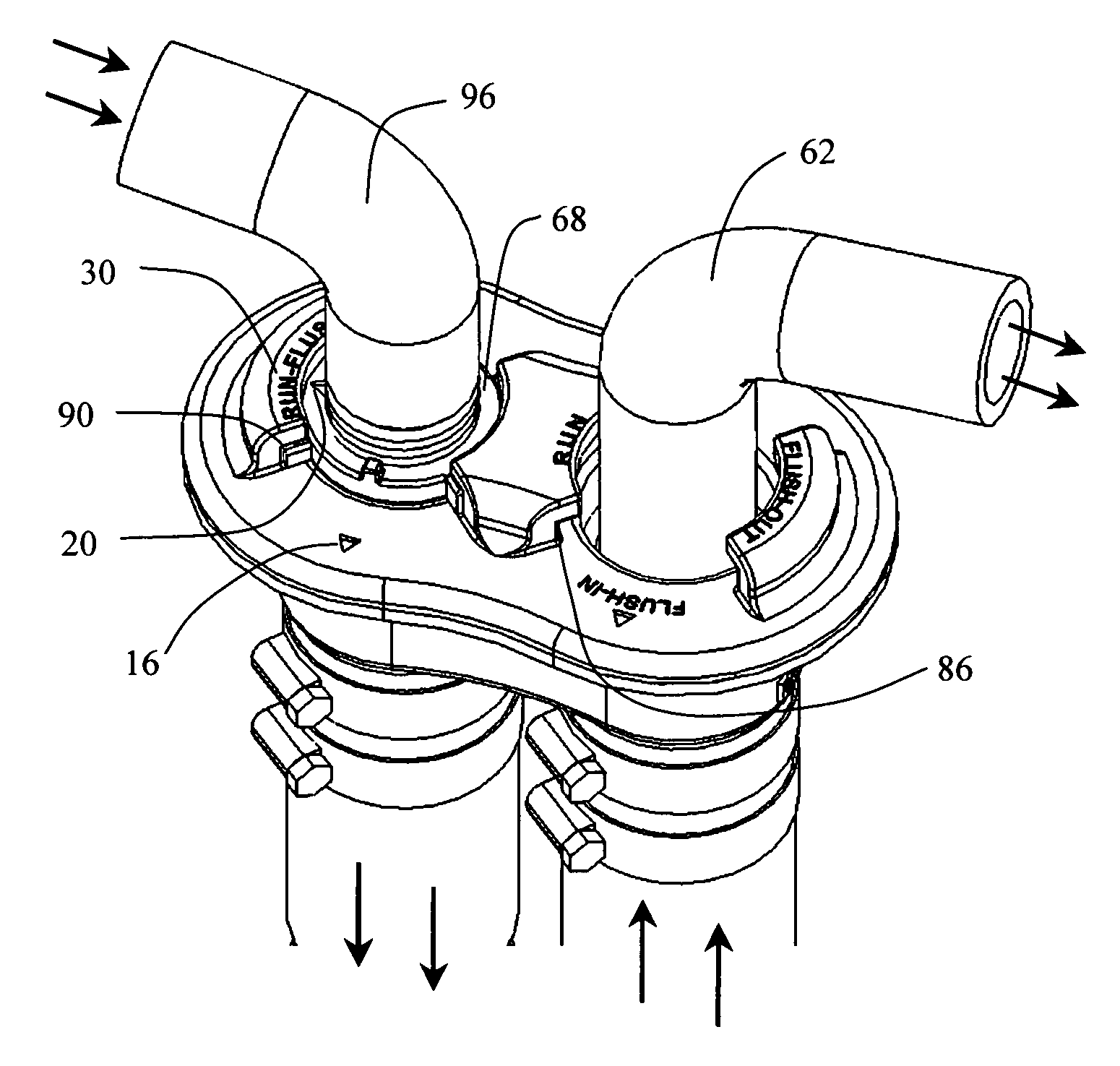

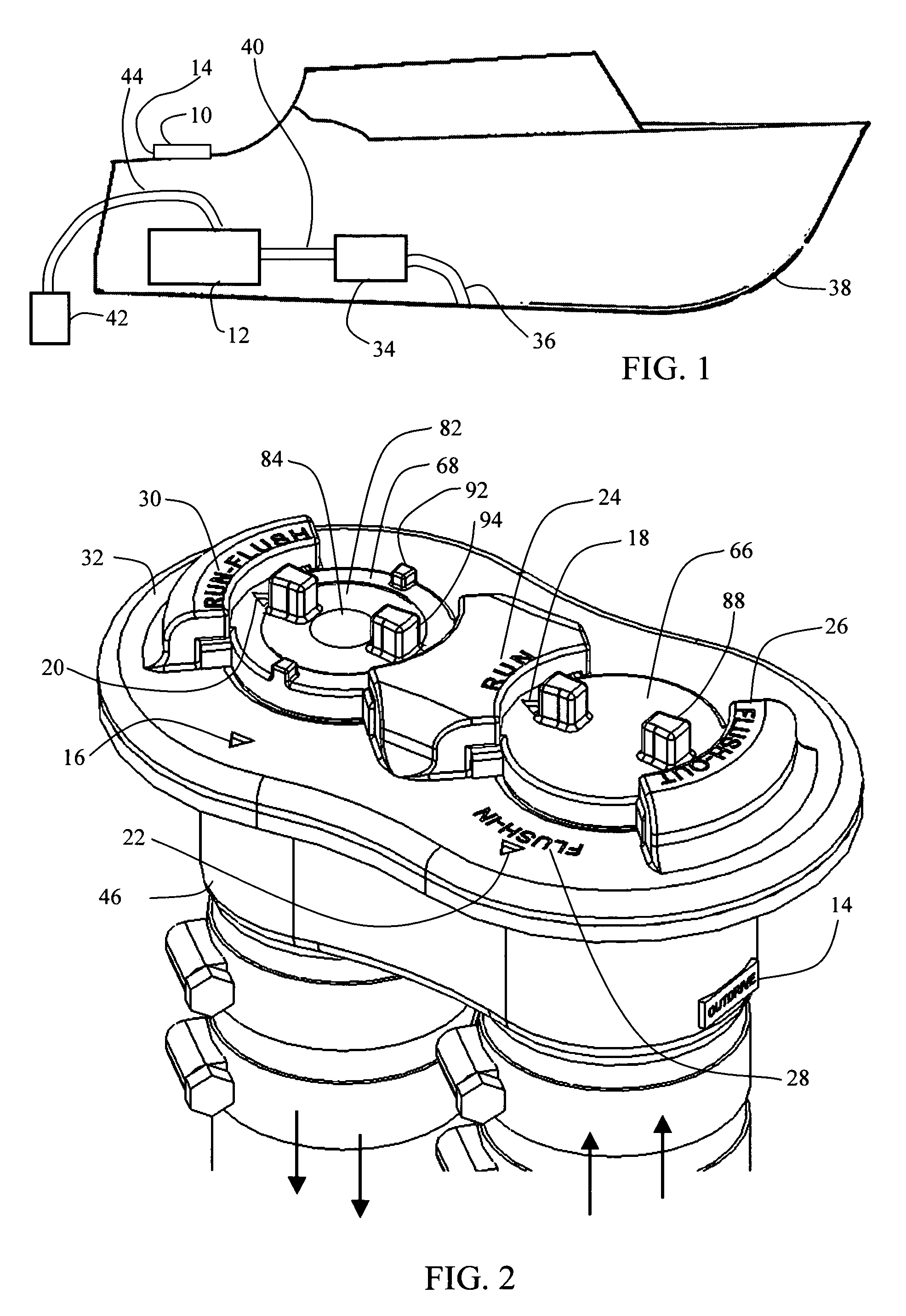

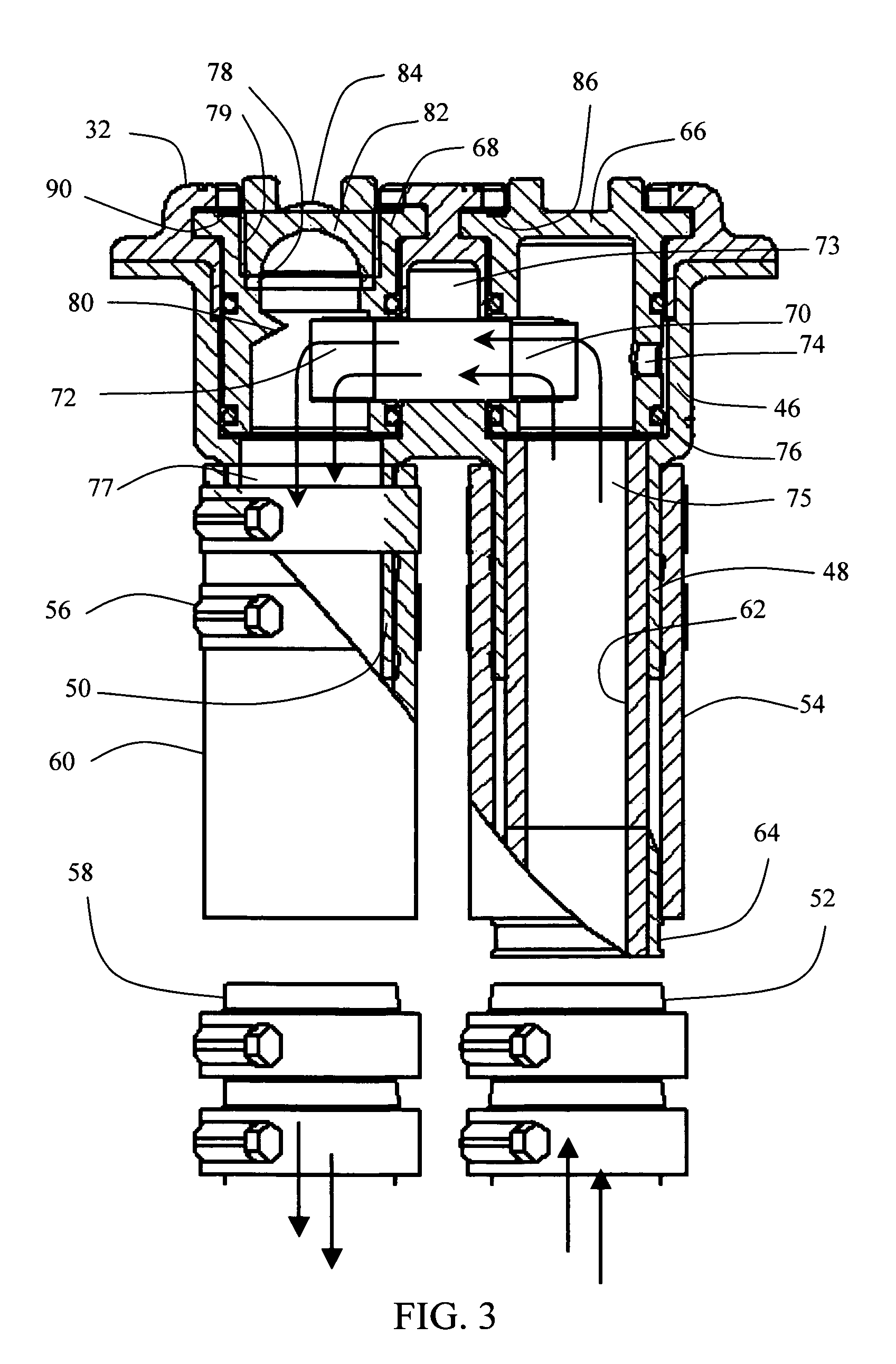

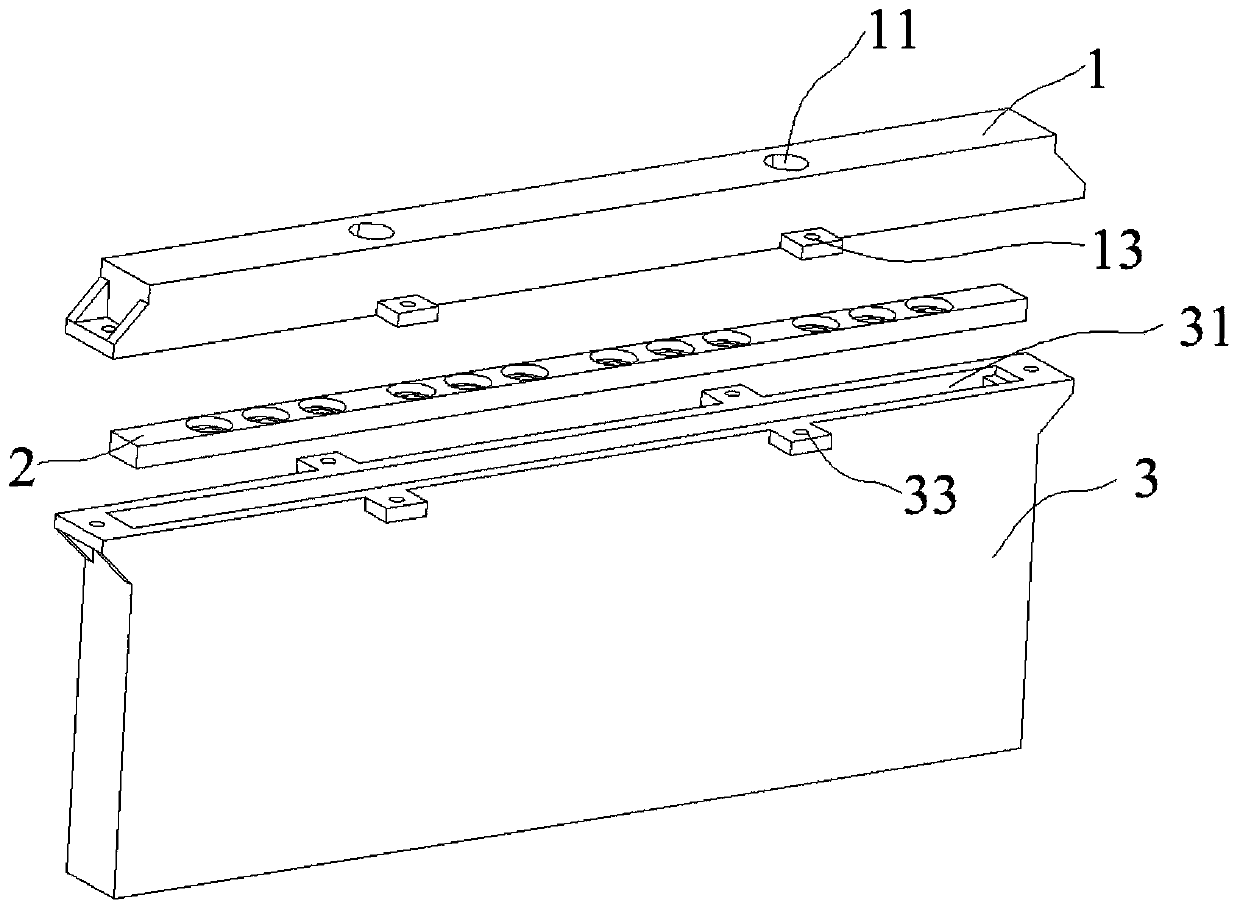

Flushing system and process

InactiveUS6945835B1Simple and inexpensive and reliableSimple designPower plants using condensersLiquid coolingAmbient waterInsertion point

A flushing system for an inboard and an inboard / outboard marine engine is inserted into the flow path normally used for conducting ambient water to the engine for cooling purposes. A first attachment means allows ambient fluid to flow into the system and a second attachment means allows for ambient fluid to flow out of the system. A first extension means connects the upstream ambient fluid to the flushing system inlet and a second extension means connects the flushing system outlet to the downstream ambient fluid allowing the flushing system to be located some distance from the insertion point.

Owner:AKHAVEIN GLENN

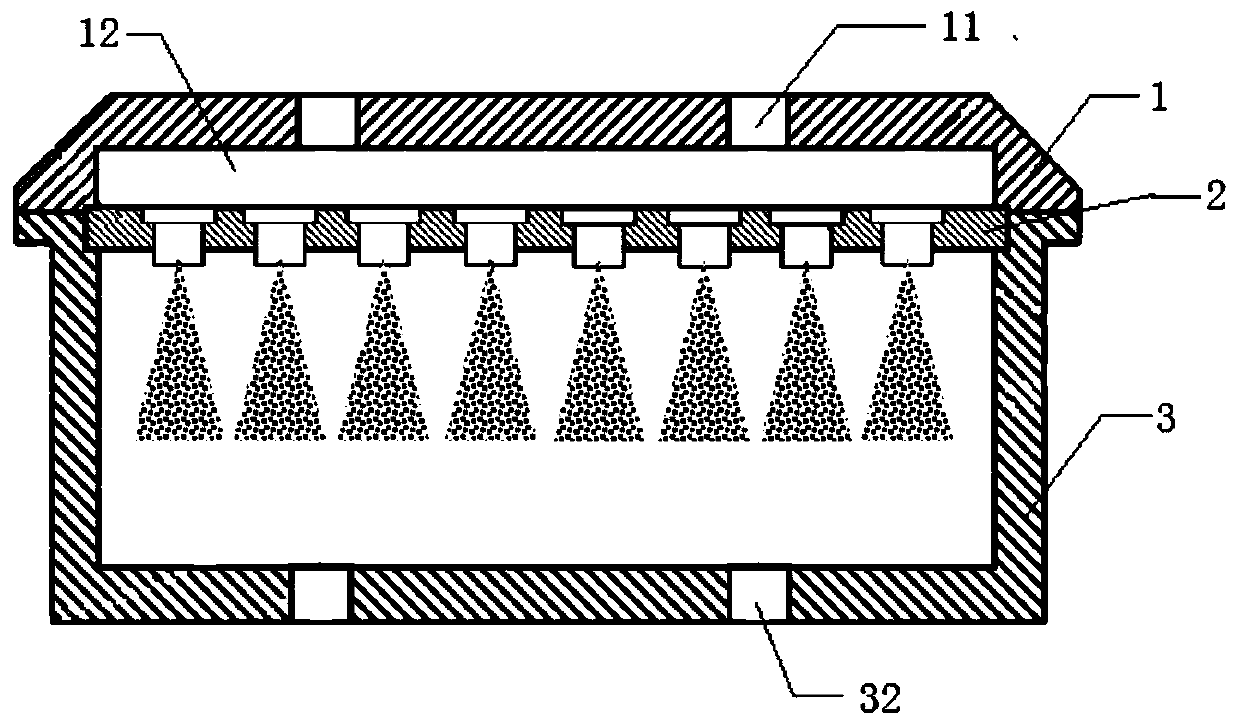

High heat flow density heat dissipation cold plate

PendingCN109830468ANo contact resistanceLess working fluidSemiconductor/solid-state device detailsSolid-state devicesSpray nozzleEngineering

The invention discloses a high heat flow density heat dissipation cold plate and relates to the technical field of electronic component heat dissipation. The high heat flow density heat dissipation cold plate comprises an upper cover plate and a cold plate body, wherein the upper cover plate is provided with a first liquid inlet; a micro nozzle plate is disposed between the upper cover plate and the cold plate body, and is provided with a plurality of micro nozzles; the first liquid inlet communicates with the micro nozzles; the cold plate body is provided therein with a cold plate cavity; thelower end of the cold plate body is provided with a first liquid outlet; and the first liquid outlet communicates with the cold plate cavity. The high heat flow density heat dissipation cold plate exchanges heat of heat-generating components by the cold plate cavity, requires less working mediums, is good in heat dissipation and low in degree of superheat and has no contact thermal resistance ona solid surface.

Owner:合肥低碳研究院

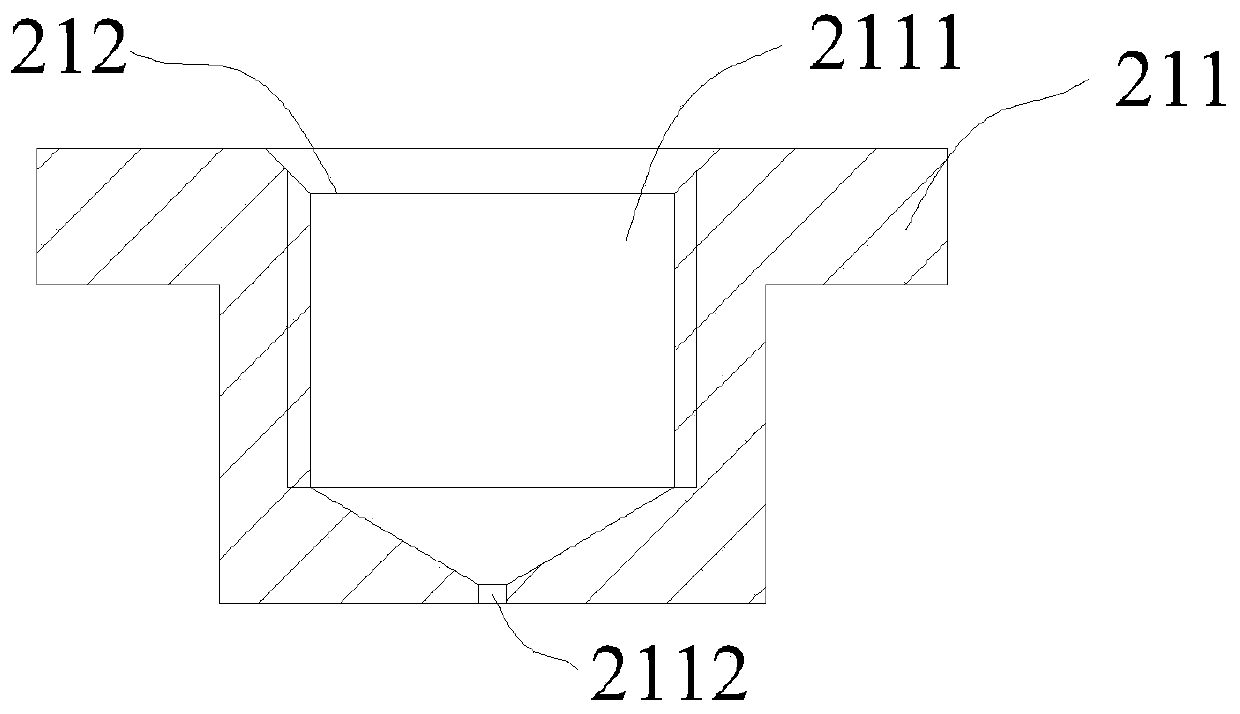

Medical vertebral arch pedicle renovating screw assembly

InactiveCN101669837ANo side effectsGood biocompatibilityInternal osteosythesisFastenersSpinal columnInternal fixation

The invention discloses a medical vertebral arch pedicle renovating screw assembly which comprises a screw sheath and a screw which are mutually matched, wherein the screw sheath has certain mechanical strength and toughness, and the medical absorbable material can effectively maintain the mechanical strength for 2 to 3 months in vivo; the screw sheath is divided into a head end and a sheath body;the head end is a cone with a sealed front end, and the sheath body is a cylinder; external threads are arranged on the outer surface of the cylinder, and a longitudinally extended triangular prism-shaped cavity is arranged in the cylinder; the cylinder is divided into three side walls by the cavity, and internal threads are designed on the inner wall of the cavity; the screw is made of medical titanium alloy and comprises a thread section and a tail part; the thread section is formed by connecting a screw tip and a screw body, and both the screw tip and the screw body are in external threaddesign; the tail part is provided with a radially communicated U-shaped groove, and internal threads are arranged on the inner wall of the U-shaped groove. The invention can improve the internal fixation stability and reliability of the spinal column in a renovating operation or the secondary screw arranging process, reduce the occurring rate of vertebral arch pedicle screw loosening and even separation and lower the failure rate of operations.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

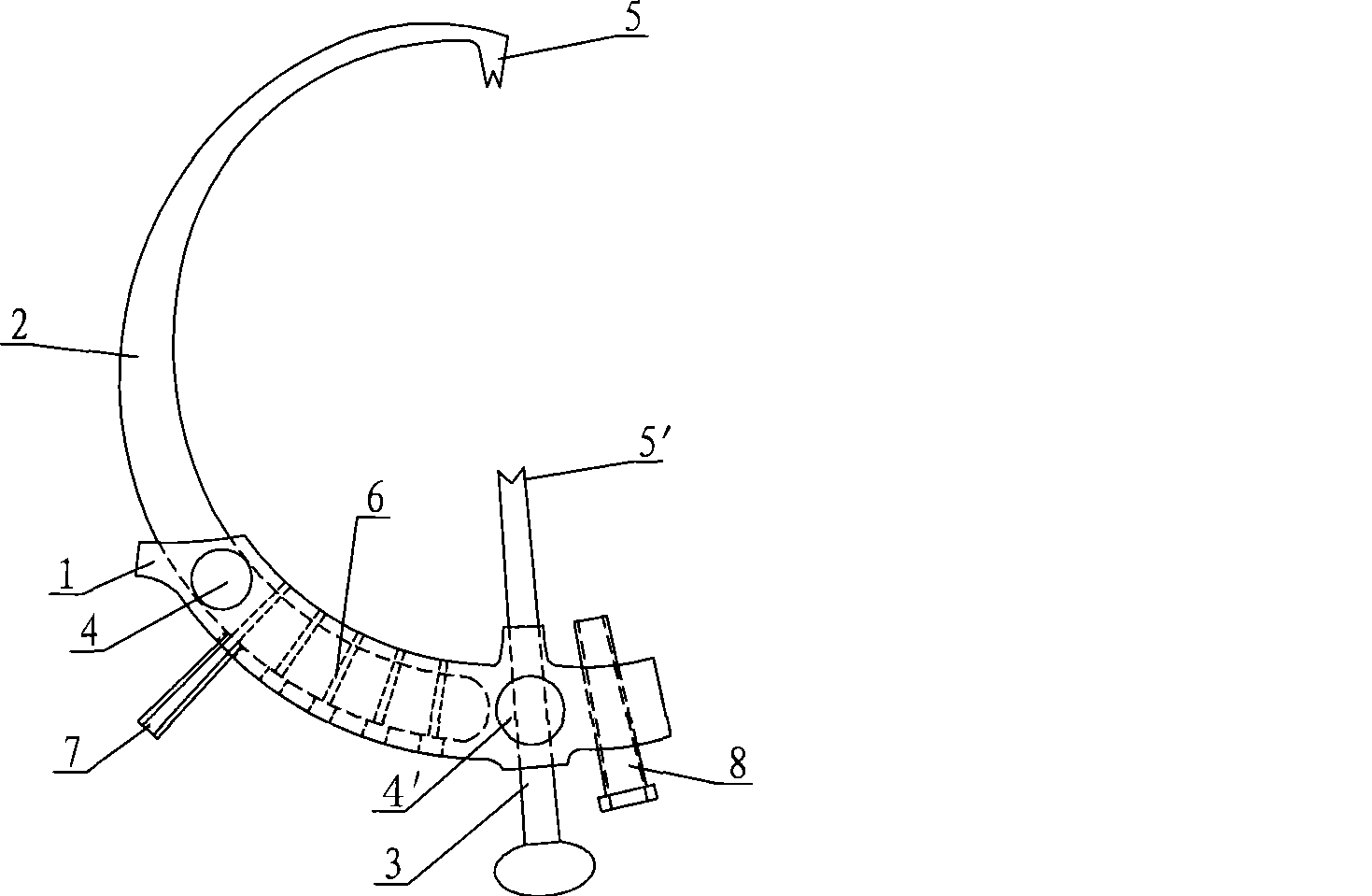

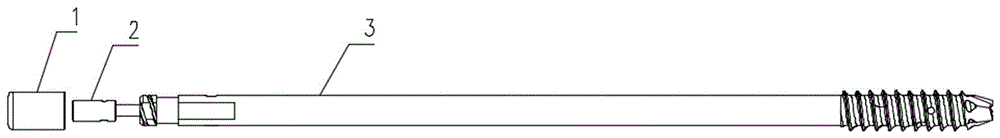

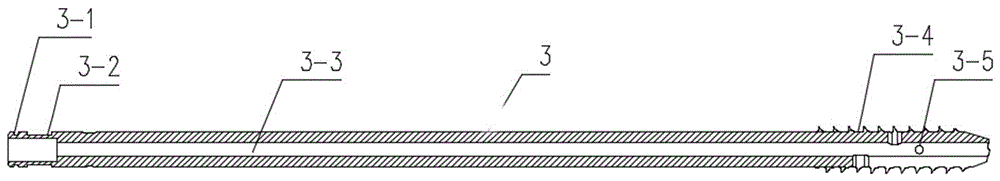

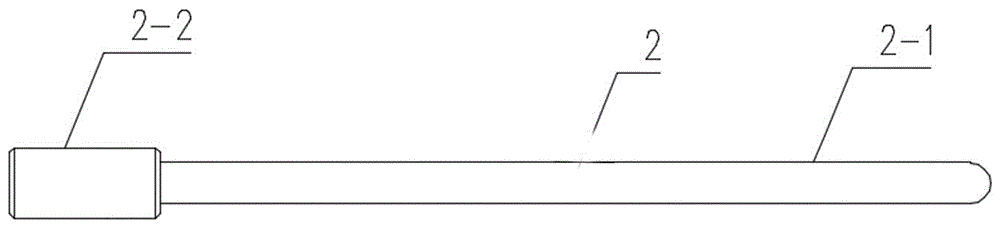

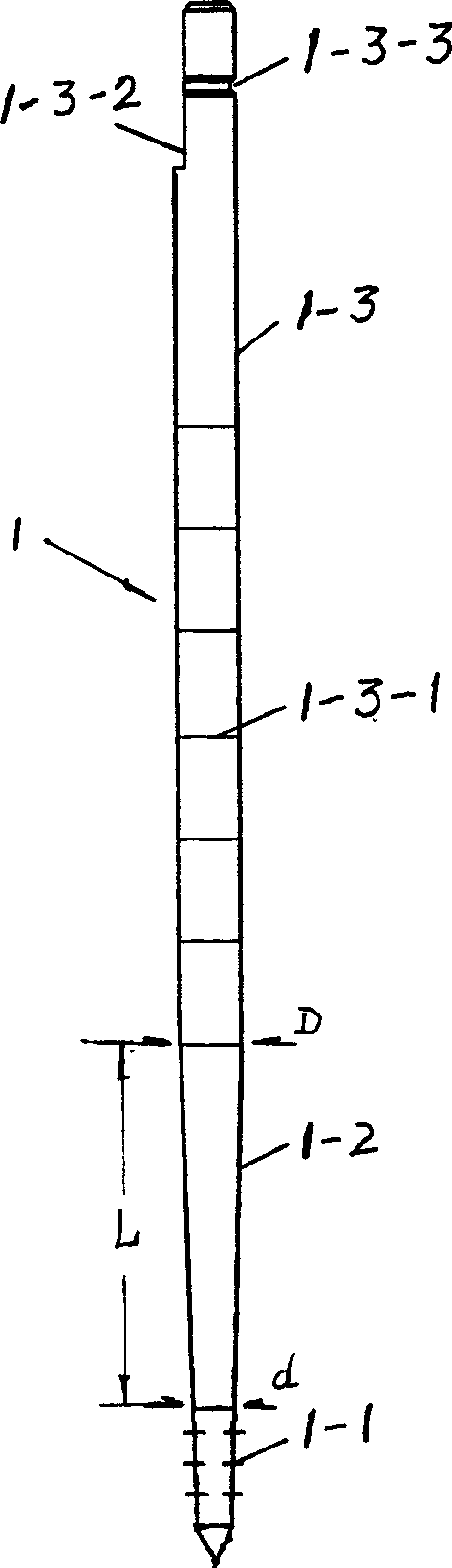

Anti-infection external fixation hollow spicule with tail cap and injection hole

The invention discloses an anti-infection external fixation hollow spicule with a tail cap and an injection hole, which relates to a hollow spicule capable of being injected with liquid, is a metal spicule required during treatment of femoral neck fracture by an external fixation support, and also can be used for fixing long bone of limbs. The anti-infection external fixation hollow spicule comprises a hollow spicule body, an inner core and the tail cap, wherein an inner core hole is formed in the hollow spicule body; a fast mounting connector and an injector connector are arranged at the tail of the hollow spicule body; a cancellous bone thread is formed in the head of the hollow spicule body; a Kirschner wire is arranged at the front part of the inner core; a short cylindrical body is arranged at the back part of the inner core; the Kirschner wire arranged at the front part of the inner core is matched with the inner core hole in the hollow spicule body closely and smoothly; the tail cap is provided with an inner core mounting hole; and a tail cap inner thread is formed in the lower end part of the inner core mounting hole. The tail cap can be quickly connected to the tail of the hollow spicule body; the tail cap inner thread is matched with the injector connector at the tail of the hollow spicule body; a seal ring is mounted in the tail cap; and the tail cap can fix the movement of the inner core and prevent liquid from flowing out and being in contact with air.

Owner:KANGHUI MEDICAL INNOVATION

On-line water quality analyzer with multi-parameter sensors

InactiveCN105928560AClean in timeHigh outputMeasurement devicesWater qualityEnvironmental engineering

The invention relates to an on-line water quality analyzer with multi-parameter sensors. The on-line water quality analyzer is installed in a device containing an aqueous medium to be monitored and used to monitor water quality of the aqueous medium to be monitored. The on-line water quality analyzer comprises a first housing, a second housing, a plurality of water quality measuring units and a cleaning unit for cleaning the water quality measuring units, wherein through holes allowing the aqueous medium to be monitored to pass through are arranged in the first housing, an accommodating chamber is arranged in the first housing and has an opening end, the first end of the second housing is connected and communicated with the opening end of the accommodating chamber, the second end of the second housing is provided with a cover plate, the water quality measuring units and the cleaning unit are received in the accommodating chamber and installed on the inner wall of the first end of the second housing, and a signal line is arranged in the second housing and connected with the water quality measuring units in a waterproof way. The on-line water quality analyzer is simple to operate and is practical. The measuring units can be cleaned timely, and the working efficiency of the water quality analyzer is improved.

Owner:YANTAI CHEMINS INSTR CO LTD

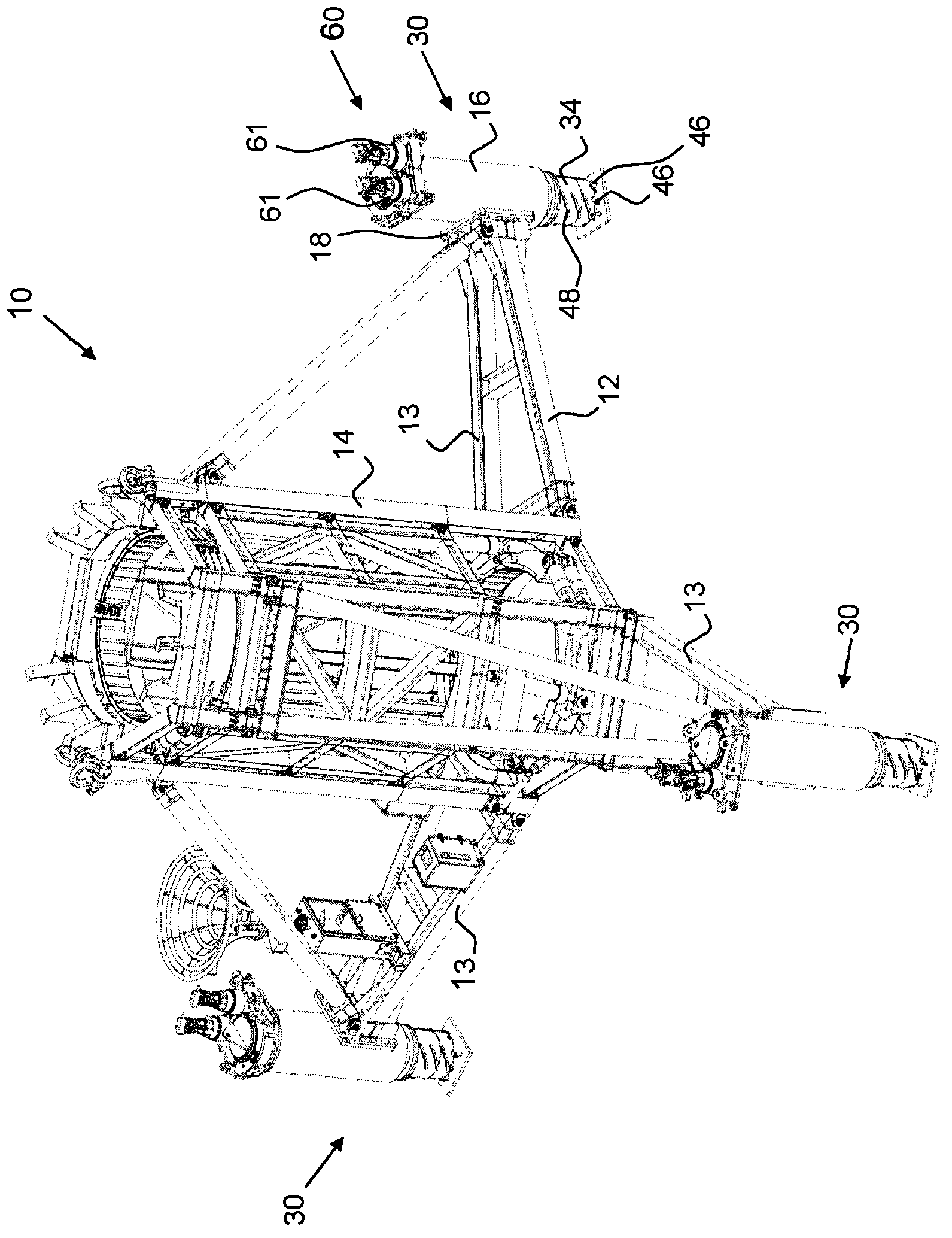

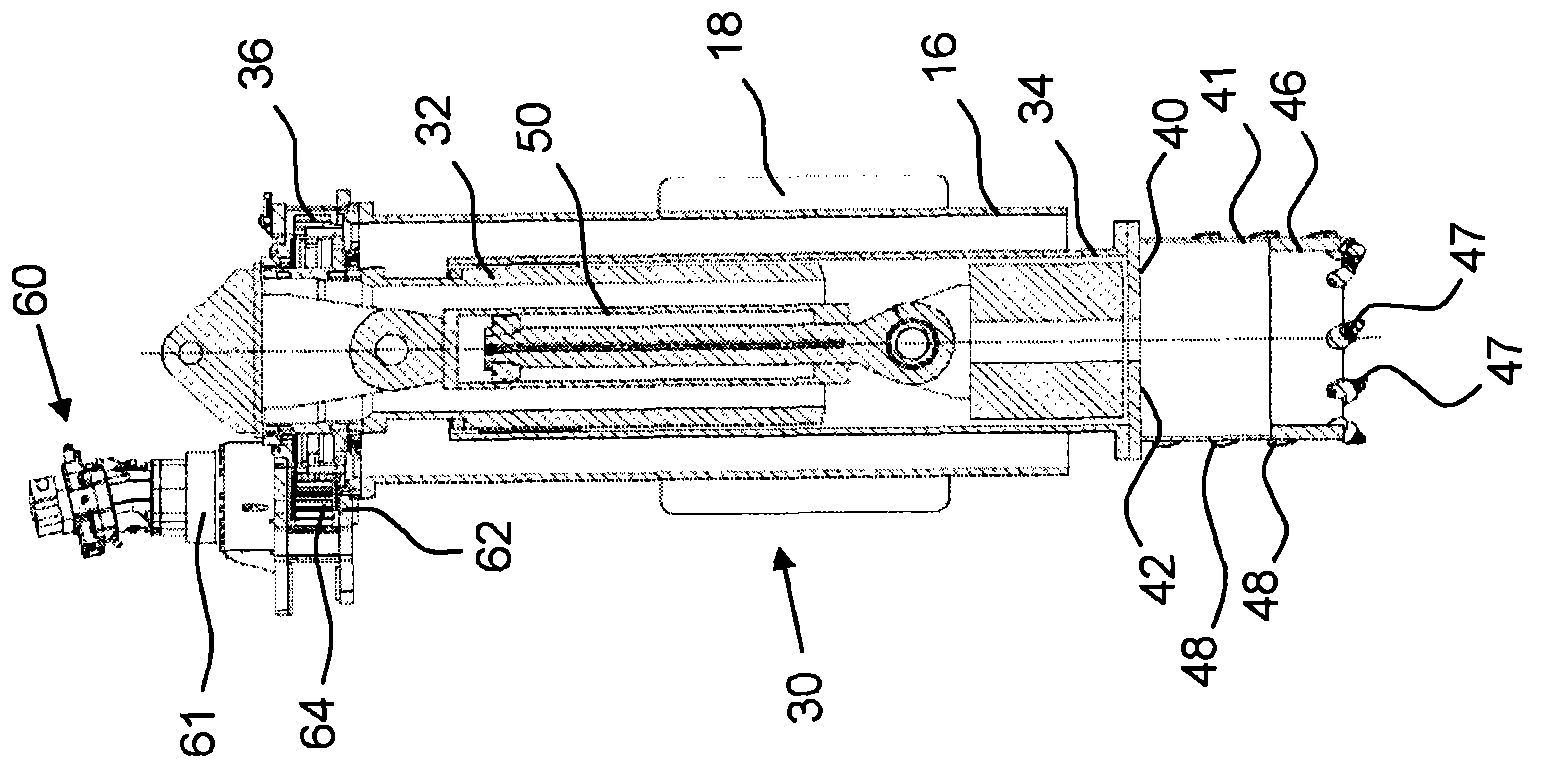

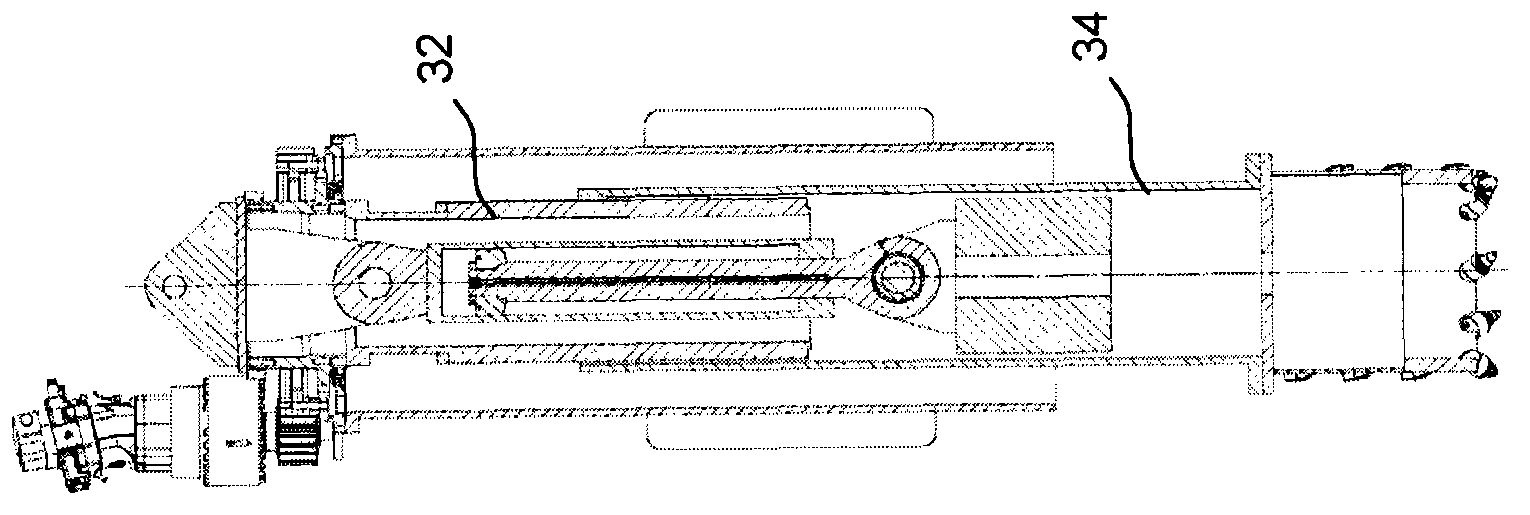

Underwater work assembly and method for anchoring the same

InactiveCN103015895AEasy to screw inReliable anchoringUnderwater drillingBulkheads/pilesMarine engineering

The present invention relates to an underwater work assembly and a method for anchoring the underwater work assembly into the bedding of lake, sea or river. The work assembly comprises the following components: a service platform which can be laid down, and a plurality of supporting legs. The plurality of supporting legs are mounted so that the supporting legs can be adjusted on the service platform for being positioned on the bedding of the lake, sea or river, and furthermore can be moved in and out by means of an actuating cylinder relative to the service platform. For improving anchoring, the invention suggests that at least one supporting leg is rotatably mounted relative to the service platform; a rotation driver which faces the supporting leg is equipped; the rotation driver is used for performing rotation driving on the supporting legs for screwing into the bedding of the lake, sea or river.

Owner:BAUER MASCH GMBH

Preparation method of high-molecular water-resistant sealant washer in iron bottle cap

A preparation method of a high-molecular water-resistant sealant washer in an iron bottle cap belongs to the technical field of food packaging. The preparation method comprises the following steps: preparation of a sealant body and glue injection moulding. The sealant body is prepared from the following ingredients (by weight): 80-120 parts of PVC paste resin, 30-60 parts of dioctylterephthalate, 15-35 parts of tributyl 2-acetylcitrate, 10-30 parts of heavy calcium carbonate, 1.5-3.5 parts of a calcium-zinc stabilizer, 0.8-1.6 parts of a white foaming agent, 0.5-1.1 parts of titanium dioxide, 0.3-0.9 part of dimethicone and 2-4 parts of rapeseed oil. After the sealant body is prepared, the inner side of a tinplate bottle cap is cleaned, and the prepared sealant body is uniformly injected onto the inner seal ring surface of the tinplate bottle cap; and after thermoforming, the nontoxic environmental-protection polyvinyl chloride sealant washer in the tinplate bottle cap is prepared. The method of the invention is simple and scientific. The prepared nontoxic environmental-protection polyvinyl chloride sealant washer in the tinplate bottle cap has excellent quality and good sealing effect, and is safe and environment friendly.

Owner:扬州市大明包装制品有限公司

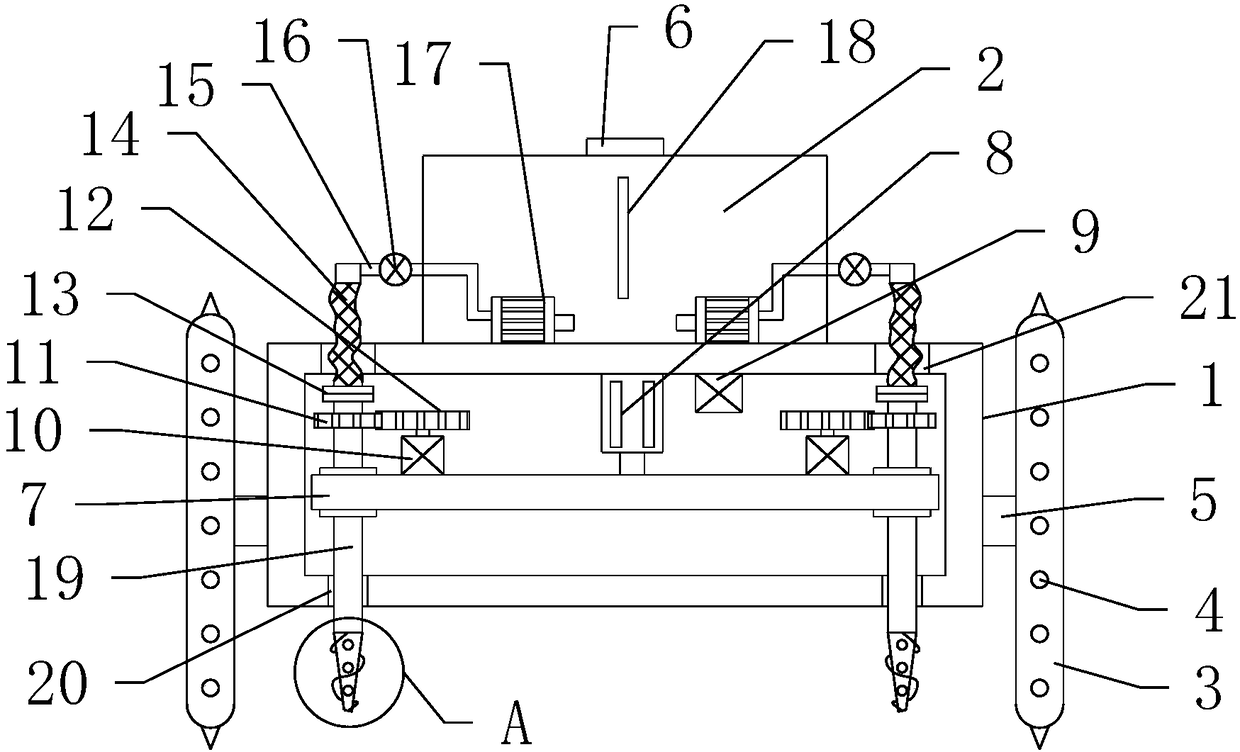

U-shaped hanging ring machining machine

InactiveCN108907741AHoles can be alignedHole size can be consistentWork clamping meansOther manufacturing equipments/toolsEngineeringPunching

The invention relates to the field of automatic assembling devices, in particular to a U-shaped hanging ring machining machine. The U-shaped hanging ring machining machine comprises a worktable, a hanging ring feeding device, a first conveying device, a first jig device, a punching device, a second conveying device, a second jig device, a bolt assembling device, a nut assembling device and two bending devices; the hanging ring feeding device is arranged on the side of the worktable, the first conveying device, the first jig device, the second conveying device and the second jig device are arranged on the worktable in sequence from left to right, two mounting grooves are formed in the first jig device, the two bending devices are arranged in the corresponding mounting grooves, the punchingdevice is arranged on the side of the first jig device, a first fixing device is arranged on the side of the first jig device, the bolt assembling device and the nut assembling device are arranged onthe two sides of the second jig device, and a second fixing device is arranged on the side of the second jig device. The machining efficiency of a U-shaped hanging ring is improved.

Owner:郑菁

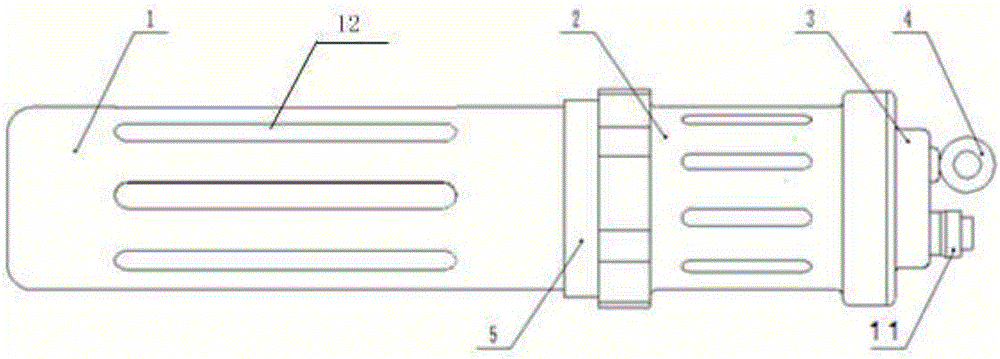

Restorer for vertebral body and puncture needle for pedicle of vertebral arch by prying operation through skin

A percutaneous vertebral body restoring apparatus is composed of two puncture needles with screwed front end for vertebral pedicle, an extending rod for increasing the length of said puncture needle in order to increase force arm, a connecting rod for locating said two puncture needles, and two combined campers for connecting said puncture needle to said connecting rod. Its advantages are low resistance for turning said needle, and less damage to soft tissue.

Owner:THE FIRST PEOPLES HOSPITAL OF CHANGZHOU

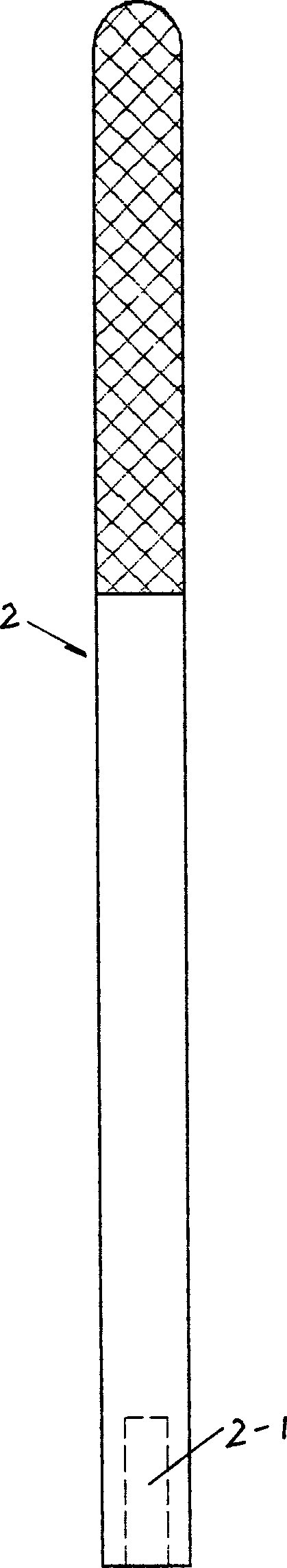

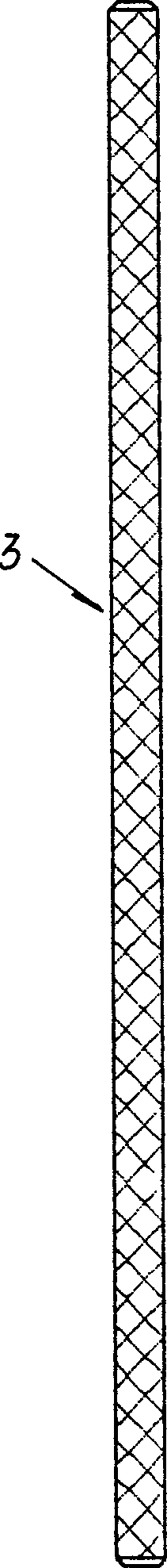

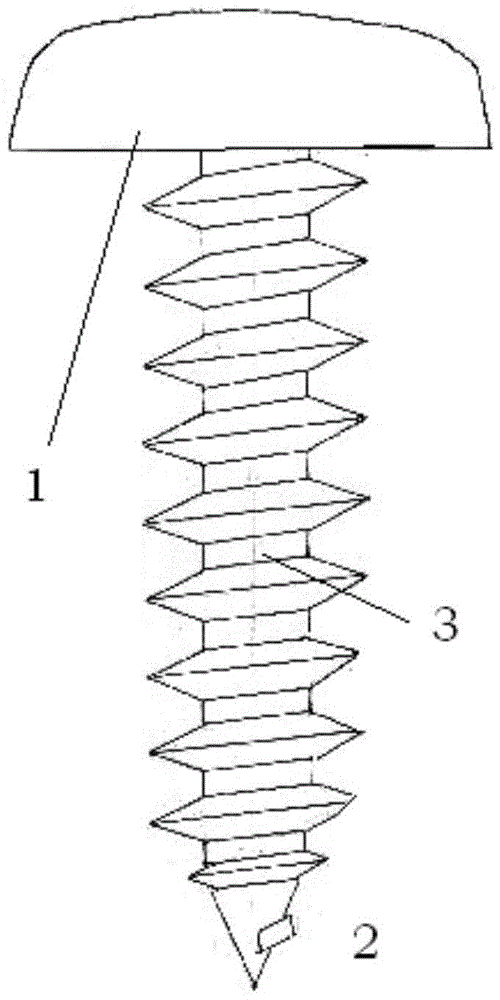

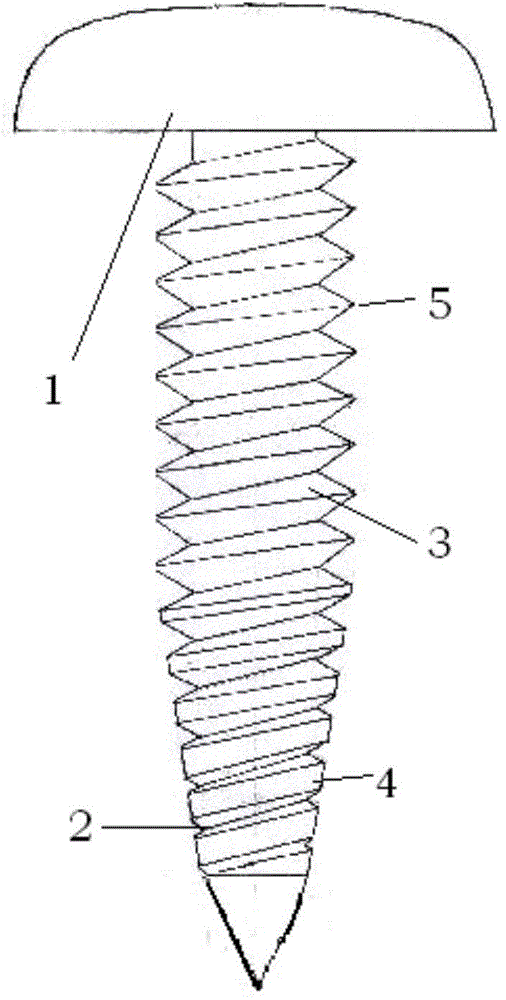

Tapping screw

The invention relates to a tapping screw, wherein the tip of a screw rod extends with reduced outer diameter; the tapping screw is characterized in that the diameter ratio of the screw pitch of screw thread to a middle screw rod is 1: (4.1-9); the tip of the screw rod is in a circular truncated cone or circular cone shape. The longitudinal section of thread teeth at the tip of the screw rod are bared teeth; thread teeth of the middle screw rod are cut teeth. The tapping screw can be easily screwed into an aluminium plate with the thickness of 4mm or 1mm, tapping is not needed to be firstly carried out, which is difficult to complete by the national standard tapping screw tooth pitch.

Owner:WUXI YUXING BUILDING HARDWARE

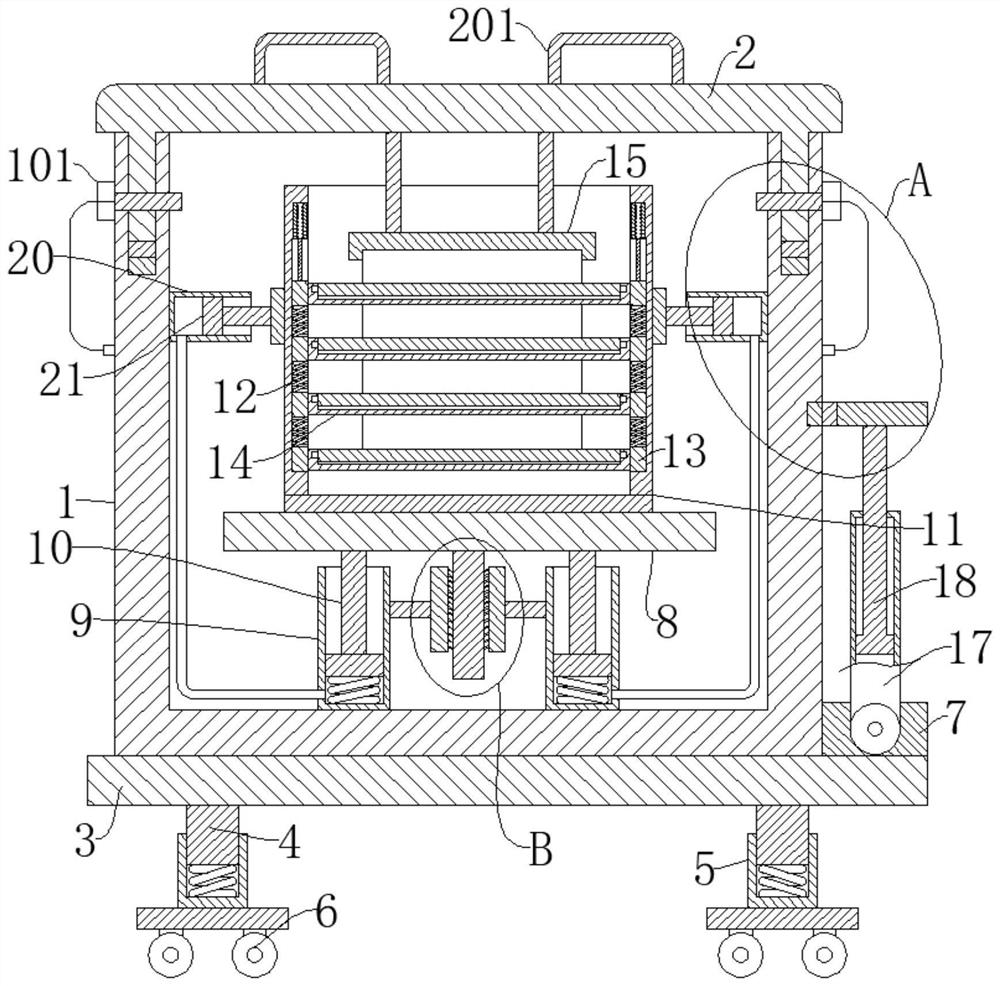

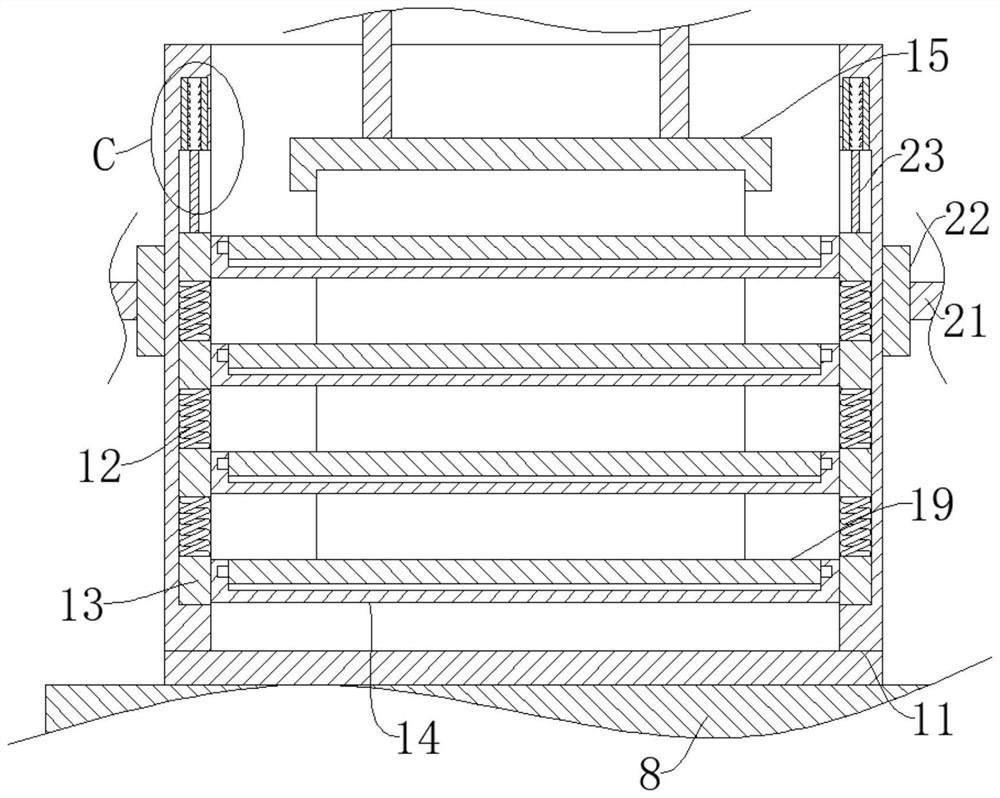

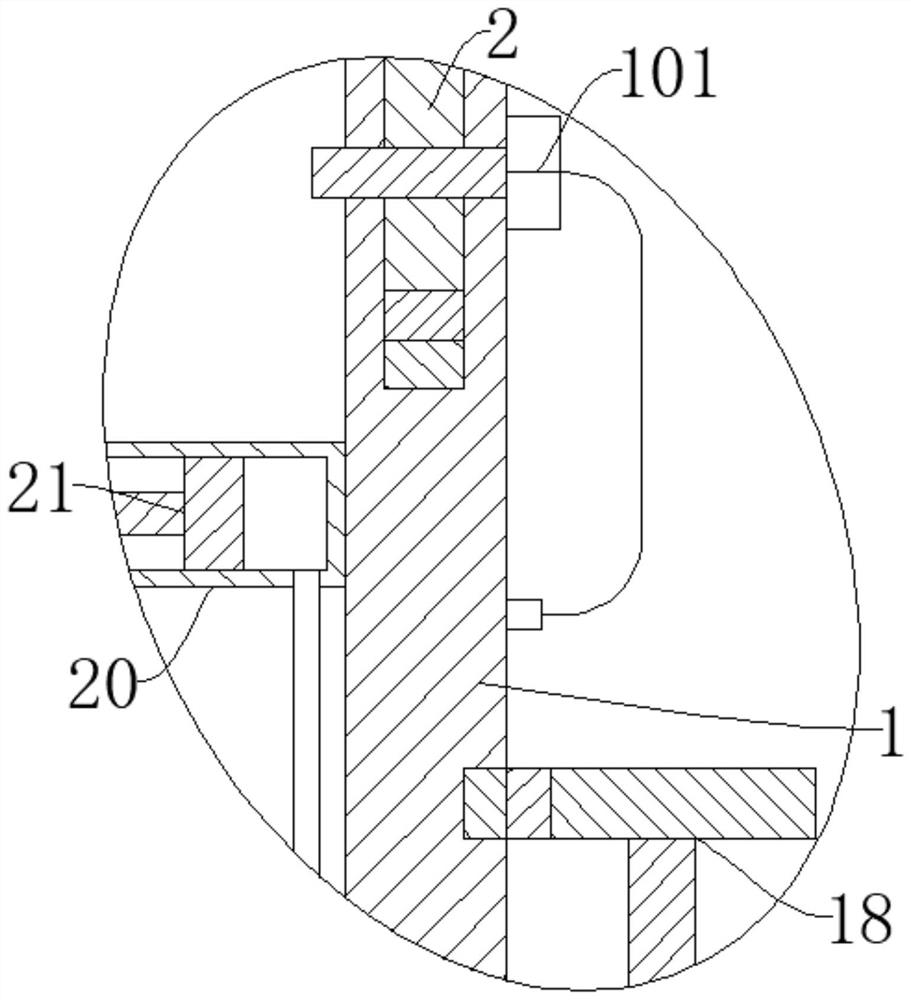

Mold conveying device for mechanical production

InactiveCN112407541AImprove stabilityPlay a shock absorbing roleClosure with auxillary devicesContainers to prevent mechanical damageProcess engineeringGas supply

Owner:深圳利朋技术研发有限公司

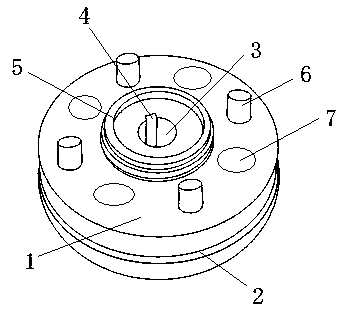

Belt wheel disc

InactiveCN103742628AReliable rotationInhibit sheddingPortable liftingGearing elementsIsosceles trapezoidEngineering

The invention discloses a belt wheel disc. The belt wheel disc comprises a wheel disc body, wherein a circle of an annular belt containing groove is formed in the middle part of the outer wall of the wheel disc body; a drive bearing mounting hole is formed in the middle part of the mounting surface of the wheel disc body; a clamping groove is formed in the hole wall of the drive bearing mounting hole; a circle of an annular bump is also arranged on the outer side of the drive bearing mounting hole; a screw thread is formed in the outer wall of the bump; four positioning pins are annularly distributed on the circumference of the bump at equal intervals and are located on the mounting surface of the wheel disc body; lightening holes are formed between adjacent positioning pins; the section of the belt containing groove is a isosceles trapezoid; the short sides are the openings of the belt containing groove. The belt wheel disc is convenient in installation as the positioning pins are arranged, can prevent a belt in high-speed rotation from falling off, reduces the weight of the belt wheel disc as the lightening holes are formed, is convenient in transportation and installation, simple in structure and easy to implement, and achieves good application prospect.

Owner:SFAM SCI & TECH JIANGSU

Rolling rounder for rolling steel bar

InactiveCN1931513AQuality improvementEasy to screw inWire articlesOther manufacturing equipments/toolsRoundingPhase difference

The steel bar end chamfering and rounding roller includes at least three eccentric chamfering and rounding shafts, each of which consists of an eccentric chamfering section, a main shaft section and an eccentric rounding section. The eccentric chamfering section and the eccentric rounding section has eccentric phase difference of 90-180 deg; the eccentric rounding section is provided with rounding wheel; the eccentric chamfering section is provided with corresponding chamfering cutter; and the main shaft section is provided with outer gears meshed to the same inner gear sleeve. There are also dialing disc, locating part, locating ring with locating notch and spring, and the locating part and the locating notch are fitted in different phases corresponding to three states, including chamfering, rounding and free position. The present invention is used in chamfering and rounding steel bar before rolling for raised final steel bar quality.

Owner:孙永林

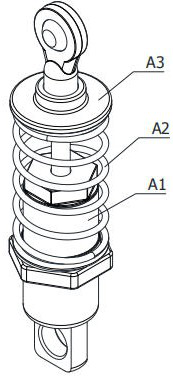

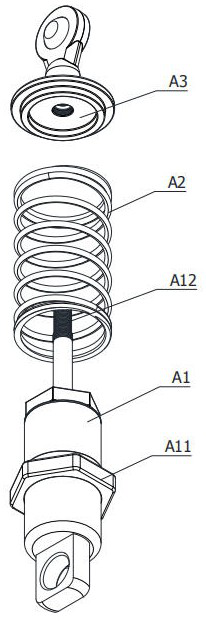

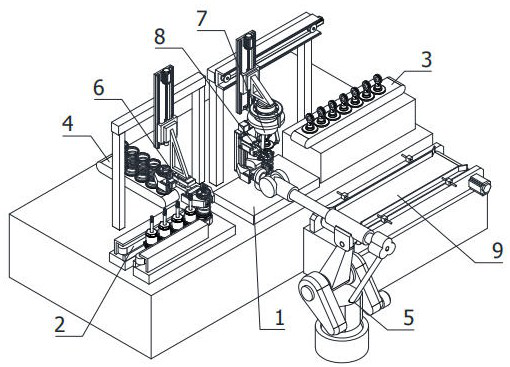

Automatic assembling equipment for automobile shock absorber

ActiveCN111805234AEasy to transportNot easy to break awayAssembly machinesEngineeringIndustrial robotics

The invention relates to the technical field of automobile shock absorber machining, in particular to automatic assembling equipment for an automobile shock absorber. The automatic assembling equipment is applied to automatic assembling of the shock absorber, the shock absorber comprises a damper, a spring and an internal thread spring cap, wherein an adjusting nut is arranged on the damper, and threads are arranged at an output shaft of the damper; and the assembling equipment comprises a fixing workbench, a clamping type damper conveying belt, a spring cap conveying belt, a spring conveyingbelt, an industrial robot, a rotary spring assembler, a three-jaw clamping rotary assembler, a spring downward-pressing shaft clamping device, and a finished product conveyor, wherein the clamping type damper conveying belt and the spring cap conveying belt are arranged on the two sides of the fixing workbench; the spring conveying belt is perpendicular to the clamping type damper conveying belt,and the output end of the spring conveying belt is located on one side of the output end of the clamping type damper conveying belt; the industrial robot is arranged on the outer side of the fixing workbench; the rotary spring assembler is arranged at the tops of the clamping type damper conveying belt and the spring conveying belt; the three-jaw clamping rotary assembler is arranged at the top ofthe fixing workbench; the spring downward-pressing shaft clamping device is arranged on the outer side of the fixing workbench; and the finished product conveyor is arranged on the outer side of thefixing workbench. The equipment is high in assembling precision and working efficiency.

Owner:广州具茨自动化设备有限公司

Deep-ditch fertilizing device of landscape garden

InactiveCN108184400AImprove absorptionSimplify the fertilization processDirect liquid fertiliser deliveryFertilizerDrive motor

The invention discloses a deep-ditch fertilizing device of a landscape garden. The device comprises a rack, a fertilizer tank, traveling wheels, a lifting plate, an electric telescoping cylinder and rotating connectors, wherein the electric telescoping cylinder is fixedly arranged on a top plate of an inner cavity of the rack; the bottom end of a telescopic rod on the electric telescoping cylinderis fixedly connected with the upper surface of the middle of the lifting plate; rotating rods are rotationally arranged at the end parts of the lifting plate; tapered blocks are arranged at the bottom ends of the rotating rods; a plurality of discharging holes communicated with inner cavities of the rotating rods are uniformly formed in the tapered blocks; driving motors for driving the rotatingrods to rotate are fixedly mounted on the lifting plate. The device can sufficiently blend a liquid fertilizer into soil, effectively improves an absorption effect of vegetation on the liquid fertilizer, and is simple in fertilizing process, economical, practical, and convenient to popularize.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

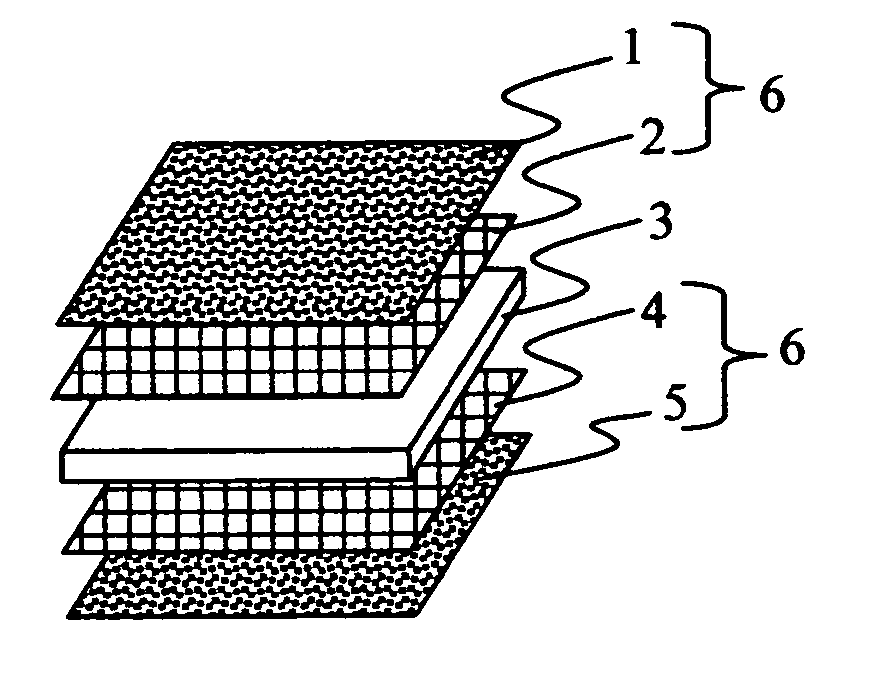

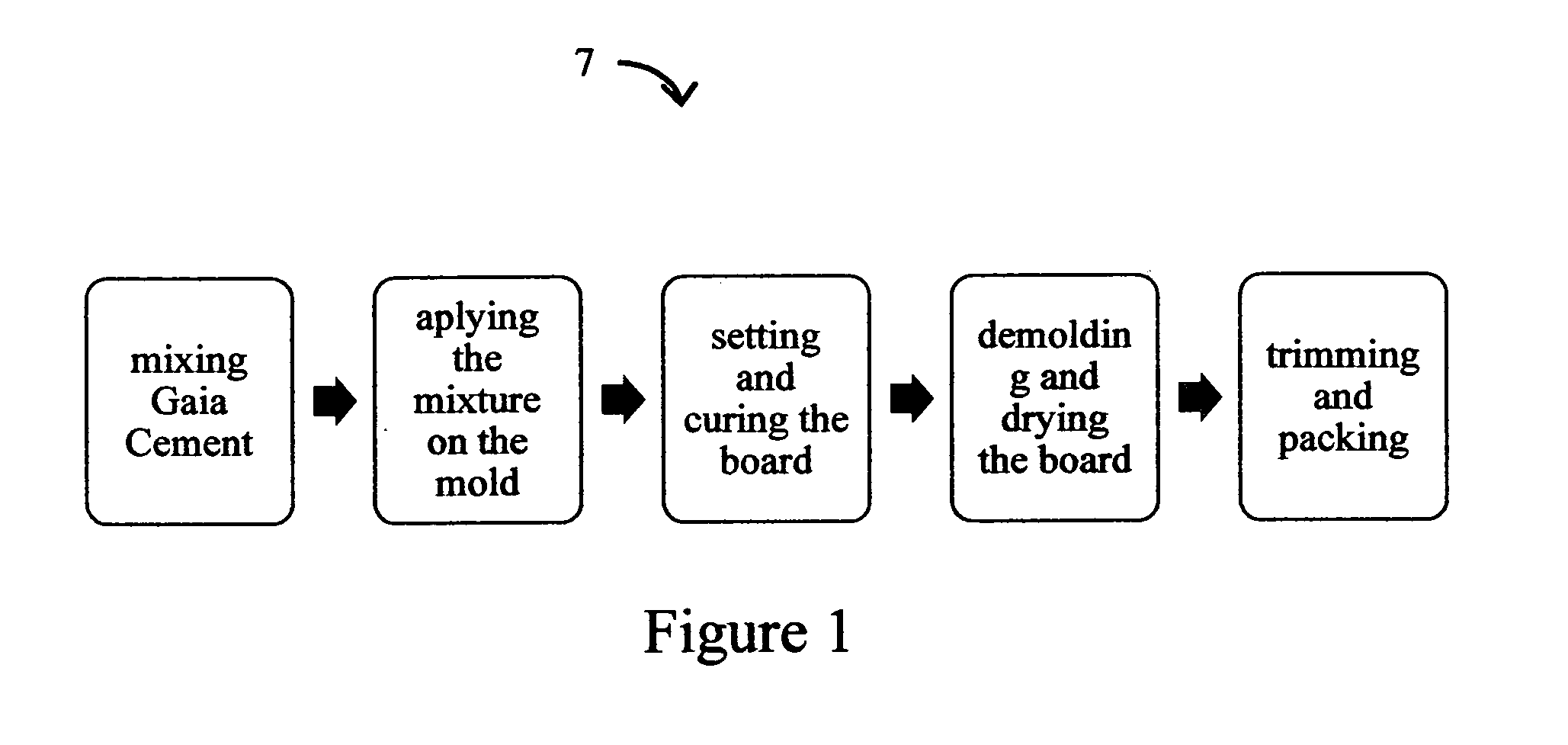

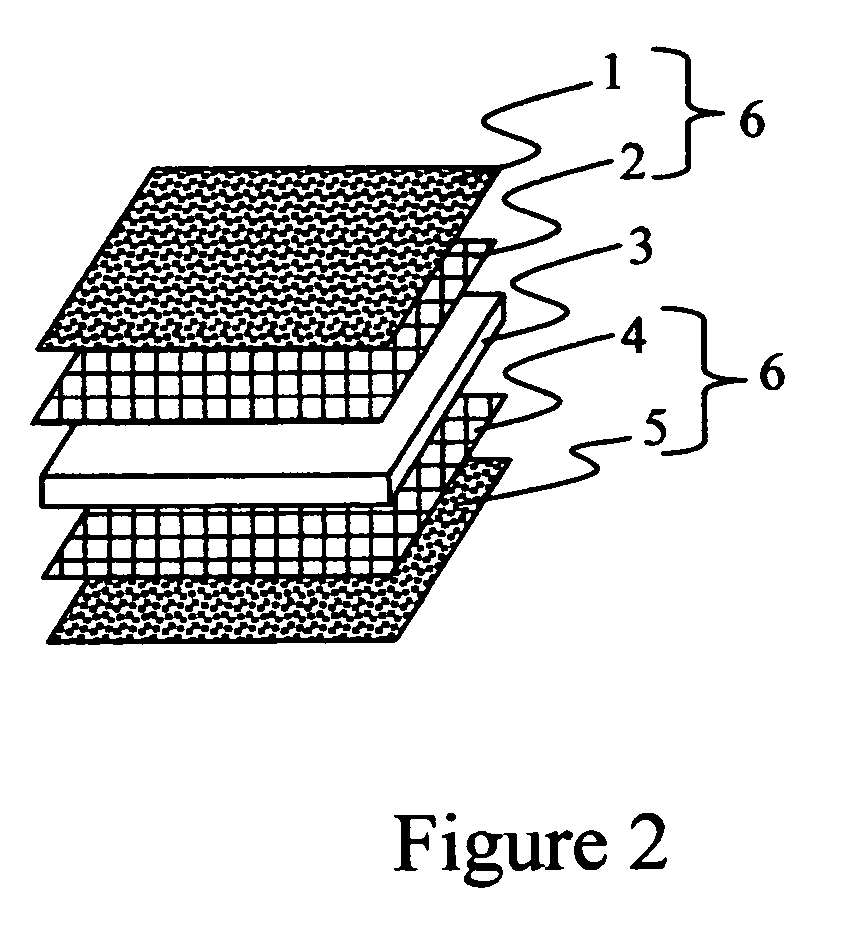

Environmentally-friendly fiber cement wallboards and methods of making the same

InactiveUS20120003461A1Easy to screw inEasy to scoreConstruction materialSolid waste managementEnvironmental resistanceGlass fiber

A manufacturing method of environmentally-friendly wallboard comprising the mixing a mortar of ash, slag, filler fibers, water and an alkali activator; and the distribution of said mortar on top of a mold corresponding to the width of the board, between single or double layers of a glass fiber web molded into each surface. Setting and curing are taking place at room temperature.

Owner:URSING JAKOB

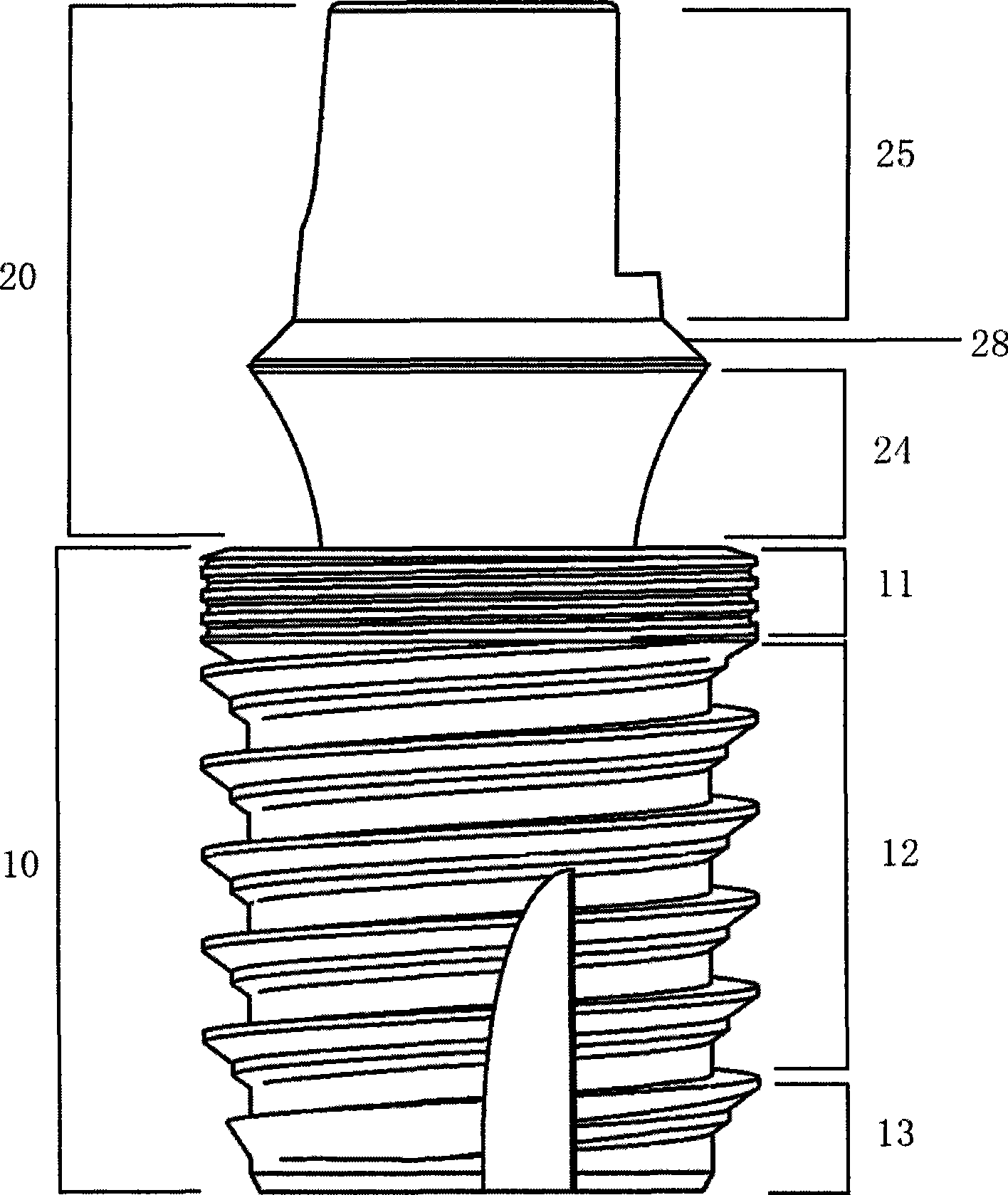

Dental implant

InactiveCN106109036AIncreased contact surface areaImprove osseointegration strengthDental implantsBone tissueDental implant

The invention belongs to the field of dental implants and in particular relates to a dental implant. The dental implant is cylindrical, and comprises a neck and a body, wherein a micro thread is formed in the periphery of the neck upwards; an external thread is formed in the periphery of the body upwards; a cavity convenient for locking is formed inside the dental implant; and a cross lock is arranged in the cavity. The dental implant disclosed by the invention can form good synosteosis with bone tissues.

Owner:JIANGSU TRAUSIM MEDICAL INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com