Drilling mechanism for case shells and case assembly system

A technology of chassis shell and drilling mechanism, which is applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc., which can solve problems such as troublesome use, difficult position adjustment, and reduced work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical scheme of the present invention will be further explained below in conjunction with the accompanying drawings of the specification:

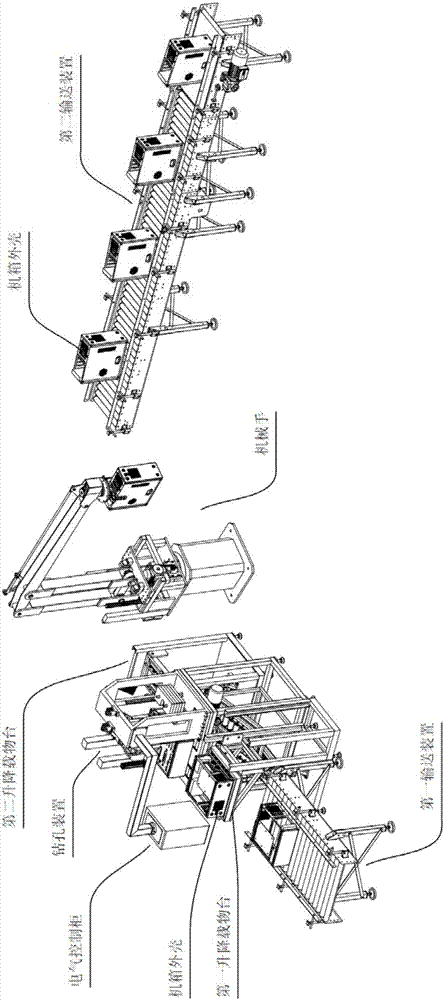

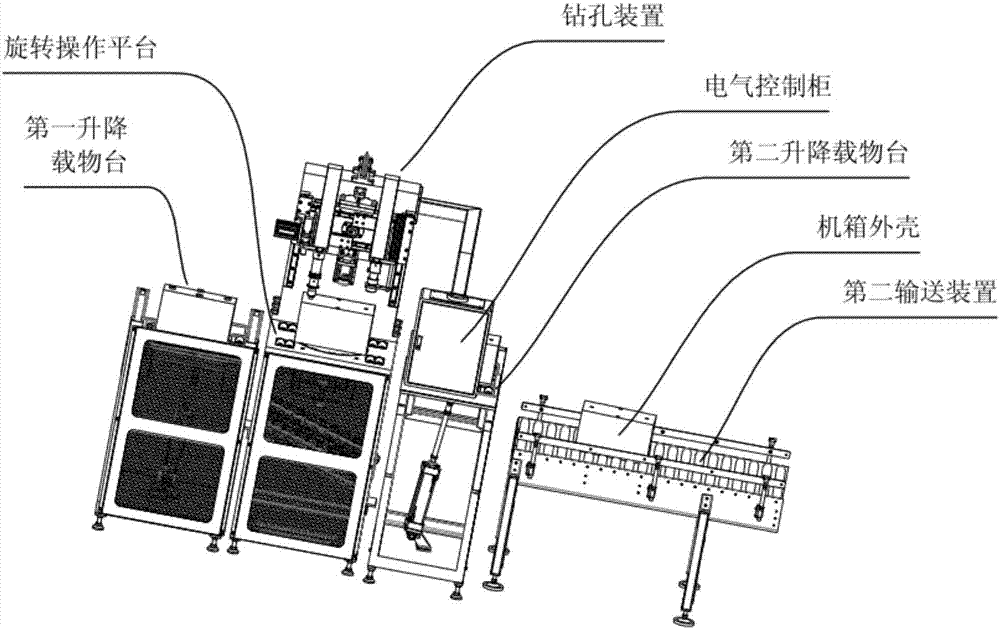

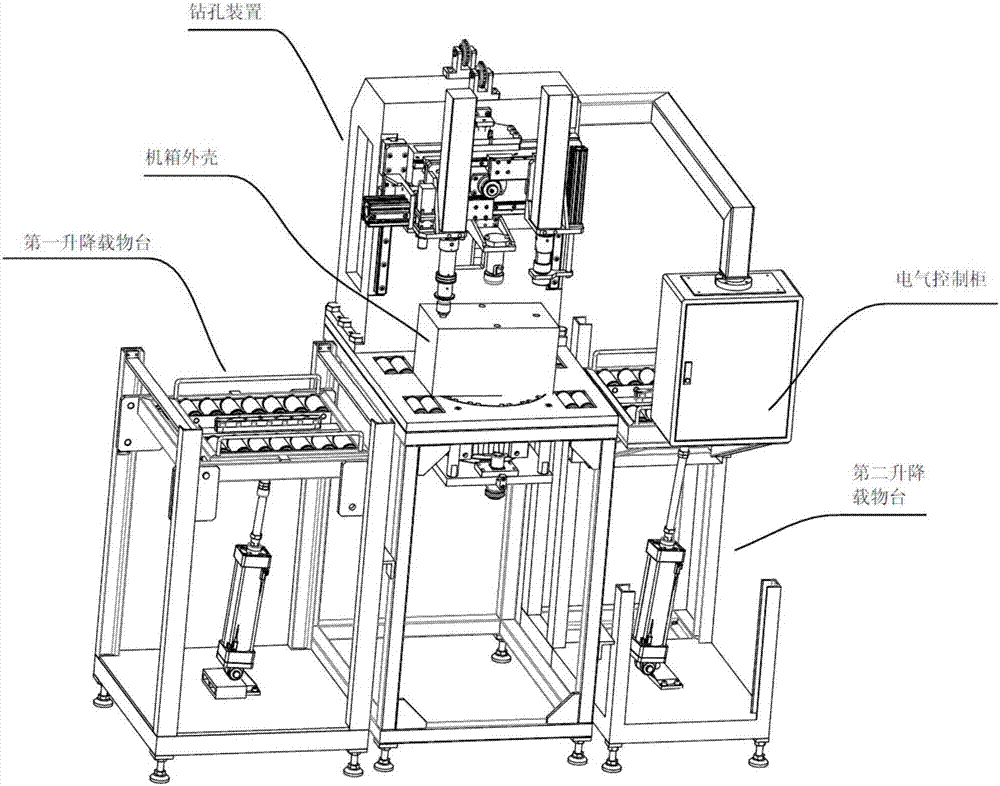

[0057] Such as Figure 1-23 As shown, the present invention provides a specific embodiment of a chassis shell drilling mechanism. A chassis shell drilling mechanism includes a first lifting platform, a drilling device, a second lifting platform, a rotating operating platform, and a chassis shell Conveying device and electrical control cabinet, in which: the first lifting platform is used to lift the chassis shell to be processed to a predetermined height and transport it to the workbench of the drilling device; the drilling device is used to lift the first lifting platform Lift and transport the chassis shell to be processed for drilling or punching; the second lifting stage is used to receive the chassis shell after drilling or punching, and raise or lower these chassis shells to a predetermined value The height enters the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com