Patents

Literature

3110results about How to "Improve support strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

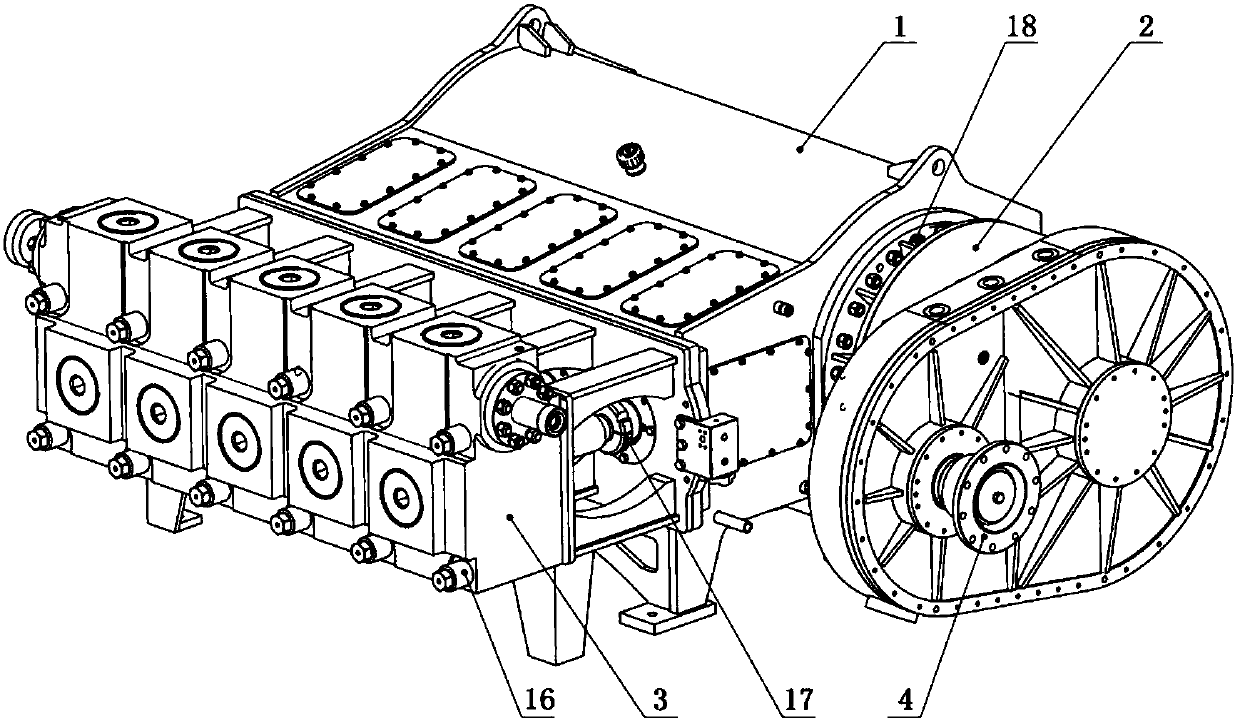

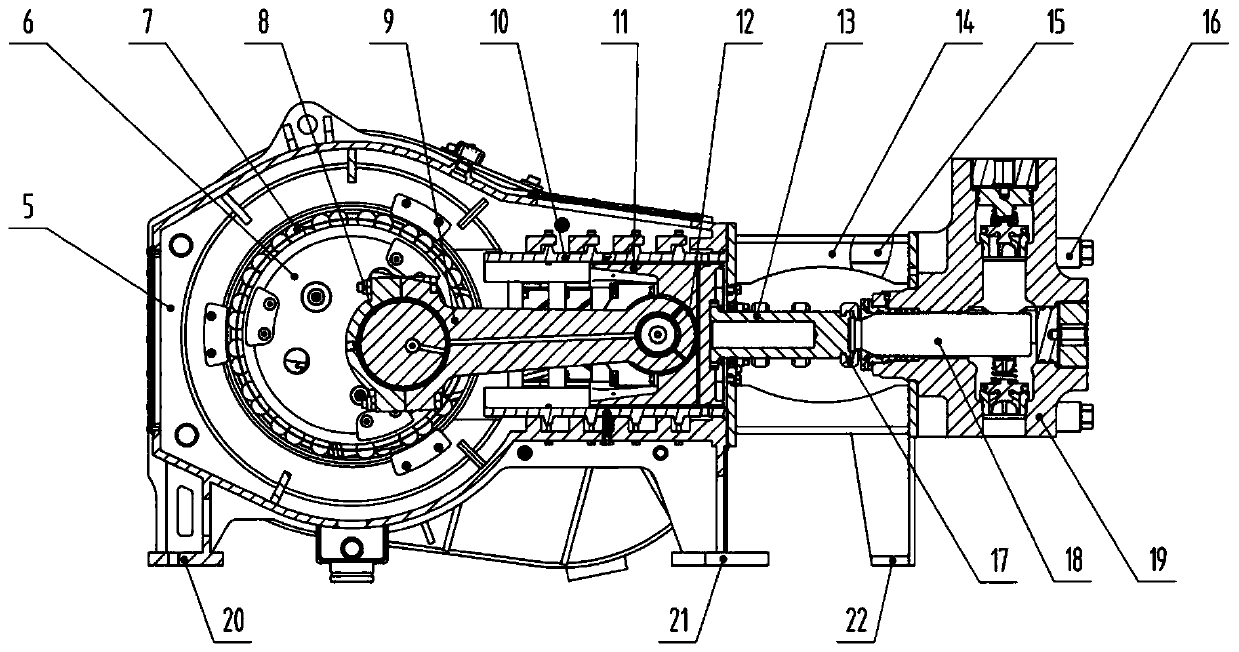

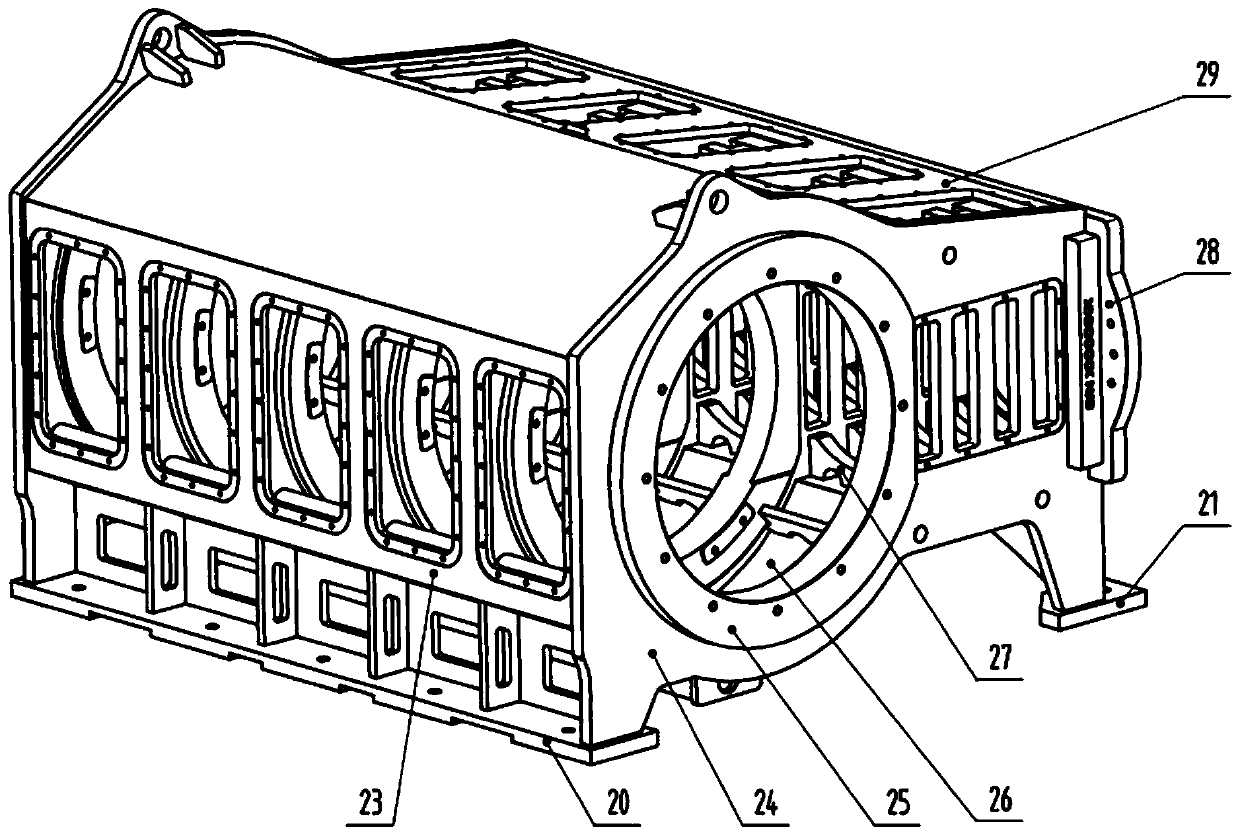

High-power five-cylinder plunger pump

PendingCN110617187AIncrease the carrying areaOptimize layoutPositive displacement pump componentsFluid removalEngineeringMechanical engineering

The invention discloses a high-power five-cylinder plunger pump. The plunger pump comprises a power end assembly, a hydraulic end assembly and a reduction gearbox assembly, wherein the power end assembly comprises a crankshaft box body, a crosshead box body and a spacer frame; the crankshaft box body, the crosshead box body and the spacer frame are sequentially connected; the hydraulic end assembly is fixed on the spacer frame; the reduction gearbox assembly is fixed on the crankshaft box body; and the cylinder spacing of the five-cylinder plunger pump is 13-14 inches, so that a guarantee is provided for the output of high power of the five-cylinder plunger pump. According to the high-power five-cylinder plunger pump, the problems that the area of a shale gas fracturing well site is narrowand the number of required fracturing equipment is relatively large are effectively solved, thus reducing the use of equipment, and facilitating the arrangement of the well site.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

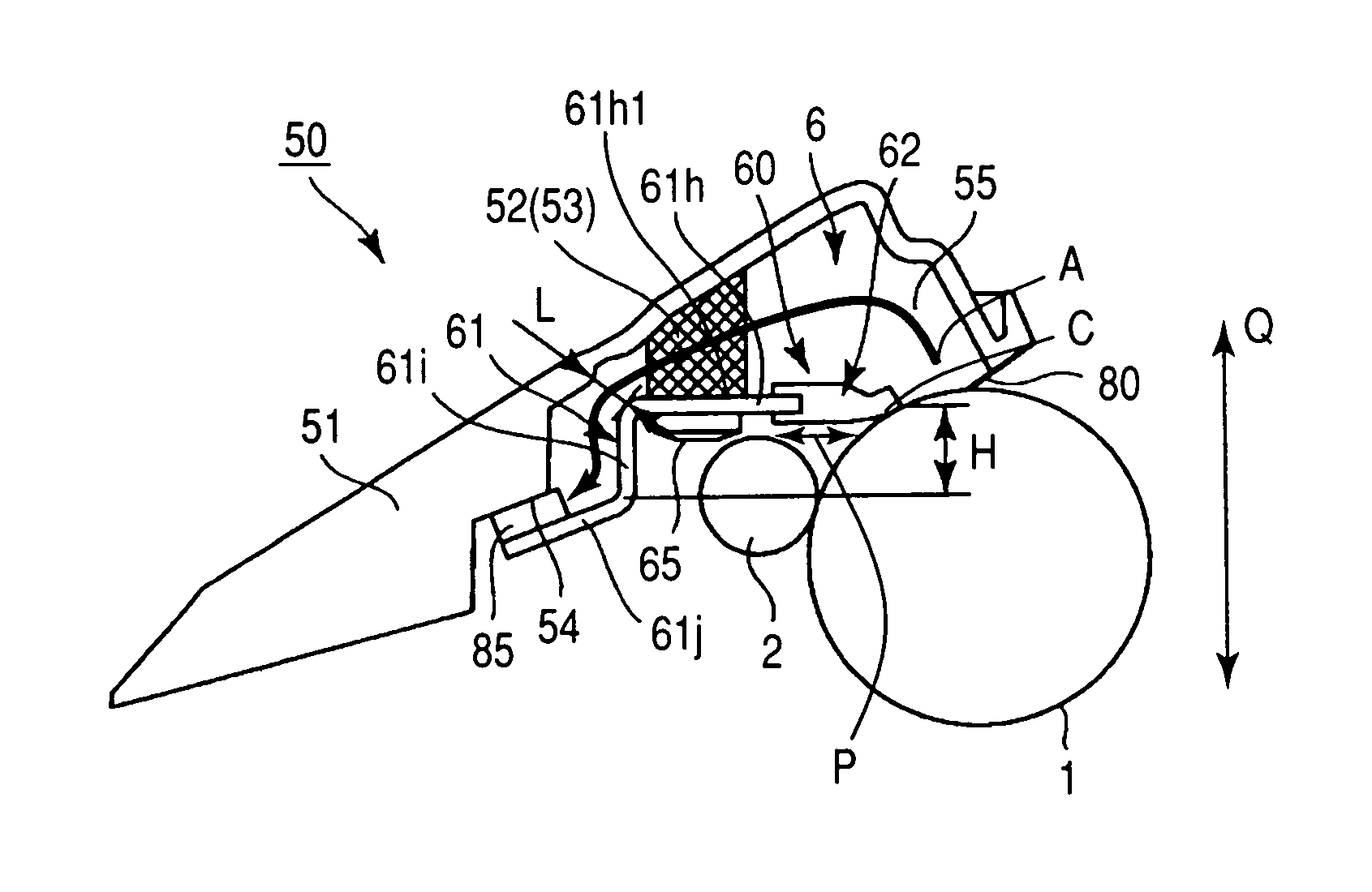

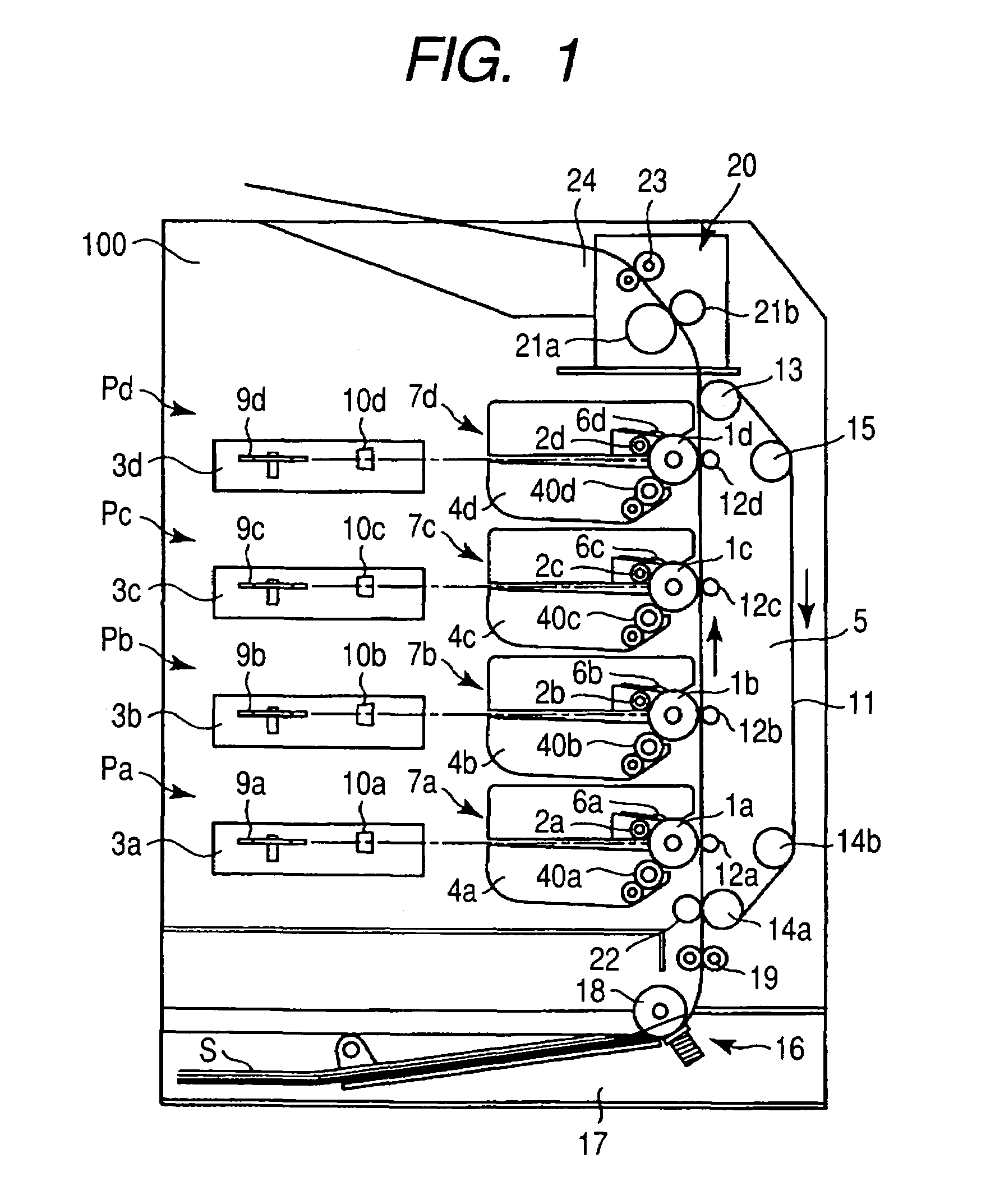

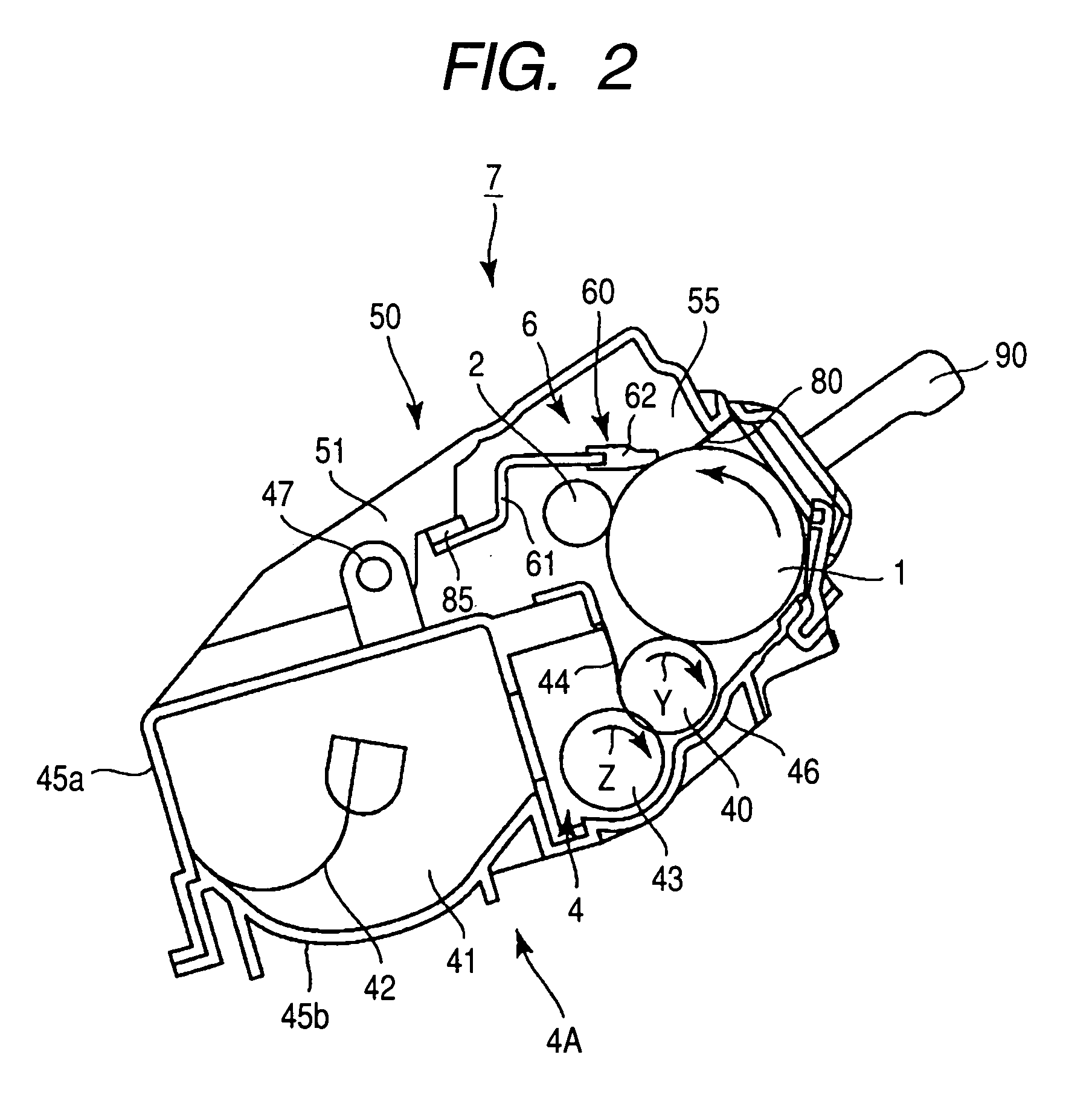

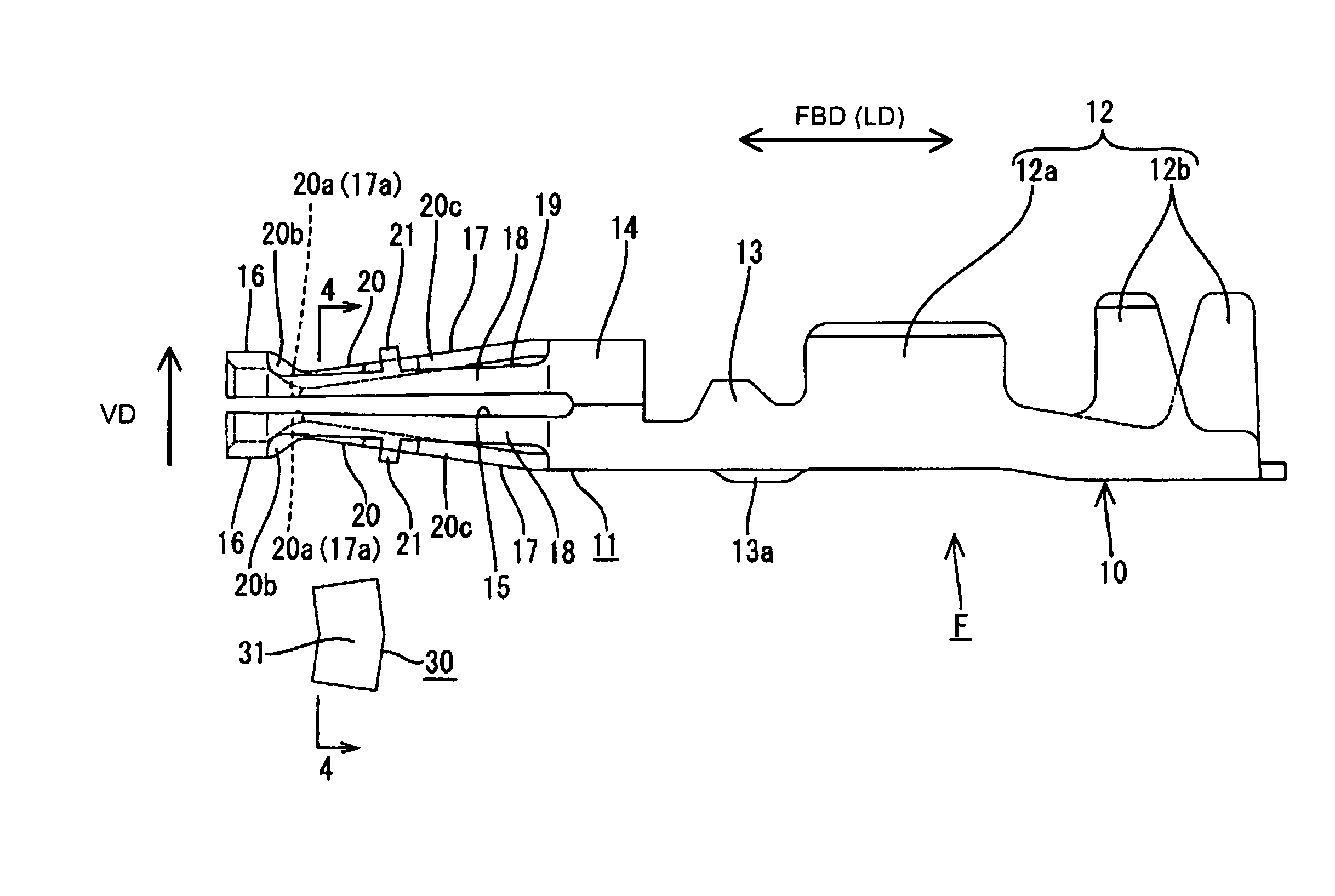

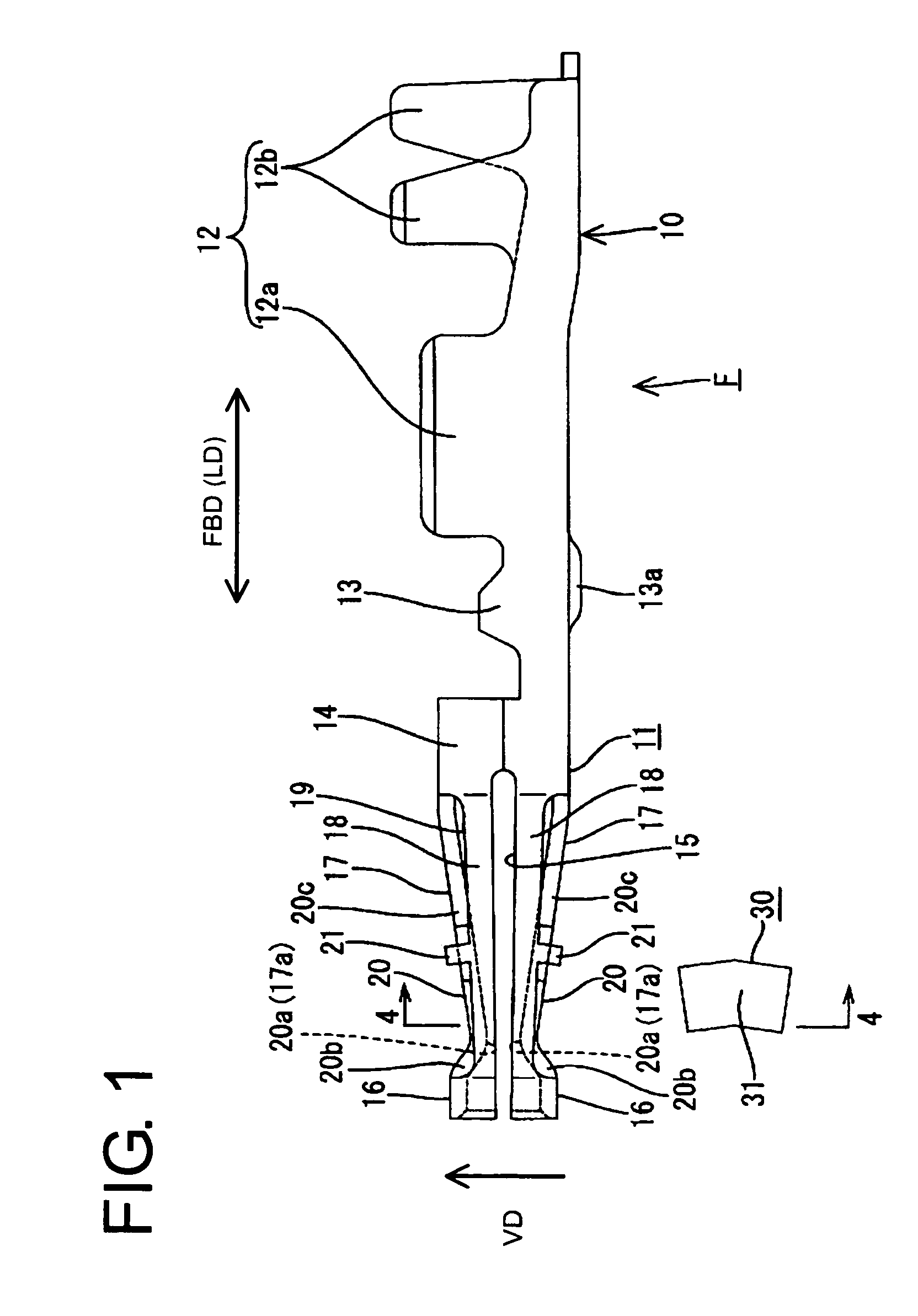

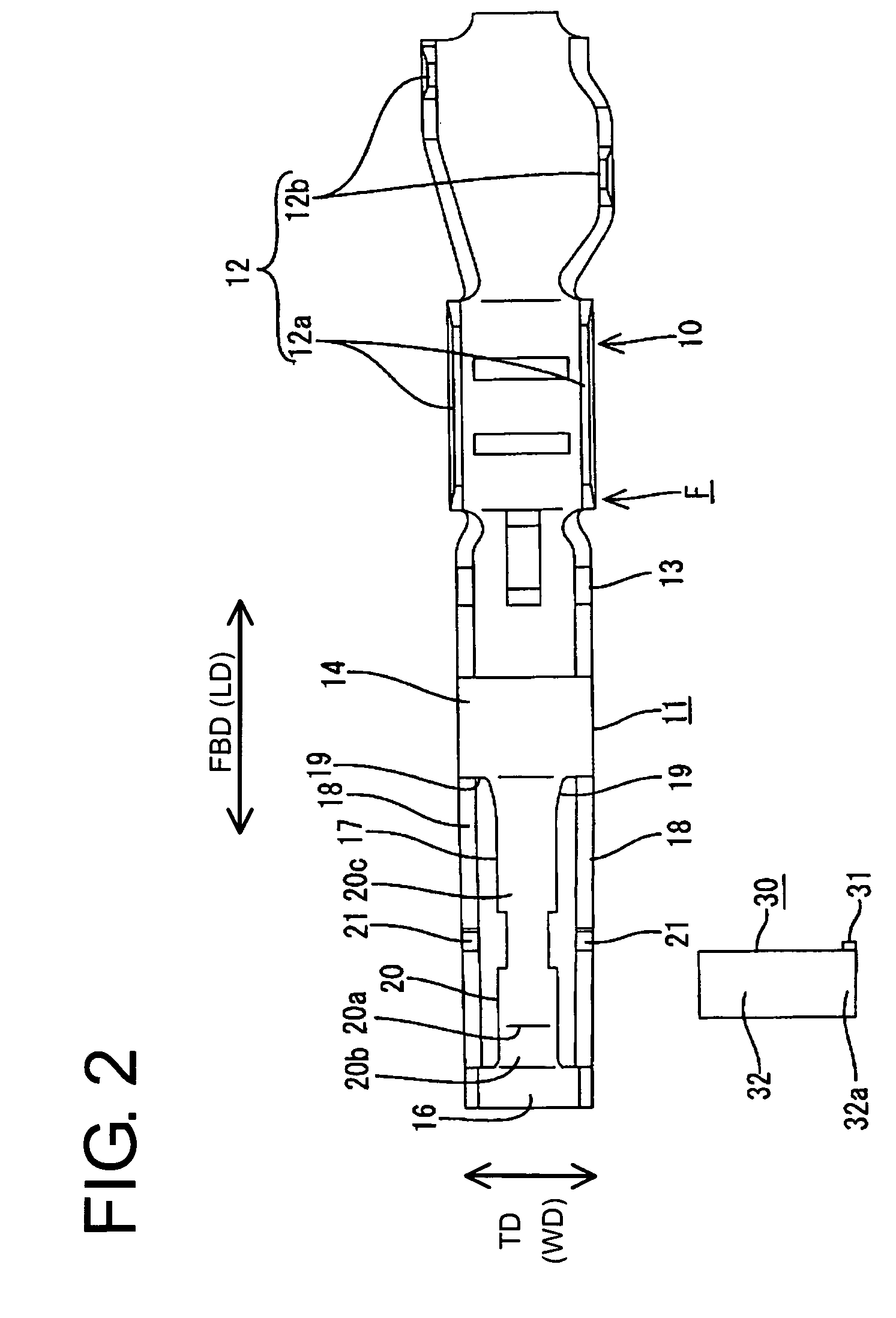

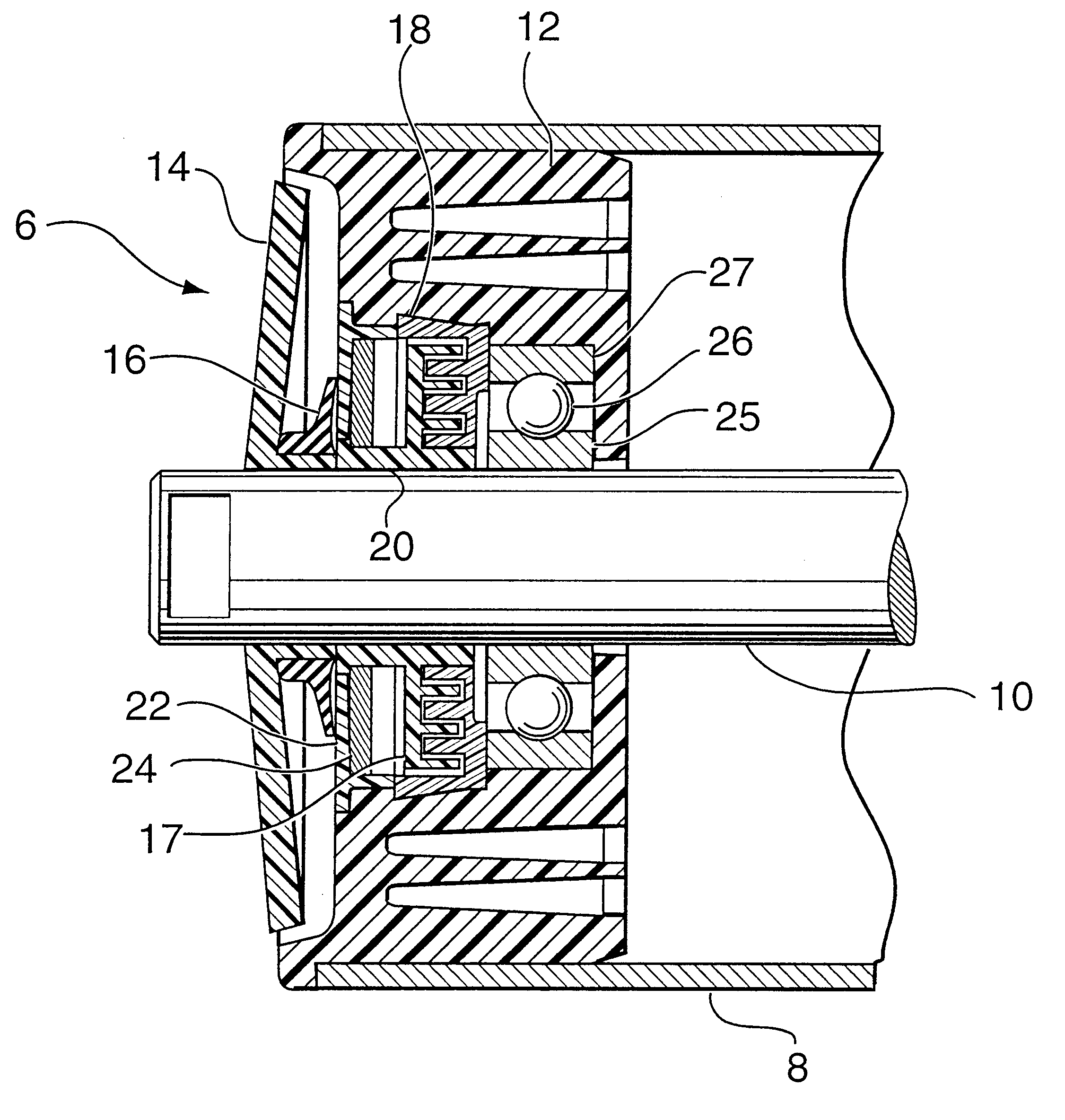

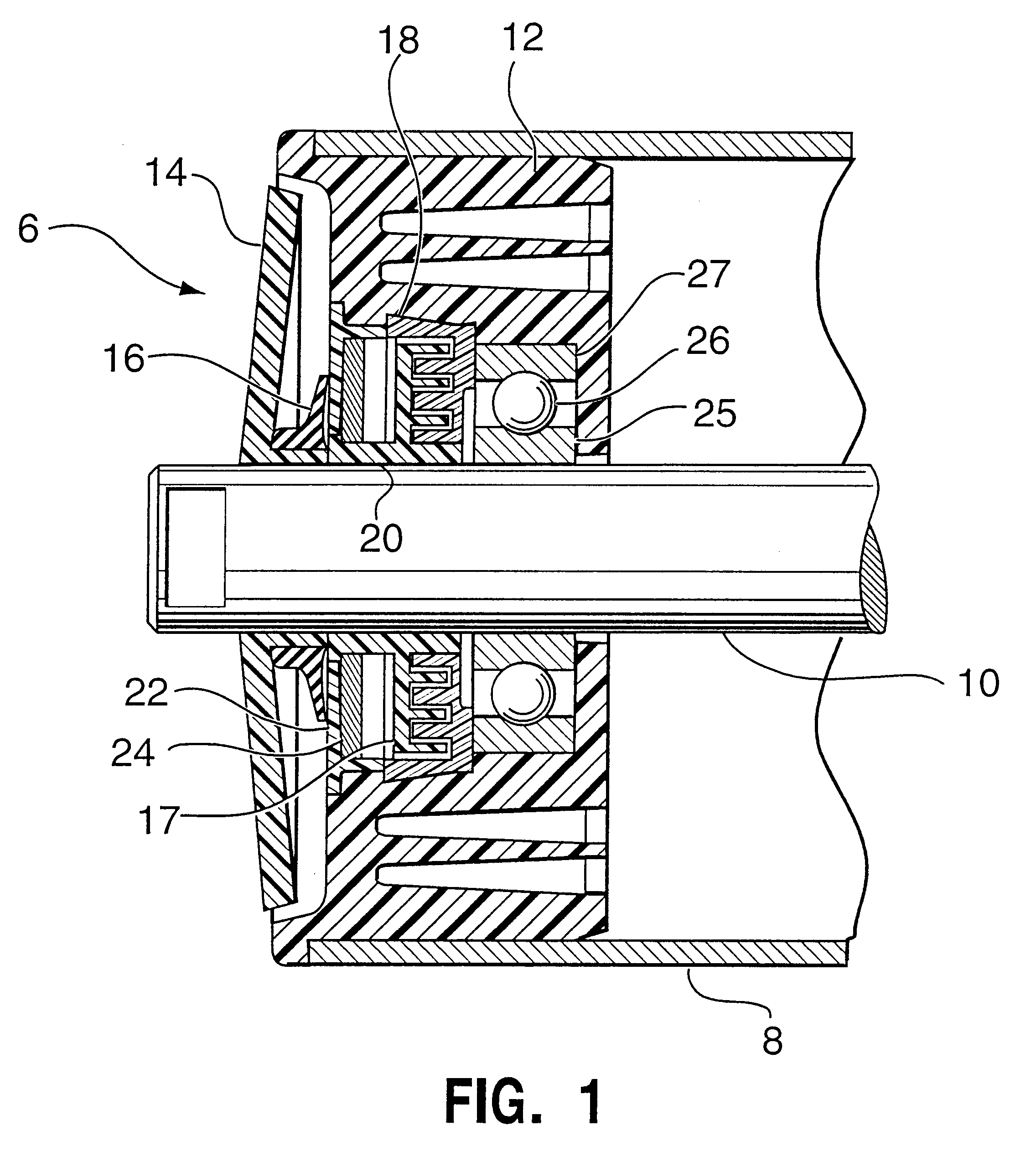

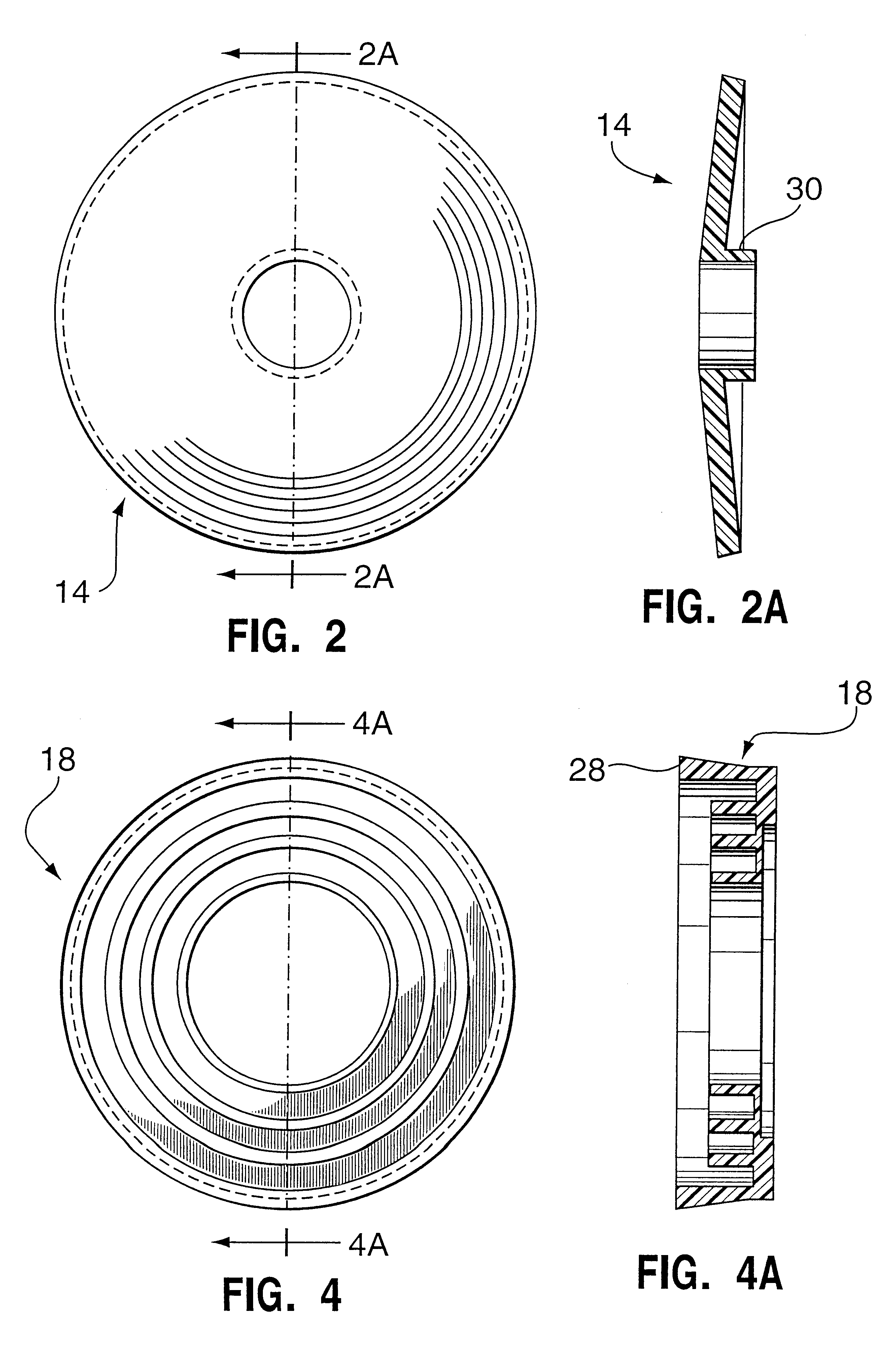

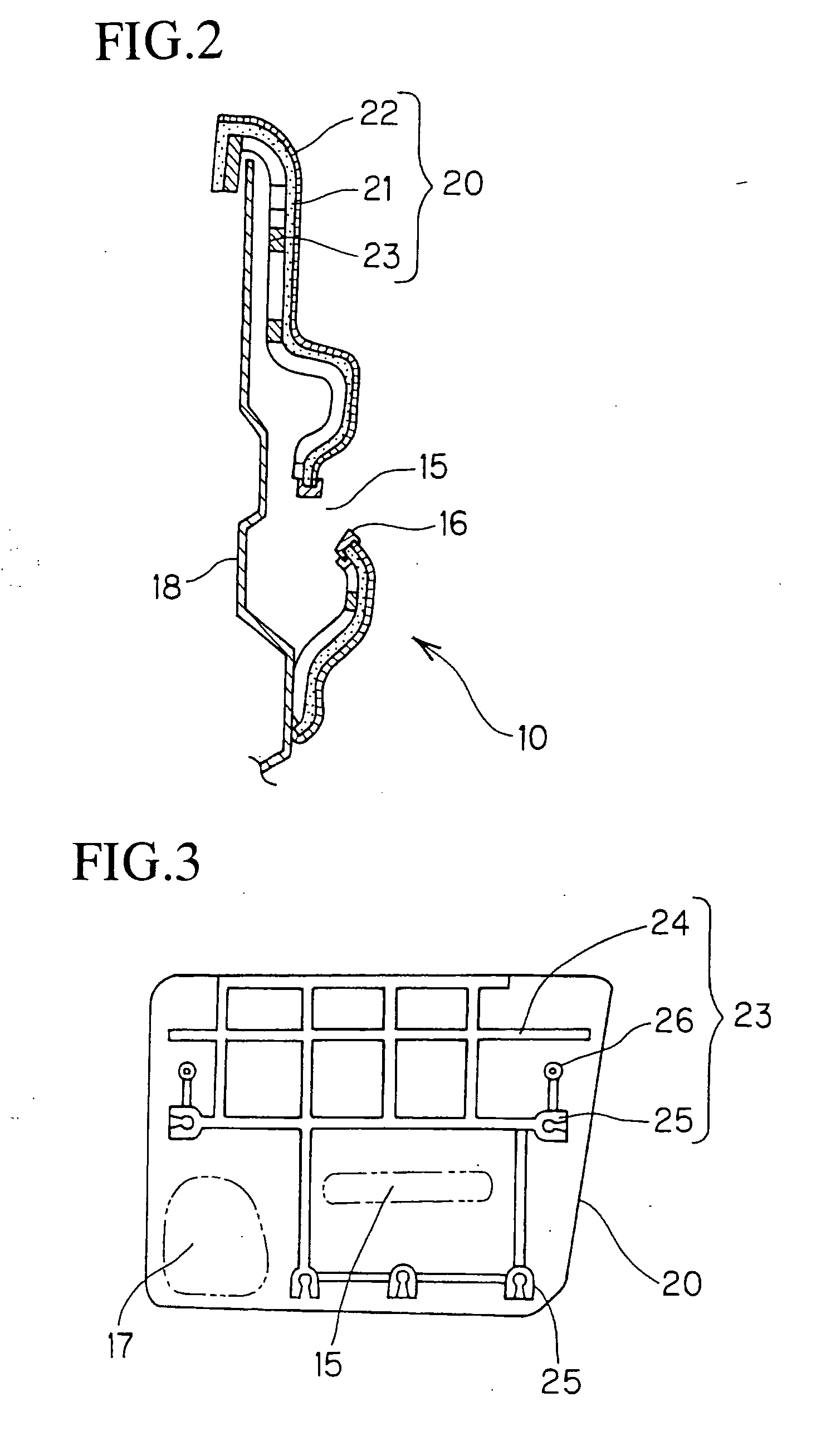

Cleaning device, process cartridge, cleaning member and electrophotographic image forming apparatus

InactiveUS7158749B2Reduce the overall heightImprove support strengthElectrographic process apparatusEngineeringImaging equipment

Owner:CANON KK

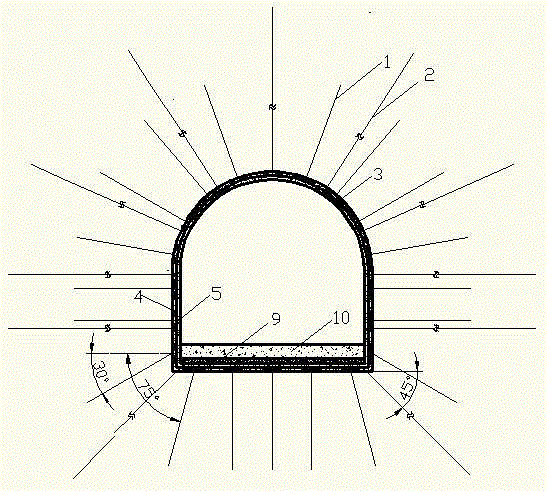

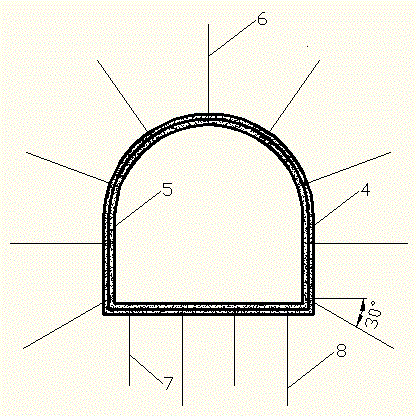

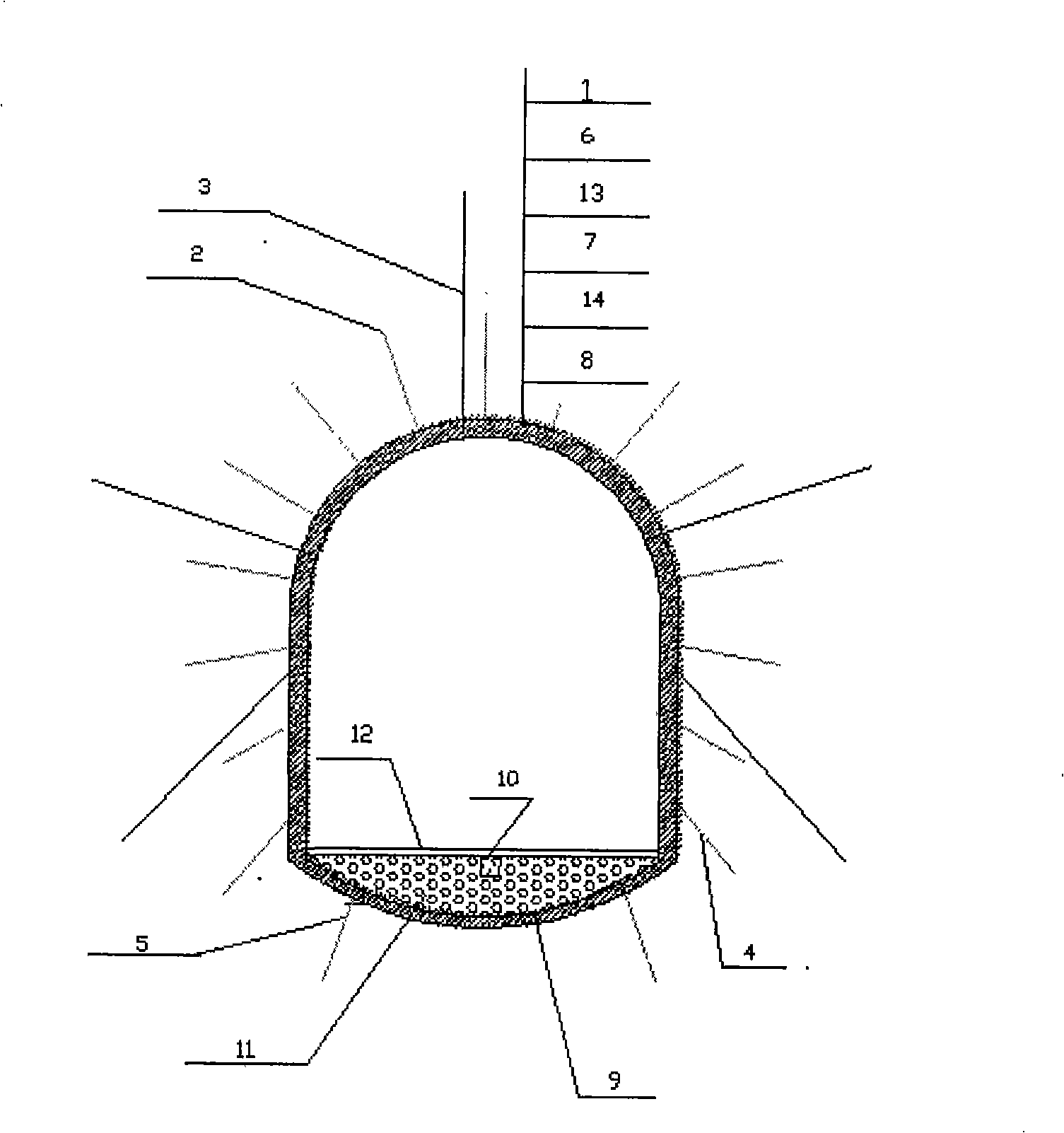

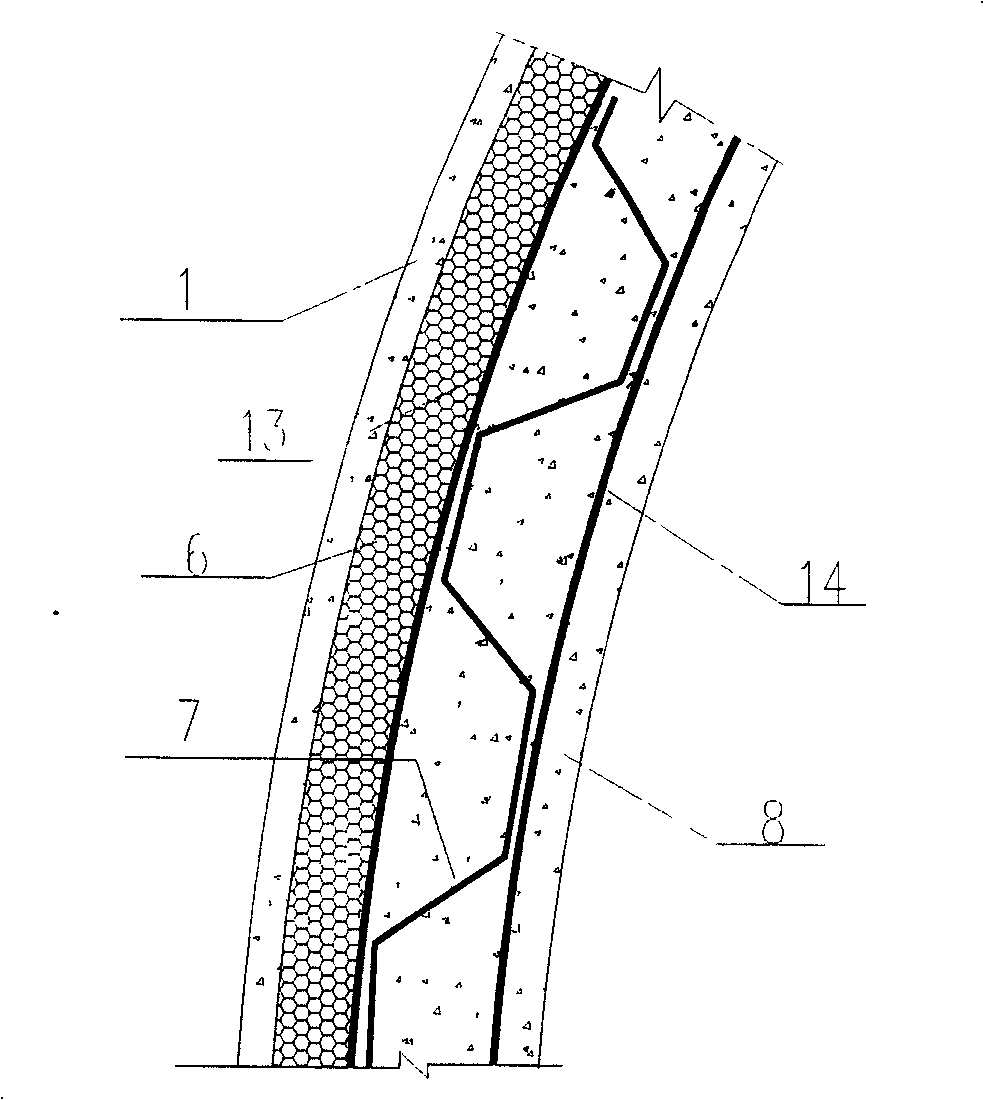

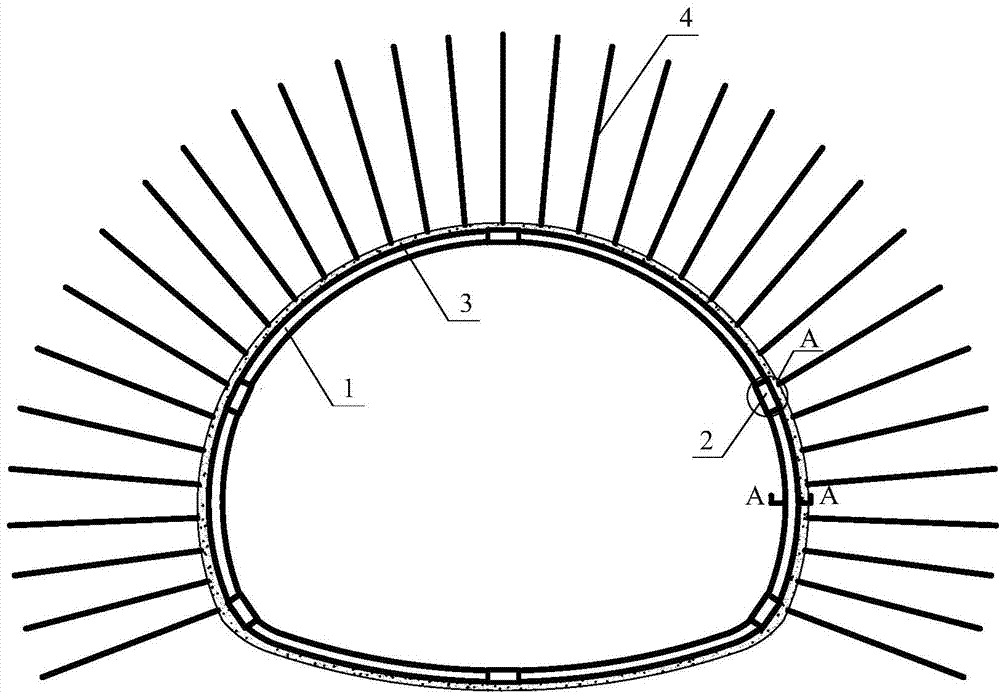

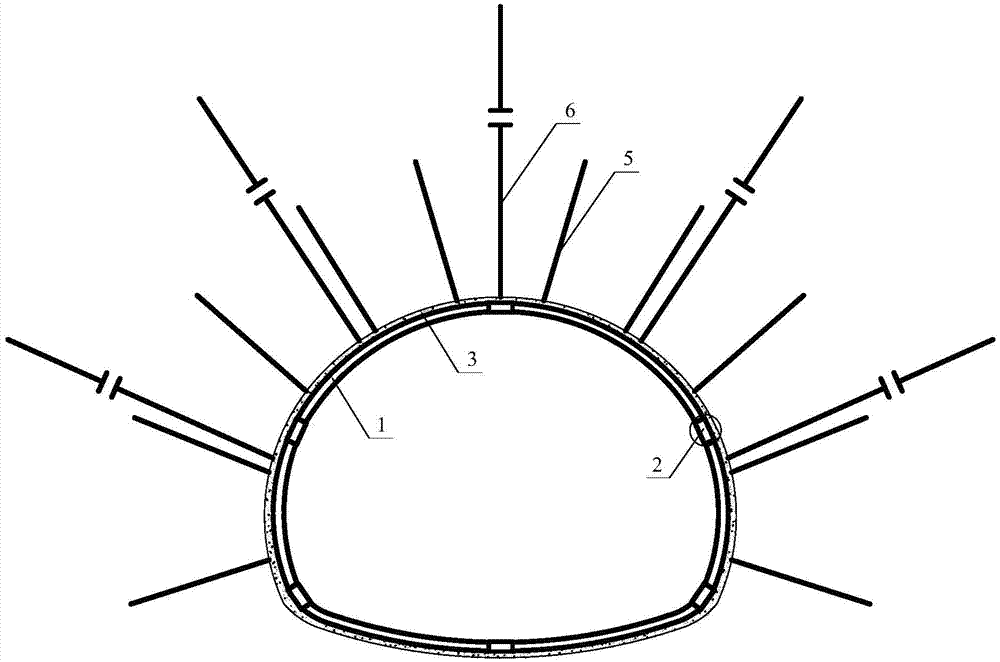

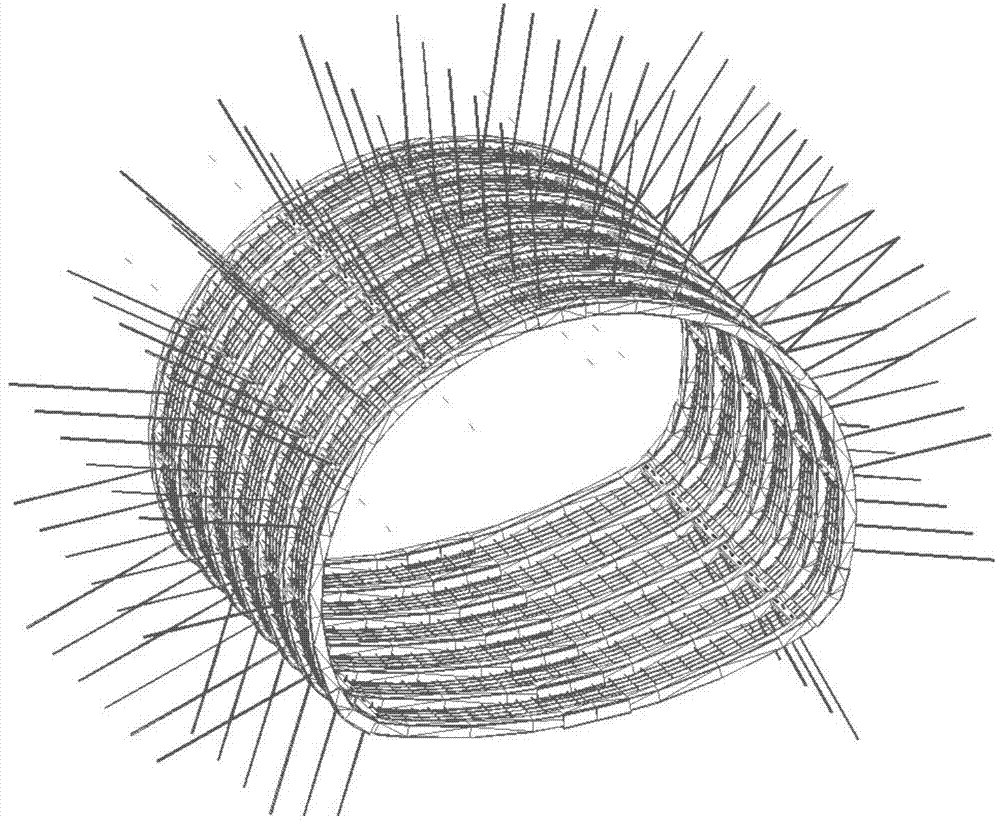

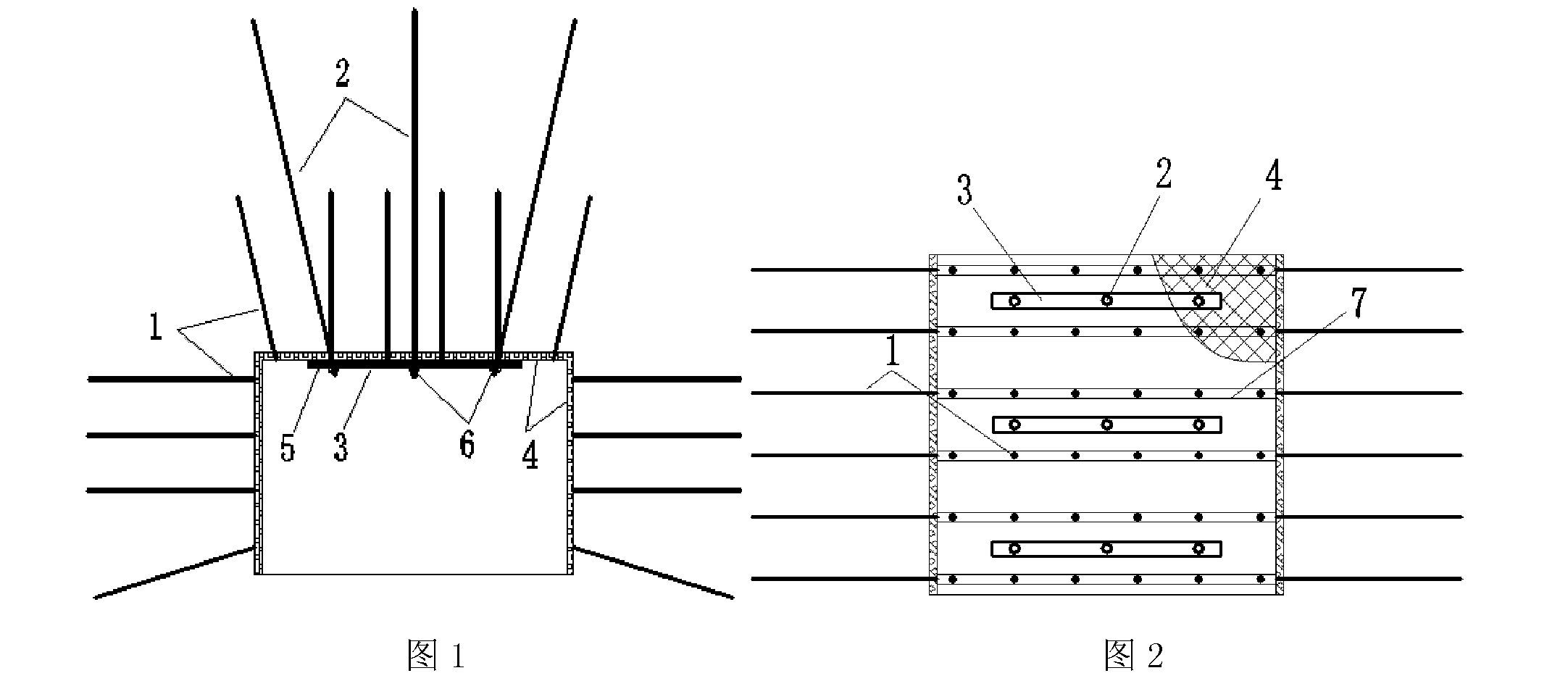

Total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for incompact and fractured soft-rock roadway

InactiveCN105178981AImprove support strengthWatch protection effect is goodUnderground chambersTunnel liningCouplingStructure of the Earth

The invention relates to a total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for an incompact and fractured soft-rock roadway. On the basis of a multilayered cooperative supporting principle, a spraying net combined isolating arch, an anchor rod extruding reinforcing arch, a total-section closed type grouting reinforcing ring and a deep slurry diffusion reinforcing arch are respectively formed on surrounding rock of the roadway from shallow to deep finally, and are combined to form a multilayered effective combined arch by a suspension effect of a high-strength grouting anchor cable, advantages of yielding supporting, bolting-grouting supporting and deep-shallow coupling supporting are combined organically, bearing range, integrity and bearing capability of a supporting structure are improved obviously, a control effect on deformation characteristics of large deformation, high speed, long duration, wide destroying range, peripheral pressing, obvious floor heaves and the like of the surrounding rock of the incompact and fractured soft-rock roadway is excellent, and various deformations of the surrounding rock of the incompact and fractured soft-rock roadway are controlled effectively. The total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method is particularly suitable for a large-section incompact and fractured soft-rock roadway of a deep well, is simple in work procedures and low in cost, and has high field promotion and application value; and parallel operation can be realized.

Owner:CHINA UNIV OF MINING & TECH

Soft expansion type wall rock tunnel support method

InactiveCN101493011AIncreased shear strengthImprove stabilityUnderground chambersTunnel liningCushionLower intensity

The invention discloses a support method of a weak expansion type surrounding rock laneway, comrprising the following steps: A. the laneway is excavated according to the sectional form, an arc pit is excavated on a bottom board of the laneway, and full face injection of a thick concrete leveling course is carried out; B. high-strength prestressed anchor and prestressed anchor cable are used for supporting the surrounding rock, an anchor rod and an anchor cable are constructed, a high-strength prestressed anchor rod uses a laevo rod body without longitudinal bar and is arranged in plum blossom shape; C. a foam cushion is laid, and the full face of the laneway is tightly stuck and paved with an initial ejection leveling course, and a gap is added and preserved in case of laneway deformation; D. a first layer of reinforcement mat is hung and tightly stuck to the foam cushion, a full face sealed type steel bar grid arching is constructed, the main bar inside the grid is bonded with the first layer of reinforcement mat, and the second layer of reinforcement mat is hung on the sealed type steel bar grid arching; E. the bottom board is constructed, a cast-in-place concrete gutter is constructed at the center part of a positive arching, and rubbles are paved at the both sides of the gutter. The method solves the problems of low intensity of surrounding rock laneway, water expansion and floor heave, thereby avoiding reclamation work of the laneway and having low cost.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

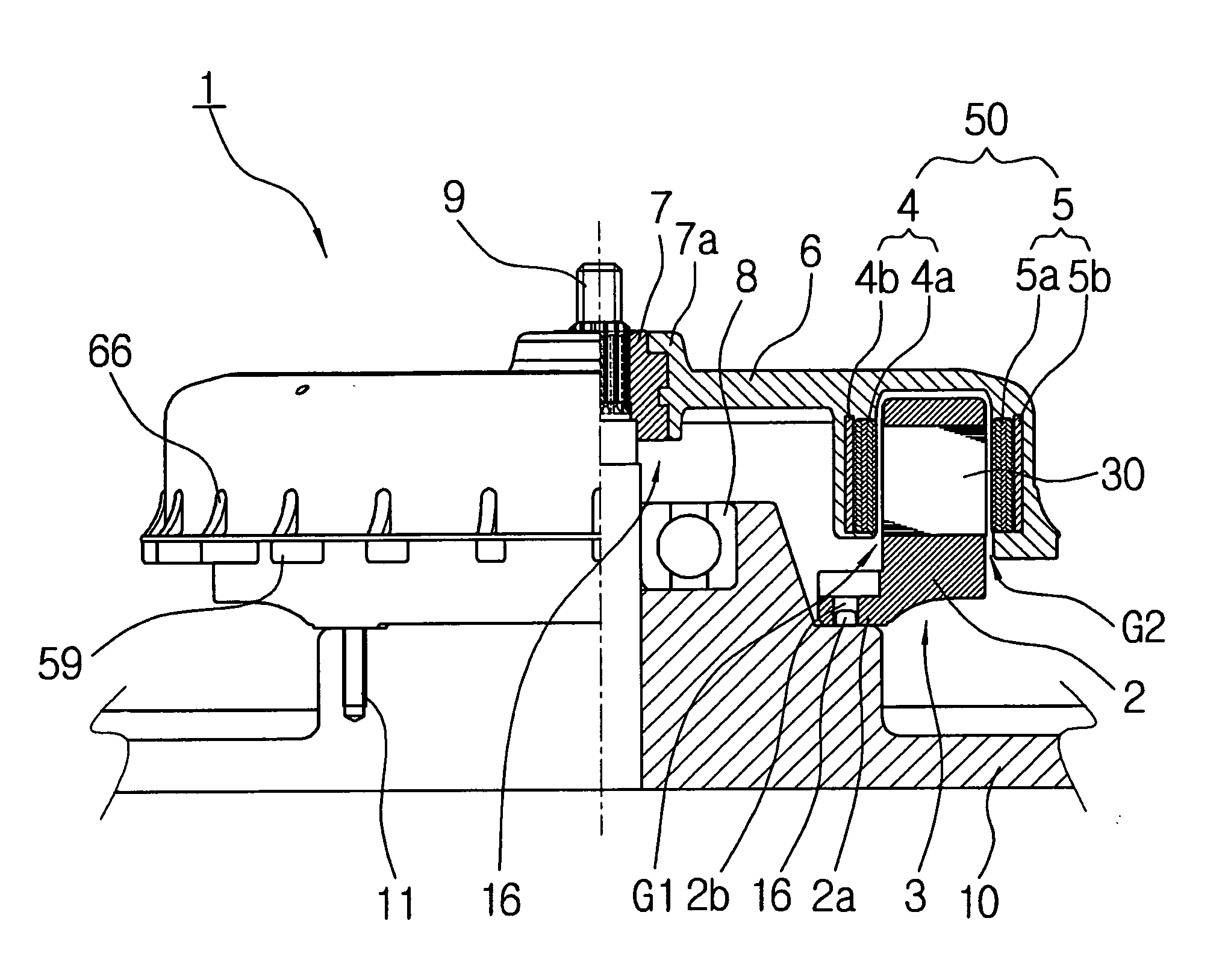

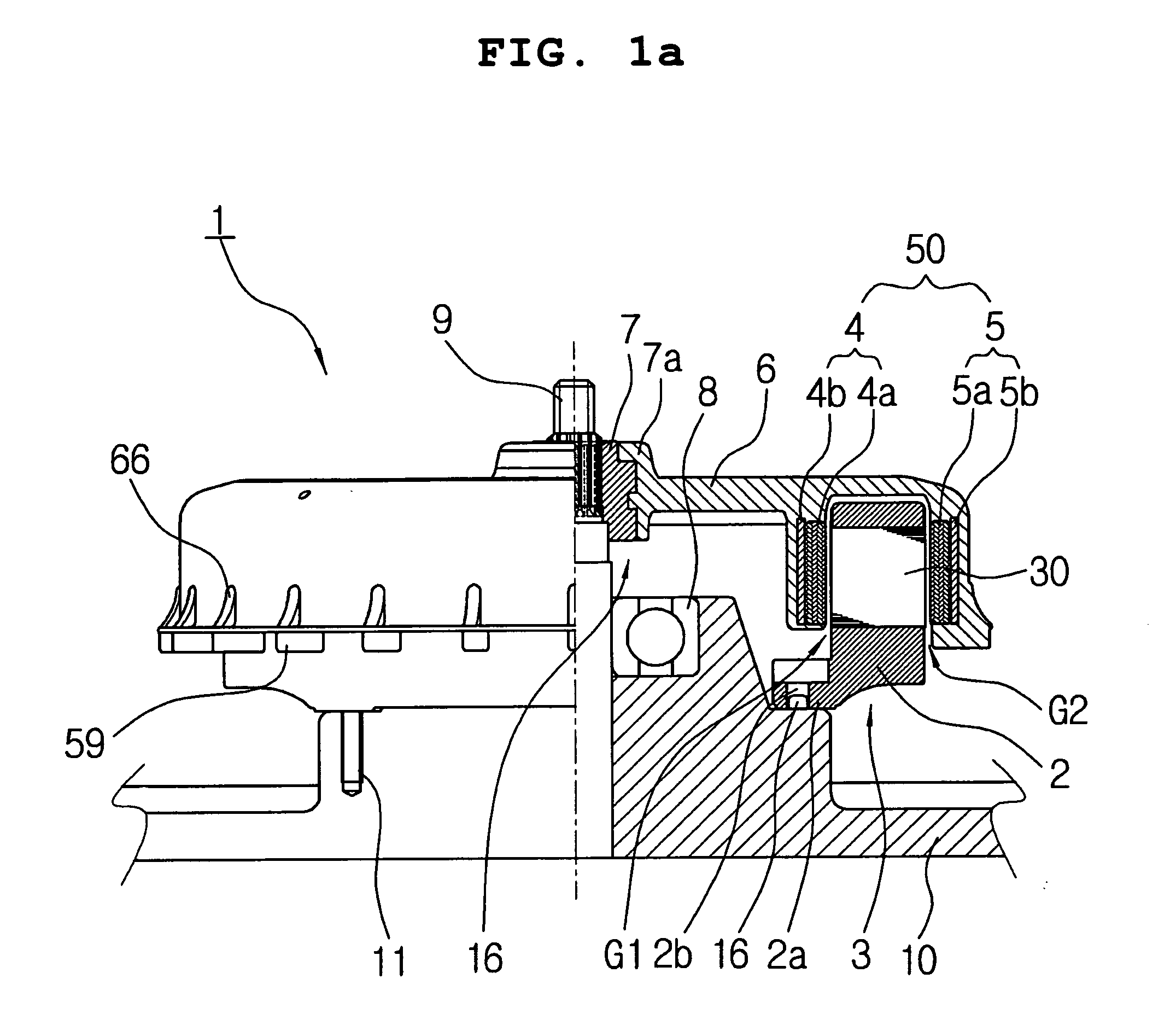

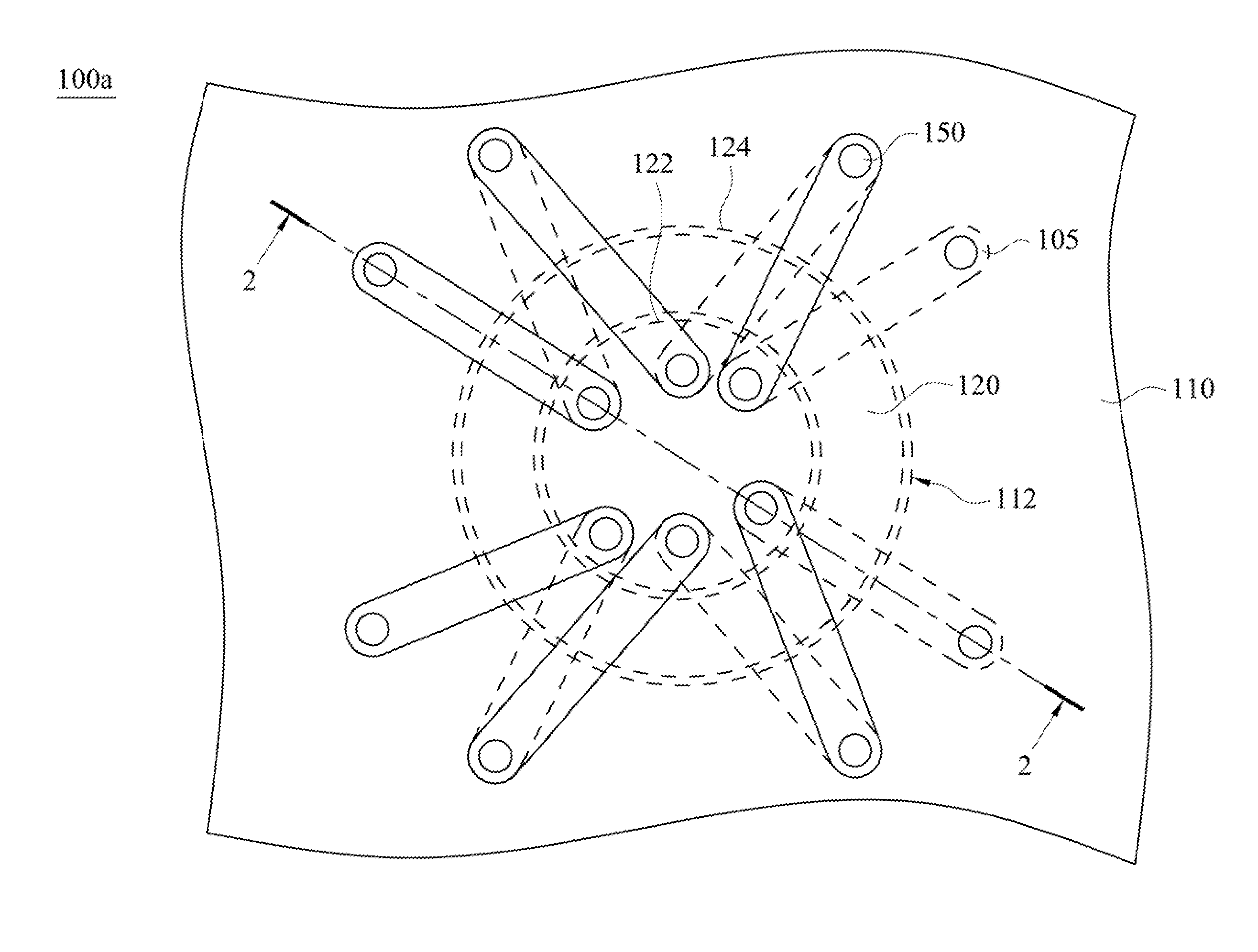

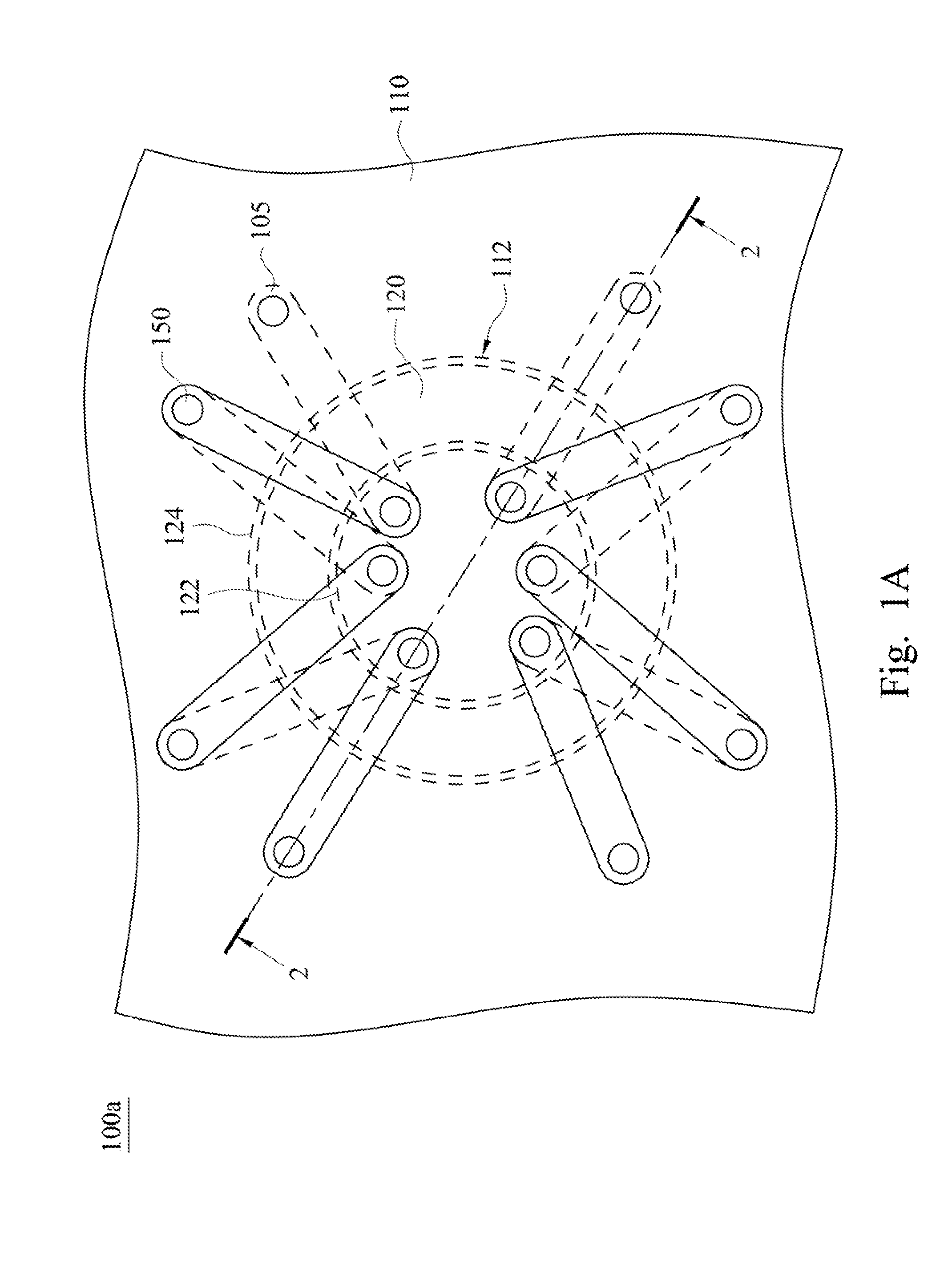

Method of making integrated stator, brushless direct-current motor of radial core type double rotor structure using the integrated stator, and method of making the same

InactiveUS20070236099A1Improve assembly productivityImprove support strengthSynchronous generatorsMagnetic circuit rotating partsStatorEngineering

Provided are a radial core type brushless direct-current (BLDC) motor and a method of making the same, having an excellent assembly capability of division type stator cores in a double rotor structure BLDC motor. The BLDC motor includes a rotational shaft, an integrated double rotor including an inner rotor and an outer rotor, and a rotor supporter wherein a trench type space is formed between the inner rotor and the outer rotor, and an end extended from the inner rotor is connected with the outer circumferential surface of a bushing combined with the rotational shaft, and an integrated stator wherein one end of the stator is disposed in the trench type space and an extension axially extended from the other end of the integrated stator is fixed to the housing of the apparatus. In the integrated stator, U, V, W phase coil assemblies are formed of a number of core groups including a number of division type cores, wherein for each phase coil assembly, the division type core groups of the U, V, W phase coil assemblies are alternately disposed in an annular form in sequence of the phases, and the respective division type core groups are integrally formed into a single body in annular form by a stator support.

Owner:AMOTECH

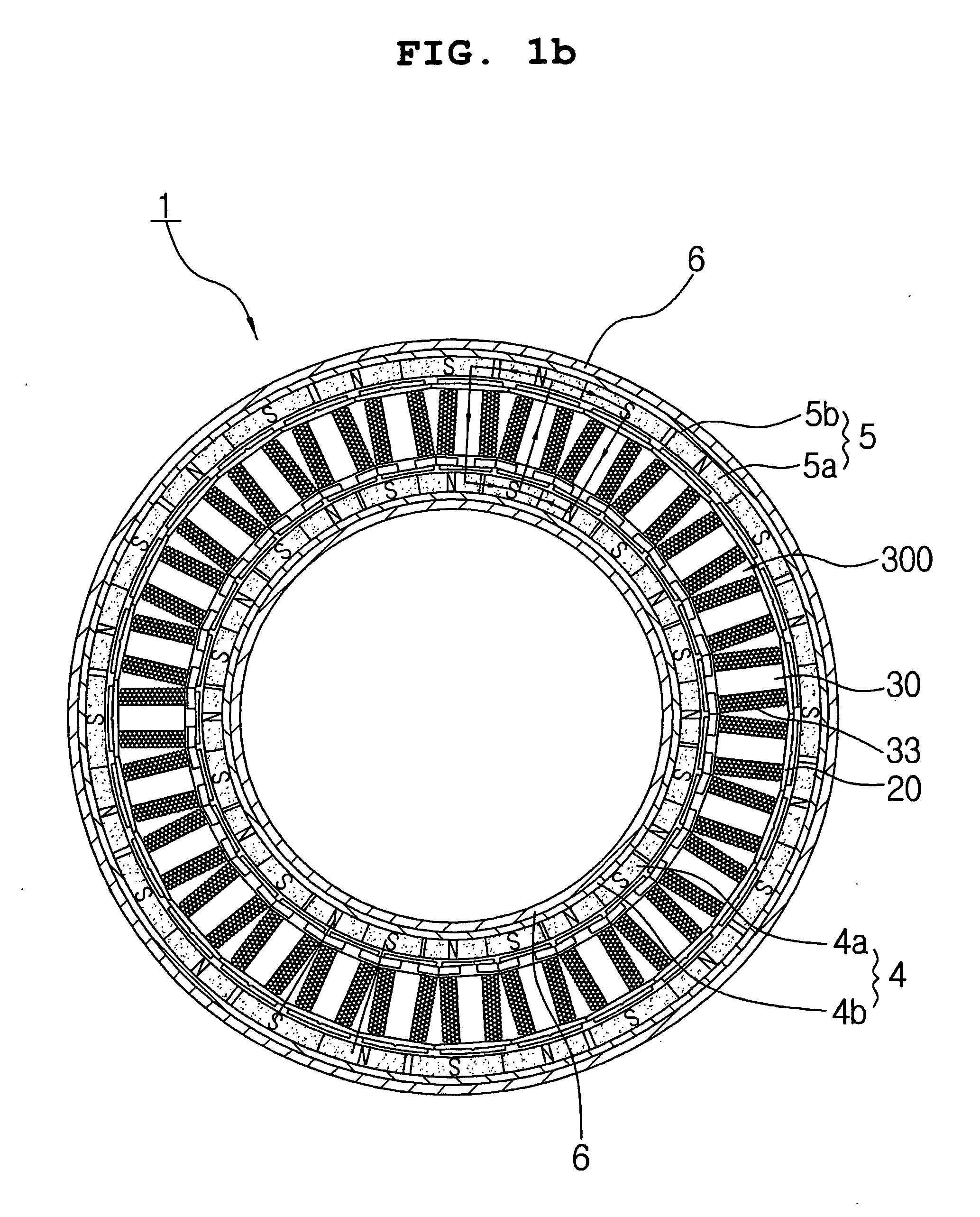

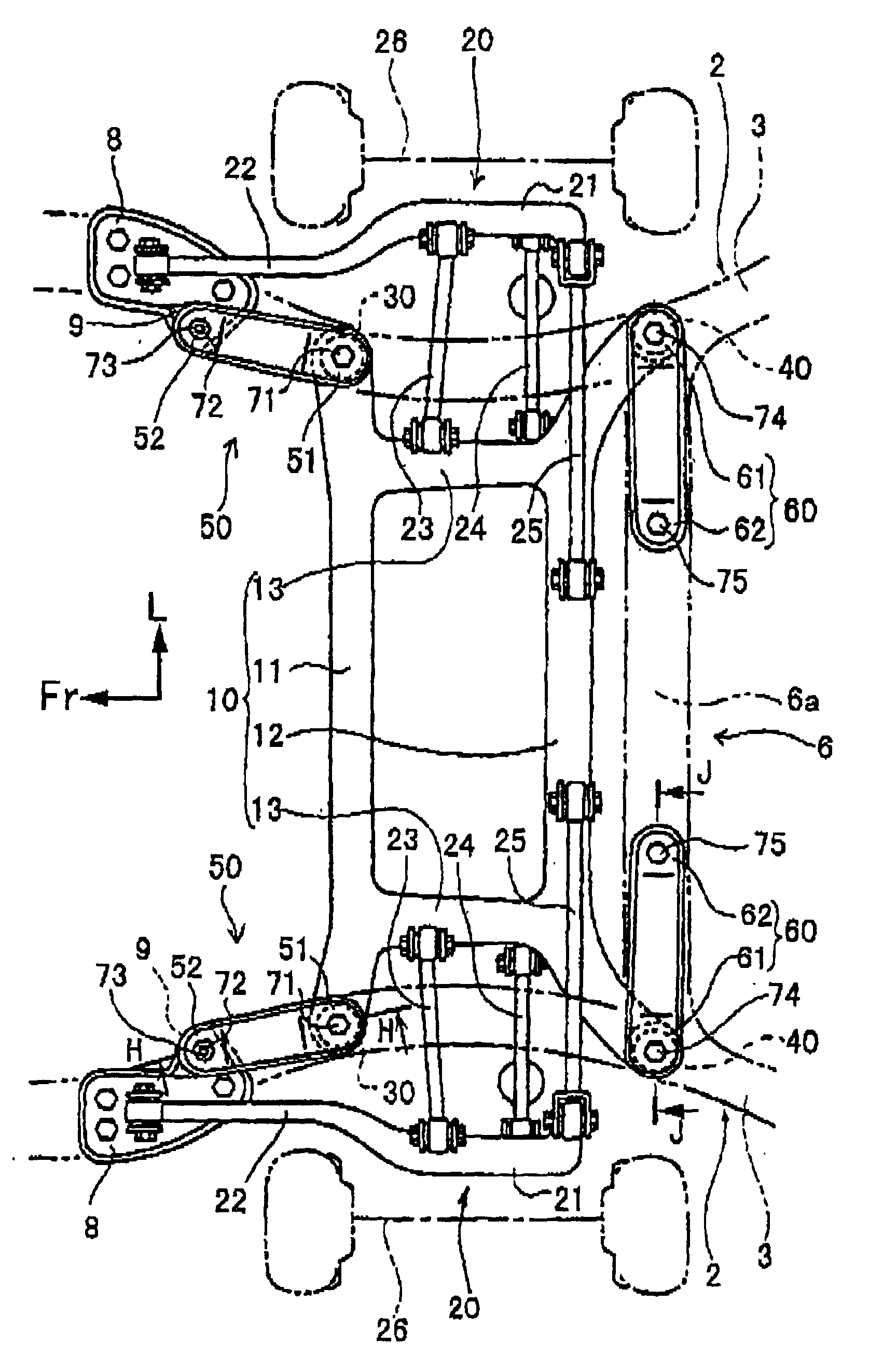

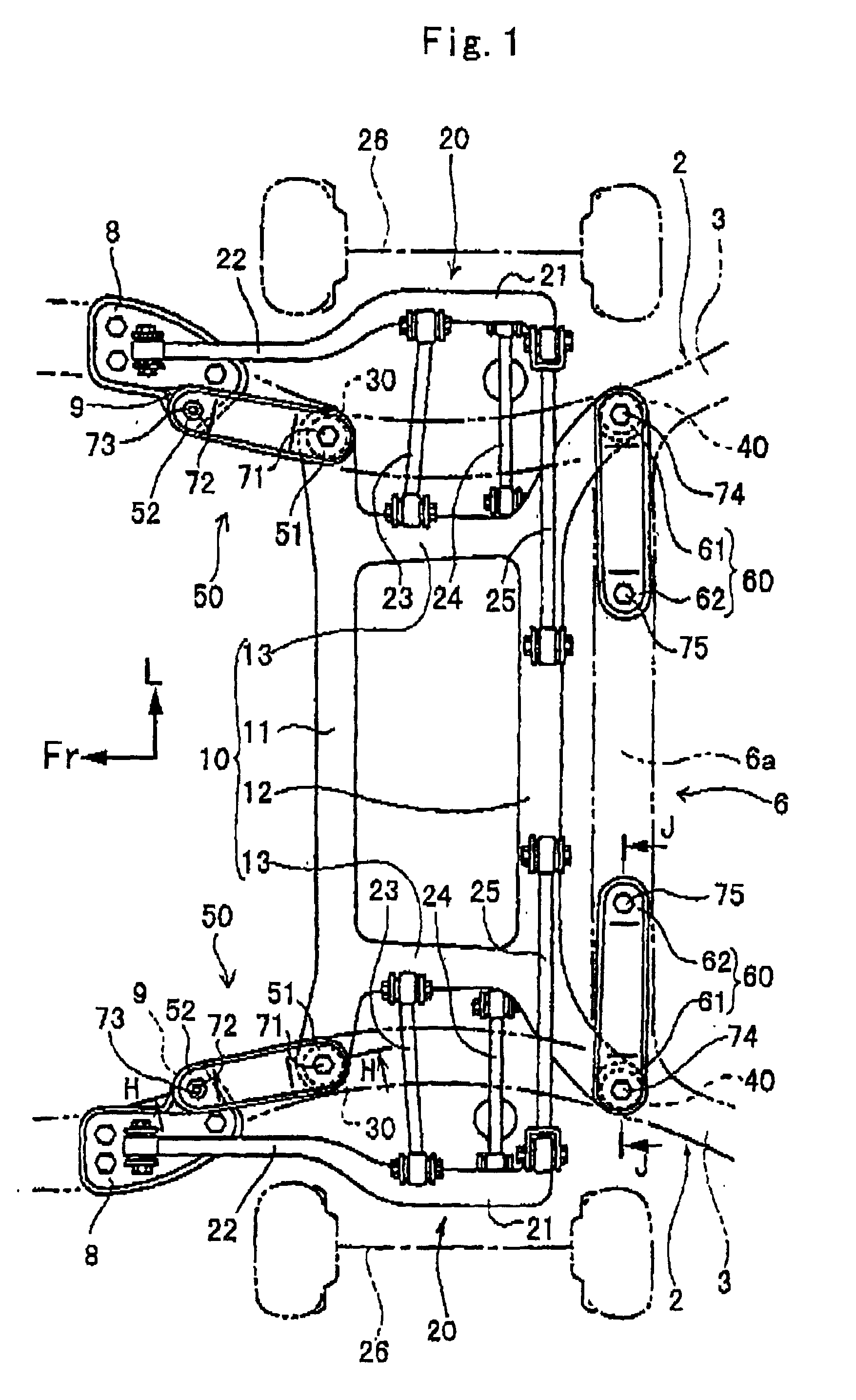

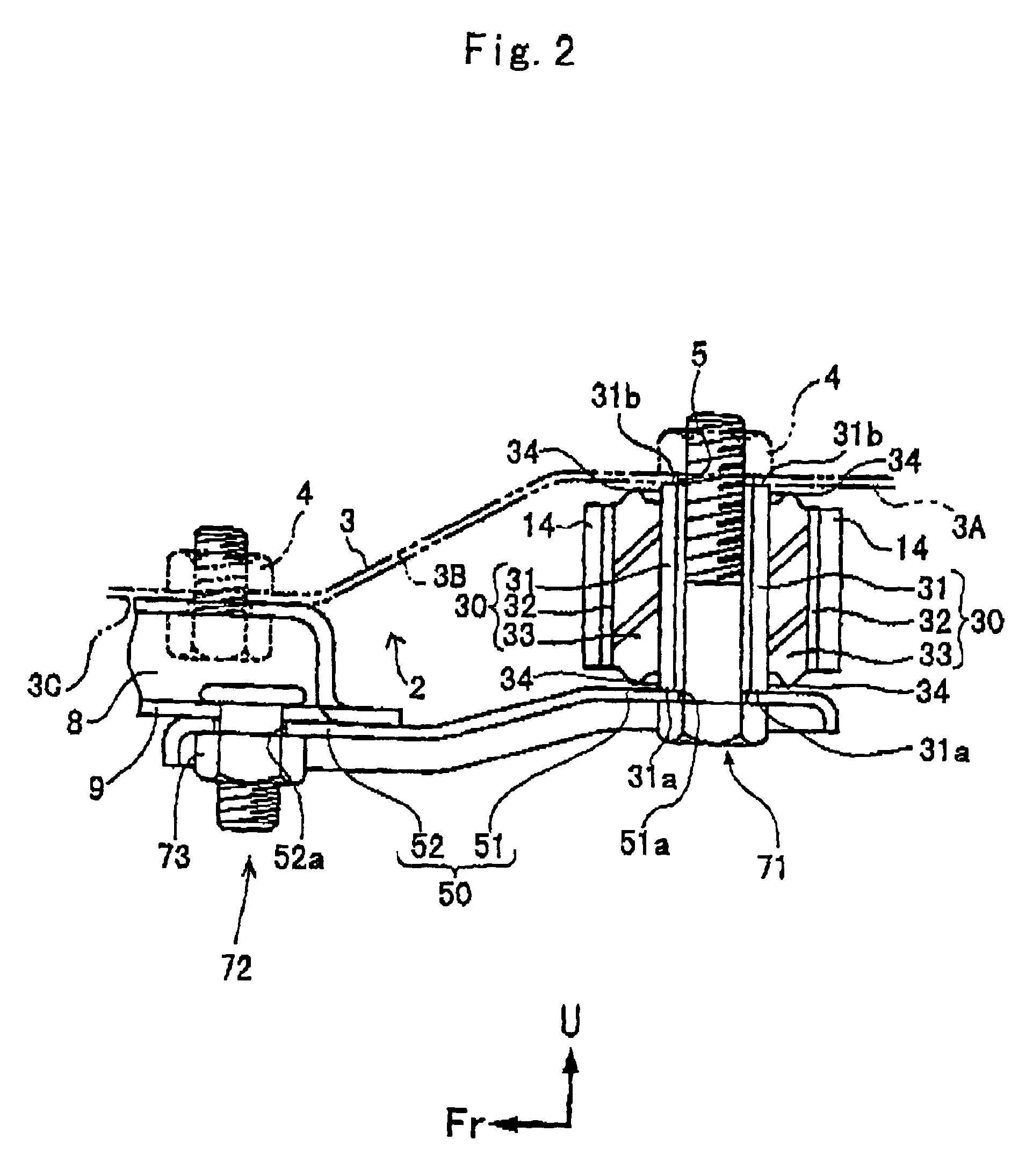

Supporting structure of sub-frame in suspension system for vehicle

InactiveUS6869090B2Improve productivityImprove rust resistanceVehicle body-frame connectionsSteering linkagesFistVehicle frame

A supporting structure of a sub-frame for a suspension system contains a body frame, a sub-frame, elastic bushings, each having an inner cylinder having a lower edge. And an outer cylinder and an elastic member are interposed between the inner and outer cylinders. The sub-frame is supported on the body frame via the elastic bushings, at least one of first stay extends along the body frame, and at least one second stay extends along the body frame in a different direction from the first stay. Both ends of each of the fist and second stays respectively are supported on the lower edge of the inner cylinder and the body frame.

Owner:SUBARU CORP

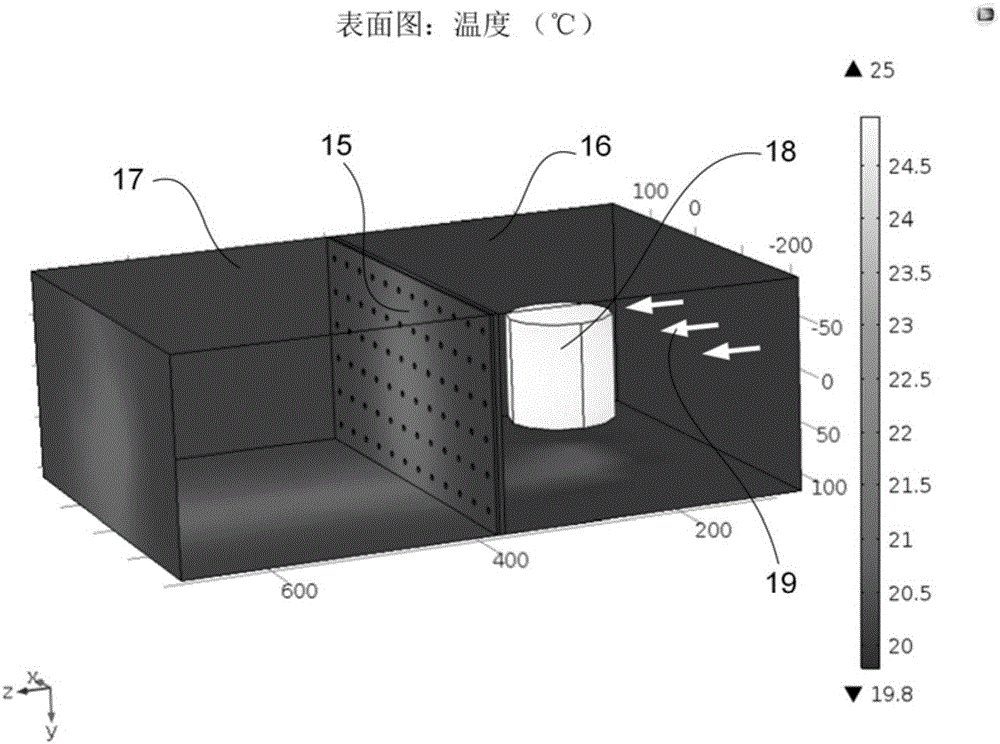

Sound-insulating, ventilating and heat transfer enhancing acoustic metamaterial unit, composite structure and preparation method

ActiveCN105845121AWorking frequency bandwidthImprove sound insulationStringed musical instrumentsSound producing devicesEngineeringComposite plate

The invention relates to a sound-insulating, ventilating and heat transfer enhancing acoustic metamaterial structural unit, which comprises a frame, wherein a restraining body is arranged inside the frame, and at least one of the upper and lower surfaces of the frame is coated with a thin film; and at least one hole is formed in the restraining body and the thin film. In addition, the invention provides an acoustic metamaterial composite plate and an acoustic metamaterial composite structure comprising the acoustic metamaterial structural unit, as well as a frequency modulation method and an assembly method. The acoustic metamaterial structural unit has sound insulation capability superior to that of an ordinary perforated plate or micro-perforated plate within a broadband, can ensure that sufficient heat flow, air flow or liquid flow can pass through smoothly, and increases heat diffusion rate of fluid media on both sides of holes and accelerates heat convection efficiency through unit localized vibration generated by the structure under excitation of acoustic waves. The acoustic metamaterial structural unit and the array composite structure have the advantages of simple assembly technology and stable working performance.

Owner:黄礼范

Female terminal fitting and method of assembling such terminal fitting

InactiveUS7094114B2Sufficient widthIncrease contact pressureCoupling contact membersClamped/spring connectionsElectrical and Electronics engineering

Owner:SUMITOMO WIRING SYST LTD

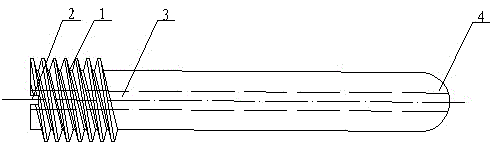

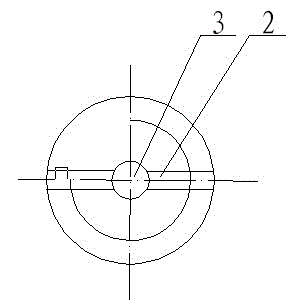

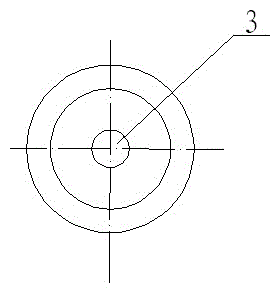

Porous tantalum rod

ActiveCN102743218AEasy to fixIncrease success rateInternal osteosythesisFastenersNeck structureRight femoral head

The invention relates to a medical implant part for femoral head joint surface depression or I-stage or II-stage femoral head necrosis, namely a porous tantalum rod. One end of the implant part is provided with a connection fastening structure connected with a bone tissue, and a through hole is formed in the center of the tantalum rod; the porous tantalum rod is made of a porous tantalum material with a foam structure of pore three-dimensional communicated distribution, and is sintered by adopting a foam impregnation method; and tantalum powder particles have a sinter neck structure on a foam frame formed by accumulating the sintered pure tantalum powder. The through hole in the porous tantalum rod facilitates accurate positioning in an operation; and a related object can be picked out and injected conveniently through the through hole, so that the effect of constant pressure reduction can be achieved.

Owner:CHONGQING RUNZE PHARM CO LTD

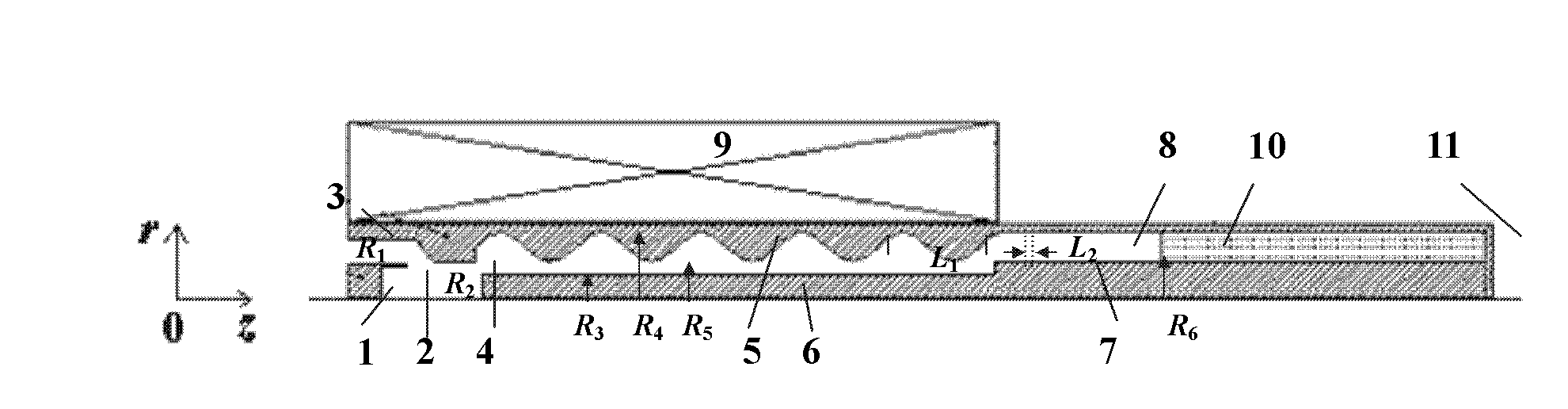

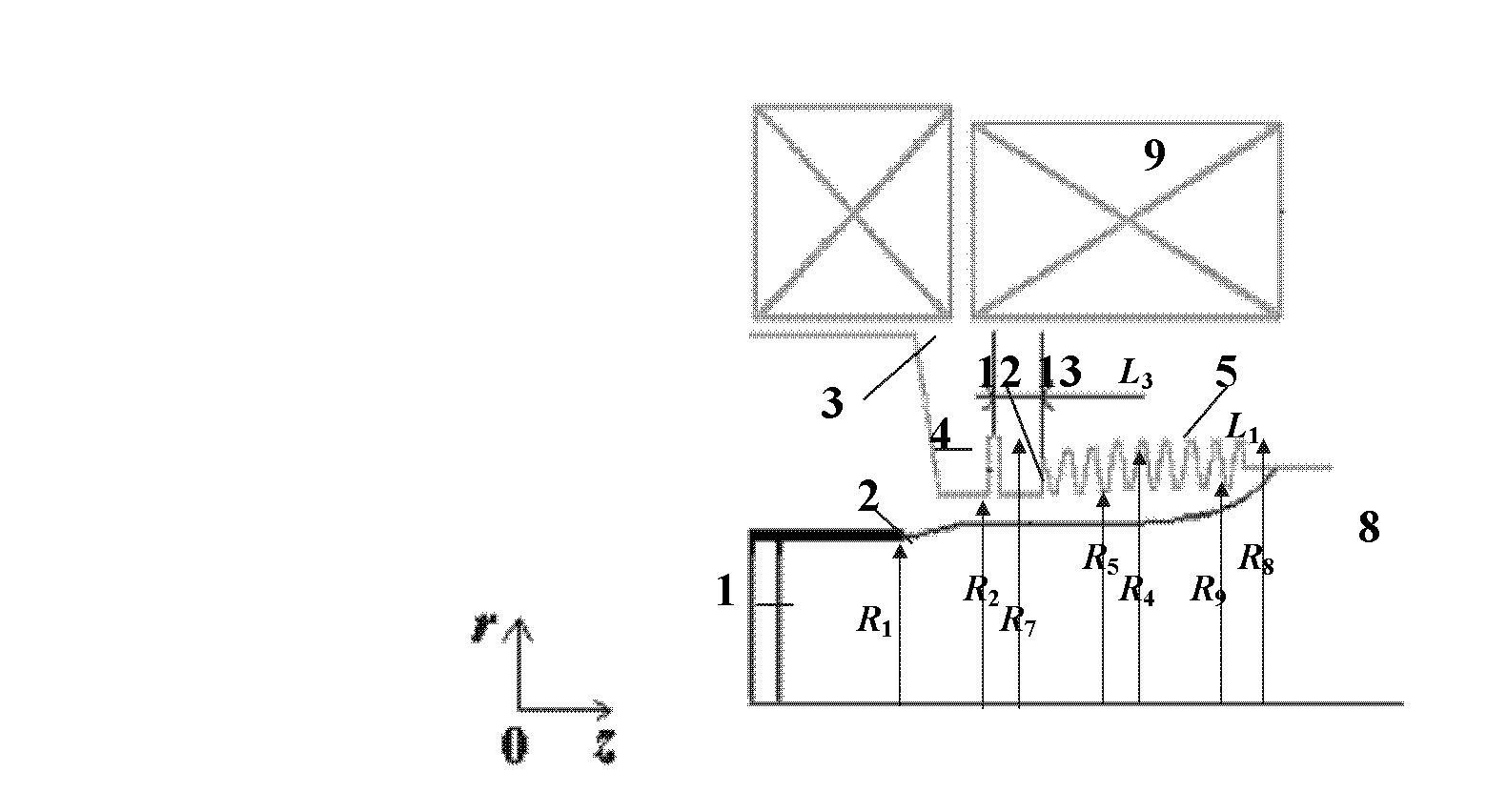

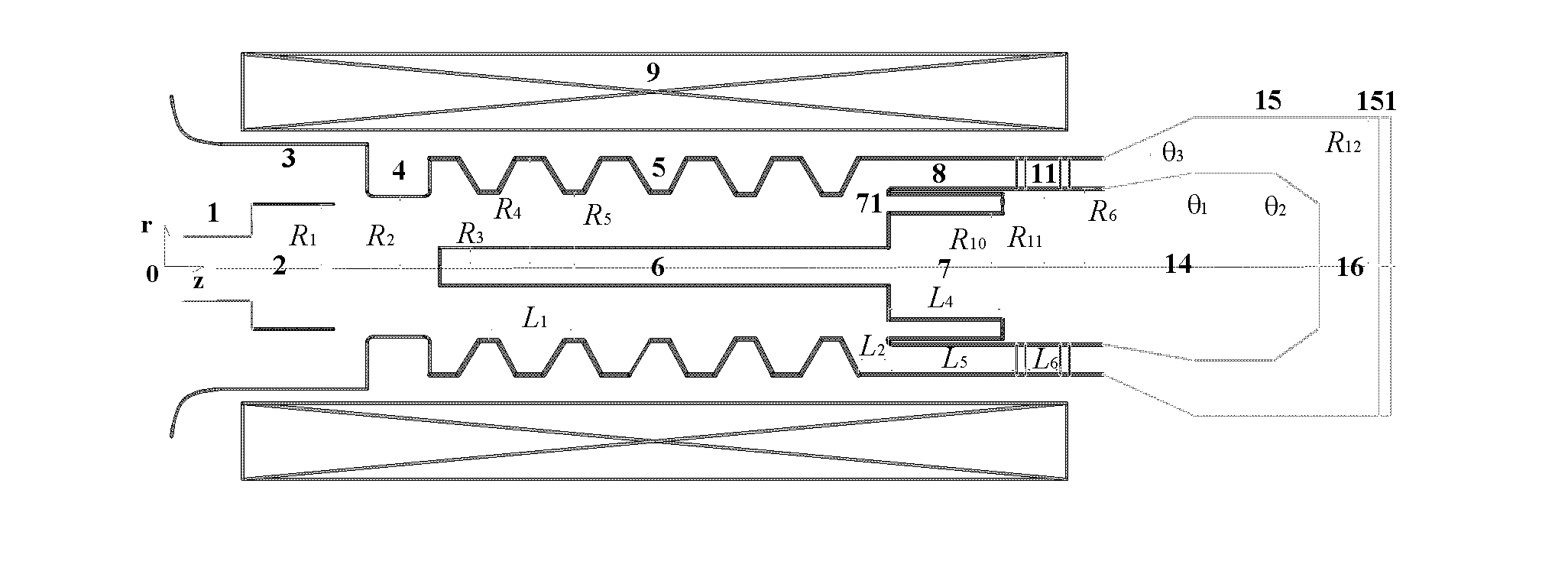

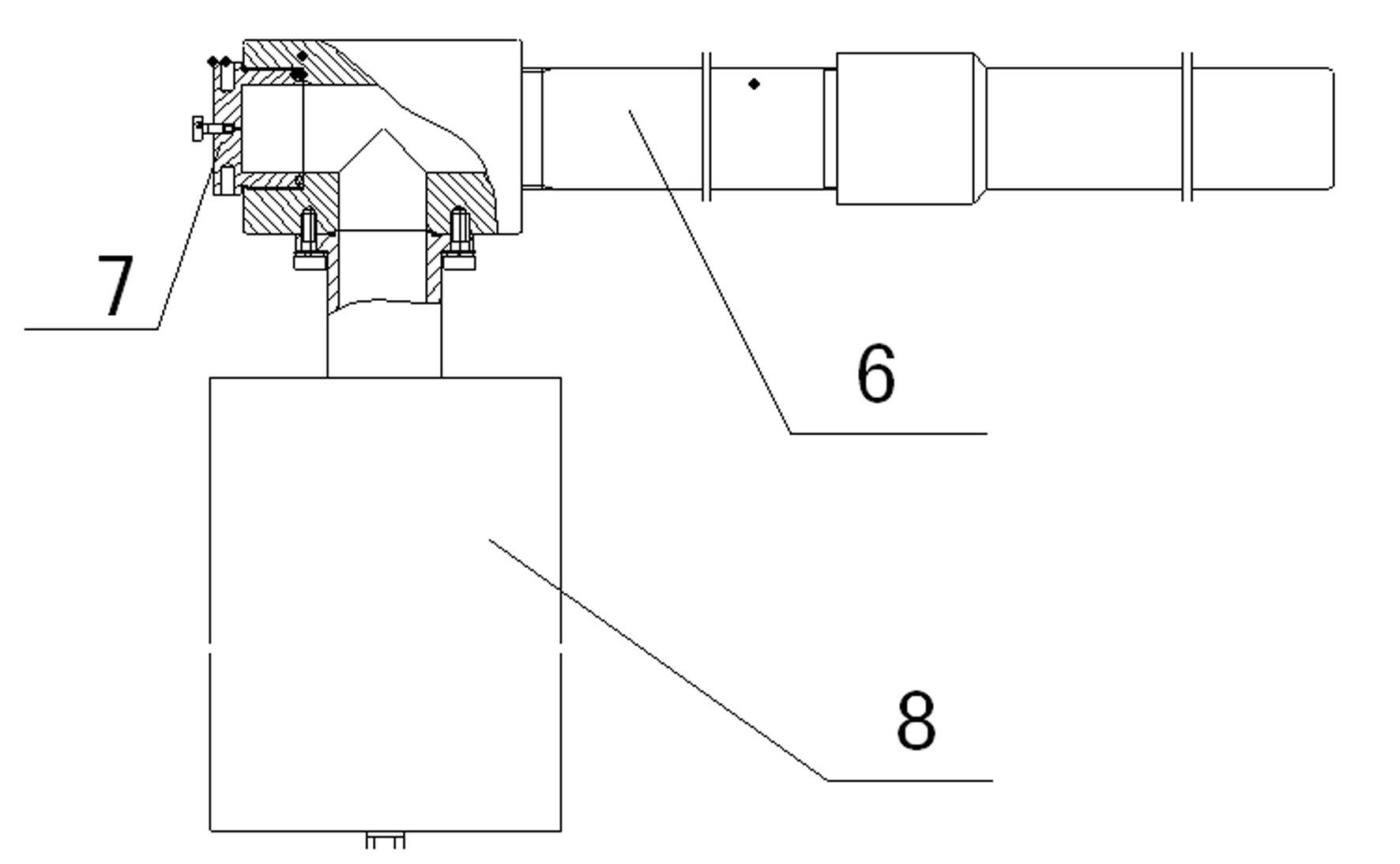

Compact relativity backward wave oscillator (RBWO) with adjustable low-frequency-range frequency

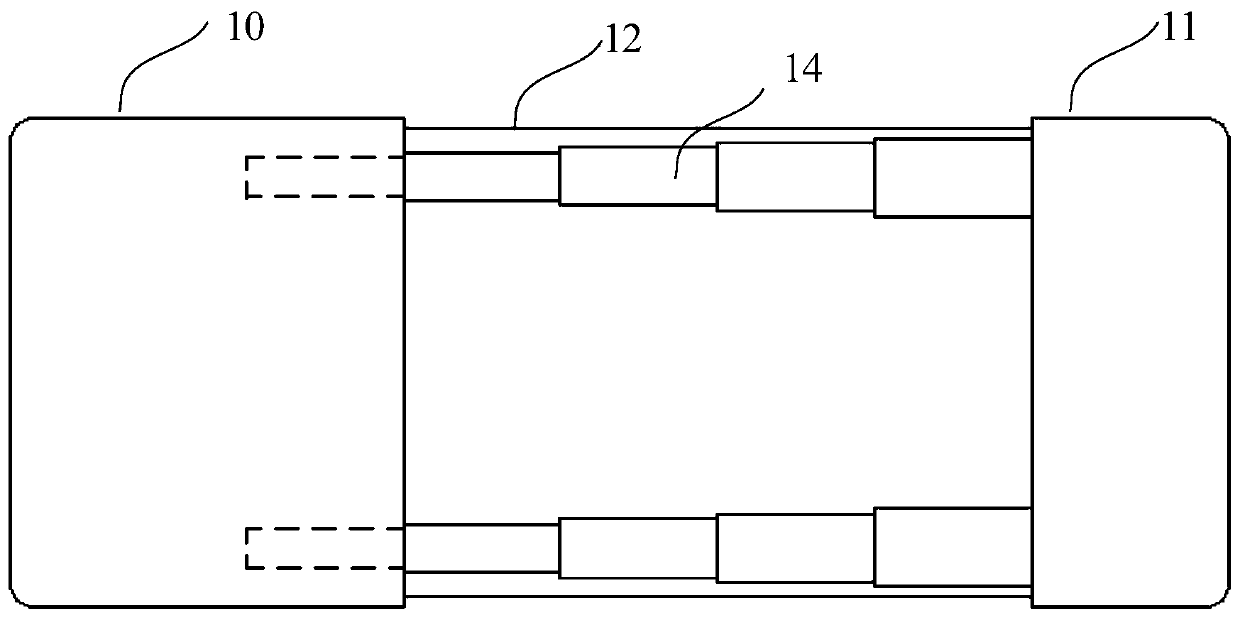

ActiveCN102208315AReduce radial sizeCan be smallTravelling-wave tubesTransit-tube collectorsWave structureElectrical conductor

The invention discloses a compact relativity backward wave oscillator (RBWO) with an adjustable low-frequency-range frequency, and the oscillator provided by the invention is used for solving the problems that the RBWO size in a low frequency range is great, and the output microwave frequency is hard to adjust. The compact RBWO is in rotational symmetry with respect to a central axis, and composed of a cathode base, a cathode, an anode outer barrel, a stop neck, a slow wave structure, an inner conductor, a collector, a microwave output port, a solenoid field, two rows of supporting rods, a mode converter, a radiation port and a sealing plate; the slow wave structure is composed of five slow wave blades, the inner surface of each slow wave blade is in a trapezoid structure; the left end face of the collector is provided with an annular groove; the left end of the mode converter is cylindrical, and the right end of the mode converter is in a tapered structure; the radiation port is cylindrical, the left end of the radiation port is in a tapered structure and the right end of the radiation port is cylindrical; the sealing plate is pressed on the radiation port; and the frequency of the output microwave is adjusted by virtue of adjusting the semi-diameter R3 of the inner conductor. The compact RBWO has the advantages of compact structure and convenient and adjustable work frequency, thereby being beneficial to outputting a long pulse of the microwave.

Owner:NAT UNIV OF DEFENSE TECH

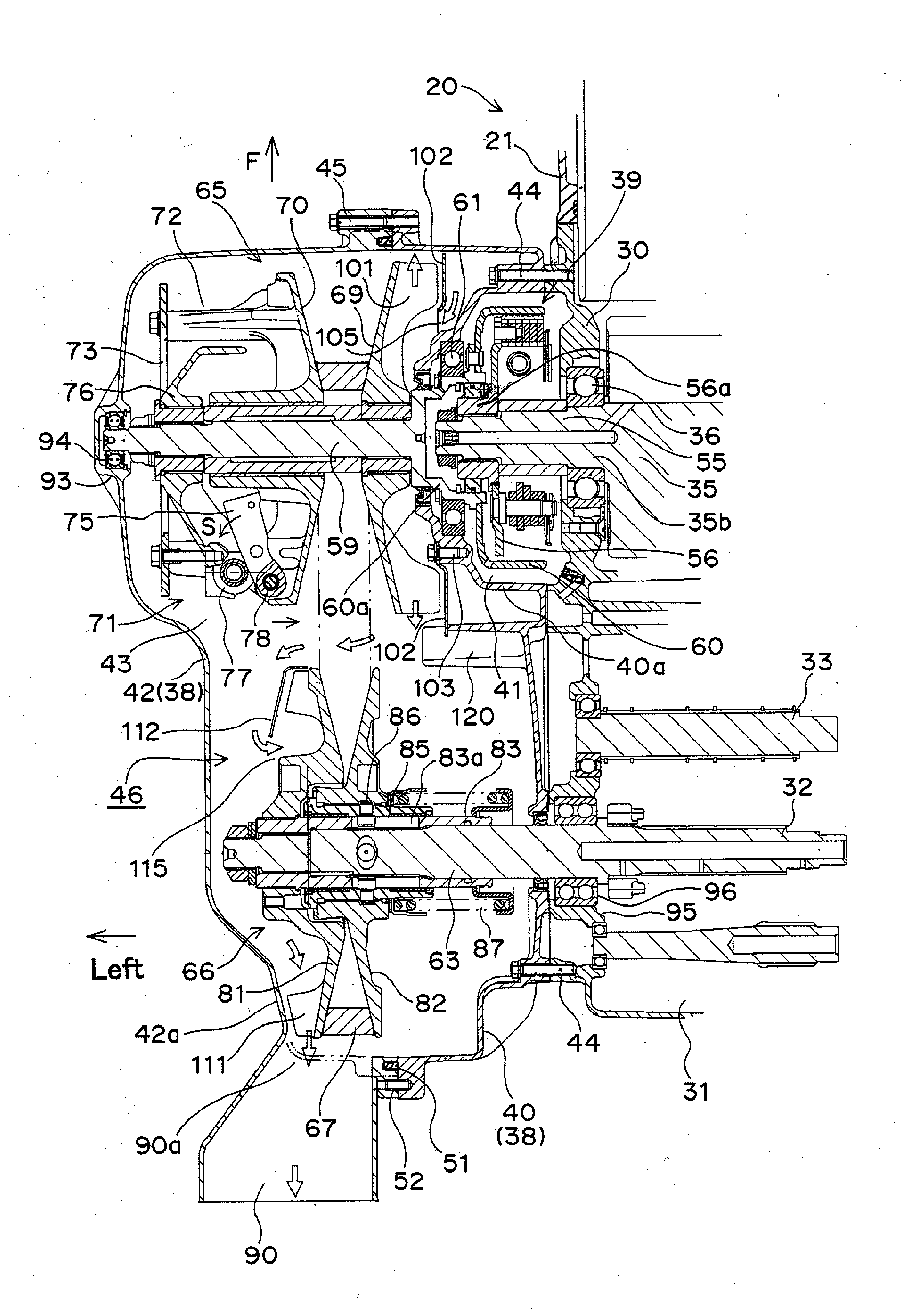

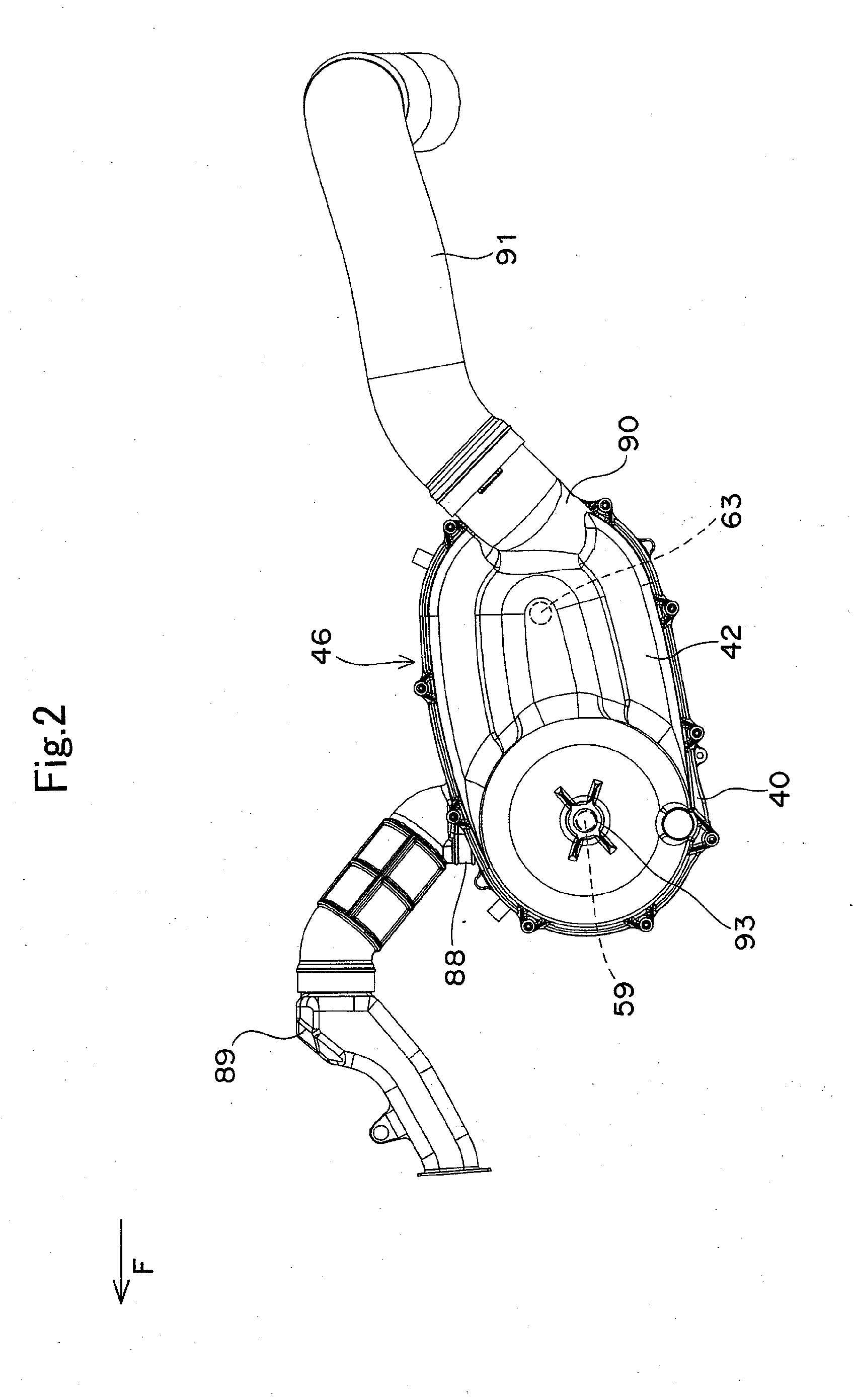

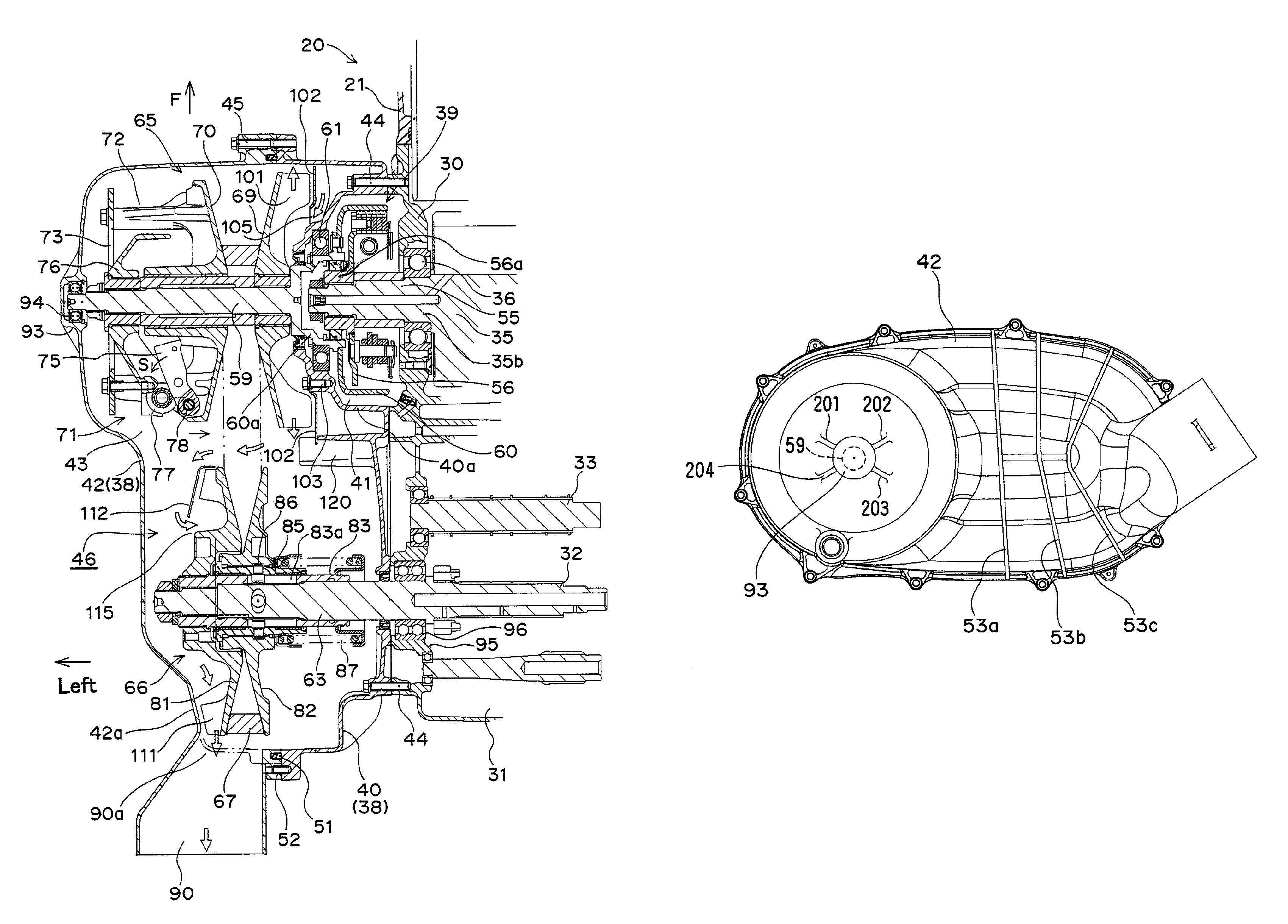

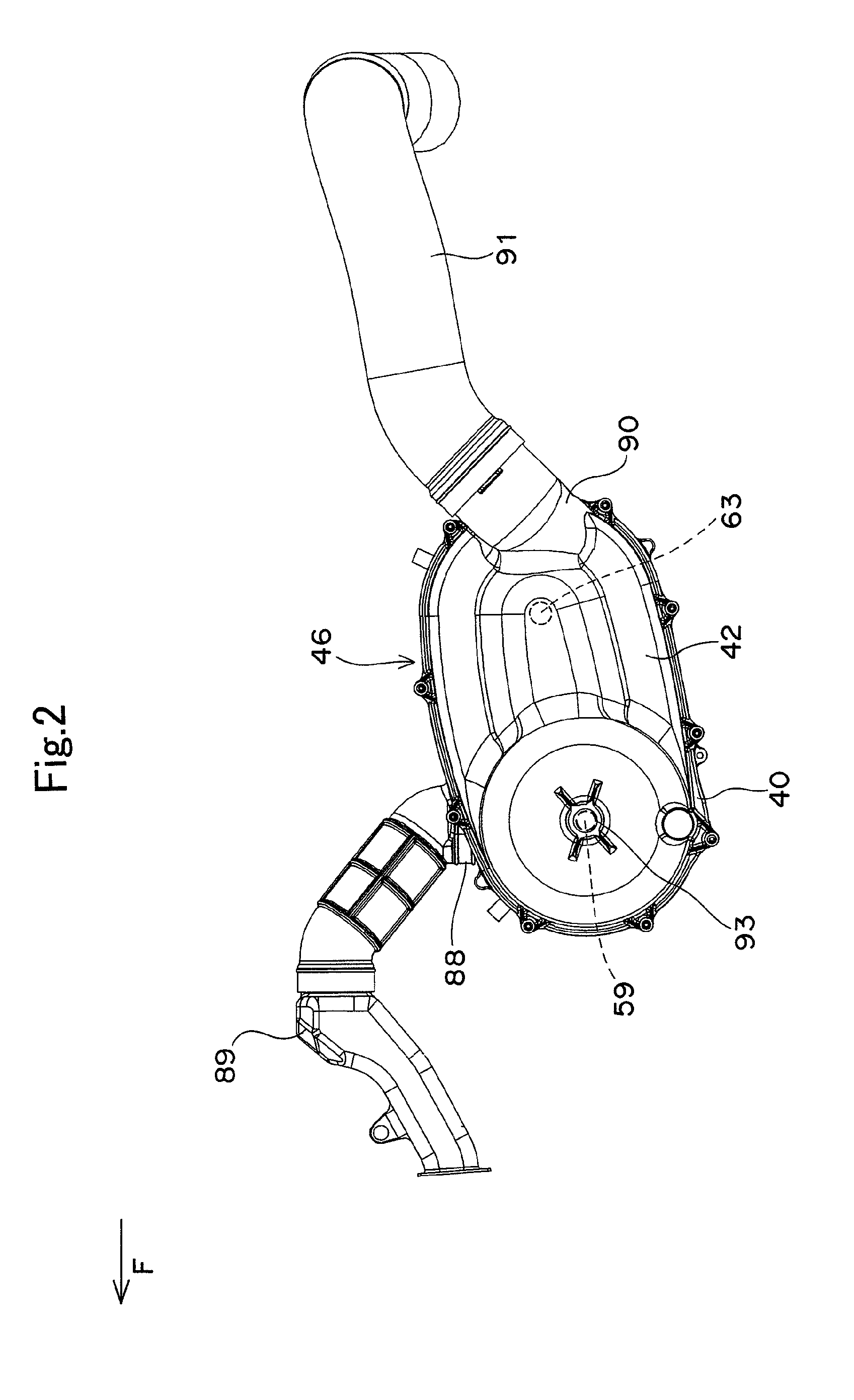

V-belt type continuously variable transmission

A V-belt type continuously variable transmission according to the present invention includes a drive pulley assembly provided in a drive shaft, a driven pulley assembly provided in a driven shaft, a V-belt looped over both the pulley assemblies, and a transmission case assembly housing both the pulley assemblies and the V-belt. One end of the drive shaft in the shaft direction is coupled to an output side rotation member of a centrifugal clutch, and the other end of the drive shaft is rotatably supported on a boss portion formed in the transmission case assembly.

Owner:KAWASAKI HEAVY IND LTD

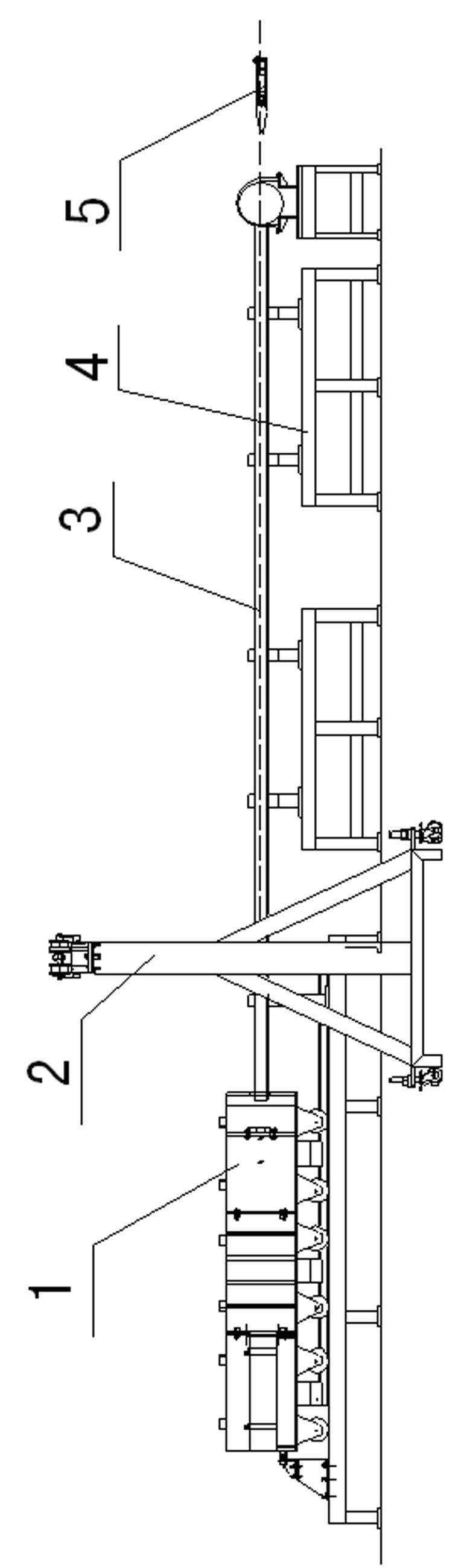

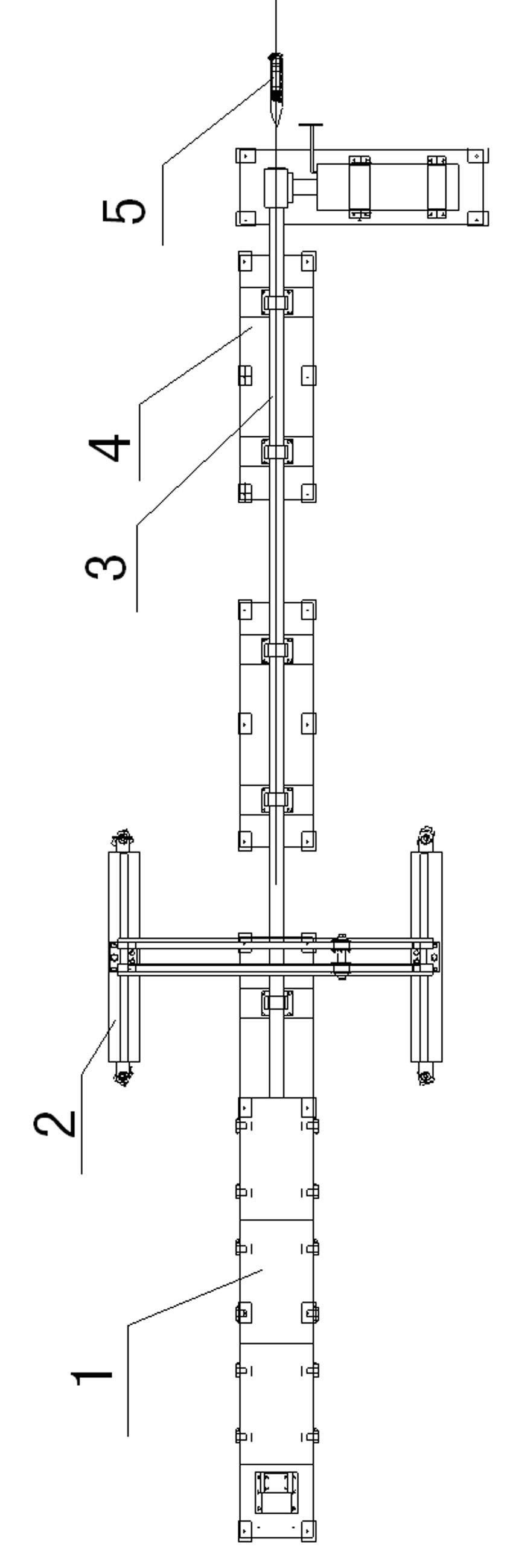

Overload test and detection device of gas gun

InactiveCN102192690ASimple and fast operationStrong reliabilityAmmunition testingOperabilityEngineering

The invention relates to an ammunition overload detection device, and in particular relates to an overload test and detection device of a gas gun, wherein the device provided by the invention can be used for solving the technical problems such as inconvenience in operation and use and the like of the existing air gun penetration test device. The overload test and detection device of the gas gun comprises a frame body which is provided with an overload test air gun launching device, a charging overload test bomb, an overload test protective box and an overload test target plate replacement device. Comprehensively, compared with the prior art, in the technical scheme provided by the invention, the target plate replacement device for an overload test, the overload test protective box and a small-size penetration test bomb are designed specially for the small-size charging and priming system air gun overload performance test, principles and methods relevant to the mechanical design are utilized, the design scheme has the characteristics of being vigorous, practicable, convenient and the like, and the overload test and detection device has the advantages of favorable practical value, reliable operability and accurate experiment result.

Owner:ZHONGBEI UNIV

Conveyor-belt roller assembly

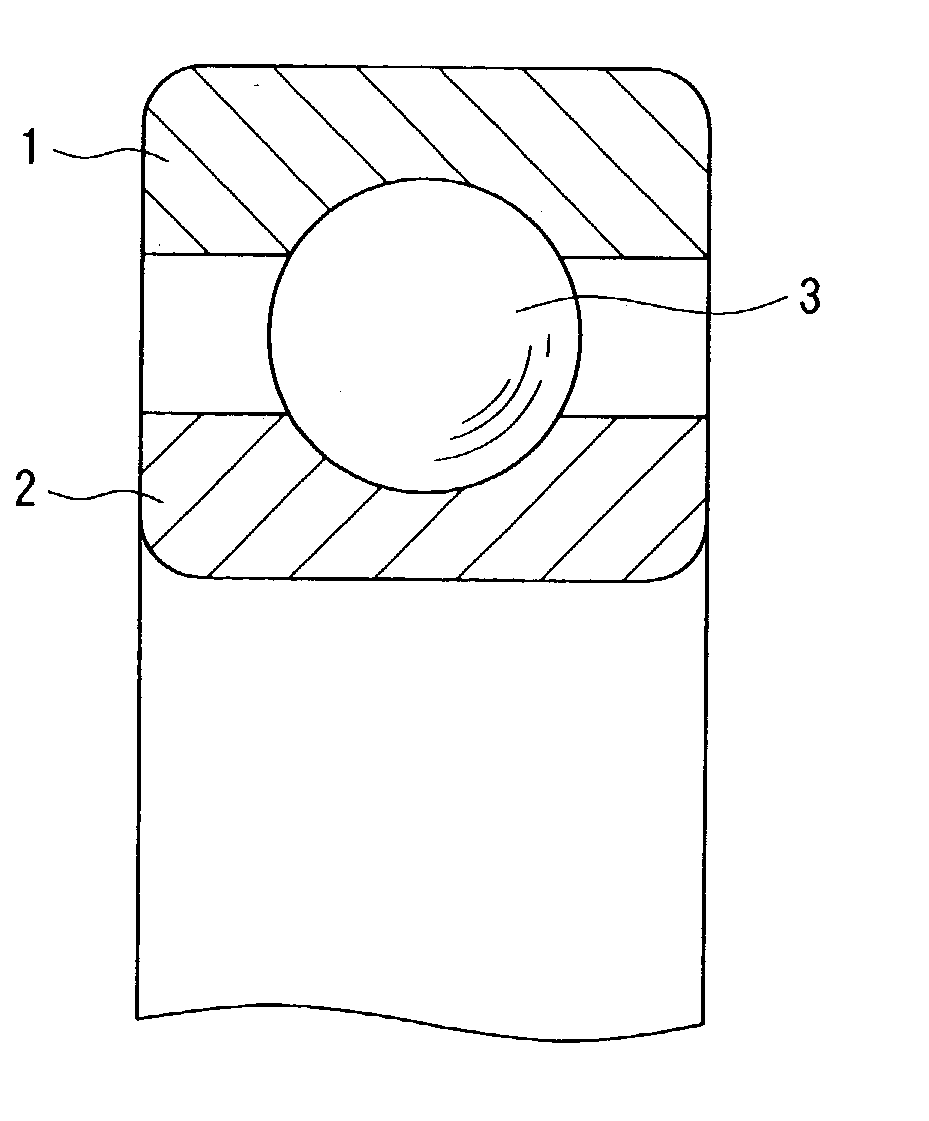

InactiveUS6234293B1Increased roller support strengthQuick and safe installationBall bearingsBearing componentsEngineeringHigh intensity

A conveyor-belt roller assembly secured inside a conveyor-belt roller and onto an inner shaft, preferably used in conveyor-belts used for carrying high loads of material in hazardous environments. The conveyor-belt roller assembly has a stationary anti-lock shield which protects the rotating exterior surface from coming into contact with the outside elements for example debris and machinery. A dust shield is also position aft of the anti-lock shield to prevent the penetration of small particles and dust into the inner workings of the conveyor-belt roller assembly. The conveyor-belt roller assembly also has deep rings in the load-bearing portion for thermal expansion and contraction as well as heat dissipation. Bridging ribs are positioned across the deep rings to greatly increase the strength and therefore load-baring capacity of the conveyor-belt roller assembly. A tapered labyrinth seal is used so that it can be press locked into position making installation quicker and easier. The main load-baring component and tapered labyrinth seal component are preferably fabricated from a high strength, heat resistant 30% glass filled polypropylene.

Owner:LUFF INDS

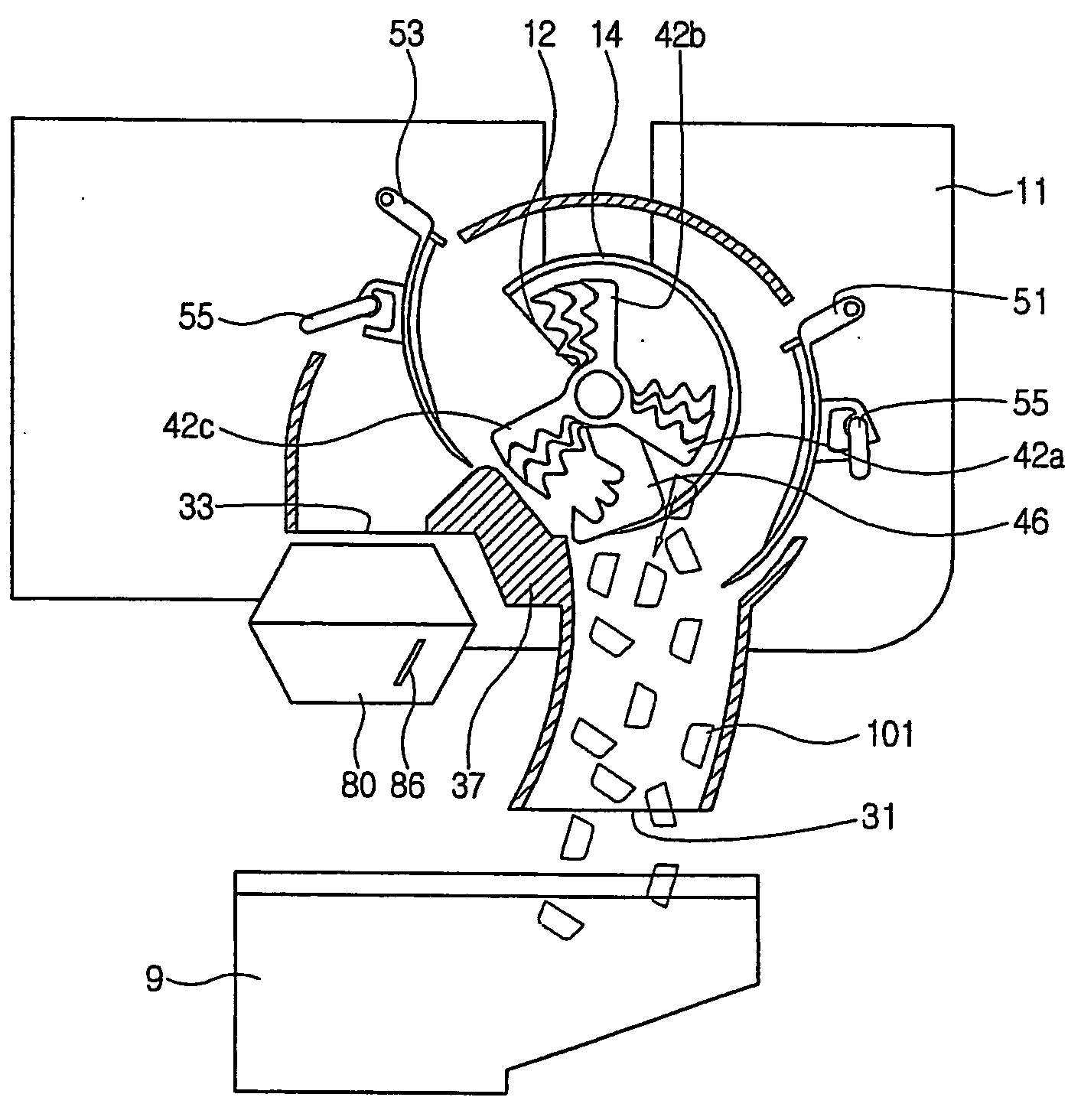

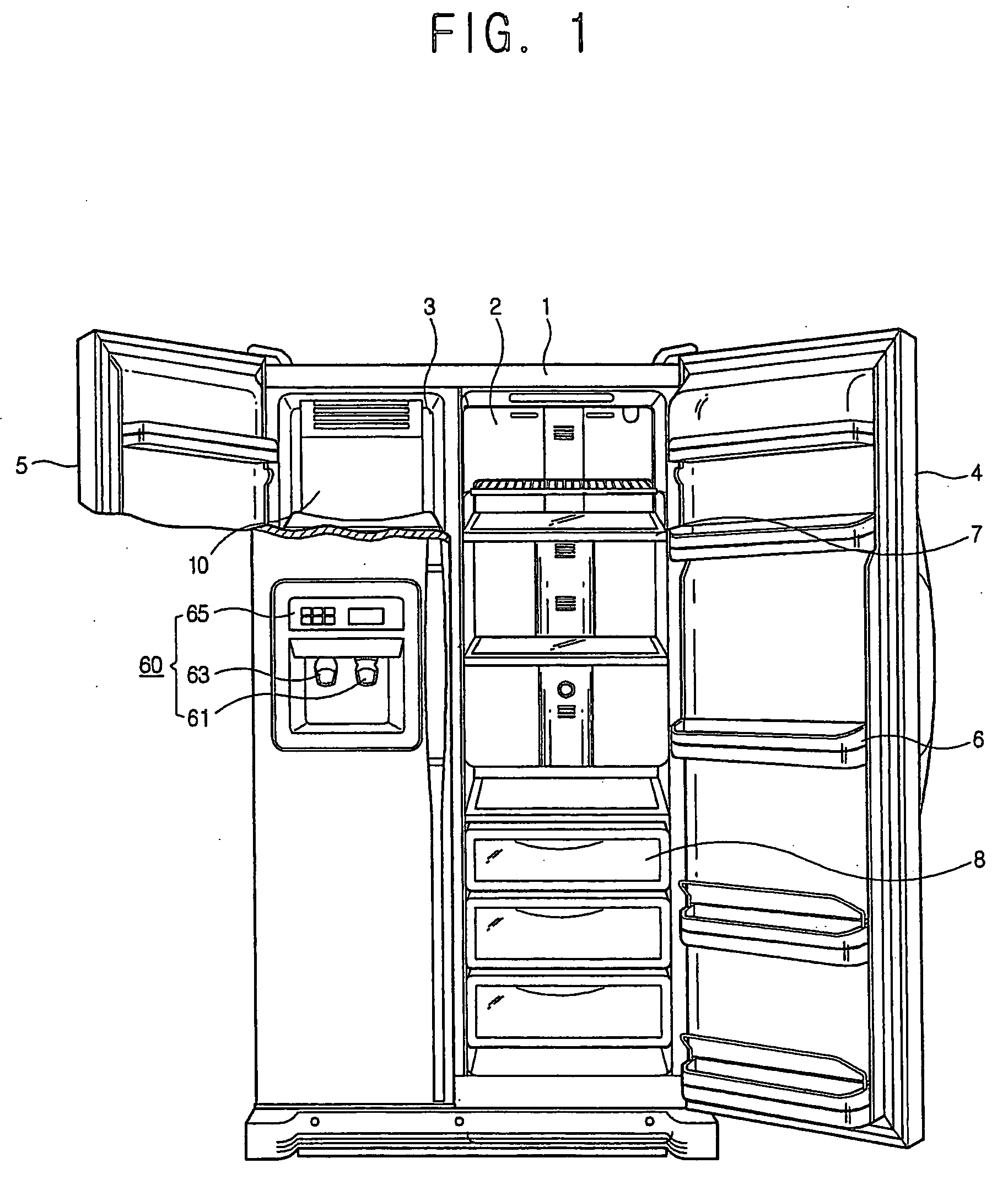

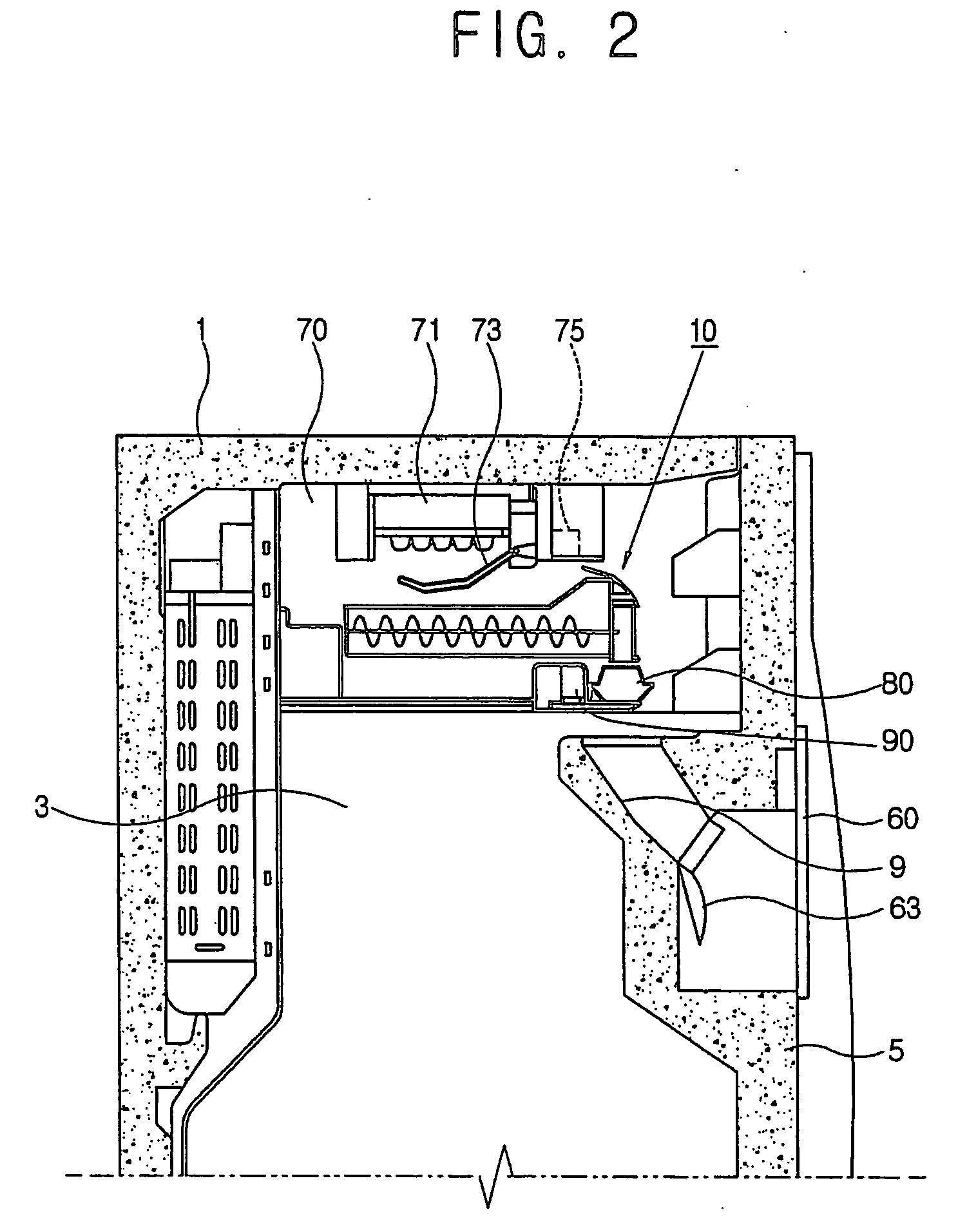

Refrigerator

InactiveUS20060248912A1Improve support strengthIncrease supplyConveyorsLighting and heating apparatusIce storageEngineering

A refrigerator having: an ice storage container in a freezer formed with an opening at a side thereof; an ice breaking part for receiving ice cubes stored in the ice storage container and making shaved ice; a rotating blade which is rotatably provided in the opening; a first discharging part for discharging the ice cubes released to the opening and crushed ice broken by the rotating blade; a second discharging part that communicates with the ice breaking part to cause the ice cubes to be released from the opening and transferred by the rotating blade into the ice breaking part; and first and second discharging levers for opening and closing the first discharging part and the second discharging part, respectively. Thus, the invention provides a refrigerator for selectively distributing and supplying ice stored within an ice storage part to a single transferring unit.

Owner:SAMSUNG ELECTRONICS CO LTD

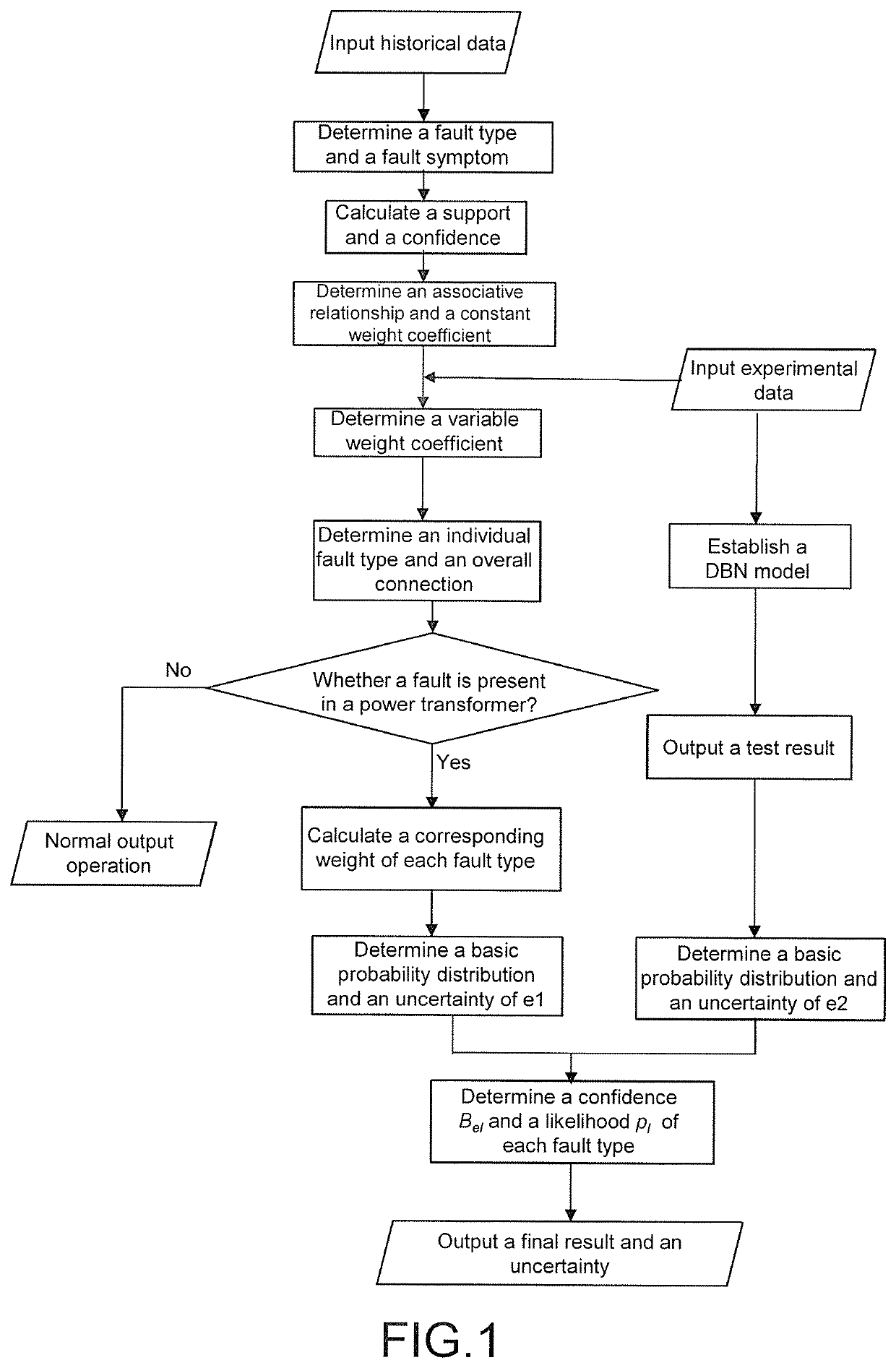

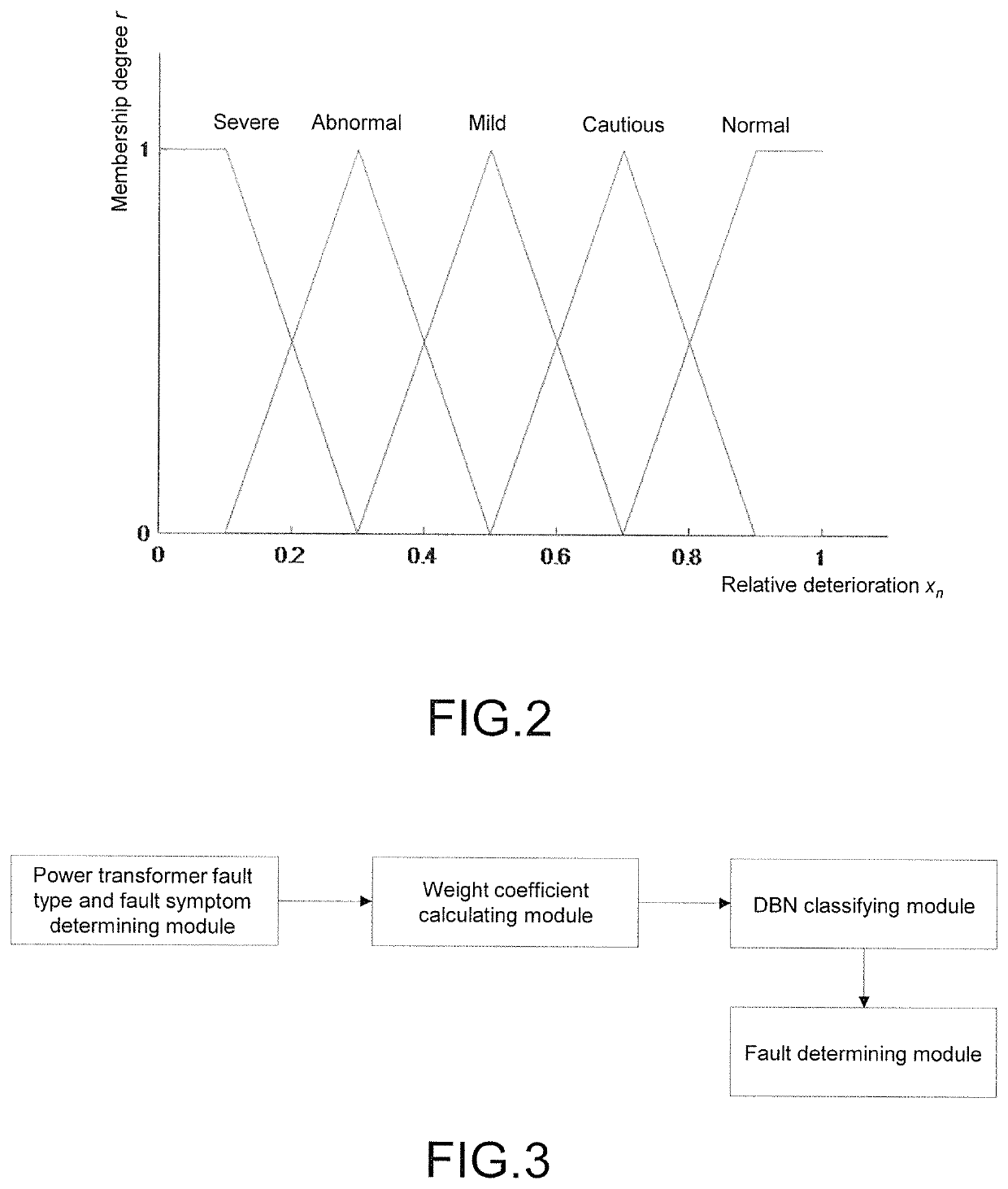

Fault locating method and system based on multi-layer evaluation model

InactiveUS20210003640A1Reduce the impactImprove support strengthTesting dielectric strengthTransformers testingFeature extractionPower transform

The disclosure discloses a fault locating method based on a multi-layer evaluation model. Firstly, determine a fault type to be inspected and a fault symptom which able to accurately and effectively reflect a power transformer operation status and determine a weight of each fault type by using an association rule and a set pair analysis. Then, establish a DBN model to perform feature extraction and classification on multi-dimensional data of a fault. Finally, perform a comprehensive evaluation on an existing diagnosis result by using the D-S evidence theory. Accordingly, the supporting strength of the common target is reinforced, while the influence of divergent targets is reduced. As a result, the uncertainty in the diagnosis result is significantly reduced. The disclosure is mainly used to monitor and diagnose a status variable of the power transformer in a real-time manner, and treats power transformer status evaluation as a multi-property decision issue.

Owner:WUHAN UNIV

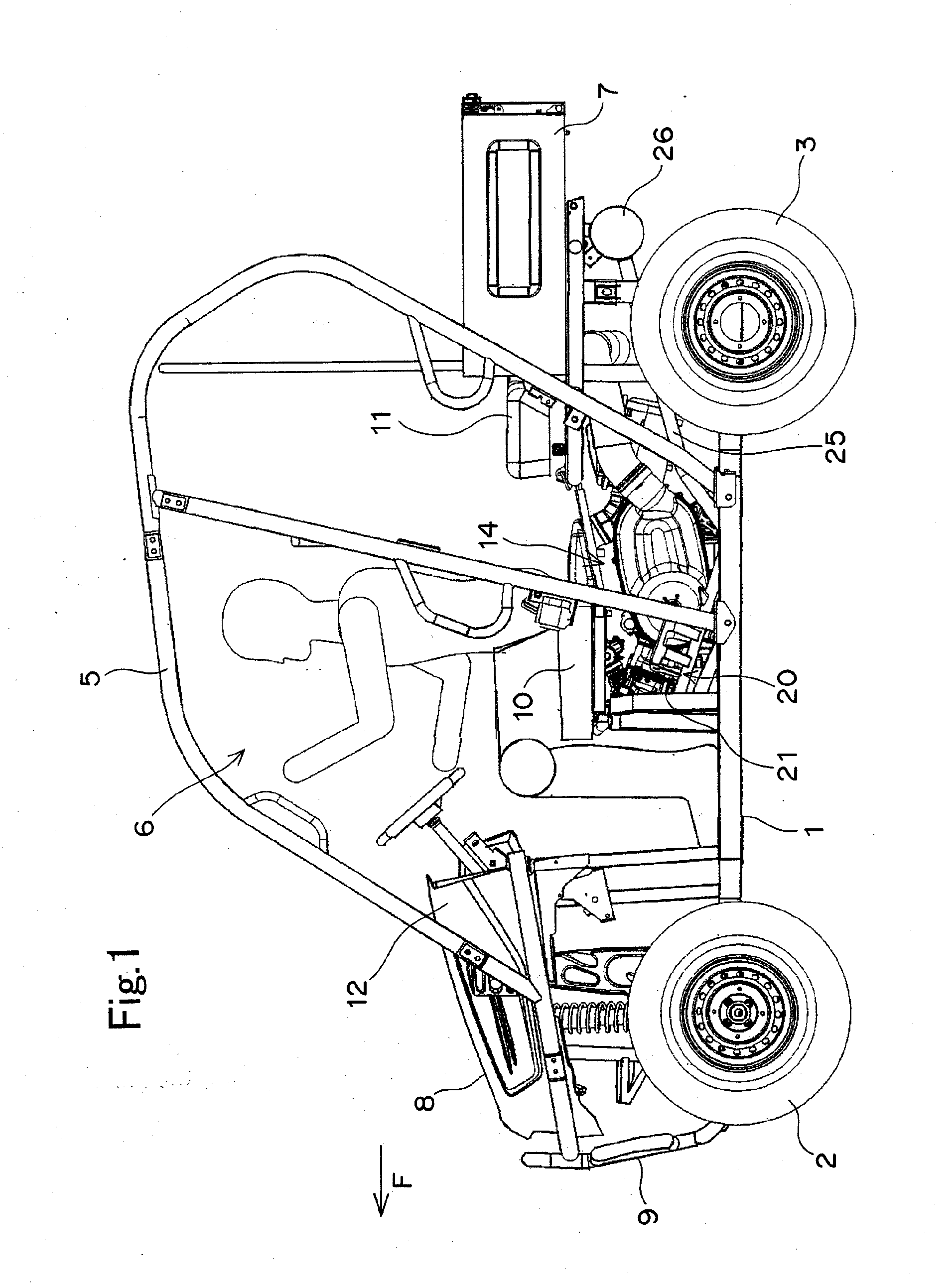

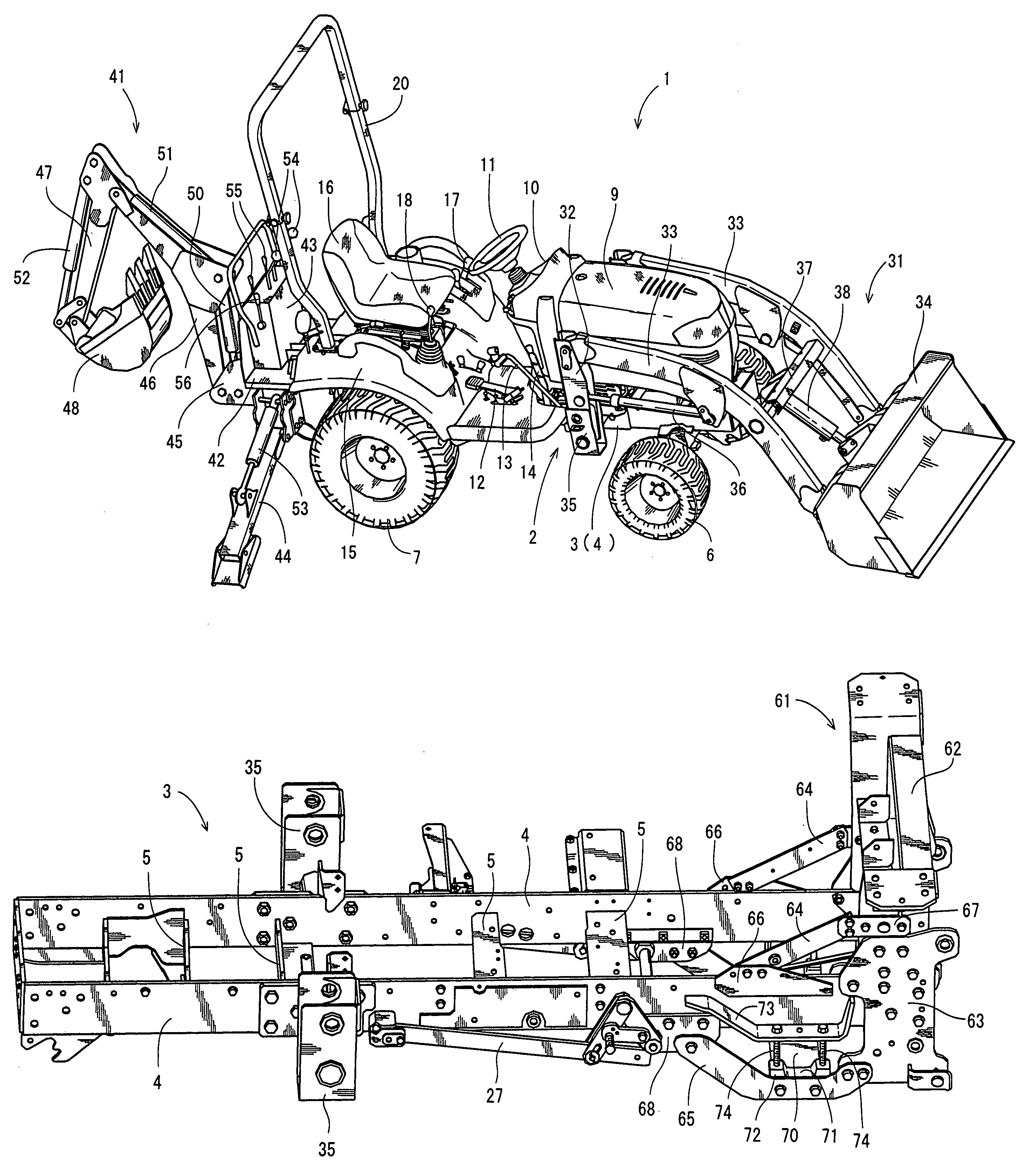

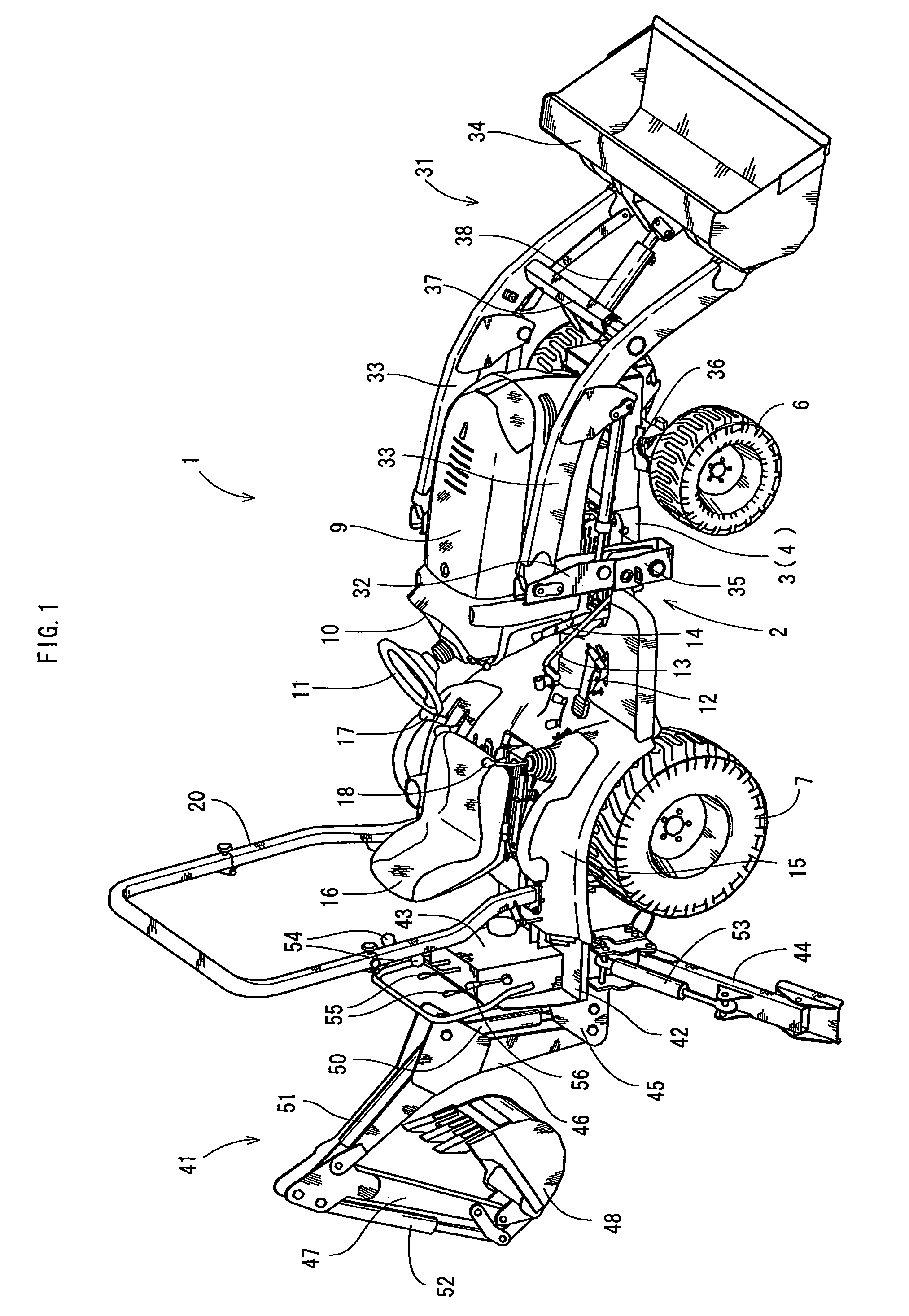

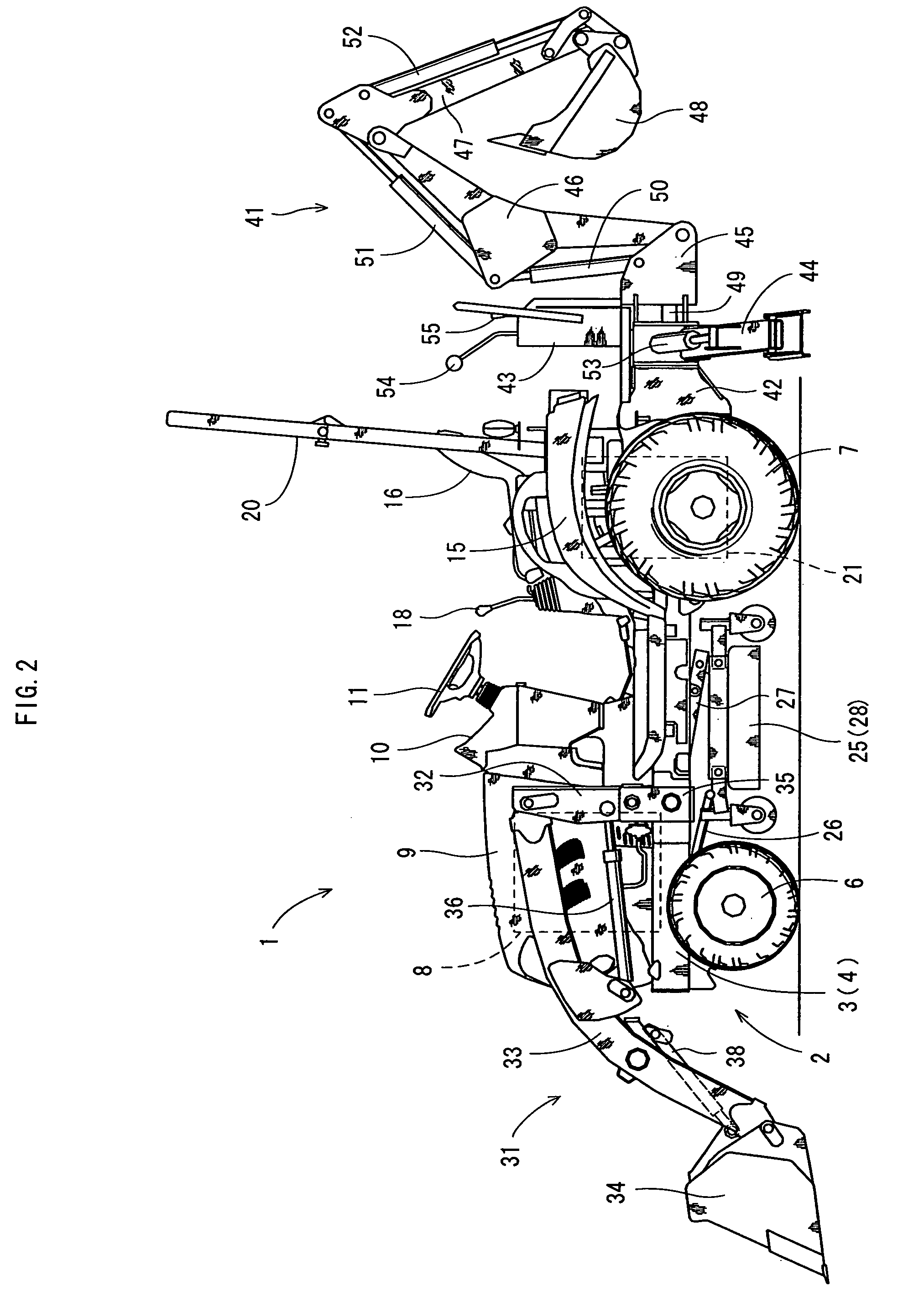

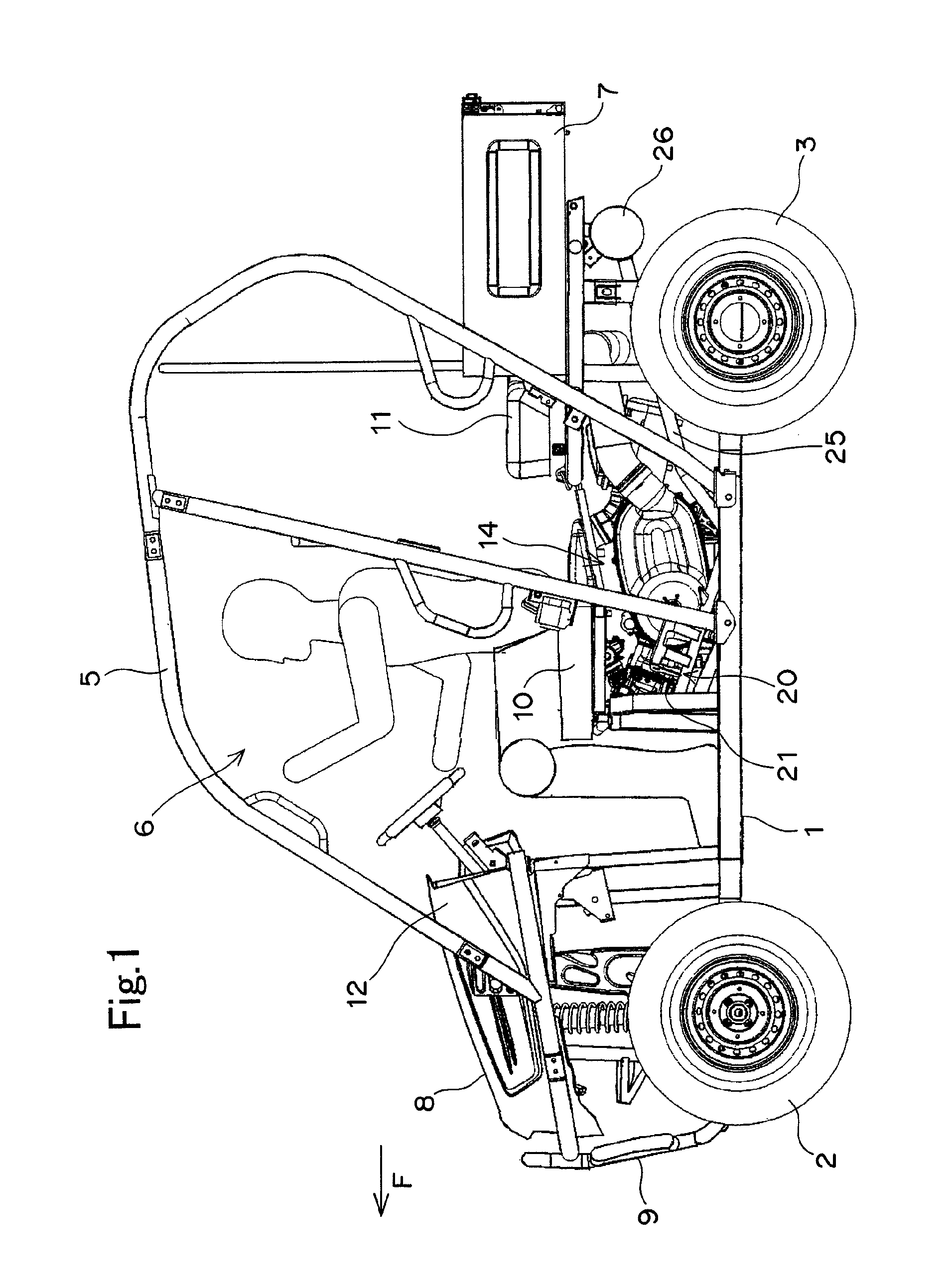

Working vehicle

InactiveUS7757805B2Improve support strengthSuppress manufacturing costMechanical machines/dredgersVehicle body-frame connectionsBraced frameBody frame

In a working vehicle in which a backhoe support frame for reinforcing is provided in a rear end portion of a vehicle body frame, and a transmission case is mounted on a rear portion of the vehicle body frame so as to be close to the backhoe support frame, each of support brackets provided in an outer side surface of a rear portion of each of main frames constructing the vehicle body frame so as to protrude outward is connected to a protruding end portion protruding to rightwardly and leftwardly relative to each of lower brace members in a reinforcing plate supporting a lower surface of the transmission case in a state in which a rear axle case protruding outward from the right and left side surfaces of the transmission case is sandwiched from upper and lower sides, in order to dissolve a risk that a load generated at a time of traveling in a backhoe installed state or at a time of an excavating work by the backhoe is propagated to the transmission case.

Owner:YANMAR POWER TECHNOLOGY CO LTD

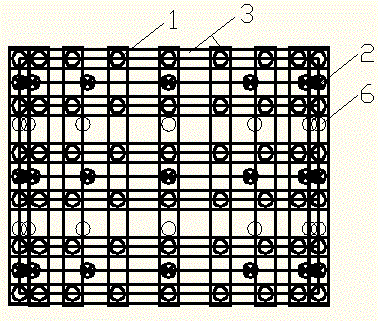

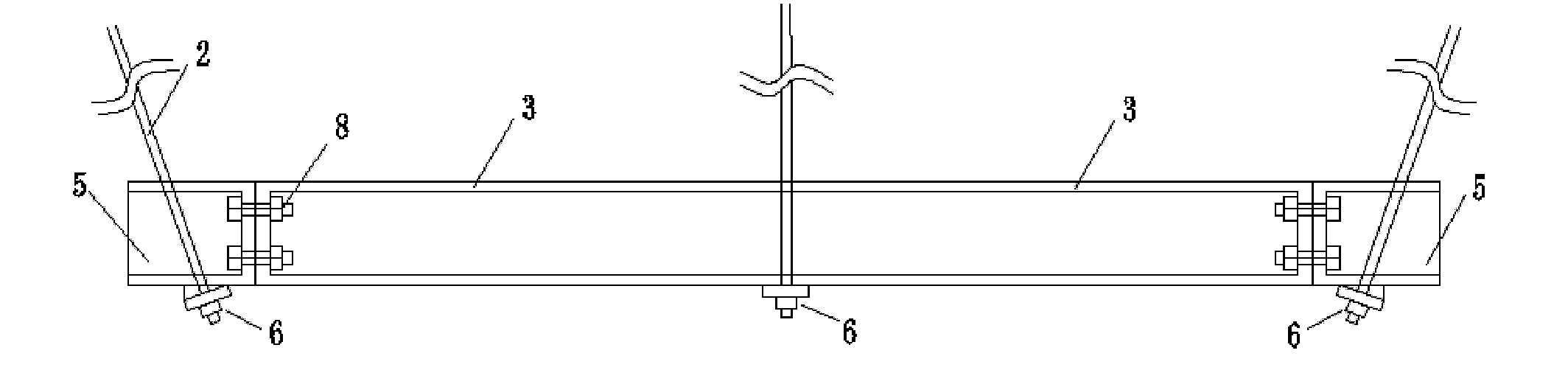

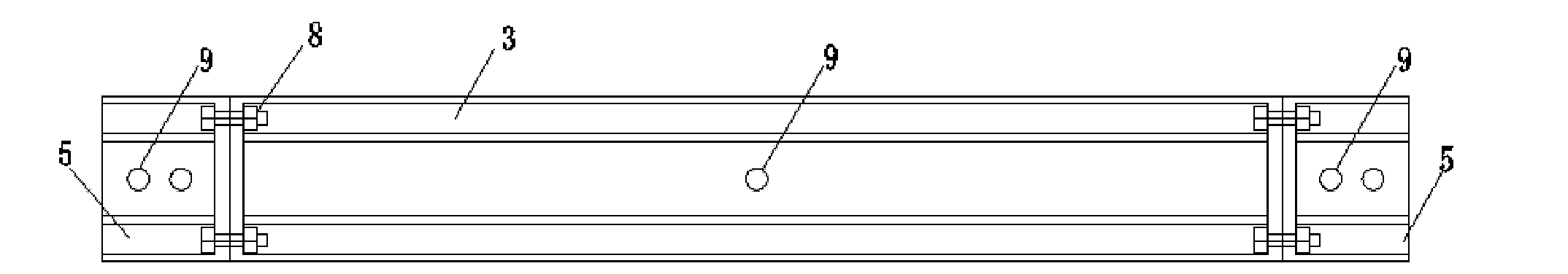

Square steel confined concrete arch center wall back filling bolting-grouting support system and construction method

InactiveCN103615273AImprove self-supporting capacityFill in timeAnchoring boltsSupporting systemRock tunnel

The invention discloses a square steel confined concrete arch center wall back filling bolting-grouting support system and a construction method. The square steel confined concrete arch center wall back filling bolting-grouting support system comprises high-strength anchor rods, grouting anchor rods, grouting anchor cables and multiple square steel confined concrete arch centers, wherein adjacent square steel confined concrete arch centers are connected through longitudinal beams, anchor rod holes are formed in the longitudinal beams, longitudinal beam anchor rods penetrate the longitudinal beams through the anchor rod holes to be anchored into a surrounding rock, a wall back filling layer is arranged between the square steel confined concrete arch centers and the surrounding rock, and the square steel confined concrete arch centers, the wall back filling layer and the tunnel surrounding rock are connected through the longitudinal beam anchor rods. The high-strength anchor rods, the grouting anchor rods and the grouting anchor cables are constructed before the square steel confined concrete arch centers are erected. The square steel confined concrete arch center wall back filling bolting-grouting support system and the construction method are applicable to supporting of underground projects including weak broken surrounding rock tunnels and the like, the square steel confined concrete arch center wall back filling bolting-grouting support system has the advantages of being high in strength, good in stability, reasonable in stress and the like, and the square steel confined concrete arch center wall back filling bolting-grouting support system and the construction method can effectively improve the primary supporting strength after tunnel excavation and ensure the stability of the tunnel surrounding rock.

Owner:SHANDONG UNIV

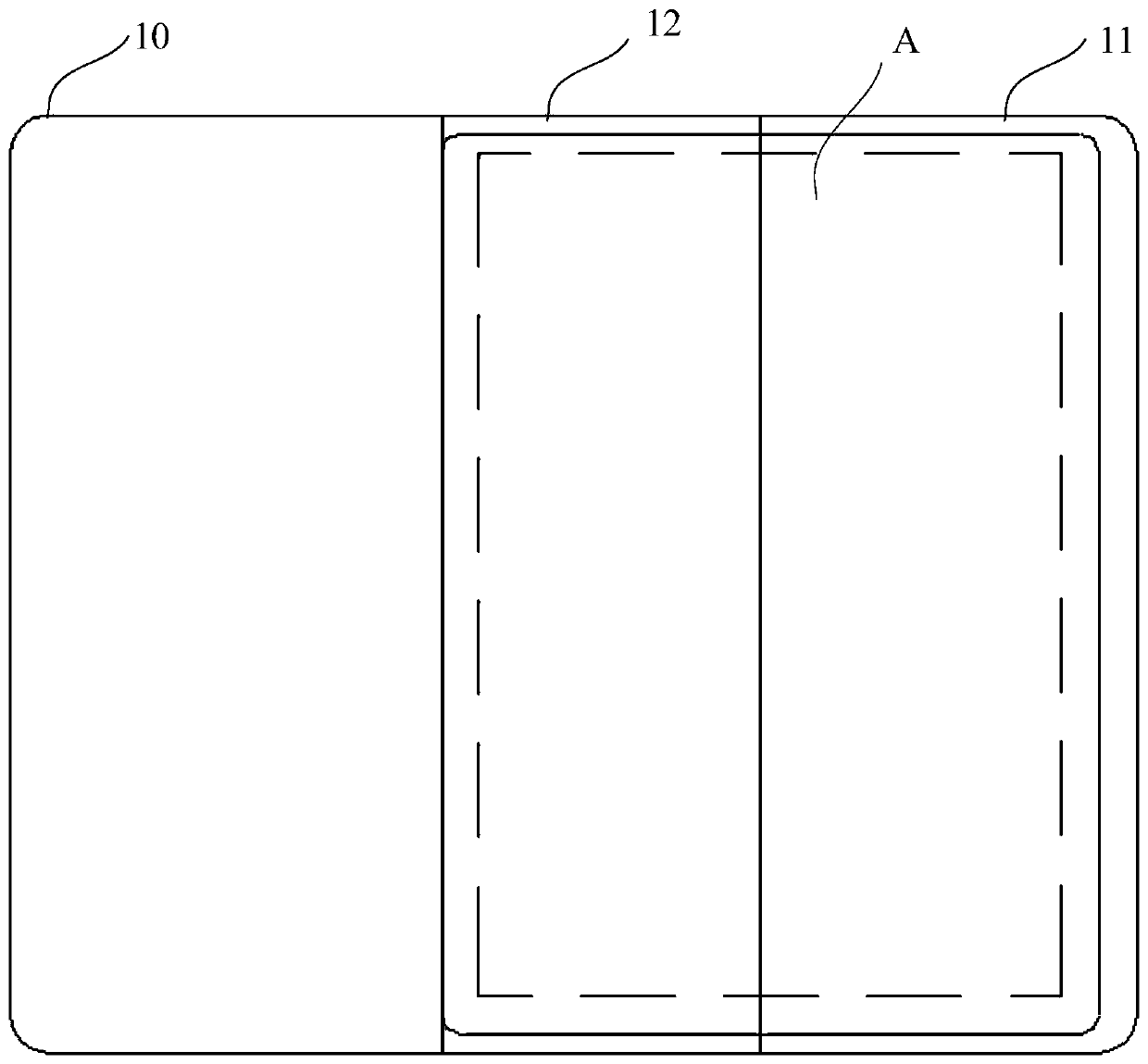

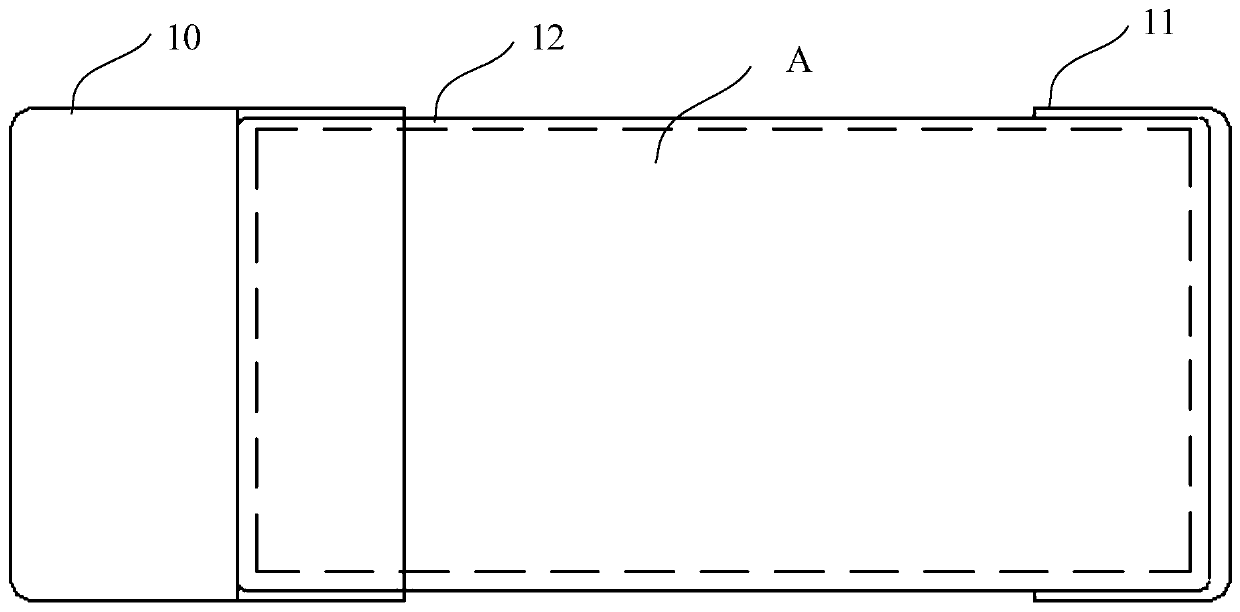

Display device and electronic equipment

ActiveCN111599278AImprove support strengthAvoid local deformationDigital data processing detailsCasings/cabinets/drawers detailsDisplay deviceElectronic equipment

The invention provides a display device and electronic equipment. The display device comprises a first shell, a second shell, a flexible screen, a supporting belt and a telescopic rod. The first shelland the second shell are oppositely arranged, an opening is formed in the position, opposite to the second shell, of the first shell, one end of the flexible screen is rolled in the first shell, andthe other end of the flexible screen extends out of the opening and is fixed to the second shell, one end of the supporting belt is rolled in the first shell, the other end of the supporting belt extends out of the opening and is fixed to the second shell, and the part, extending out of the first shell, of the supporting belt is attached to the bottom of the flexible screen, the telescopic rod isarranged at the bottom of the supporting belt, one end of the telescopic rod is fixed to the first shell, and the other end of the telescopic rod is fixed to the second shell. In the embodiment of theinvention, the supporting rod and the supporting belt can be used for supporting the flexible screen, local deformation of the flexible screen is avoided, and touch operation on the flexible screen is facilitated.

Owner:BOE TECH GRP CO LTD

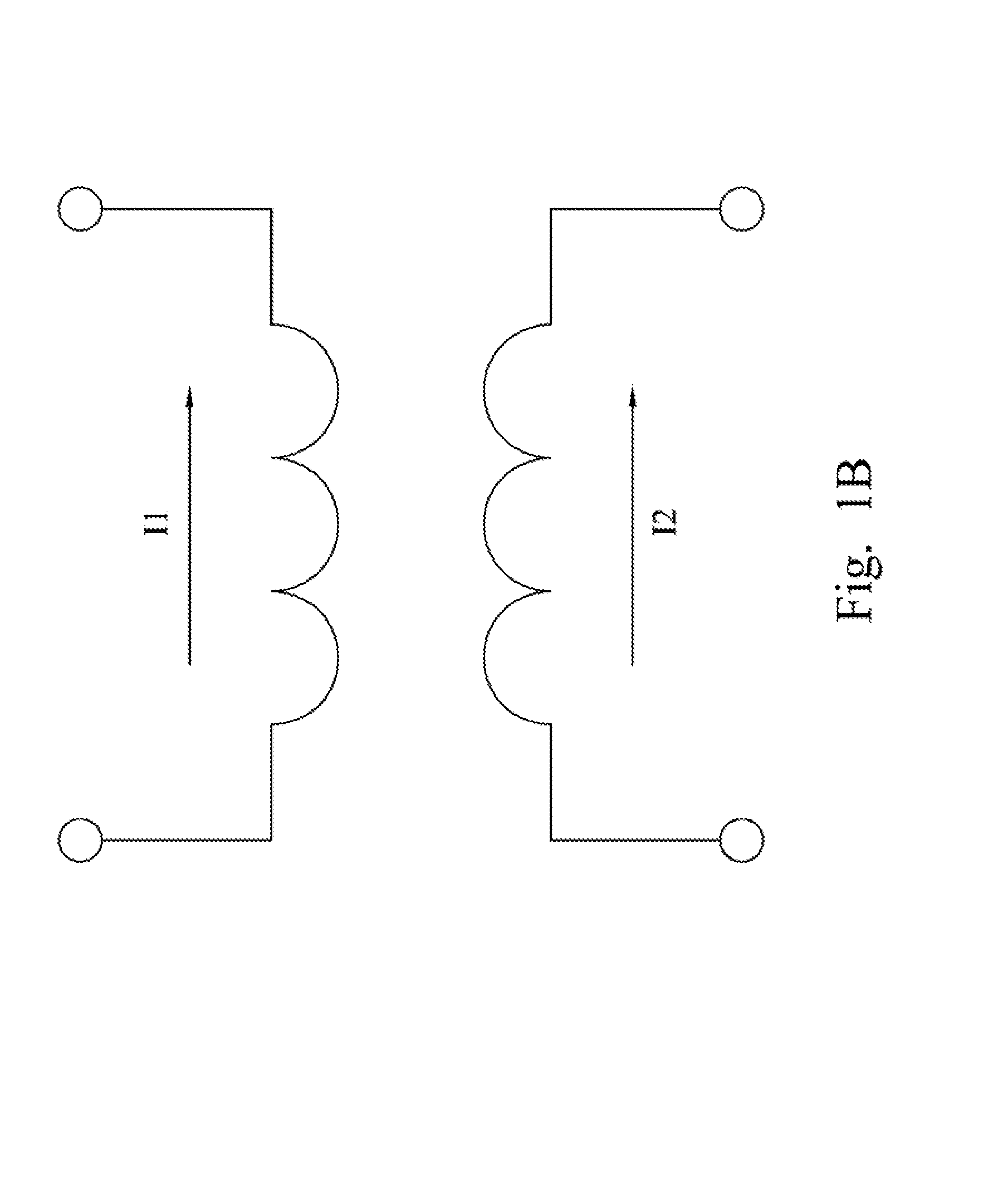

Printed circuit board package structure and manufacturing method thereof

ActiveUS20140266549A1Low costImprove support strengthTransformers/inductances coils/windings/connectionsPrinted circuit aspectsPrinted circuit boardConductive channel

A printed circuit board package structure includes a substrate having a first surface and a second surface, a ring-shaped magnetic element, an adhesive layer, conductive portions and conductive channels. The first and second surfaces respectively have first and second metal portions. A ring-shaped concave portion is formed on a position not covered by the first metal portions of the first surface. The ring-shaped magnetic element is placed in the ring-shaped concave portion. The adhesive layer covers the first metal portions and the ring-shaped magnetic element. The conductive portions are formed on the adhesive layer. The conductive channels penetrate the conductive portions, the adhesive layer, and the substrate, and are respectively located in an inner wall and outside an outer wall of the ring-shaped concave portion. Each of the conductive channels includes a conductive film electrically connects to the aligned conductive portion and second metal portion.

Owner:TRIPOD TECHNOLOGY CORPORATION

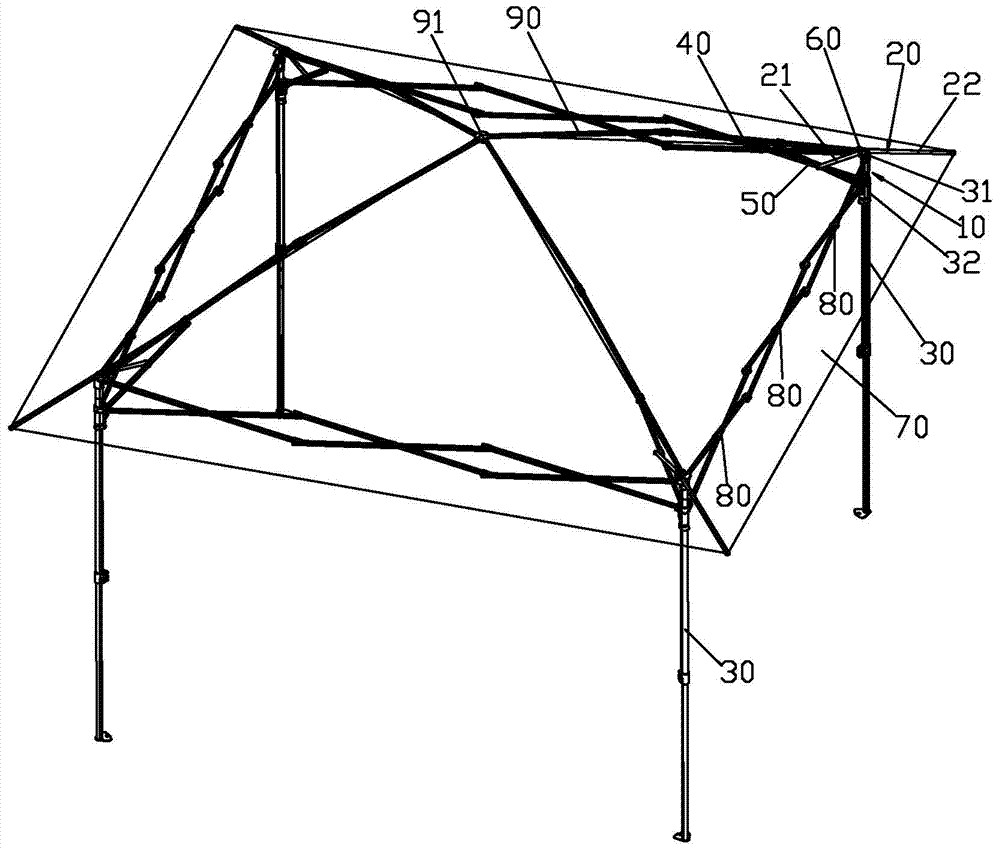

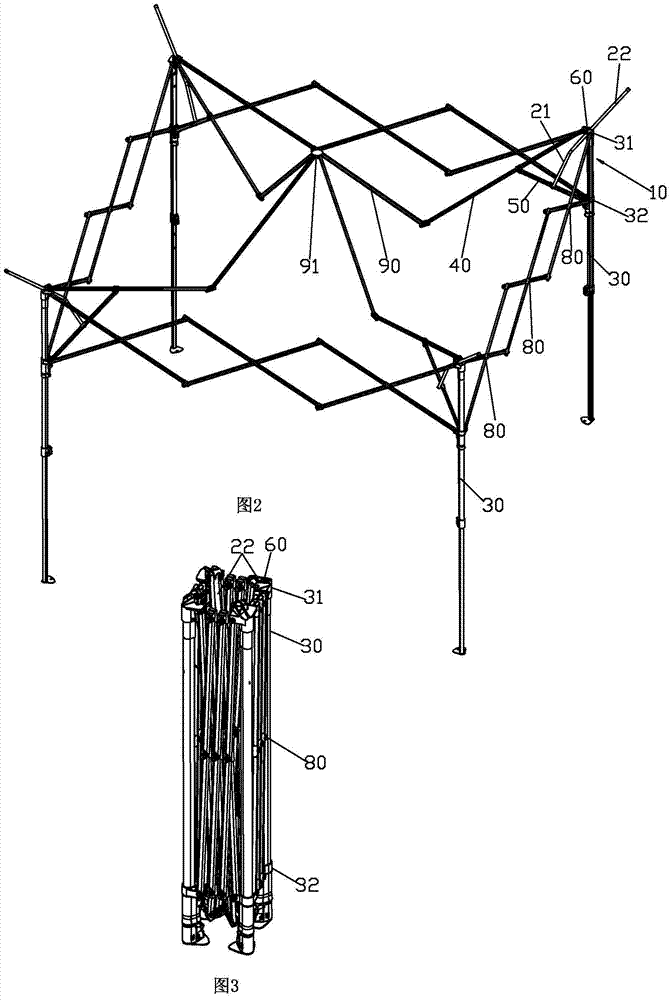

Folding tent eave frame mechanism

ActiveCN103590650AGuaranteed Relative Swipe ActivityStable and reliable supportTents/canopiesEavesEngineering

Owner:XIAMEN ROADZUP OUTDOOR PROD

Fully-mechanized caving mining process technology with large mining height in super-high seam (14-20m)

ActiveCN101967975AIncrease coal breaking effectIncrease coal discharge spaceUnderground miningSurface miningControl measureCoal mining

The invention provides a coal mining method of fully-mechanized caving mining with large mining height in a super-high seam, a coal caving process, reasonable type of a support, production capacity of equipment, comprehensive control measures of coal wall spalling of working face, a technical route for improving the recovery rate of the fully-mechanized caving face with the large mining height, and feasibility evaluation indexes (thickness of the seam, top coal cavability, coal wall stability and roof pressure strength) of the fully-mechanized caving mining with the large mining height, and further forms a whole set of fully-mechanized caving mining process technology with the large mining height. The coal mining method is that the coal cutting height is 4.2-4.8m; the length of the working face is 200-280m; and the web of a coal mining machine is 0.8-1m. The process technology can increase the coal cutting quantity by 43%, shorten the coal caving time by 9%, relatively reduce the coal caving quantity by 9%, improve the resource recovery rate by 5% and reduce the mining-caving ratio to below 1:3 by increasing the coal cutting height, and can further realize the relatively balanced production of mining and caving of the working face.

Owner:DATONG COAL MINE GRP

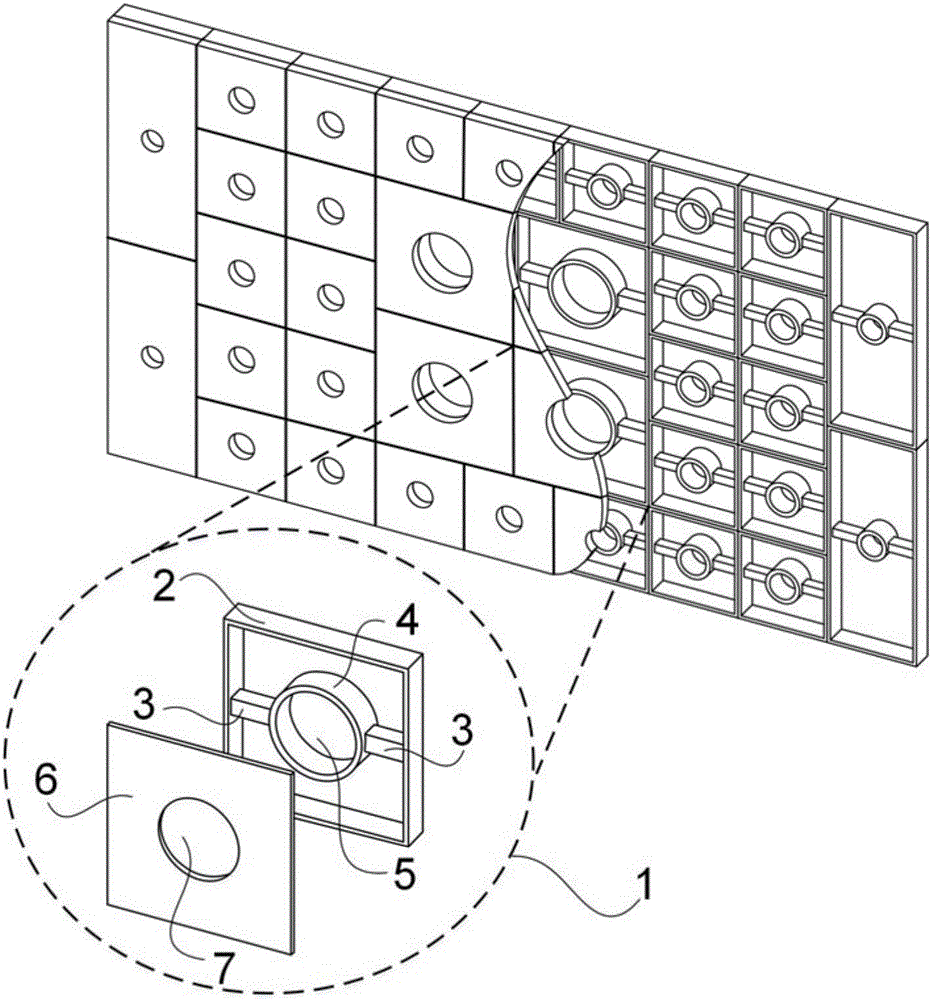

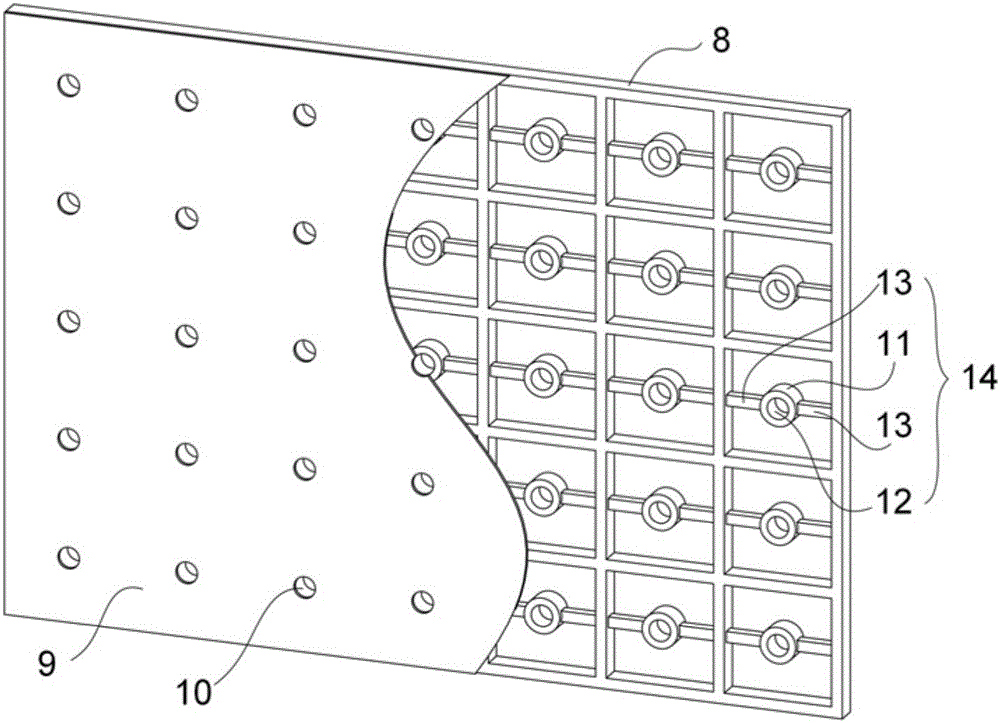

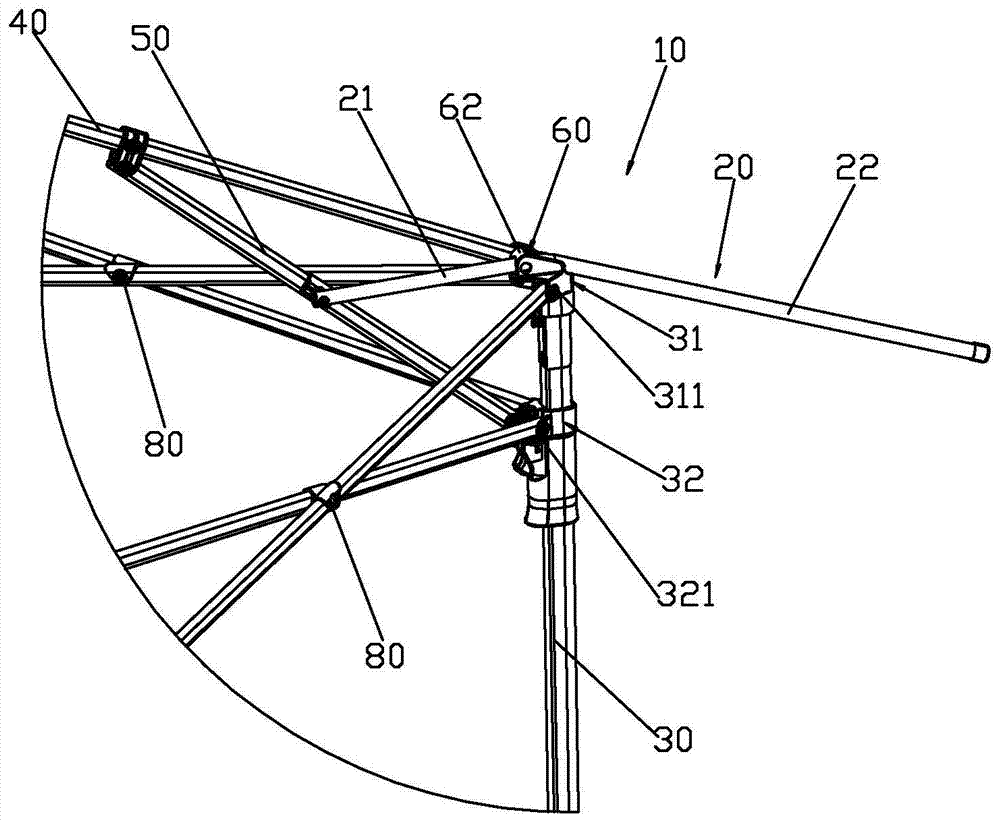

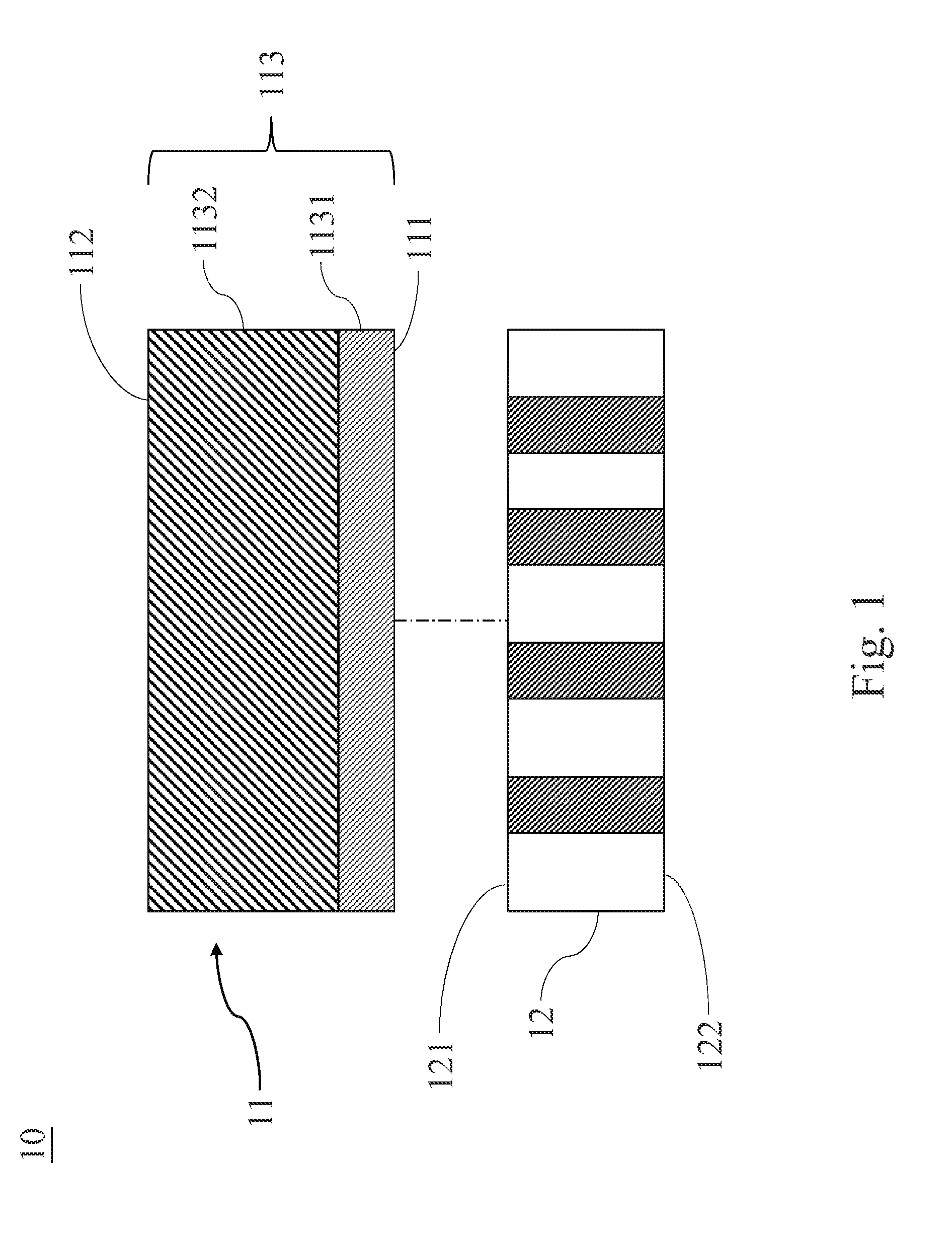

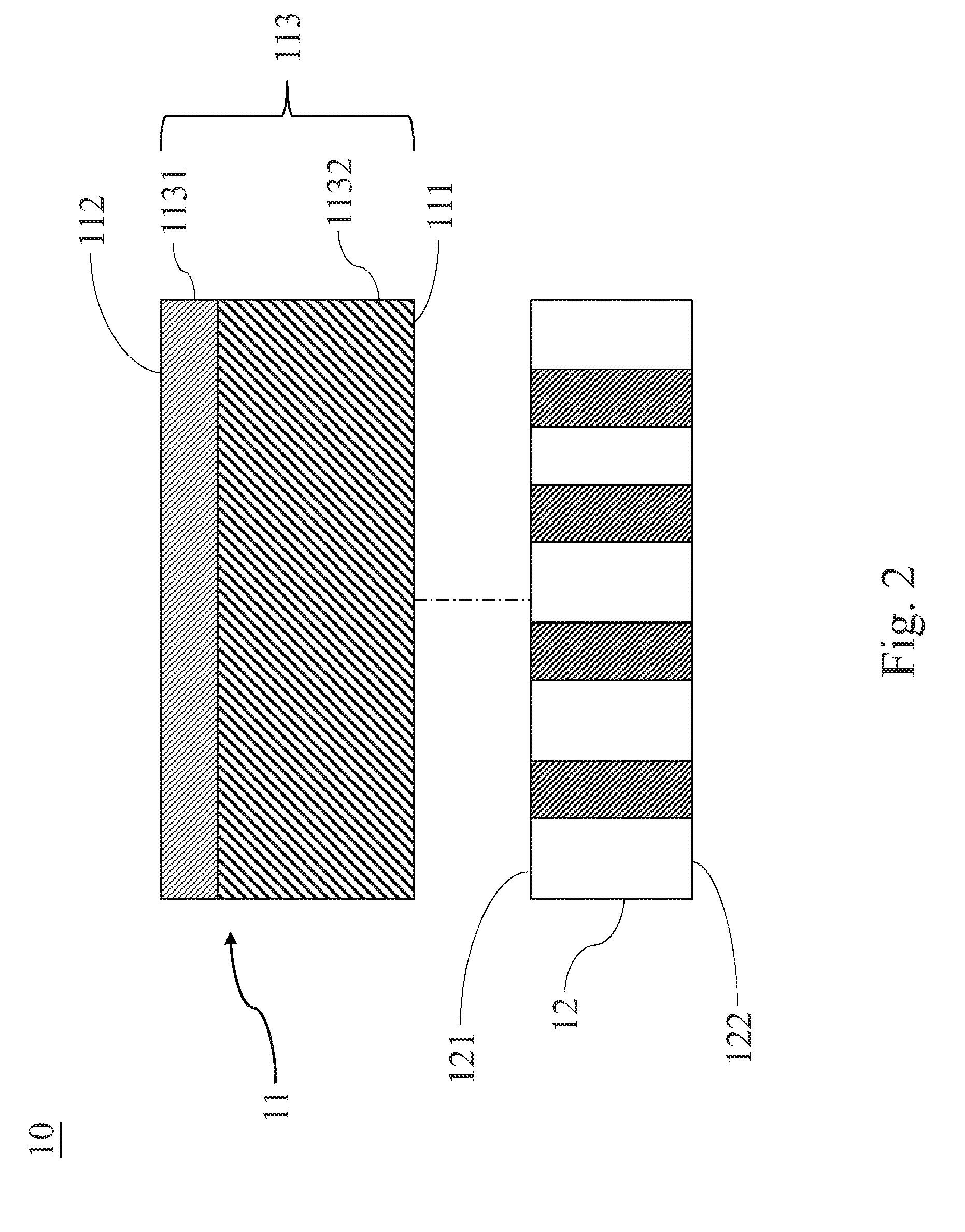

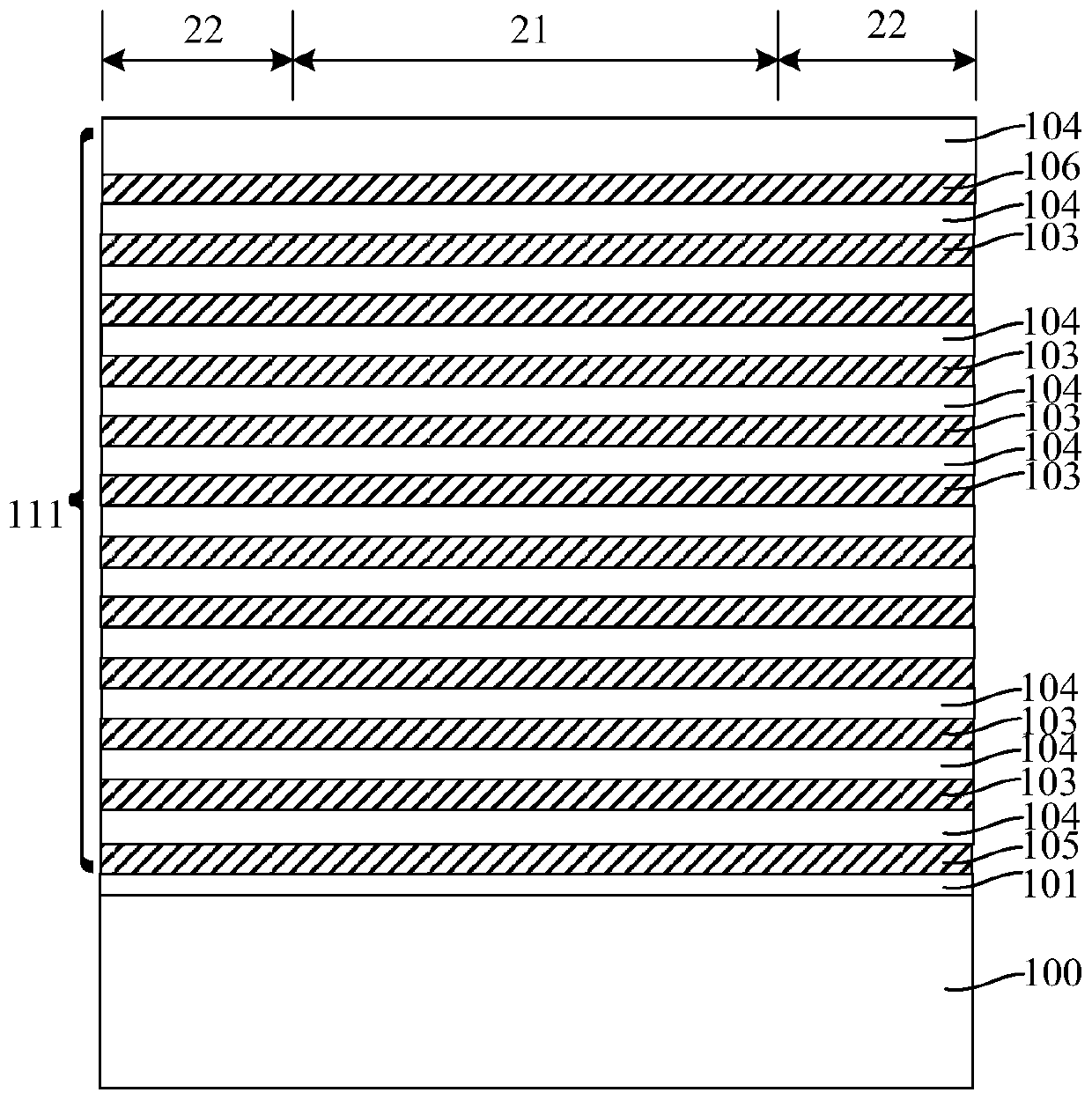

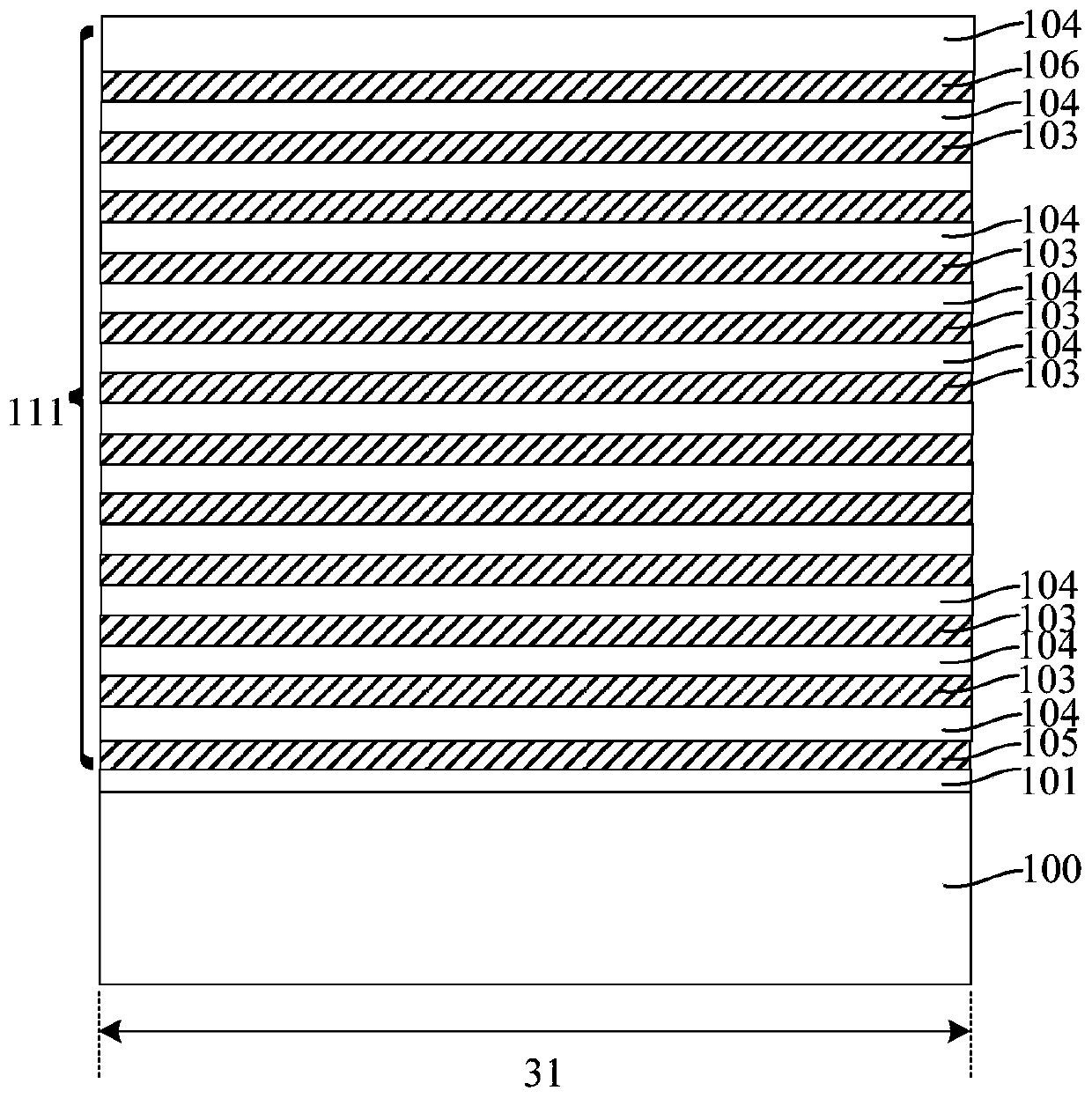

Water-proof and dust-proof membrane assembly and applications thereof

ActiveUS20110188247A1Improve support strengthImprove pressure resistanceCombination devicesDispersed particle filtrationPore diameterMembrane configuration

Disclosed is a water-proof and dust-proof membrane assembly and applications thereof. The water-proof and dust-proof membrane assembly comprises a body and a supporting member. The body is of membrane and has a first surface, a second surface, and an asymmetric porous structure formed between the first surface and the second surface of the body. The asymmetric porous structure has a thickness ranging between 1 μm and 1000 μm, a first volumetric porosity ranging between 5% and 99%. The asymmetric porous structure has plural pores, and each pore has a pore diameter between 0.01 μm and 15 μm. The supporting member is of a polymeric material and has a first contacting surface, a second contacting surface, and a second volumetric porosity which is greater than the first volumetric porosity. The first contacting surface of the supporting member is adhered to the first surface of the body.

Owner:EF MATERIALS IND

V-belt type continuously variable transmission

A V-belt type continuously variable transmission includes a drive pulley assembly provided on a drive shaft, a driven pulley assembly provided on a driven shaft, a V-belt looped over both the pulley assemblies, and a transmission case assembly housing both the pulley assemblies and the V-belt. One end of the drive shaft in the shaft direction is coupled to an output side rotation member of a centrifugal clutch, and the other end of the drive shaft is rotatably supported on a boss portion formed in the transmission case assembly.

Owner:KAWASAKI HEAVY IND LTD

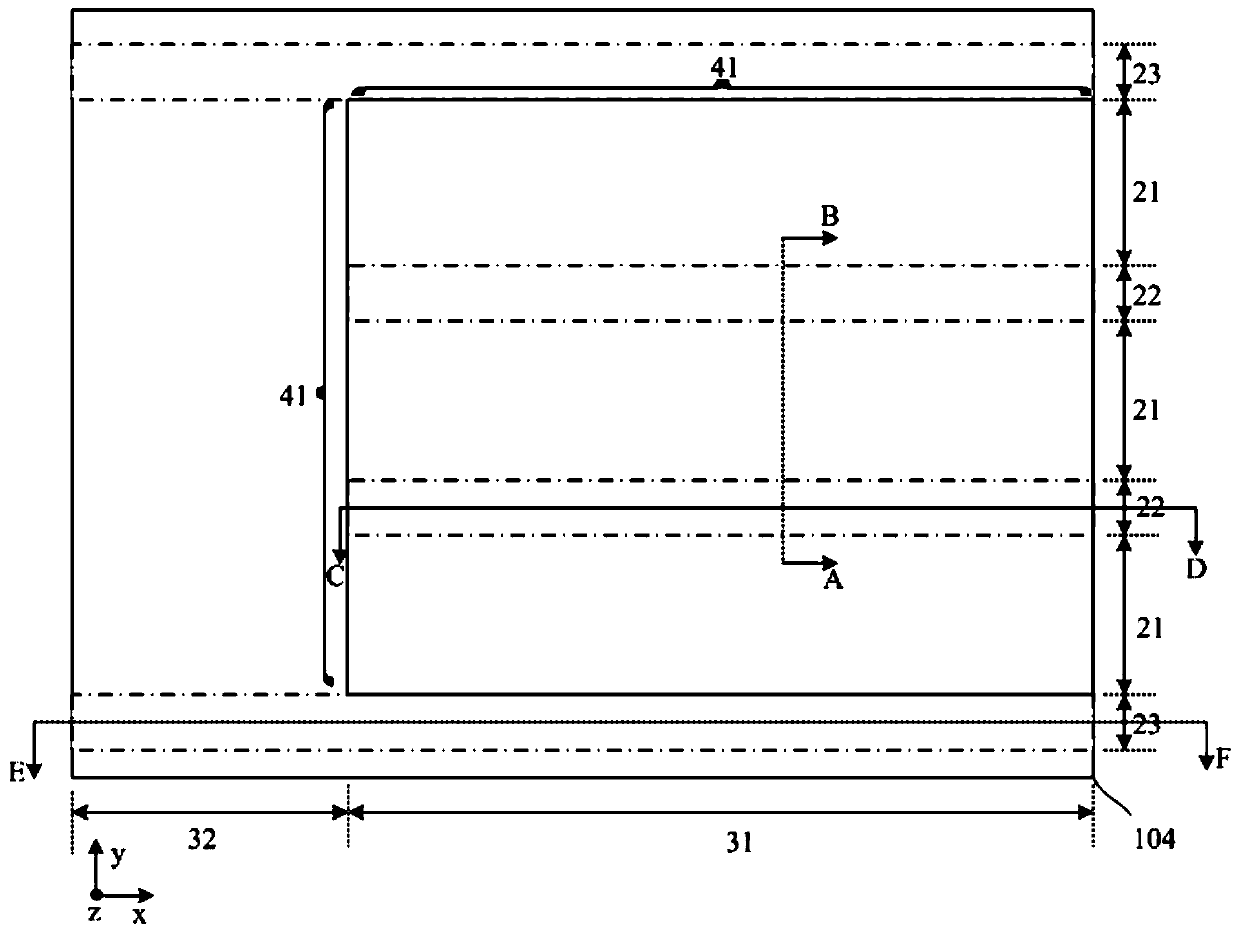

3D NAND storage device and formation method thereof

ActiveCN110176461AImprove support strengthNot easy to deformSolid-state devicesSemiconductor devicesGrid partitionComputer science

The invention discloses a 3D NAND storage device and a formation method thereof. In the formation method of the 3D NAND storage device, a selective grid sacrificial layer in a first grid partition groove area is disconnected through a first grid partition groove and a plurality of grid partition groove partition areas in the first grid partition groove area, a selective grid sacrificial layer in athrough hole area is disconnected through a selective grid partition area in the through hole area, although the selective grid sacrificial layer on the top of the first grid partition groove area isdisconnected through the first grid partition groove and the grid partition groove partition areas, the sacrificial layer at the bottom of the grid partition groove partition area still remains, namely the sacrificial layers and partition layers in each storage block when the first grid partition groove is formed are still connected together, a stacking structure can be of extremely high supporting strength when the first grid partition groove is formed, and the side wall of the first grid partition groove is unlikely to deform or incline, so that the stability of the feature size of the formed first grid partition groove is guaranteed.

Owner:YANGTZE MEMORY TECH CO LTD

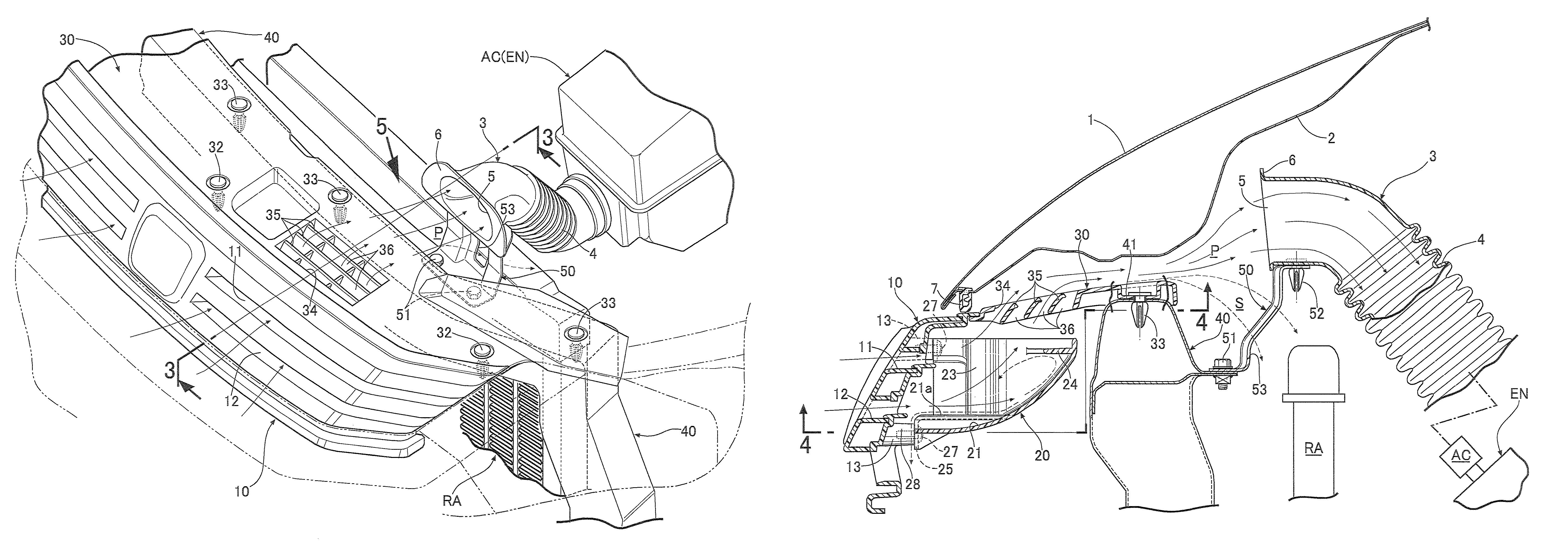

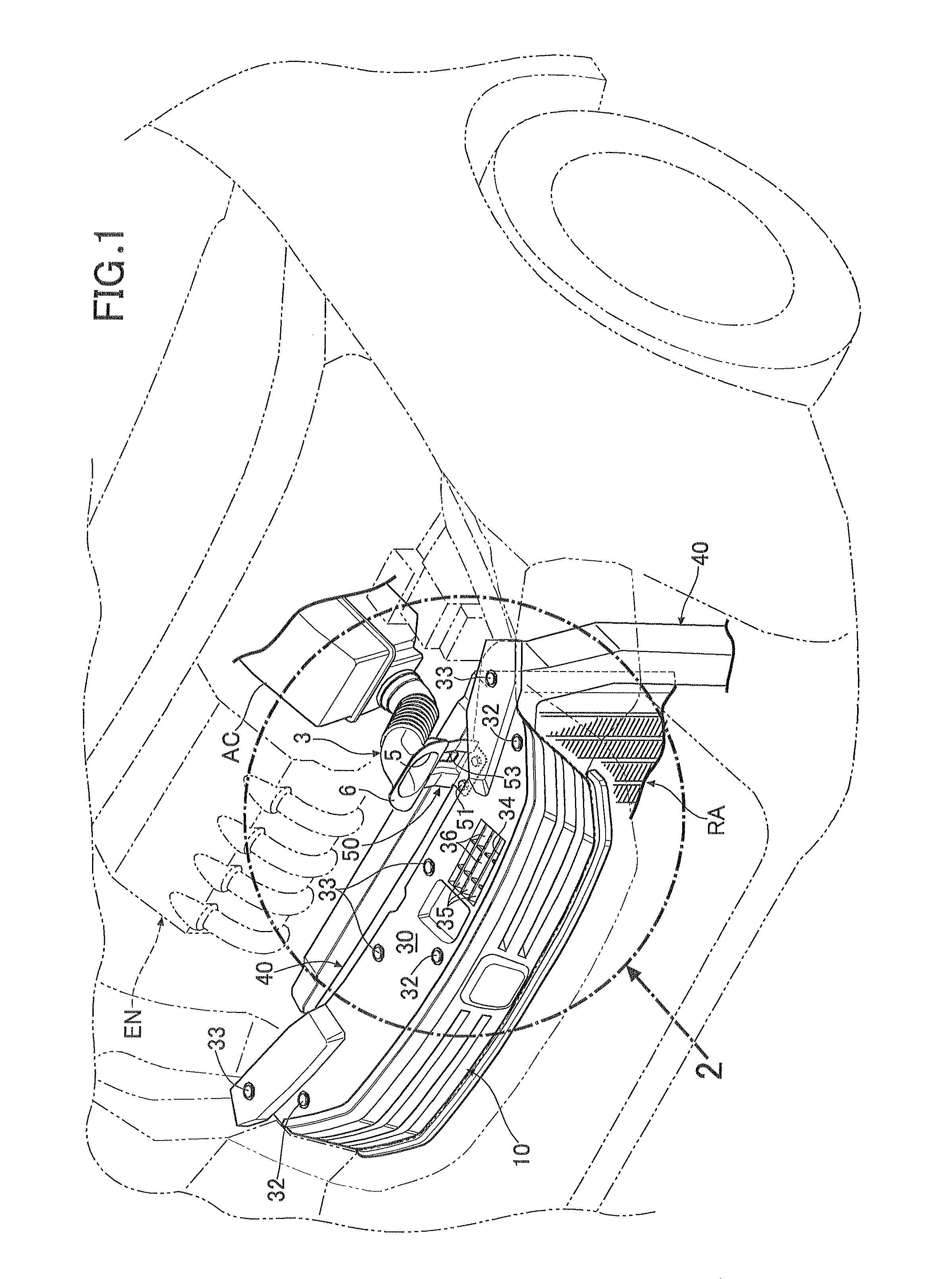

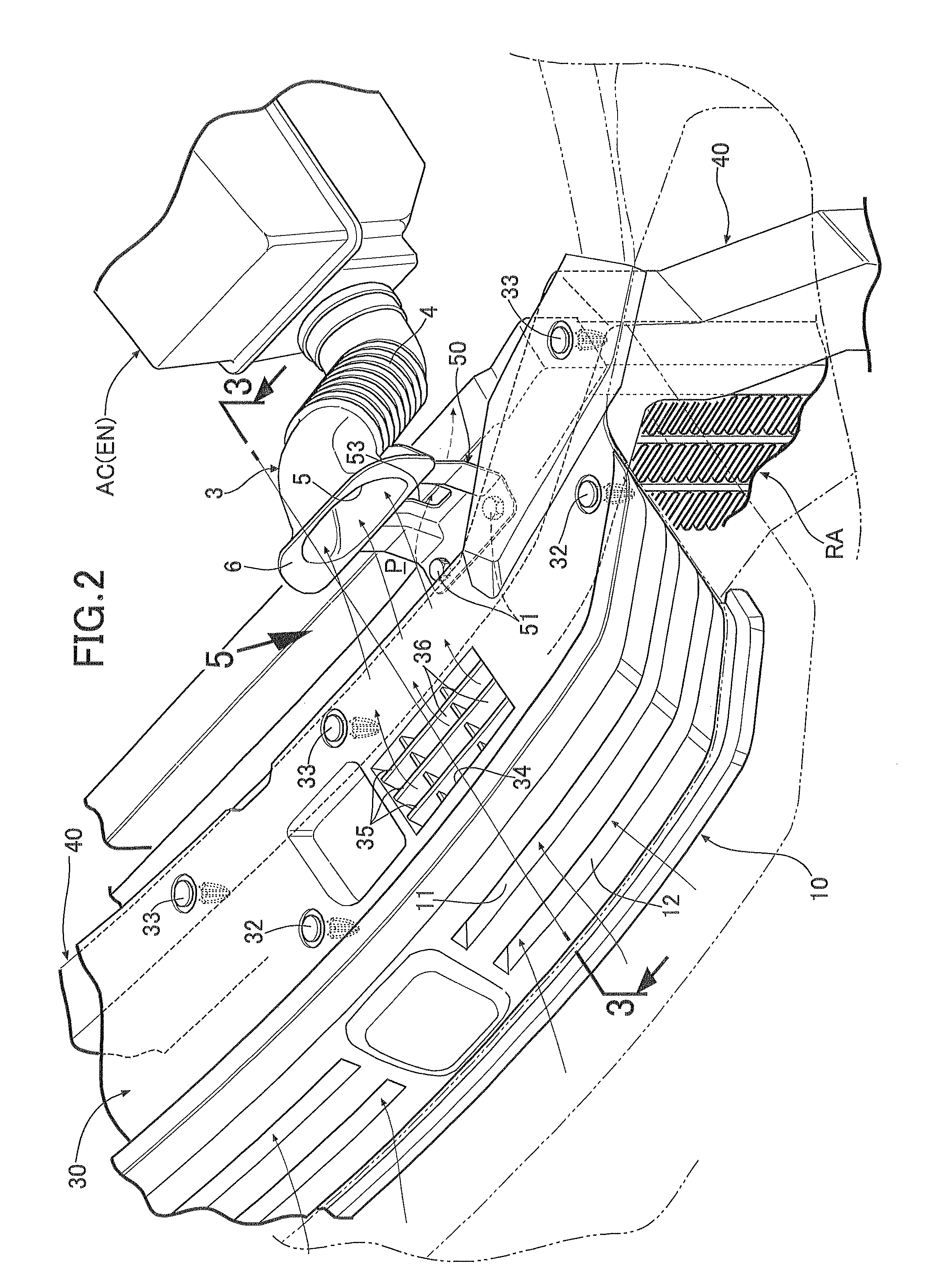

Intake air introducing structure for automobile

ActiveUS8127878B2Good lookingAdd supportInternal combustion piston enginesAir cleaners for fuelCurve shapeEngineering

Owner:HONDA MOTOR CO LTD

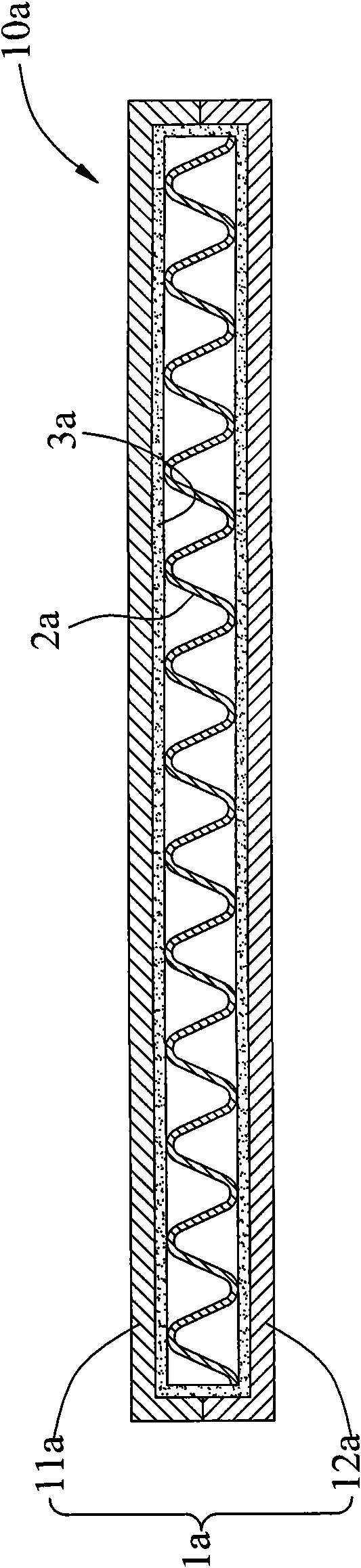

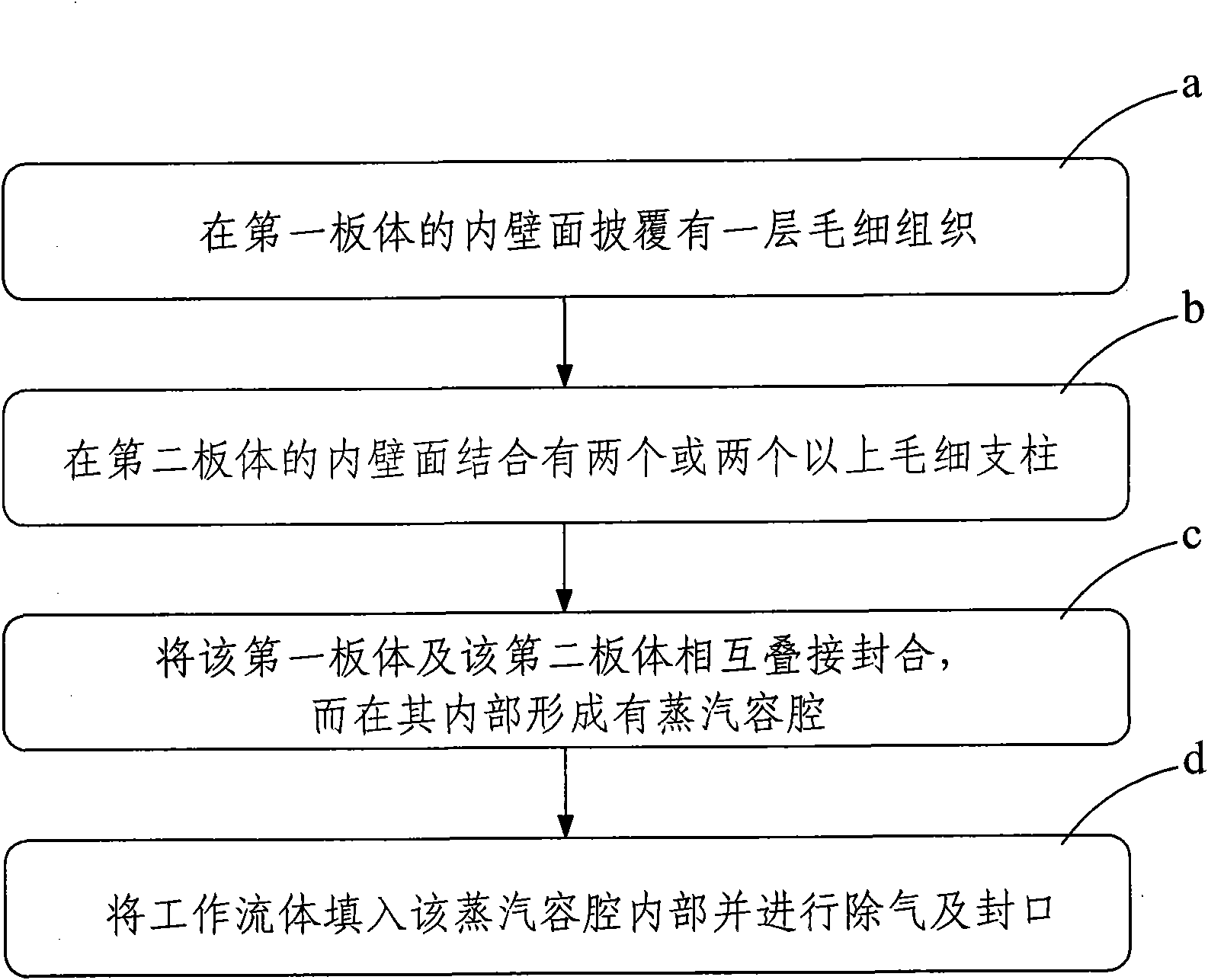

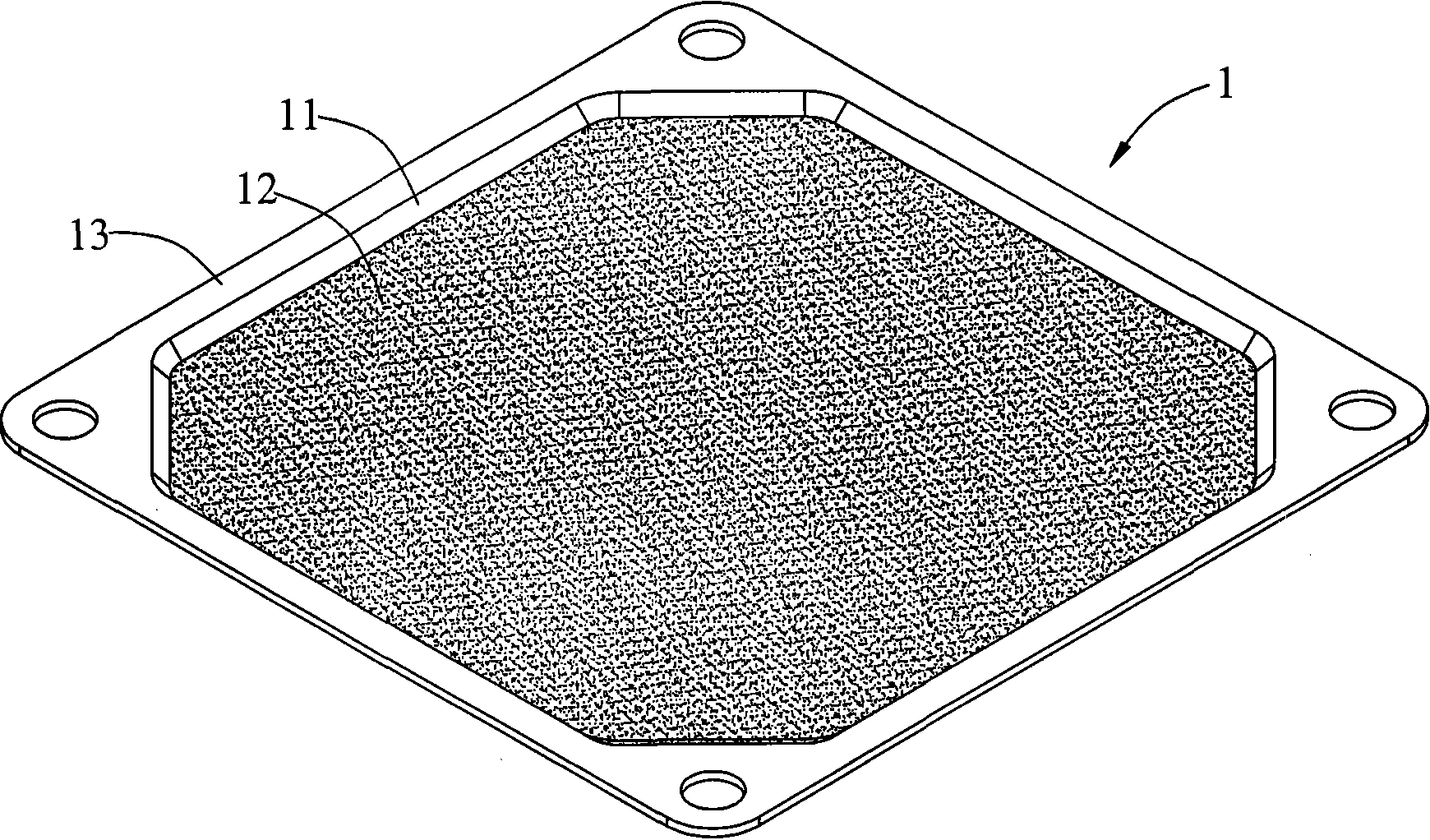

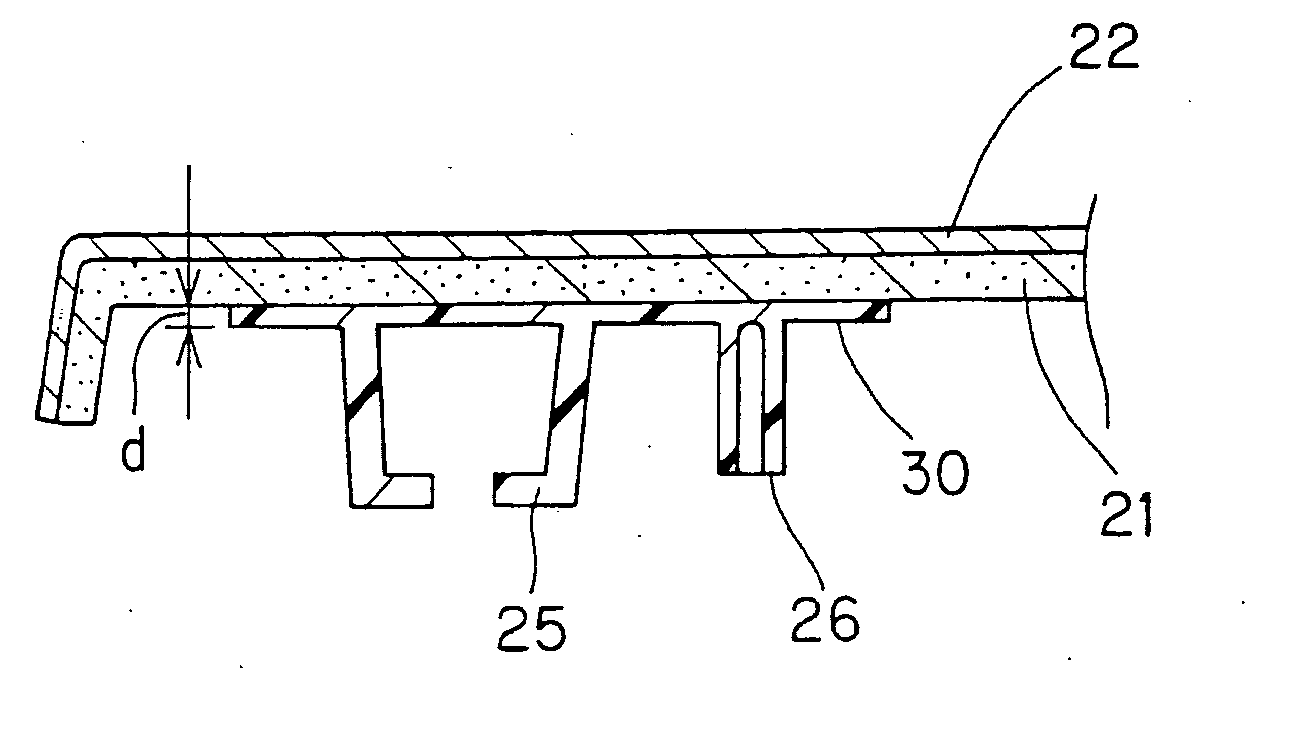

Uniform temperature plate and manufacturing method thereof

ActiveCN101614499AImprove support strengthIncrease return speedIndirect heat exchangersWorking fluidEngineering

The invention provides a manufacturing method of a uniform temperature plate, comprising the following steps: covering a capillary tissue layer on the inner wall surface of a first plate body; combining two or more than two capillary support posts on the inner wall surface of a second plate body; mutually overlapping and hermetically jointing the first plate body and the second plate body, and forming a vapour containing cavity in a jointed body of the first plate body and the second plate body; filling work fluids into the vapour containing cavity, eliminating gas contained in the work fluids, and then closing an opening of the vapour containing cavity. Besides, the invention also provides the uniform temperature plate manufactured by the method. The service life of the uniform temperature plate in prolonged by enhancing the support strength of the uniform temperature plate, increasing the back flow speed of the work fluids, effectively thinning the uniform temperature plate and enlarging the vapour space inside the vapour containing cavity.

Owner:NIDEC CHAUN-CHOUNG TECH CORP

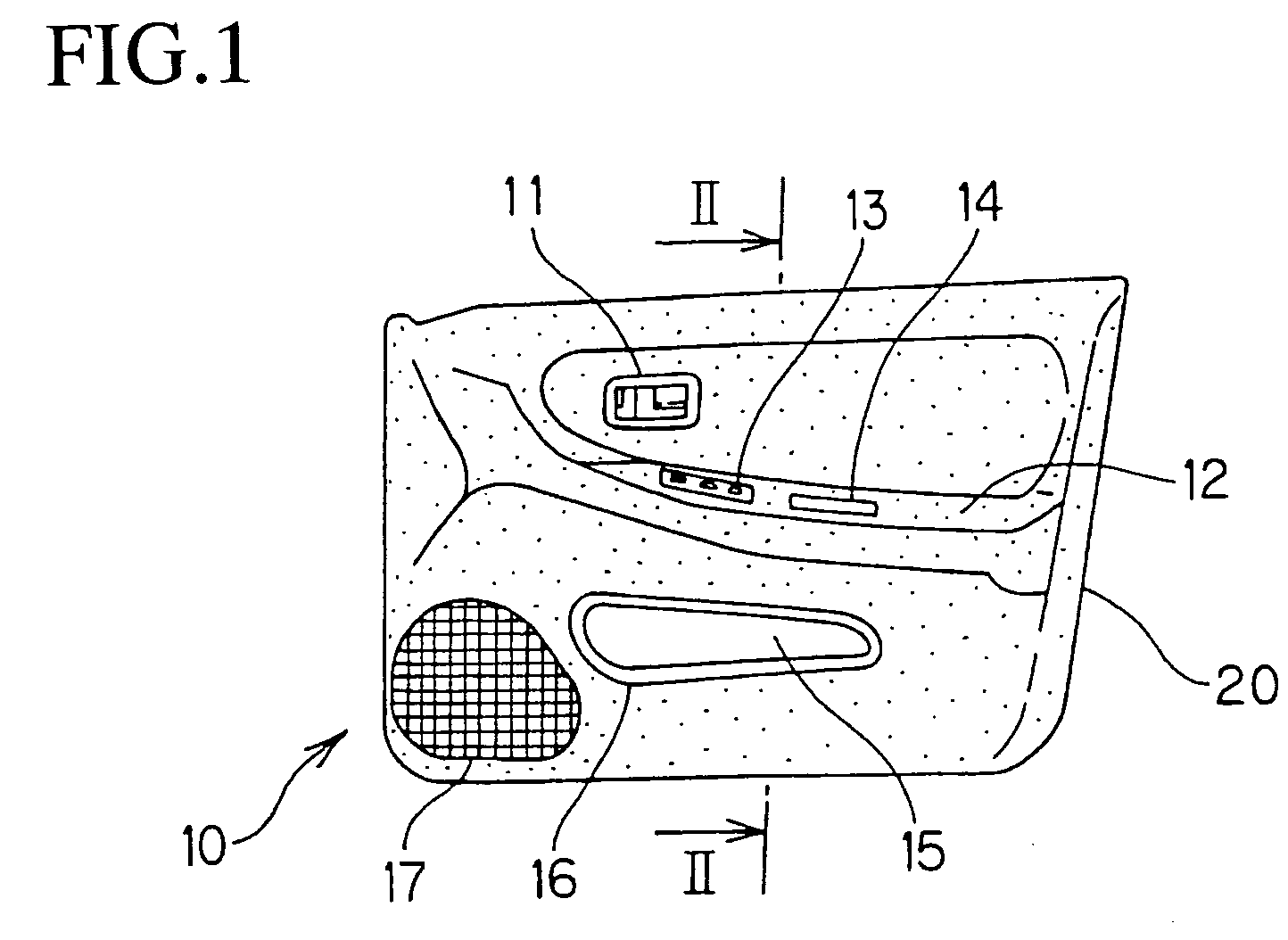

Automotive interior component and method for manufacturing the same

InactiveUS20060222841A1Reduce molded loadReduce in quantitySynthetic resin layered productsVehicle componentsDecrease weightMechanical engineering

Owner:KASAKI IND

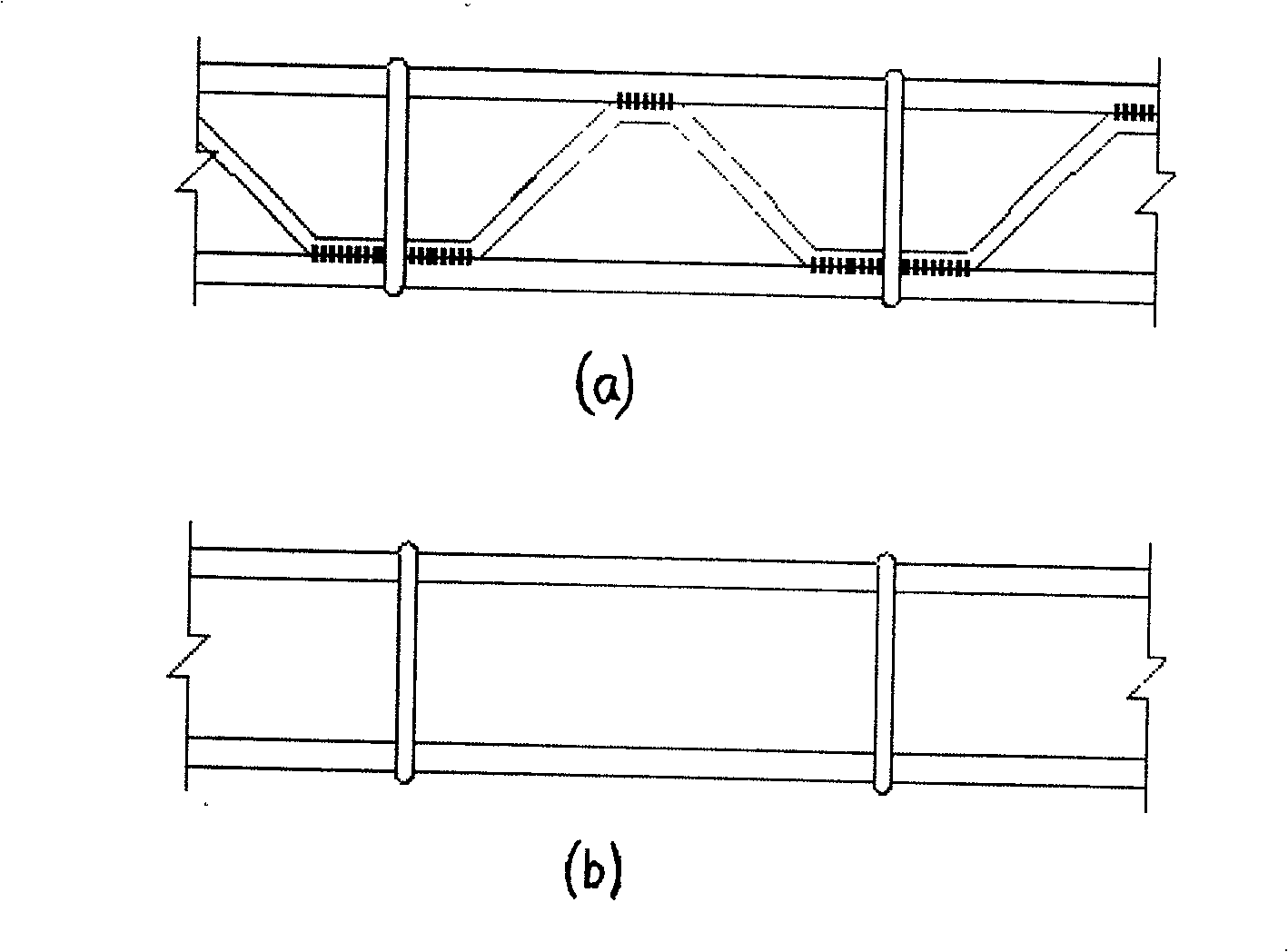

Semi-rigid abnormal beam anchor cable truss roadway supporting system

InactiveCN102182483AGuaranteed integrityEfficient deliveryMine roof capsAnchoring boltsSupporting systemRock bolt

The invention relates to a semi-rigid abnormal beam anchor cable truss roadway supporting system. A metal net is paved on the surface of a roadway, a semi-rigid abnormal beam anchor cable truss is arranged at a coal-rock roof or a roadway side, the semi-rigid abnormal beam anchor cable truss is formed by abnormal beams with semi-rigid nodes and anchor cables or anchor rods, and each abnormal beam is provided with a plurality of anchor cables or anchor rods; the anchor cables and anchor rods are anchored into a rock layer by passing through the abnormal beams and the metal net and apply a prestress to form an extrusion and annular protection function on surrounding rocks; and outer anchor ends of the anchor cables and anchor rods are provided with trays and locks, the trays and the locks make the end heads of the anchor cables or anchor rods tightly matched with the abnormal beams. The invention has the advantages that: (1), the protective surface area is large, the rigidity is high, stability is not easy to loss, and the integrality of the supporting system is ensured; (2), a steel material is saved, the cost is reduced, and the efficiency is increased; (3), the strength is high, and the regulation space of the whole supporting performance is large; and (4) the semi-rigid nodes can play a role of better flexible yield, and the stability and the safety of the whole supporting system are ensured.

Owner:SHANDONG UNIV

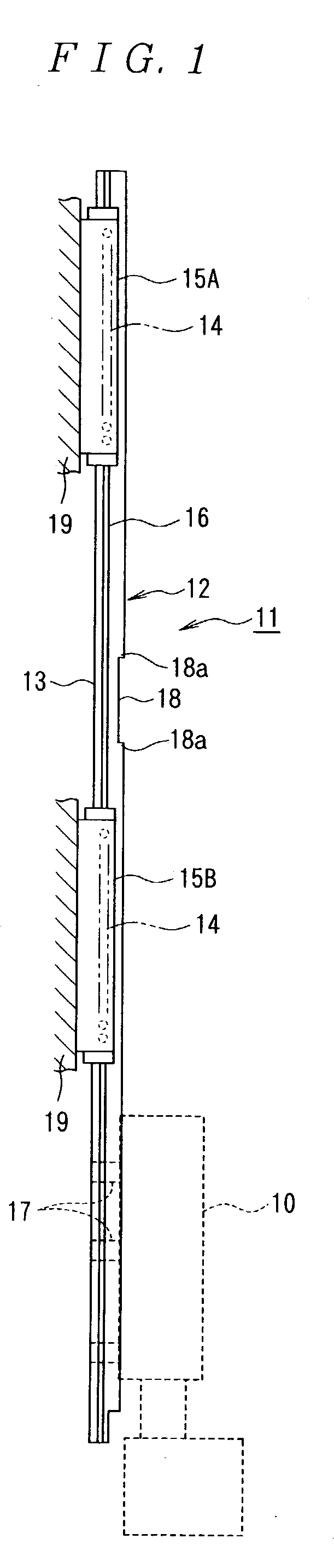

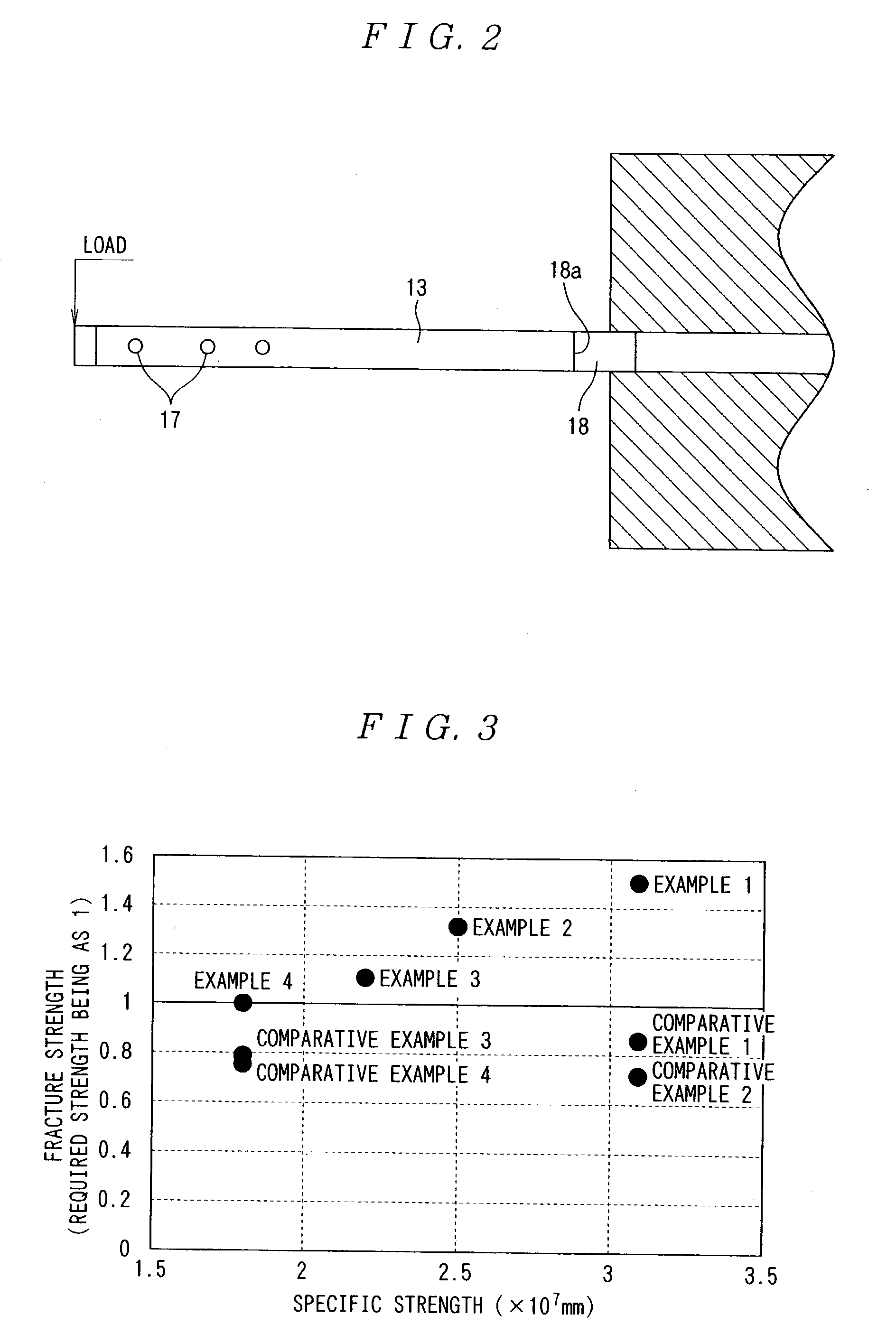

Rolling device

InactiveUS20030198417A1Accuracy be lowerImprovement in support strengthLinear bearingsShaftsMaterials scienceSpecific strength

A guide rail 13 is formed of a ceramic material having a specific strength of 2x10<7 >mm or more and has a planar part with a surface roughness of 0.5 mumRa or less. Further, the guide rail 13 has a recess 18 for avoiding interference with a part to be attached in which the corner 18a of the recess 18 is formed with a radius of curvature of 0.1 mm or more.

Owner:NSK LTD

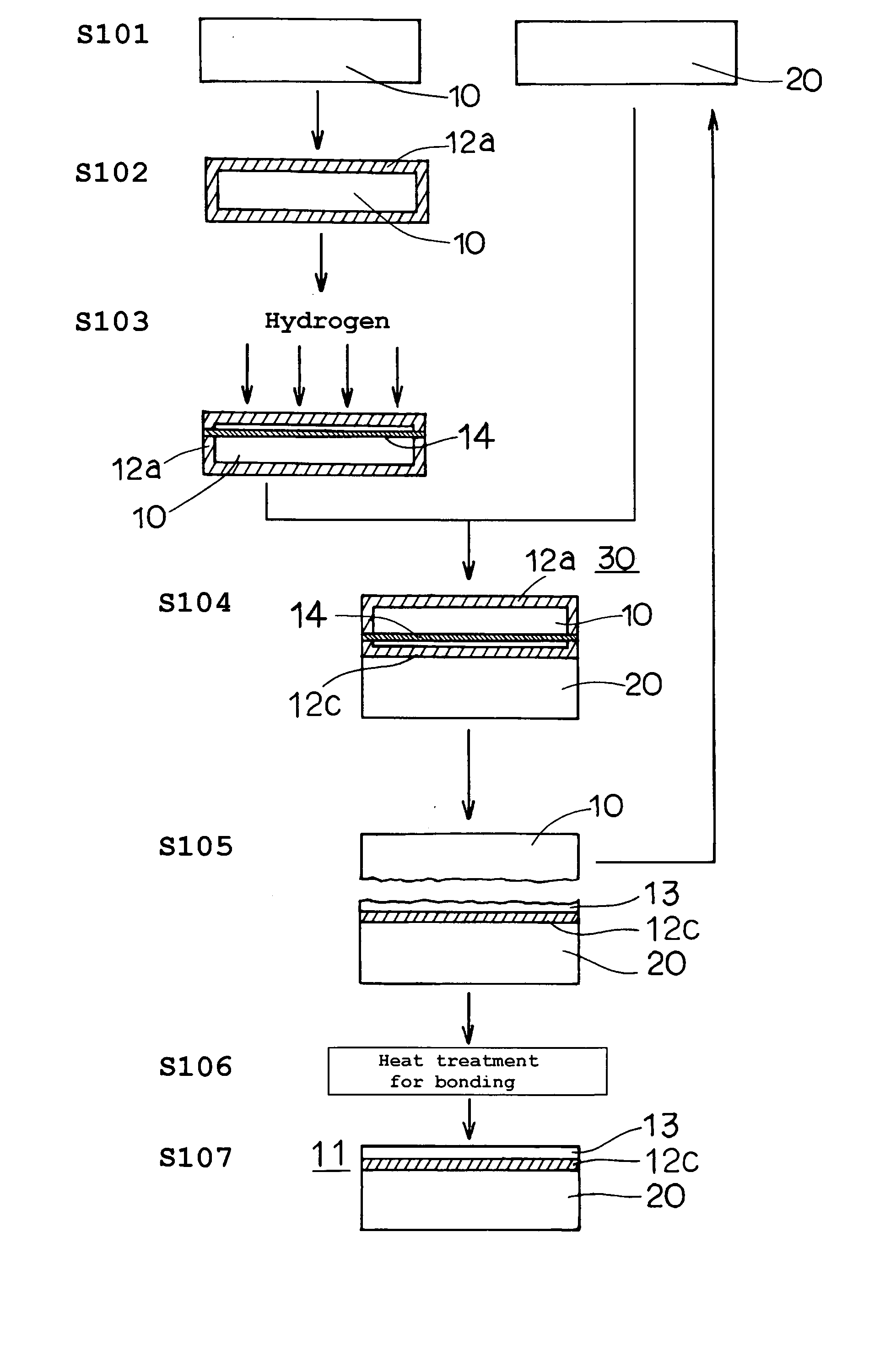

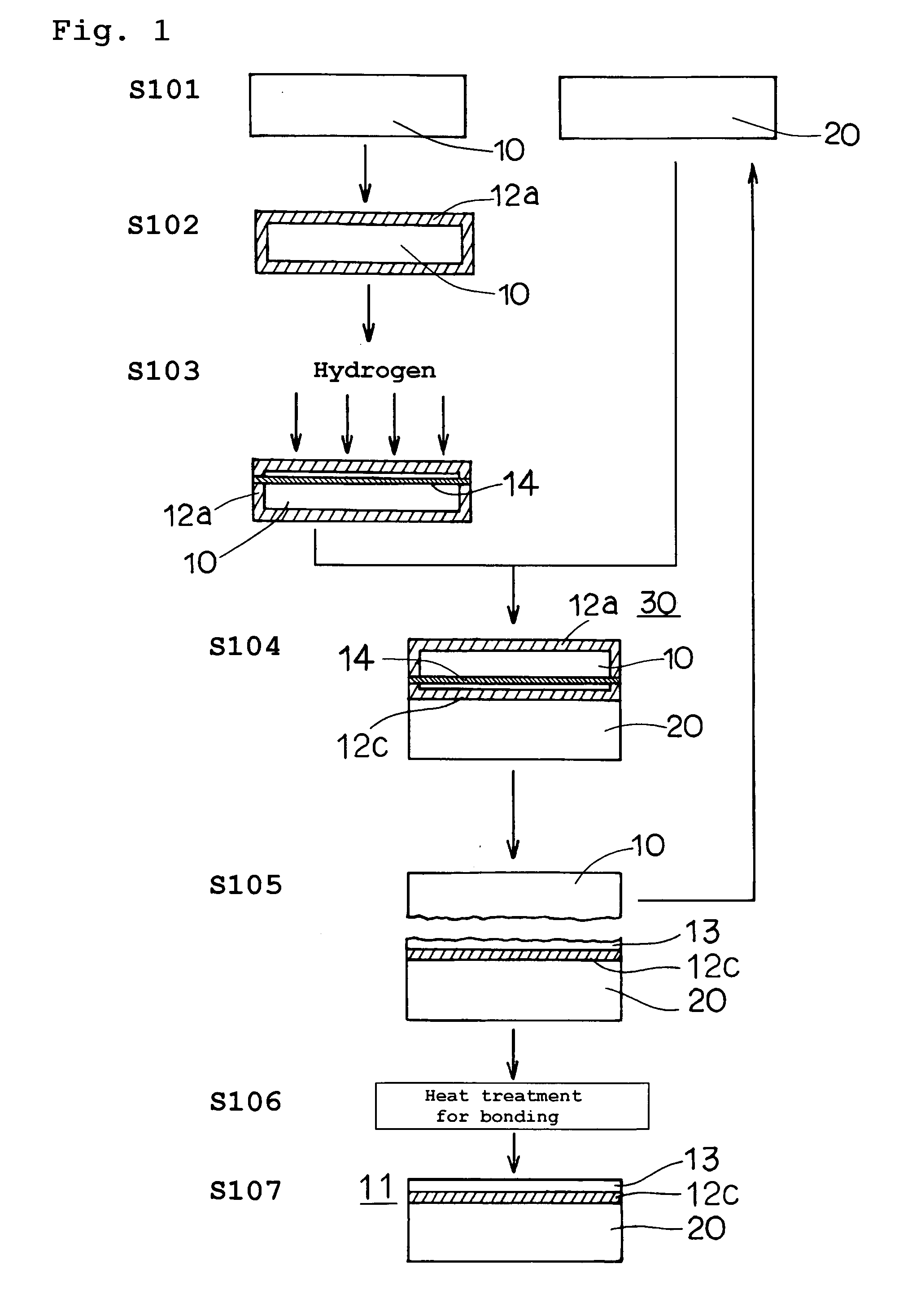

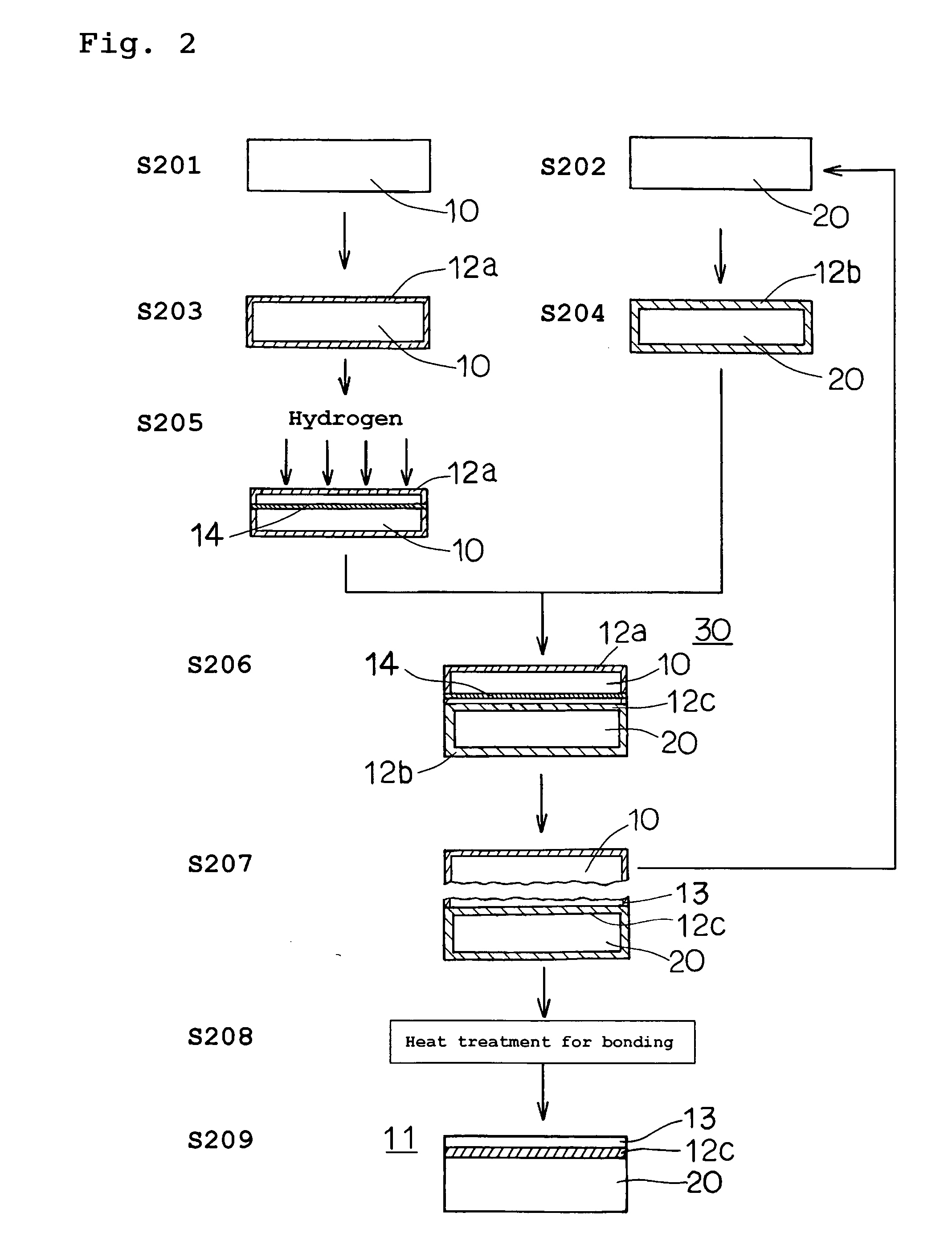

Soi wafer and its manufacturing method

InactiveUS20070032043A1Lower levels of contaminationLower Level RequirementsSolid-state devicesSemiconductor/solid-state device manufacturingWaferingMetal impurities

Since a supporting wafer contains boron of 9×1018 atoms / cm3 or more, therefore a part of the metal impurities in an active layer wafer and the metal impurities in the wafer can be captured by the boron during the heat treatment for bonding. As a result, metal contamination in the active layer can be reduced. Moreover, the wafer strength is enhanced, thus preventing the wafer slipping. Since the wafer has no COP, micro voids are not detected in the LPD evaluation of the active layer, thereby improving the reliability of the evaluation. Such a bonded wafer can be manufactured at a low cast.

Owner:SUMCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com