Overload test and detection device of gas gun

An overload test and detection device technology, applied in the direction of ammunition test, weapon accessories, ammunition, etc., can solve the problems of inconvenient operation and use, and achieve the effect of flexible use, convenient transportation and meeting the requirements of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

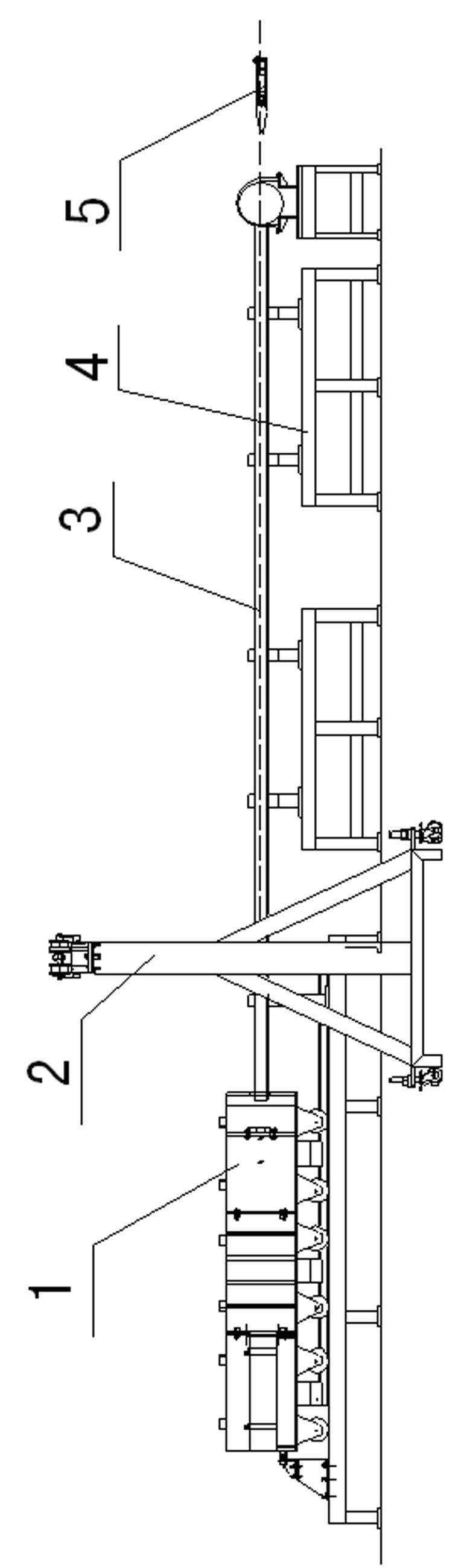

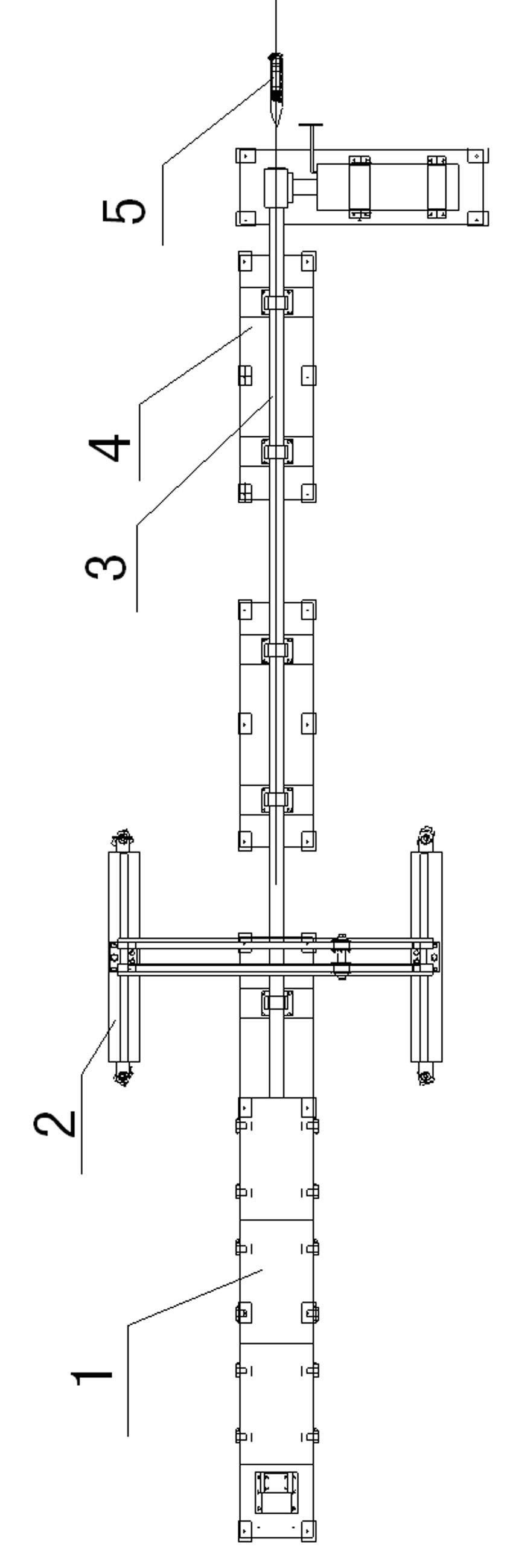

[0033] Such as figure 1 , 2 As shown, a gas cannon overload test detection device includes a frame body 4, an overload test air cannon launcher 3, a charged overload test bomb 5, and an overload test air cannon launcher 3 front end connection overload test are installed on the frame body 4 A protective box 1 and an overload test target replacement device 2 .

[0034] The following is an exploded view of each component:

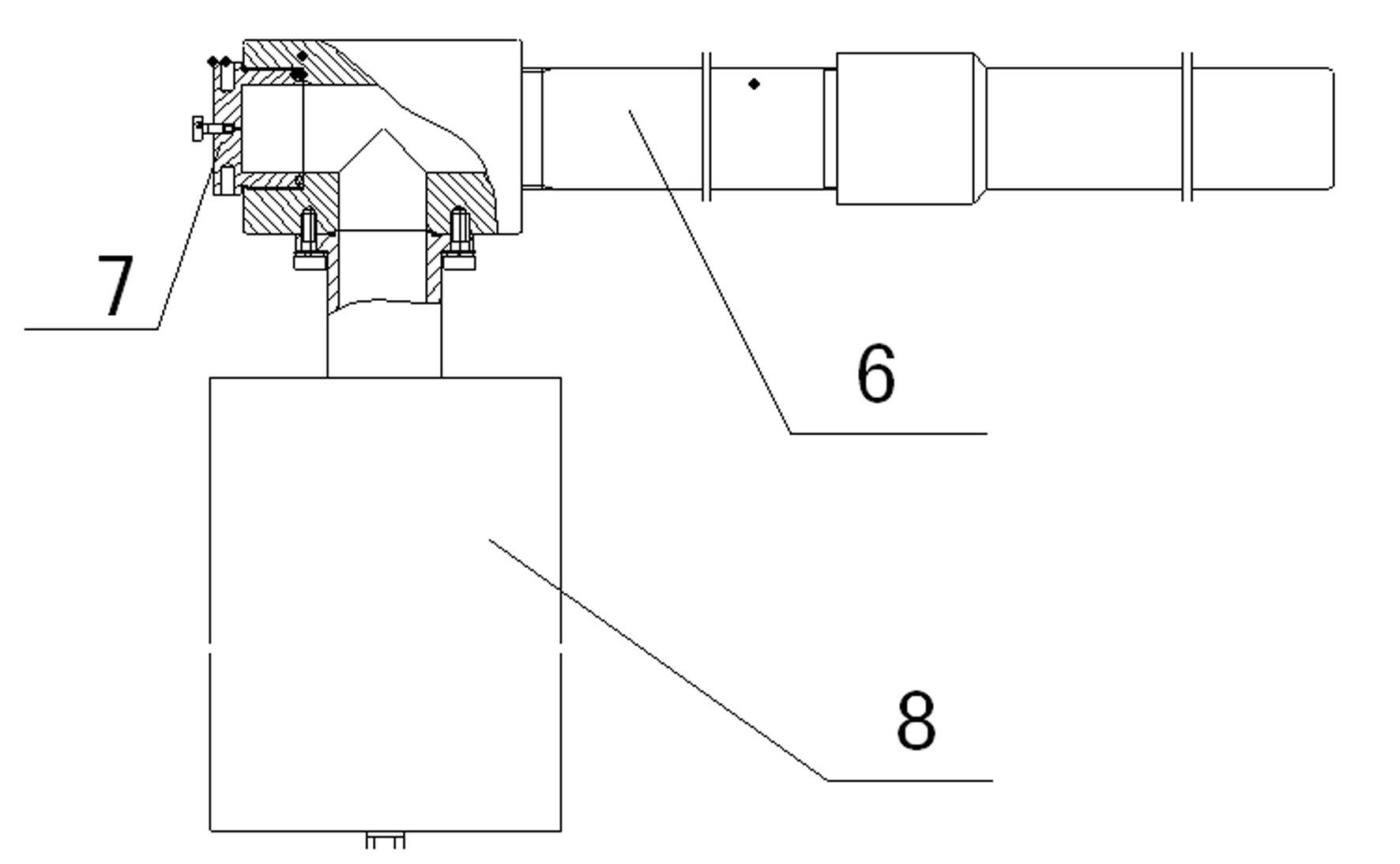

[0035] One, such as image 3 As shown, the described overload test air cannon launching device comprises an air chamber 8, a gun body 6, and the outlet of the air chamber 8 is connected to the side of the gun body 6, and the rear end of the gun body 6 is provided with a movable back cover 7, and is passed through a fixed mount. 9 is fixed on the frame body.

[0036] Such as Figure 4 , 5 As shown, the fixed frame 9 is an I-shaped steel beam, and the upper end is provided with two semicircular fixed sleeves 10, the two sides of the fixed sleeve are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com