Patents

Literature

50results about How to "Fill in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

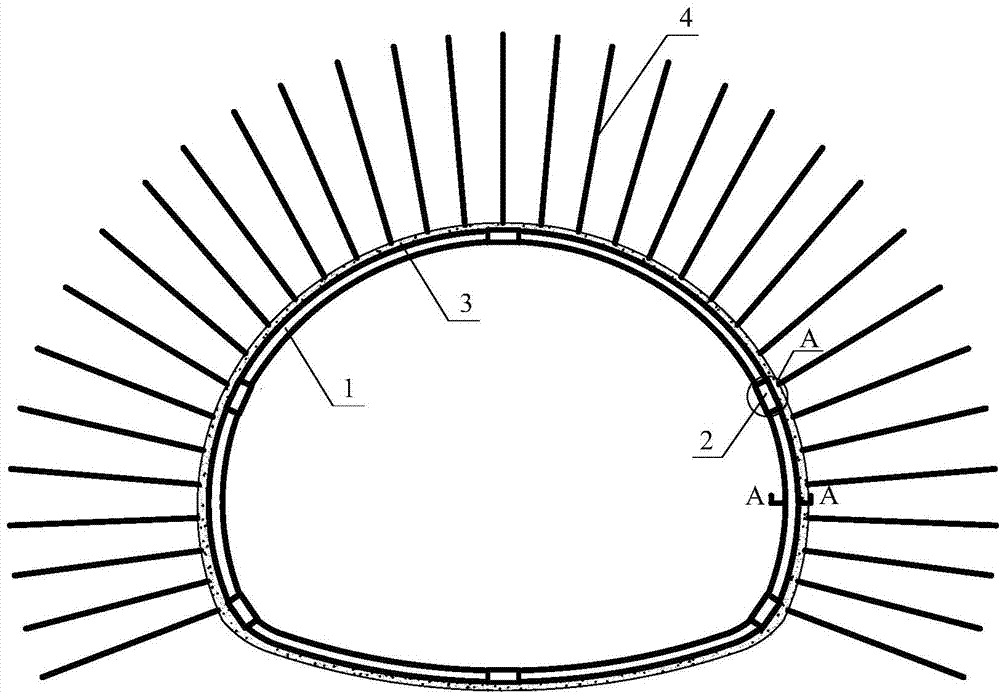

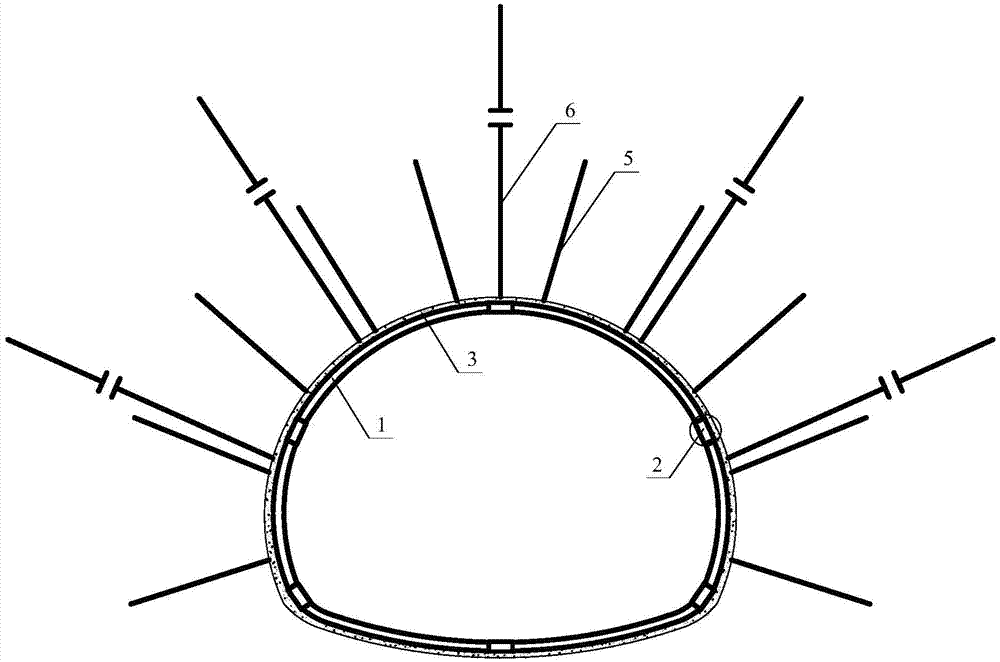

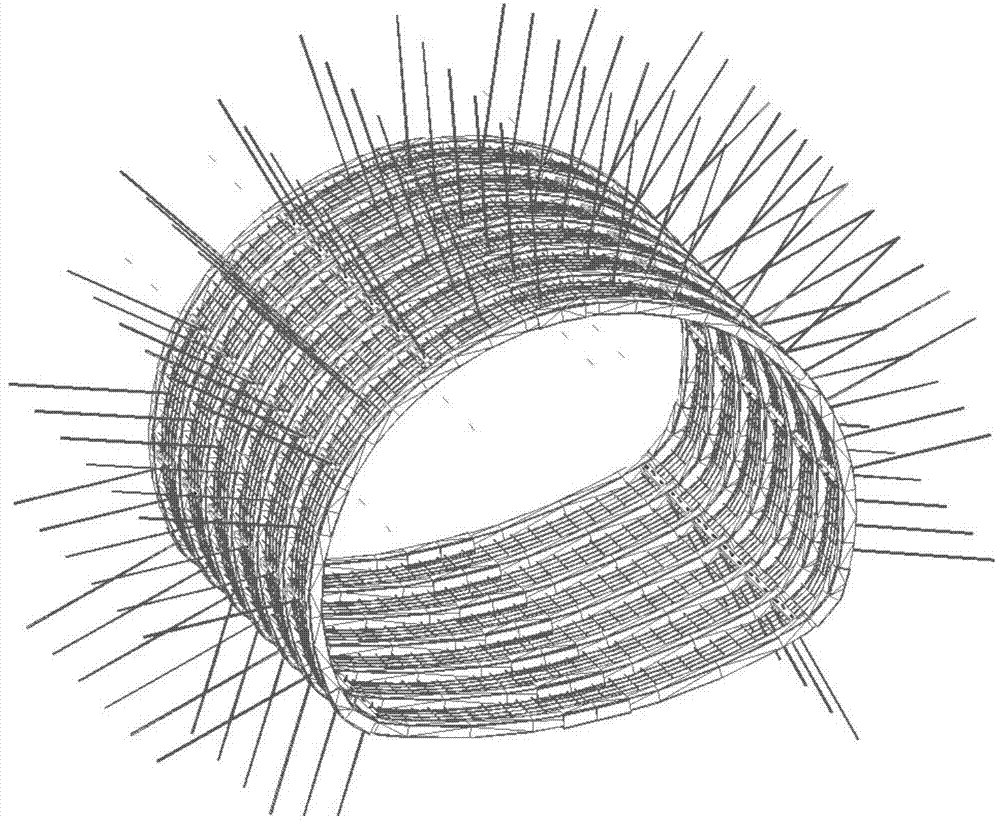

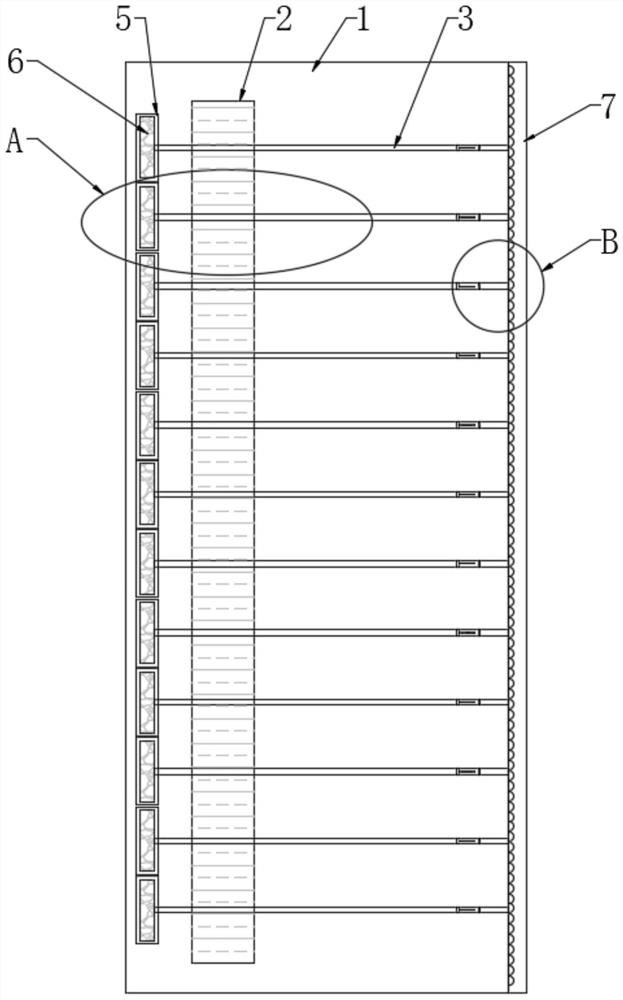

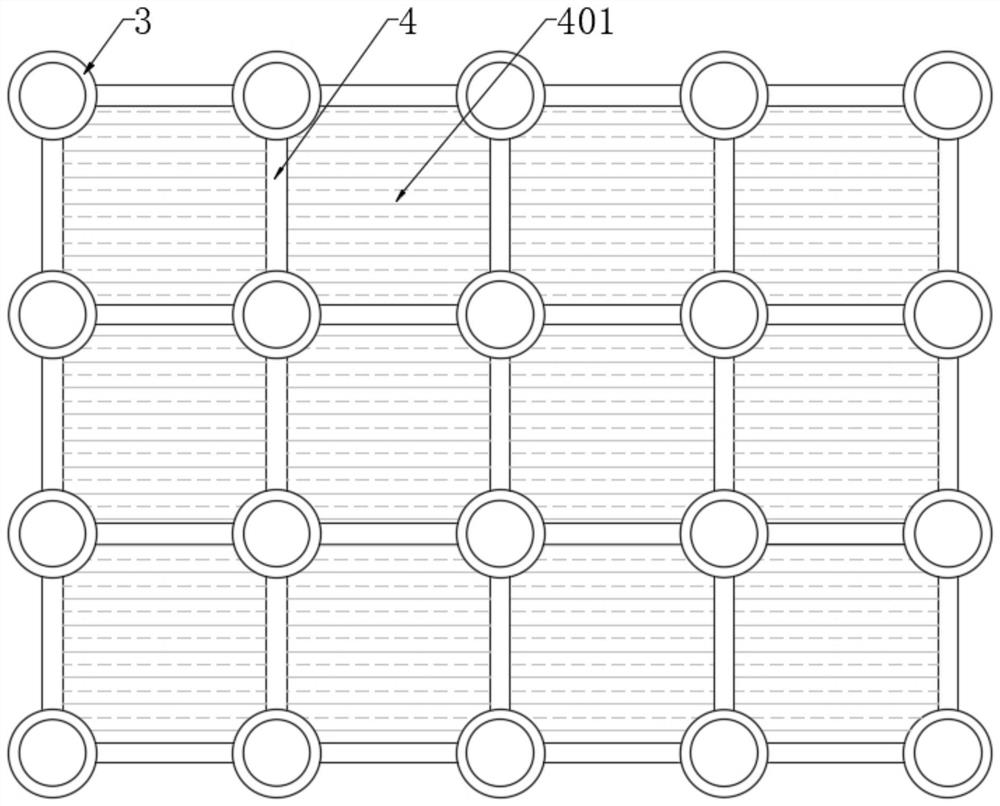

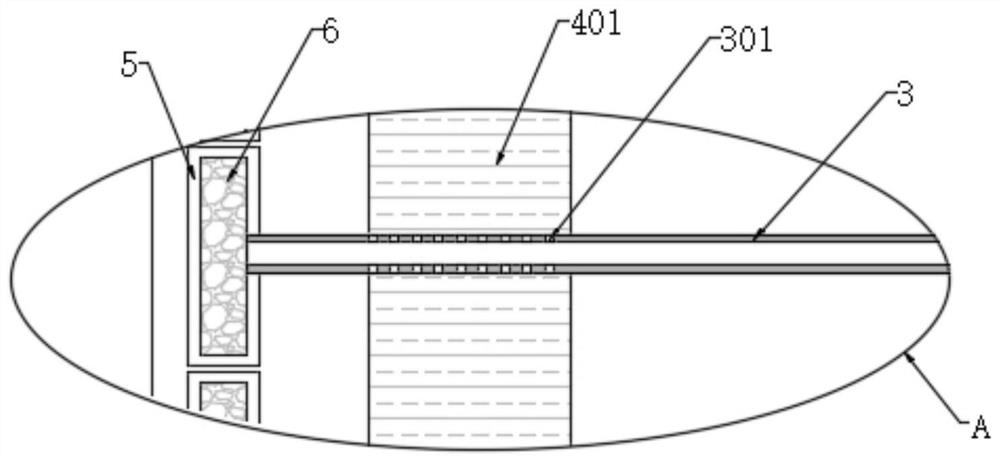

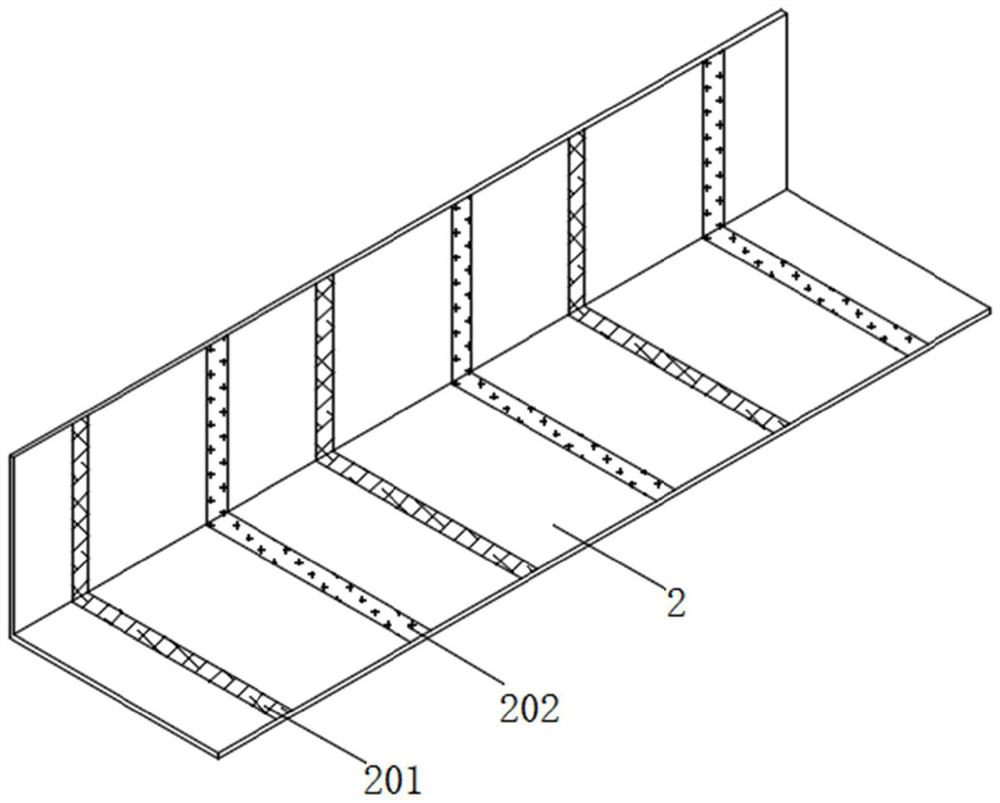

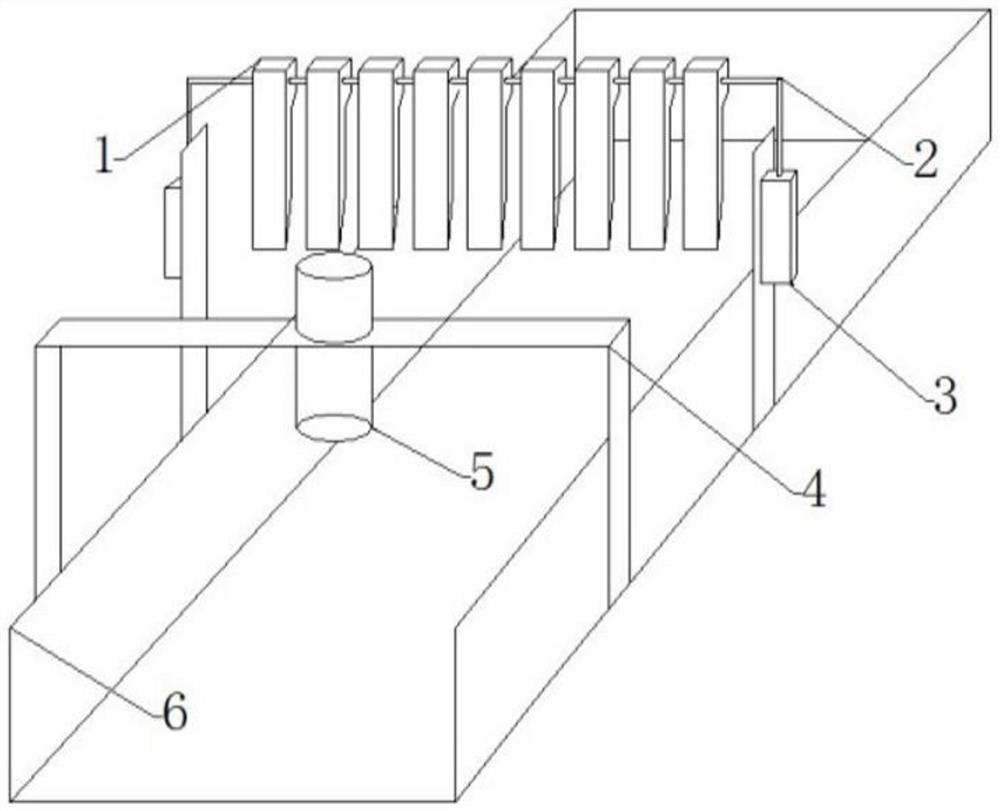

Square steel confined concrete arch center wall back filling bolting-grouting support system and construction method

InactiveCN103615273AImprove self-supporting capacityFill in timeAnchoring boltsSupporting systemRock tunnel

The invention discloses a square steel confined concrete arch center wall back filling bolting-grouting support system and a construction method. The square steel confined concrete arch center wall back filling bolting-grouting support system comprises high-strength anchor rods, grouting anchor rods, grouting anchor cables and multiple square steel confined concrete arch centers, wherein adjacent square steel confined concrete arch centers are connected through longitudinal beams, anchor rod holes are formed in the longitudinal beams, longitudinal beam anchor rods penetrate the longitudinal beams through the anchor rod holes to be anchored into a surrounding rock, a wall back filling layer is arranged between the square steel confined concrete arch centers and the surrounding rock, and the square steel confined concrete arch centers, the wall back filling layer and the tunnel surrounding rock are connected through the longitudinal beam anchor rods. The high-strength anchor rods, the grouting anchor rods and the grouting anchor cables are constructed before the square steel confined concrete arch centers are erected. The square steel confined concrete arch center wall back filling bolting-grouting support system and the construction method are applicable to supporting of underground projects including weak broken surrounding rock tunnels and the like, the square steel confined concrete arch center wall back filling bolting-grouting support system has the advantages of being high in strength, good in stability, reasonable in stress and the like, and the square steel confined concrete arch center wall back filling bolting-grouting support system and the construction method can effectively improve the primary supporting strength after tunnel excavation and ensure the stability of the tunnel surrounding rock.

Owner:SHANDONG UNIV

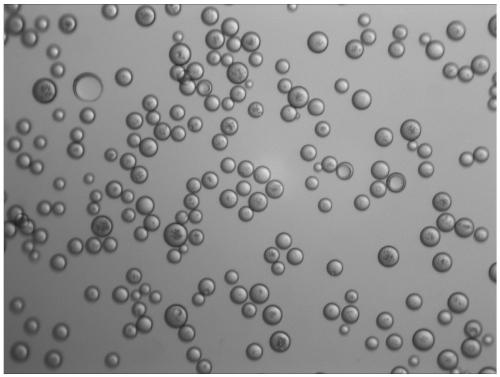

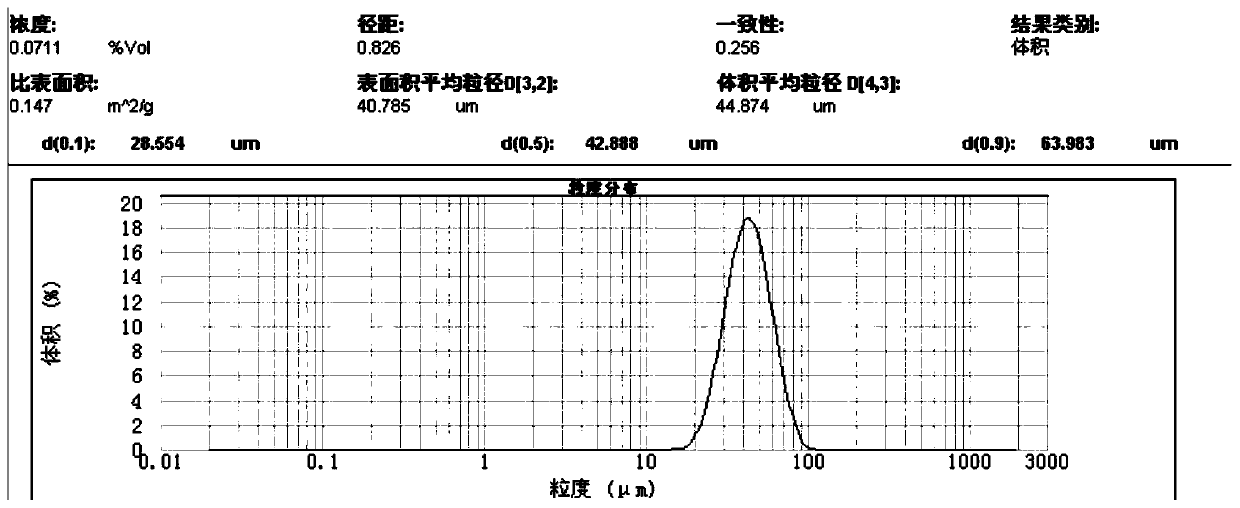

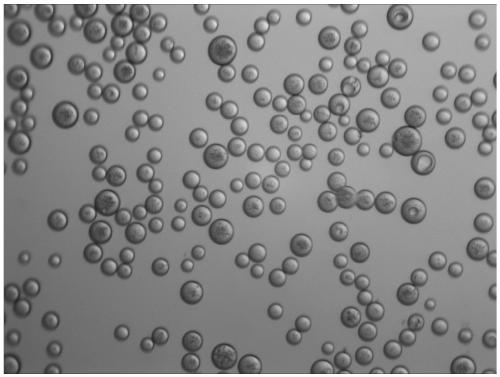

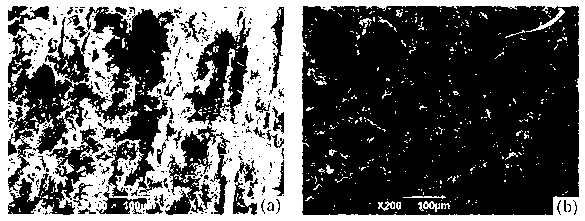

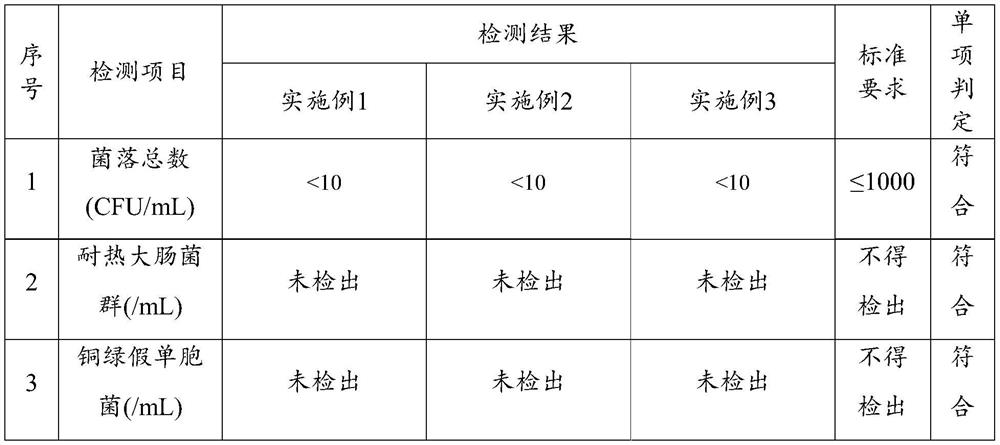

Polylactic acid porous microspheres as well as preparation method and application thereof

InactiveCN111298196AHigh recovery rateGood for volatilizationPharmaceutical delivery mechanismProsthesisFreeze-dryingFibrosis

The invention relates to a preparation method of polylactic acid porous microspheres. The method comprises the following steps: respectively preparing an oil phase solution and a water phase solution;pouring the oil phase solution into the water phase solution, and performing uniform stirring to obtain an O / W emulsion; stirring the O / W emulsion to obtain a polylactic acid microsphere suspension,screening out microspheres with a target particle size from the polylactic acid microsphere suspension, and performing collection to obtain semi-finished polylactic acid microspheres; and performing freeze-drying on the semi-finished polylactic acid microspheres to obtain the finished polylactic acid microspheres. The invention provides the polylactic acid porous microspheres, and the polylactic acid porous microspheres are prepared by using the above method. The invention also provides an application of the polylactic acid porous microspheres as a facial filler. The polylactic acid porous microspheres can produce encapsulation and fibrosis through a chronic inflammatory tissue reaction to stimulate human collagen proliferation to achieve the effect of filling beauty, and the porous structure characteristic can effectively reduce the residual of organic reagents, thereby ensuring the safety of the product.

Owner:CHANGZHOU INST OF MATERIA MEDICA

Preparation method of self-healing silicon-carbide-fiber-reinforced silicon-boron-nitrogen-carbon composite material

InactiveCN104529499AImprove high temperature stabilityHigh resistance to crystallization temperatureCarbon compositesSelf-healing

The invention relates to a preparation method of a self-healing silicon-carbide-fiber-reinforced silicon-boron-nitrogen-carbon composite material, which comprises the following steps: (1) preparing a polyborosilazane (PBSZ) precursor; dissolving the PBSZ precursor in a toluene solution under the protection of N2 to obtain a PBSZ toluene solution; transferring into a pipe furnace, crosslinking under the protection of N2, grinding and screening to obtain SiBNC precursor powder; (2) preparing SiC fibers into a prefabricated part, carrying out hot pressing on the SiBNC precursor powder and SiC fiber prefabricated part, cooling and demolding to obtain a composite material; and transferring into a pipe furnace in an N2 protective atmosphere to perform ceramization, and finally, sintering. The method is simple in technique, easy to operate and low in cost; and the prepared silicon-carbide-fiber-reinforced silicon-boron-nitrogen-carbon composite material is uniform and compact, has the advantages of favorable high-temperature stability and excellent oxidation resistance, and especially has self-healing performance.

Owner:DONGHUA UNIV

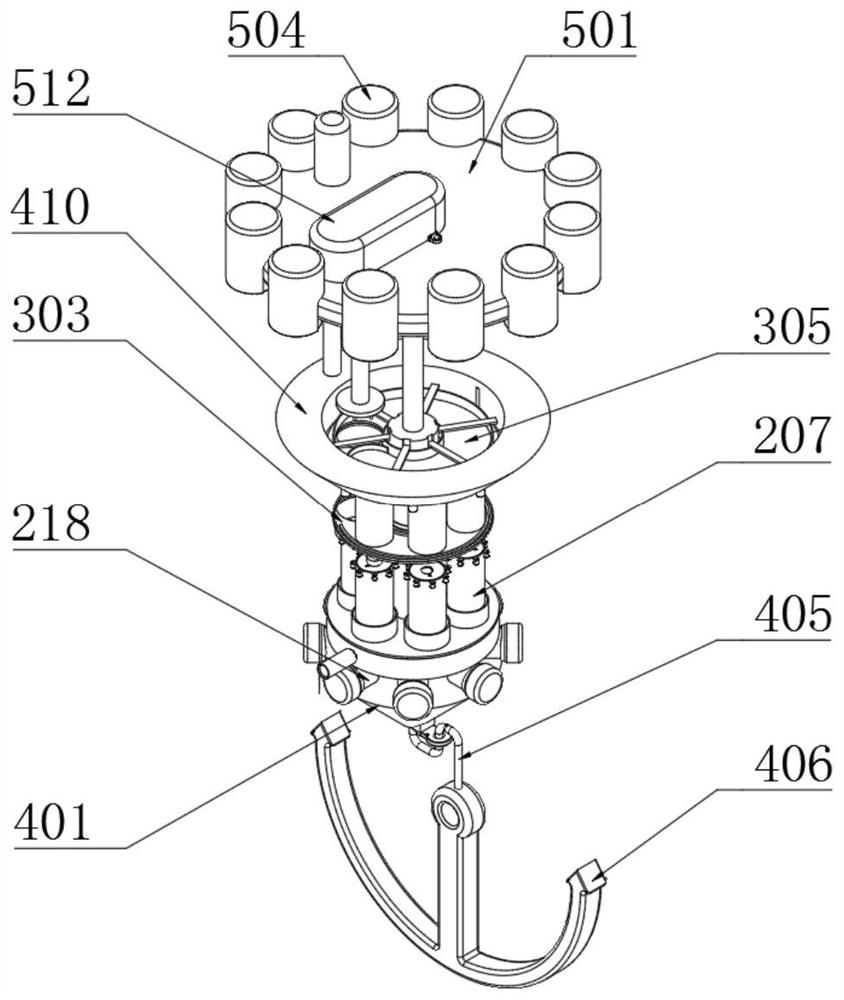

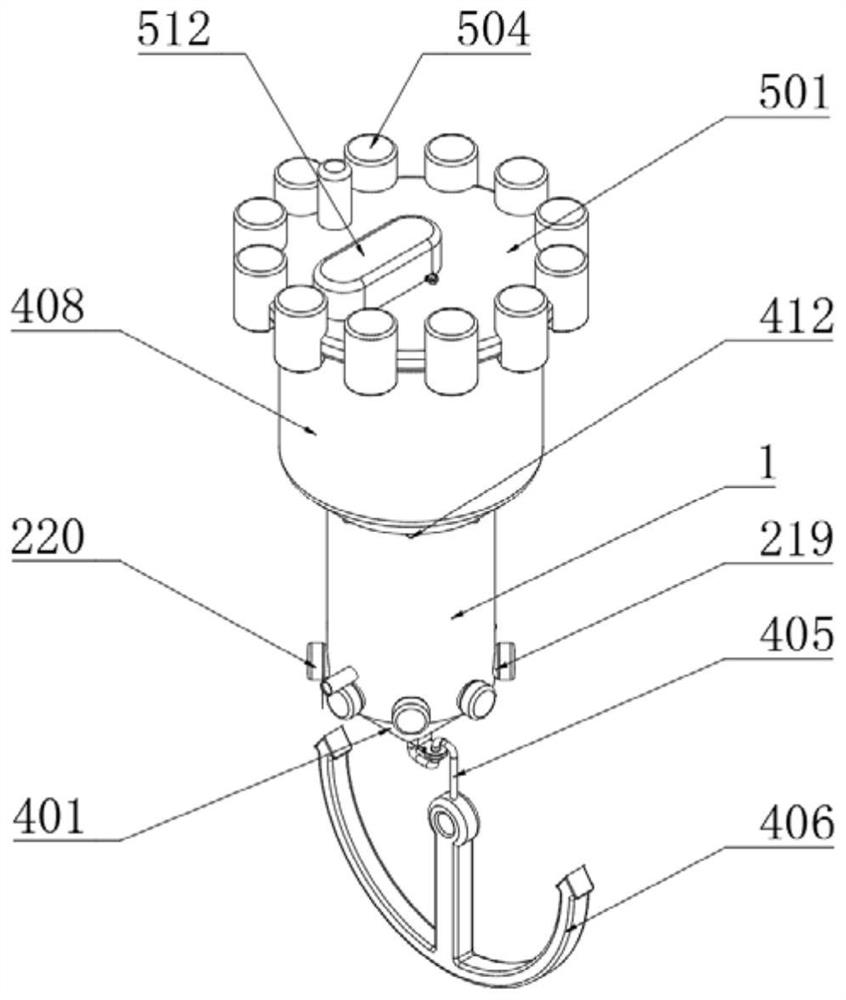

Marine detection device convenient for sampling

InactiveCN113008626AScientific and reasonable structureEasy to useWithdrawing sample devicesTesting waterWater storageBuoy

The invention discloses a marine detection device convenient for sampling. A fixed collecting plate is welded to the inner side of a mounting pipe, an ascending pipe penetrates through the top end of the fixed collecting plate, an extraction block is placed on the inner side of the ascending pipe, an extraction electric push rod is connected to the top end of the extraction block, a connecting rope is slidably clamped to one end of the inner side of a storage cylinder, and a buoy is connected to one end of the connecting rope. The other end of the connecting rope is connected with a U-shaped clamping plate, and a sealing limiting block is clamped to the inner side of the sliding opening. Sea water is discharged into the storage cylinder through the water outlet pipe, the needle cylinder principle is utilized, the sea water stably enters the storage cylinder, meanwhile, the injection height of the sea water is limited, the situation that the sea water overflows due to the fact that the sea water is injected from the top end is avoided, the service life of the sea water storage device is prolonged, and the service life of the sea water storage device is prolonged. The water inlet is limited through the limiting spring and the sealing limiting block, seawater is prevented from spilling out when the storage barrel moves, and therefore the sealing effect of the storage barrel is guaranteed, internal parts are protected, and the parts are prevented from being soaked in the seawater.

Owner:杨高盛

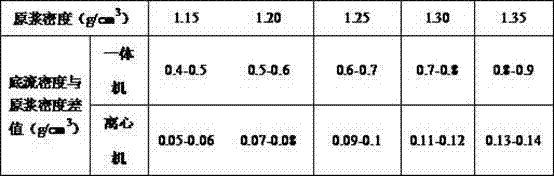

Extending method of horizontal well safe density window

ActiveCN104712287AAvoid expansionImprove pressure bearing capacityDrill bitsFlushingMud systemsWell drilling

The invention relates to an extending method of a horizontal well safe density window particularly. The extending method comprises the steps that 1 1.5% of bentonite powder, 1% of saw dust, 1% of blocking agent and 1% of mica powder are added into 100 squares of drilling fluid gradually in a borehole with a standard of 83 / 8''according to a mass-volume percent; 2 the displacement of a drilling pump is lowered when the drilling pump enters a leakage layer; 3 when the leakage layer opens, the rate of penetration is controlled, solid control is strengthened at the same time, and harmful solids in the drilling fluid are removed; 4 the well deviation in an oil shale section is controlled; 5, the orientation of the borehole is conducted with a roller bit. According to the extending method of the horizontal well safe density window, blocking agents of different granularity are added gradually through a mud system, the leak-proofing formula is improved, the concentration of the blocking agent when added into the well is guaranteed to be at 3%, blocking is strengthened, and the strength of a leaking well wall is improved; the displacement of the drilling pump is lowered, the expansion of a crack is prevented, and the collapse pressure of the balance oil shale section is lowered, so that the safe density window is extended.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

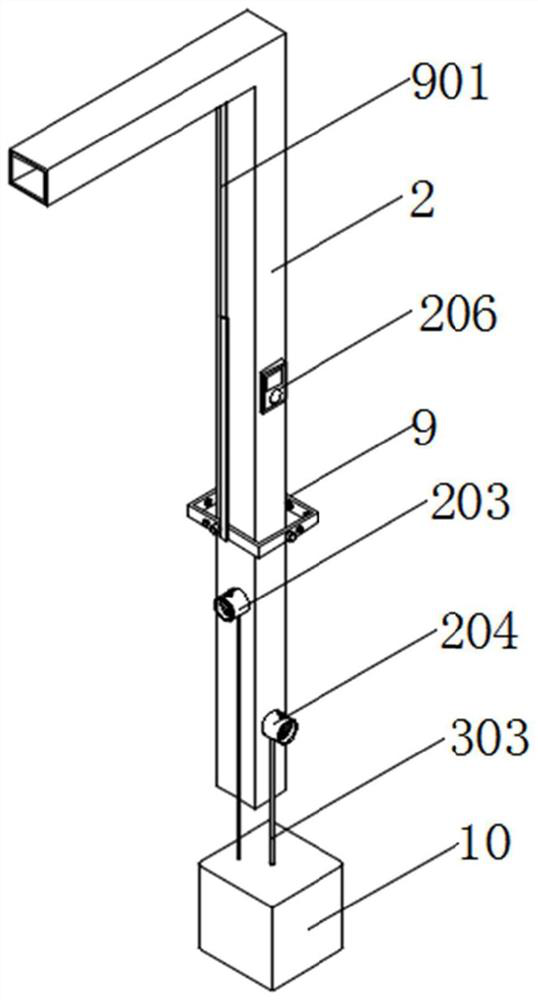

Rectifying and repair structure for inclined pile foundation

The invention discloses a rectifying and repair structure for an inclined pile foundation, applies to the field of pile foundation repair, and solves the technical problem of complicated operation ofthe pile foundation repair. According to the technical scheme, the rectifying and repair structure for the inclined pile foundation comprises a positioning device, wherein the positioning device comprises a front positioning plate and two side positioning plates in sliding connection with the front positioning plate, and a locking mechanism is arranged between each side positioning plate and the front positioning plate; a straightening device is connected with one side of the positioning device and comprises a hydraulic jack connected with the front positioning plate, the hydraulic jack comprises a cylinder body and a telescopic push rod, and a push plate is connected onto the telescopic push rod; a flow guiding groove allowing slurry to circulate is formed in one side, opposite to the telescopic push rod, of the push plate. The rectifying and repair structure for the inclined pile foundation has technical effect that for operators, the repair work of the pile foundation is simple andeasy to operate.

Owner:江苏地基工程有限公司

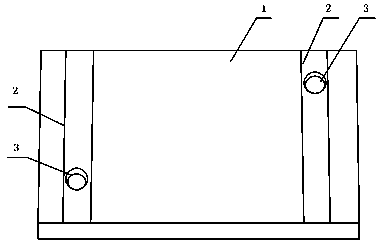

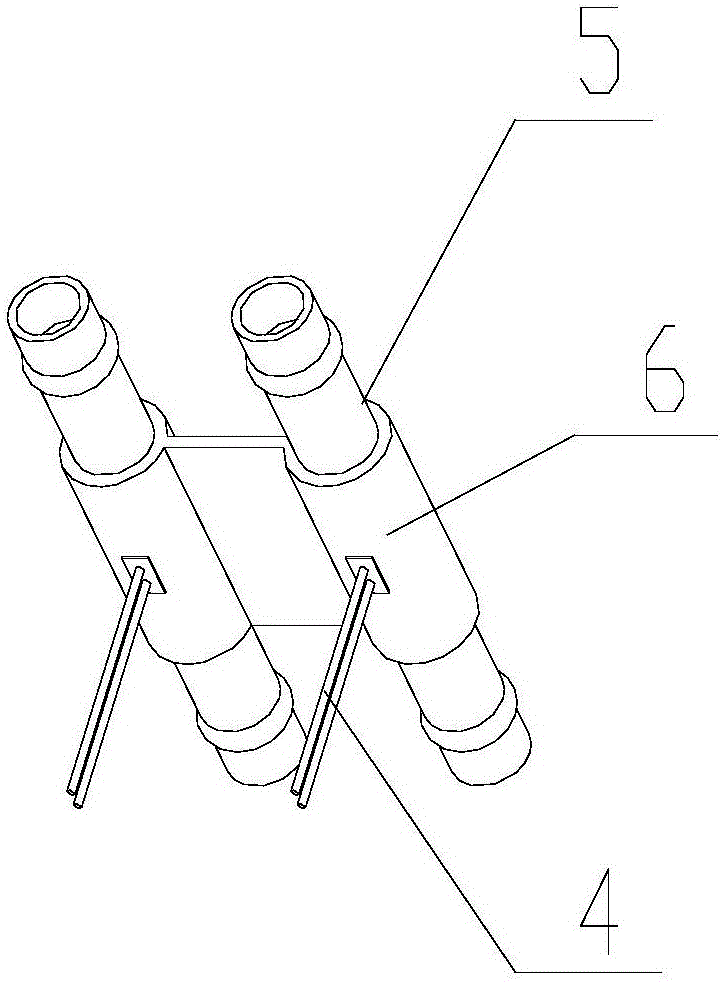

Connecting process of far infrared nano electrothermal film electrode blind holes and wire

InactiveCN103997800AFill in timeClosely connectedOhmic-resistance electrodesSilver pasteFar infrared

Provided is a connecting process of far infrared nano electrothermal film electrode blind holes and a wire. The connecting process is characterized in that two blind holes are formed in the two ends of a substrate, electrode silver paste bands at the two ends are silkscreened, the substrate and the electrode silver paste bands are heated firstly, then silver paste is injected into the blind holes, one end of the wire is placed in the blind holes, repeated drying and sintering and secondary silver paste injection are carried out at different temperatures, an electrode and the wire can be firmly connected under the condition of switch-on and high temperature, the process can improve the stability of far infrared nano electrothermal film products, the probability that the connecting wire is loosened and falls off at the high temperature is greatly reduced, and the service life of a far infrared nano electrothermal film is prolonged.

Owner:KMT纳米科技有限公司

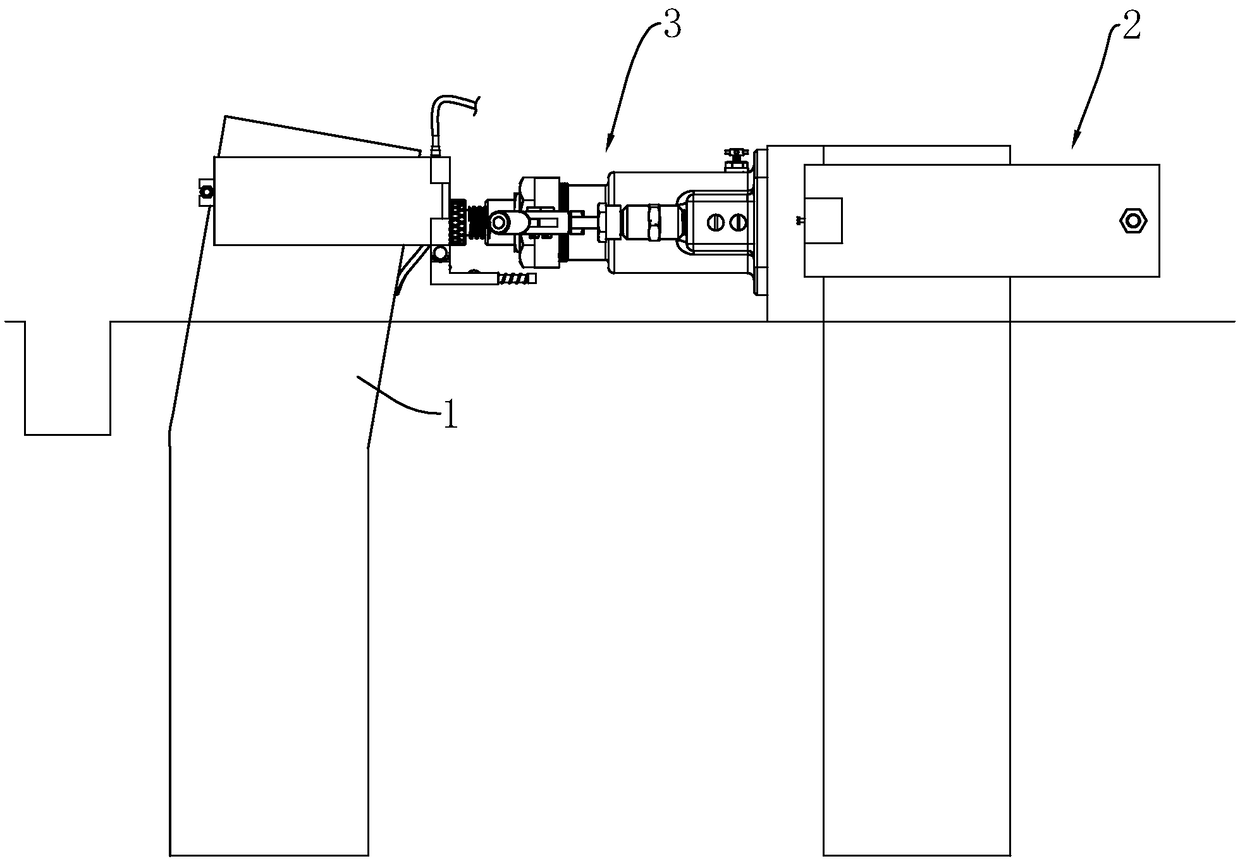

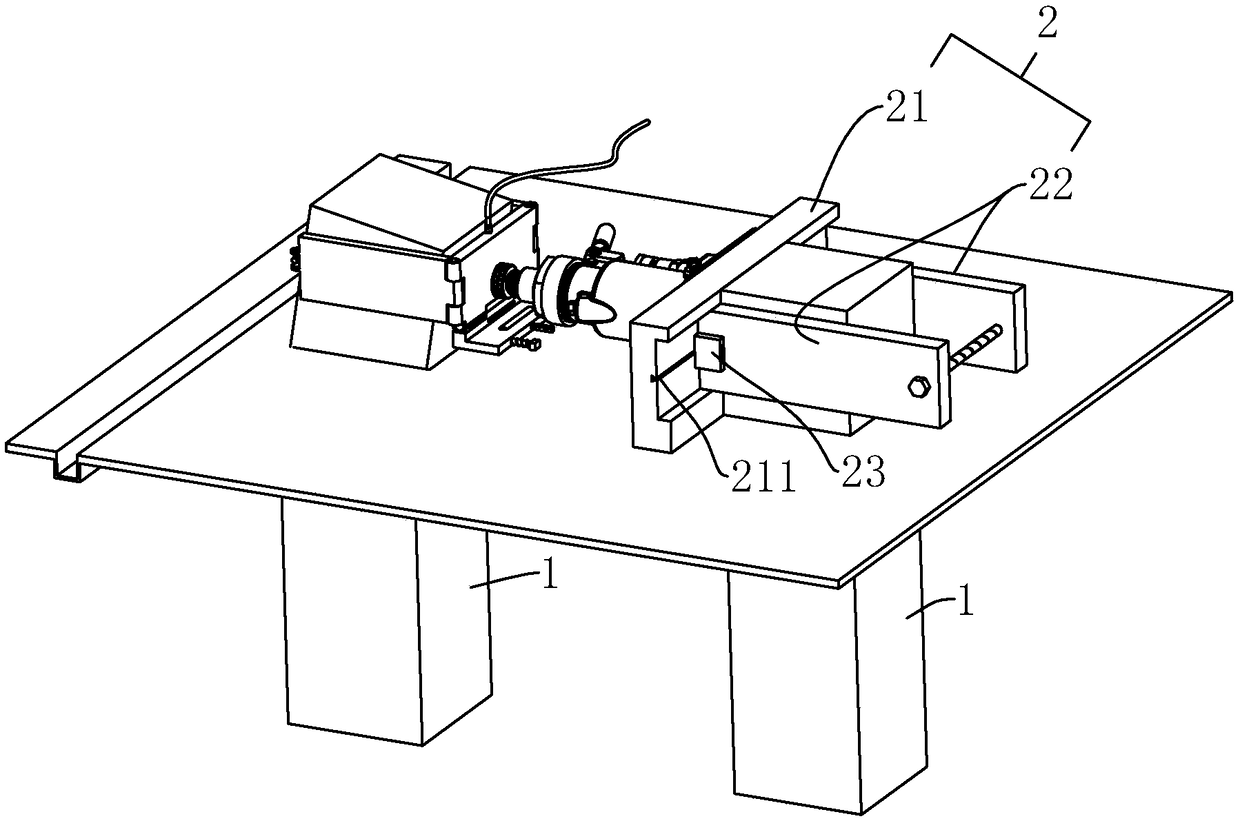

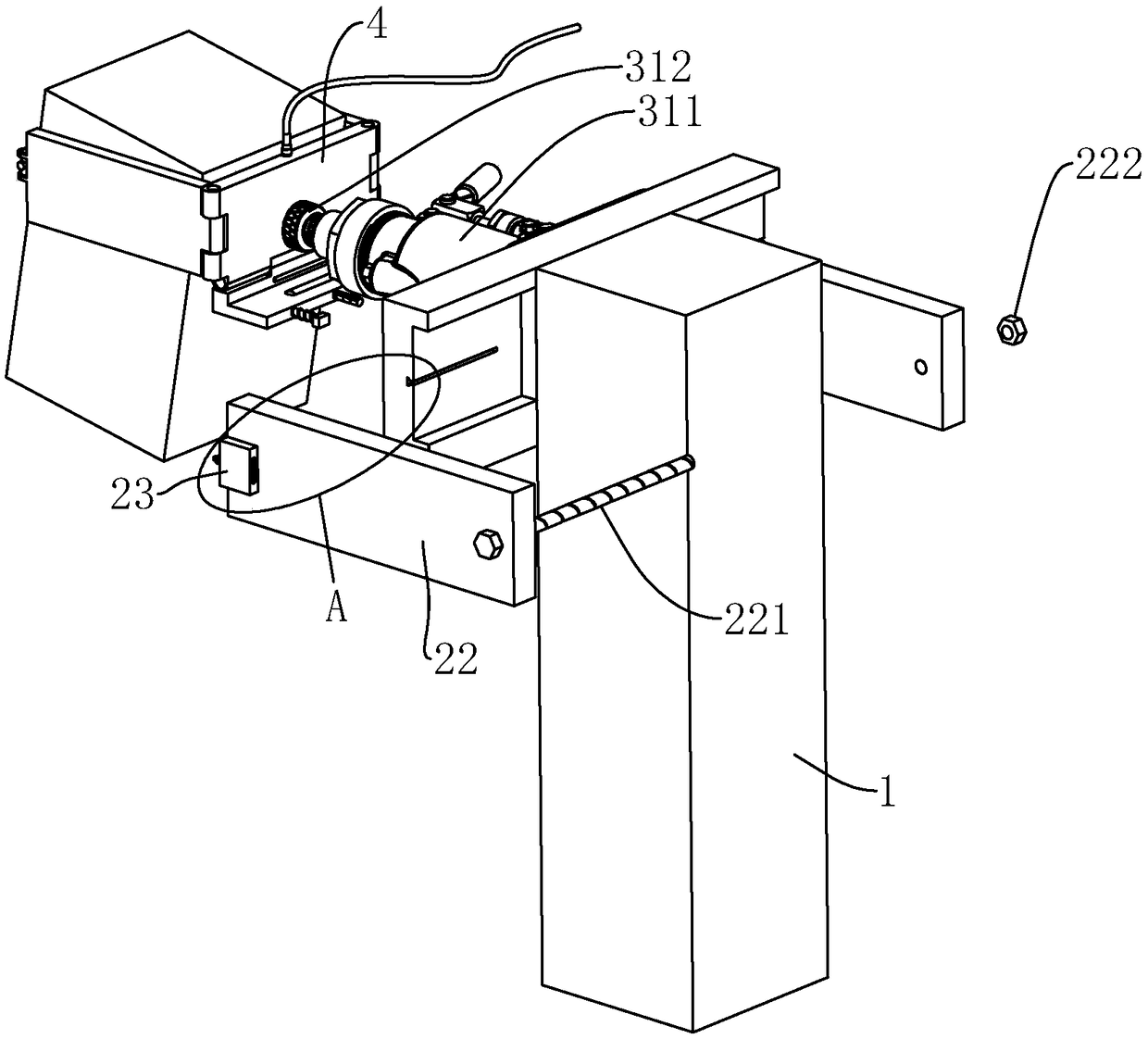

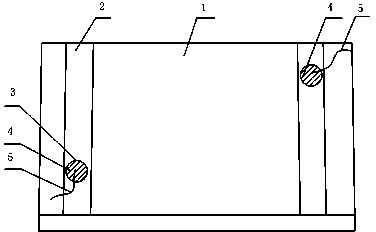

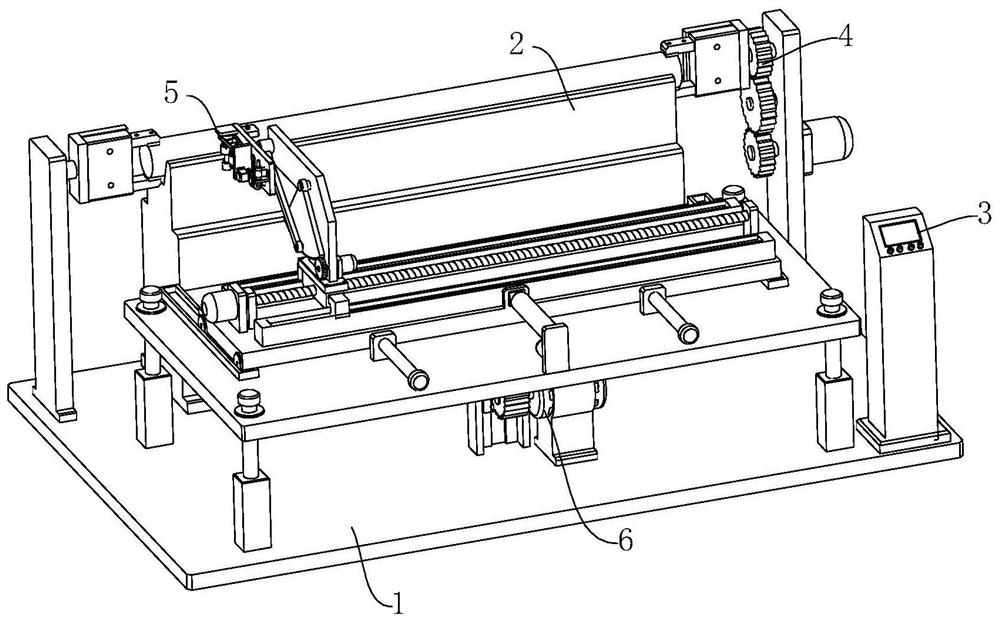

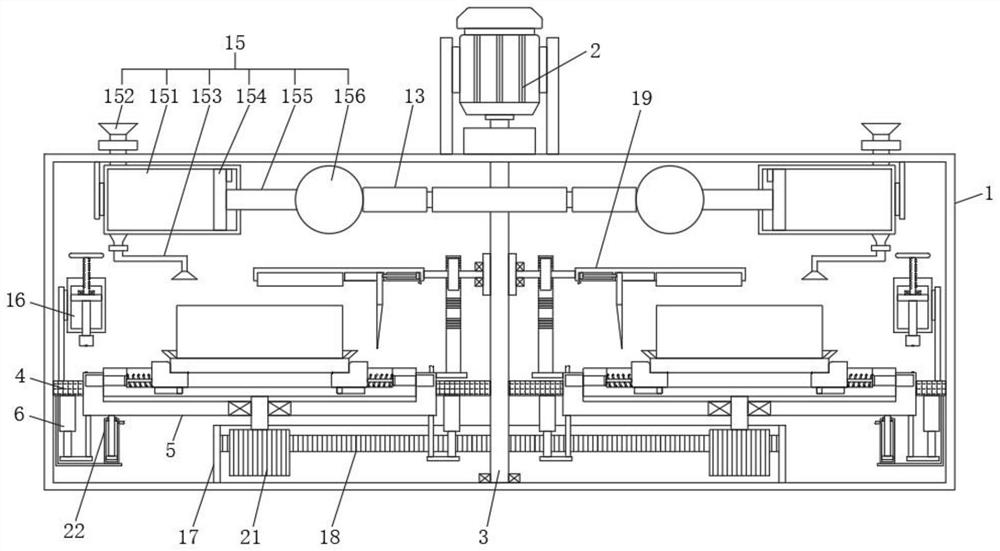

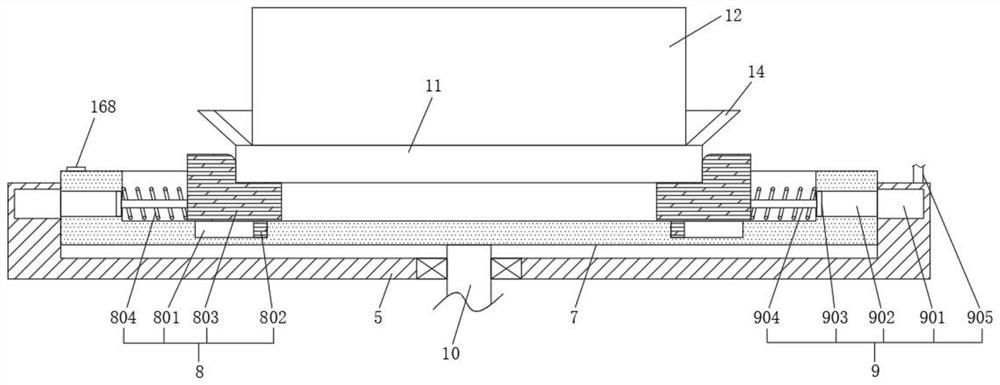

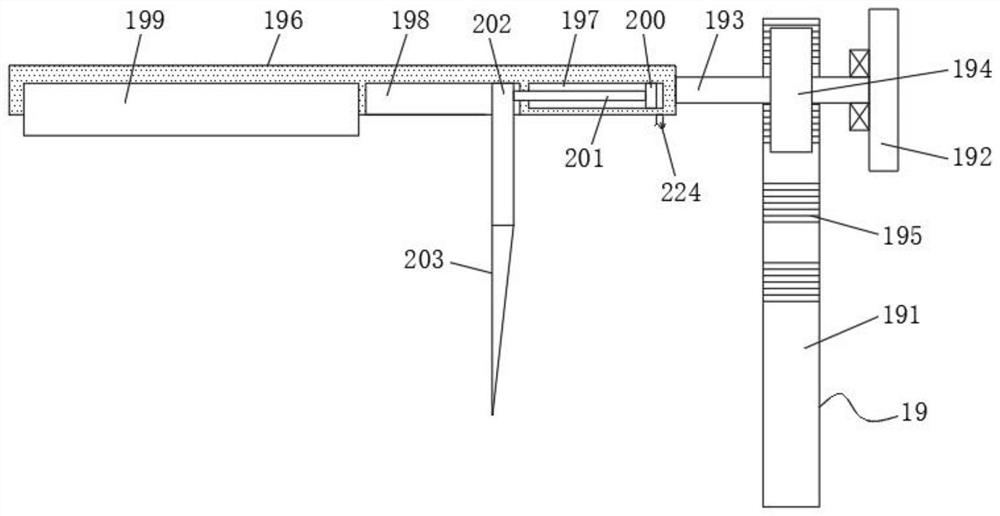

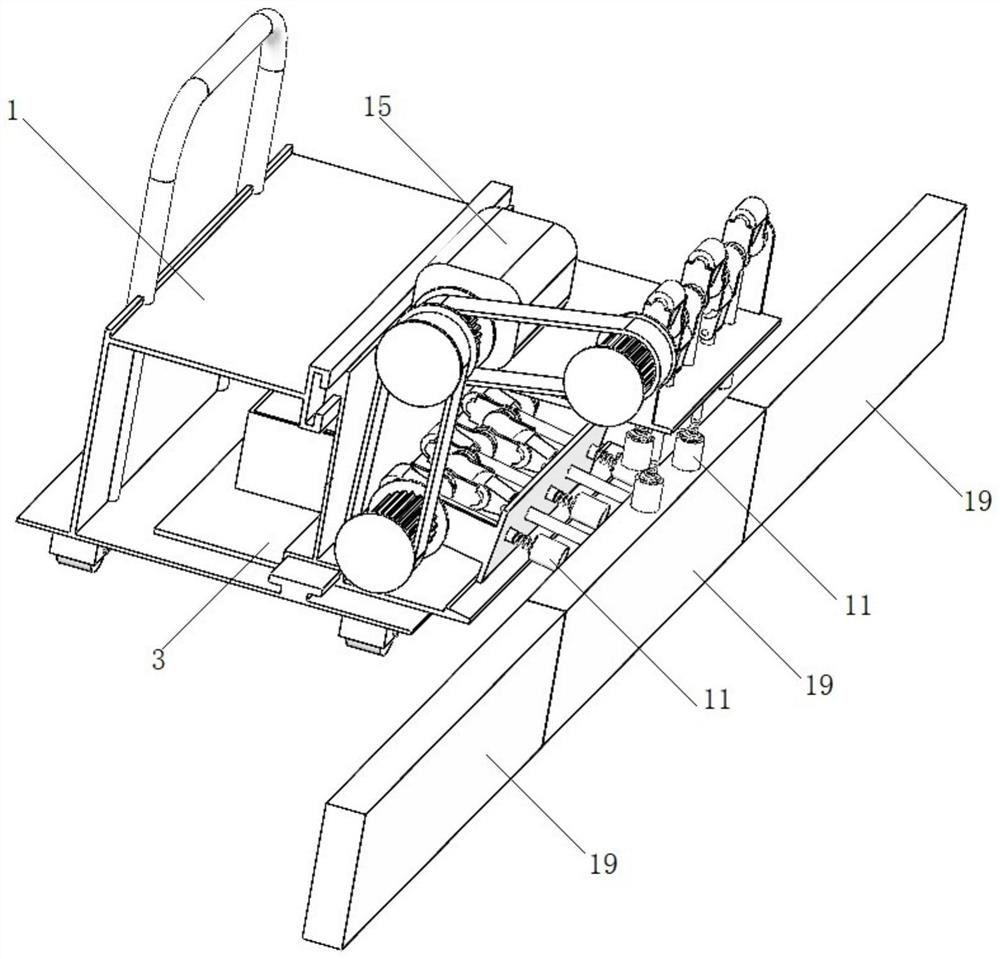

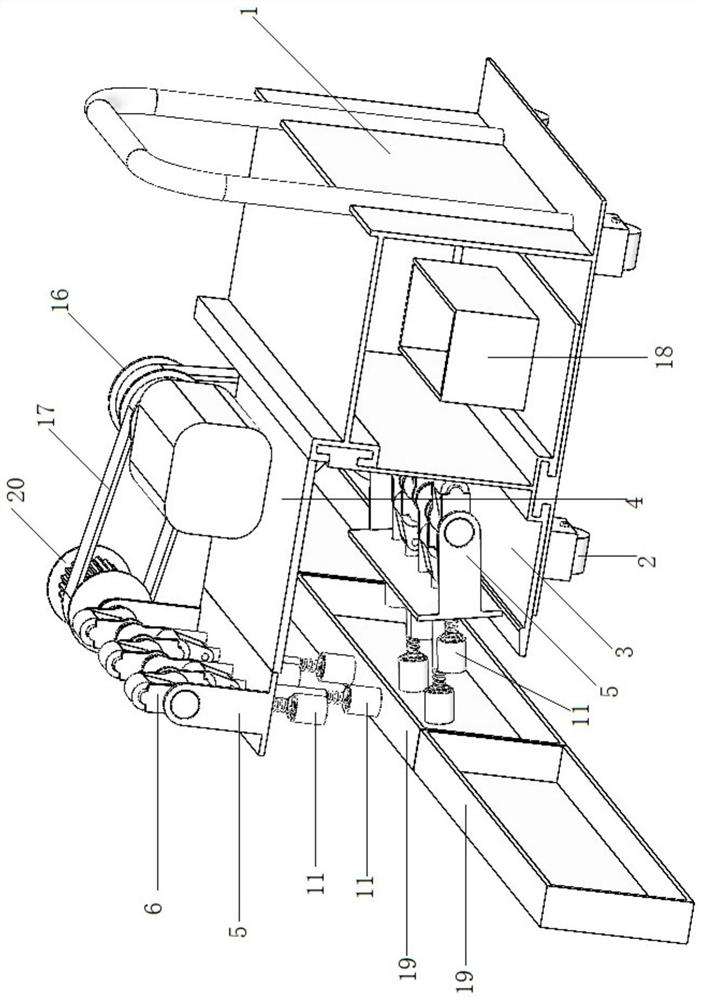

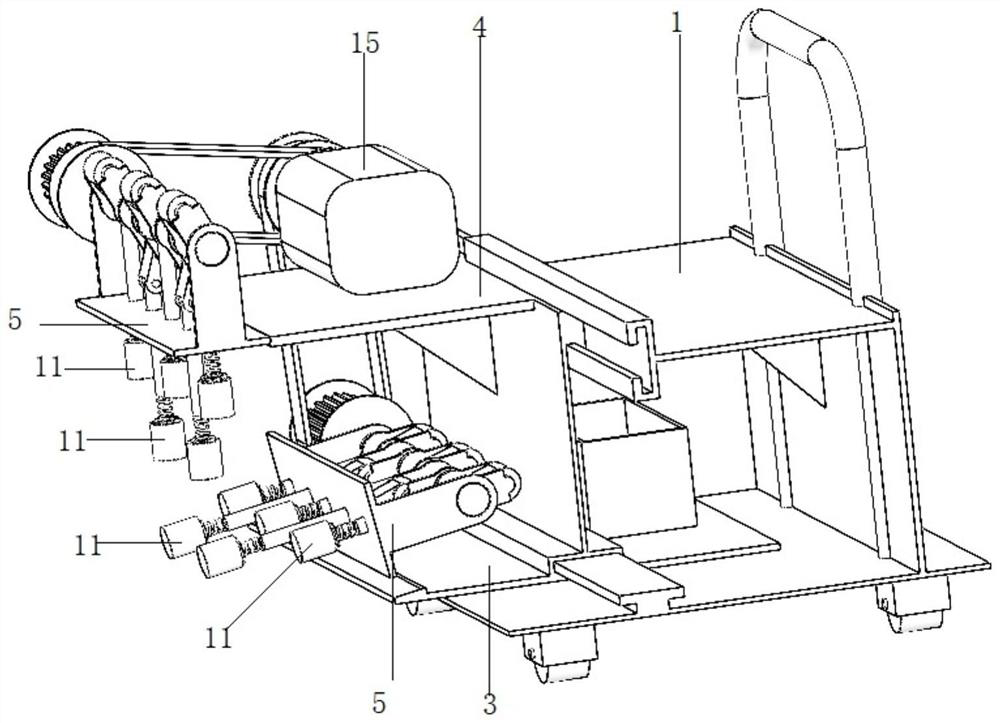

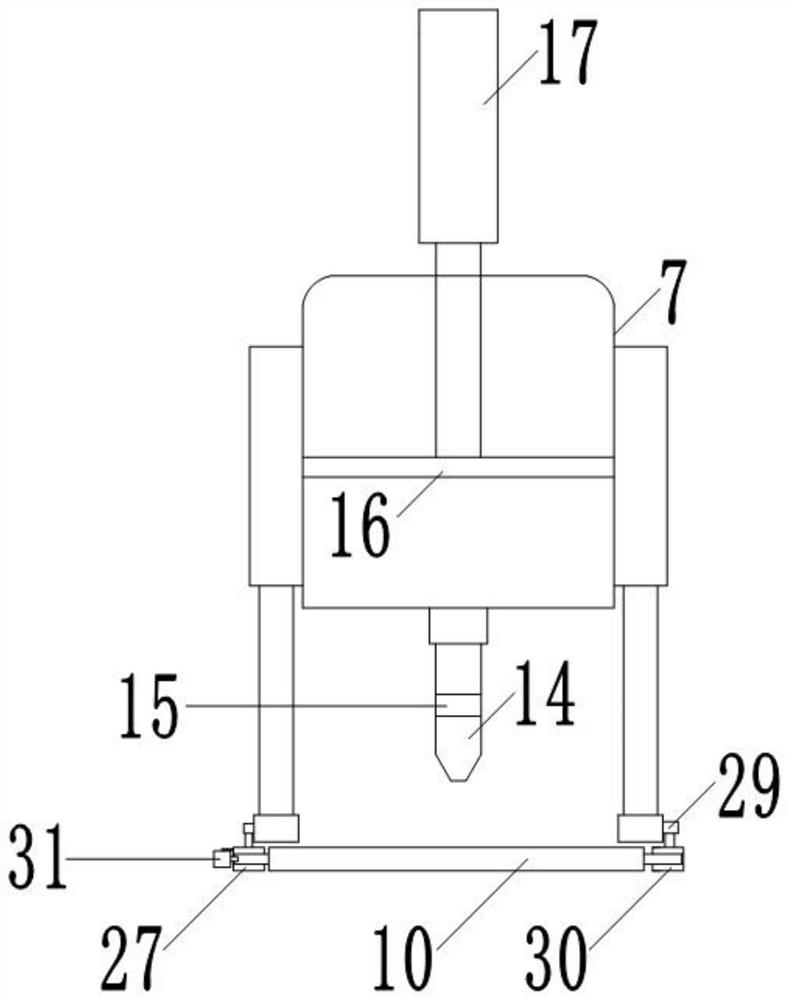

Shaft mold surface flaw detection repairing device and using method

ActiveCN111633519AGuaranteed surface finishImprove processing qualityEdge grinding machinesGrinding carriagesStructural engineeringMachining

The invention relates to the field of machining, and particularly relates to a shaft mold surface flaw detection repairing device and a using method. The shaft mold surface flaw detection repairing device comprises a base and a supporting table, and further comprises a controller, a rotating mechanism, a repairing mechanism and a lifting mechanism, wherein the rotating mechanism comprises a driving assembly and two pneumatic claws; the lifting mechanism comprises a lifting plate and a jacking assembly; the repairing mechanism comprises an ultrasonic probe, a polishing assembly and a filling assembly; a camera is mounted at the end, close to the bottom of the supporting table, of a rotating plate; and the camera, the ultrasonic probe, the driving assembly, the jacking assembly, the polishing assembly, the filling assembly and the two pneumatic claws are all electrically connected with the controller. According to the shaft mold surface flaw detection repairing device and the using method, burrs can be removed, cracks and pits can be filled at the same time, manual intervention is not needed in the repairing process, and the repairing efficiency and yield can be improved.

Owner:盐城金刚星精密锻造有限公司

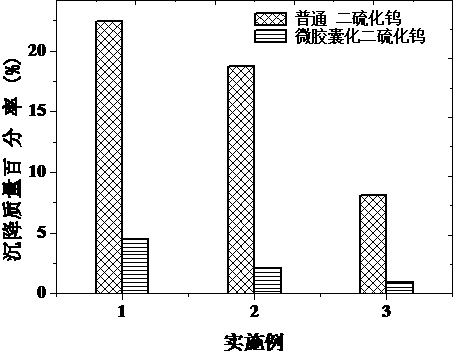

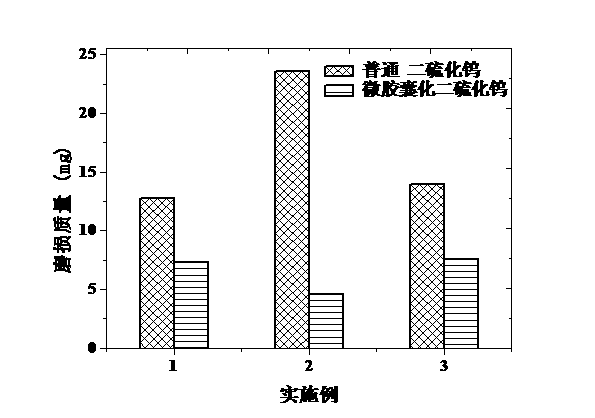

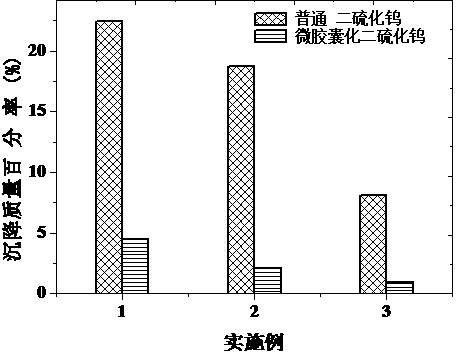

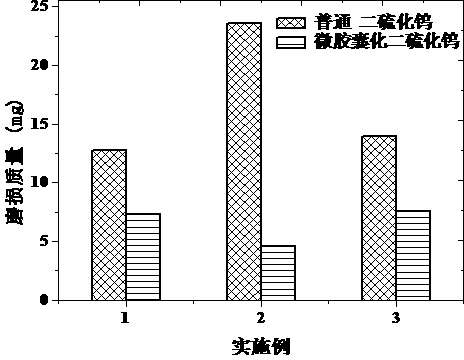

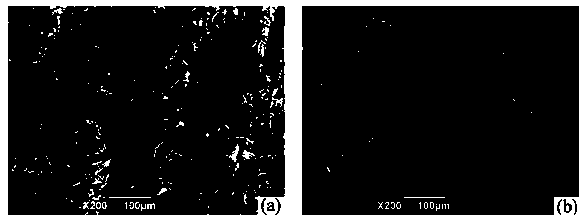

Microencapsulated tungsten disulfide dry-film lubricant

InactiveCN103060066AImprove dispersion stabilityImprove friction and wear propertiesBase-materialsMicroballoon preparationPolymer scienceDispersed media

The invention provides a microencapsulated tungsten disulfide dry-film lubricant, belonging to the technical field of preparation of dry-film lubricants. The dry-film lubricant consists of a solid lubricant, an anti-wear additive, a dispersant, an antioxidant and an adhesive matrix, wherein the solid lubricant is microencapsulated tungsten disulfide particles prepared in a dispersing medium by using a microencapsulation technology and an oil-phase separation method, and taking a semi-synthesized polymer material with a special function as a wall material. Compared with the prior art, the microencapsulated tungsten disulfide dry-film lubricant has the advantages that the microencapsulated nano tungsten disulfide micro-particles are used for preparing the dry-film lubricant, so that the dry-film lubricant has excellent dispersion stability and wear resistance; and meanwhile, the microencapsulated nano tungsten disulfide particles can fill and level up recesses on friction surfaces, can fill up worn parts in time, have a self-repairing function to ensure that the friction surfaces are always in a relatively flat state, and improve the friction reducing and resisting capacities of dual faces.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

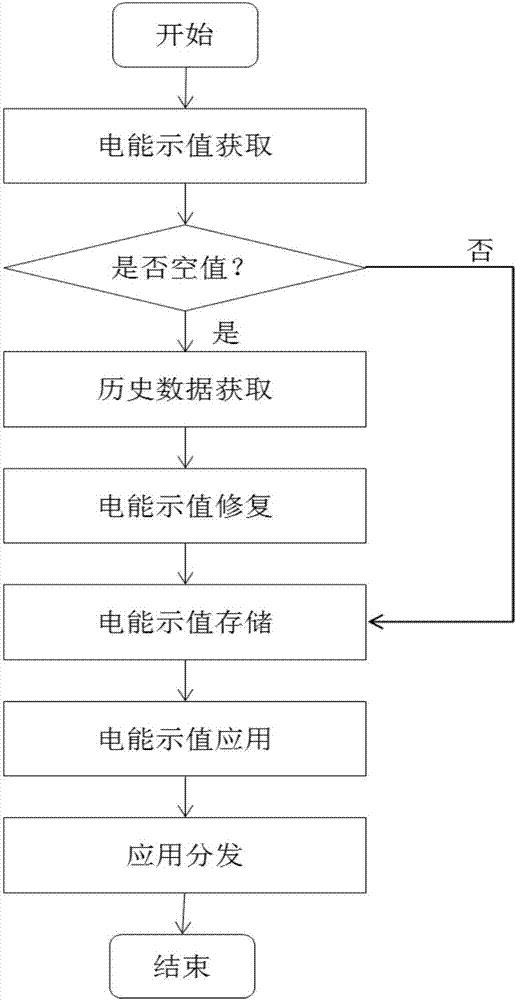

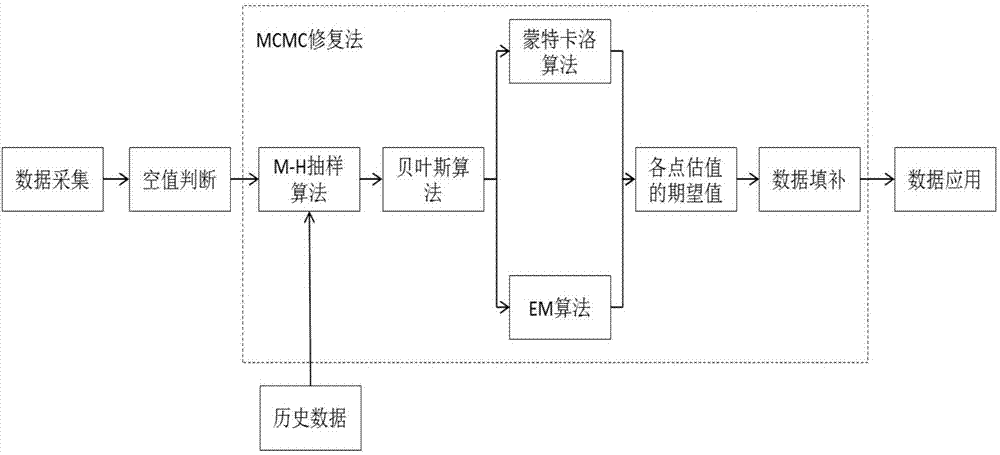

MCMC algorithm-based power acquisition data recovery method

ActiveCN107368543AFill in timeImprove usabilityData processing applicationsCharacter and pattern recognitionMissing dataPower grid

The invention relates to an MCMC algorithm-based power acquisition data recovery method, and relates to the field of power acquisition data recovery. On the basis of acquired history data, the recovery of power acquisition data empty values can be realized through an MCMC algorithm, and data filling is carried out in a manner of combining multiple algorithms, so that the filled data is relatively high in accuracy, the quantity of requiring for history data is relatively small, the recovery efficiency is relatively high and high reusability is provided. Through the method, missing data can be efficiently and correctly recovered, the accuracy of grid power statistic can be enhanced, and the problems that the realization manner is single, the filled data is relatively low in accuracy and the calculation efficiency is relatively low in the prior art are solved.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +2

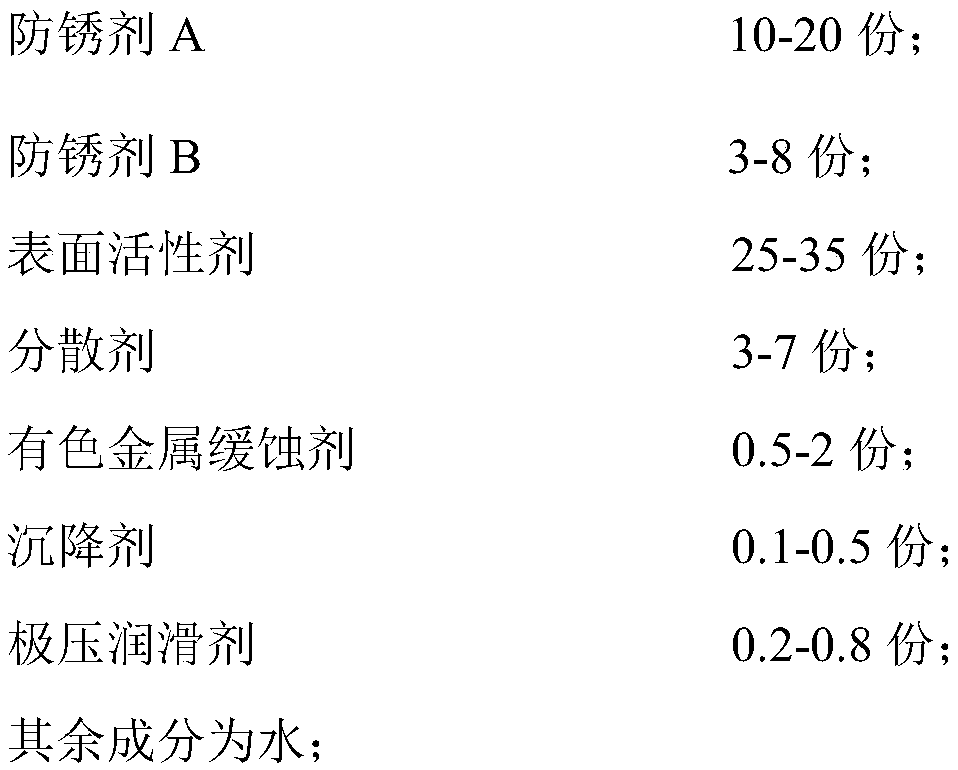

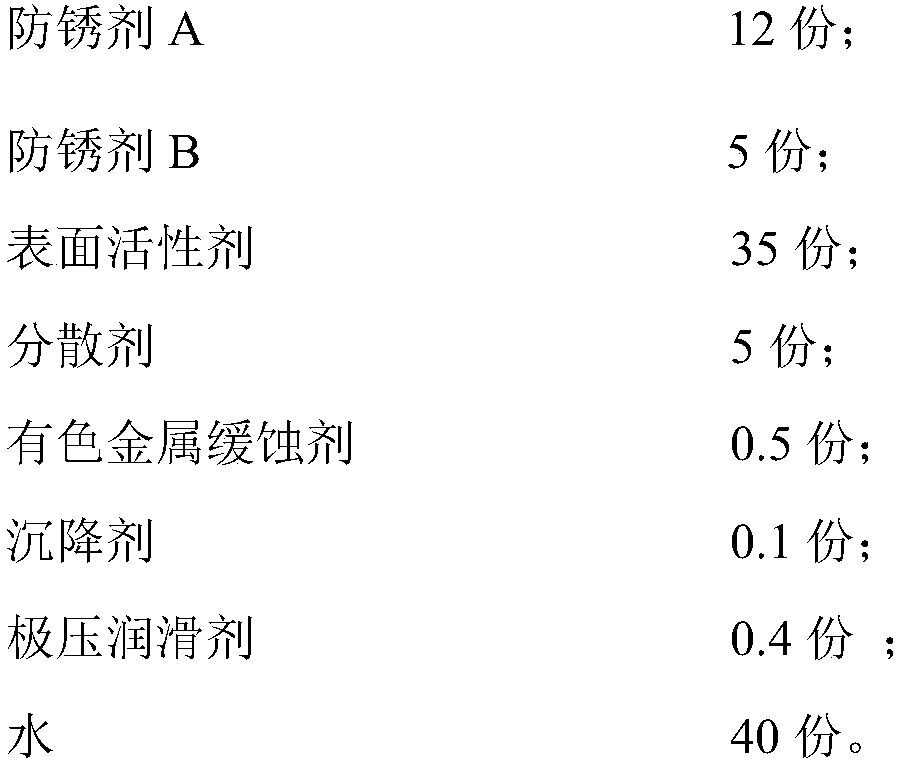

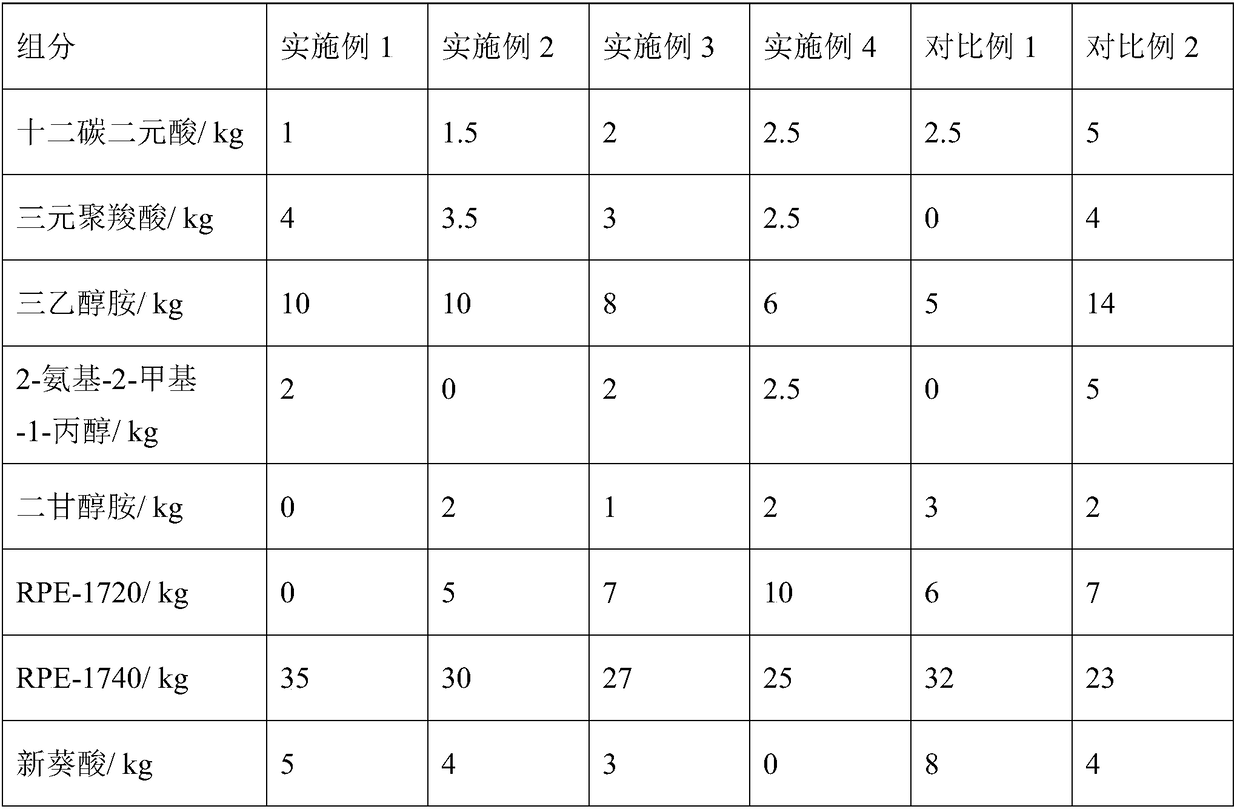

Synthesized high-gloss cutting fluid for smart phone frame and preparation method of cutting fluid

ActiveCN108998183AFast defoamingImprove processing qualityLubricant compositionWater basedEngineering

The invention discloses a synthesized high-gloss cutting fluid for a smart phone frame. The cutting fluid comprises the following components in parts by weight: 10-20 parts of a rust inhibitor A, 3-8parts of a rust inhibitor B, 25-35 parts of a surfactant, 3-7 parts of a dispersing agent, 0.5-2 parts of a nonferrous metal corrosion inhibitor, 0.1-0.5 part of a settling agent, 0.2-0.8 part of an extreme pressure lubricant and the balance of water. The invention further provides a preparation method of the synthesized high-gloss cutting fluid. The cutting fluid provided by the invention is a water-based completely-transparent liquid, so that a clean environment of a processing site is guaranteed. Rapid defoaming can be finished within 5 seconds, and the processing state of a workpiece can be clearly observed during a using process, so that the product processing quality is guaranteed. Nano particles are selected as the extreme pressure lubricant, and a maximum non-seizure load value canbe up to 1380 N, so that the anti-friction and anti-wear performance of the cutting fluid is greatly improved. The hard water adaptability is up to 20000 ppm, and the dispersion characteristic of calcium soaps and magnesium soaps are achieved, so that the cutting fluid has extremely high hard water resistance. Long-term stability of lubricating performance and cleaning performance of the cuttingfluid is guaranteed, and the service life of the cutting fluid is prolonged.

Owner:广州市方川润滑科技有限公司

Polyurethane-water glass composite grouting material and preparation method thereof

The invention relates to a polyurethane-water glass composite grouting material and a preparation method thereof, which belong to the technical field of construction materials. With lower viscosity and surface tension and high infiltration capability, silane coupling agent utilized by the invention can be rapidly spread on a constructed surface to infiltrate into cracks of a rock surface; meanwhile, inorganic groups in the silane coupling agent can react with oxide on the surfaces of the cracks to generate stable silicon-oxygen bonds, and the organic groups and NCO react to be connected onto organic macromolecules, so that the bonding strength and constructed surface infiltration of the grouting material are improved, meanwhile, a catalyst component is promoted to be uniformly dispersed into water glass, phase separation is prevented, the groutability is good, the permeability is high, and moreover, the polyurethane-water glass composite grouting material has good compressive strength;and the polyurethane-water glass composite grouting material can play the role of filling, reinforcement, waterproofing, leaking stoppage and the like for rock-soil / gravel structures, and is applicable to waterproofing and leaking stoppage for cracks and reinforcement and seepage resistance for foundations in bridges, subways, dams, rock strata, harbors, civil air defence works and the like.

Owner:徐冬

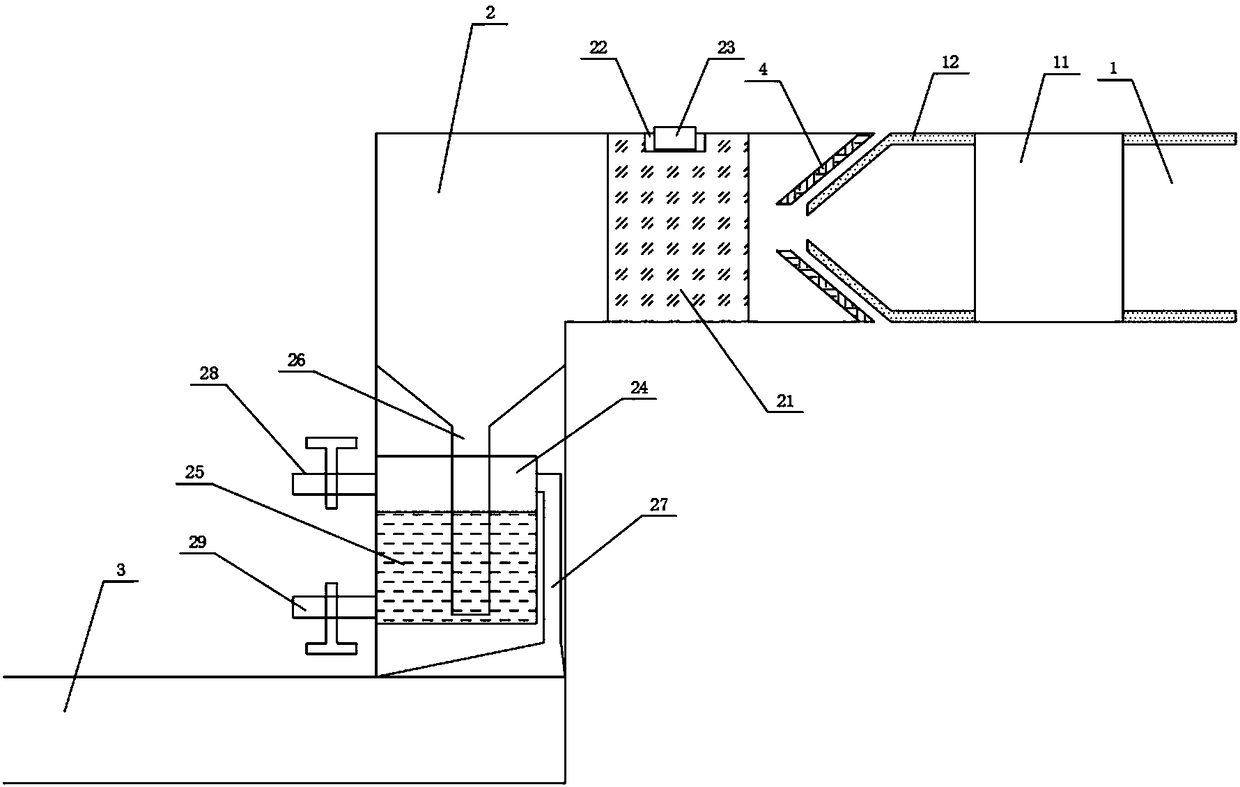

Self-repairing type heat insulation wallboard with crack reminding function

ActiveCN113090060AFill up quicklyRepair in timeCovering/liningsBuilding repairsFoaming agentEngineering

The invention discloses a self-repairing type heat insulation wallboard with a crack reminding function, and belongs to the technical field of heat insulation wallboards. The self-repairing type heat insulation wallboard with the crack reminding function comprises a wall body, a liquid storage cavity is formed in the wall body, a plurality of evenly-distributed conveying pipes are inserted into the wall body, and the conveying pipes penetrate through the liquid storage cavity; supporting partition plates are fixedly connected to the parts, in front of the interior of the liquid storage cavity, of the conveying pipes, and outer wall cracks of the wall body can be self-repaired; foaming agents are sprayed out of the wall according to the principle that the foaming agents expand when encountering air, and the outer wall cracks are rapidly filled; and meanwhile, the inner wall corresponding to the outer wall cracks generates a series of changes, people can be reminded of the condition of the outer wall, people can conveniently observe and maintain the specific position of the cracks, people can further trim the outer wall cracks more timely, the maintenance cost is effectively reduced, and the service life of the outer wall is remarkably prolonged.

Owner:南通根博新材料科技有限公司

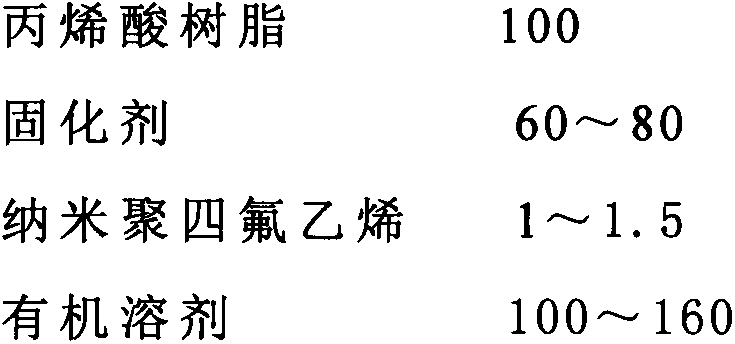

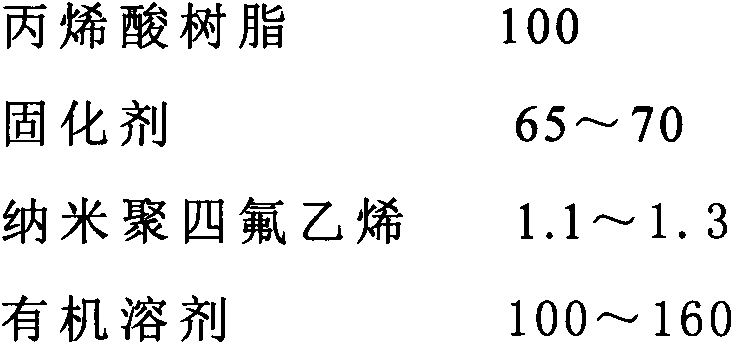

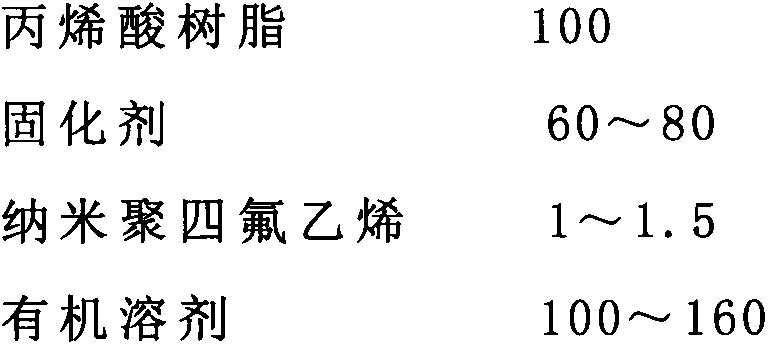

Acrylic resin paint composition

The invention discloses an acrylic resin composition which has excellent scratch resistance and friction resistance. Particularly, the scheme adds polytetrafluoroethylene, which has chemical resistance, heat resistance and applicability to occasions with high frictional property requirements, into the traditional acrylic resin paint in the form of nano dimensions, and obtains the acrylic resin paint, which has improved properties and is suitable for industrialization, without changing the original paint processing technique.

Owner:SUZHOU TAIZHENG CHEM TECH CO LTD

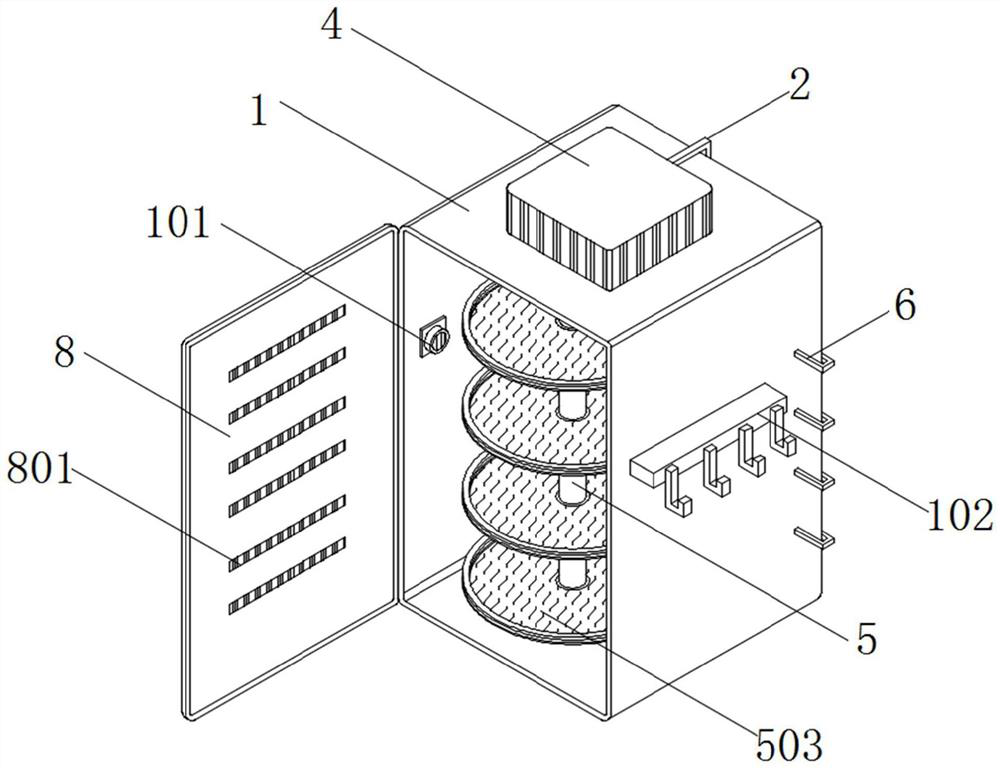

Round cake automatic smearing and rotating mechanism

The invention discloses a round cake automatic smearing and rotating mechanism which comprises a device box and a motor located in the middle of the top of the device box, the inner top of the device box is provided with a rotating shaft, and the output end of the motor is connected with the rotating shaft penetrating into the device box. And a fixed plate and a driving assembly for quantitatively controlling the cream are assembled outside the rotating shaft. The larger the size of a placing table is, the longer the length of a second connecting rod extending out of a mounting block is, so that when the rotating shaft drives the second connecting rod and an arc-shaped block to rotate, the longer the length of the second connecting rod extending out of the mounting block is, the longer the distance of a connecting ball compressed by the arc-shaped block is, and then the longer the movement distance of a third piston is, namely the more the compressed cream; in conclusion, when the size of the placing table is increased, the amount of the cream extruded by a discharging assembly is also increased, then the change of the amount of the cream of the cakes of various sizes is met, and one device can smear the cream of the cakes of various sizes.

Owner:米旗食品股份有限公司

Moisturizing and skin tendering essence and preparation method thereof

ActiveCN113384482AImprove stabilityPromote hydrationCosmetic preparationsToilet preparationsPurslane extractRed clover extract

The invention provides moisturizing and skin tendering essence. The moisturizing and skin tendering essence comprises, by weight, 1-100 parts of recombinant fibroin, 1-100 parts of a radix paeoniae alba extract, 1-100 parts of a rhizoma bletillae extract, 1-100 parts of a herba portulacae extract, 1-100 parts of a honeysuckle flower extract, 1-100 parts of a tangerine fruit extract, 1-100 parts of a red clover extract, 1-100 parts of a papaya fruit extract, 1-100 parts of a royal jelly extract and 1-100 parts of a wheat germ extract. The moisturizing and skin tendering essence has excellent moisturizing, moistening, skin tendering, anti-wrinkle, whitening and anti-allergic effects, and can prevent external irritation to the skin and consolidate the curative effect. The invention also provides a preparation method of the moisturizing and skin tendering essence. The moisturizing and skin tendering essence can play a drug effect to the greatest extent, and the moisturizing, skin-tendering and anti-aging curative effects are improved.

Owner:SHANXI QINLING QIYAO COLLABORATIVE INNOVATION CENT CO LTD

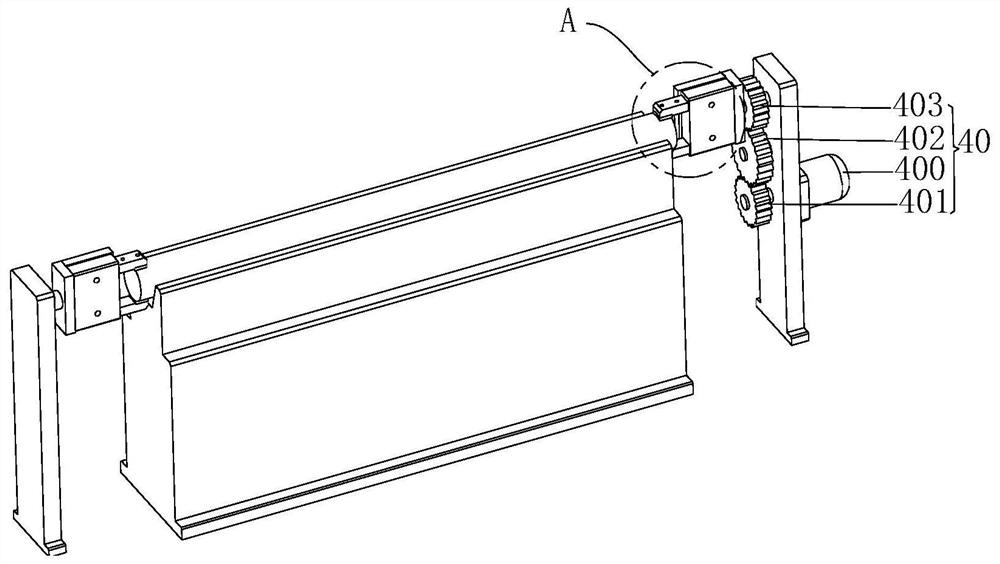

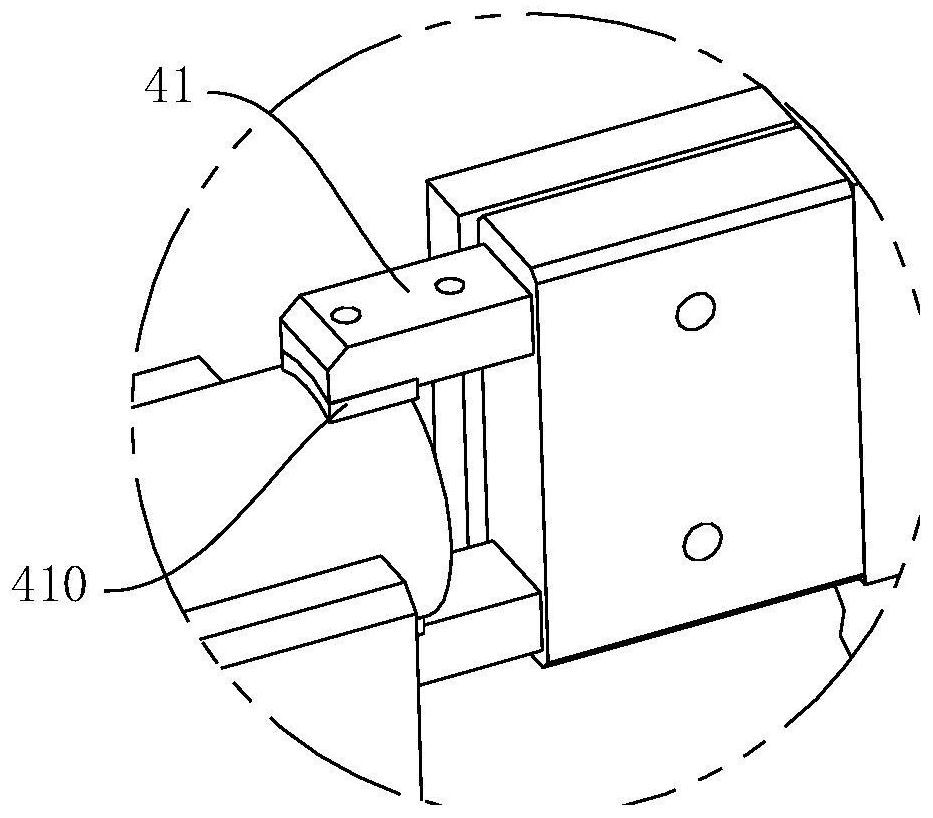

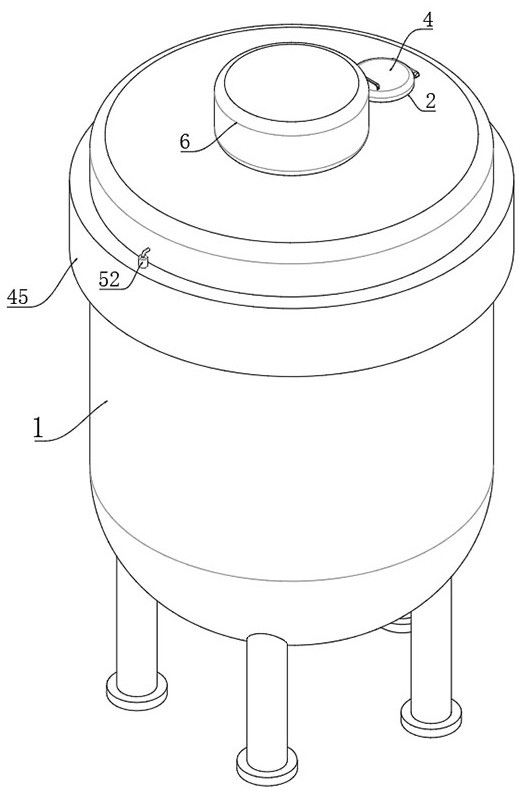

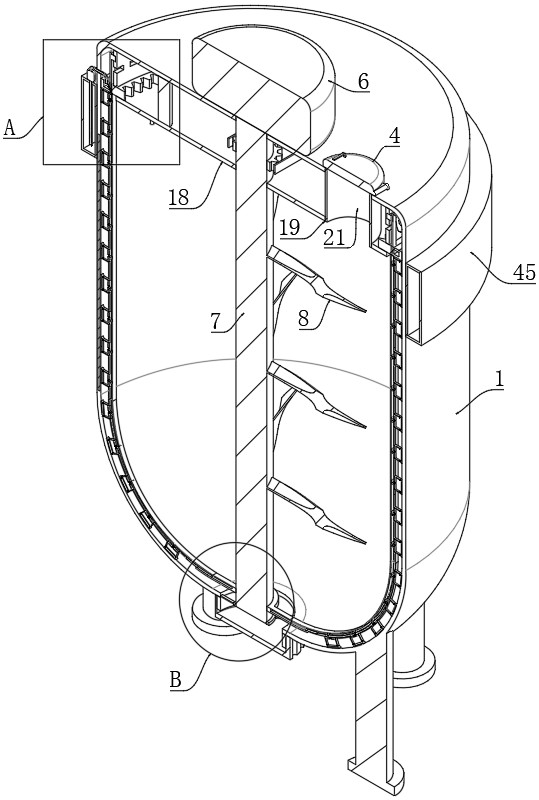

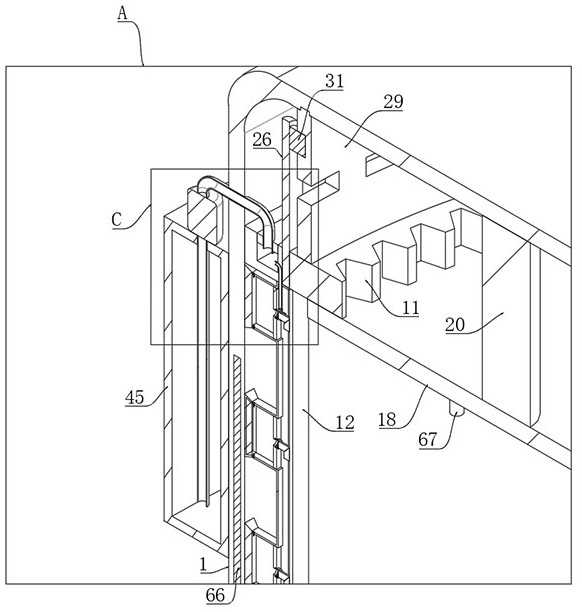

Production mixing mechanism for industrial intelligent manufacturing

ActiveCN114643006AReduce resistanceAvoid skewTransportation and packagingMixing methodsGear wheelElectric machinery

The invention relates to the technical field of production mixing, in particular to an industrial intelligent manufacturing production mixing mechanism which comprises a stirring barrel, a feeding port is formed in the top surface of the stirring barrel, a discharging pipe is fixedly communicated with the bottom surface of the stirring barrel, a sealing door is hinged to the edge of the feeding port, a sealing cover is in threaded connection with the discharging pipe, and the sealing cover is in threaded connection with the stirring barrel. A motor is fixed on the top surface of the stirring barrel, the tail end of an output shaft of the motor penetrates through the top surface of the stirring barrel, extends into the stirring barrel and then is fixedly provided with a stirring rod, and a plurality of stirring blades are fixed on the stirring rod; according to the multi-point scraping device, the resistance of a mixture to the multi-point scraping mechanism is reduced by setting up and down scraping of multiple point positions and reducing the scraping distance, and the stirring rod is linked with the transmission mechanism to drive the inner gear to rotate, so that the rotation directions of the multi-point scraping mechanism and the mixture are the same, and in the movement process of the multi-point scraping mechanism, the stirring effect is improved. And the resistance of the mixture to the multi-point scraping mechanism is further reduced.

Owner:肯拓(天津)工业自动化技术有限公司 +1

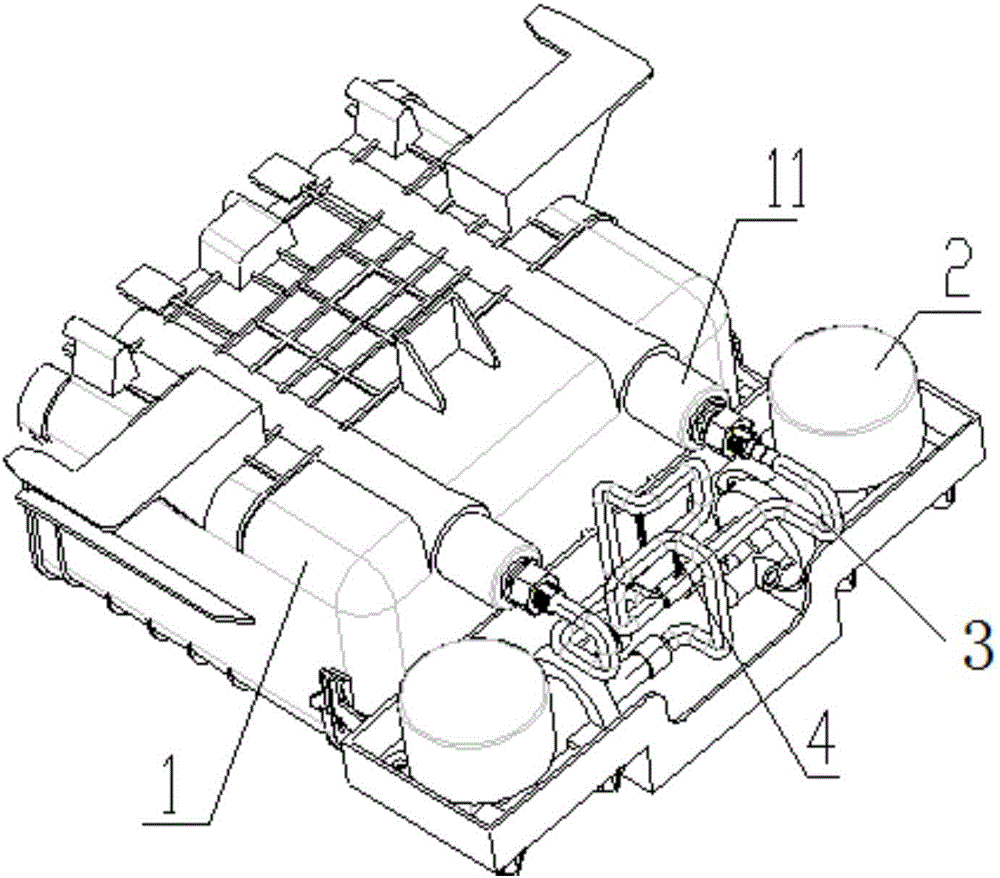

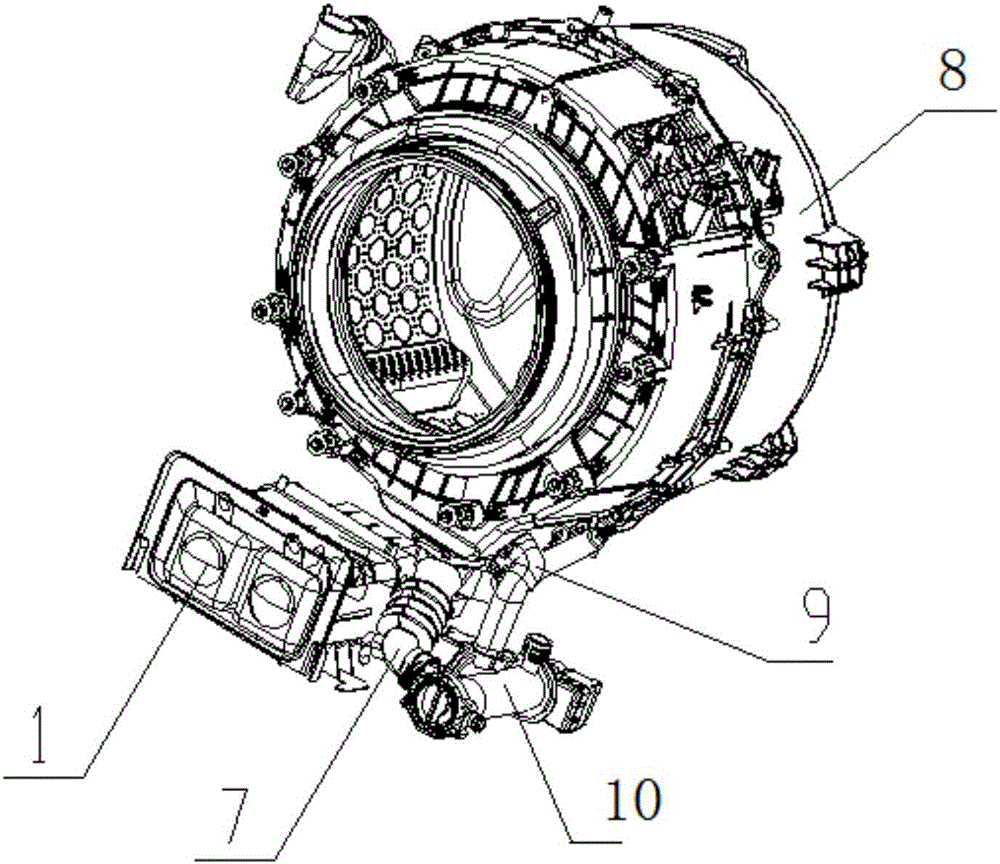

Detergent detecting and putting device

PendingCN106758013AFill in timeAffect the normal decontamination effectOther washing machinesTextiles and paperElectricityEngineering

The invention provides a detergent detecting and putting device which comprises a liquid storage box and an alarm device. The liquid storage box is provided with at least one storage box capable of storing detergent, and liquid outlets corresponding to the storage boxes are formed in the liquid storage box. The alarm device is used for triggering the alarm device to be started when no detergent exists in the liquid storage box. According to the detergent detecting and putting device, when no detergent exists in the liquid storage box, the alarm device is started to inform a user, the user can fill the liquid storage box in time, and the situation that after the detergent is used up, the normal decontamination effect of a washing machine in influenced, and water and electricity are wasted is avoided.

Owner:GREE ELECTRIC APPLIANCES INC

Automobile exhaust treatment tail pipe

InactiveCN108252782AReduce pollutionAvoid damageExhaust apparatusSilencing apparatusEcological environmentPollution

The invention discloses an automobile exhaust treatment tail pipe which comprises a primary tail pipe, a secondary tail pipe and a tertiary tail pipe. The primary tail pipe, the secondary tail pipe and the tertiary tail pipe are sequentially connected, the head end of the primary tail pipe is used for receiving exhaust discharged by an automobile, the tail end of the primary tail pipe is conical,the head end of the secondary tail pipe is in the shape of a concave cone, a sponge bin is arranged at a position close to the head end of the secondary tail pipe, a purifying tank is arranged at a position close to the tail end of the secondary tail pipe, and the head end of the tertiary tail pipe is communicated with the tail end of the secondary tail pipe. Particles in the automobile exhaust are adsorbed by the sponge bin, the conical structure of the tail end of the primary tail pipe is matched with the concave conical structure of the head end of the secondary tail pipe to prevent the particles in the exhaust from entering the automobile, the exhaust is treated by the purifying tank, the pollution degree of the exhaust is reduced, the automobile exhaust is effectively treated, exhaustpollution is relieved, the automobile cannot be damaged by the particles in the exhaust, and ecological environments are protected.

Owner:江苏悍威汽车有限公司

Drying equipment for disinfecting medical apparatus and instruments

InactiveCN114485112AImprove sterilityImprove drying rateDrying gas arrangementsDrying safety systemsEngineeringEnvironmental engineering

The drying equipment comprises a drying cabinet body and a sterile air inlet pipe, a drying adjusting box is installed at the top of the drying cabinet body, and the sterile air inlet pipe is installed on the back face of the drying adjusting box in a penetrating mode; an ultraviolet lamp ring and a heating net ring are arranged on the inner wall of the sterile air inlet pipe, a first air inlet pipe and a second air inlet pipe which are arranged up and down are installed on the surface of the sterile air inlet pipe, and electronic valves are installed on the surfaces of the first air inlet pipe and the second air inlet pipe; a temperature and humidity sensor is mounted on the surface, provided with the second air inlet pipe, of the sterile air inlet pipe; and a supporting rod is mounted on the top wall of the drying cabinet body. By arranging the sterile air inlet pipe, internal air has relatively sufficient movement duration so as to ensure that the internal air can be sterilized for sufficient duration in the process of entering the drying adjusting box through the sterile air inlet pipe, so that sterility of circulating air in the sterile air inlet pipe is realized.

Owner:广东大成金健康科技有限公司

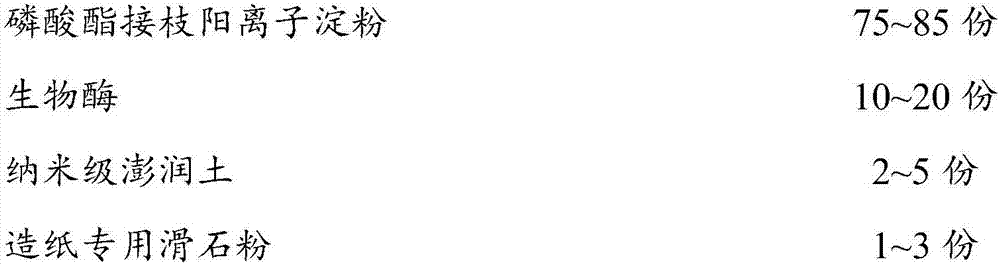

Environment-friendly deinking residue recovery and treatment production method

ActiveCN107268314AImprove retentionReduce environmental management costsPaper recyclingWaste paper working-upFlocculationEconomic benefits

The invention relates to an environment-friendly deinking residue recovery and treatment production method, which includes the following steps: deinking residue collection, flocculation pretreatment, concentration pretreatment, screw presser pressing, deinking residue dilution, deinking residue storage, deinking residue screening, dilution for concentration regulation and preparation and dosing of chemical. Deinking sludge backfill agent A and deinking sludge backfill agent B are mixed for preparation, deinking residue reacts with chemical for modification, pulp is prepared from the deinking residue, and papermaking is carried out by approach flow. According to the invention, the deinking residue is completely hermetically treated at high efficiency and automatically utilized, the problem of complete environment-friendly paper-mill deinking residue treatment is solved, the environment-friendly deinking residue treatment cost is reduced, the papermaking production cost is reduced, and the economic benefit is remarkable.

Owner:LIANSHENG PAPER IND LONGHAI

A method for producing wet-process phosphoric acid by leaching medium and low-grade phosphate rock with hydrochloric acid

ActiveCN106672930BReduce security risksReduce miningCalcium/strontium/barium chloridesCalcium/strontium/barium sulfatesPhosphoric acidEnvironment Problem

The invention relates to a method for preparing wet-process phosphoric acid by using hydrochloric acid to infiltrate low-and-medium-grade phosphorite. The method includes: directly filling a jamb with low-and-medium-grade phosphorite which is not subjected to flotation; adopting hydrochloric acid infiltration to prepare wet-process phosphoric acid; enabling sulfuric acid to react with leachate to generate ardealite. The objective of directly filling or filling bed holes with ardealite by a pump can be achieved by adopting two different modes for adding sulfuric acid, so that the objectives of fixing mining layers and lowering risk of collapse of mining holes are achieved, and a series of environment problems caused by storage of ardealite are solved. The method has the advantages of mild reaction condition, high yield and high reaction speed, and a series of industrial processes like phosphorite exploitation, beneficiation, transportation and mine hole filling are omitted directly, so that production process is greatly simplified, emission of three wastes is avoided, one-time leaching efficiency of final phosphorus is up to 52.79%, and multiple leaching efficiency can reach higher than 85%.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Concrete pouring device for highway construction

The invention discloses a concrete pouring device for highway construction, and relates to the technical field of highway construction. The device further comprises a knocking mechanism. Knocking mechanisms are respectively mounted on the bottom plate and the top plate; the knocking mechanism comprises a guide bracket, a crankshaft, a connecting rod, a push rod, a knocking head and a belt pulley; the lower end of each push rod is fixedly connected with a pressure spring; mounting blocks are fixedly connected to the lower ends of the pressure springs; a knocking head is mounted at the lower part of each mounting block; when any one or more knocking heads of the knocking mechanism on the top plate are in contact with the upper end of the template, the knocking heads of the knocking mechanism on the bottom plate are in contact with the rear end face of the template, wherein the positions of the knocking heads are corresponding and the number of the knocking heads is the same. The device has the beneficial effects that bubble discharge in concrete near the formwork can be effectively improved, and the concrete pouring quality is improved.

Owner:田建军 +6

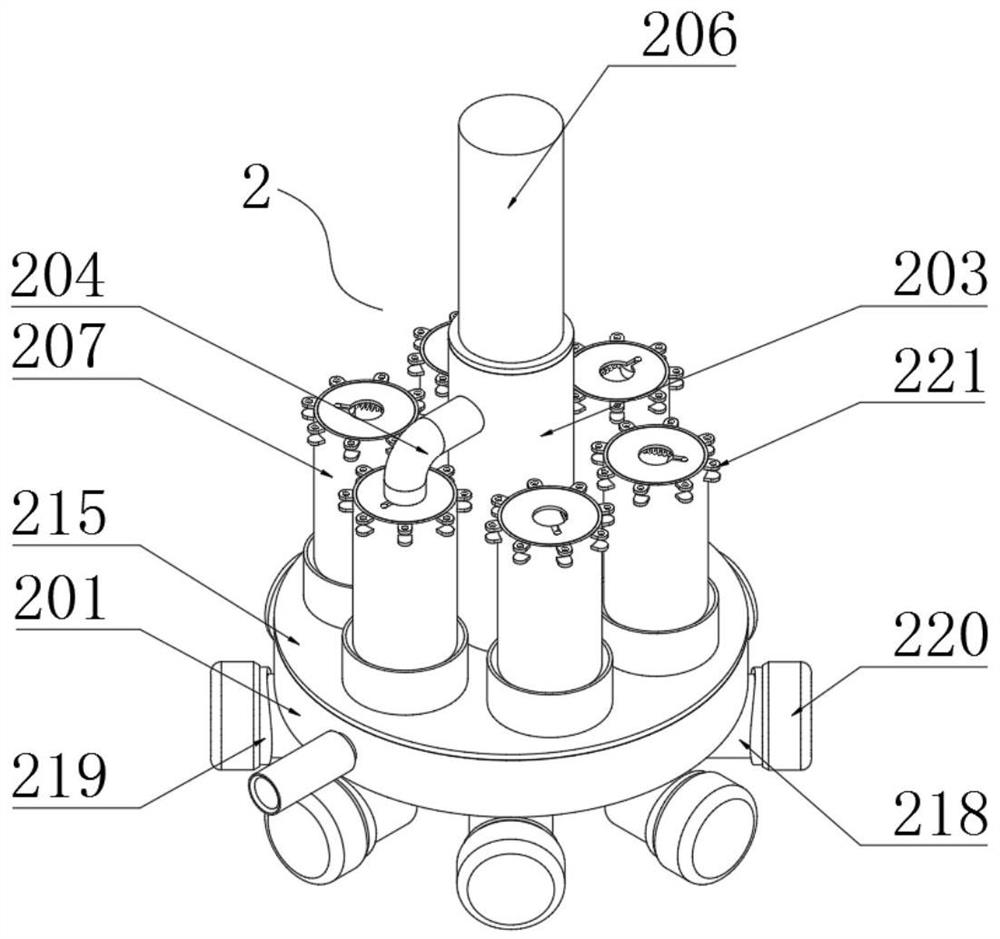

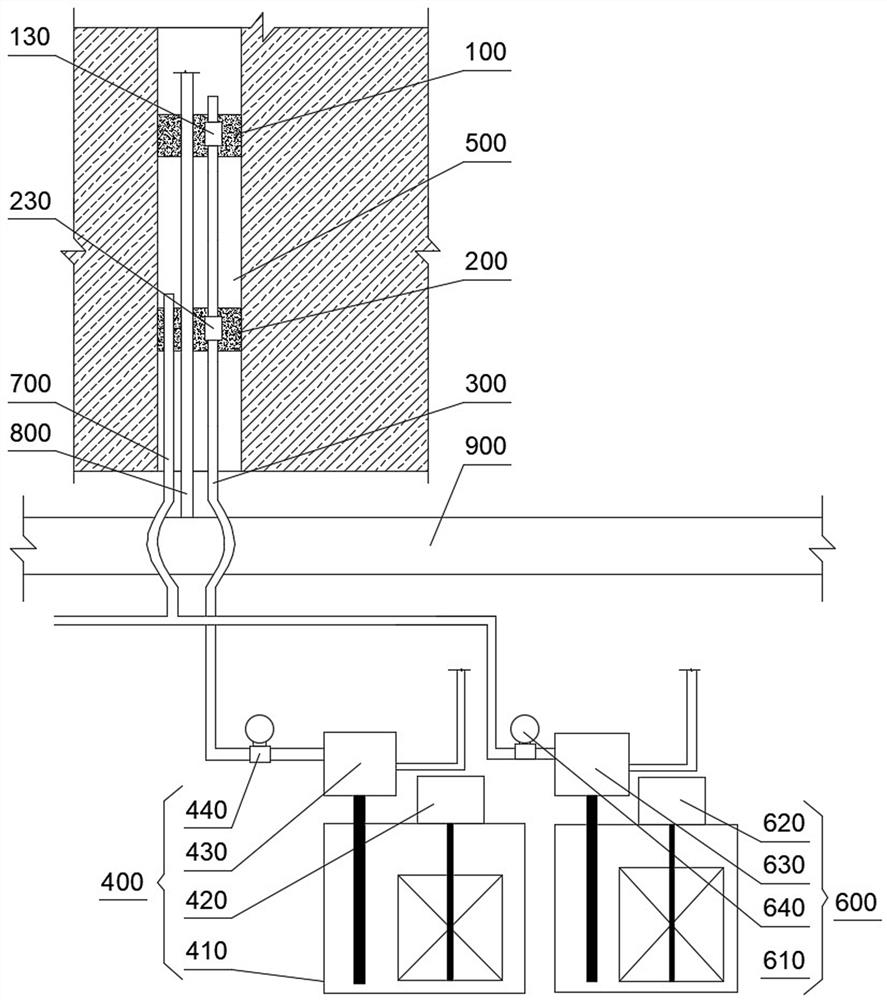

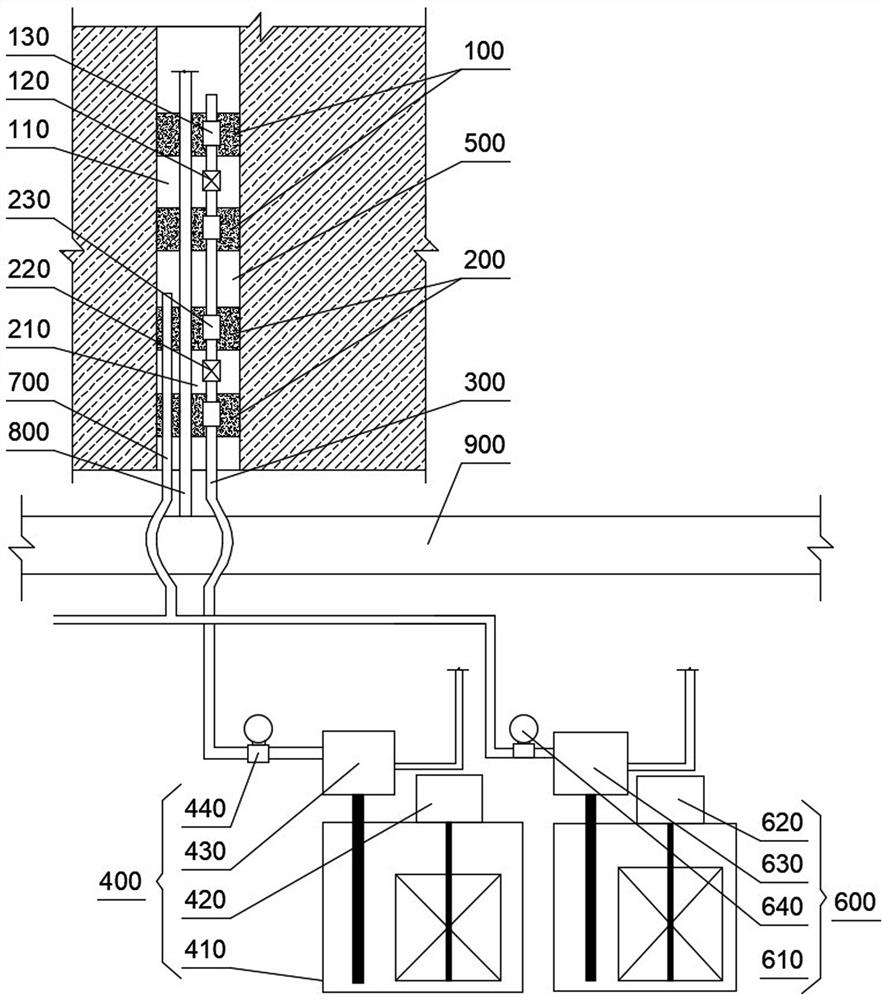

Mining gas extraction hole sealing system

PendingCN114320206AGuaranteed sealing effectImprove gas extraction concentration and efficiencyGas removalSealing/packingInjection equipmentDrill hole

The invention provides a mining gas extraction hole sealing system, which belongs to the technical field of mining hole sealing, and comprises an inner side bag type plug and an outer side bag type plug, and grouting liquid pipes are arranged in the inner side bag type plug and the outer side bag type plug in a communicating manner; the grouting equipment provides grouting liquid for the inner bag type plug and the outer bag type plug through a grouting liquid pipe; a middle mucus plugging section is formed between the inner-side bag type plugging part and the outer-side bag type plugging part, mucus injection equipment injects mucus into the middle mucus plugging section through a mucus injection pipe, and continuous pressure maintaining is carried out; according to the invention, the two ends are plugged by adopting the bags into which the slurry can be injected, the middle mucus plugging section is formed between the bags at the two ends, the non-solidified mucus is injected into the middle mucus plugging section, and meanwhile, the mucus can be supplemented in time when the pressure of the middle mucus plugging section is reduced so as to keep a certain pressure; therefore, the drilling hole sealing effect is guaranteed, the gas extraction concentration and efficiency are improved, and safe production of a coal mine is guaranteed.

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

Method for preparing wet-process phosphoric acid by using hydrochloric acid to infiltrate low-and-medium-grade phosphorite

ActiveCN106672930AReduce security risksReduce miningCalcium/strontium/barium chloridesCalcium/strontium/barium sulfatesPregnant leach solutionPhosphoric acid

The invention relates to a method for preparing wet-process phosphoric acid by using hydrochloric acid to infiltrate low-and-medium-grade phosphorite. The method includes: directly filling a jamb with low-and-medium-grade phosphorite which is not subjected to flotation; adopting hydrochloric acid infiltration to prepare wet-process phosphoric acid; enabling sulfuric acid to react with leachate to generate ardealite. The objective of directly filling or filling bed holes with ardealite by a pump can be achieved by adopting two different modes for adding sulfuric acid, so that the objectives of fixing mining layers and lowering risk of collapse of mining holes are achieved, and a series of environment problems caused by storage of ardealite are solved. The method has the advantages of mild reaction condition, high yield and high reaction speed, and a series of industrial processes like phosphorite exploitation, beneficiation, transportation and mine hole filling are omitted directly, so that production process is greatly simplified, emission of three wastes is avoided, one-time leaching efficiency of final phosphorus is up to 52.79%, and multiple leaching efficiency can reach higher than 85%.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

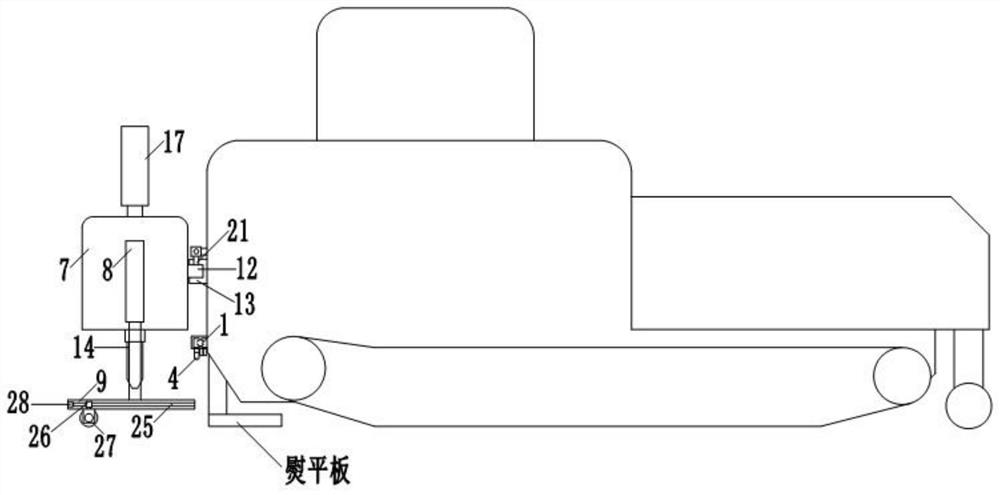

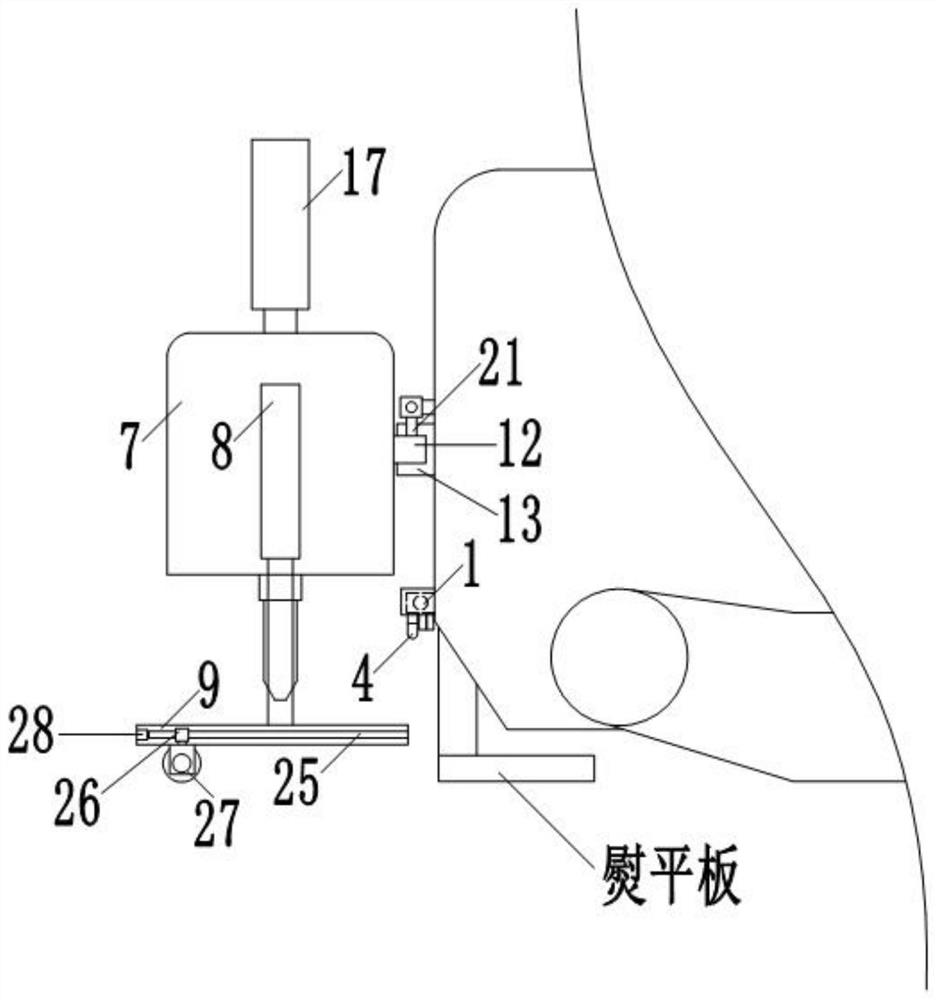

Mixing and laying device of asphalt mixture for road engineering

InactiveCN113235369AFill in timeDoes not affect the paving processRoads maintainenceLaser rangingRoad engineering

The invention provides a mixing and laying device of an asphalt mixture for road engineering. The device comprises a measuring mechanism, a material supplementing mechanism and a paving mechanism; the measuring mechanism is located behind the screed of a paver and comprises a screw, the screw is in threaded connection with a nut, and a laser range finder, a camera and a locator are fixed to the side wall of the nut; the material supplementing mechanism comprises a material storage box, the material storage box is in sliding connection with the paver through a sliding assembly, and the transverse moving mechanism drives the material storage box to transversely move; and the paving mechanism comprises a lifting part, an outer shell of the lifting part is fixed to the side wall of the material storage box, the telescopic end of the lifting part is fixedly connected with a supporting frame, a horizontal moving mechanism is fixed to the supporting frame, and a moving part of the horizontal moving mechanism is connected with the roller body to drive the roller body to longitudinally move to flatten asphalt added in the material supplementing area. The paving condition of asphalt can be monitored at any time while the asphalt is paved, materials are supplemented in time after pits appear, and the supplemented materials are flatly paved by utilizing the paving mechanism, so that the paving efficiency is improved.

Owner:河南力大建设有限公司 +1

Microencapsulated tungsten disulfide dry-film lubricant

InactiveCN103060066BImprove dispersion stabilityImprove friction and wear propertiesBase-materialsMicroballoon preparationPolymer scienceDispersed media

The invention provides a microencapsulated tungsten disulfide dry-film lubricant, belonging to the technical field of preparation of dry-film lubricants. The dry-film lubricant consists of a solid lubricant, an anti-wear additive, a dispersant, an antioxidant and an adhesive matrix, wherein the solid lubricant is microencapsulated tungsten disulfide particles prepared in a dispersing medium by using a microencapsulation technology and an oil-phase separation method, and taking a semi-synthesized polymer material with a special function as a wall material. Compared with the prior art, the microencapsulated tungsten disulfide dry-film lubricant has the advantages that the microencapsulated nano tungsten disulfide micro-particles are used for preparing the dry-film lubricant, so that the dry-film lubricant has excellent dispersion stability and wear resistance; and meanwhile, the microencapsulated nano tungsten disulfide particles can fill and level up recesses on friction surfaces, can fill up worn parts in time, have a self-repairing function to ensure that the friction surfaces are always in a relatively flat state, and improve the friction reducing and resisting capacities of dual faces.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

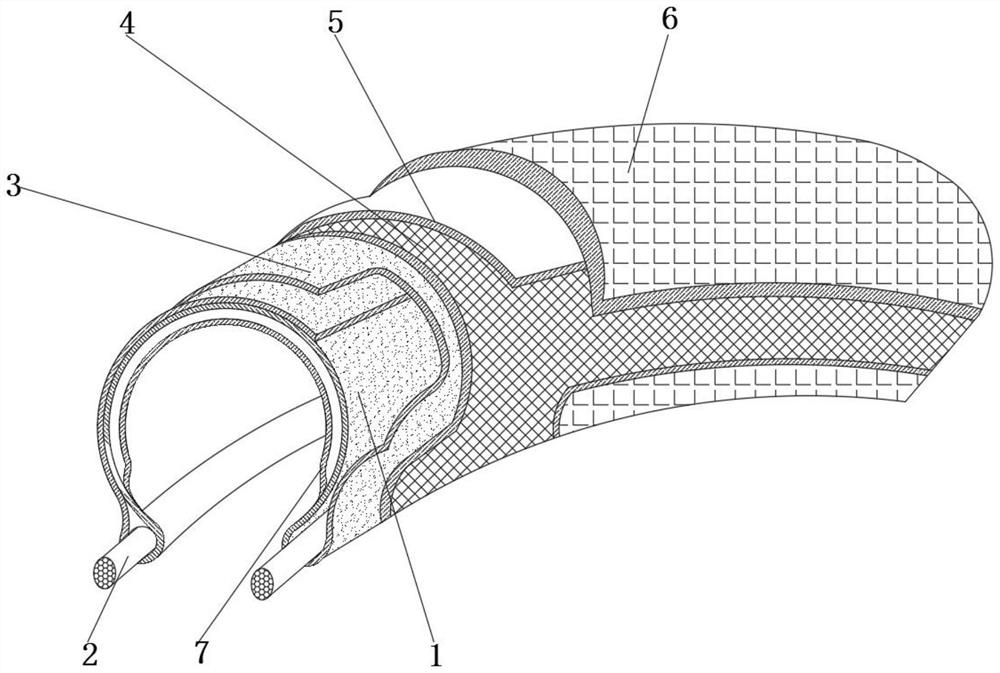

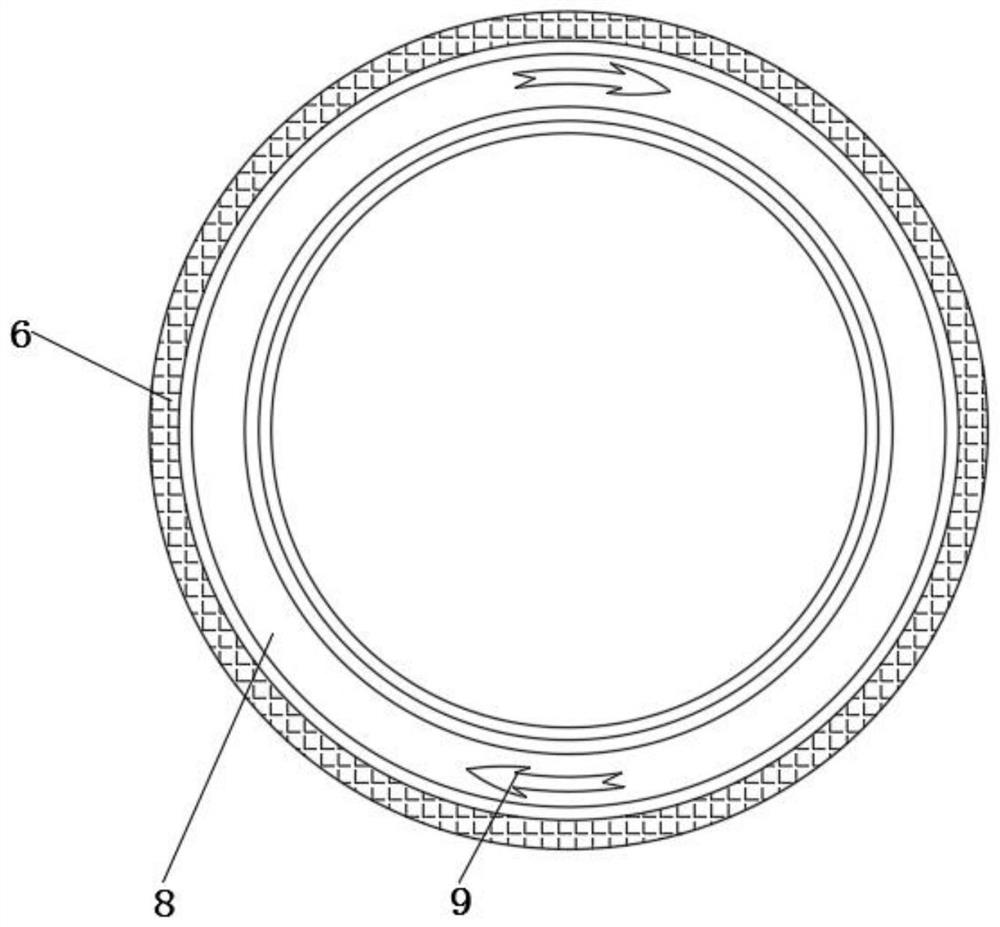

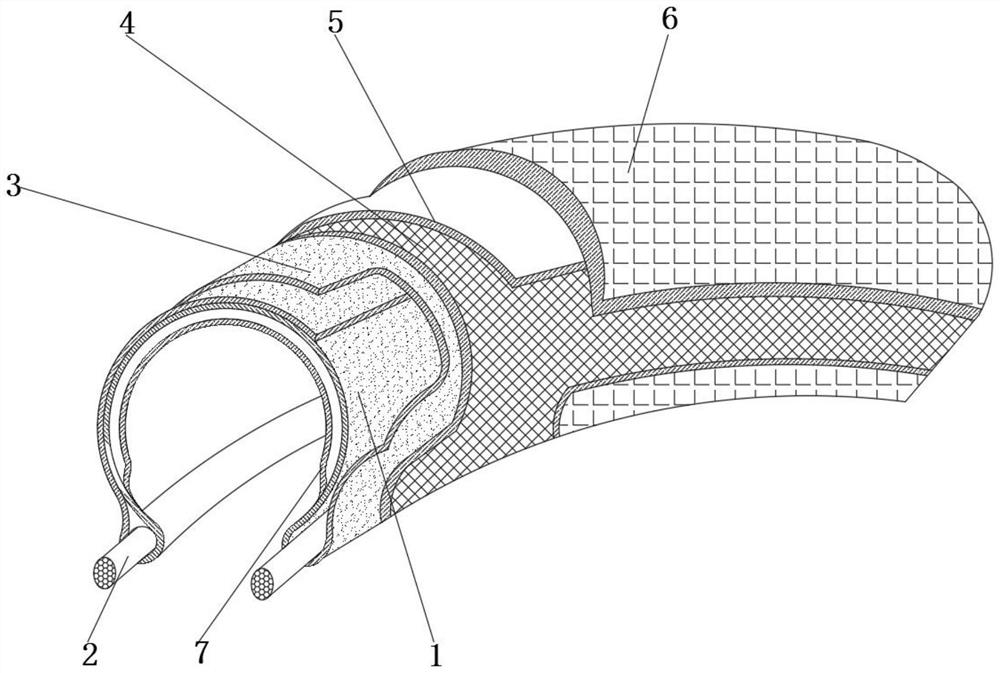

Anti-pricking and anti-stabbing type electric car cover tyre and processing method thereof

PendingCN113954584ANot functioning properlyFill in timeTyresPneumatic tyre reinforcementsTire beadVulcanization

The invention discloses an anti-pricking and anti-stabbing type electric car cover tyre and processing method thereof, the anti-pricking and anti-stabbing type electric car cover tyre comprises a lining layer, a side rubber layer and a guide arrow, a tire bead steel wire is arranged below the lining layer, a tire body layer is arranged above the lining layer, a protective layer is provided with a tread rubber layer, and a rubber injection sheet is arranged in the lining layer. The method sequentially comprises the following steps of injection foaming production, hot melting bonding pretreatment of a lining layer and an injection rubber sheet, hot melting bonding of the lining layer and the injection rubber sheet, tire bead steel wire press-in production, vulcanization pretreatment production of a tire body, high-temperature vulcanization production of a tire body semi-finished product and leakage repairing glue filling production. According to the anti-pricking and anti-stabbing type electric car cover tyre and the processing method thereof, leakage repairing glue can be contained through the glue injection sheet, so that the leakage repairing glue is not in contact with a hub and other accessories, the problem of corrosion of the leakage repairing glue and unnecessary loss are prevented, and the leakage repairing glue does not need to be cleaned when the tire is seriously damaged in the later period and needs to be replaced.

Owner:江苏益晟运动器材有限公司

Device for arranging sliced tobacco strips

PendingCN113895862AFill in timeAccurate judgmentConveyorsControl devices for conveyorsEngineeringStructural engineering

The invention discloses a device for arranging sliced tobacco strips. The device is characterized in that a first group of brackets and a second group of brackets are sequentially mounted in a crossing manner in the conveying direction of a belt conveyor, and an imaging monitoring device is mounted on a cross beam of the first group of brackets; the imaging monitoring device is located over the belt face of the belt conveyor and conducts color difference monitoring on colors on the belt face, an air cylinder is installed on a cross beam of the second group of brackets, the air cylinder is provided with a downward telescopic piston, a palladium nail is installed at the tail end of the telescopic piston, and the palladium nail makes contact with the tobacco strips to disperse the tobacco strips and fill blank leakage areas on the belt face. The imaging monitoring device and an electromagnetic valve are in signal control connection with a PLC, and the electromagnetic valve is in drive control connection with the air cylinder. Through the device, automatic judgment is achieved, the blank leakage area is filled in time, and the production quality and efficiency are guaranteed.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

A kind of preparation method of self-healing silicon carbide fiber reinforced silicon boron nitride carbon composite material

InactiveCN104529499BImprove high temperature stabilityHigh resistance to crystallization temperatureCarbon compositesTube furnace

The invention relates to a preparation method of a self-healing silicon-carbide-fiber-reinforced silicon-boron-nitrogen-carbon composite material, which comprises the following steps: (1) preparing a polyborosilazane (PBSZ) precursor; dissolving the PBSZ precursor in a toluene solution under the protection of N2 to obtain a PBSZ toluene solution; transferring into a pipe furnace, crosslinking under the protection of N2, grinding and screening to obtain SiBNC precursor powder; (2) preparing SiC fibers into a prefabricated part, carrying out hot pressing on the SiBNC precursor powder and SiC fiber prefabricated part, cooling and demolding to obtain a composite material; and transferring into a pipe furnace in an N2 protective atmosphere to perform ceramization, and finally, sintering. The method is simple in technique, easy to operate and low in cost; and the prepared silicon-carbide-fiber-reinforced silicon-boron-nitrogen-carbon composite material is uniform and compact, has the advantages of favorable high-temperature stability and excellent oxidation resistance, and especially has self-healing performance.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com