Acrylic resin paint composition

A technology of acrylic resin and resin composition, which is applied in the field of acrylic resin composition and wear-resistant acrylic resin coating composition to achieve the effects of wide sources, reduced wear and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment.

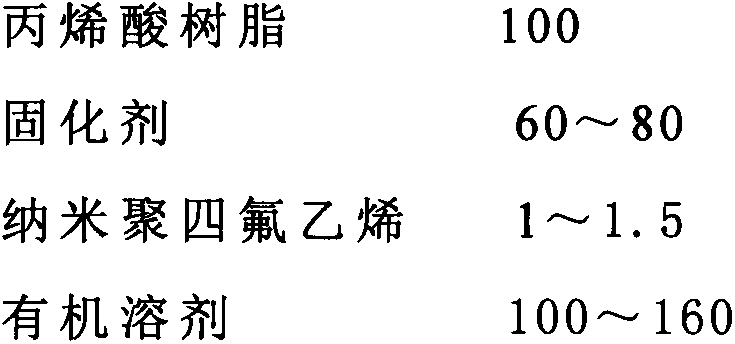

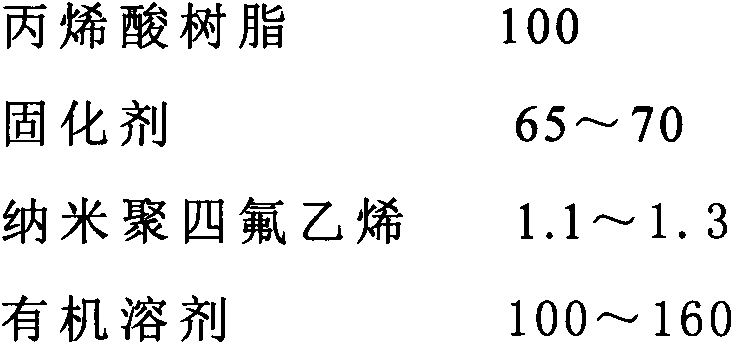

[0023] Composition formula (mass ratio) in the embodiment of table 1 and comparative example

[0024] Embodiment one Embodiment two Embodiment Three Embodiment four Comparative example one Comparative example two Acrylic 100 100 100 100 100 100 Melamine 60 40 35 70 Methyl ether acetate 80 30 40 75 Nano PTFE 1 1.5 1.1 1.3 Butanol 100 60 50 60 60 50 Xylene 20 100 100 90 80 60

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com