High strength ultrathin float glass

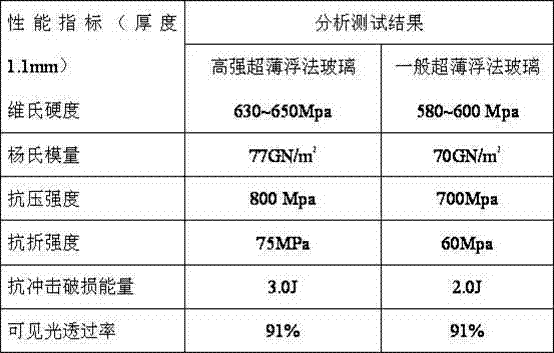

A float glass, high-strength technology, applied in the fields of high-strength ultra-thin float glass and high-end residential safety glass, can solve the problems of unavailable production of high-strength ultra-thin float glass, overcapacity of ordinary float glass, and declining economic benefits of enterprises And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

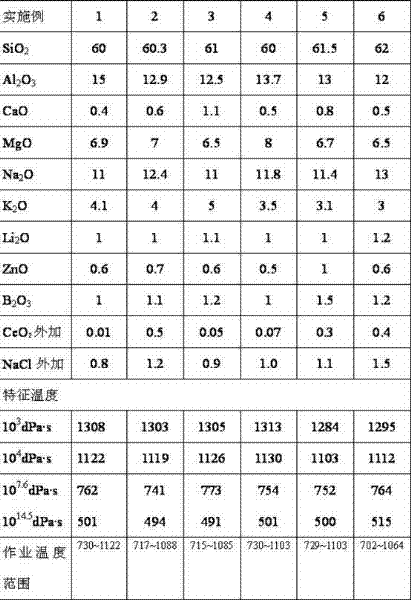

[0061] Example 1: According to the glass composition No. 1 in the table, the high-strength glass with a thickness of 1.1mm can be obtained through float process molding. The microhardness is 640MPa, the compressive strength is 807 Mpa, the flexural strength is 76.5 Mpa, and the impact resistance is damaged. Energy 2.98J high-strength ultra-thin float glass.

Example Embodiment

[0062] Example 2: According to the glass composition No. 2 in the table, the high-strength glass with a thickness of 0.55m can be obtained through float process molding, with a microhardness of 638MPa, a compressive strength of 798Mpa, a flexural strength of 70.5 Mpa, and impact resistance. 2.87J high-strength ultra-thin float glass.

Example Embodiment

[0063] Example 3: According to the glass composition No. 3 in the table, the high-strength glass with a thickness of 1.1mm can be obtained through float process molding. The microhardness is 641MPa, the compressive strength is 810 Mpa, the flexural strength is 73.5 Mpa, and the impact resistance is damaged. Energy 3.0J high-strength ultra-thin float glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com