Graphene/epoxy resin composite anticorrosive paint with high isolation and preparation method

A technology of epoxy resin and anti-corrosion coating, applied in epoxy resin coating, anti-corrosion coating, coating and other directions, can solve the problems of difficult dispersion of graphene, low graphene content, etc., and achieve simplified preparation process and process, good flexibility and impact resistance, excellent waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation process of anticorrosion coating of the present invention is as follows:

[0044] According to the formula ratio, add epoxy resin, graphene / epoxy resin masterbatch, diluent and additives into the mixer and stir at a constant speed (300-500 rpm) for 1-3 hours, so that various materials can be mixed evenly and packed A component can be obtained. After mixing components A and B evenly in proportion, it can be used. In terms of weight percentage, component A accounts for 53-93%, and component B accounts for 7-47%. In component A, the content of graphene is in the range of 0.03-2.3wt%, preferably in the range of 0.2-1.5wt%. After being applied and dried according to conventional methods, a corrosion protective coating with high barrier properties can be prepared.

Embodiment 1

[0047] Add 500g of graphene powder prepared by the intercalation exfoliation method into 30kg of hexanol, and ultrasonically disperse for 30 minutes to obtain a transiently dispersed graphene / alcohol suspension; mix the above suspension with 10kg of epoxy resin Stir mechanically for 5 hours, with a stirring speed of 200 rpm; after stirring, let it stand for 10 minutes to separate the above mixed liquid; pour out the gray-white solution in the upper layer, leaving a black viscous slurry in the lower layer, and put it in a vacuum oven Heating to 120° C. under medium vacuum, keeping the vacuum degree in the oven lower than 100 Pa; drying for 24 hours and taking it out to obtain a graphene / epoxy resin composite masterbatch with a graphene content of about 5 wt%.

[0048] In parts by weight, the raw material composition of the composite anticorrosion coating is as follows:

[0049] The ingredients of Component A are:

[0050] 100 parts of epoxy resin;

[0051] 15 parts of 5wt% gr...

Embodiment 2

[0069] In parts by weight, the raw material composition of the composite anticorrosion coating is as follows:

[0070] The ingredients of Component A are:

[0071] 100 parts of epoxy resin;

[0072] 6 parts of 5wt% graphene / epoxy resin masterbatch;

[0073] Solvents consist of the following ingredients and proportions:

[0074] 15 parts of xylene;

[0075] 15 parts of cyclohexanone;

[0076] 15 parts of n-butanol;

[0077] Additives include the following ingredients and proportions:

[0078]

[0079] The ingredients of Part B are:

[0080] 25 parts of polyamide.

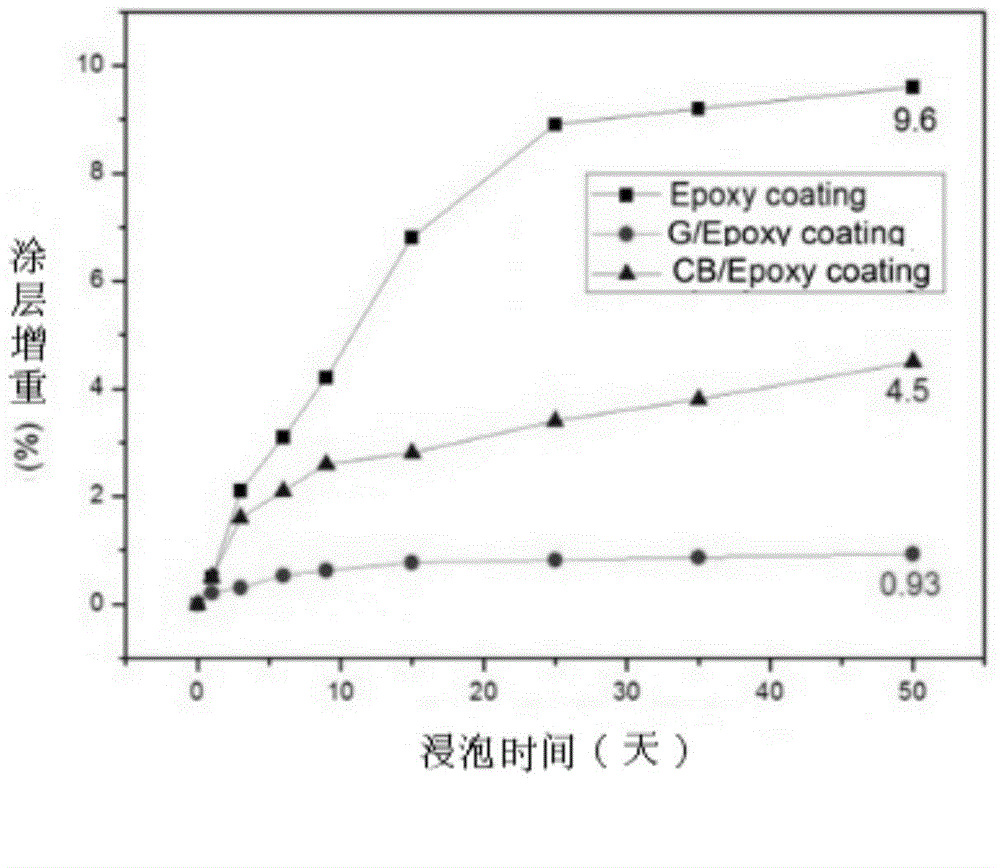

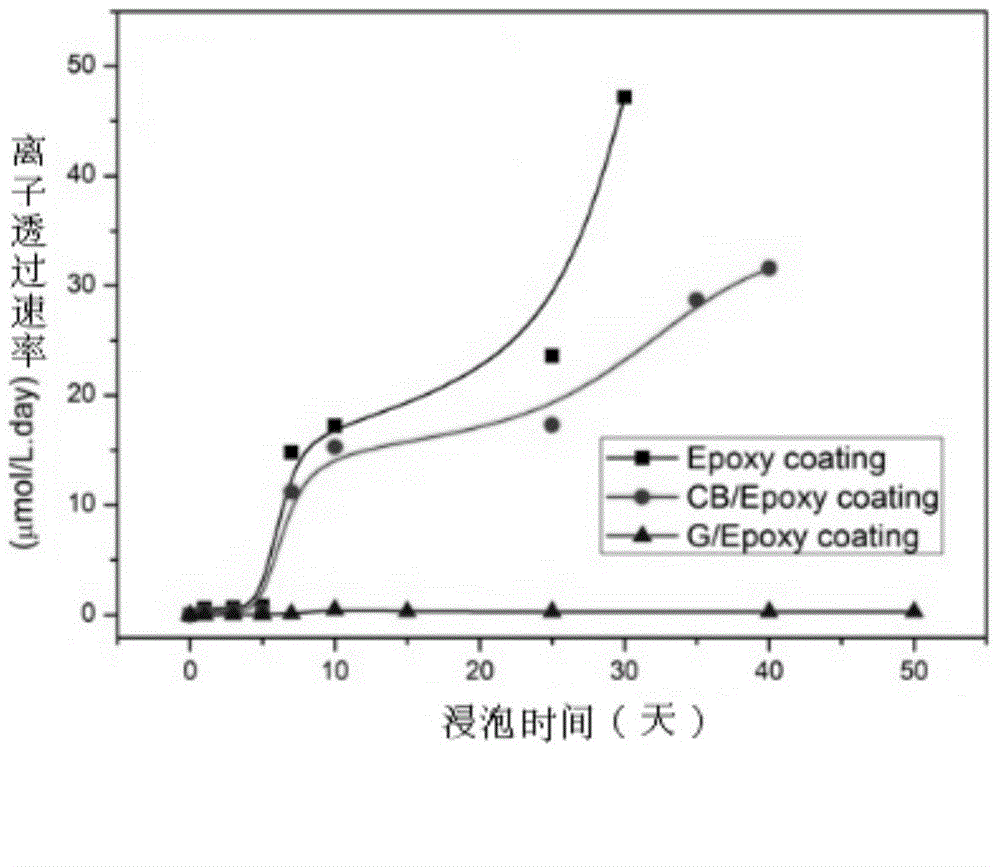

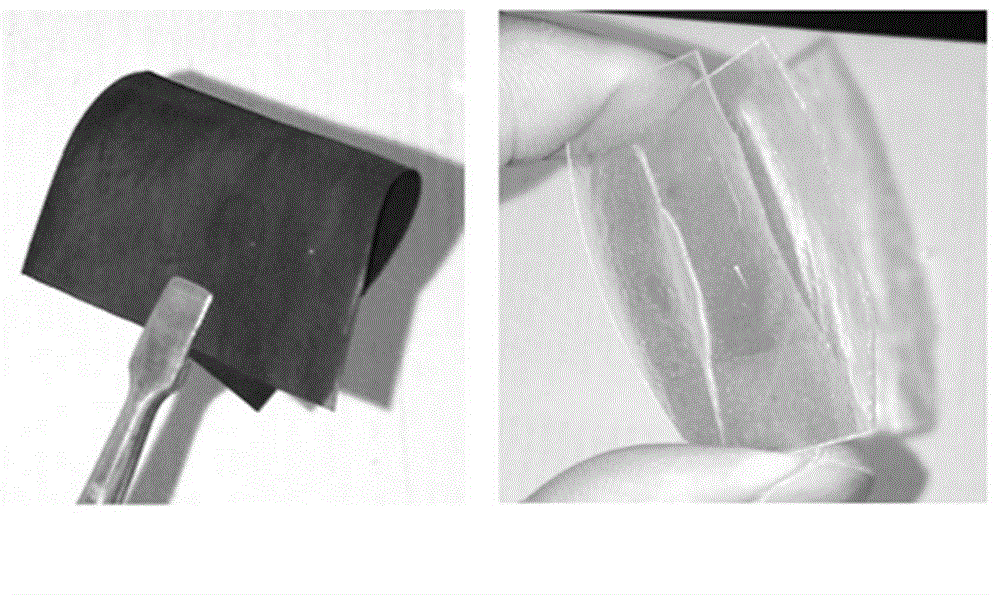

[0081] The content of graphene in the above coating is about 0.2wt%. Using the same preparation process as in Example 1 to make a composite film and coating, and to perform the same performance test, the test results similar to those in Example 1 can be obtained. It shows that the graphene / epoxy resin composite coating with high insulation can be prepared under the condition of extremely low addition amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com