Patents

Literature

539results about How to "Not easy to break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

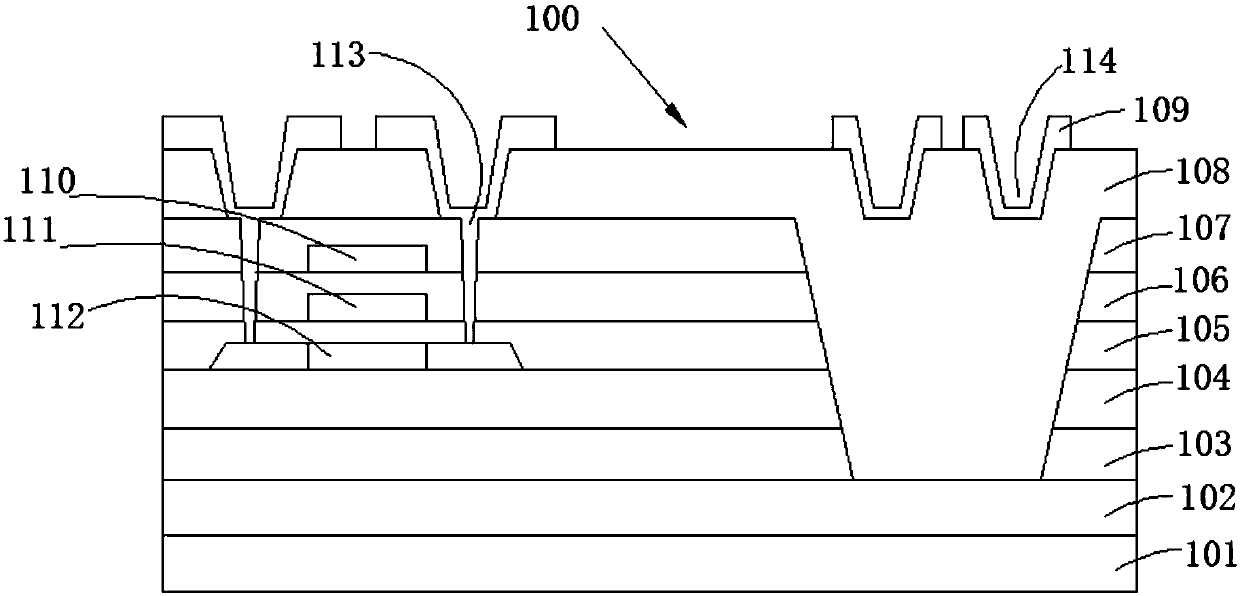

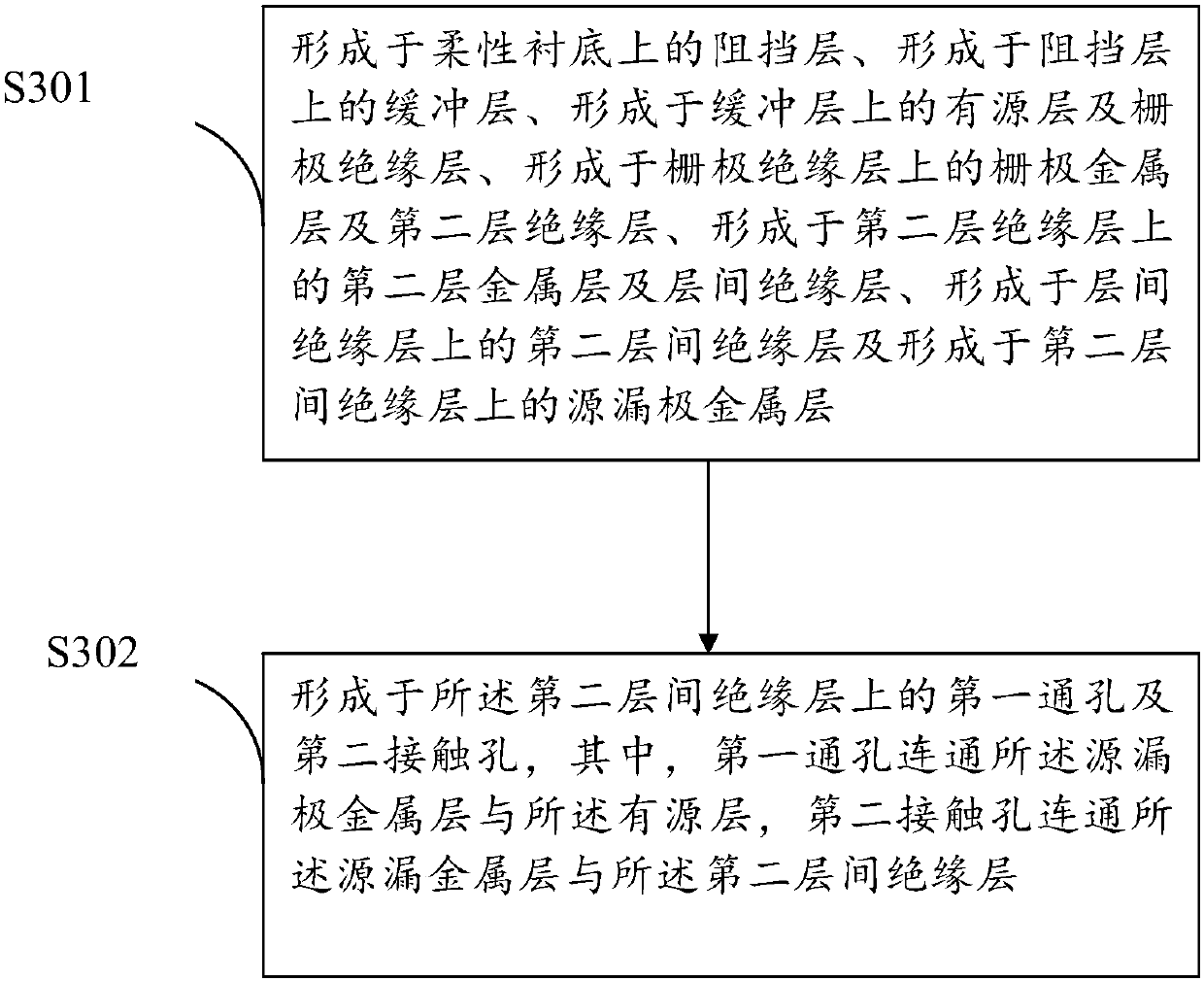

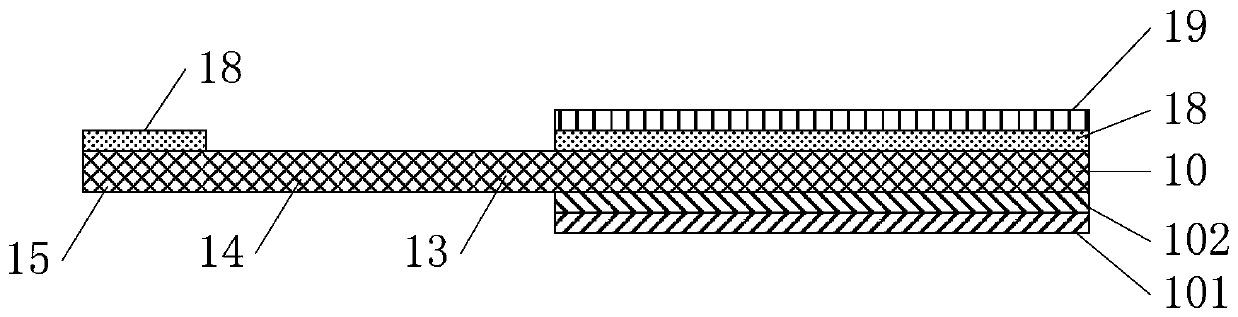

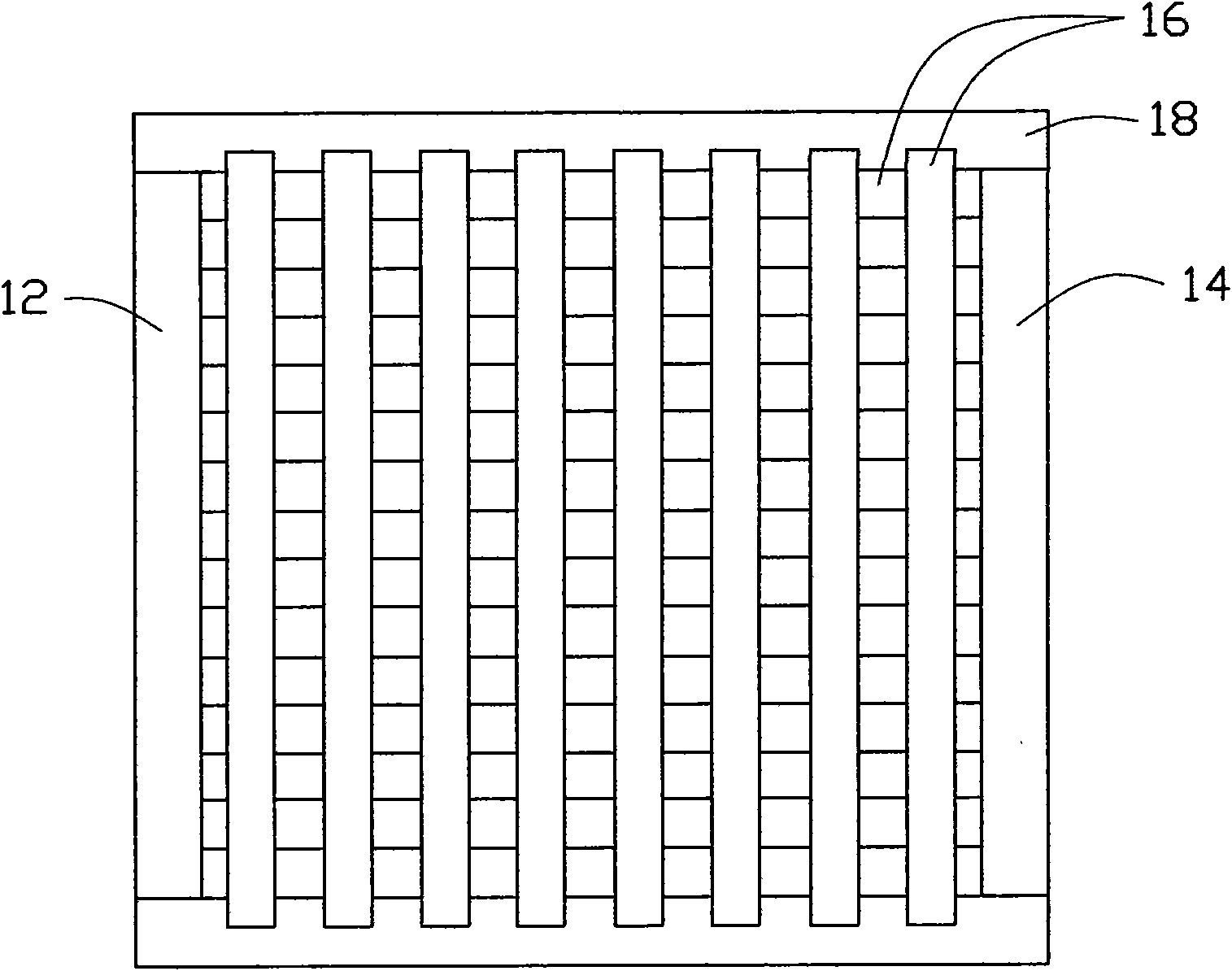

Flexible display panel, flexible display panel manufacturing method and display device

InactiveCN107910335ANot easy to breakGuaranteed normal displaySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringContact hole

The invention provides a flexible display panel including a flexible substrate, a barrier layer formed on the flexible substrate, a buffer layer formed on the barrier layer, an active layer and a gateinsulation layer formed on the buffer layer, a gate metal layer and a second insulation layer formed on the gate insulation layer, a second metal layer and an inter-layer insulation layer formed on the second insulation layer, a second inter-layer insulation layer formed on the inter-layer insulation layer and a source drain electrode metal layer formed on the second inter-layer insulation layer.The second inter-layer insulation layer is provided with a first through hole communicating the source drain electrode metal layer and the active layer and a second contact hole communicating the source drain metal layer and the second inter-layer insulation layer. The invention also provides a flexible display panel manufacturing method and a display device comprising the display panel. The flexible display panel provided by the invention can ensure normal display of the flexible display panel in a bending process.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Twist-resisting polyvinyl chloride synthetic leather and manufacturing method thereof

InactiveCN102995451AGood flexibilityHas a natural and comfortable feelSynthetic resin layered productsLaminationPolyesterStearic acid

The invention discloses twist-resisting polyvinyl chloride synthetic leather which comprises a surface layer, a foaming layer, a bonding layer and fluffing cloth. The twist-resisting polyvinyl chloride synthetic leather is characterized by being prepared from the following components in parts by weight: 50-60 parts of SG-2 PVC (Polyvinyl Chloride) resin, 30-40 parts of SG-6 PVC resin, 20-25 parts of isophthalic ester, 10-15 parts of phthalic polyester, 10-15 parts of trioctyl trimellitate, 5-6 parts of PVC color cream, 1-2 parts of zinc stearate, 1-2 parts of protein powder, 20-25 parts of zinc oxide, 10-15 parts of magnesium oxide, 10-15 parts of N660 carbon black, and 5-10 parts of modified attapulgite. Through improvement of formula and process provided by the invention, the flexibility of the synthetic leather is enhanced, and the synthetic leather has a natural and comfortable handfeel similar to that of natural leather. The synthetic leather is not easy to damage or tear within 3-5 years.

Owner:HEFEI ANSHAN COATING FABRICS

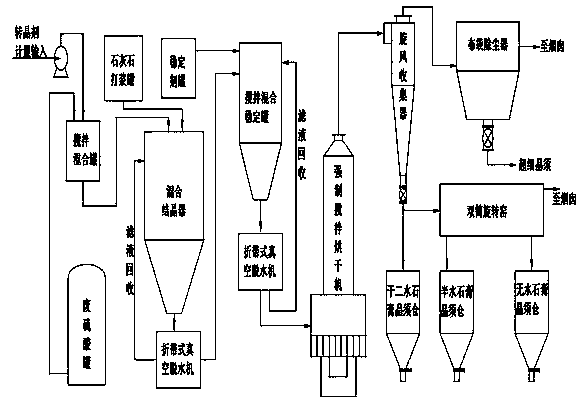

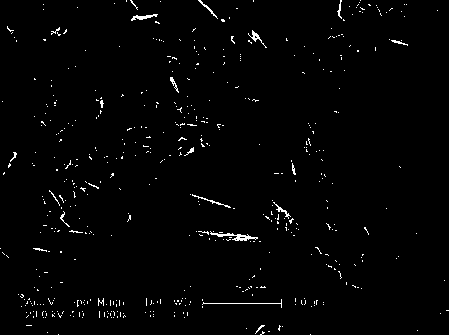

Method for integrating waste sulfuric acid treatment engineering and gypsum crystal whisker production

InactiveCN103966670ANot easy to breakSimple methodPolycrystalline material growthFrom normal temperature solutionsGypsumCalcium carbonate

The invention discloses a method for integrating waste sulfuric acid treatment engineering and gypsum crystal whisker production. According to the method, waste sulfuric acid treatment and gypsum crystal whisker production are combined, the waste sulfuric acid reacts with calcium carbonate, and a crystallizing agent and a stabilizing agent are added in the production process, thereby obtaining various gypsum crystal whisker products. The process is simple, multiple gypsum crystal whisker products can be prepared, the crystal structure of the gypsum crystal whisker is stable and not easy to break, meanwhile the waste sulfuric acid can be effectively utilized, and then environment protection and resource recycling and reuse can be effectively combined.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

Polyvinyl chloride synthetic leather for luggage and manufacturing method thereof

InactiveCN102995450AGood flexibilityHas a natural and comfortable feelPolyureas/polyurethane adhesivesSynthetic resin layered productsSurface layerGlycerol

The invention discloses polyvinyl chloride synthetic leather for a luggage. The leather comprises a surface layer, a foaming layer, a bonding layer and fluffing cloth. The surface layer is slurry prepared from the following raw materials in parts by weight: 40-50 parts of SG-3 PVC (Polyvinyl Chloride) resin, 70-80 parts of SG-5 PVC resin, 30-35 parts of glycerol triacetate, 10-15 parts of epoxidized soybean oil, 20-25 parts of glycerol triglycerate, 5-6 parts of PVC color cream, 1-2 parts of bimercapto iso-octyl acetate di-n-octyl tin, 5-10 pats of zinc oxide and 5-10 parts of modified attapulgite. Through improvement of formula and process provided by the invention, the flexibility of the synthetic leather is enhanced, and the synthetic leather has a natural and comfortable handfeel similar to that of natural leather. The synthetic leather is not easy to damage or tear within 3-5 years, and suitable for use in lug gages.

Owner:HEFEI ANSHAN COATING FABRICS

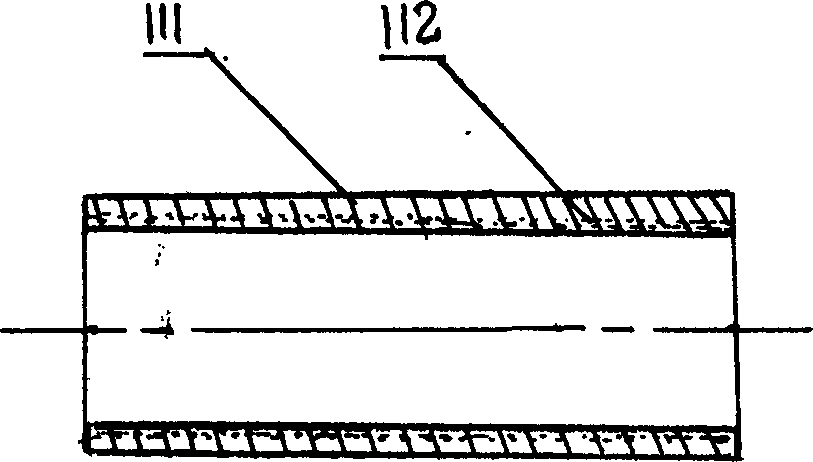

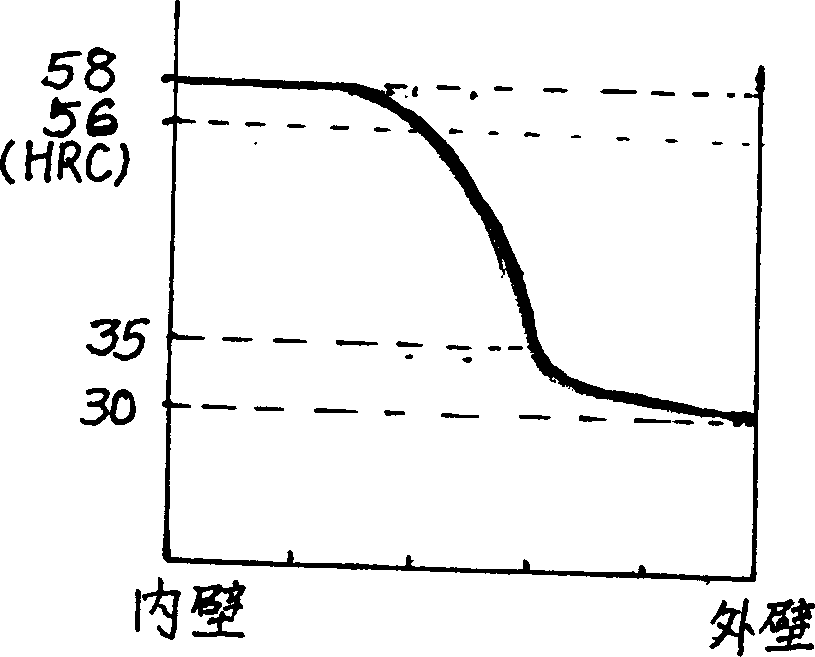

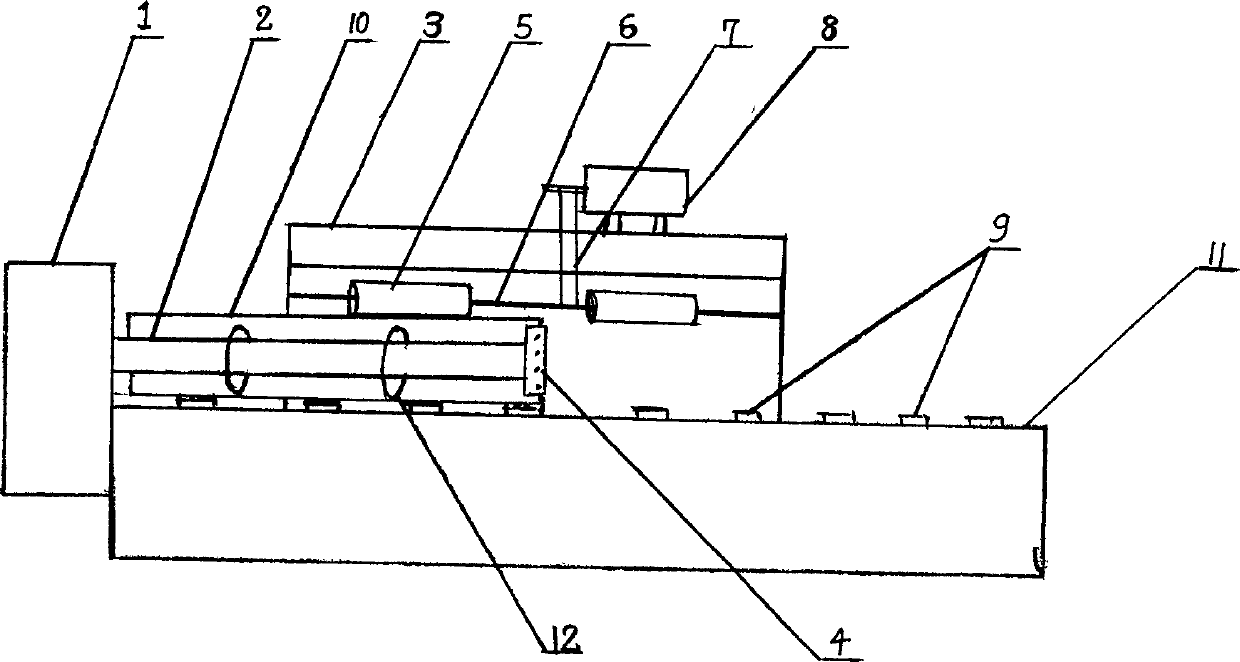

Cylinder shape pipe piece with inner harden layer and production method and equipment

InactiveCN1433942ALarge caliberSave materialIncreasing energy efficiencyFurnace typesFrictional coefficientEngineering

The present invention relates to a cylindrical pipe with internal hardened layer, its production method and special-purpose equipment. Said cylindrical pipe has small wall thickness and long length, its pipe wall has internal layer and external layer with different hardness, the hardness of its internal layer is greater than that of external layer, and said pipe is applicable for conveying material with high frictional coefficient. Its production method adopts the mode utilizing frequency to control pipe movement and proper hardening temp. range, and is special-purpose equipment is simple in structure, stable in operation, and can accurately control hardening temp., pipe moving speed nad depth of hardened layer.

Owner:王克发 +1

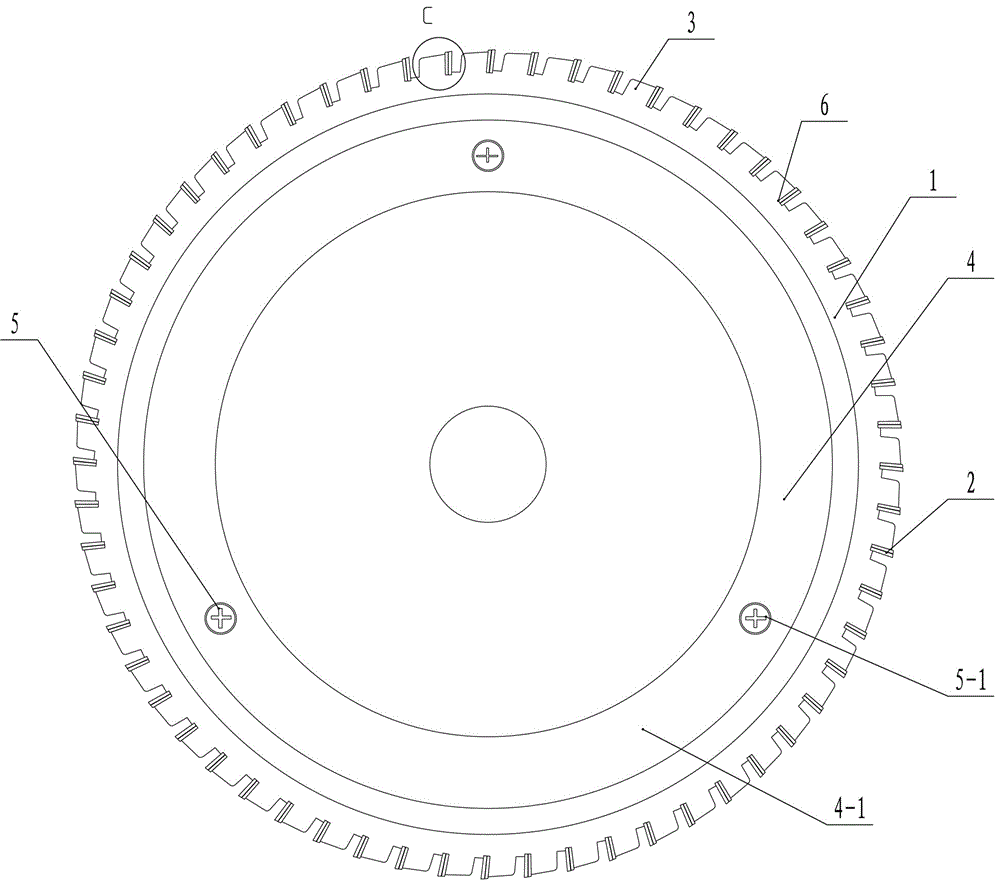

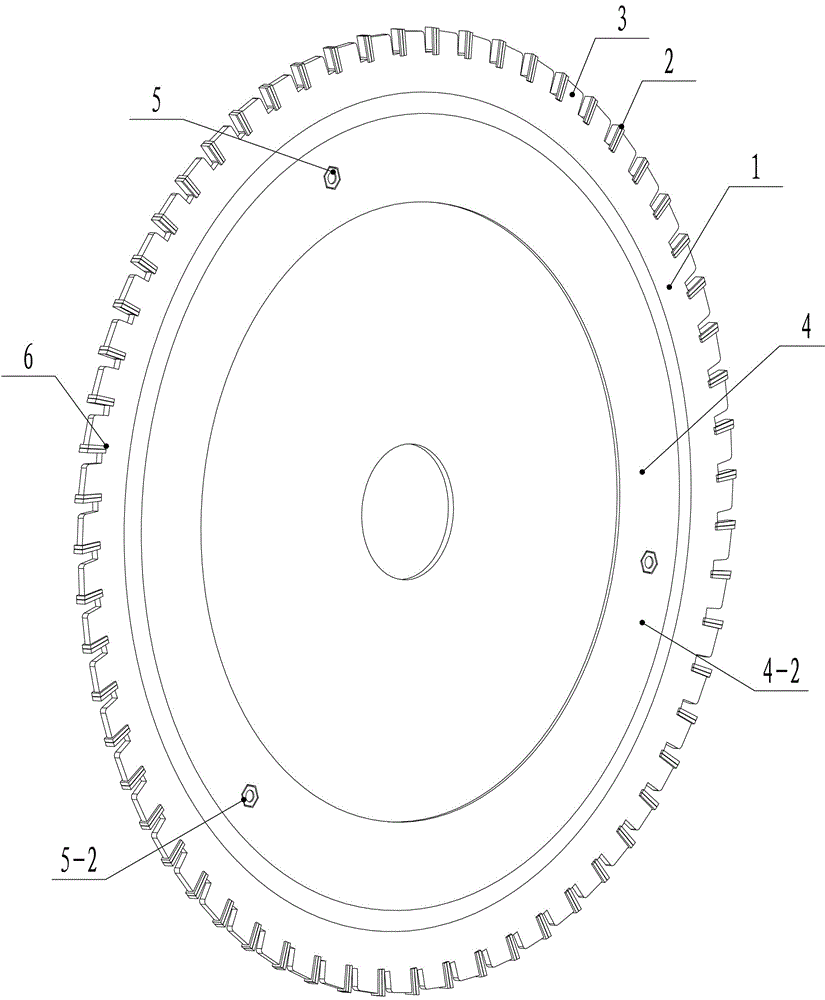

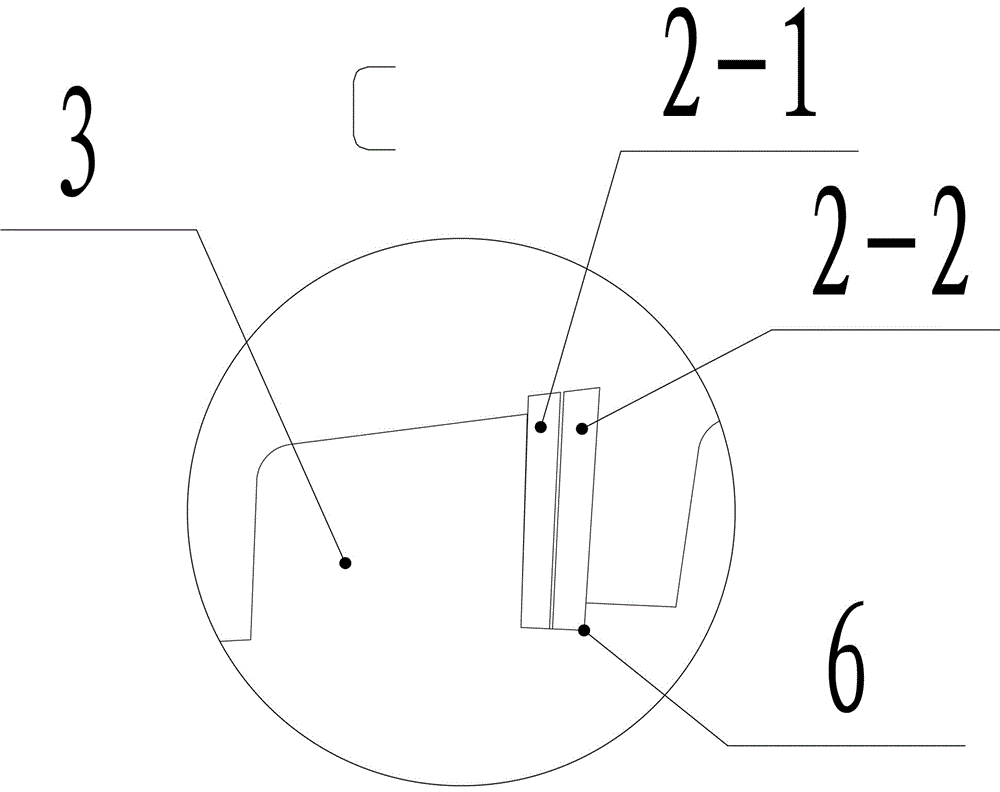

Saw web used for both cutting and grinding

ActiveCN106424940ARepair smoothImprove verticalityEdge grinding machinesMetal sawing toolsEngineeringGrinding wheel

The invention relates to a saw web used for both cutting and grinding. The saw web comprises a saw web body, double-layer cutter heads, tooth backs and a grinding wheel. Grooves are formed in the positions, on the same sides of the tooth backs, of the saw web body. The double-layer cutter heads are welded in the grooves. The grinding wheel comprises an upper grinding wheel body and a lower grinding wheel body. The upper grinding wheel body and the lower grinding wheel body are annular and arranged on the both sides of the saw web body correspondingly. The saw web body, the upper grinding wheel body and the lower grinding wheel body are provided with bolt through holes in fit with one another. The upper grinding wheel body and the lower grinding wheel body are fixed to the saw web body through bolts. By adoption of the saw web used for both cutting and grinding, a cut surface can be cut and ground at the same time, the efficiency is greatly improved, the flatness of the ground surface is improved, and the perpendicularity of the ground surface and a profile is improved; and meanwhile, by designing the embedded cutter heads, the impact resistance of saw web cutter teeth of the saw web to to-be-cut materials during cutting is greatly improved, and the cutter heads are not prone to falling off.

Owner:HEBEI JIMEIDA TOOLS CO LTD

Method for producing Tibetan medicinal herb incense with foot

The invention relates to a preparation method of incense, in particular to a 'production method of tibetan drug kusaka with incense sticks', pertaining to the field of preparation of incense. The production method of the invention comprises that raw materials are smashed to be 100-mesh to 200-mesh; the proportion of adhesive is also increased; bamboo sticks are used as the incense sticks and a modern machine is used for preparing the tibetan drug kusaka with the incense sticks. The production method of the invention perfectly combines a traditional technology and formula and modern machining and not only keeps various original active ingredients of the tibetan drug kusaka to the maximum extent, but also ensures that the tibetan drug kusaka with the incense drug has a neat shape, good flaming in an upright way (which changes the defects that the traditional tibetan drug kusaka is easy to break and can not be burnt anywhere and fully) and fresh and unique smell. The produced tibetan drug kusaka of the invention not only improves the cultural connotation and economic values of the tibetan drug kusaka, but also has a broad market prospect, thus being another blossoming flower in national brands in Tibetan.

Owner:吕坤秋

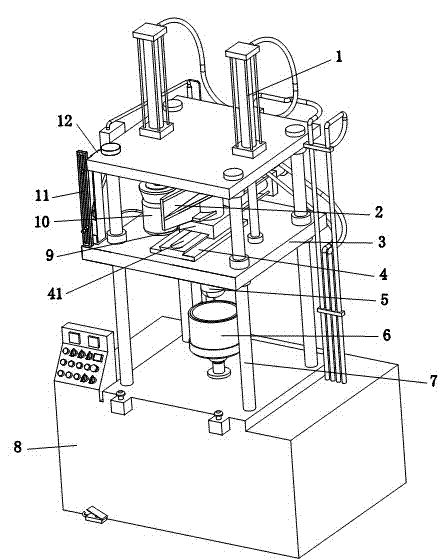

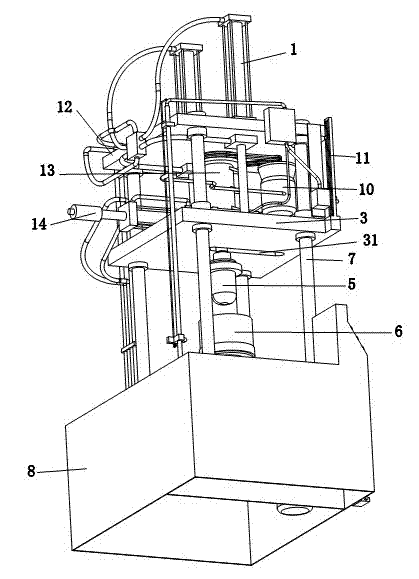

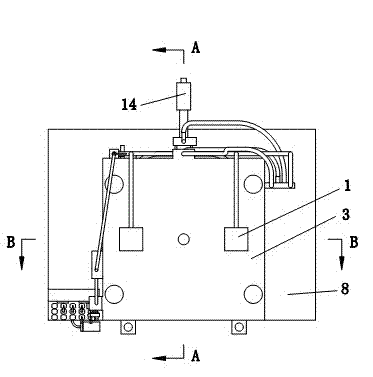

Automatic rolling forming machine for ceramic container clay blanks

The invention relates to an automatic rolling forming machine for ceramic container clay blanks. The automatic rolling forming machine comprises a frame, a ceramic container blank die and a forming rotary head. The automatic rolling forming machine is characterized by also comprising a first motor, a first rotating wheel, more than two guide posts, a first mounting plate, a slide rail, a sliding block, a second motor, a second rotating wheel, a horizontal cylinder, a second mounting plate and more than one pull cylinder, wherein the first motor is arranged below the frame, the first rotating wheel is driven by the first motor to rotate and provided with a rotating shaft, and the rotating shaft of the first rotating wheel is connected with the ceramic container clay blank die; the more than two guide posts are fixed on the frame, the first mounting plate is sleeved on the guide posts and can slide up and down, the slide rail is arranged on the first mounting plate, the first mounting plate is provided with an elongated hole, and the slide rail is provided with a slide hole; the sliding block is arranged on the slide rail and is in sliding fit with the slide rail, the second motor is arranged on the sliding block, the second rotating wheel is driven by the second motor to rotate and provided with a rotating shaft, and the rotating shaft of the second rotating wheel passes through the slide hole and the elongated hole and then is connected with the forming rotary head; the horizontal cylinder is fixed on the first mounting plate and used for pulling the sliding block to move horizontally; and the second mounting plate is fixed on the guide posts, the more than one pull cylinder is arranged on the second mounting plate, and the end of a piston rod of the pull cylinder is connected with the first mounting plate. The invention has the advantages that: the production efficiency is high, and a batch of produced ceramic container clay blanks have the same size.

Owner:佛山市简氏依立电器有限公司

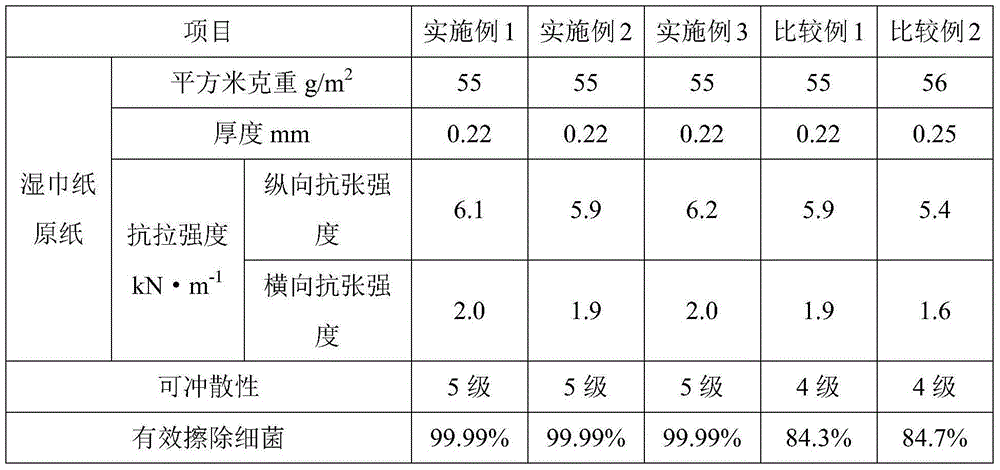

Antibacterial wet tissue paper and manufacturing method thereof

InactiveCN104998163ANot easy to breakSoft and durable paperAntibacterial agentsDomestic applicationsCoconut oilLinum

The invention relates to antibacterial wet tissue paper and a manufacturing method thereof. The antibacterial wet tissue paper comprises wetting liquid and non-woven materials soaked in the wetting liquid; the non-woven materials are wet tissue paper base paper prepared by papermaking pulp composed of, by weight of fibers, 25-28% of polylactic acid fibers, 4-6% of linen fibers, 3-5% of silk fibers and the balance wood pulp fibers; the wetting liquid is fermentation liquor obtained by performing fermentation cultivation after an appropriate amount of bacillus subtilis is inoculated into the raw materials including, by weight, 5-10 parts of corn stigmas, 15-20 parts of fructus cnidii, 8-10 parts of angelica sinensis, 10-15 parts of radix angelicae, 10-12 parts of radix stemonae, 20-30 parts of folium artemisiae argyi, 5-10 parts of bunge pricklyash leaves, 5-10 parts of rhizoma kaempferiae, 20-30 parts of lespedeza pilosa, 15-20 parts of folium isatidis, 3-5 parts of citric acid, 10-15 parts of coconut oil, 15-20 parts of flavedo and 400-500 parts of water. According to the antibacterial wet tissue paper, the dispersing performance is good, biodegradation can be performed, and multiple bacteria can be inhibited.

Owner:张进

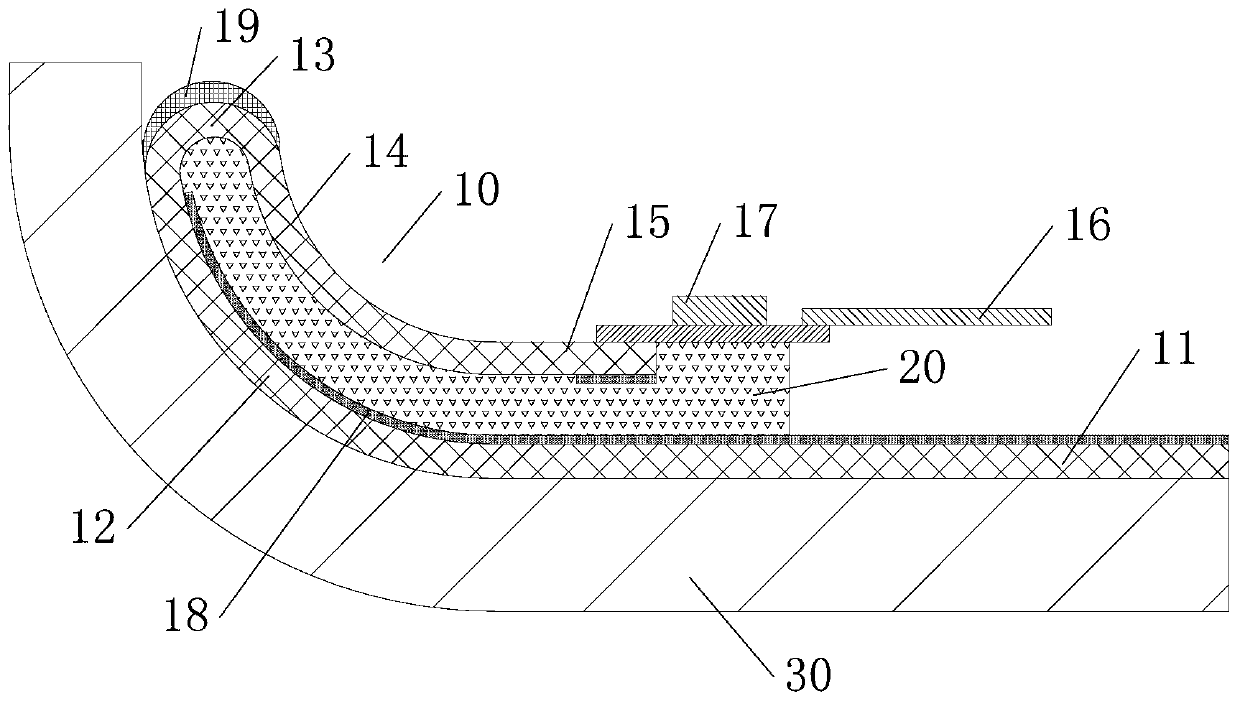

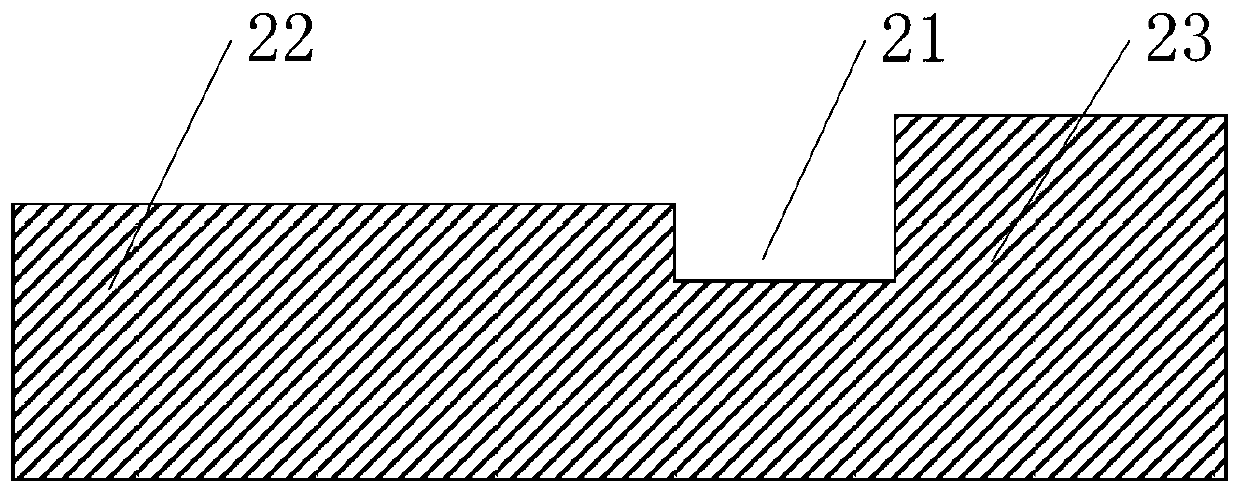

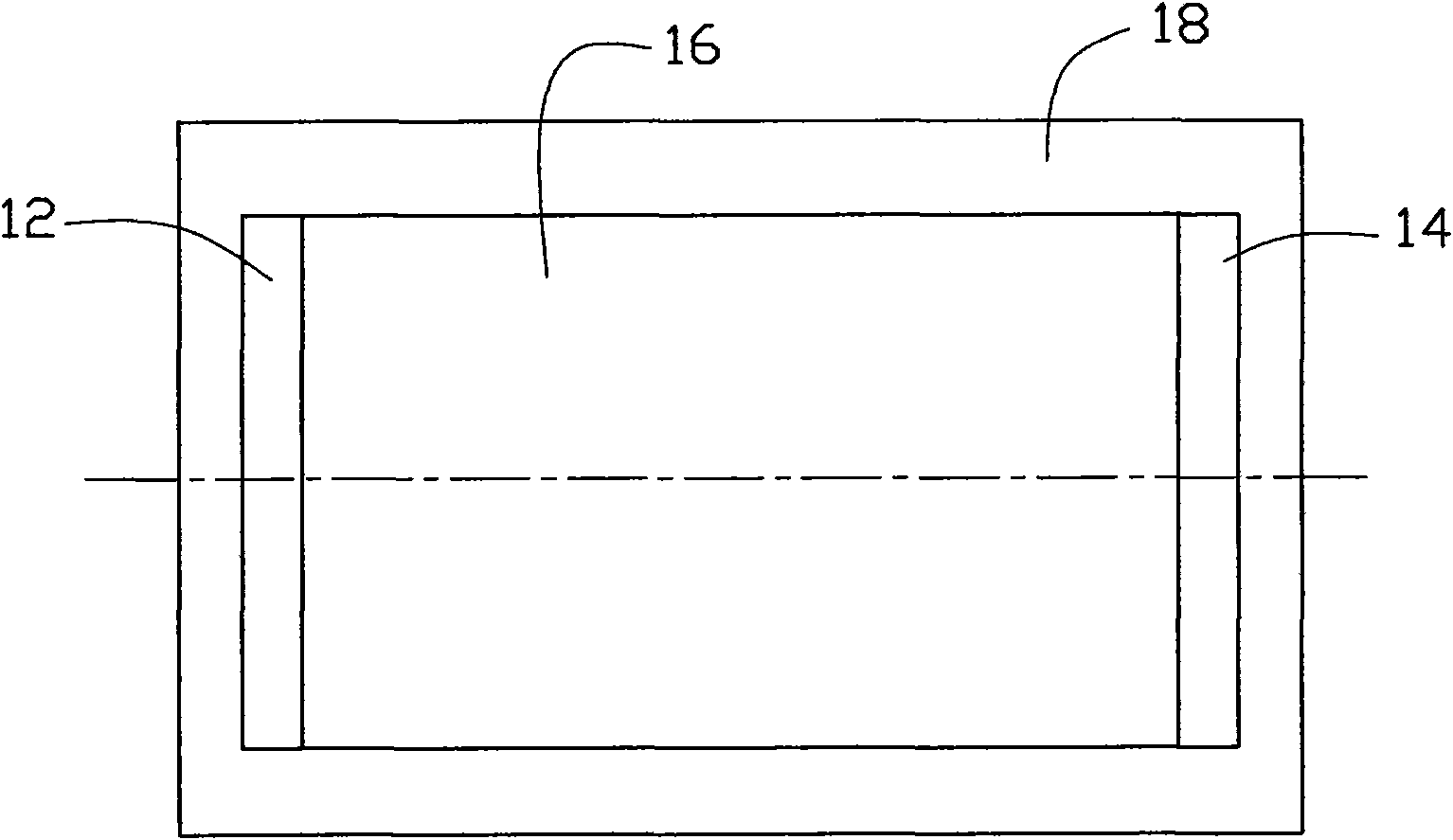

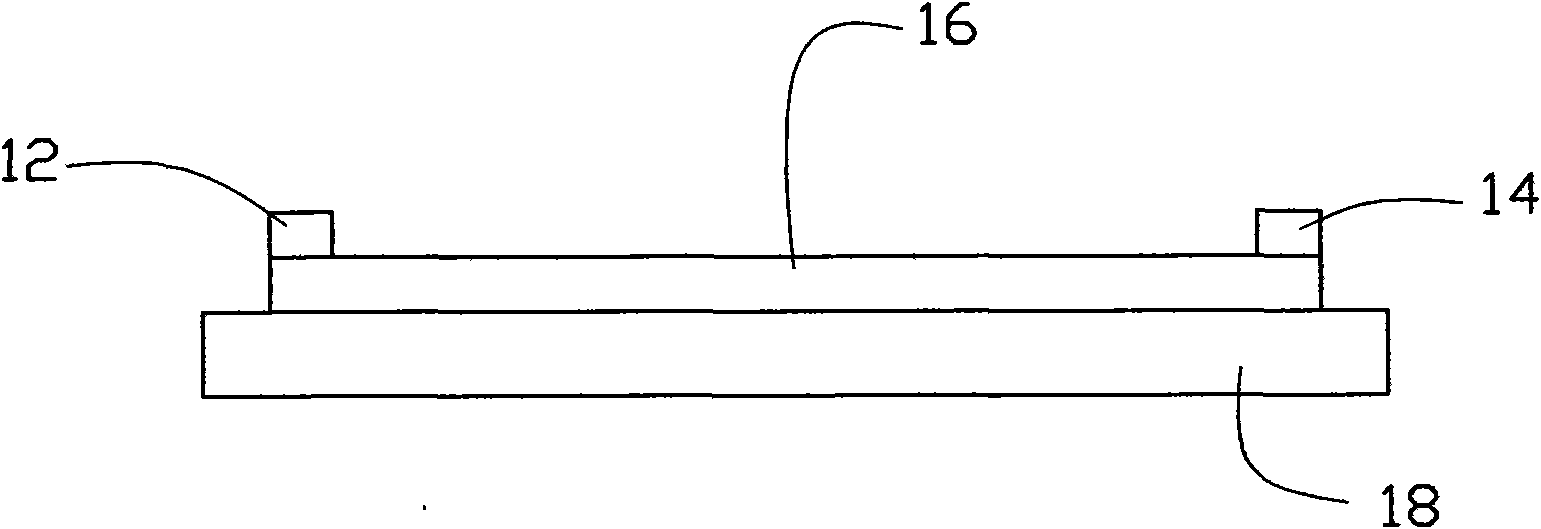

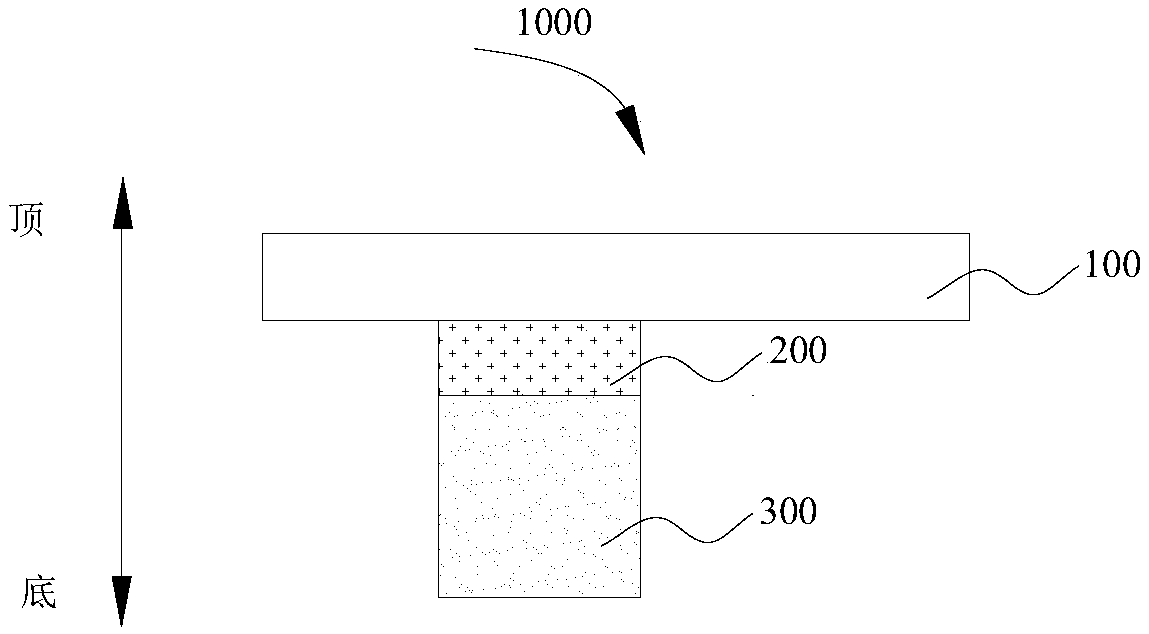

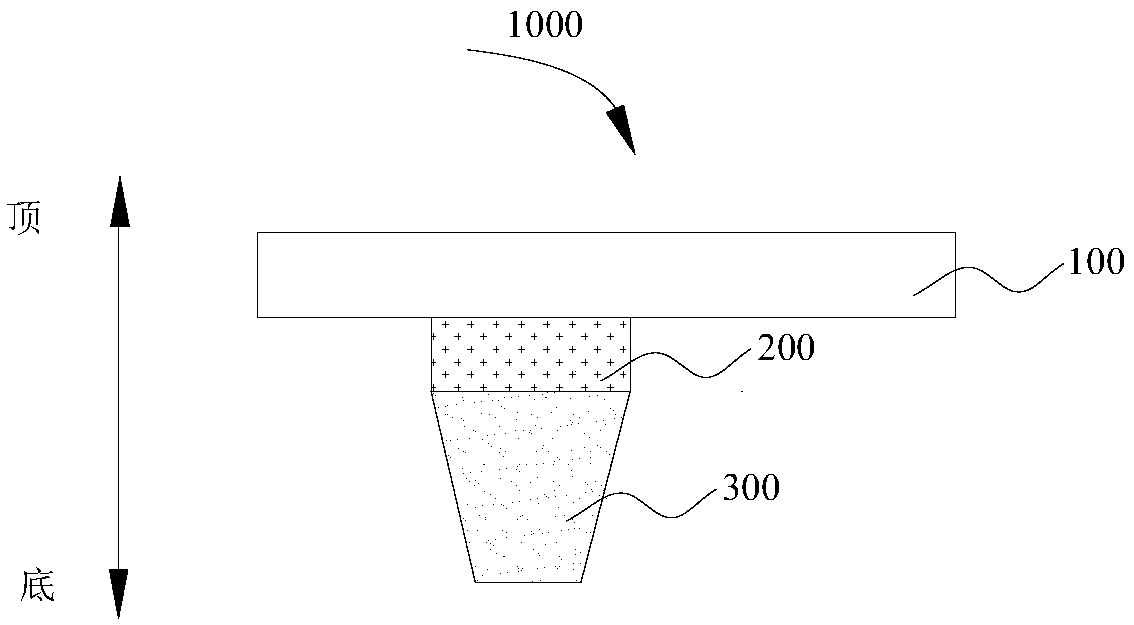

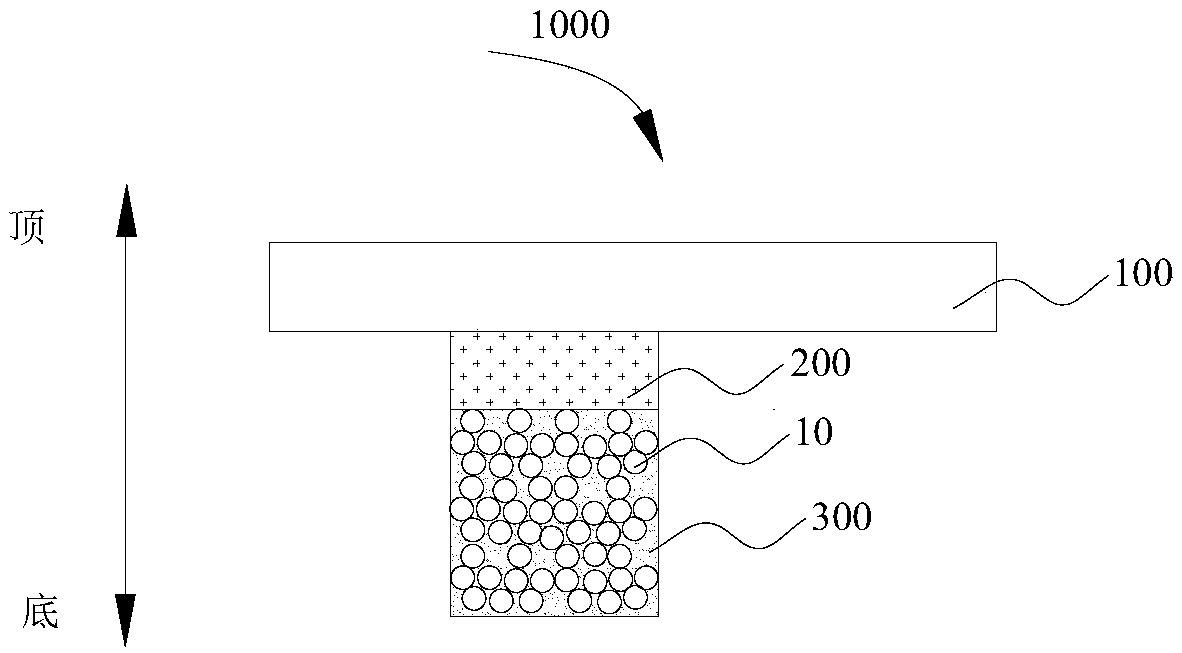

Display panel, manufacturing method thereof and display device

ActiveCN111128020ANot easy to breakReduced impact resistanceSolid-state devicesIdentification meansPhysicsMechanical engineering

The invention discloses a display panel. The display panel comprises a flexible display substrate and colloid, the flexible display substrate comprises a plane area, a first arc-shaped area, a bendingarea, a second arc-shaped area and an edge area which are connected in sequence. The shapes of the first arc-shaped area and the second arc-shaped area are matched and correspond to each other; wherein the plane area, the first arc-shaped area, the bending area, the second arc-shaped area and the edge area define a containing space, the containing space is filled with the colloid to support the second arc-shaped area, and the plane area, the first arc-shaped area, the second arc-shaped area and the edge area are bonded and fixed through the colloid. The colloid is used for filling the containing space, the situation that the impact resistance of the display panel is reduced due to the fact that the second arc-shaped area is in a suspended state is avoided, and the source-drain metal wiresin the bent area are not prone to breakage.

Owner:BOE TECH GRP CO LTD +1

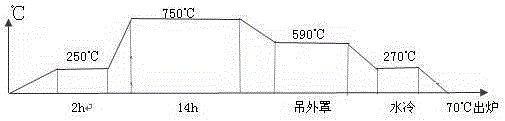

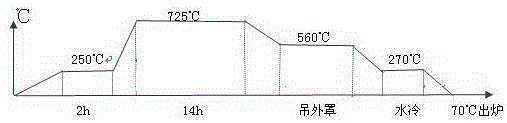

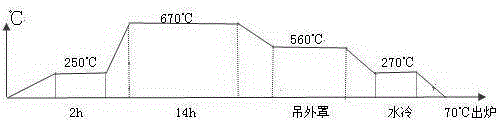

Heat treatment technology of alloy spring cold-rolled steel strip 51CrV4 of automobile clutch diaphragm

ActiveCN105401073AIncreased deformation resistanceAvoid deformationThermal insulationOxidation state

The invention discloses a heat treatment technology of an alloy spring cold-rolled steel strip 51CrV4 of an automobile clutch diaphragm. According to the heat treatment technology, blanks are subjected to cold-rolling deformation for nine times and annealing heat treatment for three times, the temperature of a heating section is controlled, the cooling temperature and speed are controlled, the atmosphere in a heating furnace is heated and subjected to thermal insulation in a non-oxidation state in the cold-rolling and annealing heat treatment processes, and an oxidized grain boundary and a decarburized layer are avoided. With the adoption of the scheme, the production cost is reduced, and the product performance meets the international standard.

Owner:SUZHOU XIANGLOU METAL PROD

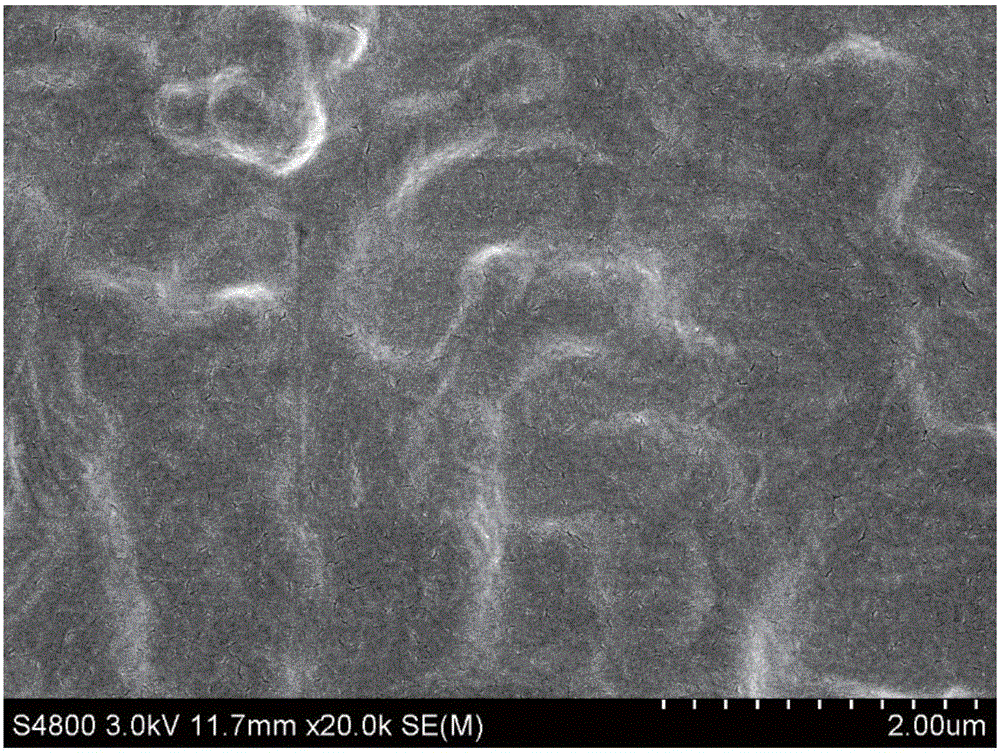

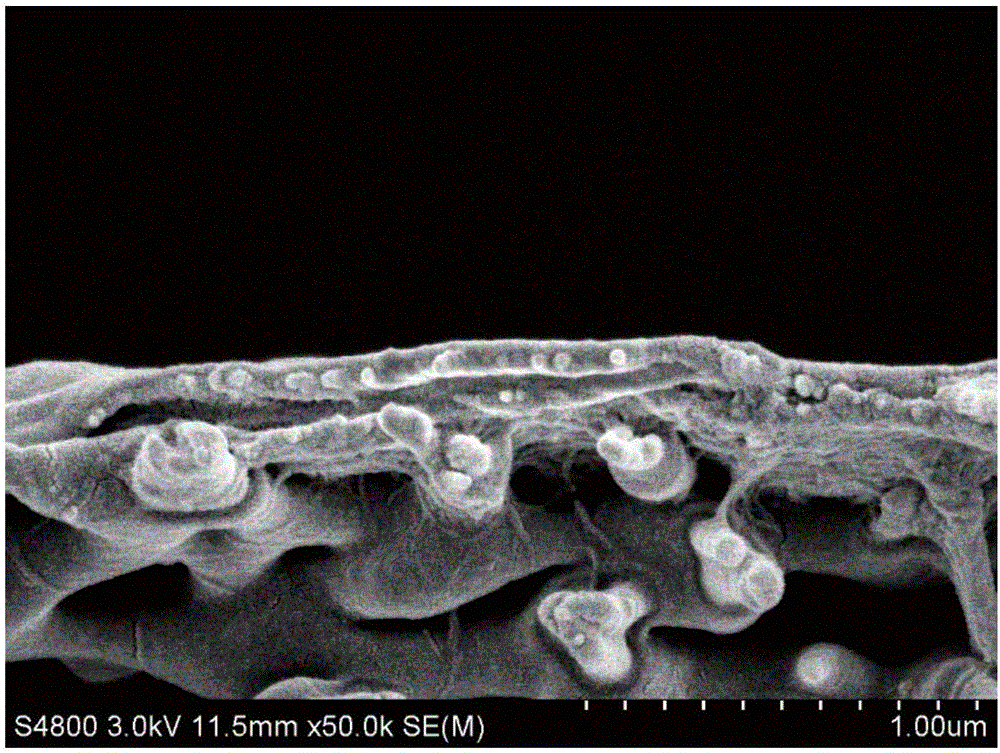

Surface heat source

ActiveCN101605409AGood flexibilityNot easy to breakIndividual molecule manipulationHeating element materialsCarbon nanotubeElectricity

The invention relates to a surface heat source, which comprises a heating element including a carbon nanotube structure which comprises a plurality of evenly distributed carbon nanatubes; and at least two electrodes spacedly arranged and electrically connected with the heating element. The surface heat source can be used for manufacturing self-heating warming clothes, warming glove or warming shoes, electric heater, infrared therapeutic apparatus, electrical heater and the like.

Owner:TSINGHUA UNIV +1

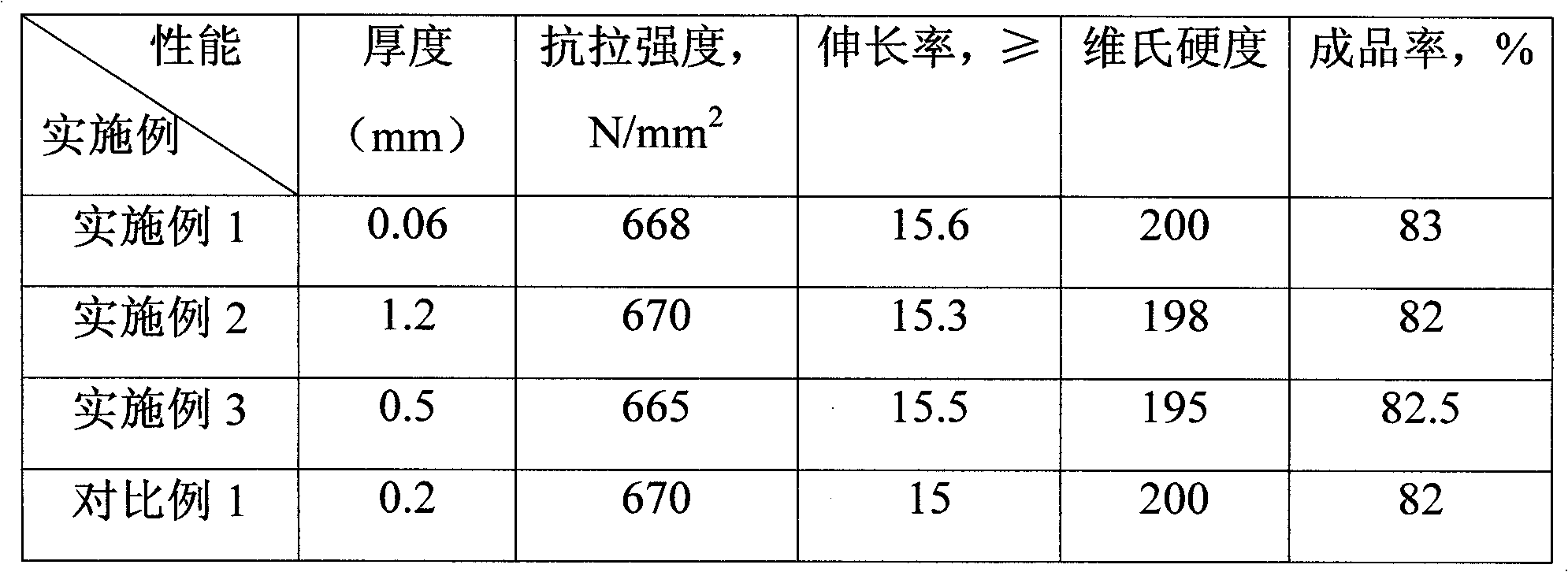

Method for preparing high-performance tin phosphorus bronze band

The invention provides a method for preparing a high-performance tin phosphorus bronze band. The method comprises the following steps of: dosing, melting, stirring, removing slag, analyzing by sampling and regulating ingredients; then carrying out horizontal continuous casting, thus a tin phosphorus bronze band coil billet with the thickness of 14.0-16.5mm, the width of 210-430mm, and the length of 45-68m is obtained by pulling, stopping and reversely returning; carrying out face milling, reducing the thickness of each face by 0.5-0.8mm through milling, rolling the coil band until the thickness of 3.4-9mm through primary direct cogging; carrying out crude rolling until the thickness of 1.2-4.5mm on the coil band after the primary intermediate annealing; carrying out acid pickling and passivation on the coil band after secondary intermediate annealing; and finally carrying out cold precision rolling, low-temperature thermal treatment of a finished product, surface acid pickling and passivation and stretch bending and leveling, wherein the band thickness after the cold precision rolling is 0.06-1.2mm, namely the band thickness of the finished product. Through utilizing the method provided by the invention, the billet uniform annealing working procedure is omitted, the production cost is lowered, and the production cycle is shortened.

Owner:宁波市鄞州锡青铜带制品有限公司

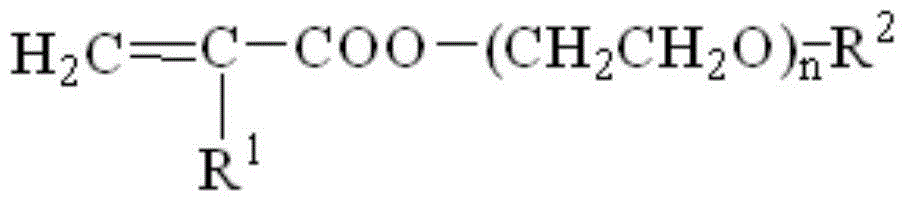

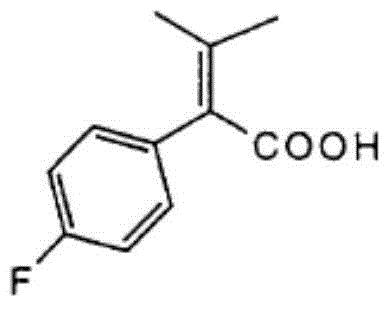

High-throughput multilayer composite nano-filtration membrane and preparation method thereof

InactiveCN106040015AImprove hydrophilic abilityImprove throughputSemi-permeable membranesCelluloseFiltration membrane

The invention discloses a high-throughput multilayer composite nano-filtration membrane and a preparation method thereof. The high-throughput multilayer composite nano-filtration membrane is obtained by loading a nanocrystalline cellulose support layer on a porous support membrane and forming a layer of polymer functional cortex on the nanocrystalline cellulose support layer through the interfacial polymerization of water-phase monomer and oil-phase monomer. Due to the fact that nanocrystalline cellulose has high hydrophilicity, the prepared multilayer composite nano-filtration membrane has the feature of high throughput. By the nanocrystalline support layer, the surface of the porous support membrane is flat, and the defects of the functional cortex of the prepared multilayer composite nano-filtration membrane are few. The macroporous structure on the surface of the porous support membrane is replaced by the nanocrystalline cellulose support layer, so that the pressure of the cortex of the composite nano-filtration membrane is dispersed under filtration operations, and structural damage cannot occur easily.

Owner:ZHEJIANG UNIV

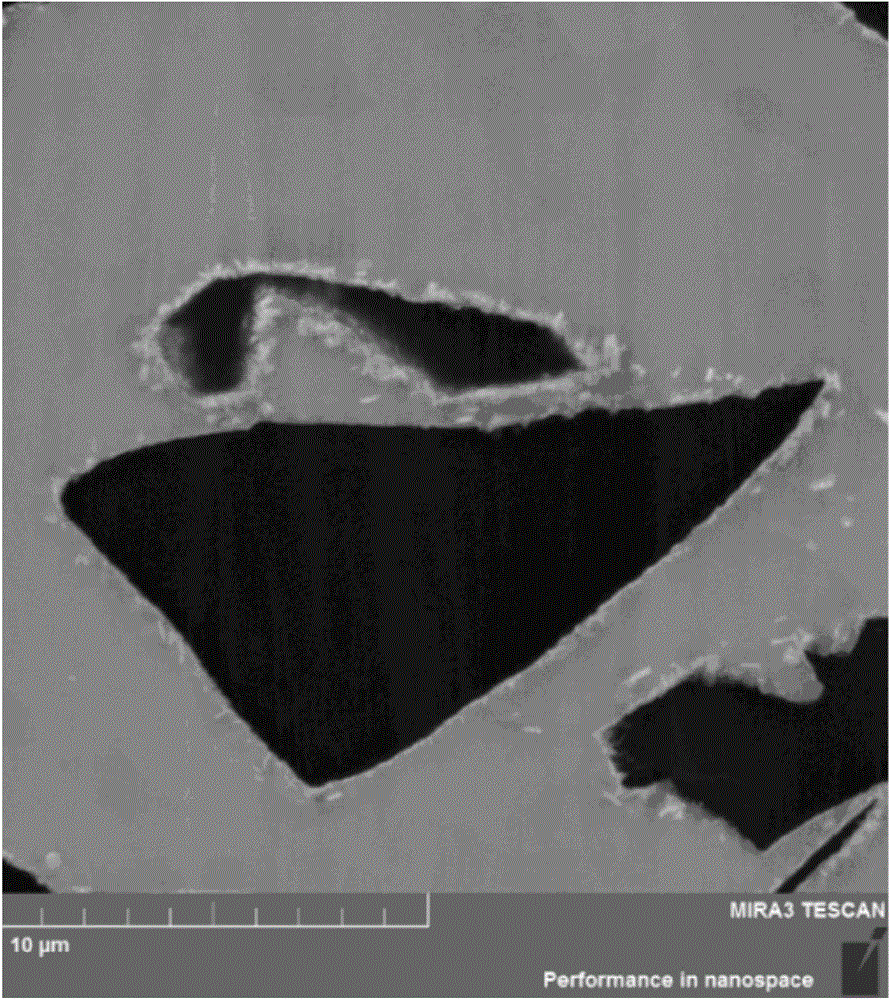

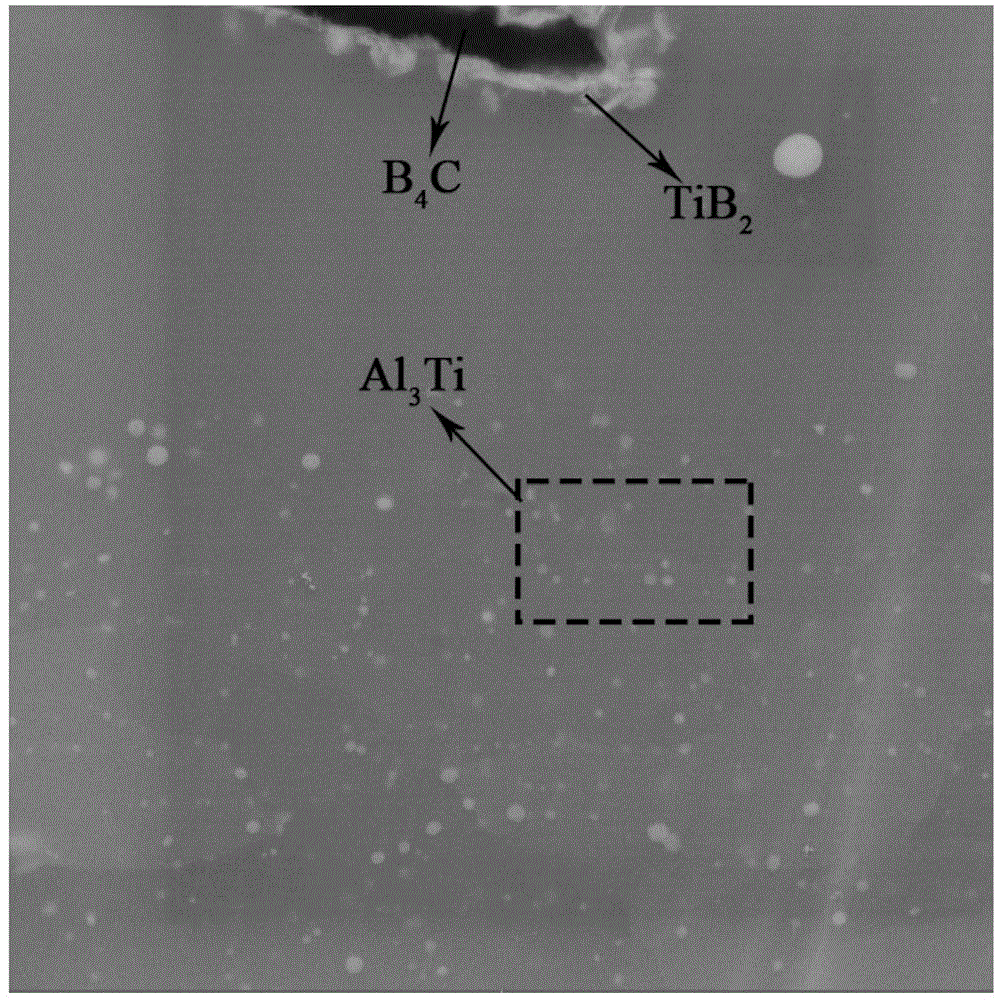

Aluminum-based boron carbide composite material and neutron absorption plate

ActiveCN104313400AImprove mechanical propertiesNot easy to breakNuclear energy generationNuclear reaction controlAl elementBoron carbide

The invention discloses an aluminum-based boron carbide composite material and a neutron absorption plate. The aluminum-based boron carbide composite material comprises the following components in percentage by mass: 15-35 percent of B4C, 0.5-7 percent of a Ti element and 60-84.5 percent of a Al element, wherein in the composite material, the existence form of the Ti element is as follows: the Ti element coats the surface of B4C particles in a TiB2 compound form. The neutron absorption plate is a plate made from the aluminum-based boron carbide composite material. The test proves that the elongation rate of the aluminum-based boron carbide composite material at normal temperature is 6-16 percent and is superior to that of the conventional composite material, and when the prepared neutron absorption plate is used, collision or thermal stress deformation can be resisted, and the plate is difficult to break, so that the storage safety performance is improved. Meanwhile, the tensile strength and neutron absorption performance can meet the application requirements.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

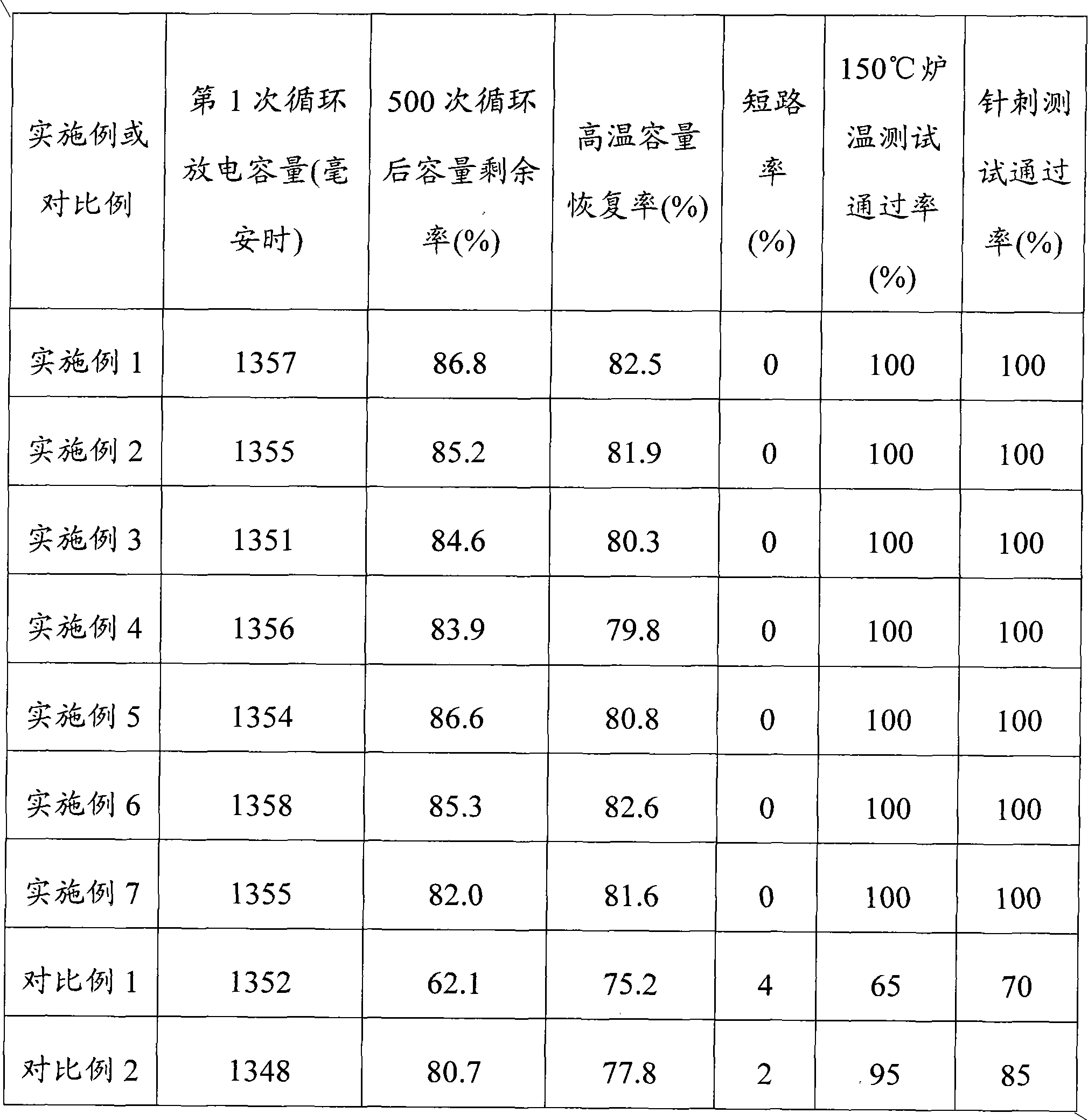

Method for preparing lithium-ion secondary battery

InactiveCN101877422AGood flexibilityNot easy to breakElectrode manufacturing processesFinal product manufactureSolventChemistry

The invention provides a method for preparing a lithium-ion secondary battery in order to solve the problem that a porous film in the conventional lithium-ion battery is easy to drop. The method comprises the following step of: preparing a positive plate and a negative plate. The method also comprises the following steps of: a) mixing inorganic filler, aqueous adhesive, additive and solvent to form paste, wherein the additive is one or more of weakly alkaline aqueous solution of amine, aqueous solution of ammonia and salt solution of ammonium, or weakly acid aqueous solution of acid organic compound, and the inorganic filler is one or more inorganic oxides which are not dissolved into the additive; and b) coating the prepared paste on at least one surface of the positive plate and / or the negative plate, and drying the positive plate and / or the negative plate to form a porous film on the surface coated with the paste. The porous film formed by adopting the technical scheme of the invention is difficult in dropping, has good flexibility and is difficult to break during processing such as winding and the like.

Owner:BYD CO LTD

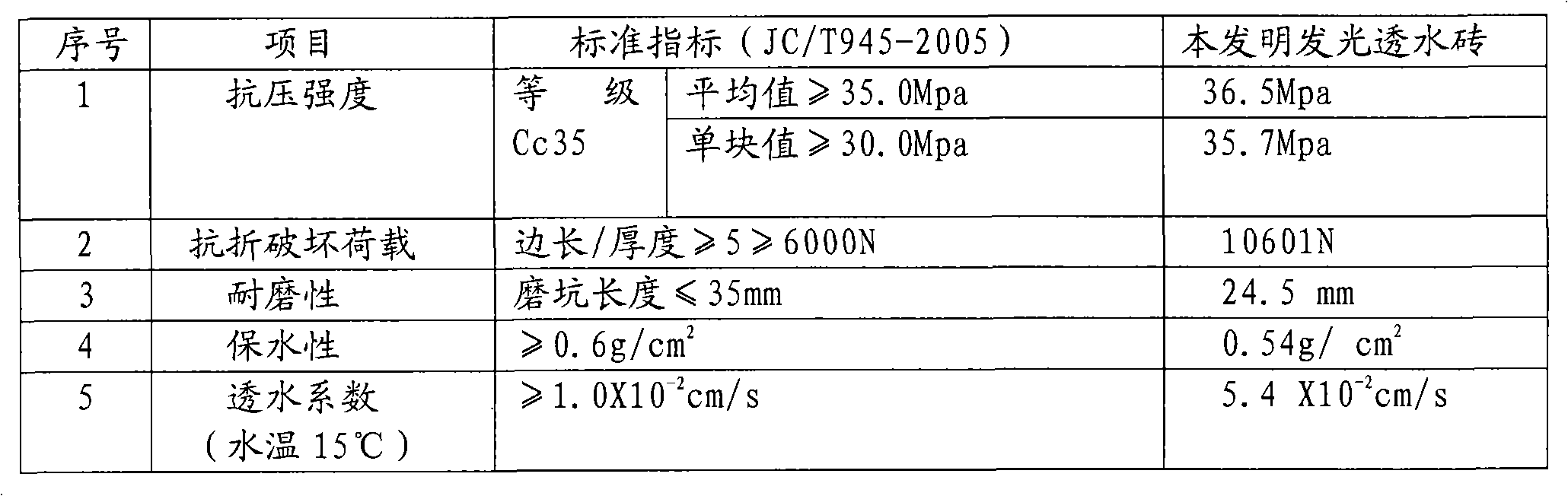

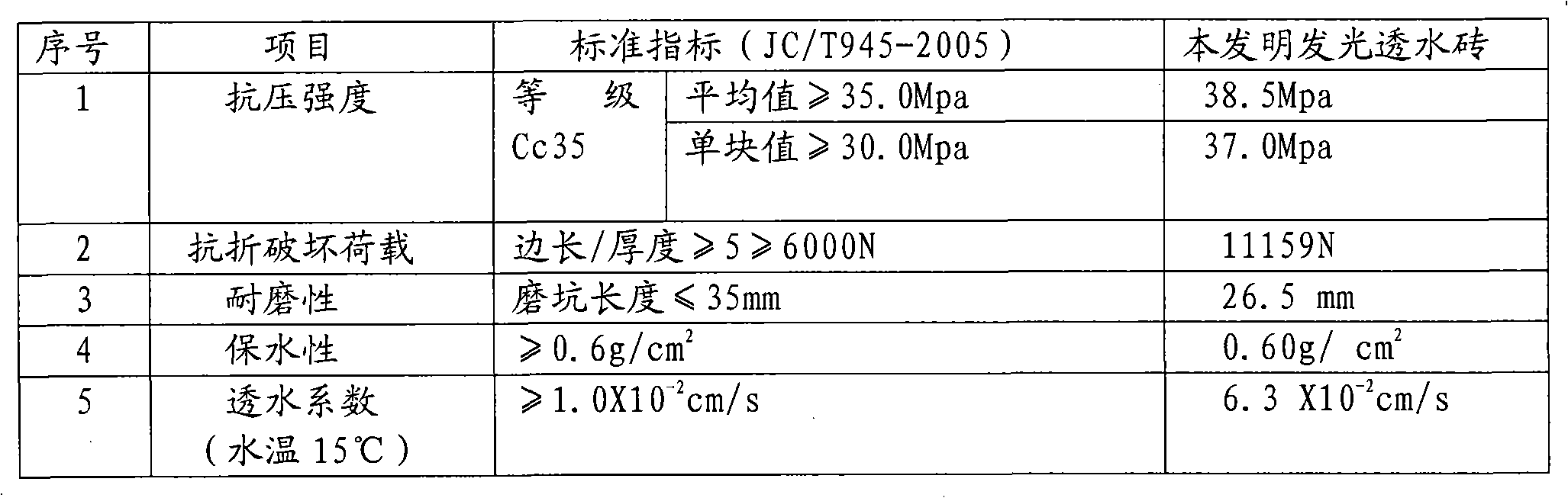

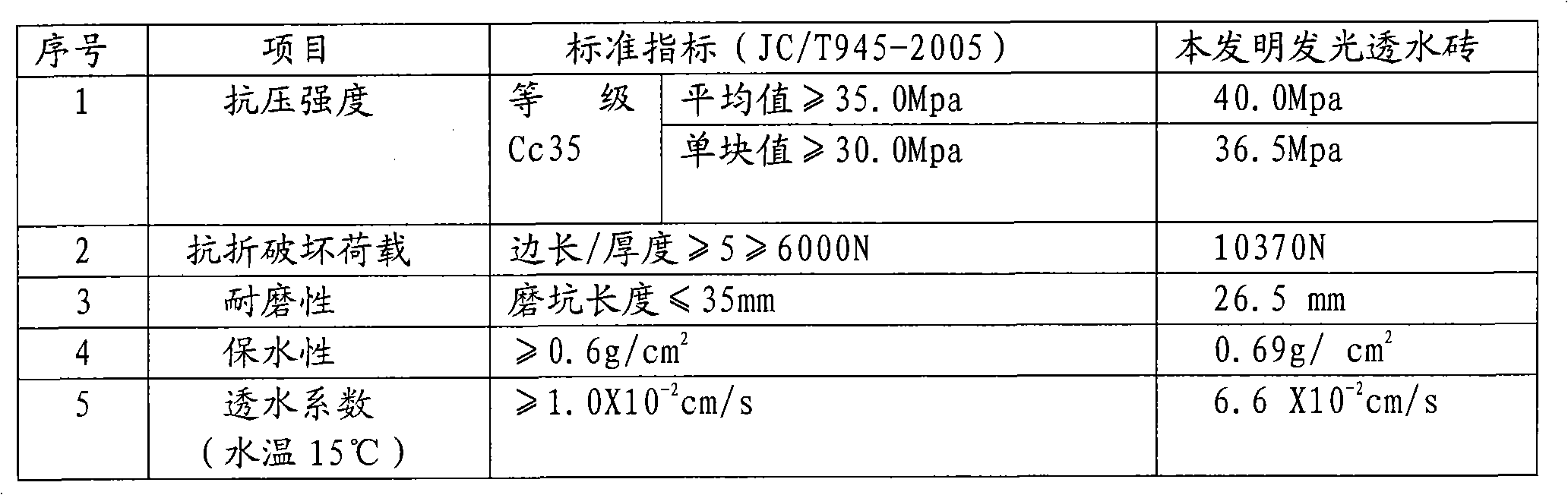

Light-emitting particles and preparation method and application thereof

The invention relates to light-emitting particles, the light-emitting particles comprise aggregates and light-emitting and / or reflective layers coated on the aggregates, wherein the light-emitting and / or reflective layers consist of bonding agents and light-emitting materials and / or reflective materials mixed in the bonding agents. The light-emitting particles can be used for manufacturing light-emitting water permeable bricks or be used for paving a pavement for forming the light-emitting water permeable pavement and the like. The light-emitting particles and products thereof have excellent water permeability, abrasion resistance and light-emitting performance.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Environment friendly sulfur coating type sustained-release chemical fertilizer

InactiveCN101343204AGood impact resistanceNot easy to breakFertilizer mixturesFertilizerPolyvinyl alcohol

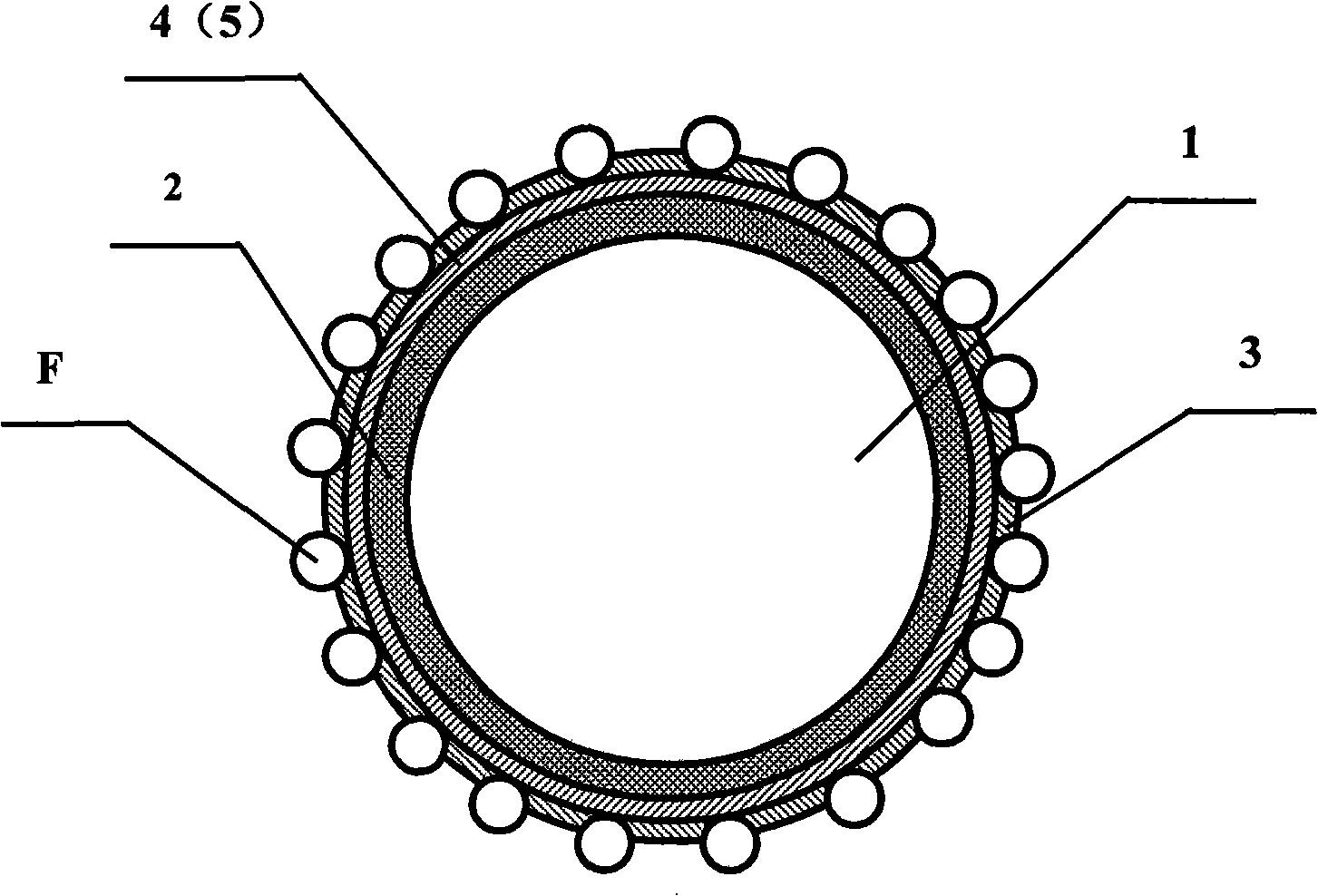

The invention discloses an environment-friendly sulfur-coated slow release fertilizer. The environment-friendly sulfur-coated slow release fertilizer is composed of a fertilizer core 1 and an outer envelope of the fertilizer core, the envelope comprises (a) a sulfur film layer 2, (b) a degradable polymer-organic polymer powder compound film layer 3, with or without (c) a degradable polymer film layer 4; wherein, the sulfur film layer is an inner layer or an intermediate layer of the whole envelope, the outer layer of the envelope is the degradable polymer-organic polymer powder compound film layer, and the external surface of the envelope is a rugged surface with raised organic polymer powder. The degradable polymer can be one or more of amido resin, polyvinyl alcohol and acetal resin of copolymer, unsaturated oil resin, biodegradation type polyester and natural polymer as well as derivates. The organic polymer powder is one or more of plant powder, animal powder and synthetic polymer powder. The sulfur-coated slow release fertilizer has advantages of stable release period and non pollution or low pollution to the environment of the enveloped body.

Owner:NANJING UNIV OF SCI & TECH

Gallium nitride-based semiconductor device with composite carbon-based substrate and manufacturing method thereof

InactiveCN101710567AAvoid deformationNot easy to breakSemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideGraphite substrate

The invention discloses a gallium nitride-based semiconductor device with a composite carbon-based substrate and a manufacturing method thereof. The supporting substrate of the gallium nitride-based semiconductor can be well combined with the epitaxial layer of the gallium nitride-based semiconductor in the aspects of expansion coefficient and deformation, can be matched with the epitaxial layer of the gallium nitride-based semiconductor with a better expansion coefficient, can not crack and deform easily, and has good conductor attributes. The invention has the concrete scheme that the gallium nitride-based semiconductor device comprises the supporting substrate for supporting the epitaxial layer of the gallium nitride-based semiconductor, and the supporting substrate is a graphite substrate of which the inside is permeated with copper having the mass percent of 10%-30%. The invention is mainly applied to an LED semiconductor device of a gallium nitride-based epitaxial layer.

Owner:LATTICE POWER (JIANGXI) CORP

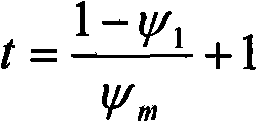

Production process of soundproof cotton

ActiveCN103568465AHigh strengthNot easy to breakLamination ancillary operationsLaminationPolypropyleneWeather resistance

The invention provides a production process of soundproof cotton. The production process comprises a cotton combing process, a melt-blowing net forming process, a covering process, an embossing and cutting process and a punching process. According to the production process of the soundproof cotton, polypropylene is melt-blown on a hollow polyester cotton roll to improve the strength of the soundproof cotton and ensure that the soundproof cotton can not be damaged easily during mounting and use, can not be aged easily and is good in weather resistance and long in service life. In the covering process of the production process of the soundproof cotton, a small amount of glue is uniformly sprayed on the surface of the hollow polyester cotton roll at first, then a non-woven fabric covering process is carried out, and a glue is added between the non-woven fabric and the hollow polyester cotton roll to ensure that the produced soundproof cotton is more stable and durable in structure, and the service life of the soundproof cotton is effectively prolonged.

Owner:芜湖跃飞新型吸音材料股份有限公司

Quick flaming mosquito-repellent incense

InactiveCN1430889AHigh strengthNot easy to breakBiocideAnimal repellantsEnvironmental chemistryCarboxymethylcellulose Sodium

A quickly burning mosquito-repellent incense is prepared from charcoal powder (60-90 wt.%), adhesive (carboxymethylcellulose sodium, sodium alginate, or starch) (3-20 wt.%), wood poder and pyrethrin dregs powder (5-25 wt.%) and allethrin (0.5-4 wt.%). Its advantages are high volatilizing rate up to 75-80%, quickly taking its effect and less environmental pollution.

Owner:庄占军

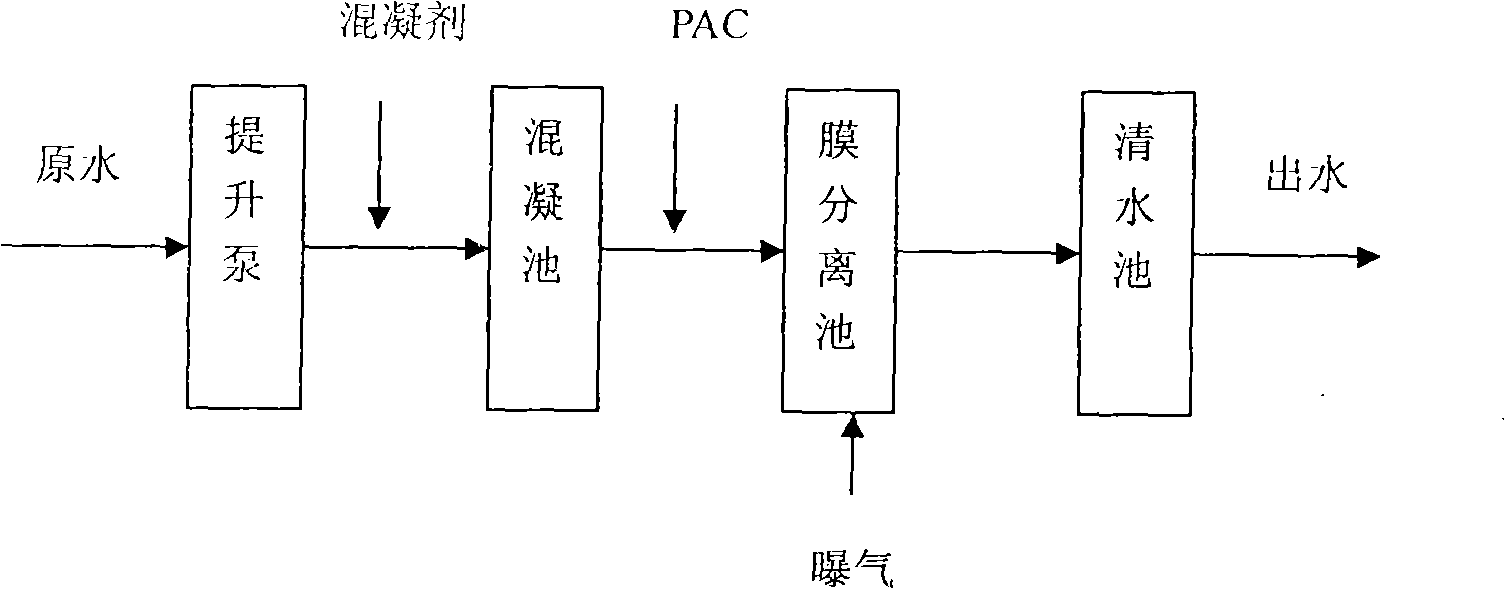

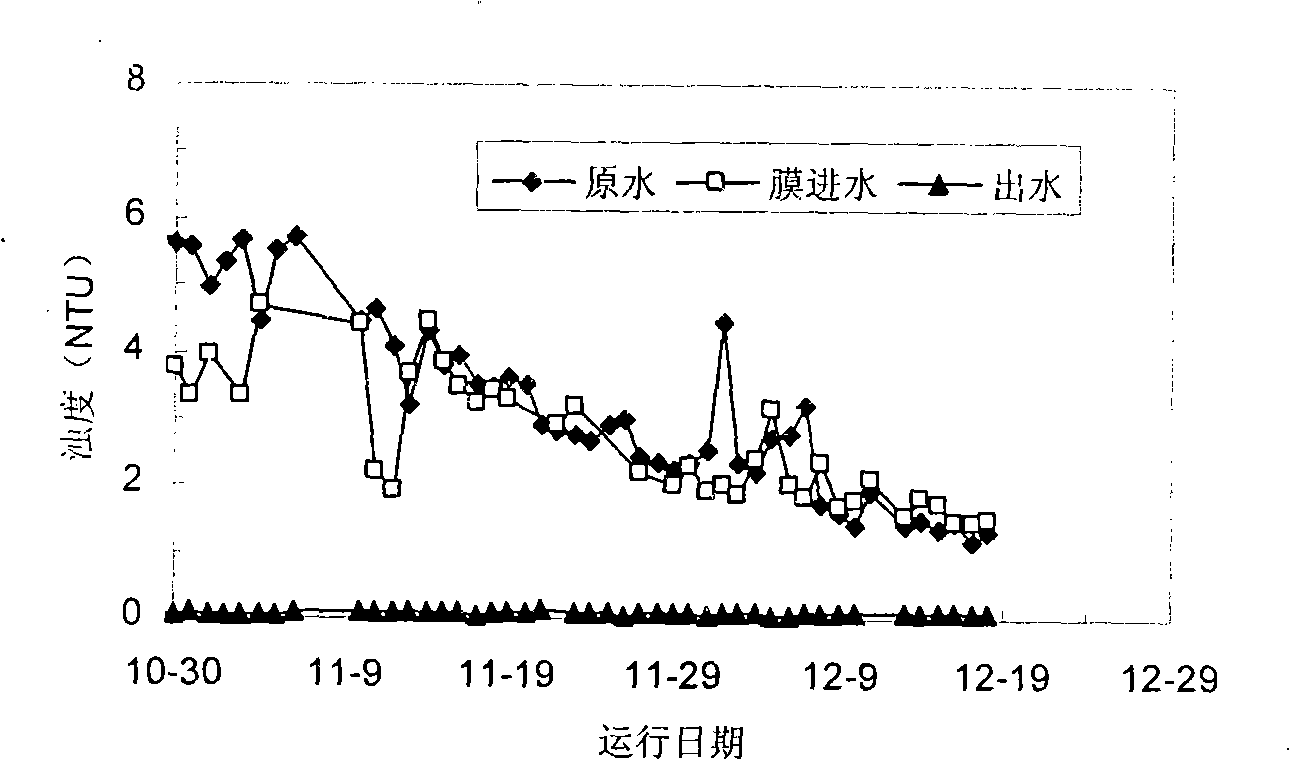

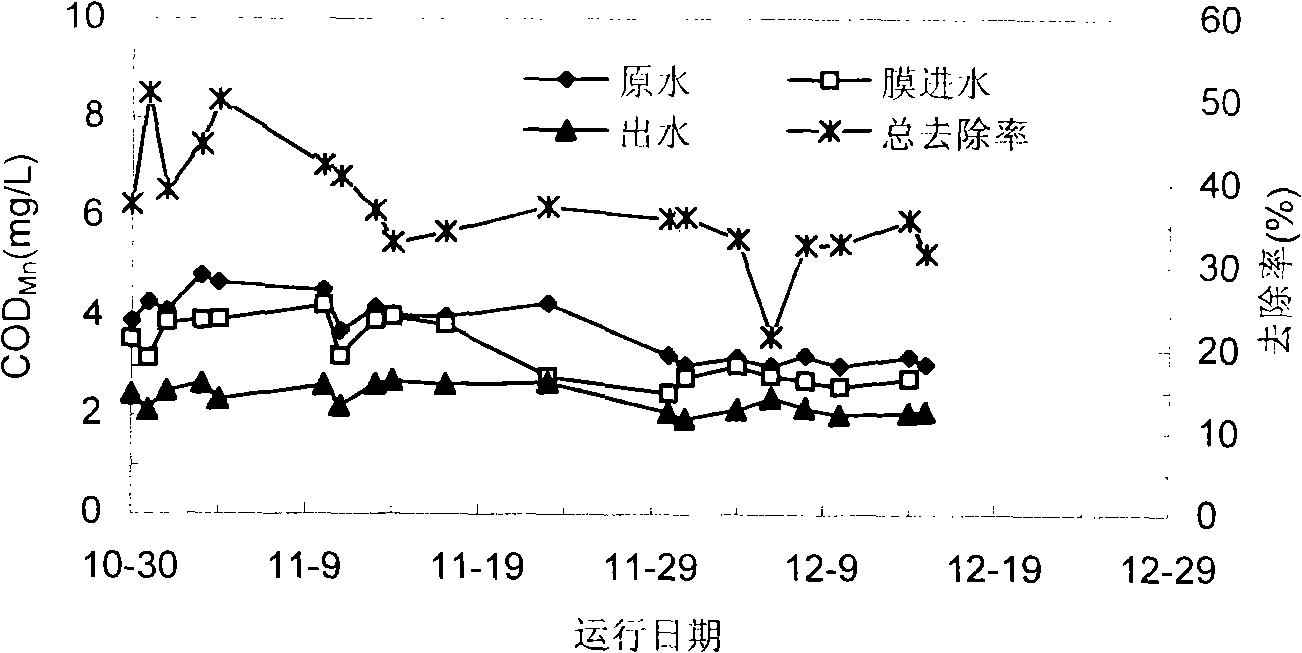

Technological process and apparatus for drinking water treatment by film method

InactiveCN101279805AEfficient removalImprove water qualityWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSuspended particlesFiltration

The invention provides a film method drinking water treatment equipment and a treatment method thereof. According to the treatment equipment of the invention, the film method drinking water treatment equipment comprises: a pretreatment unit, a coagulation tank and a film separation tank; a wide grille and a Y-shaped pipeline filter, etc. are arranged in the pretreatment unit for pre-treating the raw water and avoiding the blockage to a water pump and an inlet water meter by impurities in the raw water; the coagulation tank is a mechanical coagulation tank for coagulating the raw water; and the film separation tank adopts a curtain type membrane module structure to filter the raw water. The raw water is put with a coagulant after going through the pretreatment unit and then enters the coagulation tank, and the water treated by coagulation is treated by components of the curtain type membrane module. The drinking water treatment equipment adopts the combination of coagulation and membrane filtration to treat the micro-polluted surface water, and can fully prevent bacteria and effectively remove various suspended particles, bacteria, algae, COD and organic matters in water, thereby ensuring the excellent water quality with nearly zero water suspended substance.

Owner:TIANJIN POLYTECHNIC UNIV +1

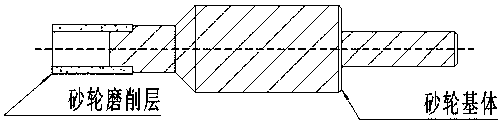

Grinding wheel applied to zirconia ceramic ferrule PC spherical surface and preparation method thereof

InactiveCN107650032ANot easy to breakImprove the finishAbrasion apparatusGrinding devicesChromiumHigh-density polyethylene

The invention relates to a grinding wheel applied to a zirconia ceramic ferrule PC spherical surface. The grinding wheel comprises a grinding wheel base body and a grinding layer, wherein the grindinglayer is mainly composed of an abrasive material, a resin binder and stuffing; the stuffing is made of polytetrafluoroethylene, high-density polyethylene and an active nano-polishing agent; the active nano-polishing agent is composed of the following raw materials of, by weight, 10%-30% of cerium oxide, 5%-15% of ferric oxide, 25%-40% of chromium dioxide and 20%-40% of flake graphite. The grinding wheel belongs to superfine powder grinding wheels, the requirements for curvature radius and high-surface quality of the ferrule PC spherical surface can be met, the grinding wheel is sharp, the shape retention property is good, the processing efficiency is high, and the no-dressing situation can be achieved during grinding.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Organic light-emitting display cover plate, manufacturing method thereof, display panel and display device

ActiveCN109037481ANot easy to breakConducive to electrical conductionSolid-state devicesSemiconductor/solid-state device manufacturingElectrically conductiveBackplane

The invention discloses an organic light-emitting display cover plate, a manufacturing method thereof, a display panel and a display device. Specifically, the invention provides an organic light-emitting display cover plate, which comprises a substrate; an auxiliary cathode disposed on the substrate; a spacer disposed on a side of the auxiliary cathode remote from the substrate, wherein the spacercomprises an electrically conductive material and the spacer is electrically connected to the auxiliary cathode. Thus, the auxiliary cathode and the cathode of the organic light-emitting display backboard can be electrically connected simply and conveniently by the spacer, the conductivity of the cathode is improved, and the performance of the organic light-emitting display panel is further improved.

Owner:BOE TECH GRP CO LTD

Road filling material prepared from slag soil and electric furnace slag and preparation method of road filling material

ActiveCN104402370ANot easy to breakWon't breakIn situ pavingsSolid waste managementSlagFilling materials

The invention discloses a road filling material prepared from slag soil and electric furnace slag and a preparation method of the road filling material. According to the total weight of the road filling material, the road filling material comprises the following components in percentage by weight: 1-12% of active micro powder, 20-50% of electric furnace slag, 20-70% of slag soil and 0.02-0.06% of an activator. According to the road filling material, the requirements of road indexes can be met; the slag soil and the electric furnace slag can be fully used.

Owner:北京元泰达环保科技有限公司

Nanometer Al2O3 composite aerosil thermal-insulation heat-preserving paint and preparation method thereof

InactiveCN105038496AImprove high temperature resistanceNot easy to breakEpoxy resin coatingsIonSal ammoniac

The invention provides a nanometer Al2O3 composite aerosil thermal-insulation heat-preserving paint. The paint is prepared from the following raw materials by weight: 32 to 35 parts of ethyl orthosilicate, a proper amount of hydrochloric acid, a proper amount of ammonia water, a proper amount of ethanol, a proper amount of deionized water, 4 to 5 parts of trimethylchlorosilane, 0.3 to 0.4 part of tetrabutyl titanate, 0.6 to 0.9 part of nanometer Al2O3, 60 to 65 parts of epoxy resin E-12, 12 to 14 parts of xylene and 7 to 7.5 parts of maleic anhydride. According to the invention, nanometer Al2O3 and silica are compounded to prepare aerogel, so the aerogel has improved high temperature resistance, hardness, dimensional stability and breaking tenacity, the water-absorbing quality of the aerogel is enhanced, the aerogel hardly ruptures, and the disadvantage that the aerogel easily breaks in the case of water absorption; thus, the paint has improved heat-preserving performance and is worth large-scale popularization and application.

Owner:DANGTU COUNTY KEHUI TRADING

Preparation method for triglycine functionalized mesoporous material surface imprinting adsorbent

InactiveCN103433005AHigh mechanical strengthNot easy to breakOther chemical processesChemistryAdsorption kinetic

The invention relates to a preparation method for a triglycine functionalized mesoporous material surface imprinting adsorbent, belonging to the technical field of preparation of environment function materials. Particularly, the synthesized mesoporous silicon base material SBA-15 is taken as the matrix, the surface of the matrix is functionalized by the triglycine, and Co (II) is chosen as a template ion to prepare a novel Co (II) surface imprinting absorbent. Static adsorption experiments are for research of performances of adsorption equilibrium, dynamics and selective recognition of the prepared imprinting absorbent, and the results show that the Co (II) imprinting absorbent prepared by the method has a rapid adsorption kinetics property and an excellent Co (II) recognition performance.

Owner:JIANGSU UNIV

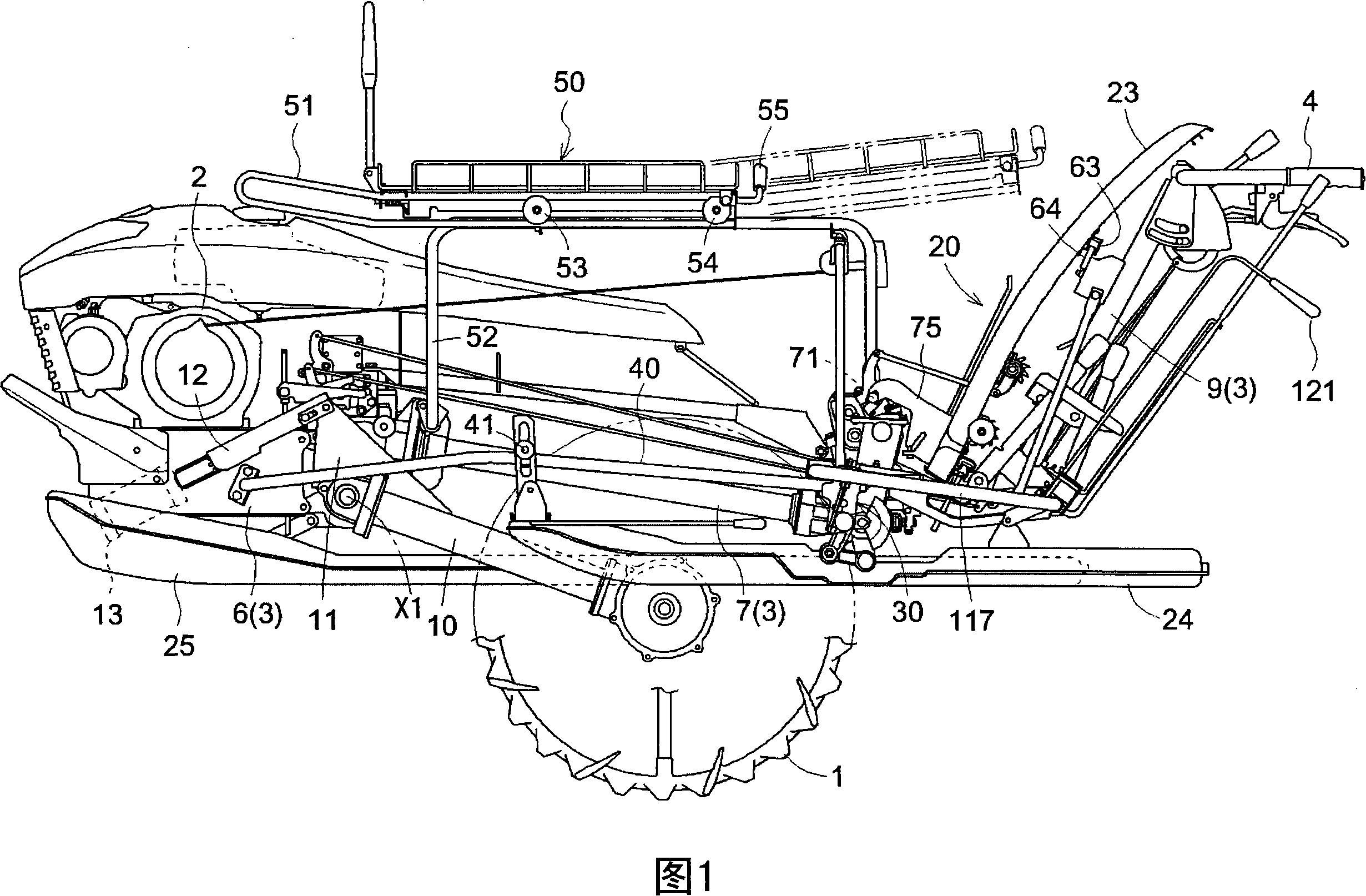

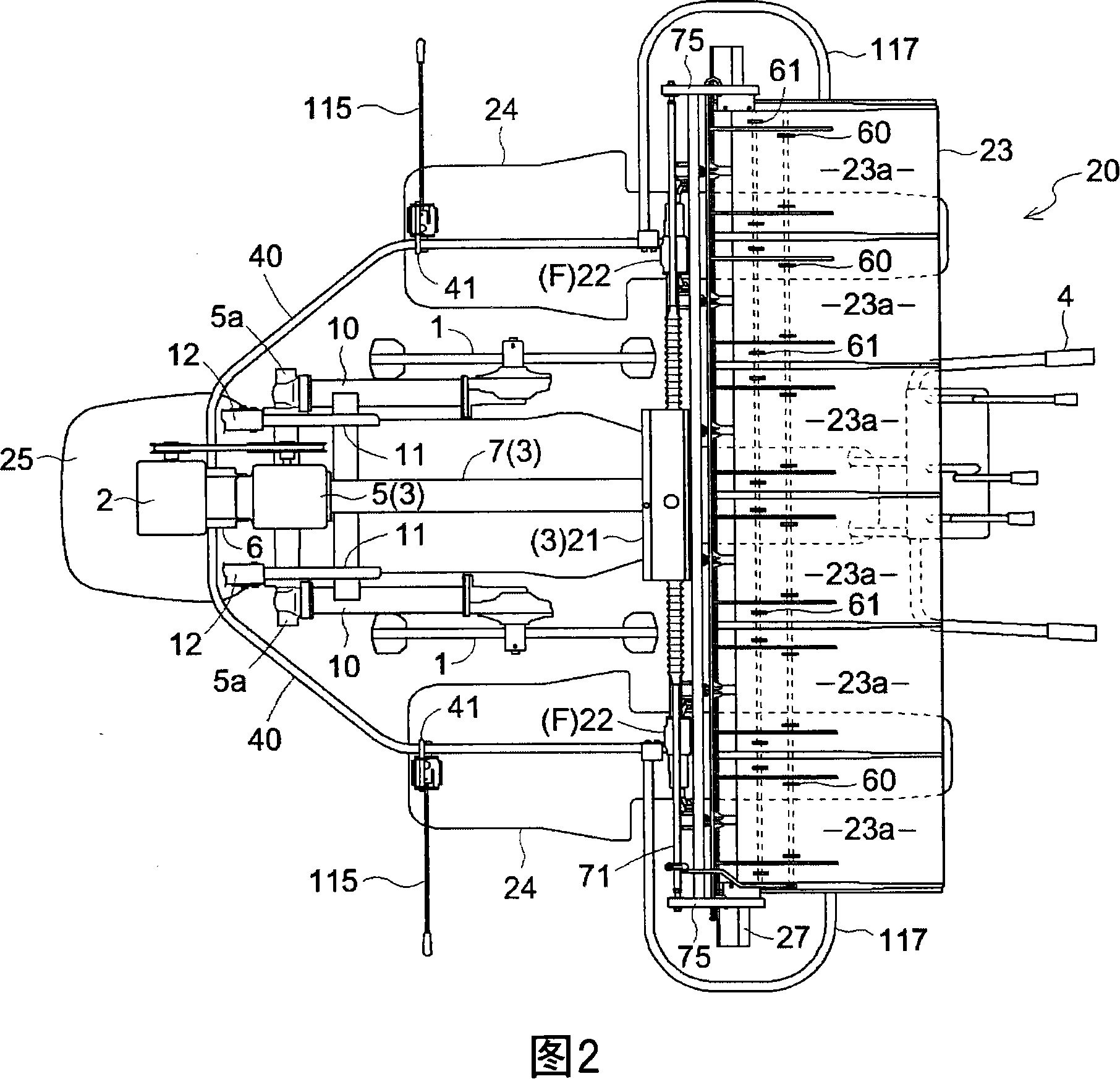

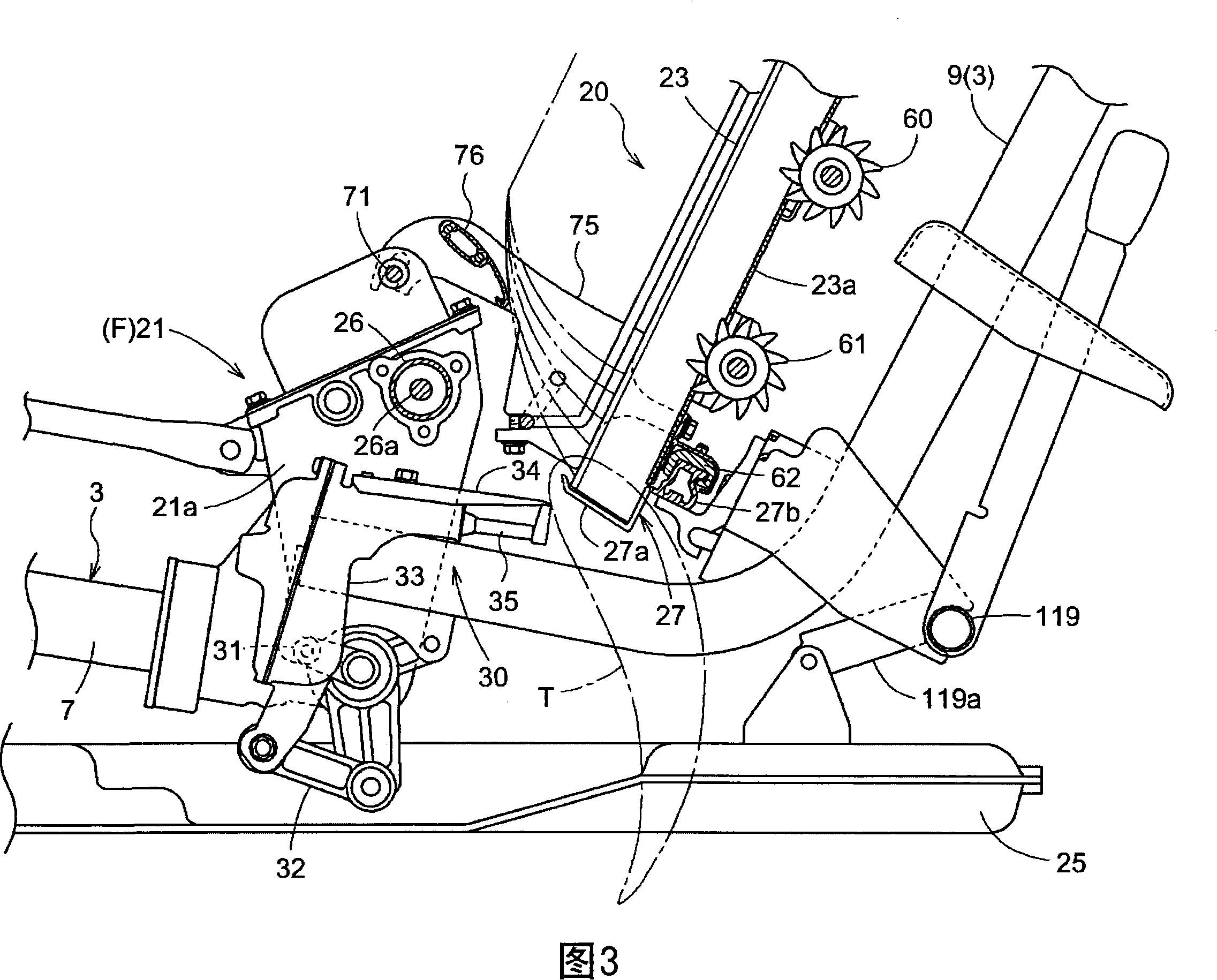

Seedling transplanting device

A machine for transplanting rice seedlings, which carrying seedlings table is assembled on a transverse transportation axis under the state that the table connects to a couple of right and left connecting support pieces. In the body, a transverse transportation axis (71) is supported with the mode of moving freely along the body horizontally, the two end of the transportation axis (71) connect with the couple of right and left connecting support pieces (75) with the mode of moving freely with one body. The transverse transportation axis (71) includes: a transverse transportation main body (71a), being supported on the body with the mode of to-and-fro moving freely; connecting axis (100, 105) connecting with two end of the transverse transportation main body (71a) through a screw with the mode of being adjusting flexibly along the transverse transportation axis moving direction; combining parts (102, 107) which locate on the couple connecting axis (100, 105) and joint to the support piece (75) with the mode of moving with one body freely along the transverse transportation axis moving direction.

Owner:KUBOTA LTD

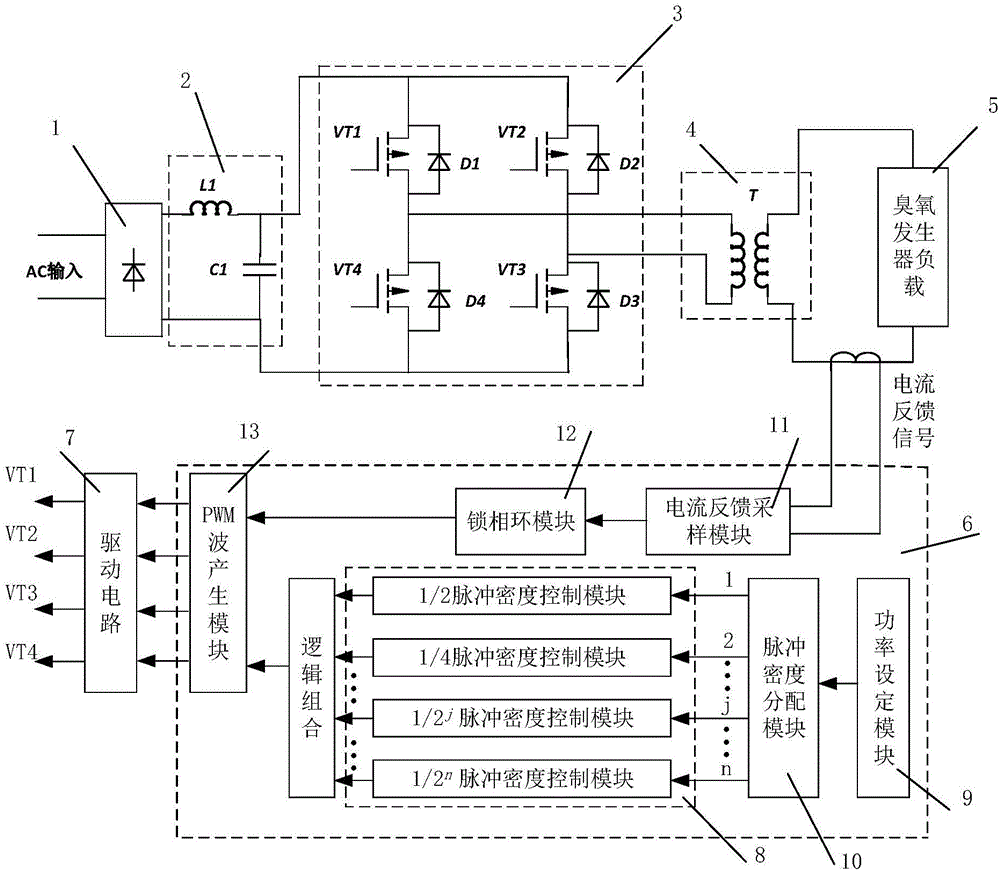

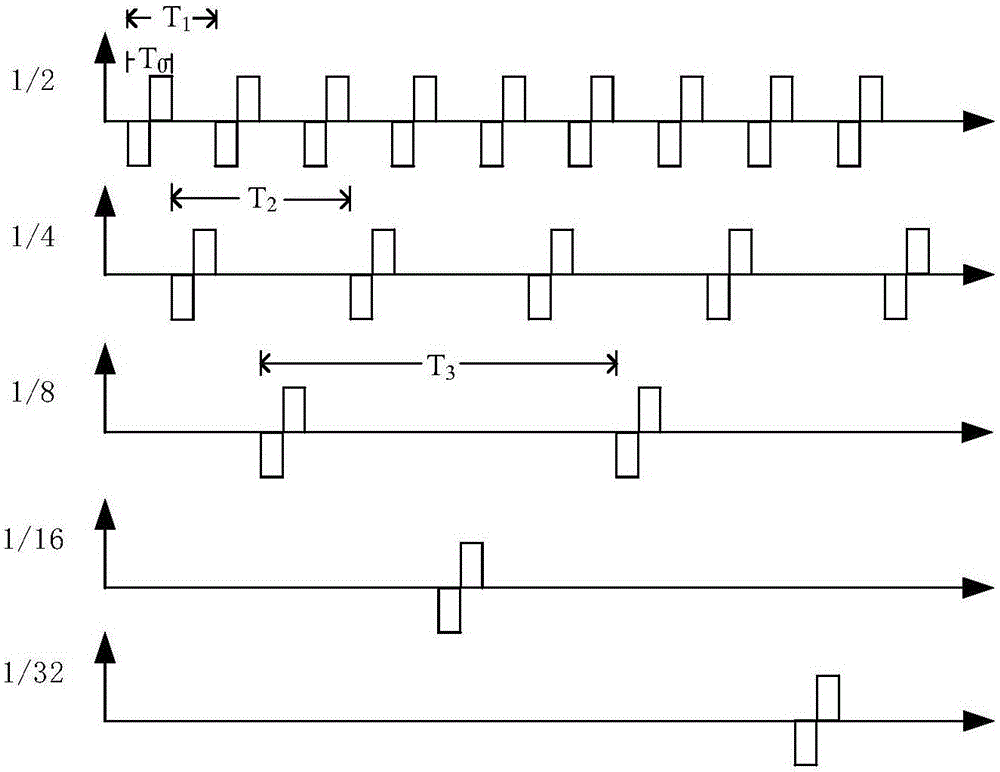

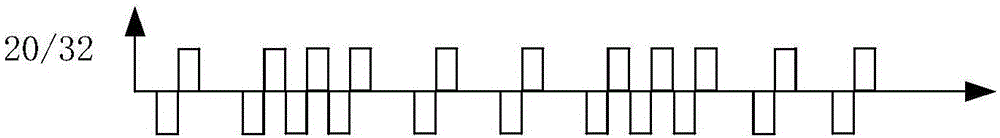

Symmetrical pulse density modulation power control-based dielectric barrier discharge ozone generator power supply source

InactiveCN106505871AReduce lossReduce volatilityEfficient power electronics conversionAc-dc conversionSoft switchingPower control system

The invention discloses a symmetrical pulse density modulation power control-based dielectric barrier discharge ozone generator power supply source. The ozone generator power supply source mainly comprises a rectifier circuit, an LC filter circuit, a single-phase full-bridge inverter circuit, a high-frequency step-up transformer, a symmetrical pulse density modulation power control system, a drive circuit and an ozone generator load. The dielectric barrier discharge ozone generator power supply source has good characteristics that load current is not easy to interrupt and the system is not easy to unlock under symmetrical pulse density modulation power control; and the condition that an ozone generator is always in an efficient discharge state can be ensured. Furthermore, various power devices in the circuit can work under a soft switching condition; high-efficiency operation of the power supply source is ensured; and the whole power supply source has the characteristics of being small in loss and simple in power regulation.

Owner:南京匹瑞电气科技有限公司

Method of producing metallic tungsten bar by acid washing and doping tungsten powder

A process for preparing tungsten bars from blue tungsten oxide powder includes proportionally mixing it with SiO2 0.25-0.5 wt.%, Al2O3 0.01-0.1 wt.% and KCl 0.3-0.5 wt.%), reducing to become doped tungsten powder, washing with hydrochloric acid and hydrofluoric acid, drying, die pressing under 20-28 MPa, and sintering. Its advantages are high strength and percentage of finished products, and stable content of K.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com