Antibacterial wet tissue paper and manufacturing method thereof

A manufacturing method and a technology for wet tissue paper, applied in the field of non-woven materials, can solve the problems of being difficult to disperse, block pipes or filters, etc., and achieve the effect of not being damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

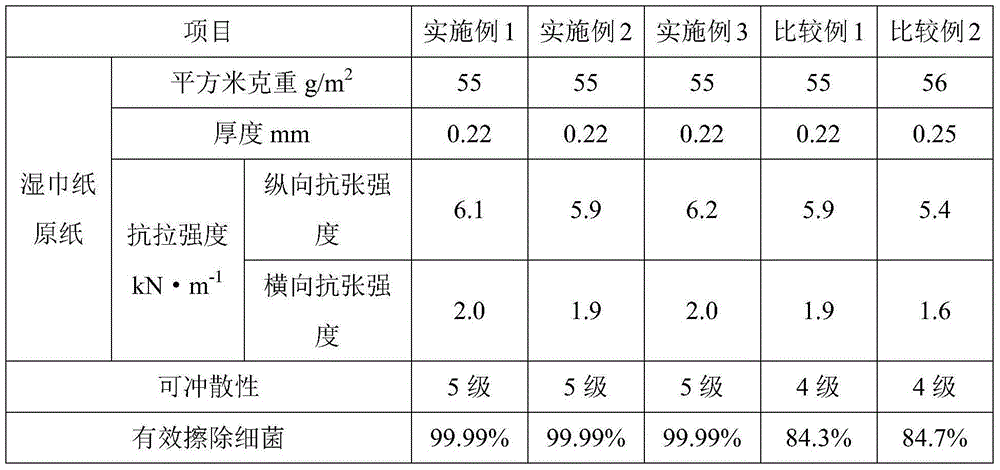

Examples

Embodiment 1

[0024] Raw materials: 25% polylactic acid fiber, 5% flax fiber, 5% silk fiber, 65% wood pulp fiber;

[0025] Non-woven production: polylactic acid fiber, flax fiber and wood pulp fiber are mixed and formed into a web by air-drying method, then dried and rolled to form a non-woven fabric, which is the base paper of antibacterial wet tissue paper; the wetting liquid is prepared in proportion by weight, The non-woven fabric is cut, folded, completely soaked in the wetting solution, put into a plastic bag and sealed.

[0026] Moisturizing solution formula: 10g corn silk, 20g cnidium, 10g angelica, 15g angelica, 12g Baibu, 30g mugwort leaves, 10g pepper leaves, 10g kaempferia, 30g iron horsewhip, 20g Daqingye, 5g citric acid, 15g coconut oil, 20g orange peel, 500g water.

[0027] The preparation method of the wetting liquid is as follows: according to the ratio, mix corn silk, cnidium, angelica, angelica, hundred leaves, mugwort leaves, pepper leaves, kaempferia, iron horsewhip, f...

Embodiment 2

[0030] Raw materials: 28% polylactic acid fiber, 6% flax fiber, 4% silk fiber, 62% wood pulp fiber;

[0031] Non-woven production: polylactic acid fiber, flax fiber and wood pulp fiber are mixed and formed into a web by air-drying method, then dried and rolled to form a non-woven fabric; the wetting liquid is prepared according to the weight ratio, and the non-woven fabric is cut, Fold it, put it in a plastic bag and seal it after fully soaking in the wetting solution.

[0032] Moisturizing solution formula: 8g corn silk, 18g cnidium, 8g angelica, 10g angelica, 12g Baibu, 28g mugwort leaves, 8g pepper leaves, 6g kaempferia, 25g iron horsewhip, 16g Daqingye, 3g citric acid, 10g coconut oil, 15g orange peel, 500g water.

[0033] The preparation method of the wetting liquid is as follows: according to the ratio, mix corn silk, cnidium, angelica, angelica, hundred leaves, mugwort leaves, pepper leaves, kaempferia, iron horsewhip, folium folium, and orange peel, and then grind the...

Embodiment 3

[0036] Raw materials: 26% polylactic acid fiber, 4% flax fiber, 3% silk fiber, 67% wood pulp fiber;

[0037] Non-woven production: polylactic acid fiber, flax fiber and wood pulp fiber are mixed and formed into a web by air-drying method, then dried and rolled to form a non-woven fabric; the wetting liquid is prepared according to the weight ratio, and the non-woven fabric is cut, Fold it, put it in a plastic bag and seal it after fully soaking in the wetting solution.

[0038] Moisturizing solution formula: 5g corn silk, 15g cnidium, 8g angelica, 10g angelica, 10g Baibu, 20g mugwort leaves, 5g pepper leaves, 5g kaempferia, 20g iron horsewhip, 15g Daqingye, 3g citric acid, 10g coconut oil, 15g orange peel, 500g water. The preparation method of the wetting liquid is as follows: according to the ratio, mix corn silk, cnidium, angelica, angelica, hundred leaves, mugwort leaves, pepper leaves, kaempferia, iron horsewhip, folium folium, and orange peel, and then grind them to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com