Patents

Literature

67results about How to "Improve compact strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing automobile connecting rod through powder metallurgy

InactiveCN103223487AEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateCadmium Cation

The invention discloses a method for manufacturing an automobile connecting rod through powder metallurgy. The method comprises the following step: the automobile connecting rod is manufactured by the following raw materials in percentage by weight: 0.4-0.6 percent of nickel, 0.4-0.6 percent of graphite, 0.6-0.8 percent of zinc oxide powder, 0.4-0.6 percent of cadmium, 0.3-0.4 percent of zinc stearate, 1-2 percent of performance additive, 4-6 percent of copper and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-silicon dioxide and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

Owner:XUZHOU DALT MECHANICAL EQUIP MFG CO LTD

Method for preparing powder metallurgy of valve seat

ActiveCN103252498AEnhance the effect of mixing and pressingHigh bulk densityPolyethylene vinyl acetateAdditive ingredient

The invention discloses a method for preparing powder metallurgy of a valve seat. The method includes: the valve seat is made of following raw materials, by weight, 0.4-0.6% of nickel, 0.2-0.3% of carbon, 0.2-0.4% of manganese sulfide, 0.2-0.3% of vanadium, 0.6-0.8% of graphite powder, 0.1-0.2% of chrome, 0.3-0.4% of silicon, 1-2% of performance additive, 10-20% of copper, and the balance iron; via adding the performance additive, superfine powder is provided in the mixed raw materials and can fill in seams among large granules, so that density of the mixed materials is improved; main ingredients of the superfine powder include nano potassium feldspar powder and calcium stearate, and the novel performance additive is obtained via agent like silane coupling agent, physical properties like abrasion performance of prepared products is further improved; and polyethylene vinyl acetate and liquid paraffin serving as lubricating agent are added in the performance additive, so that effect of the performance additive under mixed compression is strengthened, the strength of compaction of power metallurgy structural members is greatly improved under same compression force, combining shape and hole shape of the raw material granules is changed, and problem about generation of crack is solved basically.

Owner:浙江同力重型机械制造有限公司

Method for manufacturing motorcycle crank shaft through powder metallurgy

InactiveCN103223490AEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateParaffin wax

The invention discloses a method for manufacturing a motorcycle crank shaft through powder metallurgy. The method comprises the following step: the motorcycle crank shaft is manufactured by the following raw materials in percentage by weight: 0.4-0.6 percent of nickel, 0.4-0.6 percent of manganese sulfide powder, 0.4-0.6 percent of aluminium, 0.4-0.6 percent of manganese, 0.3-0.4 percent of zinc stearate, 1-2 percent of performance additive, 21-25 percent of copper and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-silicon dioxide and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, and various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

Owner:江门速龙机车制造有限公司

Method of producing metallic tungsten bar by acid washing and doping tungsten powder

A process for preparing tungsten bars from blue tungsten oxide powder includes proportionally mixing it with SiO2 0.25-0.5 wt.%, Al2O3 0.01-0.1 wt.% and KCl 0.3-0.5 wt.%), reducing to become doped tungsten powder, washing with hydrochloric acid and hydrofluoric acid, drying, die pressing under 20-28 MPa, and sintering. Its advantages are high strength and percentage of finished products, and stable content of K.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Preparation method of machine tool slider by powder metallurgy

ActiveCN103252497AEnhance the effect of mixing and pressingHigh bulk densityPolyethylene vinyl acetateCerium

The invention discloses a preparation method of a machine tool slider by powder metallurgy. The method includes that the machine tool slider is made of, by weight percentage, 0.6-0.8% of graphite, 0.2-0.4% of silicon carbide powder, 0.4-0.6% of manganese, 0.2-0.4% of nickle, 0.2-0.4% of cerium, 0.2-0.4% of titanium, 0.4-0.6% of aluminum, 1-2% of zinc, 5-8% of copper, 1-2% of performance additive and the rest iron. By the added performance additive, superfine powder is provided in mixed raw materials and can fill gaps among large particles, so that apparent density of a mixture is improved; the superfine powder is mainly composed of nanoscale iron powder and calcium stearate, and the novel performance additive is obtained through auxiliaries like silane coupling agent, so that various physical characteristics like abrasive resistance of the machine tool slider is further improved; and polyethylene vinyl acetate and liquid paraffin serving as lubricant are added into the performance additive, so that effects, in mixing and pressing, of the performance additive are enhanced, compacting strength of a powder metallurgy structural member is substantially improved under same pressing pressure, particle combining forms and pore shapes of the raw materials are changed, and generation of cracks is avoided fundamentally.

Owner:HAIAN YINGQIU POWDER METALLURGY CO LTD

Preparation method of tungsten powder used for high-density alloy

ActiveCN109261980ALarge specific surface areaAvoid high temperature and violent volatilizationHigh densityAmmonium paratungstate

The invention belongs to the technical field of powder metallurgy, and specifically relates to a preparation method of tungsten powder used for high-density alloy. The method specifically includes thefollowing steps that high-specific-surface-area tungsten oxide preparation, boat loading, reduction, cooling and sieving. The high-specific-surface-area tungsten oxide is prepared through ammonium paratungstate, hydrogen serves as a reducing agent, the high-specific-surface-area tungsten oxide can be reduced tungsten powder at high temperature more than 800 DEG C, the reduced tungsten powder is cooled in multi-stage mode, and finally, the tungsten powder is subjected to ultrasonic sieving to obtain near-spherical tungsten powder, wherein grain growth is complete, the tungsten powder is full,the activity is low, the dispersion property is good and the tungsten powder has particle morphology.

Owner:ZIGONG CEMENTED CARBIDE CORP

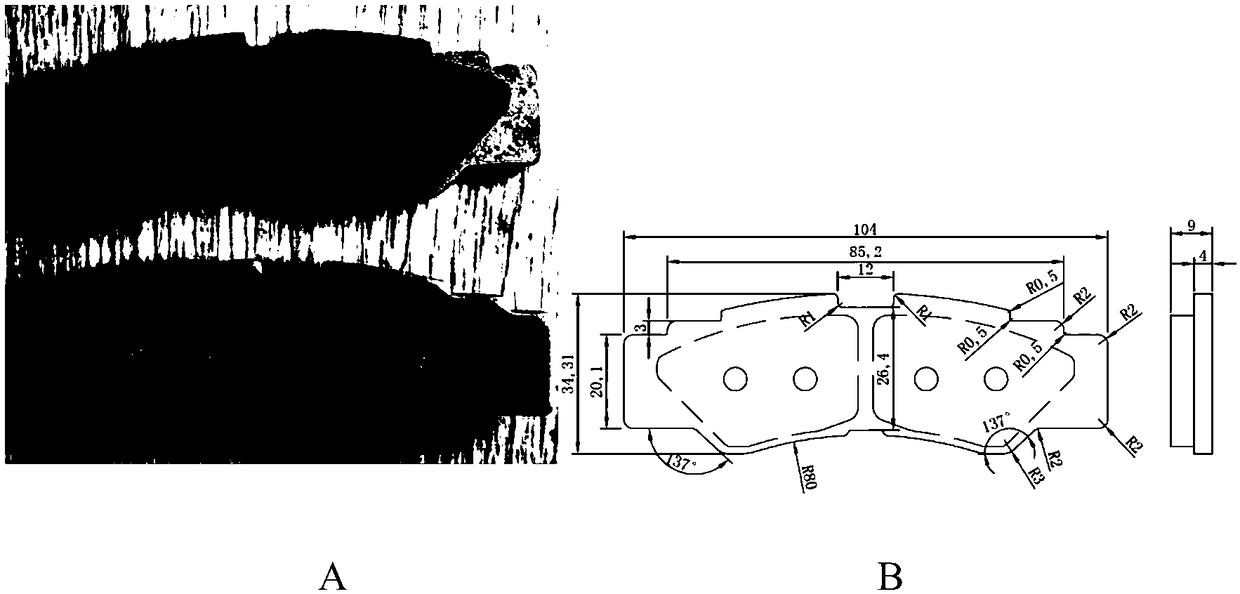

Preparation method for powder metallurgy for automotive brake valve block

InactiveCN103252492AEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateManganese

The invention discloses a preparation method for powder metallurgy for an automotive brake valve block. The preparation method includes that the automotive brake valve slice is made from raw materials, by weight percentage, 0.2-0.4% of nickel, 0.2-0.4% of cerium, 0.2-0.4% of chromium, 0.4-0.6% of emery powder, 0.6-0.8% of zinc, 0.8-1% of manganese, 0.8-1% of graphite powder, 1-2% of copper, 1-2% of performance additives and the balance ferrum. By adding the performance additives, superfine powder in mixed materials can be filled in gaps between large particles, so that apparent density of the mixed materials is improved; since main ingredients of the superfine powder are nano ferrum powder and calcium stearate and novel performance additives obtained from additives of silane coupling agent and the like further improves various physical properties of wear resistance and the like of products; and polyethylene vinyl acetate and liquid paraffin are added into the performance additives as lubricant, so that efficiency of the performance additives in mixed suppression is enhanced, pressing intensity of powder metallurgical parts under the same pressing pressure is greatly improved, particle combination forms and pore configurations of the raw materials are changed, and the problem caused by cracks is totally solved.

Owner:XUZHOU DALT MECHANICAL EQUIP MFG CO LTD

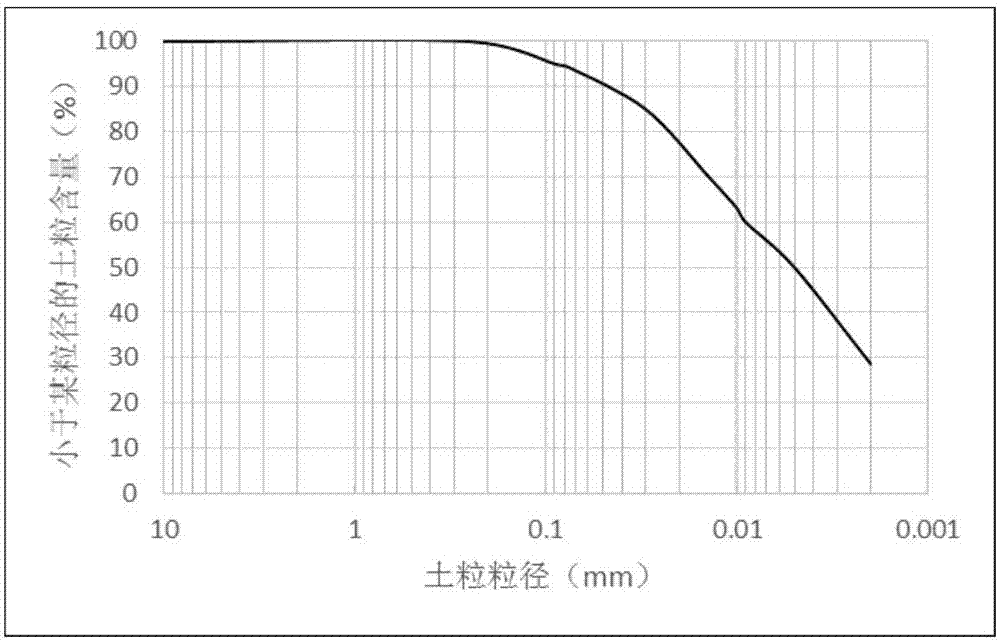

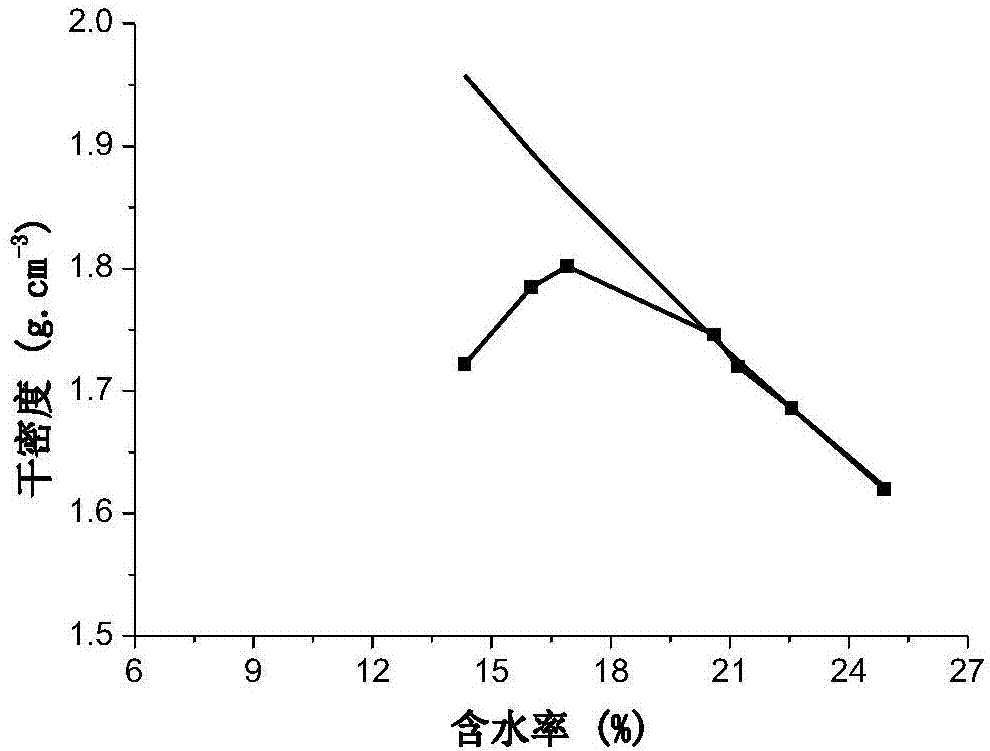

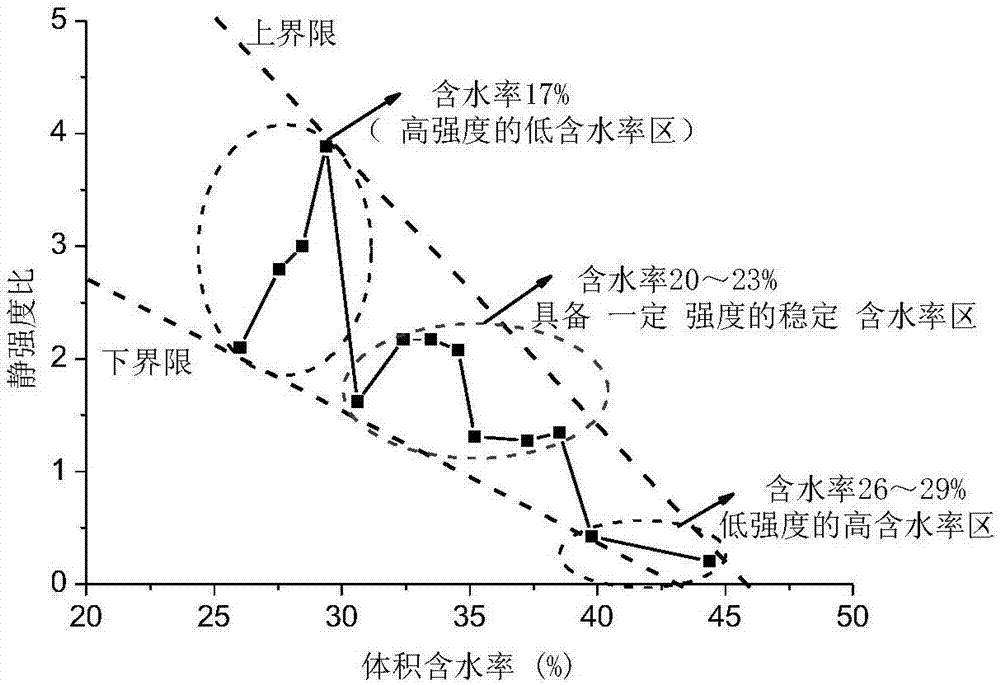

Guidepost determination method and rolling and compacting technology for rolling of high liquid limit clay road embankment in yellow river flood area

ActiveCN107476158AImprove compaction qualityImprove compact strengthRoadwaysSurface finishUltimate tensile strength

The invention discloses a guidepost determination method and a rolling and compacting technology for rolling of a high liquid limit clay road embankment in the yellow river flood area. Economical and efficient soil moisture content and compacting degree guideposts are proposed based on the physical mechanical properties of the high liquid limit clay in the yellow river flood area: the target moisture content range in the filling road embankment area is from the optimum moisture content W<opt>-2% to W<opt>+6%, and the compacting degree is not lower than 88%; in order to reach the guidepost, soil sampling and sun-curing of road embankment filling are organized reasonably and orderly, the compacting technology that a smooth-wheel roller suitable for a clay road embankment conducts static compacting for one time, a cam roller conducts strong vibration for four times and a rubber-tyred roller conducts surface finishing for one time is adopted, the compacting quality of the road embankment is improved obviously, the compacting strength of the road embankment is improved, and the problems that construction of the high liquid limit clay road embankment is difficult in rolling and compacting and the filling guidepost is not clear are solved. The filling guidepost determination method is economical, rapid and obvious in compacting effect, and has wide application prospects on filling of the high liquid limit clay road embankment.

Owner:SHANDONG UNIV

Method for preparing bearing outer ring through powder metallurgy

The invention discloses a method for preparing a bearing outer ring through powder metallurgy. The method comprises the following steps: the bearing outer ring is prepared from the following raw materials in percentage by weight: 0.6 to 0.7 percent of nickel, 0.2 to 0.4 percent of cerium, 0.2 to 0.4 percent of chromium, 0.4 to 0.6 percent of molybdenum, 0.2 to 0.6 percent of corundum powder, 0.3 to 0.4 percent of zinc stearate, 1 to 2 percent of modified aid, 30 to 45 percent of calcium carbonate and the balance of iron. The modified aid is added and ultrafine powder which can be filled in gaps of large particles is provided in mixed raw materials, so that the apparent density of the mixed materials is improved; the main components of the ultrafine powder comprise nano-iron powder and calcium stearate; the novel modified aid obtained by aids such as a silane coupling agent further improves various physical properties, such as wear resistance, of the product; and iron powder and liquid paraffin as lubricating agents are added into the modified aid, so the effect of the modified aid during mixing pressing is enhanced, the strength of pressed blanks of a powder metallurgical structural piece is greatly enhanced under the same pressing pressure, the combining shape and the pore shape of the raw material particles are changed, and crack is avoided fundamentally.

Owner:吴建平

Method for preparing plaster evacuated mould

InactiveCN101531026AReduce water-cement ratioReduce solubilitySolid waste managementMixing operation control apparatusWater basedTime extension

This invention discloses a method for preparing plaster evacuated mould, including following steps: weighting and mixing the raw material based on that the mass ratio of plaster: inorganic filling material: glass fiber: high efficiency water reducing agent (mass ratio) is 80-90:10-20:3-4:0.5:2.5; weighting water based on the cement water ratio of o.45 to 0.65 by calculating with mass, then pouring the prepared raw materials into a stirring pot, at the same time, opening the stirrer, quickly stirring for 1 to 3 min with the rotating speed of 100 to 300 r / min; coating mineral oil at the four sides and the bottom of the module, then pouring the mixed ground paste into the mould, screeding the upper surface of the plaster evacuated mould, fetching out the concretionary plaster evacuated mould from the module, finally naturally drying the mould. The product prepared by this invention has short time for drying, enlarged delayed coagulation time and can improve the intensity and the hard wearing performance.

Owner:贵州金三利科技建材有限公司

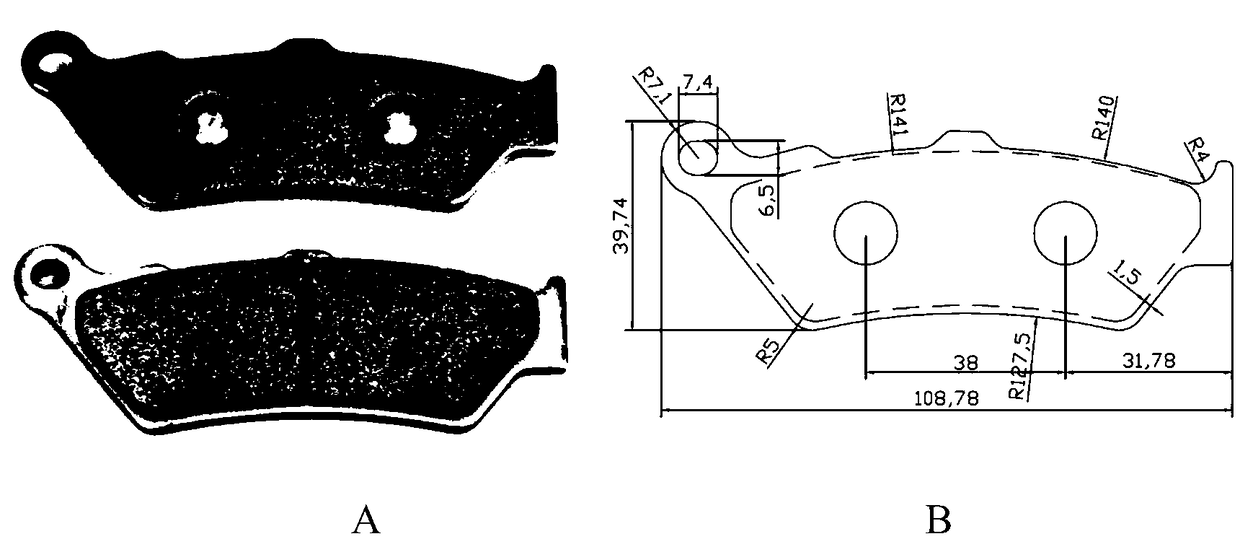

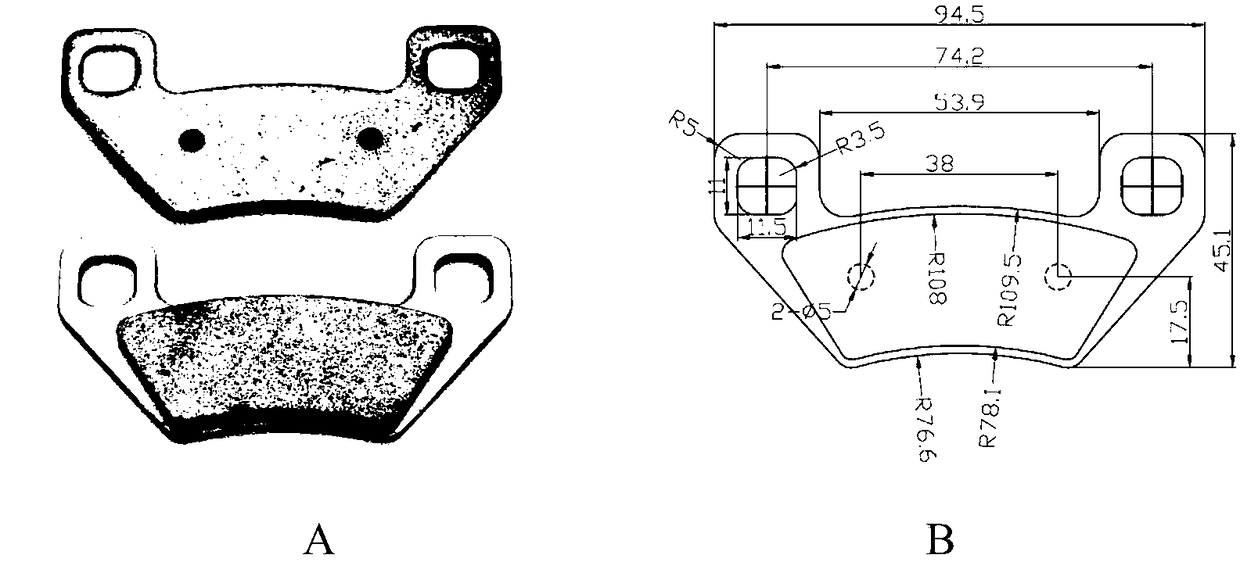

Preparation method of copper-based friction material of brake pad

ActiveCN108916277ALarge poresReduce noiseOther chemical processesFriction liningMaterials scienceDust pollution

The invention relates to a preparation method of a copper-based friction material of a brake pad. The preparation method comprises the following steps of step 1, preparing of raw materials; step 2, mixing and granulating; step 3, cold pressing and forming; step 4, preparing of steel back; step 5, cold assembly and matching; step 6, placing and charging into a furnace; step 7, hot pressing and sintering; step 8, discharging out of the furnace, and inspecting. The copper-based friction material has the advantages that by adopting the coarser flaky graphite, the dust pollution is reduced; by adding a compound anti-abrasion component, the comprehensive property of the friction material is favorably improved; by adding a certain ratio of glycerol mixed solution, rolling by hands, stirring and granulating, the uniformity and stability of each component are guaranteed, the fluidity is good, the density distribution of the press billet is uniform, and the strength of the prepared press billetis high; by adopting the high-temperature pressurizing sintering parameters, the property requirement of the friction material is guaranteed, and the connecting strength with the steel back is also guaranteed; the technology process is simple, the cost is low, the production efficiency is high, the brake noise is avoided, the heat attenuation is little, the bonding strength between the steel backand a friction block is high, and the comprehensive property is good.

Owner:滁州欧瑞斯机车部件有限公司

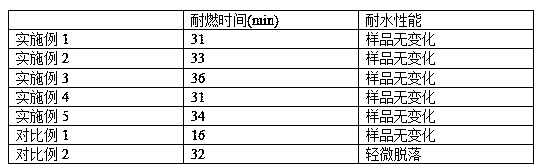

Intumescent fireproof paint and preparation method thereof

InactiveCN109929345AHigh strengthImprove fire performanceFireproof paintsDiphenyl phosphateCarbon layer

The invention provides an intumescent fireproof paint, which at least comprises the following components by weight: 20-50 parts of water, 5-30 parts of an emulsion, 3-20 parts of a pigment, 3-10 partsof isodecyl diphenyl phosphate, 20-60 parts of a composite intumescent flame retardant, 0.1-1 part of a dispersant, 0.1-1 part of a defoamer, 0.1-1 part of a thickener, 0.1-0.4 part of a pH regulator, 0-0.5 part of a bactericide, and 0-2 parts of a film-forming assistant. Through the synergistic effect of all the components, the obtained intumescent fireproof paint has the performance of environmental protection, decorativeness, color adjustability, dense and high density carbon layer, good adhesion and storage stability.

Owner:上海中南建筑材料有限公司

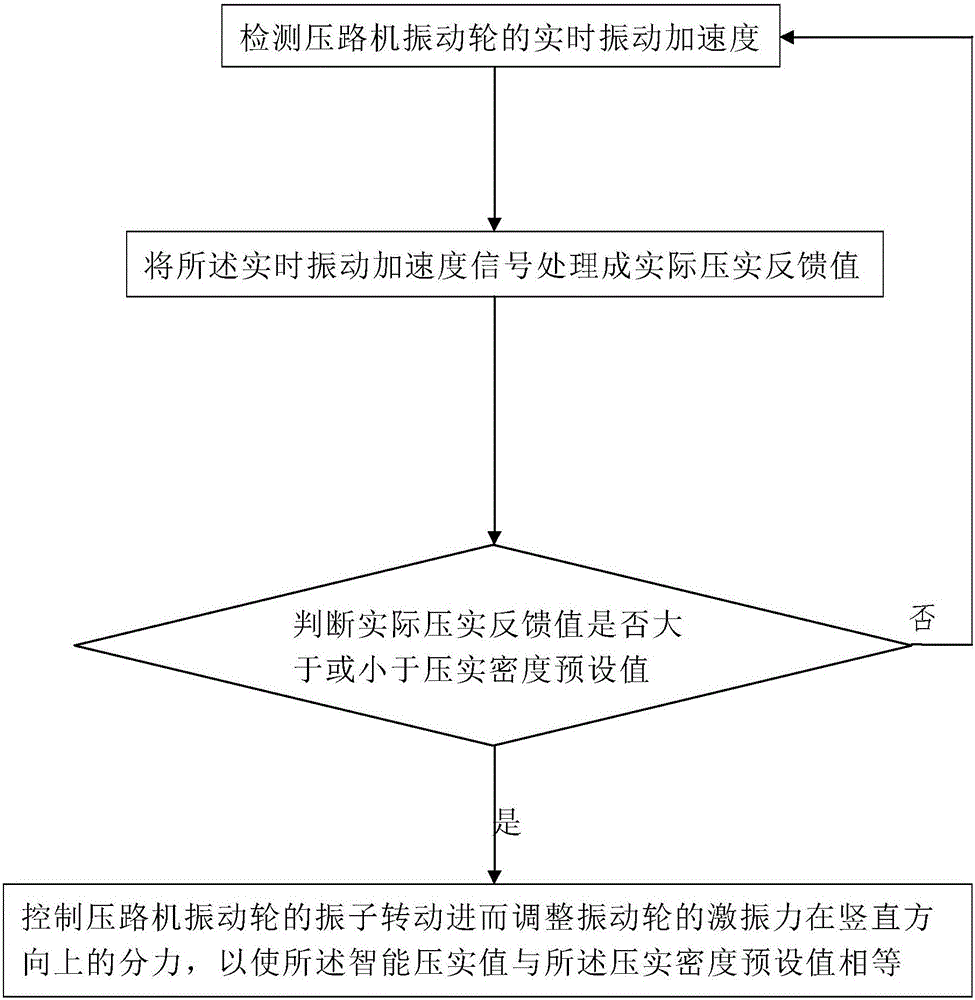

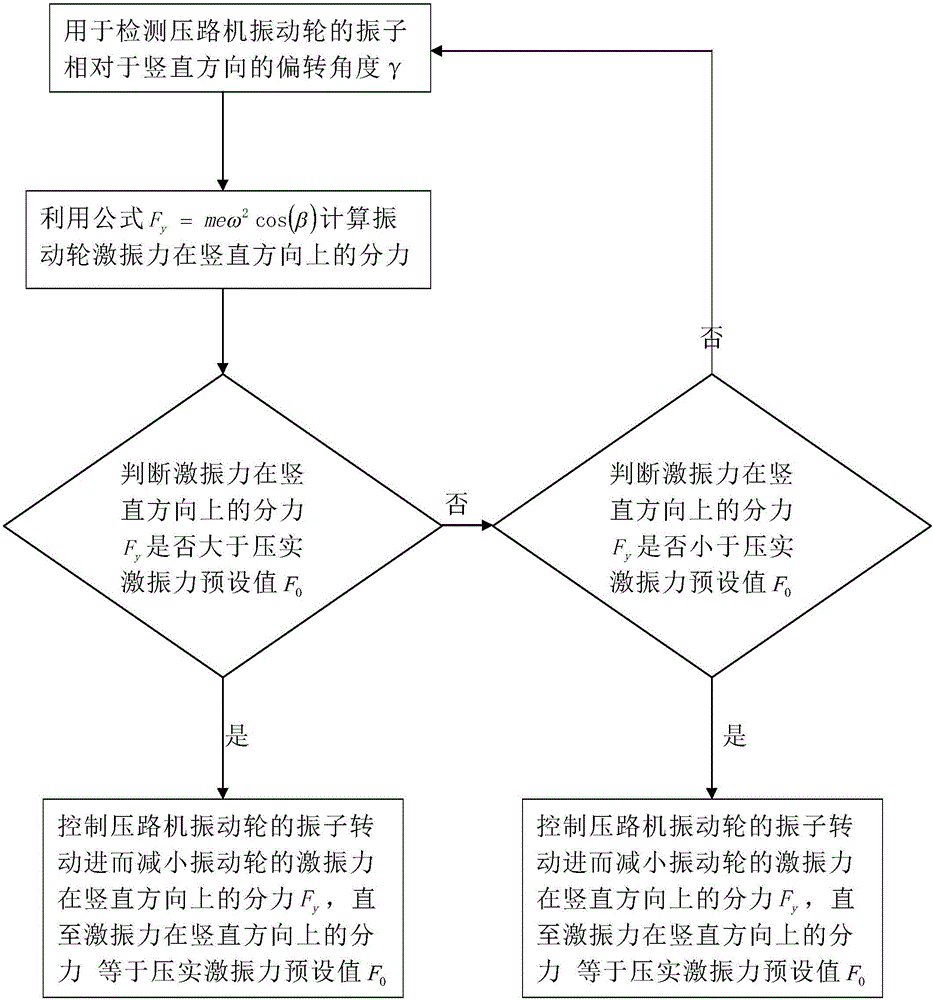

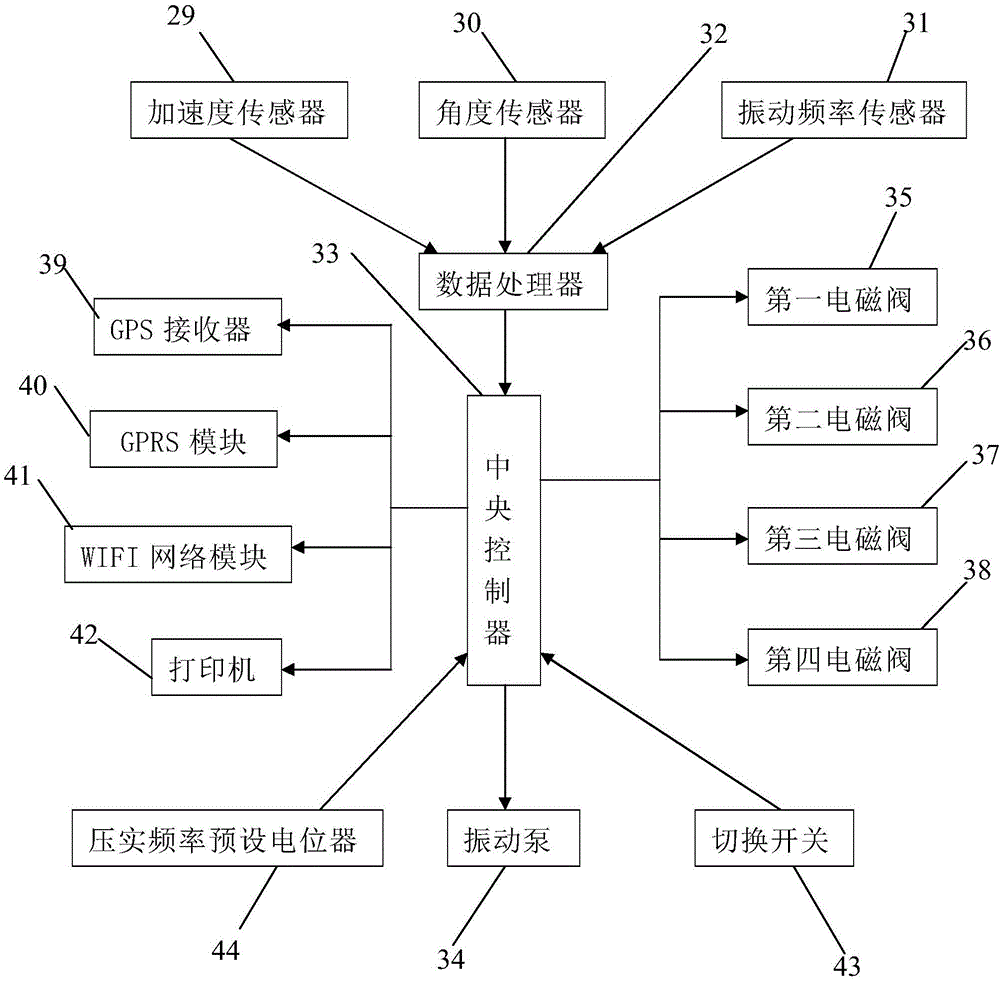

Excitation force control system and excitation force control method of intelligent steering vibratory roller

PendingCN106677032AChange the compaction strengthImprove compact strengthRoads maintainenceVibration accelerationControl system

The invention discloses an excitation force control method of an intelligent steering vibratory roller. The method comprises the following steps: detecting the real-time vibration acceleration of a vibration wheel of the roller; processing a real-time vibration acceleration signal into an actual compaction feedback value; comparing the actual compaction feedback value with a preset compaction density value so as to judge whether the actual compaction feedback value is greater or less than the preset compaction density value or not; if yes, controlling a vibrator of the vibration wheel of the roller to rotate so as to adjust the component force, along the vertical direction, of the excitation force of the vibration wheel and further enable the actual compaction feedback value to be equal to the preset compaction density value. The invention also discloses an excitation force control system, comprising a first control subsystem formed by an acceleration sensor, a data processor and a central controller. The control system and the control method are capable of controlling the excitation force in real time, and enable the excitation force direction to change steplessly within a range of 0-90 degrees, thus steplessly adjusting the component force, along the vertical direction, of the excitation force from zero to maximum.

Owner:SHAANXI JOINTARK MASCH GRP CO LTD

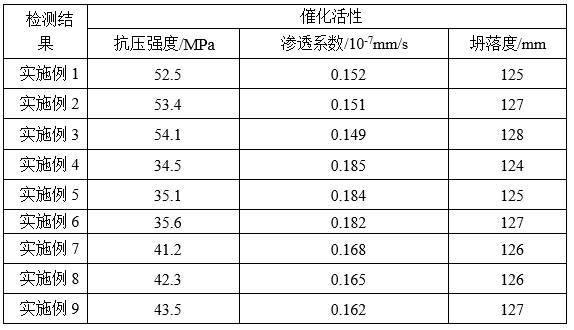

Admixture for recycled aggregate concrete and preparation method thereof

The invention relates to the field of concrete admixtures, and particularly discloses an admixture for recycled aggregate concrete and a preparation method of the admixture, and the admixture for recycled aggregate concrete comprises the following substances in parts by weight: 30-50 parts of a sulfamate water reducing agent, 20-30 parts of a polycarboxylic acid water reducing agent, 10-15 parts of nano silicon dioxide sol and 20-45 parts of water, wherein the nano silicon dioxide sol comprises hydrophilic solid silicon dioxide sol and hydrophilic porous silicon dioxide sol which are mixed at equal molar mass. The water reducing agent and the nano silicon dioxide are added into the admixture, the slump retaining effect of the concrete is improved by adding the water reducing agent firstly, and then the solid nano silicon dioxide sol and the porous nano silicon dioxide sol are compounded to serve as a filler of an internal pore structure of the recycled aggregate concrete, so that the compact strength of a concrete structure is improved; the hydration degree of the cement is reduced, and the workability, flowability and compactness of the recycled aggregate concrete are improved.

Owner:中建西部建设北方有限公司 +1

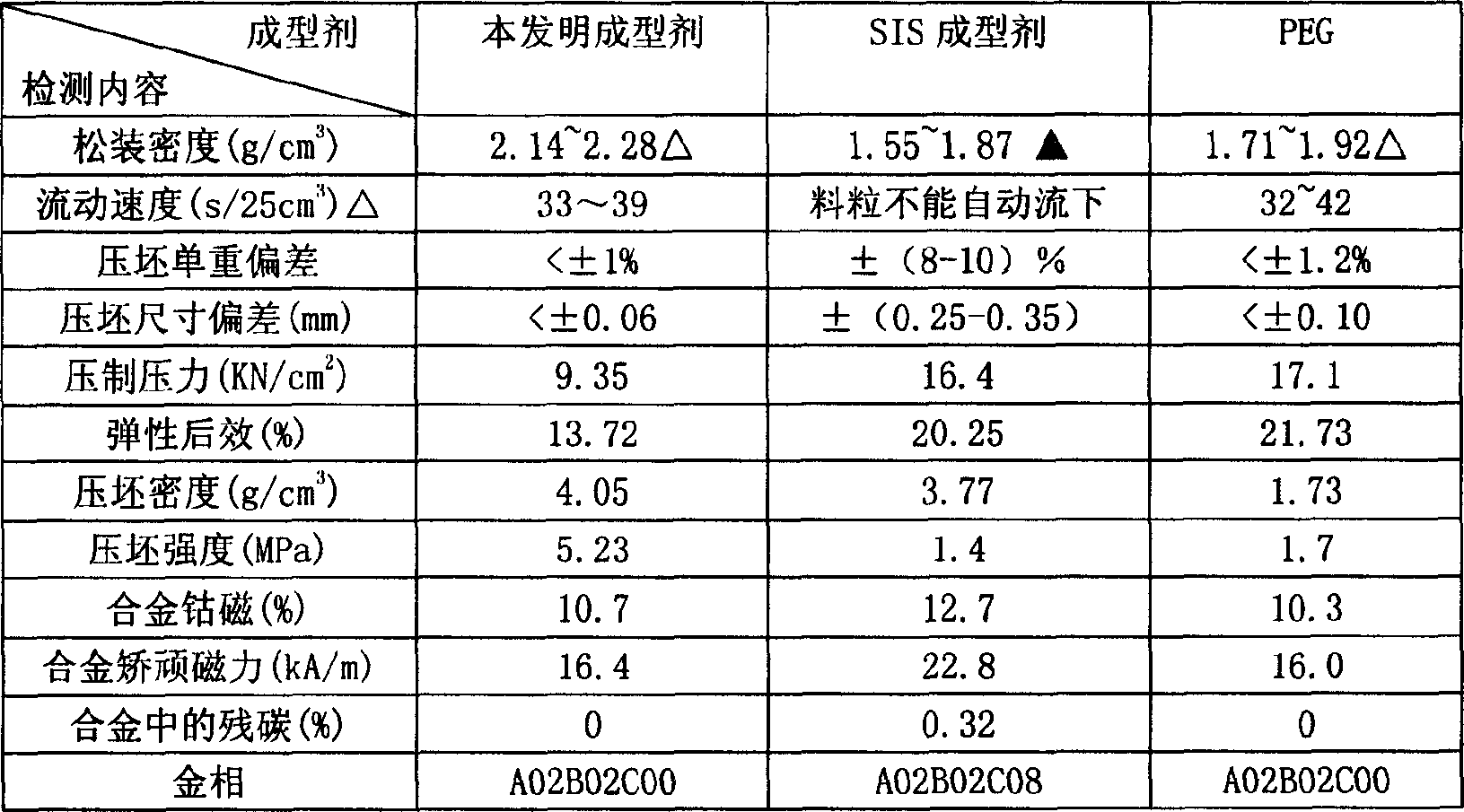

Plasticizer for ceramet production

The invention provides a plasticizer for ceramic metal production, which is prepared from 5-40% of polyvinylpyridine, 10-38% of polyethylene glycol, 2-10% of stearic acid, and 40-80% of anhydrous alcohol through heating, agitating and blending, and forming homogeneous solution. The invention can be applied into the production of cemented carbide and ceramics.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Ramming material for medium frequency furnace and preparation method of ramming material

The invention belongs to the technical field of refractory materials, in particular to a ramming material for a medium frequency furnace and a preparation method of the ramming material. The ramming material is prepared from the following components in parts by weight: 50-80 parts of bauxite, 20-30 parts of spinel, 10-20 parts of magnesite powder, 5-10 parts of thermosetting resin, 20-40 parts ofdried waste silicone sludge, 10-20 parts of silicon carbide particles with grain sizes being 1-3 mm, and 5-10 parts of graphite with the purity greater than 95wt%. The connecting strength and the compact strength of the inner structure of a cured product are relatively high, and the using effect is good. The ramming material is good in plasticity, relatively low in construction difficulty and relatively low in water-absorbing quality, and the service life of the ramming material is further prolonged compared with that of an existing ramming material. By taking the waste silicone sludge as a raw material, the production cost is lowered effectively. The product has relatively high cost performance and has relatively good market competitiveness, and the invention also provides a preparation method of the ramming material for the medium frequency furnace.

Owner:襄阳聚力新材料科技有限公司

Copper powder composition and production method thereof

The invention provides copper powder composition, which is characterized in that the copper powder composition consists of electrolytic copper powder and water atomization copper powder at the mass ratio of 1:(1.2-1.6), and a preparation method for the copper powder composition is provided. The apparent density of the copper powder composition is 3.5-4.6g / cm<3>, and the copper powder composition can be used for manufacturing friction material. The copper powder composition has the advantages of big strength, even particle size, increased apparent density and good formability.

Owner:CHONGQING YOUYAN ZHONGYE NEW MATERIAL

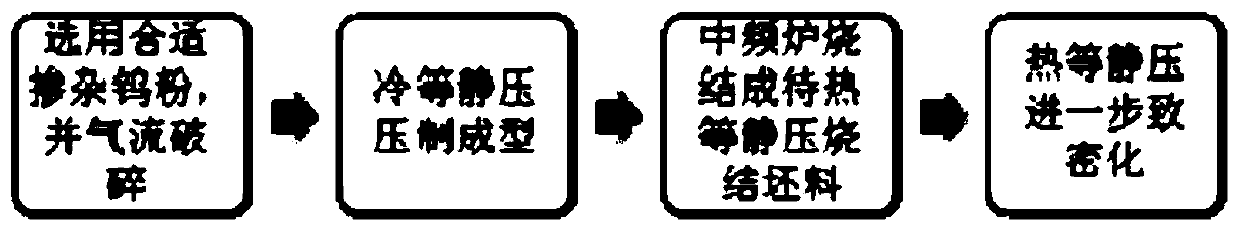

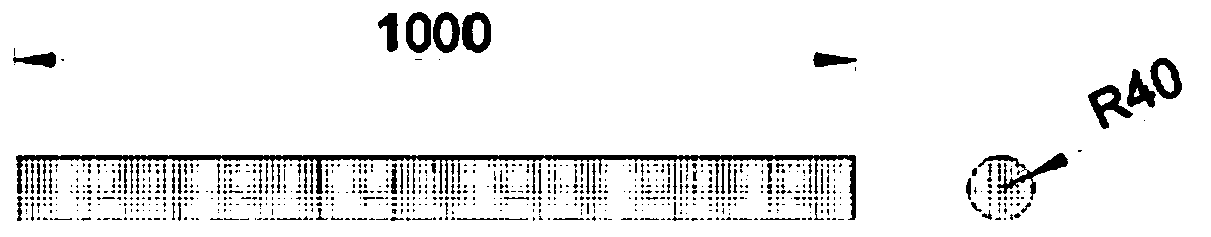

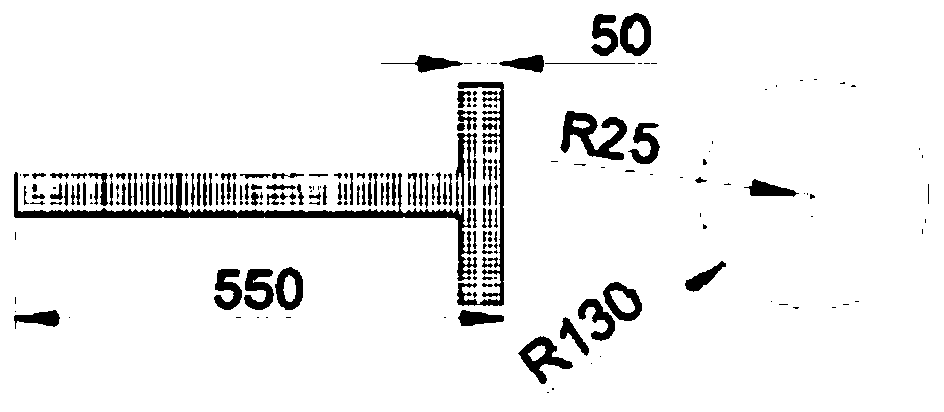

Preparation method of high-density rare earth tungsten electrode

ActiveCN110788318AImprove micro-uniformityHigh bulk densityElectric discharge tubesTransportation and packagingHigh volume manufacturingHot isostatic pressing

The invention discloses a preparation method of a high-density rare earth tungsten electrode. The method comprises the following steps of pretreatment, selecting raw material powder meeting requirements, and carrying out crushing treatment; pressing and forming, carrying out press forming treatment on the powder obtained in the pretreatment step to obtain a pressed blank; sintering, carrying out sintering treatment on the pressed blank to obtain a sintered blank; and hot isostatic pressing, carrying out hot isostatic pressing treatment on the sintered blank to obtain the high-density rare earth tungsten electrode. The preparation method has the advantages that the steps are well matched, the overall synergistic effect is obvious, the operation steps are simple and feasible, large-batch production is facilitated, the density of the prepared rare earth tungsten electrode product reaches 99.5% or above, the purity is high, the internal tissue structure is uniform, the grain size is fine,the strength is high, and the preparation method is suitable for mass production.

Owner:BAOJI JING LONG TUNGSTEN & MOLYBDENUM CO LTD +2

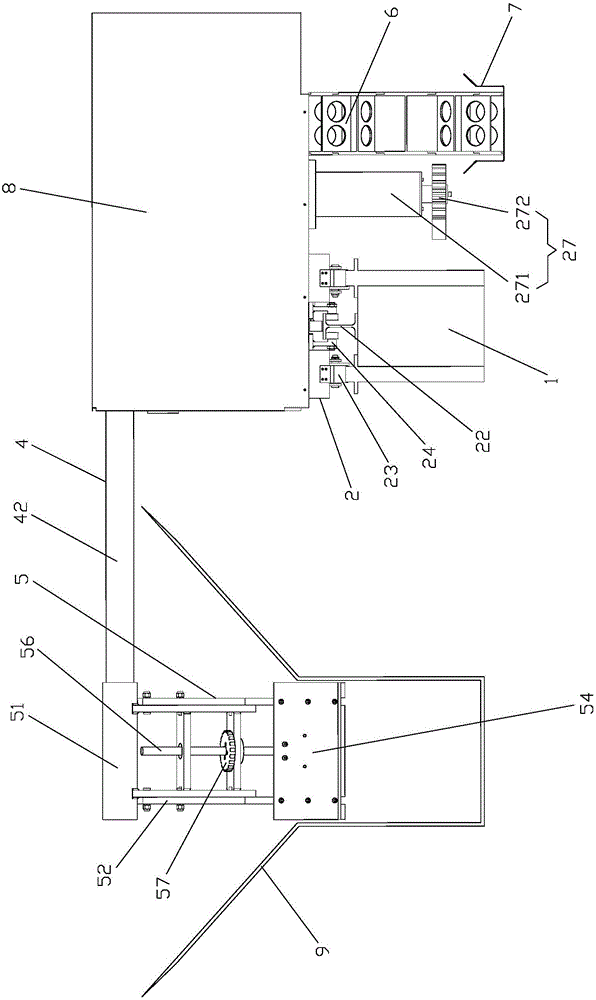

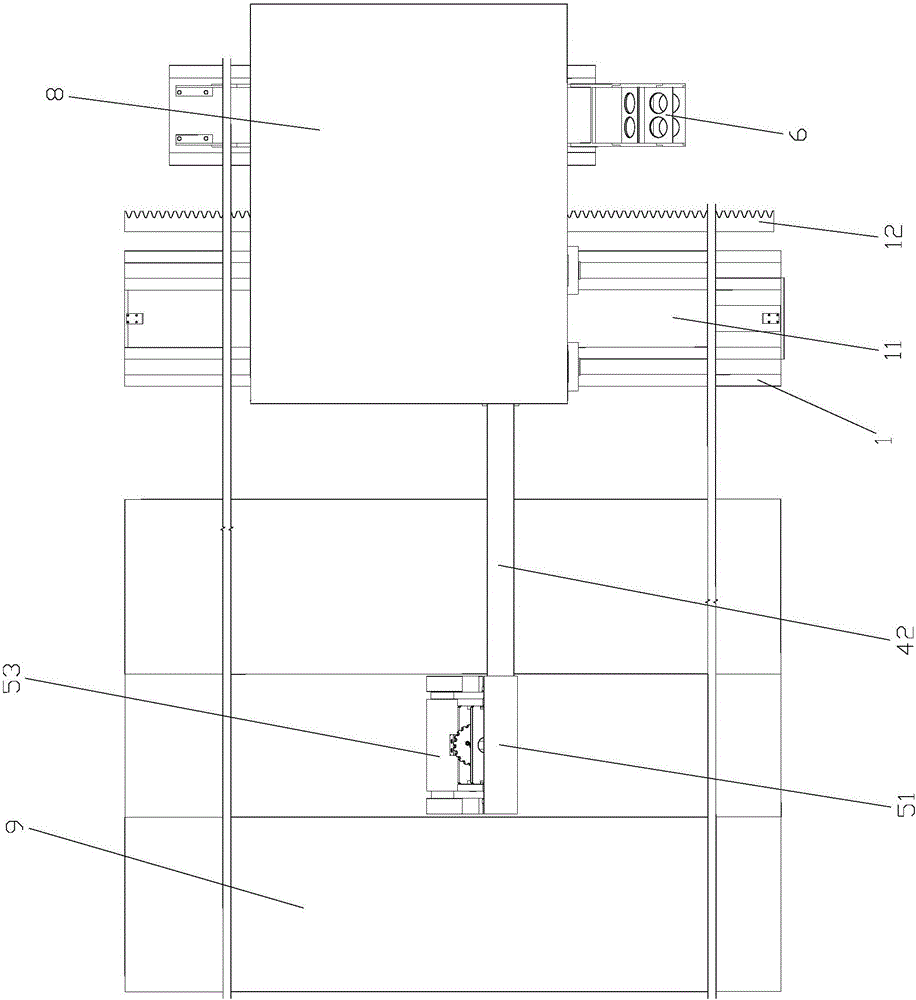

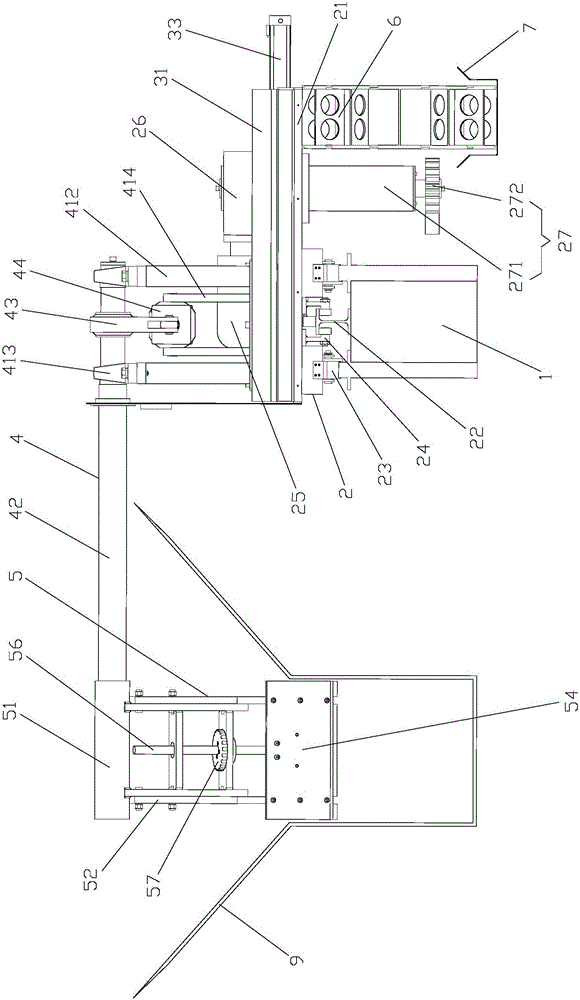

Coal leveling equipment

InactiveCN105858275AReasonable structural designImprove flat coal qualityLoading/unloadingRocker armCoal

The invention relates to coal leveling equipment which comprises an electronic control system, rollover prevention tracks, a travelling mechanism arranged on the rollover prevention tracks, a coal leveling plate telescoping mechanism, an overturning mechanism and a leveling and compacting mechanism, wherein the travelling mechanism and the coal leveling plate telescoping mechanism are both electrically connected with the electronic control system; the overturning mechanism and the leveling and compacting mechanism are driven by the coal leveling plate telescoping mechanism to realize stretching in place movement and withdrawing in place movement; the leveling and compacting mechanism rotates driven by the overturning mechanism; the overturning mechanism is composed of a main bracket, a rotary shaft, a rocker and an overturning drive device; and the leveling and compacting mechanism is composed of a transmission frame, extension plates, a roller, a scraper, a pneumatic vibrator, a regulation screw rod and a regulation nut. The coal leveling equipment can level and compact rugged coals, can effectively improve the quality of leveling the coals, improves the production efficiency, lowers the production cost and is stable in running, safe and reliable in use and high in working efficiency.

Owner:CHENGDU UNIV OF INFORMATION TECH

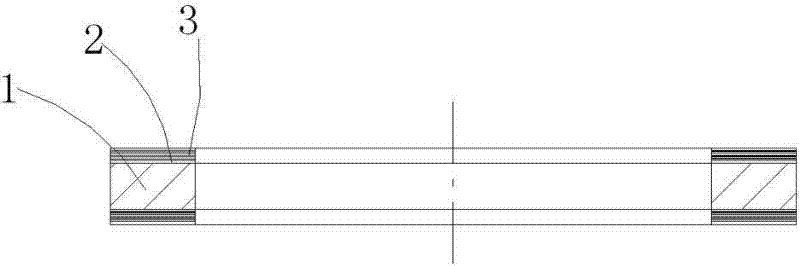

Copper-based powder metallurgy thrust ring and preparation method thereof

ActiveCN102230493AReduce molding pressureStrong compact strengthBearing componentsSliding contact bearingsManufacturing cost reductionThrust bearing

The invention discloses a copper-based powder metallurgy thrust ring and a preparation method thereof and in particular relates to a powder metallurgy thrust ring, a thrust bearing and other parts containing mixed ingredients of copper, tin, lead and graphite as well as a preparation method, wherein the parts are applied to marine gear cases. The copper-based powder metallurgy thrust ring comprises a copper core plate, wherein the copper core plate is coated with tin bronze powder serving as an adhesive bonding layer; the adhesive bonding layer is compounded with a copper-based powder metallurgy antifriction layer; and the copper-based powder metallurgy antifriction layer is obtained by fully mixing 8-10% of tin powder, 2-4% of lead powder, 1% of graphite powder and the balance of copper powder. The copper-based powder metallurgy thrust ring is obtained through the following steps: plating a copper layer; coating the adhesive bonding layer and a compound copper-based powder metallurgyantifriction layer; presintering; pressing an oil groove; resintering; and discharging. In the copper-based powder metallurgy thrust ring and the preparation method thereof, the thrust ring has the advantages of small shaping pressure and high compaction intensity, and manufacture cost is lowered; and the preparation method has the advantages of strong maneuverability and high finished product rate.

Owner:HANGZHOU FADA GEARBOX GROUP

Method for repairing brick and stone masonries through oyster shells and microorganisms

The invention relates to a method for repairing brick and stone masonries through oyster shells and microorganisms and belongs to the technical field of building repair. According to the method, water immerges into cracks of the oyster shells at first and is subjected to liquid nitrogen freezing to form ice crystals, accordingly, the size is enlarged, and the oyster shells burst open; oyster shell powder is obtained by grinding the oyster shells, fermentation liquor with the rich microorganisms is prepared through fermentation, the oyster shell powder, the fermentation liquor and collagen gel are mixed with the collagen gel as a nutrient substance and injected into cracks of the brick and stone masonries, and the microorganisms absorb carbon dioxide and heat generated in the metabolism process of the nutrient substance; and during maintenance, sprayed water, calcium carbonate in the oyster shells and carbon dioxide react to produce soluble calcium bicarbonate which immerges into the cracks of the masonries, the calcium bicarbonate forms dense calcium carbonate crystals again under the action of heat so as to block the cracks of the brick and stone masonries, and thus the purpose that the masonries are repaired is achieved. According to the method, the calcium carbonate crystals generated after repairing are compact in structure, high in intensity and free of shrinkage cracking, the aging resistance of the calcium carbonate crystals is superior to that of organic materials, and the application prospects are broad.

Owner:广州新城建筑设计院有限公司

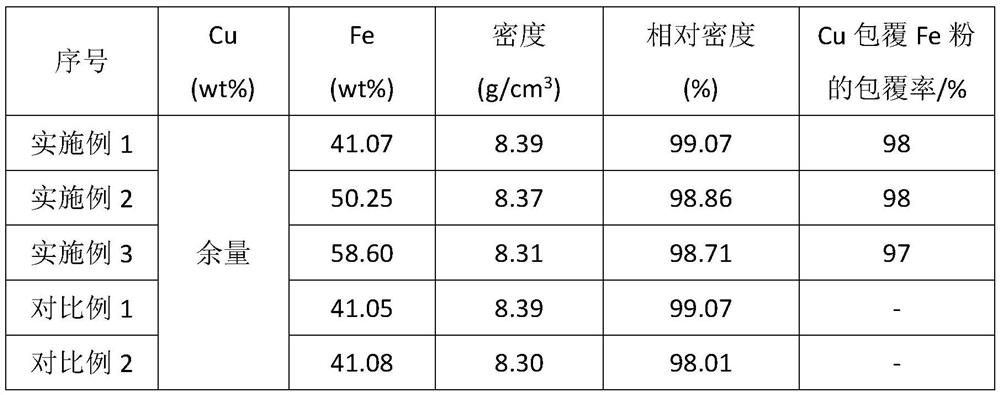

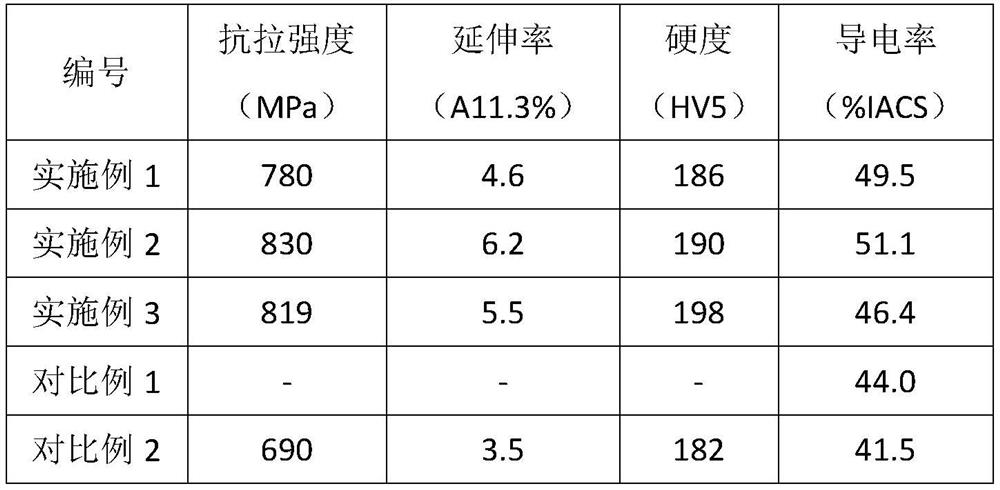

Preparation method of copper-iron alloy

ActiveCN113481405APlay the role of isolating the Fe phaseThere will be no rougheningCompression moldingIron powder

The invention discloses a preparation method of a copper-iron alloy. The preparation method is characterized in that the copper-iron alloy comprises the following components in percentage by mass: 40.0-60.0wt% of Fe and the balance Cu and inevitable impurities. The preparation method of the copper-iron alloy comprises the following steps of: 1) preparing Cu-coated Fe powder: weighing iron powder and copper oxide powder according to target components, and performing ball milling and powder mixing to obtain mixed powder, wherein the ball-to-powder ratio is (3-10): 1, the rotating speed is 200-300rpm, and the ball milling time is 20-30min; performing hydrogen reduction on the mixed powder at the reduction temperature of 250-300 DEG C for 60-120min; and after the reduction is finished, continuously heating to 700-800 DEG C, and keeping the temperature for 3-6h to obtain the Cu-coated Fe powder; and 2) performing compression molding: performing compression molding on the Cu-coated Fe powder to obtain a blank. The copper-iron alloy disclosed by the invention is uniform in copper-iron distribution and high in relative density and has excellent conductivity and mechanical properties.

Owner:JINTIAN COPPER GROUP CORP NINGBO

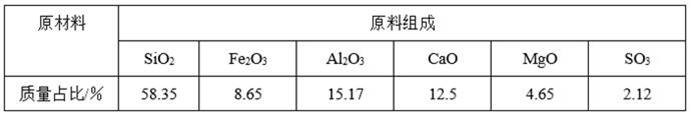

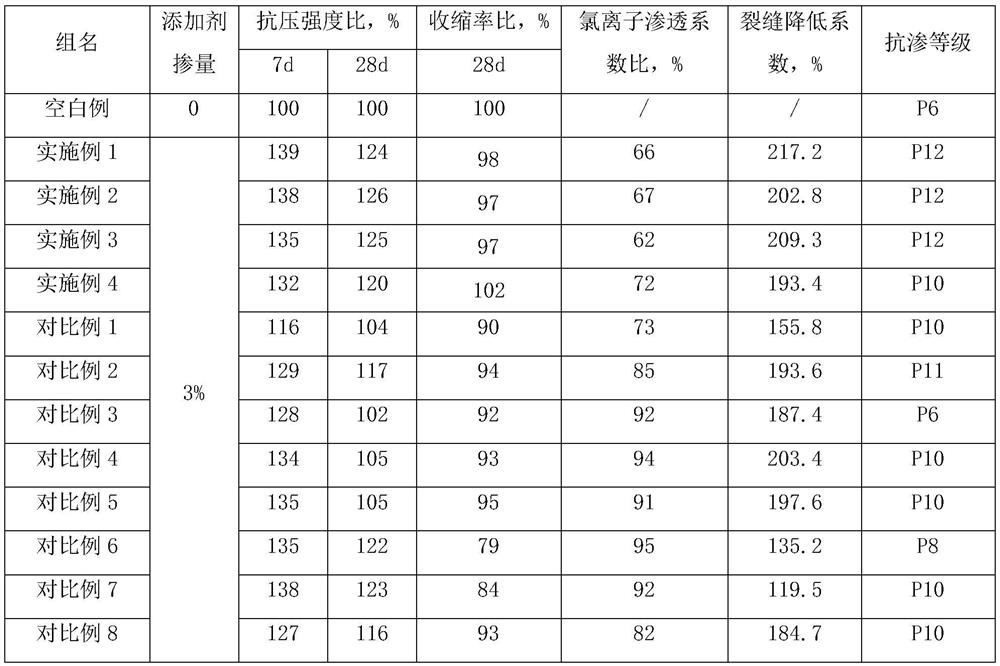

HBSY-KL type temperature-inhibiting, anti-cracking, anti-corrosion and waterproof additive for concrete

ActiveCN112194406AImprove compact strengthImprove early strengthSODIUM METAPHOSPHATECalcium silicate

The invention discloses an HBSY-KL type temperature-inhibiting, anti-cracking, anti-corrosion and waterproof additive for concrete. The HBSY-KL type temperature-inhibiting, anti-cracking, anti-corrosion and waterproof additive comprises the following raw materials in percentage by mass: 0.5-5% of nano-calcium silicate hydrate crystal seeds with a concentration of more than or equal to 0.05 mol / L,0.5-5% of modified nano-silicon dioxide, 1-5% of polyethylene glycol, 0.5-3% of citric acid or sorbitol, 0.3-0.8% of modified polystyrene, 0.5-2% of triisopropanolamine, 0.5-10% of sodium metasilicate, 1-6% of sodium hexametaphosphate or white sugar, 0.5-1% of a borate coupling agent, and the balance of water. By adopting the modified nano silicon dioxide and the modified polystyrene which are treated in a special modification mode, the compactness, the impermeability, the corrosion resistance and the waterproofness of the concrete can be effectively improved, hydration heat is inhibited, andthe early-stage strength and the later-stage strength of the concrete are improved.

Owner:HUBEI PROVINCIAL WATER RESOURCES & HYDROPOWER PLANNING SURVEY & DESIGN INST

A kind of preparation method of eccentric wheel powder metallurgy

ActiveCN103223489BEnhance the effect of mixing and pressingHigh bulk densityCranksEccentricsPolyethylene vinyl acetateMixed materials

The invention discloses a method for manufacturing an eccentric wheel through powder metallurgy. The method comprises the following step: the eccentric wheel is manufactured by the following raw materials in percentage by weight: 0.2-0.4 percent of nickel, 0.4-0.6 percent of molybdenum, 0.6-0.8 percent of tin, 0.3-0.5 percent of aluminium oxide powder, 0.8-1 percent of graphite powder, 0.4-0.6 percent of petroleum wax, 4-6 percent of copper, 1-2 percent of performance additive and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-zinc oxide powder and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, and various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

Owner:广东威强科技有限公司

Tamping device for construction

InactiveCN112343033AAchieve continuous compactionStrong compactionSoil preservationGear driveGear wheel

The invention belongs to the technical field of construction equipment, and provides a tamping device for construction. The tamping device comprises a shell a tamping hammer, a first half gear, a second half gear and a driving part, wherein the tamping hammer is slidably nested in the shell, and the upper surface of the tamping hammer is fixedly connected with a connecting column for tamping the ground; the first half gear is rotationally arranged in the shell and used for driving the connecting column to ascend; the second half gear is rotationally arranged in the shell and used for driving the connecting column to descend; the driving part is mounted in the shell, is connected with the first half gear and is used for driving the first half gear to rotate; and the first half gear is coaxially and fixedly connected with a first gear, the second half gear is coaxially and fixedly connected with a second gear, the first gear is engaged with the second gear, the first half gear drives theconnecting column to ascend, and the second half gear rotates to enable a second toothed bar to move downwards to enable the tamping hammer to descend in an accelerated mode for tamping. The tampingdevice has the advantages of being simple in structure, convenient to operate, low in production cost, capable of saving energy, good in synchronism and large in tamping force.

Owner:王世梅

Production method of sprocket powder metallurgy material

InactiveCN103252493AEnhance the effect of mixing and pressingHigh bulk densityParaffin waxPolyethylene vinyl acetate

The invention discloses a production method of sprocket powder metallurgy material. A sprocket is made from, by weight percent, 0.2-0.3% of graphite, 0.2-0.4% of nickel, 0.8-1% of molybdenum, 0.6-0.8% of nano emery powder, 0.3-0.5% of manganese sulfide, 0.8-1% of magnesia powder, 4-7% of copper, 1-2% of modifying aid, and the balance of iron. The production method has the advantages that the modifying aid is added, ultrafine powder is added in raw mixture and can fill gaps of large particles, and accordingly apparent density of the mixture can be increased; the ultrafine powder mainly comprises nano silica and calcium stearate, the novel modifying aid is obtained from aids such as silane coupling agent, and accordingly various physical properties of the finished product, such as wear resistance, are improved further; polyethylene vinyl acetate and liquid paraffin are used as lubricants added to the modifying aid, and accordingly the effect of the modifying aid in mixing and pressing is improved; compact intensity of powder metallurgical parts can be improved greatly while compacting pressure is equal, particle combination form and pore shape of the raw materials are changed, and cracking is eliminated from an origin.

Owner:广州市威强新材料实业有限公司

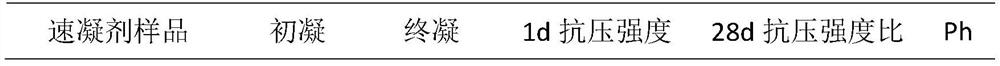

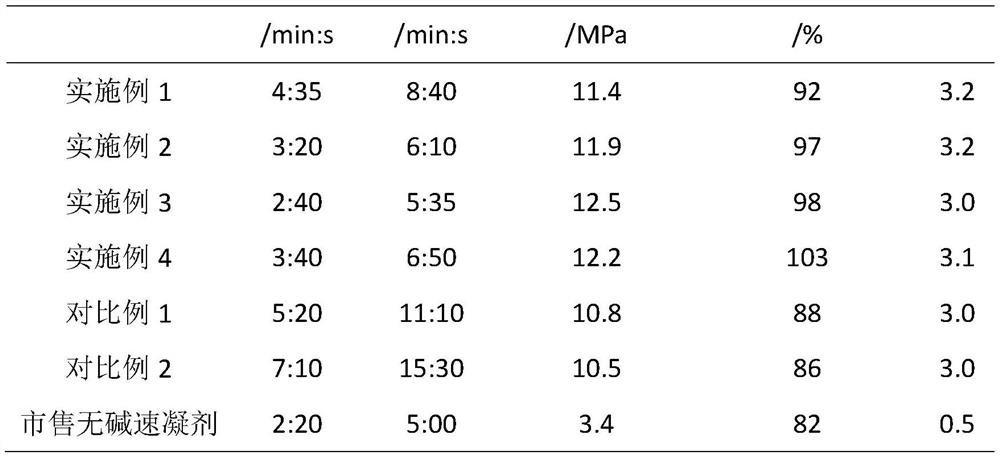

A kind of green high-early-strength low-alkali liquid accelerator and preparation method thereof

The invention discloses a green high-early-strength low-alkali liquid accelerator. The components include: aluminum sulfate: (30-60%), sodium fluoride: (5-20%), alcohol Aluminum: (4‑10%), stabilizer: (3‑10%), suspending agent: (1‑5%), defoamer: (0‑1%), and the rest is water. A low-alkali liquid quick-setting agent for shotcrete of the present invention has the advantages of low alkali, no chlorine, no corrosion to human body and machines, no irritating smell, high early strength, high late strength retention rate, good durability, etc. , can greatly reduce the risk of concrete alkali-aggregate reaction and the erosion of reinforced concrete.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Lubricant powder for powder metallurgy

InactiveCN1302879CLow discharge forceImprove compact strengthTransportation and packagingMetal-working apparatusPolyethylene oxideOligomer

The invention concerns new lubricants comprising a combination of a polyethylene oxide and an oligomer amide and an improved metallurgical powder composition comprising a major amount of an iron-based powder and a minor amount of this new lubricant. Furthermore, the invention concerns a method requiring low ejection force and low ejection energy for producing green products having high green strength. The method comprises the steps of mixing an iron-based powder and optional additives with the new lubricant and compacting the obtained powder composition.

Owner:HOGANAS AB

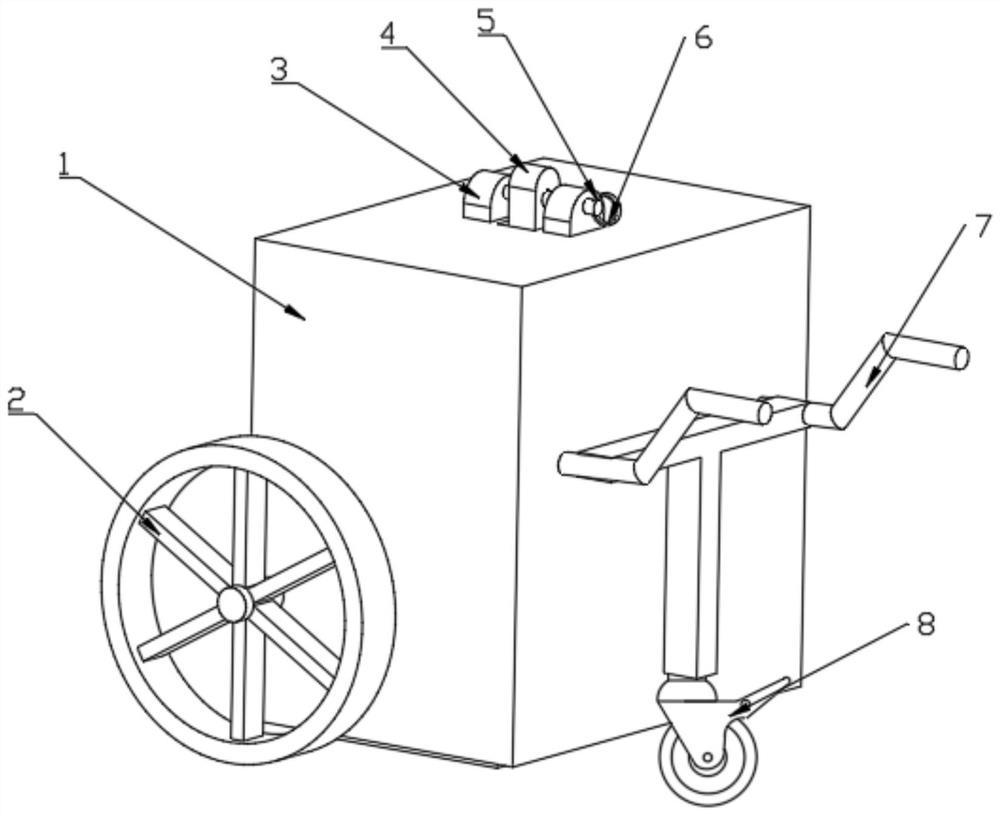

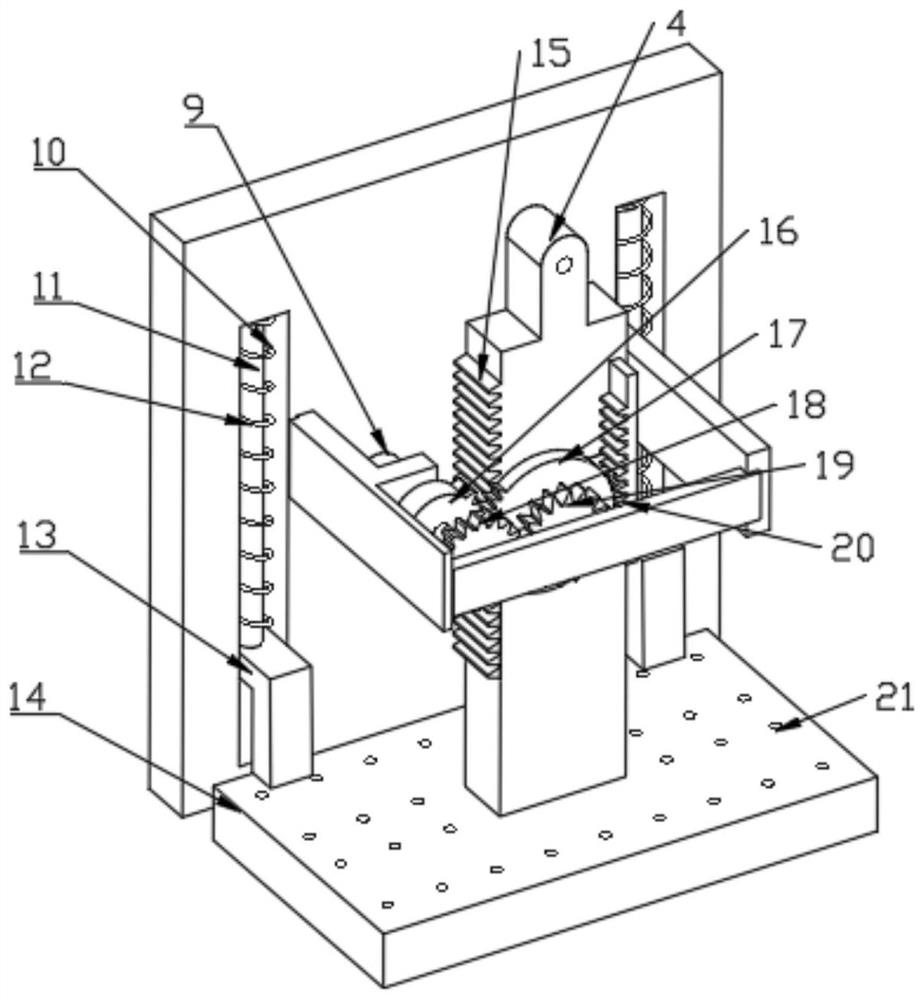

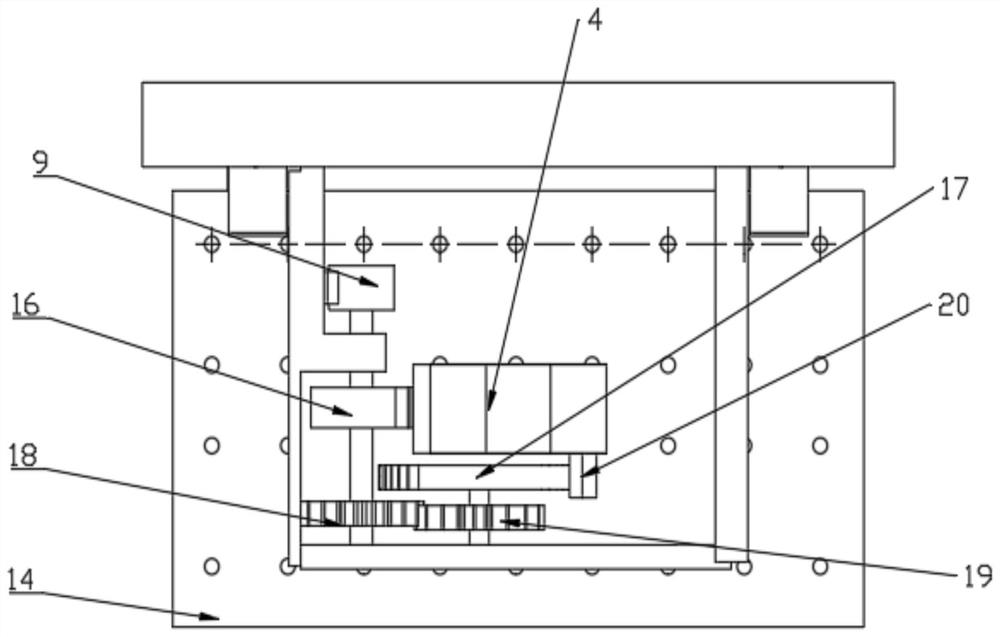

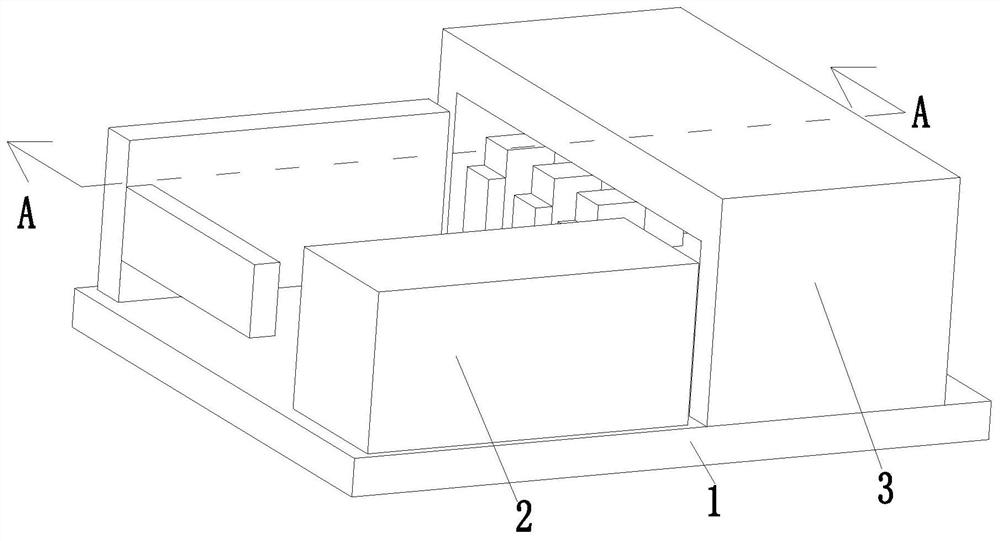

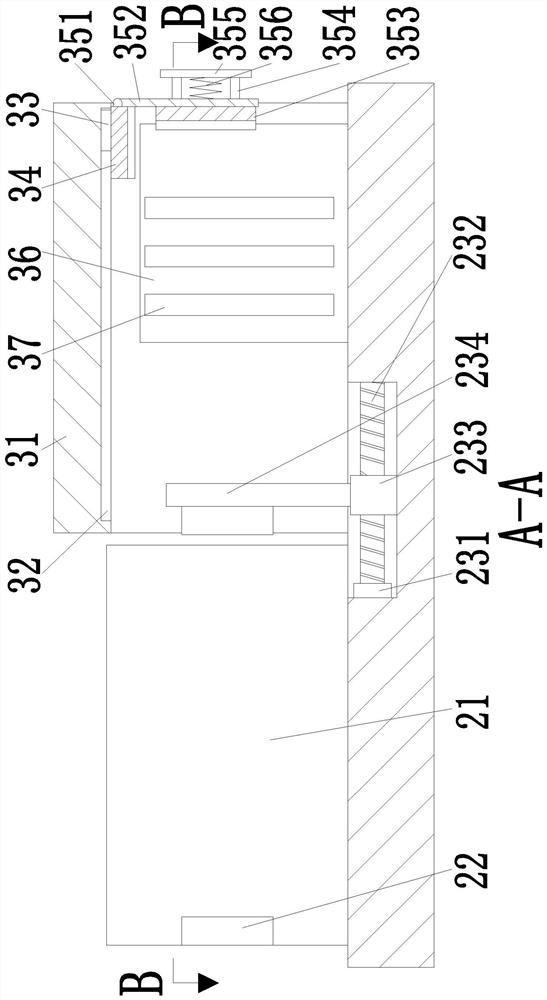

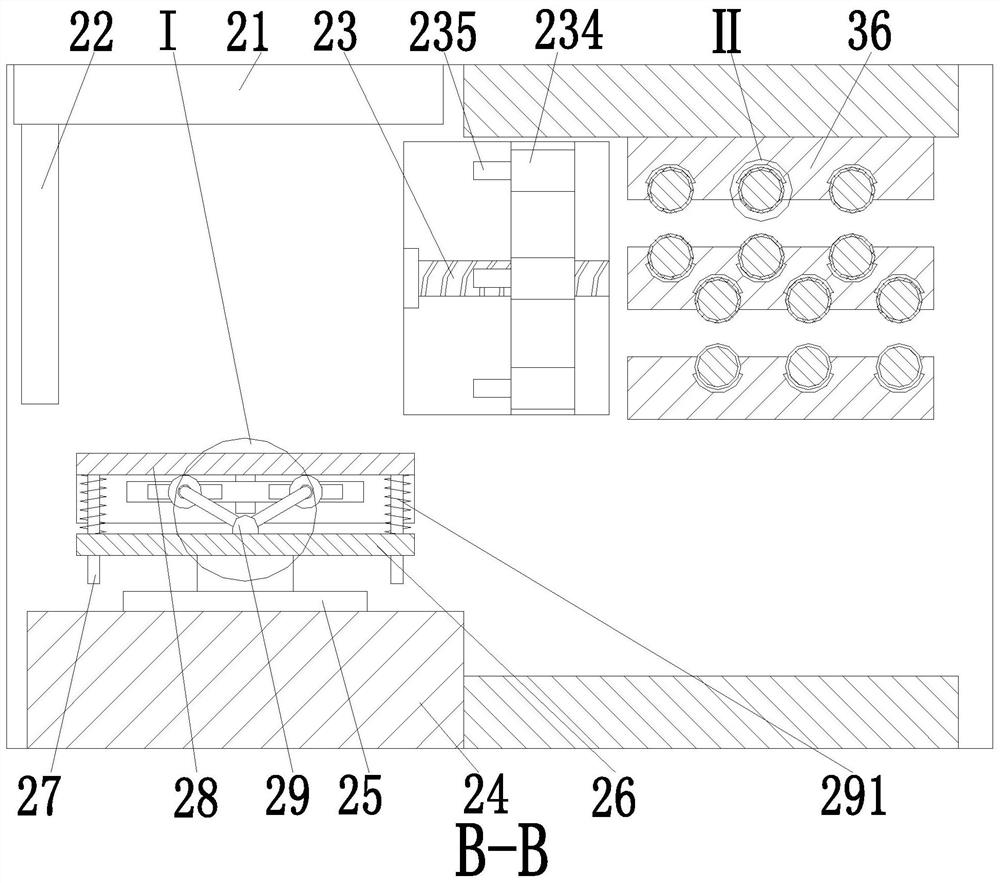

Automatic processing system for plywood production and processing method

ActiveCN113211566ASolve the problem of greatly reduced strength performanceImprove compact strengthWood veneer joiningAdhesive application devicesAutomatic processingSquare Shape

The invention relates to an automatic processing system for plywood production and a processing method. The automatic processing system comprises a base, a positioning and bonding device and a core veneer gluing device, the positioning and bonding device is arranged on the left side of the upper end of the base, and the core veneer gluing device is arranged on the right side of the upper end of the base. According to the automatic processing system for plywood production and the processing method, through a special-shaped wood board structure, a mechanism is matched with the special-shaped wood board structure, so that a wood board in bonding operation is limited and clamped, and the special-shaped wood board can be manufactured into a square shape for use in a subsequent process through cutting and the like, so that the problem that the wood board cannot be effectively clamped and fixed during bonding is solved; and through a double compaction mode of first extruding and then rolling, the compaction strength of a plywood is greatly improved, so that the problem that the strength performance of the plywood is greatly reduced due to insufficient extrusion force among part of boards when a plurality of layers of boards are bonded is solved.

Owner:柳州市东阳木业有限公司

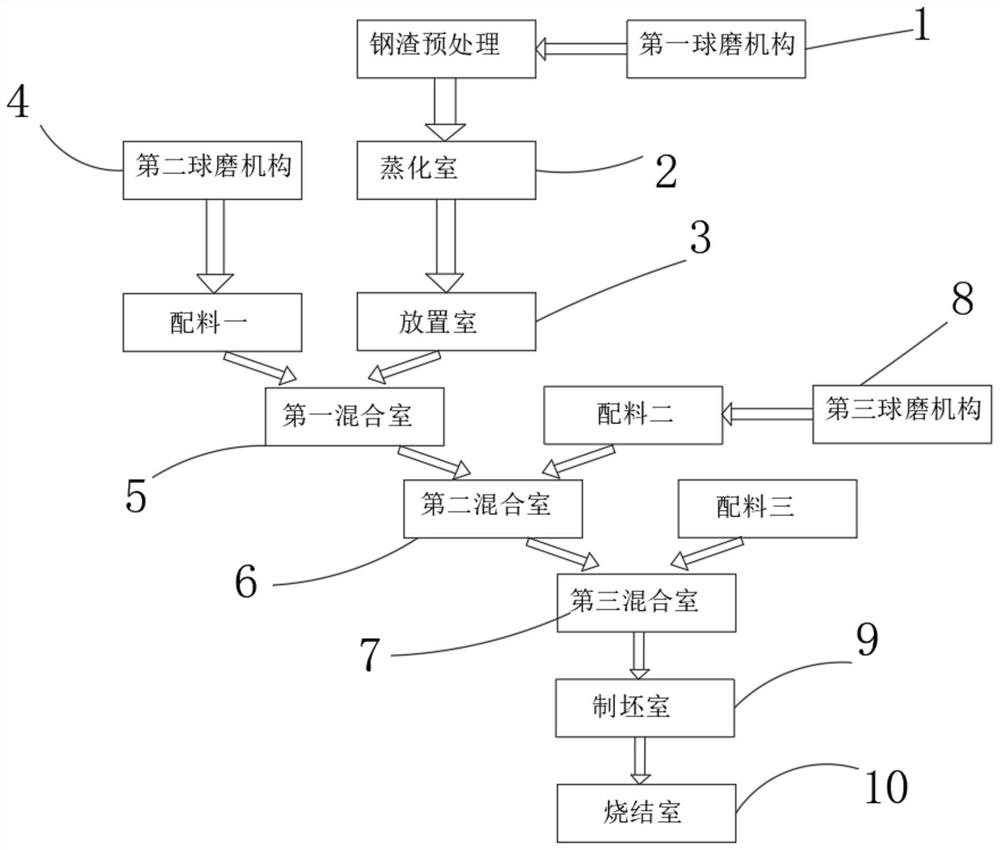

System for preparing steel slag sintered bricks

InactiveCN112979279AHigh strengthNot prone to crush damageCeramic materials productionClaywaresBrickSlag

The invention discloses a system for preparing steel slag sintered bricks. The system is characterized in that: pretreating steel slag through a first ball milling mechanism, grinding the steel slag into steel slag powder with a particle size of smaller than or equal to 0.045 mm, and subjecting the ground steel slag powder to ageing treatment and moisture drying; putting into a placing chamber; and grinding ferric oxide powder in the first ingredient through a second ball milling mechanism, mixing the ground ferric oxide powder and steel slag powder in a first mixing chamber, and then adding silicon powder and argillaceous aggregate. The perfection of ferrite crystallization is further promoted in that the melting point and the dynamic temperature of the mixture are reduced, so that the mass transfer and heat transfer conditions of a liquid phase are improved, the crystallization of minerals such as ferrite and the like can be promoted,the realization of low-temperature sintering of steel slag bricks is facilitated, quicklime is added while the steel slag bricks are mixed and put into a third mixing chamber, and hydration and hardening are promoted to improve the compact strength of brick structure. After the mixture in the third mixing chamber is subjected to blank making and standing for a period of time, the mixture is fed into a calcining kiln to be sintered, and the produced steel slag sintered bricks have the characteristics of high strength and good air permeability.

Owner:江西联达冶金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com