Patents

Literature

35results about How to "Change binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing automobile connecting rod through powder metallurgy

InactiveCN103223487AEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateCadmium Cation

The invention discloses a method for manufacturing an automobile connecting rod through powder metallurgy. The method comprises the following step: the automobile connecting rod is manufactured by the following raw materials in percentage by weight: 0.4-0.6 percent of nickel, 0.4-0.6 percent of graphite, 0.6-0.8 percent of zinc oxide powder, 0.4-0.6 percent of cadmium, 0.3-0.4 percent of zinc stearate, 1-2 percent of performance additive, 4-6 percent of copper and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-silicon dioxide and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

Owner:XUZHOU DALT MECHANICAL EQUIP MFG CO LTD

Method for preparing powder metallurgy of valve seat

ActiveCN103252498AEnhance the effect of mixing and pressingHigh bulk densityPolyethylene vinyl acetateAdditive ingredient

The invention discloses a method for preparing powder metallurgy of a valve seat. The method includes: the valve seat is made of following raw materials, by weight, 0.4-0.6% of nickel, 0.2-0.3% of carbon, 0.2-0.4% of manganese sulfide, 0.2-0.3% of vanadium, 0.6-0.8% of graphite powder, 0.1-0.2% of chrome, 0.3-0.4% of silicon, 1-2% of performance additive, 10-20% of copper, and the balance iron; via adding the performance additive, superfine powder is provided in the mixed raw materials and can fill in seams among large granules, so that density of the mixed materials is improved; main ingredients of the superfine powder include nano potassium feldspar powder and calcium stearate, and the novel performance additive is obtained via agent like silane coupling agent, physical properties like abrasion performance of prepared products is further improved; and polyethylene vinyl acetate and liquid paraffin serving as lubricating agent are added in the performance additive, so that effect of the performance additive under mixed compression is strengthened, the strength of compaction of power metallurgy structural members is greatly improved under same compression force, combining shape and hole shape of the raw material granules is changed, and problem about generation of crack is solved basically.

Owner:浙江同力重型机械制造有限公司

Method for manufacturing motorcycle crank shaft through powder metallurgy

InactiveCN103223490AEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateParaffin wax

The invention discloses a method for manufacturing a motorcycle crank shaft through powder metallurgy. The method comprises the following step: the motorcycle crank shaft is manufactured by the following raw materials in percentage by weight: 0.4-0.6 percent of nickel, 0.4-0.6 percent of manganese sulfide powder, 0.4-0.6 percent of aluminium, 0.4-0.6 percent of manganese, 0.3-0.4 percent of zinc stearate, 1-2 percent of performance additive, 21-25 percent of copper and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-silicon dioxide and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, and various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

Owner:江门速龙机车制造有限公司

Ceramic glaze with water activating function, preparation method thereof, ceramic prepared by ceramic glaze and preparation method of ceramic

The invention belongs to the technical field of ceramic and particularly relates to ceramic glaze with a water activating function, a preparation method thereof, ceramic prepared by the ceramic glaze and a preparation method of the ceramic. The ceramic glaze is prepared by, by mass percentage, 60-80% of ceramic glaze base material, 5-20% of ceramic additives with the water activating function, 5-8% of nano-zirconia, 0.5-5% of phosphate, 1-5% of nano cesium oxide, 2-8% of yttrium oxide, 1-5% of nano titanium dioxide and 3-8% of tourmaline. The preparation method of the ceramic glaze includes: ball milling the ceramic glaze base material until all the ceramic glaze base material can pass a 250-mesh sieve, adding the rest of components, adding water and ceramic diluent to prepare slurry, ball milling, and discharging. The ceramic glaze has the advantages that the ceramic glaze can acts on water molecular cluster structures to allow the hydrogen bonds to be destroyed and chemical bonds to break, large molecular clusters become small molecular clusters only containing 5-6 water molecules, toxic gas dissolved in water is released at the same time, the water become slightly alkaline, and the activity of the water is increased.

Owner:ZIBO BAIKANG ECONOMIC & TRADE

Preparation method of machine tool slider by powder metallurgy

ActiveCN103252497AEnhance the effect of mixing and pressingHigh bulk densityPolyethylene vinyl acetateCerium

The invention discloses a preparation method of a machine tool slider by powder metallurgy. The method includes that the machine tool slider is made of, by weight percentage, 0.6-0.8% of graphite, 0.2-0.4% of silicon carbide powder, 0.4-0.6% of manganese, 0.2-0.4% of nickle, 0.2-0.4% of cerium, 0.2-0.4% of titanium, 0.4-0.6% of aluminum, 1-2% of zinc, 5-8% of copper, 1-2% of performance additive and the rest iron. By the added performance additive, superfine powder is provided in mixed raw materials and can fill gaps among large particles, so that apparent density of a mixture is improved; the superfine powder is mainly composed of nanoscale iron powder and calcium stearate, and the novel performance additive is obtained through auxiliaries like silane coupling agent, so that various physical characteristics like abrasive resistance of the machine tool slider is further improved; and polyethylene vinyl acetate and liquid paraffin serving as lubricant are added into the performance additive, so that effects, in mixing and pressing, of the performance additive are enhanced, compacting strength of a powder metallurgy structural member is substantially improved under same pressing pressure, particle combining forms and pore shapes of the raw materials are changed, and generation of cracks is avoided fundamentally.

Owner:HAIAN YINGQIU POWDER METALLURGY CO LTD

Preparation method for powder metallurgy for automotive brake valve block

InactiveCN103252492AEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateManganese

The invention discloses a preparation method for powder metallurgy for an automotive brake valve block. The preparation method includes that the automotive brake valve slice is made from raw materials, by weight percentage, 0.2-0.4% of nickel, 0.2-0.4% of cerium, 0.2-0.4% of chromium, 0.4-0.6% of emery powder, 0.6-0.8% of zinc, 0.8-1% of manganese, 0.8-1% of graphite powder, 1-2% of copper, 1-2% of performance additives and the balance ferrum. By adding the performance additives, superfine powder in mixed materials can be filled in gaps between large particles, so that apparent density of the mixed materials is improved; since main ingredients of the superfine powder are nano ferrum powder and calcium stearate and novel performance additives obtained from additives of silane coupling agent and the like further improves various physical properties of wear resistance and the like of products; and polyethylene vinyl acetate and liquid paraffin are added into the performance additives as lubricant, so that efficiency of the performance additives in mixed suppression is enhanced, pressing intensity of powder metallurgical parts under the same pressing pressure is greatly improved, particle combination forms and pore configurations of the raw materials are changed, and the problem caused by cracks is totally solved.

Owner:XUZHOU DALT MECHANICAL EQUIP MFG CO LTD

Method for preparing bearing outer ring through powder metallurgy

The invention discloses a method for preparing a bearing outer ring through powder metallurgy. The method comprises the following steps: the bearing outer ring is prepared from the following raw materials in percentage by weight: 0.6 to 0.7 percent of nickel, 0.2 to 0.4 percent of cerium, 0.2 to 0.4 percent of chromium, 0.4 to 0.6 percent of molybdenum, 0.2 to 0.6 percent of corundum powder, 0.3 to 0.4 percent of zinc stearate, 1 to 2 percent of modified aid, 30 to 45 percent of calcium carbonate and the balance of iron. The modified aid is added and ultrafine powder which can be filled in gaps of large particles is provided in mixed raw materials, so that the apparent density of the mixed materials is improved; the main components of the ultrafine powder comprise nano-iron powder and calcium stearate; the novel modified aid obtained by aids such as a silane coupling agent further improves various physical properties, such as wear resistance, of the product; and iron powder and liquid paraffin as lubricating agents are added into the modified aid, so the effect of the modified aid during mixing pressing is enhanced, the strength of pressed blanks of a powder metallurgical structural piece is greatly enhanced under the same pressing pressure, the combining shape and the pore shape of the raw material particles are changed, and crack is avoided fundamentally.

Owner:吴建平

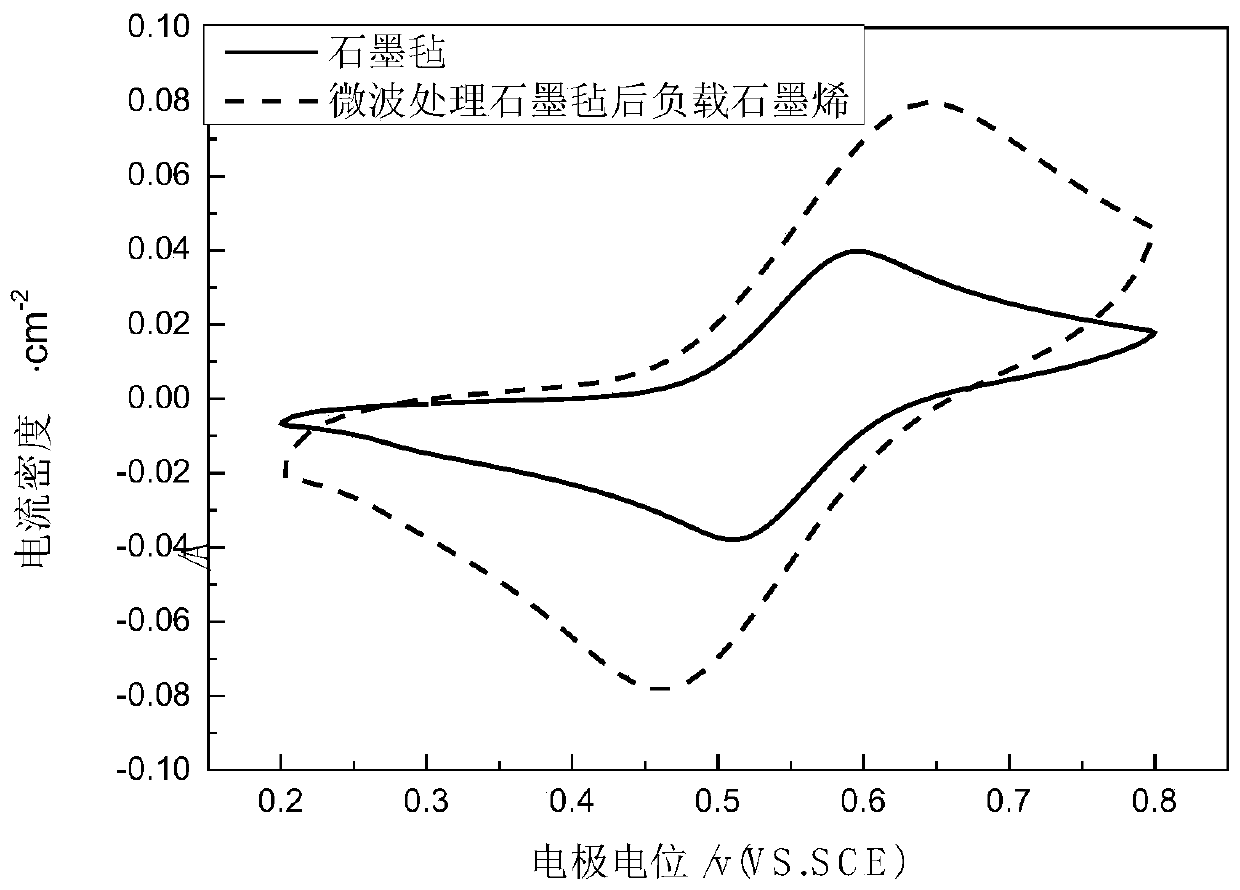

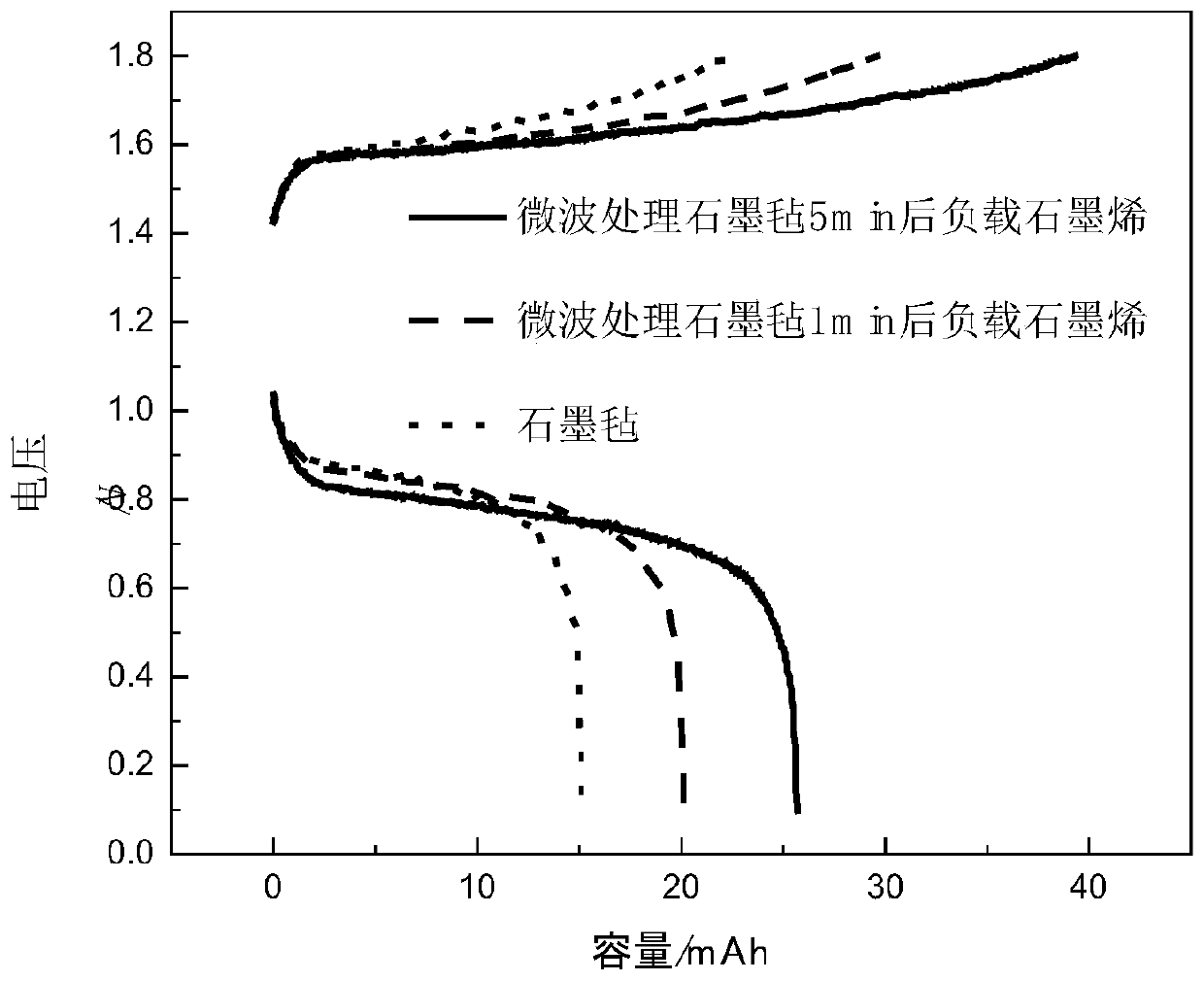

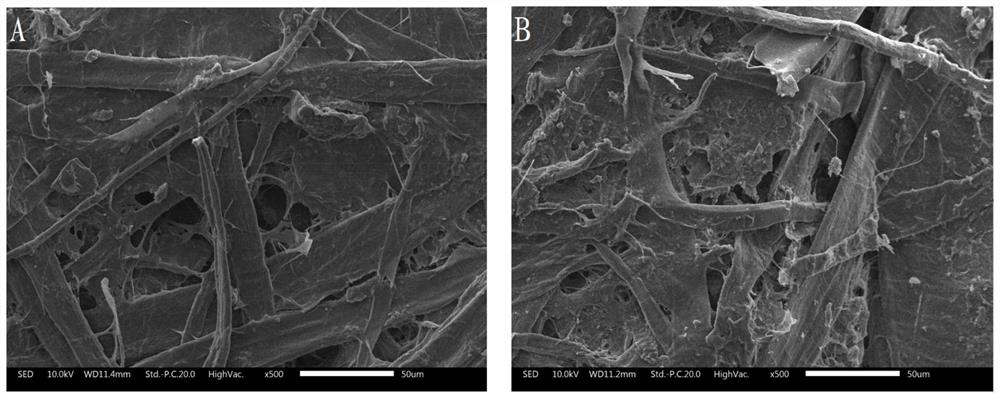

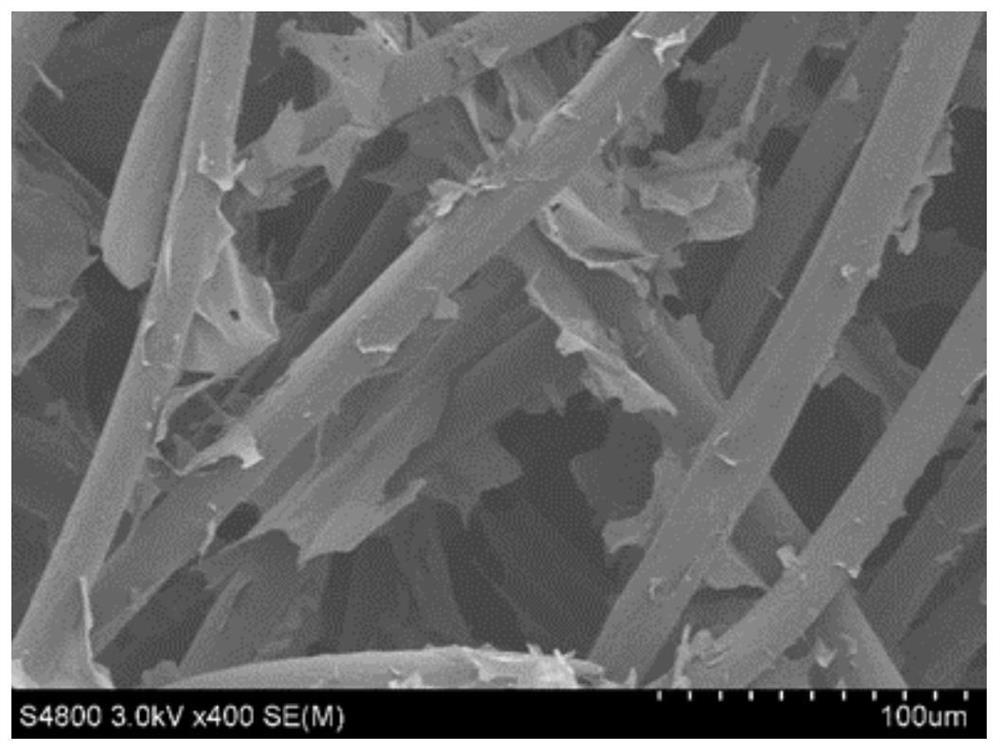

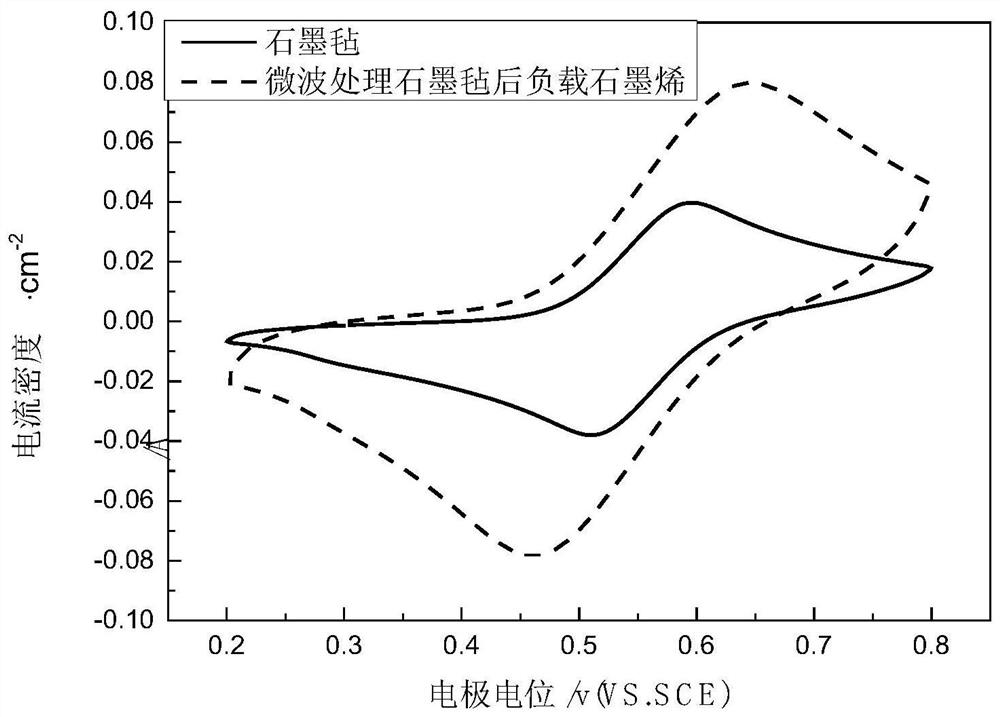

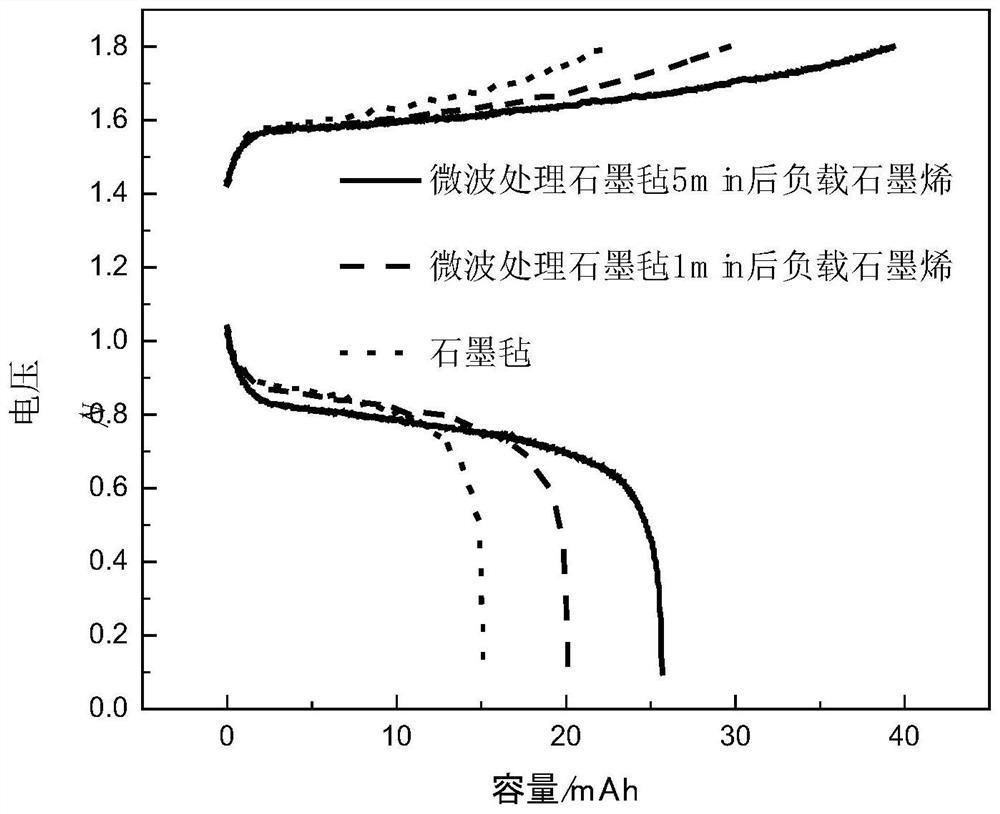

Pre-treatment method of composite electrode for TEMPO/MV flow cell

ActiveCN109921036AChange activityLower internal resistanceCell electrodesRegenerative fuel cellsFiberEthylenediamine

The invention relates to a pre-treatment method of a composite electrode for a TEMPO / MV flow cell. The pre-treatment method specifically comprises the following steps: firstly placing carbon electrodematerial in a domestic microwave oven (the power is at 300W to 800W) to treat for 1-10min, cleaning, and then placing in an aqueous solution containing ethidene diamine to soak for 12-24h, and then placing the soaked graphite felt in a hydrothermal reaction still containing graphene oxide and ethidene diamine mixed aqueous solution, reacting for 12-24h at 180 DEG C, freezing and drying to obtainthe electrode material for TEMPO / MV flow cell. The hydrophily of the graphite felt is increased, the binding force of the three-dimensional graphene and the graphite fiber is enhanced, the electrochemical activity of the electrode material is improved, and the energy efficiency and the voltage efficiency of the TEMPO / MV flow cell are improved.

Owner:TIANJIN UNIV

Method for improving performance of gypsum powder

A method for improving the performance of gypsum powder belongs to the field of gypsum powder application, and comprises the following steps: 1, selecting a coating agent capable of tightly combiningwith gypsum crystal; 2, adding a liquid coating agent to the gypsum powder; and 3, sending the gypsum powder into which the liquid coating agent is added to a coating device for coating. The method has the characteristics of greatly improving the strength, water resistance and the like of the gypsum powder.

Owner:ZHENGZHOU SUNDY BUILDING TECH

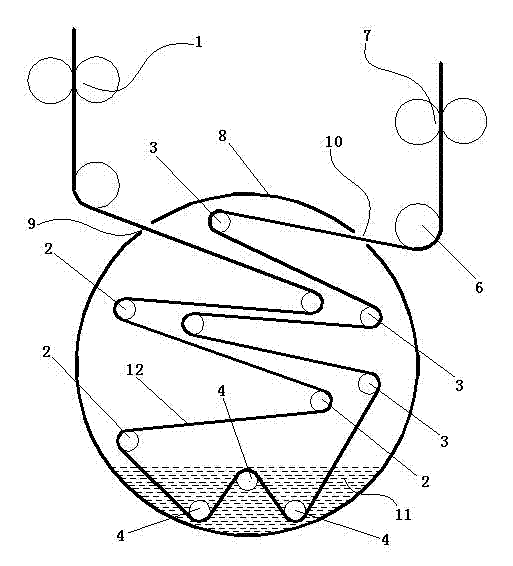

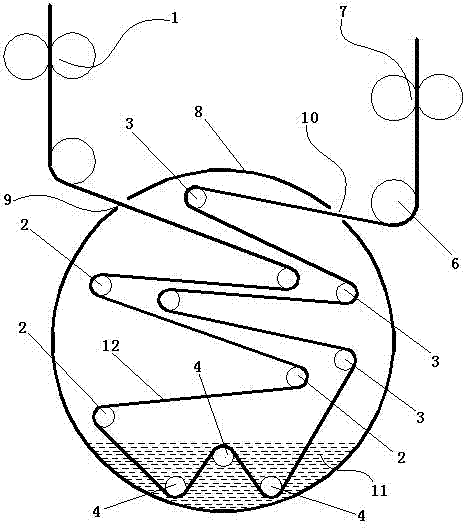

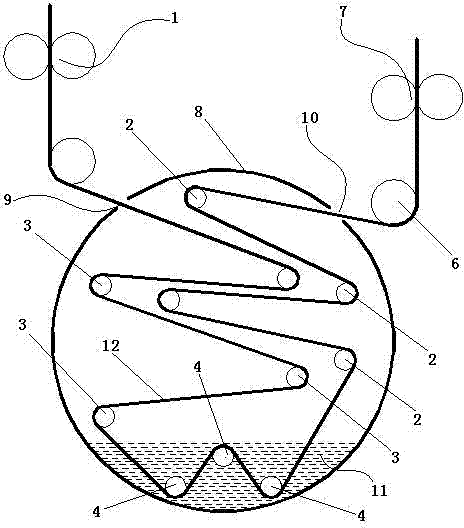

Color dyeing fabric production process of color dyeing device for rapid breathable cooling T-shirt fabric

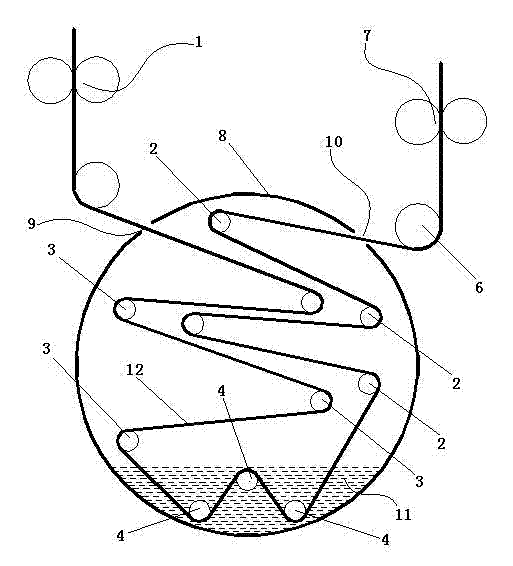

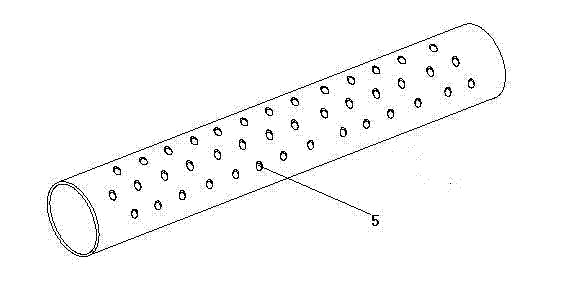

InactiveCN104499228AChange bindingImprove bindingSucessive textile treatmentsLiquid/gas/vapor textile treatmentFiberBinding ratio

The invention relates to a color dyeing fabric production process of a color dyeing device for rapid breathable cooling T-shirt fabric. The color dyeing fabric production process comprises the following steps: (1) guiding greige cloth into a dyeing and perming drum through cloth guide rollers to perform preheating and pre-dyeing treatment before color dyeing; (2) guiding the greige cloth into dyeing slurry through dip dyeing rollers and performing circulation dip dyeing treatment with the dyeing slurry; (3) guiding the dyed greige cloth onto a plurality of continuous color dyeing rollers to perform vapor color dyeing treatment through the color dyeing rollers one by one; (4) guiding the dyed cloth treated by color dyeing onto a drying drum for performing drying treatment. According to the color dyeing fabric production process disclosed by the invention, as each dip dyeing roller is provided with the circulation holes and a pump body, the full binding ratio of greige cloth and dye can be increased; before or after dip dyeing when the greige cloth enters the dyeing slurry, vapor treatment is performed on certain local areas of the greige cloth to change the binding property of fibers in the local area and the dyeing slurry, so that the binding property of fibers in the local area and the dyeing slurry is better or poorer than that of fibers at other parts and the dyeing slurry to form a color dyeing effect with different styles.

Owner:SUZHOU OUBBOO FASHION CO LTD

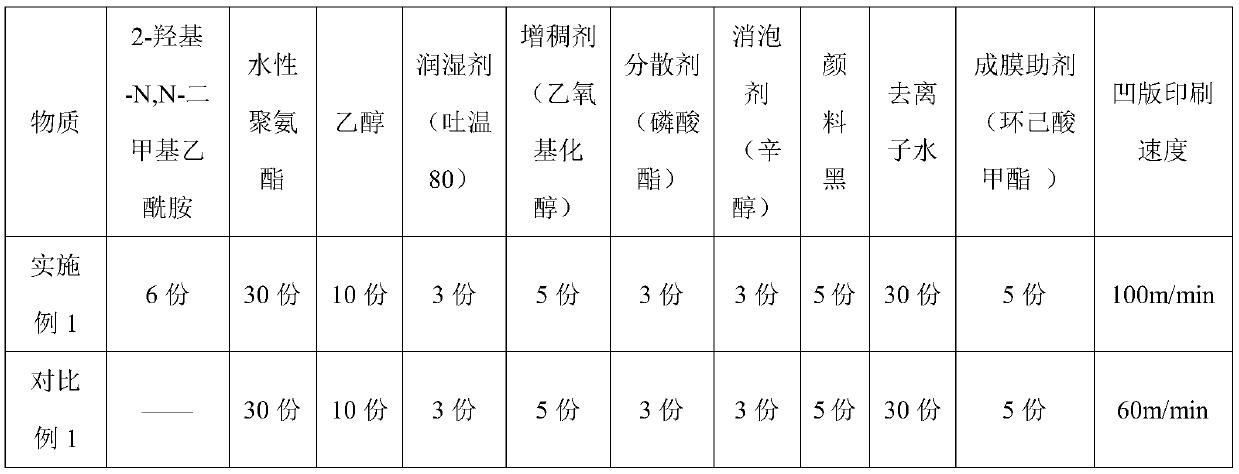

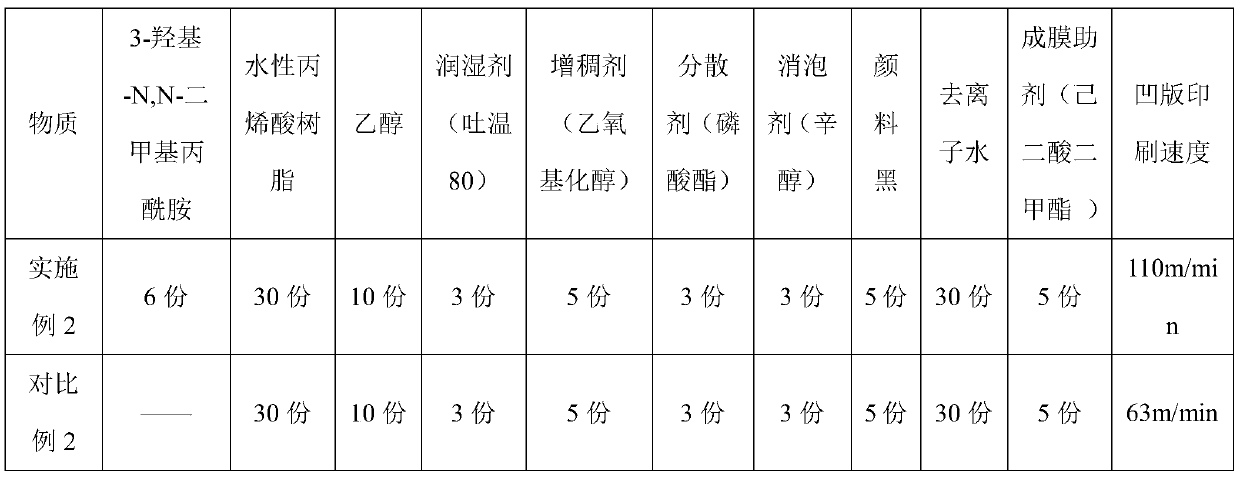

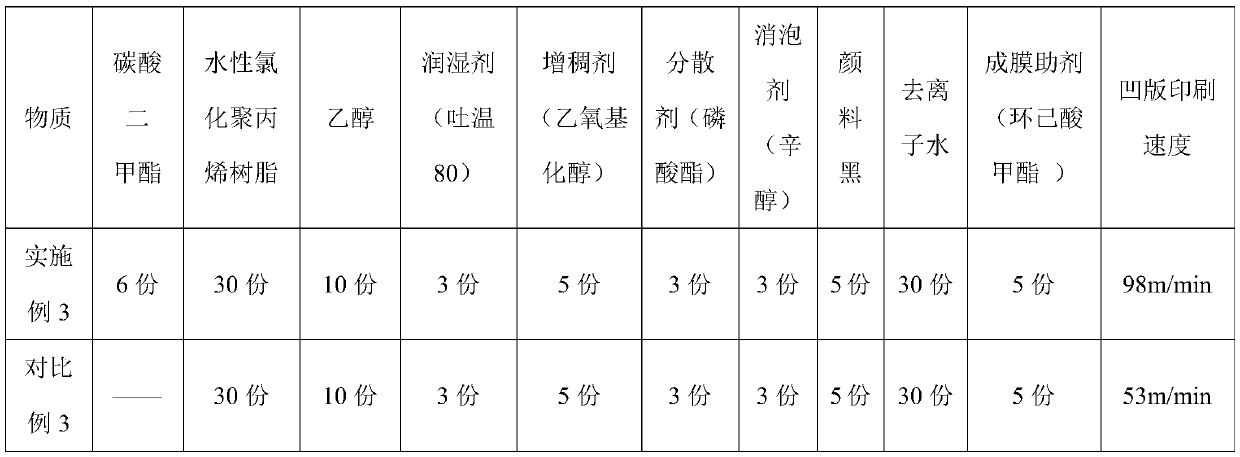

Water-based ink composition, preparation method and application thereof

InactiveCN110669378AFast dryingChange drynessInksOther printing apparatusMethyl carbonateEthyl ester

The invention relates to a water-based ink composition and a preparation method thereof. The water-based ink composition is composed of: 2-10% of a drying agent, 20-50% of water-based resin, 5-15% ofethanol, 1-5% of a wetting agent, 2-10% of a thickening agent, 1-5% of a dispersing agent, 1-5% of a defoaming agent, 2-10% of pigment, 2-10% of a film-forming assistant and 20-40% of water. Specifically, the drying agent is selected from any one or a mixture of two or more of 2-hydroxy-N, N-dimethyl acetamide, 3-hydroxy-N, N-dimethyl propionamide, N, N-dimethyl acetamide, N, N-diethyl acetamide,dimethyl carbonate, diethyl carbonate and ethyl methyl carbonate. The raw materials are mixed uniformly according to the mass ratio and are then ground till uniform dispersion, thus obtaining the water-based ink composition. The water-based ink composition can change the drying performance of water-based ink, and greatly increase the intaglio printing speed up to 115m / min.

Owner:JIANGSU UNIV OF SCI & TECH

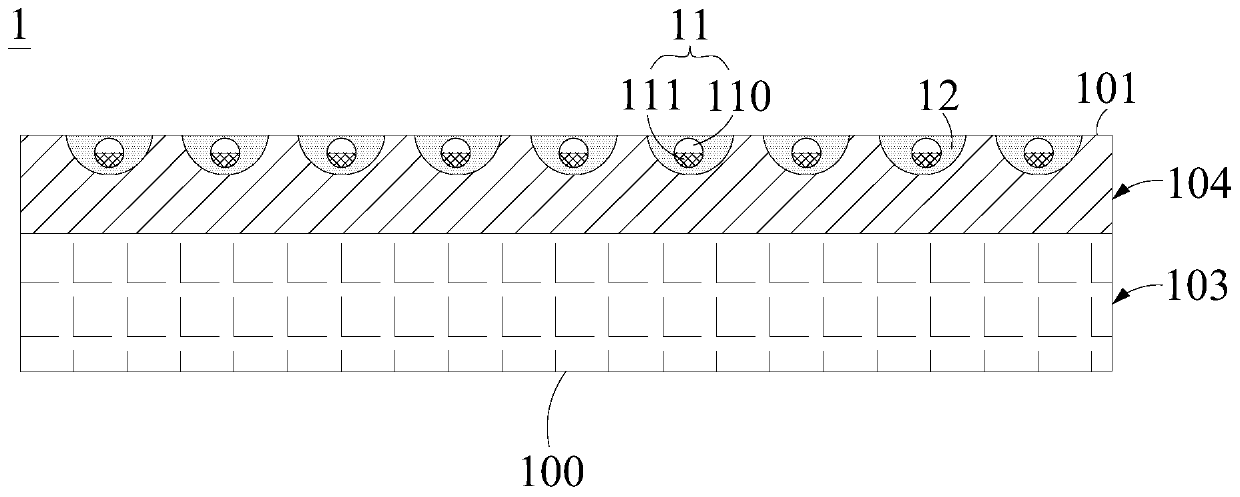

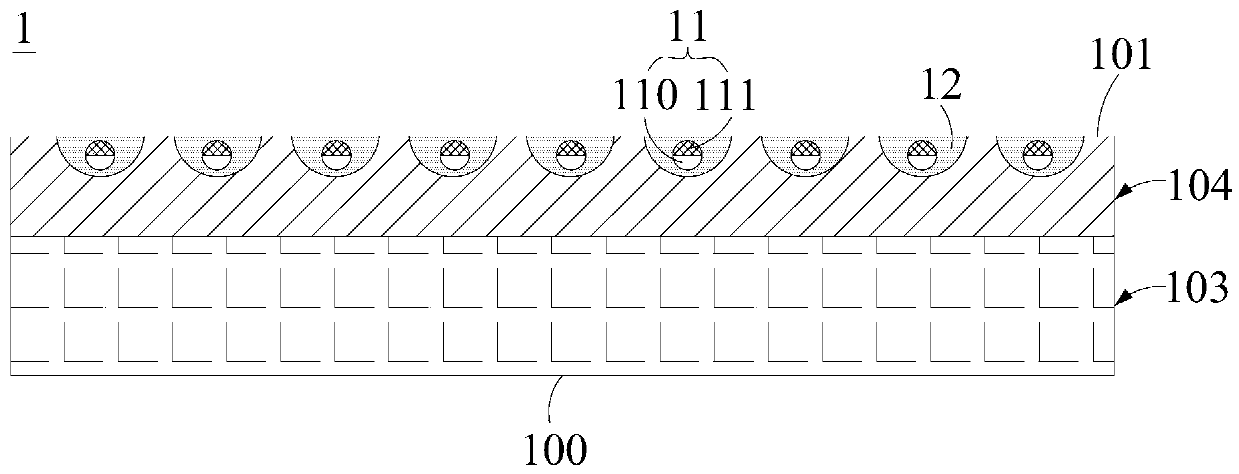

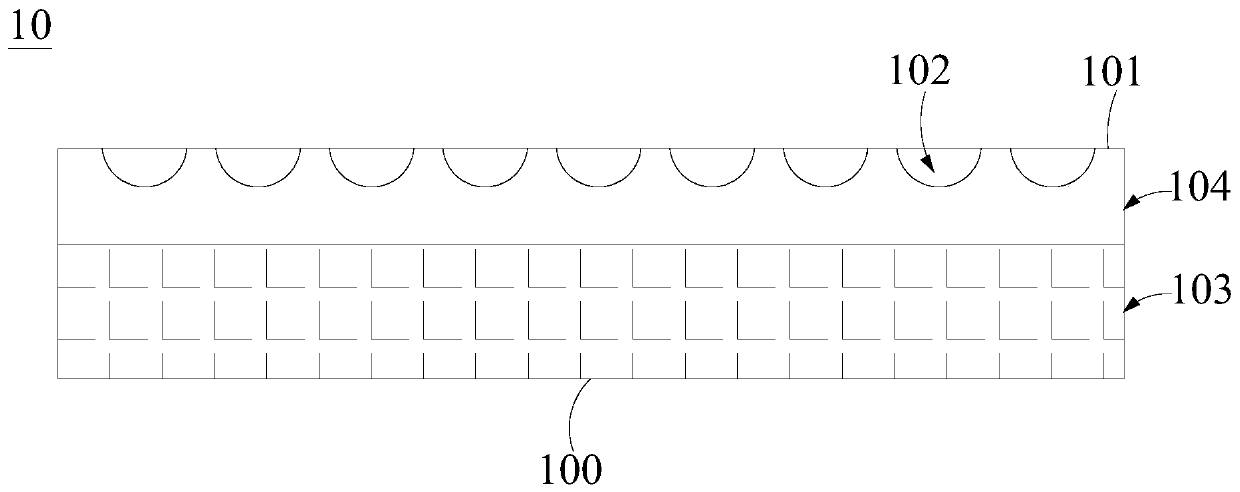

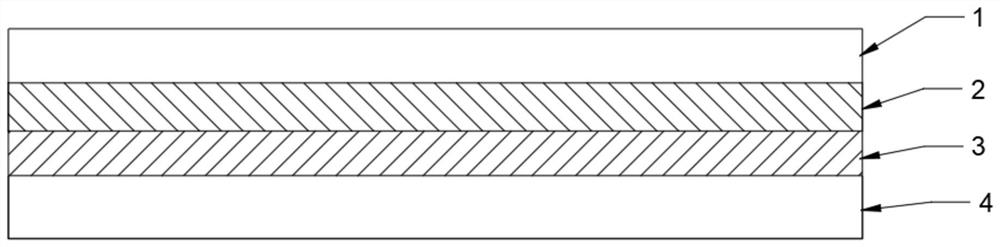

Bearing substrate and manufacturing method thereof, flexible substrate and manufacturing method thereof, and display device

ActiveCN109904352AImprove product qualityChange bindingFinal product manufactureSolid-state devicesDisplay deviceEngineering

The present invention relates to the technical field of display, especially to a bearing substrate and a manufacturing method thereof, a flexible substrate and a manufacturing method thereof, and a display device. The bearing substrate comprises: a substrate comprising a first surface and a second surface opposite to the first surface; a bonding portion arranged at the second surface and comprising magnetic particles, wherein the magnetic particles can rotate under the action of an external magnetic field, the magnetic particles comprise a first portion and a second portion, when the first portion faces one side far away from the first surface, the binding force between the bonding portion and the flexible substrate can be weakened, and when the second portion faces one side far away fromthe first surface, the binding force between the bonding portion and the flexible substrate is enhanced. The bearing substrate and the manufacturing method thereof can reduce the stripping difficultyand the stripping cost of the flexible substrate and the bearing substrate while improving the manufacturing quality of the flexible substrate.

Owner:BOE TECH GRP CO LTD

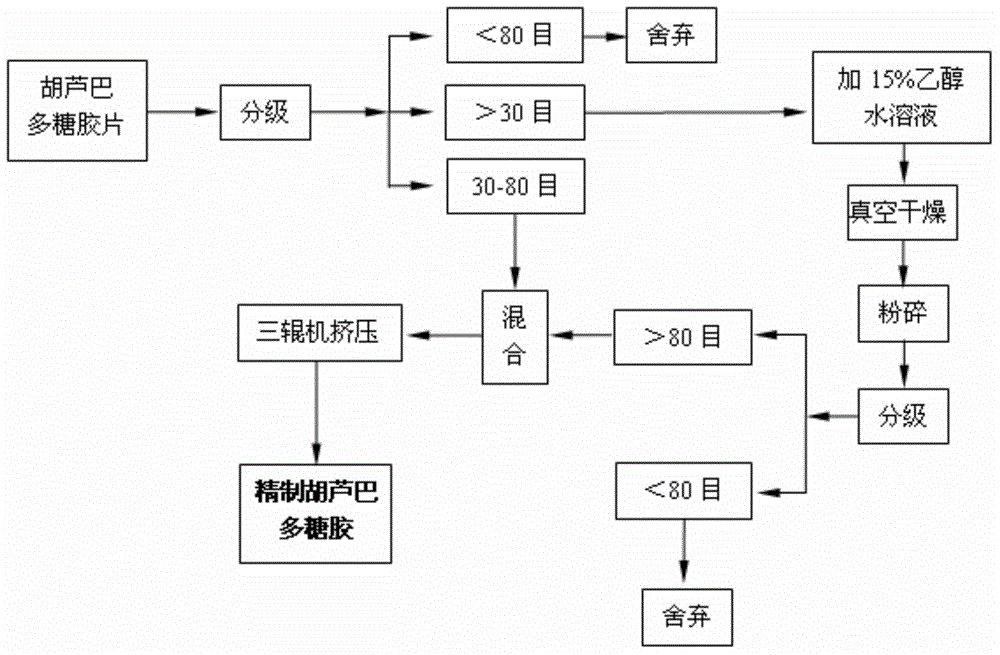

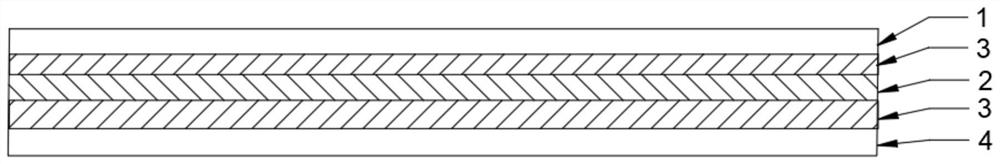

Modification method of fenugreek polysaccharide gum

The invention provides a modification method of fenugreek polysaccharide gum. Graded screening is utilized to remove impurities with high water-insoluble substance content in the fenugreek polysaccharide gum sheet; and a physical process is utilized to perform modification (wetting fenugreek polysaccharide gum with a 15% ethanol water solution) and wall-breaking tackifying treatment, thereby greatly enhancing the apparent viscosity of the fenugreek polysaccharide gun and greatly lowering the water-insoluble content in the fenugreek polysaccharide gum.

Owner:BEIJING FORESTRY UNIVERSITY

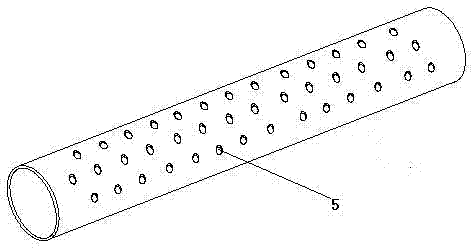

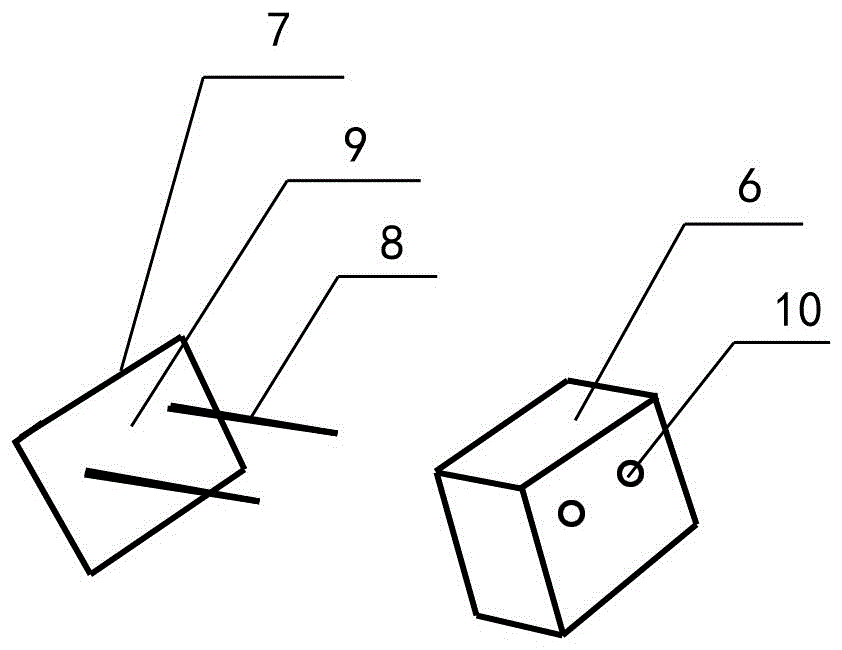

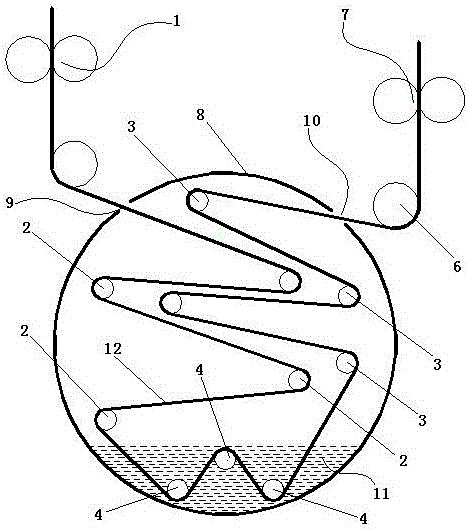

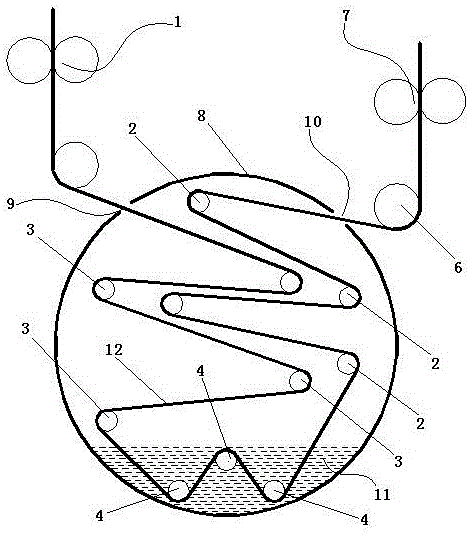

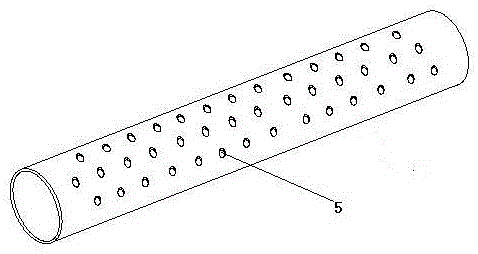

Color dyeing device for rapid breathable cooling T-shirt fabric

InactiveCN104499226ASimple structureImprove bindingTextile treatment carriersLiquid/gas/vapor textile treatmentDyeingBinding properties

The invention relates to a color dyeing device for rapid breathable cooling T-shirt fabric. The color dyeing device comprises cloth releasing rollers, a color dyeing device body, a drying drum and cloth collecting rollers arranged along a greige cloth running path in sequence; the color dyeing device also comprises a dyeing and perming drum; dyeing slurry is held at the bottom part of the dyeing and perming drum; at least one dip dyeing roller is immersed in the dyeing slurry; at least one color dyeing roller is of a cylindrical hollow structure, and a plurality of through circulation holes are formed in the cylinder wall of the at least one color dyeing roller; the color dyeing device body comprises at least one cloth guide roller, the at least one dip dyeing roller and the at least one color dyeing roller. According to the color dyeing device disclosed by the invention, as the at least one dip dyeing roller is provided with the circulation holes and a pump body, the full binding ratio of greige cloth and dye can be increased; before or after dip dyeing when the greige cloth enters the dyeing slurry, vapor treatment is performed on certain local areas of the greige cloth to change the binding property of fibers in the local area and the dyeing slurry, so that the binding property of fibers in the local area and the dyeing slurry is better or poorer than that of fibers at other parts and the dyeing slurry to form a color dyeing effect with different styles.

Owner:SUZHOU OUBBOO FASHION CO LTD

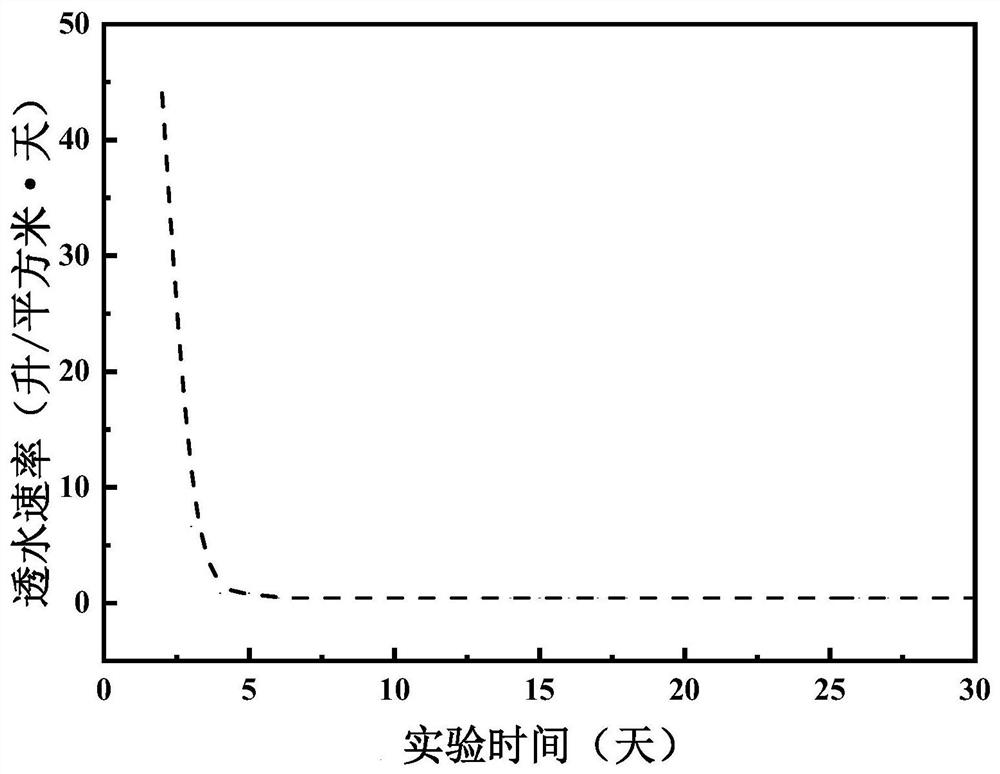

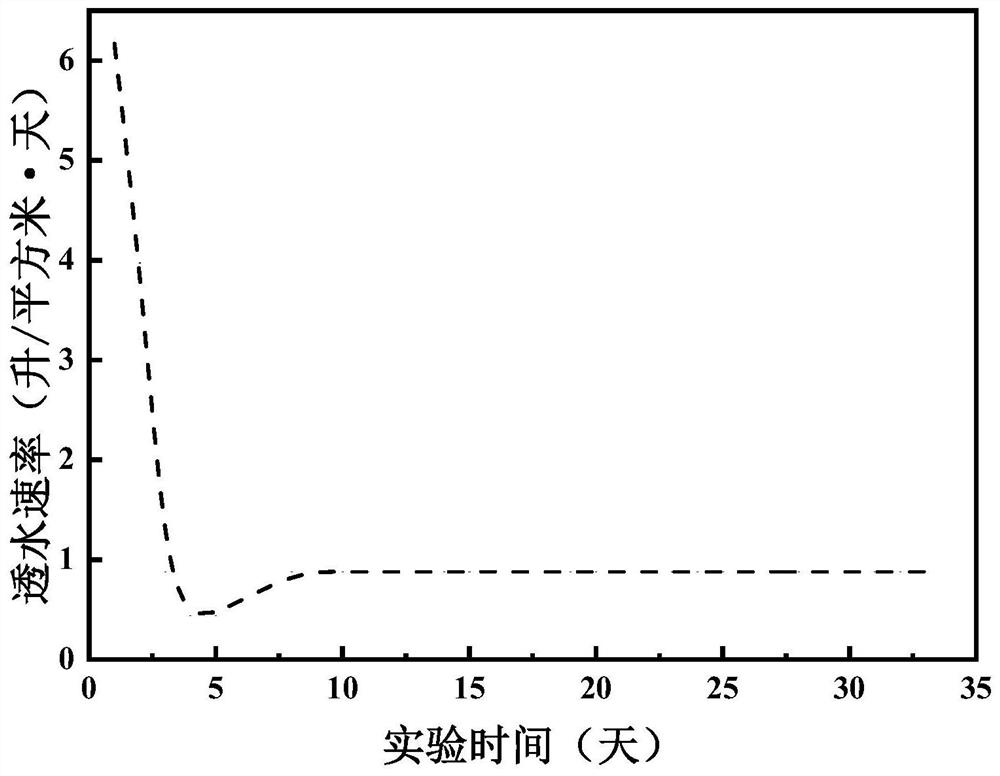

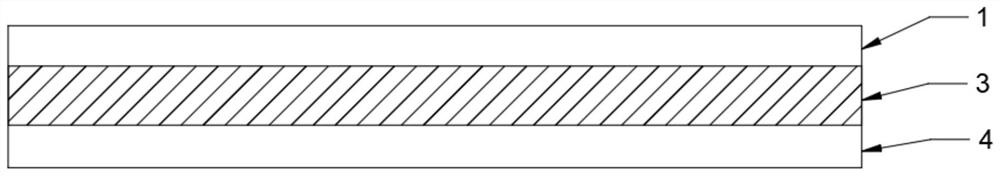

Plant fiber-based controllable permeable material and preparation method thereof

ActiveCN112982026AHigh strengthEffective control of biodegradation rateRoot feedersSpecial paperPulp (paper)Papermaking

The invention belongs to the technical field of environmental protection, and particularly relates to a plant fiber-based controllable permeable material and a preparation method thereof. The plant fiber-based controllable permeable material is prepared by the following steps: mixing plant fiber pulp, a water repellent agent and a reinforcing agent to obtain a mixed paper material; carrying out wet-process papermaking and shaping on the mixed paper material, and then drying to obtain the plant fiber-based controllable permeable material. The addition amount of the water repellent agent is 0.1%-28% of the absolute dry mass of the plant fiber pulp; the addition amount of the reinforcing agent is 0.2%-10% of the absolute dry mass of the plant fiber pulp; the water repellent agent is selected from one or more of paraffin, rosin, alkyl ketene dimer, alkenyl succinic anhydride, styrene-maleic anhydride copolymer and styrene-acrylate. The plant fiber-based controllable permeable material can effectively overcome the technical defects that a traditional water storage container made of plastic cannot be degraded in nature, and thus environmental pollution is caused, and the irrigation rate of the water storage container cannot be controlled.

Owner:JOFO GREEN CO LTD

A kind of preparation method of eccentric wheel powder metallurgy

ActiveCN103223489BEnhance the effect of mixing and pressingHigh bulk densityCranksEccentricsPolyethylene vinyl acetateMixed materials

The invention discloses a method for manufacturing an eccentric wheel through powder metallurgy. The method comprises the following step: the eccentric wheel is manufactured by the following raw materials in percentage by weight: 0.2-0.4 percent of nickel, 0.4-0.6 percent of molybdenum, 0.6-0.8 percent of tin, 0.3-0.5 percent of aluminium oxide powder, 0.8-1 percent of graphite powder, 0.4-0.6 percent of petroleum wax, 4-6 percent of copper, 1-2 percent of performance additive and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-zinc oxide powder and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, and various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

Owner:广东威强科技有限公司

Production method of sprocket powder metallurgy material

InactiveCN103252493AEnhance the effect of mixing and pressingHigh bulk densityParaffin waxPolyethylene vinyl acetate

The invention discloses a production method of sprocket powder metallurgy material. A sprocket is made from, by weight percent, 0.2-0.3% of graphite, 0.2-0.4% of nickel, 0.8-1% of molybdenum, 0.6-0.8% of nano emery powder, 0.3-0.5% of manganese sulfide, 0.8-1% of magnesia powder, 4-7% of copper, 1-2% of modifying aid, and the balance of iron. The production method has the advantages that the modifying aid is added, ultrafine powder is added in raw mixture and can fill gaps of large particles, and accordingly apparent density of the mixture can be increased; the ultrafine powder mainly comprises nano silica and calcium stearate, the novel modifying aid is obtained from aids such as silane coupling agent, and accordingly various physical properties of the finished product, such as wear resistance, are improved further; polyethylene vinyl acetate and liquid paraffin are used as lubricants added to the modifying aid, and accordingly the effect of the modifying aid in mixing and pressing is improved; compact intensity of powder metallurgical parts can be improved greatly while compacting pressure is equal, particle combination form and pore shape of the raw materials are changed, and cracking is eliminated from an origin.

Owner:广州市威强新材料实业有限公司

Iron-based amorphous alloy film and preparation method thereof, and electromagnetic shielding film and equipment applying iron-based amorphous alloy film

PendingCN114150236AImprove permeabilityImprove shielding effectVacuum evaporation coatingSputtering coatingAlloy thin filmThin membrane

The invention discloses an iron-based amorphous alloy film which comprises the following components in percentage by mass: more than or equal to 70wt% and less than or equal to 90wt% of Fe, more than or equal to 0 and less than or equal to 6wt% of Co, more than or equal to 1wt% and less than or equal to 4wt% of Si, more than or equal to 1wt% and less than or equal to 3wt% of B, more than 0.2 and less than or equal to 20wt% of Ni, more than or equal to 0 and less than 6wt% of Mo and more than or equal to 0 and less than 3wt% of C. The preparation method of the iron-based amorphous alloy film is a magnetron sputtering process, and the iron-based amorphous alloy film prepared by the process can be used for preparing a corresponding electromagnetic shielding film and equipment. The iron-based amorphous alloy film prepared by adopting the chemical component (mass percent) range and the magnetron sputtering process has the beneficial technical effect of excellent comprehensive magnetic performance, and the electromagnetic shielding film and equipment prepared from the iron-based amorphous alloy meet the application requirements of electronic shielding materials with high performance requirements.

Owner:FOSHAN CITY ZHONGYAN AMORPHOUS TECH

A kind of preparation method of motorcycle crankshaft powder metallurgy

InactiveCN103223490BEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateParaffin wax

The invention discloses a method for manufacturing a motorcycle crank shaft through powder metallurgy. The method comprises the following step: the motorcycle crank shaft is manufactured by the following raw materials in percentage by weight: 0.4-0.6 percent of nickel, 0.4-0.6 percent of manganese sulfide powder, 0.4-0.6 percent of aluminium, 0.4-0.6 percent of manganese, 0.3-0.4 percent of zinc stearate, 1-2 percent of performance additive, 21-25 percent of copper and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-silicon dioxide and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, and various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

Owner:江门速龙机车制造有限公司

A kind of preparation method of automobile connecting rod powder metallurgy

InactiveCN103223487BEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateMixed materials

The invention discloses a method for manufacturing an automobile connecting rod through powder metallurgy. The method comprises the following step: the automobile connecting rod is manufactured by the following raw materials in percentage by weight: 0.4-0.6 percent of nickel, 0.4-0.6 percent of graphite, 0.6-0.8 percent of zinc oxide powder, 0.4-0.6 percent of cadmium, 0.3-0.4 percent of zinc stearate, 1-2 percent of performance additive, 4-6 percent of copper and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-silicon dioxide and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

Owner:XUZHOU DALT MECHANICAL EQUIP MFG CO LTD

A kind of modification method of fenugreek polysaccharide gum

The invention provides a modification method of fenugreek polysaccharide gum. Graded screening is utilized to remove impurities with high water-insoluble substance content in the fenugreek polysaccharide gum sheet; and a physical process is utilized to perform modification (wetting fenugreek polysaccharide gum with a 15% ethanol water solution) and wall-breaking tackifying treatment, thereby greatly enhancing the apparent viscosity of the fenugreek polysaccharide gun and greatly lowering the water-insoluble content in the fenugreek polysaccharide gum.

Owner:BEIJING FORESTRY UNIVERSITY

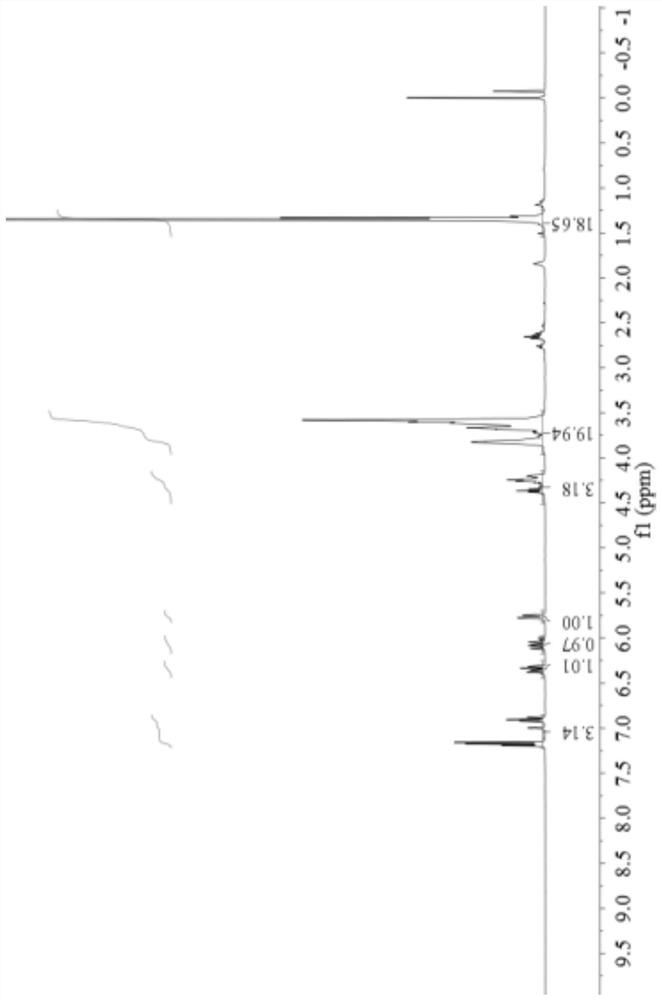

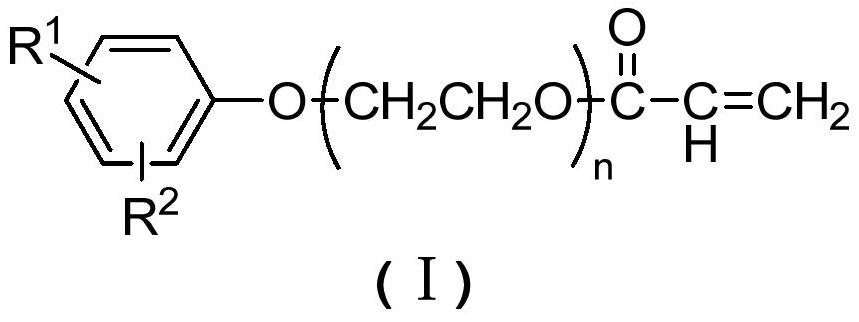

A kind of polymerizable surfactant containing aromatic hydrocarbon structure and preparation method thereof

ActiveCN110483299BRaw materials are easy to getEasy to makeOrganic compound preparationCarboxylic acid esters preparationPolymer scienceActive agent

The invention provides a polymerizable surfactant containing an aromatic hydrocarbon structure and a preparation method thereof. The surfactant has the structure shown in the following formula (I): R 1 , R 2 Each independently is selected from a hydrogen atom or an alkyl group having 1-20 carbon atoms; n=1-30. The raw materials used in the present invention are easy to obtain, simple to prepare, safe to use and convenient to store. The preparation method provided by the invention has mild reaction conditions, high yield and simple product post-treatment process.

Owner:PETROCHINA CO LTD

Ceramic glaze with the function of activating water, its preparation method and the prepared ceramics and ceramics preparation method

The invention belongs to the technical field of ceramic and particularly relates to ceramic glaze with a water activating function, a preparation method thereof, ceramic prepared by the ceramic glaze and a preparation method of the ceramic. The ceramic glaze is prepared by, by mass percentage, 60-80% of ceramic glaze base material, 5-20% of ceramic additives with the water activating function, 5-8% of nano-zirconia, 0.5-5% of phosphate, 1-5% of nano cesium oxide, 2-8% of yttrium oxide, 1-5% of nano titanium dioxide and 3-8% of tourmaline. The preparation method of the ceramic glaze includes: ball milling the ceramic glaze base material until all the ceramic glaze base material can pass a 250-mesh sieve, adding the rest of components, adding water and ceramic diluent to prepare slurry, ball milling, and discharging. The ceramic glaze has the advantages that the ceramic glaze can acts on water molecular cluster structures to allow the hydrogen bonds to be destroyed and chemical bonds to break, large molecular clusters become small molecular clusters only containing 5-6 water molecules, toxic gas dissolved in water is released at the same time, the water become slightly alkaline, and the activity of the water is increased.

Owner:ZIBO BAIKANG ECONOMIC & TRADE

Production method of sprocket powder metallurgy material

InactiveCN103252493BEnhance the effect of mixing and pressingHigh bulk densityParaffin waxPolyethylene vinyl acetate

Owner:广州市威强新材料实业有限公司

Method for preparing powder metallurgy of engine piston pin

ActiveCN103252491BEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateMixed materials

The invention discloses a method for preparing powder metallurgy of an engine piston pin. The method includes: the engine piston pin is made of following raw materials, by weight, 0.4-0.6% of nickel, 0.4-0.6% of magnesium, 0.6-0.8% of graphite powder, 0.4-0.6% of cadmium, 0.3-0.4% of zinc stearate, 1-2% of performance additive, 4-6% of copper, and the balance iron; via adding the performance additive, superfine powder is provided in the mixed raw materials and can fill in seams among large granules, so that density of the mixed materials is improved; main ingredients of the superfine powder include nano-silica and calcium stearate, the novel performance additive is obtained via agent like silane coupling agent, and physical properties like abrasion performance of prepared products is further improved; and polyethylene vinyl acetate and liquid paraffin serving as lubricating agent are added in the performance additive, so that effect of the performance additive under mixed compression is strengthened, the strength of compaction of power metallurgy structural members is greatly improved under same compression force, combining shape and hole shape of the raw material granules is changed, and problem about generation of crack is solved basically.

Owner:HAIAN YINGQIU POWDER METALLURGY CO LTD

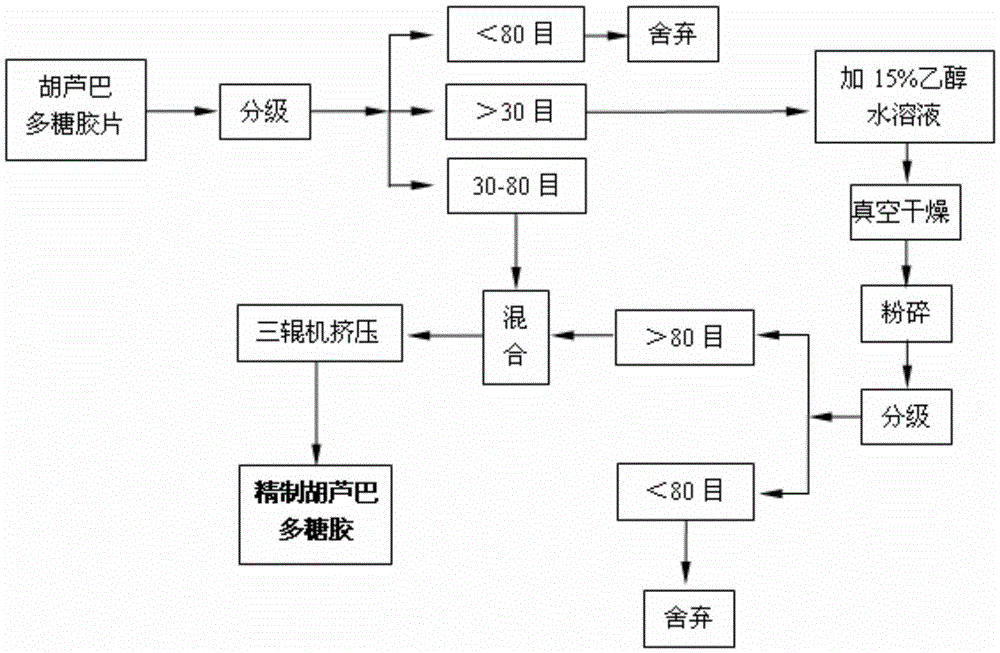

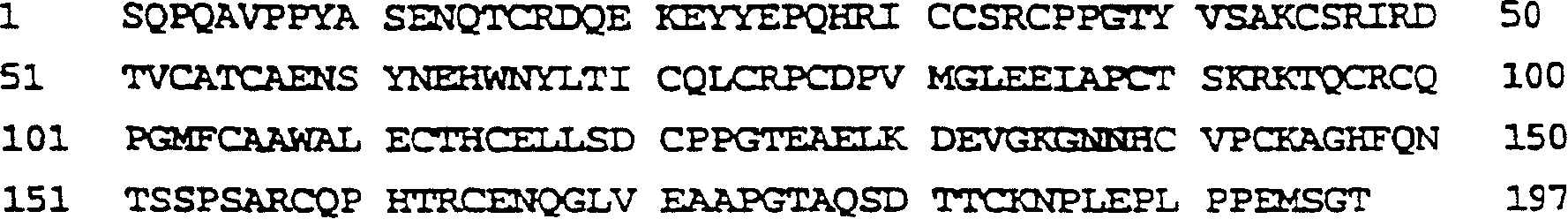

Soluble lymphotoxin-beta receptors, anti-lymphotoxin receptor antibodies, and use of anti-lymphotoxin ligand antibodies

InactiveCN100382844CSuppress immune responseChange bindingOrganic active ingredientsPeptide/protein ingredientsLymphotoxin betaToxin

Compositions and methods comprising "beta-lymphotoxin receptor blocking agents" that block beta-lymphotoxin receptor signaling and are used to modify immunological diseases, particularly antibody-mediated immune responses.

Owner:BIOGEN IDEC MA INC

A kind of pretreatment method of composite electrode for tempo/mv flow battery

ActiveCN109921036BChange activityLower internal resistanceCell electrodesRegenerative fuel cellsElectrical batteryBinding force

The invention relates to a pretreatment method for a composite electrode of a TEMPO / MV flow battery, which specifically comprises: first treating a carbon electrode material in a household microwave oven (power 300W-800W) for 1-10min, and putting it into a Soak in the aqueous solution of ethylenediamine for 12-24h, then put the soaked graphite felt into the hydrothermal reaction kettle containing the mixed aqueous solution of graphene oxide and ethylenediamine, react at 180°C for 12-24h, after freeze-drying , to obtain the electrode material for TEMPO / MV flow battery. The invention increases the hydrophilicity of the graphite felt, strengthens the binding force between the three-dimensional graphene and the graphite fiber, improves the electrochemical activity of the electrode material, and improves the energy efficiency and voltage efficiency of the TEMPO / MV flow battery.

Owner:TIANJIN UNIV

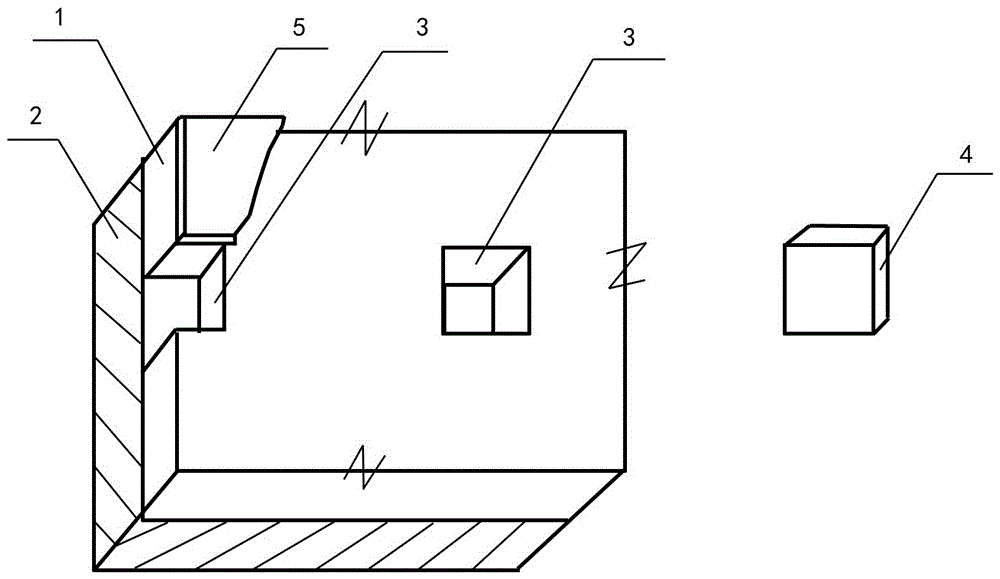

Method and structure for connection of heat preservation system and wall of building

InactiveCN106759974AChange pasteChange bindingClimate change adaptationPassive housesWindow openingEngineering

The invention relates to a method and structure for connection of a heat preservation system and a wall of a building. By adoption of the method and structure, the heat preservation system can be firmly connected with the wall, and separation, falling-off and fires cannot occur. The method comprises the steps that a plate (1) is attached to the surface of the wall (2) and provided with a through window opening (3); the window opening (3) and a blocking plate (4) mutually compensate in size, one face of the blocking plate (4) can be firmly combined with a wall face or the wall (2), and the other face of the blocking plate (4) can be firmly combined with a protective layer (5) on the outer side of the plate; and the blocking plate (4) is plugged into the window opening (3) to be firmly combined with the wall (2) and the protective layer (5).

Owner:王杏林

Preparation method for powder metallurgy for automotive brake valve block

InactiveCN103252492BEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateParaffin wax

Owner:XUZHOU DALT MECHANICAL EQUIP MFG CO LTD

Fast breathable cooling T-shirt fabric flower dyeing device

InactiveCN104499226BImprove bindingFully combinedTextile treatment carriersLiquid/gas/vapor textile treatmentFiberBinding ratio

The invention relates to a color dyeing device for rapid breathable cooling T-shirt fabric. The color dyeing device comprises cloth releasing rollers, a color dyeing device body, a drying drum and cloth collecting rollers arranged along a greige cloth running path in sequence; the color dyeing device also comprises a dyeing and perming drum; dyeing slurry is held at the bottom part of the dyeing and perming drum; at least one dip dyeing roller is immersed in the dyeing slurry; at least one color dyeing roller is of a cylindrical hollow structure, and a plurality of through circulation holes are formed in the cylinder wall of the at least one color dyeing roller; the color dyeing device body comprises at least one cloth guide roller, the at least one dip dyeing roller and the at least one color dyeing roller. According to the color dyeing device disclosed by the invention, as the at least one dip dyeing roller is provided with the circulation holes and a pump body, the full binding ratio of greige cloth and dye can be increased; before or after dip dyeing when the greige cloth enters the dyeing slurry, vapor treatment is performed on certain local areas of the greige cloth to change the binding property of fibers in the local area and the dyeing slurry, so that the binding property of fibers in the local area and the dyeing slurry is better or poorer than that of fibers at other parts and the dyeing slurry to form a color dyeing effect with different styles.

Owner:SUZHOU OUBBOO FASHION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com