Modification method of fenugreek polysaccharide gum

A technology of fenugreek and polysaccharide gum is applied in the field of modification of fenugreek polysaccharide gum, which can solve the problems of high water-insoluble matter content and low viscosity, and achieves reduction of water-insoluble matter content, high product yield and low friction. resistive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Modification of embodiment 1 fenugreek polysaccharide gum

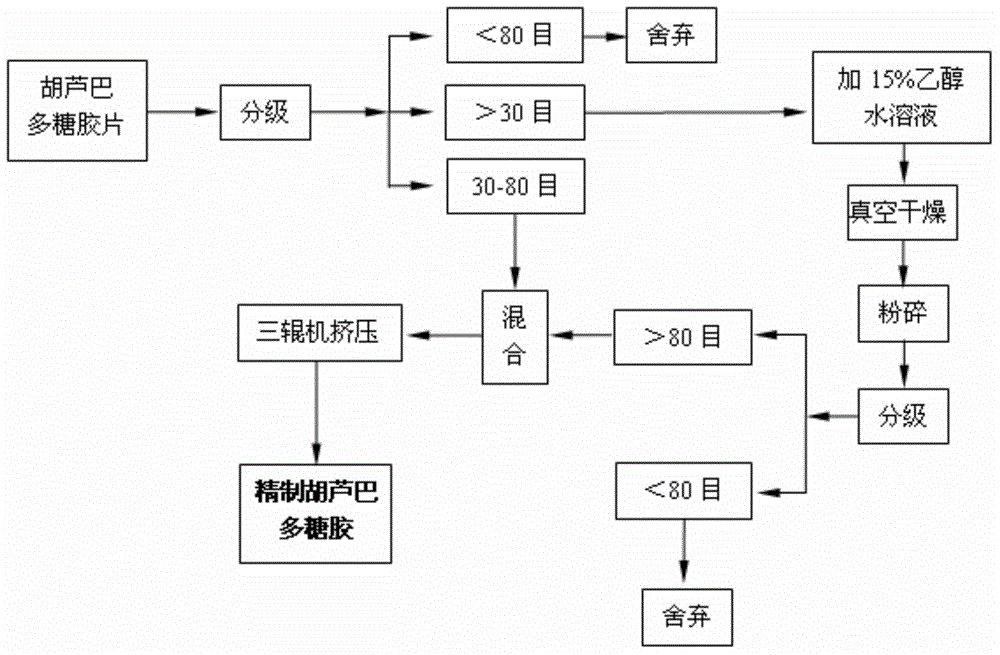

[0025] according to figure 1 The process flow chart of the modification method of the fenugreek polysaccharide gum is shown, and the fenugreek polysaccharide gum is modified.

[0026] 1. Grading and screening:

[0027] Use 30 mesh and 80 mesh standard sieves to classify and screen the unmodified fenugreek polysaccharide films, discard the films with particle diameters less than 80 mesh, and collect the films with particle diameters greater than 30 mesh and 30-80 mesh for subsequent use;

[0028] 2. Physical modification:

[0029] Fenugreek polysaccharide films with a particle size greater than 30 mesh were added to 15% ethanol aqueous solution for hydration, the solid-to-liquid ratio was 1:1, stirred evenly, the hydration time was 1 hour, and then vacuum-dried at 75°C for 10 minutes. Gently pulverize the dried film in a high-speed pulverizer while hot, and then sieve with an 80-mesh standard sieve to collect...

Embodiment 2

[0032] Example 2 Detection of Modified Apparent Viscosity and Water-Insoluble Content of Fenugreek Polysaccharide Gum

[0033] 1. The mixed rubber powder before the wall-breaking and viscosifying treatment is pulverized with a high-speed centrifuge, and the rubber powder passing through a 120-mesh sieve is tested to have an apparent viscosity of 134mPa.s and a water-insoluble content of 9.1%.

[0034] 2. The fenugreek polysaccharide gum after the wall-breaking and viscosity-increasing treatment was pulverized on a high-speed centrifuge, and the rubber powder passing through a 120 mesh sieve was tested for an apparent viscosity of 241 mPa.s and a water content of 8.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com