Water-based ink composition, preparation method and application thereof

A technology of water-based ink and composition, applied in the direction of ink, application, household utensils, etc., can solve the problems of affecting the printing speed, reducing the drying speed, and the effect is not very ideal, so as to achieve the effect of speeding up the drying speed and improving the printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

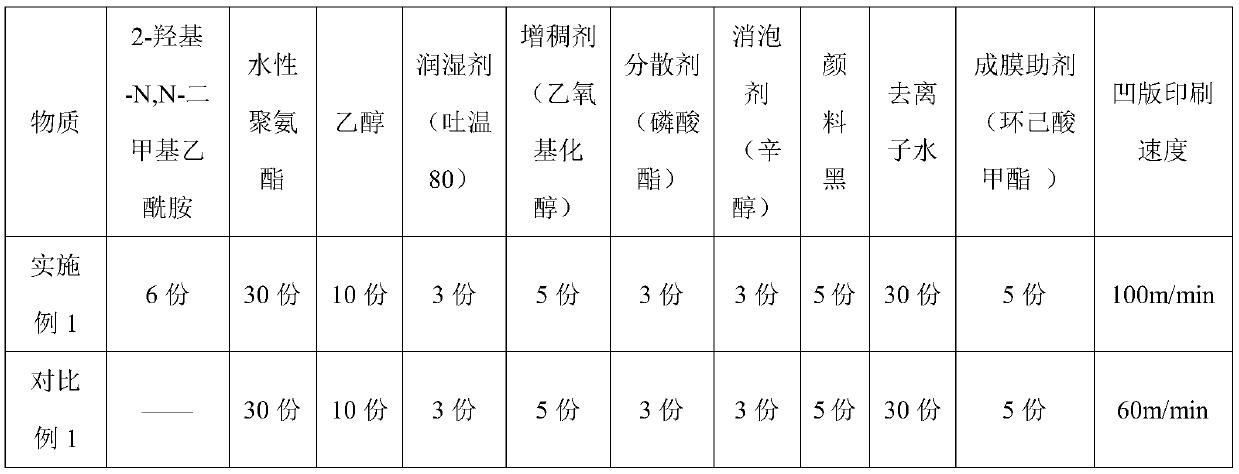

[0020] Put the raw material desiccant, water-based resin, ethanol, wetting agent, thickener, dispersant, defoamer, pigment, film-forming aid and water into the mixer according to the formula shown in Table 1, and use it at 2500rpm The mixer is stirred for 2-4 hours, and then the quick-drying water-based ink composition is obtained by using a bead mill with 0.1 mm zirconia beads for 6 hours of grinding and dispersion treatment at a speed of 1500 r / min. (According to Table 1, when the raw material does not contain desiccant, obtain the common type water-based ink composition as comparative example.)

[0021] Table 1 embodiment 1 and comparative example 1 water-based ink formula and gravure printing speed test result (mass part)

[0022]

[0023] It can be seen from Table 1 that the gravure printing speed of the water-based ink composition containing the desiccant 2-hydroxy-N,N-dimethylacetamide reached 100m / min, greatly exceeding the corresponding water-based ink composition ...

Embodiment 2

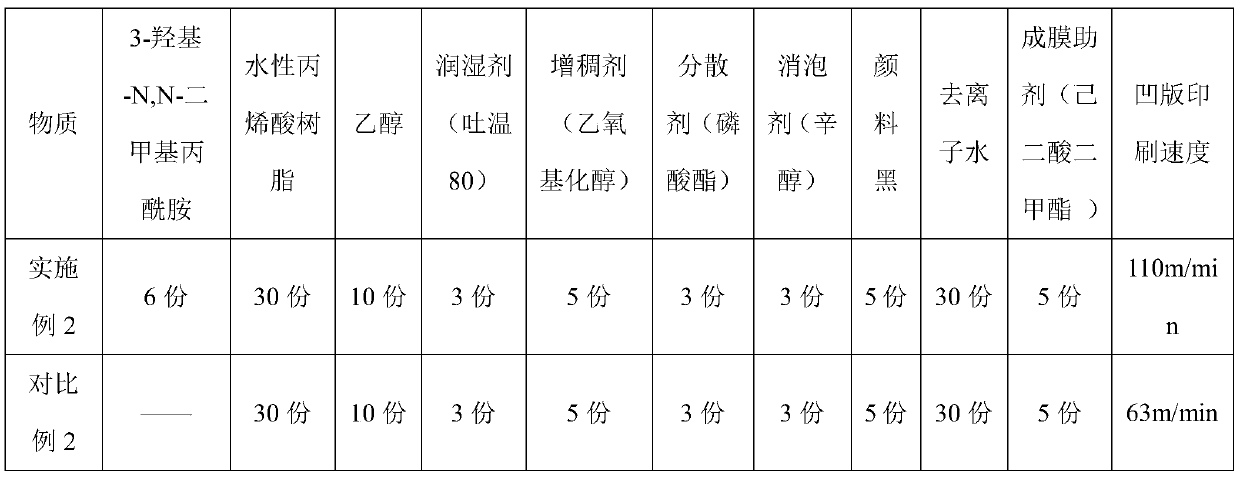

[0025] According to the formula shown in Table 2, put the raw material desiccant, water-based resin, ethanol, wetting agent, thickener, dispersant, defoamer, pigment, film-forming aid and water into the mixer respectively, and use it at 2500rpm The mixer is stirred for 2-4 hours, and then the quick-drying water-based ink composition is obtained by using a bead mill with 0.1 mm zirconia beads for 6 hours of grinding and dispersion treatment at a speed of 1500 r / min. (According to Table 2, when the raw material does not contain desiccant, obtain the common type water-based ink composition as comparative example.)

[0026] Table 2 embodiment 2 and comparative example 2 water-based ink formula and gravure printing speed test result (mass part)

[0027]

[0028] It can be seen from Table 2 that the gravure printing speed of the water-based ink composition containing the desiccant 3-hydroxy-N,N-dimethylpropionamide reached 110m / min, greatly exceeding the corresponding water-based...

Embodiment 3

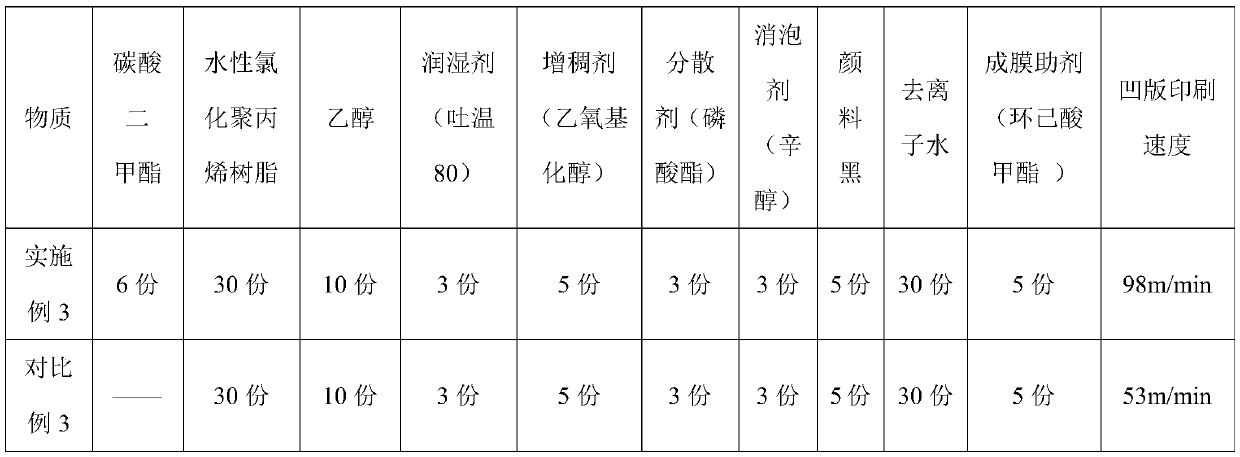

[0030] According to the formula shown in Table 3, put the raw material desiccant, water-based resin, ethanol, wetting agent, thickener, dispersant, defoamer, pigment, film-forming aid and water into the mixer respectively, and use it at 2500rpm The mixer is stirred for 2-4 hours, and then the quick-drying water-based ink composition is obtained by using a bead mill with 0.1 mm zirconia beads for 6 hours of grinding and dispersion treatment at a speed of 1500 r / min. (According to Table 3, when the raw material does not contain desiccant, obtain the common type water-based ink composition as comparative example.)

[0031] Table 3 embodiment 3 and comparative example 3 water-based ink formula and gravure printing speed test result (mass part)

[0032]

[0033] It can be seen from Table 3 that the gravure printing speed of the water-based ink composition containing the desiccant dimethyl carbonate reaches 98m / min, greatly exceeding the gravure printing speed of the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com