Room-temperature-curable aqueous anticorrosion primer used for coating external surface of construction crane and preparation method of primer

A room temperature curing, anti-corrosion primer technology, used in anti-corrosion coatings, coatings, epoxy resin coatings, etc. The film cannot be cured at room temperature, etc., to achieve the effect of strong corrosion resistance and initial water resistance, large-scale production, and rapid increase in the strength of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

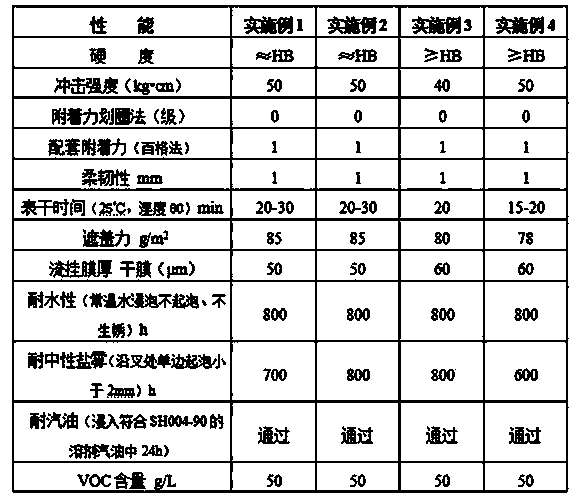

Examples

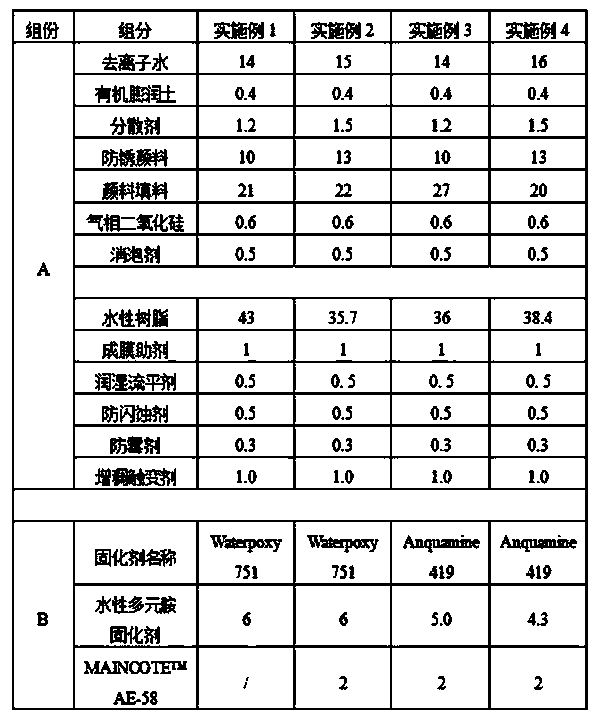

Embodiment 1

[0043] (1) Preparation of water-based color paste: Add all the deionized water into the mixing tank, add organic bentonite BENTONE EW while stirring, and then add 1 / 3 of the defoamer TEGO810, at a high speed of 2000-3000rpm / min Disperse for 20 minutes to activate the organic bentonite; then add dispersant Orotan 731A, wetting agent surfynol 104 under stirring conditions, and finally add micaceous iron oxide red, precipitated barium sulfate, talcum powder, fumed silica AEROSIL A200, zinc phosphate ZP -10, after stirring evenly, add the remaining defoamer TEGO810, disperse at a speed of 2000-3000rpm / min for 20 minutes, and then transfer to a sand mill to grind to a fineness of less than 15 microns to obtain a water-based color paste.

[0044] (2) Preparation of water-based paint: Add water-based resin Waterpoxy 1455 into the mixing tank, then add the above-mentioned finely ground water-based color paste under stirring conditions, add film-forming aid TEXANOL, wetting and leveling...

Embodiment 2

[0046] (1) Preparation of water-based color paste: Add all the deionized water into the mixing tank, add organic bentonite BENTONE LT while stirring, and then add 1 / 3 of the defoamer TEGO810, at a high speed of 2000-3000rpm / min Disperse for 20 minutes to activate the organic bentonite; then add dispersant Orotan 731A, wetting agent surfynol 104 under stirring conditions, and finally add micaceous iron oxide red, precipitated barium sulfate, talcum powder, fumed silica AEROSIL A200, phosphosilicate Zinc SZP-391 and aluminum tripolyphosphate K-white 140W, stir evenly, add the remaining defoamer TEGO810, disperse at a speed of 2000-3000rpm / min for 20 minutes, then transfer to a sand mill to grind to a fineness of less than 15 microns, Obtain water-based color paste.

[0047] (2) Preparation of water-based paint: Add water-based resin Waterpoxy 1455 into the mixing tank, then grind the above-mentioned fine water-based color paste under the condition of stirring, add film-forming a...

Embodiment 3

[0049] (1) Preparation of water-based color paste: Add all the deionized water into the mixing tank, add organic bentonite BENTONE EW while stirring, and then add 1 / 3 of the defoamer TEGO810, at a high speed of 2000-3000rpm / min Disperse for 20 minutes to activate the organic bentonite; then add the dispersant Orotan165A and Lutensit? Beads Zeeosphere400, fumed silica AEROSIL A200, zinc phosphomolybdate ZPM and aluminum tripolyphosphate K-white 140W, after stirring evenly, add the remaining defoamer TEGO810, disperse at 2000-3000rpm / min for 20 minutes, and then transfer to Grinding to a fineness of less than 15 microns with a sand mill to obtain a water-based color paste.

[0050] (2) Preparation of water-based paint: Add water-based resin AR555 into the mixing tank, then grind the above-mentioned fine water-based color paste under the condition of stirring, and finally add film-forming aid TEXANOL, wetting and leveling agent VXW-6503 and BYK333 in order , anti-flash corrosion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com