Patents

Literature

82results about How to "Strong construction adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single component air-drying water-based rust inhibiting primer with curtaining capacity and used for electrical equipment housing as well as preparation method of primer

ActiveCN104356795AShort construction intervalStrong construction adaptabilityAnti-corrosive paintsPolyurea/polyurethane coatingsAntifoam agentFirming agent

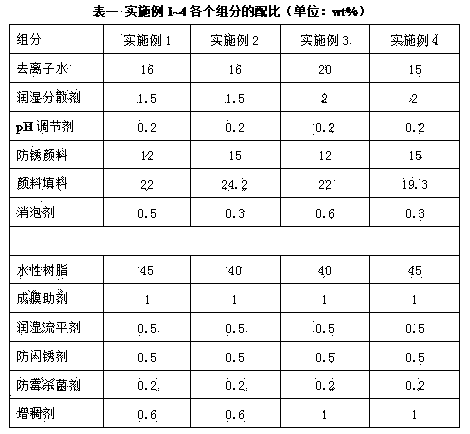

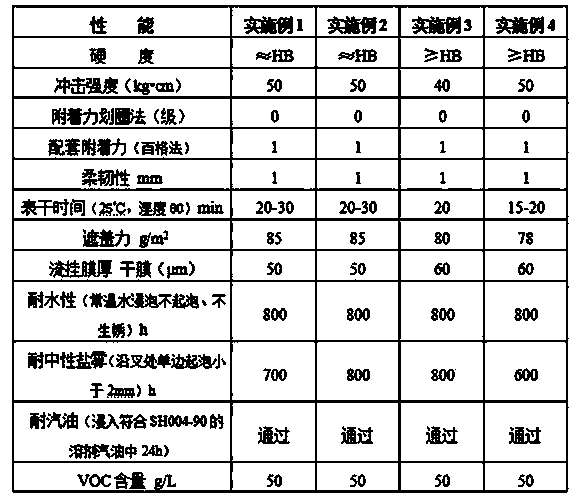

The invention discloses single component air-drying water-based rust inhibiting primer with curtaining capacity and used for an electrical equipment housing. The primer comprises components in percentage by weight as follows: 30%-50% of water-based resin, 1%-5% of a wetting dispersant, 0.1%-1% of a pH regulator, 5%-15% of rust inhibiting pigment, 15%-30% of pigment packing, 1%-8% of a coalescing agent, 0.5%-1.5 % of a wetting levelling agent, 0.5%-2% of a flash rust remover, 0.1%-1.5% of an antifoaming agent, 0.5%-2% of a thickener, 0.1%-1% of a mould-proof sterilizing agent and 5%-20% of deionized water. The invention further discloses a preparation method of the water-based rust inhibiting primer. The water-based rust inhibiting primer has lower film forming temperature, any cross-linking agent and curing agent is not required to be added, the primer can be rapidly dried and cured at normal temperature or a low-temperature baking environment ranging from 50 DEG C to 80 DEG C, construction is simple and convenient, and the product performance is comparable with that of solvent based paint.

Owner:GUANGZHOU KINTE IND

Room-temperature-curable aqueous anticorrosion primer used for coating external surface of construction crane and preparation method of primer

ActiveCN103436136AIntensity rises fastShort construction intervalAnti-corrosive paintsPolyurea/polyurethane coatingsAntifoam agentCorrosion resistant

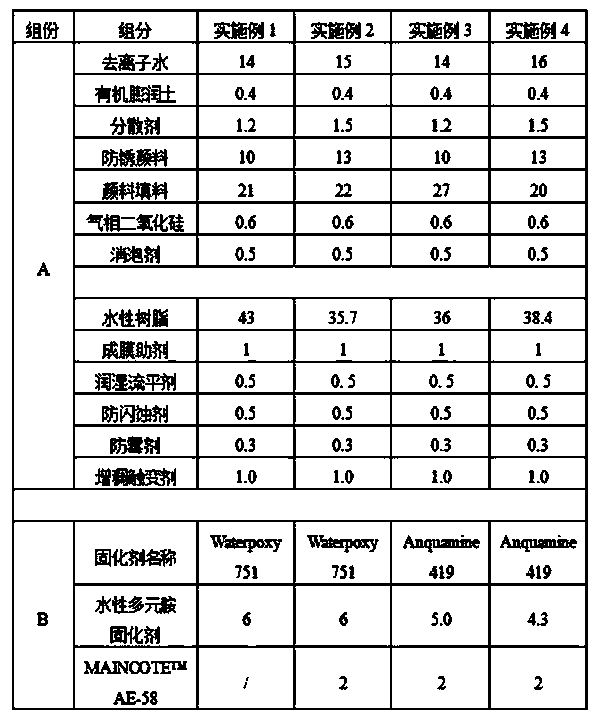

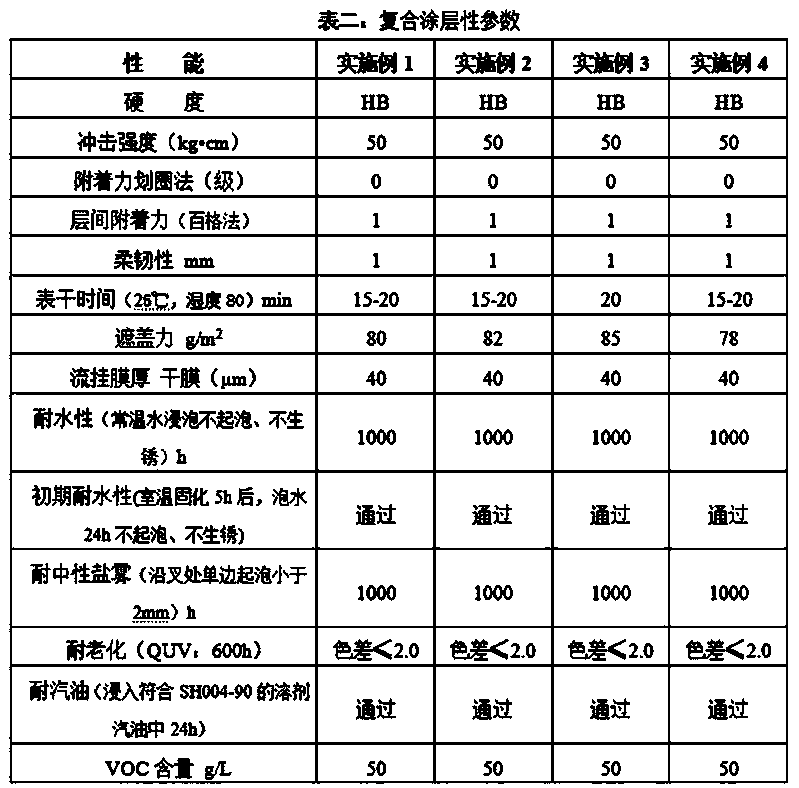

The invention discloses a room-temperature-curable aqueous anticorrosion primer used for coating the external surface of a construction crane. The primer comprises the following components by weight: 35-45% of an aqueous resin, 5-8% of a curing agent, 1-3% of a dispersant, 5-12% of an antirust pigment, 20-35% of a pigment filling material, 1-2% of an anti-settling agent, 0.5-1% of a wetting agent, 0.5-1% of a thixotropic agent, 0.5-1% of an antifoaming agent, 0.1-0.8% of a flash etching inhibitor, 0.1-0.8% of a mildew inhibitor, 1-3% of a film-forming auxiliary agent and 10-20% of deionized water. The invention also discloses a preparation method of the aqueous anticorrosion primer. The aqueous anticorrosion primer has a room-temperature-curable paint film, is energy-saving and environment friendly, and can satisfy safe production requirements of enterprises; the primer is high in solidity, low in viscosity, convenient for construction; and the coating of the primer has good corrosion resistance and water proofness, and the comprehensive properties of the coating reach performance indexes of same-type oiliness products.

Owner:GUANGZHOU KINTE IND +1

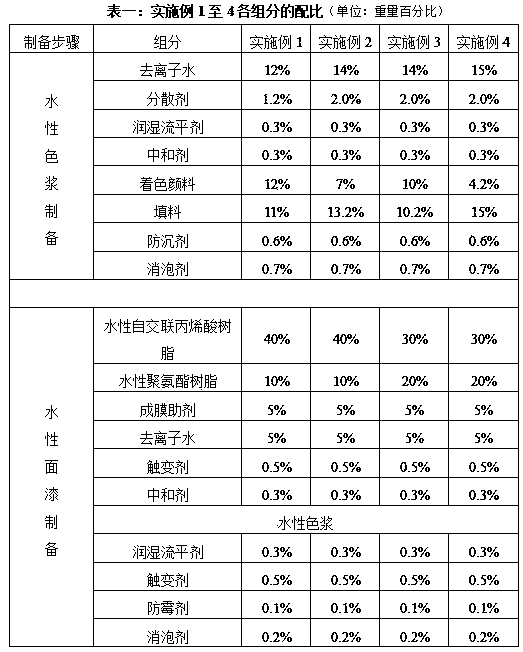

Single-component water-based natural drying finishing coat for construction crane and preparation method thereof

InactiveCN103788787AImprove water resistanceImprove aging resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxySolvent based

The invention discloses a single-component water-based natural drying finishing coat for a construction crane and a preparation method thereof. The raw material formula of the single-component water-based natural drying finishing coat comprises the following components by weight percent: 40-50% of water-based resin, 1-3% of dispersant, 4-20% of coloring pigment, 8-15% of filler, 0.5-1.5% of anti-settling agent, 0.5-1% of leveling wetting agent, 1-2% of thixotropic agent, 0.5-1% of defoamer, 0.1-0.8% of mildew preventive, 1-5% of coalescing agent, 0.5-1% of neutralizer and 10-20% of deionized water. The invention also discloses the preparation method of the single-component water-based finishing coat. The film of the water-based natural drying finishing coat is curable at the room temperature, energy-saving and environmental friendly, and capable of meeting the requirements of safe production of enterprises; in the meantime, the film is good in closure to a primer, and has excellent early-stage waterproofness and ageing resistance; the single-component water-based finishing coat is matched with a room temperature curable water-based double-component epoxy primer in use, so that the film formed is excellent in corrosion resistance, and the comprehensive properties of the single-component water-based natural drying finishing coat are up to the property indexes of similar solvent type finishing coats.

Owner:GUANGZHOU KINTE IND +1

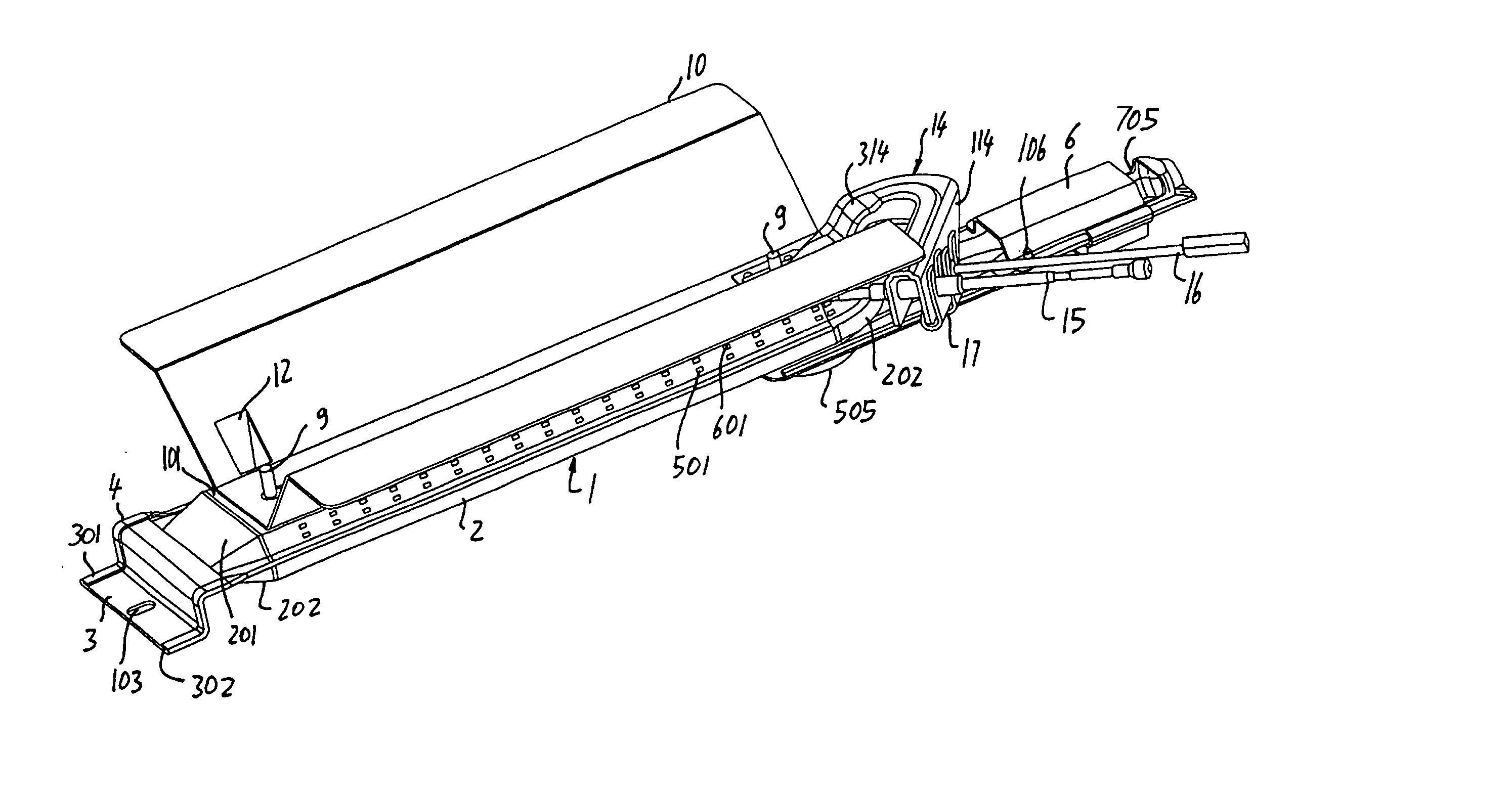

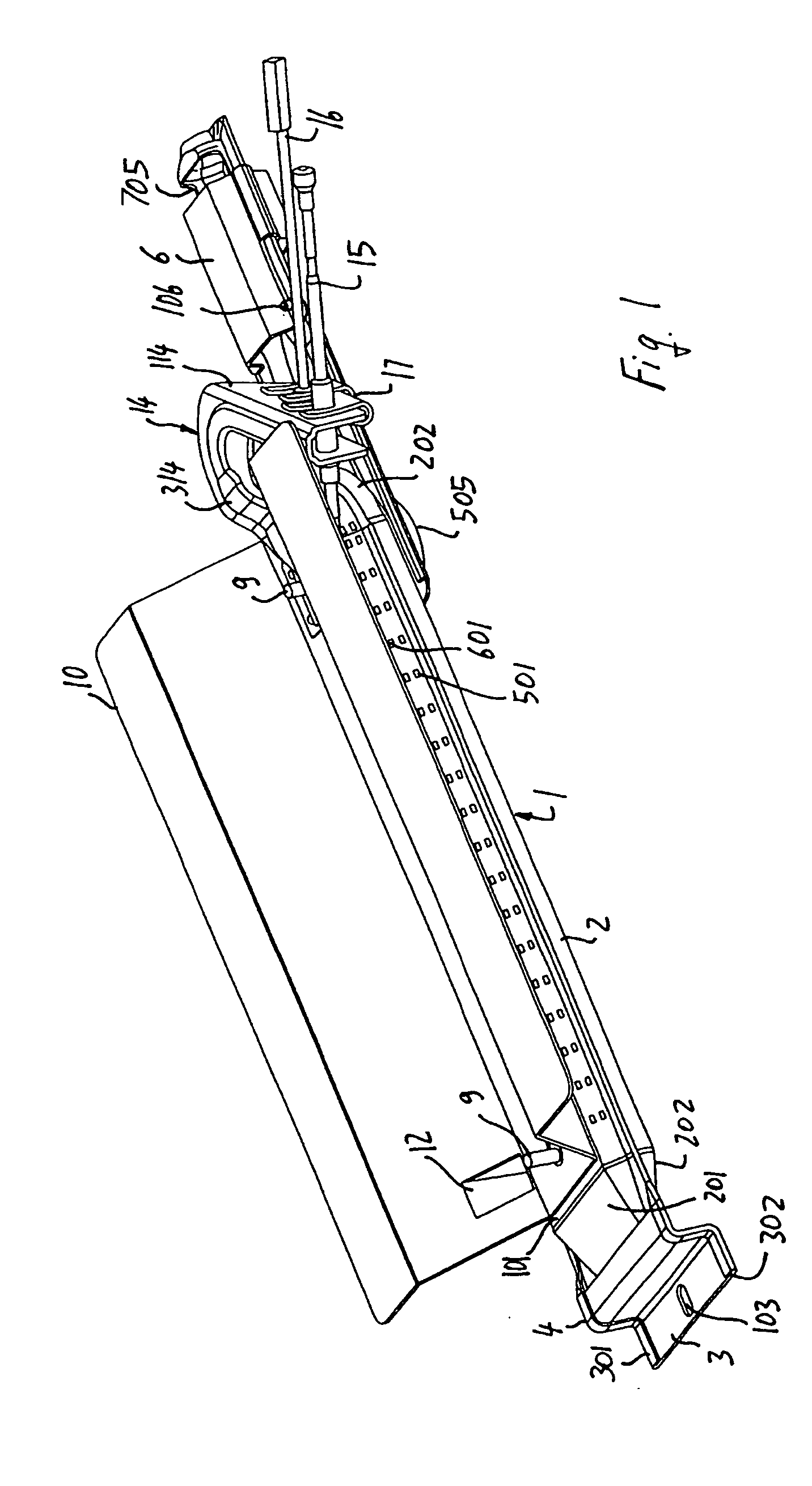

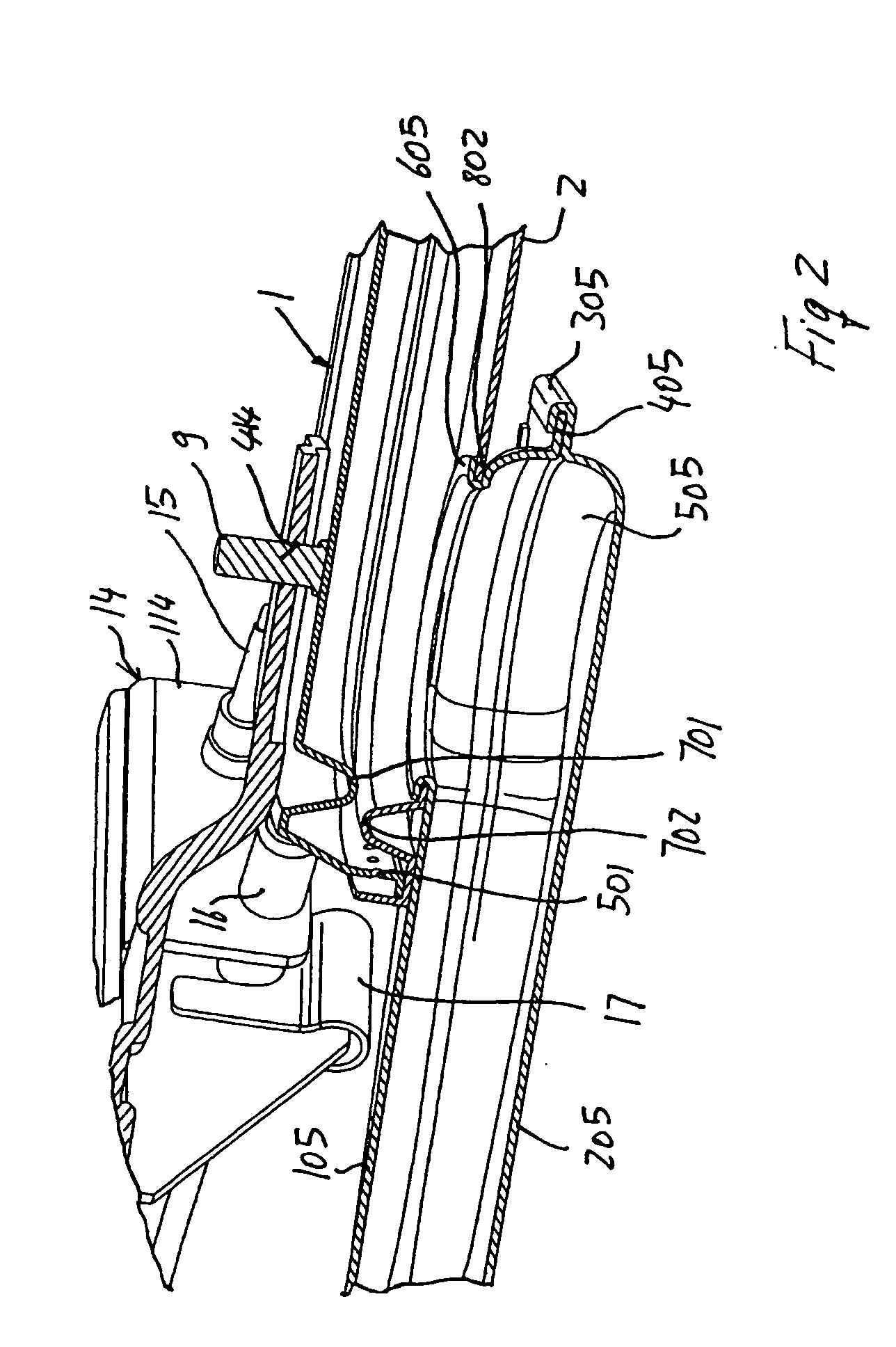

Oven or grill burner, venturi tube, mounting for a thermocouple and/or an igniter, and process for fabricating said burner

ActiveUS20050138789A1Function increaseStrong construction adaptabilityDomestic stoves or rangesBurner manufactureCombustorCoupling

The invention relates to a burner comprising two half shells, one of which is perforated, that are tightly joined together along at least a portion of their edges, so as to form a tubular body communicating with a venturi tube. At least two corresponding ends of the two half shells have a truncated profile, providing the tubular body has at least one truncated end. The invention also relates to a venturi tube for said burner that is composed of two half shells The invention further relates to a mounting for a thermocouple and for an igniter of said burner, the mounting having coupling means that cause mutual contact surfaces to be oriented in at least three non-parallel planes and that prevent mounting rotation, so that the position thereof is accurately defined. The invention also relates to a process for fabricating said burner.

Owner:CAST SPA

Quick-drying hydroxylated acrylic resin water dispersion and preparation method and use thereof

ActiveCN102161770AGood pigment wettingImprove performancePolyurea/polyurethane coatingsAcrylic resinPrepolymer

The invention relates to quick-drying hydroxylated acrylic resin water dispersion and a preparation method and use thereof, in particular to quick-drying aqueous automobile repair solid color paint prepared from the hydroxylated acrylic resin dispersion. The invention discloses a method for preparing the hydroxylated acrylic resin dispersion, which comprises: A, preparing a prepolymer of hydroxylated acrylic resin; and B, preparing aqueous prepolymer of the hydroxylated acrylic resin. And the invention also discloses a method for preparing quick-drying aqueous automobile repair solid color paint by using the dispersion. The coating of the quick-drying aqueous automobile repair solid color paint is accomplished at a low temperature or even at normal temperature, so the volatile organic compound (VOC) emission in a coating process of an automobile is reduced and energy conservation and emission reduction are realized. Thus, the quick-drying aqueous automobile repair solid color paint can be promoted and used easily.

Owner:广东绚缤材料科技有限公司

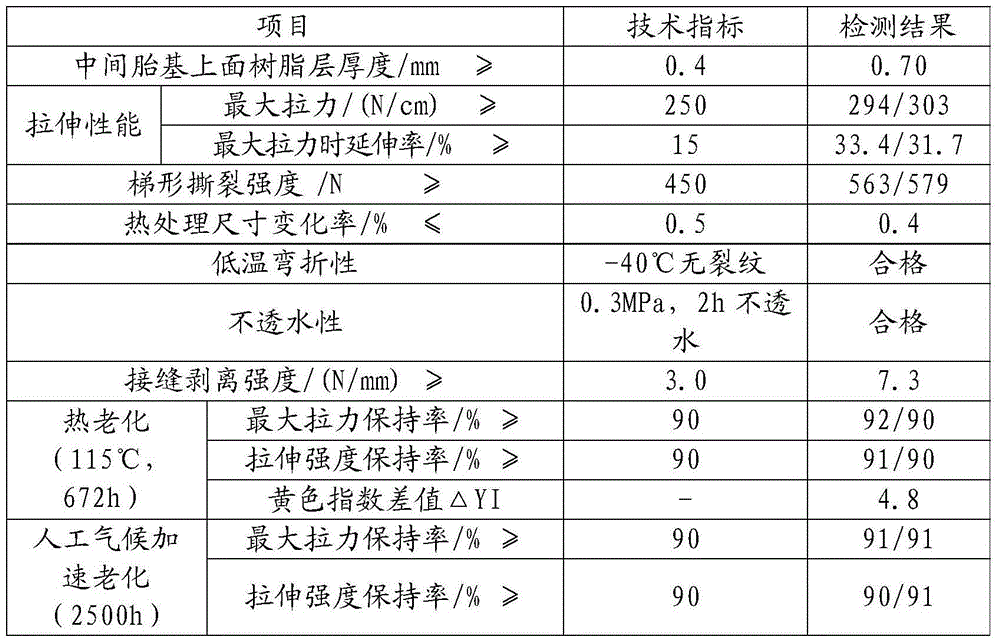

Waterproof roll and preparation method thereof

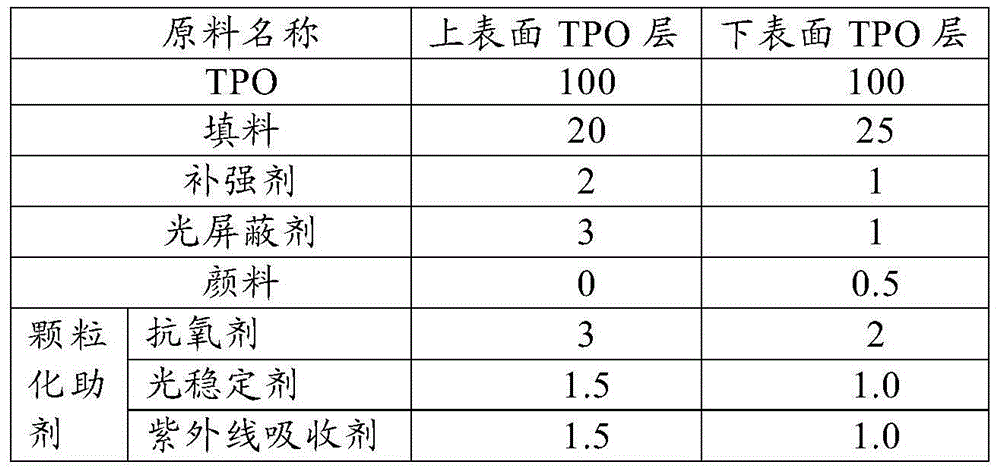

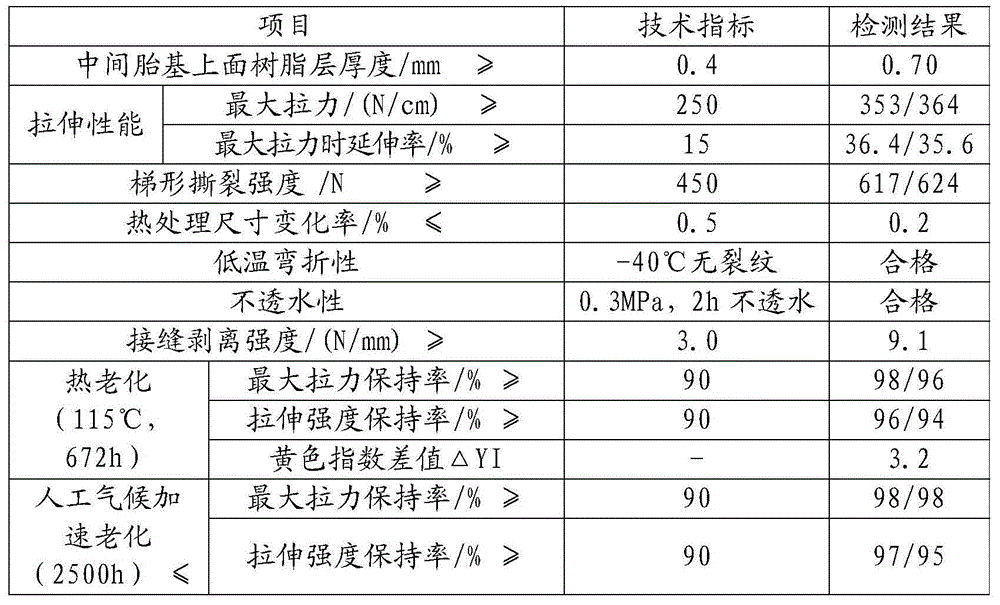

ActiveCN104669747AImprove heat aging resistanceGood weather resistanceSynthetic resin layered productsConstructions elementsThermoplasticCrazing

The invention provides a waterproof roll and a preparation method thereof, belongs to the technical field of polymer waterproof rolls, and can solve the problems of color fading, color changing, surface staining, microcracking, hairline crack and the like of a conventional TPO (thermoplastic polyolefin) roll product in the use process. The waterproof roll comprises a TPO roll layer, wherein raw materials of the TPO roll layer comprise polymeric TPO resin and a granular auxiliary; the granular auxiliary comprises an antioxidant, a light stabilizer and an ultraviolet light absorber, and the grain size of the granular auxiliary is 0.5-1.5 mm. The waterproof roll has excellent weather fastness, ageing resistance, waterproof function and fastness and reliability in construction.

Owner:苏州东方雨虹建筑材料有限公司

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

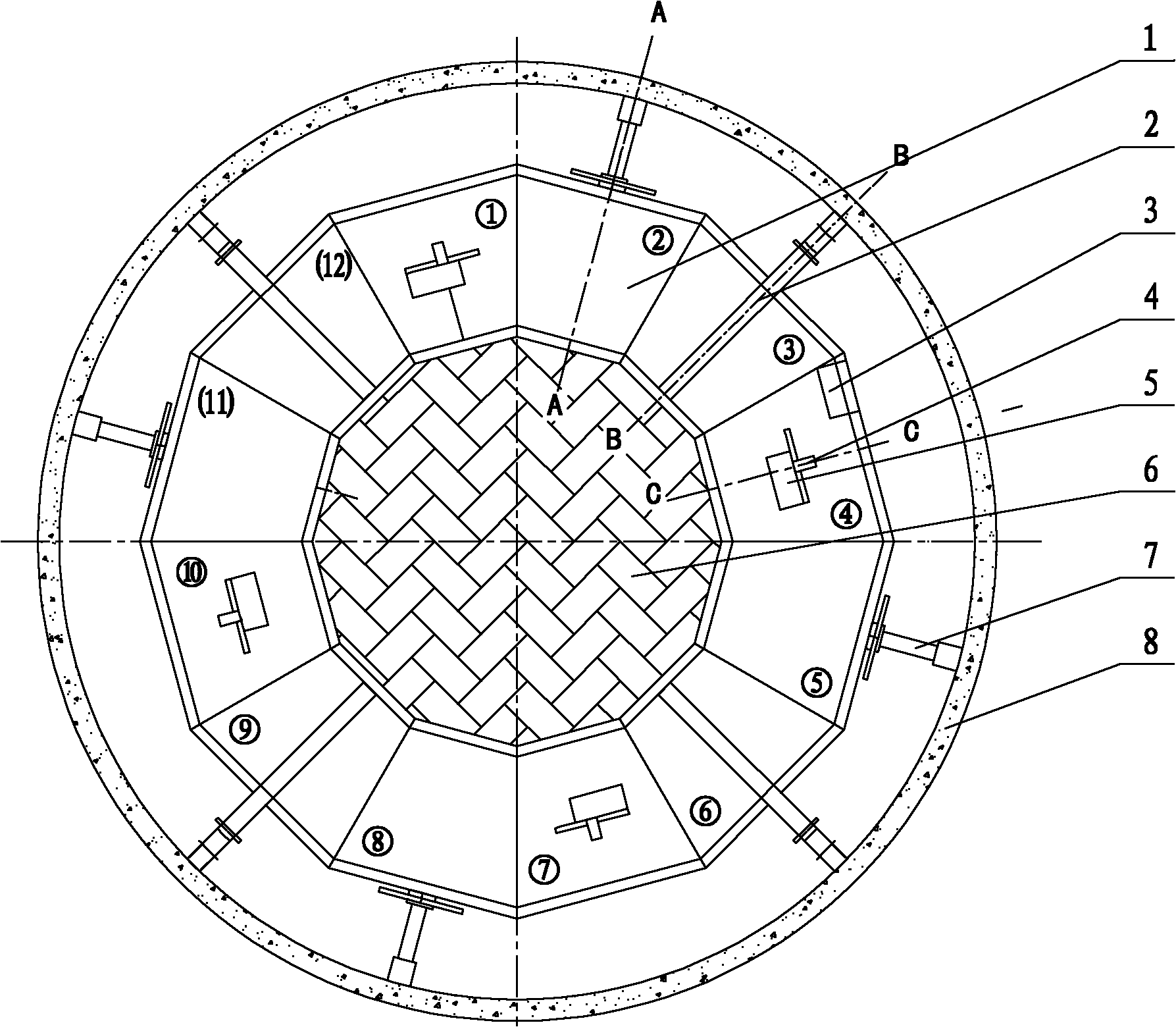

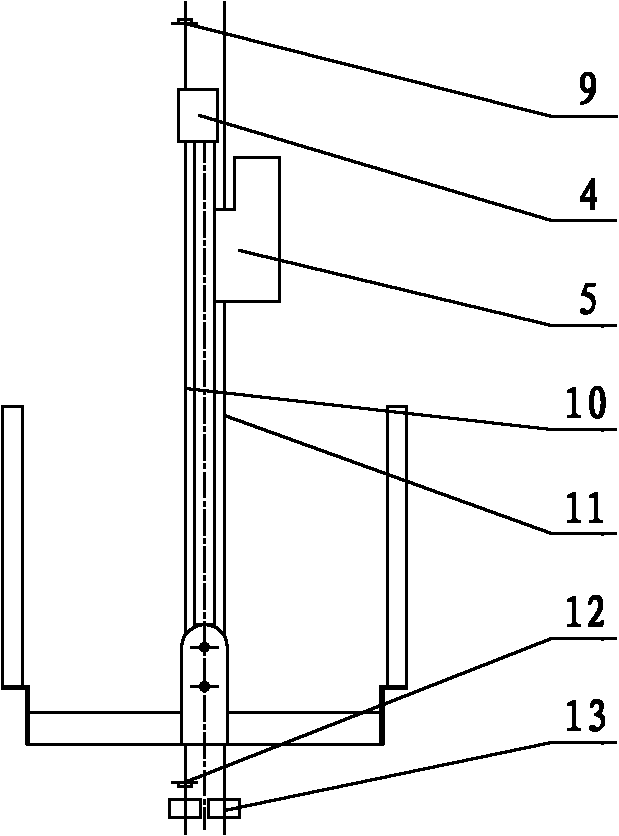

Lifting platform for shaft construction

ActiveCN102080446AAvoid shakingSimple and flexible operationScaffold accessoriesBuilding support scaffoldsElectrical controlArchitectural engineering

The invention discloses a lifting platform for shaft construction, comprising an operating platform, a lifter and an electrical control system, wherein the electrical control system controls the lifter to lift the operating platform via a working steel cable, the operating platform is composed of 6 to 12 trapezoid unit joints, at least four groups of anti-collision wall-against wheels are annularly arranged around the operating platform, and the bottom of the operating platform is circumferentially provided with at least four lead screw supporting components. The lifting platform for shaft construction has the advantages of strong construction adaptability, unlimited construction height, small floor area, good construction quality, high construction efficiency, great convenience of erection and disassembly, less labor, low labor intensity and the like. The trapezoid units, which are combined as required by construction, adapt to the construction requirement under different shaft situations, excellent convenience and flexibility are obtained during installation and usage, construction time is saved, and construction cost is lowered; the anti-collision wall-against wheels and the lead screw supporting components can be adjusted to adapt to the different requirements of shaft construction, and the lifting platform can conveniently and safely prevent the operating platform from shaking and becomes more stable and reliable as a whole.

Owner:中国水利水电第七工程局成都水电建设工程有限公司

Macromolecular adhesive cement

The invention relates to a cement-based self-leveling mortar, and more particularly relates to a macromolecular adhesive cement. The macromolecular adhesive cement comprises the components in parts by weight: 80-100 parts of water-borne epoxy resin, 16-20 parts of water-borne epoxy curing agent, 120-150 parts of complex portland cement, 30-50 parts of quartz silt powder, 10-15 parts of water, 35-50 parts of pigments and fillers, 0.3-0.5 parts of wetting dispersant, 2-6 parts of self-leveling additives, and 2-5 parts of water-borne color paste. The macromolecular adhesive cement disclosed by the invention is a single-component, dry-powder-shaped and water-borne self-leveling cement-based hard / soft type waterproof adhesion-blocking and leveling material which is processed via scientific proportioning, integrates the functions of water prevention, adhesion, blockage and leveling, as well as is non-toxic and odorless, and belongs to cement-based macromolecular polymer water-borne dry-powder waterproof mortars.

Owner:浙江西塘实业有限公司

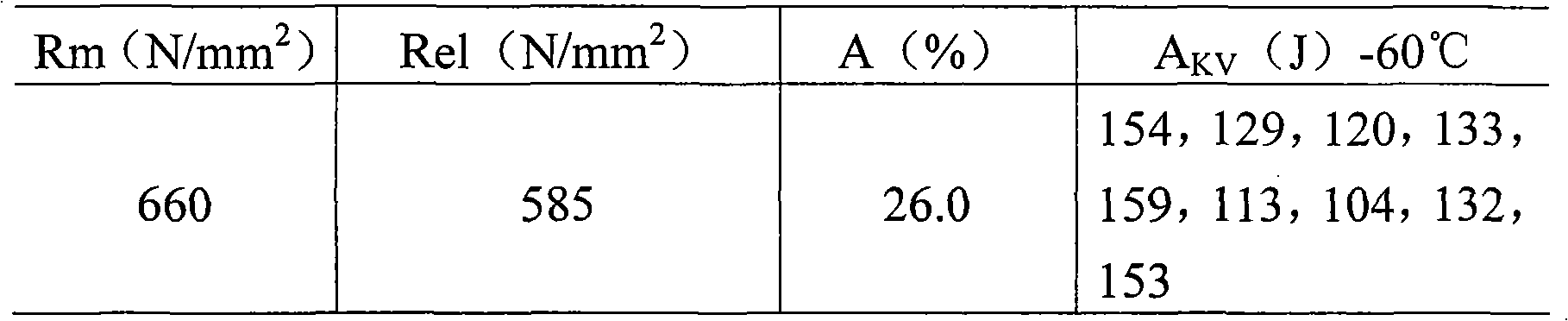

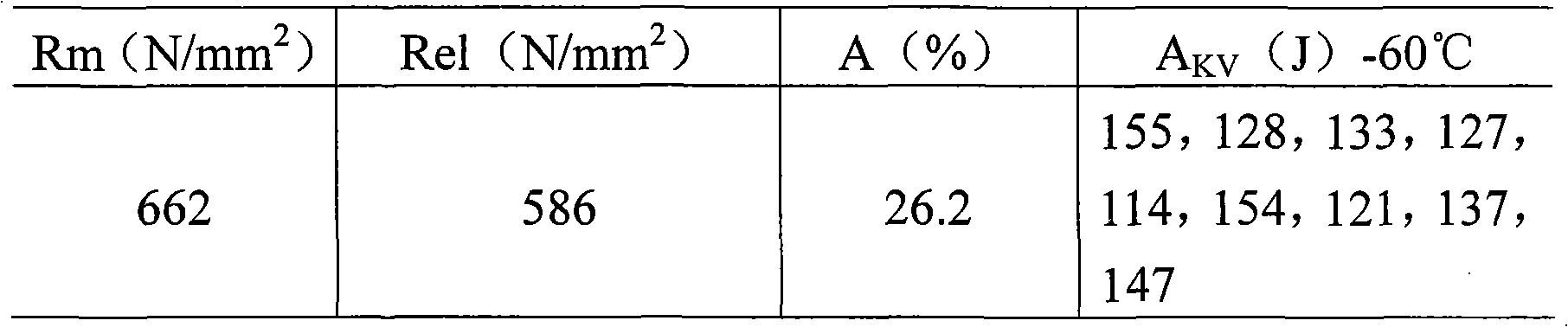

Electric welding rod for welding large scale low temperature spherical tank steel

ActiveCN101537544ASimple welding processEasy to strike the arcWelding/cutting media/materialsSoldering mediaCrack resistanceAdhesive

The invention relates to an electric welding rod for welding large scale low temperature spherical tank steel, consisting of a core welding-wire, an electrode covering and adhesive. The electric welding rod is manufactured according to the conventional manufacturing technique of the electric welding rod; the strength and the toughness of the electric welding rod can be enhanced by strictly controlling the lower percentage composition of S and P in auxiliary materials of the core welding-wire and the electrode covering. The invention has the advantages that the ultralow hydrogen sodium type electric welding rod has high strength and toughness, good welding technological properties, easy arc initiation, soft voltaic arc, little splatter, convenient slag detachability, delicate shaped weld mark, beautiful appearance and all-position welding; deposited metal is well purified and thinned, and has excellent low-temperature impact ductility and cracking resistance, low content of diffusible hydrogen as well as good performances of hot crack and cold crack resistance as well as reheating crack resistance; the welded deposited metal adapts to wide range of heat treatment parameter and has good actual construction adaptability, thus being applicable to welding a spherical tank, especially large scale spherical tanks made of propylene, ethylene and LPG.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP +1

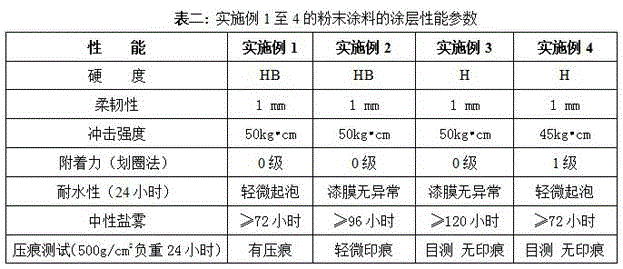

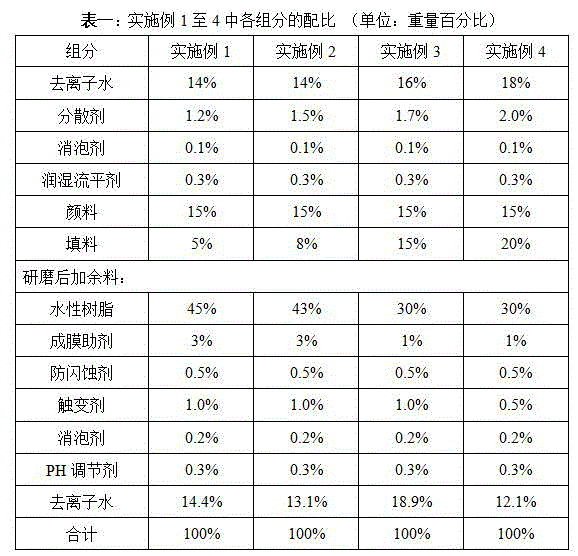

Fast-curing indentation-proof water-based paint for galvanized sheet and preparation method thereof

InactiveCN103602183AReduce usageStrong construction adaptabilityPolyurea/polyurethane coatingsEpoxy resin coatingsWater basedAssembly line

The invention discloses a fast-curing indentation-proof water-based paint for galvanized sheets. A formula of the paint comprises the following components by weight: 30-45% of water-based resin, 1-3% of a dispersant, 20-35% of a pigment filler, 0.3-1% of a wetting leveling agent, 0.5-1% of a thixotropic agent, 0.3-1% of a defoaming agent, 0.1-0.8% of a flash rust inhibitor, 1-3% of a coalescing agent, 0.1-0.5% of a pH regulator and 10-40% of deionized water. The invention also discloses a preparation method of the water-based paint. The paint film provided by the invention can cure fast, and is safe, energy-saving, environment-friendly and simple for construction, so as to meet the fast production requirements of an assembly line. The obtained galvanized sheet has excellent properties and performance indicators reaching the industrial standard for galvanized sheet coating.

Owner:GUANGZHOU KINTE IND +1

Normal-temperature quick-drying aqueous hydroxy acrylic resin and its preparation method and application

InactiveCN102627720AGood pigment wettingChange the status quo of grindingPolyurea/polyurethane coatingsAcrylic resinPrepolymer

The invention relates to a normal-temperature quick-drying aqueous hydroxy acrylic resin, specifically to a quick-drying aqueous automobile repairing solid color paint prepared from an aqueous hydroxy acrylic resin. The invention discloses a preparation method of the aqueous hydroxy acrylic resin, a preparation of a hydroxy acrylic resin prepolymer and water-borne modification of the hydroxy acrylic resin prepolymer, and a method for preparing the quick-drying aqueous automobile repairing solid color paint by the use of the above dispersion. According to the invention, the coating process is completed at normal temperature, VOC discharge during the automobile coating process is reduced, production efficiency is raised, vehicle delivery time is shortened, and the resin is convenient for popularization and application.

Owner:汤汉良

Aqueous inorganic zinc rich paint

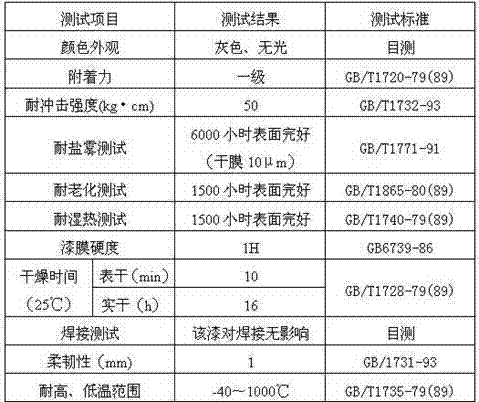

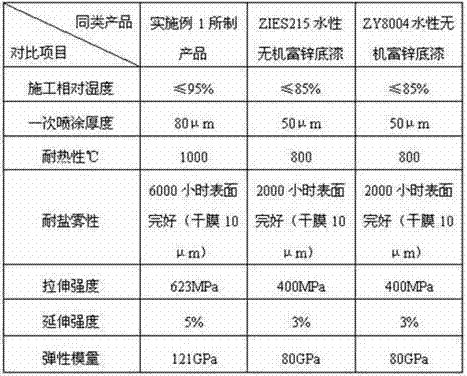

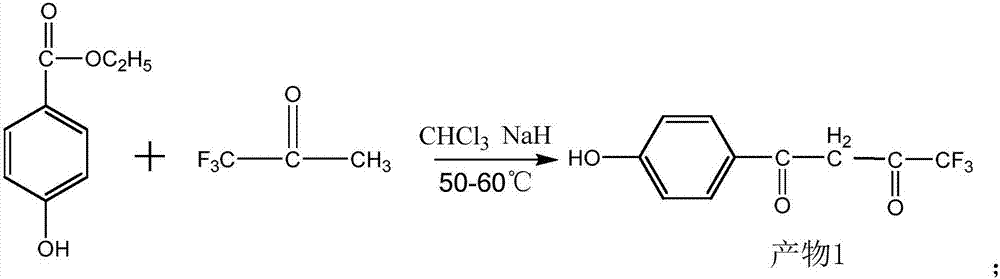

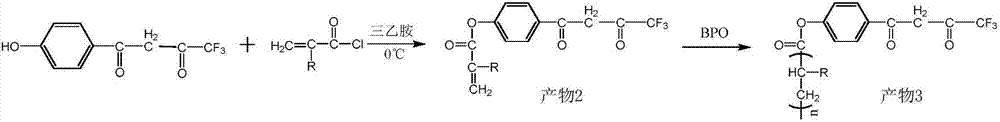

ActiveCN102898913AOvercome the disadvantage of easily forming voids in the paint filmOvercome the disadvantage of easy void formationAnti-corrosive paintsAcrylic resinSilicic acid

The invention provides an aqueous inorganic zinc rich paint, which is prepared by mixing a component A with a component B according to a weight ratio of 4:1, wherein the component A comprises 30-32% of 500-mesh spherical / flaky zinc powder, 30-32% of 800-mesh spherical / flaky zinc powder, 30-32% of 1250-mesh spherical / flaky zinc powder, 6-8% of nanometer cerium dioxide and 2-4% of 800-mesh talcum powder; and the component B comprises 38-50% of potassium silicate, 10-20% of lithium silicate, 8-10% of potassium titanate whiskers, 5-12% of aqueous self-drying organic silicon modified acrylic resin, 0.2-0.5% of defoaming agent, 0.5-1% of wetting agent and 12-20% of water. The aqueous inorganic zinc rich paint provided by the invention has the characteristics of excellent corrosion resistance, physical and mechanical properties, wet resistance, high temperature resistance and strong construction adaptability.

Owner:江苏纽克莱涂料有限公司

Waterborne nano long-acting corrosion-resistant finishing coat and preparation method thereof

The invention belongs to the technical field of corrosion-resistant coatings, and particularly relates to waterborne nano long-acting corrosion-resistant finishing coat and a preparation method thereof. The finishing coat consists of a component A and a component B. The component A consists of the following raw materials in parts by weight: 30-40 parts of acrylic acid modified polyurethane emulsion, 10-20 parts of modified nano silicon dioxide sol, 0.5-1 part of a defoaming agent, 0.3-0.8 part of a leveling agent, 5-10 parts of a cosolvent, 0.5-1 part of a thickening agent, 1-3 parts of a wetting agent and the balance of deionized water. The component B is a waterborne curing agent. The waterborne nano long-acting corrosion-resistant finishing coat has the advantages of long-lasting and excellent corrosion resistance, high substrate adhesion, high hardness, excellent friction resistance, excellent salt fog resistance, high construction adaptability and the like. The preparation method is simple, the cost is low, operation is facilitated, the waterborne nano long-acting corrosion-resistant finishing coat is environmentally friendly and pollution-free, a coated film is dry quickly, and the construction period is short.

Owner:广东绿色大地化工有限公司

Metal substrate long-lasting anticorrosive inter-coat and preparation method thereof

ActiveCN108997916AHigh mechanical strengthImprove dispersion uniformityAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention belongs to the technical field of anticorrosive coating, and in particular, relates to a metal substrate long-lasting anticorrosive inter-coat and a preparation method thereof, wherein the inter-coat is composed of a component A and a component B, and the component A is composed of the following raw materials in parts by weight: 50-60 parts of an epoxy-organosilicone resin modified acrylic resin emulsion, 12-18 parts of functionalized modified graphene, 10-20 parts of a filler, 8-15 parts of a cosolvent, 0.1-0.5 part of a defoamer, 0.5-1 part of a leveling agent, 0.3-0.8 part ofa water-based drier, 0.3-0.8 part of a thickener, 0.5-1 part of a wetting agent, and 30-35 parts of deionized water; the component B is composed of the components in parts by weight: 40-50 parts of anisocyanate curing agent, and 10-20 parts of a cosolvent. The inter-coat has the advantages of long-term excellent anticorrosive performance, strong adhesion force of the substrate, high mechanical strength, excellent friction resistance, excellent salt spray resistance, good water resistance, chemical resistance, oil resistance and impact resistance, high construction adaptability and the like.

Owner:惠州市湾厦表面处理技术有限公司

Solvent-free oil pipeline anti-corrosion and anti-drag special coating and preparation method thereof

ActiveCN111205746AImprove thixotropyEvenly dispersedAnti-corrosive paintsEpoxy resin coatingsFatty amineSolvent free

The invention discloses a solvent-free oil pipeline anti-corrosion and anti-drag special coating and a preparation method thereof, belongs to the field of anti-corrosion coatings, and solves the problems that an existing solvent-free anti-corrosion coating is high in construction difficulty, a coating is prone to scale formation and the like. The coating is prepared from two components, wherein the component I is prepared from bisphenol A epoxy resin, polyethersulfone modified epoxy resin, aromatic hydrocarbon resin, glass fiber powder, polytetrafluoroethylene wax powder, potassium hexatitanate whiskers, silica powder, a dispersing agent, a leveling agent, an epoxy active diluent, polyethylene wax powder, talcum powder, phthalocyanine blue, lemon yellow and an antifoaming agent, and the component II consists of a cashew nut shell oil modified phenolic aldehyde amine curing agent and a resin type modified fatty amine curing agent. The preparation method comprises the following steps: mixing the component I and the component II according to a mass ratio of (4-12): 1, and uniformly stirring. The coating has the advantages of favorable long-acting property, favorable flexibility, favorable temperature resistance, favorable chemical resistance, favorable drag reduction effect, environment friendliness and easiness in construction. The preparation method is simple, and the productionefficiency can be obviously improved.

Owner:西北永新涂料有限公司

High-pressure gas preservation method

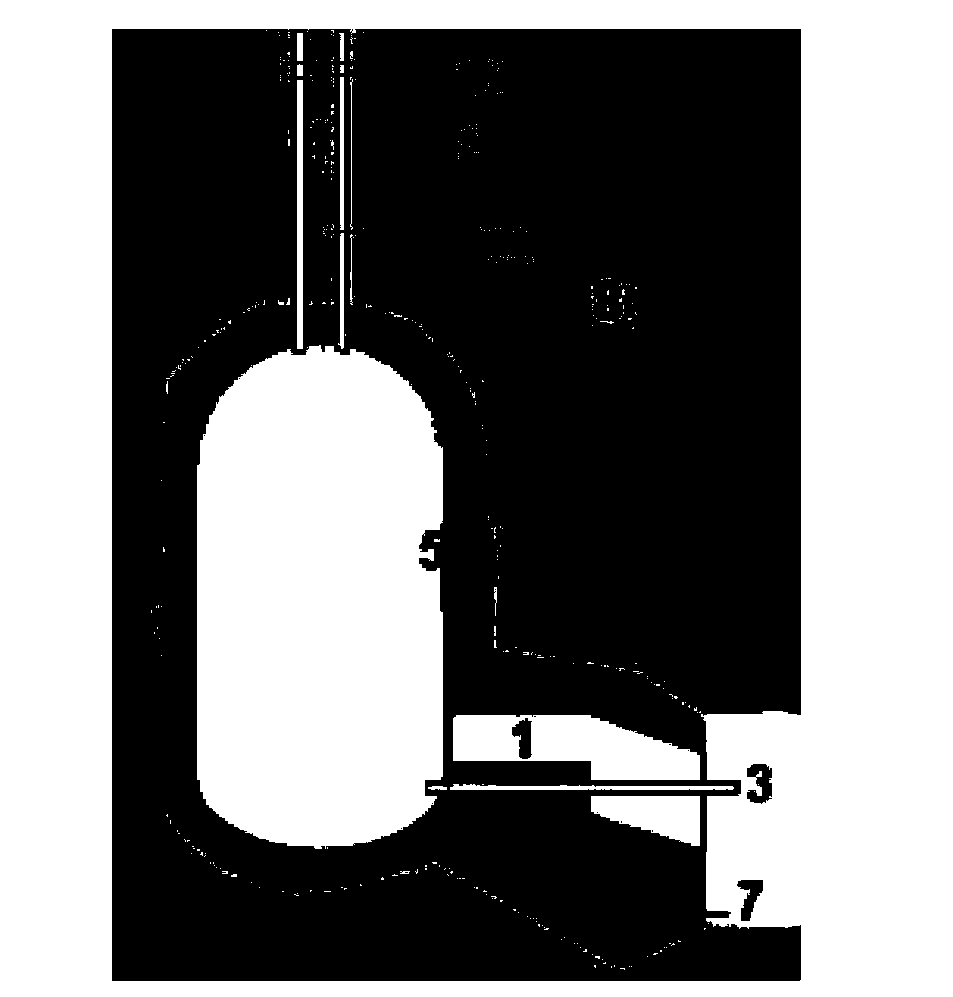

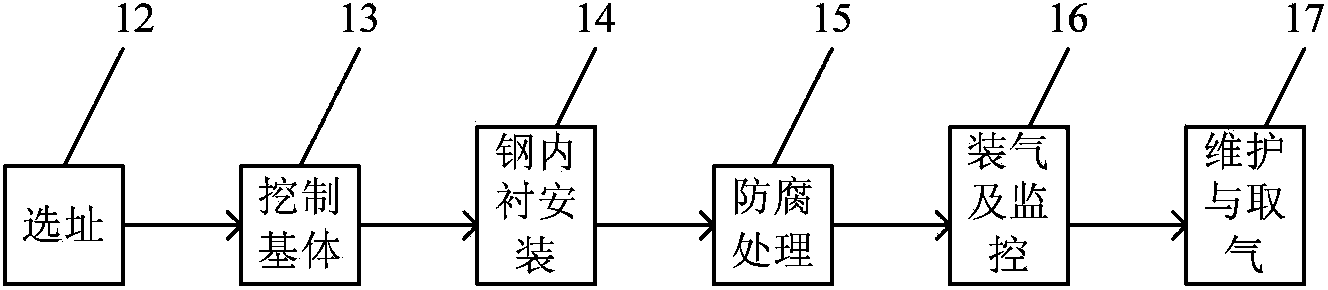

InactiveCN103423583AStrong construction adaptabilityImprove securityMining devicesContainer filling methodsWater contentRebar

The invention belongs to the technical field of gas storage, and relates to a preservation method of high-pressure gas deeply embedded underground. According to the invention, an area with hard geological structure is selected as a gas preservation site; a base is dug on the selected gas preservation site; a construction channel or a working chamber is preserved in the base; a cylindrical steel liner is welded in the inner cavity of the base through the construction tunnel and the working chamber; network steel bar concrete or network steel bar asphalt mixture is filled in the space between the steel liner and the base, and an anti-corrosion treatment is carried out on the periphery of the steel liner; compressed gas to be stored is filled into the steel liner through a gas inlet pipe and a valve on the top of the steel liner under the control of a compression pump, and the state in the steel liner is controlled through a monitoring device; high-pressure gas stored in the steel liner is monitored regularly, such that gas pressure, temperature, water content, and density parameters of high-pressure gas stored in the steel liner are controlled in real time. The process principle is reliable, storage safety is good, control is flexible, operation cost is low, and the method is environment-friendly.

Owner:COOEC ENPAL ENG

Concrete brick taking shell-animal shells as coarse aggregate and preparation method thereof

ActiveCN104496340AWide variety of sourcesAggregate cost is lowSolid waste managementAnimal ShellsBrick

A concrete brick taking shell-animal shells as coarse aggregate is mainly prepared by adding proper amount of water into the following raw materials in parts by weight: 28-32 parts of shell aggregate, 20-25 parts of a fishing net, 405-412 parts of sand, 120-128 parts of fly ash, and 370-375 parts of portland cement. The shell aggregate is a mixed aggregate of natural snail shells with different dimensions, and the fishing net is fragments which is obtained by performing crushing processing on waste fishing nets and has the maximum width no more than 1 cm. The concrete brick product is high in strength, light in self weight and strong in construction adaptability, and has the advantages of sound insulation, thermal insulation and the like at the same time because of addition of the shell aggregate. Some islands are far from mainland, high-quality construction materials and construction teams are difficult to obtain, so the manner of using local materials is well accepted, and the local characteristics of islands are be fully embodied.

Owner:ZHEJIANG UNIV

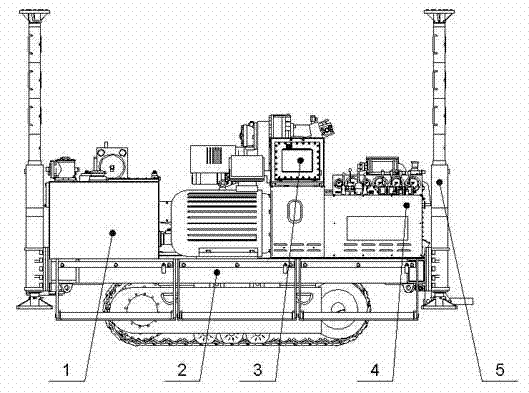

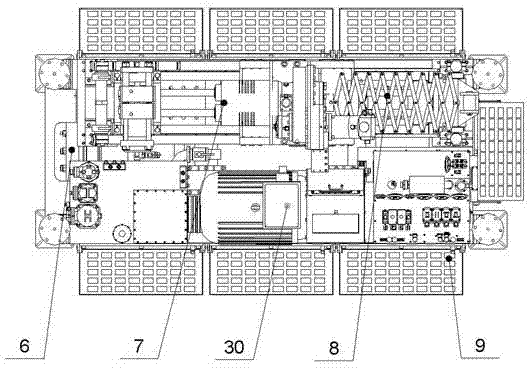

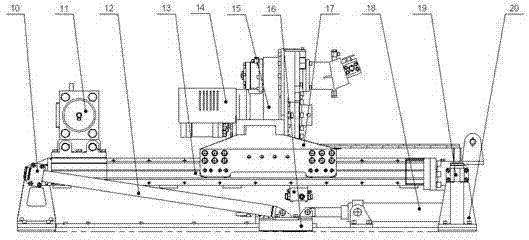

Underground coal mine multipurpose overall crawler type full-hydraulic directional drilling machine

ActiveCN103032025AStrong construction adaptabilityEasy to use and maintainDirectional drillingCoalDirectional drilling

The invention relates to the technical field of drilling equipment, in particular to an underground coal mine multipurpose overall crawler type full-hydraulic directional drilling machine. At present, more and more construction demands are needed by the underground coal mines in the gas extraction wear layer drilling construction, the gas extraction bedding drilling construction, the drainage drilling construction and the bottom plate grouting drilling construction through a precise control directional drilling machine; however, according to the existing crawler type full-hydraulic directional drilling machine for the coal mines, the angle adjusting range of a construction main shaft is smaller, an anti-explosion computer is inconvenient to mount and use, the adaptability of the drilling machine to the constructions is limited to a certain extent, and the technique adaptability is weaker. The underground coal mine multipurpose overall crawler type full-hydraulic directional drilling machine realizes that the main shaft angle can be adjusted in a range of minus 30 to 30 degrees through the connection relation among parts such as a host, an adjusting support rod, an anti-explosion computer set and the like; the anti-explosion computer is convenient to use and maintain; drilling staff operate observing holes safely and conveniently; the construction adaptability of the drilling machine is improved; and the drilling machine has the characteristics of novel structure, compact and reasonable layout, high drilling efficiency, simple and elegant appearance and the like.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Concrete building block possessing raw material containing shell-animal shells as aggregate and preparation method thereof

ActiveCN104496339AWide variety of sourcesAggregate cost is lowSolid waste managementBrickAnimal Shells

The invention relates to the field of building materials, and definitely relates to a concrete building block possessing a raw material containing shell-animal shells as an aggregate and a preparation method thereof. The concrete building block possessing the raw material containing shell-animal shells as the aggregate is prepared by adding proper amount of water into the following raw materials in parts by weight: 36-38 parts of shell aggregate, 460-469 parts of sand, 120-128 parts of fly ash, and 370-375 parts of portland cement. The shell aggregate is a mixed aggregate of natural snail shells with different dimensions. The concrete brick product is high in strength, light in self weight and strong in construction adaptability, and has the advantages of sound insulation, thermal insulation and the like at the same time because of addition of the shell aggregate. Some islands are far from mainland, high-quality construction materials and construction teams are difficult to obtain, so the manner of using local materials is well accepted, and the local characteristics of islands are be fully embodied.

Owner:ZHEJIANG UNIV

Long-lasting anticorrosive finishing paint for metal substrate and preparation method thereof

ActiveCN109337568AHigh mechanical strengthWeather resistantAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedSolvent

The invention belongs to the technical field of anticorrosive coating, and particularly relates to long-lasting anticorrosive finishing paint for a metal substrate and a preparation method thereof. The long-lasting anticorrosive finishing paint comprises a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 35-45 parts of an epoxy-organosilicone resin modified acrylate-polyurethane emulsion, 10-15 parts of functionalized modified graphene, 12-18 parts of fillers, 5-10 parts of a pigment, 8-12 parts of a cosolvent, 0.3-0.8 part of a defoaming agent, 0.5-1 part of a leveling agent, 0.5-1 part of a thickening agent, 0.5-1 part of a water-based drier, 0.8-1 part of a wetting agent and 20-30 parts of deionized water; the component B comprises the following raw materials in parts by weight: 55-65 parts of an isocyanate curing agent and 35-45 parts of a cosolvent. The long-lasting anticorrosive finishing paint for the metal substrate has the advantages of long-lasting excellent anticorrosive performance, strong substrate adhesion, high mechanical strength, excellent friction resistance, excellent salt spray resistance, strong construction adaptability and the like.

Owner:广东恒立信息科技有限公司

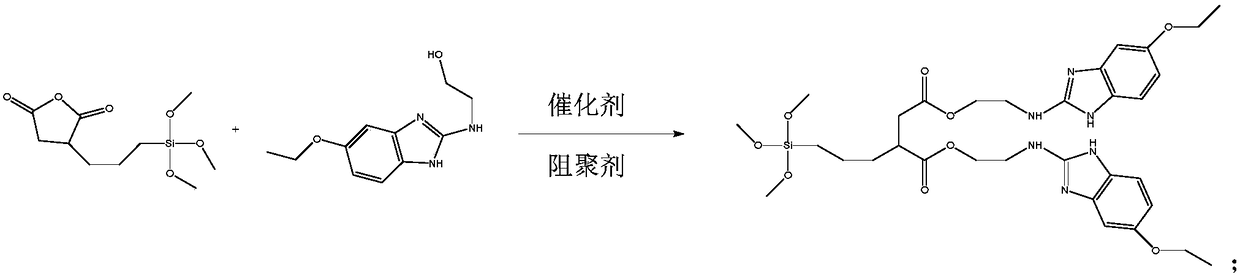

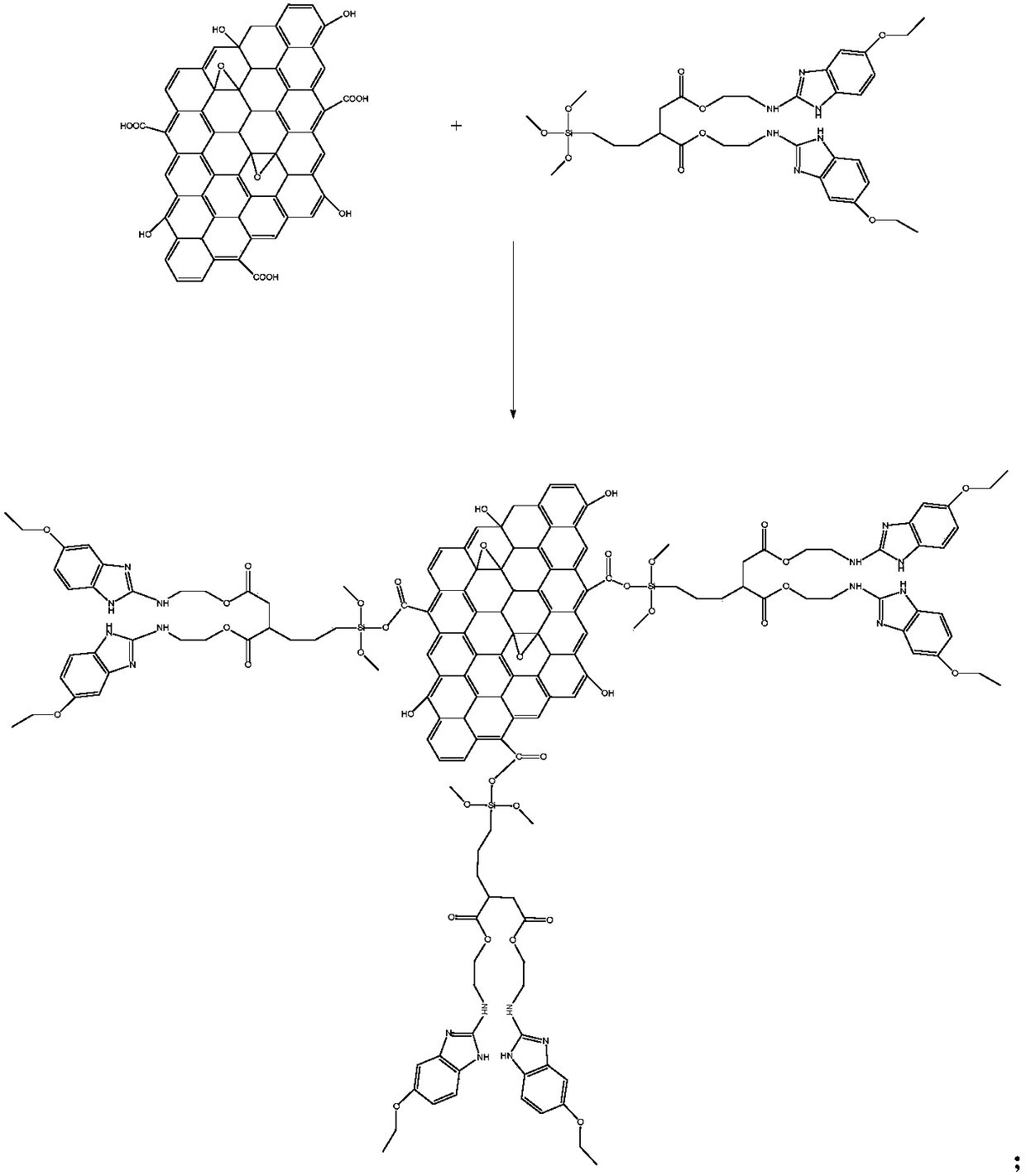

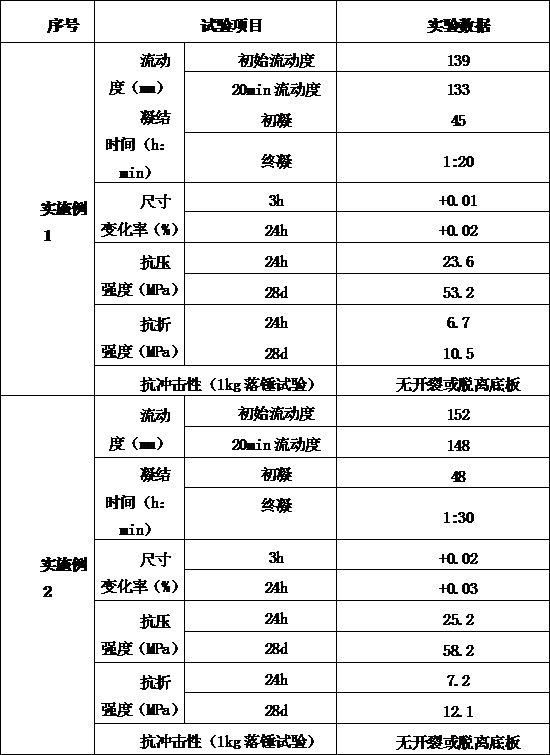

Multi-component concrete composite repair mortar

InactiveCN111875322AImprove liquidityGood self-compactnessStructural engineeringUltimate tensile strength

The invention belongs to the technical field of prefabricated building application, and particularly discloses multi-component concrete composite repair mortar, which is prepared from the following multiple mixtures according to a certain proportion: a cementing material, a mineral admixture, a plastic expanding agent and a functional additive; when multi-component concrete composite repair mortaris prepared from dry powder composed of the cementing material, the mineral admixture, the plastic expanding agent and the functional additive, the multi-component concrete composite repair mortar isprepared by stirring the dry powder and water according to the ratio of 0.11-0.16. The multi-component concrete composite repair mortar disclosed by the invention has the beneficial effects of good fluidity, strong self-compaction, high early strength, micro-expansion in volume, no collapse in later strength and good durability, and has the advantages of quick setting, quick hardening and strongconstruction adaptability.

Owner:江苏智信达建筑科技有限公司

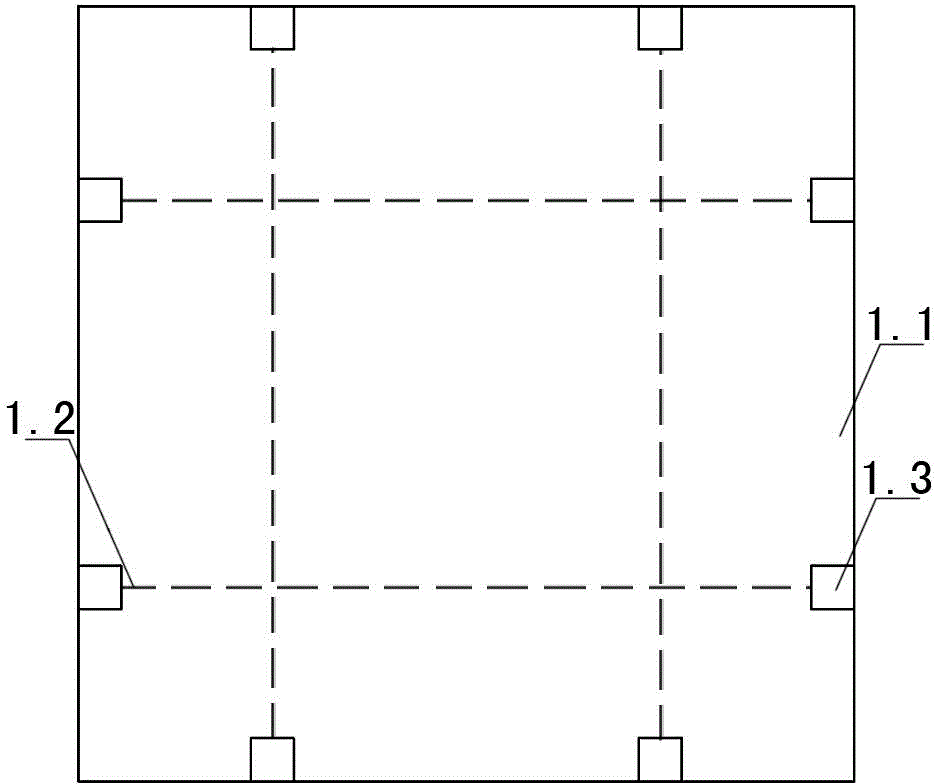

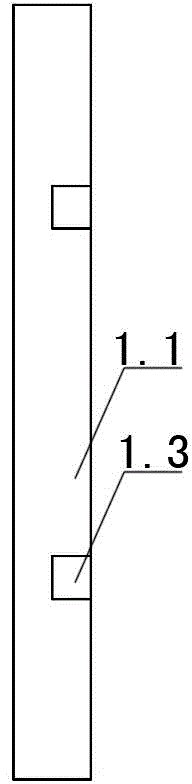

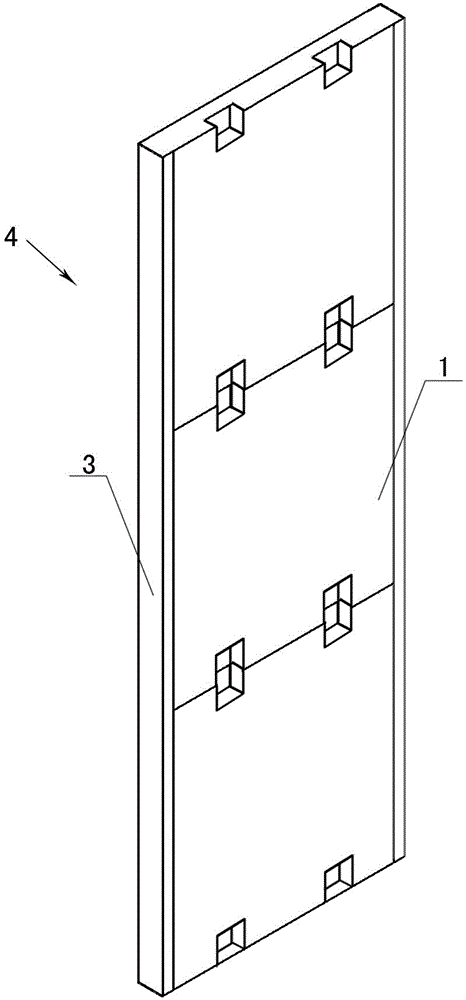

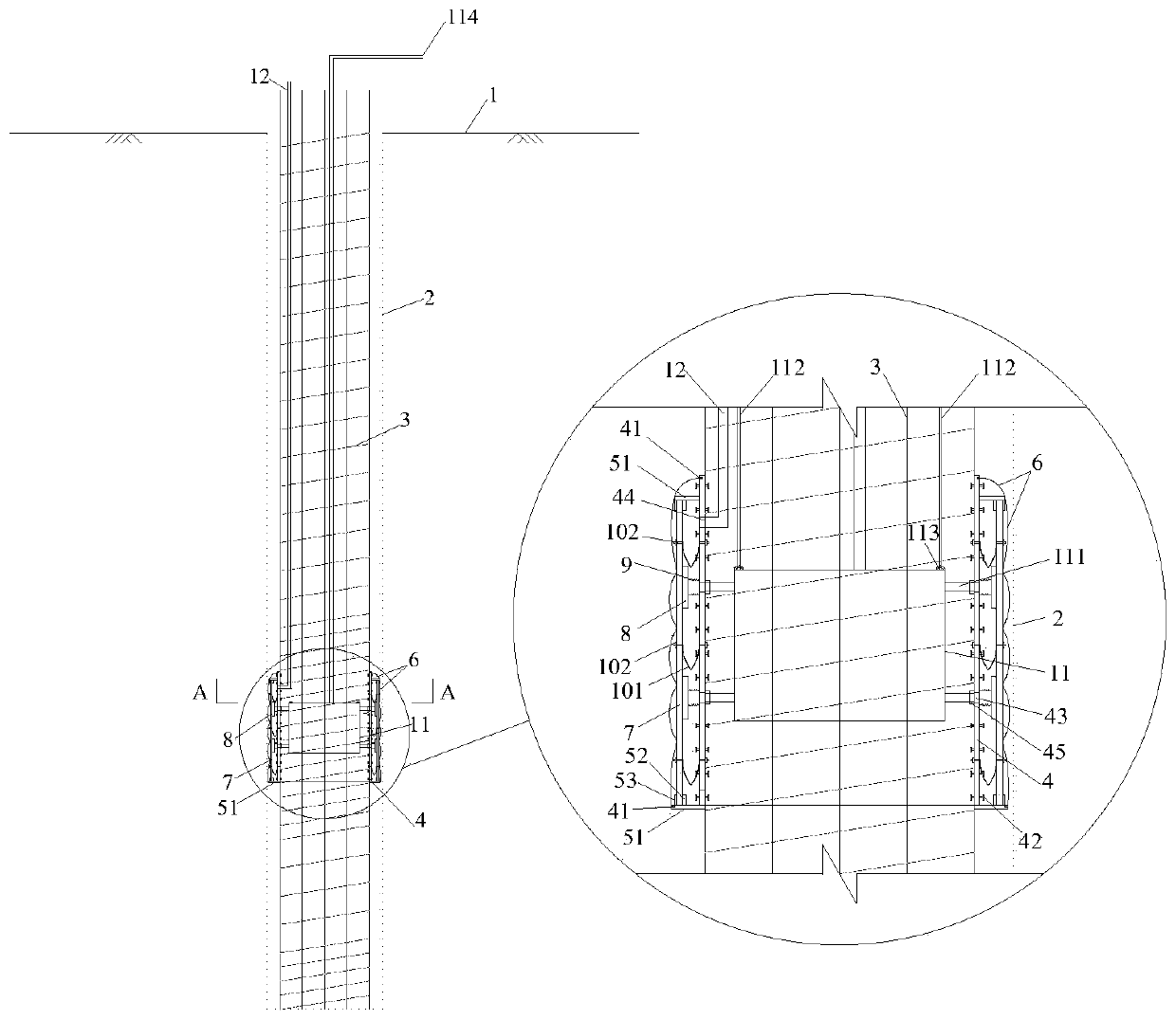

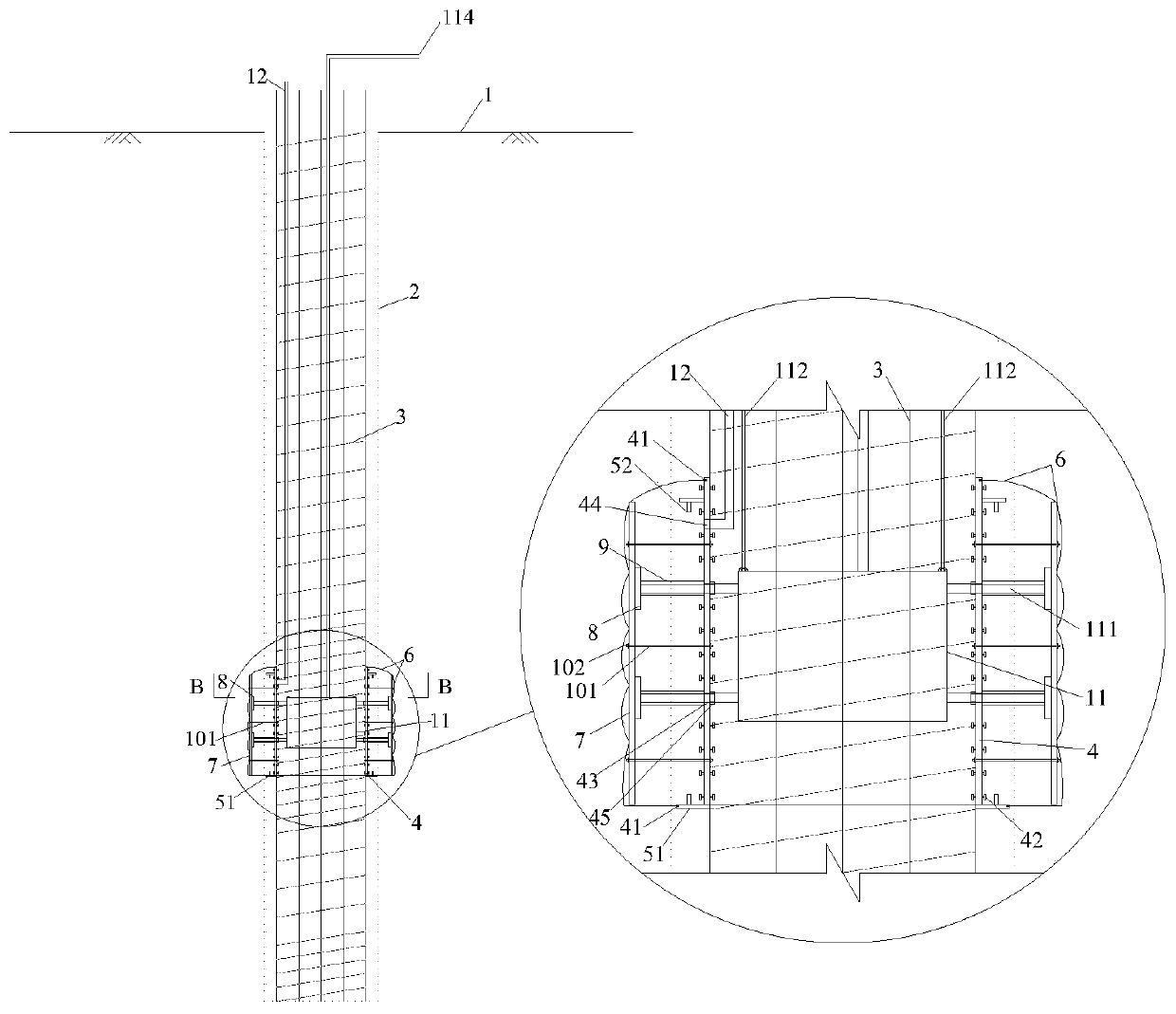

Unit type lightweight ribbed partition and construction method thereof

ActiveCN104594531ALightweight insulationMeet functional requirementsWallsThermal insulationUnit type

The invention discloses a unit type lightweight ribbed partition and a construction method thereof. The partition is connected between a roof and a ground and is composed of at least one partition board; an upper end of the partition board is fixedly connected to the roof through at least two F-shaped clips, and a lower end of the partition board is fixedly connected to the ground through at least two U-shaped clips; the F-shaped clips are horizontally arranged, the straight tail parts of the F-shaped clips are fixed with the roof through bolts, and the head ends thereof with clip slots are clamped at the two sides of the end side of the partition board; the U-shaped clips are vertically arranged, and the openings of the slots of the U-shaped clips are upward; the bottom parts of the U-shaped clips are connected to the ground through bolts, the slots of the U-shaped clips are clamped at the two sides of the end side of the partition board; the single partition board is formed by splicing three partition units to achieve the effects of light weight, heat preservation, thermal insulation and sound insulation. During construction, splicing the prefabricated partition board units into the complete partition or an infilled wall is only needed, thus, the construction speed is obvious faster than that of the traditional partitions, the construction is simple and convenient, the efficiency is high, and the quality control on site is benefited.

Owner:北京振利节能环保科技股份有限公司

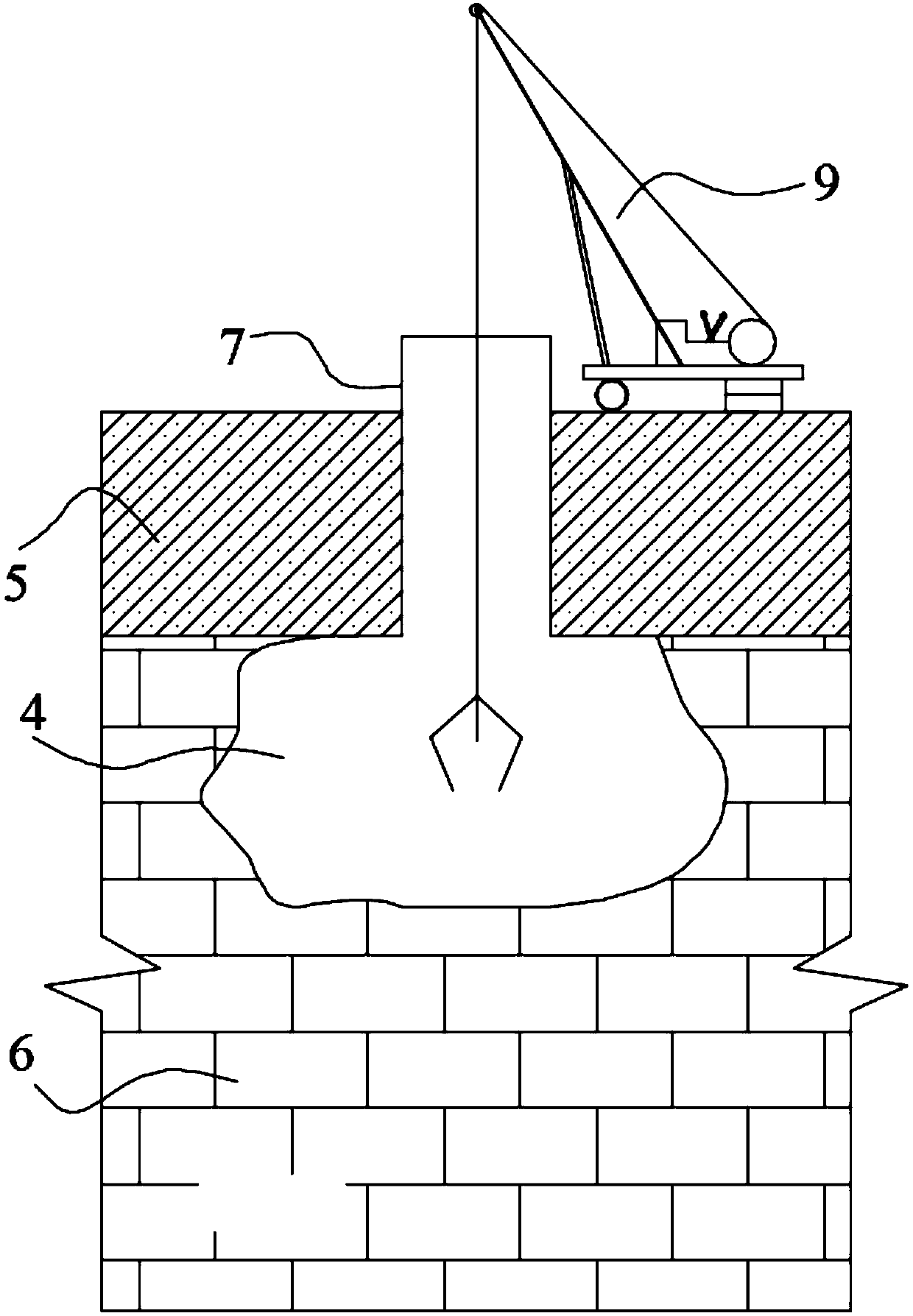

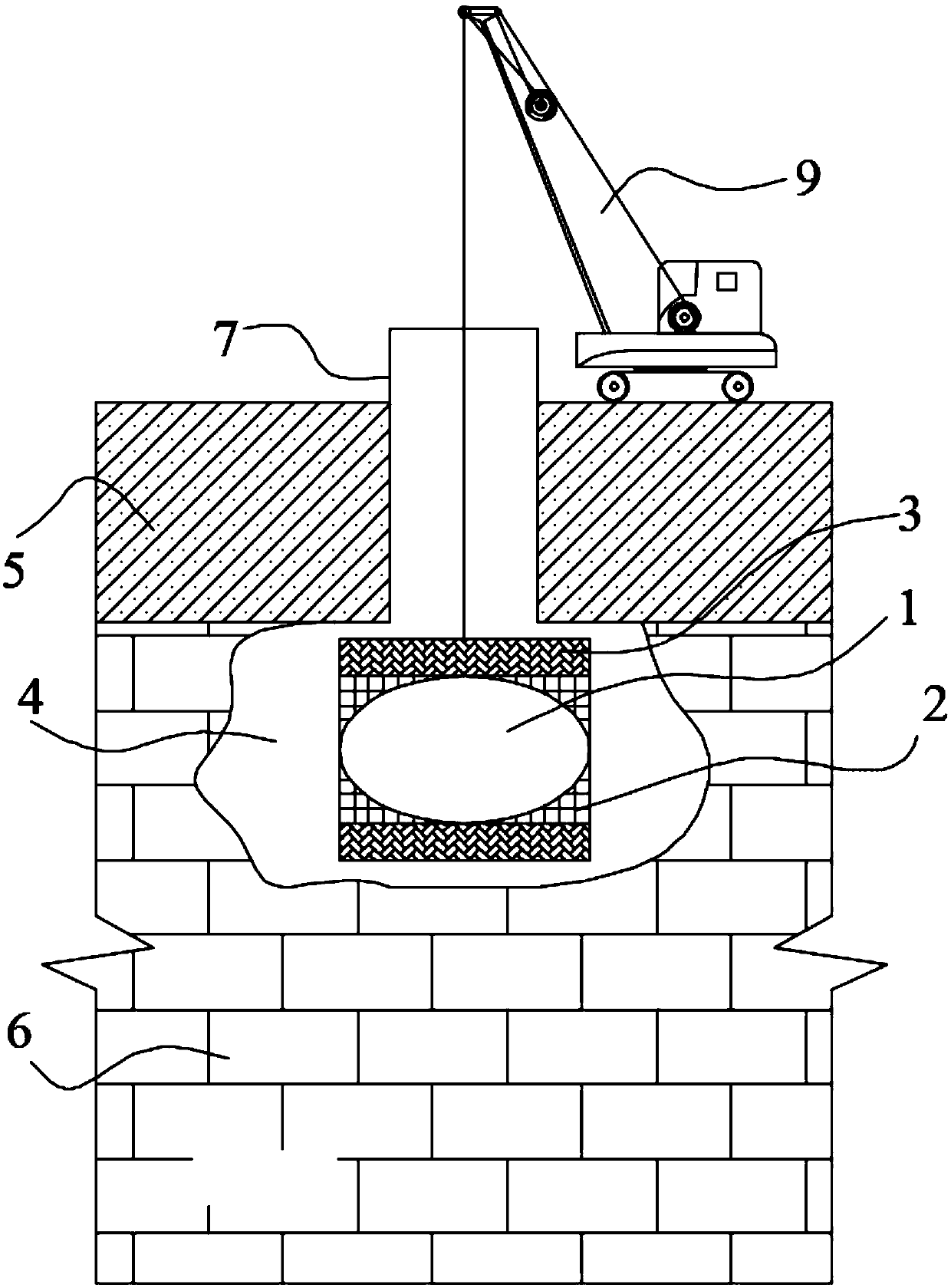

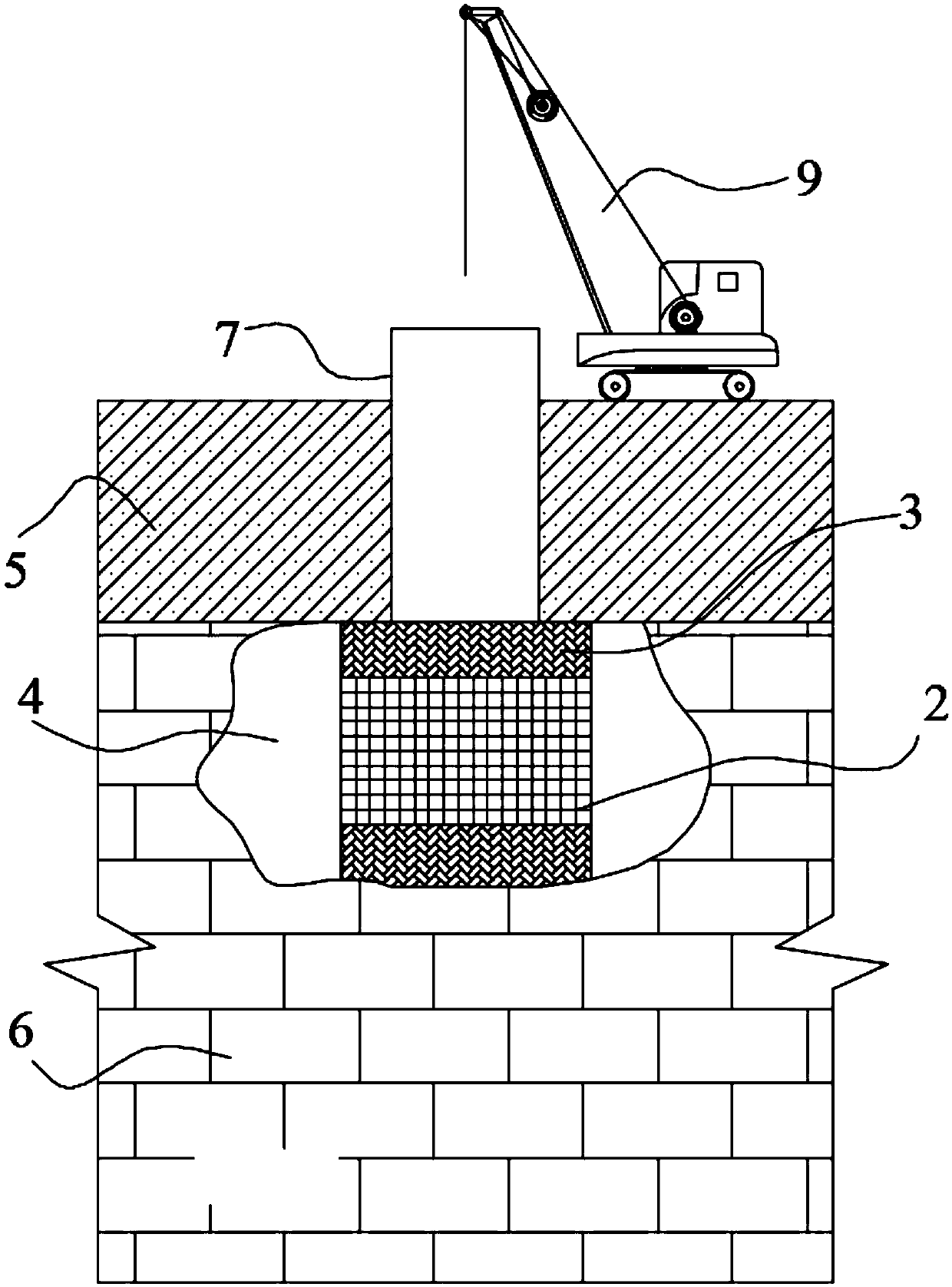

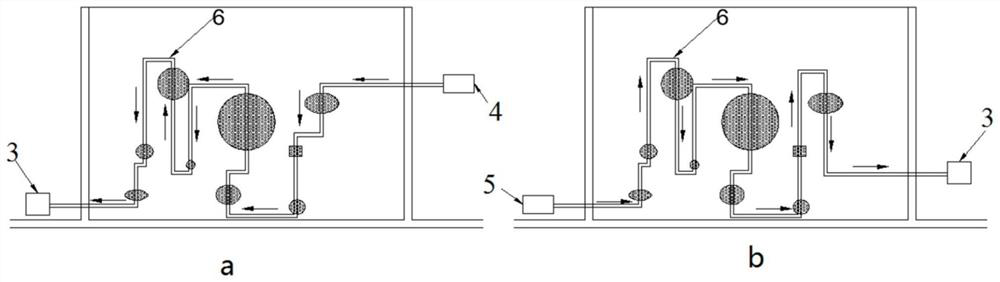

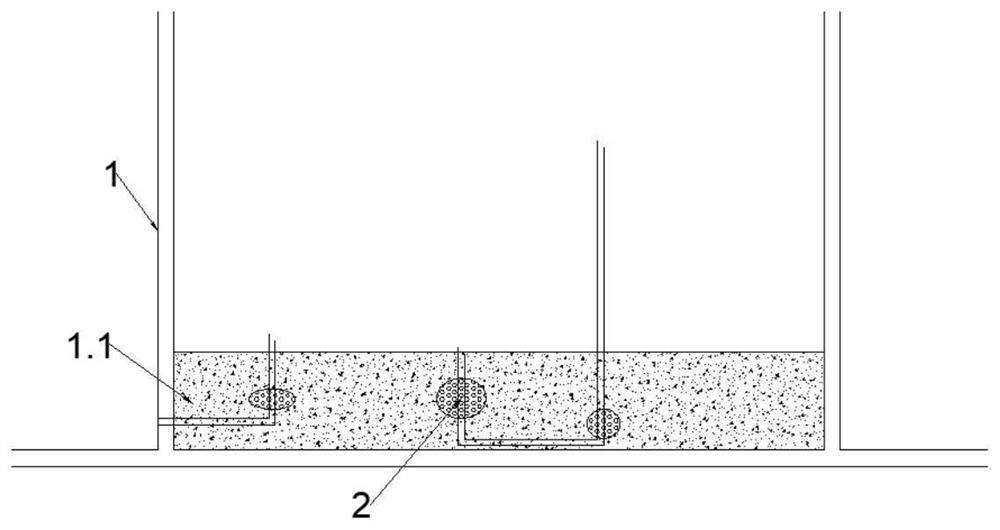

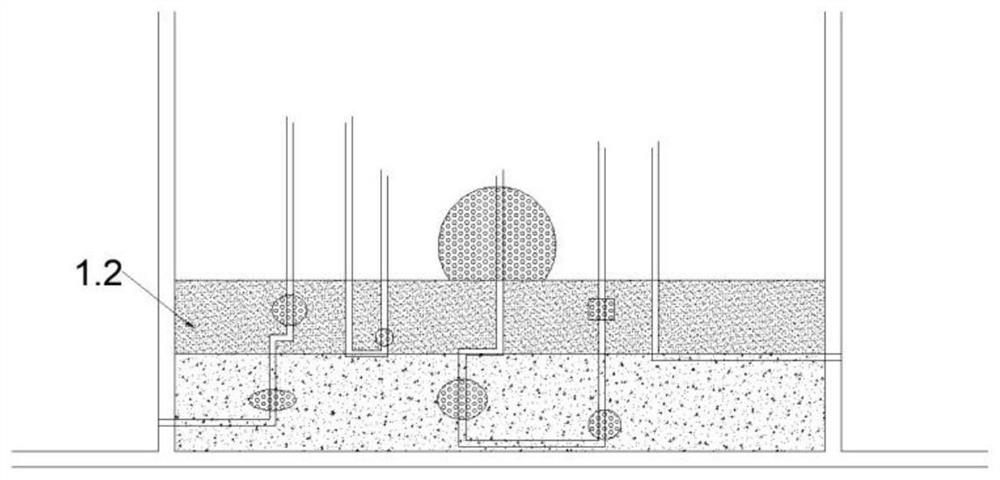

Construction method of cast-in-place pile passing through karst cave

The invention discloses a construction method of a cast-in-place pile passing through a karst cave. Firstly, the existing technology is used in drilling a hole on an upper covering layer of the karstcave, and then the expandable enclosure device is lowered into the karst cave by hoisting equipment. When the expandable enclosure device is lowered to the middle position of the karst cave, the expandable enclosure device is opened by inflating the air bag. Expanding materials are filled into the top and the bottom of the expandable enclosure device, so that the gap between the expandable enclosure device and the top and the bottom of the karst cave is filled up. After that, the air bag is recovered, and the pile hole drilling construction is carried out on the rock stratum at the bottom of the karst cave until the drilling depth reaches the designed depth of the pile body. The hole forming quality of the pile hole is detected, and the next step is carried out when the detection is qualified. The reinforcement cage is put down, and the concrete is poured into the pile body by the guide pipe. After the pile body is solidified, the construction of the cast-in-place pile is finished. Theconstruction method has the advantages of simple construction process, low cost, improved bearing capacity, small disturbance to the geological environment of the karst cave and the like.

Owner:HUBEI UNIV OF TECH

Low-cost wall brick

InactiveCN106220143AMaterial selection scienceThe preparation method is simple and easyCeramic materials productionClaywaresIndustrial constructionBrick

The invention discloses a low-cost wall brick, belonging to the technical field of building materials. The low-cost wall brick is prepared from the following raw materials: 20-30 parts by weight of cinder, 35-45 parts by weight of construction waste soil, 25-28 parts by weight of grinding wheel ash, 3-5 parts by weight of straw, 5-10 parts by weight of limestone, 1-2 parts by weight of vermiculite and 80-90 parts by weight of river water; the low-cost wall brick is prepared by the steps of pre-activating, crushing, aging in a sealing way, making adobe, drying and sintering. The low-cost wall brick is scientific in material selection and fully utilizes industrial construction waste, thus reducing the production cost and increasing the enterprise profit; a preparation method of the low-cost wall brick is advanced, and improves the activity and adhesiveness of raw materials through a pre-activating method so as to enable the raw materials to be blended together closely; therefore, the low-cost wall brick is close in texture, non-powdered, high in compressive strength and wear resistance and good in anti-cracking performance, can be used for a long time in a low-temperature environment, and is long in service life, wide in use and strong in adaptability to construction.

Owner:滁州市瑞景园林股份有限公司

Preparation method of multi-karst-cave geological model

ActiveCN111739397AStrong construction adaptabilityImprove applicabilityEducational modelsMining engineeringKarst

The invention discloses a preparation method of a multi-karst cave geological model. The preparation method comprises the steps: firstly, extracting information of a to-be-simulated geological model;then preparing a similar simulation material, a model box, a karst cave core model and a solvent flow pipe according to the extracted geological model information; secondly, selecting corresponding sizes of karst cave core molds according to geological model information, placing the karst cave core molds at corresponding positions, connecting the adjacent karst cave core molds in series through solvent circulating pipes to form a circulating pipeline, reserving an inlet and an outlet extending out of the model box at the head end and the tail end of the circulating pipeline, and then injectingthe similar simulation material into the model box for pouring; after curing, injecting a solvent capable of dissolving the karst cave core molds into the circulation pipeline through the solvent circulation device, dissolving and bringing out the karst cave core molds, and forming a simulated karst cave space; and preparing the multi-karst-cave geological model. The method can be used for various models with holes inside, the holes and the surrounding area are integrated, and reality constraint and stress conditions can be better simulated.

Owner:HUBEI UNIV OF TECH

Construction method for expanded reinforced cast-in-situ bored pile with hydraulic extruding and expanding combined bag grouting pile body

The invention relates to a construction method for an expanded reinforced cast-in-situ bored pile with a hydraulic extruding and expanding combined bag grouting pile body. The construction method is characterized by comprising the steps that after drilling is finished, a manufactured reinforcement cage and hydraulic equipment are placed in a drilled hole, a bag grouting extruding and expanding body is wrapped with a bag, then the reinforcement cage is placed in the hole to be subjected to hydraulic extruding and expanding, and finally bag grouting and concrete pouring are carried out. The construction method comprises the steps of drilling and forming the hole, manufacturing the reinforcement cage, installing a steel sleeve, an expansion plate, the bag and the like, installing the hydraulic equipment, lowering the reinforcement cage, hydraulic extruding and expanding construction, grouting the bag, pouring the concrete, and cleaning and maintenance of the hydraulic equipment. The extruding and expanding body can be unfolded in a corresponding soil layer, and reinforcing ribs are arranged in the extruding and expanding body, so that the strength of the extruding and expanding body and the interface strength between the extruding and expanding body and a pile body are improved, the contact area between the extruding and expanding body and the soil body is increased, the uplift bearing capacity is improved, the length and the distance of the cast-in-place pile are reduced, the cost is reduced, and resources are saved.

Owner:中煤长江基础建设有限公司

Antifreeze wall brick

The invention discloses an antifreeze wall brick, and the antifreeze wall brick is prepared from the following raw materials by weight: 30-40 parts of basalt, 5-8 parts of bamboo scraps, 20-25 parts of calcite, 20-30 parts of river silt, 10-20 parts of chalk soil, 50-100 parts of water, 5-10 parts of grinding wheel ash and 5-15 parts of montmorillonite by pre-activation, crushing, sealing aging, blank forming, drying and sintering. The preparation method is scientific, and the antifreeze wall brick is convenient to make, low in production cost and good in economic effect. The antifreeze wall brick is prepared from waste residues, energy is saved, the ecological environment is protected, the prepared antifreeze wall brick is strong in frost resistance, high in strength, fine and close in texture, free of crack and resistant to wear and tear, can be used under the condition of low temperature for a long time, and has strong construction adaptability.

Owner:安徽琮玥工程项目管理有限公司

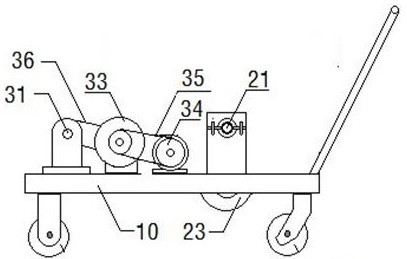

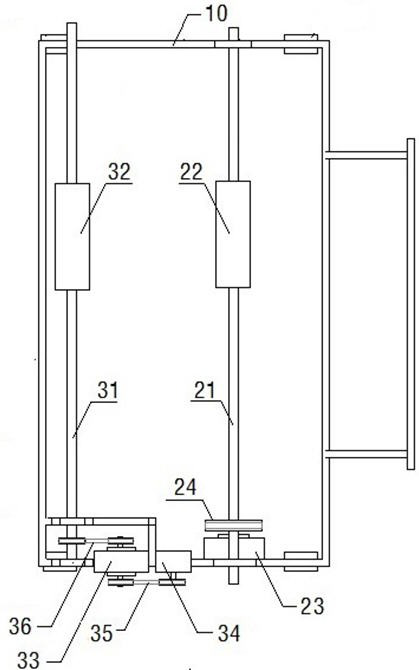

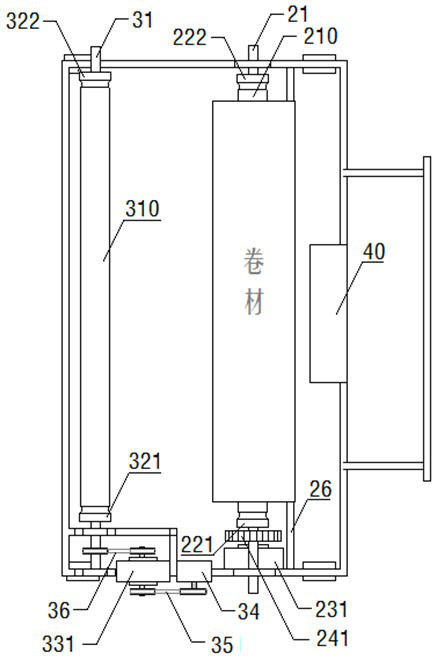

Coiled material waterproof laying equipment and coiled material waterproof laying method

PendingCN113800304AGuaranteed to lay flatOvercome the defect that the waterproof layer is prone to wrinklesProtective foundationBridge erection/assemblyArchitectural engineeringElectric machinery

The invention discloses coiled material waterproof laying equipment and a coiled material waterproof laying method, and belongs to the field of waterproof buildings. The equipment and method are used for integrated equipment operation in the waterproof construction processes such as coiled material unfolding, film collecting, laying, coiled material unfolding, film collecting and discharging, and the equipment comprises an unfolding shaft and a film collecting shaft which are rotationally connected to an equipment support. Core shaft tube locking devices are respectively mounted on the unfolding shaft and the film collecting shaft and are used for locking and fixing the coiled material and collecting the core shaft tube. An unfolding torque limiting device is used for providing tension required for unfolding the coiled material by the unfolding shaft. And a film collecting motor provides the film collecting tension required by the film collecting shaft for the recovery of a coiled material anti-sticking isolating film through the film collecting torque limitation. The equipment and method are mainly applied to spreading and laying of wet-laid or self-sticking waterproof coiled materials and discharging construction of the coiled materials.

Owner:河南舜禹防水工程有限公司

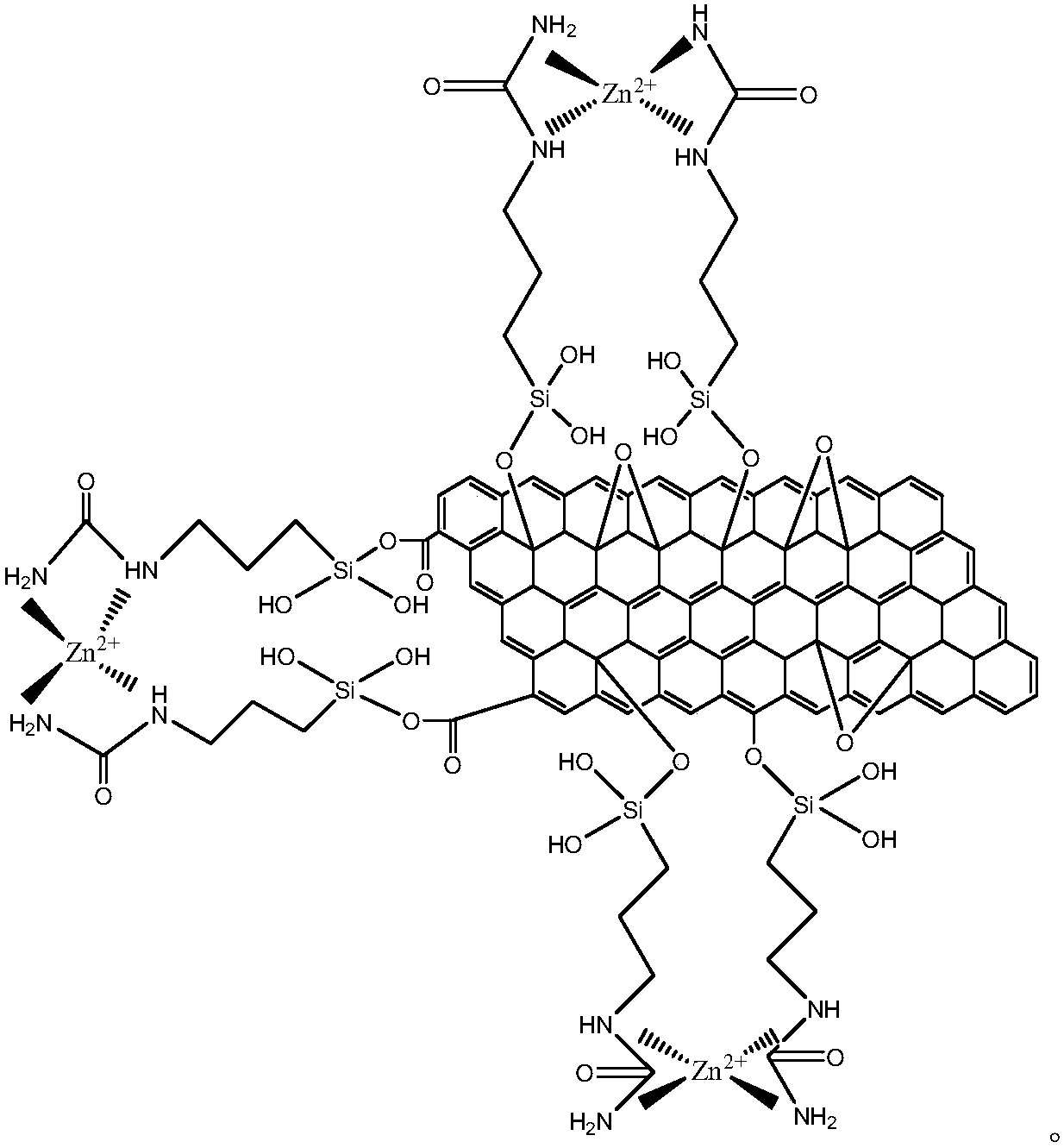

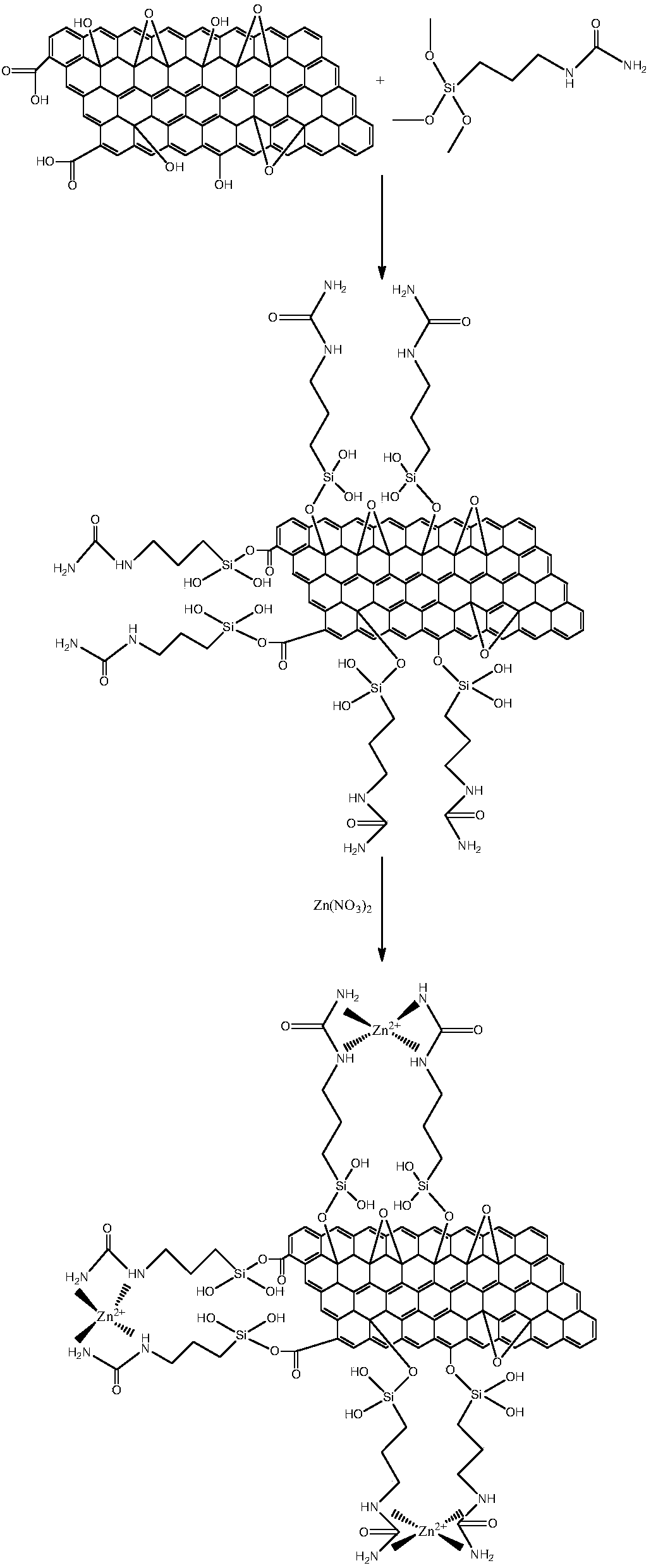

Metal base waterborne graphene modified long-lasting anticorrosive paint and preparation method thereof

ActiveCN109161258AIncrease the degree of cross-linkingGood weather resistanceAnti-corrosive paintsSolventPollution

The invention belongs to the technical field of anticorrosive coatings, and specifically relates to a metal base waterborne graphene modified long-acting anticorrosive paint and a preparation method thereof. The metal base waterborne long-lasting anticorrosive paint comprises the following raw materials in parts by weight: 40-50 parts of composite modified styrene-acrylic emulsion, 10-20 parts ofmodified graphene, 15-25 parts of pigment, 0.5-1 part of an antifoaming agent, 0.3-0.8 part of a leveling agent, 0.5-1 part of a waterborne drier, 0.5-1 part of a wetting agent, 0.8-1.2 parts of an anti-settling agent, 0.1-0.5 part of a dispersant, and 20-35 parts of deionized water. The preparation method comprises: (1) preparation of modified graphene; (2) pigment surface modification; and (3) preparation of the waterborne paint. The metal base waterborne graphene modified long-acting anticorrosive paint has the advantages of long-lasting excellent anticorrosive performance, strong base adhesion, high mechanical strength, excellent friction resistance, excellent solvent resistance and weather resistance, strong construction adaptability and the like; the preparation method is simple, easy to operate, low in raw material and energy consumption costs, environmentally-friendly and pollution-free; the coating is quickly dried, and the construction period is short.

Owner:广东绿色大地化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com