Aqueous inorganic zinc rich paint

An inorganic zinc-rich paint, water-based technology, applied in anti-corrosion coatings, coatings, etc., to achieve high strength, good air permeability, and enhanced high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation of the present invention will be described below in conjunction with the examples.

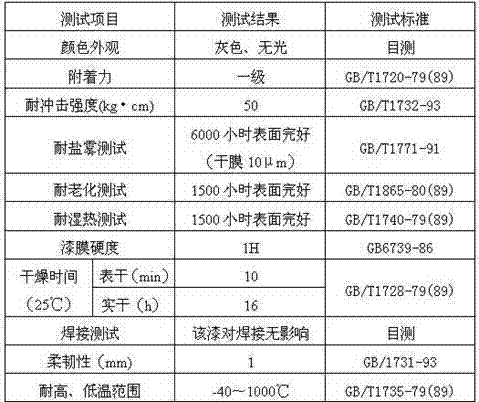

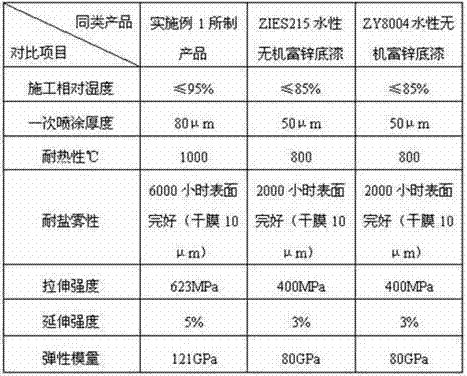

[0038] See Table 1 for the components and contents of the water-based inorganic zinc-rich paints in Examples 1-4.

[0039]

[0040] Table 1

[0041]

[0042] The preparation technology of water-based inorganic zinc-rich paint in embodiment 1~4 is as follows:

[0043] Weigh the ingredients contained in component A according to Table 1, firstly mix 500 mesh, 800 mesh, 1250 mesh spherical or flaky zinc powder, rare earth nano ceria and 800 mesh talc powder with a mixer and mix them evenly 20 min, the speed of the mixer is 40-150 rpm, and the A component is obtained.

[0044] Weigh the ingredients contained in component B as shown in Table 1, first fully stir potassium silicate and lithium silicate with a mixer for 20 minutes, and the speed of the mixer is 400-500 rpm; then slowly add potassium titanate whiskers to the above in the mixture,

[0045] Whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com