Patents

Literature

190results about How to "Facilitate industrialized mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive heating material, floor comprising same and manufacturing method

InactiveCN101600270AFacilitate industrialized mass productionLighting and heating apparatusElectric heating systemEpoxyCarboxymethyl cellulose

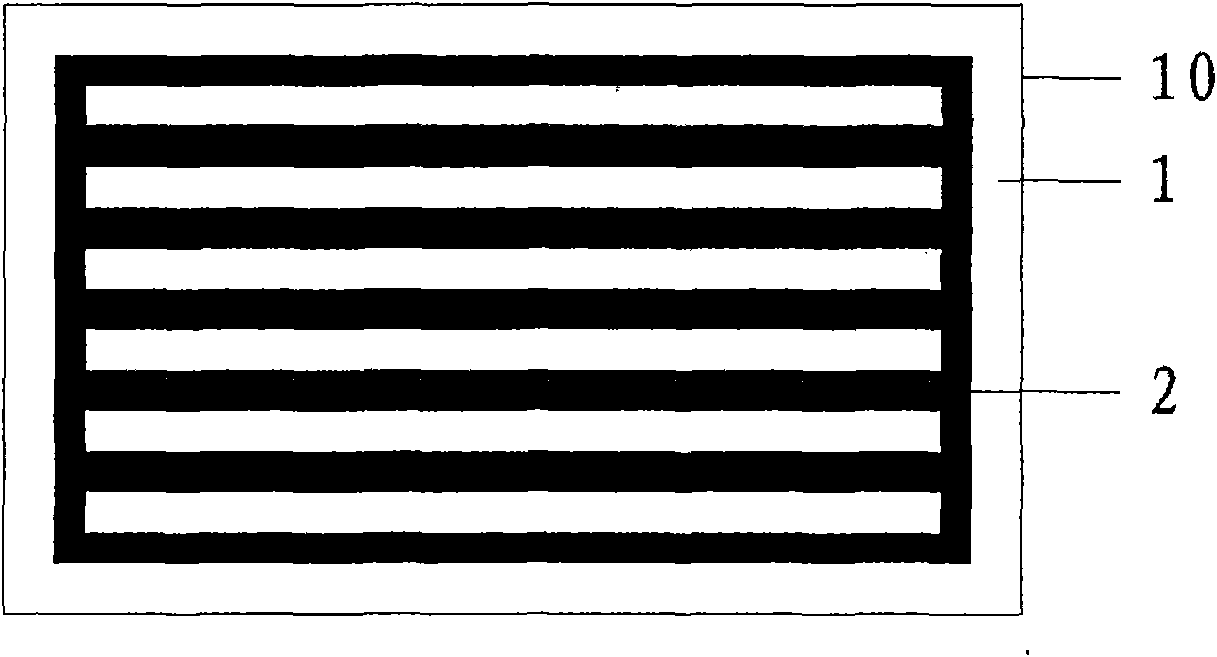

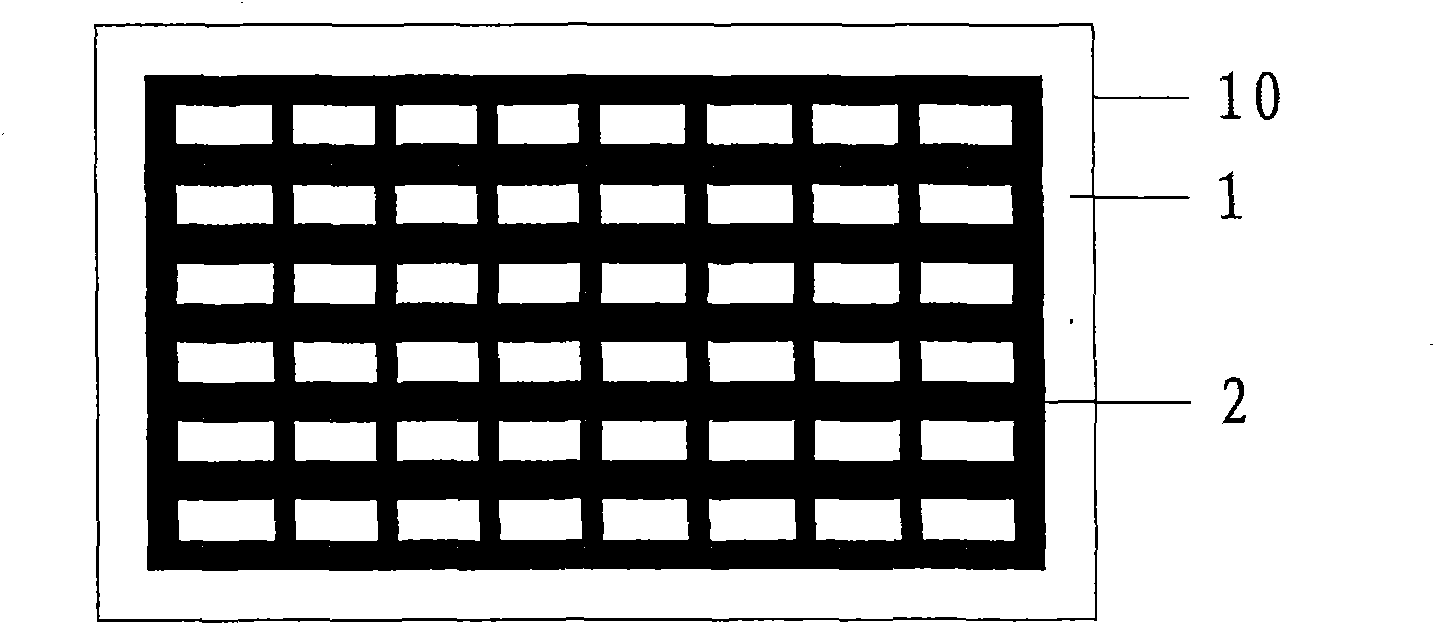

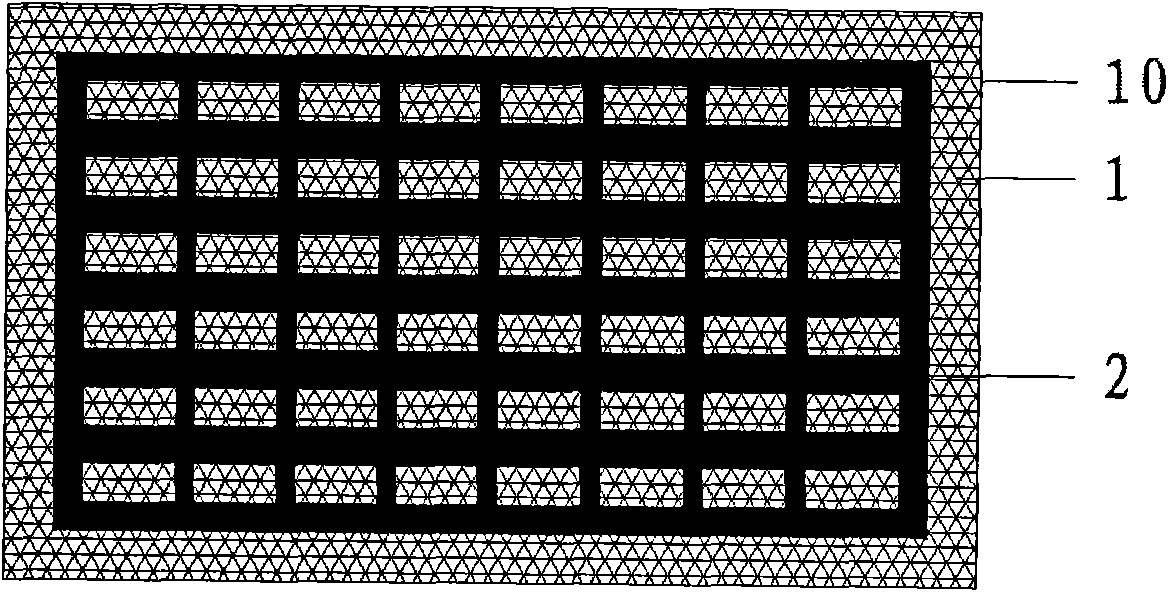

The invention relates to a conductive heating material. The material comprises a substrate and a conductive heating layer evenly adhered to the substrate, wherein the conductive heating layer is made from a conductive heating coating material; the conductive heating coating material comprises a conductive heating base material and a bonding agent; the conductive heating base material is selected from natural graphite, artificial graphite and conductive carbon black; the bonding agent is selected from acrylic resin, epoxy resin, polyurethane resin, glutin, carboxymethyl cellulose, polyvinyl alcohol, and the like; and the substrate can adopt paper in a plurality of practical implementation modes. The conductive heating material can be used to make the conductive heating floor; the surface temperature of the floor can reach 15 to 70 DEG C within 5 minutes after the floor is energized with 220V voltage; moreover, the floor can maintain stable temperature for a long time. Therefore, the conductive heating floor can be used to replace the prior ground heating system and has low cost, reliable operation, energy saving, environmental protection and convenient maintenance and replacement.

Owner:上海尚兰格暖芯科技有限公司

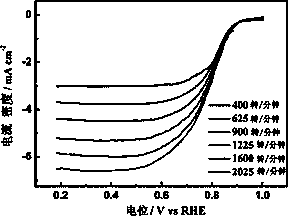

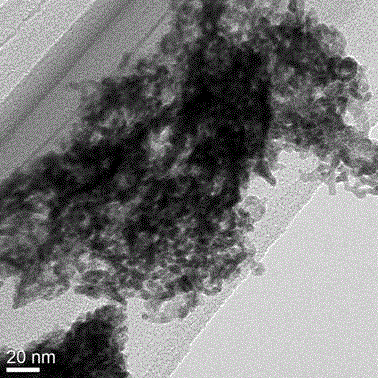

Porous nano composite material for fuel cell oxygen reduction catalyst

InactiveCN103811775AImprove cycle stabilityEasy to operateMaterial nanotechnologyPhysical/chemical process catalystsPorous carbonOxygen

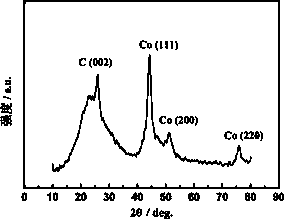

The invention discloses a porous nano composite material for a fuel cell oxygen reduction catalyst, and is an M-N-C porous nano composite material, wherein M in M-N-C refers to base metal ferrum, cobalt or nickel, N refers to nitrogen, and C refers to carbon; small-particle-size metal nano particles are uniformly dispersed and embedded in a nitrogen-doped porous carbon carrier material; the base metal nano particles have the particle size range being 5-100nm; the mass percentage of nitrogen contained in the porous carbon carrier is 3-7%. The porous nano composite material for the fuel cell oxygen reduction catalyst, which is provided by the invention, has the advantages that because of the in-situ nitrogen doping of a carbon substrate, the implant of base metal nano particles in uniform distribution and the formation of the porous structure with high specific area, the catalytic oxygen reduction capability of the porous nano composite material is improved obviously, and the cycle stability of the material is improved; a precursor prepared by the composite material is low in cost, is easy to prepare, is controlled easily in the preparation process, is simple to operate, and facilitates industrial large-scale production.

Owner:NANKAI UNIV

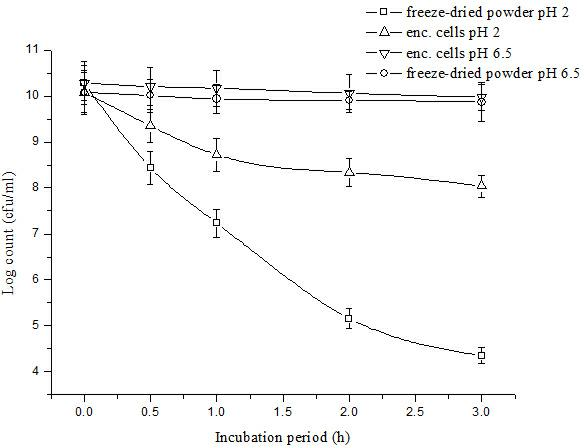

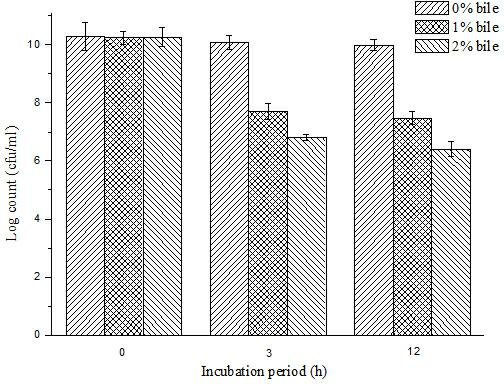

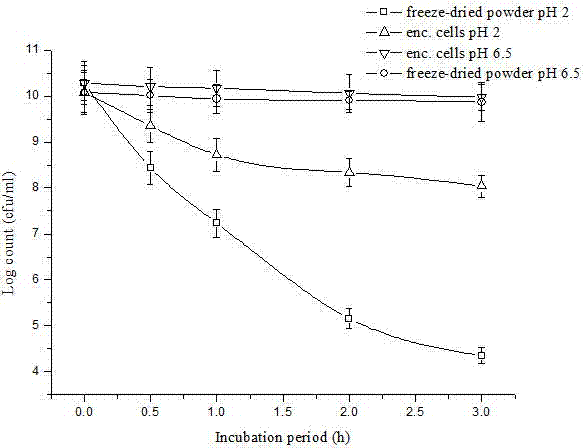

Bifidobacterium microcapsule and preparing method thereof

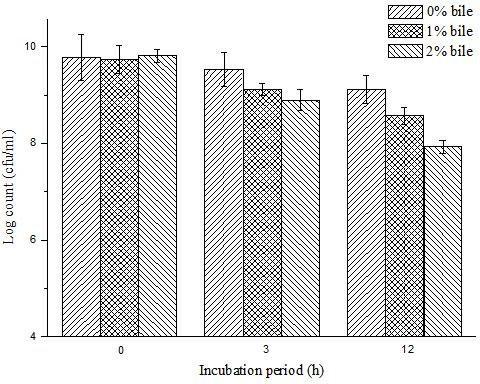

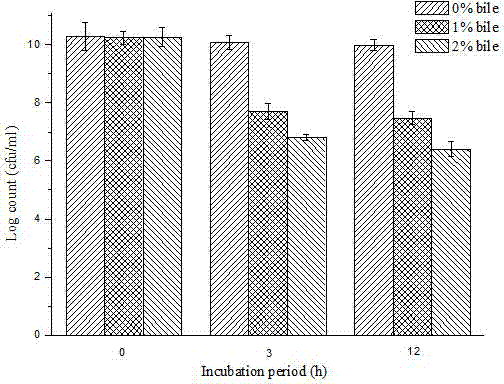

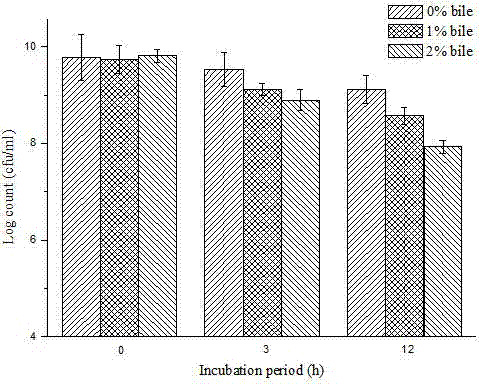

ActiveCN102210659AResistant to gastric acidBile salt resistantMetabolism disorderBacteria material medical ingredientsFreeze-dryingHigh survival rate

The invention specifically relates to a bifidobacterium microcapsule and a preparing method thereof. The bifidobacterium is obligatorily anaerobic and very sensitive to oxygen, PH, temperature, humidity, and other adverse external environment, thereby being very hard to remain activity during production, storage and transport; besides, if taken orally in a form of dry bifidobacterium powder, the bifidobacterium cannot tolerate low-pH value gastric acid, bile salt, and other environments, so a purpose that massive survived bifidobacteria arrive at an intestinal tract and colonise on the intestinal mucosa is hard to be guaranteed. The preparing method disclosed by the invention comprises the following steps of: adding freeze-dried bifidobacterium powder into a sodium alginate solution and then mixing in soybean oil, emulsifying the mixed solution and standing; centrifugally collecting micro-capsules; and drying the micro-capsules by using a vacuum freeze-drying technology. The bifidobacterium microcapsule disclosed by the invention has the advantages of gastric acid resistance, bile salt resistance and entericsolubility, high survival rate of bifidobacterium, simple preparation method, strong practicality, convenience for industrial production, and excellent storage stability and solves the problem of short storage period of probiotics preparations.

Owner:SHAANXI GIANT BIOTECHNOLOGY CO LTD

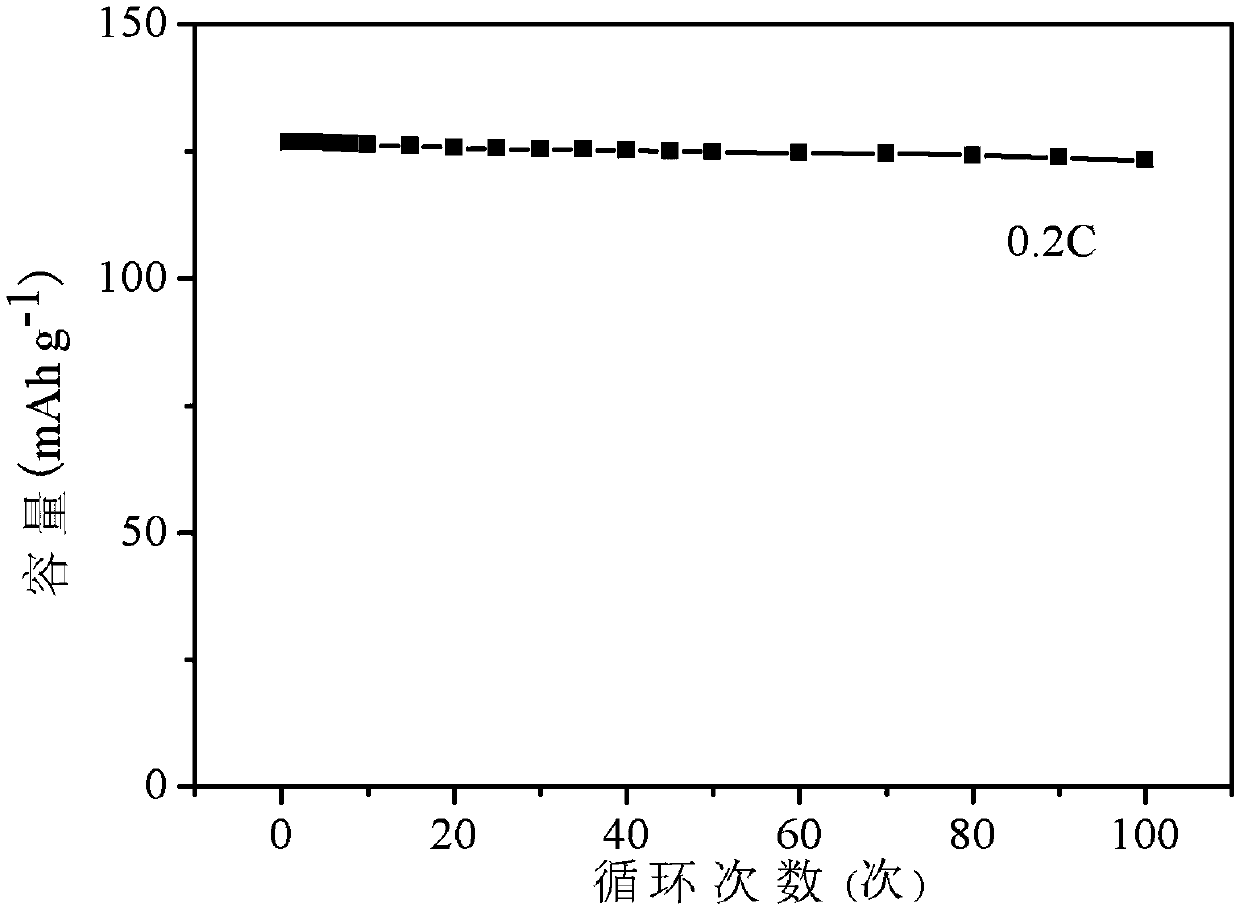

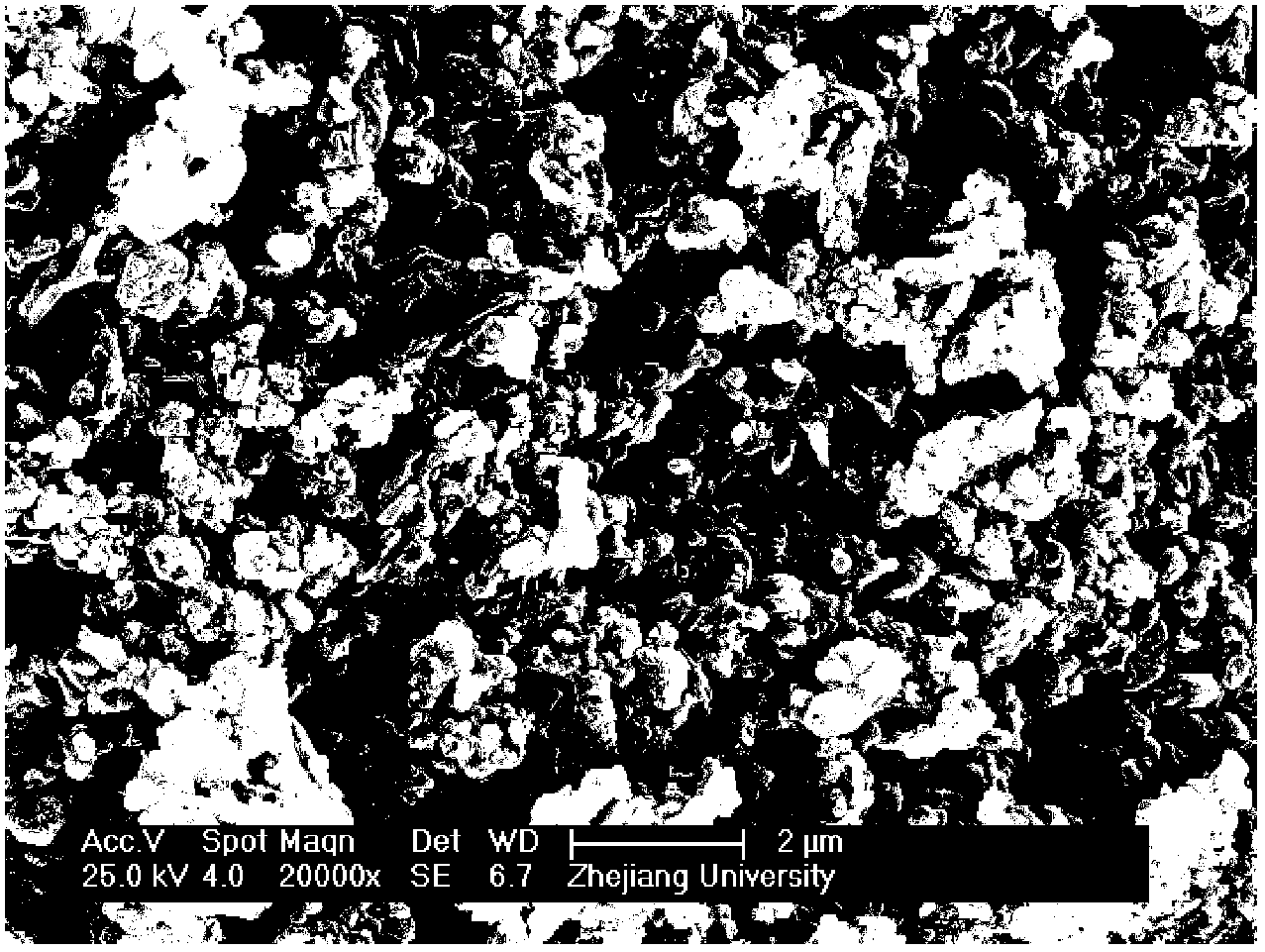

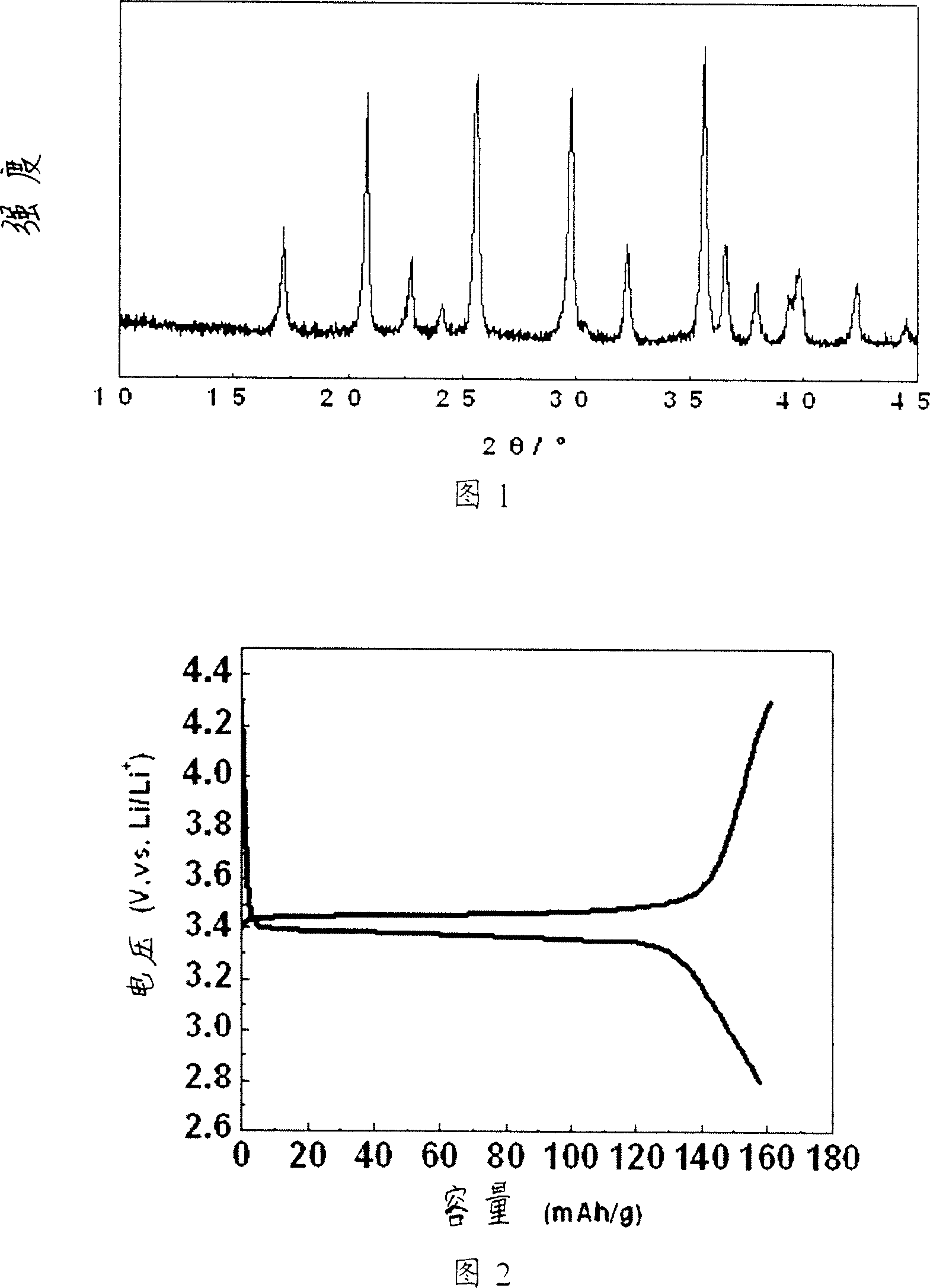

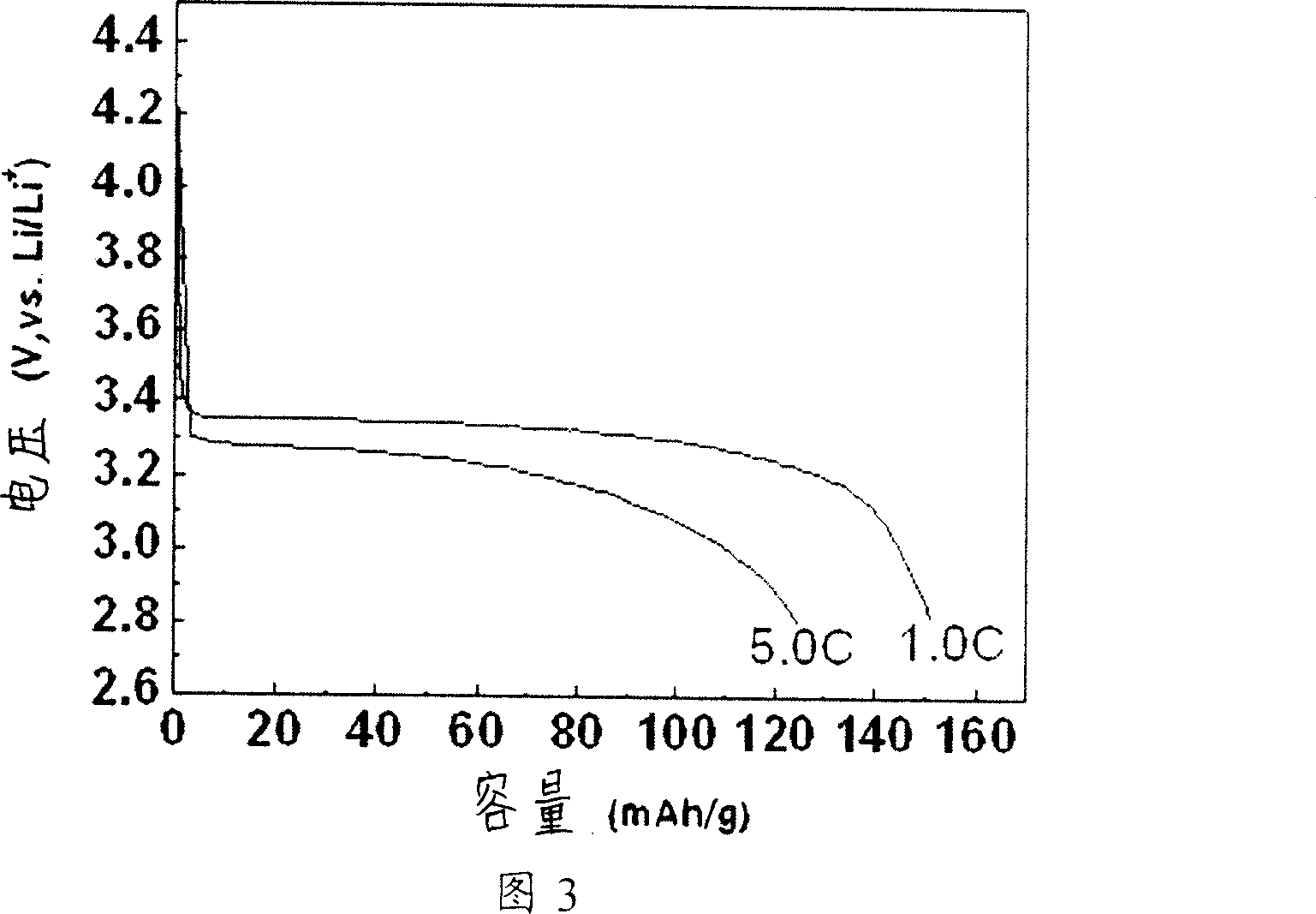

Spherical LiFexMnyPO4 anode material and preparation method thereof

InactiveCN105514430AImprove electrochemical performanceIncrease energy densityCell electrodesSecondary cellsEthylene diamineLithium

The invention discloses a spherical LiFexMnyPO4 anode material. A formula of the LiFexMnyPO4 anode material is LiFexMnyPO4, wherein x+y=1. A preparation method of the LiFexMnyPO4 anode material comprises the following preparation steps: (1) weighing an Li source, an Fe source, an Mn source and a P source, and adding into deionized water, wherein a mole ratio of the Li source, the Fe source, the Mn source and the P source is (1.0 to 1.2):x:y:(1.0 to 1.5), and x+y=1; (2) adding a carbon source compound in a solution I, and uniformly stirring to form a solution II; (3) adding a surfactant in the solution II, and stirring to obtain a solution III; (4) adding EDTA (Ethylene Diamine Tetraacetic Acid) in the solution III, and stirring to obtain a solution IV; (5) putting the solution IV in a high-pressure reaction kettle, and carrying out a hydrothermal reaction under 180 DEG C to obtain a solution V; (6) obtaining an LiFexMnyPO4 precursor after cooling the solution V; (7) putting LiFexMnyPO4 precursor powder in a tubular calcining furnace, and obtaining a carbon-coated spherical LiFexMnyPO4 anode material through grinding after cooling.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Silkworm pupa oil and extracting method and applications

InactiveCN101278743AReduce extraction timeReduce energy consumptionAnthropod material medical ingredientsMetabolism disorderSolventPharmacological action

The invention provides silkworm pupa oil, an extracting method and an application thereof. The silkworm pupa oil consists of the following components with the weight percentage of 0.2 percent of hexadecanoic acid, 1.0 percent of palmitoleic acid, 27.2 percent of oleic acid, 10.7 percent of linoleic acid, 54.6 percent of alpha-linolenic acid and 6.3 percent of other unsaturated acids. The extracting method of the silkworm pupa oil extracts unsaturated fatty acid in the silkworm pupas by a method which combines a microwave extracting technology and urea clathration. The application of the silkworm pupa oil is that the silkworm pupa oil is applied to effectively reducing the blood sugar and the level of diabetic and is especially used for preventing and curing the diabetes. The silkworm pupa oil has the advantages of shortening extracting time, reducing energy consumption, reducing solvent dosage, improving the content of necessary fatty acid and especially the content of the alpha-linolenic acid in the silkworm pupa which benefit human body, reducing the oxidative damage to the unsaturated fatty acid, protecting a double-health structure, economic and simple extracting method, being grasped easily, being convenient for realizing industrialized mass production, the more outstanding pharmacological action of the silkworm pupa oil represented in the aspect of reducing blood sugar, etc.

Owner:ZHEJIANG UNIV CITY COLLEGE

Flavor mushroom pickled vegetable product and preparing method thereof

InactiveCN101584446AFacilitate industrialized mass productionUnique flavorFood preparationEdible mushroomFood flavor

The present invention discloses a flavour mushroom pickled vegetable product and a preparing method thereof, and relates to the pickled vegetable product fermented by edible mushroom and a preparing method thereof. The preparing method comprises the following steps: selecting the mushrooms, cleaning, boiling, preparing the pickling water, pickling, mixing, packaging, sterilizing, etc. The flavour mushroom pickled vegetable product of the invention has the advantages of unique flavour, delicious taste, tender mouthfeel, excellent softness, crisp mouthfeel and better taste. The flavour mushroom pickled vegetable product of the invention is a delicious, nutritious, healthy and convenient food which integrates the functions of supplementing nutrition, nourishing and regulating the immunity of human body.

Owner:朱新成 +2

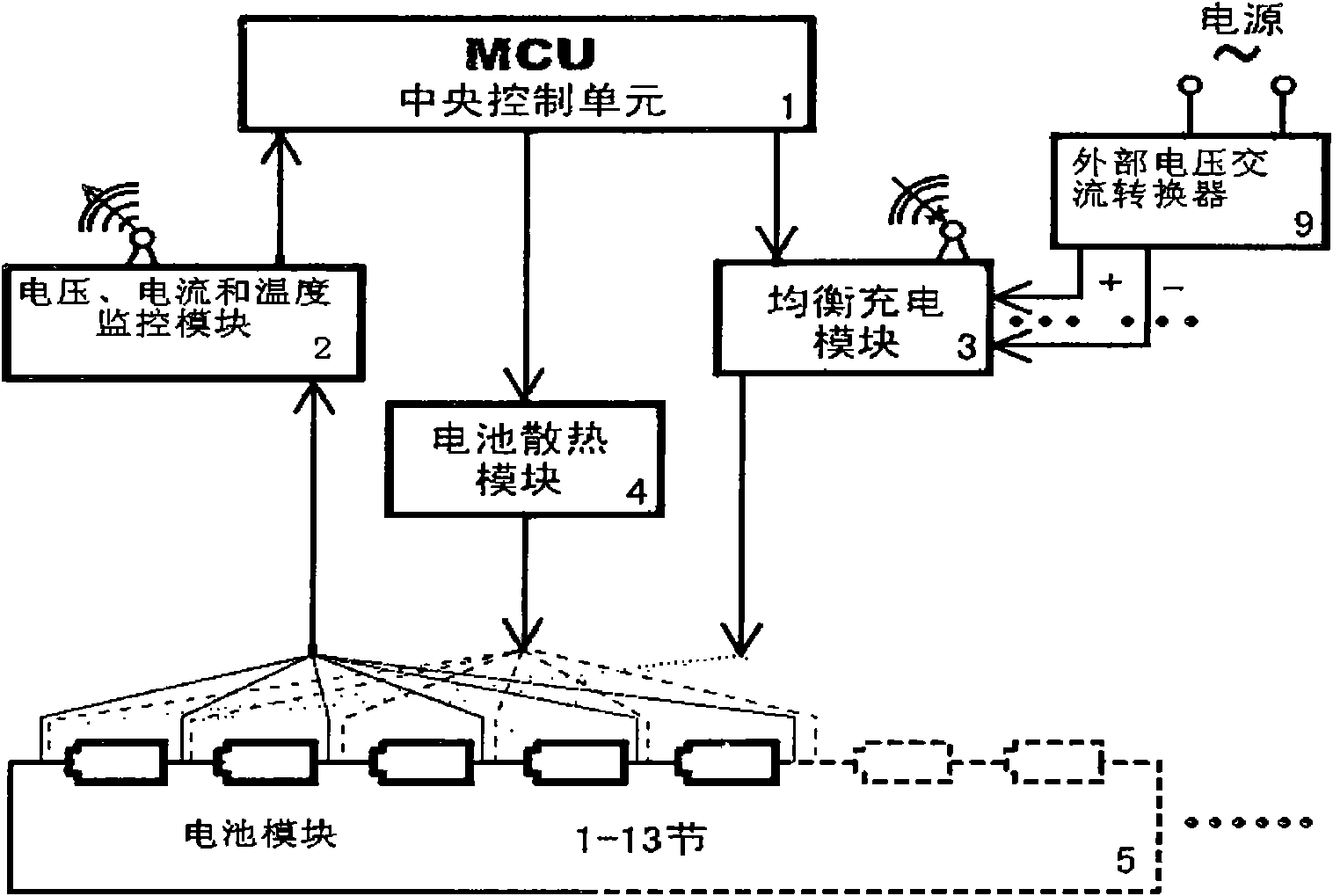

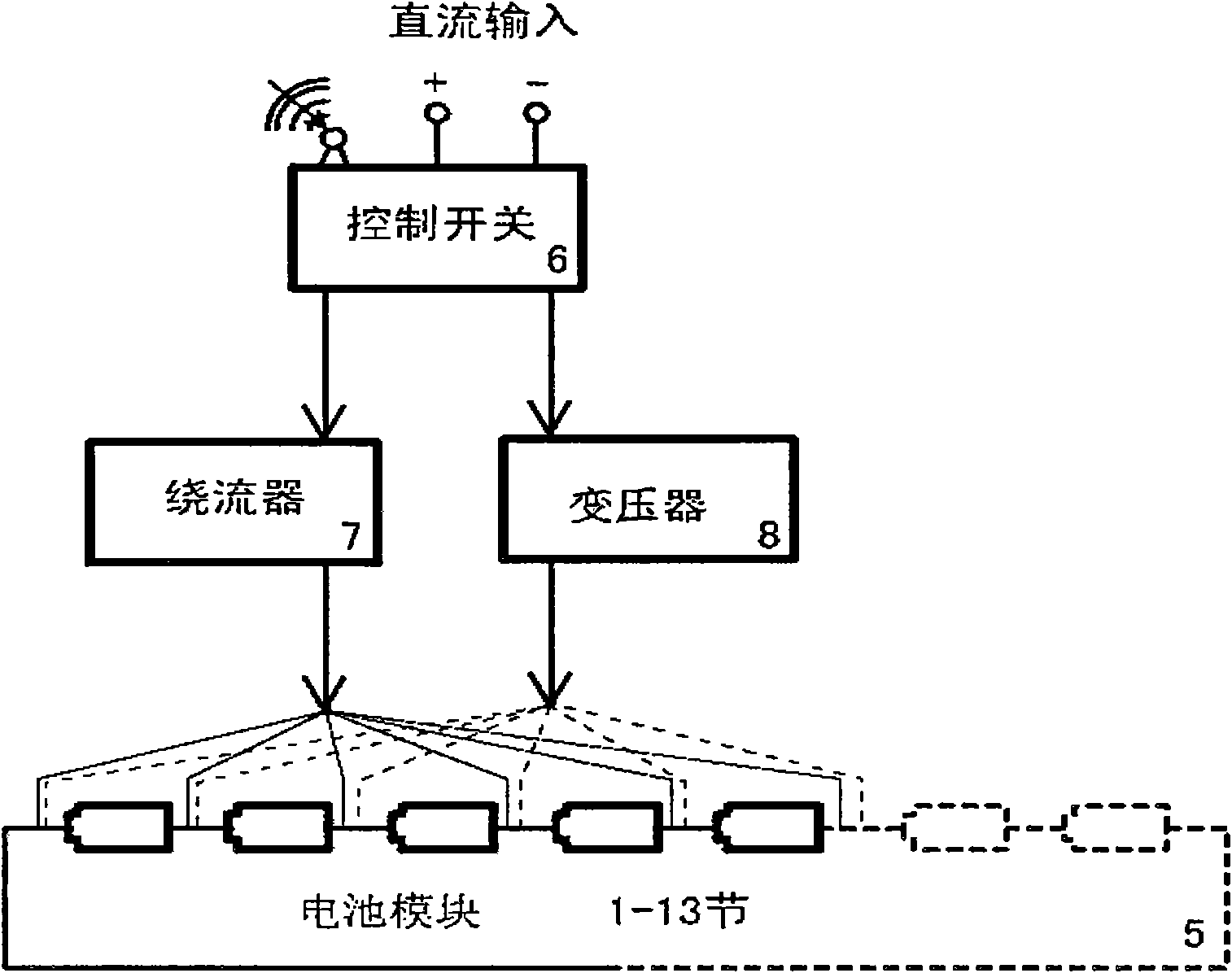

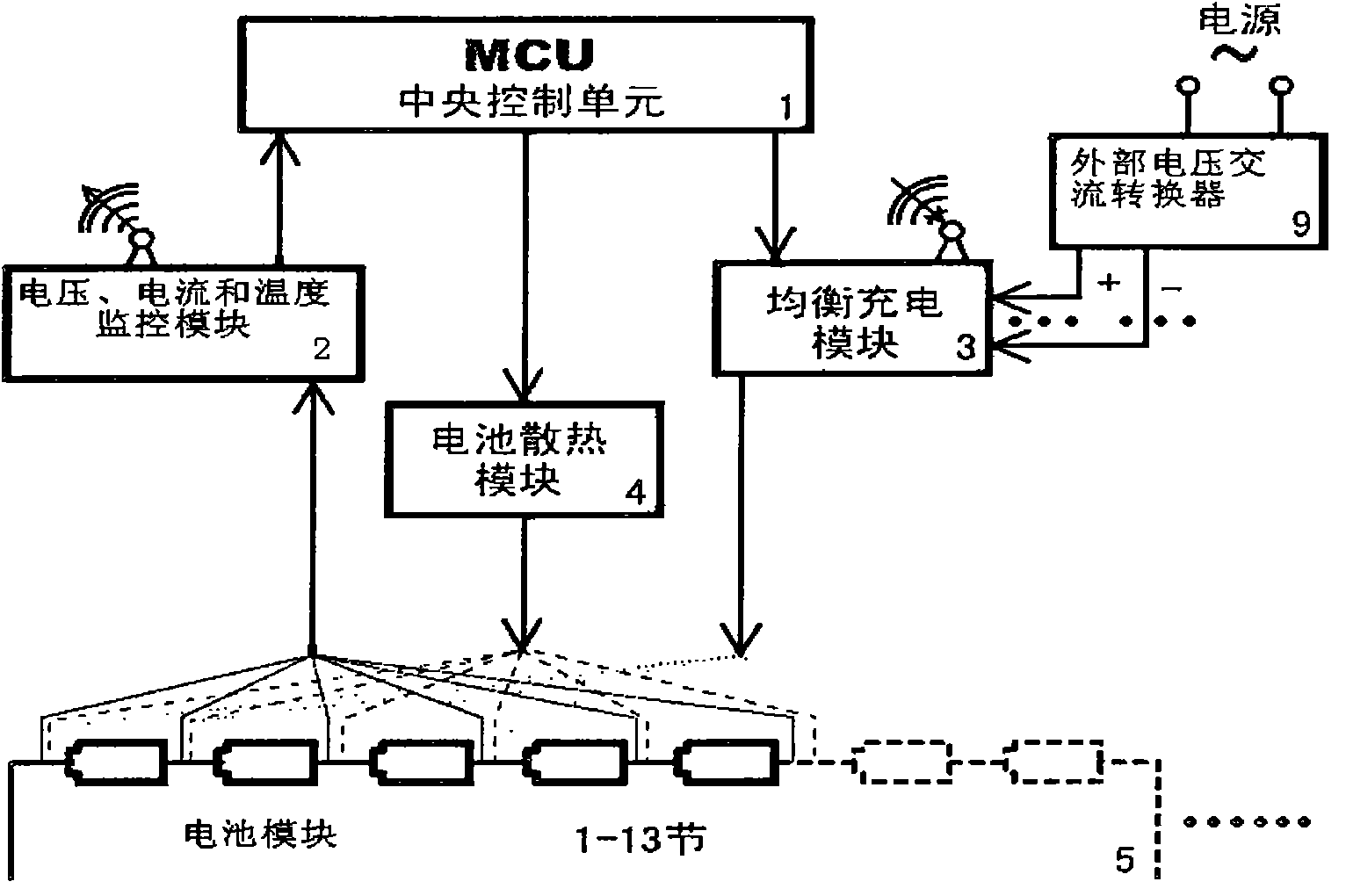

Equalizing charge management system of lithium ion power battery pack

InactiveCN101938015AShorten charging timeSimple circuit structureBatteries circuit arrangementsElectric powerControl switchLithium

The invention discloses an equalizing charge management system of a lithium ion power battery pack. The system comprises an external voltage alternating current converter, an MCU central processing unit, a voltage, current and temperature monitoring module used for monitoring battery information, a plurality of equalizing charge modules, a battery heat radiating module and a plurality of battery modules, wherein the voltage, current and temperature monitoring module feeds the monitored information back to the MCU; the MCU analyzes the information and sends a command to the equalizing charge modules and the battery heat radiating module to control charge equalization of every battery in the battery modules; each battery module is connected with one equalizing charge module; each equalizing charge module consists of a control switch, a spoiler and a transformer; the control switch is connected with the spoiler and the transformer respectively; the control switch is connected with the external voltage alternating current converter; the spoiler is connected in parallel with the battery modules; and the transformer is connected in parallel with the battery modules. The equalizing charge management system realizes high-current equalizing charge in a mode of early-constant current and later-disturbed flow.

Owner:广东卡达克汽车科技有限公司

Method for preparing lignin sodium sulfonate dispersant through advanced catalytic oxidation

ActiveCN102153764AHigh activityImprove sulfonation effectTransportation and packagingMixingSulfonatePtru catalyst

The invention discloses a method for preparing lignin sodium sulfonate dispersant through advanced catalytic oxidation, comprising the following steps: adding a catalyst to a raw material (black pulp-making liquor containing 20-60% of solid), and subjecting the pulp-making liquor to reaction for 15-120 minutes at the reaction temperature of 30-95 DEG C; adding an oxidant, subjecting the pulp-making liquor to reaction for 15-120 minutes at the reaction temperature of 30-95 DEG C, adding an acidity regulator to regulate the pH value of a reaction system to 10.5-13.5, adding alpha-hydroxymethyl sodium sulfonate, subjecting the materials to reaction for 3-8 hours at the reaction temperature of 95-150 DEG C, decreasing the temperature, and discharging the product which is brown-black liquor, and carrying out spray-drying to obtain brown solid powder. The prepared dispersant has various functions of dispersing, complexing, chelating and the like and can be used in various fields of the dye dispersant, the concrete water reducer, the coal-water slurry additive and the like. The method has the advantages of simple preparation step, low cost, readily available raw material, short production cycle, mild reaction and no discharge of 'three wastes' during production, thereby being a clean and environmental-friendly process.

Owner:FUZHOU UNIV

Acetylated hydroxypropyl potato starch, preparation method thereof and application thereof

InactiveCN101967200AAbundant raw materialsEasy to operateStarch derivtive adhesivesFood preparationFreeze thawingAcetic anhydride

The invention provides acetylated hydroxypropyl potato starch, a preparation method thereof and application thereof. The preparation method comprises the steps of: performing an etherification reaction of potato starch by adopting epoxypropane to obtain hydroxypropyl potato starch; and performing an etherification reaction by adopting acetic anhydride. The acetylated hydroxypropyl potato starch prepared according to the preparation method has the advantages of good hydrophily, vicidity and emulsibility, low pasting temperature, transparent paste liquid, weak retrogradation, high stability, high temperature resistance, acidic environment resistance, high freeze thawing stability and the like.

Owner:内蒙古奈伦农业科技股份有限公司

Octenyl succinate distarch phosphate and preparation method and applications thereof

InactiveCN102070722AAbundant raw materialsEasy to operateCosmetic preparationsToilet preparationsPhosphoric Acid EstersPotato starch

The invention provides a preparation method and applications of octenyl succinate distarch phosphate. The preparation method comprises the following steps: using potato starch and sodium trimetaphosphate (STMP) to perform crosslinking reaction, and then adding octenyl succinic anhydride which is diluted with absolute alcohol to perform esterification reaction. The octenyl succinate distarch phosphate prepared by the method has the advantages that the product has high viscosity and stability, excellent free fluidity and hydrophobicity, good emulsion stability and high temperature resistance, has acid resistance, alkali resistance and saline environment resistance and also has high freeze-thaw stability; and the special properties of potato starch can be maintained.

Owner:内蒙古奈伦农业科技股份有限公司

Silicon-carbon composite negative pole material, preparation method thereof and lithium ion battery using foamed metal as negative pole current collector

InactiveCN102694156ADistribute quicklyEvenly distributedElectrode carriers/collectorsPorosityCarbon composites

The invention discloses a silicon-carbon composite negative pole material, a preparation method thereof and a lithium ion battery using foamed metal as a negative pole current collector, belonging to the field of the lithium ion battery. The lithium ion battery using foamed metal as a negative pole current collector comprises foamed metal used as the negative pole current collector and the silicon-carbon composite negative pole material; the three-dimensional pore conduction network structure and the high porosity of the foamed metal are beneficial to the contact between silicon active substances and the current collector, and the foamed metal has high adhesion strength, so that the great volume effect of the silicon active substances can be well relieved, and the silicon active substances are not prone to fall in the charging / discharging process, thereby effectively promoting the cycling stability of the silicon-carbon composite negative pole material; the silicon-carbon composite negative pole material of which the general formula is Si-C-X has a disperse carrier and a high-capacity lithium-storing material containing the silicon active substances; and the disperse carrier is a carbon material having stable lithium-storing capacity and reversible lithium intercalation / deintercalation performance, thereby obviously improving the capacity and the rate discharging performance of the lithium ion battery.

Owner:DONGGUAN MCNAIR NEW POWER

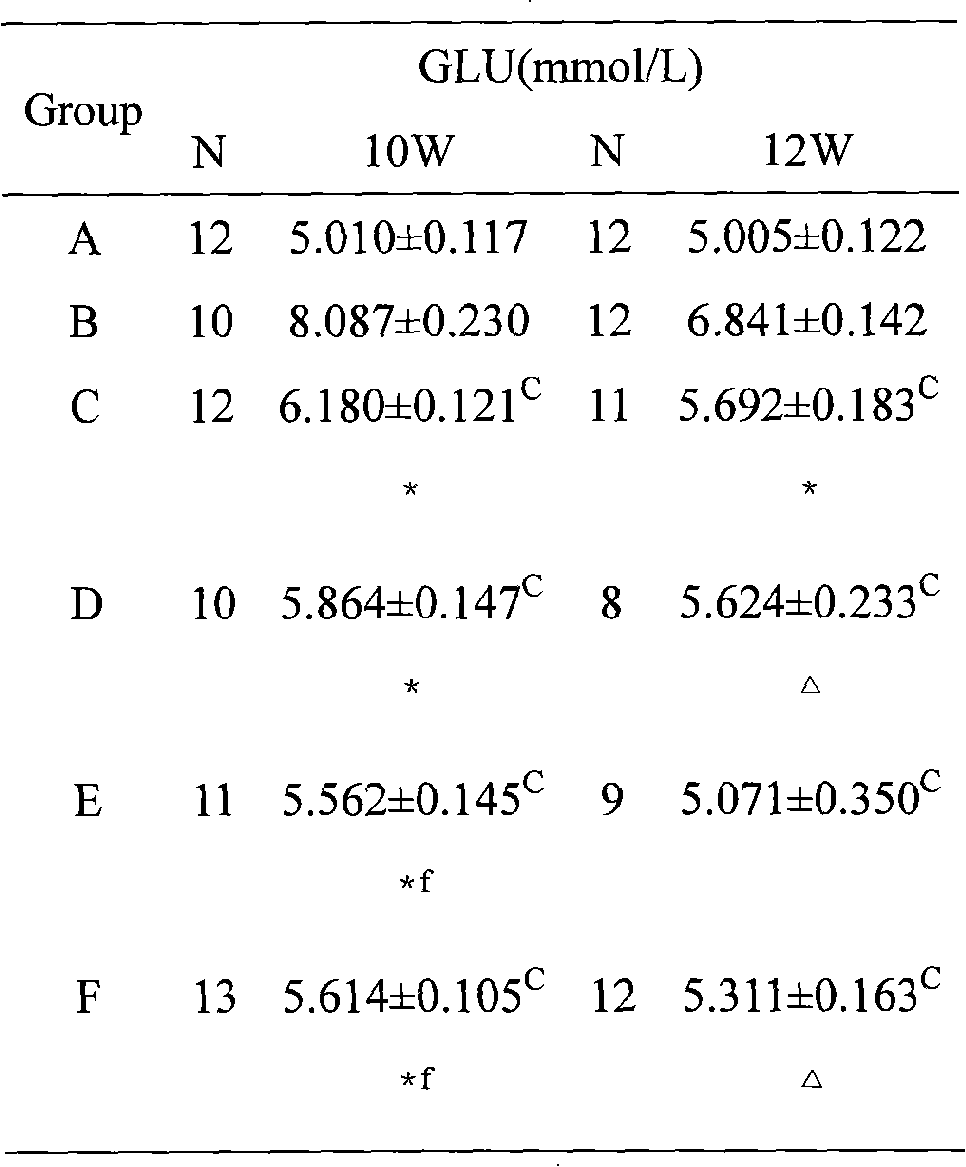

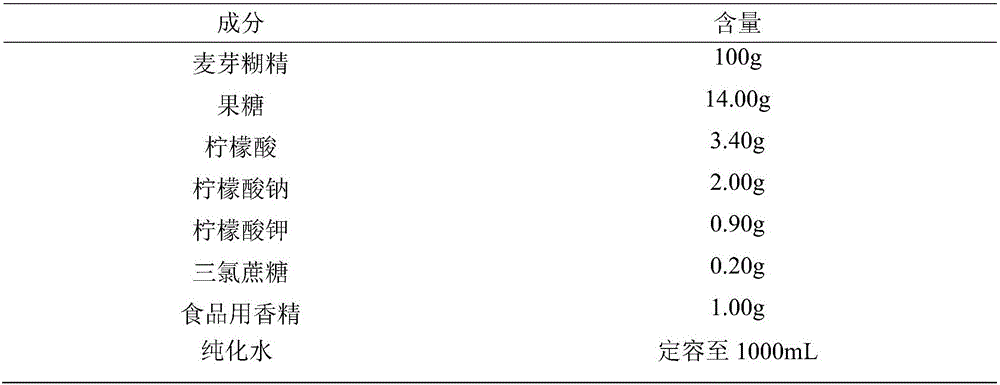

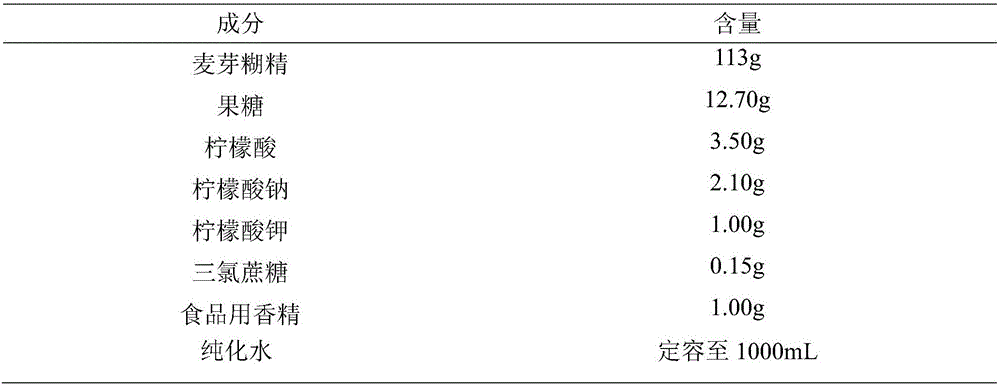

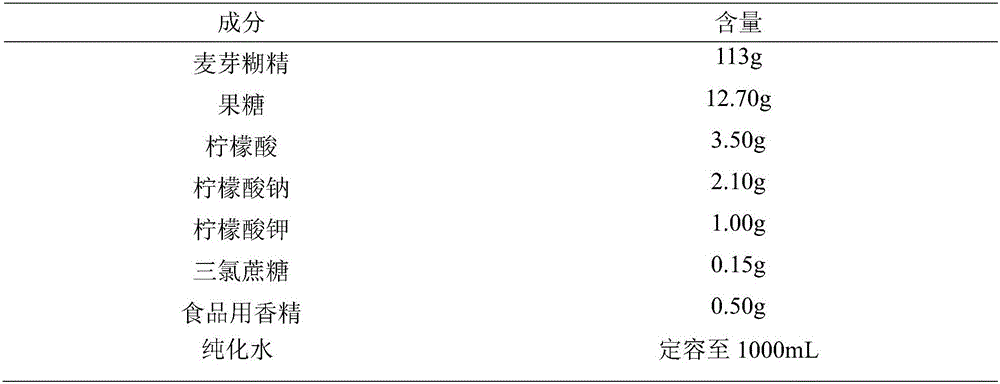

Oral glucose liquid composition

ActiveCN105747208AImprove stabilityEasy to carryOrganic active ingredientsNervous disorderOral glucoseThirst

The invention relates to an oral glucose liquid composition and a preparation method thereof. The composition is prepared from maltodextrin, fructose, citric acid, sodium citrate, potassium citrate, a sweetening agent, a food flavor and a proper amount of purified water, and is mainly used for being orally taken by a patient suffering from perioperative management before an operation. The oral glucose liquid composition is capable of changing the energy storage under a limosis condition of the patient and keeping the carbohydrate metabolism, reducing the postoperative insulin resistance, alleviating preoperative thirst, hunger and anxiety, improving the postoperation subjective symptom of the patient so as to improve consciousness, reducing the body weight loss of emaciated patients, and shortening the hospitalization time.

Owner:JIANGSU CHIA TAI FENGHAI PHARMA

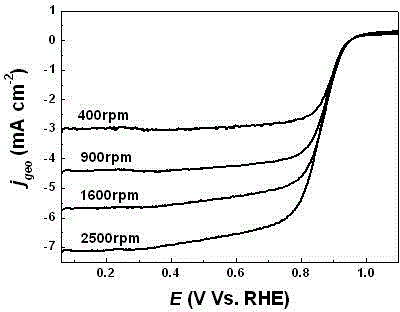

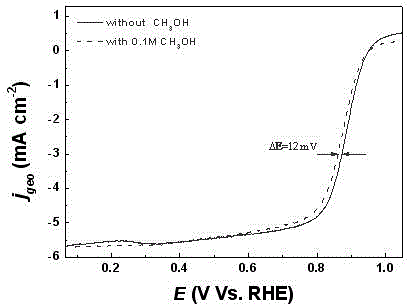

Multicomponent nano porous palladium-base alloy and preparation method thereof

The invention discloses a multicomponent nano porous palladium-base alloy and a preparation method thereof. The alloy has a three-dimensional bicontinuous ligament / channel nano porous structure. The preparation method comprises the following steps: mixing Al powder, Cu powder, Pd powder and X powder together evenly, and then performing ball milling in a ball mill for mechanical alloying treatment, thereby obtaining an Al-Cu-Pd-X precursor alloy; cleaning the Al-Cu-Pd-X precursor alloy in absolute ethyl alcohol firstly, flushing with water, and then putting into a nitric acid solution for de-alloying treatment; washing the alloy obtained after the de-alloying treatment by use of water until the washing water is neutral, next, putting the alloy in water for ultrasonic crushing so that the alloy can be dispersed evenly, and drying after the ultrasonic crushing, thereby obtaining the multicomponent nano porous palladium-base alloy. According to the preparation method of the multicomponent nano porous palladium-base alloy, the precursor alloy is prepared by use of the mechanical alloying method; the process is simple, and the production efficiency is greatly improved; the obtained nano porous palladium-base alloy is relatively small in dimension, has extremely high methanol resistance, stability and catalytic activity, and can be used as a cathode catalyst of a fuel cell.

Owner:张忠华

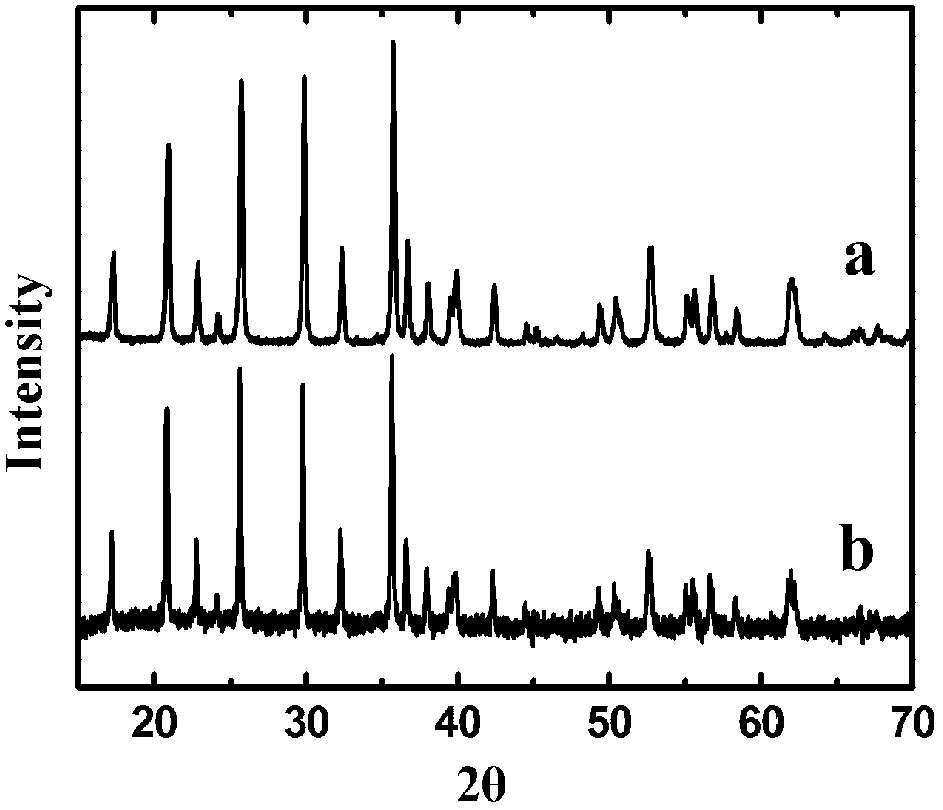

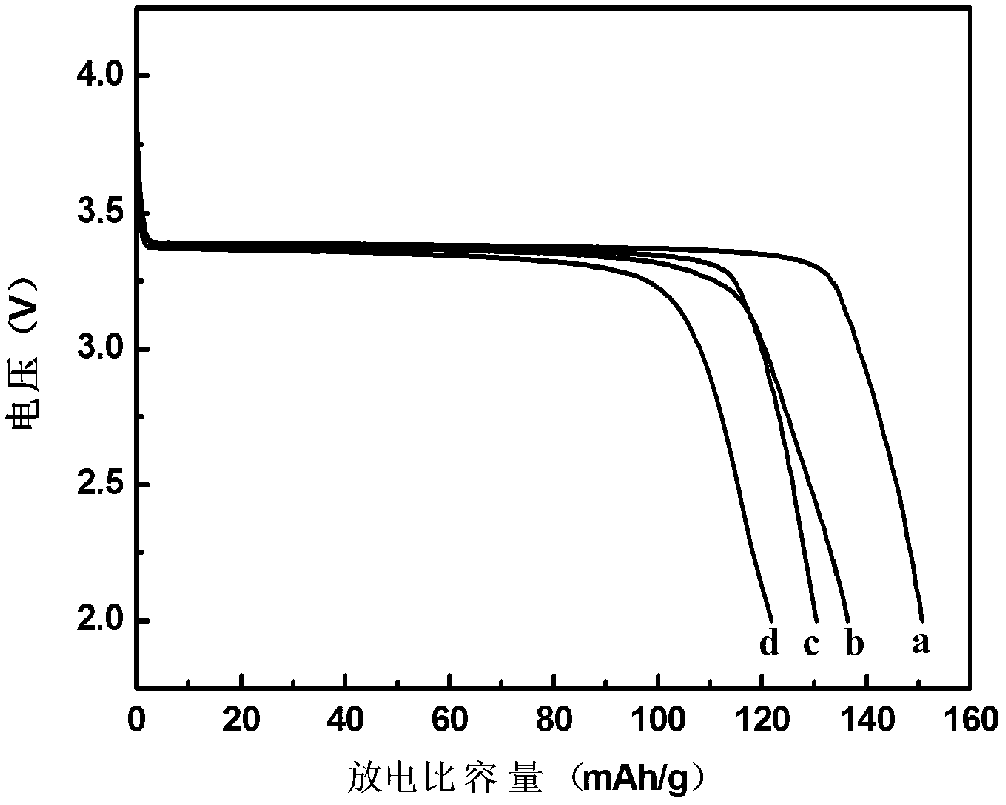

Vanadium-titanium ion-codoped lithium iron phosphate material and preparation method thereof

InactiveCN103078113AHigh discharge specific capacityImprove rate discharge performanceCell electrodesArgon atmosphereControllability

The invention provides a vanadium-titanium ion-codoped lithium iron phosphate (LiFePO4) material and a preparation method thereof. The preparation method comprises the following steps: weighing a lithium source, an iron source, a phosphorus source and a dopant according to the ionic molar ratio of Li<+>, iron ion, Ti<4+>, V<5+> and PO4<3-> as 1: (1-x-y): x: y: 1, adding a carbon source and a mixing medium, mixing uniformly by liquid-phase ball milling, placing in a nitrogen or argon atmosphere, heating up to 350-450 DEG C for pre-sintering, performing heat preservation for 4-6 hours, heating up to 650-750 DEG C for calcination, and performing heat preservation for 8-12 hours; and cooling to room temperature, and grinding to obtain the vanadium-titanium ion-codoped LiFePO4 material that has a general formula of LiFe1-x-yTixVy(PO4) / C, wherein x is smaller than or equal to 0.01 and larger than or equal to 0.005; y is smaller than or equal to 0.02 and larger than or equal to 0.005; and x+y is smaller than or equal to 0.03 and larger than or equal to 0.01. According to the invention, the vanadium-titanium ion-codoped LiFePO4 material has higher discharge specific capacity as well as preferable rate discharge performance and cycle stability, and is perfect in crystallization and smaller in particle size. The preparation method is simple in process and low in energy consumption; and the obtained material is superior in electrochemical performance, strong in controllability, and convenient for industrial mass production.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +2

Bifidobacterium microcapsule and preparing method thereof

ActiveCN102210659BResistant to gastric acidGood storage stabilityMetabolism disorderBacteria material medical ingredientsFreeze-dryingHigh survival rate

The invention specifically relates to a bifidobacterium microcapsule and a preparing method thereof. The bifidobacterium is obligatorily anaerobic and very sensitive to oxygen, PH, temperature, humidity, and other adverse external environment, thereby being very hard to remain activity during production, storage and transport; besides, if taken orally in a form of dry bifidobacterium powder, the bifidobacterium cannot tolerate low-pH value gastric acid, bile salt, and other environments, so a purpose that massive survived bifidobacteria arrive at an intestinal tract and colonise on the intestinal mucosa is hard to be guaranteed. The preparing method disclosed by the invention comprises the following steps of: adding freeze-dried bifidobacterium powder into a sodium alginate solution and then mixing in soybean oil, emulsifying the mixed solution and standing; centrifugally collecting micro-capsules; and drying the micro-capsules by using a vacuum freeze-drying technology. The bifidobacterium microcapsule disclosed by the invention has the advantages of gastric acid resistance, bile salt resistance and entericsolubility, high survival rate of bifidobacterium, simple preparation method, strong practicality, convenience for industrial production, and excellent storage stability and solves the problem of short storage period of probiotics preparations.

Owner:SHAANXI GIANT BIOTECHNOLOGY CO LTD

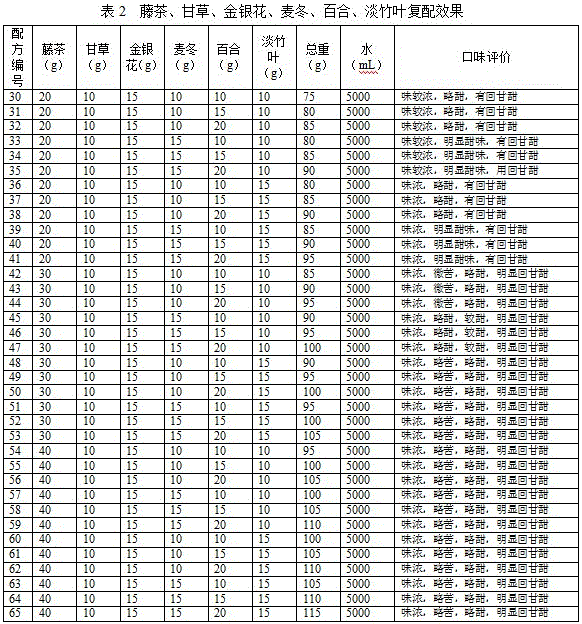

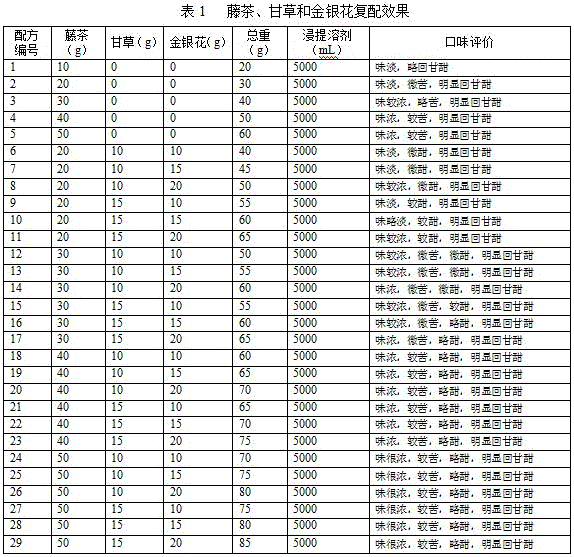

Ampelopsis grossedentata tea health-care compound beverage and preparation method thereof

InactiveCN106106942AHigh content of active ingredientsHas multiple health functionsTea substituesAlcoholAdditive ingredient

The invention provides an ampelopsis grossedentata tea health-care compound beverage and preparation method thereof. The method comprises the following steps: by taking ampelopsis grossedentata tea, radix glycyrrhizae, flos lonicerae, radix ophiopogonis, bulbus lilii, herba lophatheri, folium mori, fructus lycii, fructus momordicae and rhizoma imperatae as raw materials, crushing the raw materials, leaching the crushed raw materials by adopting water extraction, alcohol extraction or combination of alcohol extraction with water extraction, and filtering to obtain leaching solution, and collecting filtrate to obtain ampelopsis grossedentata tea health-care compound beverage. The active efficacy of active ingredients in the prepared ampelopsis grossedentata tea health-care compound beverage can be effective guaranteed not to lose, the beverage has multiple health-care efficacies through the synergistic compatibility of multiple raw materials, the overall attribute of the beverage is mild or warm, so that the beverage is more applicable to drinking of the majority of consumers, the contents of each active ingredient in the beverage is within the daily maximum usage amount range, so that the safety of the beverage can be further guaranteed, the side effect due to excessive drinking can be avoided, and the beverage is healthier.

Owner:YANGTZE NORMAL UNIVERSITY

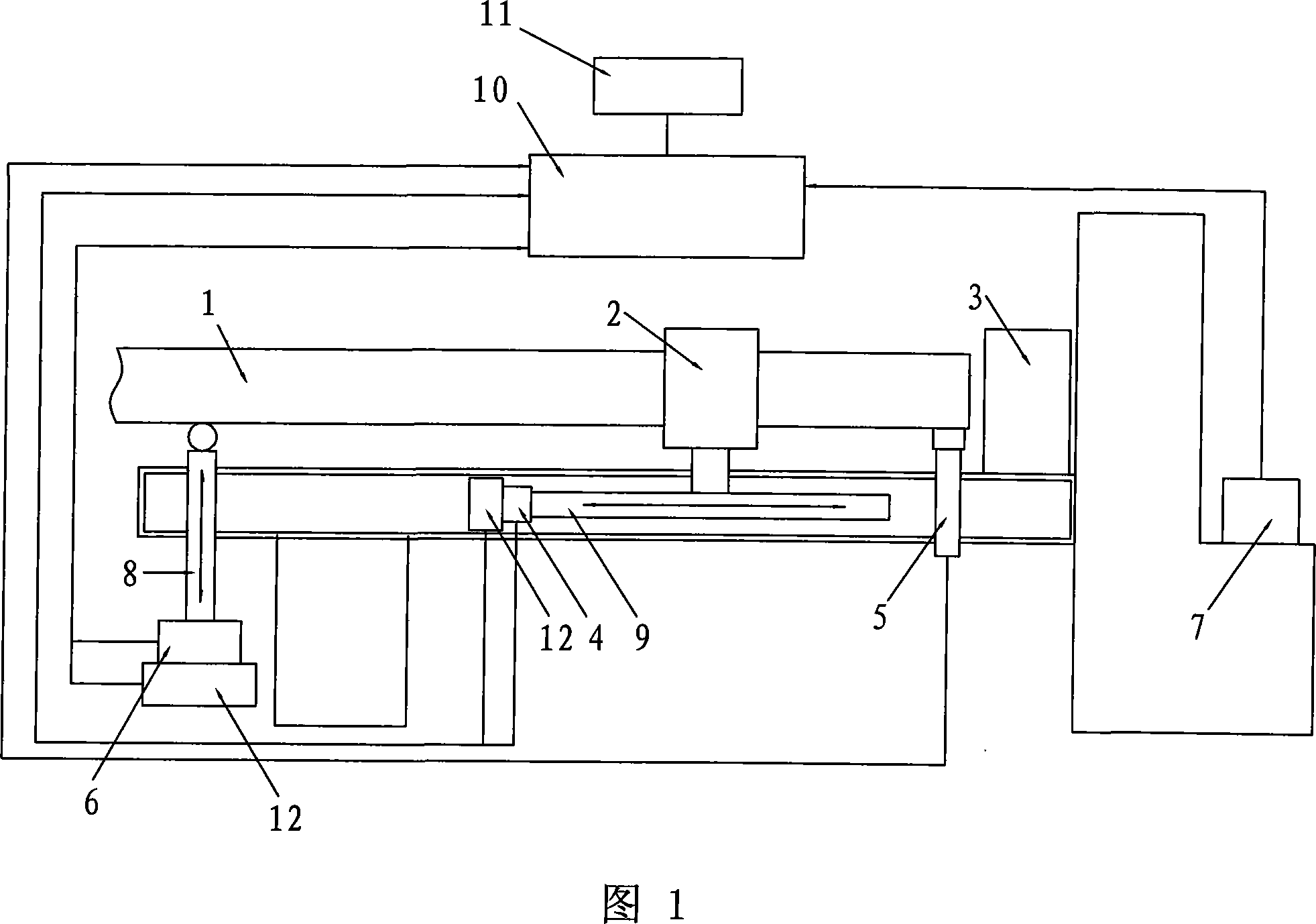

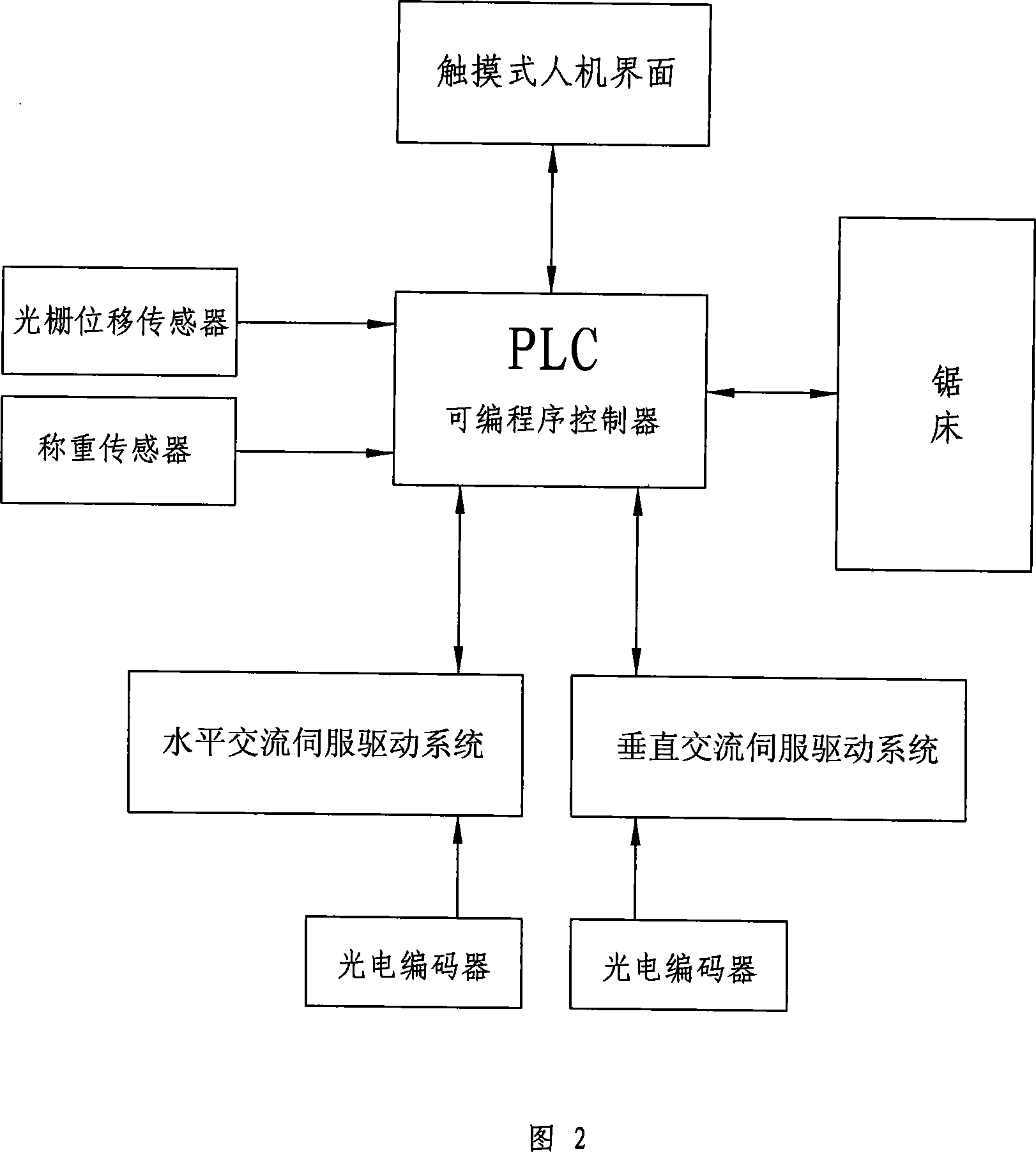

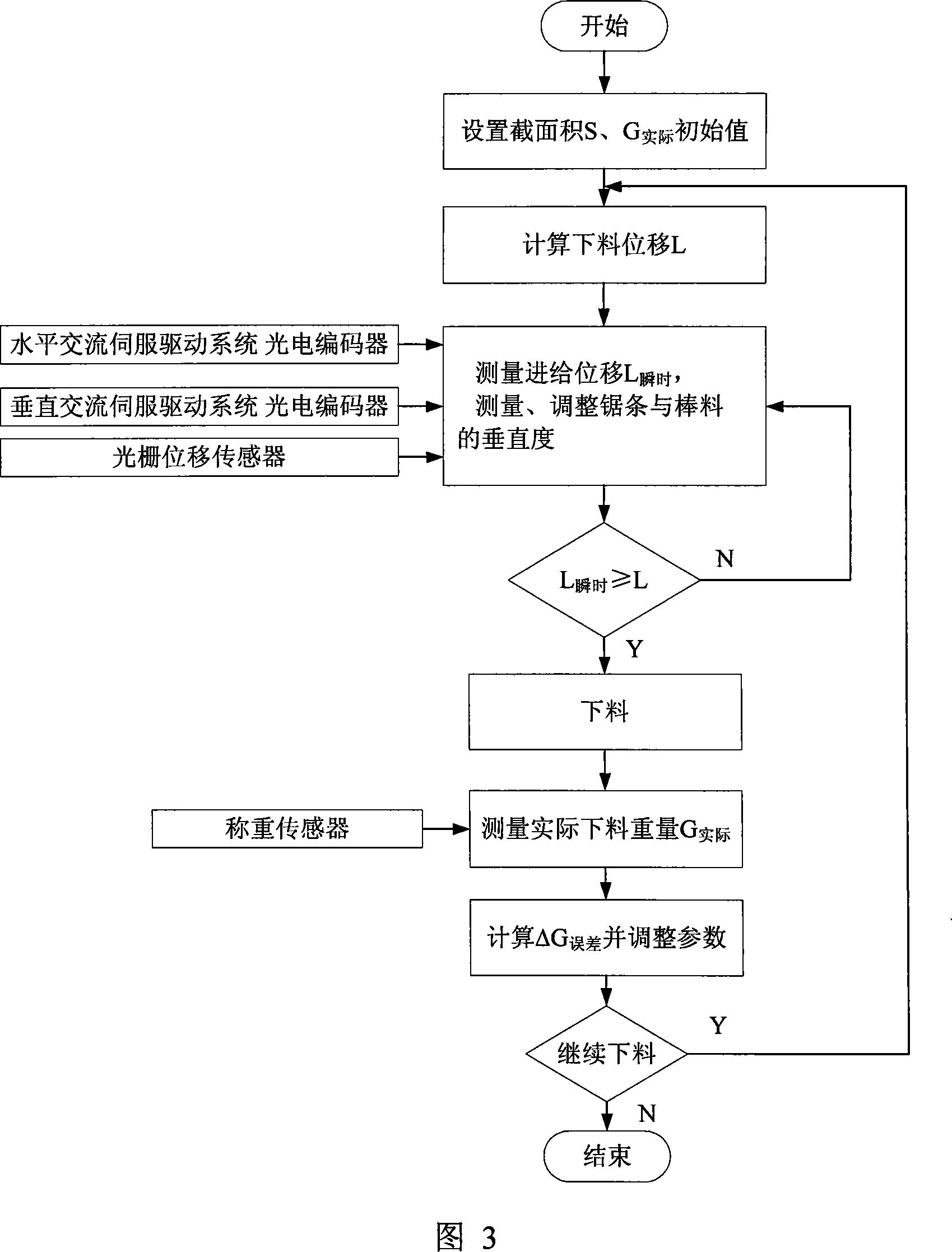

Control method for bar stock saw cutting self-adapting precision baiting

InactiveCN101135895AAccurately control the actual length accuracyRealize adaptive control of precision sawingProgramme control in sequence/logic controllersEngineeringSelf adaptive

The method comprises: using a bar stock saw automatically-adaptive lay- off system. The method comprises: a horizontal AC servo drive system is used for realizing the rod feed; a highly-accurate photoelectric encoder is used to detect the amount of fed rod; a grating shifting sensor is used to detect the height value of front end of the rod; a vertical AC servo drive system is used to adjust the height of the rear end of the rod to keep the consistency between the front end and the rear end of the rod; a highly-accurate weight sensor is used to weigh the actual weight G of the rod and to compare the actual weight of rod with the reset value, and according to the difference Delta G to adjust the cutting length.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

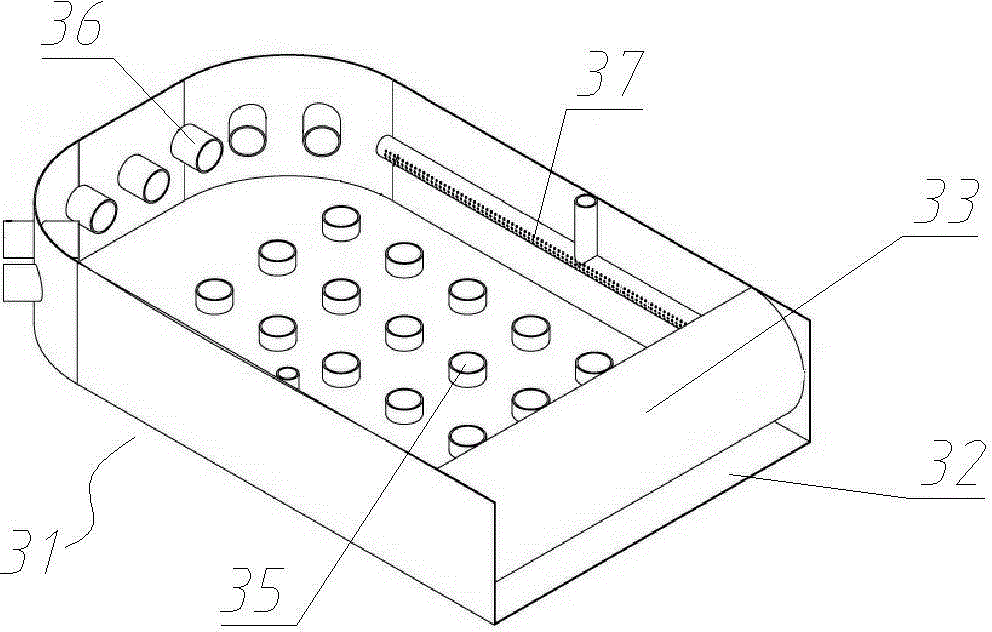

Equipment for separating current collector of lithium ion battery from active material on current collector

ActiveCN104157924AEasy to follow upAchieve separationWaste accumulators reclaimingBattery recyclingEngineeringLithium-ion battery

The invention relates to equipment for separating a current collector of a lithium ion battery from an active material on the current collector. The equipment for separating the current collector of the lithium ion battery from the active material on the current collector comprises a processing tank, wherein a scraper type conveyer belt is arranged at the lower part of the processing tank; an active material peeling device is arranged at the upper part of the processing tank; the scraper type conveyer belt comprises a horizontal conveying section and an inclined discharge section which is arranged in an inclined manner; the horizontal conveying section corresponds to the active material peeling device vertically; meshes through which the current collector cannot passing but the peeled active material can pass are formed in the body of the scraper type conveyer belt; a collecting cabin for collecting the active material which passes through the meshes is arranged below the scraper type conveyer belt; a partitioning structure is arranged between the collecting cabin and the space above the scraper type conveyer belt; a discharge hole is formed in the lower part of the collecting cabin. By adopting the equipment, separation of the current collector of the lithium ion battery from the active material and the separated collection of the current collector and the active material are conveniently achieved, so that large-scale industrial production is achieved, and environment-friendly effect is achieved.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

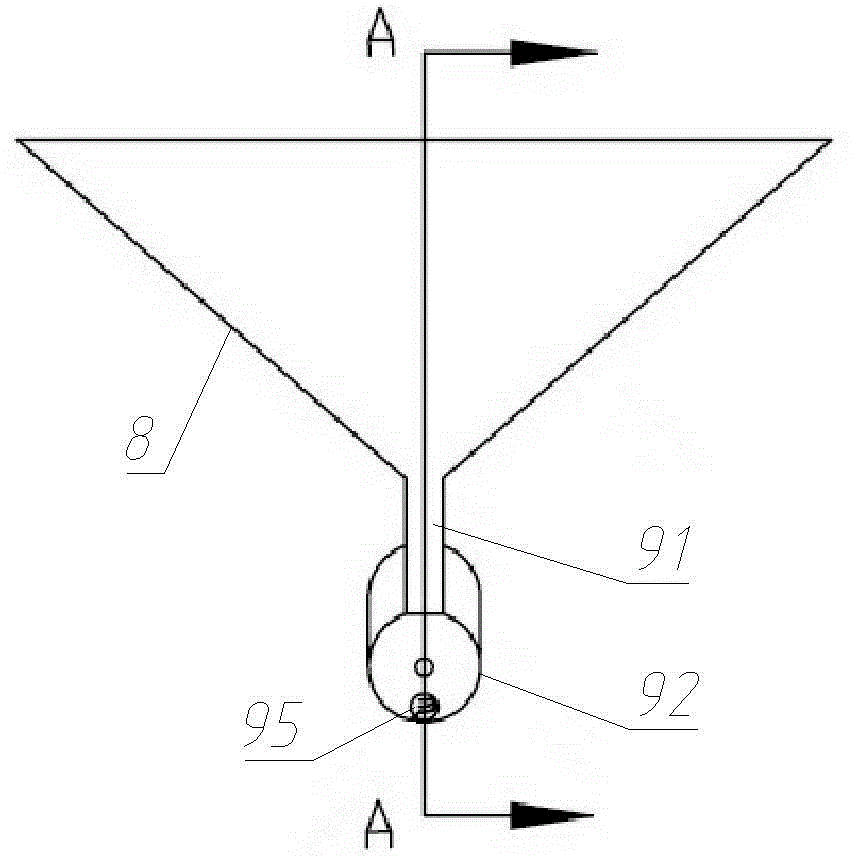

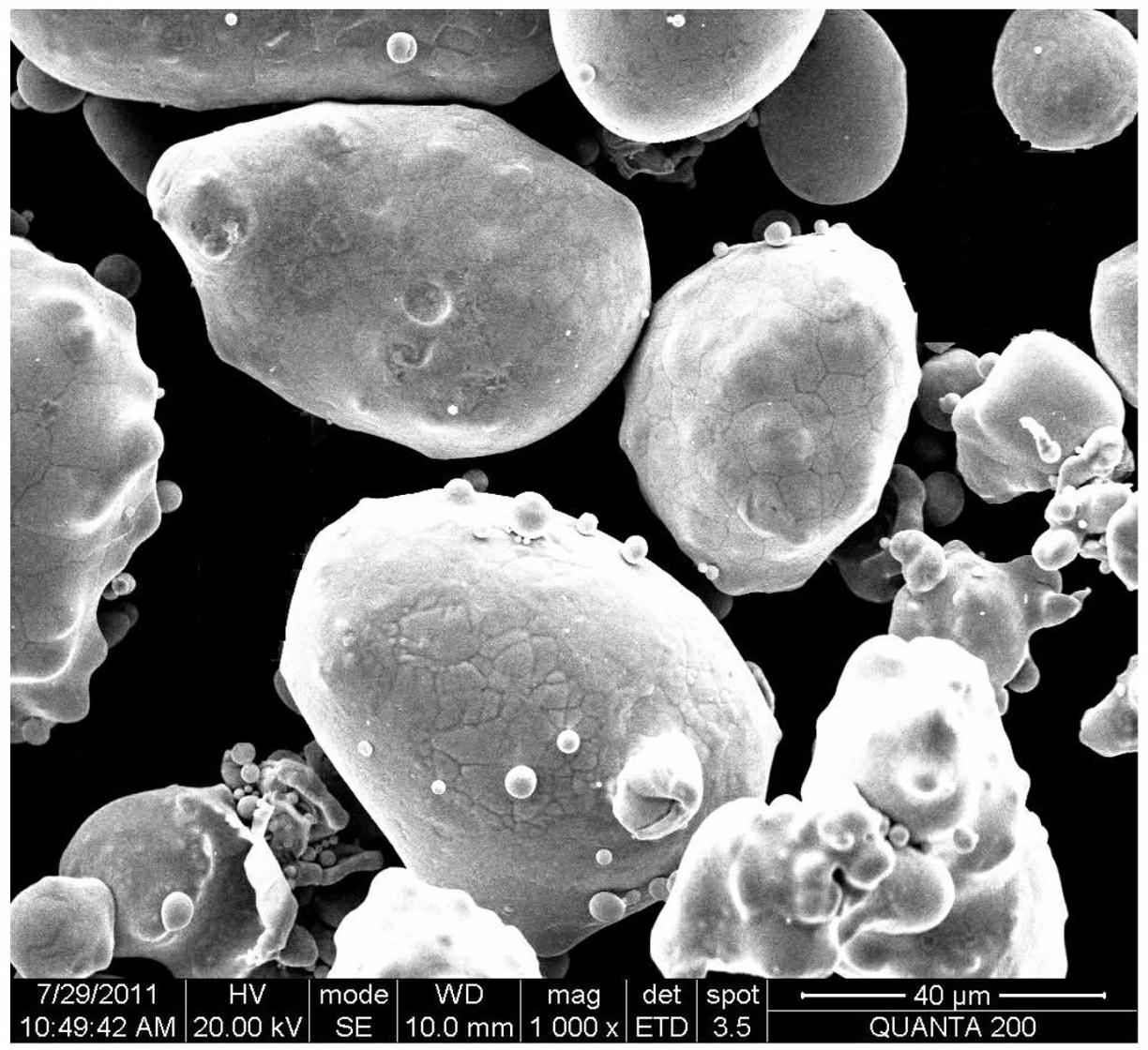

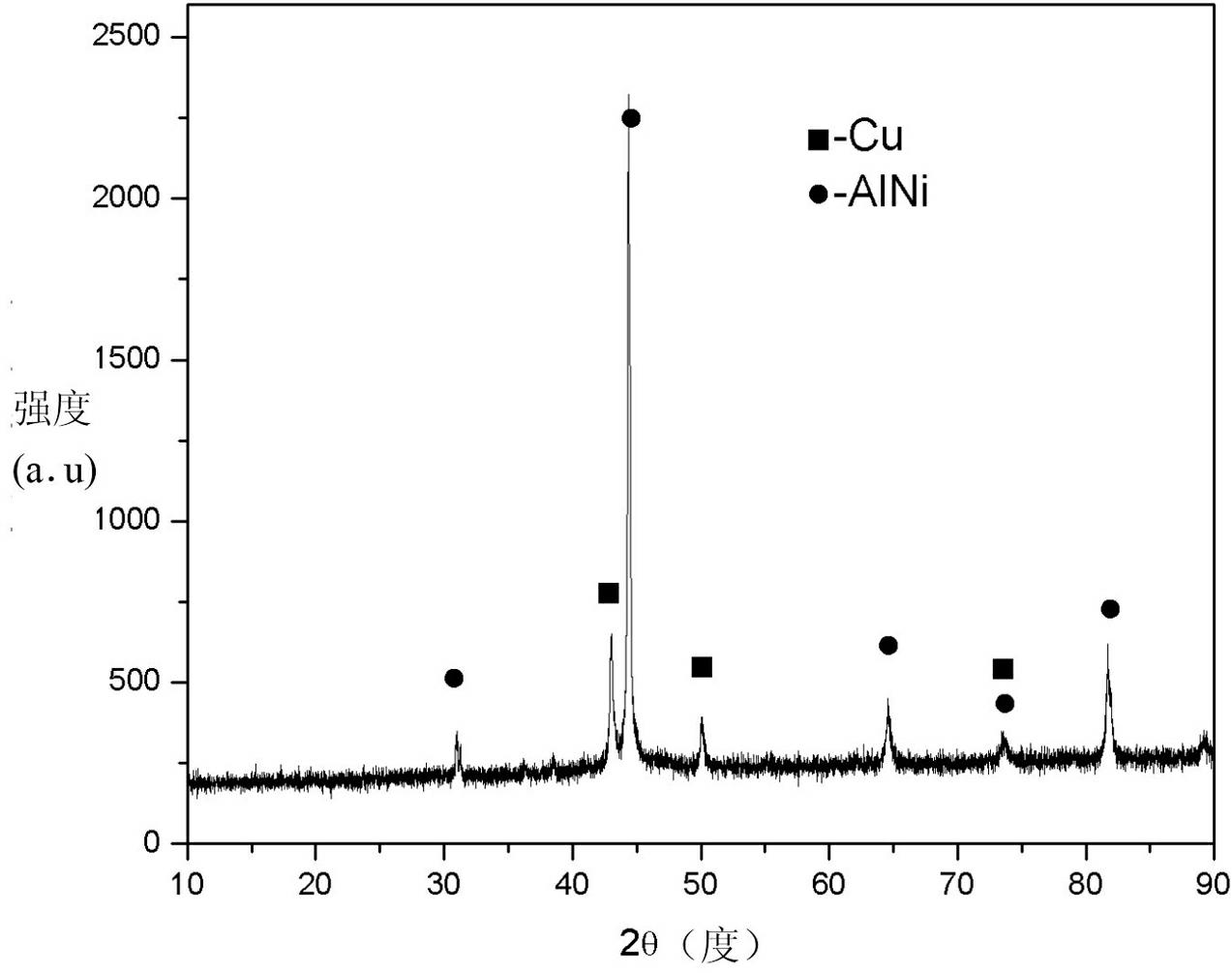

Cu-Ni-Al alloy powder and preparation method thereof

The invention discloses Cu-Ni-Al alloy powder, which is composed of metal Cu phases and AlNi intermediate phases, is free from macroscopic segregation and low in oxygen content and comprises the following components in mass fraction respectively: 25-35% of Ni, 10-15% of Al and the balance of Cu. The preparation method of the alloy powder comprises the steps of: firstly, proportioning metal Cu, metal Ni and metal Al, then heating the Cu and Ni, and adding Al for smelting after the Cu and Ni are molten; adding wood charcoal after the temperature of molten alloy reaches 1450-1550 DEG C, then adding a refining and slagclearing agent, and stirring, deslagging and refining the molten alloy; and finally, pouring the refined molten alloy into a crucible of an atomizing and rapid condensing device, and atomizing by using the atomizing and rapid condensing device for producing powder to prepare the Cu-Ni-Al alloy powder. The alloy powder disclosed by the invention has the advantages of high alloy element content, good powder purity, uniform chemical components, slight segregation, good crystallinity and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Reductive spherical cellulose adsorbent containing sulfinyl and preparation method thereof

ActiveCN102500339AIncrease contentWide variety of sourcesOther chemical processesCelluloseDisinfection by-product

The invention discloses a reductive spherical cellulose adsorbent containing sulfinyl and a preparation method of the reductive spherical cellulose adsorbent. The preparation method comprises the following steps of: dissolving cellulose by using ionic liquid, then carrying out graft copolymerization and introducing a reductive group to prepare the reductive spherical cellulose adsorbent with the grain size of 4.5-5.2 mm and the specific surface area of 180-780 m2 / g. The preparation method has simplicity and no toxicity. The reductive spherical cellulose adsorbent has better reductive adsorbability and biodegradation capacity, wide source of a cellulose material and low price, thereby generating better economic and environmental benefits on the aspects of absorbing heavy metal ions and removing chlorine-disinfecting by-products of drinking water.

Owner:FUZHOU UNIV

Milk beverage containing bifidobacteria embedded beads and preparation method thereof

ActiveCN103766486AAvoid killing effectIncrease the number of live bacteriaMilk preparationLow activityViable count

The invention discloses a milk beverage containing bifidobacteria embedded beads and a preparation method of the milk beverage to solve the problems of low activity, short storage time and difficulty in storage of bifidobacteria in a bifidobacteria milk beverage product. The milk beverage contains the bifidobacteria embedded beads. The preparation method comprises the following two steps: firstly, preparing the bifidobacteria embedded beads; secondly preparing the milk beverage containing the bifidobacteria embedded beads. According to the milk beverage, the problems of low viable count, short storage time, difficulty in reaching the intestinal tract and the like of the bifidobacteria in the milk beverage are effectively solved, the viable count, the activity and the storage time of the bifidobacteria are effectively ensured, and the probiotic effect of the bifidobacteria on a human body is achieved. The preparation method is mild in preparation conditions, is simple and convenient, and is suitable for large-scale industrialization production.

Owner:GANSU ACAD OF SCI INST OF BIOLOGY

Quaternization lignin-base dispersing agent and preparation process and application thereof

The invention discloses a quaternization lignin-base dispersing agent and a preparation process and application thereof. The preparation process comprises the following steps: reacting benzoic acid, phenol and an aldehyde compound for 0.5-3h at the temperature of 60-110 DEG C, wherein the mass fraction of the aldehyde compound is 1.0-9.0 percent; adding black pulping liquor of which the solid content is 18.3-60 percent, raising the temperature to 20-80 DEG C, adding a sulfonic amino compound of which the mass fraction is 1.3-8.0 percent, adjusting the pH value to 10.0-13.5, and adding a sulfonating agent of which the mass fraction is 2.5-11.0 percent; enabling reaction for 2-5h at the temperature of 95-180 DEG C, and then adding a quaternization reagent of which the mass fraction is 4.0-10.0 percent, enabling reaction for 2-4h at the temperature of 70-100 DEG C, performing cooling and discharging to obtain brown liquid, and performing spray drying to obtain a solid powder product. The quaternization lignin-base dispersing agent has multiple functions of dispersing, complexing, chelating and the like, and can be applied to multiple fields of dye dispersing agents, concrete water reducing agents, ceramic additives and the like.

Owner:FUZHOU UNIV

Composite doping modification lithium-ion battery anode material and its manufacture method

InactiveCN1964105AImprove UIEnhanced ionic conductivity and electronic conductivityElectrode manufacturing processesChemical/physical/physico-chemical processesIonRare-earth element

The disclosed preparation method for anode material of composite doped modified Li-ion cell comprises: mixing the Li-source compound, P-source compound, Fe-source compound, crystal phase doped M (rare earth element) compound and non-crystal phase doped element C to heat for 5-20h at 250-400Deg; cooling, and grinding to obtain the reaction predecessor contained PO43-, Li+, Mn+, Fe2+ and carbon black; calcining for 10-40h at 500-800Deg to cool and obtain the final product. This invention improves material electrochemical property and fit to industrial production.

Owner:SOUTH CHINA UNIV OF TECH

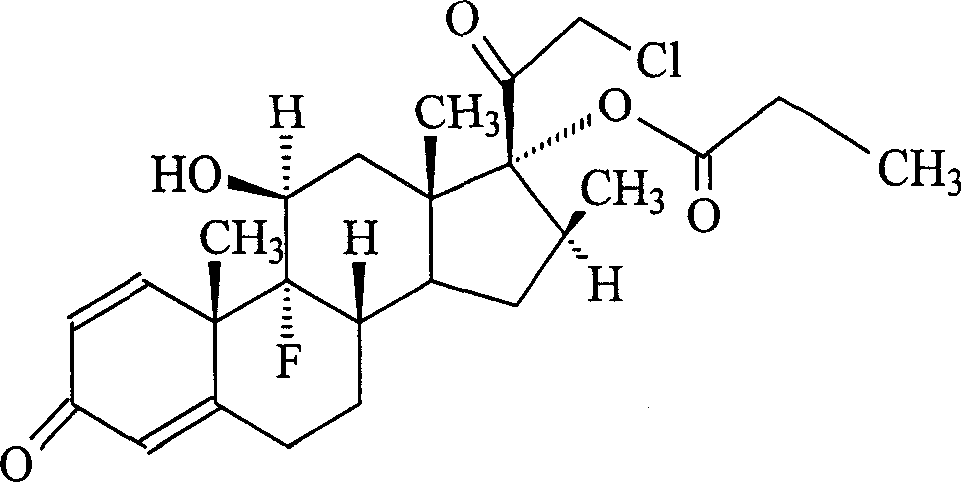

Preparation method of propionic acid clobetasol

The invention discloses a preparing method of chlorotestosterone betaprodine, which comprises the following steps: blending betamisong 17-propionic ester sulphonation and anhydrous lithium chloride with the rate at 1: 1-2; dissolving in the DMF to do chloridization reaction; elutriating through icy water; drying through centrifuging to obtain rough product; dissolving rough product in the carbinol or alcohol; adding activated charcoal; decoloring; filtering; recycling activated charcoal; condensing the filtrate; crystallizing; dehydrating; drying to obtain the product.

Owner:ZHEJIANG DINGTAI PHARMA

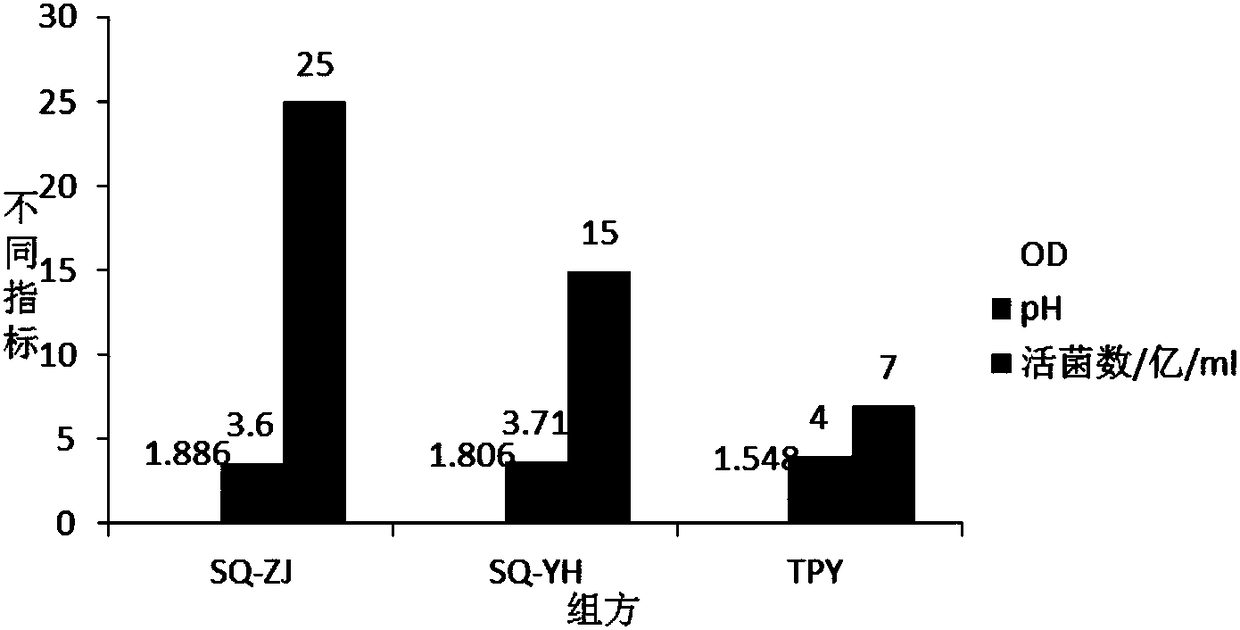

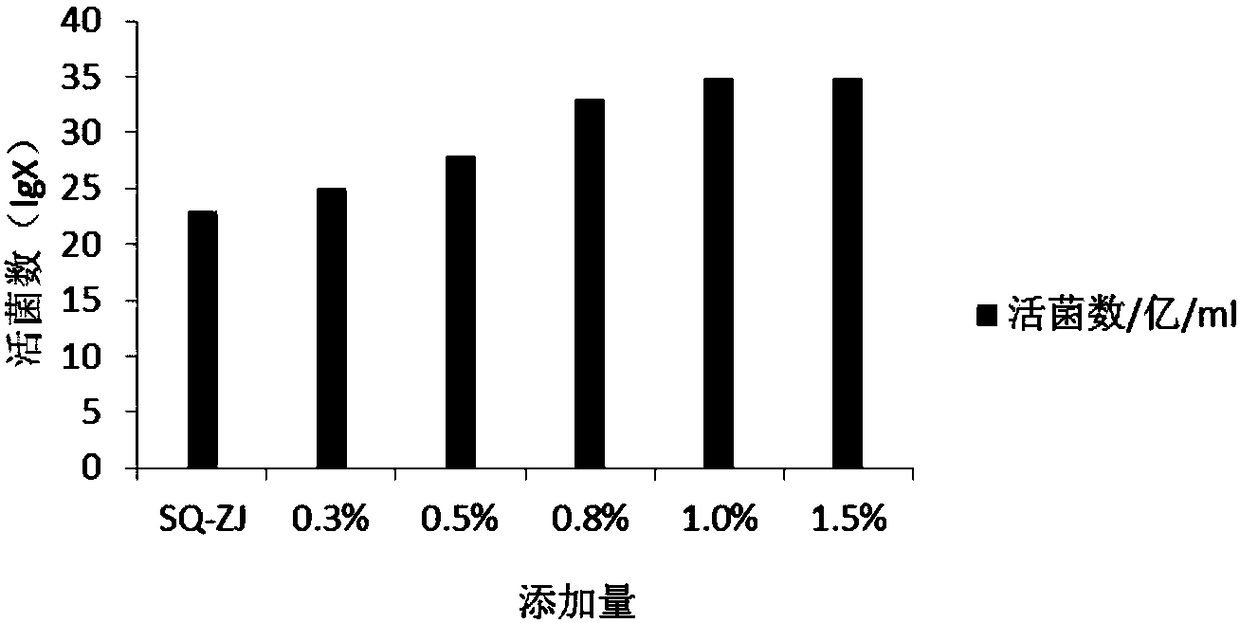

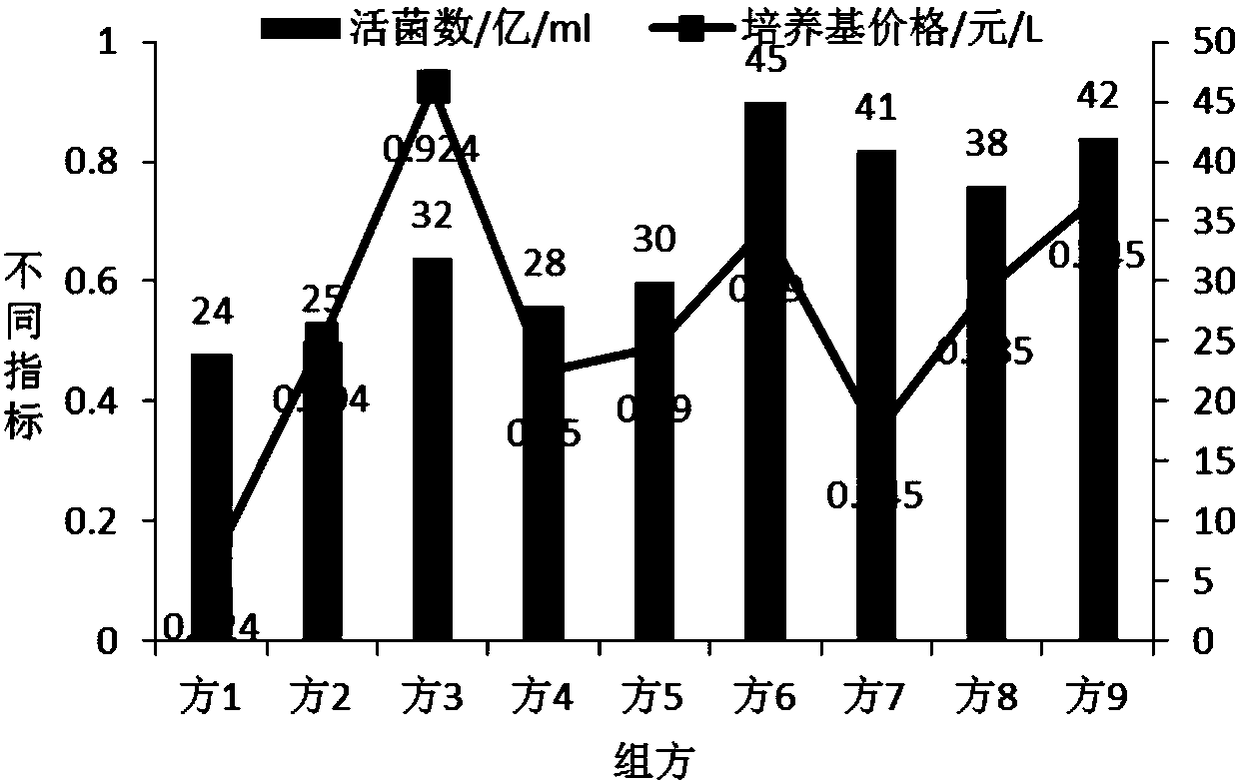

Industrial high-density mixed fermentation culture medium of bifidobacterium and lactobacillus, fermentation culture method and fungus powder embedding method

The invention provides an industrial high-density mixed fermentation culture medium of bifidobacterium and lactobacillus, a fermentation culture method and a fungus powder embedding method. The fermentation culture medium is prepared from the following components: 0.3 to 1.5 percent of corn slurry dry powder, 0 to 1.8 percent of soya peptone, 0 to 1 percent of fructooligosaccharide, 0.5 to 1 percent of glucose, 0.4 to 1.35 percent of dipotassium phosphate, 0.4 percent of potassium dihydrogen phosphate, 0.015 to 0.02 percent of magnesium sulfate, and 0.05 percent of L-cysteine hydrochloride; orthe fermentation culture medium is prepared from the following components: 0.3 to 1.5 percent of the corn slurry dry powder, 0 to 1 percent of beef extract, 0 to 1 percent of the fructooligosaccharide, 0.5 to 1 percent of the glucose, 0.4 to 1.35 percent of the dipotassium phosphate, 0.4 percent of the potassium dihydrogen phosphate, 0.015 to 0.02 percent of the magnesium sulfate and 0.05 percentof the L-cysteine hydrochloride; the fermentation method comprises strain activation and culture, first-grade strain culture, second-grade seed solution preparation, 200L small tank culture in a workshop and 1T large tank culture in the workshop. Comparing the relatively traditional TPY culture medium, the viable count improves 10 times or more and the cost is reduced by 60 percent, meanwhile, according to the formula, raw materials are easy to obtain and the components are simple, so that the fermentation culture medium is suitable for industrial production requirements. The fungus powder embedding method is adopted so that the human body and external environment tolerance capability of strains is greatly improved.

Owner:山东凤凰生物科技股份有限公司

Preparation method of rice bran nutrient

The invention discloses a preparation method of rice bran nutrient. The rice bran nutrient extracted and separated by using the preparation method contains a plurality of nutrition constituents such as rice bran protein, rice bran polysaccharide, rice bran fiber, phytic acid, minerals and the like. The preparation method is simple and helpful for the industrial large-scale production. The preparation method disclosed by the invention comprises the following steps of: (1) cleaning, drying and crushing 1000 parts of rice bran, screening by using a 80-mesh sieve, carrying out muggy and high-temperature vapour treatment at 85 DEG C for 5-10 min, gradually heating up to 105 DEG C in 10-15 min, and carrying out heat preservation treatment for 10-15 min; (2) adding the materials obtained in the step (1) into petroleum ether with the weight of 2-3 times, stirring at 55-58 DEG C for 0.5-0.8 h, filtering and drying filter residue at 105 DEG C for 0.5-1.5 h; (3) mixing the materials obtained in the step (2) by using a hydrochloric acid water solution with the pH value of 5.0-5.5 in the material-liquid weight ratio of 1:(8-10), adding 15-25 parts of combined enzyme A, keeping at 38-45 DEG C, stirring and reacting for 1-2 h, carrying out centrifugalization at 3500-4000 r / min, and collecting supernate; (4) adding 15-20 parts of combined enzyme B into the supernate obtained in the step (3), keeping at 55-60 DEG C, stirring and reacting for 1-2 h, carrying out centrifugalization at 3500-4000 r / min, and collecting the supernate; and (5) carrying out vacuum concentration at 50-55 DEG C on the supernate obtained in the step (4), and carrying out freeze drying at subzero 20-25 DEG C to obtain the rice bran nutrient.

Owner:ANHUI YANZHIFANG FOOD

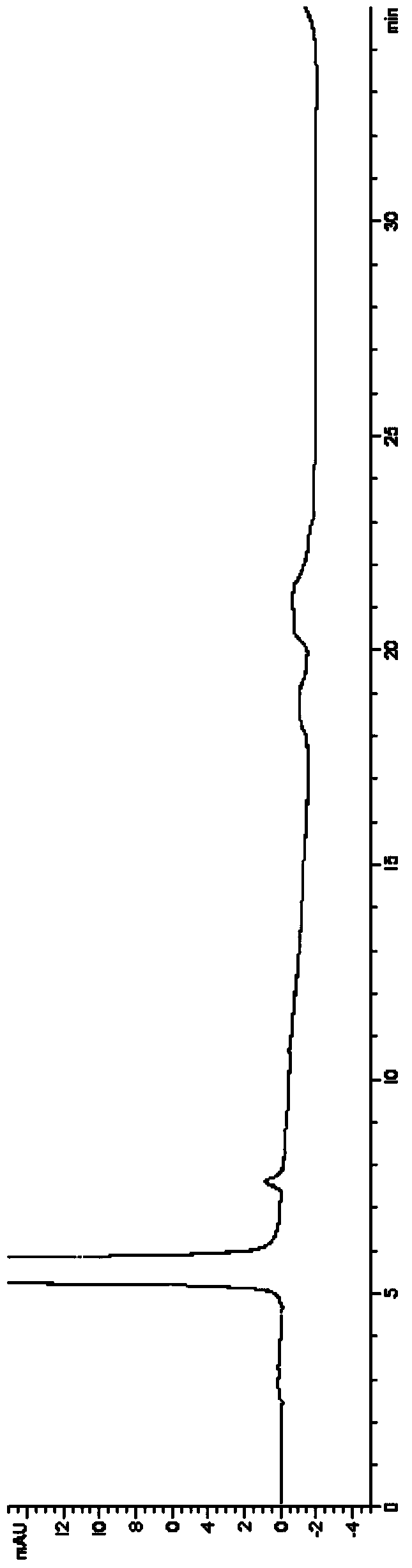

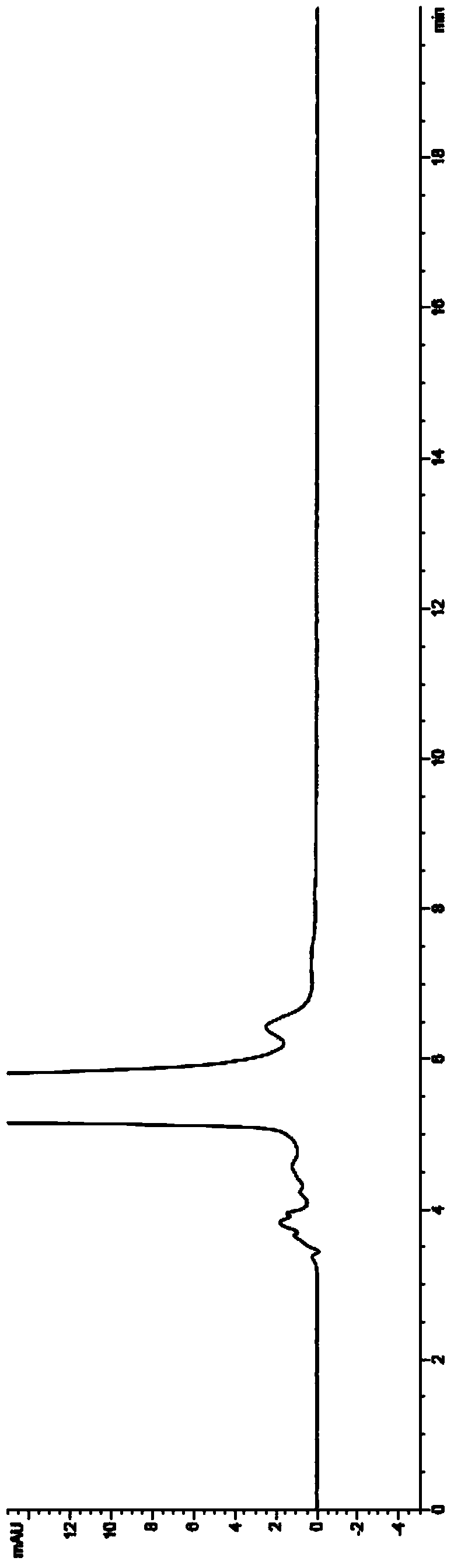

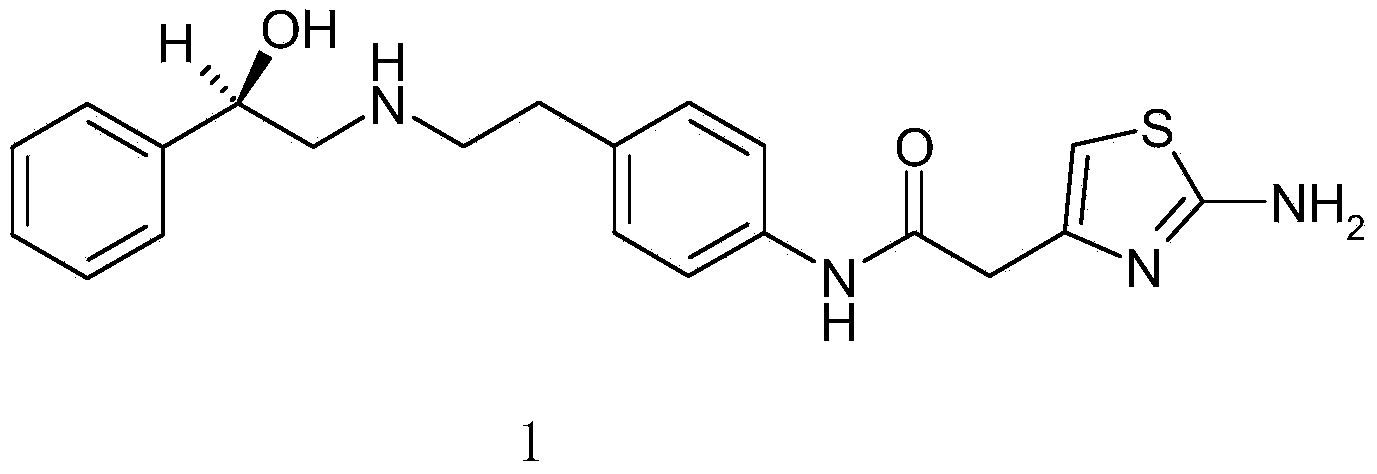

Preparation method of mirabegron

ActiveCN103864713AReduce pollutionEase of industrial productionOrganic chemistryBulk chemical productionThiazolePhenethyl alcohol

The invention discloses a preparation method of mirabegron. The preparation method comprises the following steps: I, carrying out a reaction on 2-(2-aminothiazole-4-) acetic hydrochloride shown in a structural formula 5 and an amino protective agent to obtain a compound shown in a structural formula 4; II, carrying out a condensation reaction on the compounds shown in the structural formulae 3 and 4 in the presence of a condensating agent and an acid-binding agent to obtain a compound shown in the structural formula 2; and III, carrying out a substitution reaction on the compound shown in the structural formula 2 and (R)-2-amino-1-phenethyl alcohol under the effect of the acid-binding agent, and after reaction, adding a deprotection group agent to remove the protective group to obtain mirabegron shown in a structural formula 1. The method provided by the invention is few in technological step in the synthetic process, simple, high in yield and free from highly toxic products and suitable for industrialized production on a large scale.

Owner:JIANGXI SYNERGY PHARMA

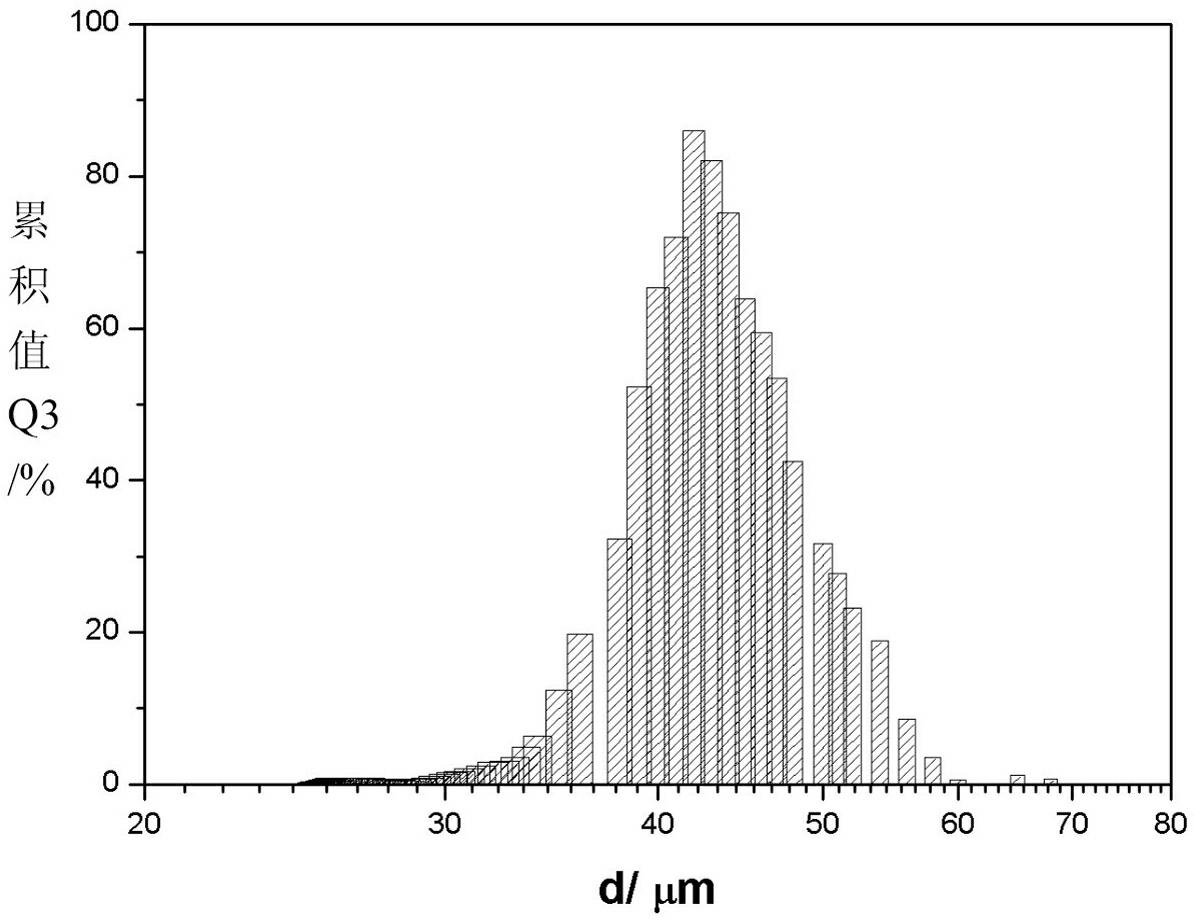

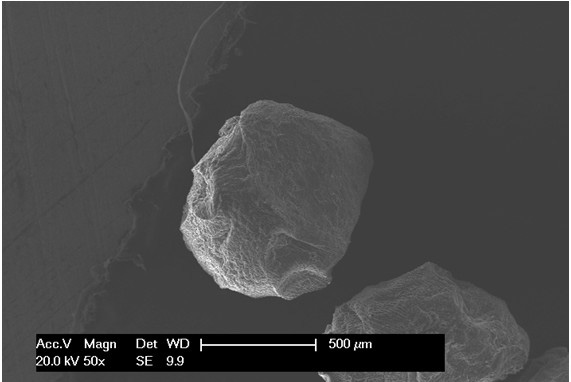

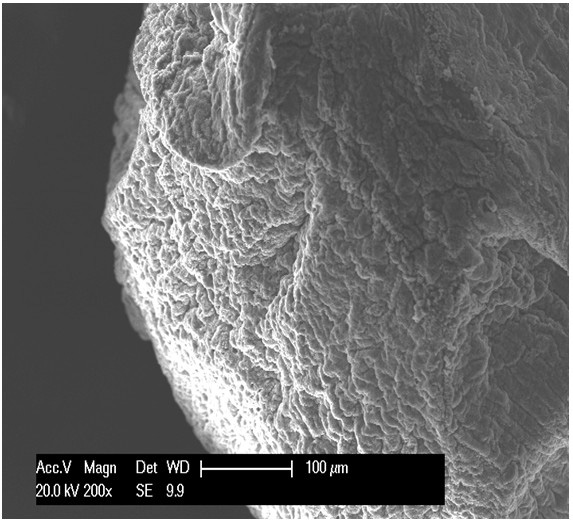

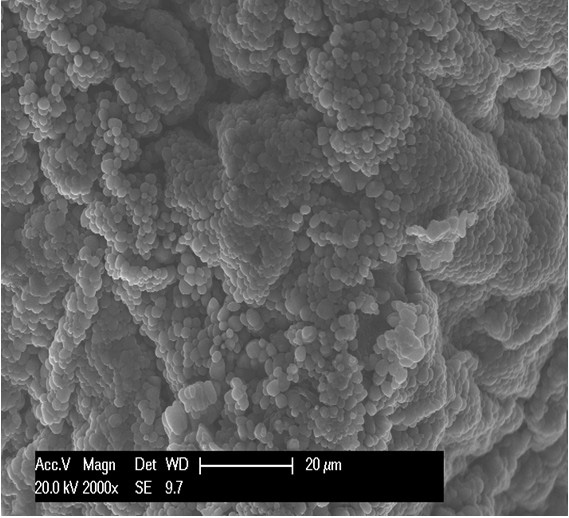

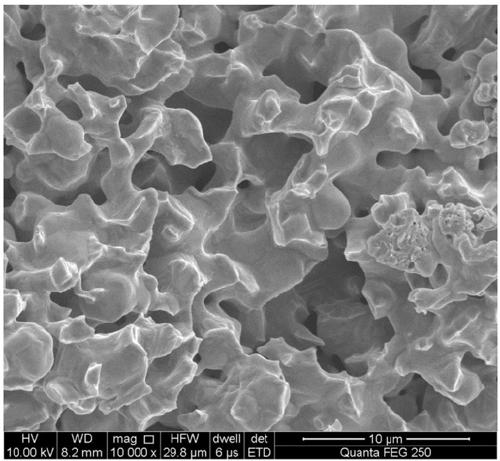

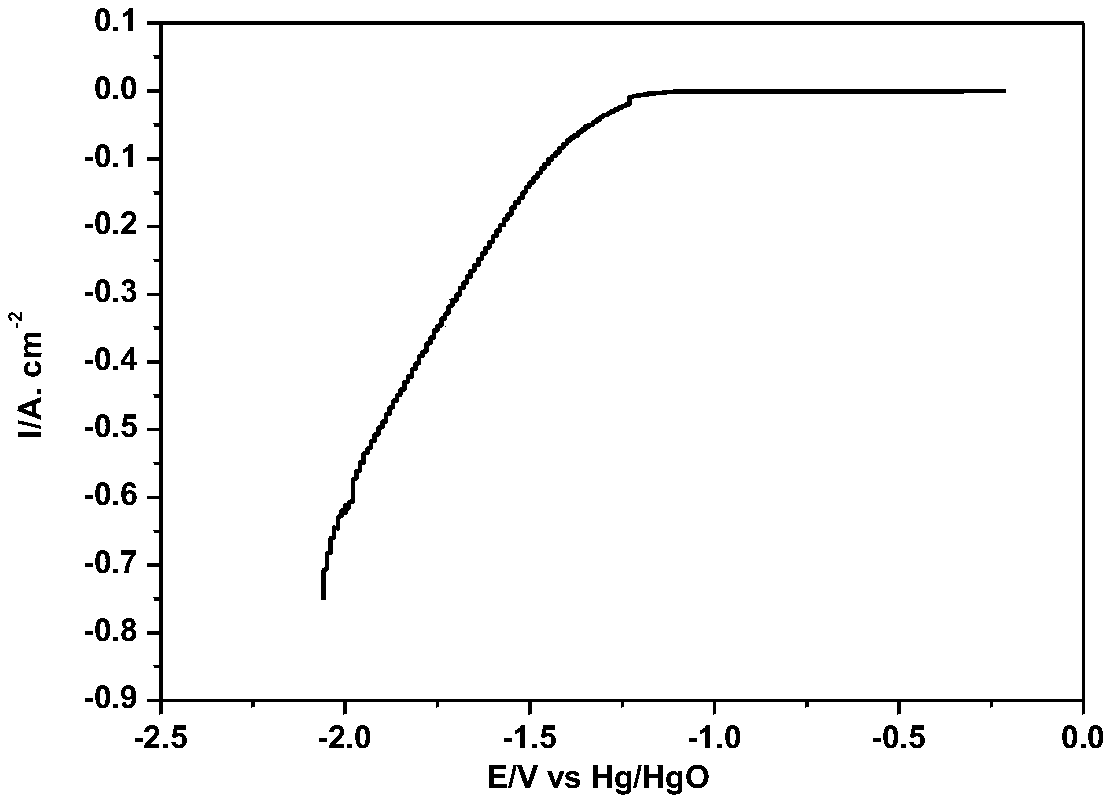

Preparation method of pre-alloyed porous nickel-based electrolytic hydrogen evolution cathode material

InactiveCN109267084AStable physical and chemical propertiesLarge specific surface areaElectrode shape/formsIron powderHydrogen

The invention provides a Ni-Fe-Mo-Mn porous material. The Ni-Fe-Mo-Mn porous material is prepared by the steps of accurately weighing 15 to 21 percent of ferro-molybdenum, 11 to 16 percent of ferro-manganese, 7 to 9 percent of iron powder the balance of nickel, preparing pre-alloyed powder by adopting an atomization technology and sintering in vacuum. The porous material prepared by the inventionhas abundant, uniform and controllable pores and has the advantages of large specific surface area, low hydrogen evolution overpotential, good catalytic performance, good corrosion resistance, stableworking performance, simple and environment-friendly preparation technology and the like; the preparation cost is low and the technology is simple and easy to realize. The porous material prepared bythe invention can be used as the electrolytic hydrogen evolution cathode material.

Owner:XIANGTAN UNIV +1

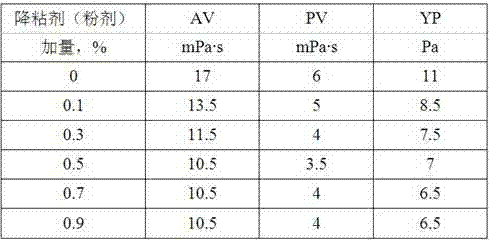

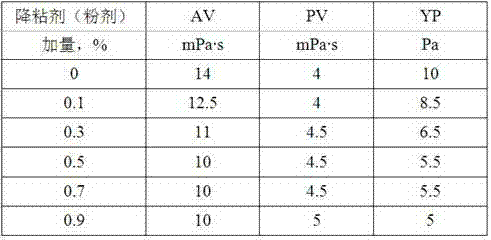

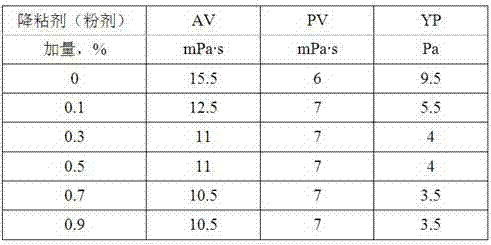

Composite lignin-base viscosity breaker for drilling fluid and preparation method thereof

ActiveCN102888212AStrong temperature resistanceGood synergyDrilling compositionLignosulfonatesEnvironmental geology

The invention discloses a composite lignin-base viscosity breaker for a drilling fluid and a preparation method thereof. The preparation method comprises the following steps: (1) carrying out sulfonation reaction to obtain lignosulfonate; (2) preparing ferrimanganic salt; and (3) preparing ferrimanganic lignosulfonate. In the composite lignin-base viscosity breaker for a drilling fluid, the water-insoluble substance content is at most 0.5%, the calcium sulfate content is at most 1.0%, the iron content is 3-5%, the complexation degree is at least 75%, and the relative molecular weight Mn is 5000-20000. The method has the advantage of low production cost; and the prepared viscosity breaker can display favorable viscosity breaking effect of the inorganic viscosity breaker, and also has favorable temperature resistance and salt resistance of the lignin viscosity breaker, thereby having favorable synergistic action. The preparation technique is simple and does not generate secondary pollution.

Owner:FUZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com