Control method for bar stock saw cutting self-adapting precision baiting

A precision blanking and self-adaptive technology, applied in electrical program control, program control in sequence/logic controllers, etc., can solve the problem of large bar weight error, large bar curvature, and large differences in cross-sectional shape and size. Large and other problems, to achieve the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

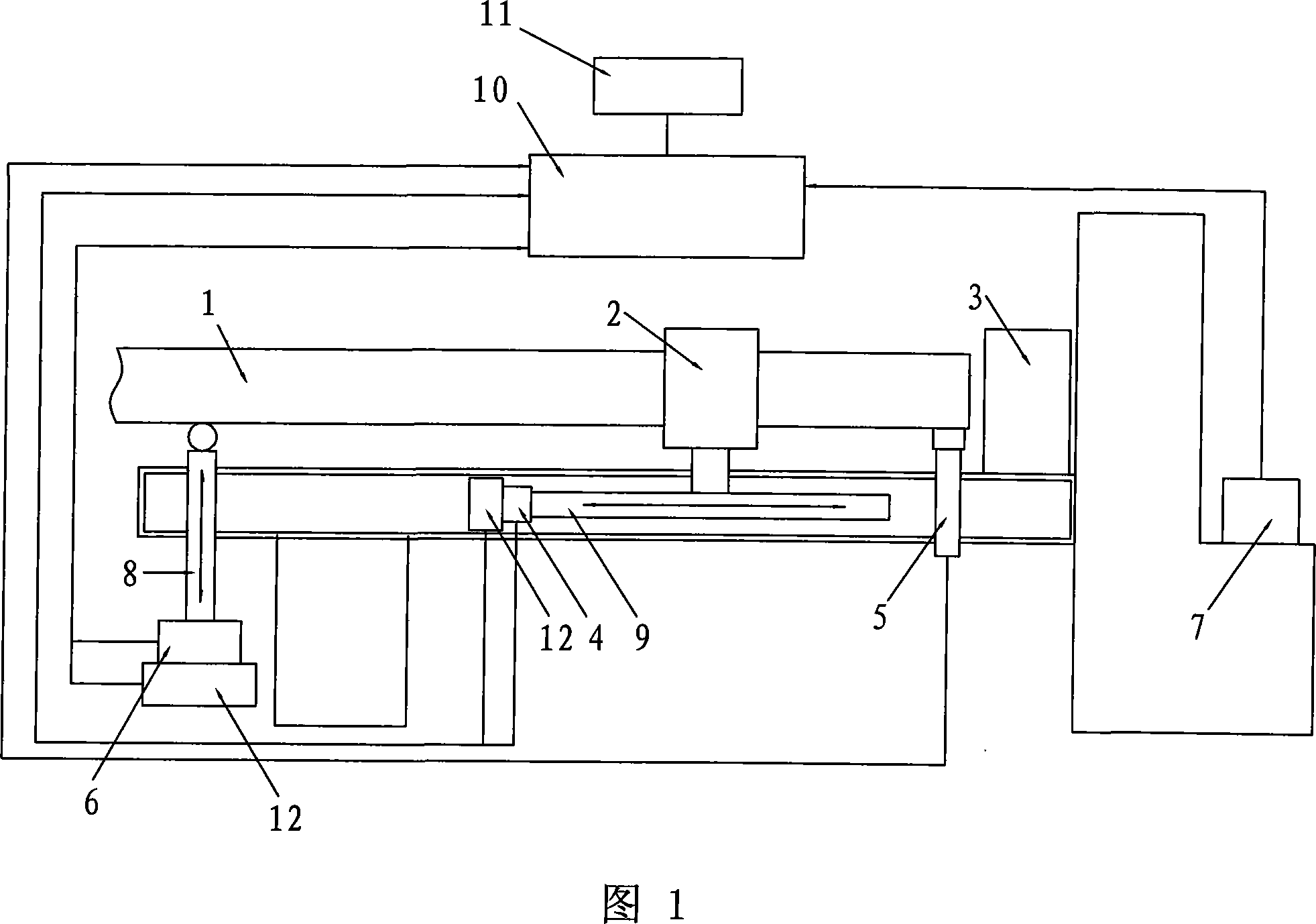

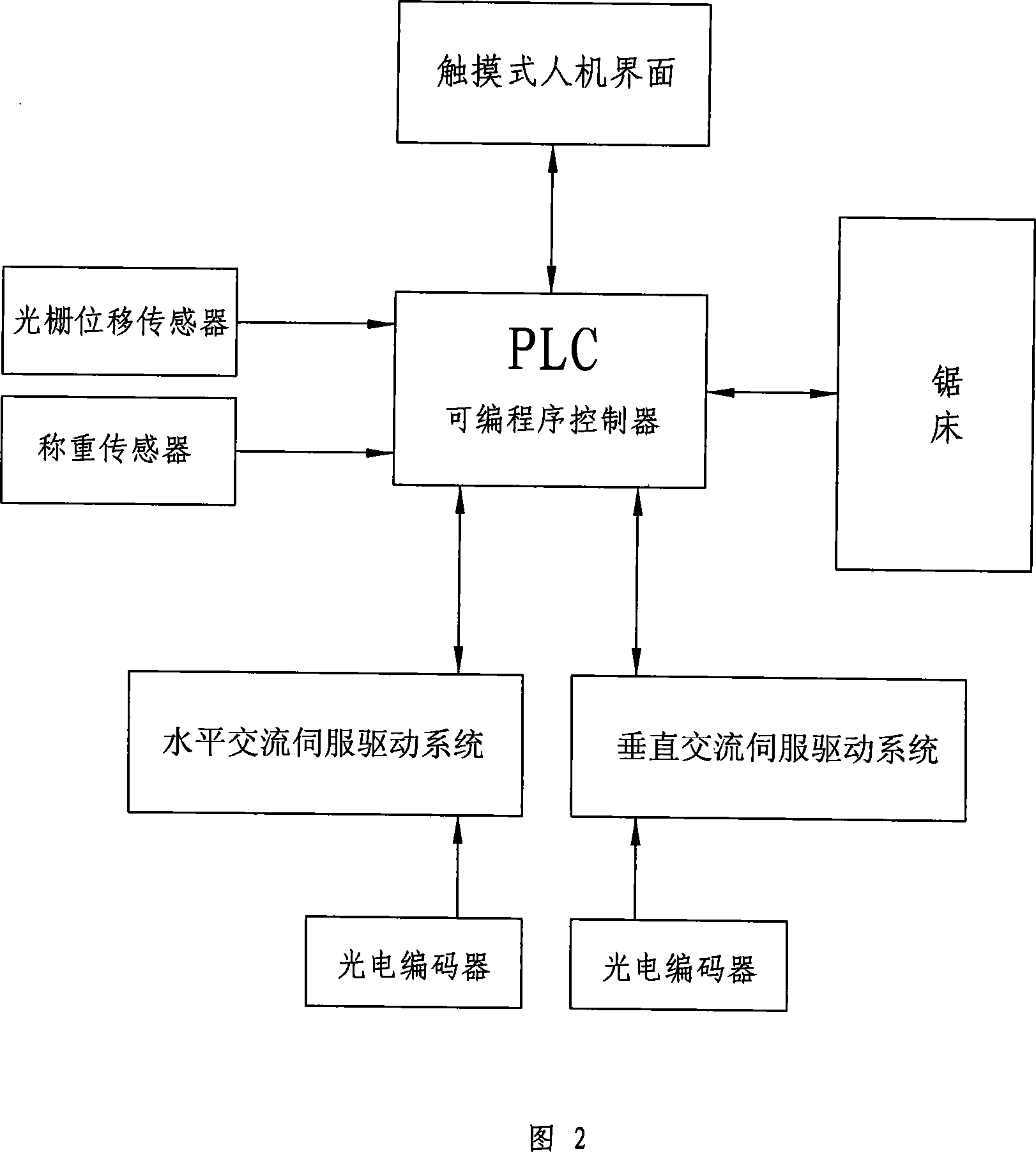

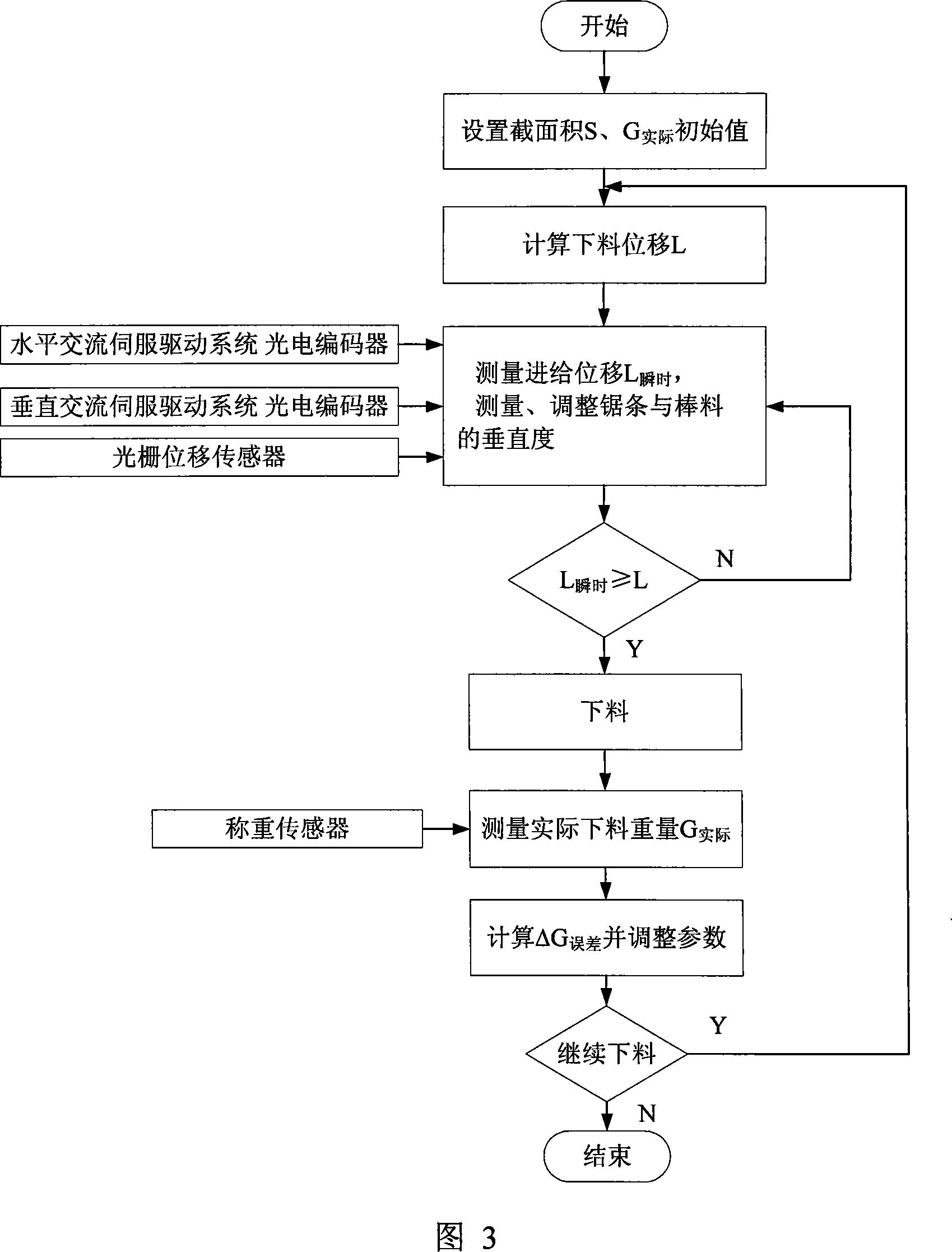

[0032] Embodiment: See Fig. 1, Fig. 2, Fig. 3, a kind of control method of self-adaptive precision blanking of bar sawing, it has used a kind of sawing machine shown in Fig. 1, horizontal AC servo drive system 4, vertical AC Self-adaptive precision blanking system for bar sawing composed of servo drive system 6, high-precision photoelectric encoder 12, grating displacement sensor 5, PLC programmable controller 10, touch-type man-machine interface 11, and high-precision weighing sensor 7 , which is characterized by the following control steps:

[0033] a. Turn on the machine, start the bar blanking system, and input the cross-sectional area S and blanking weight G of the bar 1 by touching the man-machine interface 11 设定 , PLC programmable controller 10 according to the cross-sectional area S of the bar 1 and the blanking weight G 设定 Calculate the blanking length L of bar 1,

[0034] Cutting length L=G 设定 / (density P×sectional area S);

[0035] b. The PLC programmable contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com