Patents

Literature

134 results about "Cutting self" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Guava cutting seedling-raising method

InactiveCN104396666AHigh rooting rateHigh activityCultivating equipmentsHorticulture methodsEngineeringTemperature difference

The invention provides a guava cutting seedling-raising method comprising the steps of A, cutting slip selection, B, cutting preparation, C, cutting, and D, cutting post treatment. According to the invention, half-lignified softwood branches are adopted as cutting slips. Compared with that adopting hardwood branches, a rooting rate is improved. Before cutting insertion, the lower ends of the cutting slips are soaked by a growth regulator. After the cutting slips are inserted into a seedbed, the growth regulator is added in the medium around the cutting slips. With the effects and influences of the two applications of the growth regulators on the lower ends of the cutting slips, the cutting slip activity and the rooting rate can be greatly improved. Water mist is sprayed intermittently to the cutting slips, such that humidity in the sunshade shed can be effectively maintained, and cutting slip rooting can be promoted. The seedbed is subjected to a heating treatment, such that the influence of diurnal temperature difference on the cutting slips can be prevented, and a normal cutting slip rooting environment is ensured. In summary, the cutting method provided by the invention has the advantages of simple steps, convenient management, short period, and high survival rate. With the method, a large amount of seedlings can be cultivated within a short period of time.

Owner:陆川县大鹏现代农业发展有限公司

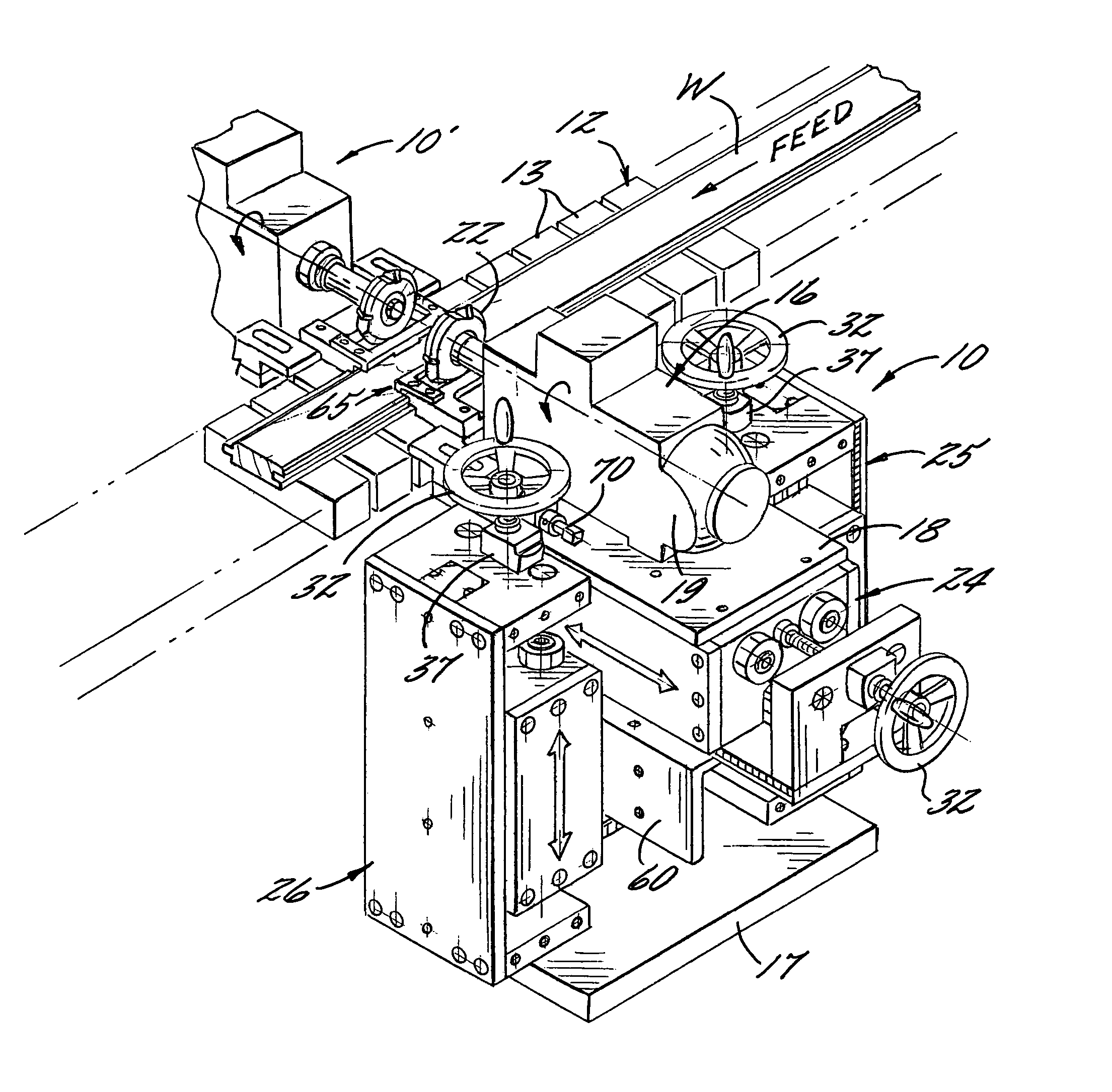

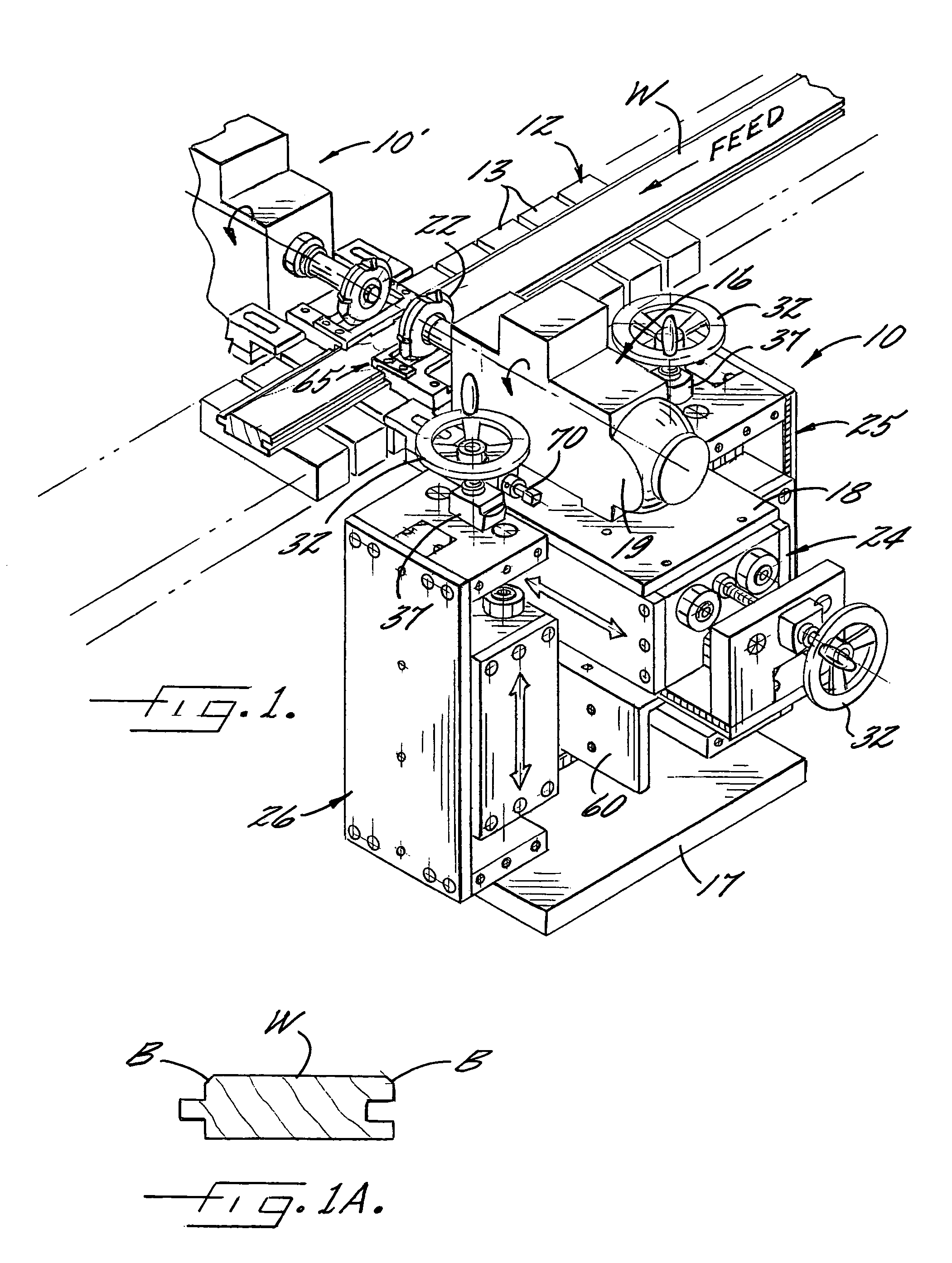

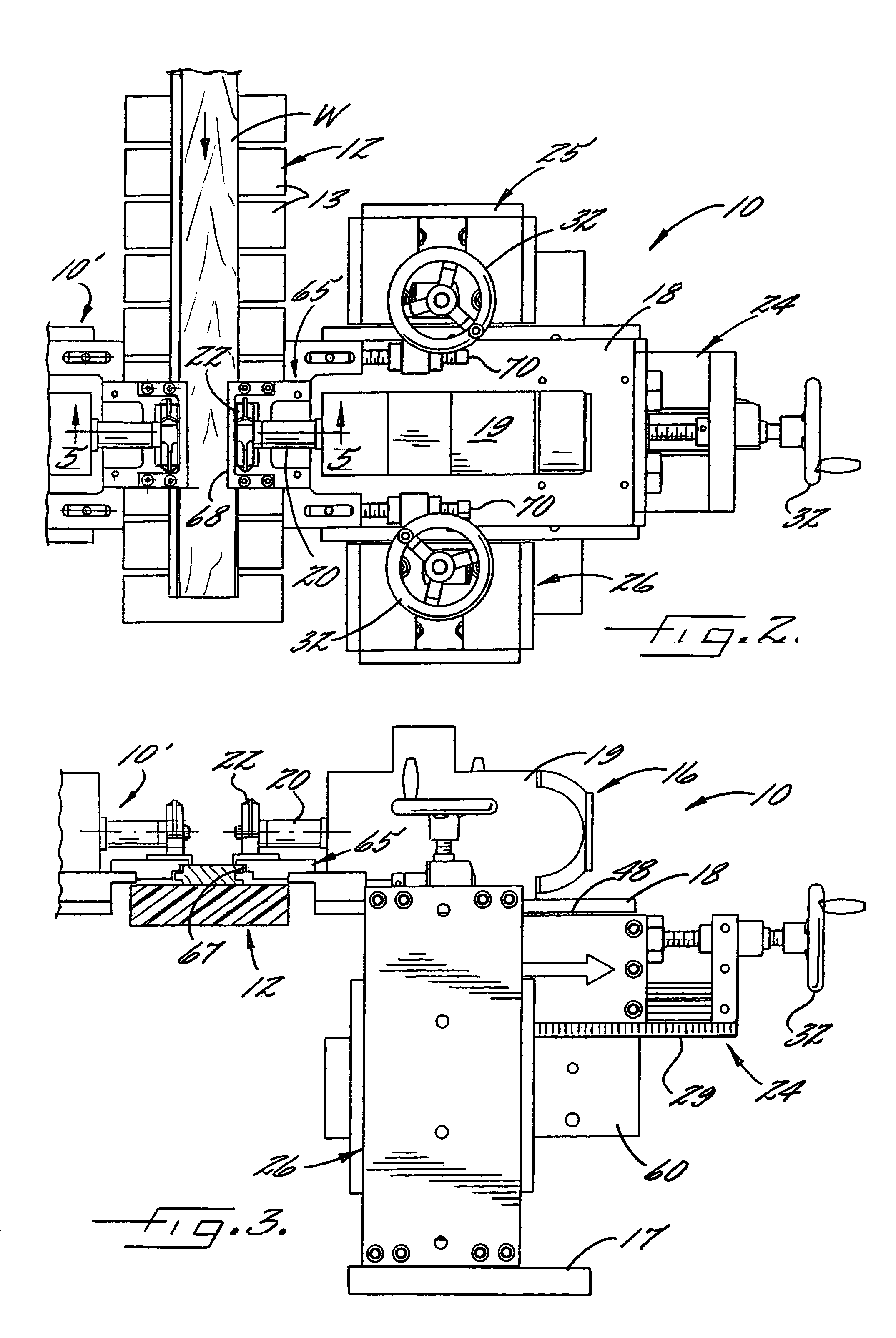

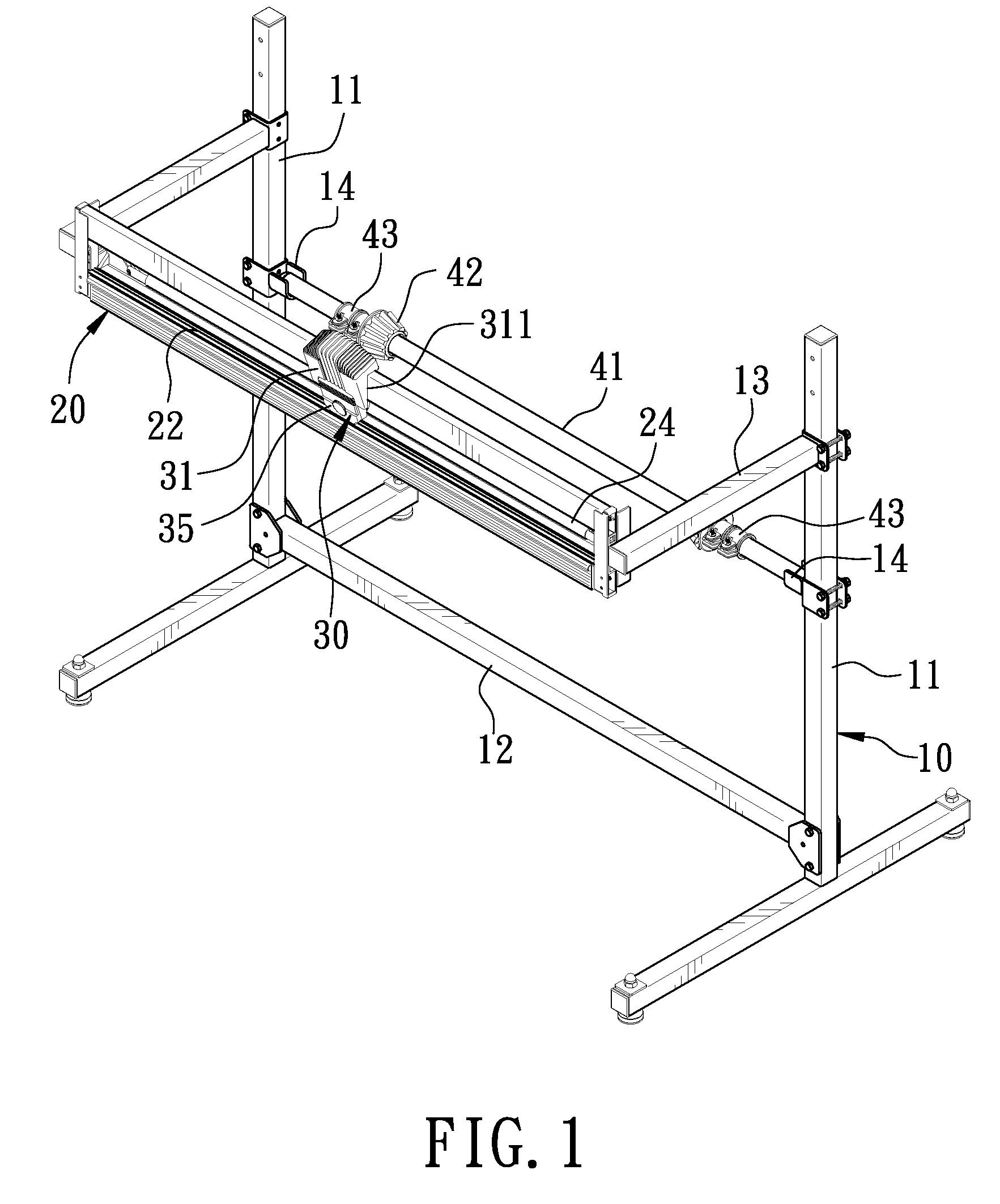

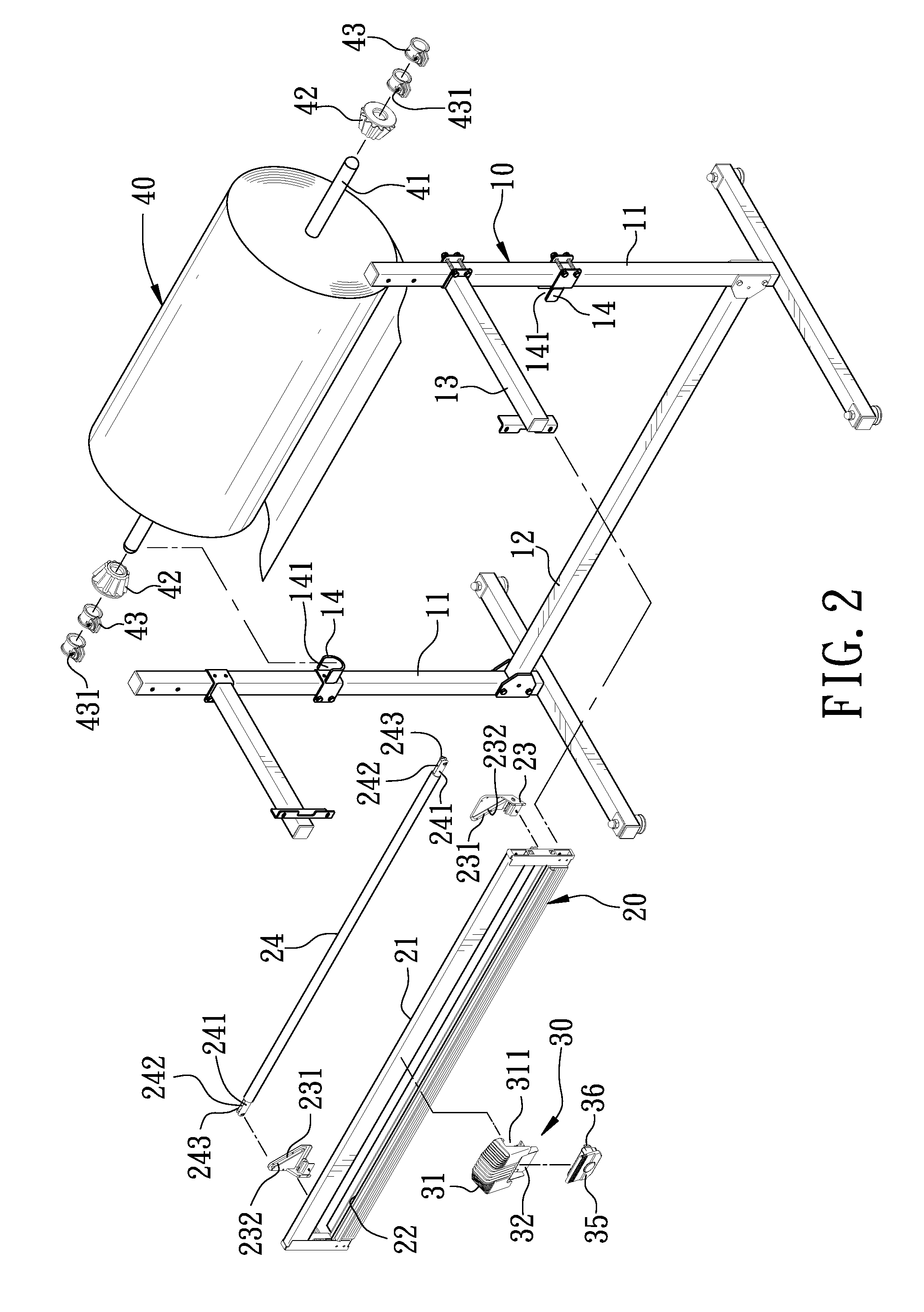

Workpiece beveling machine

Owner:HASKO

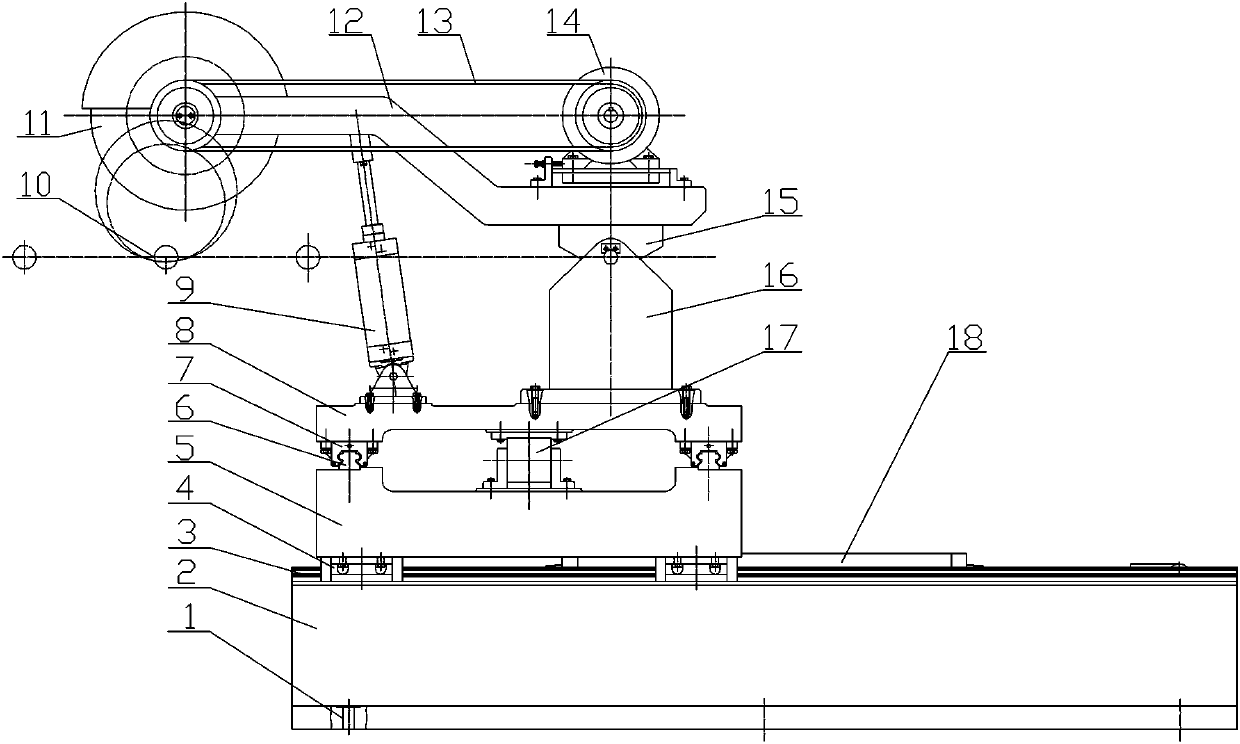

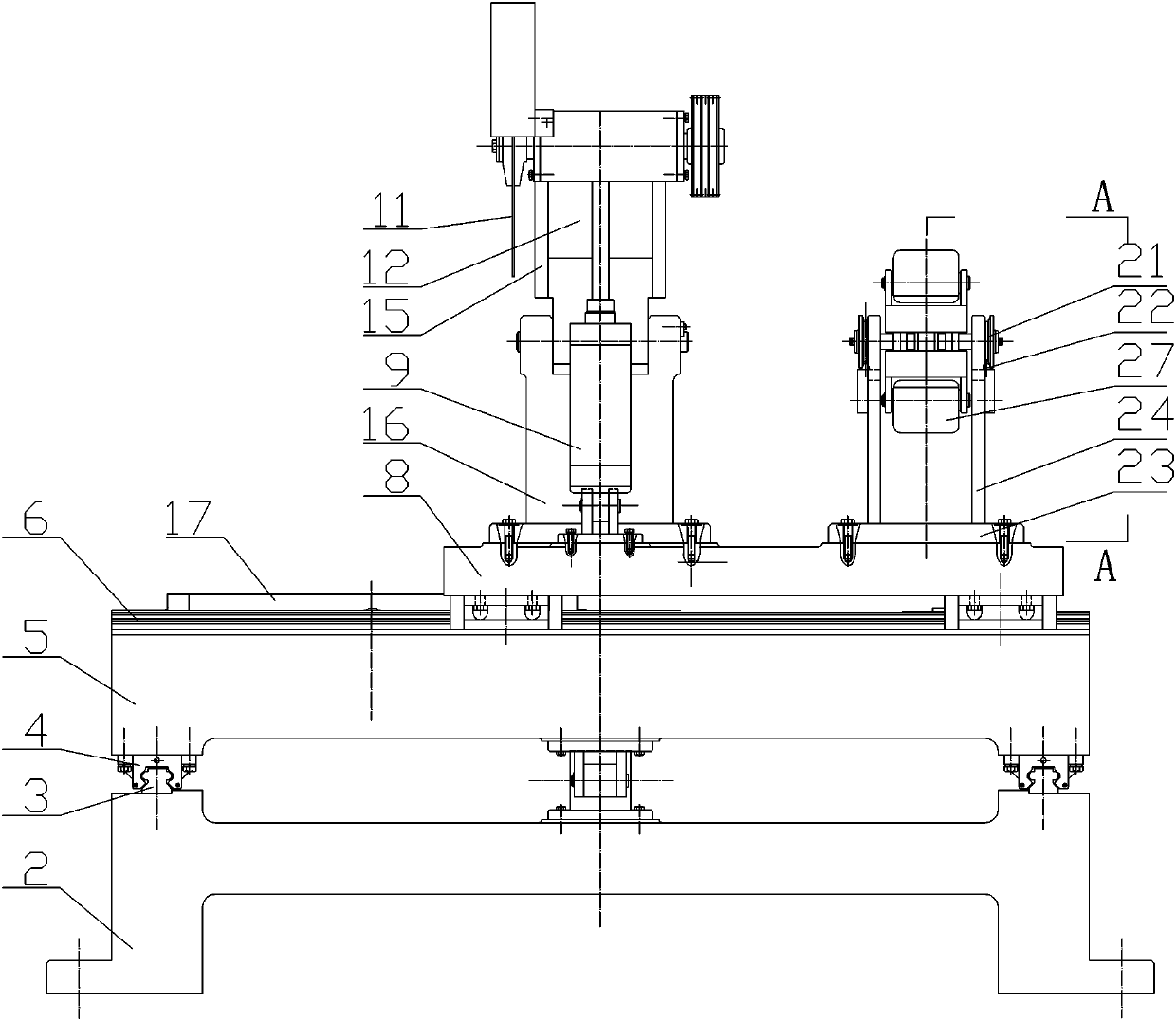

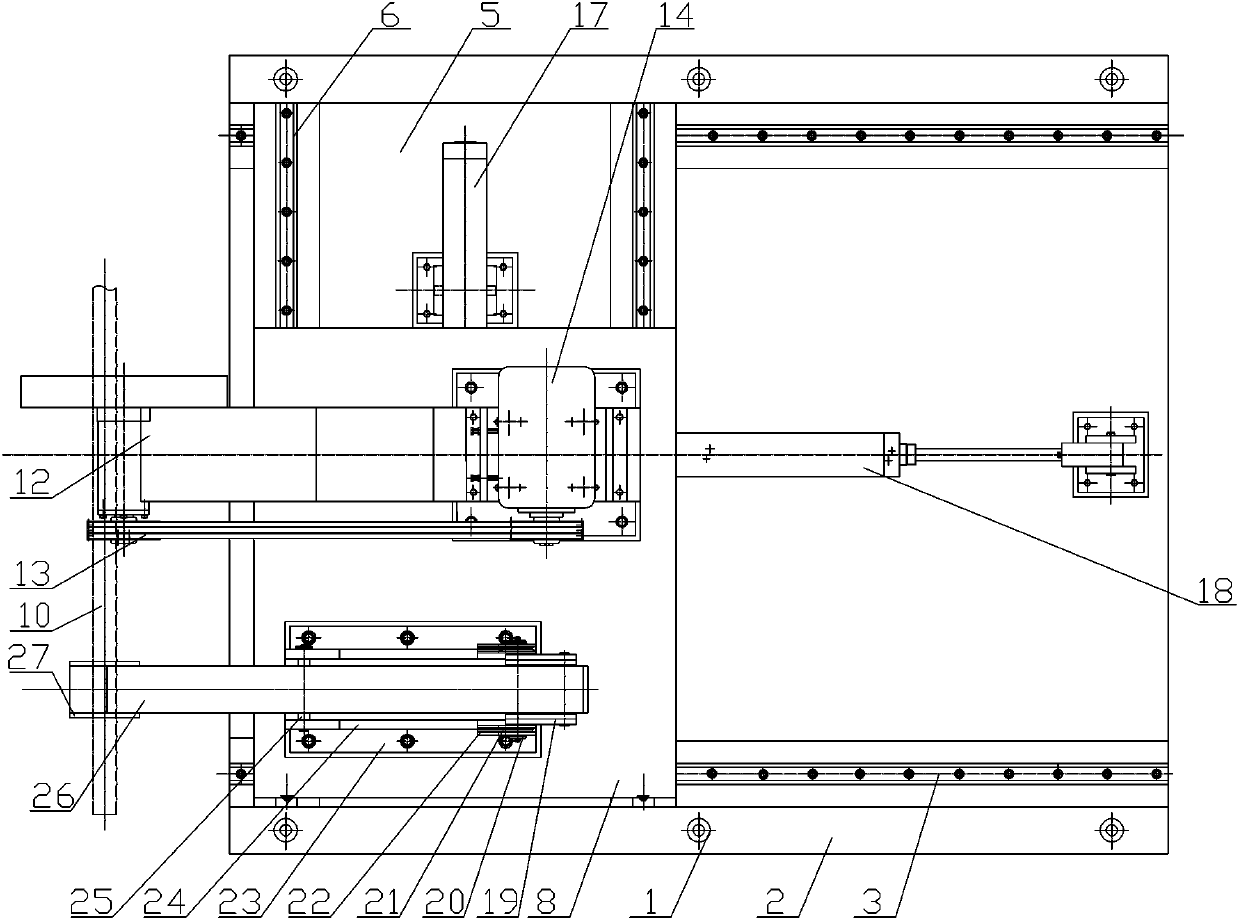

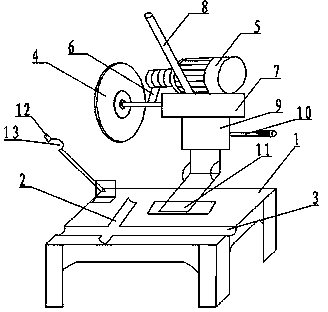

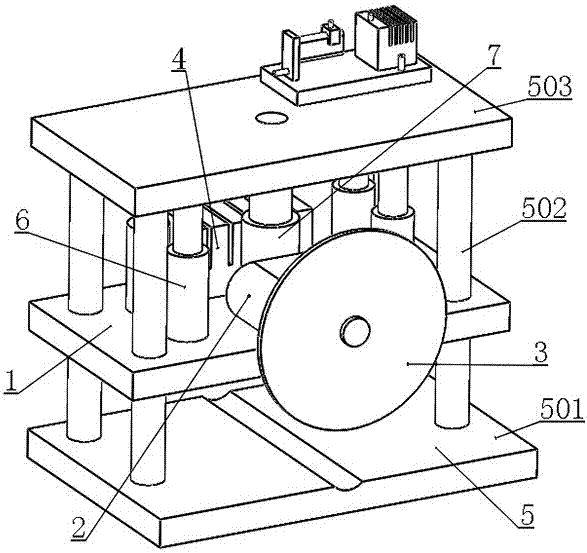

Steel pipe cutting machine tool

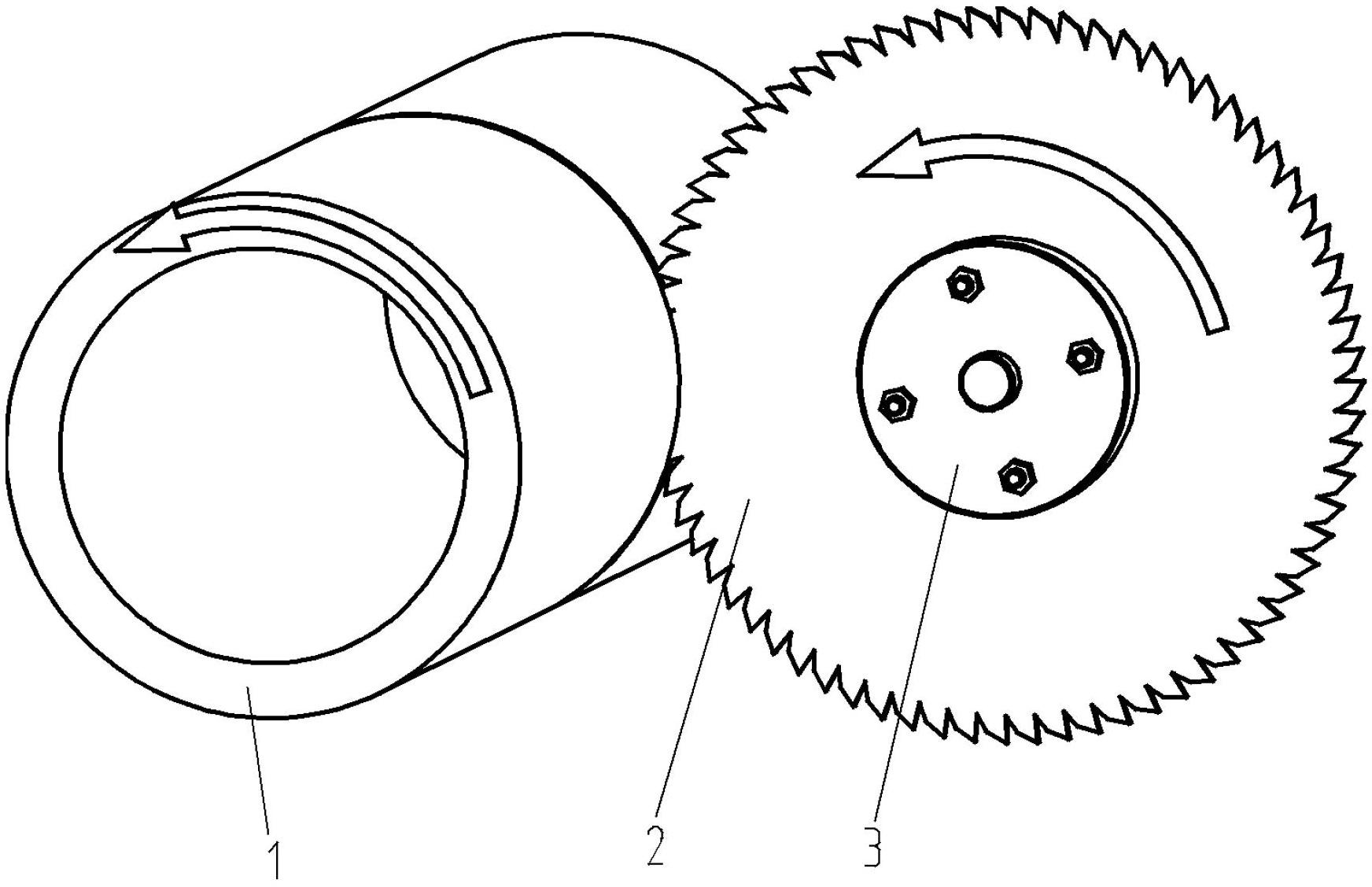

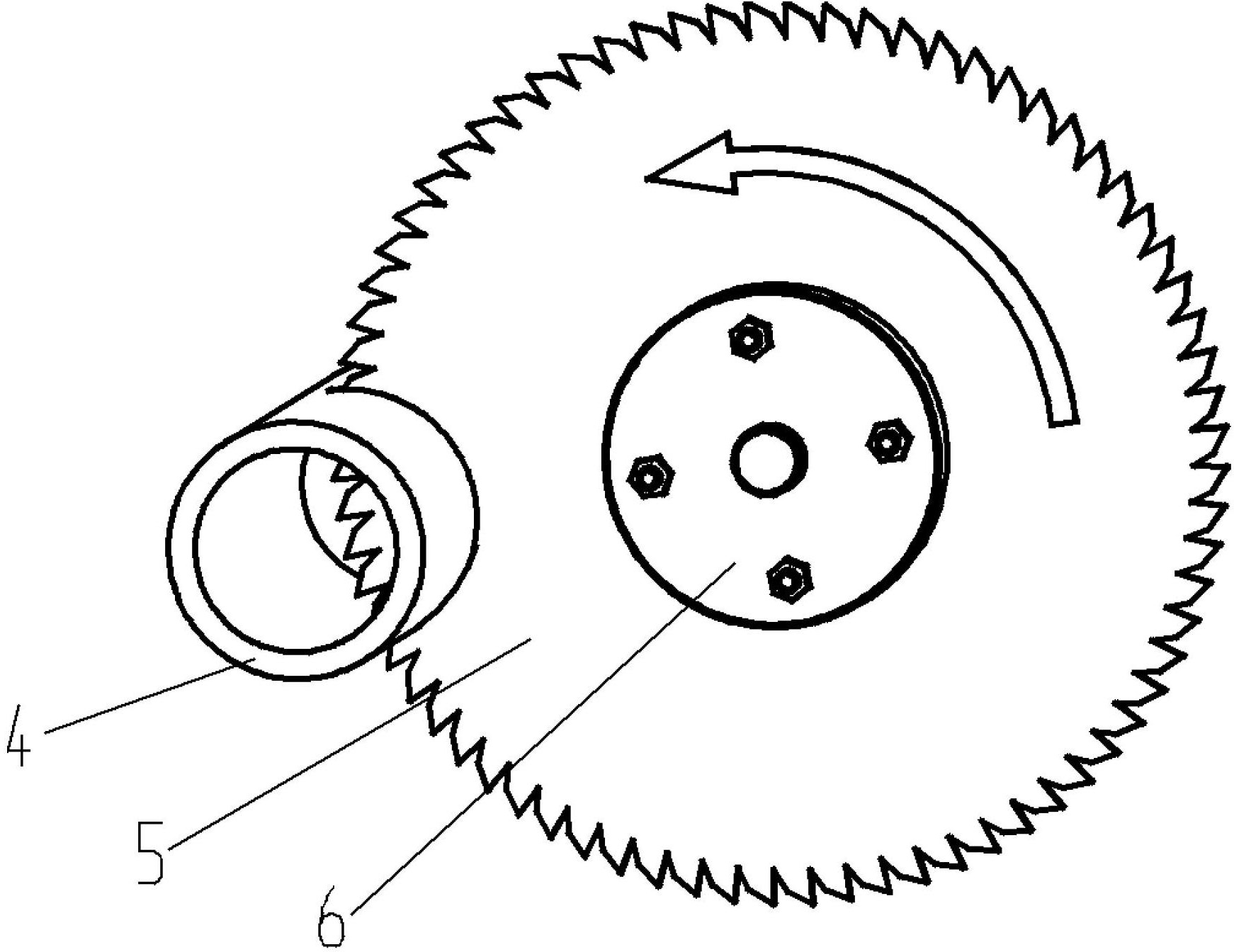

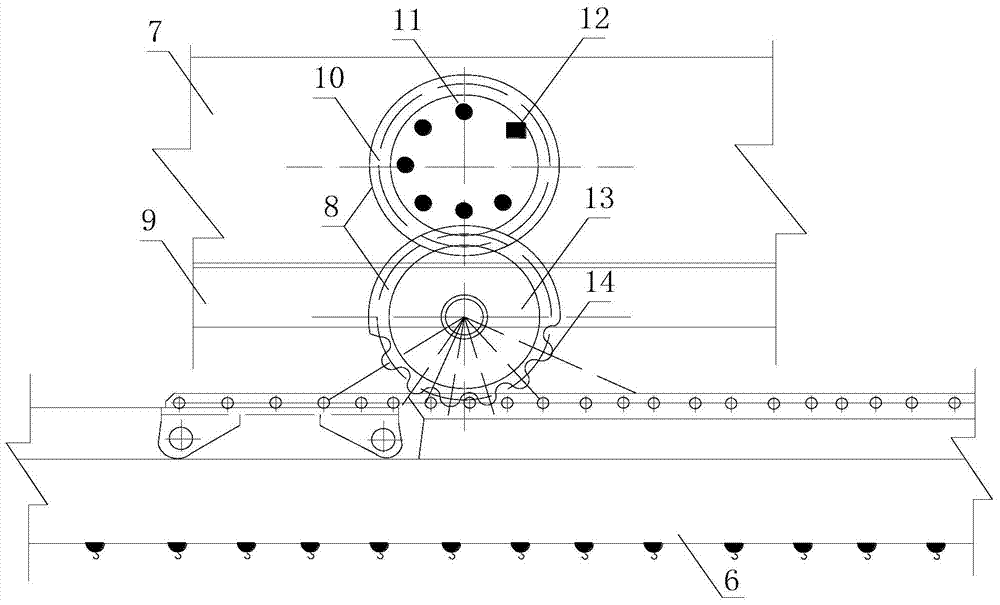

InactiveCN102658399AThe overall thickness is thinHigh precisionMetal sawing devicesDriving apparatusLow speedEngineering

The invention discloses a steel pipe cutting machine tool, which is used for cutting large / medium-caliber steel pipes, and comprises a spindle rotating mechanism, a spindle lifting mechanism, a cutting mechanism, a supporting mechanism and a chuck clamping and unclamping device. According to the steel pipe cutting machine tool, a cutting mode of simultaneously rotating a saw blade and the steel pipes along an axis is adopted, when the saw blade rotates at a high speed and feeds and cuts the steel pipes along the radial direction of the steel pipes, the steel pipes rotate around the own axis at low speed, so that the saw blade cuts the steel pipes toward the axis along the outer circumference of the steel pipe; and therefore, the steel pipes can be cut off when the inner walls of the steel pipes are cut by the saw blade. Compared with the prior art, the steel pipe cutting machine tool has the advantages that the feeding distance is greatly shortened, the cutting speed is increased, the diameter of the saw blade is not required to be large, the thickness of the saw blade is small, and the precision and finish of the cutting section are greatly improved; and meanwhile, the energy loss and material loss of the steel pipe cutting machine tool are greatly reduced, and the current industrial requirements for environment friendliness and low carbon are met.

Owner:贺伟

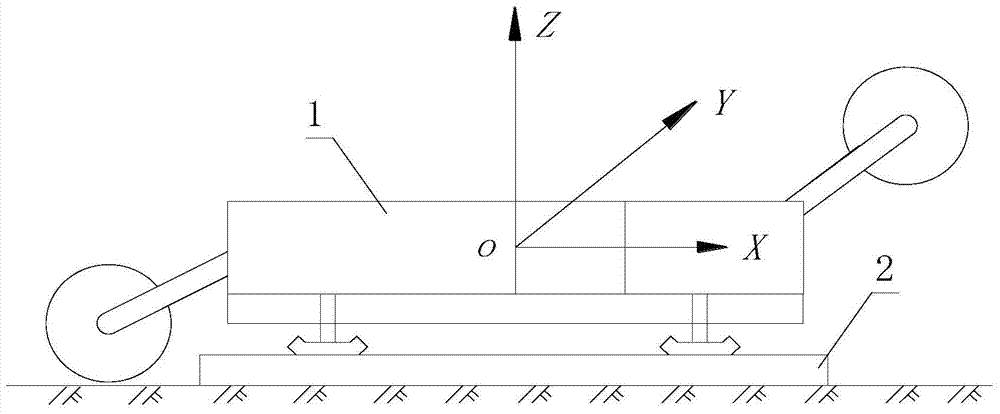

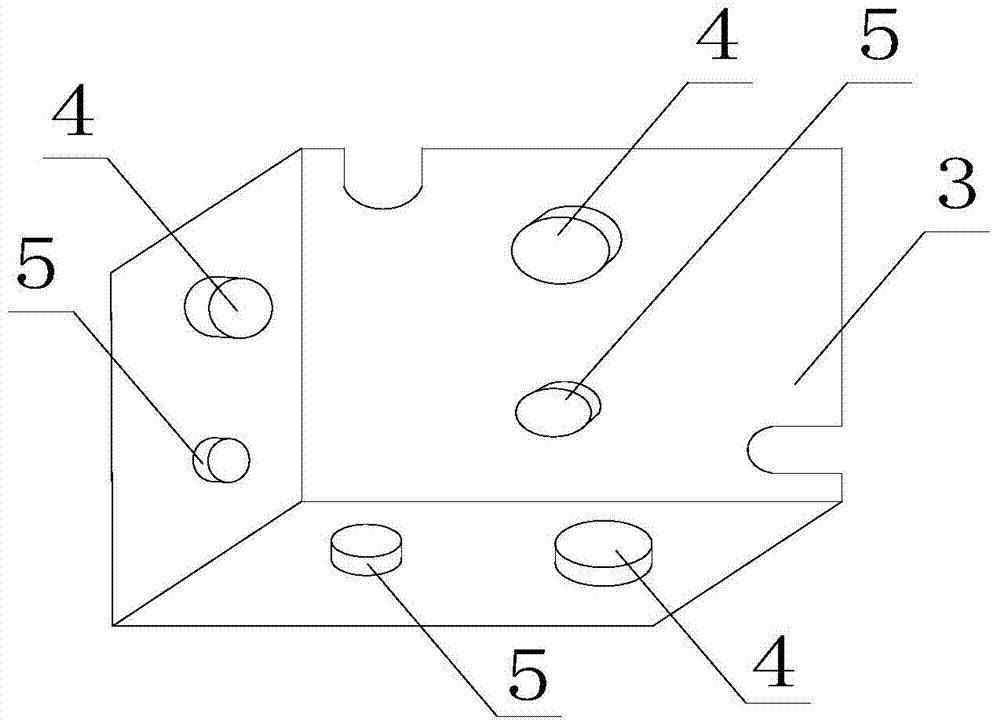

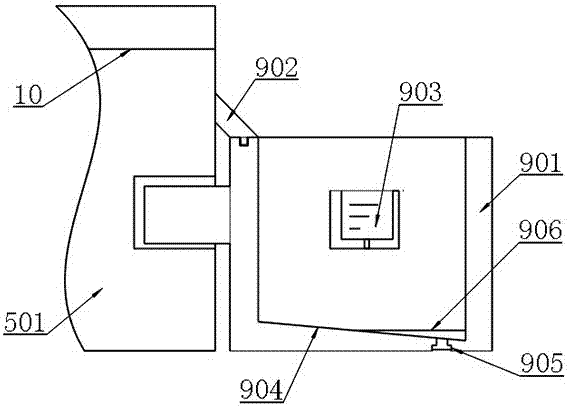

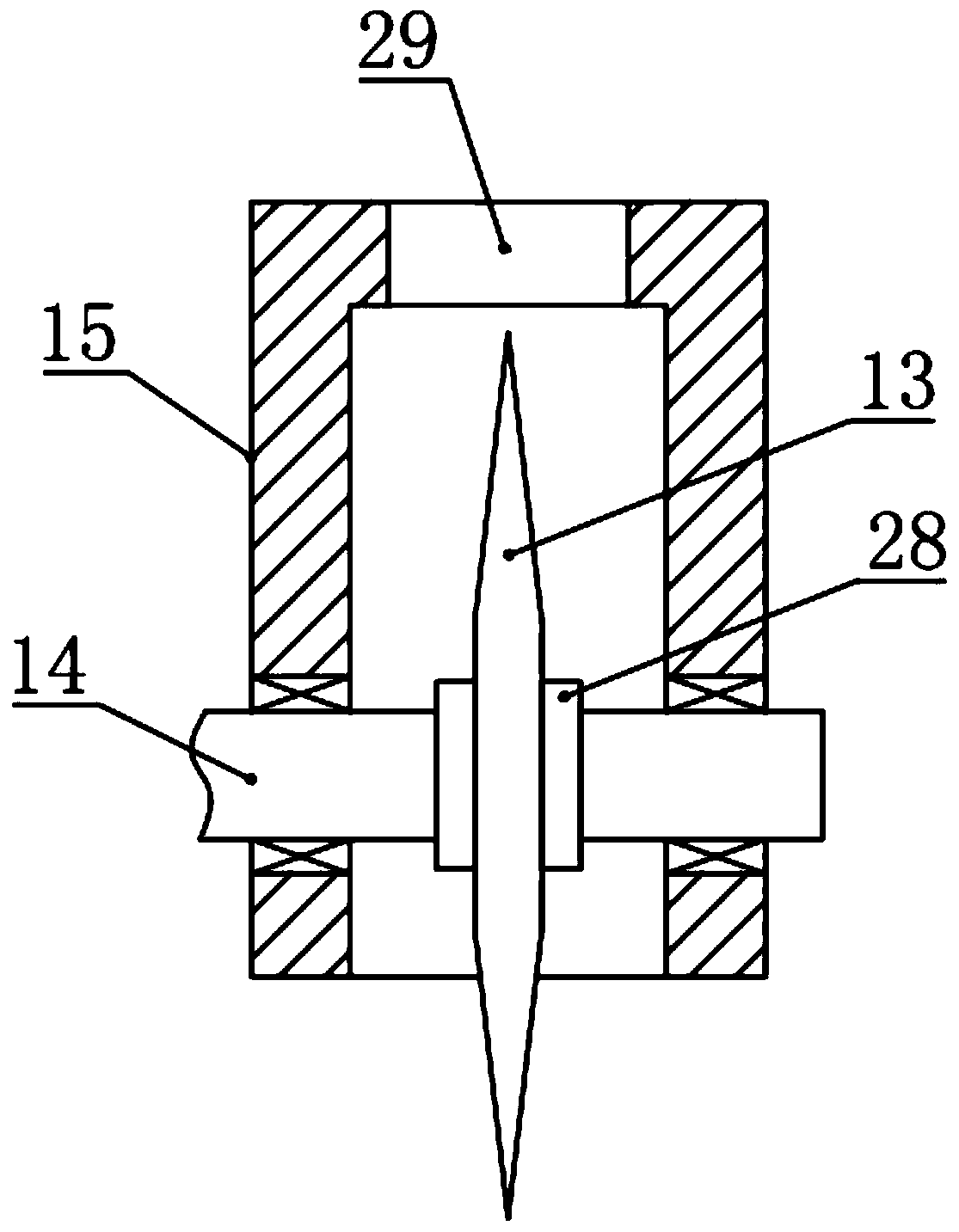

Test method for automatic memorization and coal cutting self-positioning device of manless working face coal mining machine

ActiveCN103776463AImprove the design of automated controlsEasy to useMeasurement devicesAccelerometerAutomatic control

The invention discloses a test method for an automatic memorization and coal cutting self-positioning device of a manless working face coal mining machine and belongs to a method for testing a coal mining machine positioning device. By using the test method, a test experiment on the self-positioning device for automatic memorization and coal cutting of the manless working face coal mining machine is designed according to the self-positioning feature of the automatic memorization and coal cutting of the manless working face coal mining machine; the method comprises the following steps: firstly mounting an IMU (inertia measurement unit) inertia measurement component in the middle of a coal mining machine model, wherein the IMU inertia measurement component comprises three gyroscopes and three accelerometers of which the measurement directions are perpendicular, and a speedometer is arranged on a scraper conveyer in a simulation manner; then supplying research contents and steps of the test experiment, and designing two test lines of linear running and feeding running according to the change of a coal cutting line of the coal mining machine in site; finally analyzing the applicability, the reliability and the precision of the self-positioning device according to an acquired test data result. The test method disclosed by the invention has an important significance on improvement on the design of automatic control on the coal mining machine, improvement on the usability and the working reliability of equipment and prolonging of the service life.

Owner:CHINA UNIV OF MINING & TECH

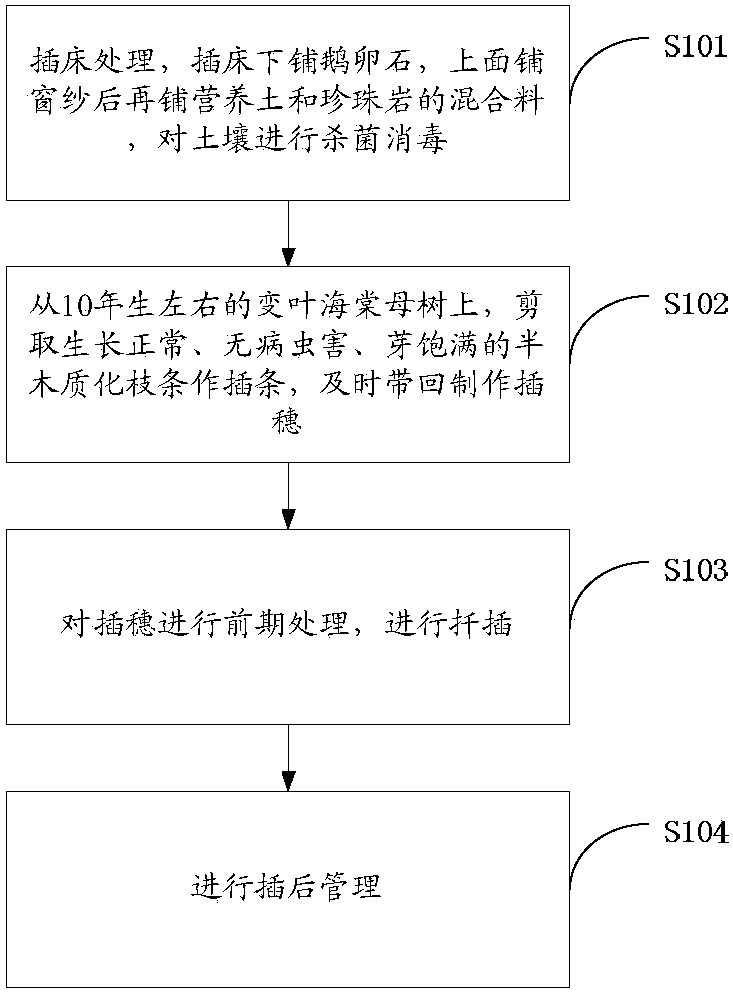

Cutting seedling method for malus toringoides

The invention discloses a cutting seedling method for malus toringoides. The cutting seedling method for the malus toringoides comprises the following steps of treating a cutting bed; laying cobblestones under the cutting bed; laying a window gauze on the cutting bed; laying mixing materials comprising nutrient soil and perlite on the window gauze; sterilizing soil; shearing semi-lignified branches, which grow normally, are not affected by plant diseases and insect pests and have plump buds, from a malus toringoides seed tree with the age about 10 years; timely bringing back the branches and manufacturing cutting slips; performing earlier-stage treatment on the cutting slips and performing cutting; and performing management after cutting. By using the cutting seedling method, the operation is simple, the yield is high, requirements on production of nursery-grown plants of the malus toringoides can be met, and the nutrient soil 3 and the perlite 1 serve as a cutting medium which is loose and breathable, has rich nutrition and can provide nutrition for the nursery-grown plants during earlier-stage growth. After the cutting slips are rapidly dipped in 1200mg / L of naphthaleneacetic acid liquor, cutting can be directly performed on the cutting slips, the cutting time is shortened, and the work efficiency is improved; the cutting yield is higher than 90%; the nursery-grown plants grow healthily and strongly; and the excellent performance of the maternal malus toringoides is kept. Compared with a seed raising method, the cutting seedling method has the advantages that cutting propagation is not limited by seasons, branches can be treated by cutting immediately after being shearing from the tree, and the operation is simple and feasible.

Owner:SICHUAN AGRI UNIV

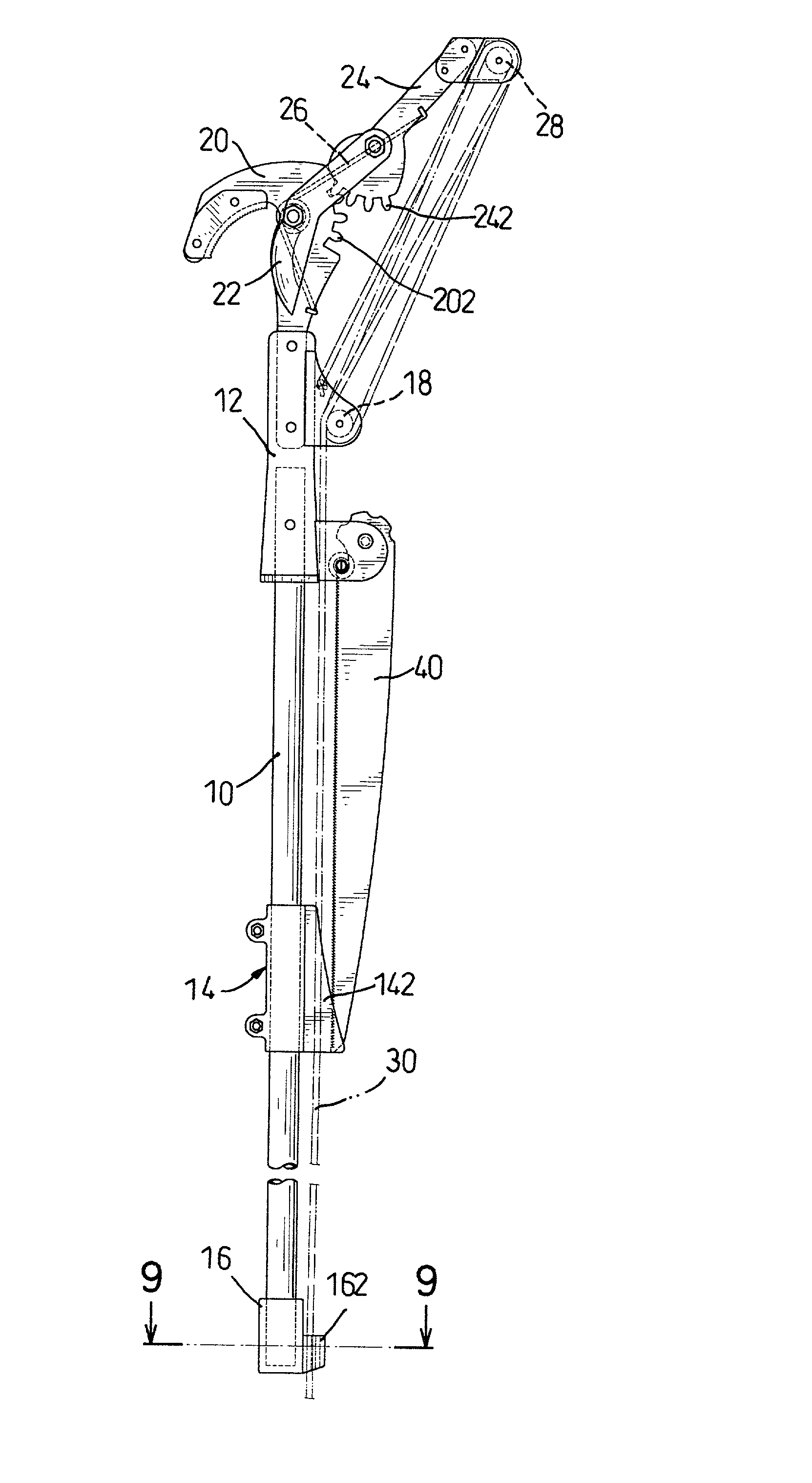

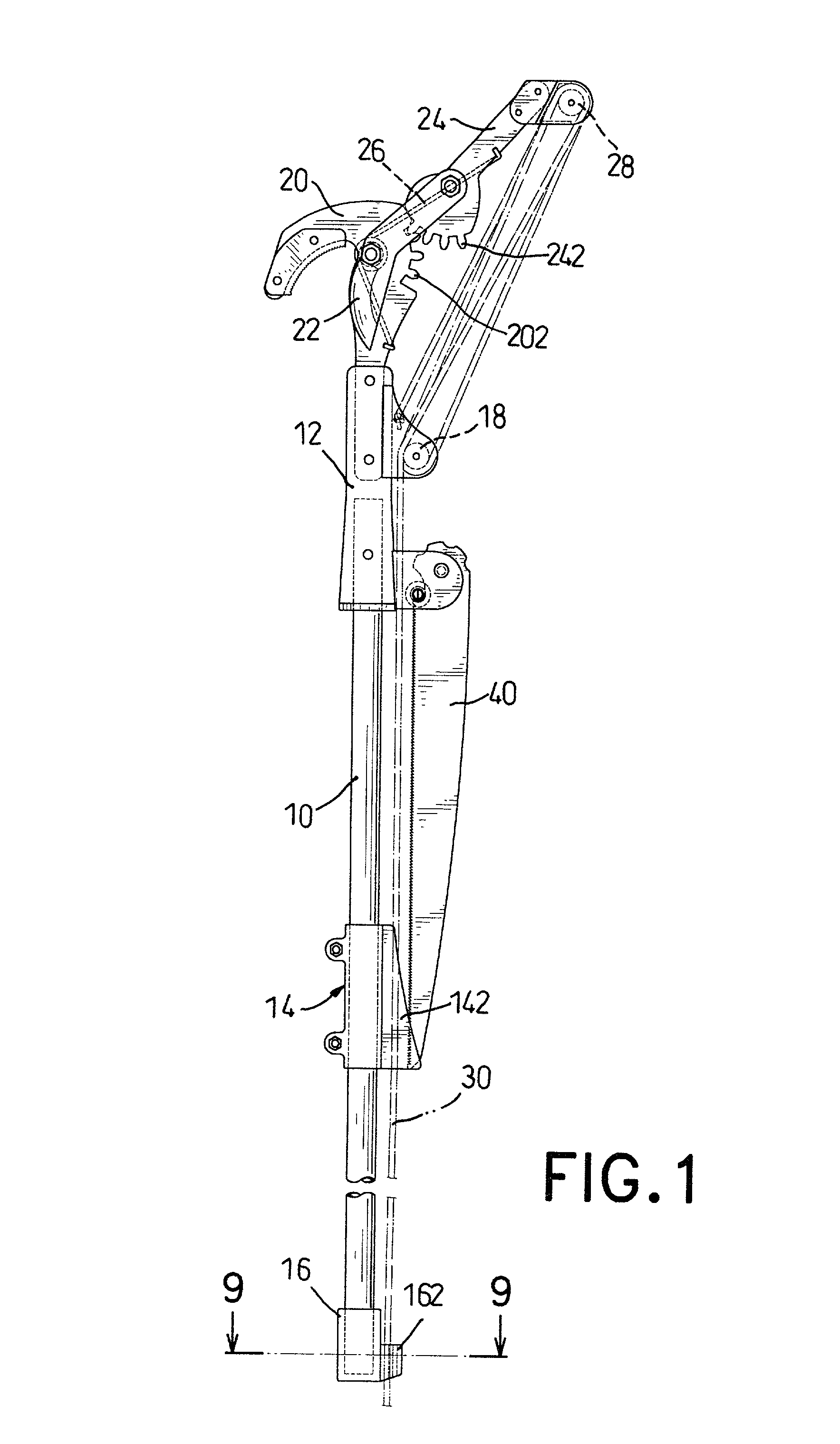

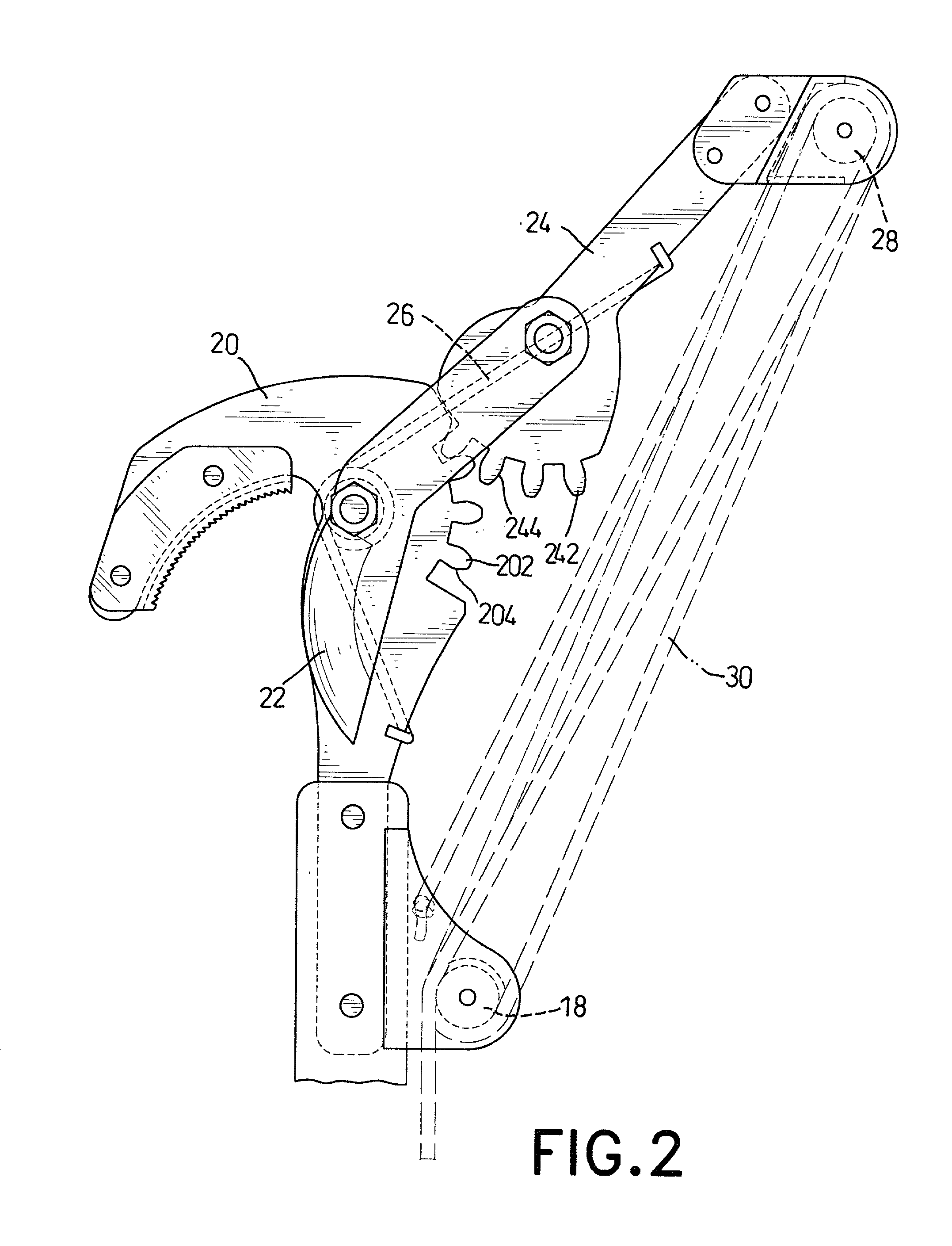

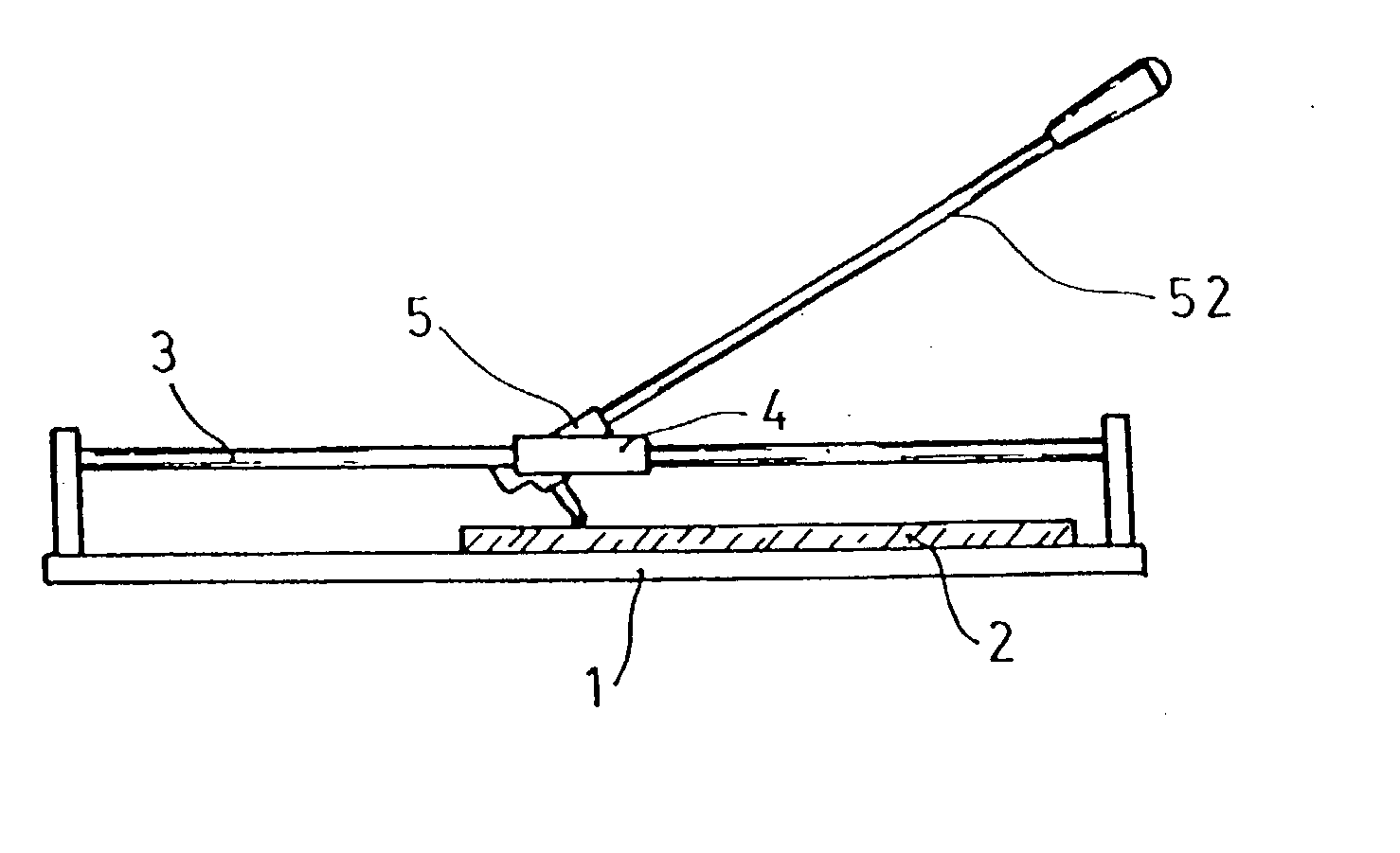

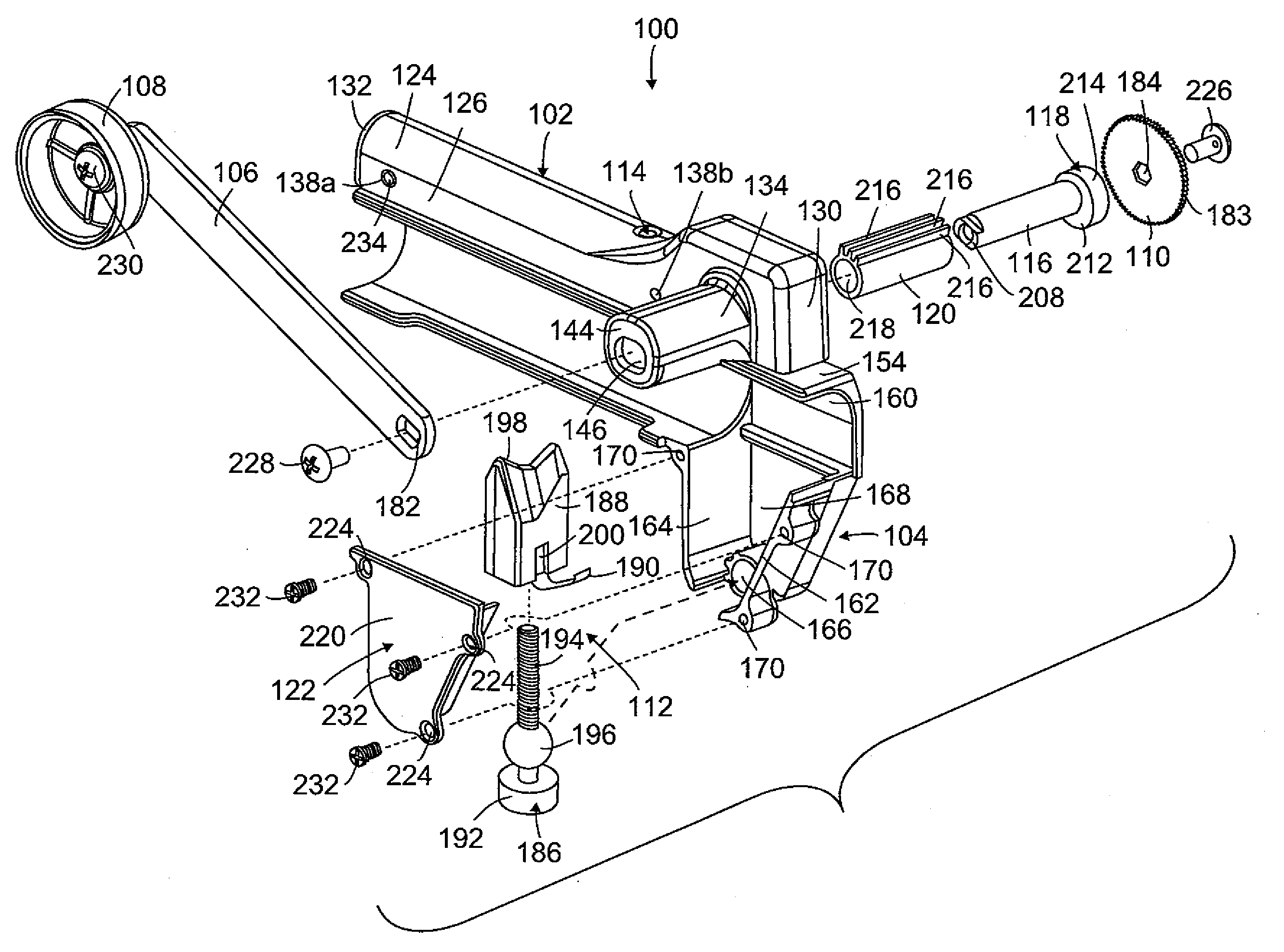

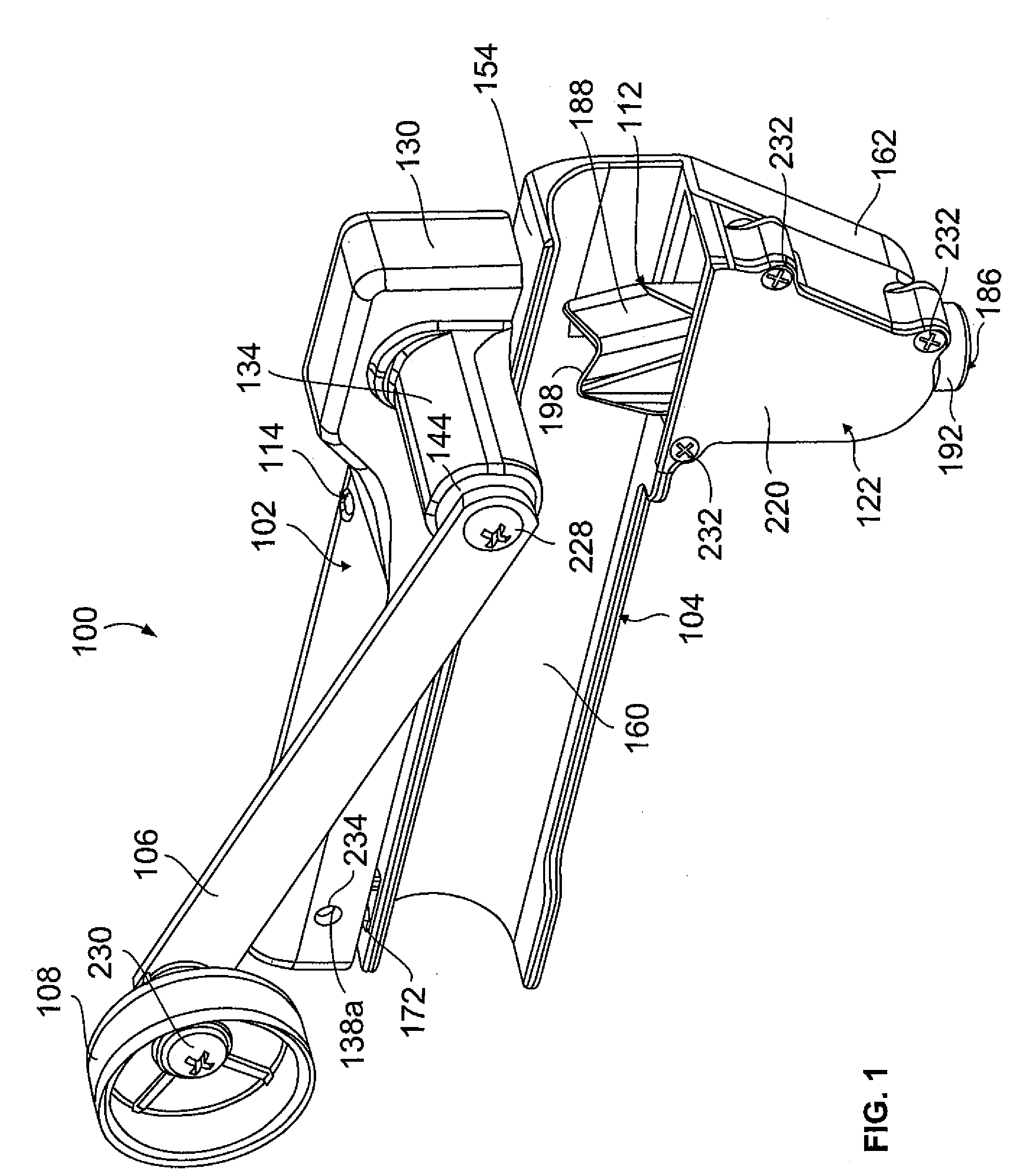

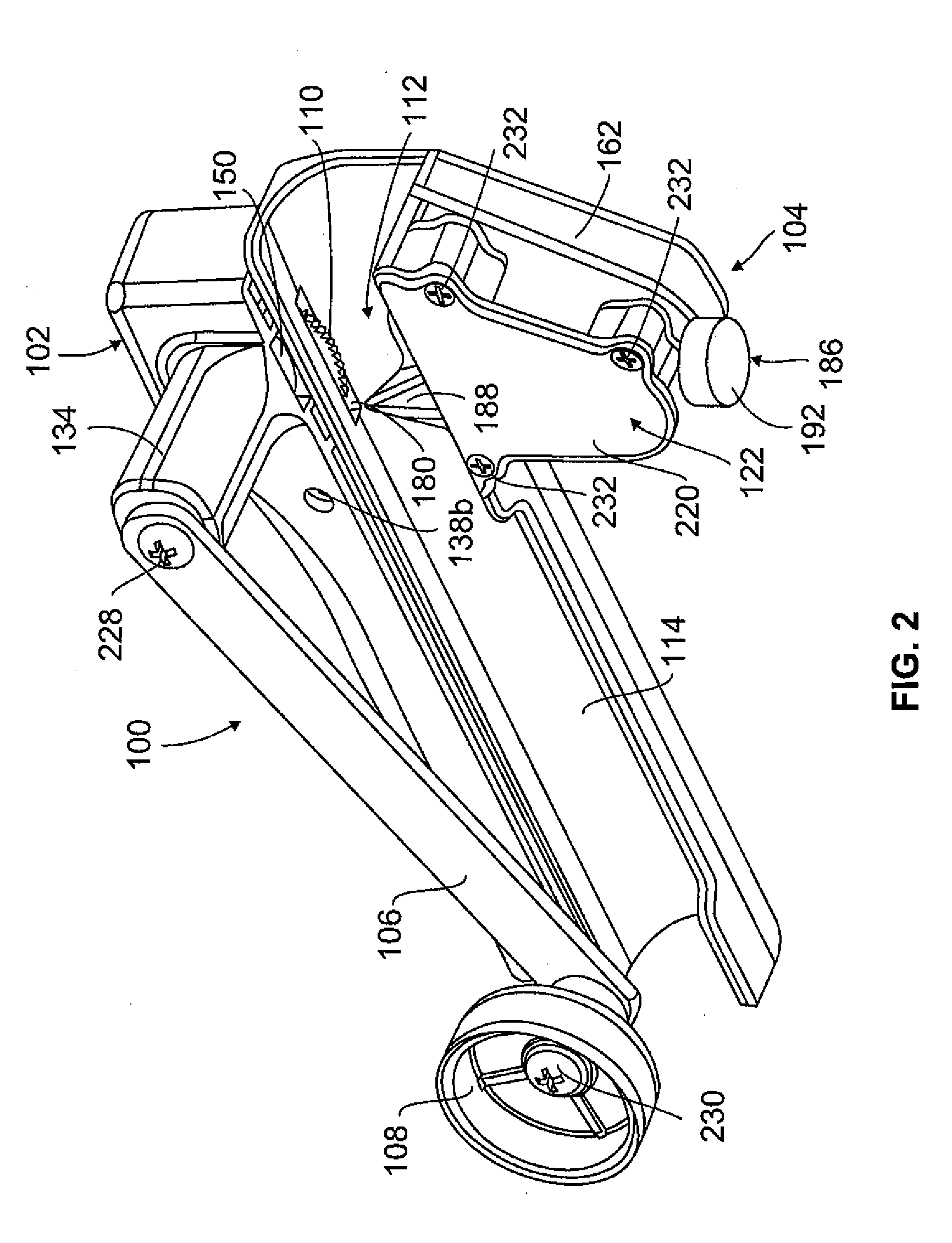

Tree pruner

InactiveUS20030177644A1Easy to cutIncrease the itineraryCuttersCutting implementsKnife bladesCutting self

A tree pruner has a support rod, a cutting set and pull cord. The cutting set is mounted on the top end of the support rod and has a fixed blade, a moving blade and a driving lever. The fixed blade is securely connected to the top end of the support rod and has multiple fixed teeth formed on an edge of the fixed blade. The cutting blade is pivotally attached to the fixed blade. The driving lever is pivotally attached to one end of the cutting blade and has multiple moving teeth formed on the driving lever to engage with the fixed teeth on the fixed blade. With such a cutting set, the travel of pulling the pull cord can be increased, such that the cutting set can cut off with ease a tree part with a large diameter.

Owner:CHENG KUN CHIA

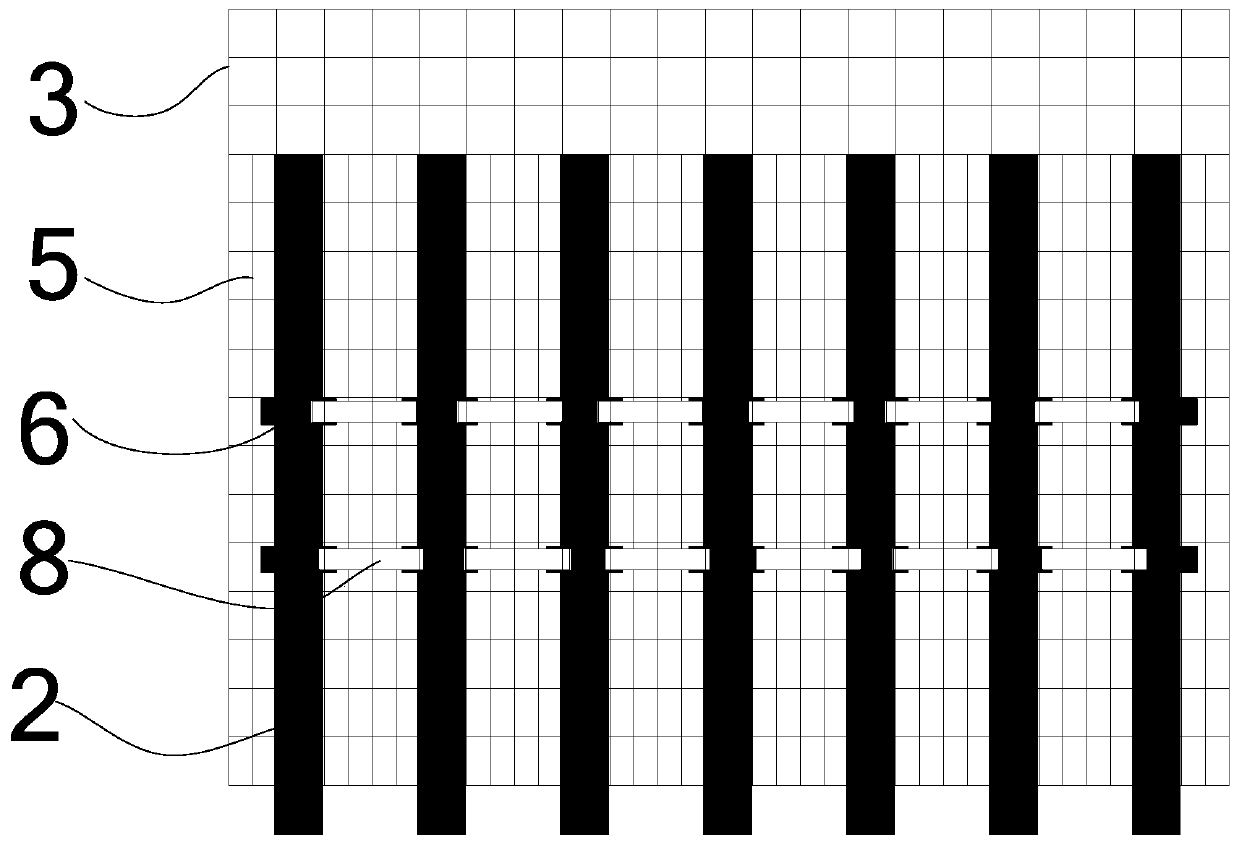

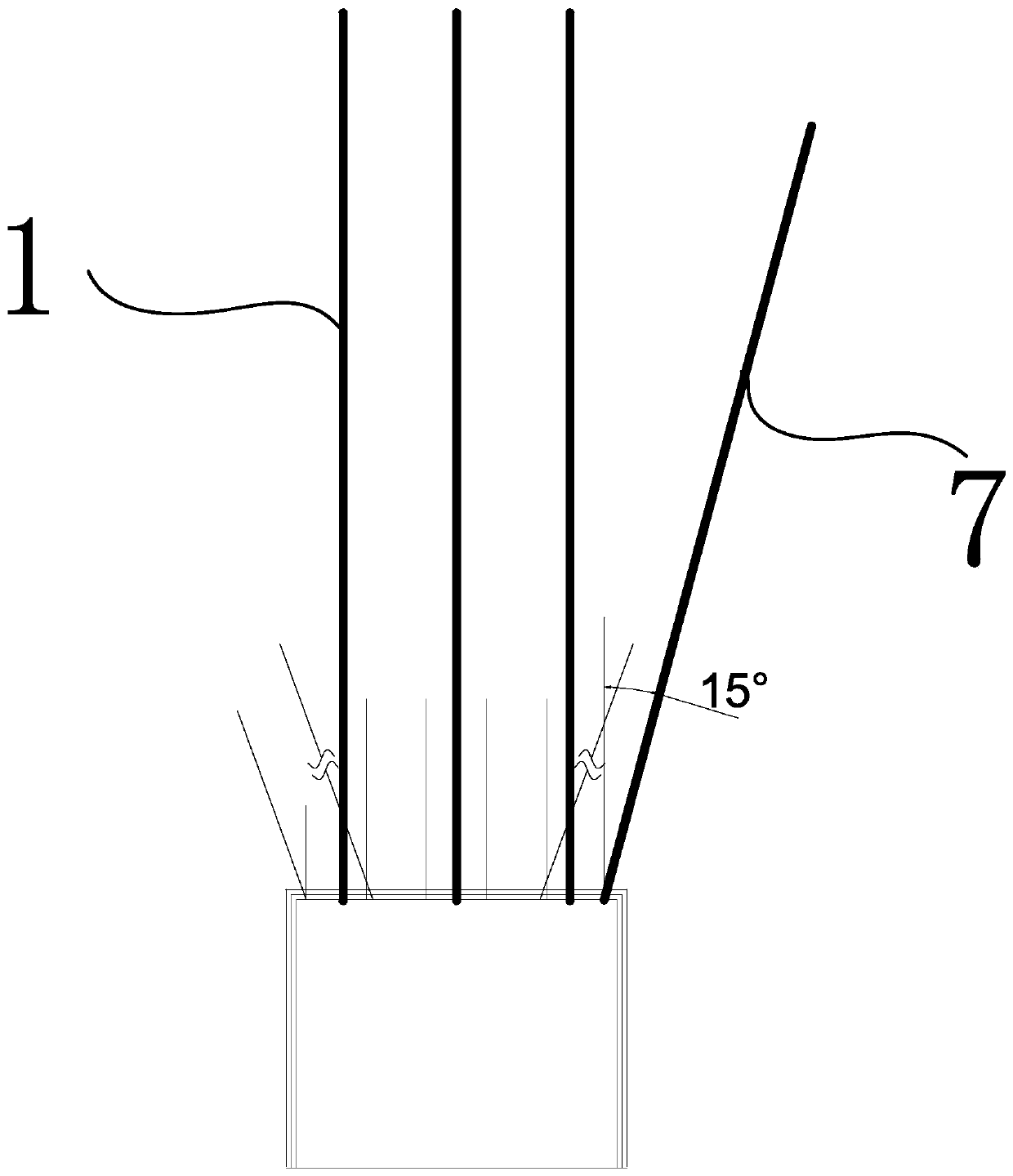

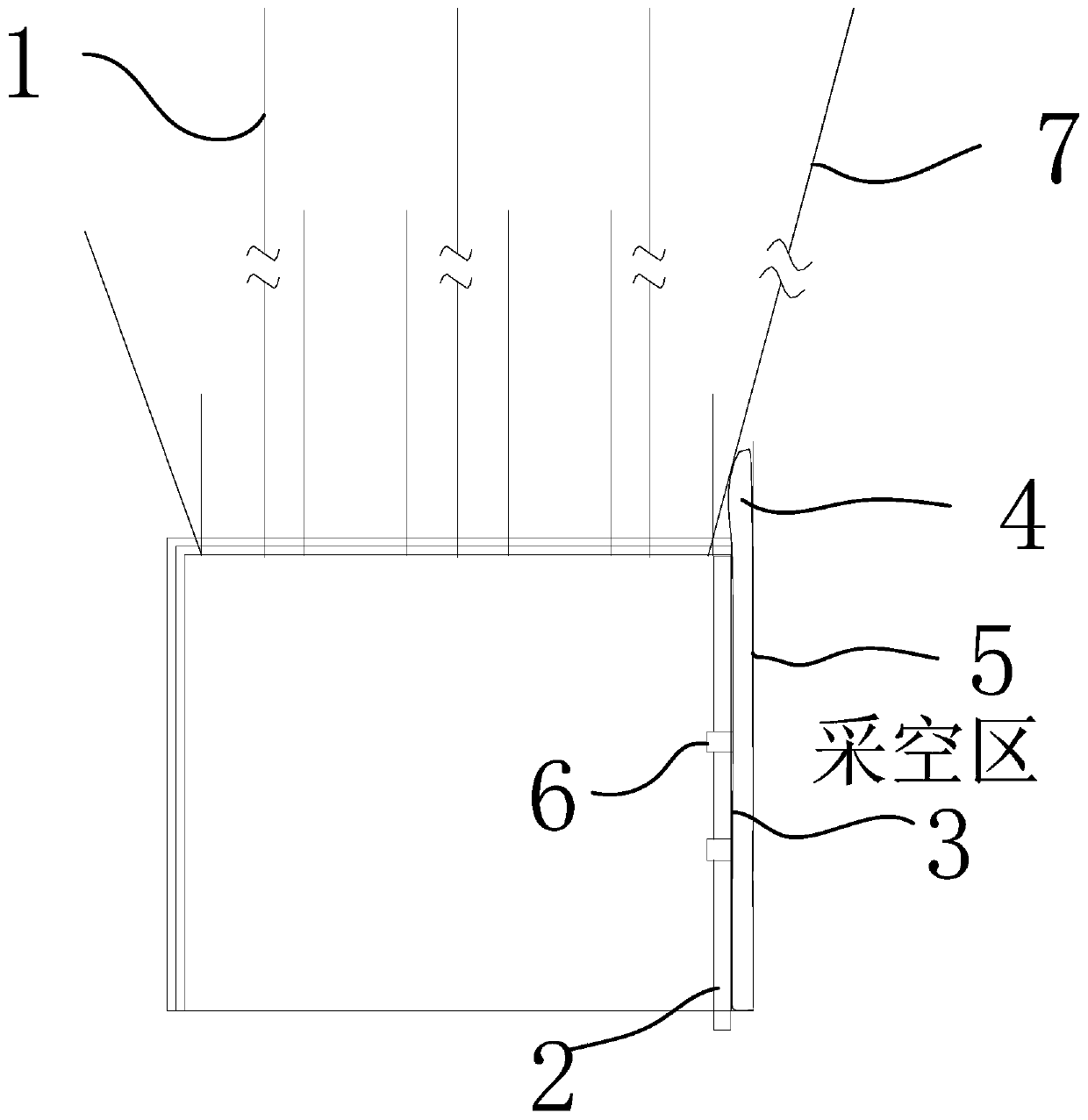

Roof-cutting self-tunneling coal-pillar-free mining method for coal seam easy to spontaneously combust

ActiveCN109915138AReduce stress transferIncrease the ability to resist dynamic pressureUnderground miningSurface miningEngineeringLarge deformation

The invention relates to the technical field of coal mining, in particular to a roof-cutting self-tunneling coal-pillar-free mining method for a coal seam easy to spontaneously combust. The method comprises the following steps of: additionally driving a constant-resistance anchor cable on a roof for reinforcing and supporting; conducting directional pre-splitting blasting joint cutting on the sideroadway roof of a goaf; erecting a single hydraulic prop in a temporary supporting area; arranging a gangue blocking support column close to the side of the goaf behind the stope face, and fixing a first metal net on one side, close to the goaf, of the gangue blocking support column; laying a flexible mold bag on the side, close to the goaf, of the first metal net, laying a second metal net on the side, close to the goaf, of the flexible mold bag, and synchronously laying the flexible mold bags forwards along with forward movement of a coal mining support of the working face; and pouring a quick-setting elastic material into the flexible mold bags. A pre-splitting joint-cutting technology is matched with a constant-resistance anchor cable support to weaken stress transfer of the roof andimprove the dynamic pressure resistance of the roadway; and the quick-setting elastic material capable of generating large deformation is combined with the gangue blocking structure, so that the goodsealing effect of the goaf is ensured while yielding deformation is realized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

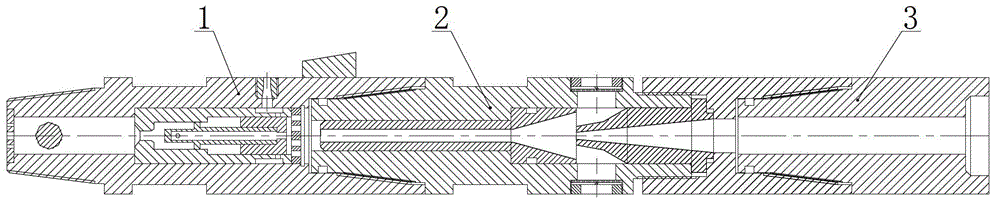

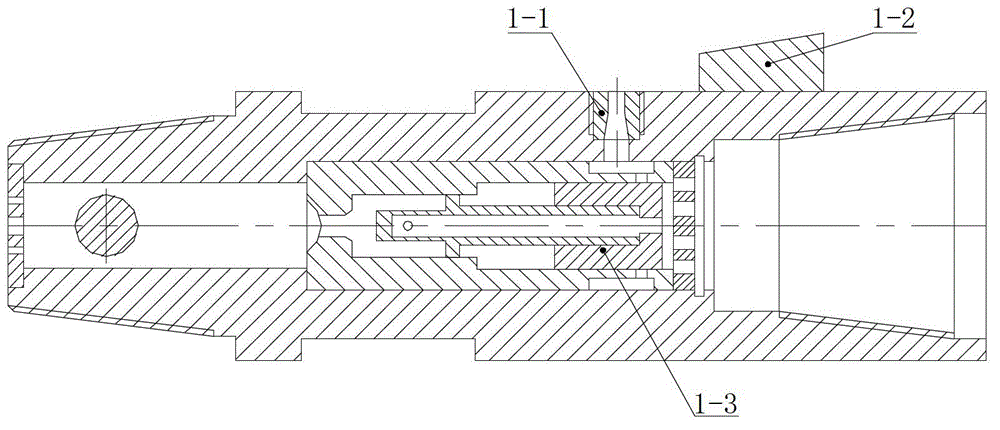

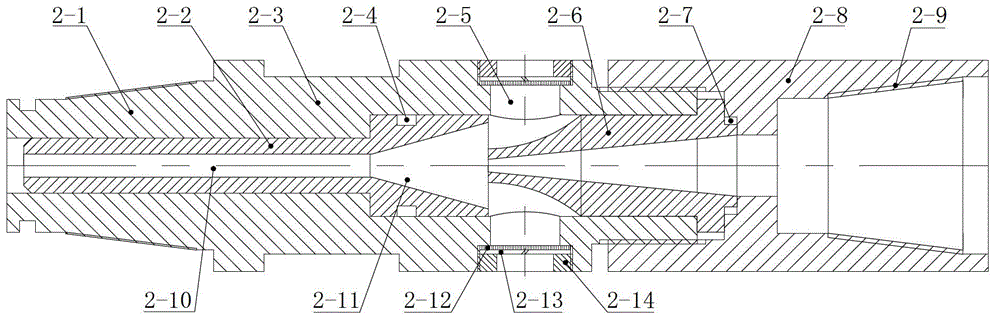

Device and method for underground coal mine hydraulic slit cutting self-suction type material abrading jet flow generation

Owner:CHONGQING UNIV

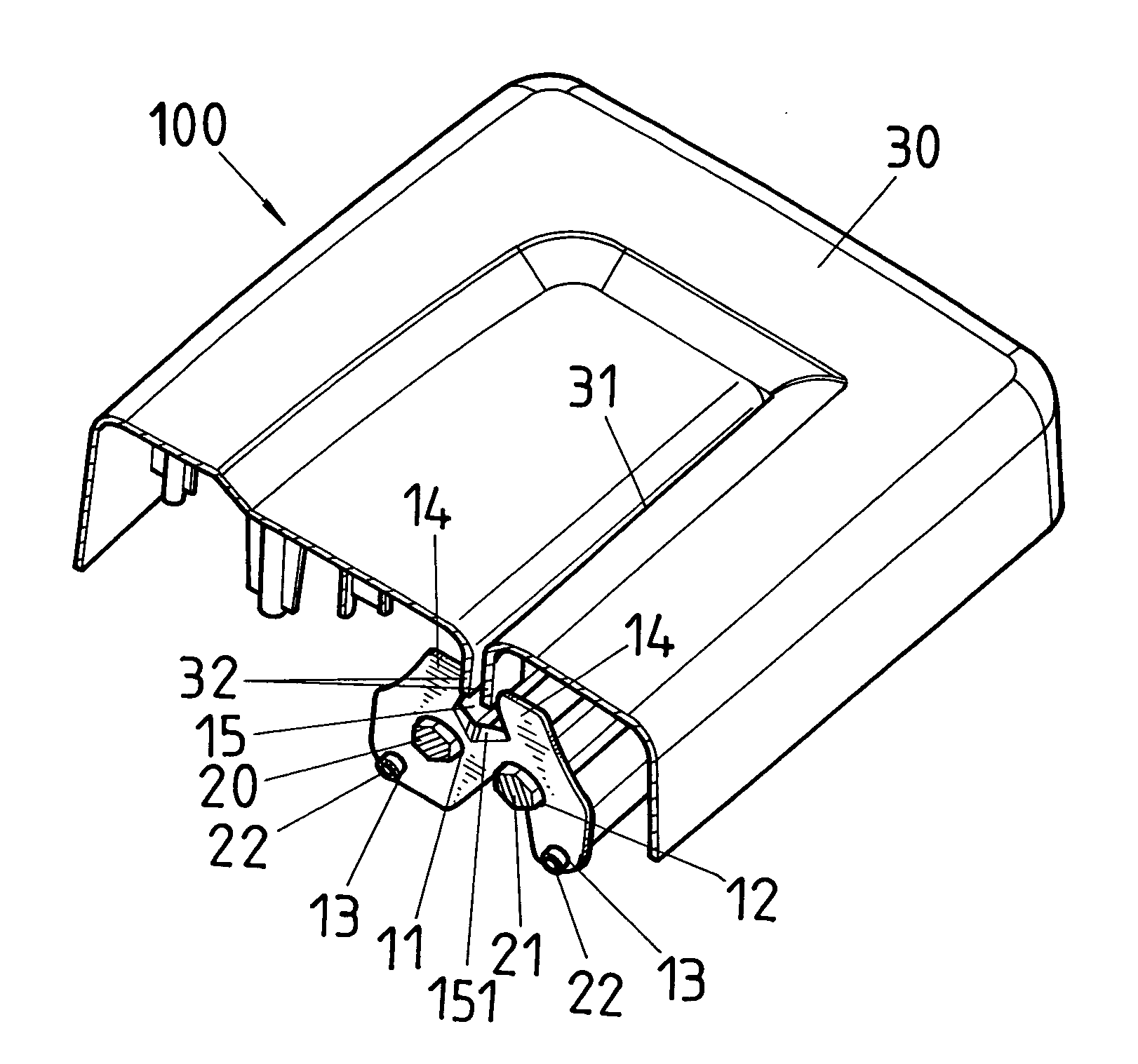

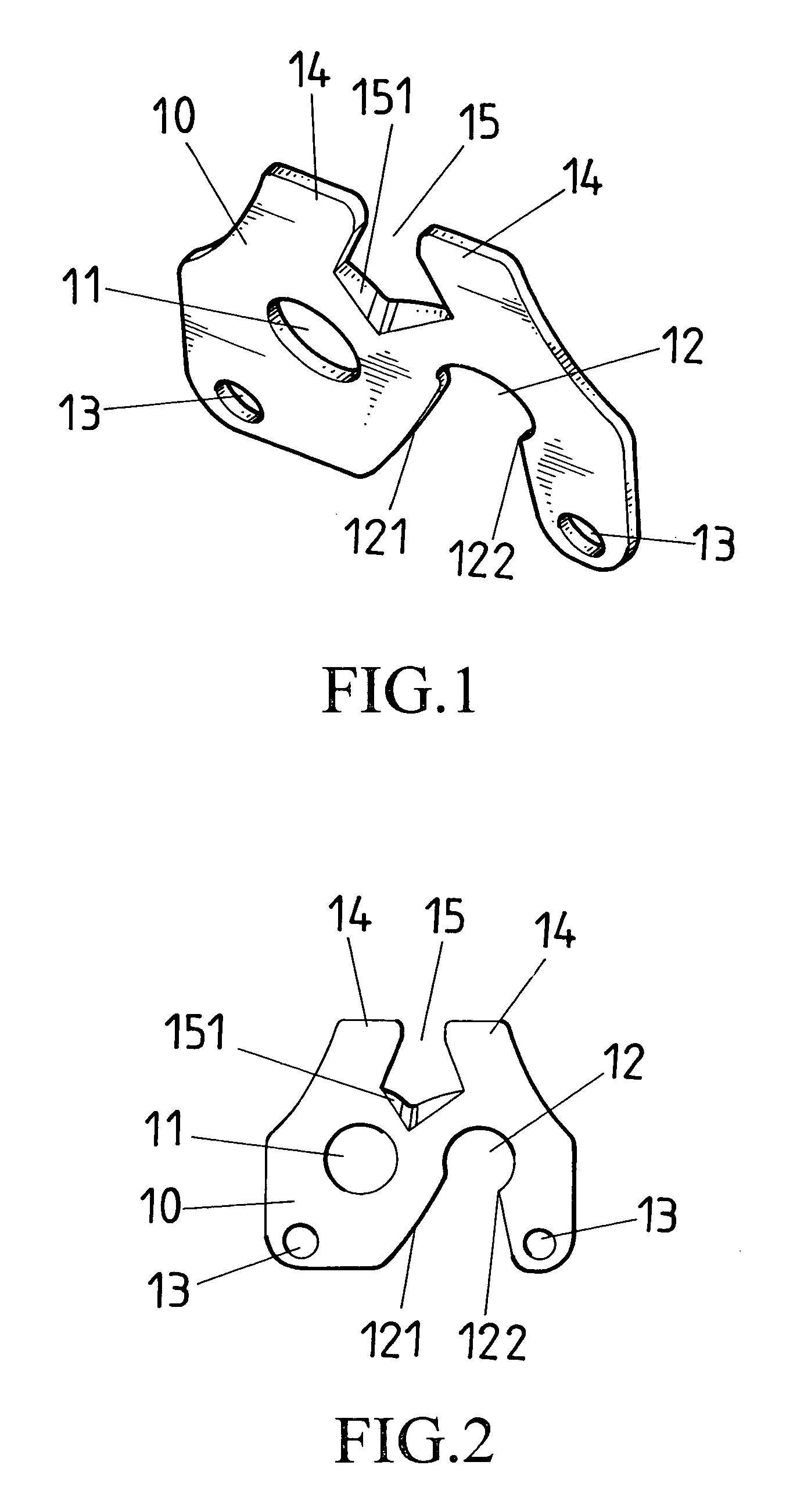

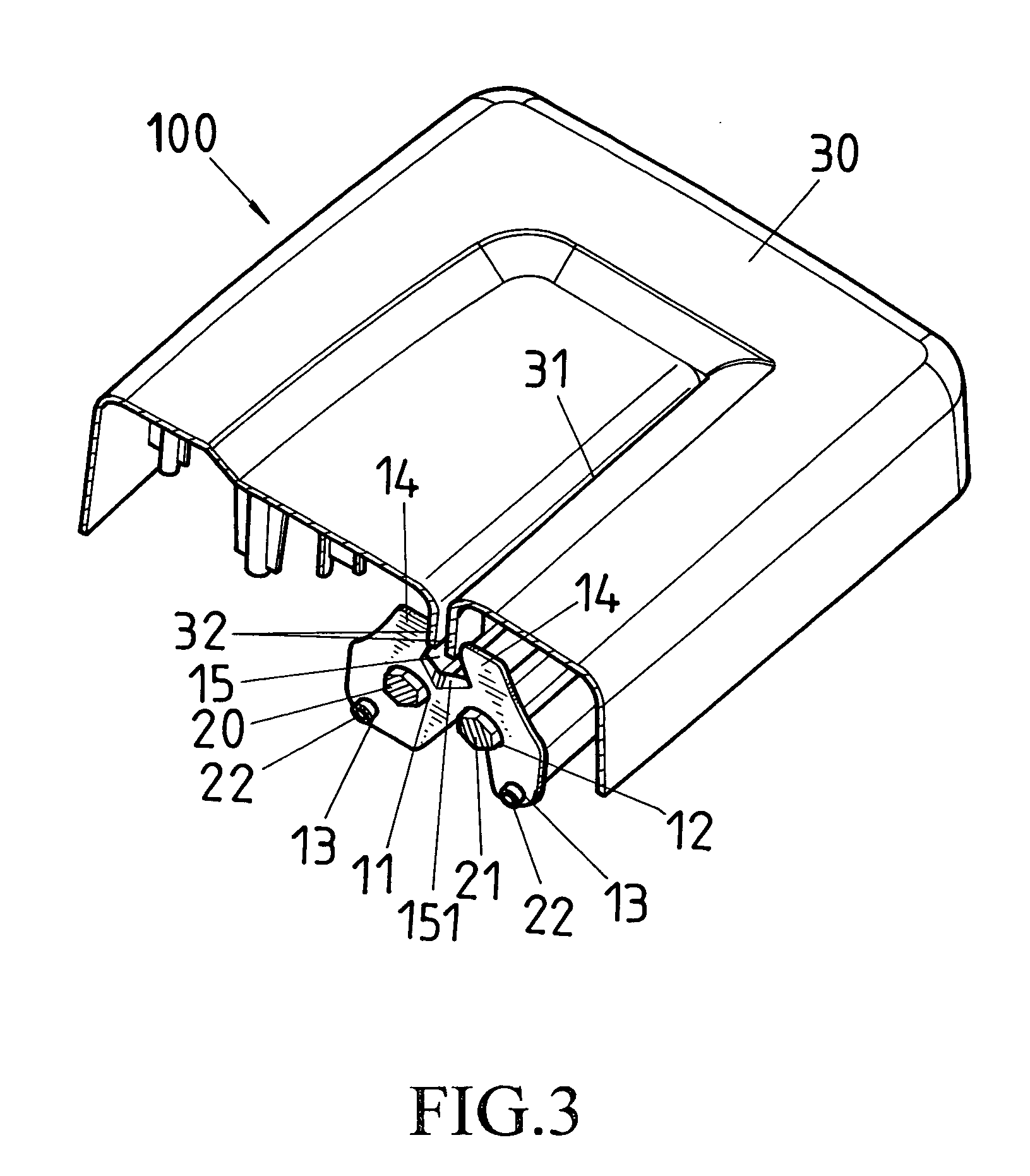

Cutter for cutting a coiled band

A cutter for cutting a coiled band includes a main body, and a cutting base installed on the main body, having a rectangular frame and a cutting groove formed in the long bottom side of the frame. Respectively fixed at one side and two ends of the cutting base is a sliding plate that has a sliding rail pivotally connected with two ends of a pressing rod respectively, so as to let the front end of the coiled band pass under the pressing rod to run out of the frame while having the pressing rod lifted up. Then, the pressing rod is released to press on the coiled band so as to let a knife unit pivotally connected with the main body flatly and securely cut the coiled band. The cutter is convenient and safe to use, with a cut band being flat and straight.

Owner:YU CHEN HSIU MAN

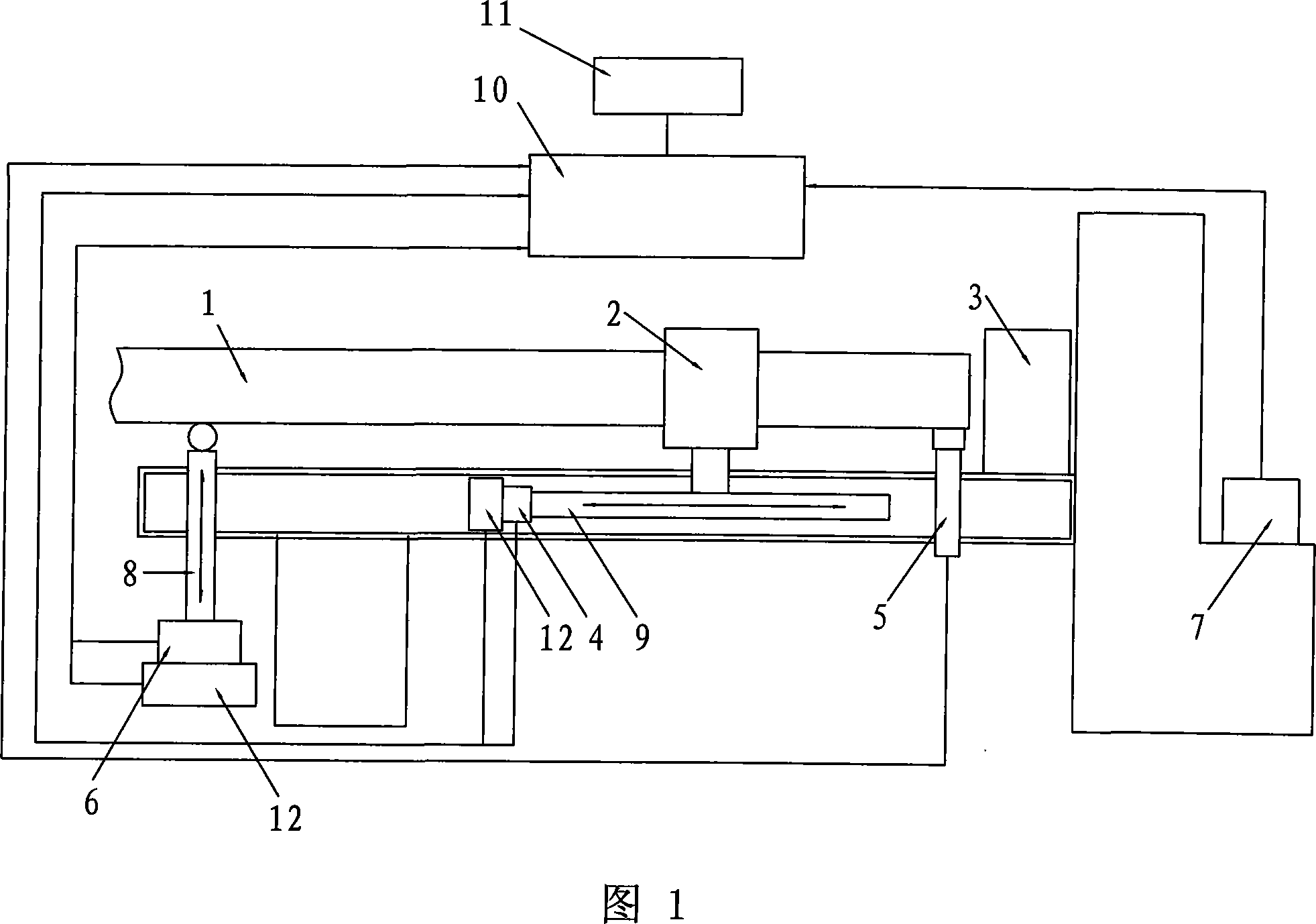

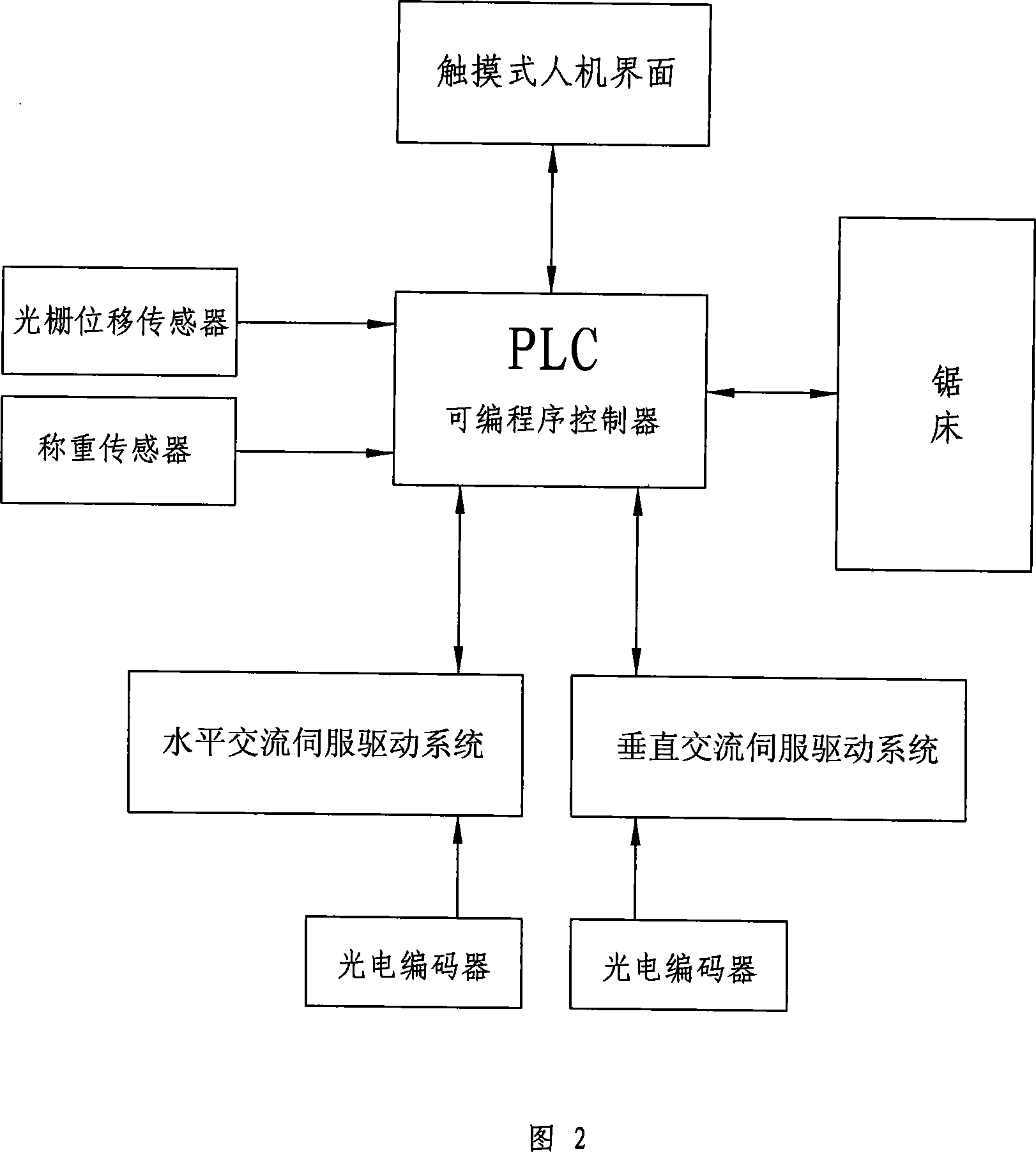

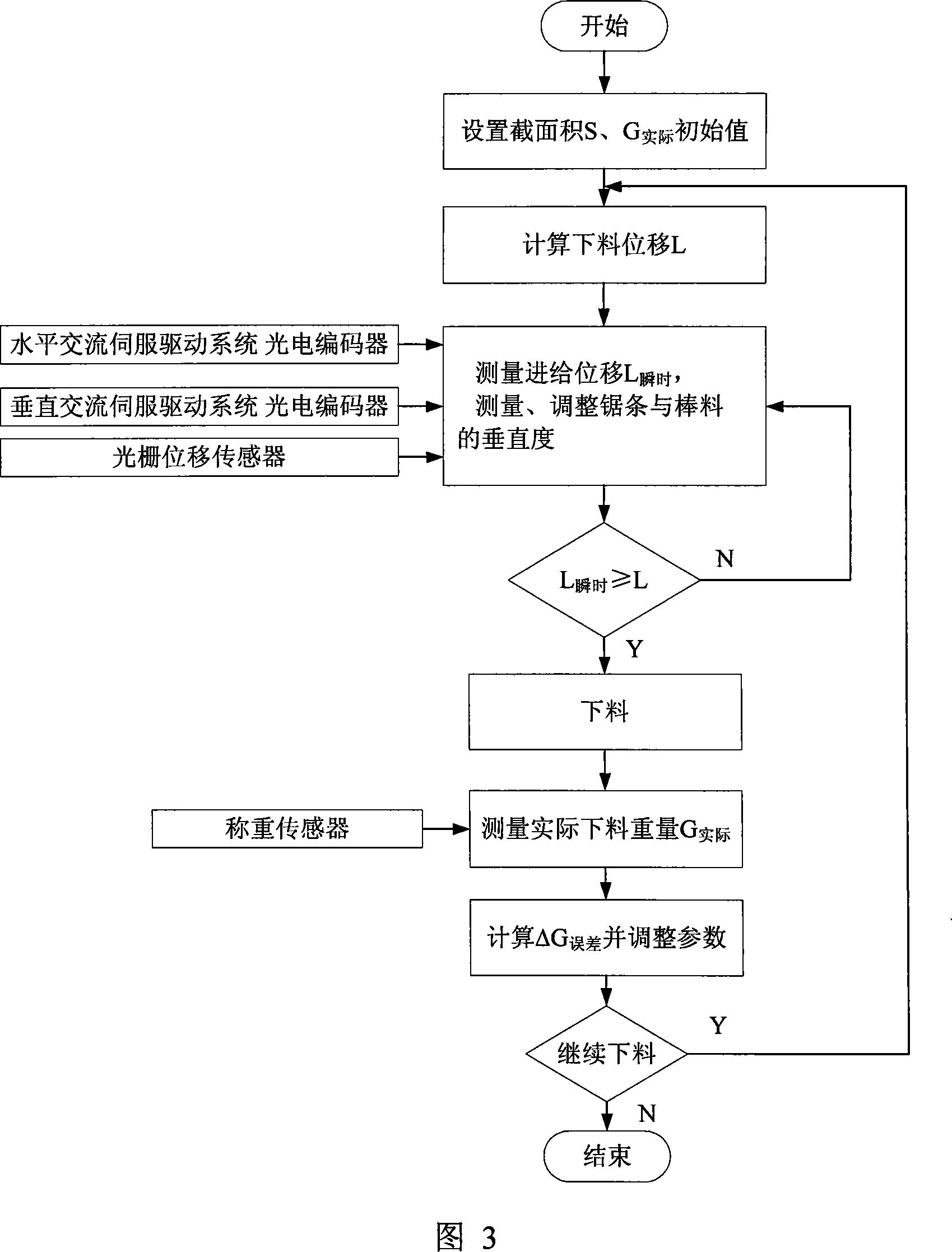

Control method for bar stock saw cutting self-adapting precision baiting

InactiveCN101135895AAccurately control the actual length accuracyRealize adaptive control of precision sawingProgramme control in sequence/logic controllersEngineeringSelf adaptive

The method comprises: using a bar stock saw automatically-adaptive lay- off system. The method comprises: a horizontal AC servo drive system is used for realizing the rod feed; a highly-accurate photoelectric encoder is used to detect the amount of fed rod; a grating shifting sensor is used to detect the height value of front end of the rod; a vertical AC servo drive system is used to adjust the height of the rear end of the rod to keep the consistency between the front end and the rear end of the rod; a highly-accurate weight sensor is used to weigh the actual weight G of the rod and to compare the actual weight of rod with the reset value, and according to the difference Delta G to adjust the cutting length.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

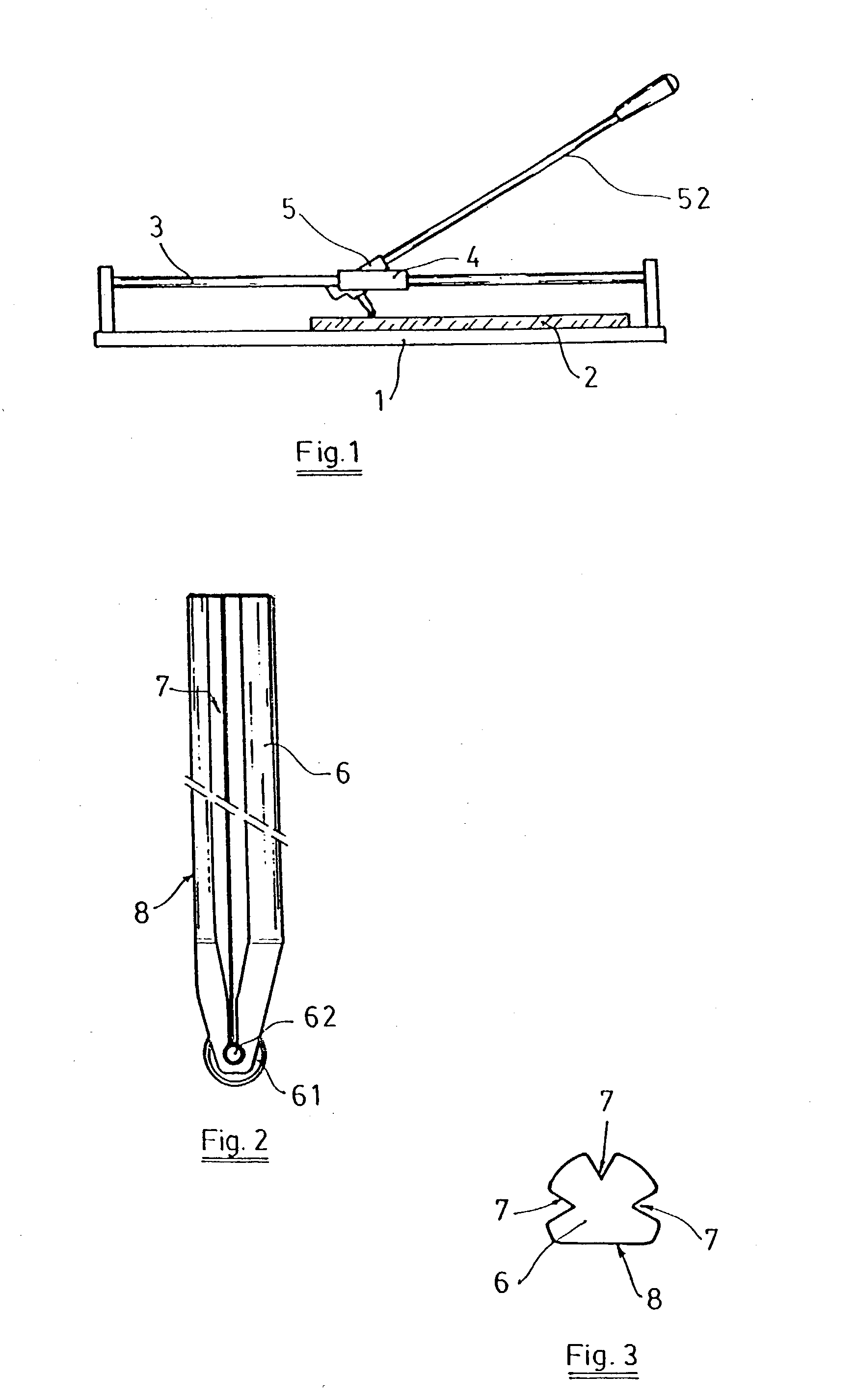

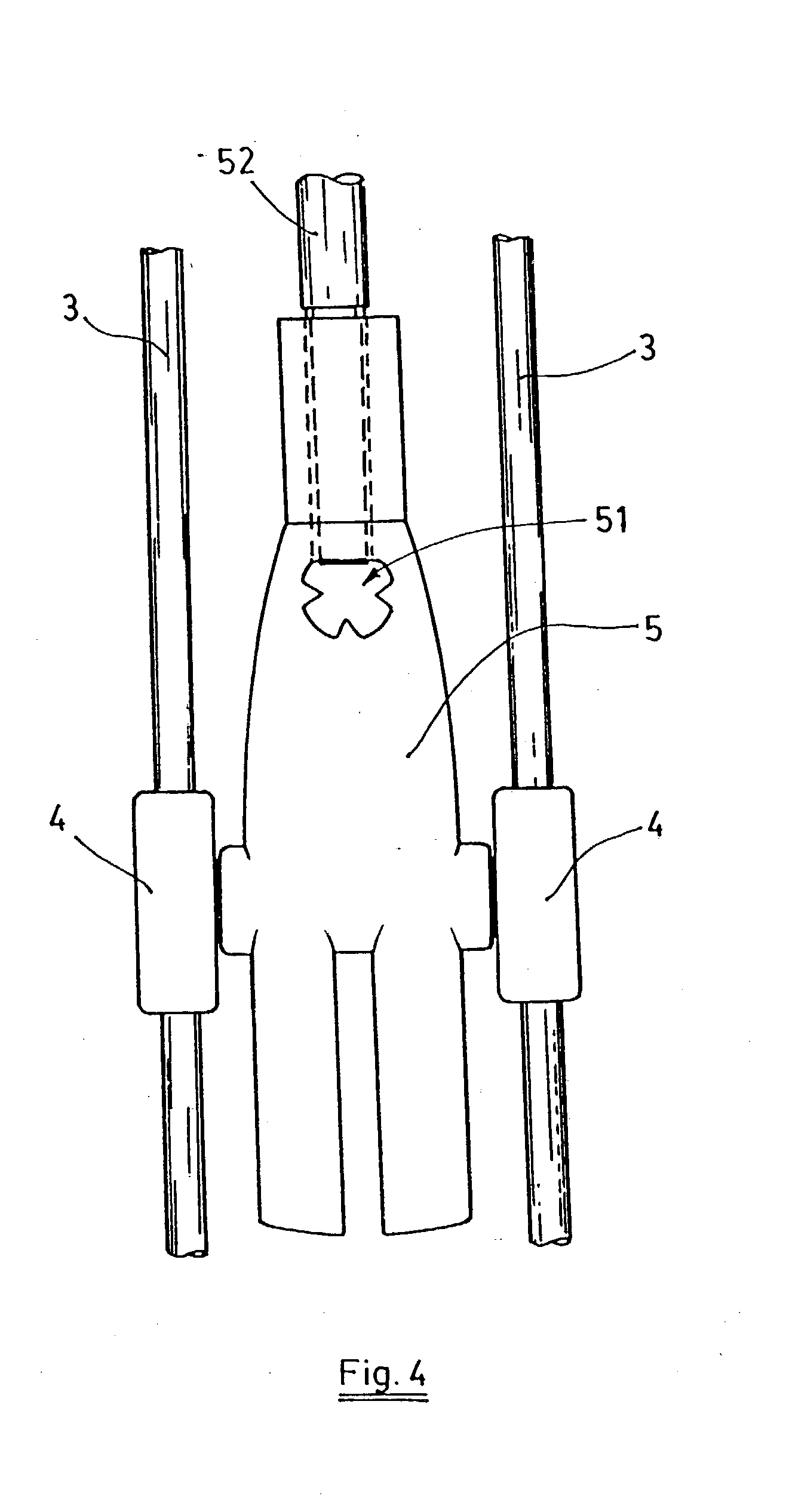

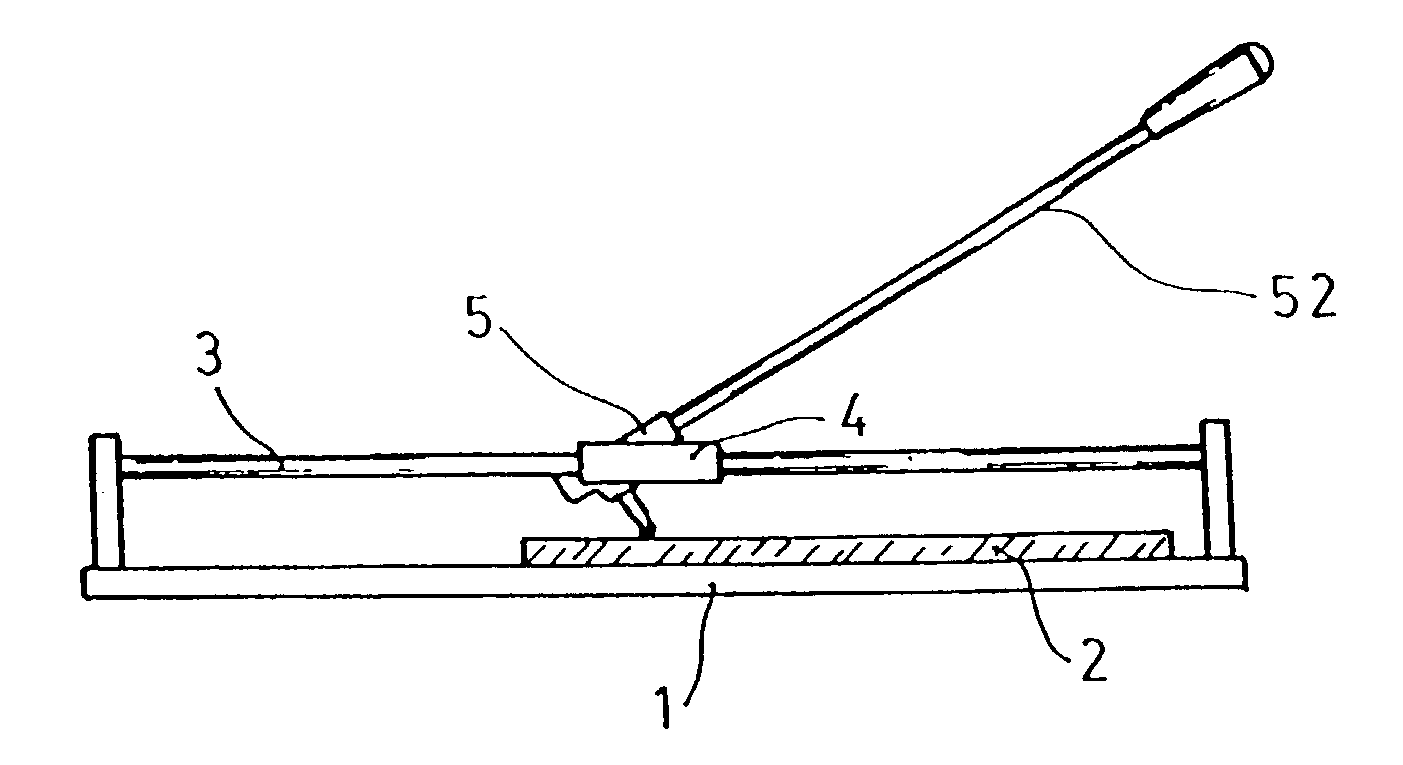

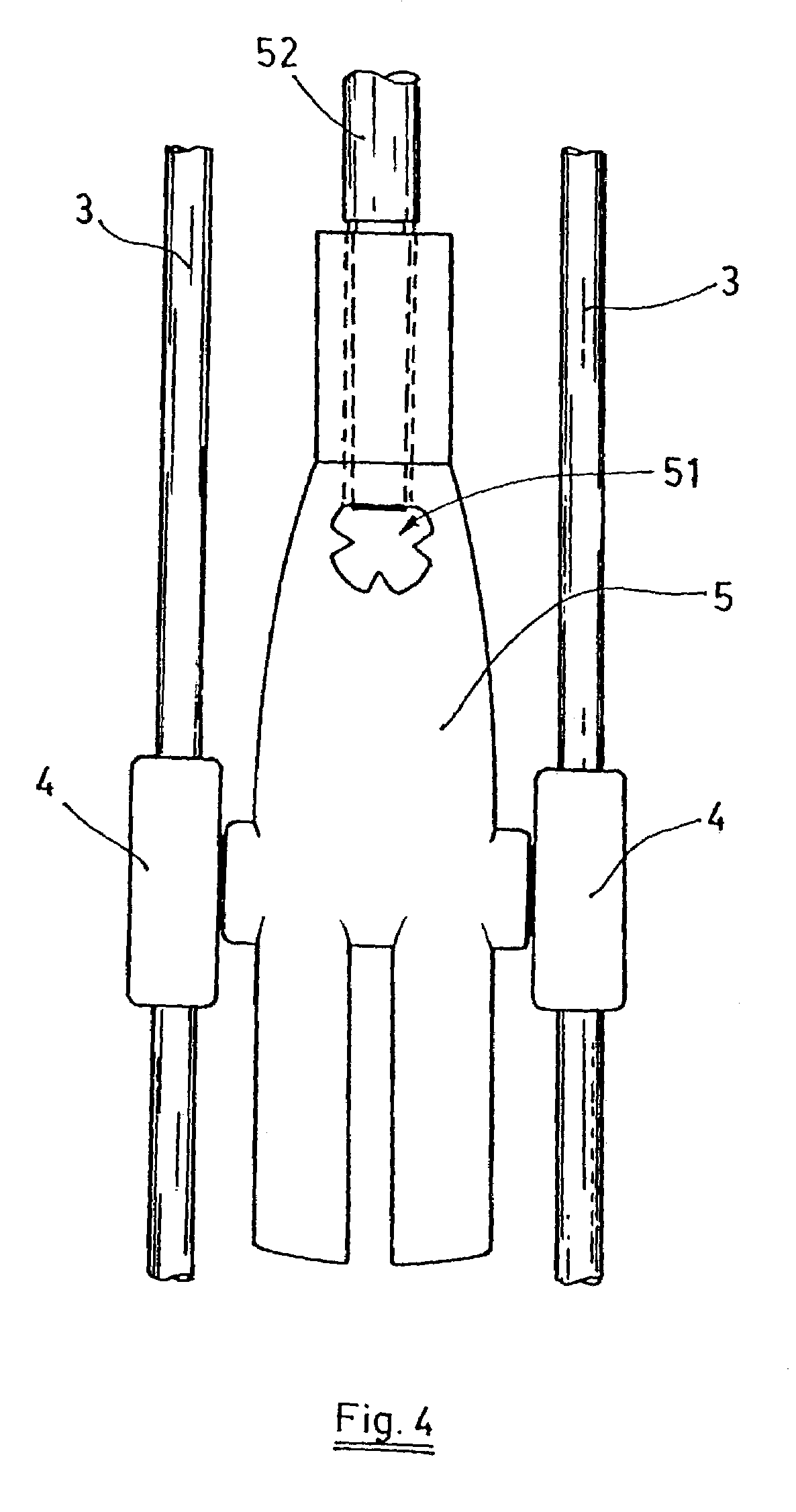

Ceramic cutters

InactiveUS20030047056A1Large contact surfaceReduce frequencyMetal working apparatusStone-like material working toolsLongitudinal planeGrating

Said improvements can be used for cutters provided with a base to support the ceramic piece that is to be cut, longitudinal guides for displaceable assembly of a support on which a collapsible cutting wheel holder is mounted, said holder being provided with a threaded hole hole for mounting an actuating lever that makes it possible to press and displace the cutting wheel on the ceramic piece by marking the breaking or cutting line thereof. The periphery of the handle of the cutting wheel has at least three longitudinal grooves having any given geometry with the purpose of reducing the frequency of vibration thereof during grating of the ceramic pieces, and at least one longitudinal plane that is co-planar or projects inward relative to the general outer surface of the handle for actuating the end of the lever intended for the immobilization thereof in the cutting wheel holder.

Owner:GERMANS BOADA SA

Novel grape breed cultivation method

The breeding process of new grape variety features that by adopting dragon eye as female parent and muscat grape as male parent and through eliminating anther cap and stamen of female parent and bagging in blooming period, cutting self-bloomed blossom of male parent after 3-5 days and artificial pollination to the female parent; obtaining seed from mature fruit in autumn, sun shining for 14-18 days, soaking in water for 24-30 hr, setting the soaked seed in cloth bag and in flower pot for cold storage for 4 months; seeding in next spring in green house and subsequent conventional cultivation to obtain fruit of new variety. The fruit of new grape variety has high yield, shape similar to dragon eye, blue black fruit, high sugar content, thick pulp, small seed, rich flavor of muscat grape and other features.

Owner:刘万成

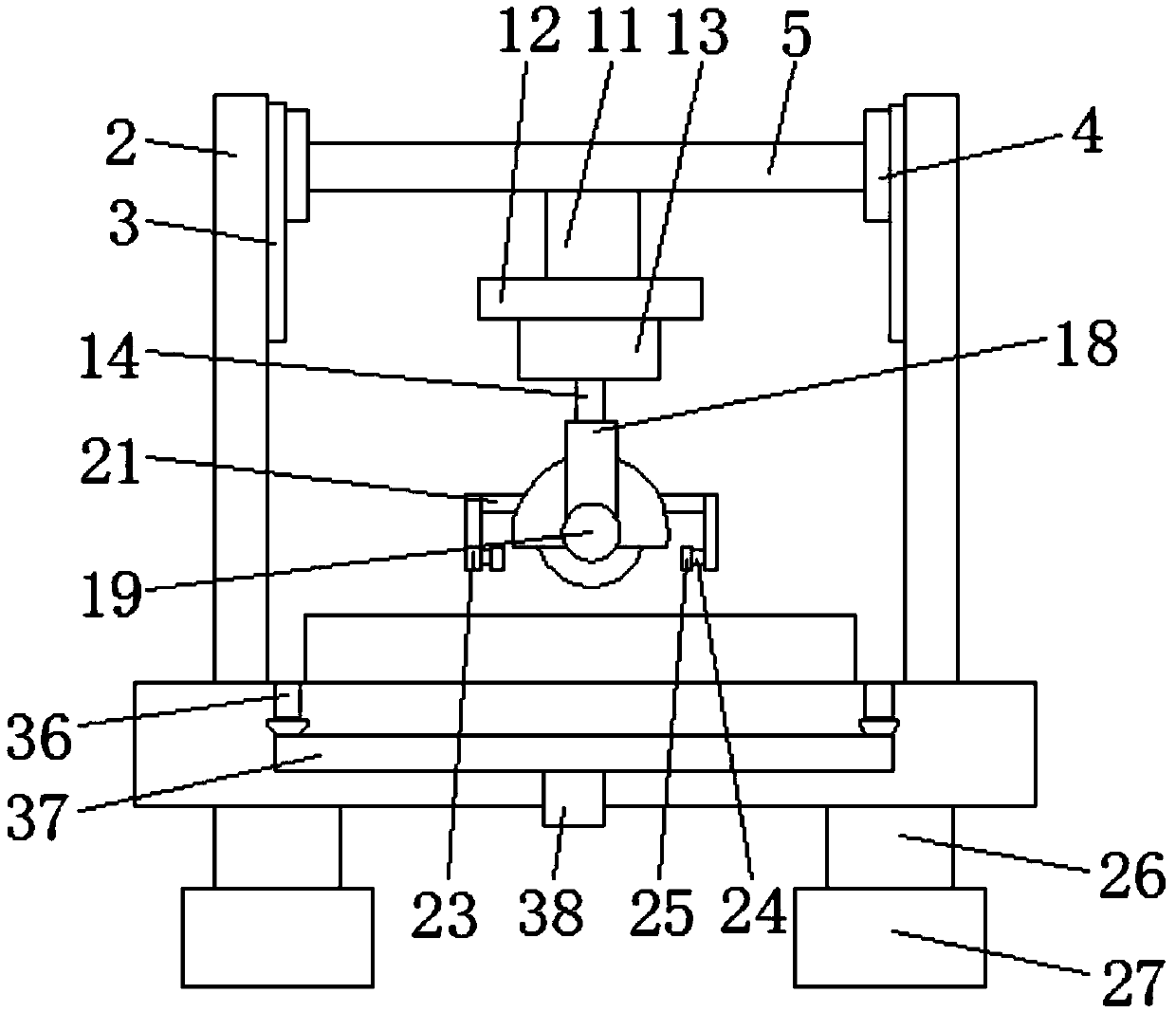

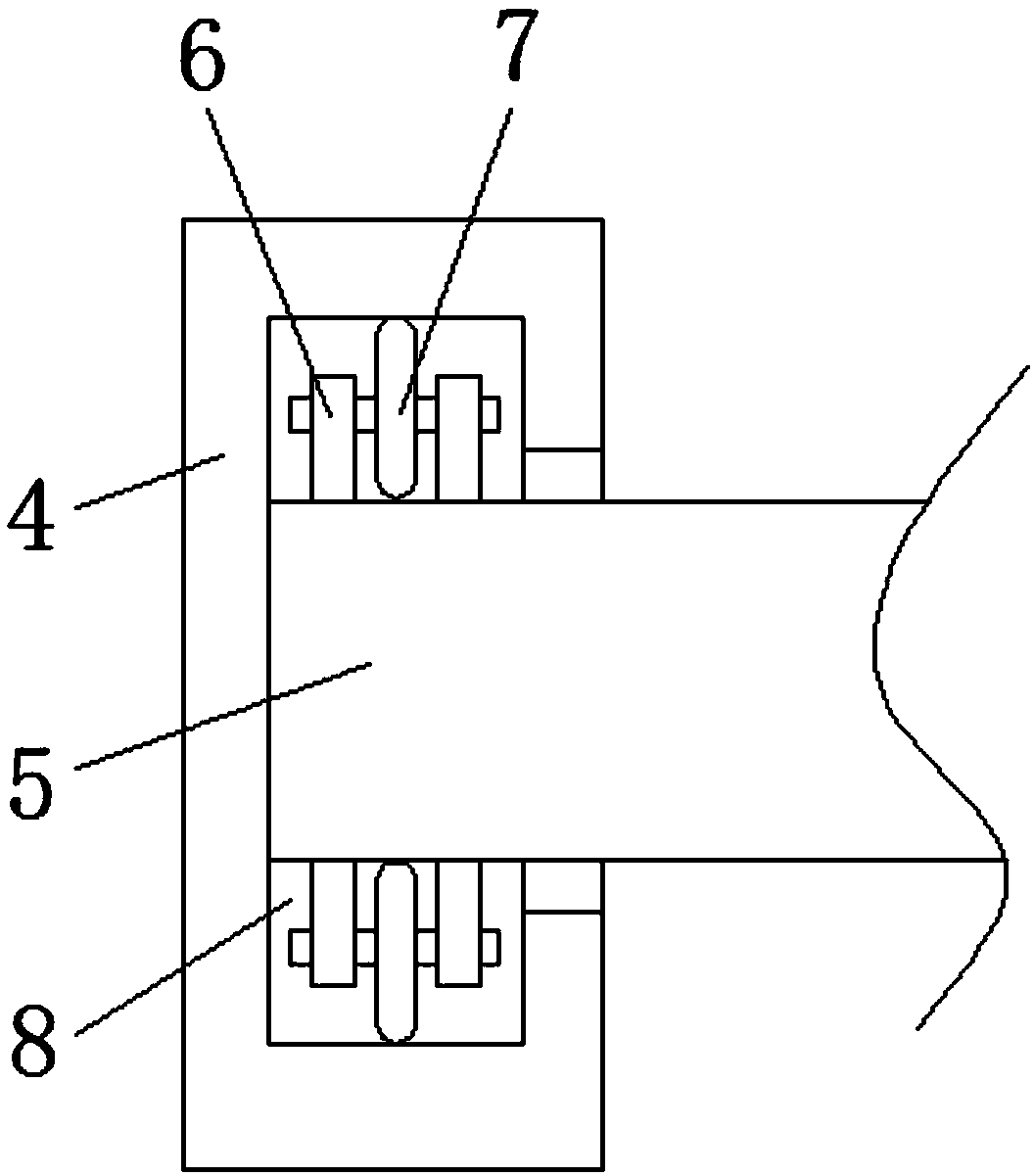

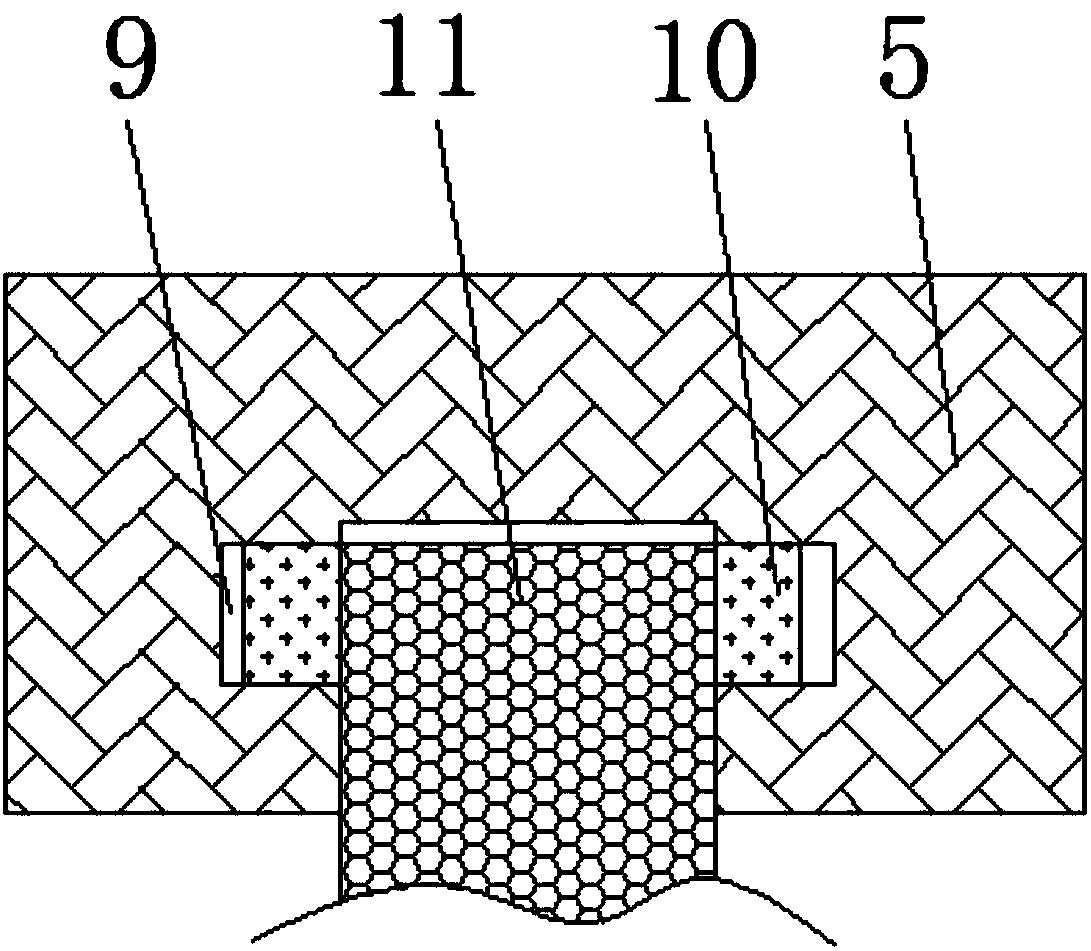

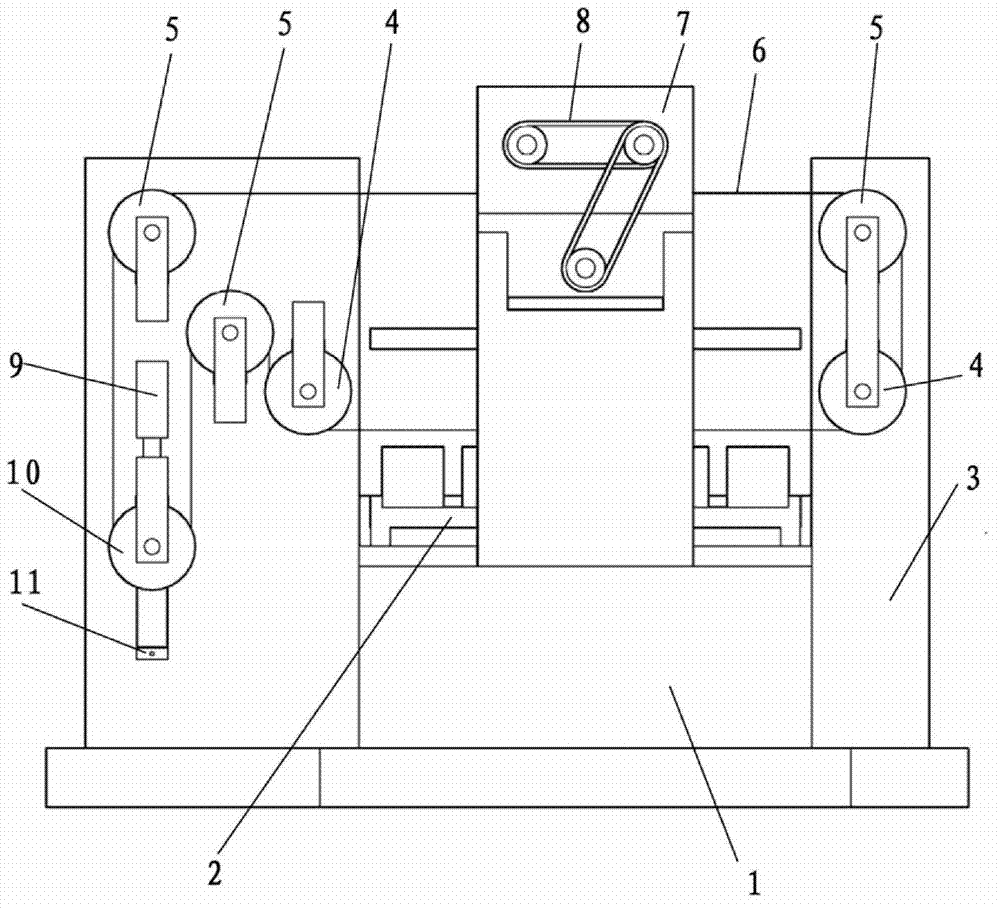

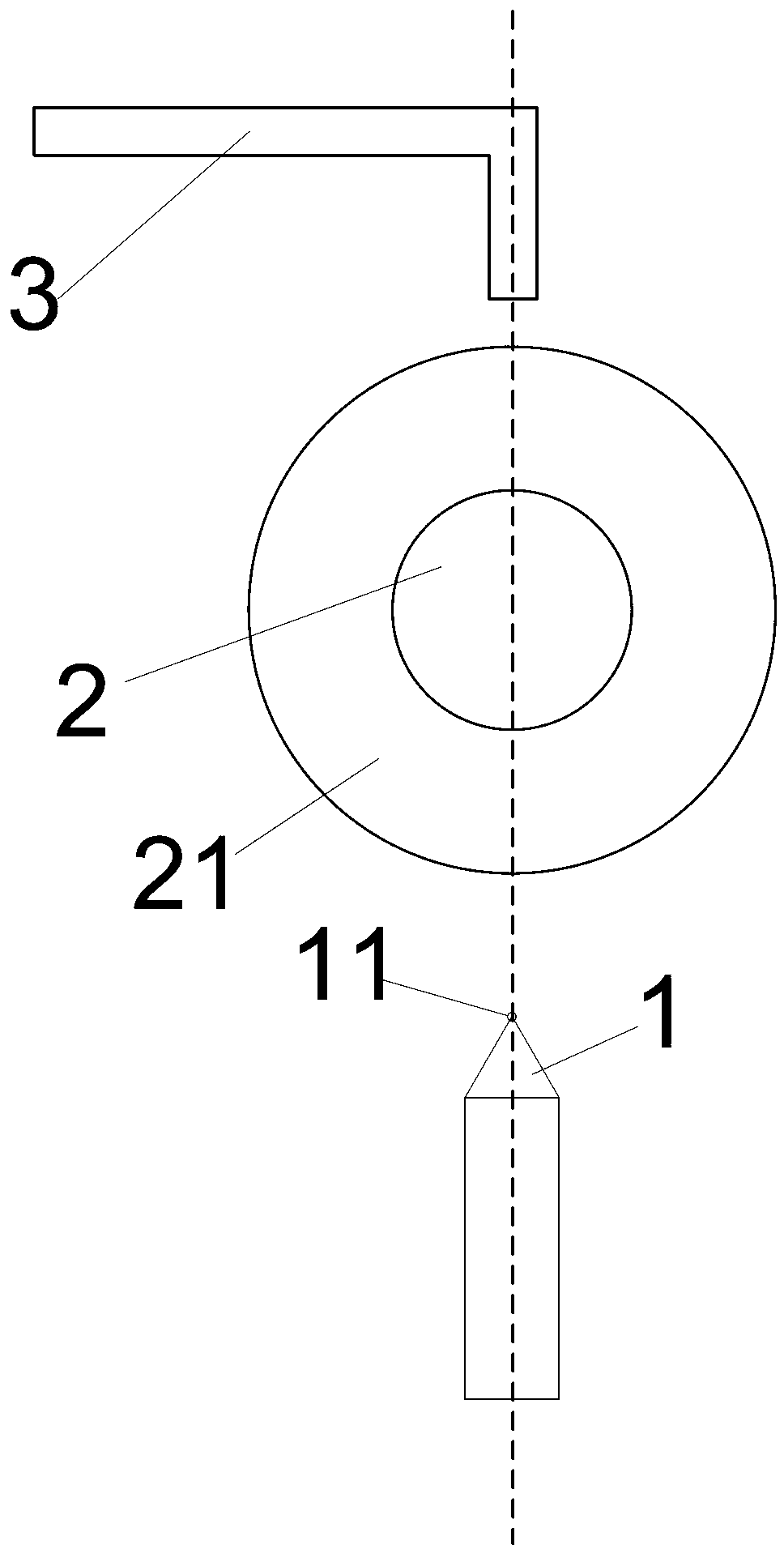

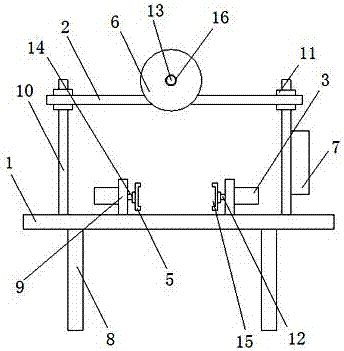

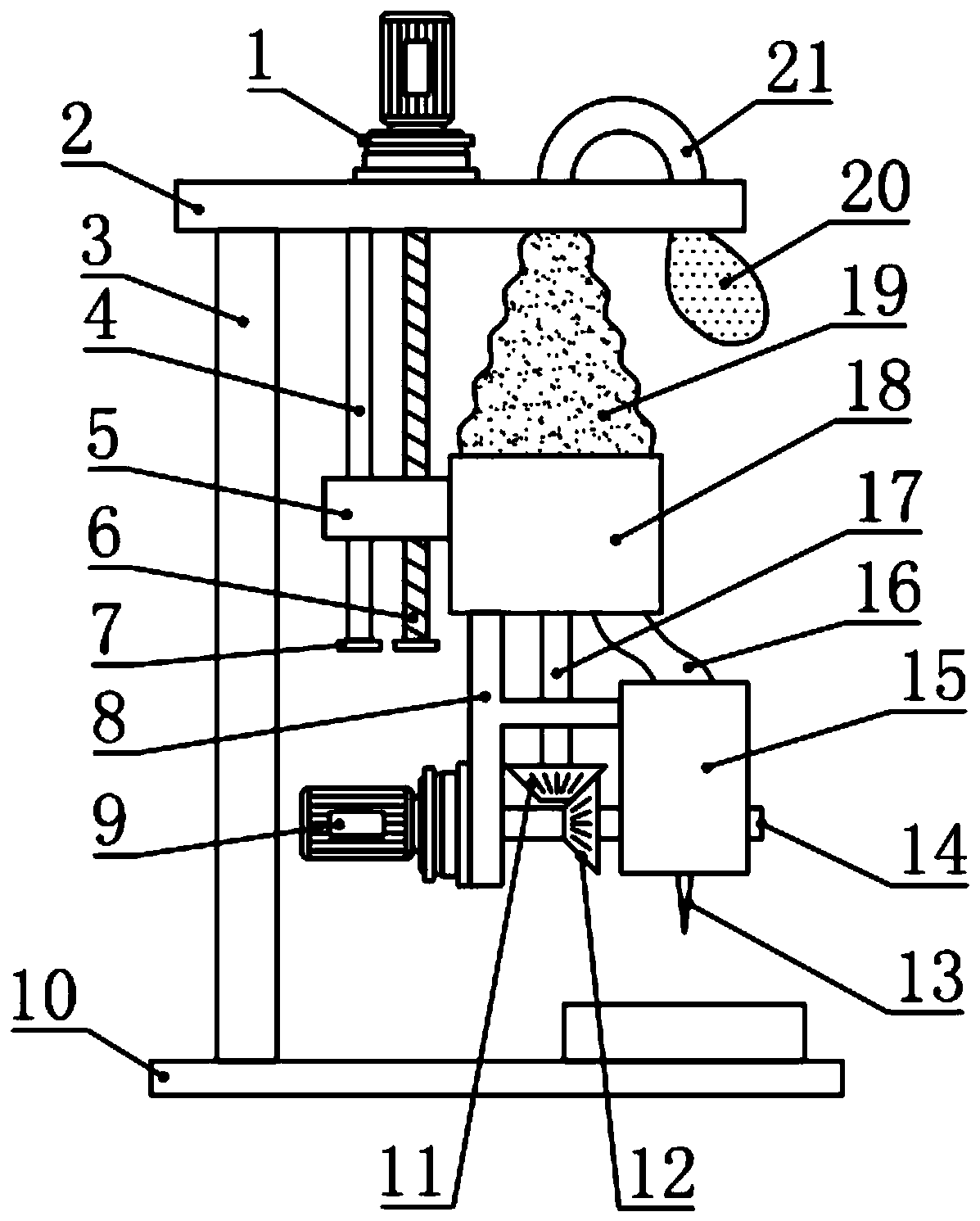

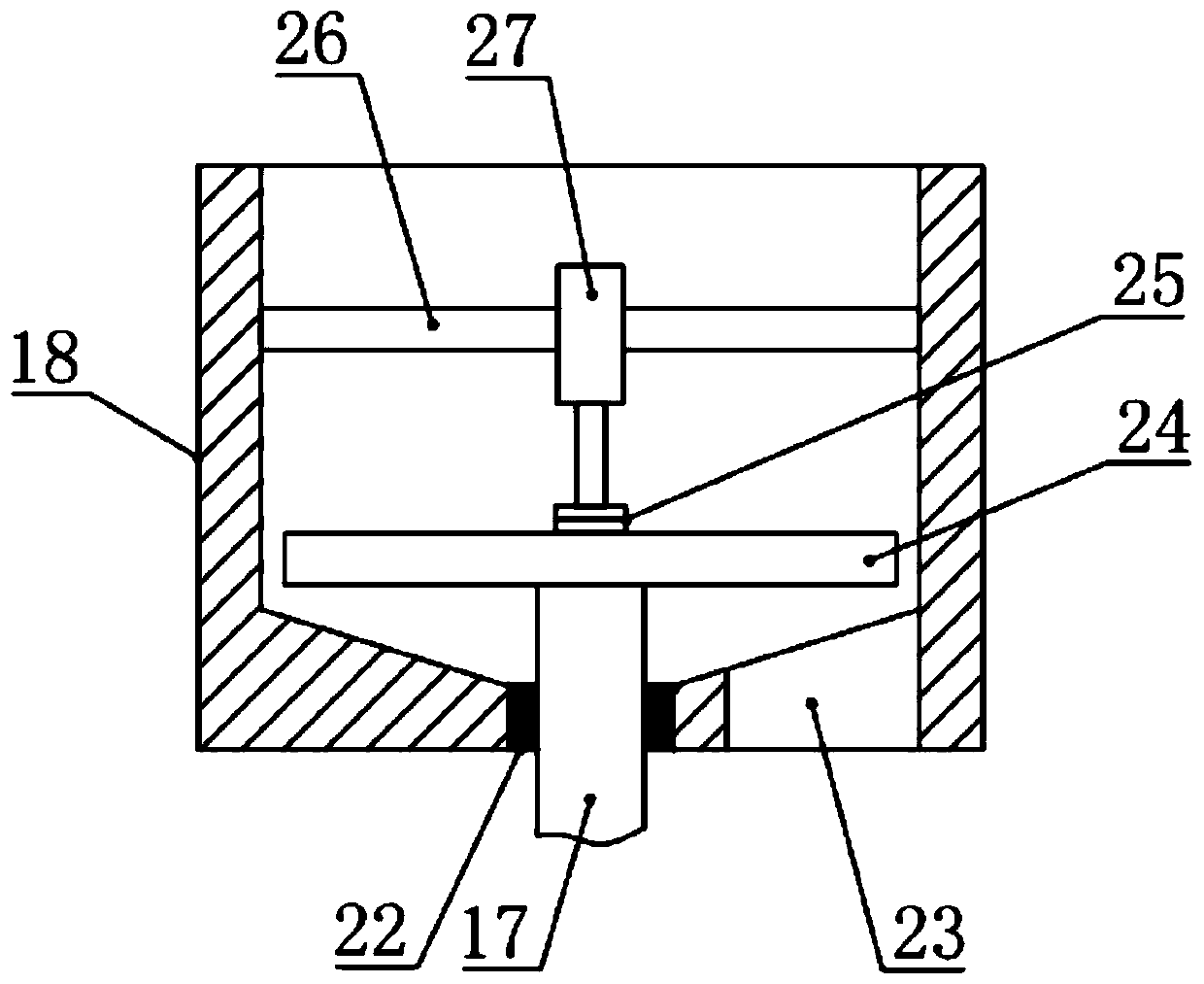

Marble cutting equipment

InactiveCN107672063ASolve manual handlingHeight adjustableWorking accessoriesStone-like material working toolsEffective heightSlide plate

The invention discloses a marble cutting equipment, comprising a base, two symmetrical support columns are fixedly connected to the top of the base, and first sliding rails are fixedly installed on the opposite surfaces of the two support columns, the first A sliding plate is clamped on the sliding rail. The marble cutting equipment can move the support rod up and down under the action of the sliding plate through the set slide rail, which can effectively adjust the height of the cutting wheel, and the set first pulley can make the support rod move forward and backward. The movement ensures that the cutting wheel can move back and forth to cut the marble, and solves the problem that manual handling of marble cutting requires manual handling. The left and right movement of the cutting wheel ensures the accuracy of marble cutting, solves the problem of inaccurate and wasteful materials in manual handling of marble cutting scale, and effectively improves the production efficiency.

Owner:郑艳峰

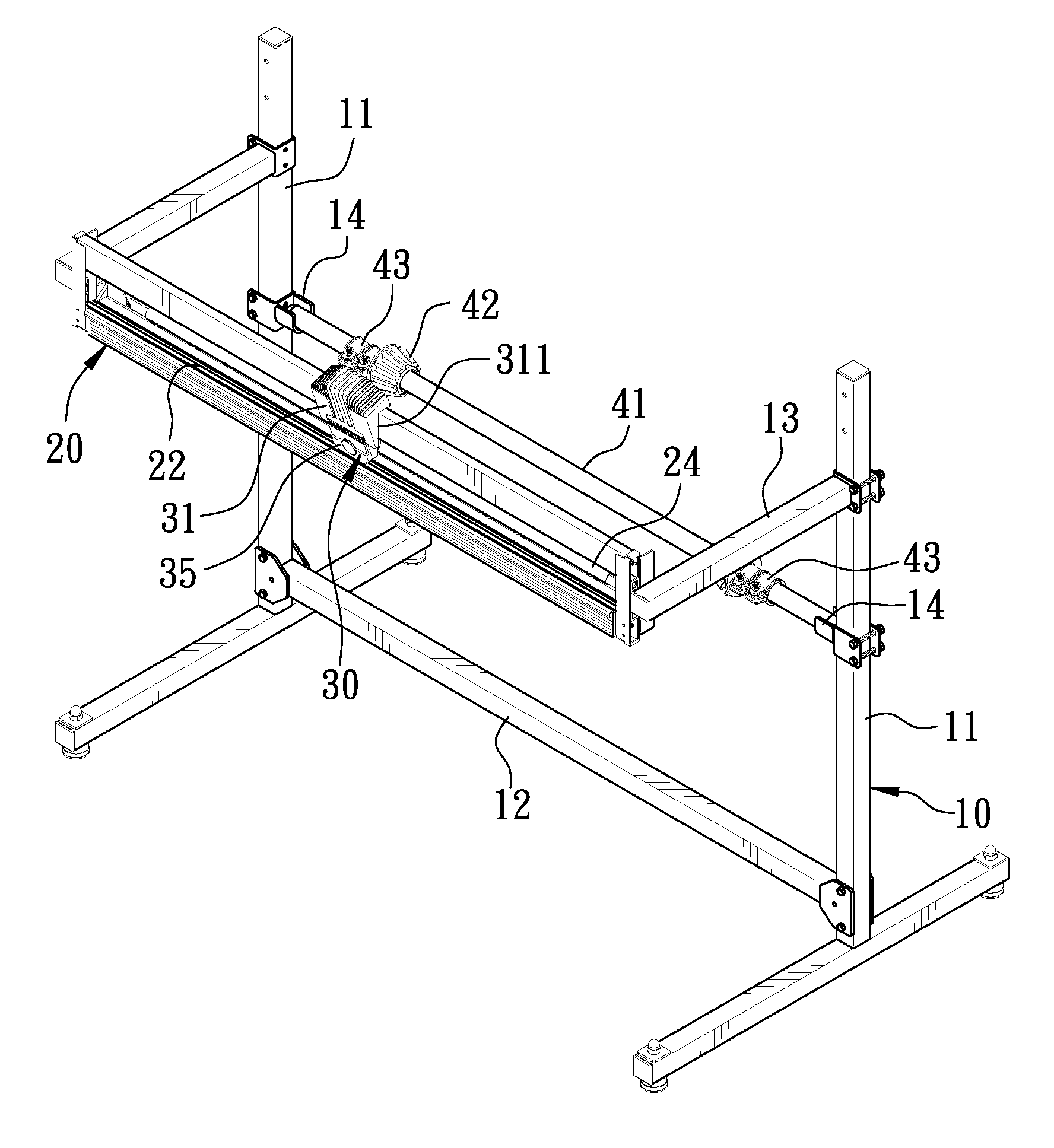

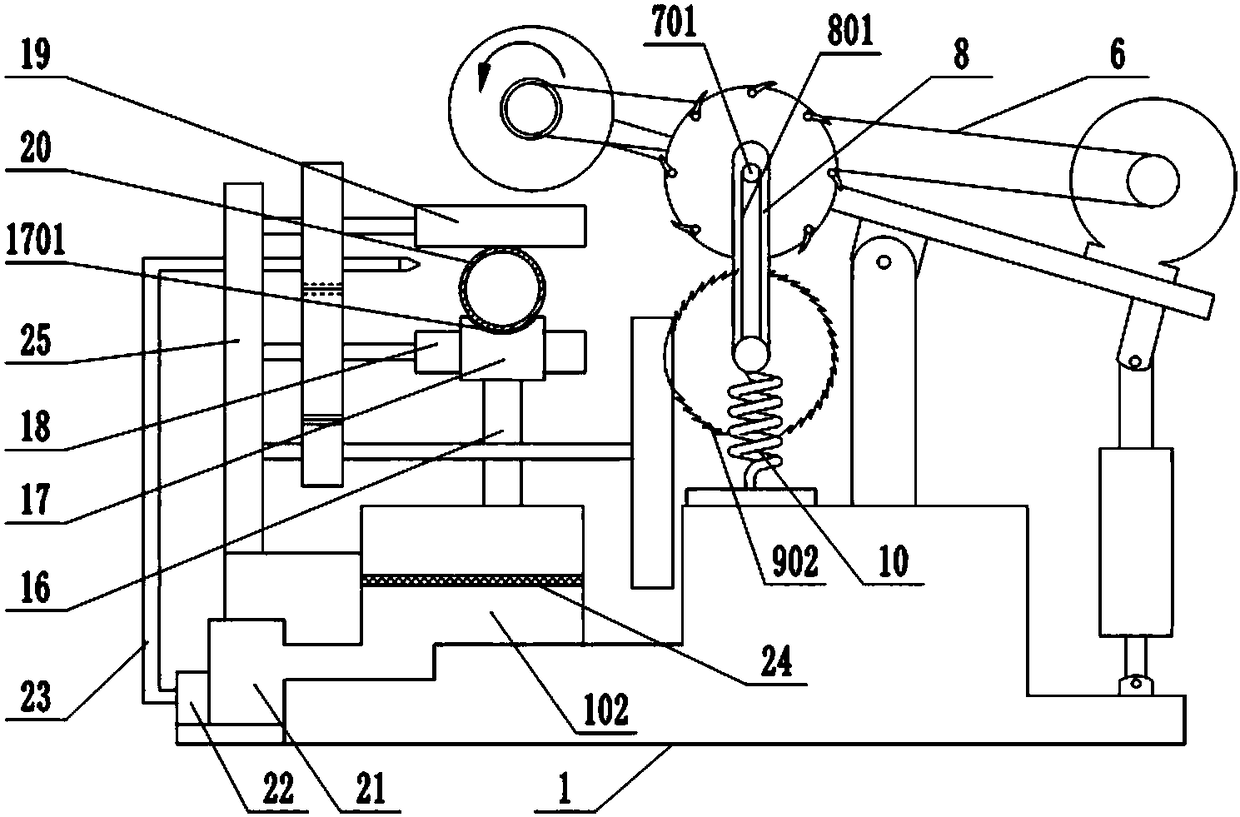

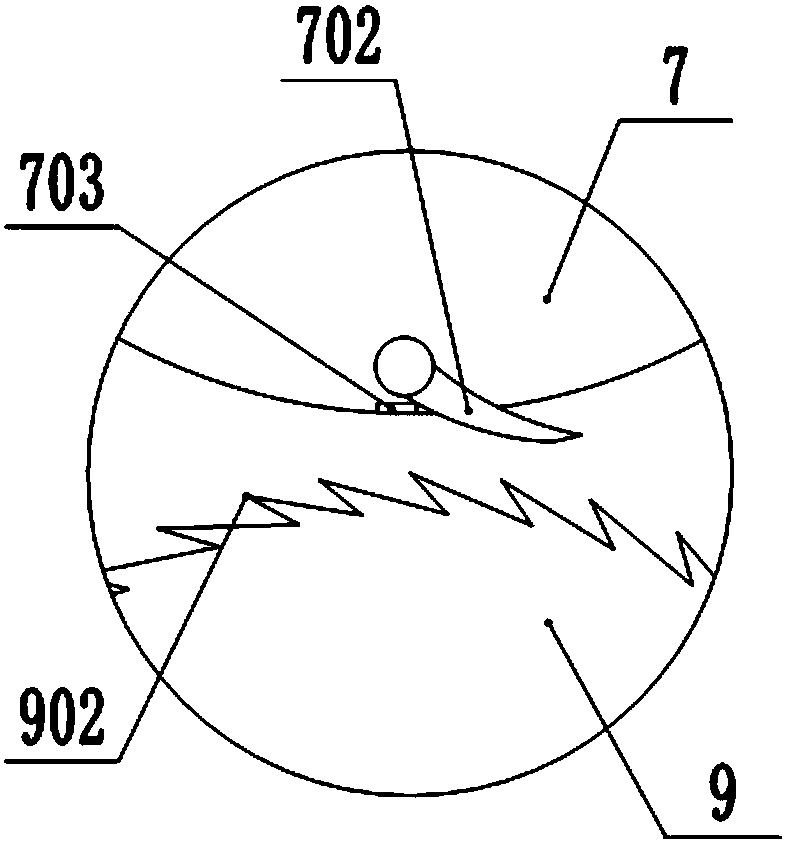

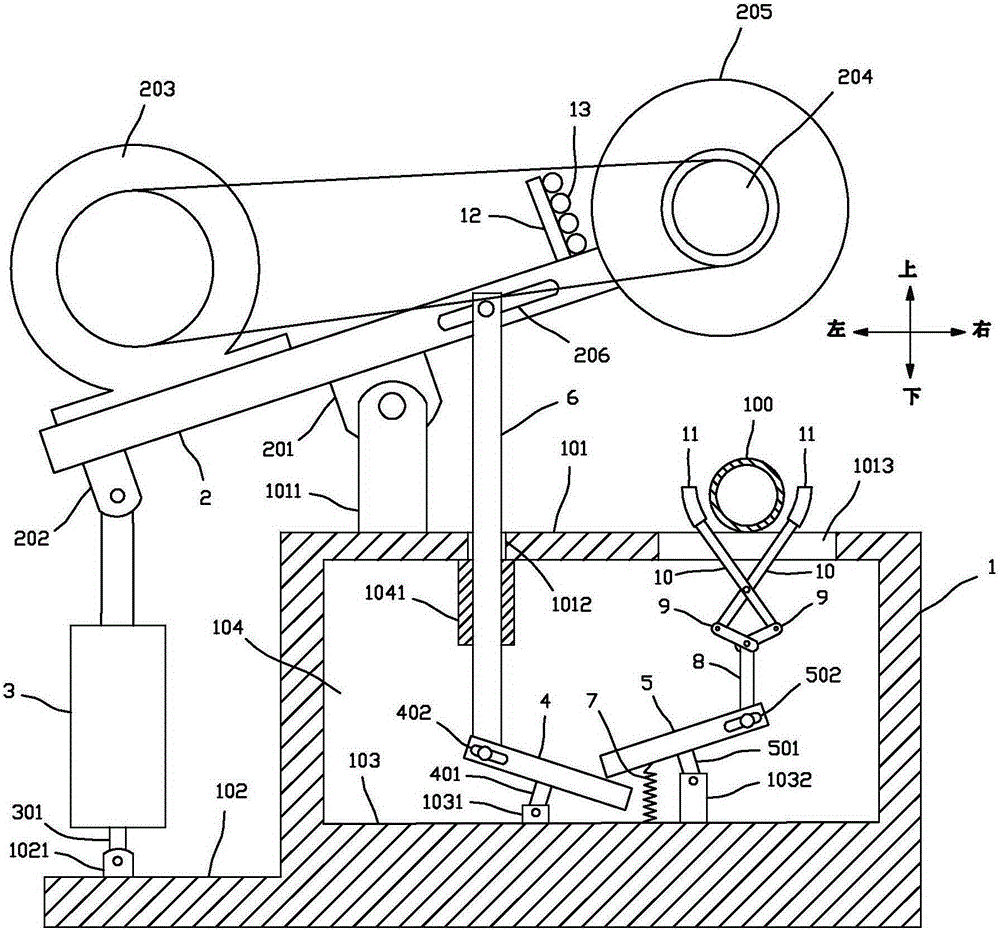

Continuous cutting device

ActiveCN108115193AImprove cutting efficiencyIncrease productivityLarge fixed membersTube shearing machinesAgricultural engineeringTelescopic cylinder

The invention relates to the technical field of machining equipment, and discloses a continuous cutting device which comprises a rack with a first supporting stand column. A rotating plate is arrangedon the first supporting stand column, a telescopic cylinder is hinged to one end of the rotating plate, the telescopic cylinder and the rack are fixedly connected, a cutting wheel is installed on therotating plate, a first rotating wheel is connected to the rotating plate, a second rotating wheel is connected to the first rotating wheel, a first transmission wheel is connected to the second rotating wheel, the first transmission wheel is connected with a second transmission wheel, a third transmission wheel is connected to the second transmission wheel, a fourth transmission wheel is connected to the third transmission wheel, a lower roller is connected to the third transmission wheel, an upper roller is connected to the fourth transmission wheel, and a transmission rail is arranged on one side of the lower roller. Due to telescoping of the telescopic cylinder, the rotating plate is driven to turn over, in the process that the rotating plate is turned over, the upper roller and the lower roller drive tubes to move in a transmission rail, and the tubes are cut by a cutting wheel. The continuous cutting device has the advantage that the tubes surrounding in a tube coiler can be continuously cut.

Owner:宁波隆锐机械制造有限公司

Ceramic cutters

InactiveUS7013785B2Easy constructionReduce vibrationMetal working apparatusStone-like material working toolsEngineeringScrew thread

A ceramic cutting device having a base, longitudinal guides mounted to the base, and a support movably mounted on the longitudinal guides. A cutting-wheel handle holder is pivotably mounted to the support. A cutting-wheel handle is mounted to the handle holder and the cutting wheel is mounted to the handle. An actuating lever is mounted in a threaded hole in the handle holder so as to immobilize the handle so that the handle can apply pressure on a ceramic piece to be cut via the cutting wheel. The cutting wheel handle has an outer periphery with at least three longitudinally extended rebates which have a geometry that reduces the frequency of vibration during scoring of the ceramic piece by the cutting-wheel. The handle further has at least one longitudinally extending planar surface for engaging with the actuating lever.

Owner:GERMANS BOADA SA

Pipe cutting device

InactiveCN105269617AReduce errorsReduce error rateMetal working apparatusEngineeringProcedural approach

The invention discloses a pipe cutting device. The pipe cutting device comprises an air cylinder, a first rotary board, a transmission rod, a second rotary board, a third rotary board, a first drive rod, two second drive rods, two third drive rods and two chucks. A cutting wheel is installed on the first rotary board. When the air cylinder drives the first rotary board to rotate, the cutting wheel moves up and down; when the first rotary board rotates, the first rotary board drives the two chucks to be folded or unfolded sequentially through the transmission rod, the second rotary board, the third rotary board, the first drive rod, the two second drive rods and the two third drive rods, so that the two chucks clamp or release a pipe to be cut. Meanwhile, the first rotary board is provided with an infrared ray heating tube and can heat the cutting wheel when the cutting wheel cuts the plastic pipe. When the pipe is cut, a clamping mechanism is driven in a mechanical transmission mode to automatically clamp the pipe, and manual control or program control is not needed.

Owner:NINGBO FUSHI AUTOMOBILE COMPONENTS

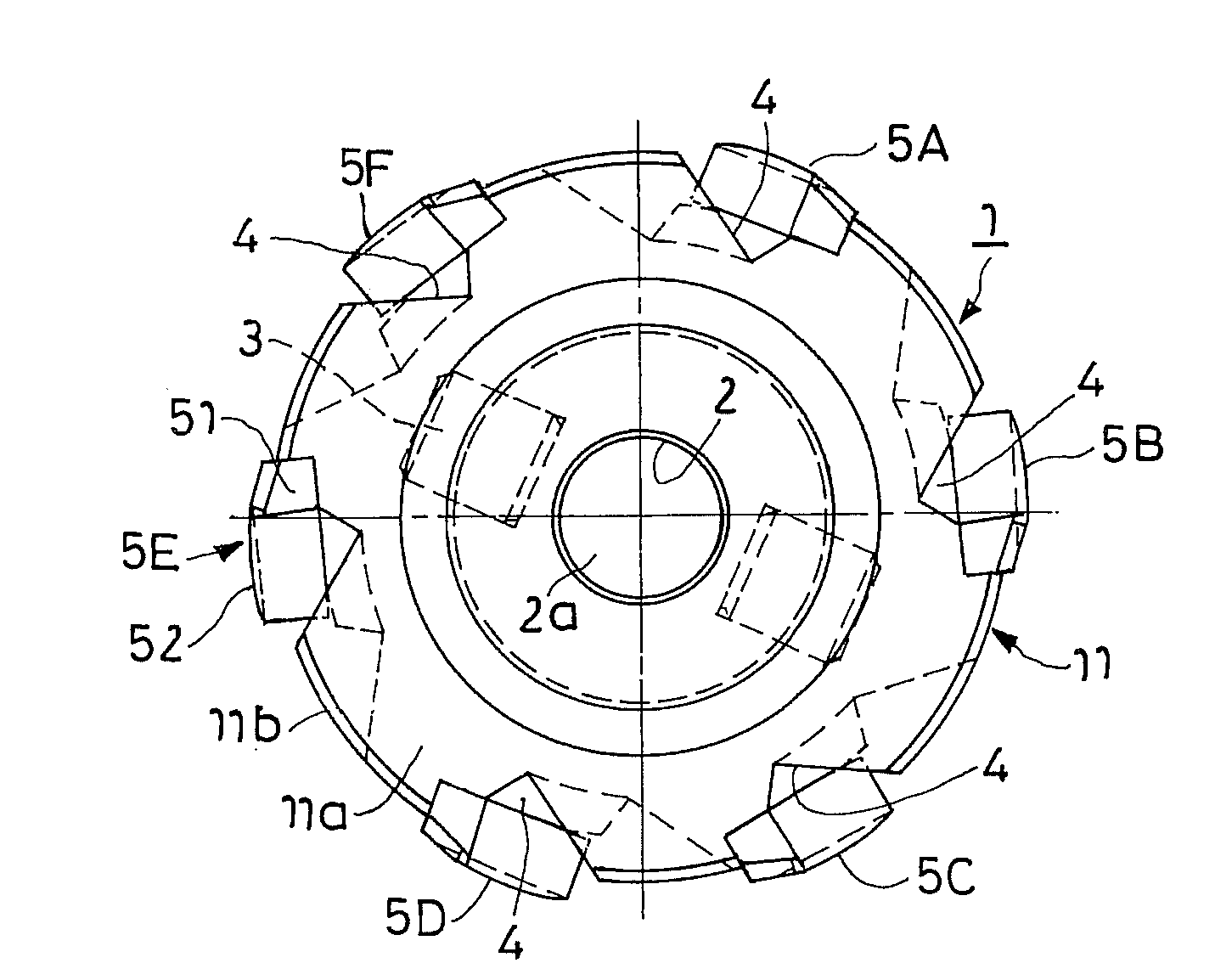

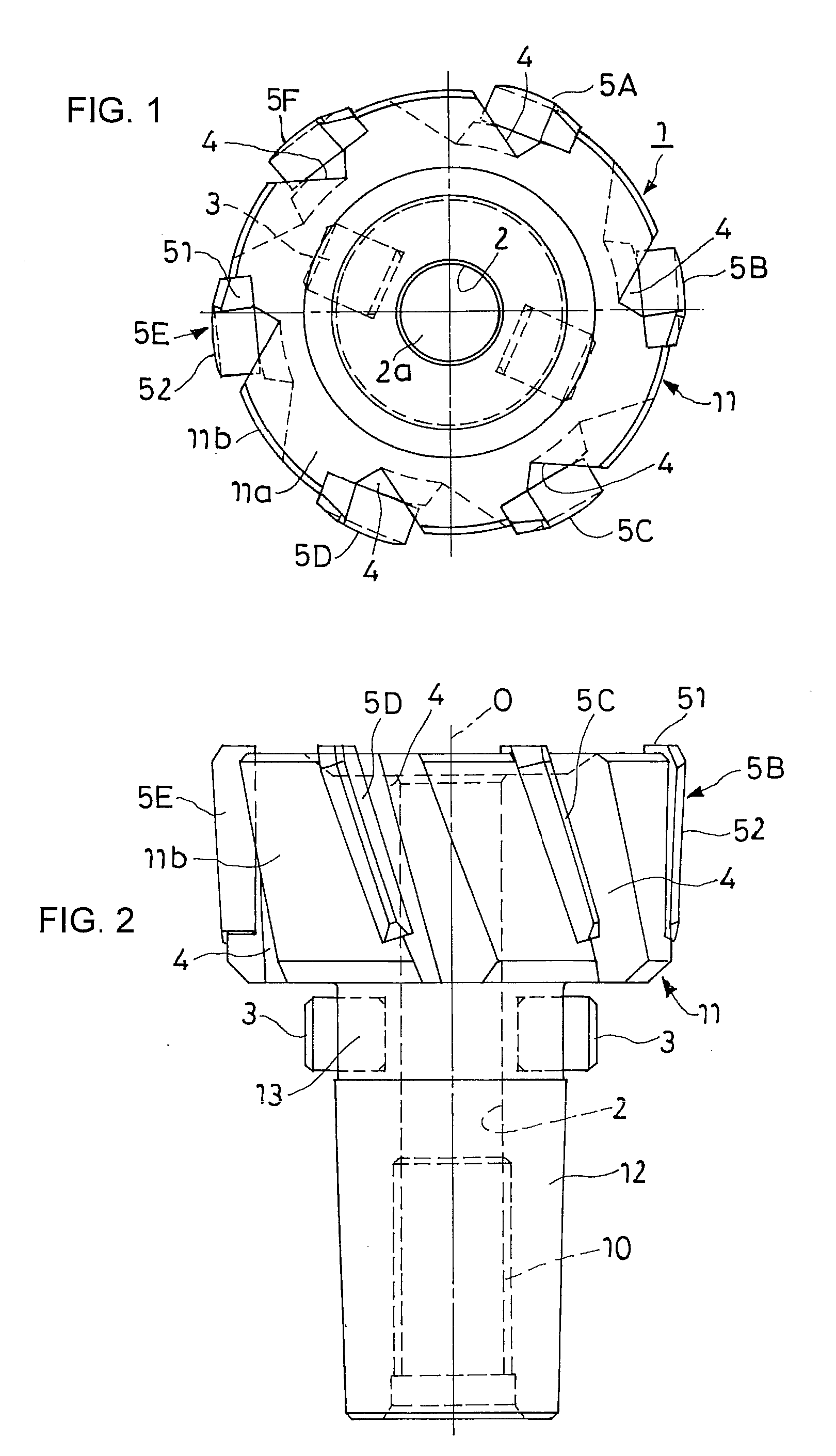

Machine reamer

ActiveUS20070237593A1Increased durabilityImprove machine performanceWood turning toolsTransportation and packagingEngineeringReamer

A machine reamer has blades to which a work material is not easily adhered by heat even if a cutting speed is increased, and hence high processing efficiency can be obtained. Additionally, the cutting edge of the blade is only slightly worn down even if heavy cutting is performed, and hence excellent durability and an extremely long machine life can be obtained. A plurality of slender blades is erected on the outer peripheral part of a reamer head body. Different kinds of materials are used to make the blades.

Owner:YUNITAKKU

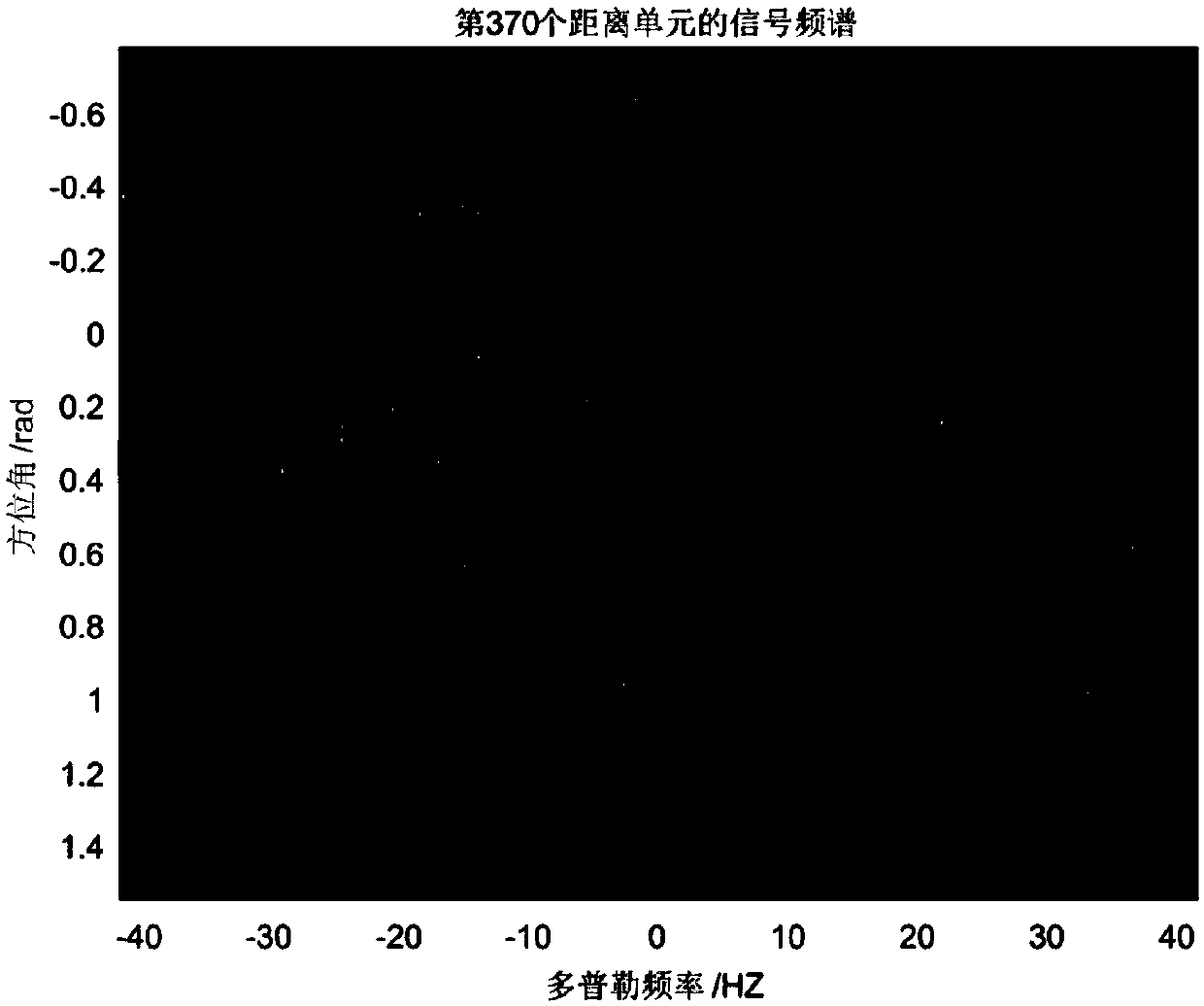

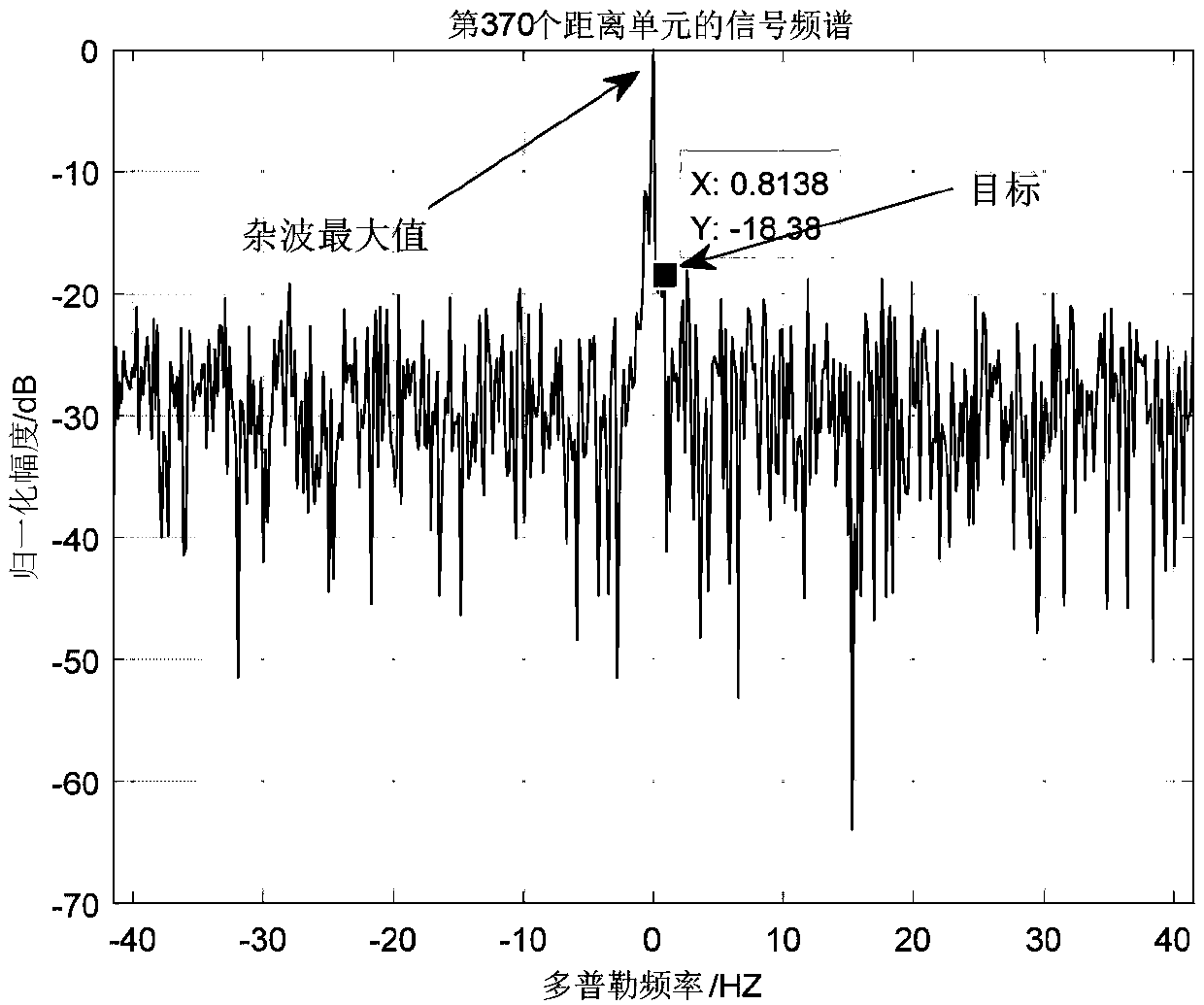

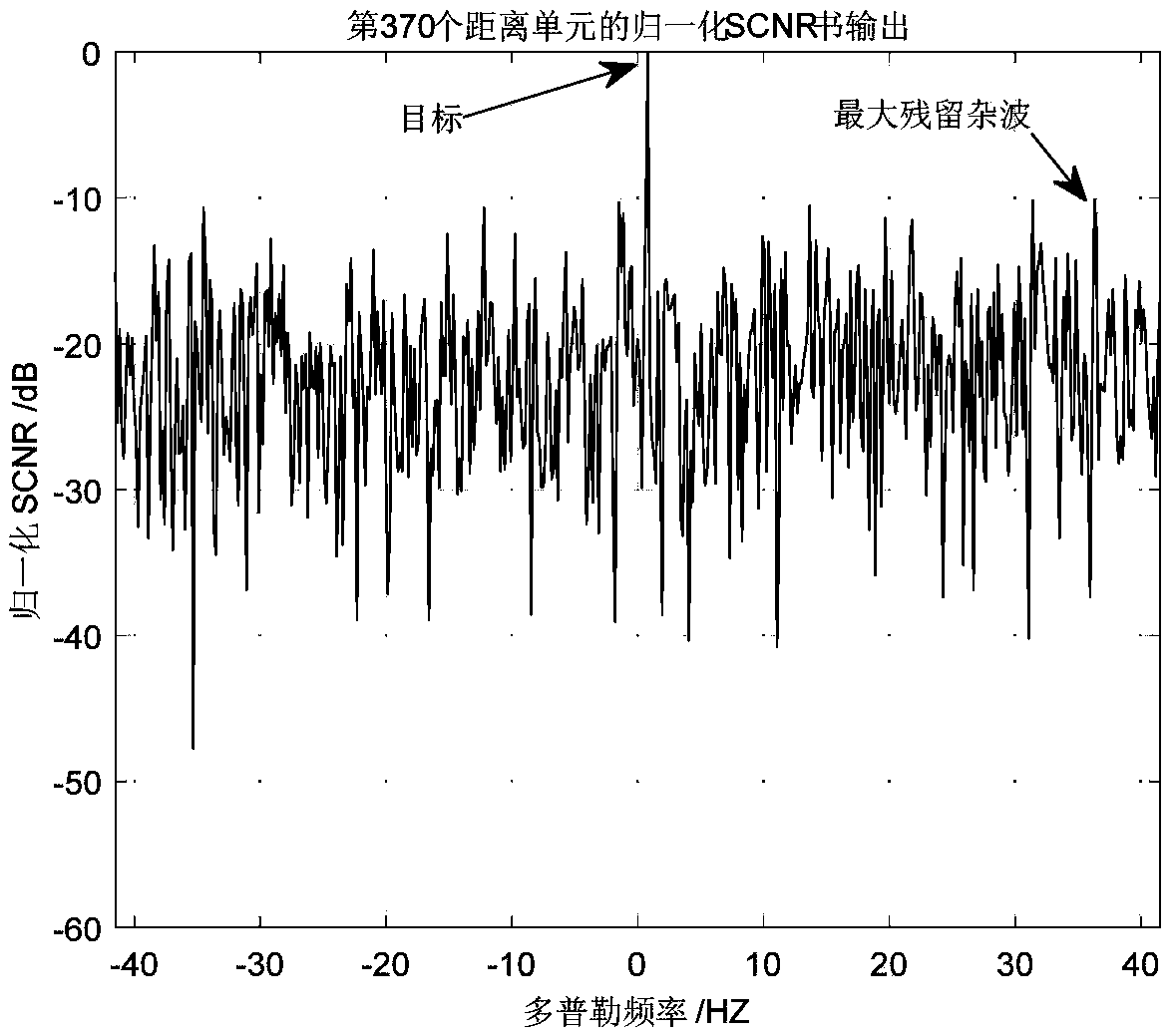

STAP clutter covariance matrix estimation method

The invention belongs to the technical field of radars, and particularly relates to a STAP clutter covariance matrix estimation method based on CUT self priori knowledge. The invention discloses the clutter covariance matrix estimation method based on CUT self priori knowledge. The method comprises the following steps of firstly, reconstructing clutter of a to-be-detected frequency channel of CUT,further extracting clutter of other frequency components except the to-be-detected frequency from the CUT, and finally calculating the clutter covariance matrix of the CUT by the reconstructed clutter. By adoption of the method, the problem of estimation of the clutter covariance matrix in the STAP is solved, the estimated clutter covariance matrix is more accurate, and the rejection performanceof the clutter is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

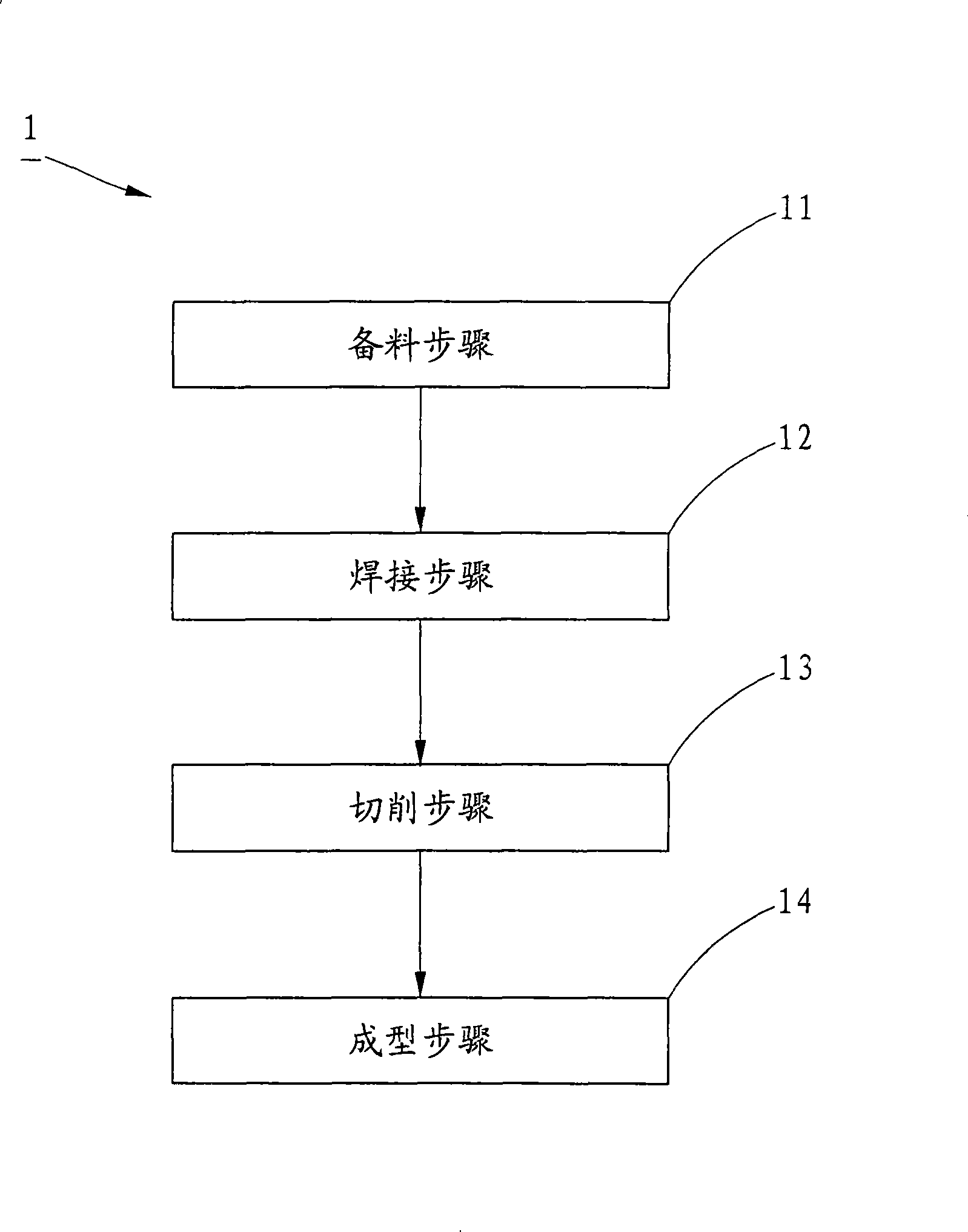

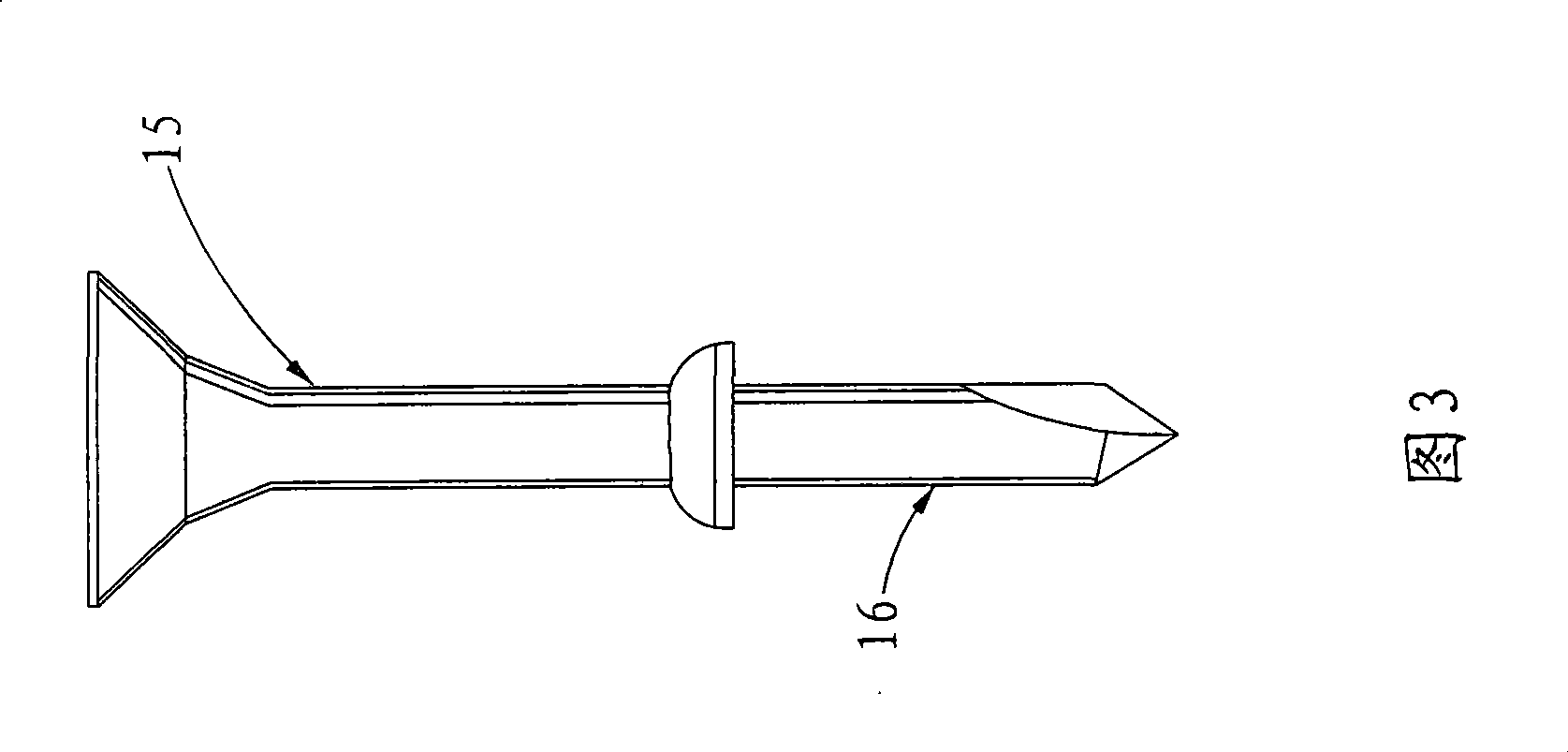

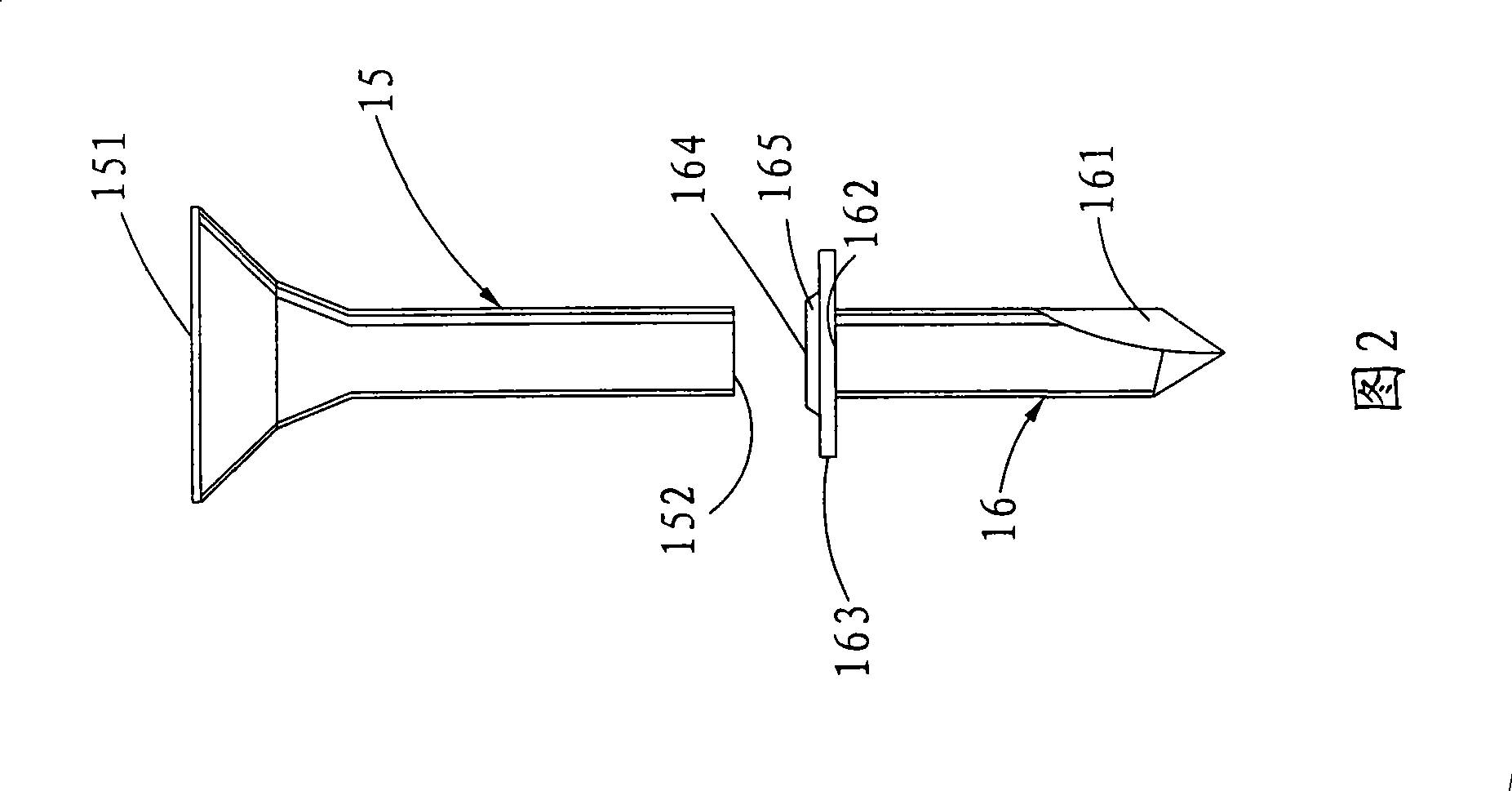

Manufacture method of composite screw

The invention relates to a method for producing a screw of composite material. The method comprises the steps of material preparation, welding, cutting and shaping in sequence, wherein, in the material preparation step, two different materials are divided into a rod body part and a drilling tail part; a welding part is formed on the rod body part, and a taper body is formed on the drilling tail part. Through the taper surface formed on the taper body, not only air can be smoothly exhausted when the rod body part is welded with the drilling tail part (namely, the welding step), so as to avoid air covering in the welding process, and ensure that pores can not appear at the welding positions, but also the composite blank can not be deflected after welding; finally, through the cutting of residual material in the cutting step, and shaping operations of screw thread rolling and the like, the screw of the composite material can be shaped, therefore, the quality of the screw of the composite material can truly be improved through the method.

Owner:TOP WELL TECH CORP

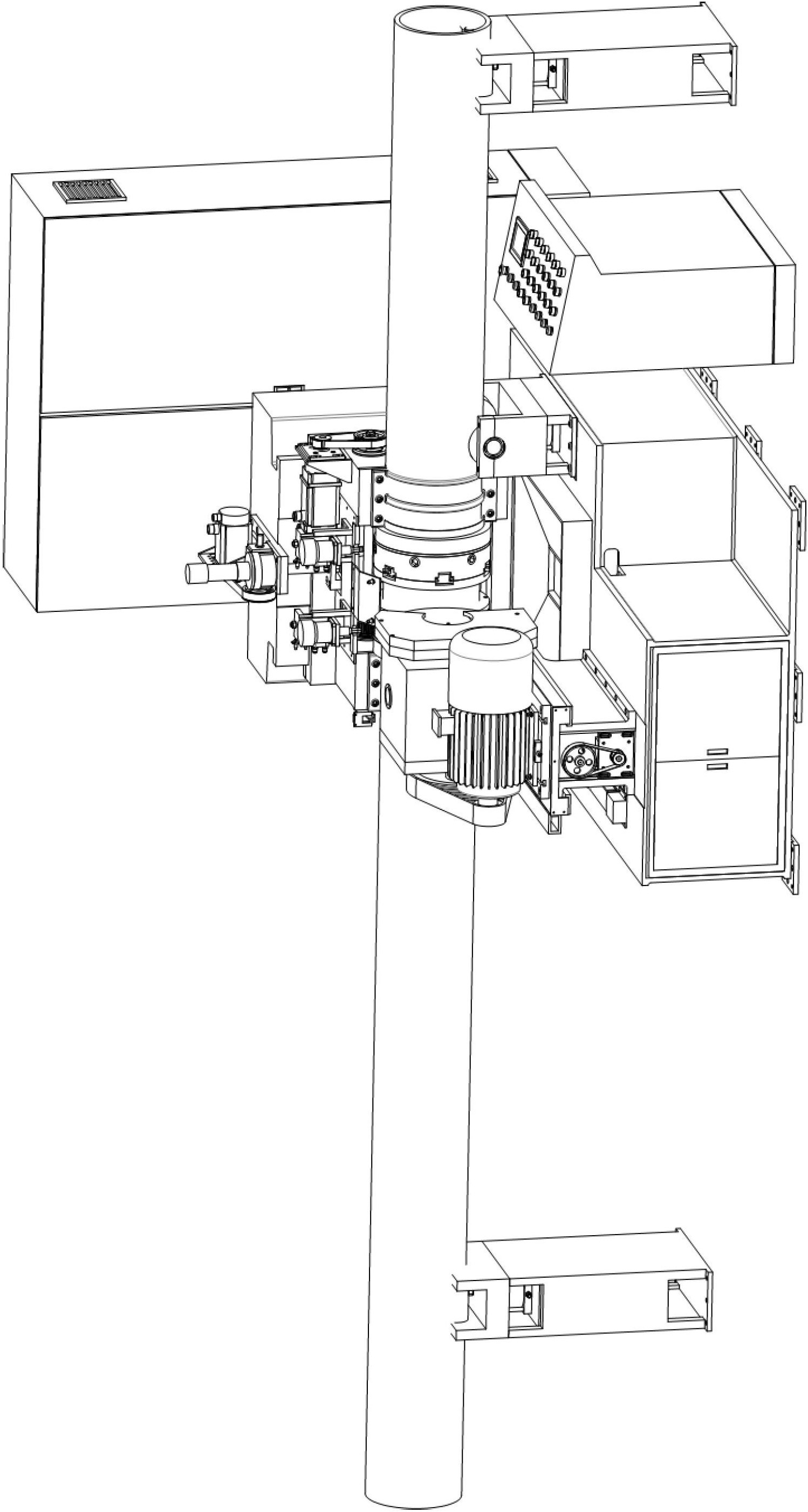

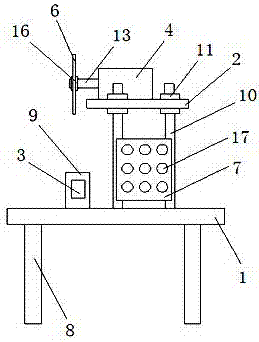

Fully-automatic cutting machine for building pipe cutting

InactiveCN110340437ARealize automatic cuttingSave human effortMetal sawing devicesWire cuttingFully automatic

The invention provides a fully-automatic cutting machine for building pipe cutting. The fully-automatic cutting machine for building pipe cutting comprises a rack, wherein a planar slide mechanism used for driving a cutting device and a clamping device to move in the transversal direction or the longitudinal direction is installed at the top of the rack; the cutting device and the clamping deviceare fixedly installed on a top slide table of the planar slide mechanism; the cutting device comprises a cutting base, the cutting base is fixedly installed on the top slide table, a top support seatis hinged to the top of the cutting base through a pin shaft, a cutting arm is fixed to the top of the top support seat, a cutting saw blade is installed at the tail end of the head part of the cutting arm, a main shaft of the cutting saw blade forms belt transmission with an output shaft of a cutting motor through a belt, and the cutting motor is fixedly installed on the cutting arm through a motor base; and a feeding mechanism used for driving the cutting arm to pitch is installed between the cutting arm and the top slide table. The cutting machine is used for automatic cutting for buildingpipes, and then effectively improving the cutting quality and effectively increasing the cutting efficiency, and lowering the labor intensity of working personnel.

Owner:湖北乾奥建设工程有限公司

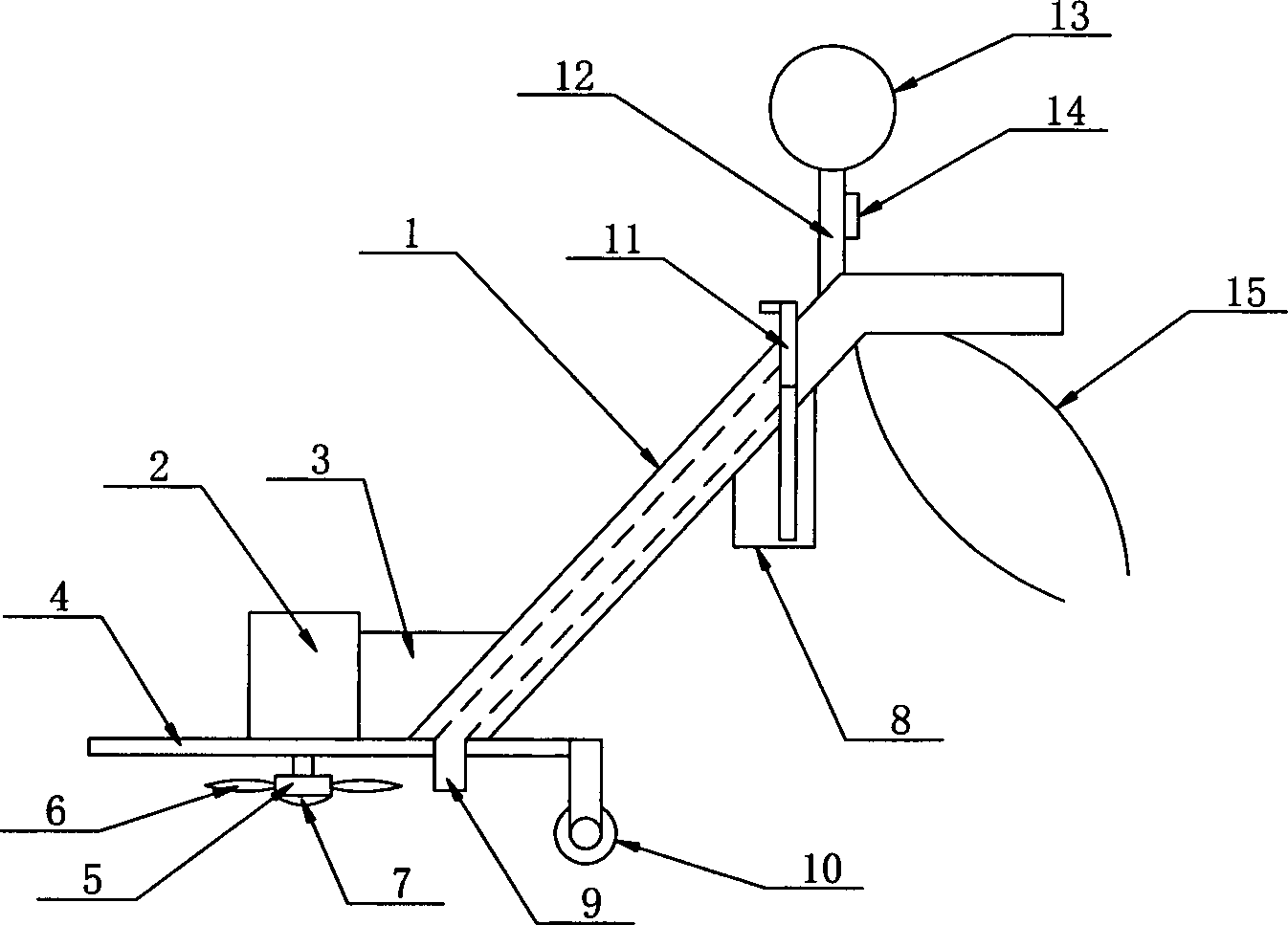

Multifunctional electrodynamic type grass cutter

InactiveCN103444352ASimple and fast operationFunction increaseMowersWatering devicesAgricultural engineeringMechanical equipment

The invention provides a multifunctional electrodynamic type grass cutter, relating to the technical field of agricultural mechanical equipment. An installation plate is installed on the lower end of a machine frame of the multifunctional electrodynamic type grass cutter; an idler wheel is installed on one end of the installation plate; a motor is installed on the installation plate; a cutting wheel is installed on a spindle of the motor; one side of the motor is provided with a storage battery; grass cutting blades are installed on the cutting wheel; an anti-clamping blade is installed on the lower end of the cutting wheel; a water tank is installed on the machine frame; an electrodynamic hydraulic mechanism is installed on the water tank; a spray nozzle is installed on the lower side of the installation plate; the spray nozzle is connected with the water tank through a water pipe; a support is installed on the machine frame; a bladeless fan is installed on the support; a thermometer is installed on the support; shoulder straps are installed on the machine frame. By the adoption of a shoulder strap type structure, the multifunctional electrodynamic type grass cutter is time-saving, labor-saving, convenient to operate, various in function and simple in structure.

Owner:CHANGJIU ENERGY SAVING TECH SERVICES

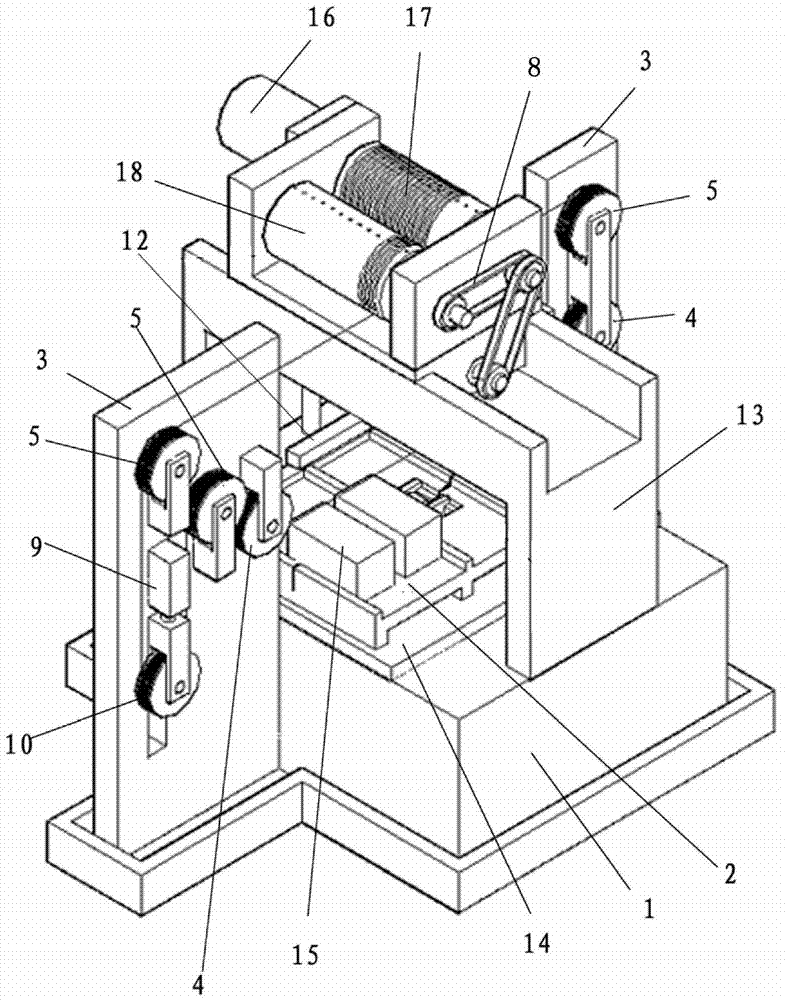

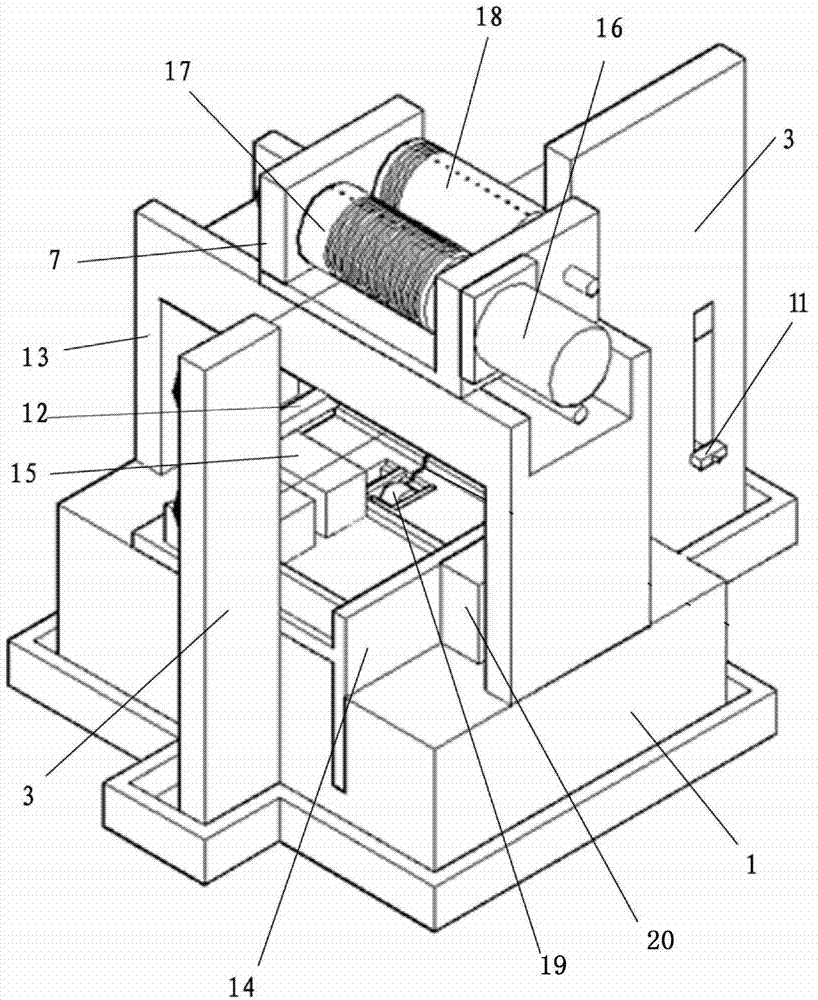

Diamond wire electrical discharge machine capable of completely flat wiring

ActiveCN103395130AReduce replacement frequencySave time and costFine working devicesStone-like material working toolsSerial codeCutting self

The invention relates to a diamond wire electrical discharge machine capable of completely flat wiring, and aims to provided the diamond wire electrical discharge machine having the advantages that a diamond wire is long in service life, wheels are free of abrasion, wiring is simple, structure is simple, size is small and cost is low on the basis of guaranteeing the normal cutting function. The technical scheme is that the diamond wire electrical discharge machine capable of completely flat wiring comprises a machine body, a wire storing mechanism, a wire conveying mechanism and a lifting platform, and the wire storing mechanism, the wire conveying mechanism and the lifting platform are all disposed on the machine body. The diamond wire electrical discharge machine is characterized in that the wire conveying mechanism comprises a group of forward wheels, a group of tensioning wheels and a group of cutting wheels, each of the forward wheel, the tensioning wheel and the cutting wheel is provided with at least two grooves arraying along the axial direction of the same, the grooves with the same serial number in all the forward wheels, the tensioning wheels and the cutting wheels form one group, namely a wire conveying channel of the diamond wire, and groove bottoms of all the grooves of the same group locate in the same plane.

Owner:曹爱苗

Guide-cutting plate of a cutting wheel for a paper shredder

InactiveUS7753301B1Improve chopping effectOperational securityCocoaGrain treatmentsEngineeringRabbet

A guide-cutting sheet of a cutting wheel for a paper shredder is characterized in that two sides of a centerline of a planar linear guide-cutting sheet are opened respectively with blade shaft transfix holes corresponding to a spacing between the blade shafts of two parallel cylindrical rotary cutting wheels; below or above two blade shaft transfix holes are opened respectively with fixing rod transfix holes, corresponding to a spacing between two fixing rods; the centerline part above two blade shaft transfix holes is opened with a rabbet which can be latched at two aperture walls of a strip-shape aperture on a face cover; and a bottom of the rabbet is provided with a concaved knife-edge which can cut off paper sheets.

Owner:LO EMILY

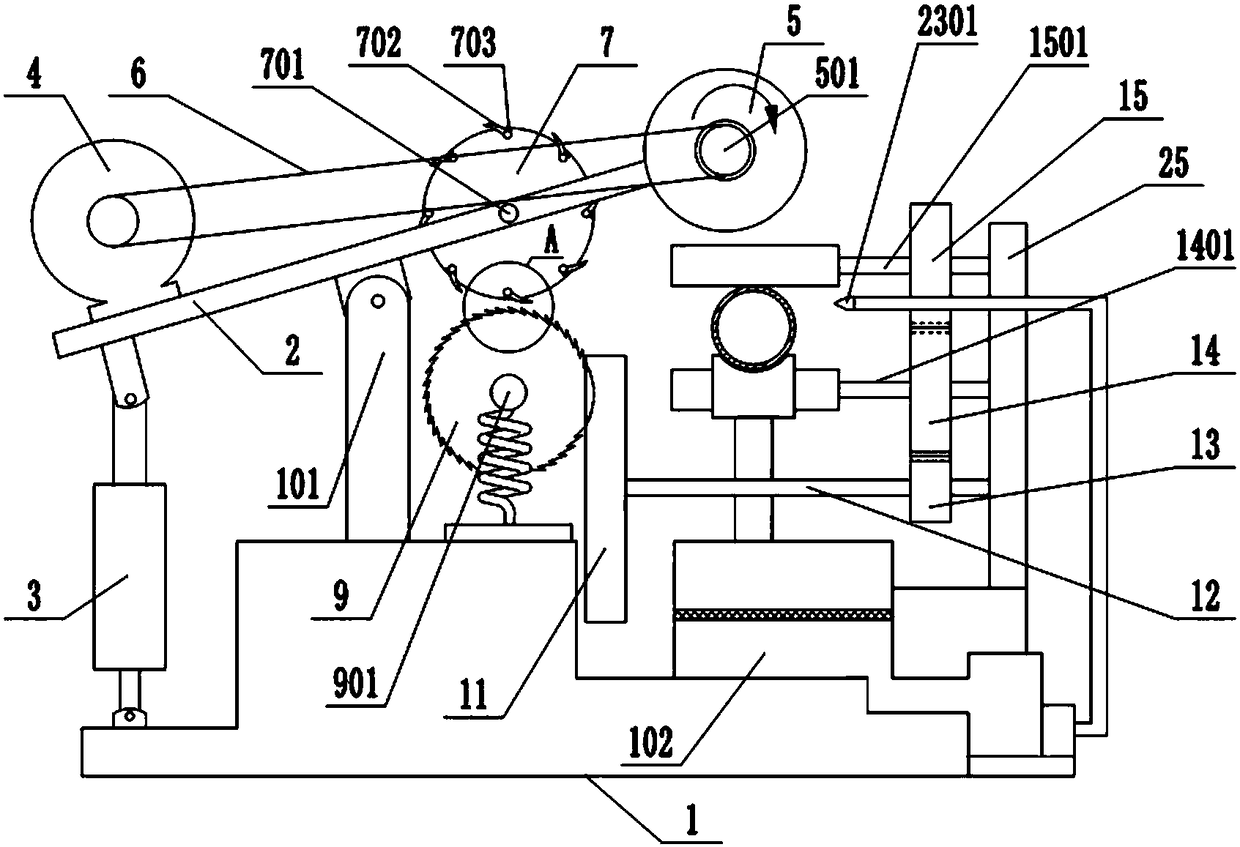

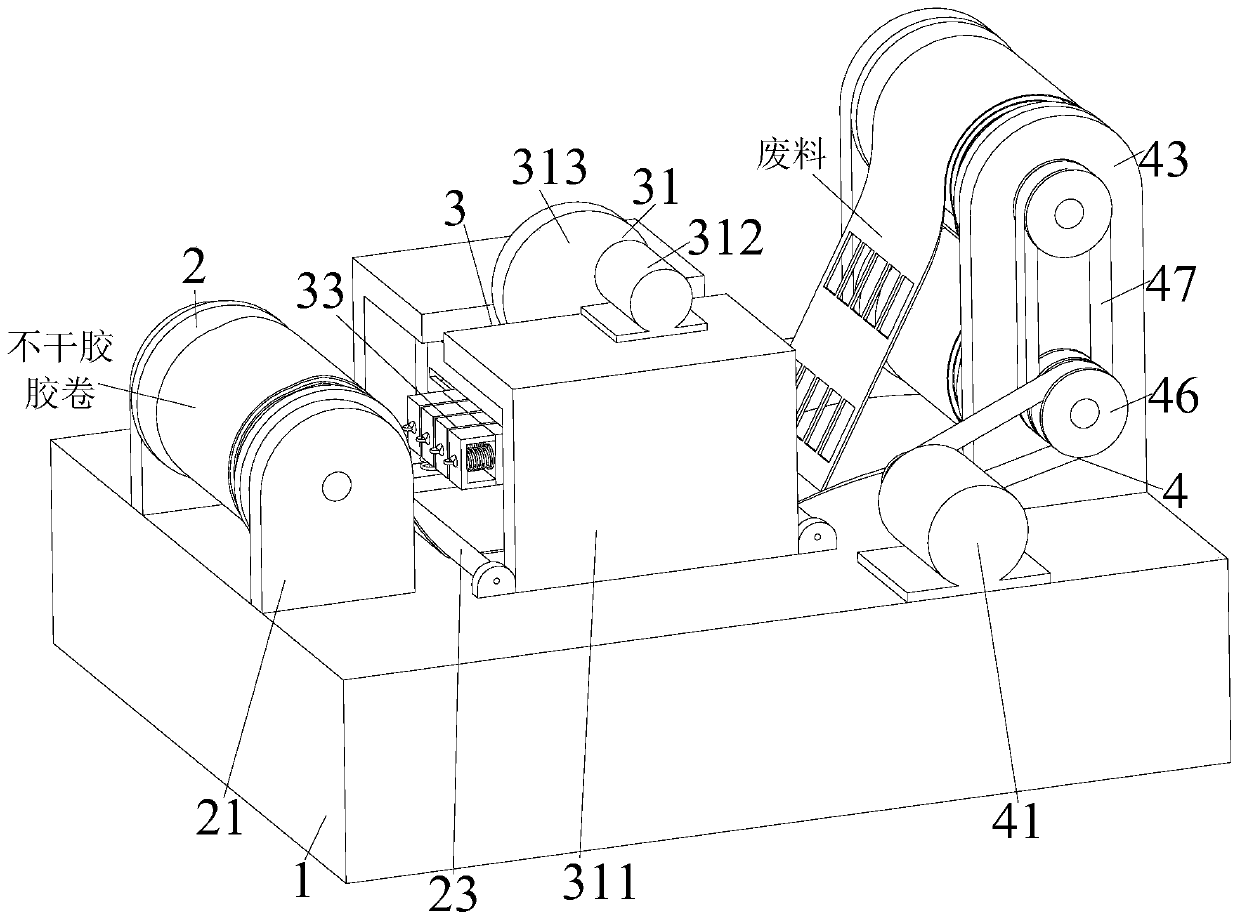

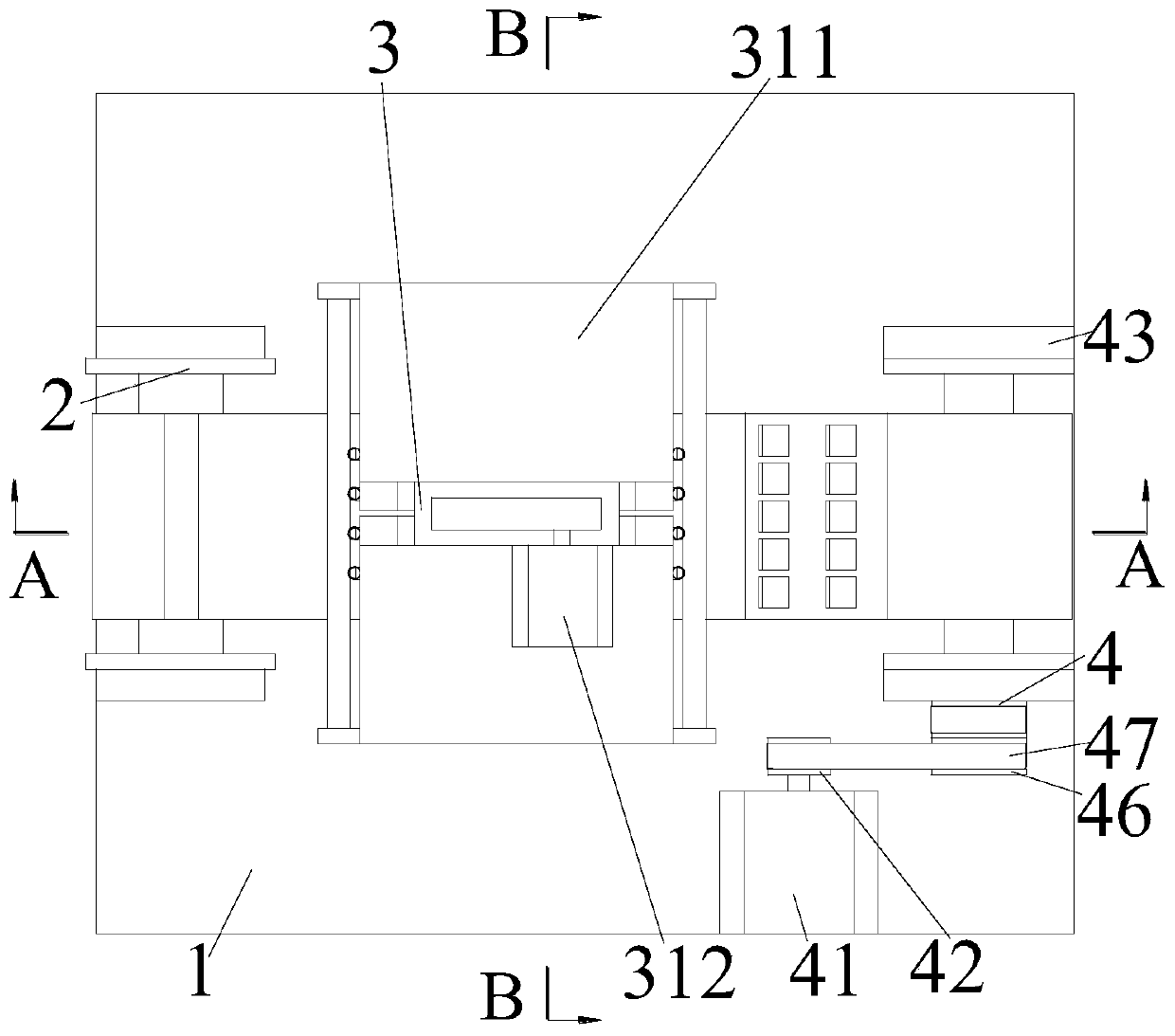

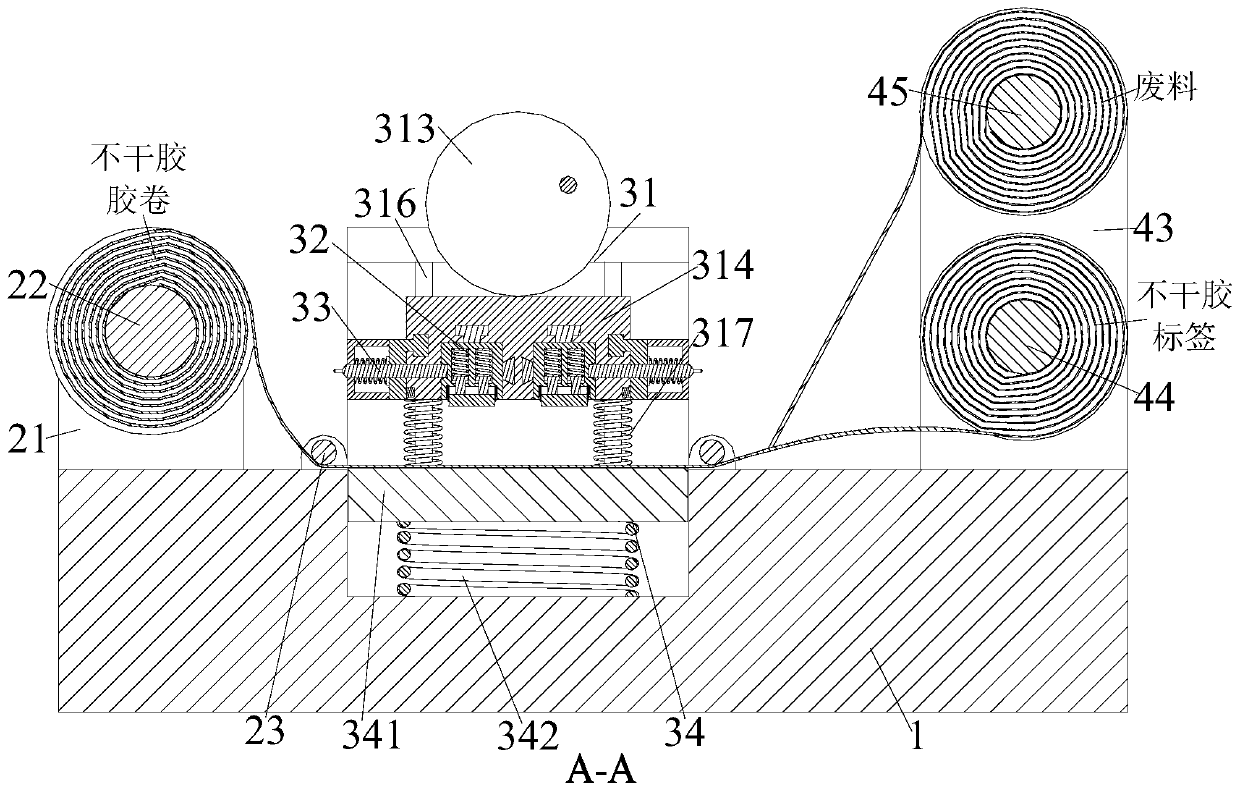

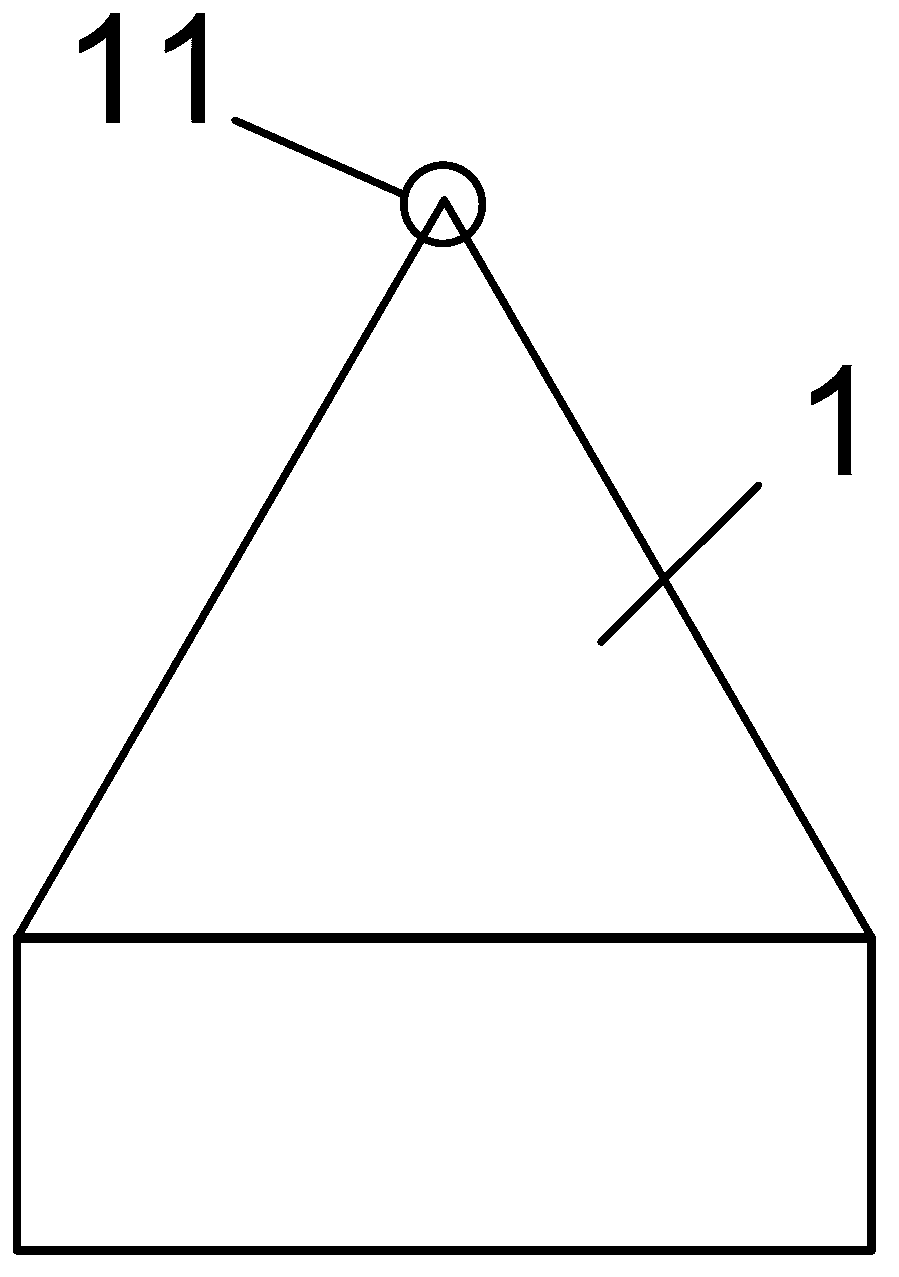

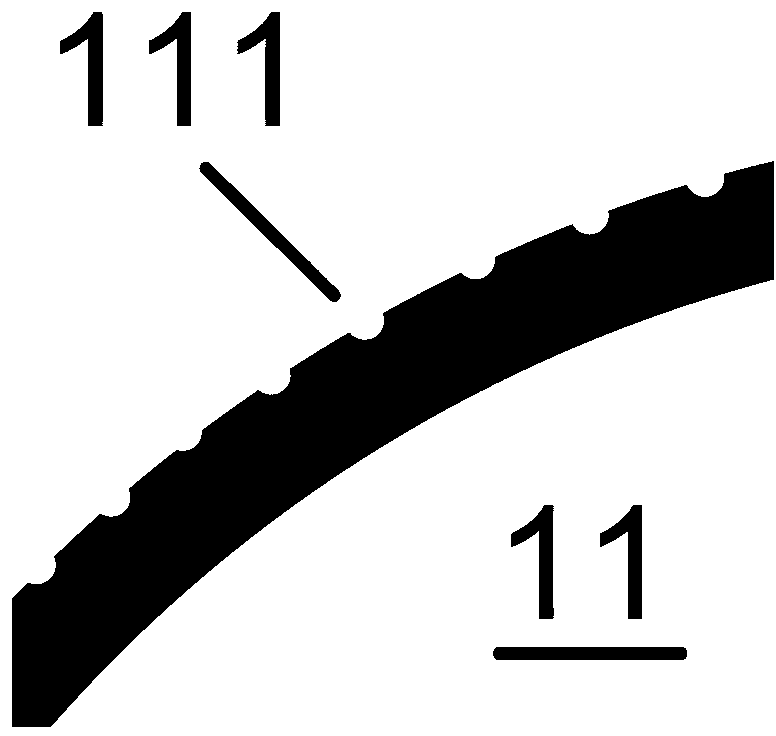

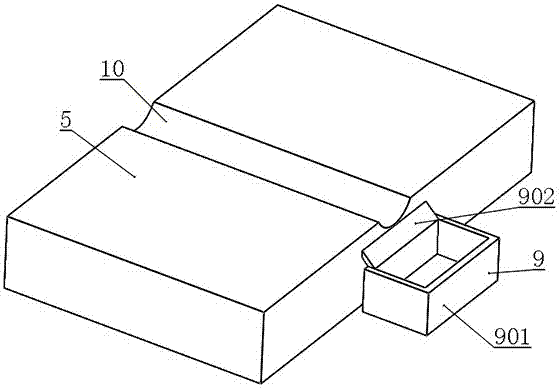

Self-adhesive label production system

ActiveCN111498548AShorten production timeAvoid creasesArticle deliveryWebs handlingAdhesiveWorkbench

The invention relates to a self-adhesive label production system. The self-adhesive label production system comprises a workbench, a feeding device, a cutting device and a winding device; the left side of the upper end of the workbench is provided with the feeding device; the right end of the feeding device is provided with the cutting device; and the winding device is arranged at the right end ofthe cutting device. The self-adhesive label production system provided by the invention can solve the problems that during manual cutting, a left-adhesive roll is first unwound and is then cut; aftercutting is ended, the cut self-adhesive roll is manually discharged; the manual cutting process is complicated; when the existing self-adhesive label manufacturing equipment is used for producing self-adhesive labels, the unwound self-adhesive roll is first locked and fixed; after being locked and fixed, the self-adhesive roll is directly cut by the cutting mechanism; after cutting is ended, theprocessed self-adhesive roll is wound and discharged by the winding mechanism; the processing process is not continuous, so the production efficiency of the self-adhesive labels is reduced, and the like.

Owner:河北万杰机械科技股份有限公司

Mechanism and method for automatically cleaning cutting wheel

InactiveCN103316869AReduce the impactGuaranteed cleanlinessCleaning using toolsCleaning using liquidsProduction lineMotor drive

The invention provides a mechanism and a method for automatically cleaning a cutting wheel. The mechanism comprises a cleaning roller, a lifting device, a motor and a cleaning fluid drip tube; the cleaning roller comprises at least one layer of cleaning media; the lifting device drives the cleaning roller to be in contact with the cutting wheel or to be separated from the cutting wheel; the motor drives the cleaning roller to rotate; the cleaning fluid drip tube is arranged above the cleaning roller and regularly drips cleaning fluid to the cleaning roller. The method includes that the cleaning roller descends, is in contact with the cutting wheel and rotates, and the cleaning media clean the surface of the cutting wheel; the cleaning roller ascends and is reset. The mechanism and the method for automatically cleaning the cutting wheel have the advantages that grooves of the cutting wheel can be regularly cleaned by the aid of an automatic roller mechanism, manual cleaning operation is replaced, and cleaning operation is executed under the regular and quantitative control, so that the cleanness of the cutting wheel can be kept, cleaning labor and working hours can be saved, influence on an upstream sheet supply production line is greatly reduced, and the production efficiency is improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Cable cutter with reciprocating cutting wheel for cutting flexible cable

ActiveUS20080301950A1Prevent the shaft from wobbling or twistingMetal working apparatusCable installation apparatusReciprocating motionEngineering

A cutting tool includes a frame, a shaft, a cutter and a cam. The shaft is rotatable about an axis. The cutter is coupled to the shaft such that rotation of the shaft about its axis causes rotation of the cutter about the shaft's axis. The cam is positioned around the shaft such that the cam contacts the frame upon rotation of the shaft. The cam has a cam surface which is distanced away from the axis of the shaft a varying amount such that contact of the cam with the frame upon rotation of the shaft causes the shaft, and thus the cutter, to reciprocate in a generally transverse direction relative to the axis of the shaft.

Owner:GREENLEE TEXTRON

Efficient cutting device

InactiveCN107160471AEasy to replaceImprove stabilityMetal working apparatusRotational axisOperating table

The invention discloses an efficient cutting device which comprises an operating table, a locating plate, air cylinders, a motor, limiting blocks, a cutting wheel and a control box. The efficient cutting device is characterized in that the operating table is arranged on a support, the operating table is provided with fixing plates and locating rods, the locating plate is arranged on the locating rods through connecting nuts, the air cylinders are arranged on the fixing plates, adjusting rods are arranged on the air cylinders, the motor is arranged on the locating plate, and a rotating shaft is arranged on the motor. According to the efficient cutting device, the limiting blocks are arranged on the adjusting rods of the air cylinders, limiting grooves are formed in the limiting blocks, decoration members can be fixed firmly through the limiting grooves, the stability of the decoration members in the cutting process can be improved, then cutting quality of the decoration members is improved, the limiting blocks are arranged to be of a replaceable structure, the different limiting blocks can be replaced conveniently according to the different decoration members, then the application range of the cutting device is enlarged, and working efficiency of the cutting device is improved.

Owner:芜湖瑞德机械科技有限公司

Circular pipe cutter

InactiveCN104385332AImprove cutting efficiencyAvoid personal injuryMetal working apparatusEngineeringPerpendicular direction

The invention discloses a circular pipe cutter. The circular pipe cutter comprises three components of a base, a cutting device and a motor, wherein four fixed base legs are arranged below the base for supporting the base; a cutting wheel groove and a workpiece groove are formed in the upper end surface of the base; the cutting wheel groove fits a cutting wheel of the cutting device; the workpiece groove is used for storing a circular pipe workpiece to be cut; the cutting wheel groove and the workpiece groove are arranged in a perpendicular direction; meanwhile, a workpiece fixed lever is arranged on the upper end surface of the base; the cutting device consists of the cutting wheel; and the cutting wheel is driven through belt transmission by the motor. The circular pipe cutter has the advantages of simple structure, high workpiece cutting efficiency, high safety coefficient and prevention of personal injury of operators.

Owner:SUZHOU HUIFENG MACHINERY EQUIP

Plastic pipe fitting cutting device with dust storing function

InactiveCN108000593AEasy to recycleImprove storage effectUsing liquid separation agentMetal working apparatusPipe fittingEngineering

The invention relates to a plastic pipe fitting cutting device with a dust storing function. The plastic pipe fitting cutting device comprises a cutting mounting plate, a cutting motor, a cutting wheel and a battery pack, wherein the cutting motor is arranged on the cutting mounting plate, and the battery pack is used for supplying power for the cutting motor. The plastic pipe fitting cutting device is characterized in by further comprising a base unit, a tensioning unit and a driving unit, wherein the base unit is used for enabling the cutting mounting plate to conduct plugging mounting and limit sliding; the tensioning unit is arranged on the cutting mounting plate and is used for enabling the cutting mounting plate to hanging in the air in waiting on the base unit in an elastic tensioning mode; the driving unit is arranged on the base unit and is used for enabling the cutting mounting plate to conduct declining cutting in a mode of rejecting magnetic force. A dust storing unit usedfor storing dust is arranged on the side face, close to the cutting wheel, of the base unit in a mode of water adsorption. The plastic pipe fitting cutting device has the advantages of convenience andfastness in cutting operation, high cutting stability, precise cutting, good dust storage effect and convenience in dust recovery.

Owner:安徽省华财塑胶科技有限公司

Mechanical automatic cutting device with dust collecting cover

InactiveCN110497465AMove up and down to adaptImprove the effect of gathering and conveyingDirt cleaningMetal working apparatusFixed frameEngineering

The invention relates to the field of cutting devices, in particular to a mechanical automatic cutting device with a dust collecting cover. The mechanical automatic cutting device comprises a top frame, a stand column, a base and a cutting wheel. A dust suction cylinder is arranged on the lower side of the top frame and is driven by a longitudinal driving device arranged on the top frame to move up and down. A cross shaft is supported and fixed to the lower side of the dust suction cylinder through a fixing frame and is driven by a second motor to rotate. The cutting wheel is arranged on the cross shaft. A dust collection cover is arranged on the outer side of the cutting wheel in a covering manner, is fixedly connected with the fixing frame, and is further connected with the dust suctioncylinder through a connecting pipe. The dust suction cylinder is further provided with a dust suction mechanism which can be in control linkage fit with the cross shaft. The top of the dust suction cylinder is further connected with a telescopic corrugated cylinder. The telescopic corrugated cylinder is connected with a dust collection cloth bag through an inverted U-shaped pipe. According to themechanical automatic cutting device, through the selective matching of dust removal and cutting linkage, dust generated during cutting can be removed while cutting, the energy is saved, the environment is protected, and the health of workers is facilitated.

Owner:YANTAI ENG & TECH COLLEGE YANTAI TECHNICIAN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com