Mechanism and method for automatically cleaning cutting wheel

A technology for automatic cleaning and cutting knives, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems affecting equipment output, save cleaning manpower and working hours, reduce The impact of the upstream film supply line and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

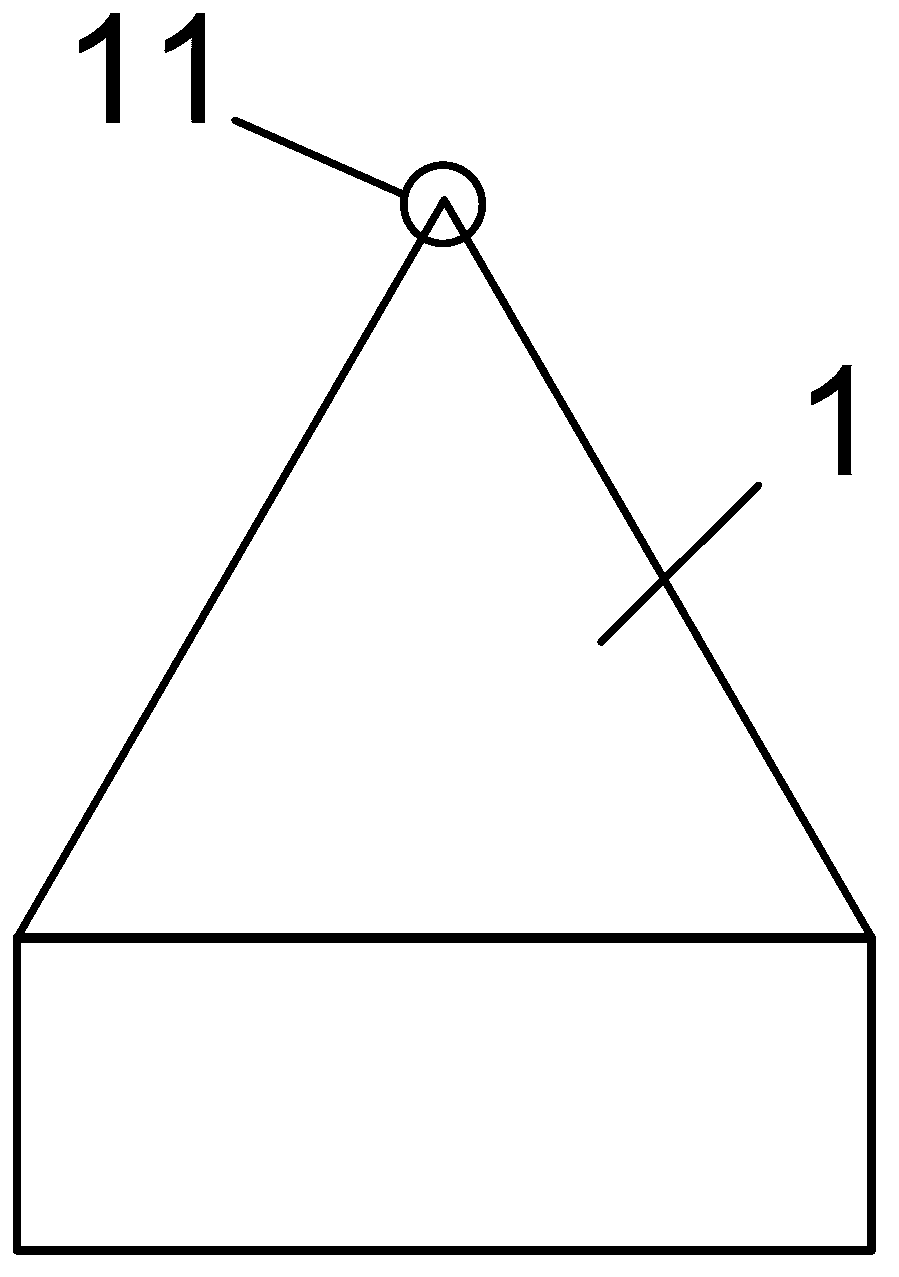

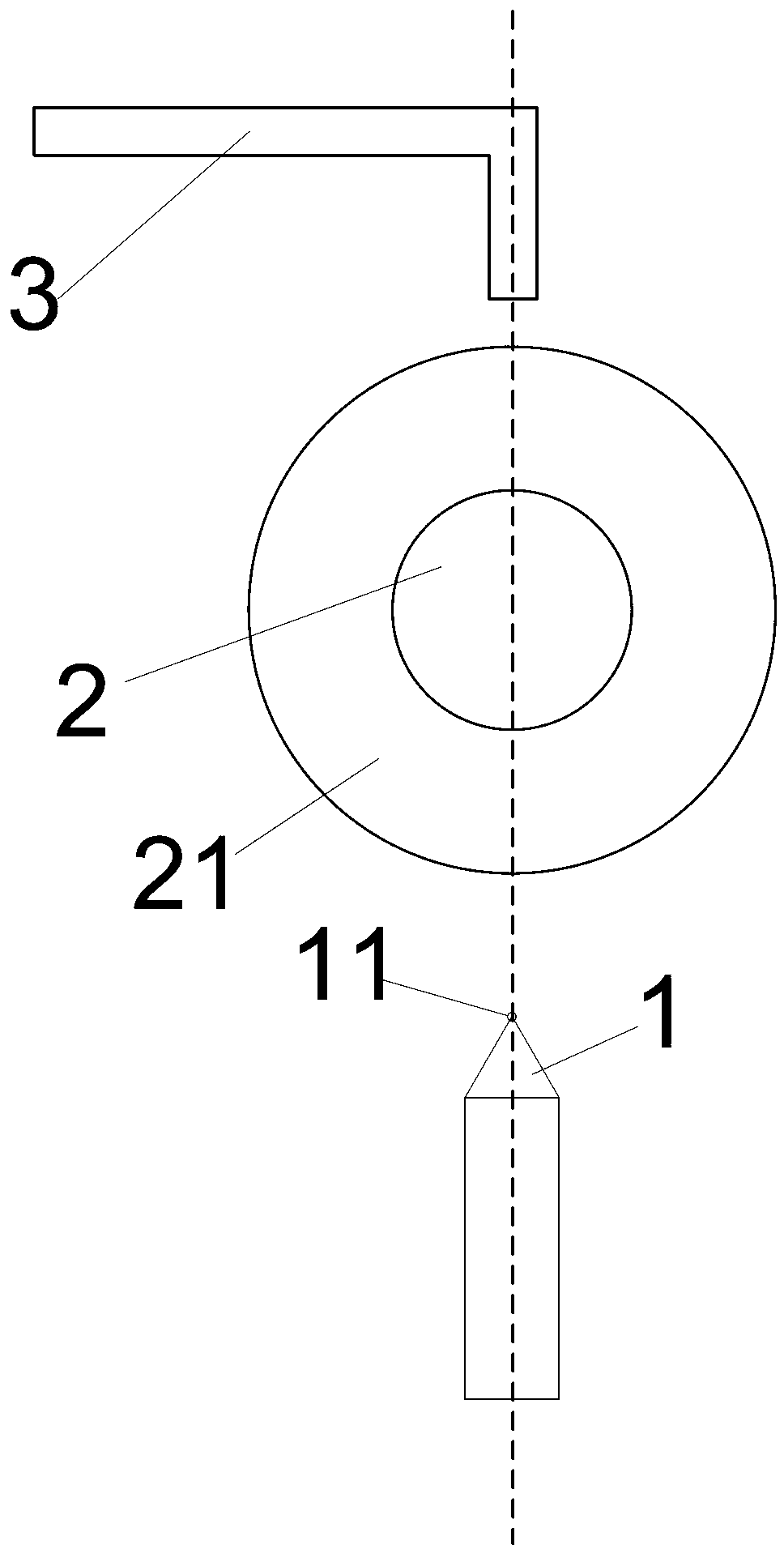

[0060] image 3 According to the first embodiment of the present invention, a schematic structural diagram of the automatic cleaning mechanism of the cutting wheel of the present invention is shown. Such as image 3 As shown, the cutting wheel automatic cleaning mechanism of the present invention is used to clean the cutting wheel 11 on the cutting knife 1, including: cleaning roller 2, lifting device (not shown in the figure), motor (not shown in the figure) and cleaning dropper 3 .

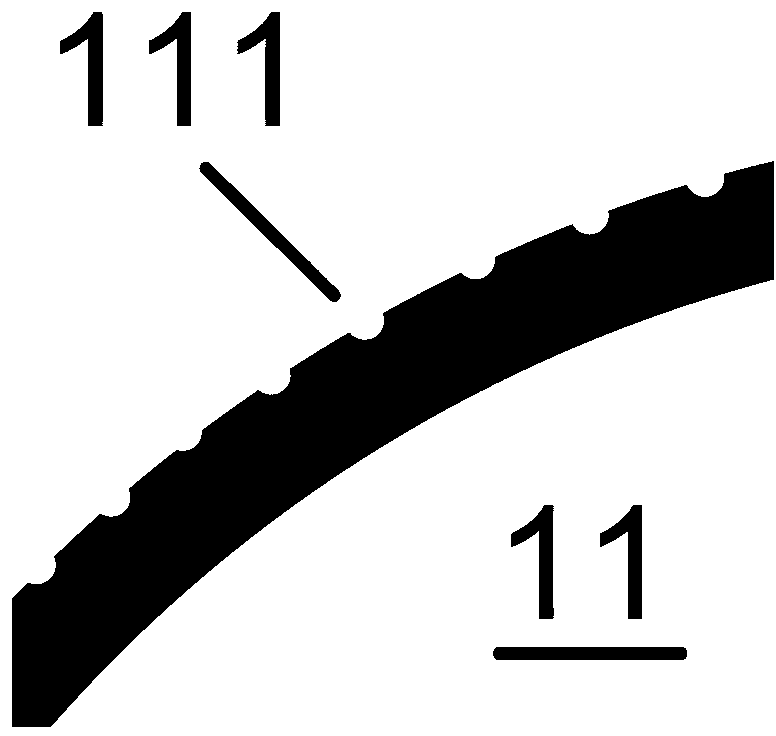

[0061] The cleaning roller 2 is arranged above the cutter wheel 11 . The cleaning roller 2 comprises a layer of cleaning medium 21 . The cleaning medium 21 is coated on the outer surface of the cleaning roller 2 . The material of the cleaning medium 21 is a porous absorbent body. In this embodiment, the material of the cleaning medium 21 is sponge, but it is not limited thereto.

[0062] The lifting device drives the cleaning roller 2 to contact or leave the cutter wheel 11 . The lifting ...

no. 2 example

[0071] A glass cutting device of the present invention is to combine the cutting wheel automatic cleaning mechanism in the first embodiment into the glass cutting production line equipment, which includes at least one cutting wheel, at least one conveying device for transporting glass plates, and the above-mentioned Cutting knife wheel automatic cleaning mechanism. The cutting knife wheel automatic cleaning mechanism is used to clean the cutting knife wheel on the cutting knife, including: cleaning roller, lifting device, motor and cleaning liquid drop tube.

[0072] The cleaning roller is arranged above the cutter wheel. Cleaning rollers consist of a layer of cleaning media. The cleaning medium is coated on the outer surface of the cleaning roller. The material of the cleaning medium is a porous absorbent body. In this embodiment, the material of the cleaning medium is sponge, but not limited thereto.

[0073] The lifting device drives the cleaning roller to contact or le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com