Device and method for underground coal mine hydraulic slit cutting self-suction type material abrading jet flow generation

A hydraulic cutting and abrasive jet technology, which is applied in the direction of mining fluid, earth drilling, wellbore/well parts, etc., can solve the problems of poor cutting effect and insufficient cutting ability of pure water jet, and achieve simple structure and high efficiency. Optimum, low drag loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below by means of the accompanying drawings and examples.

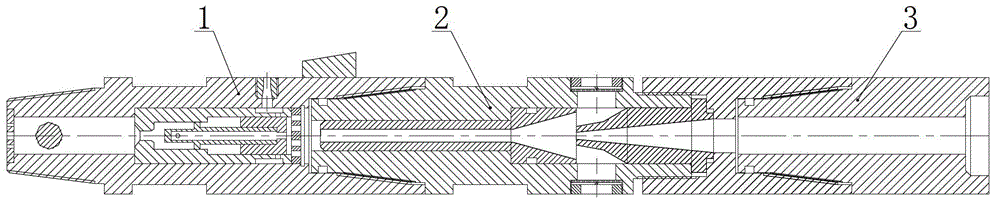

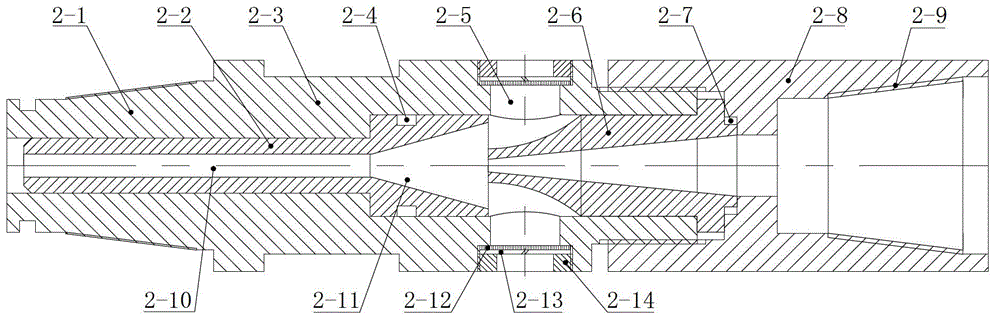

[0024] combine Figure 1 to Figure 3 , the implementation of the hydraulic slotting self-priming abrasive jet generating device used in underground coal mines is now described:

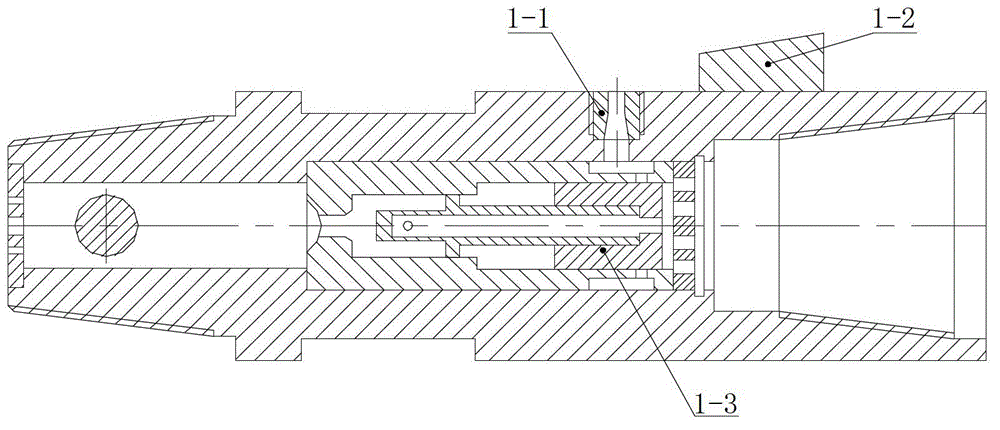

[0025] The coal mine underground hydraulic slotting self-priming abrasive jet generating device includes a front-end slotting device 1 and a self-priming device 2 .

[0026] combine figure 2 It can be seen that the front end slotter 1 is a hollow structure that runs through front and back, and radial nozzles 1-1 are installed in the radial direction, which are jet flow generating devices. The reversing valve core 1-3 is installed in the middle of the slit device. When the water pressure reaches the threshold value of the reversing spool, the radial water hole on the reversing spool is opened, and the radial nozzle is connected with the slit device, and the slit device Enter the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com