Patents

Literature

53results about How to "Good seam effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

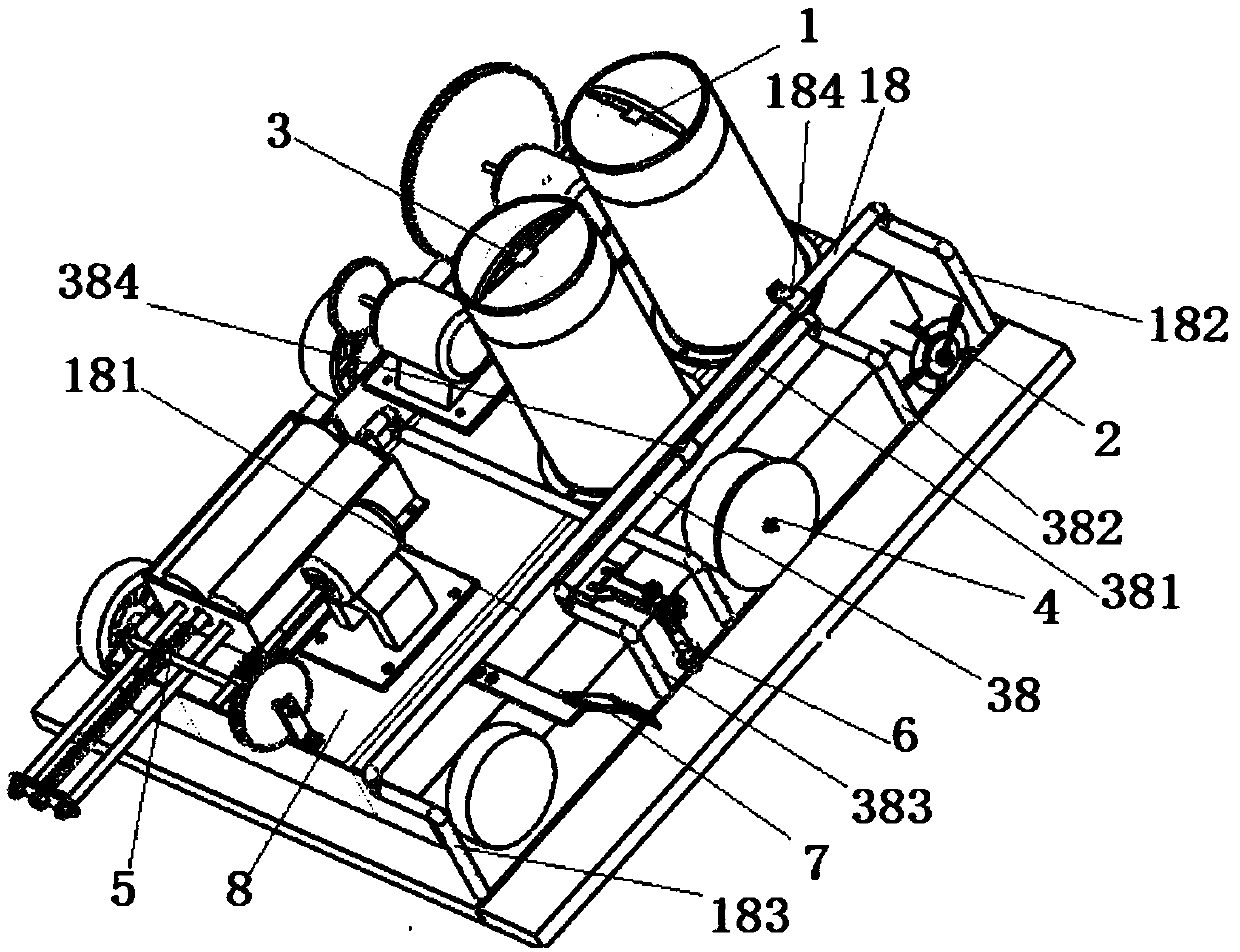

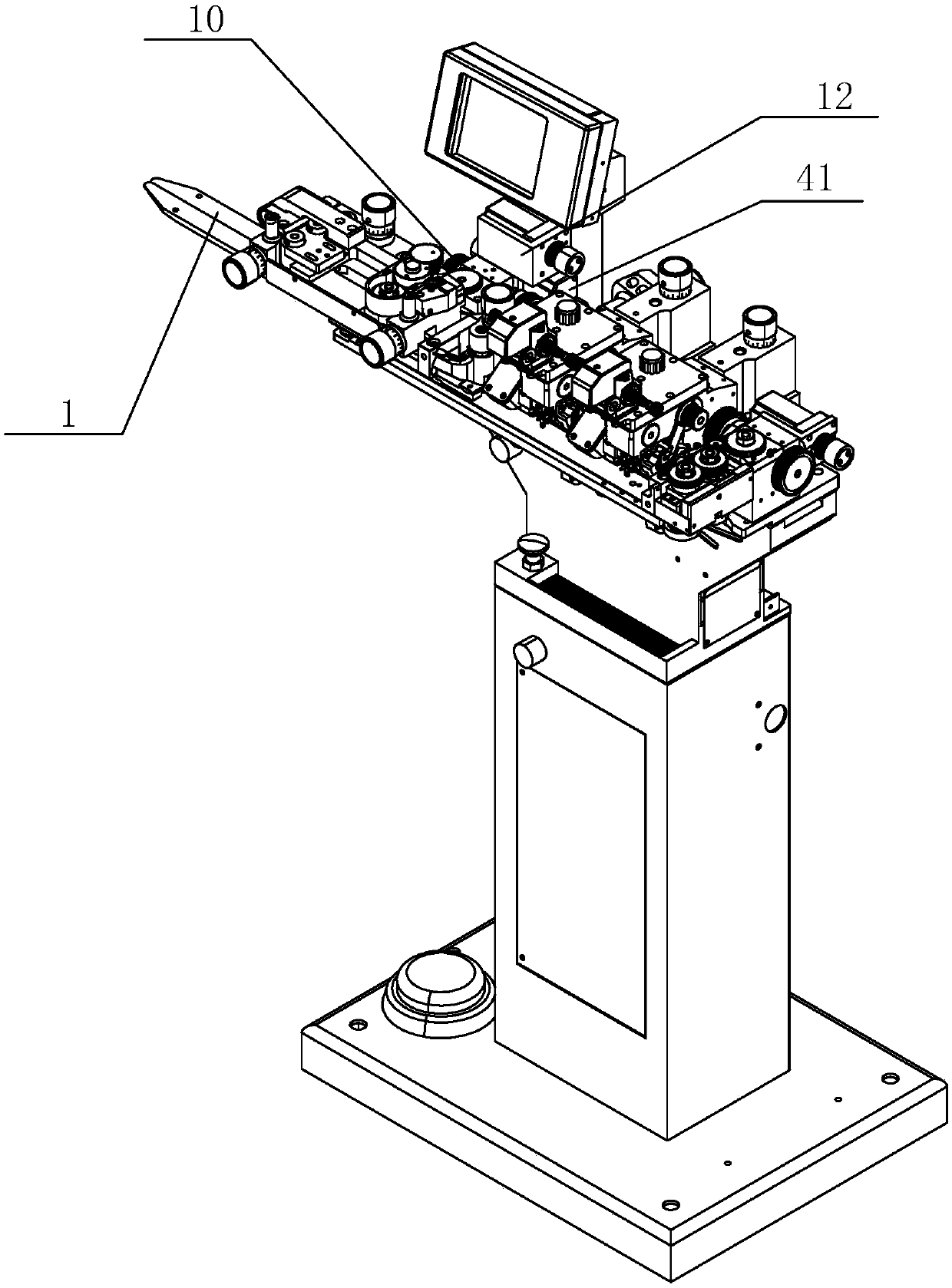

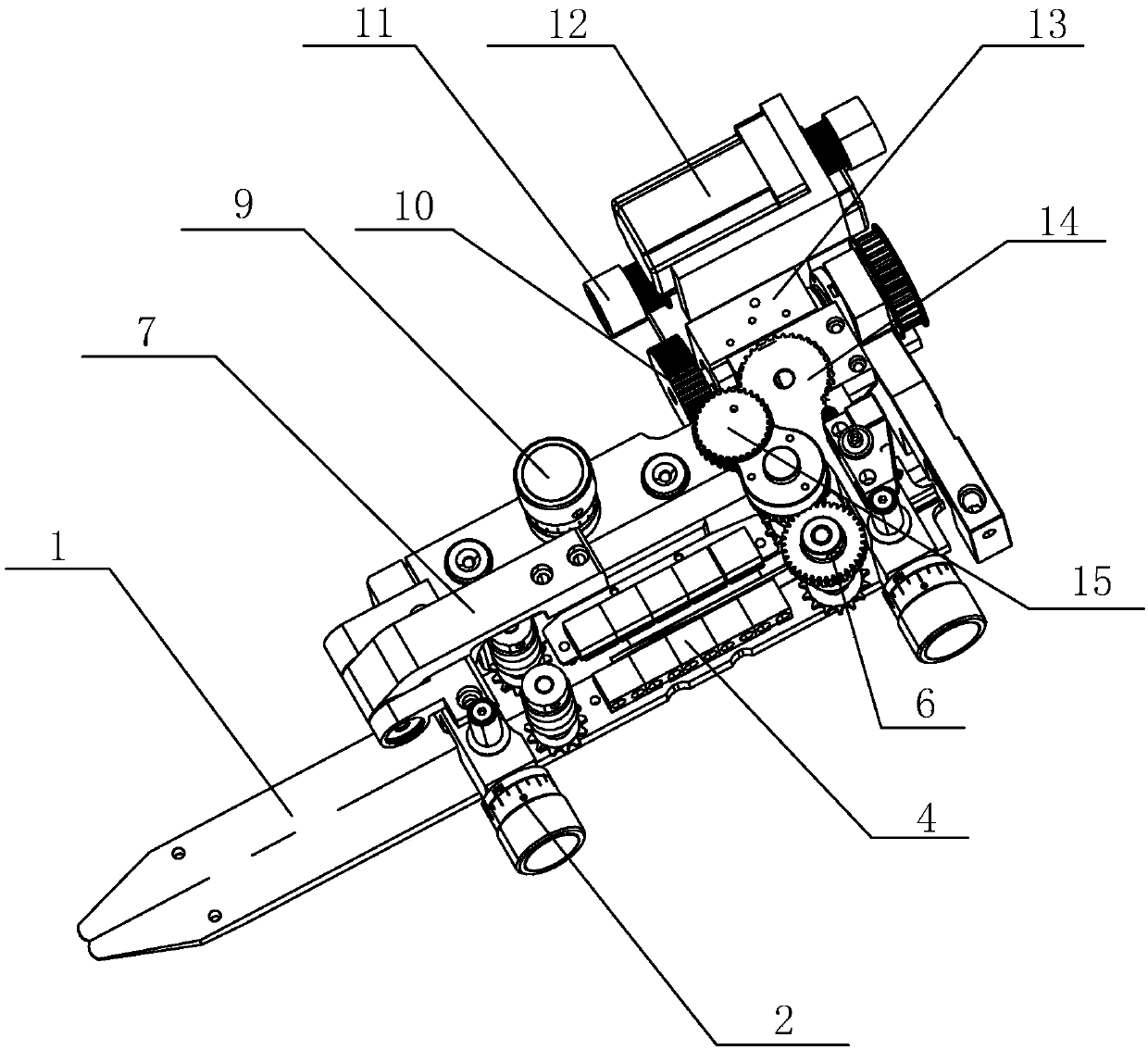

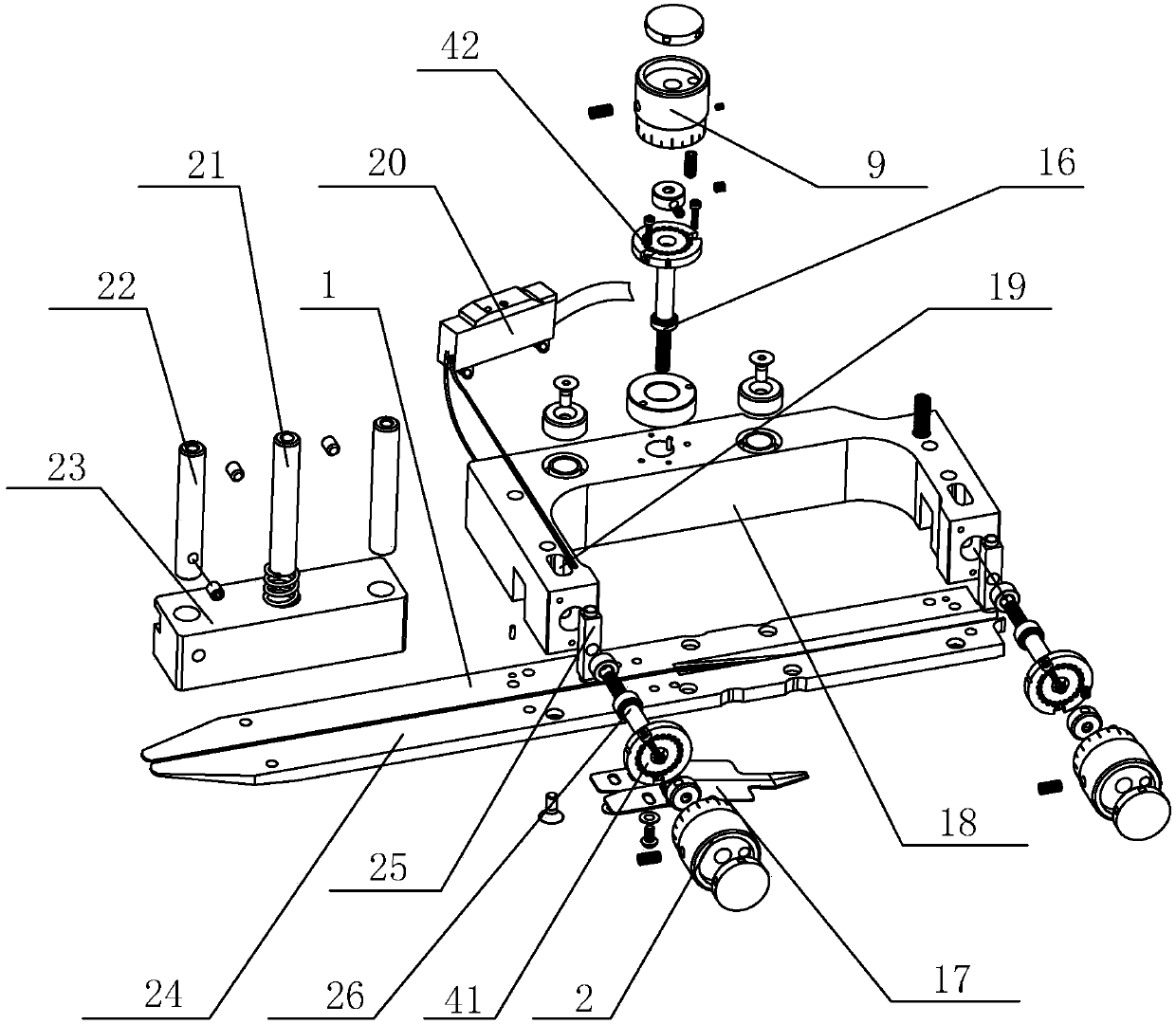

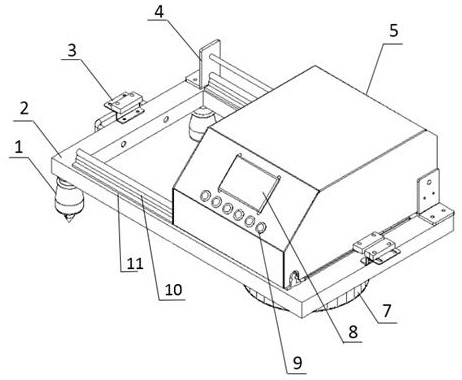

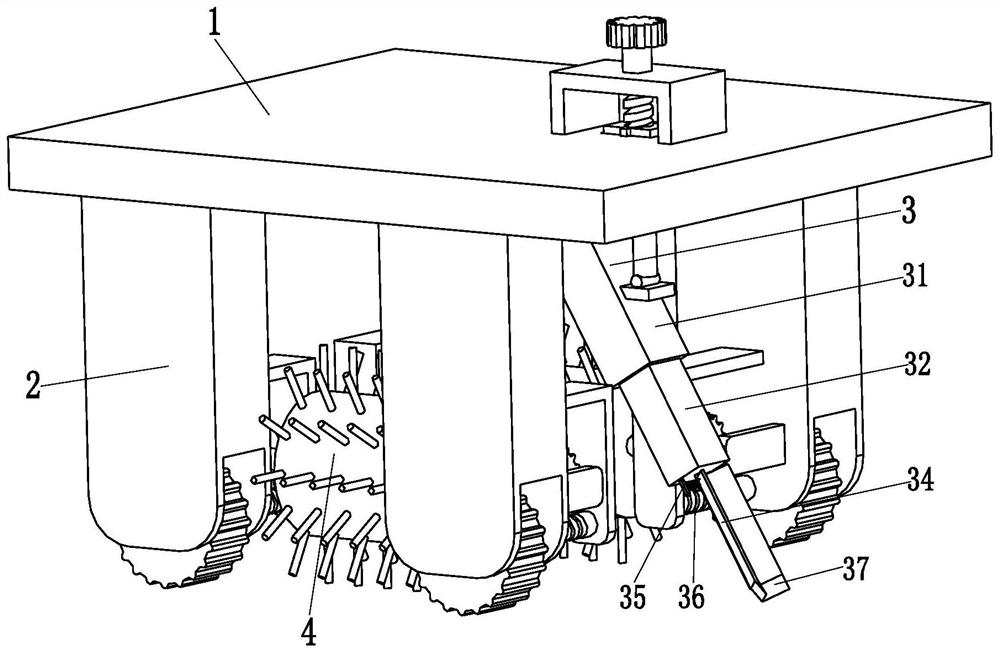

Robot for ceramic tile seam beautifying

ActiveCN106988513AChange the defects of manual operationImprove work efficiencyBuilding constructionsSpray nozzleEngineering

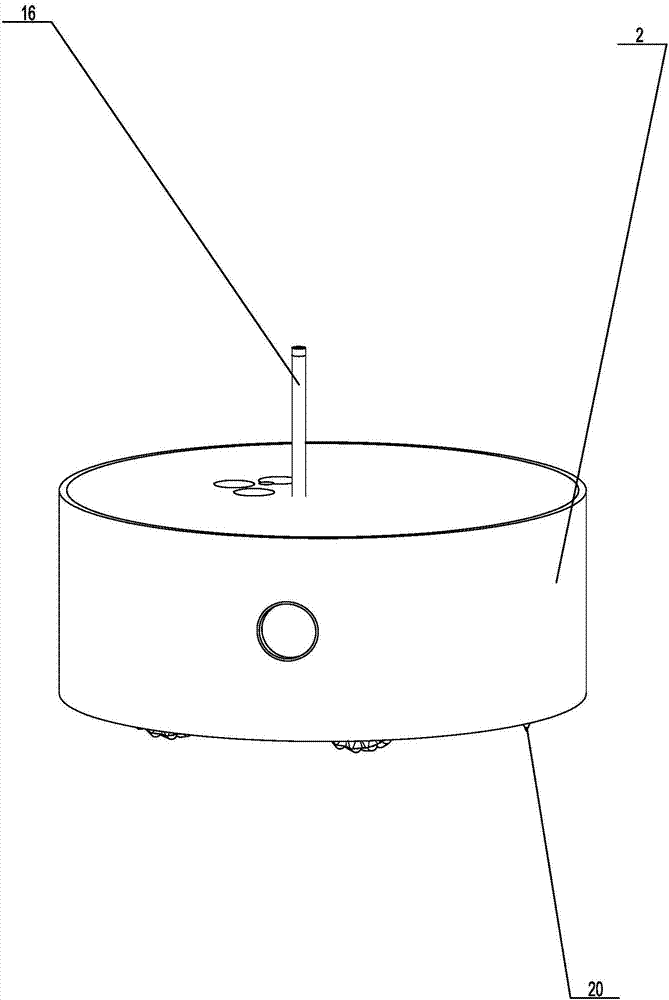

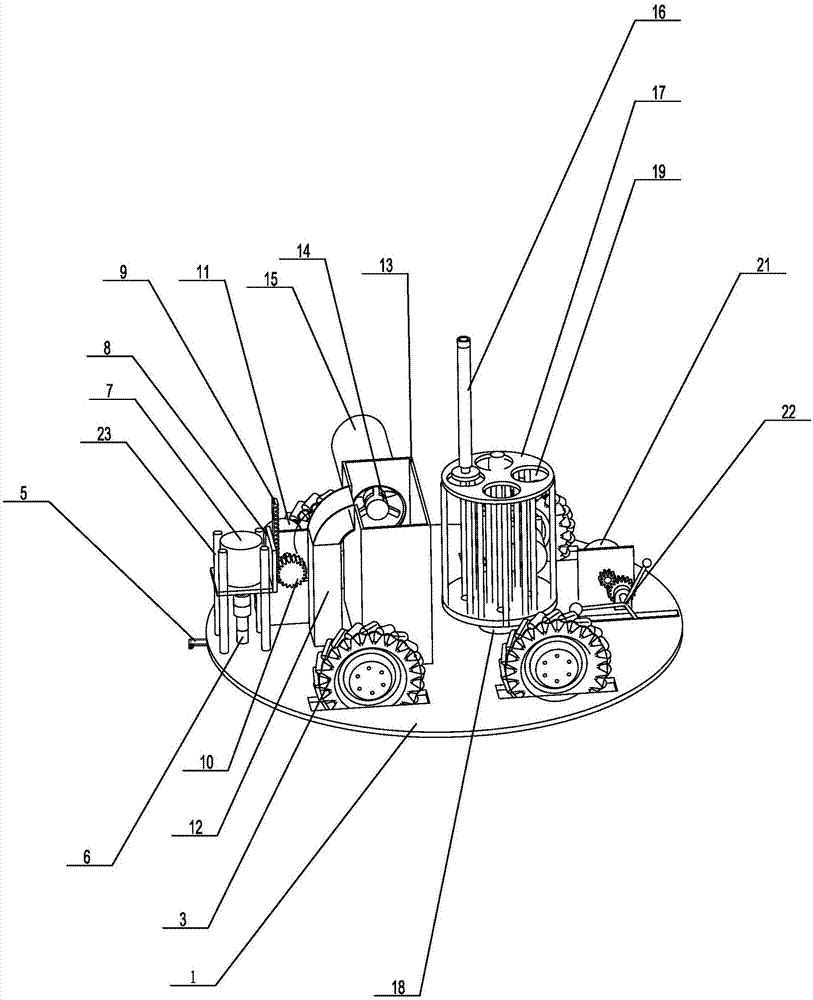

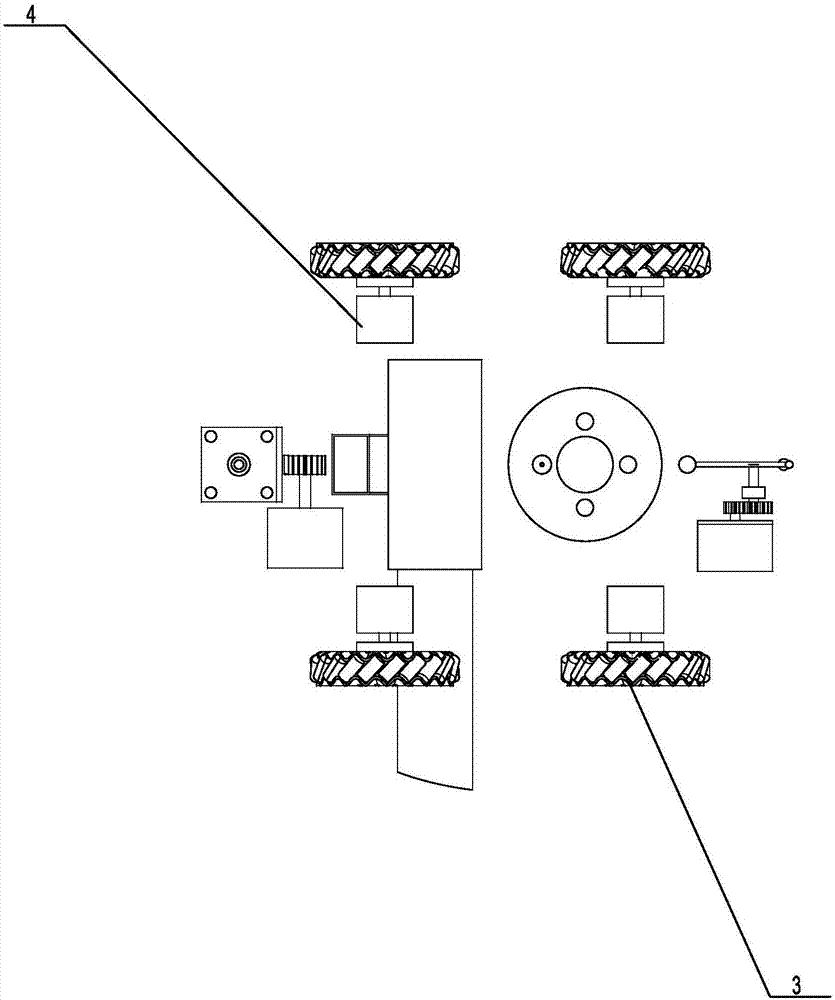

The invention discloses a robot for ceramic tile seam beautifying. The robot for ceramic tile seam beautifying comprises a chassis, a main shell, a driving mechanism, a cleaning mechanism, and a seam beautifying mechanism and a seam pressing mechanism; the driving mechanism comprises four mecanum wheels, four running driving motors and an industrial camera; the cleaning mechanism comprises a cleaning cutting tool, a cutting tool motor, a rack, a gear, a geared motor, a sweep-up pipe, a dust suction box, an exhaust fan and an exhaust pipe; the seam beautifying mechanism comprises an electric push rod, a sealant drum, a drum motor and a nozzle; the seam pressing mechanism comprises a seam pressing motor and a seam pressing ball rod; and the running driving motors, the driving mechanism, the cleaning mechanism and the seam beautifying mechanism are all controlled by an intelligent control system. The robot for ceramic tile seam beautifying can complete polishing, dedusting, agent injecting, seam pressing and other procedures in the ceramic tile seam beautifying working one time, the defects of existing manual operations are changed, mechanical automatic operation is achieved, and the robot for ceramic tile seam beautifying not only is high in working efficiency, but also is good in seam beautifying effect, low in seam beautifying cost, and easy to popularize.

Owner:QINZHOU UNIV

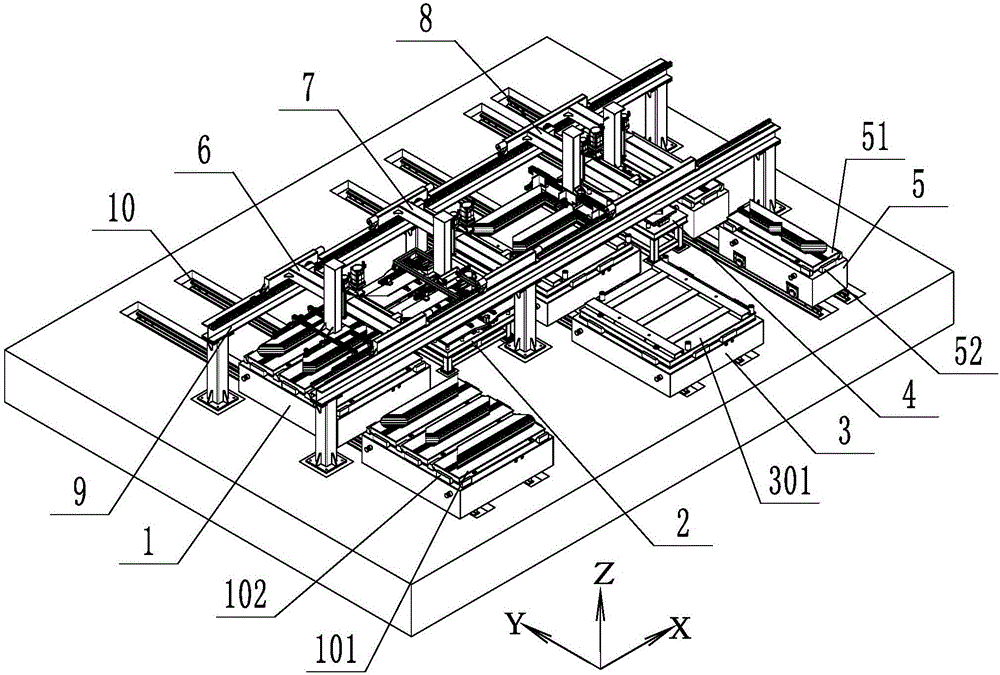

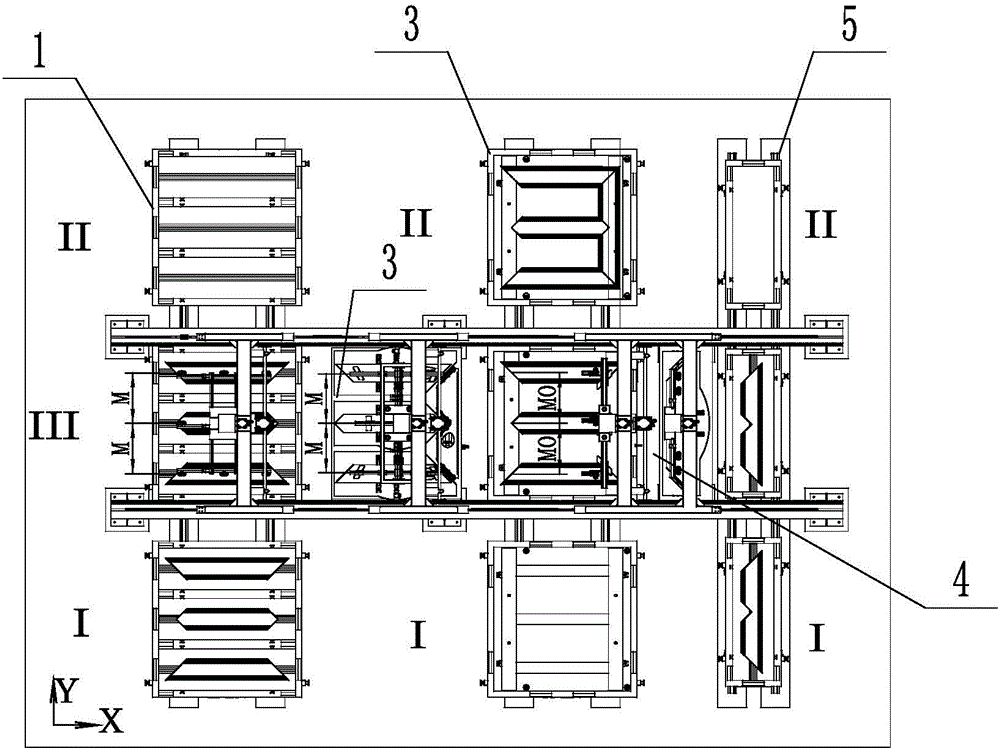

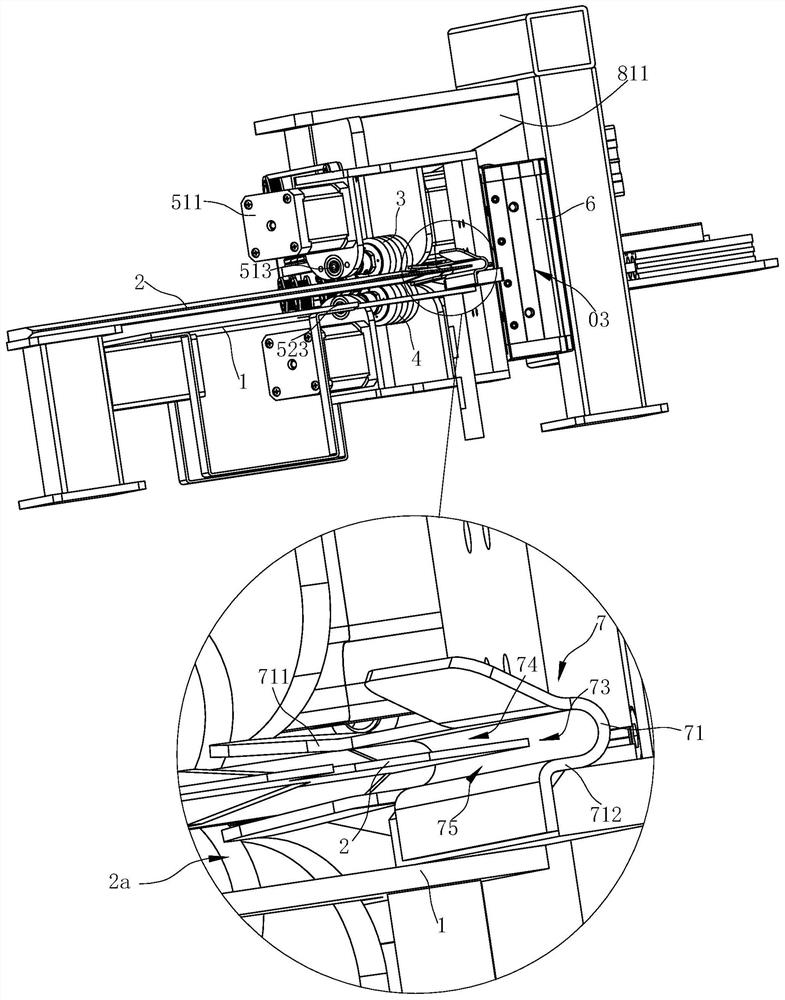

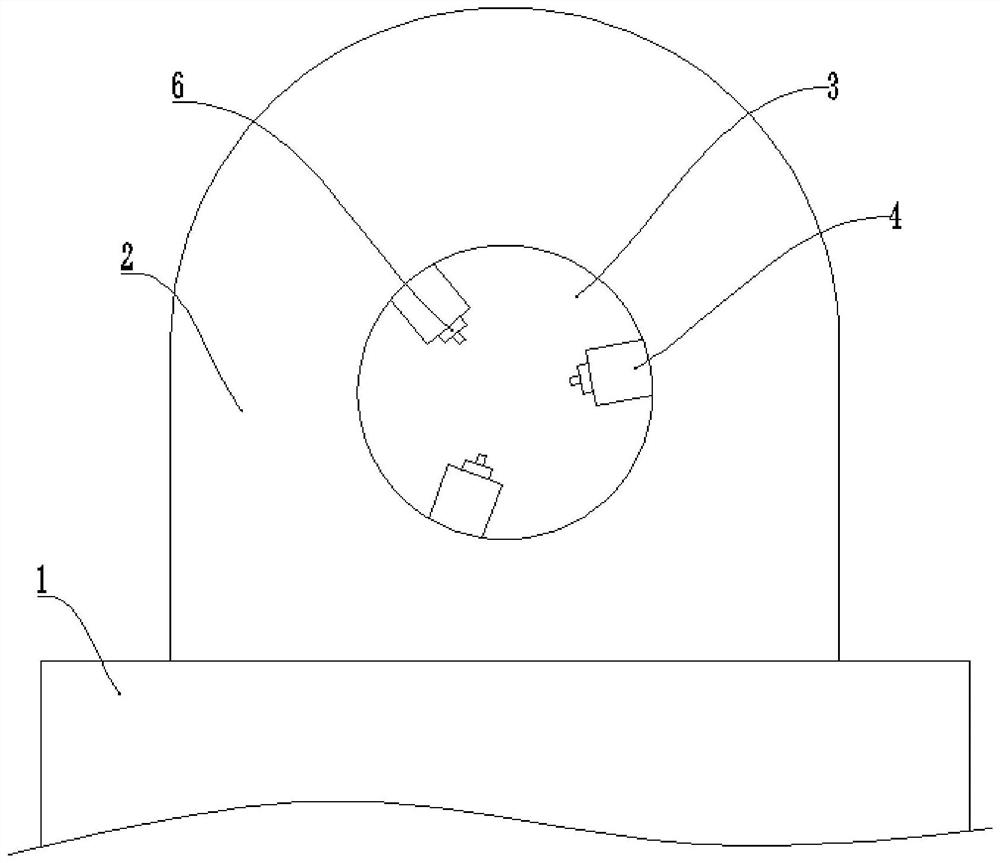

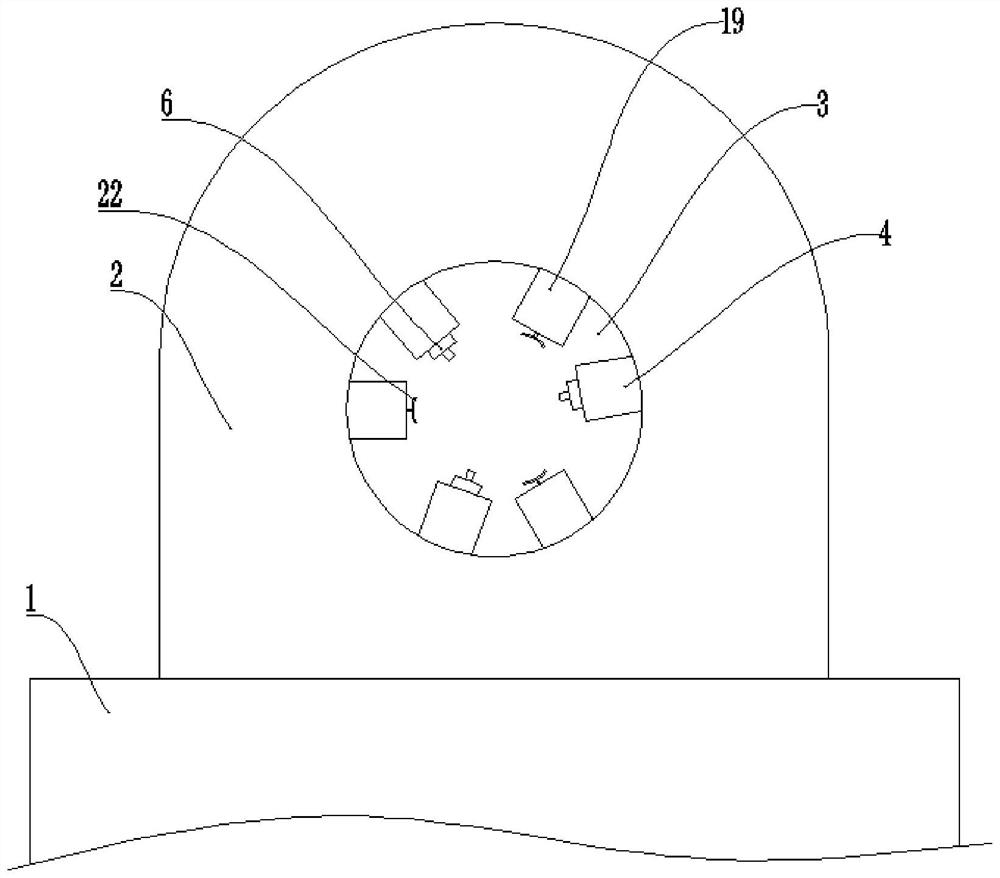

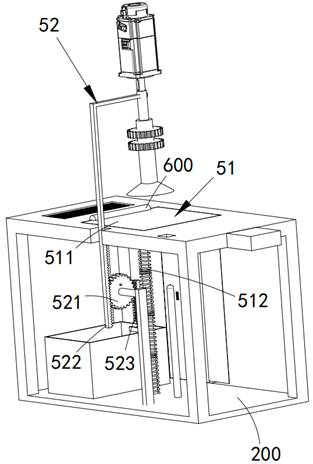

Automatic transformer iron core stacking system

ActiveCN106697973AGuaranteed alignmentIncrease productivityStacking articlesDe-stacking articlesChinese charactersTransformer

The invention discloses an automatic transformer iron core stacking system which comprises a preparation station I area, a turnover station II area and a work station III area, and the preparation station I area and the turnover station II area play corresponding roles alternatively. The work station III area comprises a three-pillar-piece single-layer automatic stacking system, a servo stacking opposite seaming mechanism and an extra-thin-piece X-axis Y-axis bidirectional centering platform. The work station III area is divided into a ground layer and an overhead layer, and the ground layer is provided with a pillar piece feeding station, a pillar piece centering station, a final assembly station, a lower yoke piece centering station and a lower yoke piece feeding station in sequence in the X direction; and the overhead layer is provided with a pillar piece A mechanical arm, a pillar piece B mechanical arm and a lower yoke piece mechanical arm in sequence in the X direction. According to the automatic transformer iron core stacking system, when pieces are taken, whether multiple pieces are taken or not can be recognized automatically, and stacking of an iron core shaped like a Chinese character 'shan' can be completed according to requirements; and the automatic transformer iron core stacking system has the advantages of being high in efficiency and stable in quality, and a plenty of manpower can be saved.

Owner:JINAN AOTTO TECH

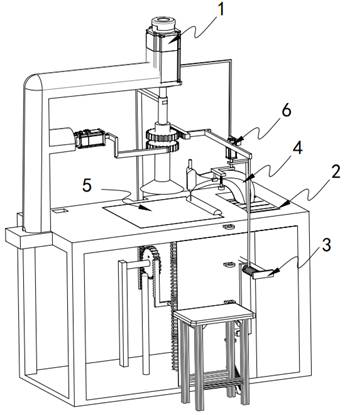

Joint cleaning and filling device

The invention discloses a joint cleaning and filling device. The device comprises a base, a joint cleaning device, a glue injecting device and a guide driving device; the joint cleaning device is arranged at the front end of the right side of the base, the joint cleaning device is used for cleaning sundries in a to-be-treated joint; the guide driving device is arranged at the rear side of the joint cleaning device. Accordingly, by adopting the guide driving device, the joint cleaning and filling device moves along ceramic tile joints, and in the moving process, by means of the cleaning deviceat the front end of the device, the sundries in the joint are preliminarily cleaned away; by means of the glue injecting device, filler injecting of the joint is achieved; the structure is compact, the time needed in the working process is greatly shortened, while all work is completed, the requirements on workers are low, and the work efficiency is better improved.

Owner:CHANGAN UNIV

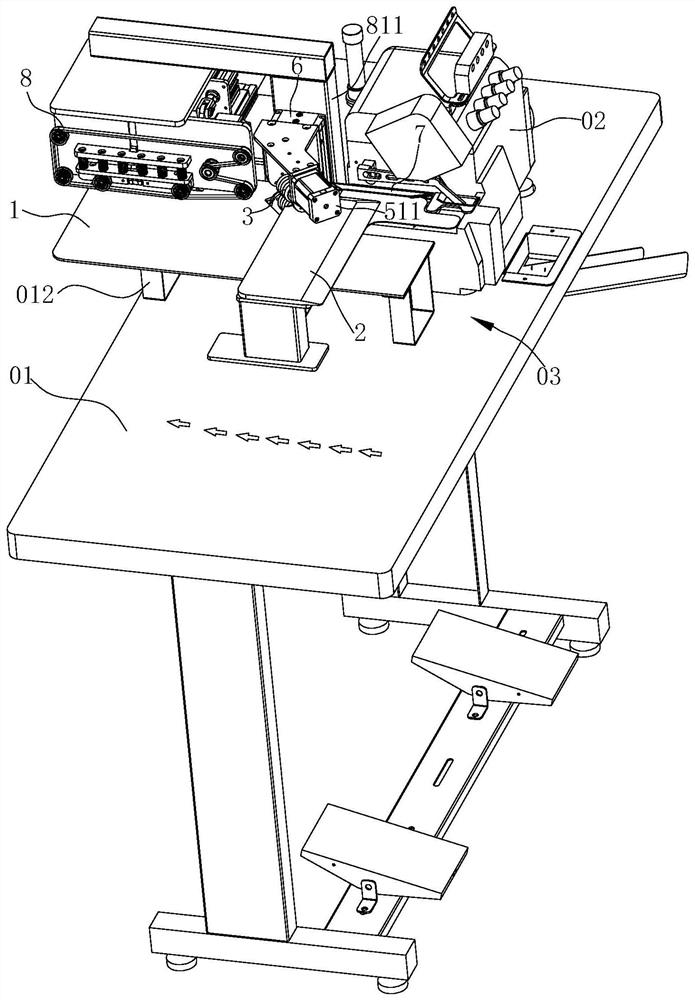

Efficient sock butend sewing machine rivaling manual butend sewing

ActiveCN107761262AReduce widthLow failure rateWork-feeding meansCombination sewing machinesIndustrial engineeringSewing machine

The invention discloses an efficient sock butend sewing machine rivaling manual butend sewing. The efficient sock butend sewing machine comprises a butend sewing motor for driving the sock butend sewing machine and a conveying motor for driving a sock conveying system; the efficient sock butend sewing machine is characterized in that the sock conveying system comprises a front-section conveying system body, a rear-section conveying system body, a butend sewing machine body, two machine heads and two lifting systems, wherein the butend sewing machine body, the two machines head and the two lifting systems are arranged on a mounting platform board. According to the efficient sock butend sewing machine rivaling manual butend sewing, the sewing width is small, the sewing speed ratio is adjustable, and the two machine heads share one center shaft, so that sewing lines of secondary sewing are highly consistent in coaxality.

Owner:ZHEJIANG ROSSO EQUIP MFG

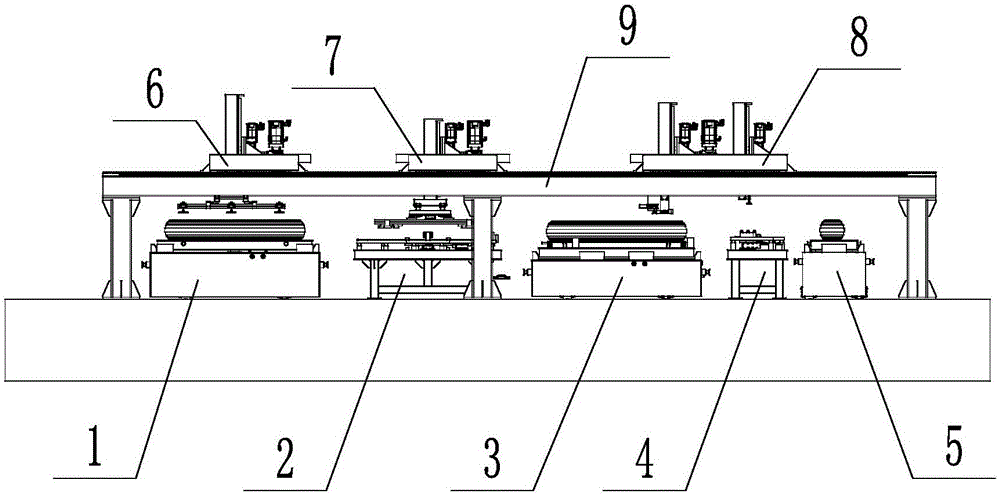

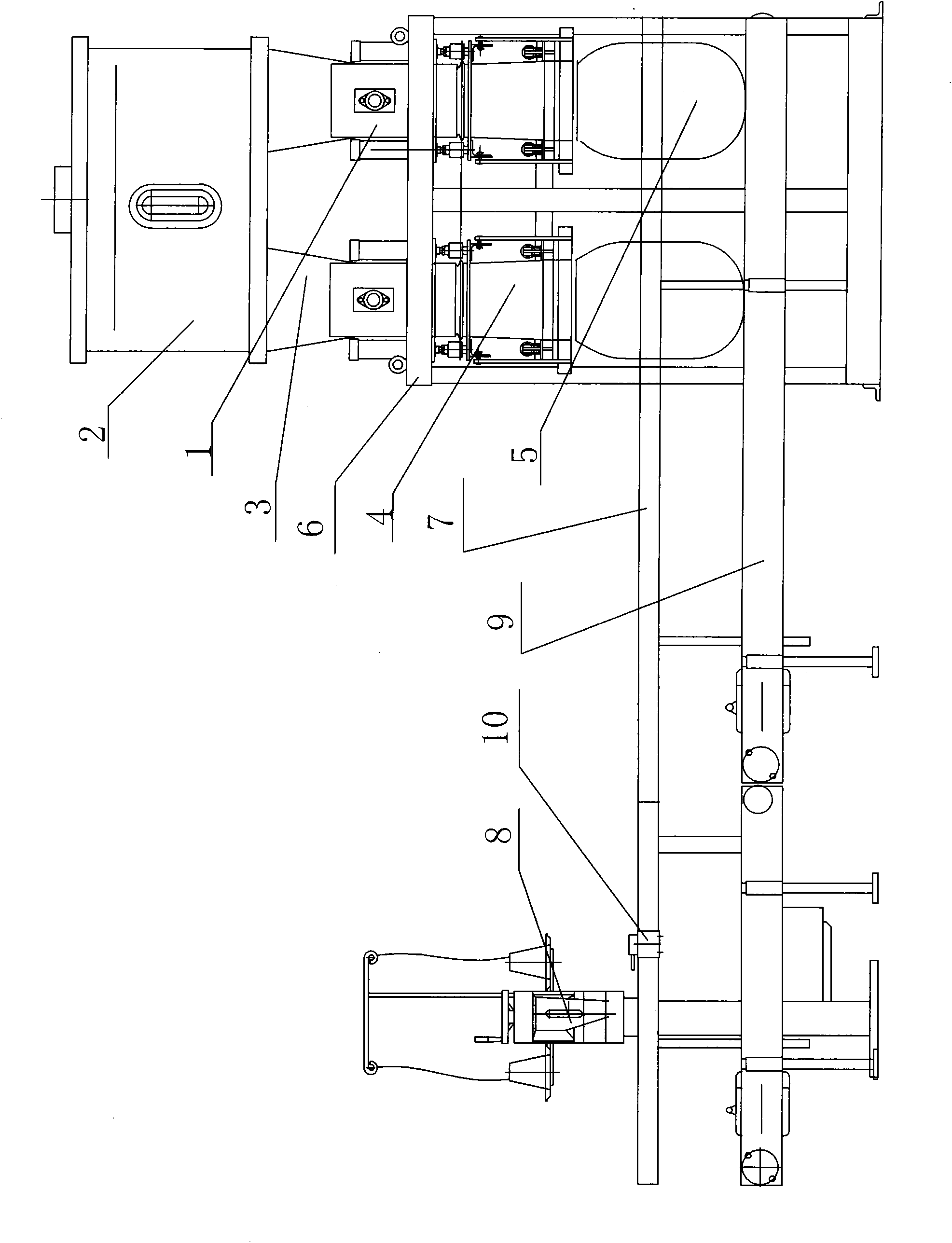

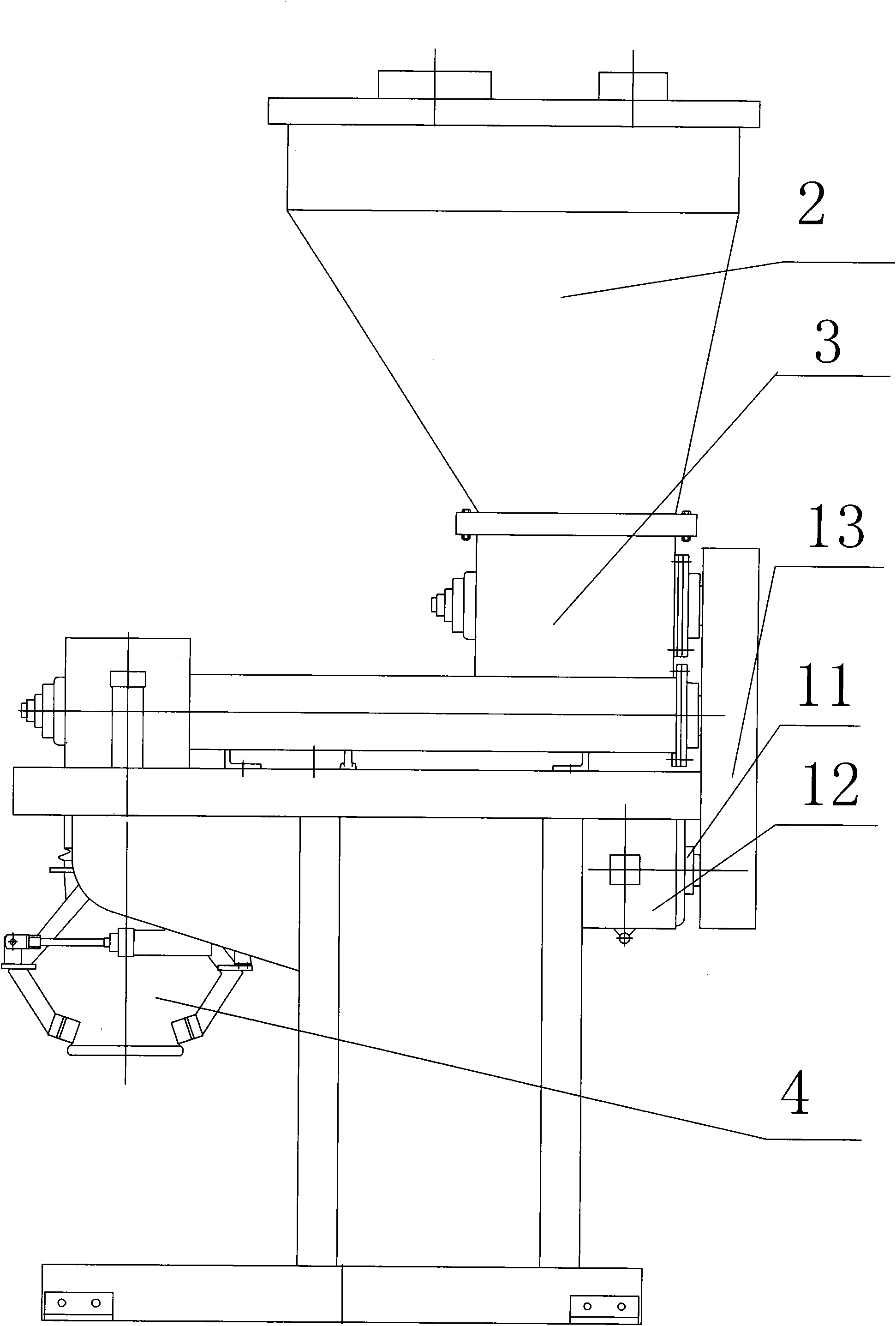

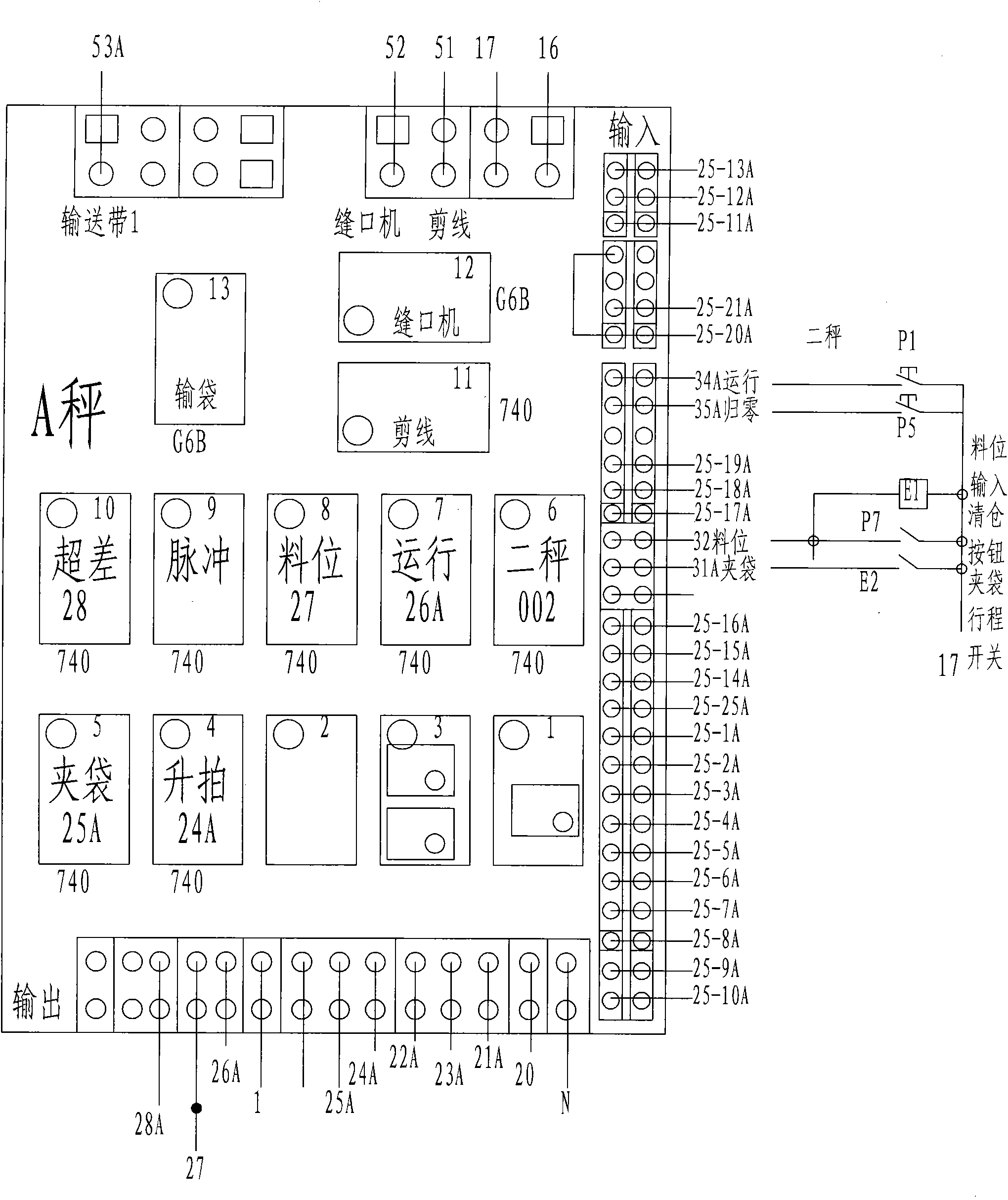

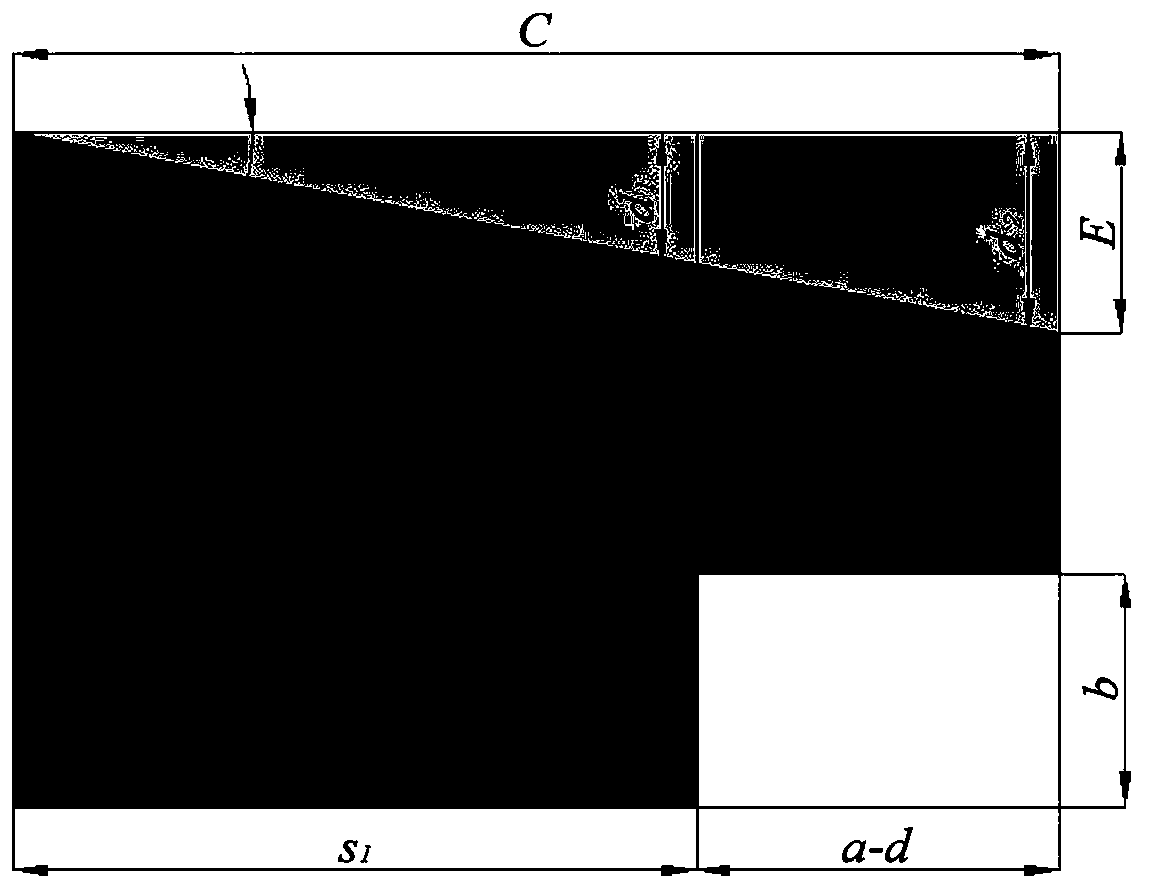

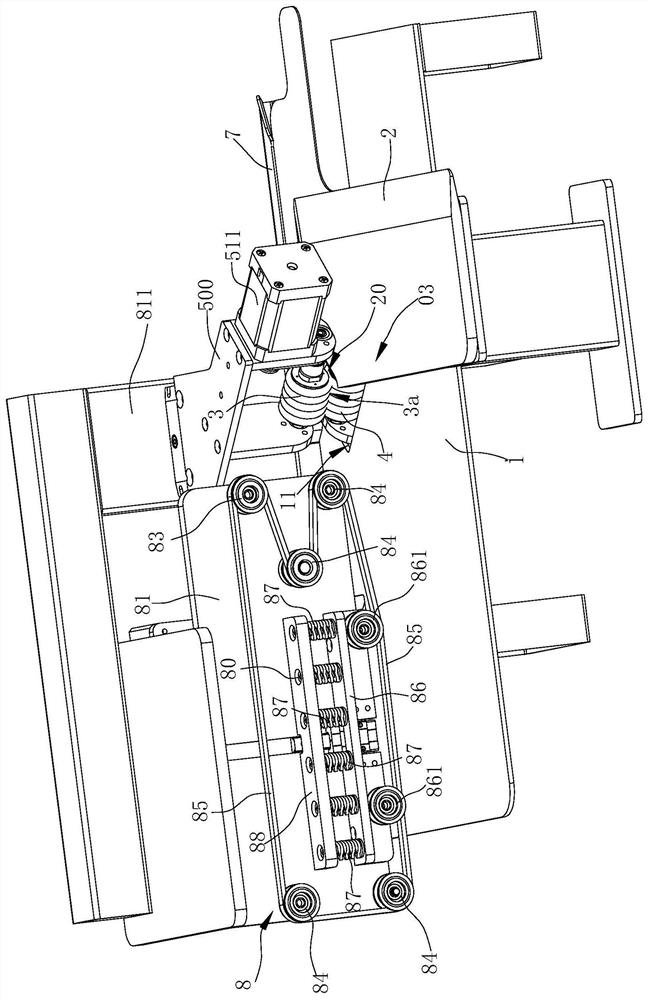

Double station flour packing machine and packing method thereof

ActiveCN101934870ASmall footprintAccelerateWrapper twisting/gatheringPackaging automatic controlPower unitSingle station

The invention relates to a double station flour packing machine and a packing method thereof. The existing flour packing machine is in single-station type and double-station type, the single-station type packing machine is low in working efficiency, the double-station type packing machine is complex in mechanical structure, and two sewing machines are adopted, cost is high, working procedure is complex, operation is difficult, trouble is caused in the working procedure, and mechanism is difficult for maintenance when in failure. The double-station flour packing machine comprises a feed bin (2) provided with a power unit, the bottom of the feed bin is correspondingly connected with a pair of feeders (1) which are connected, the bottom of the feeder is correspondingly connected with a bag clamping mechanism (4), the bottom of the bag clamping mechanism is provided with a connecting port which is connected with a feed bag; the bag clamping mechanism is loaded in a frame (6), the frame is internally provided with a conveyer, and the conveyer (7) is connected with a sewing machine (8). The invention is used for double station packing of flour.

Owner:哈尔滨联科自动化技术开发有限公司

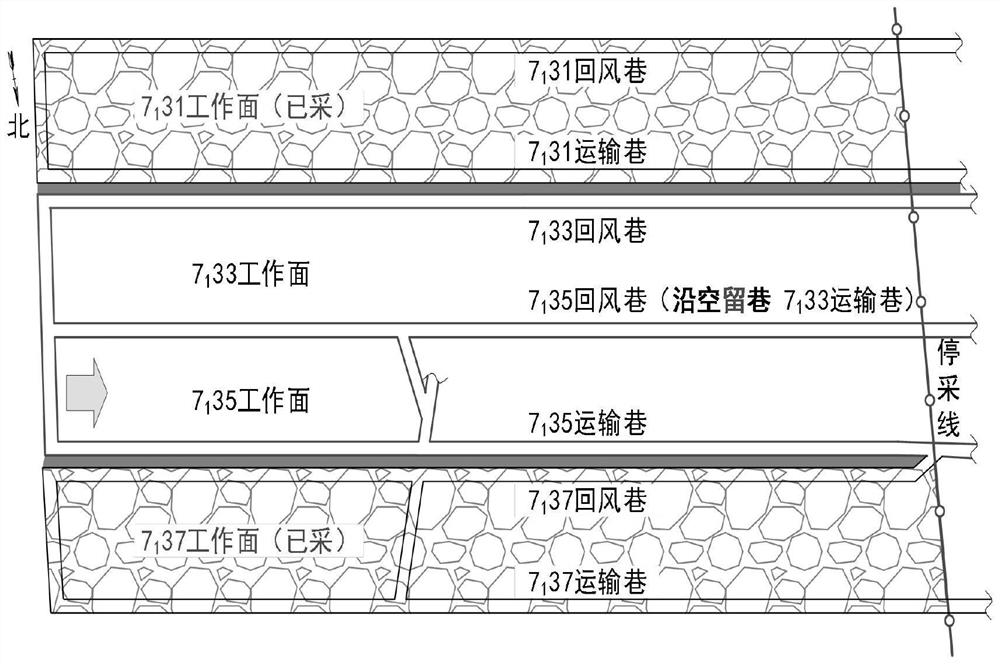

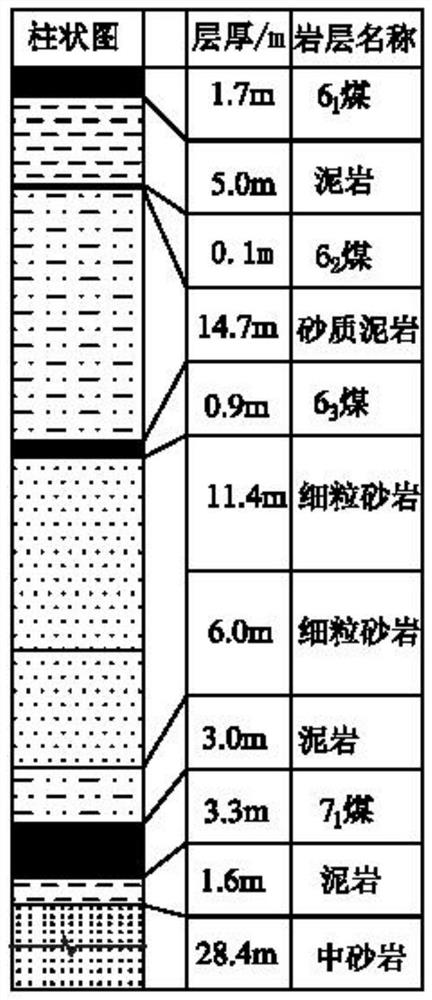

Topping method in small coal pillar exploitation technology

ActiveCN110644994AReduce labor intensitySimple processUnderground miningSurface miningMining engineeringStructural engineering

The invention discloses a topping method in the small coal pillar exploitation technology. The topping method includes the following steps that firstly, the overlying strata performance and the occurrence state of a certain roadway top plate are systematically analyzed according to a certain roadway early borehole columnar section provided by a mine party and a columnar section acquired in recentborehole detection, and multiple cutting positions are selected out; analysis of each cutting position on the stability of the certain roadway top plate and the stability of an adjacent roadway coal pillar is analyzed through theoretical calculation of the stability of the roadway top plate and the stability of the roadway coal pillar, and the cutting position is determined; and after the cuttingposition is determined, a KLJ7 chain arm topping machine is used for carrying out cutting along a determined cutting path. The cutting position of the roadway top plate is scientifically determined, equipment is reasonably operated, by means of a mechanical topping manner, cut seams are straight, cutting surfaces are smooth, and the unloading effect is ideal. By means of the topping manner, the problems that during exploding pre-splitting, cracks are obstructed, the cracks are twisted, and the caving resistance of the top plate is large are solved.

Owner:晋能控股煤业集团有限公司综采装备安装分公司

Treating method for light inner wall plate seam of building

The treating method for light inner wall board seam is to smear the mixture of atomic ash and special curing agent to the seam. The mixture has relatively high adhesion capacity, and using it in treating the seam will result in smooth wall surface without cracking. The said method may be used also in repairing fracture and other faults in light inner wall board in low cost. The present invention has the advantages of high treating effect, high construction quality and high construction efficiency.

Owner:葛福祥

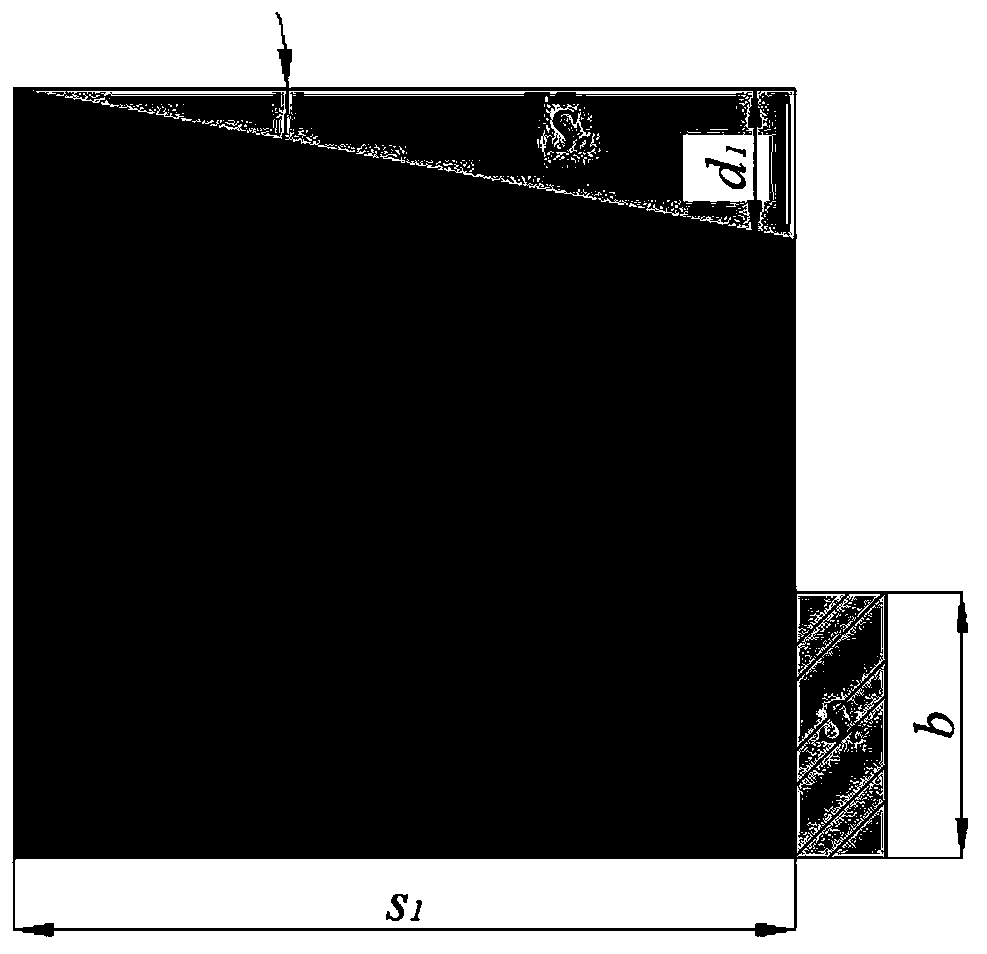

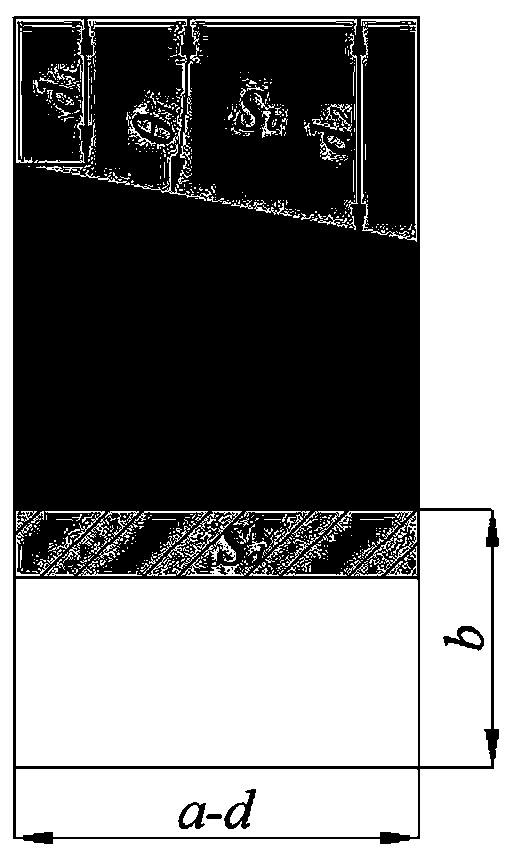

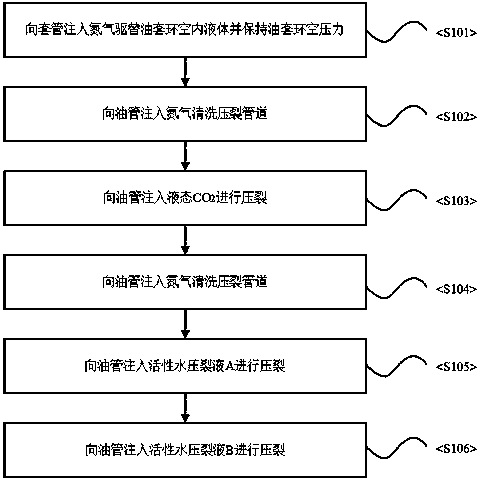

Coal bed gas-liquid CO2 and active water collaborative fracturing technique method

The invention provides a coal bed gas-liquid CO2 and active water collaborative fracturing technique method. The coal bed gas-liquid CO2 and active water collaborative fracturing technique method includes the following steps that (1) nitrogen is injected into a sleeve, thus liquid in the annulus of the oil sleeve is displaced, and the pressure in the oil sleeve annulus is maintained; (2) nitrogenis injected into an oil pipe to clean a fracturing pipeline; (3) liquid CO2 is injected into the oil pipe, and fracturing is conducted; (4) nitrogen is injected into the oil pipe to clean the fracturing pipeline; (5) an active water fracturing fluid A is injected into the oil pipe, and fracturing is conducted; and (6) an active water fracturing fluid B is injected into the oil pipe, and fracturingis conducted. According to the coal bed gas-liquid CO2 and active water collaborative fracturing technique method, the liquid CO2 and the active water are successively injected to fracture, advantages of two fracturing methods are provided, and the fracturing transformation effect of a coal reservoir is enhanced.

Owner:SOUTHWEST PETROLEUM UNIV

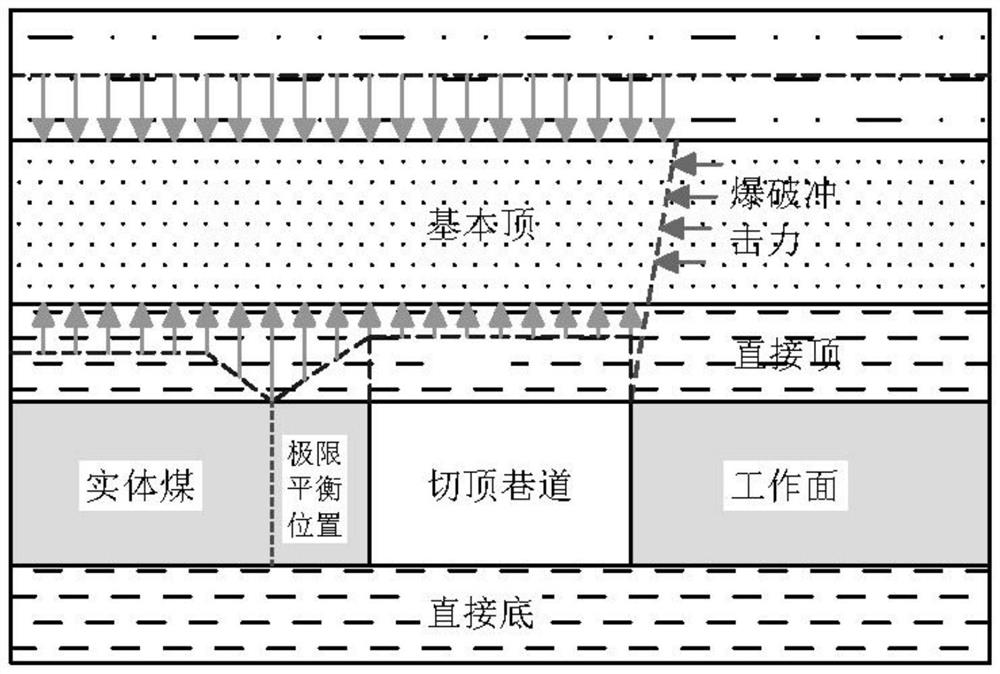

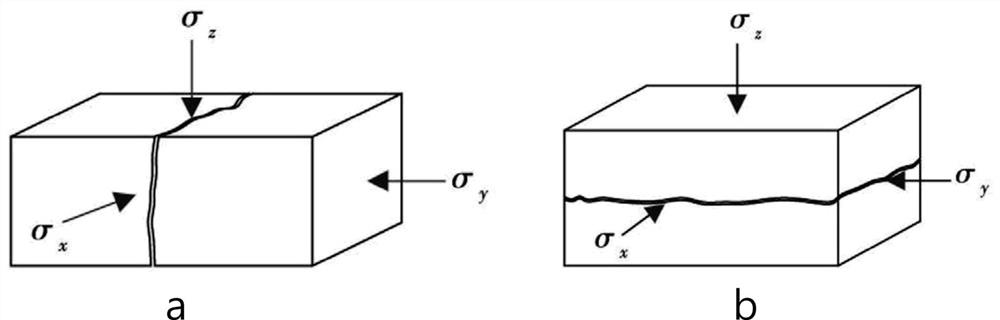

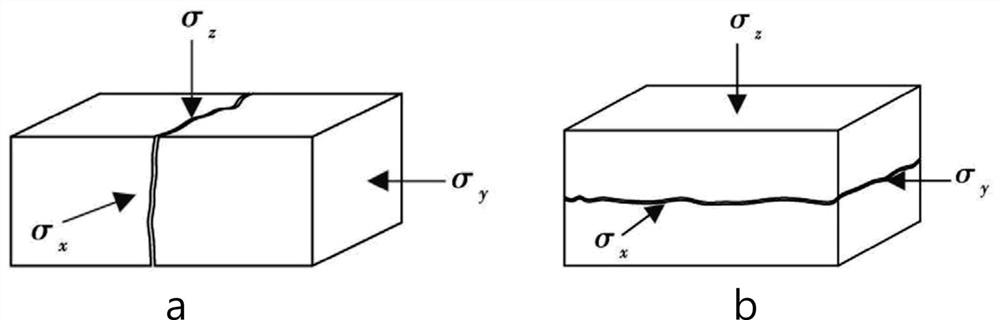

Method for calculating explosive amount in coal-pillar-free roof-cutting entry retaining pre-splitting blasting

ActiveCN112052574AGood seam effectAvoid casualtiesSustainable transportationBlastingTEX-explosiveMechanical models

The invention relates to the technical field of coal mining blasting, and in particular relates to a method for calculating explosive quantity in coal-pillar-free roof-cutting entry retaining pre-splitting blasting. The method comprises the steps of 1 obtaining an expression of stress borne by a blast hole wall due to the fact that stress waves are gradually attenuated when being propagated in a rock body, and establishing a seam forming condition taking the tensile strength of the rock as a standard,and obtaining a theoretical expression of the minimum explosive quantity required by seam forming; and 2 considering the stability of the basic roof, establishing a basic roof mechanical model under the dynamic and static coupling effect, analyzing a basic top tensile stress field under the stress wave effect, and constructing a basic roof stability criterion taking the rock tensile strength as a standard to obtain a maximum explosive quantity theoretical expression under the condition ofensuring the stability of the basic roof. The method has the advantages that the maximum explosive load and the minimum explosive load which guarantee the stability of the roof and the joint cutting effect during blasting can be theoretically calculated, a theoretical basis for scientifically selecting the explosive loads and the blast hole spacing is established, and meanwhile, the safety of underground blasting operation is effectively improved.

Owner:EAST CHINA UNIV OF TECH

Tile extrusion type beauty sewing device for indoor decoration

The invention discloses a tile extrusion type beauty sewing device for indoor decoration. The device comprises a device body, the device body is provided with a base, a level instrument is arranged onthe base, the device body is provided with a glue bin, the top of the glue bin is provided with a motor, an output end of the motor is provided with a stirring paddle, a material discharging hopper is arranged at the lower portion of a heating cover, the bottom of the discharging hopper is provided with a fixing pipe, the bottom of the fixing pipe is provided with a rotating pipe, a glue outlet is formed in the bottom of the rotating pipe, the device body is provided with a pressing plate, the upper portion of the pressing plate is provided with a fixing plate, the middle of the fixing plateis provided with a pull rod, and the end portion, near a through hole, of the pull rod is provided with a clamping plate. The tile extrusion type beauty sewing device for indoor decoration is simple in structure, convenient to use, beauty sewing is efficiently carried out on the tiles, in the process of movement, the device maintains stability through the action of the pressing plate abutting on the tiles, the quality of the beauty sewing is improved, the stability of glue bleeding of the device body is ensued, the uniform glue exporting is ensured, the effect of the beauty sewing is improved,the use is convenient, and the practicability is strong.

Owner:陈钦先

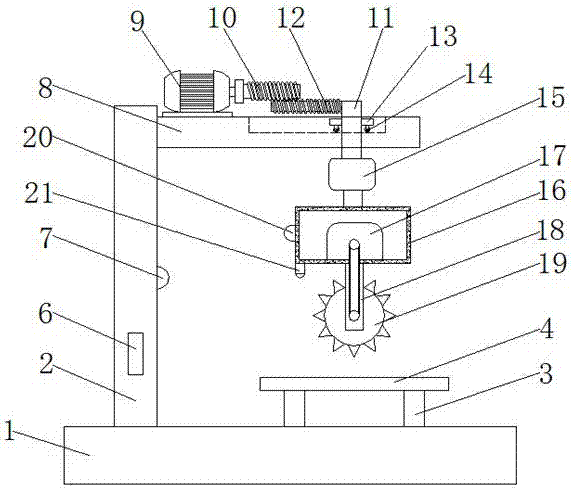

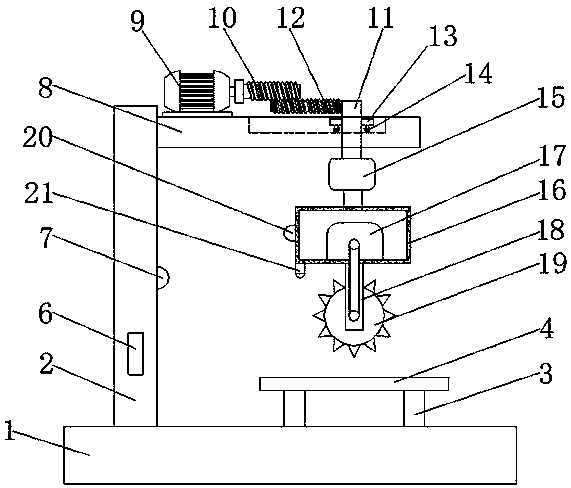

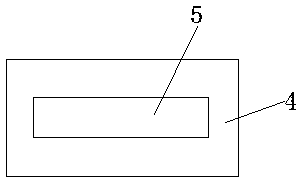

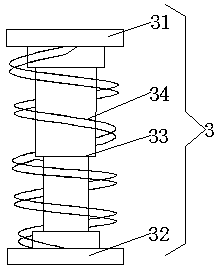

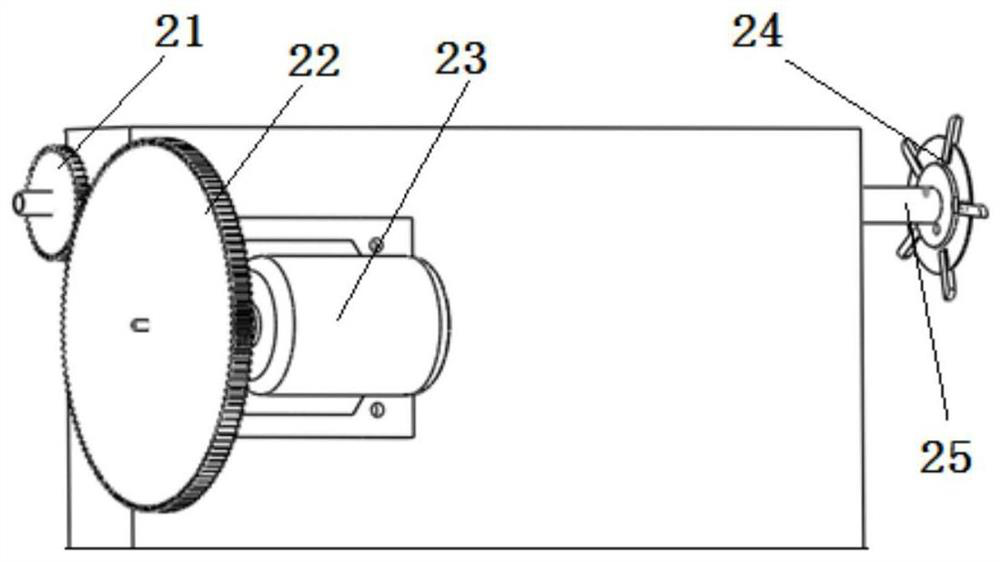

High-efficient carton seam cutting machine

ActiveCN106891572AGood seam effectImprove efficient cutting effectBox making operationsPaper-makingStopped workCarton

The invention discloses a high-efficiency carton slitting machine, which comprises a base. The top of the base is provided with a support plate and two support devices in turn from left to right. The top of the support device is fixedly connected with a workbench. The top of the workbench is provided with an elongated groove, the front surface of the support plate is fixedly installed with a controller, and the middle part of one side of the support plate is equipped with a first infrared sensor. In this high-efficiency carton slitting machine, the controller controls the first motor and the second motor to work, and under the action of the first screw, support rod, second screw, support block and roller, the adjustment effect of the slitting teeth is achieved. , through the combined use of the first infrared sensor and the second infrared sensor, when the first infrared sensor and the second infrared sensor trigger signals, the controller controls the cylinder to stop working, and under the action of the distance sensor, the The accuracy of cutting seams further improves the efficient cutting effect of cartons.

Owner:MACROSCOPIC CENTURY TIANJIN CO LTD

Double-cartridge blasting method and accurate positioning device as well as positioning method for charging

The invention provides a double-cartridge blasting method and an accurate positioning device as well as positioning method for charging. Through the double-cartridge blasting method and the accurate positioning device as well as positioning method, the asymmetric damage effect can be avoided, the damage to surrounding rock can be effectively reduced, and the construction efficiency can be improved. The double-cartridge blasting method comprises the following steps: step 1, blasting parameters are determined according to a single-cartridge blasting design method; step 2, the total charging quantity of each double-cartridge group is determined according to the double-cartridge charging quantity and corresponding double cartridges are selected; step 3, the cartridge center distance is determined, that is, the center distance between two cartridges in each double-cartridge group is set to be 1 to 2 times of the cartridge diameter; step 4, for each blasting hole, each double-cartridge groupis mounted by adopting the accurate positioning device for charging according to the diameter of the blasting hole and the cartridge center distance, the preset center distance between the two cartridges in each double-cartridge group is kept, and the two cartridges in each double-cartridge group are symmetrically arranged; and step 5, the mounting operation in step 4 is continuously performed according to the blasting parameters, the double cartridges are mounted in each blasting hole, and a trigger is arranged.

Owner:WUHAN UNIV OF TECH

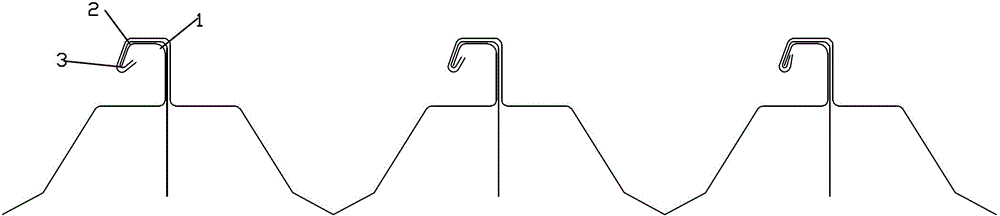

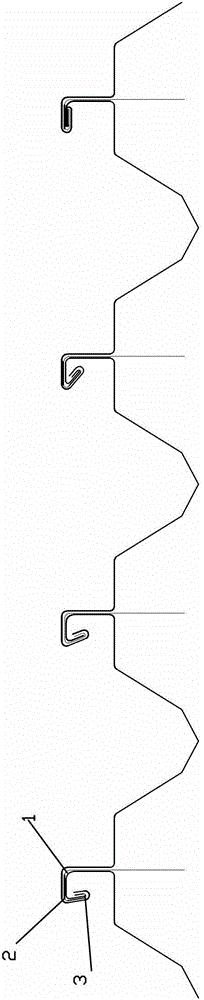

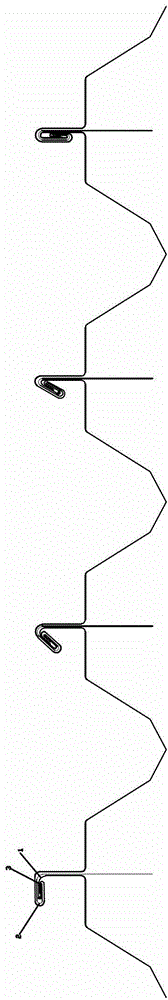

Metal roof panel whipstitching method

InactiveCN102877599AFully consider the mechanical propertiesNo damageRoof covering using slabs/sheetsStructural engineeringMechanical engineering

The invention relates to an operating method in the field of machinery, in particular to a metal roof panel whipstitching method. The metal roof panel whipstitching method comprises the following steps of: (1) setting an angle of 90 degrees in a part to be whipstitched of a metal roof panel as a first angle, inwards bending a transverse edge of the first angle to be a second angle of 110 degrees, and bending a longitudinal edge of the second angle to form a third angle of 0 to 5 degrees; (2) continuously bending the second angle of the part to be whipstitched to form an angle of 0 to 5 degrees; and (3) continuously bending the first angle of the part to be whipstitched obtained in step (2) to form an angle of 0 to 5 degrees. The metal roof panel whipstitching method is easy to operate and control and good in whipstitching effect.

Owner:绍兴精功环境科技有限公司

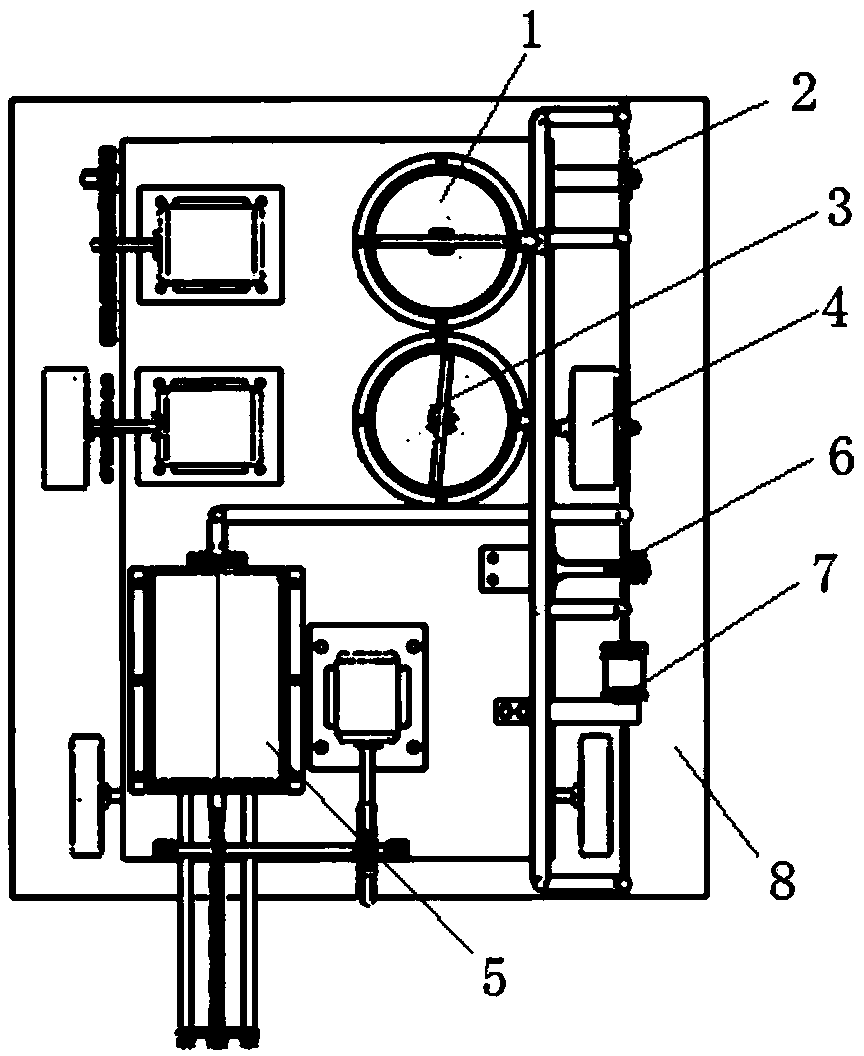

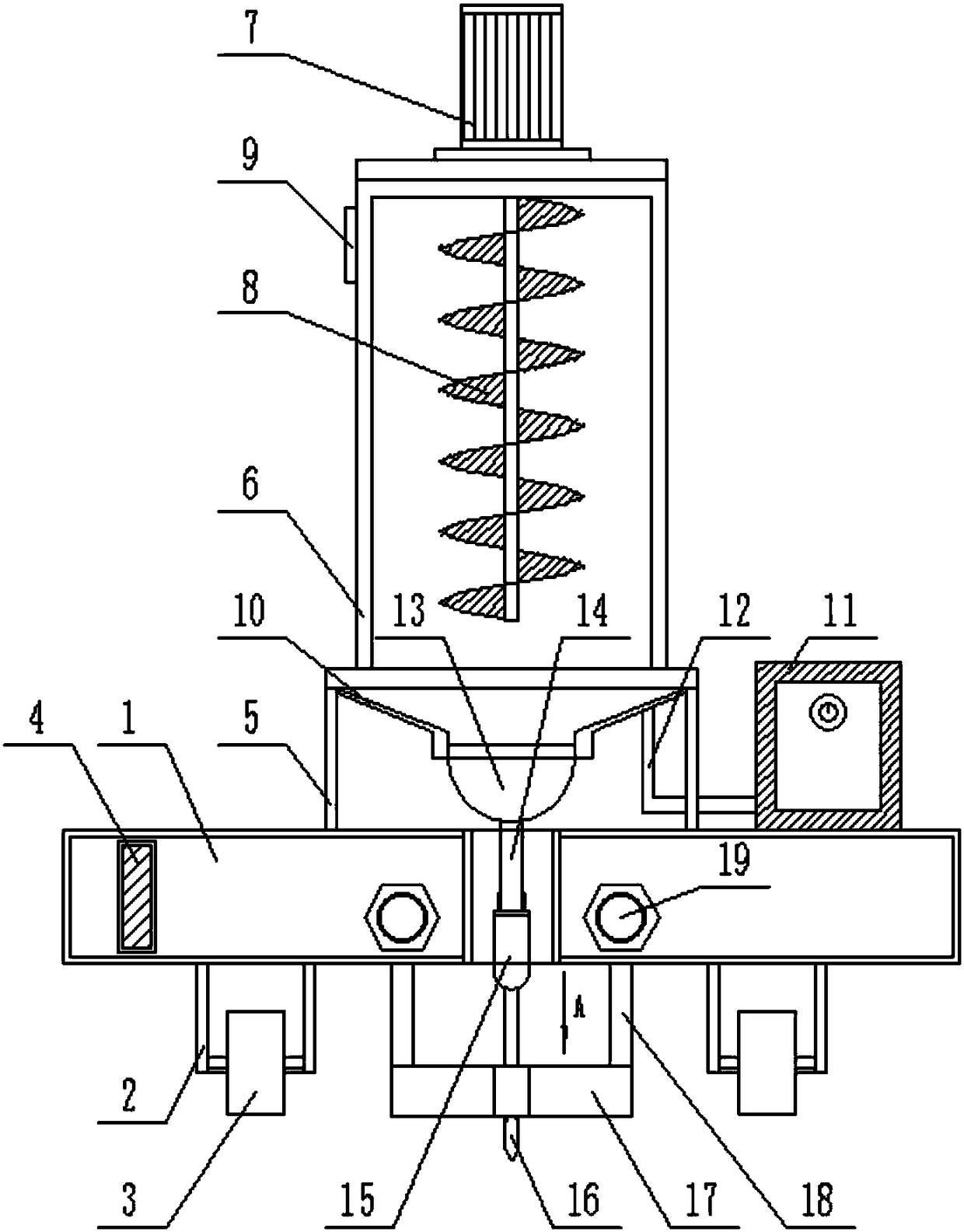

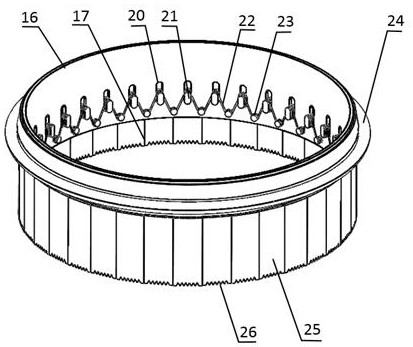

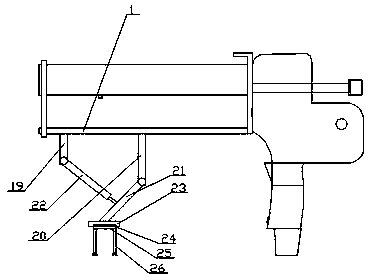

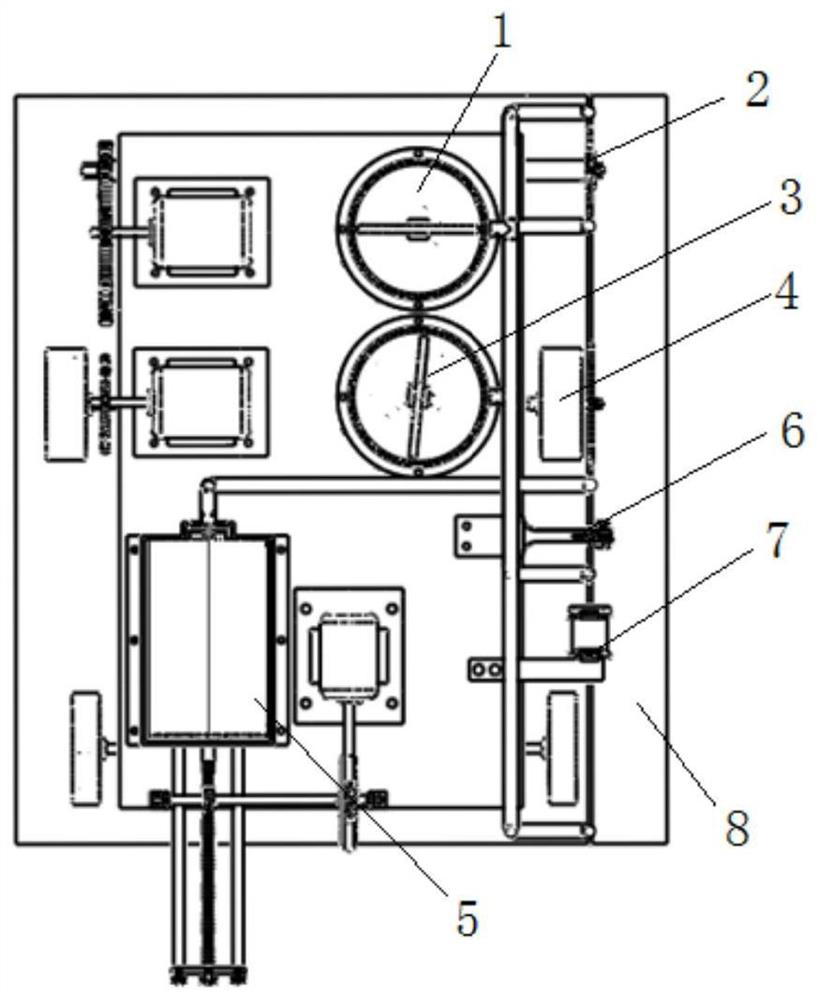

Soil carbon flux measurement device

ActiveCN110824140BStrong representativeStrong movement precisionEarth material testingMicrocomputerSample plot

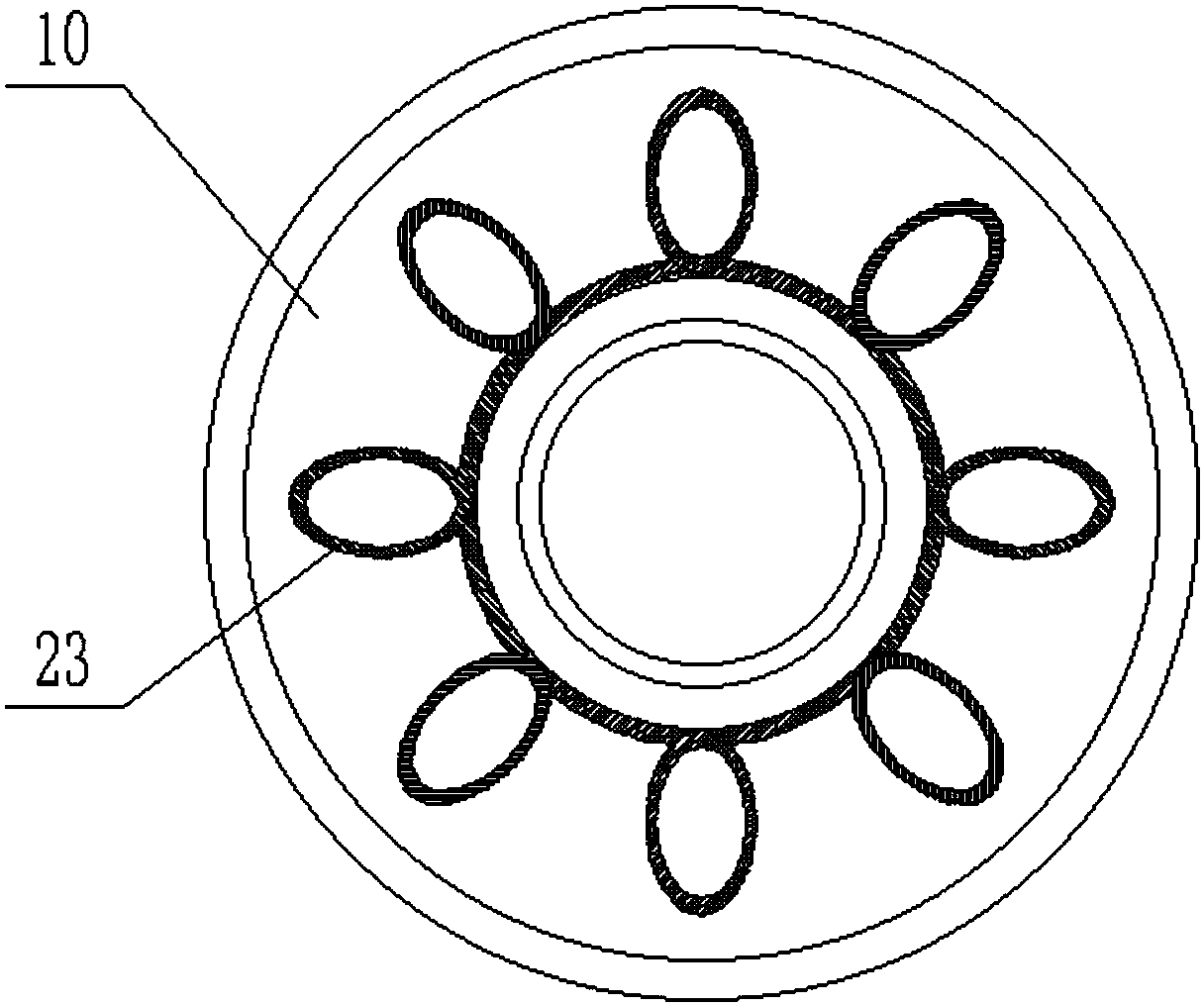

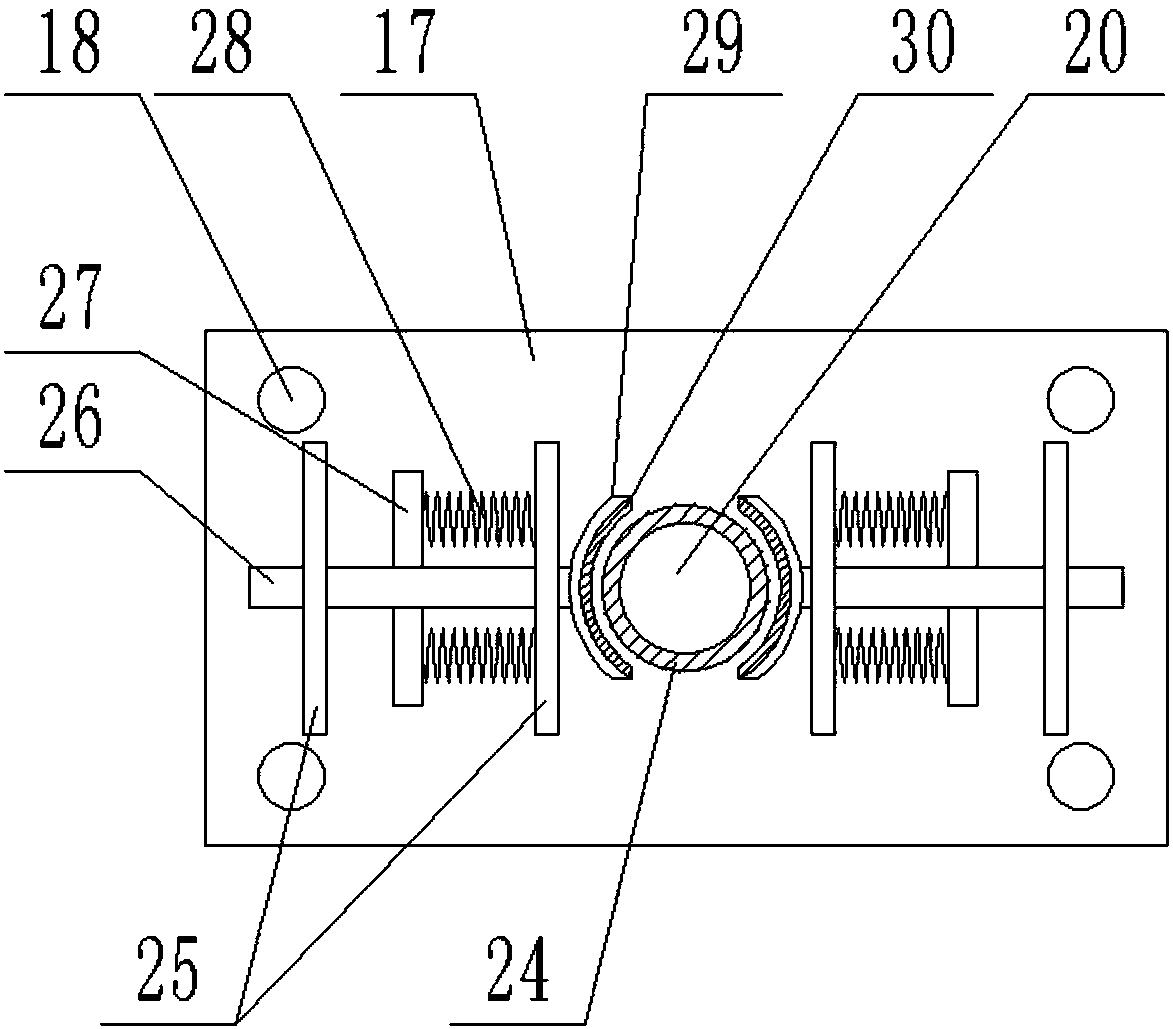

The invention discloses a soil carbon flux measuring device. The device comprises an air storage cylinder (7), a base (2), a rack (4), a movable air storage cylinder cover (12), a cylinder cover lifting device (13), a cylinder cover translation device (15), a sensor, a display and a system control microcomputer, an air storage cylinder is formed by combining an upper fixed cylinder body (16), a lower movable cylinder body (17) and a thin elastic sleeve (24) sleeving the two cylinder bodies, the lower movable cylinder body is defined by a plurality of arc-shaped surface sliding pieces which arelongitudinally and circumferentially arranged, and each arc-shaped surface sliding piece can be adjusted in an up-down telescopic mode along with unevenness of a sample plot. The device is speciallyused for measuring the carbon flux of the soil, and has the advantages of strong adaptability to the surface condition of the ample plot to be measured, high sealing performance, strong representativeness of collected and extracted sample gas, conformity to design requirements, low error and the like. Power transmission of translation or vertical lifting of the device is carried out under the two-dimensional condition, positioning is accurate, the joint closing performance is good, and faults and damage are not likely to happen.

Owner:ZHEJIANG FORESTRY UNIVERSITY

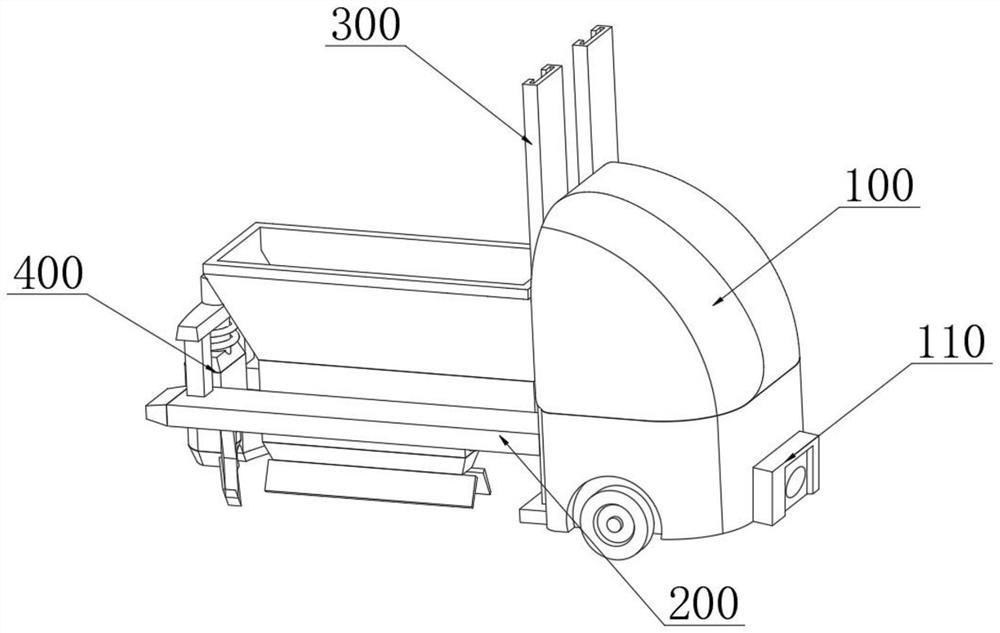

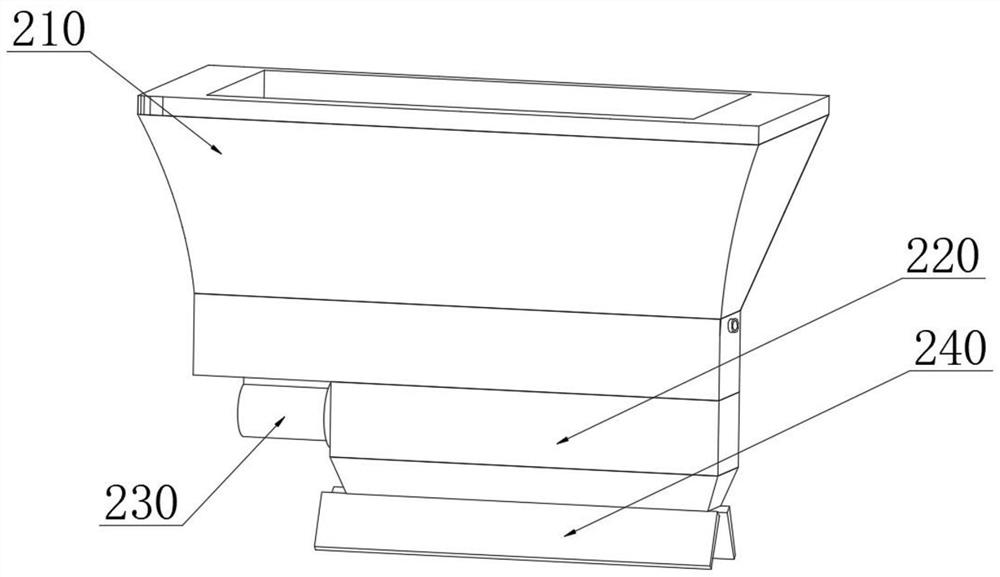

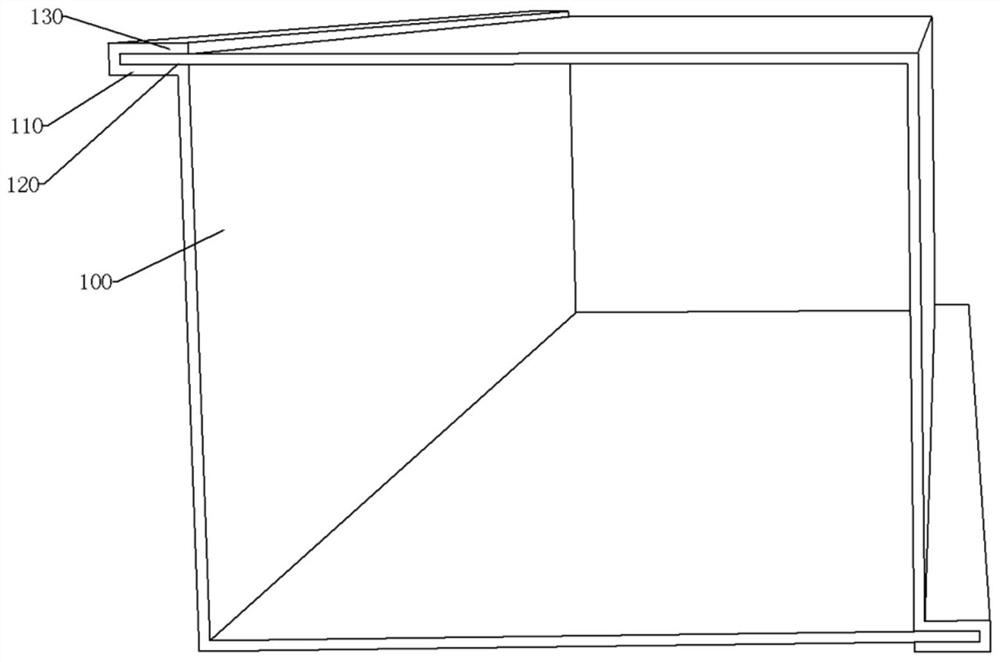

Automatic floor tile seam beautifying device for indoor decoration design

InactiveCN113846823AImprove work efficiencyHigh degree of automationBuilding constructionsAgricultural engineeringElectric machinery

The invention discloses an automatic floor tile seam beautifying device for indoor decoration design. The automatic floor tile seam beautifying device comprises an AGV moving vehicle body, a filling seam beautifying mechanism, a lifting frame assembly and a recycling and trowelling mechanism, the lifting frame assembly is fixedly mounted on one side of the AGV moving vehicle body, and a control module electrically connected with the input ends of the filling seam beautifying mechanism, the lifting frame assembly and the recycling and trowelling mechanism is arranged in the AGV moving vehicle body; and the filling seam beautifying mechanism comprises a seam beautifying filling hopper, a material pressing bin, a driving motor and a protective rubber plate, and the bottom end of the seam beautifying filling hopper is fixedly connected with the top face of the material pressing bin. According to the automatic floor tile seam beautifying device for indoor decoration design, automatic filling and seam beautifying are carried out through the filling seam beautifying mechanism, guided seam filling is carried out through the AGV moving vehicle body, automatic seam beautifying is carried out through driving glue filling of the filling seam beautifying mechanism under the directional movement of the AGV moving vehicle body, the automation degree of equipment is improved, integrated movable filling, trowelling and residual glue recycling are completed, and the working efficiency of seam beautifying of working floor tiles is improved.

Owner:江苏久之宸装饰工程有限公司

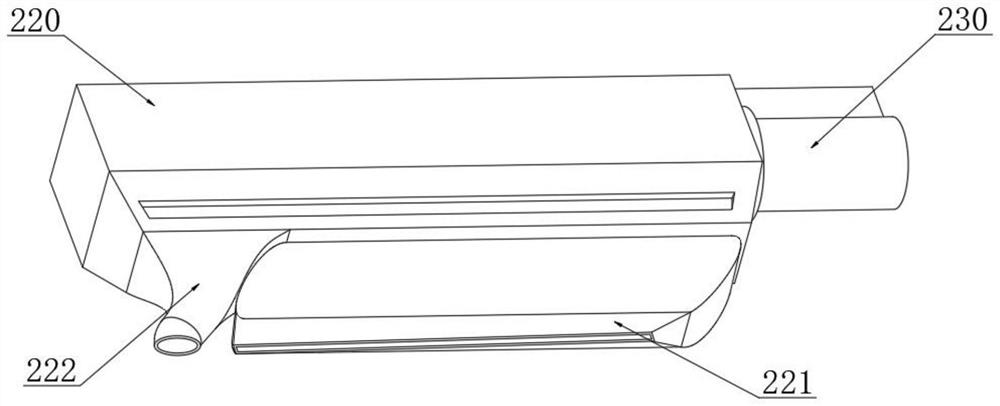

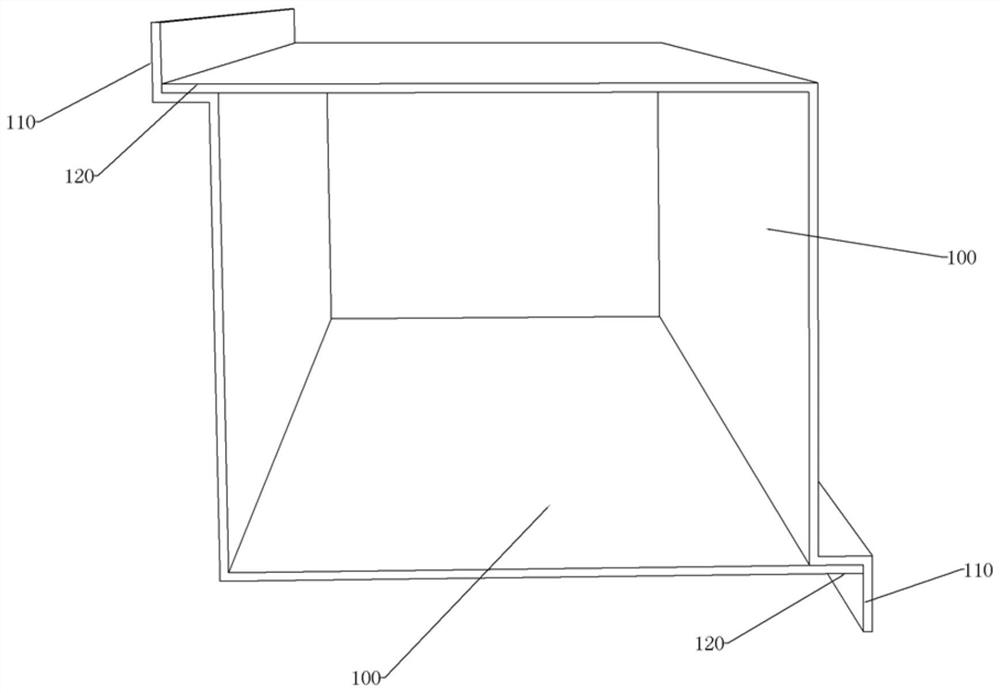

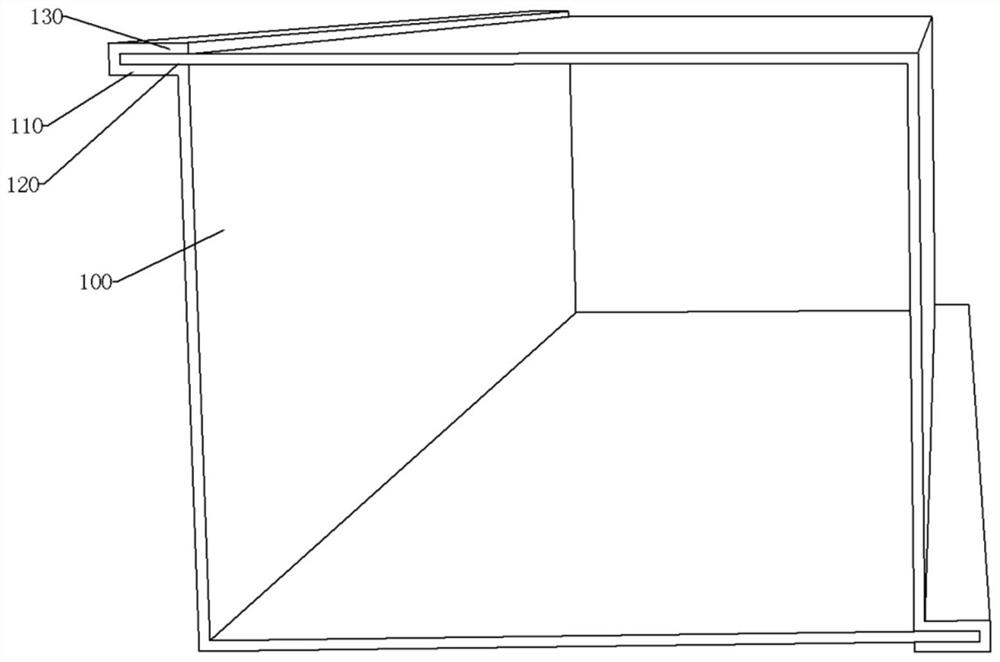

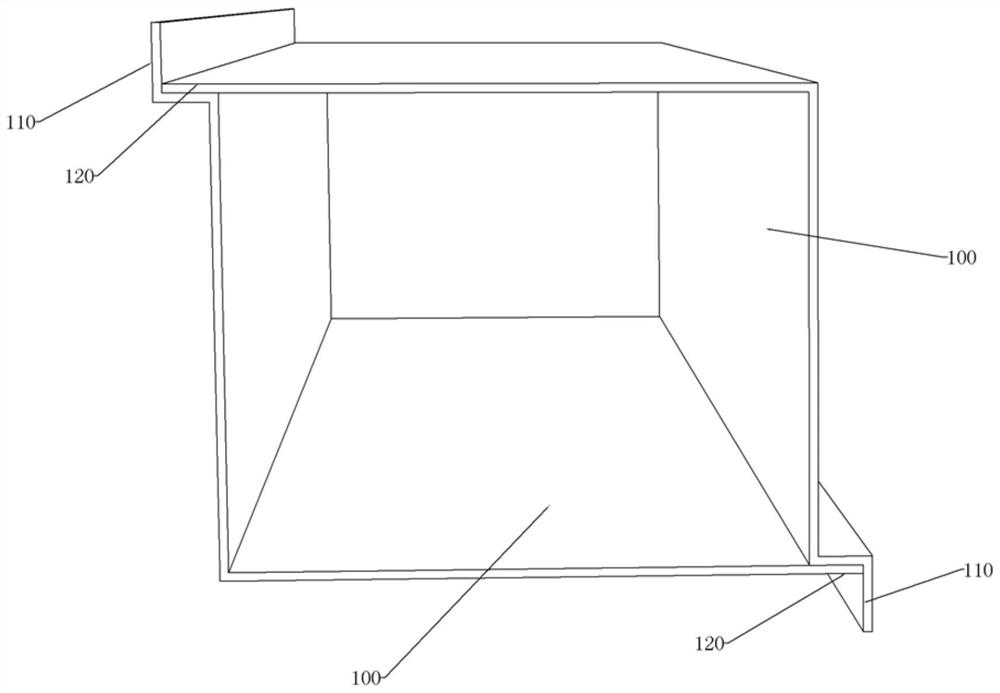

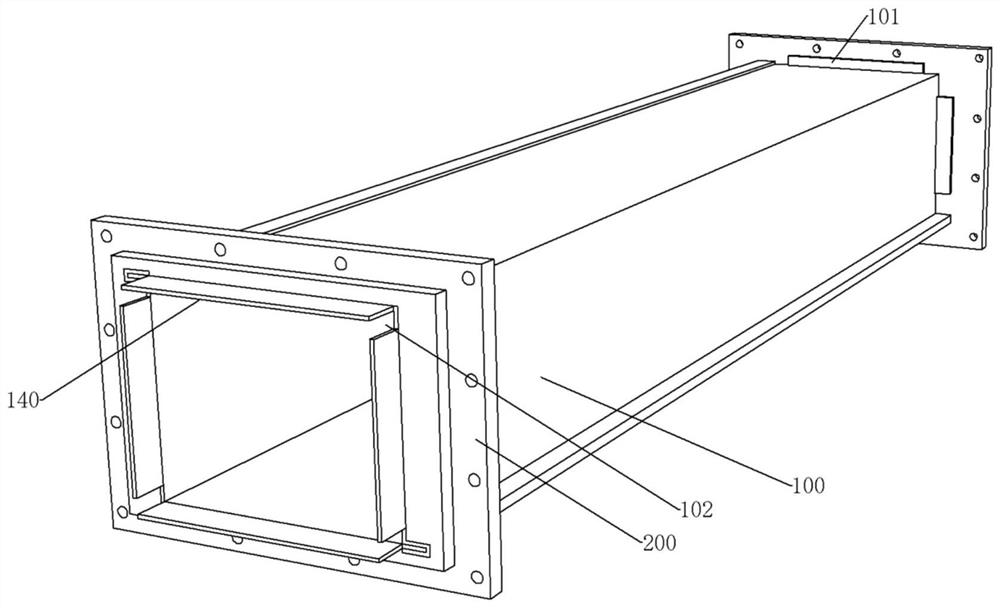

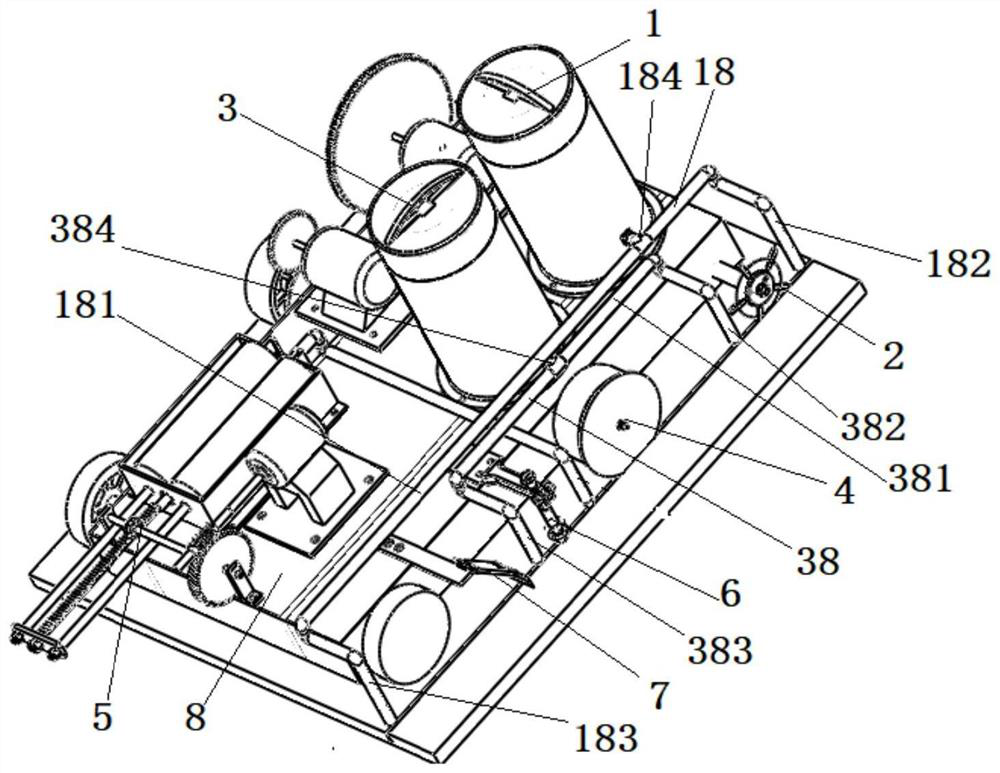

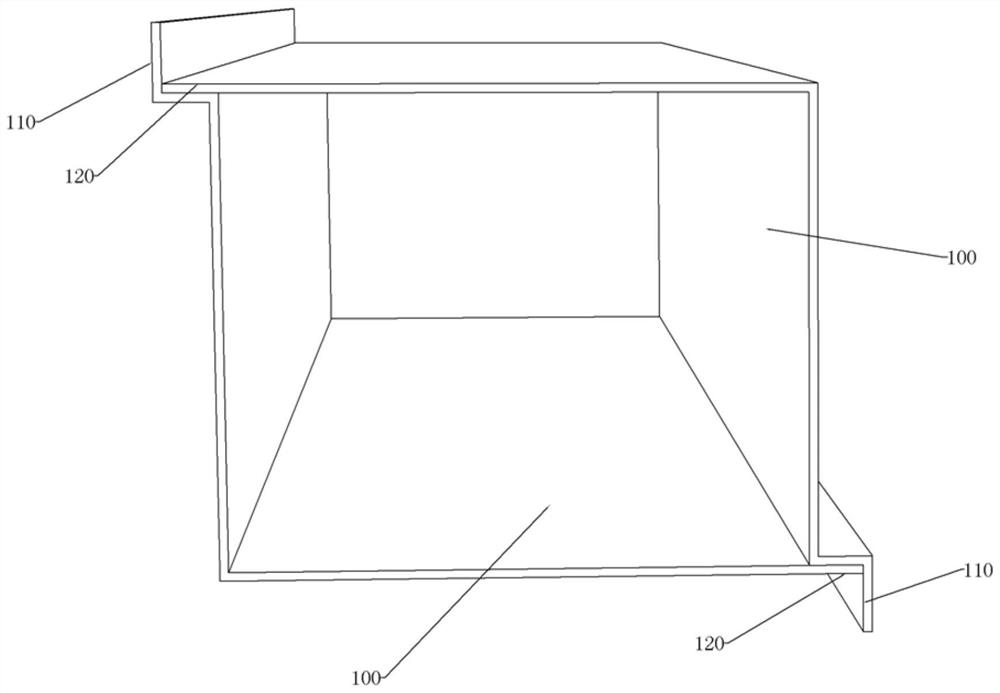

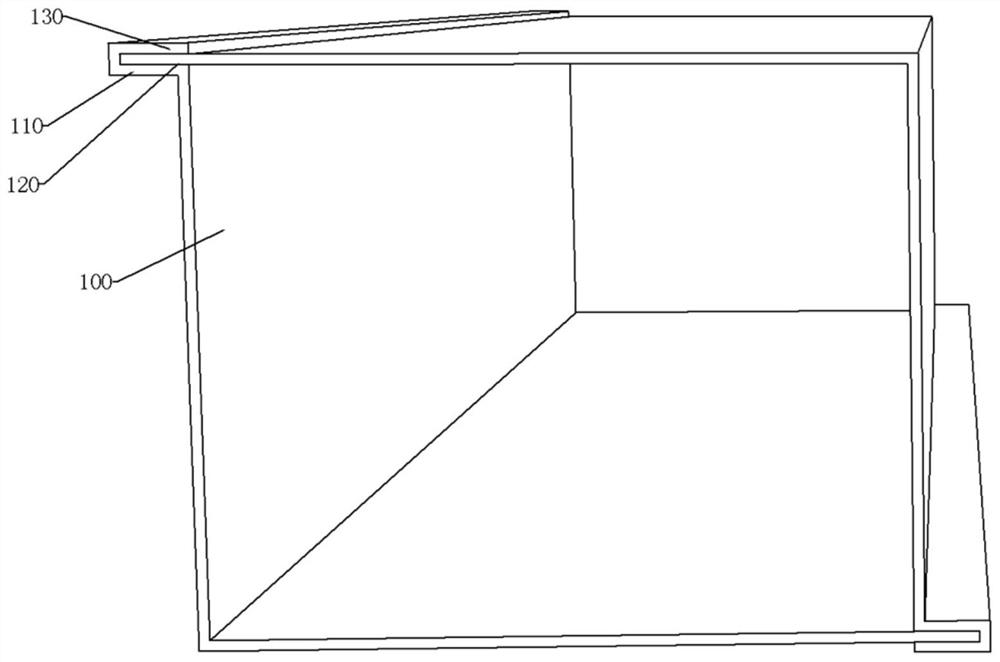

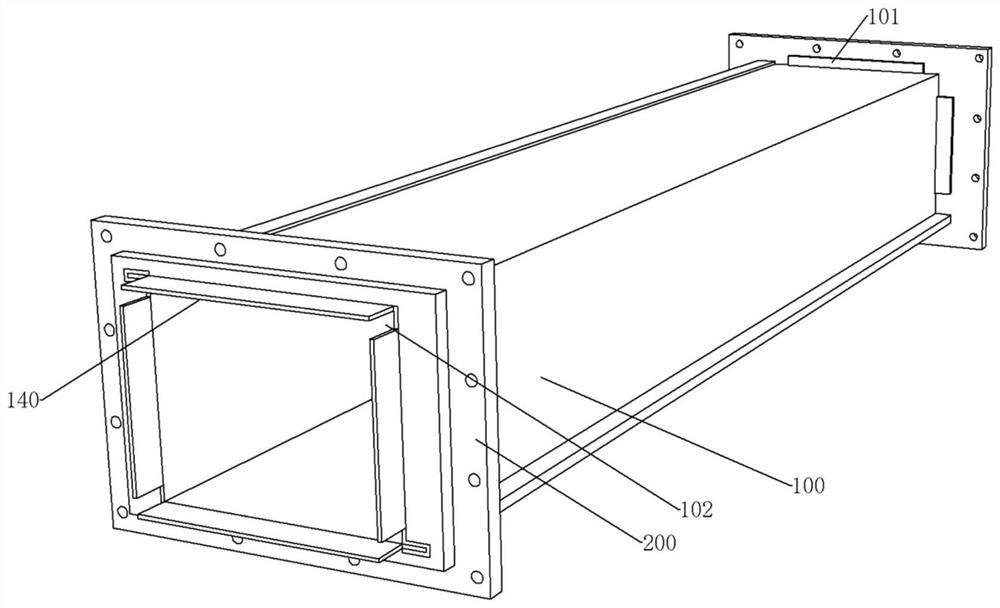

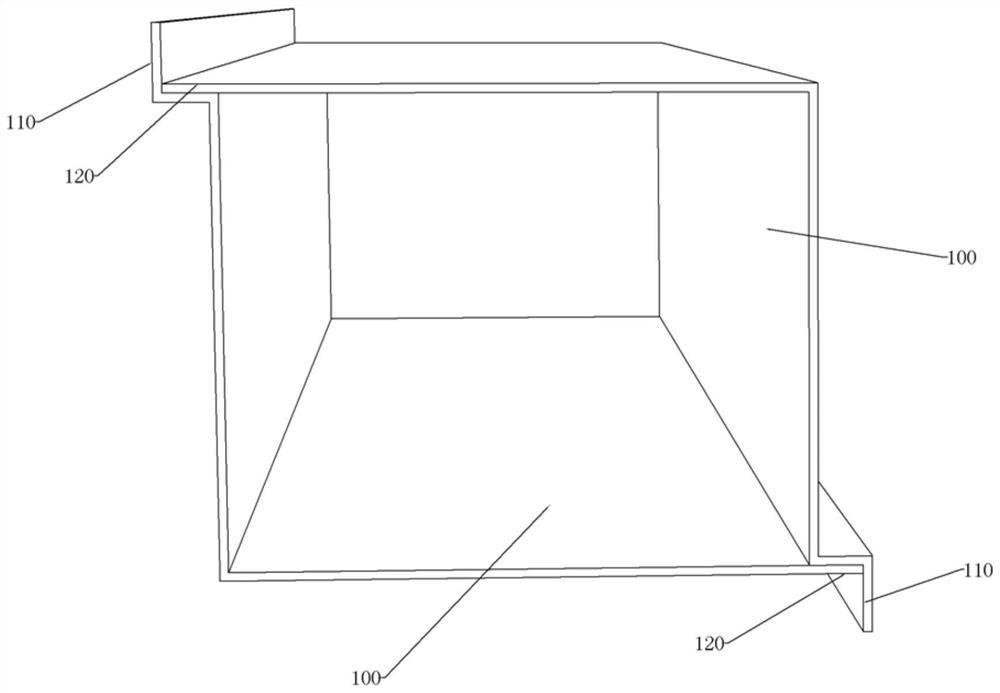

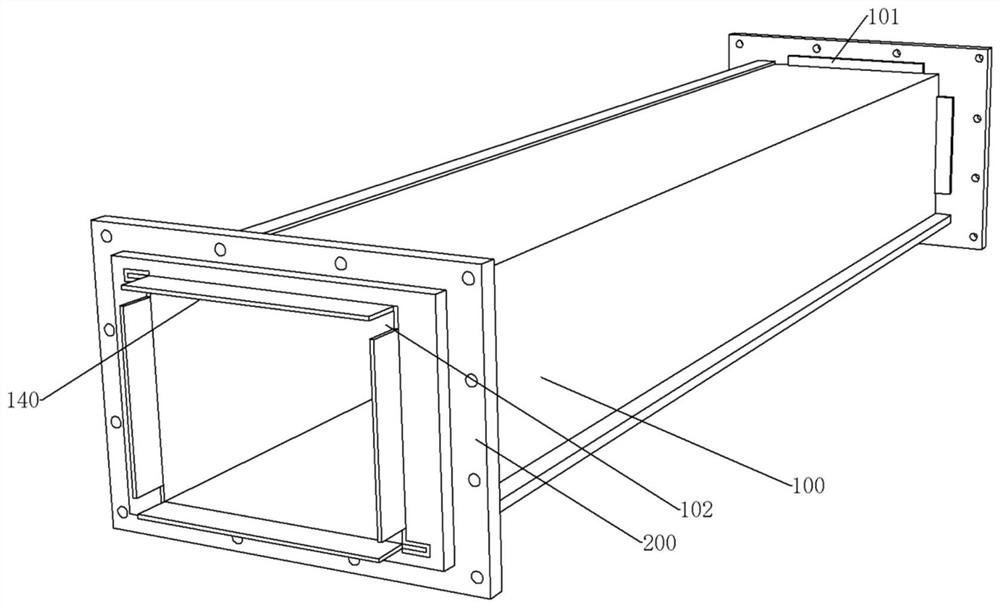

Flange installation module and fire-fighting air duct production line with flange installation module

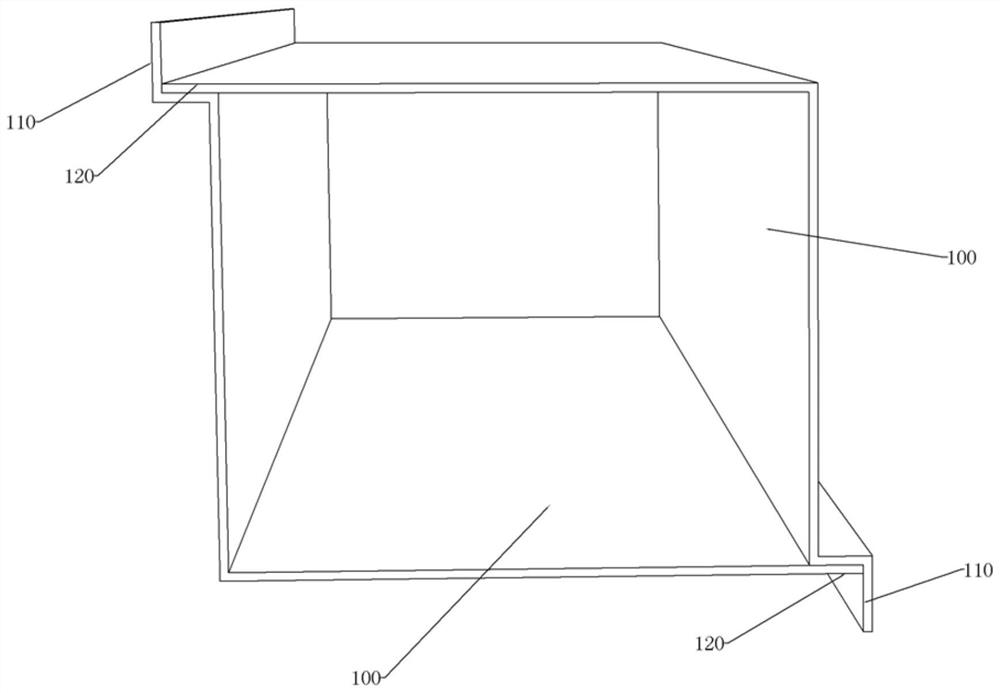

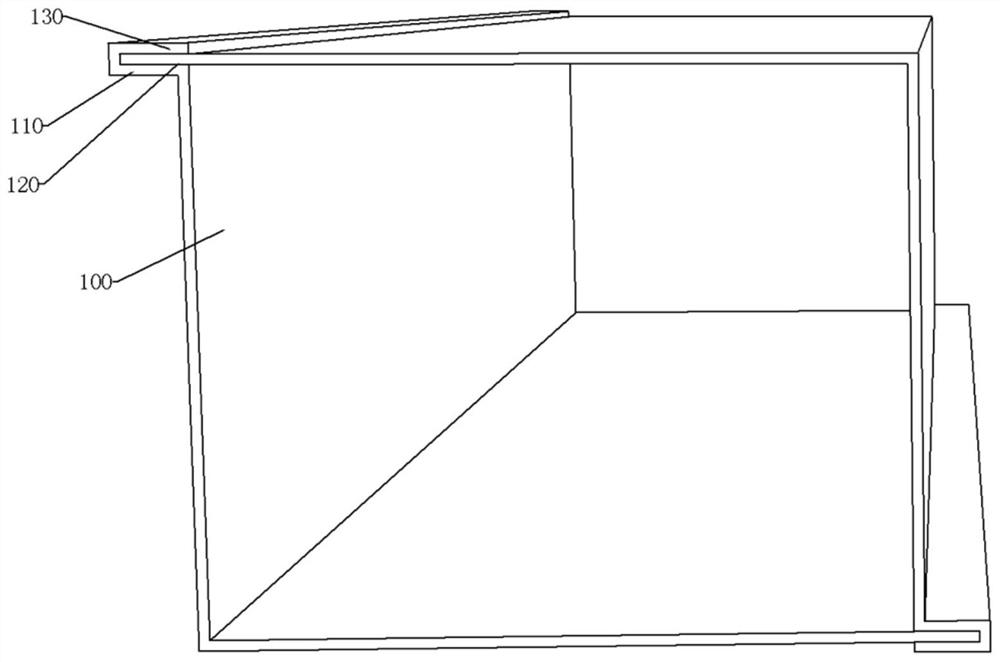

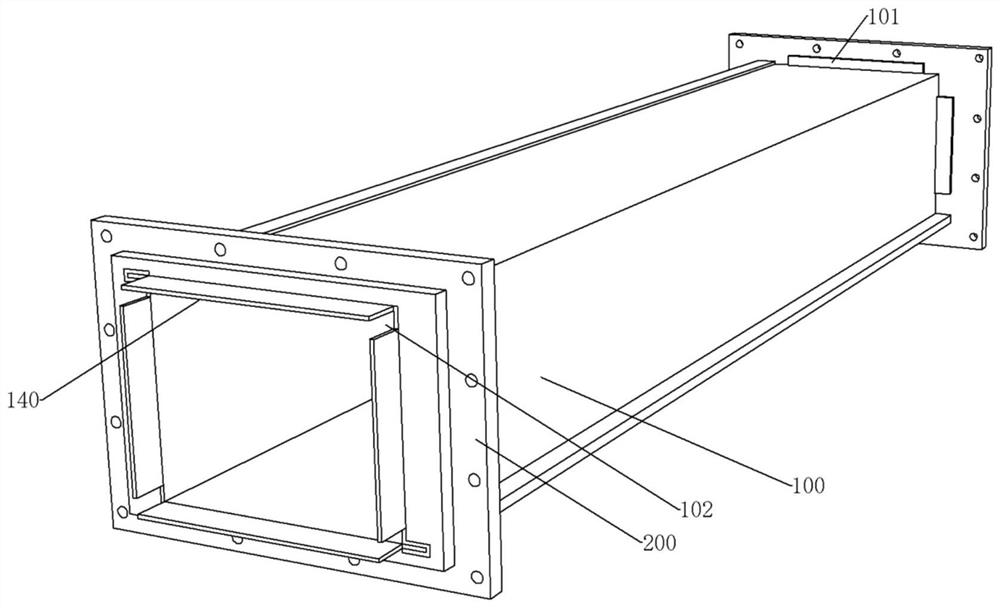

ActiveCN112008374ARealize automatic stitchingIncrease productivityMetal sawing devicesMetal working apparatusProduction lineIndustrial engineering

The invention discloses a flange installation module and a fire-fighting air duct production line with the flange installation module. The fire-fighting air duct production line with the flange installation module comprises a platform module, a detection module, a grooving module, a conveying module, a flange sleeving module and the flange installation module. The platform module is used for splicing and sewing a fire-fighting air duct, wherein the spliced fire-fighting air duct is 100-1, and the hemmed fire-fighting air duct is 100-2. The detection module is used for detecting the flatness ofa sewn first hemming part. The grooving module is used for cutting bending grooves in the two ends of the fire-fighting air duct correspondingly, and a second hemming part without hemming is obtained. The conveying module is used for clamping the sewn fire-fighting air duct through a clamping mechanism and conveying the fire-fighting air duct. The flange sleeving module is used for taking out flanges from the interior of a storage side plate and then respectively enabling the flanges to sleeve the two ends of the fire-fighting air duct. The flange installation module is used for hemming the second hemming part without hemming towards a clamping part so that the second hemming part can clamp and fixe the flanges between flange bosses and the second hemming part. According to the flange installation module and the fire-fighting air duct production line, automatic sewing, detection, flange sleeving and flange fixing of the fire-fighting air duct can be realized.

Owner:CHONGQING VOCATIONAL INST OF ENG

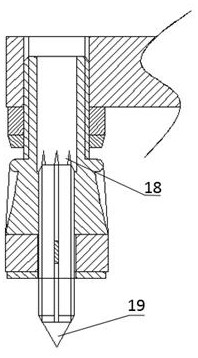

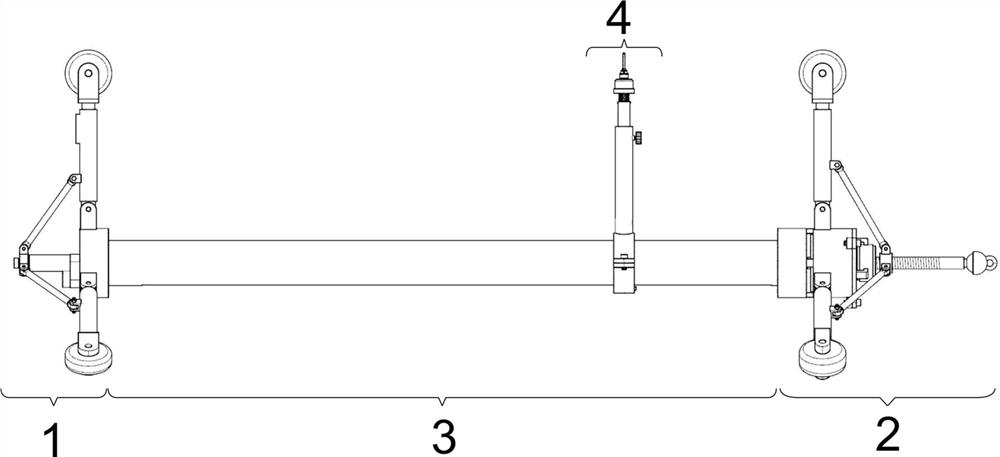

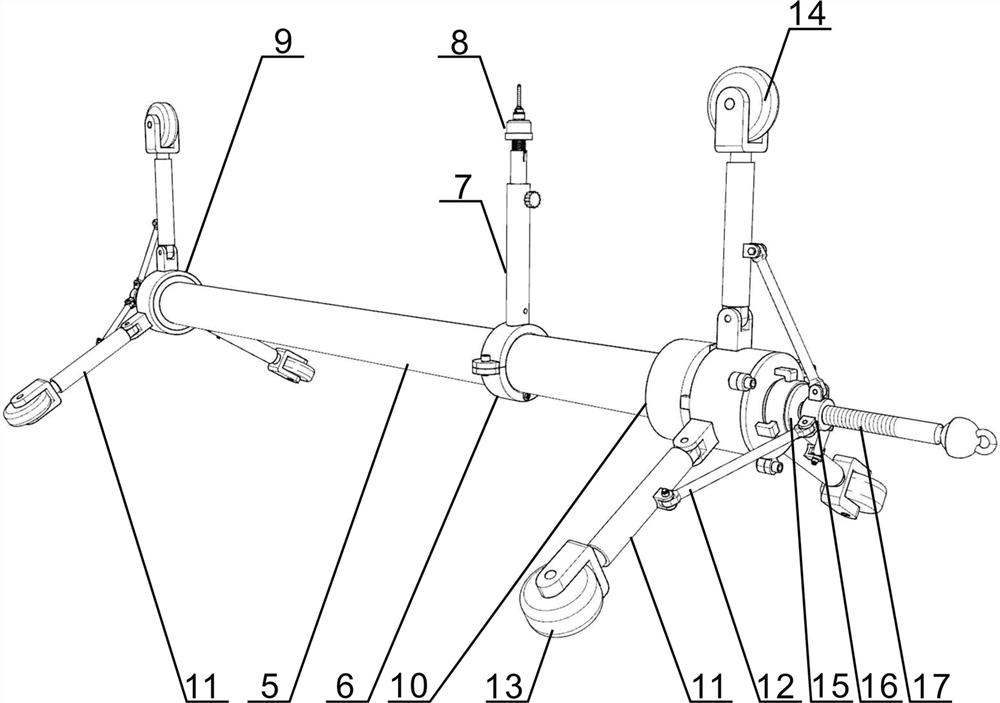

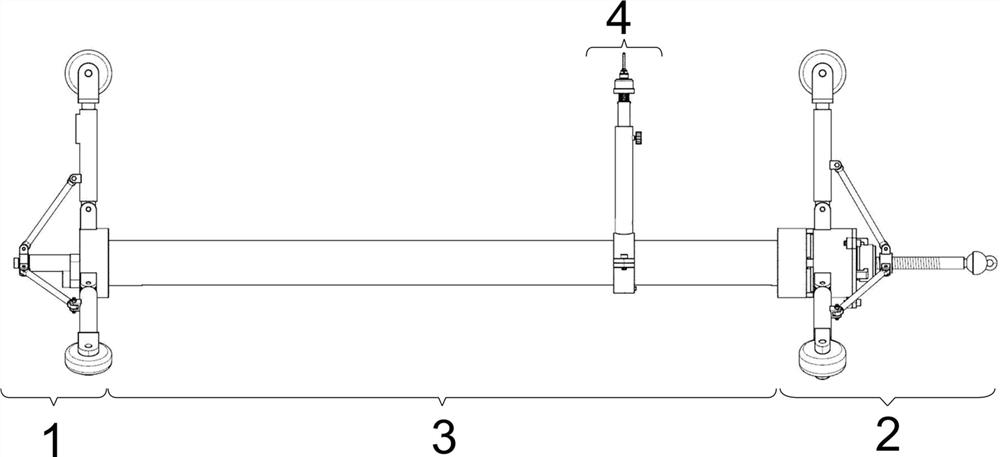

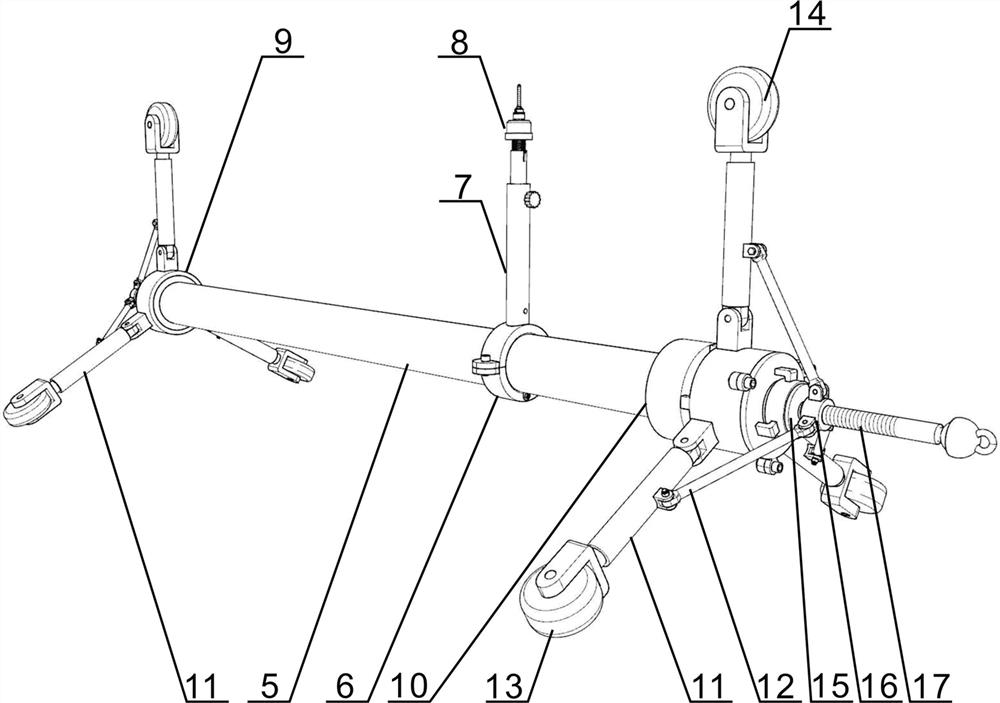

High-voltage electric pulse hydraulic fracturing method for coal and rock mass and guiding fracture forming device

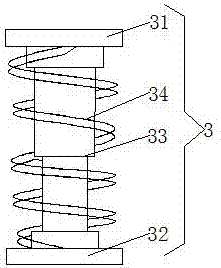

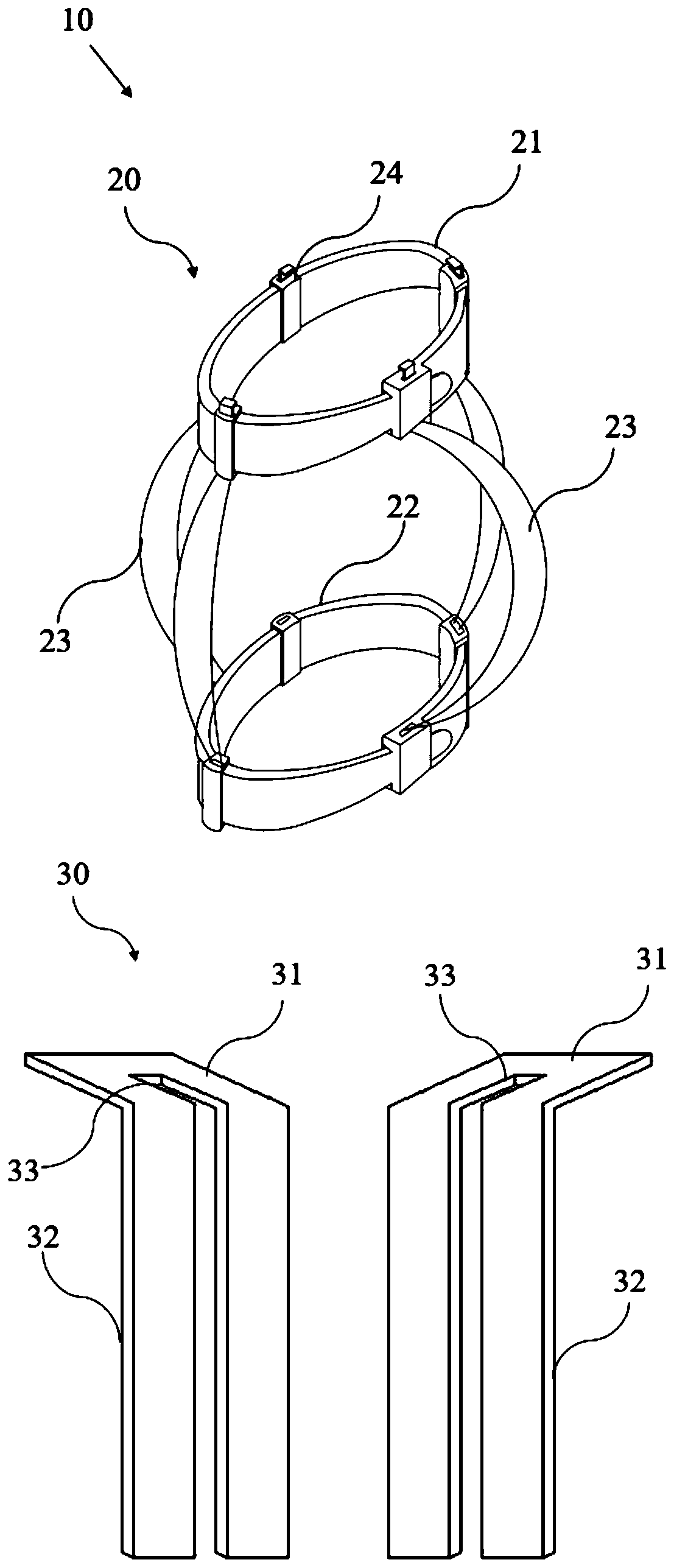

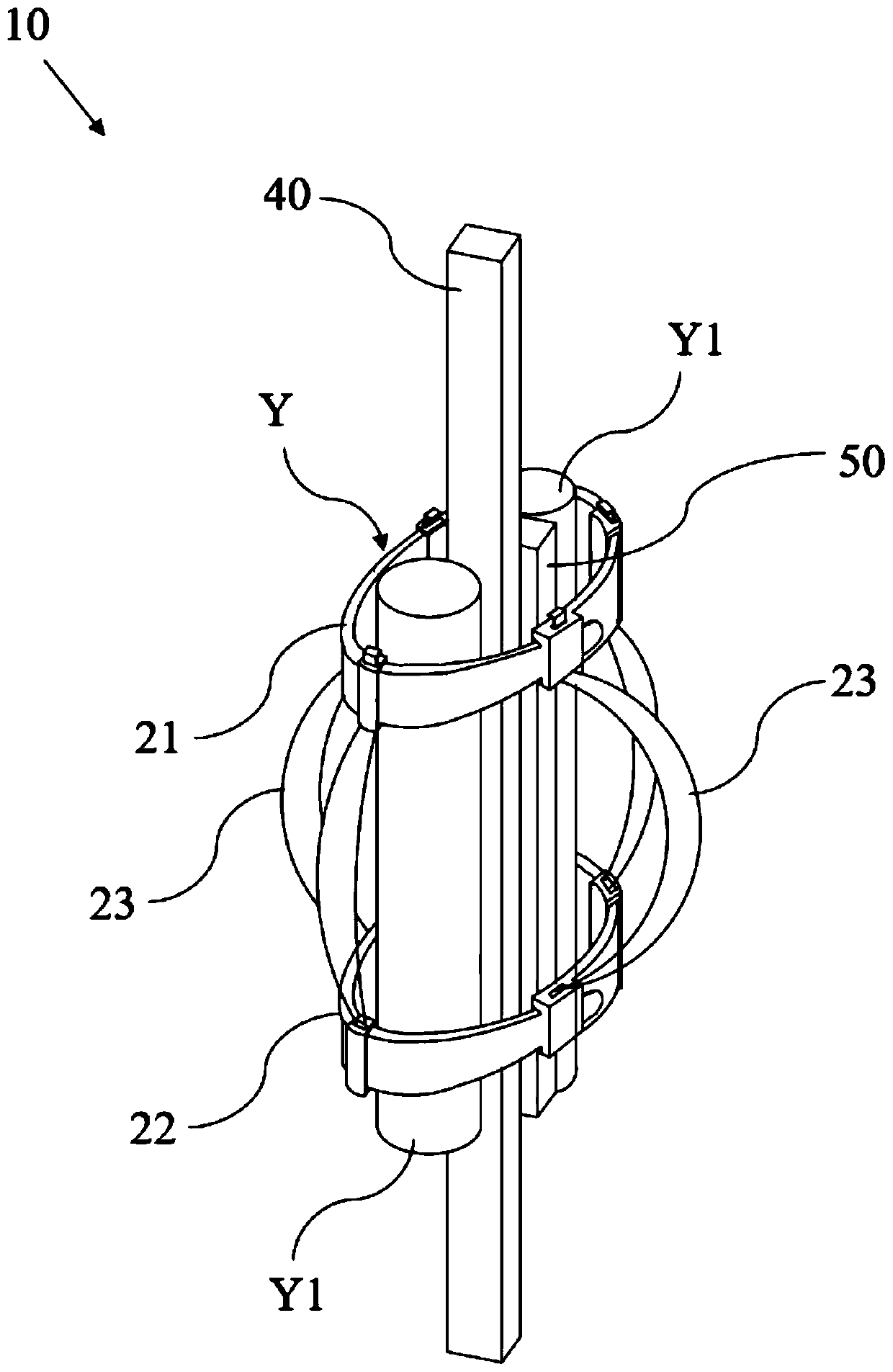

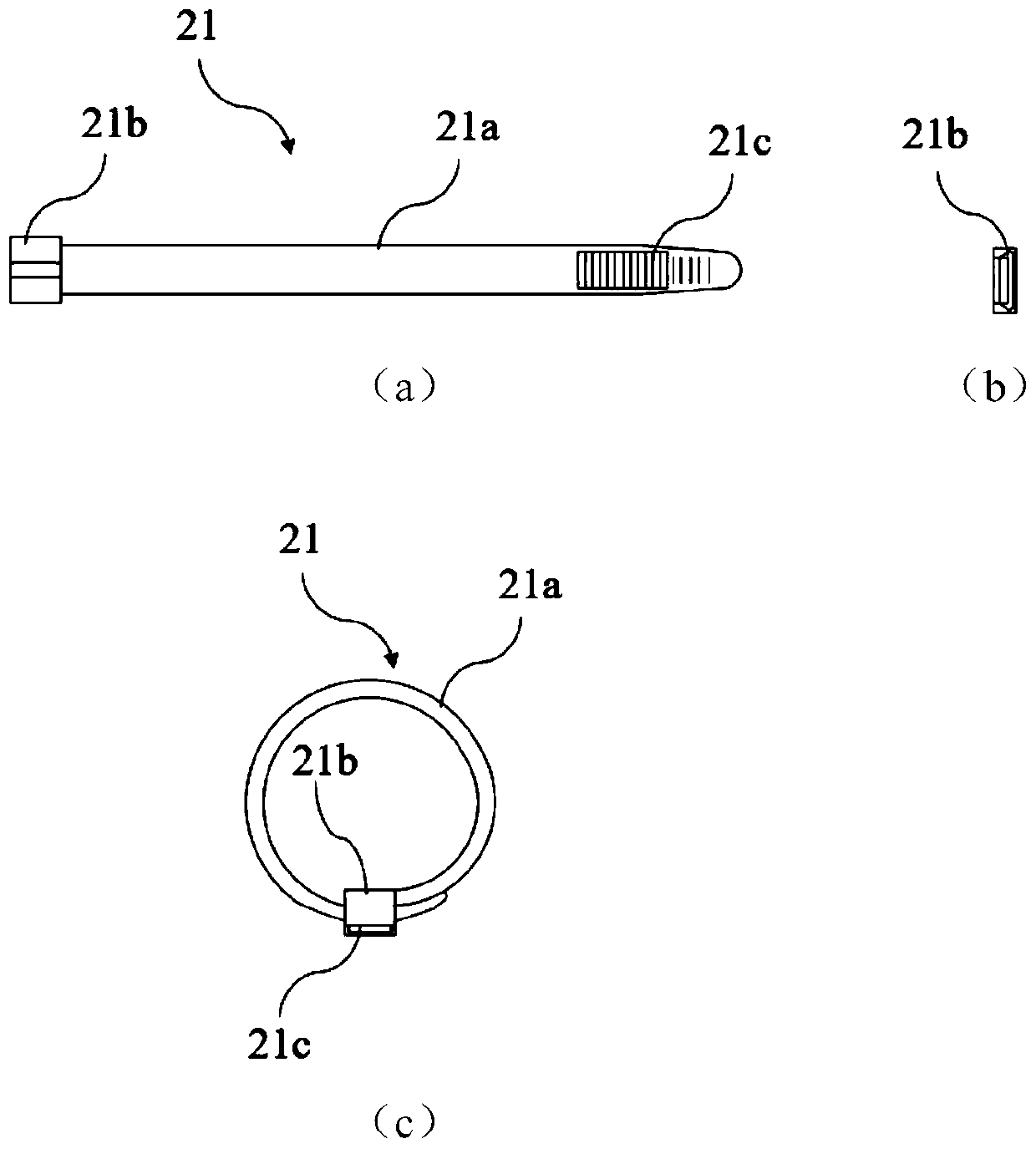

ActiveCN112943172AIncrease flexibilityPrevent disengagementFluid removalEngineeringHydraulic fracturing

The invention belongs to the technical field of unconventional natural gas exploitation through high-voltage electric pulse hydraulic fracturing, and particularly relates to a high-voltage electric pulse hydraulic fracturing method for a coal and rock mass and a guiding fracture forming device. The method includes the steps that before unconventional gas production, drilling is carried out on the surface of a production area, guided fractures are set on a wellbore by using the guiding fracture forming device, then a wellhead is sealed, and fracturing is conducted on the wellbore by using a high-voltage electric pulse hydraulic fracturing technology, so that ideal cracks are generated in coal rock, a migration channel of unconventional natural gas in a coal rock layer is increased and opened up, and the gas mining efficiency is improved. The guiding fracture forming device can walk in a drilling well, and an arranged fracture forming part can rotate around a shaft along a guiding part and move in the axial direction. According to the guiding fracture forming device, the fracture forming part can do combined motion of combining the axial direction and the winding axis along the guiding part, so that the fracture forming part can form a guide fracture in the wellbore according to a preset path by controlling the motion of the fracture forming part.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

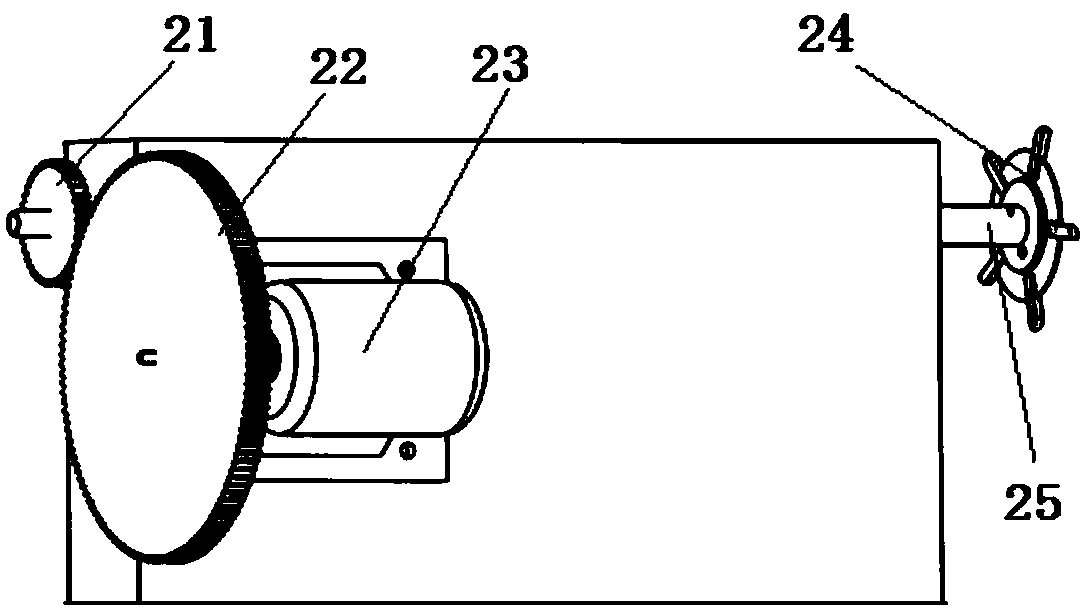

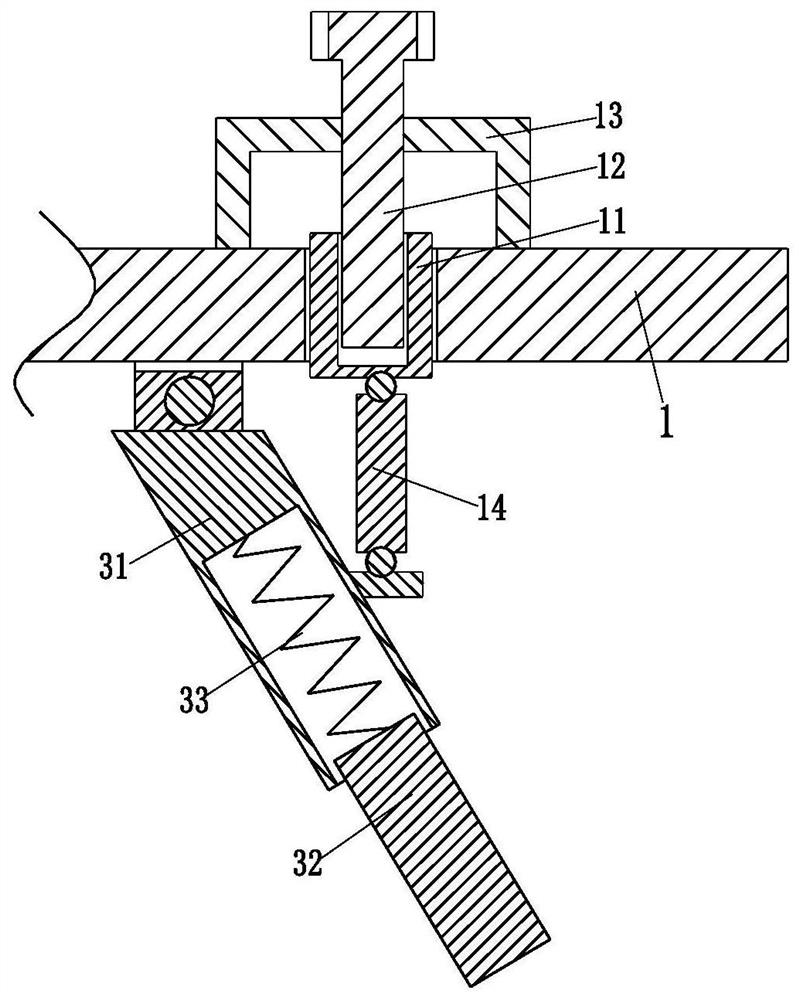

Cleaning mechanism of electric seam-beautifying glue gun

InactiveCN108720738AEasy to adjust the angleSimple structureCarpet cleanersFloor cleanersCircular discElectrical and Electronics engineering

The invention relates to a cleaning mechanism of an electric seam-beautifying glue gun. The cleaning mechanism comprises a first collecting column and a second collecting column which are vertically arranged below an electric seam-beautifying glue gun shell, wherein the first collecting column is arranged in front of the second collecting column; the first collecting column is shorter than the second collecting column; a third collecting column is movably connected to the lower side of the second collecting column; the third collecting column inclines towards the first collecting column; a fourth collecting column is arranged between the lower end of the first collecting column and the middle position of the third collecting column; a cleaning assembly is movably connected to the lower endof the third collecting column; the cleaning assembly comprises a disc connected to the lower end of the third collecting column; an inwardly sunk ring-shaped threaded groove is formed in the centerof the lower end surface of the disc; the threaded groove and the disc are concentrically arranged; a connecting disc is arranged below the disc; the connecting disc is clamped into the threaded groove; a front cleaning brush and a back cleaning brush are arranged on the lower end surface of the connecting disc. The cleaning mechanism has the advantages of simple structure, capability of cleaningquickly, improvement on the working efficiency and convenience in detachment.

Owner:NANTONG ZHONGLV GEAR CO LTD

A high-efficiency carton cutting and sewing machine

ActiveCN106891572BGood seam effectImprove efficient cutting effectBox making operationsPaper-makingStopped workCarton

The invention discloses a high-efficient carton seam cutting machine, which comprises a base. A support plate and two support devices are sequentially arranged on the top part of the base from left to right; a workbench is fixedly connected to the top parts of the support devices; an elongated slot is formed in the top part of the workbench; a controller is fixedly arranged at the front surface of the support plate; and a first infrared sensor is arranged in the middle of one side of the support plate. According to the high-efficient carton seam cutting machine, the controller controls a first motor and a second motor to work; under the action of a first screw rod, a support rod, a second screw rod, a support block and a rolling wheel, a regulating effect on seam-cutting teeth is achieved; through the cooperative use of the first infrared sensor and a second infrared sensor, when the first infrared sensor and the second infrared sensor trigger signals, the controller control an air cylinder to stop working; and in addition, under the action of a distance sensor, the accuracy during seam cutting is improved, and the high-efficient seam cutting efficiency on a carton is further improved.

Owner:MACROSCOPIC CENTURY TIANJIN CO LTD

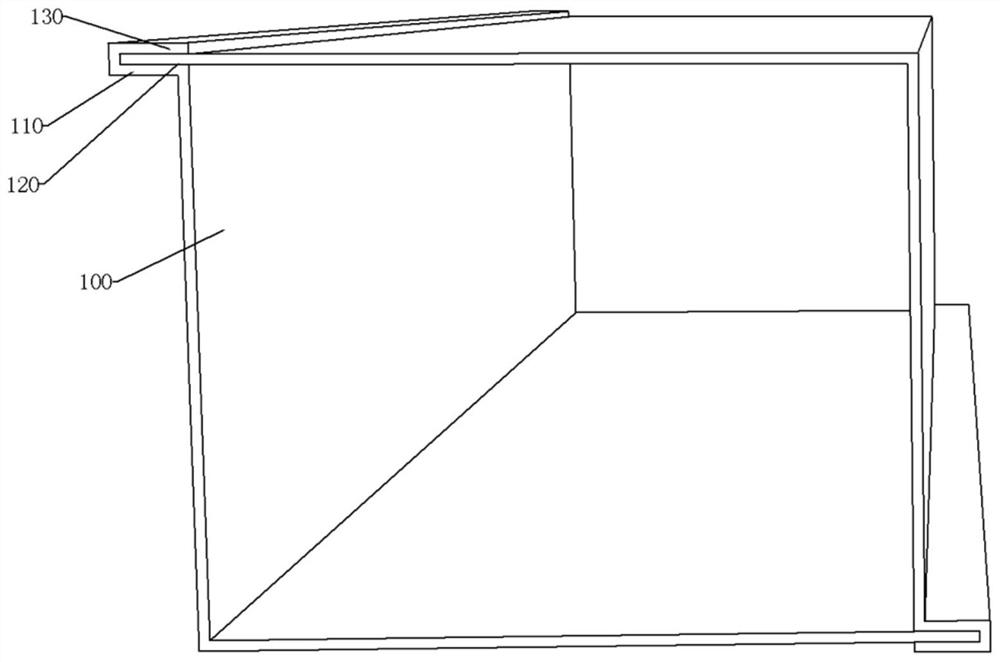

Seam spreading-open mechanism and seam spreading-open machine with seam spreading-open mechanism

PendingCN112030381ATo achieve the purpose of seamSeam smoothWorkpiece carriersWork-feeding meansEngineeringMechanical engineering

The invention relates to a seam spreading-open mechanism and a seam spreading-open machine with the seam spreading-open mechanism. The seam spreading-open mechanism comprises an operation table boardwhich is basically horizontally arranged. The spreading-open mechanism is characterized by further comprising a supporting plate, two rollers and a driving mechanism, the supporting plate is located on the operation table board, a gap allowing lower-layer cloth of double-layer cloth to penetrate through is reserved between the supporting plate and the operation table board, and the first side edgeof the supporting plate extends in the conveying direction of the cloth and is used for making contact with the sewing position of the double-layer cloth. The two rollers are arranged up and down andare adjacent to the first side edge of the supporting plate, the extending directions of the axes of the two rollers are consistent, and a gap for the double-layer cloth to pass through is formed between the two rollers; and the power output end of the driving mechanism is in driving connection with the corresponding rollers, so that at least one layer of cloth in the double-layer cloth in the gap is driven to move in the direction away from the first side edge. In the whole seam spreading-open process, only the two rollers need to be matched with the first side edge of the supporting plate,and the seam spreading-open effect is good.

Owner:浙江凌志智能科技有限公司

A production line of a conveying module and its fire-fighting air duct

ActiveCN112008432BRealize automatic stitchingIncrease productivityOther manufacturing equipments/toolsMetal working apparatusProduction lineStructural engineering

The invention discloses a conveying module and a production line for fire-fighting air ducts. The production line for fire-fighting air ducts includes: a platform module for splicing and sewing fire-fighting air ducts; The air cylinder; the detection module, used to detect the flatness of the stitched first hemming part; the grooving module, used to cut out bending grooves at both ends of the fire-fighting air cylinder respectively, to obtain the unhemmed second hemming part; Conveyor module, used to clamp and sew the fire-fighting blower through the clamping mechanism, and transport the fire-fighting blower; sleeve flange module, used to take out the flange from the storage side plate, and then set them on both ends of the fire-fighting blower The flange module is used to crimp the uncrimped second crimping part to the engaging part, so that the second crimping part fastens and fixes the flange between the flange boss and the second crimping part between. The invention can realize the automatic sewing, detection, fitting flange and fixing flange of the fire-fighting air duct.

Owner:CHONGQING VOCATIONAL INST OF ENG

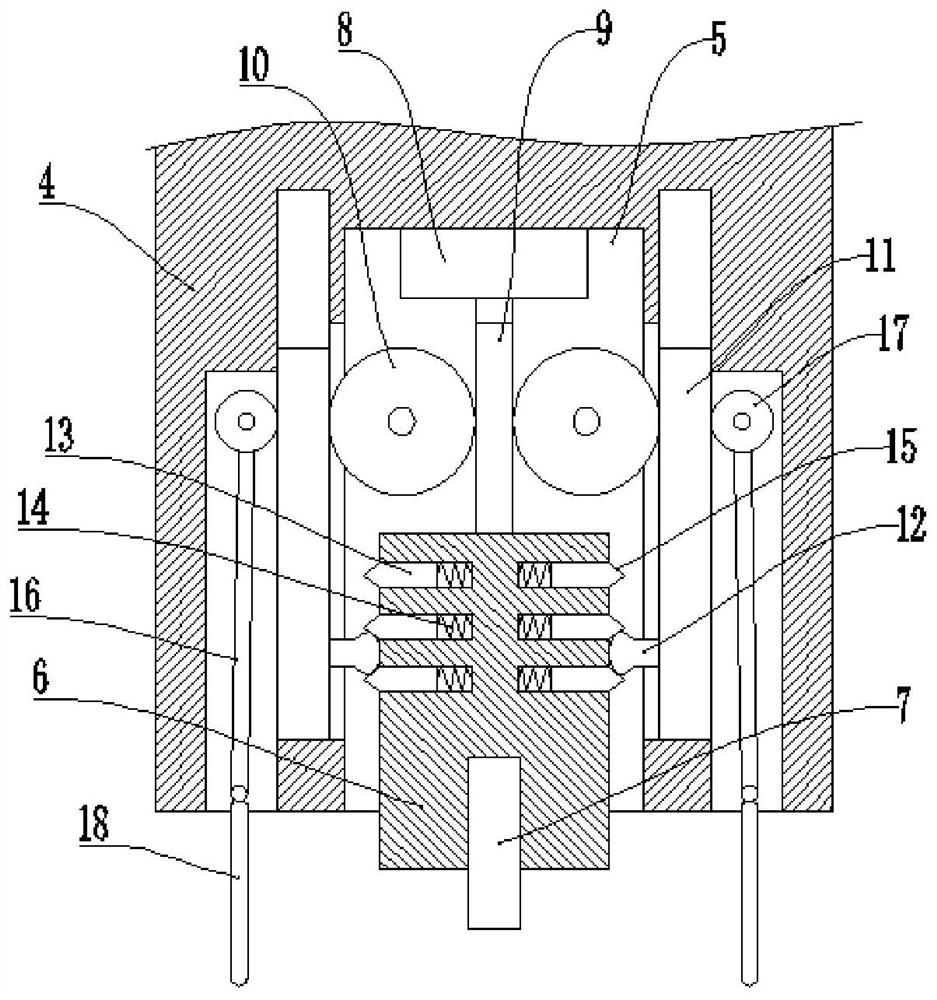

Steel pipe rod joint device

ActiveCN111215824BAchieve positioningPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesPipeWorkbench

The invention relates to the technical field of bar welding; it discloses a steel pipe rod seam closing device, including a workbench, on which a clamping mechanism for a steel pipe reel and a welding torch for seaming the gap of the steel pipe reel are arranged, and the clamping The mechanism includes a vertical plate fixed on the workbench and a circular hole opened on the vertical plate. The inner wall of the circular hole is provided with at least three retractable clamping parts for clamping the steel pipe reel at an equidistant distance on the inner wall of the circular hole. . This scheme mainly solves the problem that the joint effect is affected due to poor positioning effect when the steel pipe reel is jointed.

Owner:重庆市荣昌区永世光电设备有限公司

A grooving module and its fire-fighting air duct production line

ActiveCN112008431BRealize automatic stitchingIncrease productivityOther manufacturing equipments/toolsProduction lineStructural engineering

Owner:CHONGQING VOCATIONAL INST OF ENG

Automatic edge sealing device for imitated rattan plaited chair cushion

ActiveCN114134650ANeat and beautiful seamsAvoid deformationWorkpiece carriersWork-feeding meansEngineeringChair cushion

The invention relates to an automatic edge sealing device for a rattan-imitated chair cushion, and the device comprises a control mechanism which comprises a pressing assembly and a rotating assembly; the cutting mechanism comprises a slitting assembly and a first transmission assembly; a sewing mechanism; the discharging mechanism comprises a lifting assembly arranged on the operation table, a second transmission assembly which is in synchronous transmission with the downward pressing assembly and is used for driving the lifting assembly to move in the vertical direction, and a limiting assembly which is installed on the operation table and is used for controlling the lifting assembly to automatically rotate for discharging; the cutting-off mechanism is used for automatically cutting off the edge sealing strips of the group of bolsters subjected to edge sealing; the rattan chair bolster sewing machine solves the technical problems that in the rattan chair bolster production process, the peripheral hems of the bolster are manually sewn, the edge cutting work of hemming strips and the rotation work of the bolster need to be completed with one hand, misoperation is prone to occurring, the speed is low, and the production efficiency is low.

Owner:ANHUI DAIJIA CRAFT CO LTD

A seam cleaning and filling device

ActiveCN109537858BLower requirementCompact structureBuilding constructionsEngineeringMechanical engineering

Owner:CHANGAN UNIV

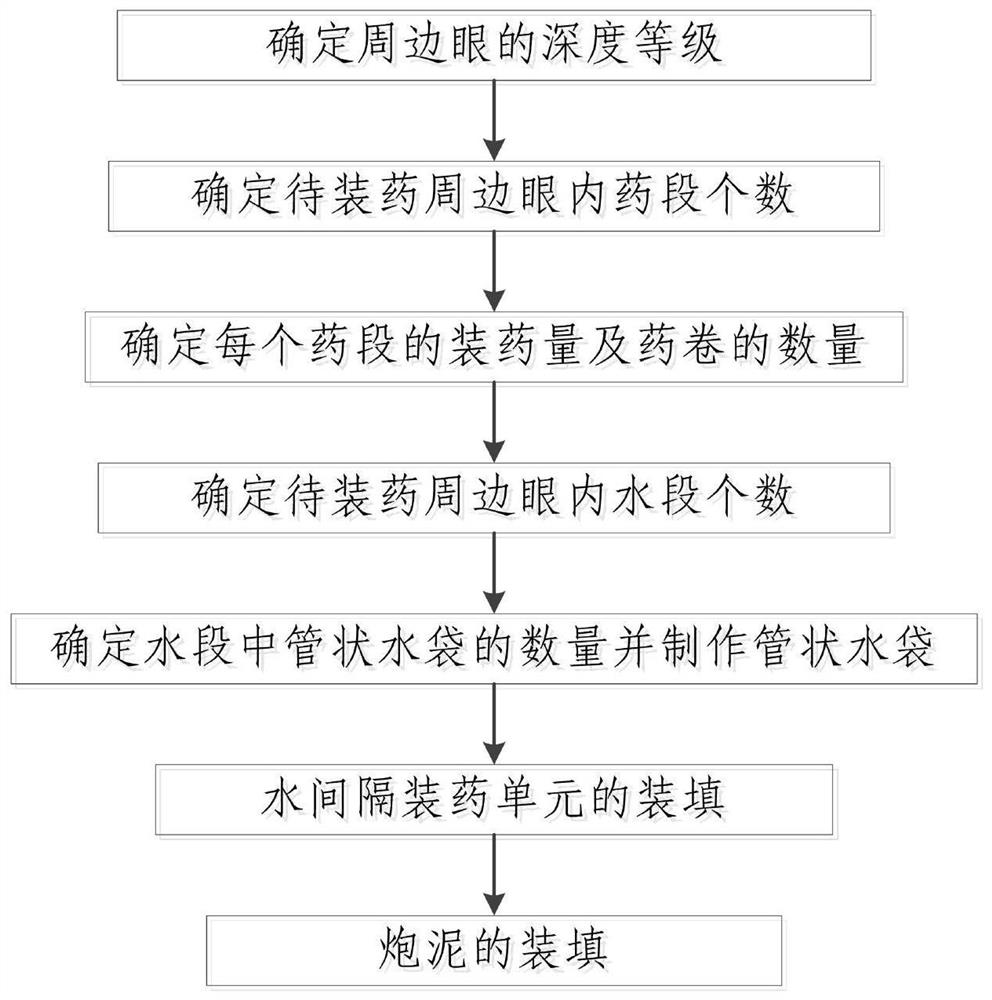

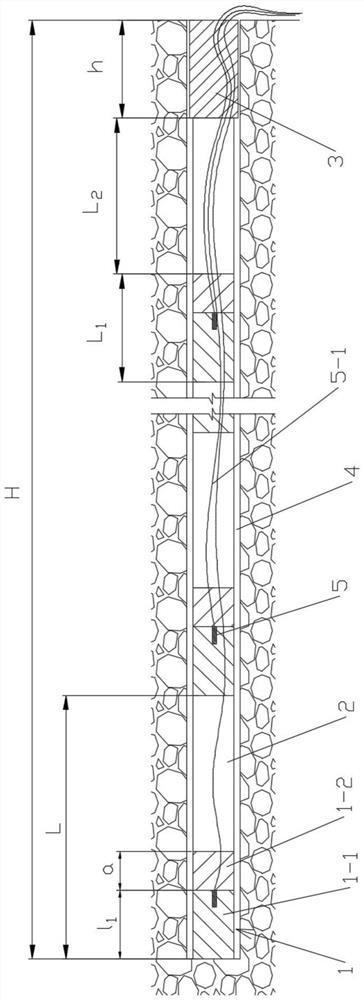

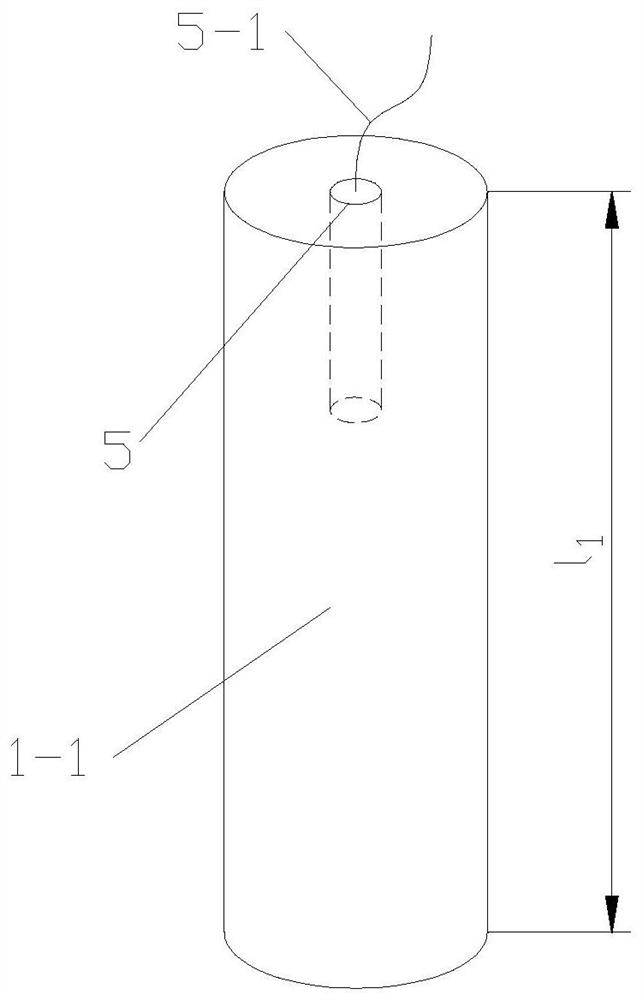

A kind of tunnel smooth blasting method of surrounding eye water interval charging method

ActiveCN109211043BReduce concentrationReduce pollutionBlastingTunnelsArchitectural engineeringMechanical engineering

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

A kind of sleeve flange module and its fire-fighting air duct production line

ActiveCN112008375BRealize automatic stitchingIncrease productivityMetal sawing devicesMetal working apparatusProduction lineIndustrial engineering

The invention discloses a flange module and its production line for fire-fighting air ducts. The production line for fire-fighting air ducts includes: a platform module for splicing and sewing fire-fighting air ducts; The fire-fighting air cylinder; the detection module is used to detect the flatness of the stitched first hemming part; the grooving module is used to cut out bending grooves at both ends of the fire-fighting air cylinder respectively to obtain the second hemming without hemming part; delivery module, used to clamp and sew the fire blower through the clamping mechanism, and transport the fire blower; sleeve flange module, used to take out the flange from the storage side plate, and then set them on the fire blower respectively Both ends; equipped with flange modules, used to crimp the uncrimped second crimping part to the engaging part, so that the second crimping part can fasten and fix the flange on the flange boss and the second crimping between sections. The invention can realize the automatic sewing, detection, fitting flange and fixing flange of the fire-fighting air duct.

Owner:CHONGQING VOCATIONAL INST OF ENG

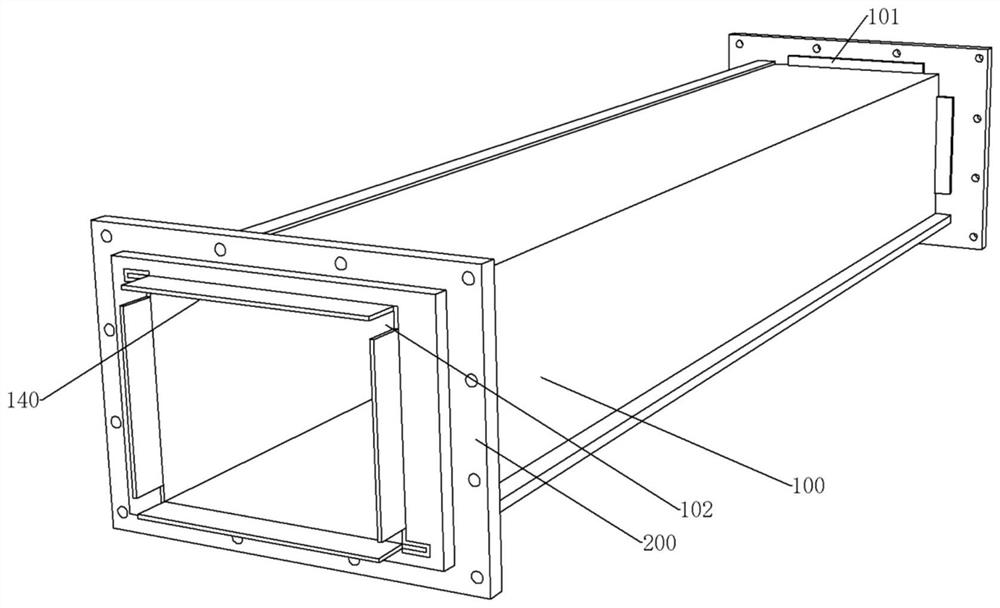

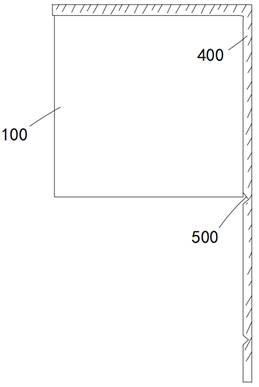

Detection module and fire-fighting air duct production line thereof

InactiveCN112108535ARealize automatic stitchingIncrease productivityElectric/magnetic roughness/irregularity measurementsMetal working apparatusProduction lineStructural engineering

The invention discloses a detection module and a fire-fighting air duct production line thereof. The fire-fighting air duct production line comprises a platform module, a detection module, a groovingmodule, a conveying module, a flange sleeving module and a flange mounting module, wherein the platform module is used for splicing and sewing a fire-fighting air duct; the spliced fire-fighting air duct is a fire-fighting air duct on which hemming is finished; the detection module is used for detecting the flatness of a sewn first crimping part; the grooving module is used for cutting bending grooves in the two ends of the fire-fighting air duct respectively to obtain a second crimping part which is not crimped; the conveying module is used for clamping the sewn fire-fighting air duct througha clamping mechanism and conveying the fire-fighting air duct; the flange sleeving module is used for taking out flanges from a storage side plate and then respectively sleeving the two ends of the fire-fighting air duct with the flanges; and the flange mounting module is used for crimping the second crimping part which is not crimped towards a clamping part, so that the second crimping part clamps and fixes the flanges between flange bosses and the second crimping part. According to the fire-fighting air duct production line, automatic sewing, detection, flange sleeving and flange fixing ofthe fire-fighting air duct can be realized.

Owner:CHONGQING VOCATIONAL INST OF ENG

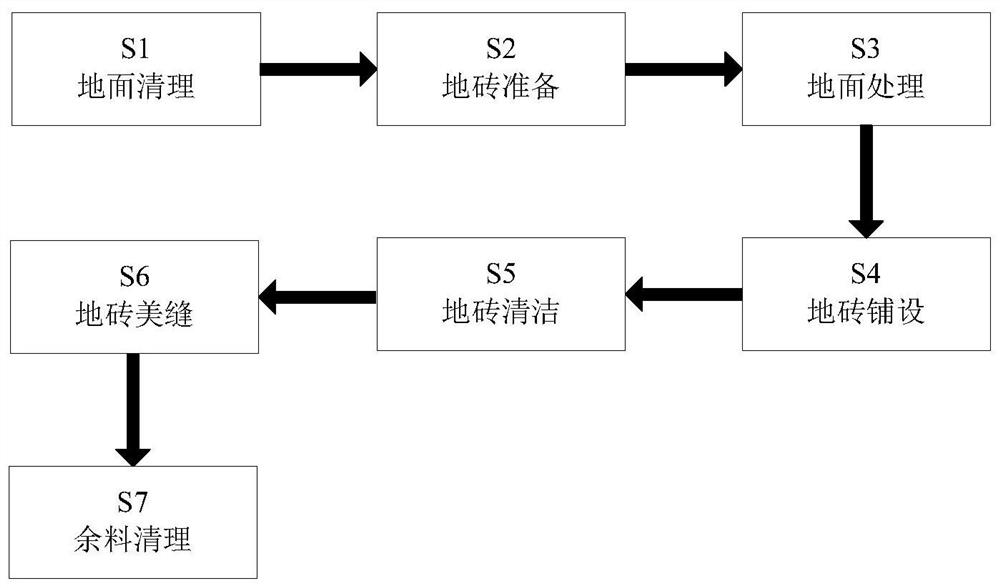

A construction method for laying floor tiles for building decoration

Owner:中国黄金集团建设有限公司

High-voltage electric pulse hydraulic fracturing coal rock mass method and guide fracture opening device

ActiveCN112943172BIncrease flexibilityPrevent disengagementFluid removalEngineeringHydraulic fracturing

The invention belongs to the technical field of high-voltage electric pulse hydraulic fracturing to exploit unconventional natural gas, and specifically includes a high-voltage electric pulse hydraulic fracturing method for fracturing coal and rock mass and a device for opening guiding cracks. Before natural gas extraction, drilling is carried out on the surface of the mining area, and a pilot crack opening device is used to open a pilot fracture on the wellbore, and then the wellhead is sealed, and the high voltage electric pulse hydraulic fracturing technology is used to fracture the wellbore, thereby Ideal fissures are generated in the coal rock to increase and open up the migration channel of unconventional natural gas in the coal rock layer, thereby improving the gas extraction efficiency. The guide fracture opening device can travel in drilling, and the provided slit part can rotate around the axis and move along the axial direction along the guide part. The slotted part in the device can perform a combined movement along the guide part in the axial direction and around the axis. Therefore, by controlling the movement, the slotted part can open a pilot fracture on the well wall according to a preset path.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com