Automatic edge sealing device for imitated rattan plaited chair cushion

The technology of an edge banding device and a chair pad is applied in the field of automatic edge banding devices for imitation rattan chair pads, which can solve the problems of low production efficiency, manual sewing, misoperation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

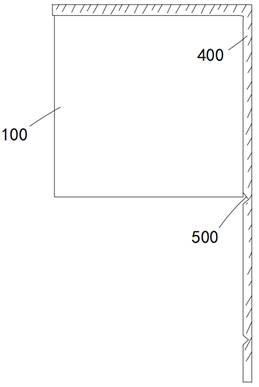

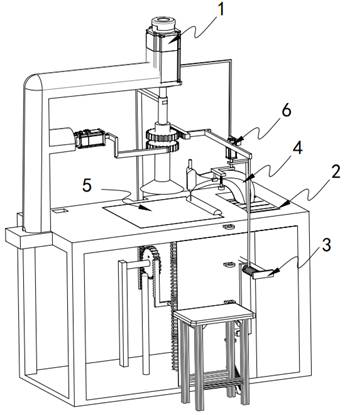

[0063] like figure 1 , figure 2 As shown, a device for edge sealing of rattan chair cushions includes a control mechanism 1 installed above the console 2, which includes a pressing component 11 for pressing a square-shaped pillow 100 And a rotating assembly 12 for driving the pressing assembly 11 to perform intermittent rotation;

[0064] The cutting mechanism 3, the cutting mechanism 3 includes a cutting assembly 31 installed on the side wall of the operation table 2 and is synchronously driven with the pressing assembly 11 and used to drive the cutting assembly 31 to cut and seal the edge horizontally The first transmission assembly 32 of the bar 400 opening;

[0065] A sewing mechanism 4, which is installed on the operating table 2 and is used to sew the edge strip 400 into the surrounding of the pillow 100;

[0066] The discharge mechanism 5, the discharge mechanism 5 includes a lifting assembly 51 arranged on the operating table 2, a second gear that is synchronously ...

Embodiment 2

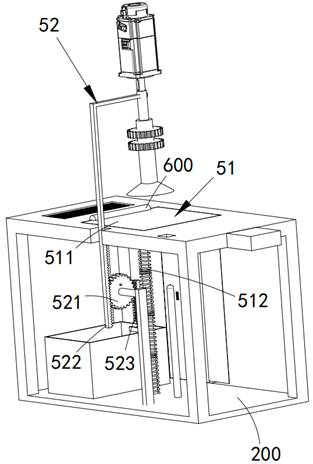

[0111] like image 3 , Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0112] further, such as image 3 As shown, the lifting assembly 51 includes:

[0113] Lifting plate 511, the lifting plate 511 is matched and arranged in the square groove penetrating through the operating table 2 and located directly below the final shaft 112, and the pillow 100 is placed on the lifting plate 511 for edge sealing operation;

[0114] The third elastic unit 512 is vertically and rotatably disposed on the base below the lifting plate 511 .

[0115] In this embodiment, by setting the limit component 53 to cooperate with the lifting component 51, the lifting component 51 is automatically turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com