Patents

Literature

50results about How to "Save extra power output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

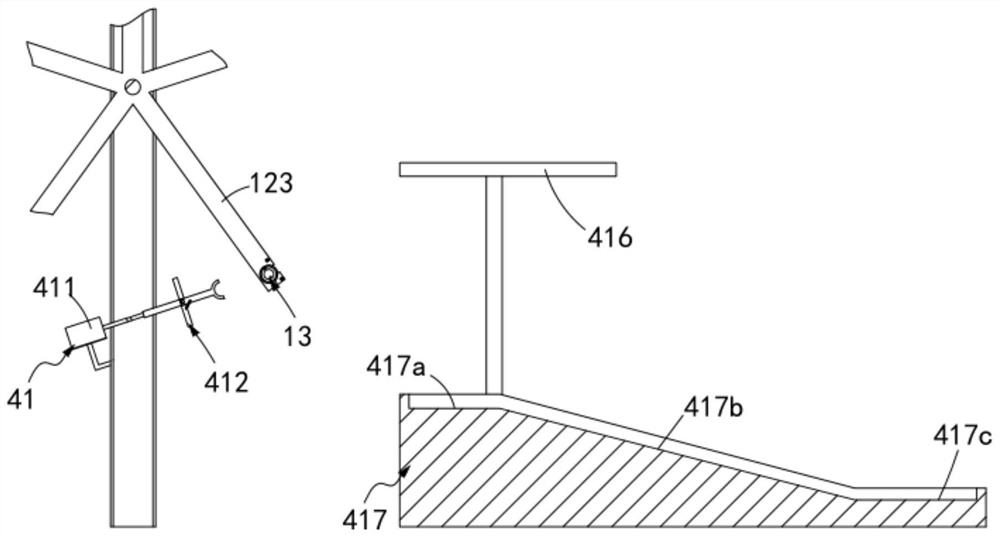

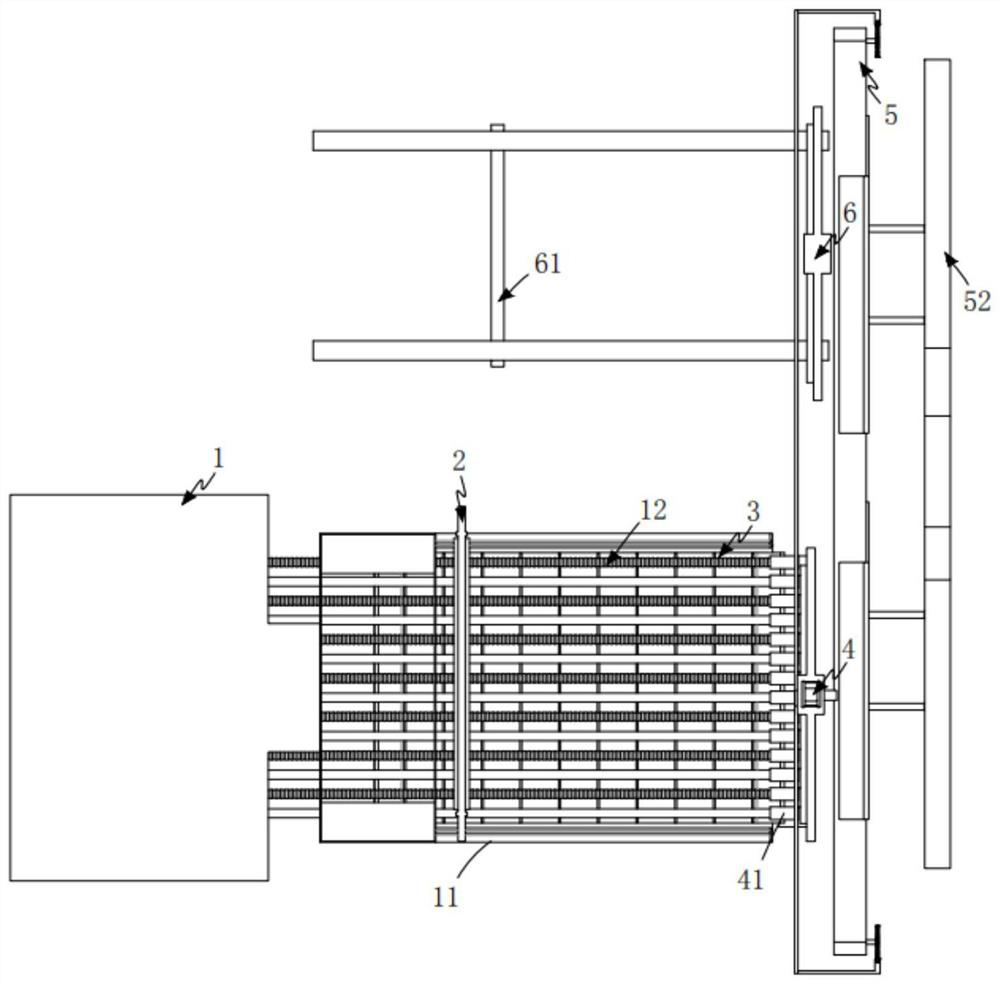

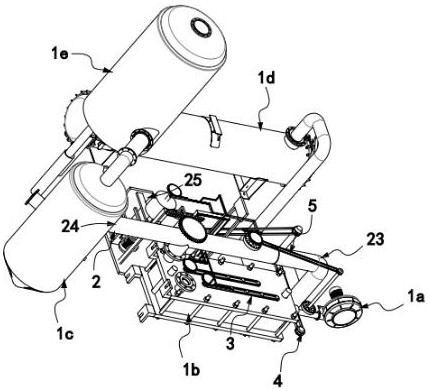

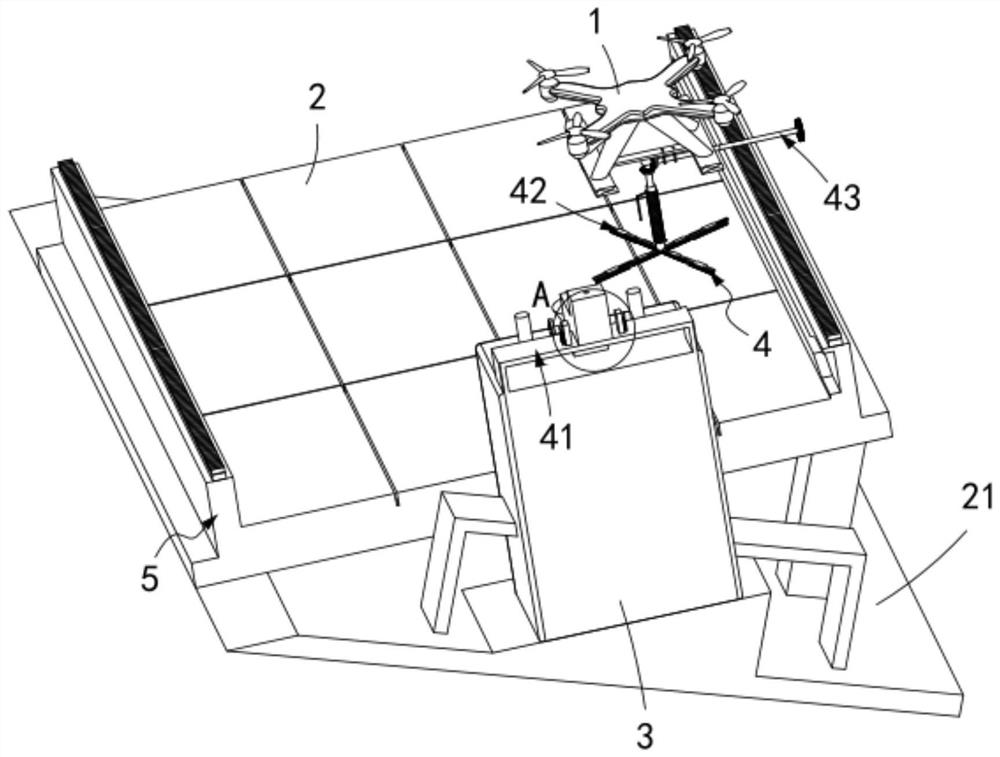

Solar photovoltaic panel surface cleaning unmanned aerial plane

ActiveCN110745245AFull scrubbing jobLight in massAircraft componentsEnergy efficient board measuresSurface cleaningUncrewed vehicle

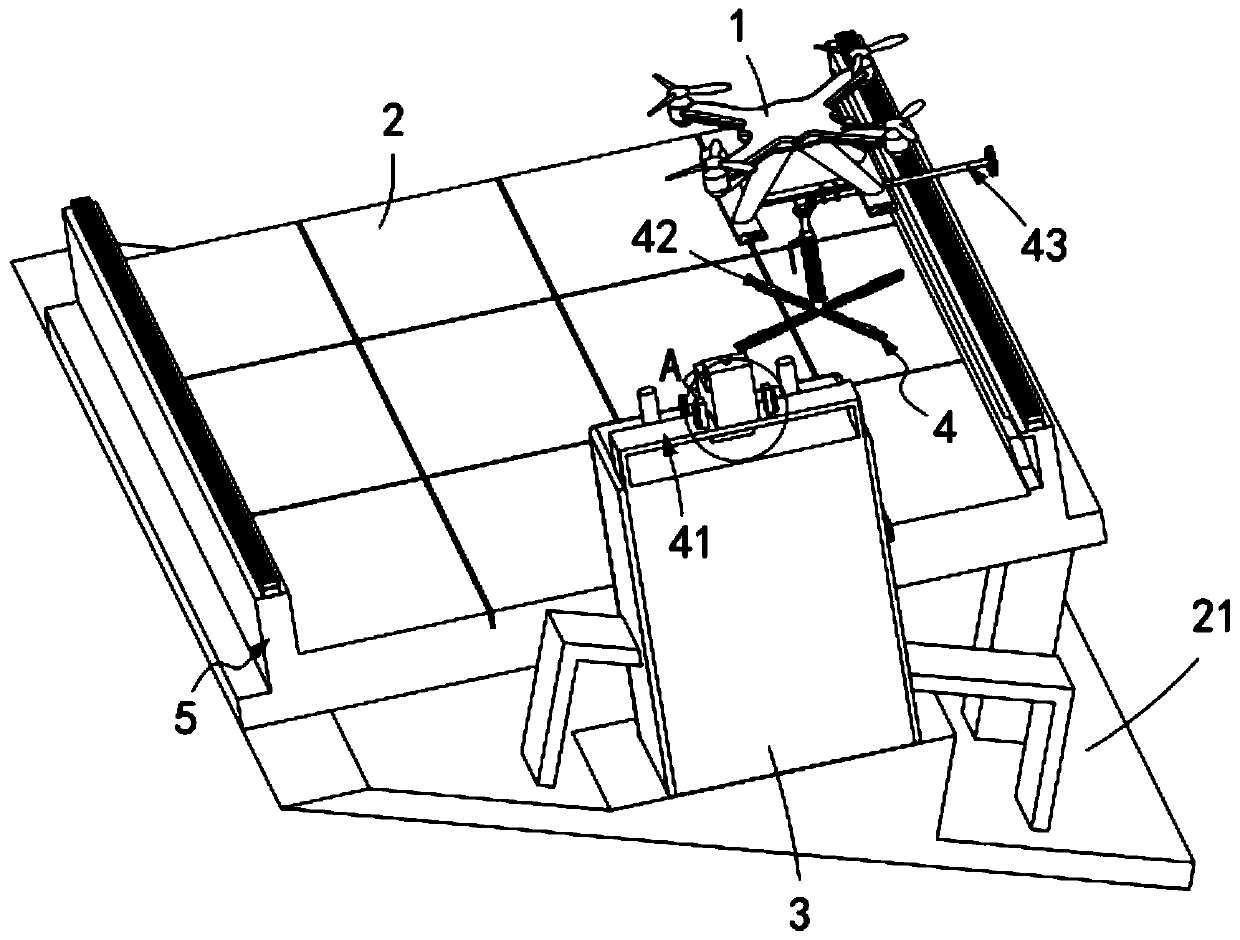

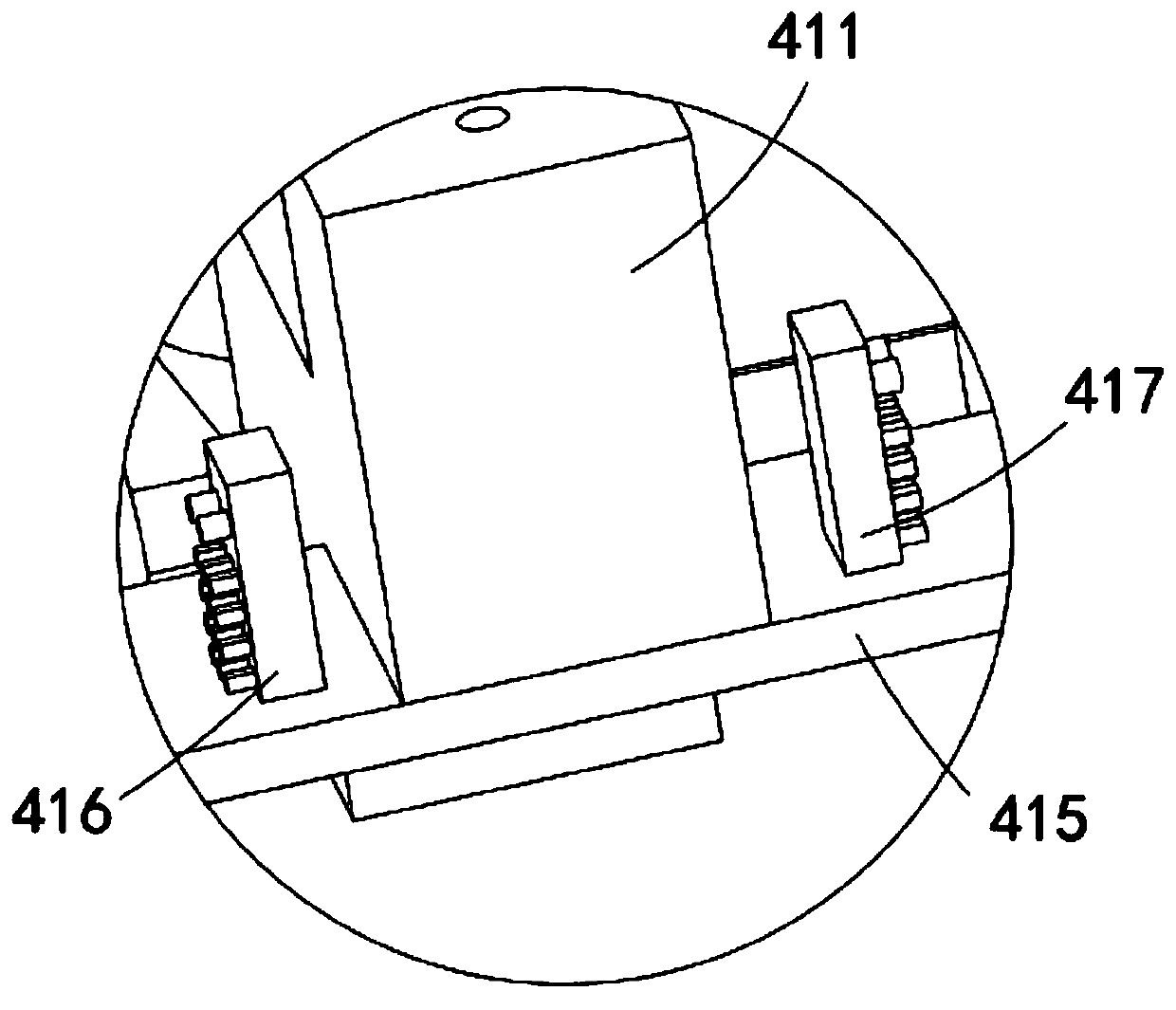

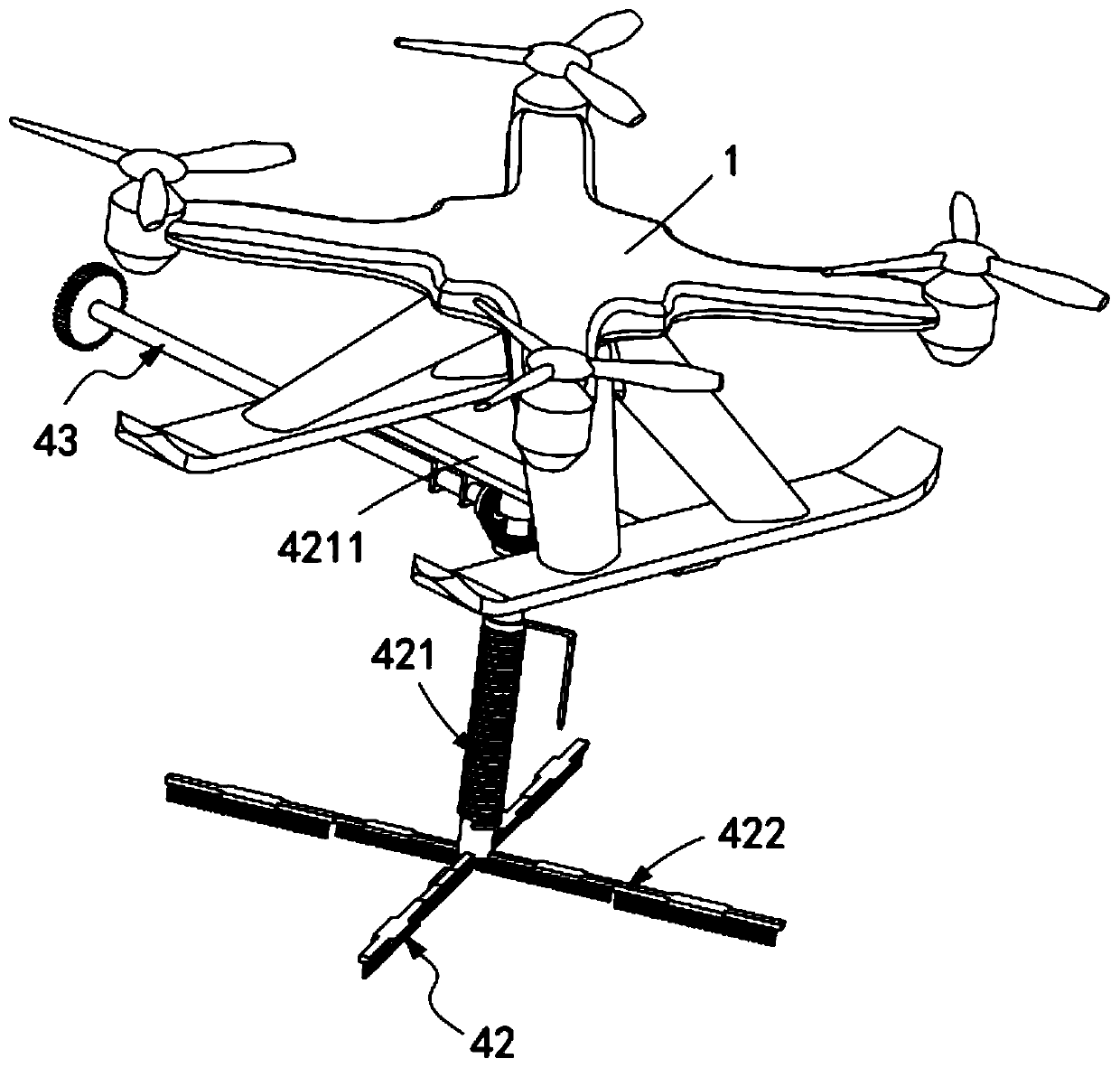

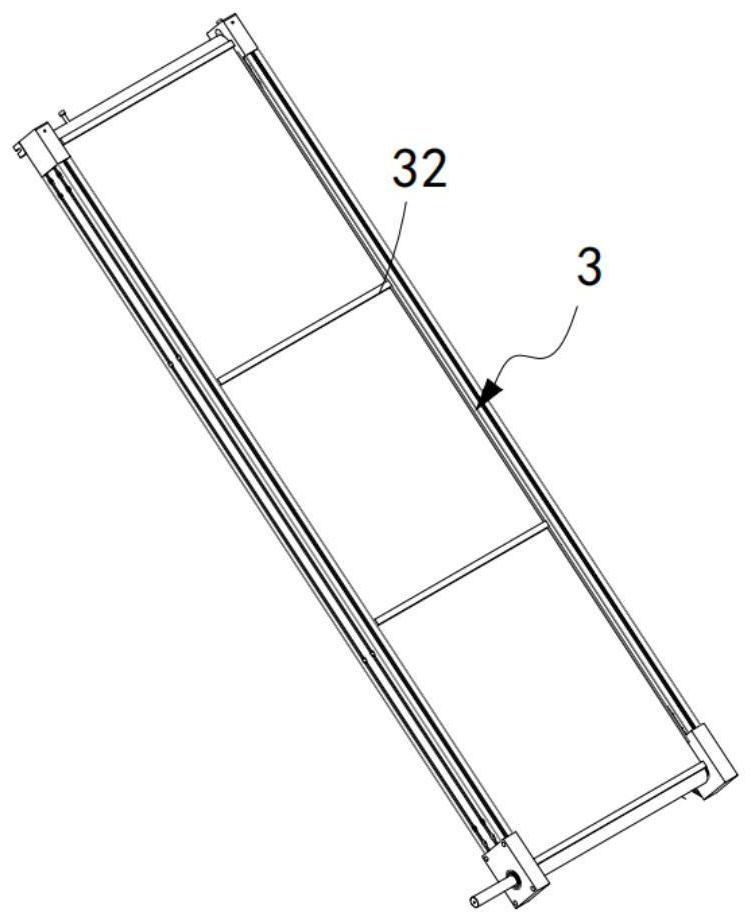

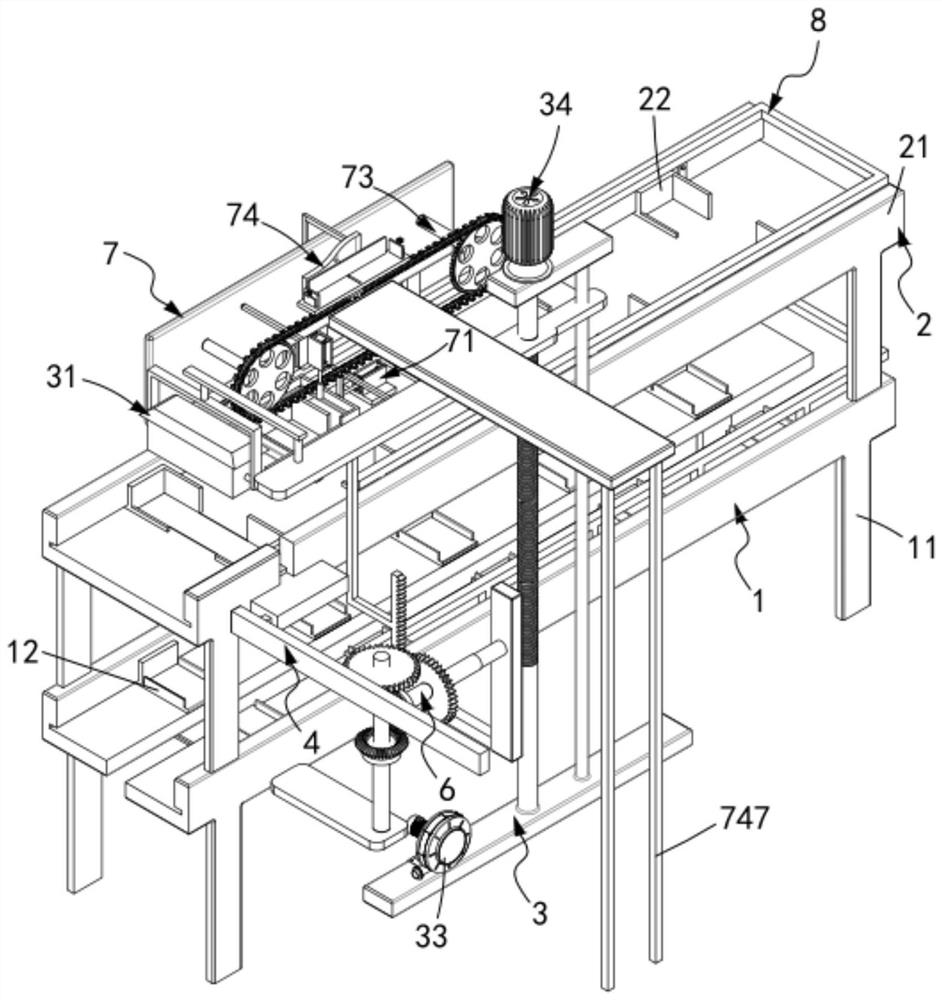

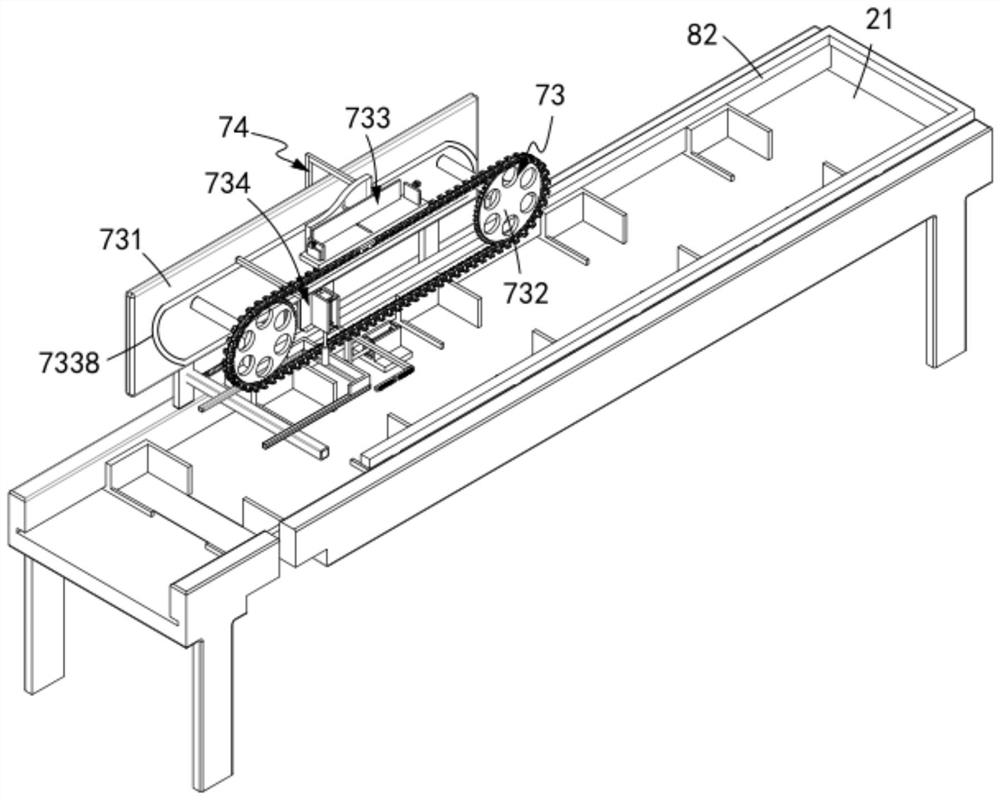

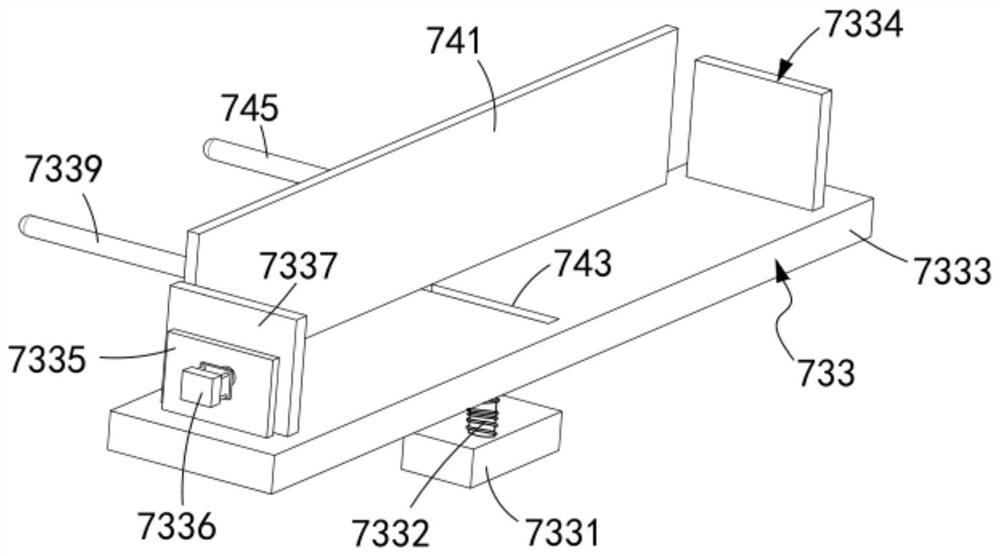

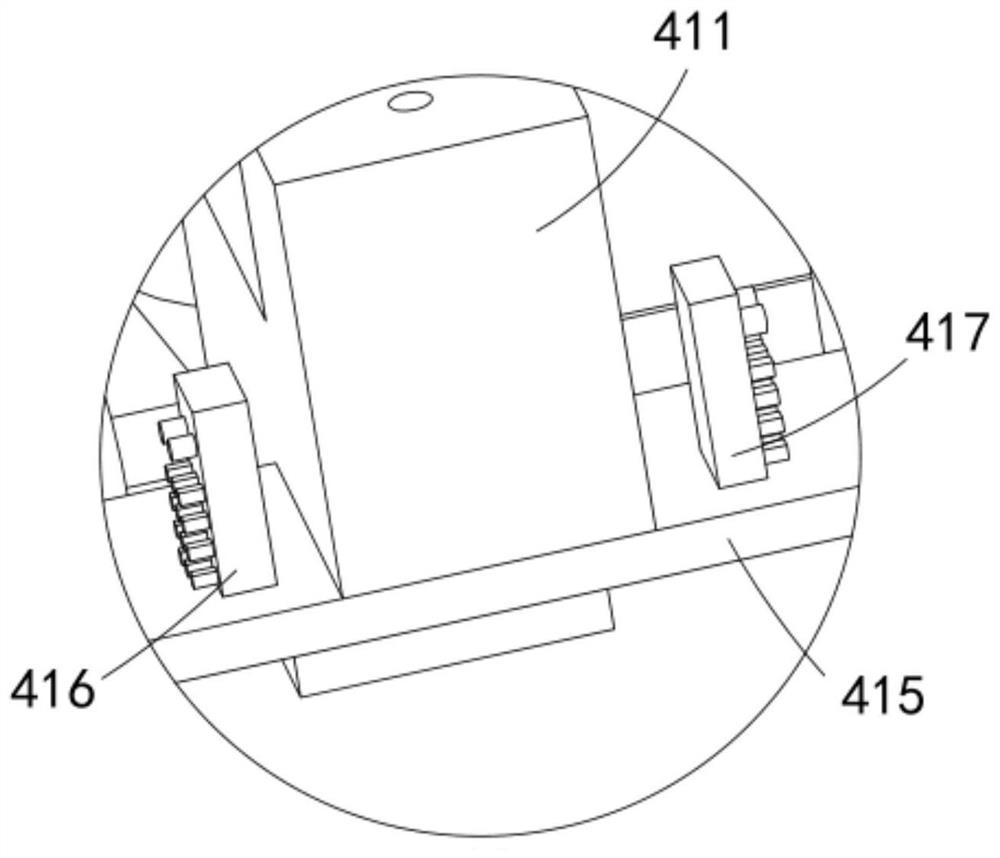

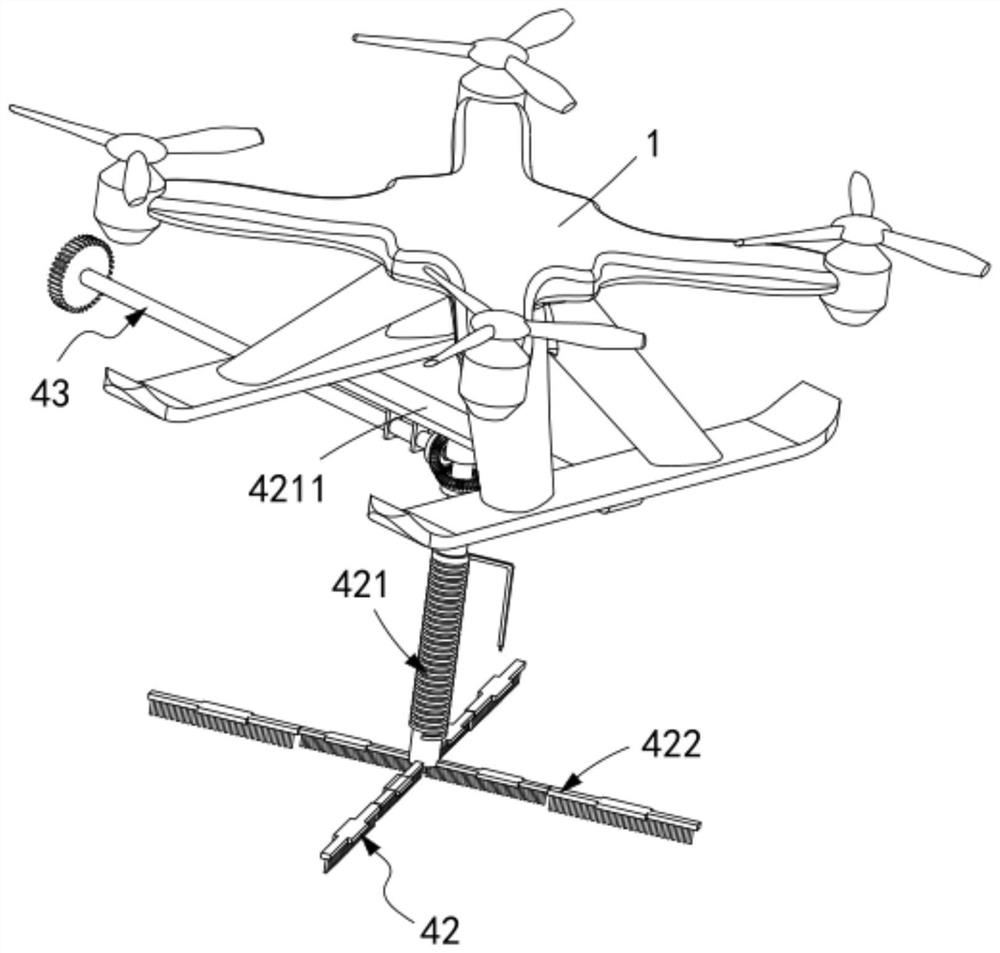

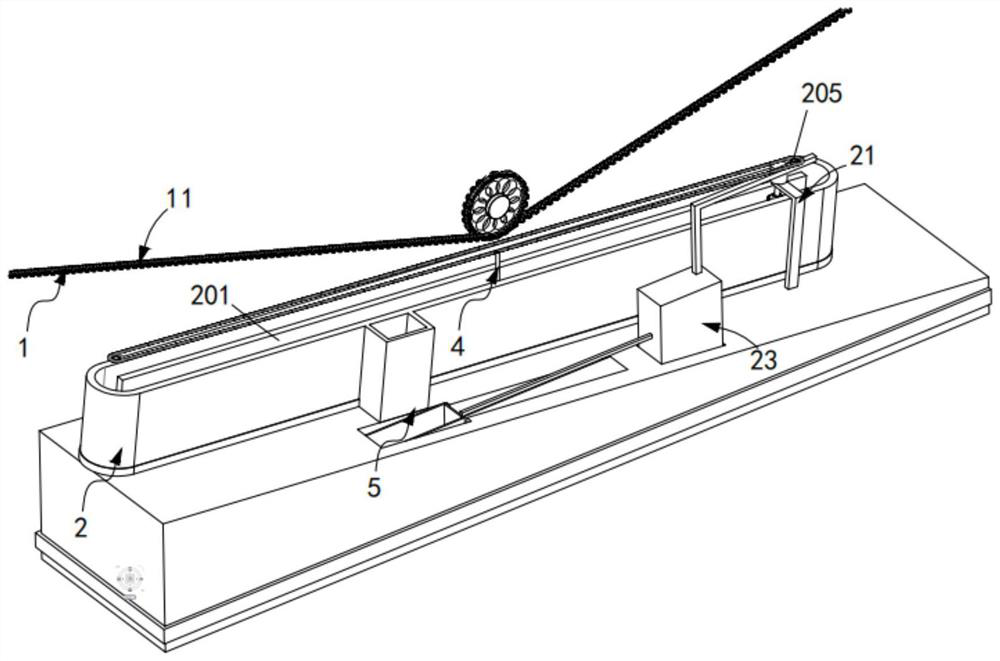

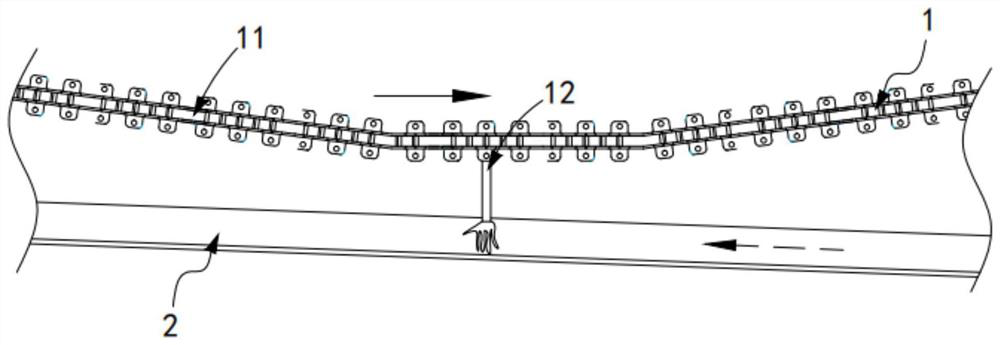

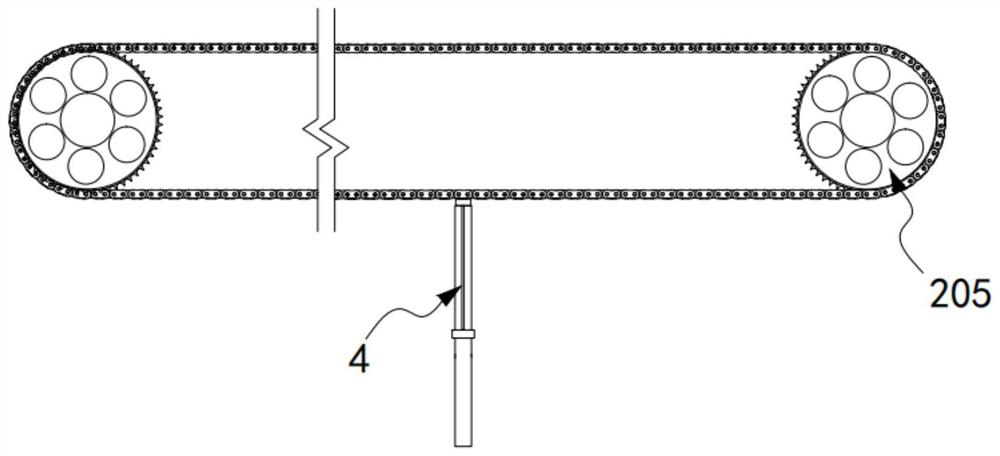

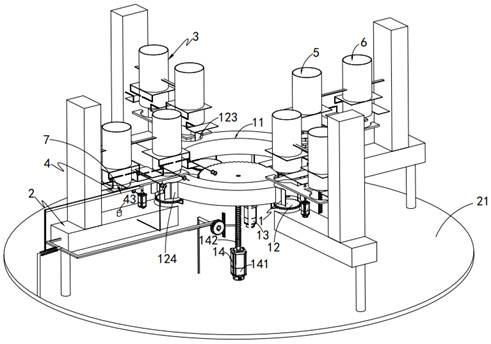

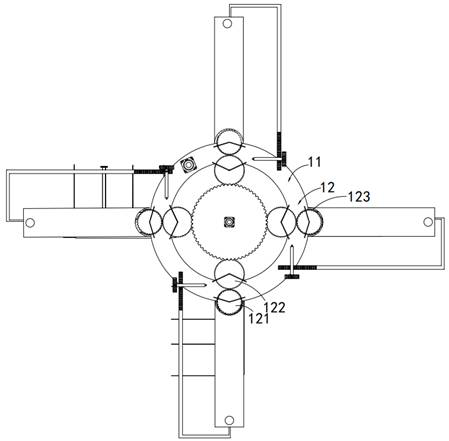

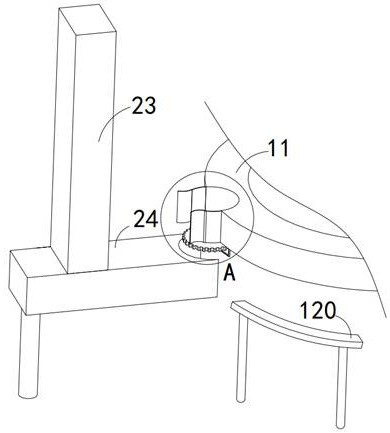

The invention relates to a solar photovoltaic panel surface cleaning unmanned aerial vehicle. The solar photovoltaic panel surface cleaning unmanned aerial vehicle comprises an unmanned aerial vehicle, a solar panel, a cleaning storage tank, a cleaning mechanism, and a guide component, wherein an installation frame is arranged below the solar panel; the cleaning storage tank is installed on the mounting frame and is arranged in parallel with the solar panel, and a water inlet is arranged on the cleaning storage tank; the cleaning mechanism comprises a water feeding component which intermittently communicates with the cleaning storage tank, a flushing component which is arranged below the unmanned aerial vehicle and is connected with the water feeding component, and a transmission componentwhich is arranged on the unmanned aerial vehicle and is used for driving the flushing component to rotate; and the guide component limits the flight guide of the unmanned aerial vehicle. During the flight process of the unmanned aerial vehicle, the flushing component is rotated through the transmission component, and then the surface of the solar panel is flushed by matching with the water feeding component. The solar photovoltaic panel surface cleaning unmanned aerial vehicle solves the technical problem of poor cleaning effect when water is sprayed on the surface of the solar panel withoutdirectly brushing the solar panel.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

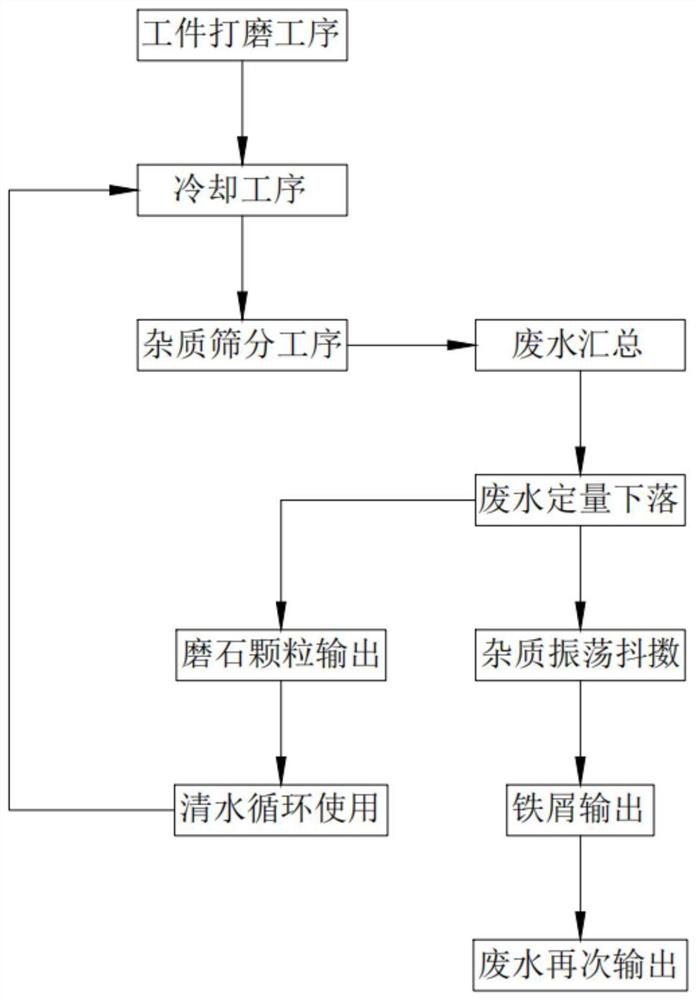

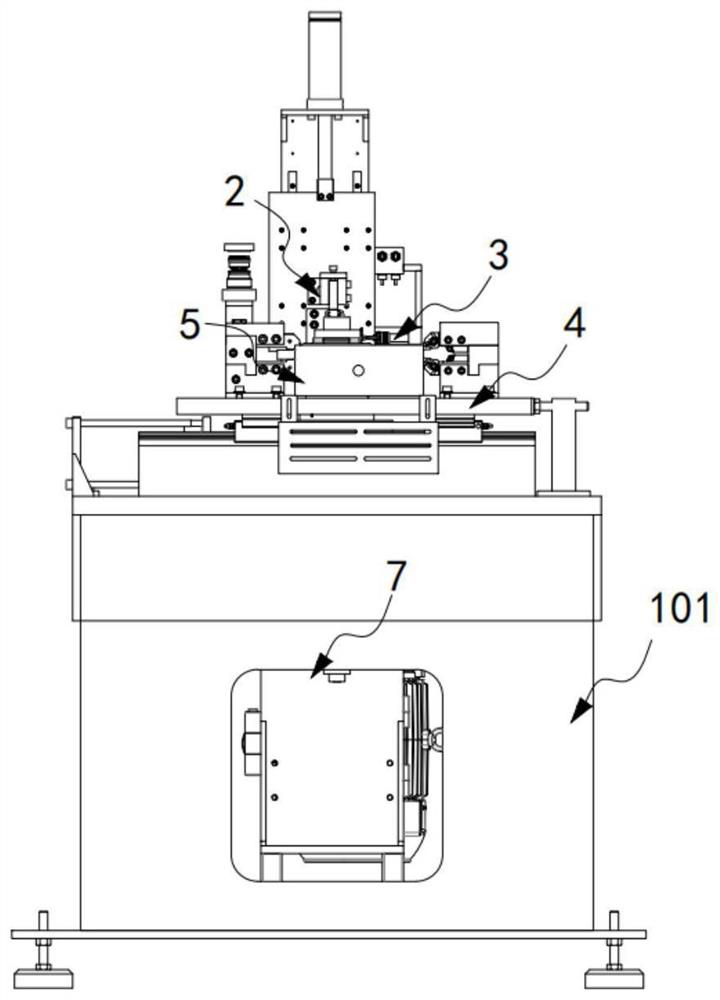

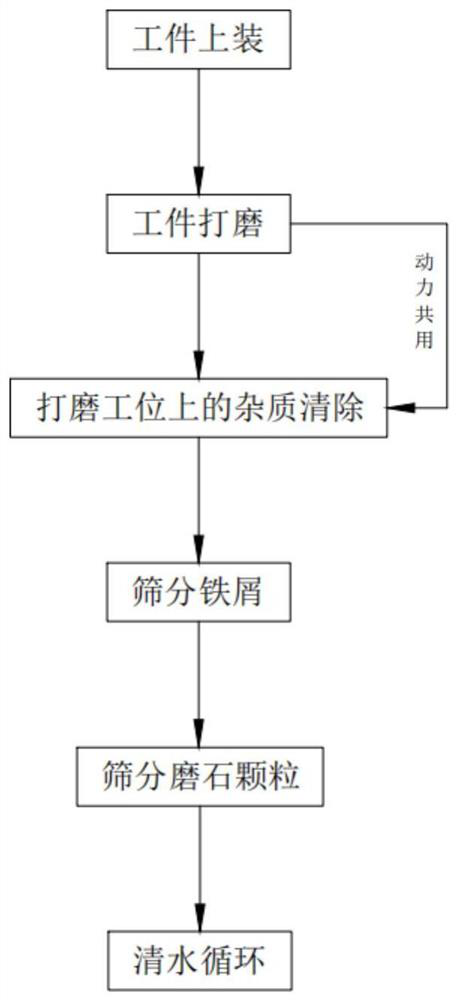

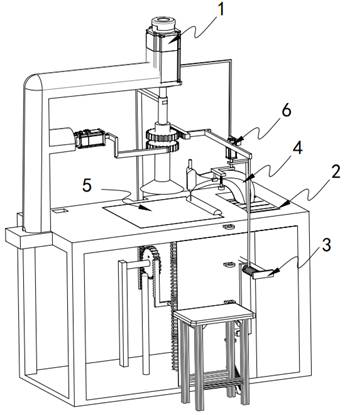

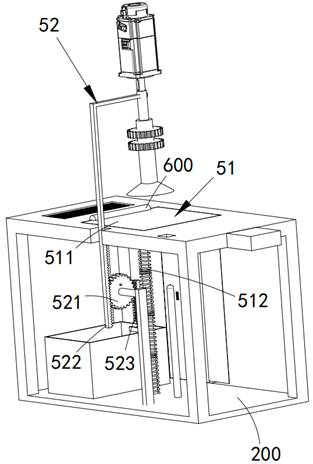

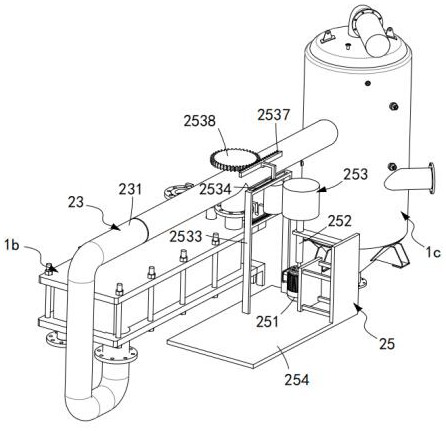

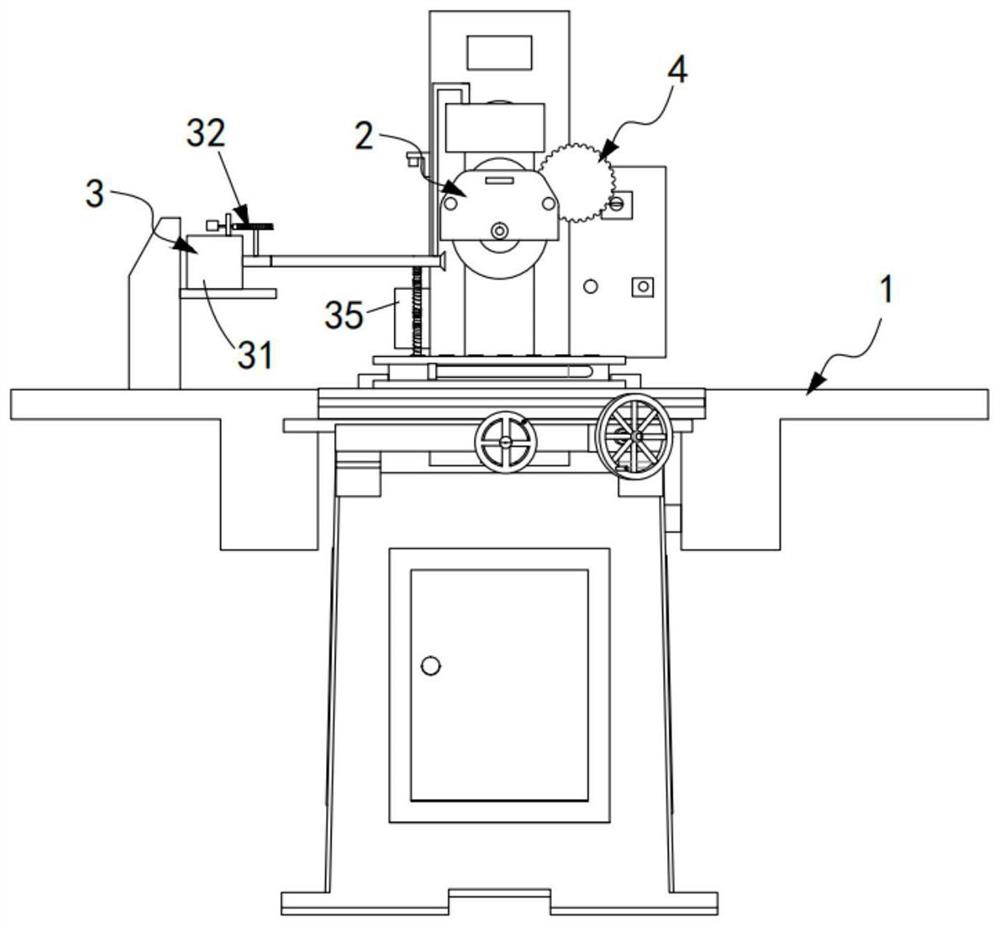

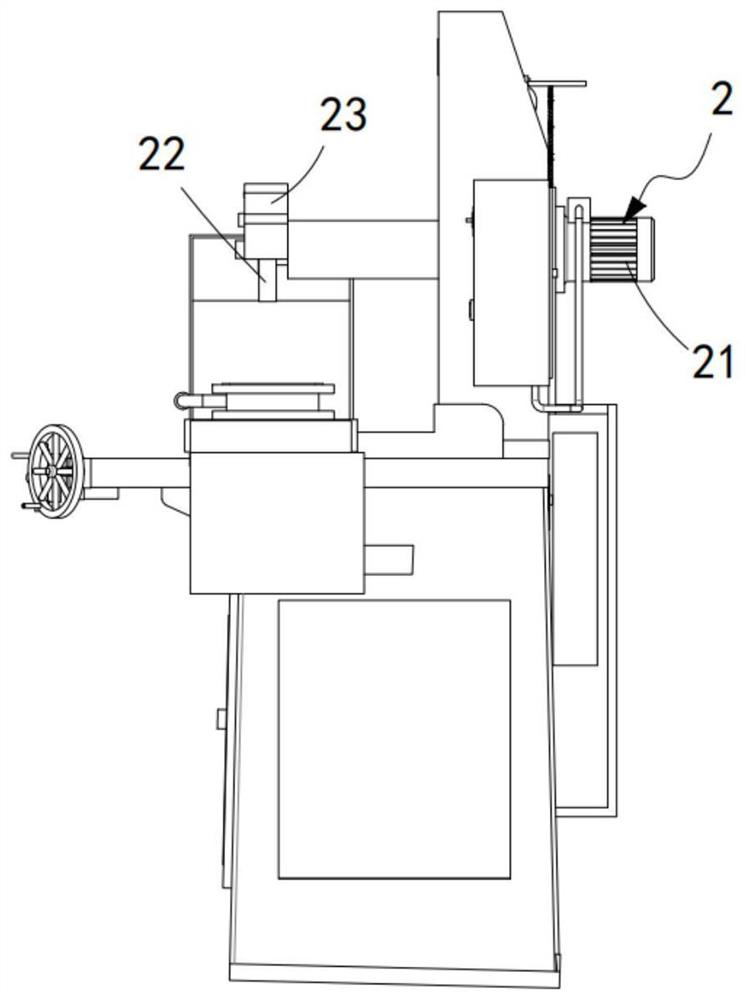

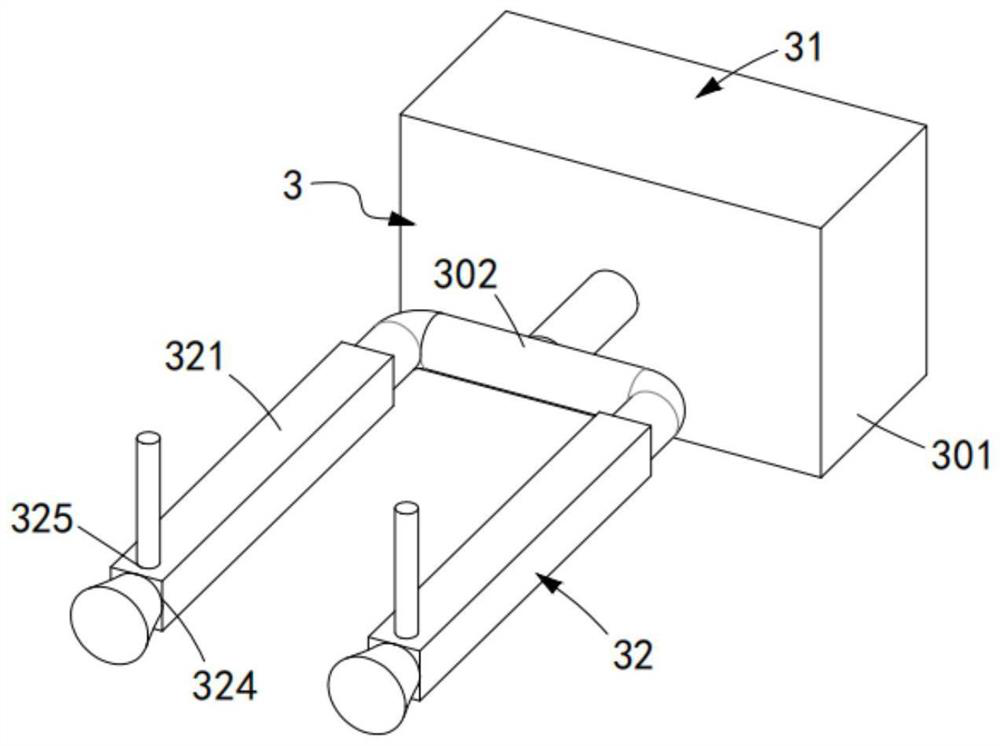

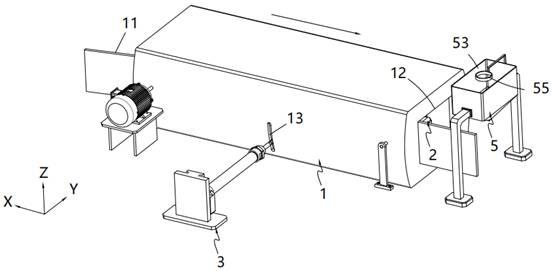

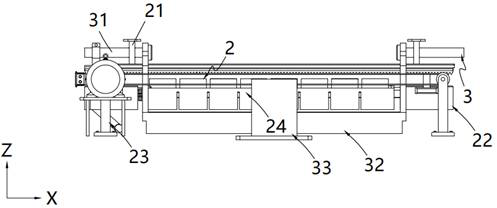

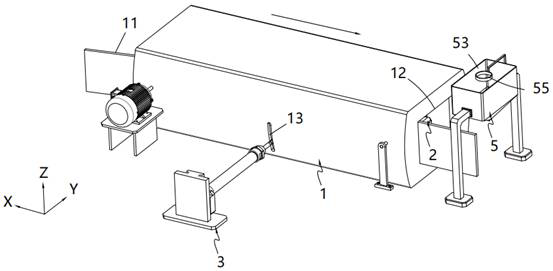

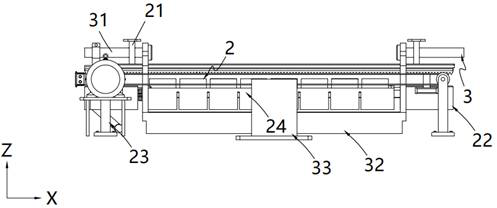

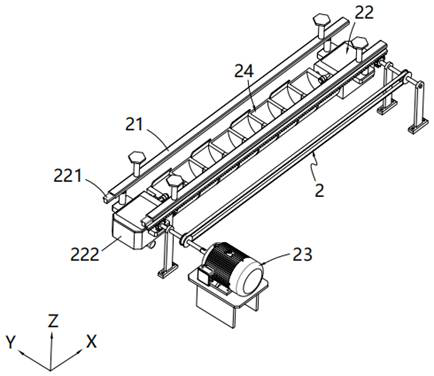

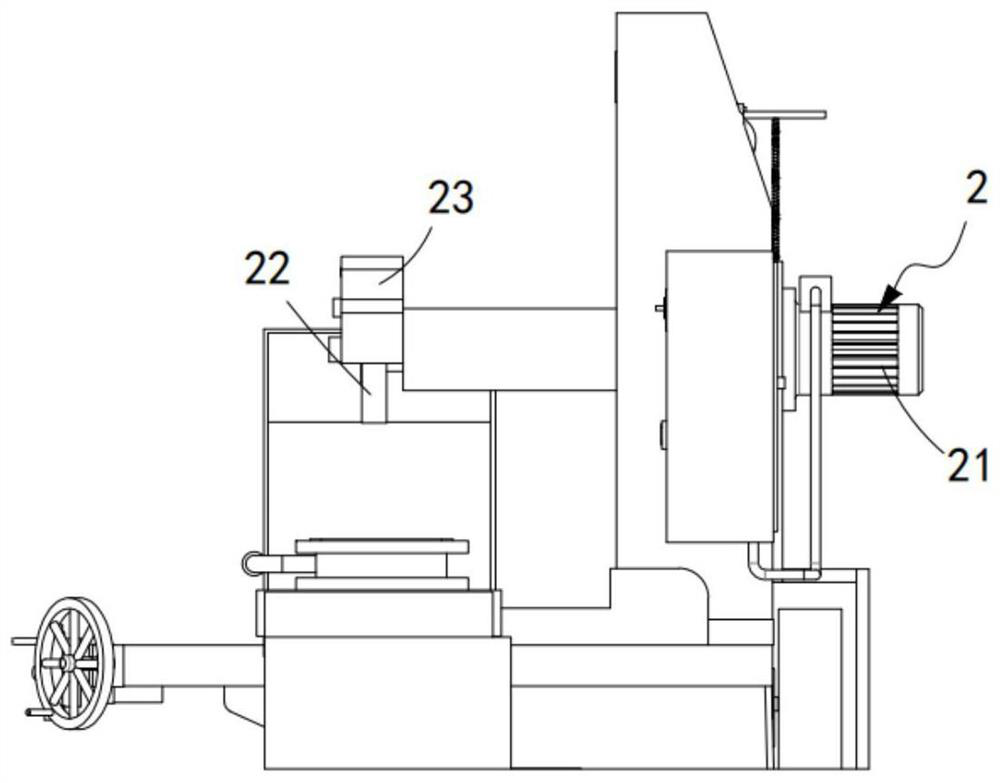

Cooling liquid recovery process for six-axis grinding machine

InactiveCN112621567AEasy to useAchieve clearingGrinding/polishing safety devicesPhysical chemistryWastewater

The invention relates to a cooling liquid recovery process for a six-axis grinding machine. The process comprises a workpiece grinding process, a cooling process and an impurity screening process, wherein the impurity screening process comprises the following steps: 1, gathering wastewater; 2, quantitatively dropping the wastewater; 3, shaking off impurities by oscillation; 4, outputting scrap iron; 5, outputting clean water; 6, outputting millstone particles; and 7, recycling clear water. The technical problems that scrap iron and millstone particles cannot be discharged in time, consequently, the water flow is low, output of much water cannot be achieved, and nearly equal amount of water circulates and flows back in time are solved.

Owner:浙江威步机器人股份有限公司

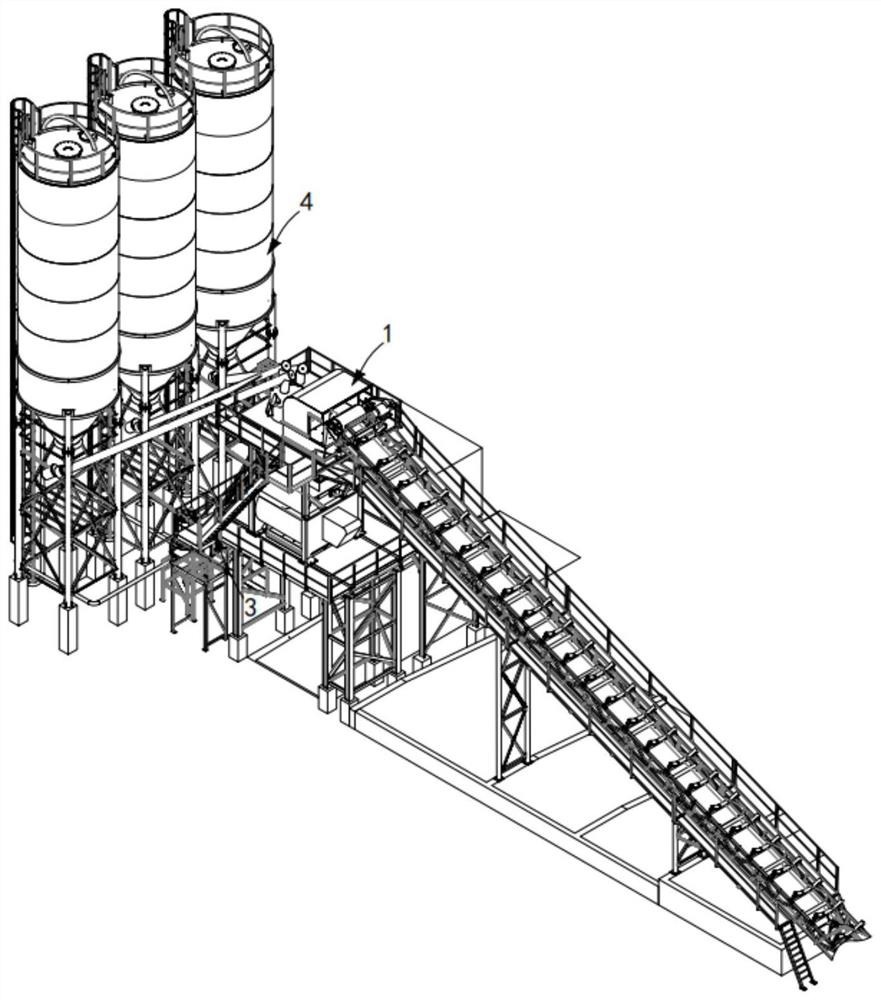

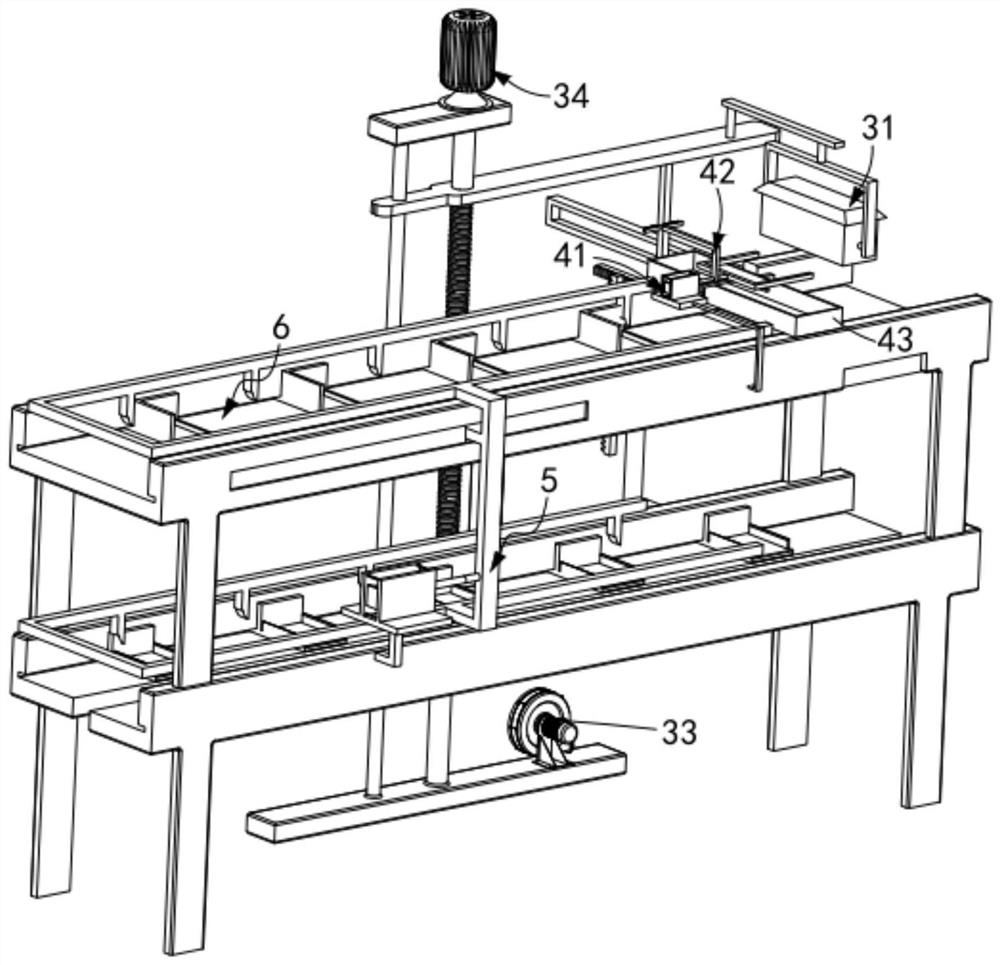

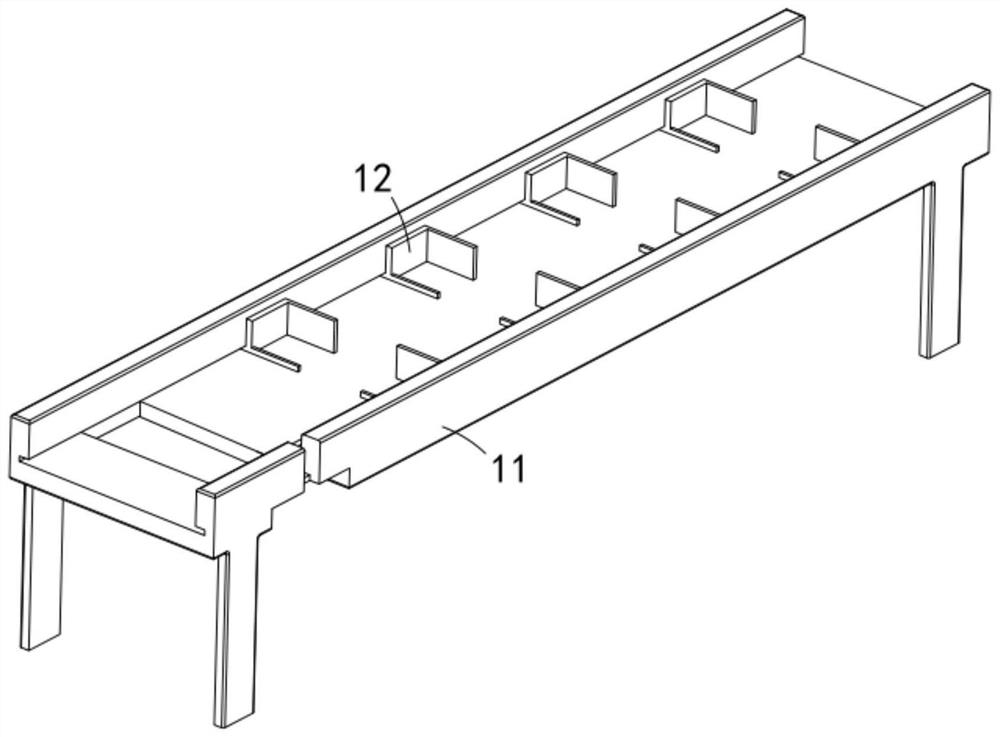

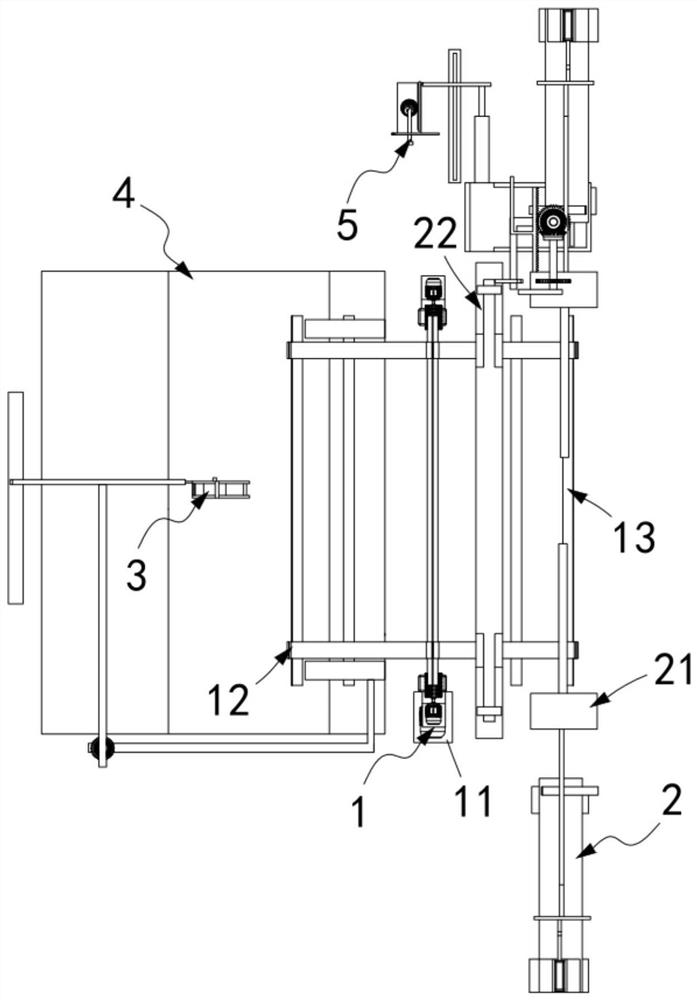

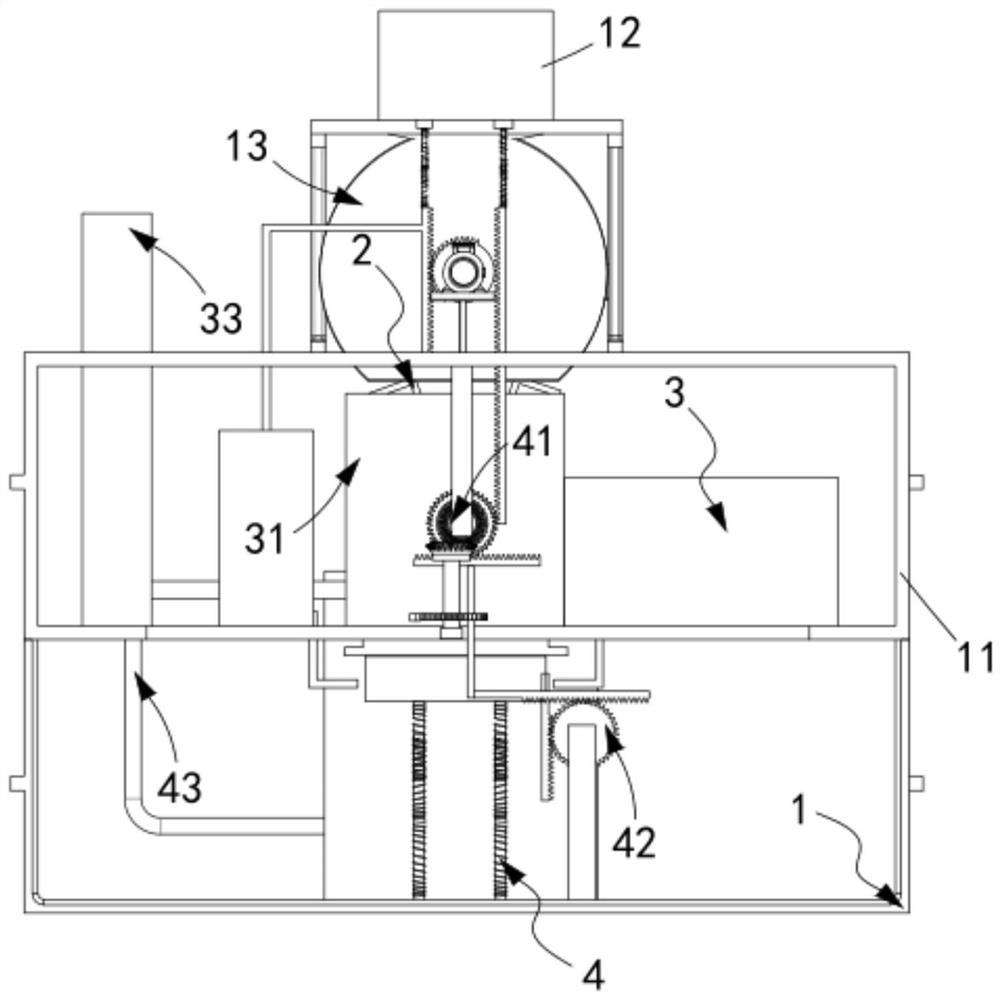

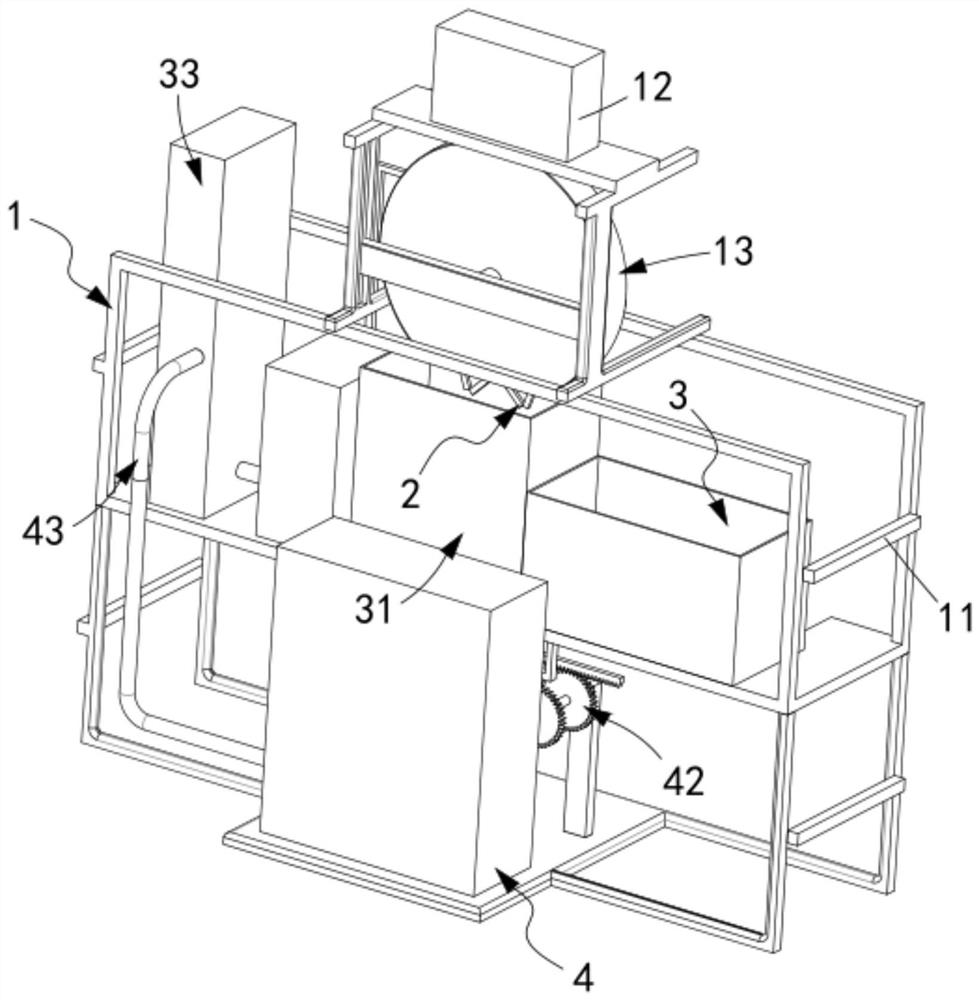

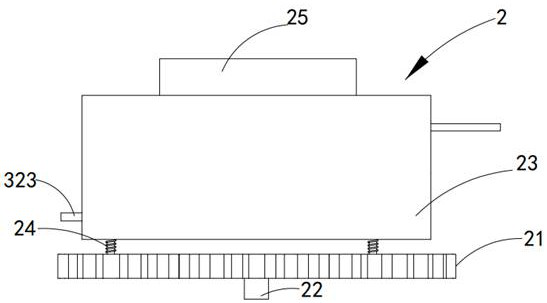

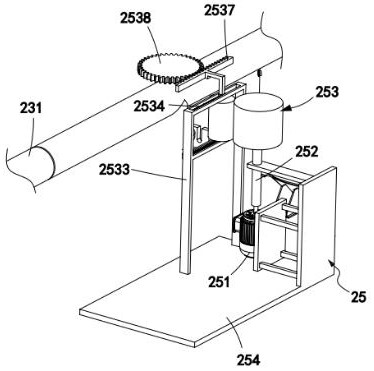

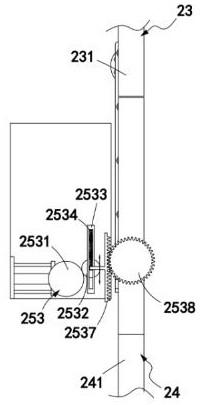

Accurate batching system for rubber and plastic processing

InactiveCN112622085ASimple structureReduce manufacturing costProcess engineeringIndustrial engineering

The invention relates to an accurate batching system for rubber and plastic processing. The accurate batching system comprises a feeding mechanism, a raw material proportioning mechanism, a conveying mechanism and a mixer, wherein the feeding mechanism comprises a driving assembly, a discharging assembly and a shaking assembly; the raw material proportioning mechanism comprises a balance assembly, a control assembly, a limiting assembly, a first adjusting assembly and a second adjusting assembly; the conveying mechanism is arranged at the lower end of the balance assembly and comprises a push-out assembly for driving the balance assembly to discharge and a horizontal conveying assembly arranged below the push-out assembly; and the mixer is arranged at an input port of the horizontal conveying assembly. The technical problems that in the material taking work of various assistants, the steps are tedious, the amount is not easy to control, the assistants need to be manually blended combined with a weighing device little by little, meanwhile, the proportioning accuracy is poor, and the automation degree is low are solved.

Owner:CHANGXING HELIJIA PLASTIC PROD CO LTD

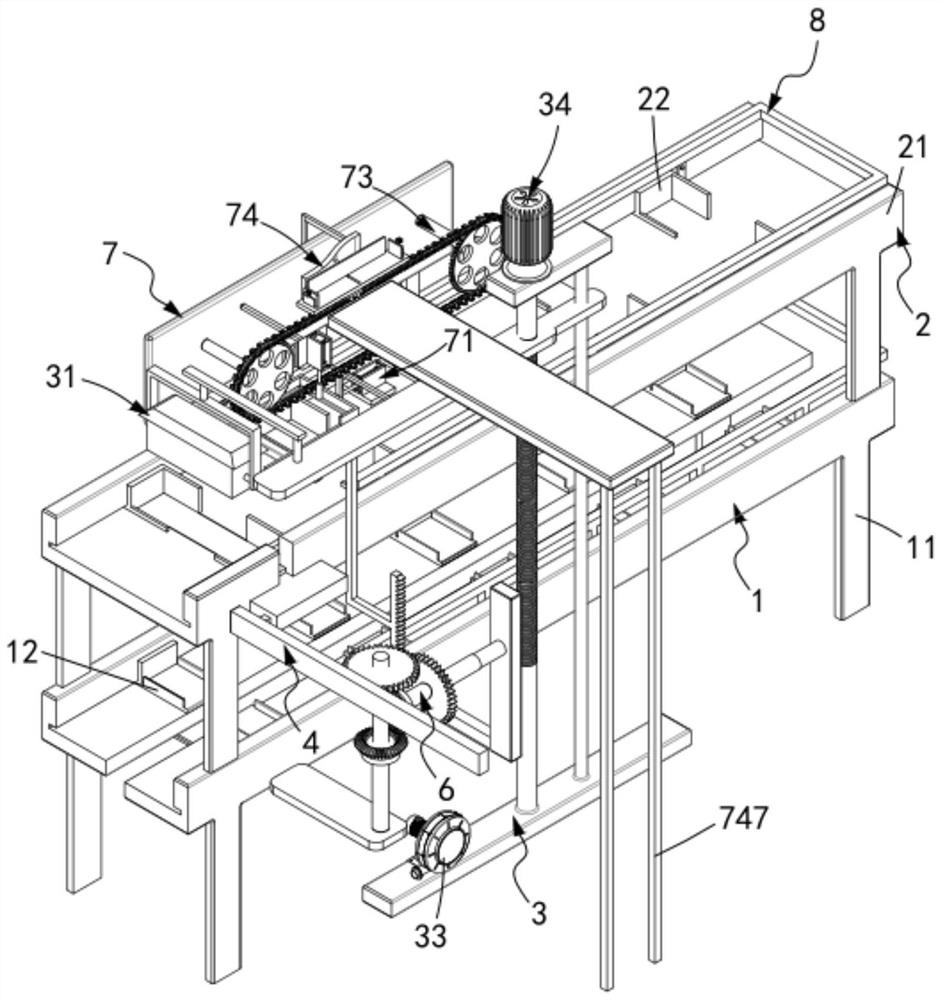

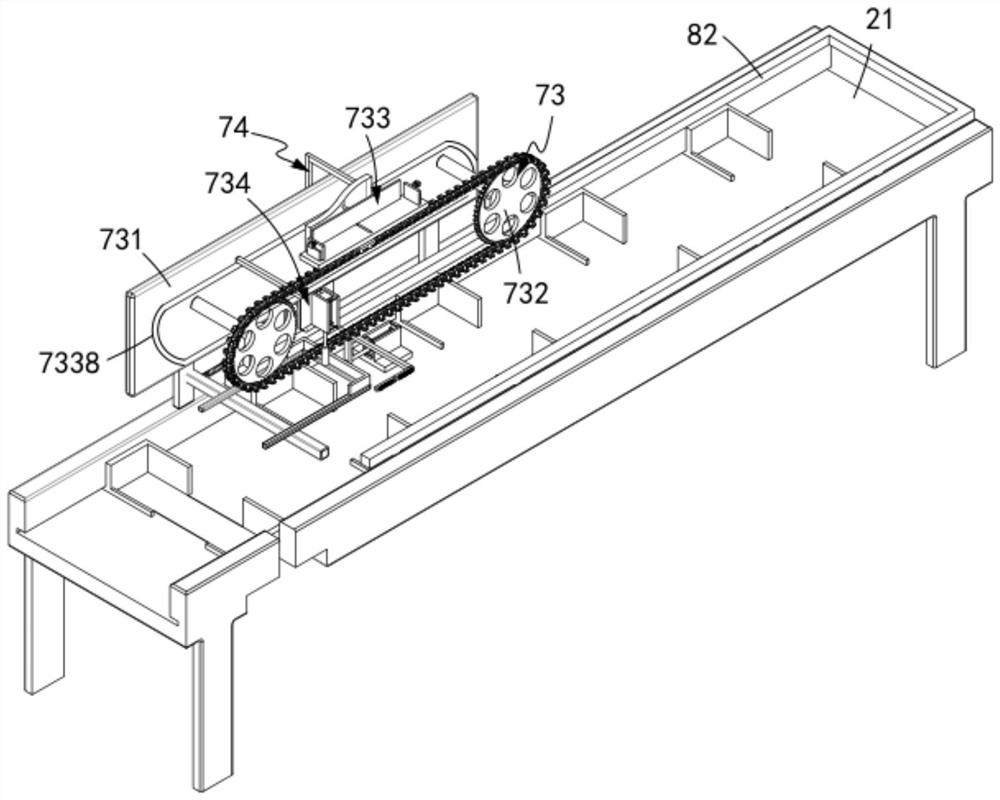

Automatic charging plug assembling device

InactiveCN111817110AHigh outputHigh degree of automation of work outputContact member assembly/disassemblyEngineeringStructural engineering

The invention relates to an automatic charging plug assembling device. The device comprises: a plug transmission mechanism which comprises a transmission track a and a bearing plate a; a shell transmission mechanism which is arranged above the plug transmission mechanism and comprises a transmission track b and a bearing plate b; an automatic assembling mechanism which is located at the assemblingstation and comprises a first adsorption assembly, a second adsorption assembly, a vacuum pump and a lifting assembly, wherein a horizontal pushing assembly is arranged on the assembling station andis in synchronous transmission with the lifting assembly through a first transmission part; and a finished product discharging mechanism which comprises a stripping assembly, a control assembly, a switching assembly and an arrangement assembly, wherein a driving mechanism intermittently and synchronously moves the bearing plate a and the bearing plate b towards the output end of the shell transmission mechanism. The technical problems that a plug is not easy to stand on a table top, a shell needs to be placed on the table top through manual overturning, the work is tedious, and the automationdegree is poor are solved.

Owner:长兴梦晨节能设备有限公司

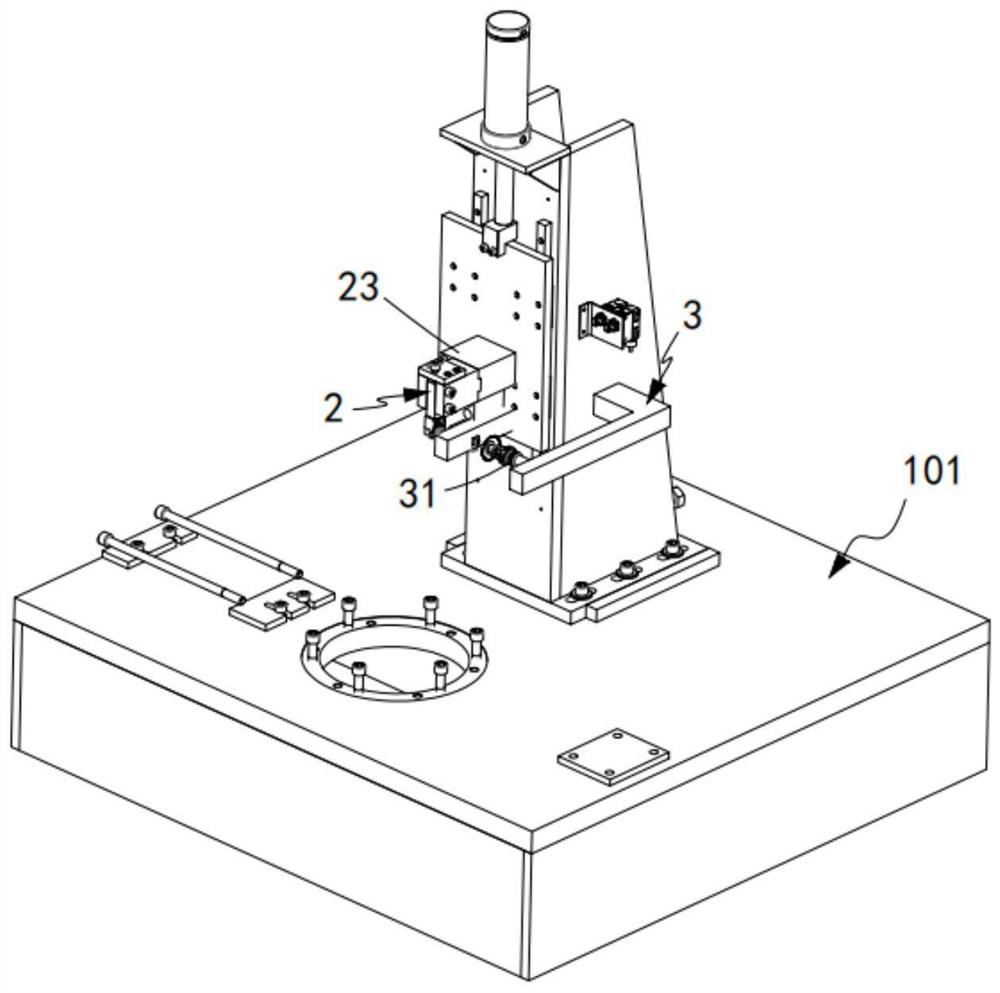

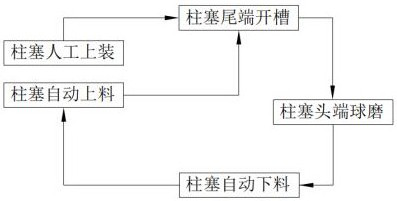

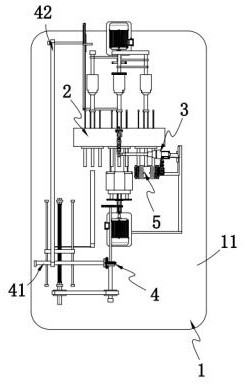

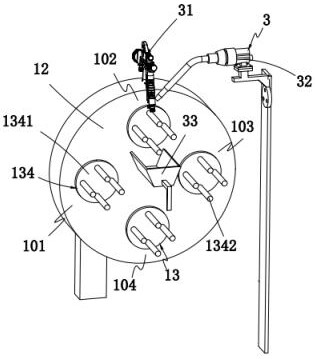

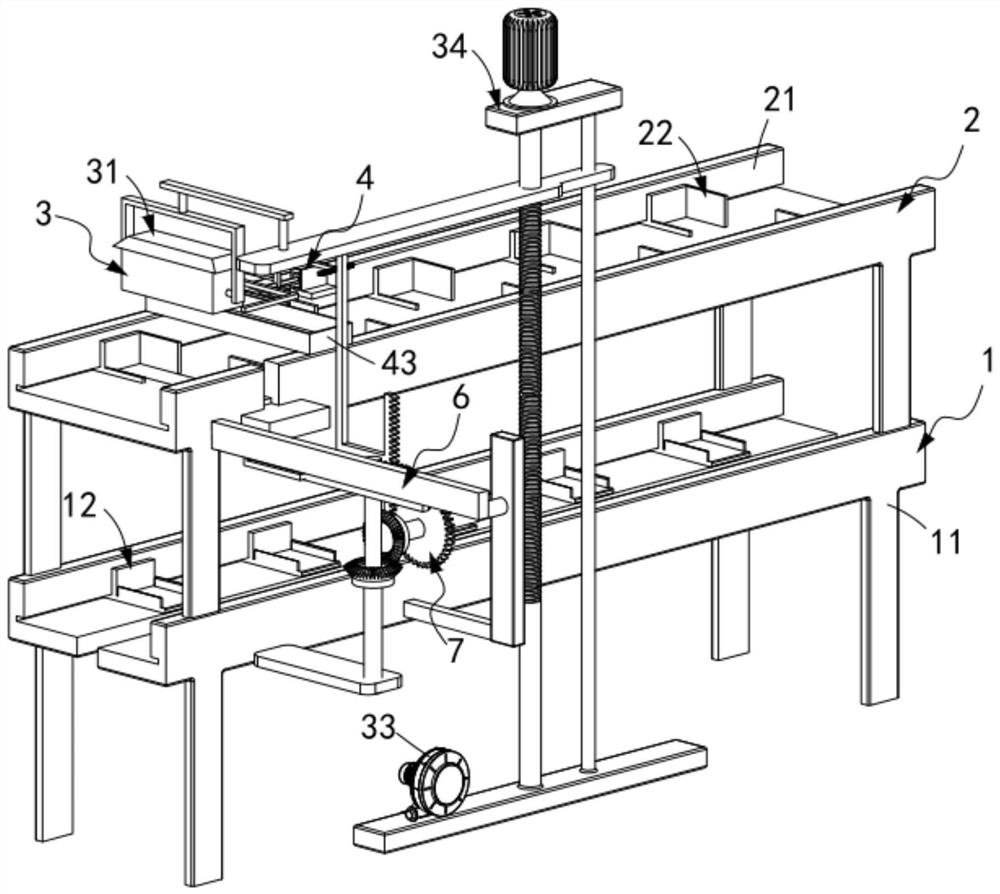

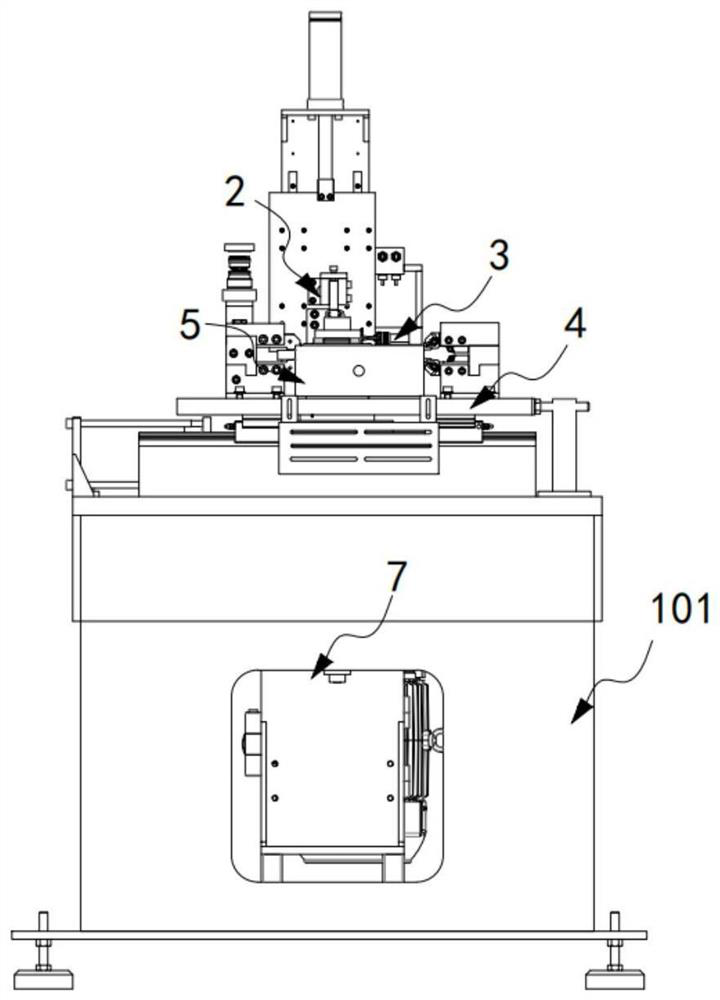

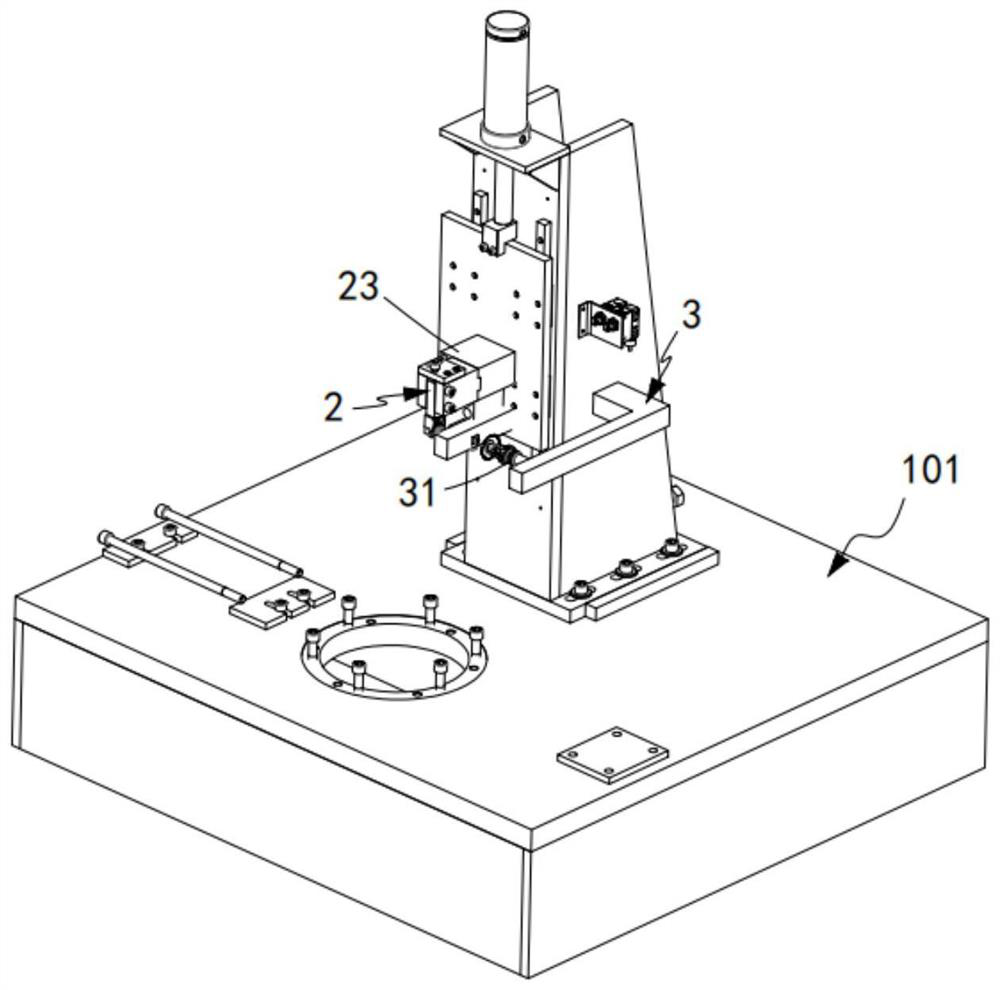

High-precision plunger forming process

InactiveCN113601124ASave extra processing timeIncrease productionOther manufacturing equipments/toolsMetal working apparatusEngineeringMachining

The invention provides a high-precision plunger forming process. The high-precision plunger forming process comprises the following steps that 1, plungers are manually loaded; 2, the tail ends of the plungers are slotted, a clamping part moves to a second driving assembly, a clamping assembly is matched with a positioning shaft to clamp the plungers, a slotting mechanism carries out slotting work on the plungers, and after slotting work of all the plungers is completed, a first driving assembly drives a rotary disc to continue to rotate to drive the plungers to be switched to a ball milling station; 3, the head ends of the plungers are ball-milled; 4, the plungers are automatically discharged; and 5, the plungers are automatically fed. The problems that when the plungers are machined again, the plungers are manually loaded to a machining lathe, and after machining is completed, the plungers are manually taken down and stored, so that the manual labor force is consumed, and meanwhile the plunger machining efficiency is very low are solved.

Owner:JIANGSU HENGYUAN HYDRAULIC

Assembly device for charger shell production

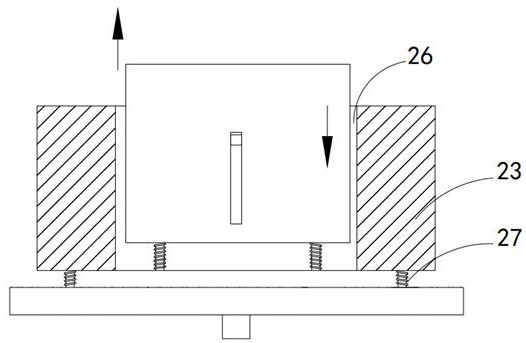

InactiveCN111805210AAvoid damageHigh degree of automationMetal working apparatusEngineeringVacuum pump

The invention relates to an assembly device for charger shell production. The assembly device comprises a plug conveying mechanism, a shell conveying mechanism, an automatic assembly mechanism and a finished product discharging mechanism, wherein the plug conveying mechanism comprises a conveying track a and a bearing plate a; the shell conveying mechanism is arranged above the plug conveying mechanism and comprises a conveying track b and a bearing plate b; the automatic assembly mechanism is positioned at an assembly station and comprises a first adsorption assembly, a second adsorption assembly, a vacuum pump and a lifting assembly; the finished product discharging mechanism comprises a stripping assembly, a control assembly and a collecting box; the shell conveying mechanism and the plug conveying mechanism realize intermittent movement of the bearing plate a and the bearing plate b towards the output end of the shell conveying mechanism through a driving mechanism; and a horizontal pushing assembly is arranged at the assembly station, penetrates through the conveying track b and is in smooth transition connection with the conveying track b. The assembly device solves the technical problems that charger shells need to be placed manually by two hands at the same time, in addition, the alignment precision is poor, and defective products are prone to being generated.

Owner:长兴梦晨节能设备有限公司

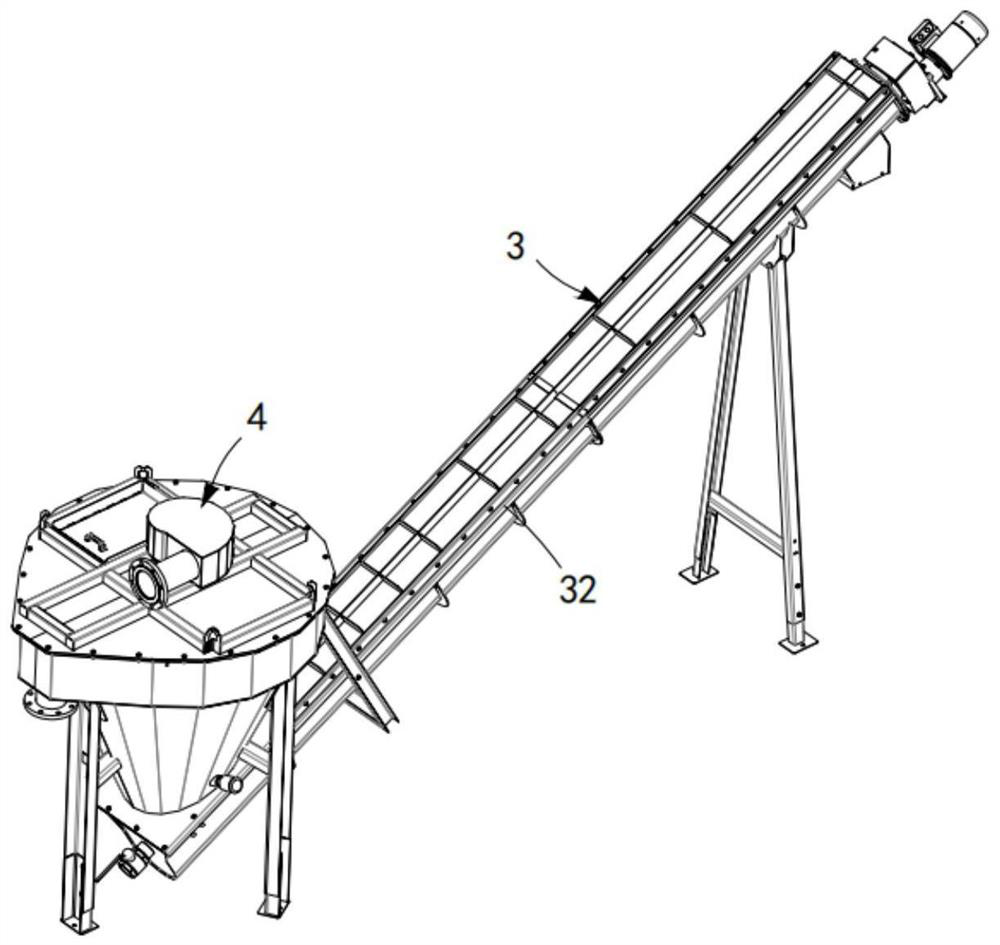

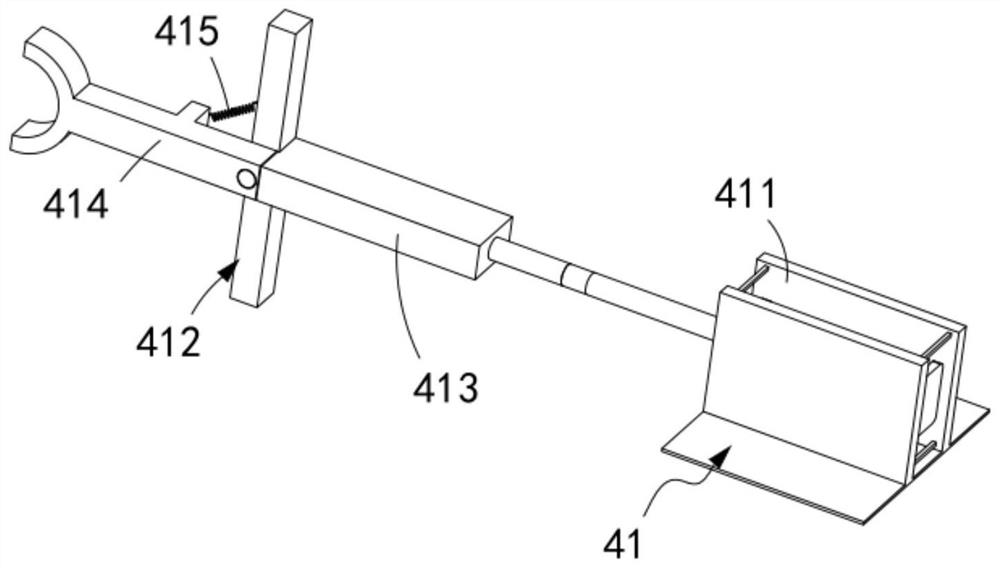

Automatic winding equipment for production of diversion net porous isolation film composite material

InactiveCN111634730AClose working relationshipHigh degree of automationWebs handlingMachineIsolation membrane

The invention relates to automatic winding equipment for production of a diversion net porous isolation film composite material. The equipment comprises a switching mechanism, a replacement mechanism,a glue sealing mechanism, an output mechanism and an input mechanism, wherein the switching mechanism comprises a machine frame, a revolving assembly and a winding roller element, and a winding station, a packaging station, an output station, an upper roller station and a station to be replaced are sequentially arranged on the revolving assembly in the circumferential direction; the replacementmechanism comprises a winding mechanism and a cutting mechanism, and the winding mechanism cooperates with the winding roller element to complete the clamping work of a finished product; the glue sealing mechanism is used for automatic finishing touches of composite diversion net tail after cutting on the winding roller element; the output mechanism comprises an outgoing assembly and a first linkage assembly; and the input mechanism comprises an installation assembly and a second linkage assembly. According to the equipment, the technical problems that manual automatic installation of new winding rollers after replacing rollers and manual discharging work of old winding rollers after the completion of the winding work are required, the work efficiency is low, and additional manual labor output is required are solved.

Owner:潘利斌

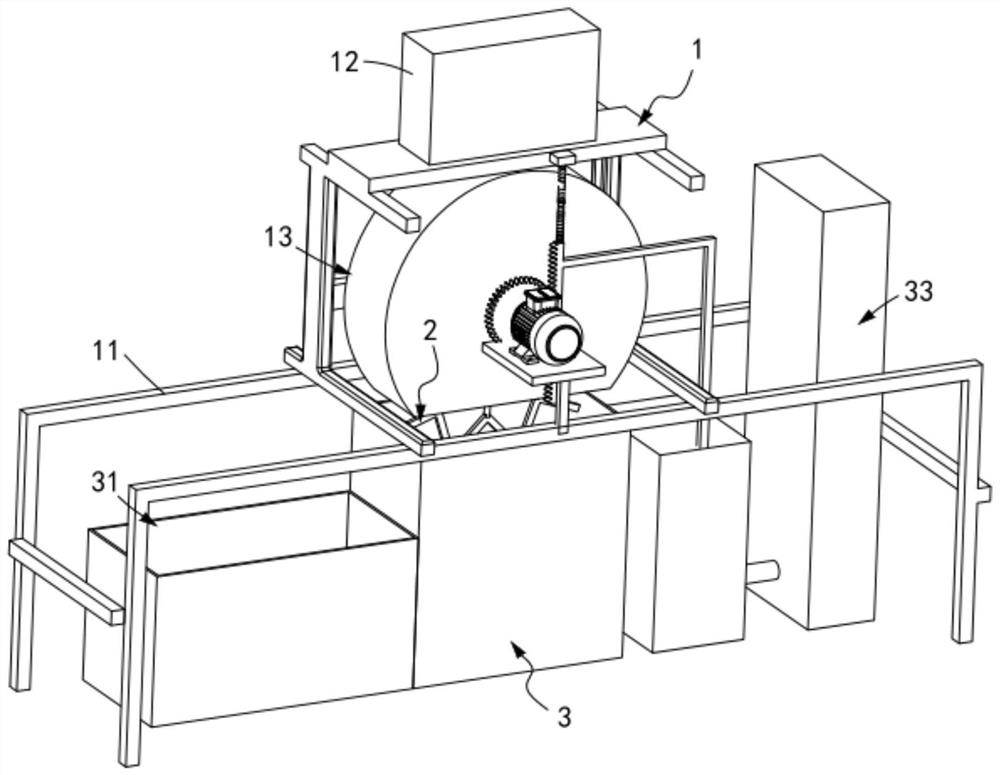

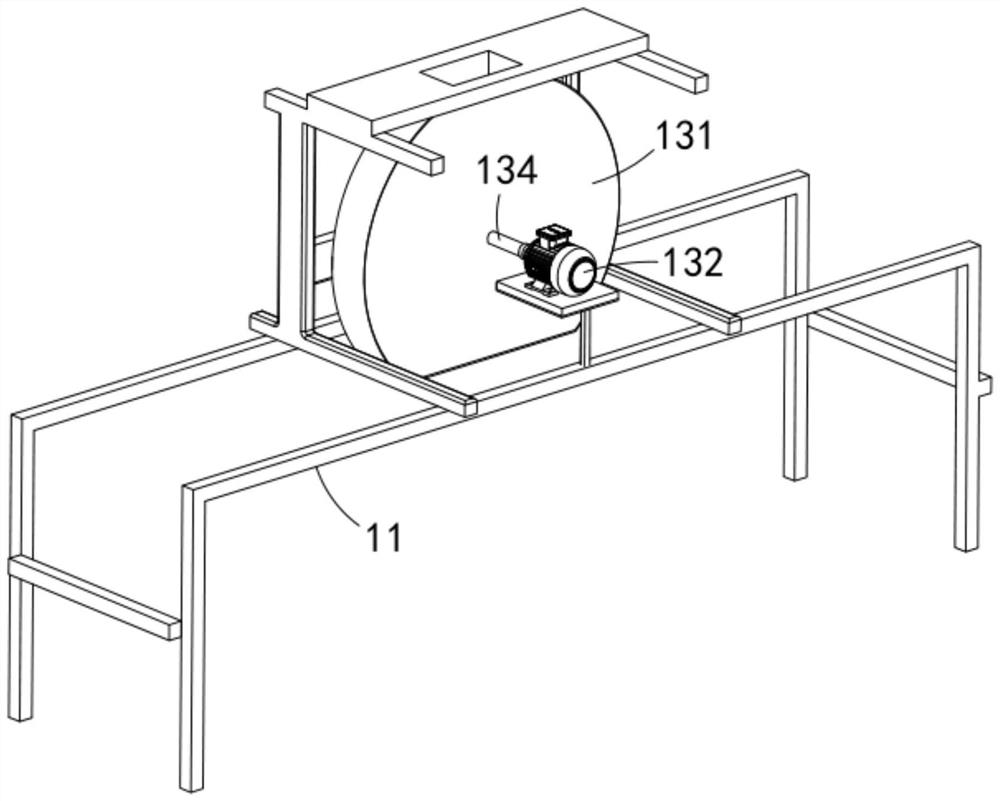

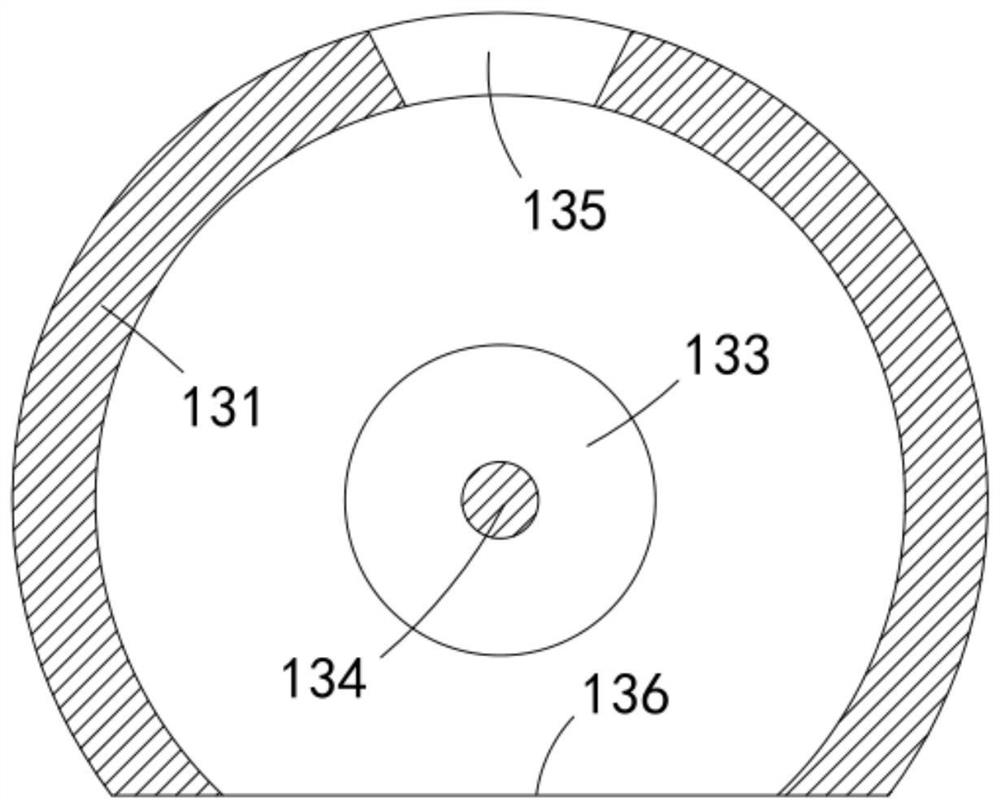

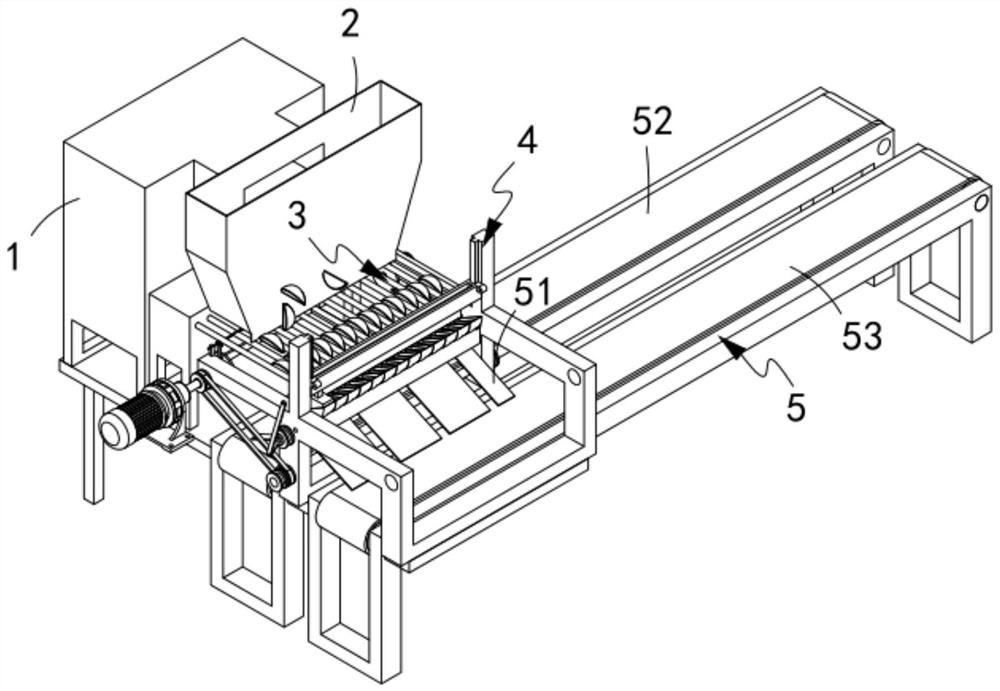

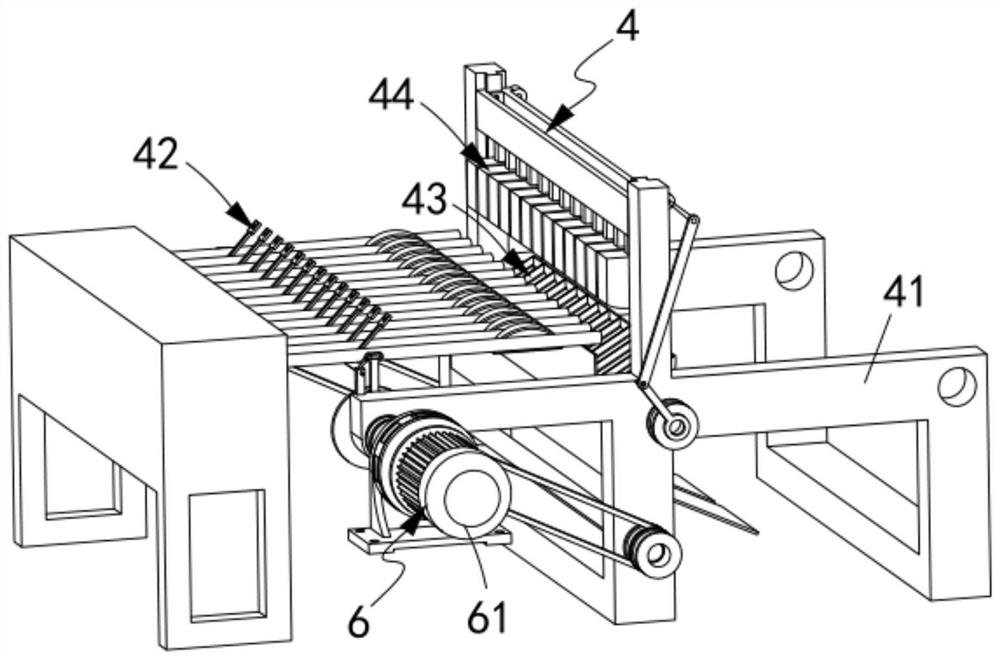

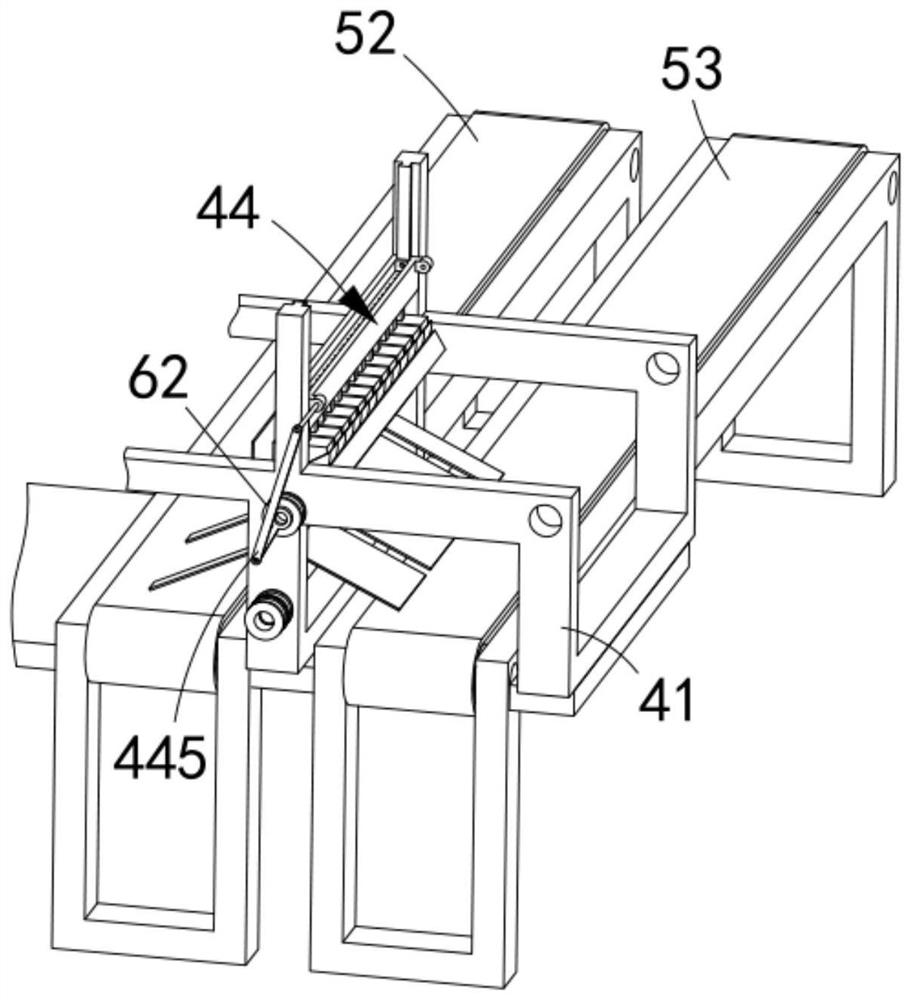

Peanut oil processing and shelling equipment

InactiveCN111841863ARealize automatic outputAvoid accumulationFatty-oils/fats productionHuskingMechanical engineeringIndustrial engineering

The invention relates to peanut oil processing and shelling equipment. The equipment comprises a mounting mechanism, a shelling mechanism, and a separation mechanism, wherein the mounting mechanism comprises a discharging tank arranged on a rack and a driving assembly arranged below the discharging tank; the shelling mechanism comprises a conveying assembly driven to rotate along the circumferenceby the driving assembly and a material pressing assembly mounted on the driving assembly and matched with the conveying assembly to grind peanuts; and the separation mechanism comprises a screening assembly arranged below the driving assembly, a guiding assembly arranged on the other side of the material pressing assembly relative to the screening assembly and matched with the conveying assemblyto pull out a shell in the screening assembly, and a pressurizing assembly communicated with the screening assembly and in synchronous conveying with the driving assembly. The equipment disclosed by the invention solves the technical problems that separating work of the peanut kernel and peanut shell is complex, manual quality inspection work is needed, and the automation degree is low.

Owner:袁明杰

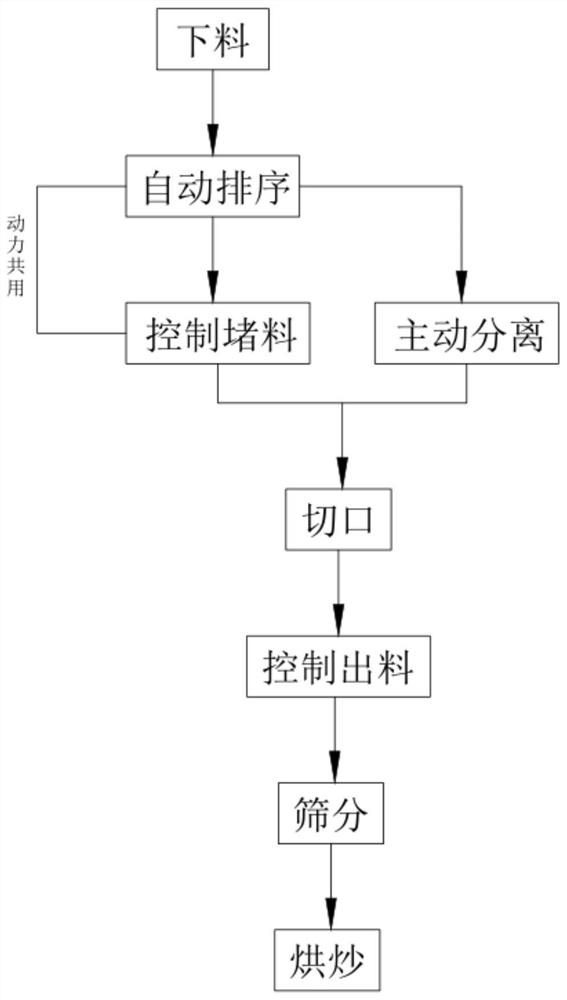

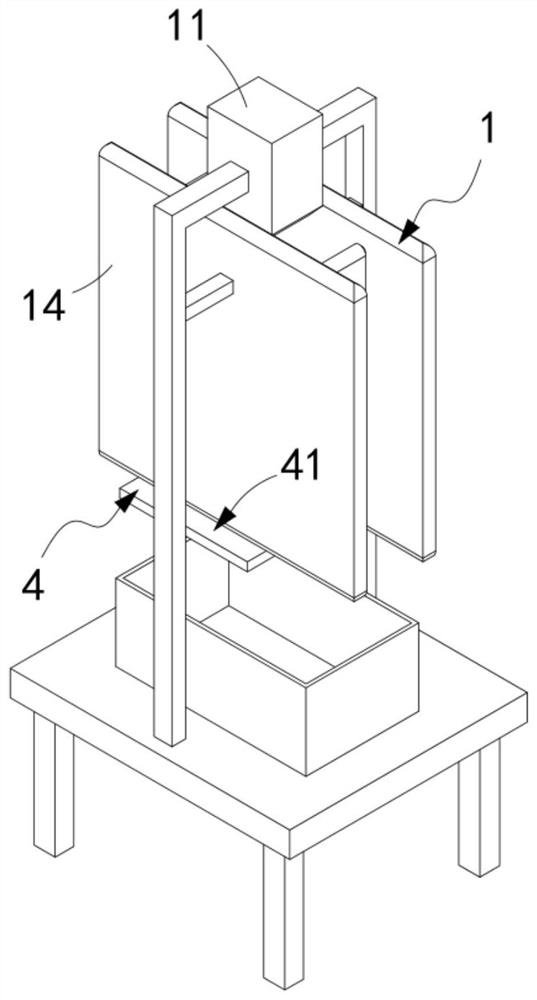

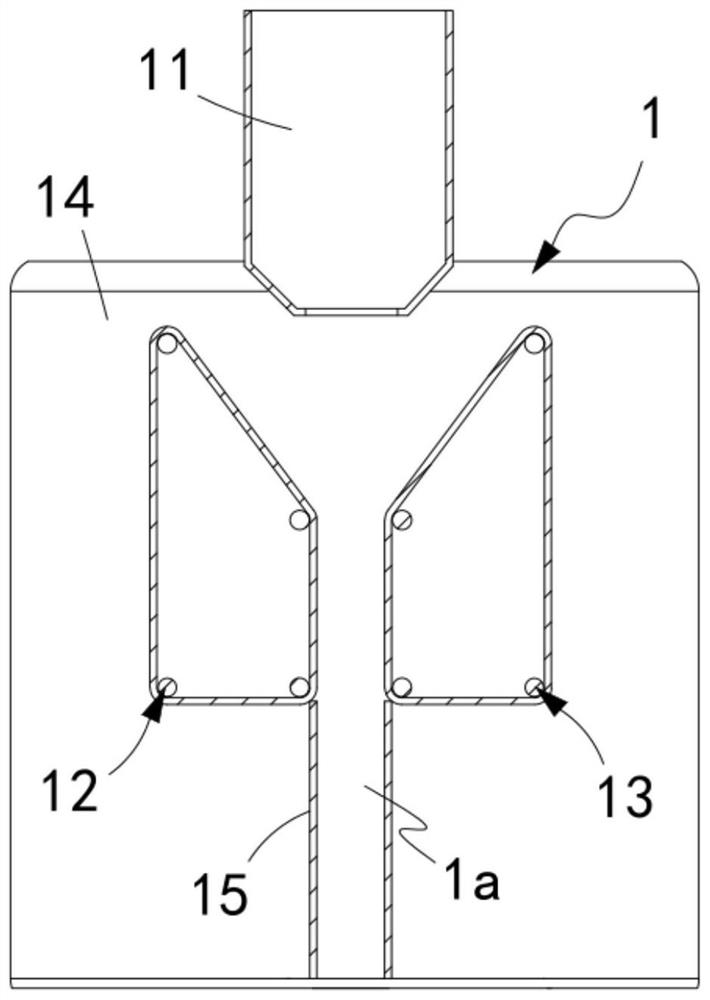

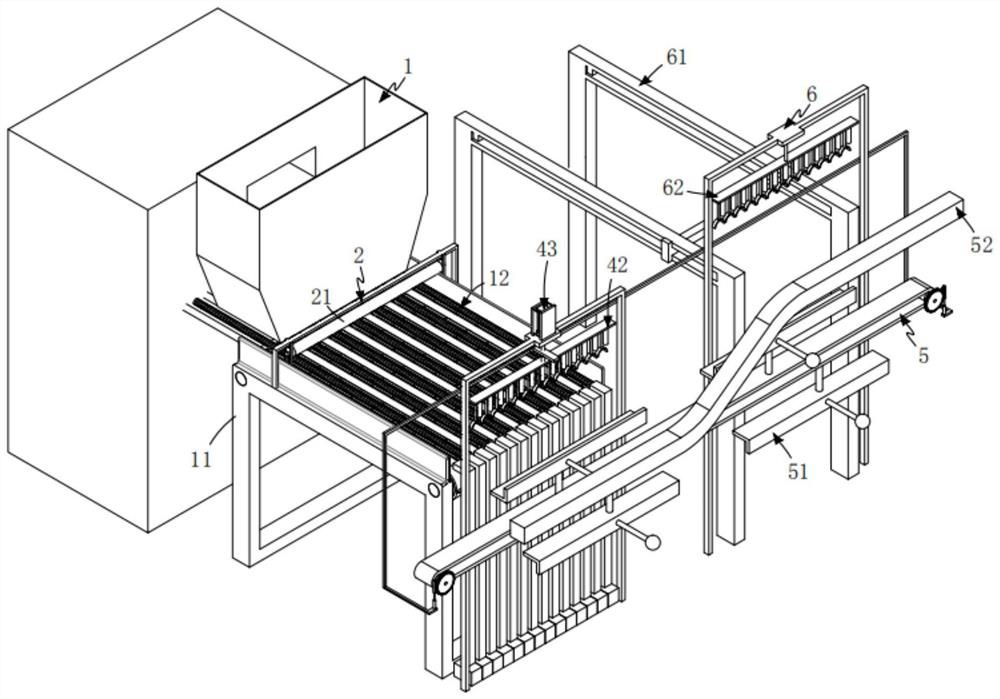

Processing technology of stir-fried pumpkin seeds convenient to shell

The present invention relates to a processing technology of stir-fried pumpkin seeds convenient to shell. The processing technology comprises the following steps: step one, feeding; step two, automatic sequencing; step three, controlling material blocking; step four, active separation, wherein in synchronization with the step three, a material blocking assembly drives a transmission assembly to synchronously transmit, the transmission transmission assembly drives a supporting rod to move, and inserting assemblies move towards gaps between two adjacent pumpkin seeds and realize separation of the integrally bonded pumpkin seeds in the moving process; step five, cutting, wherein a translation process of the inserting assemblies drives an opening mechanism to synchronously move to complete anautomatic cutting operation of middle parts of the pumpkin seeds; step six, discharging controlling; step seven, screening; and step eight, baking and frying. The processing technology solves technical problems that partial pumpkin seeds are adhered together under adhesion of the pulp and not separated thoroughly due to incomplete cleaning, and the targeted single cutting operation of the pumpkinseeds cannot be realized during the cutting operation.

Owner:阜阳运筹生产力促进中心有限公司

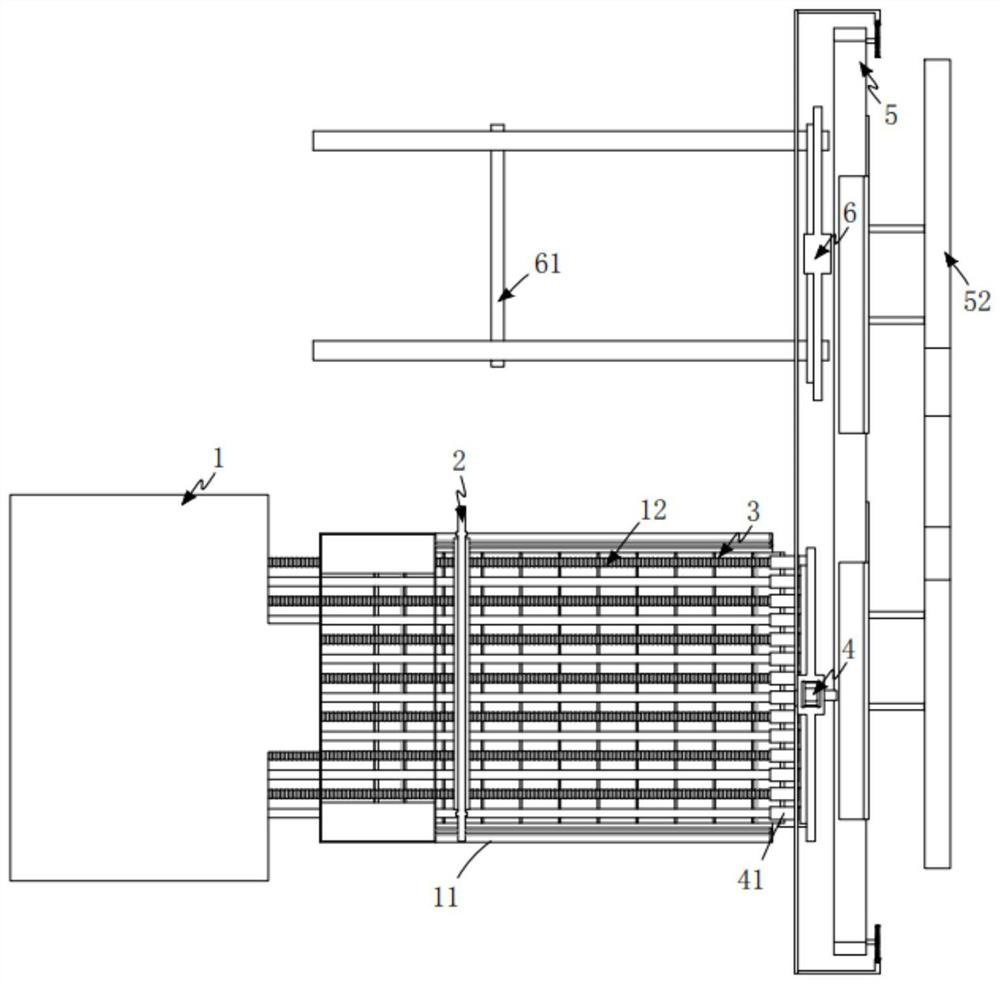

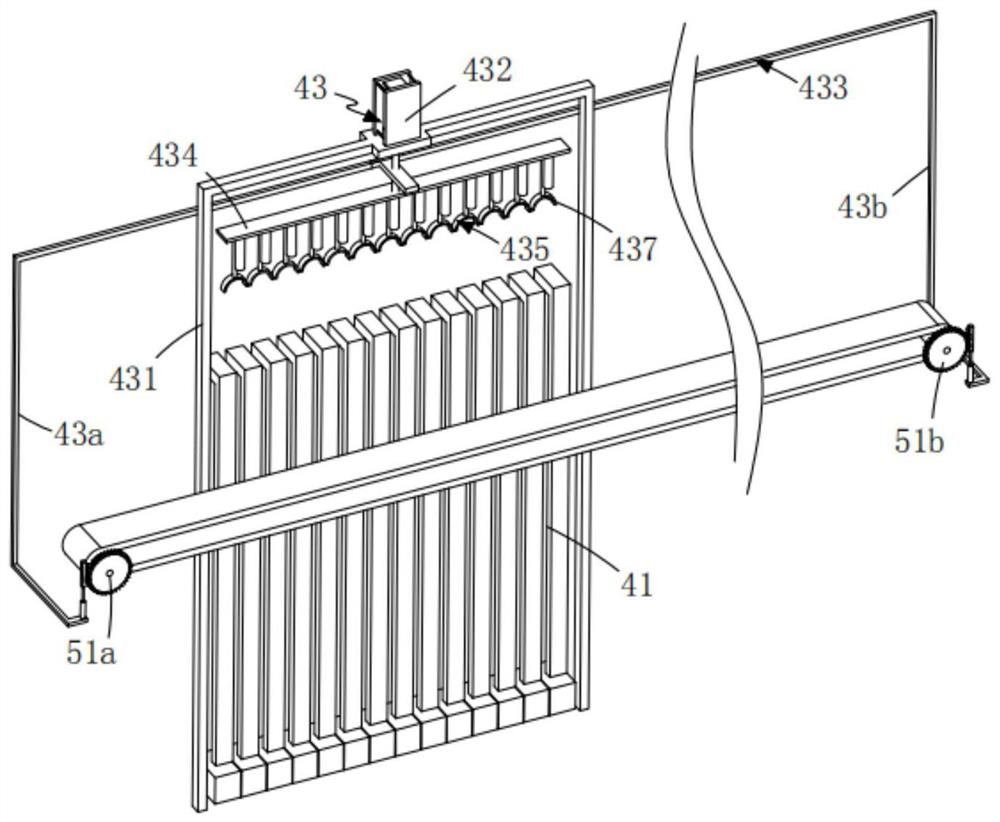

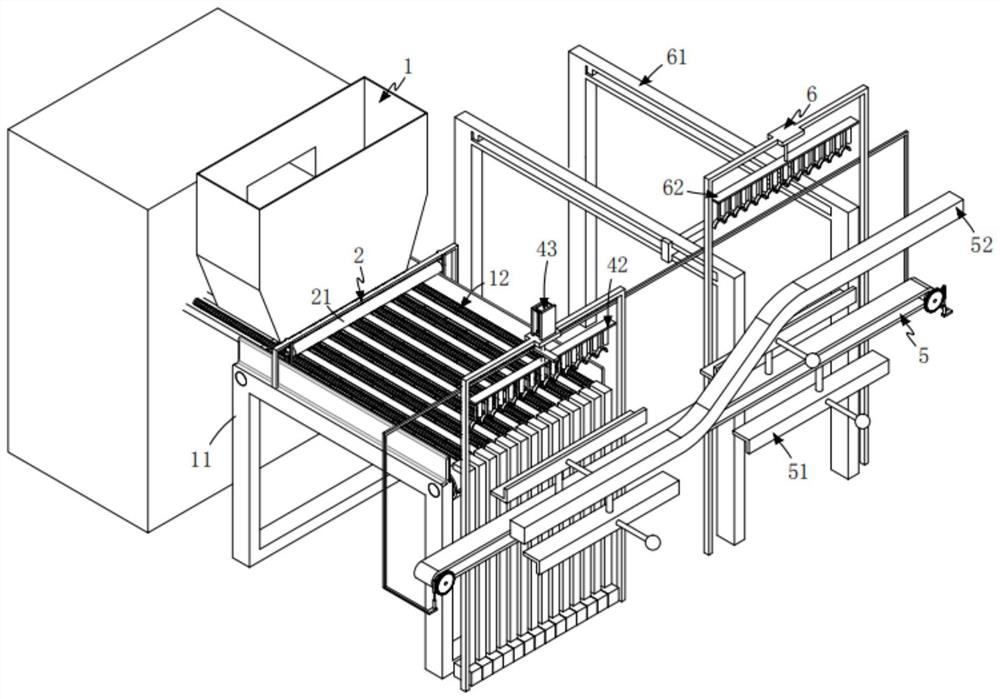

Semi-automatic assembly equipment for electronic components for electric appliances

InactiveCN112318005ACloselySave effective land occupationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention relates to semi-automatic assembly equipment for electronic components for electric appliances. The equipment comprises a laying mechanism, a height limiting mechanism, a deviation rectifying mechanism, a first welding mechanism, a transport mechanism and a second welding mechanism, wherein the laying mechanism comprises a rack and first transmission assemblies; a roll shaft of the height limiting mechanism is driven by a third driving mechanism to rotate; the deviation rectifying mechanism comprises second transmission assemblies, spacing assemblies and a first guide assembly, and the spacing assemblies at two sides are provided with top bracing assemblies separately; the first welding mechanism comprises welding platforms, first welding head groups and a third transmissionassembly; the transport mechanism comprises a feeding assembly, a second guiding assembly and a collecting bin; and the second welding mechanism comprises a wiring board positioning tool, second welding head groups and a fourth transmission assembly. According to the semi-automatic assembly equipment, the technical problems that a coil, a contact plate and static contacts need to be positioned atthe same time, clamping is tedious, assembling and spot welding cannot be rapidly conducted, and the equipment is not suitable for batch production are solved.

Owner:HUZHOU TEACHERS COLLEGE

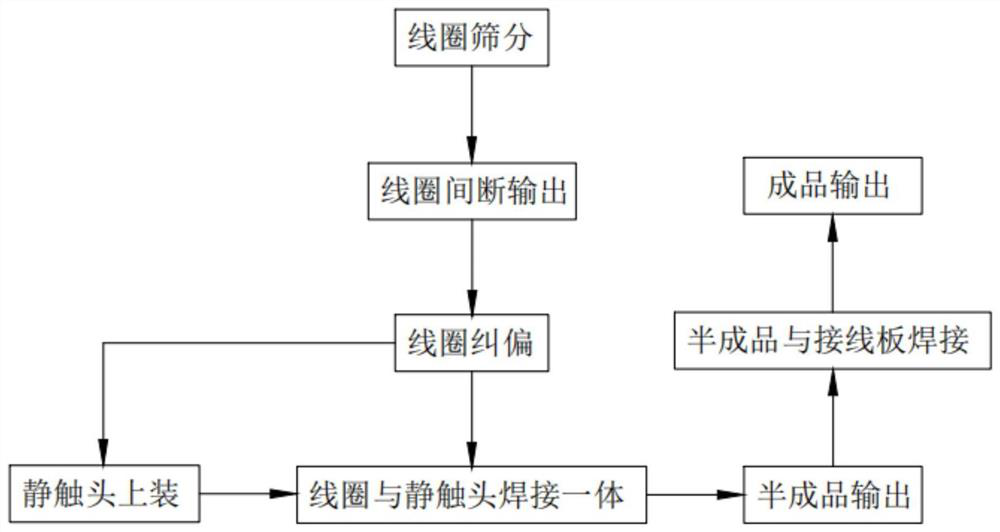

Semi-automatic assembling process for electronic components for electric appliances

InactiveCN112404835ACloselyHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesGear driveGear wheel

The invention relates to a semi-automatic assembling process for electronic components for electric appliances. The semi-automatic assembling process for the electronic components for the electric appliances comprises the following steps of 1, screening coils; 2, intermittently outputting the coils; 3, correcting the deviations of the coils; 4, welding the coils and the static contacts into a whole; 5, loading the static contacts, wherein the static contacts are manually placed on a static contact positioning tool at the input end of a chain wheel and chain transmission unit b in sequence, a first one-way rack vertically moves downwards while a linear air cylinder is started, a first driving gear is driven to rotate, the first driving gear drives the chain wheel and chain transmission unitb to transmit, and the chain wheel and chain transmission unit b drives the static contact positioning tool to be transmitted to the position under a first welding head set and waits for completing welding work; 6, outputting semi-finished products; 7, welding the semi-finished products and wiring boards; and 8, outputting finished products. According to the semi-automatic assembling process forthe electronic components for the electric appliances provided by the invention, the technical problems that the coils, contact plates and the static contacts need to be positioned at the same time, clamping is tedious, assembling and spot welding cannot be rapidly conducted, and an existing process is not suitable for batch production are solved.

Owner:HUZHOU TEACHERS COLLEGE

Cooling liquid treatment process for four-shaft grinding machine for machining of milling cutter

InactiveCN112643413AClean up thoroughlyEasy to cleanSievingGas current separationMilling cutterWater flow

The invention relates to a cooling liquid treatment process for a four-shaft grinding machine for machining of a milling cutter. The cooling liquid treatment process includes the following steps of: step 1, loading a workpiece, namely firstly manually placing the workpiece on a workbench of a bearing mechanism; step 2, polishing the workpiece; step 3, removing impurities at a grinding station during the step 2; step 4, screening iron scraps; step 5, screening millstone particles; and step 6, circulating clear water, putting the clear water on the lower layer of a collecting basket into a water collecting frame, and finally allowing water flow in the water collecting frame to enter a cooling mechanism through a connecting pipe of a circulating assembly under the action of a water pump so as to be repeatedly used. The cooling liquid treatment process provided by the invention solves the technical problems that due to the fact that impurities cannot be discharged in time, blockage of discharged materials is likely to occur, and when water flow is output downwards, impurities are output with the water flow, and accordingly a workpiece is abraded when accessories are ground and machined.

Owner:张达宇

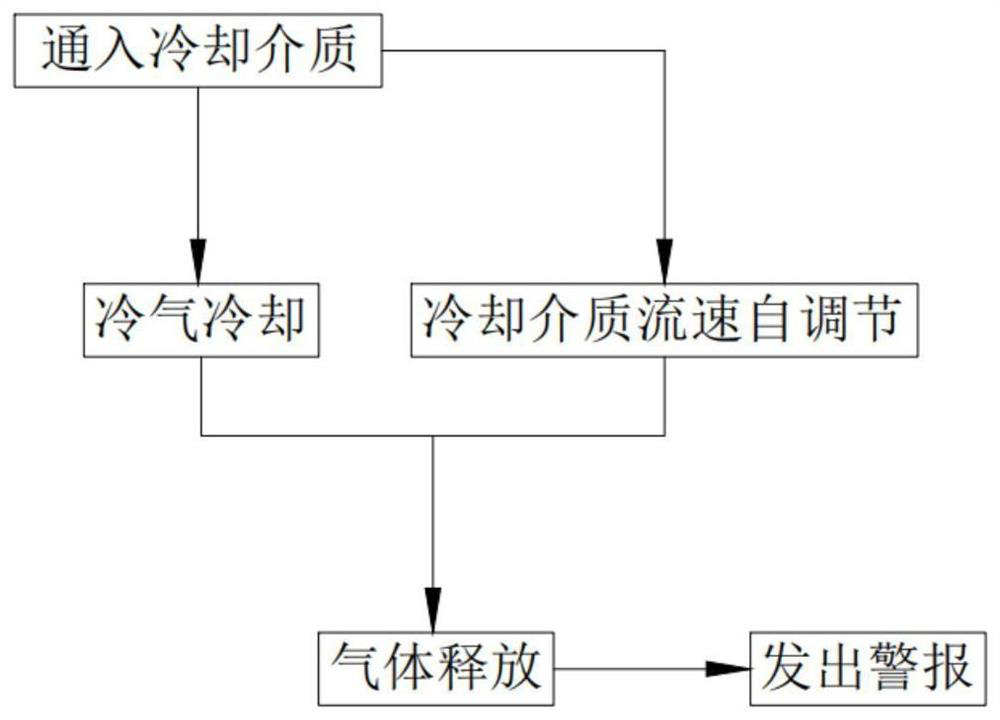

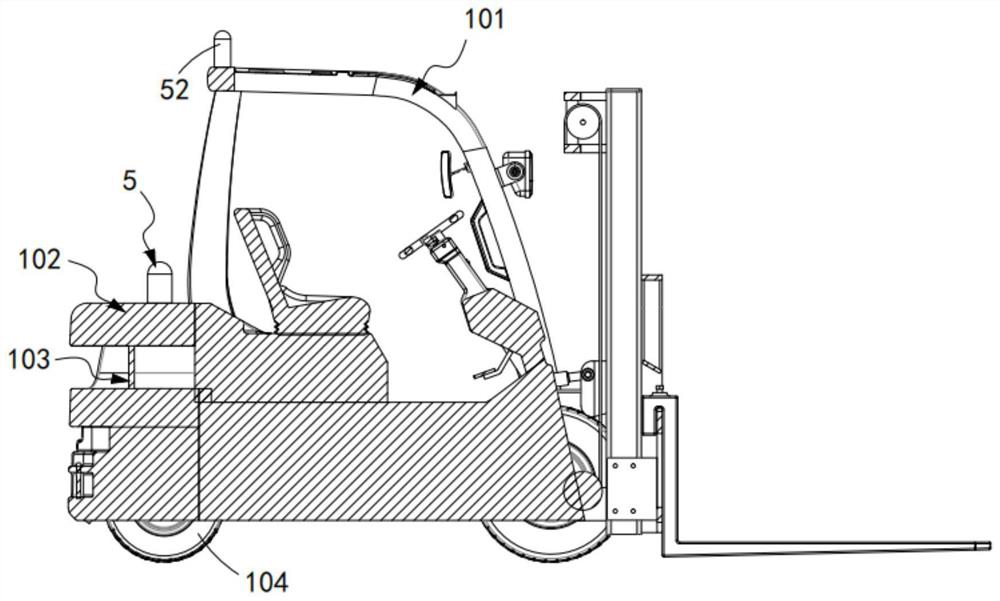

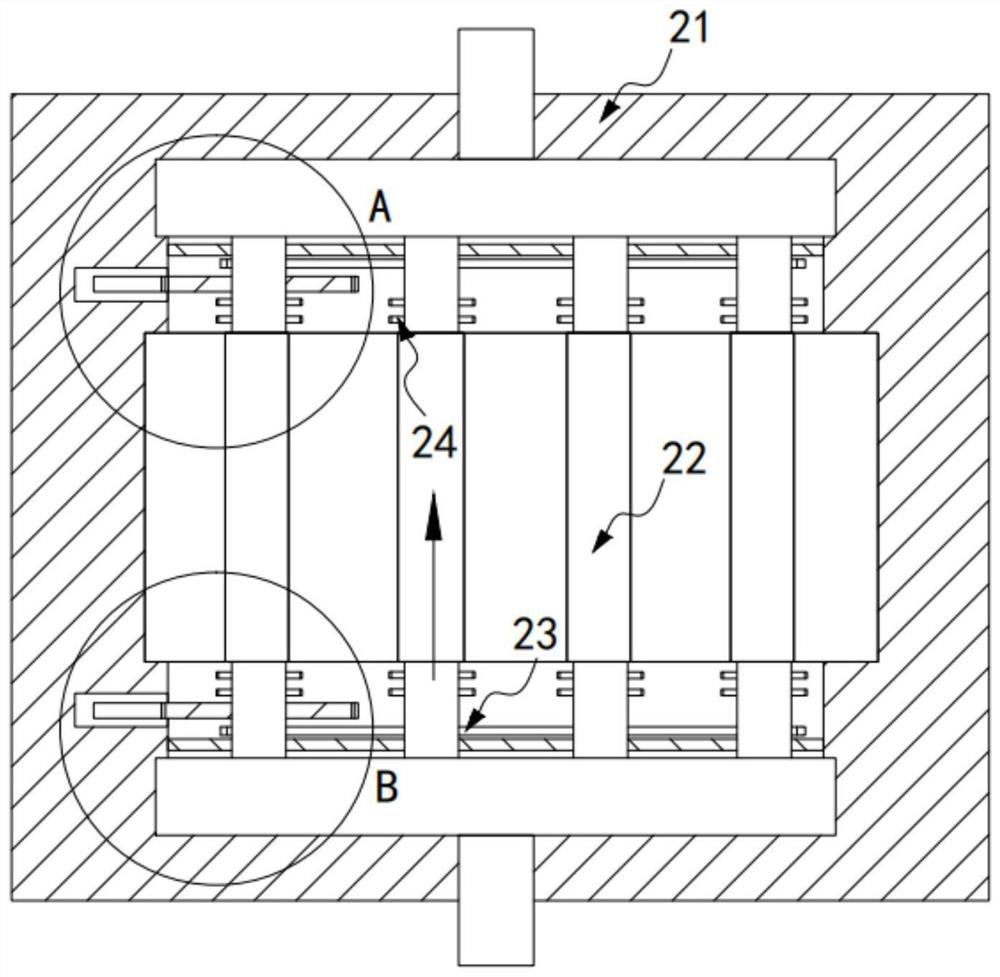

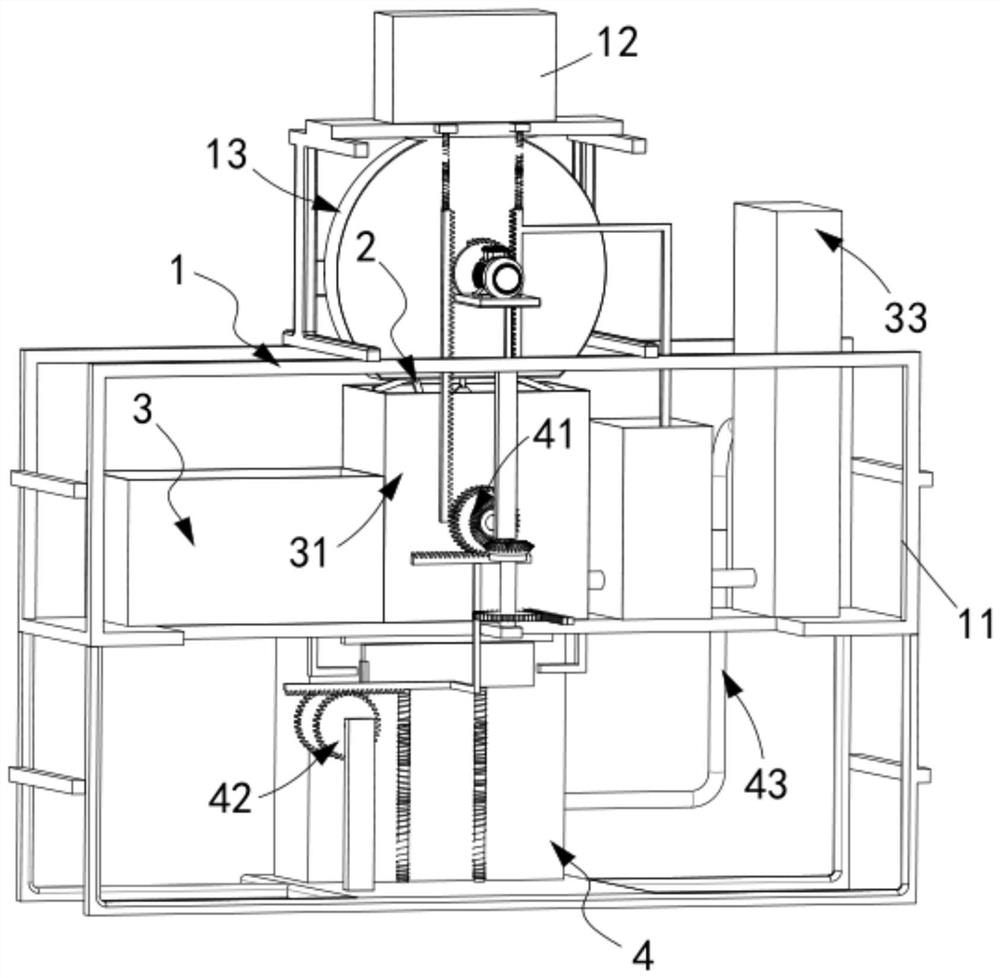

Rapid heat dissipation method for forklift control system

InactiveCN112408268ARealize automatic output workRapid coolingSafety devices for lifting equipmentsThermodynamicsControl system

The invention relates to a rapid heat dissipation method for a forklift control system. The rapid heat dissipation method comprises the steps that 1, a cooling medium is introduced; 2, hot air coolingis conducted; 3, the flow speed of the cooling medium is adjusted automatically and is synchronous with the second step; 4, air is released; and 5, an alarm is given. The rapid heat dissipation method solves the technical problems that in the driving process of a forklift, heat emitted by a heat dissipation element is not used due to different forklift speeds, and consequently the heat dissipation effect is poor through the same heat dissipation manner and degree.

Owner:张达宇

Shell breaking and screening integrated device for peanuts

InactiveCN111869891AImplement automatic tieringRealize automatic outputVegetable peelingHuskingEngineeringStructural engineering

The invention relates to a shell breaking and screening integrated device for peanuts. The shell breaking and screening integrated device for peanuts comprises a mounting mechanism comprising a discharging barrel and a driving assembly, a shelling mechanism comprising a transmission assembly driven by the driving assembly to rotate along the circumference and a material pressing assembly mounted on the driving assembly, a separating mechanism comprising a screening assembly arranged below the driving assembly, a guiding assembly and a pressurizing assembly which communicates with the screeningassembly and is in synchronous transmission with the driving assembly, and a discharging mechanism comprising a material pushing assembly which is horizontally arranged in the screening assembly in asliding manner and is in synchronous transmission with the driving assembly, a control assembly which is in synchronous transmission with the material pushing assembly and is vertically arranged in the screening assembly in a sliding manner, and a material receiving assembly which is used for receiving materials and is connected with the pressurizing assembly. The shell breaking and screening integrated device for peanuts solves the technical problems that shelling, peeling and screening of the peanuts cannot be completed integrally, and the working efficiency is low.

Owner:袁明杰

Forming device for cake blank processing

ActiveCN114794180AIncrease productivitySkip the heavy liftingCharging/discharging ovensDough processingProcess engineeringMechanical engineering

The invention provides a forming device for cake blank processing, which comprises an automatic transmission device, a plurality of groups of bearing mechanisms are sequentially arranged along the transmission direction of the automatic transmission device, and the bearing mechanisms are transmitted from a feeding station to a baking station under the driving of the automatic transmission device. The bearing mechanism is matched with the baking mechanism on the baking station to form cake liquid into cake blanks, and circumferential baking work of each cake blank is completed while a plurality of groups of cake blanks are separated, so that the problems that some cake baking machines can only bake a small amount of cakes at a time, the production efficiency is low, and the production cost is low are solved. The problem that cakes are burnt due to too high temperature caused by non-uniform heating of the cakes in the baking process due to the fact that the cakes need to be taken out of the oven next time after one-time baking is completed is solved.

Owner:安徽品滋味食品股份有限公司

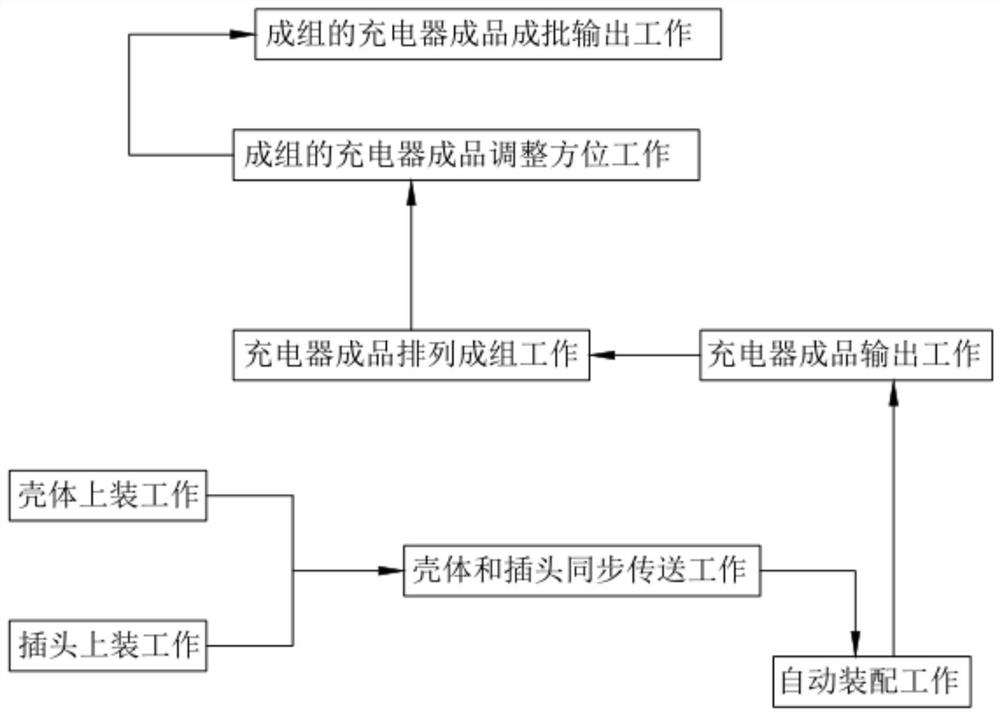

Automatic assembling production technology for chargers

InactiveCN111761323AHigh structural connectivityIncrease productivityMetal working apparatusCartonProcess engineering

The invention relates to an automatic assembling production technology for chargers. The automatic assembling production technology for the chargers comprises the first step of shell loading work; thesecond step of plug loading work; the third step of shell and plug synchronous conveying work; the fourth step of automatic assembling work; the fifth step of charger finished product output work; the sixth step of charger finished product group arranging work; the seventh step of grouped charger finished product orientation adjusting work, wherein after charger finished products are arranged into groups, a clamping piece moves downwards under driving of a pressing piece and clamps the grouped charger finished products, and after clamping is finished, the grouped charger finished products areconveyed under driving of a chain wheel and chain unit with the sides, with plugs, of the grouped charger finished products facing upwards; and the eighth step of grouped charger finished product batched output work. The automatic assembling production technology for the chargers solves the technical problems that workers need to load charger finished products into cartons one by one, time and effort are consumed, and the production efficiency is low.

Owner:长兴梦晨节能设备有限公司

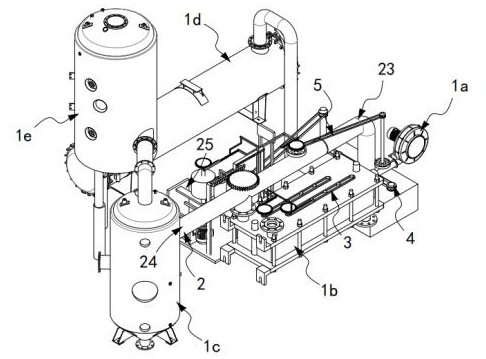

Waste gas treatment device for UV photocureable coating equipment

PendingCN113713557AGuaranteed stabilityRaise the temperature fullyDispersed particle separationVapor condensationCondensed waterEngineering

The invention relates to a waste gas treatment device for UV photocureable coating equipment. The devicecomprises a fan, a heat exchanger, a rotary separator, a cold water tower and a gas-liquid mixing tower, and further comprises a switching mechanism, a cooling mechanism and a heat dissipation mechanism; a water outlet of the heat dissipation mechanism is communicated with the cold water tower, and a water inlet of the heat dissipation mechanism is communicated with the heat exchanger and the rotary separator; the switching mechanism comprises a tee joint, a switching plate, a circulating mechanism, an output mechanism and a temperature control precision meter; and an adjusting assembly is further arranged at the air outlet of the fan and used for controlling the air outlet amount of the air outlet. The waste gas treatment device solves the technical problems that when waste gas in the heat exchanger is condensed, condensed water becomes hot after heat exchange with the waste gas, and if the condensed water is not discharged in time, the heated waste water can cause the poor condensation effect in the heat exchanger; and that even if the condensed water is discharged in time, the hot water directly enters the cold water tower, cold water in the cold water tower becomes hot, and energy loss is serious.

Owner:瑞润化工(南通)有限公司

Automatic edge sealing device for imitated rattan plaited chair cushion

ActiveCN114134650ANeat and beautiful seamsAvoid deformationWorkpiece carriersWork-feeding meansEngineeringChair cushion

The invention relates to an automatic edge sealing device for a rattan-imitated chair cushion, and the device comprises a control mechanism which comprises a pressing assembly and a rotating assembly; the cutting mechanism comprises a slitting assembly and a first transmission assembly; a sewing mechanism; the discharging mechanism comprises a lifting assembly arranged on the operation table, a second transmission assembly which is in synchronous transmission with the downward pressing assembly and is used for driving the lifting assembly to move in the vertical direction, and a limiting assembly which is installed on the operation table and is used for controlling the lifting assembly to automatically rotate for discharging; the cutting-off mechanism is used for automatically cutting off the edge sealing strips of the group of bolsters subjected to edge sealing; the rattan chair bolster sewing machine solves the technical problems that in the rattan chair bolster production process, the peripheral hems of the bolster are manually sewn, the edge cutting work of hemming strips and the rotation work of the bolster need to be completed with one hand, misoperation is prone to occurring, the speed is low, and the production efficiency is low.

Owner:ANHUI DAIJIA CRAFT CO LTD

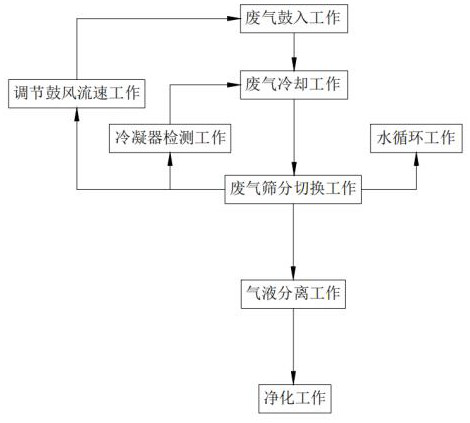

Waste gas recovery method applied to soft-touch leather coating production

ActiveCN113694711ARaising the Cooling Sufficiency ProblemImprove connectivityDispersed particle separationVapor condensationWater circulationProcess engineering

The invention relates to a waste gas recovery method applied to soft-touch leather coating production. The method comprises the following steps: 1, waste gas blowing-in work; 2, waste gas cooling work; 3, waste gas screening switching work; 4, air blowing flow speed adjusting work; 5, condenser detecting work; and 6, water circulation work which is synchronous with the step 3, wherein a fifth transmission assembly is driven by a driving mechanism, so that water with relatively high temperature in a water tank is rapidly stirred under the stirring action of a stirring assembly, the flow speed of the water in the water tank is increased, the water in the water tank is rapidly cooled, meanwhile, waste gas in a first connecting pipe is cooled by utilizing the water after heat loss; 7, gas-liquid separation work; and 8, purification work; the technical problem that the temperature of output waste gas does not reach the standard due to the fact that the refrigeration environment in a heat exchanger becomes poor when the heat exchanger is used for a long time is solved.

Owner:瑞润化工(南通)有限公司

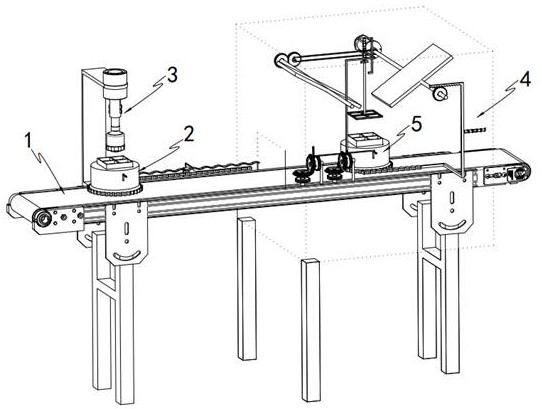

Garlic screening and slicing all-in-one machine

InactiveCN111604957ASave raw materialsImprove output qualityMetal working apparatusGradingAllium sativumMechanical engineering

The invention relates to a garlic screening and slicing all-in-one machine. The garlic screening and slicing all-in-one machine comprises a rack, a garlic clove machine, a discharging conveying belt,the garlic clove machine is arranged on one side of the head of the discharging conveying belt, the garlic screening and slicing all-in-one machine further comprises a screw rod conveying device and aslicing device; the discharging conveying belt comprises a screening rail obliquely arranged downwards in the vertical direction, a belt conveying belt a and a belt conveying belt b, the belt conveying belt a and the belt conveying belt b are arranged at the output end of the screening rail, the screening rail is composed of a qualified product part located in the middle and defective product parts symmetrically arranged on the two sides of the qualified product part, the output ends of the defective product parts and the qualified product part are output in a back-to-back mode, the belt conveying belt a is used for conveying garlic slices on the qualified product part backwards, and the conveying belt b is used for conveying the garlic slices on the qualified product part backwards. According to the garlic screening and slicing all-in-one machine, the technical problems that sliced garlic cloves are different in size and specification and poor in garlic slice quality are solved.

Owner:阜阳佰恩得新材料技术有限公司

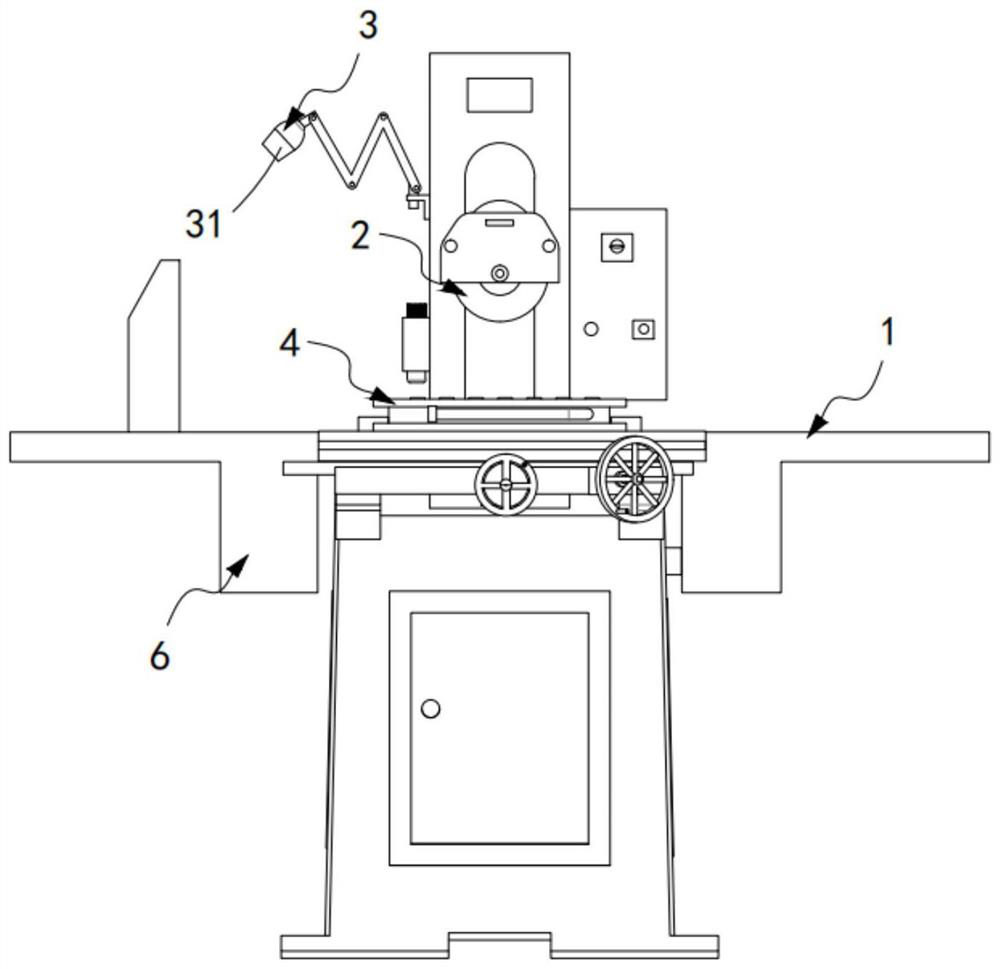

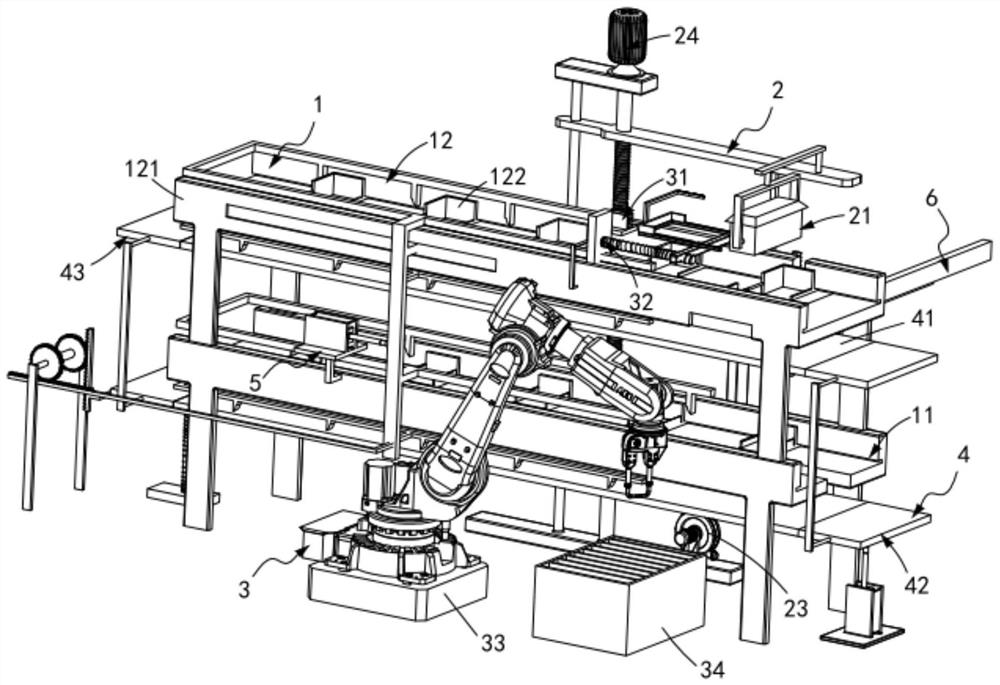

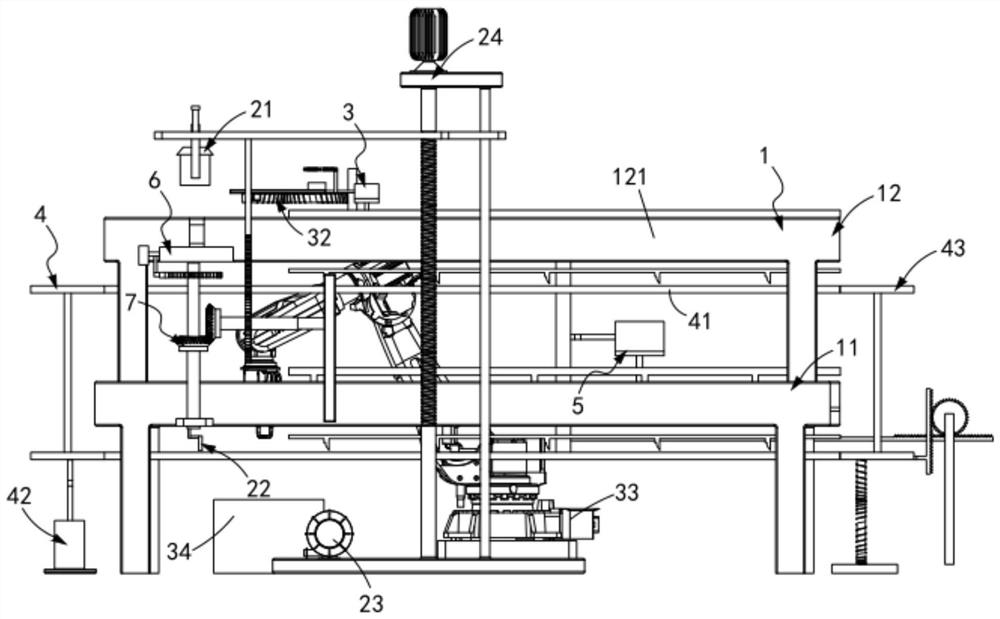

Automatic production device for numerical control lathe accessories

ActiveCN112496961AExtended service lifeLess cleaningGrinding feed controlAbrasive surface conditioning devicesProcess engineeringWater storage tank

The invention relates to an automatic production device for numerical control lathe accessories. The automatic production device comprises a grinding machine, a grinding mechanism, a cooling mechanismand a flushing mechanism. The cooling mechanism comprises a water storage tank, water outlet assemblies, an adjusting assembly arranged at the output end of the water storage tank and used for controlling water to intermittently enter any water outlet assembly, control assemblies which are arranged below the water outlet assemblies and are in synchronous transmission with the adjusting assembly,and a collecting box arranged between the two control assemblies. One side of any control assembly is provided with a push-out assembly used for pushing out impurities on the control assemblies and completing cleaning work of the water outlet ends of the corresponding water outlet assemblies at the same time. The flushing mechanism comprises a brushing assembly and an impurity removing assembly, and a flow speed detection assembly is arranged on the brushing assembly and used for driving the adjusting assembly to automatically rotate. The automatic production device solves the technical problems that an inner filter barrel needs to be stopped for cleaning work, work is tedious, labor is wasted, and the automation degree is low.

Owner:乐清市虹桥职业技术学校

A solar photovoltaic panel surface cleaning drone

ActiveCN110745245BFull scrubbing jobLight in massAircraft componentsEnergy efficient board measuresSurface cleaningEngineering

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

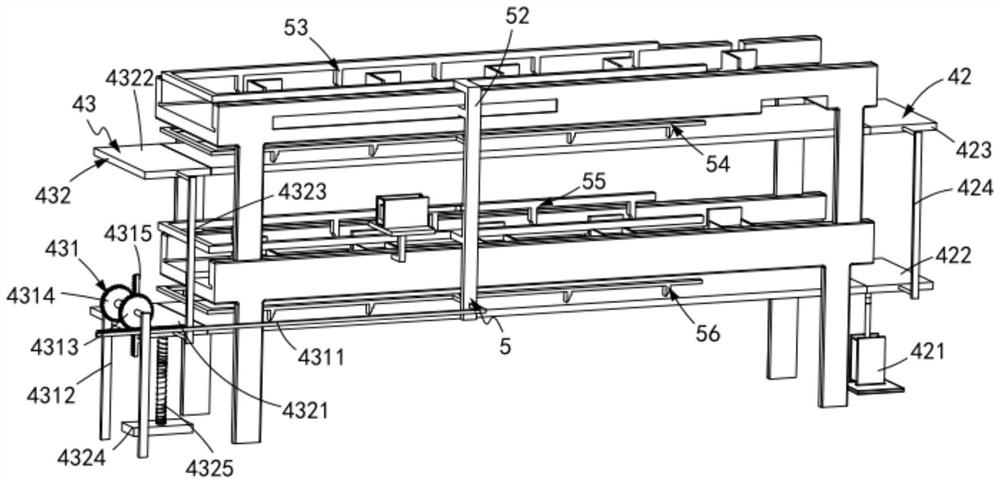

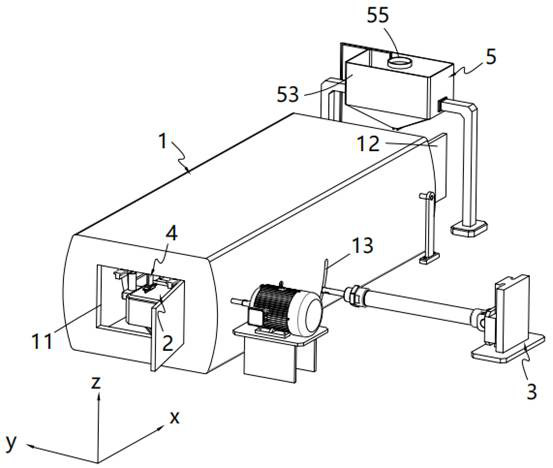

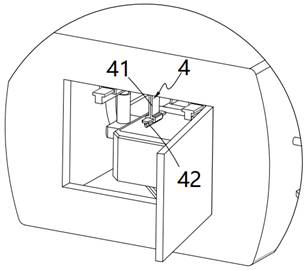

An intelligent manufacturing device for baked edible food

ActiveCN113545372BImprove brittlenessImprove drying effectBaked article fillingBaking ovenEngineeringMechanical engineering

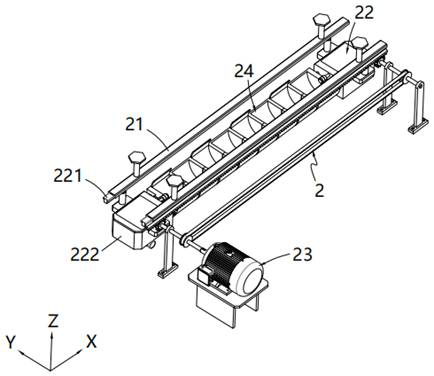

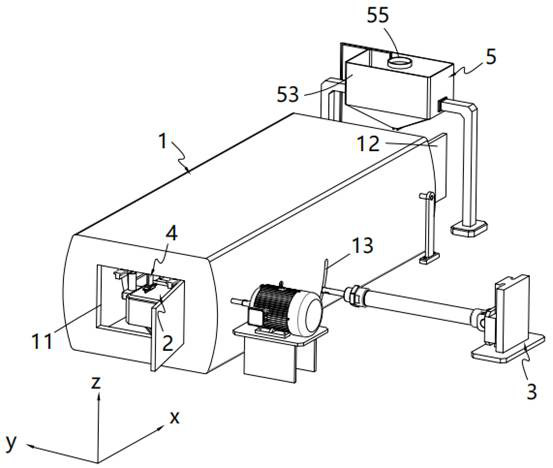

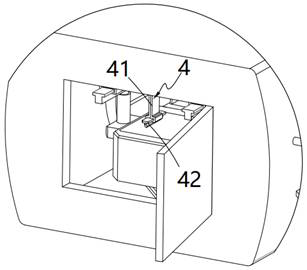

The invention relates to an intelligent manufacturing device for baked edible food, comprising an oven; the oven is provided with an inlet and an outlet along its length direction, and the side wall of the oven is provided with a first waist groove, the inlet and the outlet The switch is driven by an electrical signal; a transmission mechanism; the transmission mechanism includes a support track, a moving assembly slidably arranged under the support track, a first drive assembly, and a bearing assembly mounted on the moving assembly and arranged along the length direction of the oven; mechanism; the material shaking mechanism includes a support shaft, a tumbling assembly and a second drive assembly; two sets of support shafts are arranged and are located at the end of the oven; the incision mechanism, the incision mechanism includes a cutter assembly installed on the support shaft; adding auxiliary materials The auxiliary material feeding mechanism is arranged outside the baking box and at the output end of the transmission mechanism; the invention solves the technical problem that the bottom of the bread cannot be fully heated when the bread is baked, resulting in poor baking effect.

Owner:阜阳市家居乐食品有限公司

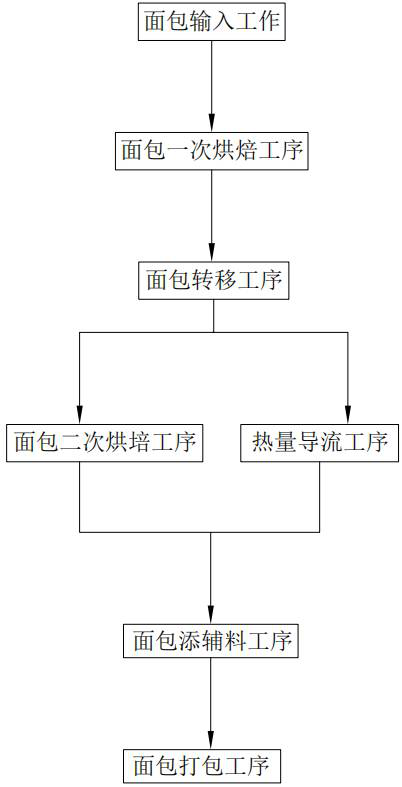

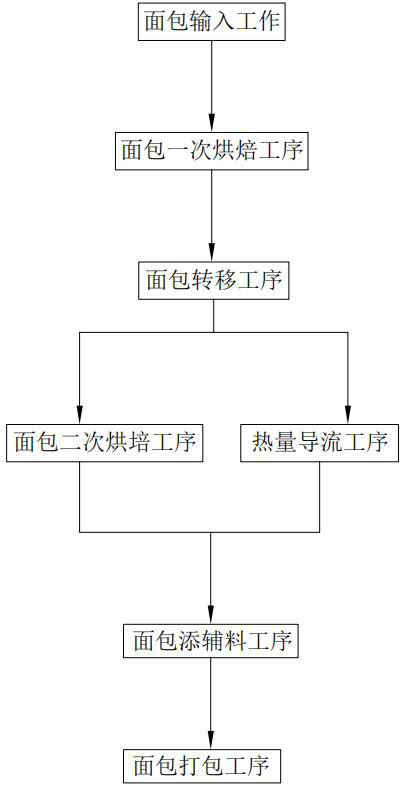

Automatic processing technology for high-fiber bread

ActiveCN113575625AImprove brittlenessImprove drying effectBaked article fillingFood processingFiberHeat flow

The invention relates to an automatic processing technology of high-fiber bread. The automatic processing technology comprises the following steps: step 1, a bread input procedure; step 2, a primary baking process of the bread; step 3, a bread transferring process; step 4, a secondary baking process of the bread; step 5, a heat flow guiding procedure; step 6, adding auxiliary materials into the bread; step 7, a bread packaging procedure: after all the bread is subjected to the cream applying work, the bread is manually packaged; the technical problems that after baking, materials such as melon seeds and cream need to be scattered on the bread, then the bread needs to be accurately positioned, and a large amount of waste can occur due to scattering of the materials are solved.

Owner:阜阳市家居乐食品有限公司

Intelligent manufacturing device for baking edible food

ActiveCN113545372AImprove brittlenessImprove drying effectBaked article fillingBaking ovenMechanical engineeringIndustrial engineering

The invention relates to an intelligent manufacturing device for baking edible food. The intelligent manufacturing device comprises a baking box, a conveying mechanism, a material shaking mechanism, a notching mechanism and an auxiliary material adding mechanism. An inlet and an outlet are formed in the baking box in the length direction of the baking box, a first waist groove is formed in the side wall of the baking box, and the inlet and the outlet drive a switch through electric signals. The conveying mechanism comprises a supporting rail, a moving assembly arranged below the supporting rail in a sliding manner, a first driving assembly and a bearing assembly installed on the moving assembly and arranged in the length direction of the baking box. The material shaking mechanism comprises supporting shafts, a rolling assembly and a second driving assembly. The two supporting shafts are located at the head end and the tail end of the baking box. The notching mechanism comprises a cutter assembly mounted on the supporting shafts; the auxiliary material adding mechanism is arranged outside the baking box and located at the output end of the conveying mechanism; and the device solves the technical problem that when bread is baked, the bottom of the bread cannot be fully heated, and the baking effect is poor.

Owner:阜阳市家居乐食品有限公司

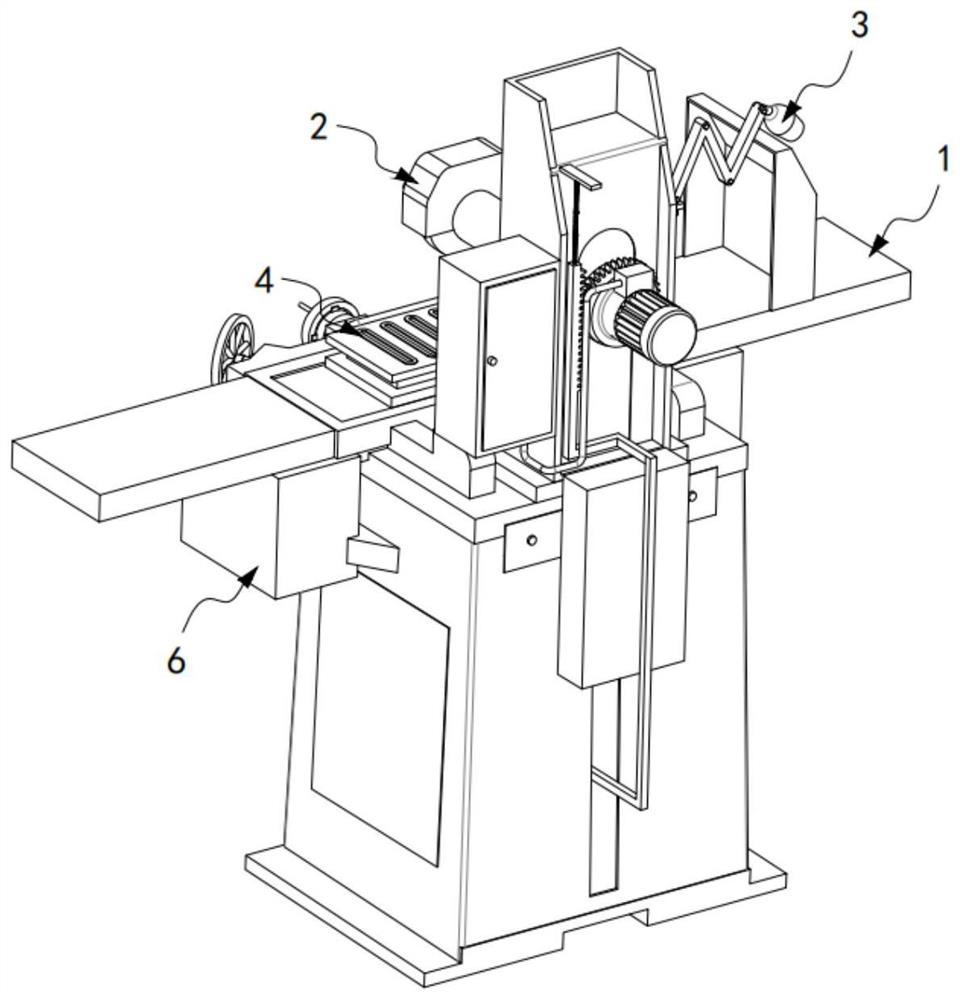

Chipping separation device of machining grinding machine

InactiveCN112548864AGood for recyclingIncrease profitGrinding/polishing safety devicesScrapEngineering

The invention relates to a chipping separation device of a machining grinding machine. The chipping separation device comprises the grinding machine, a grinding mechanism, a cooling mechanism, a bearing mechanism, two sets of impurity removing mechanisms which are symmetrically arranged on the two sides of the bearing mechanism and used for collecting impurities on the bearing mechanism, a scrap iron filtering mechanism arranged below the impurity removing mechanism and communicating with the impurity removing mechanism and a millstone particle filtering mechanism arranged below the scrap ironfiltering mechanism, and the other end of the millstone particle filtering mechanism communicates with the cooling mechanism. The impurity removing mechanisms and the grinding mechanism are in synchronous transmission work through a first transmission mechanism. The scrap iron filtering mechanism and the grinding mechanism are in synchronous transmission work through a second transmission mechanism. The millstone particle filtering mechanism and the second transmission mechanism are in synchronous transmission work through a third transmission mechanism. According to the chipping separation device of the machining grinding machine, the technical problems that scrap iron and millstone particles cannot be discharged in time, consequently, nearly equal amount of water cannot circulate and flow back in time when the water is output are solved.

Owner:浙江威步机器人股份有限公司

Automatic assembling device for production of charger housing component

InactiveCN111775108AAvoid damageHigh degree of automationMetal-working hand toolsConveyor partsProcess engineeringManipulator

The invention relates to an automatic assembling device for production of a charger housing component. The automatic assembling device comprises a raw material conveying mechanism, an automatic assembly mechanism, a finished product discharging mechanism, a swing mechanism and a drive mechanism, wherein the raw material conveying mechanism comprises a plug conducting component and a housing conducting component; the plug conducting component and the housing conducting component comprise a conveying rail and a bearing plate; the automatic assembly mechanism is located at an assembly station andcomprises a first sucking component, a second sucking component, a vacuum pump and a lifting component; the finished product discharging mechanism comprises a stripping component and a stacking component; one side of the finished product discharging mechanism is provided with a manipulator; the manipulator is used for together taking out chargers that are horizontally stacked on the stripping component and placing the chargers inside a packing box; the swing mechanism comprises a connecting rail, a lifting member and a transfer component; and a flatly-push component is arranged at the assembly station. The automatic assembling device provided by the invention solves the technical problems that the assembling equipment and the discharging equipment are dispersedly distributed, feeding anddischarging are implemented by a worker, transfer is implemented manually, the automation degree is low and the yield is low.

Owner:长兴梦晨节能设备有限公司

A kind of automatic processing technology of high fiber bread

ActiveCN113575625BImprove brittlenessImprove drying effectBaked article fillingFood processingFiberProcess engineering

The invention relates to an automatic processing technology for high-fiber bread, which comprises: step 1, a bread input process; step 2, a primary baking process of bread; step 3, a bread transfer process; step 4, a secondary baking process of bread; Flow process; step 6, adding auxiliary materials to bread; step 7, bread packing process, after all the bread is finished with cream, the bread is manually packed; the invention solves the need to sprinkle ingredients on the bread after baking, such as melon seeds, Cream, etc., and then need to accurately locate the bread, otherwise there will be technical problems of a lot of waste.

Owner:阜阳市家居乐食品有限公司

Automatic gluing equipment for butyronitrile gloves

ActiveCN112974130AImprove gluing effectIncrease profitLiquid surface applicatorsSpraying apparatusRubber materialProcess engineering

The invention relates to automatic gluing equipment for butyronitrile gloves. The automatic gluing equipment comprises a glove conveying mechanism, a steeping vat body, a transmission mechanism, a chain mechanism, a cleaning mechanism, a first impurity collection mechanism and a second impurity collection mechanism, wherein a partition plate is arranged in the middle of the steeping vat body in the length direction of the steeping vat body, and a gluing space and an impurity discharging space are formed between the steeping vat body and the partition plate; the transmission mechanism comprises a rotating component, a bubble removing component and a cooling component; and the first impurity collection mechanism comprises a first discharging component and a first collection component. The automatic gluing equipment solves the technical problems that bubbles are hidden in the rubber material, and the glove and the rubber material temperature are not easy to control, so that the soaking condition is inappropriate, the needle hole phenomenon of the glove is finally caused, and the product quality is reduced.

Owner:阜阳市茂泰商贸有限公司

Quick assembling equipment for anti-stroboscopic square bubble of thunder guest

ActiveCN114643475ASave self-test workImprove work efficiencyAssembly machinesMetal working apparatusStructural engineeringLight fixture

The invention relates to a safety lamp automatic assembling device which comprises an efficient assembling mechanism, a supporting rotary disc of the efficient assembling mechanism, a plurality of sets of screwing assemblies, a lamp cover component feeding mechanism and a part discharging mechanism which are sequentially arranged in the circumferential direction of the supporting rotary disc. The turnover assembly is arranged in the outer circumferential direction of the supporting rotary disc and rotates discontinuously, the discharging assembly a is installed at one end of the turnover assembly and used for discharging core base components, and the discharging assembly b is installed at the other end of the switching mechanism relative to the discharging assembly a and used for discharging material packages. The problems that due to manual assembly, the number of working procedures is large, material packages are often missed, and the working efficiency is low are solved.

Owner:安徽突飞电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com