Accurate batching system for rubber and plastic processing

A batching system and precise technology, applied in the field of rubber and plastics, can solve the problems of poor ratio accuracy, low degree of automation, and difficult to control the quantity, and achieve the effect of accurate batching, high degree of automation, and uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

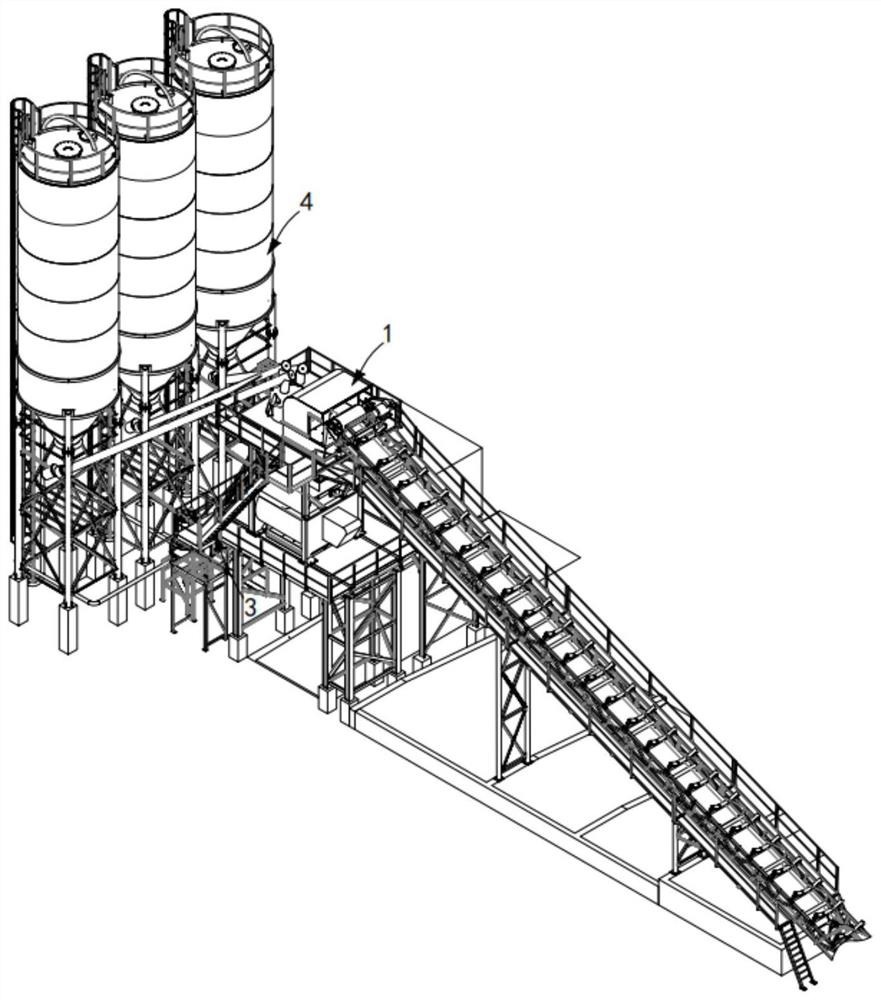

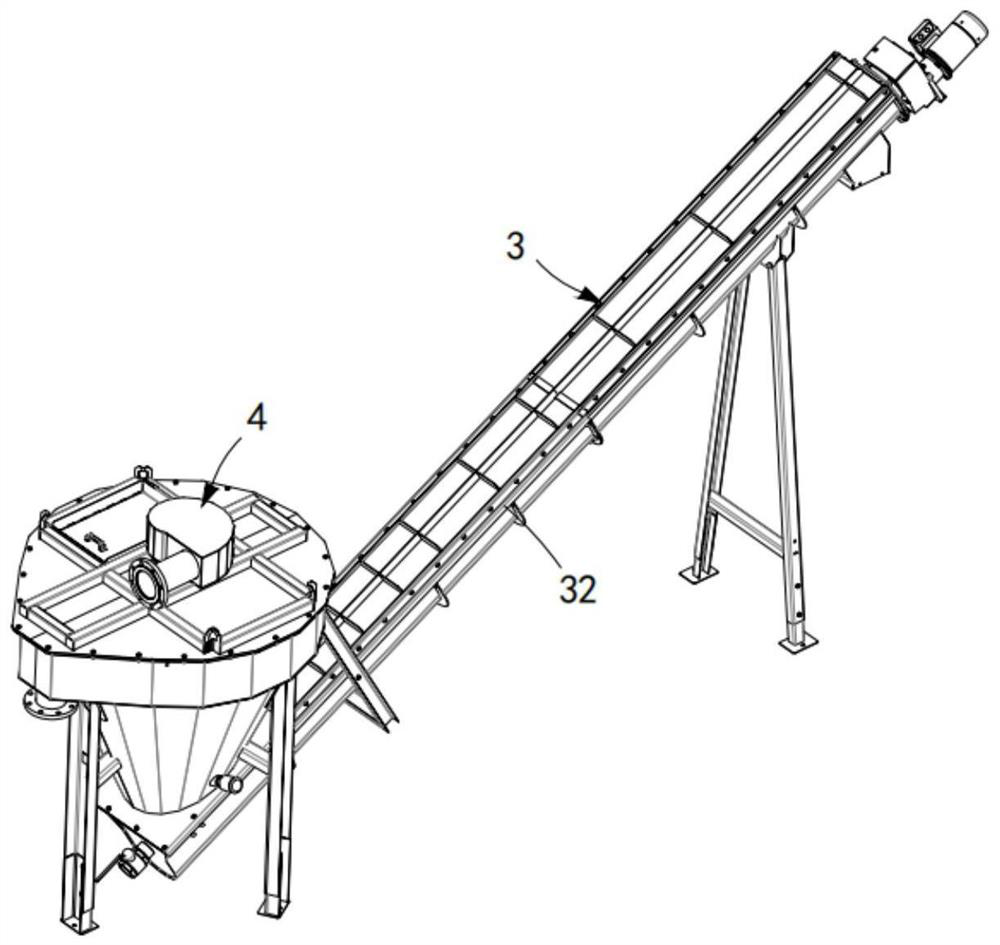

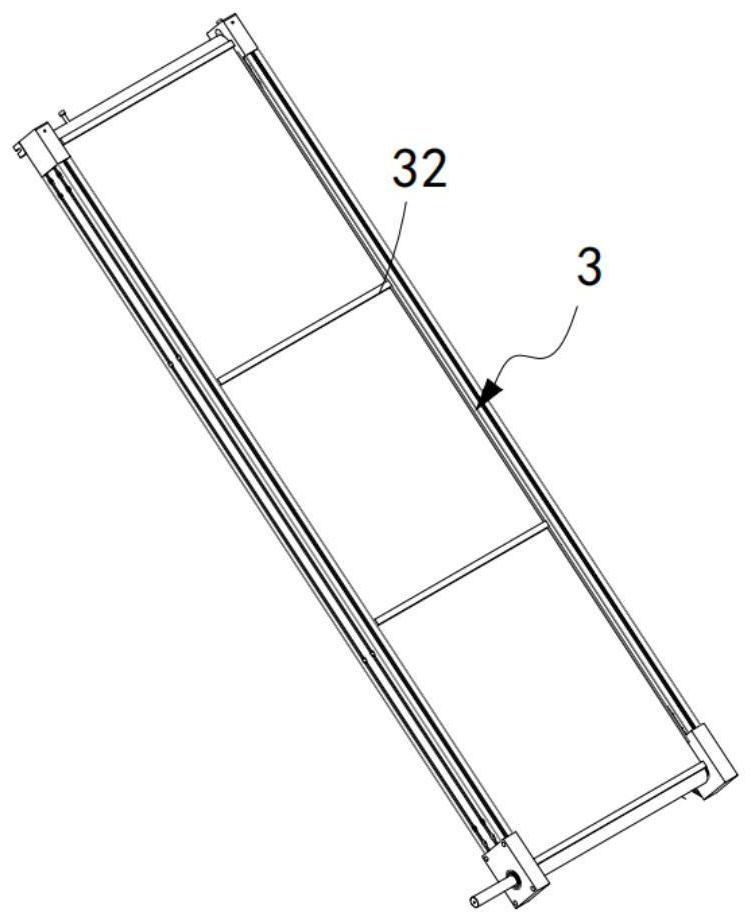

[0063] Such as Figure 1 to Figure 4 As shown, a precision batching system for rubber and plastic processing, including:

[0064] The feeding mechanism 1, the feeding mechanism 1 includes a drive assembly 11, a discharge assembly 12 arranged on one side of the drive assembly 11 and driven by the drive assembly 11 to rotate intermittently, and a discharge assembly 12 arranged on the discharge assembly 12 and drive the shaking assembly 13 synchronously with the driving assembly 11;

[0065] Raw material proportioning mechanism 2, said raw material proportioning mechanism 2 includes a balance assembly 21 arranged below the feeding mechanism 1, a control assembly 22 synchronously driven with the balance assembly 21, and a control assembly 22 arranged at the discharge assembly 12- The limit assembly 23 on the side and used to control the rotation of the discharge assembly 12 and the first adjustment assembly 24 that is synchronously driven with the control assembly 22 and used to ...

example 1

[0070] In addition, it should be noted that during the rotation of the discharge assembly 12, even if the discharge assembly 12 is thrown on the discharge, the states of the three raw materials are in the same state, so it can also ensure that the foaming agent, foaming aid, lubrication The ratio between the three agents is constant.

[0071] further, such as Figure 5 As shown, the drive assembly 11 includes:

[0072] Drive motor 111, described drive motor 111 is installed on the frame 112 and its output end is arranged vertically upwards;

[0073] A rotating shaft 113, the rotating shaft 113 is coaxial with the output end of the driving motor 111 and is synchronously driven; and

[0074] Epicyclic gear 114 , the epicyclic gear 114 is coaxial with the rotating shaft 113 and is synchronously driven.

[0075] further, such as Figure 5 to Figure 8 As shown, the discharge assembly 12 includes:

[0076] A turntable 121, the turntable 121 is installed on the frame 112 through...

Embodiment 2

[0107] Such as Figure 14 to Figure 15 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0108] further, such as Figure 14 to Figure 15 As shown, the ejection assembly 31 includes:

[0109] The transmission member 311, the transmission member 311 includes a horizontal push cylinder 3111, a first connecting rod 3112 arranged at the output end of the flat push cylinder 3111, a second connecting rod 3113 arranged at the upper end of the first connecting rod 3112 , a telescopic unit f3114 fixedly connected to the second connecting rod 3113 , a material baffle 3115 arranged on the second connecting rod 3113 corresponding to the notch 127 , and a material stopper 3115 arranged under the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com