Automatic production device for numerical control lathe accessories

An automatic production, CNC lathe technology, applied in the direction of grinding automatic control devices, grinding machine parts, abrasive surface adjustment devices, etc., can solve the problems of low degree of automation, waste of labor, cumbersome work, etc. The effect of reducing cleaning work and saving power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

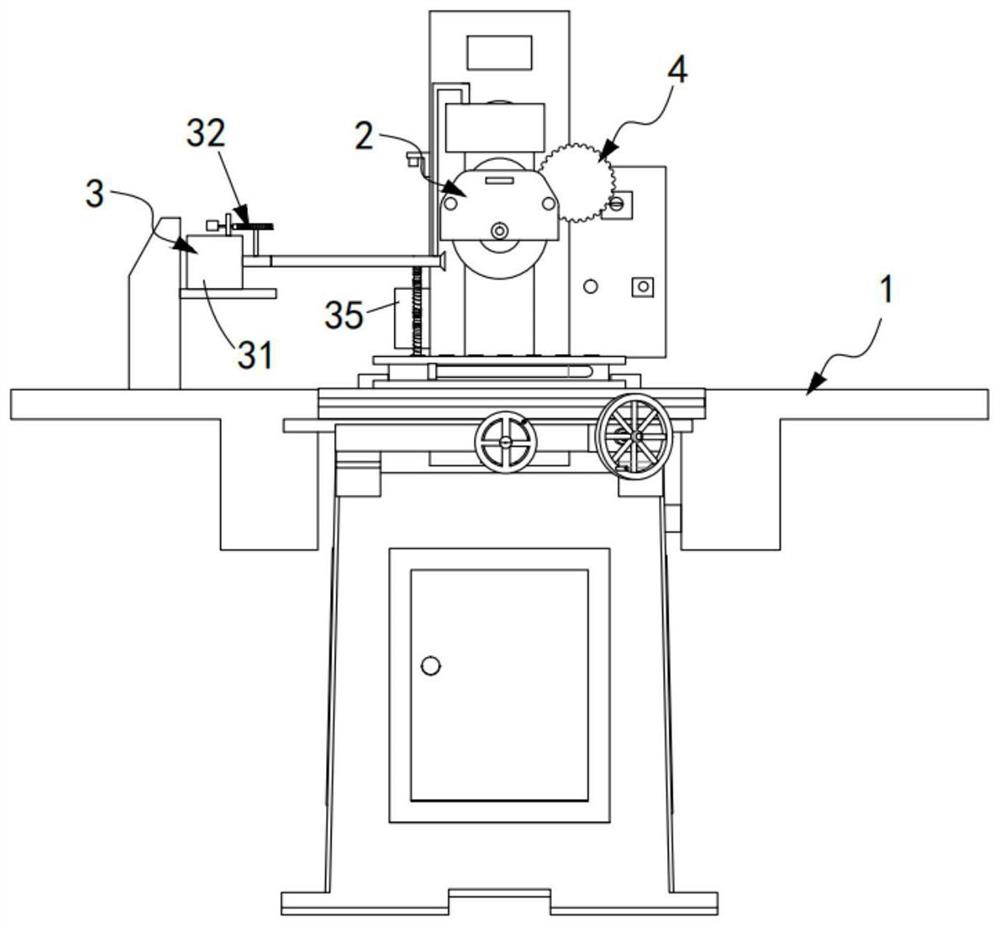

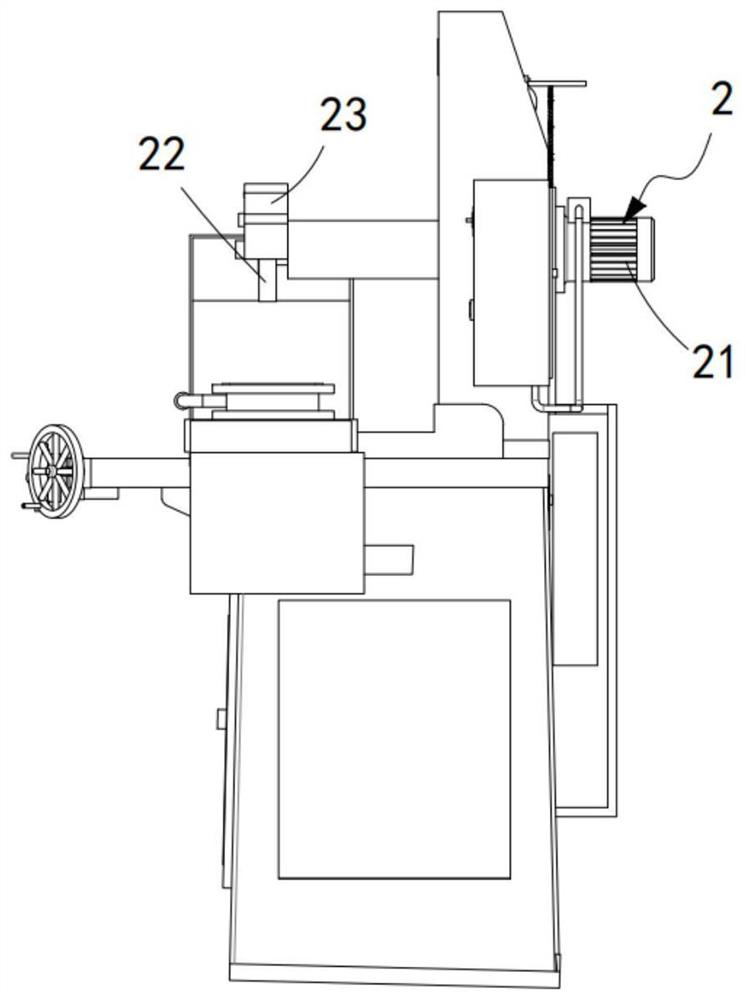

[0071] Such as figure 1 As shown, an automatic production device for CNC lathe accessories, including a grinding machine 1, a grinding mechanism 2 arranged on the grinding machine 1, a cooling mechanism 3 installed on the grinding machine 1 and arranged on one side of the grinding mechanism 2 And a flushing mechanism 4 arranged above the grinding mechanism 2;

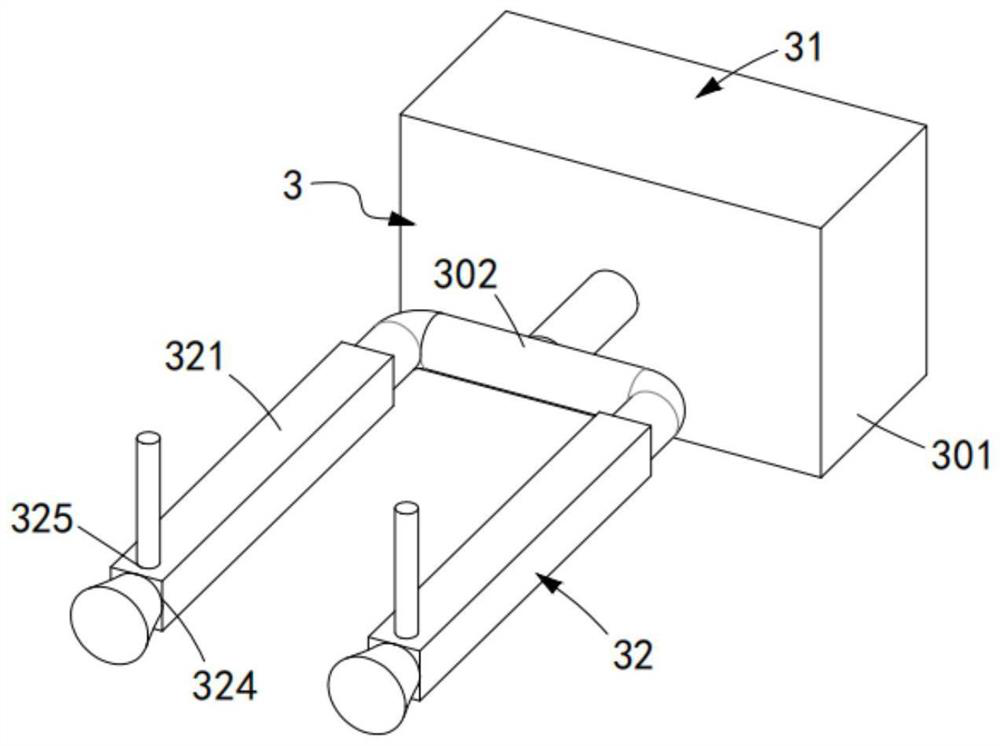

[0072] The cooling mechanism 3 includes a water storage tank 31, two sets of water outlet assemblies 32 arranged symmetrically on both sides of the water storage tank 31, and set at the output end of the water storage tank 31 to control water intermittently entering any of the water storage tanks. The adjustment assembly 33 of the water outlet assembly 32, the control assembly 34 arranged under the water outlet assembly 32 and synchronously driven with the adjustment assembly 33, and the collection box 35 arranged between the two control assemblies 34, any of the control assemblies One side of the component 34 is provi...

Embodiment 2

[0121] Such as Figure 11 to Figure 13 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0122] further, such as Figure 11 to Figure 13 As shown, the brush assembly 41 includes

[0123]A connecting pipe 411, one end of the connecting pipe 411 communicates with the second outlet 325; and

[0124] A water outlet chamber 412, the water outlet chamber 412 is installed on the grinder 1 and communicated with the other end of the connecting pipe 411, the lower end of the water outlet chamber 412 is provided with a first nozzle 413 and it faces the side of the impurity removal assembly 42 A second nozzle 414 is opened on one side.

[0125] further, such as Figure 13 As shown, the impurity re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com