Patents

Literature

410results about How to "Less clean up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

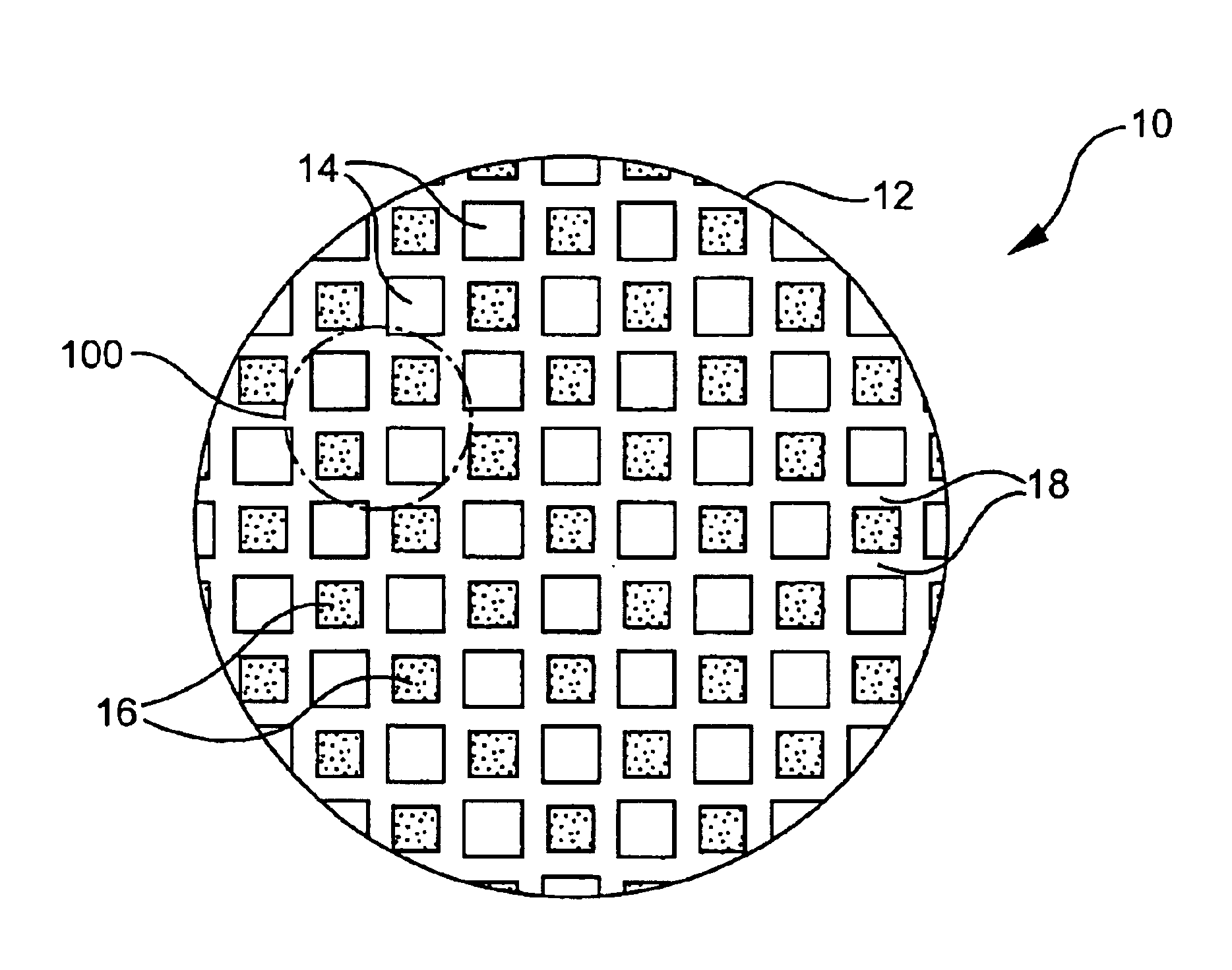

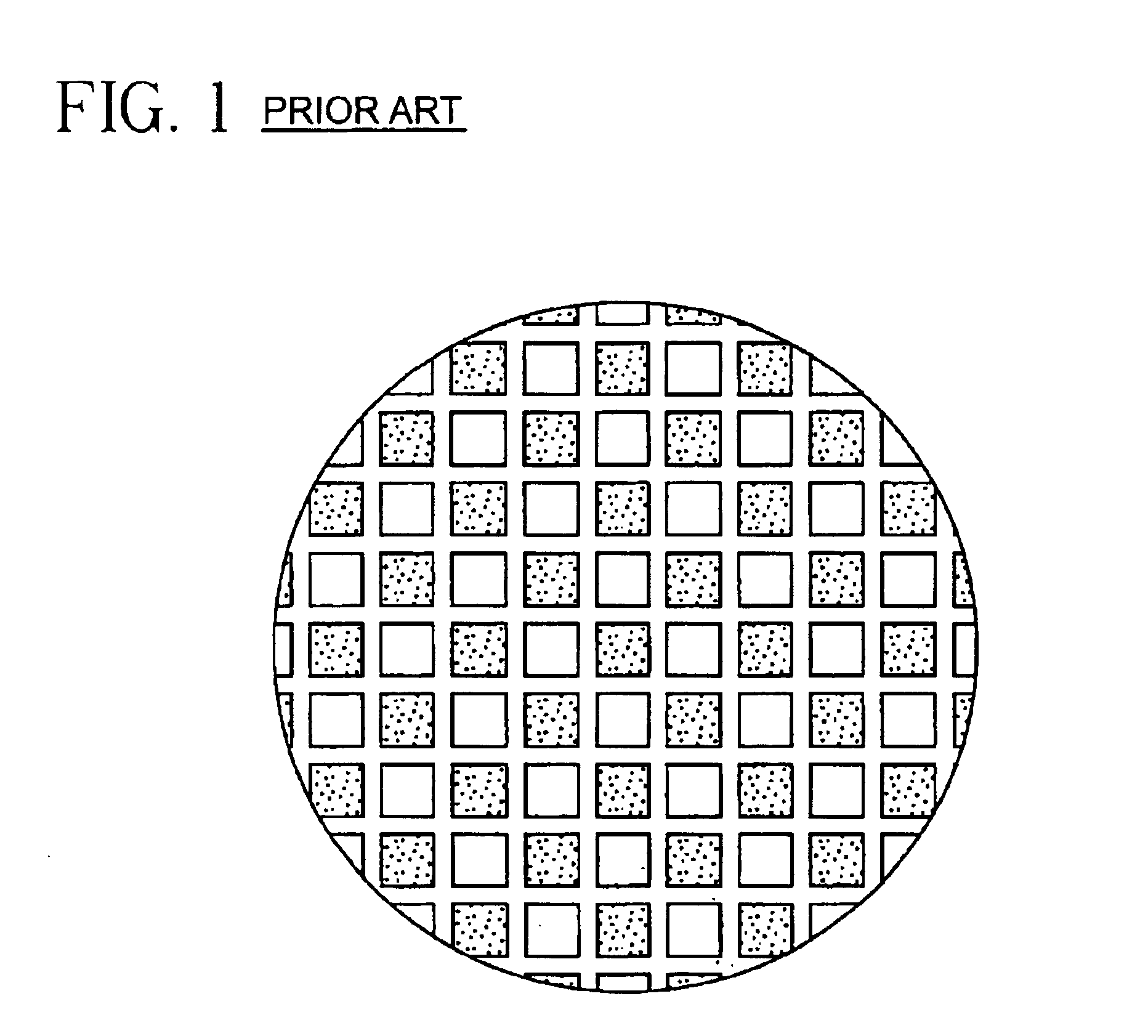

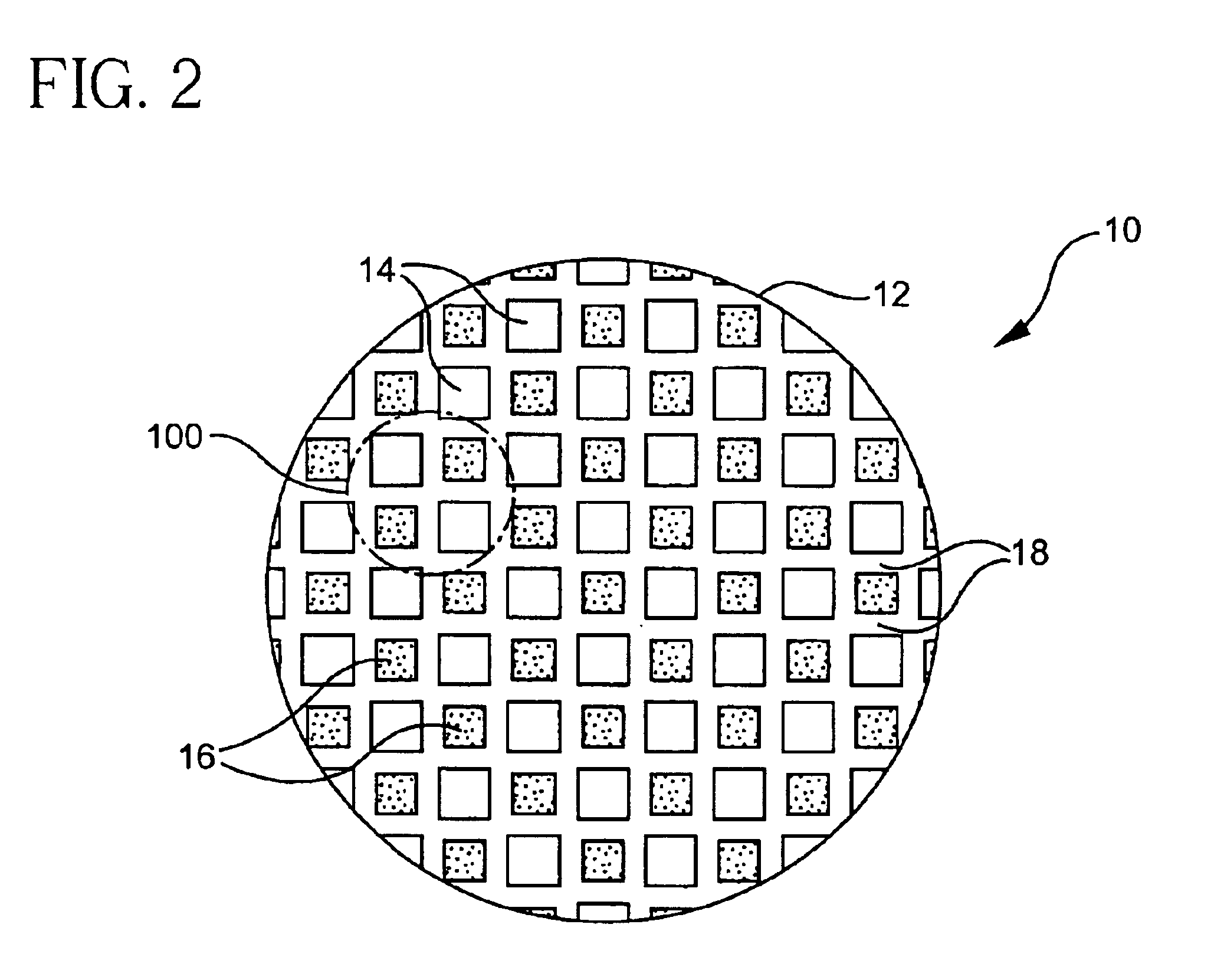

Filter with varying cell channels

InactiveUS6843822B2Increase capacityEfficient and cost-effectiveCombination devicesInternal combustion piston enginesSquare cross sectionHoneycomb structure

Owner:CORNING INC

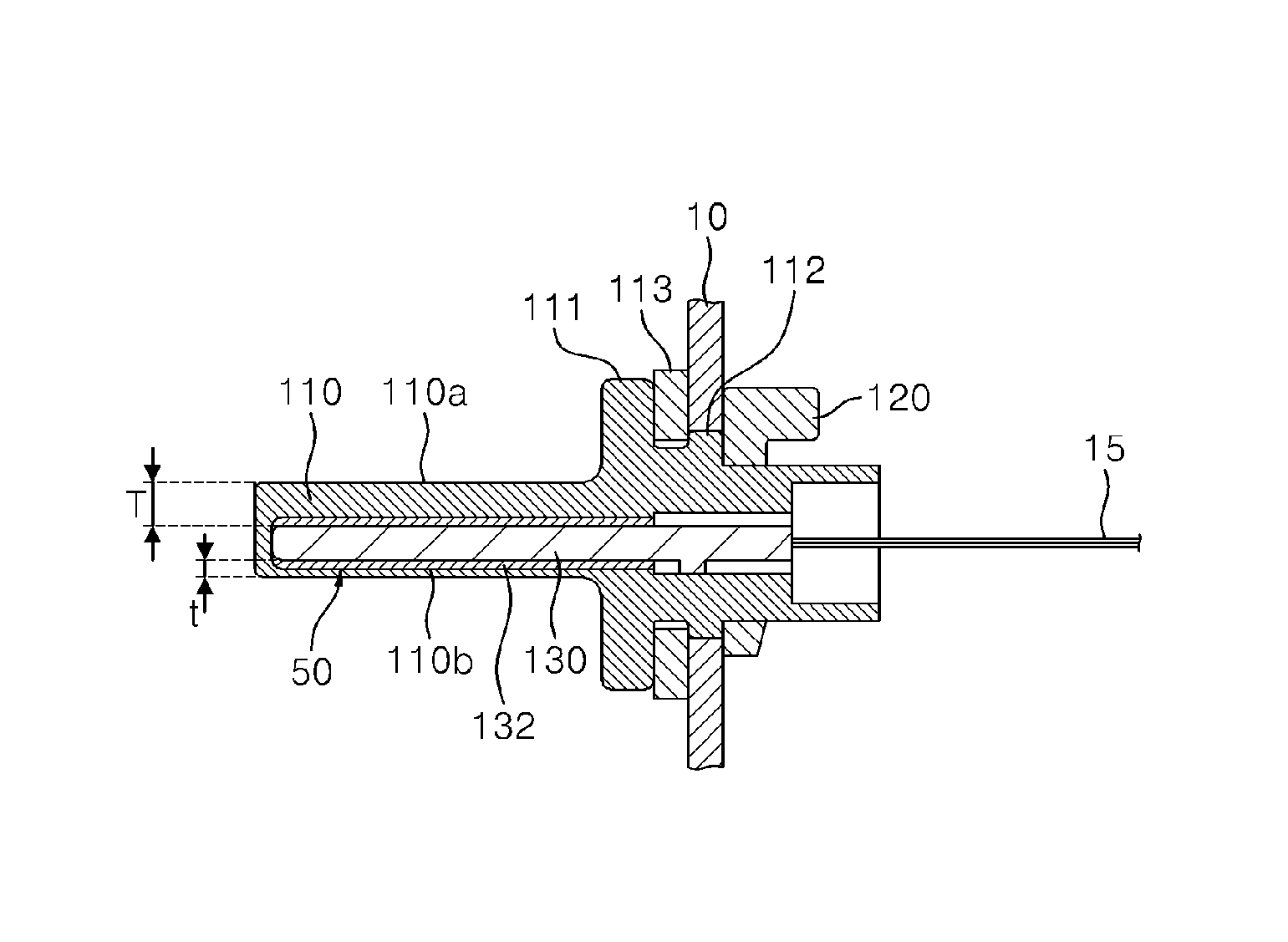

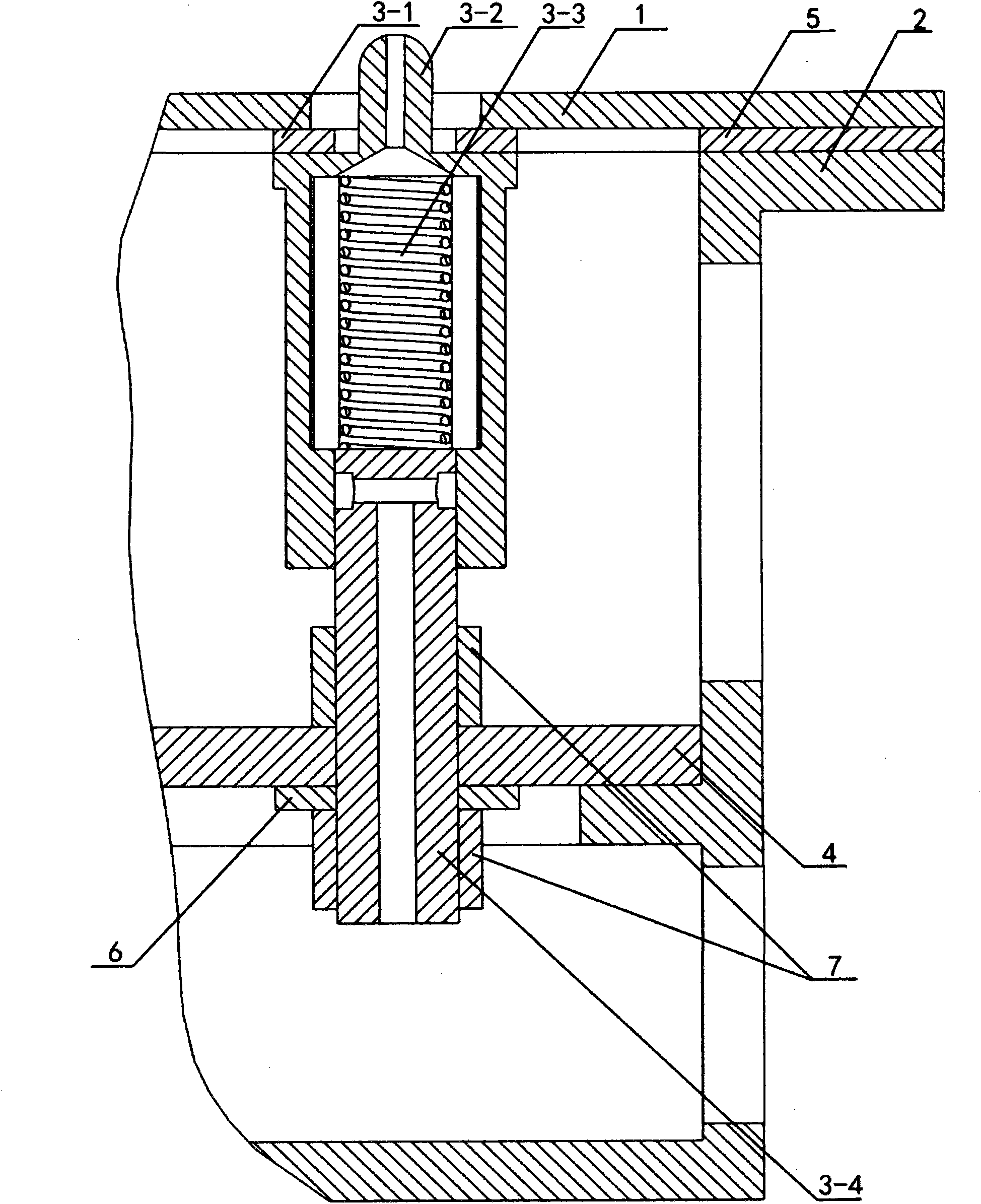

Water level sensing apparatus

ActiveUS8667840B2Increase intervalLess clean upMachines/enginesLubrication indication devicesCapacitanceBody contact

There is provided a water level sensing apparatus including: a body disposed to be exposed within a liquid tank and having an accommodating space therein; and a capacitance detecting unit accommodated in the accommodating space of the body, wherein the capacitance detecting unit compares an upper side capacitance value and a lower side capacitance value and turns on or off an output signal. Because a changeable reference that the capacitance values of a reference surface and a detected surface of the body are simultaneously changed is used, even if the body comes in contact with moisture or debris, the reference surface and the detected surface are equally affected by the moisture or debris, thus reducing the occurrence of malfunction.

Owner:WOONGJIN COWAY

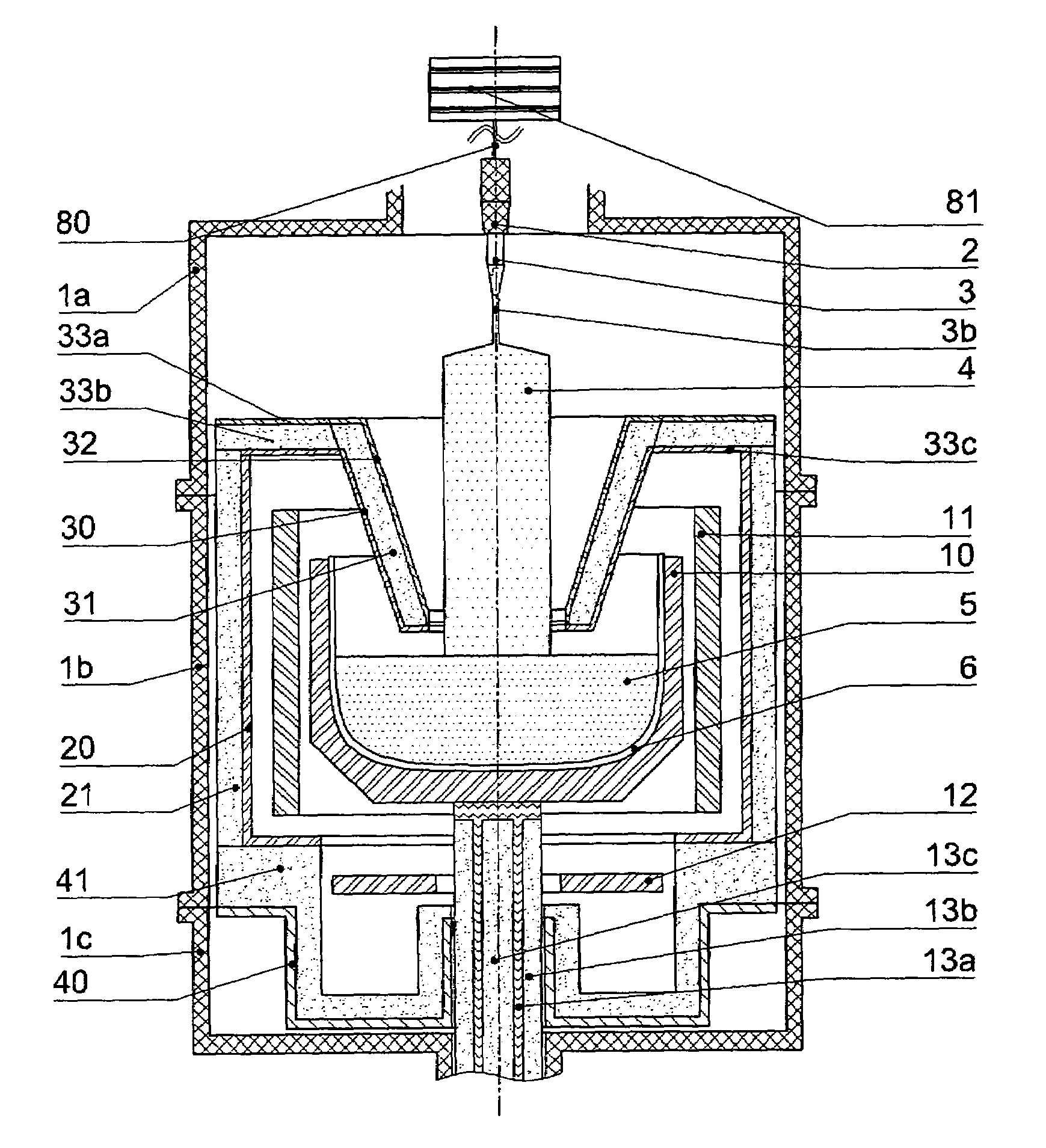

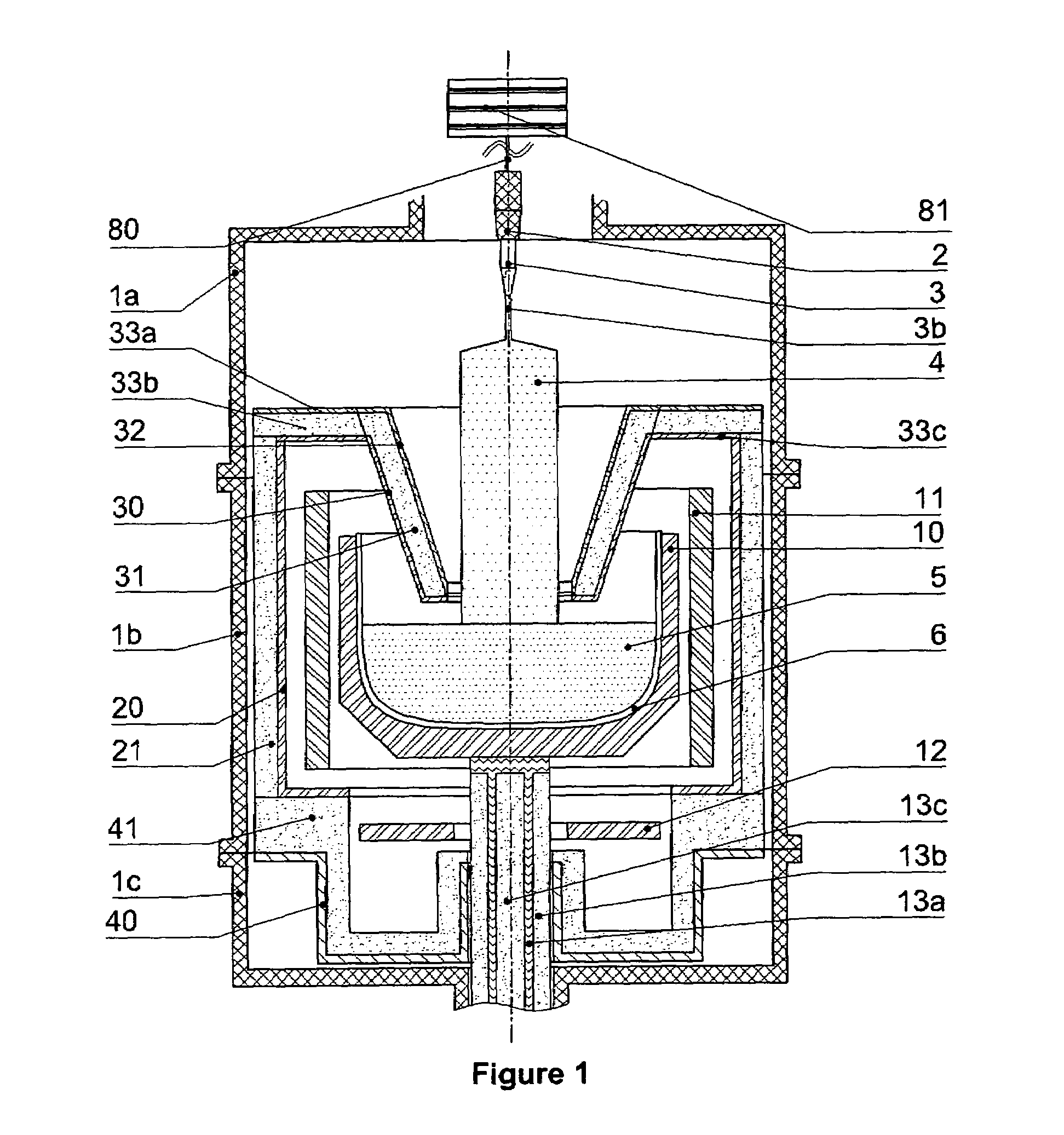

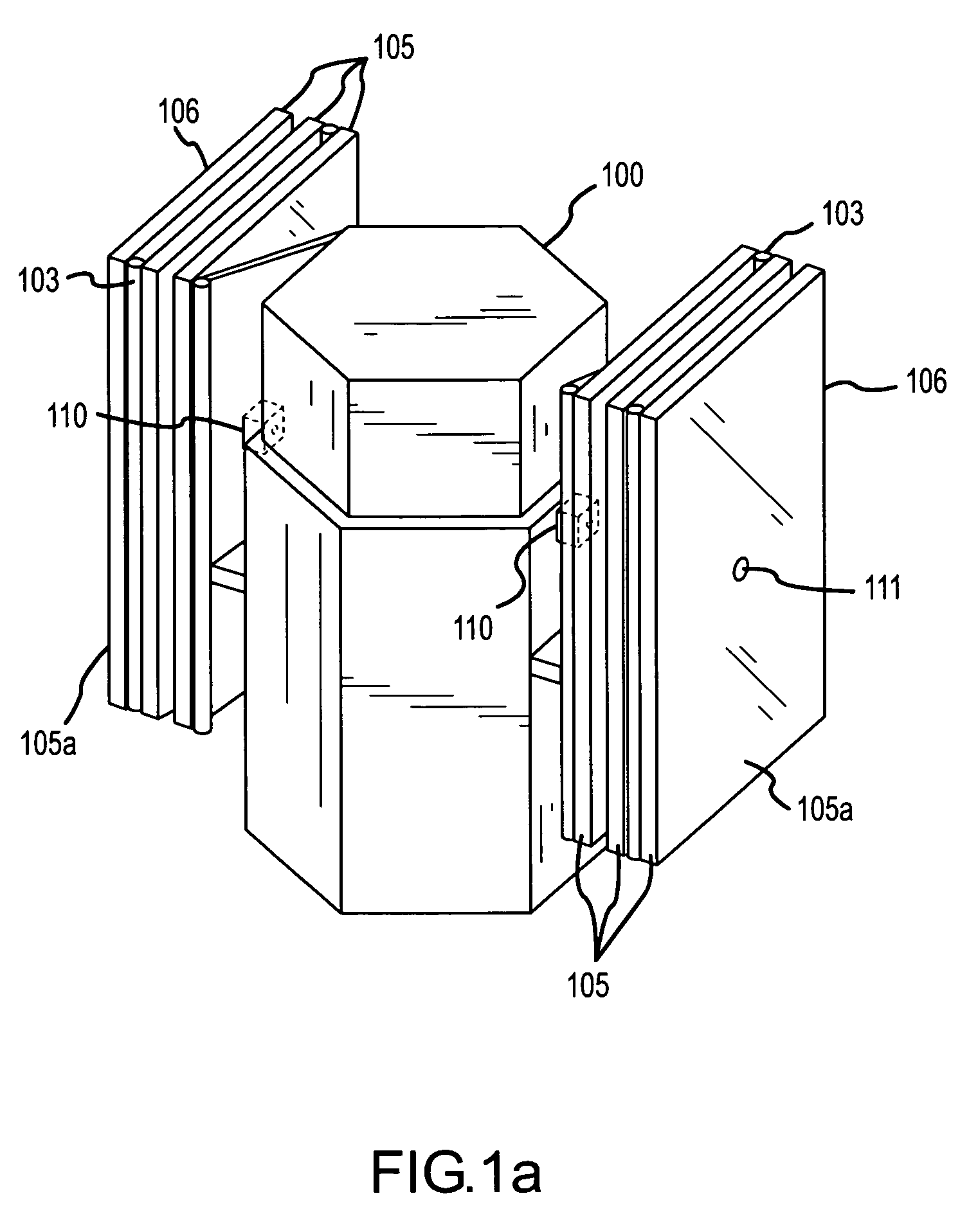

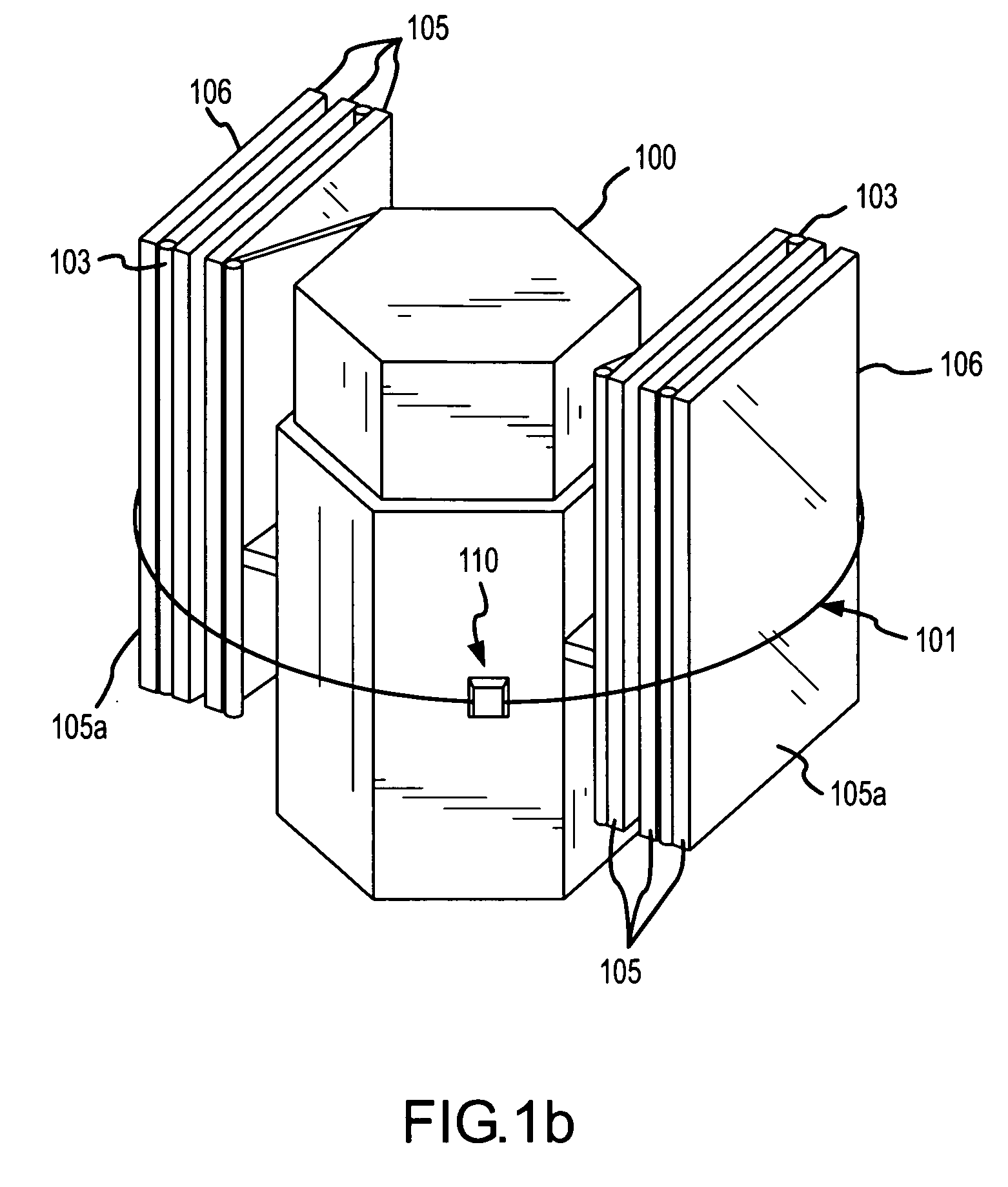

Crystal manufacturing

ActiveUS20080053372A1Low production costImprove productivityAfter-treatment apparatusPolycrystalline material growthHot zoneProduction rate

An implementation of a Czochralski-type crystal growth has been shown and embodied. More particularly, a furnace with suitable insulation and flow arrangement is shown to improve the cost-efficiency of production of crystals. That is achieved by the shown new hot-zone structure, gas flows and the growth process which can decrease the power consumption, increase the lifetime of hot-zone parts and improve the productivity, e.g., by giving means for opening the hot-zone and easily adapting the hot-zone to a new crystal diameter.

Owner:OKMETIC OY

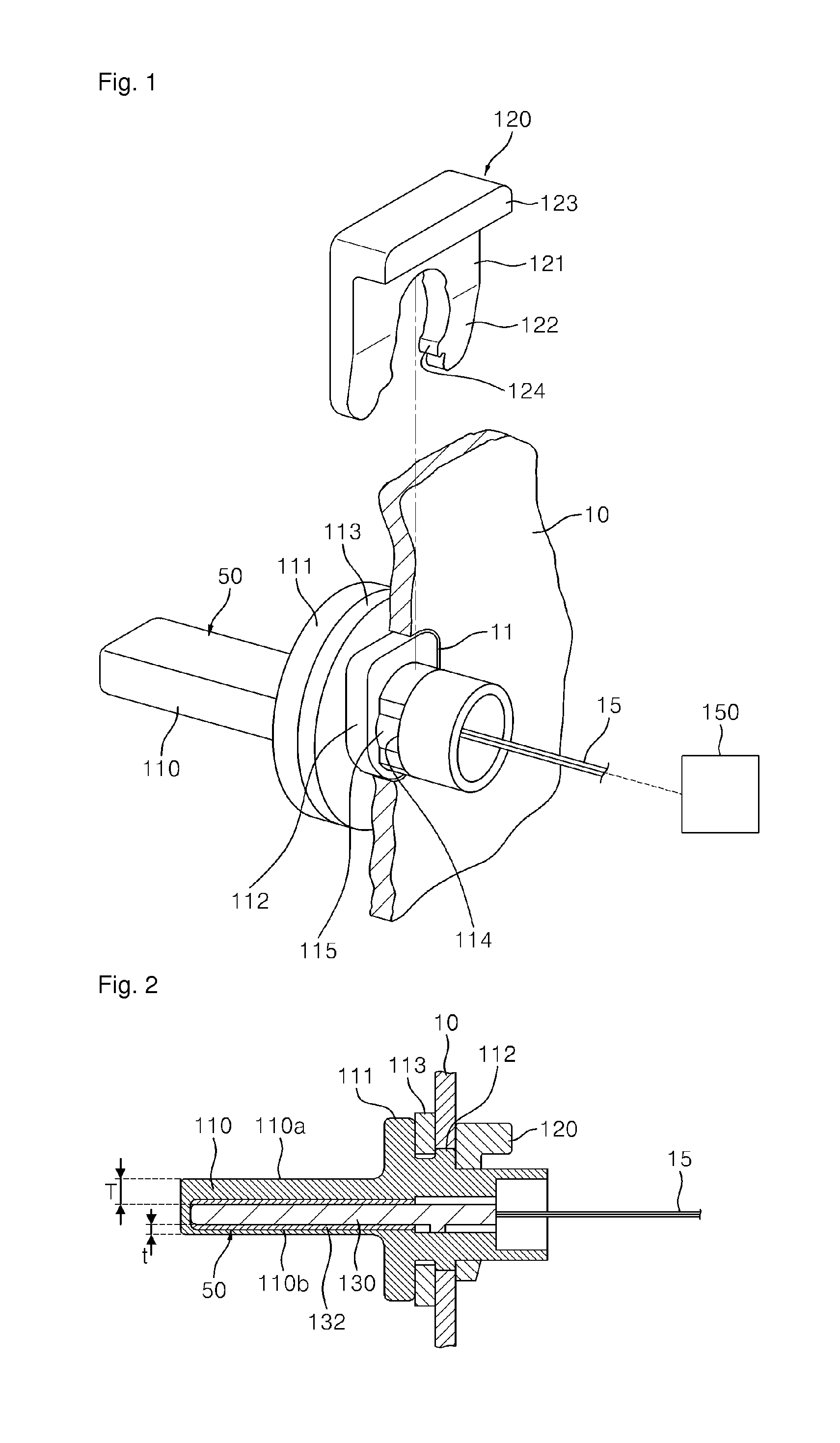

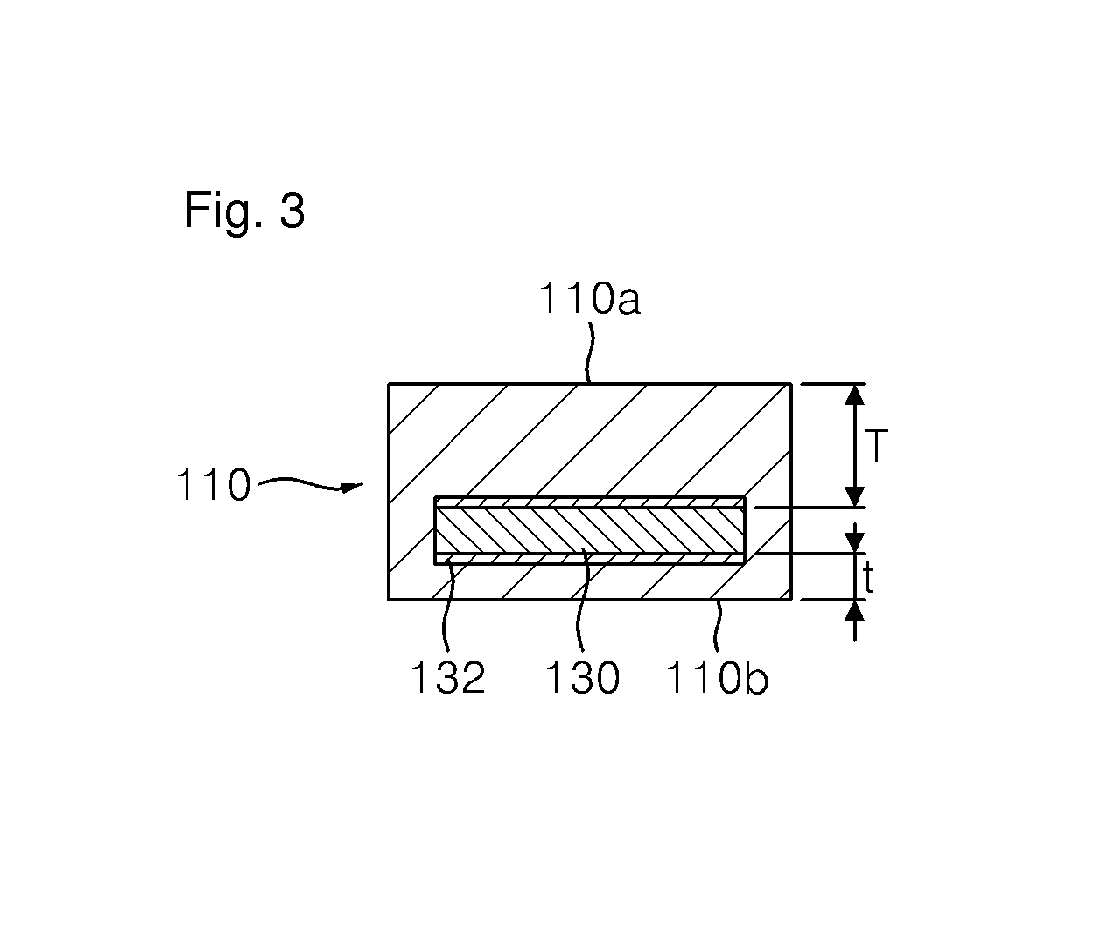

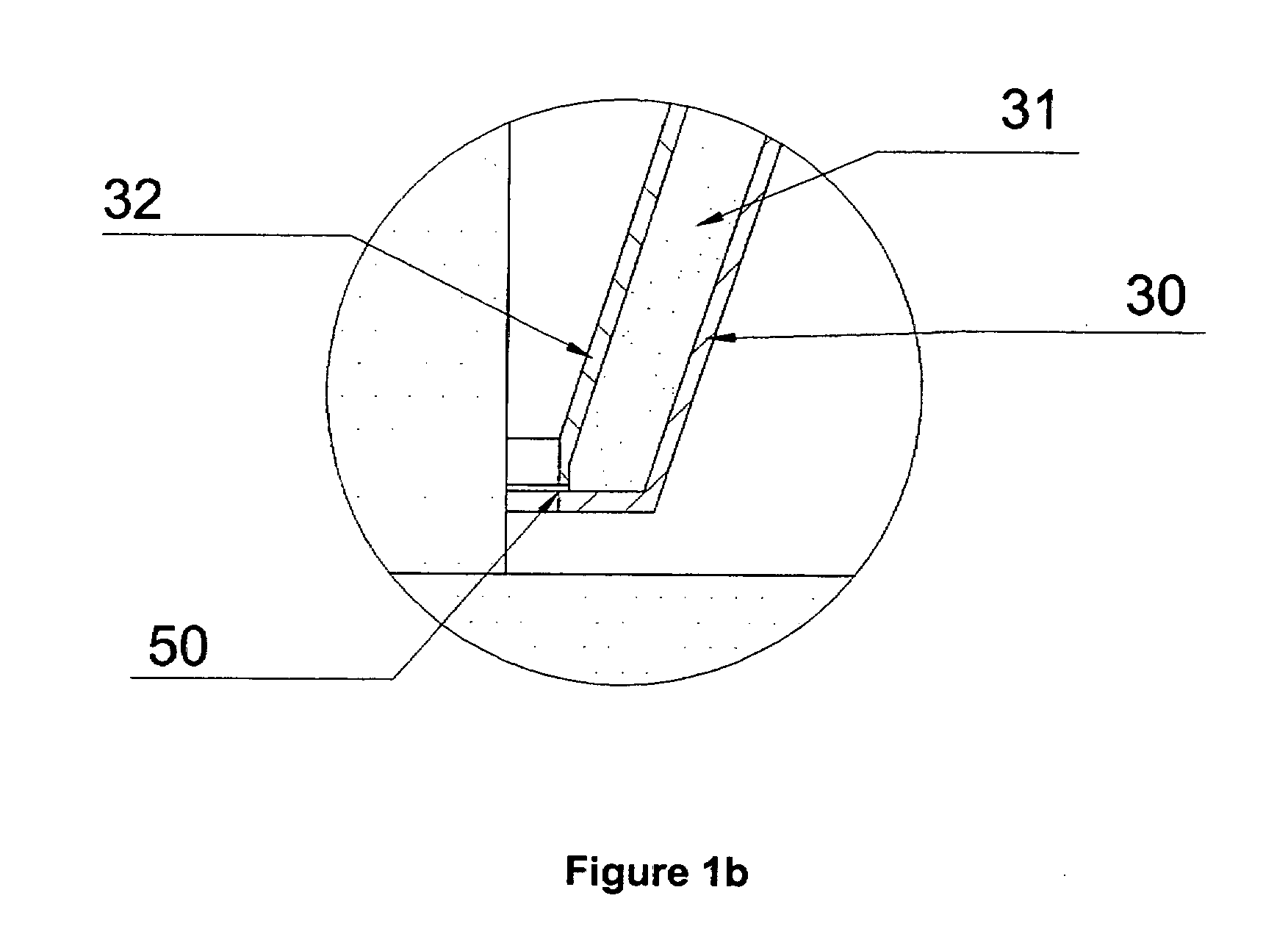

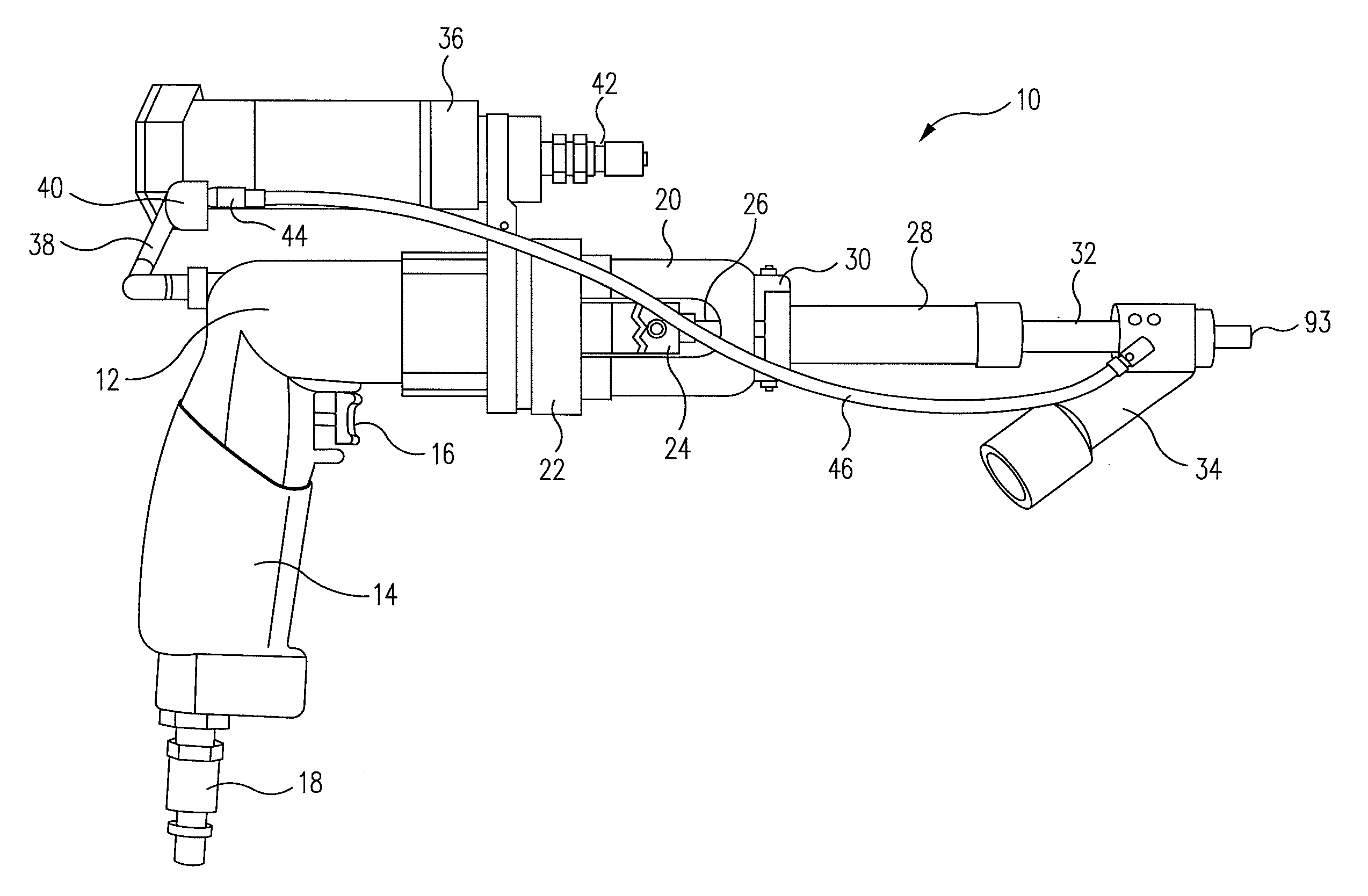

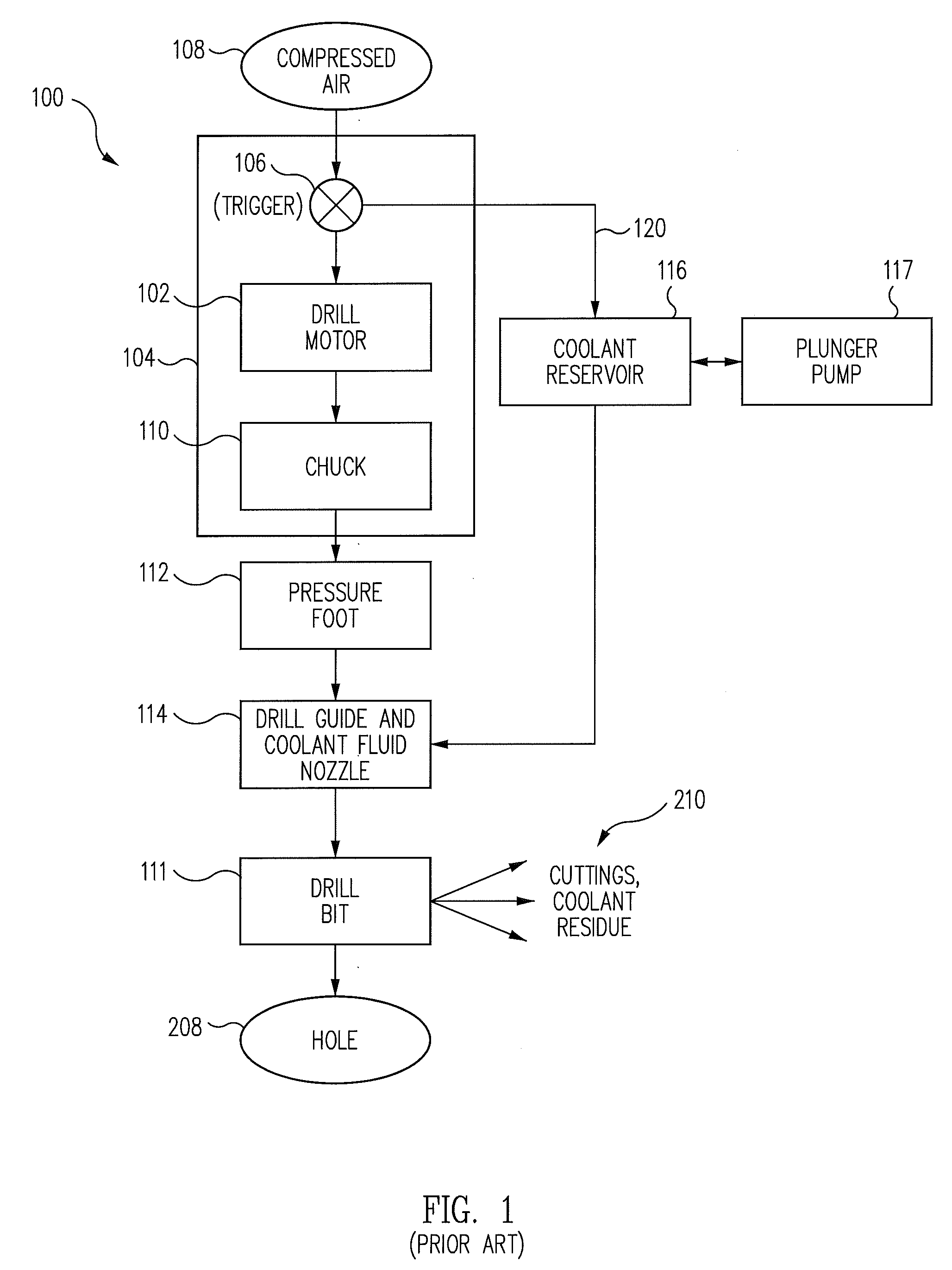

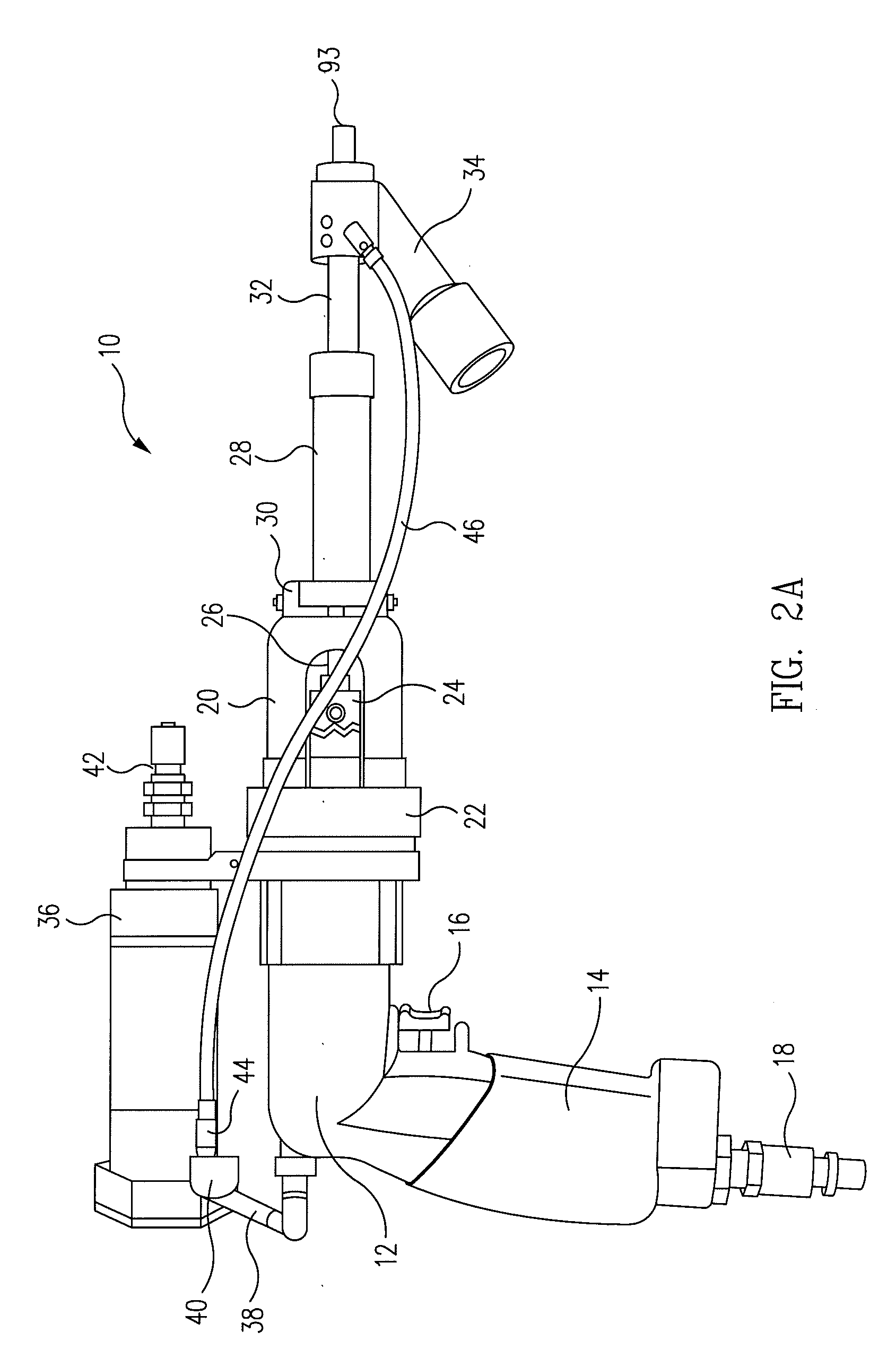

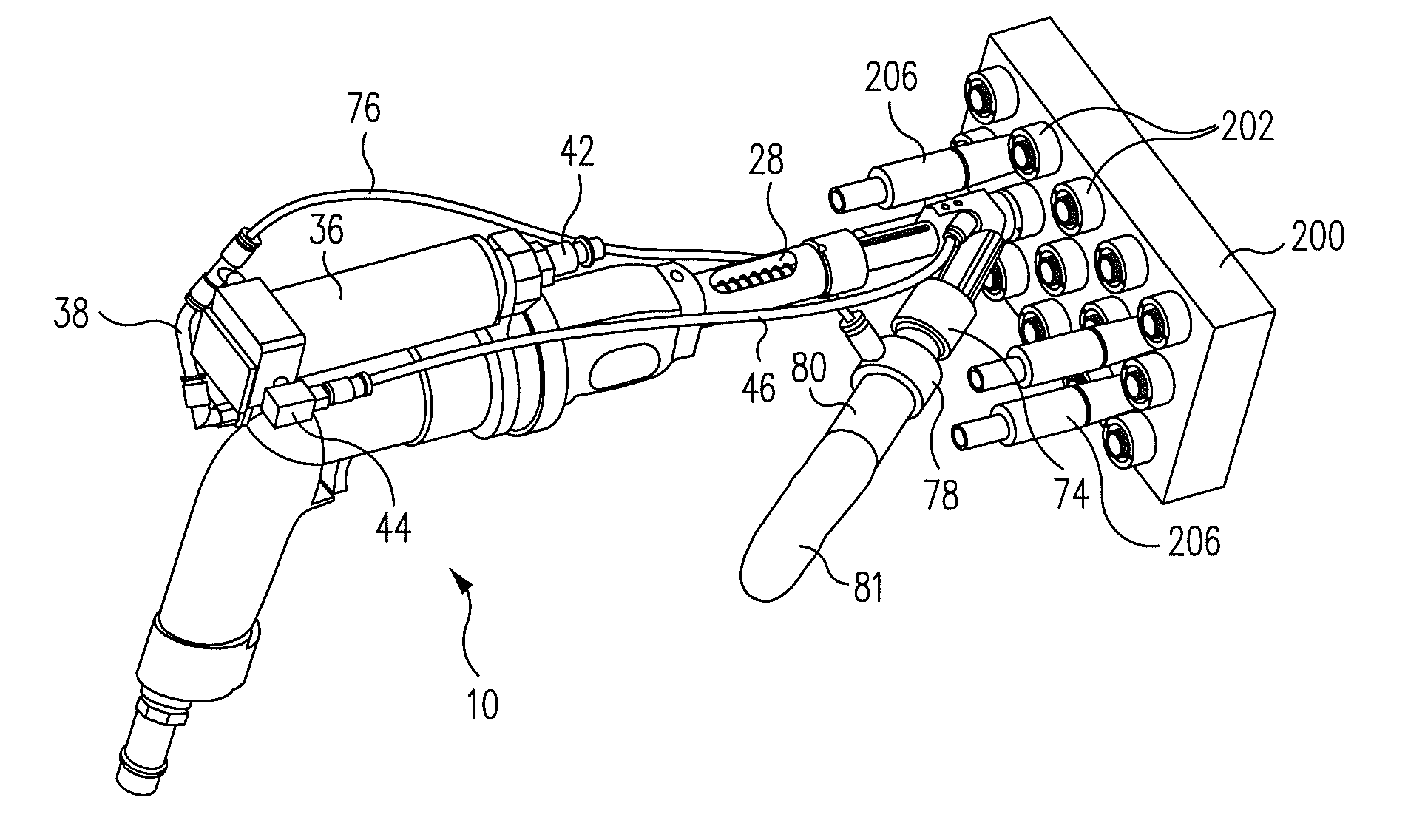

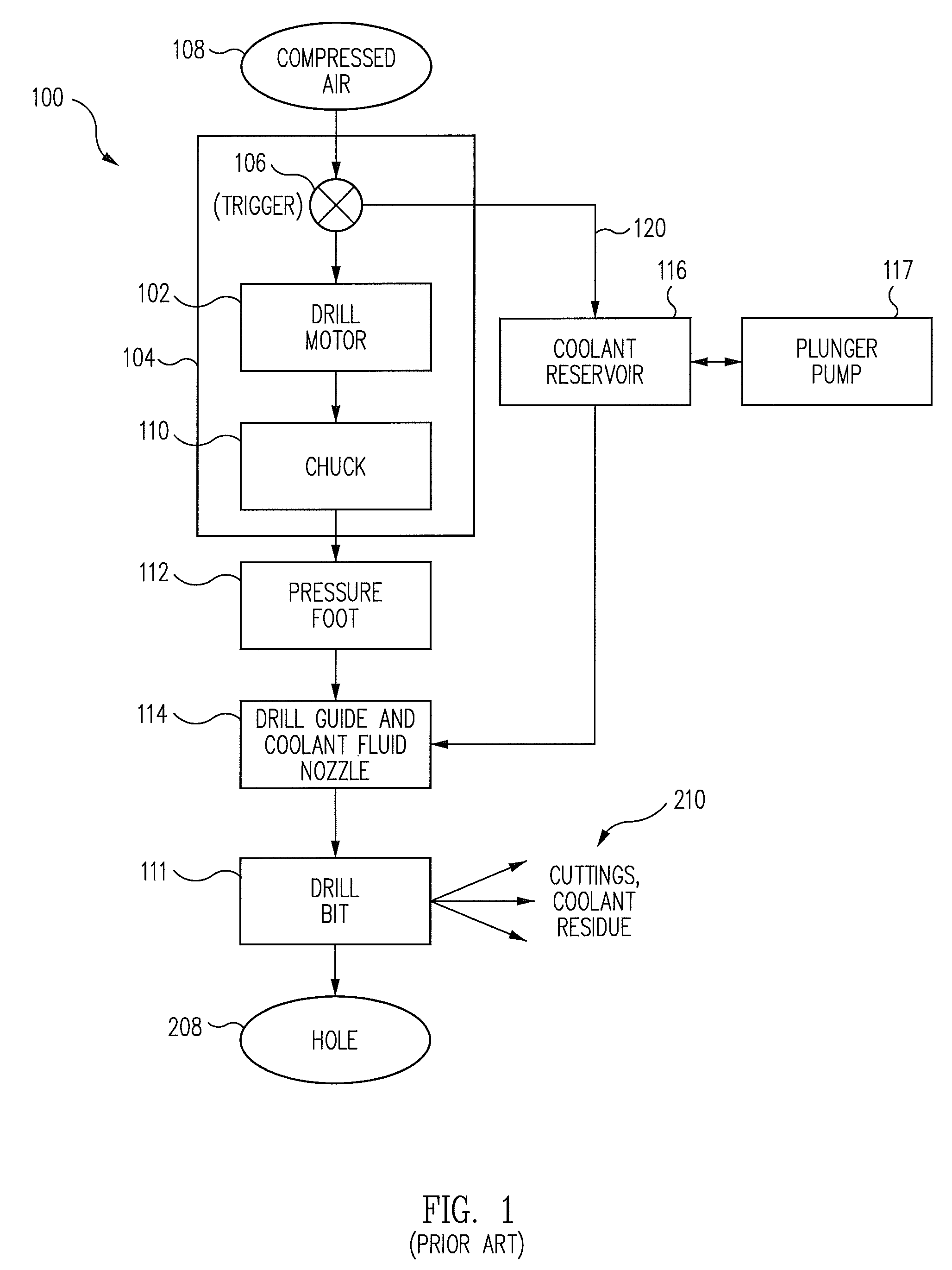

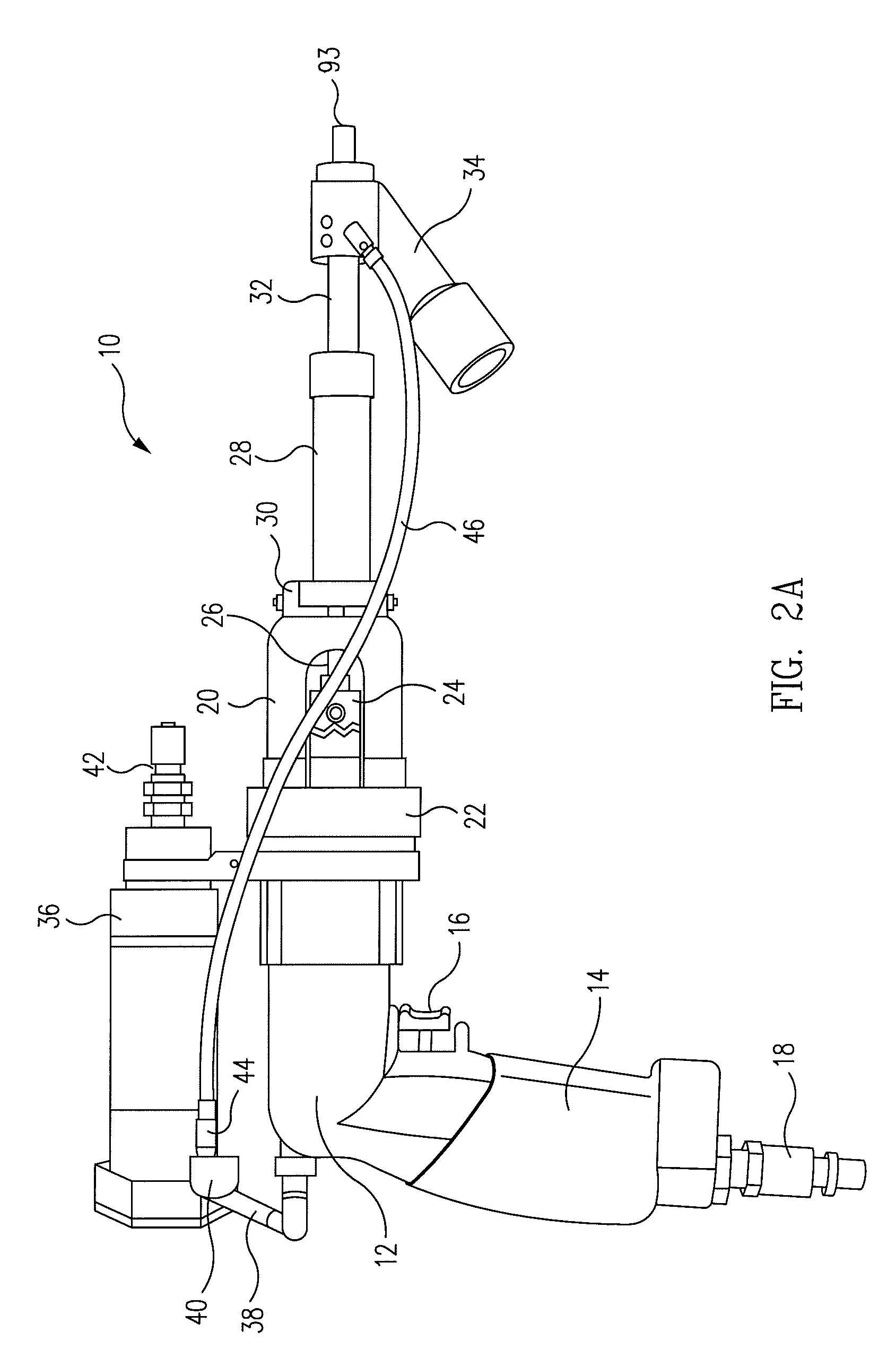

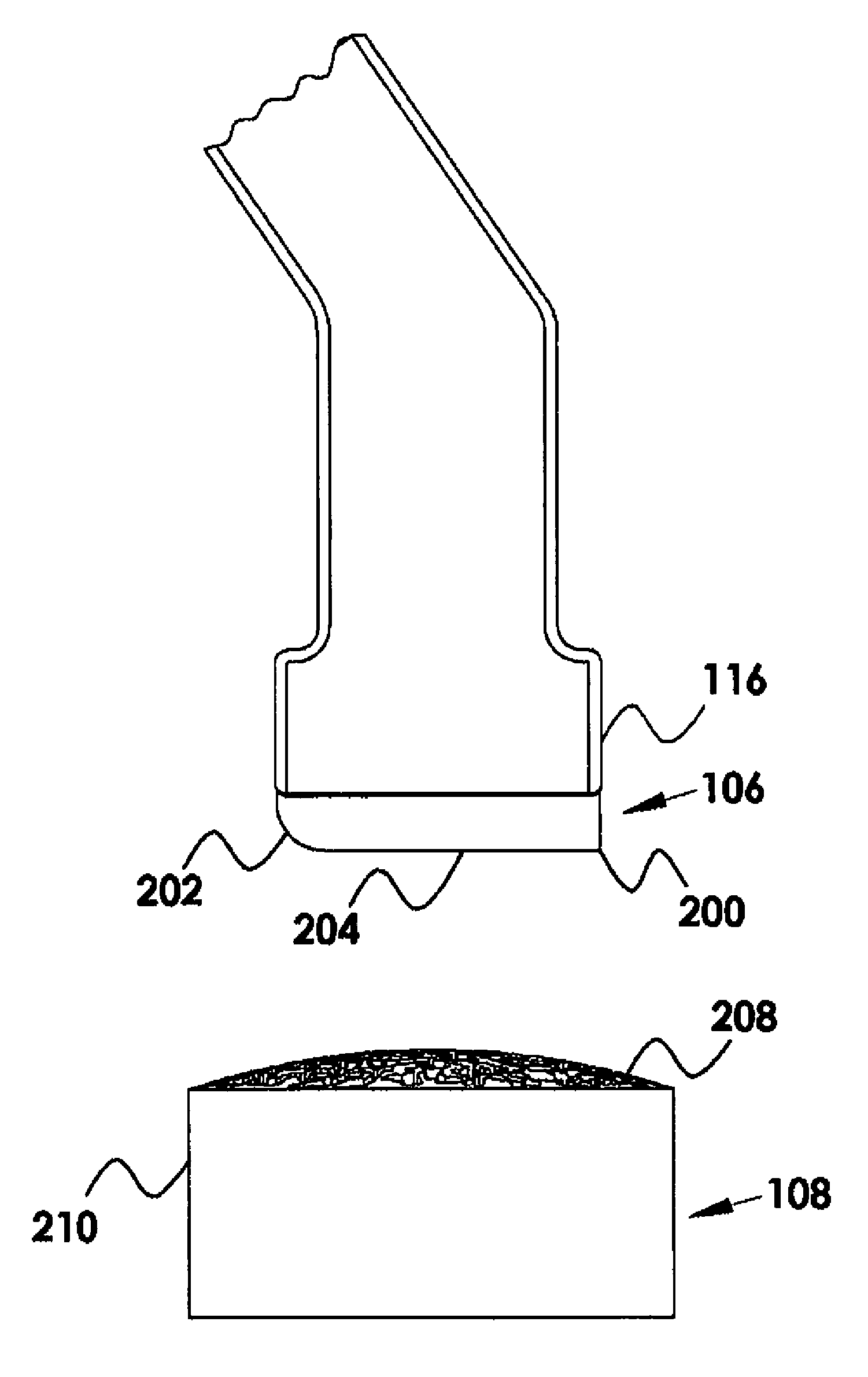

High speed hand drill with swiveling pressure foot and integrated vacuum pickup and coolant delivery duct

ActiveUS20090214307A1Improve tool ergonomicsImproved drill guideDrilling/boring measurement devicesThread cutting feeding devicesHand heldEngineering

A high speed handheld power drill includes a housing with a motor, a chuck rotationally driven by the motor, and a drill bit clamped in the chuck. A pressure foot is mounted on the housing for coaxial rotation about the drill bit and lockable in a selectable angular position relative to the housing. A drill guide is slidably disposed within the pressure foot at an outer end thereof and biased for coaxial sliding movement between the drill bit and pressure foot. A vacuum cuttings pickup and coolant fluid delivery tool is coupled to the drill guide and arranged to deliver coolant fluid to the drill bit and to remove drill cuttings and coolant fluid and vapor therefrom during drilling. A coolant fluid reservoir is coupled to the drill motor housing and adapted to deliver selectably metered amounts of coolant fluid to the cuttings pickup and coolant delivery tool during drilling.

Owner:THE BOEING CO

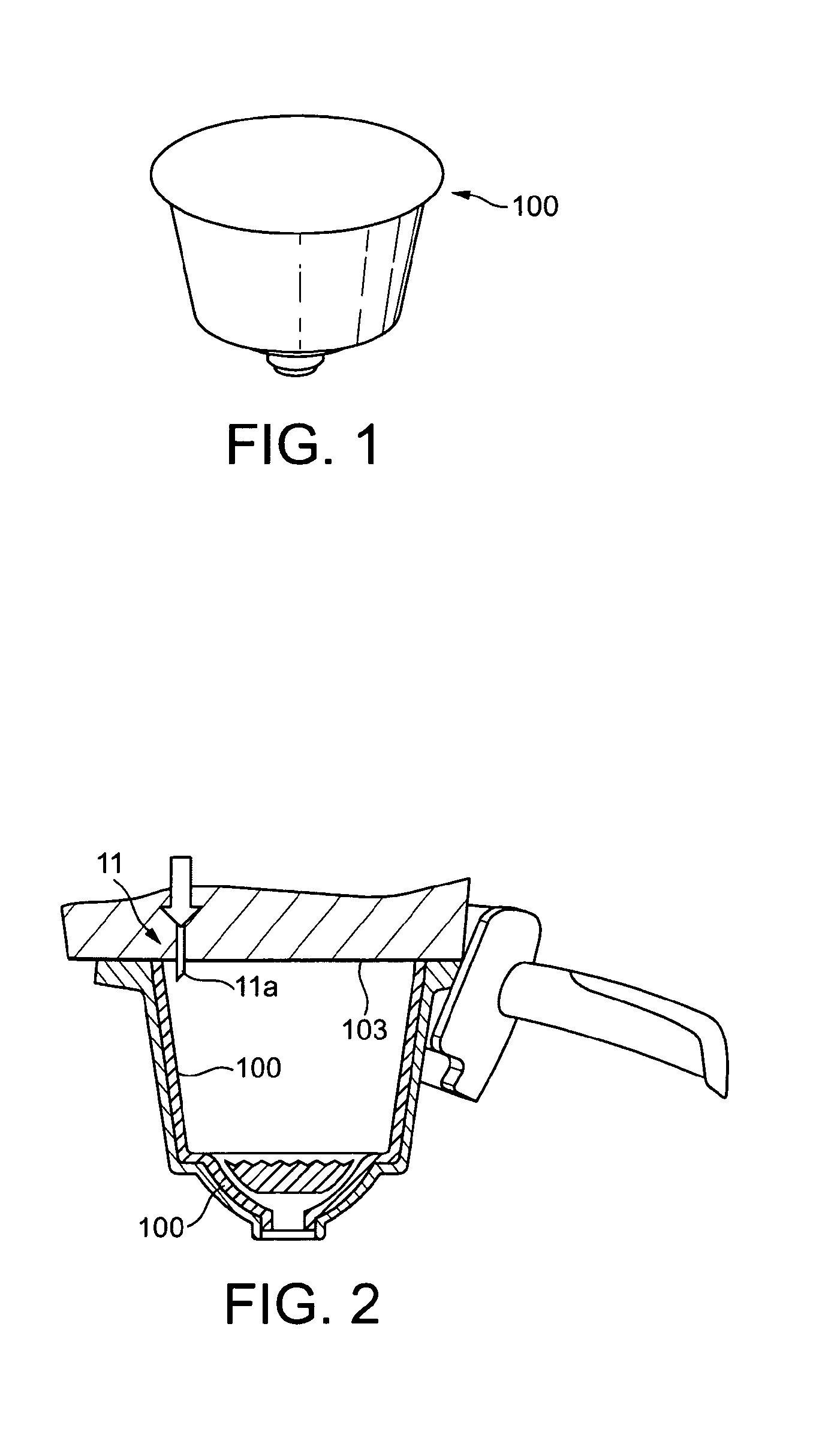

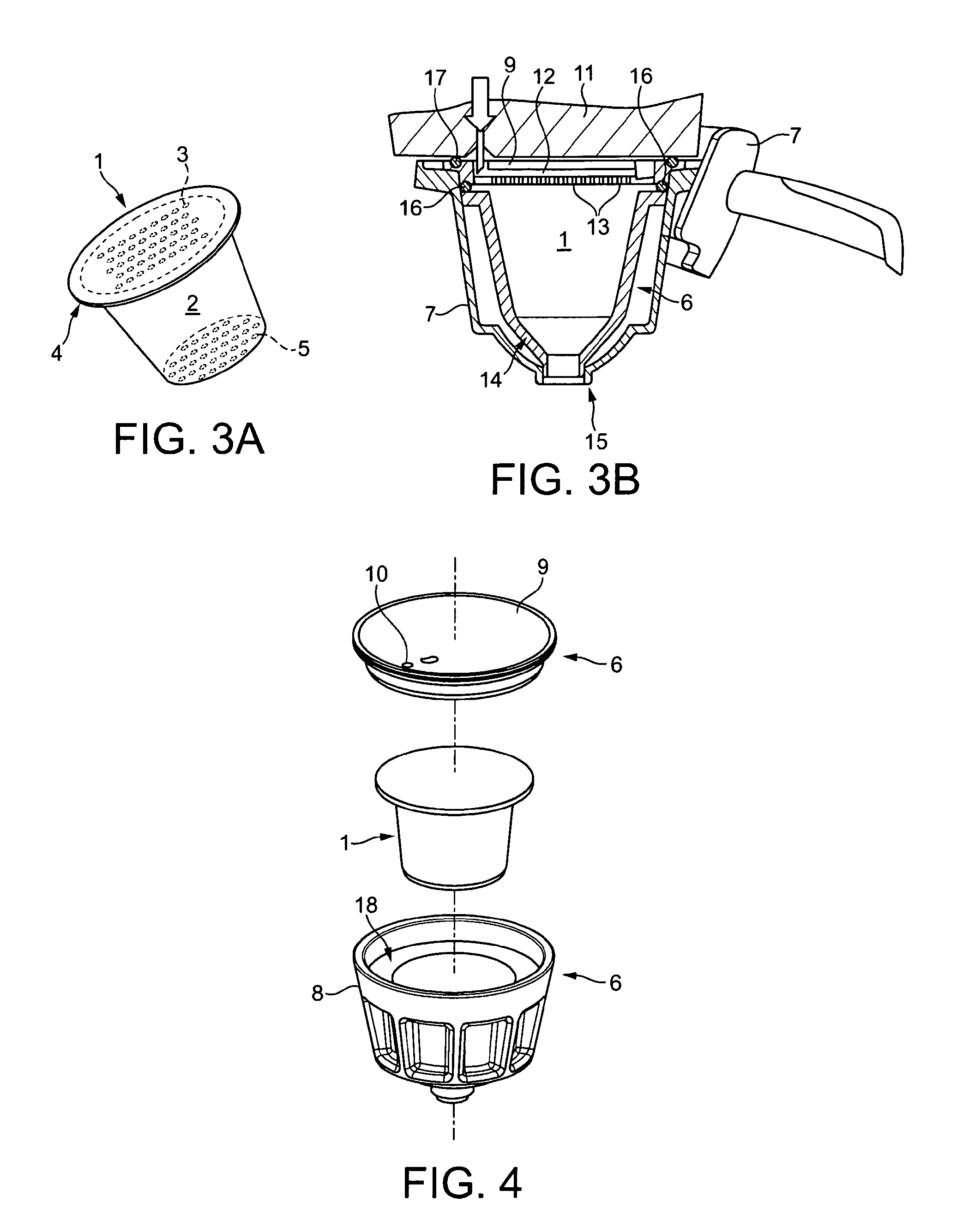

Device for adapting a food capsule into a capsule holder

ActiveUS20130133522A1Increase heightRemove cleanFlexible coversWrappersFood ComponentAdditive ingredient

The present invention concerns an adapting device (6) for adapting a capsule (100) into the capsule holder (7) of a food machine when said capsule or pod (100) is smaller than capsules or pods originally designed for insertion into said capsule holder, said machine comprising a fluid injection element (11) for circulating a fluid through the capsule to a discharge opening, said capsule comprising a body enclosing a food ingredient to be dissolved and / or extracted so as to produce a food product, and further comprising circumferential edges (4, 22), said device comprising: a holding portion for holding at least a portion of said capsule, and sealing means (16, 17, 32) for circumferentially adapting to the capsule holder and / or to the fluid injection element, and / or to the capsule outside surface, in a leak-tight manner so that the fluid flow is directed solely from the fluid injection element (11) through the capsule, to a discharge opening.

Owner:SOC DES PROD NESTLE SA

Artificial culture method and culture medium for fruiting bodies of cordyceps militaris

The invention discloses an artificial culture method and a culture medium for fruiting bodies of cordyceps militaris. Based on the culture medium in a 500mL culture bottle, the culture medium comprises the following components: 20 to 25g of cottonseed hull and 120 to 140mL of nutrient solution, wherein the nutrient solution comprises the following components in part by weight: 2.0 to 3.0 parts of wheat flour, 1.0 to 1.5 parts of soya flour, 3.0 to 4.0 parts of white sugar, 0.1 to 0.2 part of magnesium sulfate, 0.1 to 0.2 part of potassium dihydrogen phosphate, 0.05 to 0.1 part of zinc sulfate, 0.05 to 0.1 part of sodium chloride and 95 to 105 parts of water, and the pH value of the nutrient solution is 6 to 8. The artificial culture method comprises the following steps of: preparation of the culture medium, sub-packaging, sterilization, cooling, inoculation, culture and harvesting of fruiting bodies. The invention has the advantages of simple operation, high efficiency, energy conservation, short culture period, high yield of fruiting bodies, and no pollution or solid wastes.

Owner:LUDONG UNIVERSITY

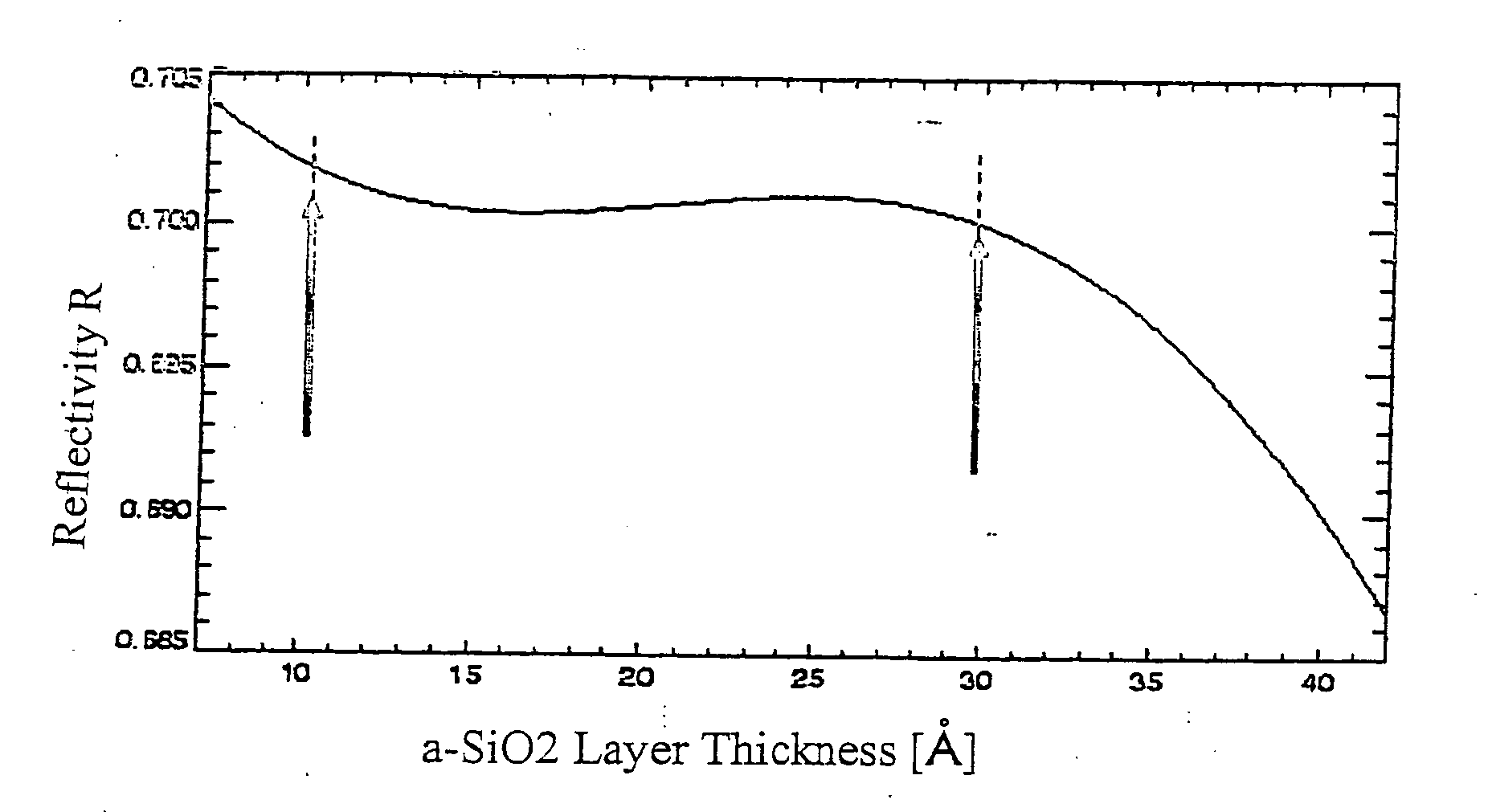

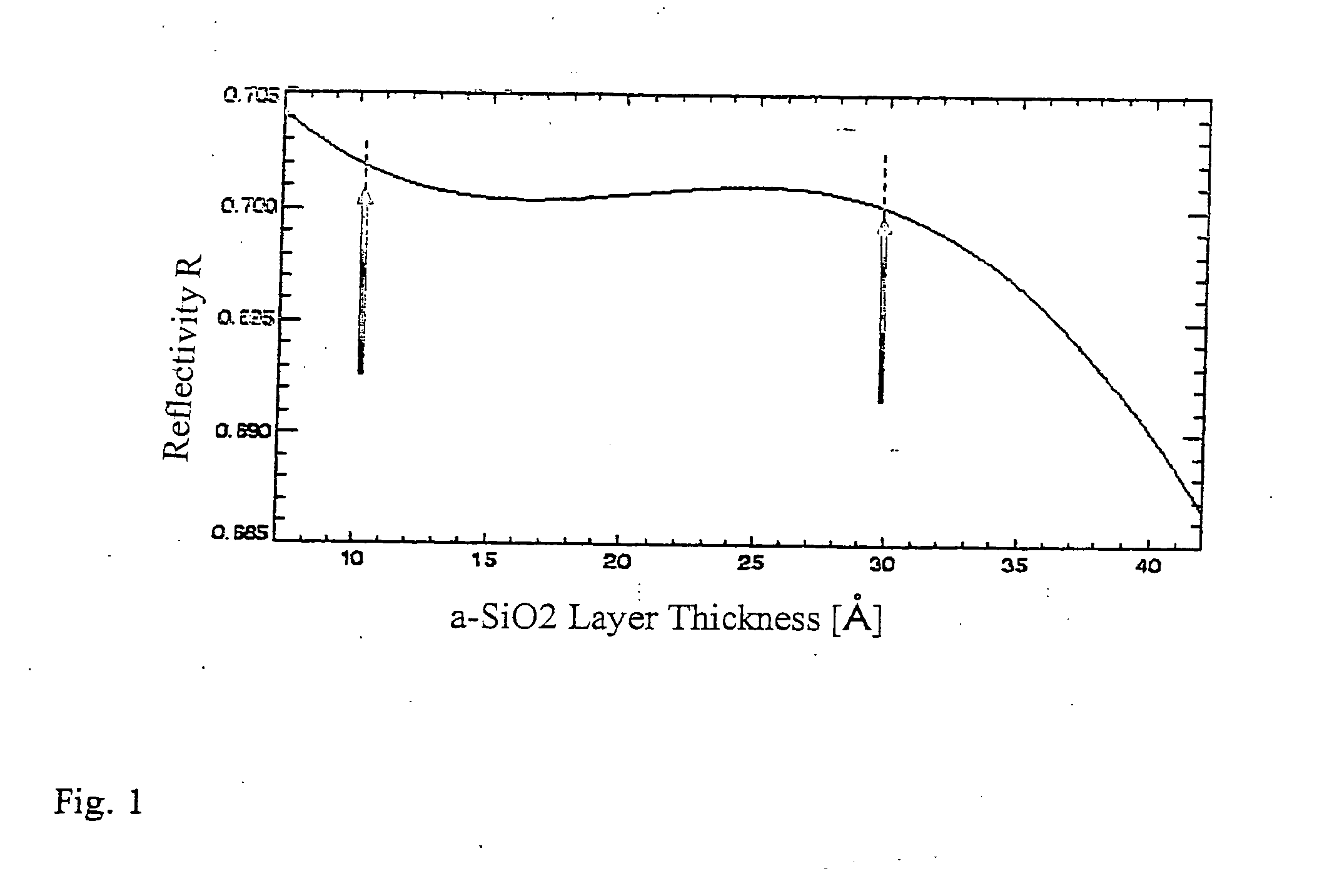

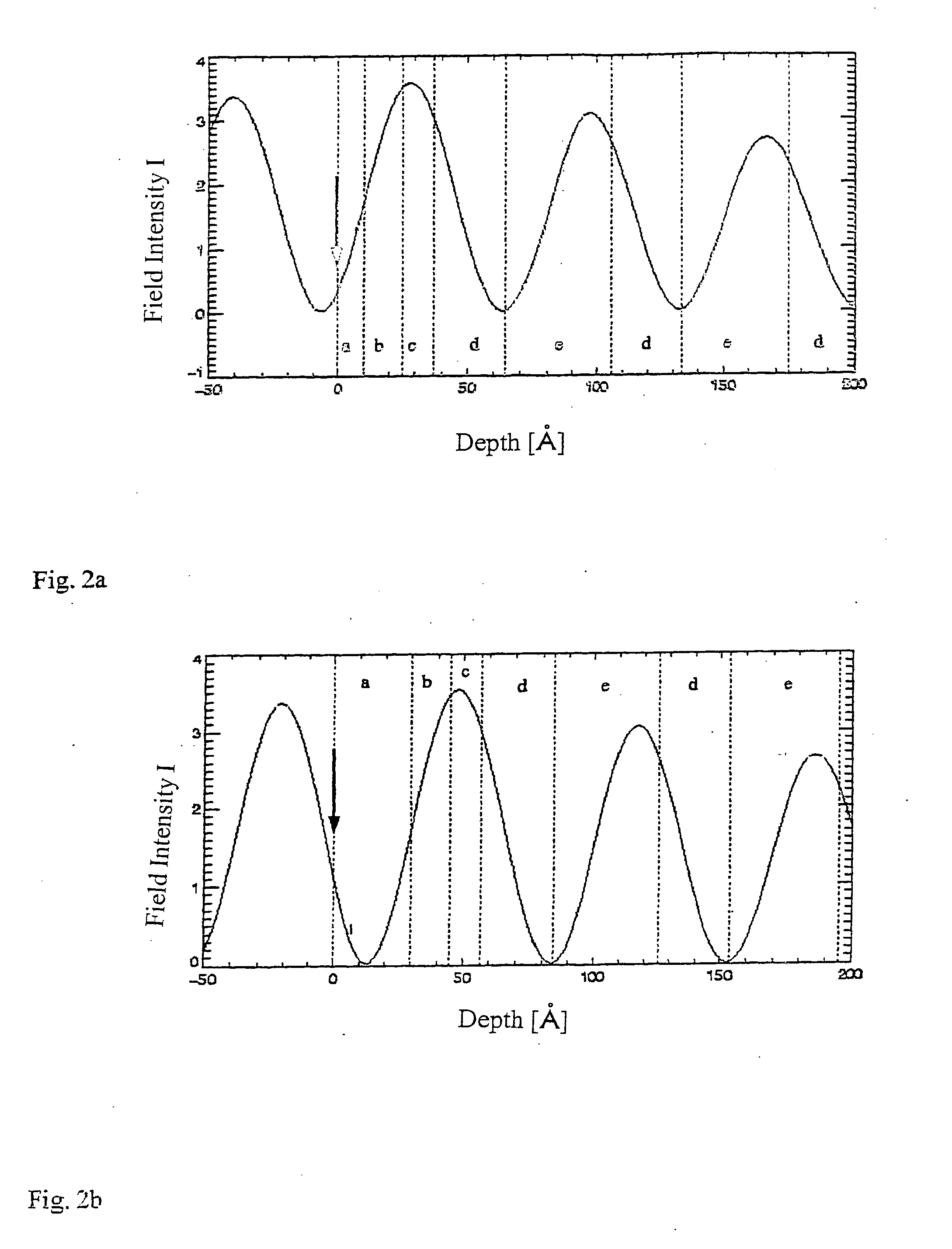

Reflective optical element and EUV lithography appliance

InactiveUS20060066940A1Reduce layeringReduce probabilityMirrorsNanoinformaticsCatoptricsOptical property

The invention relates to a reflective optical element and an EUV lithography appliance containing one such element, said appliance displaying a low propensity to contamination. According to the invention, the reflective optical element has a protective layer system consisting of at least one layer. The optical characteristics of the protective layer system are between those of a spacer and an absorber or correspond to those of a spacer. The selection of a material with the smallest possible imaginary part and a real part which is as close to 1 as possible in terms of the refractive index leads to a plateau-type reflectivity course according to the thickness of the protective layer system between two thicknesses d1 and d2. The thickness of the protective layer system is selected in such a way that it is less than d2.

Owner:CARL ZEISS SMT GMBH

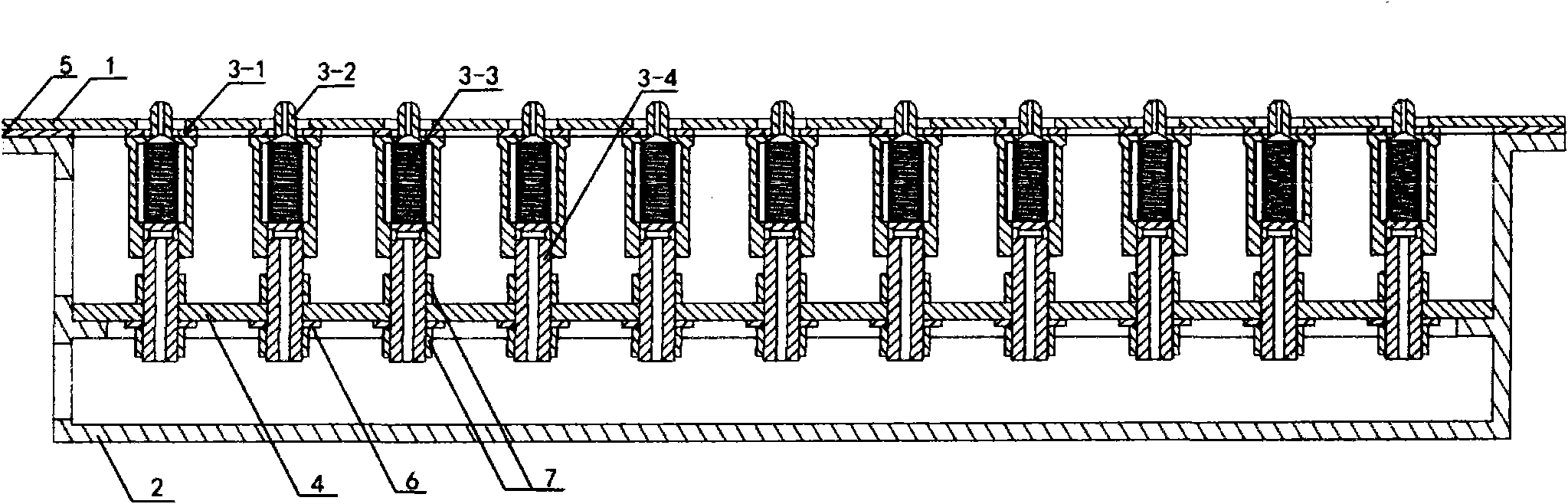

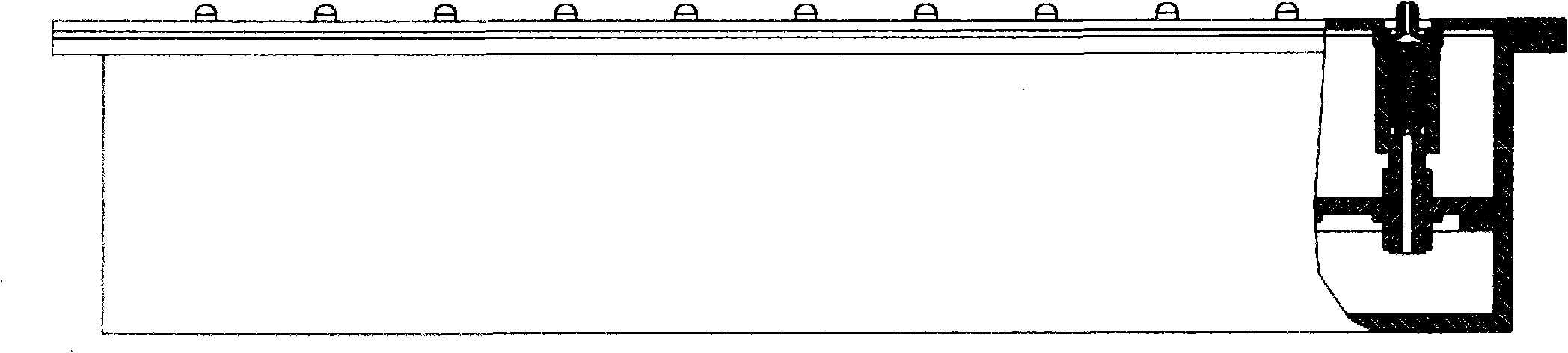

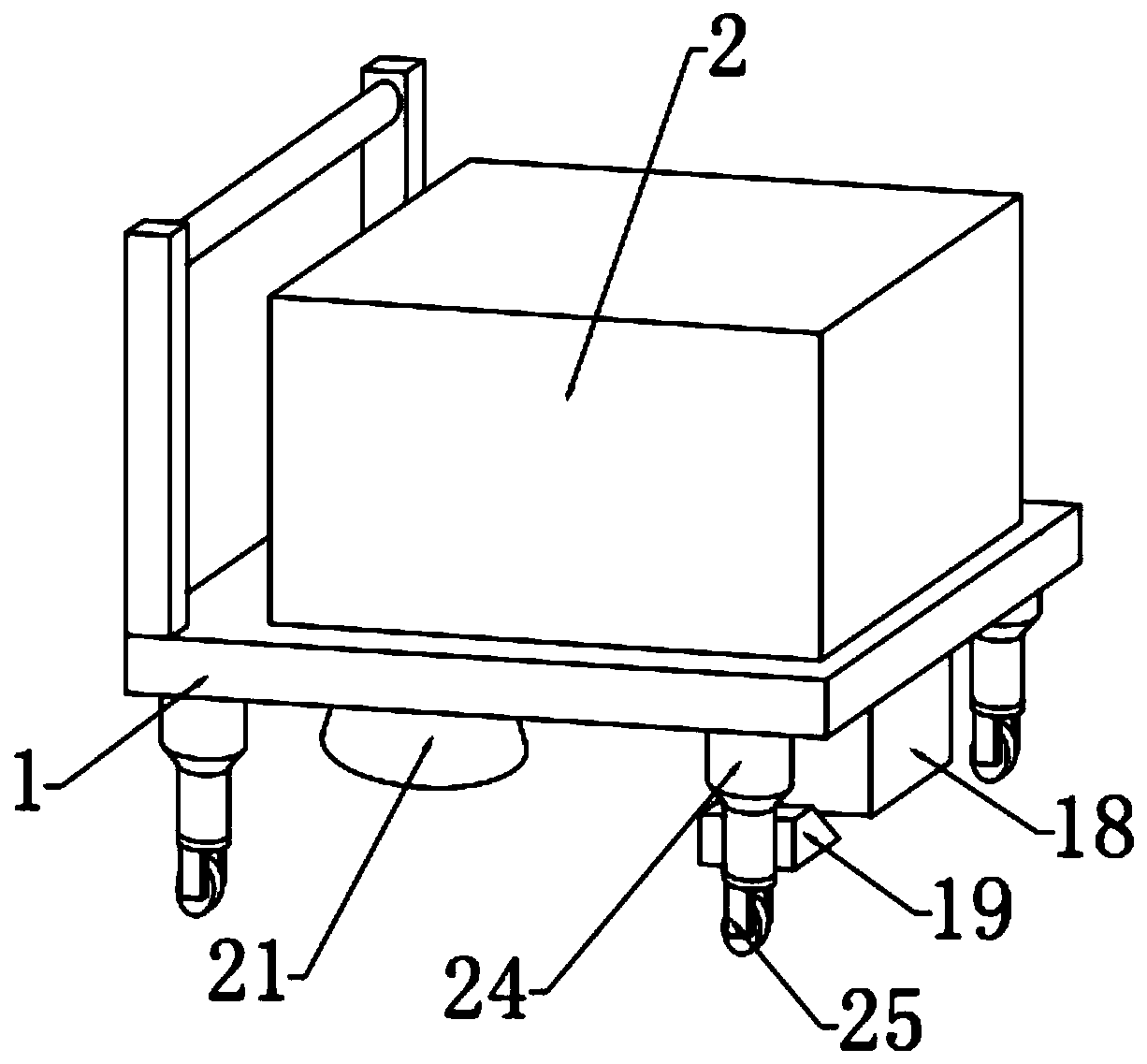

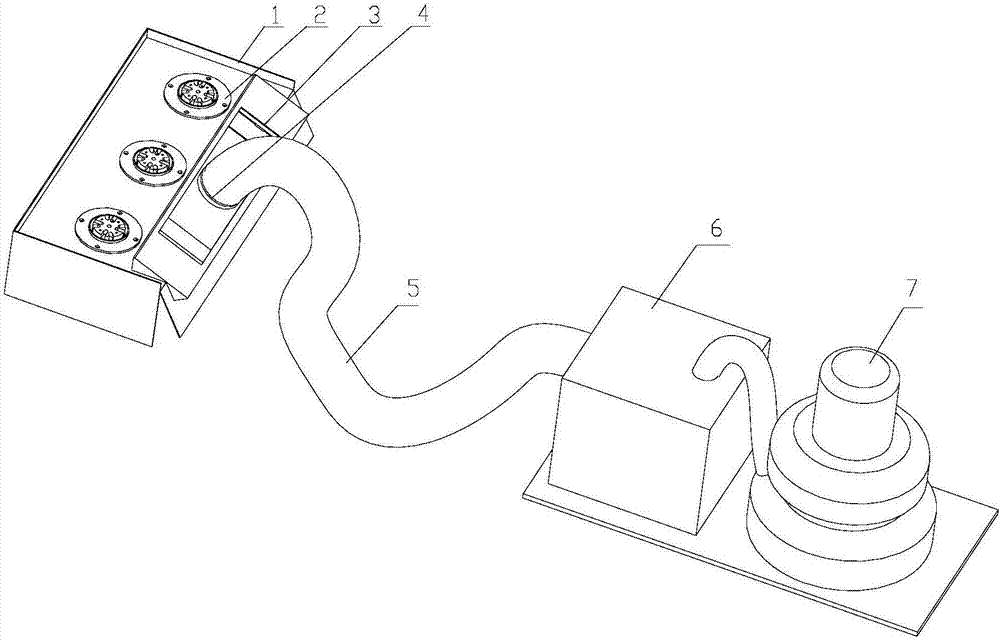

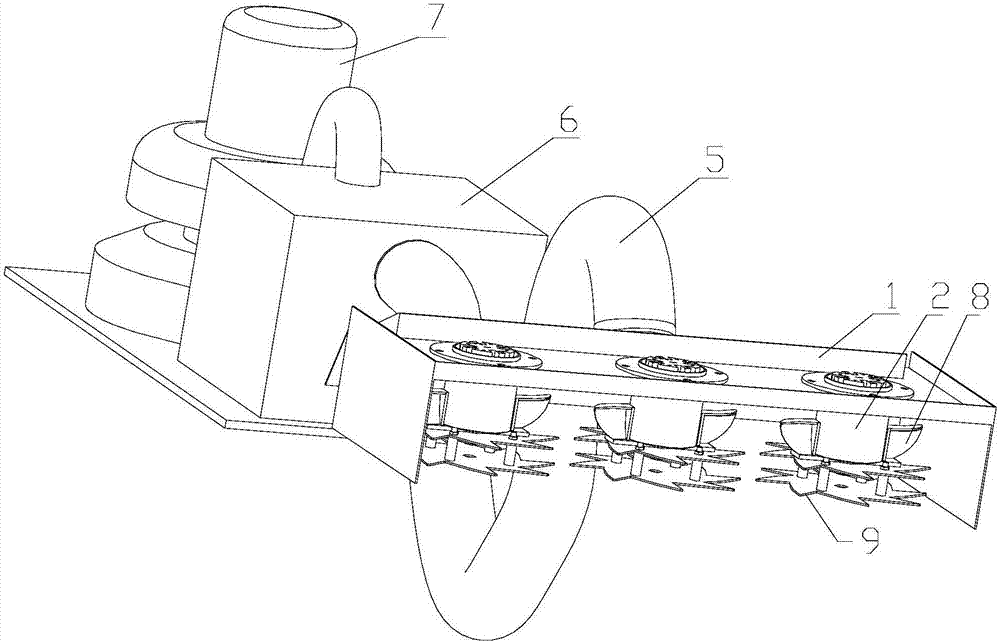

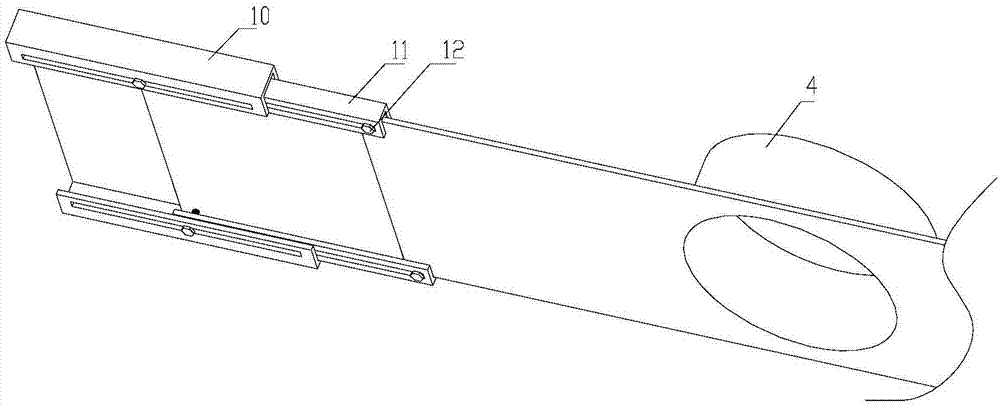

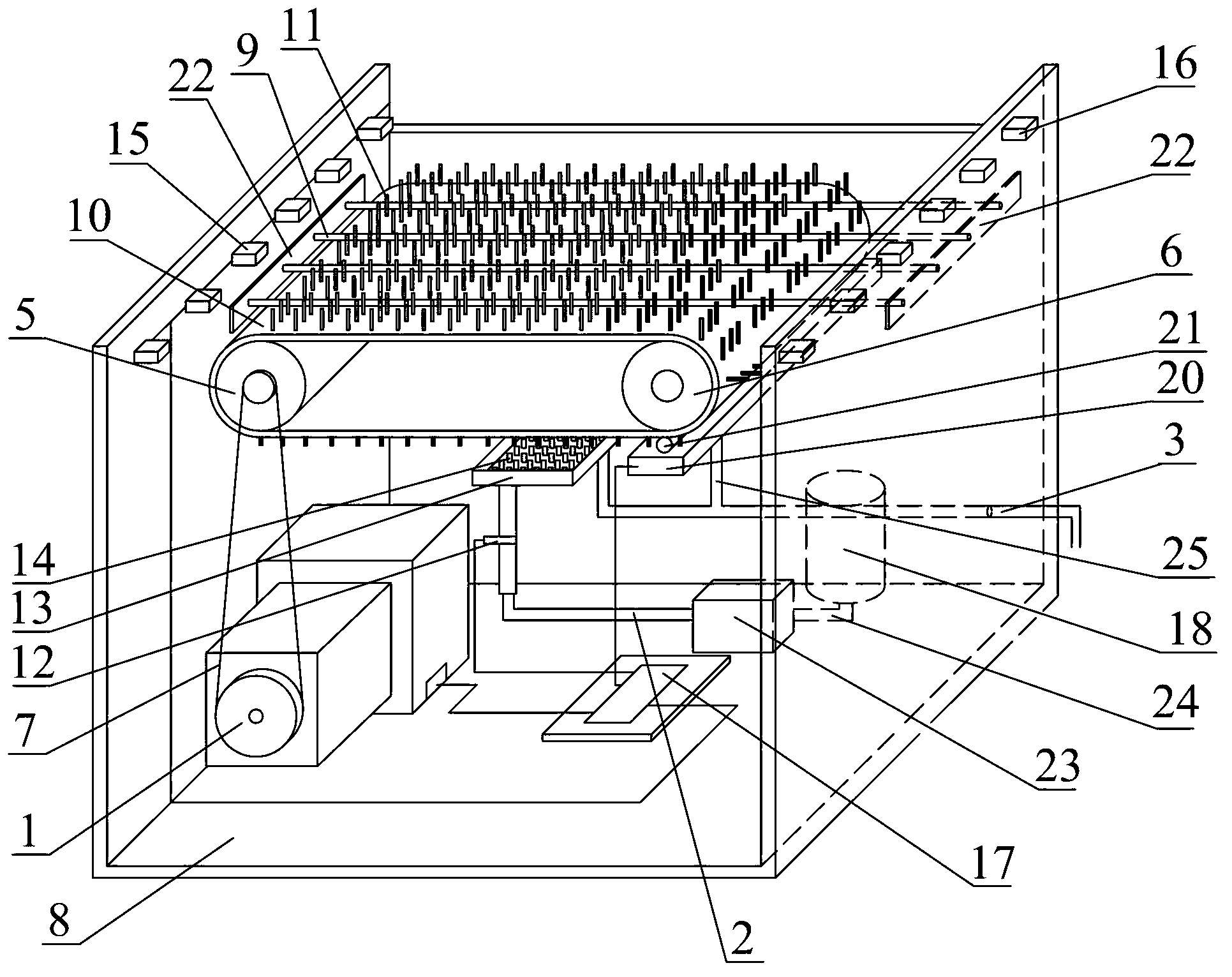

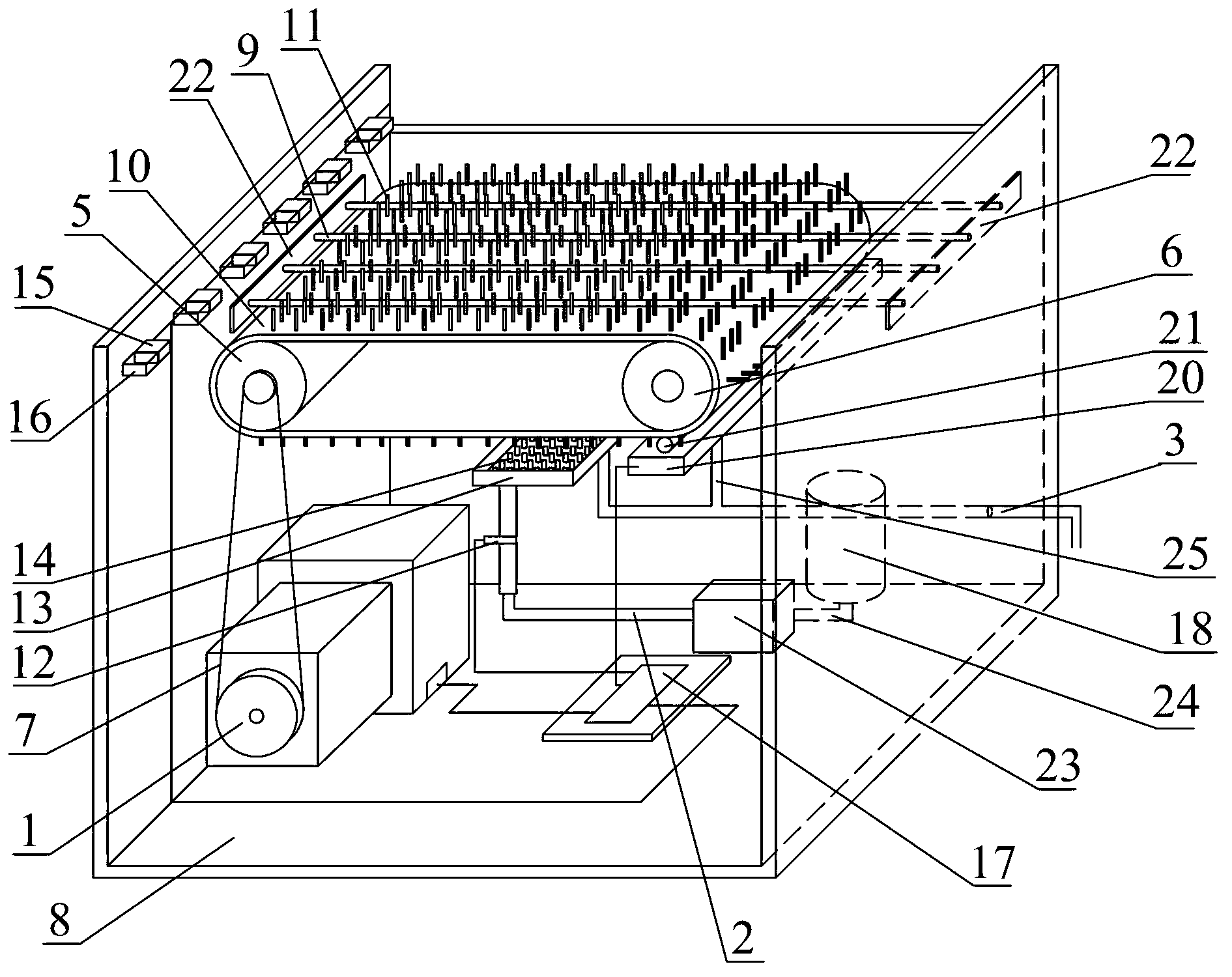

Vacuum dust removal foot pad

The invention discloses a vacuum dust removal foot pad device capable of automatically absorbing sole dust, scraps and attached dirt. The device is an environment-friendly dust removal device. The device solves the problems of sanitation and environmental protection of indoor public places such as factories, restaurants, large supermarkets, office buildings, airports, markets and the like and households. The device has the main application that: the device is arranged at the indoor area entry, and when a person steps on and passes through the device, the device automatically absorbs the attached dirt of the sole so as to avoid bringing the dirt inside. The basic structure of the device comprises an upper cover plate, a bottom framework box and an inner air blowing and dust absorbing trigger mechanism. Isometric spherical raised bulbs are densely distributed on the surface of the upper cover plate, and the lower part of the upper cover plate is connected with the trigger mechanism. When the feet of the person step on the raised bulbs, a starting mechanism in the device is triggered, pores in the middle of the bulbs blow air under positive pressure, meanwhile, four sides of the bulbs absorb dust under negative pressure, and the dirt attached to the soles is absorbed in a multi-point dust absorbing mode through the clearance between the plunger bulbs and the circular holes of the upper cover plate.

Owner:LIAONING CKRS INTELLIGENT EQUIP CO LTD

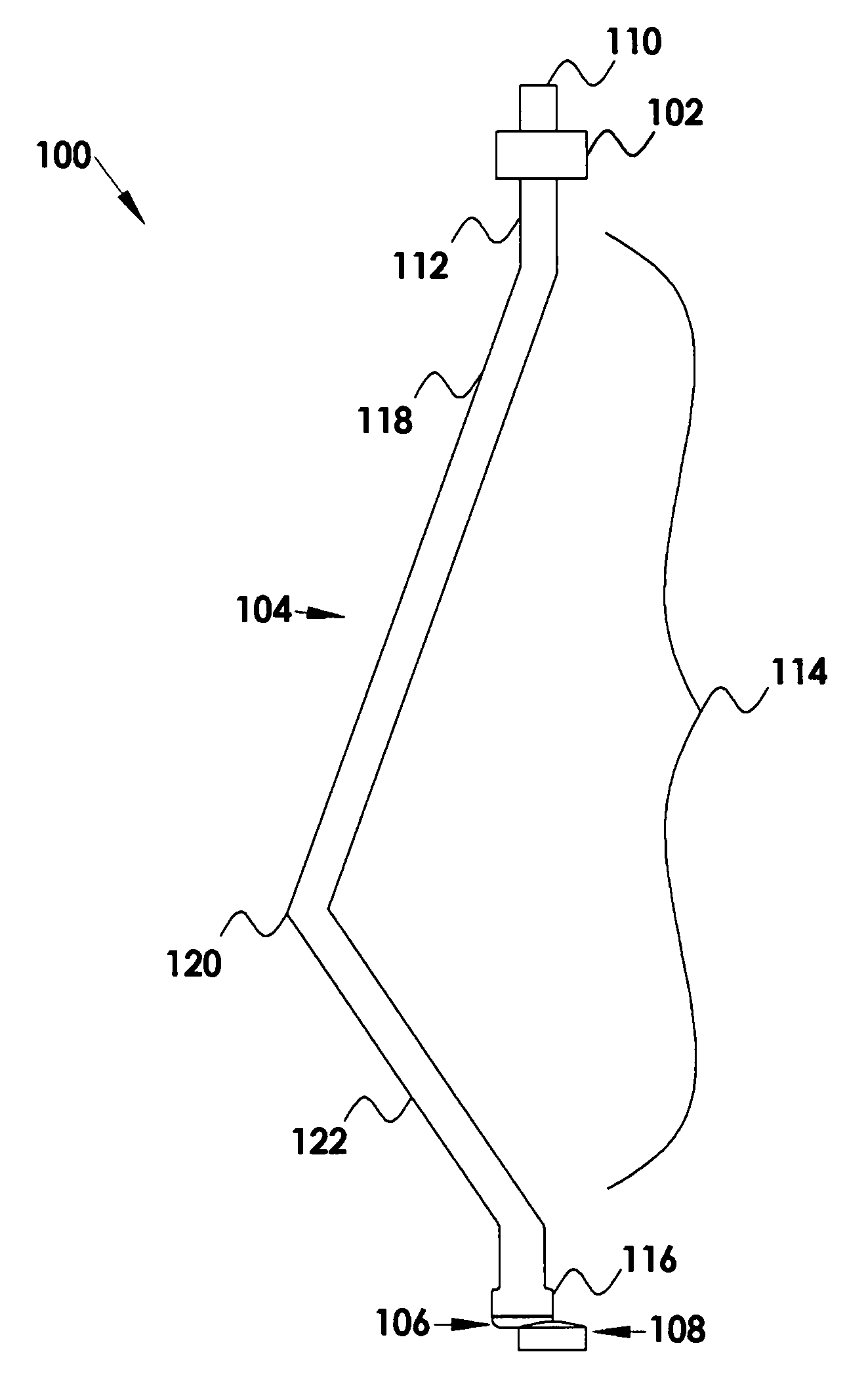

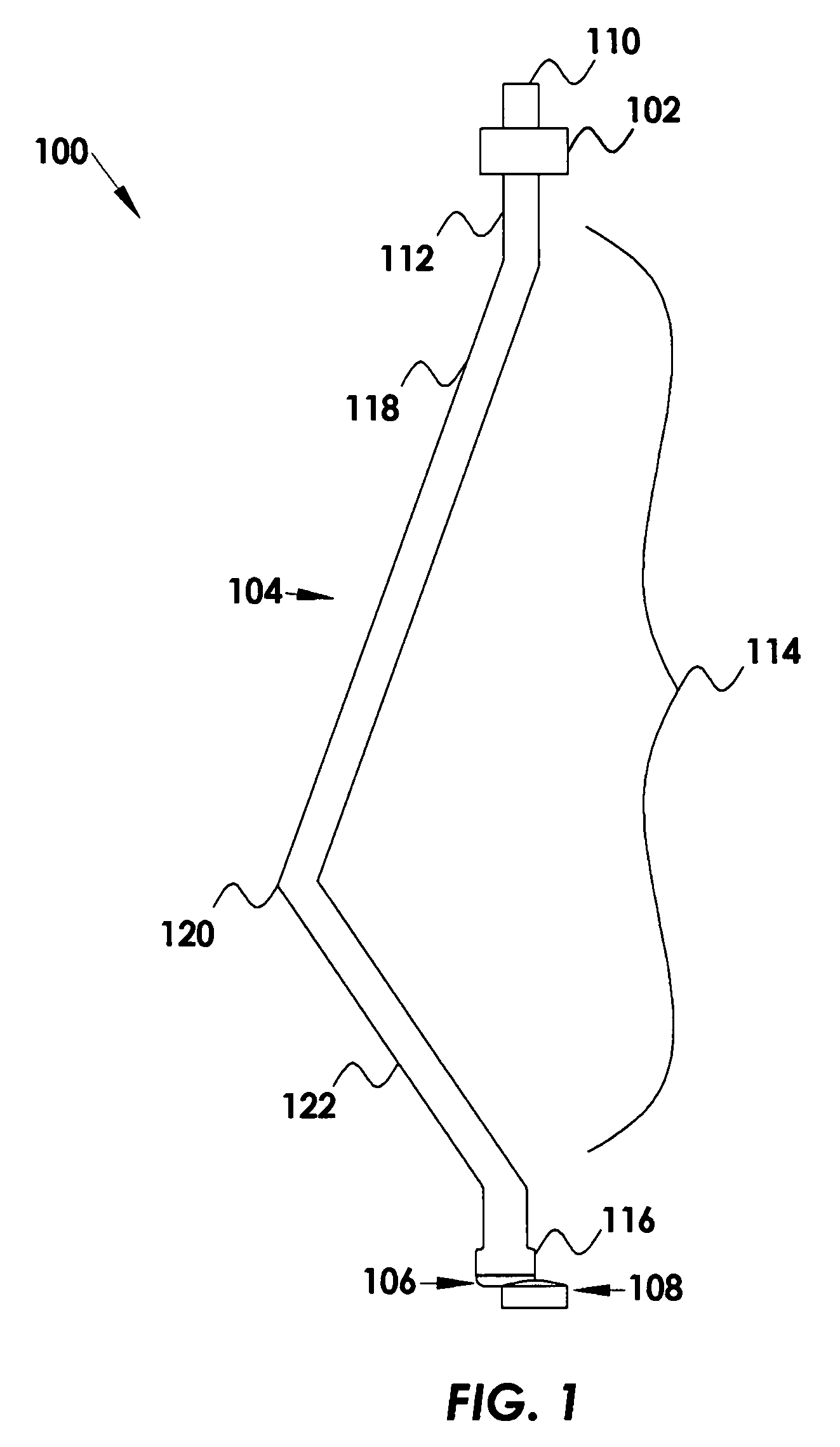

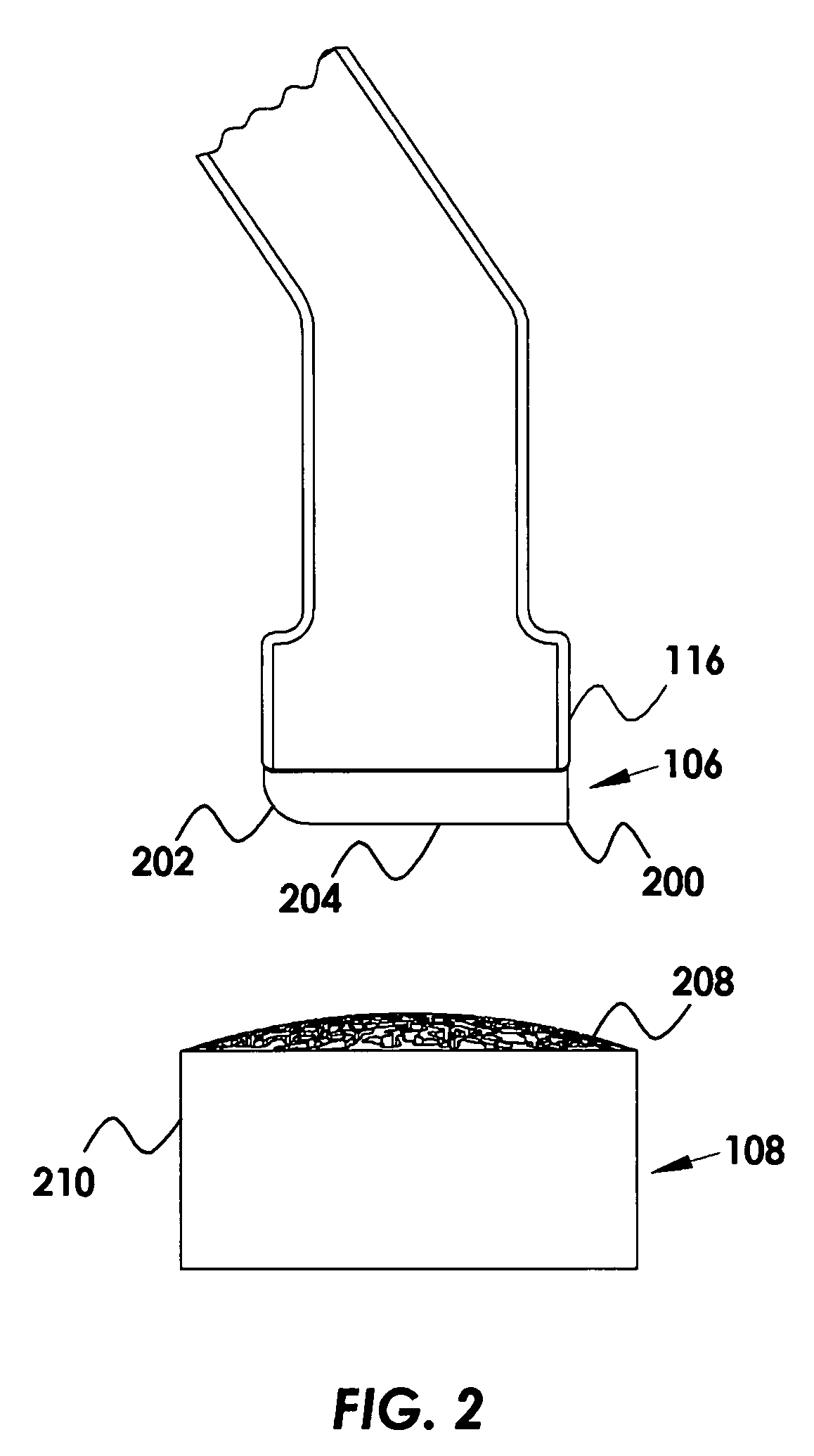

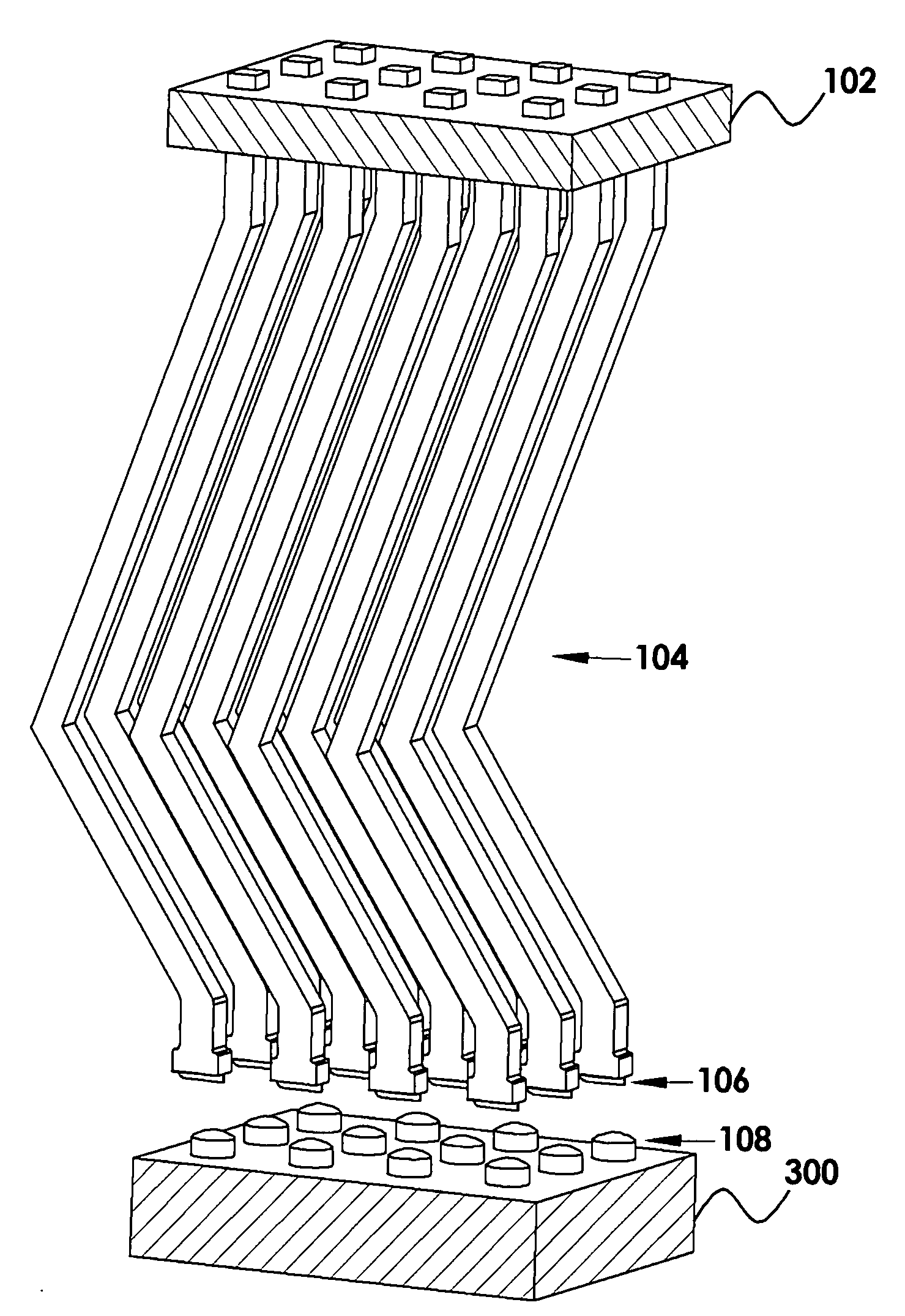

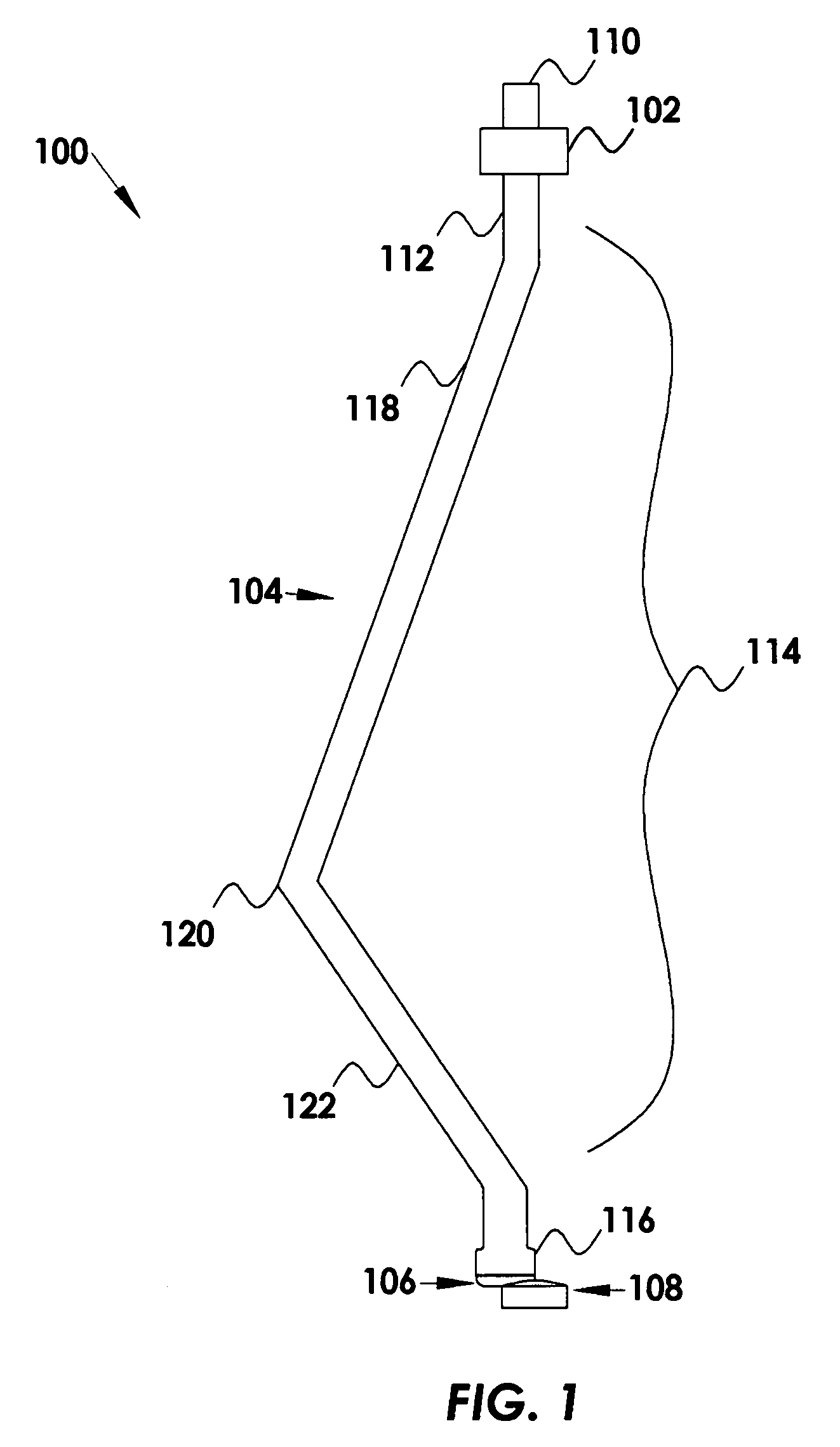

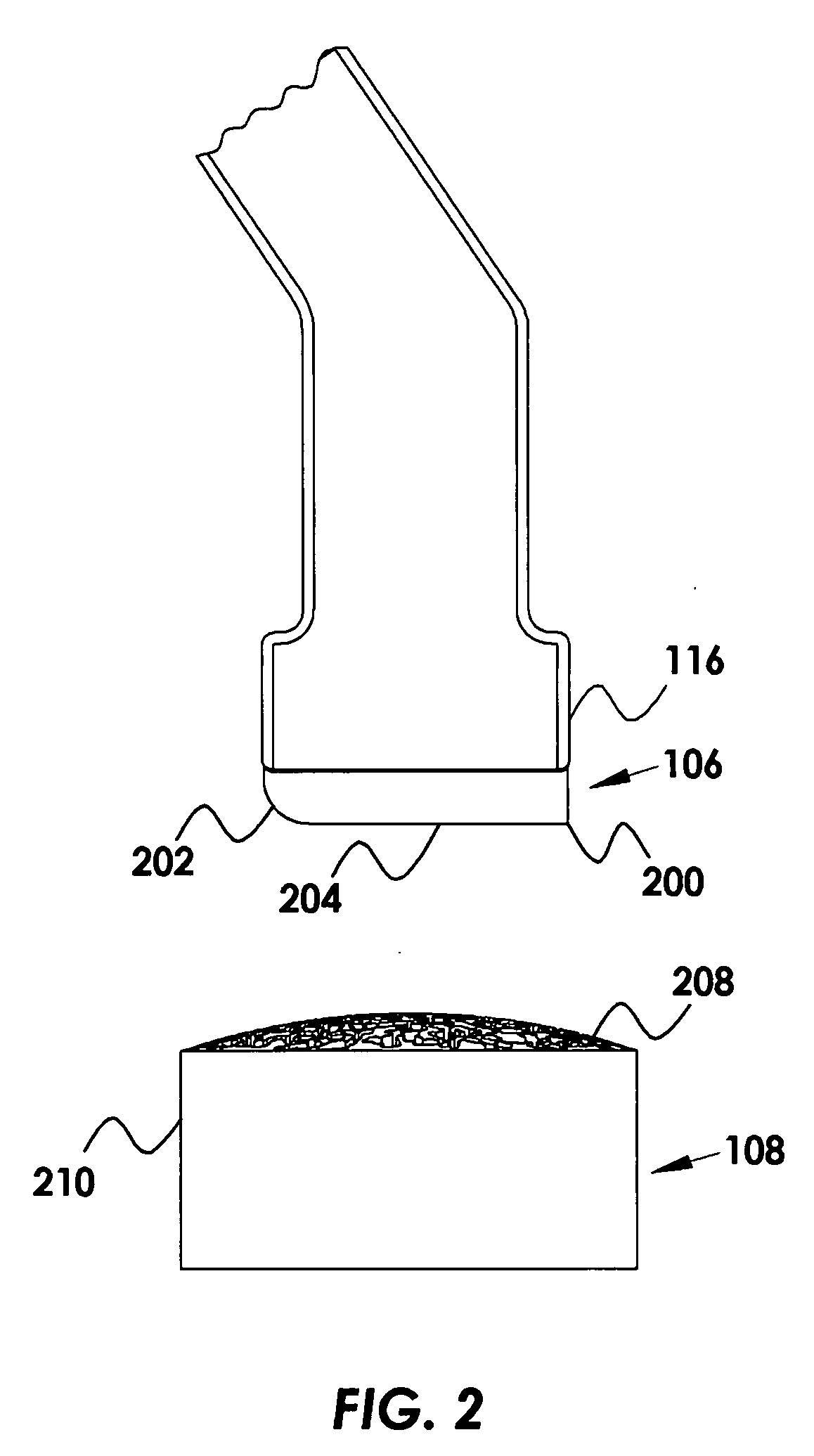

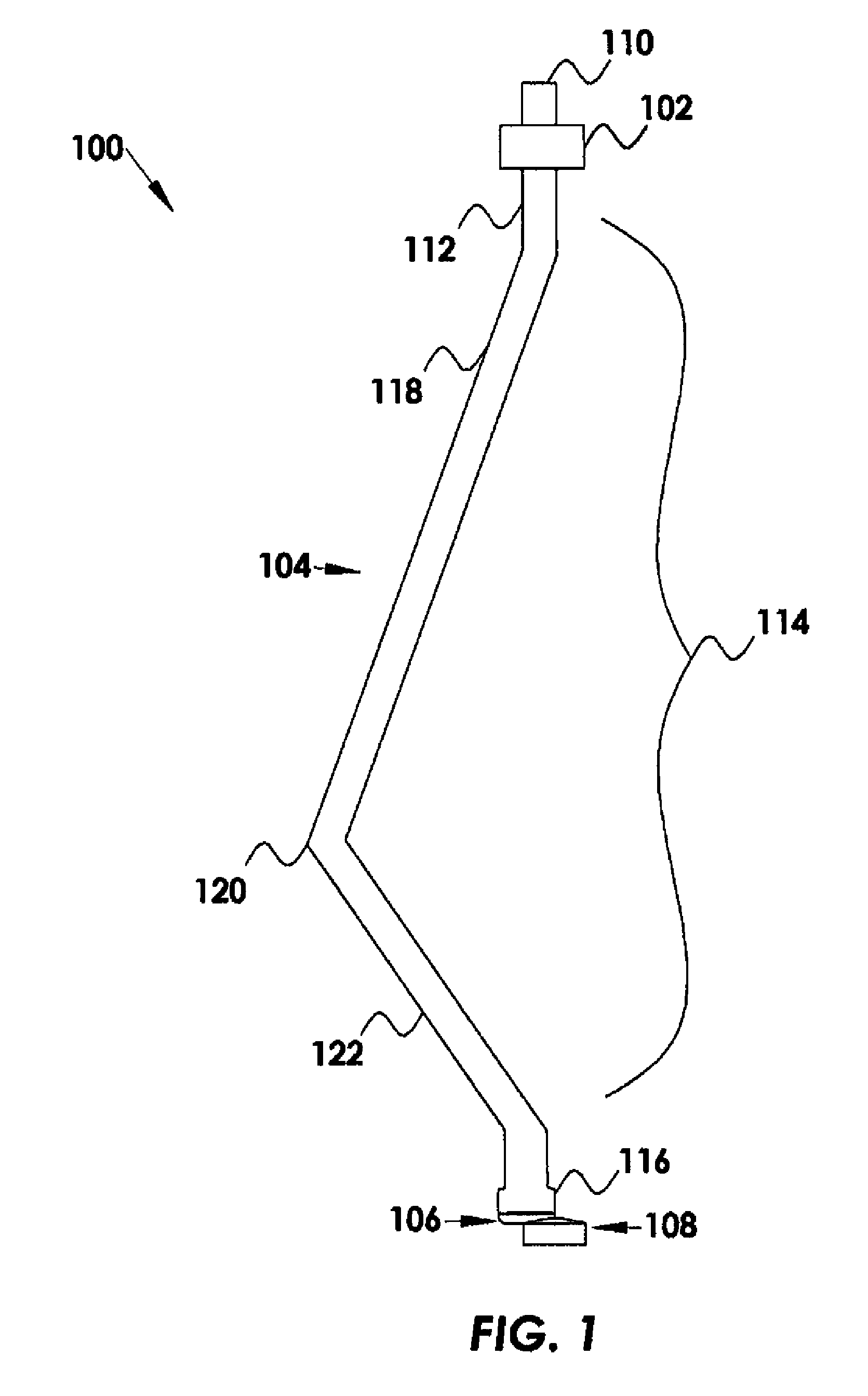

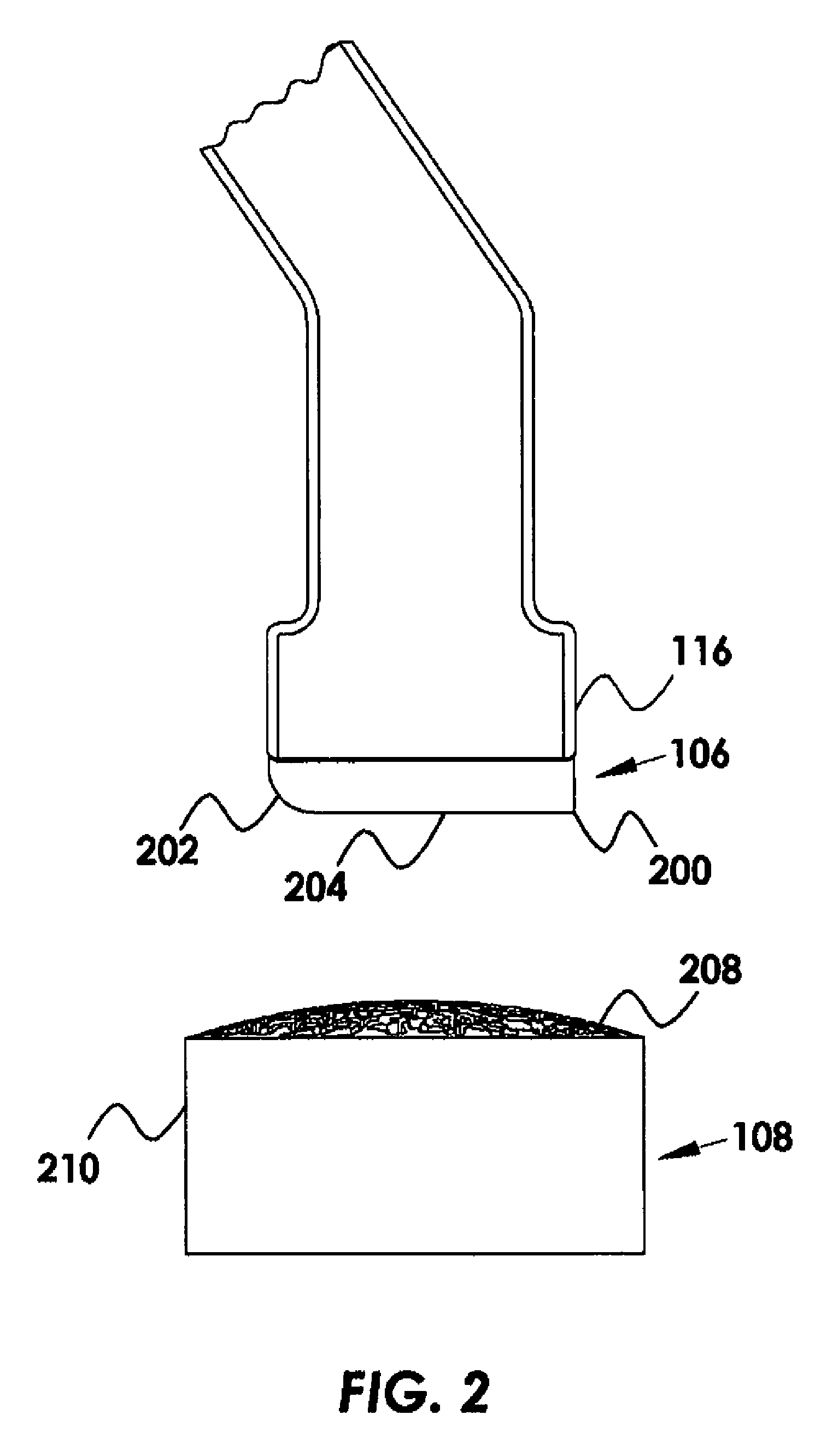

Probe skates for electrical testing of convex pad topologies

ActiveUS7436192B2Easy to controlLess clean upElectrical measurement instrument detailsManufacture of electrical instrumentsRound backElectrical testing

A probe for engaging a conductive pad is provided. The probe includes a probe contact end for receiving a test current, a probe retention portion below the contact end, a block for holding the probe retention portion, a probe arm below the retention portion, a probe contact tip below the arm, and a generally planar self-cleaning skate disposed perpendicular below the contact tip. The self-cleaning skate has a square front, a round back and a flat middle section. The conductive pad is of generally convex shape having a granular non-conductive surface of debris and moves to engage the skate, whereby an overdrive motion is applied to the pad causing the skate to move across and scrub non-conductive debris from the pad displacing the debris along the skate and around the skate round back end to a position on the skate that is away from the pad.

Owner:MICRO PROBE

Environmentally friendly, multi-purpose refluxing cleaner

ActiveUS20120264673A1Safer to use and handle and storeLow costDetergent mixture composition preparationDetergent solventsCleaning methodsSolvent

A solvent blend cleaner useful for reflux cleaning of chemical manufacturing equipment, including that used in manufacturing pharmaceuticals, comprises a blend of environmentally friendly and safe solvents selected on the basis of specific criteria, such as vapor pressure, vapor density, boiling point, specific heat, and heat of vaporization, among other things; achieves excellent cleaning even upon further dilution with water; and avoids the disadvantages associated with the use of conventional commodity solvents in reflux cleaning methods. Desired solvency, cleaning and wetting properties of the inventive formulations in use can be achieved through blending of solvents having the selected criteria. Additives, such as surfactants, can be added to enhance cleaning and lower solvent requirements.

Owner:AMERICAN STERILIZER CO

Probe skates for electrical testing of convex pad topologies

ActiveUS20080001613A1Improve mean time between failuresEasy to controlElectrical measurement instrument detailsElectrical testingRound backElectrical testing

A probe for engaging a conductive pad is provided. The probe includes a probe contact end for receiving a test current, a probe retention portion below the contact end, a block for holding the probe retention portion, a probe arm below the retention portion, a probe contact tip below the arm, and a generally planar self-cleaning skate disposed perpendicular below the contact tip. The self-cleaning skate has a square front, a round back and a flat middle section. The conductive pad is of generally convex shape having a granular non-conductive surface of debris and moves to engage the skate, whereby an overdrive motion is applied to the pad causing the skate to move across and scrub non-conductive debris from the pad displacing the debris along the skate and around the skate round back end to a position on the skate that is away from the pad.

Owner:MICRO PROBE

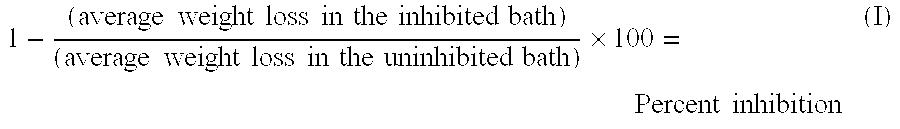

Stable acid inhibitor formulations with improved performance, lower toxicity and minimal environmental issues

InactiveUS20060180795A1Great metal corrosion protectionExtended shelf lifeOrganic detergent compounding agentsOther chemical processesNuclear chemistryIngested food

Aqueous concentrates of non-toxic corrosion inhibitors, preferably storage-stable, useful in acidic cleaning solutions for cleaning the surfaces of metal that contacts food or potable water, the concentrates comprising at least one polymer, which may be protein-derived or synthetic; at least one iodine ion providing compound; an acidifier; and optionally, at least one anionic, nonionic or amphoteric surfactant; at least one coupling agent; and a pH adjuster; the concentrates being substantially free of nonylphenol derivatives and compounds containing elemental iodine and providing an improved acid inhibition and less foaming than similar compositions comprising nonylphenol derivatives and elemental iodine when mixed with aqueous acidic cleaners; acidic solutions prepared therefrom; and methods of their use.

Owner:HENKEL KGAA

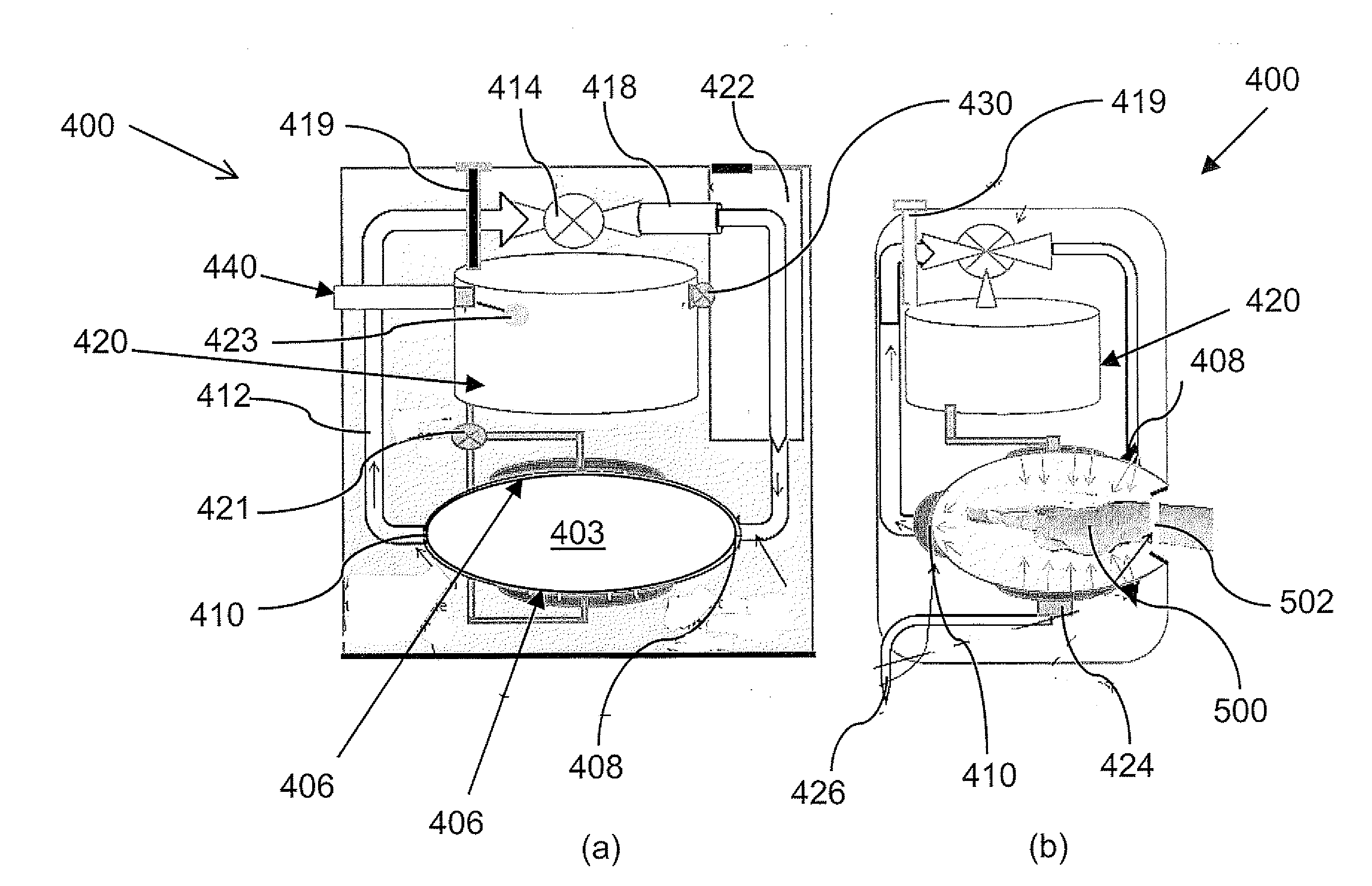

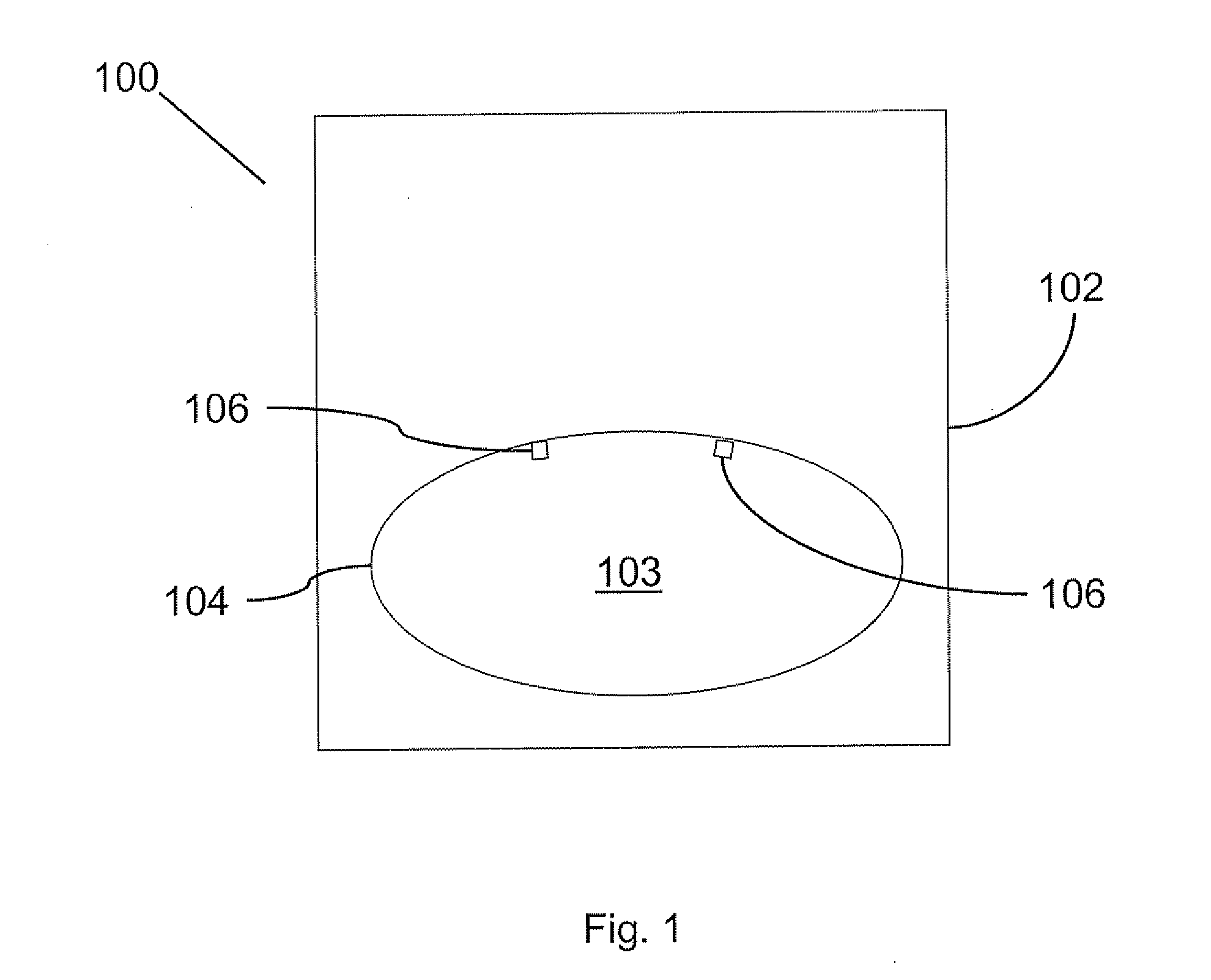

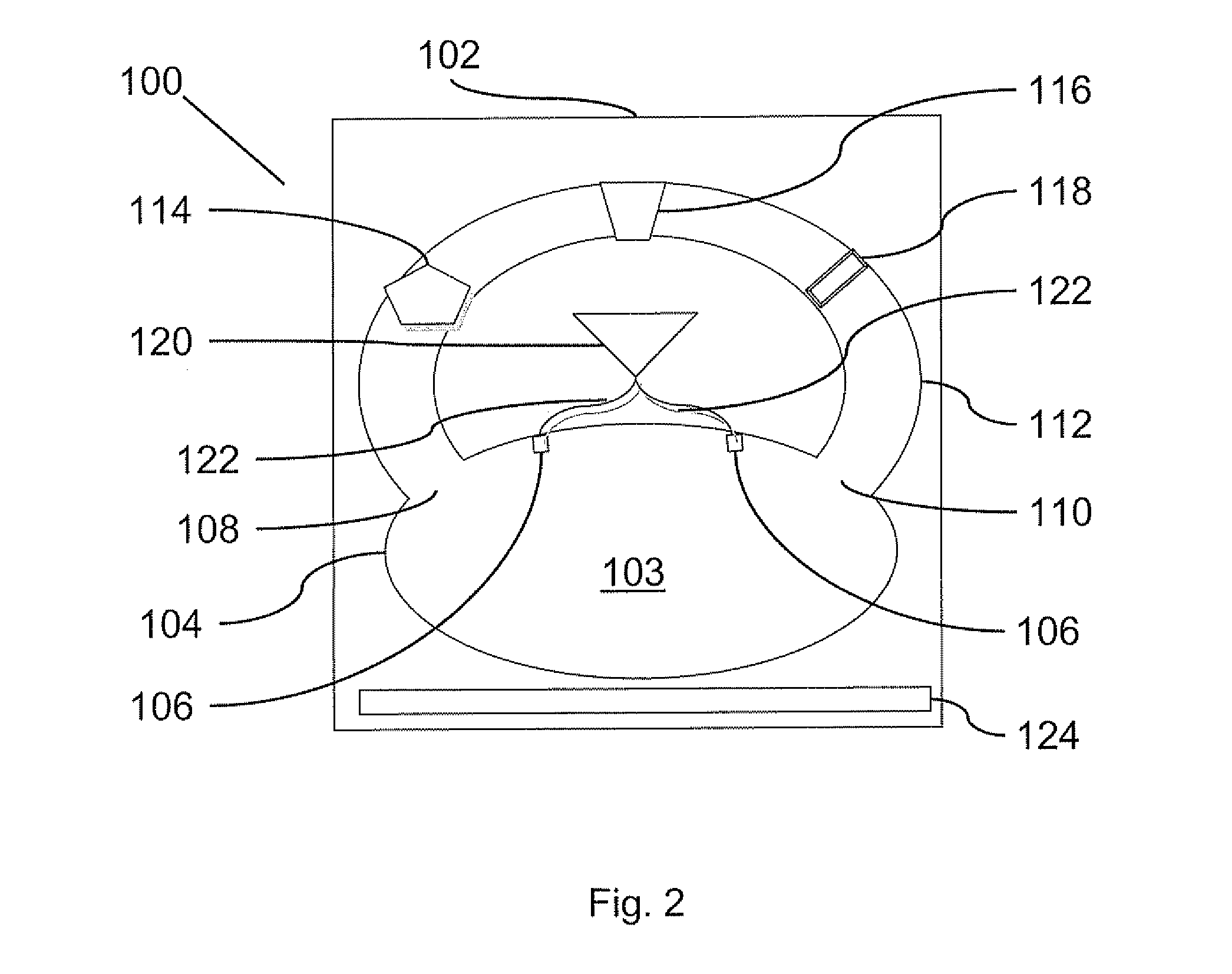

Apparatus For Drying and Sanitizing Hands

ActiveUS20150048160A1Reduce the impactImprove drying efficiencyExhaust apparatusElement comparisonEngineeringAirflow

An apparatus for sanitizing hands (400) comprising a housing (402) having a hand placement area (403) and a hand sanitizing means (420, 421, 406) to in use spray a hand sanitizing fluid into the placement area (403), and means (414) to provide an airflow to dry hands in the placement area.

Owner:GRAYDON BRIAN

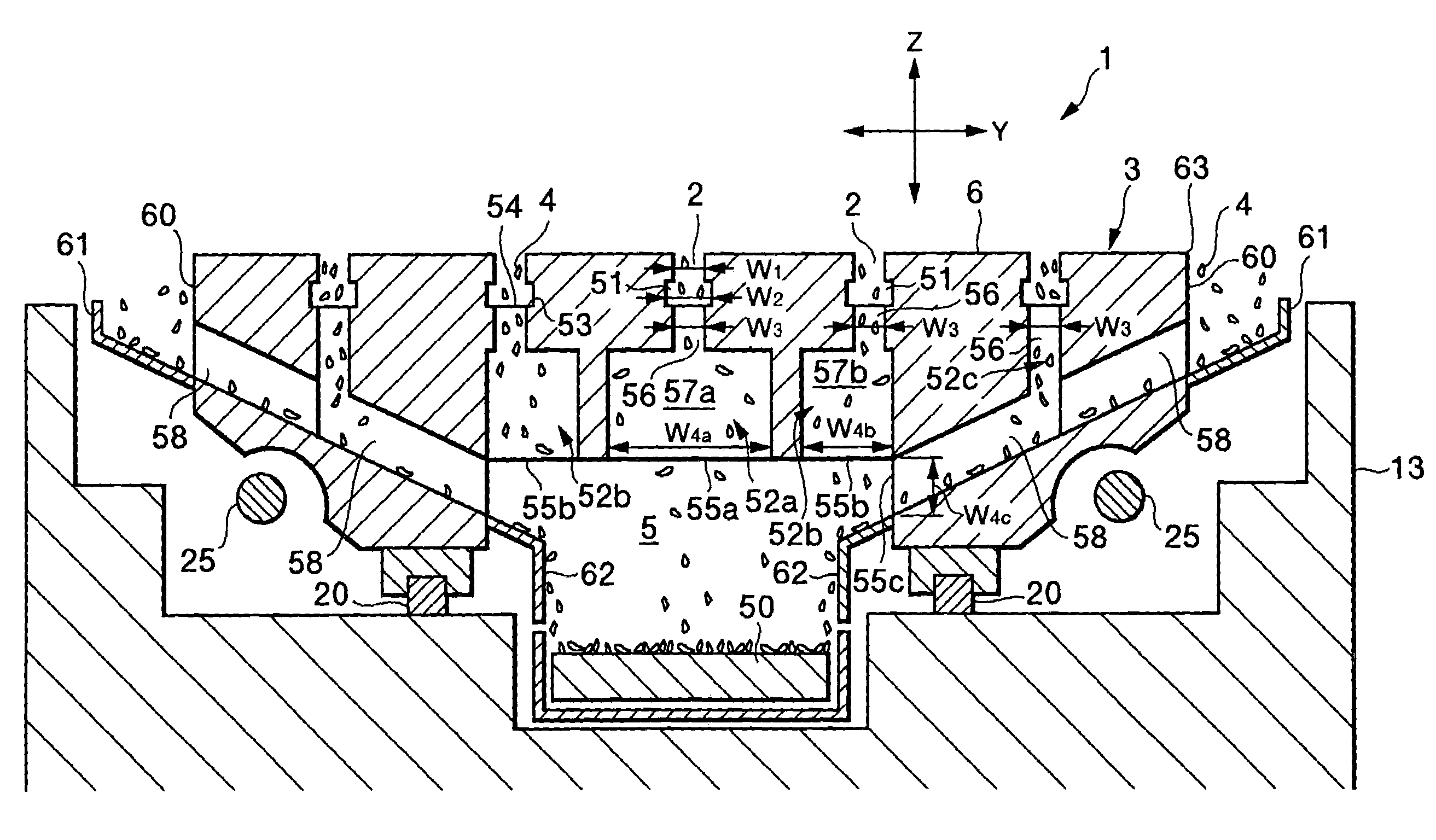

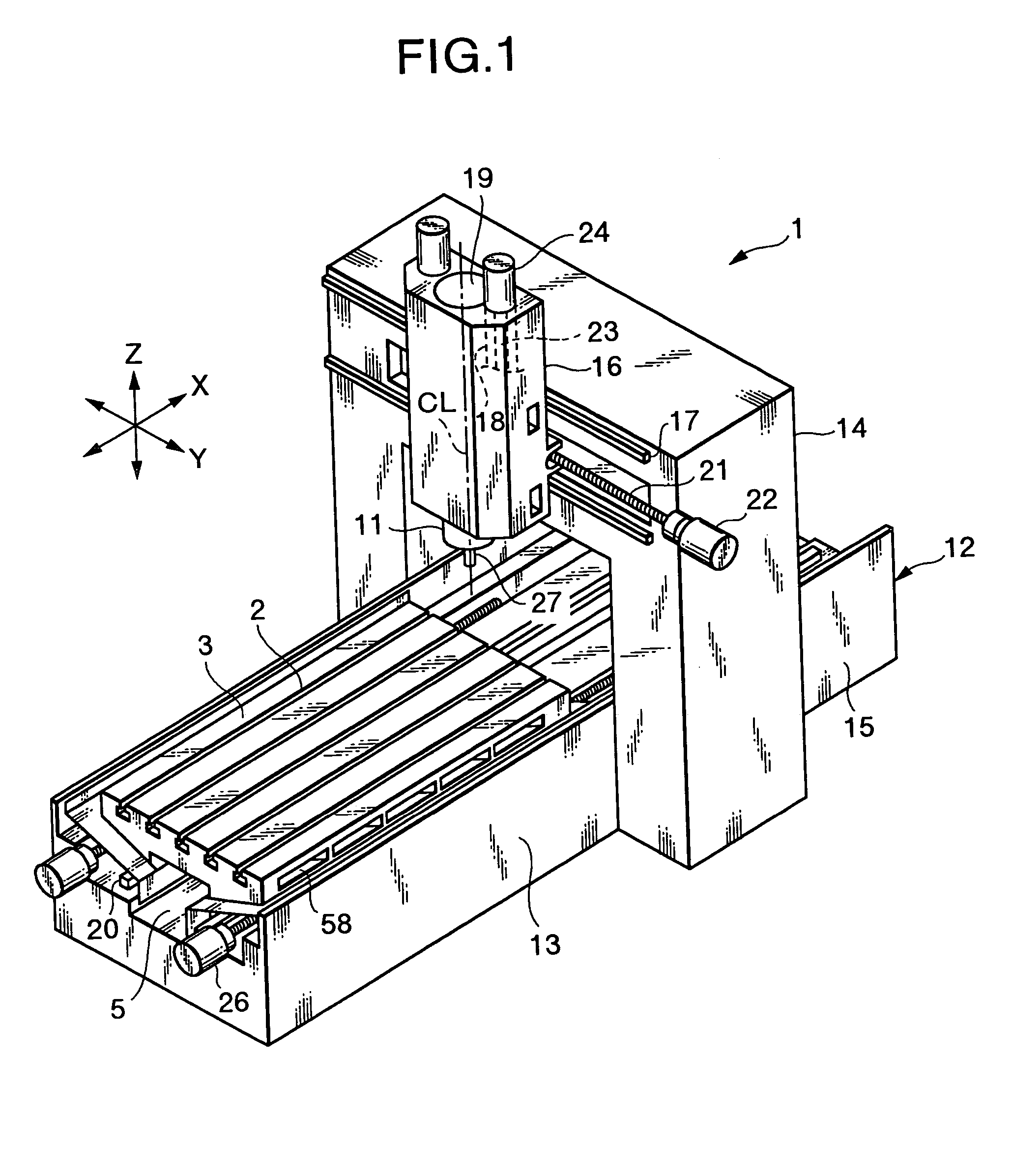

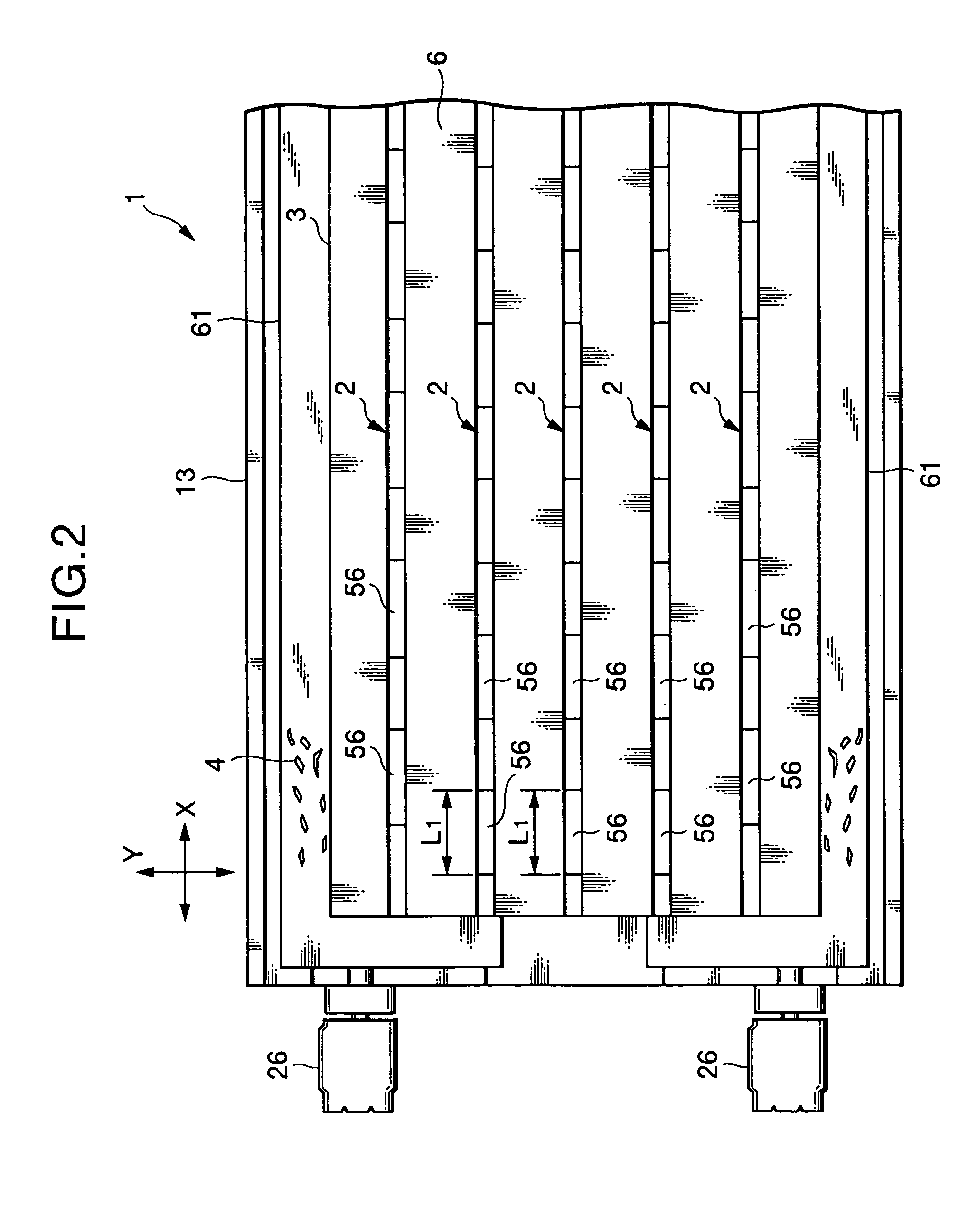

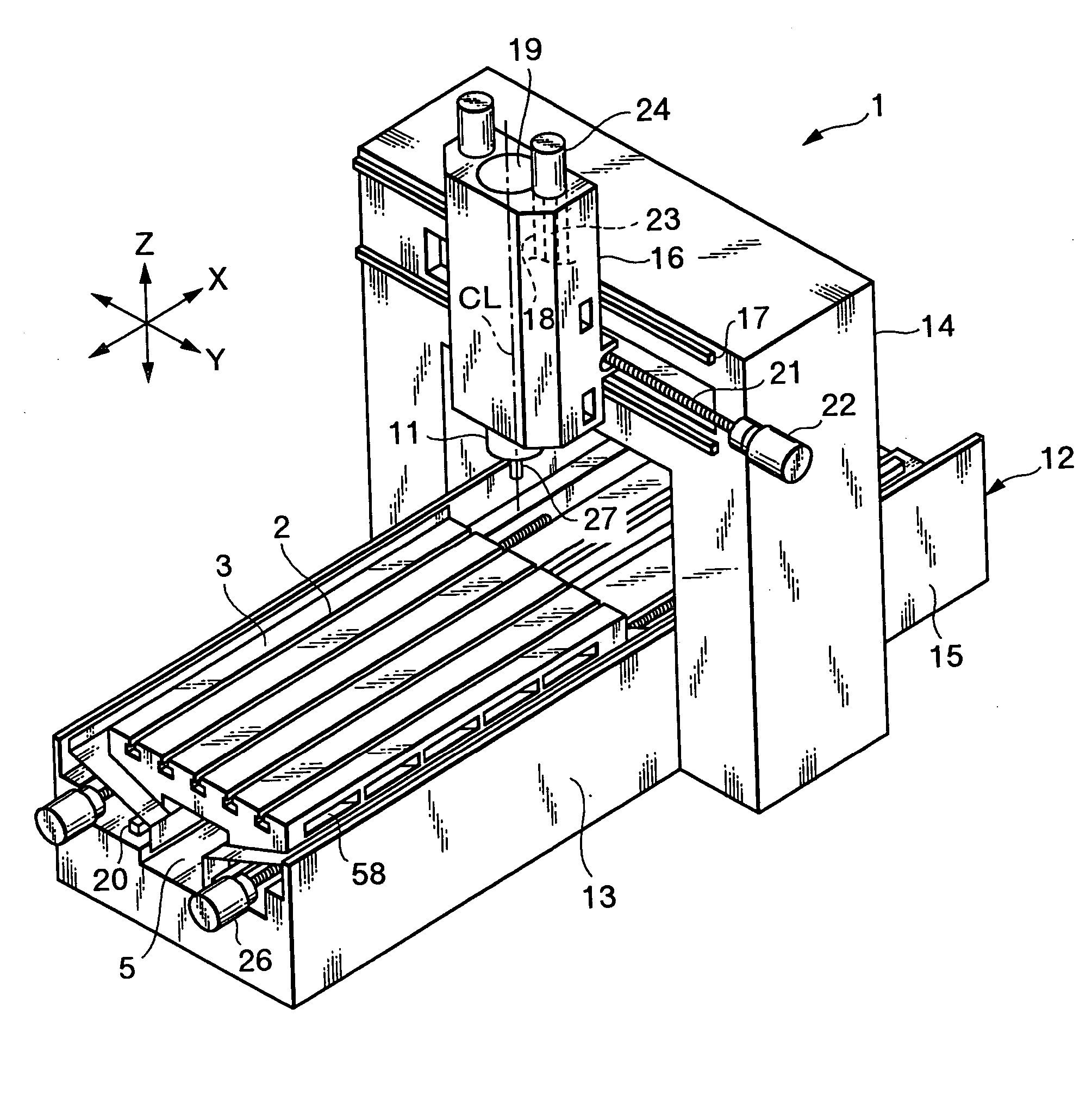

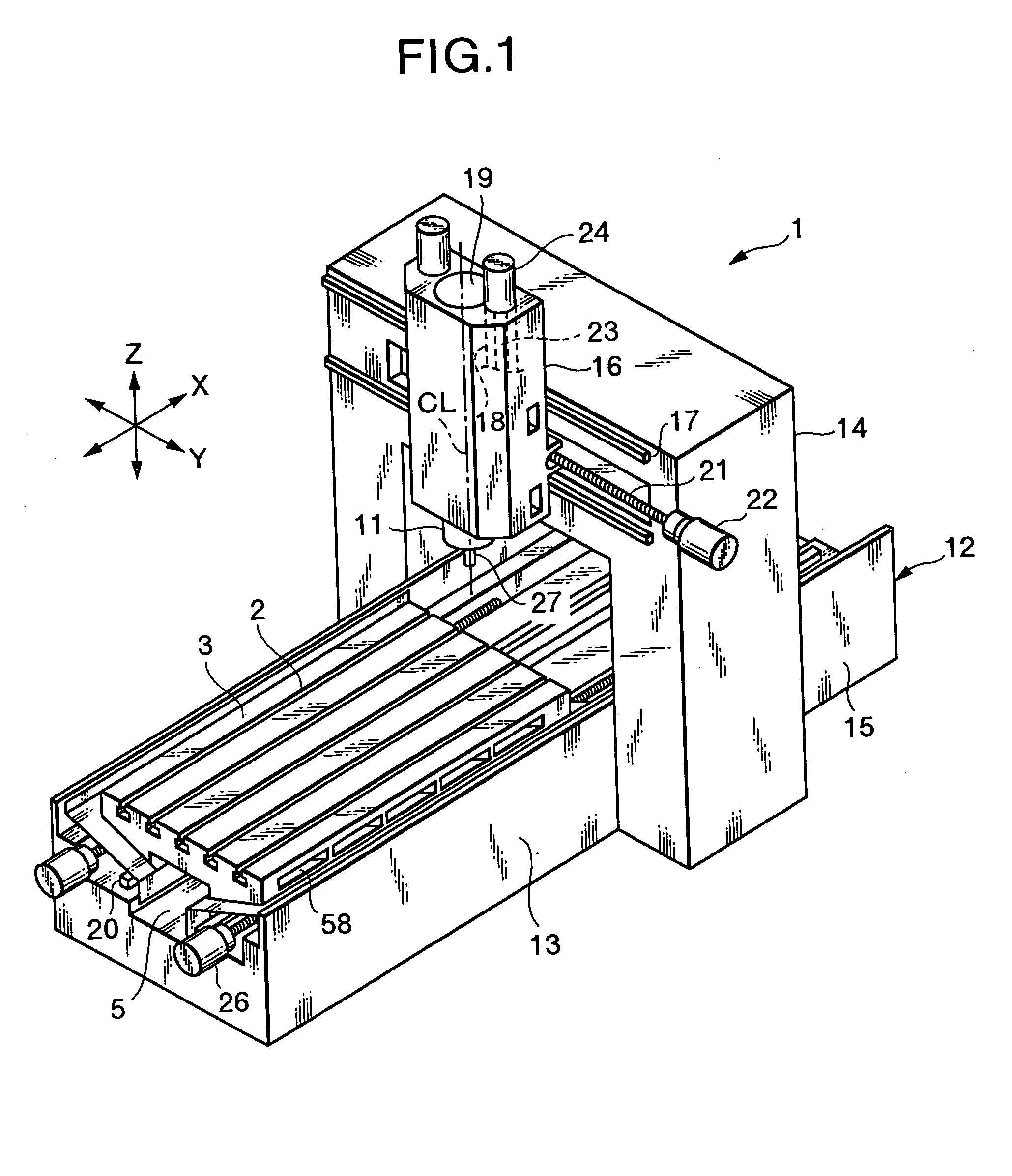

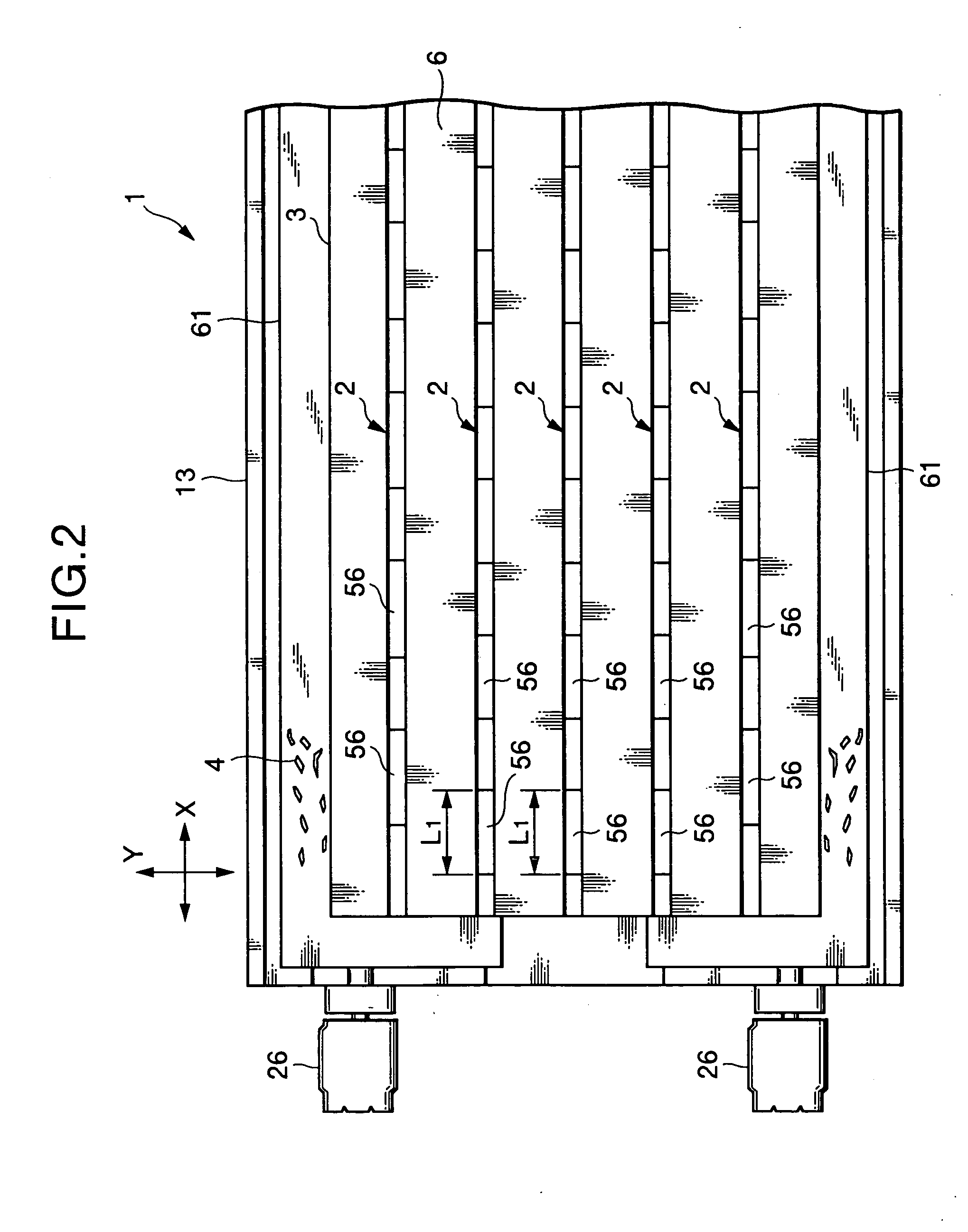

Machine tool

InactiveUS7044693B2Less clean upWork lessPlaning/slotting machinesMilling machinesEngineeringMachine tool

In a double housing machining center, a table having a plurality of T slots on its top surface is arranged substantially in a horizontal direction. A lower space, into which chips are received, is provided under the table. A plurality of through-holes, being in fluid communication with bottom portions of the T slots and passing through the table to reach the lower space, is scattered and formed in the table. The chips introduced into the T slots are discharged into the lower space through the through-holes. Thus, the chips splashed down onto the table and introduced into the T slots are readily removed and the cleaning work of the table is reduced.

Owner:DMG MORI CO LTD

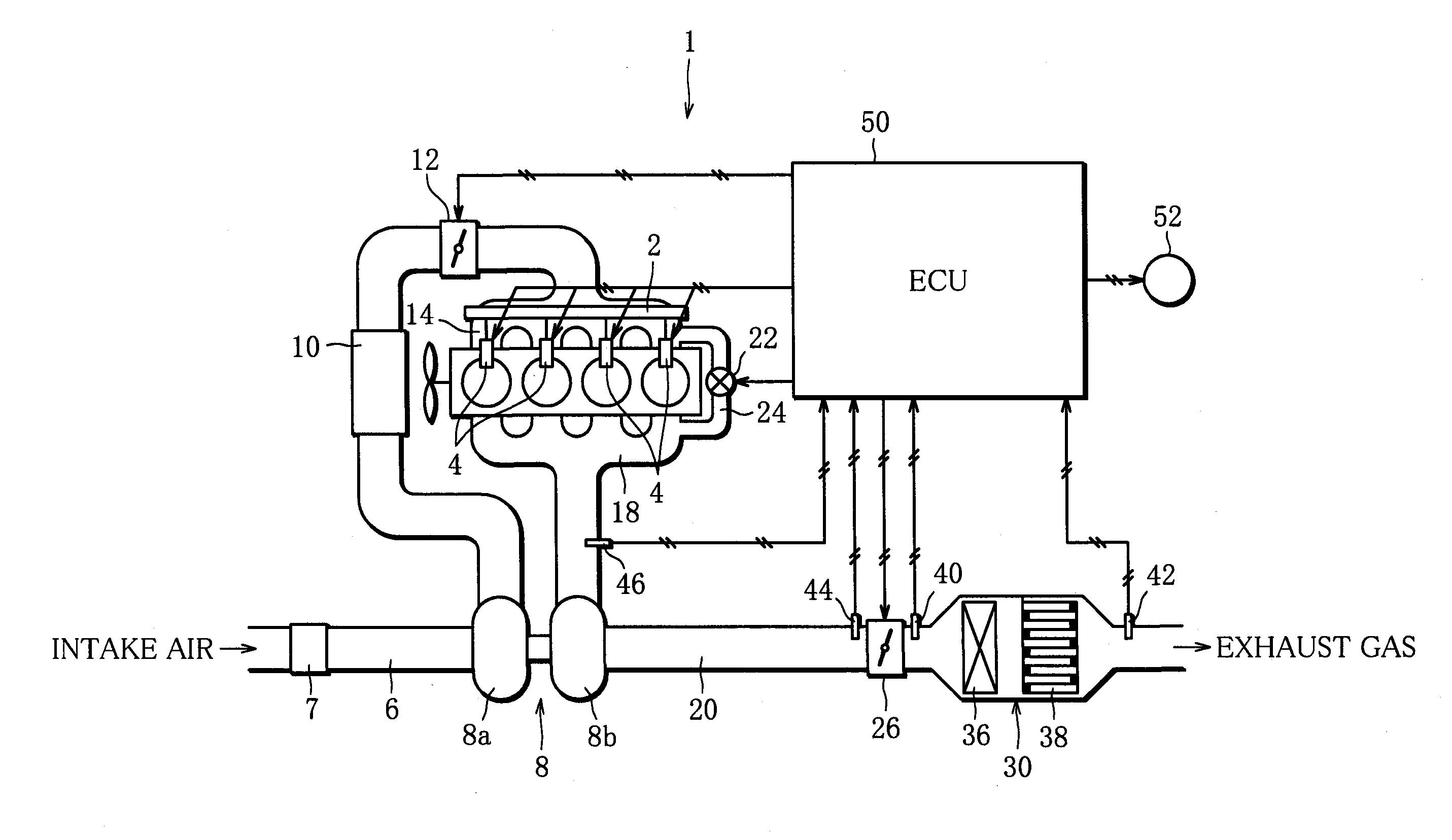

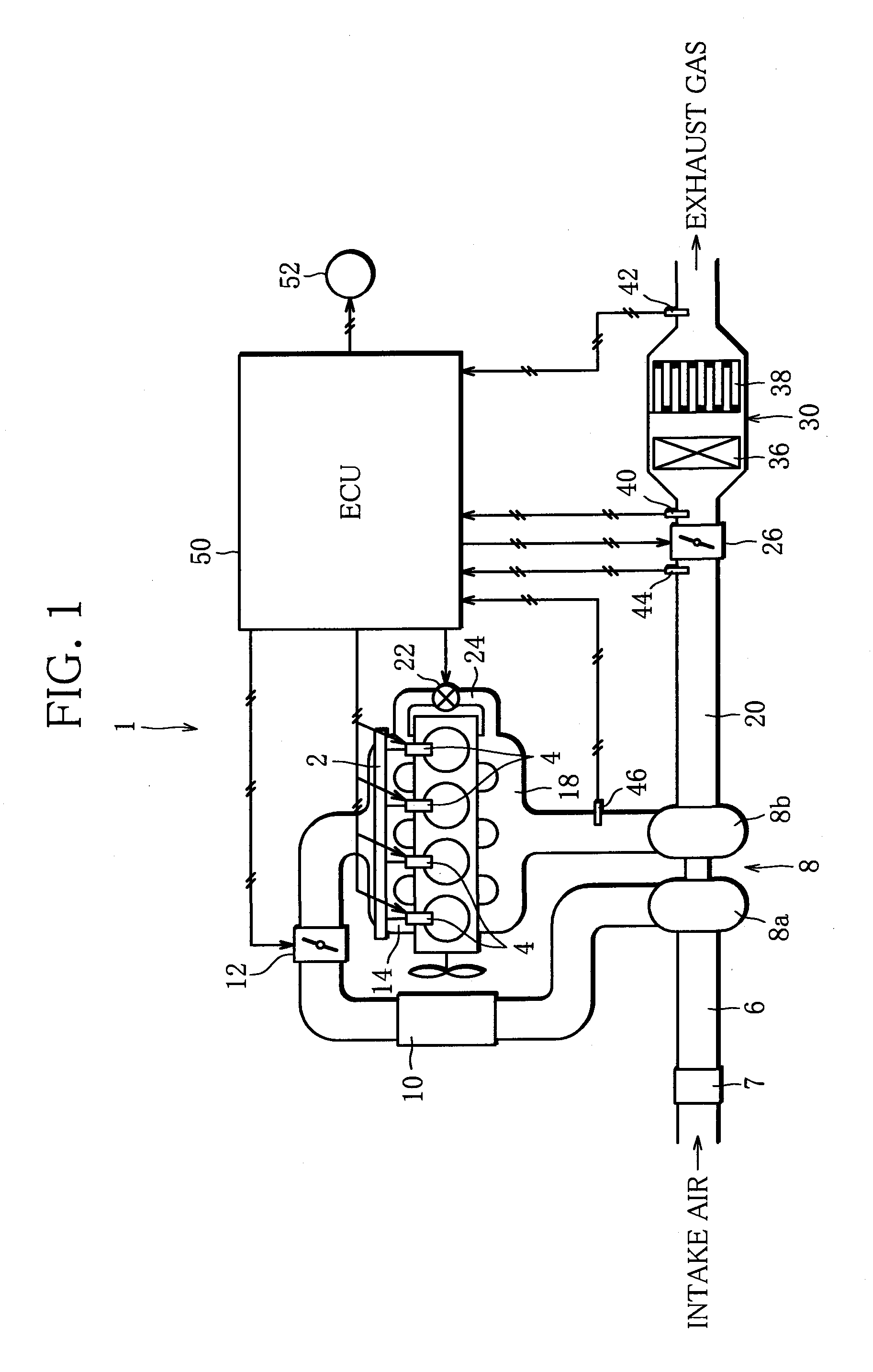

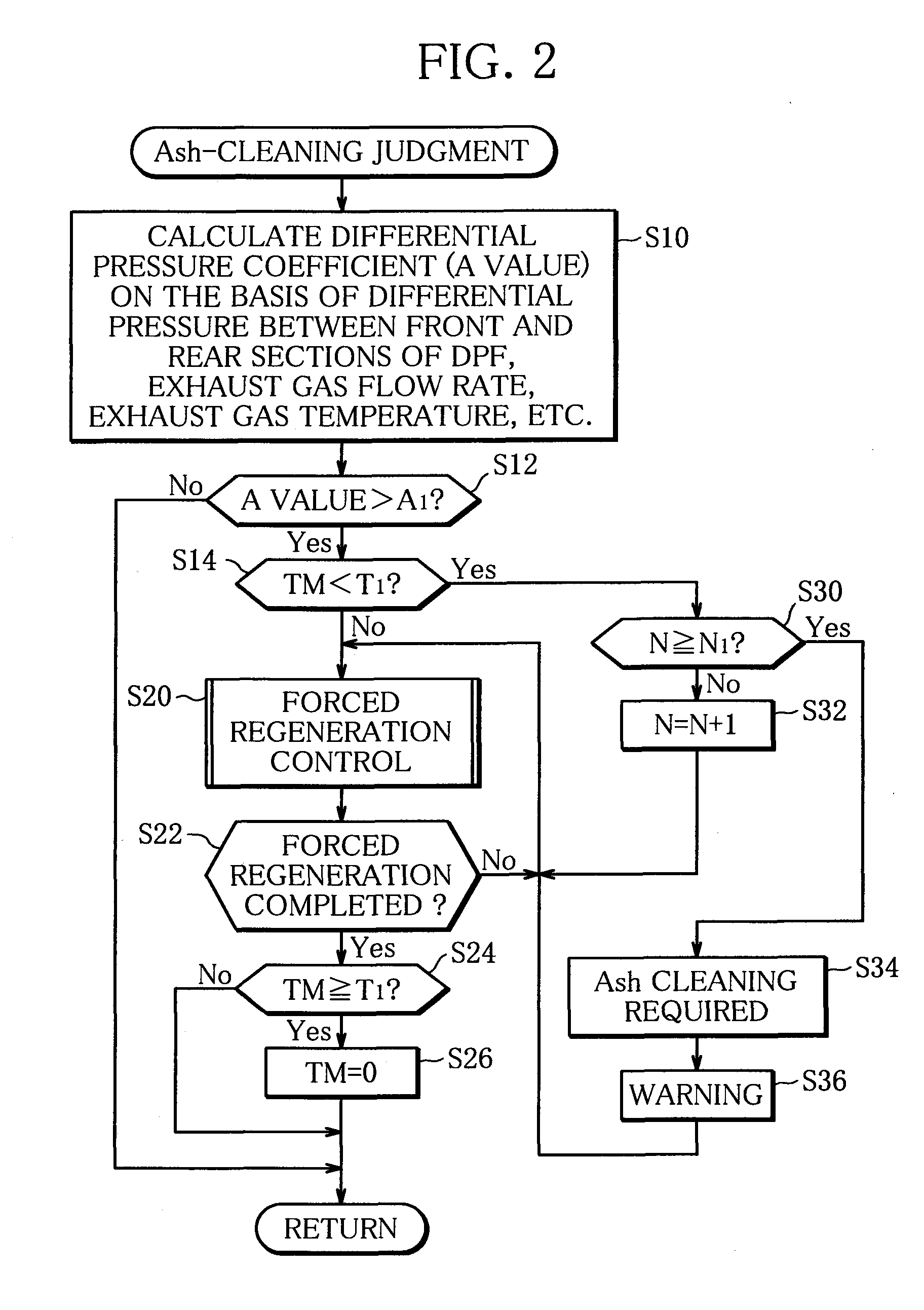

Exhaust aftertreatment device

InactiveUS20100242443A1Eliminate the effects ofAccurate assessmentInternal combustion piston enginesExhaust apparatusParticulatesEngineering

When an estimated value (A value) of an accumulation amount in a filter for trapping particulate matter reaches a prescribed value A1 corresponding to a prescribed accumulation amount Qm of the particulate matter and ash (S12), the forced regeneration of the filter is performed (S20); and when the estimated value (A value) reaches the prescribed value A1 again before the elapsed time since the completion of the forced regeneration of the filter reaches a prescribed time period T1 (S12, S14), it is judged that the amount of the ash accumulated in the filter is equal to or larger than a regulation amount (cleaning is required).

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

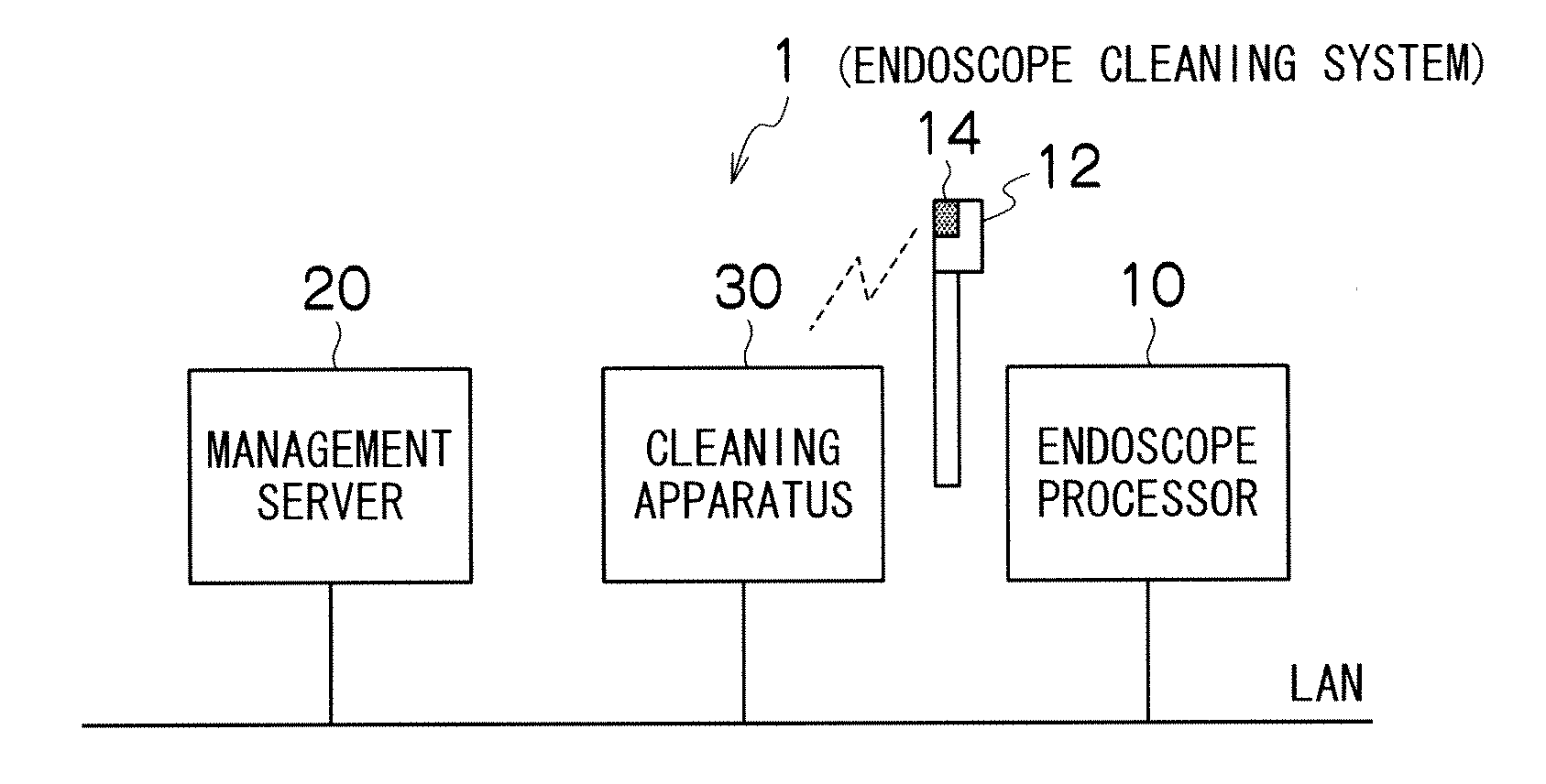

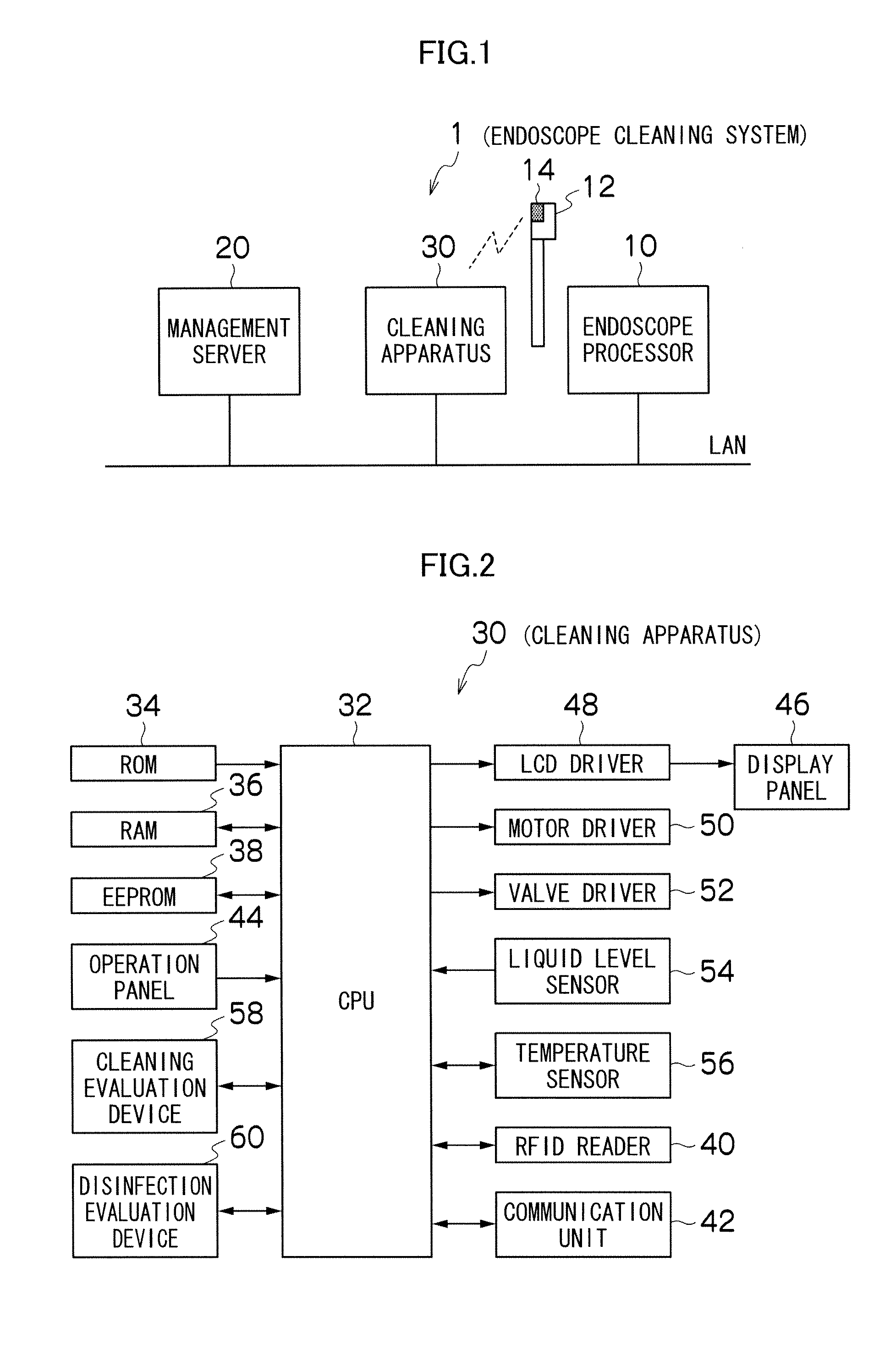

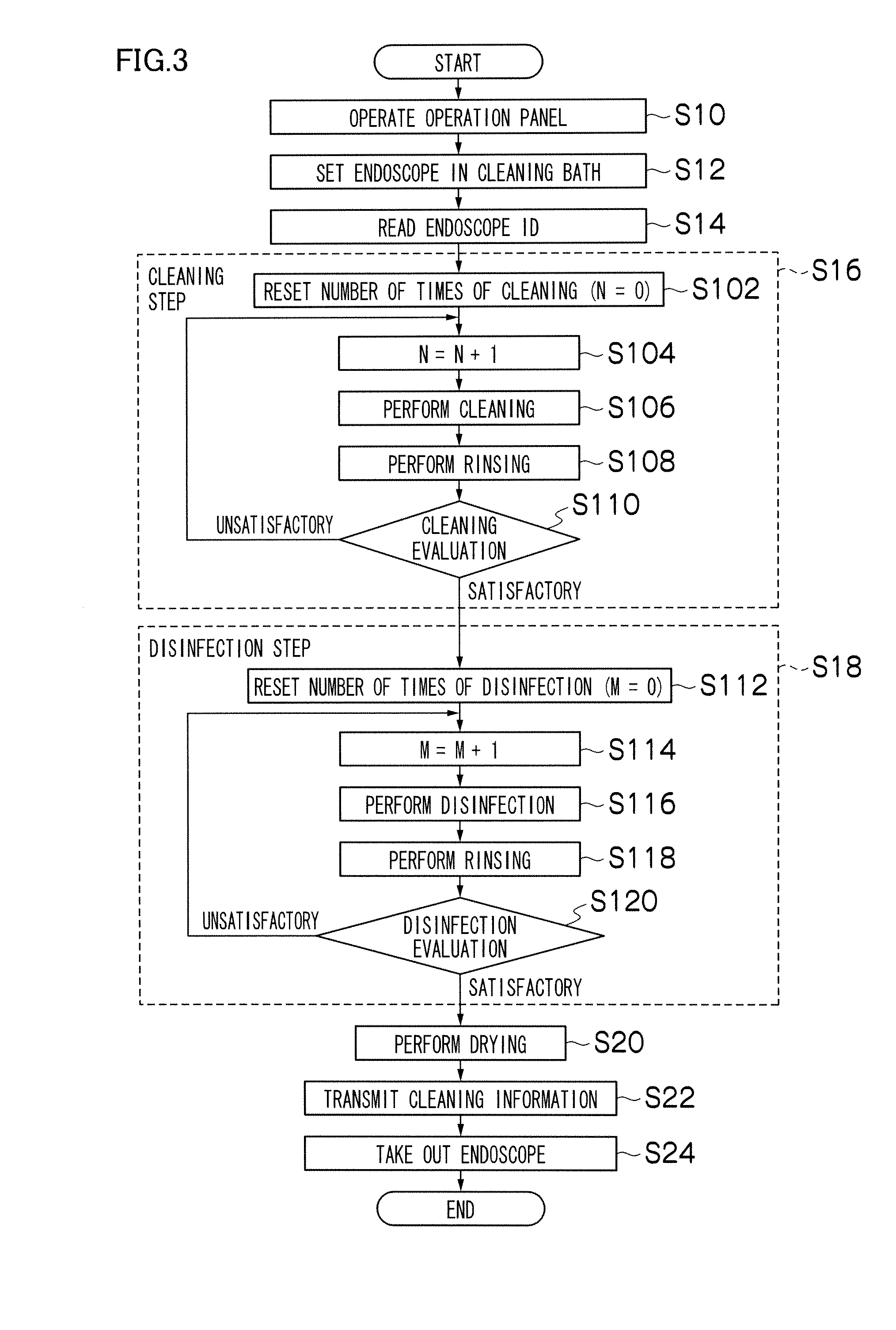

Endoscope cleaning system and endoscope cleaning method

InactiveUS20120073614A1Eliminate attachmentLess clean upEndoscopesDisinfectionSubject matterEndoscope

An endoscope cleaning system of one aspect of the subject matter includes: a first cleaning device configured to clean an endoscope; a second cleaning device configured to clean the endoscope according to a method different from that of the first cleaning device; and a cleaning evaluation device configured to determine whether or not a cleaning level of the endoscope cleaned by one of the first cleaning device and the second cleaning device satisfies a predetermined criterion, wherein one of the first cleaning device and the second cleaning device cleans the endoscope in accordance with a determination result of the cleaning evaluation device.

Owner:FUJIFILM CORP

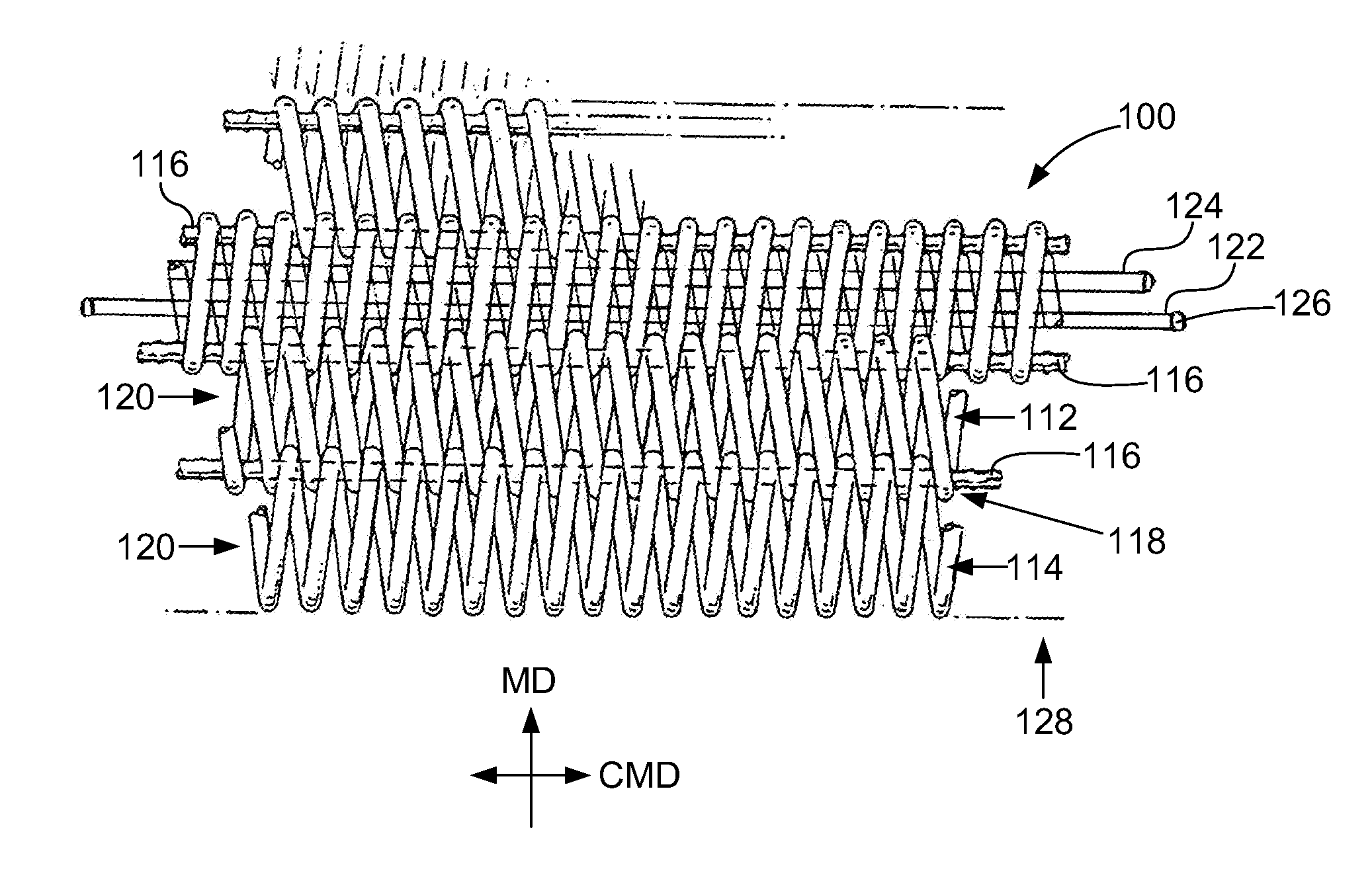

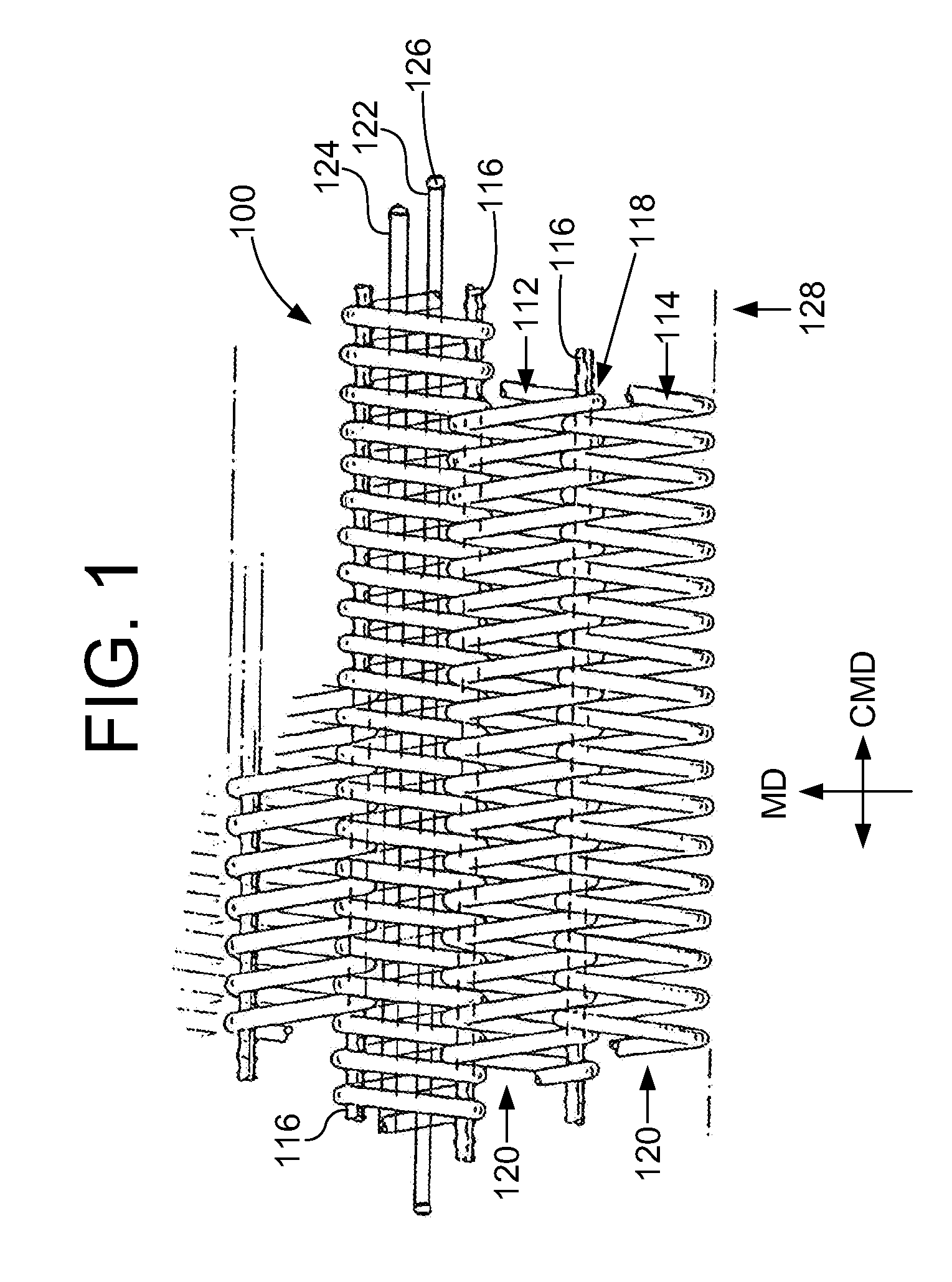

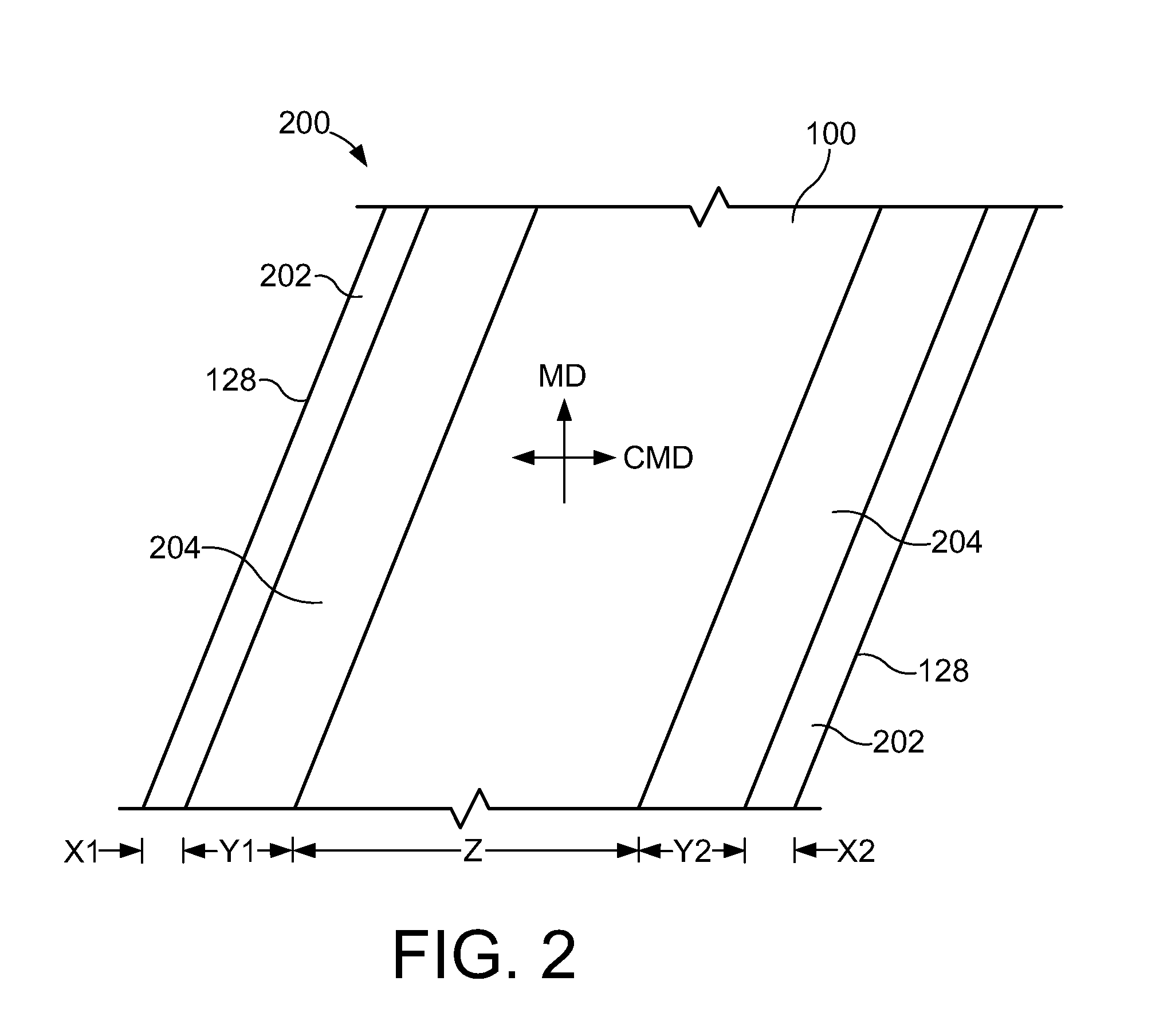

Industrial fabric with wear resistant coating

InactiveUS20110146913A1High strengthPrevent “shocking” of nearby personnelMechanical working/deformationLaminationYarnWear resistant

An industrial fabric used in the manufacture or processing of at least one material web includes a base fabric having a board side and a machine side. The base fabric includes a plurality of spirals extending in a cross machine direction (CMD). The spirals are interconnected together with each other along adjacent peripheral edges to form a spiral link fabric. The base fabric has opposite lateral side edges extending in a machine direction (MD). One or more electrostatic control yarns are positioned within a corresponding spiral and extend in the CMD direction to the lateral side edges. A pair of conductive edge coatings are applied to at least the board side of a respective lateral side edge for a predetermined width. The conductive edge coatings and the one or more electrostatic control yarns form an electrostatic grid. A pair of wear resistant coatings are applied to an area adjacent a respective conductive edge coating such that a substantially constant spacing between the wear resistant coatings corresponds to a minimum expected working width of the industrial fabric. The wear resistant coatings are wear resistant with a hardness of between approximately 50 to 66 Shore A Durometer Hardness, and a coefficient of friction greater than approximately 2 on the board side. The industrial fabric has a completely non-marking seam because of its integral nature with the base fabric and the equal amount of the wear resistant coating at the seam and the edges.

Owner:VOITH PATENT GMBH

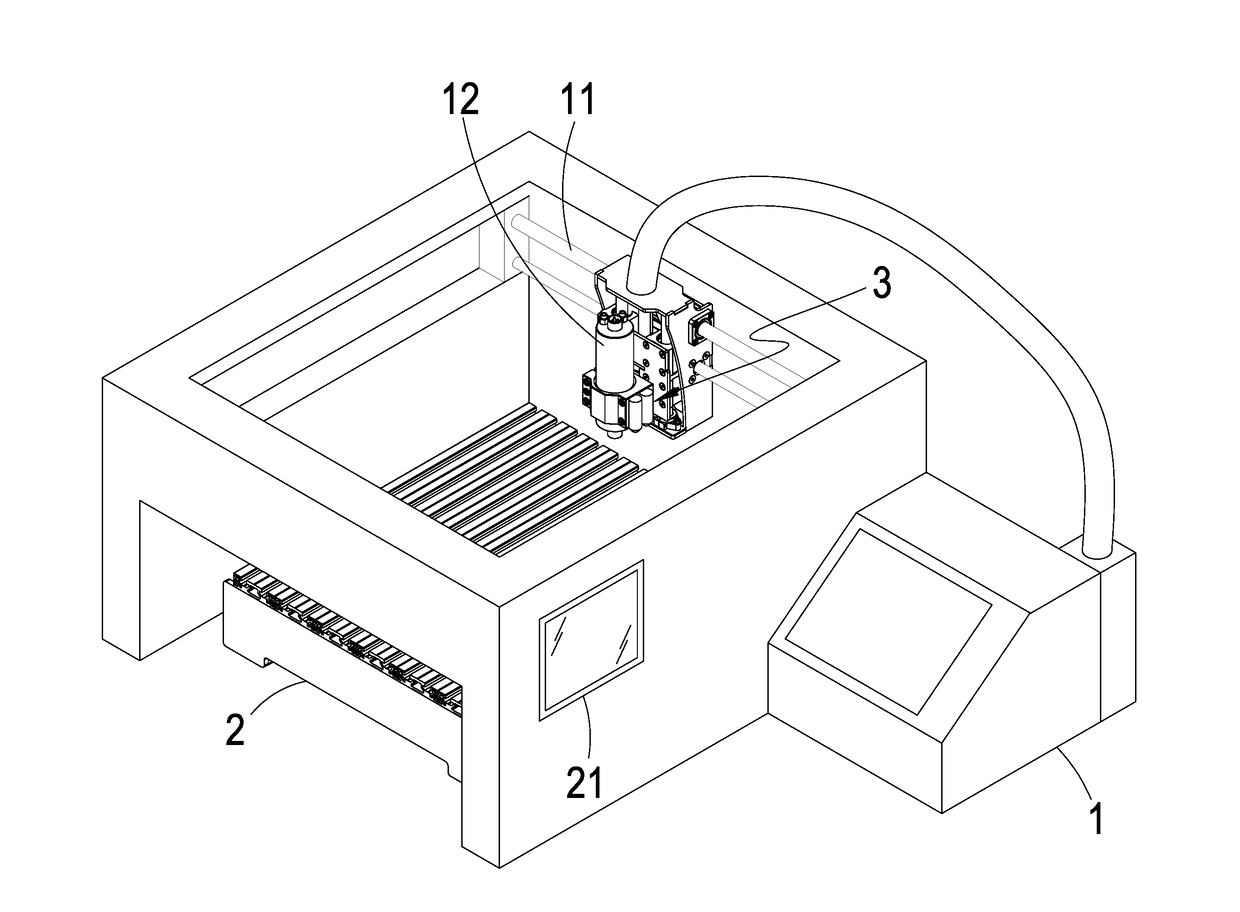

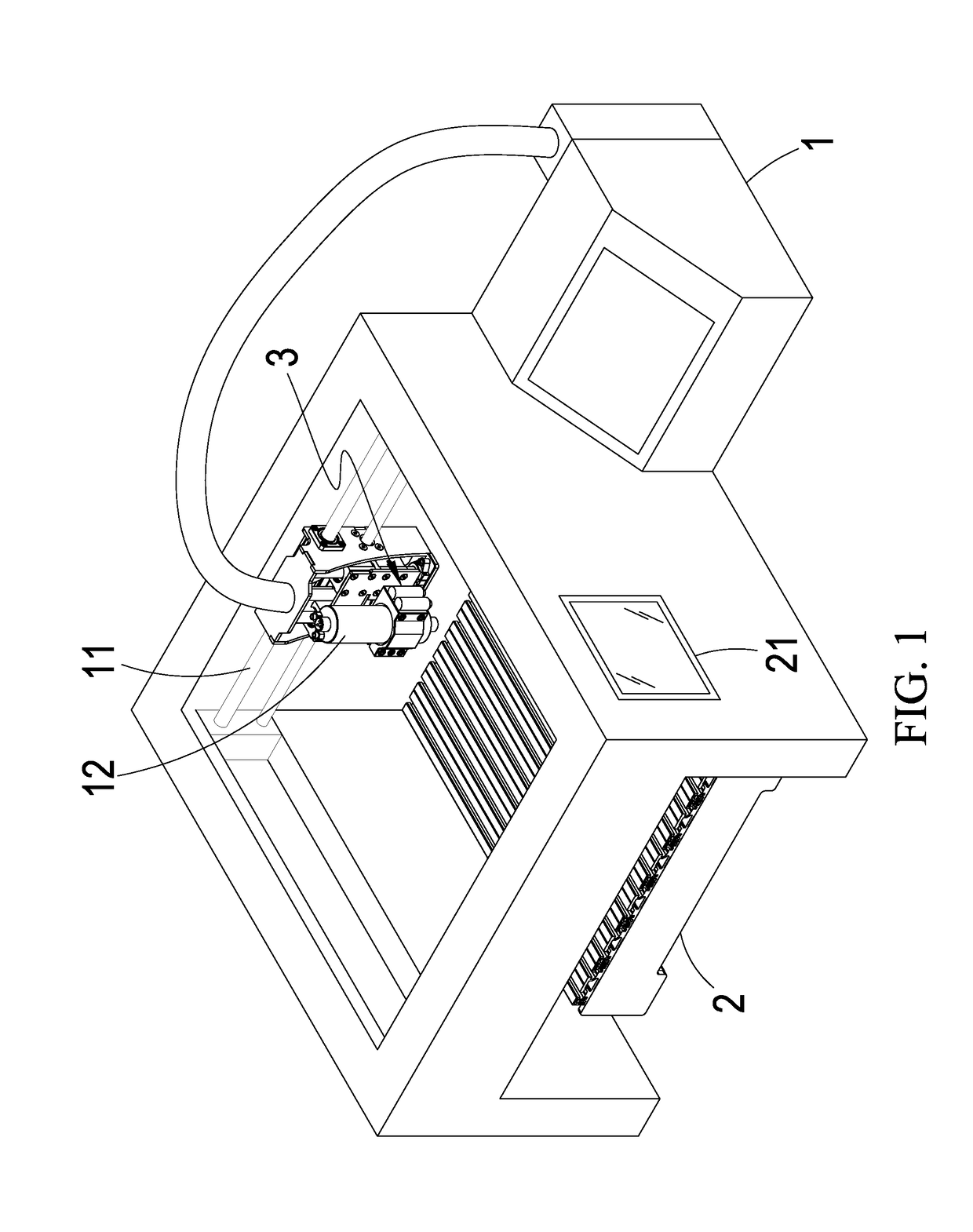

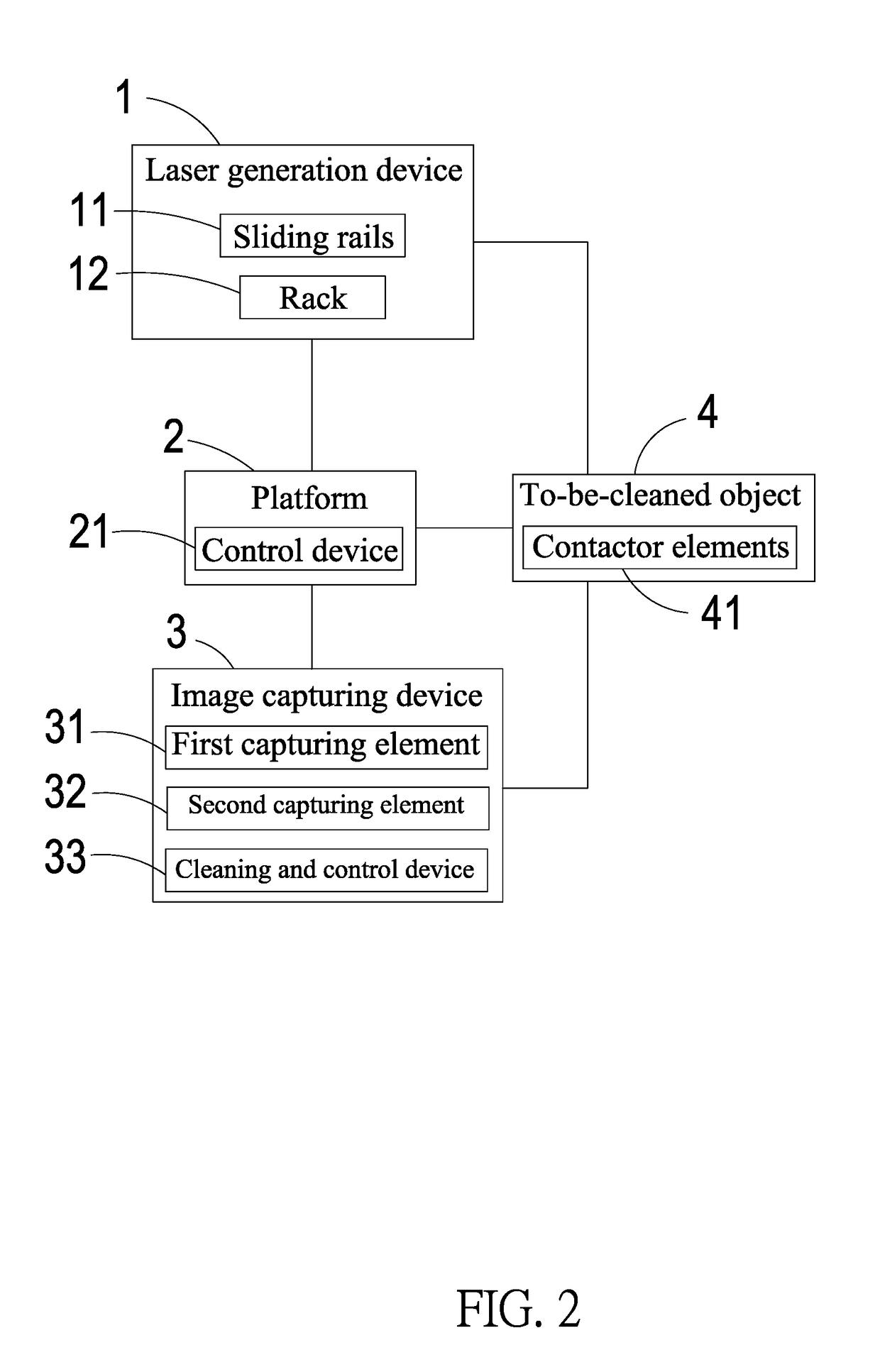

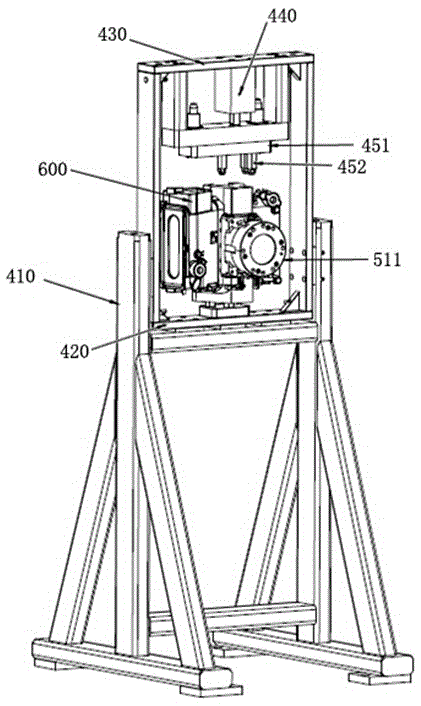

Structure of laser cleaning machine

InactiveUS20170276703A1Deteriorated functionDeteriorated shape deformationElectrical measurement instrument detailsWelding/cutting auxillary devicesEngineeringProcess information

The structure of a laser cleaning machine contains a laser generation device for cleaning a to-be-cleaned object, a platform for supporting the to-be-cleaned object under a projection path of the laser generation device, an image capture device configured on the laser generation device, and a cleaning and control device inside the image capturing device for setting a traversal path of the laser generation device and for processing information obtained by the image capturing device. The image capturing device contains a first capturing element and a second capturing element to a side of the first capturing element. The cleaning and control device obtains the location distribution and the precise coordinate of each contactor element on the to-be-cleaned object, and then determines an optimized traversal path and instructs the laser generation device to conduct cleaning accordingly so as to achieves high-quality and highly efficient cleaning.

Owner:GIGA SOLUTION TECH

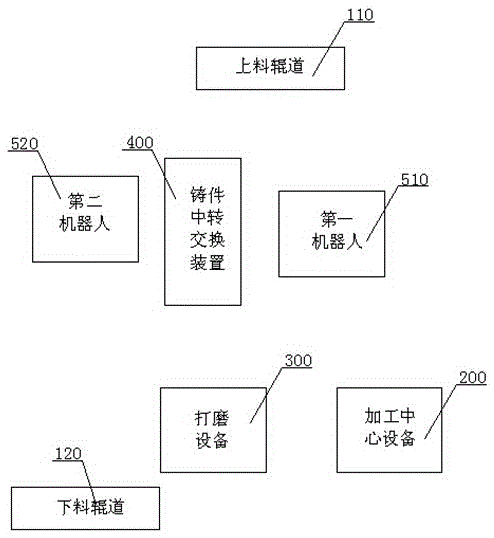

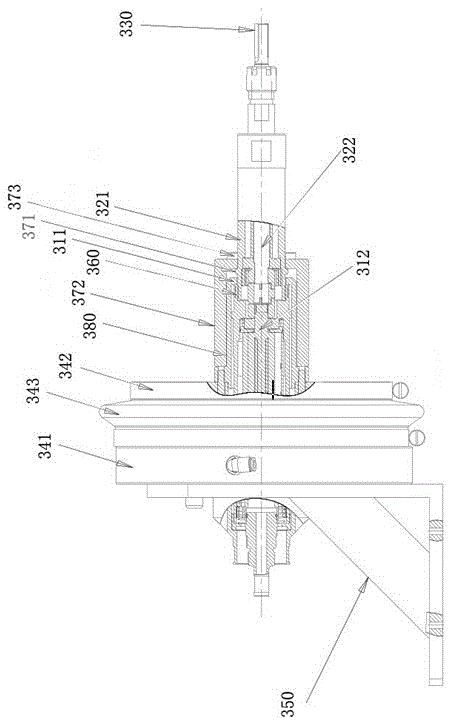

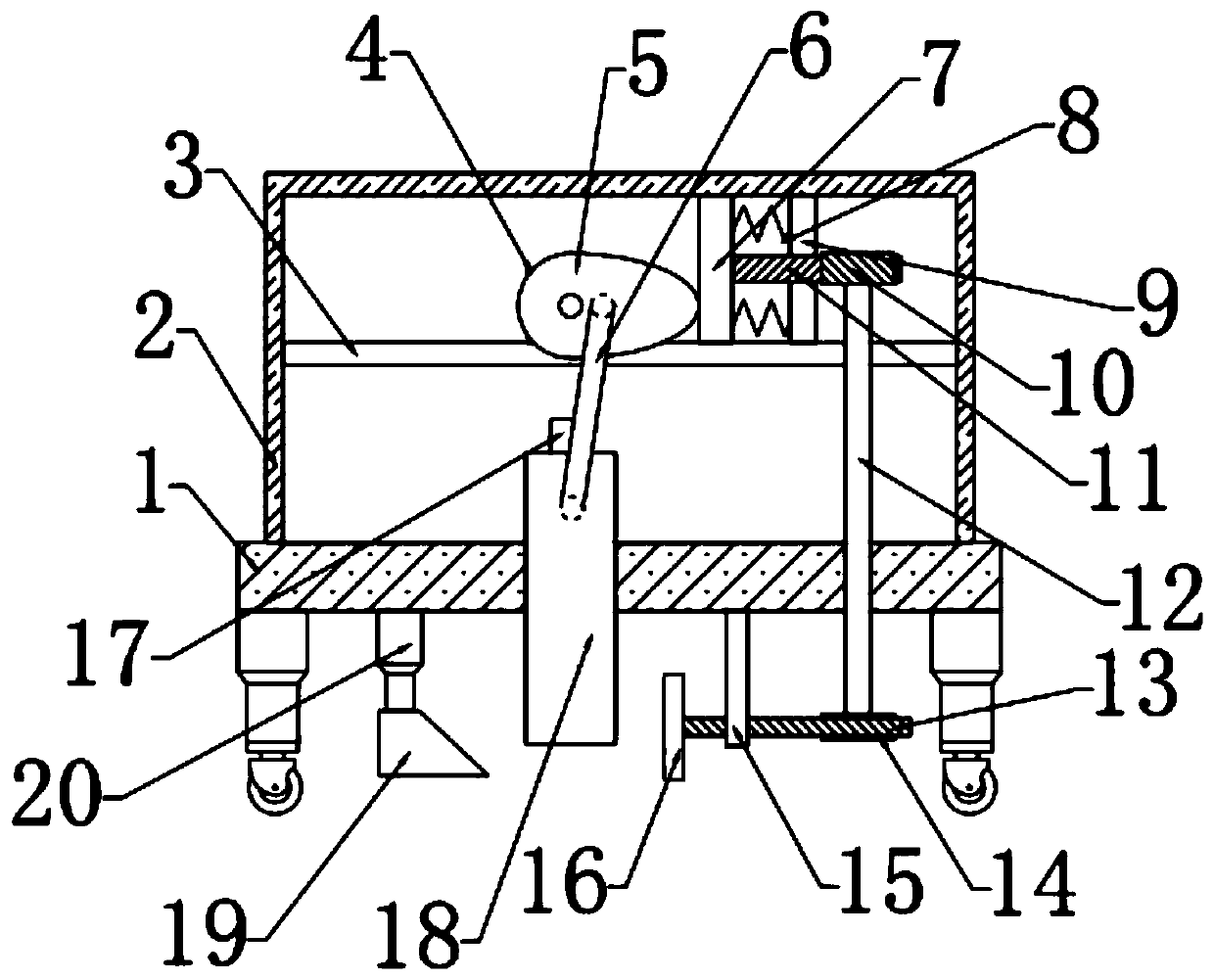

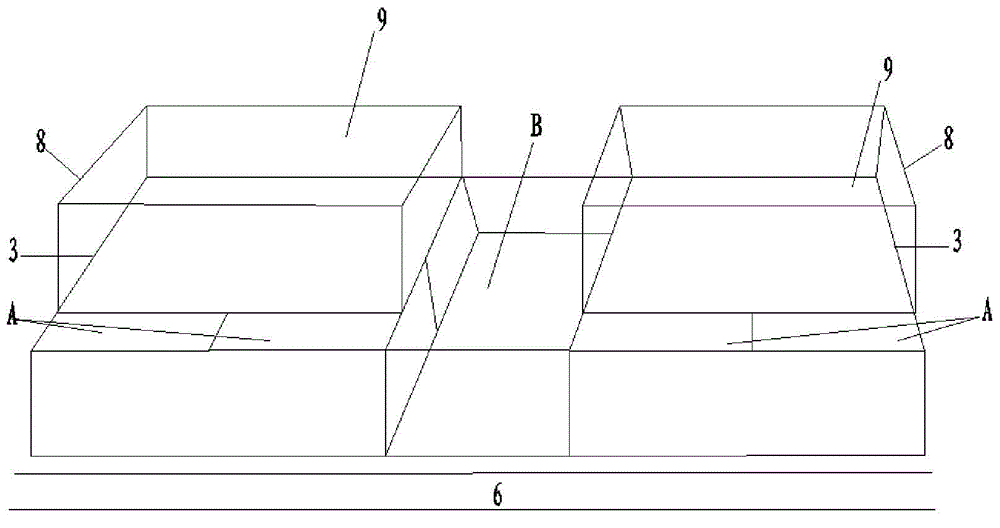

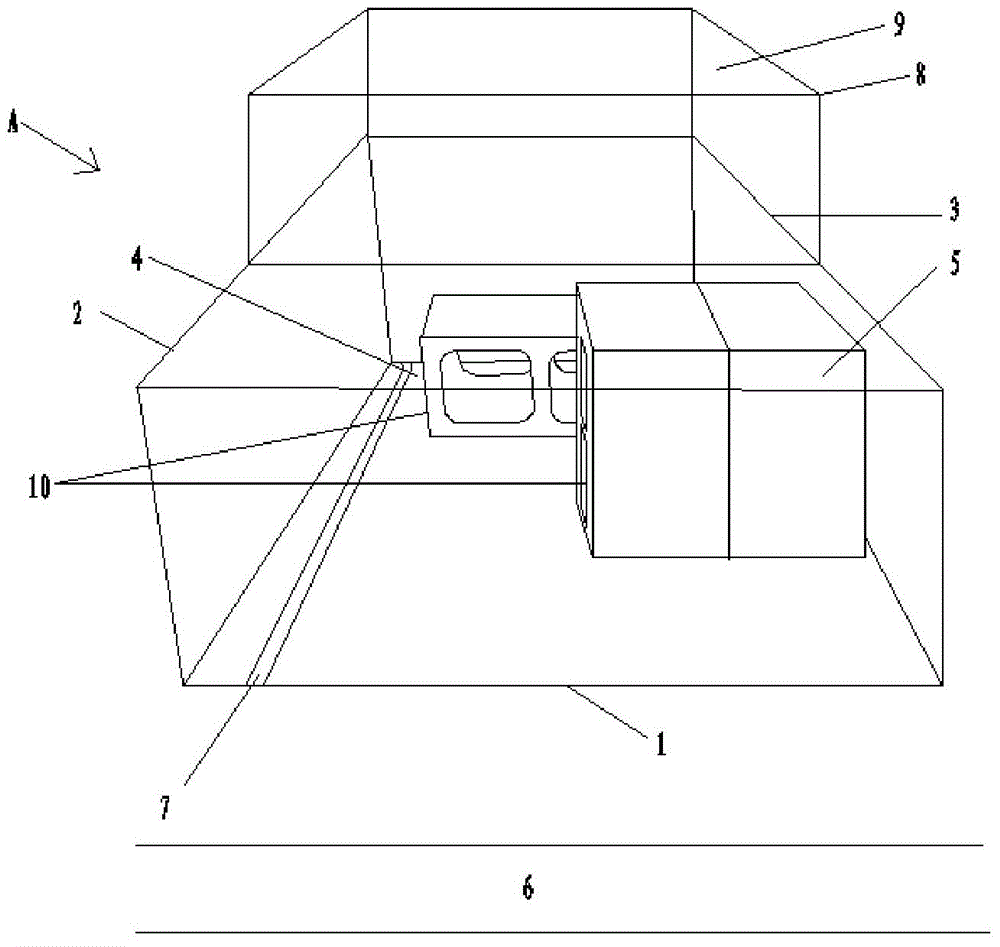

Casting cleaning unit and method

The invention discloses a casting cleaning unit which comprises a casting transit exchange mechanism. The casting transit exchange mechanism comprises a bottom support, an exchange platform, an upper support, a drive device and a positioning device. The positioning device comprises an installation plate and at least two ejecting rods. The installation plate is connected to the power output end of the drive device. The upper ends of the ejecting rods are connected to the installation plate. The lower ends of the ejecting rods are right opposite to the exchange platform. A robot system comprises a first robot and a second robot. The first robot is arranged on the feed side of the casting transit exchange mechanism. The second robot is arranged on the discharge side of the casting transit exchange mechanism. The casting cleaning unit is suitable for automatic unit product price multi-procedure conditions, reliable and stable in positioning, suitable for positioning castings of various types, and suitable for being shared by various product parts; the mechanism is simple in structure, low in manufacturing cost and high in cost performance. The invention further discloses a casting cleaning method.

Owner:SUZHOU MINGZHI TECH

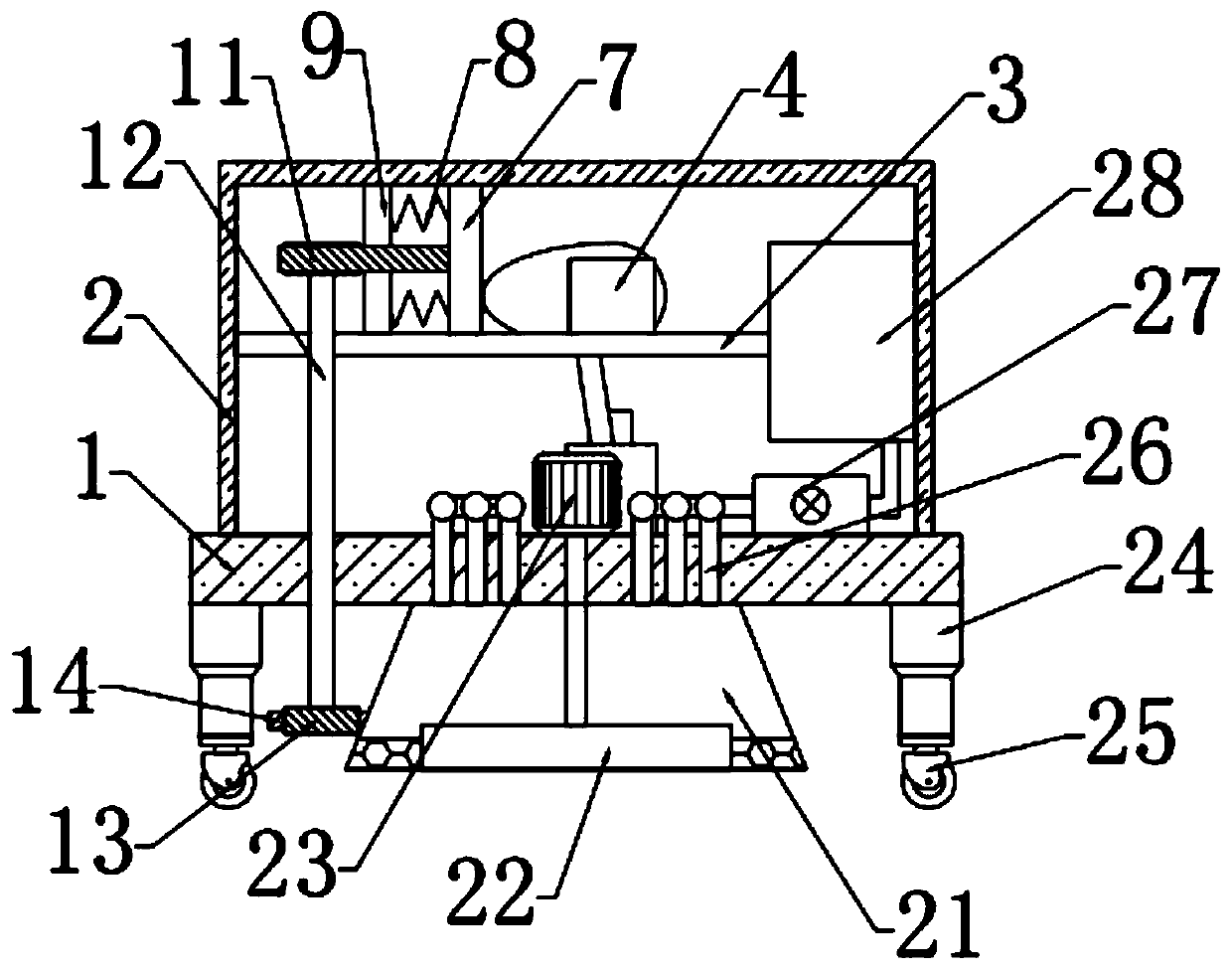

Ground surface dressing device for building construction

ActiveCN110052911ARealize up and down reciprocating motionEasy to polishBuilding repairsPlane surface grinding machinesReciprocating motionArchitectural engineering

The invention relates to the technical field of building construction, in particular to a ground surface dressing device for building construction. The ground surface dressing device for building construction comprises a base. The top of the base is fixedly connected with a shell. A fixing rod is arranged on the right side of the inner portion of the shell. A crushing mechanism is arranged on thefixing rod. A polishing mechanism is arranged on the left side of the crushing mechanism. The left side of the shell is fixedly connected with a push rod. According to the ground surface dressing device for building construction, through arrangement of a first motor, a cam, a connection rod and a crushing press block, the crushing press block can conduct vertical reciprocating motion and impact and crush cement blocks protruding from the cement ground, so that the ground surface is dressed; through arrangement of a transmission device, a scraper blade and a crushed cement collecting box, it can be achieved that when the crushing press block moves upwards, the scraper blade pushes crushed blocky cement into the crushed cement collecting box, and then the polishing wheel can conveniently polish the ground; and through arrangement of a dustproof cover, an exhaust fan and a dust collection box, dust and chips can be removed, and dust pollution to the environment is reduced.

Owner:江苏复华光电科技有限公司

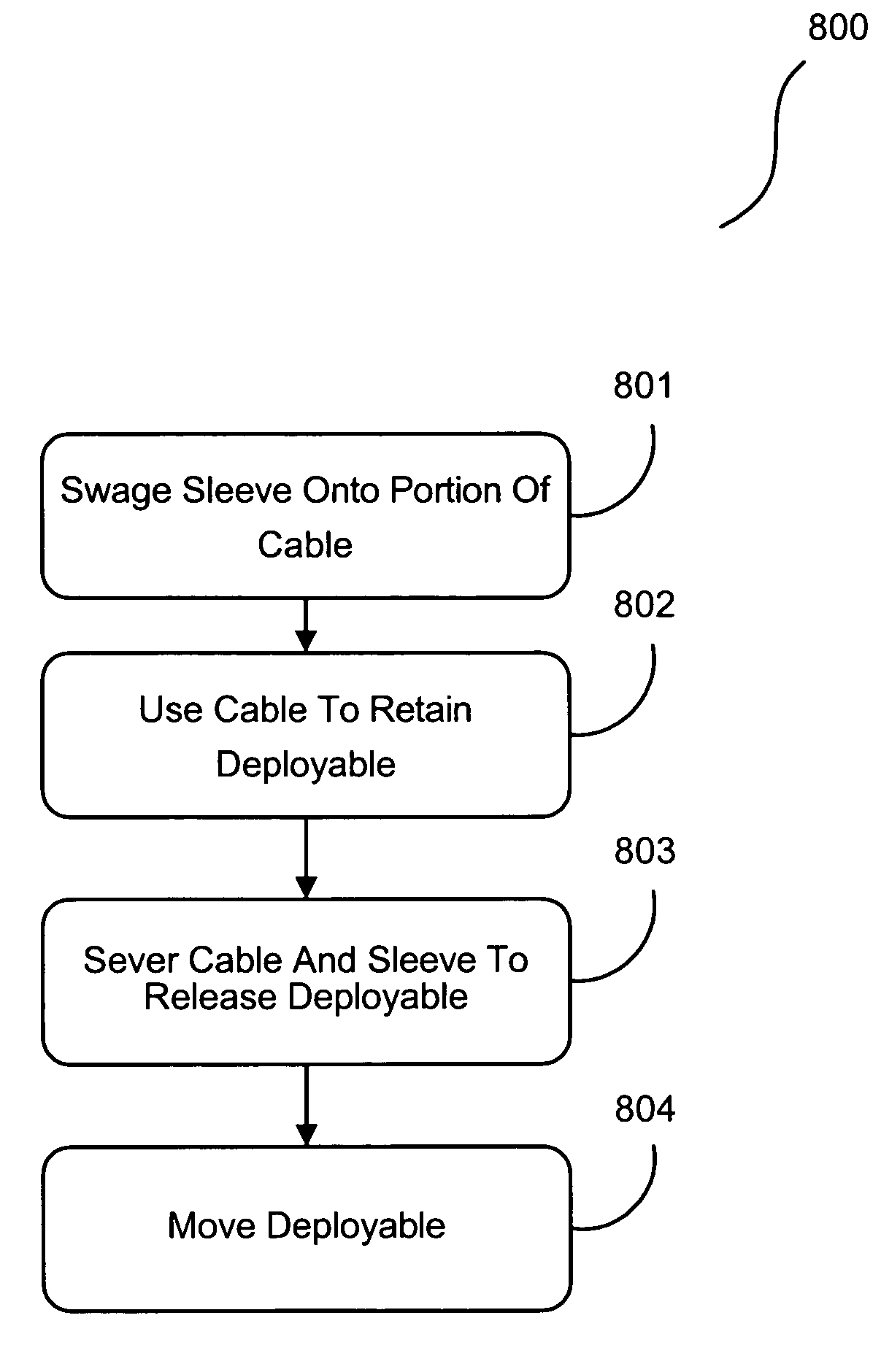

Swaged cable deployment in space

ActiveUS7278612B1Eliminate such splayingMaintain integrityCosmonautic vehiclesCosmonautic propulsion system apparatusEngineeringElectric cables

A cable restraint / deployment mechanism is disclosed for deploying an object in space from a spacecraft. To deploy the object, the cable restraint / deployment mechanism cuts a cable attached to the spacecraft and the object. For example, a spacecraft may include a solar panel array that is restrained by the spacecraft in a stowed form through the use of a wire rope cable. The cable may be affixed at one end to a deployable object. The other end of the cable is affixed to the spacecraft through a cutting mechanism, such as a pyrotechnically actuated cutting device. The cutting mechanism cuts the cable at a swaged sleeve of the cable. The swaged sleeve of the cable substantially prevents splaying of the cable and cutting debris.

Owner:LOCKHEED MARTIN CORP

Machine tool

InactiveUS20050069392A1Work lessLess clean upPlaning/slotting machinesMilling machinesEngineeringMachine tool

In a double housing machining center, a table having a plurality of T slots on its top surface is arranged substantially in a horizontal direction. A lower space, into which chips are received, is provided under the table. A plurality of through-holes, being in fluid communication with bottom portions of the T slots and passing through the table to reach the lower space, is scattered and formed in the table. The chips introduced into the T slots are discharged into the lower space through the through-holes. Thus, the chips splashed down onto the table and introduced into the T slots are readily removed and the cleaning work of the table is reduced.

Owner:DMG MORI SEIKI CO LTD

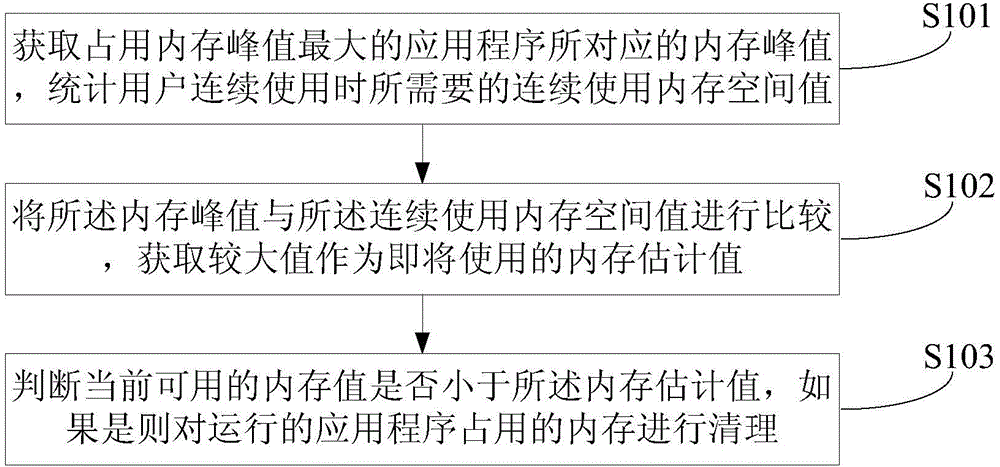

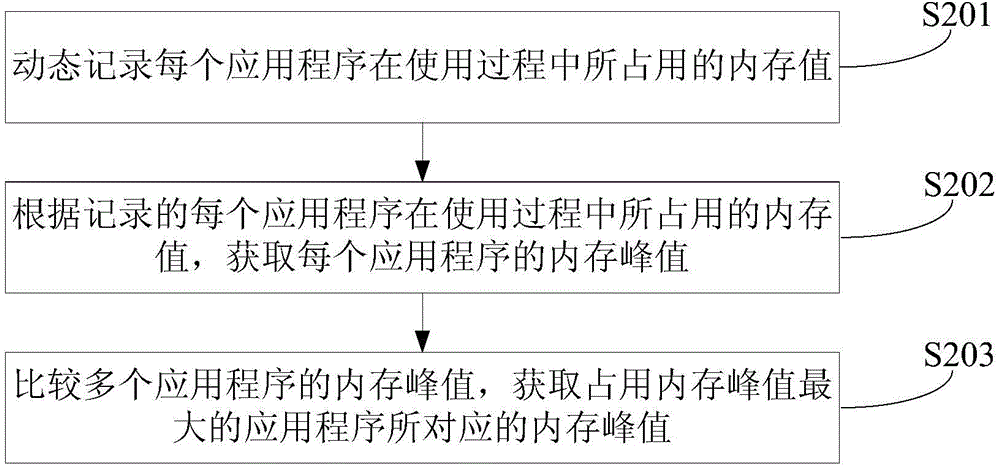

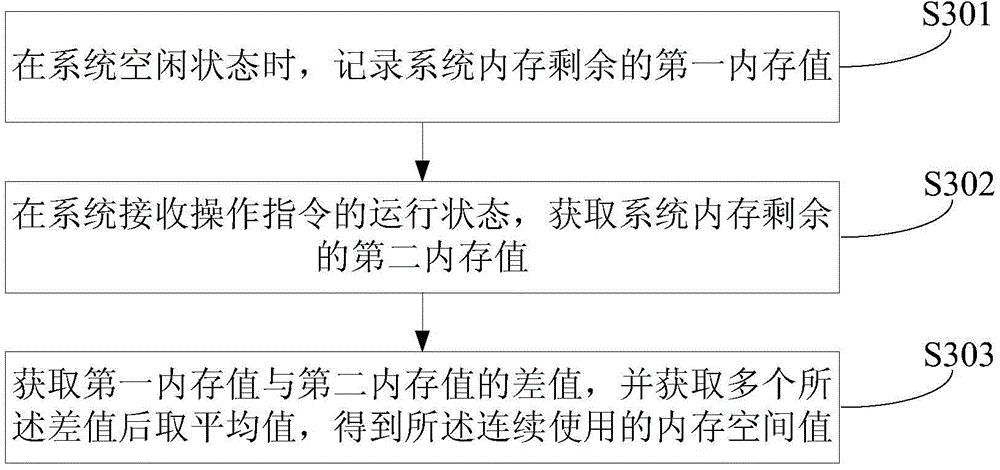

Internal storage recovery method and device

ActiveCN104484282ARun fastLess clean upMemory adressing/allocation/relocationRecovery methodContinuous use

The invention belongs to the field of internal storage recovery and provides an internal storage recovery method and device. The method comprises the steps of obtaining the internal storage peak value corresponding to an application program occupying the maximum internal storage peak value, and calculating the continuous use internal storage space value needed by users in continuous use; comparing the internal storage peak value and the continuous use internal storage space value, and obtaining the larger value as the internal storage estimation value to be used; judging whether the current available internal storage value is smaller than the internal storage estimation value, and if yes, cleaning the internal storage occupied by the run application program. According to the internal storage recovery method and device, whether the internal storage is enough can be estimated according to the internal storage value needed by the users and the maximum internal storage value needed by programs, and the internal storage can be cleaned when the needed internal storage value is estimated to be larger than the available internal storage. Compared with the prior art, unnecessary cleaning of the internal storage can be reduced more, and the running speed of the application programs can be increased further.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

High speed hand drill with swiveling pressure foot and integrated vacuum pickup and coolant delivery duct

ActiveUS8337124B2Improve tool ergonomicsImproved drill guideDrilling/boring measurement devicesThread cutting feeding devicesEngineeringDrill cuttings

A high speed handheld power drill includes a housing with a motor, a chuck rotationally driven by the motor, and a drill bit clamped in the chuck. A pressure foot is mounted on the housing for coaxial rotation about the drill bit and lockable in a selectable angular position relative to the housing. A drill guide is slidably disposed within the pressure foot at an outer end thereof and biased for coaxial sliding movement between the drill bit and pressure foot. A vacuum cuttings pickup and coolant fluid delivery tool is coupled to the drill guide and arranged to deliver coolant fluid to the drill bit and to remove drill cuttings and coolant fluid and vapor therefrom during drilling. A coolant fluid reservoir is coupled to the drill motor housing and adapted to deliver selectably metered amounts of coolant fluid to the cuttings pickup and coolant delivery tool during drilling.

Owner:THE BOEING CO

Energy-conserving, environment-friendly and recyclable thermosetting resin composite material and application thereof

The invention discloses an energy-conserving, environment-friendly and recyclable thermosetting resin composite material and an application thereof. The material comprises the following raw materials in percentage by weight: 20 to 75 percent of filler, 18 to 60 percent of unsaturated resin substrate, 6 to 18 percent of modified additive and 1 to 1.5 percent of pigment. According to the material and the application thereof, an injection process is adopted, high mechanical automation degree, low labor intensity and high yield are ensured; the material is not required to be burnt at high temperature for a long time, so that the energy consumption is greatly lowered; the composite material is high in toughness, strong in strength, resistant to impact, anticorrosive, environment-friendly, flame-retardant, free of radiation and heavy metal and recyclable, and can be used for manufacturing roofs, wall surfaces and grounds in bathrooms, kitchens and other rooms as well as shells of products such as bathroom cabinet panels, bathroom cabinets, tables, tea tables, switch socket panels, hand dryers and hair dryers, patterned panels, which have different artistic effects and impressions such as recesses and bumps, stripes and waves, and are attractive in appearance, high in artistic quality and strong in stereoscopic impression, and various artistic effects of wood grains, marble veins, leather grains and metallic texture can be achieved.

Owner:SHANGHAI HUDA INVESTMENT & DEV +1

Bamboo rat ecological breeding method

The invention discloses a bamboo rat ecological breeding method comprising the following steps: (1) bamboo rats are placed into breeding tanks of an imitation ecological breeding unit, wherein the breeding unit comprises at least two breeding tanks arranged on the left and the right; a certain space is left between the two breeding tanks, such that a first planting tank is formed; each of the breeding tanks is enclosed by a bottom plate, side enclosure plates and a cover plate; cement prefabricated parts provided with holes are placed in the tanks, such that each breeding tank is divided into a rest zone and a living zone; one side of the cement prefabricated part is close to a right side enclosure plate, and the other side has a certain distance from a left side enclosure plate; drainage grooves are arranged on the bottom plates; second planting tanks enclosed by separation plates are arranged on the top of the cover plates, wherein the living zones are partially or completely exposed; the bottom plates, the cover plates and the separation plates are prepared with cement plates or stone plates; soil is laid in the first and second planting tanks; (2) the bamboo rats are fed at dusk every day; and (3) crops are planted in the first and second planting tanks and are used as a bamboo rat feed; and bamboo rat manure is directly added into the planting tanks and is used as a fertilizer.

Owner:重庆市铜梁区骏豪竹鼠养殖股份合作社

Probe skates for electrical testing of convex pad topologies

InactiveUSRE43503E1Easy to controlLess clean upElectrical measurement instrument detailsManufacture of electrical instrumentsPower flowRound back

A probe for engaging a conductive pad is provided. The probe includes a probe contact end for receiving a test current, a probe retention portion below the contact end, a block for holding the probe retention portion, a probe arm below the retention portion, a probe contact tip below the arm, and a generally planar self-cleaning skate disposed perpendicular below the contact tip. The self-cleaning skate has a square front, a round back and a flat middle section. The conductive pad is of generally convex shape having a granular non-conductive surface of debris and moves to engage the skate, whereby an overdrive motion is applied to the pad causing the skate to move across and scrub non-conductive debris from the pad displacing the debris along the skate and around the skate round back end to a position on the skate that is away from the pad.

Owner:MICRO PROBE

Device for hedge pruning, branch crushing and adsorption

The invention discloses a device for hedge pruning, branch crushing and adsorption. The device comprises a knife rest cover, a pruning and branch crushing device, pruning knives, branch crushing knives, a garbage collecting box and a draught fan. An adsorption opening capable of sliding left and right is formed in the upper end of the knife rest cover. The pruning and branch crushing device comprises driving motors, and the driving motors are all arranged in the knife rest cover. Two pruning knives are arranged on a rotary shaft of the corresponding driving motor in a spaced mode. The branch crushing knives are arranged above the pruning knives. The garbage collecting box is connected with the adsorption opening through a suction tube. The draught fan is connected with the garbage collecting box. According to the device for hedge pruning, branch crushing and adsorption, after a hedge is pruned and subjected to branch crushing through the pruning and branch crushing device, the draught fan generates suction force to suck broken branches and leaves into the garbage collecting box to be collected, ground sweeping work is reduced accordingly, the labor intensity is reduced, and the efficiency is improved.

Owner:GUANGXI UNIV

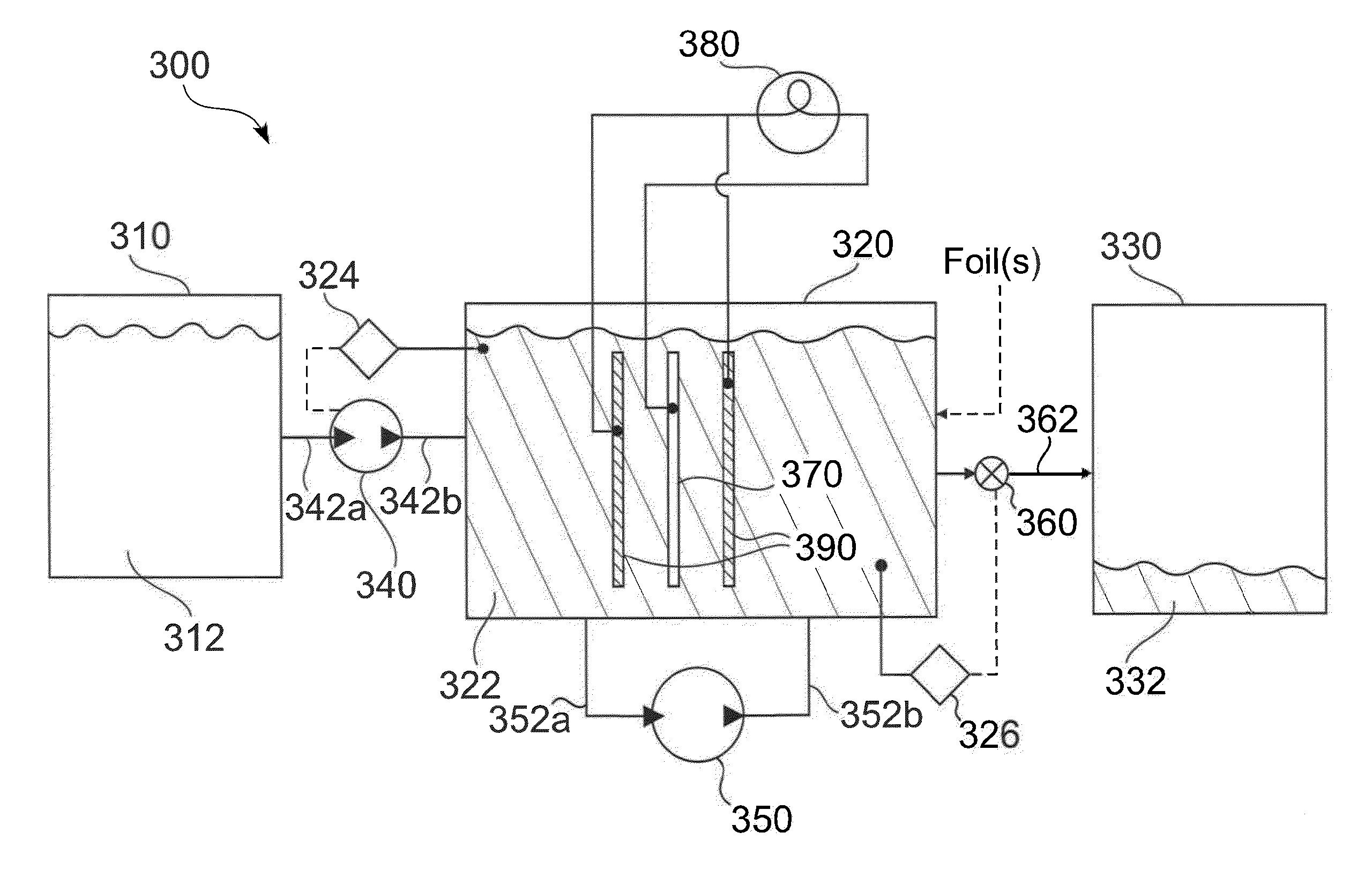

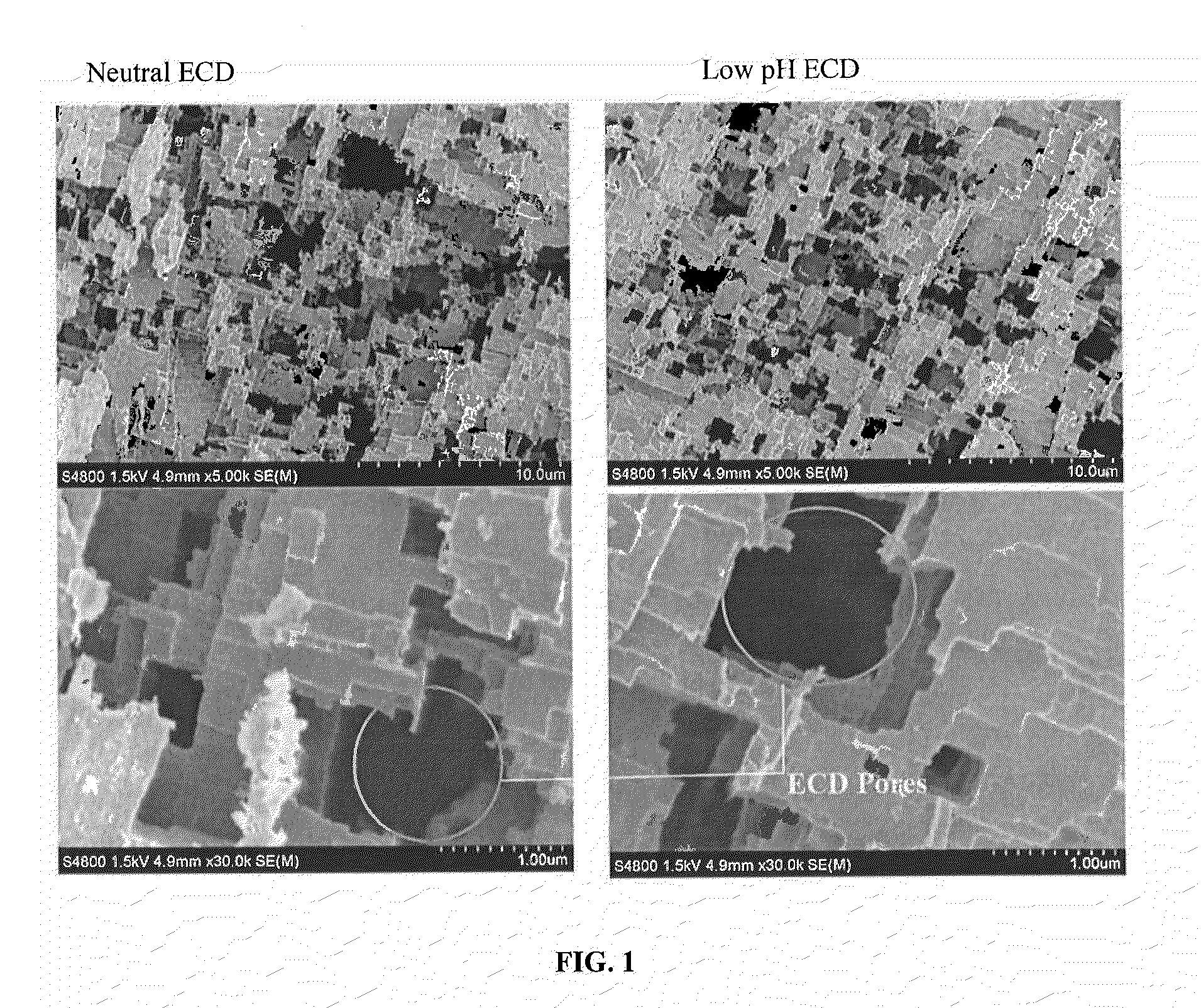

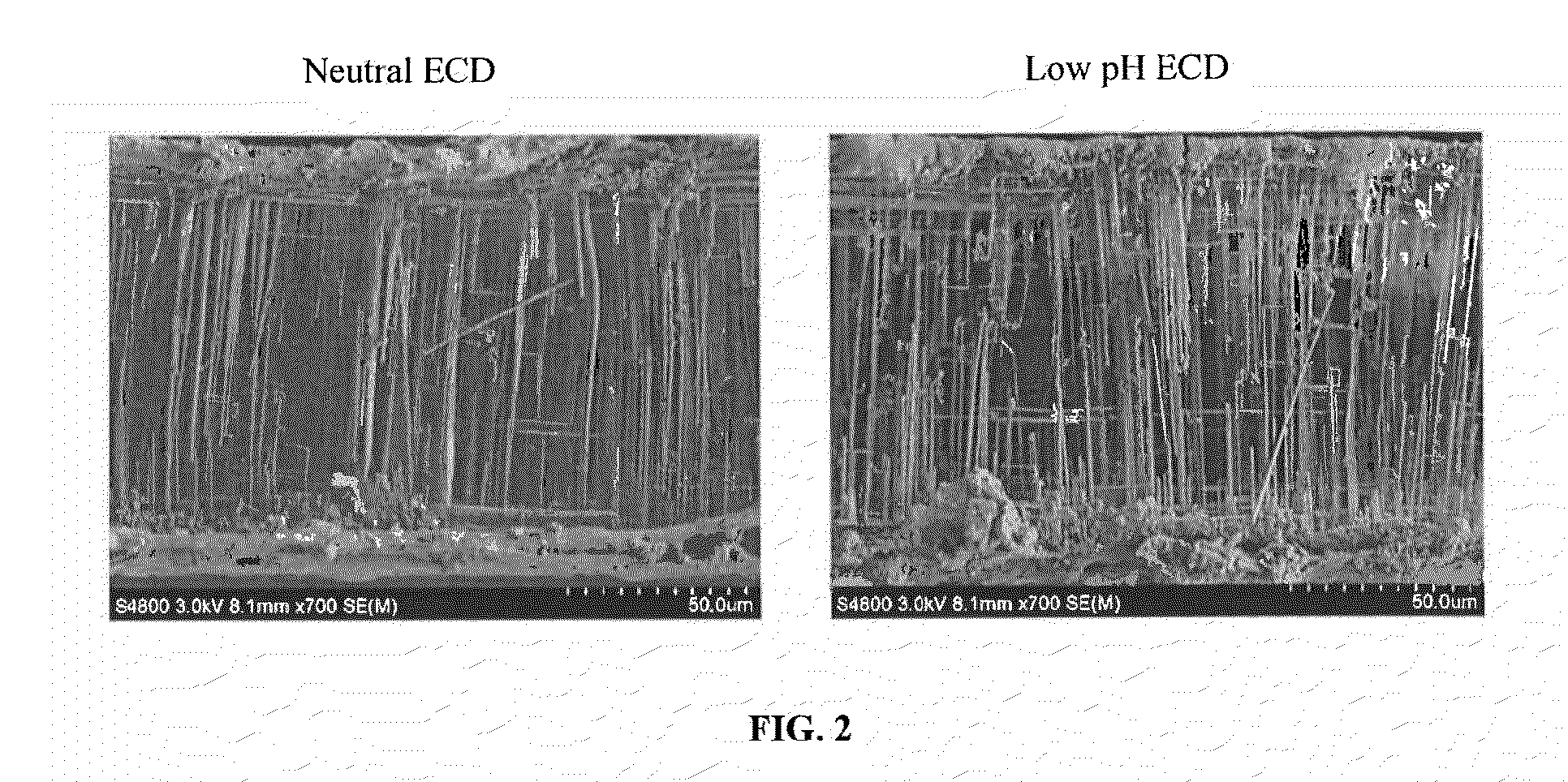

Electrochemical drilling system and process for improving electrical porosity of etched anode foil

ActiveUS20130264196A1Shorten production downtimeLess clean upCellsElectrolytic capacitor manufacturePorosityElectrolysis

A process for creating porous anode foil for use in an electrolytic capacitor of an implantable cardioverter defibrillator is provided. The process includes electrochemical drilling a plurality of etched metal foils in sequence one after the other in a bath containing electrochemical drilling (ECD) solution initially having a pH of less than 5. Alternatively, an etched foil sheet may be passed through the bath in a substantially continuous manner such that a portion of said etched foil sheet is in contact with the ECD solution is electrochemically drilled to generate pores. Electrochemical drilling is achieved when a current is passed to the foil or portion of the foil sheet in solution, ECD replenishment solution having a pH of less than about 5 is added from a feed reservoir to the bath at such a rate so as to maintain a pH in the ECD solution in the bath of less than about 5, and ECD solution in the bath is removed to a waste reservoir at the substantially the same rate as the addition of the ECD replenishment solution to the bath.

Owner:PACESETTER INC

Sole automatic-cleaning device

The invention provides a sole automatic-cleaning device, and belongs to the field of indoor environment cleaning. The sole automatic-cleaning device aims to resolve the problems that for an existing indoor clean-keeping mode like doormat placement, soles can not be effectively cleaned, and indoor cleanness can not be guaranteed effectively. The upper end of a box is open, a rotary shaft of a motor is in transmission connection with a first transmission shaft, the first transmission shaft is in transmission connection with a second transmission shaft through a cleaning belt, foot rest levers are arranged above the upper surface of the cleaning belt, cleaning bristles are arranged on the outer surface of the cleaning belt, and the bristles on the upper end portion of the cleaning belt stretch above the foot rest levers. An infrared sensor signal receiving terminal and an infrared sensor signal emitting terminal are fixedly arranged on the inner walls of two opposite side surfaces of the box respectively, the infrared sensor signal receiving terminal right faces the infrared sensor signal emitting terminal, the motor is connected with the signal output end of a control board, and the infrared sensor signal receiving terminal is connected with the signal input end of the control board. The sole automatic-cleaning device is used for cleaning the soles and guaranteeing cleanness of the indoor floor.

Owner:湖南哈工机器人研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com