Reflective optical element and EUV lithography appliance

a technology of optical elements and lithography equipment, applied in the field of refractive optical elements, can solve the problems of substantial reflection loss of functional optical surfaces, inability to prevent hydrocarbons and/or other carbon compounds from being inside the appliance, and carbon-containing contamination films on the optical elements, so as to reduce the deposition of contamination on the protective layer system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0030] On a Mo / Si multilayer system located on a substrate of amorphous silicon dioxide, consisting of 50 pairs of 2.76 nm molybdenum and 4.14 nm amorphous silicon (a-SiO2), a three-layer protective layer system is deposited. The protective layer system borders on the uppermost molybdenum layer of the multilayer system with a Y-layer 1.2 nm thick. On the Y-layer is placed a 1.5 nm Y2O3 layer. At the vacuum side, the protective layer system is closed by a 1 nm thick amorphous silicon dioxide layer. The choice of the materials and their thickness is based on the criteria of the invention. In particular, the materials are also selected so as to suppress carbon build-up (Y2O3, a-SiO2) or to be inert to energy injection (Y, a-SiO2).

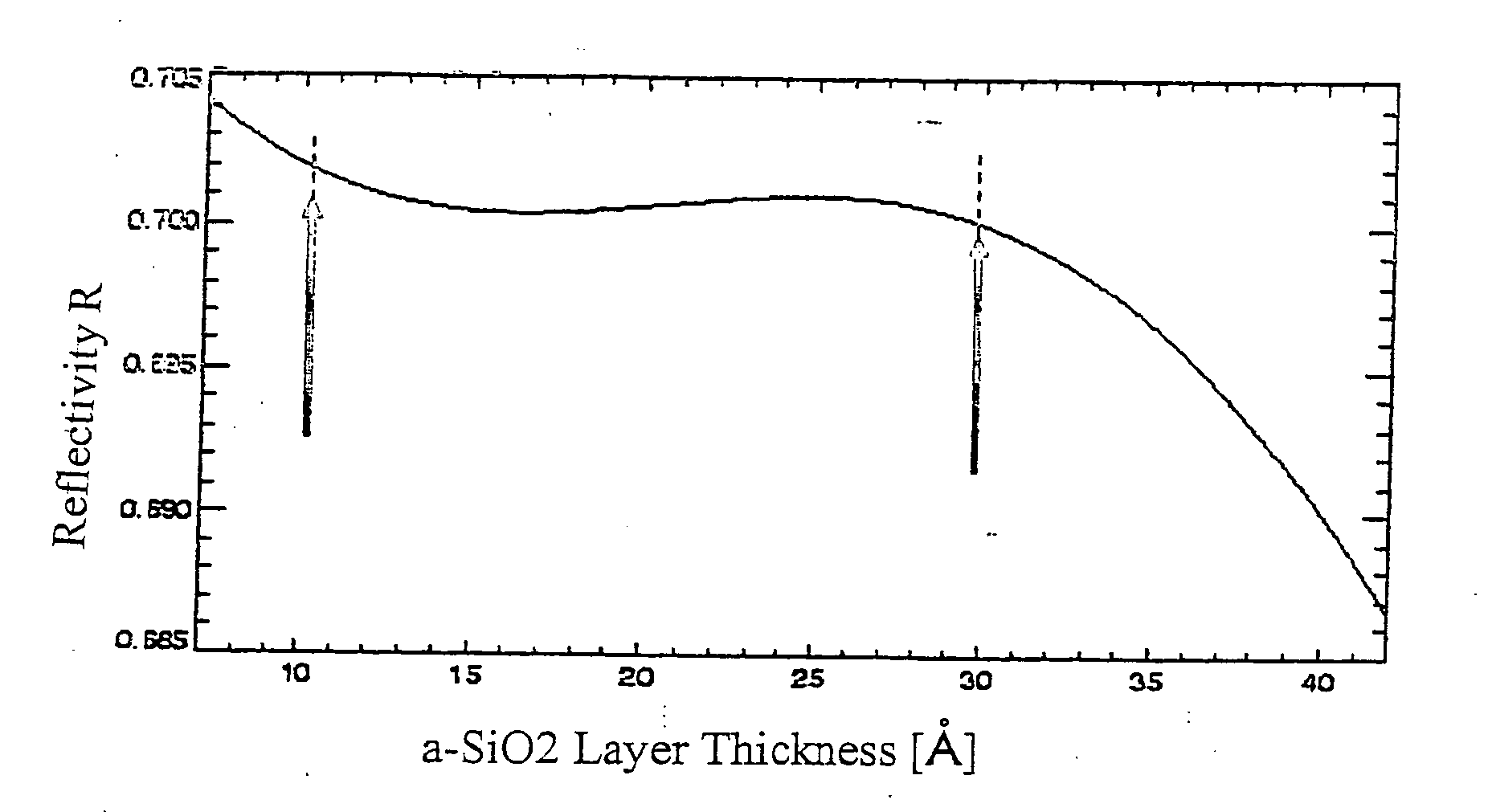

[0031] Disregarding the interface and surface roughness, one obtains a reflectivity of 70.2% at an operating wavelength of 13.5 nm for an angle of incidence of 0° with the normal to the surface. FIG. 1 shows the reflectivity of the entire reflective optical e...

example 2

[0037] On a multilayer system of 50 Mo / Si pairs located on an amorphous silicon dioxide substrate, optimized for an operating wavelength of 13.5 nm, a protective layer system of a 2.0 nm thick cerium layer, which adjoins the topmost molybdenum layer of the multilayer system, and a 1.5 nm thick silicon dioxide layer is placed. The minimum of a standing wave produced by reflection on the uncontaminated reflective optical element at operating wavelength λB lies in the vacuum, 0.05λB from its surface. For a maximum reflectivity of 70.9% at an operating wavelength of 13.5 nm and a tolerated reflectivity decrease of 1%, a carbon contamination layer can tolerate a thickness of up to 3.5 nm (see FIG. 5). This reflective optical element as well is suitable for use in an EUV lithography appliance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com