Patents

Literature

72 results about "Carbon contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chunk polycrystalline silicon and process for cleaning polycrystalline silicon chunks

InactiveUS20130216466A1Easy to disassemblePrevent penetrationPolycrystalline material growthSiliconMetallurgyCarbon contamination

The invention provides chunk polycrystalline silicon having a concentration of carbon at the surface of 0.5-35 ppbw. A process for cleaning polycrystalline silicon chunks having carbon contaminations at the surface, includes a thermal treatment of the polycrystalline silicon chunks in a reactor at a temperature of 350 to 600° C., the polycrystalline silicon chunks being present in an inert gas atmosphere during the thermal treatment, and the polycrystalline silicon chunks after the thermal treatment having a concentration of carbon at the surface of 0.5-35 ppbw.

Owner:WACKER CHEM GMBH

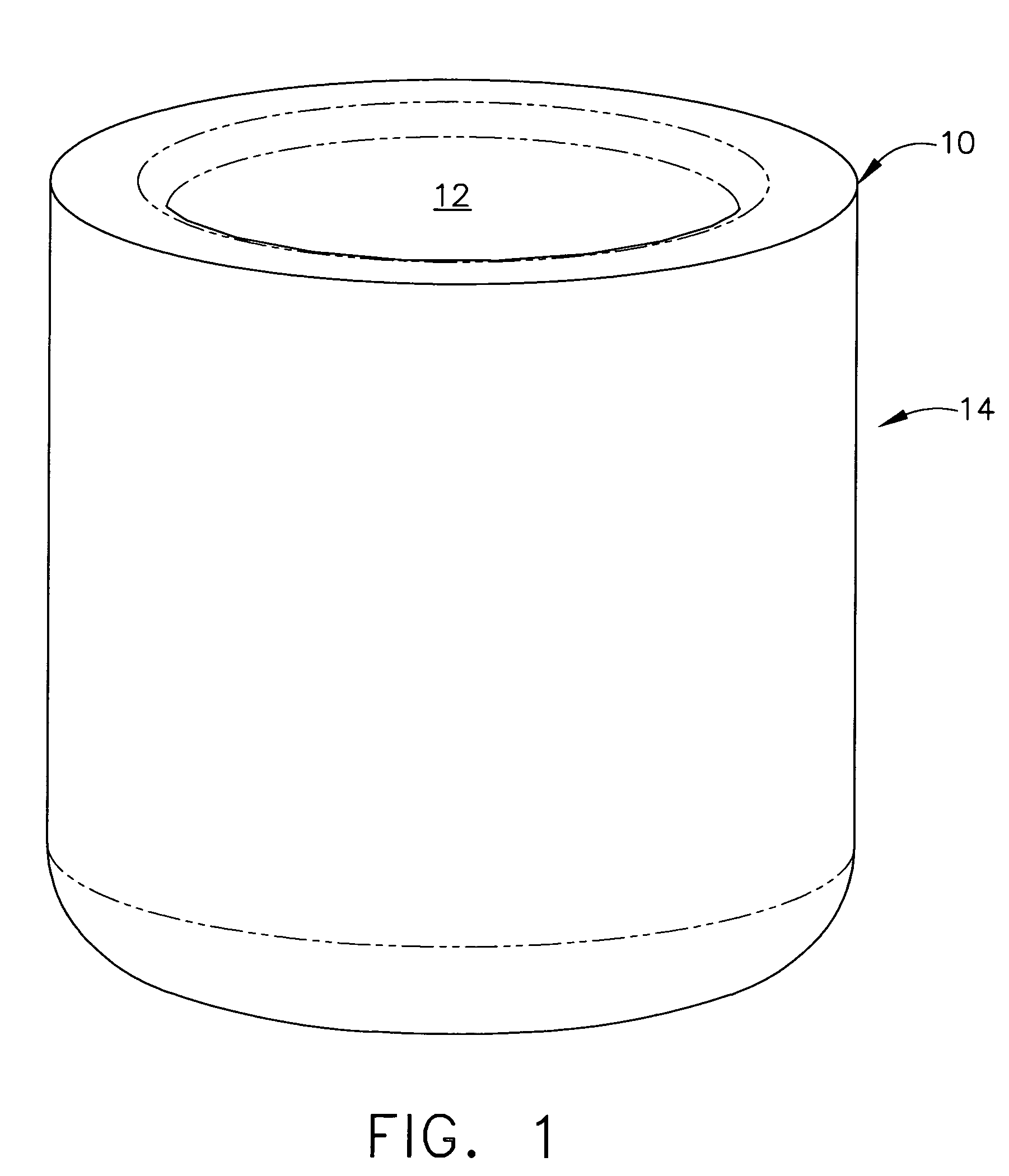

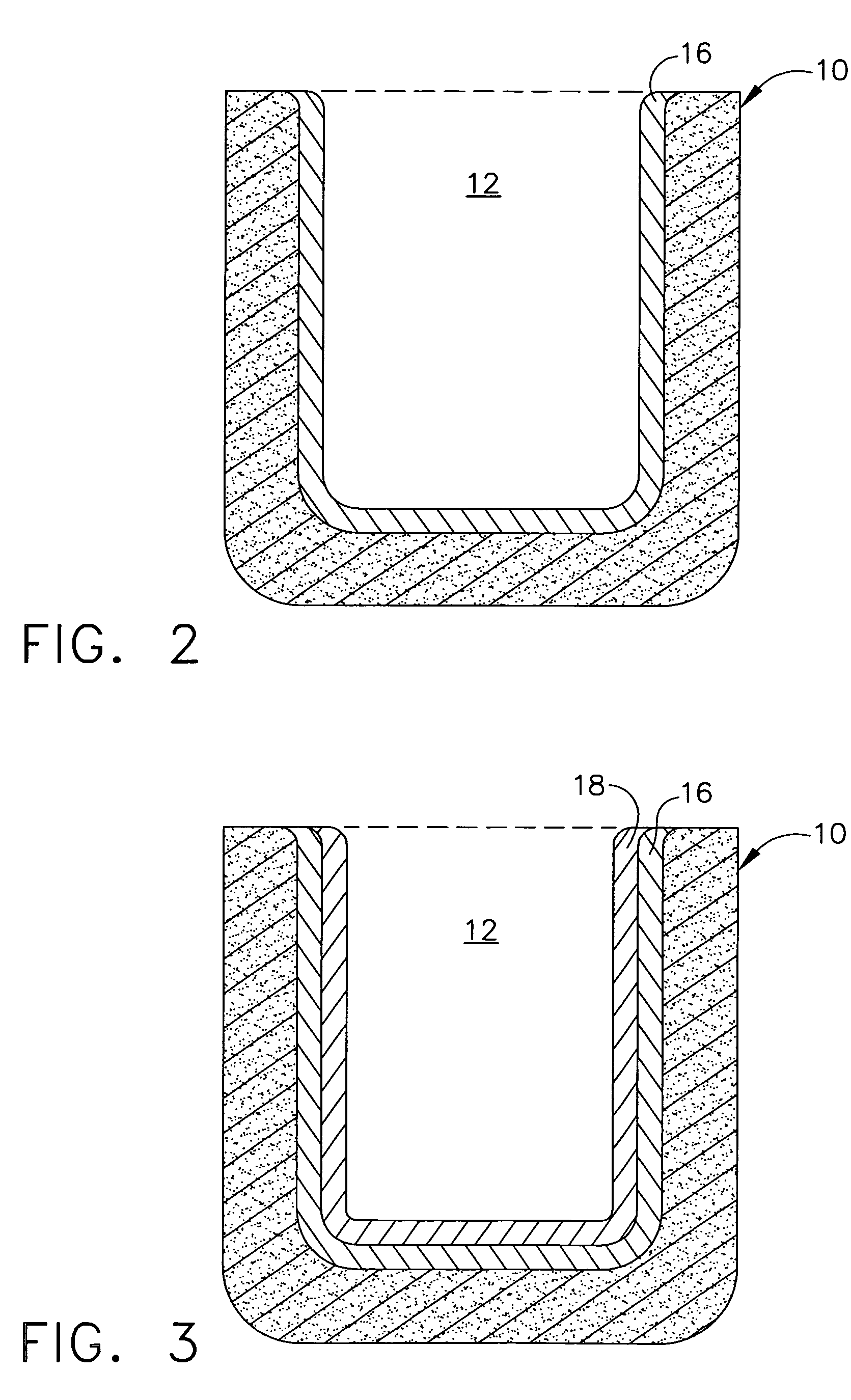

Methods for reducing carbon contamination when melting highly reactive alloys

InactiveUS20080156147A1Reduce carbon pollutionMelt-holding vesselsCrucible furnacesCarbon contaminationAlloy

Methods for reducing carbon contamination when melting highly reactive alloys involving providing a graphite crucible having an interior, applying at least a first protective layer to the interior of the graphite crucible, placing a highly reactive alloy into the crucible having the first protective layer, and melting the highly reactive alloy to obtain a melted alloy having reduced carbon contamination.

Owner:GENERAL ELECTRIC CO

Methods for reducing carbon contamination when melting highly reactive alloys

InactiveUS7582133B2Reduce carbon pollutionMelt-holding vesselsCrucible furnacesCarbon contaminationAlloy

Methods for reducing carbon contamination when melting highly reactive alloys involving providing a graphite crucible having an interior, applying at least a first protective layer to the interior of the graphite crucible, placing a highly reactive alloy into the crucible having the first protective layer, and melting the highly reactive alloy to obtain a melted alloy having reduced carbon contamination.

Owner:GENERAL ELECTRIC CO

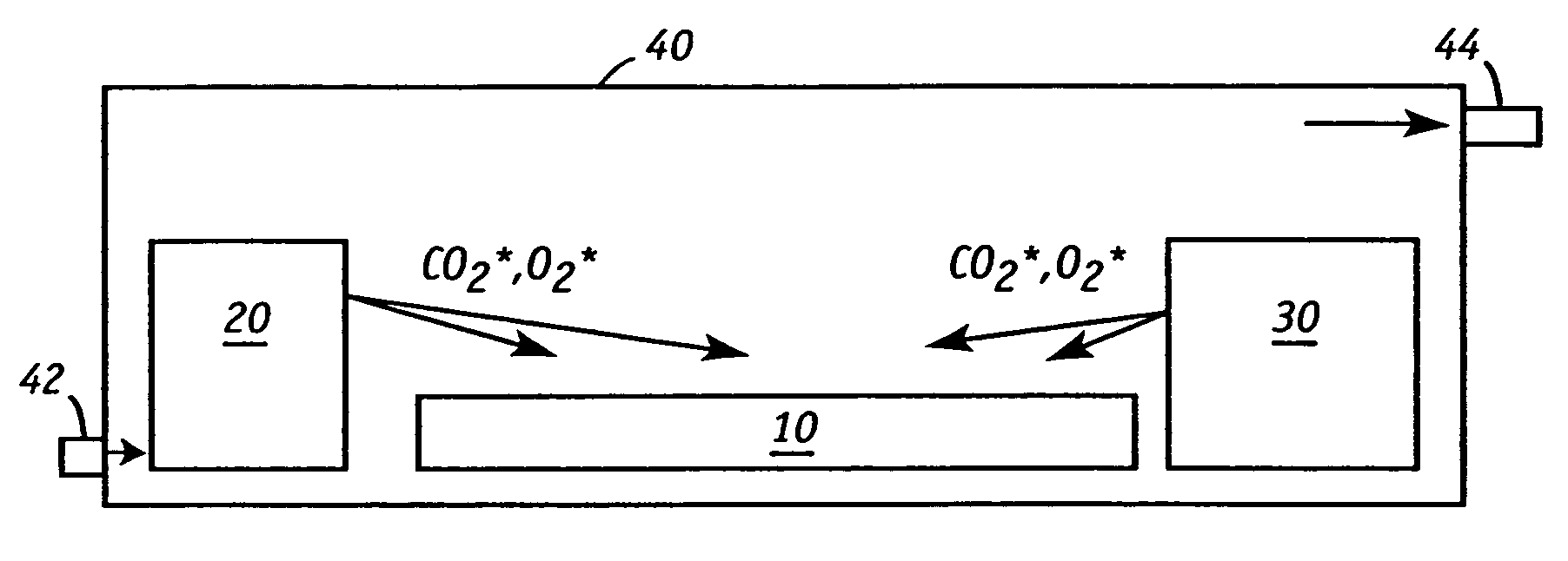

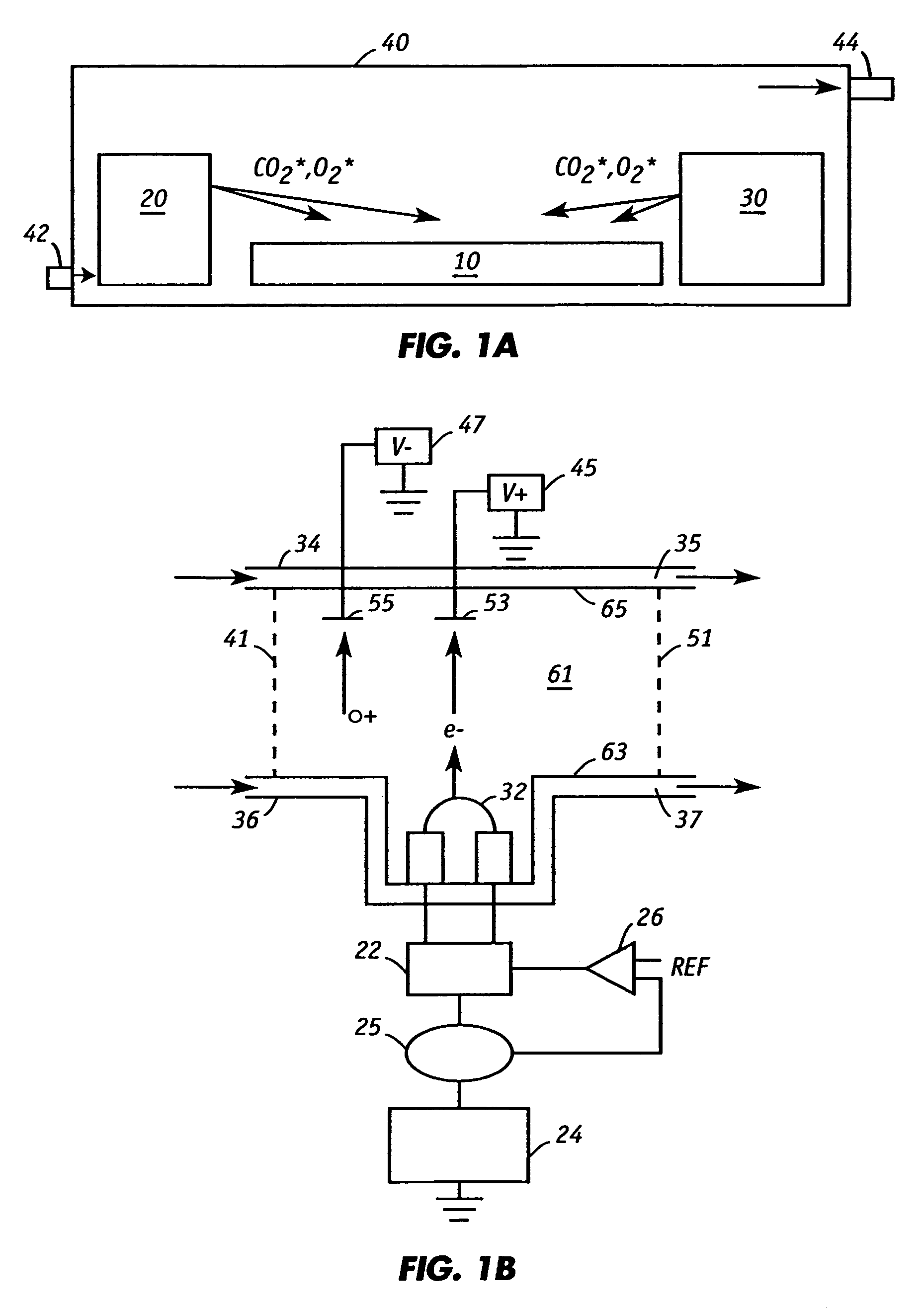

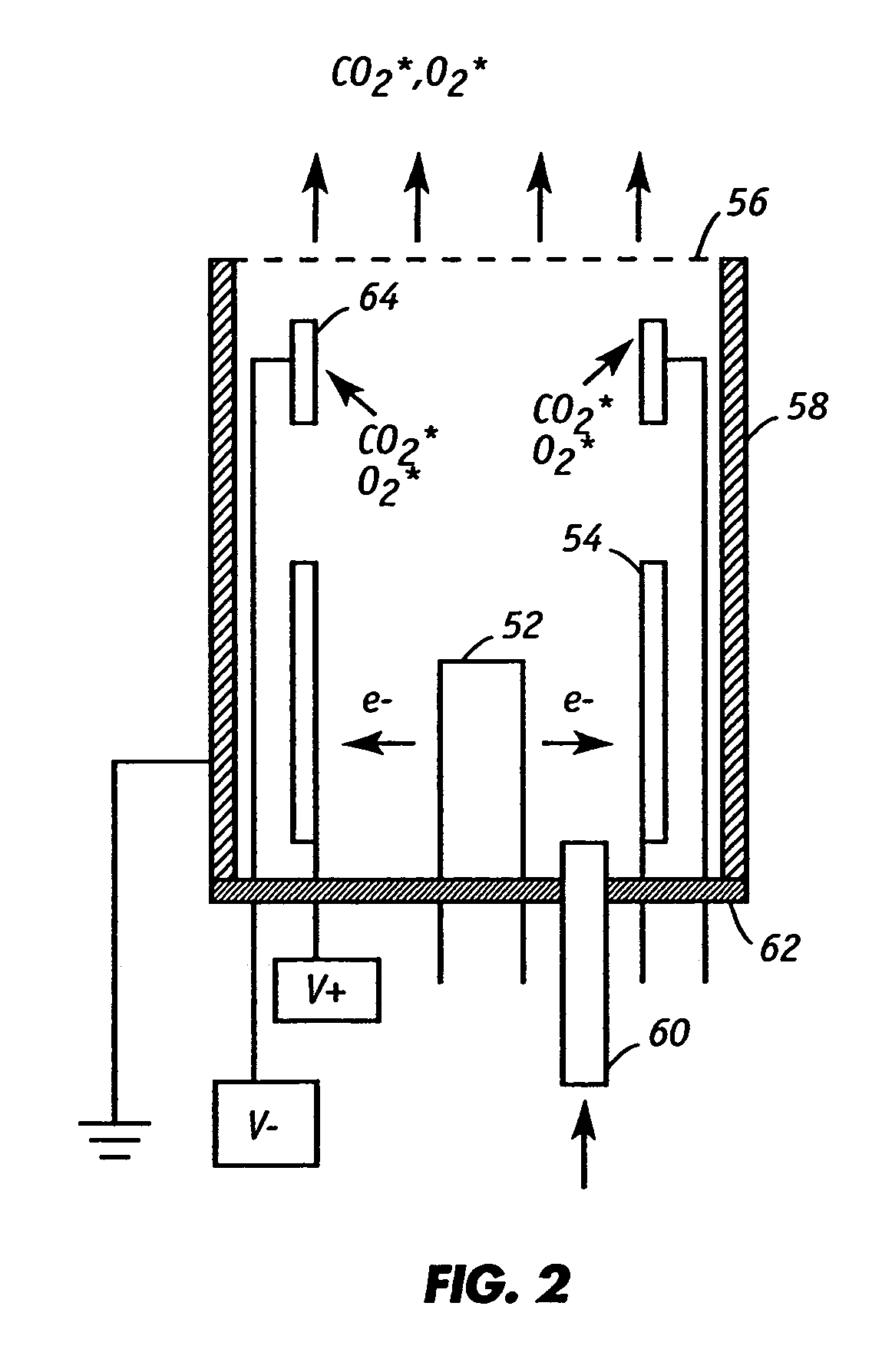

Method for in-situ cleaning of carbon contaminated surfaces

InactiveUS7147722B2Electric discharge tubesElectrostatic cleaningCarbon contaminationOptical surface

Activated gaseous species generated adjacent a carbon contaminated surface affords in-situ cleaning. A device for removing carbon contamination from a surface of the substrate includes (a) a housing defining a vacuum chamber in which the substrate is located; (b) a source of gaseous species; and (c) a source of electrons that are emitted to activate the gaseous species into activated gaseous species. The source of electrons preferably includes (i) a filament made of a material that generates thermionic electron emissions; (ii) a source of energy that is connected to the filament; and (iii) an electrode to which the emitted electrons are attracted. The device is particularly suited for photolithography systems with optic surfaces, e.g., mirrors, that are otherwise inaccessible unless the system is dismantled. A method of removing carbon contaminants from a substrate surface that is housed within a vacuum chamber is also disclosed. The method employs activated gaseous species that react with the carbon contaminants to form carbon containing gaseous byproducts.

Owner:EUV

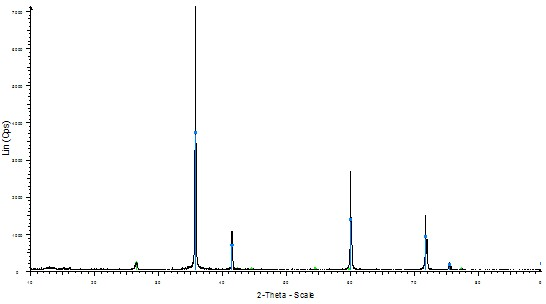

Carbon contamination-preventing coating of carbon material for polysilicon ingot furnace and preparation process thereof

ActiveCN102409405AAvoid pollutionImprove bindingPolycrystalline material growthSingle crystal growth detailsCarbon contaminationIngot

The invention relates to a carbon contamination-preventing coating of a carbon material for a polysilicon ingot furnace and a preparation process thereof. The component of the coating is silicon carbide, and the preparation process is in-situ growth on a carbon material surface through silicon-carbon interaction, and comprises the following steps: applying a uniformly-distributed silicon source on the carbon material surface, performing heat preservation at a high temperature to generate silicon-carbon interaction on the surface so as to form a silicon carbide layer in situ. The process of the invention can prepare a silicon carbide crystal coating which is dense and well combined with the carbon material, can effectively prevent contamination of the silicon material caused by carbon material temperature-resistant structural members during the production process of a polysilicon ingot furnace, and reduce the carbon content of the polysilicon ingot furnace.

Owner:江西硅辰科技有限公司

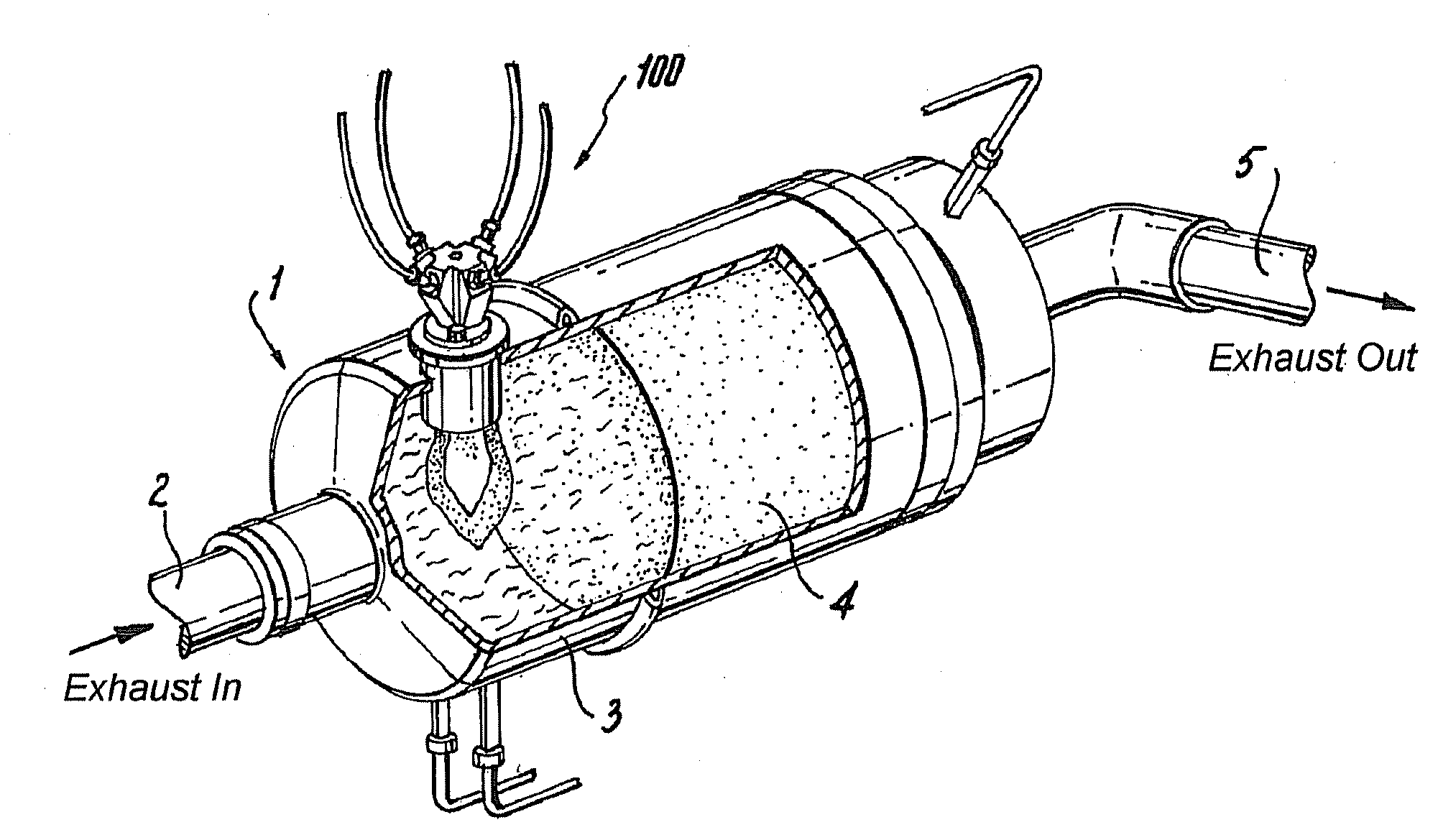

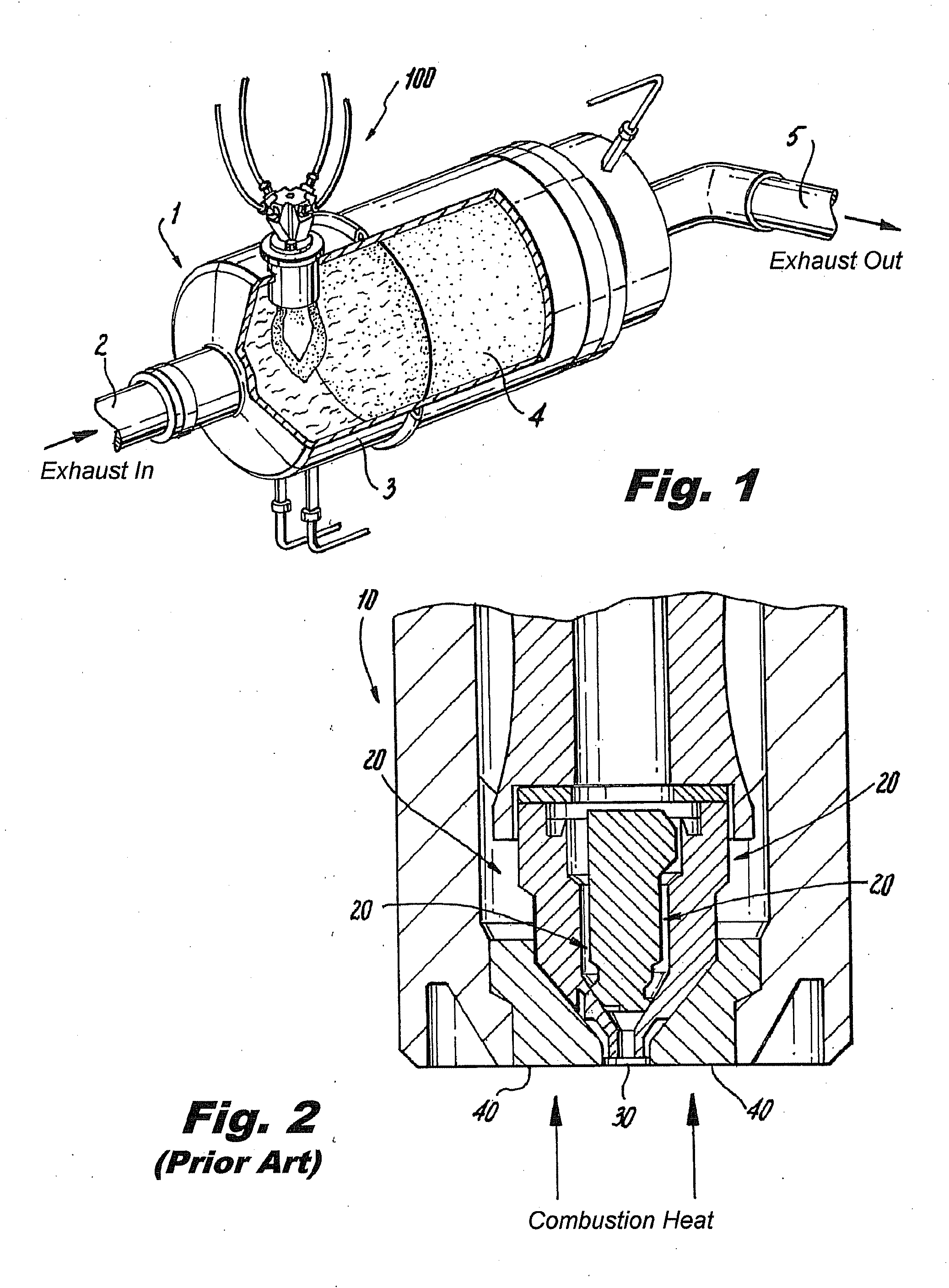

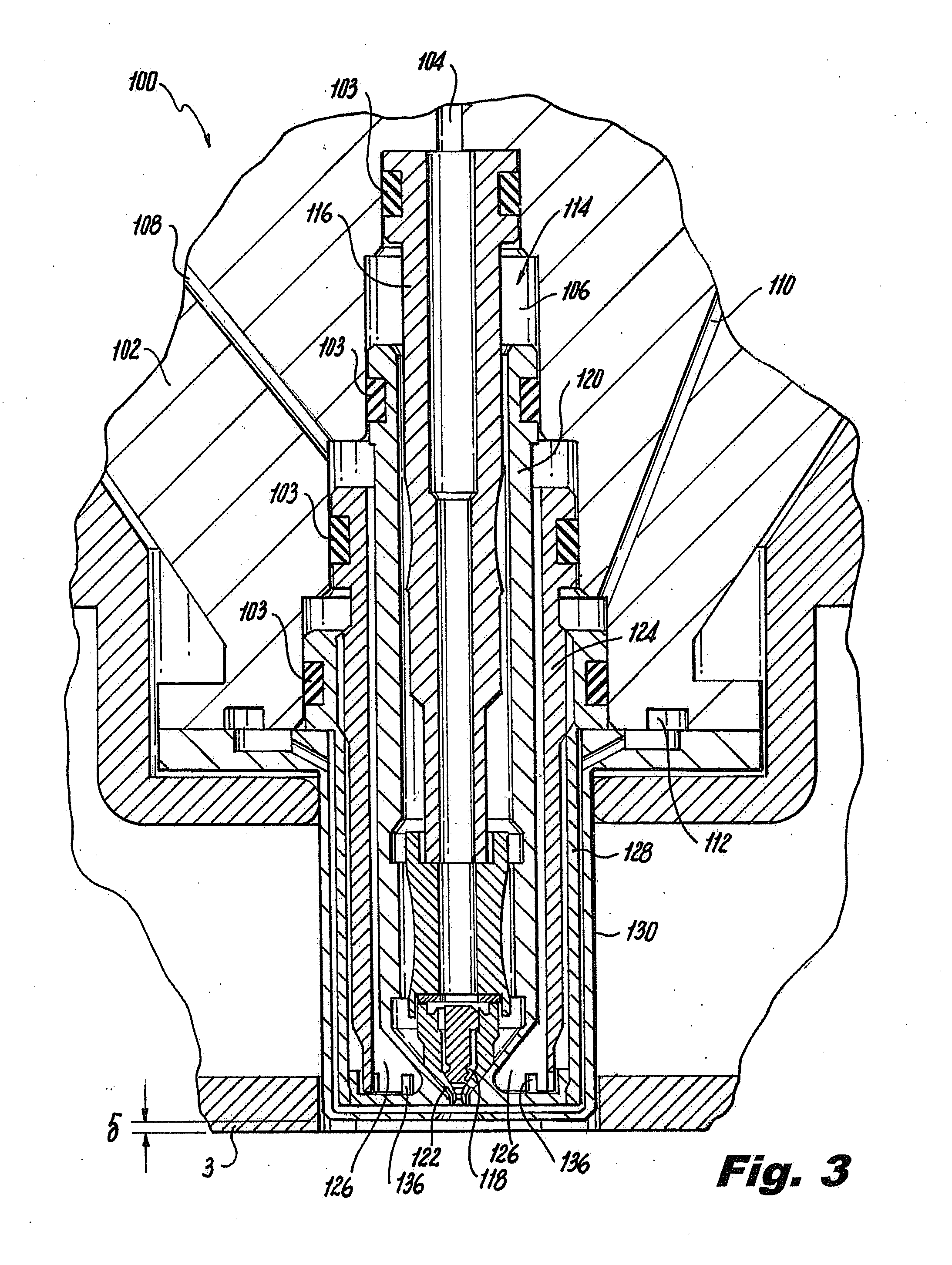

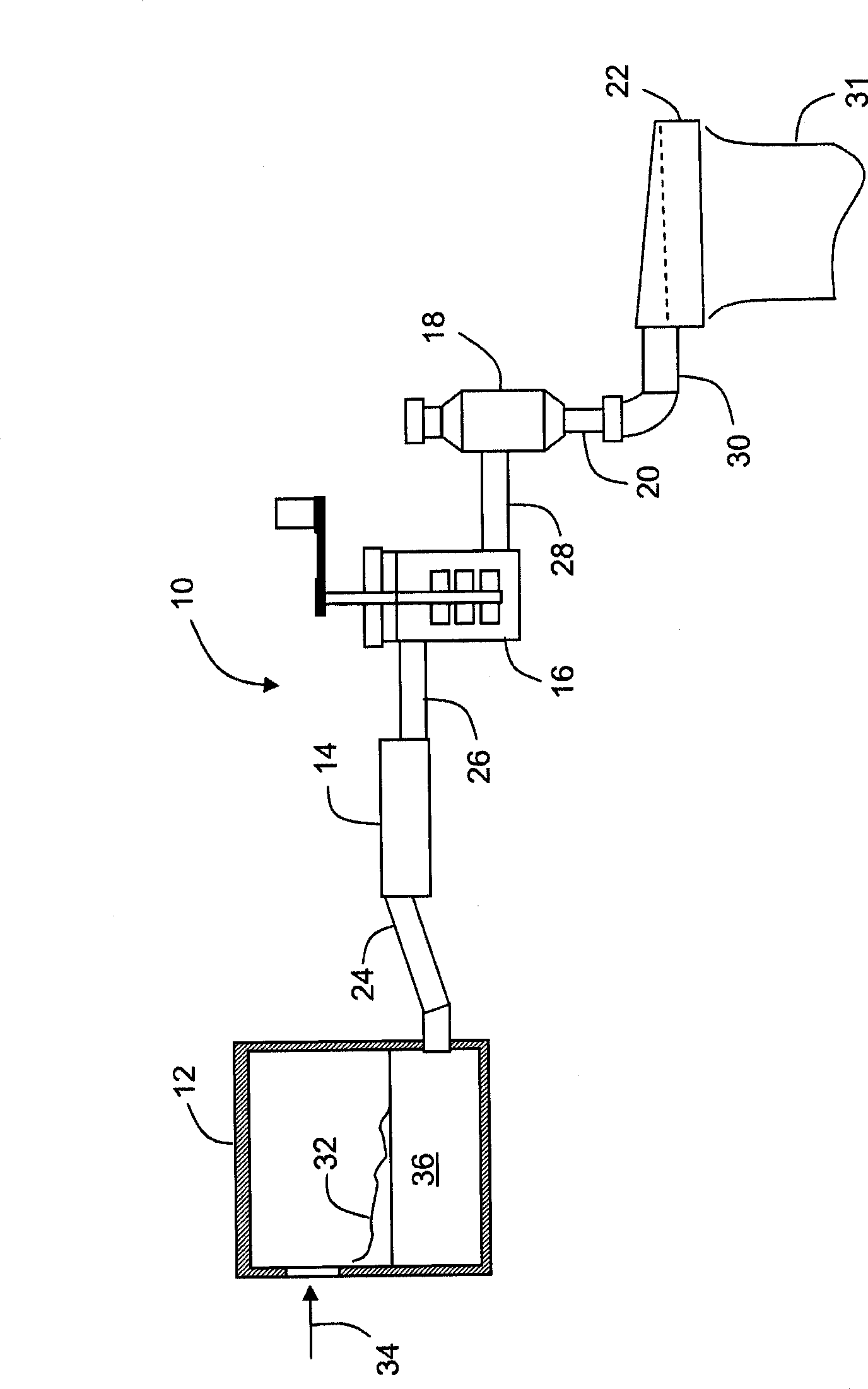

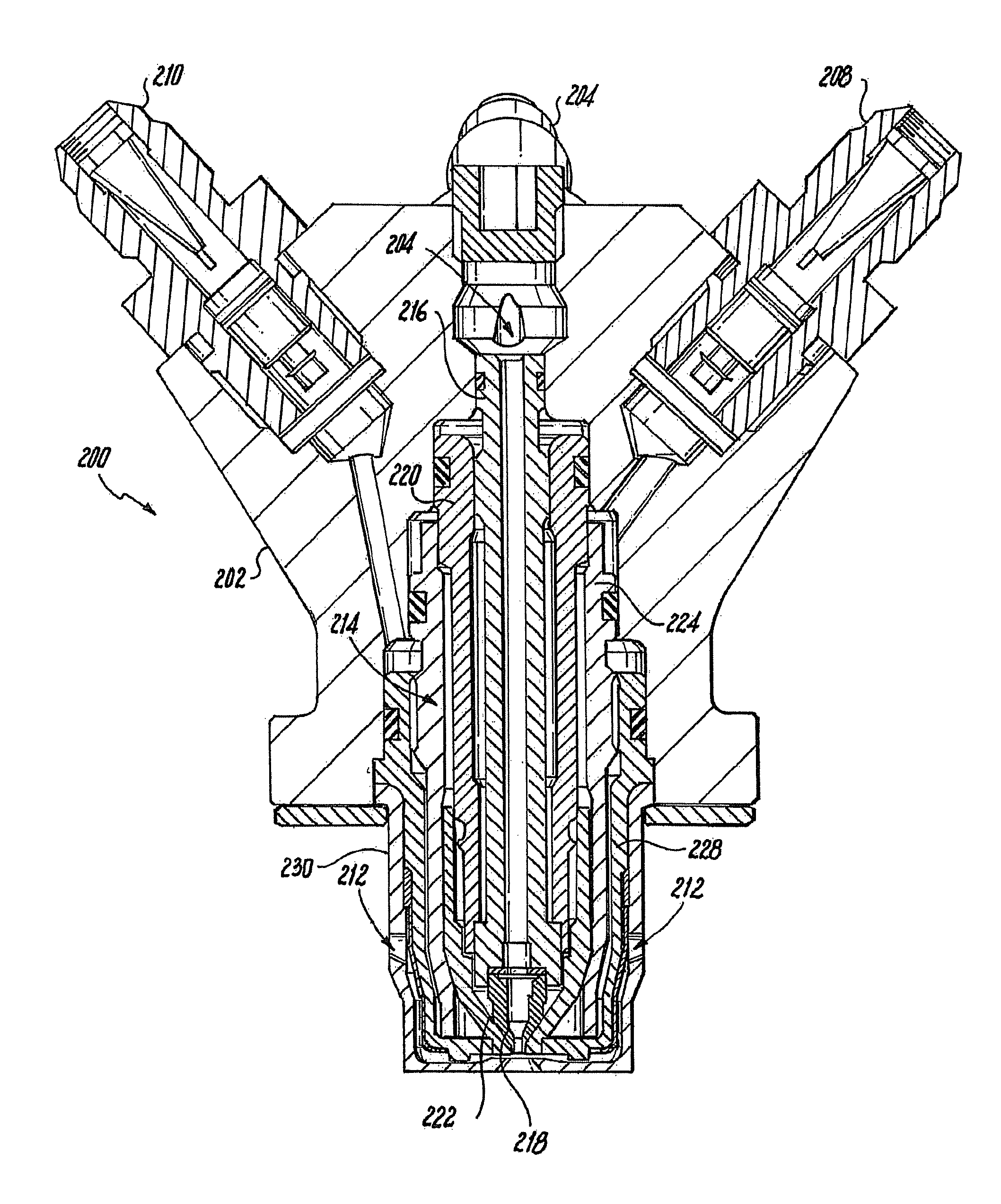

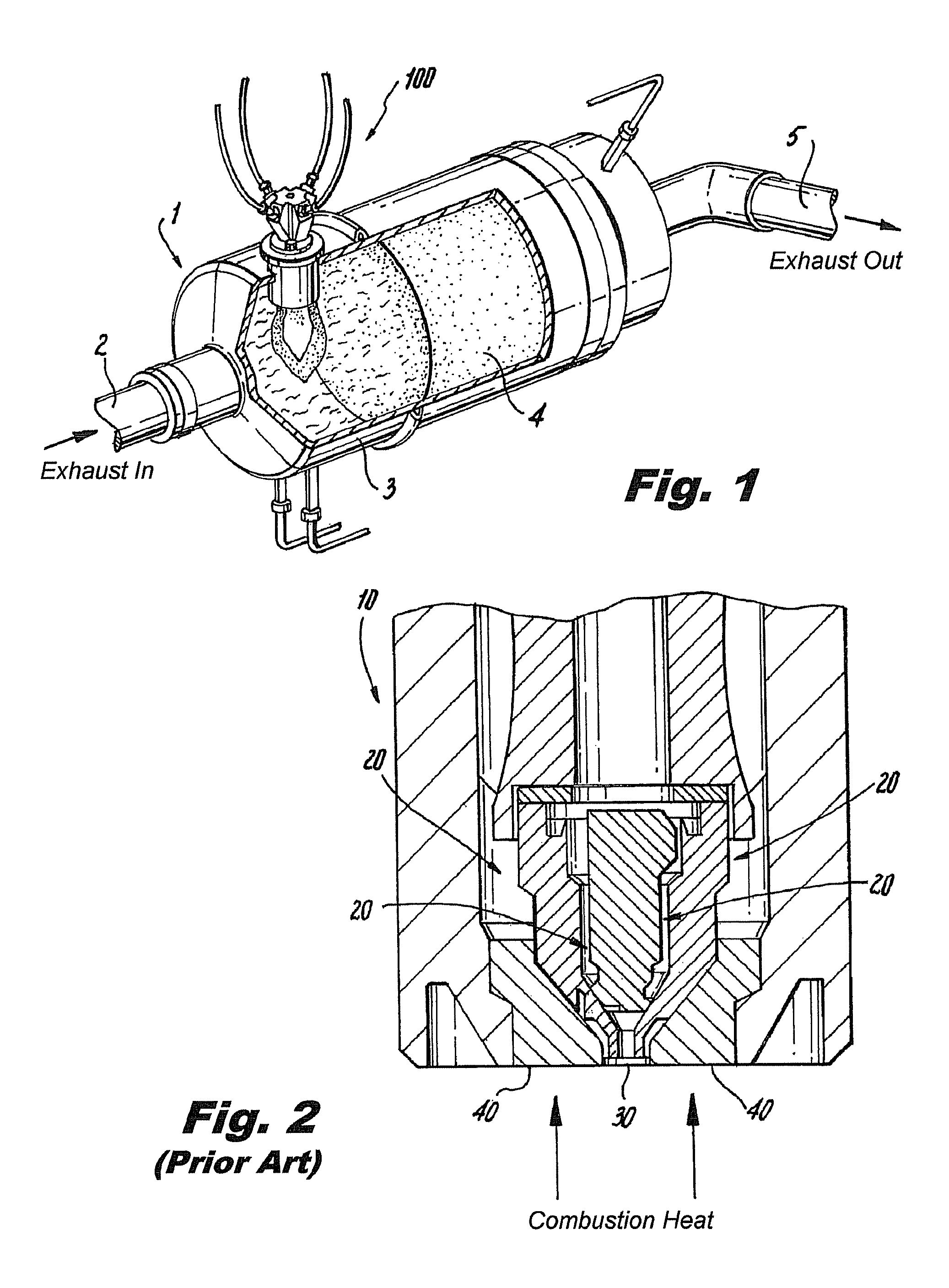

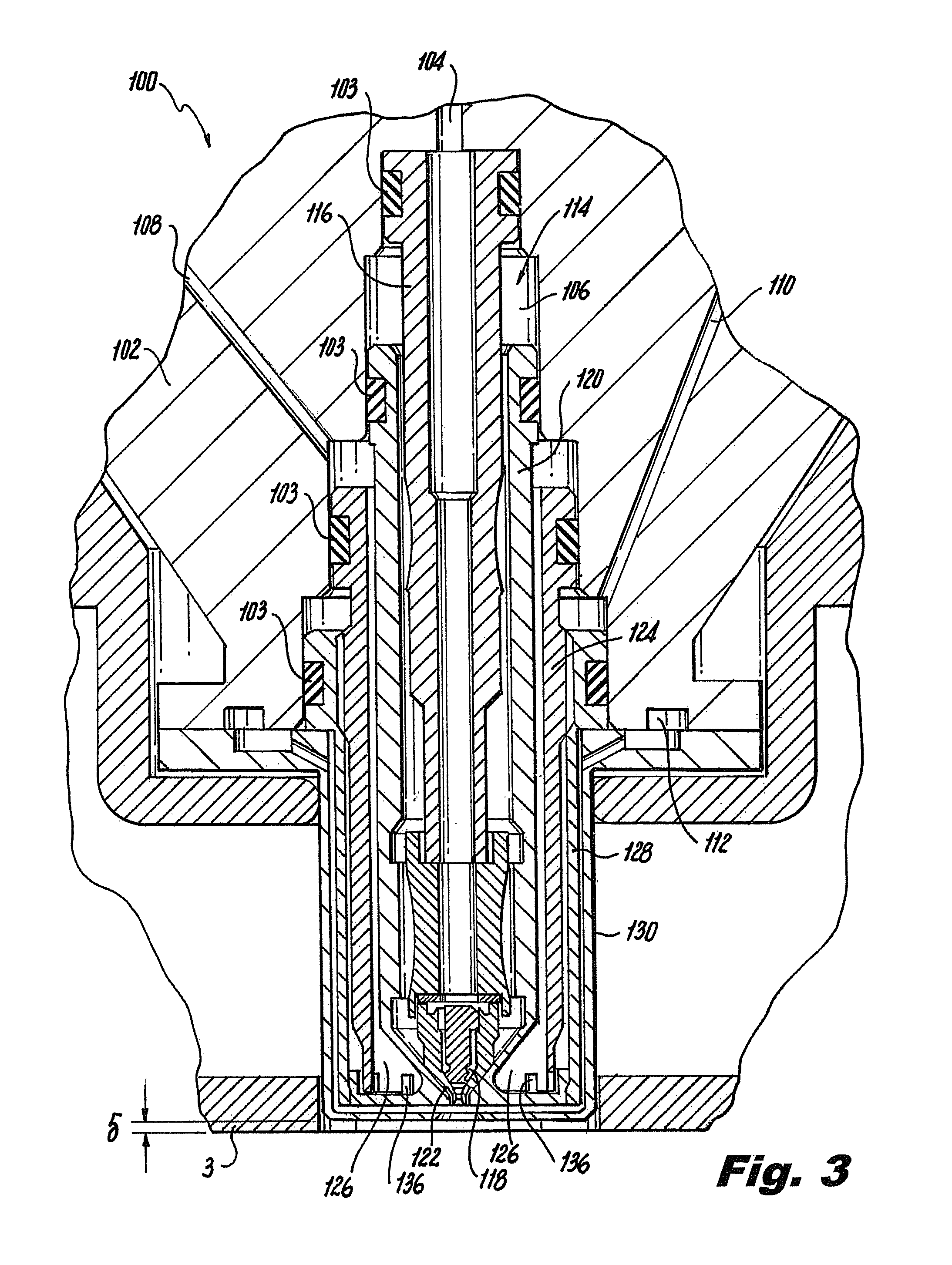

Carbon contamination resistant pressure atomizing nozzles

ActiveUS20120074243A1Reduce carbon depositionInternal combustion piston enginesExhaust apparatusInterior spaceAtomizer nozzle

A pressure atomizing nozzle for injecting fuel includes an inlet housing configured to thermally isolate the interior space from external conditions and to remain relatively cool under operation so as to substantially eliminate heat soak back from the inlet housing to the interior space thereof after operation. First and second coolant conduits cool the nozzle tip region actively during operation and passively after operation. A cooling air jacket is configured to thermally isolate inboard components from exterior conditions, to provide clean air during operation to the nozzle tip region for diluting carbon to reduce carbon deposits in the nozzle tip region and for cooling the same, and to provide passive cooling to the nozzle tip region after operation.

Owner:COLLINS ENGINE NOZZLES INC

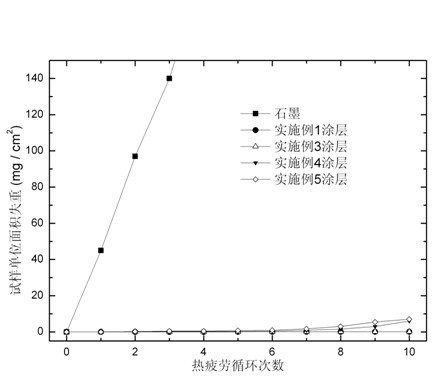

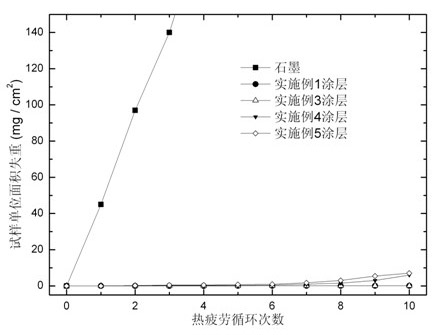

Composite carbon-resisting coat and method for preparing the same on substrate

The present invention discloses a composite carbon-blocking coating material and a method for preparing a composite carbon-blocking coating on the substrate, the composite carbon-blocking coating material is composed of a transition layer and a carbon-blocking layer, the transition layer is SiC or Mo material and the carbon-blocking layer is Y2O3 material. The thickness of the transition layer is 40-120 mu m, and the thickness of the carbon-blocking layer is 100-250 mu m. The graphite crucible which is prepared with SiC-Y2O3 or Mo-Y2O3 composite carbon-blocking coating is smelted in the vacuum inducing smelting furnace for preparing the Ti-base alloy, when the smelting temperature gets to 1700-1750 DEG C the chemical reaction between the carbon element and Ti active metal in the graphite crucible is effectively prevented, the carbon pollution is avoided and the purity of the material being smelted is increased.

Owner:BEIHANG UNIV

Compound separated carbon coating used for polysilicon ingot furnace, preparation method, graphite plate and polysilicon ingot furnace

ActiveCN105112995AEliminate sources of pollutionEliminate generationPolycrystalline material growthSingle crystal growth detailsCarbon coatingSilicon oxide

The present invention discloses a compound separated carbon coating used for a polysilicon ingot furnace, and the compound separated carbon coating is used to coat the surface of a carbon material device inside an ingot furnace to prevent carbon contamination.The compound separated carbon coating is characterized by comprising a first coating which coats on the surface of the carbon material device and is made of metallic tungsten or metallic molybdenum and a second coating which coats on the first coating; the second coating is a silicon nitride layer or a laminated layer of the silicon nitride layer and a silicon oxide layer; the thickness of the first coating is 0.02-300 microns and the thickness of the second coating is 0.02-300 microns. The present invention also discloses a preparation method for the compound separated carbon coating; meanwhile, the present invention also discloses a graphite plate comprising the compound separated carbon coating and a polysilicon ingot furnace. According to the present invention, the compound separated carbon coating coats on the surface of the carbon material device inside the polysilicon ingot furnace to eliminate production of carbon monoxide, thereby lowering impurities in ingot polysilicon and impurity derivation dislocation, and improving quality of crystals so as to further improve transformation efficiency of a solar cell.

Owner:TRINASOLAR CO LTD +1

Method for preparing nickel-tungsten bimetallic carbide catalyst by organic-inorganic hybrid route and application of nickel-tungsten bimetallic carbide catalyst

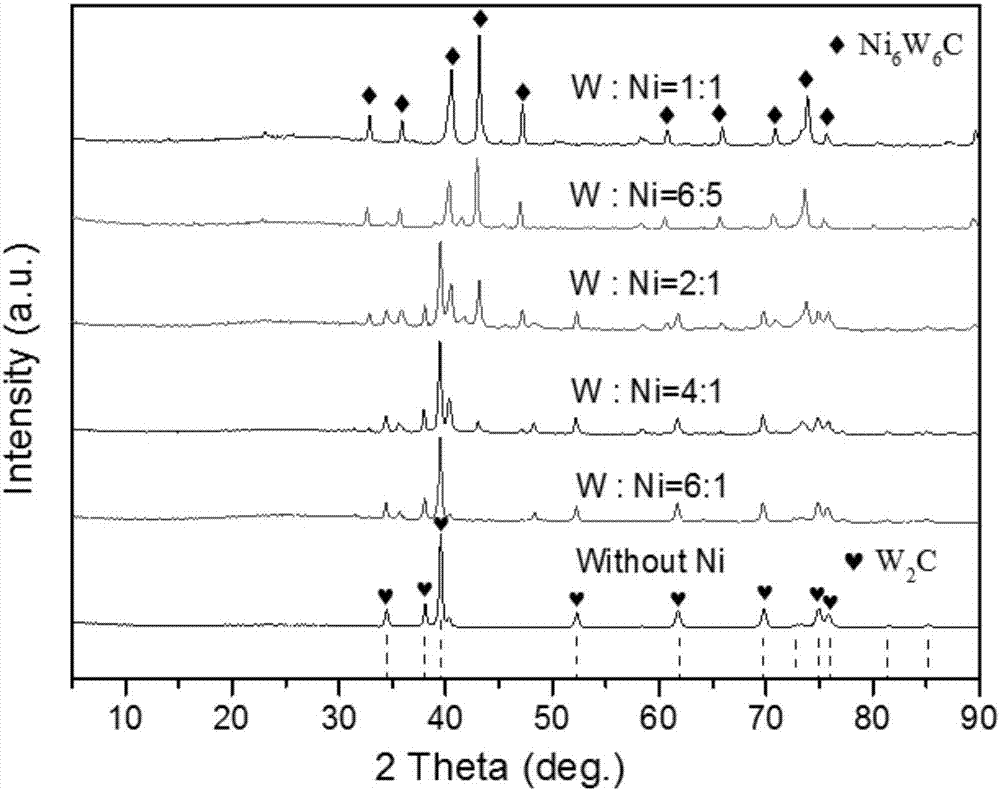

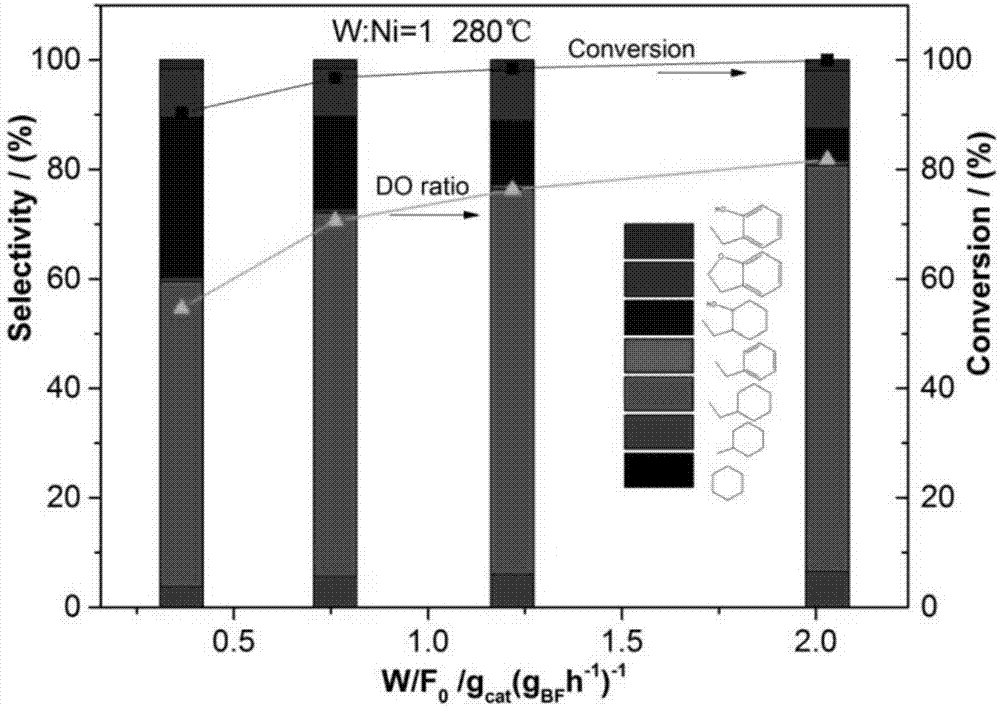

ActiveCN107511159AEasy to operateEnergy-saving product granulesChemical industryCatalyst activation/preparationDeoxygenationTungsten

The invention discloses a method for preparing a nickel-tungsten bimetallic carbide catalyst by an organic-inorganic hybrid route and application of the nickel-tungsten bimetallic carbide catalyst, and belongs to the technical field of material preparation and application. The method is characterized in that pure phase Ni6W6C and W2C and Ni6W6C composite materials with different Ni contents are synthesized by the organic-inorganic hybrid route and both exhibit a nano-particle stacking and aggregation form with a length of about 0.3-4 mu m and a diameter of about 300-900 nm. The BET specific surface area of the nickel-tungsten bimetallic carbide ranges from 17.6 m<2> / g to 15.7 m<2> / g. Compared with the traditional arc melting method and temperature programmed reduction method, the method provided by the invention has the advantages of low temperature, simple operation, energy saving, small product particles and less surface carbon pollution. The industrial application prospect is optimistic, the prepared bimetallic carbide catalyst can be applied to hydrogenation, hydrogenolysis, dehydrogenation, deoxygenation, isomerization, methane syngas, water-gas shift, hydrogen evolution reaction and catalyst support and the like.

Owner:DALIAN UNIV OF TECH

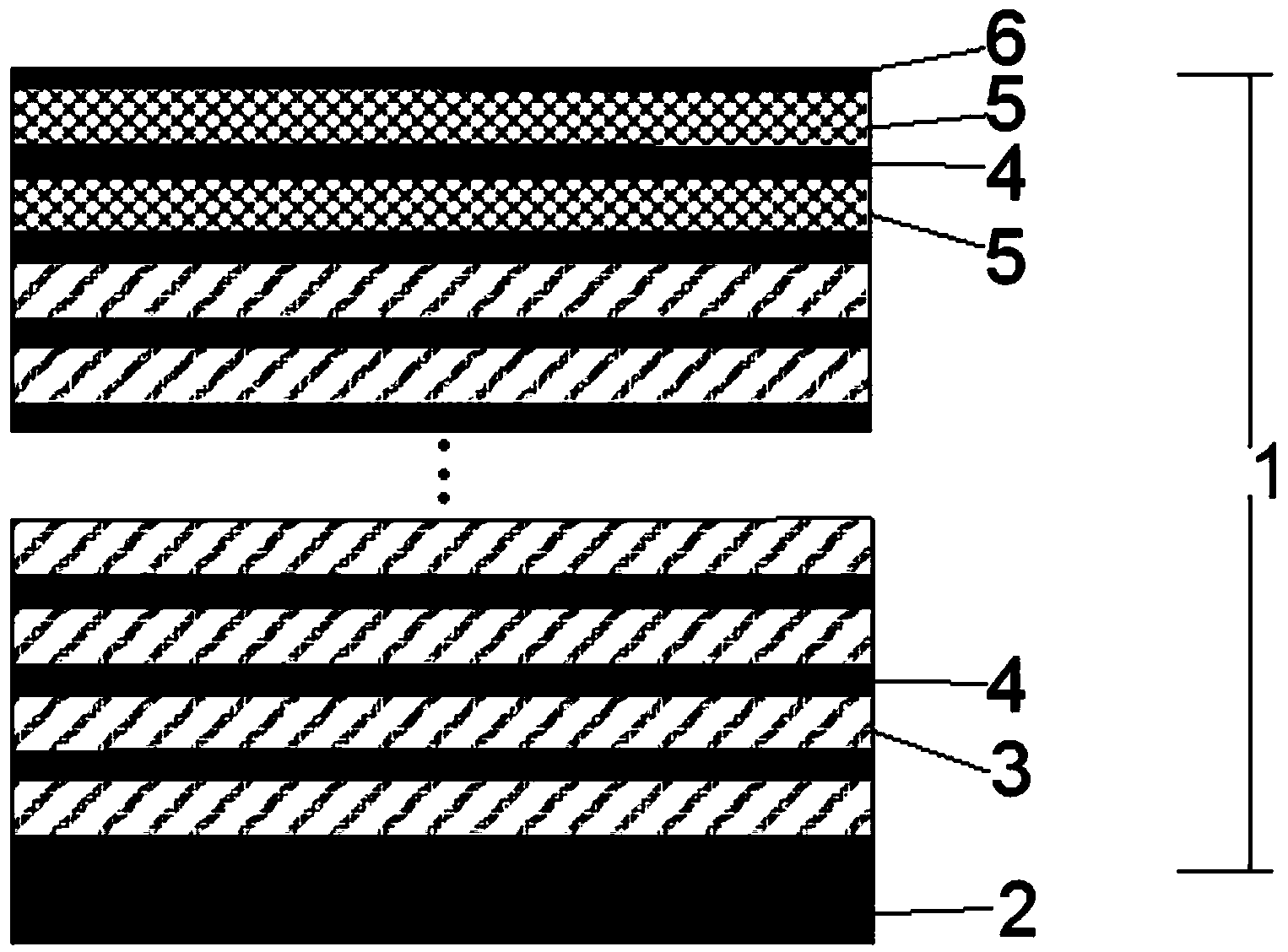

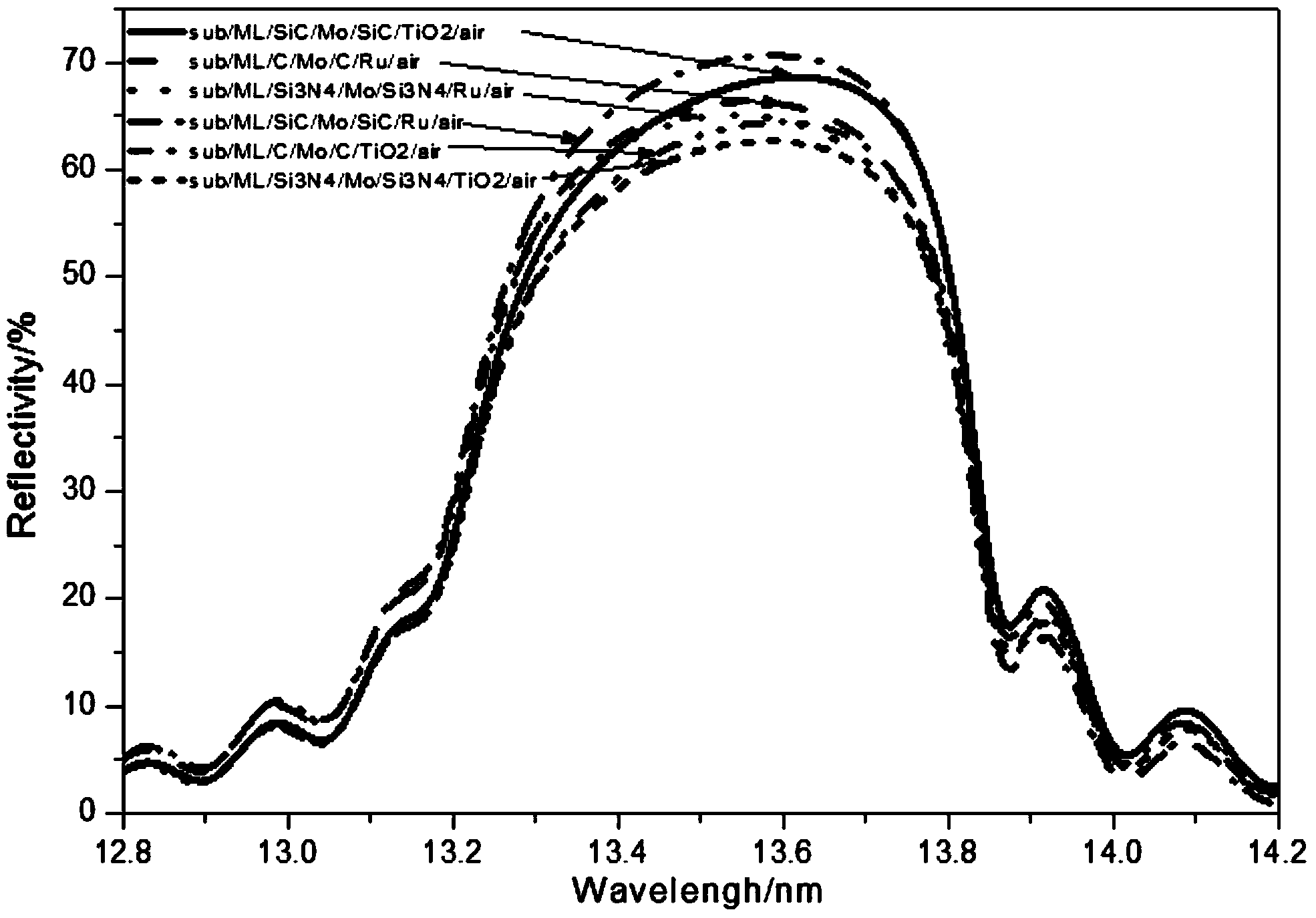

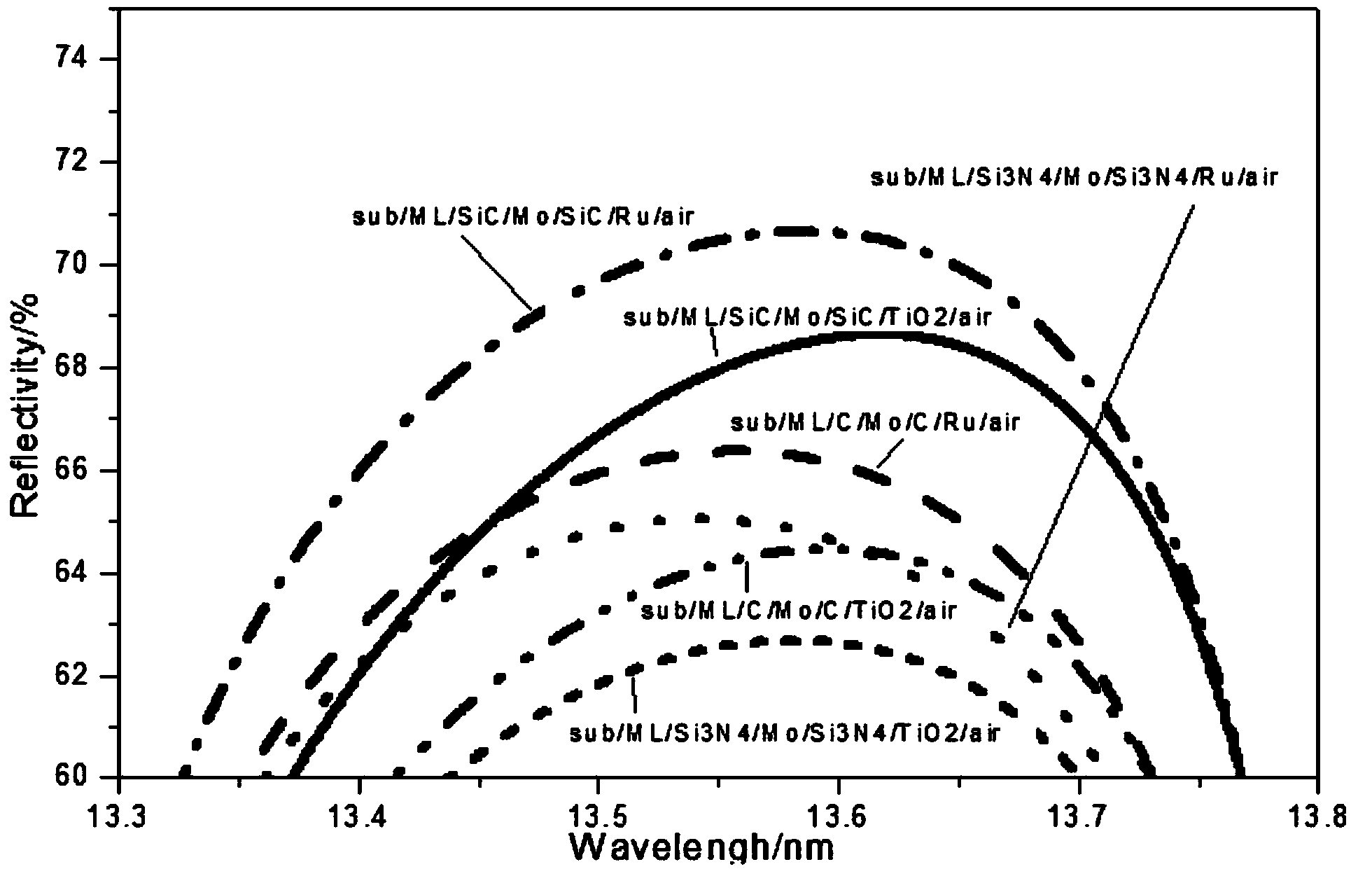

Multilayer film improving extreme ultraviolet spectral purity and oxidation resistance

The invention relates to a multilayer film improving extreme ultraviolet spectral purity and oxidation resistance, and belongs to the field of extreme ultraviolet lithography. On the premise that the small reflectivity loss of the 13.5 nm position of the multilayer film is ensured, the reflectivity of an out-of-band wave band, oxidation of the multilayer film and surface layer carbon contamination sedimentation are effectively restrained. The multilayer film sequentially comprises a substrate, multiple layer periods of Si layers / Mo layers, a spectrum purification layer, a Mo layer, a spectrum purification layer and a protection layer. On the basis of not changing the appearance of a film system, not increasing the number of optical elements and not adding extra machining steps, the spectrum purification layer and the protection layer are manufactured; under the condition that the reflectivity loss can be omitted, the imaging quality and the photoetching quality of a photoetching system are improved by restraining the out-of-band wave band, the oxidation of reflection layers and the sedimentation of carbon-contaminated layers.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

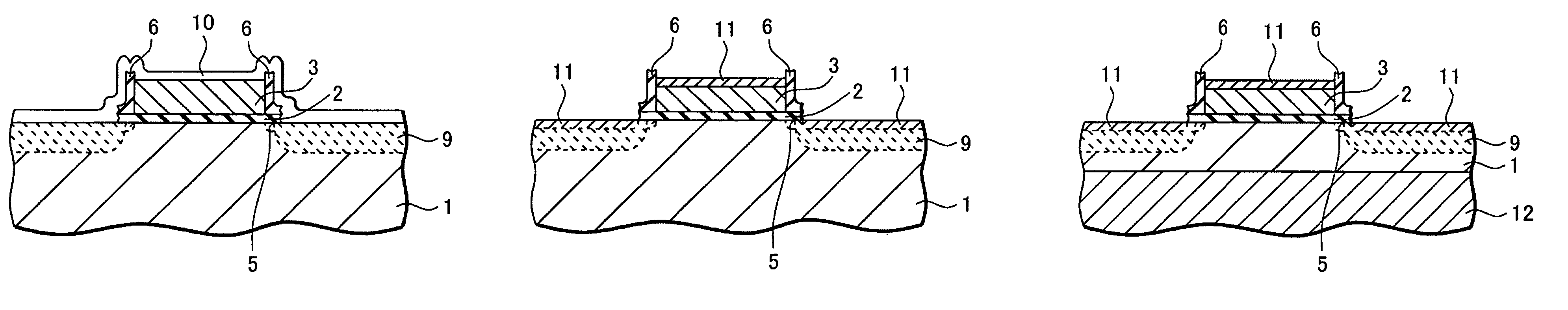

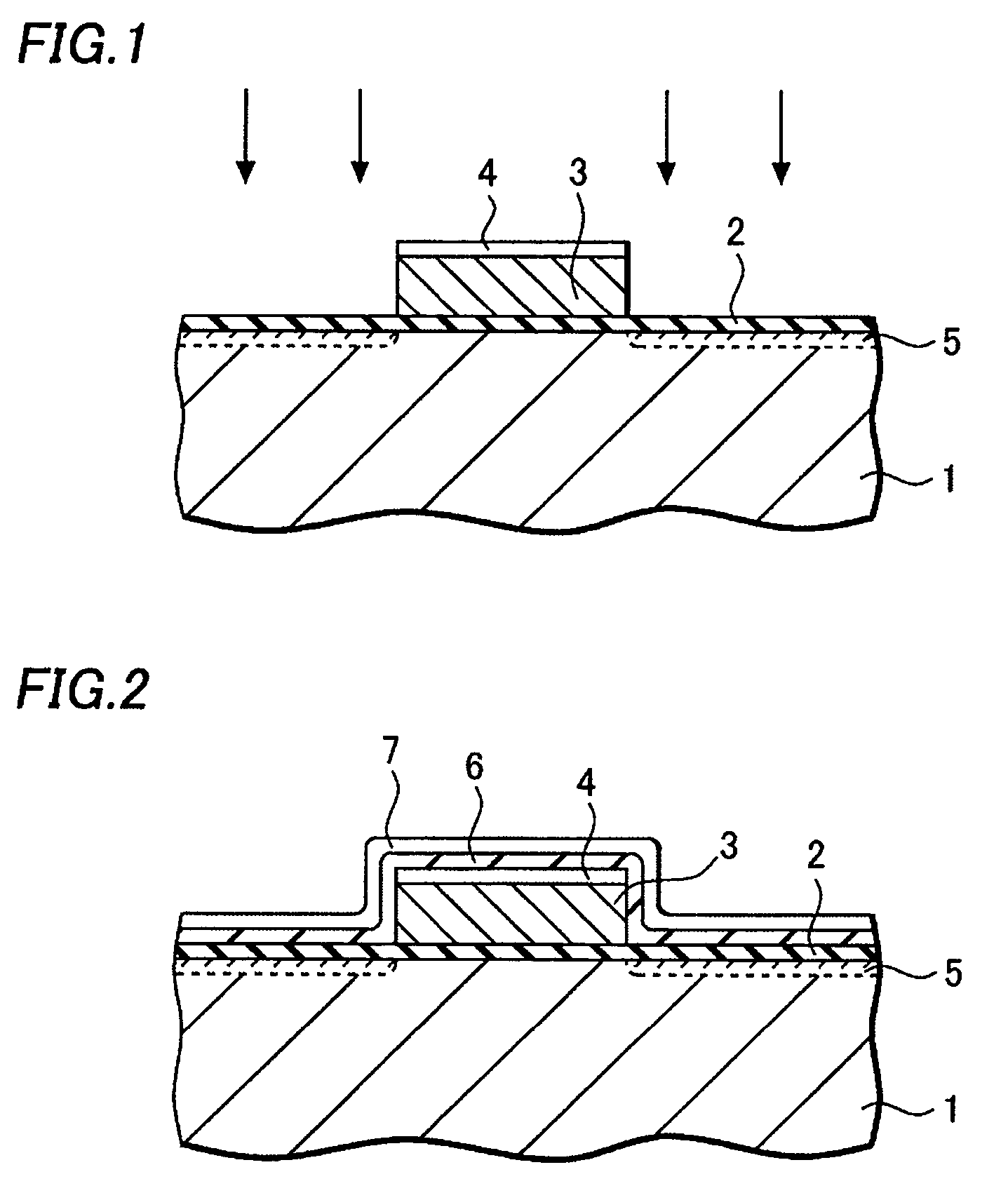

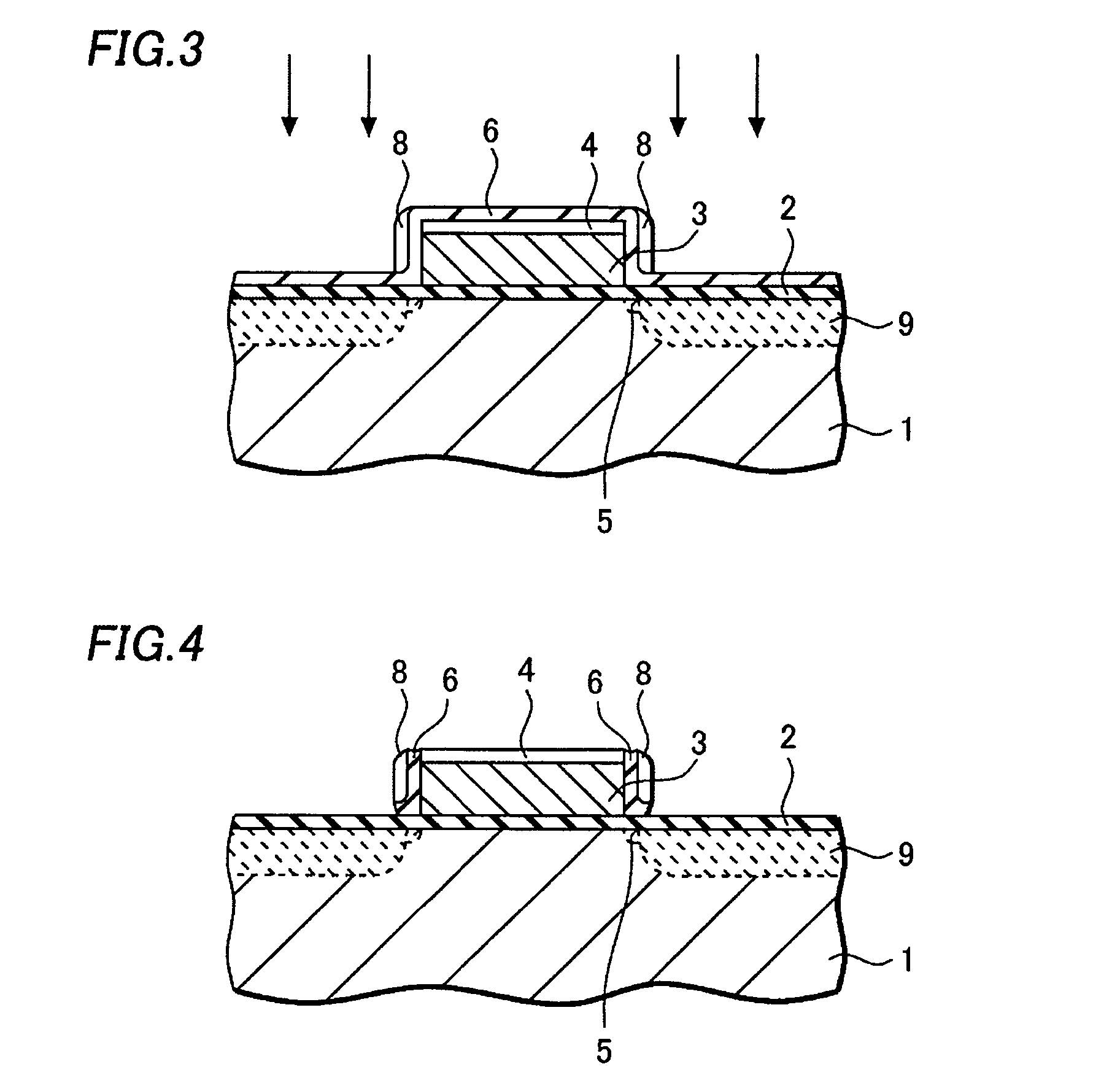

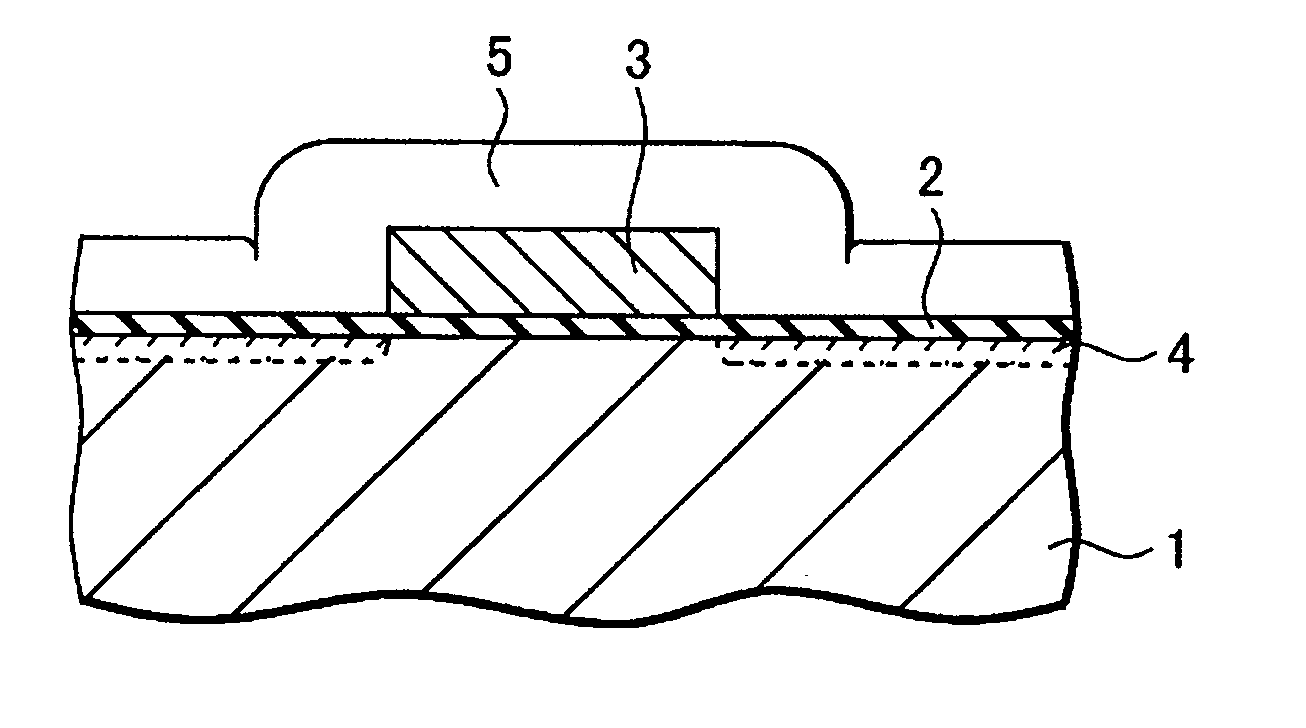

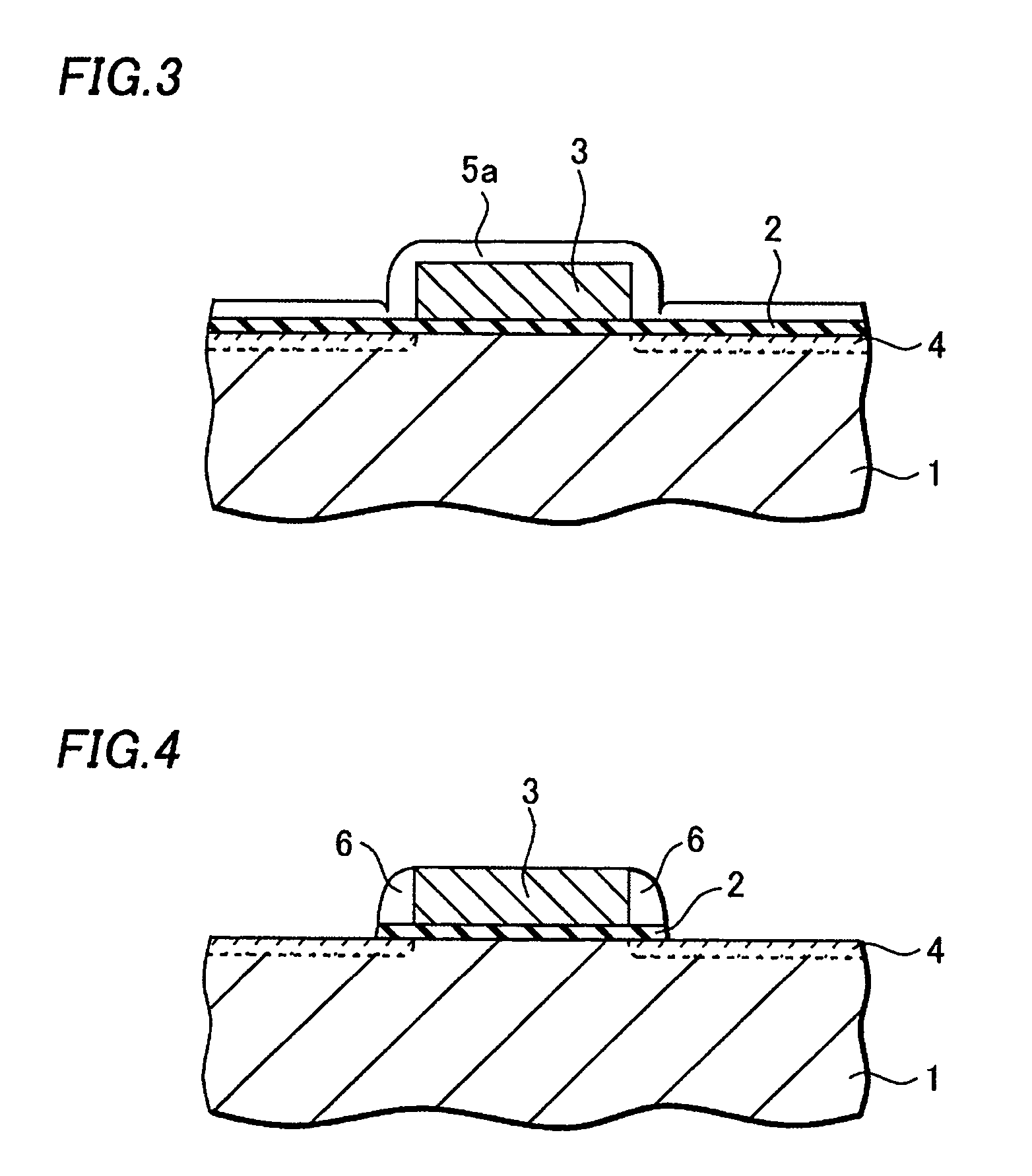

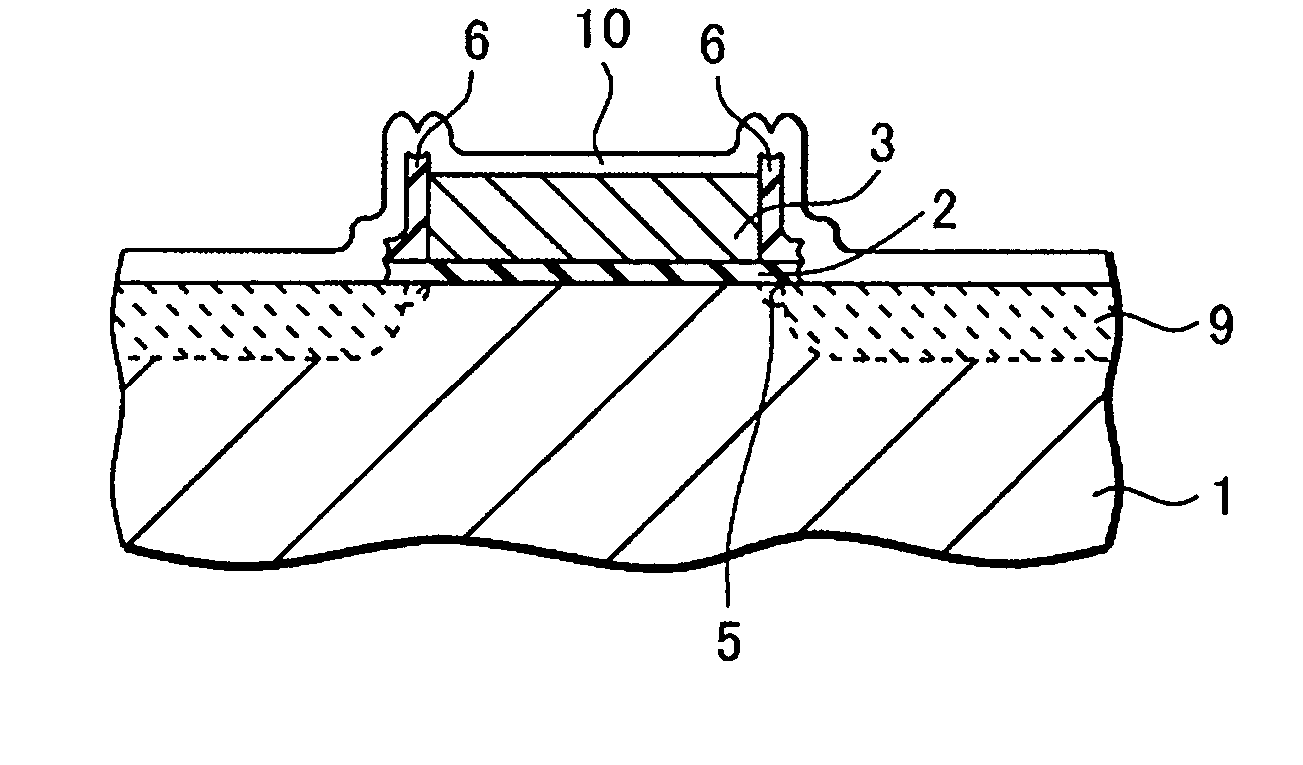

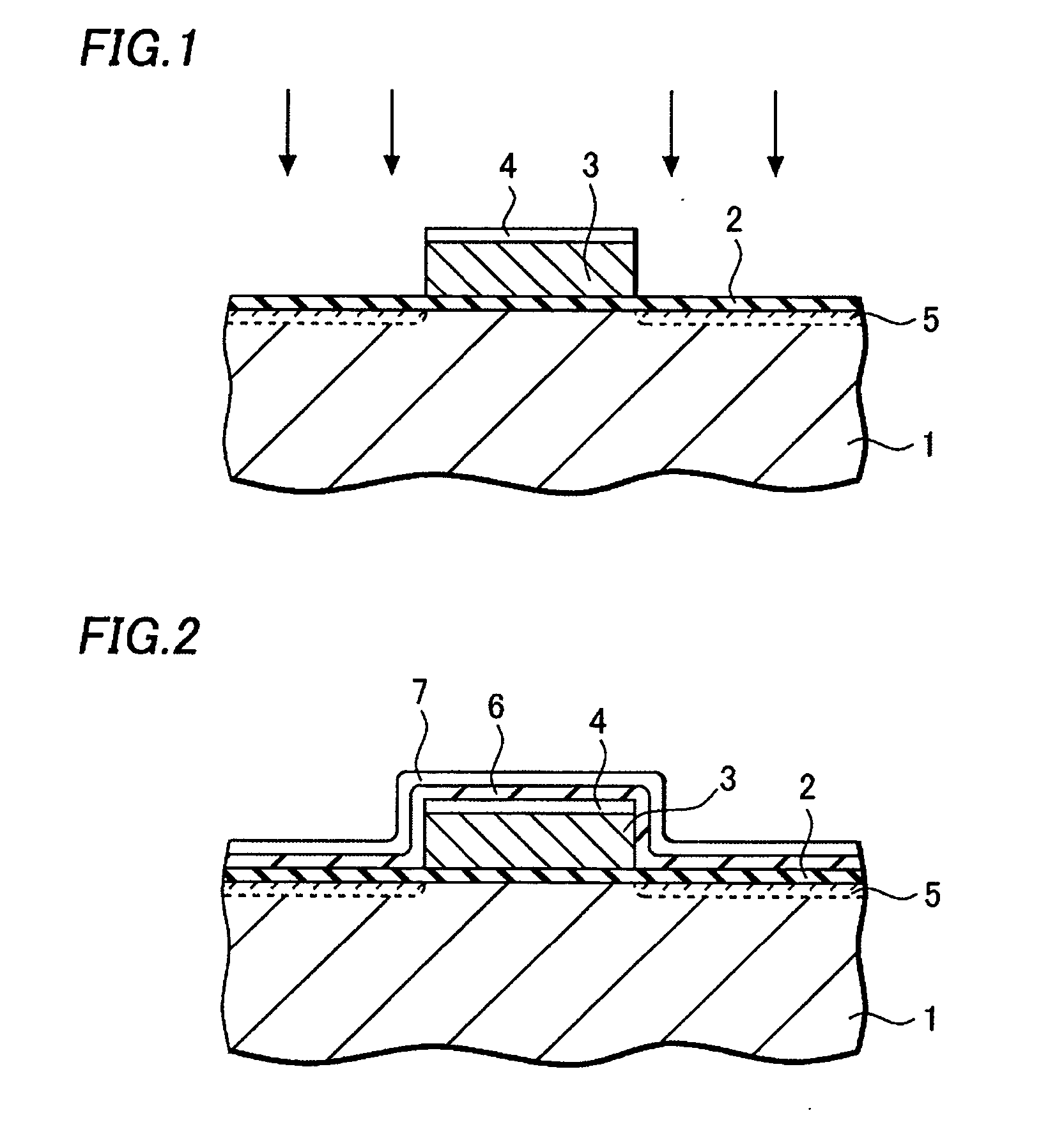

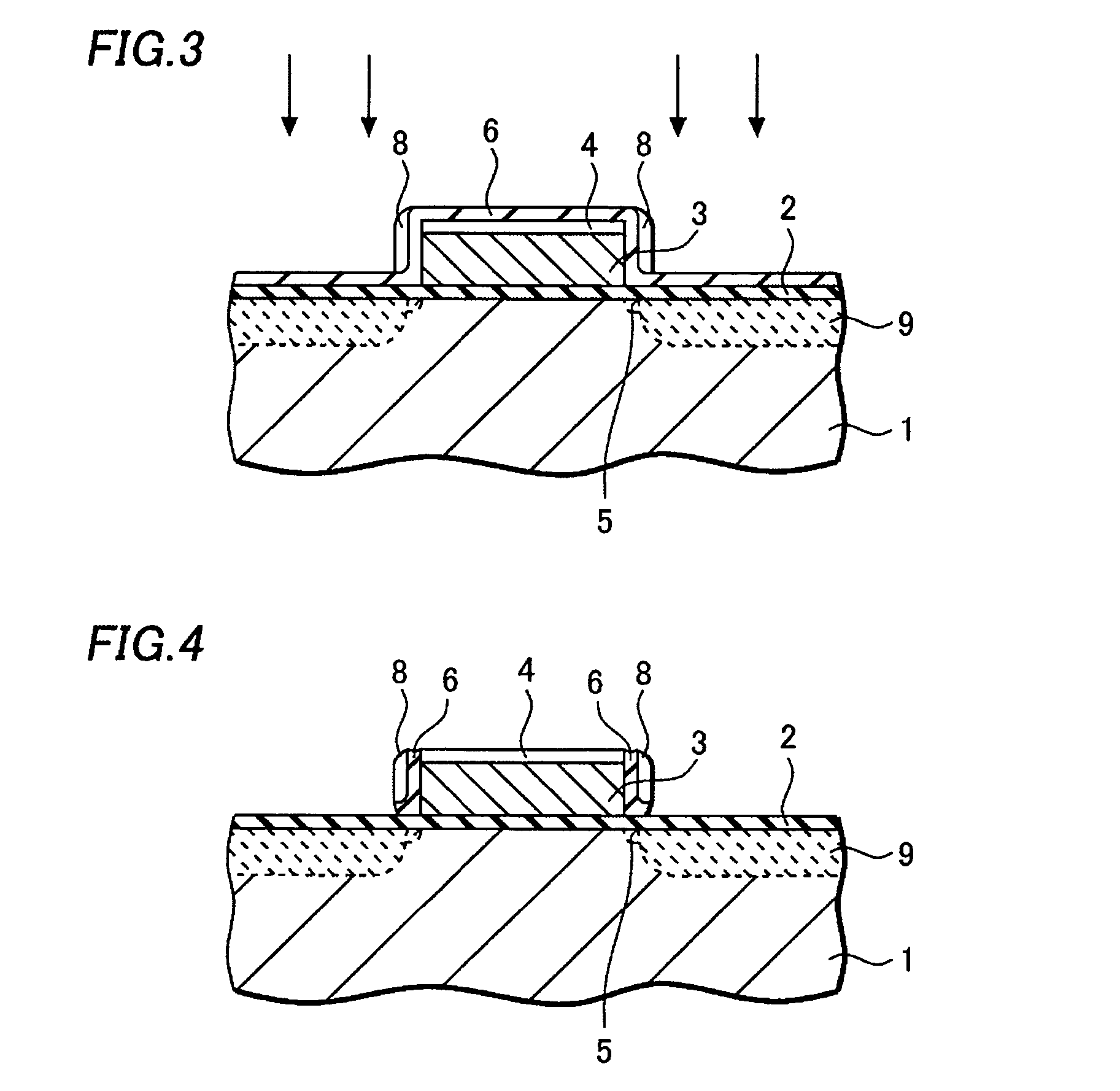

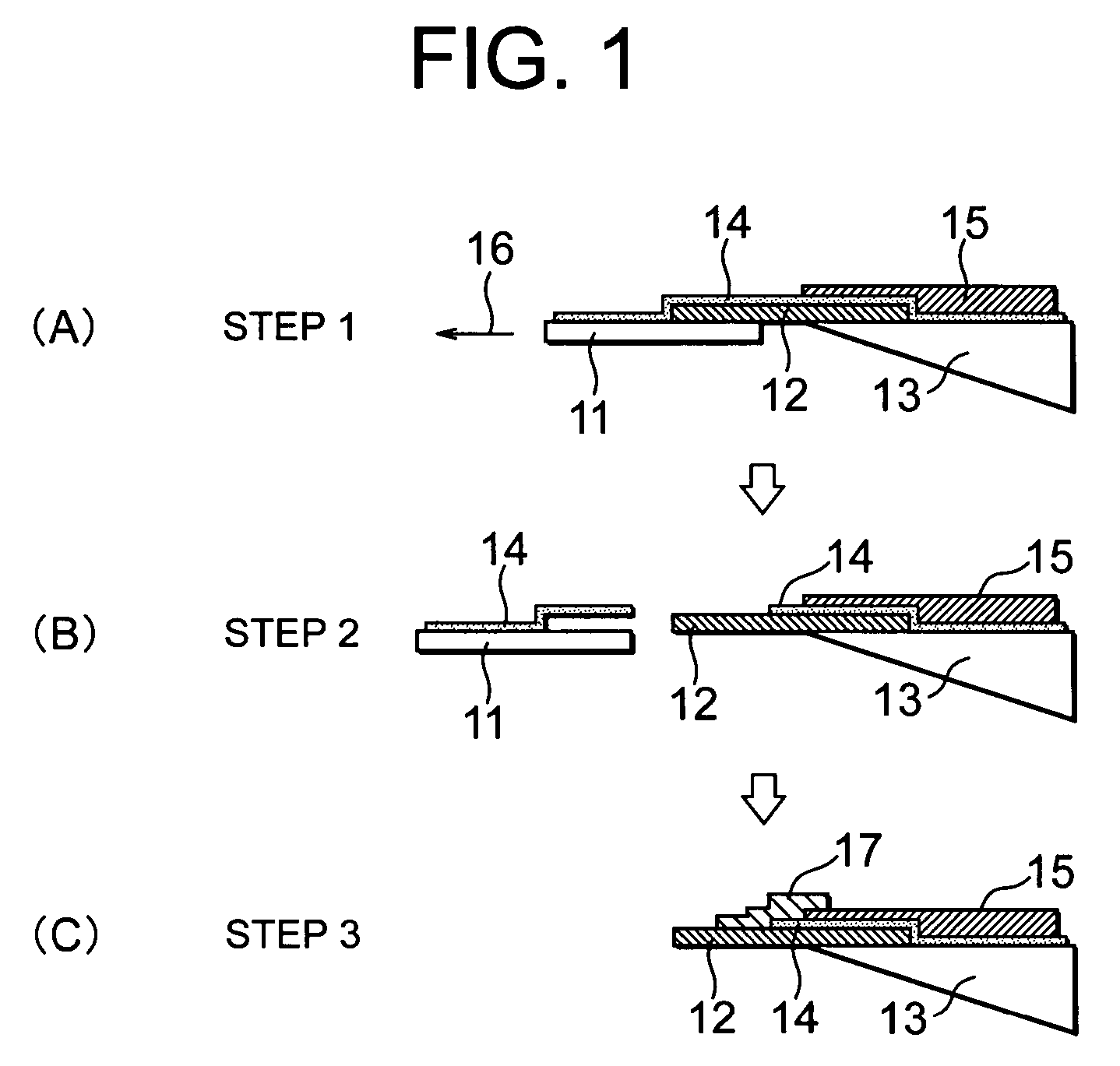

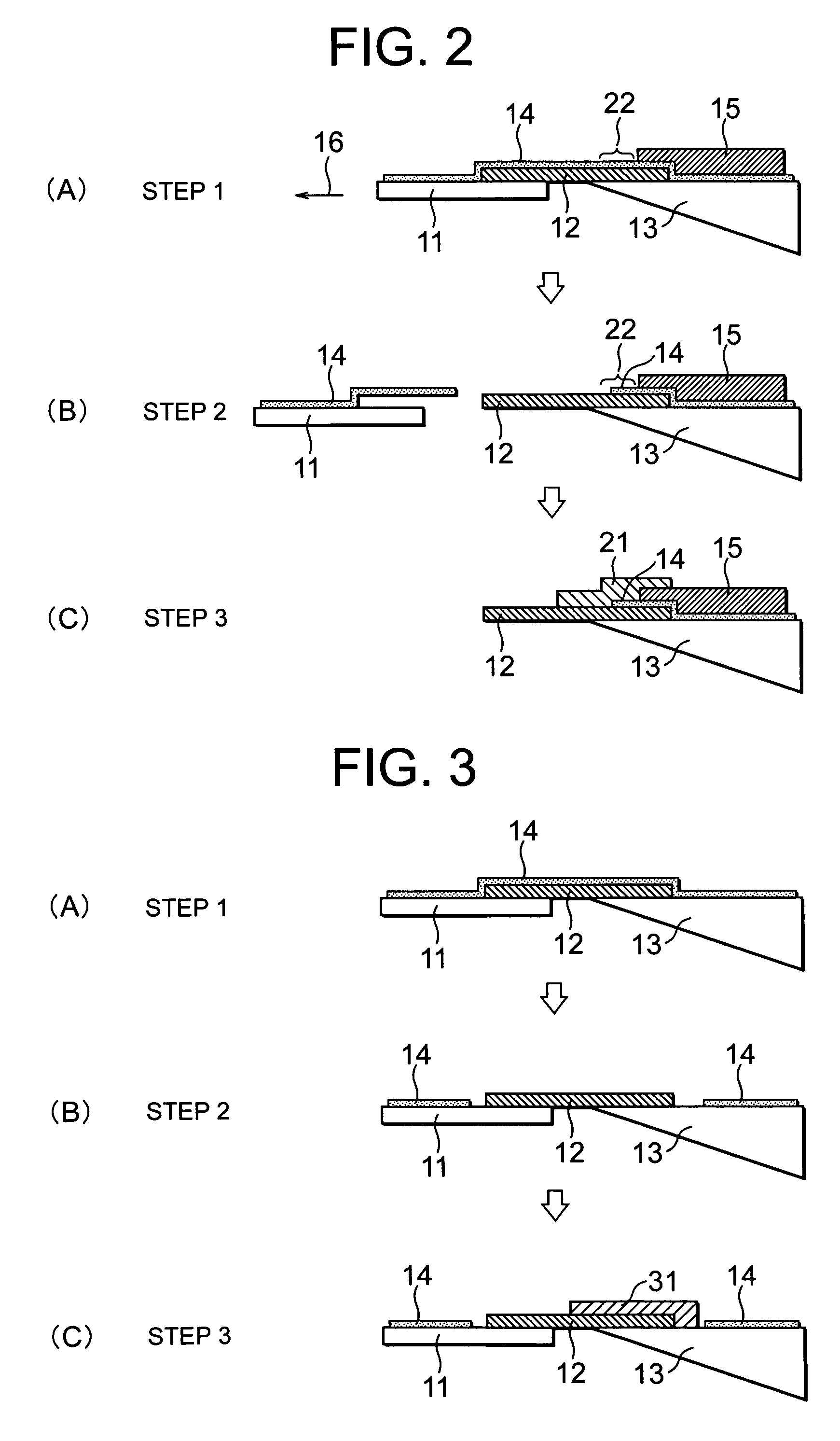

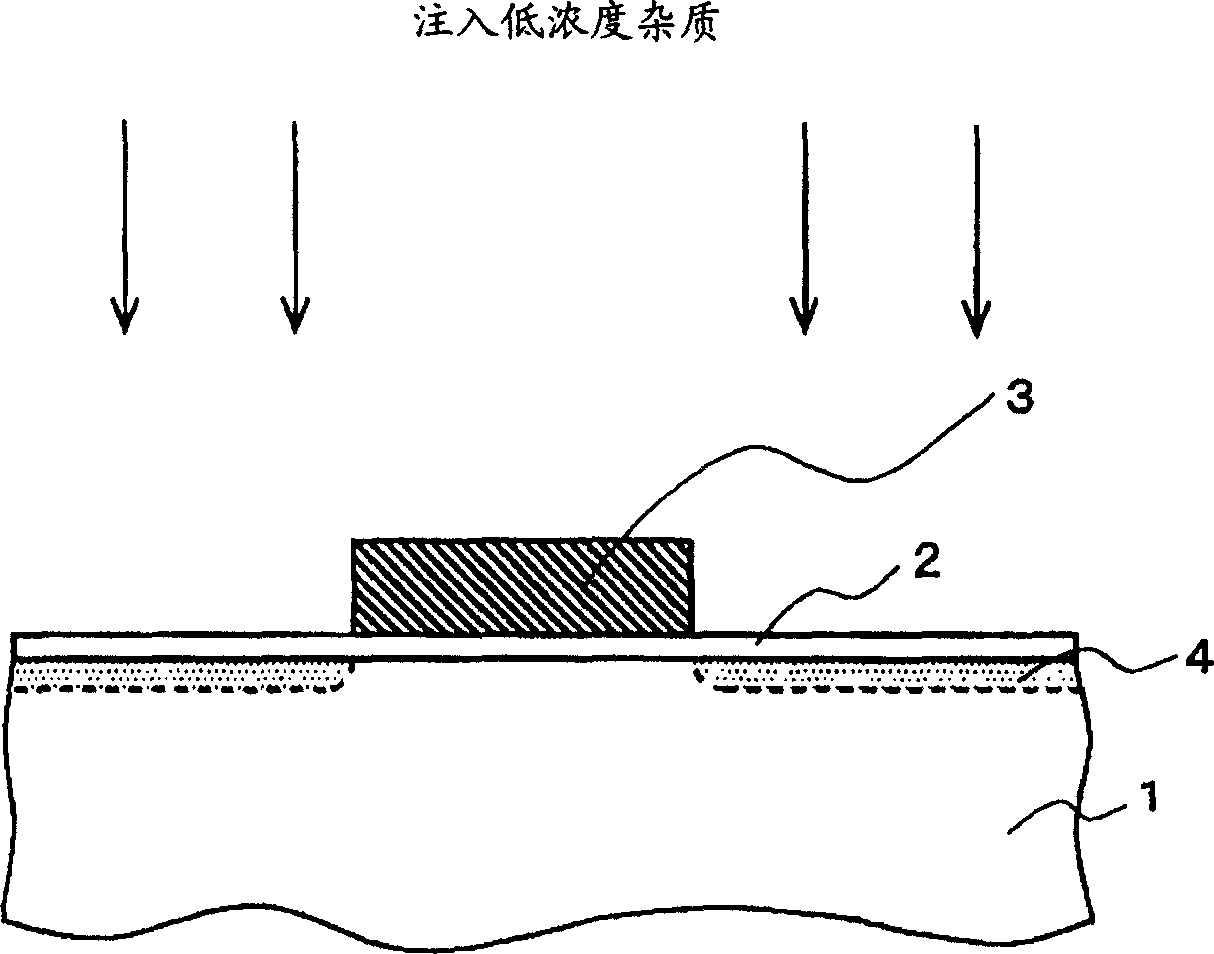

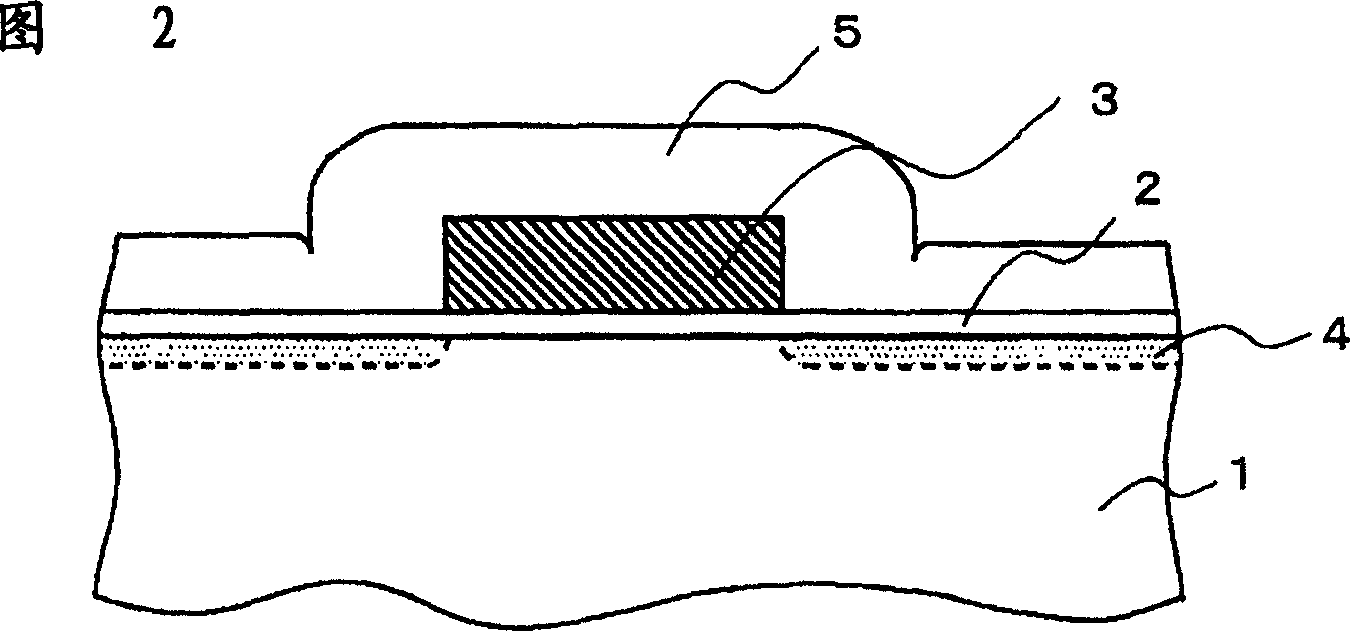

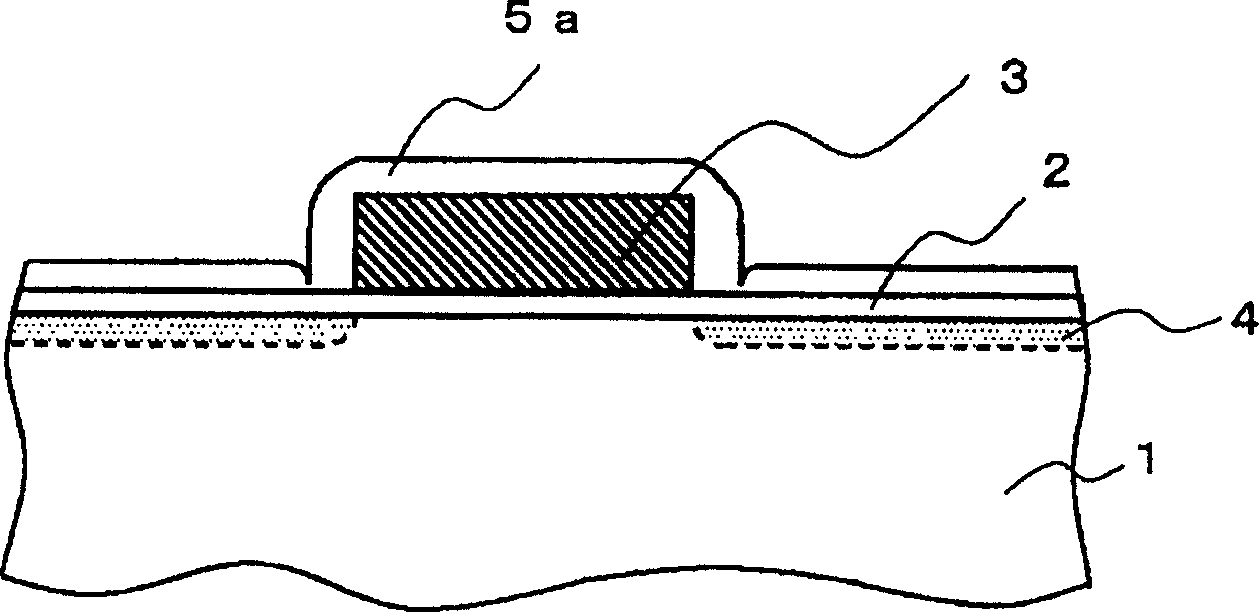

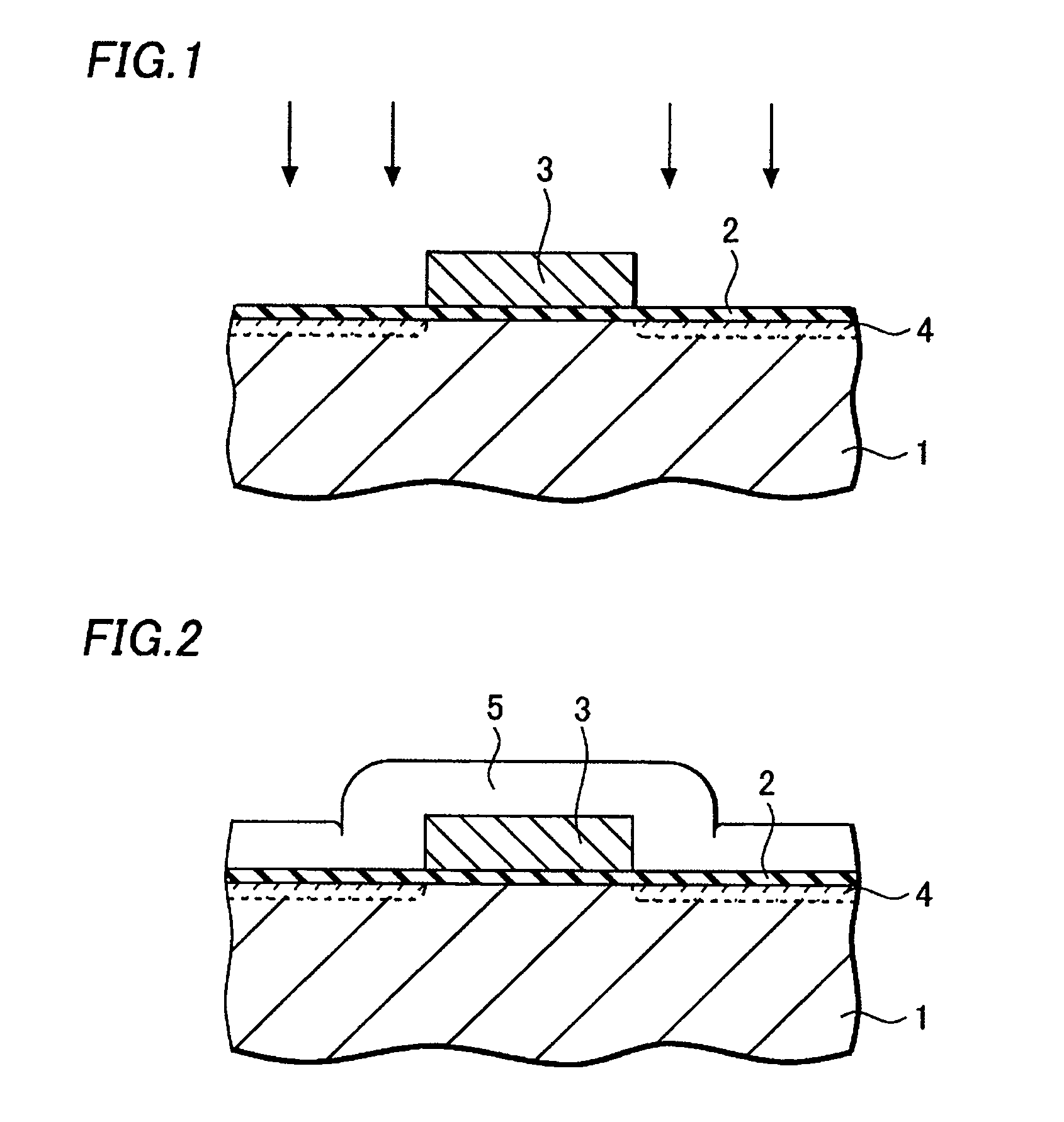

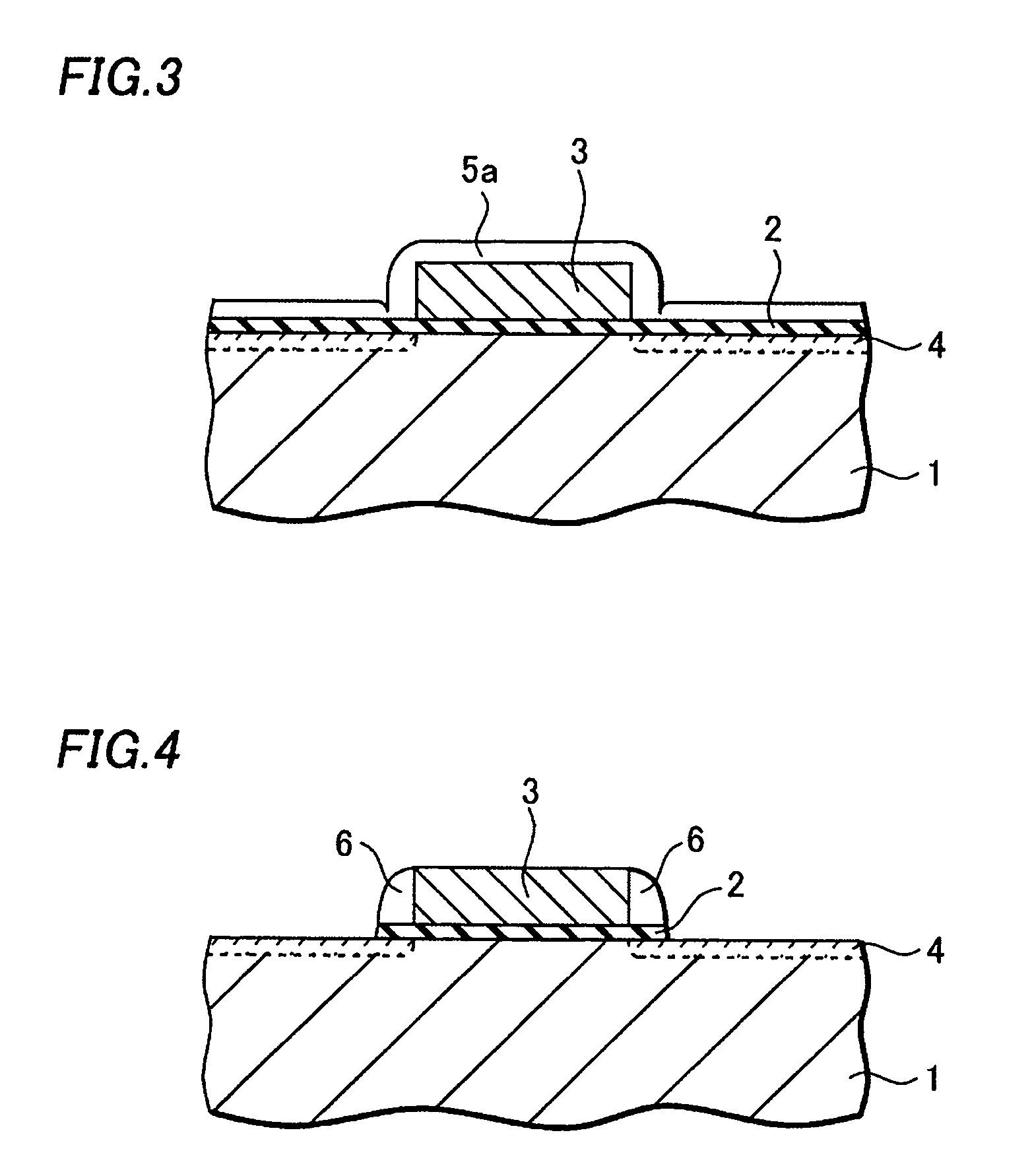

Manufacturing method of semiconductor device

InactiveUS6987062B2TransistorSemiconductor/solid-state device manufacturingSalicideCarbon contamination

This invention offers a manufacturing method which does not cause a reduction in thickness of a silicon substrate or a carbon contamination in forming a transistor having an LDD stricture and silicide layers formed by a salicide technology. After a gate electrode is formed on the silicon substrate through a gate insulation film, an insulation film made of the same material as the gate insulation film is formed on the gate electrode. A first insulation film made of a material different from the material of the gate insulation film and the insulation film on the gate electrode and a second insulation film made of the same material as the material of the gate insulation film and the insulation film on the gate electrode are formed over the silicon substrate. Spacers made of the second insulation film are formed by dry-etching. Then the LDD structure and openings for forming the silicide layers are formed using wet-etching. As a result, the transistor having the LDD structure and the silicide layers formed by the salicide technology is manufactured without causing the reduction in thickness of the silicon substrate or the carbon contamination.

Owner:SANYO ELECTRIC CO LTD

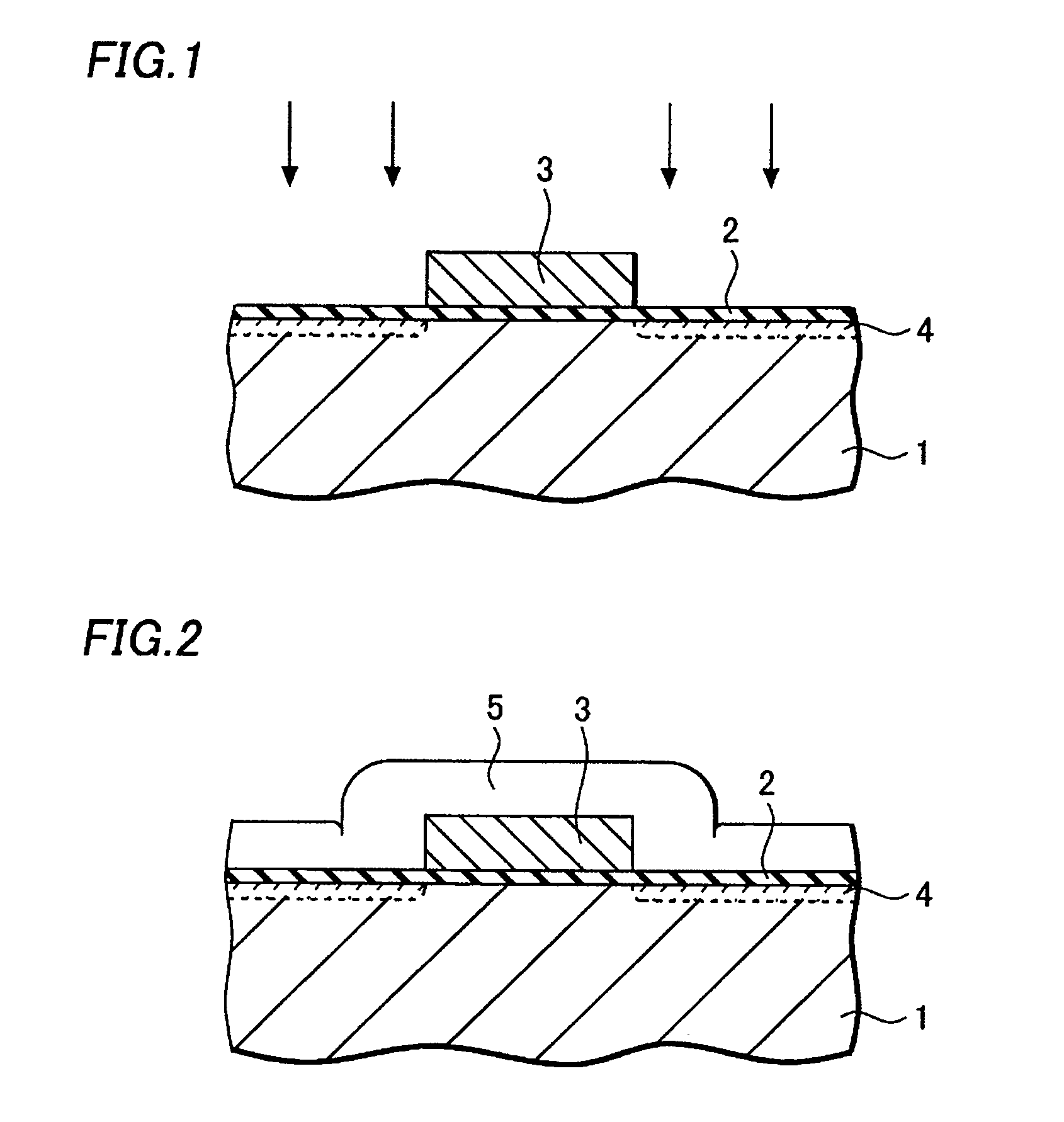

Manufacturing method of semiconductor device

InactiveUS20050136629A1Large selection ratioReduce thicknessTransistorSemiconductor/solid-state device manufacturingDevice materialHigh doses

An LDD structure and a silicide layer are formed without a reduction in thickness of a silicon substrate or a carbon contamination. Forming a spacer on a sidewall of a gate electrode is performed in two process steps, i.e. dry-etching and wet-etching. Also, a silicon nitride film used as a buffer film in injection of high dose of impurities is removed by wet-etching. As a result, the reduction in thickness of the silicon substrate and the carbon contamination can be prevented. In addition, variation in depth of the high and low impurity concentration regions and silicide forming region with locations on the wafer can be suppressed because of high selection ratio available with the wet-etching.

Owner:SANYO ELECTRIC CO LTD

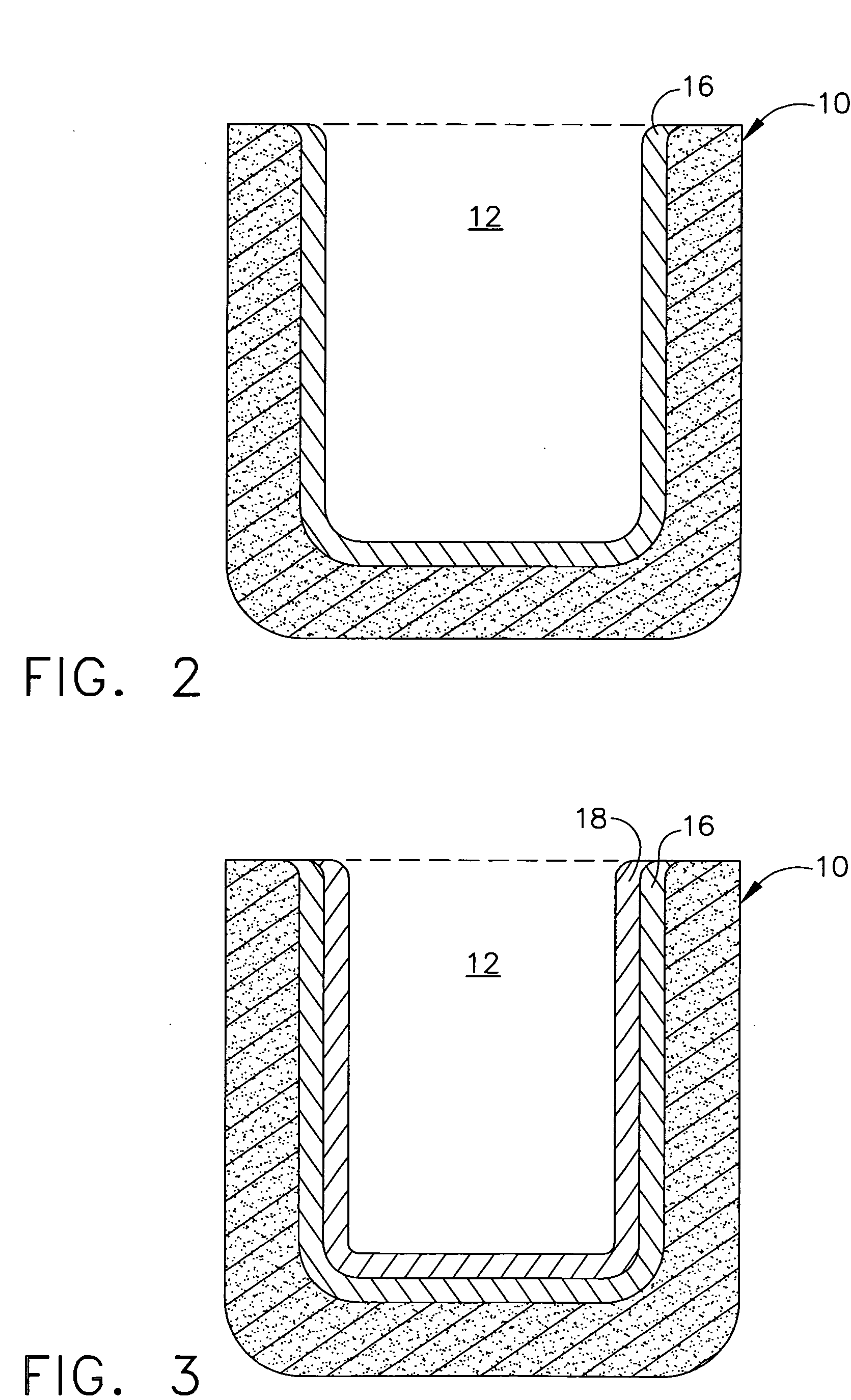

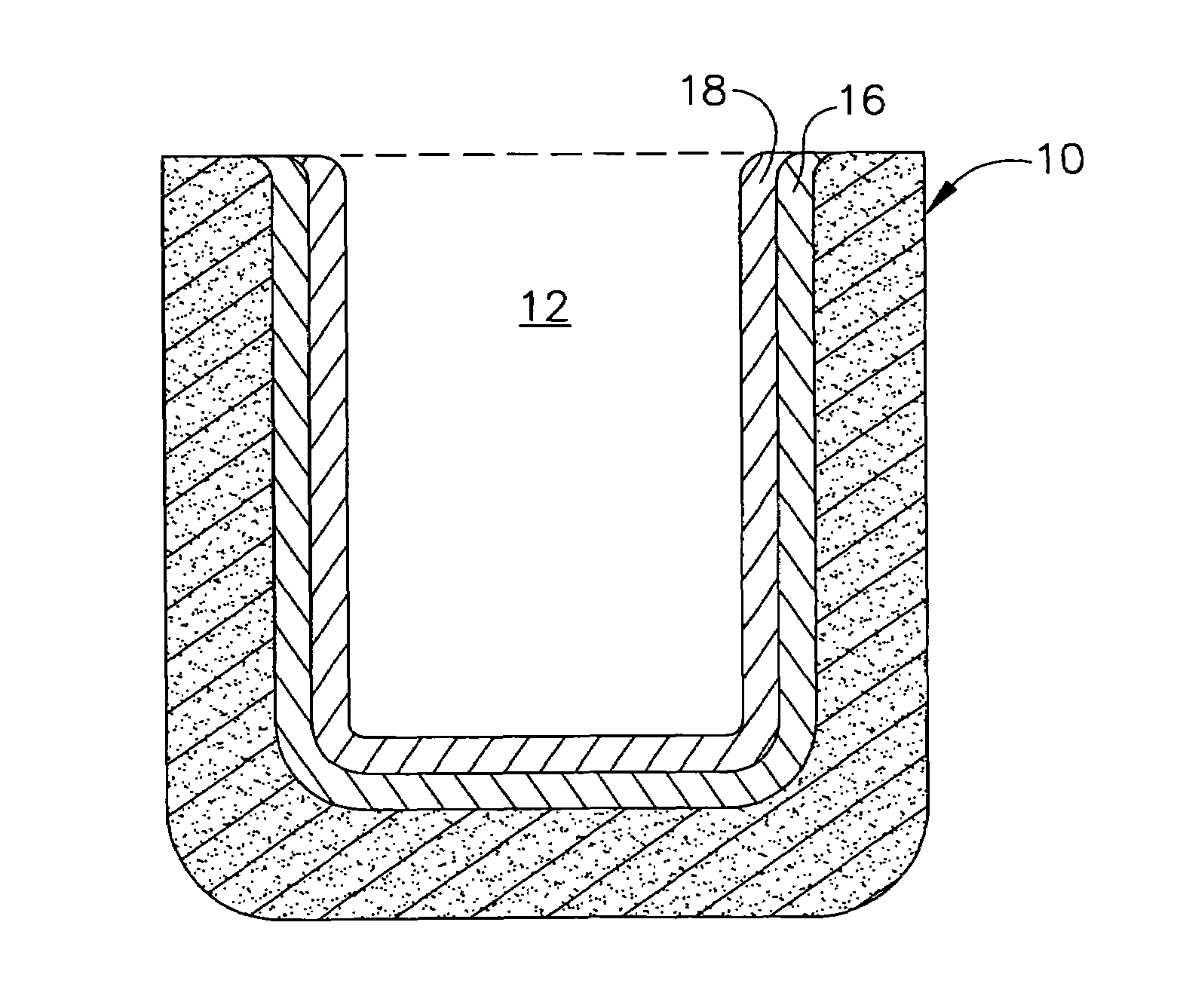

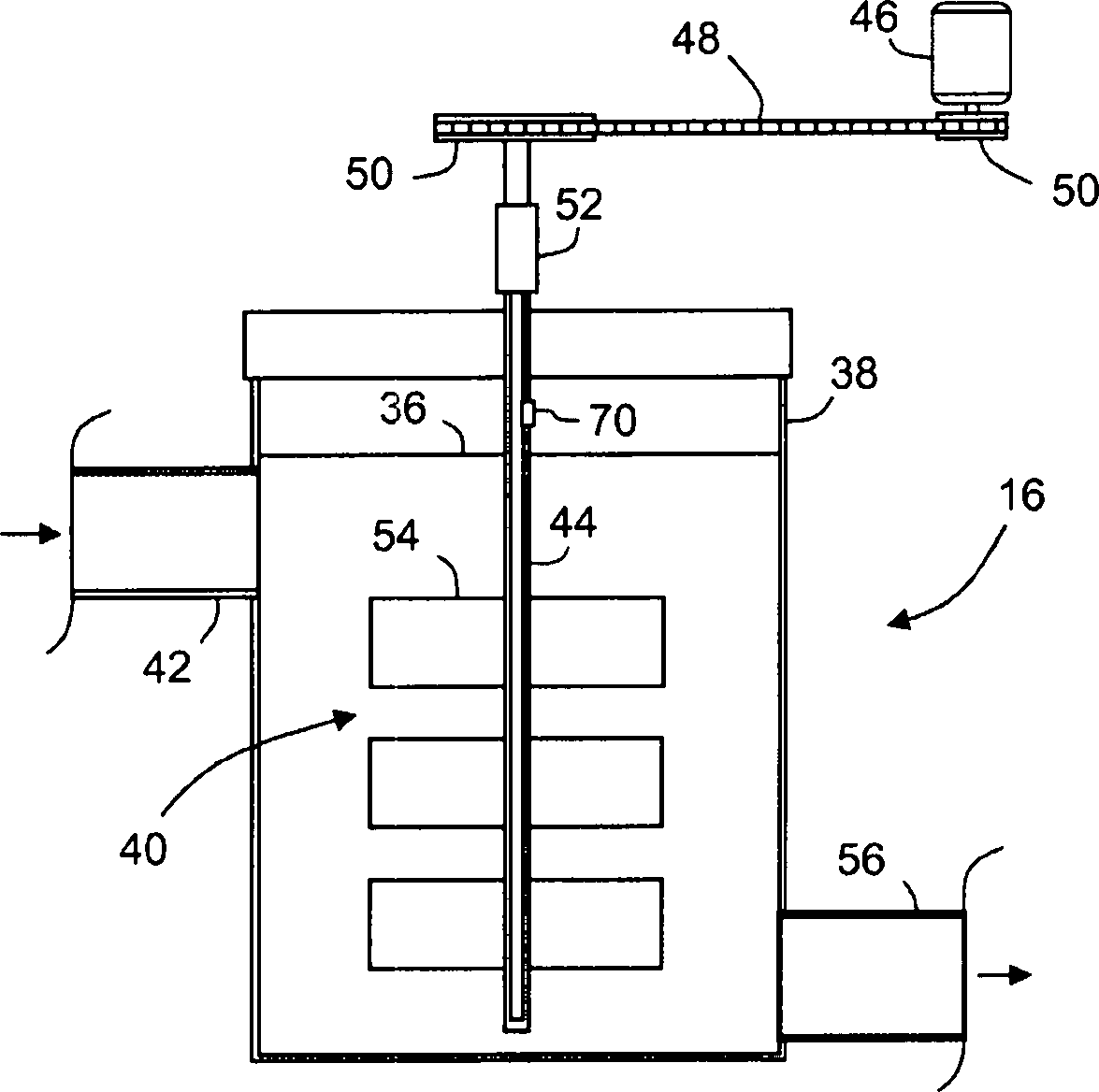

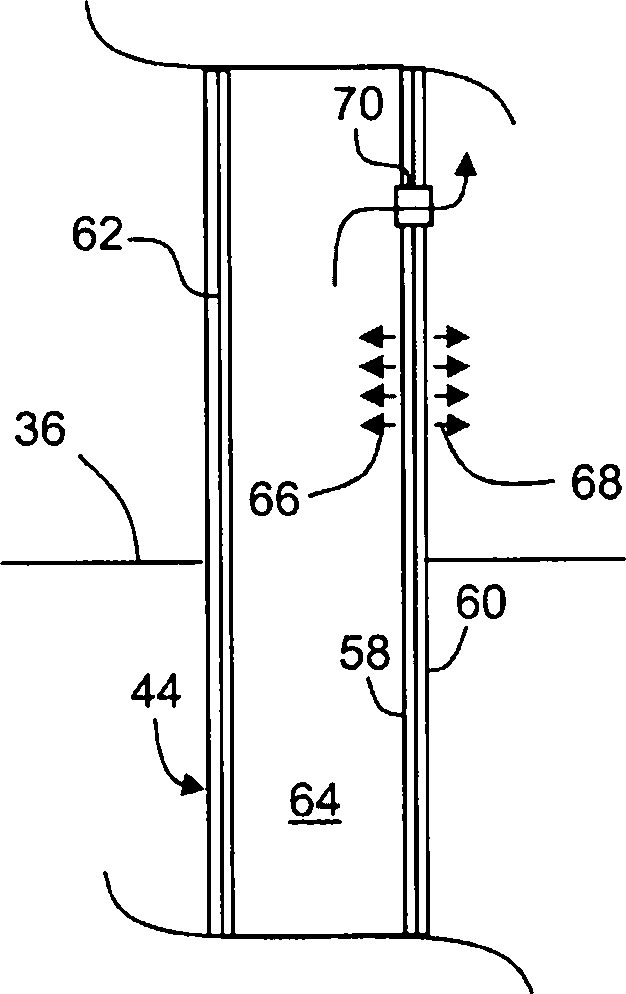

Furnance employing components for use with graphite hot zone

InactiveUS20140261158A1Avoid pollutionPolycrystalline material growthFrom melt solutionsCrucibleCarbon contamination

A furnace for growing sapphire crystal in which the furnace comprises a furnace housing; a hot zone which comprises insulation and a heater which are both accommodated within the furnace housing; a crucible located within the hot zone and the crucible has an opening. Either a crucible lid covers the opening of the crucible, and the crucible lid has a first conduit which extends therefrom or a crucible enclosure surrounds at least a side wall and a top portion of the crucible and the crucible enclosure is impermeable to at least carbon preventing carbon contamination of a melt contained within the crucible.

Owner:ADVANCED RENEWABLEENERGY COMPANY

Manufacturing method of semiconductor device

InactiveUS20050136603A1TransistorSemiconductor/solid-state device manufacturingSalicideDevice material

This invention offers a manufacturing method which does not cause a reduction in thickness of a silicon substrate or a carbon contamination in forming a transistor having an LDD stricture and silicide layers formed by a salicide technology. After a gate electrode is formed on the silicon substrate through a gate insulation film, an insulation film made of the same material as the gate insulation film is formed on the gate electrode. A first insulation film made of a material different from the material of the gate insulation film and the insulation film on the gate electrode and a second insulation film made of the same material as the material of the gate insulation film and the insulation film on the gate electrode are formed over the silicon substrate. Spacers made of the second insulation film are formed by dry-etching. Then the LDD structure and openings for forming the silicide layers are formed using wet-etching. As a result, the transistor having the LDD structure and the silicide layers formed by the salicide technology is manufactured without causing the reduction in thickness of the silicon substrate or the carbon contamination.

Owner:SANYO ELECTRIC CO LTD

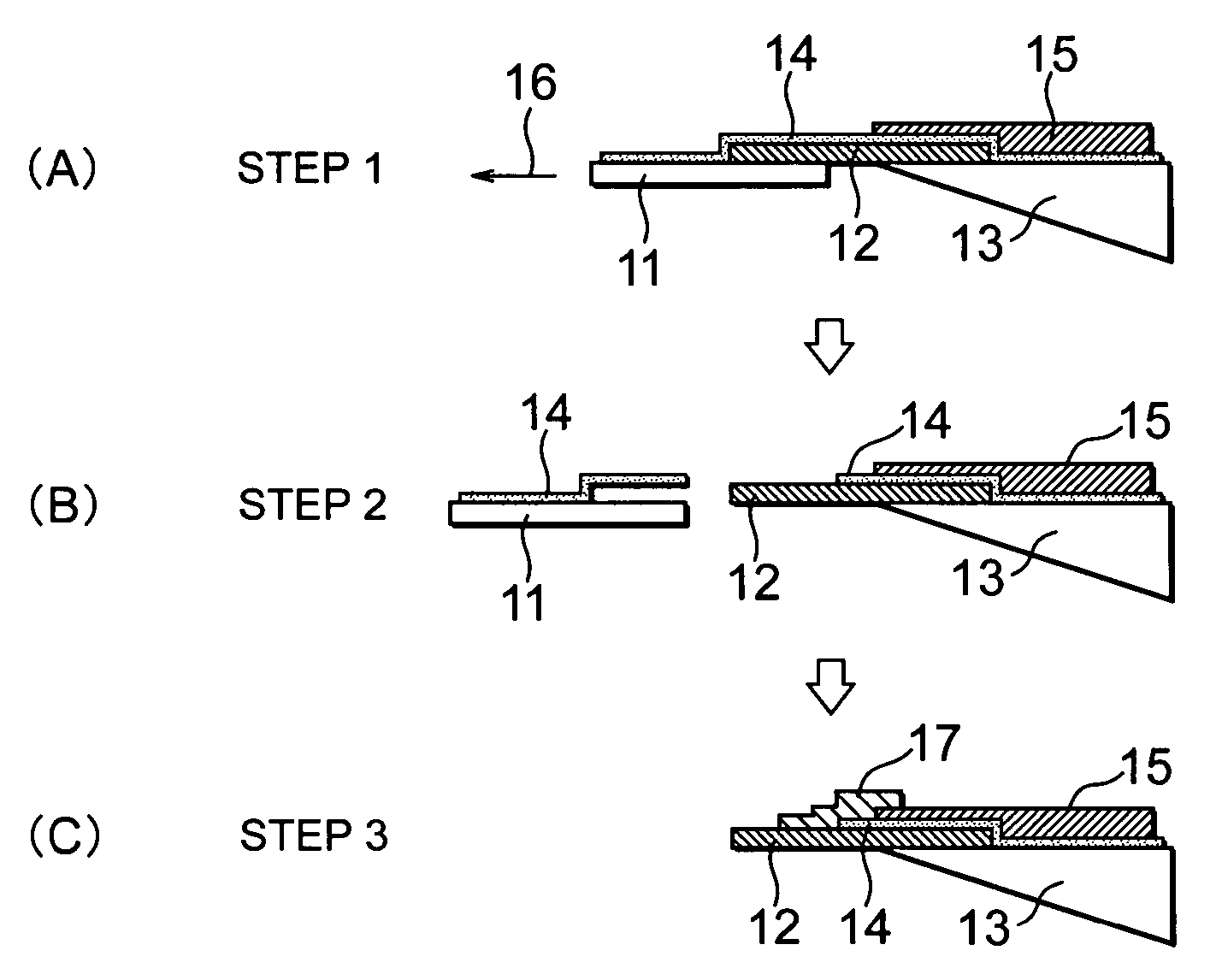

Probe manufacturing method, probe, and scanning probe microscope

InactiveUS7388199B2High strengthImprove conductivityMaterial analysis using wave/particle radiationNanosensorsMicroscopic observationCarbon contamination

A probe is made by attaching a carbon nanotube 12 to a mounting base end 13, which eliminates the effects of a carbon contamination film, to increase the bonding strength, increase the conductivity of the probe, and strengthen the bonding performance thereof by coating the entire circumference of the nanotube and the base with a coating film, rather than coating just one side. The work of mounting the carbon nanotube and mounting base end are performed under observation by a microscope. Further, the carbon contamination film 14 formed by an electron microscope is stripped off at a stage before bonding by the coating film.

Owner:VIVENTIA BIOTECH +1

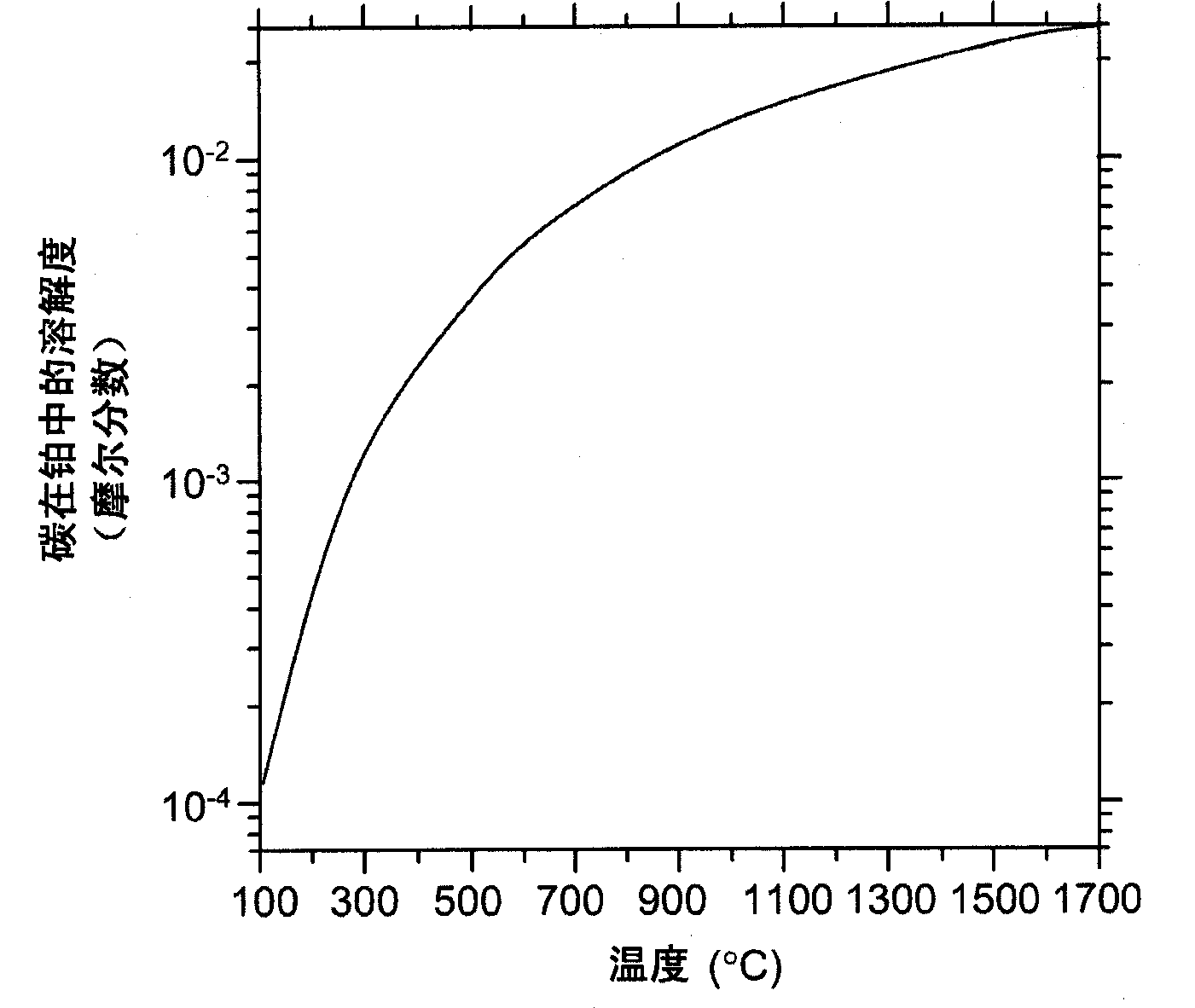

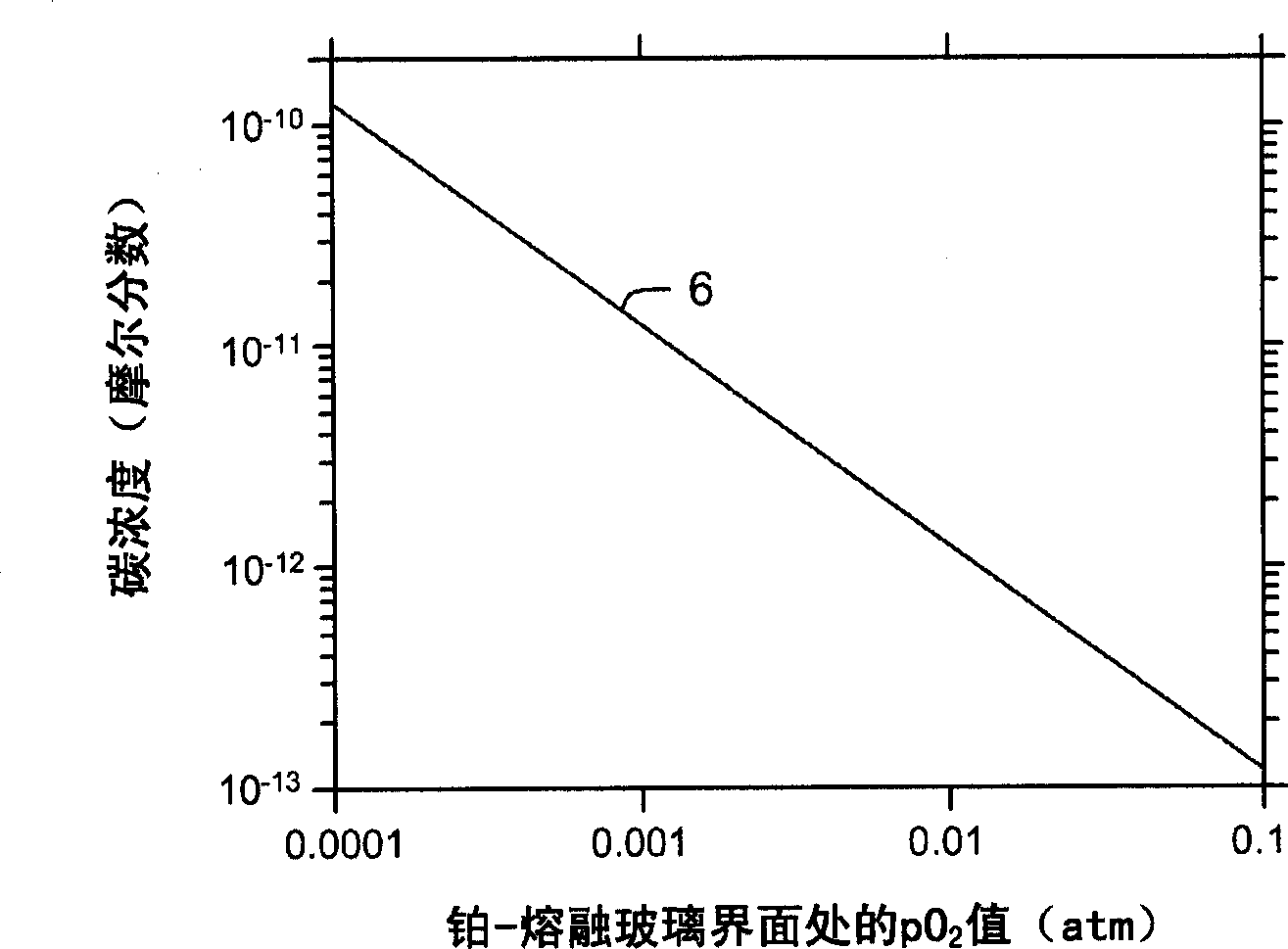

Method for eliminating carbon contamination of platinum-containing components for a glass making apparatus

In the formation of sheet material from molten glass, molten glass is formed in a melting furnace and transported through a precious metal delivery system to the forming apparatus. Disclosed herein is a method to mitigate carbon contamination of individual components of the precious metal delivery system prior to and / or during their use. The method involves positioning an oxygen generating material within portions of a precious metal component, and may comprise one or more heat treating steps of the component in an oxygen-containing atmosphere.

Owner:CORNING INC

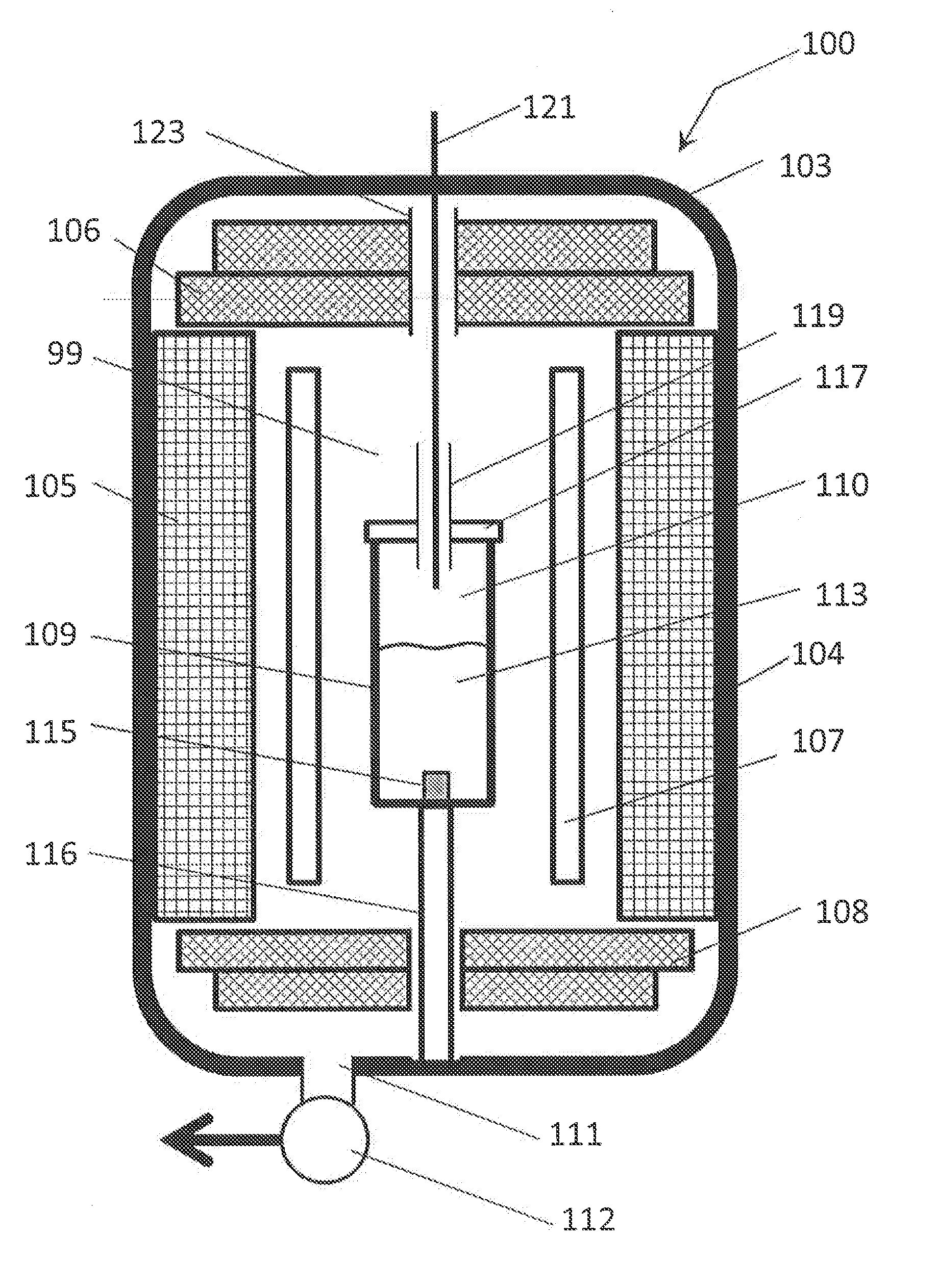

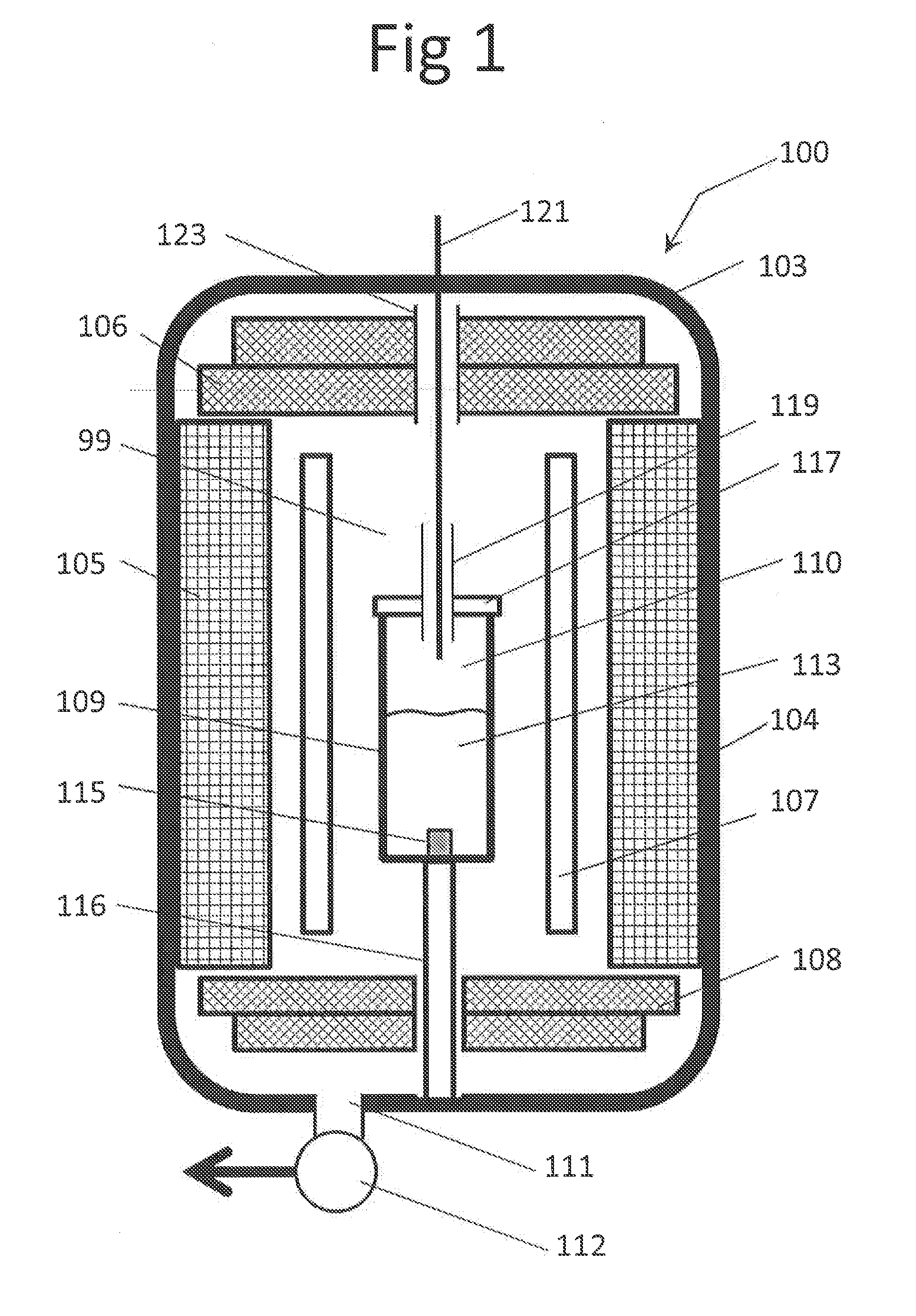

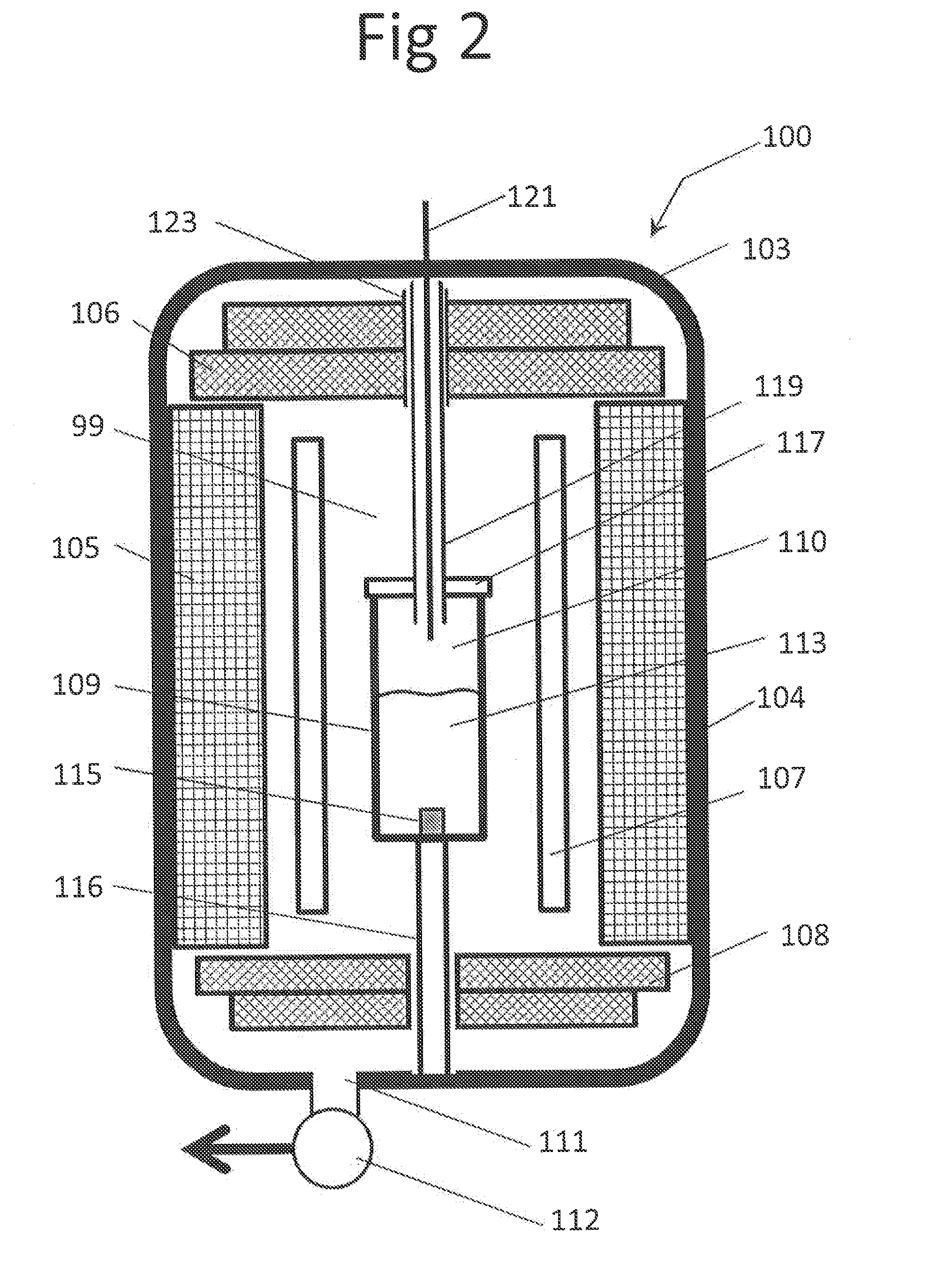

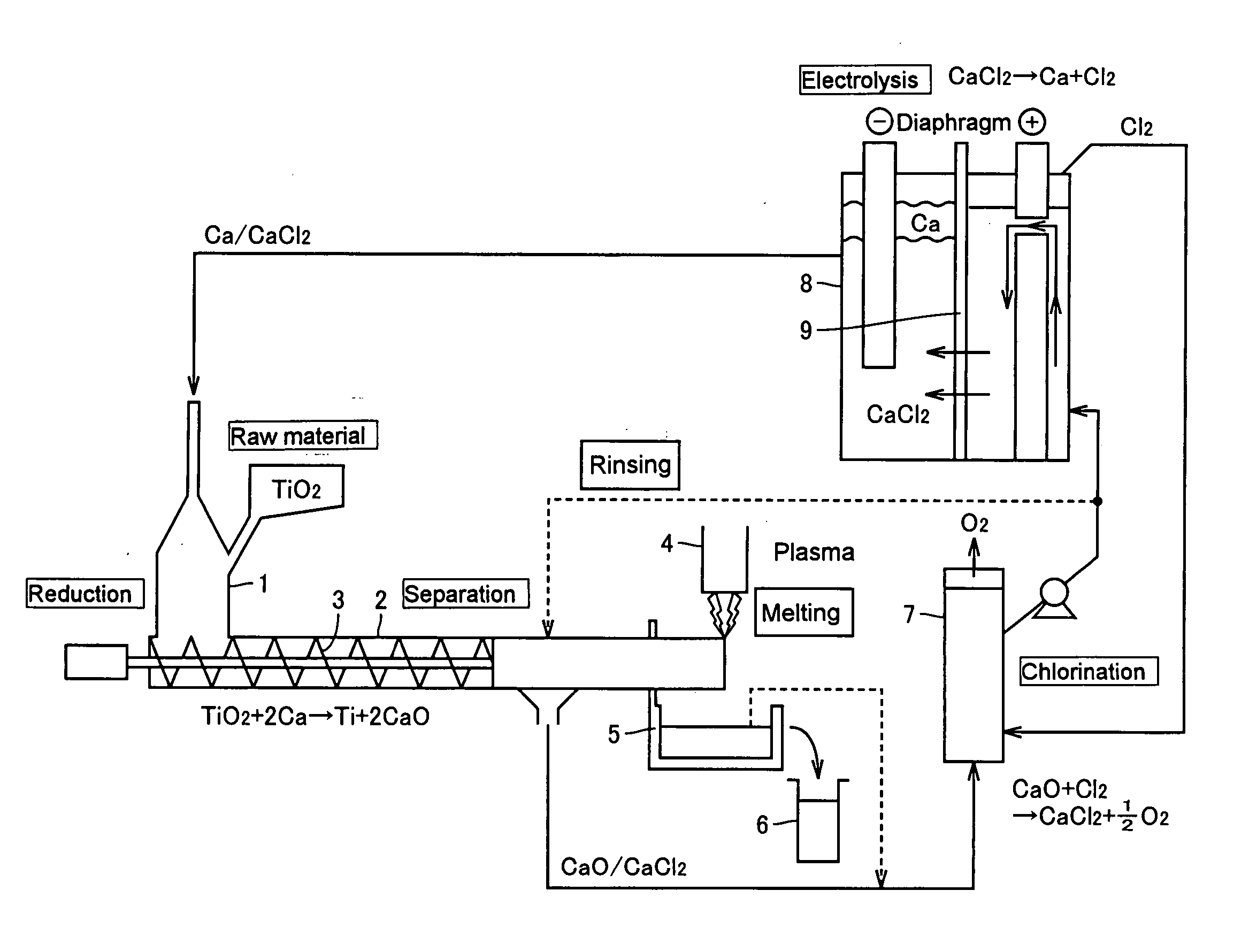

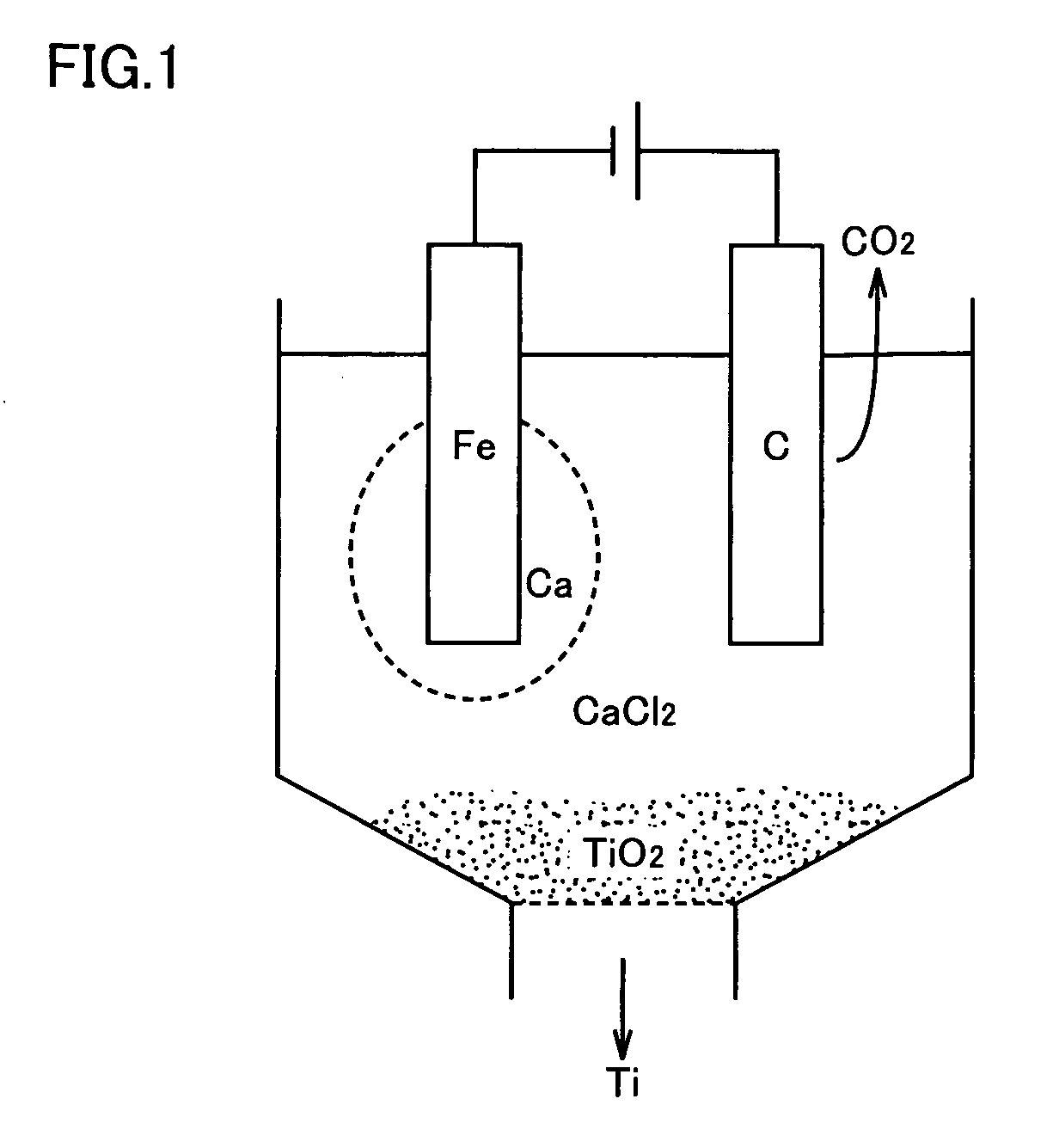

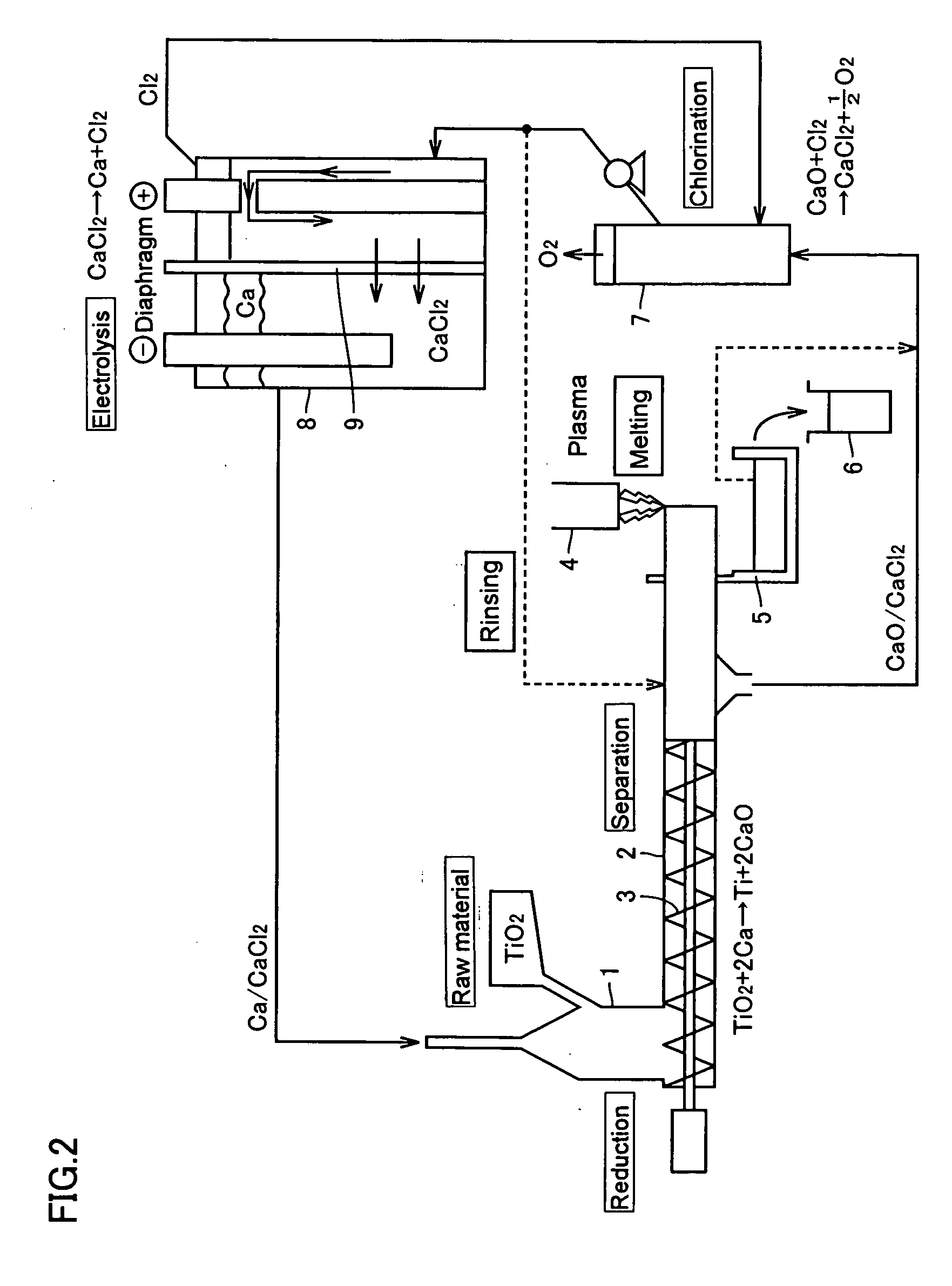

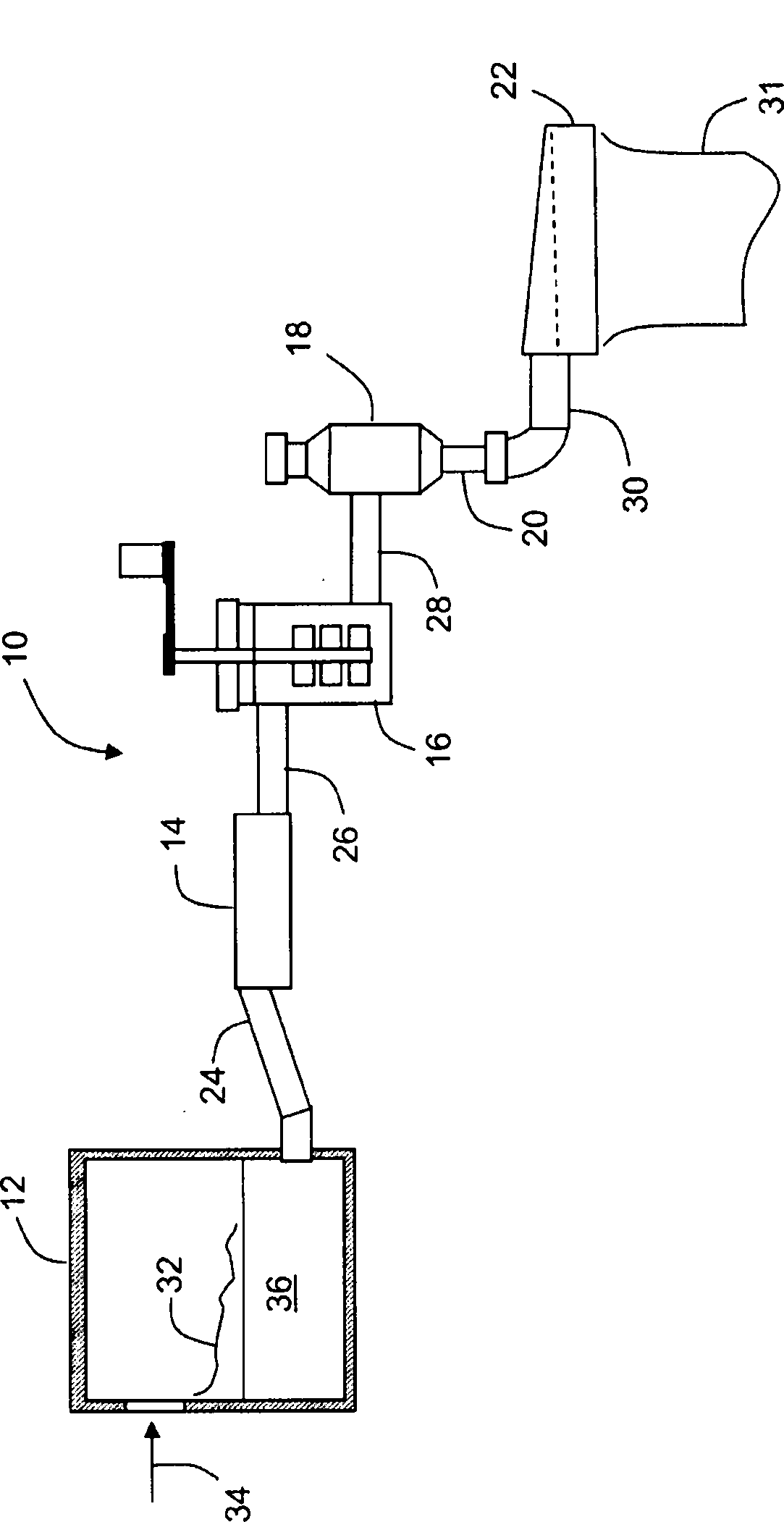

Method and apparatus for producing metal

InactiveUS20060219053A1High productQuality improvementElectrolysis componentsElectric furnaceProduction rateElectrolysis

The present invention relates to a method for producing a metal by a direct oxide reduction process with Ca. A CaCl2-based molten salt containing Ca is held in a reduction chamber 1, a metal oxide is introduced into the molten salt in the reduction chamber 1, and the metal oxide is reduced with the Ca in the molten salt to form said metal. The metal formed in the molten salt is separated from the molten salt in a separation means 2, and the molten salt deprived of the metal is introduced into a chlorination chamber 7 and subjected to chlorination treatment with chlorine gas to eliminate the byproduct CaO in the molten salt. The molten salt after chlorination treatment is introduced into an electrolysis chamber 8 and electrolyzed for the formation of Ca and chlorine from CaCl2, and the thus-formed Ca or Ca-containing molten salt is transferred from the electrolysis chamber 8 to the reduction chamber 1. The chlorine obtained in the electrolysis chamber 8 is used in the chlorination chamber 7. Thus, the present invention provides a metal production method and an apparatus wherein high levels of productivity are obtained and the product metal can be inhibited from carbon contamination due to CaO, without any generation of CO2 from the production process, while their being based on the direct oxide reduction process comprising the step of reducing a metal oxide with Ca.

Owner:OSAKA TITANIUM TECHNOLOGIES

Semiconductor device and method for making same

InactiveCN1612308ANo pollutionHas stable propertiesTransistorSemiconductor/solid-state device manufacturingSalicideHigh doses

Disclosed is a manufacturing method of a semiconductor device. An LDD structure and a silicide layer are formed without a reduction in thickness of a silicon substrate or a carbon contamination. Forming a spacer on a sidewall of a gate electrode is performed in two process steps, i.e. dry-etching and wet-etching. Also, a silicon nitride film used as a buffer film in injection of high dose of impurities is removed by wet-etching. As a result, the reduction in thickness of the silicon substrate and the carbon contamination can be prevented. In addition, variation in depth of the high and low impurity concentration regions and silicide forming region with locations on the wafer can be suppressed because of high selection ratio available with the wet-etching.

Owner:SANYO ELECTRIC CO LTD

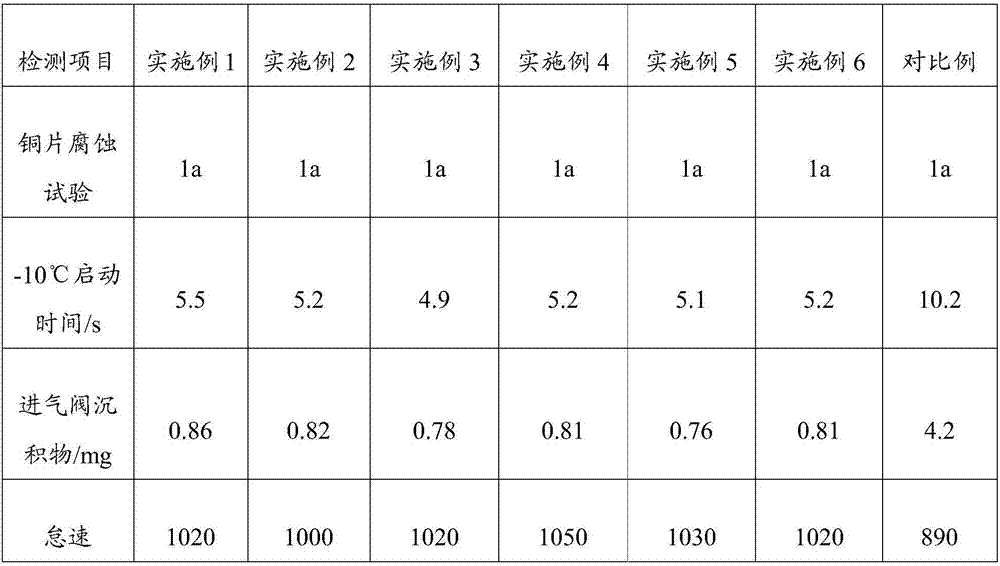

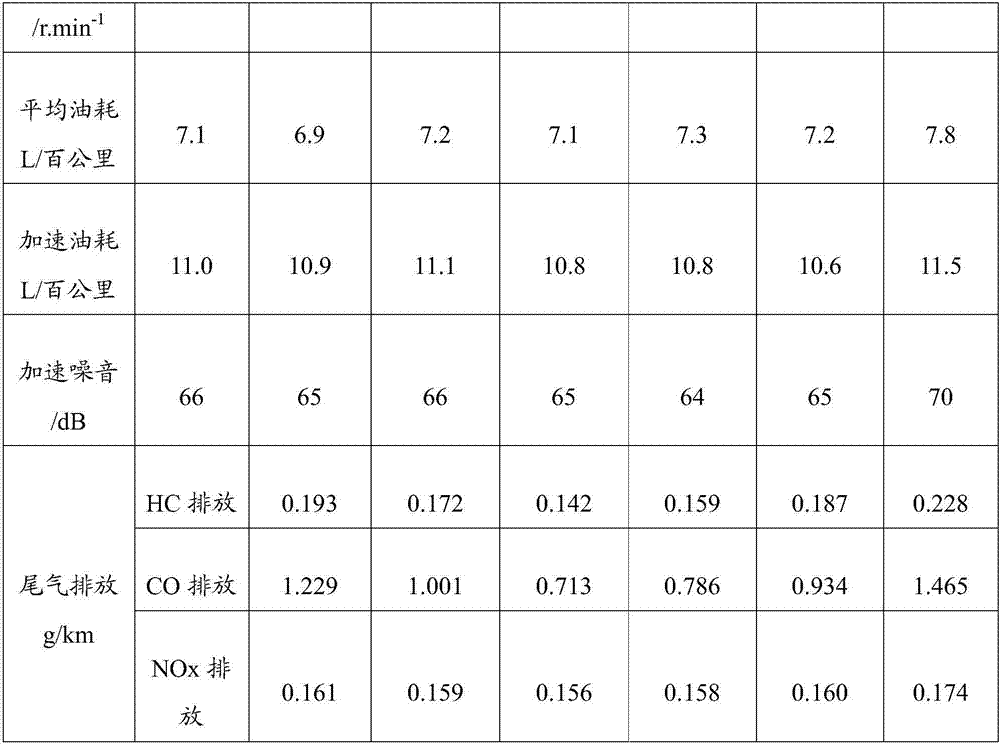

Efficient, energy saving and power improving fuel additive and preparation method thereof

ActiveCN107312579AImprove combustion efficiencyBurn completelyLiquid carbonaceous fuelsCombustionExhaust gas emissions

The invention discloses an efficient, energy saving and power improving fuel additive. The efficient, energy saving and power improving fuel additive is prepared from, by weight, 20-40 parts of lauric isopropanolamide, 10-15 parts of polyisobutylene sulfide phosphating barium salt, 5-10 parts of polyisobutylene diimide, 0.5-1 part of an organosilicon compound, 0.5-1 part of sulfide plant fatty acid ester, 0.5-1 part of octyl glycoside, 10-25 parts of petroleum ether, 5-15 parts of a combustion improver and 0.1-0.2 part of a surfactant, wherein the combustion improver is obtained by mixing hydroxyethylferrocene with polyvinyl methyl ether according to the weight ratio of 1:1-3. The invention further provides a preparation method of the efficient, energy saving and power improving fuel additive. By the arrangement, combustion efficiency of fuel can be remarkably improved, the fuel can be combusted completely, engine power is improved, fuel consumption is reduced, carbon contamination can be removed, exhaust gas emission is reduced, and wide application prospect is achieved.

Owner:深圳市百顺源节能科技有限公司

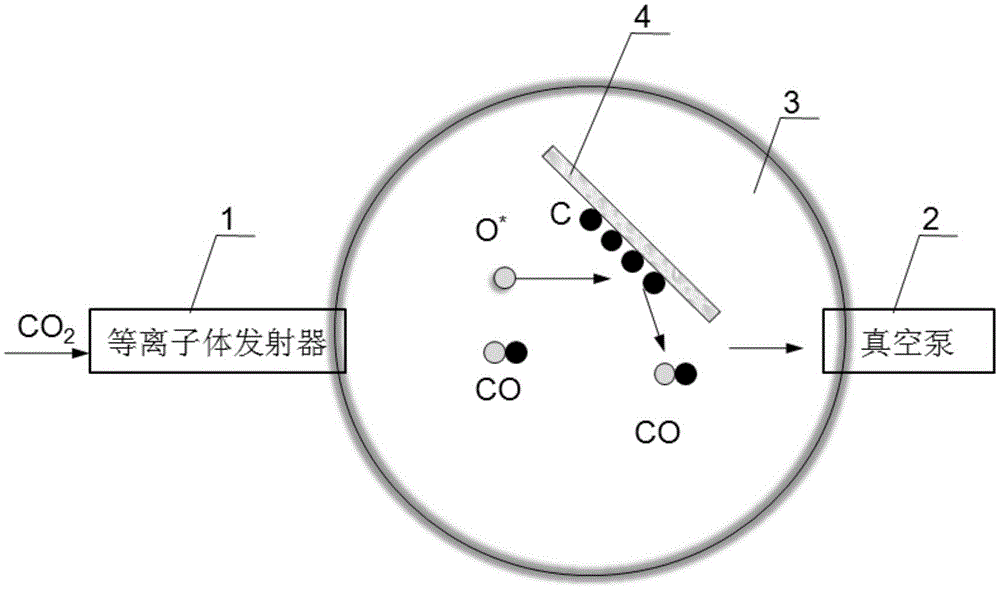

Carbon pollution cleaning method of EUV optical element

InactiveCN104834187AAvoid damageRestore reflectivityFlexible article cleaningPhotomechanical exposure apparatusCarbon contaminationPollution

The invention provides a carbon pollution cleaning method of an EUV optical element, comprising the following steps: 1) placing the optical element in a cleaning cavity and vacuumizing the cleaning cavity; 2) injecting carbon dioxide in the cleaning cavity via a plasma transmitter to fill the cleaning cavity with the carbon dioxide in a plasma state, and cleaning the carbon pollution through oxidation reaction between the carbon dioxide in the plasma state and deposited carbon on the surface of the optical element. The cleaning method is simple, convenient and low in cost with less harm to the optical element.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Carbon contamination resistant pressure atomizing nozzles

A pressure atomizing nozzle for injecting fuel includes an inlet housing configured to thermally isolate the interior space from external conditions and to remain relatively cool under operation so as to substantially eliminate heat soak back from the inlet housing to the interior space thereof after operation. First and second coolant conduits cool the nozzle tip region actively during operation and passively after operation. A cooling air jacket is configured to thermally isolate inboard components from exterior conditions, to provide clean air during operation to the nozzle tip region for diluting carbon to reduce carbon deposits in the nozzle tip region and for cooling the same, and to provide passive cooling to the nozzle tip region after operation.

Owner:COLLINS ENGINE NOZZLES INC

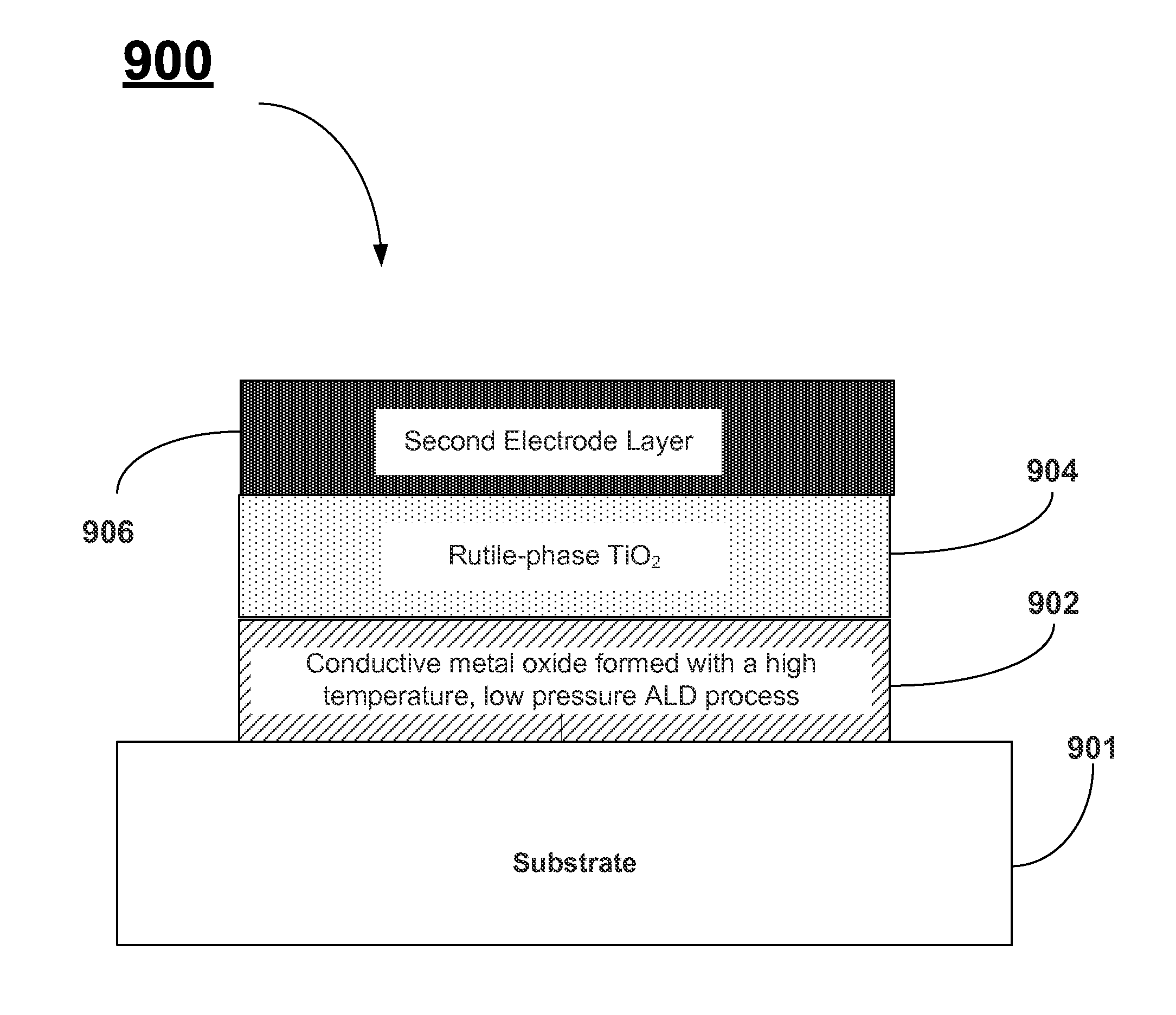

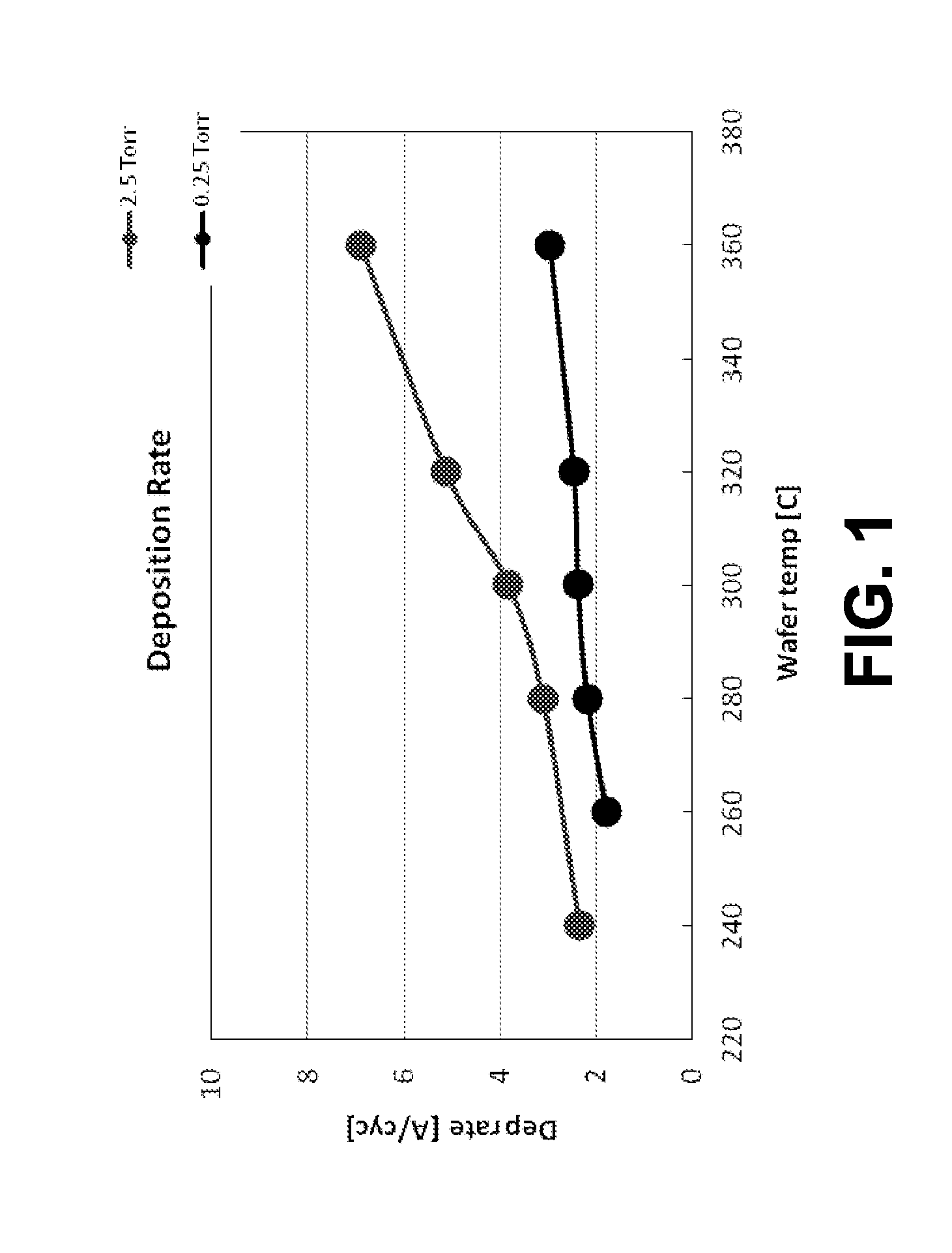

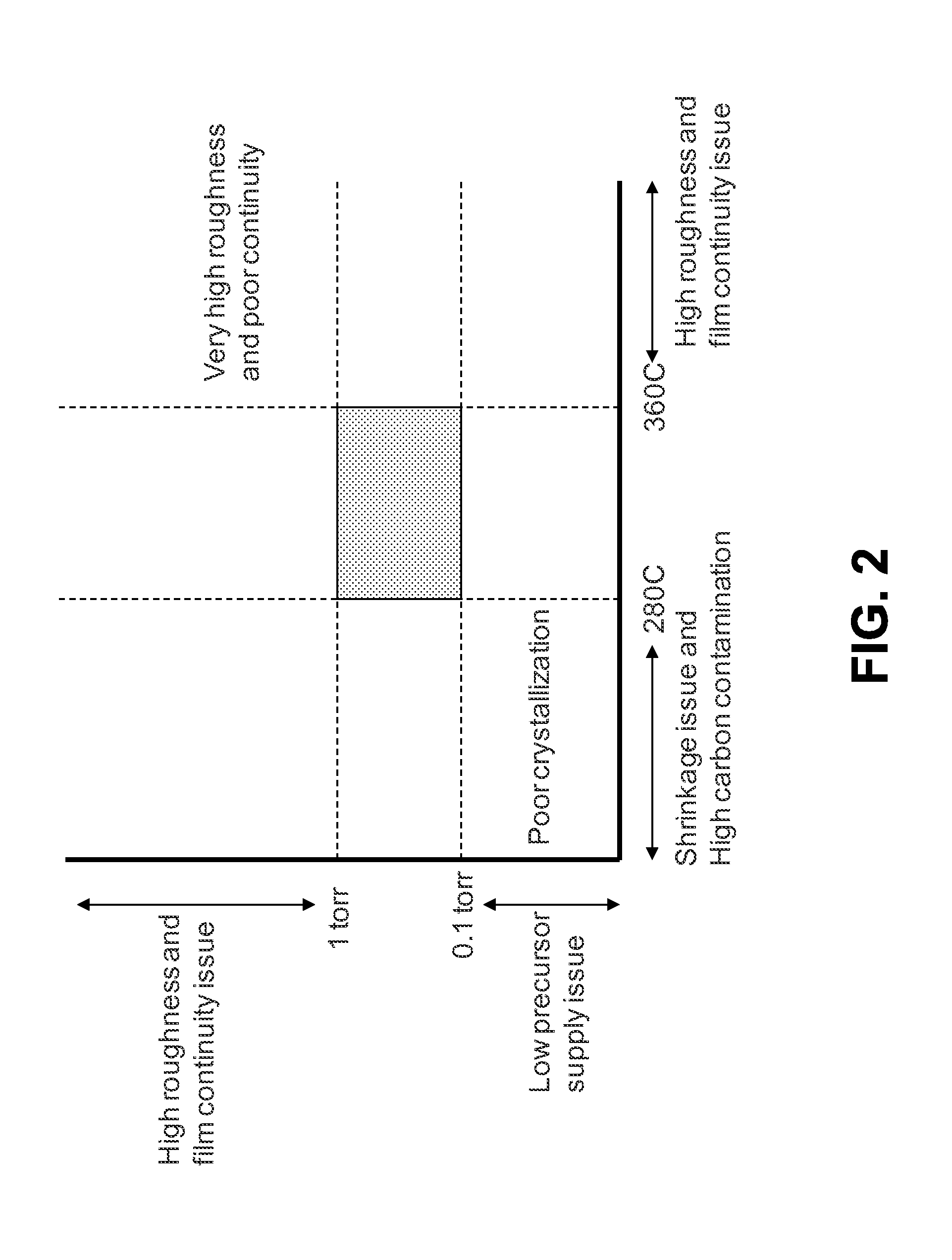

High Temperature ALD Process of Metal Oxide for DRAM Applications

InactiveUS20140080284A1Reduce stressSemiconductor/solid-state device manufacturingCapacitorsMetal-insulator-metalHigh density

A first electrode layer for a Metal-Insulator-Metal (MIM) DRAM capacitor is formed wherein the first electrode layer contains a conductive metal oxide formed using a high temperature, low pressure ALD process. The high temperature ALD process results in a layer with enhanced crystallinity, higher density, reduced shrinkage, and lower carbon contamination. The high temperature ALD process can be used for either or both the bottom electrode and the top electrode layers.

Owner:INTERMOLECULAR +1

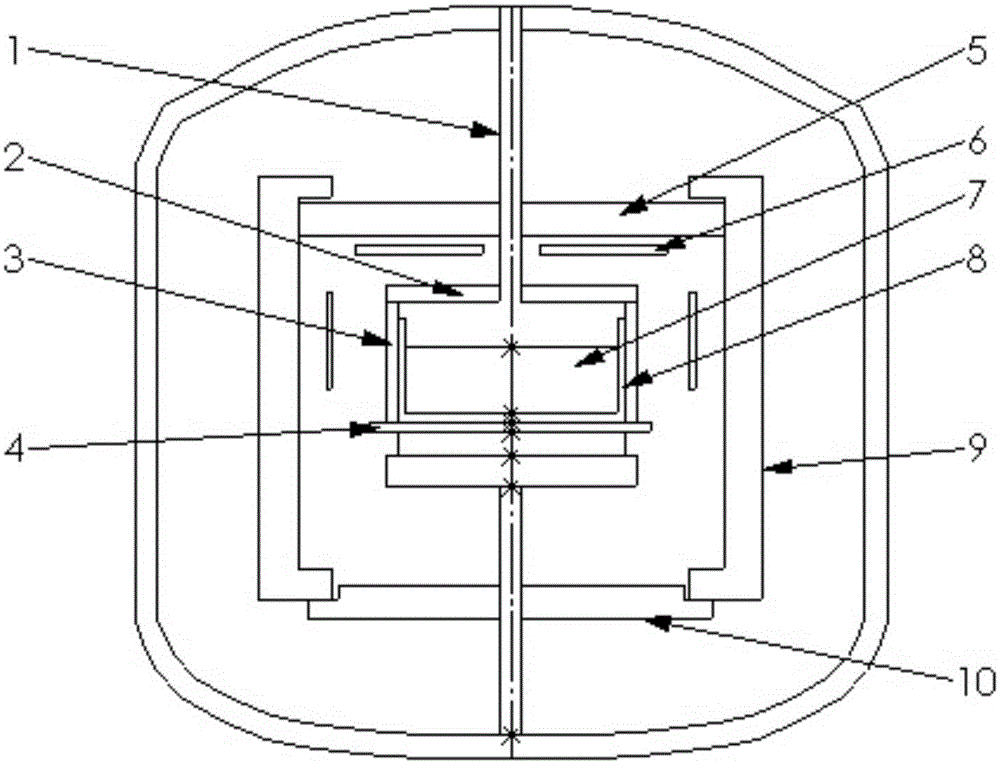

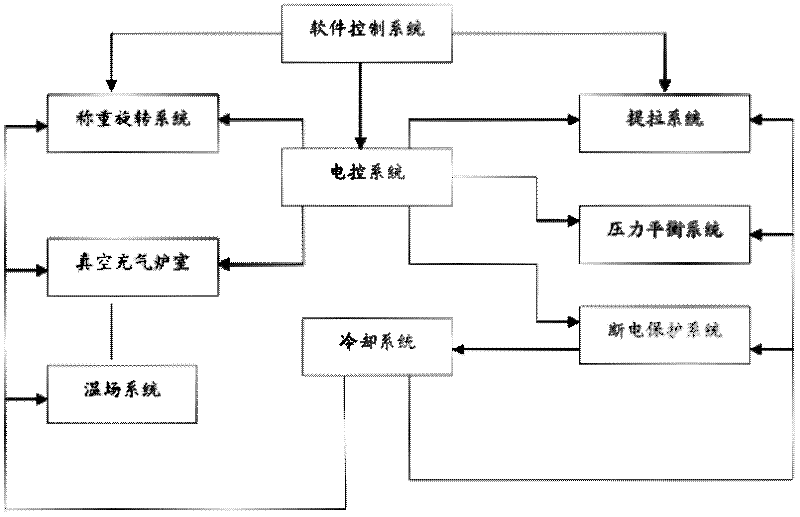

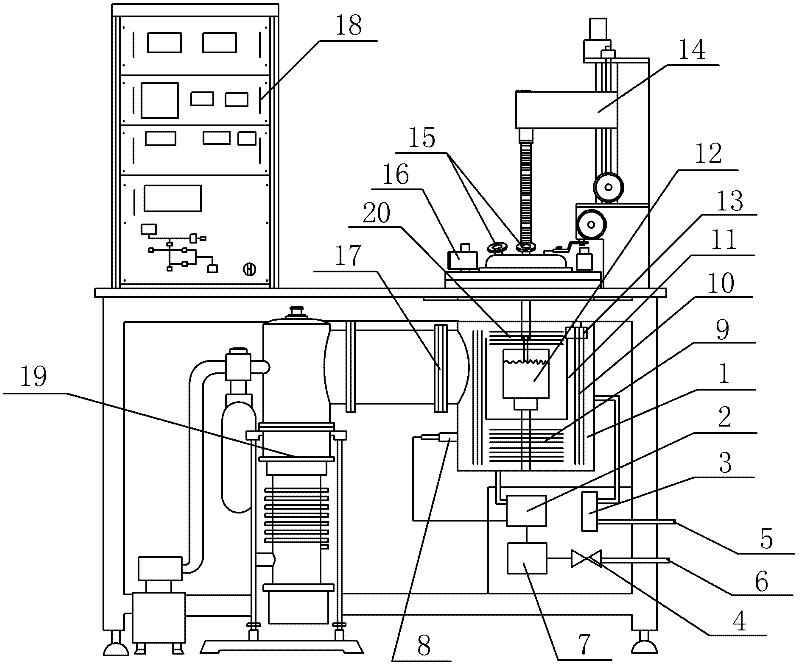

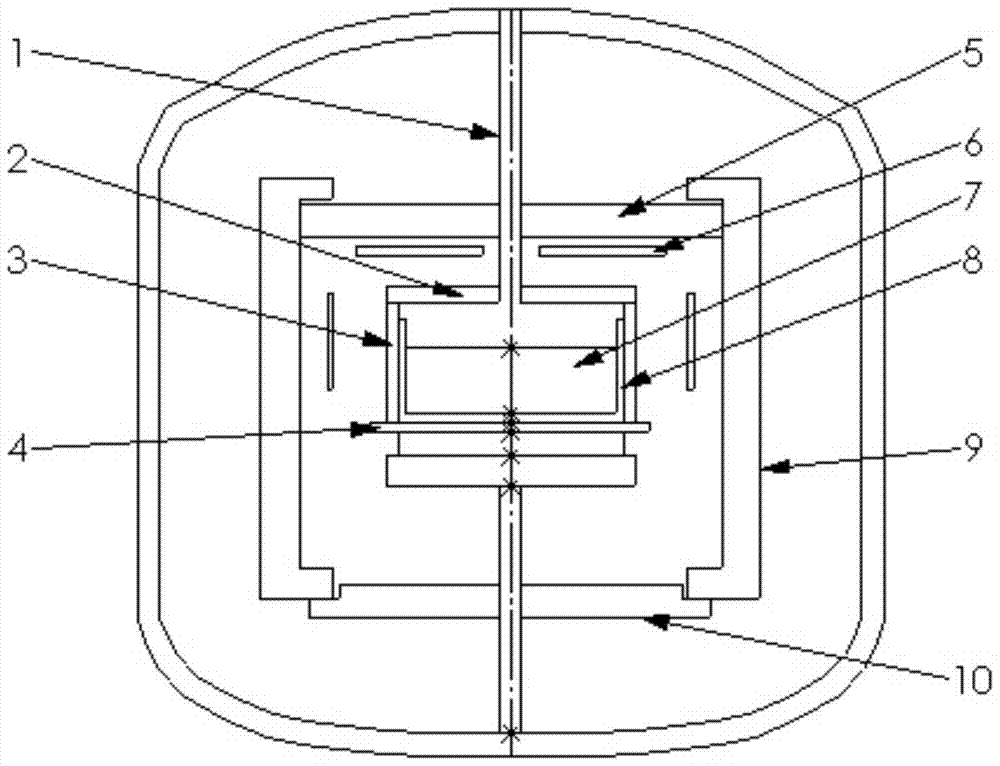

Controllable reducing atmosphere Kyropoulos furnace

ActiveCN102560637ASolve pollutionMeet the militaryPolycrystalline material growthUnder a protective fluidHigh power lasersEngineering

The invention discloses a controllable reducing atmosphere Kyropoulos furnace. The Kyropoulos furnace comprises a software control system, an electric control system, a lifting system, a pressure balancing system, a power-off protection system, a cooling system, a rotary weighing system, a vacuum charging furnace chamber and a thermal field system. The Kyropoulos furnace is characterized by further comprising a set of low vacuum pressure balancing system. According to the controllable reducing atmosphere Kyropoulos furnace, by introducing the low vacuum pressure balancing system and re-integrating the vacuum system, the control system, the thermal field system and the protection system of a traditional Kyropoulos device, the crystal growth and annealing can be completed in one step. Meanwhile, the problem of carbon element and molybdenum element contamination existing in the thermal exchange method and the temperature gradient method is effectively solved and the carbon contamination caused by external factors in the crystal growth process can be avoided. By the controllable reducing atmosphere Kyropoulos furnace provided by the invention, large-sized optical-level sapphire or titanium sapphire crystal can be obtained to meet the needs of high-power lasers in military and civil use in domestic and oversea areas.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Hydrocarbon conversion process to remove carbon residue contaminants

ActiveUS20140001094A1Reduce carbon levelTreatment with plural serial stages onlyTreatment with hydrotreatment processesIonPollutant

The invention involves a process for hydrocarbon conversion. The process can include providing a feed to a primary upgrading zone and then treating the product from the primary upgrading zone with a feed-immiscible ionic liquid to remove carbon residue compounds.

Owner:UOP LLC

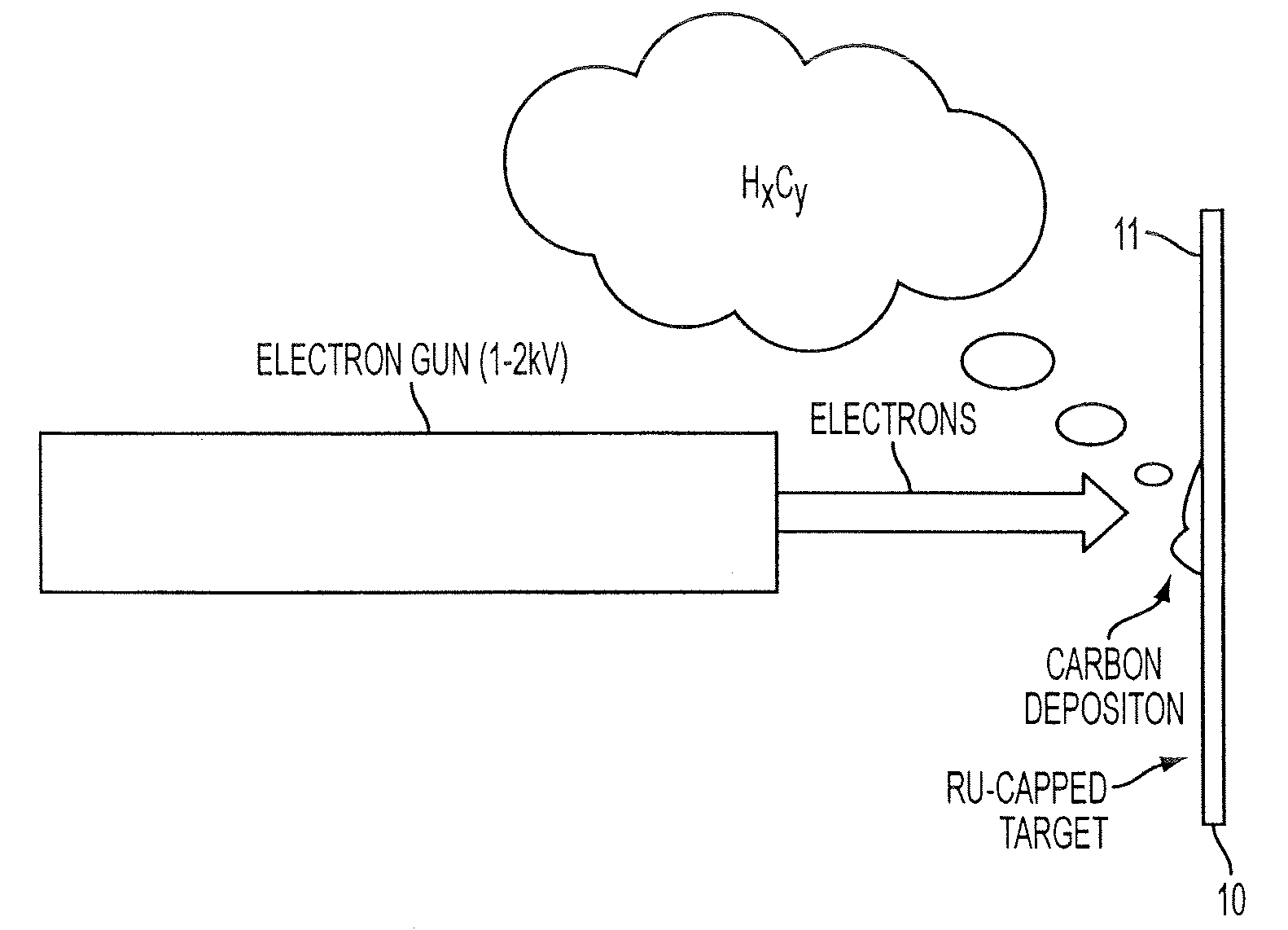

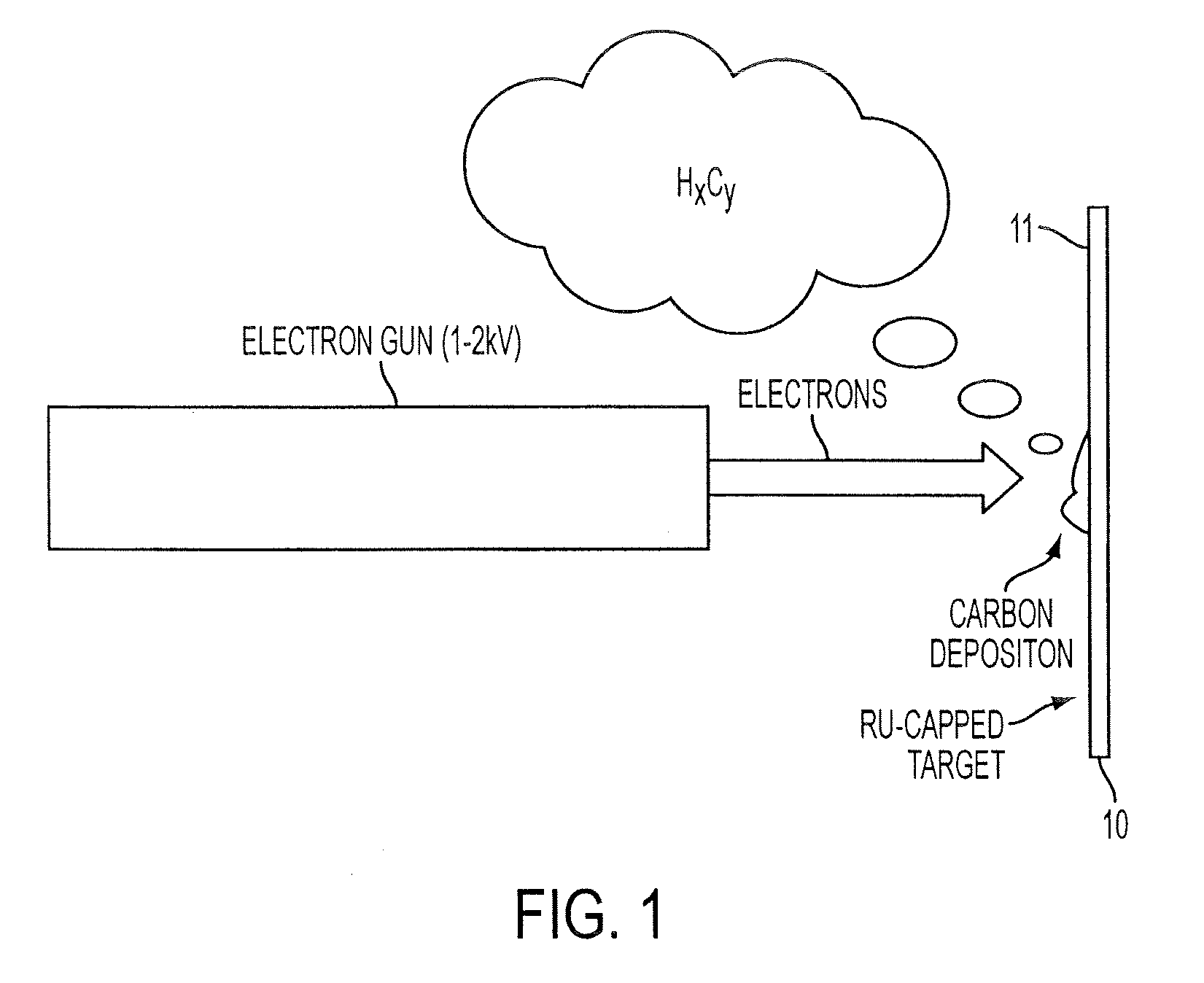

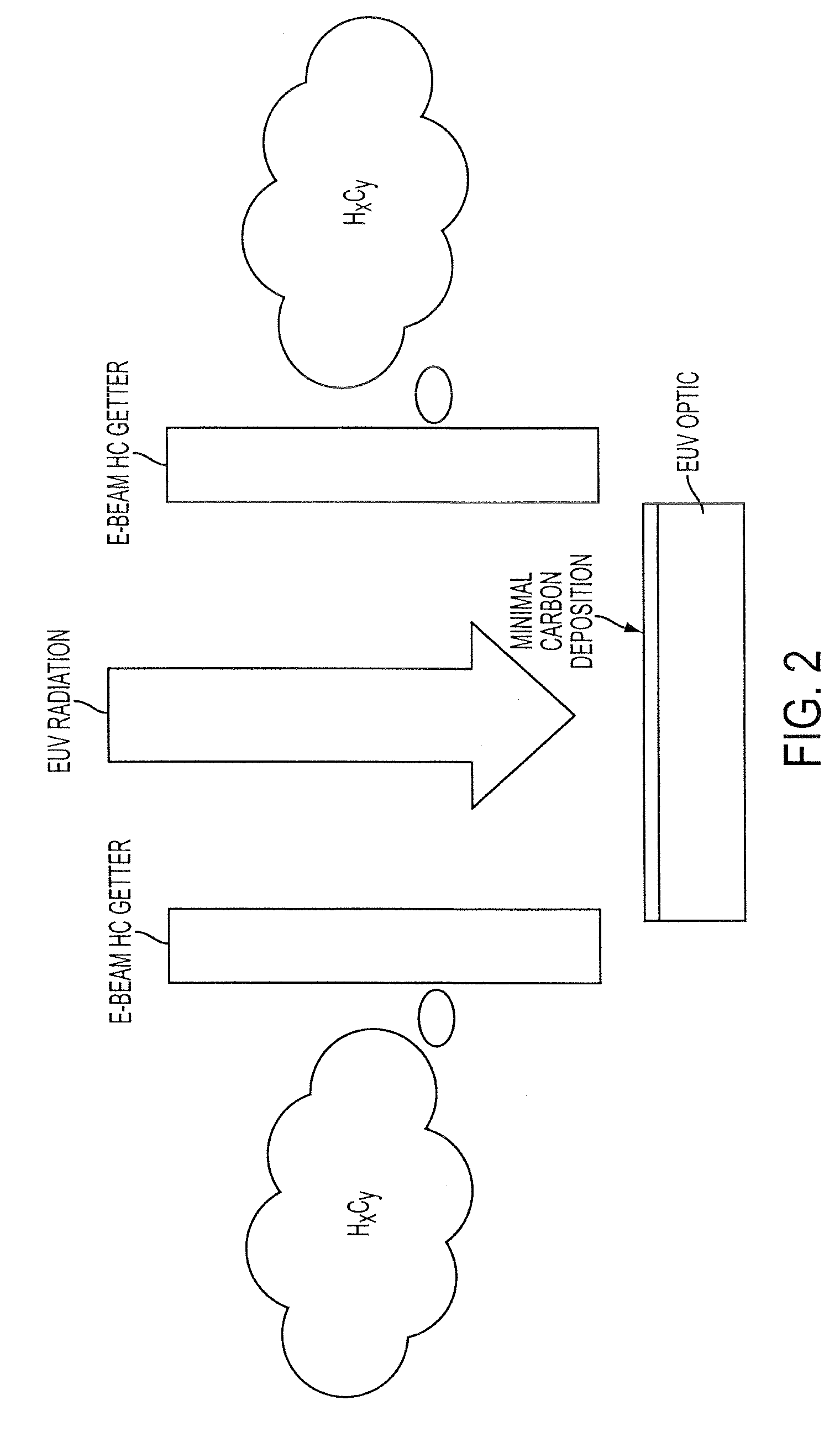

Hydrocarbon getter for lithographic exposure tools

ActiveUS20090002647A1Reduce carbon depositionAvoid adverse of adverse carbon depositionPhotomechanical apparatusSemiconductor/solid-state device manufacturingHigh energyGetter

Carbon contamination of optical elements in an exposure tool is minimized by incorporating a hydrocarbon getter. Embodiments include EUV lithography tools provided with at least one hydrocarbon getter comprising a substrate and a high energy source, such as an electron gun or separate EUV source, positioned to direct an energy beam, having sufficient energy to crack heavy hydrocarbons and form carbon, on the substrate. Embodiments also include exposure tools equipped with a hydrocarbon getter comprising an energy source positioned to impinge a beam of energy on a quartz crystal thickness monitor, a residual gas analyzer, and a controller to control the electron-current and maintain the amount of hydrocarbons in the system at a predetermined low level.

Owner:ADVANCED MICRO DEVICES INC

Composite carbon barrier coating for polysilicon ingot furnace and preparation method, graphite guard plate, polysilicon ingot furnace

ActiveCN105112995BEliminate sources of pollutionEliminate generationPolycrystalline material growthSingle crystal growth detailsCarbon compositesSilicon oxide

The invention discloses a composite carbon barrier coating for a polycrystalline silicon ingot furnace, which is used to coat the surface of a carbon material device in the ingot furnace to prevent carbon pollution, and is characterized in that: the composite carbon barrier coating includes coating A first coating composed of metal tungsten or metal molybdenum coated on the surface of the device, and a second coating coated on the first coating, the second coating is a silicon nitride layer or a silicon nitride layer In the laminated layer formed with the silicon oxide layer, the thickness of the first coating is 0.02-300 microns, and the thickness of the second coating is 0.02-300 microns. The invention also discloses a method for preparing the composite carbon barrier coating; at the same time, the invention also discloses a graphite guard plate and a polysilicon ingot furnace comprising the composite carbon barrier coating. The present invention eliminates the generation of carbon monoxide by coating the composite carbon barrier layer on the surface of the carbon material device in the polycrystalline ingot furnace, thereby reducing the impurities in the ingot polysilicon and the dislocations derived from the impurities, improving the crystal quality, and further Improve the conversion efficiency of solar cells.

Owner:TRINA SOLAR CO LTD +1

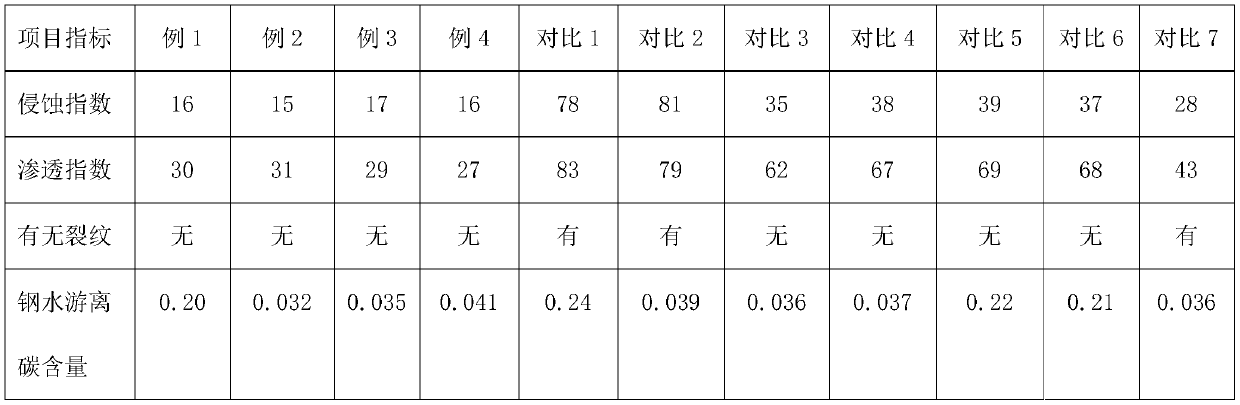

Environment-friendly carbon-free dry material

The invention discloses an environment-friendly carbon-free dry material, and belongs to the technical field of refractory materials. The dry material comprises sintered magnesia, hydrated sodium metasilicate, hydrated magnesium sulfate and boride. The dry material has a low erosion index and a low permeability index, and can adsorb impurities in molten steel in the molten steel refining process,so that the cleanliness of the molten steel is improved, and the carbon pollution of the molten steel can be reduced; and the dry material can prolong the service life of the tundish permanent lining,and is not sintered and easy to turn over after being used.

Owner:秦皇岛市首耐新材料有限公司

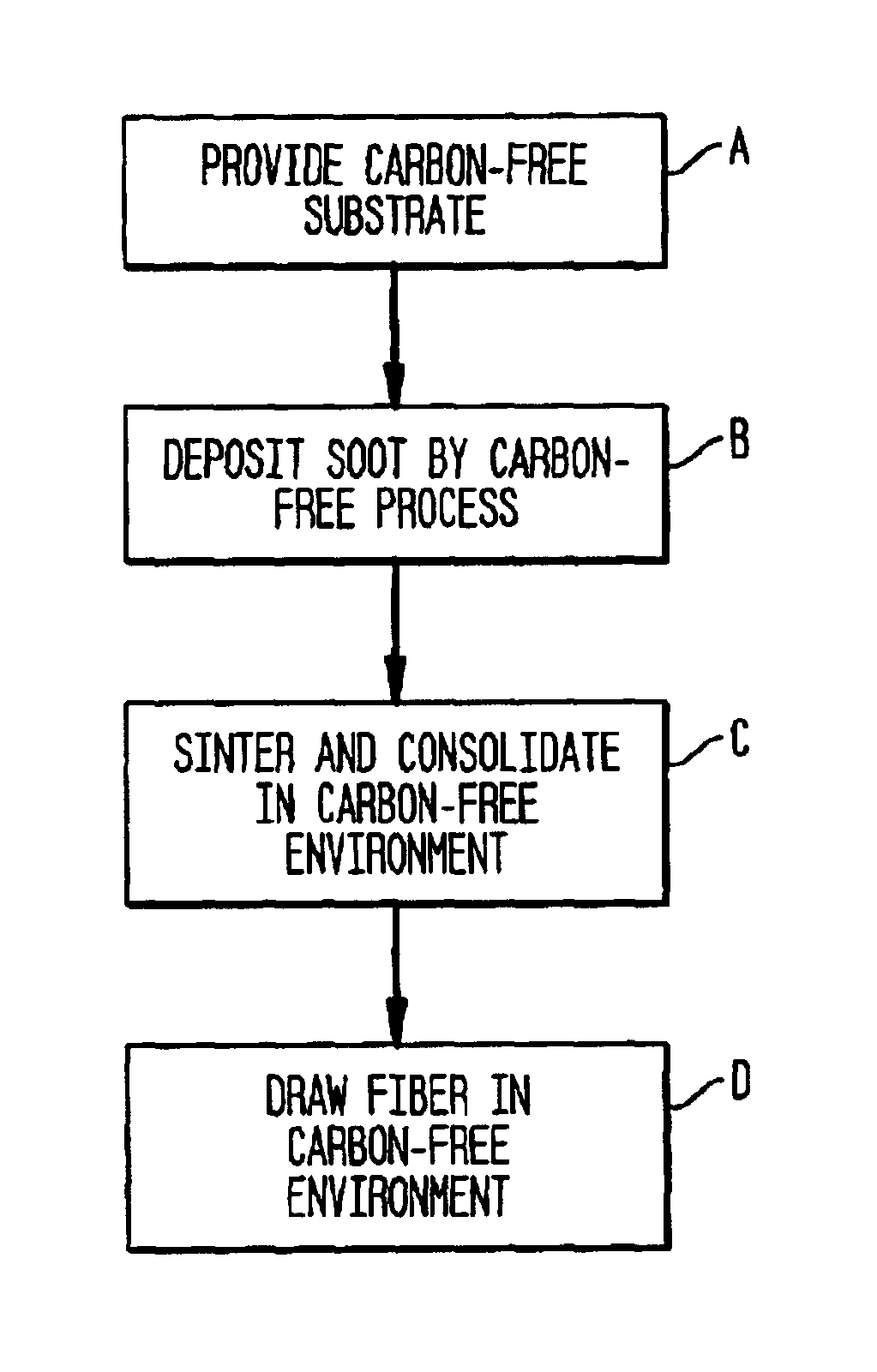

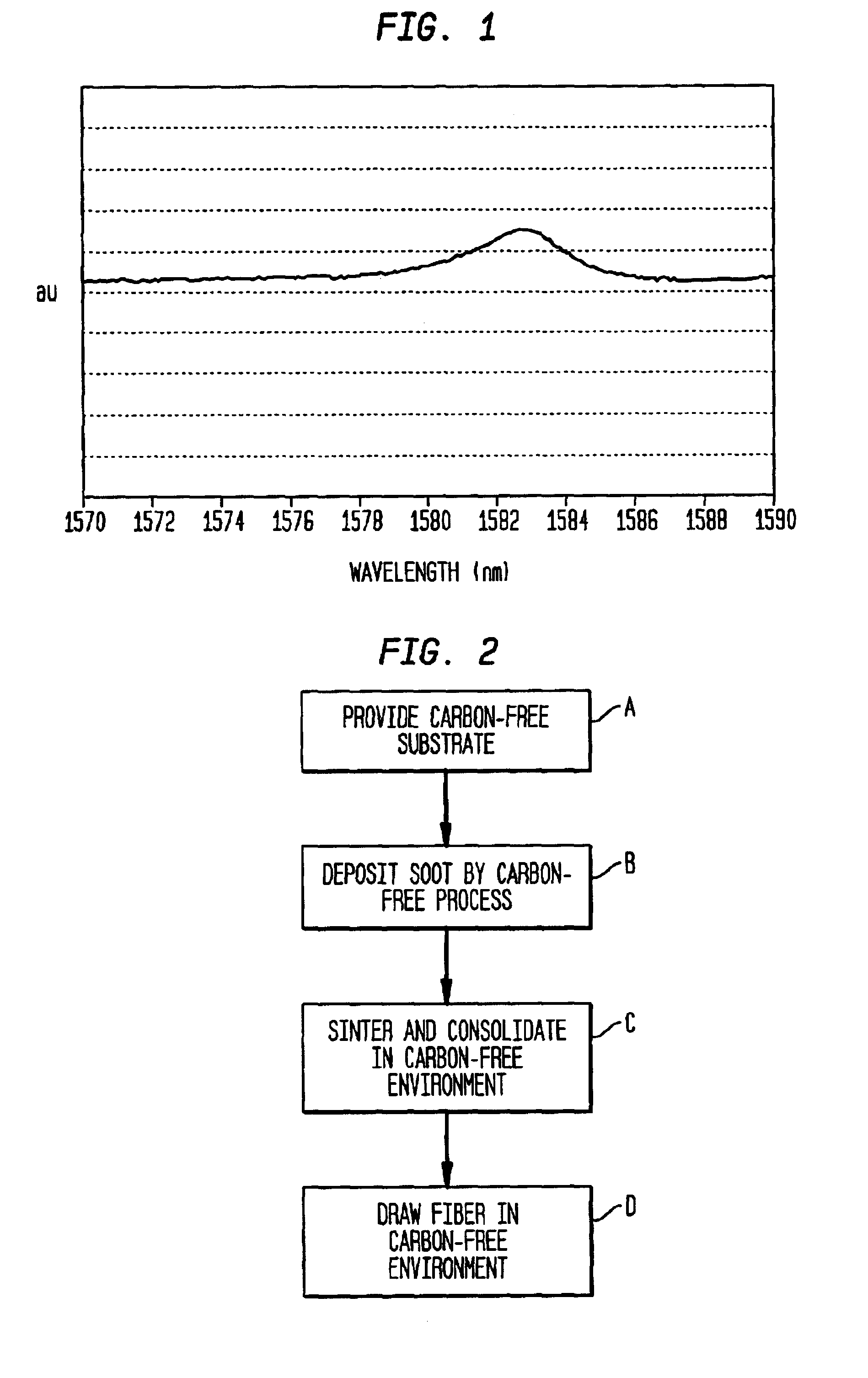

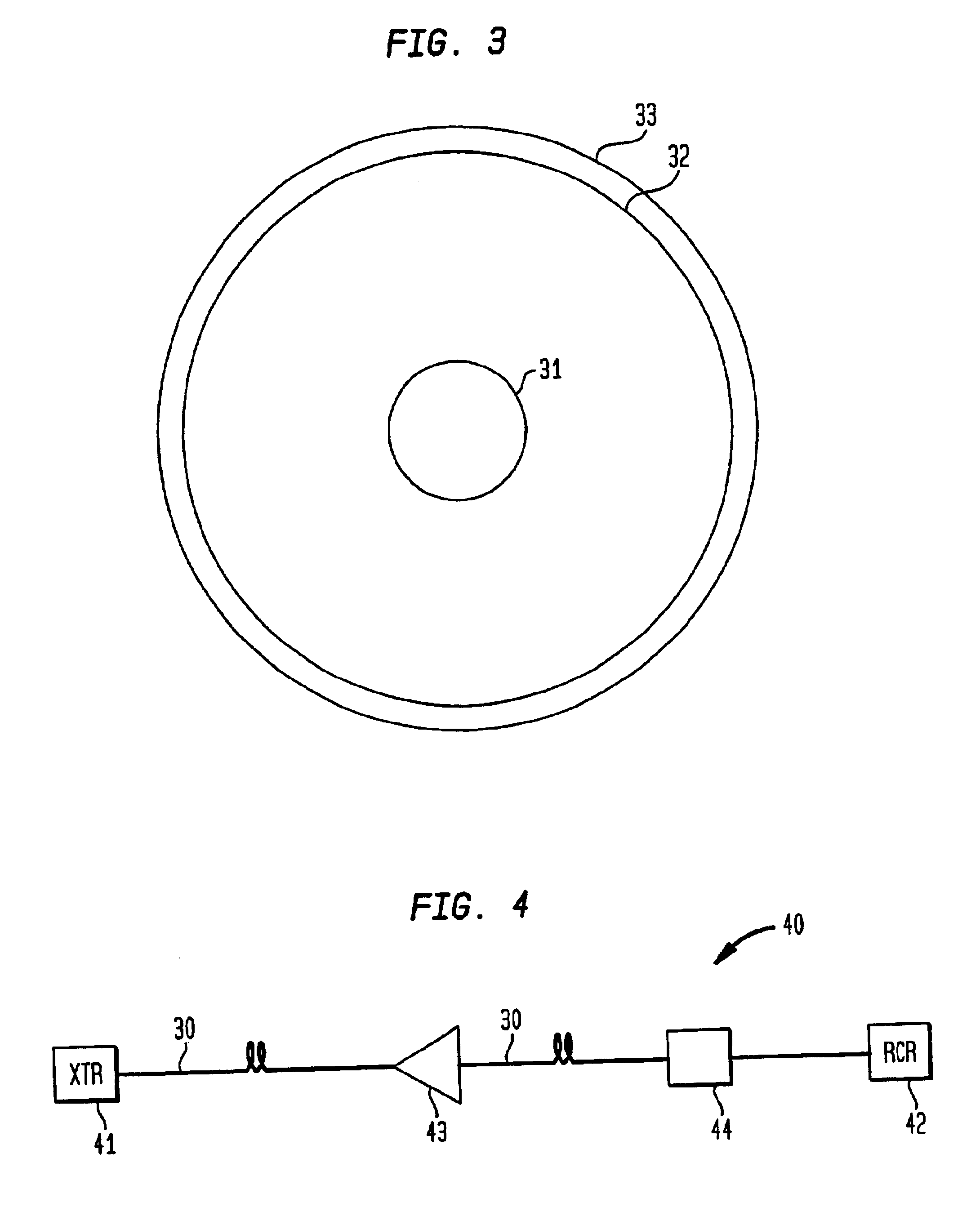

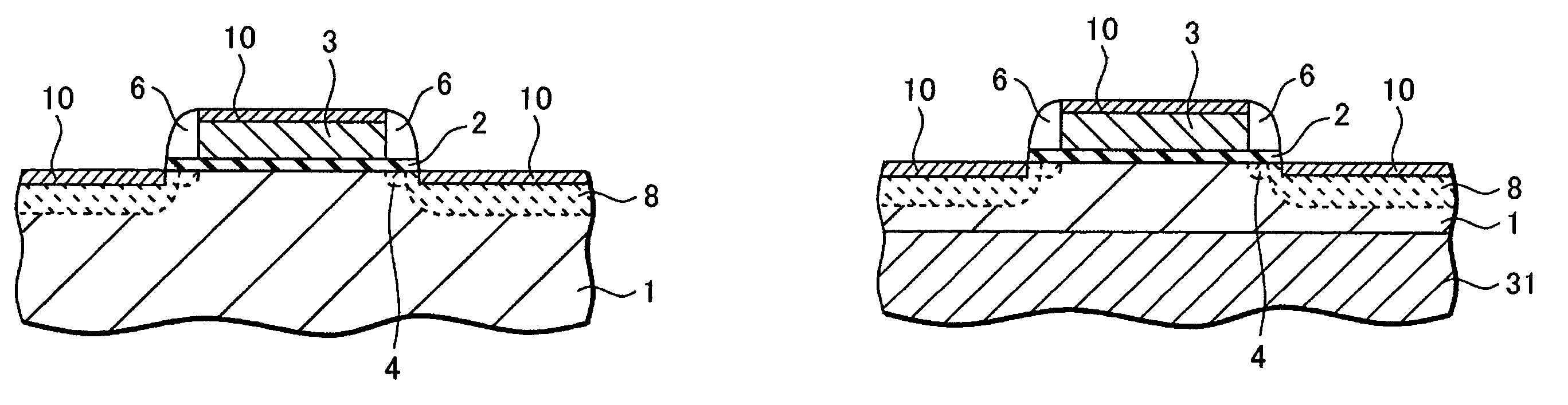

Method of making optical fiber with reduced E-band and L-band loss peaks

Applicants have discovered the existence of loss peaks in optical fiber transmission systems using wavelengths in the E-band and the L-band. Specifically, they have discovered the existence of narrow loss peaks at 1440 nm, 1583 nm and 1614 nm. Because the peaks are relatively narrow, they cannot be easily removed by conventional gain equalizers in long haul transmission systems, and although the peaks are relatively small, they can nonetheless cause transmission channels to drop out in amplified DWDM transmission systems. Applicants have further discovered that these loss peaks are due to carbon contamination of the transmission fiber. Thus optical fibers should be fabricated essentially free of carbon contamination. This means eliminating carbon-containing reagents in preform and tube-making processes.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

Manufacturing method of semiconductor device

InactiveUS7022575B2Reduce thicknessBig ratioTransistorSemiconductor/solid-state device manufacturingSalicideHigh doses

An LDD structure and a silicide layer are formed without a reduction in thickness of a silicon substrate or a carbon contamination. Forming a spacer on a sidewall of a gate electrode is performed in two process steps, i.e. dry-etching and wet-etching. Also, a silicon nitride film used as a buffer film in injection of high dose of impurities is removed by wet-etching. As a result, the reduction in thickness of the silicon substrate and the carbon contamination can be prevented. In addition, variation in depth of the high and low impurity concentration regions and silicide forming region with locations on the wafer can be suppressed because of high selection ratio available with the wet-etching.

Owner:SANYO ELECTRIC CO LTD

Method for eliminating carbon contamination of precious metal components

In the formation of sheet material from molten glass, molten glass is formed in a melting furnace and transported through a precious metal delivery system to the forming apparatus. Disclosed herein is a method to eliminate carbon-containing contamination of individual components of the precious metal delivery system prior to their installation and use. The method comprises one or more heat treating steps in an oxygen-containing atmosphere prior to and / or during assembly of the component.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com