Multilayer film improving extreme ultraviolet spectral purity and oxidation resistance

A spectral purification layer and anti-oxidation technology, applied in the field of multilayer films, can solve the problems of easy occurrence of oxide layer and carbon pollution deposition layer, pollution oxide layer, affecting the inhibition effect of spectral purification layer, etc., so as to improve the imaging quality and use Longevity, the effect of improving spectral purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

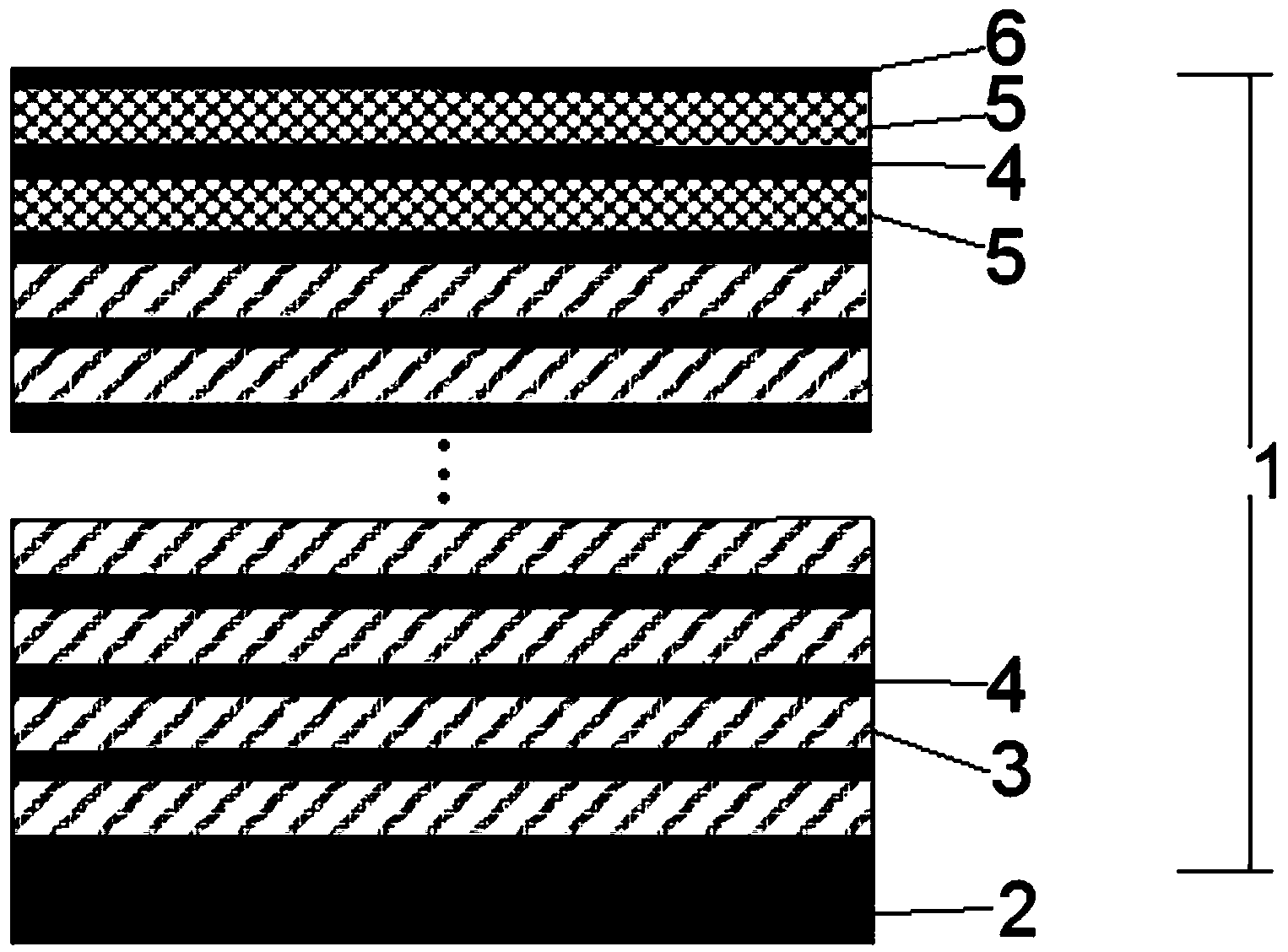

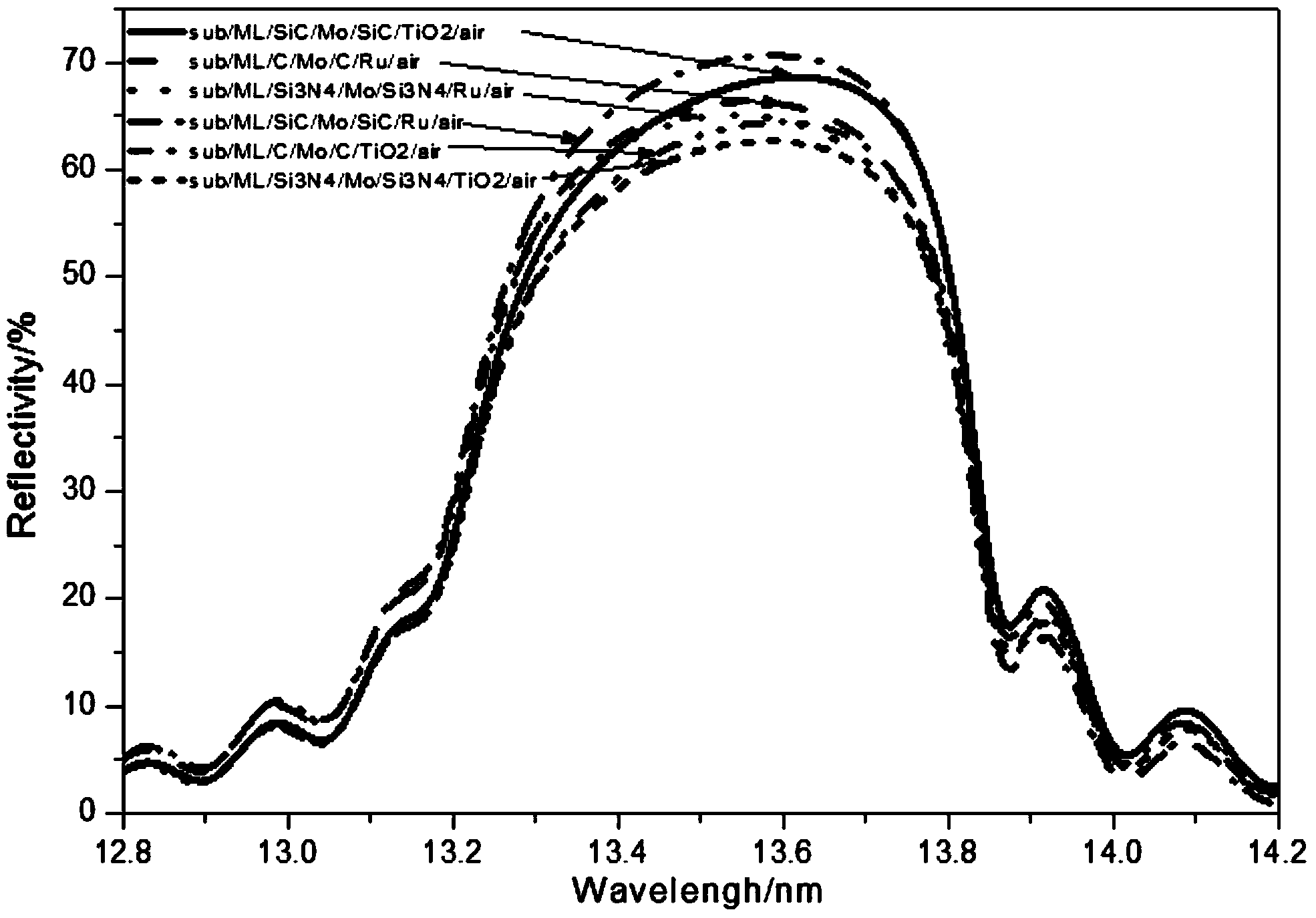

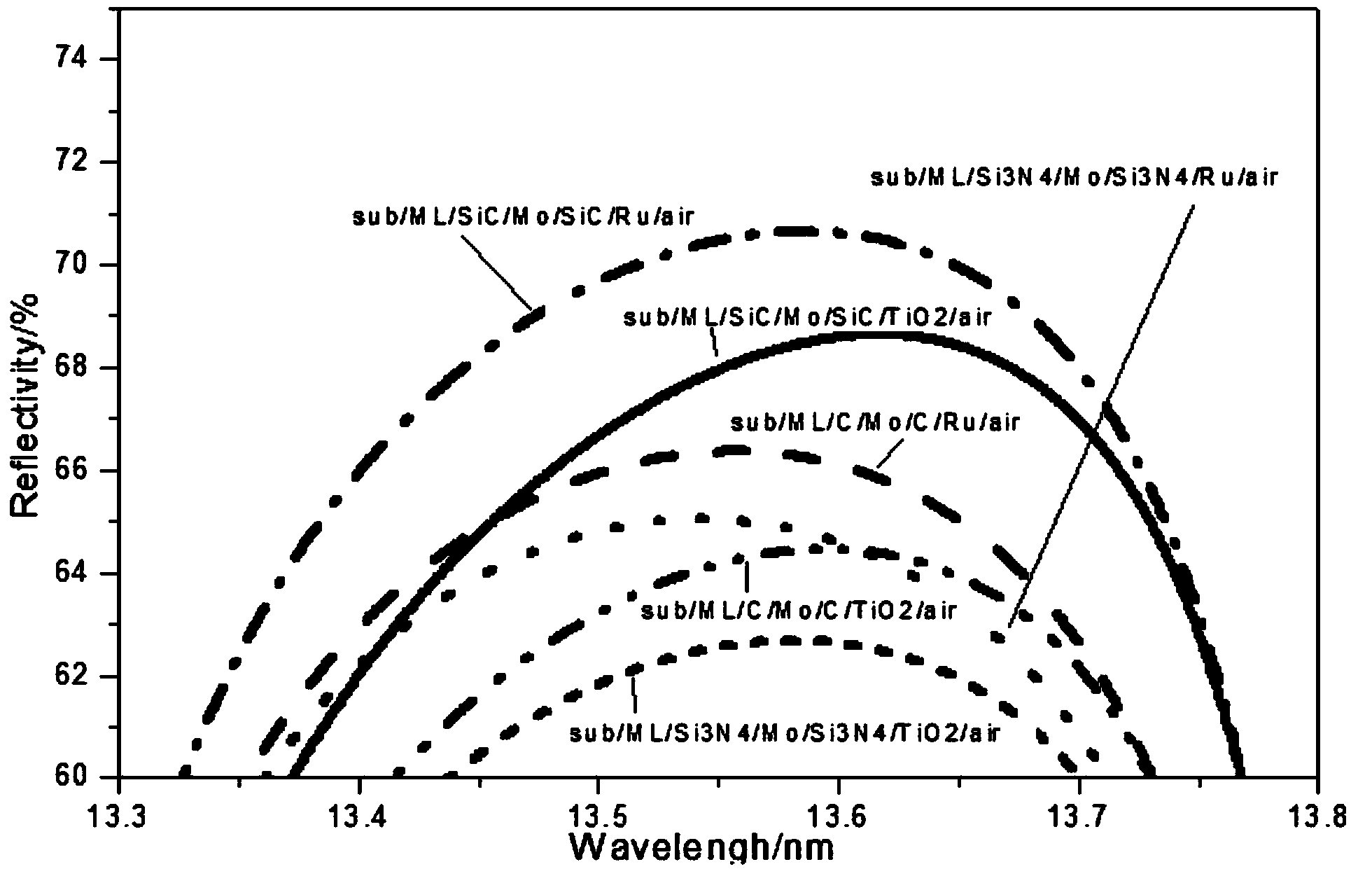

[0036] Such as figure 1 As shown, the structure of the multilayer film 1 is composed of 40 cycles of Si layer 3 / Mo layer 4, spectral purification layer 5, Mo layer 4, spectral purification layer 5 and protective layer 6. The multilayer film 1 is disposed on the substrate 2, wherein the corresponding Si layer 3 and the corresponding Mo layer 4 constitute a period, and the period thickness is 7 nm. The thickness of each spectral purification layer 5 is 3 nm, and the material is C material. The thickness of the uppermost protective layer 6 is 2 nm, and the material is Ru. Because the existence of the spectral purification layer 5 will make the multilayer film 1 less reduce the reflectance at 13.5nm, its out-of-band band, especially 160nm ~ 240nm, will have an effective inhibitory effect on the reflectivity; Layer 6 effectively reduces the oxidation of the upper film. Applying the multilayer film 1 to the substrate 2 is preferably a magnetron sputtering technology, where the Si...

Embodiment 2

[0038] The structure of the multilayer film 1 is composed of 40 cycles of Si layer 3 / Mo layer 4, spectral purification layer 5, Mo layer 4, spectral purification layer 5 and protective layer 6. The multilayer film 1 is disposed on the substrate 2, wherein the corresponding Si layer 3 and the corresponding Mo layer 4 constitute a period, and the period thickness is 7 nm. The thickness of each spectral purification layer 5 is 5 nm, and the material is SiC. The thickness of the uppermost protective layer is 1nm, the material is TiO 2 . Because the existence of the spectral purification layer 5 will make the multilayer film 1 less reduce the reflectance at 13.5nm, its out-of-band band, especially 160nm ~ 240nm, will have an effective inhibitory effect on the reflectivity; Layer 6 effectively reduces the oxidation of the upper film. Applying the multilayer film 1 to the substrate 2 is preferably a magnetron sputtering technology, where the Si layer 3 and the Mo layer 4 are DC ma...

Embodiment 3

[0040] The structure of the multilayer film 1 is composed of 40 cycles of Si layer 3 / Mo layer 4, spectral purification layer 5, Mo layer 4, spectral purification layer 5 and protective layer 6. The multilayer film 1 is disposed on the substrate 2, wherein the corresponding Si layer 3 and the corresponding Mo layer 4 constitute a period, and the period thickness is 7 nm. The thickness of each spectral purification layer 5 is 4.2nm, and the material is Si 3 N 4 . The thickness of the uppermost protective layer is 3nm, the material is TiO 2 . Because the existence of the spectral purification layer 5 will make the multilayer film 1 less reduce the reflectance at 13.5nm, its out-of-band band, especially 160nm ~ 240nm, will have an effective inhibitory effect on the reflectivity; Layer 6 effectively reduces the oxidation of the upper film. Applying the multilayer film 1 to the substrate 2 is preferably a magnetron sputtering technology, where the Si layer 3 and the Mo layer 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com