Efficient, energy saving and power improving fuel additive and preparation method thereof

A high-efficiency, energy-saving, additive technology, applied in the field of fuel additives, can solve the problems of secondary pollution and unsatisfactory effects, and achieve the effects of reducing corrosion, improving combustion efficiency, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

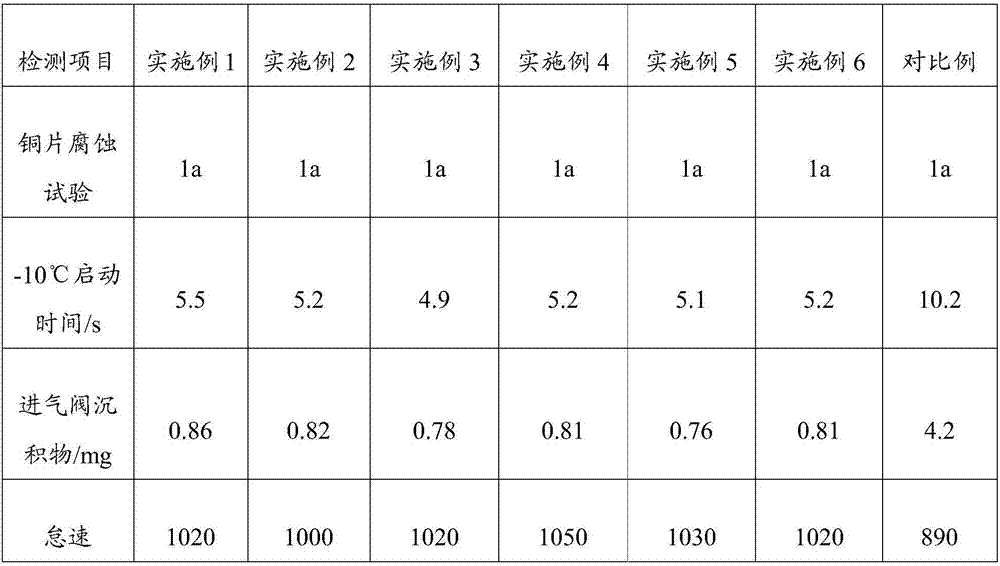

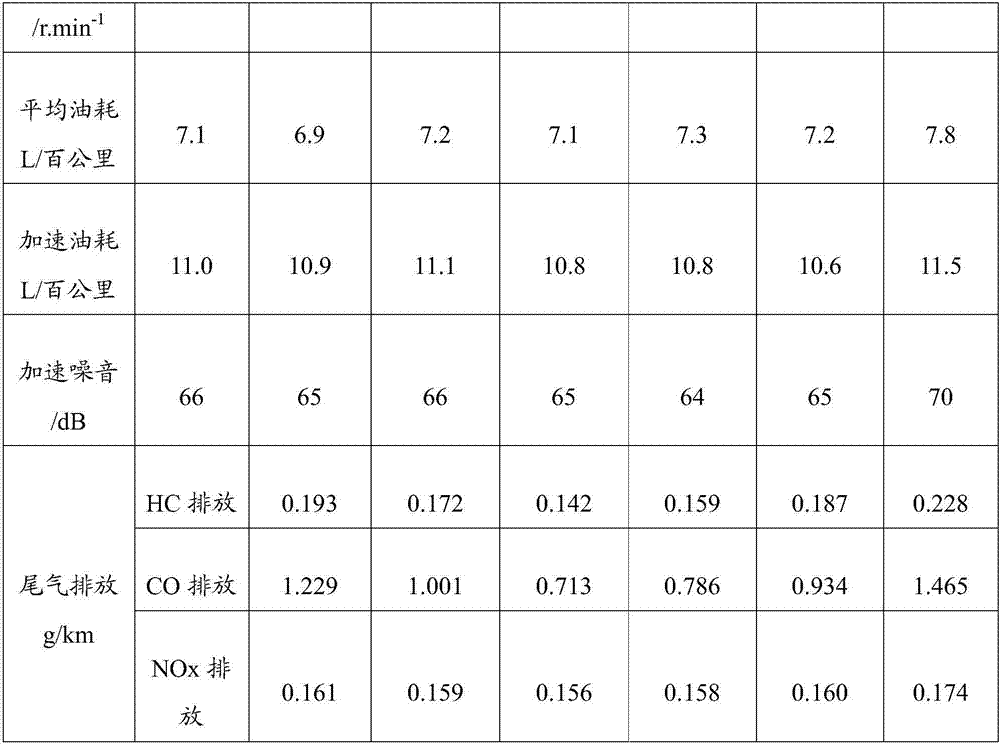

Examples

Embodiment 1

[0031] A high-efficiency, energy-saving and power-enhancing fuel additive. The raw materials for its preparation are composed of the following components in parts by weight: 20 parts of lauryl isopropanolamine, 15 parts of polyisobutylene sulfur phosphide barium salt, polyisobutylene polysuccinyl 10 parts of amine, 0.5 part of hydroxyl silicone oil, 0.6 part of sulfurized vegetable fatty acid ester, 0.8 part of octyl glucoside, 10 parts of petroleum ether, 5 parts of combustion enhancer, 0.1 part of glyceryl monostearate;

[0032] Among them, the combustion enhancer is obtained by mixing methyl ferrocenemethanol and polyvinyl methyl ether in a weight ratio of 1:1.

[0033] Specifically follow the steps below:

[0034] Step 1, weigh methylferrocenemethanol and polyvinyl methyl ether according to the weight ratio of 1:1, then mix them at room temperature, and stir for 30min at the speed of the mixer at 1000r / min, after the stirring is completed, the combustion accelerant is obta...

Embodiment 2

[0039] A high-efficiency, energy-saving and power-enhancing fuel additive. The raw materials for its preparation are composed of the following components in parts by weight: 30 parts of lauryl isopropanolamine, 12 parts of polyisobutylene sulfur phosphide barium salt, polyisobutylene polysuccinyl 8 parts of amine, 0.5 part of methyl silicone oil, 1 part of sulfurized vegetable fatty acid ester, 1 part of octane glycoside, 20 parts of petroleum ether, 10 parts of combustion enhancer, 0.1 part of sorbitan fatty acid;

[0040] Wherein, the combustion enhancer is obtained by mixing methyl ferrocenemethanol and polyvinyl methyl ether in a weight ratio of 1:1.5.

[0041] The preparation method is the same as that of Example 1, except that the formula is changed into that of Example 2.

Embodiment 3

[0043] A high-efficiency, energy-saving and power-enhancing fuel additive. The raw materials for its preparation are composed of the following components in parts by weight: 40 parts of lauryl isopropanolamine, 10 parts of polyisobutylene sulfur phosphide barium salt, polyisobutylene polysuccinyl 5 parts of amine, 1 part of carboxyl silicone oil, 0.5 part of sulfurized vegetable fatty acid ester, 0.5 part of octyl glucoside, 25 parts of petroleum ether, 15 parts of combustion enhancer, 0.2 part of vegetable oleic acid;

[0044] Among them, the combustion enhancer is obtained by mixing methyl ferrocenemethanol and polyvinyl methyl ether in a weight ratio of 1:2.

[0045] The preparation method is the same as in Example 1, except that the formula is changed into that of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com