Carbon pollution cleaning method of EUV optical element

A technology for optical components and carbon pollution, applied in chemical instruments and methods, cleaning methods and utensils, cleaning flexible objects, etc., can solve the problems of damaging the surface of optical components, changing the multilayer film structure of EUV optical components, etc., achieving low cost, The effect of less damage and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

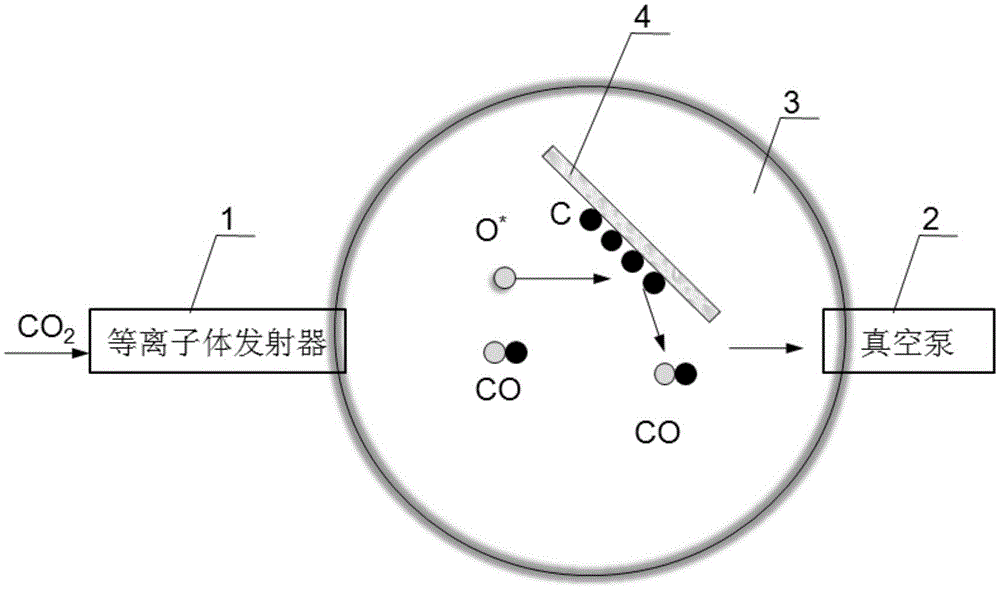

[0033] see figure 1 , where 1 represents the plasma emitter, 2 represents the vacuum pump, 3 represents the cleaning chamber, and 4 represents the optical component sample contaminated by carbon exposure. The specific cleaning process is:

[0034] 1) Put the optical element sample 4 contaminated by carbon exposure into the cleaning chamber 3, and use the vacuum pump 2 to vacuum the cleaning chamber 3, and the vacuum degree is required to reach 10 -5 above mbar;

[0035] 2) Start the plasma emitter 1 and inject carbon dioxide with a supply flow rate of 2 sccm, so that the entire cleaning chamber 3 is filled with plasma carbon dioxide, and the surface carbon-contaminated sample 4 is immersed in the plasma carbon dioxide atmosphere, so that carbon dioxide and The deposited carbon reacts to generate carbon monoxide to realize the cleaning of the optical element sample, and the vacuum pump 2 pumps out the carbon monoxide generated in the cleaning chamber 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com