Carbon contamination-preventing coating of carbon material for polysilicon ingot furnace and preparation process thereof

A polycrystalline silicon ingot furnace and carbon material technology, which is applied in the direction of polycrystalline material growth, single crystal growth, crystal growth, etc., can solve the problems of not meeting the needs of long-term use, carbon pollution of silicon melt, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

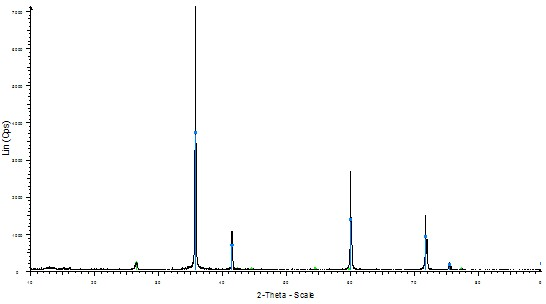

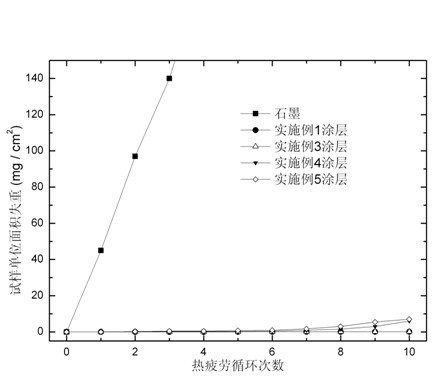

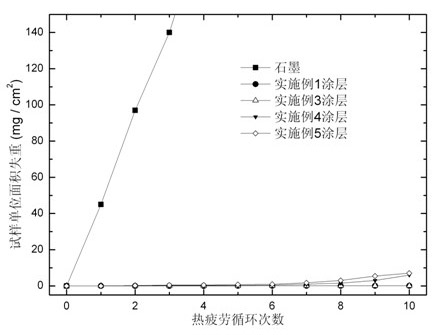

[0019] An anti-carbon pollution coating of carbon materials for polysilicon ingot furnaces, which is composed of silicon carbide. The preparation process is as follows: using silicon melt as the silicon source, and burying a graphite test block in a pure silicon raw material in a quartz crucible, The total amount of silicon material ensures that the graphite test block can be completely immersed in silicon melt after its melting. Heat this quartz crucible in an argon-protected resistance furnace to 1450°C to melt the silicon material, and then keep it for 20 minutes, then use a graphite clamp to clamp the graphite test block out of the melt. After the furnace is powered off, the graphite is cooled down. The test block is taken out of the furnace; HF-HNO with a volume ratio of 3: 1: 15 3 -H 2 O mixed acid solution dissolves and removes the remaining silicon on the surface of the graphite test block, and then rinses with deionized water to obtain it.

Embodiment 2

[0021] An anti-carbon pollution coating of carbon materials for polysilicon ingot furnaces. The composition is silicon carbide. The preparation process is as follows: using silicon melt as the silicon source, the carbon-carbon composite material test block is buried in a pure quartz crucible. In the silicon raw material, the total amount of silicon material ensures that the carbon-carbon composite material test block can be completely immersed in silicon melt after its melting. The quartz crucible was heated to 1450℃ in an argon-protected resistance furnace to melt the silicon material, and then kept for 20 minutes, then the carbon-carbon composite material test block was clamped out of the melt with a graphite clamp, and the furnace was powered off. After cooling, take the carbon-carbon composite test block out of the furnace; use HF-HNO with a volume ratio of 3: 1: 15 3 -H 2 The O mixed acid solution dissolves and removes the remaining silicon on the surface of the carbon-carb...

Embodiment 3

[0023] An anti-carbon pollution coating of carbon materials for polysilicon ingot casting furnaces. The composition is silicon carbide. The preparation process is: using silicon powder as the silicon source, mixing silicon powder with water, ethanol and polyethylene glycol into a slurry, and spraying On the graphite surface, after drying, heat it to 1460°C under the protection of argon in a resistance furnace for 60 minutes and then cool it down in the furnace.

[0024] The preparation method of the slurry is as follows: mixing silicon powder, water, ethanol, and polyethylene glycol in a weight ratio of 20:100:50:80, and stirring for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com