Patents

Literature

49results about How to "Shorten production downtime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molded fiber manufacturing

InactiveUS20050150624A1Reduce energy consumptionPrevent air infiltrationFibreboardWater-repelling agents additionFiberMolded pulp

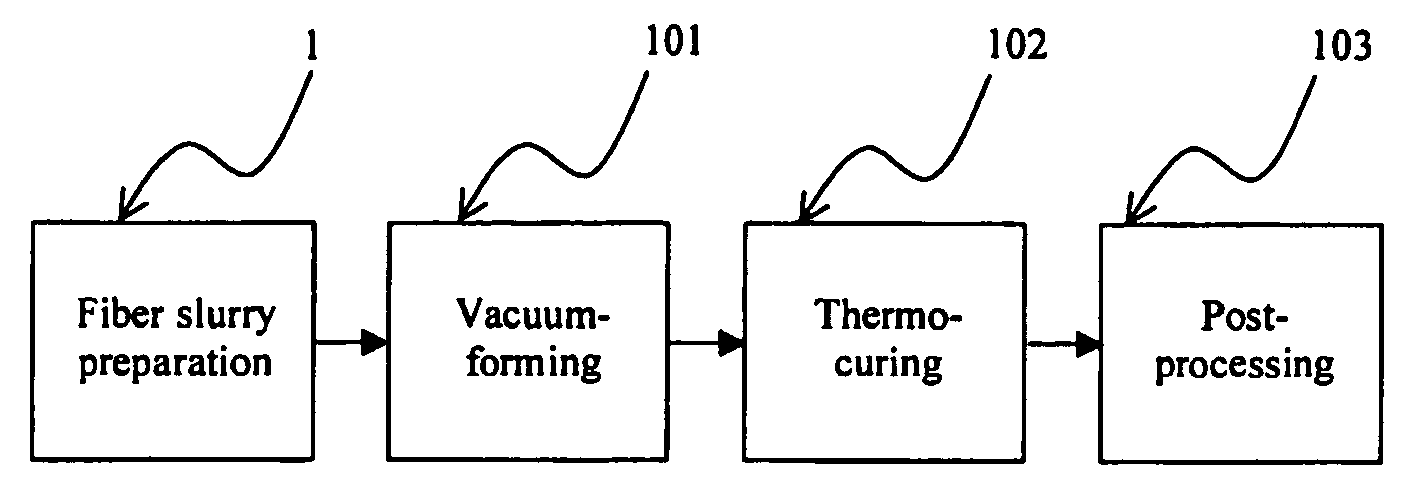

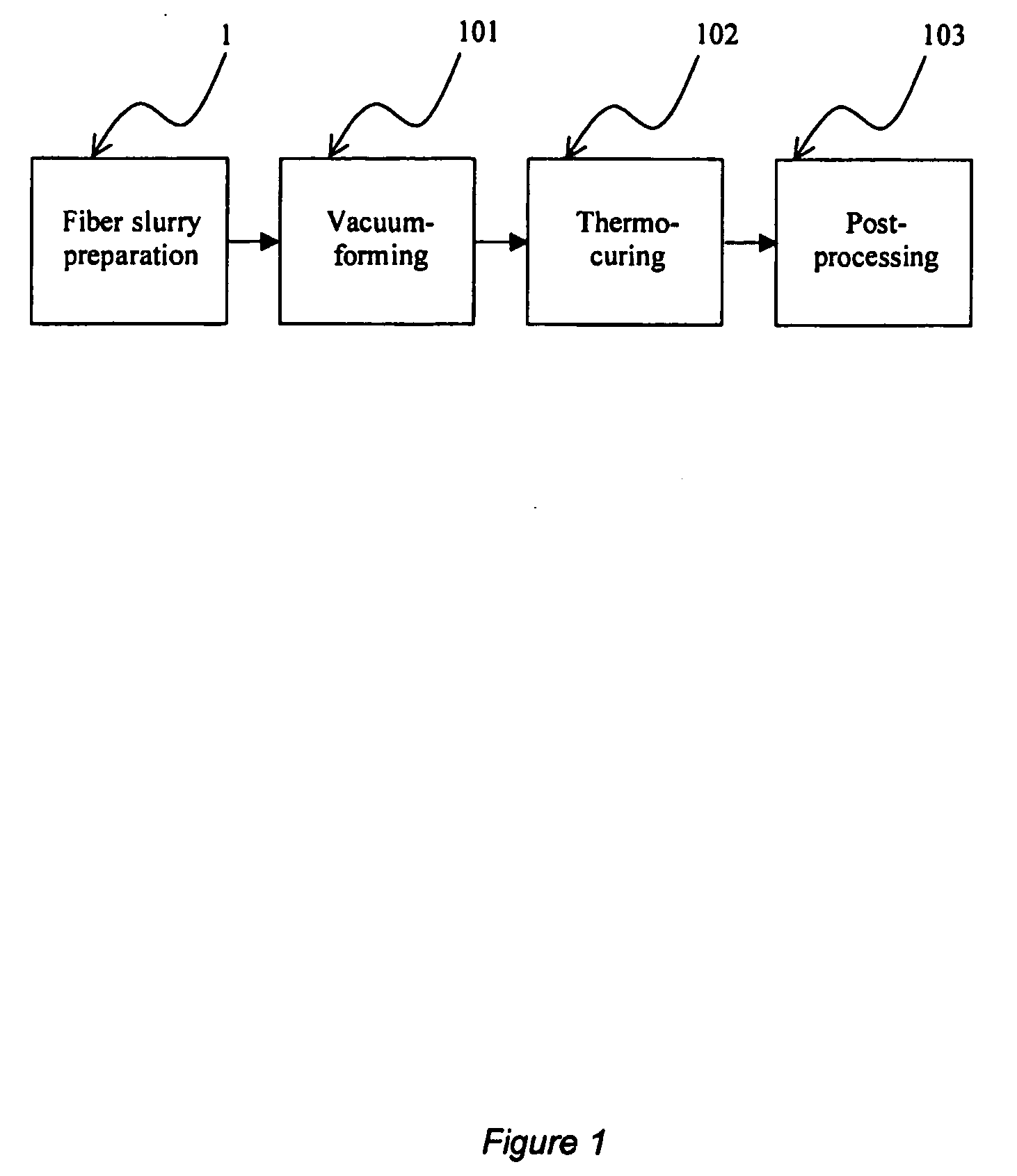

Molded fiber products using agriculture residues are economical and environmentally beneficial. Molded fiber manufacturing is different from molded pulp. The present invention discloses a method of and an apparatus for the manufacturing of molded fiber shaped body (10) using low consistency fiber slurry (12) subject to vacuum-forming and thermo-curing. The use of porous material as mold inserts for both vacuum-forming (101) and thermo-curing (102) stations provides improved productivity and enables ease of mold release. The incorporation of self-cleaning techniques further ensures consistent performance of the manufacturing system.

Owner:GRENIDEA TECH PTE

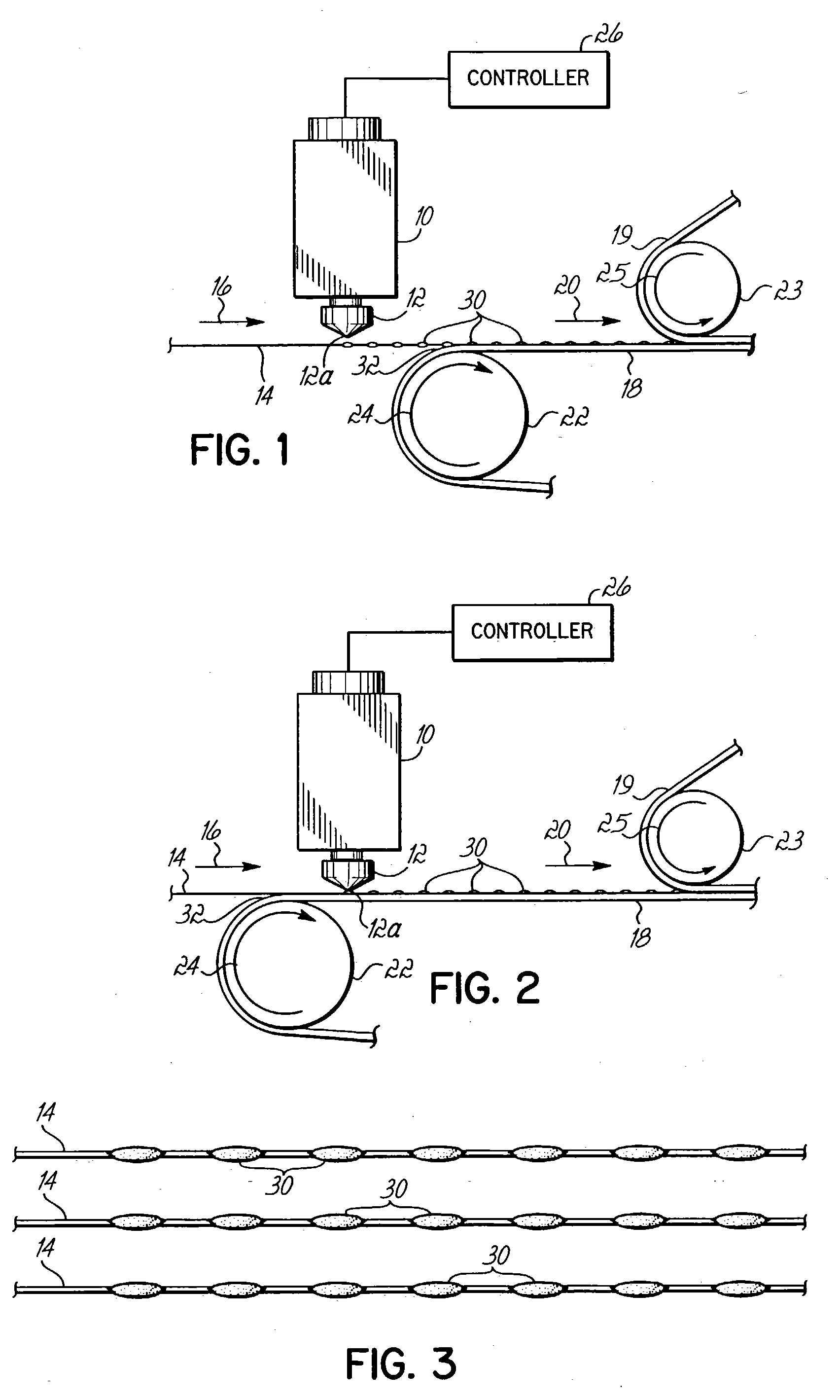

Method of securing elastic strands to flat substrates and products produced by the method

PendingUS20050013975A1Cost reductionIncrease creep resistanceLiquid surface applicatorsPersonal careEngineeringAdhesive

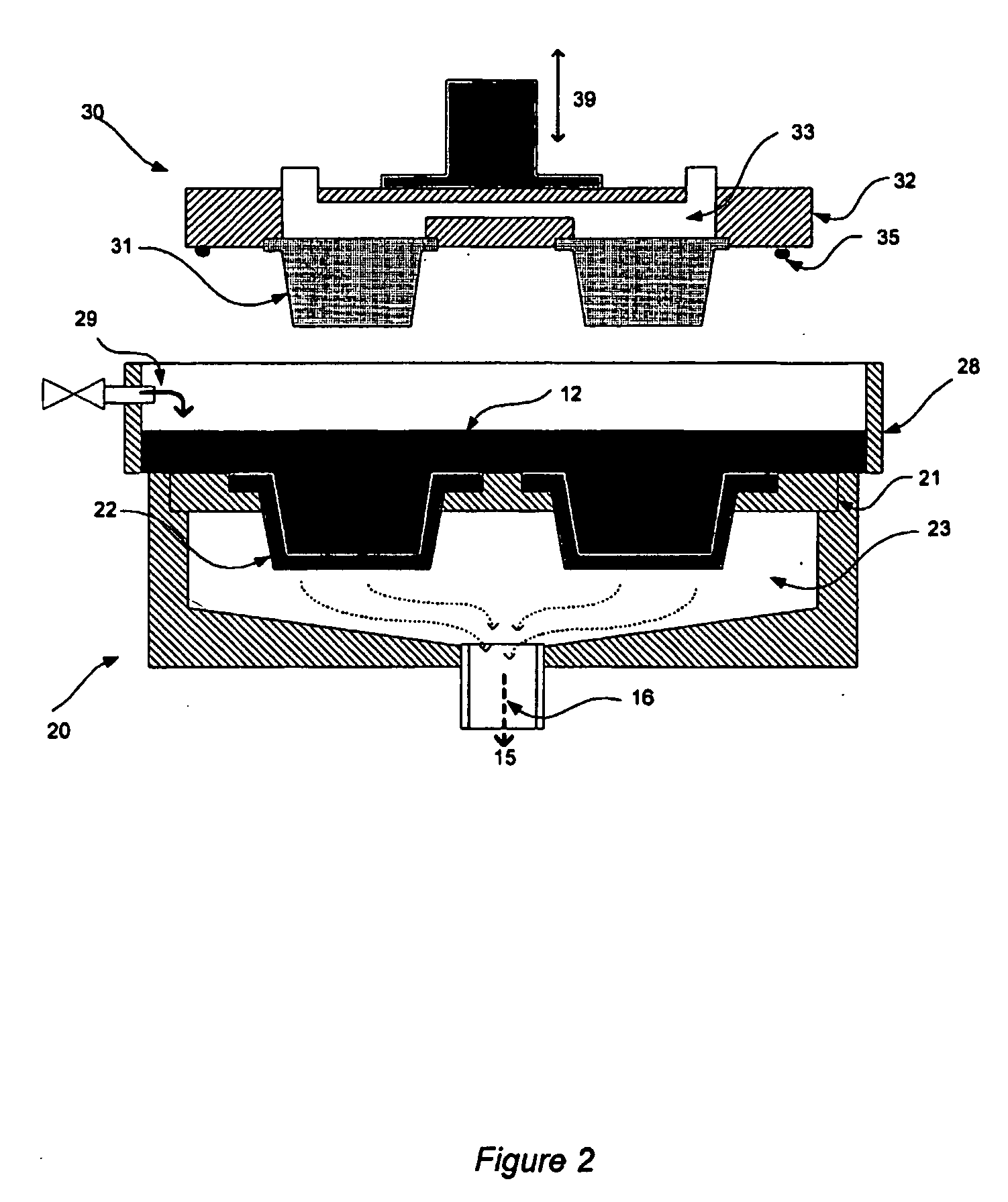

A method of securing an elastic strand to a sheet of material includes moving the elastic strand and the sheet in a converging manner from a position in which the elastic strand is spaced from the sheet to another position in which the elastic strand contacts one surface of the sheet. Discrete elongate segments of adhesive are intermittently applied to the strand. The elongate segments of adhesive secure the strand to the sheet. Various articles of manufacture may be formed using the method, including hygienic articles such as diapers.

Owner:NORDSON CORP

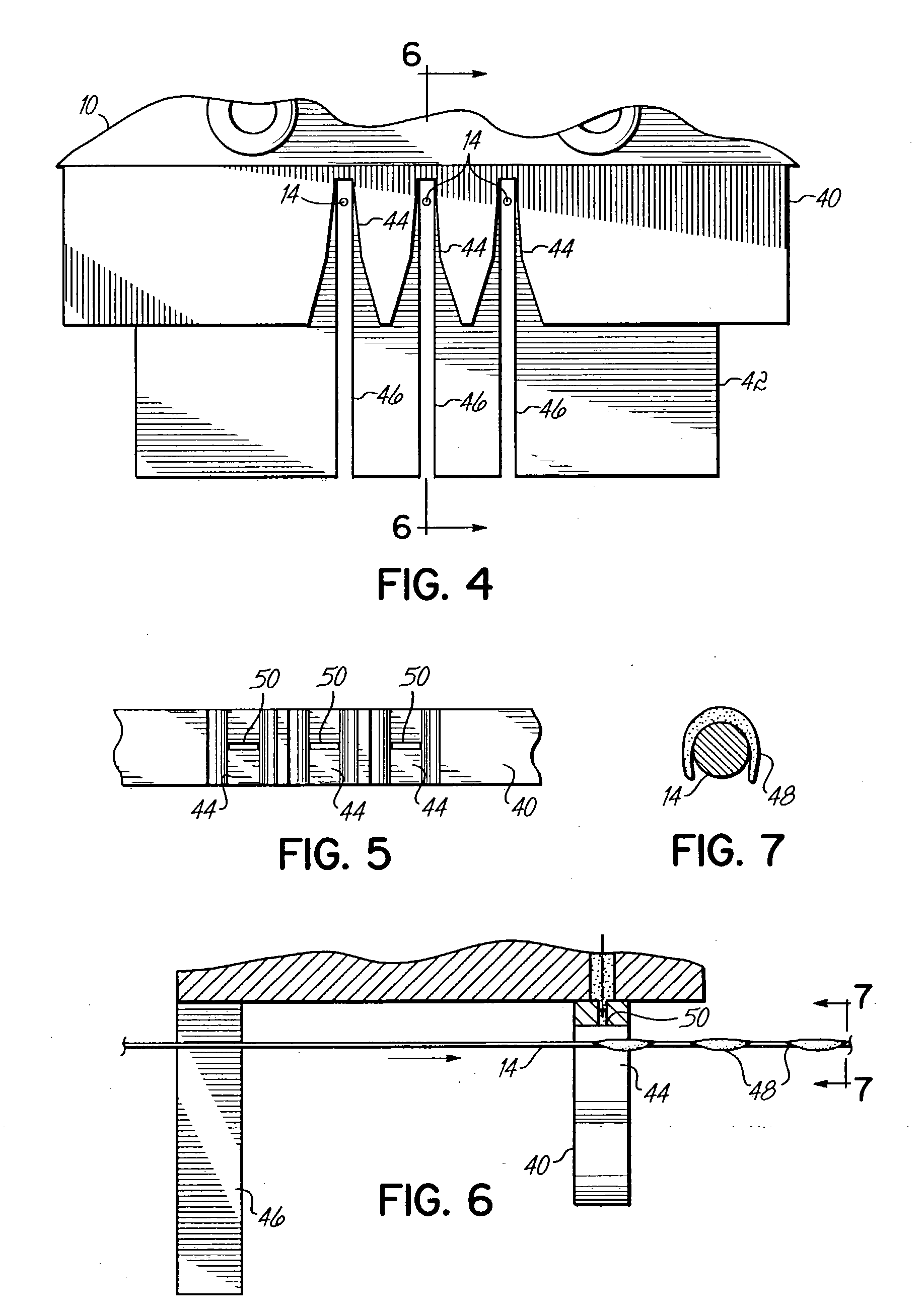

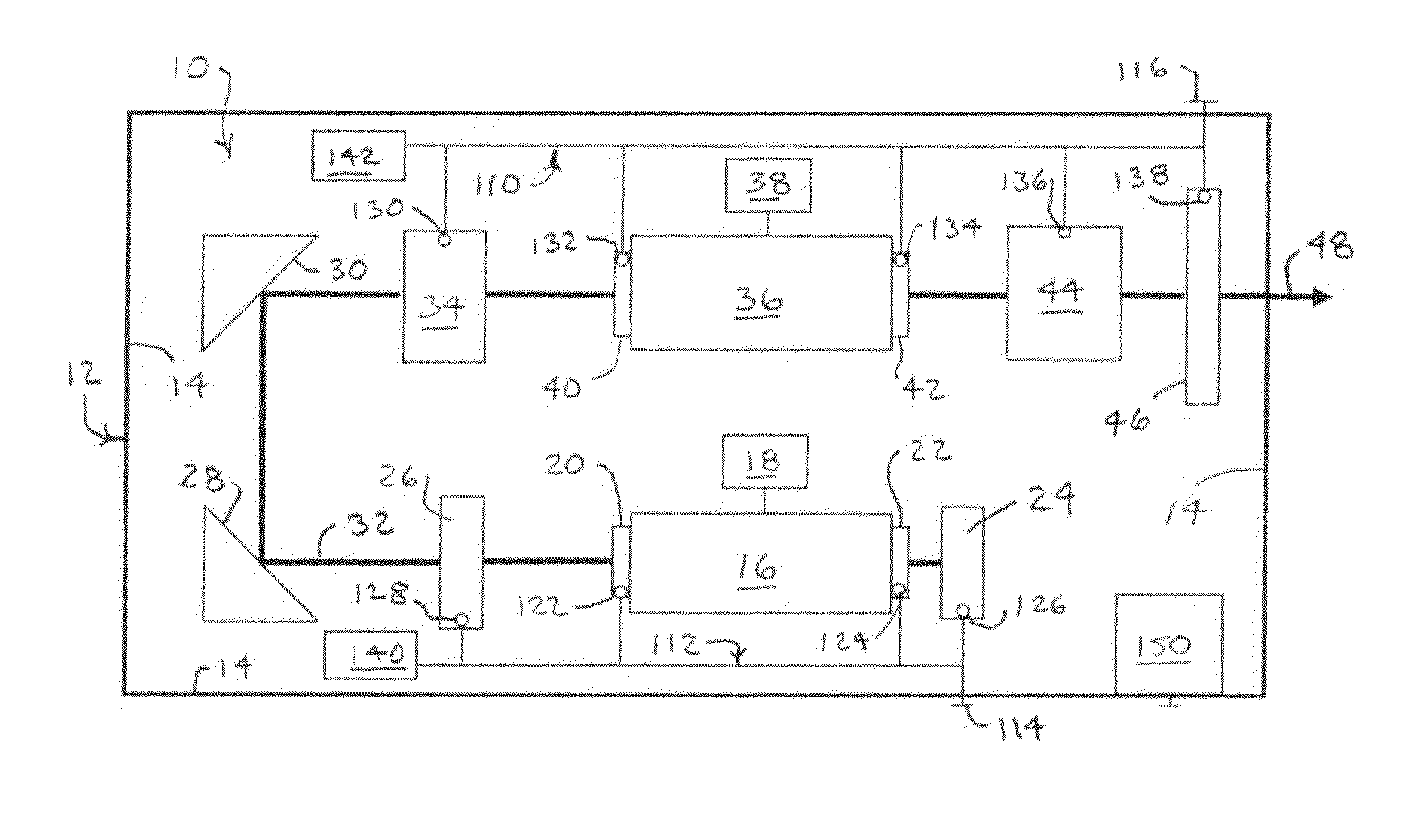

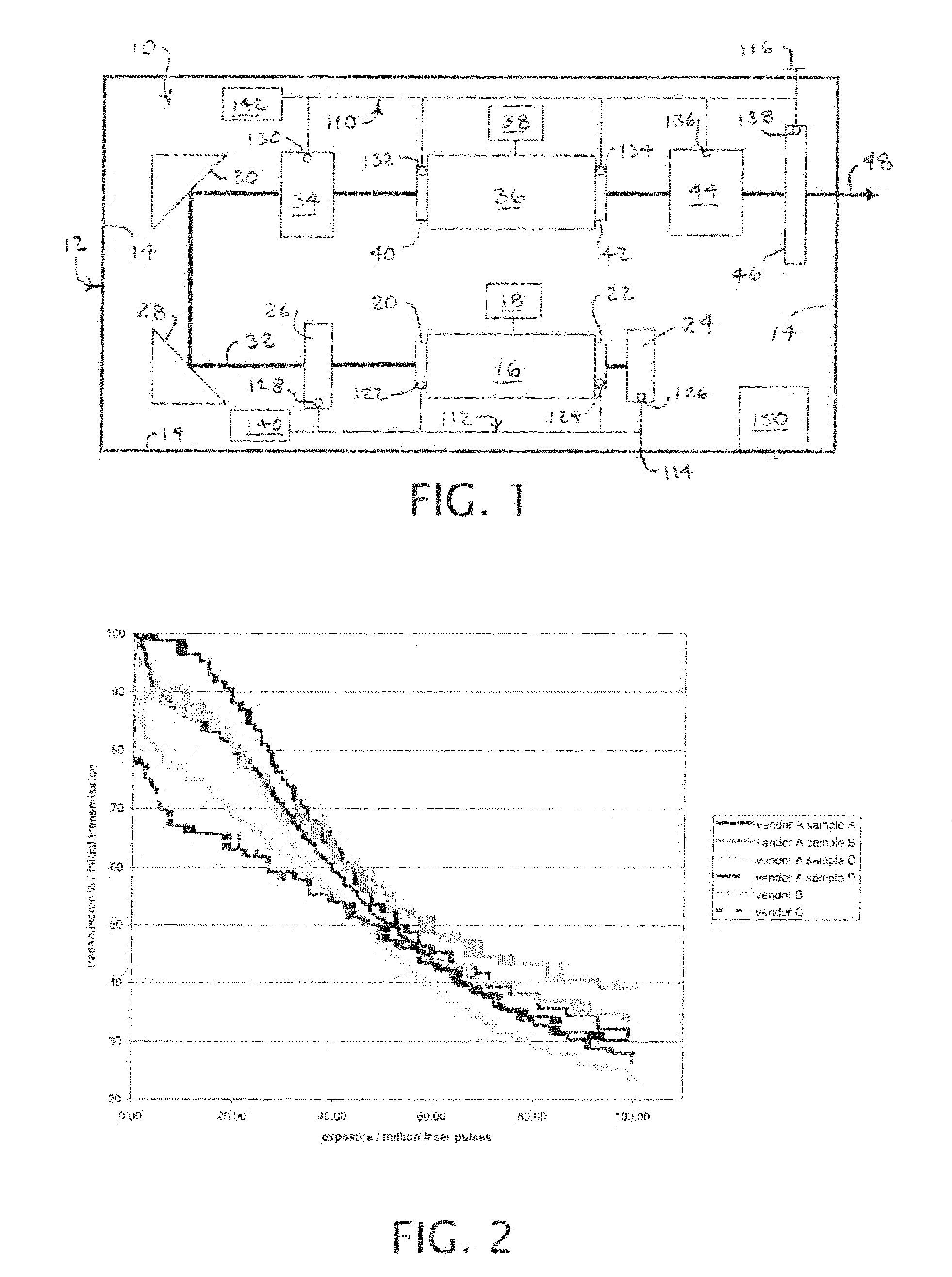

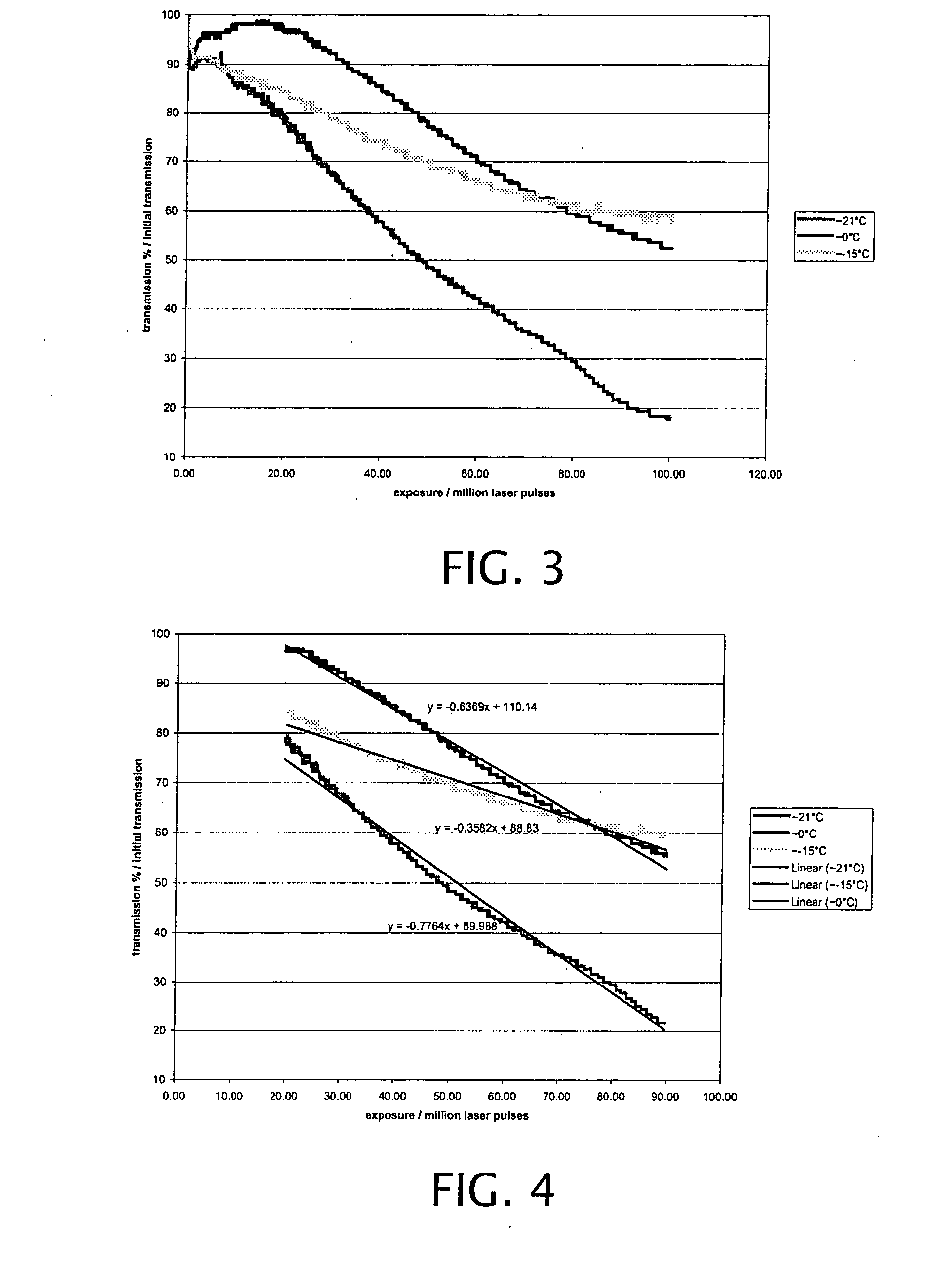

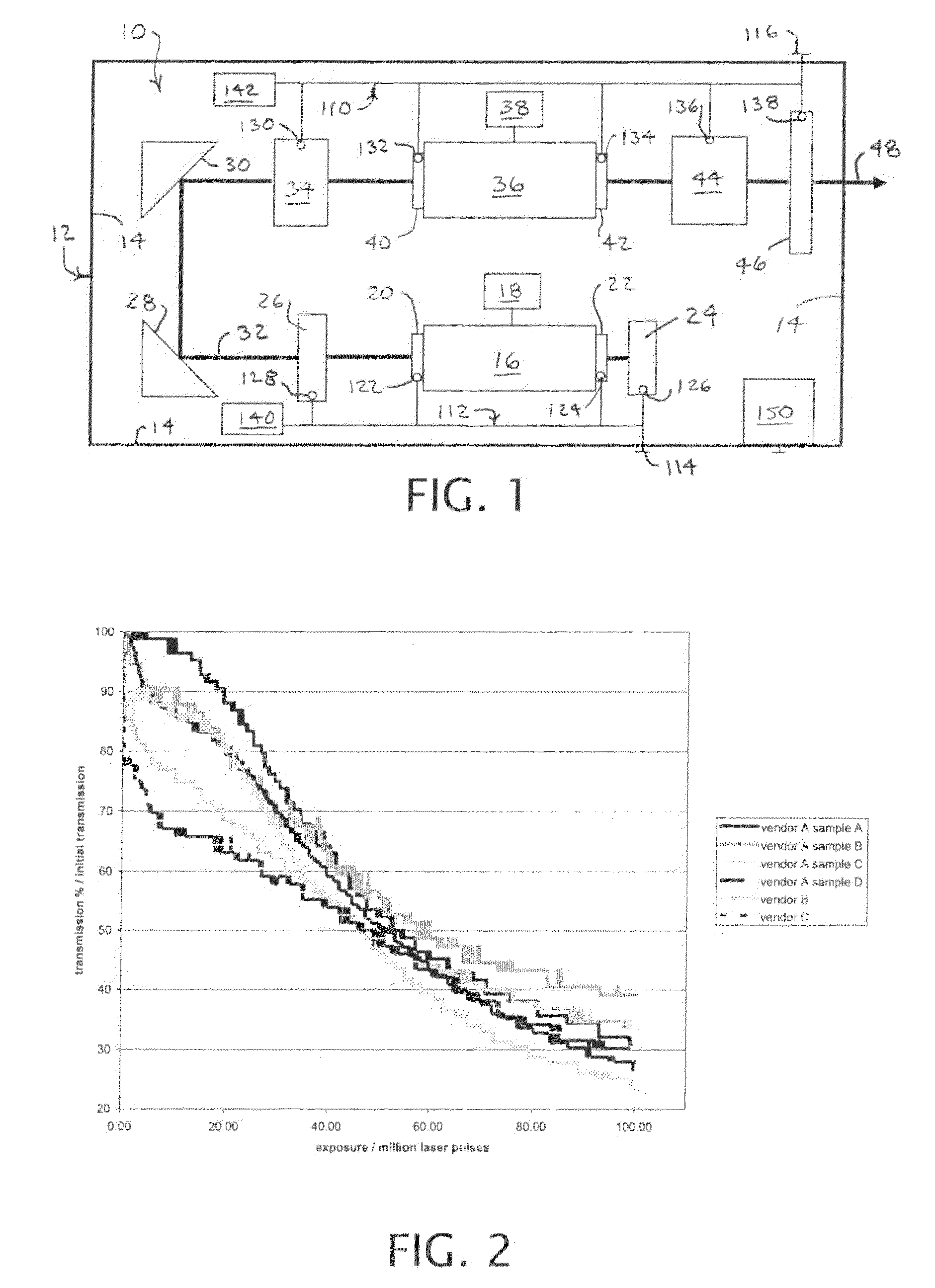

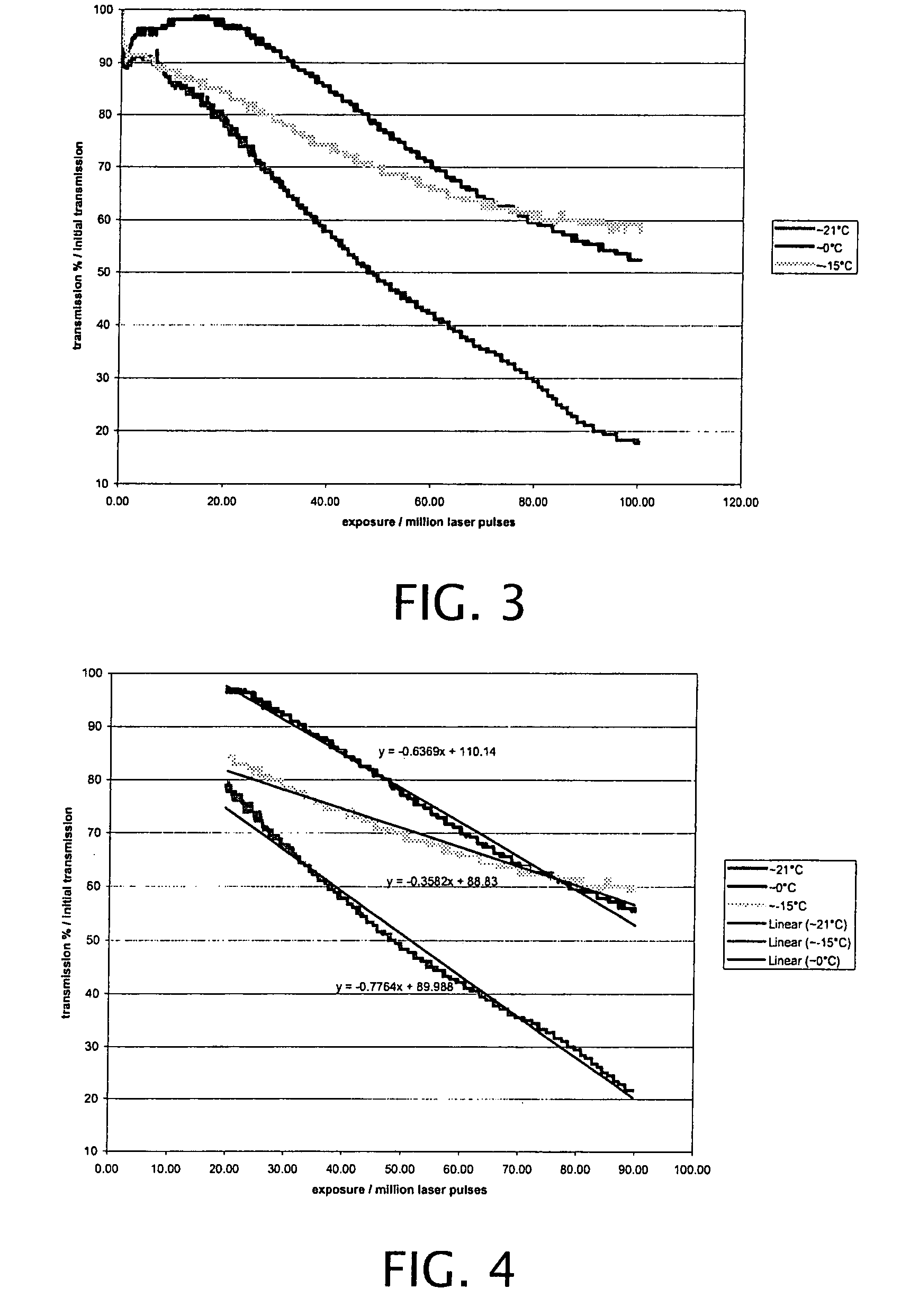

Active cooling of crystal optics for increased laser lifetime

InactiveUS20080198882A1Reduce degradationLow costPhotomechanical apparatusMountingsActive coolingTransmittance

A laser beam is generated and transmitted within an enclosed pathway through at least one crystal optic at a power density that progressively degrades transmissivity of the crystal optic with accumulating fluence. The crystal optics are cooled below normal operating temperatures to slow the progressive degradation in the transmissivity of the crystal optics with the accumulating fluence or to accommodate a higher power density without correspondingly increasing the progressive degradation in transmissivity.

Owner:CORNING INC

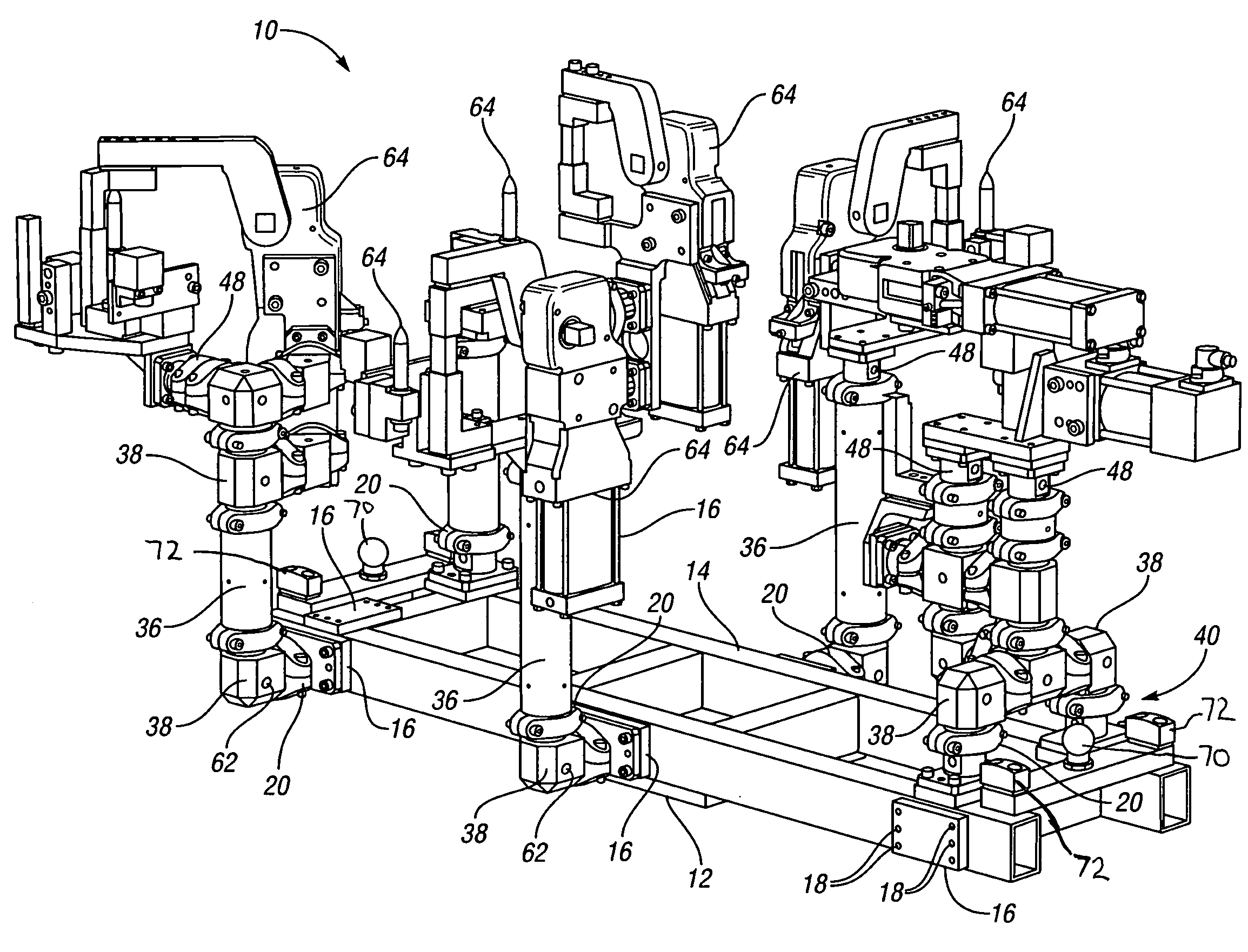

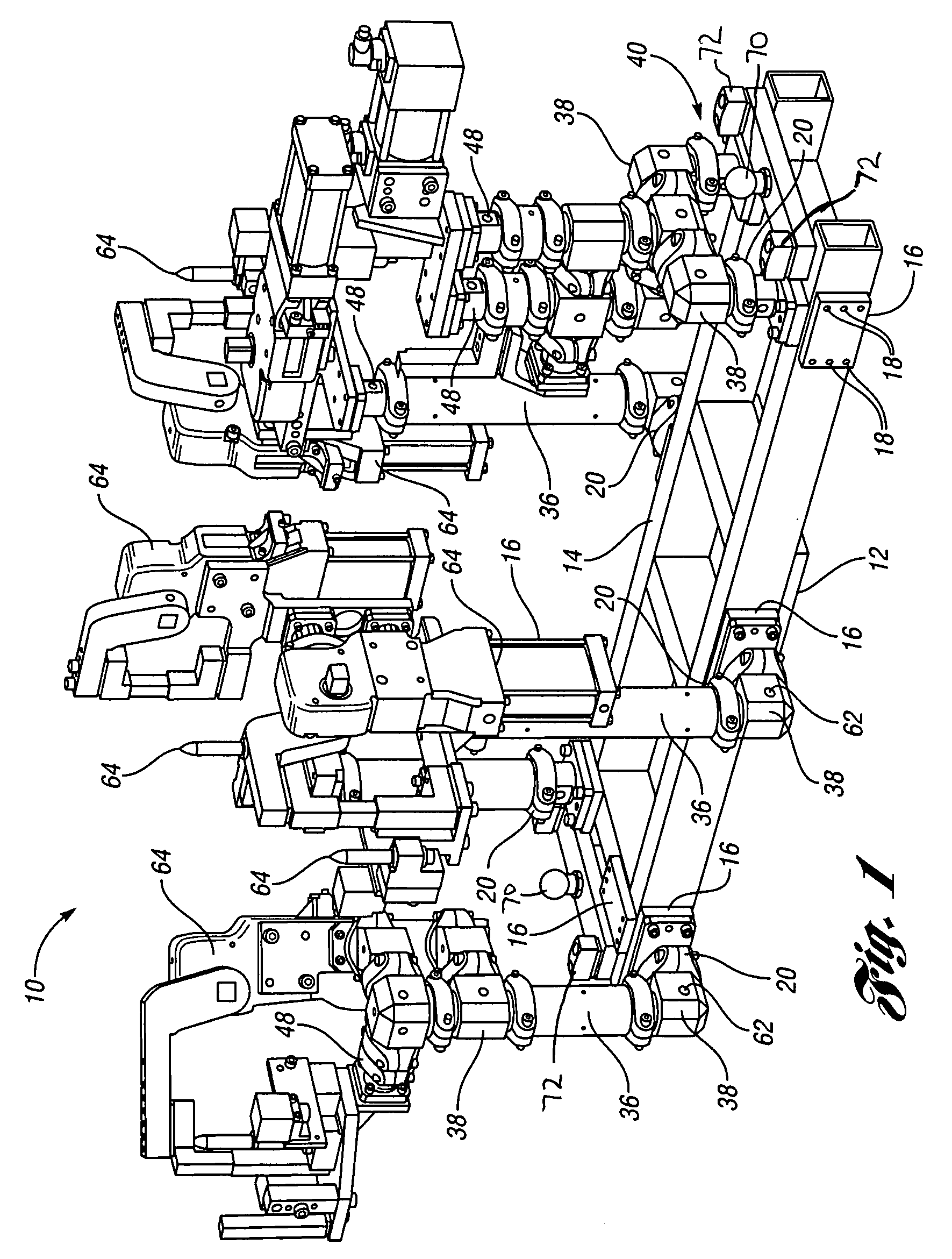

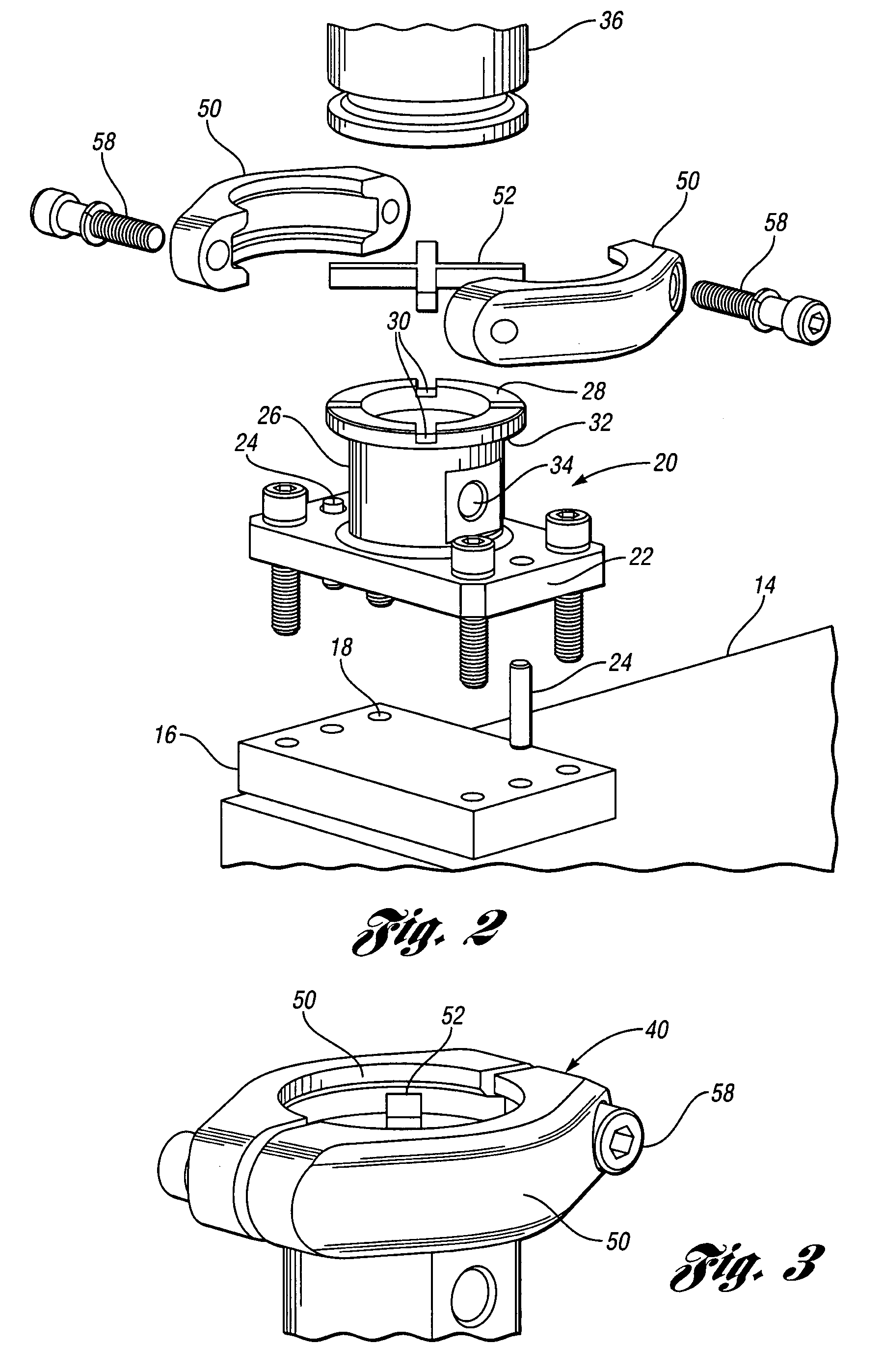

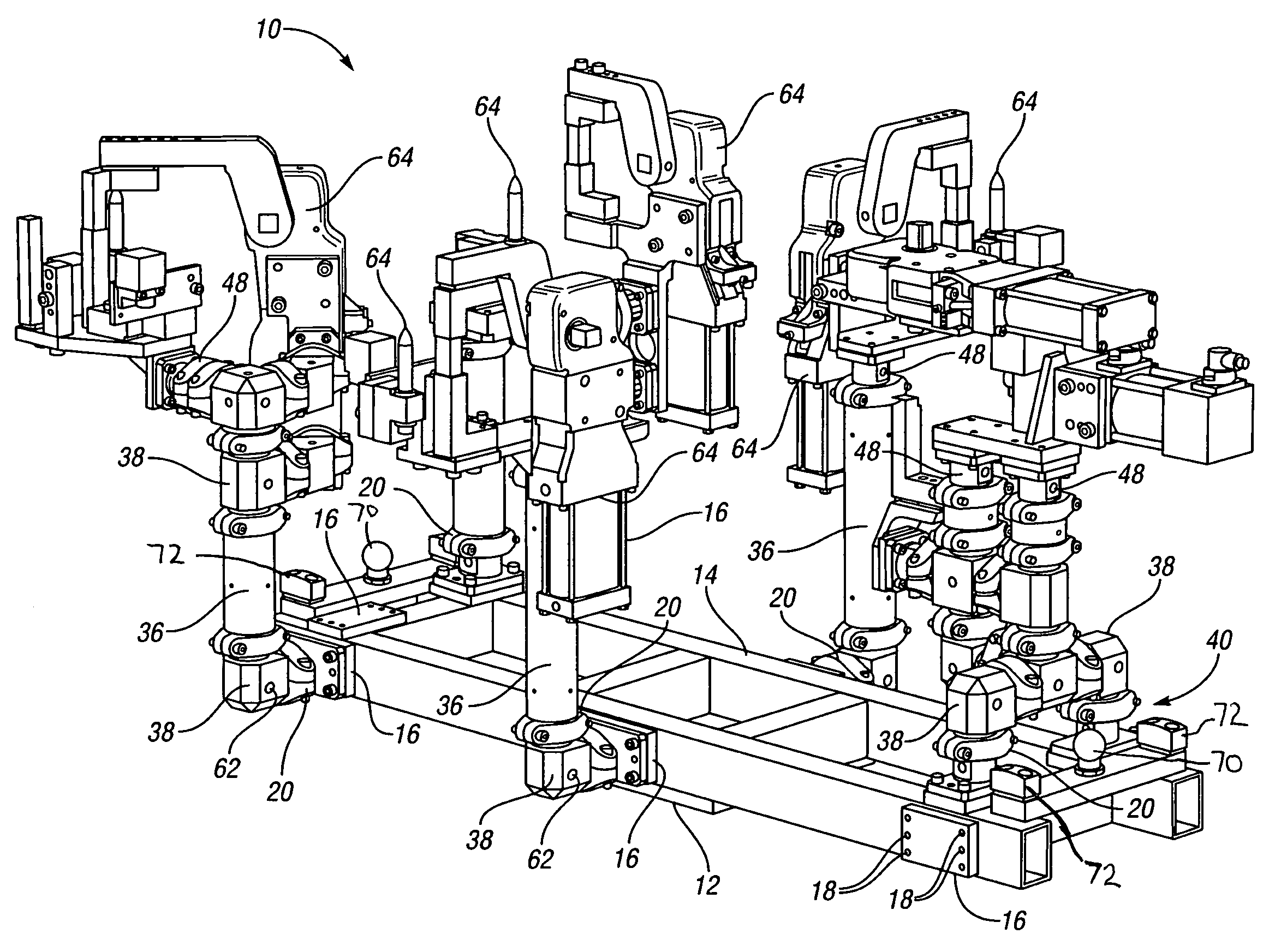

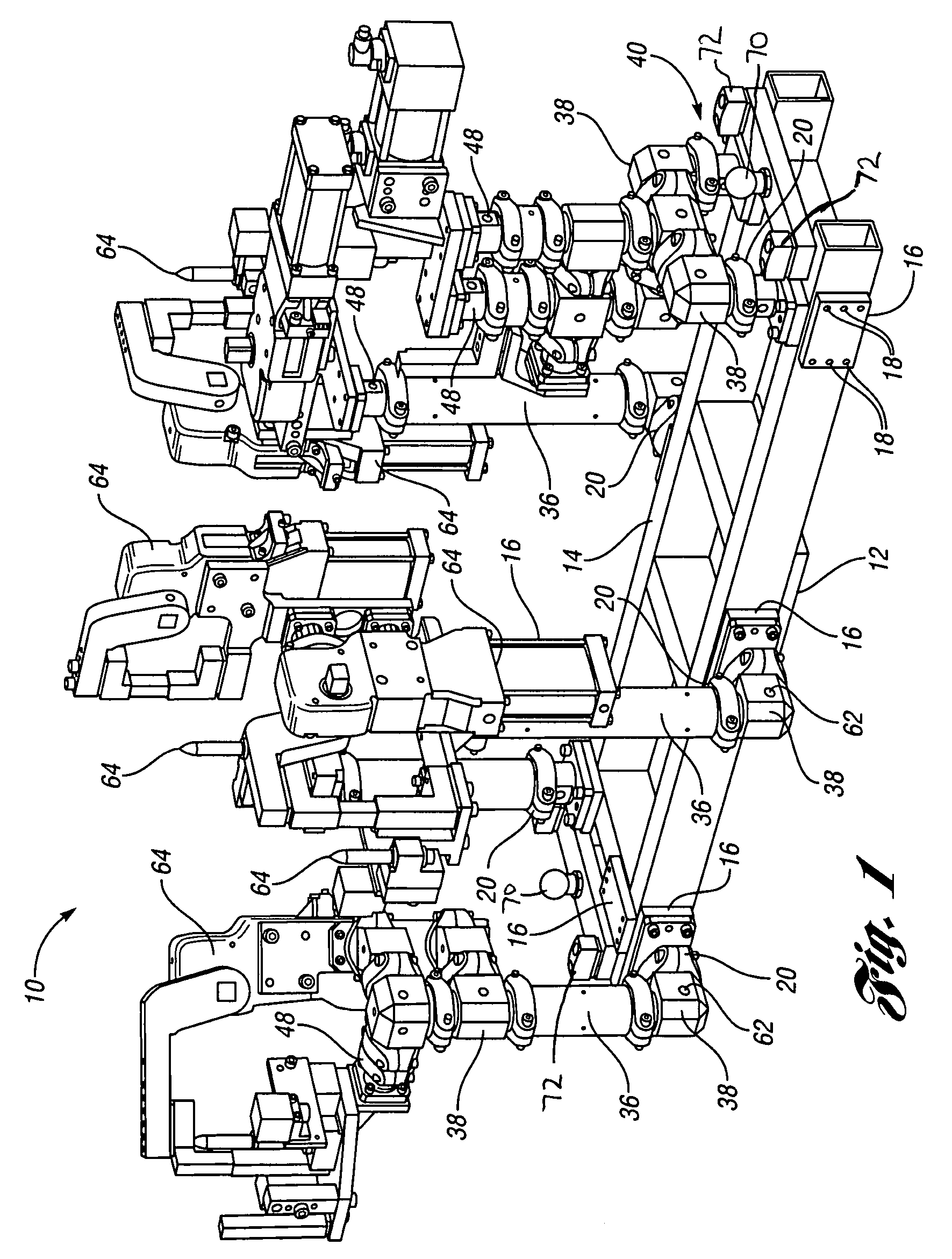

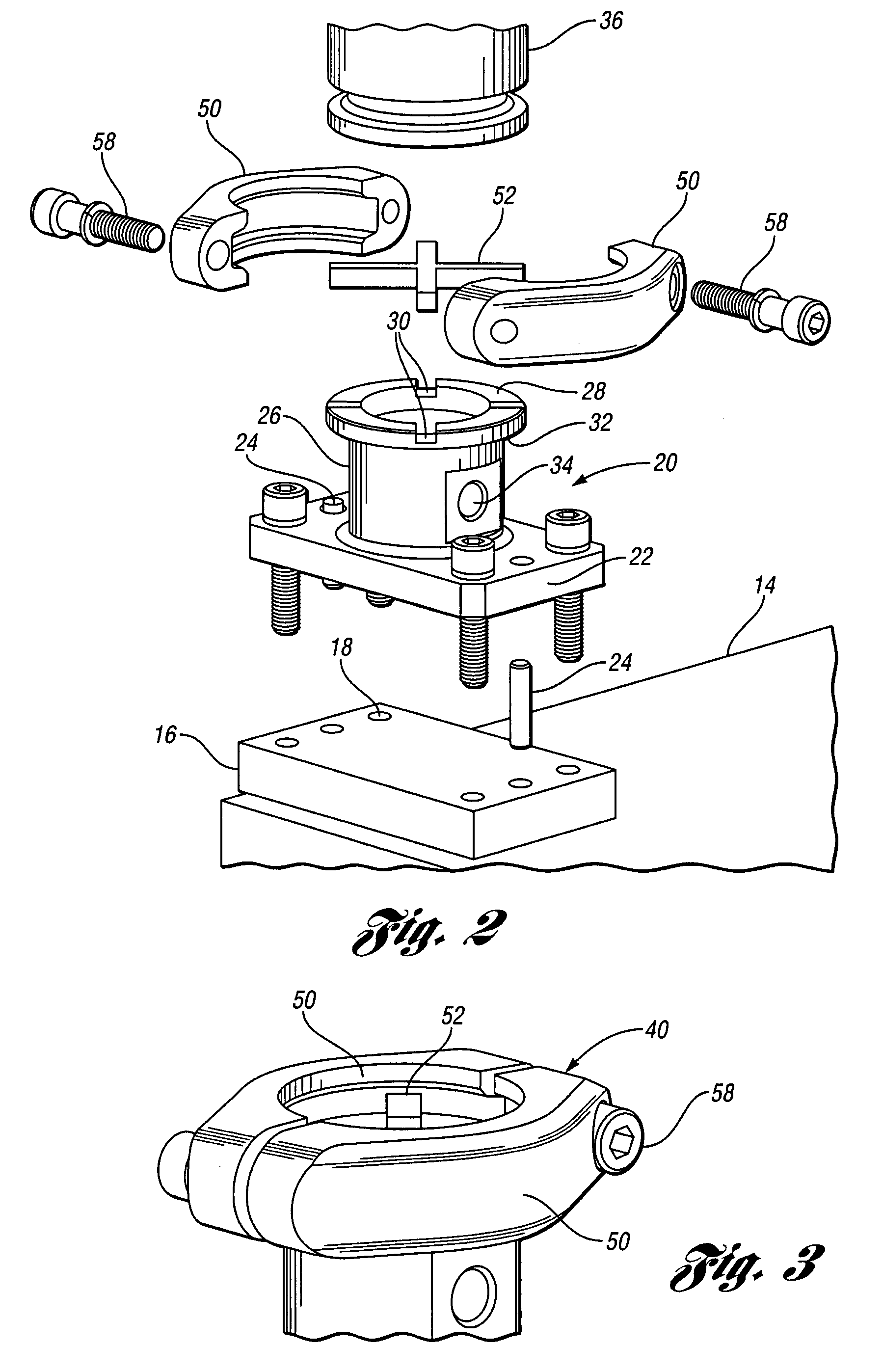

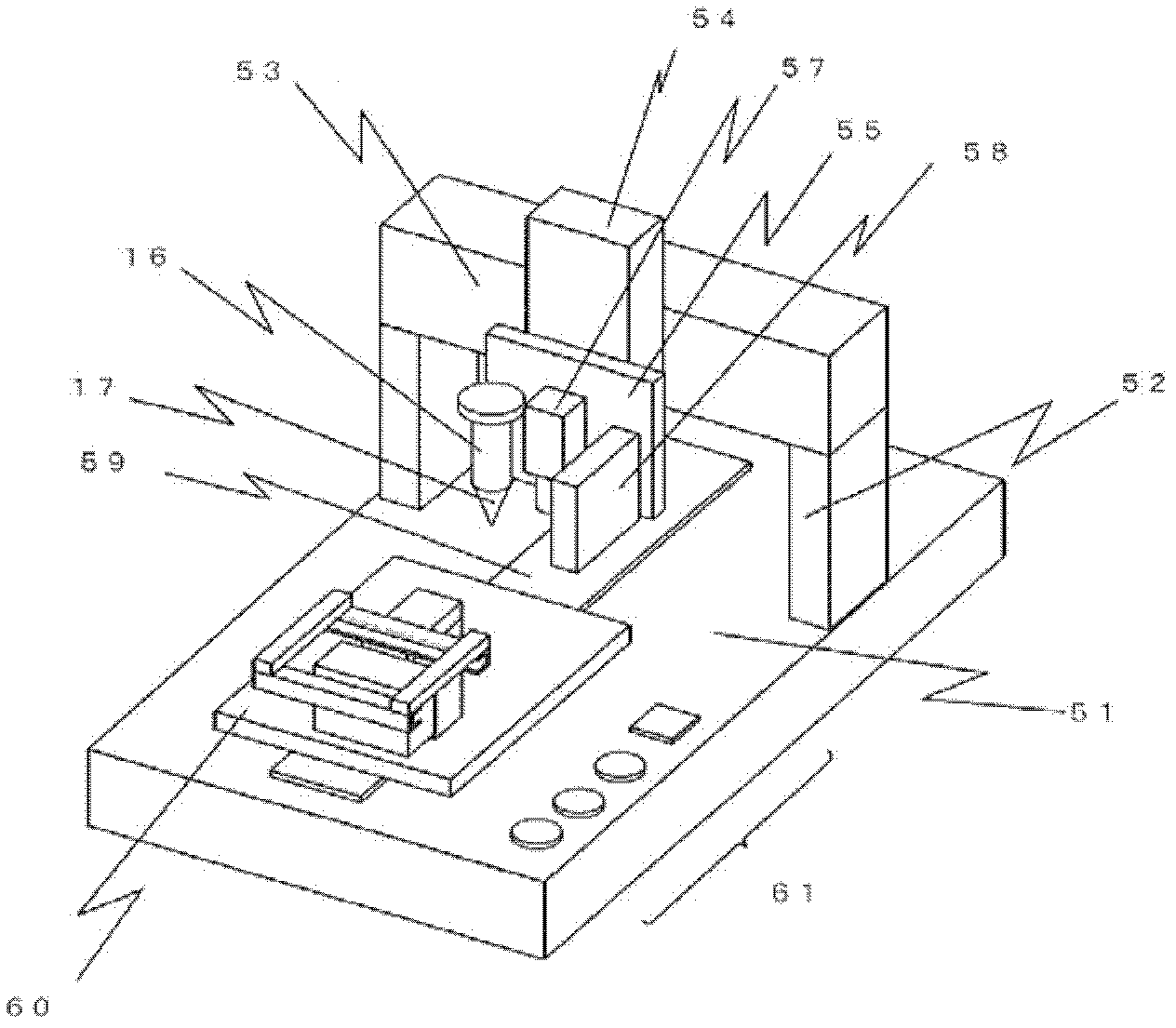

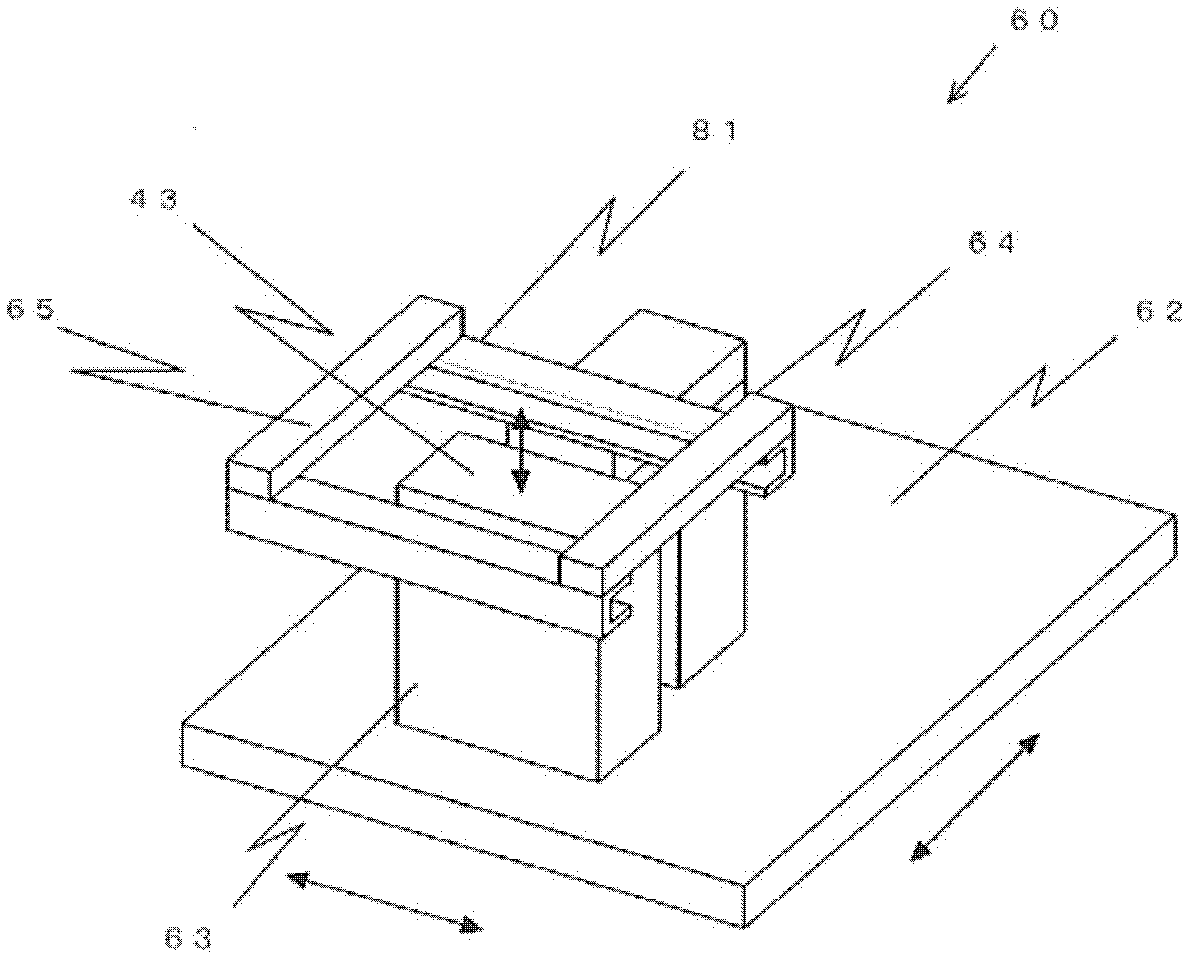

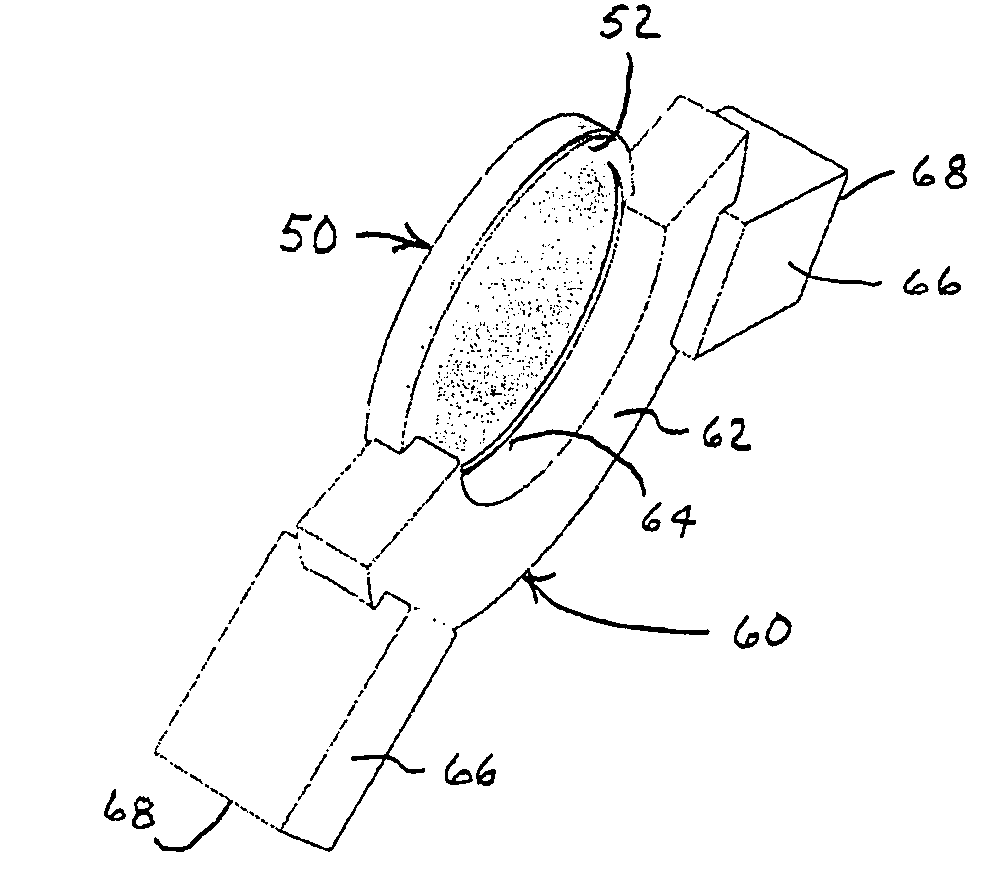

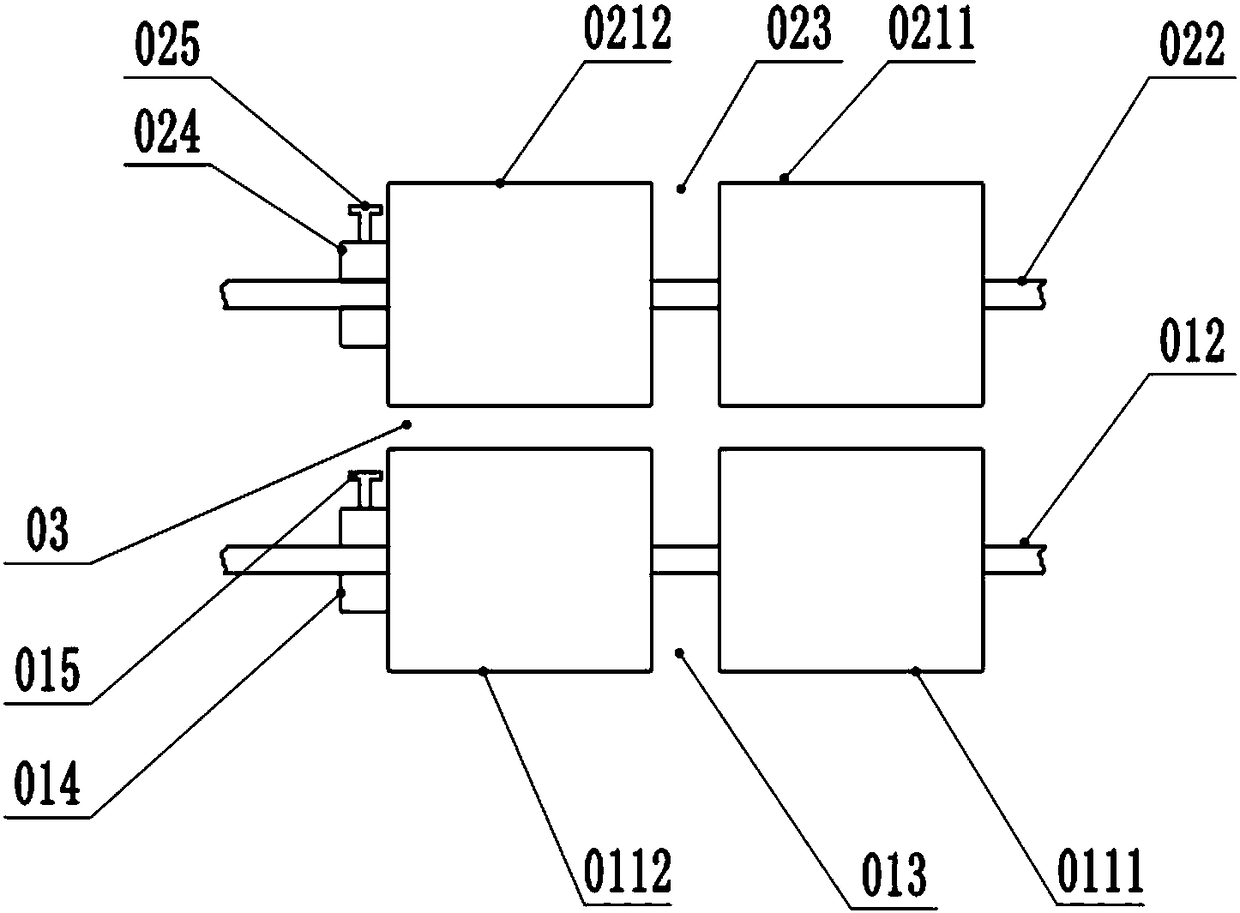

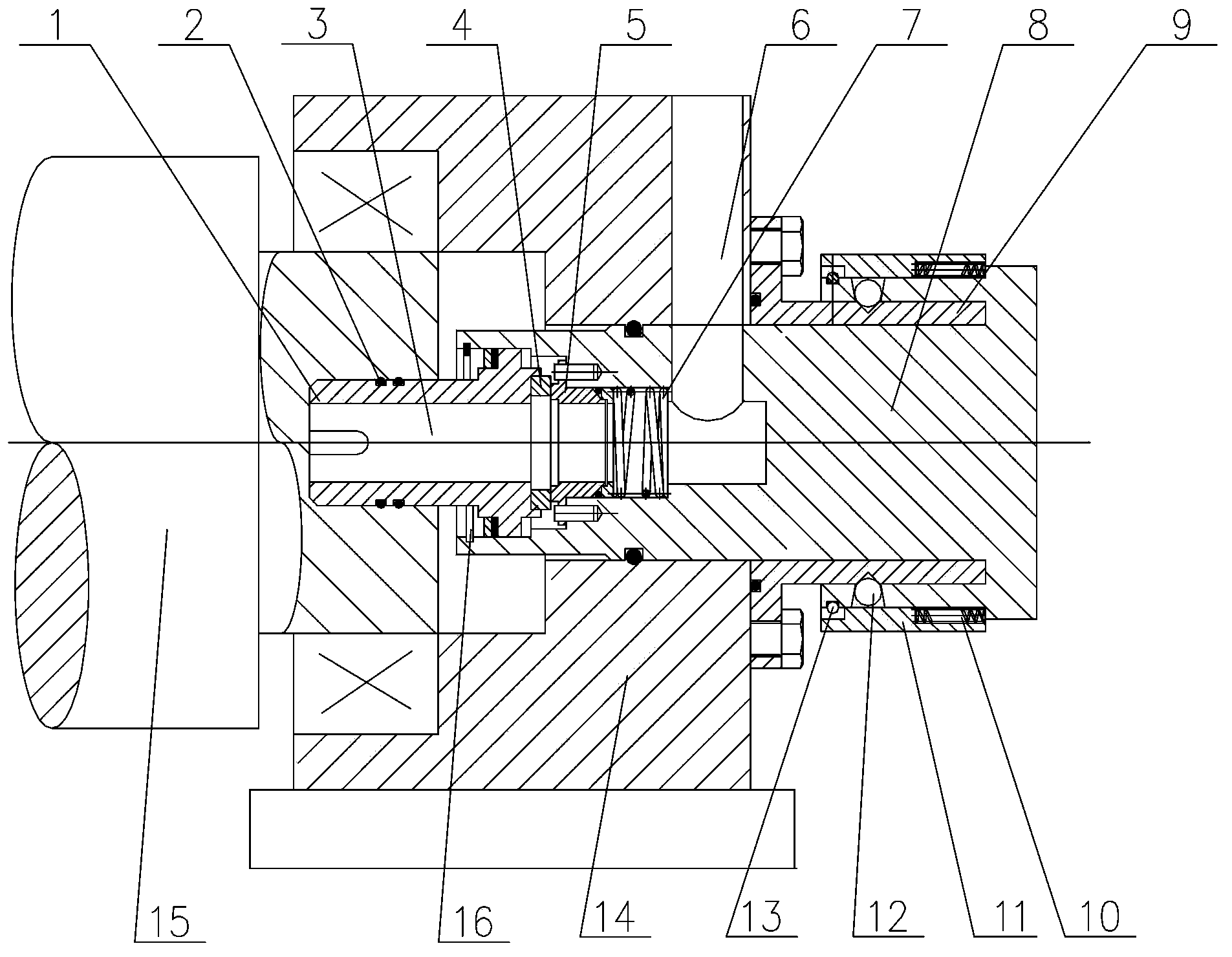

Geometric end effector system

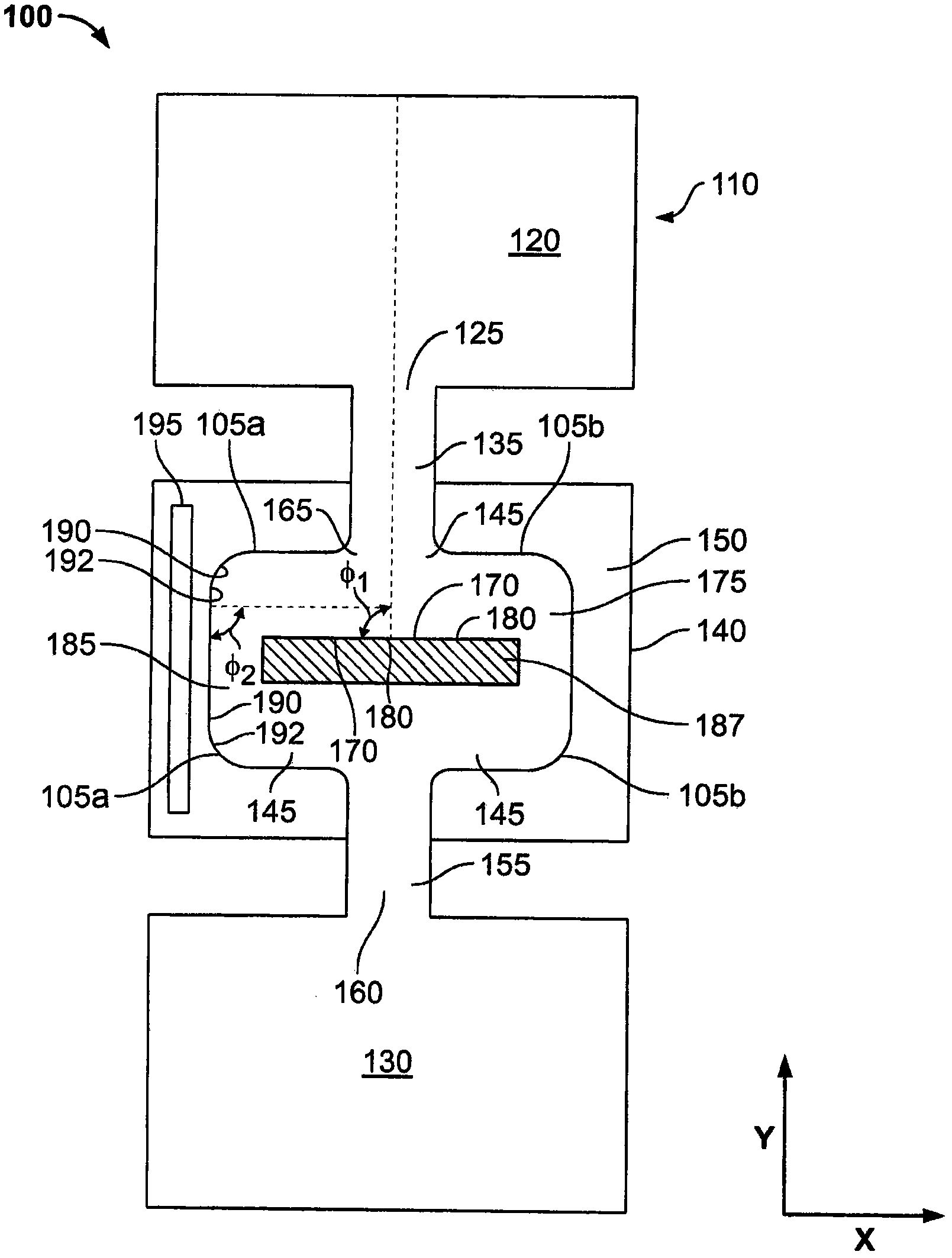

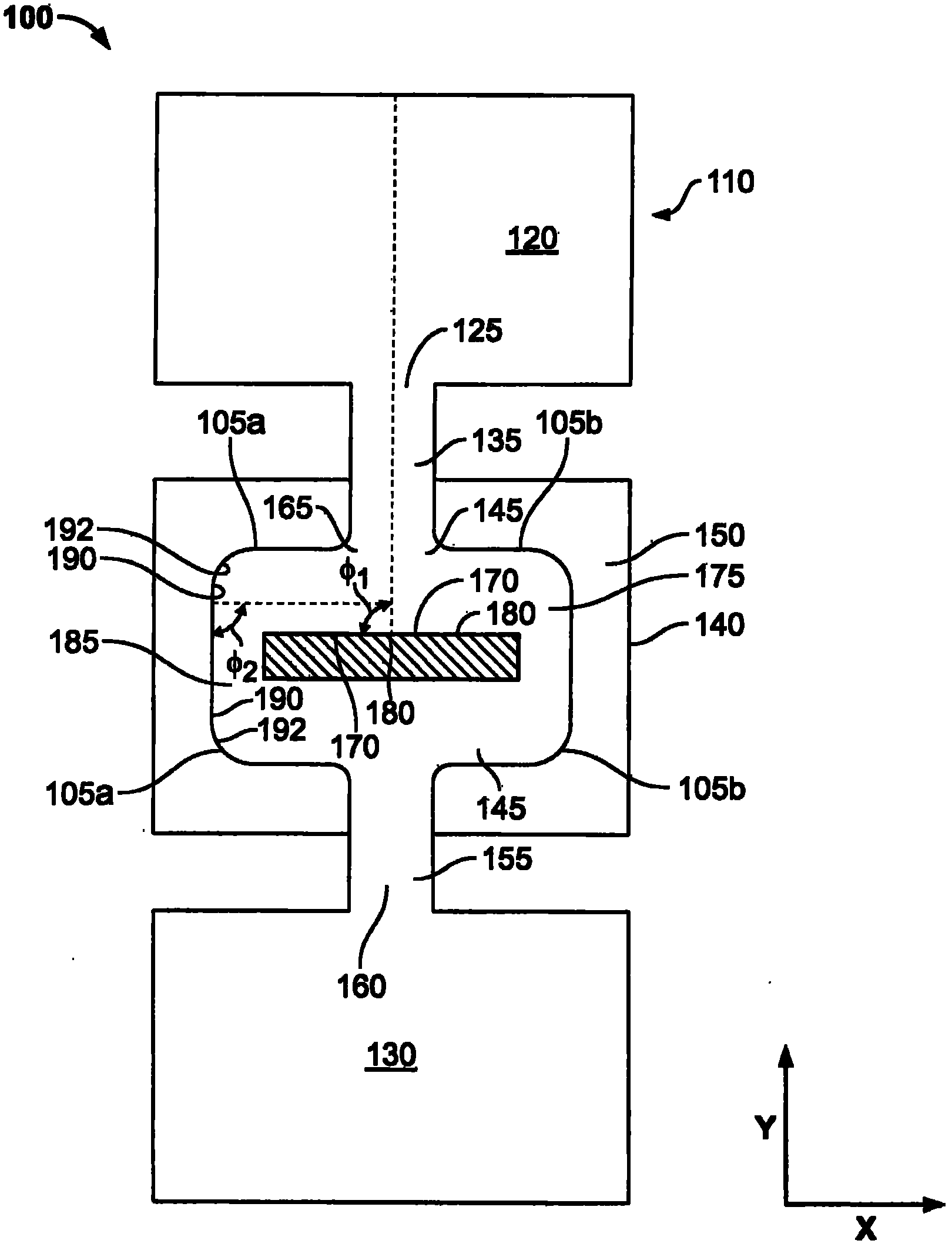

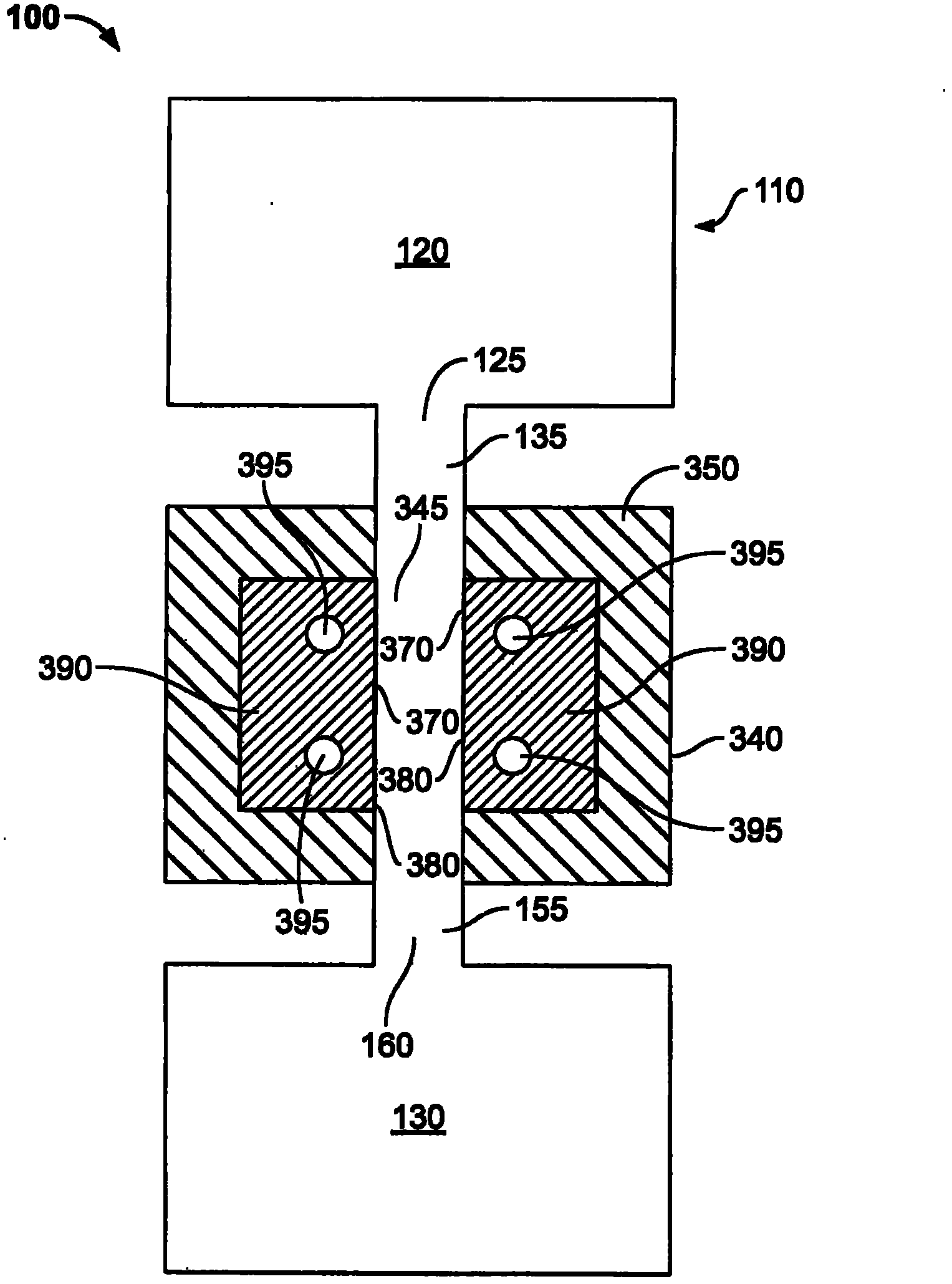

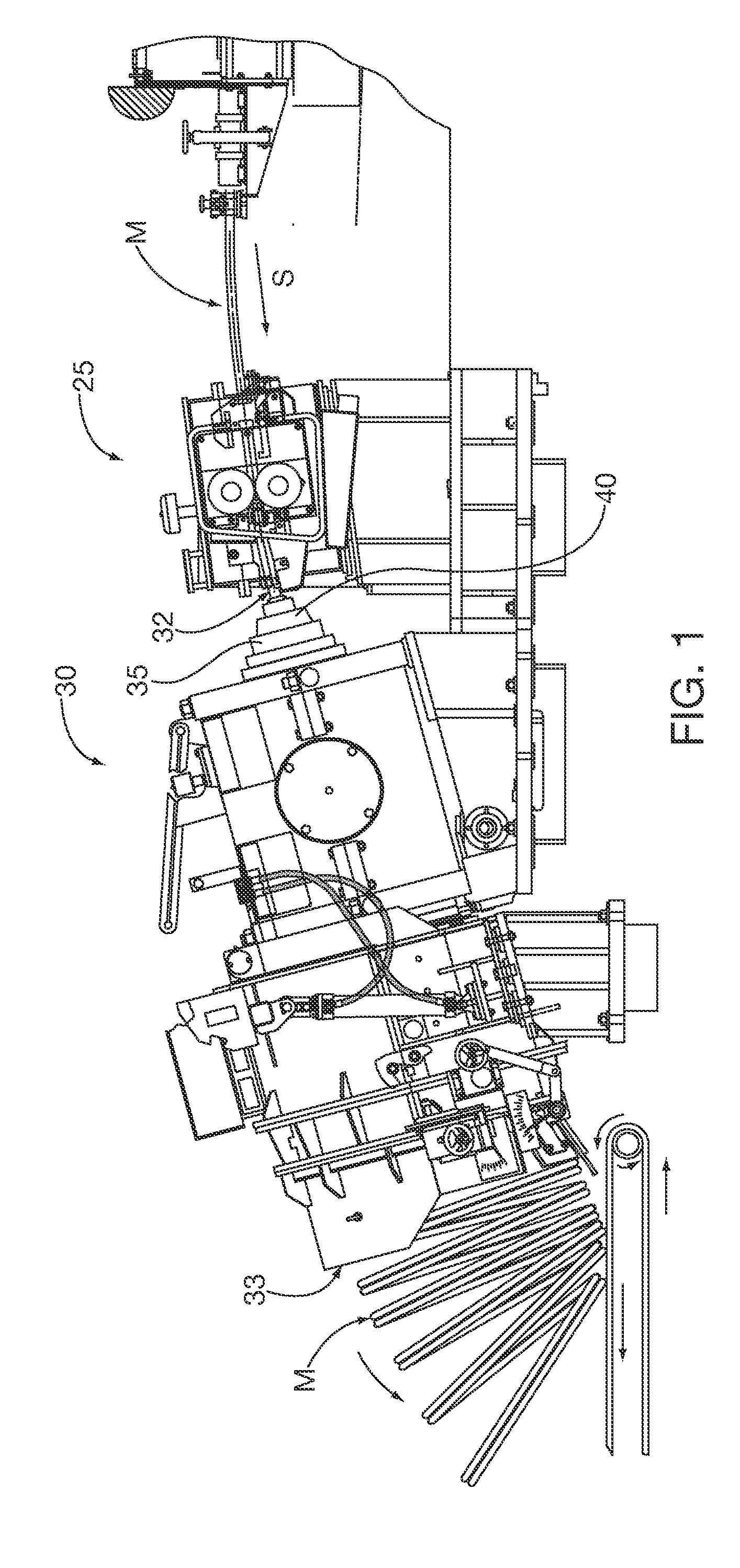

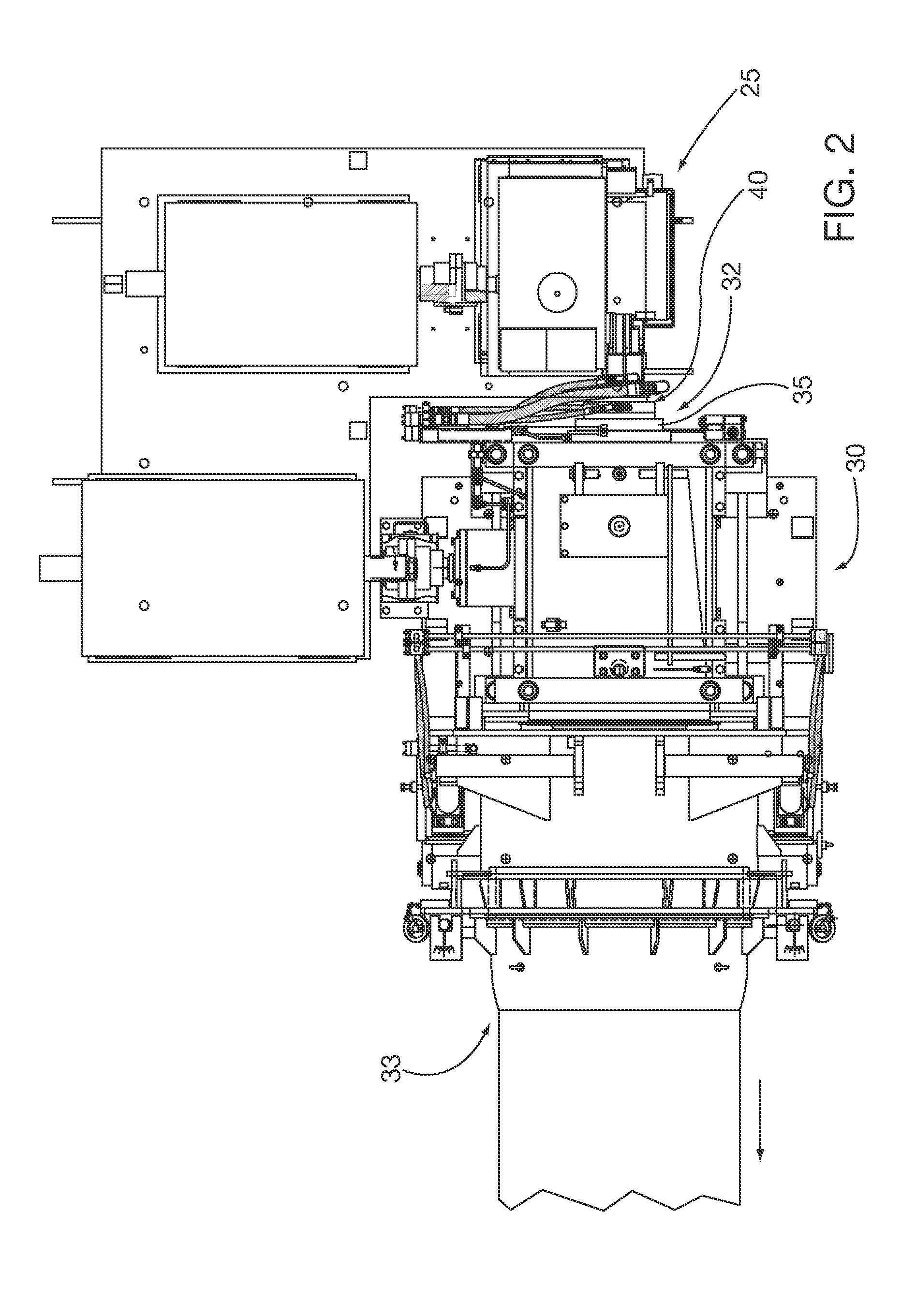

ActiveUS20080012517A1Shorten production downtimeEliminate needProgramme-controlled manipulatorMechanical apparatusActuatorRobot

A geometric end effector system for use on a robot. The system includes a platform and a frame secured to the platform. At least one base is arranged at a predetermined position on the frame. The system also has an anchor mount secured to the base and a component connected to an end of the anchor mount by a collar assembly. A key is arranged between the component and the anchor mount.

Owner:DELAWARE CAPITAL FORMATION INC

Multi-step process for the manufacture of therapeutic protein

InactiveUS20060246537A1Shorten production downtimeImprove abilitiesPeptide/protein ingredientsBiochemistry apparatusCulture cellTherapeutic protein

A process for the production of therapeutic protein is provided, which includes the steps of preparing nutrient medium for culturing of cells to express the protein, culturing the cells in the presence of the nutrient medium to express the protein, preparing protein separation solution for isolating the protein, formulating the isolated protein, and storing the formulated protein, at least three of these steps being carried out in separate disposable containers made of flexible film, at least the interior of said surface of said container being made of fluoropolymer.

Owner:EI DU PONT DE NEMOURS & CO

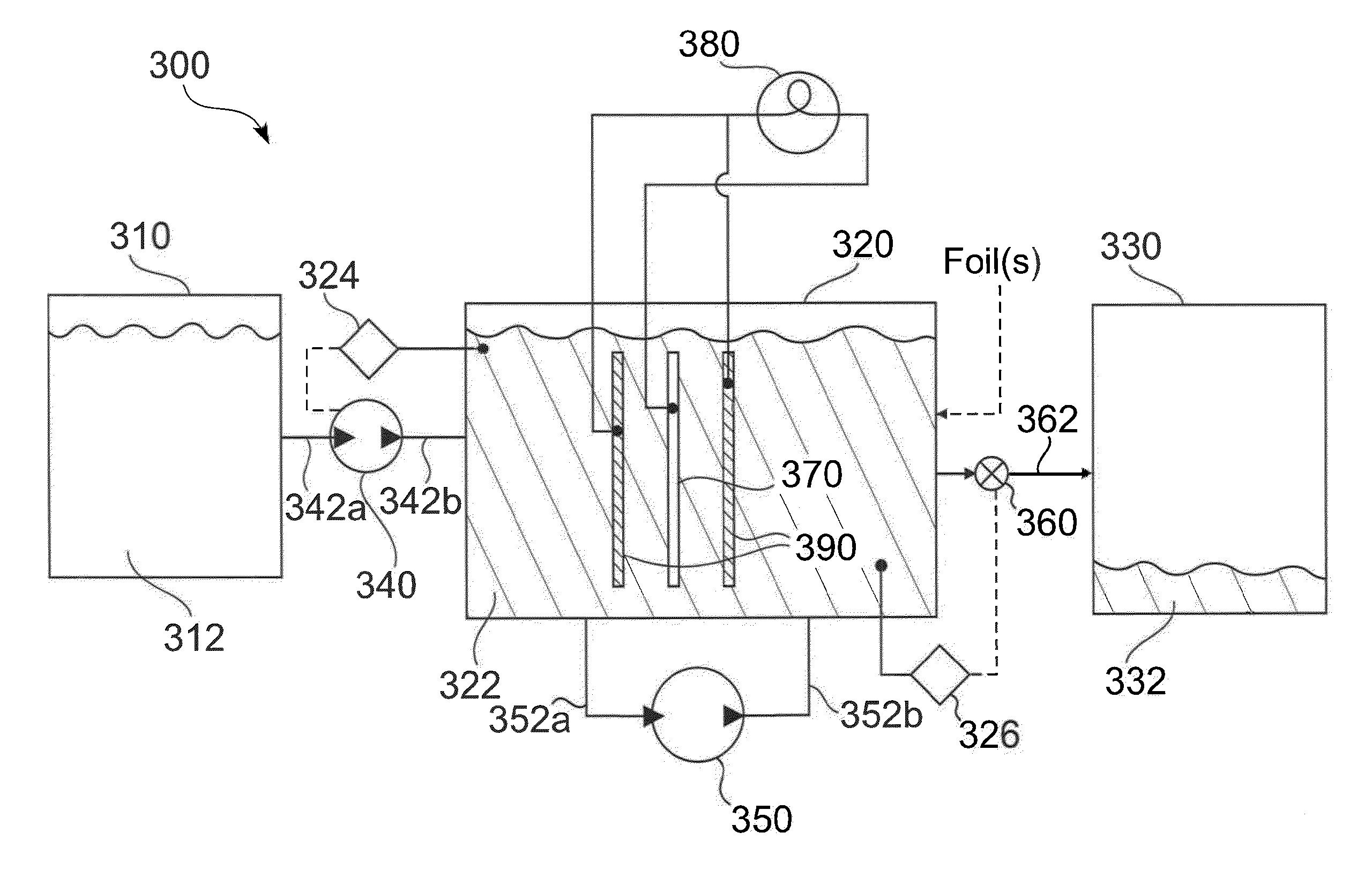

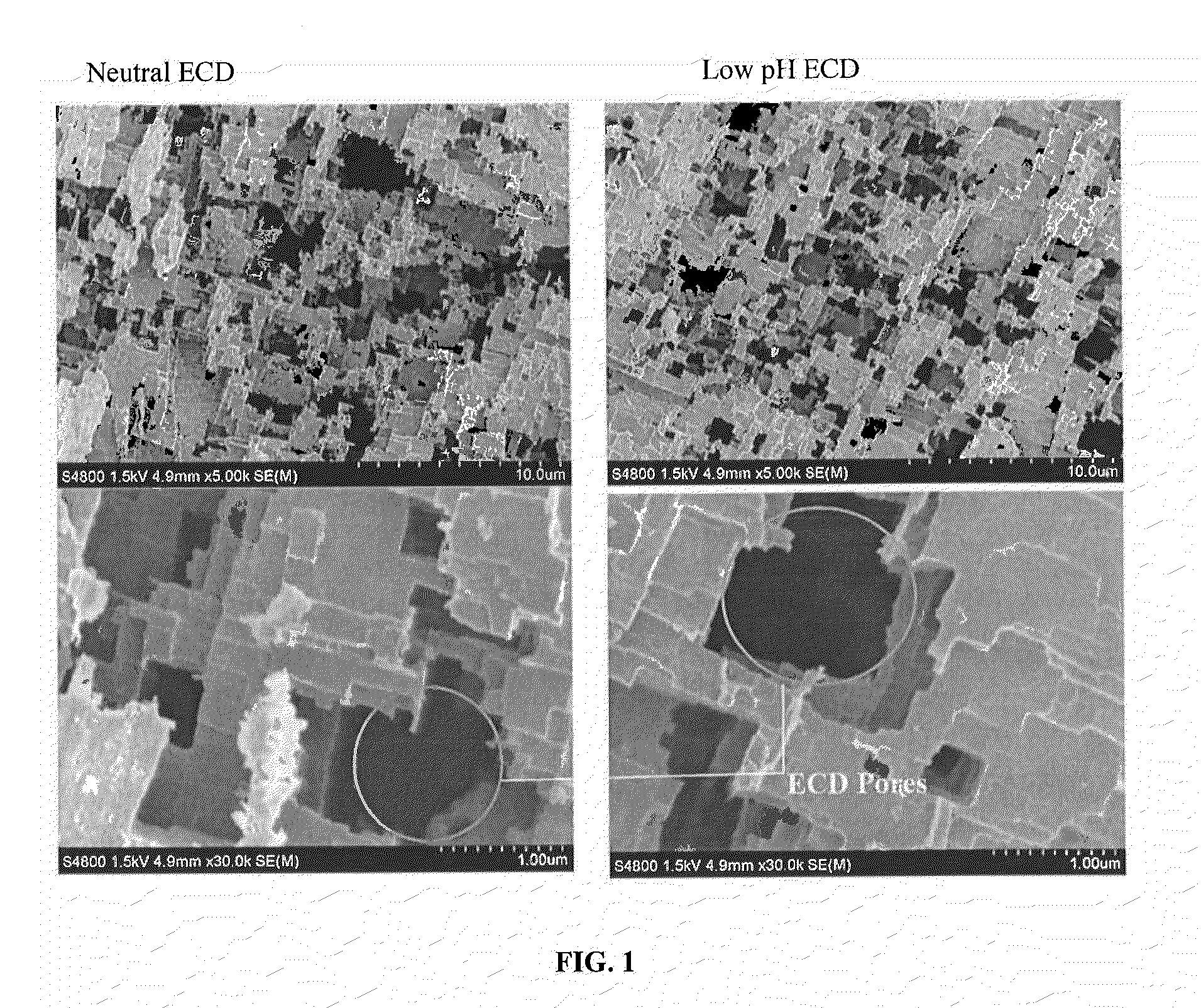

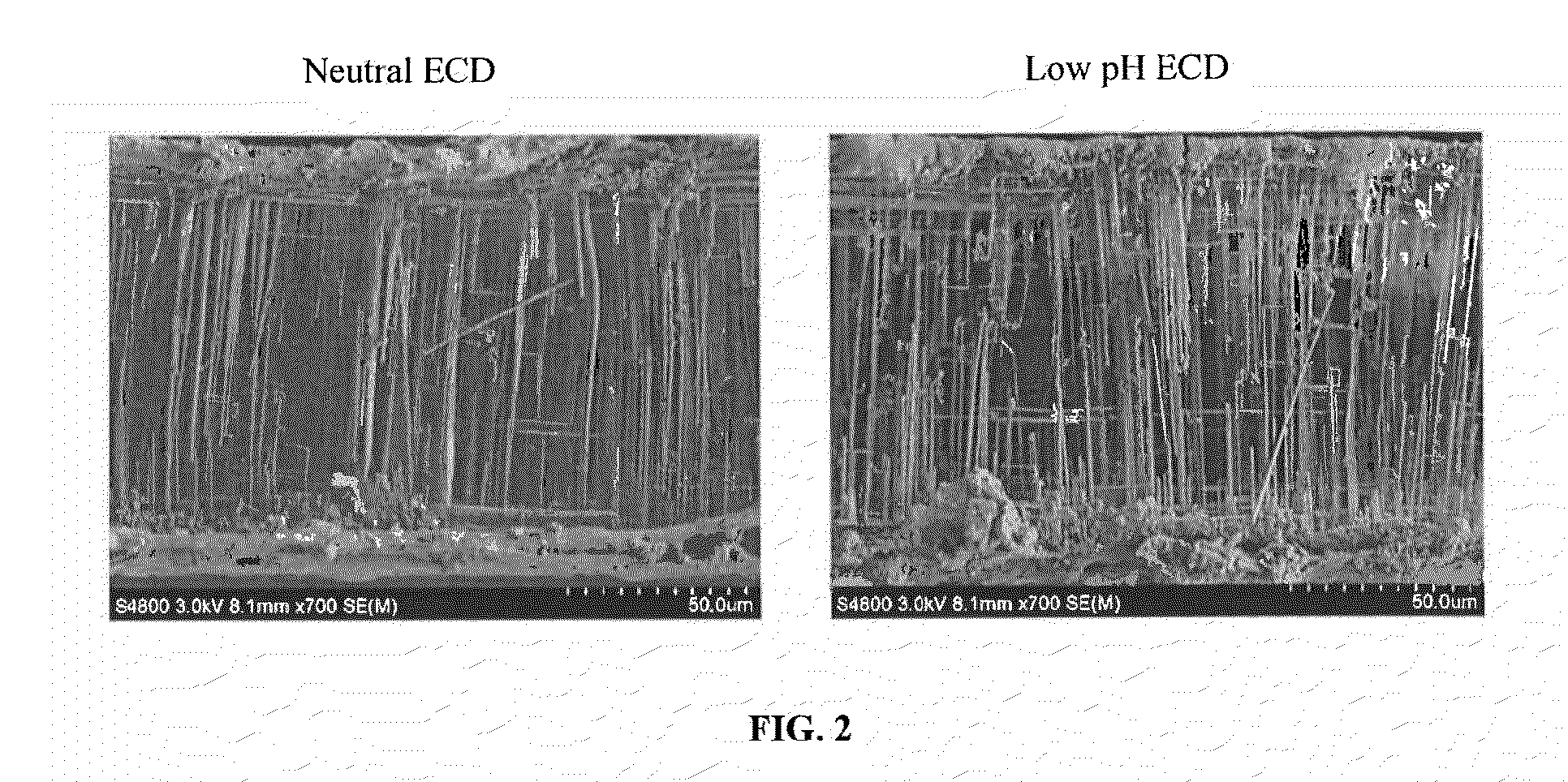

Electrochemical drilling system and process for improving electrical porosity of etched anode foil

ActiveUS20130264196A1Shorten production downtimeLess clean upCellsElectrolytic capacitor manufacturePorosityElectrolysis

A process for creating porous anode foil for use in an electrolytic capacitor of an implantable cardioverter defibrillator is provided. The process includes electrochemical drilling a plurality of etched metal foils in sequence one after the other in a bath containing electrochemical drilling (ECD) solution initially having a pH of less than 5. Alternatively, an etched foil sheet may be passed through the bath in a substantially continuous manner such that a portion of said etched foil sheet is in contact with the ECD solution is electrochemically drilled to generate pores. Electrochemical drilling is achieved when a current is passed to the foil or portion of the foil sheet in solution, ECD replenishment solution having a pH of less than about 5 is added from a feed reservoir to the bath at such a rate so as to maintain a pH in the ECD solution in the bath of less than about 5, and ECD solution in the bath is removed to a waste reservoir at the substantially the same rate as the addition of the ECD replenishment solution to the bath.

Owner:PACESETTER INC

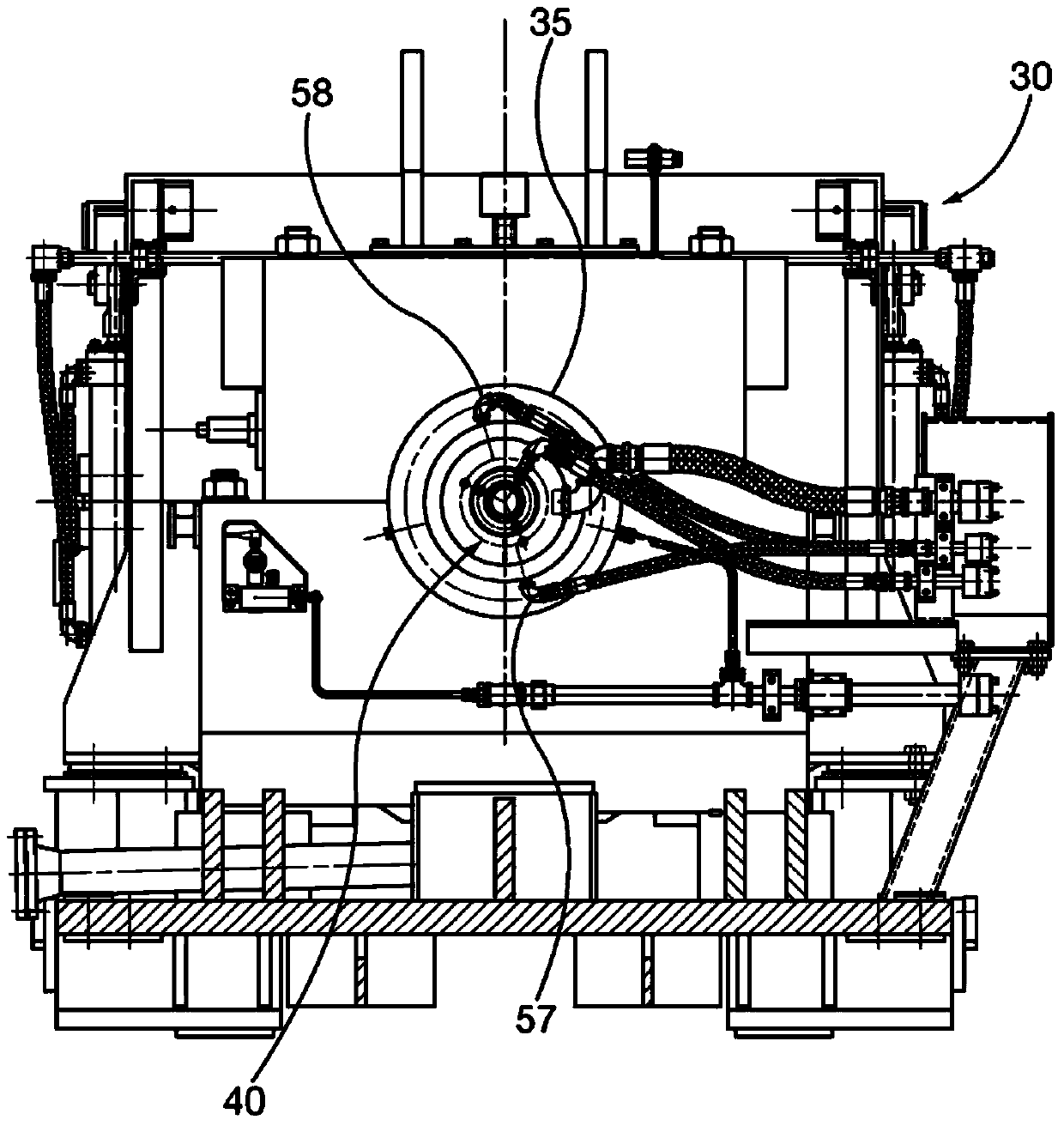

Geometric end effector system

ActiveUS7609020B2Shorten production downtimeEliminate needProgramme-controlled manipulatorMechanical apparatusActuatorRobot

A geometric end effector system for use on a robot. The system includes a platform and a frame secured to the platform. At least one base is arranged at a predetermined position on the frame. The system also has an anchor mount secured to the base and a component connected to an end of the anchor mount by a collar assembly. A key is arranged between the component and the anchor mount.

Owner:DELAWARE CAPITAL FORMATION INC

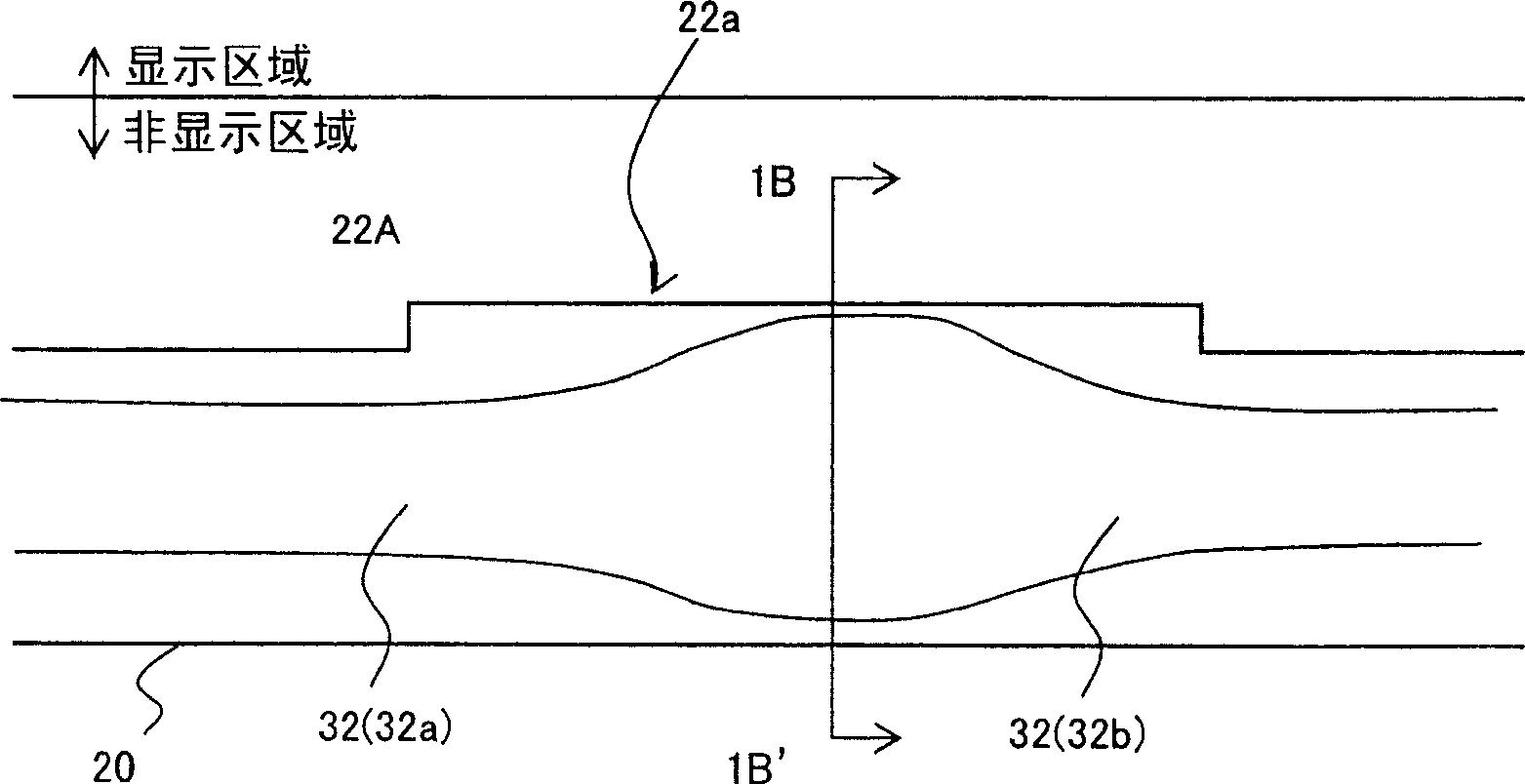

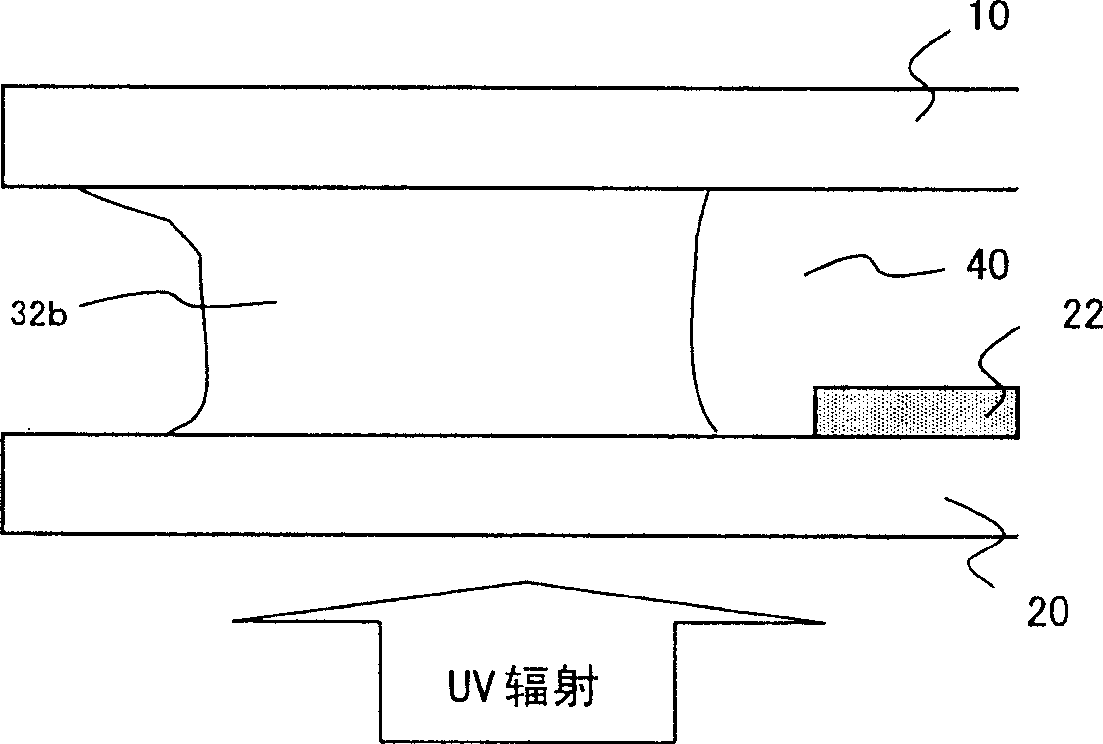

Liquid crystal display panel and method for producing the same

ActiveCN1721957APrevent leakageWill not harmNon-linear opticsLight irradiationLiquid-crystal display

The method of the present invetion includes the steps of: (A) providing a first substrate, and a second substrate, wherein the first substrate includes a first light shielding layer provided within a non-display region, the first light shielding layer including a light-transmitting portion provided near an outer boundary of the first light shielding layer, the light-transmitting portion comprising a recess or an opening; (B) drawing a seal pattern with a sealant, the seal pattern being drawn outside the first light shielding layer so as to surround the display region, comprising the substeps of: (B1) beginning application of the sealant near the light-transmitting portion, (B2) applying the sealant along an outer periphery of the first light shielding layer, and (B3) forming a junction with the sealant having been applied near the light-transmitting portion; (C) applying a liquid crystal material within the display region surrounded by the sealant; (D) attaching the first substrate and the second substrate; and (E) performing light irradiation from the first substrate side to cure the sealant.

Owner:SHARP KK

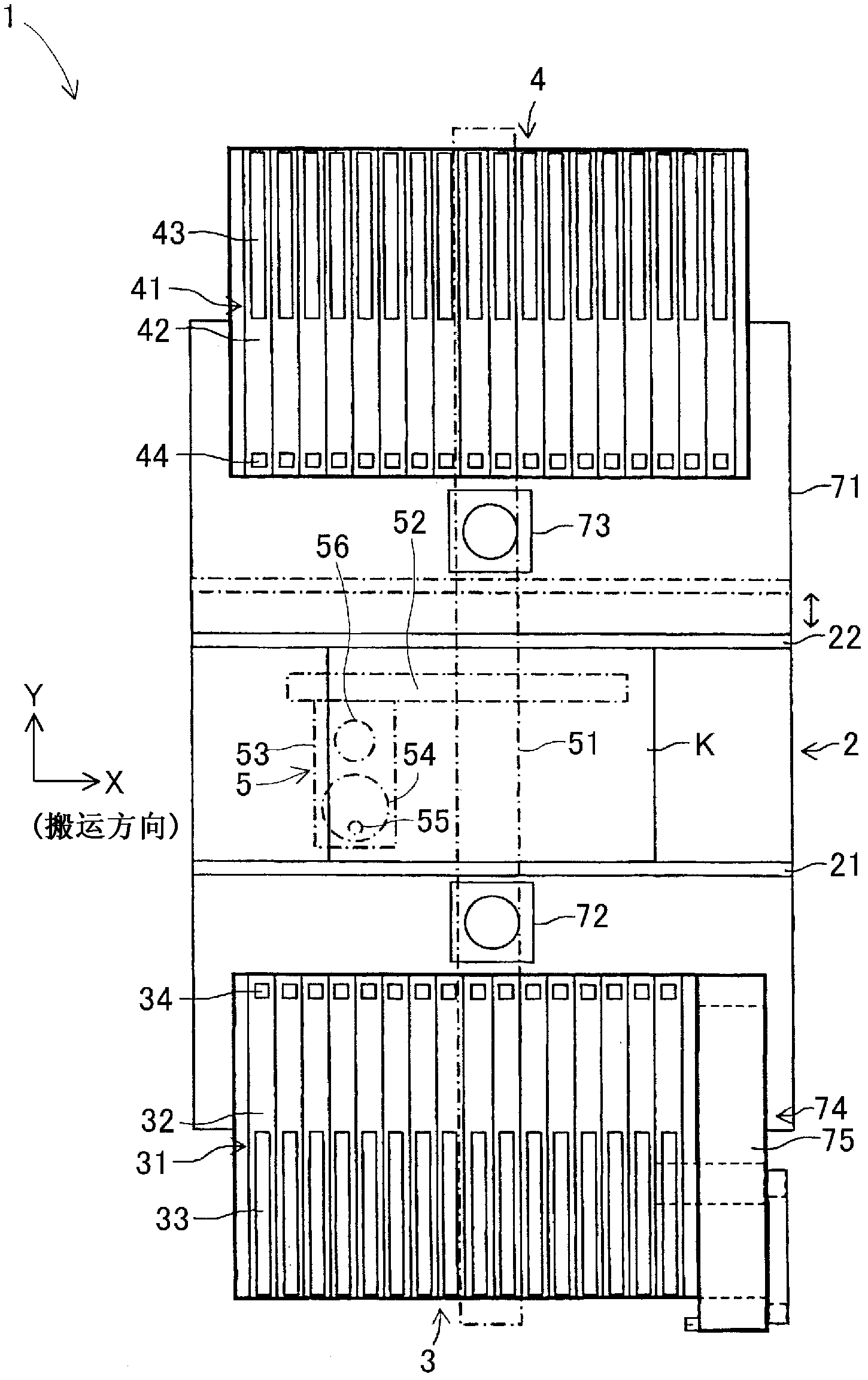

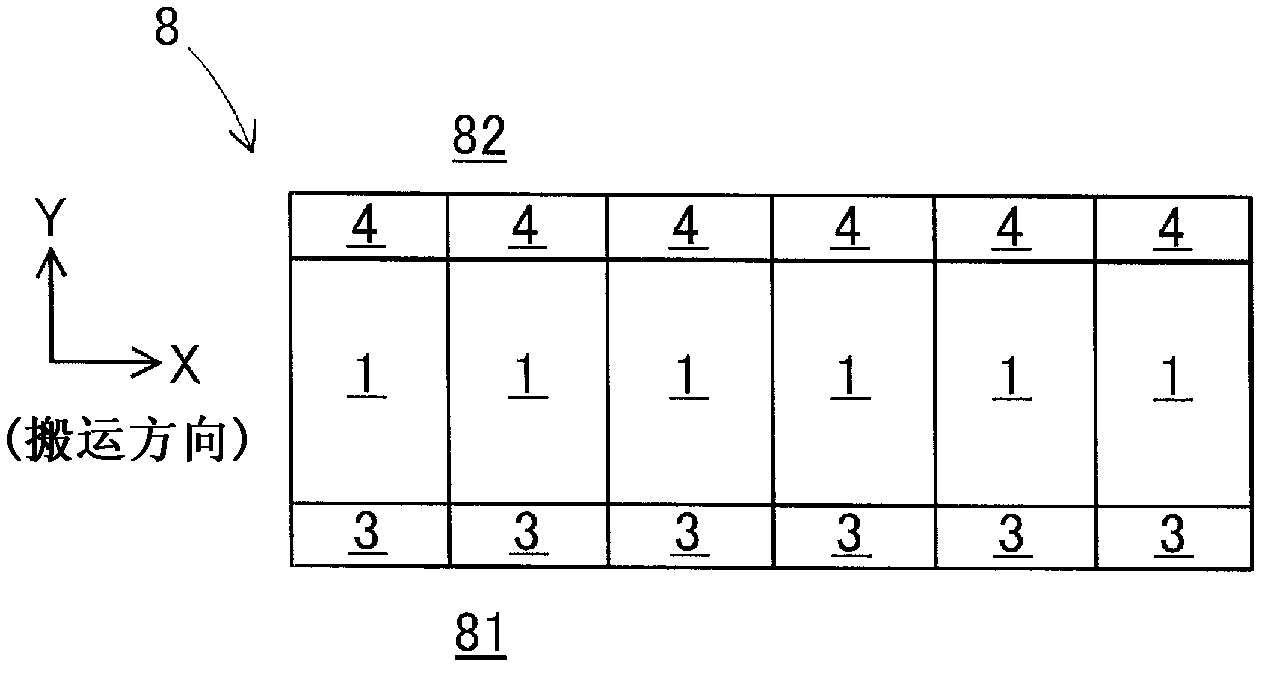

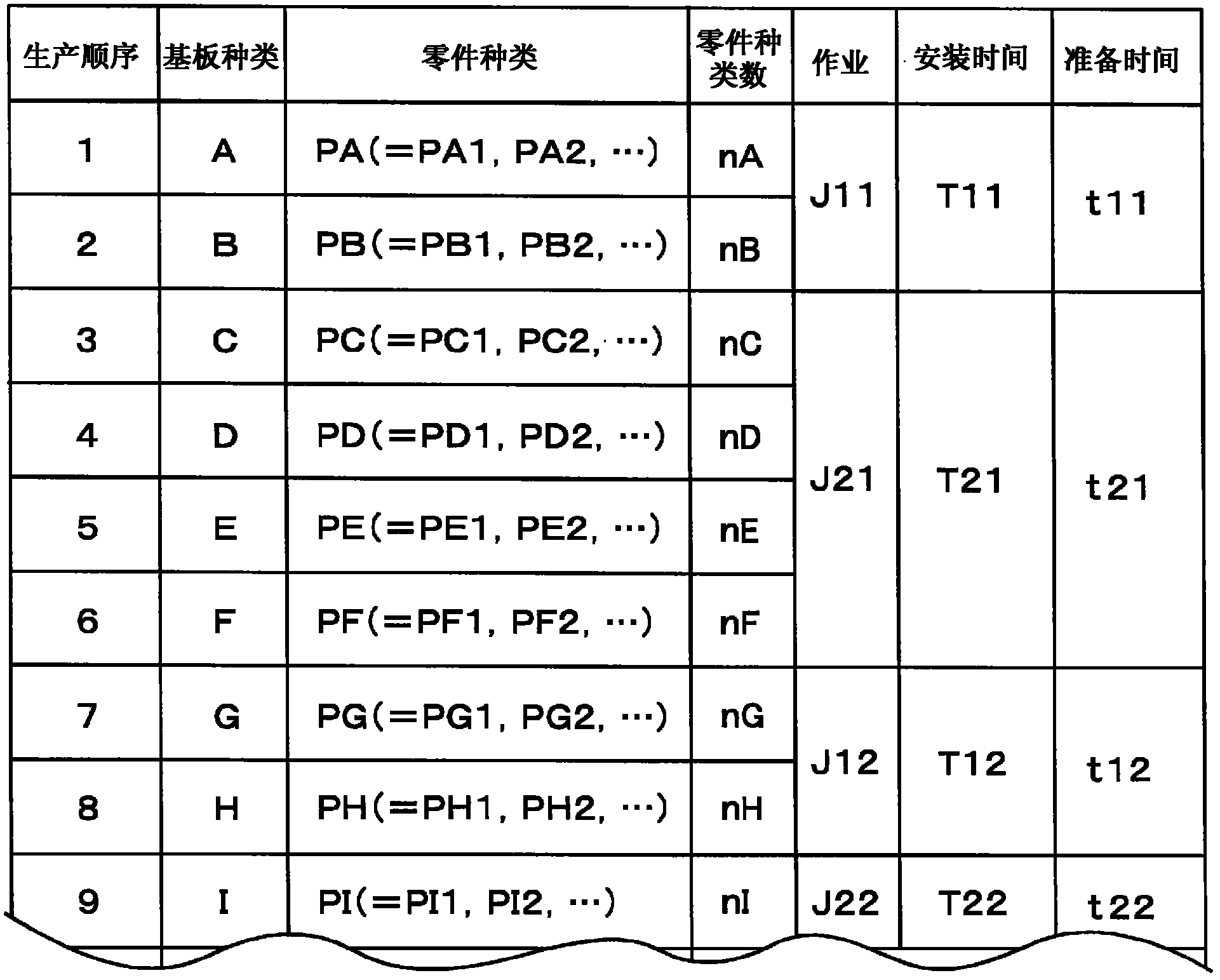

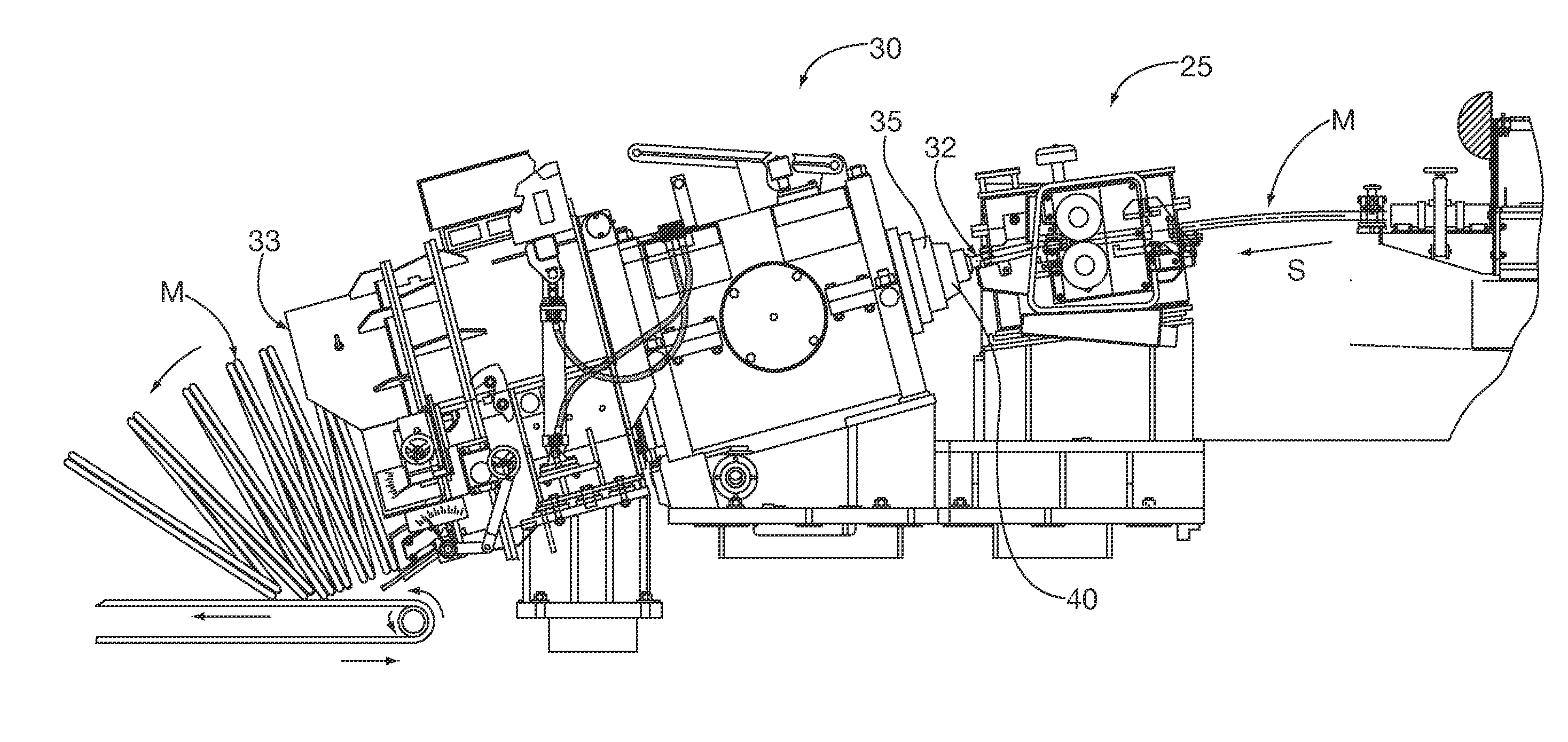

Part installation method of part assembly line

ActiveCN102762086AImprove work efficiencyNo production interruptionElectrical componentsSubstrate typeAssembly line

The invention provides a part installation method of a part assembly line. The part installation method realizes no overlapping of motion paths of operators performing part supply work related to types of substrates in production and part preparation work related to types of substrates to be produced, guarantees high operation efficiency and largely prevents production halts during the production of multi-operation production mode. In the part installation of the part assembly line with multiple stages of part installation machines arranged in parallel, the following steps are conducted in each stage of the part installation machines: the types of substrates produced according to the production order are distributed to substrate types on sides of first and second part feed devices alternatively; when a part transfer device selects parts from one of first and second part feed devices and installs the parts on substrates of the substrate types on the side of one part feed device, part receiving devices are disposed on the other part feed device; and the part receiving device are used for receiving parts being produced after production of the substrate types on the side of one part feed device and being of the types for the substrates of the substrate types on the side of the other part feed device.

Owner:FUJI KK

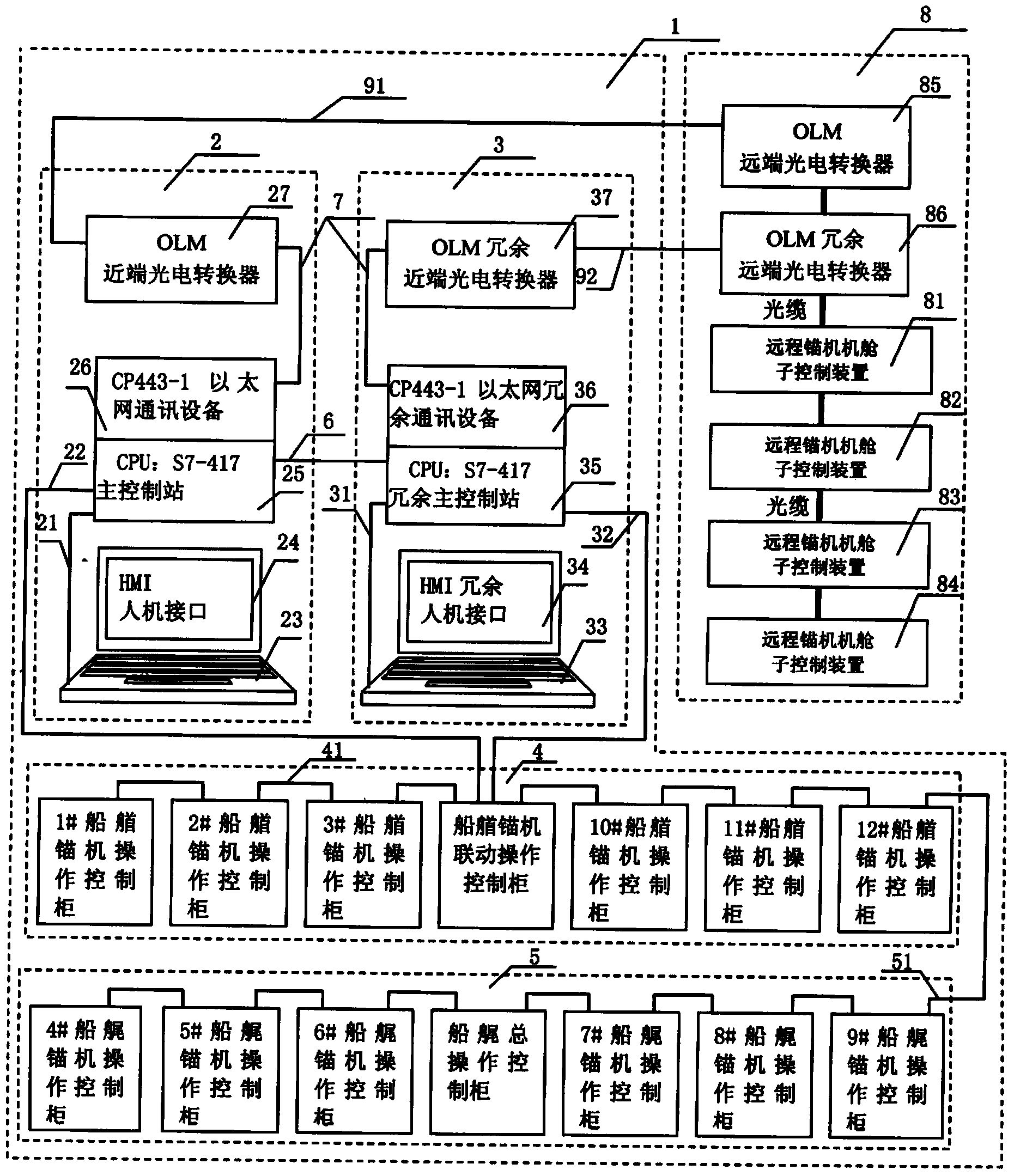

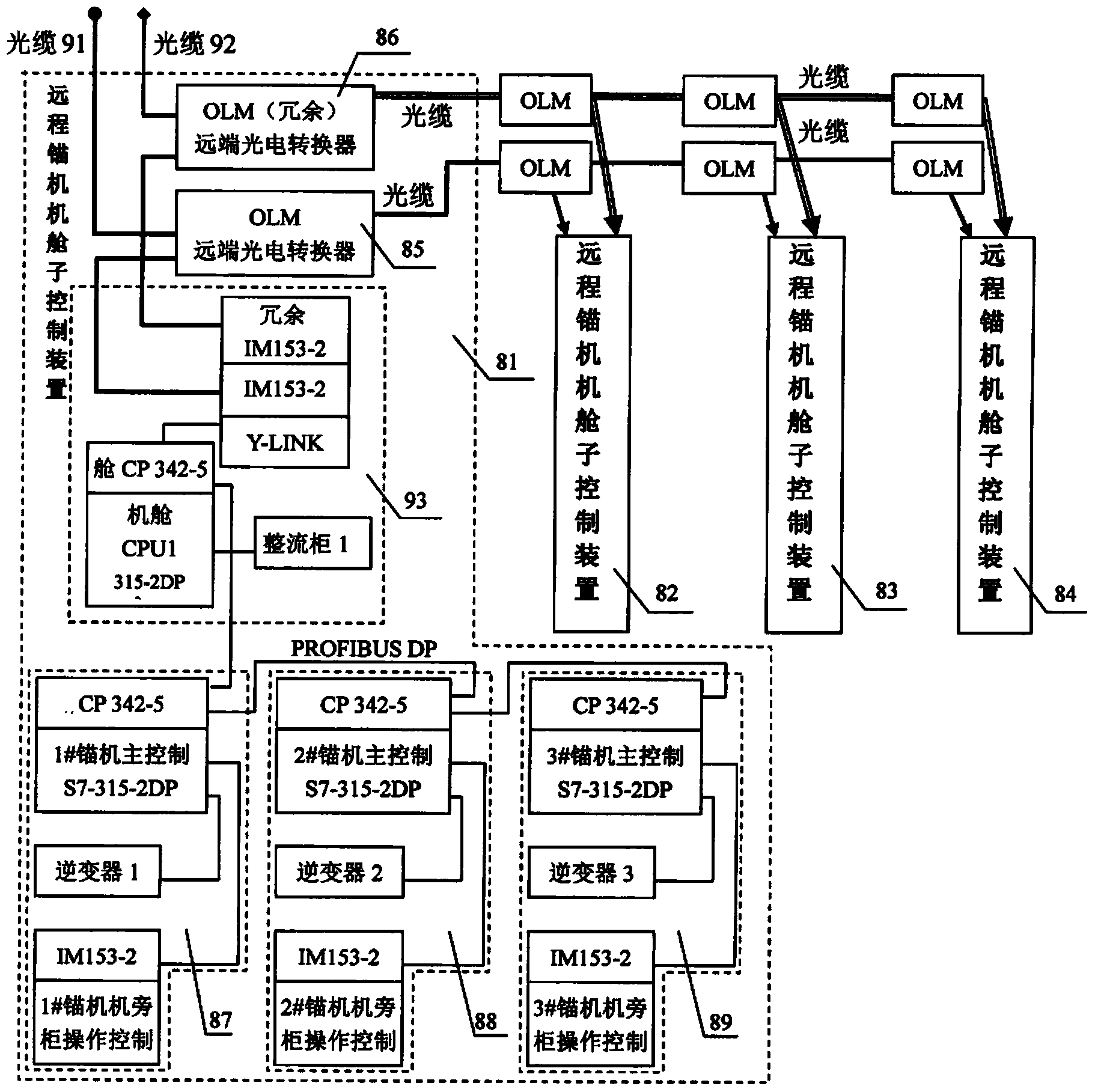

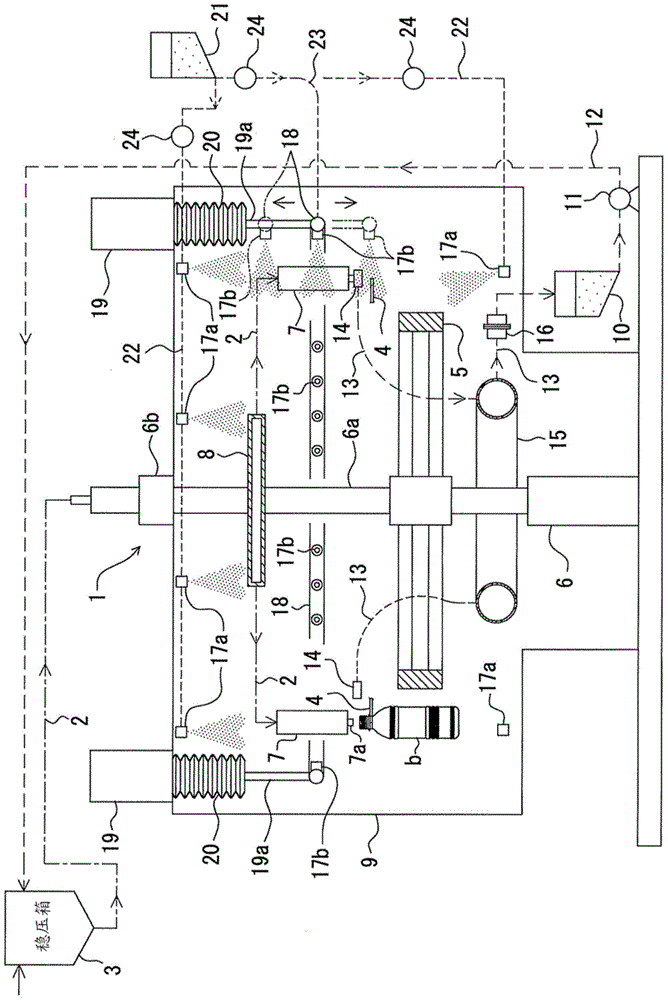

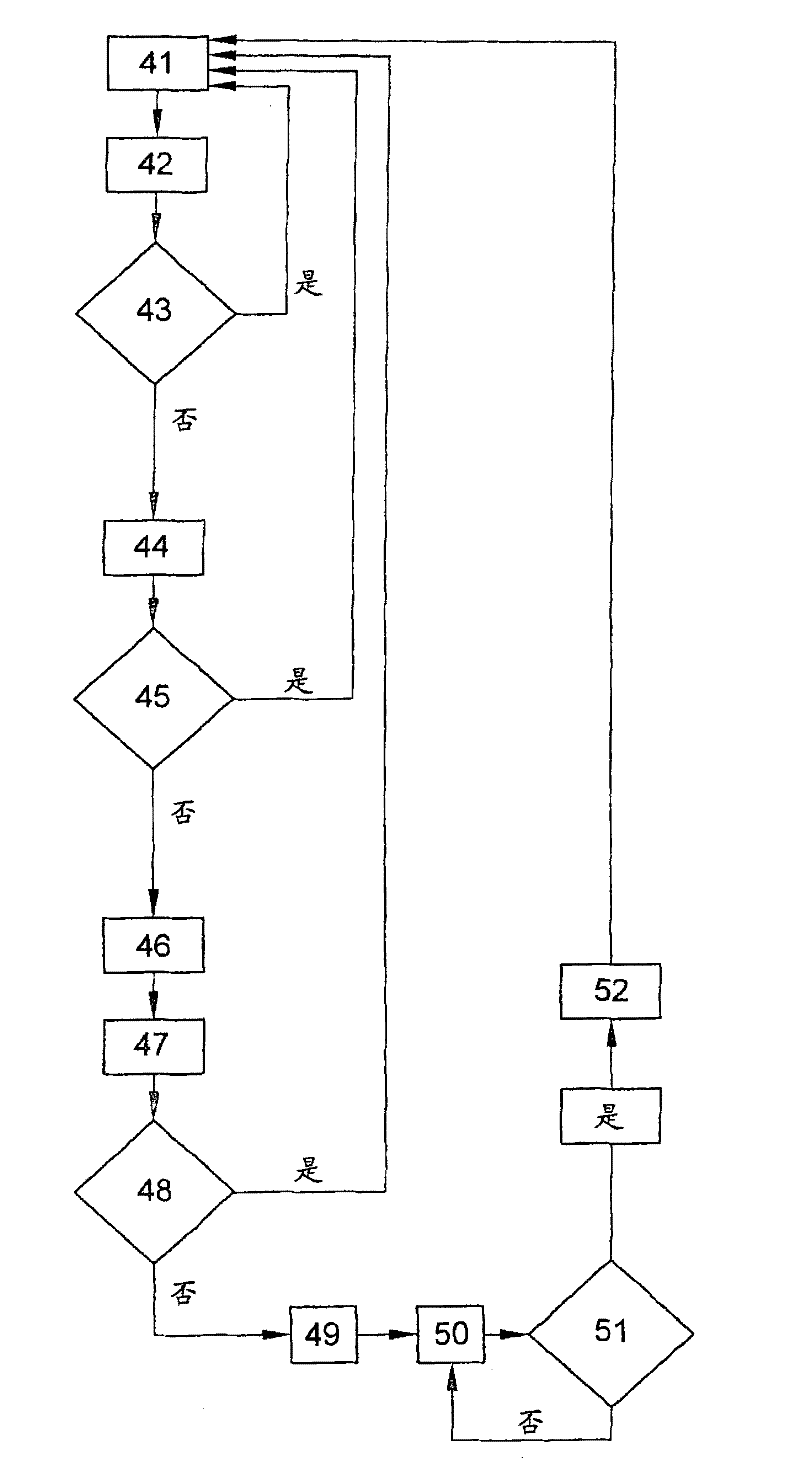

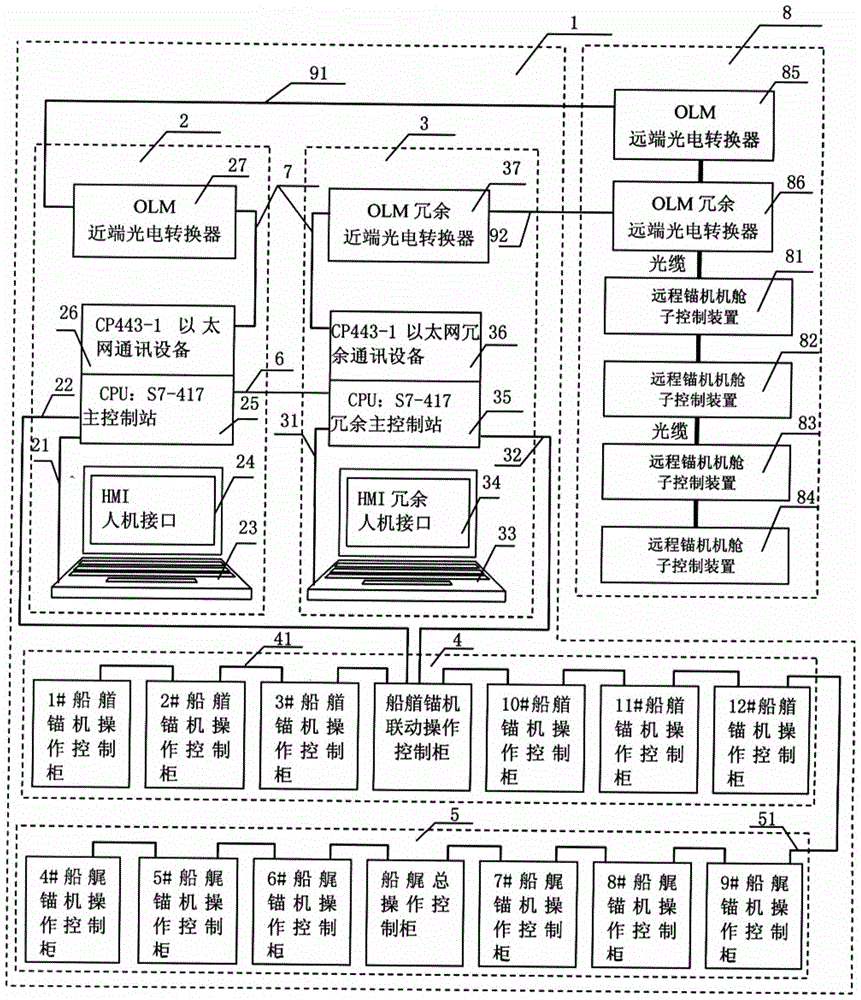

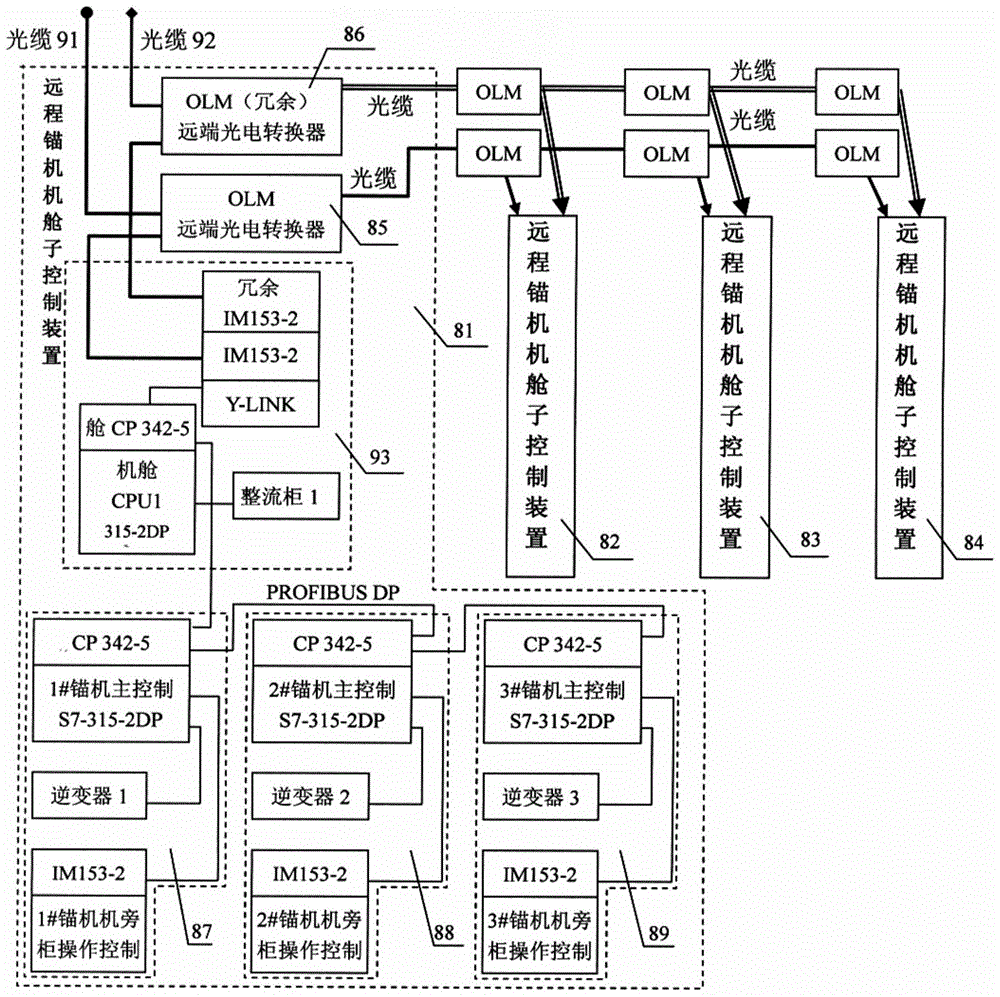

Smooth brake control system of multiple constant-tension anchor gears for pipe-laying ship

ActiveCN103885399AReduce production downtimeSmooth brakingWaterborne vesselsProgramme total factory controlWork statusControl bus

The invention discloses a smooth brake control system of multiple constant-tension anchor gears for a pipe-laying ship, comprising a cockpit operation control center and a remote anchor gear engine room control device. The cockpit operation control center is connected to the remote anchor gear engine room control device through an optical cable and used for controlling the multiple anchor gears and collecting traveling state data of the multiple anchor gears. A bow anchor gear control platform and a stern anchor gear operation control platform are in interactive transmission with information of controlling the anchor gear and the operation control center of the engine room cab through a control bus; the control device of the remote anchor gear engine room connects the bow linkage control cabinet, the stern linkage control cabinet to the main control station of a cockpit monitoring center in order to realize the data collection and monitoring of all operation control cabinets in the cockpit. The invention reduces production downtime, realizes smooth braking of multiple anchors, guarantees working state of multiple anchor gears and thus realizes the smooth movement and positioning of the pipe-laying ship.

Owner:CHINA NAT OFFSHORE OIL CORP +2

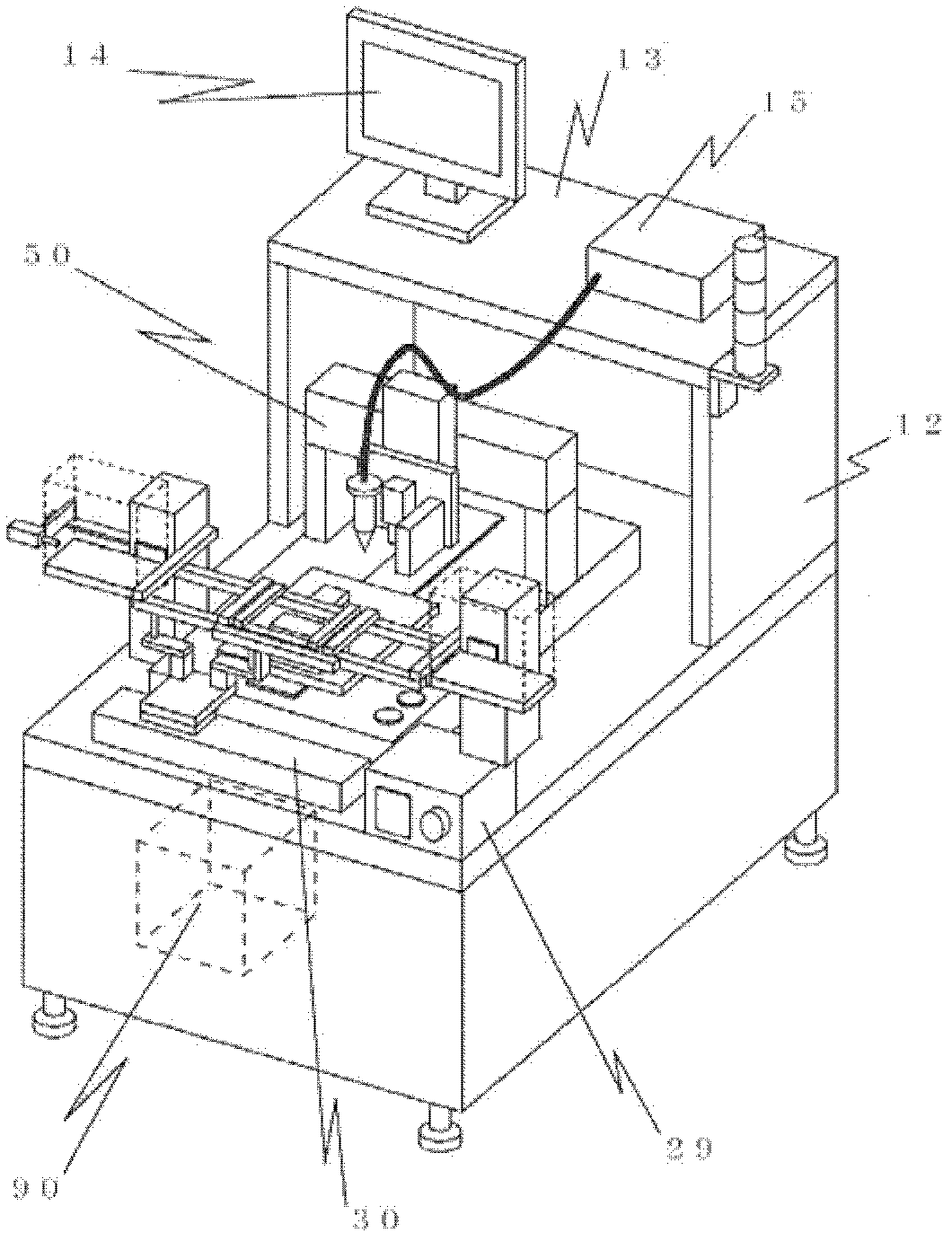

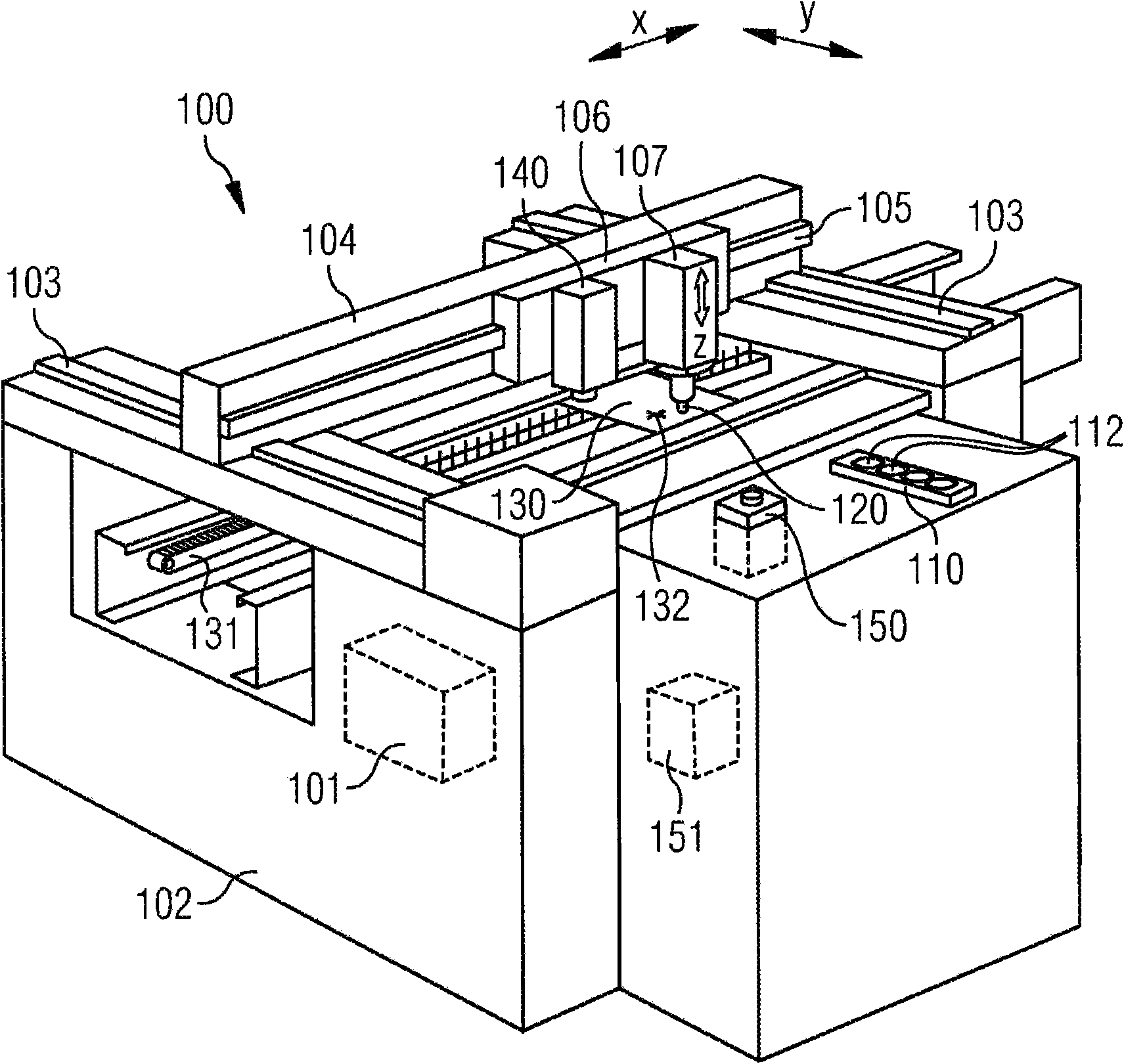

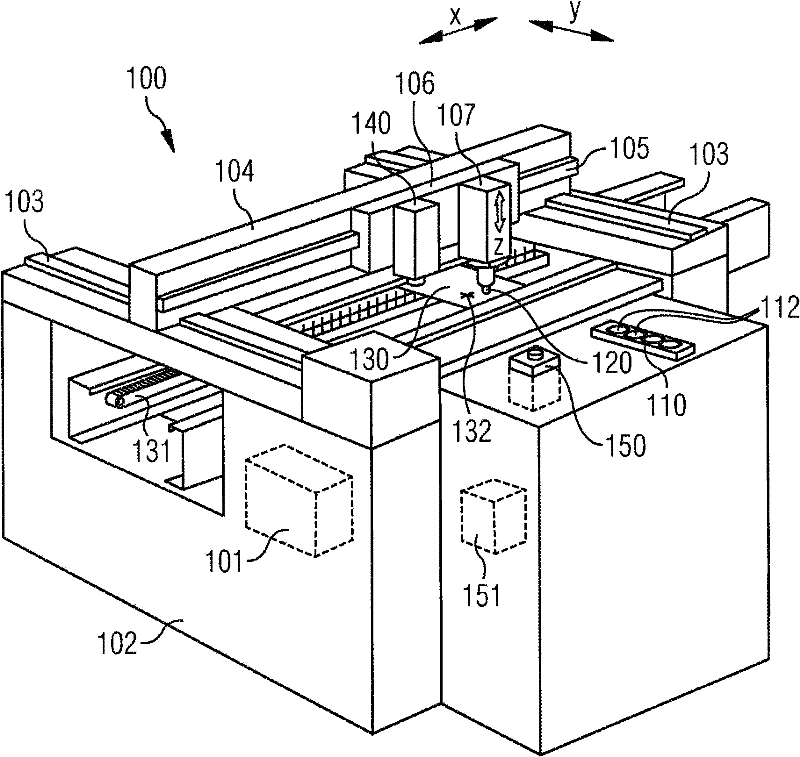

Operating device

ActiveCN102497937AReduce production downtimeSave labor and timeLiquid surface applicatorsCoatingsRelative displacementEngineering

Disclosed is an operating device which can flexibly accommodate changes in production volume and which can be used as a fully automatic operating device having a conveyance mechanism for a workpiece or as a semi-automatic operating device (a desktop robot) wherein the workpiece is manually attached and detached. A fully automatic operating device is provided with a mount on which a conveyance unit for conveying a workpiece is arranged, and a desktop operating unit which is detachably arranged on the mount. The desktop operating unit is provided with a workpiece holder for holding a workpiece, an operating head, and a relative displacement unit which moves the workpiece holder and the operating head relative to one another, and is able to carry out alone the desired operation on the workpiece held in the workpiece holder. The workpiece holder has a conveyance position, wherein the workpiece holder is connected to the conveyance unit, and an operating position, wherein the workpiece holder separates from the conveyance unit and carries out the desired operation on the workpiece.

Owner:MUSASHI ENG INC

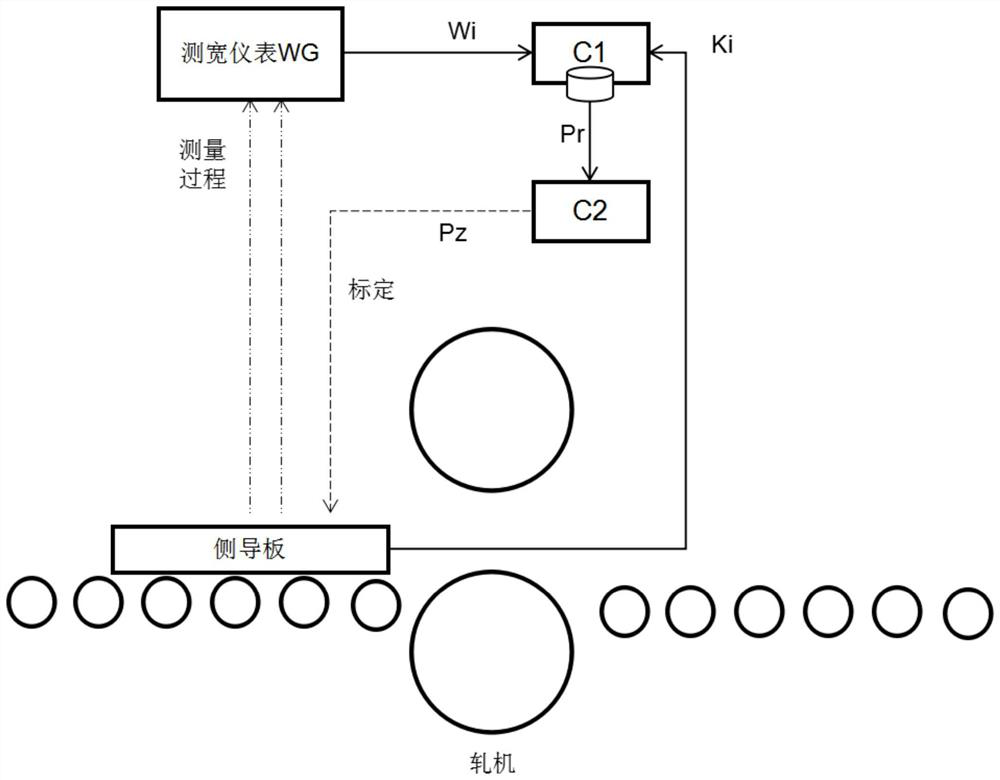

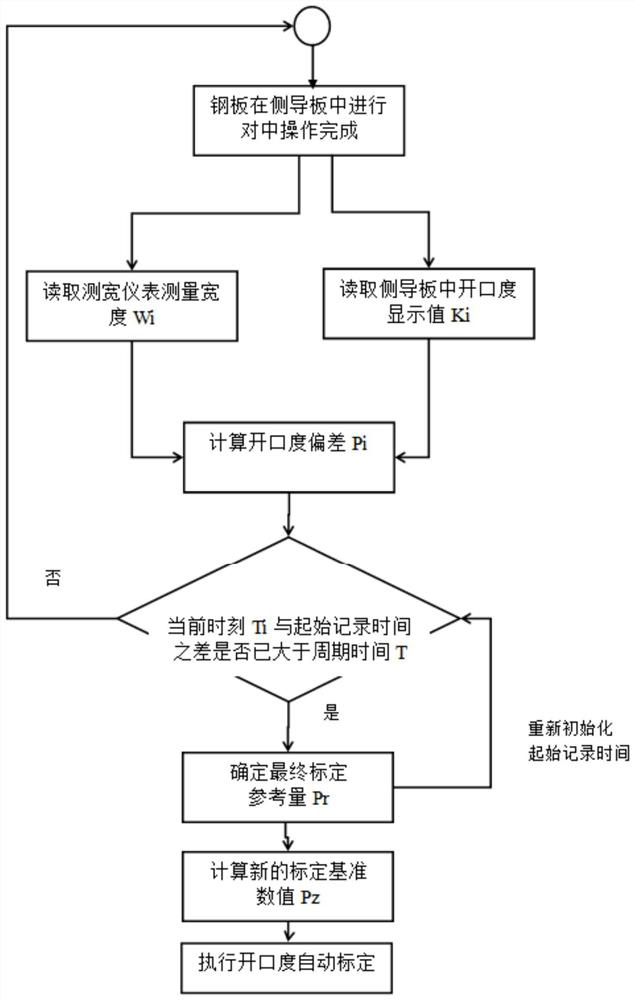

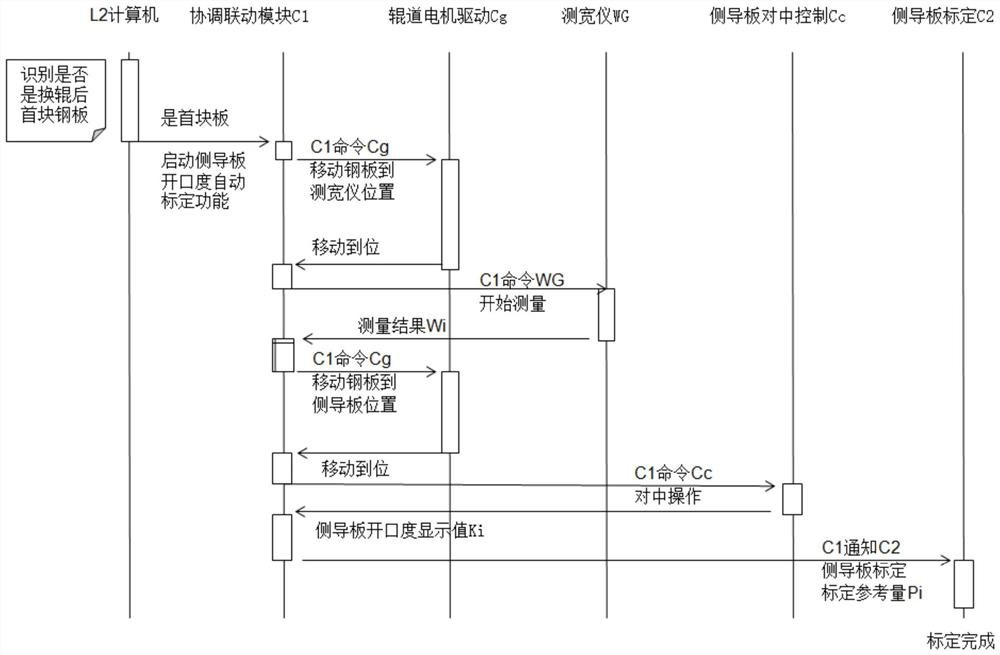

Full-automatic calibration method for opening degree of side guide plate of heavy and medium plate mill

ActiveCN113275392AReduce calibration timeShorten production downtimeGuiding/positioning/aligning arrangementsMeasuring devicesProduction lineStructural engineering

The invention discloses a full-automatic calibration method for the opening degree of a side guide plate of a heavy and medium plate mill. The full-automatic calibration method is suitable for a modern heavy and medium plate production line with a steel plate profile gauge (POG) or a width gauge arranged above the side guide plate. A periodic calibration calculation module is additionally arranged in an automatic system, and after the module calculates the width deviation value of a plurality of side guide plates and the profile gauge in an accumulative mode, data filtering is carried out, and the calibration value of the side guide plates is adjusted in a self-adaptive mode. According to the full-automatic calibration method, the time and the labor cost of the opening degree calibration operation of the side guide plates are saved, the safety risk is reduced, and the precision of the measurement width of the side guide plates is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

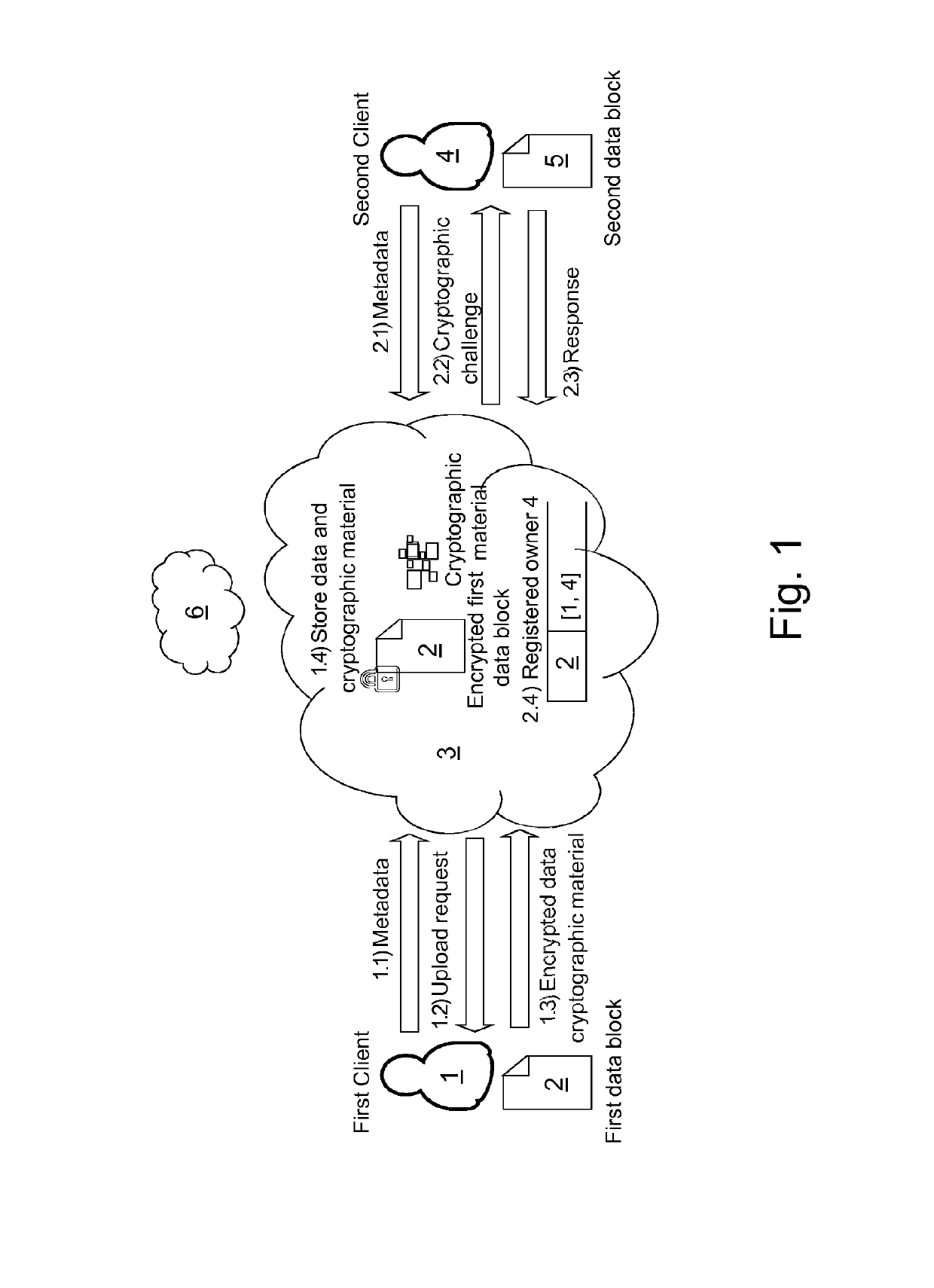

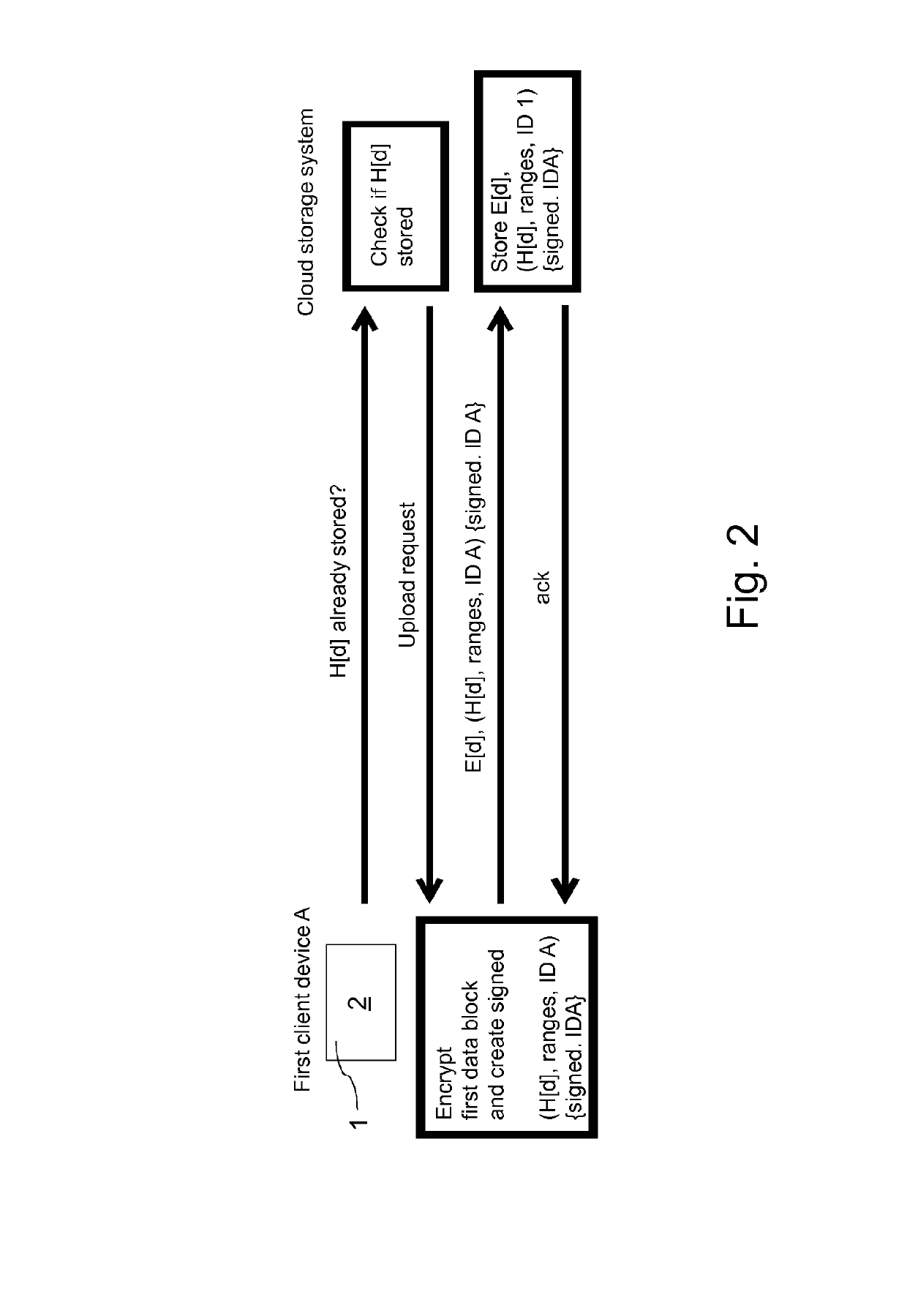

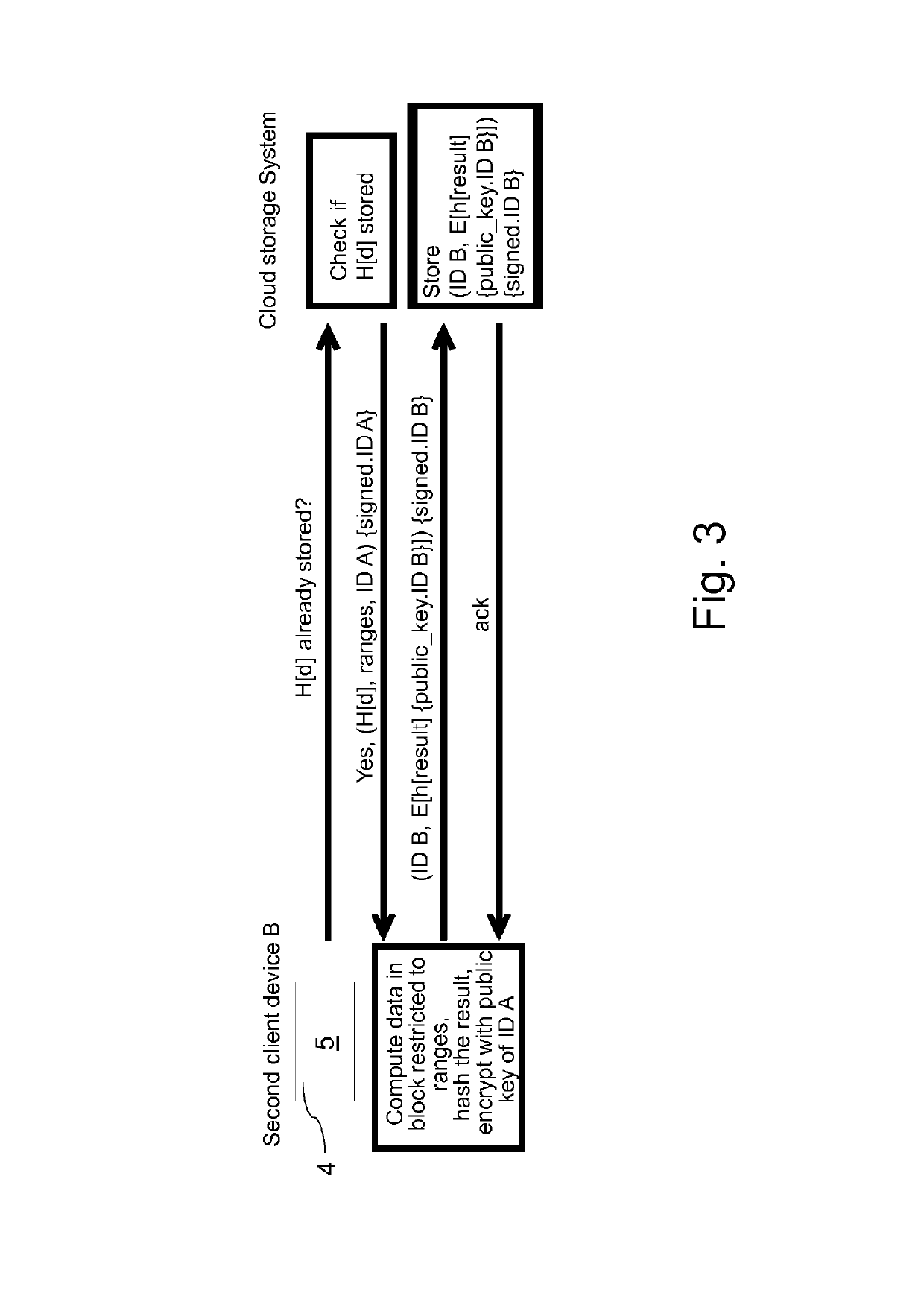

Method for storing data blocks from client devices to a cloud storage system

ActiveUS20190171847A1Secure measureData smoothingKey distribution for secure communicationInput/output to record carriersComputer hardwareCloud storage system

The invention relates to a method for storing data blocks from client devices to a cloud storage system, the method includes the steps of: d) storing an encrypted first data block and a challenge of the first data block of a first client device on the cloud storage system, e) determining if a hash of a second data block of a second client device stored on the cloud storage system equals the hash of the first data block, f) if yes, transmitting the challenge of the first data block from the cloud storage system to the second client device, g) extracting, at the second client device, the bits at the positions or at the range contained in the challenge, hashing the extracted bits, encrypting the hashed bits with a public key of the first client device or of the second client device and uploading the encrypted bits from the second client device to the cloud storage system, and h) storing the encrypted bits from the second client device on the cloud storage system.

Owner:ABB (SCHWEIZ) AG

Active cooling of crystal optics for increased laser lifetime

InactiveUS7903351B2Reduce degradationLow costPhotomechanical apparatusLaser constructional detailsActive coolingTransmittance

A laser beam is generated and transmitted within an enclosed pathway through at least one crystal optic at a power density that progressively degrades transmissivity of the crystal optic with accumulating fluence. The crystal optics are cooled below normal operating temperatures to slow the progressive degradation in the transmissivity of the crystal optics with the accumulating fluence or to accommodate a higher power density without correspondingly increasing the progressive degradation in transmissivity.

Owner:CORNING INC

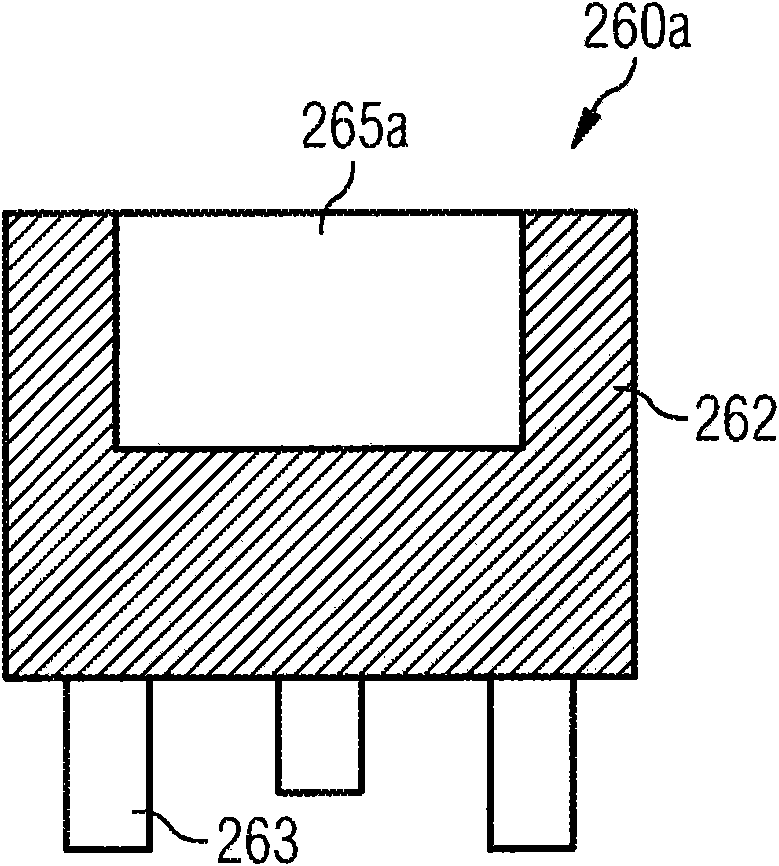

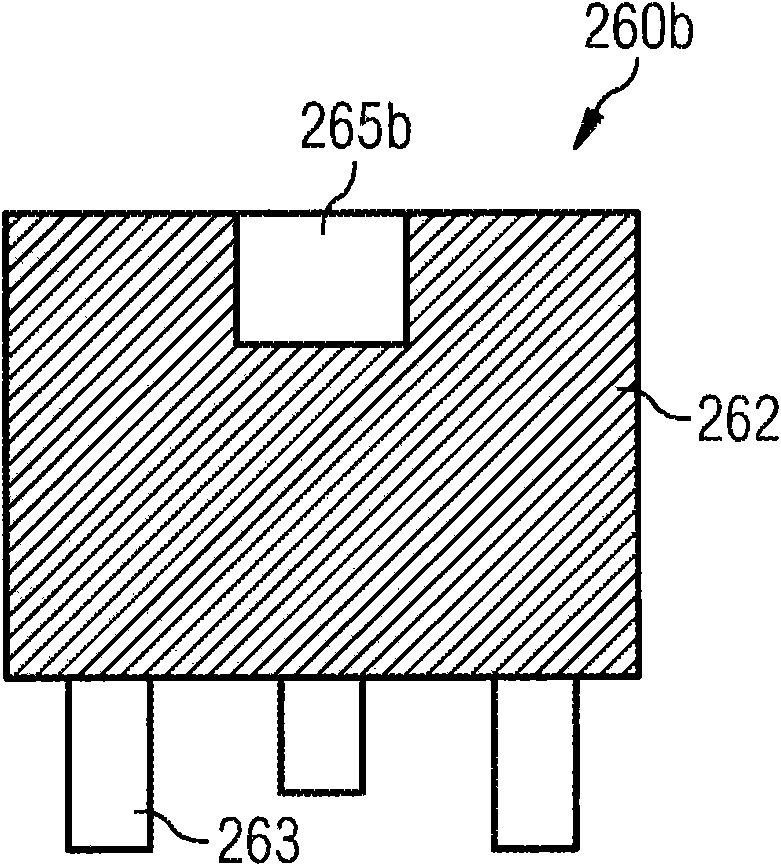

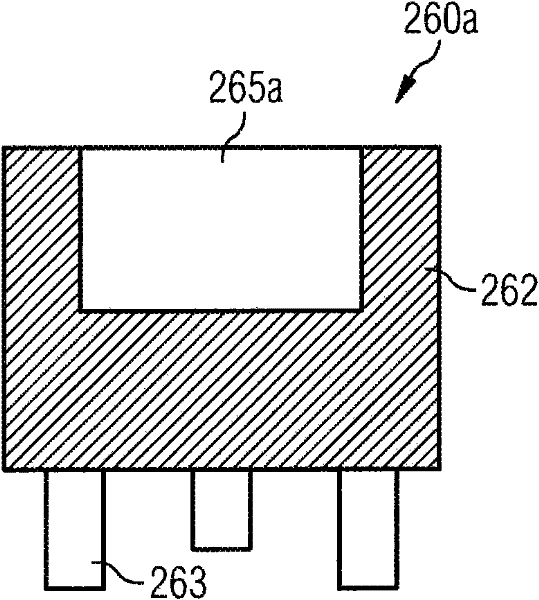

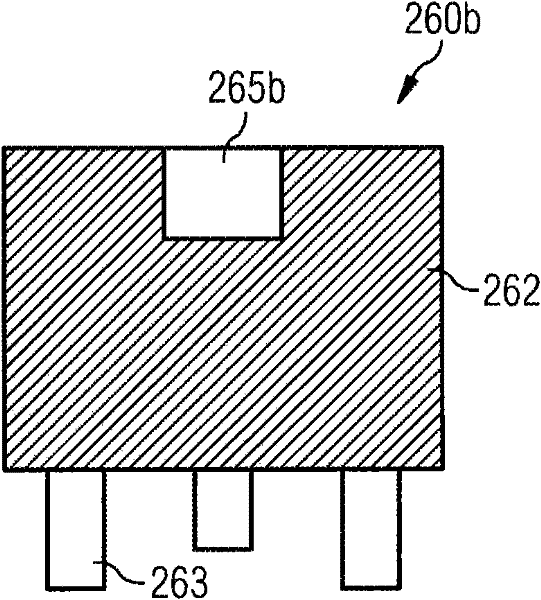

Identification of an electronic component using different component descriptions

InactiveCN101595772AEasy to identifyAvoid production stoppageElectrical componentsImaging processingElectronic component

The present application describes a method for automatically identifying an electronic component (260a, 260b) using image processing. The method has the following steps: (a) loading a data record having different descriptions of the visual appearance of the electronic component (260a, 260b) into a data processing device (151), (b) loading a picture of the electronic component (260a, 260b) which has been taken by a camera (150) into the data processing device (151), and (c) comparing at least one feature of the different descriptions with at least one feature (265a, 265b) of the picture, with the component (260a, 260b) being identified as corresponding to the data record if the at least one feature (265a, 265b) of the picture corresponds to at least one feature of the data record within a prescribed tolerance.

Owner:ASM ASSEMBLY SYST GMBH & CO

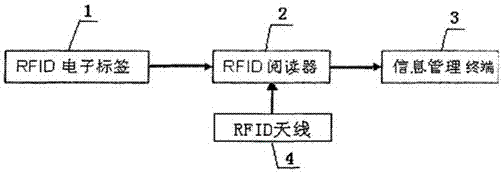

Intelligent supervisory system applied to flame-retarding conveying belt under coal mine

InactiveCN107985957ANon-contactWorking distanceConveyorsControl devices for conveyorsSignal onComputer terminal

The invention provides an intelligent supervisory system applied to a flame-retarding conveying belt under a coal mine. The intelligent supervisory system applied to the flame-retarding conveying beltunder the coal mine mainly comprises an RFID electronic tag, an RFID reader, an RFID antenna and an information management terminal. The RFID electronic tag is arranged in the conveying belt product.The RFID antenna is connected with the RFID reader. The RFID reader is connected with the information management terminal. The RFID reader reads a signal on the electronic tag and then transmits thesignal to the information management terminal. The RFID-based supervisory system for the conveying belt has a series advantages of non-contact characteristic, long working distance, high precision, automatic and rapid information collection, good environment adaptability and the like, fills the blank of intelligent supervision of the conveying belt in use, can replace traditional manual input andcan achieve more timely and comprehensive input, and the use and maintenance operating efficiency of the coal mine is improved; and based on the advanced automatic recognition function, the intelligent supervisory system can easily complete tasks which are difficult to complete by workers in the prior art, and the product competitiveness is improved.

Owner:NINGSHUN GROUP

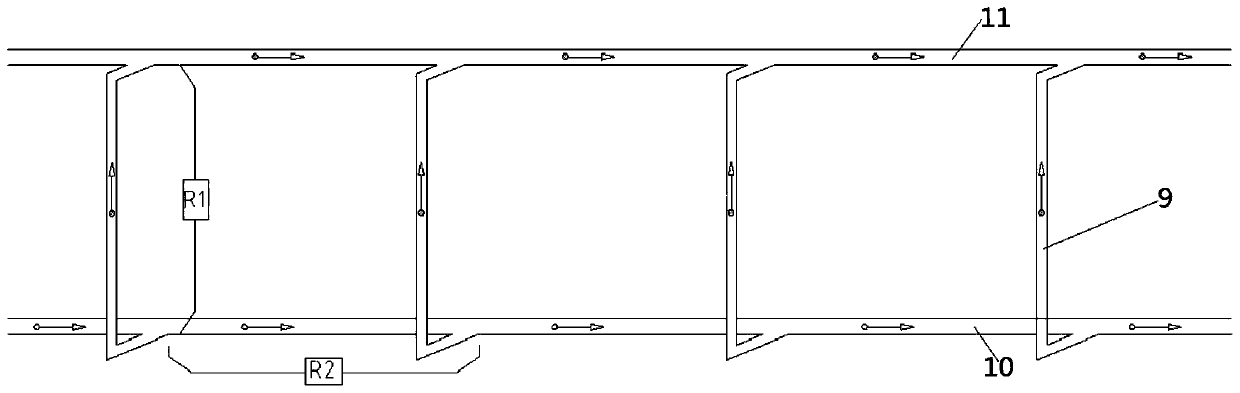

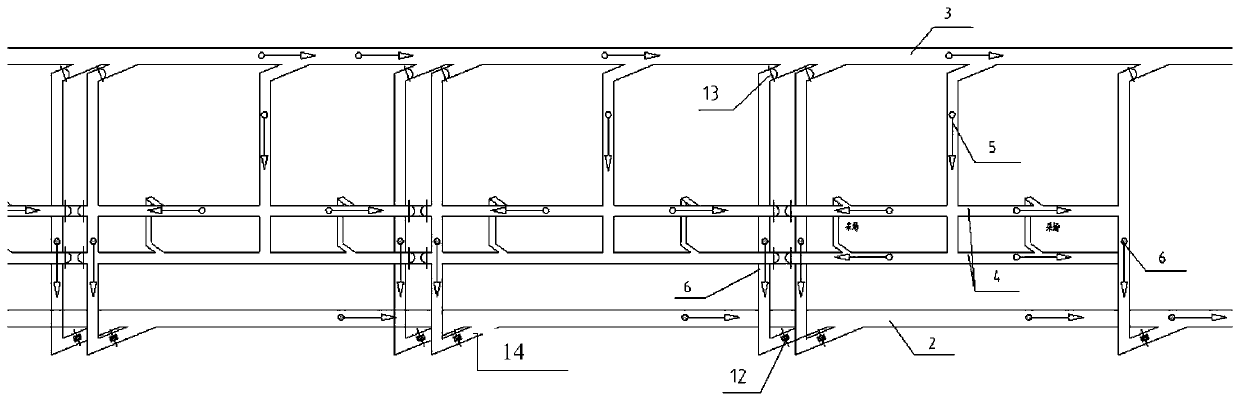

Underground mine ventilating system and air quantity distribution method

ActiveCN110953010AReduce the number of mining pits at the same timeIncrease ventilation timeTunnel/mines ventillationAir volumeMining engineering

The invention provides an underground mine ventilating system and an air quantity distribution method, and aims to solve the problem of simultaneously mining and ventilating for multiple middle sections of an underground mine. The constructed mine ventilating system takes a panel as a smallest ventilating unit; a special tail gate is utilized as a panel tail gate, and a gate which does not take the main function is taken as a panel main air inlet gate which communicates with each mining sub-section gate through a panel air-return inclined drift; an air flow purifying device and a cooling and heat exchange device are arranged in the panel air inlet gate, so that inlet air flow is purified and cooled; and a mine ventilating system with a function of isolating contaminated air from fresh airis formed. In the constructed ventilating system, two panel air quantity distribution methods are disclosed, the first method refers to controlling section dimension of each air-return inclined driftin each panel to balance air quantity of each panel, and the second method refers to arranging an intelligent regulating air window in the air-return inclined drift and a disc air-return stone gate linked with the tail gate to regulate ventilation amount of each panel.

Owner:CINF ENG CO LTD

Straightener

PendingCN108598010AStraightening effect is stableImprove efficiencySemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:连云港瑞而盛电子科技有限公司

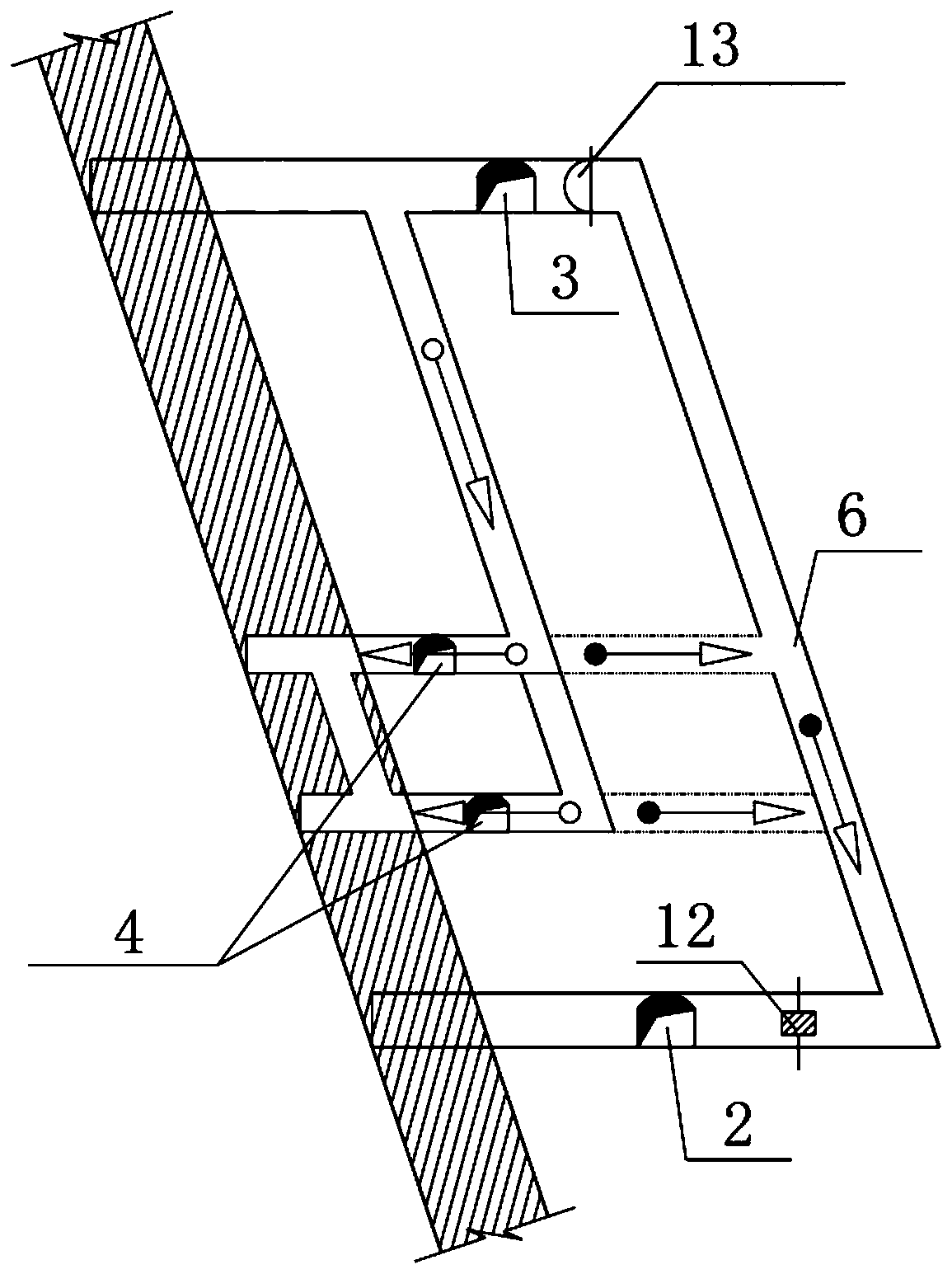

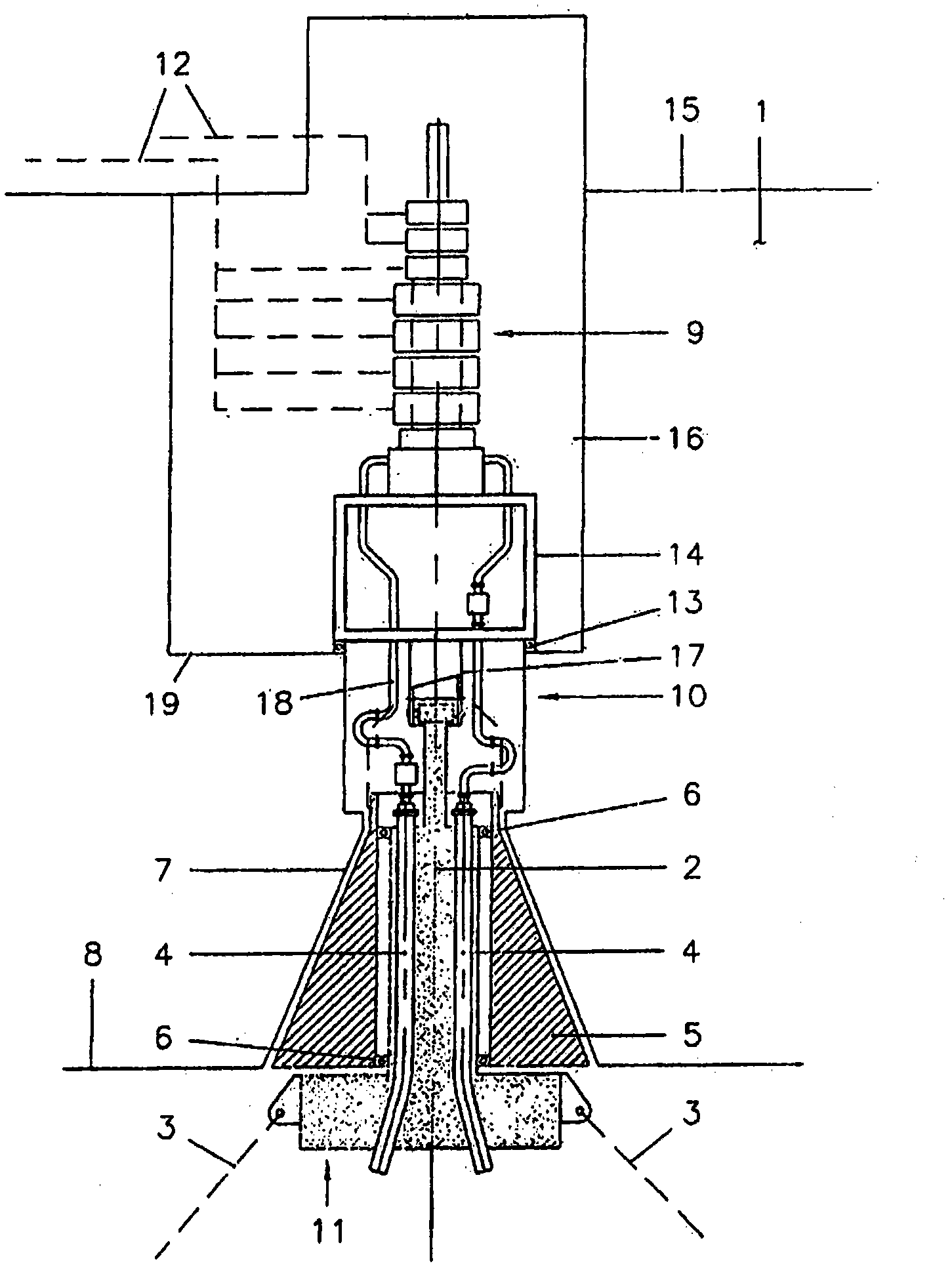

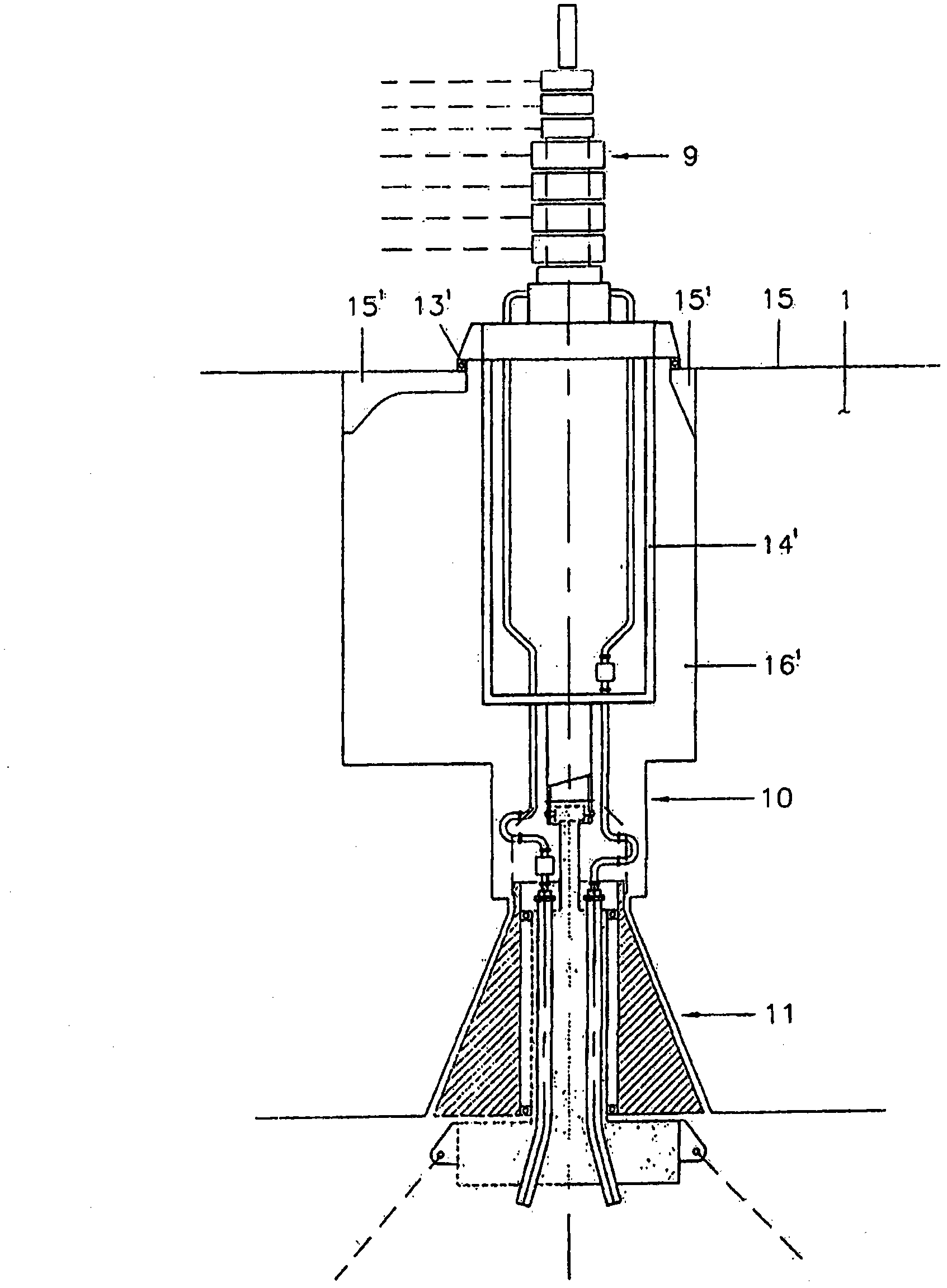

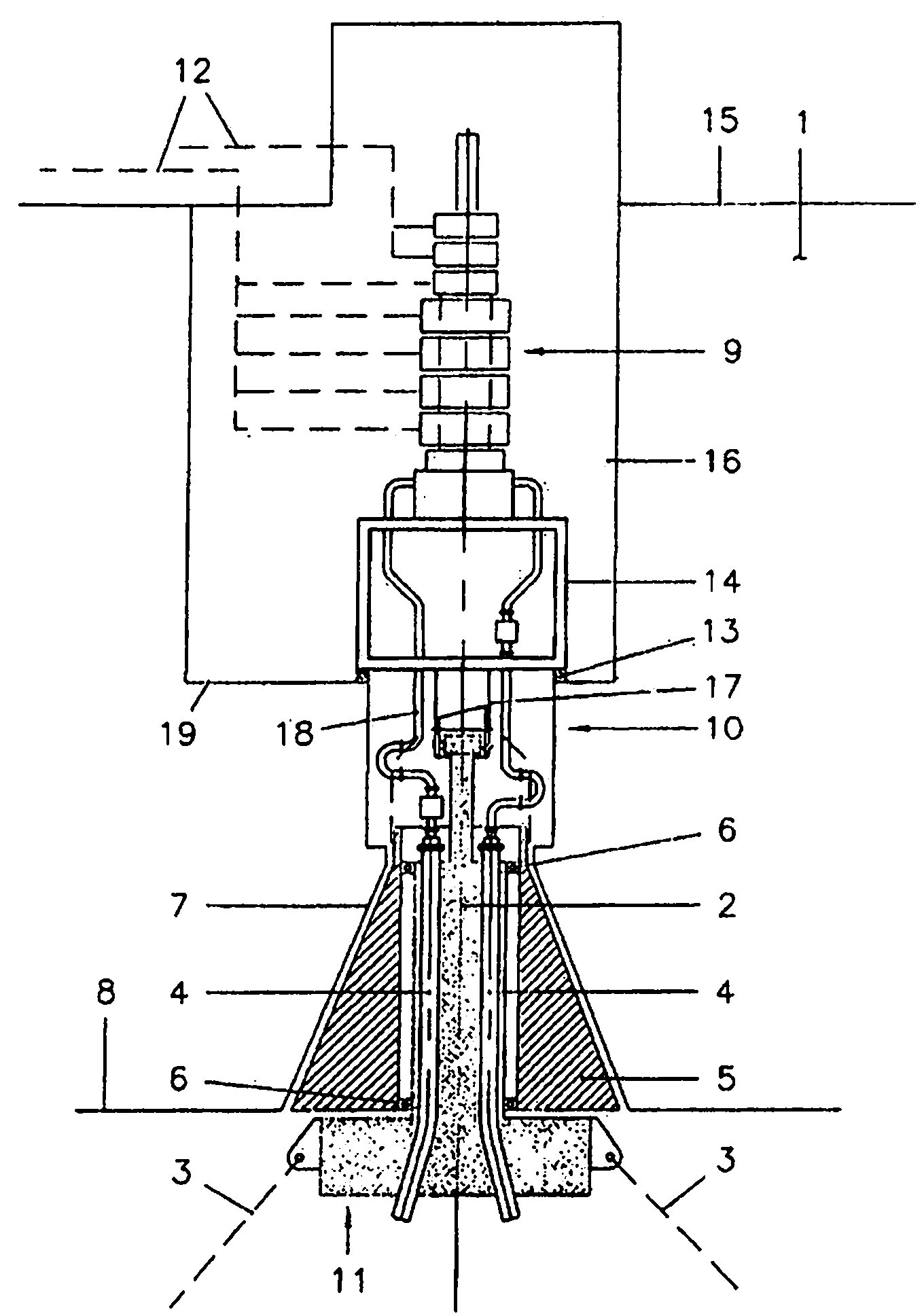

Disconnectable mooring assembly

A disconnectable mooring assembly for a vessel (1) comprises a mooring buoy (11) and a swivel positioned above the mooring buoy. The mooring buoy is provided with a central member (2) for being anchored to the seabed and comprises a number of passages each adapted for receiving a riser (4). The mooring buoy further comprises an outer member (5) surrounding the central member and capable of a rotation relative thereto. Said outer member is adapted to be housed in and locked to a corresponding receiving opening of the vessel. The swivel is located above the mooring buoy in such a manner that an interspace is defined between the mooring buoy and the swivel.

Owner:BLUEWATER ENERGY SERVECES BV

Particle trap for a plasma source

InactiveCN102217028AReduce recombinationLess recombinationElectric discharge tubesGas separationRemote plasmaGas passing

Owner:MKS INSTR INC

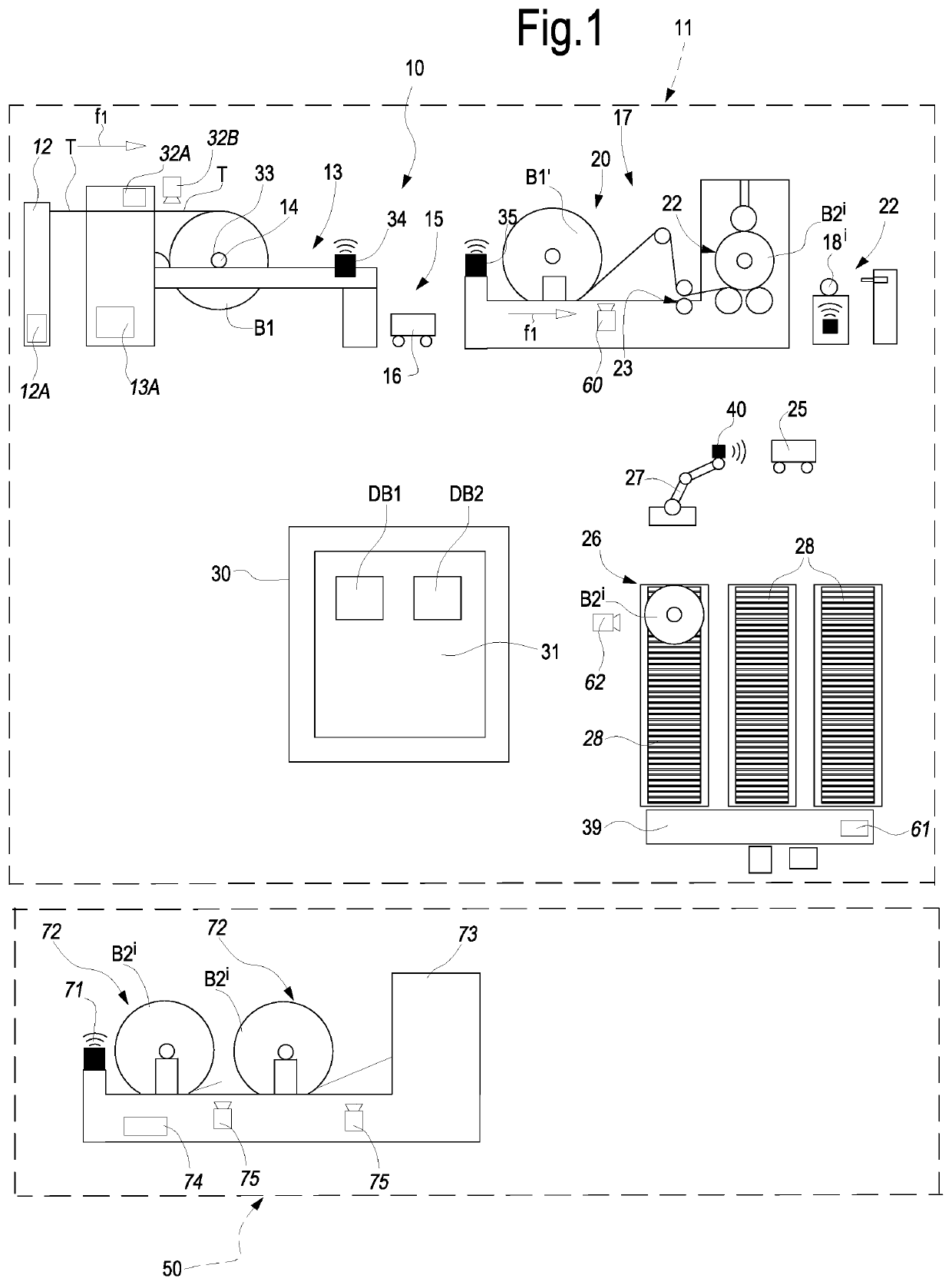

Method for predicting the presence of product defects during an intermediate processing step of a thin product wound in a roll

PendingUS20210261374A1Great degree of predictionGreat degreeProgramme controlWebs handlingProcess engineeringComputer science

Method for predicting the presence of product defects during an intermediate processing step of a thin product wound in a roll, which provides for—receiving a roll of thin product that has been assigned a unique identification code stored in a database system, this latter containing process and / or product parameters detected in the production steps of said thin product wound in said roll upstream of said intermediate processing step, associated with said unique identification code,—accessing said database system,—entering one or more of the process and / or product parameters associated with the unique identification code of said roll contained in said database system in a predictive model, which uses a correlation, created by means of machine learning logics, from historicized values related to the process and / or product parameters output from said intermediate processing step and historicized values related to process and / or product parameters of the same rolls detected in the production steps of said rolls upstream of said intermediate processing step, in order to predict product parameters output from said intermediate processing step,—comparing said aforesaid product parameters with respective predefined limit values,—generating predictive diagnosis information of thin product defects based on the result of said comparison.

Owner:ITAL TECH ALLIANCE SRL

Identification of an electronic component using different component descriptions

InactiveCN101595772BEasy to identifyAvoid production stoppageElectrical componentsImaging processingElectronic component

The present application describes a method for automatically identifying an electronic component (260a, 260b) using image processing. The method has the following steps: (a) loading a data record having different descriptions of the visual appearance of the electronic component (260a, 260b) into a data processing device (151), (b) loading a picture of the electronic component (260a, 260b) which has been taken by a camera (150) into the data processing device (151), and (c) comparing at least one feature of the different descriptions with at least one feature (265a, 265b) of the picture, with the component (260a, 260b) being identified as corresponding to the data record if the at least one feature (265a, 265b) of the picture corresponds to at least one feature of the data record within a prescribed tolerance.

Owner:ASM ASSEMBLY SYST GMBH & CO

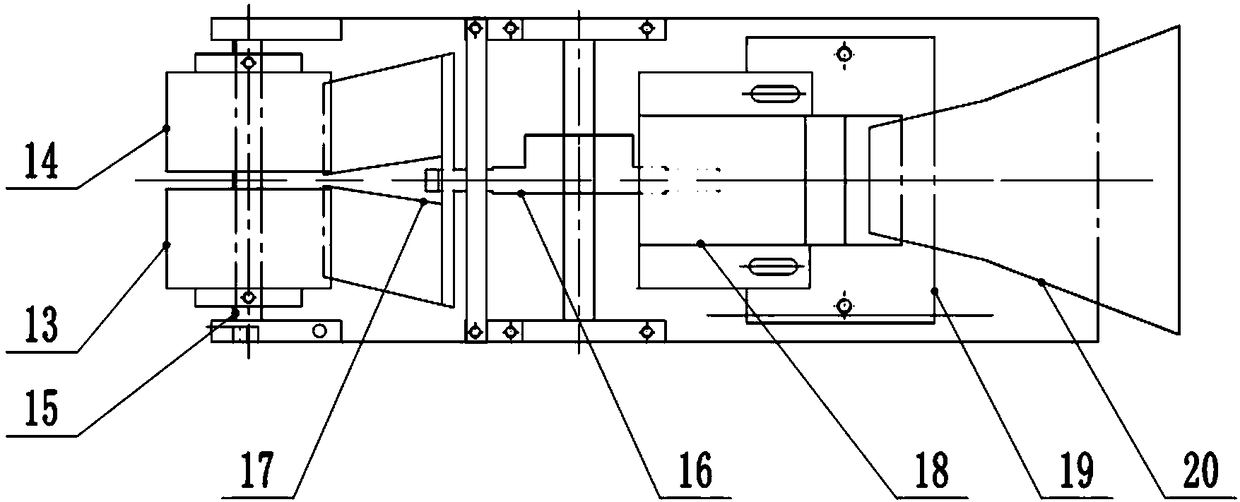

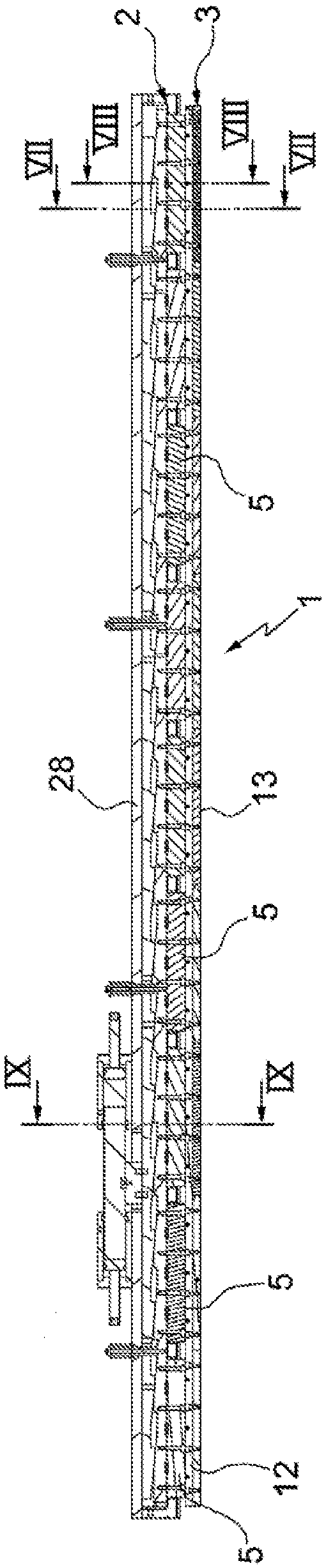

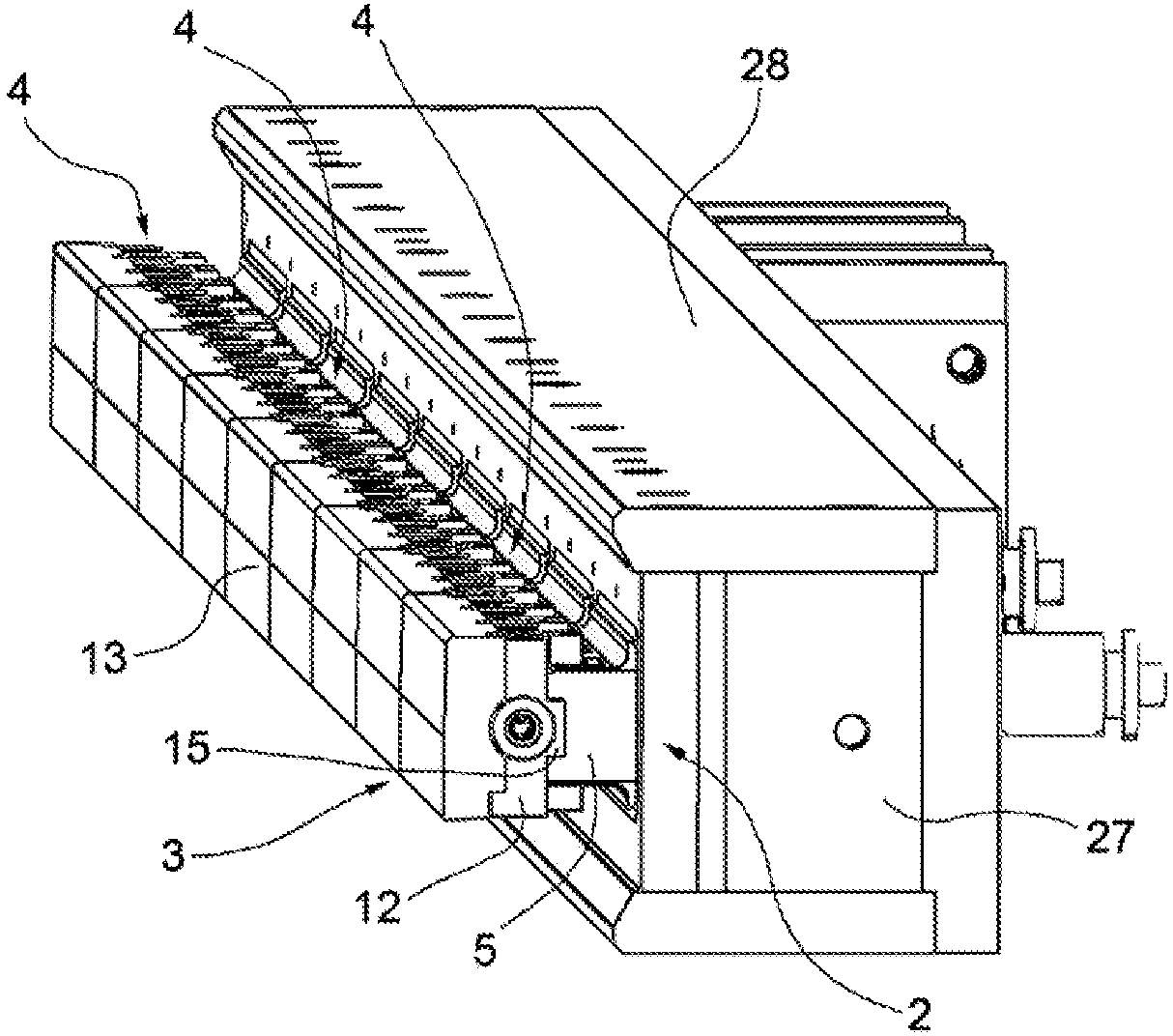

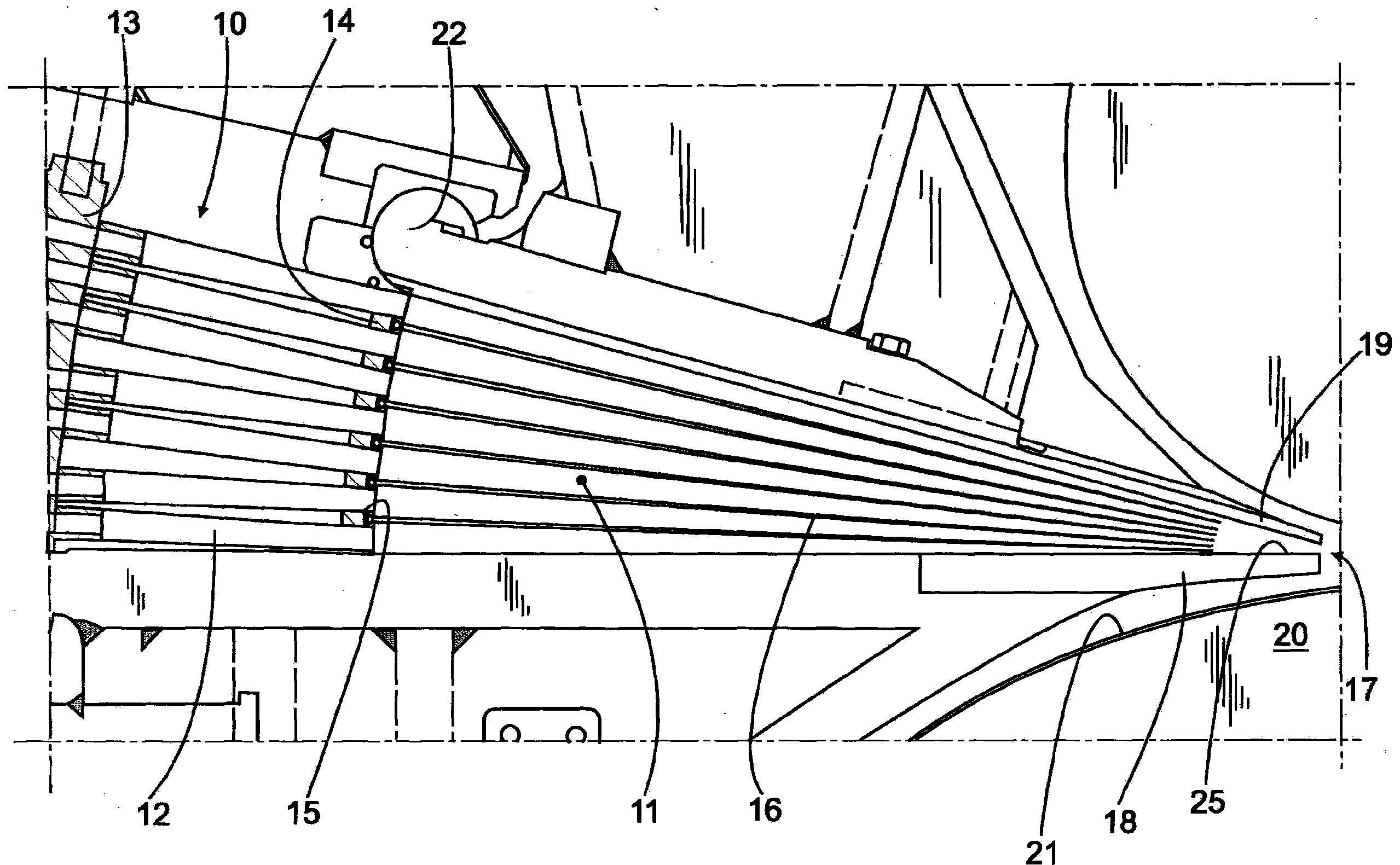

An end panel group of a press for ceramic products and the like

InactiveCN107567373AShorten production downtimeCeramic shaping liningsEngineeringMechanical engineering

An end panel group (1) of a press for ceramic products and the like, comprising at least one support (2) associable with fixed or movable parts of the press and at least one terminal element (3) associated with the support (2) and adapted to delimit at least one side, or at least one portion of a side, of a pressing cavity provided in the press; the end panel group (1) comprises means for the removable connection (4), of clamping type, of the terminal element (3) to the support (2).

Owner:SITI B&T GRP

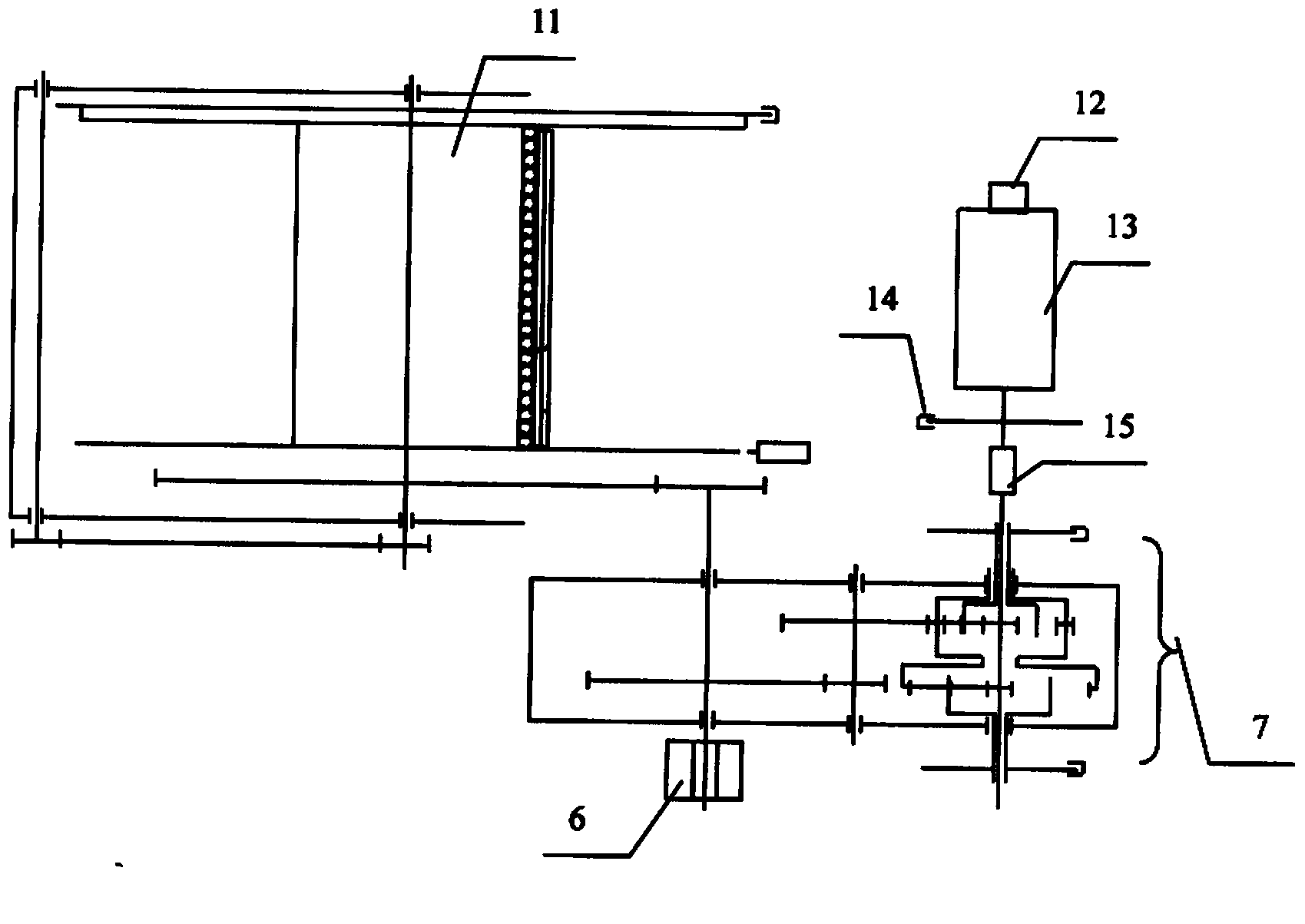

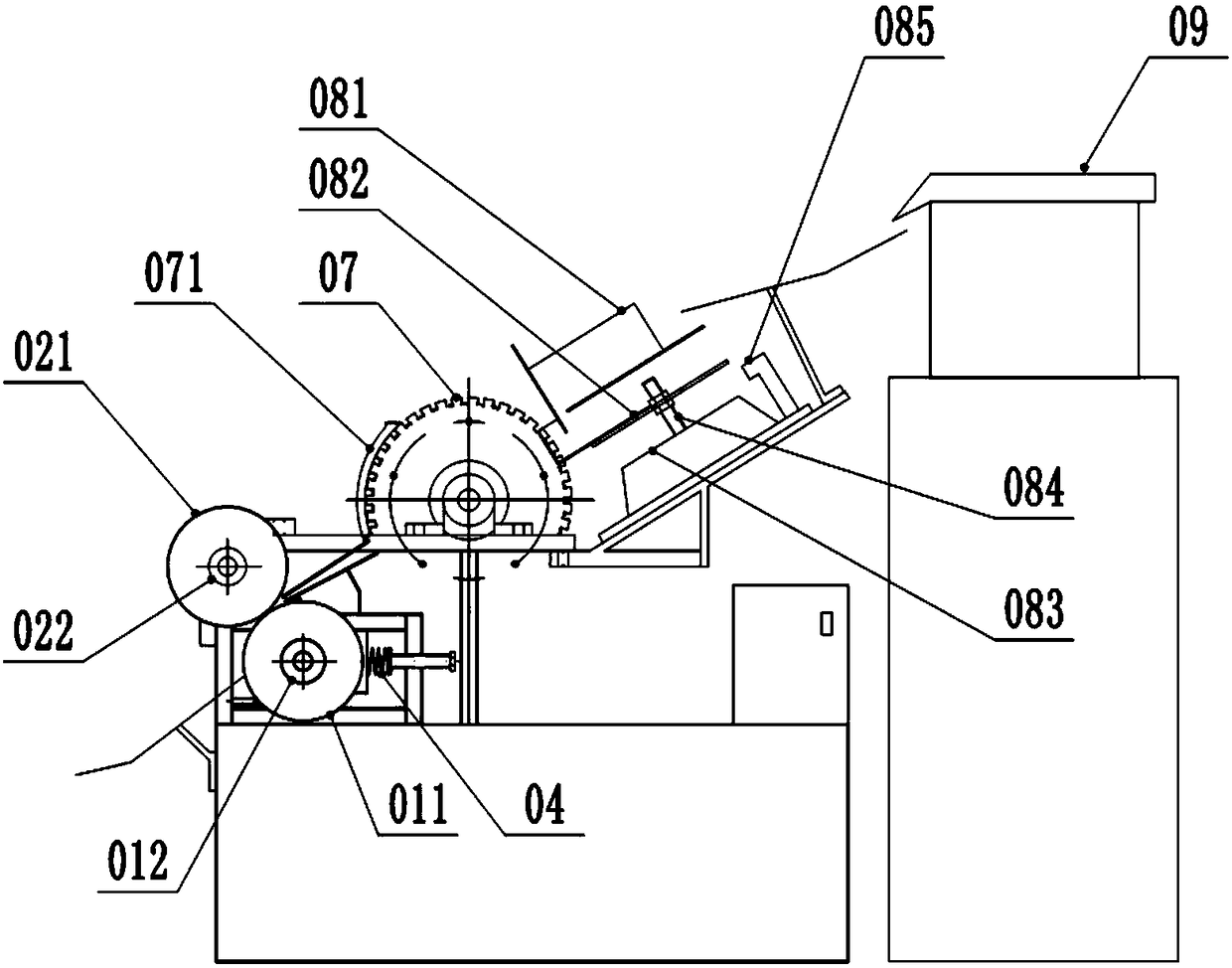

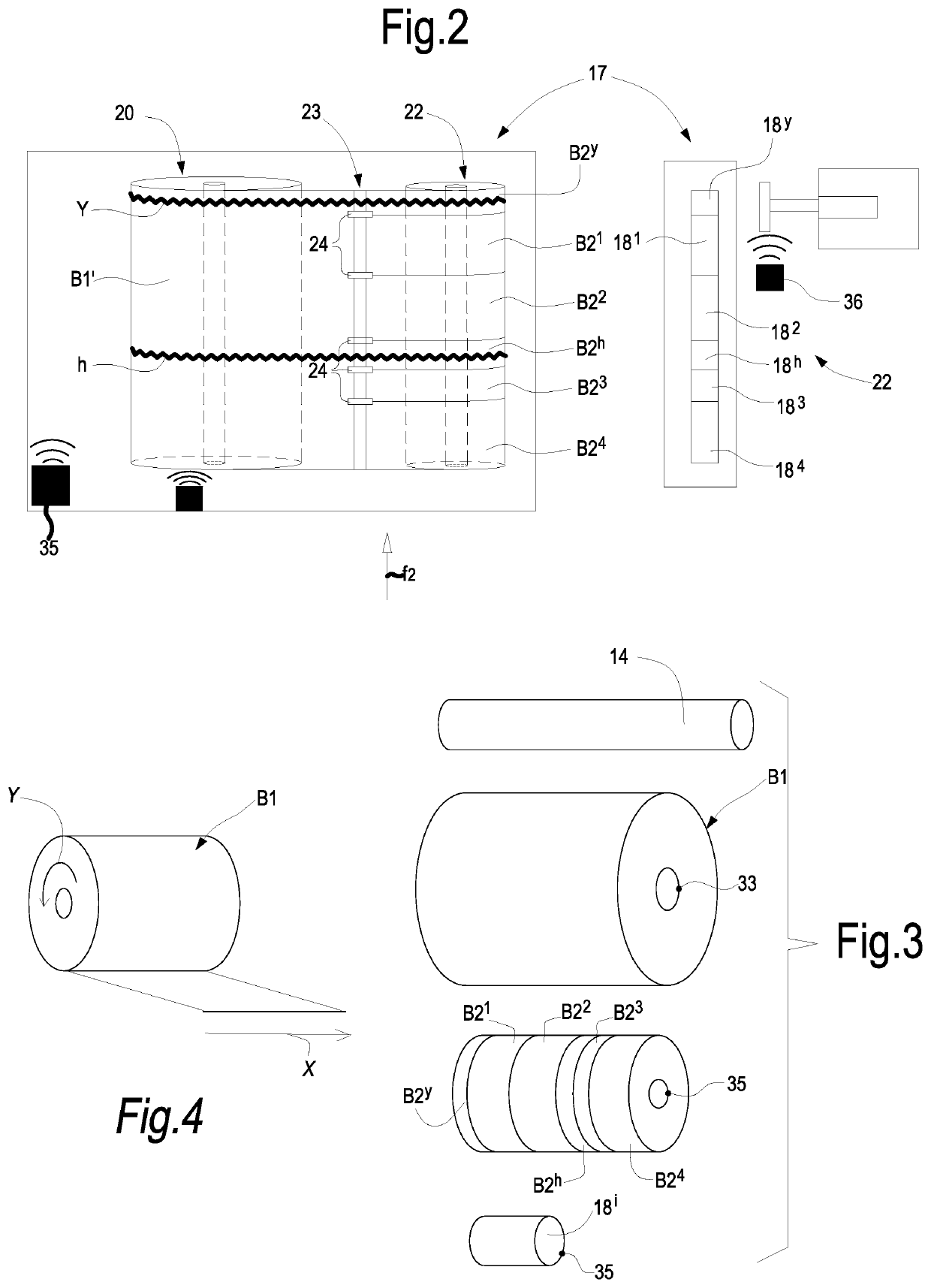

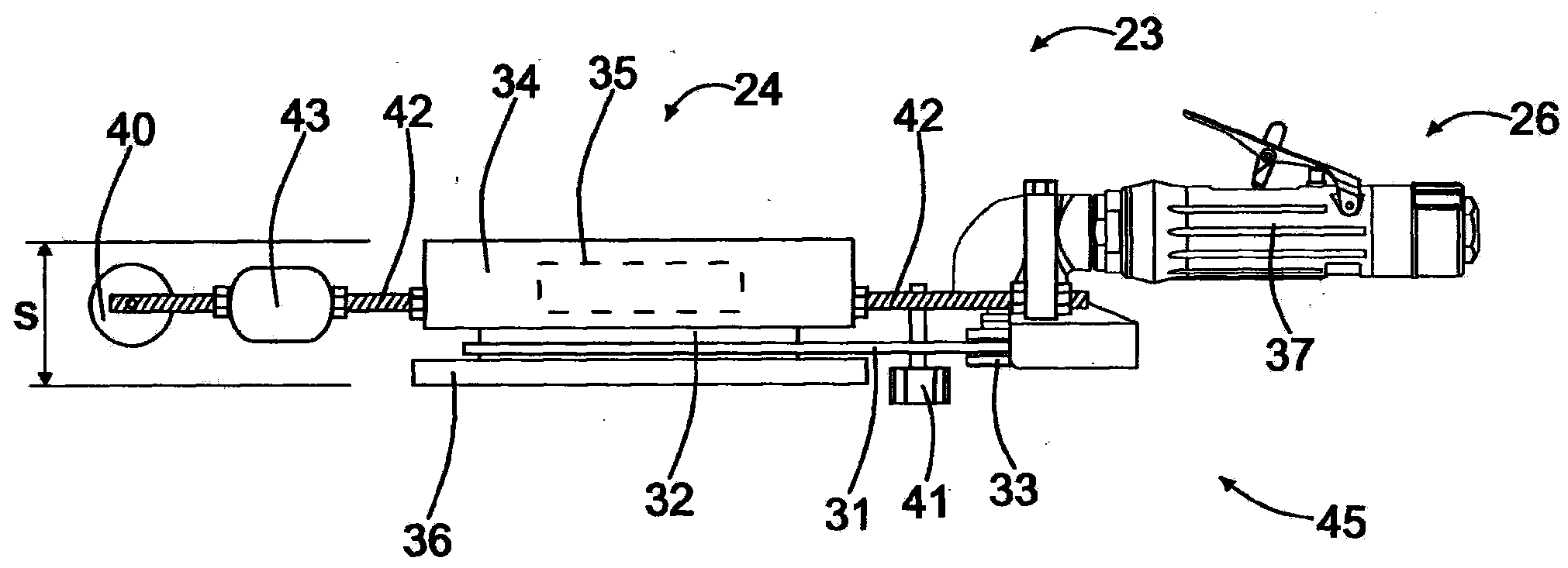

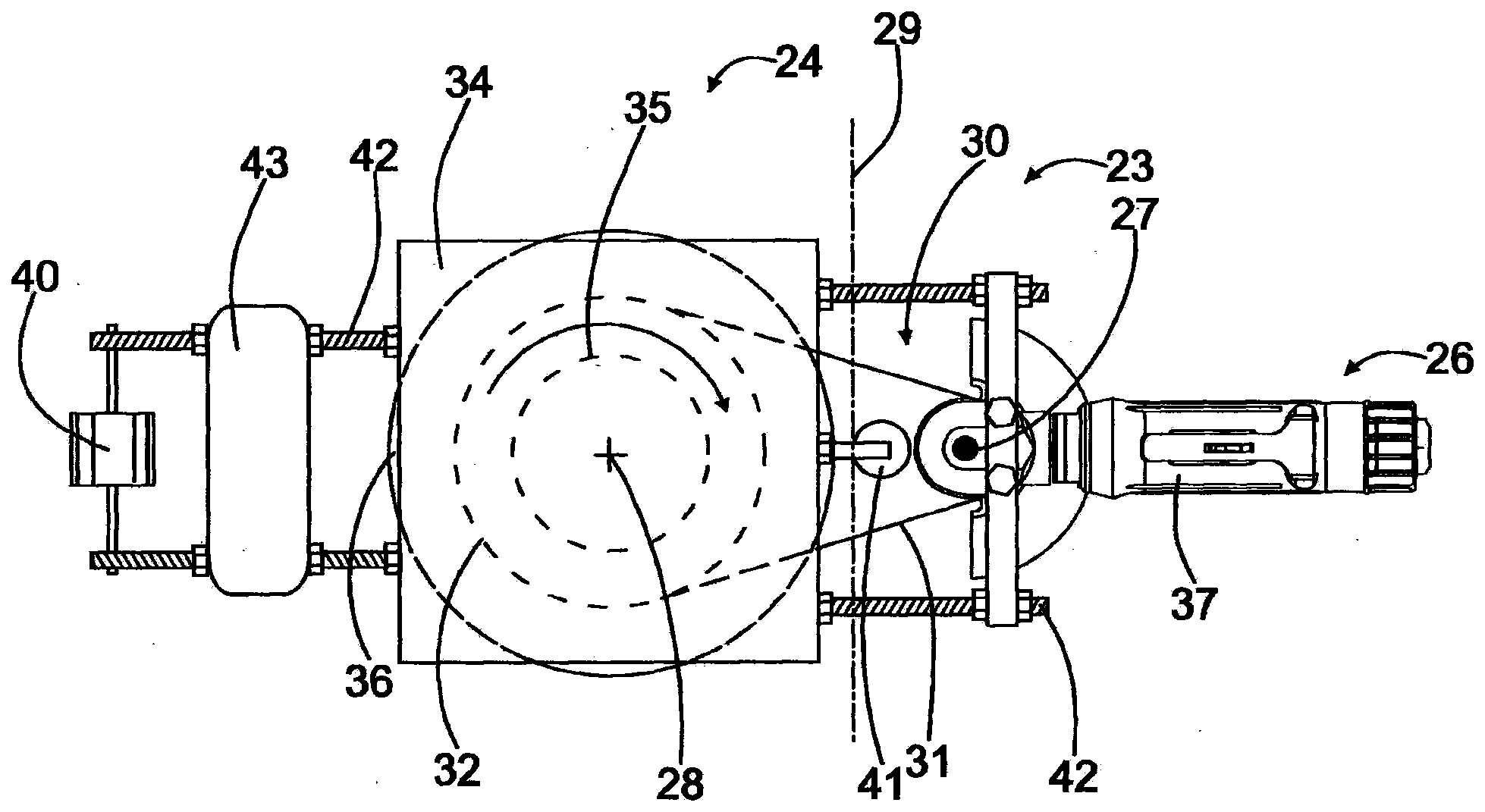

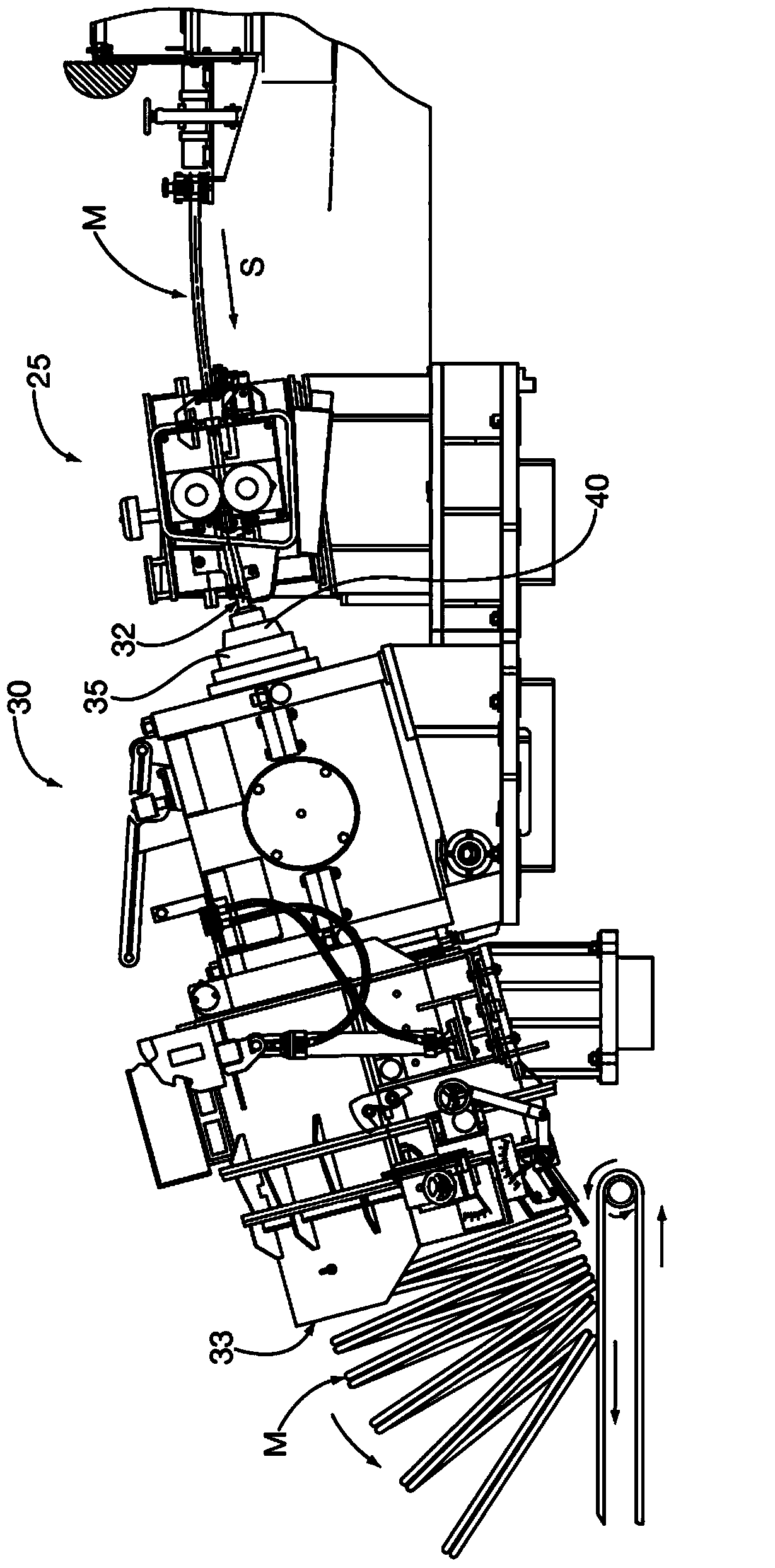

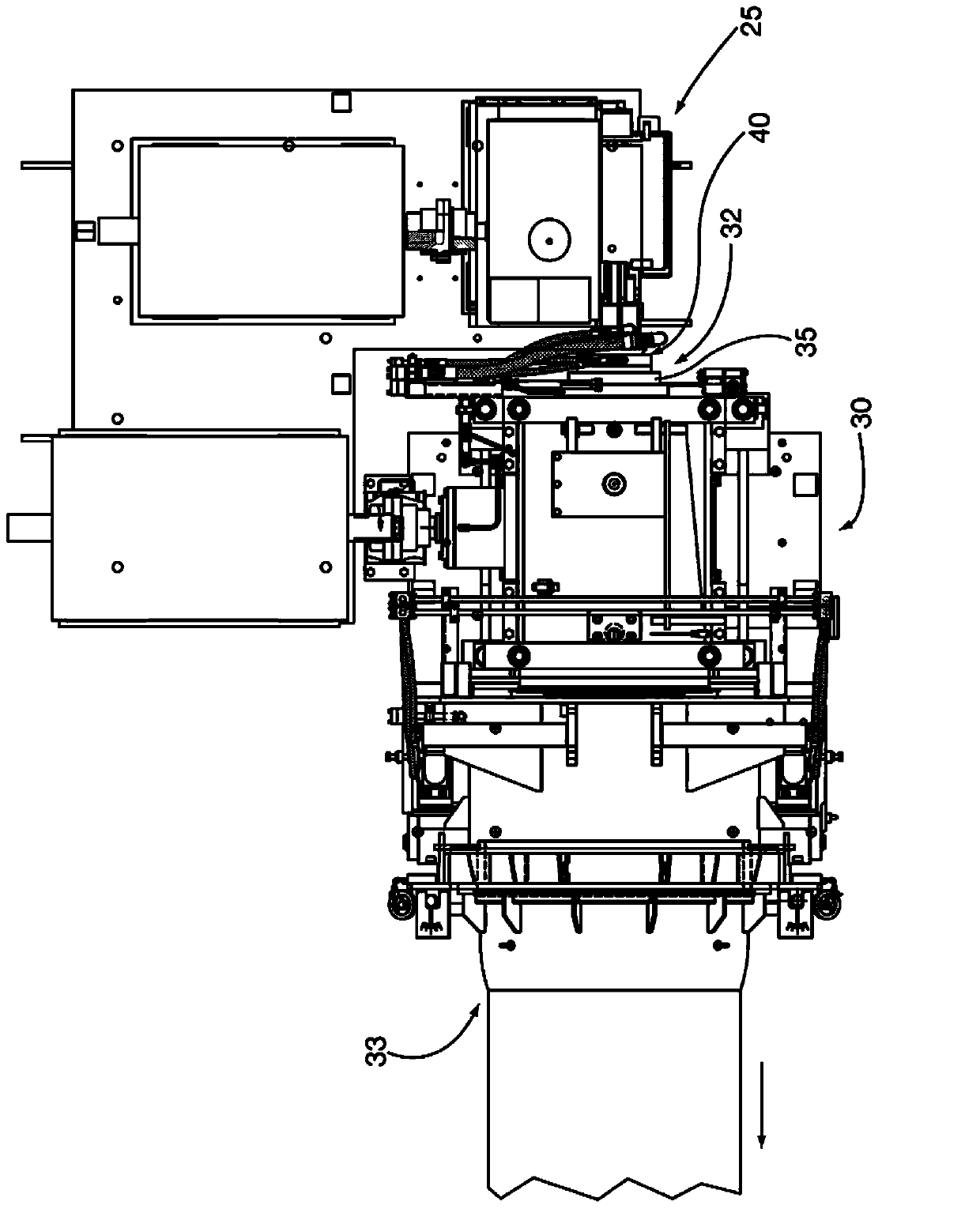

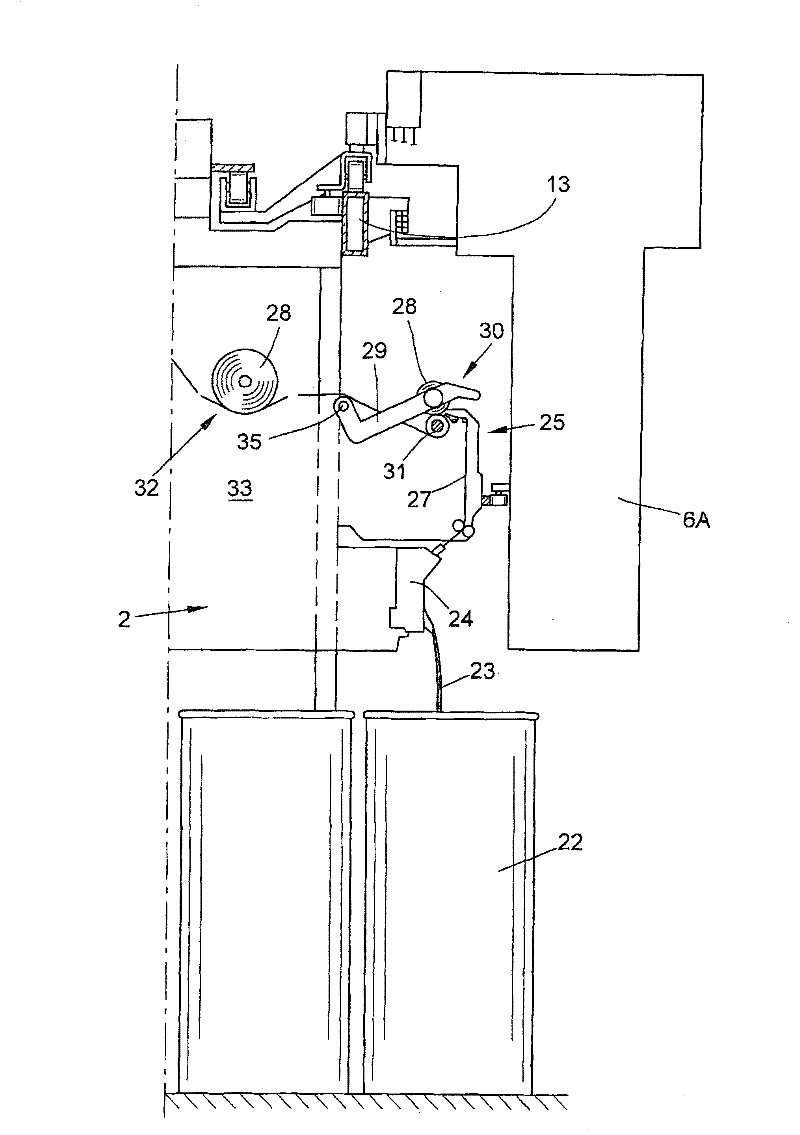

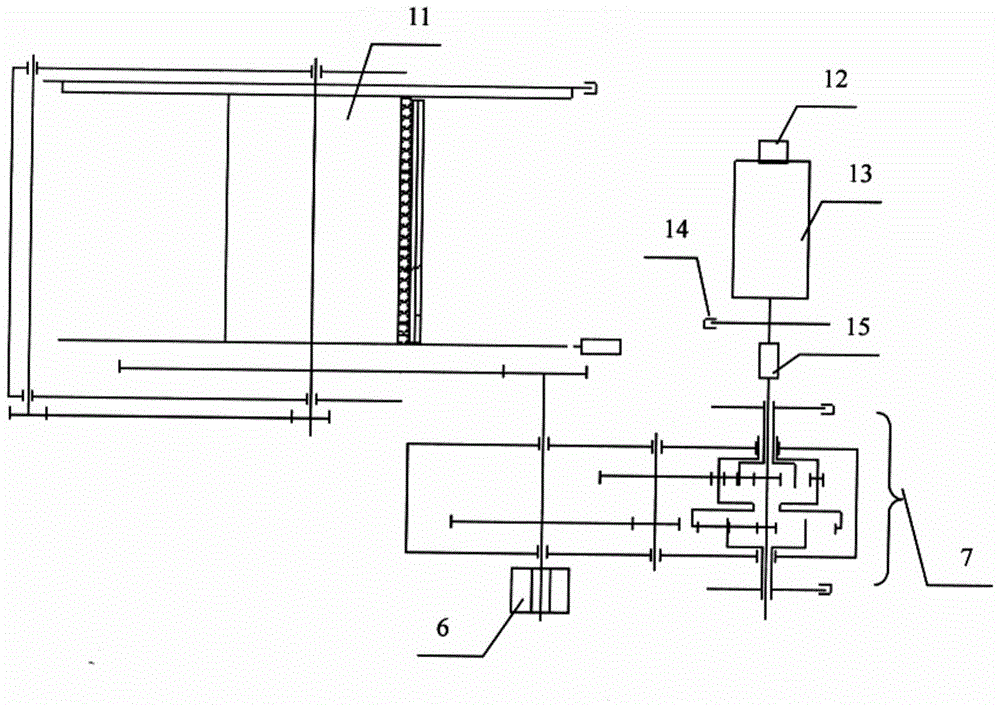

Device and method for conditioning the flow surface of the headbox of a fiber web machine

The invention relates to a device for the conditioning of the flow surface in the headbox of a fiber web machine. The device comprises a frame structure (23) and a conditioning element (24) arranged in the frame structure (23) for the conditioning of the flow surface (25) of the slice channel (11) of a headbox. The height dimension s of the conditioning element (24) is equal to or less than 60 mm. An actuator (26) is also arranged in the frame structure (23) for operating the conditioning element (24). The conditioning element (24) is a grinding disc (36). The invention also relates to a method for the conditioning of the flow surface in the headbox of a fiber web machine.

Owner:VALMET TECH OY

Modular coolant jacket for rolling mills and rolling mill laying head comprising such a coolant jacket

A modular coolant water jacket has a coolant tube cartridge portion (60) and a selectively separable outer flange portion (50). Separation of the larger diameter outer flange portion from the cartridge portion facilitates axially oriented insertion and removal of the cartridge tube portion in radially confined spaces. Modular construction also facilitates reuse of the outer flange portion and replacement of only a worn cartridge tube portion.

Owner:PRIMETALS TECH USA

Quick change type cooling water joint for continuous caster sector driving roller

The invention discloses a quick change type cooling water joint for continuous caster sector driving roller. The joint comprises a fixed joint body arranged in the through hole of a sector driving roller base; a rotary joint body connected with a sector driving roller is arranged in a front section mounting hole of the fixed joint body; the fixed joint body is fixedly connected with the sector driving roller base via a flange tube fitted on the rear section of the fixed joint body; the tube wall of the flange tube is embedded in the rear section U shaped ring groove of the fixed joint body; wedge shaped grooves are formed on the outer wall of the U shaped ring groove and the tube wall of the flange tube, corresponding in position, and loaded with steel balls; and an outer sleeve is arranged on the outer wall of the U shaped ring groove, positions the fixed joint body and the flange tube together under the condition that the outer sleeve covers the steel balls, and separates the fixed joint body from the flange tube under the condition that the steel balls moves out of the outer sleeve. The inventive joint has good assembly precision, is adaptive in axial movement and convenient to assemble / disassemble, reduces equipment repair and maintenance workloads and operation time, shortens production shutdown time, and improves equipment continuous production operation efficiency.

Owner:武汉华德环保工程技术有限公司

Purification method and device for filling machine

ActiveCN105073626BAvoid residueEasy to cleanFilling device cleaningCleaning using liquidsWorking fluidSpray nozzle

A method and device for purifying a filling machine, which performs COP and One or both of the SOPs, when executing one or both of the COP and the SOP, make at least the movable spray nozzle (17b) opposite to the filling machine (1) from the outer periphery of the filling machine (1) in the filling machine (1) The up and down direction reciprocates, and the prescribed working fluid is sprayed to the outside of the filling machine (1) in a prescribed order, thereby purifying the filling machine. Thereby, the downtime of the beverage filling operation is shortened.

Owner:DAI NIPPON PRINTING CO LTD

Modular Coolant Jacket for Rolling Mills

InactiveUS20130062447A1Easy to reuseLimiting repair expenseGrain treatmentsMetal working apparatusConfined spaceEngineering

A modular coolant water jacket has a coolant tube cartridge portion and a selectively separable outer flange portion. Separation of the larger diameter outer flange portion from the cartridge portion facilitates axially oriented insertion and removal of the cartridge tube portion in radially confined spaces. Modular construction also facilitates reuse of the outer flange portion and replacement of only a worn cartridge tube portion.

Owner:PRIMETALS TECH USA

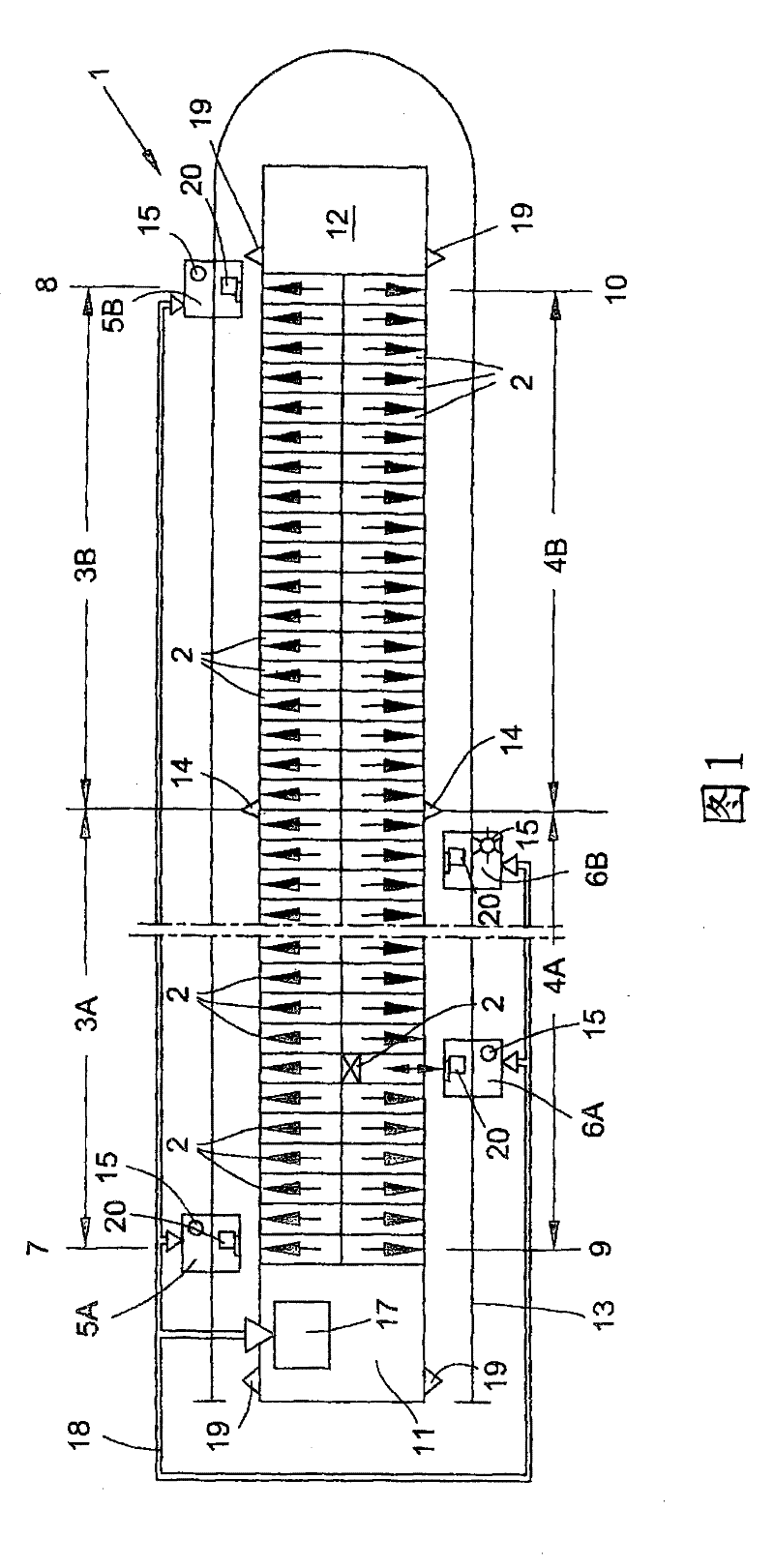

Method of operating a textile machine and textile machine for carrying out the method

InactiveCN101463514BReduce production stopsReduce data volumeTextiles and paperCommunications systemReliability engineering

The invention relates to a method for operating a textile machine (1) comprising a plurality of work stations (2) consisting of at least one maintenance unit and a textile machine for carrying out the method (5A, 5B, 6A, 6B) maintenance, the at least one maintenance group performs at least one maintenance operation at the requested station (2), the at least one maintenance operation includes at least one partial task, in order to perform the at least one maintenance operation , the station (2) requests the maintenance unit to perform the maintenance operation through the communication system (18, 20) of the textile machine (1), and the feasibility of the maintenance operation is checked in order to check the functionality of the maintenance unit, wherein, after determining In the event of a malfunction of the maintenance unit, information is sent via the communication system (18, 20) of the textile machine (1) to all relevant workstations (2) about the presence of a malfunction which prevents the execution of maintenance operations or at least Execution of a partial task.

Owner:SAURER GERMANY GMBH & CO KG

Steady brake control system for multiple constant tension windlasses used in pipe-laying ships

ActiveCN103885399BSmooth brakingEasy to moveWaterborne vesselsProgramme total factory controlDowntimeControl system

The invention discloses a smooth brake control system of multiple constant-tension anchor gears for a pipe-laying ship, comprising a cockpit operation control center and a remote anchor gear engine room control device. The cockpit operation control center is connected to the remote anchor gear engine room control device through an optical cable and used for controlling the multiple anchor gears and collecting traveling state data of the multiple anchor gears. A bow anchor gear control platform and a stern anchor gear operation control platform are in interactive transmission with information of controlling the anchor gear and the operation control center of the engine room cab through a control bus; the control device of the remote anchor gear engine room connects the bow linkage control cabinet, the stern linkage control cabinet to the main control station of a cockpit monitoring center in order to realize the data collection and monitoring of all operation control cabinets in the cockpit. The invention reduces production downtime, realizes smooth braking of multiple anchors, guarantees working state of multiple anchor gears and thus realizes the smooth movement and positioning of the pipe-laying ship.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com