Full-automatic calibration method for opening degree of side guide plate of heavy and medium plate mill

A calibration method and technology of side guides, applied in guiding/positioning/alignment devices, metal rolling, metal rolling, etc., can solve the problem of affecting the opening degree accuracy of side guides, affecting the width accuracy of side guides, and measuring width values of side guides Minor problems, to achieve the effect of shortening production downtime, ensuring production safety, and saving calibration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

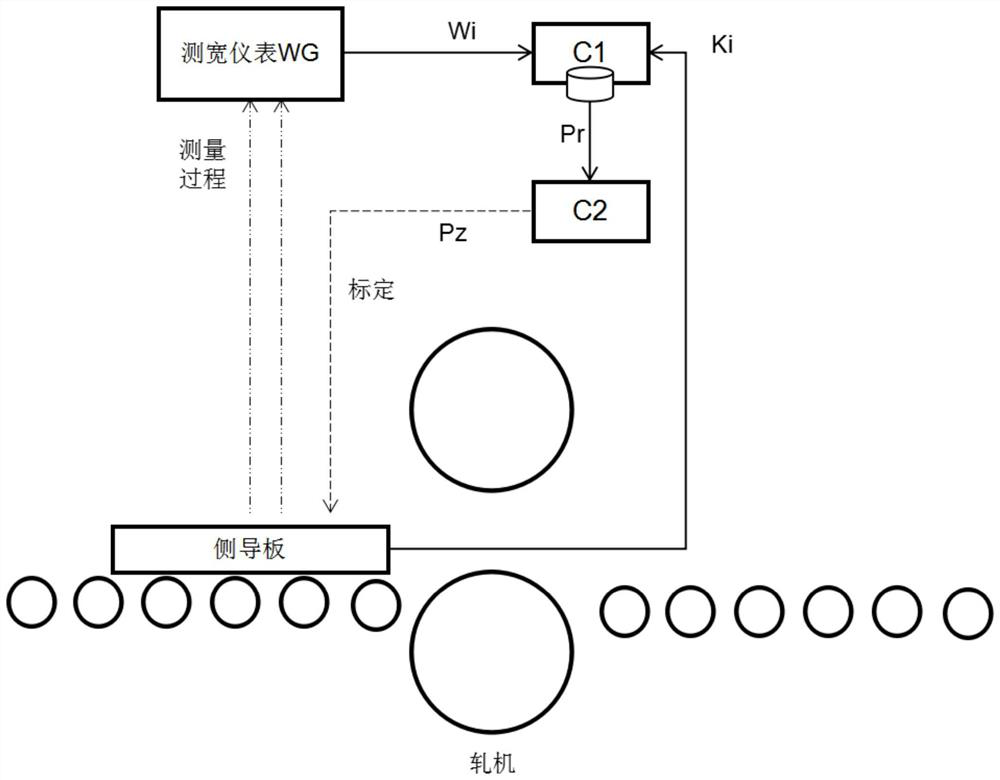

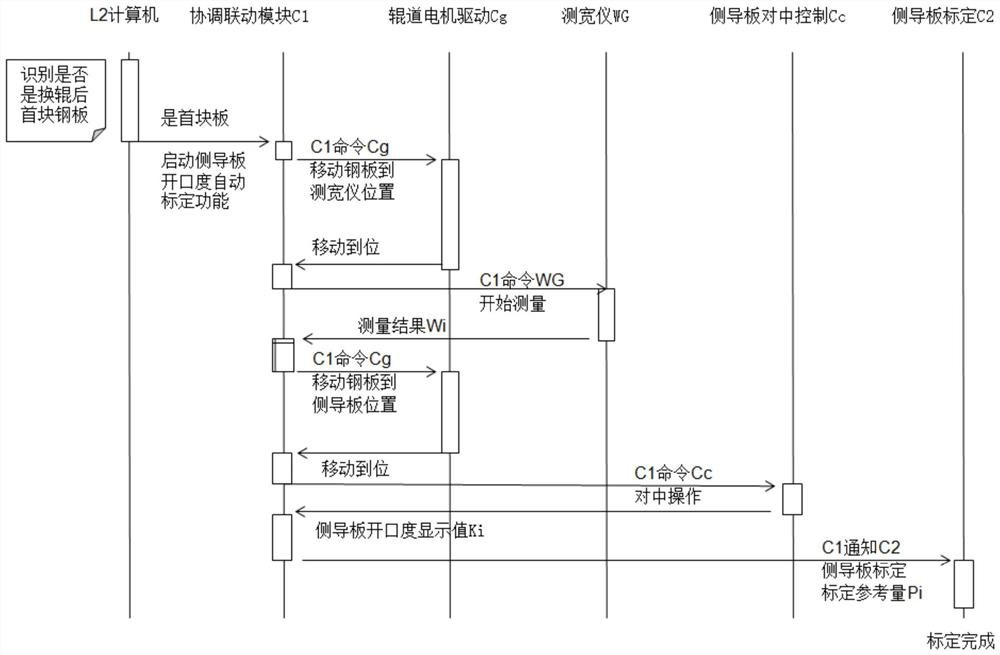

[0058] For the medium and heavy plate production line with a plate profile gauge (POG) installed above the side guide plate of the finishing mill.

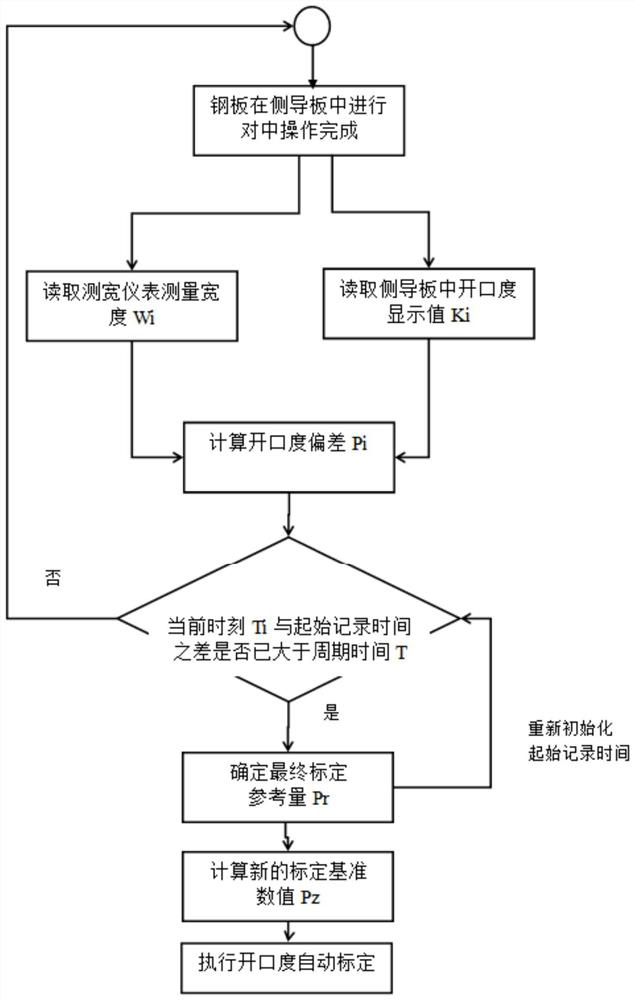

[0059] After the centering operation of the steel plate, the display value Ki of the opening of the side guide plate and the steel plate width data Wi measured by POG are sent to the calculation module C1.

[0060] During the cycle time (T=1.2 hours) of the calculation module C1, 20 steel plate width measurement data Wi and the corresponding display value Ki of the opening of the side guide plate were recorded, and the list is as follows:

[0061]

[0062]

[0063] After sorting Pi, exclude the 20% with the largest positive deviation and the 20% with the largest negative deviation.

[0064]

[0065]

[0066] The remaining data were averaged to obtain Pr=-8.58mm.

[0067] The calibration reference quantity Pr is input to the execution module C2, and the new side guide plate reference data Pz is calculated in the execut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com