Patents

Literature

35results about How to "Improve width precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

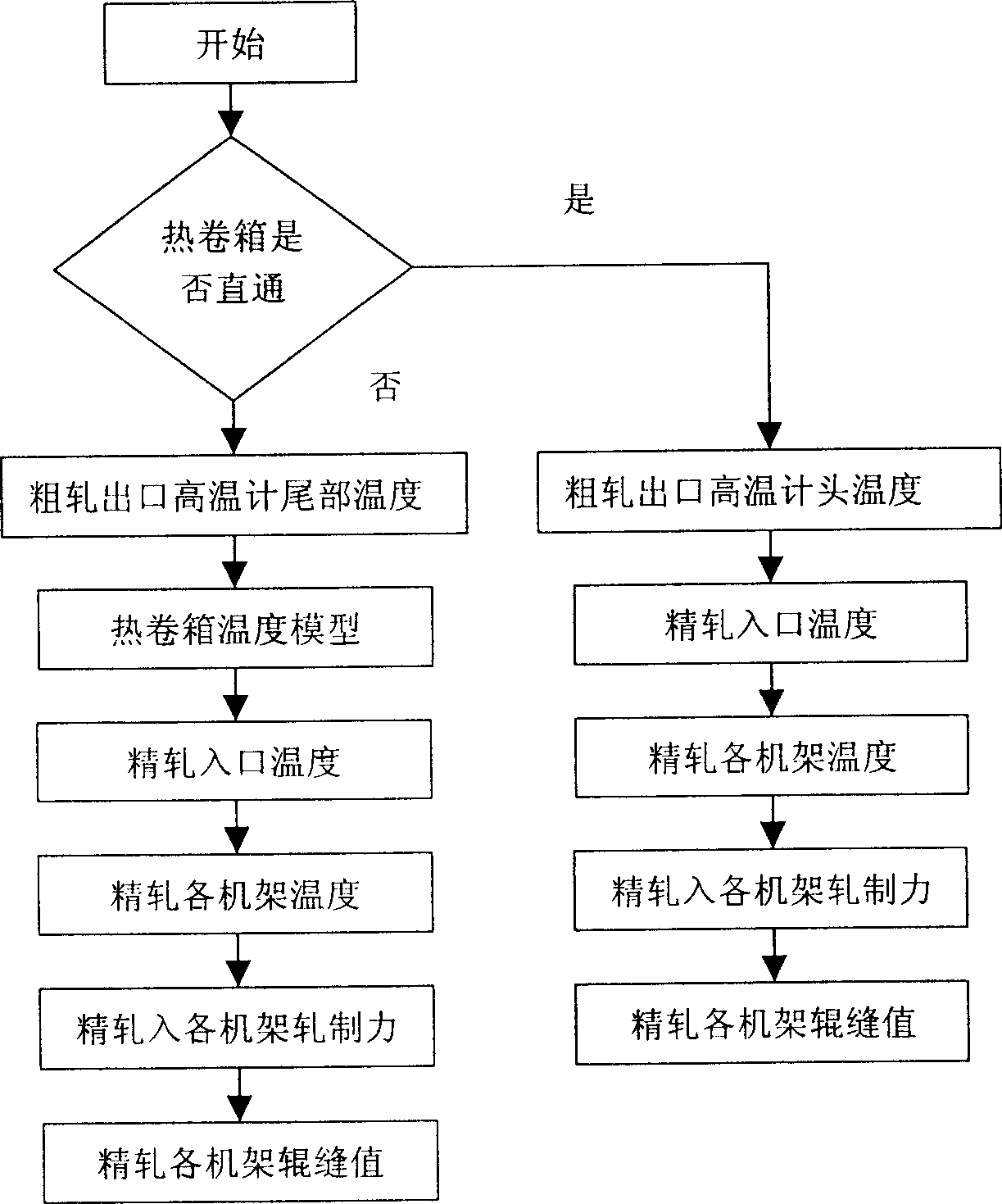

Mthod for controlling roller gap of precision rolling machine of band steel

InactiveCN1483526AImprove accuracy andImprove thickness accuracy and yieldRoll force/gap control deviceProfile control deviceInlet temperatureEngineering

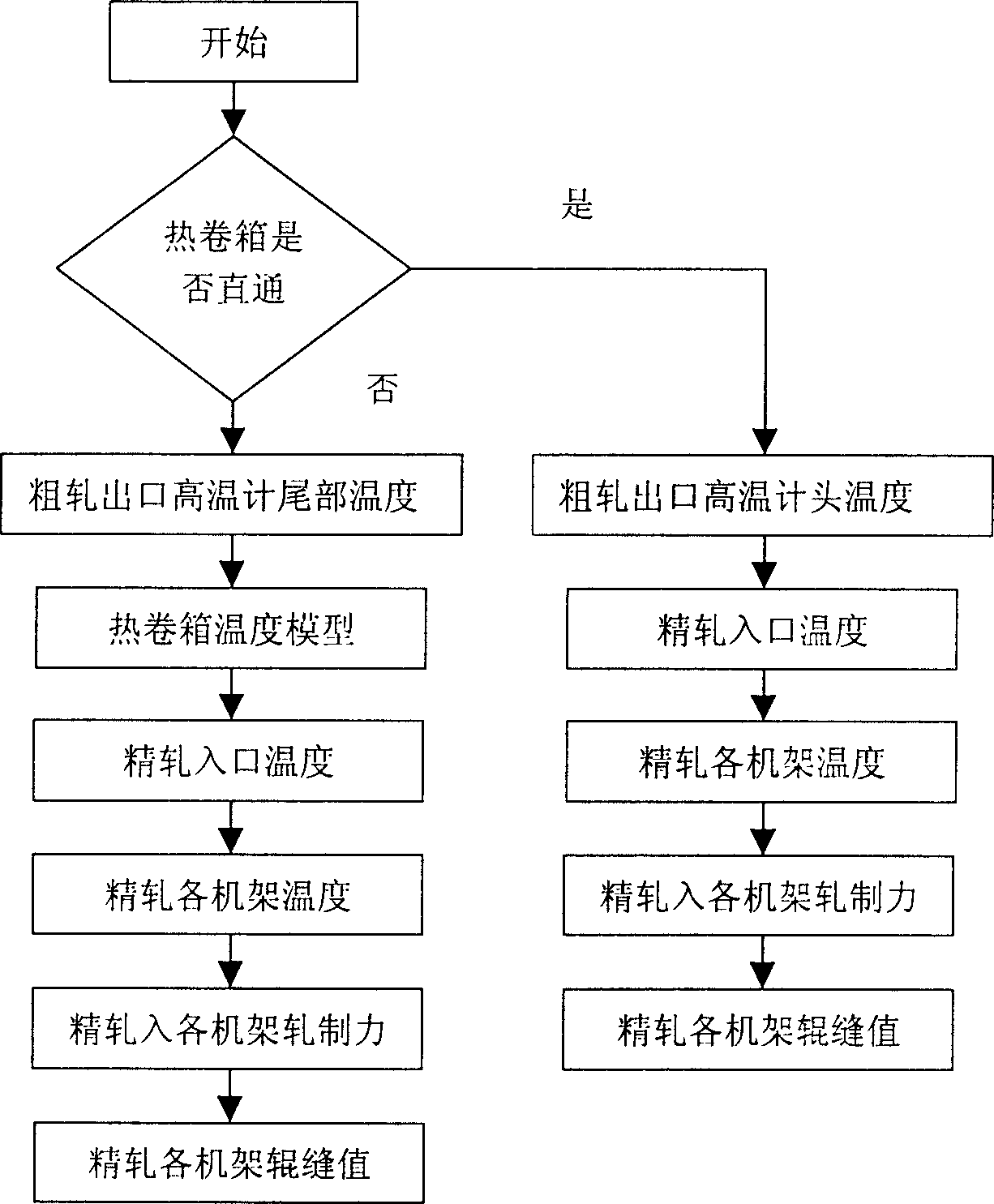

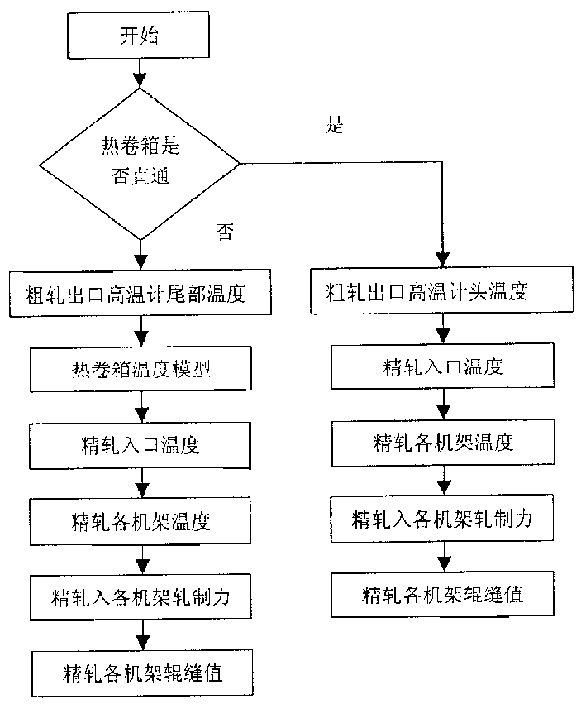

The present invention relates to a control method of roll gap of steel strip finishing rolling, mill, mainly including: using computer to successively calculate finishing rolling inlet temp. value, temp. values of all the machine frames of finishing rolling mill, rolling force values of all the machine frames and roll gap values of all the machine frames, setting and using computer to control PLC, and utilizing PLC to regulate screwdown motor and hydraulic device to regulate roll gap. Said invention also provides the mathematical model of finishing rolling inlet temperature, it can accurately control the accuracy of the roll gap, and can raise its production efficiency.

Owner:ANGANG STEEL CO LTD

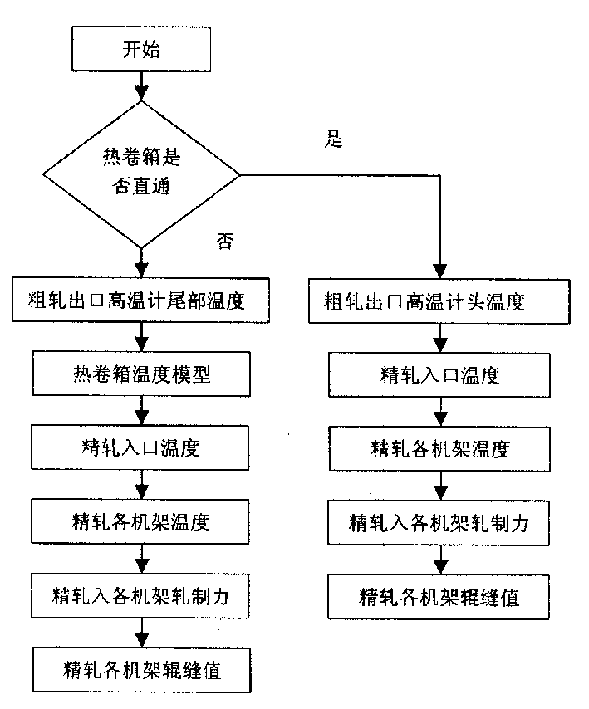

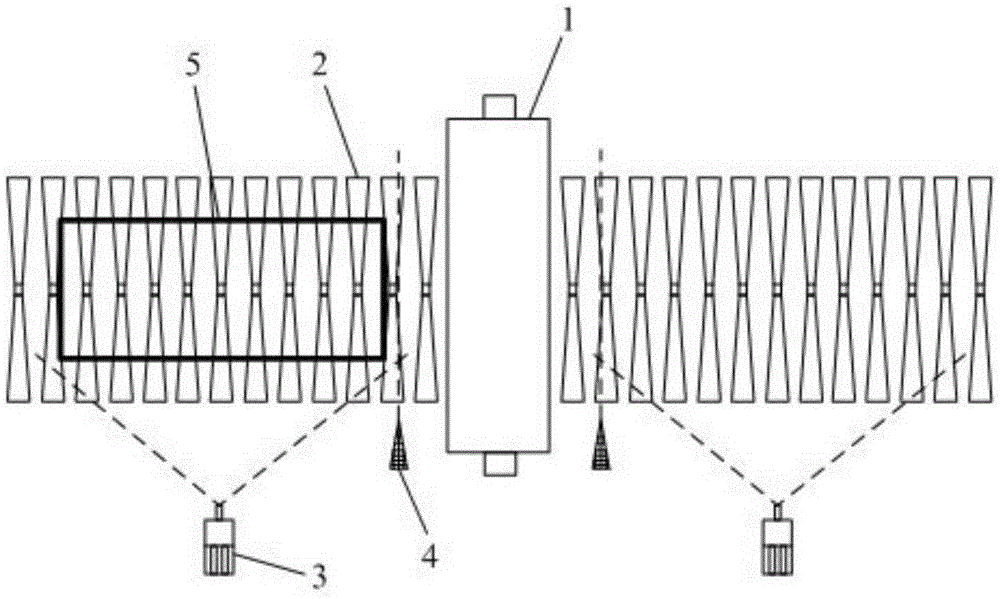

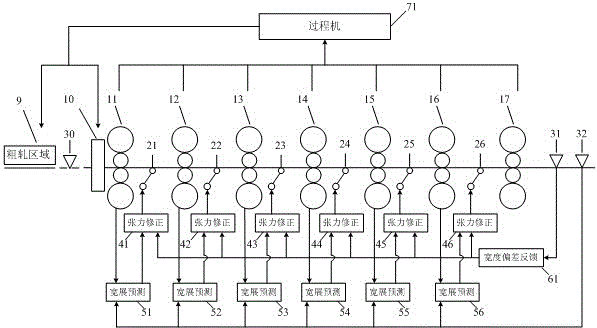

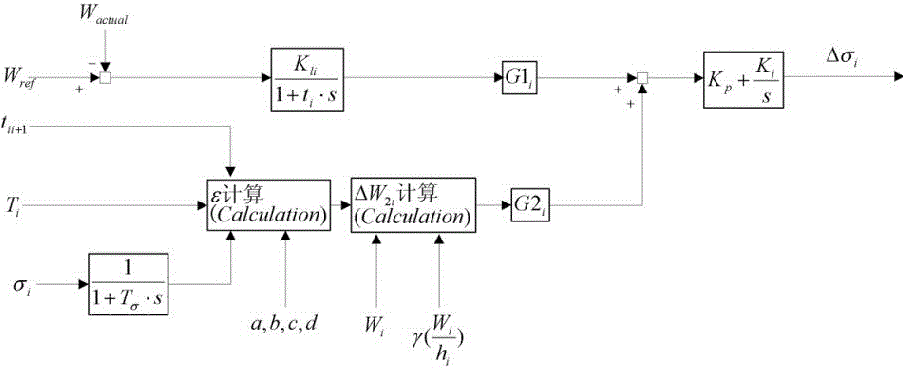

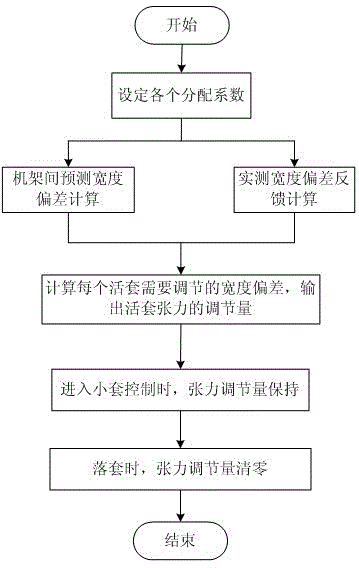

Automatic control method of width of hot continuous rolling and finish rolling strip steel

ActiveCN103286141AReduce Width FluctuationImprove width precisionMetal rolling stand detailsAutomatic controlTime changes

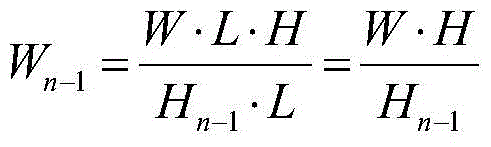

The invention relates to the field of strip steel hot rolling, in particular to a control method of the width of hot rolling strip steel. An automatic control method of the width of hot continuous rolling and finish rolling strip steel comprises the steps as follows: a temperature change model of the strip steel in a finish rolling process is built, sensitivity coefficients are calculated, and temperature reference values of the strip steel at rack outlets are calculated; temperature modification values of the strip steel at the rack outlets are calculated, and temperature prediction values are obtained in combination of the temperature reference values and the temperature modification values; real-time change values of the width of the strip steel are calculated; feedback deviation values of the width of the strip steel are obtained through comparison, and the feedback deviation values are distributed to racks, so that feedback deviation values of the width of the strip steel, which are required to be adjusted by the racks, are obtained; and tension of loops among the racks are adjusted in combination of the real-time change values of the width of the strip steel and the feedback deviation values of the width of the strip steel, so that the width of the steel strip is controlled. The method can well guarantee that the width of the strip steel after finish rolling can fluctuate nearby set values, the width accuracy of a strip product is finally improved, and accordingly, the utilization rate of a material by a downstream user is remarkably increased.

Owner:BAOSHAN IRON & STEEL CO LTD

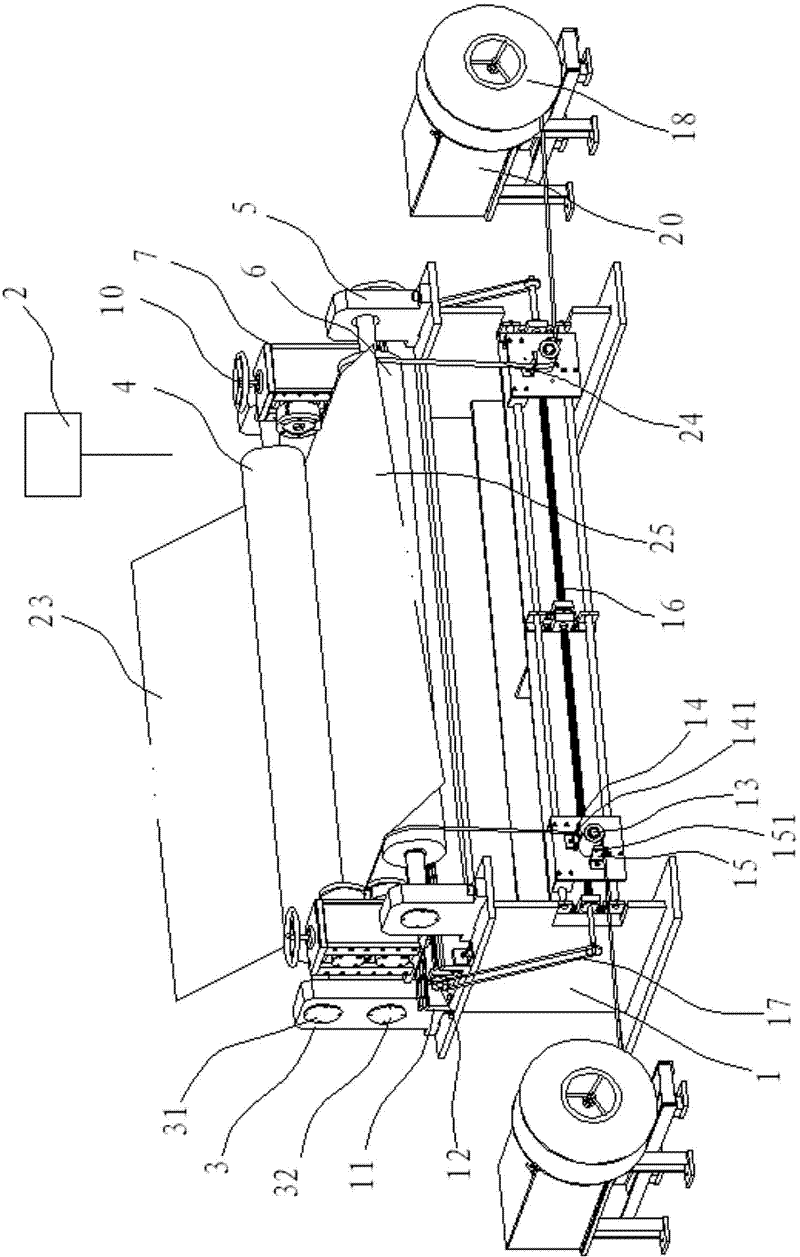

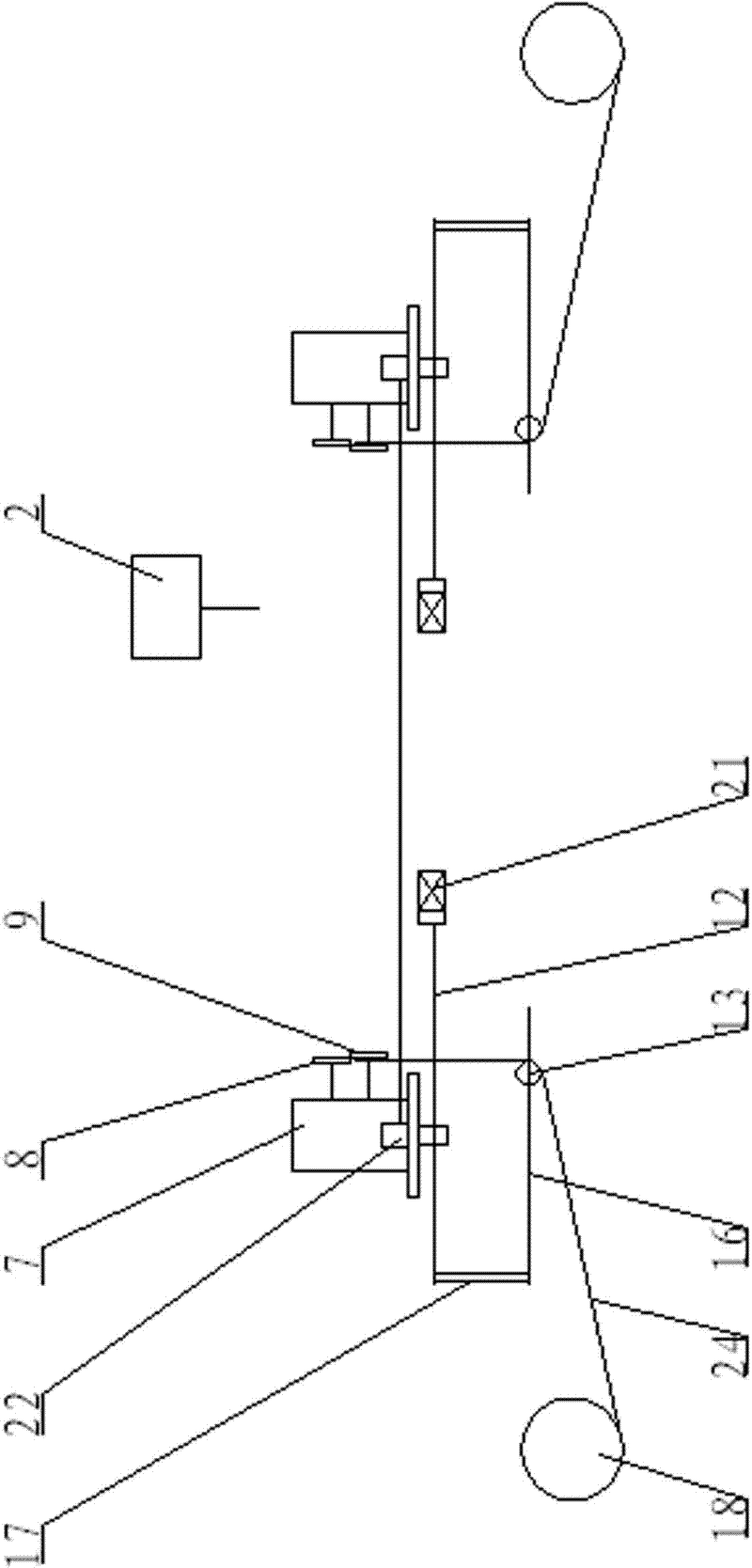

A trimming machine for printing

InactiveCN102294704AAdjustable spacingImprove applicabilityMetal working apparatusLow noiseProduction line

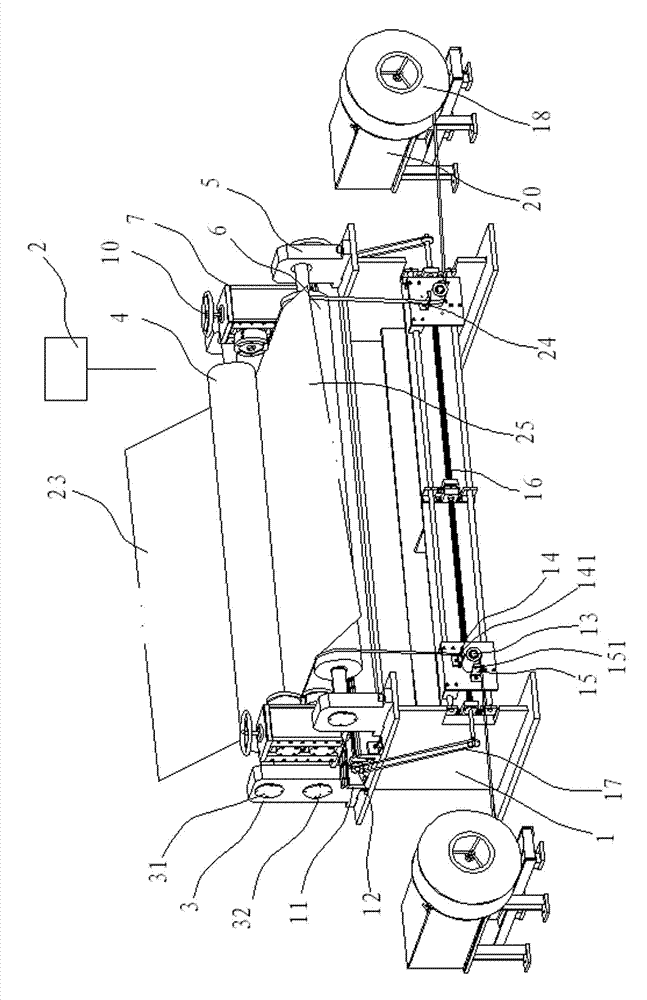

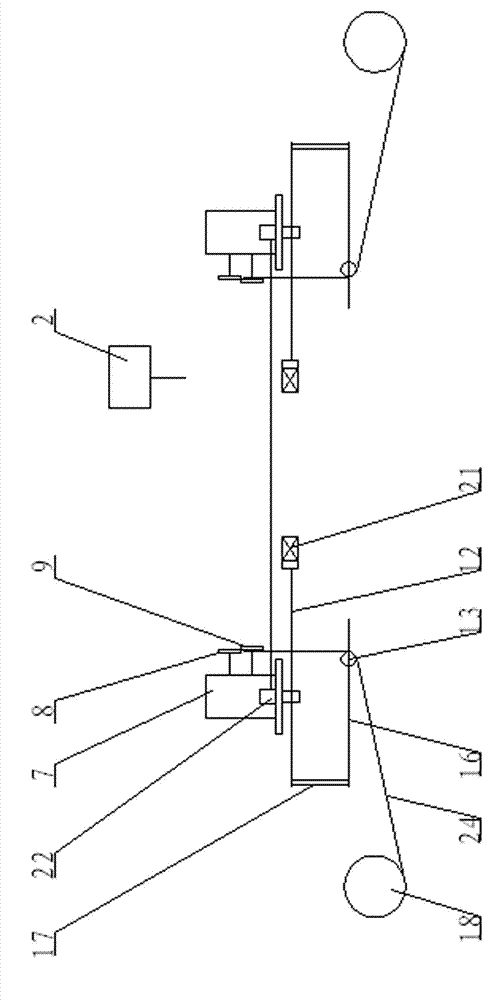

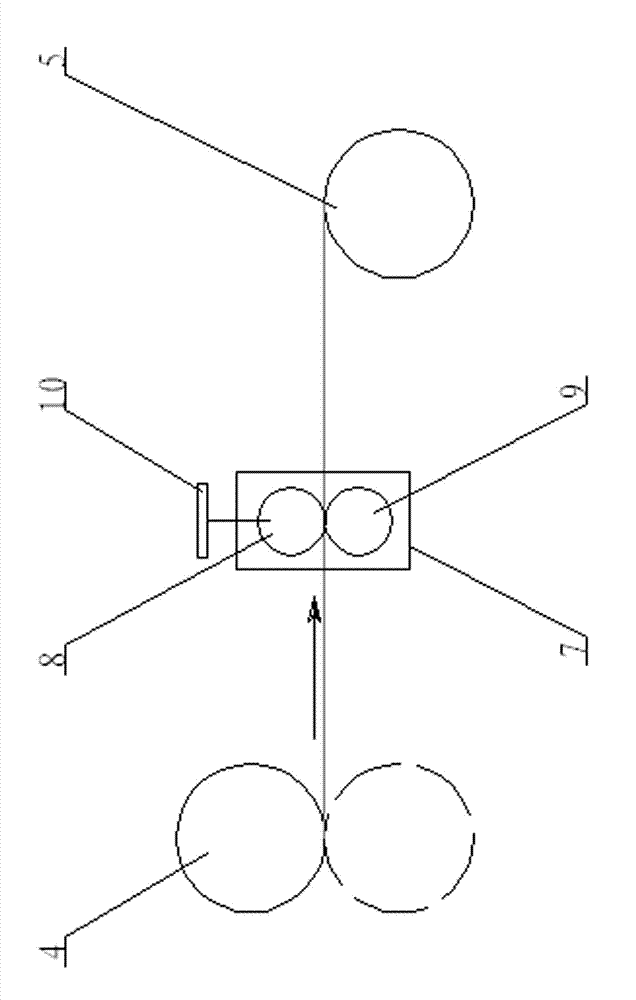

The invention relates to an edge trimmer for printing, which comprises a transmission device, a cutting device, a display control device, a collection guide device and a collection device which are all arranged on a rack. A front and a rear turning rolls are adopted to guide plates to be divided into rim charges at both sides and a finished plate in the middle under the action of an adjustable upper and an adjustable lower blades, the rim charges at the two sides are limited by a steering wheel, and are automatically collected by the collection device, so real-time longitudinal fixed width trimming without stopping the trimmer is realized, the edge trimmer is convenient to operate, can realize edge trimming and forming at one time without secondary edge trimming, has high trimmed plate width precision, low noise, a long service life, safety and reliability, and can be widely applied in online automatic edge trimming of the coordinated test program (CTP) plate, the computer to conventional plate (CTCP), the process status (PS) plate and other barrel production lines at various speeds.

Owner:JIANGSU ZHONGKEDA PRINTING TECH

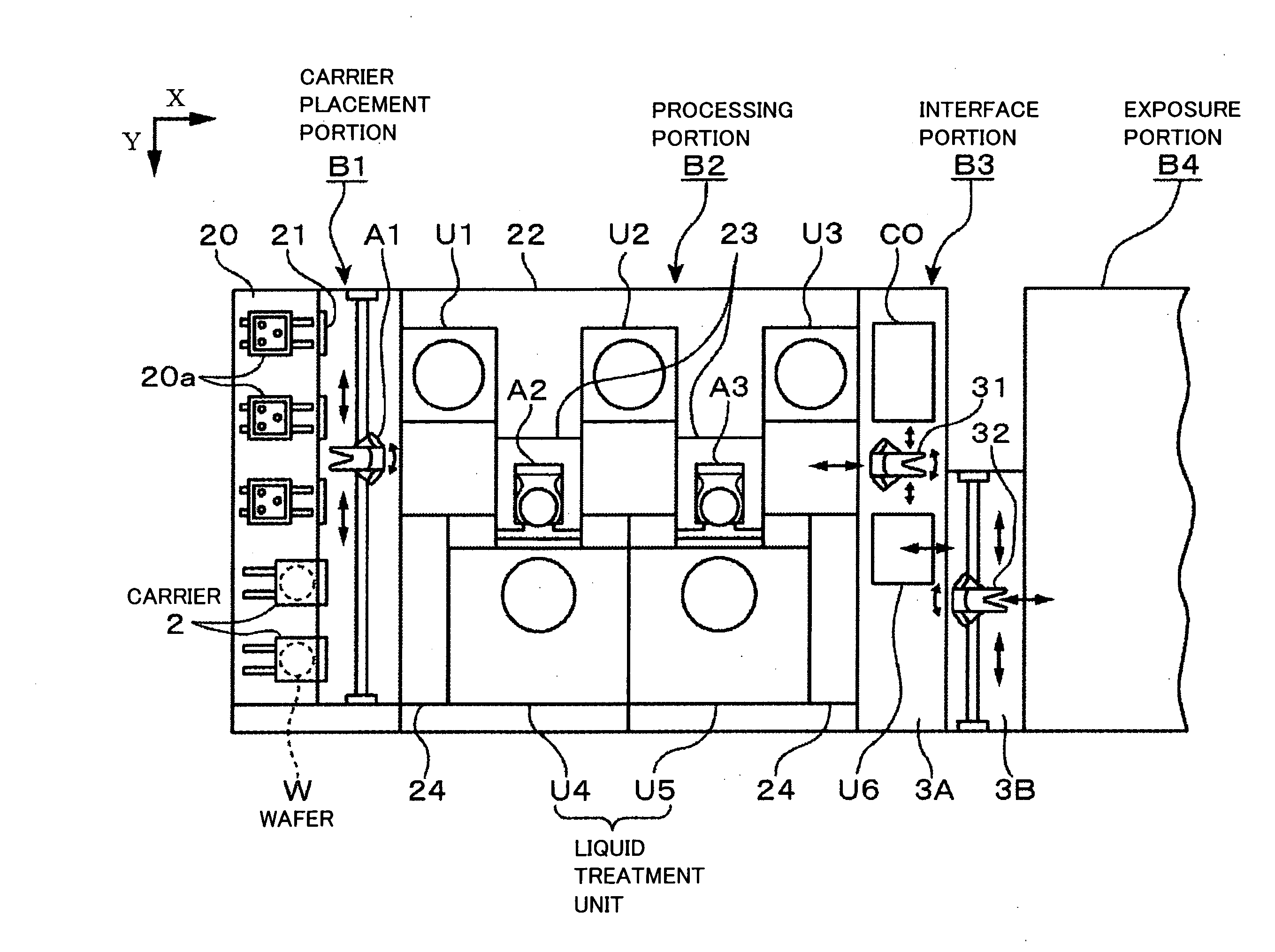

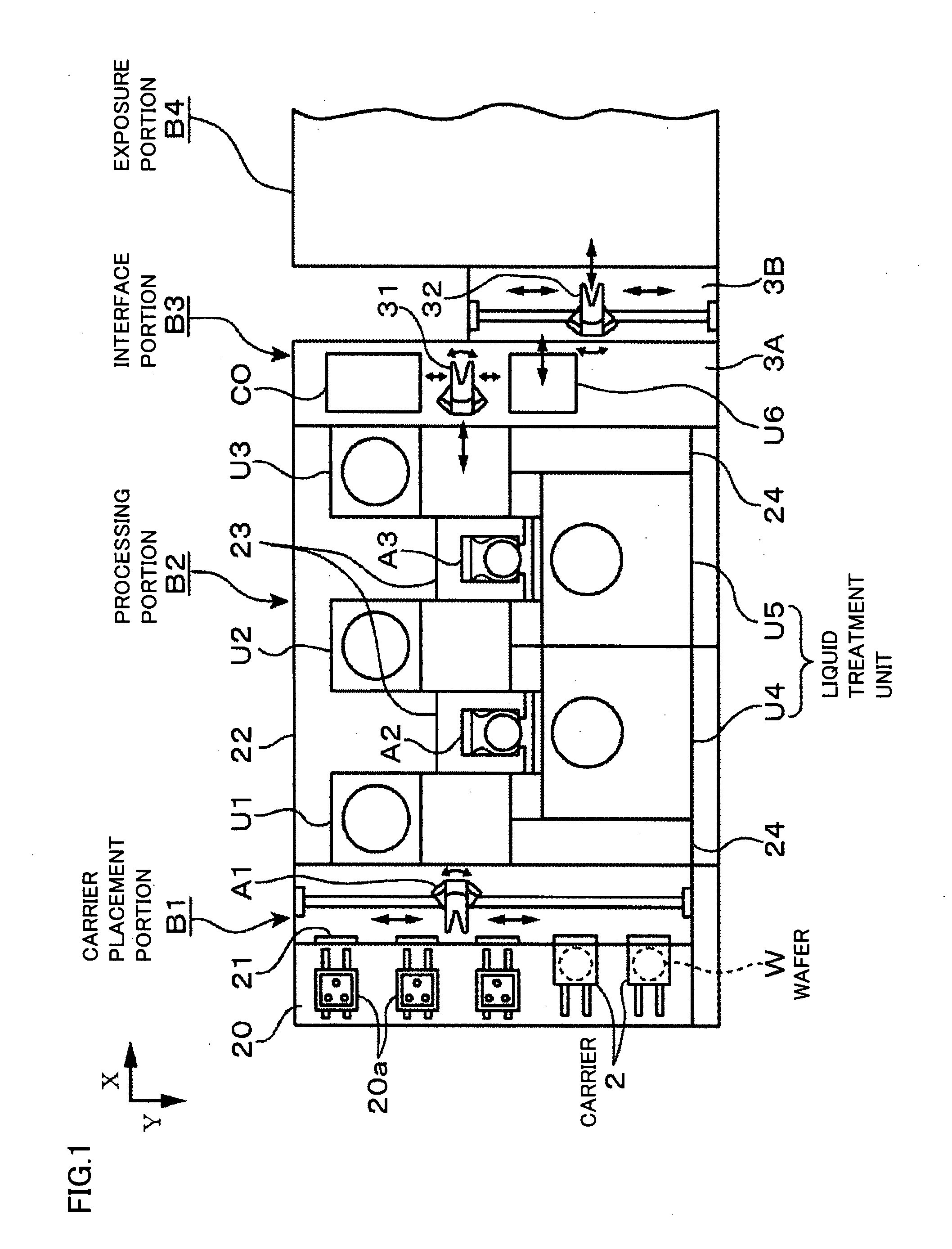

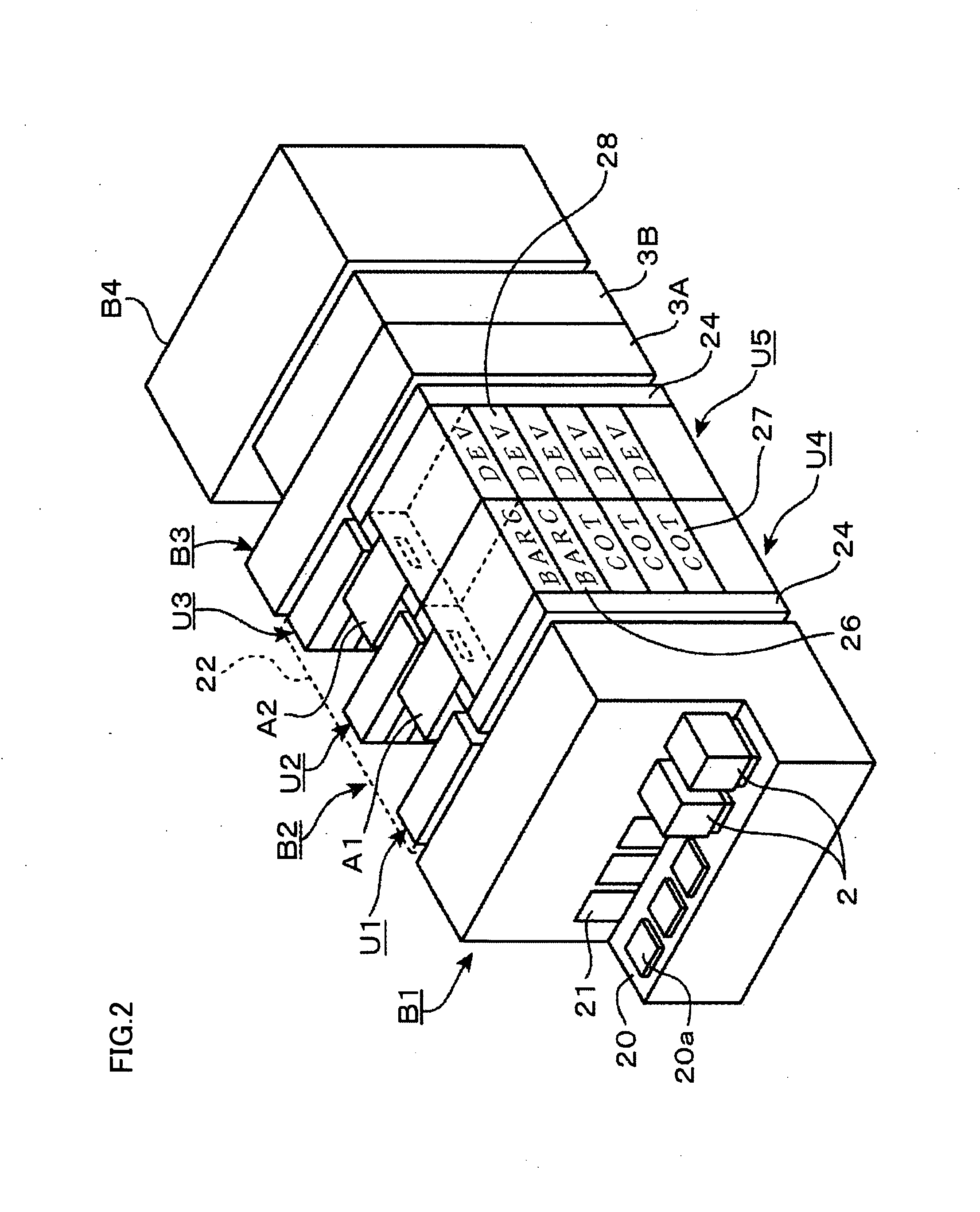

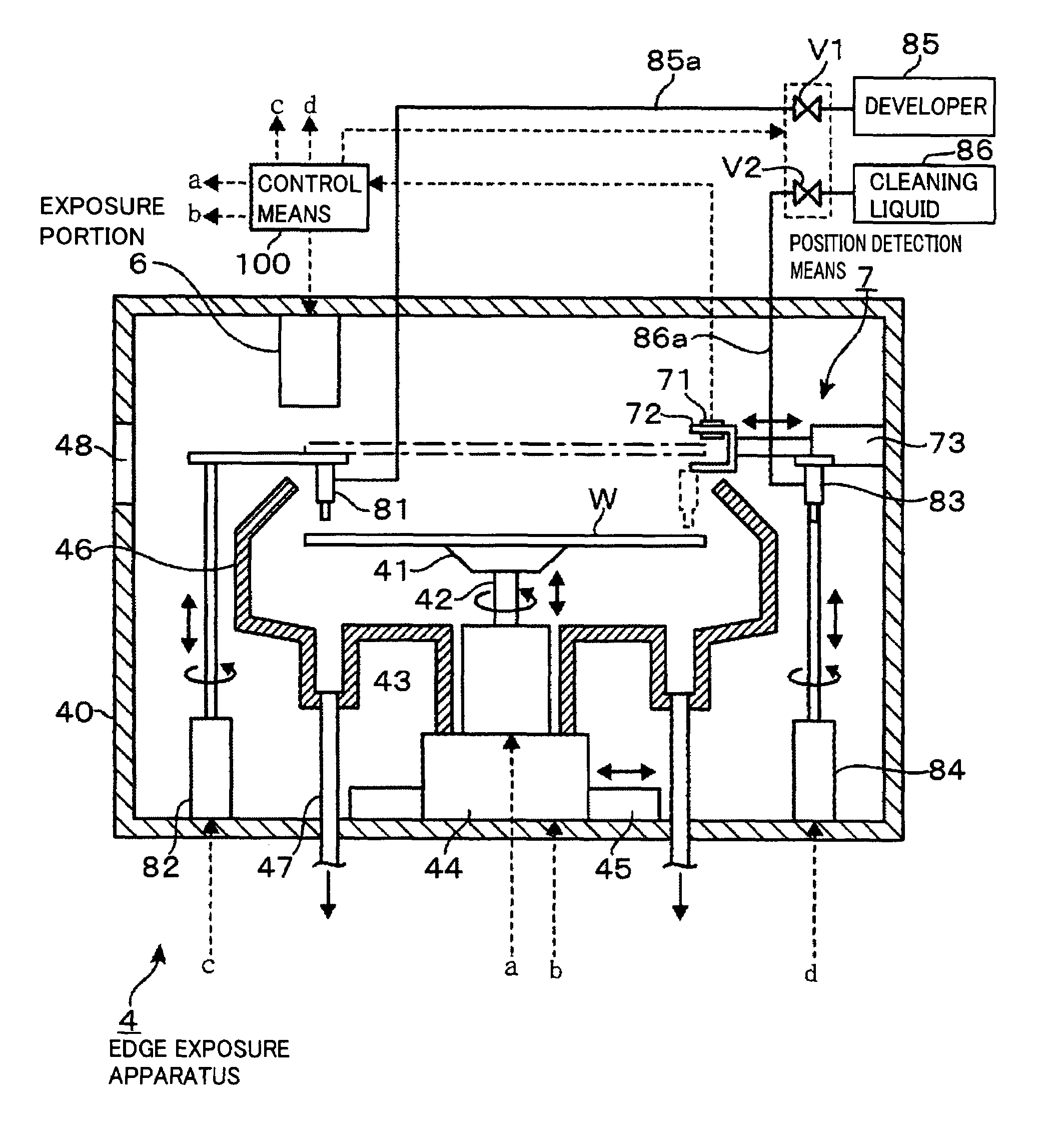

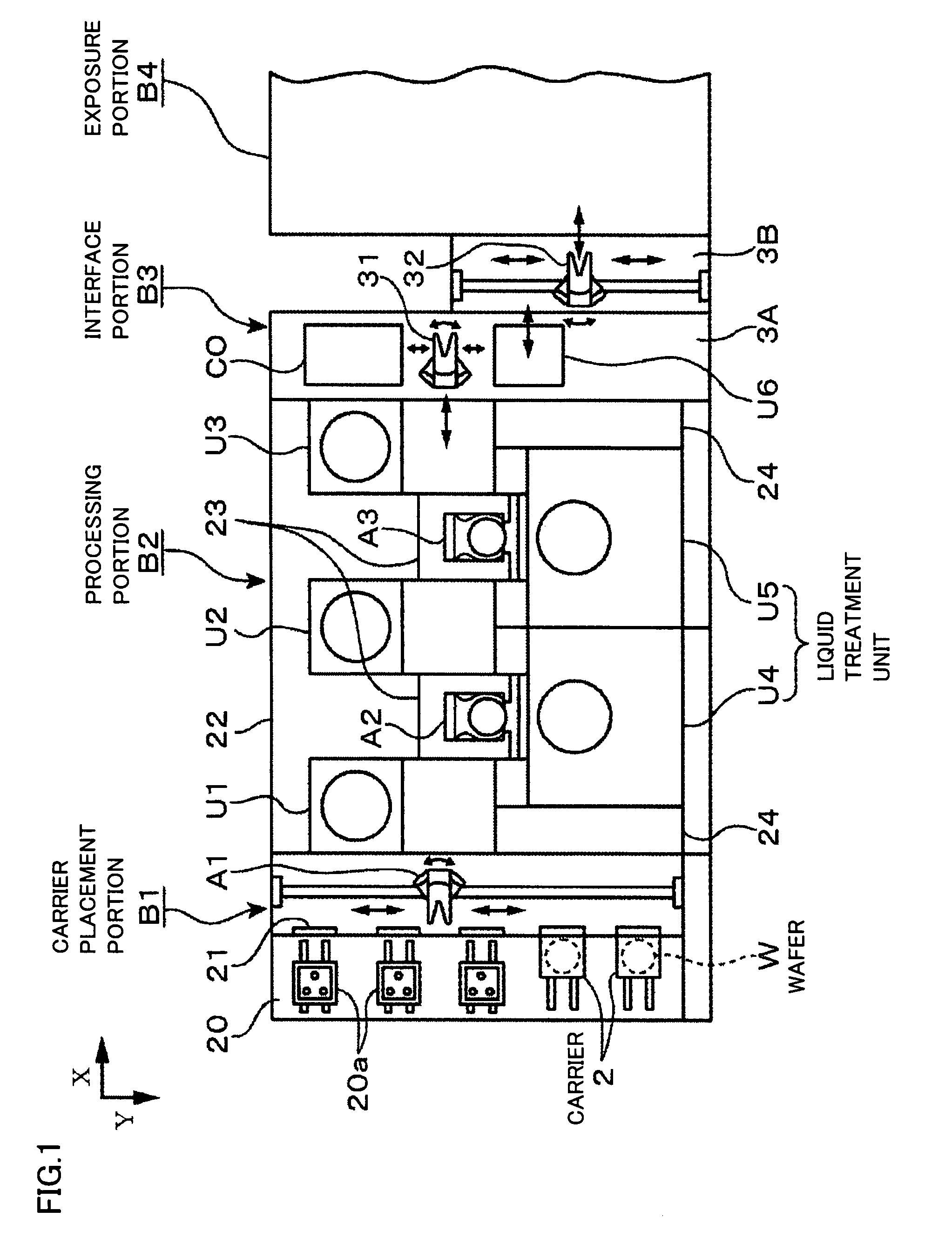

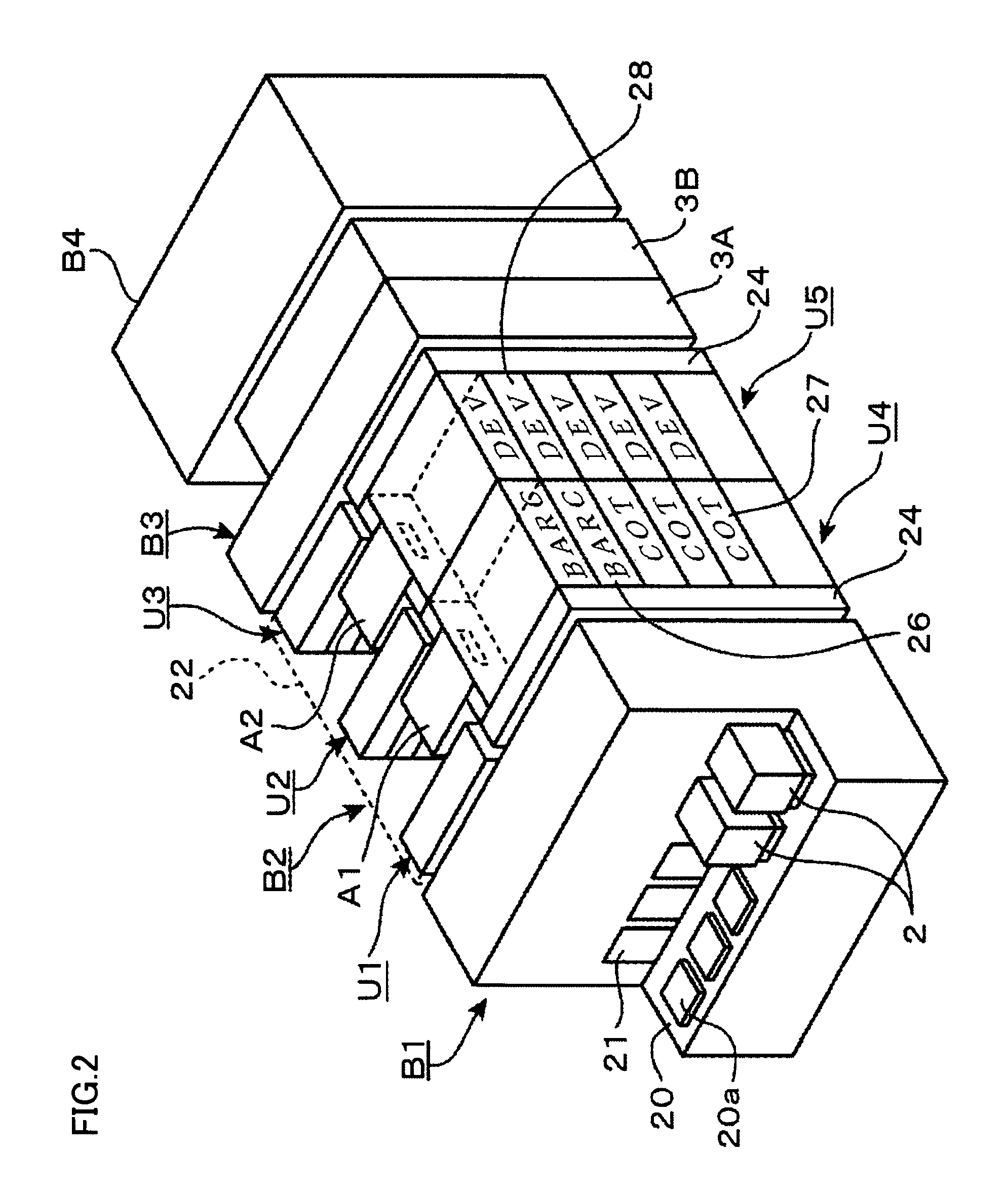

Edge exposure apparatus, coating and developing apparatus, edge exposure method and coating and developing method, and storage medium

InactiveUS20080088809A1High accuracy of shapeHigh accuracy of widthLiquid surface applicatorsLiquid processingResistEngineering

An edge exposure apparatus performing an exposure process on an edge portion of a wafer having a coating film (resist film) formed thereon includes position detection means for detecting positional data of an outer edge of a wafer held by a spin chuck, an exposure portion for performing an exposure process on the edge portion of the wafer, a development nozzle supplying a developer to the exposed region, and alignment means for horizontally moving the spin chuck. An exposure process is performed by the exposure portion on the edge portion of the wafer held by the spin chuck while the alignment means is controlled, based on the positional data of the outer edge of the wafer which is detected by the position detection means, such that the positional relation between the outer edge of the wafer and the exposure portion is kept constant.

Owner:TOKYO ELECTRON LTD

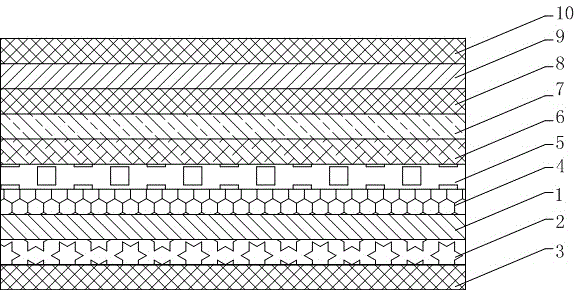

Stereoscopic texture decorative metal plate and production method thereof

PendingCN105856748AIncrease productivityRich appearanceLamination ancillary operationsLaminationMetal substrateSi substrate

The invention provides a stereoscopic texture decorative metal plate, which comprises a metal substrate, a chemical treatment layer and a back paint layer are provided on the back side of the metal substrate from up to down in order, the chemical treatment layer, a prime coat, a floating coating, 1-4 layer of stereoscopic texture layers and a protection film are provided at the right side of the metal substrate from down to up in order. The invention also provides a method for producing the stereoscopic texture decorative metal plate. According to the invention, an intaglio printing technology is used for a continuous coating process of a colorful pre-coated metal plate, and the intaglio printing technology, a drying mode, an etching printing roller making mode for realizing the stereoscopic texture are optimized, touch and visual senses for the stereoscopic texture can be guaranteed, and the efficient production and maneuverability of the stereoscopic texture decorative metal plate can be finally realized.

Owner:合肥河钢新材料科技有限公司 +1

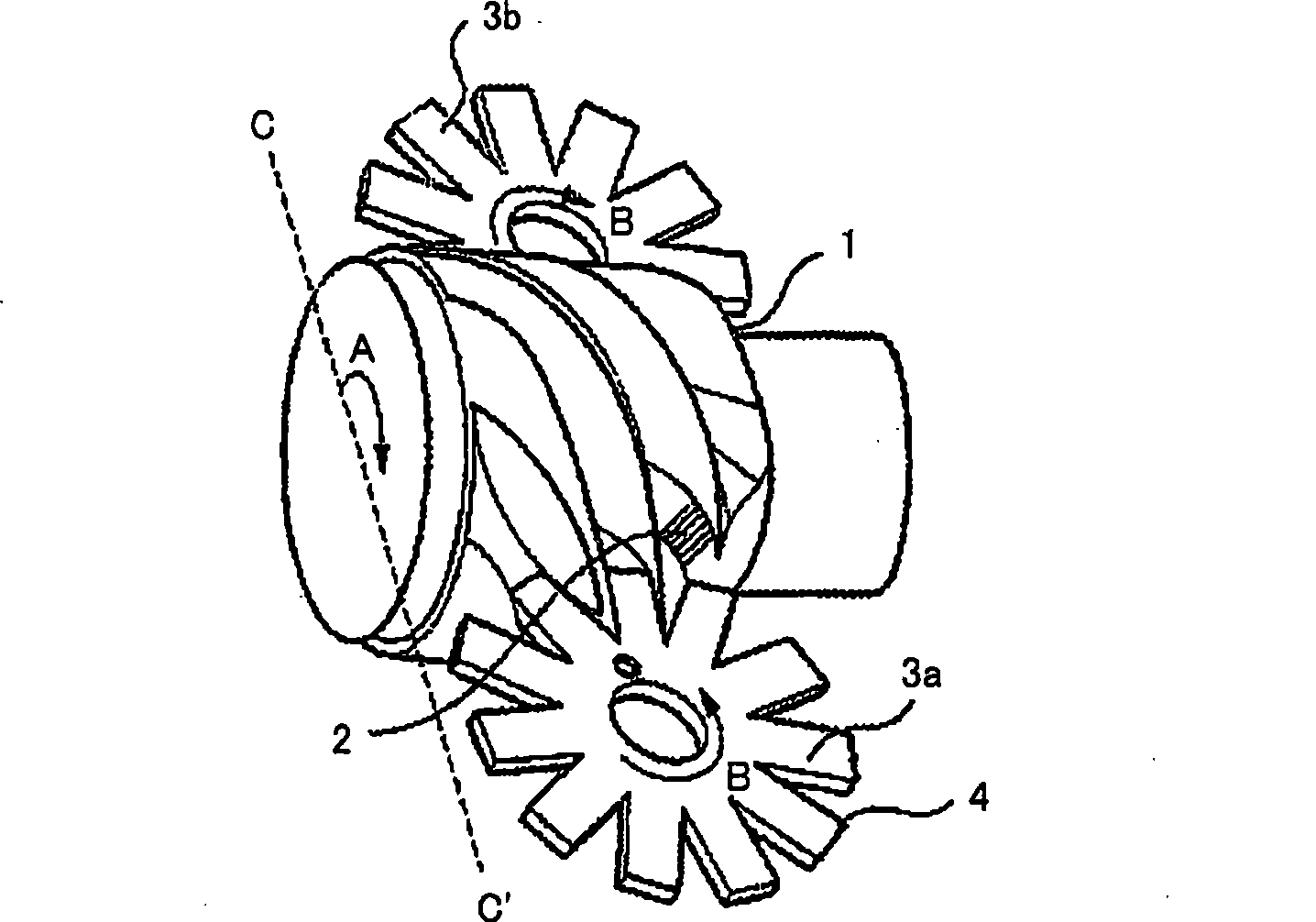

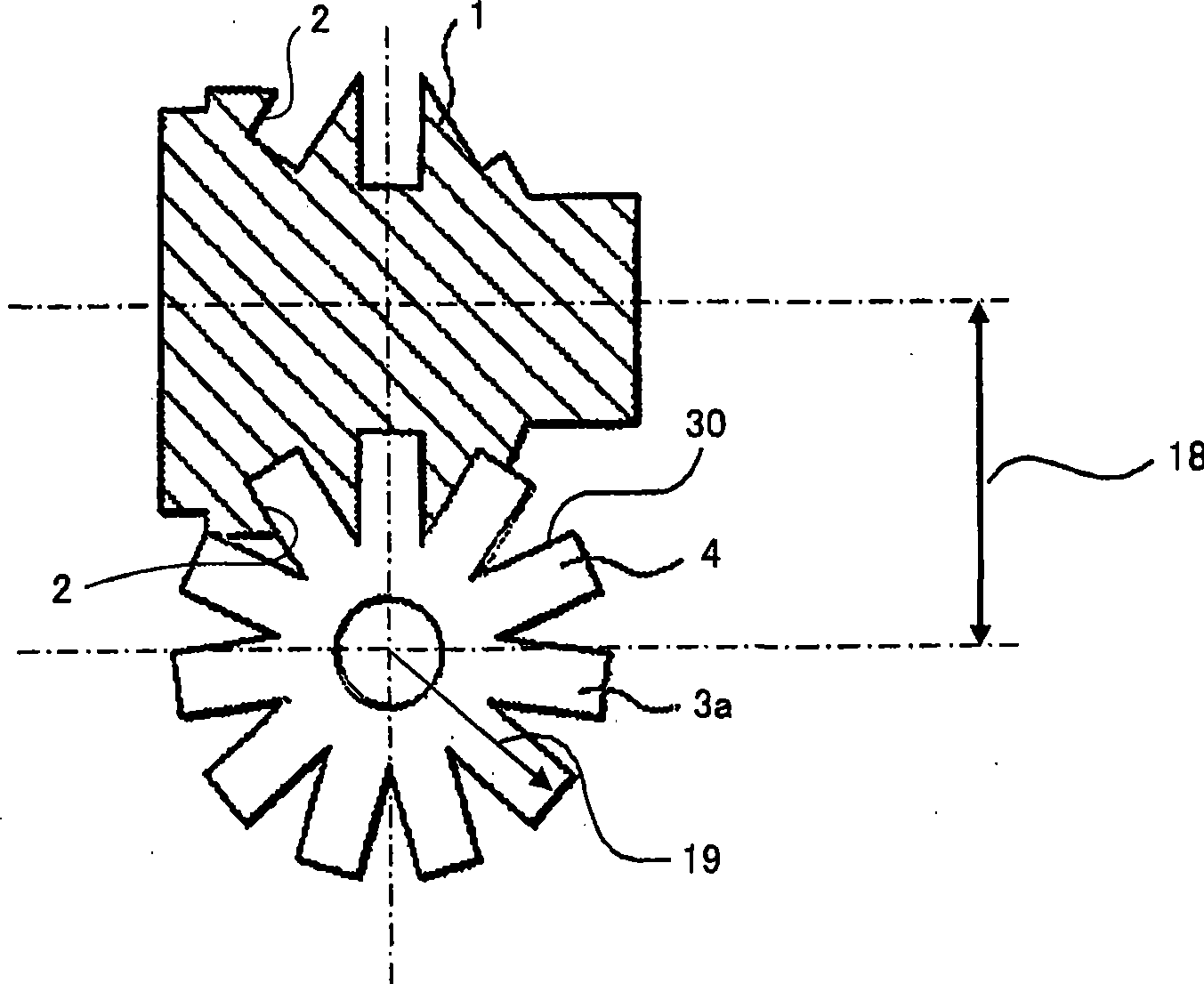

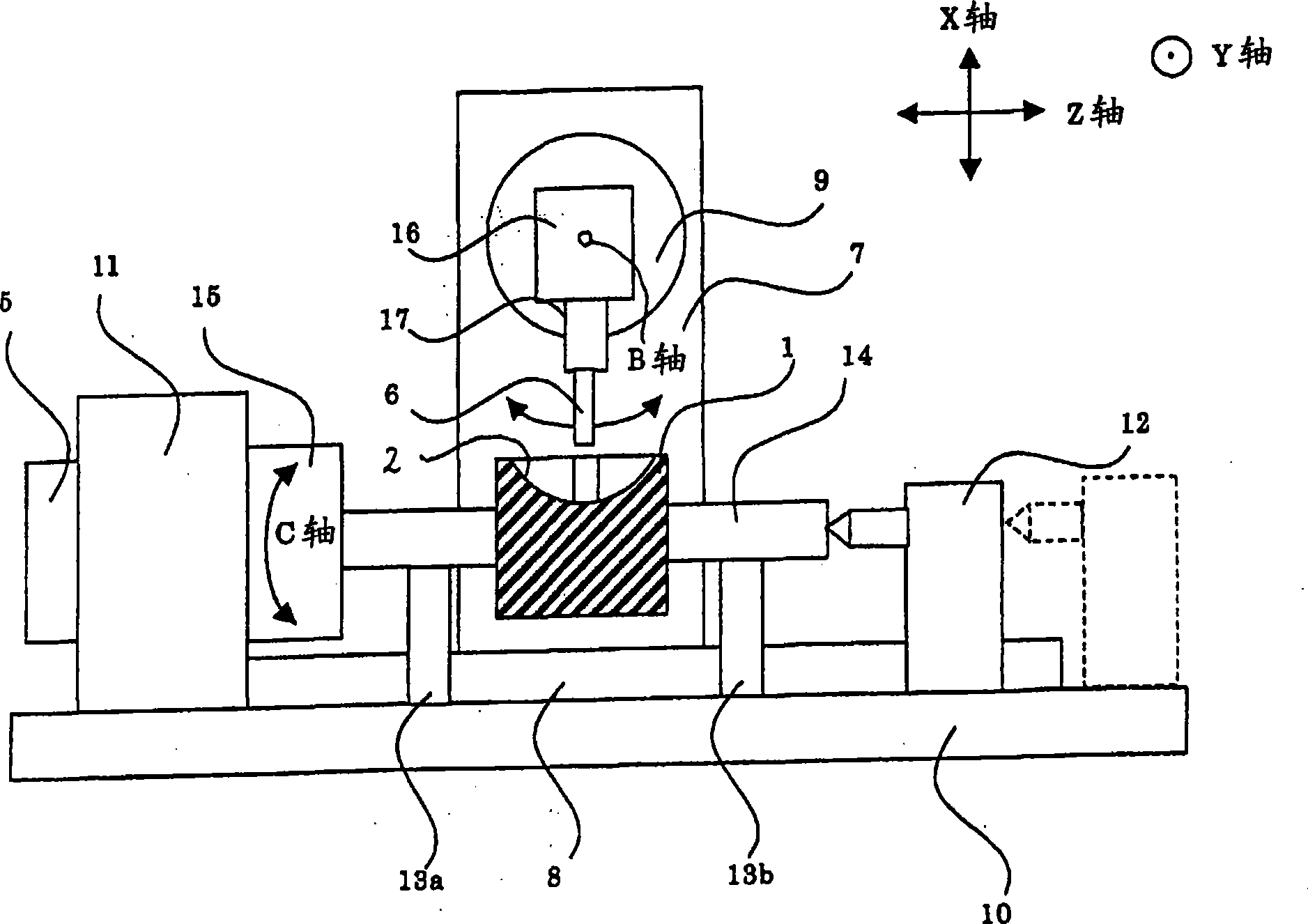

Method and apparatus for working a screw rotor, end mill for working , and method of manufacturing a screw compressor

ActiveCN101518843AImprove width precisionEasy to processMilling equipment detailsGear teeth manufacturing toolsGas compressorMilling cutter

A method of improving working of grooves of a screw rotor, in particular, working of grooves side in working efficiency, a working apparatus, a working tool, and a method of manufacturing a screw compressor are provided. A method of controlling rotation of a work and turning of a tool at a time to form a screw tooth space based on a five-axis NC machine, and a special end mill having a cutting edge of a short length and a neck portion provided between the cutting edge and a shank portion to be made thin is used to perform working in grooves side finish working process.

Owner:MITSUBISHI ELECTRIC CORP

Production method of hot dipped steel coil

ActiveCN103103538AOvercome the defect of low width precisionImprove width precisionHot-dipping/immersion processesNiobiumManganese

The invention provides a production method of a hot dipped steel coil. The method comprises steps of hot rolling, cold rolling, annealing, galvanizing and straightening on a billet. The batching temperature of the hot rolling is 500-550 DEG C; and the billet contains, calculated by a total weight of the billet, 0.04-0.1 wt% of carbon, 0.2-0.5 wt% of manganese, 0.06-0.09 wt% of phosphorus and 0.015-0.03 wt% of niobium. The method provided by the invention can obtain structural hot dipped steel coil with high width precision, and yield strength level of grade 350M Pa.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

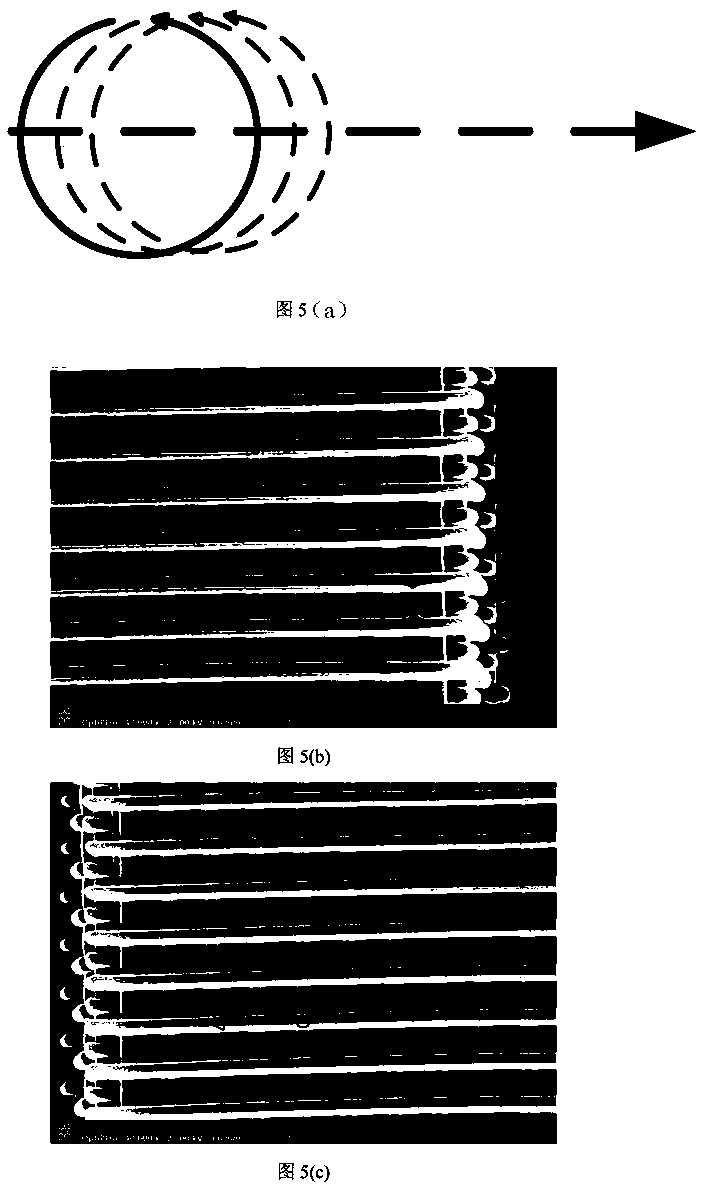

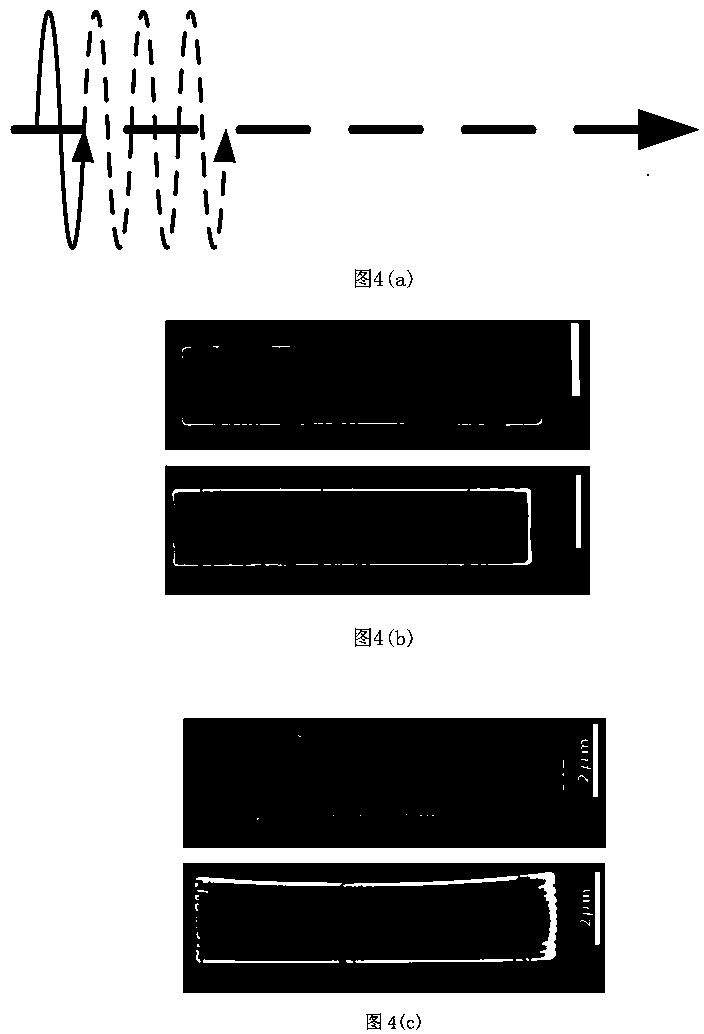

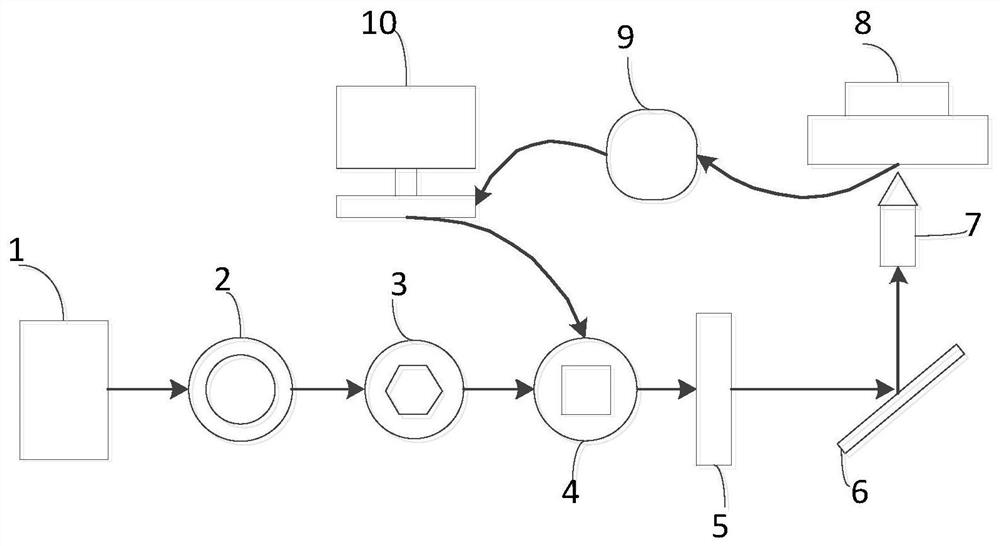

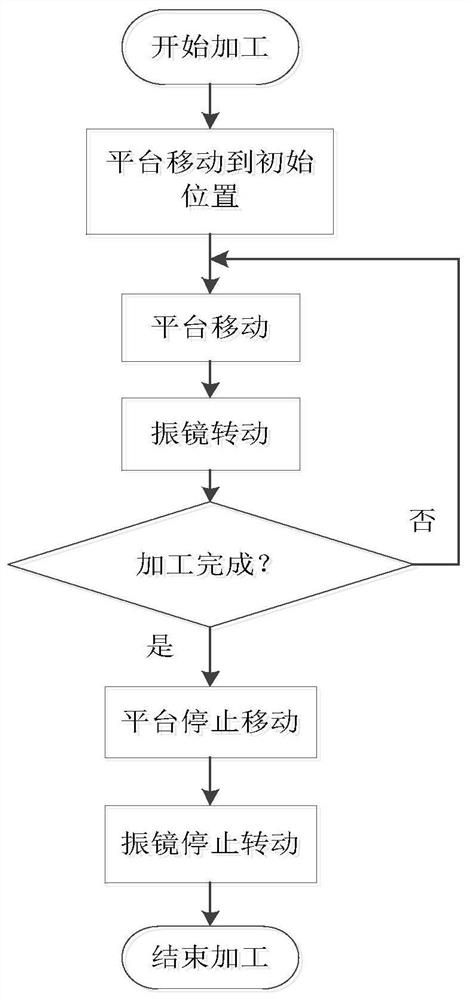

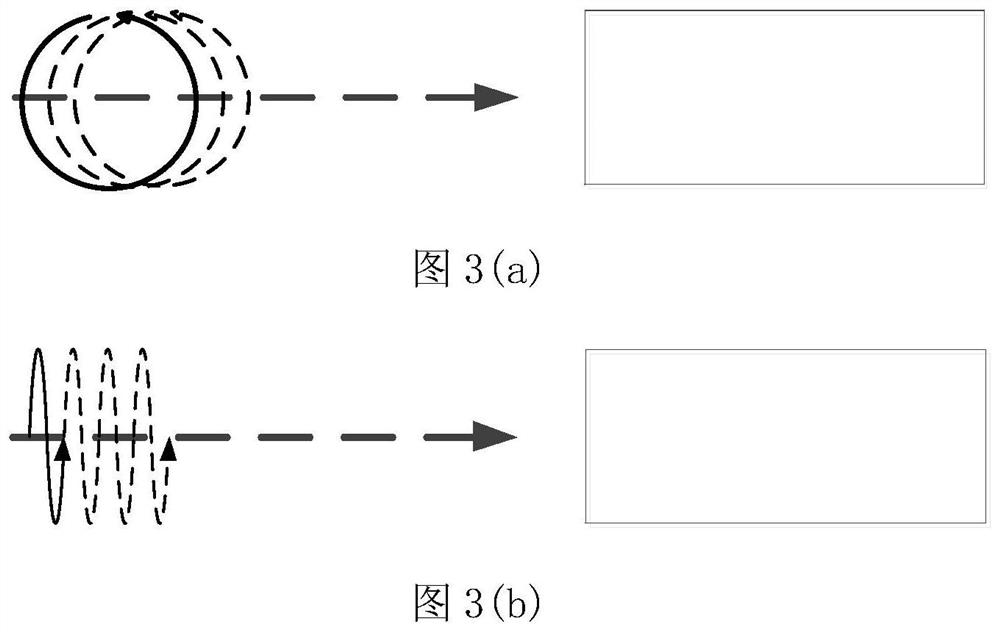

A manufacture method for improving three-dimensional micro-nano structure base on composite scanning

ActiveCN108983555AShorten the timeCompact structurePhotomechanical exposure apparatusMicrolithography exposure apparatusMicro nanoLight spot

The invention discloses a method for improving three-dimensional micro-nano structure based on composite scanning. The method includes such steps as coating photoresist on substrate; Adjusting the light signal emitted from the laser light source according to the exposure demand of the photoresist; passing the adjusted laser beam is firstly through a two-dimensional vibrating mirror, and then focusingon a designated position in the photoresist through an objective lens; dividing the three-dimensional structure model to be processed into a plurality of two-dimensional planes along the longitudinal axis direction; importing the spatial coordinate information of all the points which are combined into a three-dimensional model structure into the control system of the machining platform. The micro-moving platform moves under the preset motion trajectory of the control system, and the photoresist is exposed according to the motion trajectory of the platform under the irradiation of the laserbeam. While the micro-moving platform moves along the preset trajectory, the two-dimensional vibrating mirror vibrates in another vibration mode, that is, the exposure trajectory of the light spot focused in the photoresist is composed of the superposition of the two-dimensional vibrating mirror trajectory and the three-dimensional micro-nano-moving platform trajectory.

Owner:JINAN UNIVERSITY

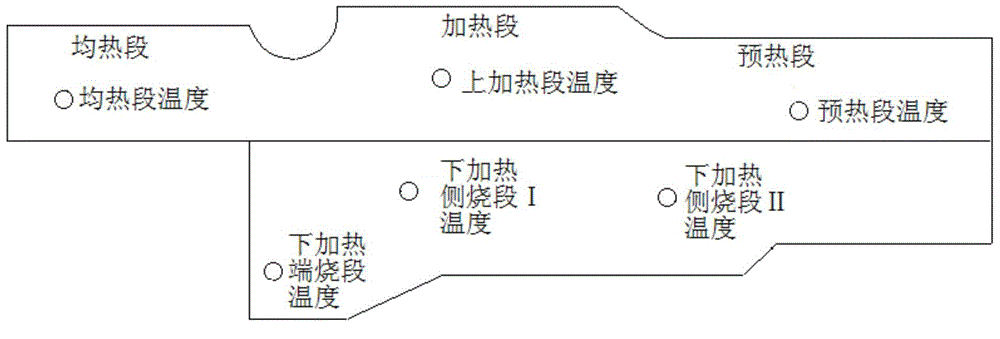

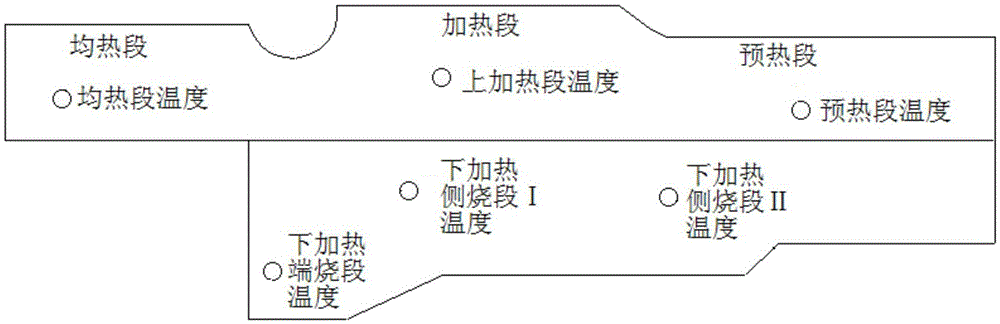

Production control method of narrow strips for cutting dies

ActiveCN104084430AIncrease loading capacityImprove width precisionTemperature control deviceRoll speed control deviceProcess engineeringContinuous rolling

The invention discloses a production control method of narrow strips for cutting dies. According to the method, the preheating section temperature is controlled to be in a range of 500-750 DEG C, the upper heating section temperature is controlled to be in a range of 1150-1220 DEG C, the lower heating side firing section temperature is controlled to be in a range of 1190-1290 DEG C, the lower heating end firing section I temperature is controlled to be in a range of 1200-1300 DEG C, the lower heating end firing section II temperature is controlled to be in a range of 1100-1200 DEG C, the soaking section temperature is controlled to be in a range of 1150-1230 DEG C, the rough machine initial rolling temperature is controlled to be in a range of 1060-1160 DEG C in a controlled rolling process, a continuous rolling unit initial rolling temperature is controlled to be in a range of 1000-1050 DEG C, the final rolling temperature is not higher than 900 DEG C, the curling temperature is not higher than 650 DEG C, and an intermediate rolling unit and a finish rolling unit adopt plain roller rolling machines, so that defects of coarse grains, poor bending performance and the like cannot occur easily during rolling, the product quality is guaranteed, the production efficiency is improved, and the narrow strips which are good in bending performance and anti-fatigue performance and used for the high-strength cutting dies are produced.

Owner:NANJING IRON & STEEL CO LTD

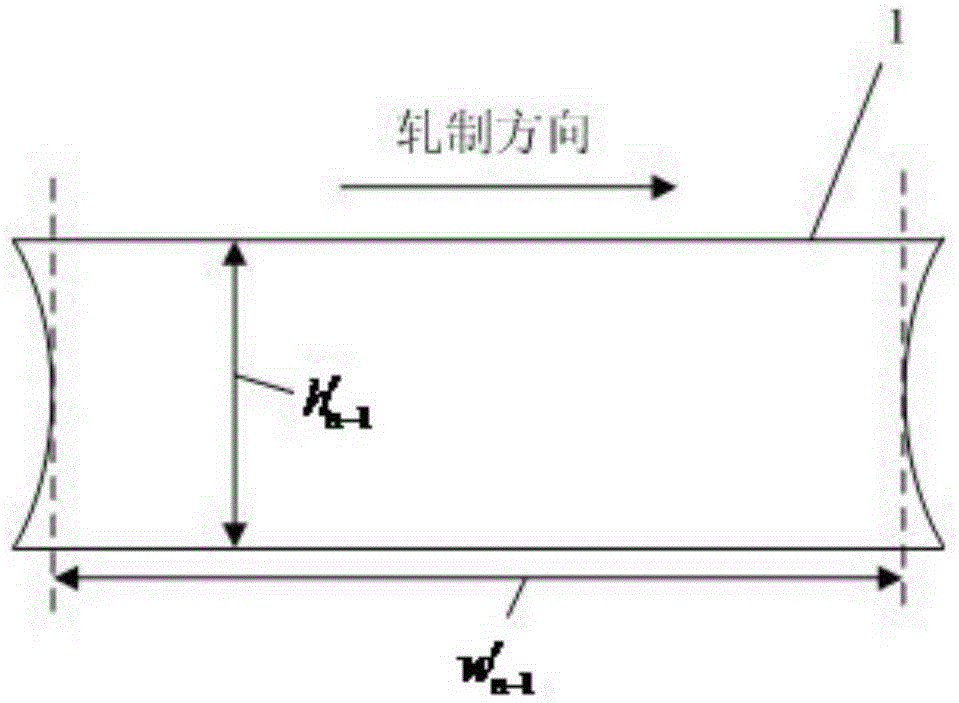

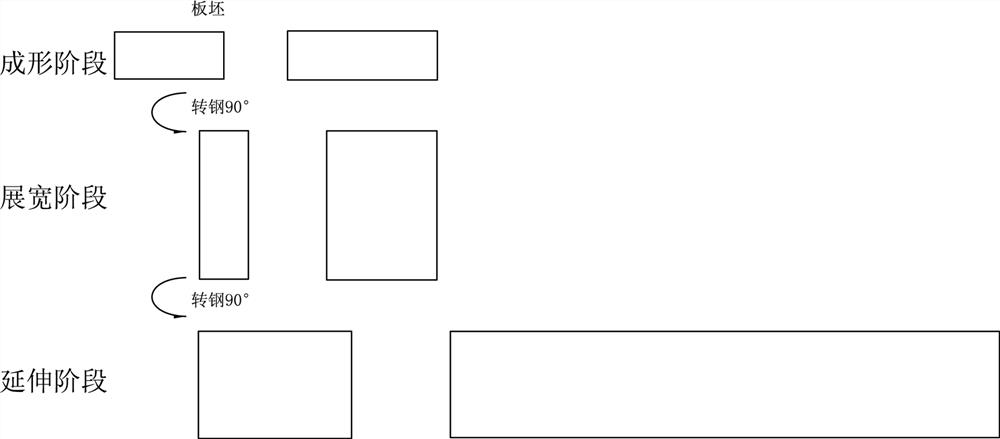

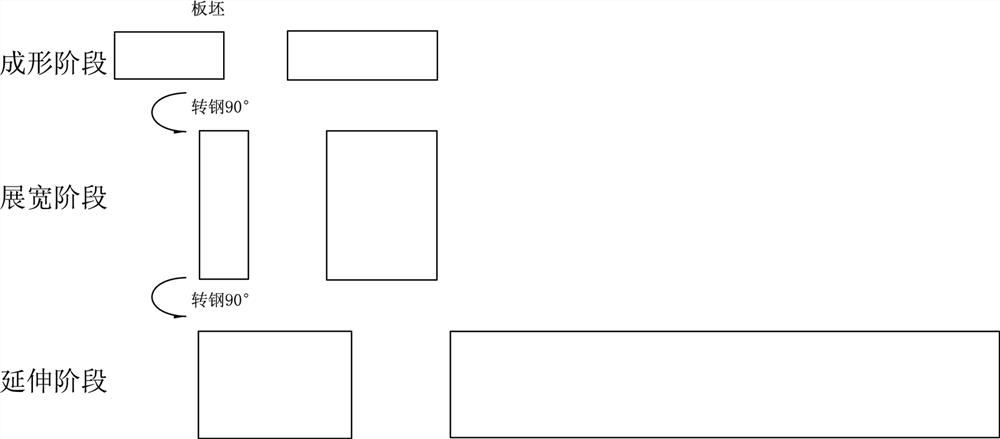

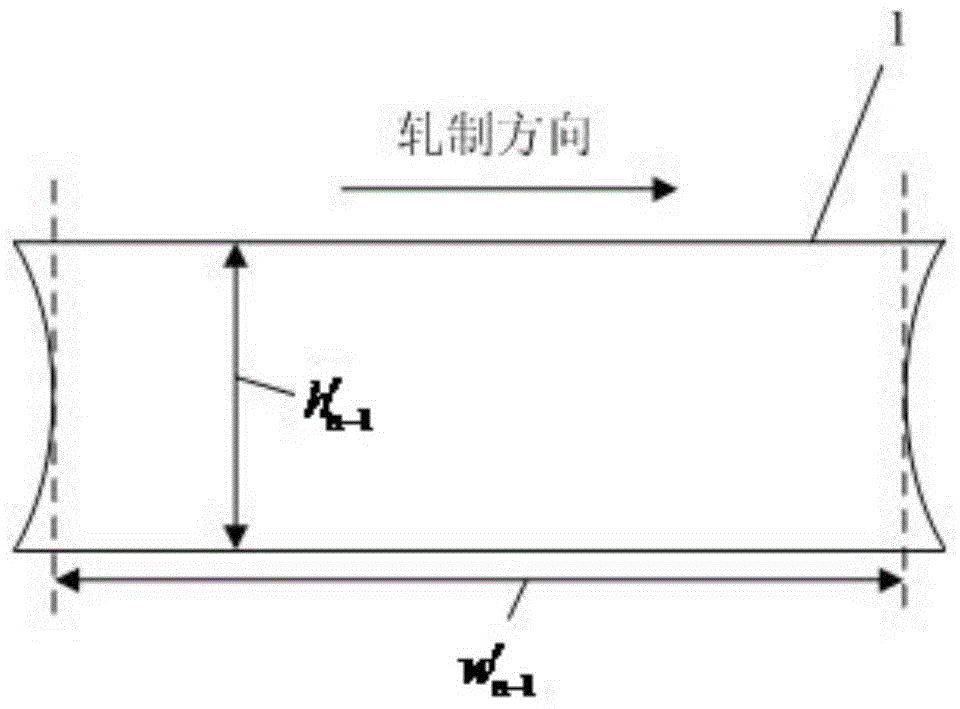

Method for controlling transverse rolling width and longitudinal rolling width of moderately-thick plate

ActiveCN105290116AImprove width precisionAvoid calculation errorsMetal rolling stand detailsRoll mill control devicesThick plateMaterials science

The invention discloses a method for controlling transverse rolling width and longitudinal rolling width of a moderately-thick plate, and relates to the technical field of pressure processing of metals. The method comprises the following steps: A, setting rolling procedures, wherein the rolling reduction of all passes before the last pass in the transverse rolling stage is set according to the maximum allowable load which can be borne by a rolling machine; B, shooting a shape image of the side surface of a rolling part in front of an inlet of the last pass so as to obtain the ratio of the effective width of the middle part of the rolling part in the image to the thickness of the rolling part in the image, and synchronously measuring the actual thickness of the rolling part at the moment to obtain the width deviation; C, calculating the compensation rolling reduction of the last pass of the rolling part according to the width deviation, summing the compensation rolling reduction and the set rolling reduction of the last pass to obtain the compensated rolling reduction of the last pass, and then adjusting the roll gap value of the last pass or the last two passes according to the compensated rolling reduction, so as to obtain the expected effective width of the middle part of the finished product of the rolling part. Compared with the prior art, the method has the advantage that the width accuracy of the moderately-thick plate in the transverse rolling stage can be effectively improved.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

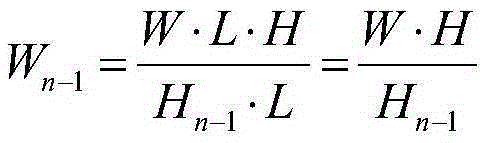

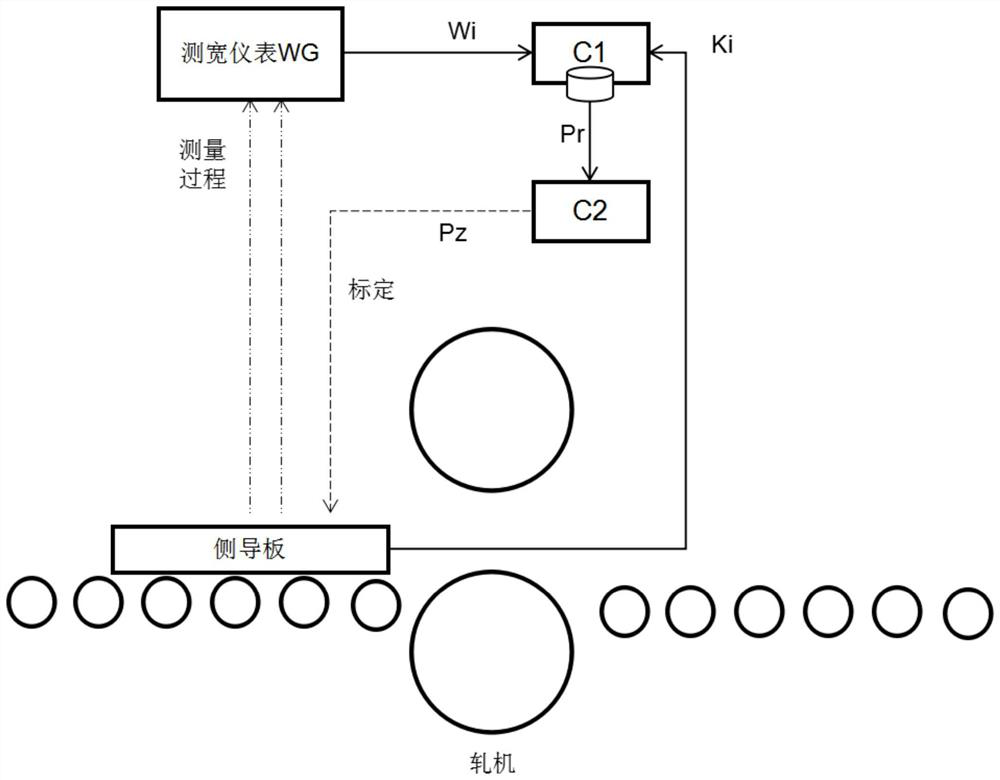

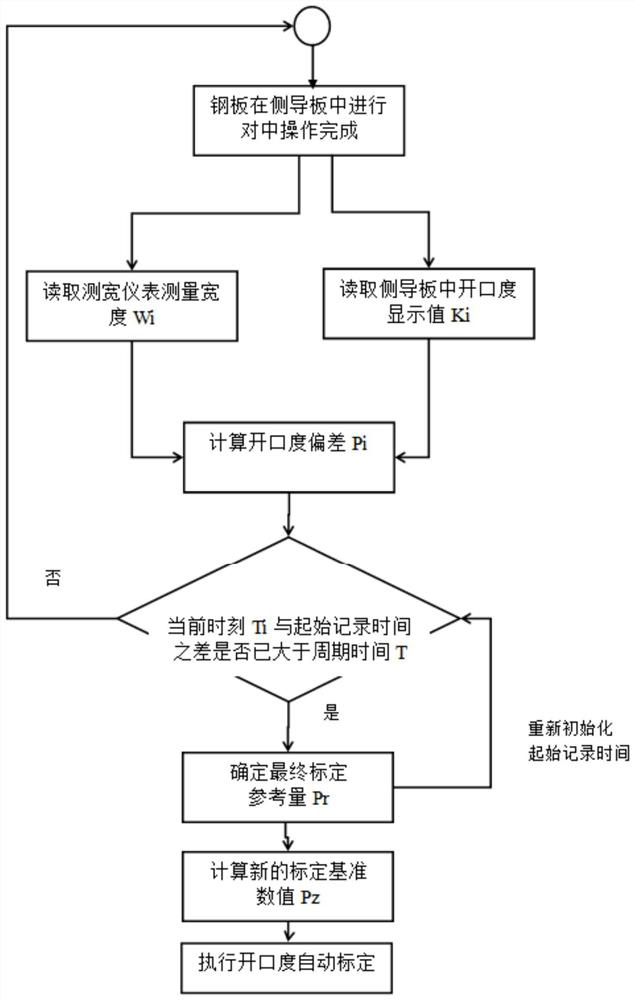

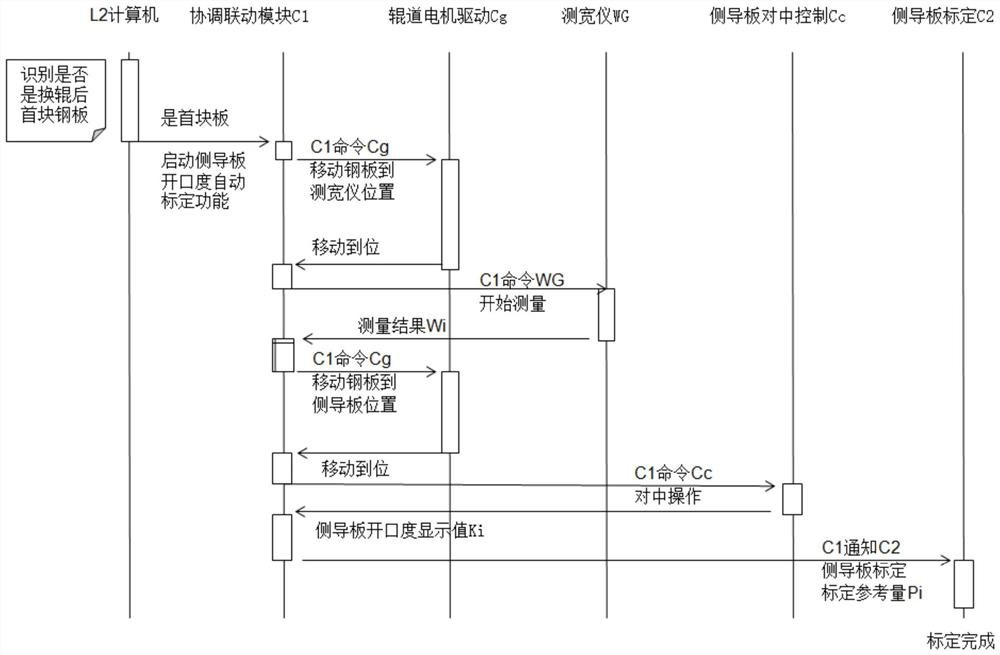

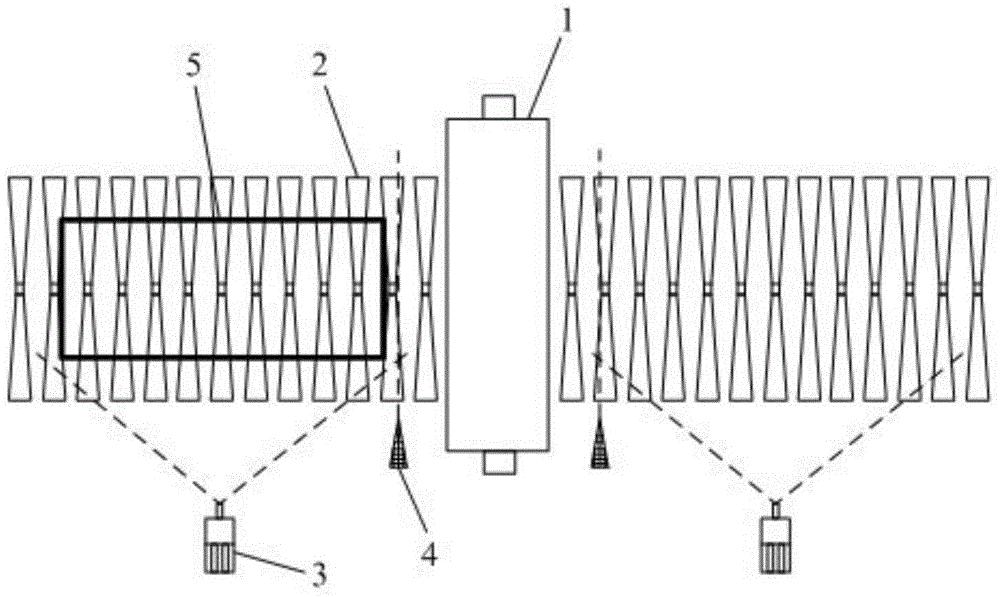

Full-automatic calibration method for opening degree of side guide plate of heavy and medium plate mill

ActiveCN113275392AReduce calibration timeShorten production downtimeGuiding/positioning/aligning arrangementsMeasuring devicesProduction lineStructural engineering

The invention discloses a full-automatic calibration method for the opening degree of a side guide plate of a heavy and medium plate mill. The full-automatic calibration method is suitable for a modern heavy and medium plate production line with a steel plate profile gauge (POG) or a width gauge arranged above the side guide plate. A periodic calibration calculation module is additionally arranged in an automatic system, and after the module calculates the width deviation value of a plurality of side guide plates and the profile gauge in an accumulative mode, data filtering is carried out, and the calibration value of the side guide plates is adjusted in a self-adaptive mode. According to the full-automatic calibration method, the time and the labor cost of the opening degree calibration operation of the side guide plates are saved, the safety risk is reduced, and the precision of the measurement width of the side guide plates is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

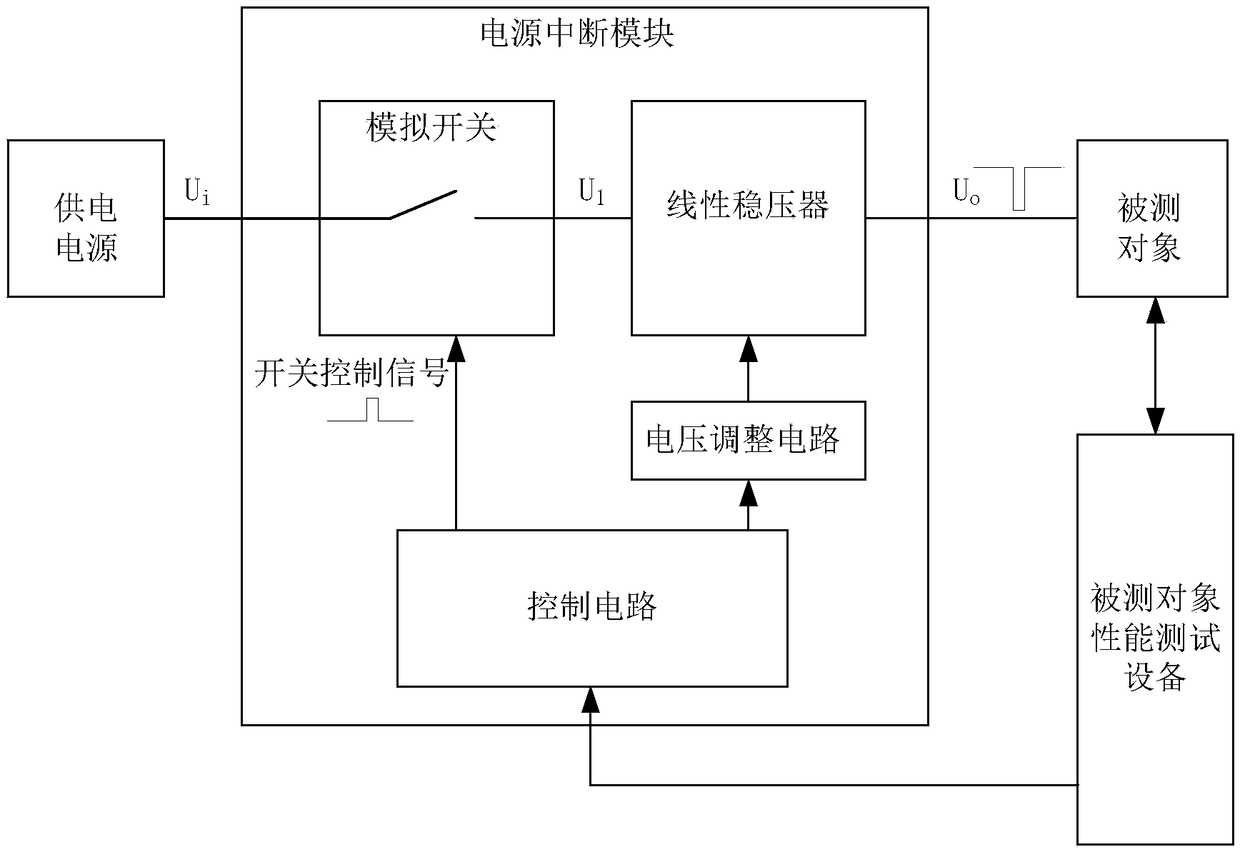

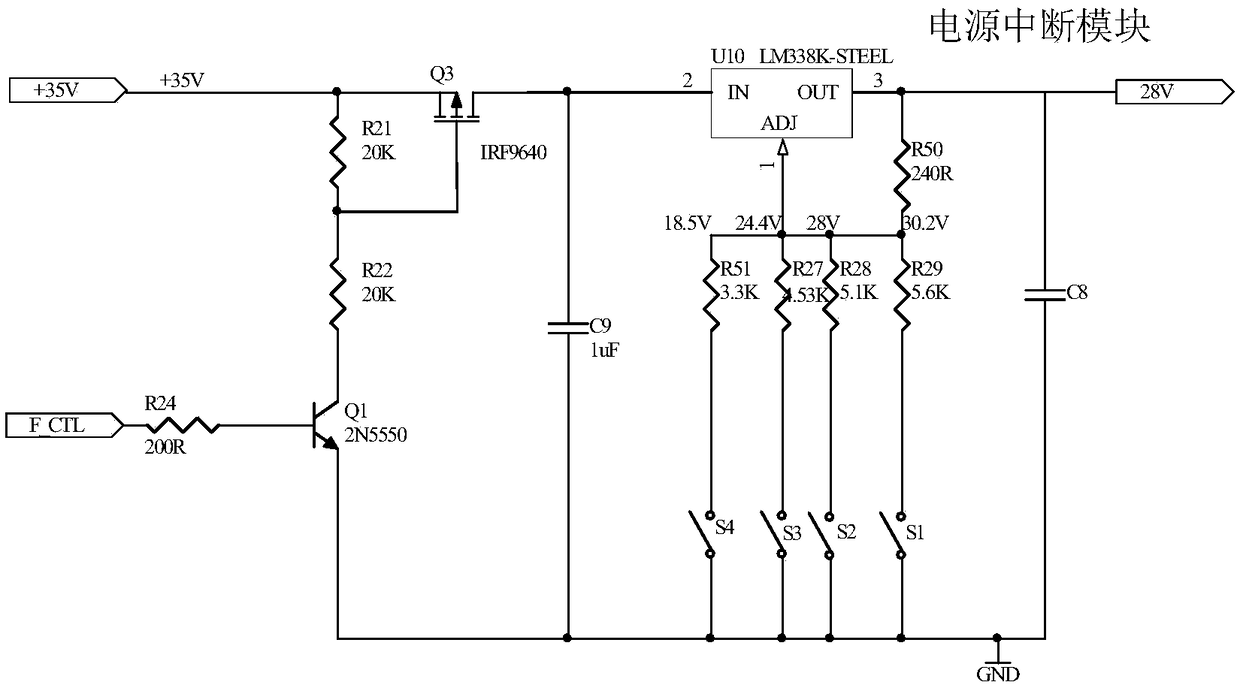

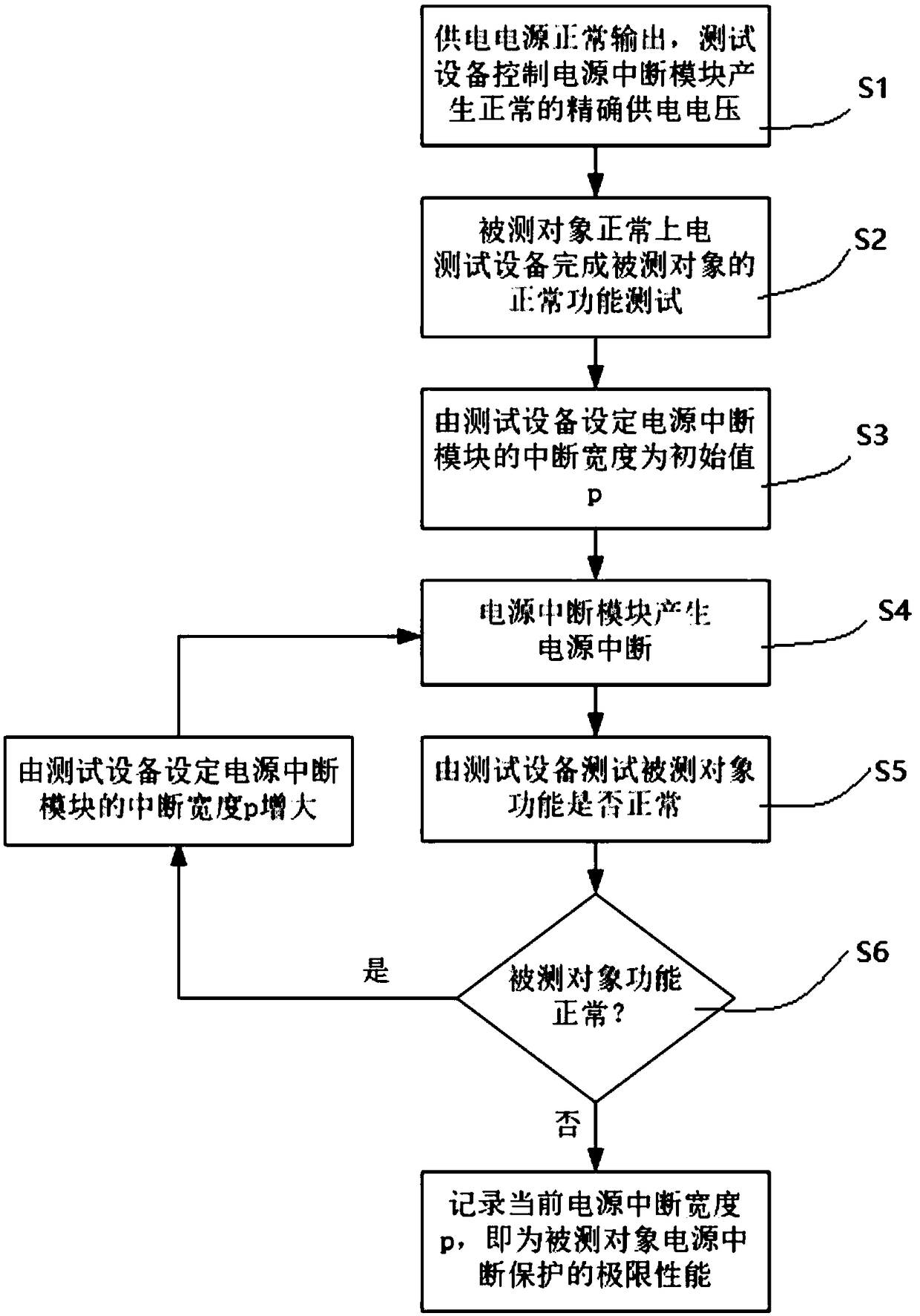

Power interruption test system for precision power supplies and test method thereof

InactiveCN109342931AHigh precisionSimple designElectronic protection circuit testingControl flowEngineering

The invention discloses a power interruption test system for precision power supplies and a test method thereof. The power interruption test system for precision power supplies includes an interruption performance test device connected with a tested device, and a power supply. The power interruption test system is characterized in that a power interruption module is arranged between the power supply and the tested device, and the interruption performance test device is in feedback control connection with the power interruption module. The method comprises the following steps: the power supplyoutputs power normally; and the interruption performance test device makes the power interruption module output a normal precise supply voltage through feedback control. The control flow of the powerinterrupt test system is simple. The performance of a power interruption protection circuit can be accurately tested. The power interruption width test is highly precise and accurate. The influence ofon-off and load on the voltage is avoided. The method is simple and fast in test.

Owner:丰县航天三优科技有限公司

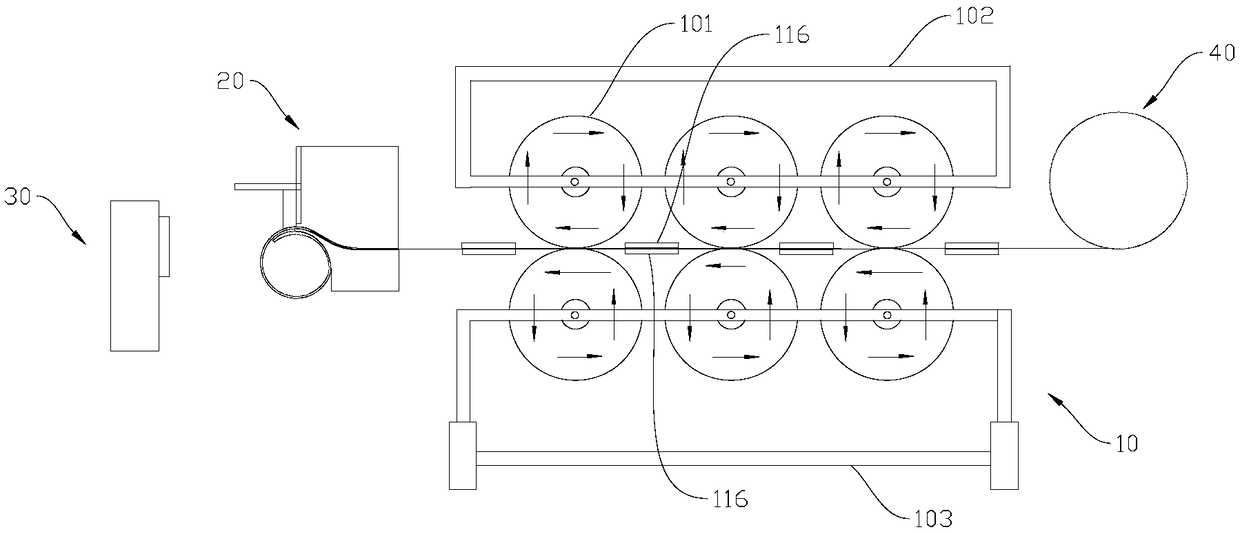

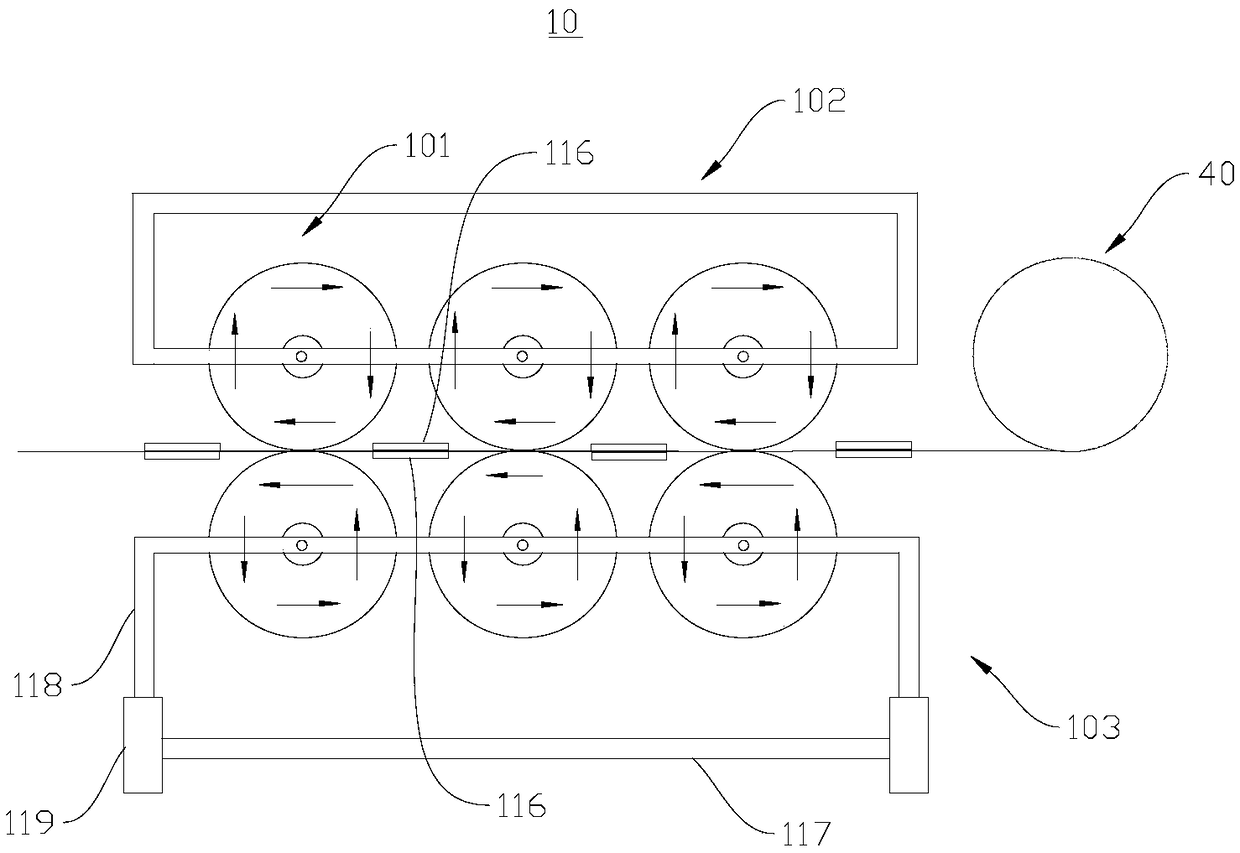

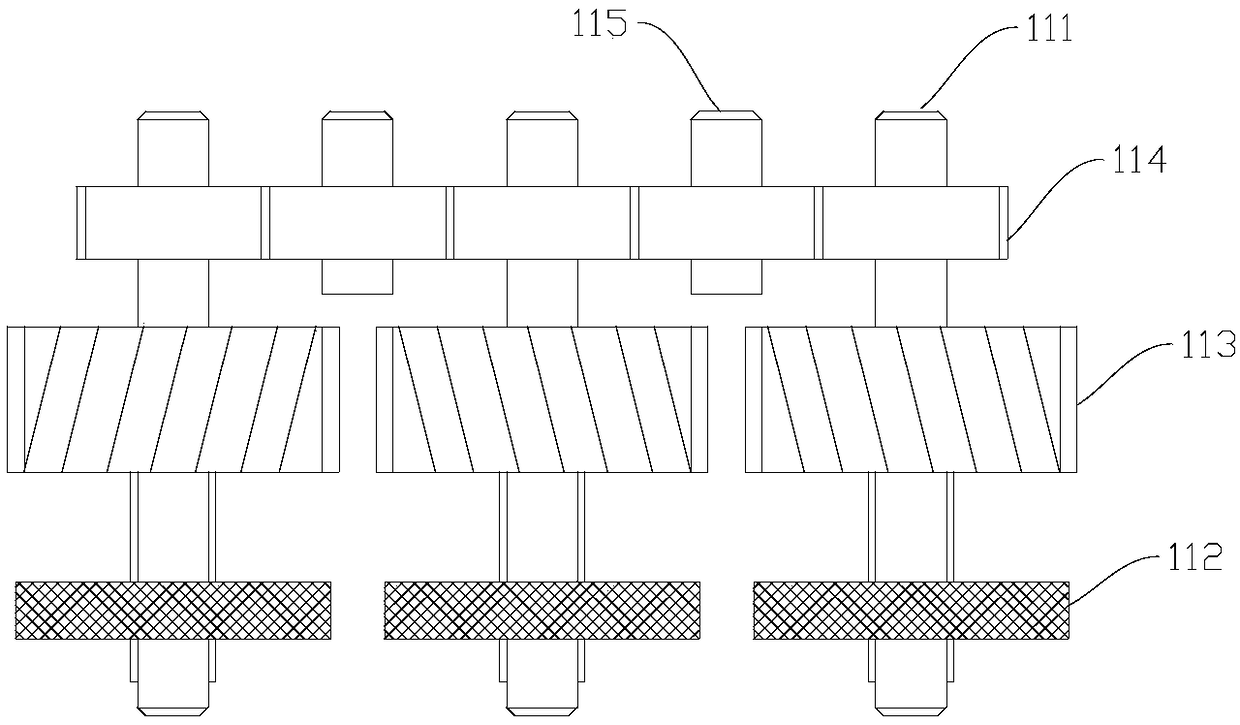

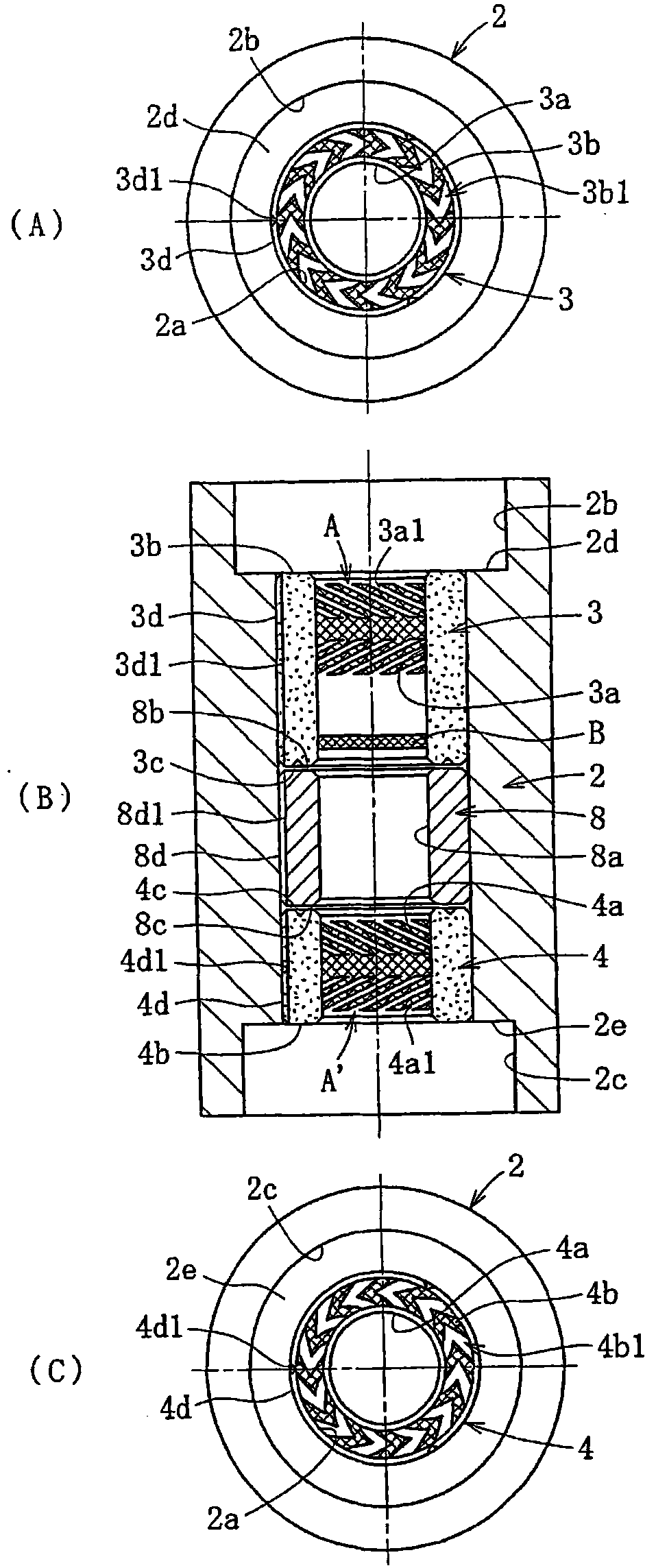

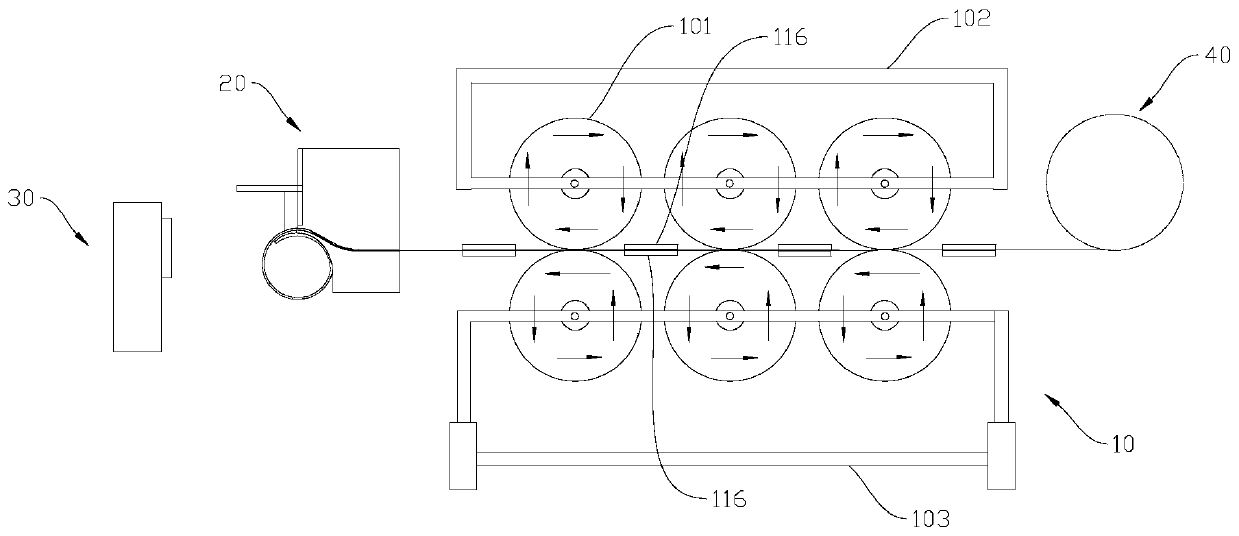

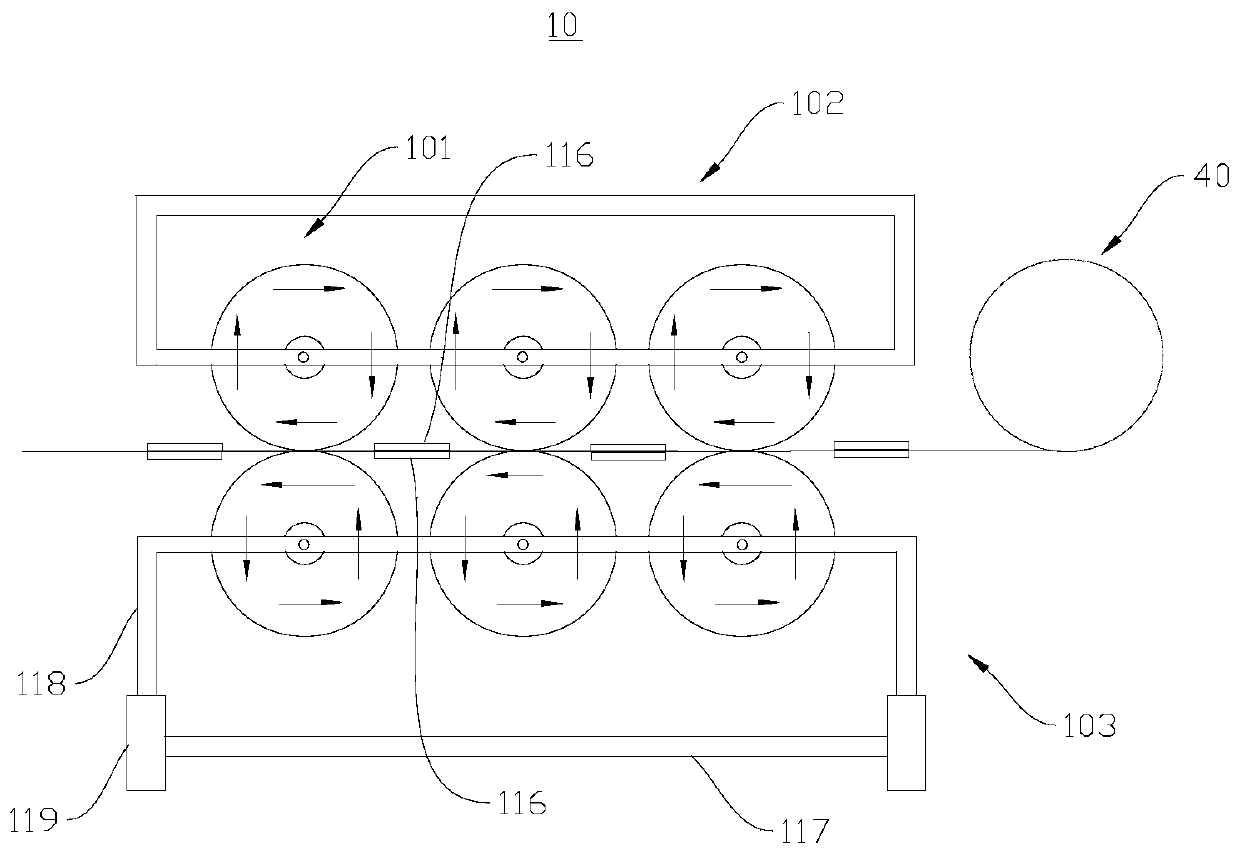

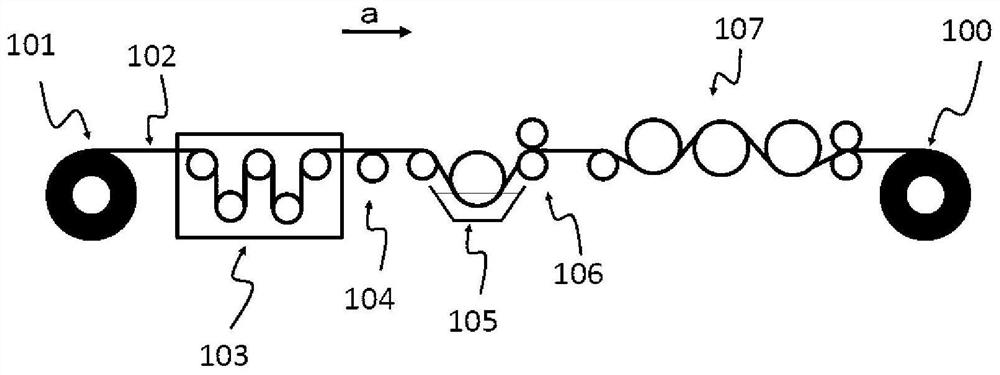

Metal coiled material machining system and method

The invention discloses a metal coiled material machining system and method, and belongs to the field of material forming and machining. The metal coiled material machining system comprises a shape correcting and feeding device, a forming device and a material cutting machine. The feeding side of the shape correcting and feeding device corresponds to a to-be-formed coiled material, the dischargingside of the shape correcting and feeding device corresponds to the feeding side of the forming device, accordingly, blanks obtained after shape correcting are conveyed into the forming device to be formed, and the discharging side of the forming device is provided with the material cutting machine. By means of the metal coiled material machining system and method, automatic, stable and continuousproduction of coiled material products can be achieved, the product quality is reliable, and high size precision and product size adjusting sensitivity and flexibility are achieved.

Owner:成都浩益科技有限公司

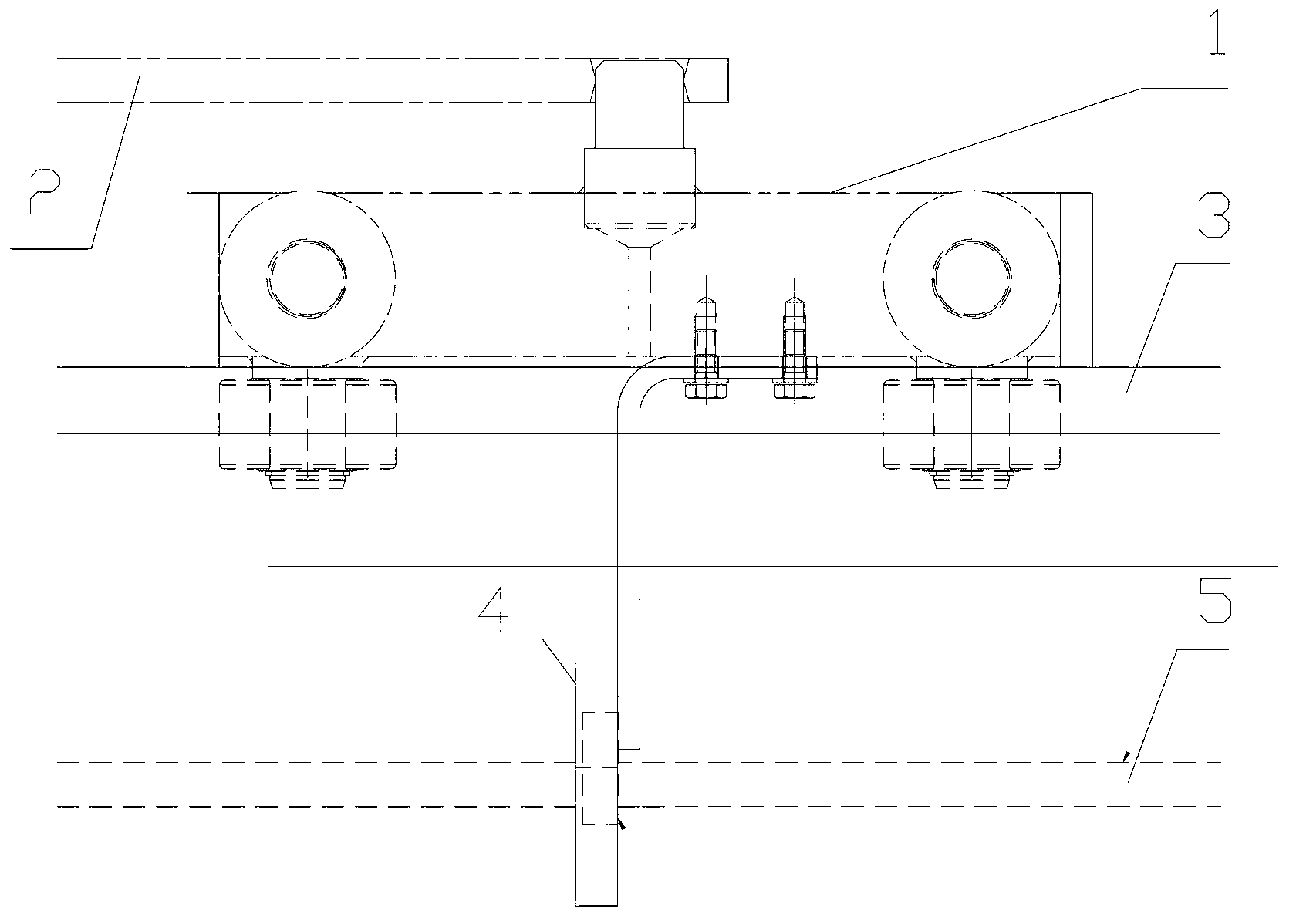

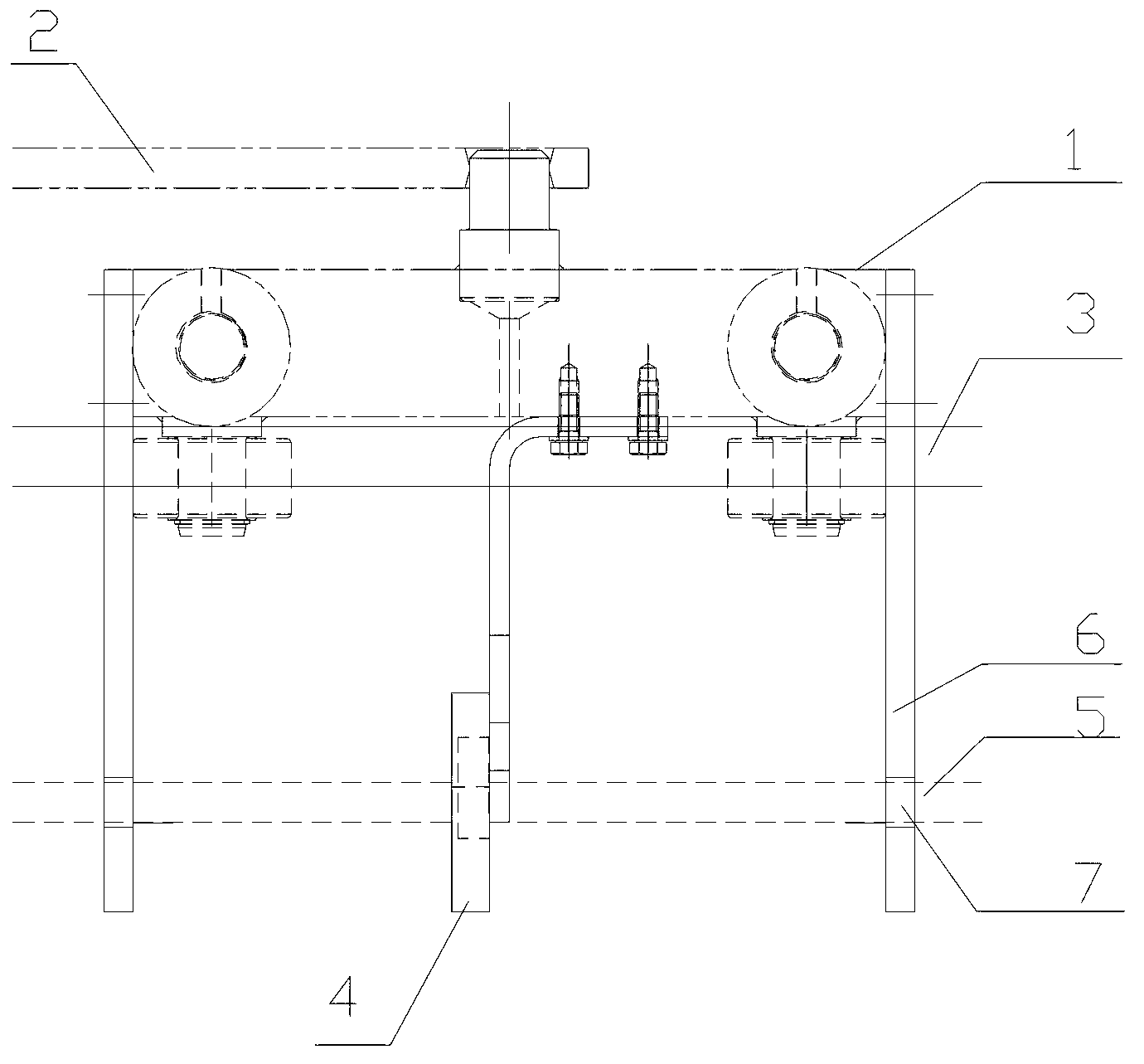

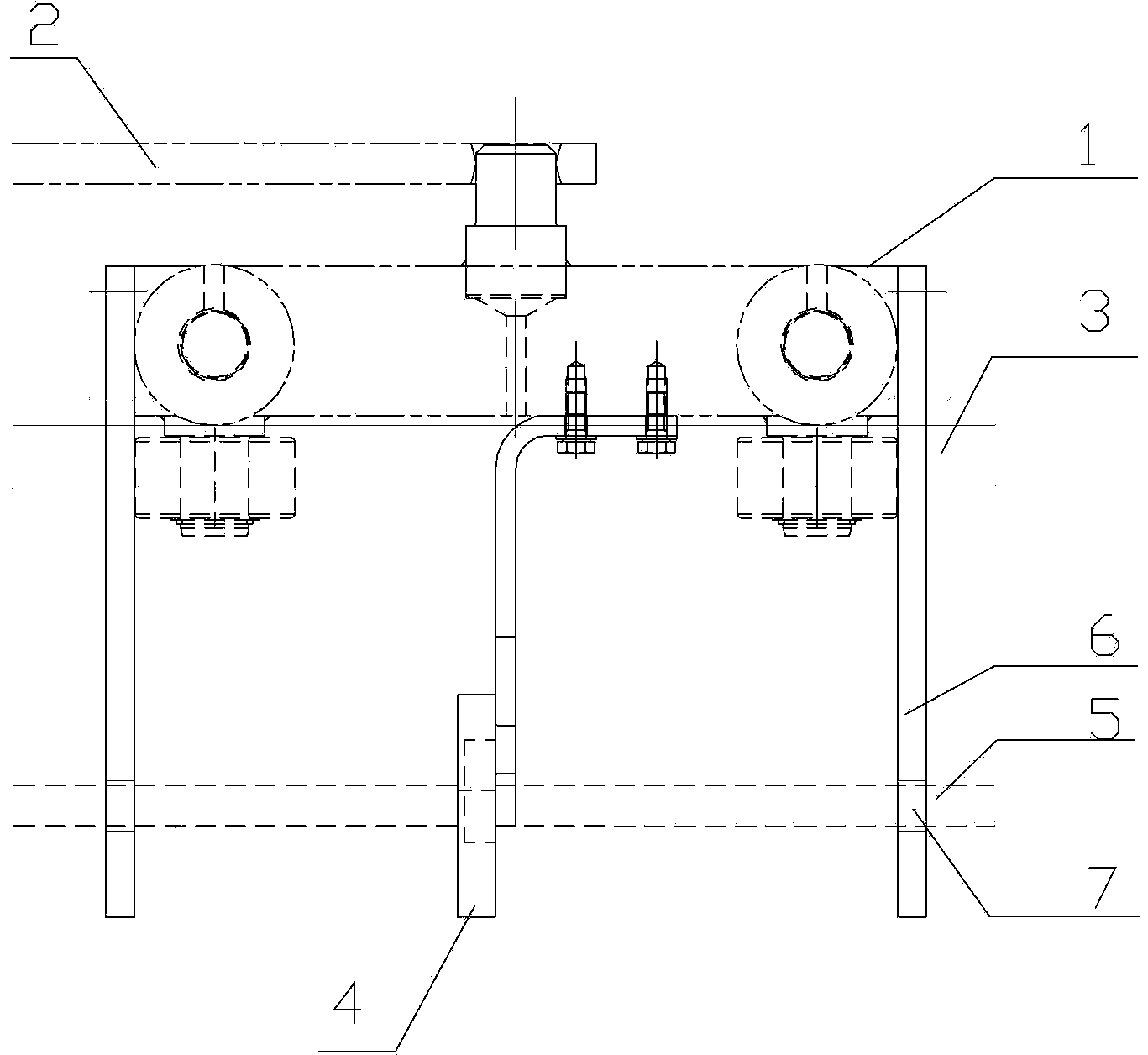

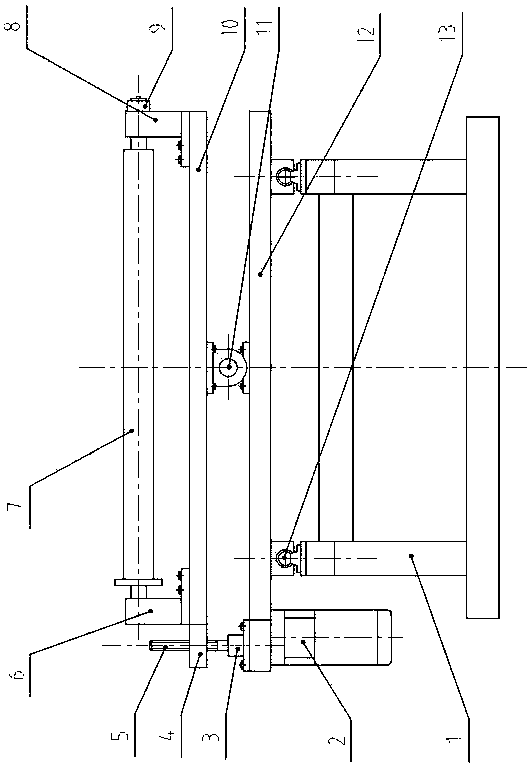

Displacement sensor traveling positioning device

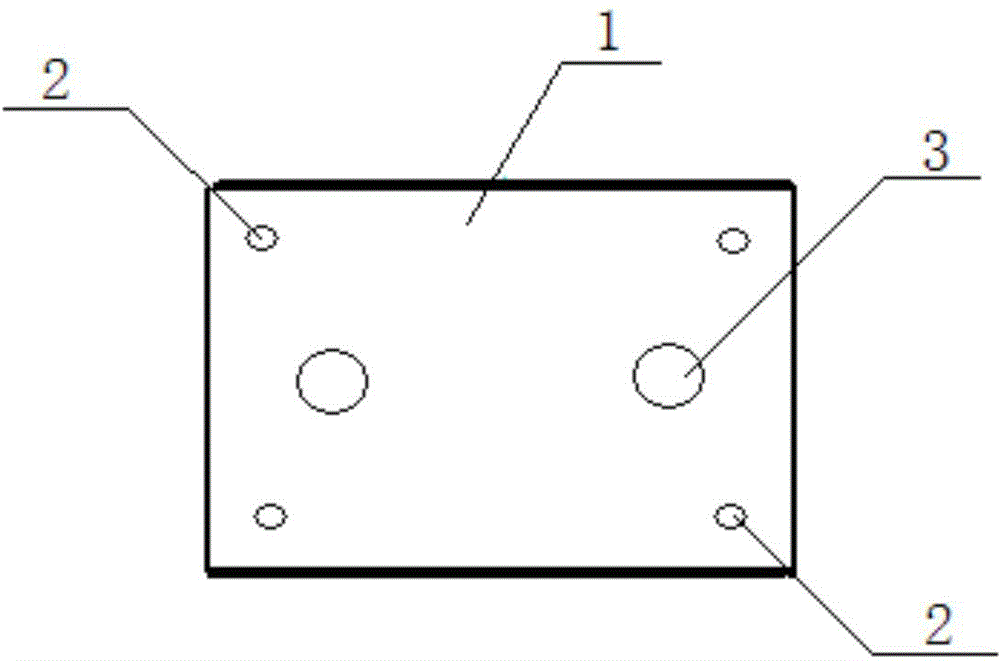

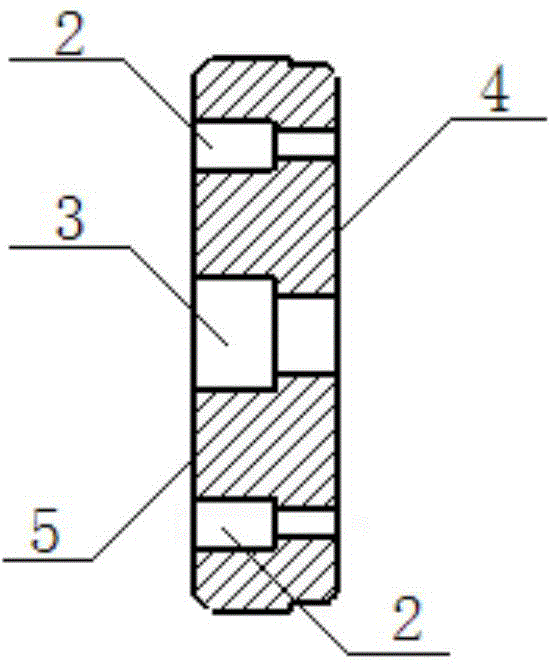

ActiveCN103056725AThe location information is accurateImprove width precisionMeasurement/indication equipmentsShearing machine accessoriesEngineeringMechanical engineering

The invention discloses a displacement sensor traveling positioning device comprising a traveling cart, a traveling cart fixing device, a slide rail and induction rings. The displacement sensor traveling positioning device further comprises strip-shaped displacement sensors and fixed plates. The fixed plates are respectively vertically fixed at the front end and the rear end of the traveling cart and provided with through holes at the lower ends. The strip-shaped displacement sensors penetrate through the through holes and the induction rings and are supported by the through holes. During steel rolling, the strip-shaped displacement sensors vibrate along with the induction rings, relative positions of the strip-shaped displacement sensors and the induction rings are kept fixed, and accordingly, position information of plates detected by the strip-shaped sensors is more accurate, and width accuracy of the plates is improved.

Owner:LAIWU IRON & STEEL GRP

Mthod for controlling roller gap of precision rolling machine of band steel

InactiveCN1216699CHigh precisionImprove width precisionRoll force/gap control deviceProfile control deviceMathematical modelEngineering

The present invention relates to a control method of roll gap of steel strip finishing rolling, mill, mainly including: using computer to successively calculate finishing rolling inlet temp. value, temp. values of all the machine frames of finishing rolling mill, rolling force values of all the machine frames and roll gap values of all the machine frames, setting and using computer to control PLC, and utilizing PLC to regulate screwdown motor and hydraulic device to regulate roll gap. Said invention also provides the mathematical model of finishing rolling inlet temperature, it can accurately control the accuracy of the roll gap, and can raise its production efficiency.

Owner:ANGANG STEEL CO LTD

Automatic Control Method of Strip Width in Hot Continuous Rolling Finishing

ActiveCN103286141BReduce Width FluctuationImprove width precisionMetal rolling stand detailsAutomatic controlAutomatic train control

The invention relates to the field of strip steel hot rolling, in particular to a control method of the width of hot rolling strip steel. An automatic control method of the width of hot continuous rolling and finish rolling strip steel comprises the steps as follows: a temperature change model of the strip steel in a finish rolling process is built, sensitivity coefficients are calculated, and temperature reference values of the strip steel at rack outlets are calculated; temperature modification values of the strip steel at the rack outlets are calculated, and temperature prediction values are obtained in combination of the temperature reference values and the temperature modification values; real-time change values of the width of the strip steel are calculated; feedback deviation values of the width of the strip steel are obtained through comparison, and the feedback deviation values are distributed to racks, so that feedback deviation values of the width of the strip steel, which are required to be adjusted by the racks, are obtained; and tension of loops among the racks are adjusted in combination of the real-time change values of the width of the strip steel and the feedback deviation values of the width of the strip steel, so that the width of the steel strip is controlled. The method can well guarantee that the width of the strip steel after finish rolling can fluctuate nearby set values, the width accuracy of a strip product is finally improved, and accordingly, the utilization rate of a material by a downstream user is remarkably increased.

Owner:BAOSHAN IRON & STEEL CO LTD

Edge exposure apparatus, coating and developing apparatus, edge exposure method and coating and developing method, and storage medium

InactiveUS7651285B2High accuracy of shapeHigh accuracy of widthLiquid surface applicatorsLiquid processingResistEngineering

Owner:TOKYO ELECTRON LTD

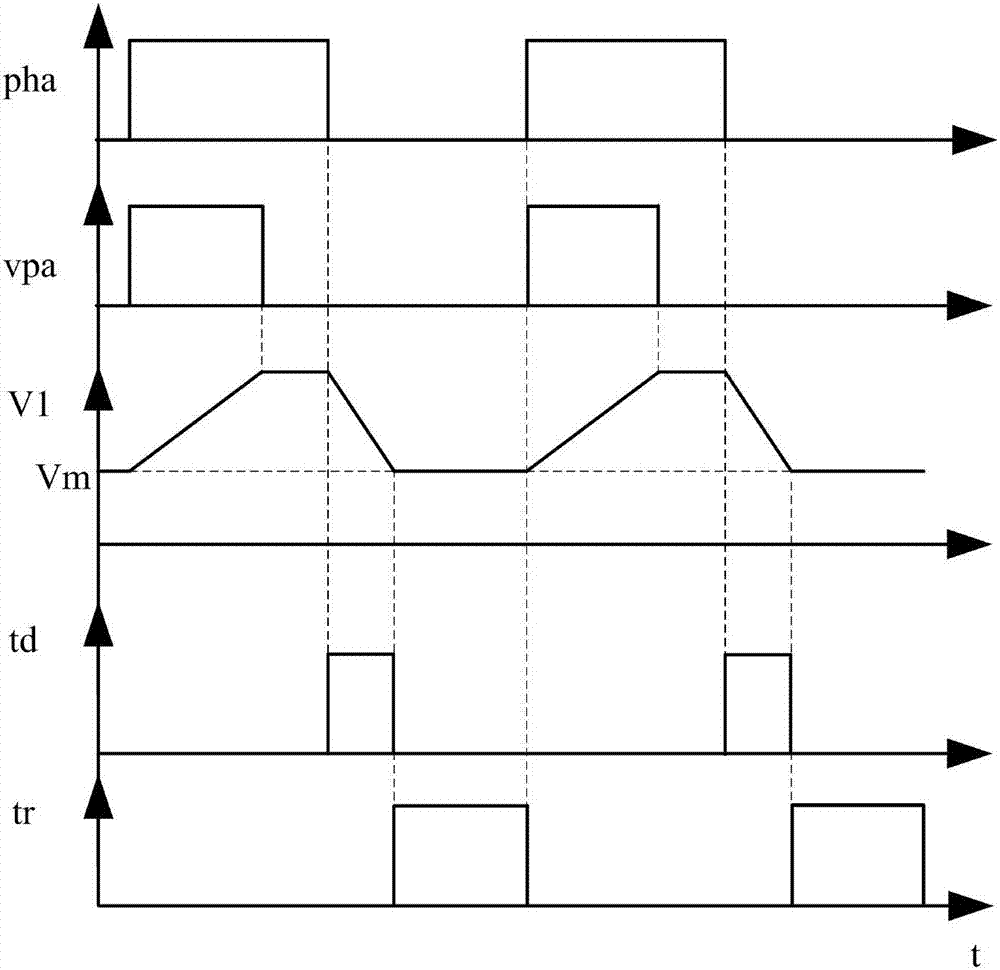

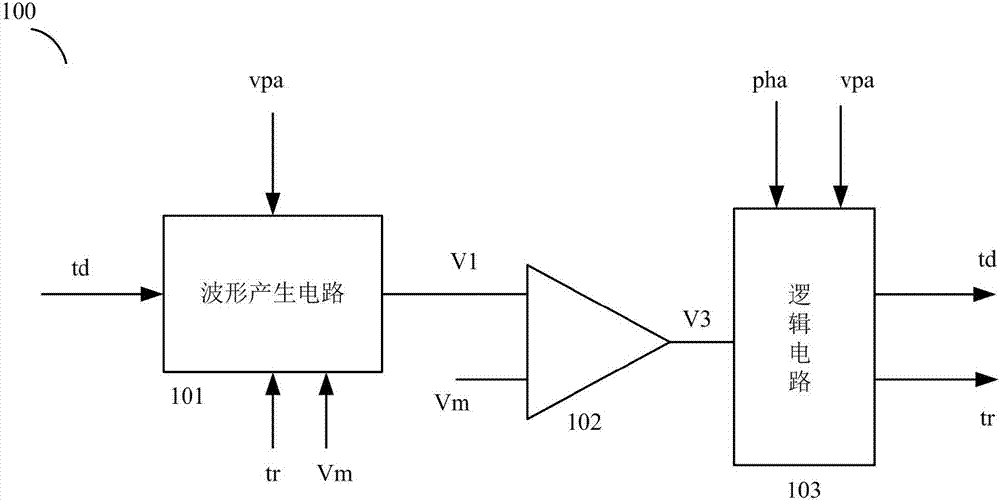

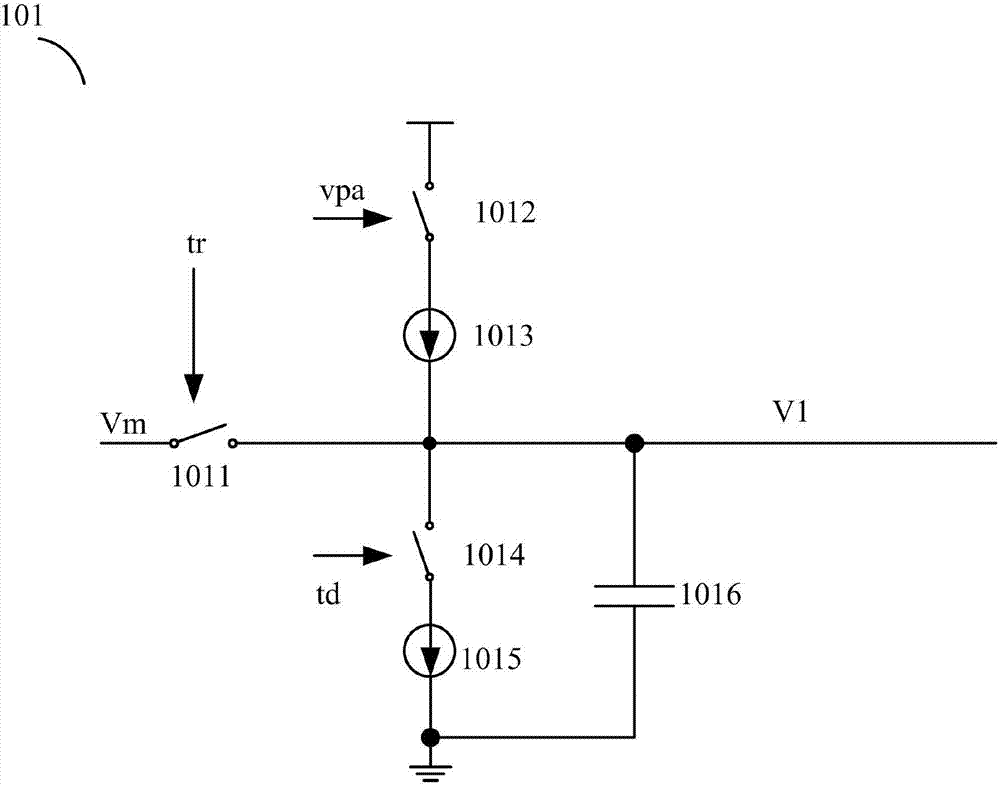

Pulse generation circuit, current detection circuit, switching power supply and pulse generation method

ActiveCN107425830AImprove width precisionReduce areaEfficient power electronics conversionPulse duration/width modulationPower flowControl signal

The invention discloses a pulse generation circuit, a current detection circuit, a switching power supply and a pulse generation method. An input pulse signal and a periodic signal become valid from invalid at a same moment; the time when the periodic signal is valid is longer than the time when the pulse signal is valid; the pulse signal and the periodic signal have a same cycle; a first control signal and a second control signal are invalid when the input pulse signal is valid; a first voltage is linearly increased when the input pulse signal is valid; when the periodic signal is valid and the input pulse signal is invalid, the voltage keeps unchanged; when the periodic signal becomes invalid from valid, the voltage starts to be linearly decreased and the first control signal becomes valid from invalid; when the first voltage is decreased to a fixed voltage, the first control signal becomes invalid from valid, and the second control signal becomes valid from invalid; the first voltage is kept at the fixed voltage till the input pulse signal becomes valid from invalid, and the second control signal becomes invalid from valid; and the first control signal is a signal for characterizing a specific pulse width.

Owner:JOULWATT TECH ZHANGJIAGANG INC LTD

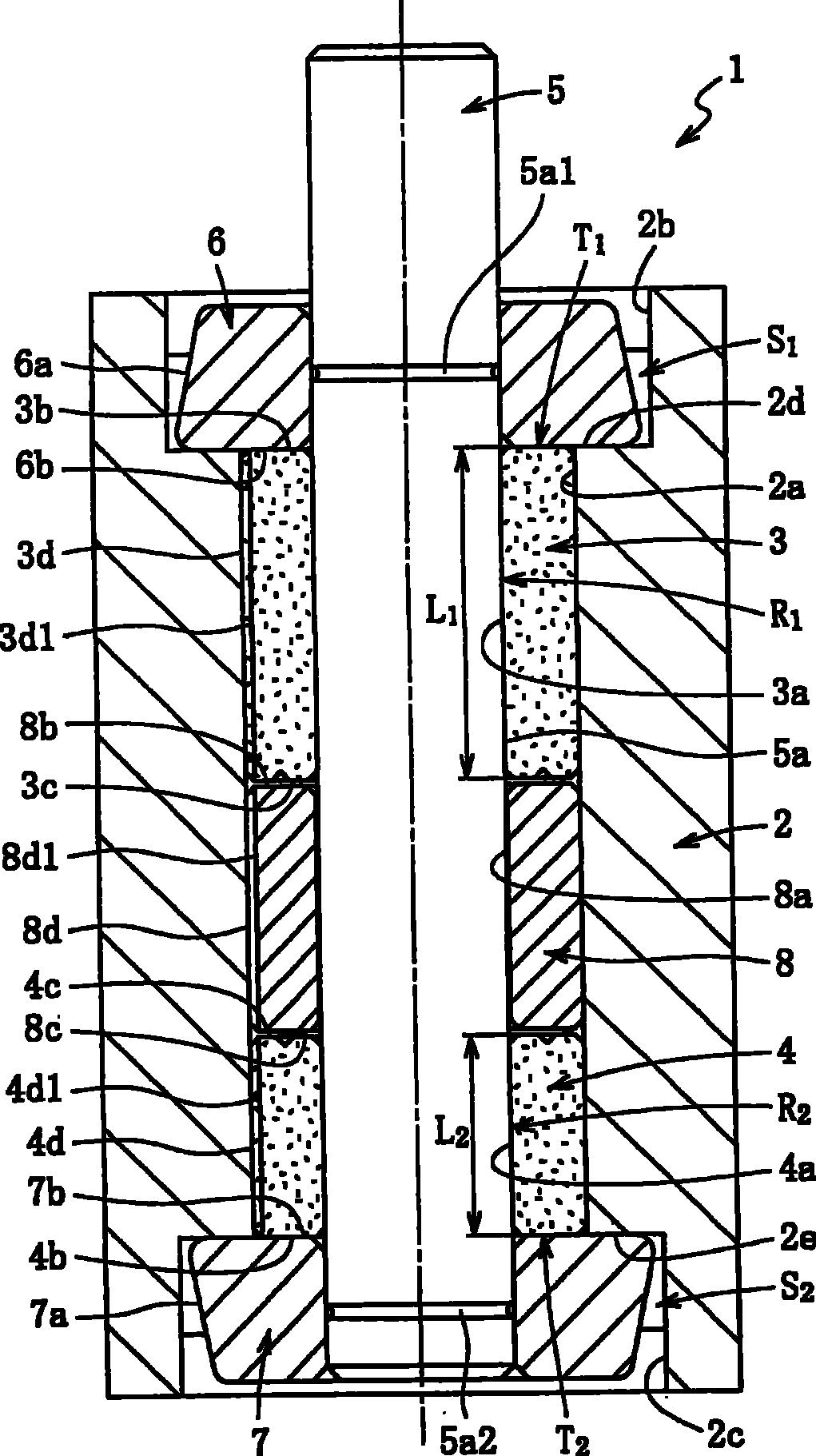

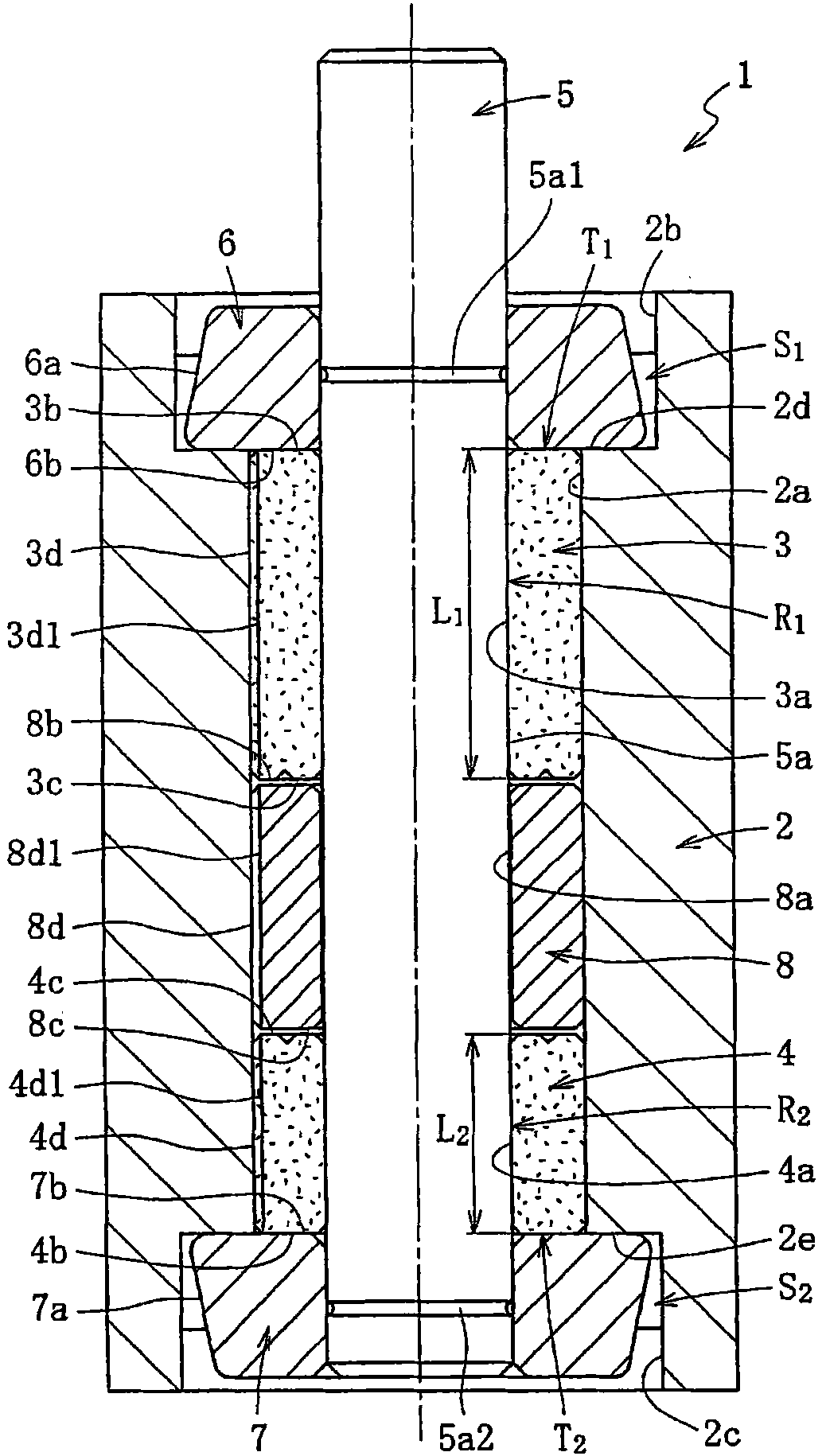

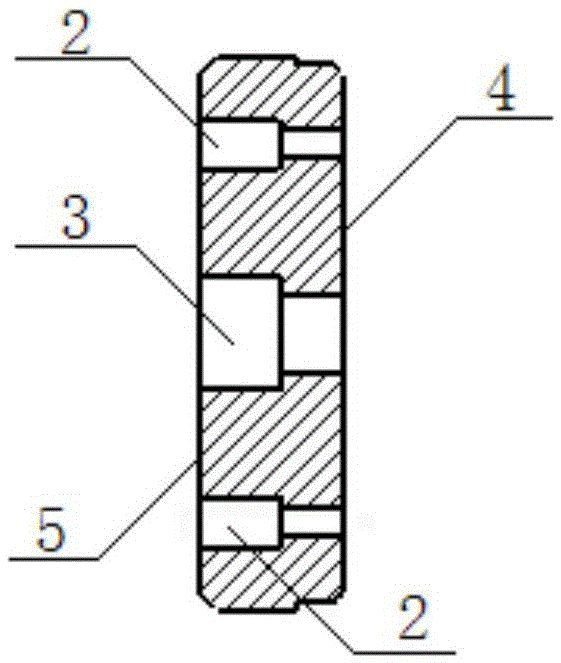

Fluid bearing device

InactiveCN101405513BAvoid loss of concentricityImprove work efficiencySliding contact bearingsMechanical energy handlingAxial lengthEngineering

The present invention provides a fluid bearing device which has excellent moment rigidity and an improved working efficiency in assembling and parts control, and in which a bearing sleeve can be easily manufactured. A plurality of bearing sleeves are axially disposed in the fluid bearing device. The bearing sleeves (3, 4) are so formed that their axial lengths are different from each other.

Owner:NTN CORP

Displacement sensor traveling positioning device

ActiveCN103056725BThe location information is accurateImprove width precisionMeasurement/indication equipmentsShearing machine accessoriesEngineeringCart

The invention discloses a displacement sensor traveling positioning device comprising a traveling cart, a traveling cart fixing device, a slide rail and induction rings. The displacement sensor traveling positioning device further comprises strip-shaped displacement sensors and fixed plates. The fixed plates are respectively vertically fixed at the front end and the rear end of the traveling cart and provided with through holes at the lower ends. The strip-shaped displacement sensors penetrate through the through holes and the induction rings and are supported by the through holes. During steel rolling, the strip-shaped displacement sensors vibrate along with the induction rings, relative positions of the strip-shaped displacement sensors and the induction rings are kept fixed, and accordingly, position information of plates detected by the strip-shaped sensors is more accurate, and width accuracy of the plates is improved.

Owner:LAIWU IRON & STEEL GRP

A metal coil processing system and processing method

The invention discloses a metal coiled material machining system and method, and belongs to the field of material forming and machining. The metal coiled material machining system comprises a shape correcting and feeding device, a forming device and a material cutting machine. The feeding side of the shape correcting and feeding device corresponds to a to-be-formed coiled material, the dischargingside of the shape correcting and feeding device corresponds to the feeding side of the forming device, accordingly, blanks obtained after shape correcting are conveyed into the forming device to be formed, and the discharging side of the forming device is provided with the material cutting machine. By means of the metal coiled material machining system and method, automatic, stable and continuousproduction of coiled material products can be achieved, the product quality is reliable, and high size precision and product size adjusting sensitivity and flexibility are achieved.

Owner:成都浩益科技有限公司

Cutting and grinding correcting device for rubber transmission belt

InactiveCN107866861AHigh tape width accuracyStrong applicabilityGrinding machinesMetal working apparatusEngineeringTransmission belt

A rubber transmission belt cutting, grinding and correcting device, which is characterized in that it adopts the adjustment method of adjusting the left and right of the driven roller, which overcomes the low width precision of the belt produced by cutting and grinding in the traditional way of adjusting the left and right of the driven roller. It is suitable for the deviation correction process of the rubber transmission belt in the cutting and grinding work.

Owner:刘成其

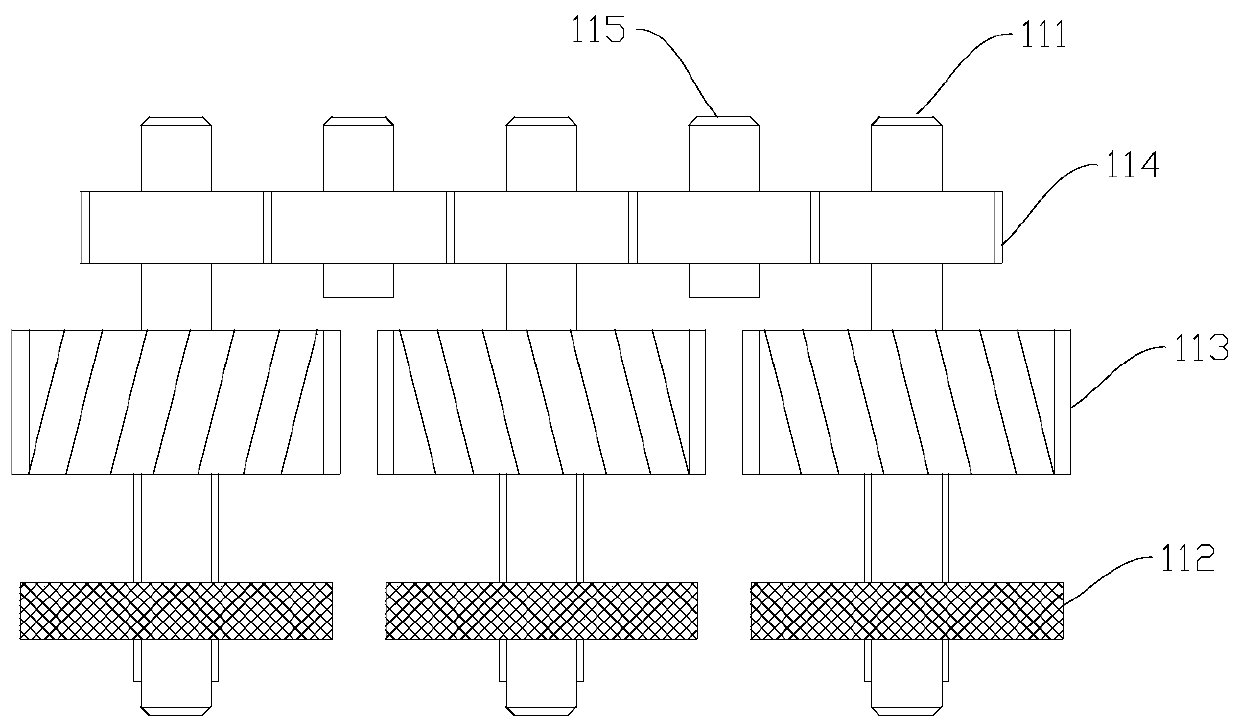

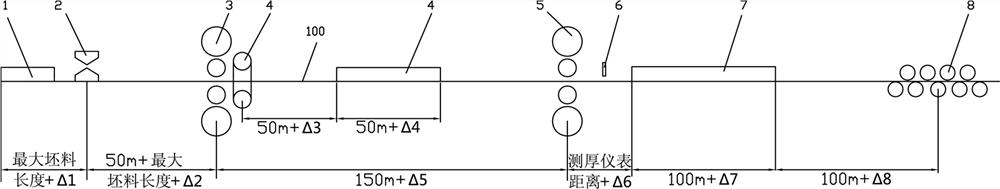

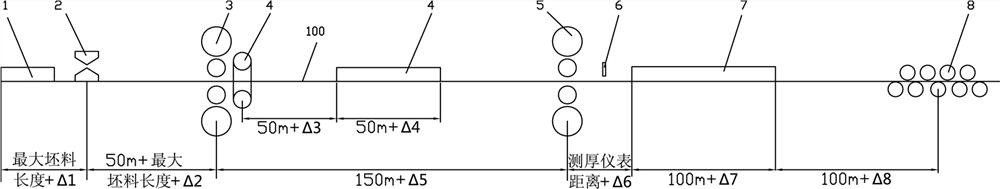

Thick plate rolling line and production method thereof

ActiveCN112570450AImprove width precisionEnsure rolling rhythmMetal rolling arrangementsThick plateRolling mill

The invention discloses a thick plate rolling line and a production method thereof. The thick plate rolling line comprises a descaling box, a large side pressure device, a roughing mill, an intermediate water cooling device, a finishing mill, a thickness gauge, an post-rolling cooling device and a hot straightener which are sequentially arranged along a conveying roller way. According to the thickplate rolling line, the maximum rolling length can be increased to 100 m, the limitation that the maximum blank length cannot exceed the effective roller body length is broken through, longer blankscan be produced, and the unit weight of rolling is remarkably increased; and the steel plate rolling rhythm and the steel plate width precision are obviously improved.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

A processing method for improving three-dimensional micro-nano structures based on composite scanning

ActiveCN108983555BShorten the timeCompact structurePhotomechanical exposure apparatusMicrolithography exposure apparatusNano structuringLight spot

The invention discloses a method for improving three-dimensional micro-nano structure based on composite scanning. The method includes such steps as coating photoresist on substrate; Adjusting the light signal emitted from the laser light source according to the exposure demand of the photoresist; passing the adjusted laser beam is firstly through a two-dimensional vibrating mirror, and then focusingon a designated position in the photoresist through an objective lens; dividing the three-dimensional structure model to be processed into a plurality of two-dimensional planes along the longitudinal axis direction; importing the spatial coordinate information of all the points which are combined into a three-dimensional model structure into the control system of the machining platform. The micro-moving platform moves under the preset motion trajectory of the control system, and the photoresist is exposed according to the motion trajectory of the platform under the irradiation of the laserbeam. While the micro-moving platform moves along the preset trajectory, the two-dimensional vibrating mirror vibrates in another vibration mode, that is, the exposure trajectory of the light spot focused in the photoresist is composed of the superposition of the two-dimensional vibrating mirror trajectory and the three-dimensional micro-nano-moving platform trajectory.

Owner:JINAN UNIVERSITY

A production control method of narrow strip steel for die cutting

ActiveCN104084430BIncrease loading capacityImprove width precisionTemperature control deviceRoll speed control deviceMetallurgyContinuous rolling

The invention discloses a production control method of narrow strips for cutting dies. According to the method, the preheating section temperature is controlled to be in a range of 500-750 DEG C, the upper heating section temperature is controlled to be in a range of 1150-1220 DEG C, the lower heating side firing section temperature is controlled to be in a range of 1190-1290 DEG C, the lower heating end firing section I temperature is controlled to be in a range of 1200-1300 DEG C, the lower heating end firing section II temperature is controlled to be in a range of 1100-1200 DEG C, the soaking section temperature is controlled to be in a range of 1150-1230 DEG C, the rough machine initial rolling temperature is controlled to be in a range of 1060-1160 DEG C in a controlled rolling process, a continuous rolling unit initial rolling temperature is controlled to be in a range of 1000-1050 DEG C, the final rolling temperature is not higher than 900 DEG C, the curling temperature is not higher than 650 DEG C, and an intermediate rolling unit and a finish rolling unit adopt plain roller rolling machines, so that defects of coarse grains, poor bending performance and the like cannot occur easily during rolling, the product quality is guaranteed, the production efficiency is improved, and the narrow strips which are good in bending performance and anti-fatigue performance and used for the high-strength cutting dies are produced.

Owner:NANJING IRON & STEEL CO LTD

A thick plate rolling line and its production method

ActiveCN112570450BImprove width precisionEnsure rolling rhythmMetal rolling arrangementsThick plateRolling mill

A thick plate rolling line and its production method, the thick plate rolling line includes a descaling box, a large side pressure device, a rough rolling mill, an intermediate water cooling device, a finishing mill, a thickness gauge, a post-rolling Cooling device and heat straightening machine. The thick plate rolling line of the present invention can increase the maximum rolling length to 100m, and break through the limitation that the maximum billet length cannot exceed the effective roll body length, and can produce longer billets, and the rolling unit weight is significantly improved; the rolling rhythm of the steel plate, The width accuracy of the steel plate has been significantly improved.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

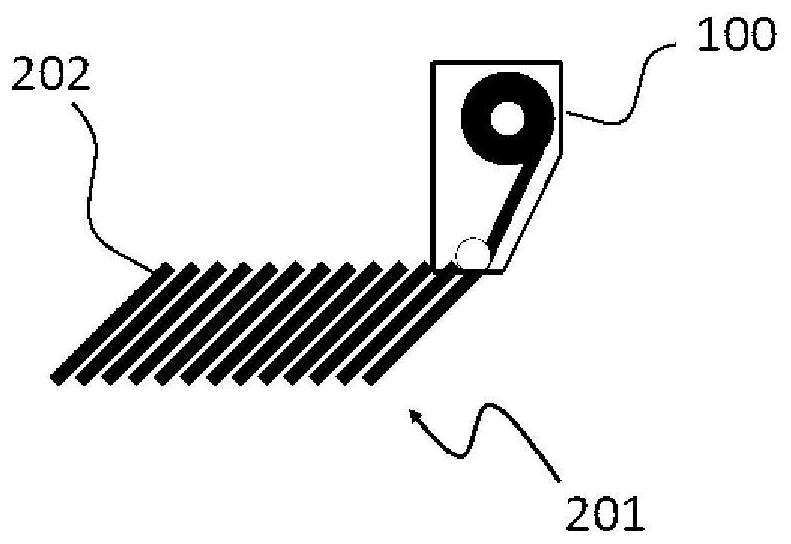

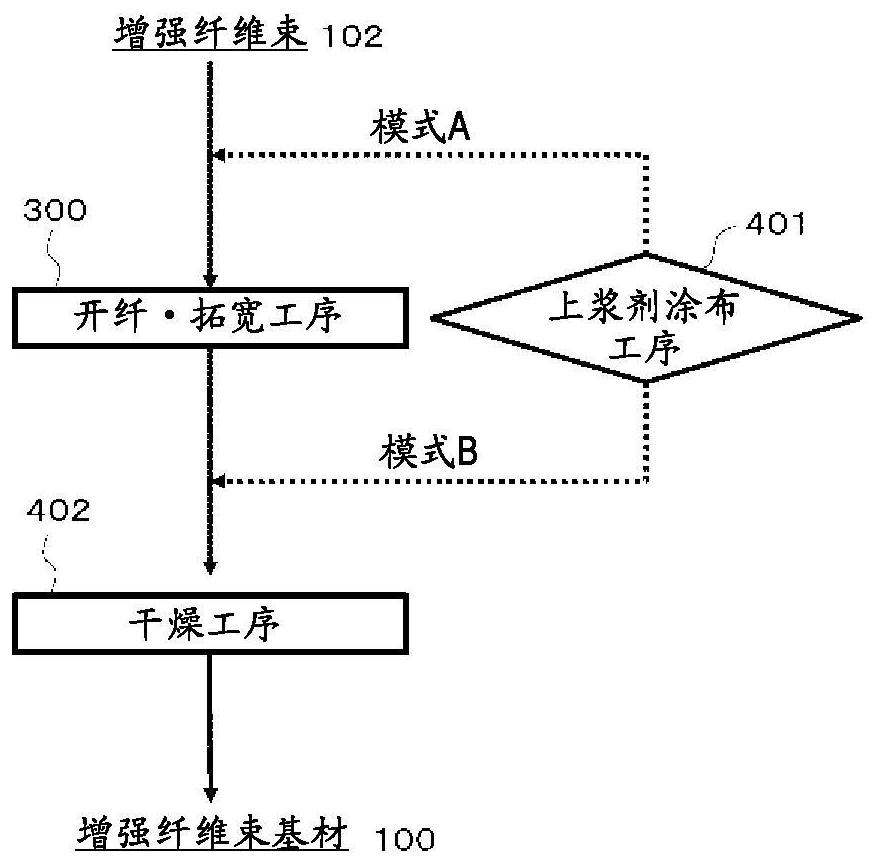

Reinforced fiber bundle base material and manufacturing method thereof, and fiber-reinforced thermoplastic resin material using same and manufacturing method thereof

ActiveCN111565902BNo reaggregationGood relaxing effectCarbon fibresWoven fabricsPolymer scienceFiber bundle

A reinforcing fiber bundle base material, wherein a sizing agent containing at least a polyamide-based resin is attached to the surface of the reinforcing fiber, and the number of fibers per unit width contained in the reinforcing fiber bundle is 600 or more per mm and less than 1,600 / mm, and the drape value of the reinforcing fiber bundle is not less than 120 mm and not more than 240 mm. Also, a method for producing a reinforcing fiber bundle base material, a fiber-reinforced thermoplastic resin material using a reinforcing fiber bundle base material, and a method for producing the same. We provide reinforced fiber bundle base materials with excellent shape stability and impregnation properties that can be applied to various molding methods such as fiber placement and fiber-reinforced thermoplastic resin molding materials.

Owner:TORAY IND INC

Width Control Method for Longitudinal and Transversal Rolling of Medium and Heavy Plate

ActiveCN105290116BImprove width precisionAvoid calculation errorsMetal rolling stand detailsRoll mill control devicesThick plateHorizontal and vertical

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

A kind of production method of hot dipped steel coil

ActiveCN103103538BOvercome the defect of low width precisionImprove width precisionHot-dipping/immersion processesNiobiumManganese

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Edge trimmer for printing

InactiveCN102294704BAdjustable spacingImprove applicabilityMetal working apparatusLow noiseProduction line

The invention relates to an edge trimmer for printing, which comprises a transmission device, a cutting device, a display control device, a collection guide device and a collection device which are all arranged on a rack. A front and a rear turning rolls are adopted to guide plates to be divided into rim charges at both sides and a finished plate in the middle under the action of an adjustable upper and an adjustable lower blades, the rim charges at the two sides are limited by a steering wheel, and are automatically collected by the collection device, so real-time longitudinal fixed width trimming without stopping the trimmer is realized, the edge trimmer is convenient to operate, can realize edge trimming and forming at one time without secondary edge trimming, has high trimmed plate width precision, low noise, a long service life, safety and reliability, and can be widely applied in online automatic edge trimming of the coordinated test program (CTP) plate, the computer to conventional plate (CTCP), the process status (PS) plate and other barrel production lines at various speeds.

Owner:JIANGSU ZHONGKEDA PRINTING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com