A trimming machine for printing

A technology of trimming machine and frame, which is applied in metal processing and other directions, can solve the problems of different plate sizes, low work efficiency, time-consuming and laborious, etc., and achieve the effect of fast plate width information, convenient cutting adjustment, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

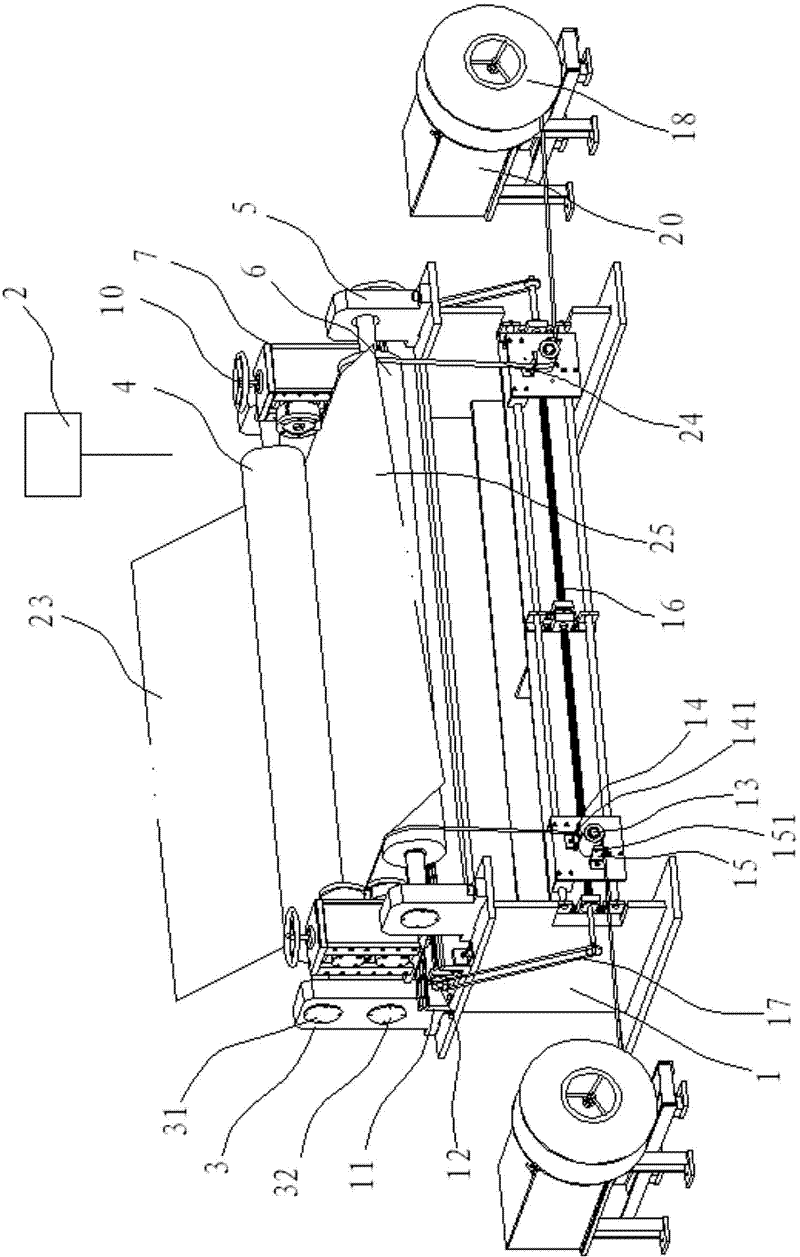

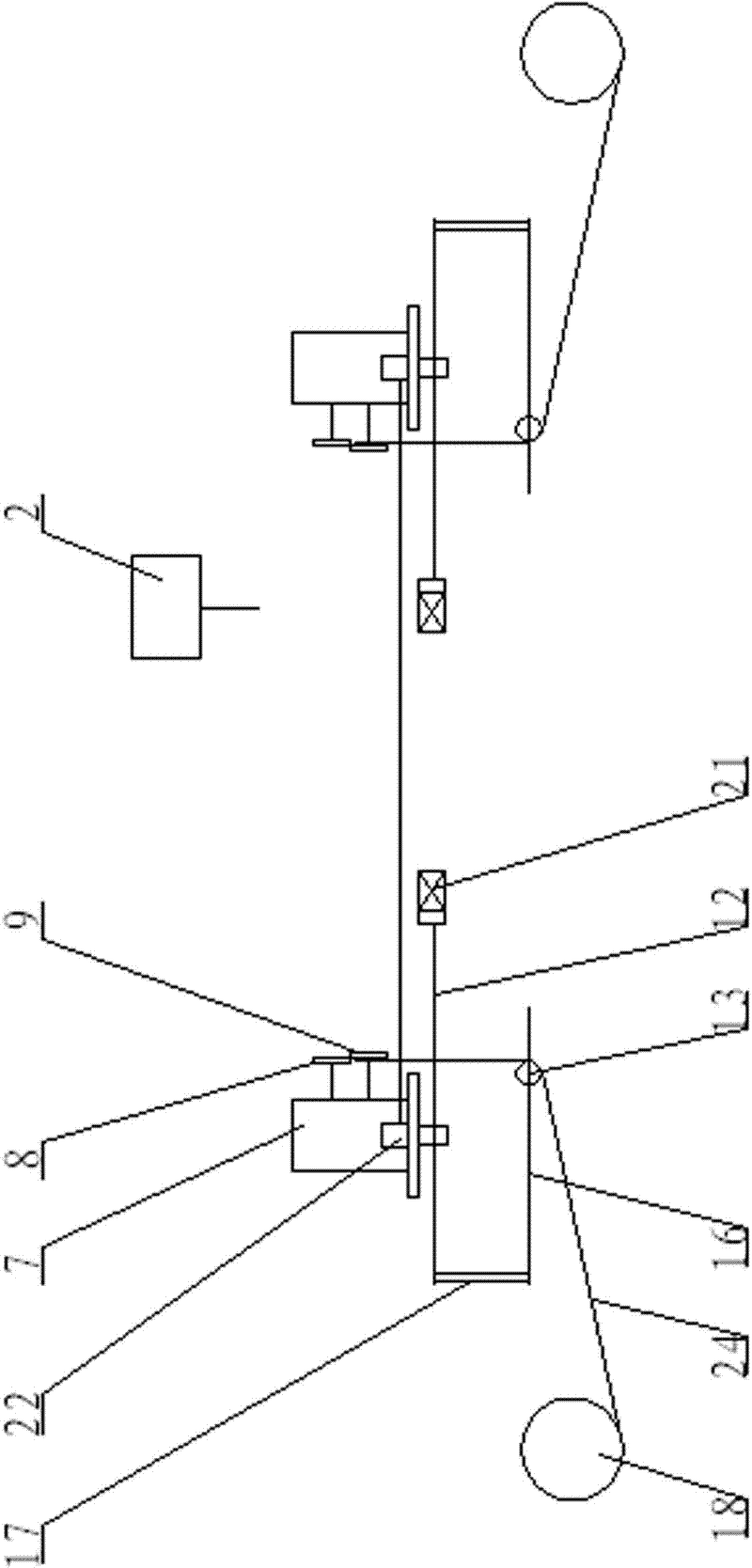

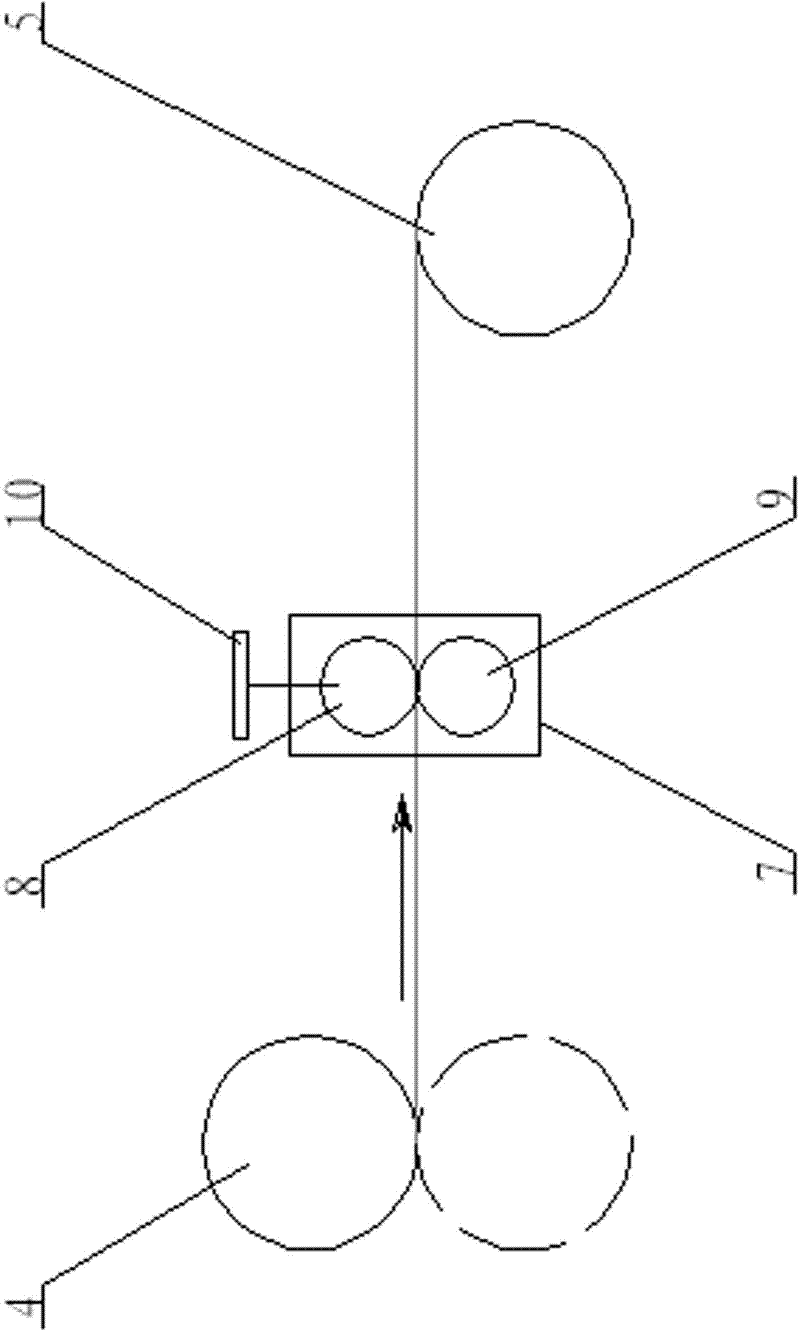

[0022] Figure 1-4 As shown, a printing trimming machine includes a frame 1, a display control device 2, a front steering roller bracket 3, a front steering roller 4, a rear steering roller bracket 5, a rear steering roller 6, a knife rest assembly, a track base 11, Knife rest screw mandrel 12, steering wheel screw mandrel 16, synchronous belt 17, material receiving guiding device and material receiving device. Two front steering roller brackets 3 and two rear steering roller brackets 5 are respectively provided at the front and rear of the two ends of the frame 1, and the upper and lower mounting holes 31, 32 arranged up and down are arranged on the two front steering rollers 3, and the front steering rollers 4 Both ends are supported and installed in any one of the upper and lower mounting holes, and the two ends of the rear steering roller 5 are supported on the rear st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com