Slicing device capable of adjusting thickness

A technology of slicing device and thickness adjustment, applied in metal processing and other directions, can solve the problems of troublesome sample feeding and unloading, high price, sliding, etc., to achieve the effect of adjustable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing. But the content of the present invention is not limited thereto.

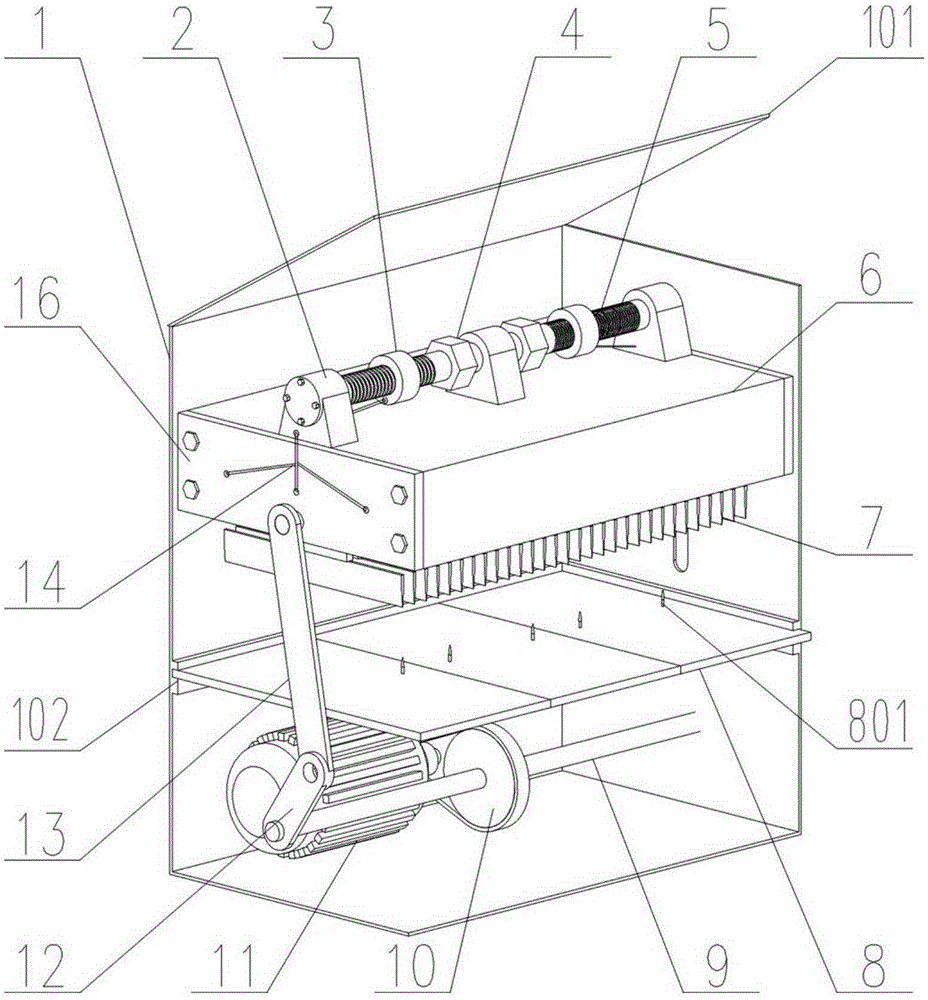

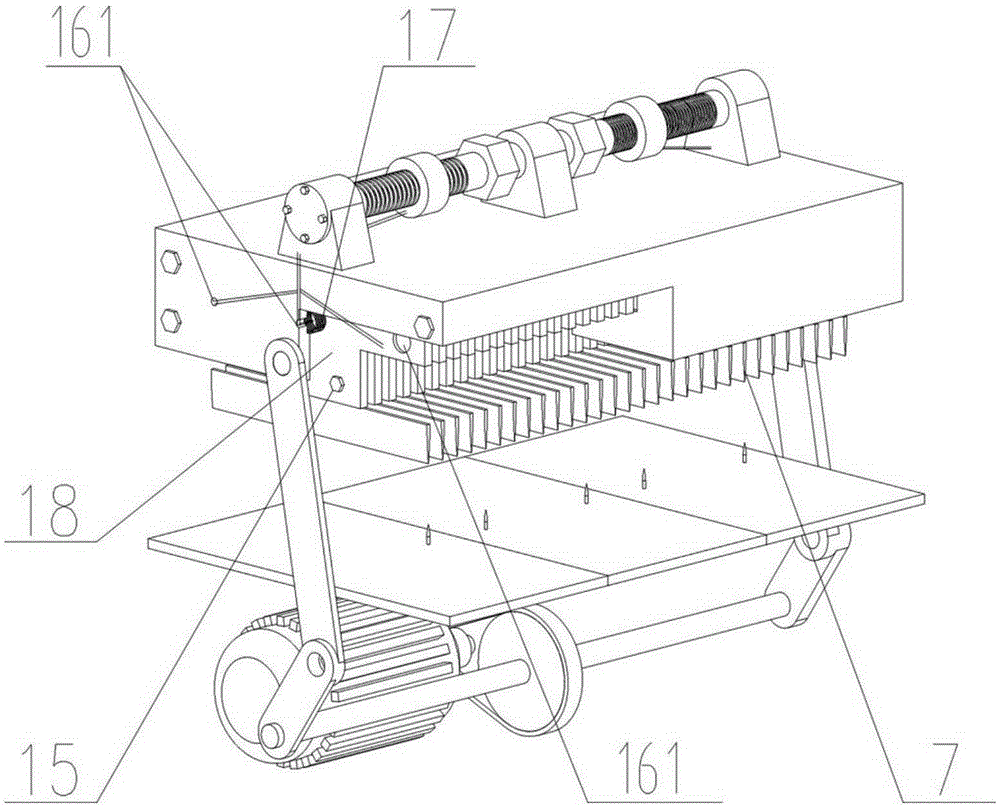

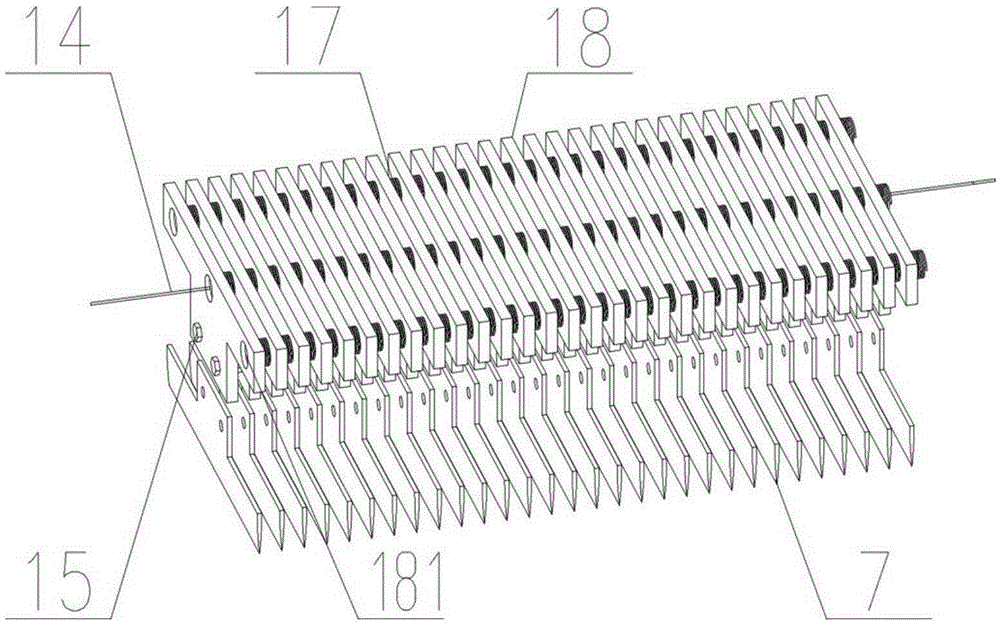

[0031] Such as Figure 1~4 Among them, a slicing device with adjustable thickness includes a cutter device, a thickness adjusting device and a lifting drive device arranged in a box body 1; a box cover 101 is hingedly arranged on the box body 1 . The cutter device includes a plurality of knife seats 18 sleeved on the slide bar side by side, and a spring set 17 is provided between the plurality of knife seats 18 through a spring seat 181 , that is, a spring is arranged between each knife seat 18 . In a preferred solution, a plurality of knife seats 18 are movably connected with the slide bar, and each knife seat 18 slides along the slide bar. The knife holders 18 located at both ends are connected with the thickness adjusting device through a stay cord 14;

[0032] The knife seat 18 is fixedly provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com