Method of preparing phase-change energy-accumulation material microemulsion

A phase change energy storage material and technology of energy storage material, which are applied in the field of preparation of phase change energy storage material microemulsion, can solve the problems of thermodynamic instability, phase separation, demulsification, etc. Specific heat capacity, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

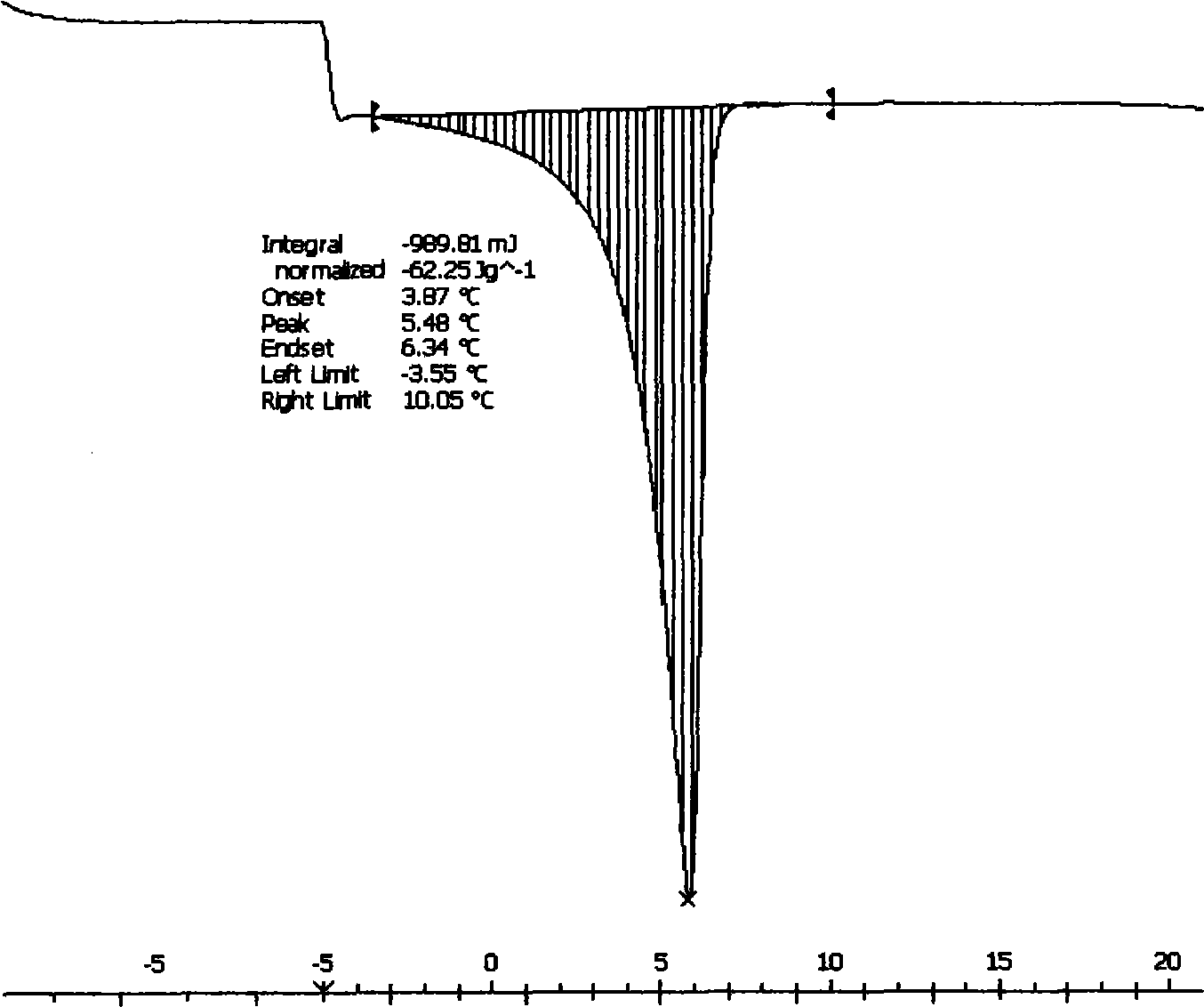

Image

Examples

Embodiment 1

[0025] At 40°C, add 6g of 20 to a 250ml three-neck flask # Phase-change paraffin, 0.82g Span80, 1.32gTween80, 1.54g n-butanol, 0.48g NaCl, 50g distilled water, stirred at 400rpm for 5min, left to stand until the bubbles were completely eliminated (about 15min), and the product was completely transparent light yellow O / W type microemulsion. Phase change energy storage material (20 in this example) in the microemulsion # The content of phase change paraffin) is 10wt%.

Embodiment 2

[0027] At 50°C, add 6g of 30 to a 250ml three-neck flask # Phase change paraffin, 0.75g Span20, 1.25g emulsifier OP10, 1.62g n-butanol, 0.42g NaCl, 50g distilled water, stir at 500rpm for 5min, let it stand until the bubbles are completely eliminated (about 15min), the product is completely transparent shallow Yellow O / W microemulsion. Phase change energy storage material (30 in this example) in the microemulsion # The content of phase change paraffin) is 10wt%.

Embodiment 3

[0029] At 30°C, add 12g tetradecane, 0.9g Span65, 1.55g Pingpingjia, 1.62g n-pentanol, 0.52g NaCl, 56g deionized water into a 250ml three-necked flask, stir at 400rpm for 15min, and let it stand until the bubbles are completely Elimination (about 15min), the product is a completely transparent colorless O / W microemulsion. The content of the phase change energy storage material (tetradecane in this example) in the microemulsion is 20wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com