Patents

Literature

286 results about "Tetradecane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetradecane is an alkane hydrocarbon with the chemical formula CH₃(CH₂)₁₂CH₃. Tetradecane has 1858 structural isomers.

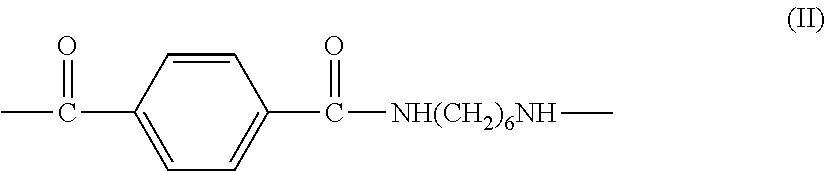

Salt resistant polyamide compositions

Polyamides made from 1,6-hexanediamine, and the dicarboxylic acids 1,10-decandioic acid, 1,12-dodecanedioic acid, or 1,14-tetradecanedioic acid and terephthalic acid in specified proportions are particularly resistant to salt stressed (induced) corrosion cracking. This makes them particularly useful as vehicular parts which may be exposed to salts. Particularly when these polyamides contain tougheners and / or plasticizers they are especially useful for hoses and tubes.

Owner:EI DU PONT DE NEMOURS & CO

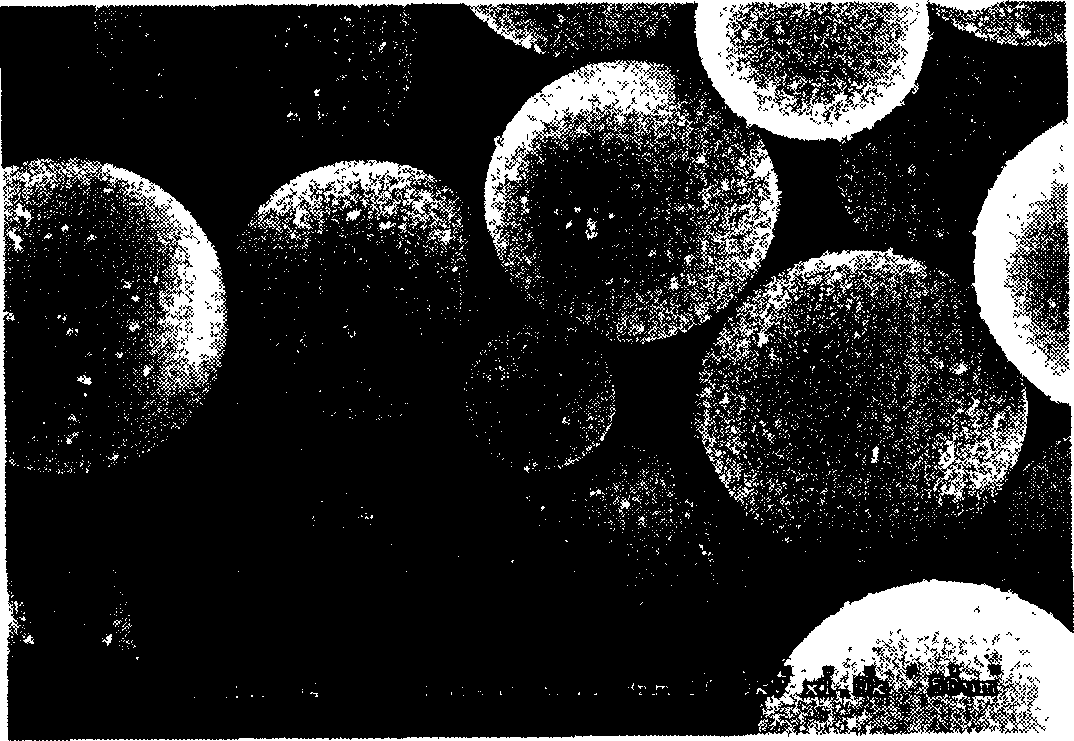

Phase change energy storage microcapsule of composite shell and its making method

InactiveCN1570014ASmooth and dense surfaceComplete appearanceHeat-exchange elementsMicroballoon preparationHexadecaneComposite construction

The invention discloses a phase change energy storage microcapsule of composite shell and its making method, wherein the core material of the microcapsule employs tetradecane, pentadecane or hexadecane, the shell layer has a composite construction, the inner layer is melamine resin, the outer layer is PEG200 modified melamine resin, or PEG200 modified melamine, or copolycondensation resin of methyl poultry manure amine, acetyl poultry manure amine or benzene substituted melamine.

Owner:TIANJIN UNIV

Fixed shape phase-change material based on tetradecane and method for producing the same

ActiveCN101423749AKeep shapeMaintain strengthHeat-exchange elementsPolymer scienceWorking temperature

The invention discloses a figuration phase change material based on tetradecane. The figuration phase change material is formed by mixing and processing the tetradecane with the mass percentage between 30 and 80 percent and the balance being a polymer framework material, wherein the polymer framework material is one or a combination of polyethylene (PE), styrene-butadiene-styrene copolymer (SBS) or styrene-isoprene-styrene copolymer (SIS). The invention has the tetradecane absorbed and / or wrapped in the specific polymer material as a framework. Because the polymer material as the framework can not be deformed in the working temperature range (20 below zero to 40 DEG C for example) of the tetradecane, the shape of the material can be kept, and the problems about collapse or flowing and leakage can not occur. Therefore, the obtained figuration phase change material can be widely applied to the low-temperature preservation and transportation of medicines, foods and the like.

Owner:FIELD OPERATION BLOOD TRANSFUSION INST OF PLA SCI ACAD OF MILITARY

700V high-voltage aluminum electrolytic capacitor electrolyte

InactiveCN106252079AHigh molecular weightLow mobilityLiquid electrolytic capacitorsSalicylic acidGluconic acid

Disclosed is a 700V high-voltage aluminum electrolytic capacitor electrolyte. The electrolyte comprises 50-80% of main solvent, 20-50% of auxiliary solvent, 5-20% of main solute, 2-10% of auxiliary solute, 0.1-1% of auxiliary additive and 5-15% of spark additive, wherein the main solute comprises one or more of azelaic acid, ammonium hydrogen azelate, ammonium sebacate, decane dicarboxylic acid, 7, 9-dimethyl-7, 9-dimethoxy carbonyl-1, 11-dodecane dicarboxylic acid, and 7, 8-dimethyl-7, 8-dimethoxy carbonyl-1, 14 tetradecane dicarboxylic acid; and the auxiliary solvent comprises one or more of ammonium salicylate, salicylic acid, oxalic acid, malonic acid, succinic acid, ammonium benzoate, ammonium maleate, ammonium hydrogen maleate, ammonium adipate and hexanedioic acid. The spark voltage of the electrolyte is greater than 700V; and in addition, the electrolyte is simple to prepare, stable in performance and excellent in related parameters.

Owner:HUNAN AIHUA GRP

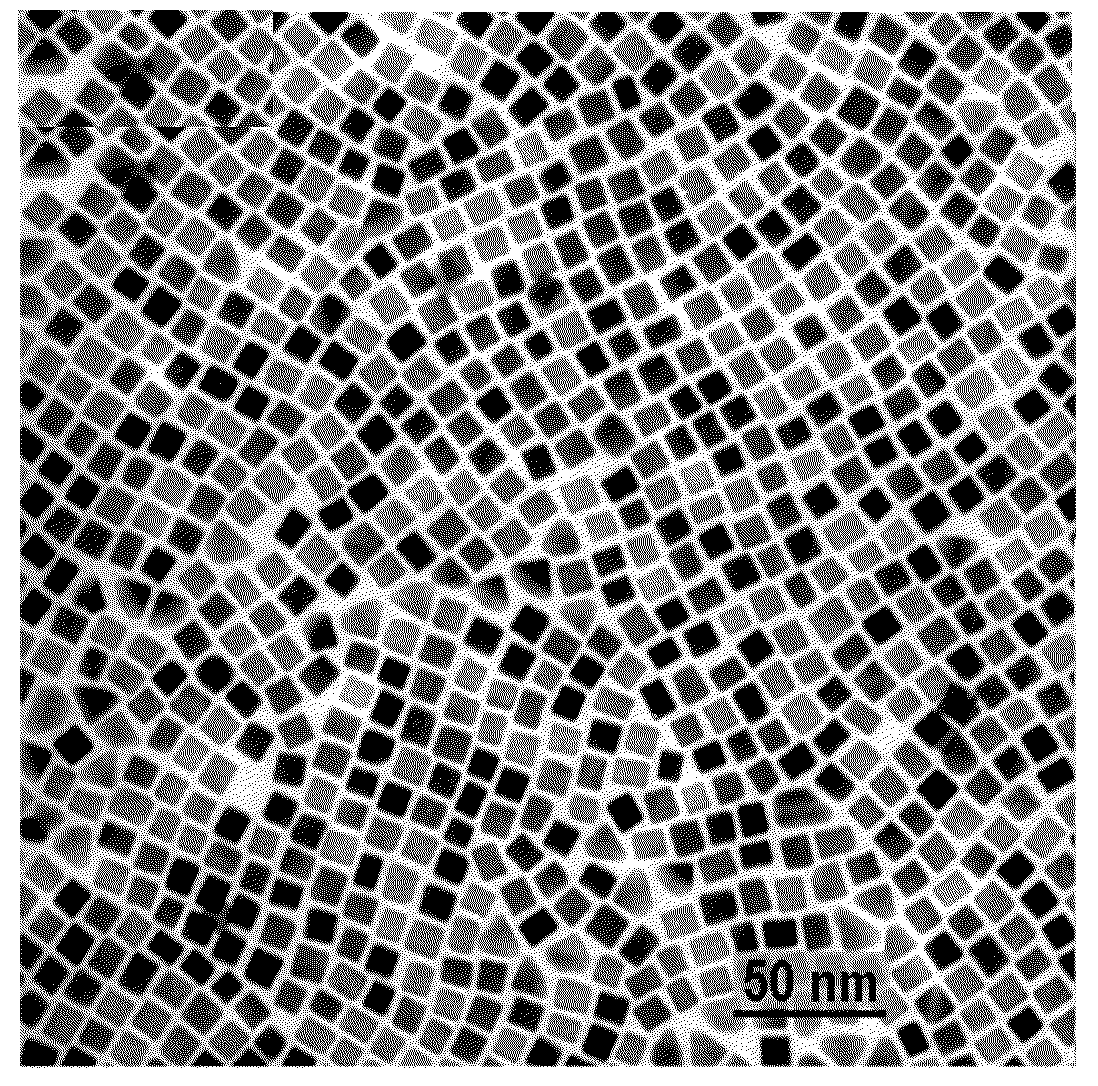

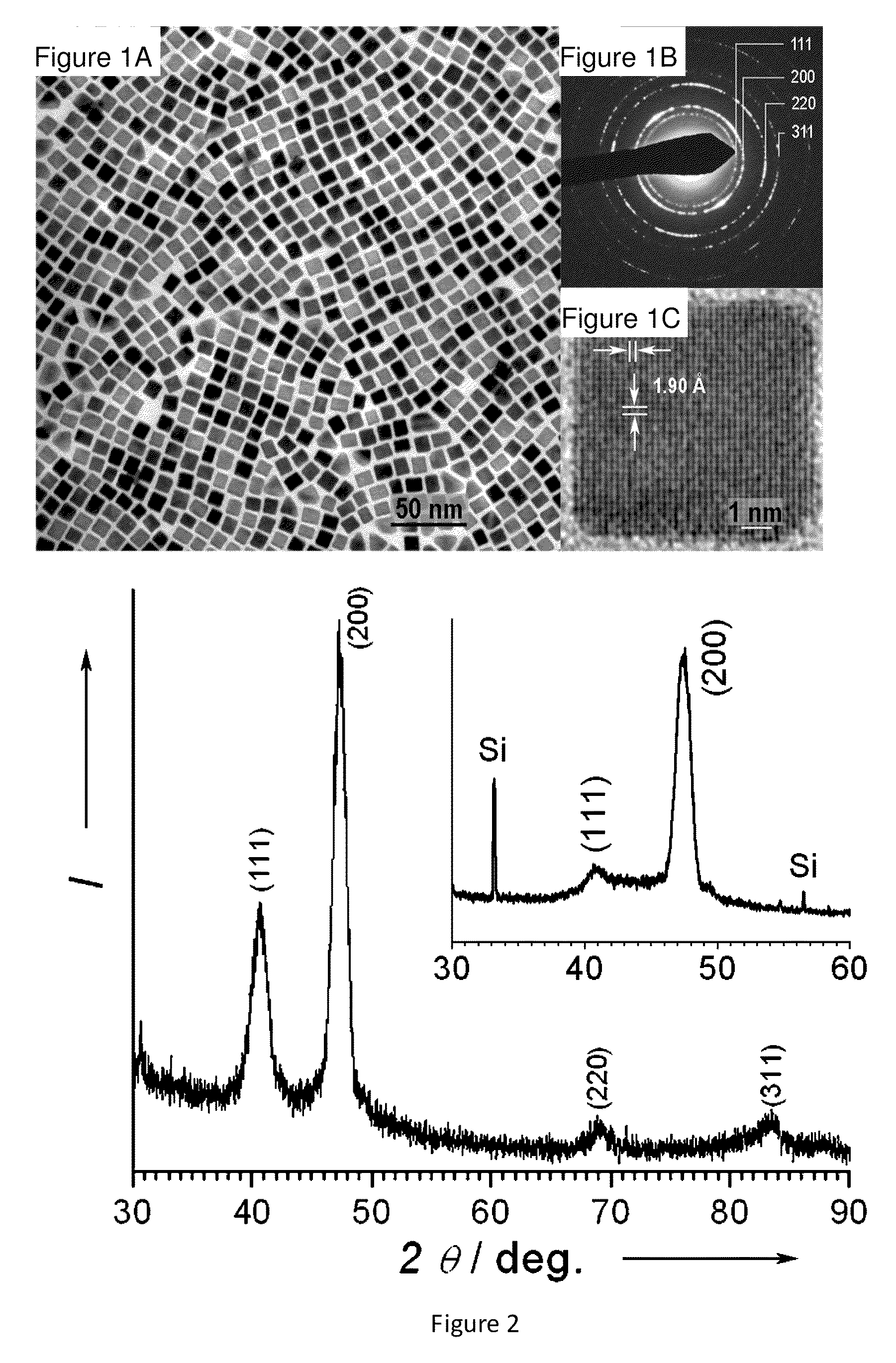

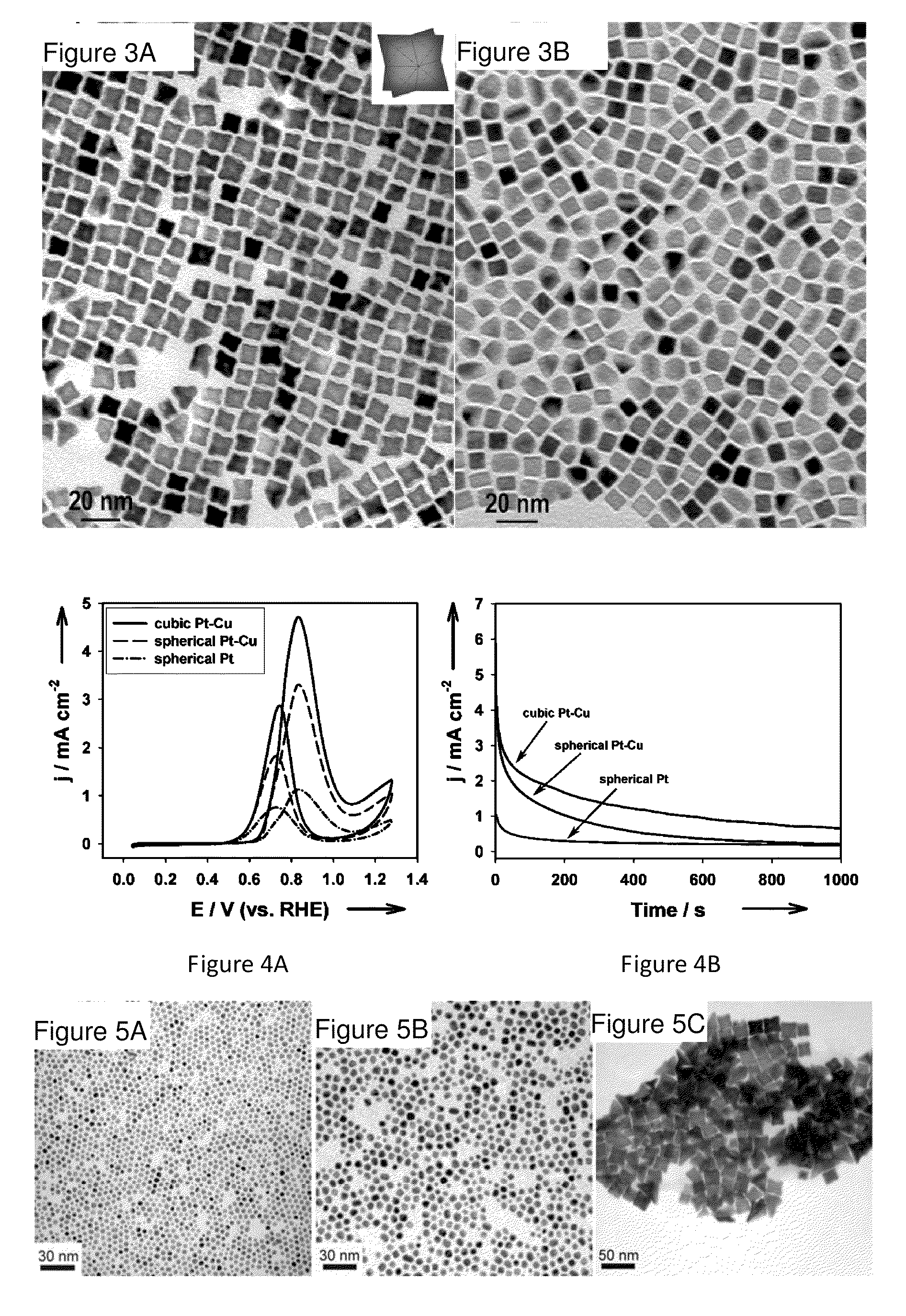

Catalytic platinum-copper alloy nanoparticles

High-quality bimetallic PtxCu100-x (x=54-80 at. %) nanocubes can be prepared from a hot organic solution. Synthetic conditions, such as the ratio of oleylamine / tetraoctylammonium bromide as well as the doses of 1-dodecanethiol and 1,2-tetradecanediol have been optimized to ensure a formation of Pt—Cu nanocubes. Electrochemical evaluation shows that the catalytic activity of Pt60Cu40 nanocubes for methanol oxidation is superior, in comparison with those of spherical Pt60Cu40 nanocubes and Pt nanocubes with similar sizes, implying that the {100}-terminated Pt60Cu40 nanocubes offer a higher activity for methanol oxidation reaction than those with mixed crystallographic facets do. As another example, it was identified that Pt80Cu20 nanocubes is the best electrocatalyst on the basis of the maintainable electrocatalytic activity (which is even slightly superior to that of pure Pt nanocubes) and remarkable long-term stability (˜300 hours vs 3 hours for Pt nanocubes) when being performed towards formic acid oxidation reaction.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

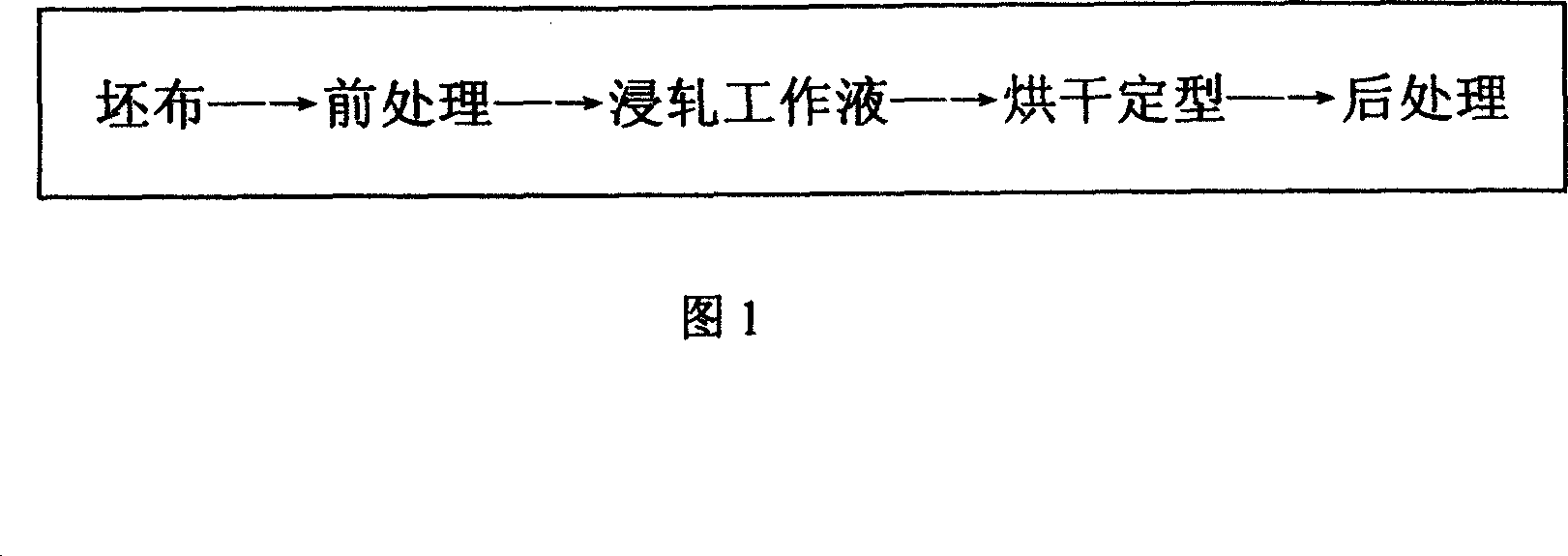

Method for preparing bidirectional thermal-adjustable fabric with phase change polyurethane heat-sensitive material microcapsule

InactiveCN1966846AMeet different requirements for temperature comfortReduce the difficulty of productionFibre treatmentMicroballoon preparationFiberHeat sensitive

The phase change polyurethane heat sensitive microcapsule dual thermoregulation material starts with making microcapsules in wrapping heat sensitive material with polyurethane, then sticks the microcapsule to the fiber surface of fabrics, with the heat sensitive materials being mixed by one or more of the tetradecane, octacontane, arachidonic acid, and docosane. It can control body temperature within certain range through dual thermal control. It can be used in the production of any kind of fiber dual thermal control material with less difficulty for manufacturing.

Owner:华明浩

Multifunctional viscose with functions such as temperature regulation and bacterium resistance, preparation method of viscose and fabric

PendingCN110284209AStable temperatureProtect human healthArtificial filaments from viscoseViscosePhase-change material

The invention provides a multifunctional viscose with functions such as temperature regulation and bacterium resistance, a preparation method of the viscose and a fabric. The multifunctional viscose comprises a graphene component and phase-change microcapsule particles; the phase-change microcapsule particles comprise polymer capsule walls and phase-change materials embedded in the polymer capsule walls; the phase-change materials are selected from one or more of n-tetradecane, n-pentadecane, n-hexadecane, n-heptadecane, n-octadecane, n-nonadecane, n-eicosane and polyethylene glycol E600. According to the multifunctional viscose, by mainly using the heat storage function of the phase-change materials and the heat conduction function of graphene, the viscose can regulate the temperature and balance the heat. The graphene component has the bacterium resistance and far-infrared transmission capacities. When the multifunctional viscose is used as the garment fabric, the temperature and humidity micro-environment of the human body can keep balance, the human body keeps a good and comfortable wearing environment as long as possible, the multifunctional viscose has the bacterium resistance function, and the health of the human body is protected.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

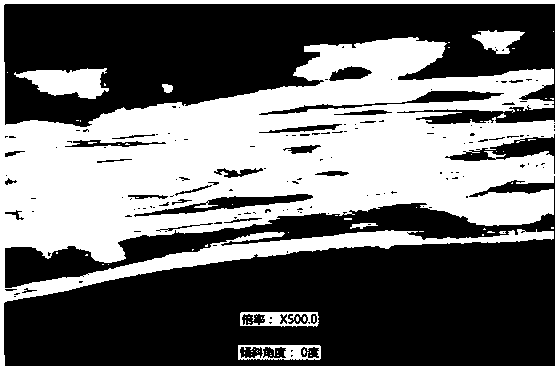

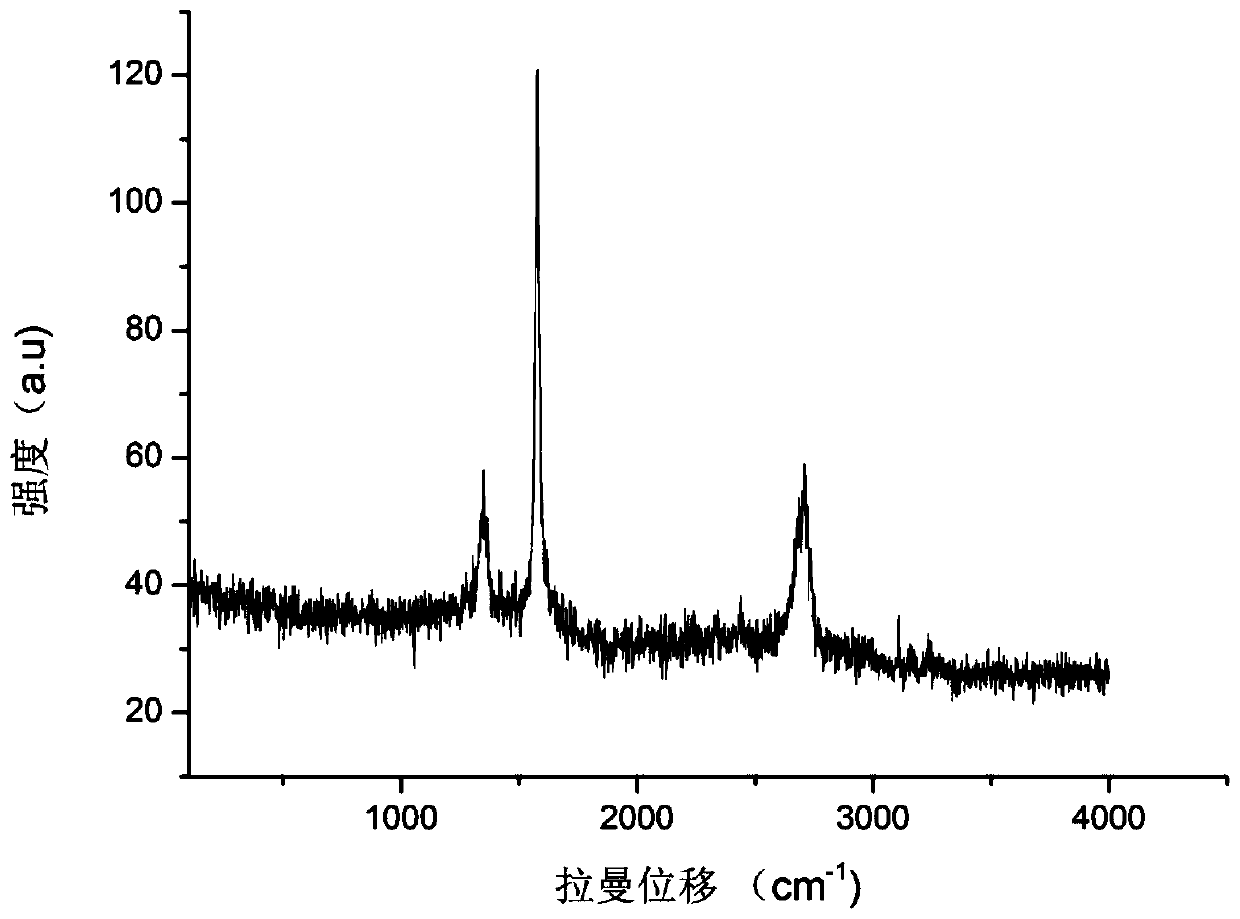

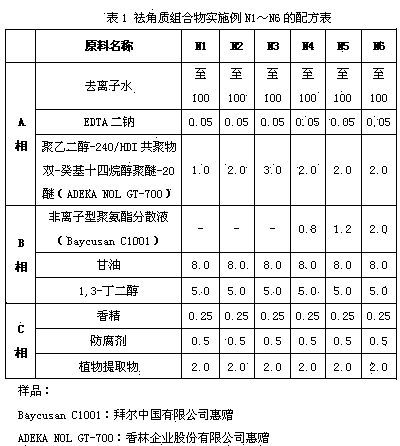

Non-ionic composition used for removing keratin and preparation method of non-ionic composition

ActiveCN103705428ABrighten the appearanceGood experienceCosmetic preparationsToilet preparationsPolymer scienceCutin

The invention relates to a non-ionic composition used for removing keratin. The non-ionic composition comprises the following components by weight percent: 0.5-5% of non-ionic polyurethane dispersion liquid, 0.5-5% of non-ionic emulsifier, 0.5-5% of plant extract, 5-20% of moisturizer and the balance of deionized water and additive, wherein the non-ionic emulsifier is polyethylene glycol-240 / hexamethylene diisocyanate copolymer dual-decyl tetradecane alcohol polyether-20 ether; active ingredient in the plant extract is gallogen. According to the non-ionic composition, the non-ionic polyurethane dispersion liquid is used as a film-forming agent to be twisted, the non-ionic emulsifier is used for thickening, non-ionic safe raw material is adopted, feeling is close to skin, a zwitterion complex doe not need to be formed, matrix with low pH value is not needed, and the non-ionic composition is safe, non-irritation, bright white in appearance, smooth and elastic, good in use experience feeling, obvious in immediate effect, moderate and safe, and has the effect of softening the keratin for a long time.

Owner:SHANGHAI INOHERB COSMETIC

Method for improving hydrophilicity of polypeptide membrane by using polylactic acid and polyacrylic acid

The invention discloses a method for improving the hydrophilicity of a polypeptide membrane by using polylactic acid and polyacrylic acid. The method comprises the following steps: (1) adding a polypeptide homopolymer, diisocyanate, a catalyst and a solvent into a dry reactor, reacting for 40-50 minutes at the temperature of 40-50 DEG C, and then, removing superfluous diisocyanate by a dialysis method, so as to obtain a polypeptide homopolymer containing terminal -NCO groups; (2) adding the polypeptide homopolymer containing terminal -NCO groups, a catalyst and a solvent into a dry reactor, then, adding polylactic-acid mono tetradecyl ether, and reacting for 50-60 minutes at the temperature of 40-50 DEG C, so as to obtain a polypeptide-polylactic acid diblock copolymer; (3) adding the polypeptide-polylactic acid diblock copolymer, polyacrylic acid and a solvent into a dry reactor, stirring and mixing for 60-70 minutes at the temperature of 40-50 DEG C, then, carrying out membrane forming by a tape casting method, and drying, thereby obtaining a target product of the method. According to the method, the preparation process is simple, and the hydrophilicity of the obtained modified membrane is improved greatly.

Owner:SHANDONG UNIV OF TECH

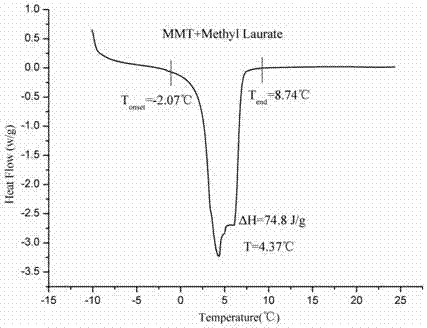

Preparation method of clay-based composite phase-change energy storage deicing (snow melting) material

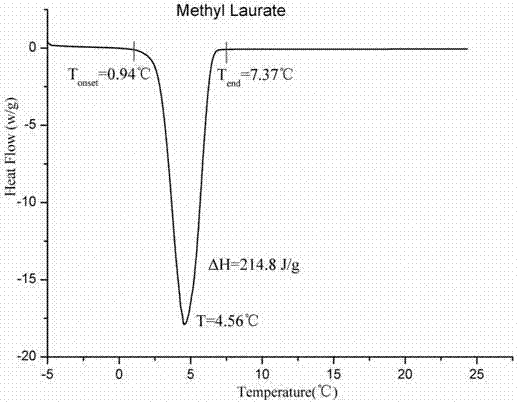

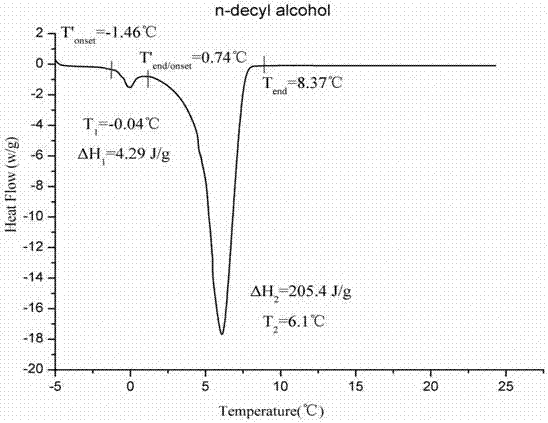

The invention discloses a preparation method of a clay-based composite phase-change energy storage deicing (snow melting) material. The preparation method is characterized in that a composite phase-change energy storage material is prepared from a low-temperature organic phase-change material and a clay material, wherein the low-temperature organic phase-change material is prepared by single-element or multi-element mixing of various organic phase-change materials and is then physically compounded with the treated clay to prepare the clay-based composite phase-change energy storage deicing (snow melting) material. The low-temperature organic phase-change material is selected from polyethylene glycol-300, polyethylene glycol-400, polyethylene glycol-500, polyethylene glycol-600, decyl alcohol, undecanol, dodecanol, heptylic acid, octanoic acid, nonanoic acid, capric acid, methyl laurate, methyl myristate, methyl palmitate, tetradecane, pentadecane, hexadecane, heptadecane, octodecane, nonadecane and the like. The clay material is selected from kaolinite, montmorillonite, bentonite, vermiculite, halloysite, sepiolite, attapulgite, perlite, diatomite, rectorite, zeolite, silicon dioxide, dolomite, calcite and illite. The prepared composite phase-change energy storage deicing (snow melting) material is proper in phase-change temperature (0-5 DEG C), high in phase-change latent heat and high in heat stability.

Owner:CENT SOUTH UNIV

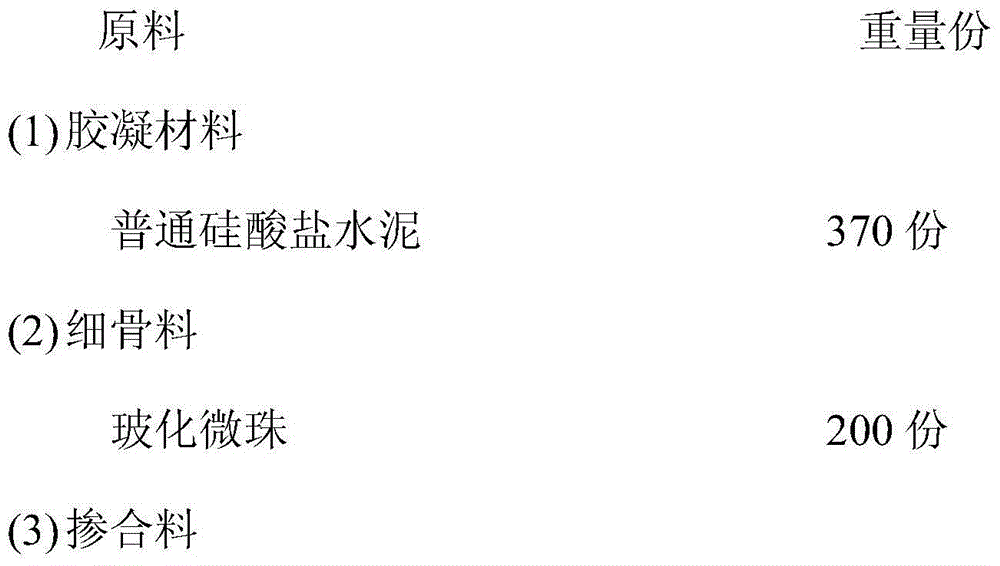

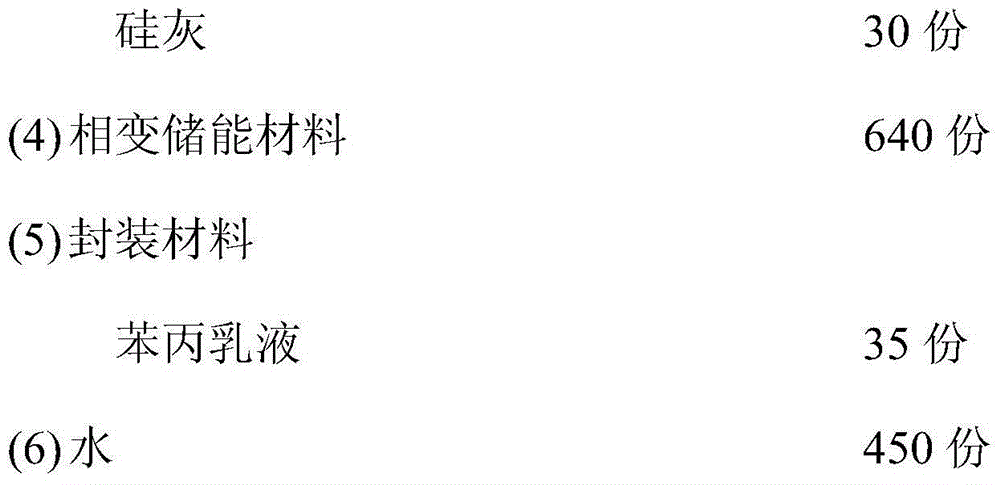

Phase-change and energy-storage mortar of ternary composite paraffin/glazed hollow beads and preparation method of phase-change and energy-storage mortar

InactiveCN104446238AEfficient storageStable and reliable storageHeat-exchange elementsCrack resistanceThermal insulation

The invention relates to a thermal insulation mortar material and a preparation method thereof, and particularly relates to a phase-change and energy-storage mortar of ternary composite paraffin / glazed hollow beads, which has good thermal insulation properties and is capable of improving the energy utilization rate and adjusting the indoor temperature, and a preparation method of the phase-change and energy-storage mortar. The phase-change and energy-storage mortar of the ternary composite paraffin / glazed hollow beads is prepared from the following raw materials: 370-380 parts of 42.5-level ordinary portland cement, 30-35 parts of silica fume, 200-240 parts of glazed hollow beads, 420-460 parts of water, 30-50 parts of a styrene-acrylic emulsion, and 600-750 parts of mixed paraffin which is compounded by 3# liquid paraffin, normal tetradecane and solid sliced paraffin of which the melting point is 48-50 DEG C at the ratio of 1 to 2 to 7 in a physical blending manner. Compared with ordinary mortar, the heat retaining property, the crack resistance, the weather fastness and the like of the mortar are improved; the fluctuation range of indoor temperature can also be retarded; the duration of indoor comfort temperature is increased; the living comfortability is improved; energy storage and utilization are achieved by effectively utilizing latent heat of phase change of the phase-change material; and energy sources are saved.

Owner:SHENYANG JIANZHU UNIVERSITY

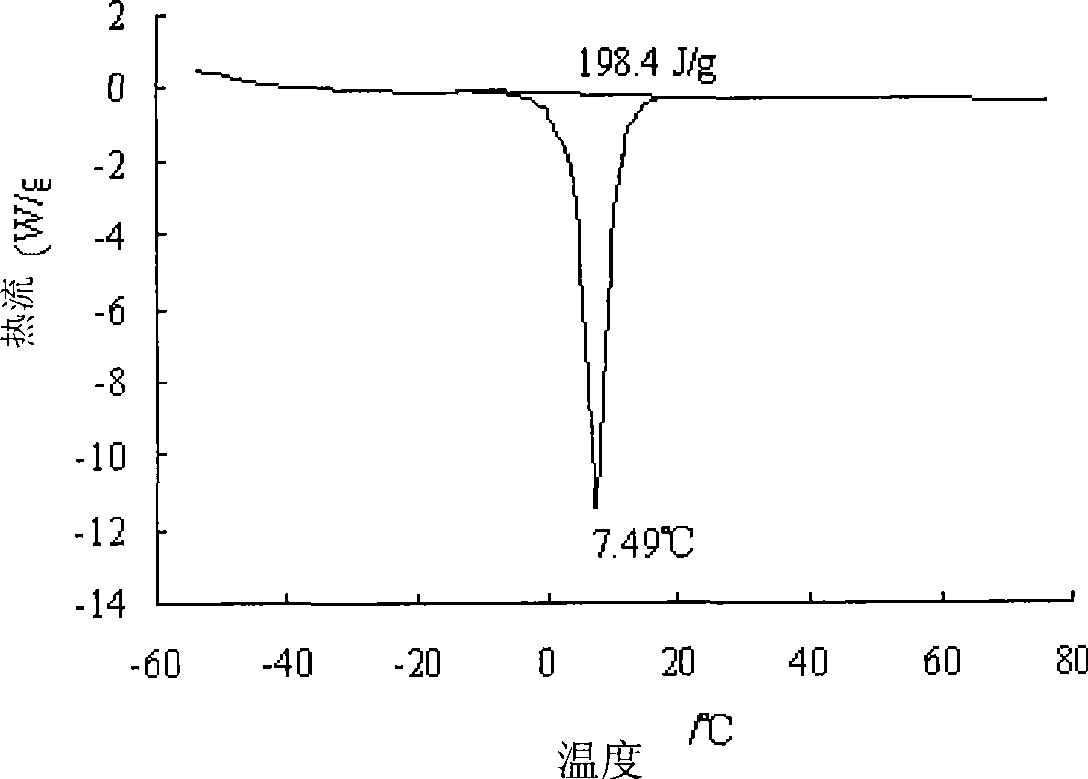

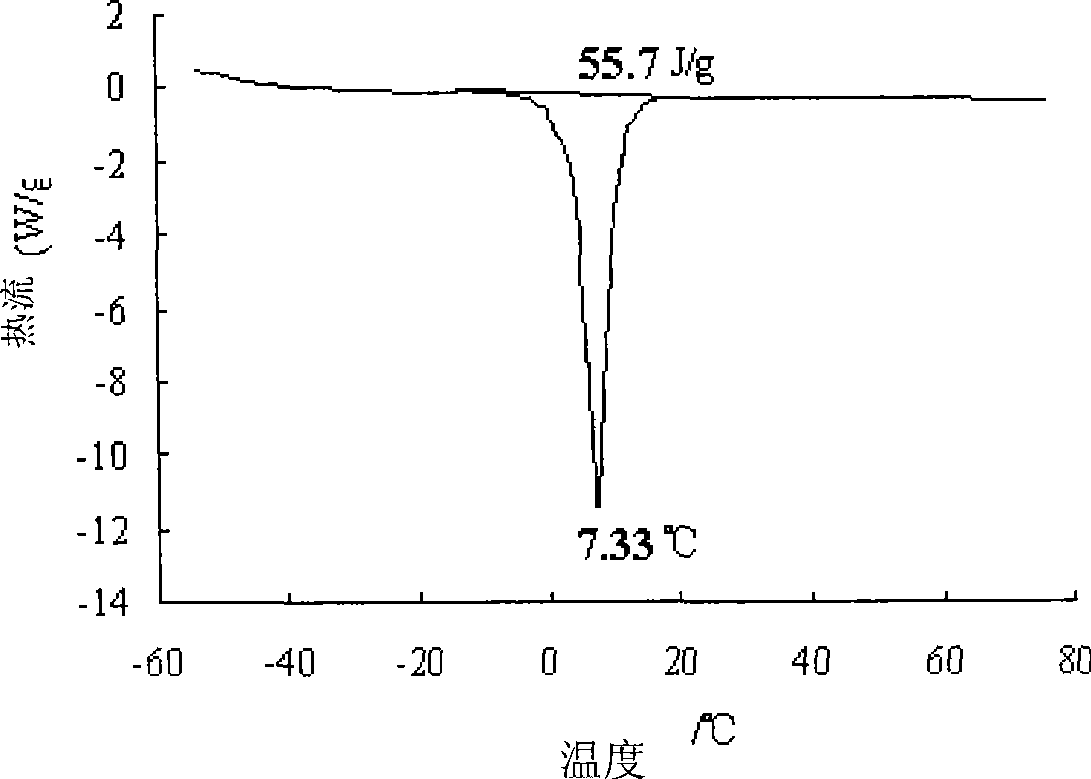

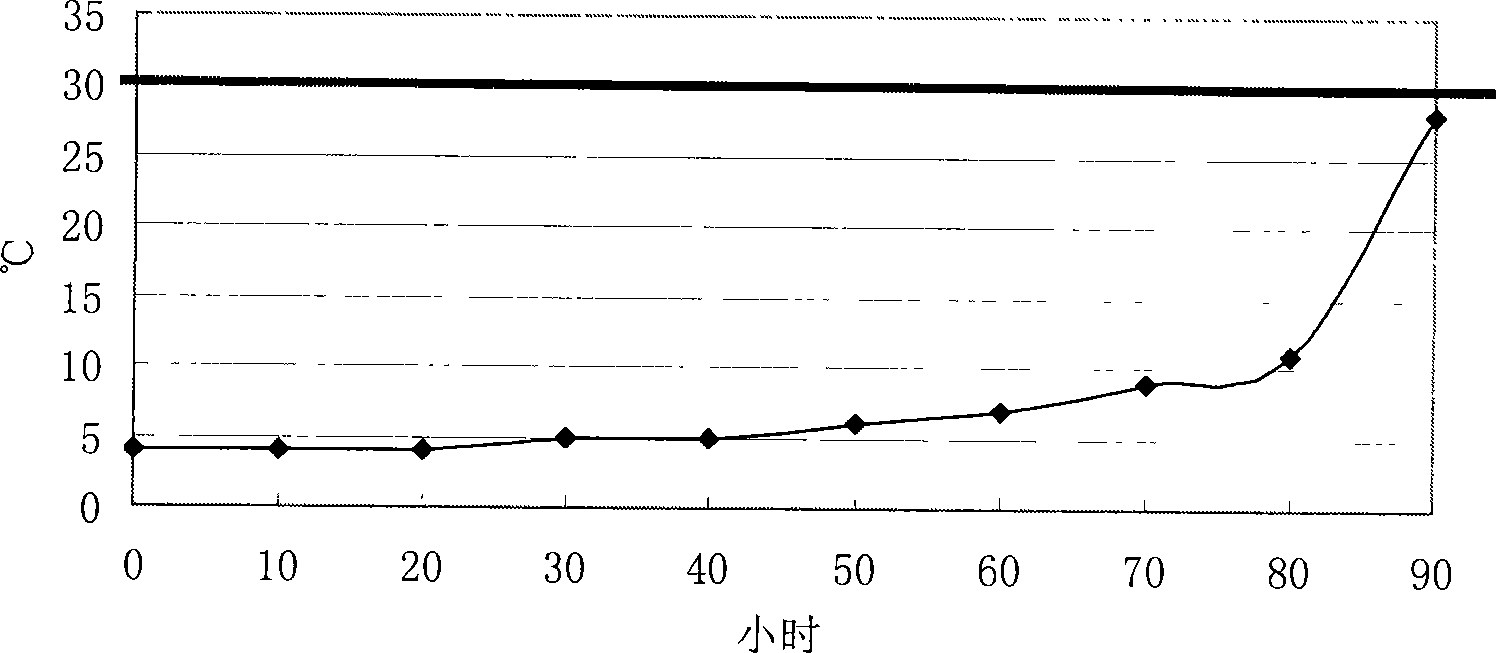

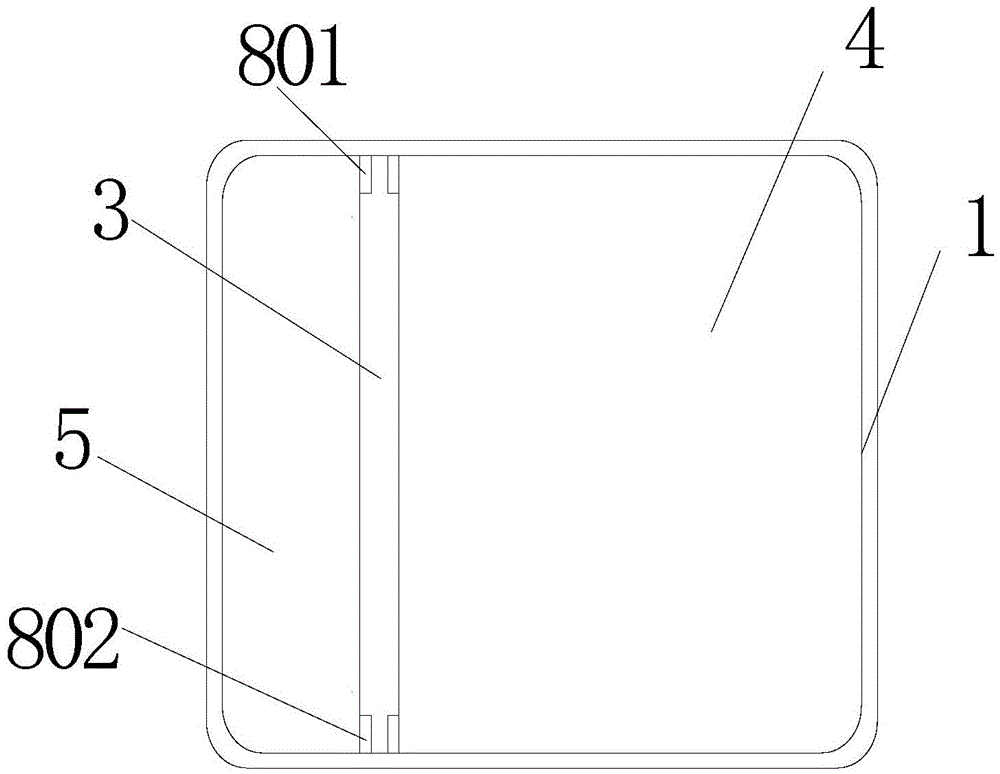

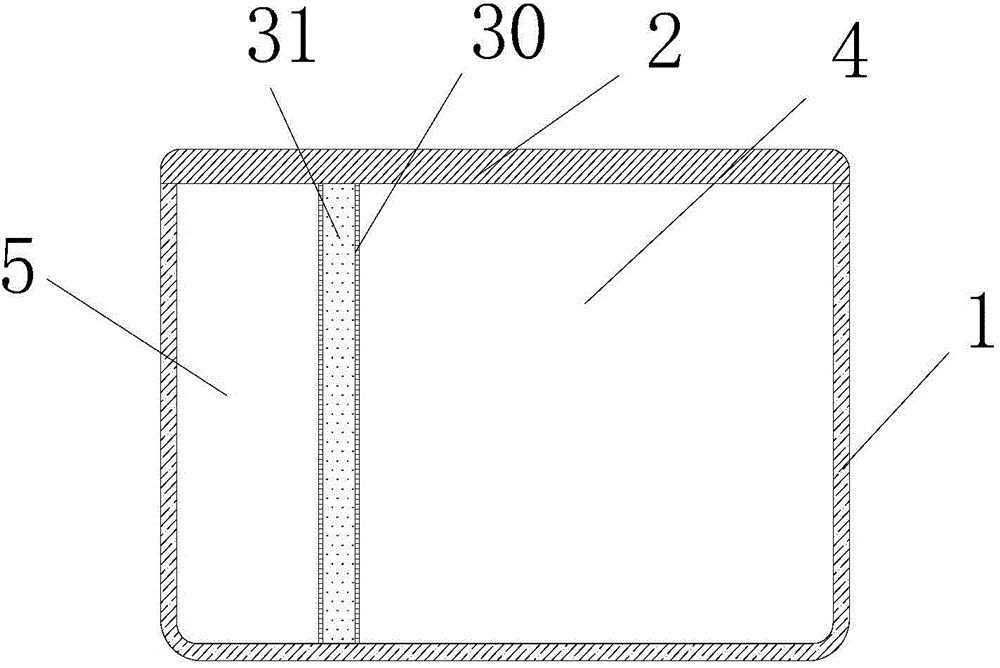

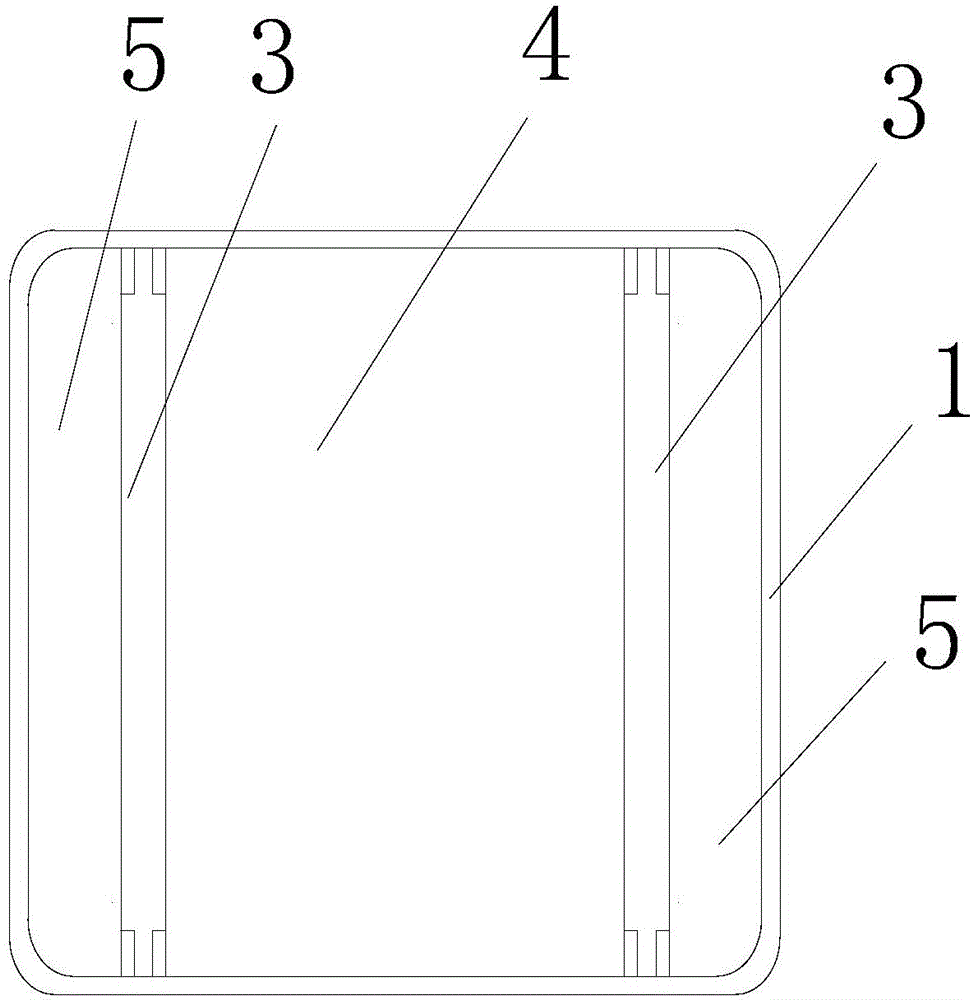

Medicine thermal insulation box with precise temperature control function, thermal insulation method and novel application of tetradecane

InactiveCN104816883AIncrease temperatureImprove qualityHeat-exchange elementsShock-sensitive articlesTemperature controlAnti freezing

The invention discloses a medicine thermal insulation box with a precise temperature control function, a medicine thermal insulation method, and a novel application of tetradecane. The medicine thermal insulation box with the precise temperature control function comprises a thermal insulation box body having a containing chamber, and an upper thermal insulation box cover which can be covered on the thermal insulation box body. The containing chamber is divided into a medicine containing chamber and a cold source containing chamber by a heat accumulation partitioning board. The heat accumulation partitioning board comprises a housing, and a heat accumulation agent which is sealed inside the housing and is of a phase-change temperature of 3-7 degrees centigrade. The medicine thermal insulation box with the precise temperature control function or the medicine anti-freezing thermal insulation method can utilize the heat energy of the heat accumulation agent to neutralize the cold energy of the cold source; in the process of delivering the heat energy, the heat accumulation agent can be solidified and discharge the heat energy when the temperature of the heat accumulation agent drops to the phase-change temperature, so as to further neutralize the cold energy of the cold source, thereby preventing the medicine from being frozen due to the excessively low temperature.

Owner:北京优冷冷链科技有限公司

Preparation method of polypeptide-poly trimethylene carbonate-MPEGPLA (mono-methoxyl poly(ethylene glycol)-poly(lactic acid) dual-graft copolymer

The invention discloses a preparation method of a polypeptide-poly trimethylene carbonate-MPEGPLA (mono-methoxyl poly(ethylene glycol)-poly(lactic acid) dual-graft copolymer. The preparation method adopts the following steps: 1) adding a polypeptide homopolymer, poly trimethylene carbonate mono-tetradecyl ether, a solvent and a catalyst to a drying reactor, and stirring the materials at 55-58 DEG C to react for 2-3 days in the inert atmosphere, thus obtaining a polypeptide-poly trimethylene carbonate graft copolymer; 2) adding the polypeptide-poly trimethylene carbonate graft copolymer, the catalyst, the solvent and MPEGPLA to the drying reactor, and stirring the materials at 55-58 DEG C to react for 2-3 days in the inert atmosphere, thus obtaining the target object. The preparation method is simple in process, and the obtained target object is a novel degradable biological material.

Owner:SHANDONG UNIV OF TECH

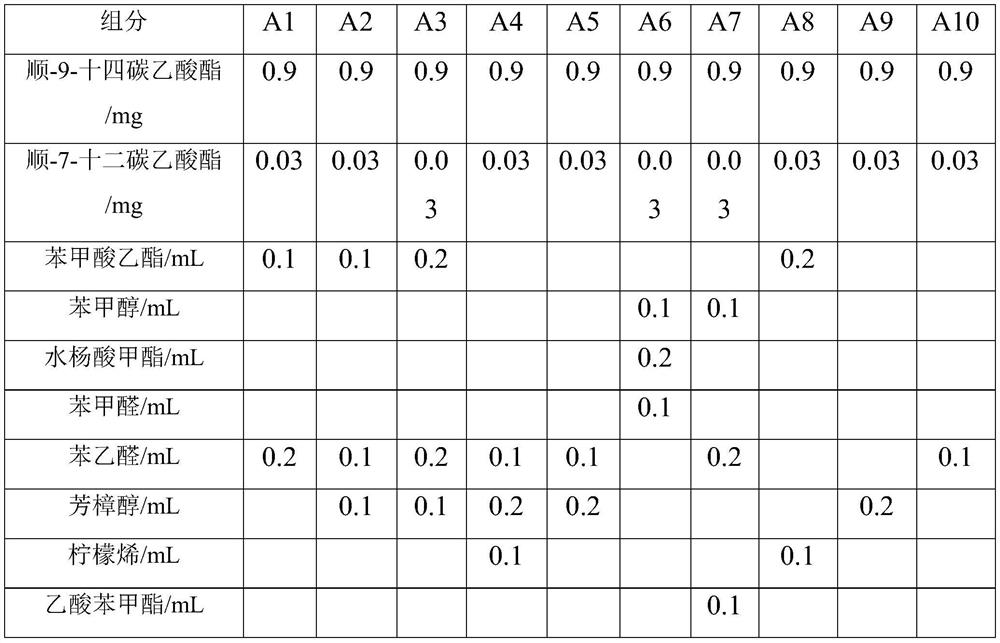

Grassland spodoptera litura adult attractant and trapping device containing attractant

ActiveCN111685118AGood lure effectSolve the difficulty that is hard to lureBiocidePest attractantsBenzoic acidDodecane

The invention relates to a grassland spodoptera litura adult attractant based on a plant volatile matter and a trapping device comprising the grassland spodoptera litura adult attractant. The grassland spodoptera litura adult attractant is composed of a sex attractant and the plant smell volatile matter. The sex attractant is prepared from cis-9-tetradecane acetate and cis-7-dodecane acetate; theplant smell volatile matter is one or more of ethyl benzoate, benzyl alcohol, methyl salicylate, benzaldehyde, phenylacetaldehyde, limonene, linalool and benzyl acetate. The adult attractant for the grassland spodoptera litura has a good attracting effect on the grassland spodoptera litura through synergistic interaction of the sex attractant and the plant smell volatile matter, can attract part of female insects, can be used for monitoring and large-area prevention and control of the grassland spodoptera litura, and has a good application prospect.

Owner:漳州市英格尔农业科技有限公司

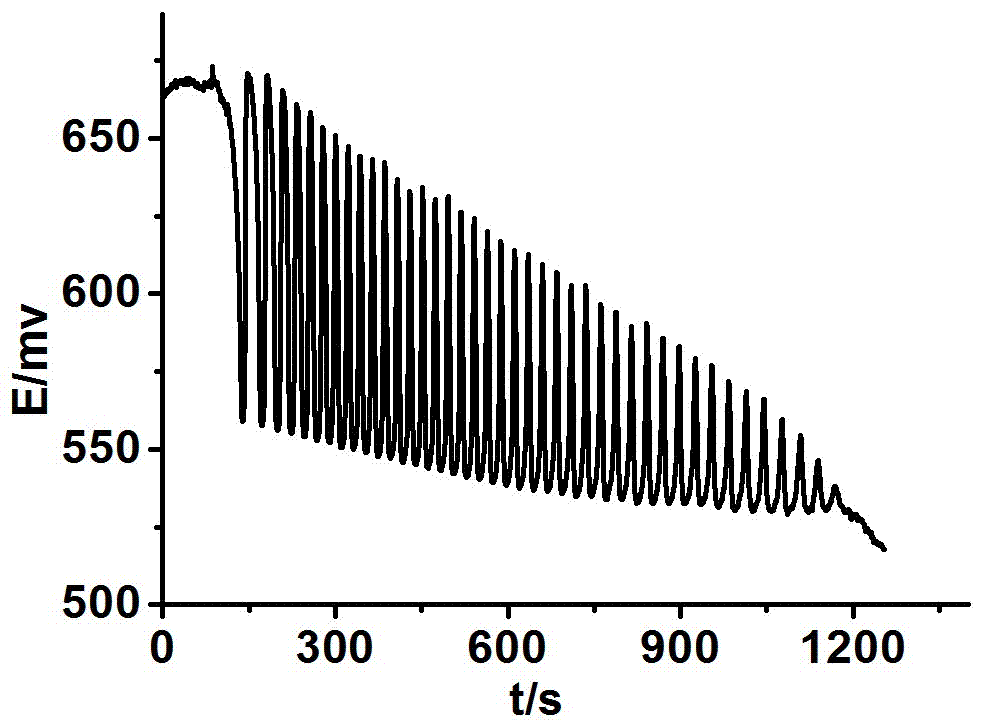

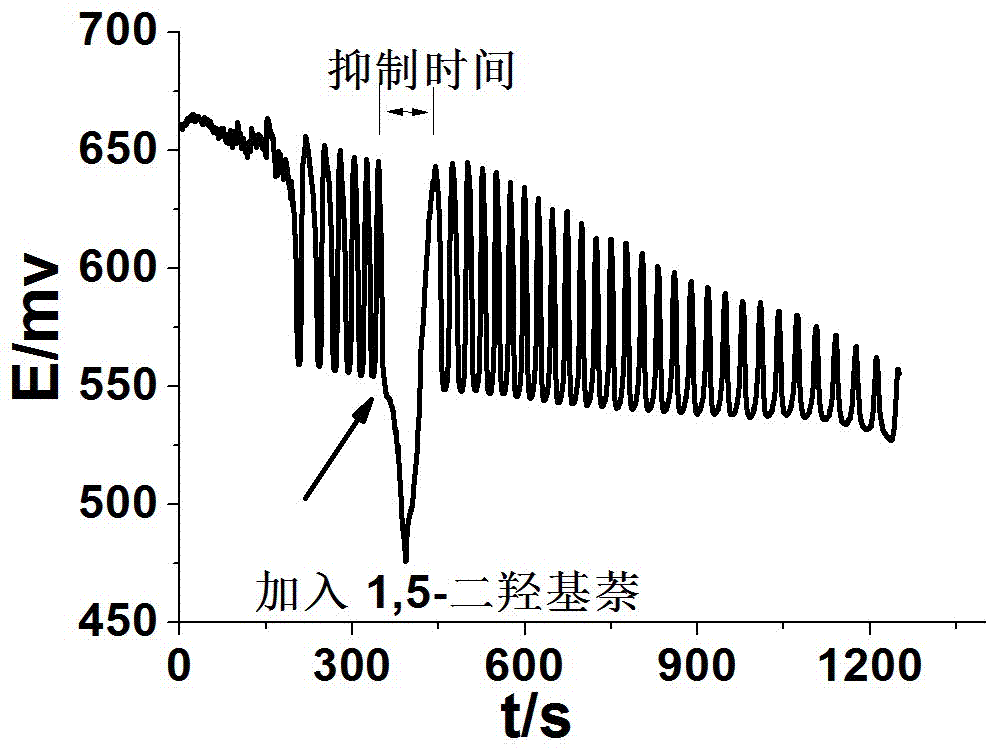

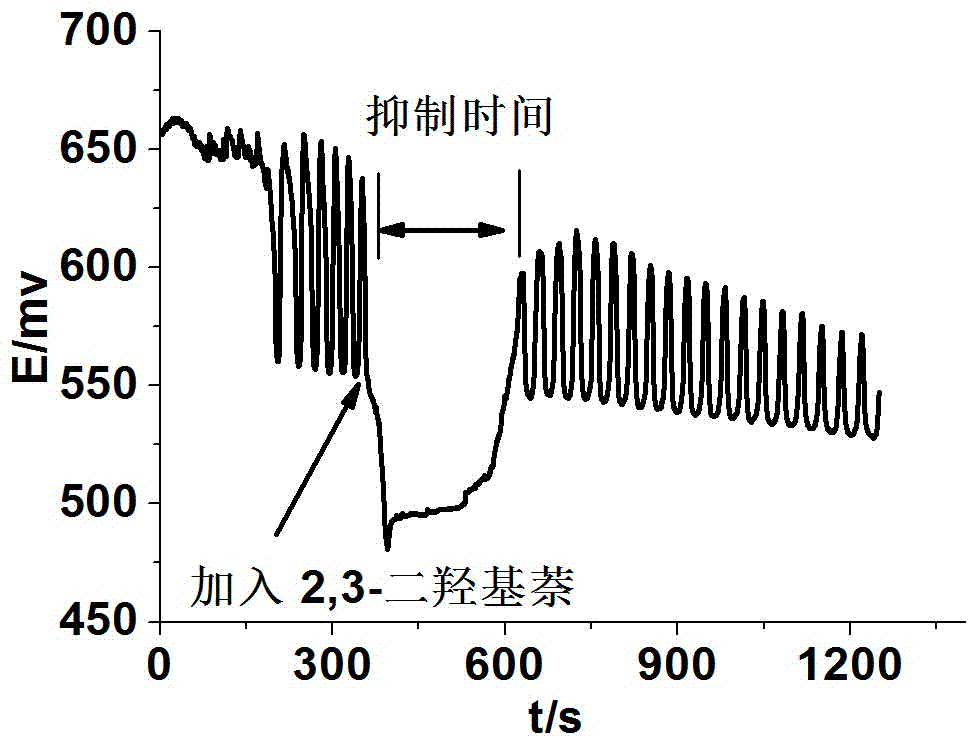

Method for identifying four kinds of dioxynaphthalene isomeride

The invention discloses a method for identifying four kinds of dioxynaphthalene isomeride. The method is characterized in that an H2SO4-KIO3-[NiL](ClO4)2-propane diacid-H2O2 nonlinear chemical oscillation system is utilized as identifying solution, and the four kinds of dioxynaphthalene isomeride can be further identified according to different oscillation responses generated by the four kinds of dioxynaphthalene isomeride of 1,5-dioxynaphthalene, 2,3-dioxynaphthalene, 2,7-dioxynaphthalene and 1,4-dioxynaphthalene. The L in the [NiL](ClO4)2 is 5,7,7,12,14,14-hexamethyl-1,4,8,11-tetraaza tetradecane-4,11-diene. An oscillation pattern provided by the identifying method has more intuition, not only can conveniently and quickly identify the four kinds of dioxynaphthalene isomeride of 1,5-dioxynaphthalene, 2,3-dioxynaphthalene, 2,7-dioxynaphthalene and 1,4-dioxynaphthalene, but also can be further widely applied to other isomeride; furthermore, the identifying method is simple in equipment and high in accuracy, and is easy to operate and observe.

Owner:ANHUI UNIVERSITY

Corrosion-resistant, moisture-resistant and wear-resistant paint for ships and preparation method thereof

InactiveCN104312412AImprove water resistanceImprove corrosion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsCarbon fibersAluminum silicate

The invention discloses corrosion-resistant, moisture-resistant and wear-resistant paint for ships and a preparation method thereof. The corrosion-resistant, moisture-resistant and wear-resistant paint is prepared from 30-36 parts by weight of aliphatic polyurethane acrylate resin, 14-16 parts by weight of vinisol, 5-7 parts by weight of self-crosslinked acrylic emulsion, 0.4-1.0 part of glycerol monolaurate, 0.3-0.6 parts by weight of nanometer ferroferric oxide, 0.3-0.6 parts by weight of methyl benzimidazolecarbamate, 0.3-0.5 parts by weight of tetrachloroisophthalonitrile, 3-5 parts by weight of polyacrylate, 2-3 parts by weight of ricinoleic acid, 2-3 parts by weight of aluminum triphosphate, 2-3 parts by weight of carbon fibers, 4-6 parts by weight of vinyltriamine, 8-11 parts by weight of modified waste clay-bonded sand, 12-14 parts by weight of modified asphalt, 2-3 parts by weight of ultrafine alumina silicate, 5-7 parts by weight of xylene, 7-10 parts by weight of n-tetradecane, 6-8 parts by weight of butyl acetate and 1-2 parts by weight of cobalt-manganese-rare earth alloy. The vinisol used in the paint for ships can improve paint film water resistance, corrosion resistance and toughness. The used carbon fibers have good acid and alkali corrosion resistance. The used modified waste clay-bonded sand can solve the problem of environmental pollution and can improve paint film wear resistance and prolong a service life. The used modified asphalt improves paint corrosion resistance, adhesion, oxidation resistance and weatherability. Therefore, the corrosion-resistant, moisture-resistant and wear-resistant paint has excellent moisture resistance and wear resistance.

Owner:TIANCHANG JULONG TRAVEL PAINT

Electric spark processing liquid

An electric spark processing liquor belongs to the technical field of electric discharge processing liquor which is formed by mixing solvent oil and tetradecane alkane according to a weight percentage of 1:1 to 2.5. One advantage of the electric spark processing liquor provided by the invention is that the service life can reach 16 to 30 months; a second advantage is that a flash point (cut) can reach 105 to 110 DEG C; a third advantage is that content of aromatic hydrocarbon is low which is equal to or lower than 0.5 percent and the viscosity is suitable with movable viscosity of 2.1mm<2>s.

Owner:CHANGSHU ZHOUHANG RUNDA CHEM FACTORY

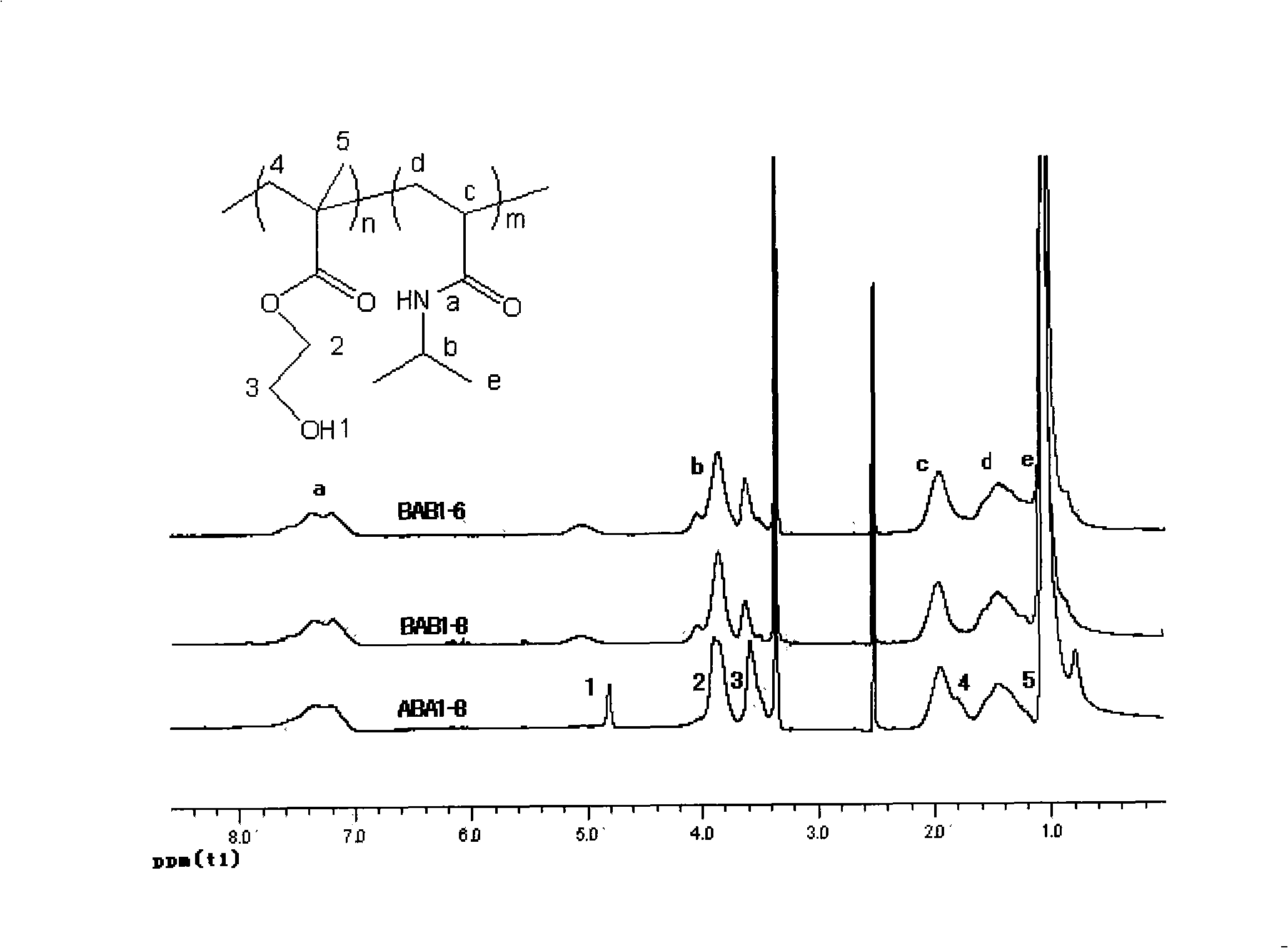

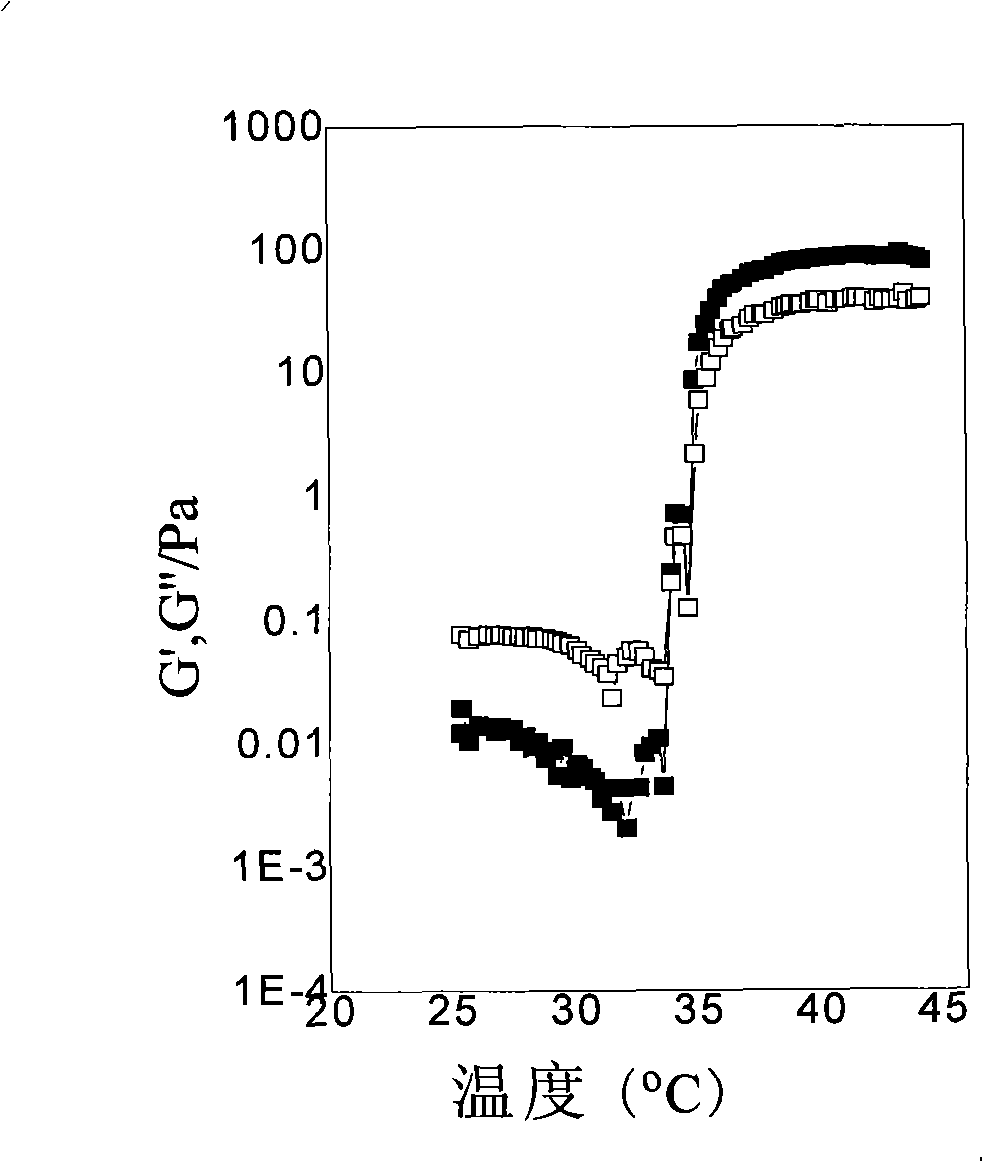

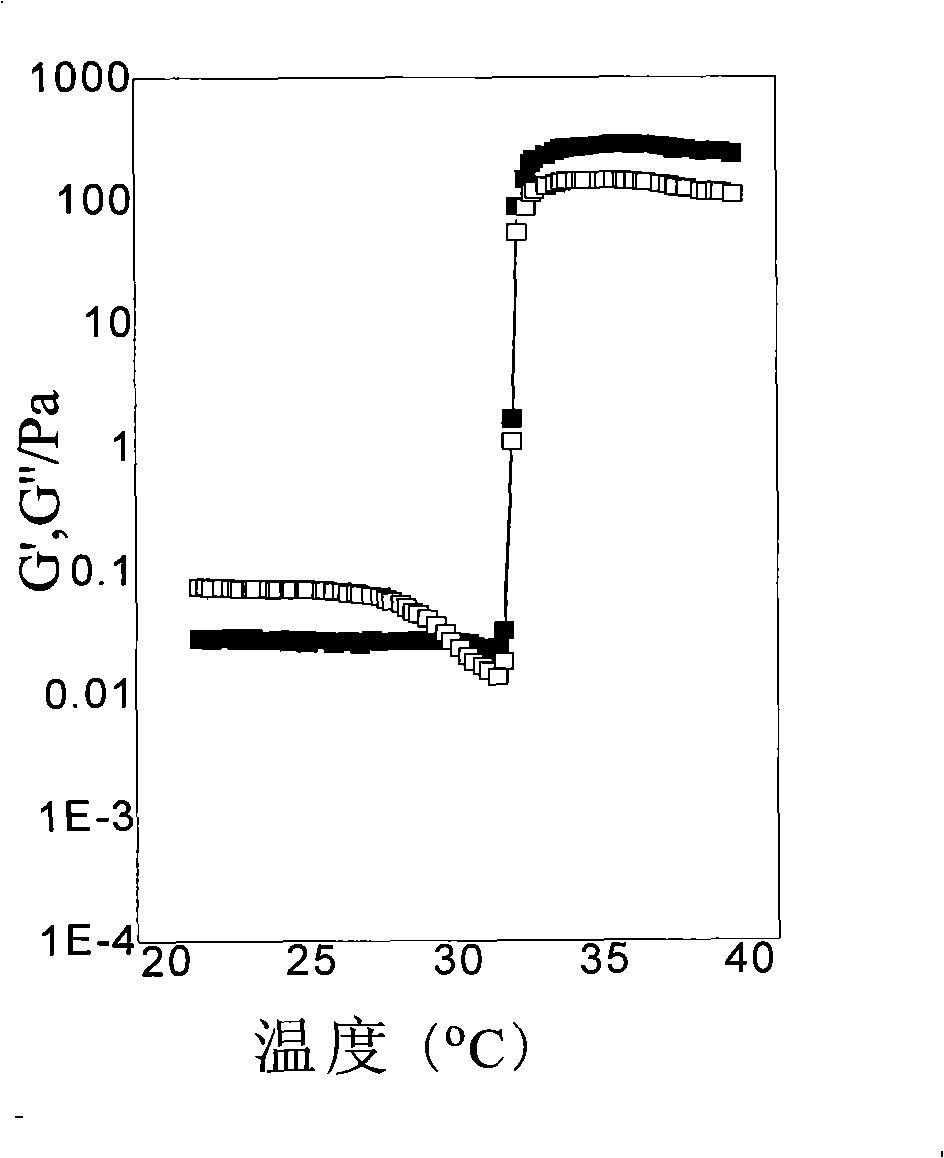

Temperature-induced gelatinizing-in-situ triblock copolymer, preparation method and applications

InactiveCN101307123AGood biocompatibilityFast transitionSurgeryPharmaceutical non-active ingredientsBiocompatibility TestingOxygen

The invention discloses a triblock copolymer by temperature induction and in-situ gelation, a method for preparing the triblock copolymer and an application of the triblock copolymer. The triblock copolymer comprises an ABA type and a BAB type, wherein, a section A is a polyN-isopropyl acrylamide; a section B is polymethacrylic acid-2-hydroxylethyl ester. The copolymer preparation process comprises the following steps that: the N-isopropyl acrylamide and the polymethacrylic acid-2-hydroxylethyl ester are used as monomers; m-2,5- dibromo adipate diethyl ester is used as a bifunctional initiator; and cuprous chloride, 1,4,8,11- tetramethyl-1,4,8,11-tetranitrogen heterocyclic ring tetradecane are used as a catalytic system; various compositions are prepared to a methanol solution and added into a mesonephric tube; oxygen in the system is removed by liquid nitrogen; and the ABA or the BAB type triblock copolymer is synthesized in the methanol solution at a temperature of 25 DEG C through feeding in sequence. The triblock copolymer, the method and the application have the advantages that: LCST(lower critical solution temperature) of the copolymer is controlled to between 26 and 34 DEG C, which is close to human temperature; the time for sol-gel transition is controlled within 60 minutes; and the copolymer has good biocompatibility and can be used as a vascular embolization material.

Owner:TIANJIN UNIV

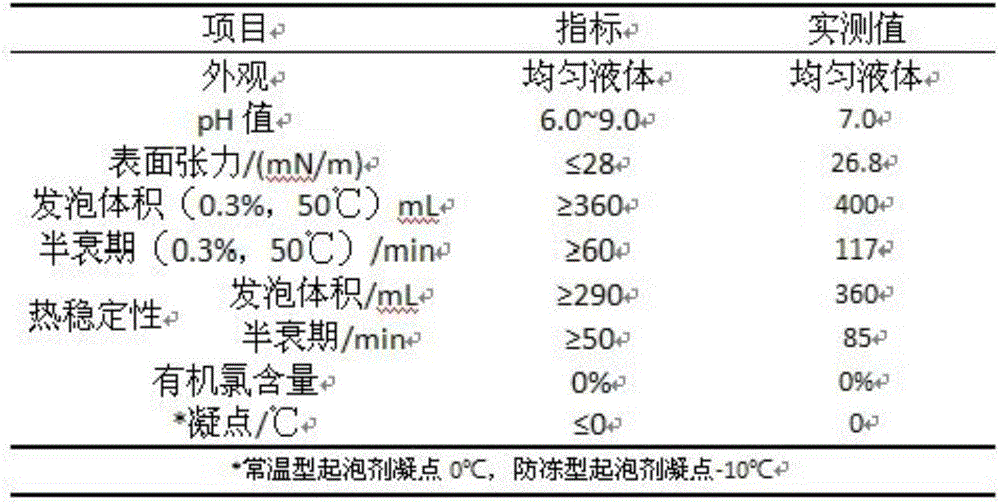

Foaming agent for oilfield, and preparation method thereof

InactiveCN106433580AReduce interfacial tensionGood compatibilityDrilling compositionBetaineActive agent

The invention provides a foaming agent for an oilfield. The foaming agent is prepared from the following raw materials in parts by weight: 2-6 parts of a sulfonic acid group-containing surfactant, 3-8 parts of a carboxylic acid group-containing surfactant, 6-12 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 2-5 parts of N,N-dimethyldodecylamine-N-oxide, 1-6 parts of tetradecyl-2-dimethyl betaine, 0.1-0.8 part of glycerol, 0-15 parts of methanol, and 57-72 parts of water. The invention further provides a preparation method of the foaming agent for the oilfield. The foaming agent for the oilfield introduces the sulfonic acid group and the carboxylic acid group, the reasonable compounding of the sulfonic acid group and carboxylic acid group can play a synergistic effect, and ultra-low oil-water interfacial tension can be achieved under high salinity. The foaming agent can be used for oil-gas field development operation of production well acidification, oil-gas well pigging and washing, gas well fracturing, gas well drainage gas recovery and the like, and has the characteristics of being resistant to temperature, strong in salt-resistant capability, high in foaming number, high in foaming quality, fine and stable in foam, and compatible with other auxiliaries used in the oilfield.

Owner:富象油气技术服务有限公司

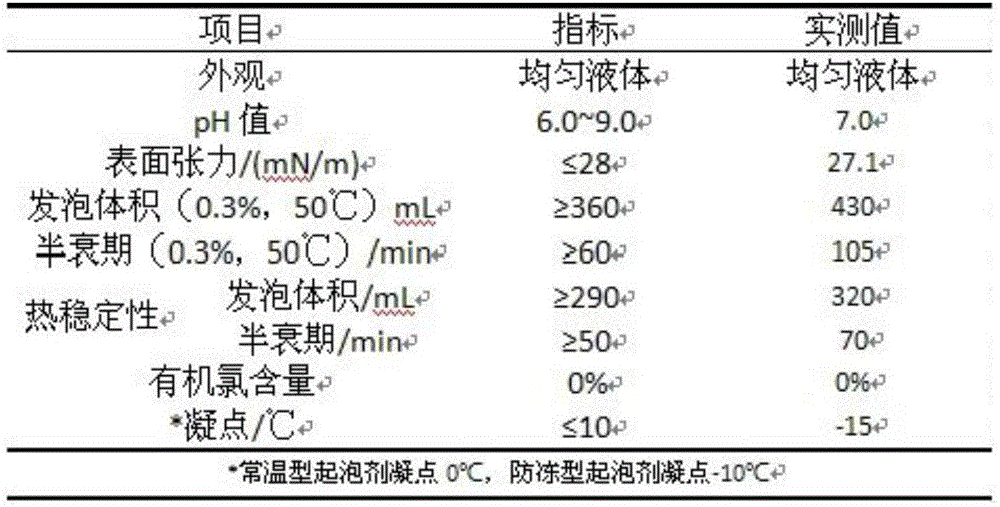

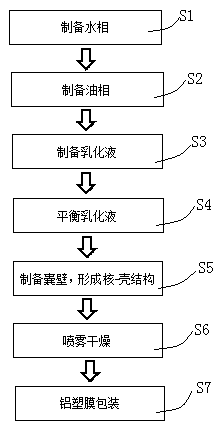

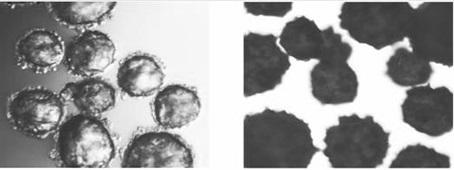

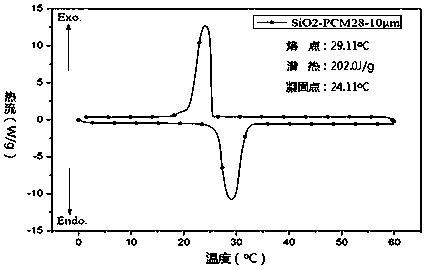

Organic phase change microcapsule, organic phase change microcapsule composite heat dissipation material and preparation method thereof

InactiveCN111518517AHigh thermal conductivityPrevent leakageHeat-exchange elementsPhase change enthalpyParaffin wax

Firstly, the invention provides an organic phase change microcapsule. The phase change microcapsule has a core-shell structure, the core is a capsule core, and the capsule core comprises one or more components of paraffin, n-octadecane and n-tetradecane; the shell is a capsule wall and comprises a silicon dioxide component; the particle size of the phase change microcapsule is 100-200 [mu] m, thephase change enthalpy is 120-200 KJ / Kg, and the phase change temperature is 29-40 DEG C. Secondly, the invention provides an organic phase change microcapsule composite heat dissipation material whichcomprises an aluminum plastic film and the organic phase change microcapsule, and the organic phase change microcapsule is coated with the aluminum plastic film so that the unstable capsule core material can be protected from being eroded by the external environment. Finally, the invention provides a preparation method of the organic phase change microcapsule composite heat dissipation material.The preparation method sequentially comprises the following steps: preparing a water phase, preparing an oil phase, preparing an emulsion, preparing a capsule wall, carrying out spray drying, packaging with the aluminum plastic film and the like, and has the advantages of simplicity and rapidness in operation and suitability for industrial production.

Owner:惠州德赛信息科技有限公司 +1

Papermaking wastewater treatment agent and preparation method thereof

ActiveCN105399194AEfficient removalEasy to transportWater treatment compoundsSpecific water treatment objectivesTert butylPolyacrylamide

The invention relates to a papermaking wastewater treatment agent and a preparation method thereof. The treatment agent comprises the following components in parts by mass: 90-115 parts of tetraethylene pentamine, 30-50 parts of sodium carbonate, 15-30 parts of diatomite, 4-12 part of powdered carbon, 0.001-0.005 part of ethylenediamine tetraacetic acid disodium salt, 0.0001-0.0005 part of polyacrylamide, 0.0003-0.0007 part of dimethyl ethanolamine, 0.08-0.35 part of tertiary butyl hydrogen, 0.3-0.9 part of mercaptobenzothiazole, 0.00005-0.00015 part of potassium peroxide, 0.002-0.004 part of calcium hydroxide, 0.00005-0.00015 part of dithiothreitol, 0.2-0.55 part of zinc sulfate, and 0.03-0.06 part of tetradecyltributylphosphonium chloride. The treatment agent provided by the invention can effectively remove harmful substances in papermaking wastewater.

Owner:JIANGSU GAIYA ENVIRONMENTAL SCI & TECH CO LTD

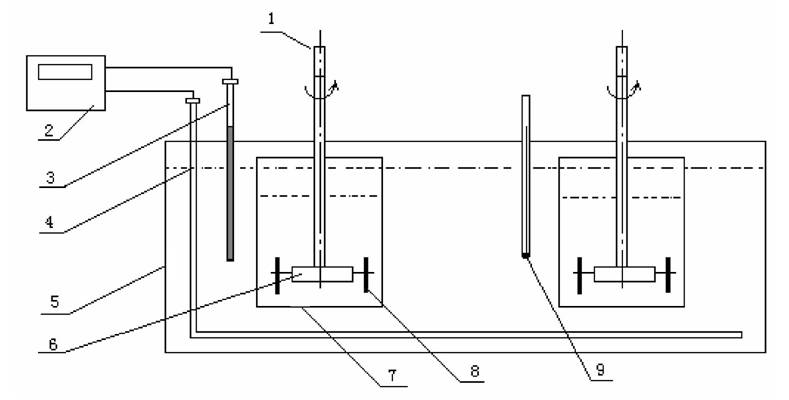

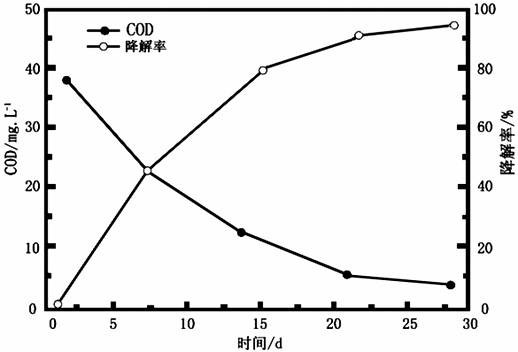

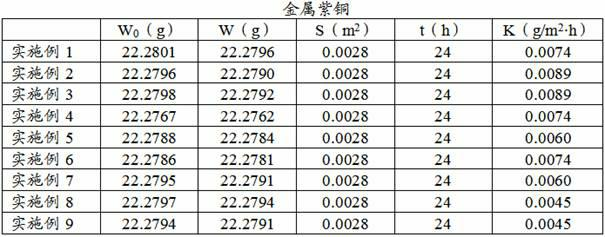

Method for preparing degradant of Venetian acinetobacter tetradecane by semisolid fermentation method based on using bagasse as immobilized carrier

The invention discloses a method for preparing degradant of Venetian acinetobacter tetradecane by a semisolid fermentation method based on using bagasse as immobilized carrier. In the invention, expanding cultivation is carried out on the Venetian acinetobacter by preparing conventional inorganic salt culture medium, and bagasse is utilized as immobilized carrier to prepare the degradant capable of efficiently degrading tetradecane in waste water and liquid waste. The process of the method is as follows: carrying out grinding, sieving and high pressure sterilization on bagasse after bagasse iscleaned and dried; introducing Venetian acinetobacter and bagasse powder in the inorganic salt culture medium, stirring and blending, and then carrying out liquid swing bed shaking primary culture; adding bagasse powder after 6 to 12h primary culture, mixing evenly and culturing again; and filling a double-layer gauze mesh bag with the culture, tying and then suspending the mesh bag in waste water required to be degraded. By adopting the method, the degradation ratio of 50.0mg / L tetradecane can be up to 89%, the degradation ratio to tetradecane with the same concentration can be kept at 96-98%, and has a wonderful effect on degrading alkane in diesel oil.

Owner:FUJIAN NORMAL UNIV

Environmentally-friendly composite rust mud stripping agent and preparation method thereof

The invention belongs to the technical field of cleaning of an industrial circulating water system, and particularly discloses an environmentally-friendly composite rust mud stripping agent and a preparation method thereof. The stripping agent mainly comprises the following components in percentage by weight: 5-8 percent of tetradecyl dimethyl benzyl ammonium bromide, 2-5 percent of sodium polyacrylate and the balance of water. The preparation method comprises the following steps of: (1) adding the tetradecyl dimethyl benzyl ammonium bromide and the sodium polyacrylate into a preparation container and stirring until the mixture is uniform after addition is finished; and (2) adding water into (1) to fix volume and stirring until the mixture is uniform to prepare a finished product. Througha large number of scientific experiments and internal practical application of several years, the rust mud stripping agent has a good stripping effect on rust mud and biological slime, and metal corrosion and environmental pollution can be avoided.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

Pavement material with wide phase change temperature zone and preparation method thereof

The invention discloses a pavement material with a wide phase change temperature zone and a preparation method thereof. The pavement material comprises a shape-stabilized phase change material and asphalt, wherein a mass ratio of the shape-stabilized phase change material to the asphalt is 1:(5-20); the shape-stabilized phase change material is prepared by mixing tetradecane / carrier, pentadecane / carrier, hexadecane / carrier, heptadecane / carrier, octodecane / carrier, nonadecane / carrier, eicosane / carrier and polyethylene glycol / carrier; and a mass ratio is 1:1:(1-3):(1-3):(1-3):(1-3):1:1. The shape-stabilized phase change material of different phase change temperatures is doped into the asphalt, so that the asphalt concrete pavement temperature is regulated, the adaptability on the outside temperature change is enhanced, the temperature rise rate inside large-volume asphalt concrete is effectively reduced, time-to-peak force is delayed, the influence of freezing-thawing cycle and extremely high or low temperature on the concrete pavement performance is reduced, thermal cracks occurring in the asphalt concrete can be prevented, the durability of the material is improved, and the service life is prolonged.

Owner:ZHEJIANG OCEAN UNIV

Tea tree essential oil mosquito-repellent incense

ActiveCN103931677AFresh and fragrantStrong repellent effectBiocidePest repellentsTriptonidePiperonyl butoxide

The invention discloses tea tree essential oil mosquito-repellent incense. The tea tree essential oil mosquito-repellent incense is composed of following raw materials in parts by weight: 0.2-0.6 part of tea tree essential oil, 0.01-0.03 part of triptonide, 0.2-0.8 part of dimefluthrin, 0.05-0.15 part of (1R)-chrysanthemolactone, 0.02-0.06 part of piperonyl butoxide and 100 parts of normal tetradecane in a mixing manner. The tea tree essential oil mosquito-repellent incense disclosed by the invention has a fresh and aromatic taste and has a relatively strong repelling effect on mosquitoes.

Owner:佛山市南海添惠日化有限公司

Wood preservative

InactiveUS20060189497A1High flash pointReduce the possibilityBiocideOrganic detergent compounding agentsEthylenediamineCopper sulfate

A wood preservative composition for treating wood to impart biocide and antimicrobial characteristics to wood contains a mixture of one or more cleaning members containing quaternary salts, an aromatic quaternary salt, a copper sulfate, a glycol ether and a chelator, mixed with water. The preferred active members are tetradecyltrimethylammonium bromide, tetrasodium ethylenediaminetetraacetic acid, benzethonium hydrochloride, copper sulfate pentahydrate and 2-butoxyethanol. The chelator is tetrasodium salt ethylenediamine of tetraacetic acid (EDTA).

Owner:JENEVEIN EARL

Method for improving hydrophilicity of polypeptide membrane by using polylactic acid and polyacrylic acid

The invention discloses a method for improving the hydrophilicity of a polypeptide membrane by using polylactic acid and polyacrylic acid. The method comprises the following steps: (1) the synthesis of a polypeptide-polylactic acid graft copolymer: adding a polypeptide homopolymer, polylactic-acid mono tetradecyl ether, a solvent and a catalyst into a dry reactor, and reacting for 2-3 days at the temperature of 55-57 DEG C in an inert atmosphere while stirring, filtrating, dialyzing and drying, so as to obtain the polypeptide-polylactic acid graft copolymer; (2) the preparation of a polylactic acid and polyacrylic acid modified polypeptide membrane: adding the polypeptide-polylactic acid graft copolymer, polyacrylic acid and a solvent into a dry reactor, stirring and mixing for 40-60 minutes at the temperature of 45-50 DEG C in an inert atmosphere, then, carrying out membrane forming by a tape casting method, and drying, thereby obtaining the target product of the method. According to the method, the preparation process is simple and is easy to grasp, and the hydrophilicity of the obtained modified membrane is improved greatly.

Owner:SHANDONG UNIV OF TECH

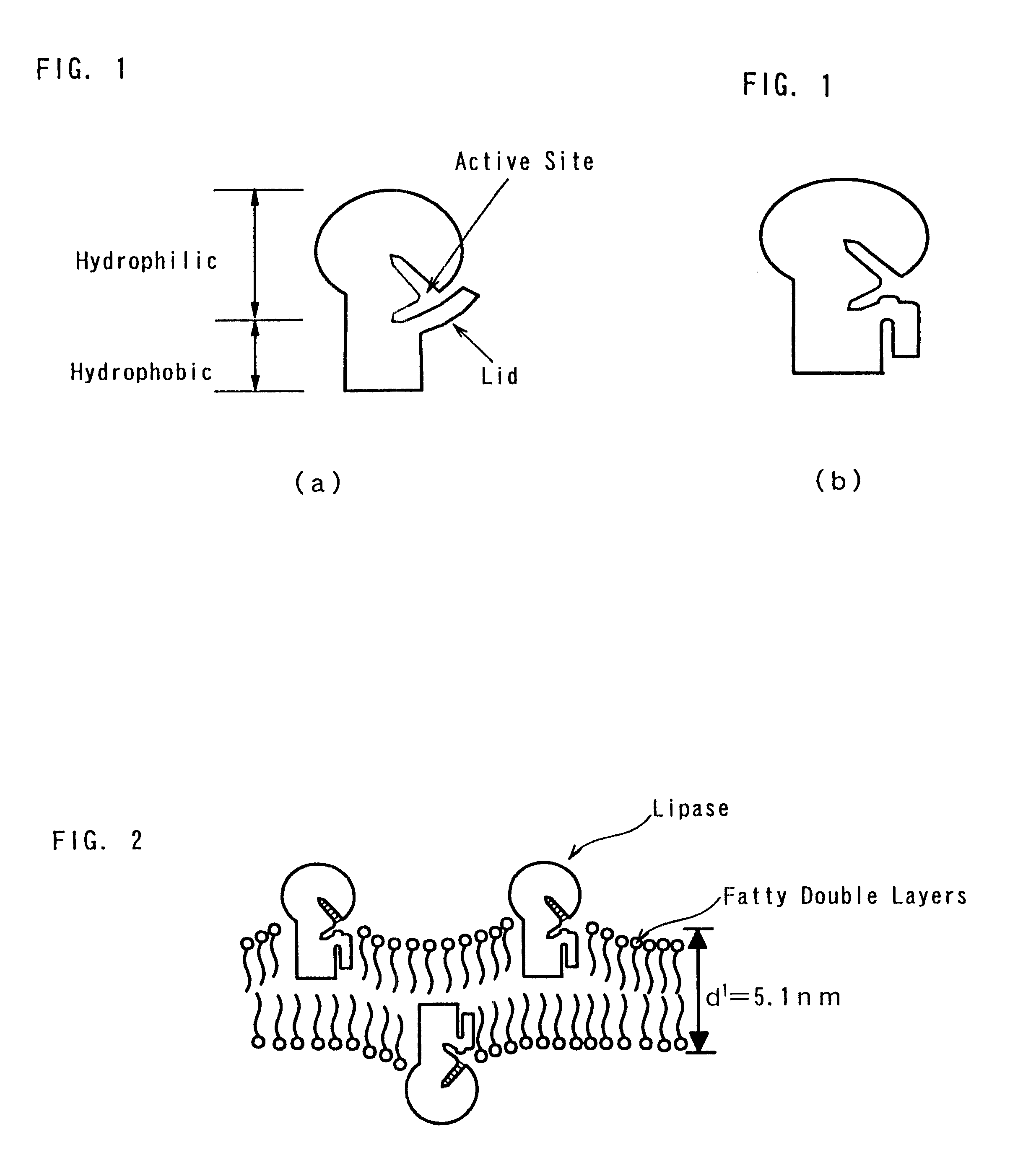

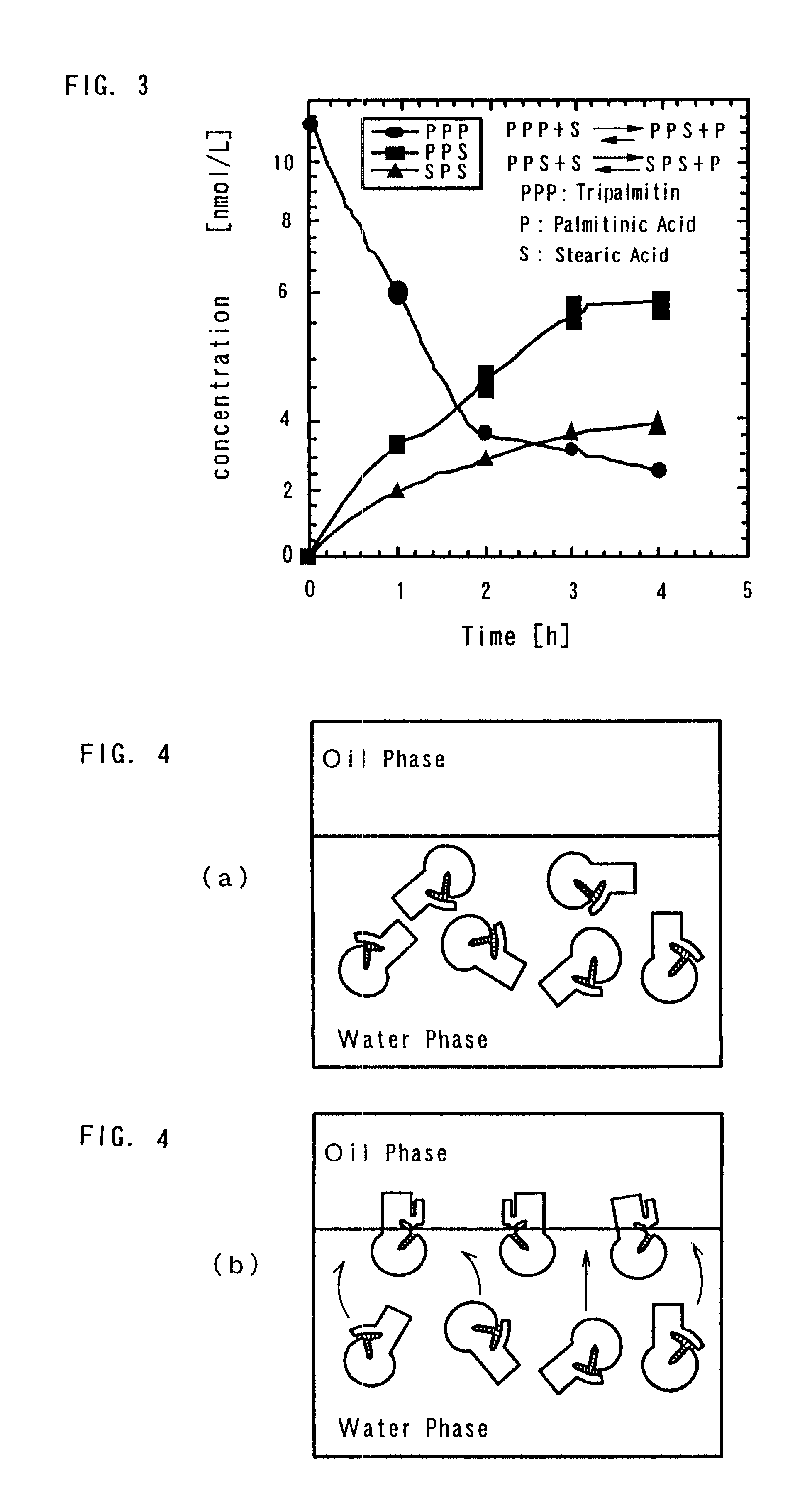

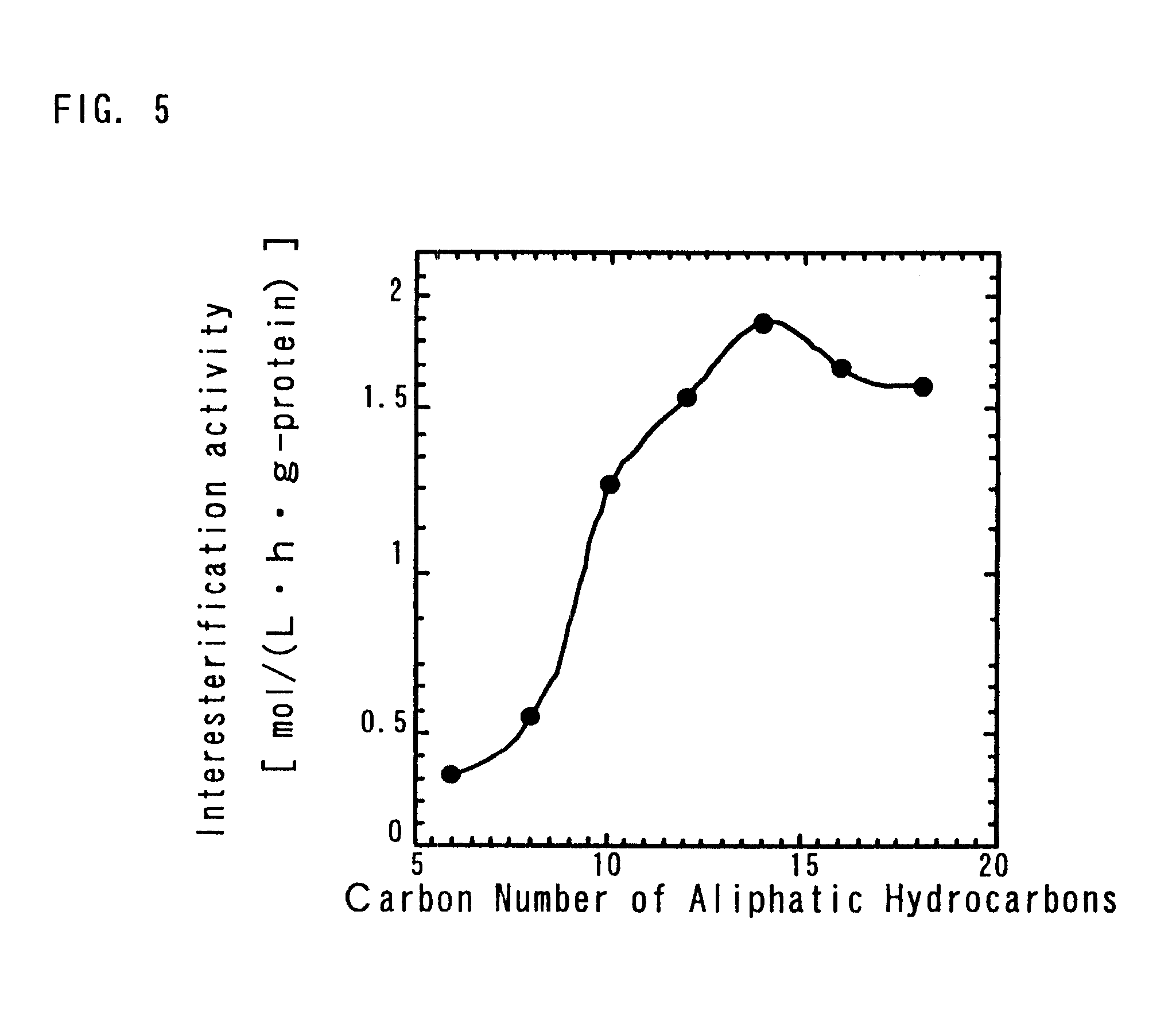

Method of producing activated lipase

A method is disclosed for activating a lipase by adding a solution of lipase in an aqueous buffer at a pH near neutrality to an organic phase, e.g., tetradecane. Under these conditions lipase is activated as a function of an organic-and-water boundary surface between the organic and water phases. The lipase that is activated in this manner remains active even after lyophilization to remove the water and the organic phase. This activated lipase efficiently catalyzes a fat reforming reaction in non-aqueous and nano-aqueous conditions.

Owner:NAT FOOD RES INST +1

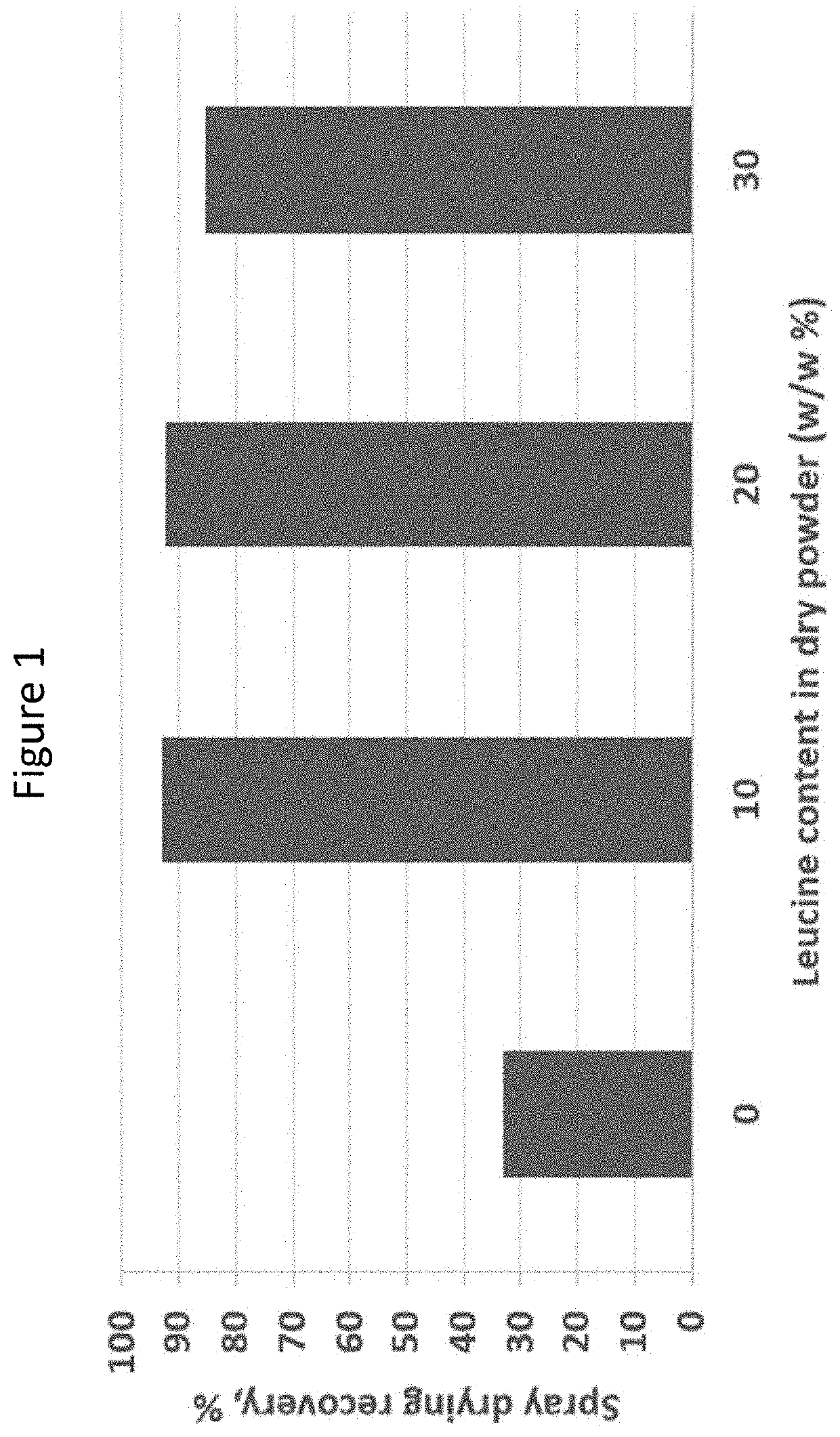

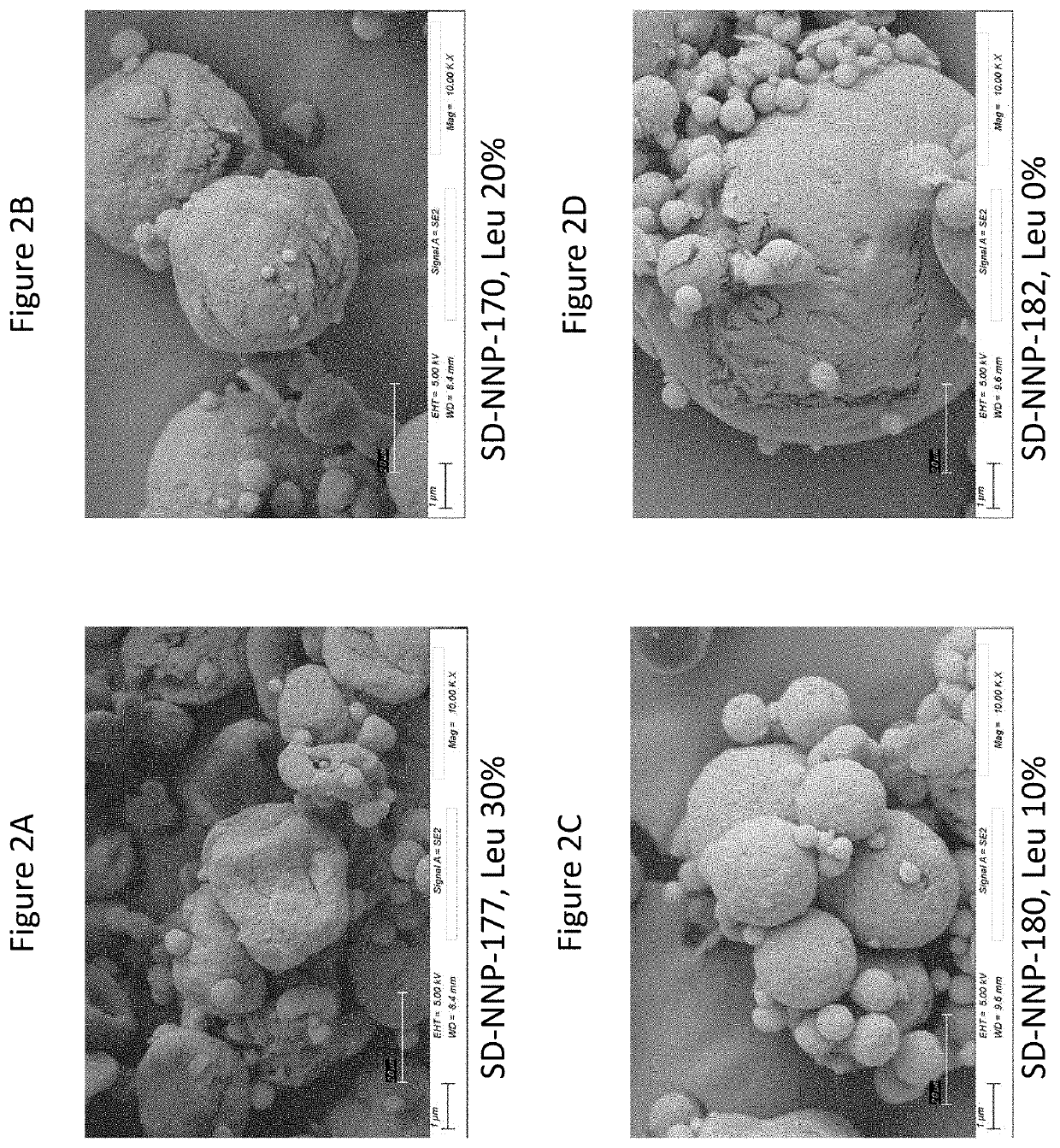

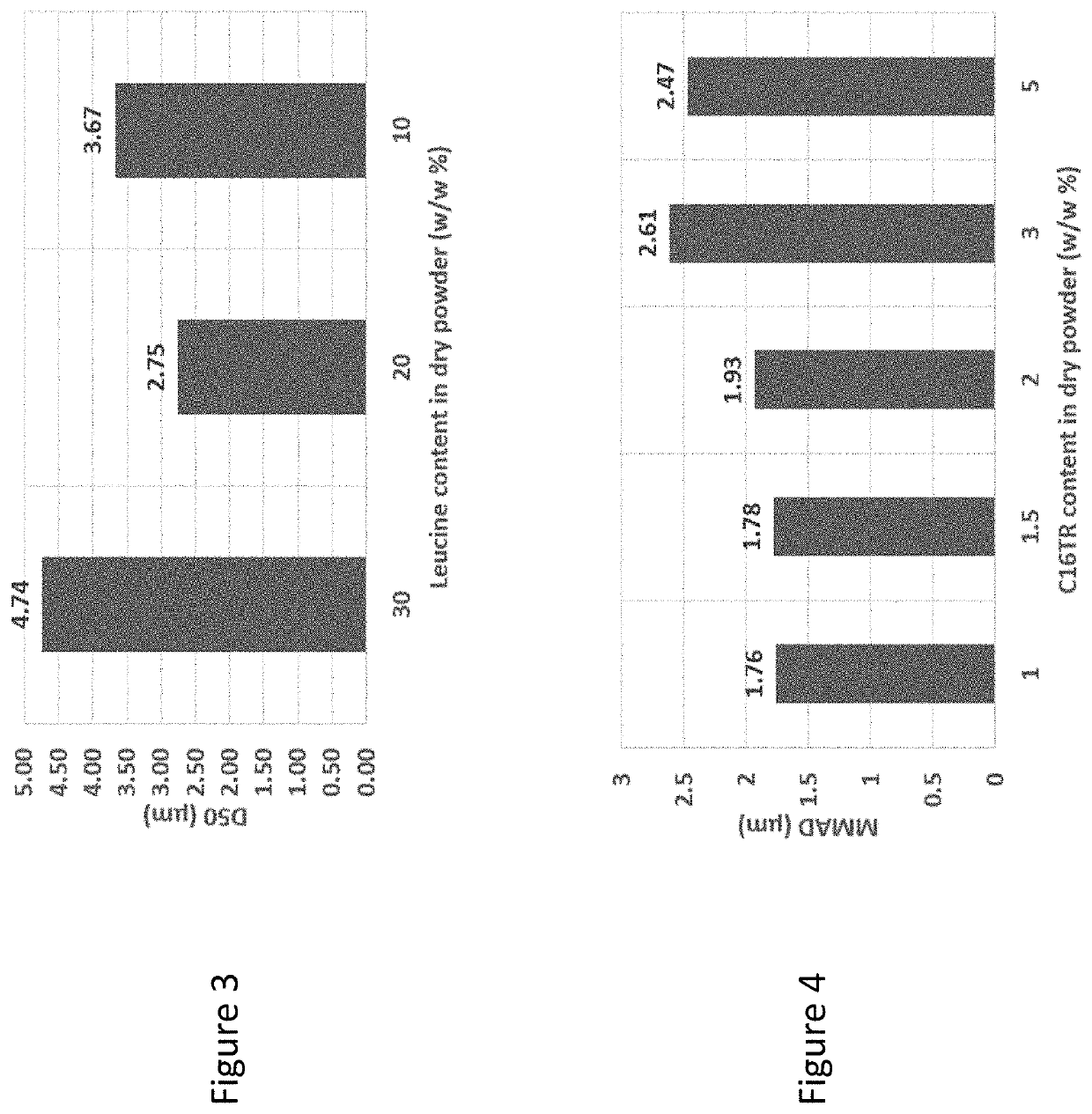

Dry powder compositions of treprostinil prodrugs and methods of use thereof

The present disclosure provides a dry powder composition of treprostinil prodrugs and a method of treating pulmonary hypertension (e.g., pulmonary arterial hypertension), portopulmonary hypertension, or pulmonary fibrosis in a patient in need thereof. The dry powder composition includes (a) from about 0.1 wt % to about 3 wt % of a compound of Formula (I):or an enantiomer, diastereomer, or a pharmaceutically acceptable salt thereof, (b) from about 0.01 wt % to about 3 wt % of DSPE-PEG2000, (c) from about 10 wt % to about 50 wt % of leucine, and the balance being (d) a sugar selected from the group consisting of trehalose and mannitol. The entirety of (a), (b), (c), and (d) is 100 wt %, and R1 is tetradecyl, pentadecyl, hexadecyl, heptadecyl, or octadecyl. The method includes administering an effective amount of the dry powder composition to the lungs of the patient by inhalation via a dry powder inhaler. In certain compositions and methods provided herein, R1 is hexadecyl, e.g., linear hexadecyl.

Owner:INSMED INC

ZSM-5 molecular sieve containing phosphorus in crystal, synthetic method and application thereof

ActiveCN106315615AReduce exchangeHigh catalytic activityCatalytic crackingMolecular sieve catalystsAlkali metalZSM-5

The invention discloses a synthetic method of ZSM-5 molecular sieve containing phosphorus in crystal. The method comprises the following steps: (1) quaternary ammonium hydroxide and tetrabutylphosphonium hydroxide and an aluminium source are mixed, a mixture is treated in an enclosed reaction vessel for 0.1-5 hours at 50-190 DEG C and cooled, an intermediate product is obtained, and an aluminium source is an aluminium source without alkali metal ions; (2) the intermediate product in the step (1) and a silicon source and water are uniformly mixed in order to obtain a mixture; (3) the mixture in the step (2) is placed in the enclosed reaction vessel for hydrothermal crystallization and products are recycled. The synthesized ZSM-5 molecular sieve containing phosphorus in crystal can be used as an active component for catalysis of tetradecane with higher cracking conversion rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com