Patents

Literature

260 results about "Well drainage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Well drainage means drainage of agricultural lands by wells. Agricultural land is drained by pumped wells (vertical drainage) to improve the soils by controlling water table levels and soil salinity.

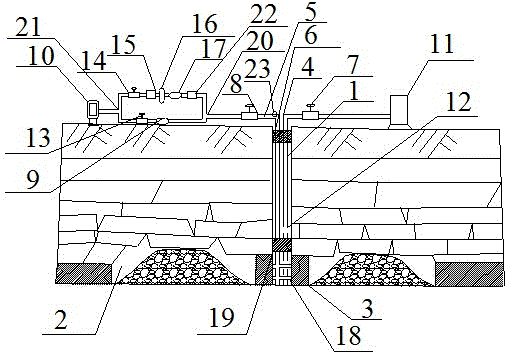

System and method for increasing drainage quantity of coal bed gas of ground well drainage goaf

ActiveCN105114038AExtend the effective service periodLow extractionFluid removalMining engineeringCoal pillar

The invention discloses a system and a method for increasing drainage quantity of coal bed gas of a ground well drainage goaf and belongs to the technical field of coal bed gas drainage. The method includes: constructing a drainage well between adjacent goaf holes, sequentially sending a drainage pipe and a flow injection pipe in, and arranging sealing sections I and II; opening a valve I and a valve III, injecting 30-60 MPa of supercritical CO2 into the flow injection pipe until pressure indicating number declines suddenly; opening a valve II to enable a ground drainage station to drain the coal bed gas, recording initial gas flow, repeating replacement of coal bed gas with CO2 when coal bed gas flow declines 30% of the initial gas flow again, and stopping coal bed gas drainage until the coal bed gas flow declines to 16% of the initial gas flow finally. By the system and the method, concentration of drained coal bed gas is increased effectively, and cost for separation and purification is lowered; supercritical CO2 jet flow is adopted to break coal columns, so that threshold pressure is low, breaking speed is high, no pollution is caused to a coal bed gas reservoir, and rock breaking efficiency can be improved substantially.

Owner:TAIYUAN UNIV OF TECH

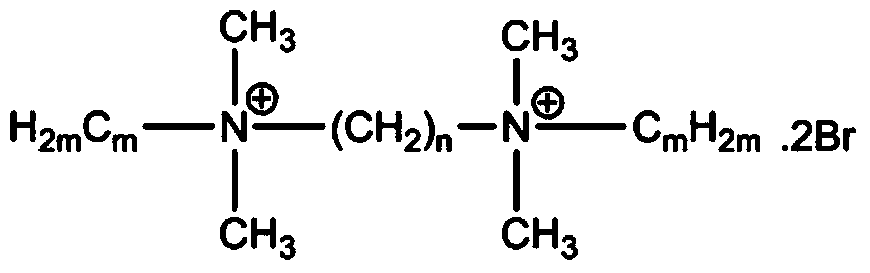

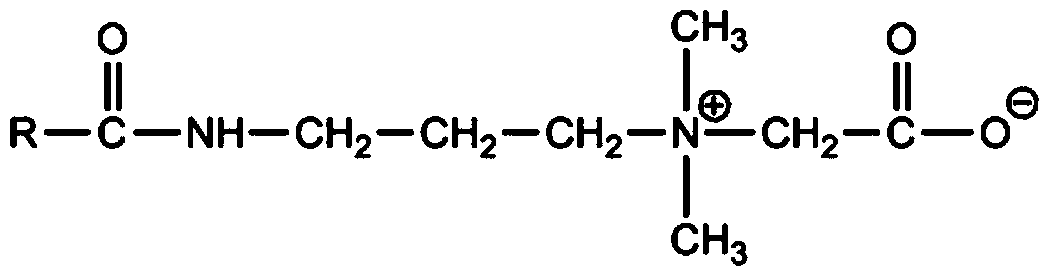

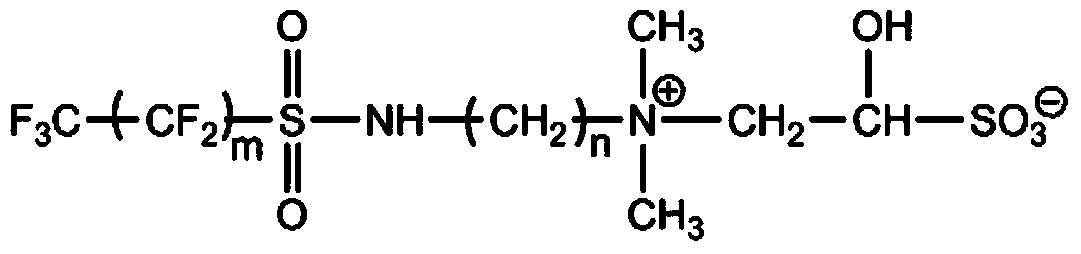

Foam drainage agent for gas well drainage gas recovery

ActiveCN104140802AImprove stabilityGood water carrying effectDrilling compositionBond energyChemical agent

Belonging to the technical field of oil-gas field chemical agents, the invention relates to a foaming drainage agent for gas well drainage gas recovery. The foaming drainage agent for gas well drainage gas recovery is formed by mixing of a gemini surfactant, a zwitterionic surfactant, a high-bond energy surfactant and a macromolecular polymer. The foaming drainage agent provided by the invention has high temperature environment resistance (up to 180DEG C), suitability to environment with wide pH value (of 1-10), high mineralization degree resistance (greater than or equal to 320000mg / L), and resistance to hydrogen sulfide and carbon dioxide atmosphere (with the hydrogen sulfide partial pressure being greater than or equal to 25% and the carbon dioxide partial pressure being greater than or equal to 20%). And the foaming drainage agent also has the advantages of excellent foaming performance, good foam stability, good water-carrying effect, low surface tension, and foam volume mostly higher than 8 times.

Owner:CHINA PETROLEUM & CHEM CORP +1

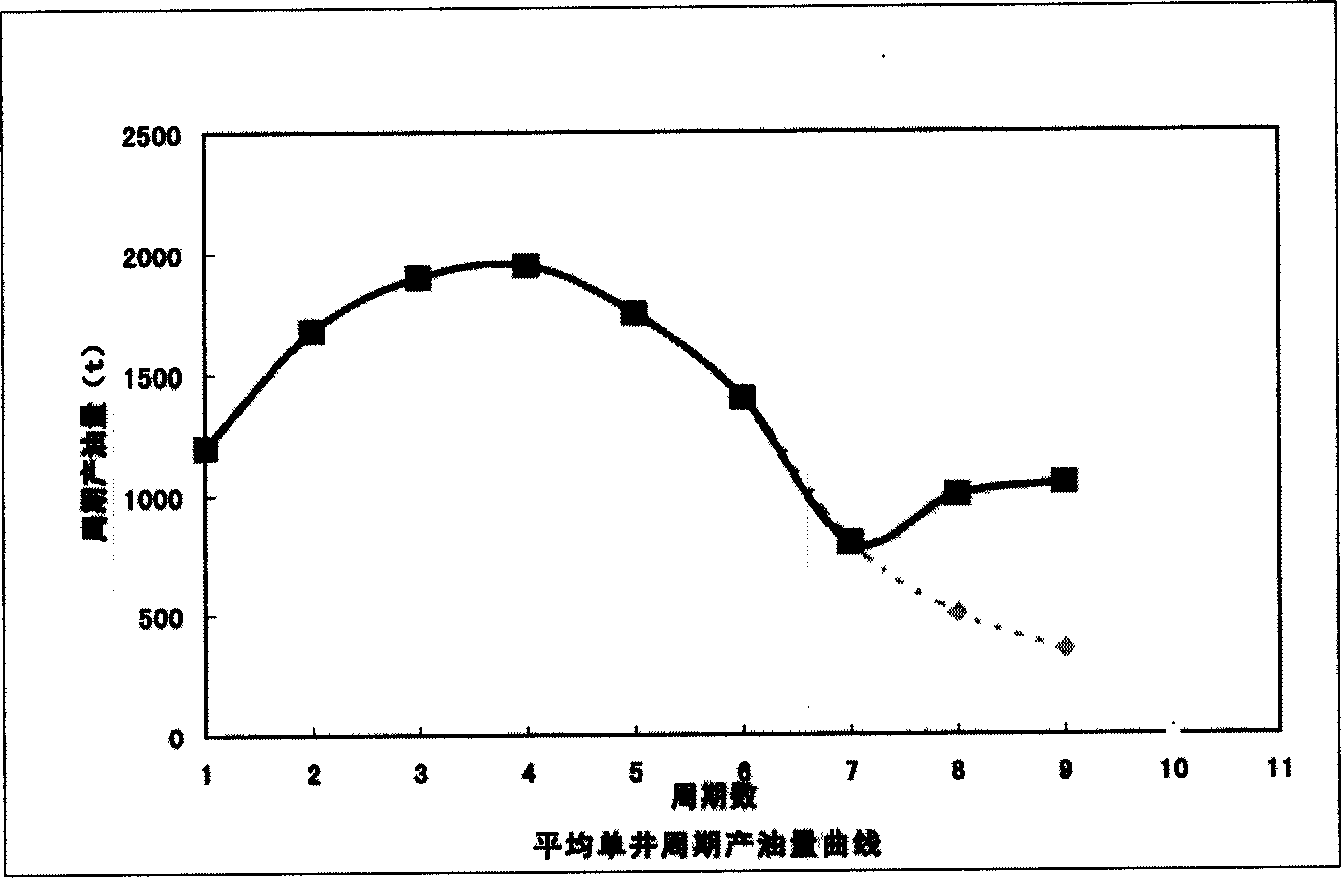

Method of integral throughput in multiple wells for extracting thick oil

InactiveCN1601052APrevent steam channelingSupplementary pressure energyFluid removalPorosityLayer thickness

The invention is a method for multi-well cyclic steam stimulation thickened oil recovery by thermal recovery-steam injection technique, selecting: oil-layer depth in oil reservoir<1800m, residual oil saturation > 0.40, total oil-layer thickness > 5.0m, net-total thickness ratio >0.4, oil-layer porosity >0.15, and permeation rate variation coefficient <0.8; placing adjacent steam channeling wells and steam channeled wells (above two) together in the same group, simultaneously making steam injection in the well drainage sequence or block cluster well sequence, where steam injection strength of single well is 50-200 cu m / m and the well-bottom dryness fraction is greater than 50%, then stewing them, and finally opening them for production in the same sequence as above-mentioned. It can prevent steam channeling and interference between wells, effectively supplements pressure energy to oil layers and helps enlarge the steam spread range, and can increase the oil-layer pressure by about 2MPa as compared with single well steam stimulation method. It can both increase single-well output and prolong the life of steam stimulation.

Owner:PETROCHINA CO LTD

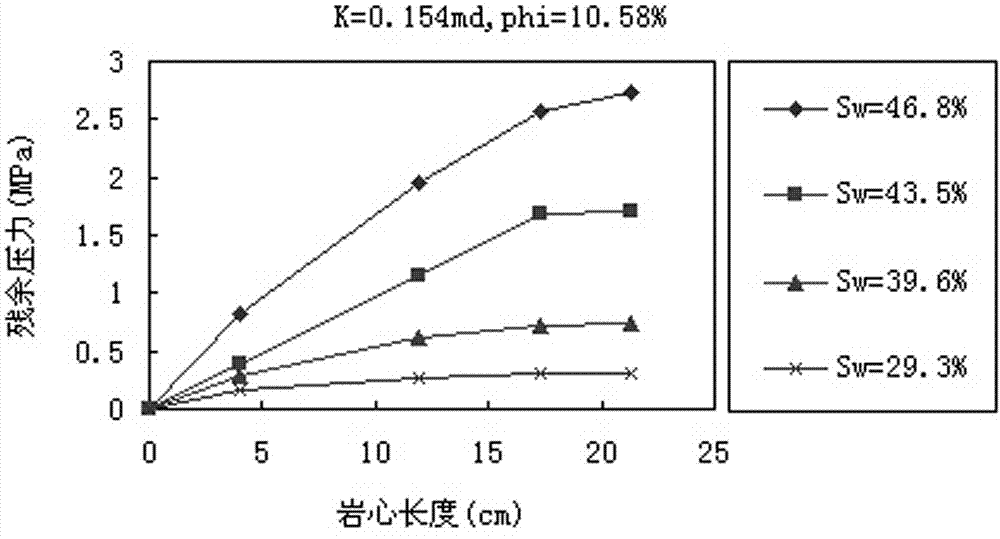

Estimation method for recovery ratio and limit drainage radius of low-permeability gas well

InactiveCN104504230AThe method is simple and fastFluid removalSpecial data processing applicationsEstimation methodsPeriod spotting

The invention discloses an estimation method for a recovery ratio and a limit drainage radius of a low-permeability gas well. The estimation method comprises the following steps: estimating the limit drainage radius, and estimating the recovery ratio, wherein an estimation formula of the limit drainage radius is Re=(Pi-Pw) / [Theta];the step of estimating the recovery ratio comprises the following substeps: S1) calculating the volume (Vp=Pi[a0b0ze+1 / 2(a0+b0)c*Z<2>e+1 / 3C<2>Z<3>e]) of an elliptical table; S2) calculating the volume (V=Pi(a0+Re)(b0+Re)h) of an elliptical cylinder of a drainage area; and S3) calculating the recovery ratio ER=Vp / V. The estimation method has the following beneficial effects that the method is simple and quick, integrates the influences of a startup pressure gradient, a pressure-break length scale and well point abandonment pressure, brings forward a practical method used for estimating the average startup pressure gradient within the gas well drainage range by the early-period spot-measurement static pressure data of production performance, realizes the early evaluation of the limit drainage radius and the recoverable reserve of the gas well, and provides guidance for designing the reasonable well spacing of a low-permeability gas reservoir.

Owner:SOUTHWEST PETROLEUM UNIV

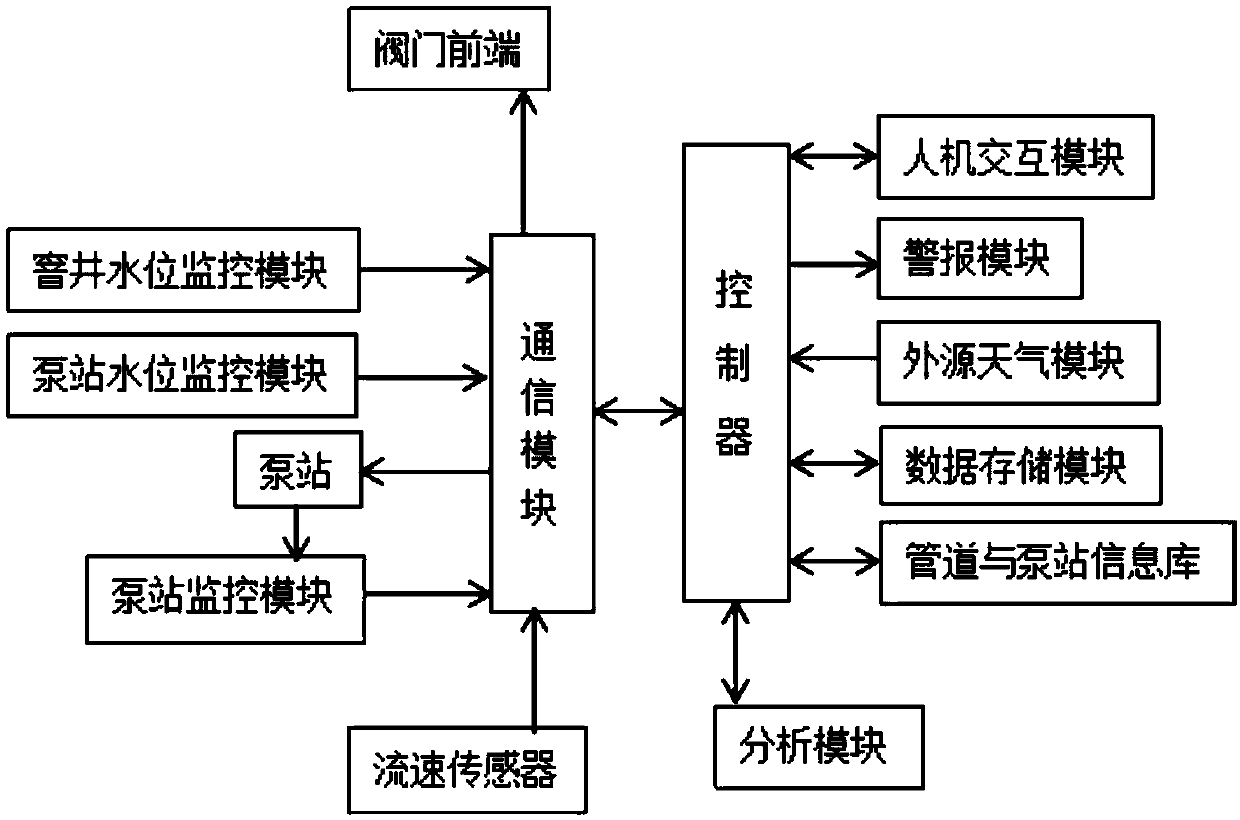

Big data-based urban drainage network monitoring control system

InactiveCN109577449AReduce the chance of waterloggingImprove water storage capacityGeneral water supply conservationSewerage structuresInformation repositoryEngineering

The invention discloses a big data-based urban drainage network monitoring control system. The big data-based urban drainage network monitoring control system comprises a man-machine interaction module, an alarming module, an external source weather module, a data storage module, a pipe and pump station information base, an analyzing module, a flow sensor, a pump station, a pump station monitoringmodule, a pump station water level monitoring module, an inspection well water level monitoring module and a valve front end. The big data-based urban drainage network monitoring control system can analyze and compute water drainage in an urban drainage network through the analyzing module to adjust the drainage velocity of the pump station in work and reduce the start-stop frequency of the pumpstation, and meanwhile, timely empty a water collecting well through the connected external source weather module to improve the water storage capacity of the drainage network in rain and reduce the possibility of urban flooding; besides, by analyzing the water flow in drainage pipes through the analyzing module, the big data-based urban drainage network monitoring control system can help timely discover damaged or blocked section and implement dredging, maintenance and replacement operation to ensure normal operation of an urban drainage system.

Owner:HARBIN UNIV

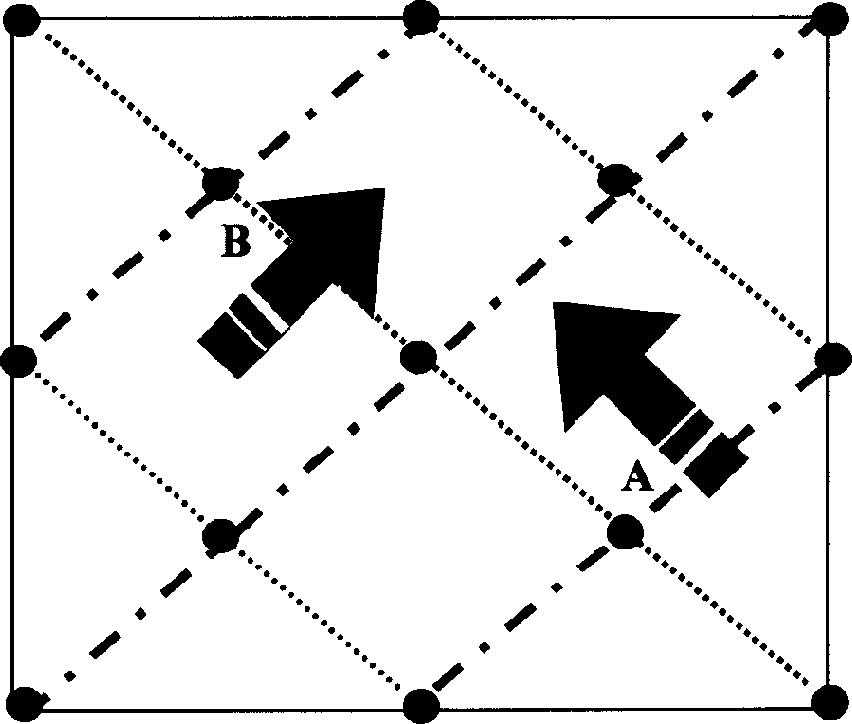

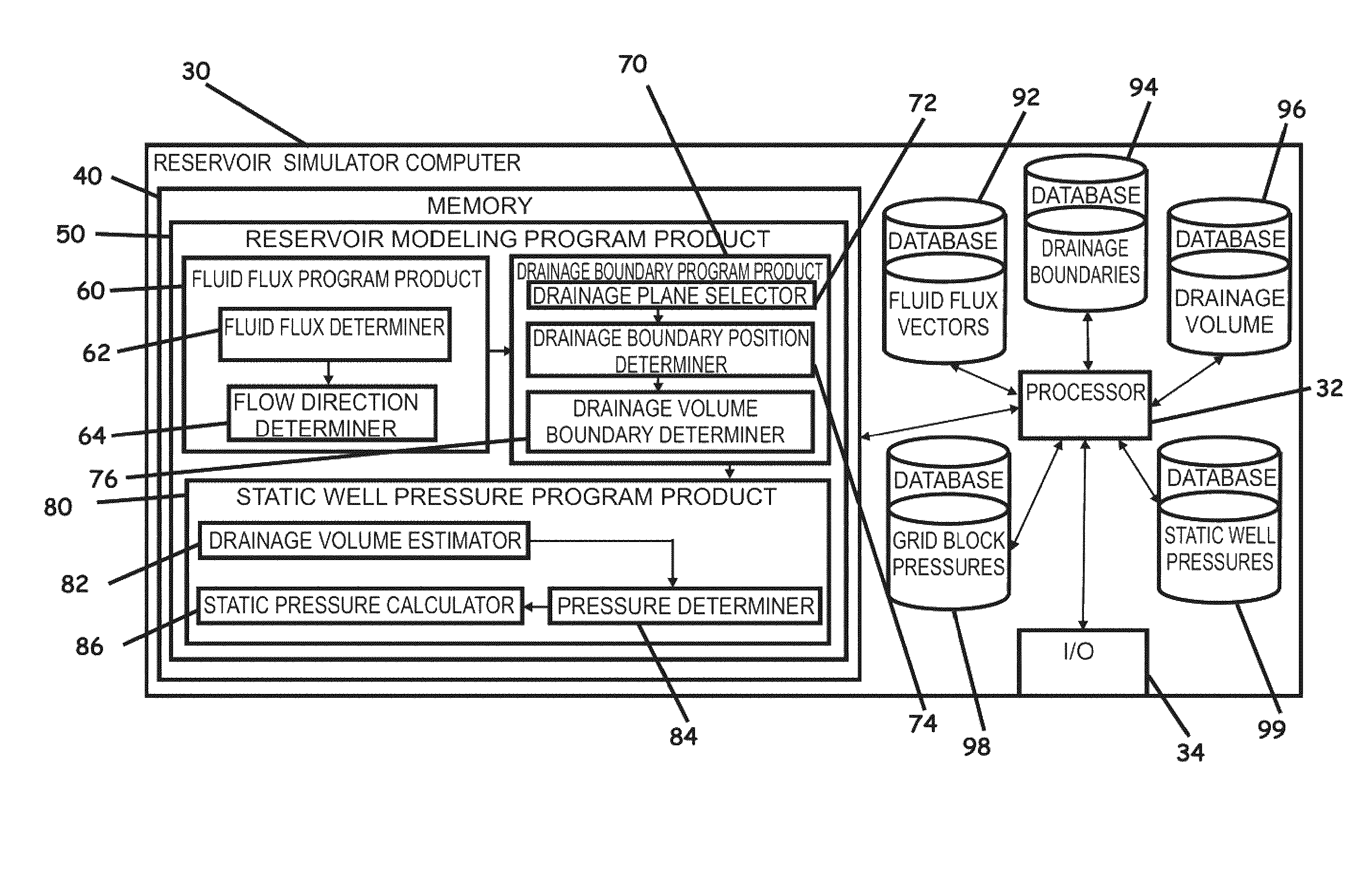

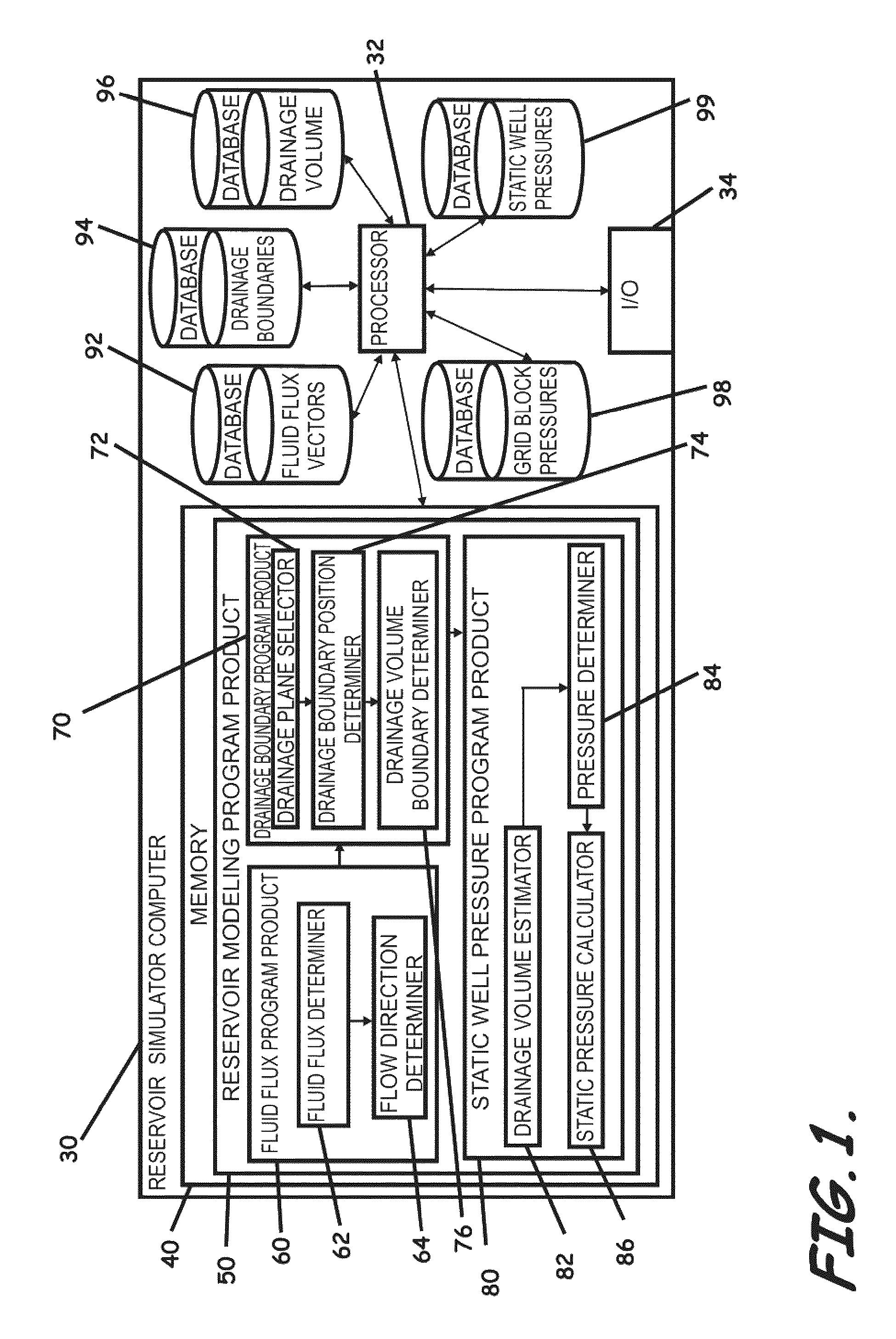

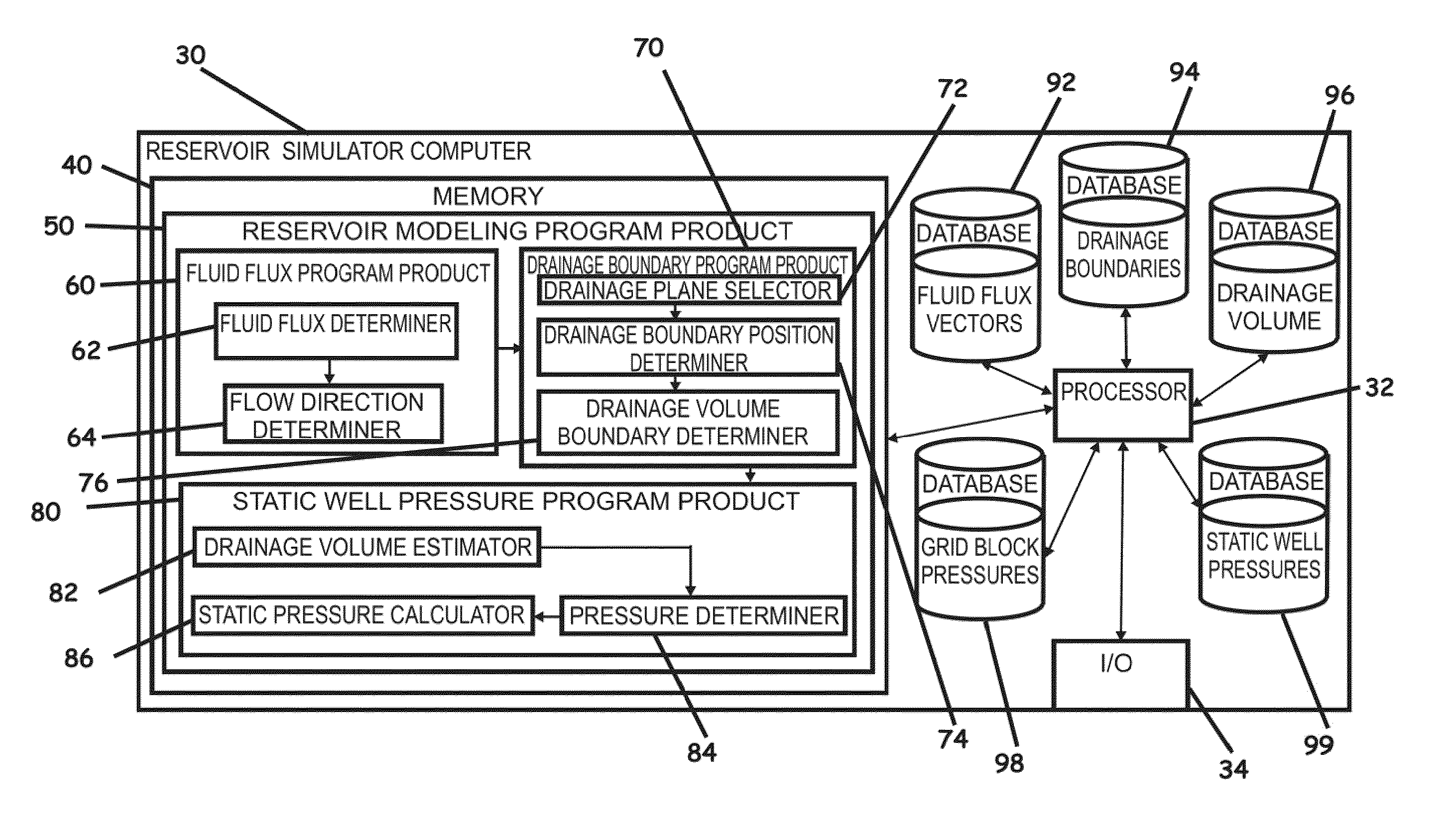

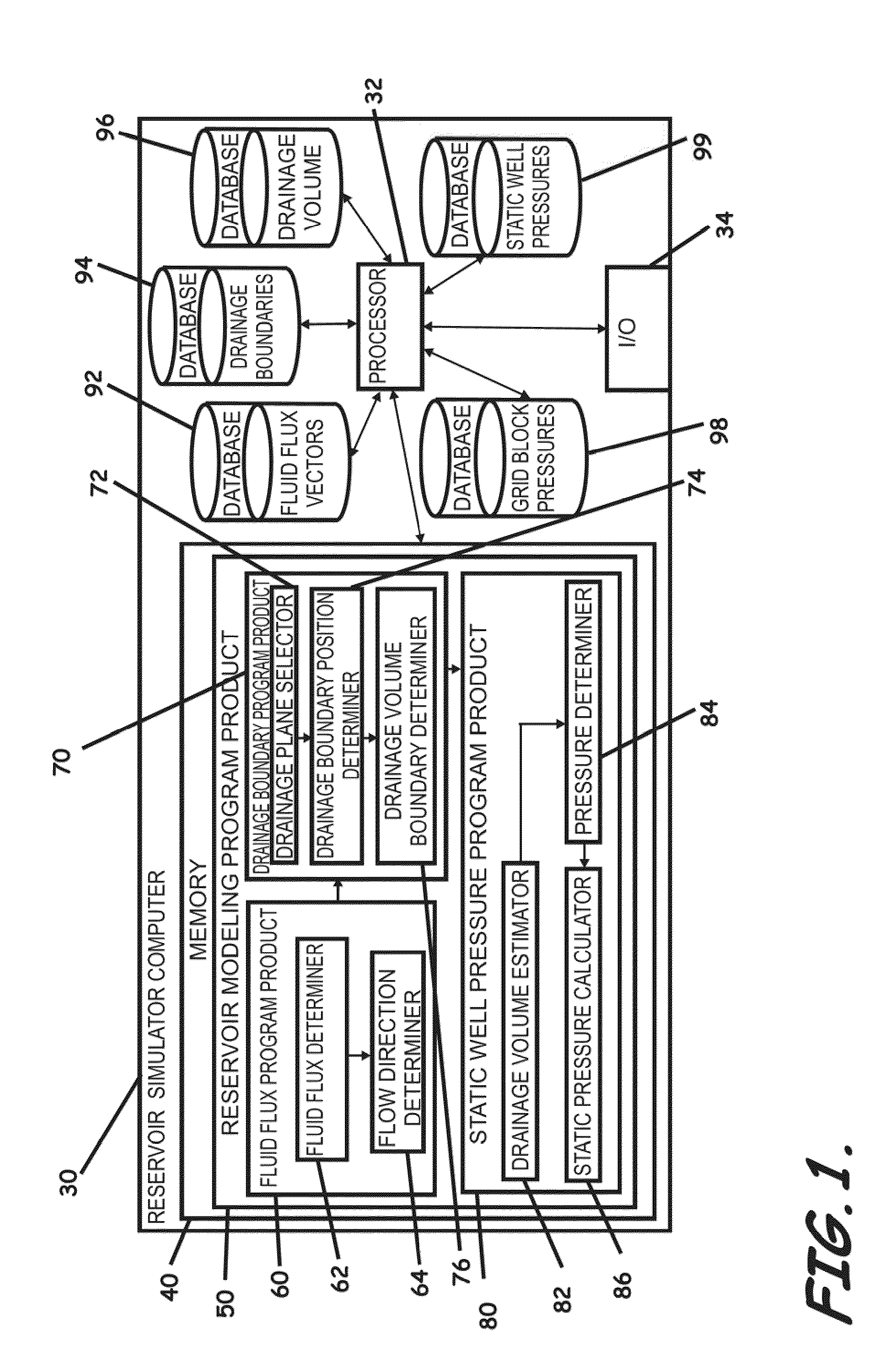

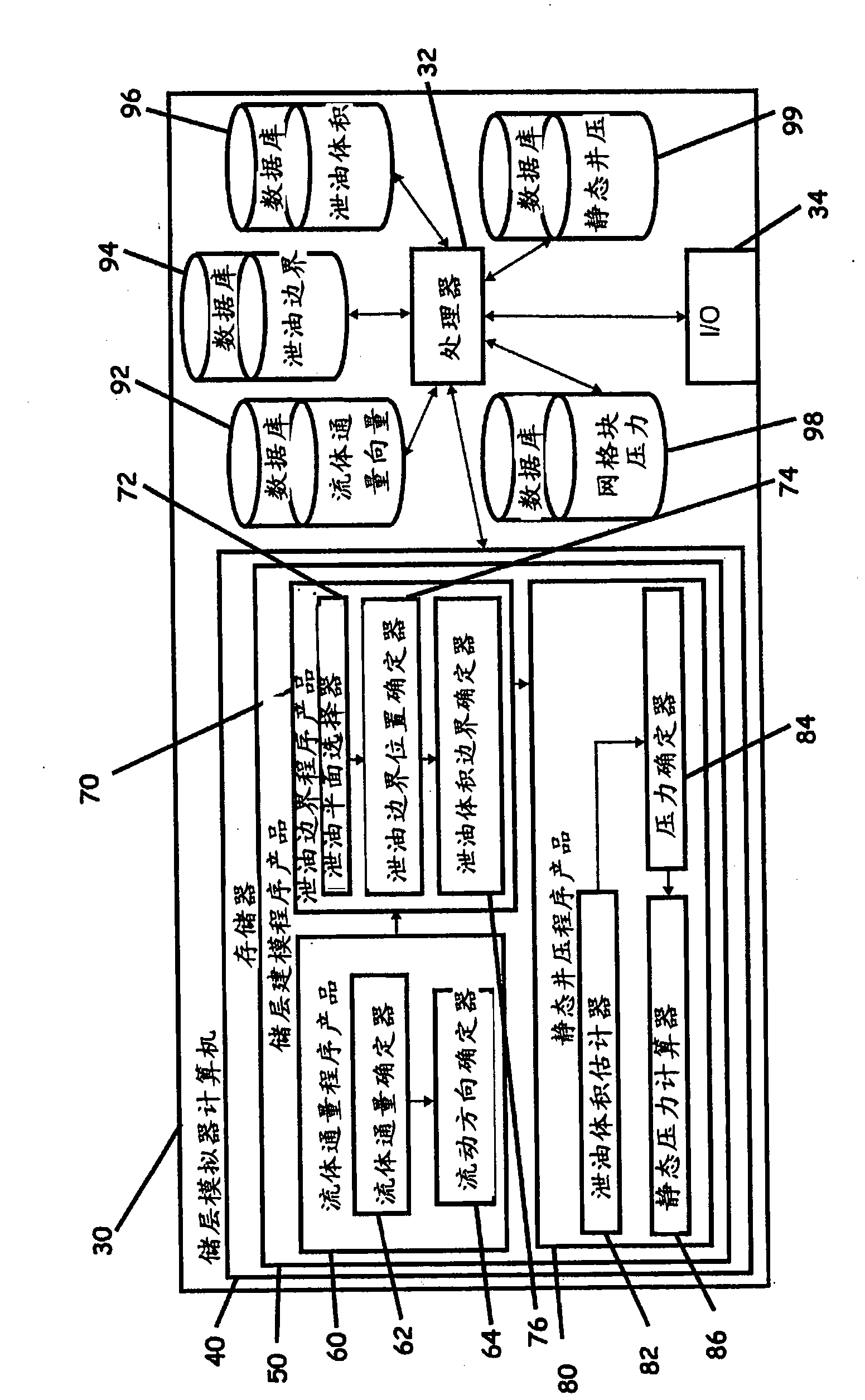

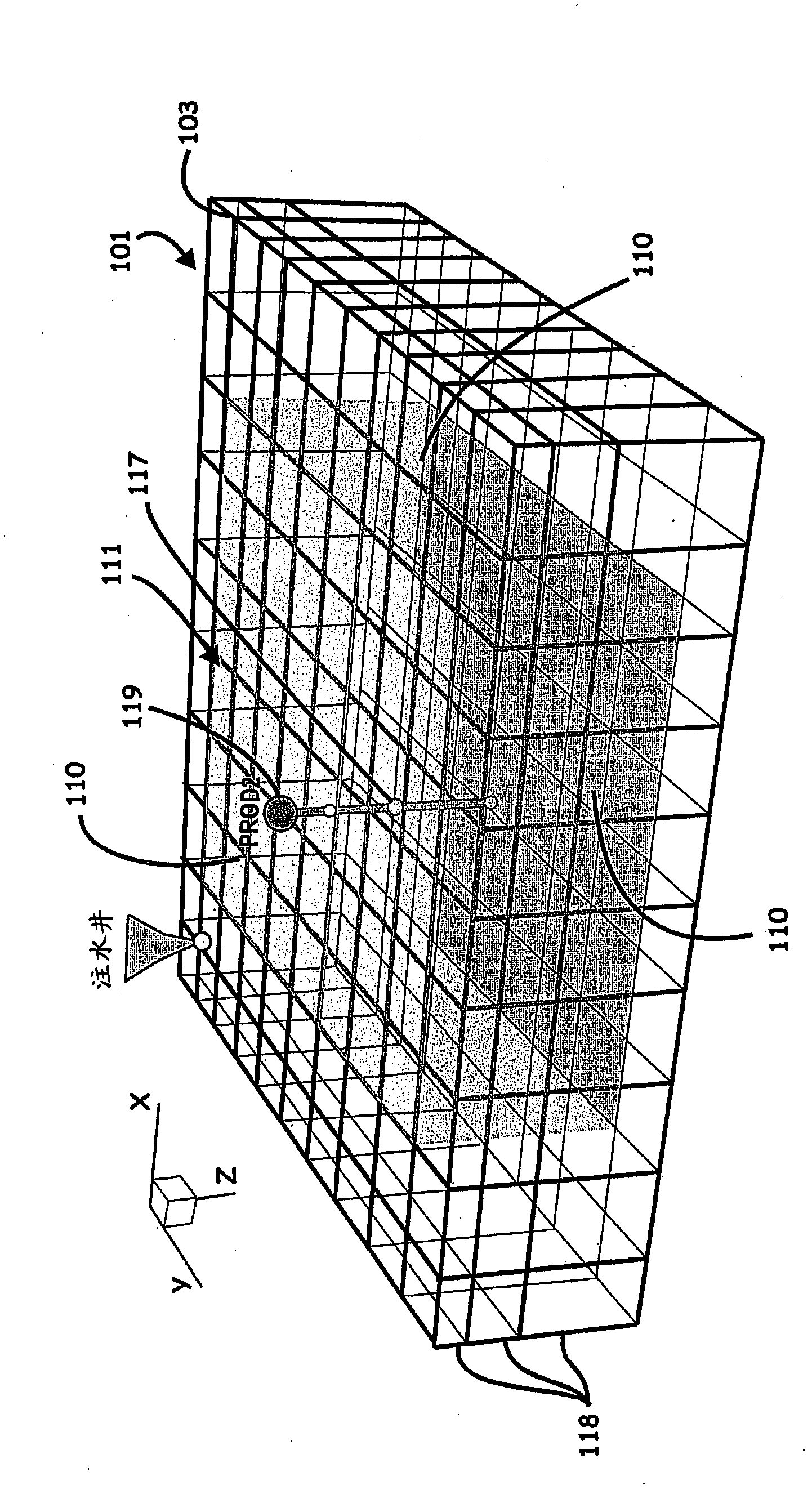

Systems, computer implemented methods, and computer readable program products to compute approximate well drainage pressure for a reservoir simulator

ActiveUS8589135B2Accurately approximatedIncrease pressureElectric/magnetic detection for well-loggingSurveyVolume averageComputer science

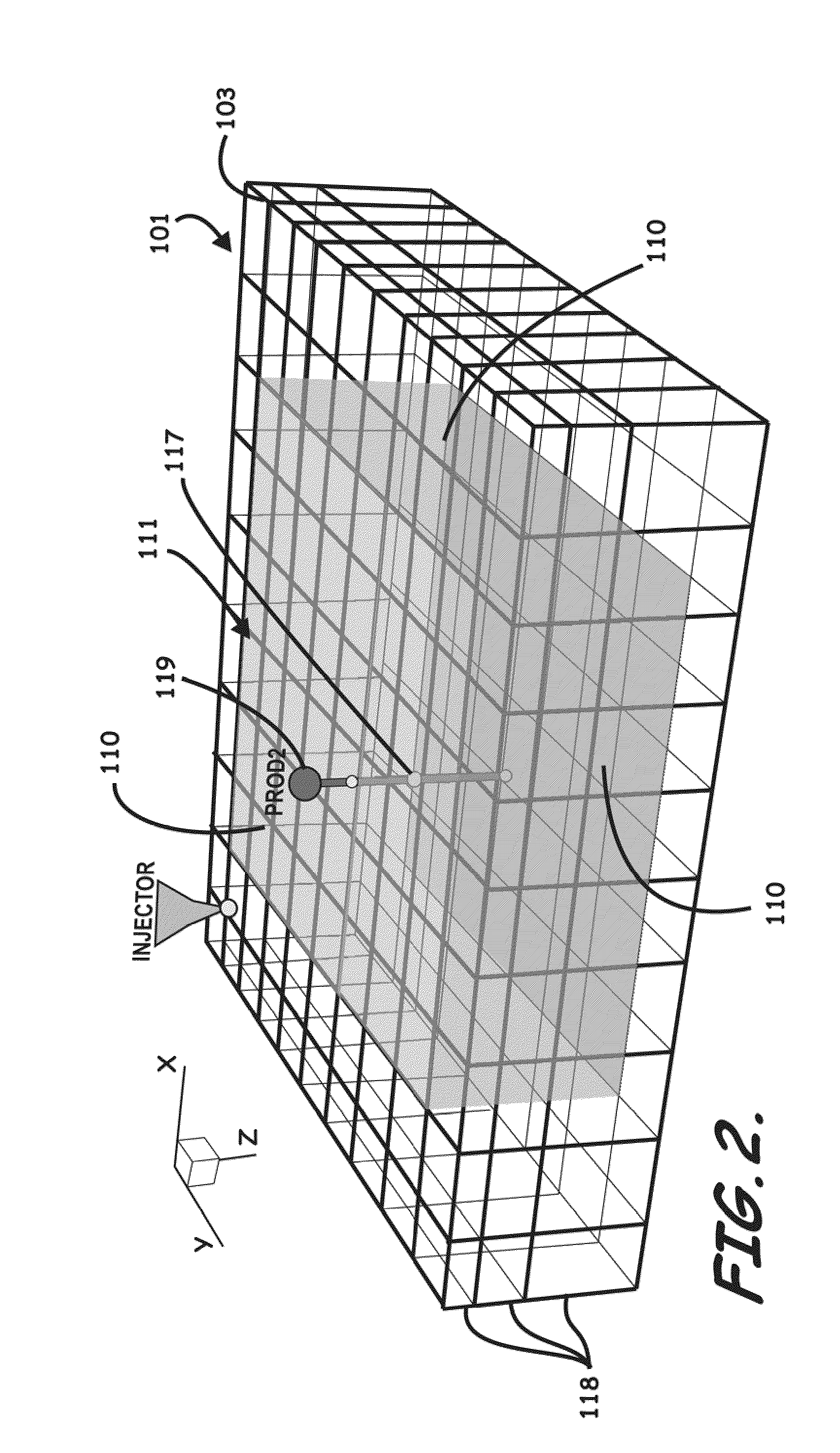

Systems, computer implemented methods, and program products to determine approximate static well pressures for one or more arbitrary shaped wells by estimating the drainage volume of the one or more wells, are provided. The drainage volume of the one or more wells, for example, can be estimated from the one or more computed fluid flow flux vectors, and the approximate static well pressures for the one or more wells can be subsequently calculated by taking the pore volume average of the dynamic grid block pressures within the drainage volume of the one or more wells. The one or more fluid flow flux vectors can be calculated at each iteration in a numerical reservoir simulator as a part of standard simulator computations, negating a need for additional, extraneous computations to calculate effective drainage volume of the one or more wells.

Owner:SAUDI ARABIAN OIL CO

Systems, Computer Implemented Methods, and Computer Readable Program Products to Compute Approximate Well Drainage Pressure for a Reservoir Simulator

ActiveUS20100286971A1Accurately approximatedIncrease pressureElectric/magnetic detection for well-loggingSurveyVolume averageComputer science

Systems, computer implemented methods, and program products to determine approximate static well pressures for one or more arbitrary shaped wells by estimating the drainage volume of the one or more wells, are provided. The drainage volume of the one or more wells, for example, can be estimated from the one or more computed fluid flow flux vectors, and the approximate static well pressures for the one or more wells can be subsequently calculated by taking the pore volume average of the dynamic grid block pressures within the drainage volume of the one or more wells. The one or more fluid flow flux vectors can be calculated at each iteration in a numerical reservoir simulator as a part of standard simulator computations, negating a need for additional, extraneous computations to calculate effective drainage volume of the one or more wells.

Owner:SAUDI ARABIAN OIL CO

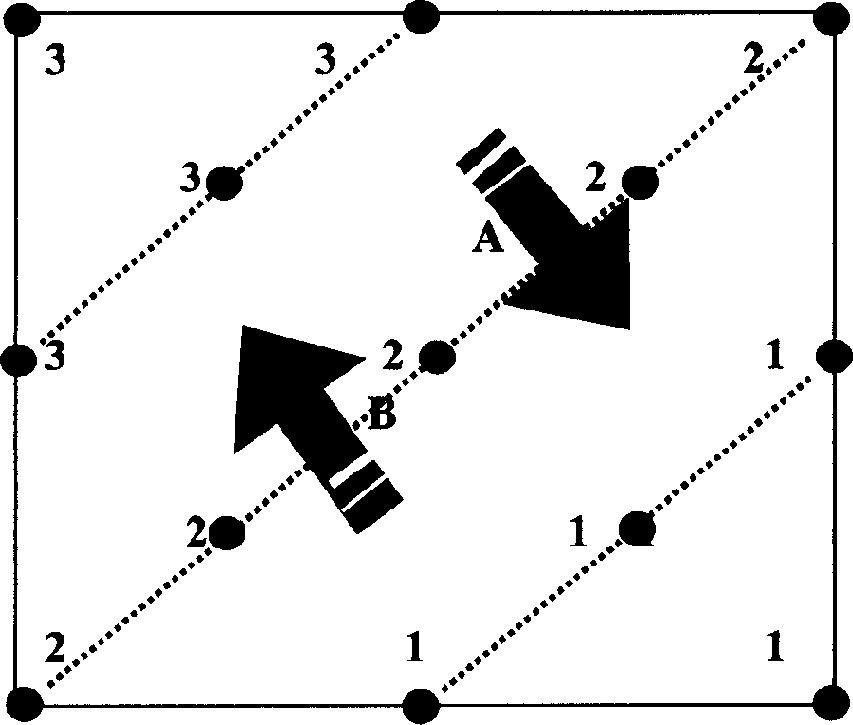

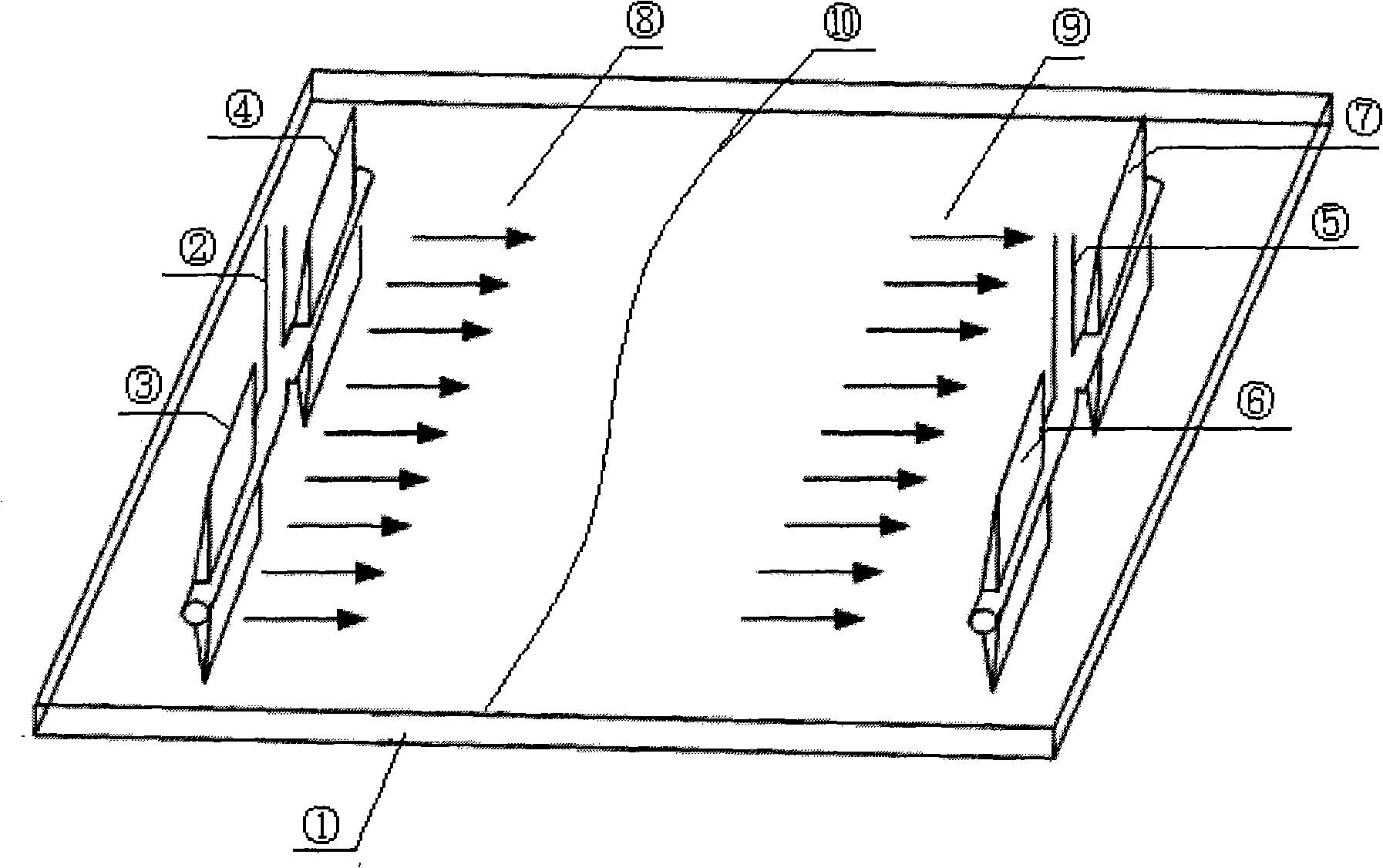

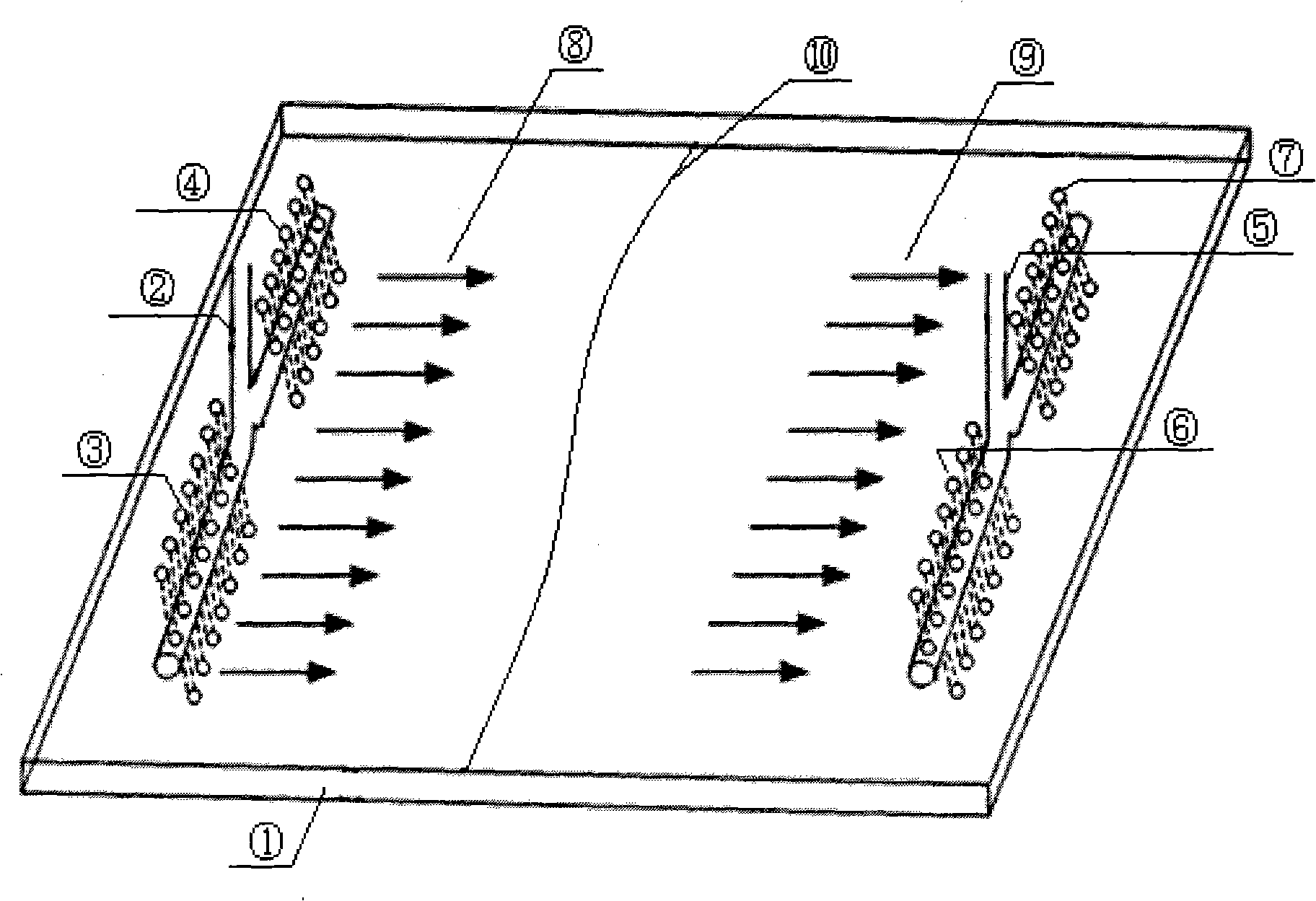

Straight-line parallel flow water injection oil extraction method

The invention relates to a linear parallel-flow water-injection oil excavating method, belonging to the gas field excavating method technical field. The method is characterized in that a plurality of horizontal production wells and a plurality of horizontal water-injection wells are obtained by drilling an oil layer which is suitable for injecting water and excavating with the horizontal wells; the production wells and the water-injection wells are respectively arranged at a certain interval in a row; an injecting well drainage and a production well drainage are alternately arranged and are parallel with each other; the water-injection well and the production well are either single pitshaft horizontal wells or horizontal branch wells; two branches of each horizontal branch well have certain horizontal section lengths and have opposite directions in the same vertical plane; and the horizontal section of each horizontal well is perforated from up to down and is fractured so as to generate an eyelet or a crack, the crude excavation is carried out through injecting water from the water-injection well to the oil layer. The linear parallel-flow water-injection oil excavating method is applied, the fingering phenomenon of the injected water can be improved, the utilization rate of the injected water is improved, the production of residual oil is reduced, recovery percent of the water-injection oil excavating for oil is improved, the waste of oil resource is reduced, and economic benefits for oil-field development is improved greatly.

Owner:YANGTZE UNIVERSITY

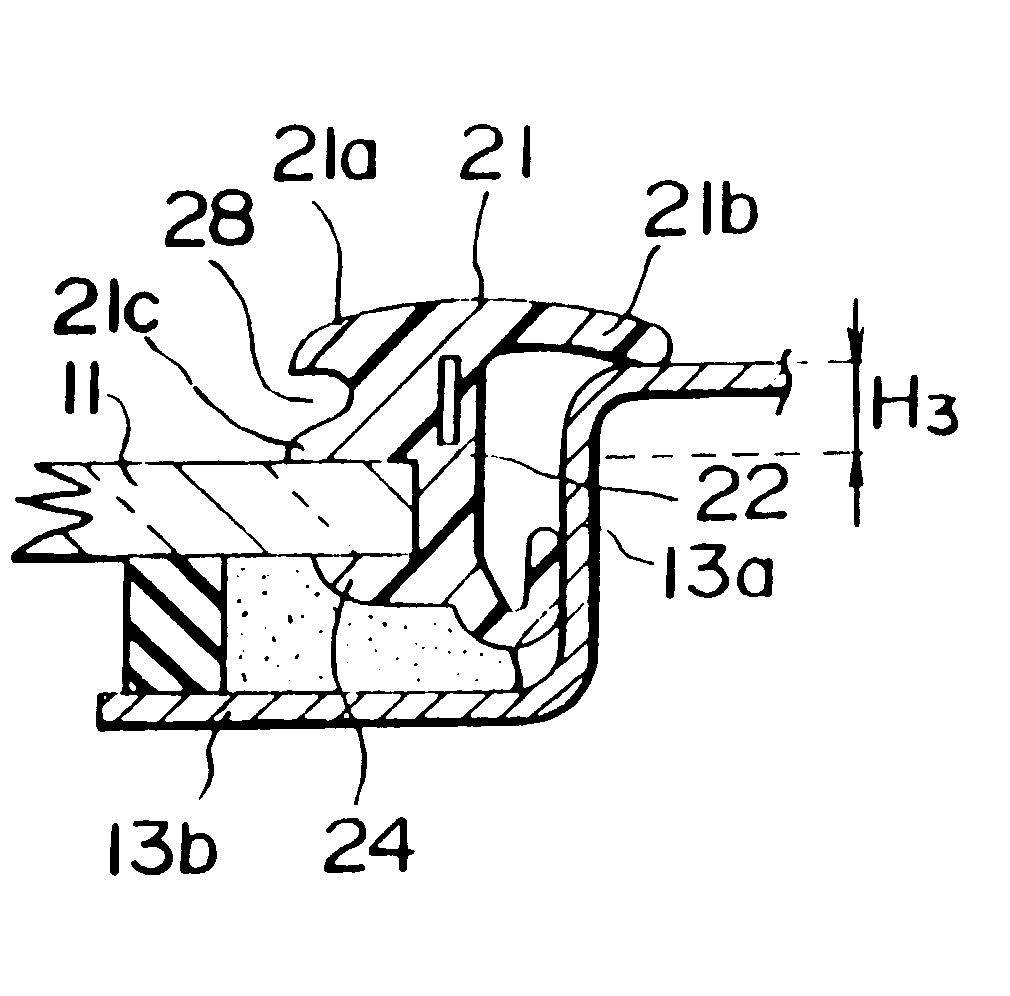

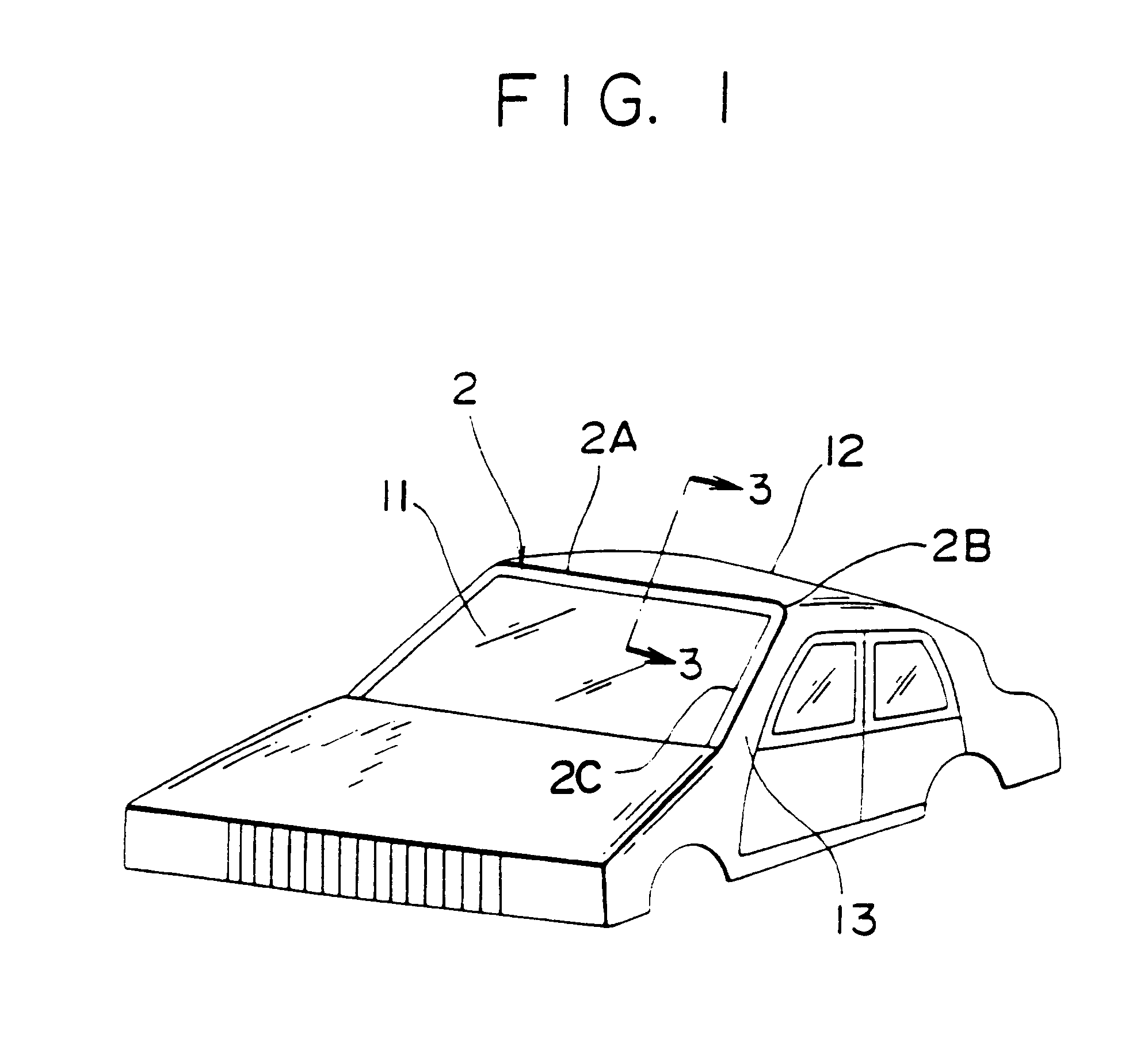

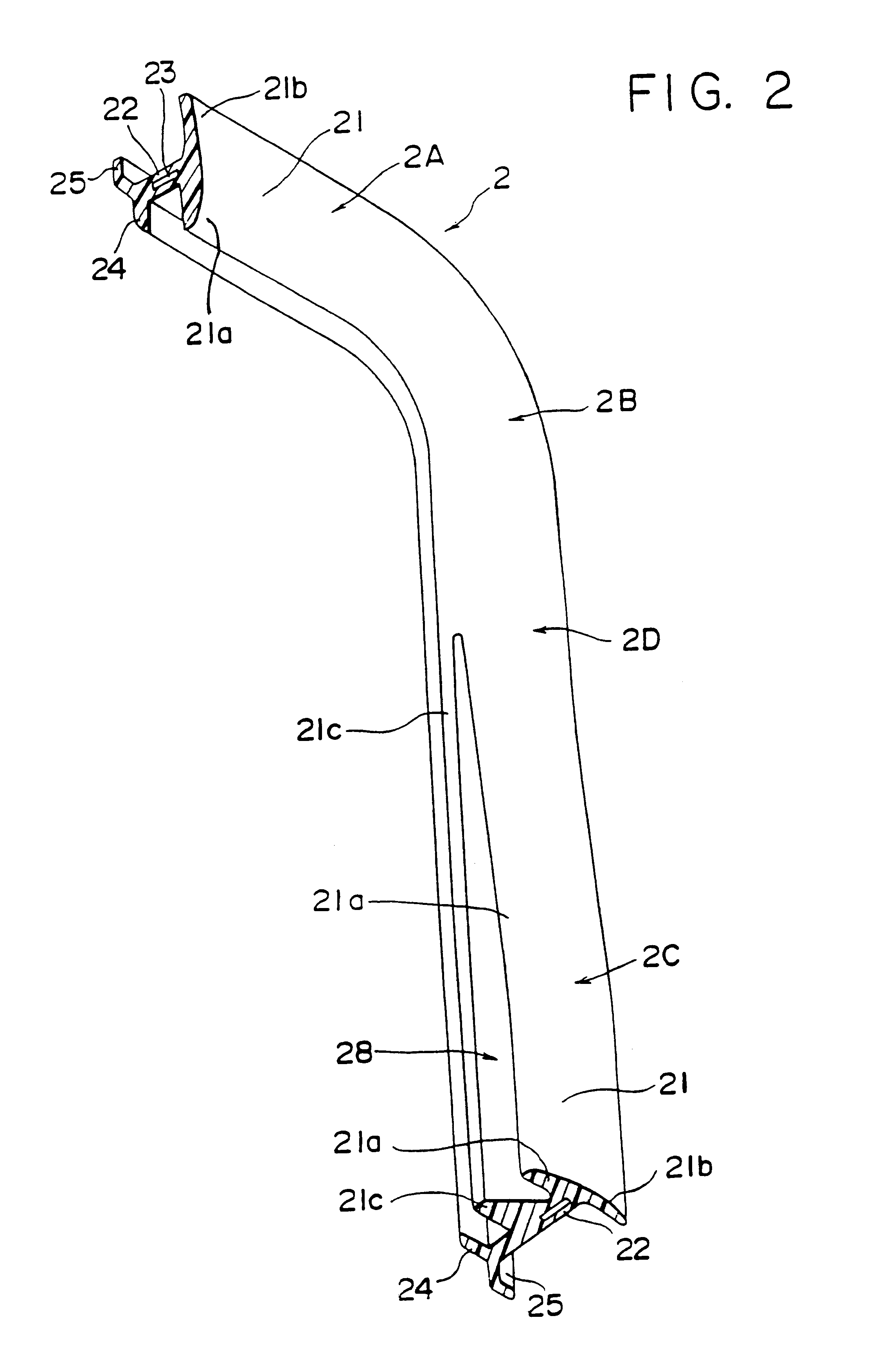

Automobile windshield molding and the method of producing the same

A windshield molding which is installable in the space between a windshield and a periphery of a window opening of a vehicle body panel. The windshield molding includes a pair of extruded side molding parts, a pair of extruded corner molding parts, and an extruded upper molding part integral with and extending between the side and corner molding parts. Each of the side molding parts associated with each side edge of the windshield is greater in thickness as compared with the upper end corner molding parts, where a water drain channel is formed. A windshield molding is also provided which drains rainwater smoothly through the rainwater groove provided at necessary sections and having a different depth in the longitudinal direction for better drainage which can be produced simply and continuously as a single molding without the addition of cutting or other processes.

Owner:TOKAI KOGYO CO LTD

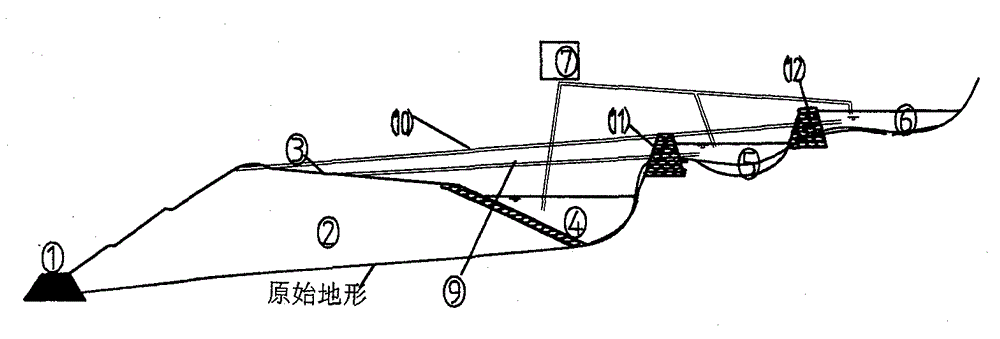

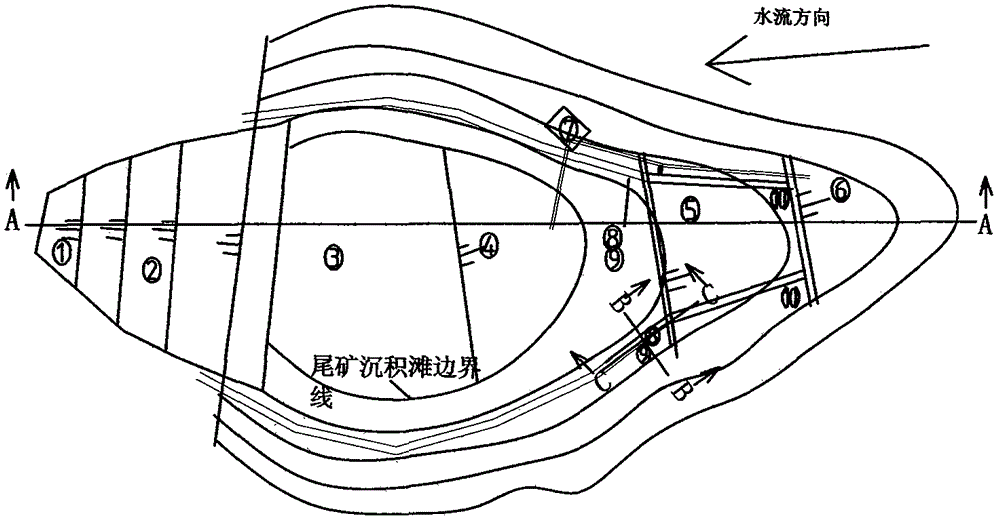

Ecological restoration method for tailing depot reclamation after tailing depot closure

InactiveCN104831678AEnsure safetyQuick drainageWatering devicesArtificial water canalsWater storageDry season

The invention discloses an ecological restoration method for tailing depot reclamation after tailing depot closure. According to the ecological restoration method, a water storage system, a water drainage system and an irrigation system are designed; construction restoration measures adopted by each system accord with environmentally friendly ecological restoration; an interrelated overall system can be formed through the water storage system, the water drainage system and the irrigation system; much water can be impounded in dry seasons so as to be used for irrigation, and floodwaters can be rapidly drained in flooding in rainy seasons, and therefore, the safety of a tailing depot can be ensured, and gravity irrigation can be realized; and regulation can be performed according to the needs of crops, water level in the tailing depot, and weather conditions. The ecological restoration method of the invention can be applied to reclamation ecological restoration and effective utilization of tailing depots after tailing depot closure in various kinds of mines.

Owner:王剑

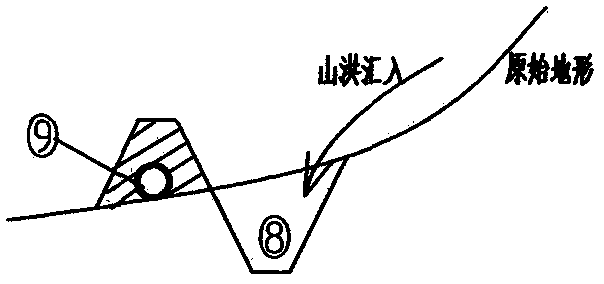

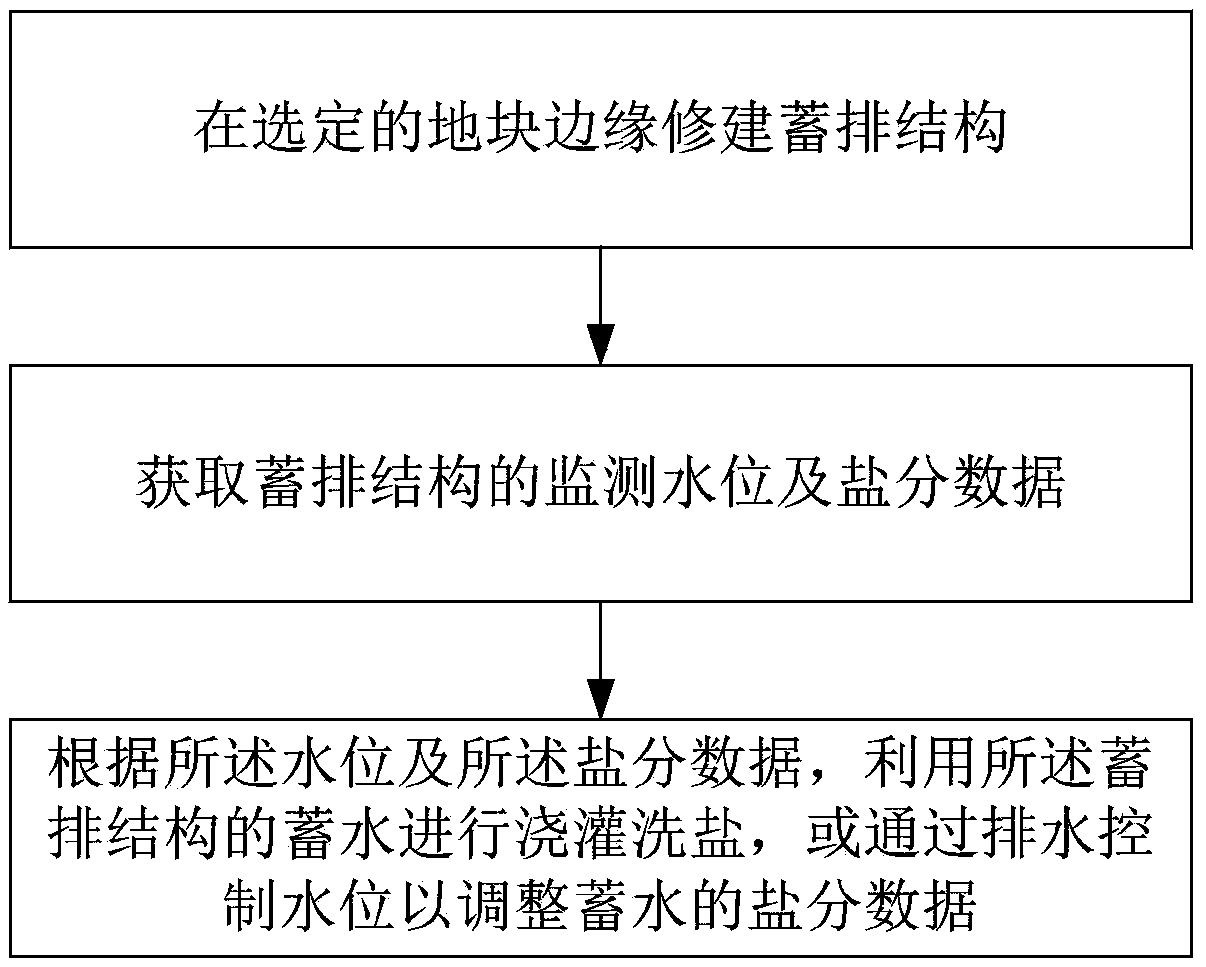

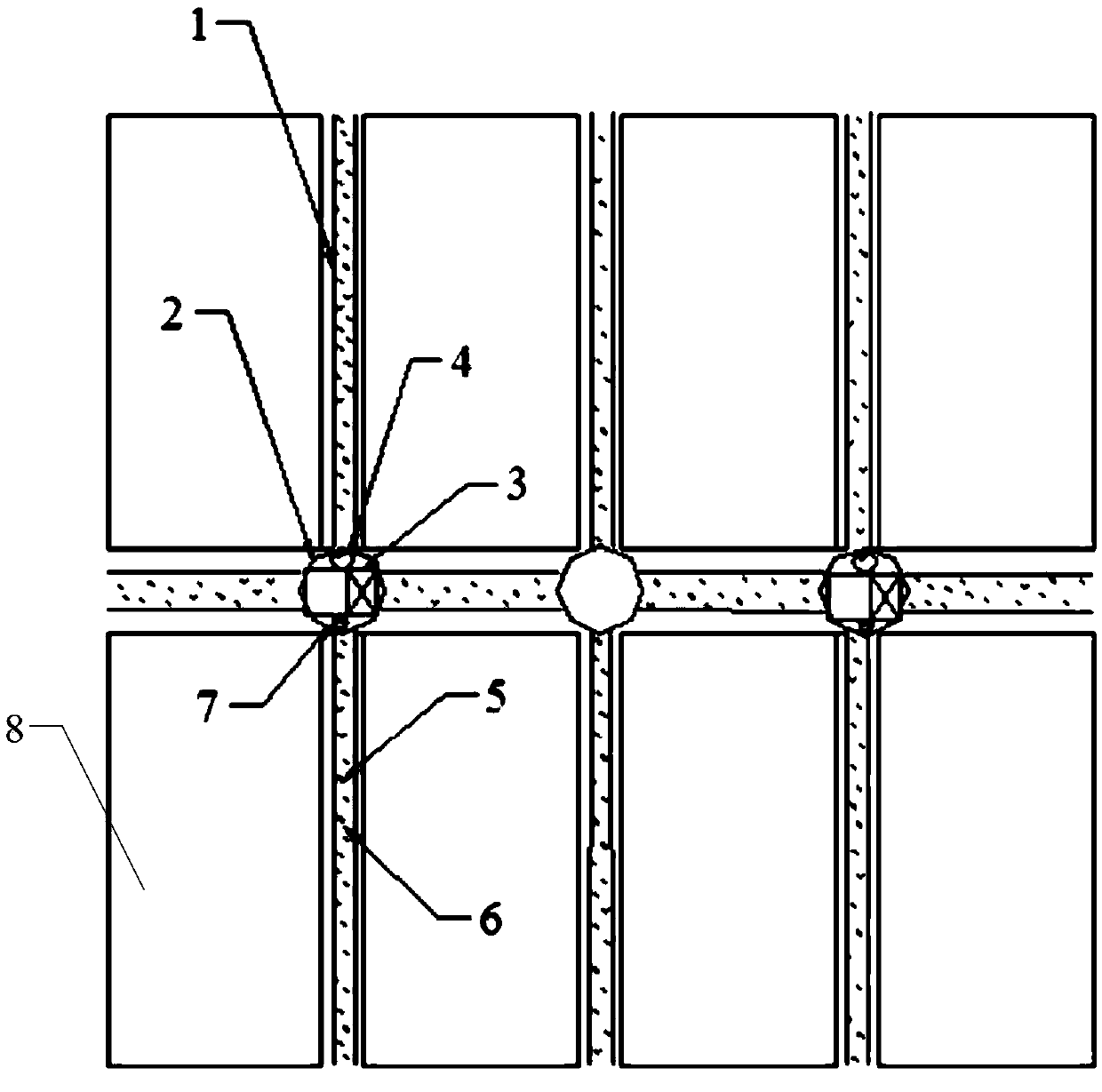

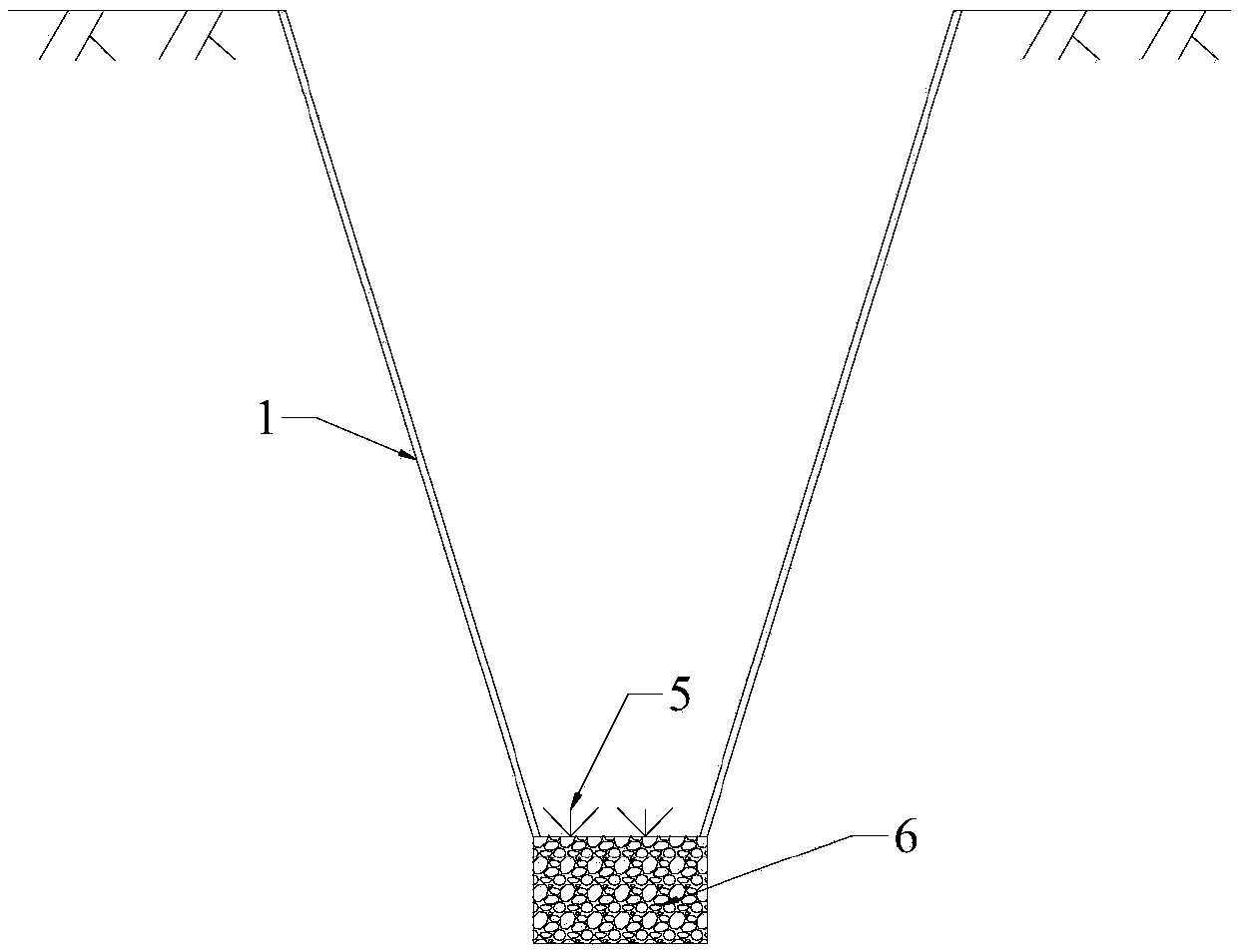

Saline-alkali soil improvement method and system

ActiveCN105359660AIncrease profitConserve fresh water resourcesSoil lifting machinesClimate change adaptationAlkali soilResource consumption

The invention discloses a Saline-alkali soil improvement method and system; the method comprises the following steps: building a storage-drainage structure on the edge of a selected plot; obtaining a monitoring water level and salinity data of the storage-drainage structure; using storage water of the storage-drainage structure to irrigate and leach the salt according to the monitoring water level and the salinity data, or controlling the water level so as to adjust storage water salinity data through water drainage. The method suits coastal near field, can scientifically adjust coastal near-surface underground water level, can improve rainwater utilization rate, can reduce fresh water resource consumption needed for improving solonchak, can improve area soil environment, and is very suitable for periodicity alkalization soil in the coastal region.

Owner:JIANGSU WATER CONSERVANCY SCI RES INST

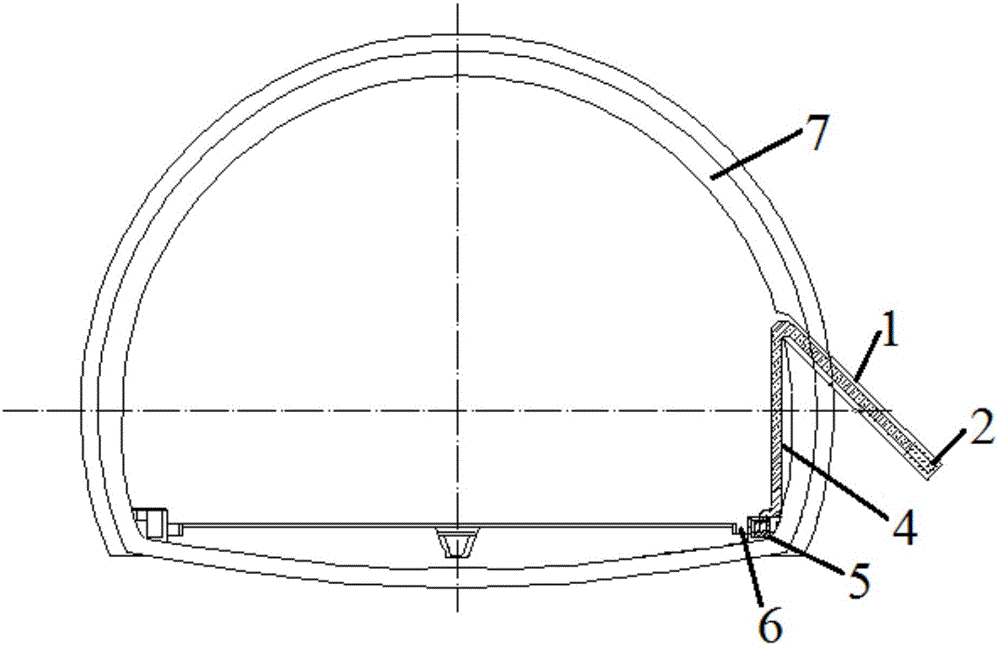

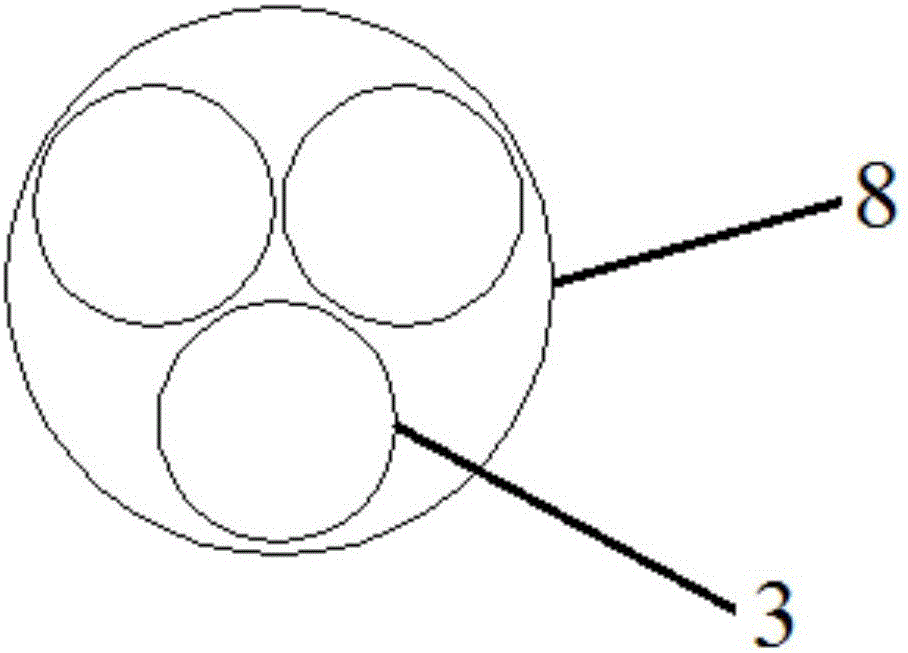

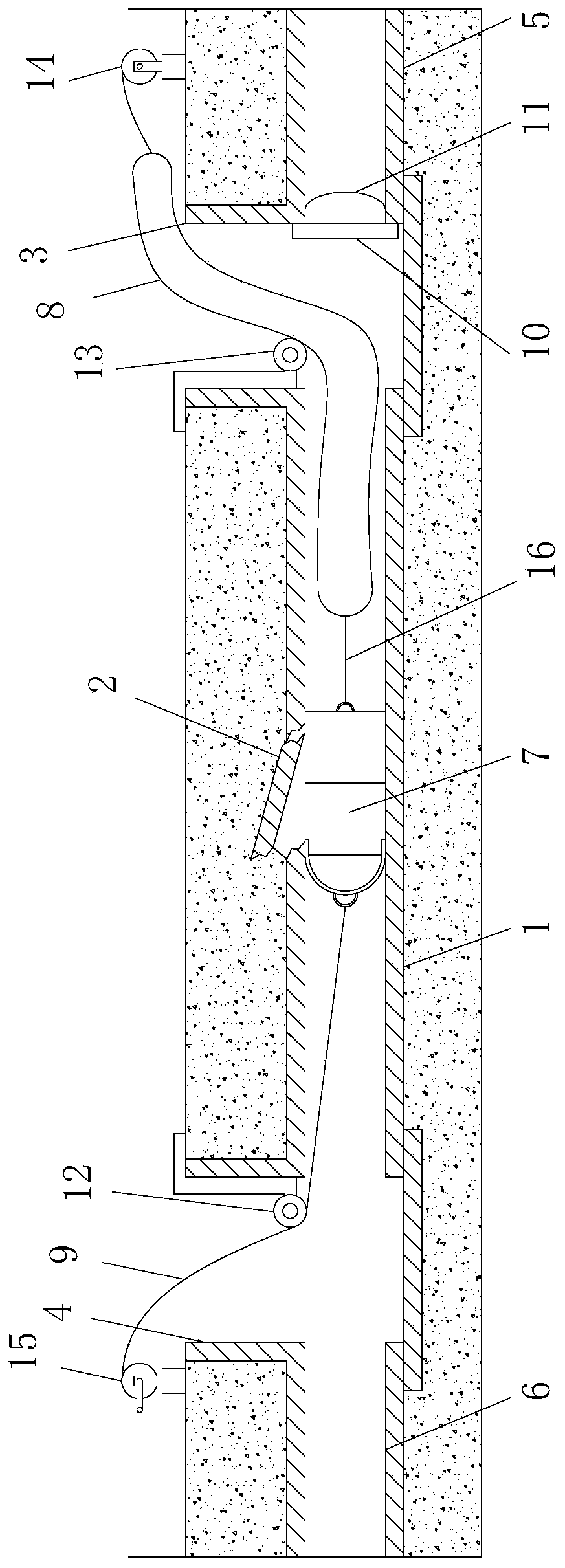

Tunnel siphon water drainage system and construction method thereof

The invention relates to a tunnel siphon water drainage system and a construction method thereof. The water drainage system comprises a drilling hole which is formed in a water seepage point in the wall of a tunnel, a water reservoir arranged on the bottom of the drilling hole, a siphon sleeve communicated with the water reservoir, a water storage barrel and a longitudinal water drainage ditch, wherein an included angle between the drilling hole and a vertical direction is 45-75 degrees; one end of the siphon sleeve is inserted into the drilling hole and is communicated with the water reservoir, and the other end of the siphon sleeve is vertically guided out from the drilling hole, and is arranged in the water storage barrel; a water outlet of the siphon sleeve is lower than the water reservoir by 40-60 cm; during construction, drilling is firstly carried out, the water reservoir and the water storage barrel are arranged, and the two ends of the siphon sleeve are separately inserted into the water reservoir and the water storage barrel. Compared with the prior art, the tunnel siphon water drainage system has the advantages that underground water near the water seepage point in the tunnel wall can be discharged timely, power is not needed to be additionally provided in a water drainage process, water drainage flow and a flow process are automatically controlled by water level changes, and smooth water drainage is effectively guaranteed.

Owner:TONGJI UNIV

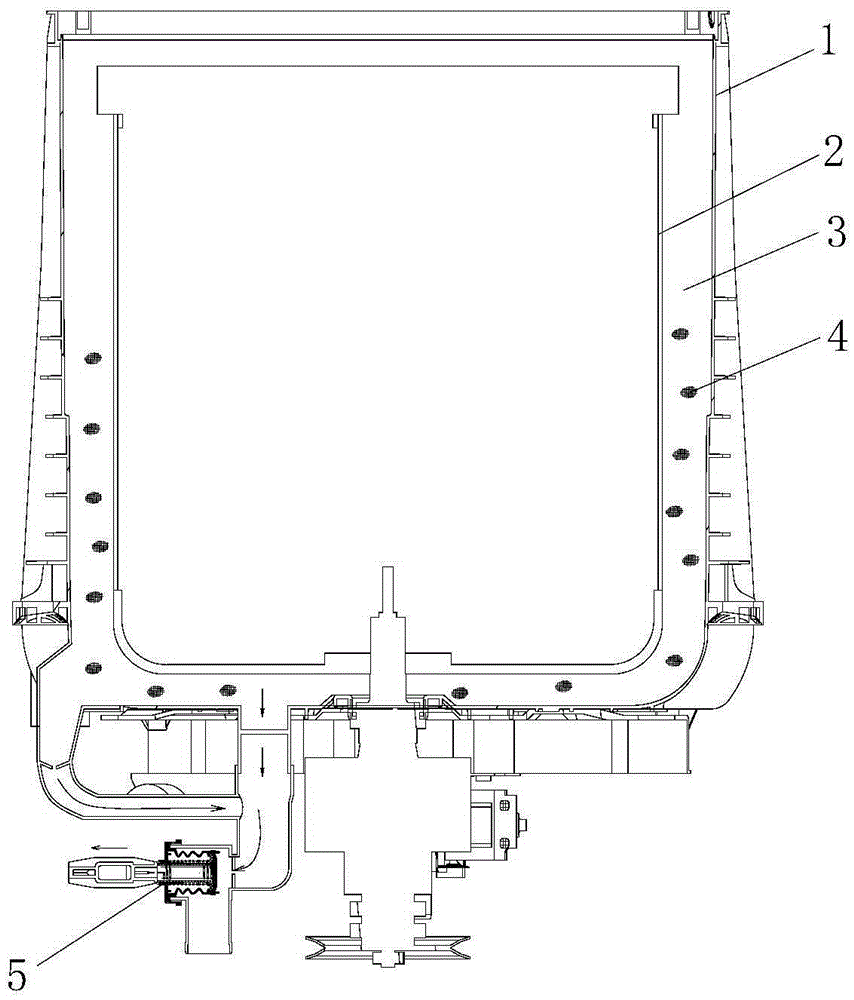

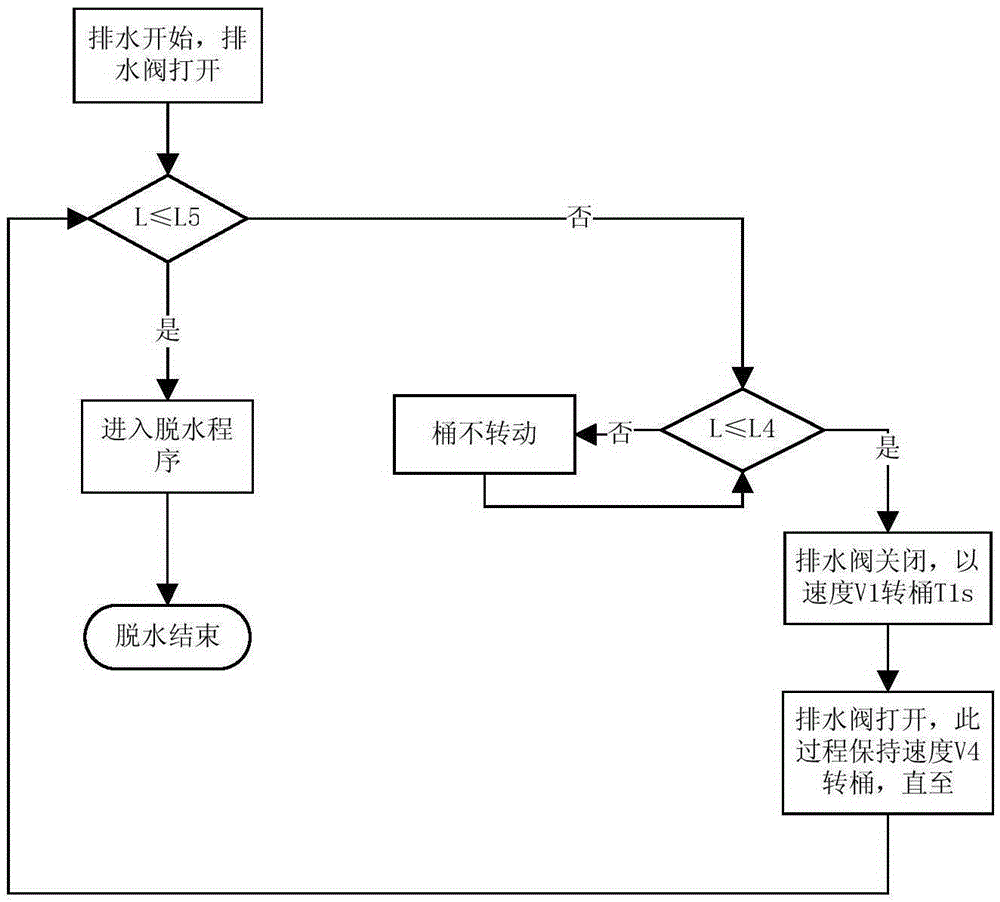

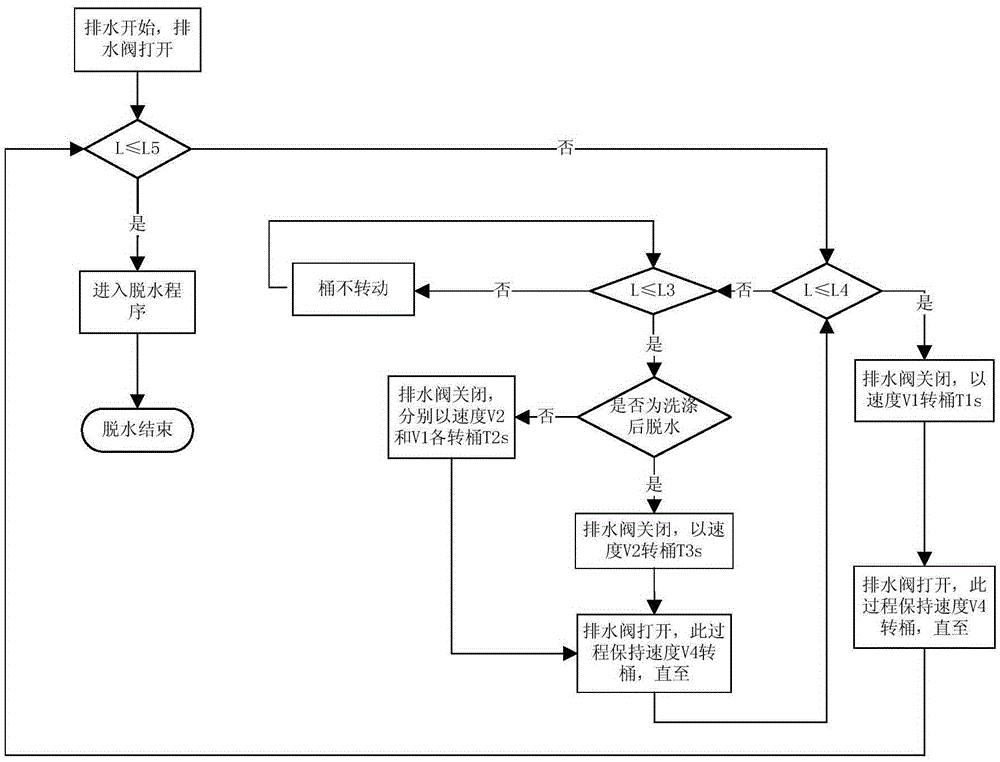

Water drainage and dehydration control method of self-cleaning washing machine

ActiveCN106676820AAvoid generatingAvoid breedingOther washing machinesControl devices for washing apparatusWater flowEngineering

Owner:QINGDAO HAIER WASHING MASCH CO LTD

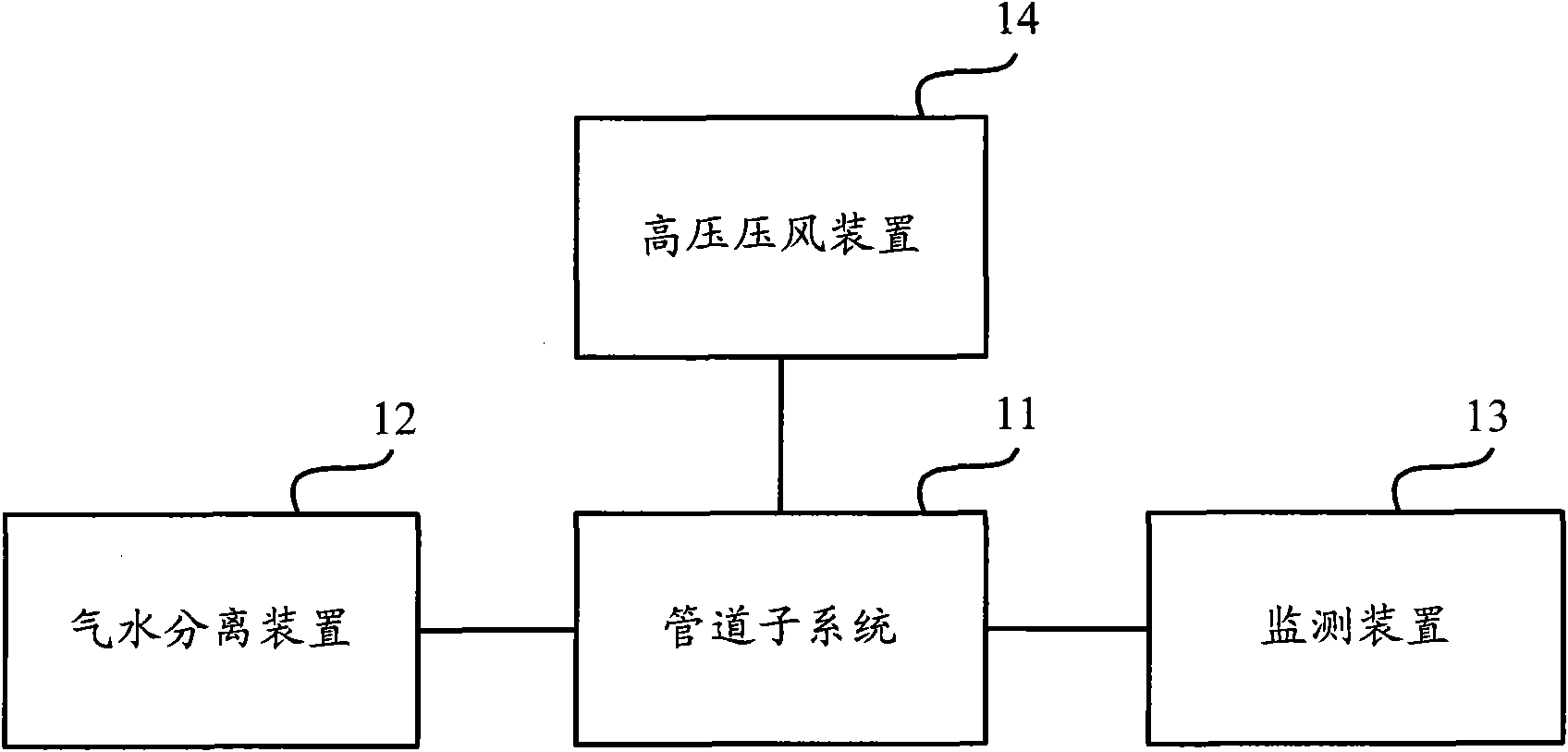

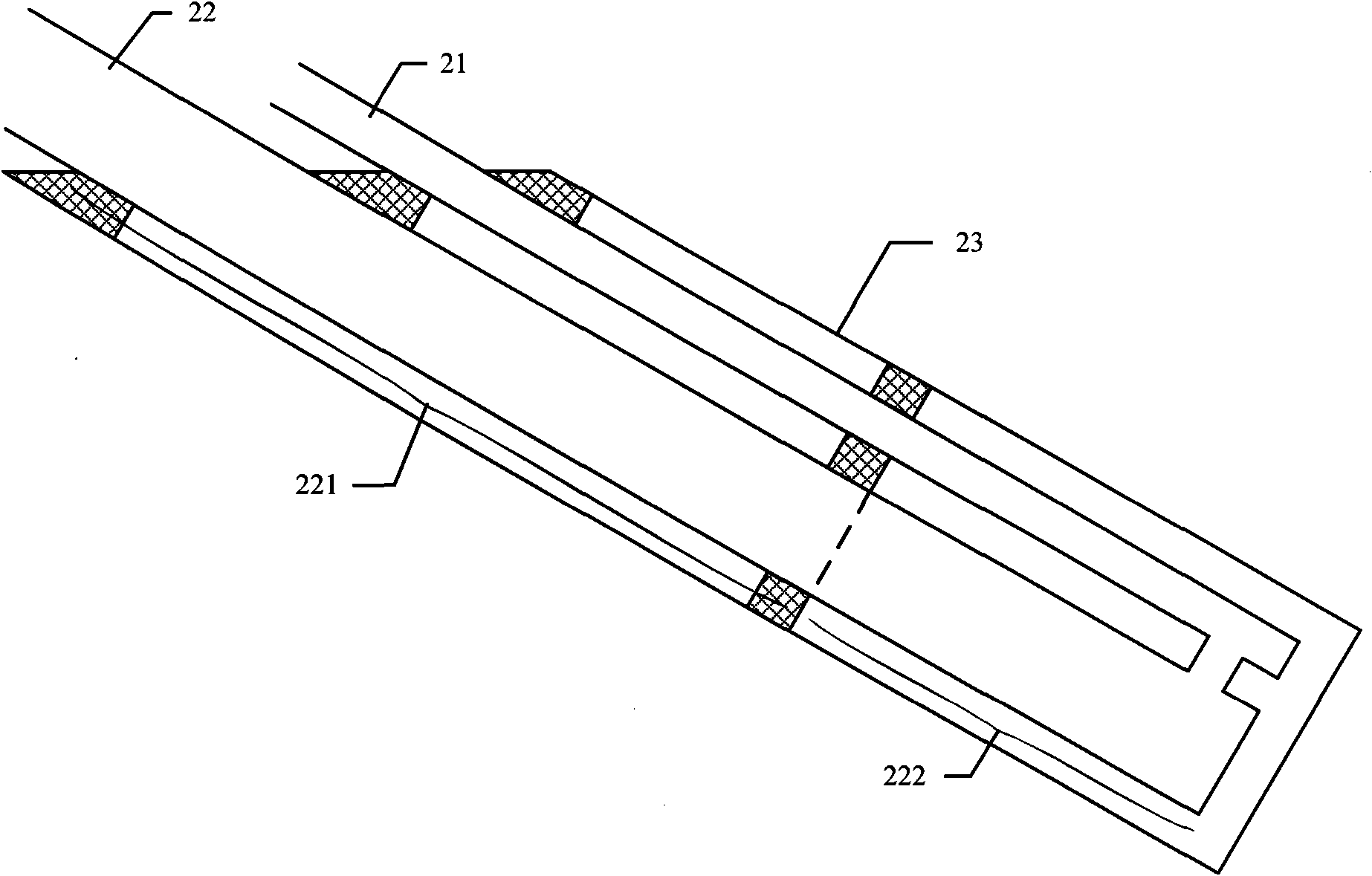

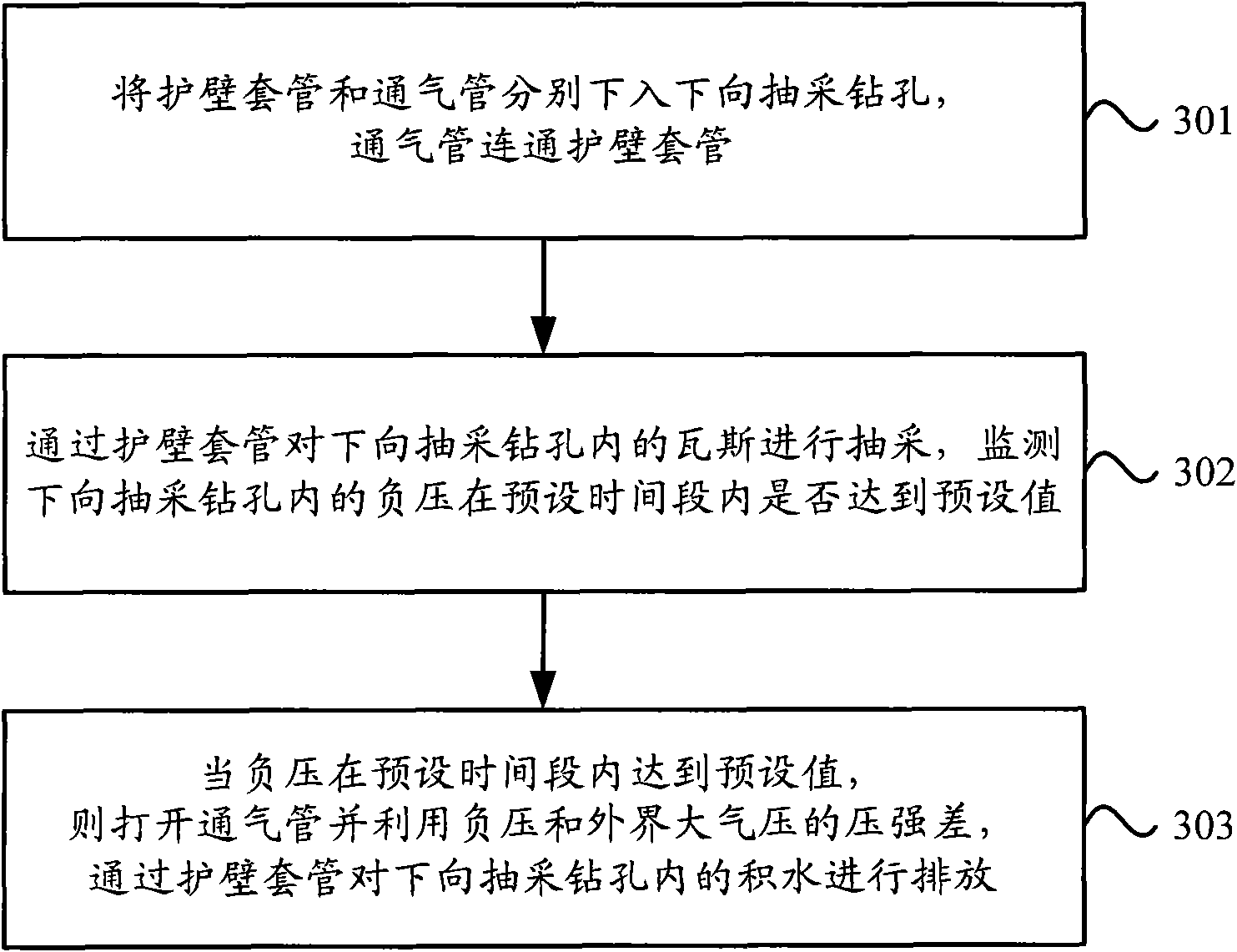

Water drainage system and method based on downward drainage borehole

ActiveCN102102530ASolve the technical defects of continuous extractionContinuous extractionDrainageGas removalBreatherAtmospheric pressure

The invention provides a water drainage system and method based on a downward extraction borehole, wherein the method comprises the following steps: tripping a protection casing and a breather pipe in the downward extraction borehole, wherein the breather pipe is communicated with the protection casing; extracting gas in the downward extraction borehole through the protection casing, and monitoring whether the negative pressure in the downward extraction borehole reaches the preset value in a preset period; when the negative pressure reaches the preset value in the preset period, opening the breather pipe and employing the pressure difference of the negative pressure and the outside atmospheric pressure to drain the logged water in the downward extraction borehole through the protection casing. The drainage system and method based on downward extraction borehole provided by the invention solve the technical defect in prior art that the logged water in the downward extraction borehole influences continuous gas extracting.

Owner:HUAINAN MINING IND GRP

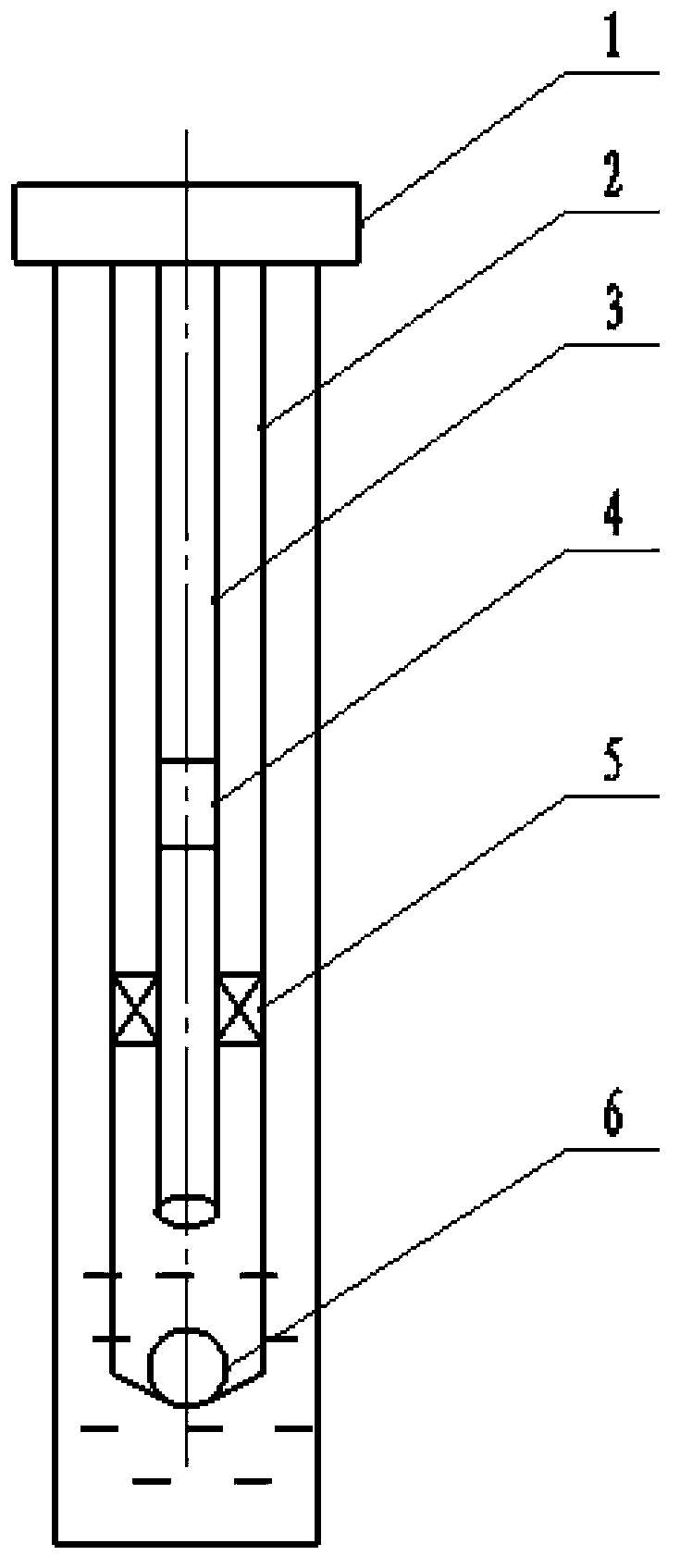

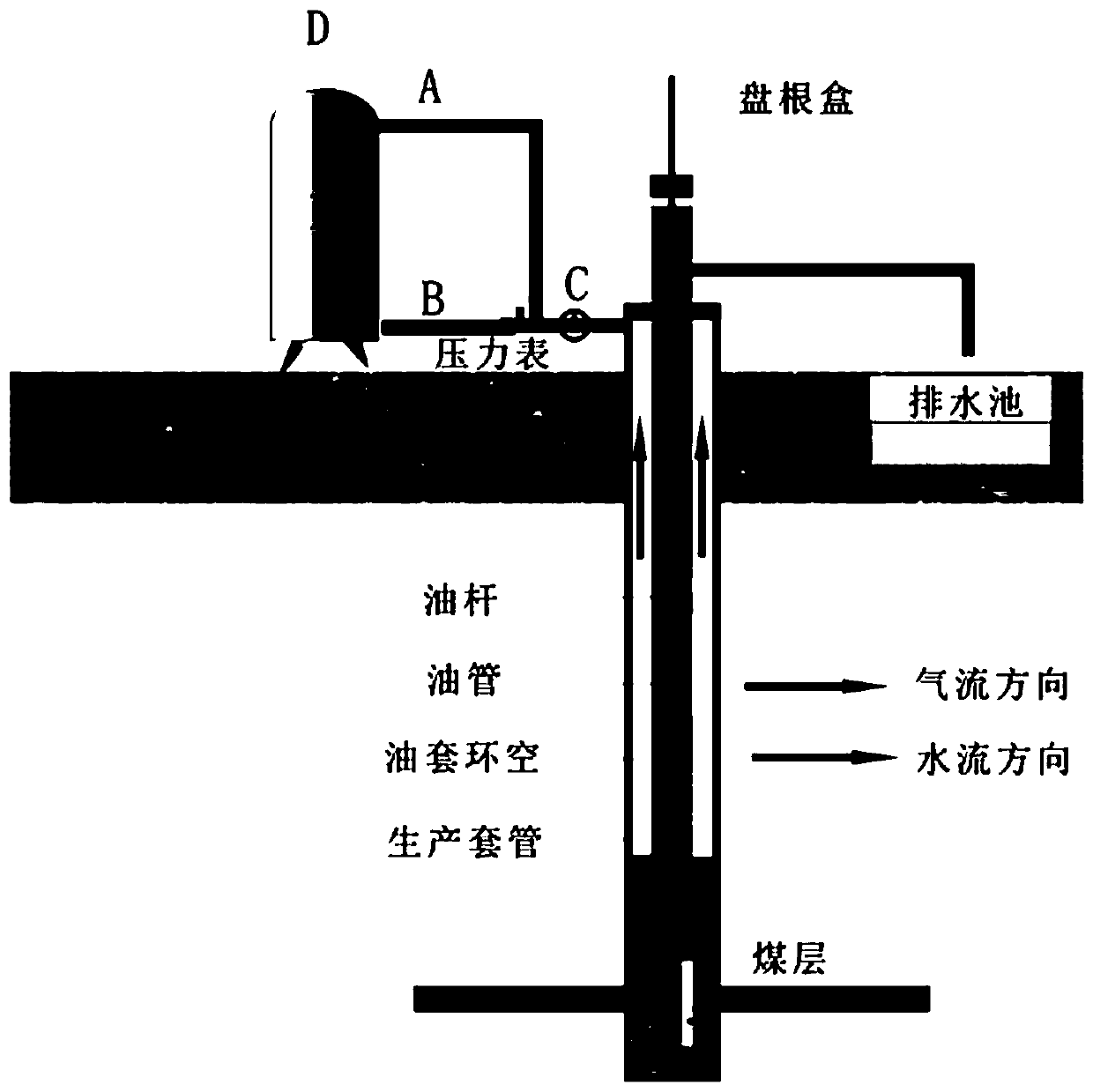

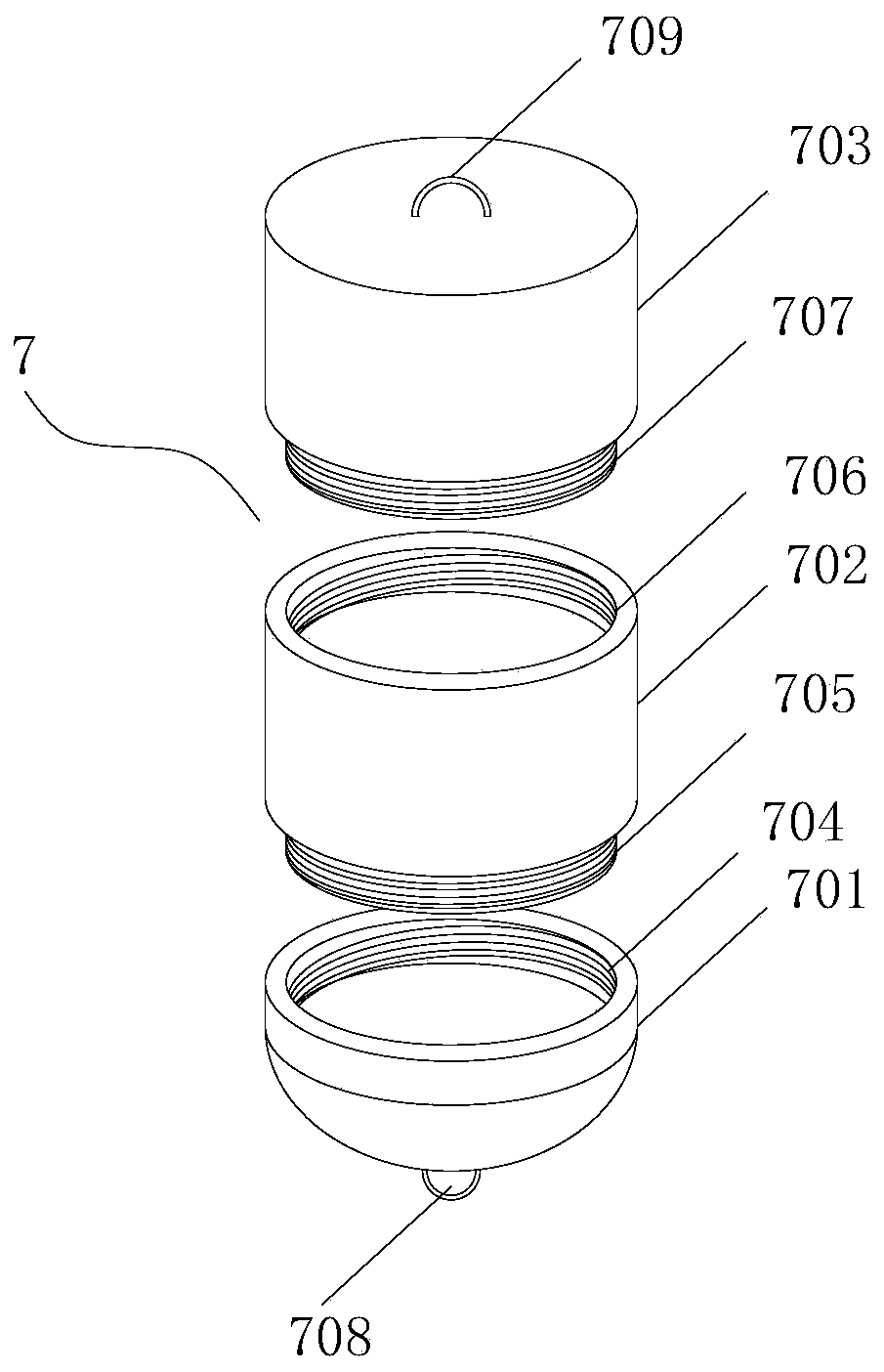

Medium- and shallow-gas well drainage technique pipe and drainage method

ActiveCN103670336ATo achieve the purpose of drainageSimple construction equipmentFluid removalWellboreWell drainage

The invention discloses a medium- and shallow-gas well drainage technique pipe and a drainage method. The technique pipe consists of a surface pump, an oil pipe, a small-diameter oil pipe, a hydraulic jet pump, an insert seal packer and a special bottom valve. The insert seal packer is disposed between the oil pipe and the small-diameter oil pipe, the oil pipe is connected with the insert seal packer in a threaded manner, the special bottom valve is connected with the oil pipe in a threaded manner, the hydraulic jet pump is disposed in the middle of the small-diameter oil pipe, and the small-diameter oil pipe is connected with the surface pump in a threaded manner. The drainage method includes laying down the technique pipe and draining accumulated liquid at the bottom of the well. By the technique pipe and the drainage method, accumulated liquid at the bottom of the medium- and shallow-gas well can be effectively drained, and the purpose of draining liquid from a well shaft to cause flowing of gas is achieved.

Owner:PETROCHINA CO LTD

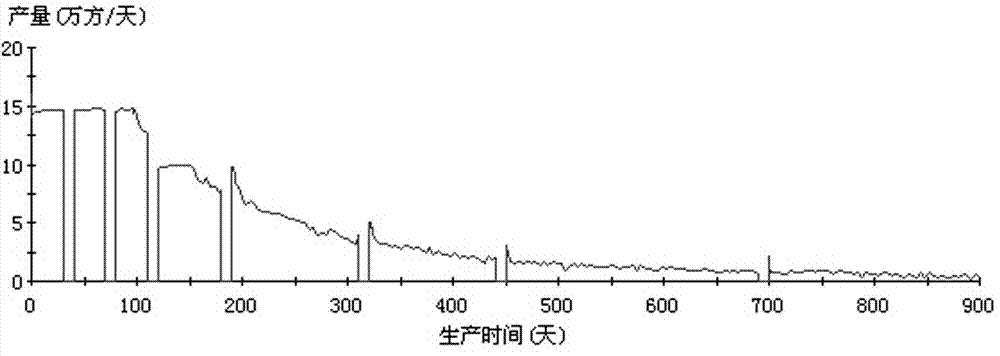

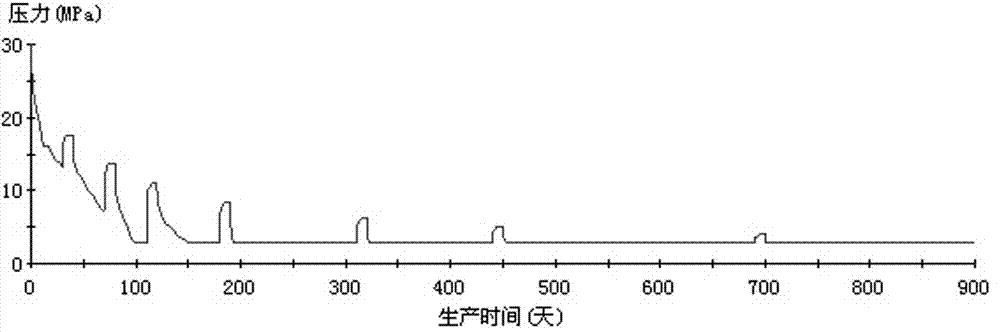

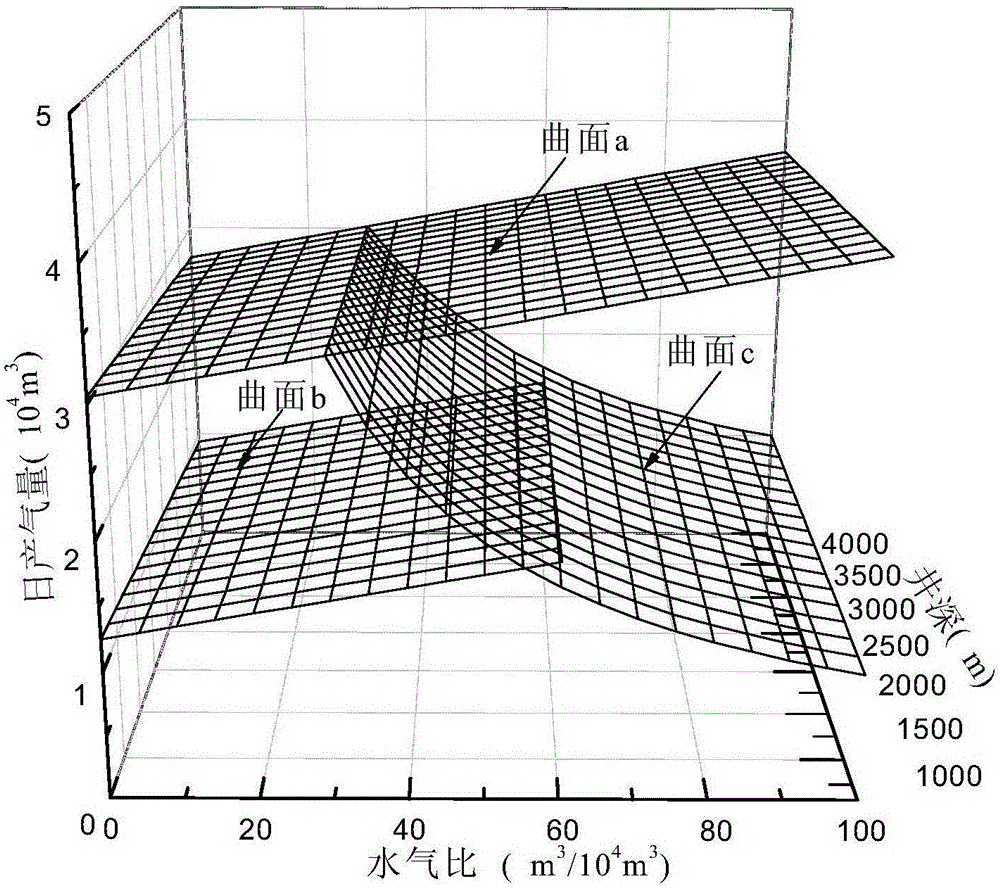

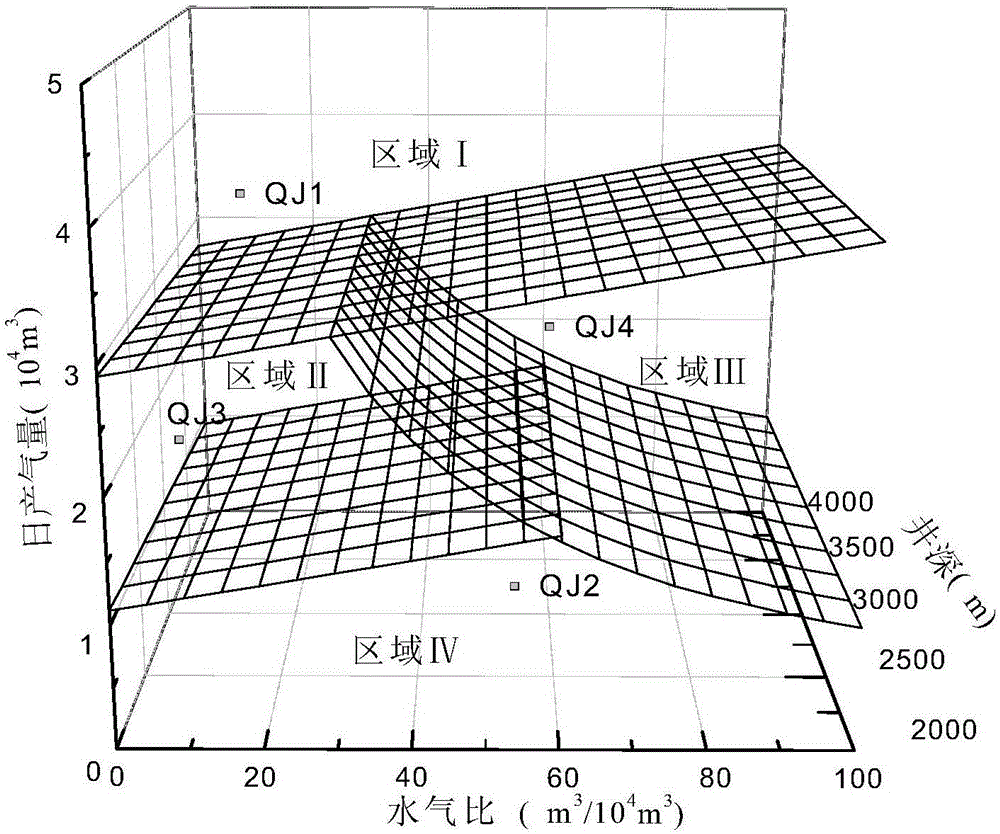

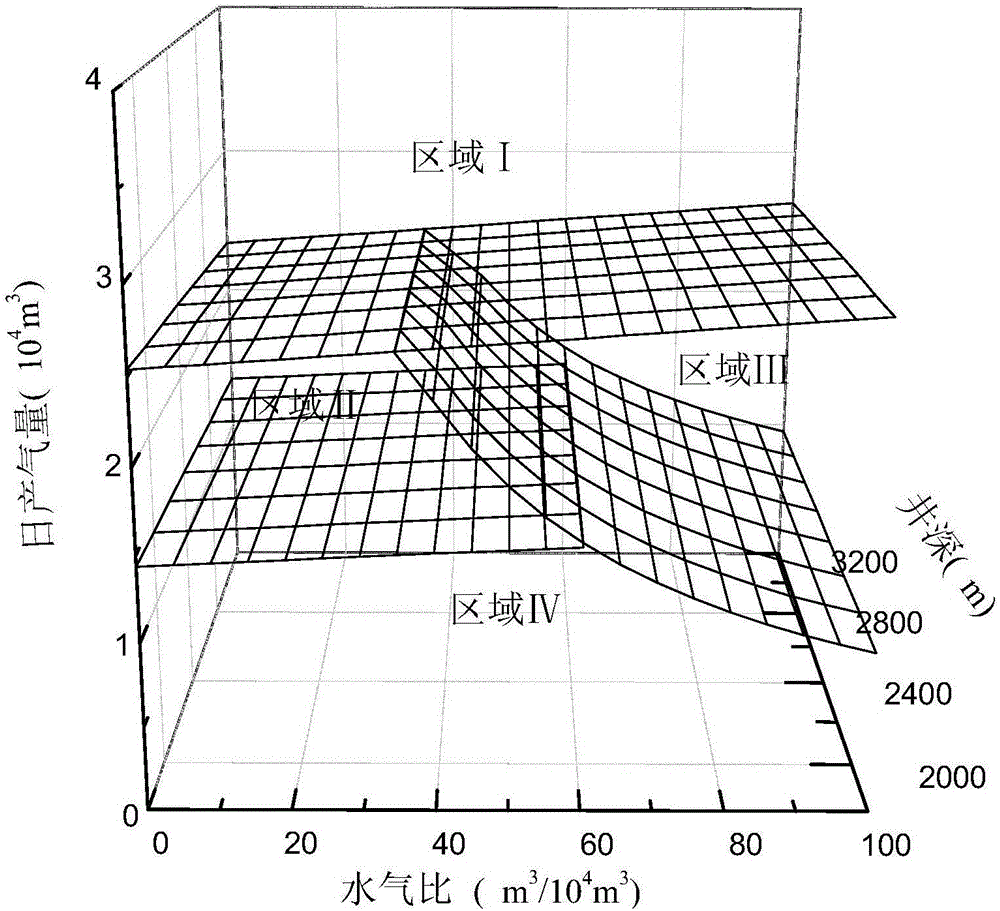

Building method and application of three parameter-gas well drainage gas recovery technology optimizing model

ActiveCN106570273ADrainage gas recovery process is simpleDrainage gas recovery process is fastSpecial data processing applicationsDepth in a wellFlow curve

The invention relates to the technical field of natural gas exploitation and in particular relates to a building method and an application of a three parameter-gas well drainage gas recovery technology optimizing model. A difficulty of rapid selection of drainage gas recovery technology for water-producing gas well is solved. The building method comprises steps of first, collecting production parameters of a water-producing gas well of a gas field, then calculating different daily gas production of a given oil pipe aperture and natural gas critical liquid carrying flow under a water-gas ratio at different well depths, drawing out natural gas critical liquid carrying flow curves (a,b) of maximum and minimum oil pipe apertures on daily gas production, water-gas ratio and well depth three-dimensional model, and drawing out a curve (c) with liquid production amount being 95m<3> on the three-dimensional model. The natural gas critical liquid carrying flow calculated by the method meets on-site production condition in a better way; and the building method is advantaged by quick determination of gas well drainage gas recovery technology based on simple parameters such as daily gas production, water-gas ratio and the well depth.

Owner:PETROCHINA CO LTD +1

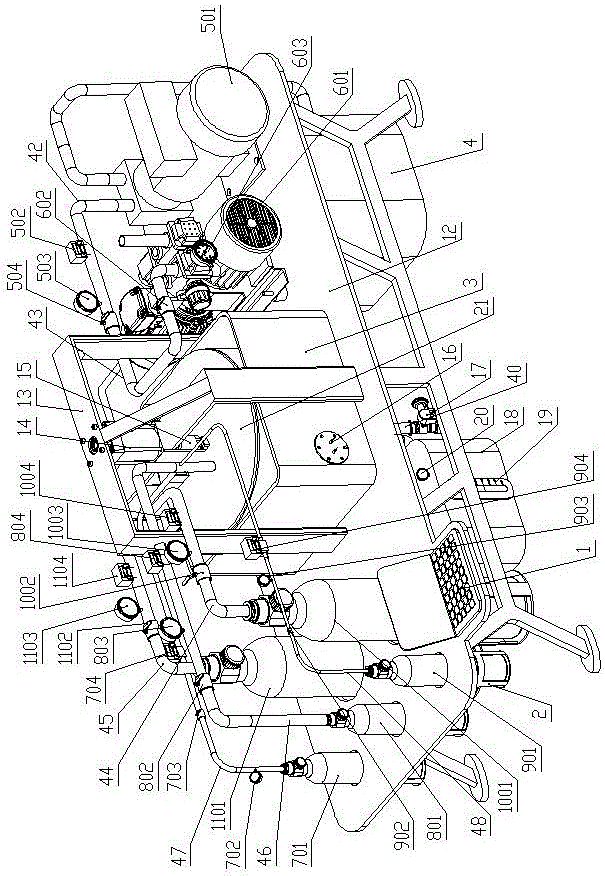

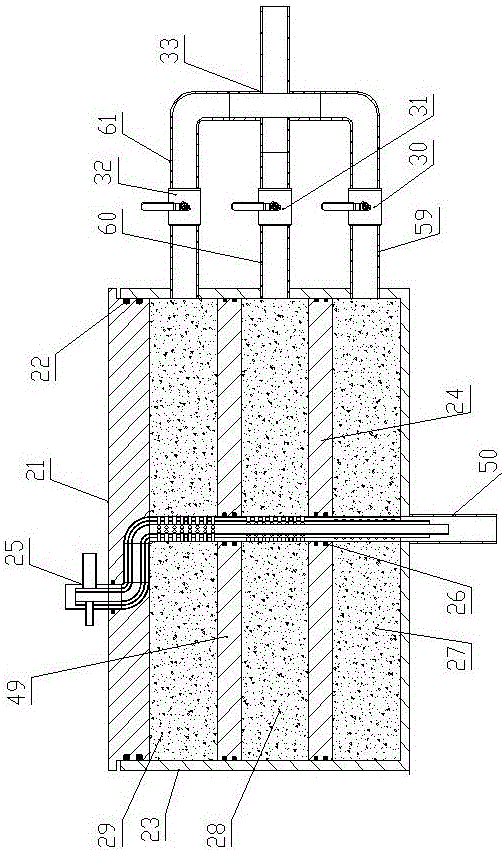

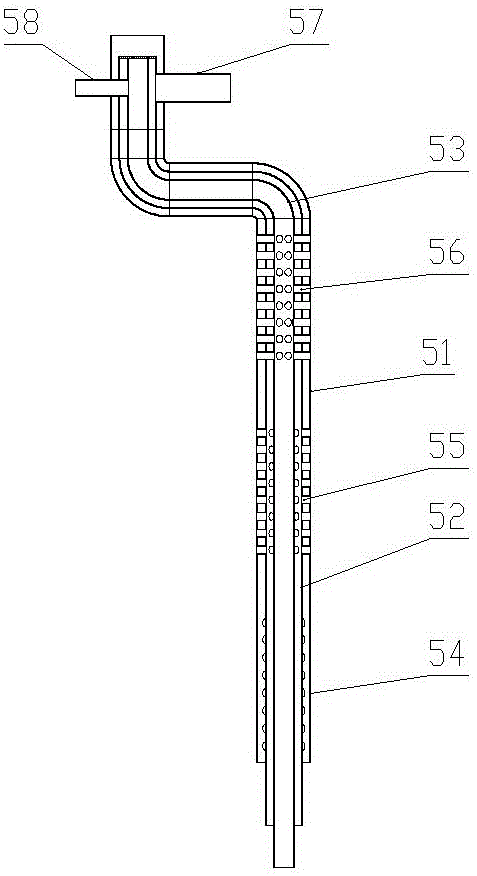

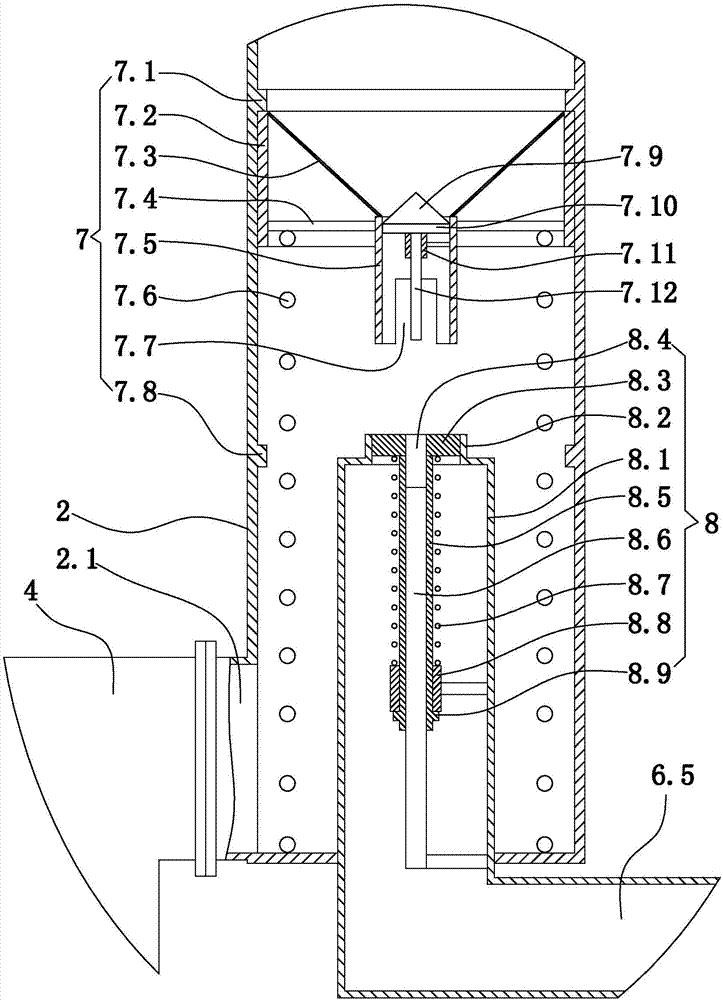

Physical simulation device for multiple seam gas well drainage and production and experimental method thereof

ActiveCN106812523AAccuracy of experimental resultsRestore formation conditionsSurveyConstructionsGas cylinderMethane gas

The invention provides a physical simulation device for multiple seam gas well drainage and production. The device comprises a controlling computer, an experimental table, a hydraulic cylinder support rack, a boosting water pump, a vacuum pump, a first level coal seam methane recycling bottle, a second level coal seam methane recycling bottle, a methane gas supply cylinder, a helium gas storage bottle, a hydraulic cylinder, a coal seam boosting water tank, a water returning tank, a thermal water tank and a coal seam boosting chamber. The side portion of the coal seam boosting chamber is connected with a water gas multi-purpose pipeline. A three-channel gas recycling pipe is arranged in the coal seam boosting chamber. The invention further discloses an experimental method of the multiple seam gas well drainage and production. According to the physical simulation device for multiple seam gas well drainage and production and experimental method thereof, the coal samples with physical property parameters similar to the coal seam to be simulated is selected to make the experiment results more accurate, the fracture treatment is imposed on the coal sample before the experiment to form an artificially modified seam network in the condition of a reservoir stratum. The device and method can be directly used for the simulation of the water drainage and gas mining in multiple seams, provide the basis for predicting the drainage and mining effects in actual production process and making reasonable drainage and mining regulation.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Efficient flowback method of pulverized coal for coal-bed gas well

InactiveCN109252820ASimple Security InjectionImprove pump efficiencyCleaning apparatusFlushingCarrying capacityHigh pressure

The invention relates to the technical field of coal-bed gas drainage and mining, in particular to an efficient flowback method of pulverized coal using a chemical detergent. The chemical detergent with high foaming quality and high coal-carrying capacity is prepared according to pulverized coal characteristics. An injection device good in simplicity and safety is invented; a safety injection measure and post-injection drainage and mining management method are formulated. Upon injection of the chemical detergent, an additional high-pressure pump is not required; pipeline connection allows thechemical detergent to flow into a casing annulus via self-gravity after tank pressure and casing annulus pressure are balanced. The chemical detergent is injected into the casing annulus; pulverized coal near a wellbore area and a pumping inlet is cleaned; foam generated by the chemical detergent is used to return the pulverized coal to the surface, so that pulverized coal cleaning and pump efficiency improving are achieved. The method herein is simple and feasible, good in safety and high in efficiency. In late coal-bed gas well drainage and mining, intermittent drainage and mining or reinjected water treatment is performed; the pulverized coal can be discharged to the surface with produced water, and pump jamming and other issues are avoided.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

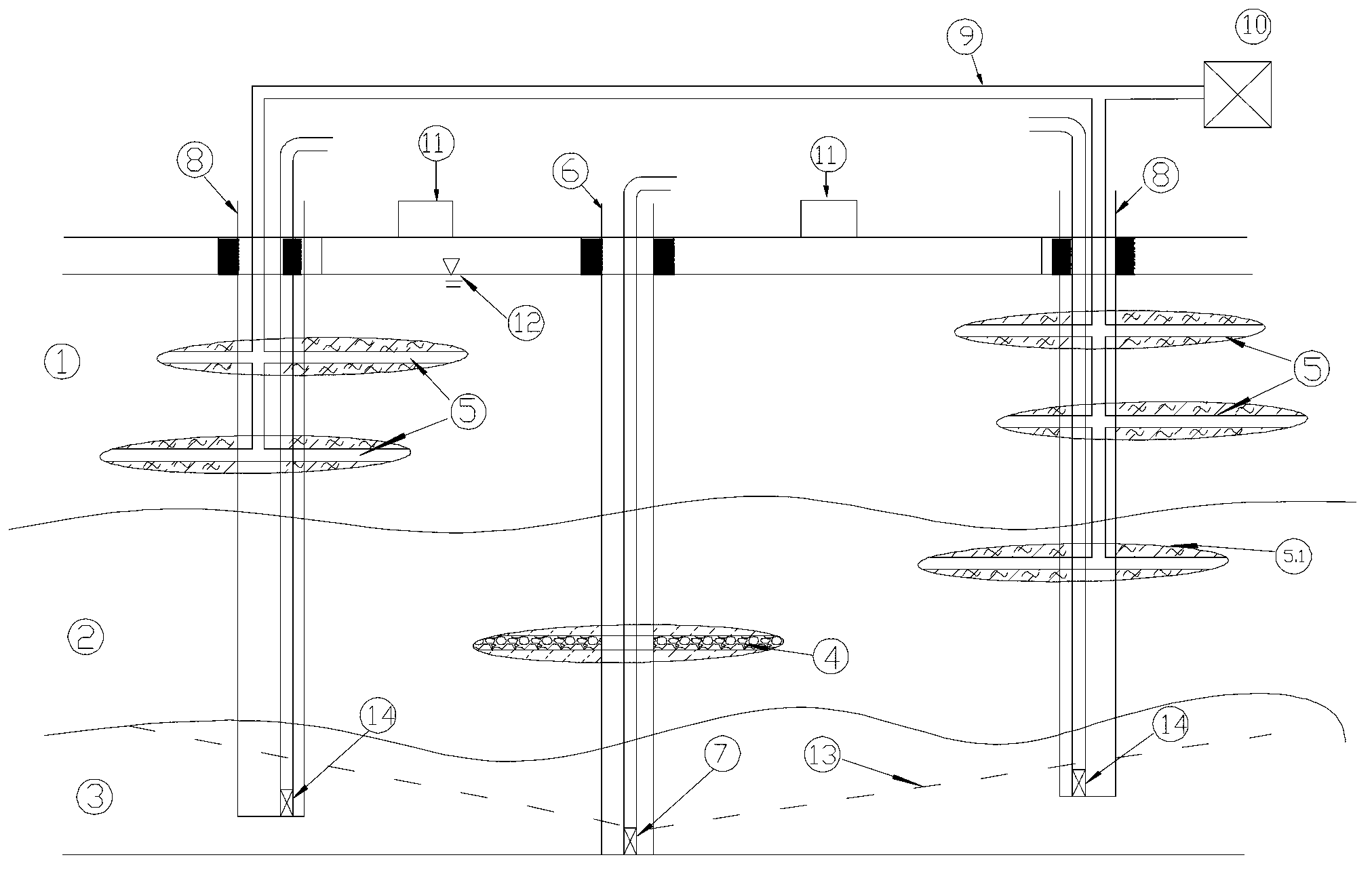

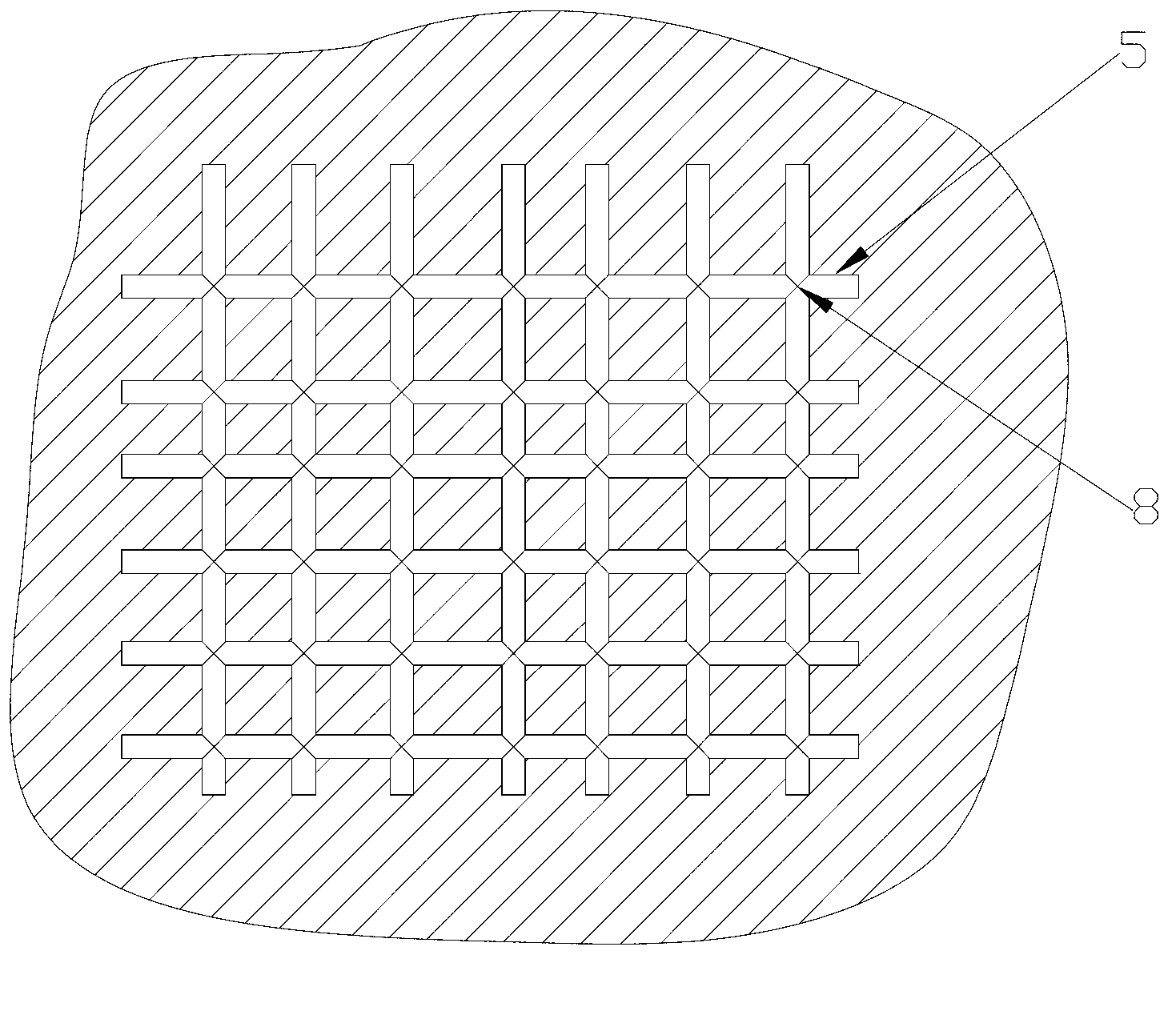

Stereo combined power drainage solidifying system and method for soft soil foundation of heterogeneous field

ActiveCN103215945AEasy to handleShort construction periodSoil preservationWork periodVacuum pressure

The invention discloses a stereo combined power drainage solidifying system and method for a soft soil foundation of a heterogeneous field. The drainage solidifying of soft soil is accelerated by performing stereo combined drainage formed by combining gravity water pumping and vacuum pressure drainage on the soft soil foundation of the heterogeneous field to be treated and performing power pressing on the soft soil foundation of the heterogeneous field to be treated. The stereo combined power drainage solidifying method disclosed by the invention is a novel power drainage solidifying method with a good treatment effect, a short work period, low construction cost and a wide application range, is suitable for the soft soil foundation treatments of the heterogeneous field with blow-filling (backfilling) materials, sandy soil, sludge-containing cohesive soil or powder soil, mixing filled mud and sand and mud-sand interactive soil layers existing under original mud flats, and can overcome the treatment problem of the soil foundation brought by the heterogeneous field.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

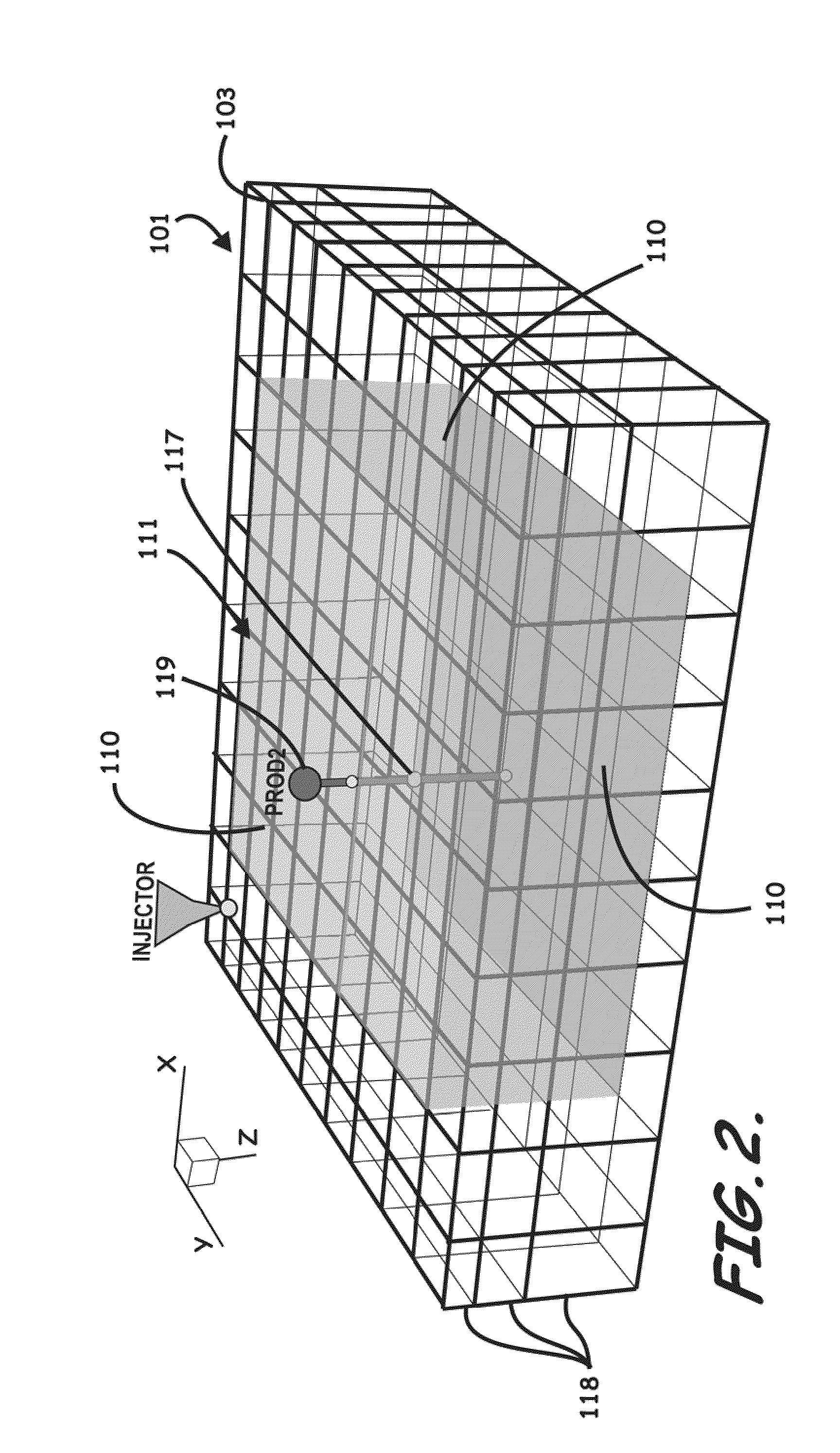

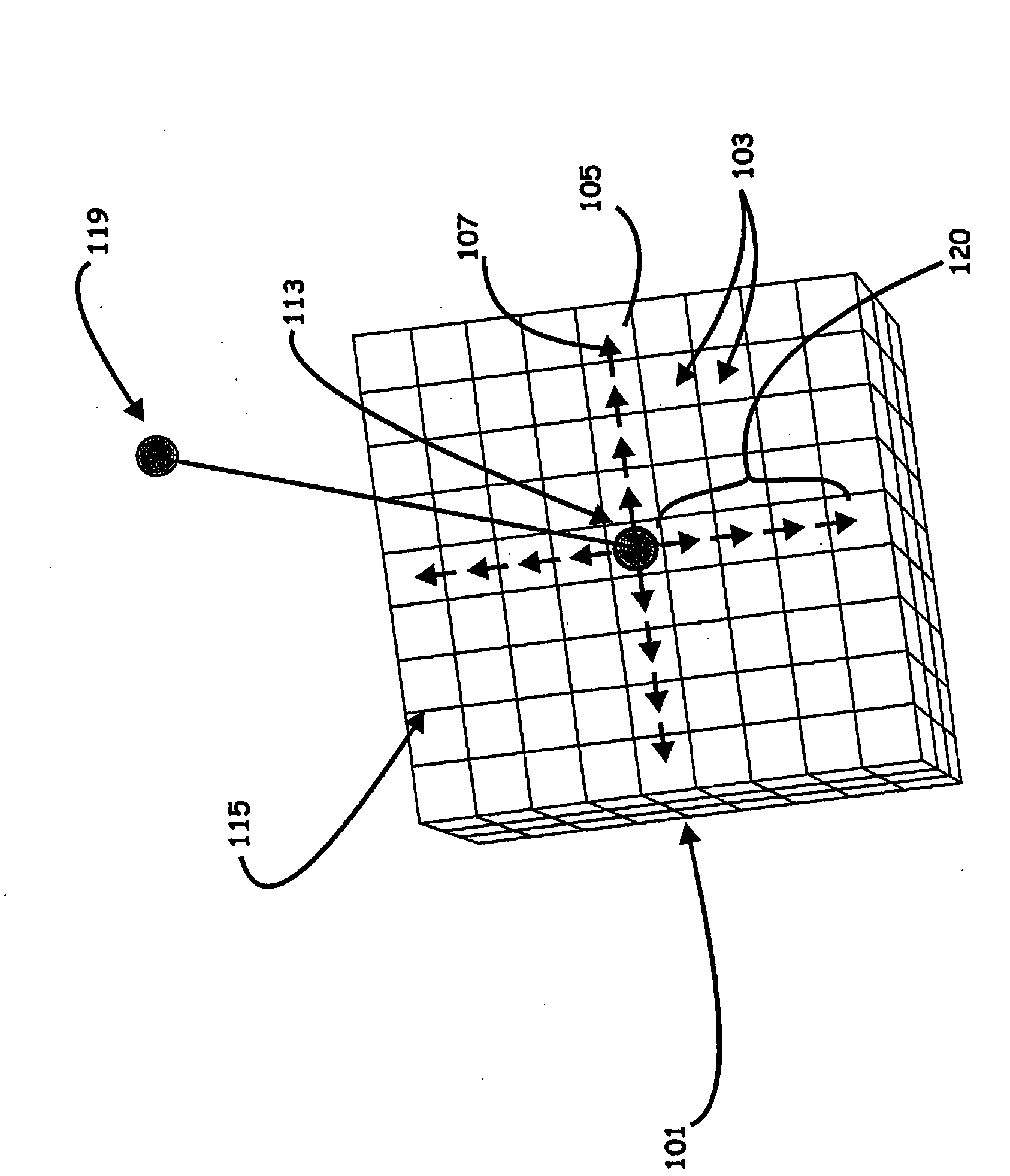

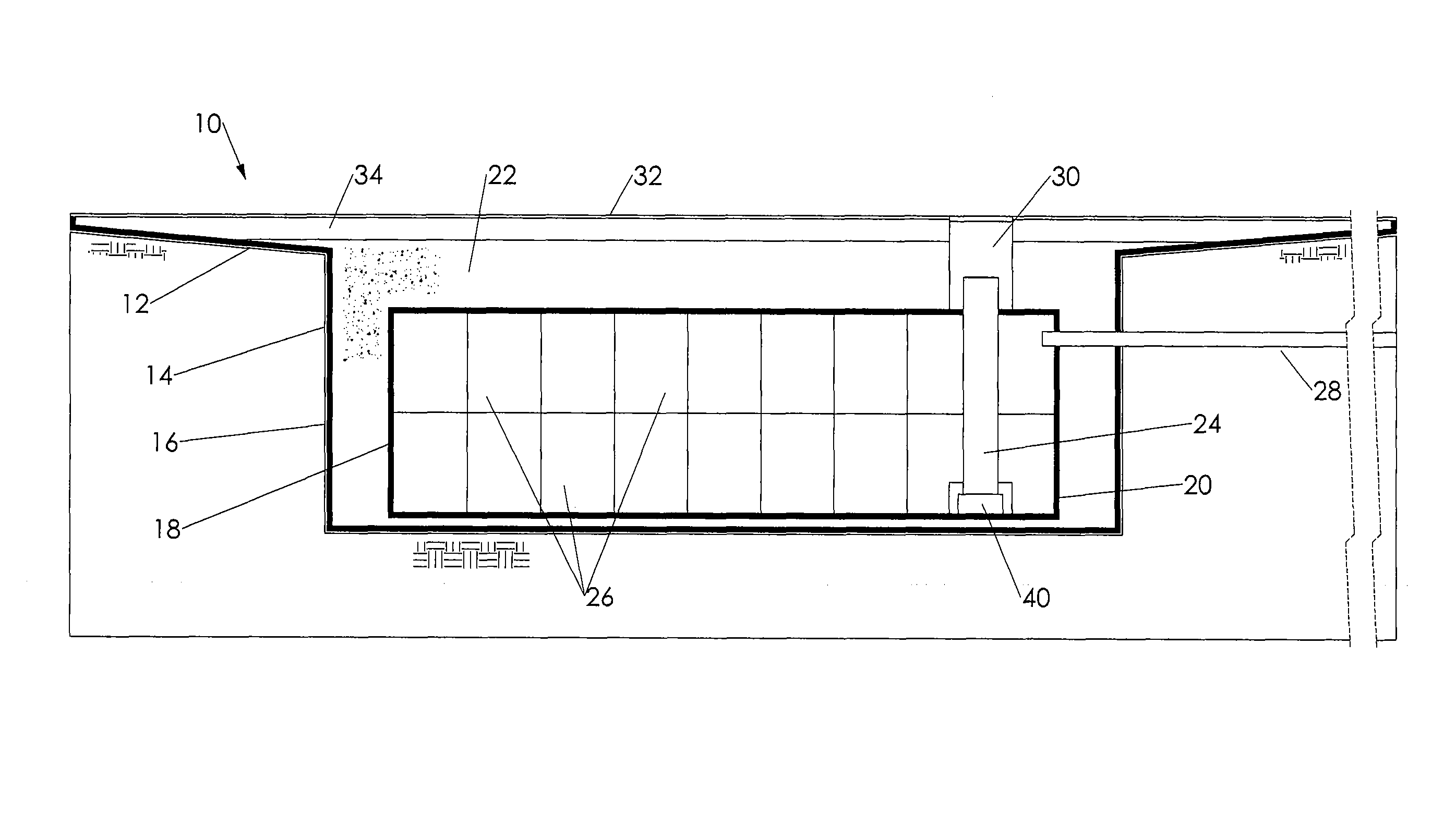

Systems, computer implemented methods, and computer readable program products to compute approximate well drainage pressure for a reservoir simulator

Systems, computer implemented methods, and program products to determine approximate static well pressures for one or more arbitrary shaped wells (119) by estimating the drainage volume (111) of the one or more wells (119), are provided. The drainage volume (111) of the one or more wells (119), for example, can be estimated from the one or more computed fluid flow flux vectors (107), and the approximate static well pressures for the one or more wells (119) can be subsequently calculated by taking the pore volume average of the dynamic grid block pressures within the drainage volume (111) of the one or more wells (119).; The one or more fluid flow flux vectors (107) can be calculated at each iteration in a numerical reservoir simulator as a part of standard simulator computations, negating a need for additional, extraneous computations to calculate effective drainage volume (111) of the one or more wells (119).

Owner:SAUDI ARABIAN OIL CO

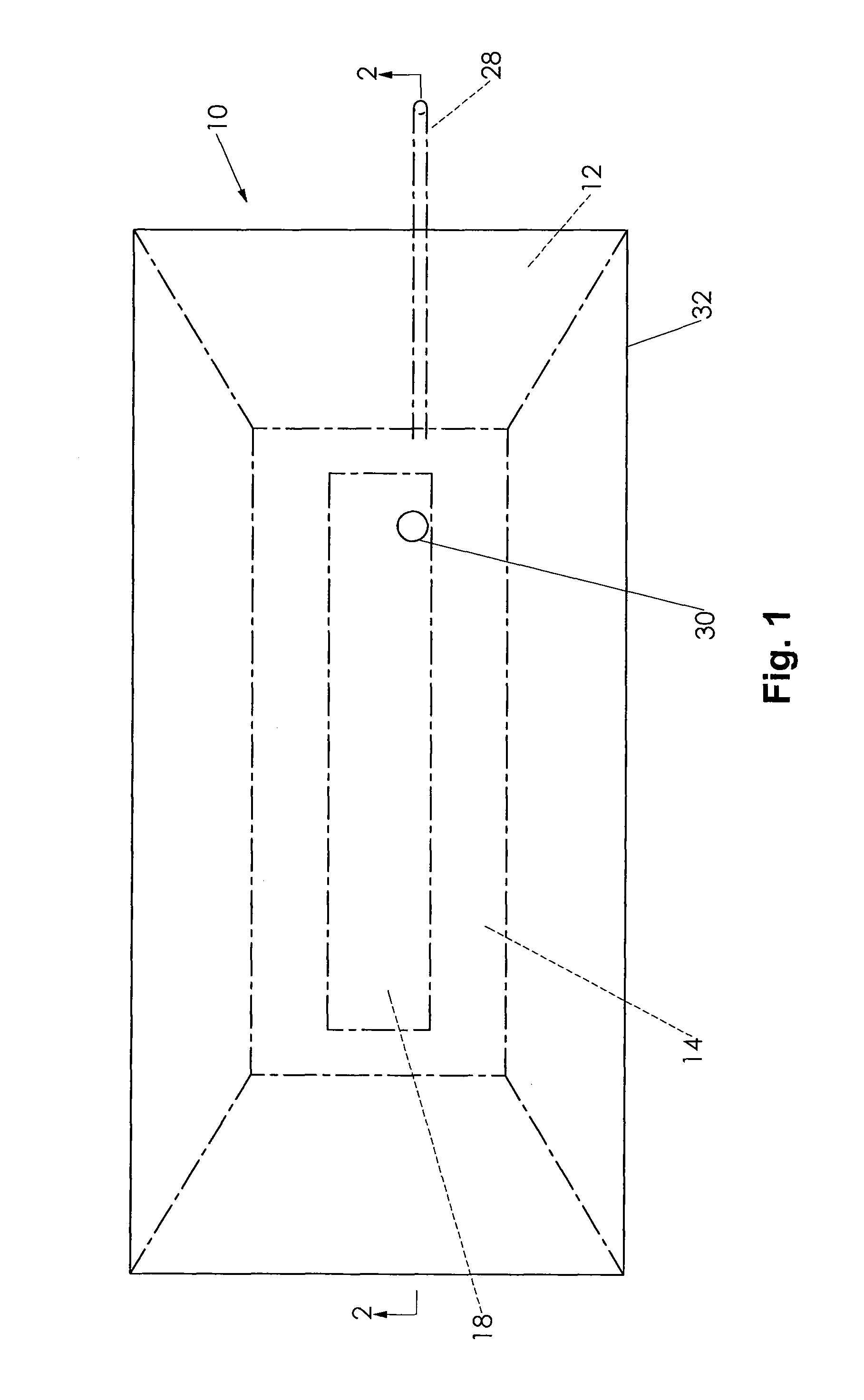

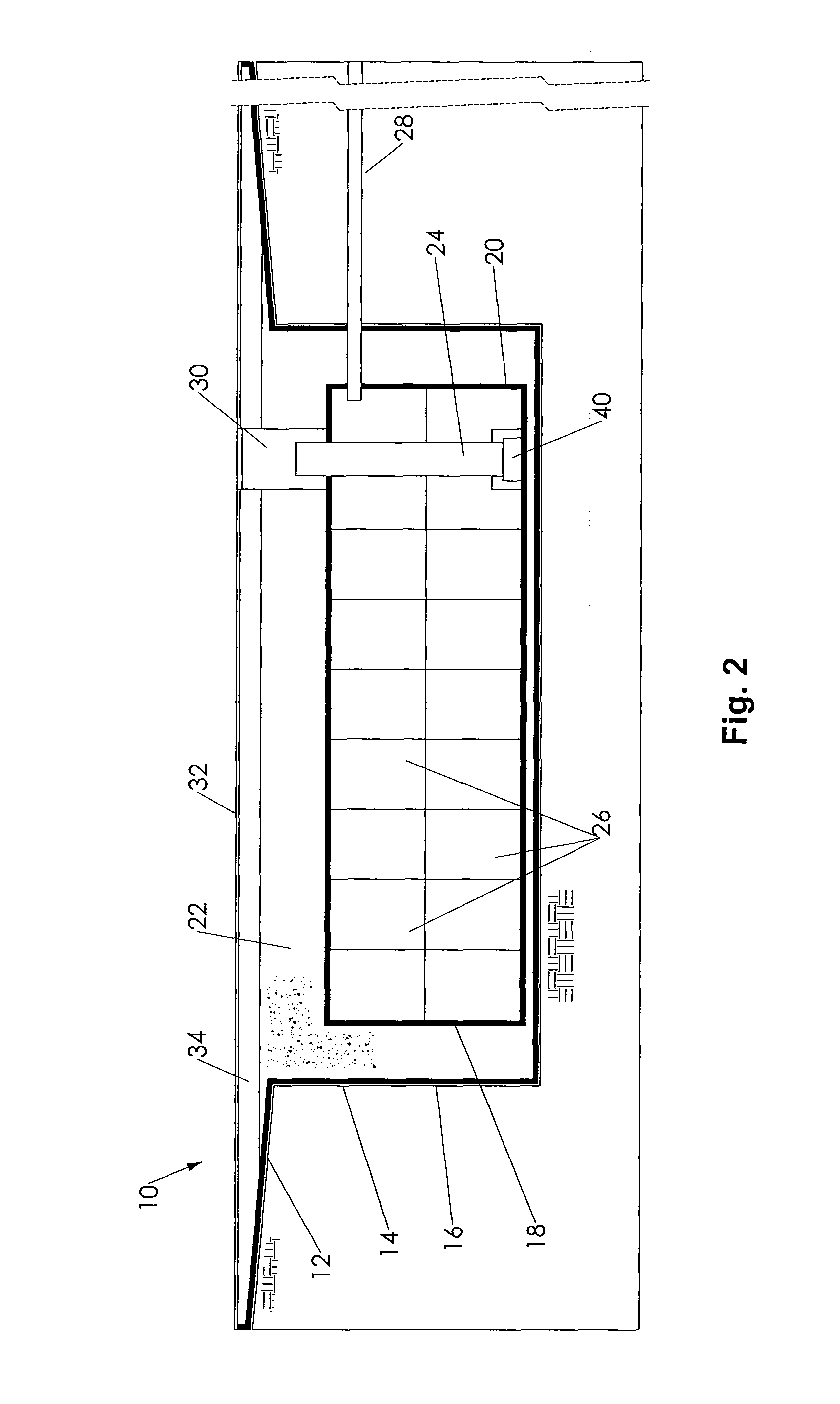

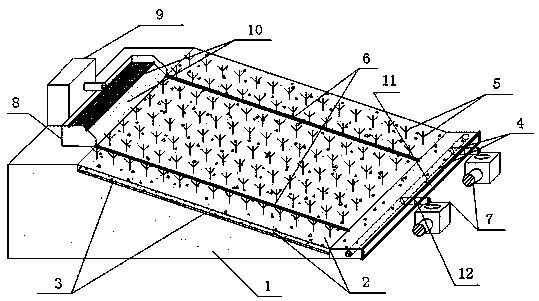

Water drainage and harvesting system for an artificial turf environment

InactiveUS8221029B2Rapidly and efficiently drains water from the playing surfaceMinimizes water lossMining devicesGeneral water supply conservationWater storageArtificial turf

A water drainage and harvesting system for use with an artificial turf field comprises permeable synthetic turf, permeable impact-absorbing sub-base material beneath the turf, a water collection basin below the field, a water reservoir below the collection basin, the basin and reservoir having an impermeable liner, a water tank in the reservoir, and a conduit from the tank that allows for filtered water to be pumped to the ground surface for reuse. The disclosure further relates to a method for the construction of such a water storage and conveyance system.

Owner:SANCHEZ TANYA R

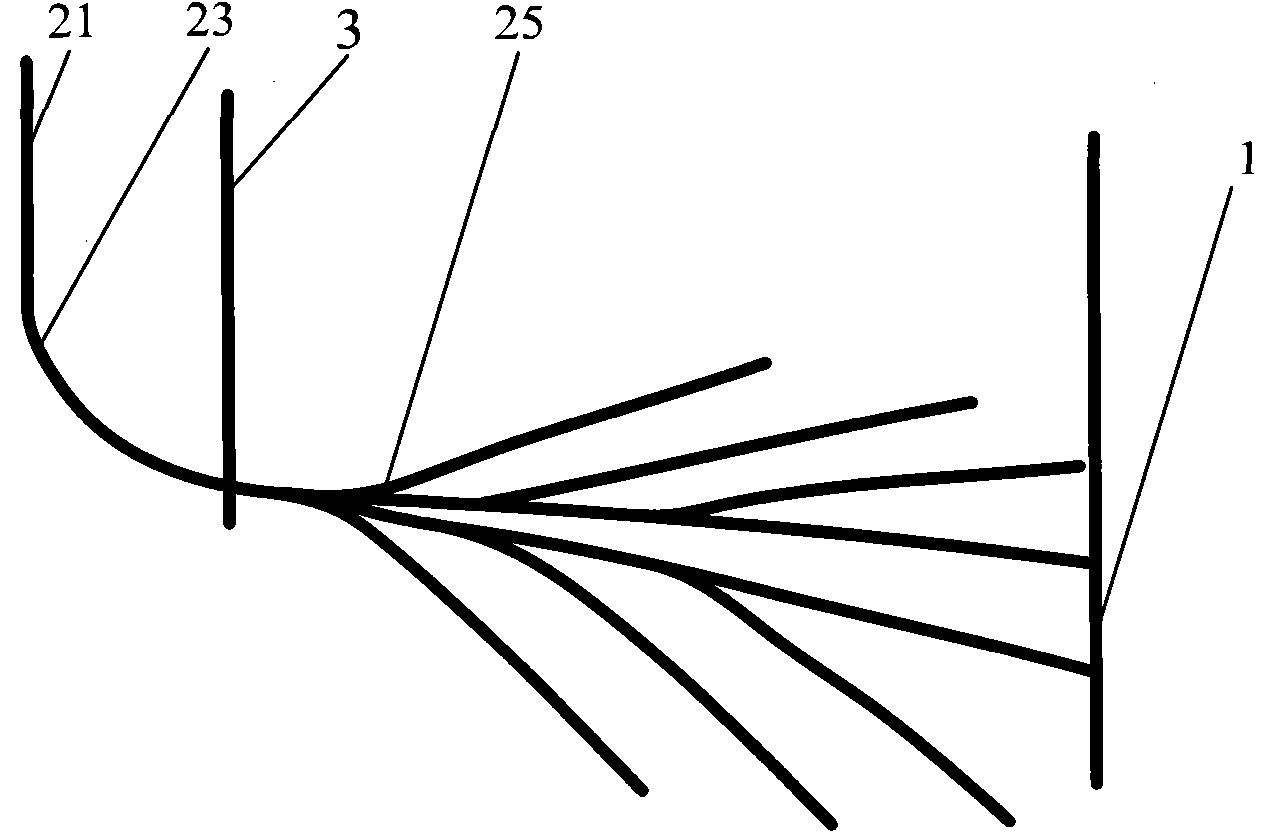

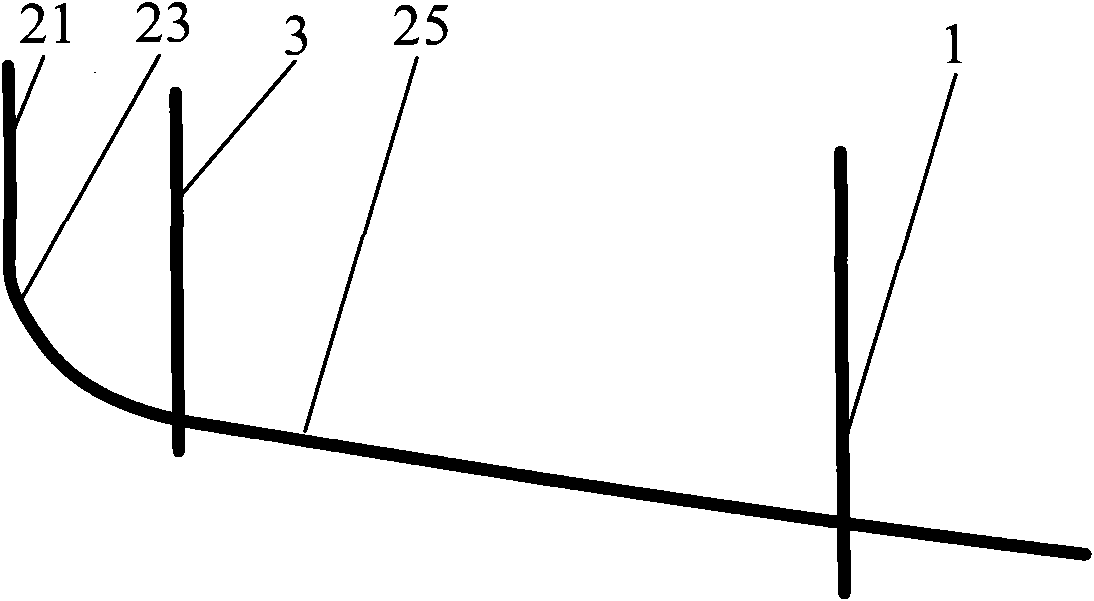

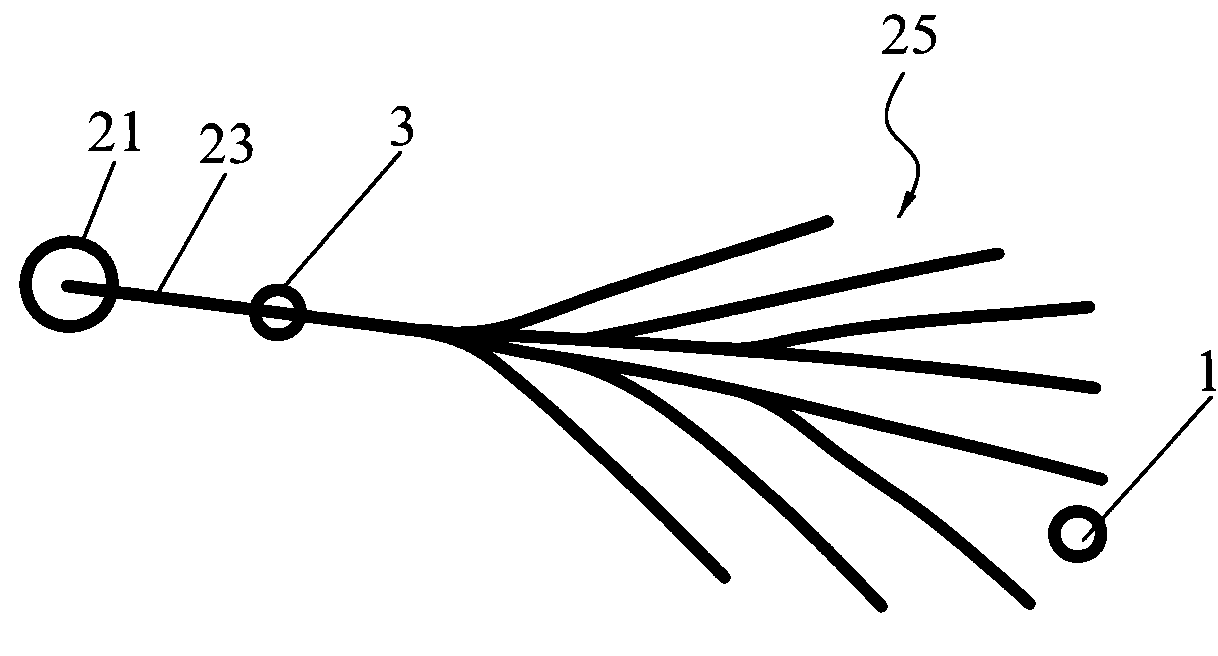

Coal bed methane multi-branch horizontal well system and auxiliary discharge well thereof

InactiveCN101979828ATo achieve the purpose of gas analysisReduce fluid pressureFluid removalDesorptionWell drilling

The invention discloses an auxiliary discharge well matched with a coal bed methane multi-branch horizontal well. The multi-branch horizontal well comprises a straight well section, a deflection section and a horizontal section which comprises a plurality of wellbores; and the auxiliary discharge well is arranged on the coal bed relief declination side in the horizontal section of the multi-branch horizontal well. In the invention, the auxiliary discharge well adopts a mode of arranging the drilling engineering at the tail end of the horizontal section of the horizontal well to reduce liquid pressure in branches and produces channels in a target geologic body by utilizing a newly drilled well to make the target geologic body communicated with the multi-branch horizontal well and assist the multi-branch horizontal well in draining and decompressing so as to fulfill the aim of gas desorption in the geologic body, improve the development efficiency of an assisted well and increase the well producing rate of the multi-branch horizontal well. Meanwhile, the invention also provides a coal bed methane multi-branch horizontal well system.

Owner:BEIJING ORION ENERGY TECH DEV

Harmless treatment agent for waste drilling fluid

InactiveCN104944480AAvoid the risk of environmental pollutionIn line with the general policy of energy saving and emission reductionWaste water treatment from quariesWater/sewage treatment by neutralisationWater useHazardous substance

The invention relates to a harmless treatment agent for waste drilling fluid and mainly solves the problem that secondary pollution is easily caused since harmful substances cannot be removed basically by the conventional waste drilling fluid curing treatment method. The harmless treatment agent for the waste drilling fluid comprises the following components in percentage by weight: 1.0-1.5 percent of a pH modifier, 0.7-1.0 percent of a heavy metal remover, 2.0-2.5 percent of an oxide remover, 1.5-2.0 percent of a flocculating agent, 0.05-0.1 percent of a coagulant aid and 2.0-2.5 percent of a decolorizer. After treatment of the harmless treatment agent for the waste drilling fluid, the liquid phase of the product can be used as oil field injection water, and the solid phase of the product can be used for well field paving, and well drainage highway maintenance, so that recycling of waste is realized.

Owner:BEIJING AOYIER ENG TECH

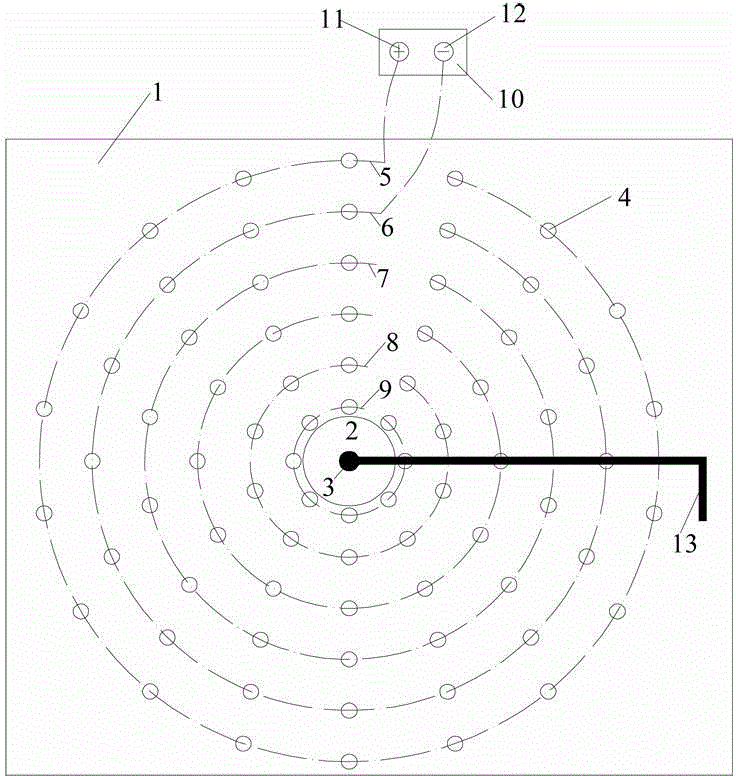

Treatment method for soft clay foundations of annular electroosmosis single well drainage

InactiveCN104594333AOvercoming Difficult ProblemsRealize on-site processingSoil preservationSoft clayEngineering

The invention discloses a treatment method for soft clay foundations of annular electroosmosis single well drainage. The method comprises the steps of excavating a single well, driving electrodes, conducting electroosmosis, conducting drainage and the like, wherein electrode annular arrays are driven into the soft clay foundations for multiple circles and distributed in the shape of a plum blossom; each circle of the electrodes is connected separately through a wire, the outermost circle of the wire is connected with a positive pole of a direct-current power supply, and a circle, next to the outermost circle, of the wire is connected with the negative pole of the direct-current power supply; circular electroosmotic flow from outside to inside is formed in clay through turning on the direct-current power supply, so that each two adjacent circles of electrodes are electrified from outside to inside in sequence; electroosmosis steps above are repeated till the water in the soft clay in the treatment scope is drained into the single well, and the water in the single well is drained into the earth surface. According to the treatment method for soft clay foundations of annular electroosmosis single well drainage, the operation is simple, and drainage reinforcement of the soft clay foundations is applicable.

Owner:HOHAI UNIV

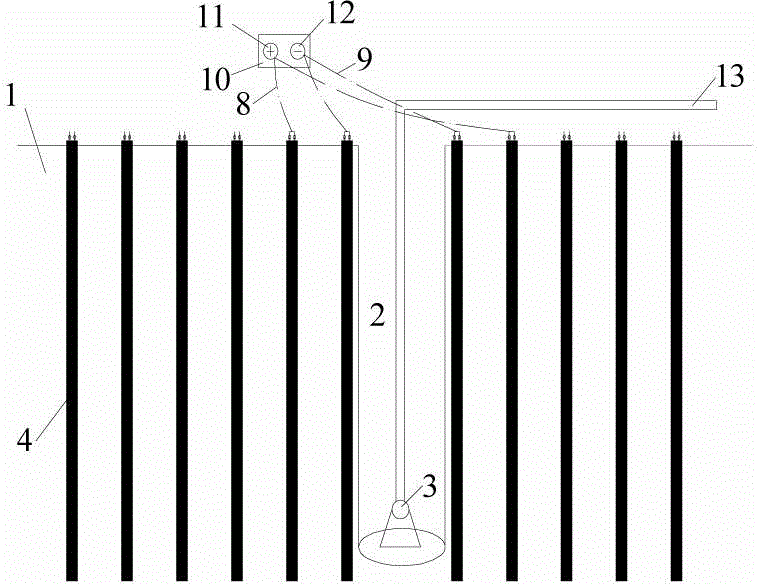

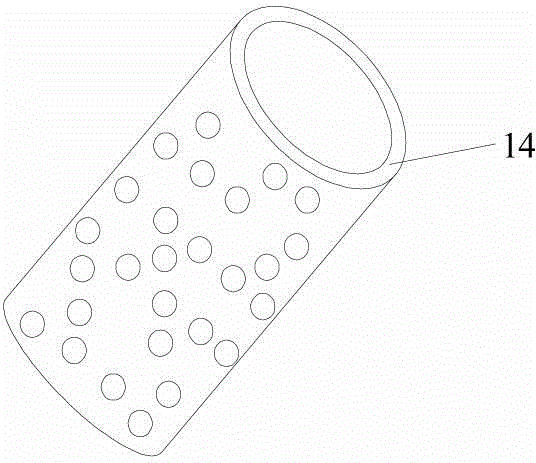

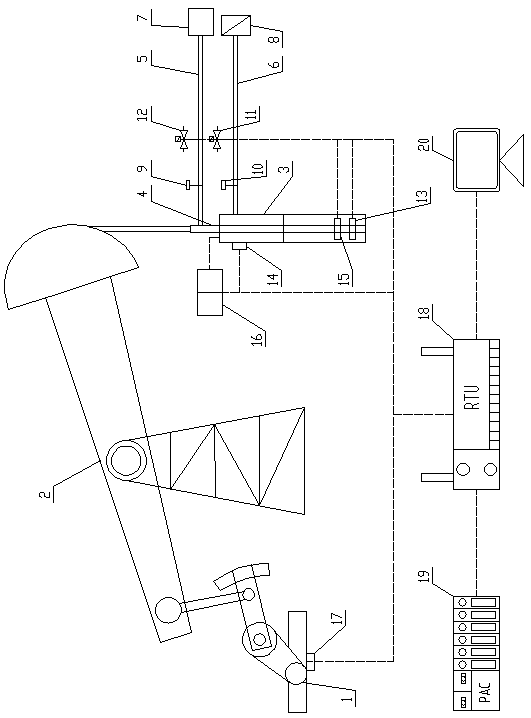

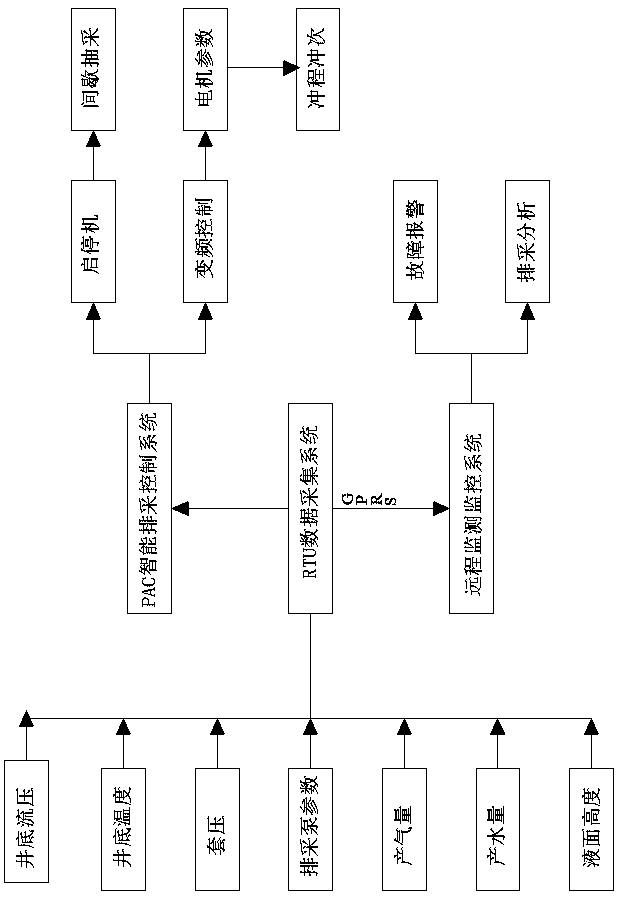

Intelligent remote control system for coal-bed gas well drainage and mining device and control method thereof

InactiveCN108756820AReal-time pressure riseReduce controlSurveyConstructionsReal-time dataRemote control

The invention discloses an intelligent remote control system for a coal-bed gas well drainage and mining device. The intelligent remote control system comprises coal-bed gas well parameter monitoringequipment, a data collecting system, an intelligent drainage and mining control system and a remote monitoring and controlling system. The coal-bed gas well parameter monitoring equipment mainly comprises a gas flowmeter, a liquid flowmeter, a downhole flow pressure sensor, a casing pressure sensor, a temperature sensor, a liquid level testing device and a frequency converter. The invention further discloses a remote control method of the intelligent remote control system for the coal-bed gas well drainage and mining device. According to the intelligent remote control system for the coal-bed gas well drainage and mining device and the remote control method thereof, intelligent drainage and mining of different types of coal-bed gas wells are achieved according to the drainage and mining features of different geology types of coal-bed gas wells and of different stages; remote real-time monitoring and controlling of drainage and mining of coal-bed gas wells are achieved, and a remote usercan check, query and store detailed real-time data and historical data in a remote mode; and the user can conduct parameter setting and instruction control comprising on-site operation and remote control on the frequency converter.

Owner:山西工程技术学院

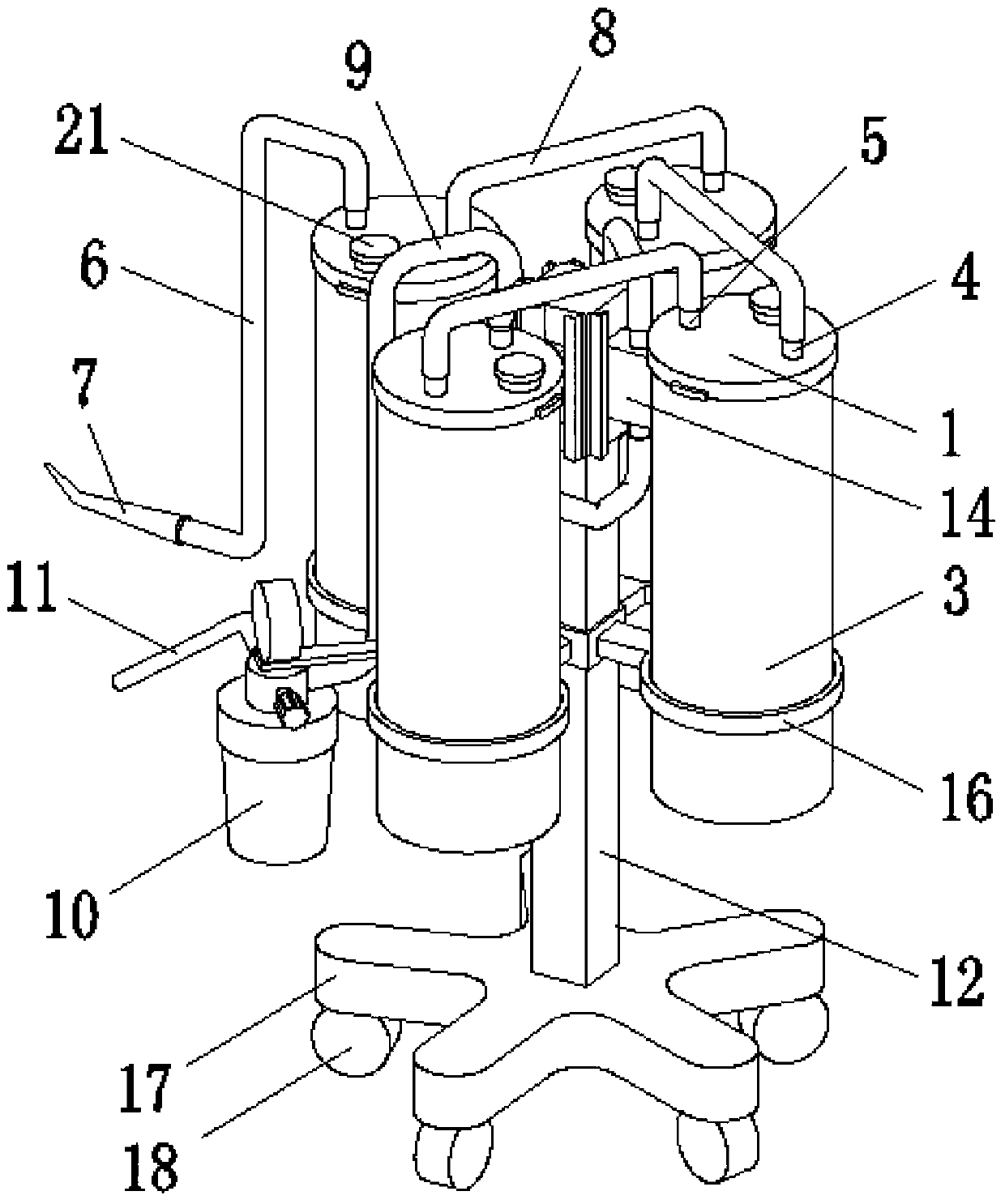

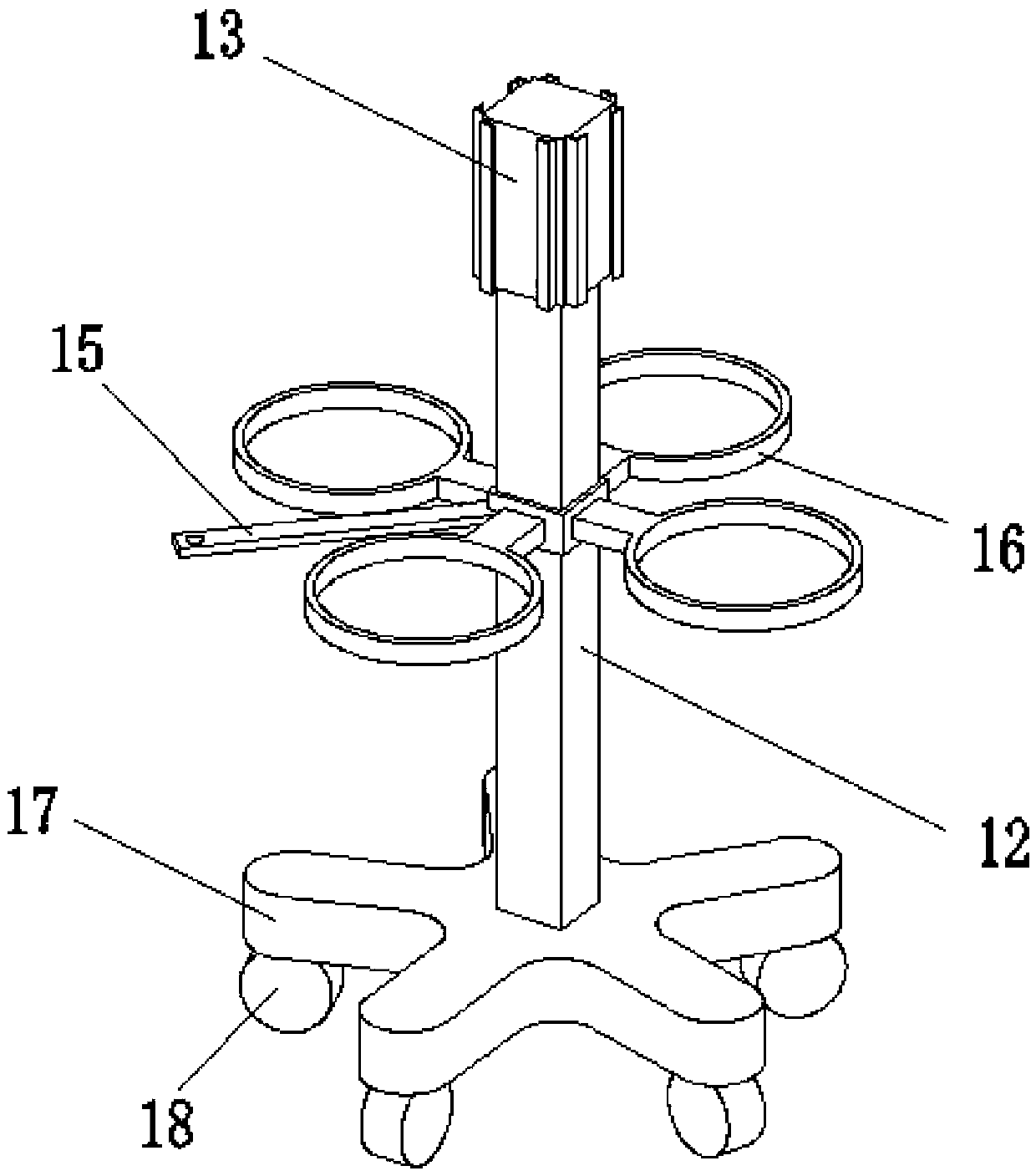

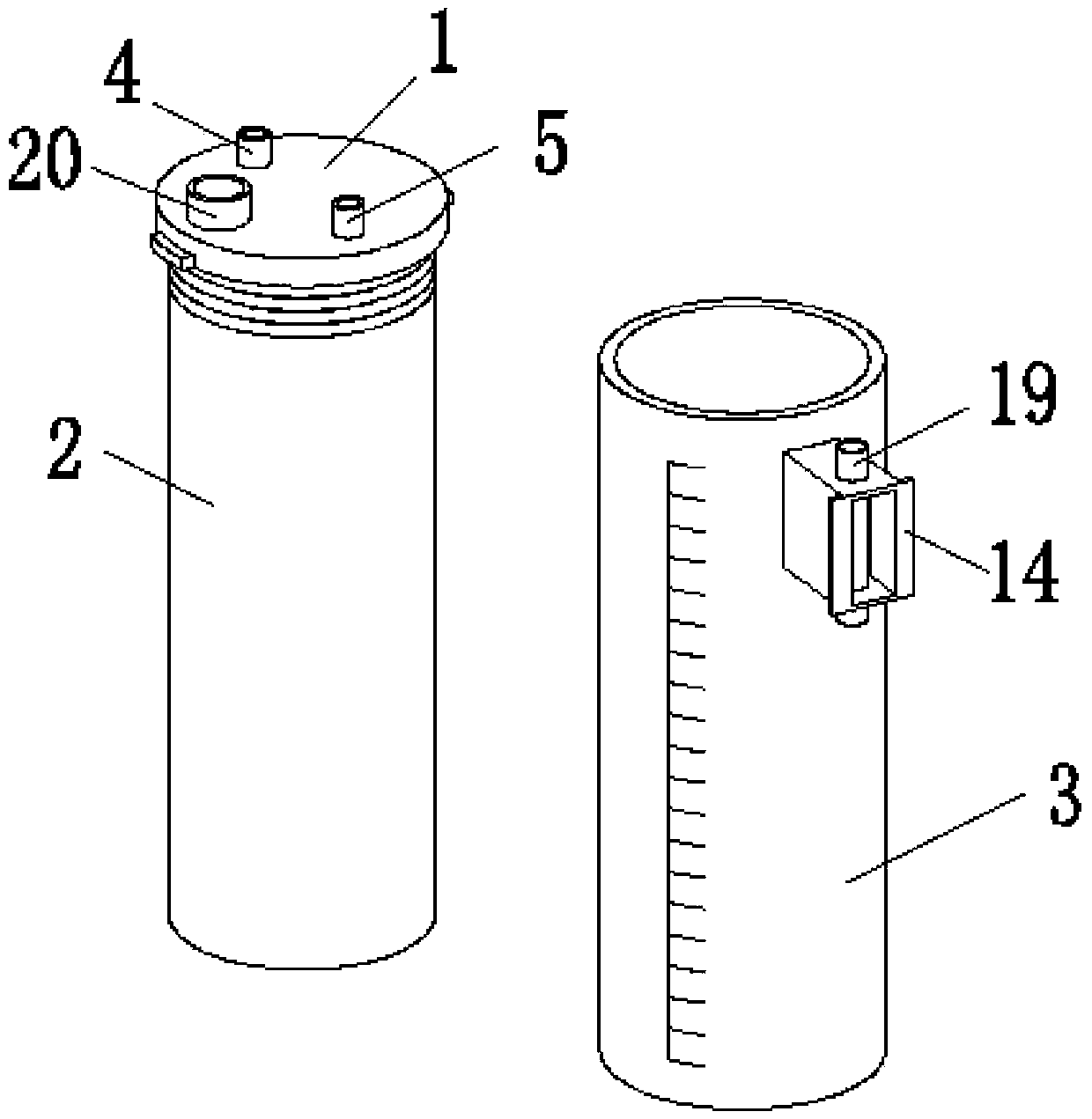

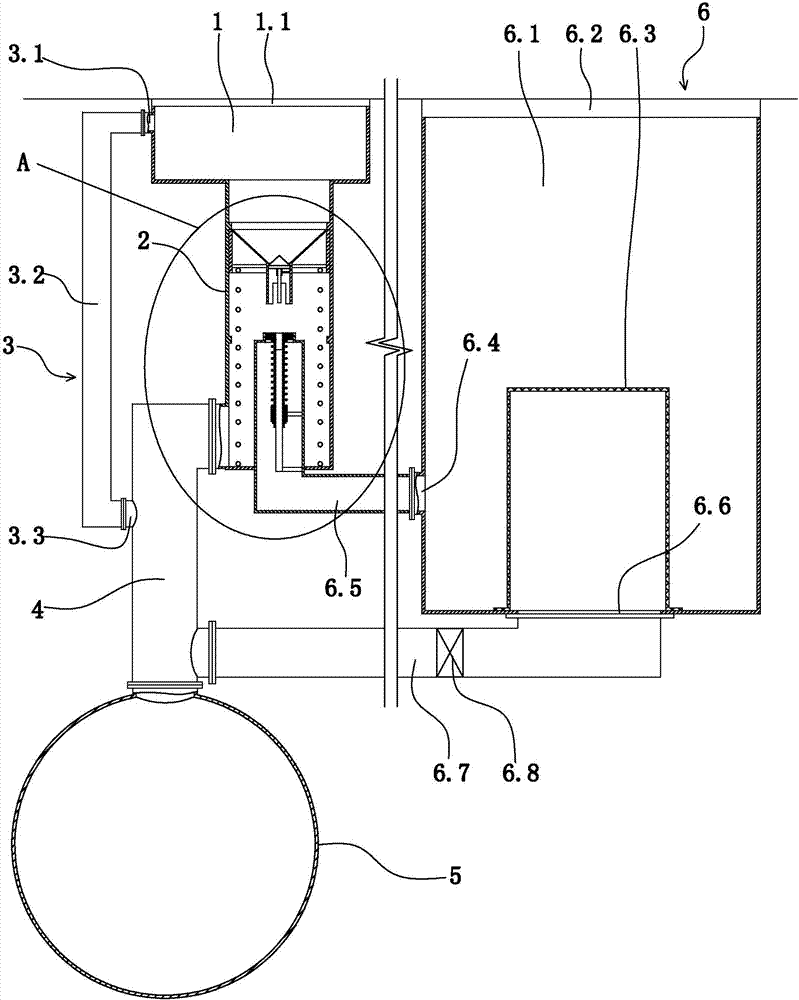

Combined negative pressure drainage device

The invention discloses a combined negative pressure drainage device. The device comprises a plurality of drainage bottle components which are sequentially connected in series, wherein each drainage bottle component comprises a cover body, a negative pressure drainage bag and a jacket bottle; a drainage tube is connected to a drainage tube joint of the drainage bottle component at the front end of the drainage bottle components connected in series, and a drainage joint is connected to the other end of the drainage tube; a negative pressure tube is connected to a negative pressure tube joint of the drainage bottle component at the tail end of the drainage bottle components connected in series, and the other end of the negative pressure tube is connected with a pressure control valve which is connected with a negative pressure device through a negative pressure device connecting tube. According to the combined negative pressure drainage device, the drainage bottle components are connected in series, so that the drainage capacity is improved; negative pressure suction force is provided by the negative pressure device, so that a better drainage effect is achieved, and pressure differences between the negative pressure drainage bags and the jacket bottles can be kept stable; the jacket bottles can be used for many times, so that the practicability of the whole device is improved.

Owner:SUZHOU YAXIN MEDICAL ARTICLES

Municipal administration path drainage structure with emergent drainage function

ActiveCN107268763AAvoid cloggingReduce usageFatty/oily/floating substances removal devicesSewerage structuresRoad surfaceEngineering

The invention discloses a municipal administration path drainage structure with an emergent drainage function. The municipal administration path drainage structure can effectively solve the problems that due to the fact that a drainage pipeline is blocked, the amount of surface gathered water is excessively large, and normal use of the road surface is seriously affected. The municipal administration path drainage structure comprises a sink arranged on the road surface, a drainage pipeline embedded underground, a vertical flow guiding pipeline, a water drainage connecting pipeline and an emergent drainage device, wherein a rainwater perforated strainer is arranged at the upper end of the sink, the vertical flow guiding pipeline is located below the sink, the upper end of the vertical flow guiding pipeline is communicated with the bottom face of the sink, a flow guiding pipeline drainage outlet is formed in the lower portion of the outer side face of the vertical flow guiding pipeline, and a filter net device is located at the portion, above the flow guiding pipeline drainage outlet, inside the vertical flow guiding pipeline, the upper end of the water drainage connecting pipeline is connected with the flow guiding pipeline drainage outlet, and the lower end of the water drainage connecting pipeline is communicated with the drainage pipeline.

Owner:ZHEJIANG XINGTAI CONSTR

Underground traction type trenchless pipeline repair method

ActiveCN110726033AFacilitate repair workExtended service lifePipe elementsSoil preservationChemical groutingArchitectural engineering

The invention is applicable to the technical field of pipeline repair, and provides an underground traction type trenchless pipeline repair method. Firstly, a baffle is installed in a first construction well at one side of a collapse position of a pipe body to seal an input pipeline for draining water to the first construction well, a guide block is placed in the pipe body from the first construction well, one end of the guide block is connected with one end of a hose, then the front end of the guide block is dragged to move to a second construction well, and the guide block is moved to the collapse position of the pipe body to support the collapse position, soil reinforcing slurry is filled in the soil layer around the collapse position, the soil reinforcing slurry is a polyurethane chemical grouting material, after the reinforcing slurry is solidified, the guide block is continuously dragged, the hose is put in the pipe body and completely covers the collapse position, the hose is made to adhere to and be solidified with the inner wall of the pipe body, so that the collapse position of the pipe body is sealed and repaired, the whole process does not need to excavate the ground, the influence on environment and traffic is small, and the service life of a pipeline can be prolonged.

Owner:南京华享环境科技有限公司

Scouring-resistant permeable ecological protection surface for cohesive soil slopes and construction method thereof

The invention discloses a scouring-resistant permeable ecological protection surface for cohesive soil slopes and a construction method thereof. The protection surface comprises a cohesive soil slope,sand-gravel protective layers cemented to the surface and the bottom of the cohesive soil slope and vegetation growing through the sand-gravel protective layer from the surface of the cohesive soil slope. The invention also discloses a construction method of the protection surface at the same time. The protection surface disclosed by the invention has the advantages that the sand-gravel protective layers, clay and the vegetation form an integer so as to form an ecological slope with high drainage property and strong soil conservation capacity; compared with slope protecting structures such asconcrete and the like, the protection surface disclosed by the invention is ecological and friendly to environment, short in construction period and low in cost; compared with a plant slope protecting layer, the sand-gravel protective layers have the advantages of certain scouring resistance, better drainage property and stronger ability to resist harsh environment; in addition, the problem thatmicrobial cementation technology is difficult to be applied to clay slopes is solved; and the construction process is simple and the quality is controllable.

Owner:HOHAI UNIV

Split type intelligent plunger with pulley mechanism

InactiveCN109723408AReal-time control of motion speedAvoid damageFlexible member pumpsFluid removalDual mechanismButterfly valve

The invention relates to the field of gas well drainage and gas production, in particular to a split type intelligent plunger with a pulley mechanism. The split type intelligent plunger with pulley mechanism is characterized in that the intelligent plunger comprises a plunger body, a pulley mechanism at the lower end of the plunger body, a plunger sleeve, a spring slip arranged in the plunger sleeve, an open butterfly valve with a locking device, an upper buffer, a lower buffer, a self-adaptive valve mechanism arranged in the lower buffer and a pressure sensor, a temperature sensor, a speed sensor and a microprocessor control attached to the plunger body and the plunger sleeve; the speed of the plunger body and the plunger sleeve in the ascending or descending process is controlled by controlling the action of the pulley mechanism. Compared with the prior art, the split type intelligent plunger with pulley mechanism has the advantages that the defect that the speed of the plunger usedfor draining water in the prior continuous production operation without closing the well is not controllable is solved, and the problem that an underground or wellhead accident is caused due to serious collision between the plunger body and the plunger sleeve in the a ascending or descending process is effectively avoided.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com