Split type intelligent plunger with pulley mechanism

A split-type, pulley technology, applied in the fields of mining fluids, mechanical equipment, machines/engines, etc., can solve the problem of uncontrollable movement speed of the plunger, and achieve the goal of shortening the ascending time, enhancing the stability and drainage efficiency, and improving the drainage efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

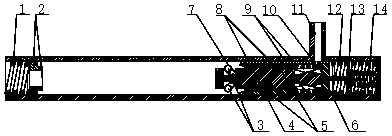

[0038] Embodiment 1: as image 3 As shown, at the top end, the plunger body (4) and the plunger sleeve (7) are thrown into the gas well as a whole.

Embodiment 2

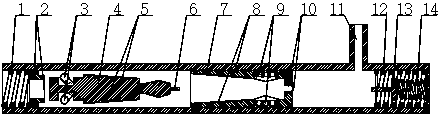

[0039] Embodiment 2: on the basis of embodiment 1, as Figure 4 As shown, the plunger body (4) is separated from the plunger sleeve (7) under the action of the push rod of the top limiter, and then falls first.

Embodiment 3

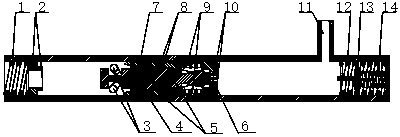

[0040] Embodiment 3: on the basis of embodiment 2, as Figure 5 As shown, the plunger body (4) performs a free-fall motion in the wellbore until it reaches the optimal speed range calculated by the previous dynamic model.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com