Patents

Literature

415results about How to "Guaranteed smooth execution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

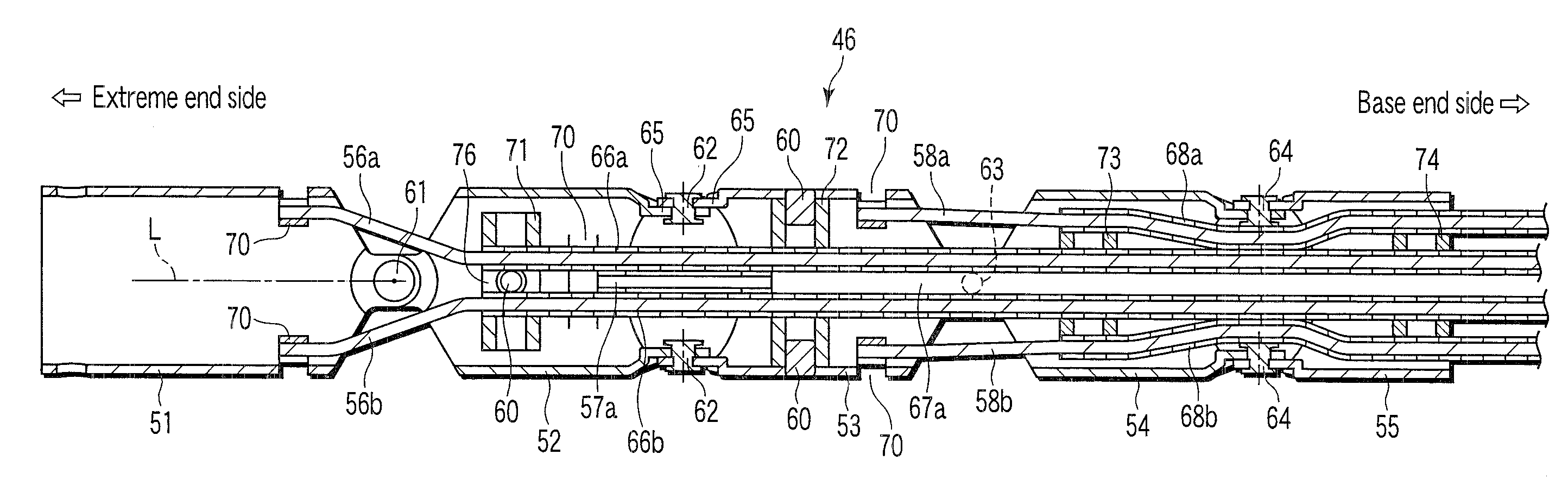

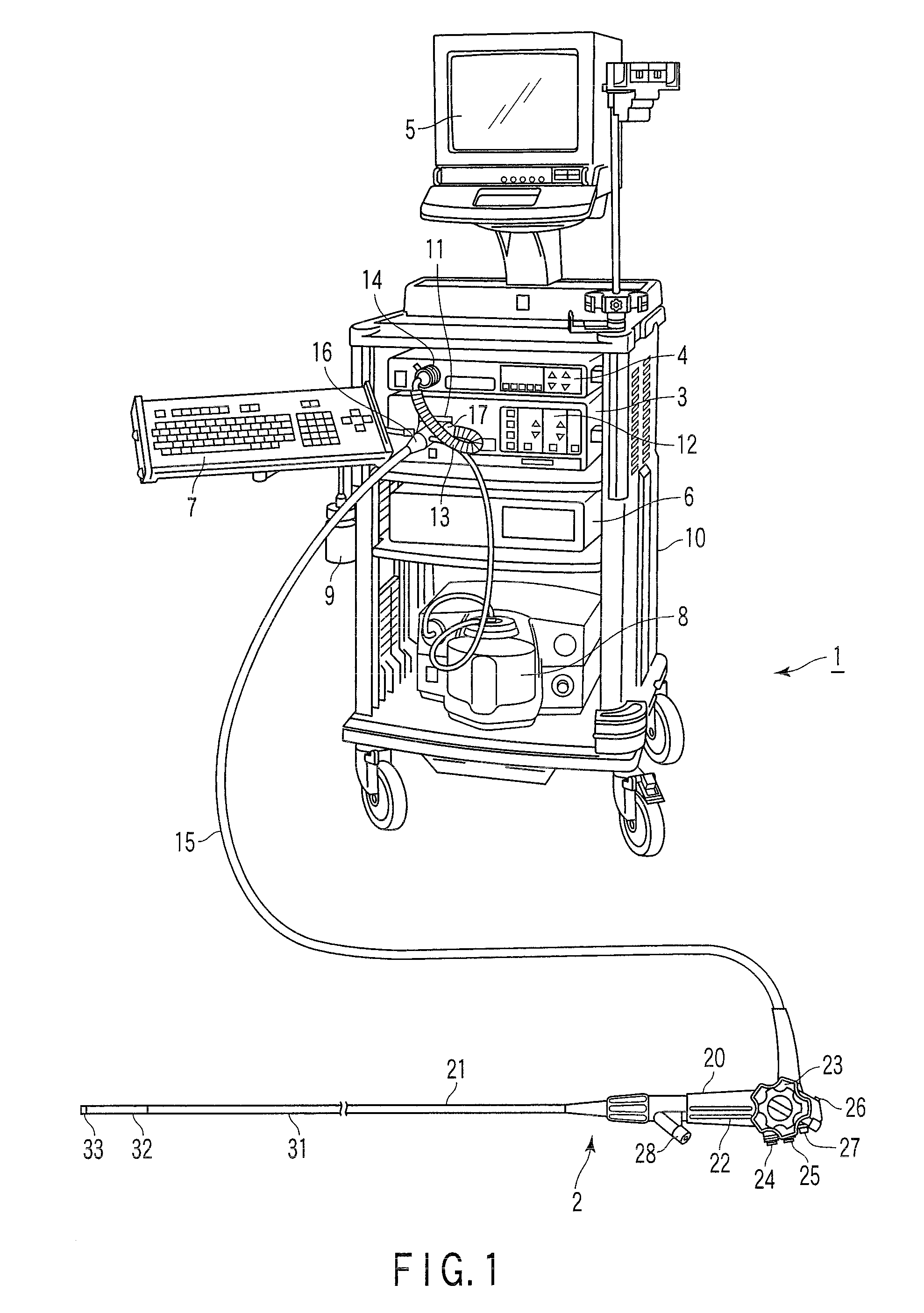

Multijointed bending mechanism and multijointed medical equipment having multijointed bending mechanism

InactiveUS20100004508A1Smoothly executedReduced diameterEndoscopesSurgical manipulatorsSacroiliac jointEngineering

Owner:OLYMPUS MEDICAL SYST CORP

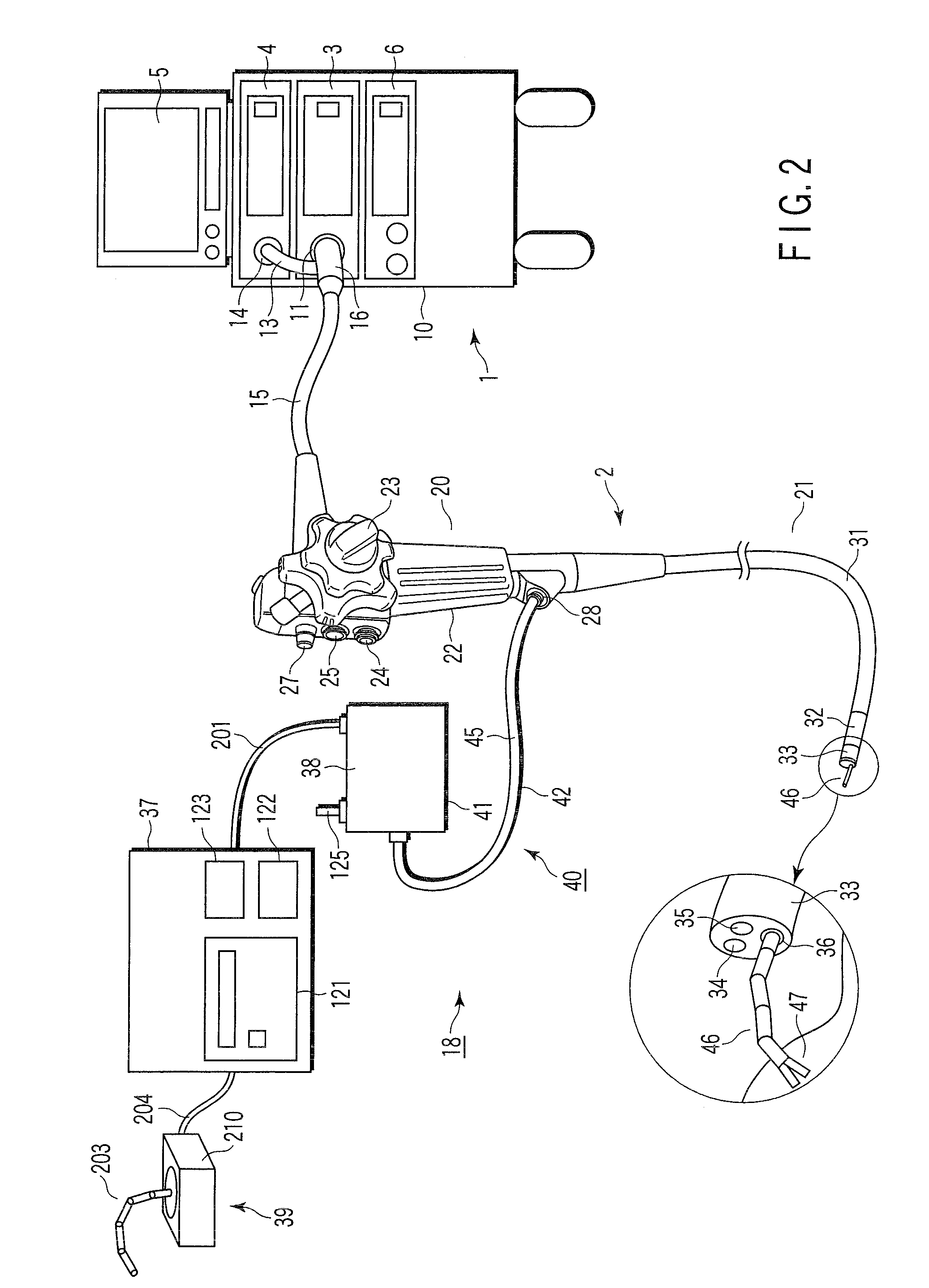

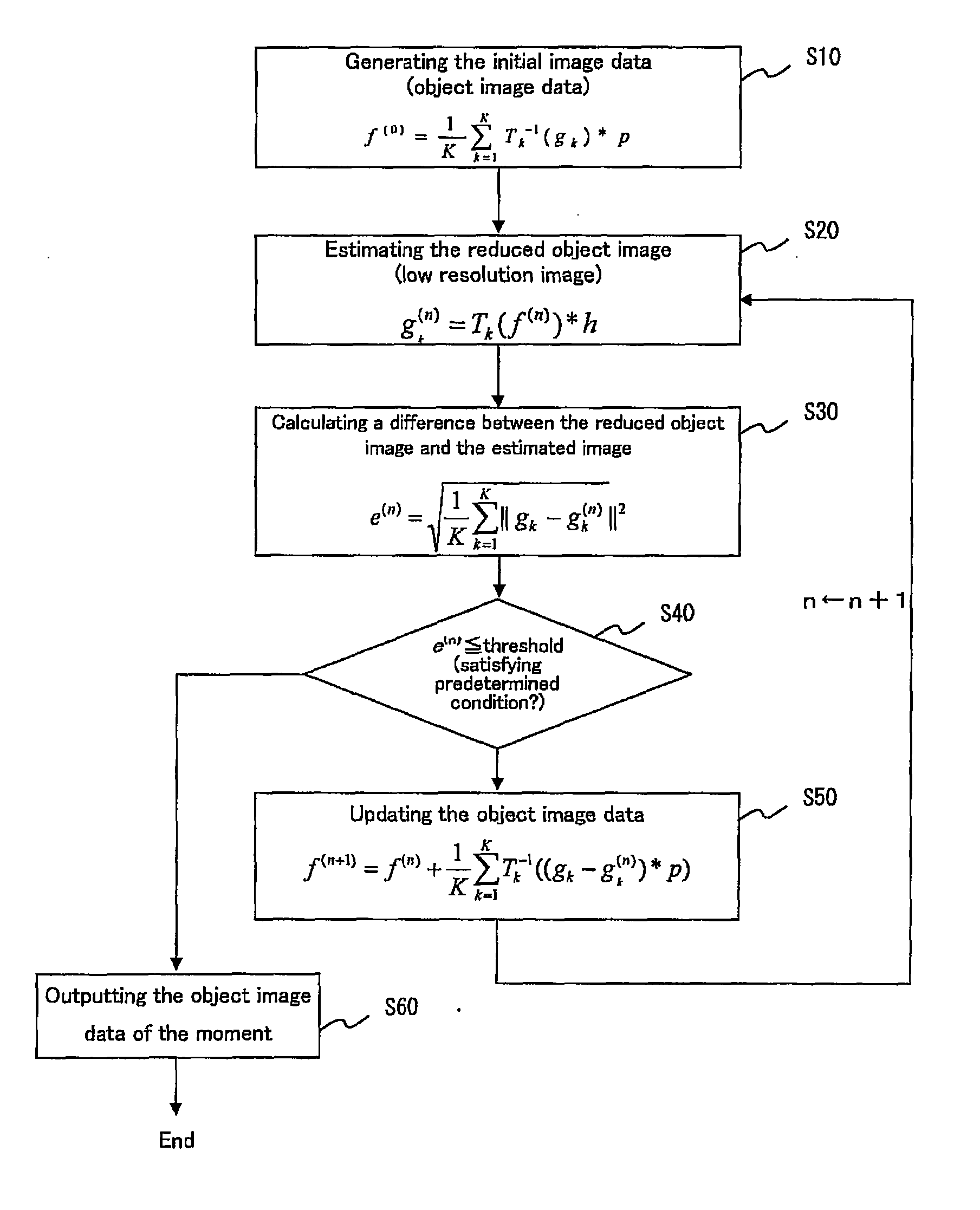

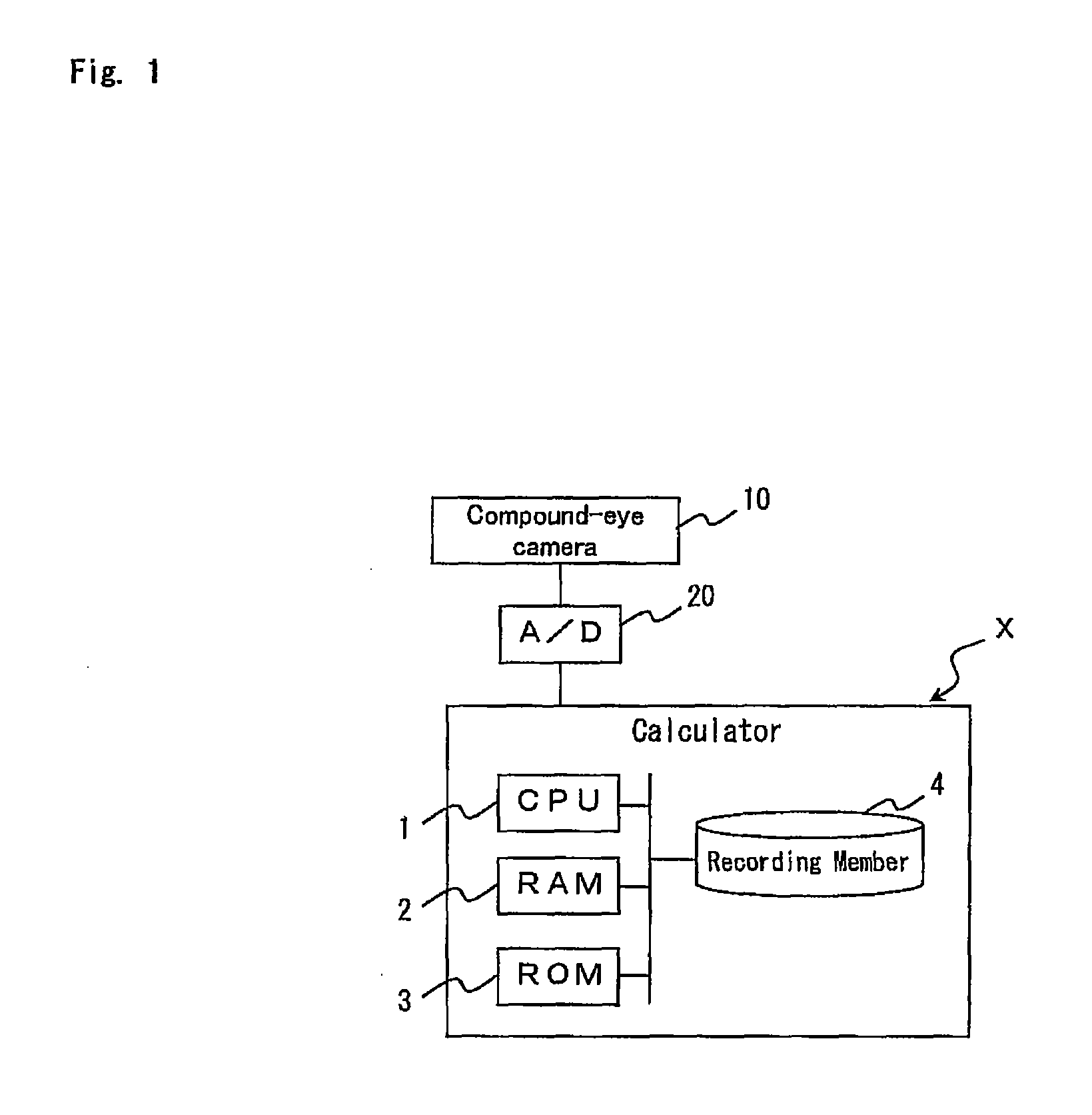

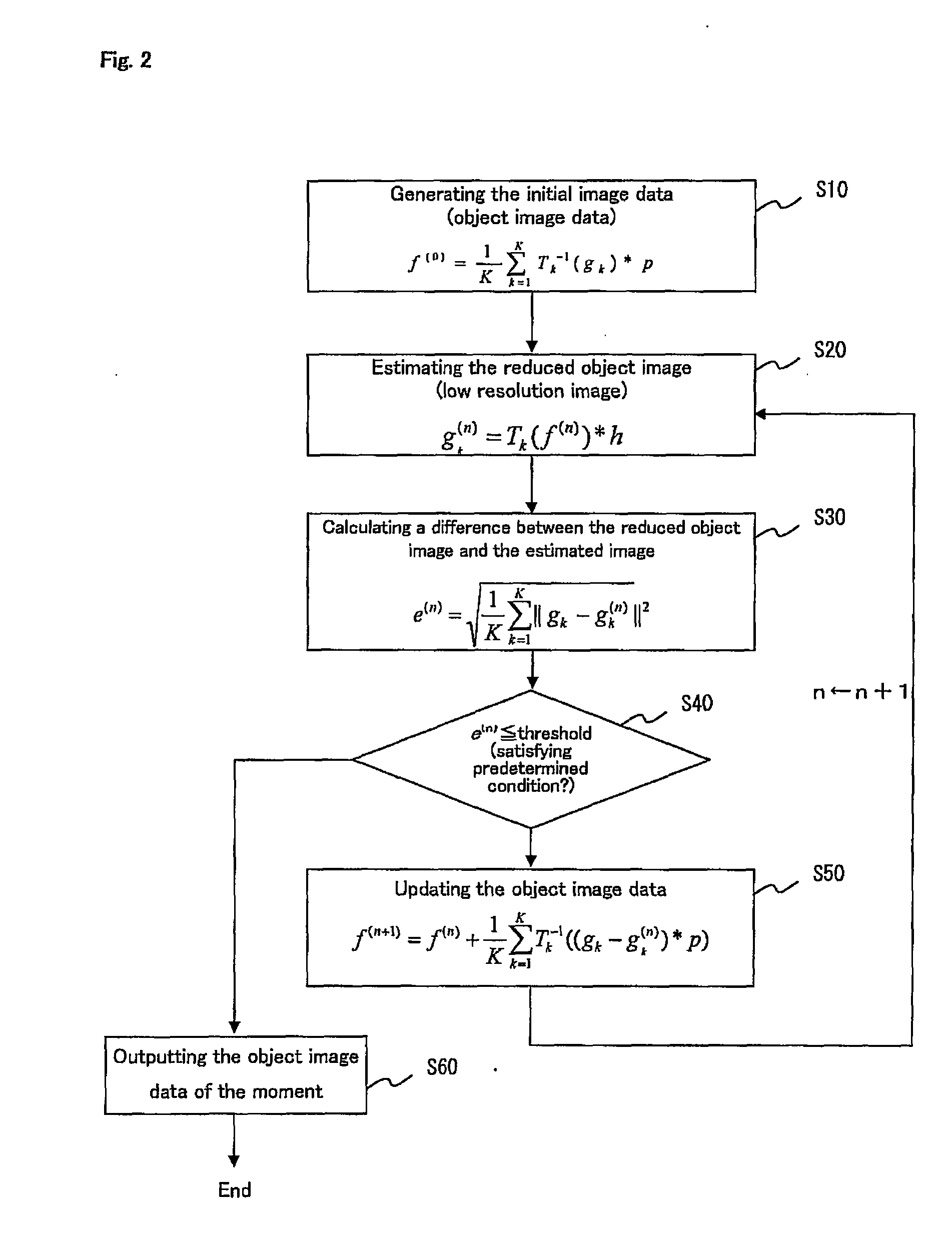

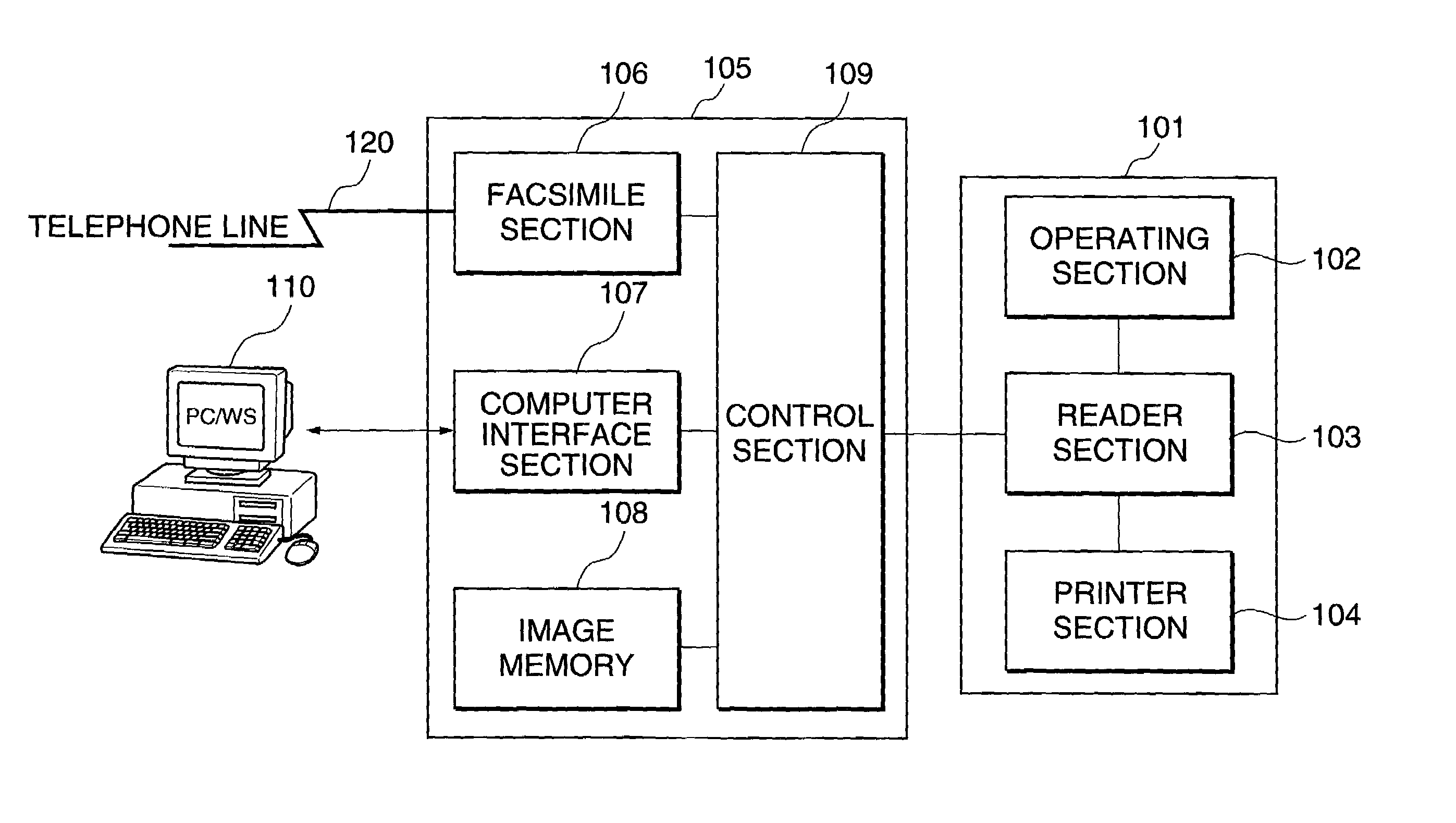

Apparatus and method for image configuring

ActiveUS20070160310A1Compensate for misalignmentGuaranteed smooth executionTelevision system detailsGeometric image transformationComputer visionImaging data

Using image data on a plurality of reduced object images to calculate a shift amount in regard to the gap of relative positions between the reduced object images by a correlation calculation between the reduced object images. A conversion equation is obtained from the shift amount for geometric projection process from the object image to each of the reduced object images. Initial image data on a single object image is generated using image data on the plurality of reduced object images. This and the aforementioned conversion equation, are used to estimate images of each of the reduced object images. A difference between the estimated image of each of the reduced object images and each of the reduced object images is projected in the reverse process of the aforementioned geometric projection process, to update the image data on the single object image. The processes are repeated until the difference satisfies a predetermined condition and a high resolution object image is outputted.

Owner:JAPAN SCI & TECH CORP

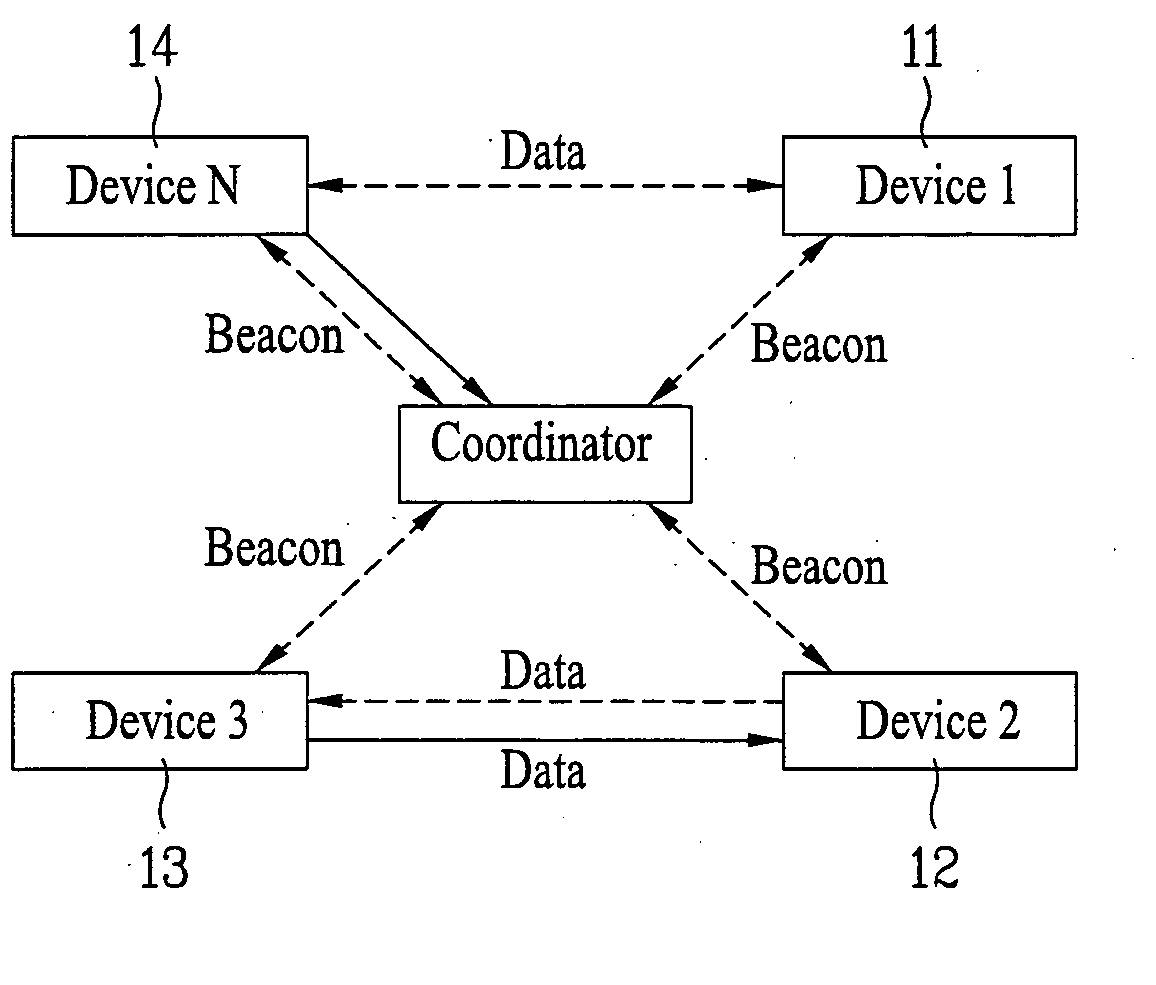

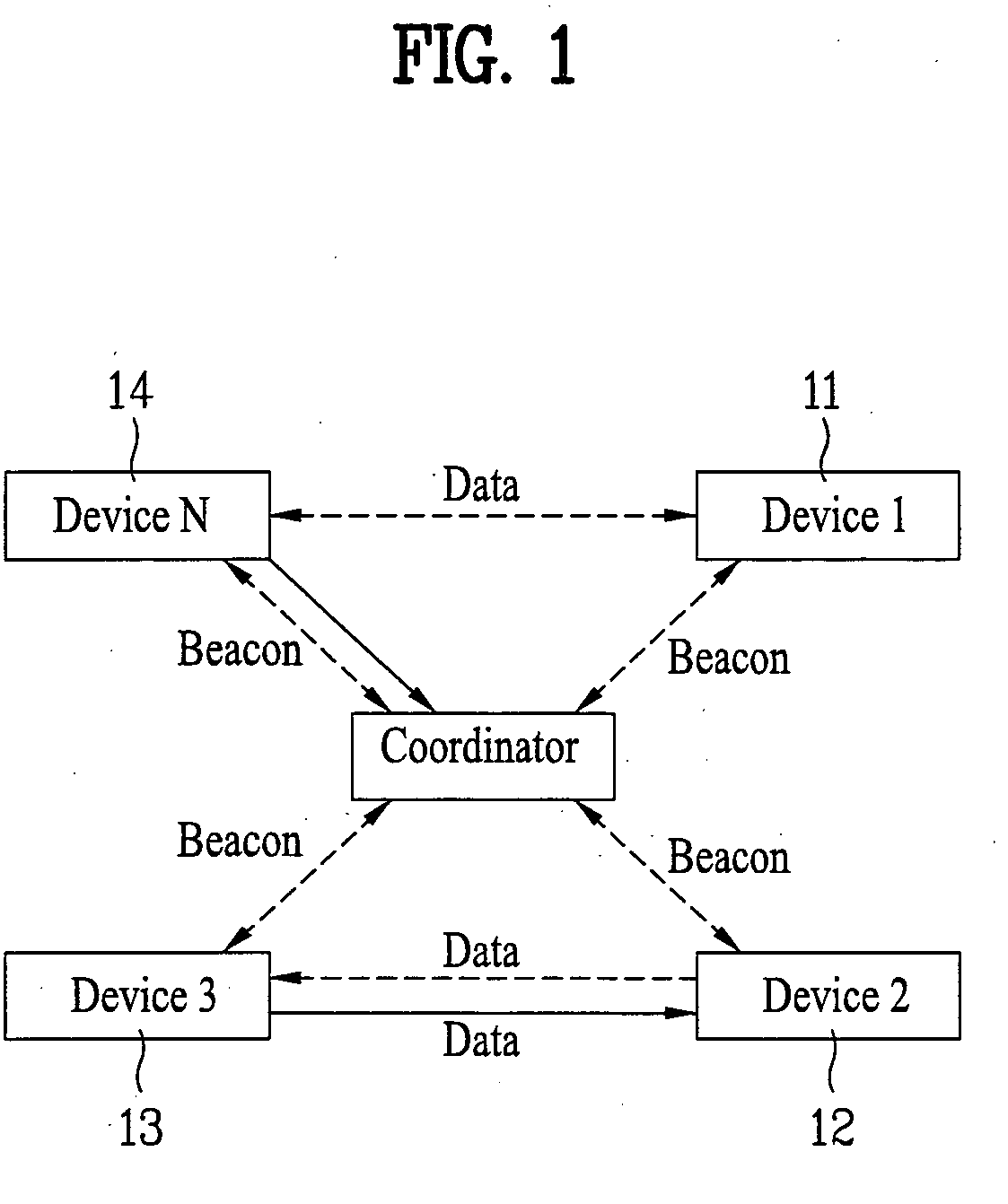

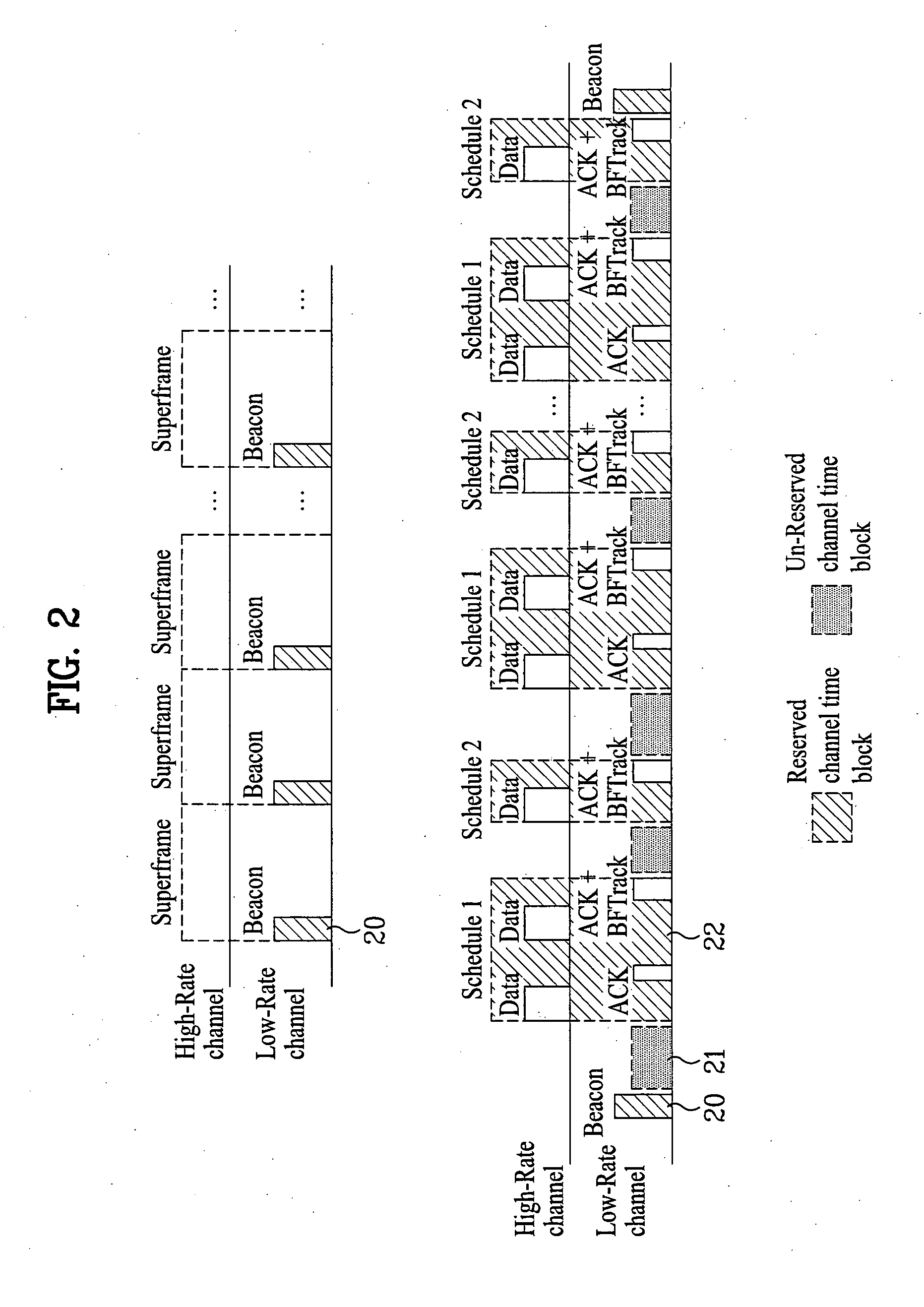

Method for managing the power in the wireless network

ActiveUS20110051638A1Saves power of performingGuaranteed smooth executionPower managementEnergy efficient ICTData transmissionNormal mode

Disclosed are methods for managing a power in a wireless network communication. One of the methods provides checking whether information on a request for a mode change is received for a prescribed channel time in a manner that a device configuring a network enters a power save mode in the course of not performing data transmission / reception and that a modem enters an awake state from a sleep state for the prescribed channel time. And, the prescribed channel time is determined to correspond to a time for transmitting a beacon. According to a preferred embodiment, a modem of a device in a power save mode enters an awake state for a channel time period for broadcasting a beacon and then checks whether information on a power management mode change is received. If the information does not exist, a sleep state is reentered. If the power management mode change (PMMC) information is received, a power is managed by performing data transmission / reception in a manner of switching to a normal mode.

Owner:LG ELECTRONICS INC

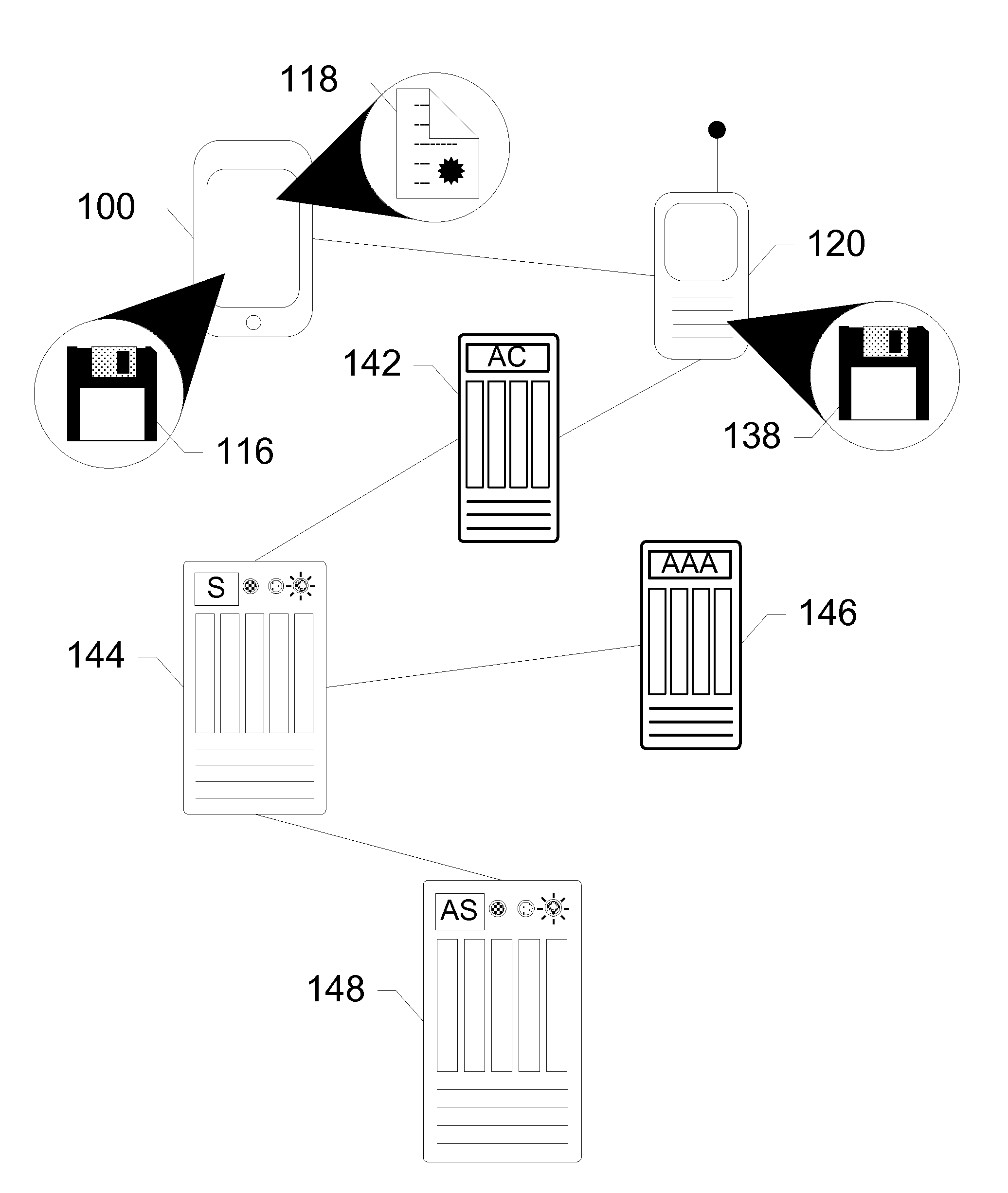

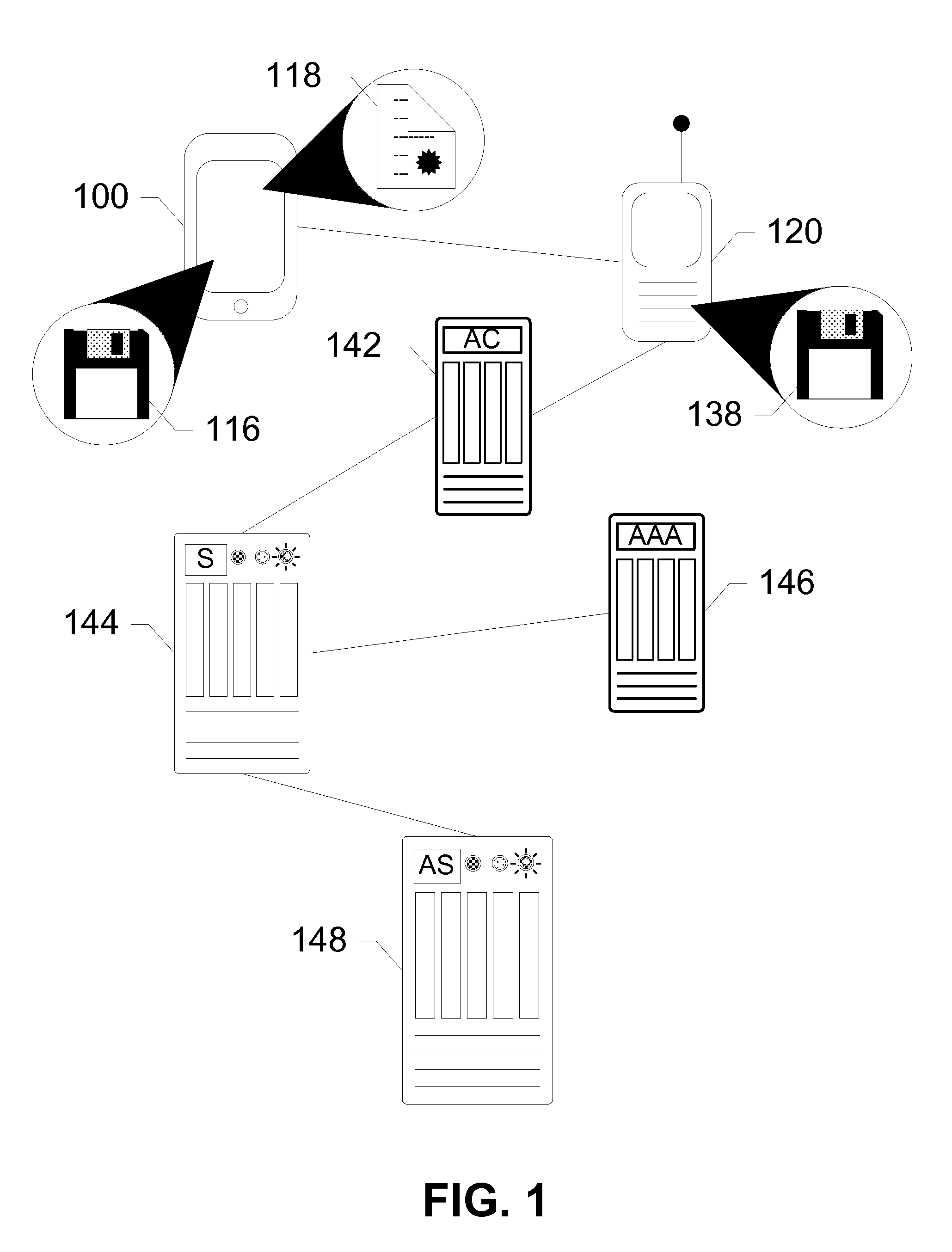

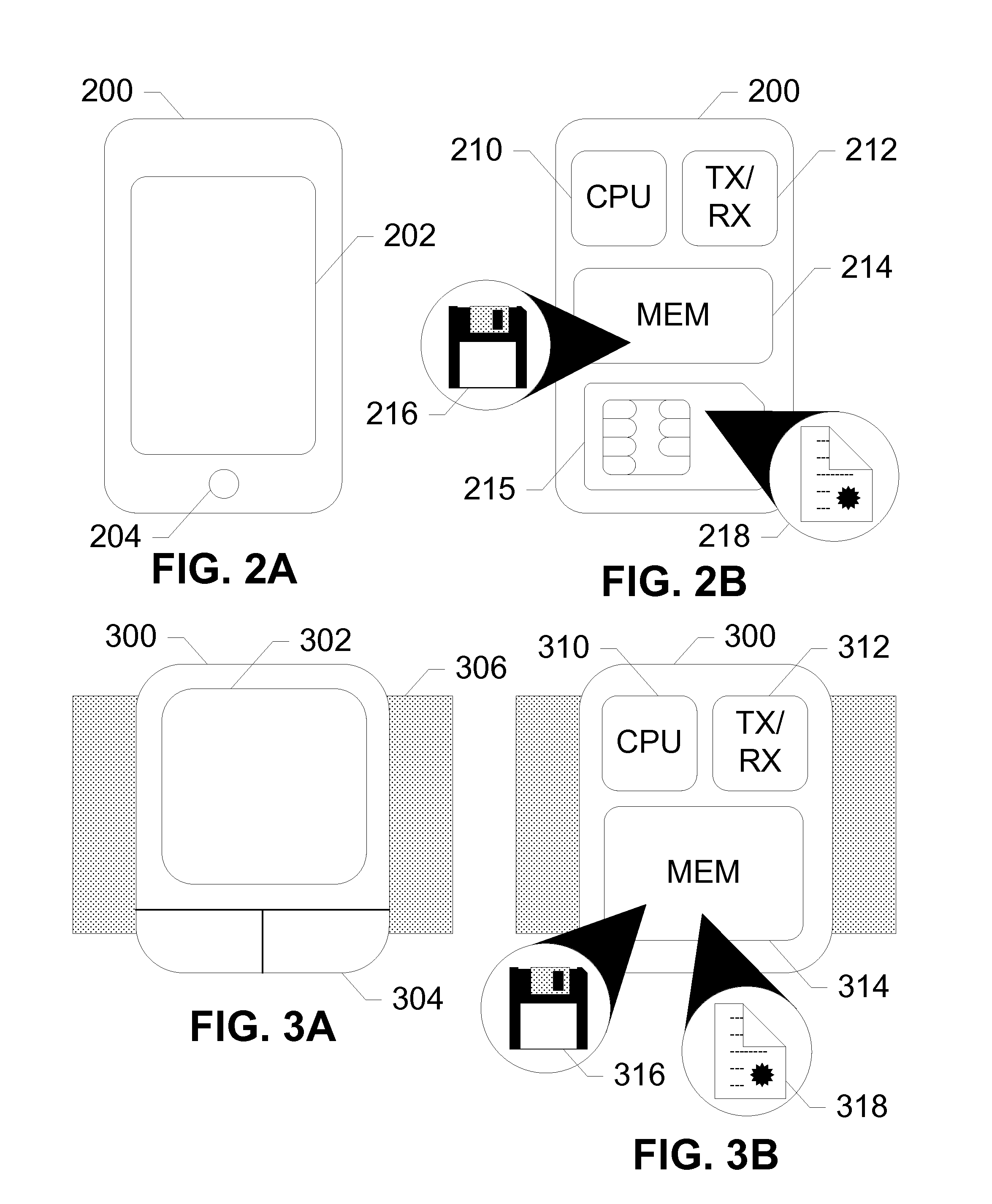

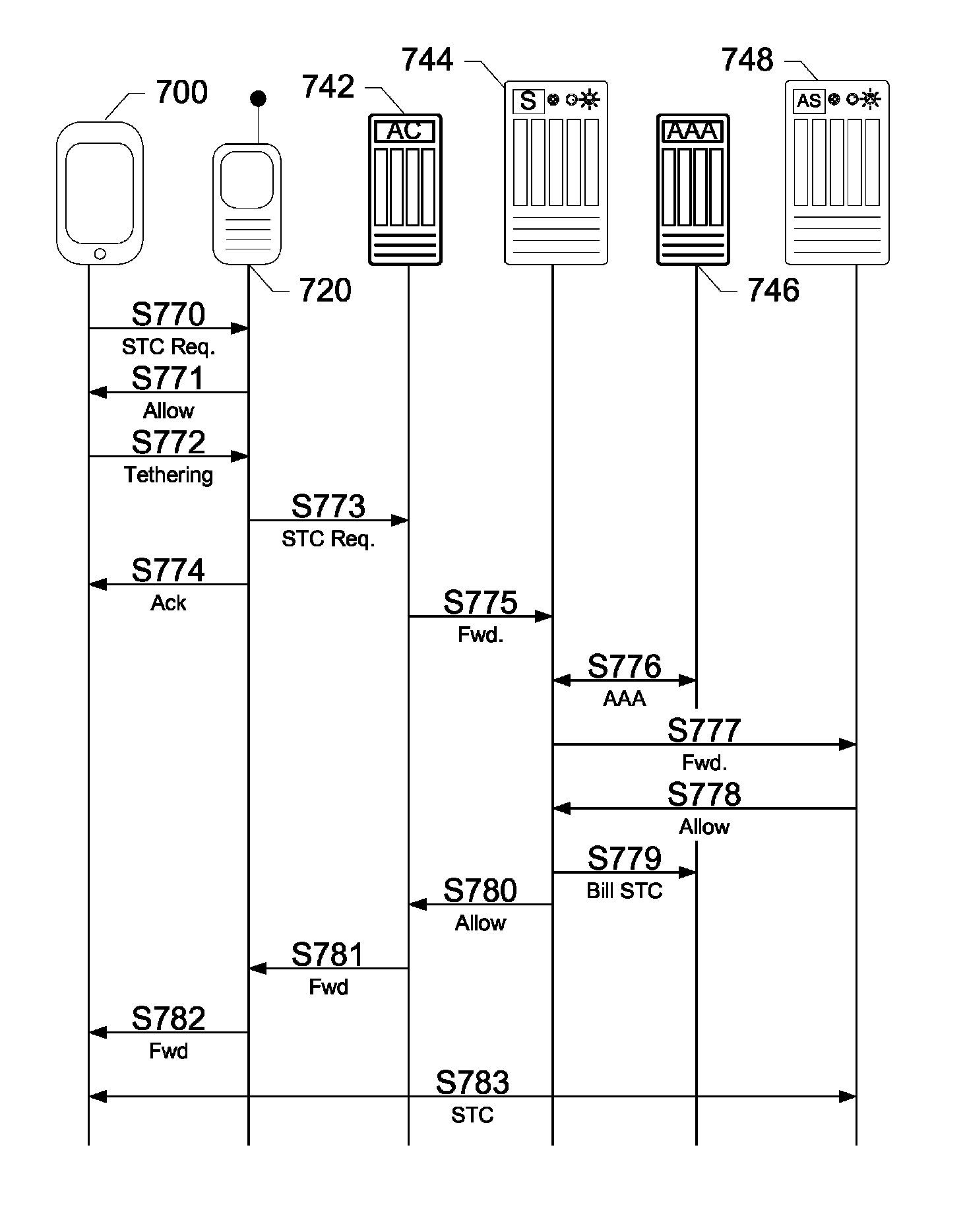

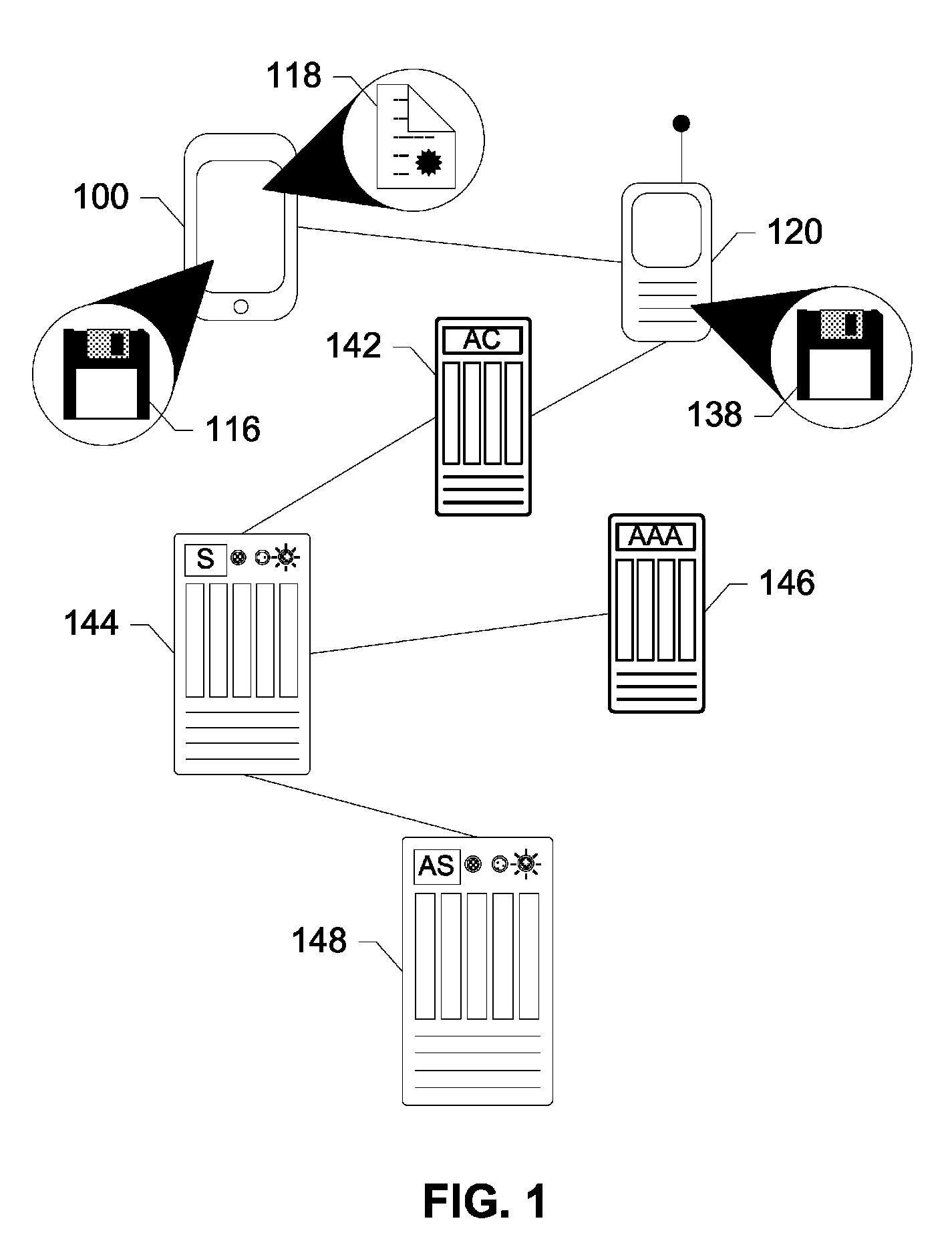

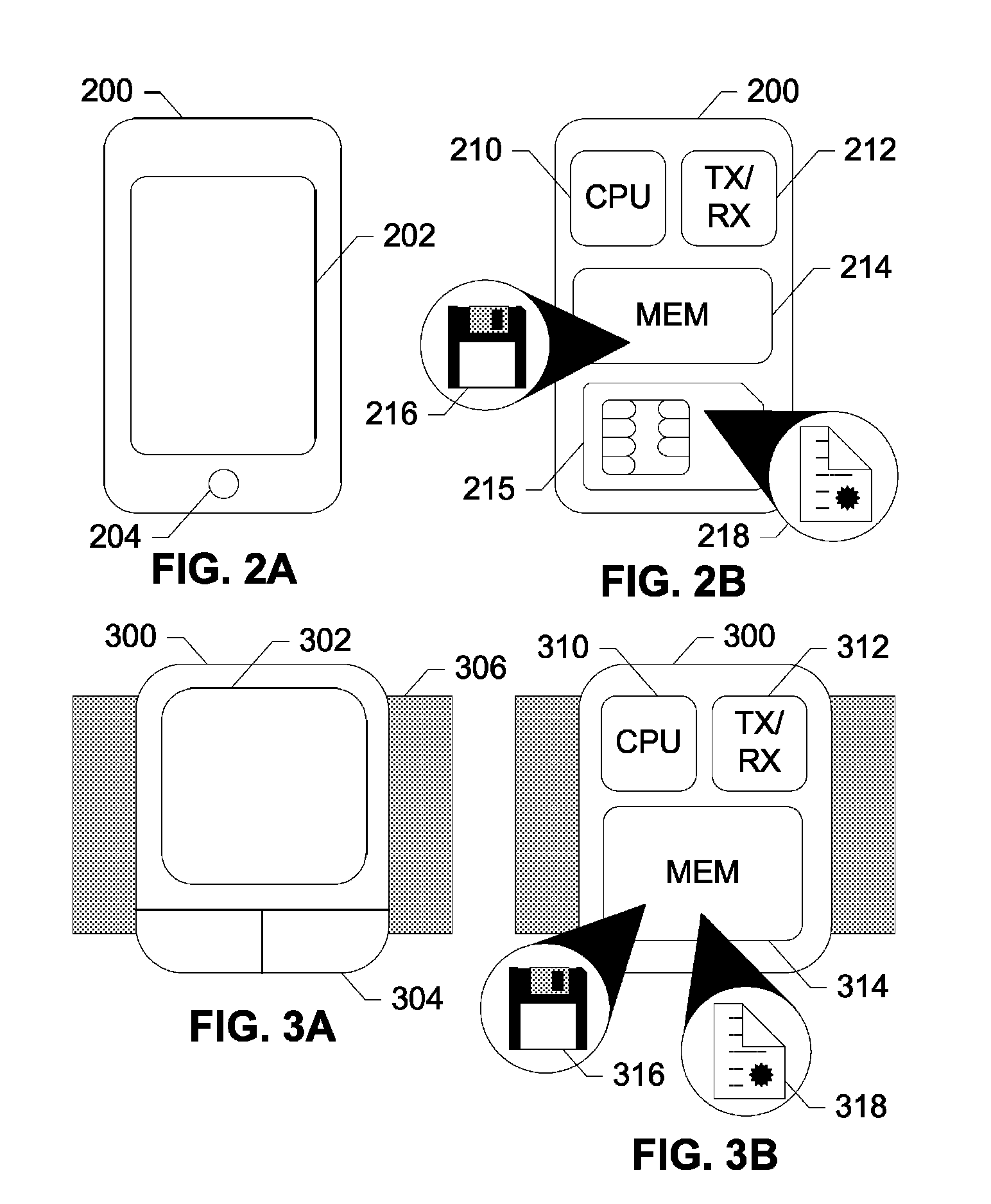

Devices, Systems, and Methods for Sponsored Tethered Connectivity

ActiveUS20120264375A1Reduced functionalityPrevents misuse and fraudAccounting/billing servicesTelephonic communicationApplication serverMobile device

Devices, systems, and methods are disclosed which relate to establishing an STC connection by tethering a special purpose connected device (SPCD) through a tethering mobile device having network access. The SPCD accesses an application server on the network, and is authenticated before service to the SPCD begins. Once authenticated, the service provider is billed for the STC connection instead of a user of the tethering mobile device.

Owner:AT&T INTPROP I L P

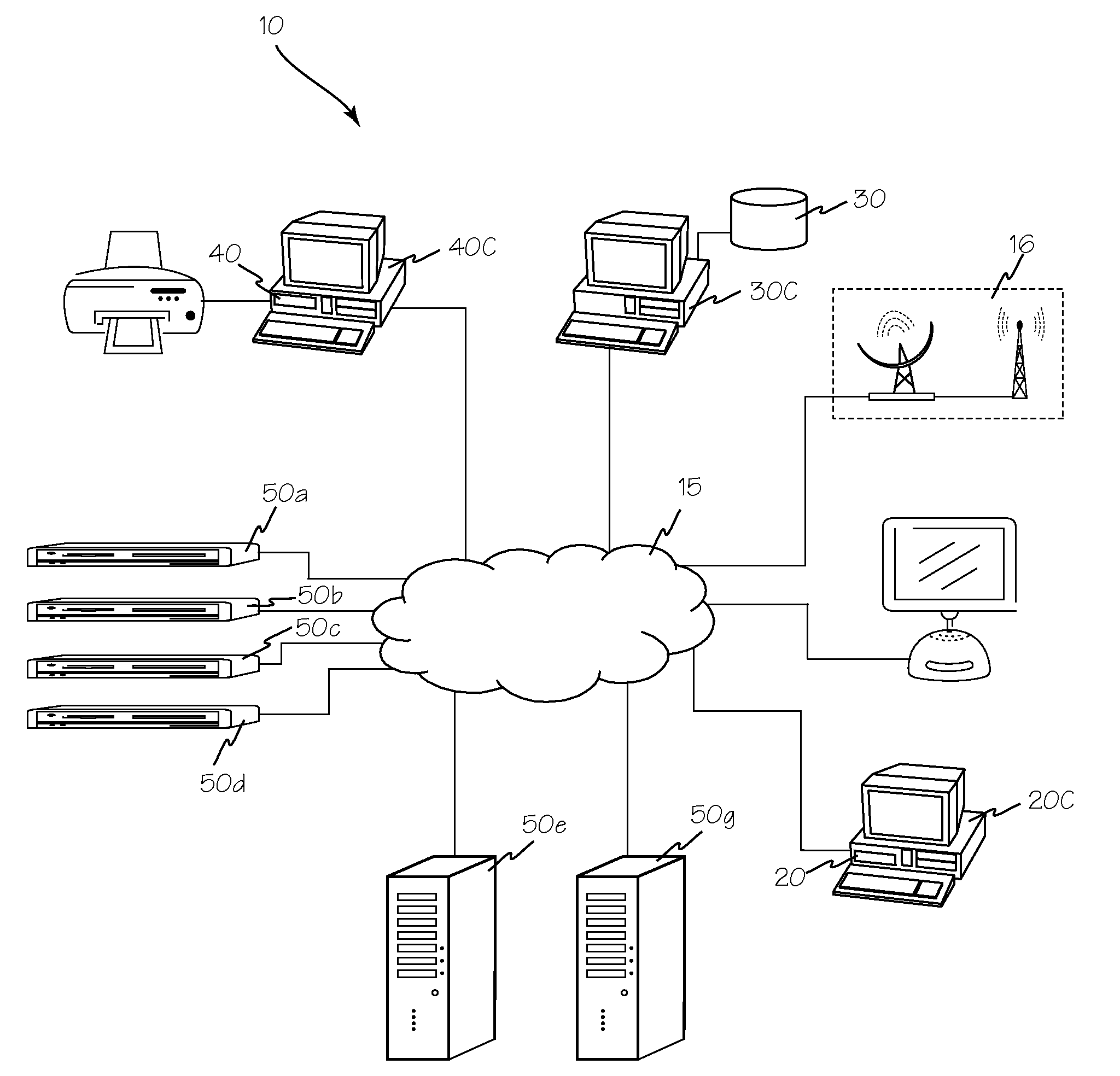

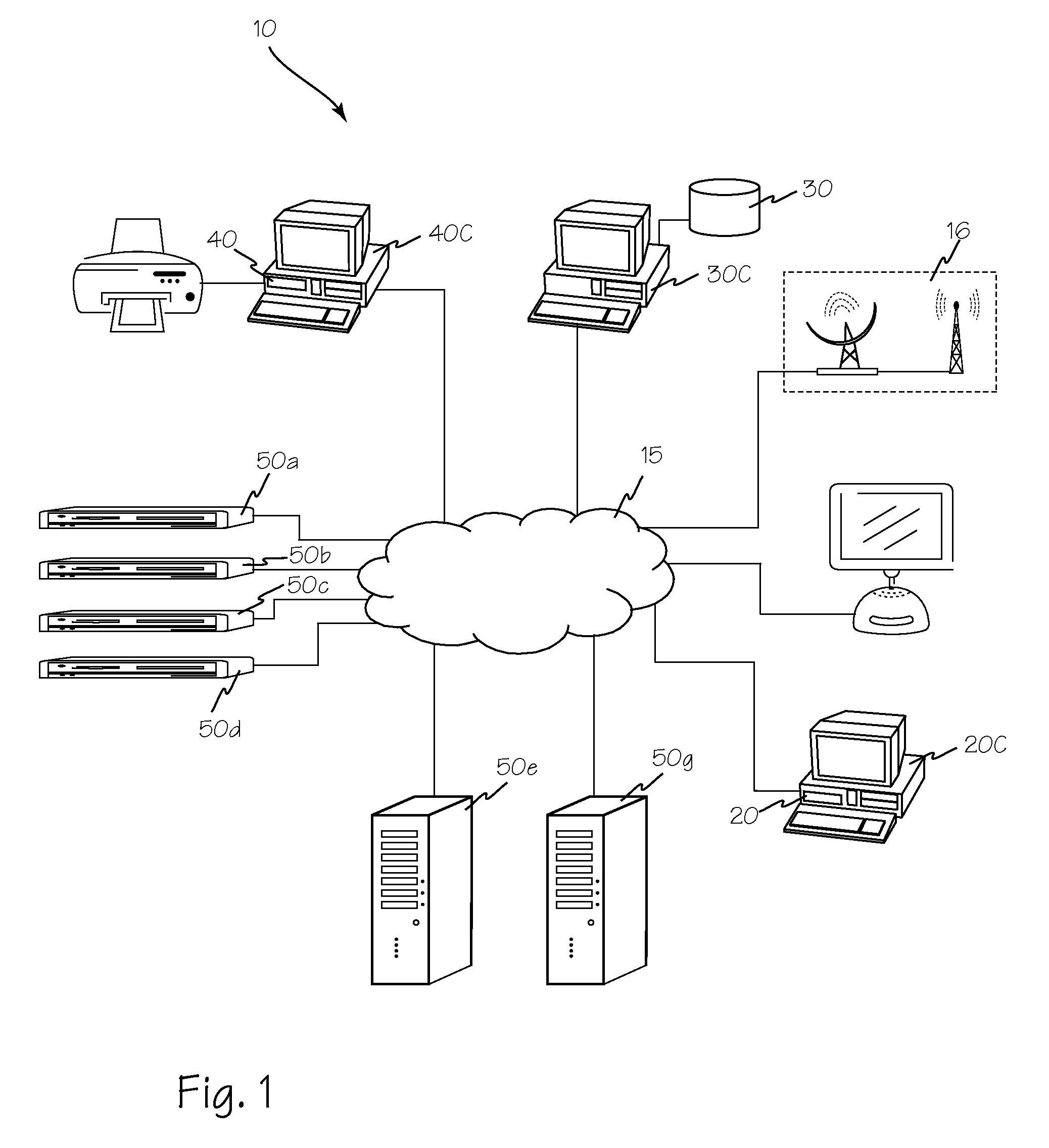

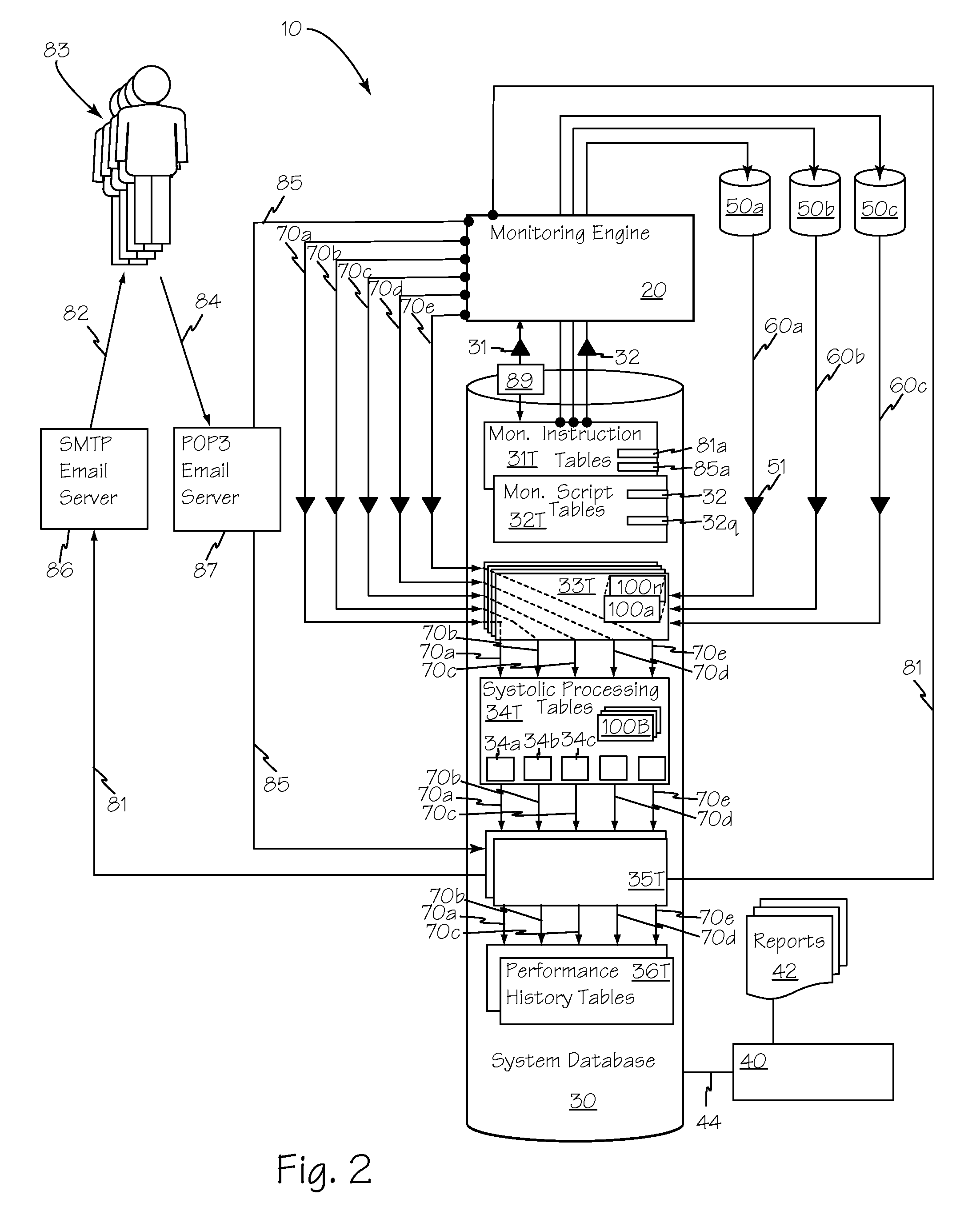

Method and Apparatus for Monitoring Network Servers

InactiveUS20090063509A1Satisfies needReduce in quantityTransmissionSpecial data processing applicationsMonitoring systemUser interface

A server monitoring system includes one or more monitoring engines running on a computer, a system database running on a computer, and a user interface running on a computer to remotely monitor one or more servers across any suitable network and provide alerts and status via either user interface computer or a suitable remote notification system.

Owner:ALPHA TECHN

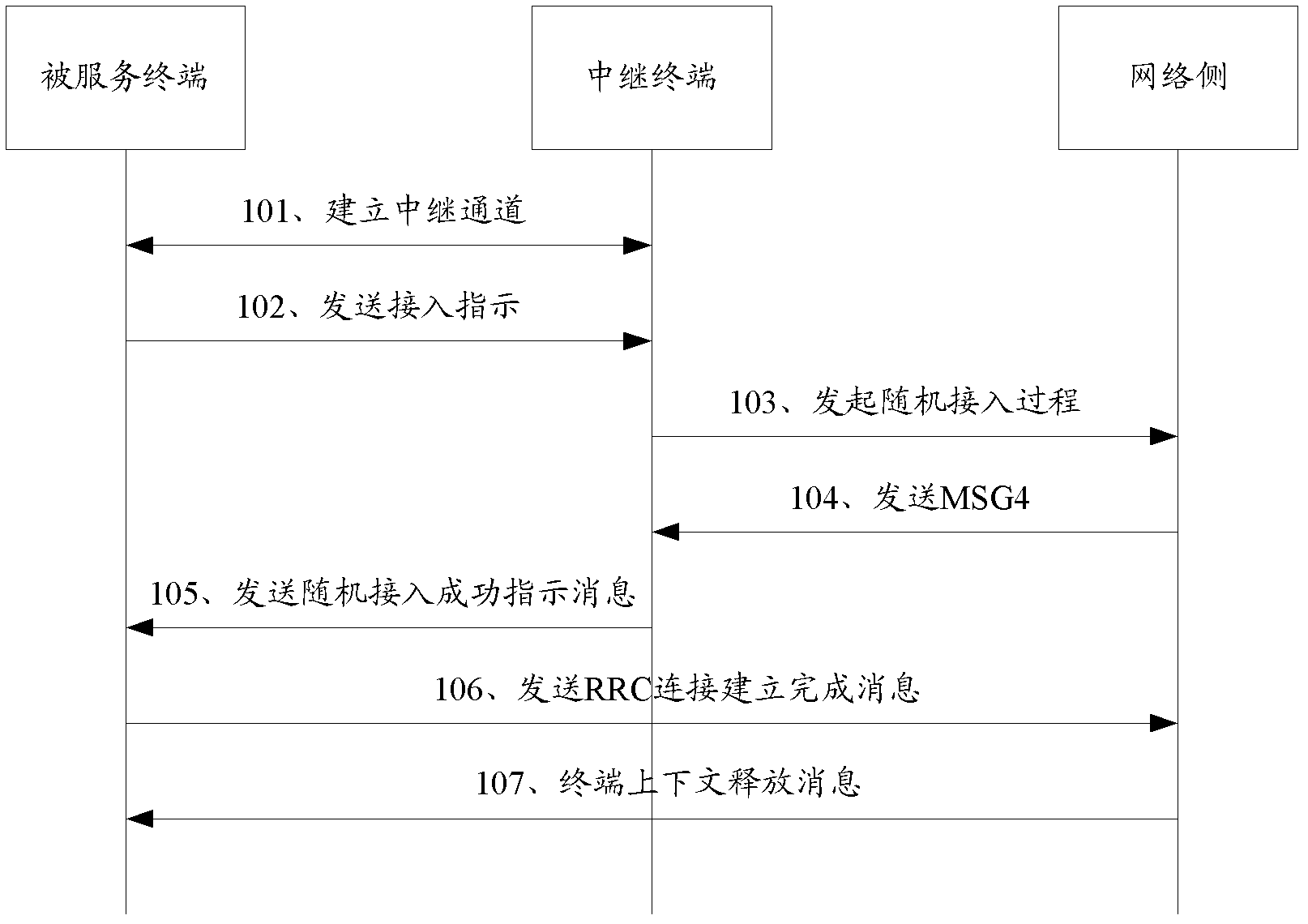

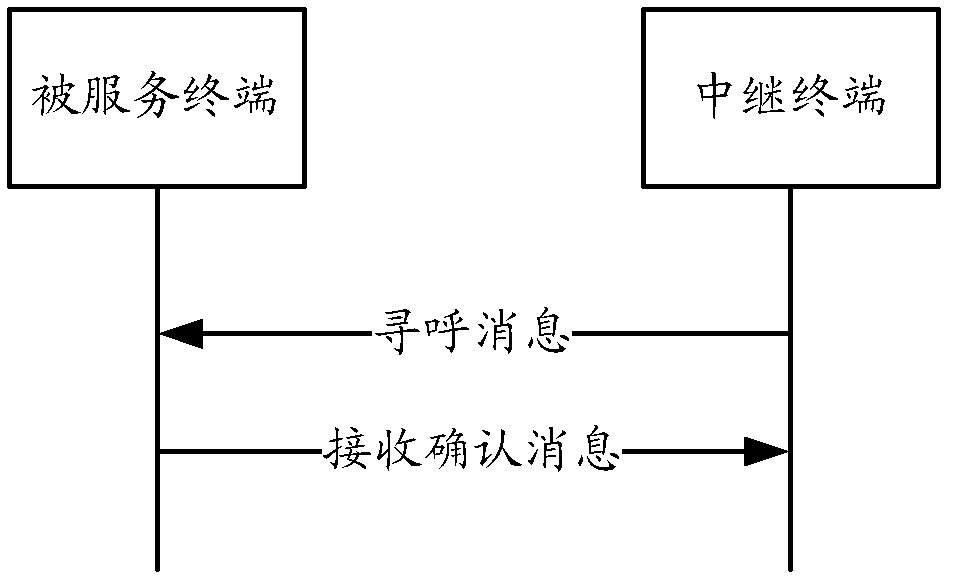

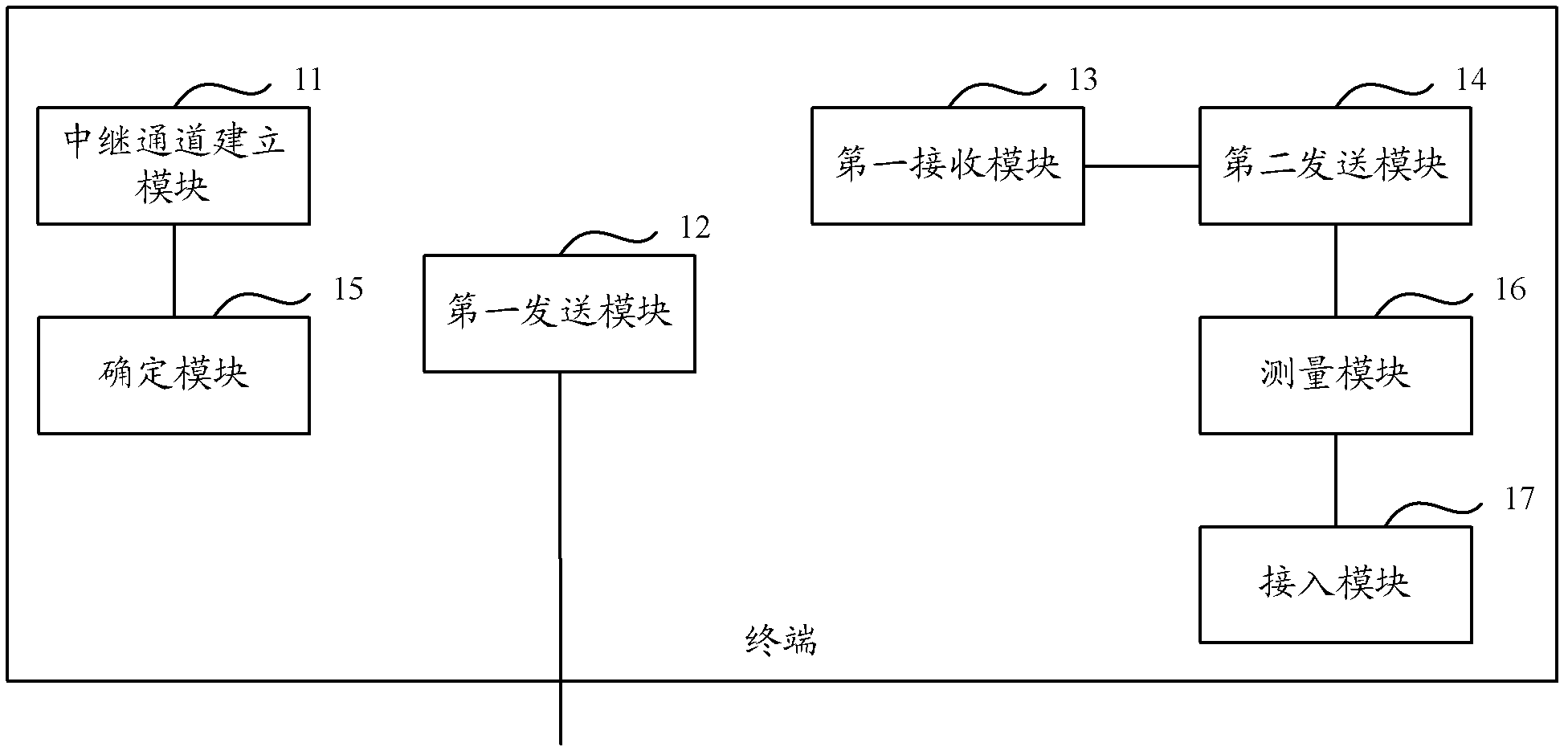

Method, terminal and system for accessing network

InactiveCN102811497AGuaranteed data transfer rateGuaranteed smooth executionAssess restrictionConnection managementAccess networkThe Internet

The embodiment of the invention provides a method, a terminal and a system for accessing the network. In the method, a relay channel is established between a served terminal in which the information channel quality is lower than a first set value and a relay terminal in which the information channel quality is higher than a second set value, and the relay terminal with the higher information channel quality is used for connecting the served terminal with the lower channel information quality with the Internet. Compared with the scheme that the served terminal in which the channel quality is lower than the first set value is directly connected with the network side in the prior art, the data transmission rate between the served terminal and the relay terminal can be guaranteed by the relay channel, and because the information channel quality of the relay terminal is better, the data transmission rate between the relay terminal and the network side is guaranteed, so that data can be transmitted at a high data transmission rate between the served terminal and the network side, and the business with high requirement on the data transmission rate can be successfully carried out.

Owner:CHINA MOBILE COMM GRP CO LTD

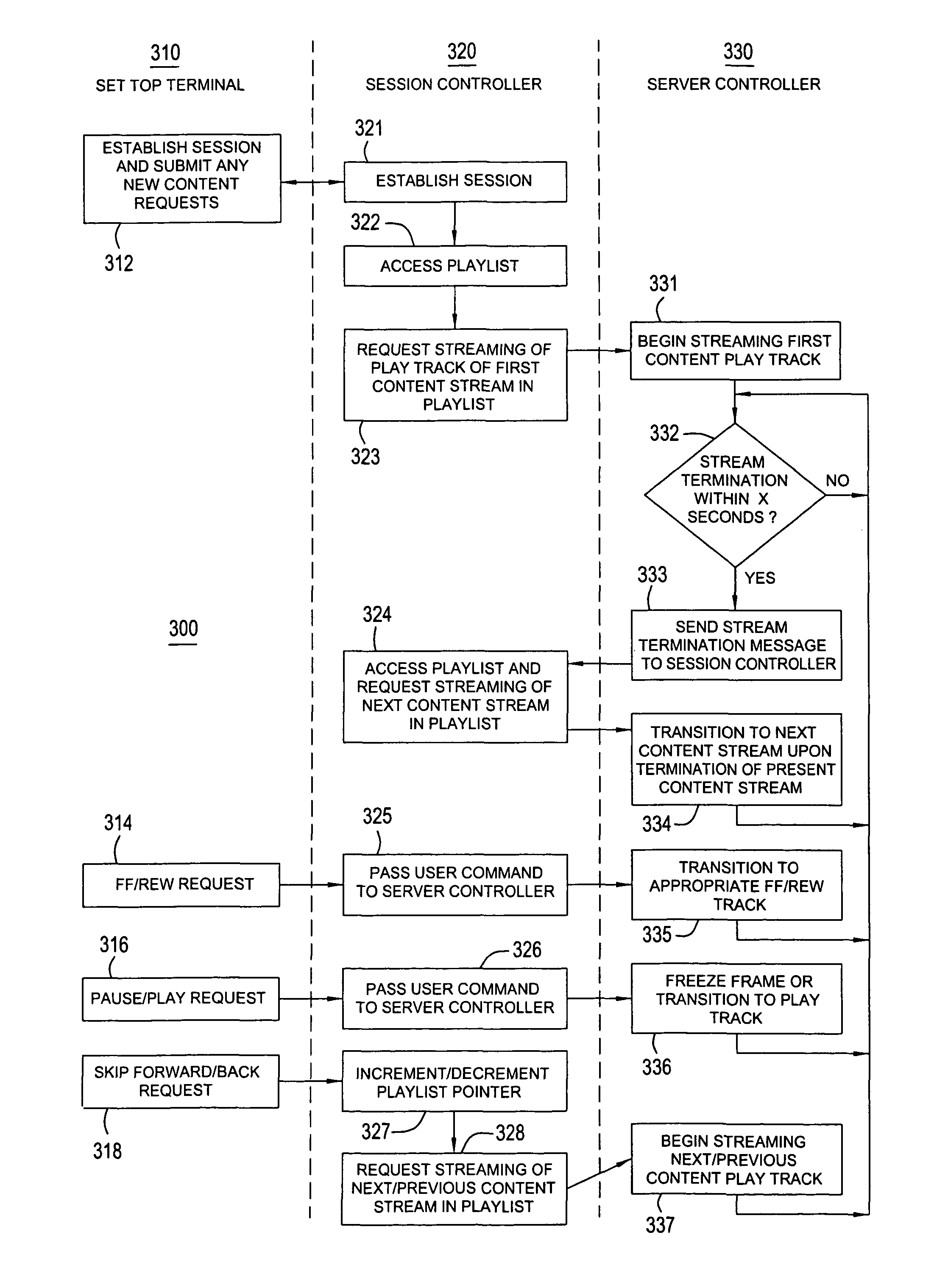

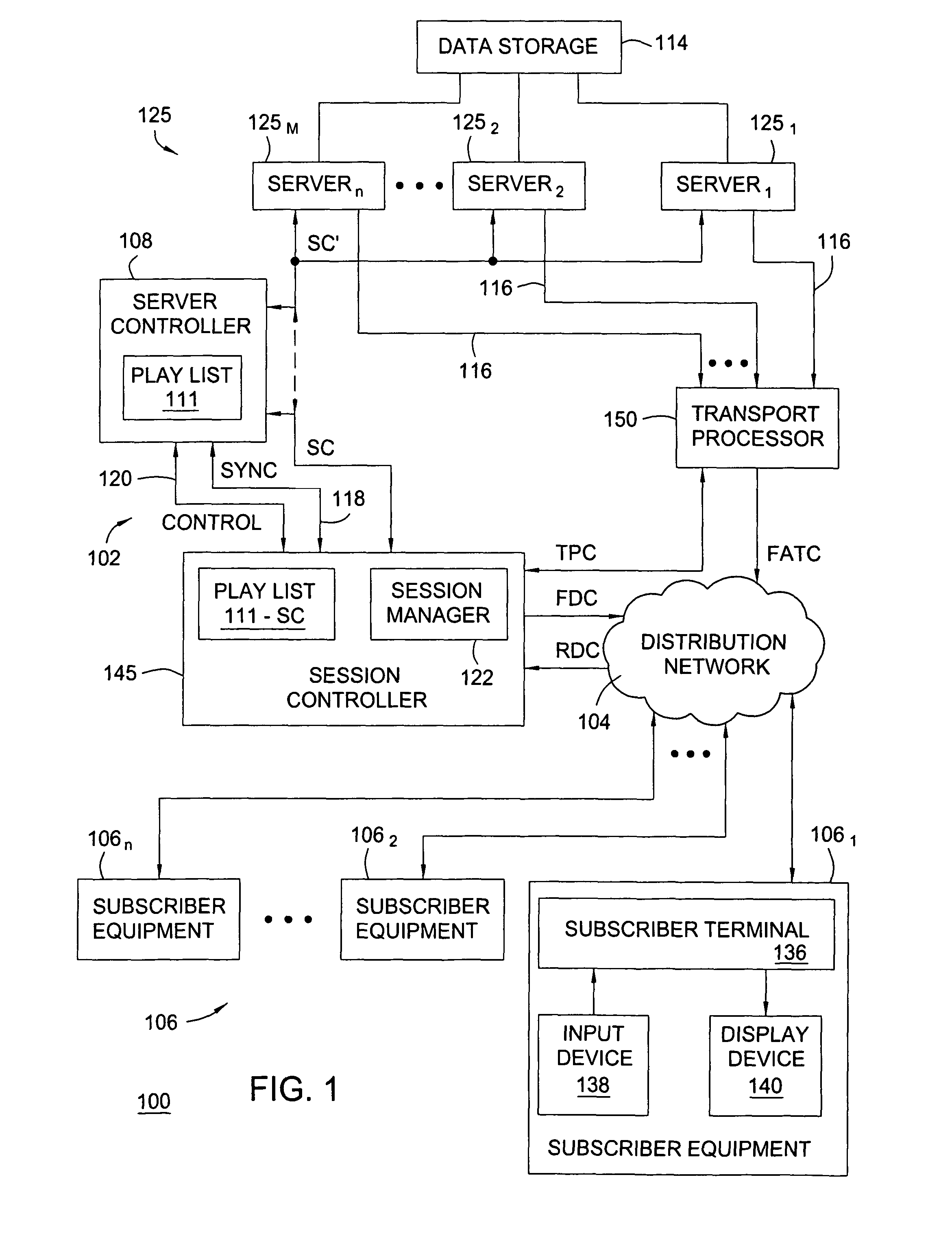

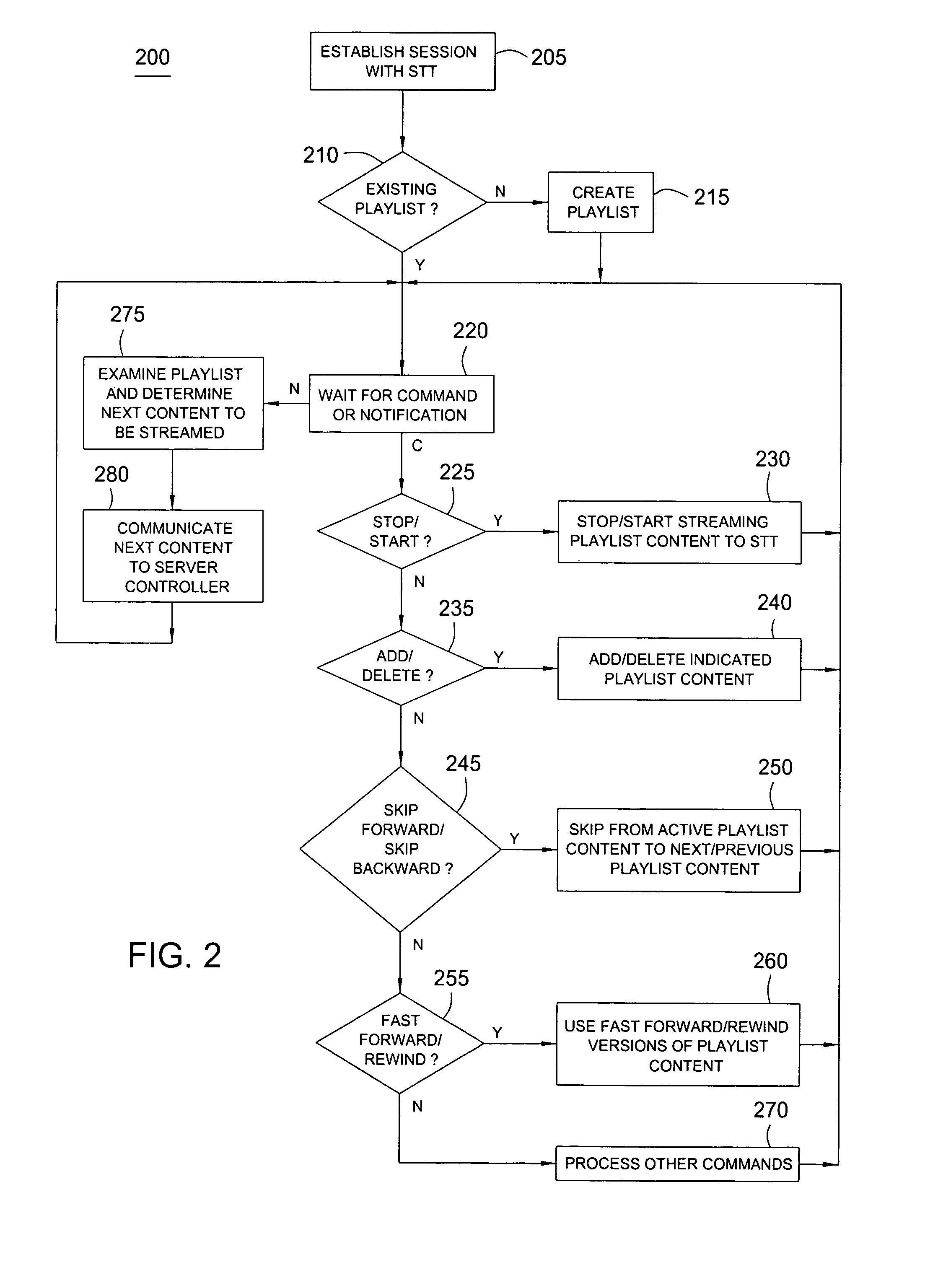

Method for reducing latency in an interactive information distribution system

InactiveUS8065708B1Lower latencyGuaranteed smooth executionPulse modulation television signal transmissionTwo-way working systemsComputer networkDistribution system

A method and apparatus for reducing latency caused by information server processing of subscriber request wherein a plurality of content streams defined by a playlist are sequentially provided to a subscriber in a substantially seamless manner and wherein the playlist is updated and otherwise maintained in response to subscriber commands and requests.

Owner:COX COMMUNICATIONS

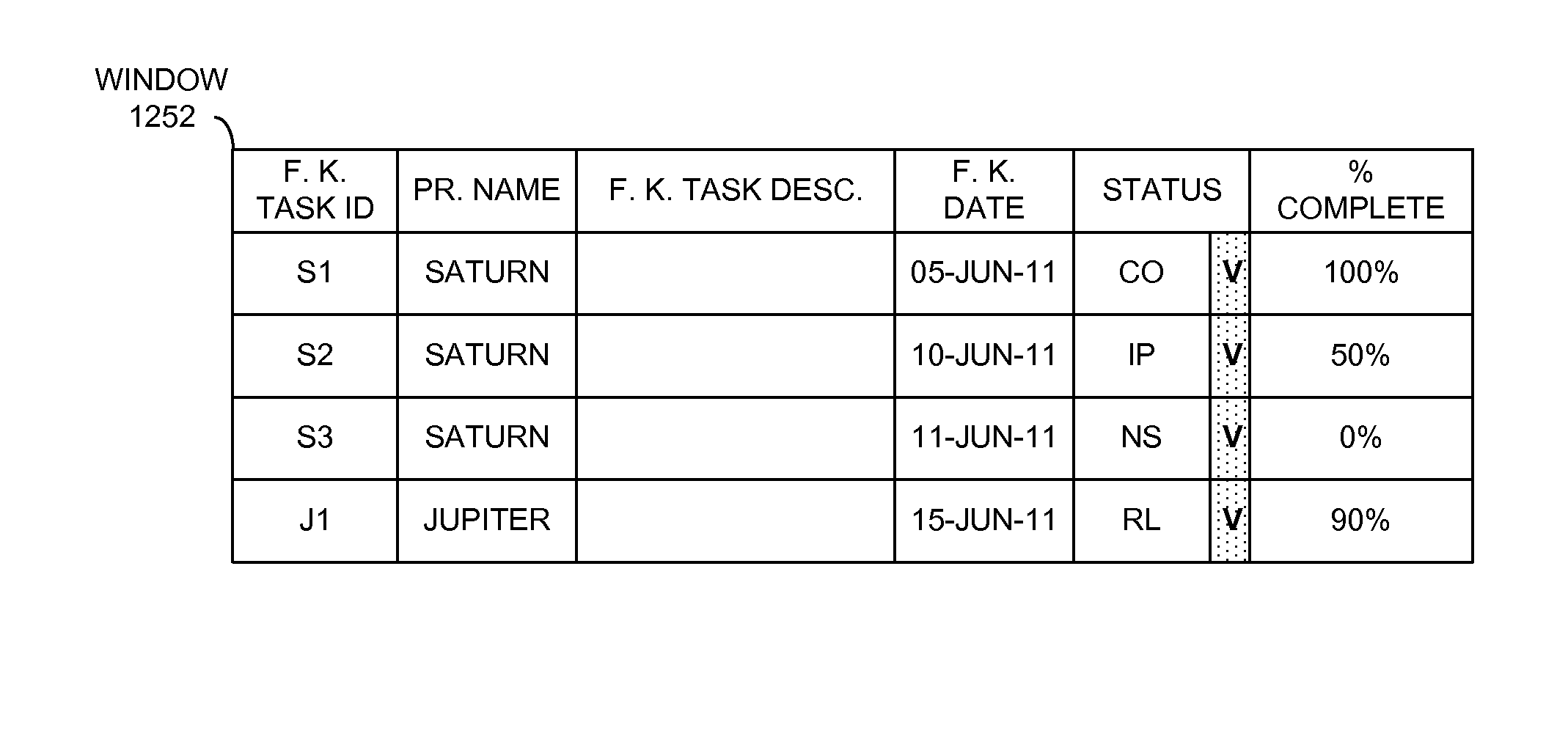

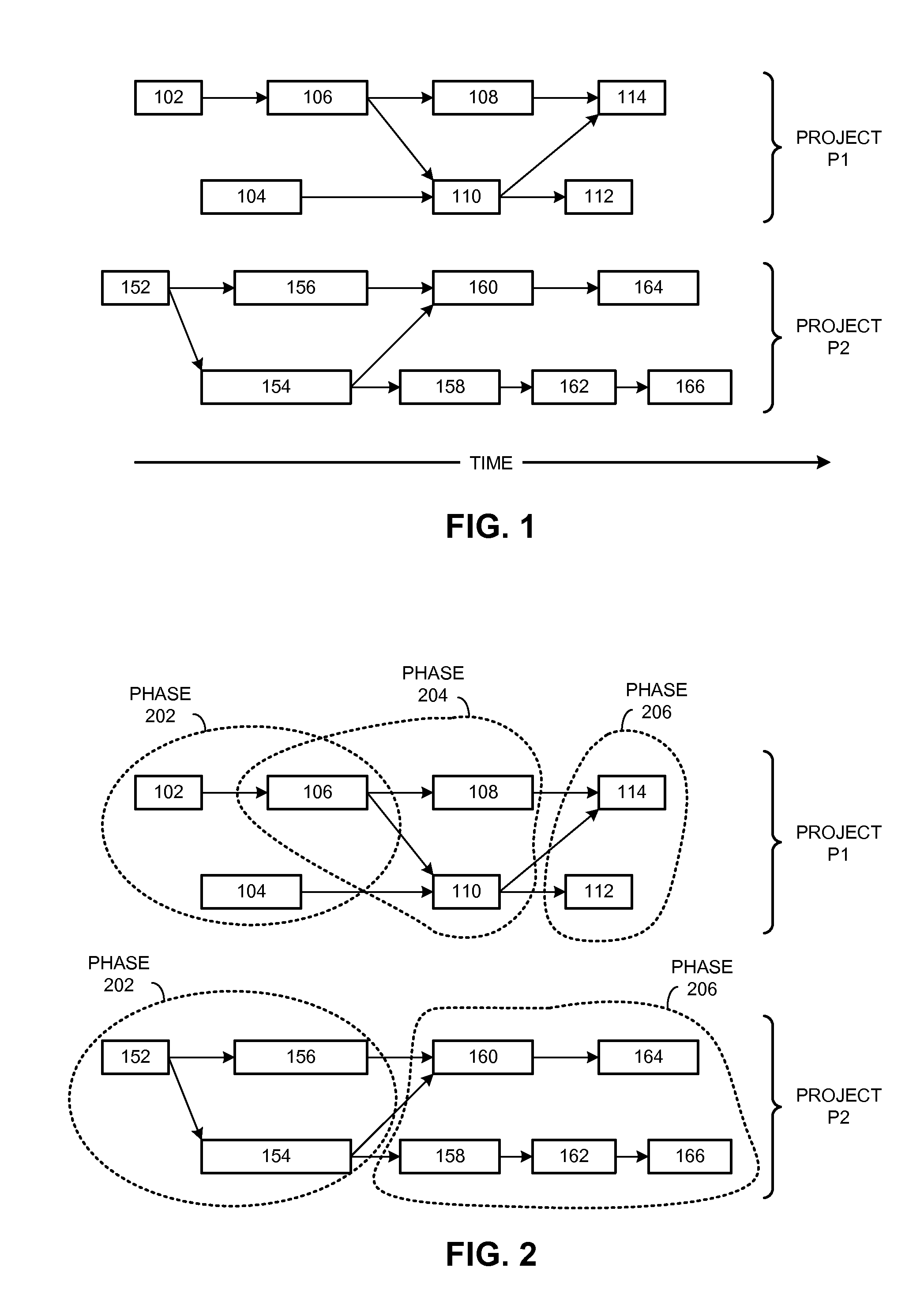

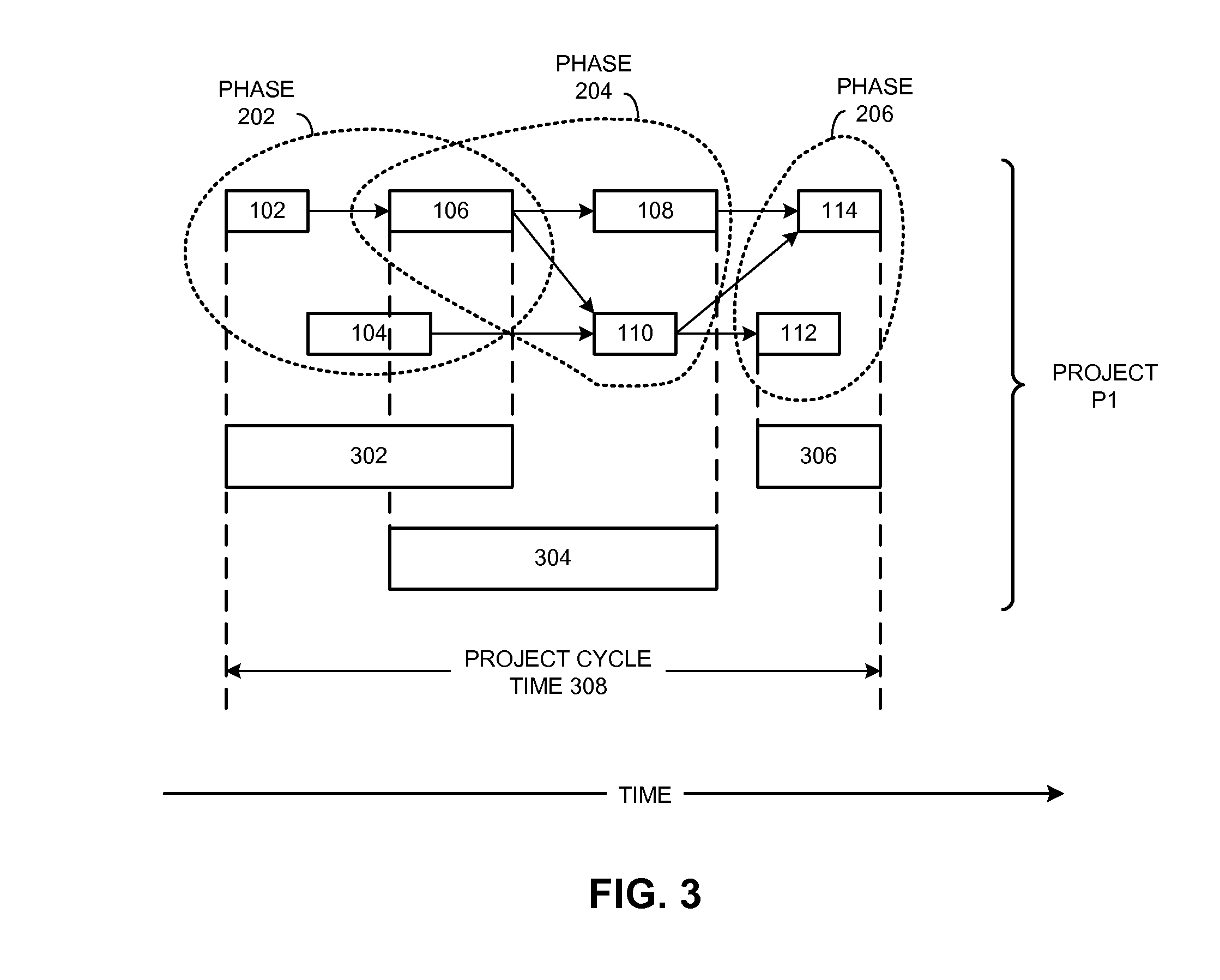

Full-kit management in projects: checking full-kit compliance

Methods and apparatuses are described for creating and using full-kit tasks, monitoring the progress of full-kit tasks, determining full-kit dates, checking compliance of release conditions associated with full-kit tasks, and / or computing and reporting full-kit task delays. A full-kit task can be used in the project plan to represent the preparations that are required or recommended to be performed before executing a set of tasks. The full-kit task can be a zero-duration task that has a full-kit date and that includes a list of items which need to be completed by the full-kit date. The full-kit task is capable of being in one of the following states: not started, in progress, released, and completed. In some embodiments, the set of tasks associated with the full-kit task can only be started if the full-kit task is either in the released state or the completed state.

Owner:REALIZATION TECH

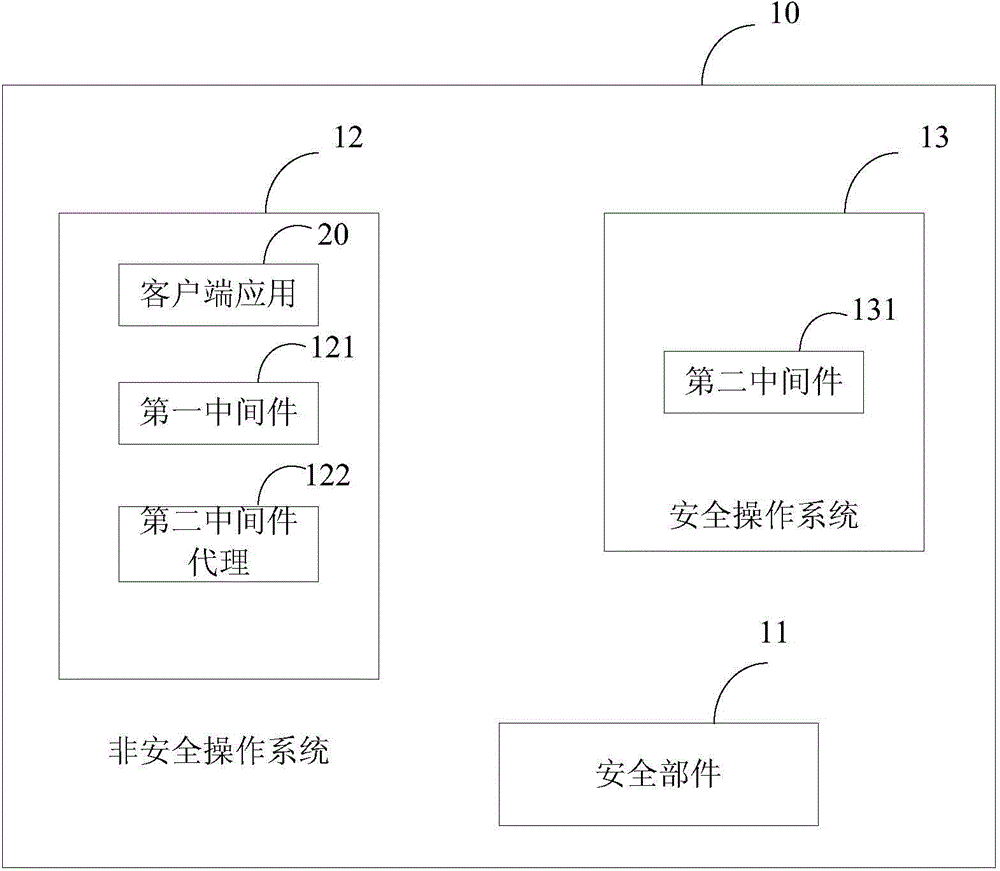

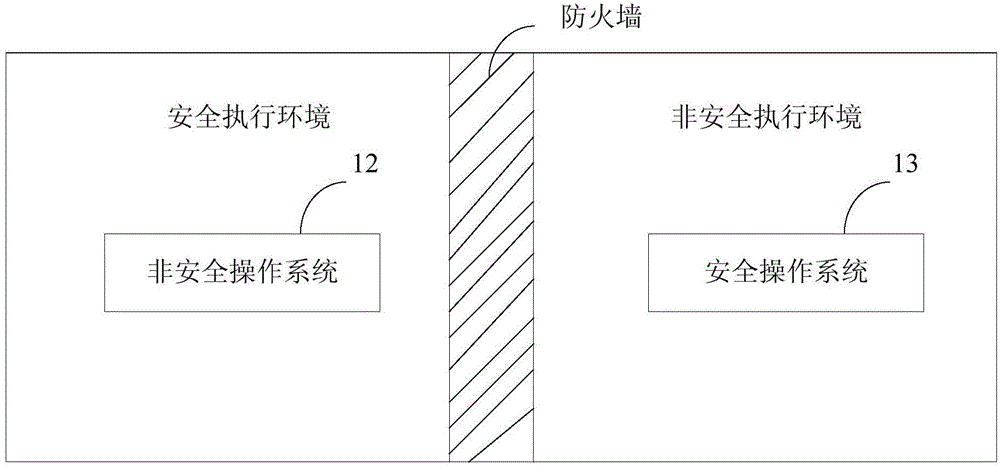

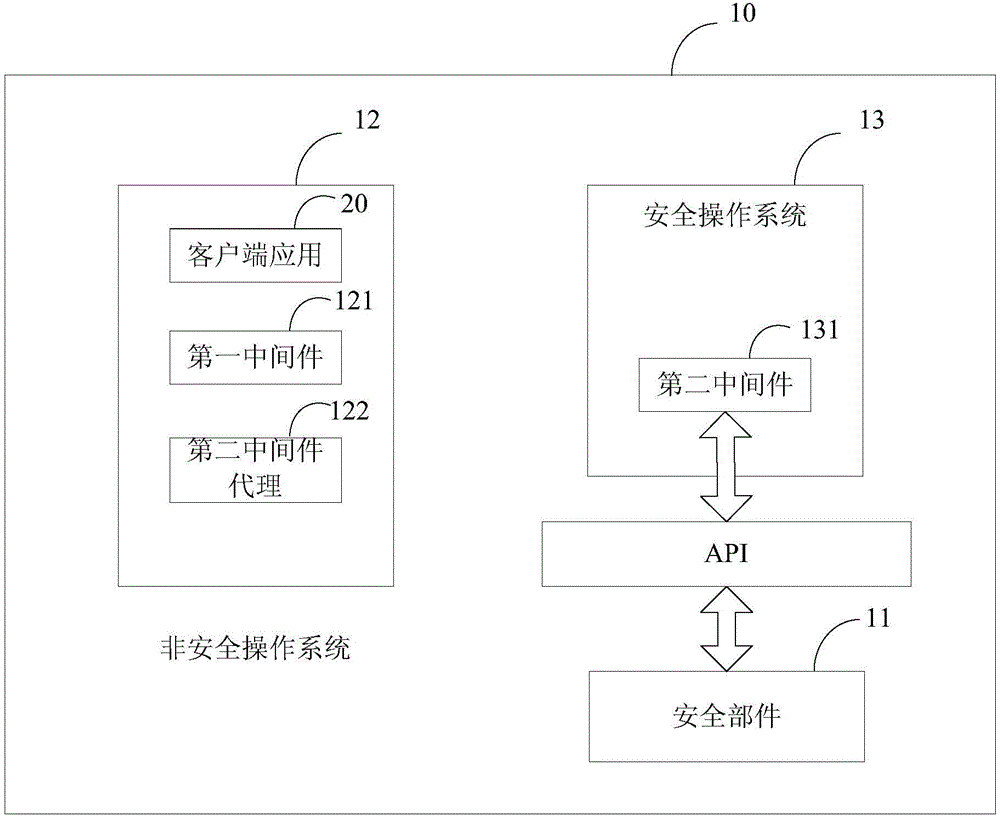

Device for safeguarding operational security of client side

InactiveCN104102876ALow costReduce complexityPlatform integrity maintainanceOperational systemClient-side

An embodiment of the invention discloses a device for safeguarding operational security of a client side. The device comprises a security part, an unsecure operating system, a secure operating system, a first middleware proxy, a second middleware proxy and second middleware, wherein the first middleware proxy and the second middleware proxy operate in the unsecure operating system, and the second middleware operates in the secure operating system. Client-side applications are installed on the unsecure operating system and directly call first middleware and call the second middleware through the second middleware proxy. Sensitive data in the client-side applications are stored in the security part, the first middleware is used for completing a part of service functions in the client-side applications in the unsecure operating system, and the second middleware is used for completing another part of service functions of the client-side applications by interacting with the security part in the unsecure operating system. According to the embodiment, potential security hazards of operations completed by the client side are reduced or even avoided.

Owner:WATCHDATA SYST

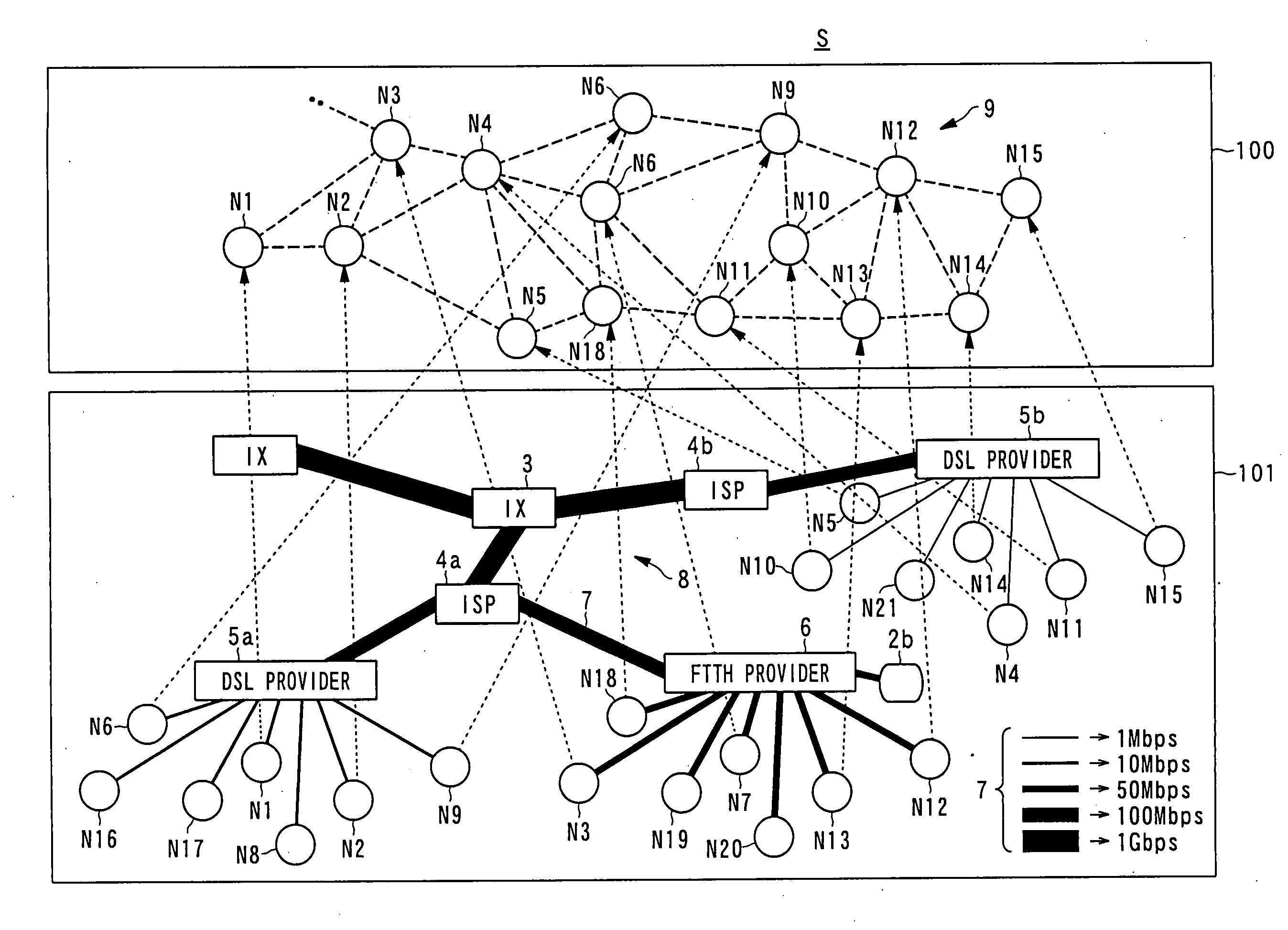

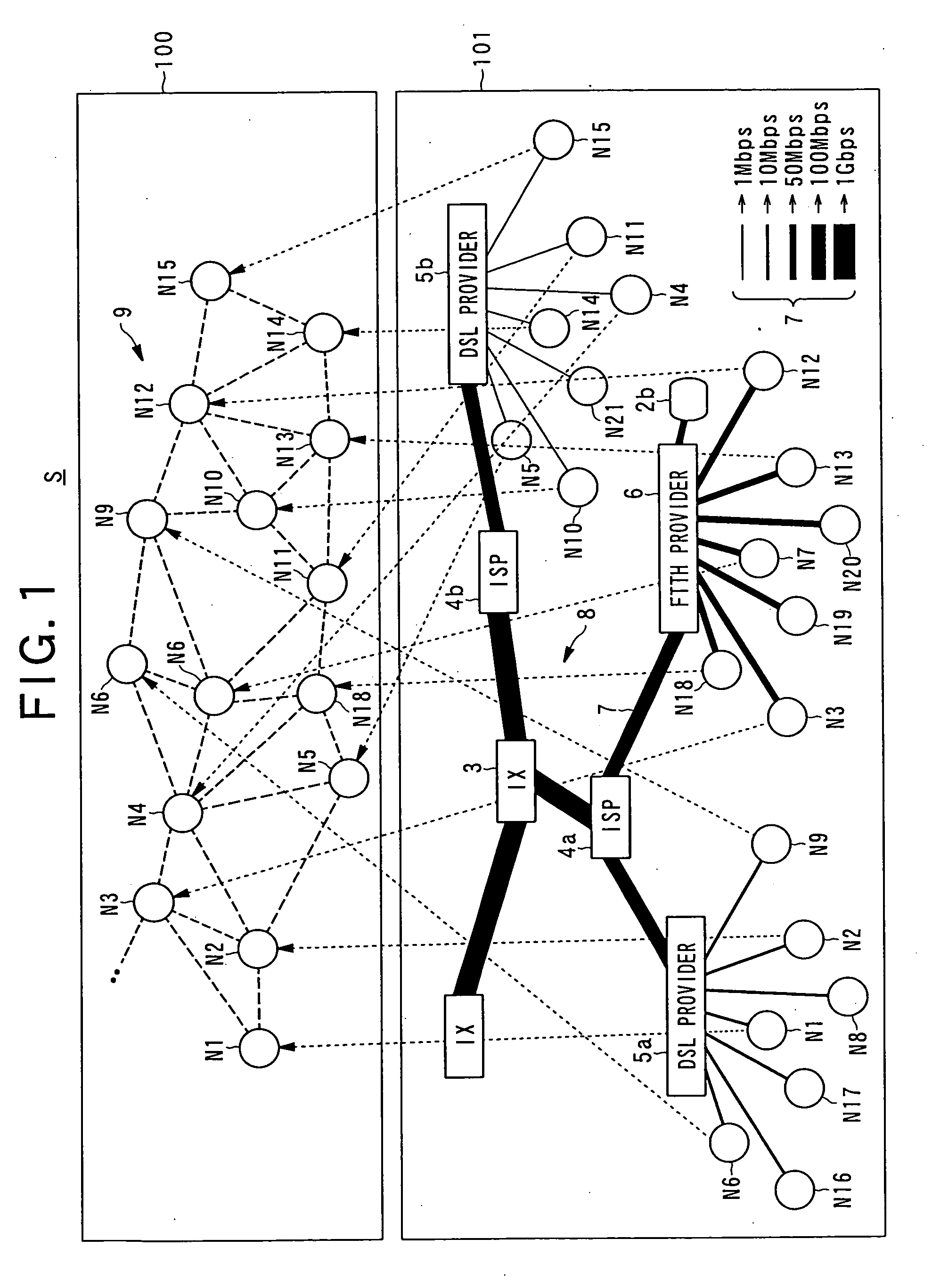

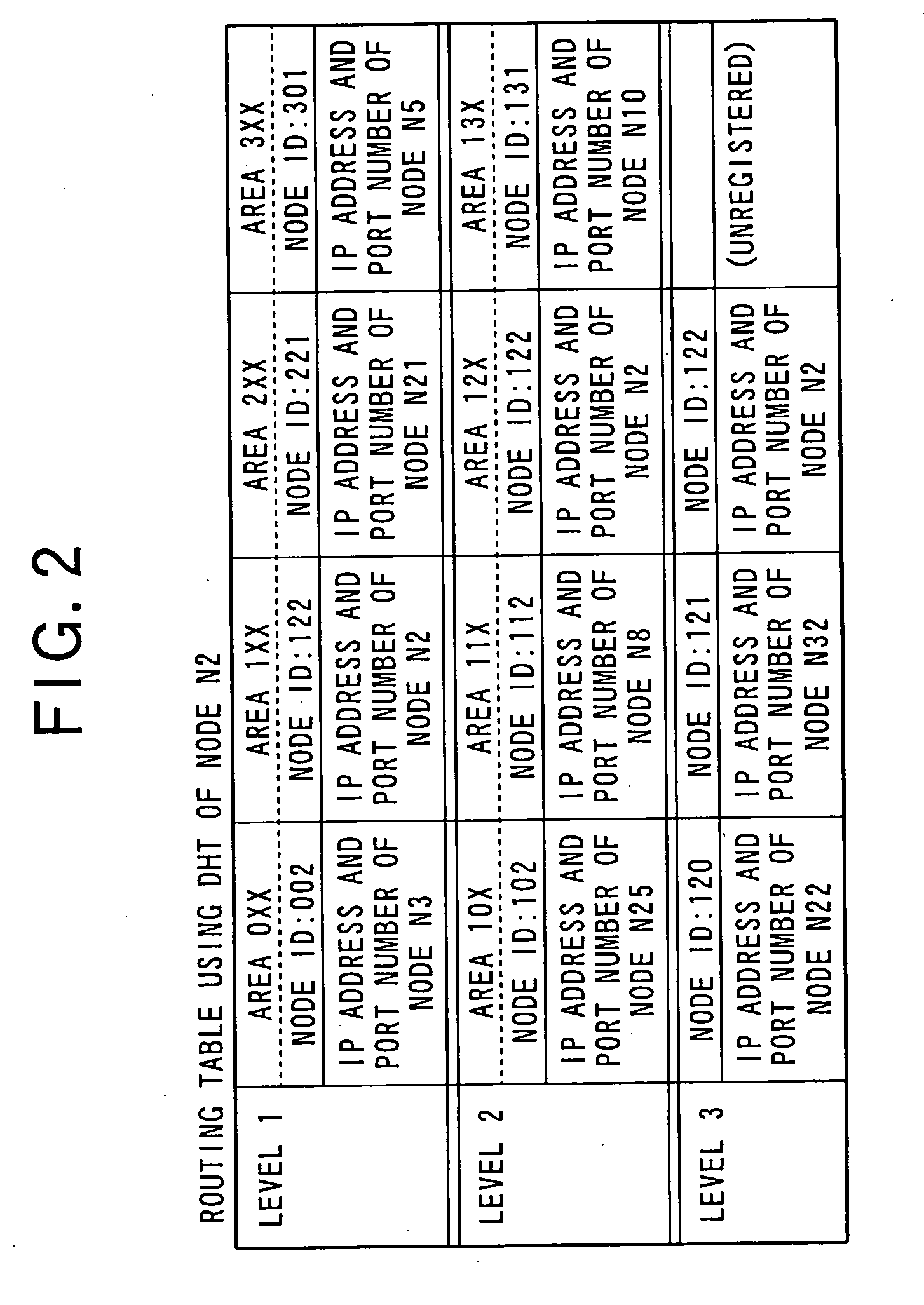

Content distributed-storage system, frame image obtaining method, node device, and recording medium on which node processing program is recorded

InactiveUS20090083809A1Smoothly executeGuaranteed smooth executionTelevision system detailsTwo-way working systemsDistributed memory systemsComputer hardware

In a content distributed-storage system in which divided content data obtained by dividing content data of a single unit having a plurality of pieces of frame image data into a plurality of pieces is stored so as to be distributed to a plurality of node devices, unique identification information is assigned to each of the divided content data, each of the node devices can obtain the divided content data on the basis of the identification information.In the system, content catalog information having the identification information of at least one piece of the divided content data and key frame information including information indicative of an offset position of the frame image data in each of the divided content data, is stored. An instruction related to playback of the content data from the user is received.

Owner:BROTHER KOGYO KK

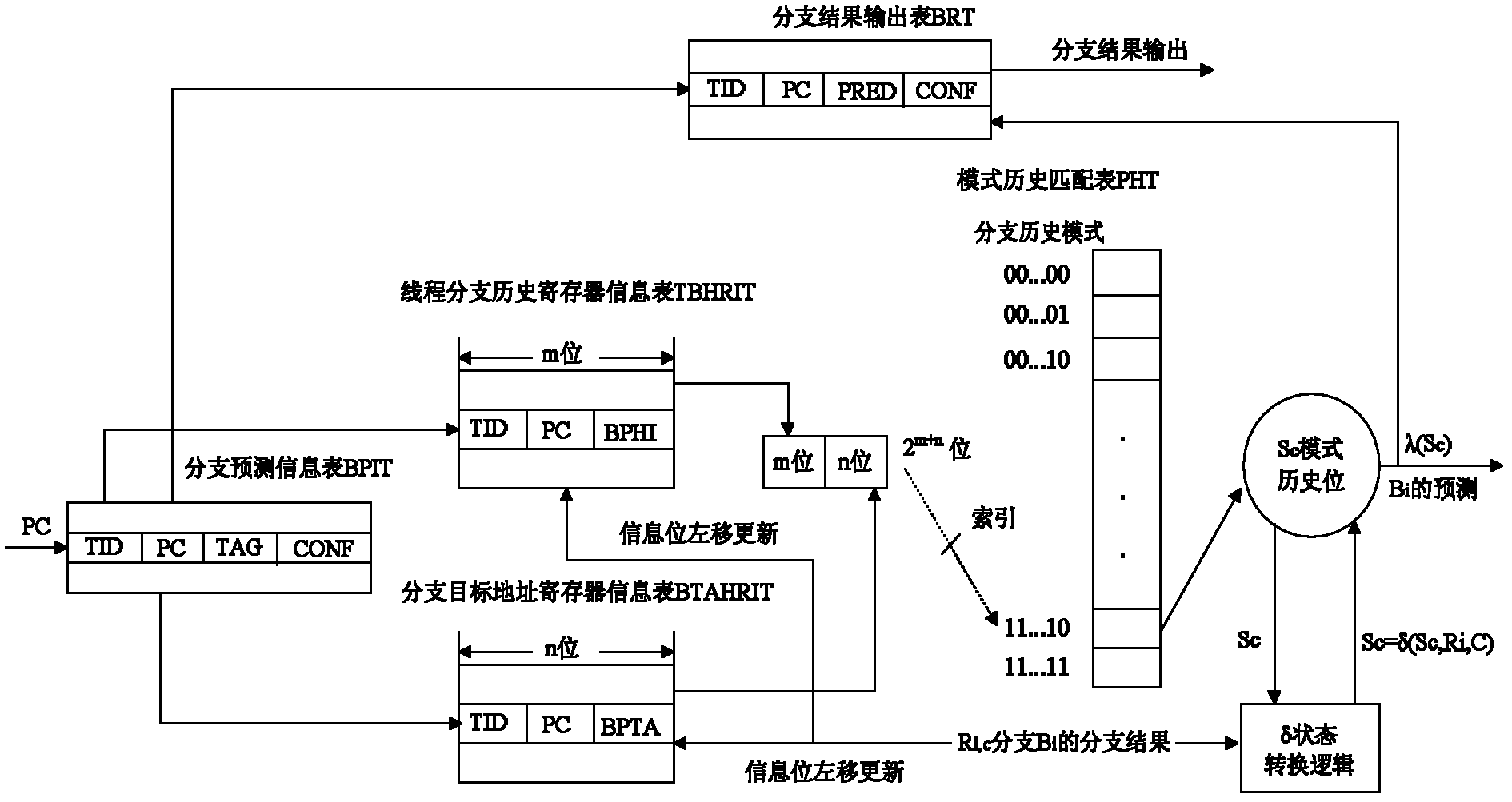

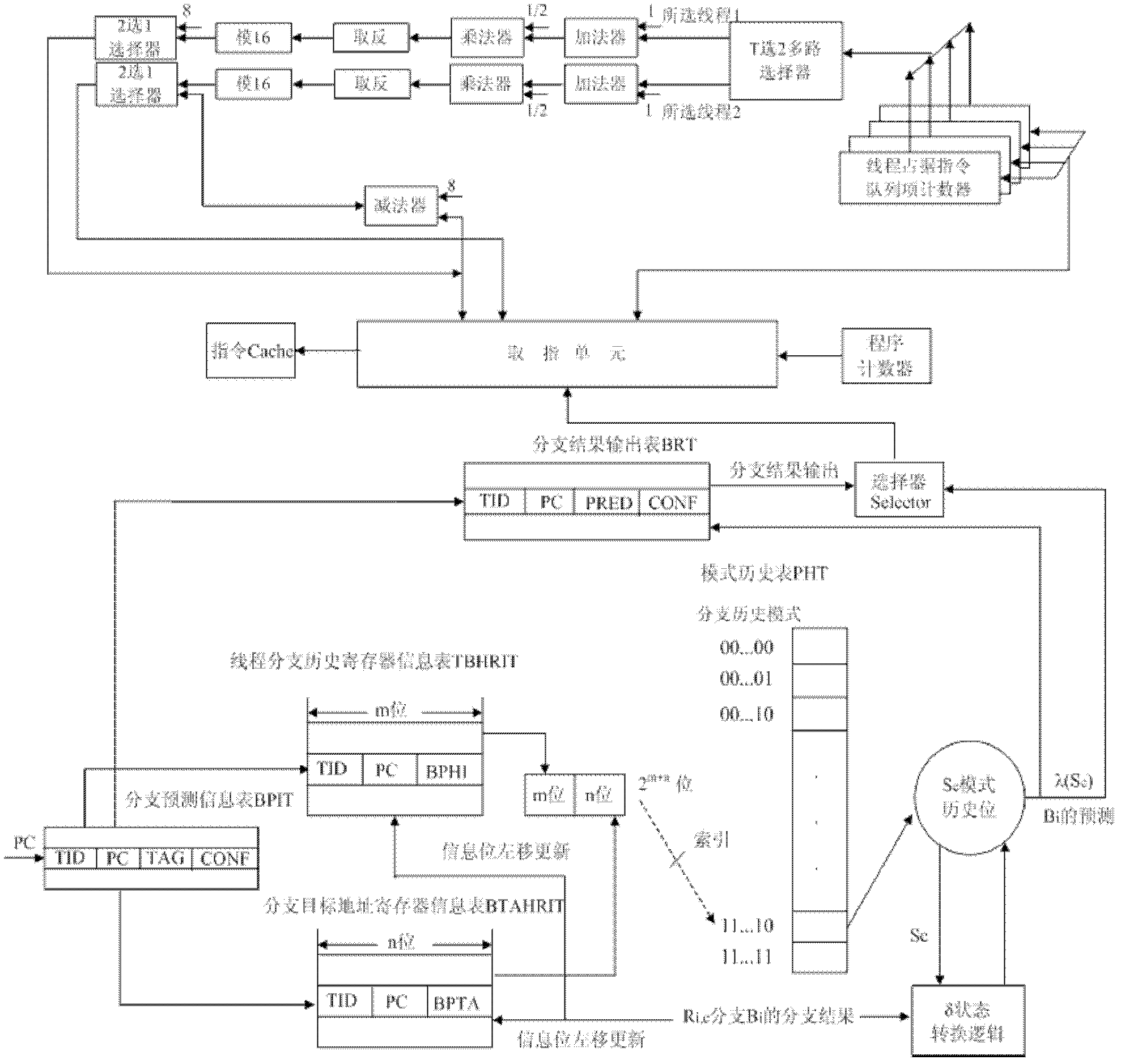

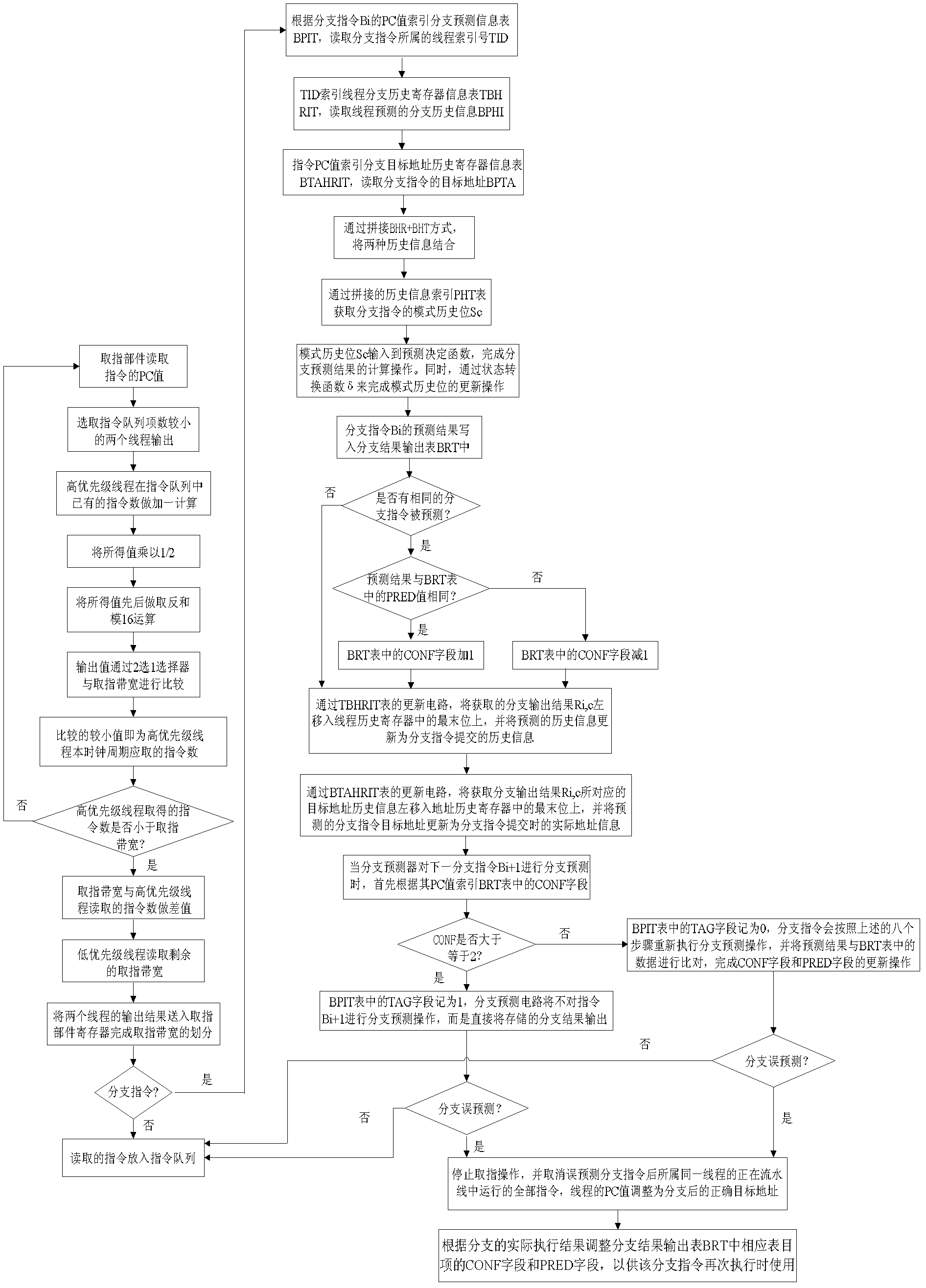

Instruction acquisition control method based on simultaneous multithreading

InactiveCN102566974AImprove superiorityAdvancing Predictive Execution SpeedConcurrent instruction executionMemory systemsFailure ratePattern matching

The invention provides an instruction acquisition control method based on simultaneous multithreading, which includes the steps: in each clock cycle of a processor, reading a PC (personable computer) value of instructions by an instruction acquisition component according to a program counter, selecting two threads with high priority as instruction acquisition threads firstly, and then computing the actual instruction number required by each instruction acquisition thread so as to read the instructions; according to an IPC (inter-process communication) value and the Cache failure rate, enabling a dual-priority resource allocation mechanism to compute system resources required by the threads in an instruction acquisition stage and complete dynamic allocation of the resources; matching a TBHBP (thread branch history branch predictor) with the instruction acquisition operations of the instruction acquisition component, acquiring a pattern type match position Sc by connecting global historical information with local historical information read by a branch instruction Bi to utilize as an index of a secondary PHT (pattern history table), and inputting computed results to a BRT (branch result table); and when the branch instruction Bi is executed again, judging whether CONF fields are larger than or equal to 2 or not by the aid of a selector, directly outputting the recorded branch results if the CONF fields are larger than or equal to 2, and finally placing the acquired instruction into an instruction Cache, so that all operations of instruction acquisition control are completed.

Owner:HARBIN ENG UNIV

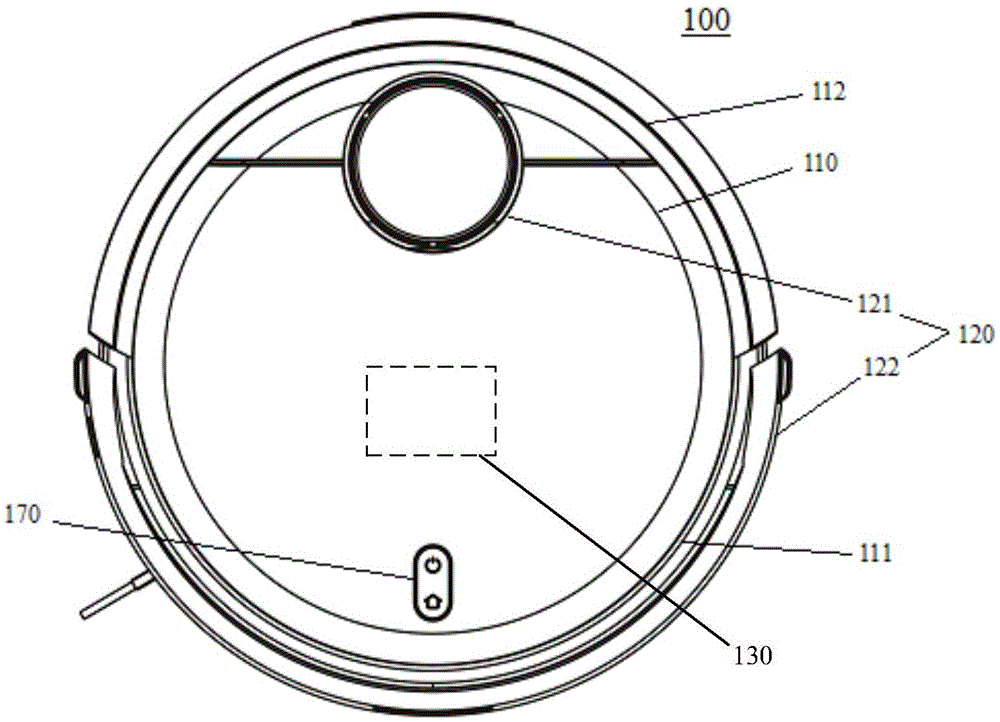

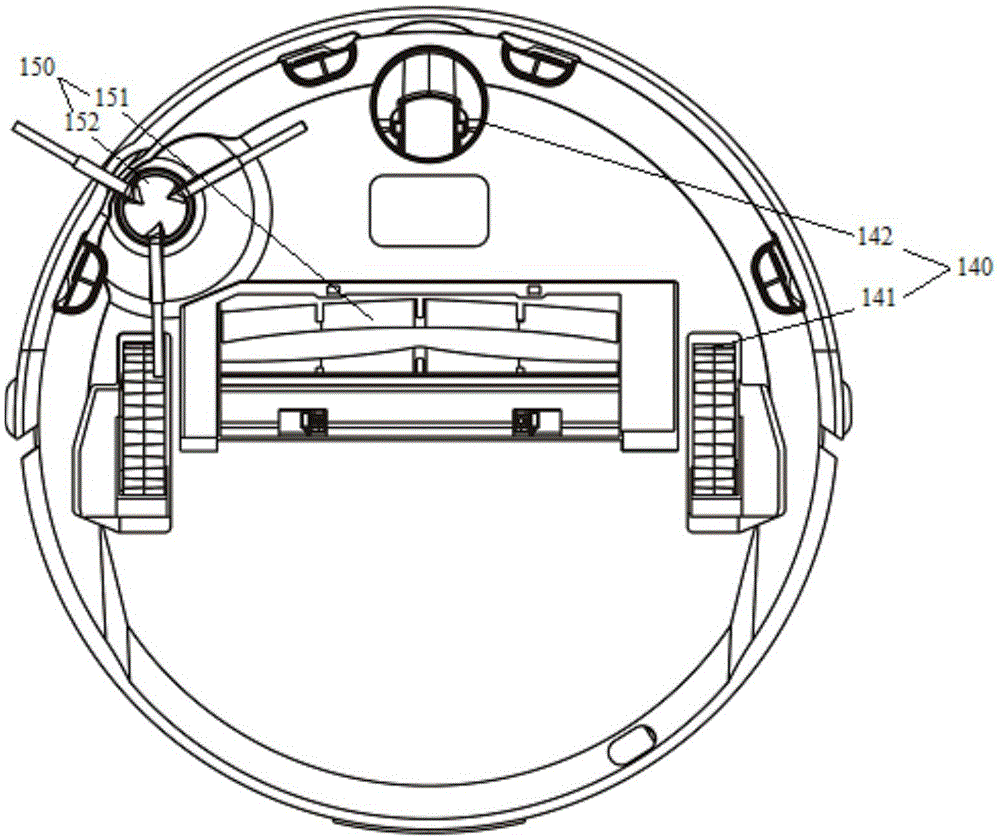

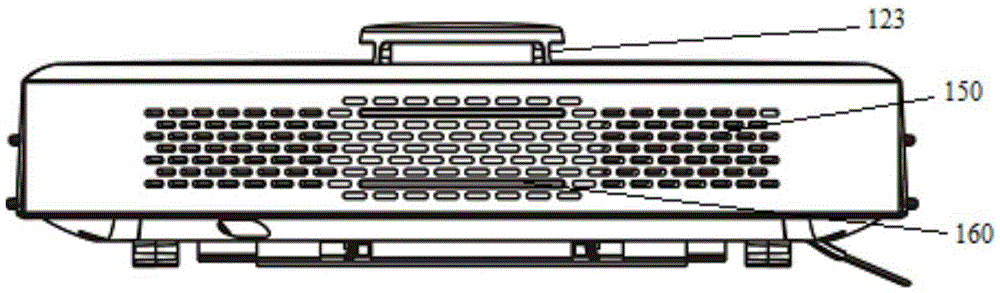

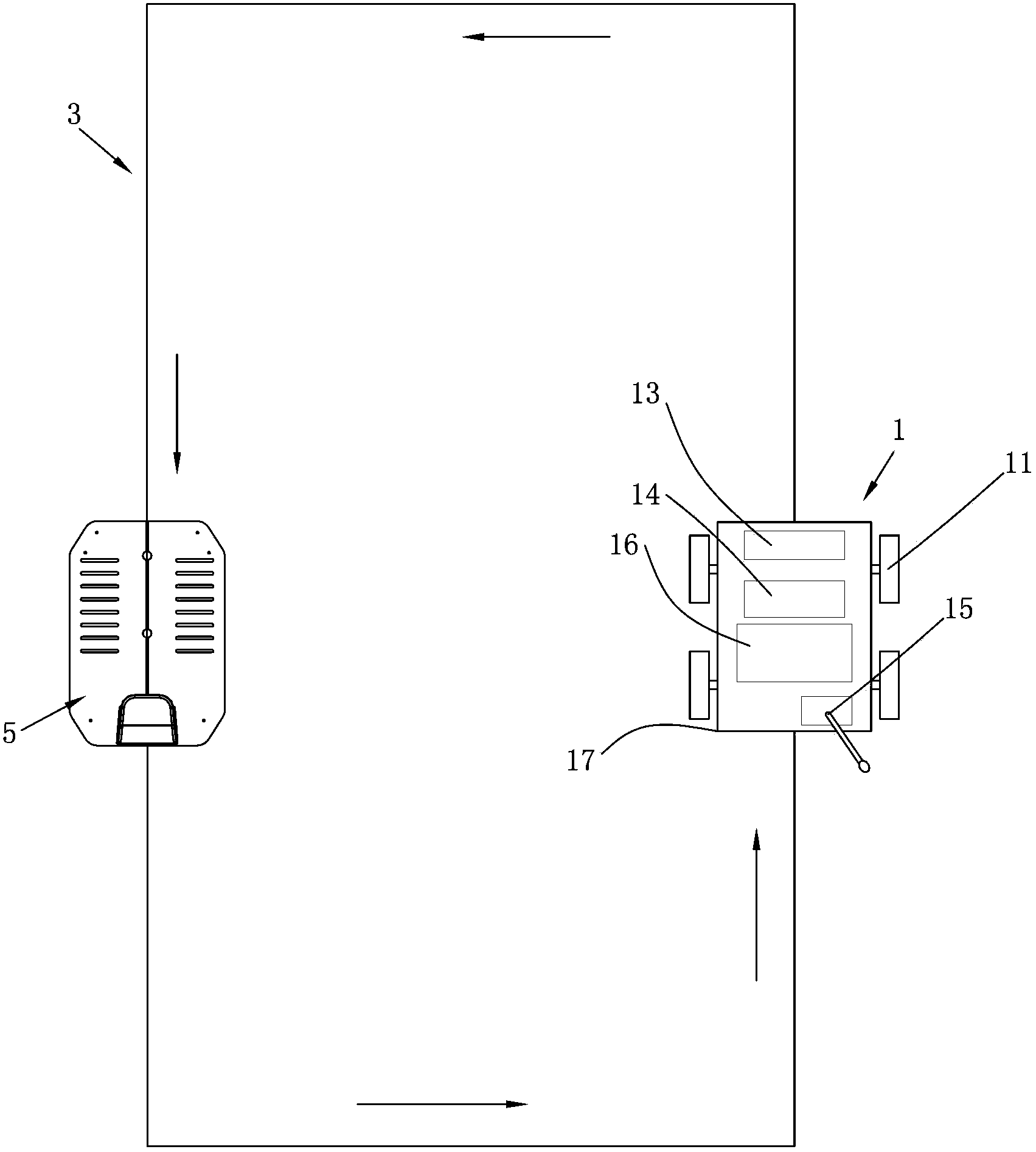

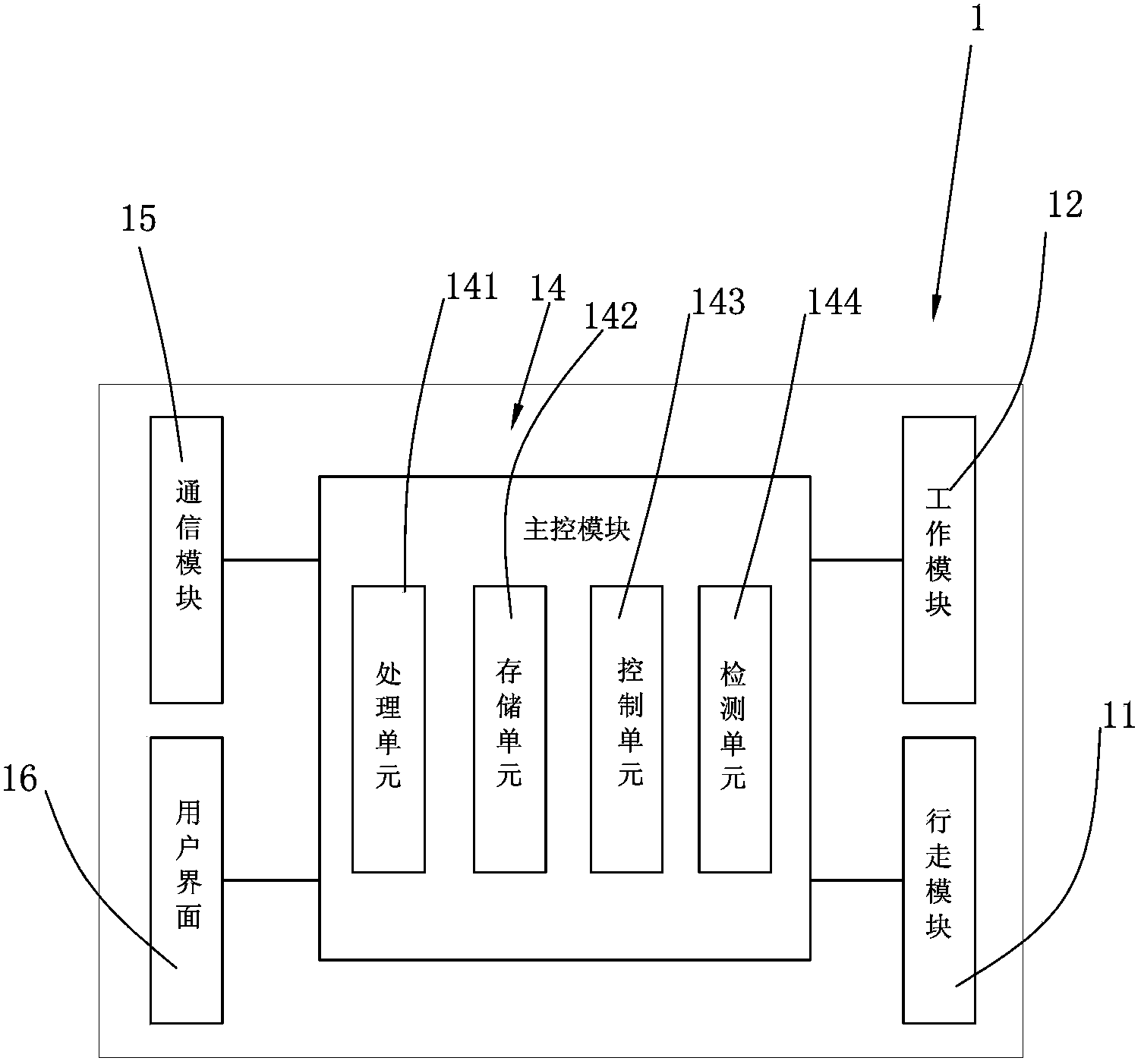

Automatic cleaning equipment and anti-jamming handling method and device for automatic cleaning equipment

ActiveCN105982624AGuaranteed smooth executionAutomatic obstacle detectionTravelling automatic controlAnti jammingAutomatic test equipment

Owner:XIAOMI INC +1

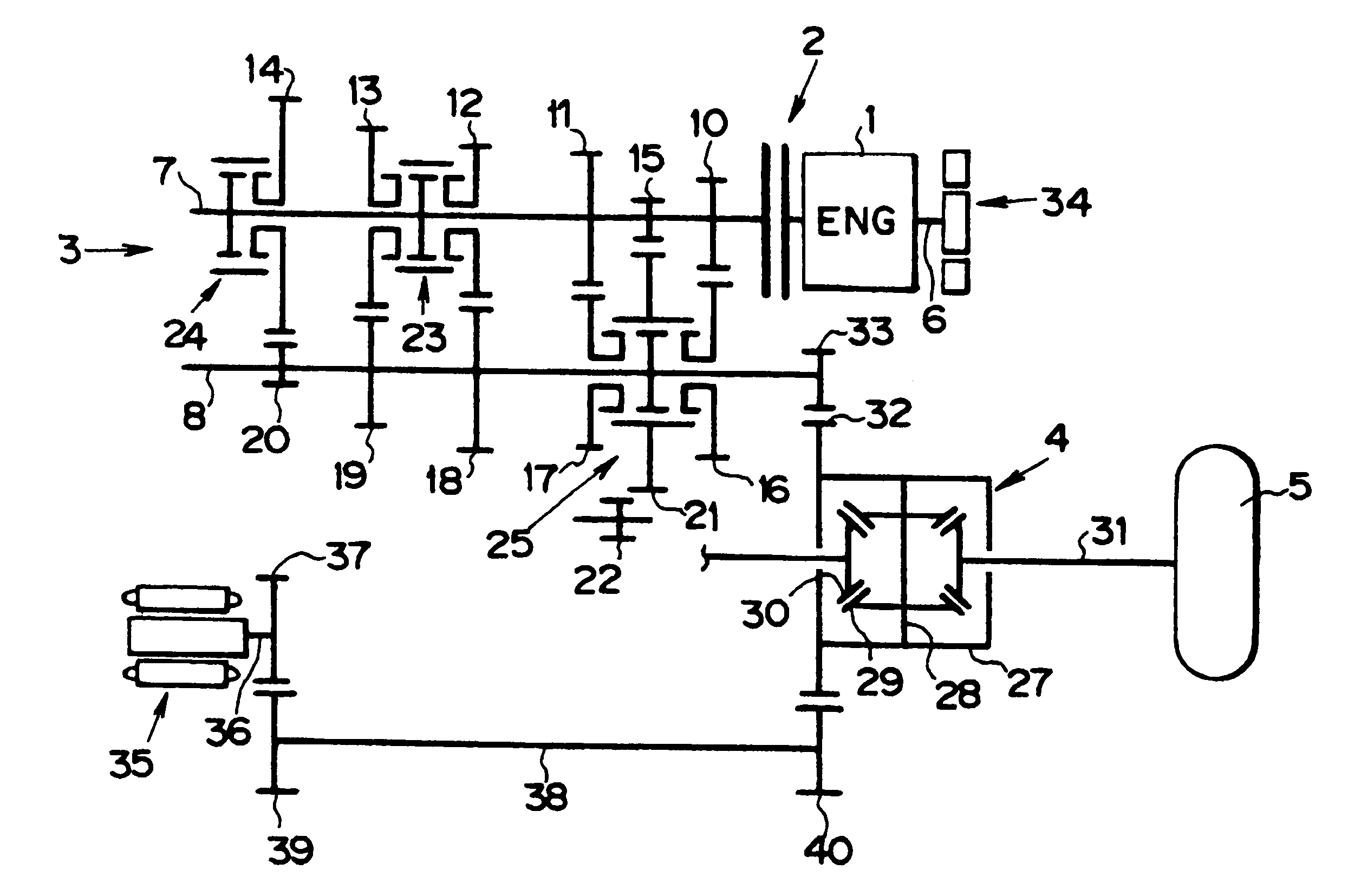

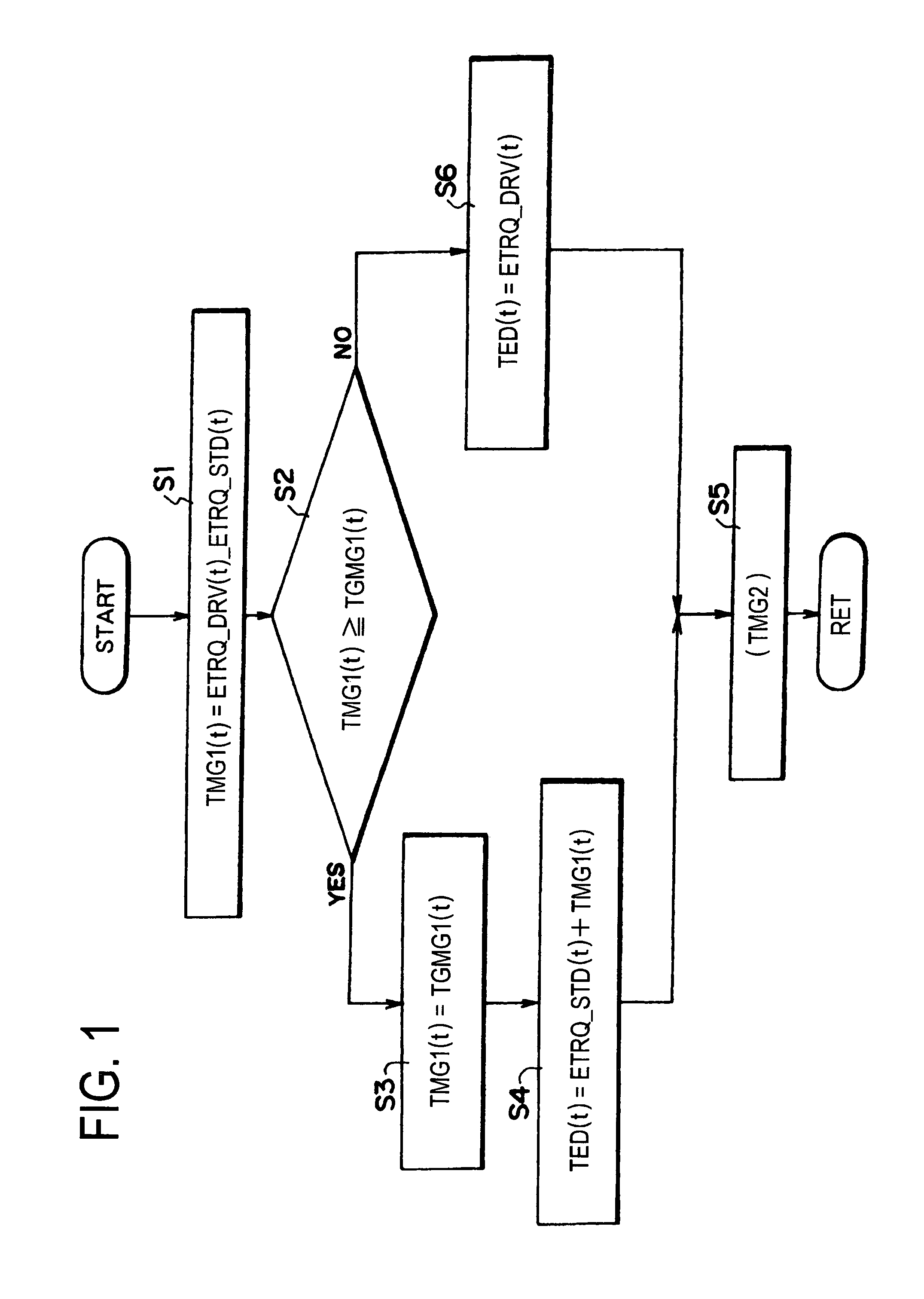

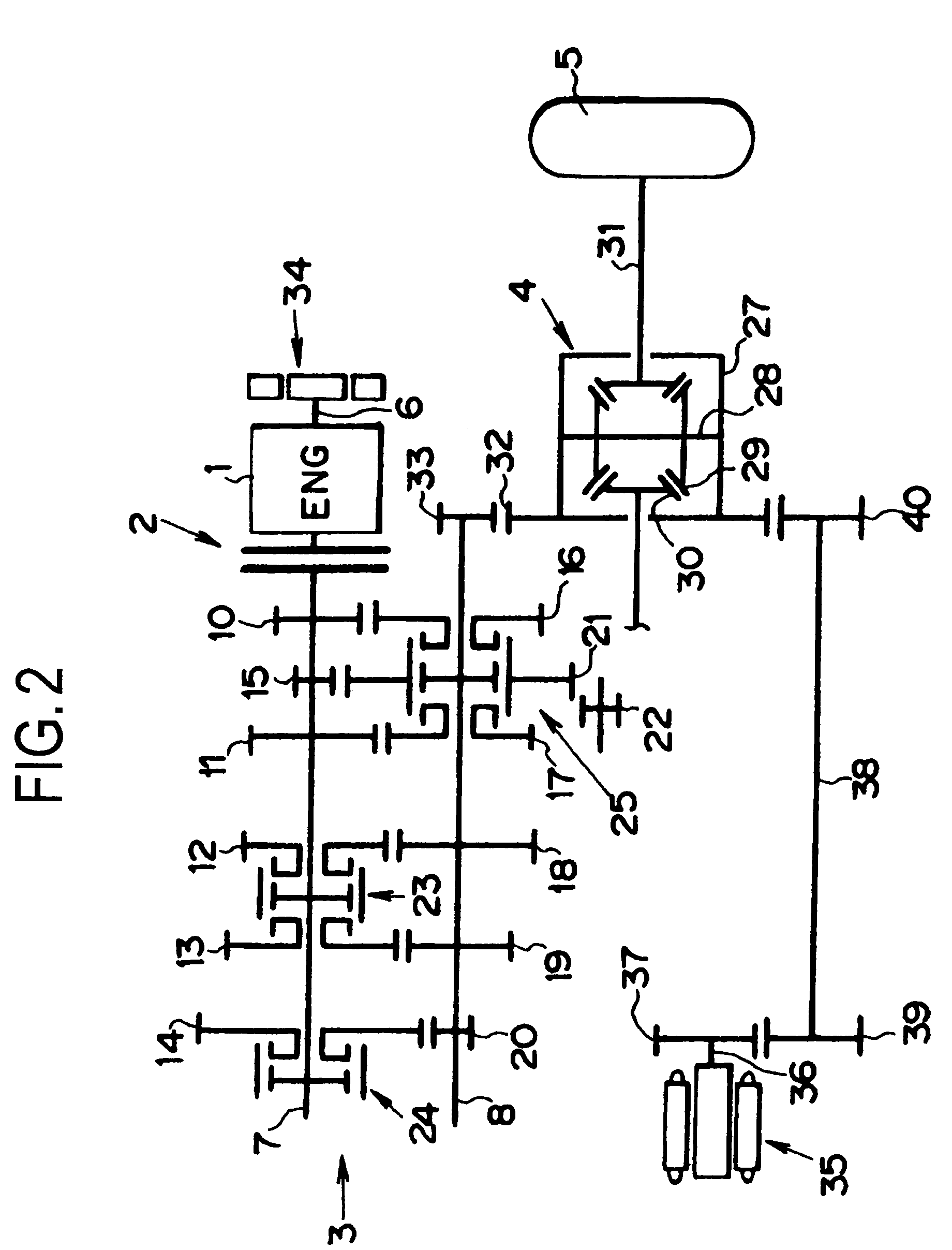

Shift control system for hybrid vehicles

ActiveUS6976934B2Suppresses growthGrowth inhibitionElectric propulsion mountingPropulsion using engine-driven generatorsClutchVariator

A shift control system for hybrid vehicles which is constructed to transmit a motive energy of the prime mover to a wheel via a clutch and a transmission, comprises an electric power generating means for generating an electric power by the motive energy of the prime mover, and for supplying the generated electric power to an electric motor, when executing a gear shift of the transmission and transmitting the motive energy of the motor to the wheel.

Owner:TOYOTA JIDOSHA KK

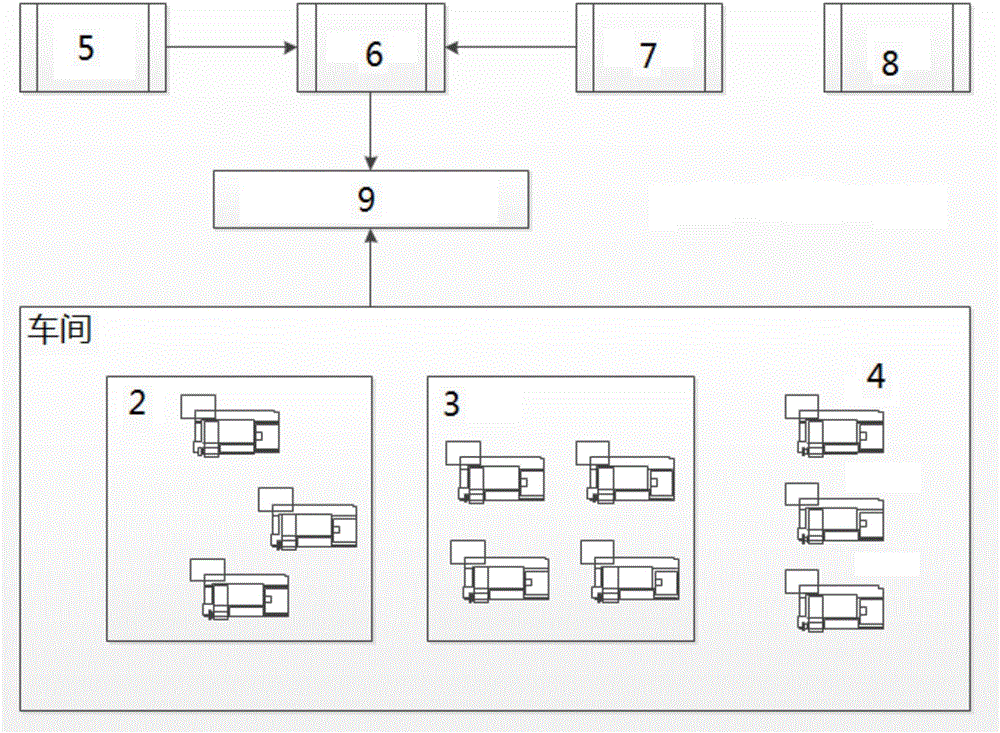

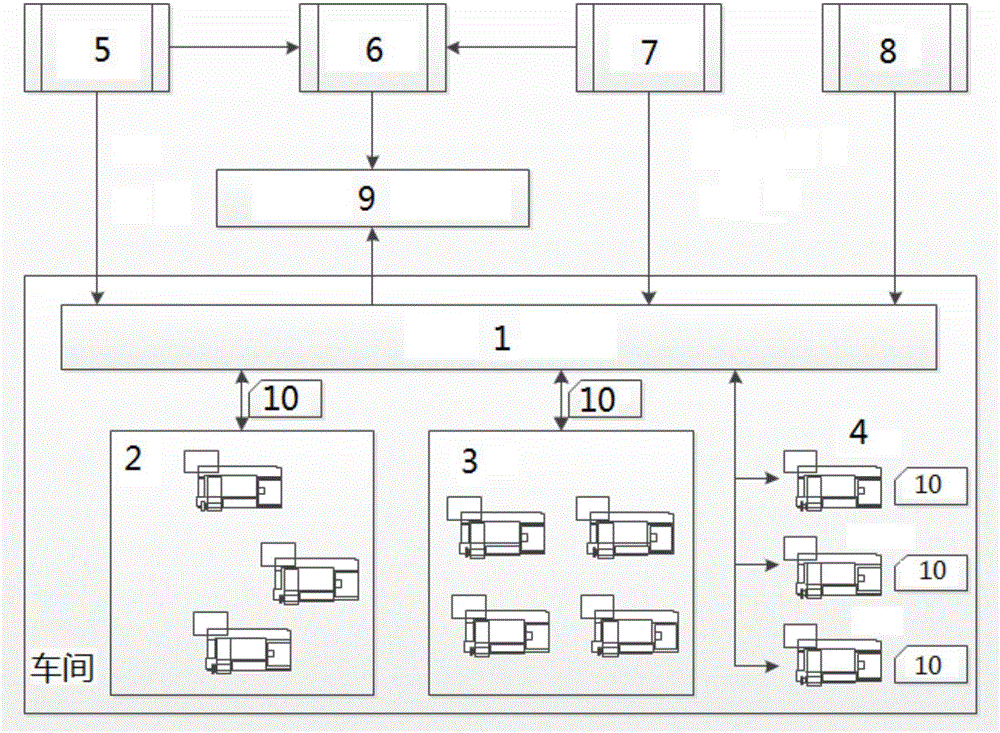

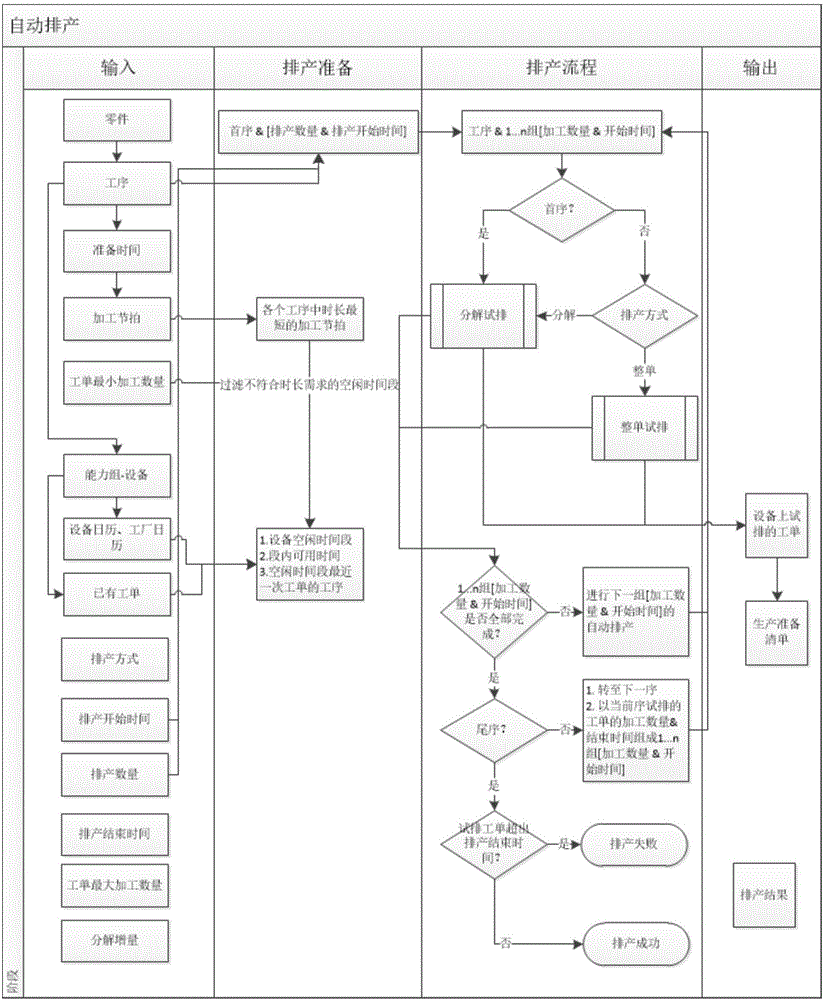

Workshop production plan scheduling system and method oriented to discrete manufacturing

InactiveCN106779308AIncrease productivityIncrease in daily outputResourcesProcess systemsProgram planning

The invention relates to a workshop production plan scheduling system and method oriented to discrete manufacturing. The system comprises a workshop plan scheduling system arranged in a workshop, wherein the workshop plan scheduling system is connected with manufacturing units used for finishing a work order plan, an ability group units and other equipment, and the manufacturing units, the ability group units and other equipment are arranged in the workshop; the workshop plan scheduling system is also connected with a warehouse system, an ERP (Enterprise Resource Planning) or MRP (Manufacturing Resource Planning) system, a human resource system and a process system; the ERP or MRP system is connected with the workshop plan scheduling system through an interaction module; and the interaction module is used for issuing a production plan and reporting a workshop production plan finishing situation in real time. By use of the system, production factors, including an equipment load, an equipment calendar, a process flow, a manufacturing beat, a work order transferring way and the like, are comprehensively considered, a practical production task is split into each executable work order, the manufacturing time and the manufacturing amount of each work order are set for each work order, an enterprise manager can be more favorably assisted in tracking and monitoring a whole production process, and meanwhile, the convenience and the maneuverability of production dispatching and scheduling are both given consideration.

Owner:智能云科信息科技有限公司

Robot, control method thereof and robot system

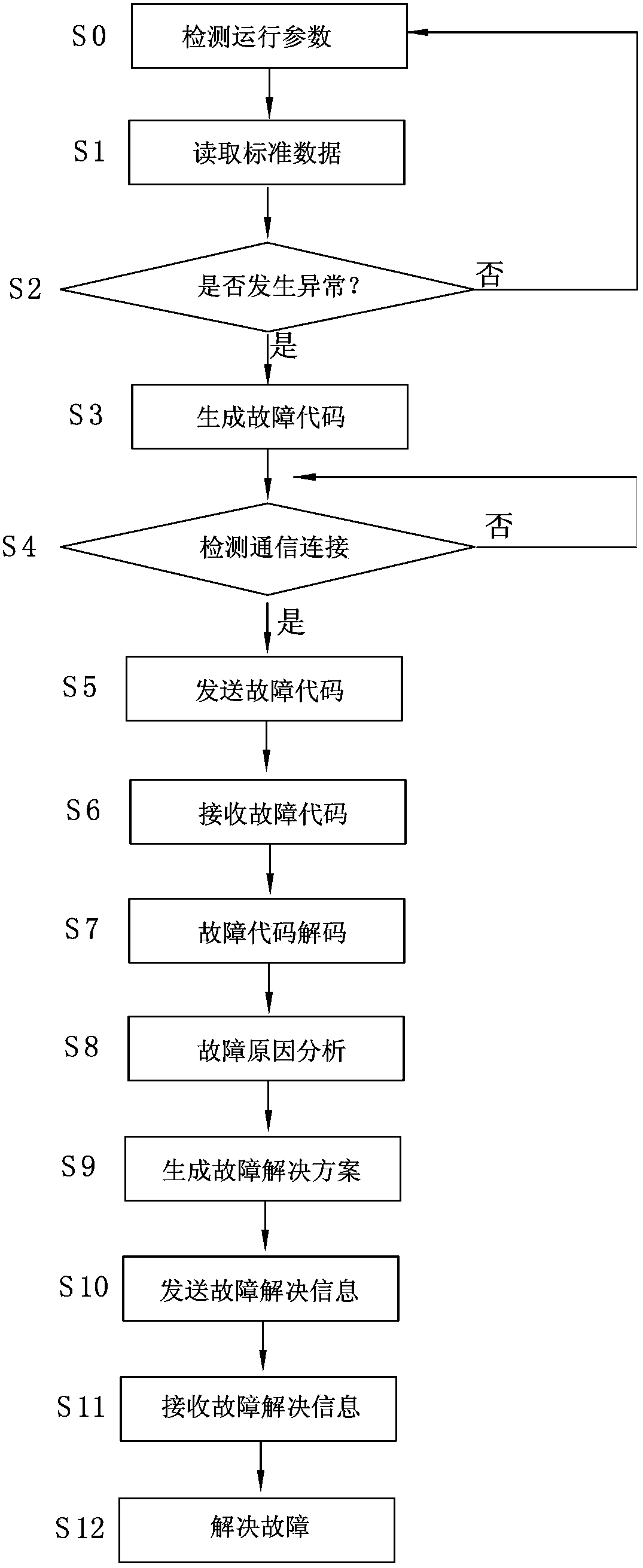

InactiveCN103576567AGuaranteed smooth executionGood experienceElectric testing/monitoringProgramme control in sequence/logic controllersService departmentEmbedded system

A control method of a robot comprises the following steps of detecting the operating parameters of the robot, generating fault information when the operating parameters are abnormal, sending the fault information to a remote service center, and receiving fault solution information returned by the remote service center. When the robot breaks down, a user can know the fault timely and can remotely learn a fault elimination method, the robot does not need to be sent to a maintenance service department to be detected and maintained every time, and convenience is brought for the user.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

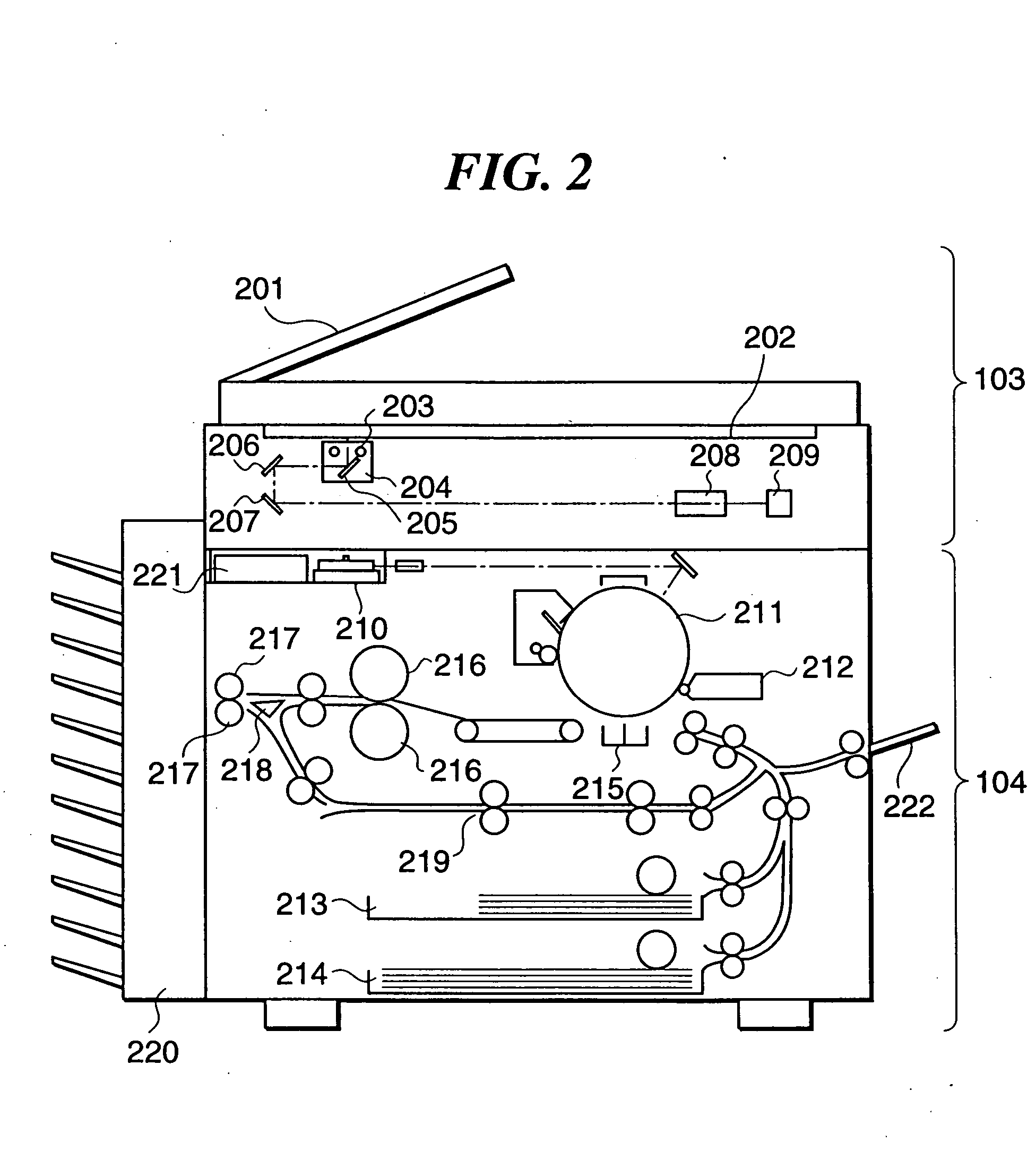

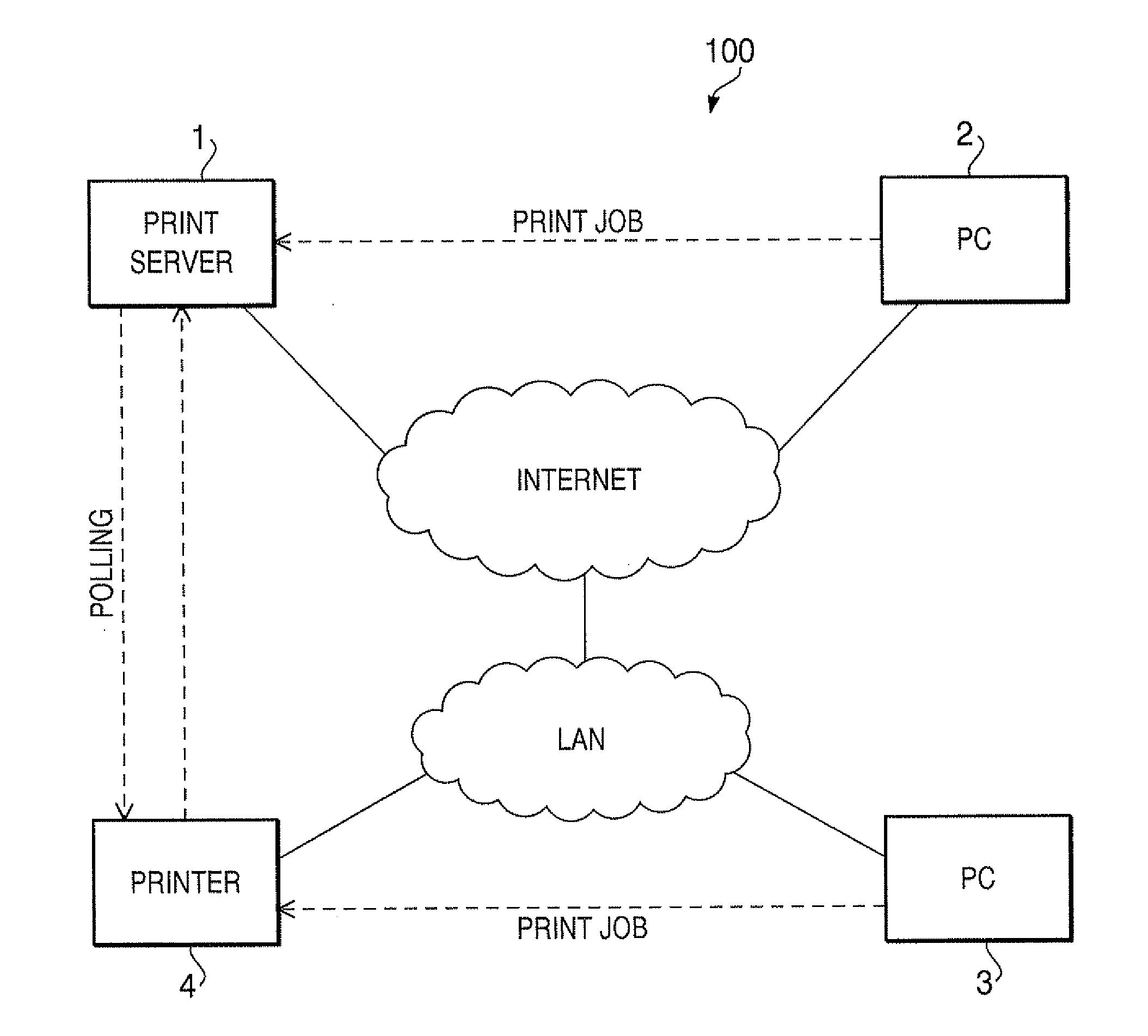

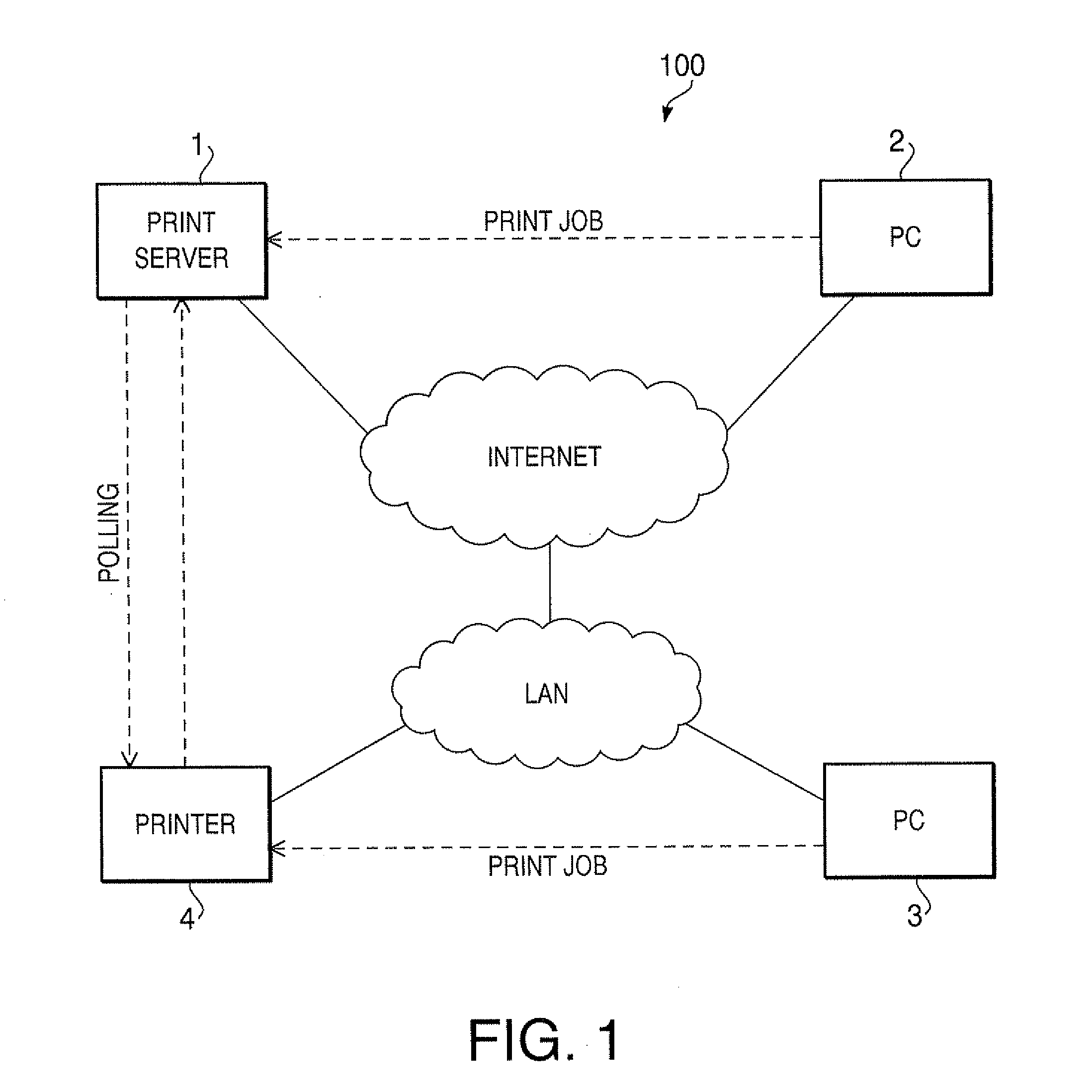

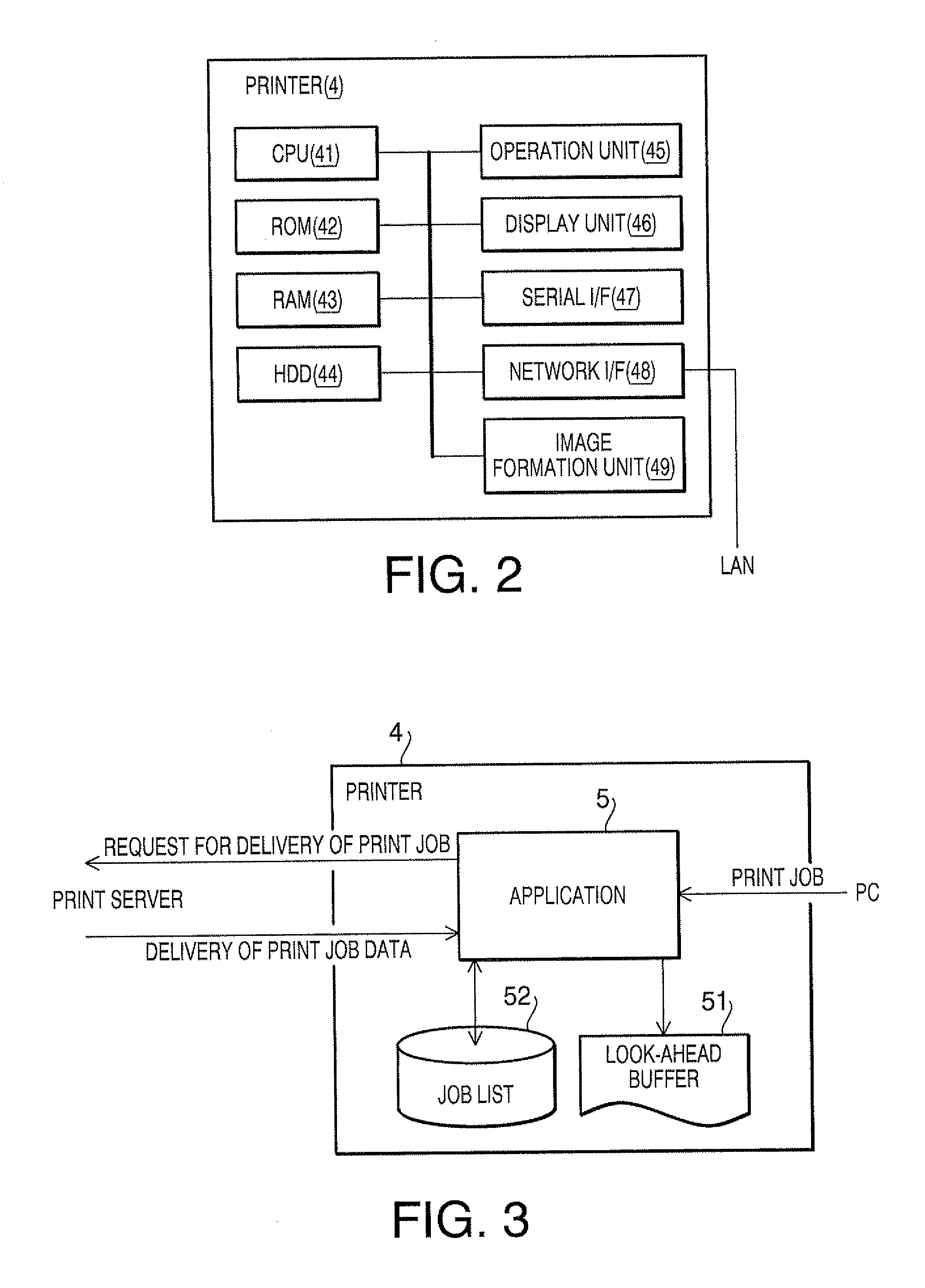

Push-type pull printing system, pull printing method, and image forming apparatus

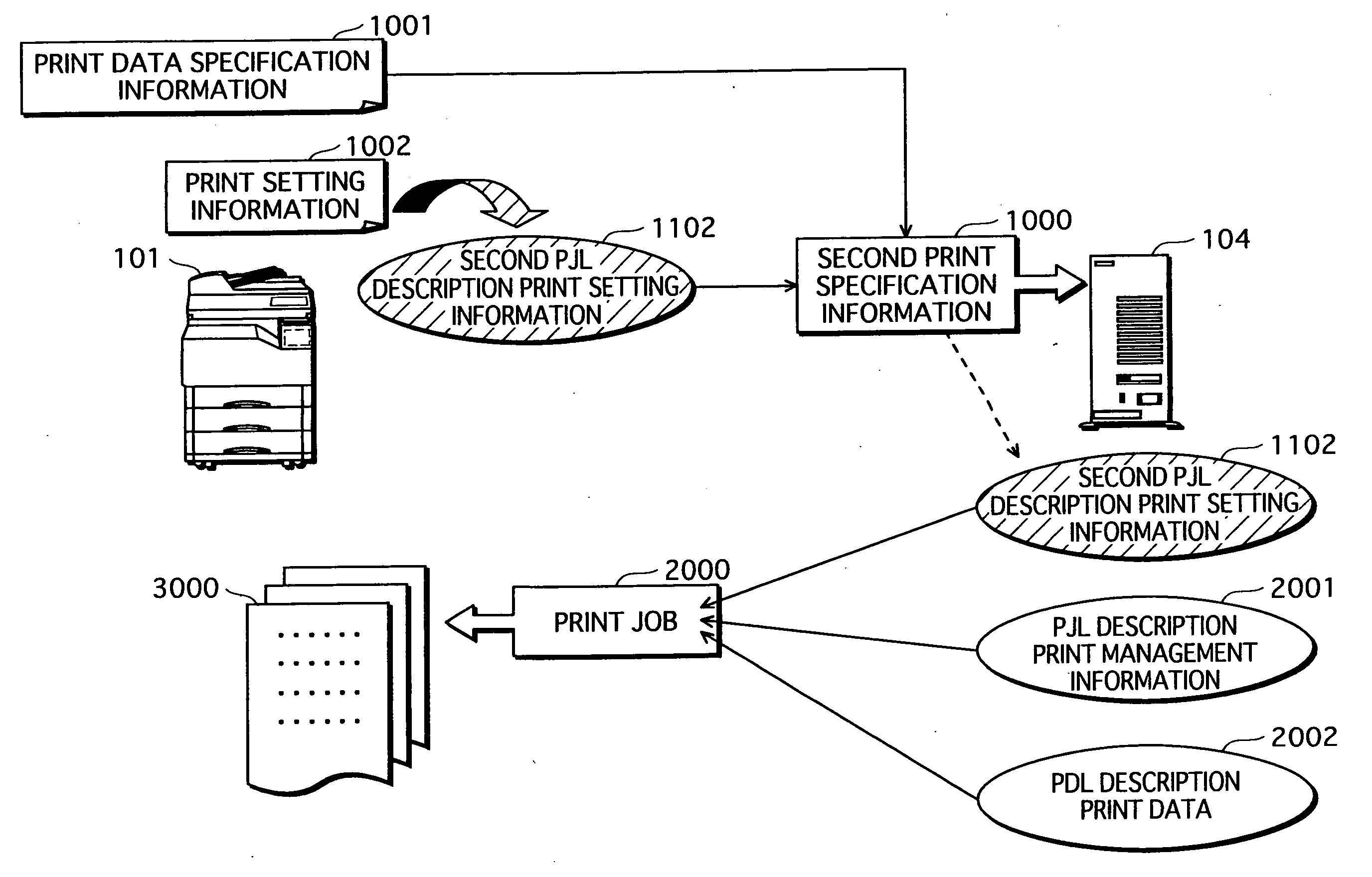

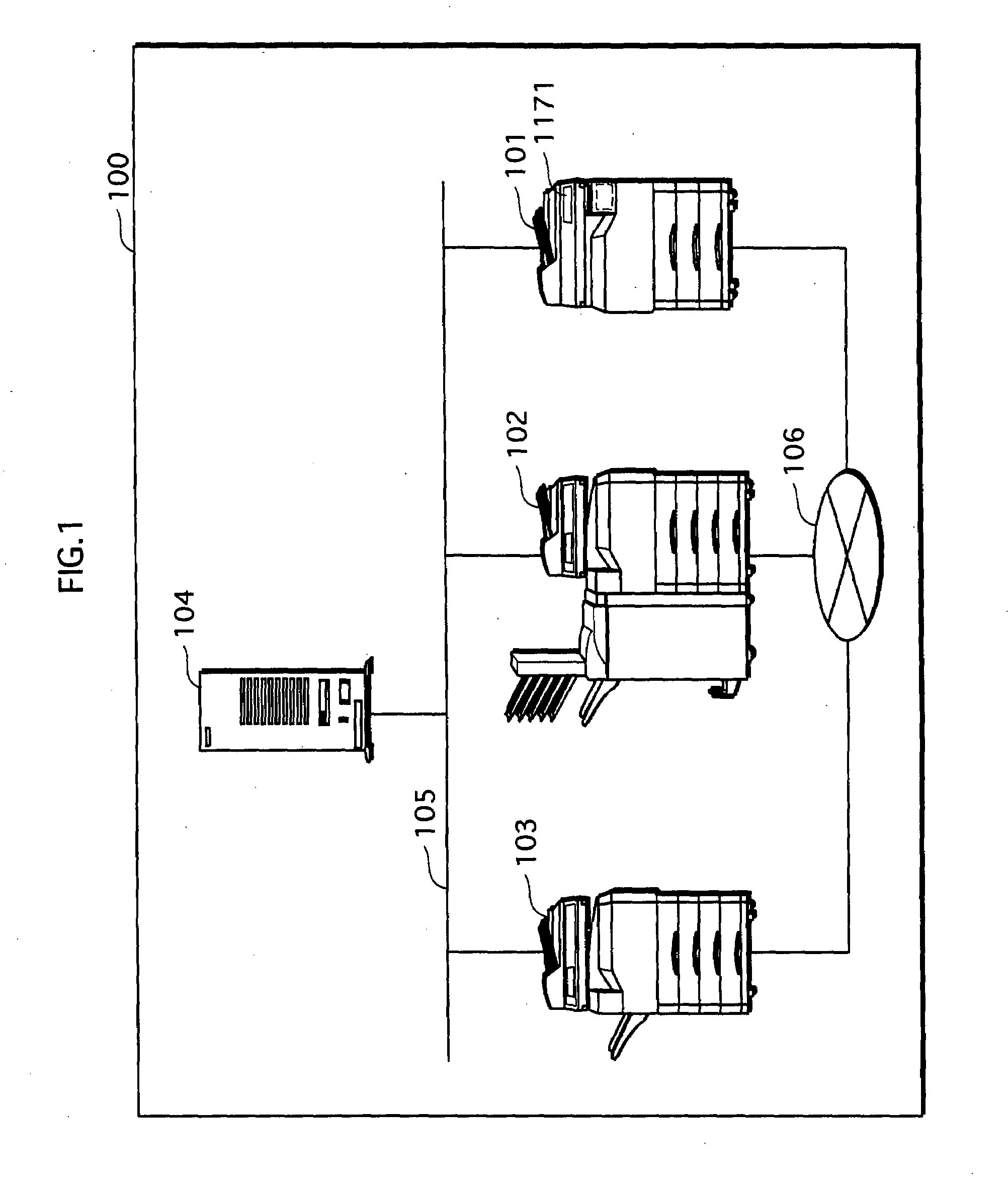

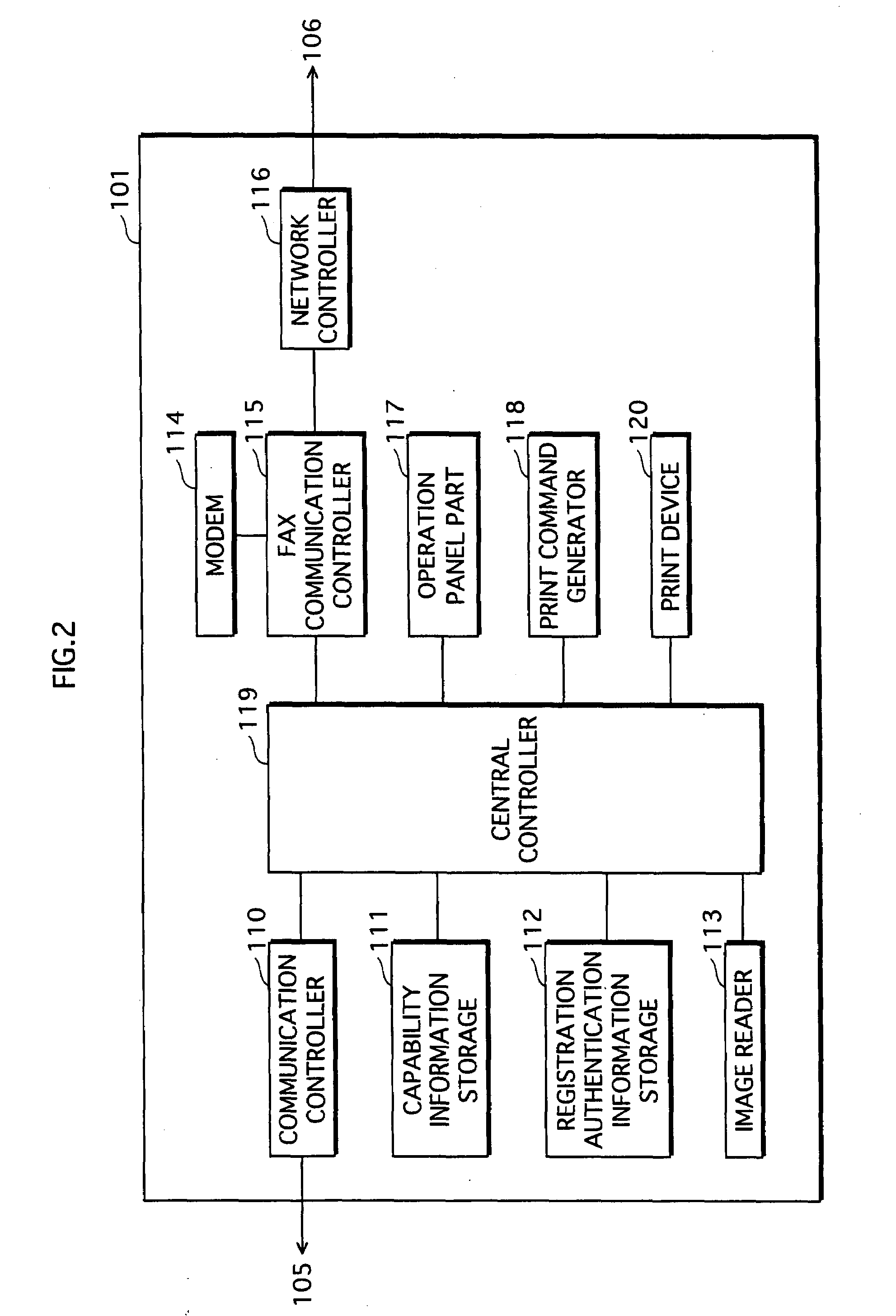

ActiveUS20080209419A1Leakage of authentication information can be preventedPrevent leakageMultiprogramming arrangementsSpecial data processing applicationsImage formationDatabase

A push-type pull printing system comprising a server and an image forming apparatus, the server sending, to the image forming apparatus, a print job including print data and a print condition instruction command for the print data, and the image forming apparatus executing a print process based on the print job. Here, the image forming apparatus comprises an input receiver operable to receive an input of a print condition, a converter operable to convert the inputted print condition, before being transmitted to the server, to an instruction command in a description language interpretable by the image forming apparatus, and a transmitter operable to transmit the converted instruction command to the server; and the server comprises a job transmitter operable to receive the converted instruction command from and send the print job to the image forming apparatus, the print job including the instruction command as the print condition instruction command.

Owner:KONICA MINOLTA BUSINESS TECH INC

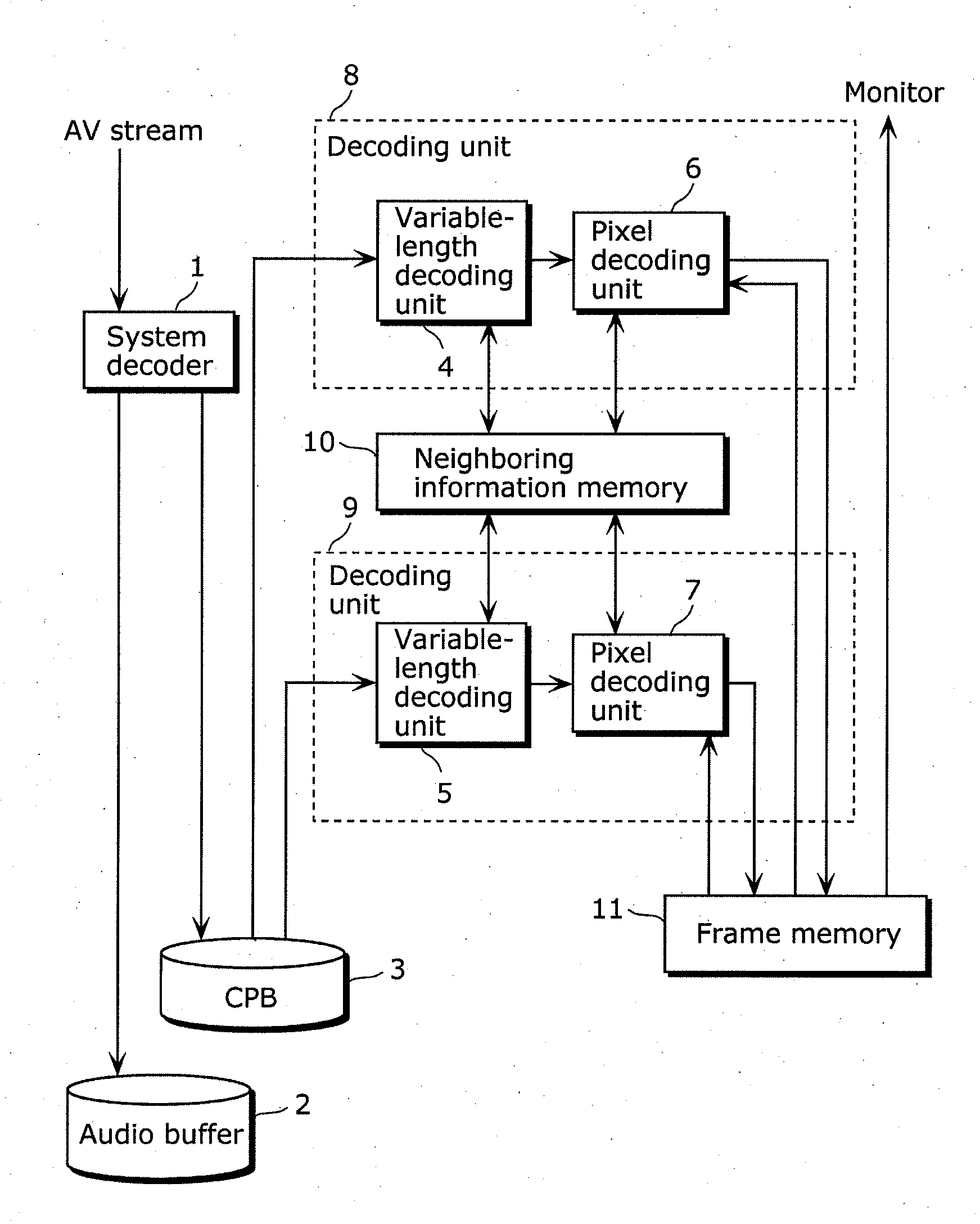

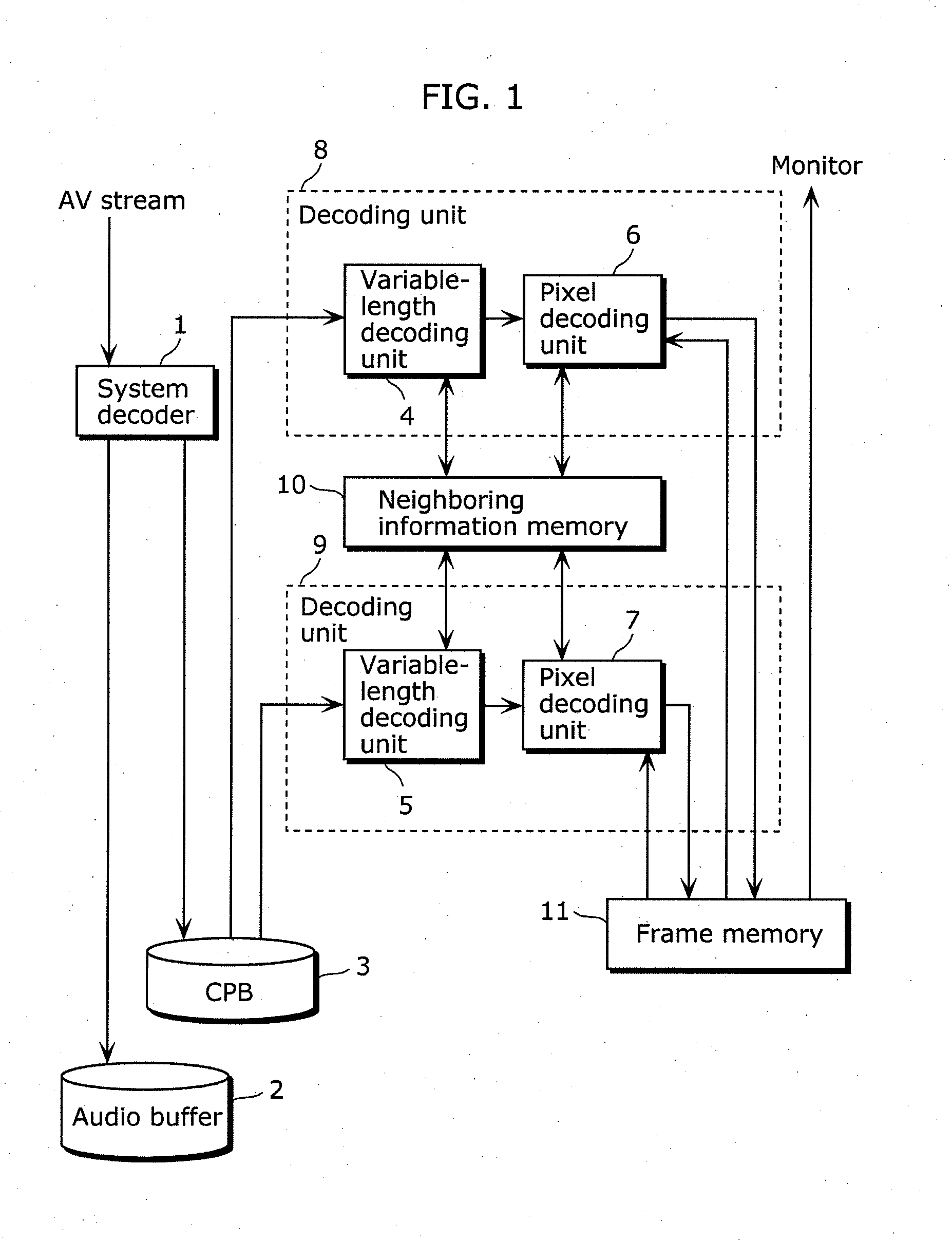

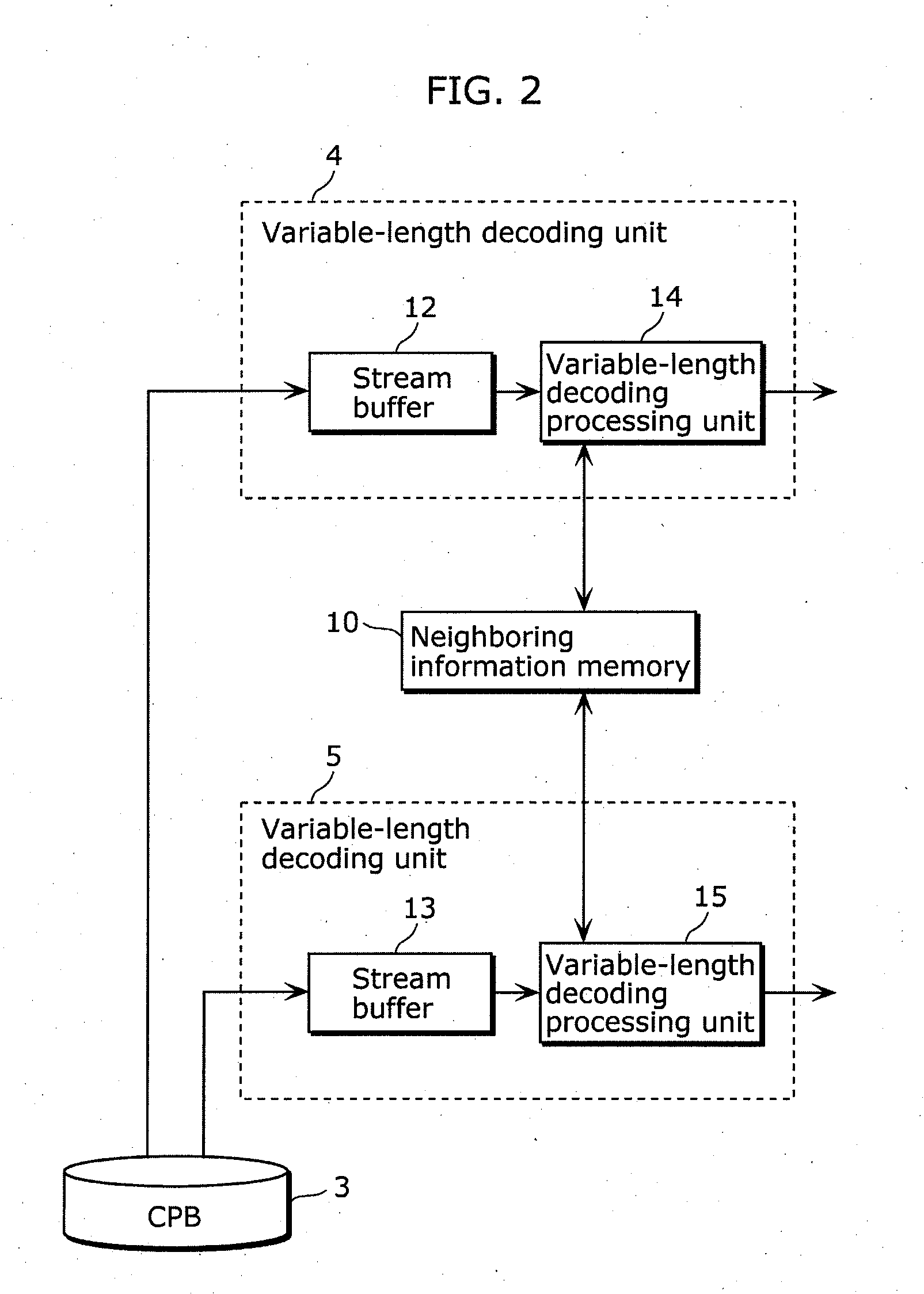

Image decoding device, image coding device, image decoding method, image coding method, program, and integrated circuit

InactiveUS20120099657A1Guaranteed smooth executionColor television with pulse code modulationColor television with bandwidth reductionAlgorithmEngineering

An image decoding device and an image coding device are each capable of using spatial dependence across a boundary between slices to smoothly execute parallel processing. The image decoding device includes: a first decoding unit (801) decoding a block in a first slice; a second decoding unit (802) decoding a block in a second slice; and a first storage unit (811) storing inter-slice neighboring information (i) generated by decoding a boundary block included in the first slice and adjacent to the second slice and (ii) referenced when a boundary neighboring block included in the second slice and adjacent to the boundary block is decoded. The first decoding unit (801) generates the inter-slice neighboring information by decoding the boundary block and stores the generated information into the first storage unit (811). The second decoding unit (802) decodes the boundary neighboring block by reference to the stored inter-slice neighboring information.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

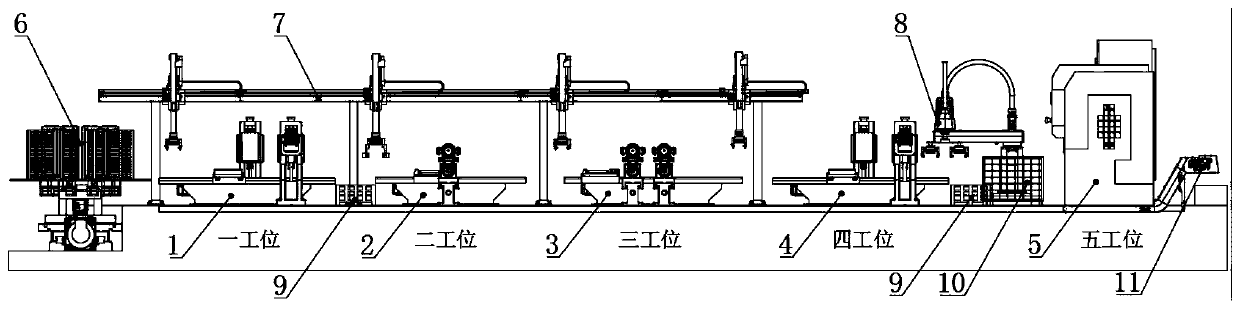

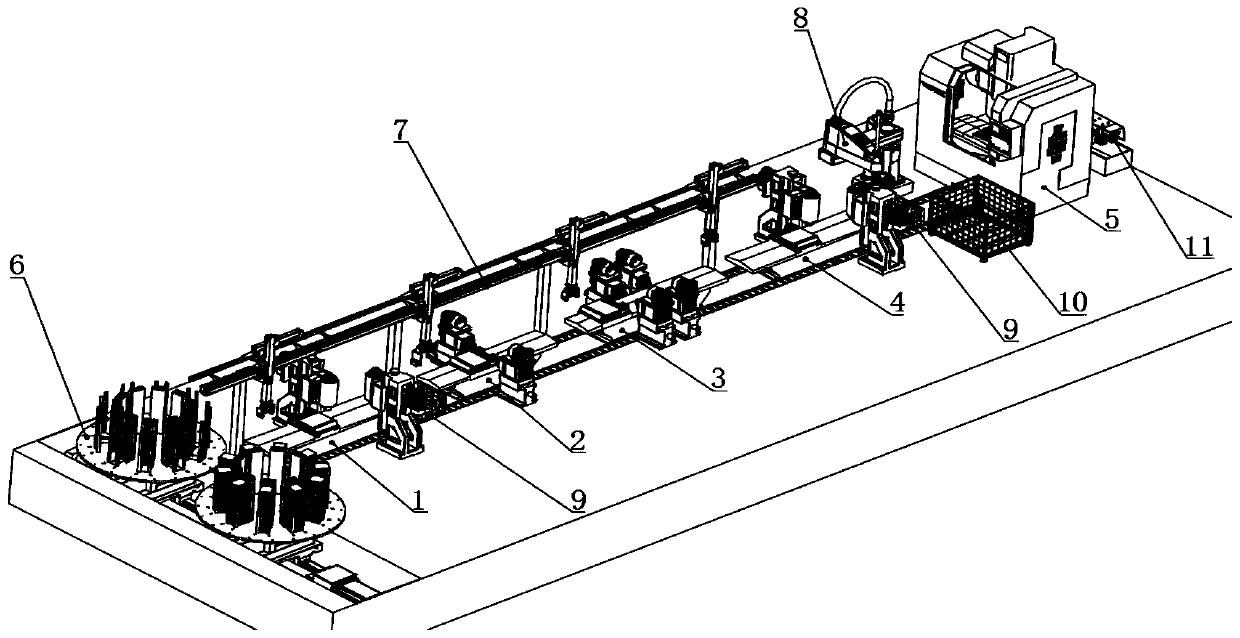

Intelligent plate part machining production line provided with universal equipment and special equipment

ActiveCN110773779AGuaranteed production efficiencyImprove production efficiencyOther manufacturing equipments/toolsMilling equipment detailsProduction lineRobot hand

The invention provides an intelligent plate part machining production line provided with universal equipment and special equipment. Four special machining tools and a universal machining tool are sequentially and linearly arranged from an automatic feeding device, wherein the four special machining tools are located on a first station, a second station, a third station and a fourth station, and the universal machine tool is located on a fifth station; a truss conveying transport device is arranged behind the first station, the second station, the third station and the fourth station in parallel, and four mechanical arms are arranged on the truss transport device to transfer materials on the corresponding stations; a four-axis manipulator is arranged between the fourth station and the fifthstation and is used for transferring the materials between the fourth station and the fifth station and discharging finished products; industrial cameras are arranged on the second-station mechanicalarm and the four-axis manipulator and are used for recognizing defective products; waste boxes are arranged between the first station and the second station as well as between the fourth station andthe fifth station and are used for storing the defective products; a discharging box is arranged on the front side of the fifth station and is used for storing the finished products; and a scrape conveying mechanism is arranged below the whole production line and is used for collecting and transferring scrapes. According to the intelligent plate part machining production line, the universal equipment and the special equipment are combined, and flexible clamps and sliding rail cylinders are used, so that the production line is flexible, the machining times of the stations are balanced, and theproduction efficiency is improved.

Owner:JIANGSU UNIV OF SCI & TECH +1

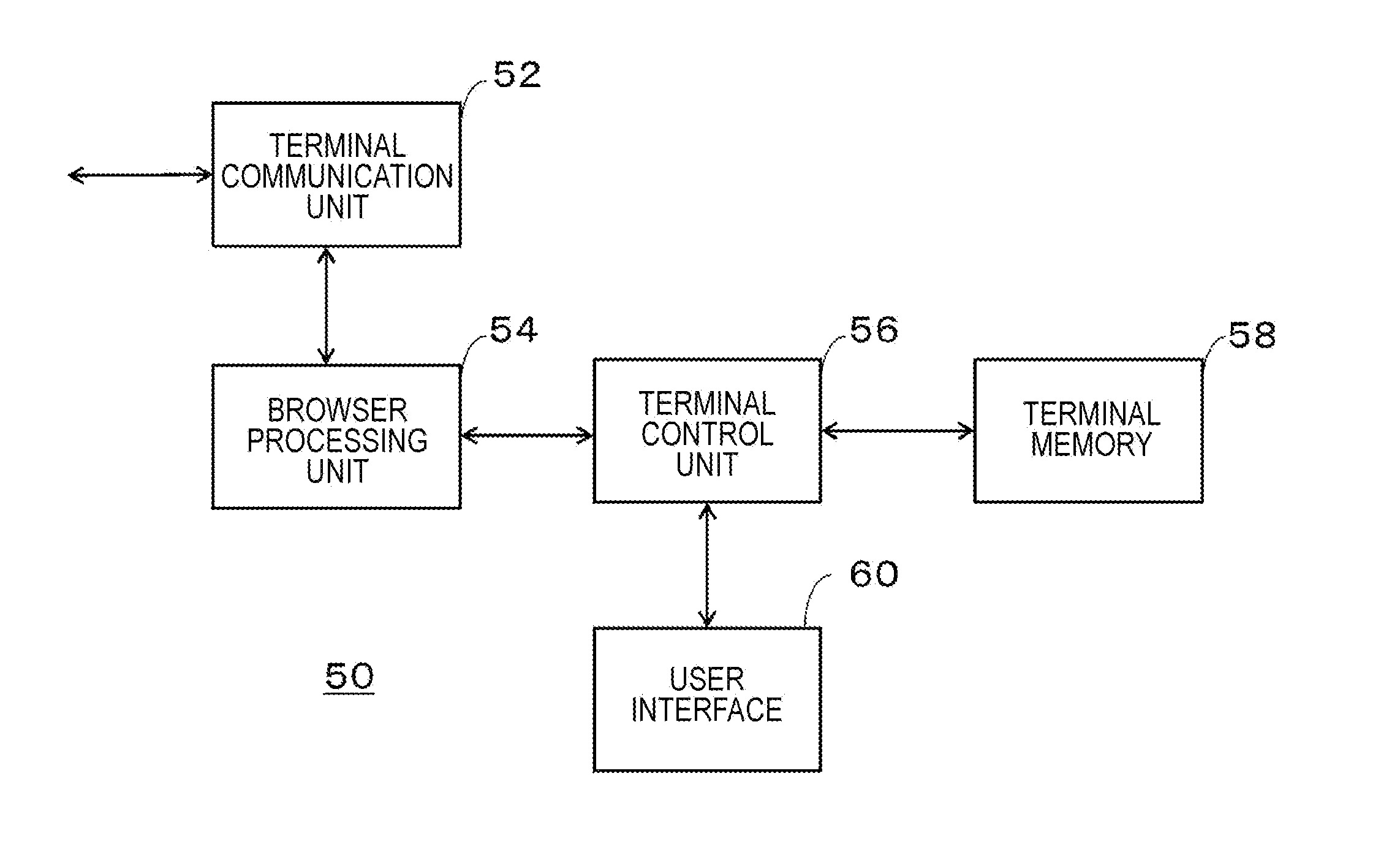

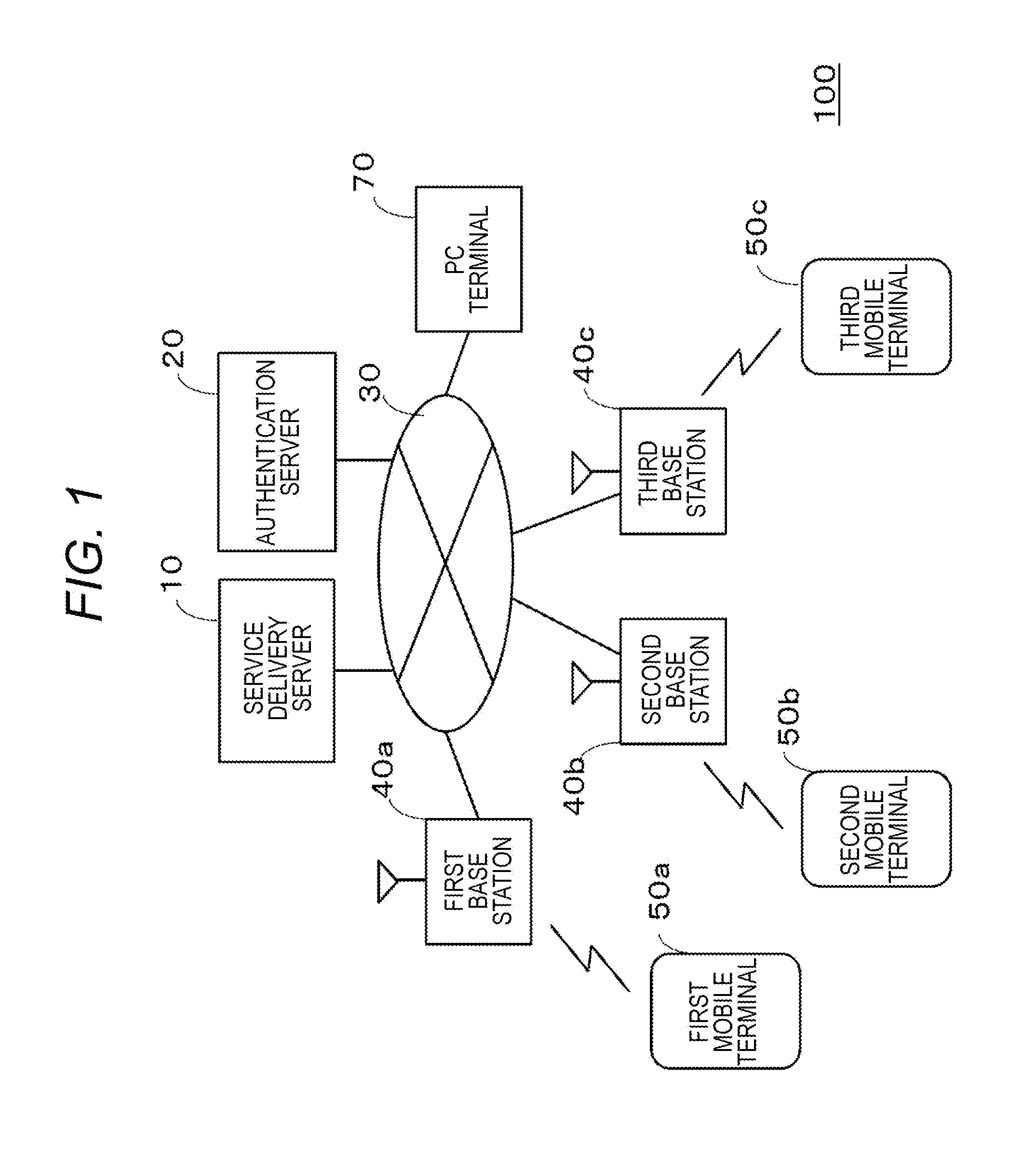

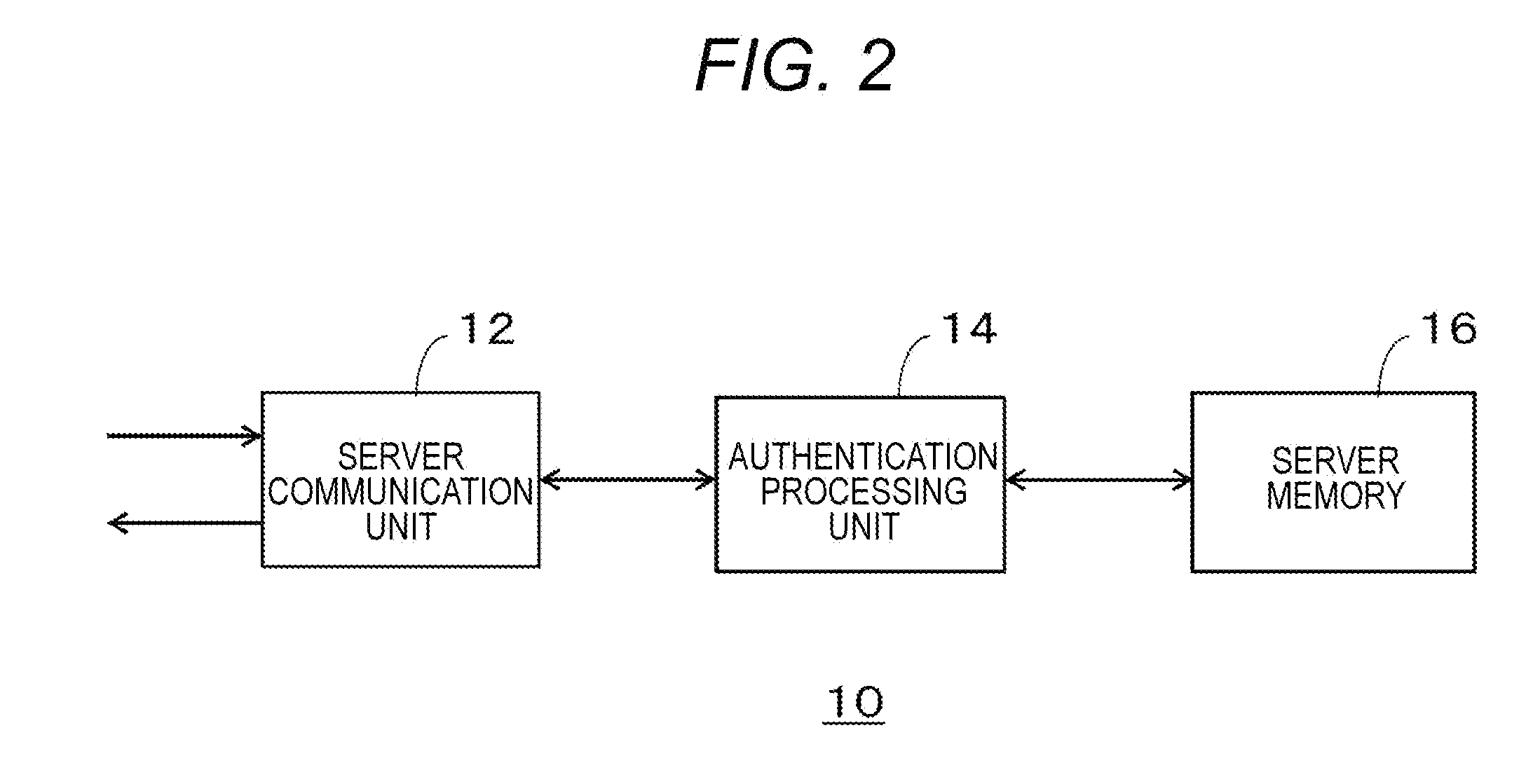

Authentication method, authentication system, and service delivery server

ActiveUS20140298441A1Secure authentication processingEfficient executionDigital data processing detailsMultiple digital computer combinationsComputer terminalAuthentication server

A client terminal transmits a signal related to an authentication request to a service delivery server through a browser every time an application is started by an instruction from a user. Upon receiving the authentication request from the client terminal, an authentication server executes authentication processing in cooperation with the service delivery server based on authentication information of an application of the client terminal, a session of which has been established, and stored in the service delivery server, and user information related to the user stored in the authentication server.

Owner:DENA CO LTD

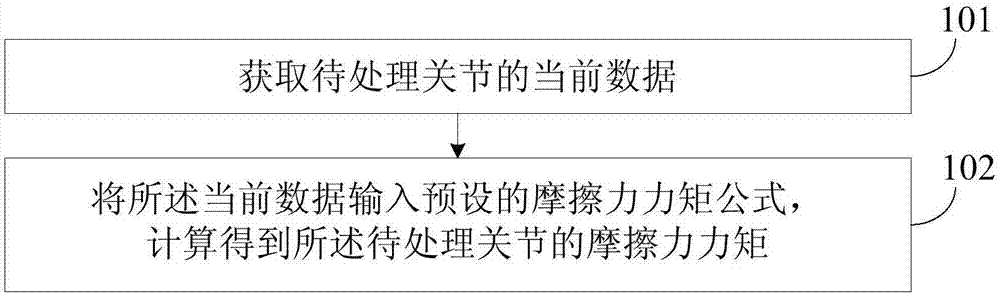

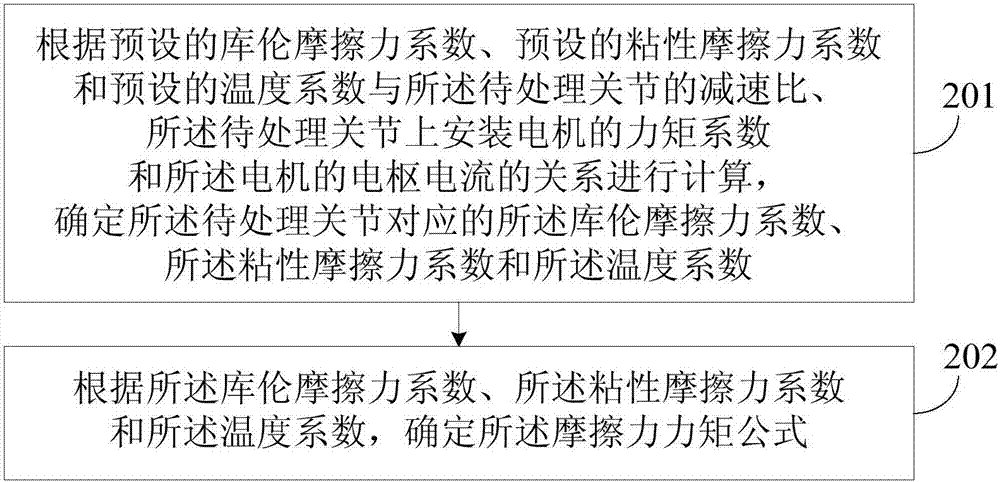

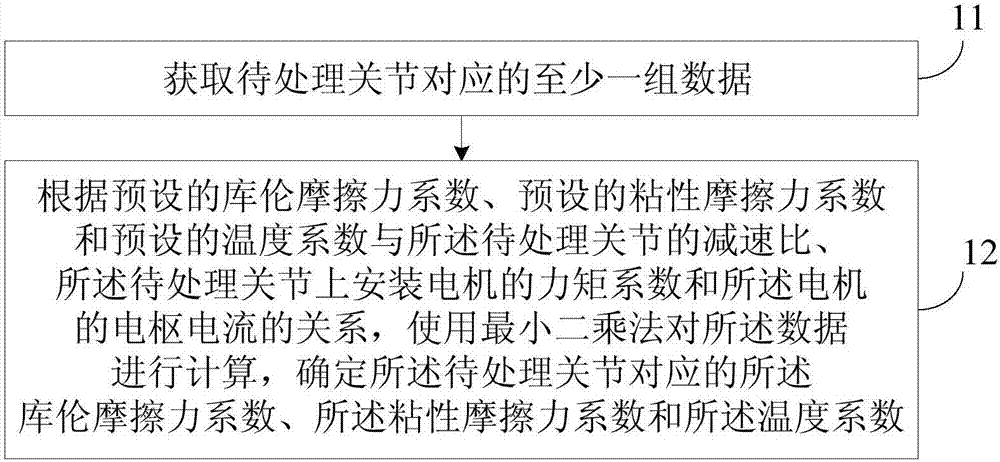

Calculation method and device for joint external force moment and robot

ActiveCN106994686AEasy to dragGuaranteed accuracyProgramme-controlled manipulatorEngineeringFriction force

The embodiment of the invention provides a calculation method and device for joint external force moment and a robot. Joints of the robot are provided with motors and tilt angle sensors. The method comprises the steps that current data of the joint to be processed is acquired, wherein the current data comprises the angular speed and the temperature of the joint to be processed; and the current data is input to a preset friction force moment formula, and through calculation, the friction force moment of the joint to processed is obtained. The joints of the robot are further provided with the tilt angle sensors. The method further comprises the steps that the posture information of current installation of the robot is determined through the tilt angle sensor installed on the joint to be processed, and the gravity moment corresponding to the joint to be processed is calculated according to the posture information. By applying the calculation method and device for the joint external force moment and the robot, the friction force moment and the gravity moment corresponding to the joints of the robot can be accurately calculated, and it can be guaranteed that an operator can successfully complete dragging teaching of the robot.

Owner:AUBO BEIJING ROBOTICS TECH CO LTD

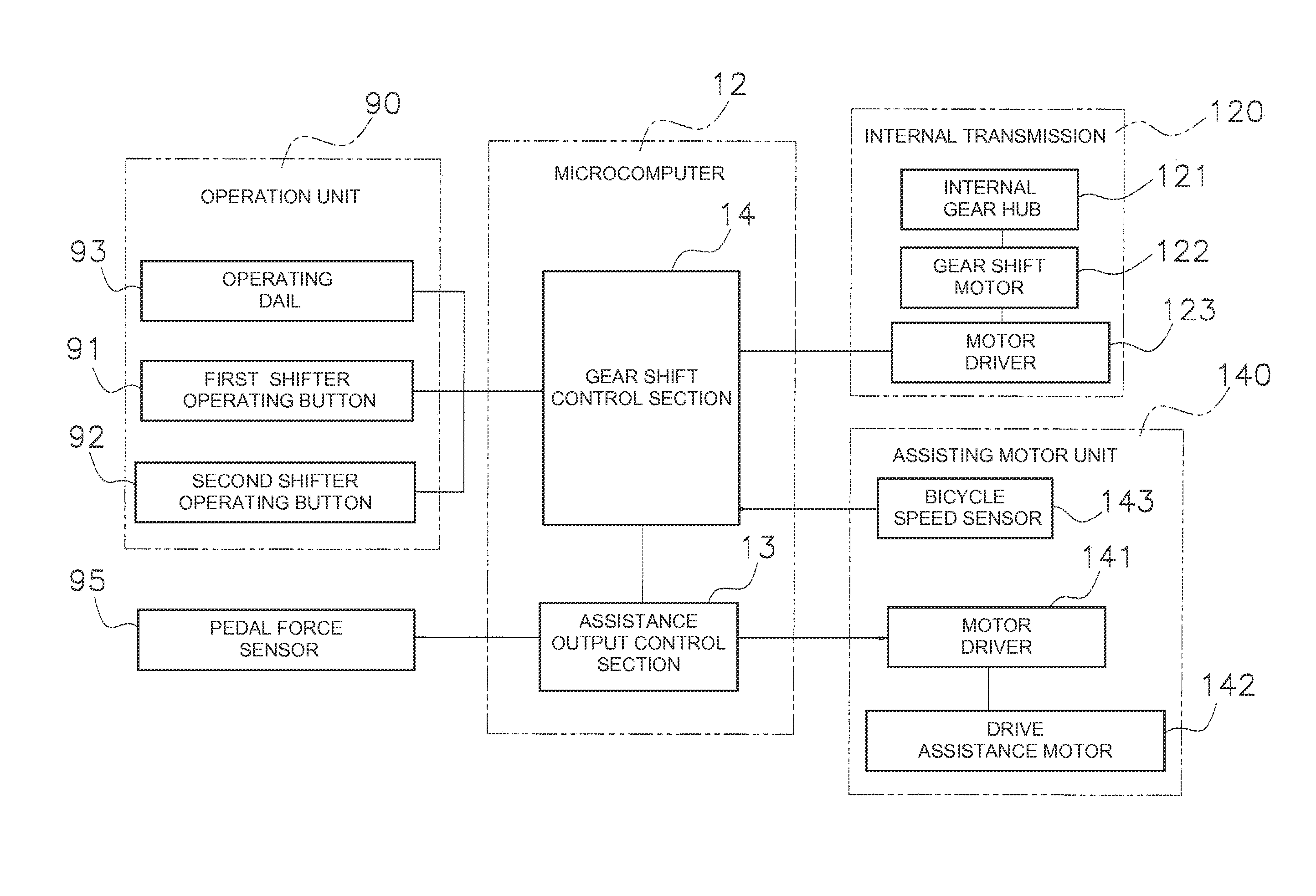

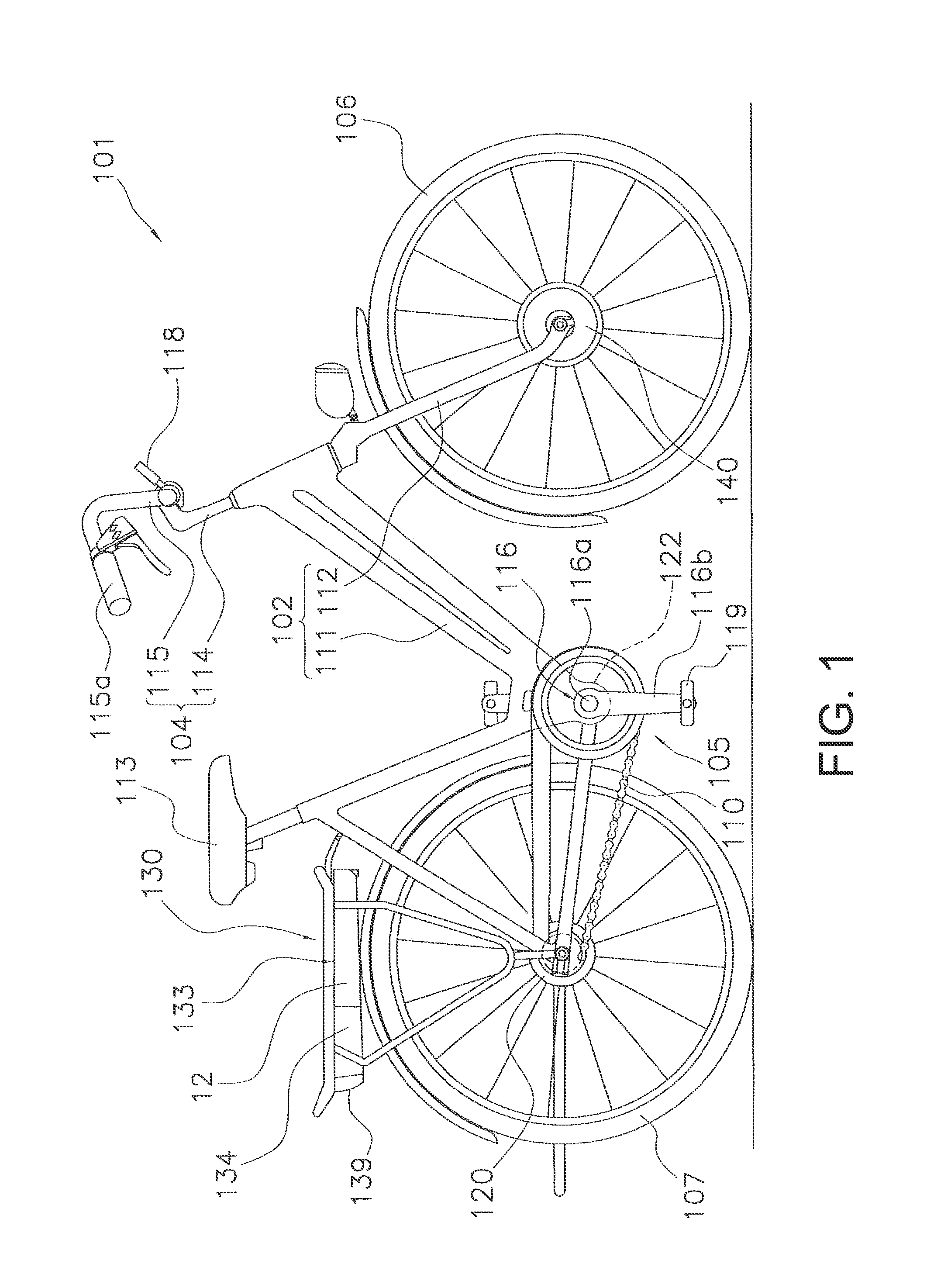

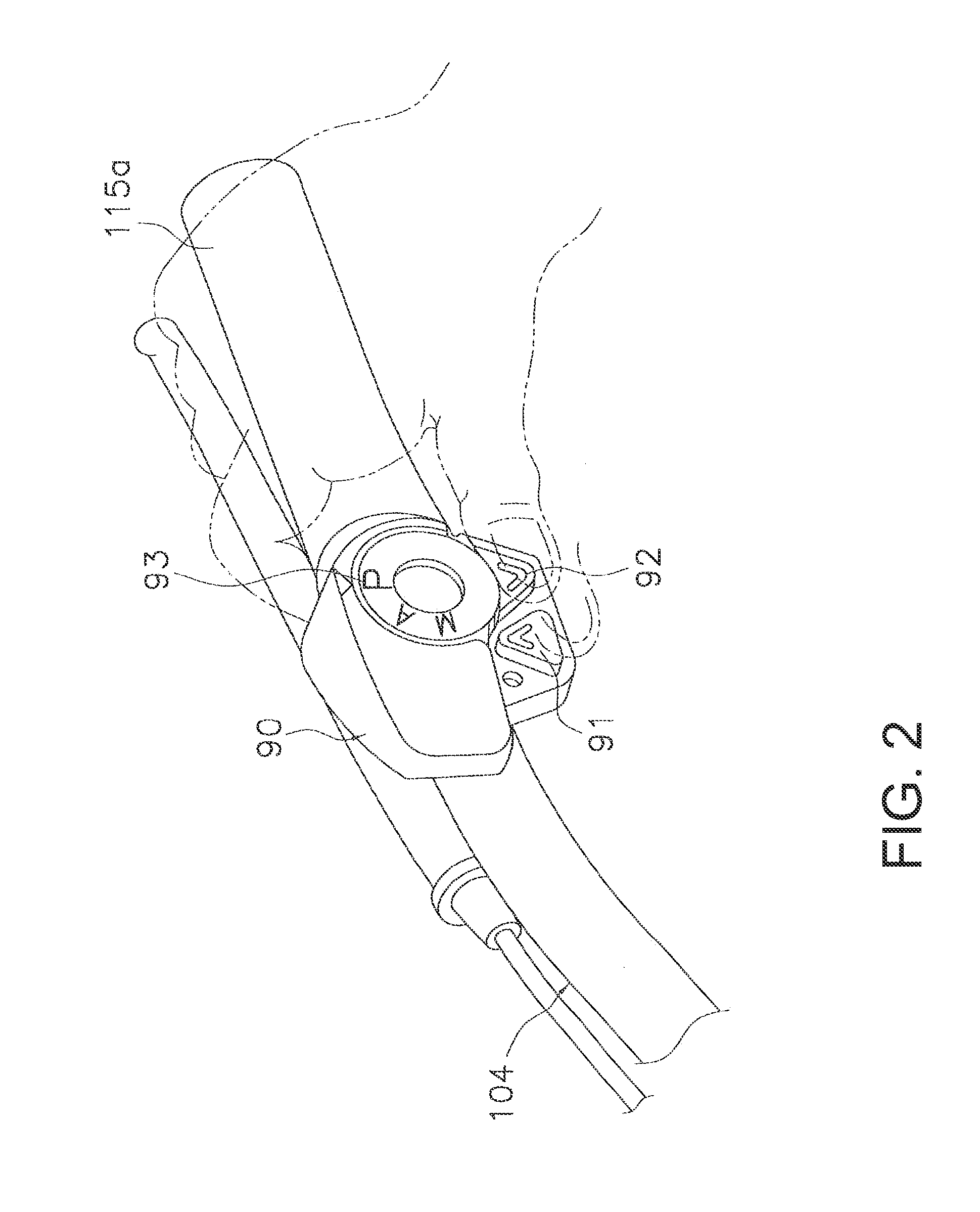

Bicycle drive apparatus

ActiveUS20130054068A1Reduce downforceGuaranteed uptimeChain/belt transmissionDigital data processing detailsMicrocomputerEngineering

A bicycle drive apparatus includes a bicycle transmission, a drive assistance electric motor and a microcomputer. The microcomputer includes an output control section that controls an output of the drive assistance electric motor, and that issues a motor output increasing command to increase the output of the drive assistance electric motor upon receiving a shift command for shifting the transmission.

Owner:SHIMANO INC

Devices, systems, and methods for sponsored tethered connectivity

ActiveUS8831517B2Without additional costPrevents misuse and fraudMetering/charging/biilling arrangementsAccounting/billing servicesApplication serverApplication software

Owner:AT&T INTPROP I LP

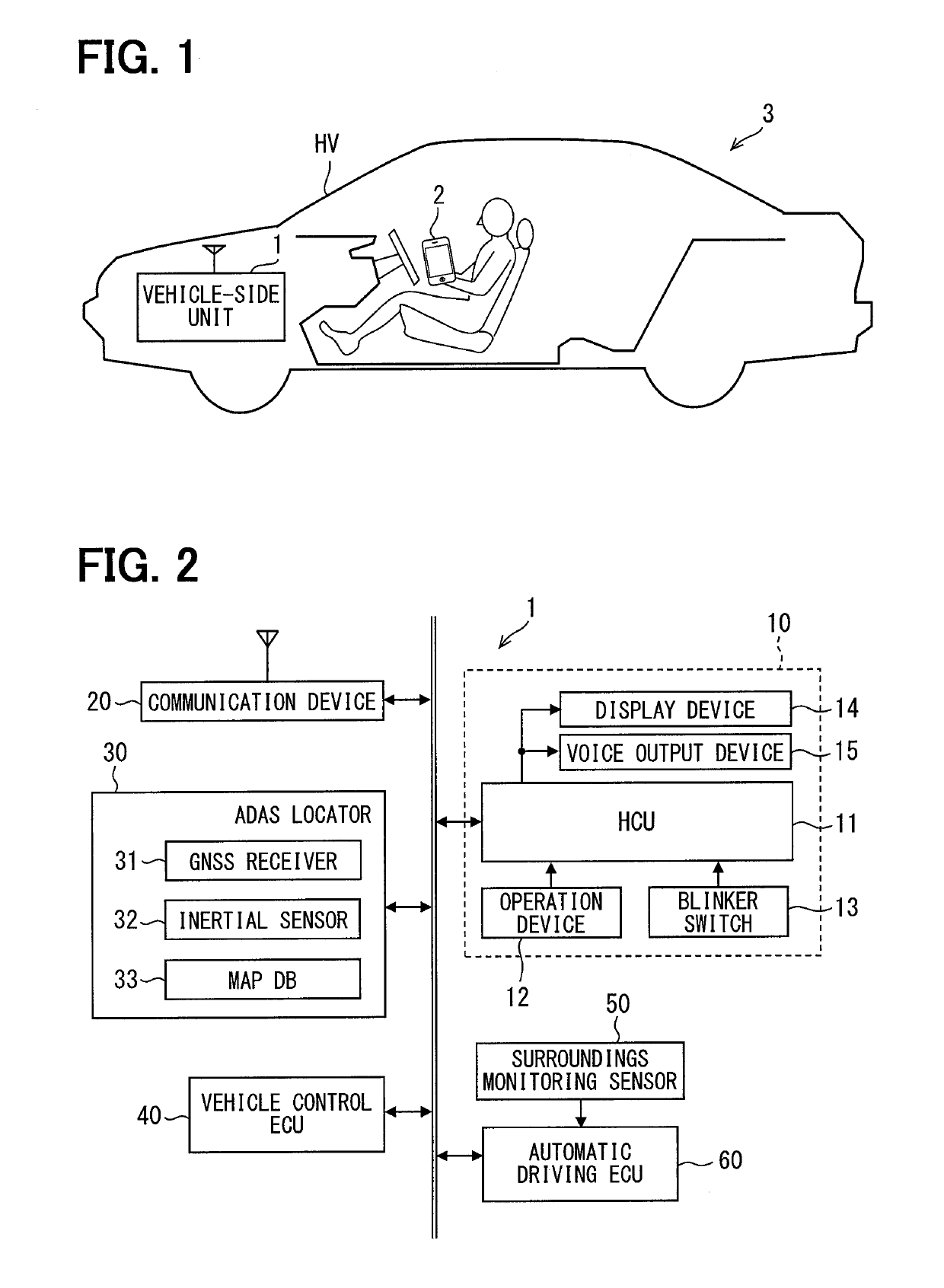

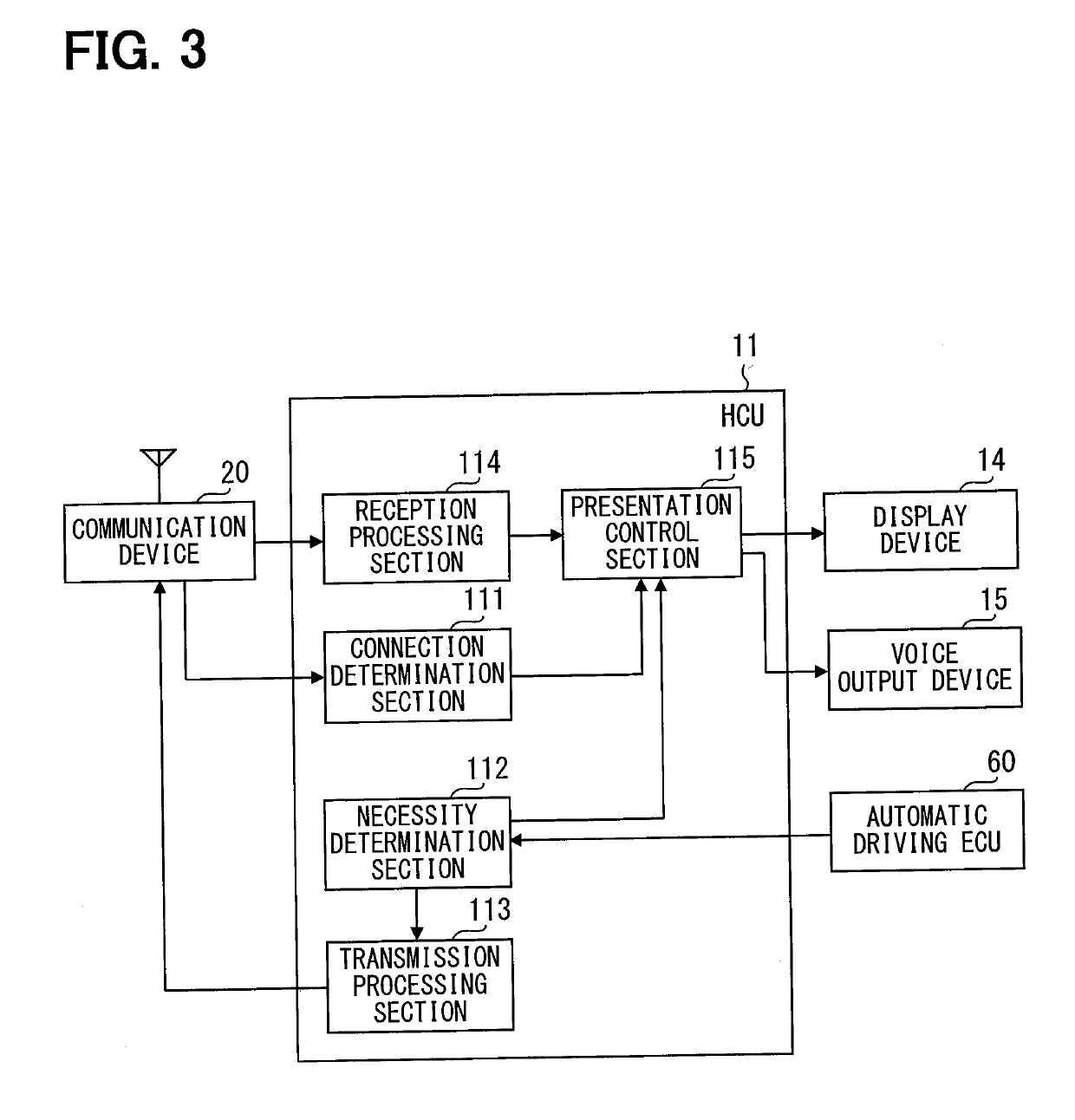

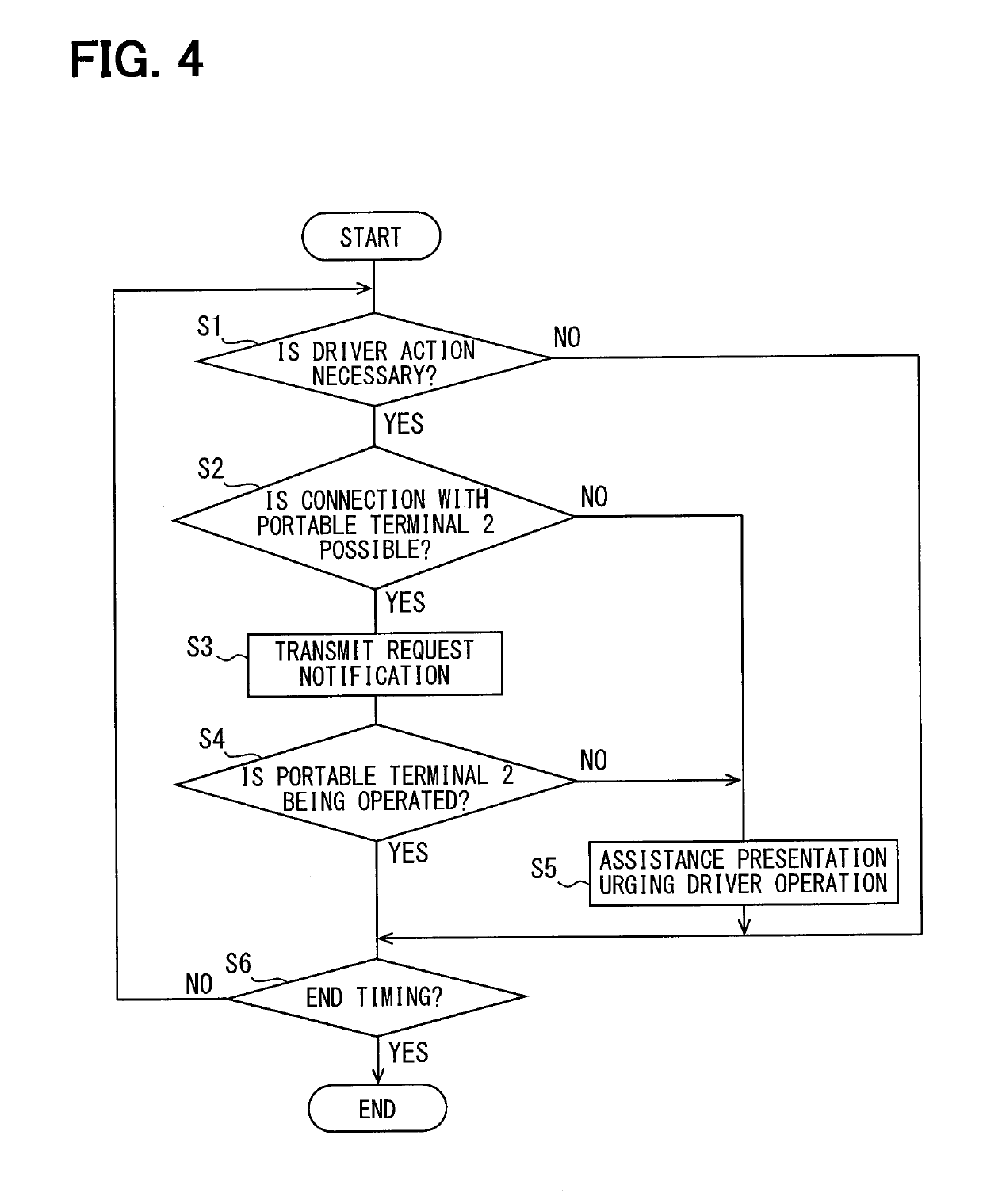

Assistance system, portable terminal, and vehicular device

PendingUS20190126942A1Guaranteed smooth executionAutonomous decision making processSignalling/lighting devicesComputer terminalEngineering

An assistance system includes: an vehicular device for a vehicle that performs an autonomous driving operation, and allows a driver action during the autonomous driving operation; and a portable terminal that is carried by the driver of the vehicle and connected to the vehicular device to communicate with the vehicular device. The vehicular device or the portable terminal includes an operation determination section that determines whether the portable terminal is being operated. The portable terminal includes a display unit that performs an assistance display for assisting an execution of the driver action which is required during the autonomous driving operation when the driver action is required during the autonomous driving operation, and the operation determination section determines that the portable terminal is being operated.

Owner:DENSO CORP

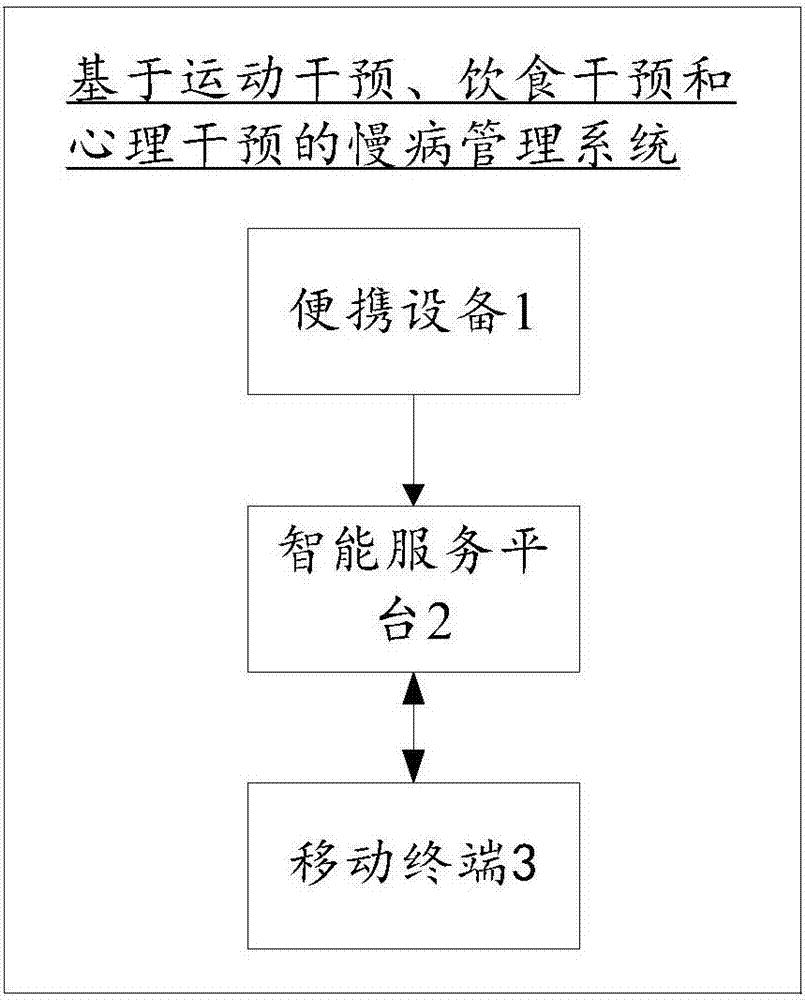

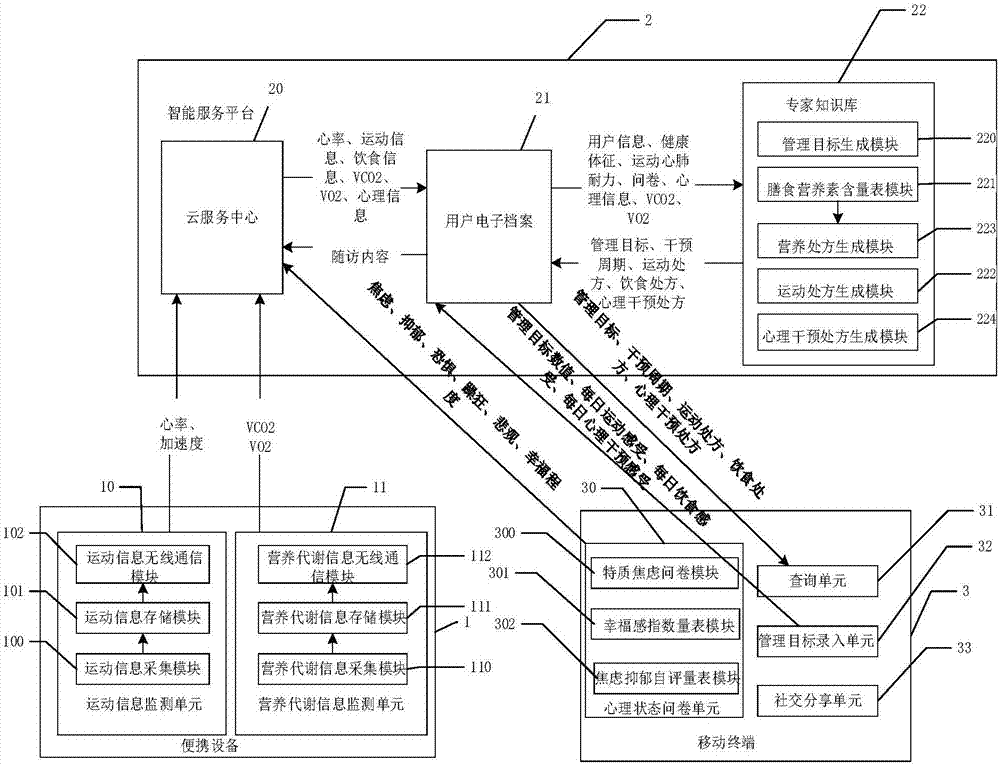

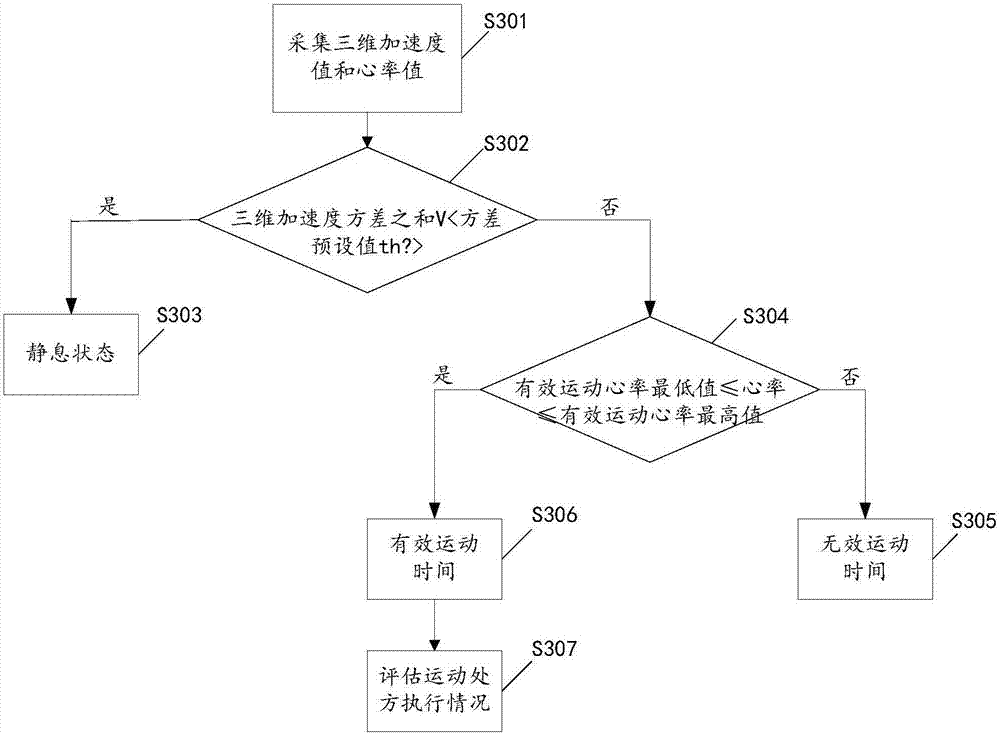

Chronic disease management system based on exercise intervention, diet intervention and mental intervention

InactiveCN107103174AGuaranteed smooth executionImprove work performanceHealth-index calculationSensorsPersonalizationClosed loop

The invention relates to the technical field of health management and specifically relates to a chronic disease management system based on exercise intervention, diet intervention and mental intervention. The system provided by the invention comprises an intelligent service platform, portable equipment and a mobile terminal, wherein the portable equipment is used to collect information and transmit the information to the intelligent service platform; the intelligent service platform is used to customize personalized exercise prescriptions, diet prescriptions and mental intervention prescriptions; and the mobile terminal is used to inquire various types of information and prescriptions and assess a user's anxiety, depression, fear, mania, pessimism and happiness degrees by questionnaires. By the invention, a closed-loop health management service can be provided for a client; personalized prescriptions can be issued based on comprehensive evaluation of a patient's health conditions, mental conditions, diet conditions and lifestyles, so that the patient can execute a scheme customized for him / her.

Owner:北京动亮健康科技有限公司

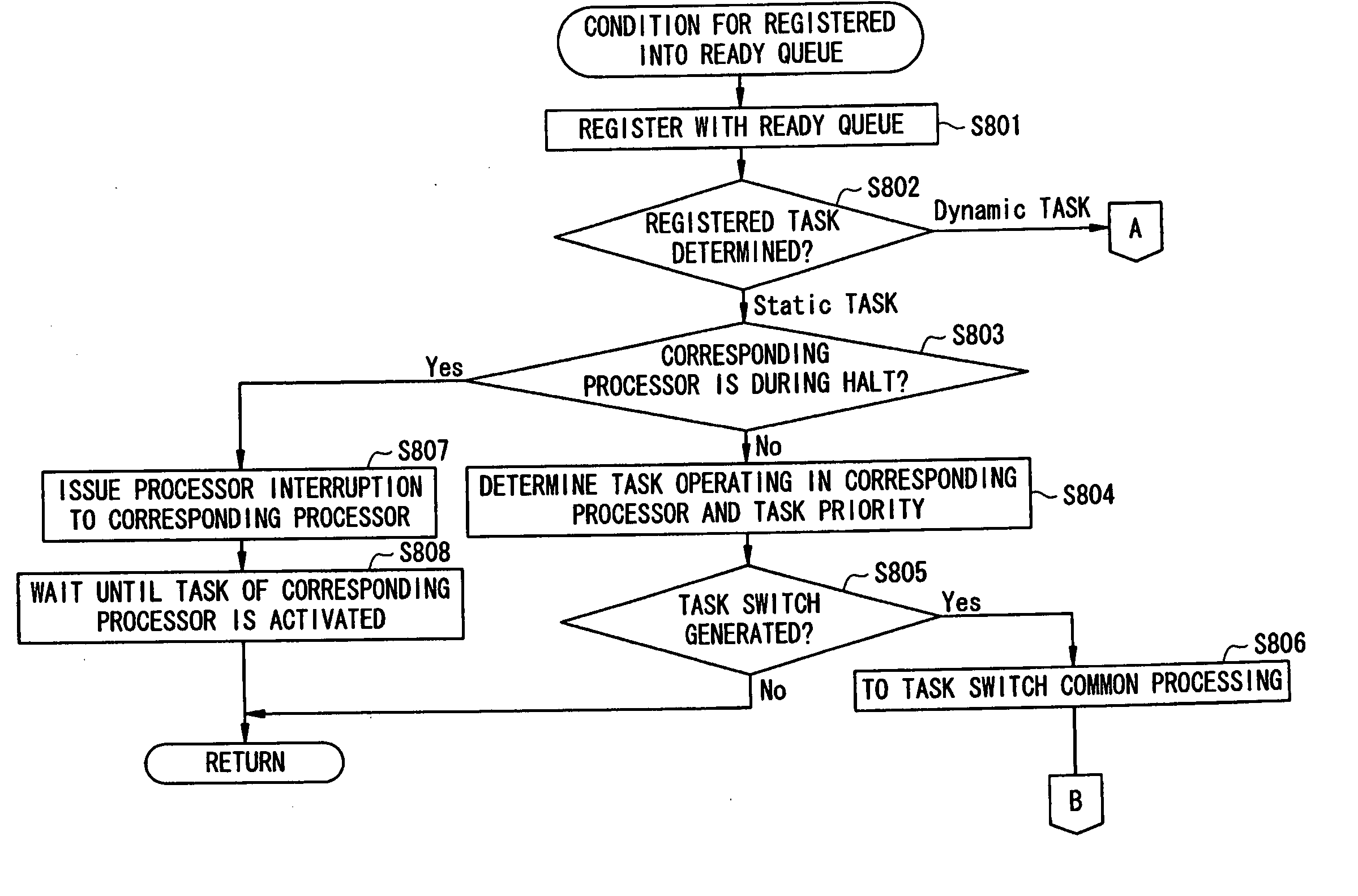

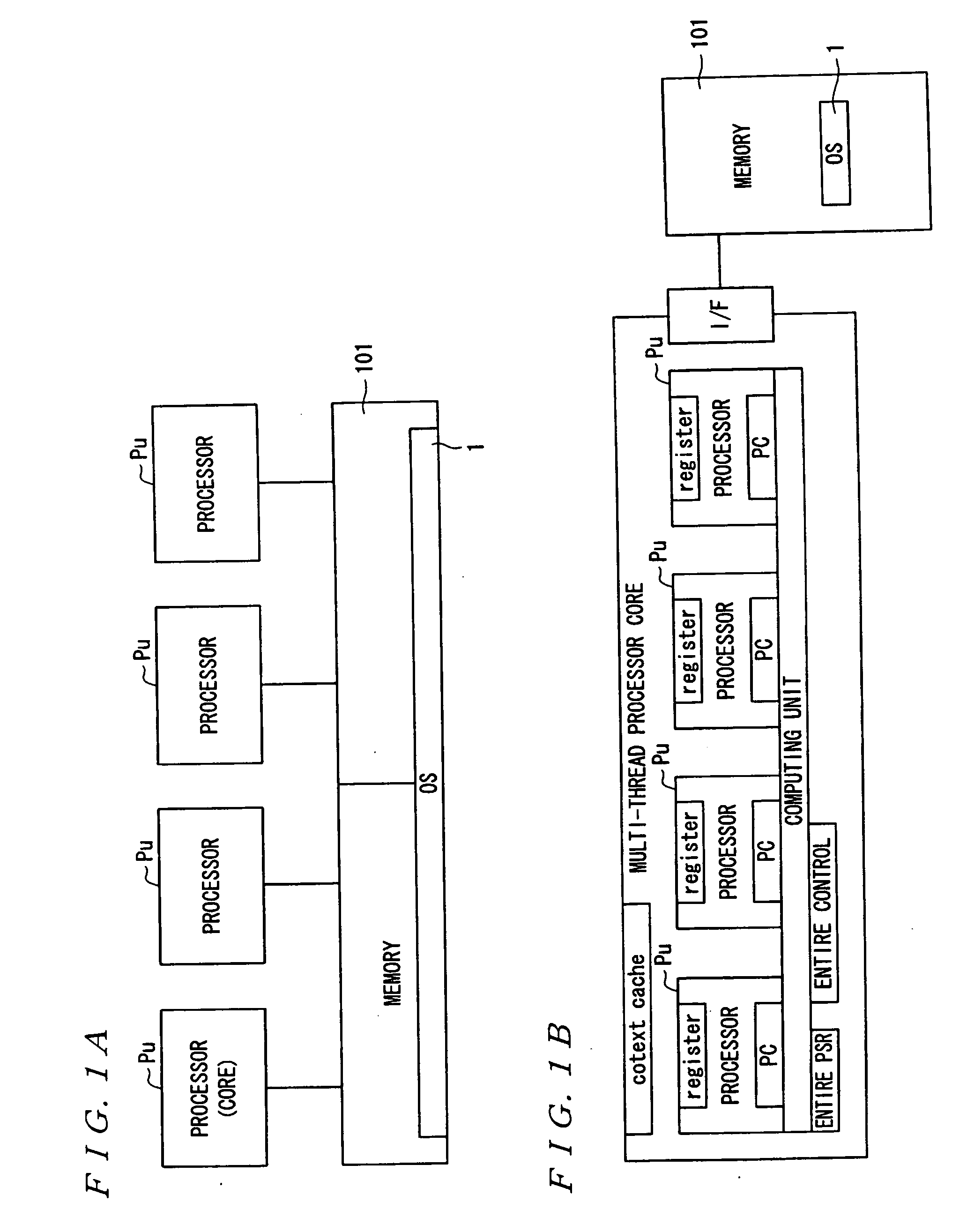

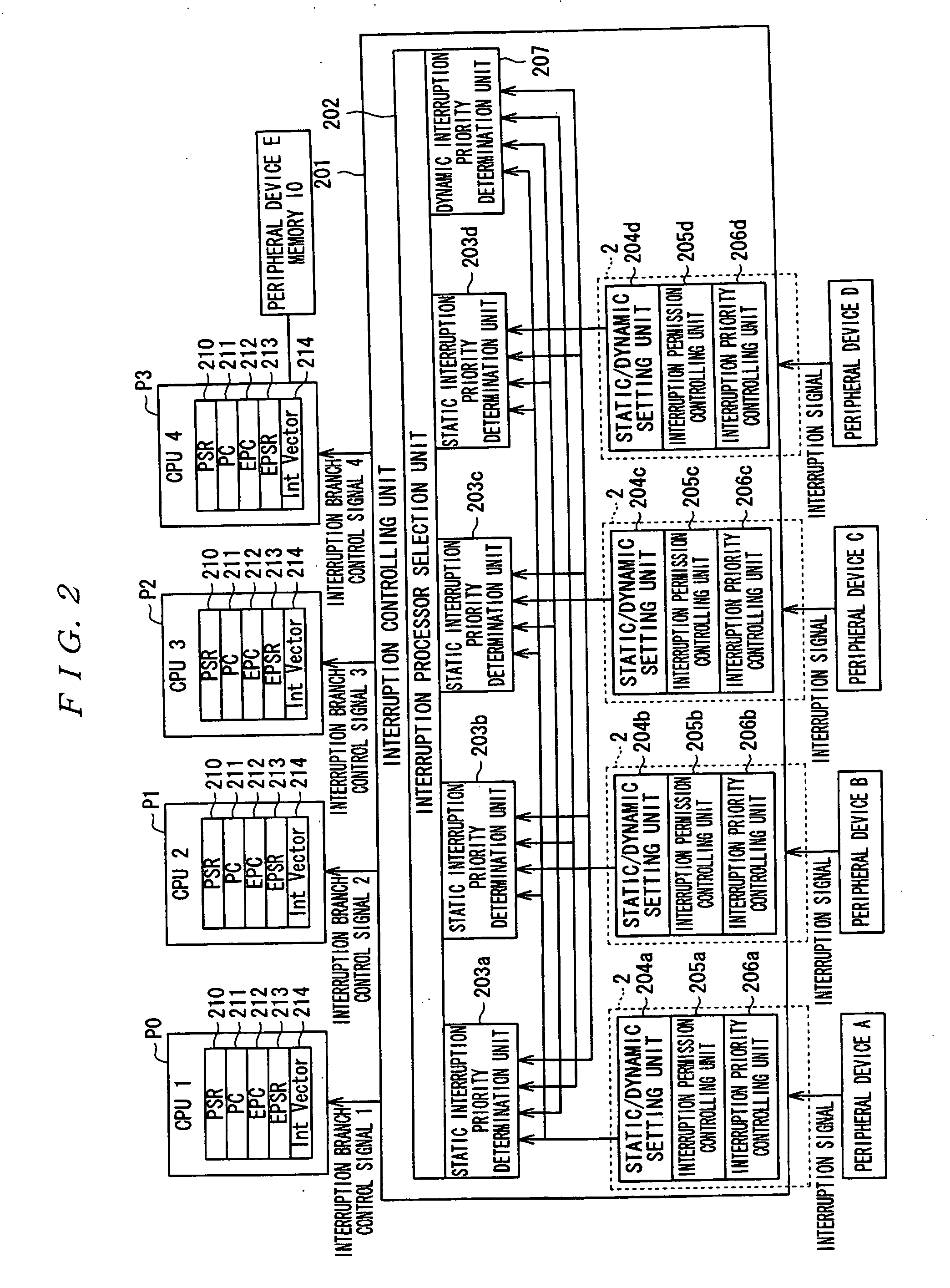

Multi-processor system and program for causing computer to execute controlling method of multi-processor system

InactiveUS20070169126A1Parallel processingGuaranteed smooth executionResource allocationMemory systemsMulti processorOperating system

A multi-processor system with a plurality of unit processors includes: a request accepting section for accepting a first request and a second request, wherein the first request is a request to execute a program that can be executed in any of said unit processors and the second request is a request to execute a program that can be executed only in a specified unit processor among said unit processors; and a unit processor allocating section for allocating the first request and the second request accepted by said request accepting section to said unit processors according to priority of the first request and the second request.

Owner:SEIKO EPSON CORP

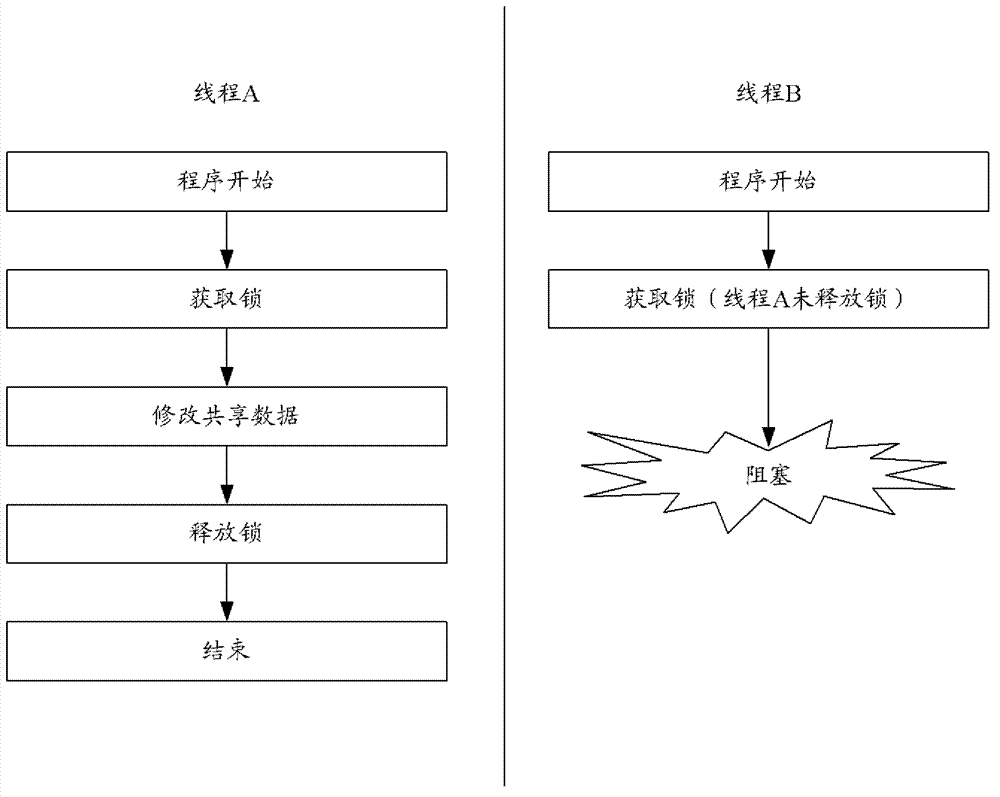

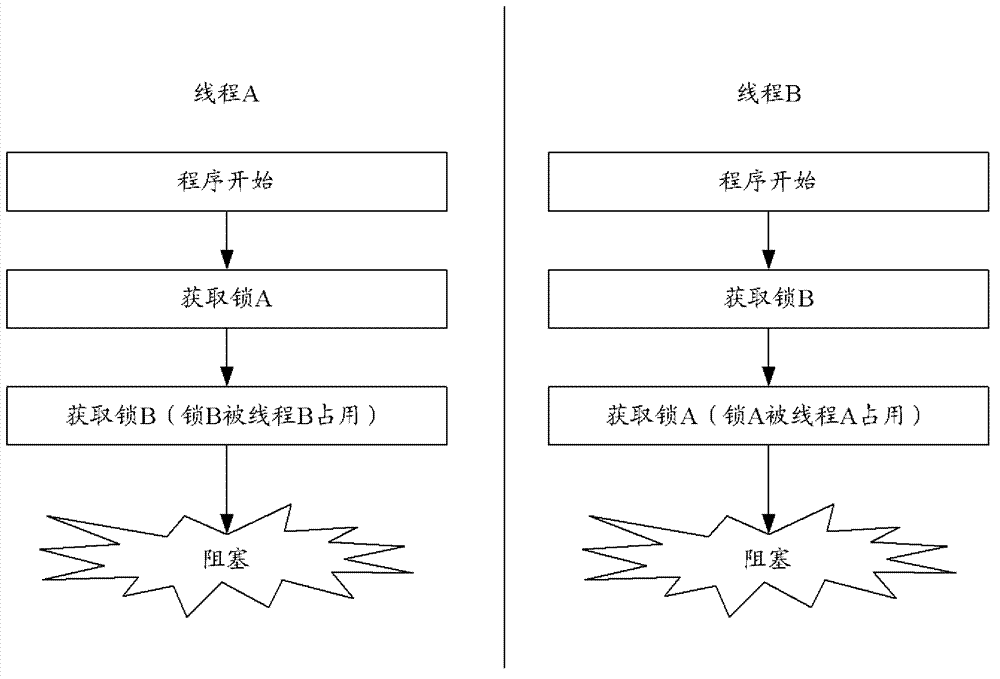

Method and device for preventing thread from blocking

ActiveCN103246552AOvercoming blockageGuaranteed smooth executionMultiprogramming arrangementsCritical sectionEvent trigger

The invention discloses method and device for preventing a thread from blocking. The method includes: after a system starts, replacing all application program interface functions used for awaiting events to be triggered so that, when one replaced application program interface function is transferred by a thread, if that the length of set waiting time is unlimited is determined, changing the length of the set waiting time to a preset value; or after a system starts, replacing all application program interface functions used for ending events so that, when one replaced application program interface function is transferred by a thread, if that critical sections occupied by the thread to be ended is not released is determined, then releasing the critical sections; or performing thread poll periodically, if that the length of blocking time of a thread exceeds a preset length of time and the thread is blocked on transferring of application program interface functions used for occupying critical sections, then releasing a critical section corresponding to a first parameter of the transferred application program interface functions. By the method, successfully execution of the program can be guaranteed.

Owner:TENCENT TECH (SHENZHEN) CO LTD

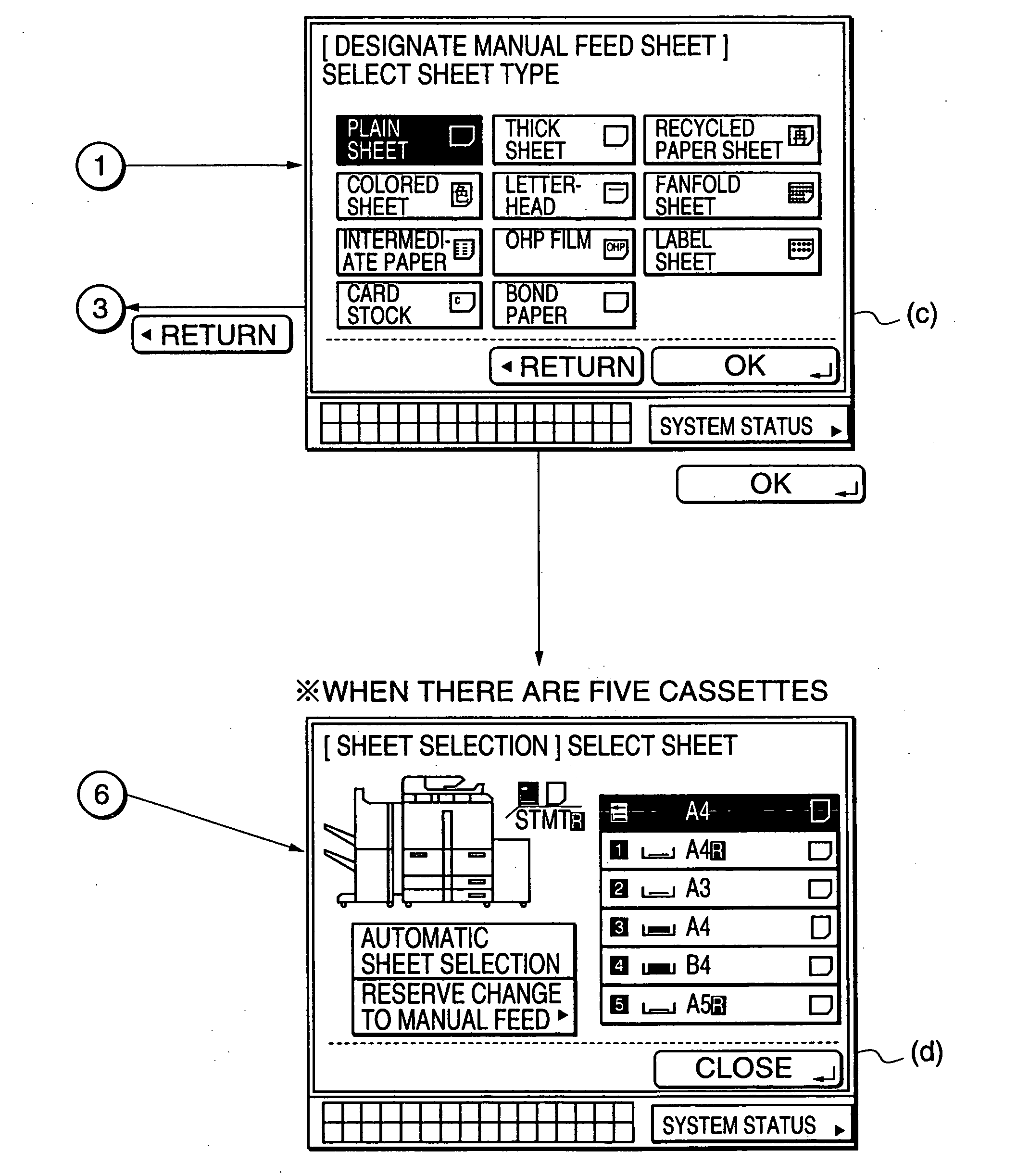

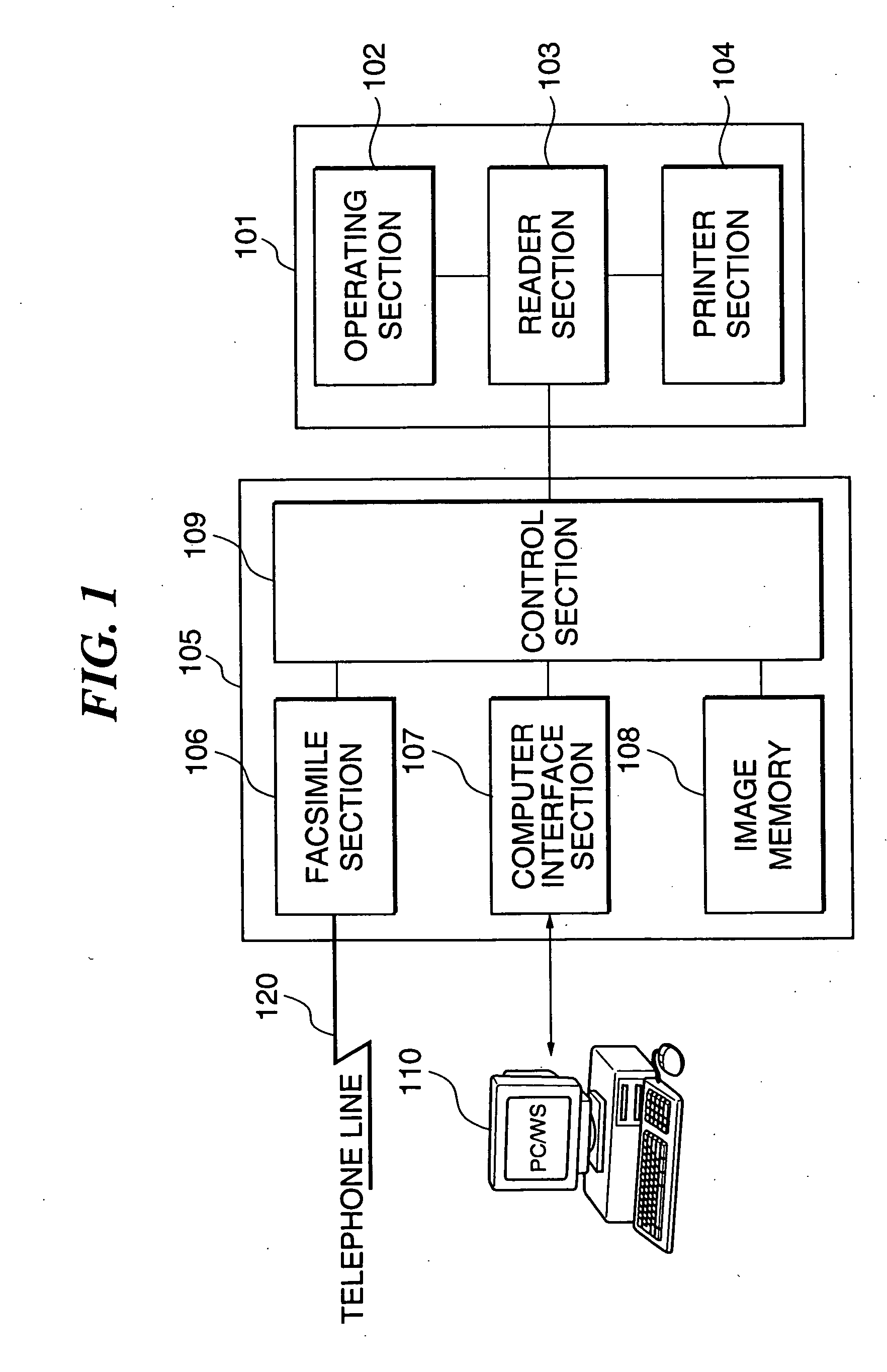

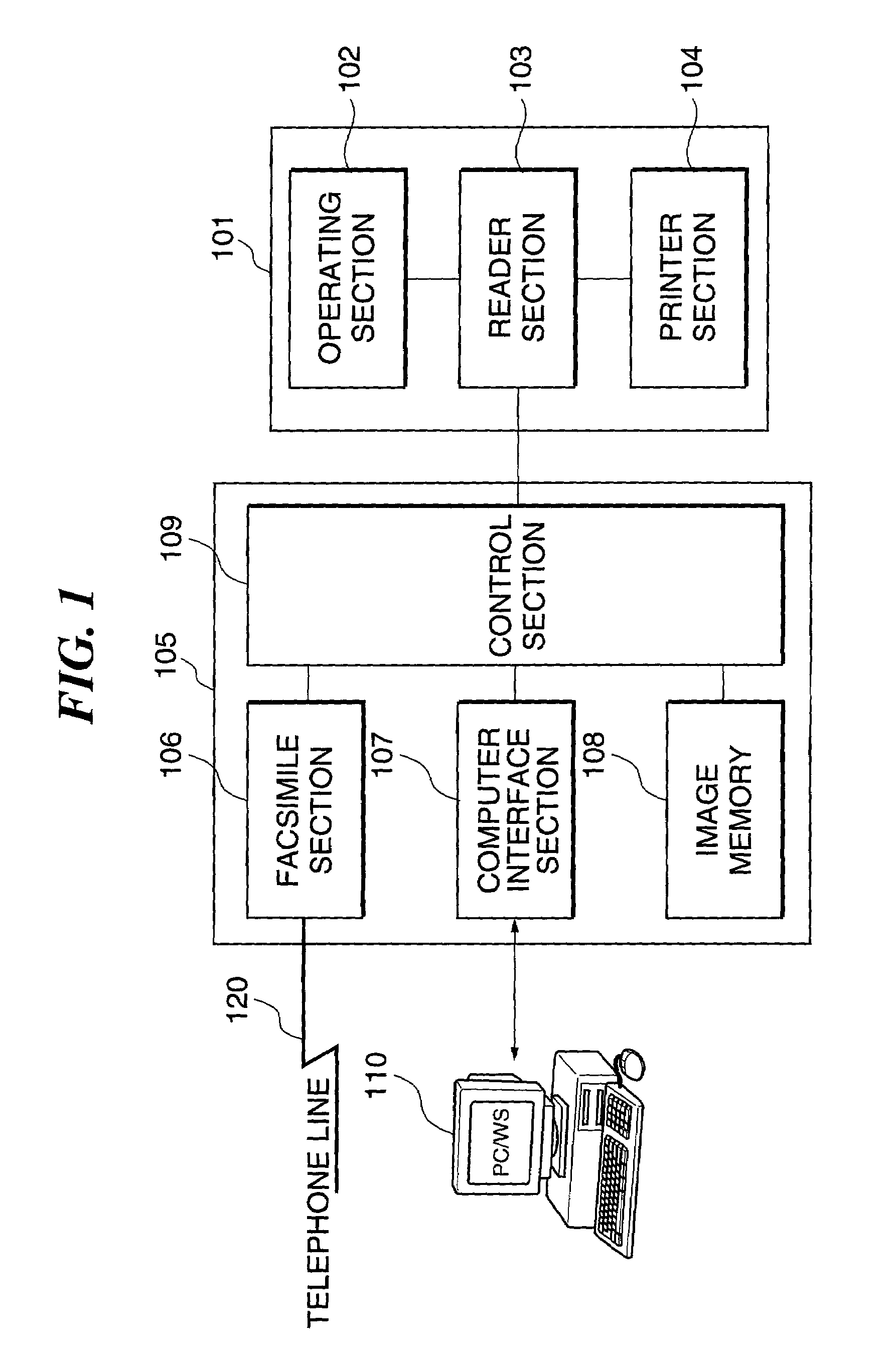

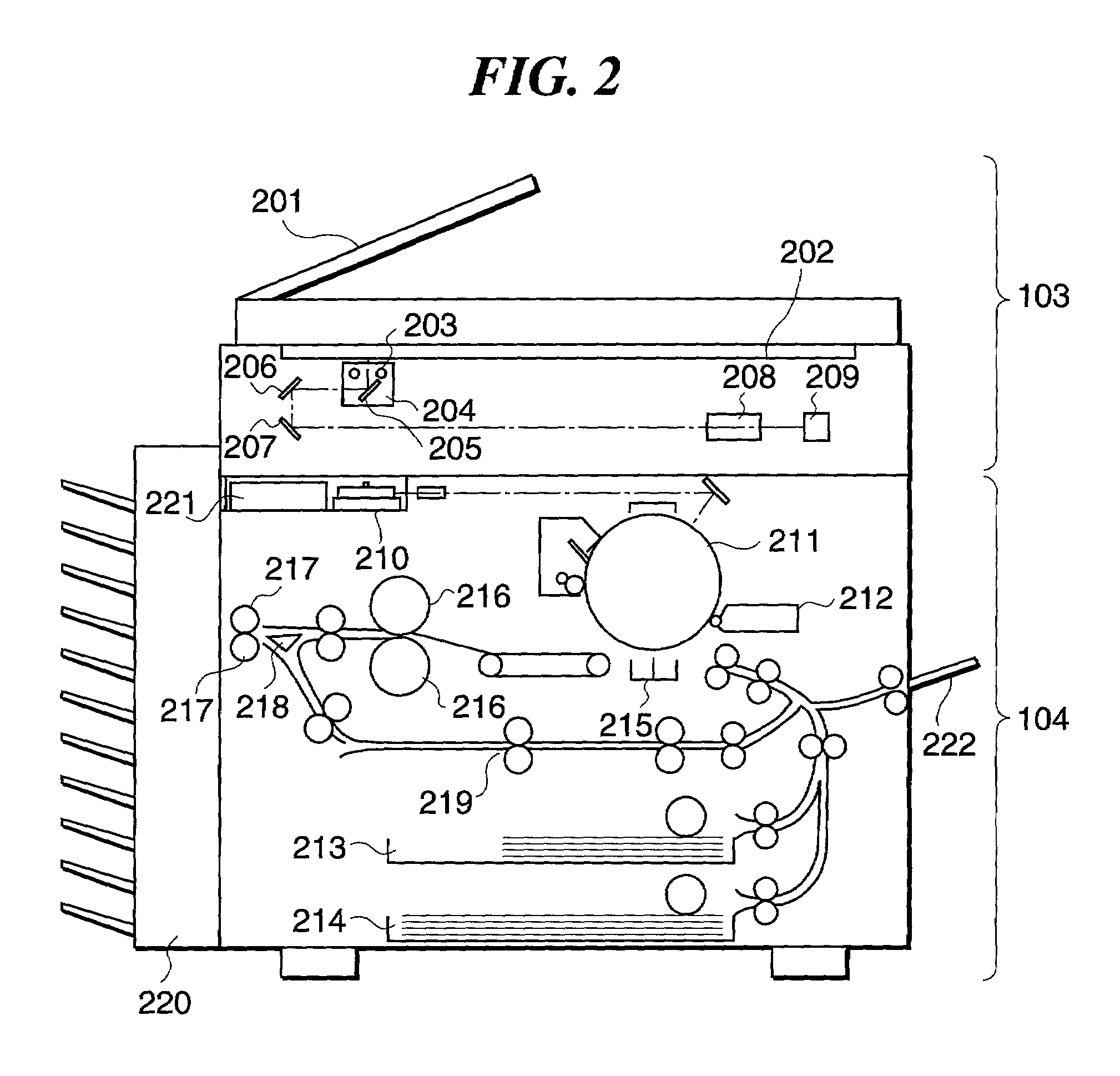

Image forming apparatus, image forming system, sheet feeding source designation control method, image formation control method, and storage media

InactiveUS20060092450A1Guaranteed smooth executionEfficient executionVisual presentation using printersElectrographic process apparatusImage formationComputer science

There are provided an image forming apparatus, an image forming system, and a sheet feeding source designation control method, which are capable of preventing a user from failing to carry out proper settings to thereby avoid printing using an undesired sheet cassette, and also capable of allowing a user to change to another type of sheet feeding than manual feeding immediately if he or she desires to do so, and storage media storing programs for executing the methods. The size of at least one sheet for manual feeding can be designated by a device or a job. It is determined whether or not a manual feed tray can be designated as a sheet feeding source if the sheet size is designated by the device or the job, and the manual feed tray is designated as the sheet feeding source when it is so determined. A sheet selecting screen is displayed on a screen for allowing a user to confirm or change the designation of the manual feed tray as the sheet feeding source upon completion of the designation, if the size is designated by the device or the job.

Owner:CANON KK

Printing device, method and computer readable medium for executing print job

ActiveUS20090086270A1Guaranteed smooth executionEasy to useVisual presentationPictoral communicationData storingData store

Owner:BROTHER KOGYO KK

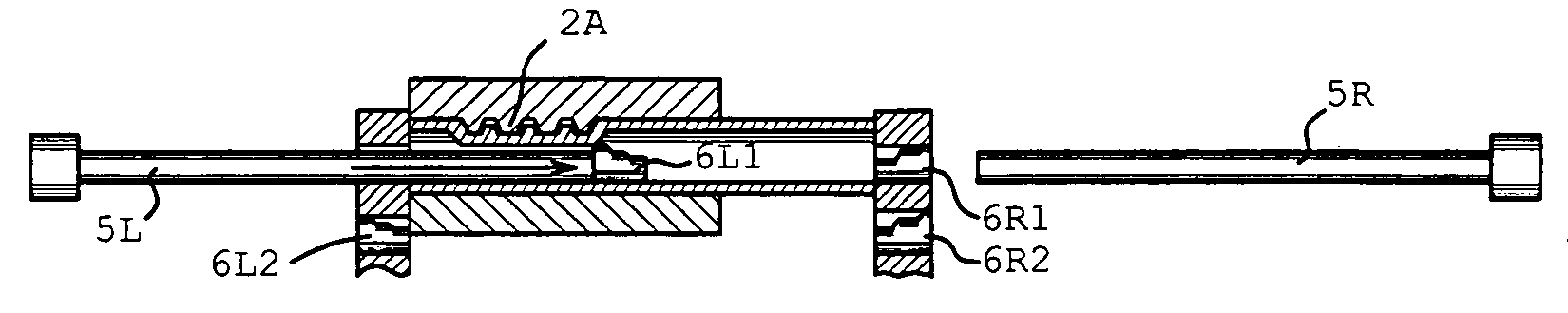

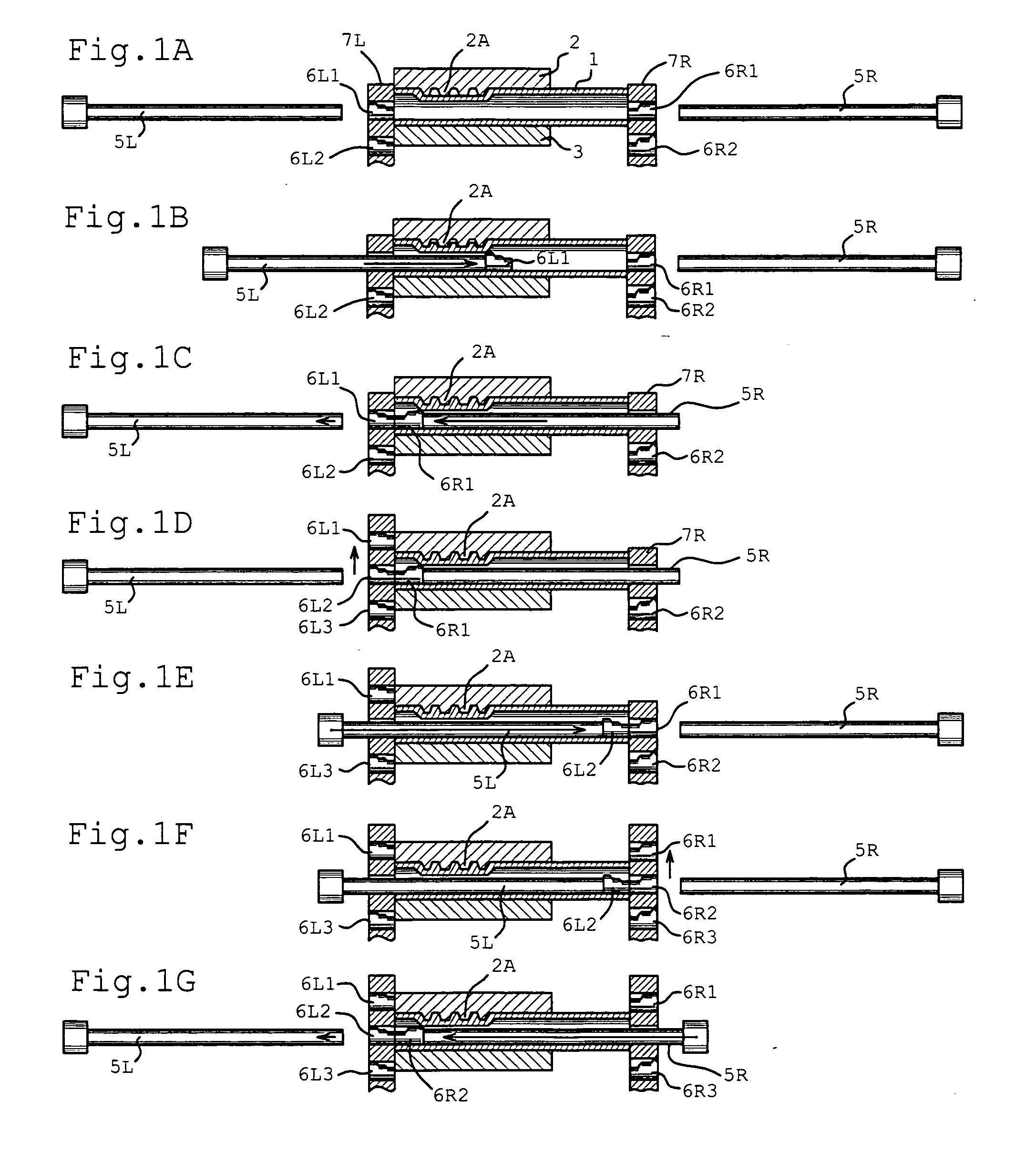

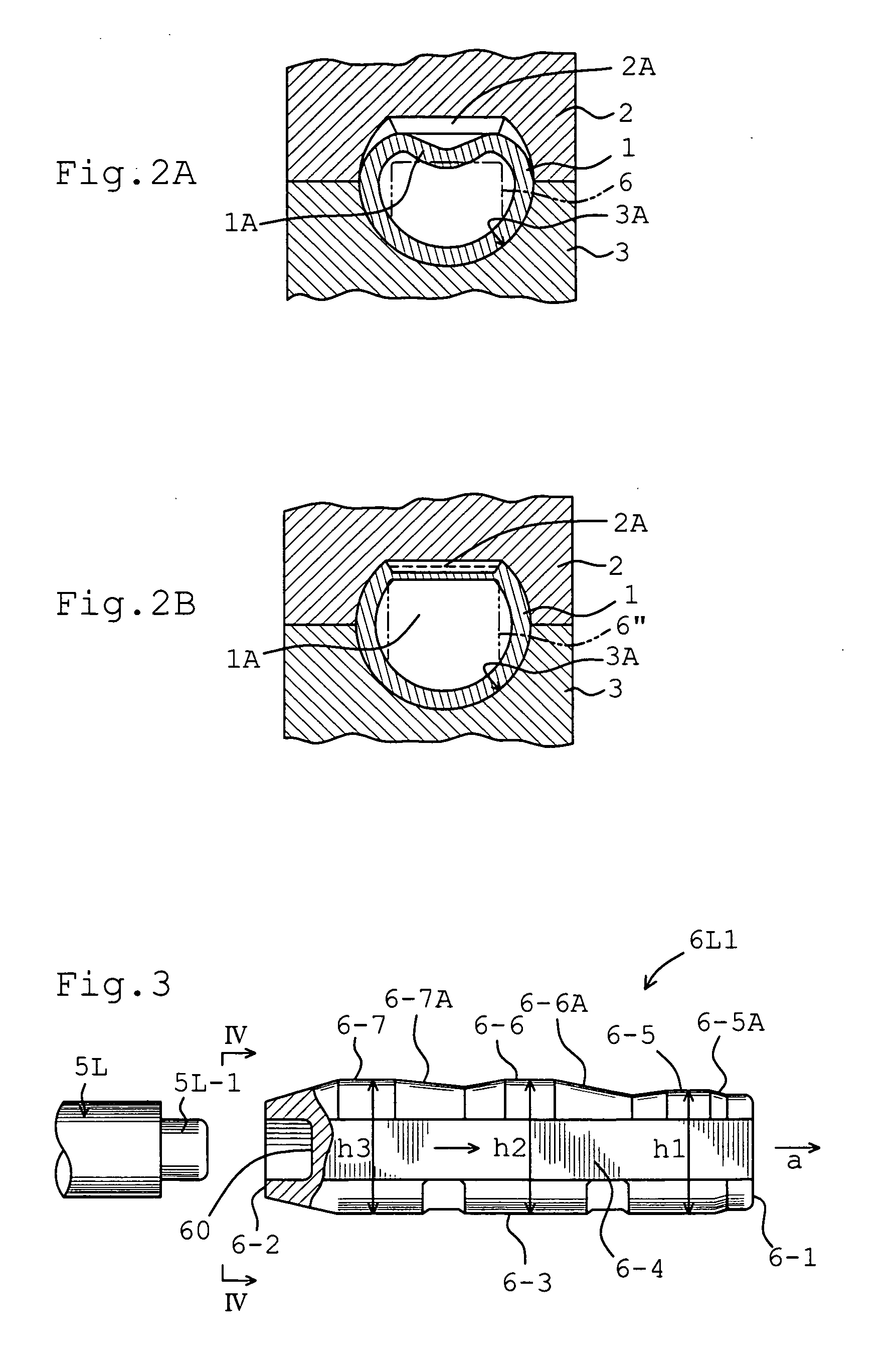

Method and apparatus for producing hollow rack bar and mandrel used for rack bar production

InactiveUS20060016238A1Low costLow running costNutsMetal-working apparatusEngineeringMechanical engineering

A system for forging a rack bar from a blank pipe. A blank pipe 1 is held between dies 2 and 3. Stockers 7L and 7R are arranged on respective sides of the die set. In the stockers 7L and 7R, left-handed shuttles 6L1, 6L2, 6L3, . . . 6Ln and right-handed shuttles 6R1, 6R2, 6R3 . . . 6Rn are stored. First, a left-handed presser rod 5L inserts the shuttles 6L1 to the blank pipe from the left-handed stocker 7L. Then, a right-handed presser rod 5R inserts the shuttles 6R1 to the blank pipe from the right-handed stocker 7R, causing the shuttles 6L1 to be entrained and returned to the left-handed stocker 7L. Vertical shift movement is alternately executed between the left-handed and right-handed stockers 7L and 7R, so that a shuttle of step-likely increased working height is selected for executing a working process.

Owner:MATSUOKA MINAKO +2

Image forming apparatus, image forming system, sheet feeding source designation control method, image formation control method, and storage media

InactiveUS7019851B2Avoid printingGuaranteed smooth executionVisual presentation using printersDigital computer detailsImage formationComputer science

There are provided an image forming apparatus, an image forming system, and a sheet feeding source designation control method, which are capable of preventing a user from failing to carry out proper settings to thereby avoid printing using an undesired sheet cassette, and also capable of allowing a user to change to another type of sheet feeding than manual feeding immediately if he or she desires to do so, and storage media storing programs for executing the methods. The size of at least one sheet for manual feeding can be designated by a device or a job. It is determined whether or not a manual feed tray can be designated as a sheet feeding source if the sheet size is designated by the device or the job, and the manual feed tray is designated as the sheet feeding source when it is so determined. A sheet selecting screen is displayed on a screen for allowing a user to confirm or change the designation of the manual feed tray as the sheet feeding source upon completion of the designation, if the size is designated by the device or the job.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com