Workshop production plan scheduling system and method oriented to discrete manufacturing

A production planning and production system technology, applied in the direction of calculation, instrumentation, data processing applications, etc., can solve the problems of cumbersome scheduling, lack of reasonable, convenient and automatic production scheduling methods, and failure, so as to improve production efficiency and planning efficiency , the effect of reducing work stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

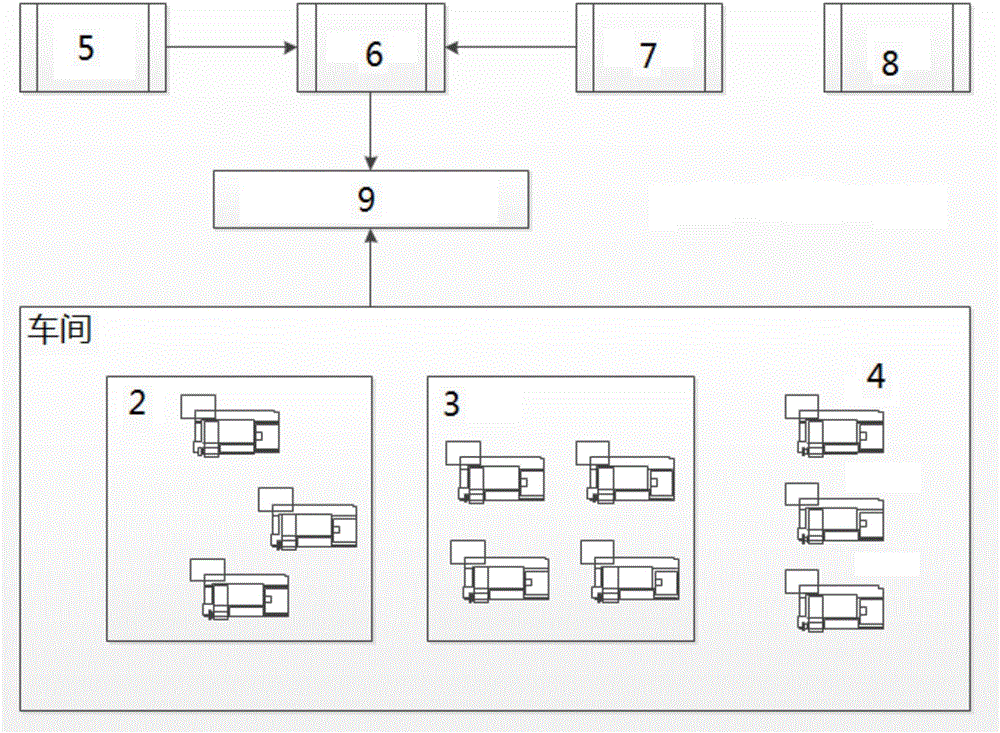

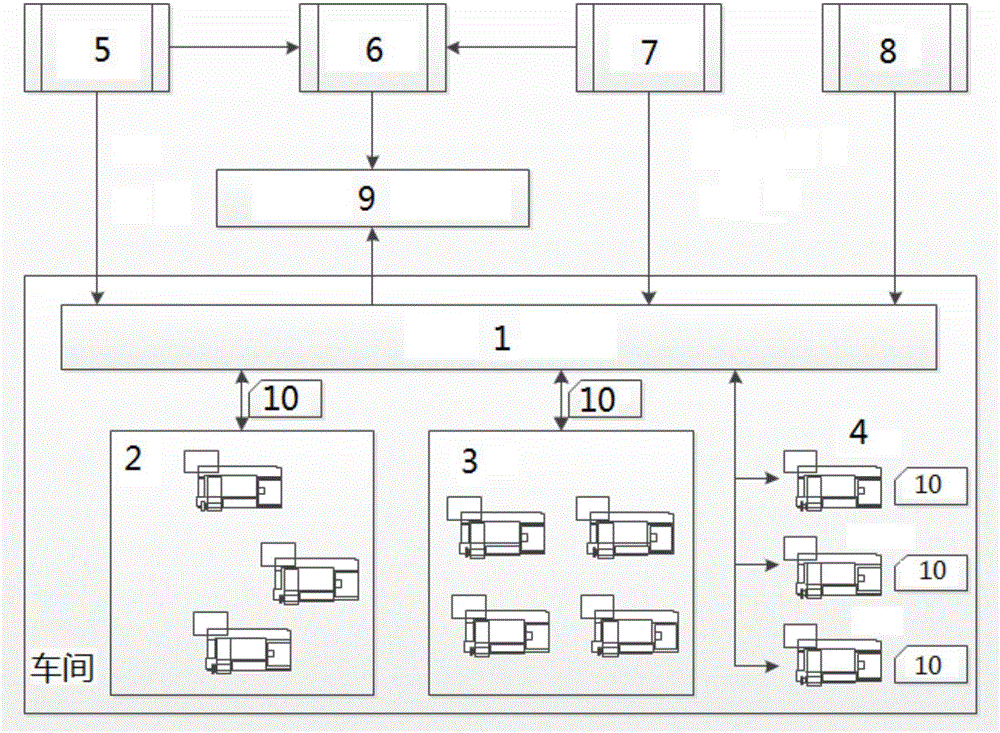

[0041] see figure 2 , which is a system of workshop production planning and scheduling for discrete manufacturing in the present invention. As shown in the figure: it includes a workshop planning and scheduling system 1 set up in the workshop. The workshop planning and scheduling system 1 is respectively connected to a number of processing units 2 and a number of capacity group units 3 set in the workshop for completing the work order plan 10 and a number of other equipment 4; the workshop planning and production system 1 is further connected to the warehouse system 5, ERP or MRP system 6, human resources system 7 and process system 8; wherein: the ERP or MRP system 6 communicates with the workshop planning through an interactive module 9 The production scheduling system 1 is connected, and the interactive module 9 is used to issue the production plan and report the completion of the workshop production plan in real time.

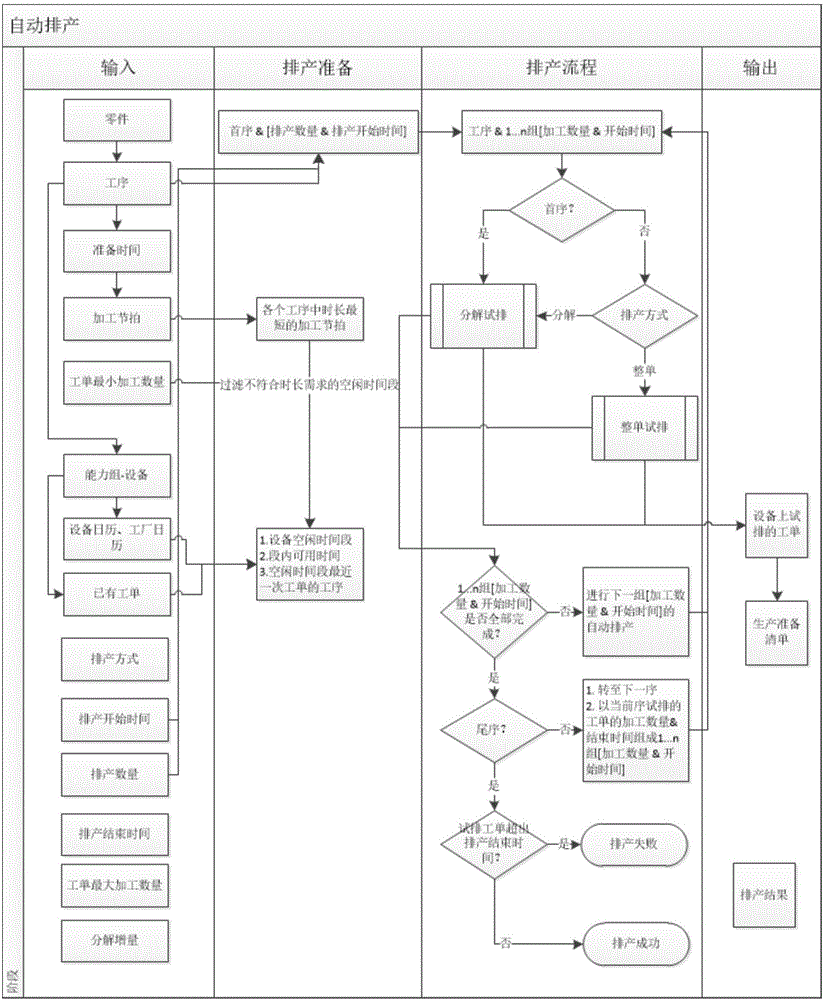

[0042] The method of workshop production planning a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com